Page 1

INSTRUCTIONS-PARTS LIST

308–937

INSTRUCTIONS

This manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

Supersedes Rev. A

Rev. D

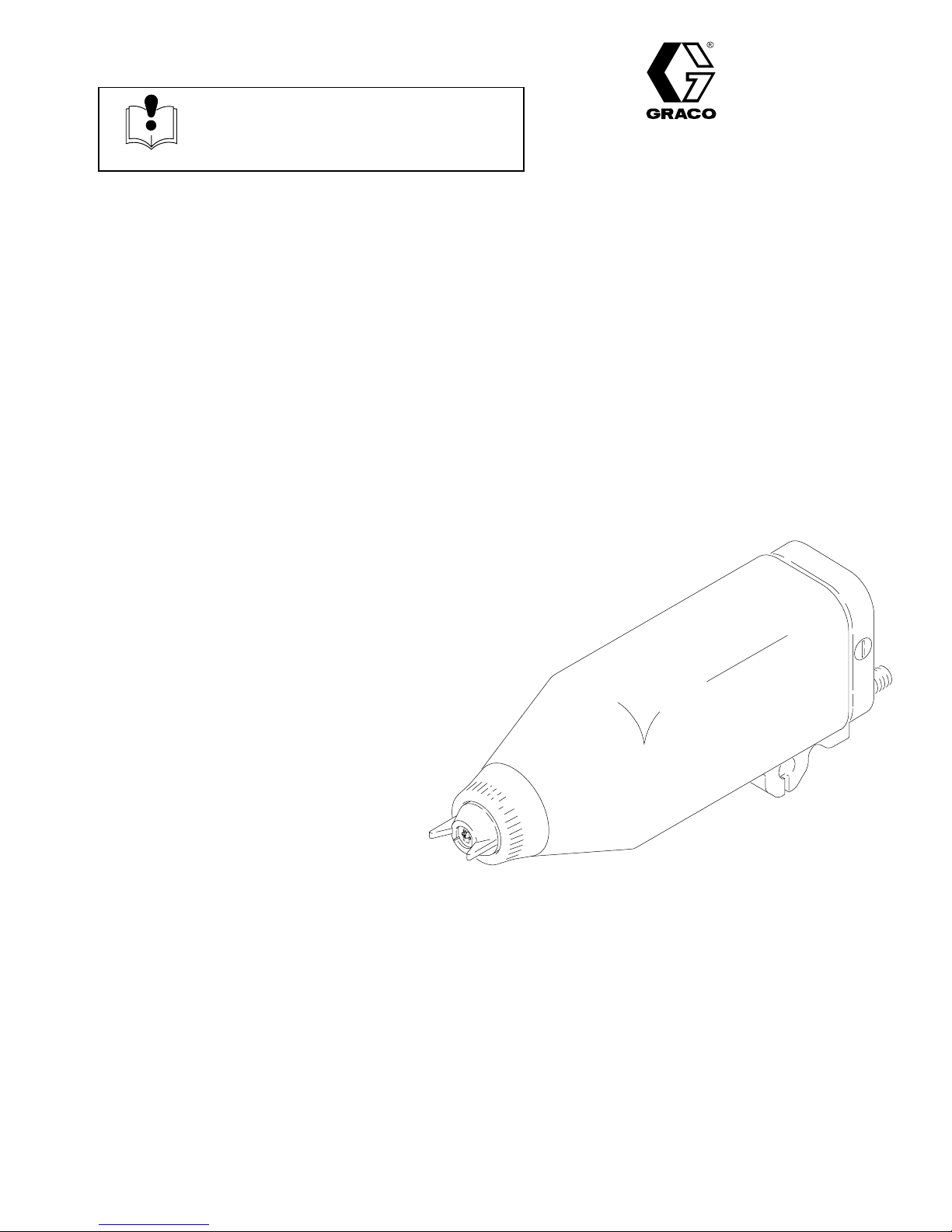

AUTOMATIC ELECTROSTATIC

Model PRO AA5500sc/UNICARB

Air-Assisted Spray Gun

100 psi (7 bar, 0.7 MPa) Maximum Working Air Pressure

3000 psi (207 bar, 20.7 MPa) Maximum Working Fluid Pressure

For use with Class I, Group D paint spray materials

Part No. 965721, Series B

Complete Spray Gun: includes spray gun, shroud,

manifold, and mounting bracket

U.S. PATENT NO. 4,290,091; 4,219,865; 4,497,447; 4,462,061; 4,660,774;

5,063,350; 5,080,289; 5,289,977

Patented 1986, 1987 Canada

Brevete 1986, 1987

U.K. PATENT NO. 2,147,158; 2,142,559B; 2,140,327–B

Other Foreign Patents Pending

UNICARB IS A REGISTERED TRADEMARK OF UNION

CARBIDE, DANBURY CT.

03228

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

COPYRIGHT 1994, GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001

Page 2

WARNING

FIRE, EXPLOSION, AND ELECTRIC SHOCK HAZARD

Improper grounding, poor air ventilation, open flames, or sparks can cause a hazardous condition and

result in a fire, explosion, or electric shock.

Electrostatic equipment must be used only by trained, qualified personnel who understand the

requirements stated in this instruction manual.

Ground the equipment, personnel in or close to the spray area, the object being sprayed, and all

other electrically conductive objects in the spray area. See Ground the System on page 14.

Check the spray gun resistance daily. See Test Gun Resistance, page 29.

If there is any static sparking while using the equipment, stop spraying immediately. Identify and

correct the problem.

Provide fresh air ventilation to avoid the buildup of flammable or toxic vapors. Interlock the gun

turbine air supply to prevent operation of the power supply unless the ventilating fans are on. See

Ventilate the Spray Booth on page 8.

When cleaning, flushing, or purging electrostatic equipment, use solvents that comply with your

local regulations. For countries following the U.S. National Fire Protection Association (NFPA) 33

requirements, use solvents with a flash point higher than 100 F (38 C) or a solvent normally

used in spray operations. For European Countries complying with EN 50053, use solvents with a

flash point as high as possible and higher than the ambient temperatures.

Use only non-sparking tools to clean residue from the booth and hangers.

Do not flush the system with the gun electrostatics turned on.

Do not turn on the gun electrostatics until all solvent is removed from the system.

Extinguish all open flames or pilot lights in the spray area.

Keep the spray area free of debris, including solvent, rags, and gasoline.

Do not store any flammable fluids in the spray area.

Do not turn on or off any light switch in the spray area while operating or if fumes are present.

Do not smoke in the spray area.

Do not operate a gasoline engine in the spray area.

TOXIC FLUID HAZARD

Hazardous fluids or toxic fumes can cause a serious injury or death if splashed in the eyes or on the

skin, swallowed, or inhaled.

Know the specific hazards of the fluid you are using. Read the fluid manufacturer’s warnings.

Store hazardous fluid in an approved container. Dispose of the hazardous fluid according to all

local, state, and national guidelines.

Wear appropriate protective clothing, gloves, eyewear, and respirator.

2 308937

Page 3

WARNING

INJECTION HAZARD

Spray from the gun, hose leaks, or ruptured components can inject fluid into your body and cause an

extremely serious injury, including the need for amputation. Splashing fluid in the eyes or on the skin

can also cause a serious injury.

Fluid injected into the skin might look like just a cut, but it is a serious injury. Get immediate medi-

cal attention.

Do not point the spray gun at anyone or any part of the body.

Do not put hand or fingers over the spray tip.

Do not stop or deflect fluid leaks with your hand, body, glove, or rag.

Do not “blow back” fluid; this is not an air spray system.

Always have the tip guard on the spray gun when spraying.

This gun differs from other Graco high-pressure electrostatic guns in that there is no diffuser in the

fluid seat. Always follow the Pressure Relief Procedure on page 17 whenever you: are instructed

to relieve pressure; stop spraying; clean, check, or service the equipment; and install or clean the

spray tip.

Tighten all the fluid connections before operating the equipment.

INSTRUCTIONS

Check the hoses, tubes and couplings daily. Replace worn, damaged, or loose parts immediately.

Permanently coupled hoses cannot be repaired; replace the entire hose.

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture, malfunction, or start unexpectedly and result

in a serious injury.

This equipment is for professional use only.

Read all the instruction manuals, tags, and labels before operating the equipment.

Use the equipment only for its intended purpose. If you are uncertain about usage, call your Graco

distributor.

Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

Check the equipment daily. Repair or replace worn or damaged parts immediately.

Do not exceed the maximum working pressure of the lowest rated system component. This equip-

ment has a 100 psi (7 bar, 0.7 MPa) maximum working air pressure and 3000 psi (207 bar,

20.7 MPa) maximum working fluid pressure.

Use fluids that are compatible with the equipment wetted parts. See the Technical Data section of

all the equipment manuals. Read the fluid manufacturer’s warnings.

Route the hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not

expose Graco hoses to temperatures above 180F (82C) or below –40F (–40C).

Do not use the hoses to pull equipment.

Wear hearing protection when operating this equipment.

Comply with all applicable local, state, and national fire, electrical, and other safety regulations.

308937 3

Page 4

Table of Contents

Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbols 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How the PRO AA5500sc/UNICAB Electrostatic

Air-Assisted Spray Gun Operates 5. . . . . . . . . . . . . . . . .

Operating the Spray Function 5. . . . . . . . . . . . . . . . . . . .

Operating the Electrostatics 5. . . . . . . . . . . . . . . . . . . . . .

Switching to the Higher or Lower kV Setting 5. . . . . . . .

Gun Features and Options 5. . . . . . . . . . . . . . . . . . . . . . .

Installation 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the System 8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warning Signs 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ventilate the Spray Booth 8. . . . . . . . . . . . . . . . . . . . . . . .

Install the Air Line Accessories 10. . . . . . . . . . . . . . . . . .

Fluid Line Accessories 11. . . . . . . . . . . . . . . . . . . . . . . . .

Install the Gun and Mounting Bracket 11. . . . . . . . . . . .

Connect the Air and Fluid Lines

to the Gun Manifold 12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Fiber Optic Cable Connection 13. . . . . . . . . . .

Optional Fiber Optic Lens Kit Installation 13. . . . . . . . .

Ground the System 14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check the Electrical Grounding 15. . . . . . . . . . . . . . . . . .

Install the Fabric Cover 16. . . . . . . . . . . . . . . . . . . . . . . . .

Service 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools Included with the Gun 31. . . . . . . . . . . . . . . . . . . . .

Prepare the Gun for Service 31. . . . . . . . . . . . . . . . . . . .

Tip Guard, Air Cap, Spray Tip, or Seat

Housing Replacement 33. . . . . . . . . . . . . . . . . . . . . . . . . .

Electrode Replacement 34. . . . . . . . . . . . . . . . . . . . . . . .

Fluid Tube Removal and Replacement 35. . . . . . . . . . .

Fluid Filter Replacement 35. . . . . . . . . . . . . . . . . . . . . . .

Piston Repair 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Barrel Removal 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid Packing Adjustment 39. . . . . . . . . . . . . . . . . . . . . . .

Fluid Needle Assembly Removal 39. . . . . . . . . . . . . . . .

Power Supply Removal and Replacement 40. . . . . . . .

Lower Voltage Setting Adjustment 40. . . . . . . . . . . . . . .

Turbine Alternator Removal and Replacement 41. . . . .

Barrel Installation 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the Gun onto the Manifold

and Mounting Bracket 43. . . . . . . . . . . . . . . . . . . . . . . . . .

Spray Gun Parts 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manifold Parts 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spray Tip Selection Chart 51. . . . . . . . . . . . . . . . . . . . .

Operation 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pressure Relief Procedure 17. . . . . . . . . . . . . . . . . . . . . .

Operating Checklist 17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting a Spray Tip 18. . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Spray Tip 19. . . . . . . . . . . . . . . . . . . . . . . . .

Setting the Atomization Fluid Pressure 20. . . . . . . . . . .

Activating and Adjusting the Electrostatics 20. . . . . . . .

Activating the kV Switch 20. . . . . . . . . . . . . . . . . . . . . . . .

Spraying 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shutdown 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Daily Care and Cleaning 21. . . . . . . . . . . . . . . . . . . . . . . .

Flush the Spray Gun 22. . . . . . . . . . . . . . . . . . . . . . . . . . .

Clean the Spray Gun 23. . . . . . . . . . . . . . . . . . . . . . . . . .

Check for Fluid Leakage 25. . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spray Pattern Troubleshooting 26. . . . . . . . . . . . . . . . . .

Gun Operation Troubleshooting 27. . . . . . . . . . . . . . . . .

Electrical Troubleshooting 28. . . . . . . . . . . . . . . . . . . . . .

Electrical Tests 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Gun Resistance 29. . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Power Supply Resistance 29. . . . . . . . . . . . . . . . . .

Test Barrel Resistance 30. . . . . . . . . . . . . . . . . . . . . . . . .

Pre-orifice Selection Chart 51. . . . . . . . . . . . . . . . . . . .

Technical Data 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Graco Warranty and Disclaimers 54. . . . . . . . . .

Graco Phone Number 54. . . . . . . . . . . . . . . . . . . . . . . .

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

corresponding instructions.

4 308937

Page 5

Introduction

How the PRO AA5500sc Electrostatic

Air-Assisted Spray Gun Operates

(Refer to page 6)

WARNING

INJECTION HAZARD

This is not an air spray gun. To reduce

the risk of an injection injury, read and

follow the Warnings on pages 2 and 3

and throughout the text of this instruction manual.

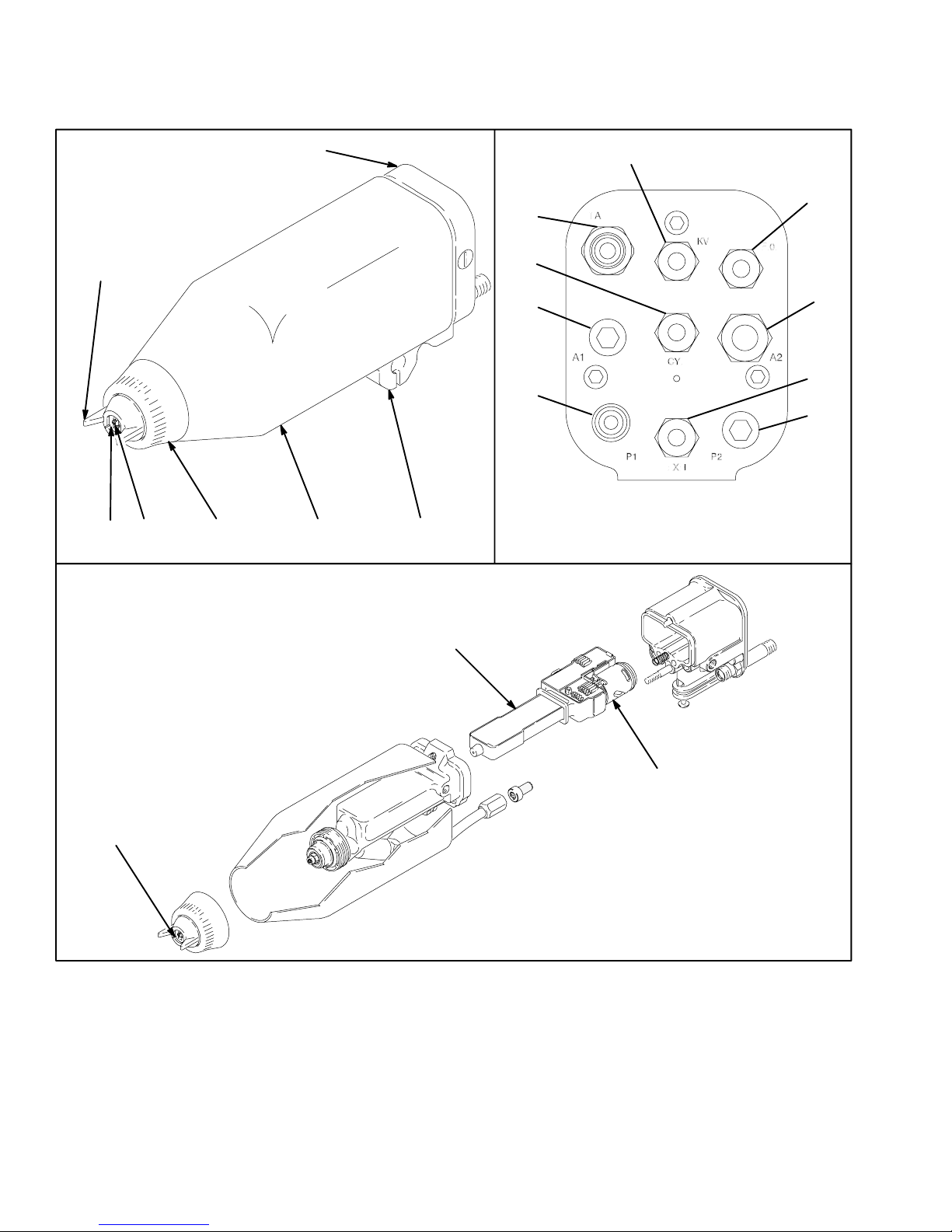

The spray tip (B) shapes the fluid into a fan pattern.

The ability of the PRO AA5500 Electrostatic Spray

Gun to spray at higher fluid pressures combined with

the addition of CO2 from the UNICARB process provides the additional power needed to atomize higher

solids materials.

Operating the Spray Function

Applying a minimum of 65 psi (4.5 bar, 0.45 MPa) air

pressure to the gun manifold’s cylinder air fitting (which

is marked “CYL”, see page 6) will retract the gun

piston, which opens the air valves and a short time

later opens the fluid needle. This provides the proper

air lead and lag when triggering the gun. A spring

returns the piston when the cylinder air is shut off.

The turbine air is exhausted into the shroud (E) and

out the back of the manifold through the fitting marked

“EXH”. The exhaust air helps keep contaminants out

and helps keep the gun clean.

Switching to the Higher or Lower

kV Setting

The gun’s full high voltage setting is 85 kilovolts. The

gun’s spraying voltage can be reduced by switching to

the low voltage setting for spraying in areas where too

much electrostatic wrap is not desirable. Applying a

minimum of 50 psi (3.5 bar, 0.35 MPa) air pressure to

the kV switch air inlet (which is marked “KV”, see page

6) will activate it and switch to the lower voltage

setting. The lower voltage is factory set to 60 kilovolts

at zero microamperes. This setting can be adjusted

from 45 to 80 kilovolts, as instructed on page 40. The

solenoid valve used to activate the kV switch must

bleed the air out of the line for the switch to draw back

to the higher voltage setting.

Gun Features and Options

The gun is designed for use with a reciprocator,

and it can be directly mounted to a one-half inch

rod. With additional brackets, the gun can be

mounted for robotic applications.

The gun is designed for quick-disconnect, which

enables the operator to quickly remove the spray

gun without disconnecting the air lines to the gun.

Operating the Electrostatics

To operate the electrostatics, air pressure is applied to

the gun manifold’s turbine air fitting (which is marked

“TA”, see page 6) through a Graco electrically conductive air hose. The air enters the manifold and is

directed to the inlet of the power supply turbine (H).

The air spins the turbine, which then provides electrical

power to the internal high voltage power supply (V).

The fluid is charged by the spray gun electrode (K).

The charged fluid is attracted to the nearest grounded

object, wrapping around and evenly coating all surfaces.

The gun functions are activated from a separate

controller that sends the appropriate signal to the

actuating solenoids (S). See Fig. 1, page 9.

An optional fiber optic readout system can be

installed to monitor the gun’s spraying voltage. A

fiber optic cable (KK) connected to the gun manifold carries the signal from the gun to a remote ES

(electrostatic) display module. See Fig. 2, page 9.

An ES Display Module (GG), P/N 224117, is available and will display the gun’s spraying voltage and

current. A battery operated ES Display Module

(FF), P/N 189762, is also available; it displays the

gun’s spraying voltage only.

308937 5

Page 6

Introduction

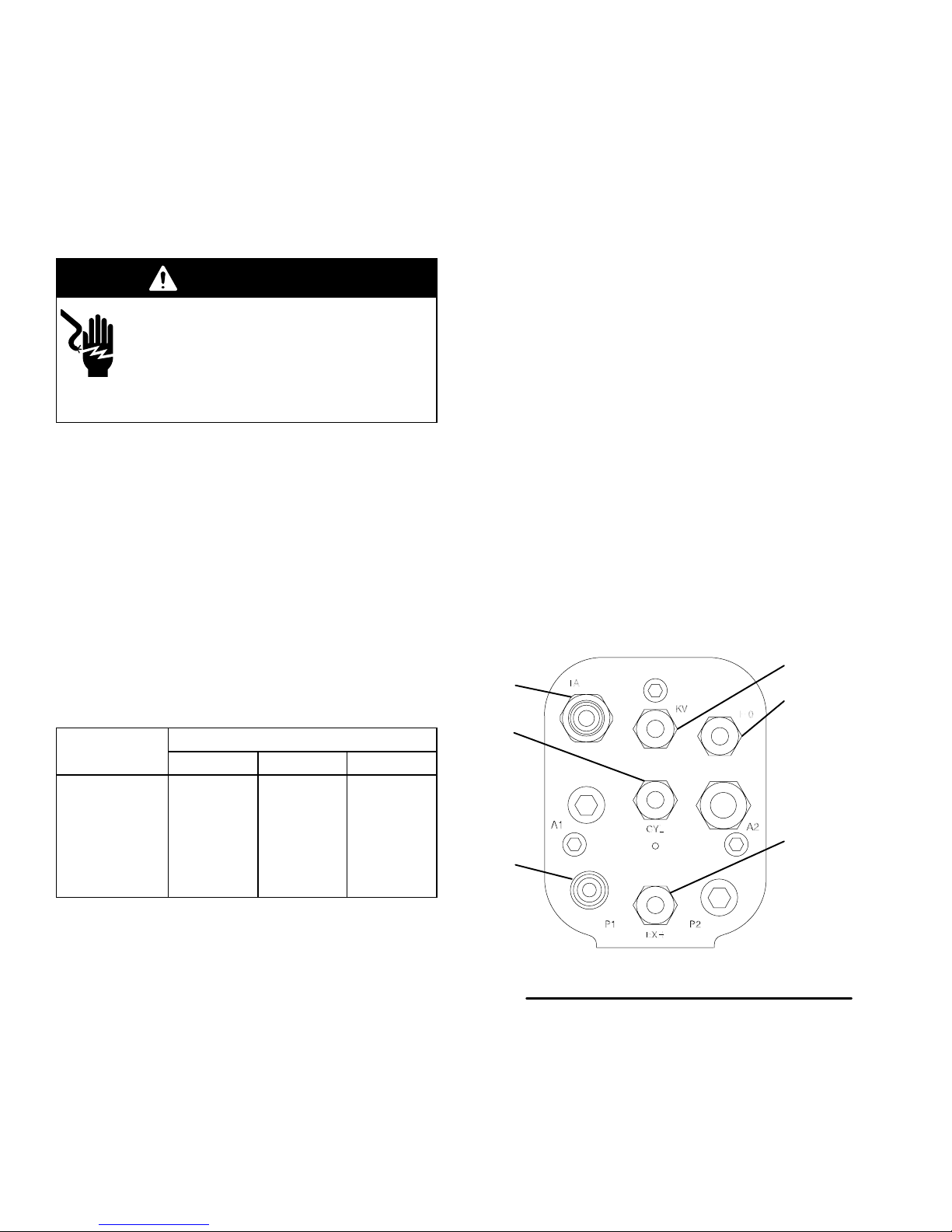

G

C

AB D E F

03228

TA

CYL

A1

P1

KV

F.O.

A2

EXH

P2

Manifold Back View

03616

K

KEY

A Air Cap (black color)

B Spray Tip (orange color)

C Tip Guard (orange color)

D Retaining Nut

E Shroud

F Mounting Bracket

G Manifold

H Turbine

J Power Supply

K Electrode

6 308937

J

H

04799

Manifold Markings

A1 not used

A2 Not used

CYL Cylinder Air Inlet Fitting

EXH Shroud Exhaust Outlet Fitting

F.O. Fiber Optic Fitting

KV kV Switch Air Inlet

P1 Fluid Supply Inlet Fitting

P2 not used

TA Turbine Air Inlet Fitting

Page 7

308937 7

Page 8

Installation

Installing the System

WARNING

FIRE, EXPLOSION, AND

ELECTRIC SHOCK HAZARD

Installing and servicing this equipment

requires access to parts which may

cause electric shock or other serious

injury if work is not performed properly.

Do not install or service this equip-

ment unless you are trained and

qualified.

Be sure your installation complies with National,

State and Local codes for the installation of

electrical apparatus in a Class

Hazardous Location.

Comply with all applicable local, state, and

national fire, electrical, and other safety regulations.

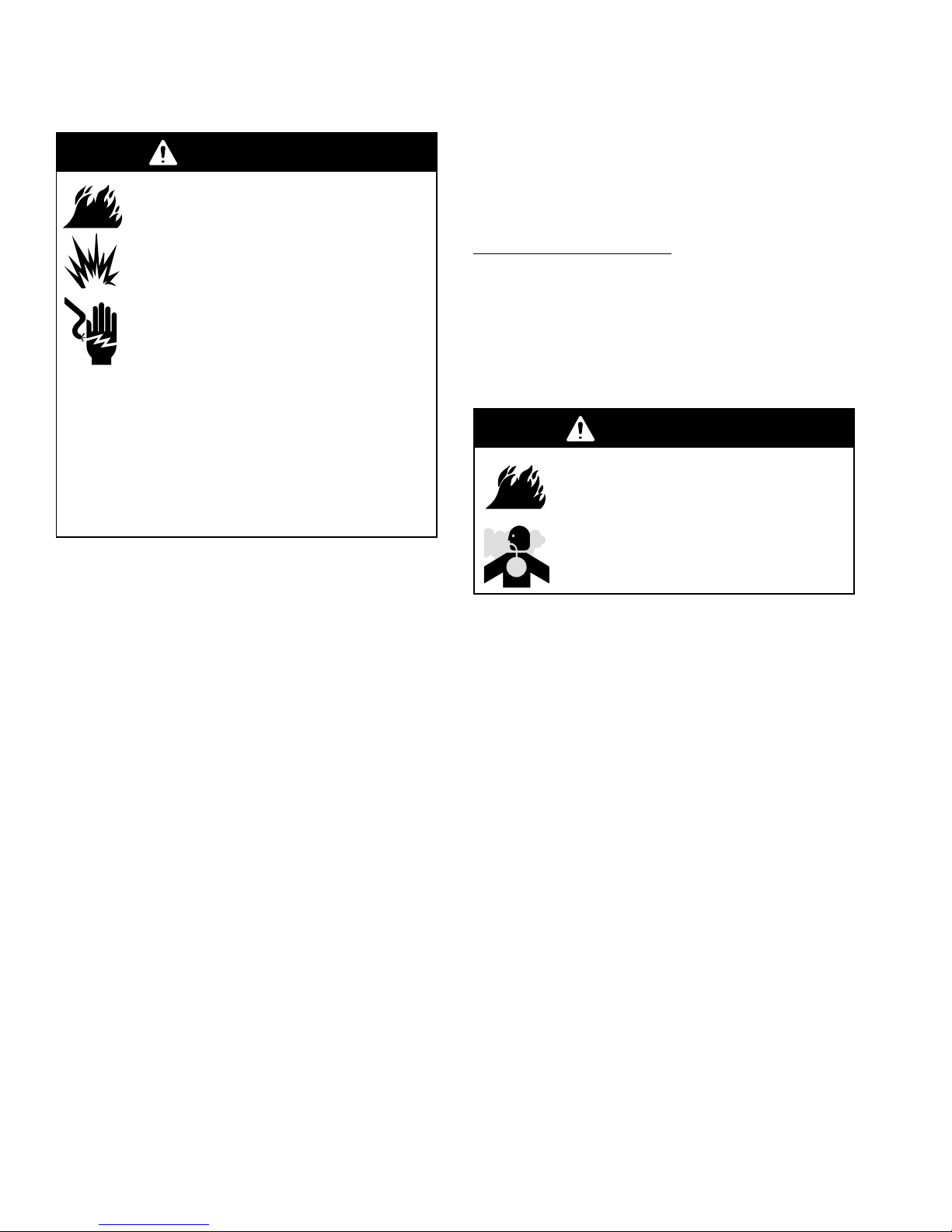

Fig. 1, page 9, shows a typical Model PRO

AA5500sc/UNICARB system. Fig. 2 shows some

possible system options.

Accessories are available from your Graco representative. Refer to the Product Data Sheet for the gun,

Form No. 305624. If you supply your own accessories,

be sure they are adequately sized and pressure rated

for your system.

For assistance in designing a system that is customized for your application, contact your Graco distributor.

I, Group D

Warning Signs

Mount the warning signs in the spray area where they

can easily be seen and read by all operators. An

English Warning Sign is provided with the gun. Additional English, French, German, and Spanish signs are

available at no charge.

Part No. Description

180060 Warning Sign (English)

180061 Warning Sign (French)

180062 Warning Sign (German)

180063 Warning Sign (Spanish)

Ventilate the Spray Booth

WARNING

FLAMMABLE OR TOXIC

VAPOR HAZARD

Provide fresh air ventilation to avoid the

buildup of flammable or toxic vapors. Do

not operate the gun unless ventilation

fans are operating.

Electrically interlock the gun turbine air supply line with

the ventilators to prevent operation of the electrostatic

power supply unless ventilating fans are on.

Check and follow all local, state, and national codes

regarding air exhaust velocity requirements. High

velocity air exhaust will decrease the operating efficiency of the electrostatic system. The minimum

allowable air exhaust velocity is 60 feet/minute (19

linear meters/minute).

8 308937

Page 9

Installation

A*R

Non-Hazardous Area Hazardous Area

BASIC SYSTEM

AA*

X

S

CC

S

Z

BB*

TA

**

KV

**

CYL

**

P1

**

S

U*

Q

H

FLUID IN-P1

K

To FLUID IN-P1 at gun

V

W

V

Fig. 1

DD

EE

FF

From coating/CO2 supply equipment

*M

Non-Hazardous Area Hazardous Area

GG HH

kV

mA

kV

JJ*

KK

Y

SYSTEM OPTIONS

Spraying Voltage

Display Module

X

F.O.

**

Fig. 2

04802

308937 9

Page 10

Installation

KEY–Fig. 1 and 2

A* Bleed-type Master Air Valve

H Fluid Shut-off Valve

K Pressure Gauge

L* Grounded Fluid Hose with spring guards

M* Fluid Drain Valve

Q Gun Air Pressure Regulator

R Main Air Line

S Solenoid Valve, requires quick-exhaust port*

U* True Earth Ground

V Fluid Hose, 1/4–18 npsm gun fluid inlet

W Mounting Bracket for 1/2 inch (127 mm) rod, P/N 189581

X PRO AA5500sc/UNICARB Spray Gun, P/N 965721

Y Shrouded/Vented waste container

Z Cylinder Air Hose, 1/4 inch (6.4 mm) O.D.

AA*Ground Wire on Graco Electrically Conductive Air Hose

BB*Graco Electrically Conductive Air Hose (Turbine Air Hose),

See page 12 for part numbers

CC kV Switch Air Hose, 1/4 inch (6.4 mm) O.D., plug the gun fitting if

it is not used

DD 24 Volt Power Supply, P/N 235301

EE 4–20 mA Outputs

FF kV Only ES Display Module (battery operated), P/N 189762

GG Full Feature ES Display Module, P/N 224117

HH Fiber Optic Cable, P/N 224680 to 224686

JJ Bulkhead, P/N 189870

KK Fiber Optic Cable, P/N 224670 to 224676

The turbine air supply must be interlocked with the spray booth

ventilation fans.

A maximum of two splices with a total of 108 feet (32.94 m) of

cable can be used. For the strongest light signals, use a minimum

number of bulkhead splices.

* Equipment required for safe operation of system. Must be pur-

chased separately.

** See page 12 for a description of the manifold connections.

Install the Air Line Accessories

WARNING

COMPONENT RUPTURE HAZARD

To reduce the risk of serious injury

due to component rupture:

The fluid supply pump must be prevented

from producing a fluid pressure greater than

the 3000 psi (207 bar, 20.7 MPa) Maximum

Working Pressure of the spray gun. For example, the air supply pressure to a 30:1

pump must not exceed 100 psi (7 bar, 0.7

MPa).

Be sure that all spray equipment and acces-

sories added to the spray system are properly rated to withstand the maximum working

pressure of your system.

1. Install a bleed-type master air valve (A) on the

main air supply line (R) to shut off all the air to the

gun. See Fig. 1, page 9.

2. To ensure a dry, clean air supply to the gun, install

an air line filter and an air and water separator on

the air lines. Dirt and moisture can ruin the appearance of your finished workpiece and can cause the

gun to malfunction.

3. Install an air regulator (Q) on each of the air supply

lines (BB, CC, Z) to control the air pressure to the

gun.

WARNING

INJECTION HAZARD

Trapped air can cause the pump to cycle

or the gun to spray unexpectedly, which

could result in a serious injury, including

injecting fluid through the skin. The solenoid valves

(S) must have a quick-exhaust port so trapped air will

be relieved between the valve and the gun when the

solenoids are shut off.

In a UNICARB process system, the compressed

2

CO

in the fluid lines provides fluid pressure even

after the fluid supply has been turned off. To reduce

the risk of injection, always relieve the fluid pressure with a fluid drain valve (M), prior to any servicing or adjustments. The fluid drain line must vent

into a shrouded/vented waste container (Y) or into

a water wash booth to help shield personnel from

fluid atomized by the CO

2

expansion.

10 308937

Page 11

Installation

Fluid Line Accessories

1. Install a fluid filter (N) and drain valve (M) in the

fluid supply. Filtering the fluid will help remove

coarse particles and sediment that could clog the

spray tip.

WARNING

INJECTION HAZARD

The fluid drain valve (M) is required in

your system to help relieve fluid pres-

sure in the fluid supply, hose and gun;

triggering the gun to relieve pressure may not be

sufficient. Install a drain valve close to the fluid

supply. The drain valve reduces the risk of serious

injury, including fluid injection and splashing in the

eyes or on the skin.

2. Install a fluid regulator in the fluid supply system to

control fluid pressure to the gun.

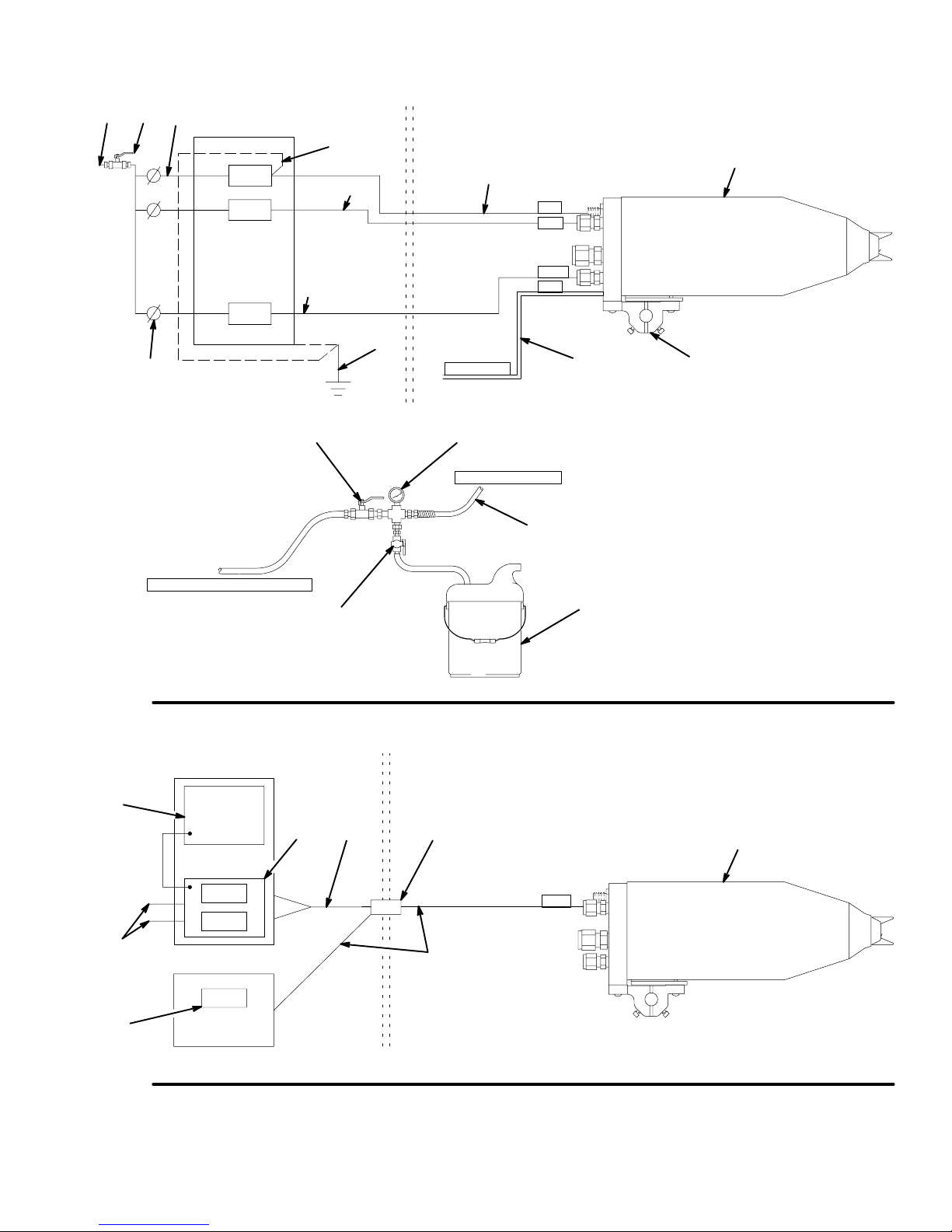

Install the Gun and Mounting Bracket

2.775 in.

(70.5 mm)

PRO AA5500sc Gun

103

0.50 in.

(12.7 mm)

rod

103

Fig. 3

NOTE: For added positioning reliability, the mounting

bracket (MM) has an 1/8 in. (3.2 mm) slot where a

locating pin (NN–not included) can be inserted through

the mounting rod (PP). See Fig. 4.

9.32 in.

(236.7 mm)

03619

NN

MM

1. Loosen the mounting bracket’s two square head

bolts (103) and slide the mounting bracket onto a

0.50 in. (12.7 mm) mounting rod. See Fig. 3.

2. Position the gun and tighten the two bolts (103)

securely.

Fig. 4

PP

03460

308937 11

Page 12

Installation

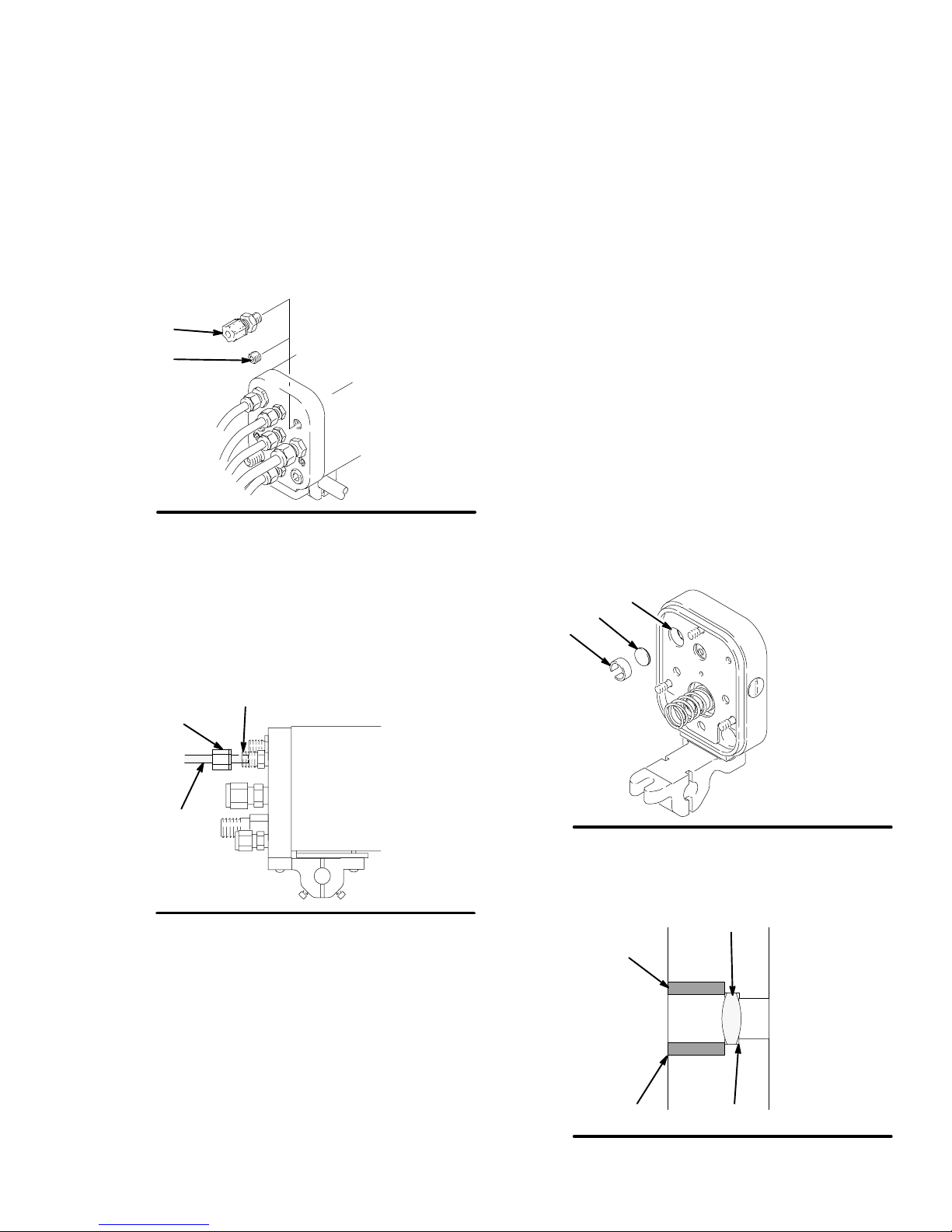

Connect the Air and Fluid Lines

to the Gun Manifold

See Fig. 1 and 2, page 9, for a schematic of air and

fluid connections. Connect the air and fluid lines to the

gun manifold as instructed at right.

Graco Electrically Conductive Air Hose

WARNING

ELECTRIC SHOCK HAZARD

To reduce the risk of electric shock or

other serious injury, the air supply hose

must be electrically connected to a true

earth ground. Use Only Graco Electrically Con-

ductive Air Supply Hose.

Connect the Graco electrically conductive air hose

(BB) to the gun turbine air inlet and connect the hose

ground wire (AA) to a true earth ground. See Fig. 1,

page 9. Check the electrical grounding of the gun as

instructed on page 15.

NOTE: The hose and the gun have special left-hand

threads to prevent connecting another type of air hose

to the gun turbine air inlet.

Graco Electrically Conductive Air Hose

Required for gun operation.

100 psi (7 bar, 0.7 MPa) Maximum Working Pressure

0.315 in. (8 mm) ID; 1/4 npsm(f) x 1/4 npsm(f) left-hand

Part No.

Length Black Hose Grey Hose Red Hose

6 ft. (1.8 m)

15 ft. (4.6 m)

25 ft. (7.6 m)

36 ft. (11.0 m)

50 ft. (15.2 m)

75 ft. (23.0 m)

100 ft. (30. 5 m)

220444

218100

218101

218102

218103

220119

220120

223068

223069

223070

223071

223072

223073

223074

235068

235069

235070

235071

235072

235073

235074

Red Hose: conductive SST wire braid for grounding, polyurethane tube and cover

Fluid Line

Before connecting the fluid line to the gun, blow it out

with air and flush it with solvent. Use solvent that is

compatible with the fluid being sprayed.

Manifold Connections (See Fig. 5)

CYL Cylinder Air Inlet Fitting

Connect a 1/4 inch O.D. tube between this fitting and

the solenoid. For quicker trigger response, use the

shortest hose length possible.

EXH Shroud Exhaust Outlet Fitting

Connect a 1/4 inch O.D. x 4 foot (1.22 m) long tube to

the fitting.

F.O. Fiber Optic Fitting (Optional)

Connect the Graco Fiber Optic Cable as instructed on

page 13.

KV kV Switch Air Inlet Fitting

Connect a 1/4 inch O.D. tube between the fitting and

the air solenoid.

P1 Fluid Supply Inlet Fitting

Connect a 1/4 inch npsm swivel fitting between the

fitting and the fluid supply.

TA Turbine Air Inlet Fitting

Connect the Graco Electrically Conductive Air Hose

between this fitting (left-hand thread) and the solenoid.

Connect the air hose ground wire to a true earth

ground.

KV

TA

F. O.

CYL

EXH

P1

Black Hose: standard hose, semi-conductive nylon core,

urethane outer

Grey Hose: more flexible (less durable) than black hose,

modified semi-conductive polyamide core, urethane cover

12 308937

Fig. 5

Manifold Back View

03616

Page 13

Installation

Optional Fiber Optic Cable Connection

An optional fiber optic fitting (37) is shipped unassembled with the gun. If an ES (kV) display module is

used, install the fitting in the manifold. See Fig. 2, page

9, for a schematic of the fiber optic connections.

1. Remove the 1/8 npt plug (115) from the manifold’s

fiber optic port, and install the black fiber optic

fitting (37). See Fig. 6.

37

115

Fig. 6

2. Remove the nut (QQ) from the fiber optic fitting

(37), and slide the nut over the end of the fiber

optic cable (RR). See Fig. 7.

3. Insert the cable (RR) into the fitting (37), and push

the cable in until it bottoms out. Tighten the nut

(QQ) to secure the cable.

03620

Optional Fiber Optic Lens Kit Installation

NOTE: The fiber optic lens kit is not included with the

gun. Order it separately; the part number is 236852.

1. Remove the gun from the manifold as instructed

on page 31.

2. Make sure the lens (TT) is clean. Push the lens

into the counterbore (VV) in the manifold fiber optic

port (SS). See Fig. 8 and 9.

3. Press the lens retainer (UU) into the manifold fiber

optic port (SS) until it is flush with the manifold

surface.

4. Assemble the gun to the manifold as instructed on

page 43.

SS

TT

UU

37

QQ

RR

Fig. 7

4. If you have two bulkhead splices in your system, it

is recommended that you install the fiber optic lens

kit, as described at right.

NOTE: Most of the fiber optic light transmission loss

occurs at the bulkhead splices. For the strongest light

signals, use a minimum number of bulkhead splices. A

maximum of two splices, with a total of 108 feet (32.94

m) of cable, is recommended.

5. See manual 308265 to install a Graco ES Display

Module.

03509A

Fig. 8

Fig. 9

UU

TT

VVSS

04798

04485

308937 13

Page 14

Installation

Ground the System

WARNING

FIRE, EXPLOSION, AND

ELECTRIC SHOCK HAZARD

When operating the electrostatic gun,

any ungrounded objects in the spray

area (such as people, containers, tools,

etc.) can become electrically charged.

Improper grounding can result in static

sparking, which can cause a fire, explosion, or electric shock. Follow the

grounding instructions below.

The following grounding instructions are minimum

requirements for a basic electrostatic system. Your

system may include other equipment or objects which

must be grounded. Check your local electrical code for

detailed grounding instructions. Your system must be

connected to a true earth ground.

1. Pump: ground the pump by connecting a ground

wire and clamp as described in your separate

pump instruction manual.

3. Electrostatic Air Spray Gun: ground the gun by

connecting the Graco Electrically Conductive Air

Hose to the turbine air inlet and connecting the air

hose ground wire to a true earth ground. Check

the electrical grounding of the gun as instructed on

page 15.

4. All air and fluid lines must be properly grounded.

5. All electric cables must be properly grounded.

6. All persons entering the spray area: their shoes

must have conductive soles, such as leather, or

personal grounding straps must be worn. Rubber

or plastic soles are not conductive.

7. Object being sprayed: keep the workpiece hangers

clean and grounded at all times. Contact points

must be sharp points or knife edges.

8. The floor of the spray area: must be electrically

conductive and grounded. Do not cover the floor

with cardboard or any non-conductive material

which would interrupt grounding continuity.

9. Flammable liquids in the spray area: must be kept

in approved, grounded containers. Do not store

more than the quantity needed for one shift.

2. Air compressors and hydraulic power supplies:

ground the equipment according to the manufacturer’s recommendations.

10. All electrically conductive objects or devices in the

spray area: including fluid containers and wash

cans, must be properly grounded.

14 308937

Page 15

Installation

1

Check the Electrical Grounding (See Fig. 10)

WARNING

FIRE, EXPLOSION, AND

ELECTRIC SHOCK HAZARD

Megohmmeter P/N 218979 (WW-see

Fig. 10) is not approved for use in a

hazardous area. To reduce the risk of

sparking, do not use the megohmmeter

to check electrical grounding unless:

The gun has been removed from the

hazardous area;

Or all spraying devices in the hazardous area

are turned off, ventilation fans in the hazardous

area are operating, and there are no flammable

vapors in the area (such as open solvent containers or fumes from spraying).

Failure to follow this warning could cause fire,

explosion, electric shock and result in serious injury

and property damage.

a. If using a black or grey turbine air hose, use a

megohmmeter (WW) to measure the

resistance. Use an applied voltage of 500

minimum to 1000 volts maximum. Resistance

should not exceed 2 megohms.

b. If you are using a red turbine air hose, use an

ohmmeter to measure the resistance.

Resistance should not exceed 100 ohms.

5. If the resistance is greater than the maximum

reading specified above for your hose, check the

tightness of the ground connections and be sure

the turbine air hose ground wire is connected to a

true earth ground. If the resistance is still too high,

replace the turbine air hose.

N

WW

1. Have a qualified electrician check the electrical

grounding continuity of the spray gun and turbine

air hose.

2. Make sure the turbine air hose (B) is connected

and the hose ground wire is connected to a true

earth ground.

3. The air and fluid supplies to the gun must be

turned off, and the fluid hose must not have any

fluid in it when checking the continuity.

4. Measure the resistance between the turbine air

inlet fitting (TA) and a true earth ground (N).

Fig. 10

TA

B

0362

308937 15

Page 16

Installation

Install the Fabric Cover

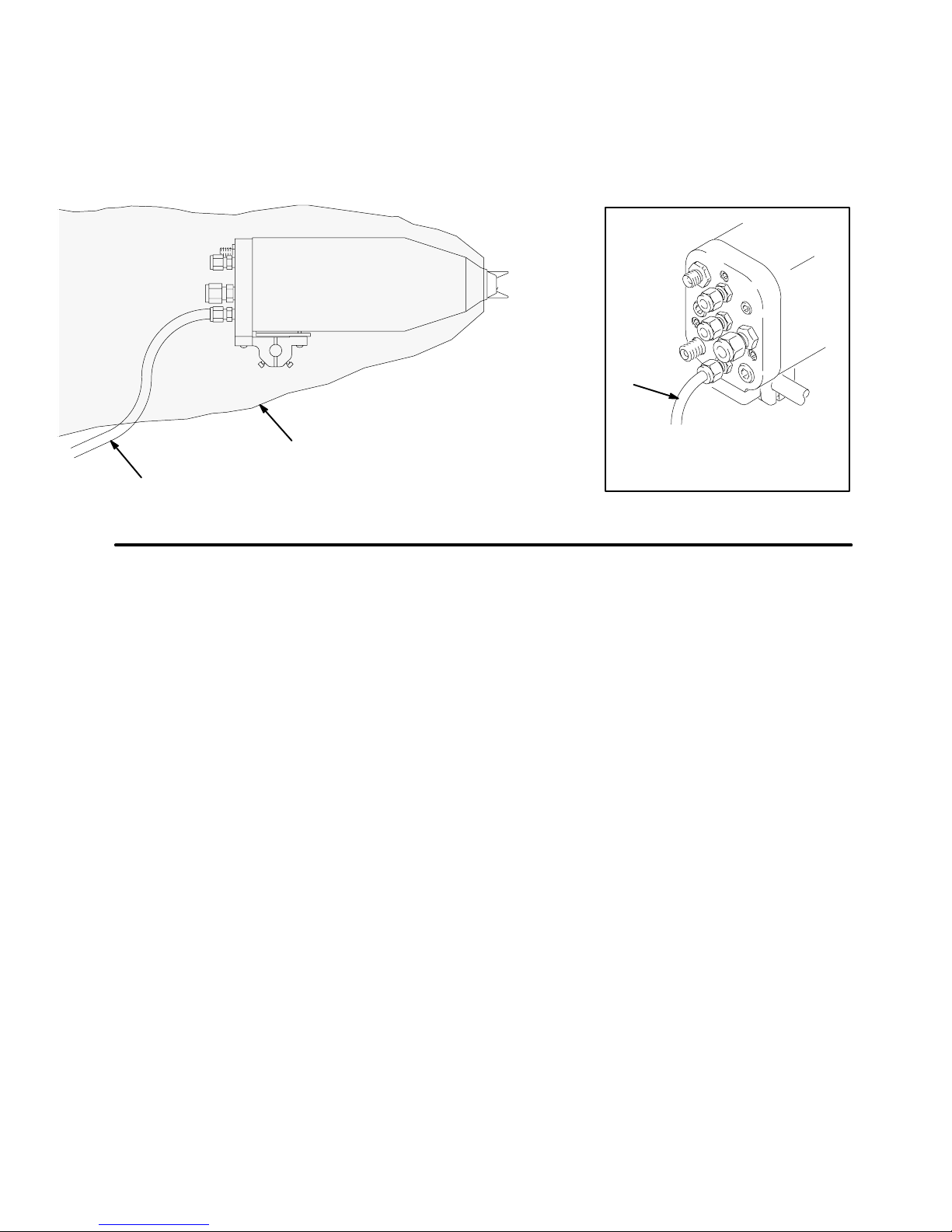

1. Install a fabric cover (XX) over the front of the gun

and slide it back to cover the exposed tubing and

hoses at the back of the manifold. See Fig. 11.

XX

YY

Fig. 11

2. Route the exhaust tube (YY) outside the cover.

This enables you to monitor the exhaust tube for

the presence of any paint or solvent. See Check

for Fluid Leakage on page 25. Strap down the

exhaust tube to prevent it from moving around.

YY

Manifold Back View

03623

03622

16 308937

Page 17

Operation

Pressure Relief Procedure

WARNING

INJECTION HAZARD

The system pressure must be manually

relieved to prevent the system from

starting or spraying accidentally. Fluid

under high pressure can be injected through the

skin and cause serious injury. To reduce the risk of

an injury from injection, splashing fluid, or electric

shock, follow the Pressure Relief Procedure

whenever you:

are instructed to relieve the pressure,

stop spraying,

check or service any of the system equipment,

or install or clean the spray tip.

1. Turn off all the air to the spray gun except the

cylinder air, which triggers the gun.

2. Turn off the fluid supply to the gun.

3. Trigger the gun into a grounded, shrouded and

vented metal waste container to relieve fluid

pressure. This may take several minutes.

4. Open the fluid supply drain valve (required in

system) to help relieve fluid pressure. In addition,

open the drain valve connected to the fluid pressure gauge (in a system with fluid regulation) to

help relieve fluid pressure in the hose and gun.

Triggering the gun to relieve pressure may not be

sufficient. Have a container ready to catch the

drainage.

5. Leave the pump drain valve open until you are

ready to spray again.

6. Turn off the main air supply by closing the bleedtype master air valve on the main air supply line.

Leave the valve closed until you are ready to spray

again.

7. If you suspect that the spray tip or hose is completely clogged or that pressure has not been fully

relieved after following the steps above, very

slowly loosen the hose end coupling and relieve

pressure gradually, then loosen completely. Now

clear the tip or hose obstruction.

Operating Checklist

WARNING

INJECTION HAZARD

The wallet sized warning card 179960,

provided with the gun, should be avail-

able and easily accessible at all times for

anyone operating or servicing this equipment. The

card contains important information on what to do if

a fluid injection injury occurs. Additional cards are

available at no charge from Graco.

Check the following list daily, before starting to operate

the system, to help ensure safe, efficient operation.

____ 1. All the operators are properly trained to

safely operate an automatic electrostatic

air-assisted spray system as instructed in

this manual.

____ 2. All the operators are trained how to properly

relieve pressure, using the Pressure Relief

Procedure at left.

____ 3. Anyone operating or servicing this equipment

has access to the wallet-sized warning card

provided with the gun.

____ 4. The warning sign provided with the gun is

mounted in the spray area where it can be

easily seen and read by all operators.

____ 5. The system is thoroughly grounded and the

operator and all persons entering the spray

area are properly grounded. See Ground

the System, page 14.

____ 6. The condition of the electrical components of

the spray gun has been checked as

instructed in Electrical Tests, page 29.

____ 7. The ventilation fans are operating properly.

____ 8. The workpiece hangers are clean and

grounded. Contact points must be sharp

points or like knife edges.

____ 9. All the debris, including flammable liquids

and rags, is removed from the spray area.

____ 10. All flammable liquids in the spray booth are

in approved, grounded containers.

____ 11. All conductive objects in the spray area are

electrically grounded and the floor of the

spray area is electrically conductive and

grounded.

____ 12. The manifold exhaust tubes have been

checked for the presence of any fluid as

instructed in Check for Fluid Leakage, page

25.

308937 17

Page 18

Operation

Selecting a Spray Tip

The fluid output and pattern width depend on the size

of the spray tip, the fluid viscosity, and the fluid pressure. Use the Spray Tip Selection Chart on page 51,

as a guide for selecting an appropriate spray tip for

your application or consult your authorized Graco

distributor. The orifice size of the spray tip is typically

one or two sizes larger than the pre-orifice size

selected below.

Selecting a Pre-Orifice

The fluid flow rate in UNICARB systems is controlled

by the pre-orifice size, in conjuction with the fluid

pressure. Use the pre-orifice selection chart on page

49 as a guide for selection.

Installing the Pre-Orifice

WARNING

To reduce the risk of a serious injury, including fluid

injection, follow the Pressure Relief Procedure on

page 17 when you stop spraying and whenever you

are instructed to relieve the pressure.

3. Place the pre-orifice (13b), with its larger hole

facing up, on top of the tip seal (13a) hole.

4. Use a large, flat object to press the pre-orifice

(13b) into the tip seal (13a), as shown in Fig. 12.

PRESS DOWN

with a large, flat

object

13b

13a

Fig. 12

5. Turn over the tip seal and pre-orifice (13a, 13b)

and insert them into the spray tip (13), wih the

pre-orifice side facing down into the spray tip. See

Fig. 13.

13a, 13b

8799A

1. Place the spray tip seal (13a) on a flat surface.

See Fig. 12.

2. Note that the hole through the pre-orifice (13b) is

larger on one side than the other.

Fig. 13

13

8799A

18 308937

Page 19

Operation

Installing the Spray Tip

WARNING

To reduce the risk of a serious injury, including fluid

injection, follow the Pressure Relief Procedure on

page 17 when you stop spraying and whenever you

are instructed to relieve the pressure.

1. Make sure there is no pressure in the system

before removing or installing a spray tip. Relieve

the system pressure.

2. Place the spray tip (13) in the air cap (15), aligning

the tab of the tip with the groove in the air cap.

See Fig. 14. Be careful not to bend the electrode

wire (15a).

15

3. Install the spray tip (13) and air cap (15), tip guard

(12), shroud (2), and retaining nut (1) onto the gun;

tighten the retaining nut firmly. See Fig. 15.

WARNING

FIRE, EXPLOSION, AND

ELECTRIC SHOCK HAZARD

To reduce the risk of fire, explosion, and

electric shock, never operate the spray

gun with a bent, damaged or missing

electrode (15a).

2

13, 15

12

1

15a

Fig. 14

13

8800A

Fig. 15

8802A

308937 19

Page 20

Operation

6

Setting the Atomization Fluid Pressure

Atomization fluid pressure will vary based on the type

of fluid used, the flow rate desired, the fluid temperature, and the percentage of CO

recommendations of your material and equipment

supplier.

2

used. Follow the

Activating and Adjusting the

Electrostatics

1. Turn on the turbine air (TA). Refer to Fig. 16.

2. The turbine air pressure should be adjusted to 30

psi (2.1 bar, 0.21 MPa) at the gun manifold inlet

when air is flowing. Do not exceed 40 psi (2.8 bar,

0.28 MPa) air pressure as there is no added

benefit and turbine life could be reduced.

Use the chart below to set the proper pressure at

the turbine hose inlet. Do not exceed these recommended pressures or turbine life will be reduced.

Turbine Air

Hose Length

ft. (m)

15 (4.6) 36 (2.5, 0.25)

25 (7.6) 38 (2.7, 0.27)

50 (15.3) 40 (2.8, 0.28)

75 (22.9) 42 (2.9, 0.29)

100 (30.5) 45 (3.1 , 0.31)

3. Check the voltage output of the gun using a high

voltage probe and meter or by reading the ES (kV)

Display Module.

NOTE: The gun’s normal high voltage reading is 60 to

70 kV. If a ball end high voltage measurement probe is

used, the gun voltage will rise to about 85 kV. This will

happen with all resistive electrostatic guns.

Dynamic pressure at the turbine

hose inlet required for full voltage

psi (bar, MPa)

The solenoid valve used to activate the kV switch must

bleed the air out of the line for the switch to draw back

to the higher voltage setting.

KV

TA

CYL

Manifold Back View

Fig. 16

0361

Spraying

WARNING

ELECTRIC SHOCK HAZARD

To reduce the risk of an electric shock,

do not touch the gun electrode or come

within 4 inches (101.6 mm) of the nozzle

during gun operation.

1. Apply a minimum of 65 psi (4.5 bar, 0.45 MPa) air

pressure to the cylinder air fitting (CYL) to activate

the on/off sequence of atomization air (A2) and

fluid (P1). Refer to Fig. 16.

2. Turn the gun functions off and on by using the air

solenoid valves on the cylinder (CYL) and turbine

(TA) air supply lines.

See Electrical Troubleshooting on page 28 to correct voltage problems.

Activating the kV Switch

Apply a minimum of 50 psi (3.5 bar, 0.35 MPa) air

pressure to the kV switch air fitting (KV) to activate it

and switch to the lower voltage setting. The lower

voltage setting is factory set to 60 kilovolts at zero

microamperes. To change this setting, see page 40.

20 308937

WARNING

FIRE AND EXPLOSION HAZARD

If any fluid leakage from the gun is detected, stop spraying immediately!

Fluid leakage into the gun shroud could

cause fire or explosion and result in

serious injury and property damage. See

Check for Fluid Leakage, page 25.

Page 21

Operation

Shutdown

WARNING

INJECTION HAZARD

To reduce the risk of a serious injury,

including fluid injection, follow the Pres-

sure Relief Procedure on page 17

when you stop spraying and whenever you are

instructed to relieve the pressure.

Maintenance

Daily Care and Cleaning

Clean all parts with a non-conductive solvent, com-

patible with the fluid being sprayed. Conductive solvents can cause the gun to malfunction.

Methylene chloride is not recommended as a

flushing or cleaning solvent with this gun as it will

damage nylon components.

Fluid in the air passages could cause the gun to

malfunction and could draw current and reduce

the electrostatic effect. Fluid in the power supply

cavity can reduce the alternator life. Whenever

possible, point the gun down while cleaning it. Do

not use any cleaning method which could allow

fluid into the gun air passages.

Do not point the gun up while cleaning it.

1. Relieve the system pressure.

2. Flush and clean the equipment. Follow the instructions in the Maintenance section, pages 21 to 25.

CAUTION

Do not immerse the gun in fluid.

03232

Do not wipe the gun with a cloth that is

heavily saturated; wring out the excess fluid.

03231

02027

308937 21

Page 22

Maintenance

Daily Care and Cleaning (continued)

WARNING

INJECTION HAZARD

To reduce the risk of a serious injury,

including fluid injection, follow the Pres-

sure Relief Procedure on page 17

before doing any maintenance on the gun or system.

Clean the fluid and air line filters daily.

Clean the outside of the gun daily with a soft cloth

dampened in a compatible solvent.

Clean the air cap, spray tip, and tip guard daily,

minimum. Some applications require more frequent

cleaning. See Clean the Spray Gun, page 23.

Replace the parts if they are damaged.

Flush the Spray Gun

WARNING

INJECTION HAZARD

To reduce the risk of a serious injury,

including fluid injection, follow the Pres-

sure Relief Procedure on page 17

when you stop spraying and whenever you are

instructed to relieve the pressure.

1. Relieve the system pressure.

2. Make sure the turbine air (TA) is turned off.

3. Remove the retaining nut (1), tip guard (12), air

cap (15), fluid tip (13), and gun shroud (2). See

Fig. 17. Set these parts aside.

NOTE: You may have to turn the air cap with the

tip guard to remove the air cap from the gun.

4. Make sure the air and paint supply is turned off.

Check the electrode wire: straighten it if it is bent

and replace it if it is broken or damaged. See

Electrode Replacement, page 34.

Check for fluid leakage from the gun and fluid

hoses. See Check for Fluid Leakage, page 25.

Tighten fittings or replace equipment as needed.

Check all of the work hangers for fluid buildup;

clean them if necessary.

Flush the gun before changing colors and when-

ever you are done operating the gun.

WARNING

FIRE, EXPLOSION, AND

ELECTRIC SHOCK HAZARD

To reduce the risk of a fire, explosion, or

electric shock, be sure the turbine air

(TA) is off before flushing the gun or any

part of the system.

22 308937

5. Turn on the solvent supply. Use the lowest possible fluid pressure when flushing.

6. Turn on the cylinder air to trigger the gun.

7. Flush the gun, spraying into a grounded metal

container until there are no traces of paint in the

solvent.

8. Turn off the solvent supply.

9. Relieve the system pressure.

2

8798A

13

15

12

1

Fig. 17

Page 23

Maintenance

Clean the Spray Gun

Equipment needed:

Soft bristle brush

Solvent compatible with fluid being sprayed

WARNING

INJECTION HAZARD

To reduce the risk of a serious injury,

including fluid injection, follow the Pres-

sure Relief Procedure on page 17

when you stop spraying and whenever you are

instructed to relieve the pressure.

Procedure:

1. Relieve the system pressure.

2. Dip the end of a soft-bristle brush into a compatible

solvent. Clean the front of the gun with the brush

and solvent. See Fig. 18. Avoid getting any fluid

into the air passages. Whenever possible, point

the gun down while cleaning it.

3. Dampen a soft cloth with solvent and wring out the

excess fluid. Wipe the exterior of the gun and

shroud clean. See Fig. 19.

Fig. 19

4. Remove the bottom fluid tube fitting (P) and filter

(4). See Fig. 20. Clean the filter in a compatible

solvent.

03235

NOTE: If it appears that there is paint inside the air

passages, remove the gun from the line for servicing.

02007

Fig. 18

03233

5. Reinstall the filter (4) and fitting (P). Do not overtighten the fitting (P) and make sure the top fluid

tube fitting (Q) remains tightened.

4

Q

Fig. 20

P

03234

308937 23

Page 24

Clean the Spray Gun

(continued)

Maintenance

WARNING

6. Clean the retaining nut, tip guard, air cap and fluid

tip with a soft brush daily, minimum. See Fig. 21.

Replace the parts if they are damaged. Be careful

not to bend, damage, or disengage the electrode

wire.

FIRE, EXPLOSION, AND

ELECTRIC SHOCK HAZARD

To reduce the risk of fire, explosion, and

electric shock, never operate the spray

gun with a bent, damaged or missing

electrode (15a).

9. Place the spray tip (13) in the air cap (15). Align

the tab of the tip with the groove in the air cap.

See Fig. 22. Be careful not to bend the electrode

wire (15a).

15

15a

13

Fig. 22

8800A

Fig. 21

03236

CAUTION

Do not use metal tools to

clean the air cap or spray tip

holes as this could scratch

them, and make sure the

electrode wire is not damaged. Scratches in the air

cap or spray tip or a damaged electrode wire can distort the spray pattern.

02001

7. Wipe off the parts with a dry cloth. Be careful not

to bend the electrode wire.

8. Check the electrode wire. Replace it if it is bent or

damaged. See page 34.

10. Install the spray tip (13) and air cap (15), tip guard

(12), shroud (2), and retaining nut (1). Tighten the

retaining nut firmly. See Fig. 23.

11. Test the gun resistance as instructed on page 29.

2

1

8802A

13,15

12

Fig. 23

24 308937

Page 25

Maintenance

Check for Fluid Leakage (See Fig. 24)

WARNING

FIRE AND EXPLOSION HAZARD

If any fluid leakage from the gun is detected, stop spraying immediately!

Fluid leakage into the gun shroud could

cause fire or explosion and result in

serious injury and property damage.

WARNING

INJECTION HAZARD

To reduce the risk of a serious injury,

including fluid injection, follow the Pres-

sure Relief Procedure on page 17

when you stop spraying and whenever you are

instructed to relieve the pressure.

During operation, periodically check the manifold

exhaust tube (YY) and both ends of the gun shroud

(ZZ) for the presence of fluid. Fluid in these areas

would indicate fluid leakage into the shroud, which

could be caused by leaks at the fluid tube connections

or fluid packing leakage.

If fluid is seen in any of these areas, stop spraying

immediately! Relieve the system pressure, then

remove the gun for repair.

Fig. 24

YY

ZZ

Check for signs of fluid leakage

where indicated by arrows.

ZZ

YY

Manifold Back View

03623

03622

308937 25

Page 26

Troubleshooting

WARNING

ELECTRIC SHOCK HAZARD

Installing and servicing this equipment

requires access to parts which may

cause an electric shock or other serious

injury if the work is not performed prop-

erly. Do not install or service this equipment unless

before doing any maintenance or service on the

gun or system.

WARNING

INJECTION HAZARD

To reduce the risk of a serious injury,

including fluid injection, follow the Pres-

sure Relief Procedure on page 17

you are trained and qualified.

NOTE: Check all possible remedies in the Troubleshooting Charts before disassembling the gun.

Spray Pattern Troubleshooting

NOTE: Some spray pattern problems are caused by the improper balance between air and fluid.

PROBLEM:

IMPROPER SPRAY

PATTERN

Fluttering or spitting spray The fluid pressure or fluid supply is insuf-

CAUSE SOLUTION

Adjust the flluid/CO2 supply system.

ficient.

There is air in the fluid supply line.

The CO

too high.

The fluid temperature is fluctuating.

2

percentage is fluctuating or is

Check; tighten the siphon hose connections;

bleed the air from the fluid line.

Check fluid/CO

Check temperature control system

2

supply system.

Irregular pattern There is fluid buildup on the spray tip or

the spray tip or pre-orifice is partially

plugged.

The spray tip or pre-orifice is damaged or

worn.

Tails in pattern The CO2 percentage is too low.

The fluid pressure is too low.

The temperature is too low

Excessive paint buildup on the

air cap and tip guard

The fluid pressure is too low. Increase the fluid pressure with the gun fluid

* Use the least fluid pressure needed for good results.

Clean the spray tip and pre-orifice; see

page 23.

Replace the damaged or worn part; see

page 33.

Increase the CO2 percentage.

Increase the fluid pressure with the gun fluid

regulator.*

Increase fluid temperature.

regulator.*

26 308937

Page 27

Troubleshooting

Gun Operation Troubleshooting

PROBLEM CAUSE SOLUTION

Leakage from fluid needle area Fluid needle packings loose

Fluid needle packing damaged

Air leakage from front of gun Piston air valve not seating properly Clean, Service; See page 36

Fluid leakage from front of gun Fluid needle worn

Fluid seat loose or worn

Spray tip loose

Tip seal damaged

“Orange Peel” finish CO2 percentage is too low

Fluid pressure too low

Spray tip or pre-orifice too large

Fluid poorly mixed or filtered

Improper thinner being used

Excessive spray fog Fluid thinned too much Properly thin fluid

No fluid sprays from gun Fluid supply low

Cylinder air pressure too low

Tighten packing nut; See page 39

Replace fluid needle; See page 39

Replace fluid needle; See page 39

Tighten or replace fluid seat

Tighten retaining nut

Replace tip seal; See page 33

Increase CO2 percentage

Increase fluid pressure with gun fluid regulator*

Use a smaller size spray tip or pre-orifice;

See page 51

Remix or refilter fluid

Use proper thinner

Check; Add fluid if necessary

Increase cylinder air pressure; 65 psi (4.5

bar, 0.45 MPa) minimum required

Spray tip or pre-orifice is dirty or clogged

Spray tip damaged

Actuator arm not adjusted properly

Piston sticking

Fluid needle damaged

Equipment covered with fluid Booth exhaust air flow too low or not

directed properly

Improper distance between gun and

workpiece

Gun shroud loose or o-ring (9) missing

Paint build-up on air cap CO2 percentage too high

Air cap dirty

Fluid doesn’t shut off properly Seat housing over-tightened

Fluid leakage buildup on fluid needle

Fluid packings too tight

Piston sticking

Air leakage from manifold Manifold not tight

Clean spray tip and pre-orifice; See page 23

Check; Replace spray tip; See page 33

Adjust the actuator arm; See page 36

Service piston o-rings; See page 36

Replace fluid needle; See page 39

Check for proper CFM; Check baffles and

direction of air flow

Adjust spraying distance to 8 to 12 inches

(203 to 305 mm)

Tighten retaining nut (1); Check o-ring (9);

See page 44

Reduce CO2 percentage

Clean air cap; See page 23

Replace seat housing; See page 33

Replace fluid needle; See page 39

Adjust fluid packings; See page 39

Service piston o-rings; See page 36

Tighten manifold screws; See page 43

* Use the least fluid pressure needed for good results.

Worn or missing o-rings

Inspect or replace o-rings (items 5 and 118);

see pages 44 and 46

308937 27

Page 28

Troubleshooting

Electrical Troubleshooting

PROBLEM CAUSE SOLUTION

Reduced fluid efficiency Improper distance between gun and

work-piece

Parts poorly grounded

High booth exhaust velocity

Fluid pressure too high

Improper fluid viscosity

Fluid resistivity too low

No or low voltage output

Turbine alternator not operating

Faulty gun resistance

Fluid leaks from needle packing and

causes short

Faulty turbine alternator

kV switch stuck on low

Operator gets shock Operator not properly grounded or is

near an ungrounded object

Adjust spraying distance to 8 to 12 inches

(203 to 305 mm)

Clean hangers; Check for proper ground on

conveyer or track

Reduce exhaust velocity within code limits

Reduce fluid pressure at fluid supply

Check supplier for proper fluid for electrostatic spray

Check fluid resistivity with paint meter and

probe

Check possible causes listed below

Check air supply to turbine inlet; See page 20

Check gun resistance; See page 29

Clean needle cavity; Replace fluid needle;

See page 39

Be sure plug is in place on back of turbine

alternator housing; Remove and test turbine

alternator; See page 41

Check switch actuation; replace if needed

Be sure floor is properly grounded; Wear

shoes with conductive soles or wear personal

grounding straps; Be sure operator is not in

contact with or carrying any metallic items

which could build up electrical charge

See Check the Electrical Grounding,

page 15

ground on conveyor or track

Check cables and connections; replace if

damaged

See other causes under Problem –

Reduced fluid efficiency, above

Operator gets shock when

touching workpiece

No or low voltage output reading

on gun display module

Gun not properly grounded

Workpiece not properly grounded. Clean workpiece hangers; Check for proper

Damaged fiber optic cable or

connection

NOTE: If using an ES Display Module, see its instruction manual, No. 308265, for further troubleshooting.

28 308937

Page 29

Electrical Tests

The performance and safety of the spray gun are

directly affected by the condition of the electrical

components contained inside the gun. The electrical

tests below can be used to determine the condition of

the power supply (27) and the barrel resistor cartridge

as well as the continuity of the electrical path between

the components.

CAUTION

The barrel resistor cartridge is part of the barrel and

is not replaceable. Refer to page 33. To avoid

destroying the gun barrel, do not attempt to remove

the barrel resistor cartridge.

Flush the gun fluid passages with solvent and air. To

get an accurate reading, the fluid hose must not have

any fluid in it.

Use megohmmeter P/N 218979 (L) and an applied

voltage of 500 volts to complete these electrical tests.

Connect the leads as shown.

test. If the resistance is correct, resume spraying or

refer to Electrical Troubleshooting on page 28 for

other possible causes of poor performance, or contact

the nearest authorized service agency.

Test Power Supply Resistance (See Fig. 26)

Remove the power supply (27) from the gun body (29)

as instructed on page 40.

Measure the resistance from the power supply’s

ground contact point (R) to the contact inside of the

power supply seal (27d) [the conductive rubber contact

may be slightly recessed into the seal].

The resistance should be 297 to 363 megohms. If the

resistance is outside the specified range, the power

supply is defective and must be replaced. If the resistance of the power supply is correct, proceed to the

next test.

NOTE: Be sure the seal (27d) is in place on the end of

the power supply before installing the power supply

back into the gun.

WARNING

FIRE, EXPLOSION, AND

ELECTRIC SHOCK HAZARD

Megohmmeter P/N 218979 is not ap-

proved for use in a hazardous area. To

reduce the risk of sparking, do not use

the megohmmeter to do electrical tests

unless:

The gun has been removed from the

hazardous area (see page 31 to remove gun);

Or all spraying devices in the hazardous area

are turned off, ventilation fans in the hazardous

area are operating, and there are no flammable

vapors in the area (such as open solvent containers or fumes from spraying).

Failure to follow this warning could cause fire,

explosion, electric shock and result in serious injury

and property damage.

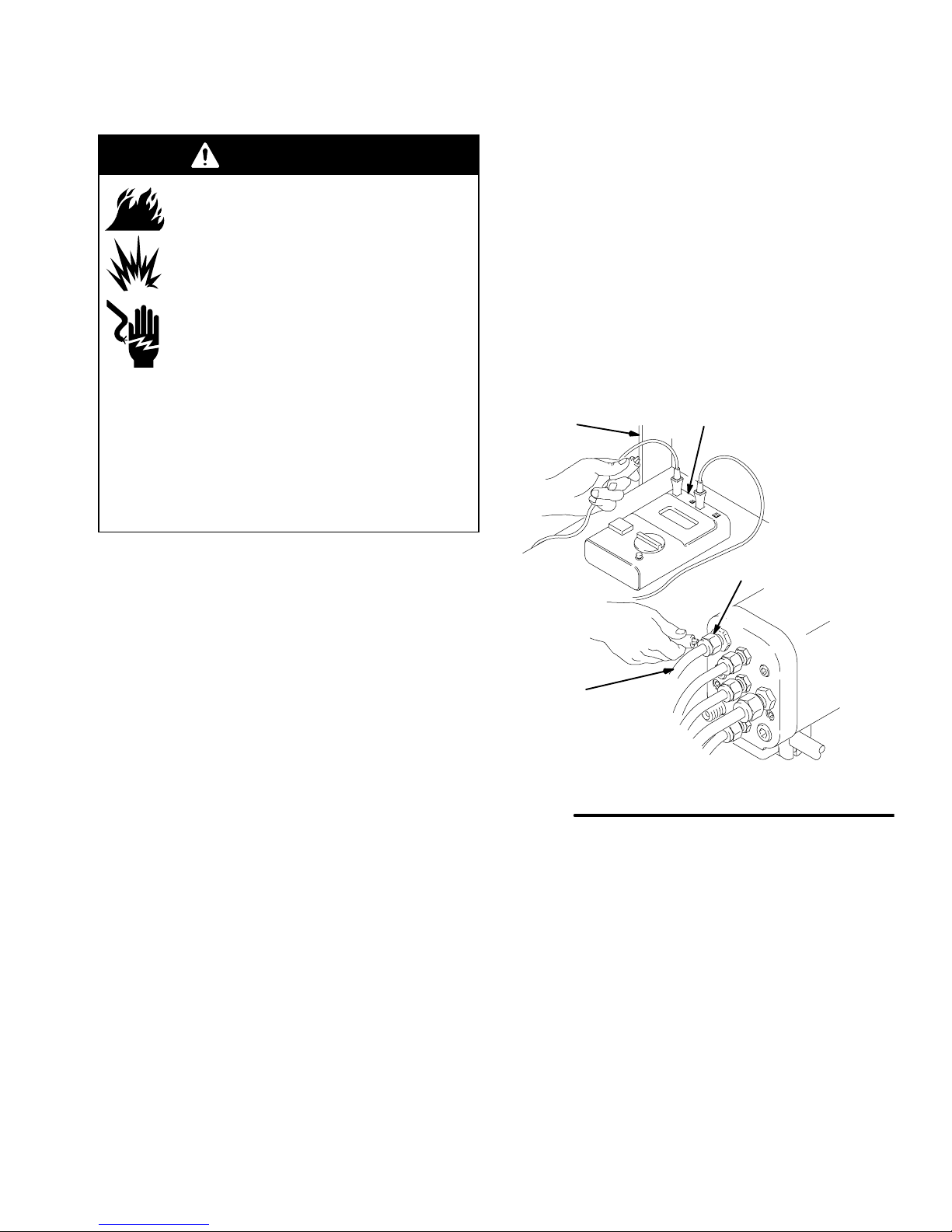

Test Gun Resistance (See Fig. 25)

L

29

15a

03624

Fig. 25

Install the spray tip, air cap, tip guard, and retaining

ring on the gun. Measure the resistance between the

end of the electrode (15a) and the gun body (29) or

turbine air inlet fitting (refer to page 6). The resistance

should be between 329 to 401 megohms. If the resistance is outside the specified range, go to the next

Fig. 26

27d

27

R

0441

308937 29

Page 30

Electrical Tests

Test Barrel Resistance (See Fig. 27)

WARNING

Measure the resistance between the barrel contact

ring (26a) and the metal contact pin (M), using a metal

rod (D) and megohmmeter as shown in Fig. 27. Be

careful not to damage or scratch the inner surfaces of

the barrel with the metal rod.

The resistance should be 19 to 29 megohms. If the

resistance is incorrect, make sure the metal contact

pin (M) and the barrel contact ring (26a) are clean.

If the resistance is still outside the specified range:

1. Remove the barrel contact ring (26a) with a small

pick. There is a wire lead in the groove that the

contact ring was removed from.

2. With the metal rod (D) still inside the barrel as

shown in Fig. 27, measure the resistance between

the wire lead and the metal rod.

FIRE, EXPLOSION, AND

ELECTRIC SHOCK HAZARD

The barrel contact ring (26a) is a conductive contact ring, not a sealing

o-ring. To reduce the risk of sparking or

electric shock, do not remove the barrel

contact ring from the barrel except to

replace it and never operate the gun

without the contact ring in place. Do not

replace the contact ring with anything

but a genuine Graco part.

E

3. If the resistance is still outside the specified range,

the gun barrel needs to be replaced.

If the resistance is correct, install a new contact

ring (26a) and press it firmly into the groove on the

front of the barrel.

Be sure the contact ring is in place before operating the gun.

26a

Fig. 27

D

Wire lead in groove

behind contact ring

03247

30 308937

Page 31

Tools Included with the Gun

Service

WARNING

Ball End Wrench

2 mm Socket Head Driver

9 mm Hex Nut Driver

Dielectric Grease

Prepare the Gun for Service

NOTE:

Check all the possible remedies in Troubleshoot-

ing, pages 26 to 28, before disassembling the gun.

If the plastic parts of the gun must be held in a vise,

use padded vise jaws to avoid damaging parts.

Only use genuine Graco parts. Do not mix or install

parts from other PRO gun models. Note that the air

cap, spray tip, and tip guard for this gun are

orange.

FIRE, EXPLOSION, AND

ELECTRIC SHOCK HAZARD

To reduce the risk of a fire, explosion, or

electric shock:

Be sure the turbine air (TA) is off

before flushing the gun or any part of

the system.

Clean all the parts with a compatible

solvent that is suitable for electrostatic equipment.

Do not service this equipment unless you are

trained and qualified.

Do not touch the gun nozzle or come within 4

inches (101.6 mm) of the nozzle during gun

operation.

CAUTION

Methylene chloride is not recommended as a flushing or cleaning solvent with this gun as it will damage

nylon components.

WARNING

EQUIPMENT MISUSE HAZARD

Do not mix or install parts from different

PRO gun models. Some PRO AA5500

Gun parts look similar to other PRO Gun

parts but they have different part numbers and they are not interchangeable.

Use of parts other than those specified

in the PRO AA5500 Gun parts list on

page 45 could alter the grounding conti-

nuity of the gun, cause parts to leak or

rupture, or cause the gun to malfunction, which

could result in a fire, explosion, electric shock, or

injection injury.

WARNING

INJECTION HAZARD

To reduce the risk of a serious injury,

including fluid injection, follow the Pres-

sure Relief Procedure on page 17

when you stop spraying, before servicing the gun,

and whenever you are instructed to relieve the

pressure.

1. Flush the gun with a compatible solvent.

2. Relieve the system pressure.

3. The service area must be clean. Remove the gun

from the worksite as instructed in the following

steps.

Continued on the next page.

308937 31

Page 32

Service

Prepare the Gun for Service (continued)

CAUTION

4. Remove the retaining nut and air cap assembly (1,

12, 13, 15) and the gun shroud (2). See Fig. 28.

You may have to turn the air cap with the tip guard

to remove the air cap from the gun.

5. Disconnect the fluid hose from the fluid inlet fitting

(3–marked P1 on the manifold). Use an open end

wrench to hold the fluid fitting hex and prevent it

from turning.

6. Loosen the bottom gun screw (21) until the gun (B)

sits loosely in the mounting bracket slot (A).

B

The piston return spring (105) is compressed

between the manifold (101) and gun body when they

are assembled. To avoid sudden movement of the

gun, loosen the bottom gun screw (21) before loosening the three manifold bolts (106). This allows the

gun to move forward gradually as the manifold bolts

are loosened. Hold the gun firmly in hand while

loosening the manifold bolts.

7. Holding the gun (B) firmly in hand, loosen the three

bolts (106) from the back of the manifold (101)

with the ball end wrench (77–not shown).

8. Remove the gun (B) from the manifold (101), and

take it to the service area.

106

105

101

1, 12, 13, 15

Fig. 28

2

102

A

3

21

03626

32 308937

Page 33

Service

Pre-OrificeTip Guard, Air Cap, Spray Tip,

or Seat Housing Replacement

WARNING

1. Prepare the gun for service as instructed on

page 31.

2. Remove the seat housing (14) with the 9 mm

driver (84), supplied. See Fig. 30.

3. Replace the tip gasket (13a) if it is damaged.

CAUTION

The barrel resistor cartridge (B) is part of the barrel

and is not replaceable. Refer to page 33. To avoid

destroying the gun barrel, do not attempt to remove

the barrel resistor cartridge.

WARNING

FIRE, EXPLOSION, AND

ELECTRIC SHOCK HAZARD

The barrel contact ring (26a) is a conductive contact ring, not a sealing o-ring.

Refer to Fig. 29. To reduce the risk of

sparking or electric shock, do not

remove the barrel contact ring from the

barrel except to replace it and never

operate the gun without the contact ring

in place. Do not replace the contact ring

with anything but a genuine Graco part.

FIRE, EXPLOSION, AND

ELECTRIC SHOCK HAZARD

To reduce the risk of fire, explosion, and

electric shock, never operate the spray

gun with a bent, damaged or missing

electrode (15a).

2

13a

13

15

12

1

26a

Fig. 29

Tighten the seat housing (14) with the 9 mm driver (84) until it is

snug, then tighten it 1/4 turn more; do not over-tighten it.

8801A

4. Install the seat housing (14) with the 9 mm driver

(84). Tighten the seat housing until it’s snug and

then tighten it 1/4 turn more; do not over-tighten.

CAUTION

To avoid damaging the seat housing and gun barrel,

never over-tighten the seat housing. Over-tightening

may affect the fluid shut-off.

5. Make sure the electrode (15a) is not bent, damaged or missing from the air cap. See Fig. 31. See

page 34 to install the electrode.

Fig. 30

14

84

B

03237

308937 33

Page 34

Service

Tip Guard, Air Cap, Spray Tip, or Seat

Housing Replacement (continued)

6. Place the spray tip (13) in the air cap (15). Align

the tab of the tip with the groove in the air cap.

See Fig. 31. Do not bend the electrode wire (15a).

7. Slide the shroud (2) onto the gun. See Fig. 29.

8. Install the spray tip (13) and air cap (15), tip guard

(12), and retaining nut (1). Tighten the retaining nut

firmly.

9. Test the gun resistance as instructed on page 29.

10. Install the gun onto the manifold and bracket as

instructed on page 43.

Electrode Replacement

WARNING

FIRE, EXPLOSION, AND

ELECTRIC SHOCK HAZARD

To reduce the risk of fire, explosion, and

electric shock, never operate the spray

gun with a bent, damaged or missing

electrode (15a).

1. Prepare the gun for service as instructed on

page 31.

2. Remove the retaining nut (1), tip guard, (12), air

cap (15), spray tip (13), and gun shroud (2) as

instructed on page 33.

3. Pull the electrode (15a) out of the backside of the

air cap with a needle nose pliers. Refer to Fig. 31.

4. Push the new electrode (15a) through the air cap

hole. Place firm finger pressure on the electrode

wire on the backside of the air cap, and make sure

the short end (BB) of the electrode engages into

the hole (CC) as shown in Fig. 32.

15a

Fig. 31

15

13

8800A

5. Slide the shroud (2) onto the gun.

6. Install the spray tip (13), air cap (15), tip guard

(12), and retaining nut (1) as instructed at left.

Tighten the retaining nut firmly.

7. Test the gun resistance as instructed on page 29.

8. Install the gun onto the manifold and bracket as

instructed on page 43.

15a 15

BBCC

Fig. 32

8804A

34 308937

Page 35

Service

Fluid Tube Removal and Replacement

To remove the fluid tube assembly (18) for cleaning or

replacement:

1. Prepare the gun for service as instructed on

page 31.

2. Disconnect the bottom fluid tube nut (C). See

Fig. 33.

3. Carefully unscrew the top fluid tube nut (D).

CAUTION

Be careful not to damage the fluid tube assembly

(18) when cleaning or installing it, especially the

sealing surface (M). See Fig. 34. If the sealing

surface is damaged, the entire fluid tube assembly

must be replaced.

Fluid Filter Replacement

1. Prepare the gun for service as instructed on

page 31.

2. Disconnect the bottom fluid tube nut (C). See

Fig. 33.

3. Remove the fluid filter (4). Clean or replace the

filter, as needed.

4. Install the fluid filter (4) and tighten the bottom fluid

tube nut (C) onto the fluid fitting (3); make sure the

top fluid tube nut (L) remains tightened.

5. Install the shroud (2), spray tip (13), air cap (15),

tip guard (12), and retaining nut (1) as instructed

on page 34. Tighten the retaining nut firmly.

6. Test the gun resistance as instructed on page 29.

7. Install the gun onto the manifold and bracket as

instructed on page 43.

Tighten the nut (L) about 1/4 to 1/2 turn past hand-tight; there

will be a gap between the nut and barrel; do not over-tighten it.

4. Apply dielectric grease to the entire length of the

plastic extension on the end of the fluid tube (18).

See Fig. 34.

5. Apply a low strength thread sealer (such as purple

Loctite) to the fluid tube nut (L) threads.

6. Install the fluid tube into the gun barrel by tightening the top fluid tube nut (L) hand-tight, then turn it

1/4 to 1/2 turn with a wrench. See Fig. 33. There

will be a gap between the nut and barrel. Do not

over-tighten it.

7. Make sure the fluid filter (4) is in place, then

tighten the bottom fluid tube nut (C) onto the fluid

fitting (3); make sure the top fluid tube nut (L)

remains tightened.

8. Install the shroud (2), spray tip (13), air cap (15),

tip guard (12), and retaining nut (1) as instructed

on page 34. Tighten the retaining nut firmly.

3

D

Fig. 33

Apply low strength (purple) Loctite or equivalent to the threads

Apply dielectric grease to the entire length of the fluid tube

plastic extension

C

4

18

03685

9. Test the gun resistance as instructed on page 29.

10. Install the gun onto the manifold and bracket as

instructed on page 43.

Fig. 34

E

CD

308937 35

2079

Page 36

Service

Piston Repair

1. Prepare the gun for service as instructed on

page 31.

2. Remove the jam nut (8), actuator arm (19), and

adjustment nut (17). See Fig. 35.

3. Push on the piston rod (23g) to push the piston

assembly out the back of the gun.

4. Inspect the o-rings (23a, 23b, 23c) and u-cup

packing (23f) for damage. See Fig. 37. Refer to

Fig. 38 to isolate any air leakage problems.

5. Lubricate the o-rings (23a, 23b, 23c) and u-cup

packing (23f) with petroleum jelly.

6. Align the two stems (23d) with the holes in the gun

body and press the piston assembly into the back

of the gun until it bottoms.

7. Installing the Actuator Arm and Nuts:

a. Install the adjustment nut (17), actuator arm

(19), and jam nut (8) onto the piston rod (23g).

See Fig. 35.

NOTE: The jam nut (8) has a slightly larger hex and a

thinner profile than the adjustment nut (17).

a. Thread the jam nut (8) flush with the end of the

piston rod (23g).Tighten the adjustment nut

(17) against the actuator arm (19). When

properly assembled, there should be about a

0.125 in. (3 mm) gap between the actuator

arm (19) and the fluid packing rod nut (U),

which allows the atomizing air to actuate

before the fluid actuates. See Fig. 36.

8191723g

Fig. 35

There should be a 0.125 in. (3 mm) gap between the actuator

arm (19) and the fluid packing rod nut (U).

19 U

Fig. 36

Apply a very light coat of lubricant to the o-rings (23a, 23b, 23c)

and u-cup (23f)

Align the two stems (23d) with the holes in the gun body and