Graco PRO 224-094, PRO 224-224, PRO 235893, PRO 235-894, PRO 308-084 Instructions Manual

...Page 1

I

NSTRUCTIONS–PARTS

This

manual contains IMPORT

ARNINGS AND INSTRUCTIONS

W

READ AND RET

AIN FOR REFERENCE

ANT

LIST

308–084

Rev. H

Supersedes

G

Model

PRO 4600SC

AUTOMATIC ELECTROSTATIC

AIR SPRA

100

psi (7 bar) MAXIMUM WORKING PRESSURE

U.S.

Patent No. 4,290,091; 4,219,865; 4,497,447; 4,462,061; 4,660,774;

5,063,350; 5,073,709; 5,080,289; 5,093,625

Patented 1986, 1987 Canada

Brevete 1986, 1987

U.K. Patent No. 2,147,158; 2,142,559B; 2,140,327B; 2,245,197B

French Patent No. 91 14488

Other Foreign Patents Pending

Part No. 224–224, Series A

Air Spray Gun, without shroud

(0.059 in. (1.5 mm) spray nozzle)

Part No. 235–893, Series A

Air Spray Gun, with standard shroud

Y GUN

0432

Part No. 235–894, Series A

Air Spray Gun, with slotted shroud

For

use when the gun is mounted in

the front position; see Fig 3 , page 6

Part No. 224–094 Series A

Gun Manifold

Must

order separately

For use with Class

.

, Group D paint spray materials

0435

Part

No. 235–893 shown

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

COPYRIGHT

1991 GRACO INC.

Page 2

WARNINGS

SERIOUS BODILY INJUR Y, EXPLOSION, FIRE, OR ELECTROST ATIC SHOCK CAN

OCCUR IF THE PRECAUTIONS BELOW ARE NOT FOLLOWED.

READ AND UNDERSTAND ALL INSTRUCTION MANUALS, T AGS, AND WARNING

LABELS BEFORE OPERATING EQUIPMENT.

ELECTROSTATIC EQUIPMENT SHALL ONLY BE USED BY TRAINED, QUALIFIED

PERSONNEL WHO SHALL BE FULL Y CONVERSANT WITH THE REQUIREMENTS

STATED WITHIN THIS INSTRUCTION MANUAL.

EQUIPMENT MISUSE HAZARD

General

Any misuse of the spray equipment or accessories, such as

over pressurizing, modifying parts, using incompatible chemicals and fluids, or using worn or damaged parts, can cause

them

or

NEVER

NEVER

ALWAYS

cleaning or removing the fluid nozzle or servicing any system

equipment.

NEVER

NEVER alter or modify any part of this equipment; doing so

could

CHECK all spray equipment regularly and repair or replace

worn

System

This

psi

gun

HAZARDOUS

Improper handling of hazardous fluids or inhaling vapors can

cause extremely serious bodily injury , even death, due to

splashing in the eyes, ingestion, inhalation, or bodily contamination. Be sure you know what fluid you are pumping and its

specific hazards. Observe all precautions when handling

known

to,

1.

2. Dispose

Safety

to rupture and result in serious bodily injury

property damage.

point the spray gun at anyone or at any part of the body

put hand or fingers over the spray nozzle.

follow the

try to stop or deflect leaks with your hand or body

cause it to malfunction.

or damaged parts immediately

Pressure Relief Procedure

.

, fire, explosion

, at right, before

.

Pressure

gun has a maximum working air and fluid pressure of 100

(7 bar). Never exceed the maximum working pressure of the

or any other component or

accessory used in the system.

FLUID HAZARD

or potentially hazardous fluids, including, but not limited

the following precautions.

Store hazardous fluids in approved containers.

Federal

wastes.

of any waste fluid according to all Local, State and

regulations pertaining to the disposal of hazardous

Fluid

Compatibility

BE SURE all fluids and solvents used are chemically compatible with

Always

erature

Pressure

.

To

the

shock,

tem, when checking or

when installing, cleaning or changing fluid nozzles, and when

ever

1. Turn

2. Turn

3. Trigger the gun into a

4. Open

5. Leave the pump drain valve open until you are ready to

3.

4.

5. Provide proper ventilation in accordance with accepted

the “Wetted Parts” shown in the TECHNICAL DATA.

read and follow the

before using the fluid or solvent in this gun.

fluid and solvent manufacturer’s lit

Relief Procedure

reduce the risk of serious bodily injury

eyes or on the

always follow this procedure

you stop spraying.

of

air.

If the air pilot fluid regulator is

ed

at the regulator air inlet to relieve pressure in the fluid line.

of

relieve

the pump drain valve, having a waste container ready

to

catch the drainage.

spray

again.

Read and follow the fluid and solvent

ture

regarding the use of protective clothing and

such as eye

Provide for the safe piping and disposal of all exhaust air

industry

Ventilate

skin, injury from moving parts or electrostatic

servicing any part of the spray system,

f all the air to the control module

f the fluid supply to the gun.

fluid pressure.

protection, respiratory protection, and gloves.

standards and governmental regulations. Refer to

the Spray Booth

grounded

, on page 6.

, including splashing

when shutting of

except the manifold

used, air pressure is need

metal waste container to

manufacturer’s litera

in

f the sys

equipment,

-

-

-

-

-

.

HOSE SAFETY

TIGHTEN

NEVER

tire

movement of the hose couplings. If any of these conditions

exist,

all fluid connections securely before each use.

use a damaged hose. Before each use, check the en

hose for cuts,

replace the hose immediately

leaks, abrasion, bulging cover

.

, or damage or

HANDLE AND ROUTE HOSES CAREFULLY. Do not pull on

hoses

-

to move equipment. Do not use fluids or solvents which

are

not compatible with the inner tube and cover of the hose.

Page 3

FIRE, EXPLOSION, OR ELECTROSTA

TIC SHOCK HAZARD

To reduce the risk of fire, explosion, or electrostatic shock,

which

may result from electrical discharge, it is essential that:

S

All parts of the electrostatic system are properly grounded.

S All personnel in or close to the spray area are properly

grounded.

S All

electrically conductive objects or devices in the spray area,

including

grounded.

When operating the electrostatic device, any ungrounded

objects in the spray area (such as people, containers, tools,

etc.)

objects

cient energy levels can ignite the fluid being sprayed, fumes

from

This

sult

Static electricity can also be generated by the flow of fluid

through the pump, hose, gun, and nozzle, but it is dissipated

through

If

you experience any arcing or feel even a slight shock,

SPRAYING

entire

starting

paint containers, wash

can become electrically charged. Arcing may

then come in contact or close to ground. Arcing of suf

solvents, dust particles, and other flammable substances.

can cause a fire, explosion, or electrostatic

in serious bodily injury and property damage.

proper grounding as described in

IMMEDIA

system. Be sure you

to spray again.

TELY

cans and tools, are properly

occur if these

shock and re

Grounding

. Check for proper grounding of the

have corrected the problem before

below

STOP

Grounding

The

following are minimum requirements for grounding a basic

electrostatic

or objects which must also be grounded. Always check your

local

your

system is connected to a true earth ground.

1.

Pump:

described

2.

Air compressors and hydraulic power supplies:

according

3.

Electrostatic

nection

Graco Electrically Conductive Air Supply Hose; see

ACCESSORIES section to order . Connect the air hose

ground

4.

Object being sprayed:

and grounded at all times. Contact points must be sharp

points

5.

All electrically conductive objects or devices

area, including paint containers and wash cans, must be

properly

system. Y

electrical code for detailed grounding instructions. Be sure

ground by using a ground wire and clamp as

in your separate pump instruction manual.

to the manufacturer’s recommendations.

to a properly grounded air supply hose. Use only the

wire to a true earth ground.

or knife edges.

grounded.

our system may include other

Air Spray

Gun:

obtain grounding through con

keep the work piece hangers clean

equipment

ground

in the spray

6.

All

persons entering the spray area:

ductive

soles, such as leather

must

be worn. Rubber or plastic soles are not conductive.

7.

The floor of the spray area

grounded. Do not cover the floor with cardboard or any

and

non-conductive material which would interrupt grounding

continuity.

8.

Flammable liquids

approved,

quantity

9.

All solvent pails:

conductive. Do not place the pail on any non-conductive

fi-

-

surface,

grounding

10.

All air and fluid lines and electric cables

grounded.

grounded containers. Do not store more than

needed for one shift.

such as cardboard or paper

continuity

in the spray area must be kept in

use only grounded metal pails, which are

must be electrically conductive

.

shoes

, or personal grounding straps

must have con

the

, which would interrupt

must be properly

-

Flushing and Cleaning Safety

To

reduce the risk of static

.

the Pressure Relief Procedure

Be

sure the turbine air (electrostatics) is

ing

or cleaning any part of the spray system.

Use

the lowest possible pressure to flush. T

grounded

To

point

metal waste container

flush or purge

equal to or greater than that of the fluid being sprayed.

equipment,

To clean the exterior of the equipment,

with

a flash point of higher than 100_ F (38

ALWAYS

the

Use

hangers.

Ventilate

To

vapors,

Check

air exhaust velocity requirements. Check and follow all local

safety

NEVER operate the spray gun unless the ventilating fans are

operating.

remove all solvent from the system before reactivating

spray gun.

only non-sparking tools to clean residue from the booth and

the Spray Booth

prevent hazardous concentrations of toxic and/or

spray only in a properly ventilated spray booth.

and follow all National, State and Local codes regarding

and fire codes and OSHA standard 1910.107.

sparking or splashing, always follow

on page 2 before flushing.

OFF before flush

.

ALWA

YS use solvents with a flash

rigger the gun into

ALWAYS use solvents

_ C).

flammable

a

-

United

States Government safety standards have been adopted under the Occupational

General Standards, Part 1910.107 and any other appropriate regulations––should be consulted in connection with the installation, operation, and

maintenance of electrostatic spray painting equipment.

IMPORTANT

Safety and Health Act. These standards––particularly the

308-0843

Page 4

TABLE OF CONTENTS

Warnings 2.

Terms 4.

Installation

Typical

Warning

Ventilate

Install

Install

Install

Connect

Check

Install

Operation

Operating

Selecting

Gun

Activating

Adjusting

Adjusting

Activating

Maintenance

Daily

Clean

Check

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Signs5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the Spray Booth6. . . . . . . . . . . . . . . . . . . . .

the Gun Controls and Display Module6. . . . .

the Gun Mounting Bracket6. . . . . . . . . . . . . . .

the Gun and Manifold6. . . . . . . . . . . . . . . . . . .

the Air

the Electrical Grounding8. . . . . . . . . . . . . . . .

the Fabric Cover8. . . . . . . . . . . . . . . . . . . . . . .

Functions9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Care and Cleaning

the Air Cap and Fluid Nozzle

for Fluid Leakage

, Fluid, and Fiber Optic Lines6. . . . .

Checklist9. . . . . . . . . . . . . . . . . . . . . . . . . .

a Fluid Nozzle and Air Cap9. . . . . . . . . . .

the Fluid T

the Spray Pattern9. . . . . . . . . . . . . . . . . . .

the T

the V

rigger Only9. . . . . . . . . . . . . . .

urbine Air Pressure

oltage Select (KV HI/LO)

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . .

. . . . . .

Service

the Gun and Relieve Pressure

Flush

Remove

Air Cap/Nozzle/Resistor Stud Replacement

Electrode

Barrel

Barrel

Fluid

Power

Power

Turbine

Service

Gun

Gun

Manifold

PRO

10.

10.

10.

11.

12.

Accessories 32

Technical

Warranty Back

Graco

Gun from Manifold & Mounting Bracket

Replacement

Removal

Installation

Packing Rod Removal and Repair

Supply Removal and Replacement

Supply Adjustment

Alternator Removal and Replacement

Notes

Parts Drawing

Parts List

Parts Drawing & List

4600HC Conversion Kit

Data

.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Phone Numbers

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . .

. . . . .

Back Cover

. . . .

.

Cover

18.

18

19.

20.

21.

22.

23.

25.

25.

25.

26.

28.

29.

30.

31.

35.

Troubleshooting

Pattern T

Spray

Gun

Operation T

Electrical T

Electrical Tests

est Gun Resistance

T

Test

Power Supply Resistance

Test

Resistor Stud Resistance

roubleshooting Chart

roubleshooting Chart

roubleshooting Chart

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . .

TERMS

13.

14.

15.

16.

16.

17.

WARNING: Alerts

CAUTION: Alerts

NOTE: Identifies essential procedures or helpful

user to avoid or correct conditions that

could

cause bodily harm.

user to avoid or correct conditions that

could cause damage to or destruction of

equipment.

information.

Page 5

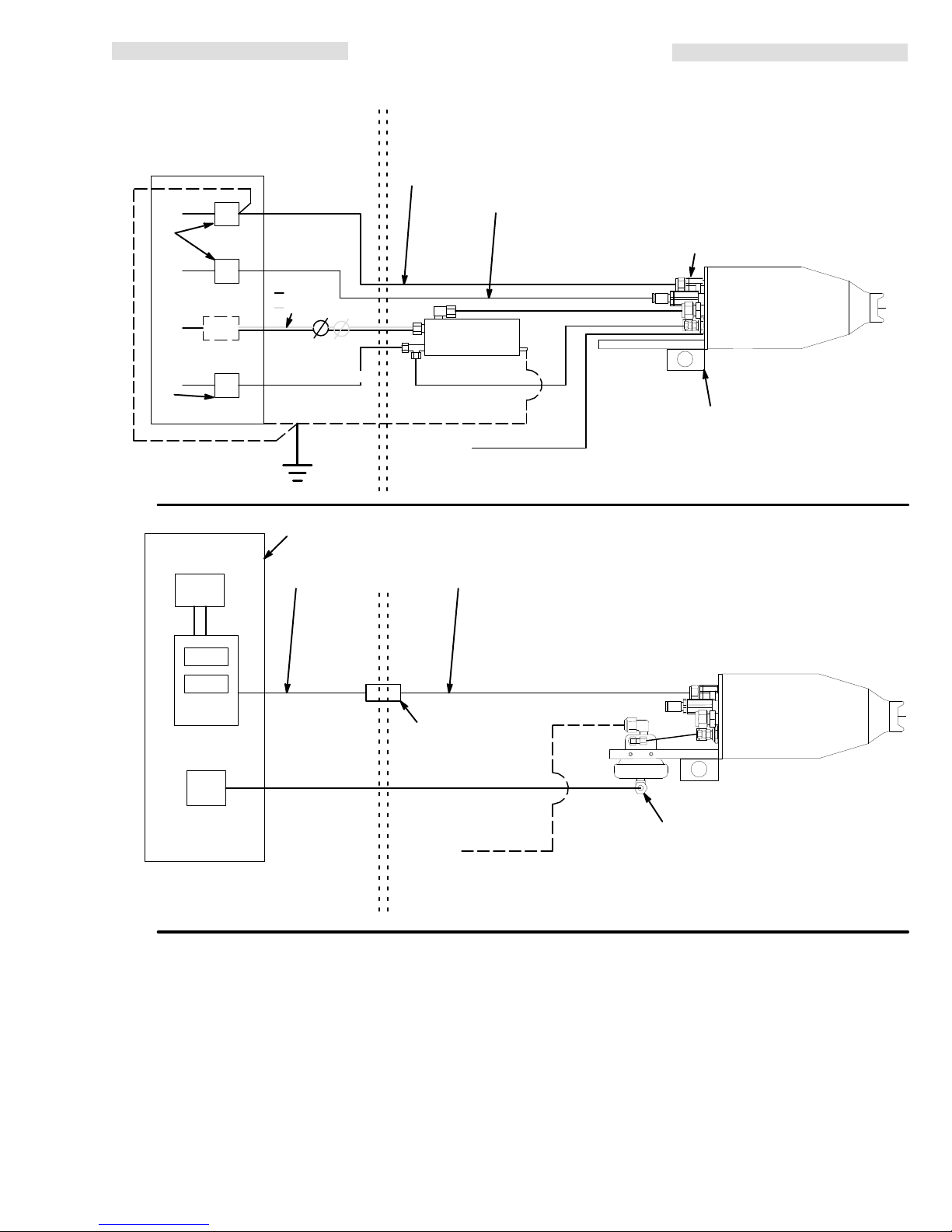

TYPICAL INSTALLATION

Non-Hazardous Area Hazardous Area

BASIC SYSTEM

Controls

Fig

1

24V Power Supply

P/N 235–301

Cabinet

Shut-off device

for fluid only

operation

Bleed valve or

3 way solenoid

Fan

Atom Air Lines

Air

Regulator

Cylinder Air Line

True

Earth

Ground

Controls

Fiber

P/N 224–680/–686

Cabinet

Optic Cable

Grounded Turbine Air

P/N

223–068/–074

KV Hi/Lo Air Line

Trigger

Module

P/N

235–768

Fluid Supply

Fiber Optic Cable

P/N 224–670/–676

Hose

(gray hose)

(if low KV setting option is desired)

Gun

Manifold

P/N 224–094

PRO 4600 Gun

P/N 224–224

(gun only

Manual

gun/shroud

Recip.

235–094

P/N

SYSTEM OPTIONS

Spraying Voltage Monitor

Air Pilot Fluid Regulator

, see

308–084 for

P/N)

Mount Assy

.

ES

Display Module

P/N

224–1

17

Pressure

Air

Control

Bulkhead

P/N 224–261

Fluid Supply

Non-Hazardous Area Hazardous Area

Fig

2

Installing the System

Fig 1 , above, shows a typical Model 4600 system. Fig

2

shows some possible system options. For

in

designing a system that is customized for your applica

tion,

contact your Graco representative.

assistance

-

Air Pilot Fluid Regula

tor

P/N 224–531

-

01769

Warning Signs

Mount warning signs in the spray area where they can

easily be seen and read by all operators. An English

Warning Sign is provided with the gun. Additional

English, French, German, and Spanish signs are available

at no charge. See

der

them.

the

ACCESSORIES

section to or

-

Page 6

INSTALLATION

WARNING

Installing and servicing this equipment requires

access

or

properly.

Do not install or service this equipment unless

Be sure your installation complies with National,

to parts which may cause electrostatic shock

other serious bodily injury if work is not performed

you

are trained and qualified.

State

and Local codes for the installation of elec

trical

apparatus in a Class , Group D Hazardous

Location.

2.3

in.

(58 mm)

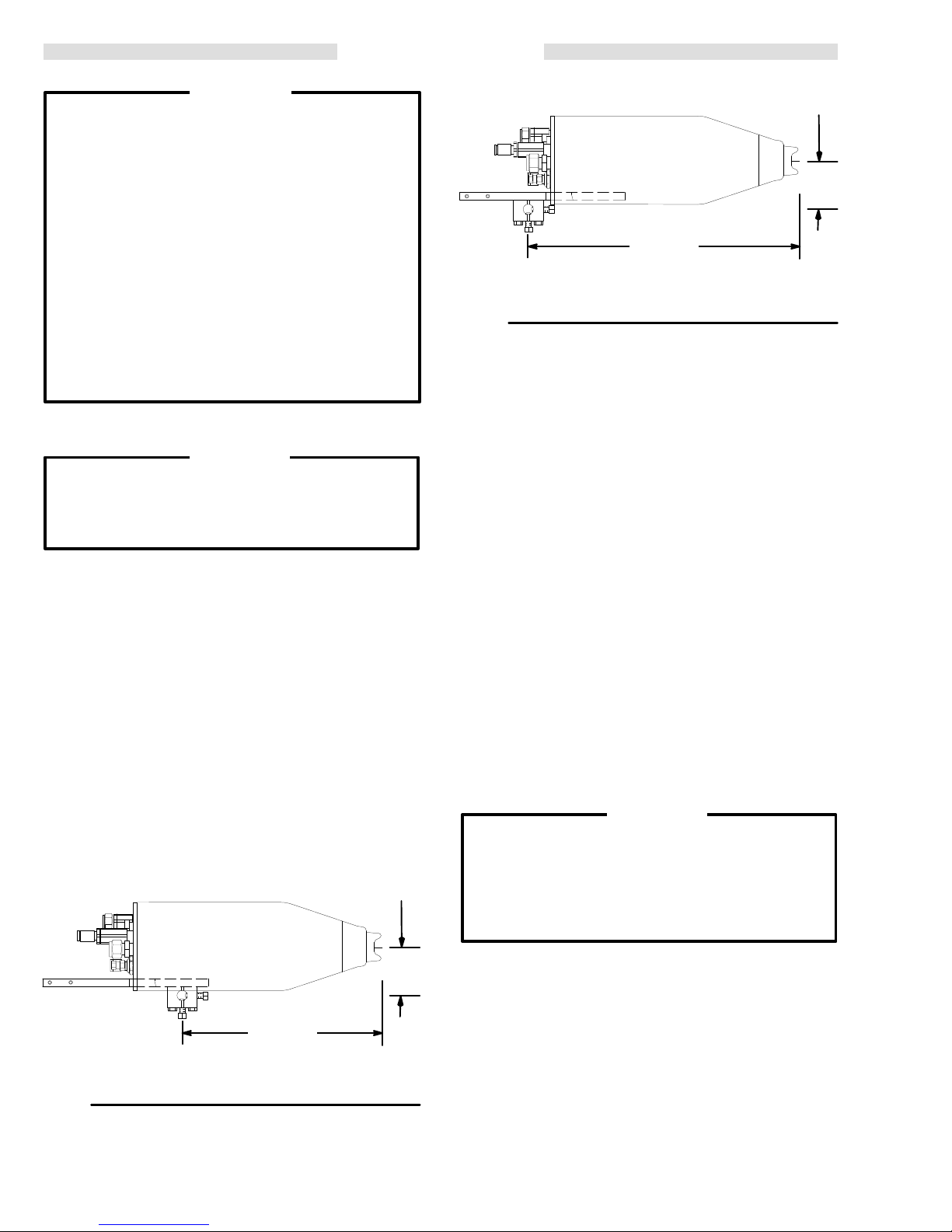

PRO

4600 Gun

with Standard Shroud

P/N 235–893

12 in.

(304 mm)

-

Fig

4

BACK MOUNTING POSITION

01876

Check and follow all local safety and fire codes,

NFPA

33, NEC 504 and 516, and OSHA standard

1910.107.

Ventilate the Spray Booth

WARNING

prevent hazardous concentrations of toxic

To

and/or

flammable vapors, spray only in a properly ventilated spray booth. Never operate the spray gun

unless

ventilation fans are operating.

Electrically interlock the gun air supply with the ventilators

to prevent gun operation without ventilating fans

op

erating. Check and follow all National, State, and Local

codes

regarding air exhaust velocity requirements.

High

velocity air exhaust will decrease the operating ef

ciency of the electrostatic system. The minimum allowable air exhaust velocity is 60 feet/minute (19 linear

meters/minute).

Install the Gun Mounting Bracket

Attach

the

mounting bracket to the robot or reciprocator

See

the

ACCESSORIES

et and mount extension options and refer to Fig 3 and

Fig

4 for mounting positions.

Fig 3

FRONT MOUNTING POSITION

section for the mounting brack

PRO

4600 Gun

with Slotted Shroud

P/N 235–894

8.8 in.

(235 mm)

2.3

in.

(58 mm)

01876

fi-

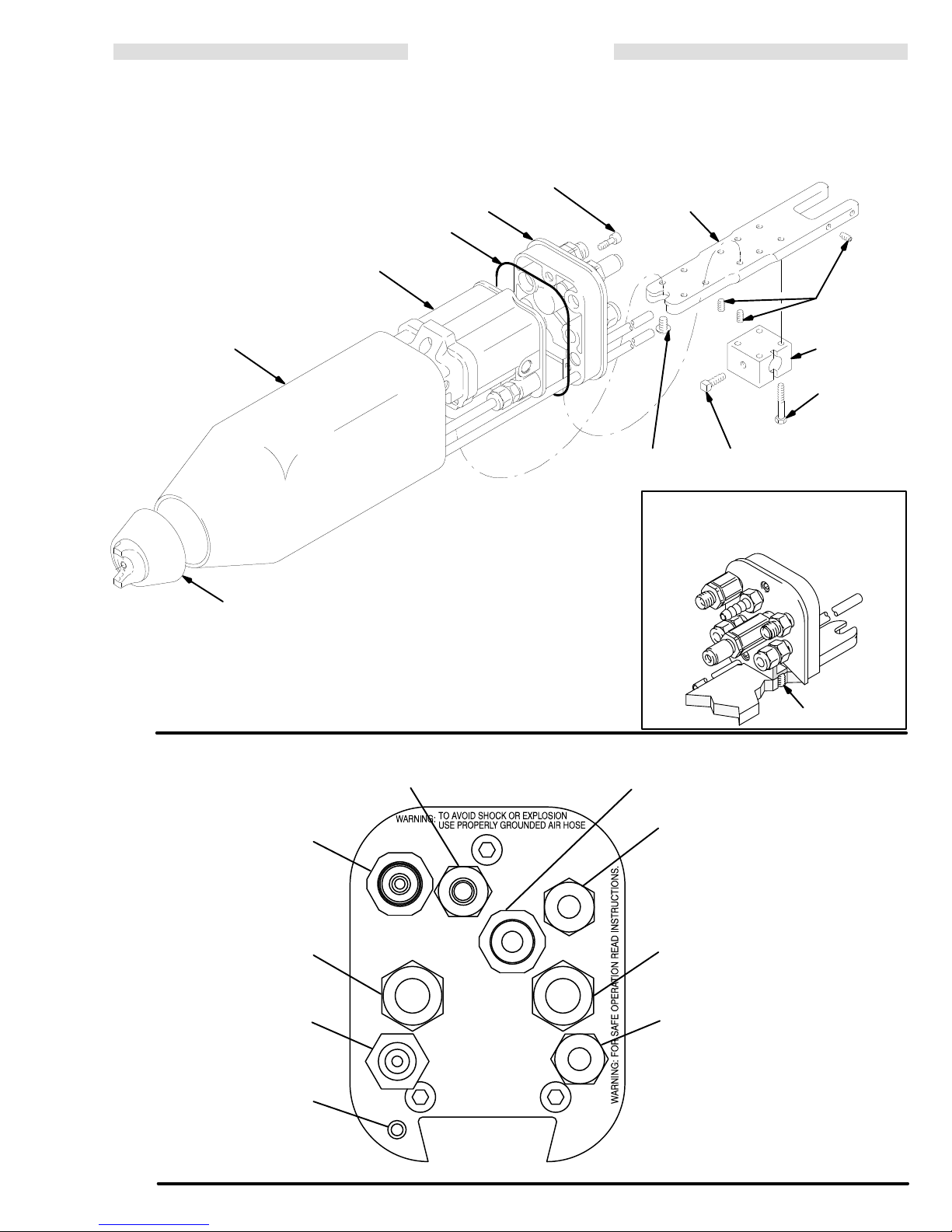

Install the Gun and Manifold (See Fig 5 )

1. Remove the air cap nut/air cap assembly and slide

the

shroud of

f the gun.

2. Connect the gun to the manifold by tightening the

three socket head cap screws; use the ball end

wrench (46), supplied. Make sure the o-ring is in

place

on the manifold.

3. Slide

the gun

and manifold along the dovetail until the

button head screw bottoms against the mounting

bracket.

-

4. Secure

the gun to the mounting bracket with the but

ton head screw , using the ball end wrench (46).

Tighten

5. Slide

ening

nut

be

the two mounting bracket setscrews.

the shroud onto the gun and secure it by tight

the air cap nut onto the gun barrel. T

just enough so that the air cap is snug

turned.

Connect the Air, Fluid, and Optional Fiber

.

Optic Lines (See Fig 6 )

-

To reduce the risk of electrostatic shock or other

serious

electrically

Only

injury

, the turbine air supply hose must be

connected to

Graco Electrically

Hose and connect the hose ground wire to a

earth

ground.

See

the

ACCESSORIES

cally

Conductive Air Supply Hose. This hose

have special left-hand threads to prevent connecting

another

Connect

gun

fluid

solvent

type of

air supply hose to the gun turbine air inlet.

the air

, fluid, and optional fiber optic

manifold as shown in Fig 6 . Before connecting the

line, blow it out with air and flush it with solvent.

that is compatible with the fluid being sprayed.

WARNING

a true earth ground.

Conductive Air Supply

section to

order Graco Electri

ighten

the

but can still

Use

true

and the gun

lines to the

Use

-

-

-

6 308-084

Page 7

INSTALLATION

To

ensure a dry

line

filter and an air and water separator on the air

Dirt and moisture can ruin the appearance of your fin-

, clean air supply to the gun, install an air

lines.

Manifold

O-Ring

Spray Gun

ished

combination air filter/moisture separator is shown in

ACCESSORIES

Socket

Head

Cap Screws

workpiece and can cause the gun to malfunction. A

the

section.

Mounting

Plate

Dovetail

Set Screws

Fig

5

Shroud

Air Cap/Air

Cap Nut

Connect

1/4” ID tube

4’ of

Button

Head

Screw

INSTALLED

0453

Connect 1/4” OD tube between

fitting and control module

Square Head

Set Screw

BACK

V

ON M

Mounting

Block

Hex Head

Cap Screws

01877

IEW OF MANIFOLD

OUNTING BRACKET

Set Screw

Connect Graco Grounded Air Hose

between fitting & control module

(left-hand thread)

ground

wire on the air hose to a true

Connect 3/8” OD tube between

fitting and control module

Connect a 1/4” npsm swivel

(included with manifold)

6

Fig

. Connect the

earth

ground.

fitting paint line

Shroud Exhaust

1/4” OD x 4’ tube

TURBINE

MAX WRP

AIR AND FLUID

100 PSI (7 BAR)

ATO M

KV

HI/LO

PAINT

EXH

CYL

F.O.

FAN

Connect Graco Fiber Optic

Cable

(see Accessories)

Connect 3/8” OD tube between

fitting and control module

Connect 1/4” OD tube between

fitting and control module

0322

Page 8

INSTALLATION

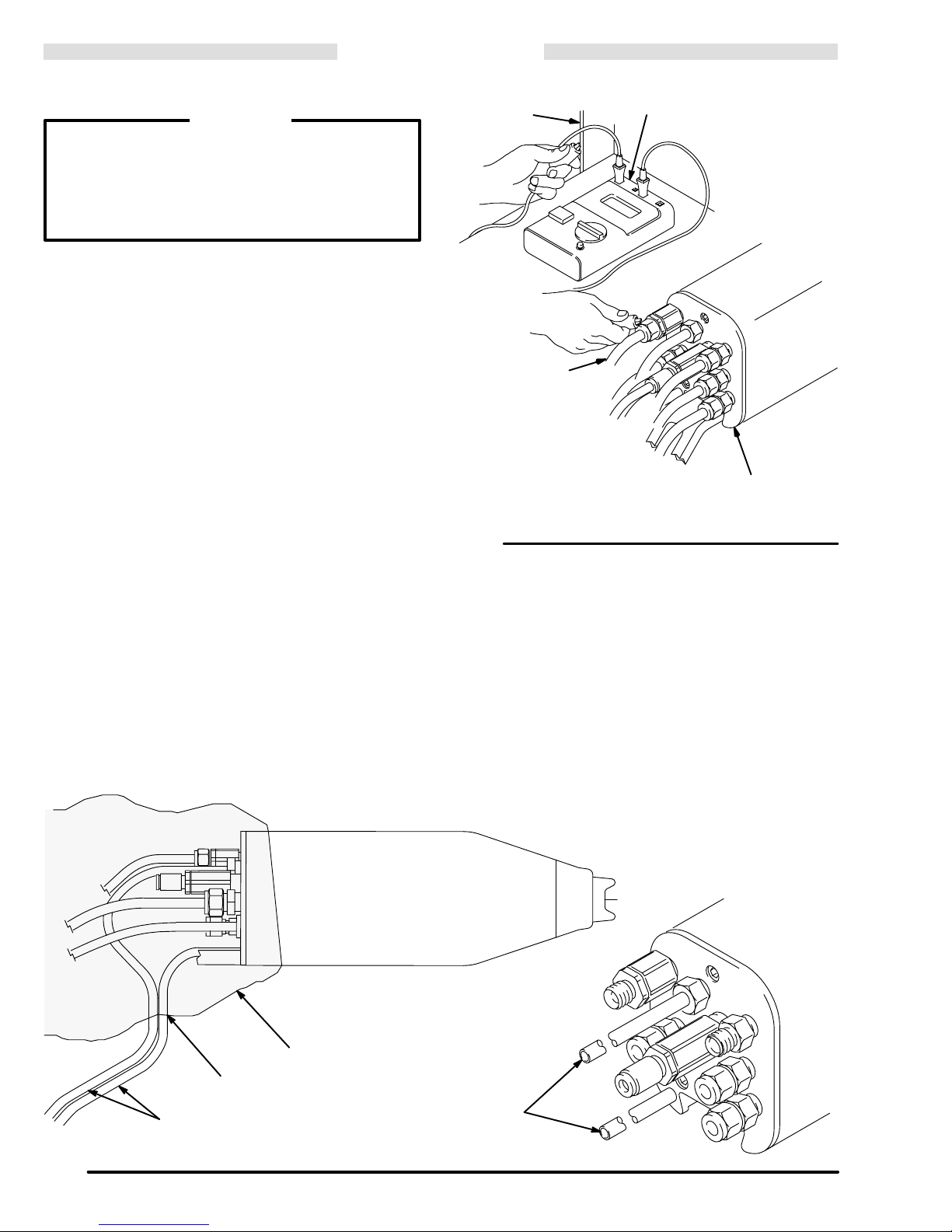

Check

the Electrical Grounding

(See Fig

7 )

WARNING

Proper electrical grounding of every part of your

system is essential. For your safety , read the

warning section, FIRE, EXPLOSION, OR

ELECTROSTATIC SHOCK HAZARD , on page

3. Ground the system as explained there. Then

your system as explained below

check

.

1. Completely turn off the air and fluid supplies to the

gun.

2. Have a qualified electrician check the electrical

grounding

continuity of the spray gun and air hose.

a. With the electrically conductive air hose con-

nected and properly grounded, use a

megohmmeter to measure the resistance

between the gun manifold and a true earth

ground.

to

Use an applied voltage of 500 minimum

1000 volts maximum.

b. If the resistance is greater than 2 megohms*,

check the tightness of the ground connections,

and be sure the air supply hose ground wire is

connected to a true earth ground. If the resistance is still greater than 2 megohms*, replace

the

air supply hose.

True Earth

Ground

Grounded

Air Hose

Fig 7

Megohmmeter

See

ACCESSORIES to

order

Gun

Manifold

0436

* If you are using the red colored hose, resis-

tance

should not exceed 100 ohms.

Install the Fabric Cover (See Fig 8 )

1. Install a fabric cover over the front of the gun and

slide

it back to

the back of the manifold. See ACCESSORIES

tion.

cover the exposed tubing and hoses at

sec

Fabric

Cover

2. Cut

-

a small slit in the cover and route the two exhaust

tubes

outside the robot

ables

you to monitor the exhaust tubes

arm or reciprocator

for the pres

. This en

ence of any paint or solvent. See Check for Fluid

Leakage

to

prevent them from moving around.

on

page 12. Strap down the exhaust tubes

-

-

Slit

0437

Fig

Exhaust T

8

ubes

Exhaust T

ubes

0438

Page 9

OPERATION

WARNING

Pressure

To

reduce the risk

splashing in the eyes or on the skin, injury from

moving parts or electrostatic shock, always follow

this

checking

when

and

1. Turn

2. T

3. Trigger the gun into a grounded metal waste

4. Open the pump drain valve, having a waste

5. Leave

If any fluid leakage from the gun is detected,

stop

the

sult in serious bodily injury and property damage.

See

Relief Procedure

of serious bodily injury

procedure when shutting of

or servicing any part of the spray system,

installing, cleaning or changing fluid nozzles,

whenever you stop spraying.

of

f the air to the control module, except for

the

manifold air

used,

air pressure is needed at the regulator air

inlet

to relieve pressure in the fluid line.

urn of

f the fluid supply to the gun.

container

container

the pump drain valve open until you are

ready

to spray again.

spraying

gun shroud could cause fire or explosion and re

Check for Fluid Leakage

. If the air pilot fluid regulator is

to relieve fluid pressure.

ready to catch the drainage.

WARNING

IMMEDIATELY!

f the system, when

Fluid leakage into

, page 12.

, including

7. Be sure all refuse is removed from the spray

booth.

8. Be sure all flammable liquids in the spray

are in approved, grounded containers.

booth

9. Be sure all conductive objects in the spray

are electrically

area

the spray area is electrically conductive and

grounded.

10. Be sure to check the manifold exhaust tubes

for the presence of any fluid as instructed in

Check for Fluid Leakage

grounded and the floor of

, page 12

.

Selecting a Fluid Nozzle and Air Cap

This

gun is supplied with fluid nozzle 185–158 (1.5 mm)

and

air cap 177–033. If your application requires a

ent nozzle and air cap combination, use instruction

manual 307–803 to select the appropriate fluid nozzle

and

air cap.

dif

fer-

Gun Functions

The

gun functions include the following:

Fluid T

rigger

(only)

-

Spray (

Turbine

V

properly

of fan air

Air

oltage Select

timed on/of

, atom air

, and paint)

f sequence

Operating Checklist

Check

the following list daily

system,

to help ensure you of safe, ef

1. Be sure all operators are properly trained to

safely operate an automatic electrostatic air

system.

spray

2. Be

sure all operators are trained how to prop

and completely relieve system pressure.

erly

3. Be sure the system is thoroughly grounded.

See FIRE, EXPLOSION OR ELECTRO-

STATIC SHOCK HAZARD on page 3, and

Check the Electrical Grounding on

page 8.

4. Be

sure the operator and all persons entering

the

spray area are properly grounded by

ing shoes with conductive soles or personal

grounding

5. Be sure ventilation fans are operating

properly.

sure the workpiece hangers

6. Be

grounded. Contact points must be sharp

points

straps.

or knife edges.

, before starting to operate

ficient operation.

are clean and

wear

the

-

-

Activating the Fluid Trigger Only

To

activate the fluid trigger alone, first relieve the air

sure

to the trigger module, then shut of

the AT

OM and F

air pressure to the CYL air supply line to activate the

mum

gun’s

fluid trigger

AN air lines. Apply 50 psi (3.5 bar) mini

.

f the air supply to

pres

Adjusting the Spray Pattern

Follow the steps below to establish the correct fluid

and

air flow. DO NOT

on

yet.

1. Adjust the fluid flow with the fluid line’ s pressure

regulator.

2. Rotate

3. Use

NOTE:

on

page 13 to correct spray pattern problems.

the air cap for the desired spray pattern.

an air pressure regulator to adjust the degree of

atomization

cy,

always use the lowest air pressure possible.

See the

turn the turbine air (electrostatics)

and pattern width. For the most ef

Spray Pattern T

OPERA

roubleshooting Chart

TION continued on next page

flow

ficien-

-

-

Page 10

OPERATION

Adjusting the Turbine Air Pressure

WARNING

The fan and atomizing air MUST be on before

turning on the turbine air . Actuating the turbine

air

without fan and atomizing air flow could damage

the gun and may create hazardous operating

conditions

damage.

1. Complete all the checks under the Operating

Checklist

2. Make

the

3. The

(2.8 bar) at the gun manifold inlet when air is flowing.

The

some

(3.5 bar) air pressure as there is no added benefit

and

and result in serious injury and property

on page 9.

sure the fan and atomizing air are on, then turn

turbine air (electrostatics) on.

turbine air pressure should be adjusted to 40 psi

gun may be operated at a lower air pressure, but

voltage loss could occur

turbine life could be reduced.

. Do not exceed 50 psi

MAINTENANCE

4. Check

NOTE:

kV.

If a ball

the

gun voltage will rise to about 85 kV

with

See the

to correct voltage problems.

the gun electrostatics display module, if used,

to

see the voltage and current output levels.

The gun’

all resistive electrostatic guns.

Electrical T

s normal high voltage output is 60 to 70

end high voltage measurement probe is used,

. This will

roubleshooting Chart on page 15

happen

Activating the Voltage Select (KV HI/LO)

To change the voltage to the lower setting, activate the

voltage select function (KV HI/LO). The lower voltage

setting

is factory set to 60 kilovolts at zero microamperes.

To

change this setting, see page 25.

The valve used to activate the KV HI/LO switch must

bleed

the air out of the line for the switch to draw back

the

high setting.

to

WARNING

reduce the risk

To

splashing

shock, always follow the Pressure Relief Proce-

dure Warning on page 9 when shutting of f the

system,

ing, servicing, installing, cleaning or changing any

part

Clean all parts with a non-conductive solvent,

compatible with the fluid being sprayed. Conductive

in the

when you

in the system.

solvents can cause the gun to malfunction.

Methylene chloride

flushing

damage nylon components.

Immersing

as a cleaning method. Solvent left in gun passages

could

draw current and reduce the electrostatic ef fect.

Solvent

alternator

or cleaning solvent with this gun as it will

the gun

result in a poor quality paint finish and may

in the power supply cavity can reduce the

life.

of serious bodily injury

eyes or on the skin or electrostatic

stop spraying and before check

CAUTION

is not recommended as a

in solvent is not recommended

, including

Daily Care and Cleaning

1. Clean

2. Clean the outside of the gun daily with a soft cloth

-

3. Clean the air cap and fluid nozzle daily , minimum.

4. Check the electrode wire. Straighten if bent, and

5. Check for any fluid leakage from the gun and fluid

6. Check all of the work hangers for material build-up;

To

shock, BE SURE the turbine air (electrostatics) is

off

the fluid and air line filters daily

dampened

Some applications require more frequent cleaning.

Replace

aged.

replace if broken or damaged. See Replacing the

Electrode

hoses.

clean

reduce the risk of fire, explosion, or electrostatic

before flushing the gun or

in a compatible solvent.

the fluid nozzle and air cap if they are dam

See

Clean the Air Cap and Fluid Nozzle

Needle

See

them if necessary

.

Check for Fluid Leaks.

.

WARNING

any part of the system.

.

.

-

10 308-084

7. Flush the fluid passages by alternating solvent and

air.

Flush before

are

done operating the gun.

changing colors and whenever you

Page 11

Clean the Air Cap and Fluid Nozzle

MAINTENANCE

Equipment

Soft bristle brush (supplied)

Solvent compatible with fluid being sprayed

needed:

Procedure:

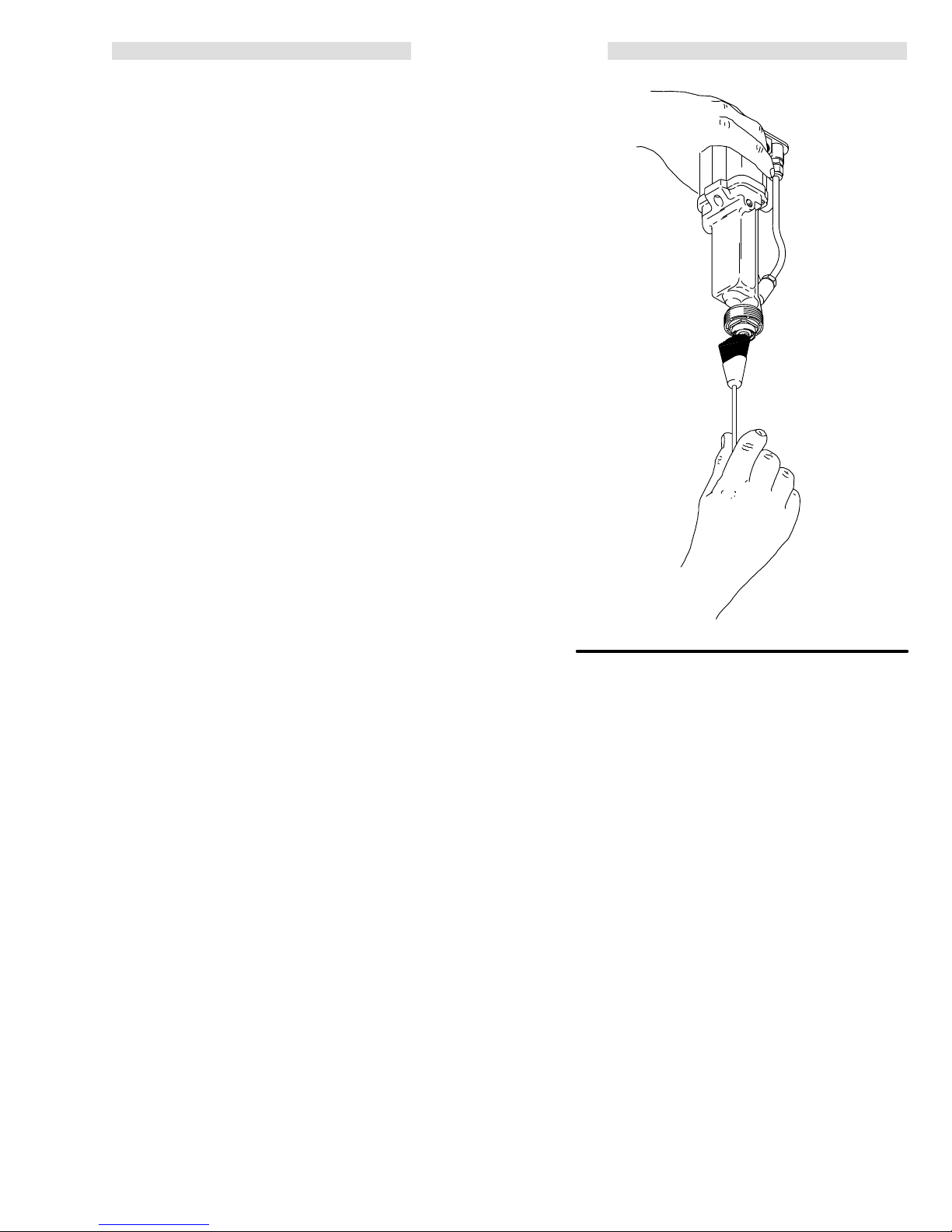

1. Follow

2.

3.

4. Carefully

the

Pressure Relief Procedure W

page

9.

Remove the air cap assembly and gun shroud.

Clean the air cap, fluid nozzle, and front of the

gun, using the soft bristle brush and solvent. Point

the gun down while cleaning to prevent dirty sol

vent from running back into the air passages. See

Fig 9 .

Do not use metal tools to clean the air cap holes

as this may scratch them, and make sure the elec

trode wire is not damaged. Scratches in the air cap

holes or a damaged electrode wire can distort the

spray pattern.

reinstall the air cap assembly

ing the electrode. Tighten the retaining nut until it is

snug,

allowing the air cap to turn with resistance.

. A

void bend

arning

on

-

-

-

Fig 9

0439

MAINTENANCE continued on next page

308-08411

Page 12

Check for Fluid Leakage (See Fig 10 )

WARNING

If any fluid leakage from the gun is detected,

spraying

stop

the gun shroud could cause fire or explosion and

result

in serious bodily injury

IMMEDIATELY!

and property damage.

Fluid leakage into

Fabric

Cover

MAINTENANCE

During

operation, periodically

haust

tubes and both ends of the gun shroud for the pres

ence of fluid. Fluid in these areas would indicate fluid

leakage

If fluid is seen in any of these areas, stop spraying

immediately!

page

9, then remove the gun for repair

into the shroud.

Follow

the

Gun Shroud

check the two manifold ex

Pressure Relief Procedure

.

-

-

on

0437

Fig

10

Check for signs

of fluid leakage

where indicated

by arrows

Exhaust T

ubes

0438

12 308-084

Page 13

SPRAY PA

Installing

ous

and

To

the Pressure Relief Procedure

the

and

servicing this equipment requires access to parts which may cause electrostatic shock or other seri

bodily injury if the work is not performed properly. Do not install or service this equipment unless you are trained

qualified.

reduce the risk of serious bodily injury

system.

TTERN TROUBLESHOOTING CHART

WARNING

, including splashing fluid or solvent in the eyes or on the skin, always follow

on page 9 before checking, adjusting, cleaning or repairing the gun or any part of

-

NOTE:

Check all possible remedies in the T

PROBLEM: CAUSE

IMPROPER SPRA

PATTERN

Fluttering

or spitting

Y

spray

Insuf

Loose fluid nozzle or damaged

fluid nozzle taper seat.

Dirt between fluid nozzle, taper

seat and body

Loose or cracked coupler at

fluid inlet.

Loose fluid tube in tank.

Fluid build-up on air cap; partially

clogged horn holes. Full air pressure from clean horn hole forces

fan pattern toward clogged end.

Bent electrode.

Damaged fluid nozzle or air

cap holes.

Fluid build-up on the perimeter

of fluid nozzle orifice, or partially

clogged fluid nozzle orifice

roubleshooting Charts before disassembling the gun.

SOLUTION

ficient fluid supply

.

.

Adjust fluid regulator or fill fluid tank.

T

ighten or replace fluid nozzle.

See page 19.

Clean. See page 1

T

ighten or repair

Tighten.

Clean with soft implement or

submerge in suitable solvent and

wipe clean. See page 1

Straighten electrode

Replace damaged part. See

page 19.

Remove obstruction. Never use

wire or hard instruments. See

page 1

1.

1.

.

1.

Streaks

NOTE: Some

improper patterns are caused by the improper balance between air and fluid.

Bent electrode.

T

oo high fan air pressure.

Fluid too thin.

Not enough fluid pressure

Low fan air pressure

Fluid too thick

T

oo much fluid.

Last coat of fluid applied too wet.

T

oo much air pressure.

Insuf

ficient air pressure.

Non-uniform spray pattern.

Straighten electrode

Reduce air pressure or adjust fan

air adjusting valve.

Regulate fluid viscosity

Increase fluid pressure.

Increase air pressure.

Regulate fluid viscosity

Reduce fluid flow

Apply drier finish with multiple

strokes.

Use least air pressure necessary

Increase air pressure.

Clean or replace air cap. See

page 1

1.

.

.

.

308-08413

.

Page 14

GUN

PROBLEM CAUSE SOLUTION

Leakage from fluid

packing area

OPERA

Worn

TION TROUBLESHOOTING CHART

fluid rod packings or fluid rod

Replace fluid rod packings or rod.

See page 23.

Fluid leakage from front

of gun

“Orange Peel” finish

Excessive spray fog

No fluid sprays from gun

Fluid rod worn or damaged

W

orn fluid seat

Piston seal or o-ring damaged

Loose resistor stud

Loose fluid nozzle

Damaged resistor stud o-ring

Insuf

ficient air pressure Increase air pressure, use least air

Fluid poorly mixed or filtered

Improper thinner being used

oo much air pressure

T

Fluid thinned too much

Fluid low Check, add fluid if necessary

Damaged air cap

Dirty or clogged fluid nozzle

Replace fluid rod. See page 23.

Replace fluid nozzle and/or

electrode. See page 19 and 20.

Replace seal and/or o-ring and

lubricate.

T

ighten resistor stud. See page 19.

T

ighten fluid nozzle. See page 19.

Replace o-ring. See page 19.

pressure needed for good results.

Remix or refilter fluid.

Use proper thinner

Reduce air pressure, use least air

pressure needed for good results.

Properly thin fluid.

Replace air cap.

Clean fluid nozzle. See page 1

.

.

1.

Equipment covered

with fluid

Dirty air cap

Damaged fluid nozzle

Piston not actuating

Actuator arm out of position

Exhaust air flow insufficient

or not directed properly

Improper distance between gun

and workpiece

Misalignment between air cap

and fluid nozzle

Air

Cap

Fluid Nozzle

ALIGNED MISALIGNED

Replace fluid nozzle. See page 19.

Check cylinder (CYL) air

Check actuator arm (29) and

nuts (25, 7). See page 21.

Check for proper CFM; check

baf

fles and direction of air flow

Adjust spraying distance to

8 to 12 inches (203 to 305 mm).

Remove and clean air cap and fluid

nozzle. See page 1

them.

Or replace fluid nozzle and air cap.

See page 19.

.

.

1. Then reinstall

14 308-084

Page 15

ELECTRICAL

PROBLEM CAUSE SOLUTION

TROUBLESHOOTING CHART

Poor wrap-around

Improper

and workpiece

Parts poorly grounded

High booth exhaust velocity

Atomizing air pressure too high

Fluid pressure too high

Improper fluid viscosity

Fluid resistivity too low

No or low voltage output

T

urbine alternator not operating

Faulty gun resistance

Fluid leaks from fluid rod packing

and causes short

Faulty turbine alternator

distance between gun

Adjust spraying distance to

8 to 12 inches (203 to 305 mm).

Clean hangers, check for proper

ground on conveyer or track.

Reduce exhaust velocity within

code limits.

Reduce atomizing air pressure.

Reduce fluid pressure.

Check supplier for proper fluid for

electrostatic spray

Check fluid resistivity with paint

meter and probe.

Check possible causes listed below

Check air supply to gun.

Check gun resistance. See page 16.

Clean fluid rod cavity

See page 23.

Be sure plug is in place on back of

turbine alternator housing. Remove

and test turbine alternator

.

, replace packing.

. See page 25.

.

Operator gets shock

Operator gets shock

when touching workpiece

No or low voltage output

reading on gun display

module

KV HI-LO switch stuck on low

Operator not properly grounded

or is near an ungrounded object

Gun not properly grounded

W

orkpiece not properly

grounded

Damaged fiber optic cable or

connection

Check switch actuation; replace if

needed.

Be sure floor is properly grounded.

W

ear shoes with conductive soles

or wear personal grounding straps.

Be sure operator is not in contact

with or carrying any metallic items

which could build up electrical charge.

See

Check the Electrical Grounding

Clean workpiece hangers. Check for

proper ground on conveyor or track.

Check cables and connections.

Replace if damaged.

See other causes under

“Poor wrap-around”, above.

Problem

–

.

308-08415

Page 16

ELECTRICAL TESTS

The

performance of

the condition of the electrical components contained

inside

the gun. The electrical tests below can

determine

resistor

path

Use

an

applied voltage of 500 volts to complete these

tests. Connect the leads as shown.

cal

the condition of the

stud (2) as well as the continuity

between the components.

megohmmeter 218–979 (see

Remove the gun from the manifold and bracket, as

instructed on page 18, before performing the electrical

tests.

reduce the risk

To

fire,

explosion, or electrostatic shock

serious

bodily injury

in the hazardous area. Remove the gun from the

hazardous

the spray gun is directly af

power supply (40) and the

ACCESSORIES

WARNING

of sparking, which could cause

, do not use the megohmmeter

area before testing it.

fected by

be used to

of the electrical

) and

electri

and result in

KEY

A Megohmmeter

28 Electrode

39 Gun

-

A

Body

39

Test Gun Resistance (See Fig 11 )

Measure

(28) and the gun body (39). The resistance should be

between 329 to 401 megohms. If the resistance is outside the specified range, go to the next test. If the

resistance is correct, refer to the Electrical

Troubleshooting Chart on page 15 for other possible

causes

the resistance between the end of the

of poor performance.

electrode

Test Power Supply Resistance (See Fig

12 )

Remove the power supply (40) from the gun body (39).

See

page 25.

Measure

contact

ply seal (40d)

slightly

The resistance should be 297 to 363 megohms. If the

resistance

ply

the

the resistance from the power supply’

point (EE) to the contact inside of the power

s ground

sup

[the conductive rubber contact may be

recessed into the seal]

is outside the specified range,

. See Fig 12 .

the power sup

is defective and must be replaced. If the resistance

power supply is correct, proceed to the next test.

of

28

Fig 1

1

0440

KEY

A Megohmmeter

EE Ground

40

40d Seal

Contact Point

Power Supply

A

-

-

If you still have problems, refer to the Electrical

Troubleshooting Chart for other possible causes of

poor performance, or contact the nearest authorized

service

agency

.

Fig

40d

12

40

EE

0441

Page 17

ELECTRICAL TESTS

Test Resistor Stud Resistance

(See Fig 13 )

Remove

Stud Replacement. Check the resistance between the

black resistor stud ring contact (D) and the needle contact

ring

The resistance should be 21 to 29 megohms. If the

resistance

gun

resistance is outside the specified range, the resistor is

defective

Air

the resistor stud. See

ring (E). Y

ou may have to press down on the contact

Air Cap/Nozzle/Resistor

(D) in several places to get a good reading.

is correct, make sure the metal contact in the

barrel and the needle contact ring

and the

resistor stud (2) must be replaced. See

Cap/Nozzle/Resistor Stud Replacement

(E) are clean. If the

.

WARNING

The resistor stud contact ring (D) is a conductive

contact ring, NOT a sealing o-ring. T o reduce the

risk

of sparking, which could

cause fire, explosion,

or electrostatic shock and result in serious injury ,

DO

NOT

remove the resistor stud contact ring (D)

from the resistor stud or operate the gun without

the contact ring in place. DO NOT replace the resistor

stud with anything but a genuine Graco

part.

KEY

D Resistor

E

Needle Contact Ring

E

Fig

13

Stud Contact Ring

D

0442

308-08417

Page 18

SERVICE

WARNING

Installing and servicing this equipment requires

access to parts which may cause electrostatic

shock

or other serious

bodily injury if the work is not

performed properly . Do not install or service this

equipment

unless you are trained and qualified.

NOTE: Check all possible remedies in the

Troubleshooting

Charts

before disassembling the gun.

Flush the Gun and Relieve Pressure

WARNING

To

reduce the risk

shock,

BE SURE the turbine air (electrostatics)

off

before flushing the gun.

of fire, explosion, or electrostatic

is

CAUTION

Methylene chloride

flushing

or cleaning solvent with this gun as it will

is not recommended as a

damage nylon components.

Before

removing the gun for service, flush it by alternat

ing

solvent and air

cedure,

at right.

. Then

follow the

Pressure Relief Pro

Service Notes:

If the plastic parts of the gun must be held in a vise,

ONLY

use padded vise jaws to avoid damaging parts.

WARNING

Pressure Relief Procedure

To

reduce the risk

of serious bodily injury

splashing in the eyes or on the skin, injury from

moving parts or electrostatic shock, always follow

procedure when shutting of

this

checking

when

and

1. Turn

2. T

or servicing any part of the spray system,

installing, cleaning or changing fluid nozzles,

whenever you stop spraying.

of

f the air to the control module, except for

the

manifold air

used,

air pressure is needed at the regulator air

inlet

to relieve pressure in the fluid line.

urn of

f the fluid supply to the gun.

. If the air pilot fluid regulator is

f the system, when

3. Trigger the gun into a grounded metal waste

container

to relieve fluid pressure.

4. Open the pump drain valve, having a waste

container

5. Leave

ready

ready to catch the drainage.

the pump drain valve open until you are

to spray again.

Remove the Gun from the Manifold and

-

the Mounting Bracket (See Fig 14 )

-

1. Remove

shroud.

2. Loosen the three socket head cap screws and the

button head screw, using the ball end wrench (46)

supplied.

the air

cap/air cap nut assembly and the gun

, including

ALWAYS

or repair

Air

Cap/

Air

Cap Nut

remove the gun from the worksite for service

. The service or repair area must be clean.

Spray Gun

Shroud

3. Remove

the gun from the manifold.

Manifold

O-Ring

Head

Button

Screw

Socket Head

Cap Screws

Fig 14

18 308-084

01179

Page 19

SERVICE

Air Cap/Nozzle/Resistor Stud

Replacement

CAUTION

SURE to

BE

removing

drain

the gun

in

the gun from entering the air passages.

1. Point

fluid

nozzle (14) and resistor stud

the

nozzle wrench (48). This helps drain the gun and

prevent any paint or solvent left in the gun from

entering

If

the resistor stud remains in the gun when the fluid

nozzle is removed, start the nozzle thread onto the

stud

and pull the stud out.

2. Using

resistor

resistor stud contact ring (D) is a conductive con

The

tact

ring, NOT a

sparking, which could cause fire, explosion, or electrostatic shock and result in serious injury, DO NOT

remove

erate the gun without the contact ring in place. DO

NOT replace the resistor stud with anything but a

genuine

hold the front end of the gun up while

the nozzle and resistor stud. This helps

and prevent any paint or solvent left

the front end of the gun up while removing the

(2) assembly with

the air passages. See Fig 15 .

an

8 mm hex key (A), unscrew and remove the

stud (2). See Fig 16 .

WARNING

sealing o-ring. To reduce the risk of

the contact ring from the resistor stud or op

Graco part.

KEY

6,

D Contact

2

Resistor Stud

6, 16,

43

Air Cap Assembly

9

Retaining Ring

12 O-Ring

14

Fluid Nozzle

28 Electrode

31 O-Ring

Nozzle

48

Wrench

Ring

16, 43

12

9

28

14

2

D

48

31

-

Fig 15

0443

14

Torque

10 in-lbs

(1.12 N

to

m)

2

KEY

A

8 mm Hex Key

2

Resistor Stud

14

Fluid Nozzle

T

o install the resistor stud:

3. Lightly lubricate the o-ring (31) with petroleum jelly

and

install it on the resistor stud (2).

4. Using an 8 mm hex key (A), install the resistor stud

(2) in the fluid nozzle (14). T ighten to 10 in-lb

(1.12 N

m).

Make sure the electrode (28) is tightened properly ,

as

shown in Fig 17 , page 20.

5. Install the fluid nozzle (14) and resistor stud (2)

assembly with the nozzle wrench (48). Tighten until

the

fluid nozzle seats in the gun barrel (1/8 to 1/4

past

hand-tight).

turn

6. Install the air cap assembly (6, 16, 43), o-ring (12),

and retaining ring (9). T est gun resistance as

instructed

on page 16.

A

Fig 16

0444

308-08419

Page 20

SERVICE

Electrode Replacement

1. Remove the air cap, nozzle and resistor stud as

described in Air Cap/Nozzle/Resistor Stud

Replacement.

2. Unscrew

with the electrode tool (47) provided. Be careful not

to

damage the contact wire. See Fig 17 .

If

the fluid rod turns, hold the back end of the fluid rod.

3. Apply low-strength

thread

Refer

Hold the back end of the fluid rod to prevent it from

turning

DO

To avoid damaging the plastic threads or contact

wire,

4. Install the fluid nozzle and resistor stud assembly .

Install

as

and remove the fluid needle/electrode (28)

(purple)

Loctite or equivalent

sealant to the electrode and fluid rod threads.

to

SER

VICE NOTES

while installing the new

, page 25.

electrode finger tight.

NOT over tighten the electrode.

CAUTION

be very careful when installing the electrode.

the air cap assembly

. T

est the gun resistance

instructed on page 16.

KEY

28 Electrode

47 Electrode Tool

Apply

low-strength

(purple)

Loctite

or equivalent

47

28

Fig

17

0445

Page 21

SERVICE

Barrel Removal

1. Carefully

(19)

nut

2.

Remove the jam nut (25) and actuator arm (29).

NOTE:

or

installing the jam nut and actuator arm.

3. Using

three

4. Hold the gun body (39) with one hand and pull the

barrel

See

To avoid damaging the power supply

the

necessary, gently move the barrel from side to

side

loosen the fluid fitting nut (21). Pull the tube

out of the fitting. Make sure both ferrules and the

stay with the tube. See Fig 19 .

The fluid nozzle must be in place when

the ball end wrench (46), supplied, loosen

removing

the

socket head cap screws (15). See Fig 20 .

(10) straight

away from the body to remove it.

Fig 18 .

CAUTION

, always pull

gun barrel straight away from the gun body

to free the power supply from the gun body

. If

.

KEY

10 Gun

39

Gun Body

40

Power Supply

Barrel

10

39

40

KEY

7 Jam

10

Gun Barrel

19

Fluid T

21

Fluid Fitting Nut

Fig

19

Nut

ube

25

29

39

Jam Nut

Actuator Arm

Gun Body

10

Fig 18

25 29 7

19

0447

39

21

0446

308-08421

Page 22

Barrel Installation

1. Be

sure the gaskets (23 & 40a) and spring (1

place.

See Fig 20 . Replace if damaged.

SERVICE

1) are in

4.

Install the fluid tube back into the fluid fitting (21).

5. Install

the actuator arm (29) and jam nut (25), with the

jam

nut assembled flush to the end of the rod.

2. Place

the barrel (10) over the power supply (40) and

onto

the gun body (39). Make sure the fluid rod spring

(11)

is seated properly

.

3. Tighten the three socket head cap screws (15)

oppositely

and evenly with the ball end wrench (46).

Tighten the cap screws to 18 in-lbs (2 N m)

MUM

(about a half turn past snug).

DO NOT

tighten.

CAUTION

To

avoid damaging the gun,

DO NOT

over

tighten

the cap screws (15). Tighten the screws to 18 inlbs (2 N m)

snug),

MAXIMUM

using the wrench (46) supplied only

(about a half turn past

.

KEY

10 Gun

11 Spring

15

21

23 Gasket

25

29

39

40

40a Gasket

Barrel

Cap Screws

Fluid T

ube Fitting

Jam Nut

Actuator Arm

Gun body

Power Supply

15

MAXI-

over

There

should be about a 1/16 in. gap between the ac

tuator

arm (29) and the nut on the fluid shaft. When

the gun is triggered, the electrode needle should

draw back 3 to 4 mm. If necessary , adjust the jam

nuts

to obtain these dimensions.

The

jam nut

from

loosening during operation.

6. T

est the gun resistance as instructed on page 16.

must be tightened securely to prevent it

39

40a

40

23

-

Fig 20

10

21

29

25

11

0457

Page 23

SERVICE

Fluid Packing Rod Removal and Repair

NOTE: The fluid packing rod can be replaced as

individual parts or as an assembly . If the assembly is

purchased,

1. Remove

2. Remove

tor stud and electrode as described in Electrode

Replacement.

3. Remove

9

Clean all parts in non-conductive solvent

compatible

or

cause the gun to malfunction.

4. Check

necessary.

Before installing the fluid packing rod assembly (3),

clean the internal surfaces of the barrel with a soft

brush or cloth. Check the inside of the barrel for

marks from high voltage arcing. If the marks are

present,

5.

If the parts are purchased separately ,

them as instructed in steps 6 to 9 and as shown in

Fig 22 .

If installing the complete fluid rod assembly ,

step

it is pre-adjusted at the factory

.

the jam nut (25) and arm (29). See Fig 20 .

the air cap assembly

the fluid packing

, fluid nozzle and resis

rod assembly (3), using the

mm hex nut driver (45). See Fig 21 .

CAUTION

with the fluid being used, such as xylol

mineral spirits. Use of conductive solvents can

all the parts for wear or damage and replace if

replace the barrel.

assemble

go to

10, on page 24.

-

KEY

3 Fluid

45

Packing Rod Assembly

Hex Nut Driver

3

45

Fig 21

6. Place

7. Fill

the packing nut (3c) and o-ring (3g) on the fluid

rod

(3b). The flats on the packing nut must be facing

toward

the back of the fluid rod.

the entire inner cavity of the spacer (3d) with the

dielectric grease included with the gun. Place the

spacer

on the fluid rod (3b), in the direction shown in

Fig

22 . Generously apply the grease to the outside

of

the spacer

.

0448

KEY

E Nut

3 Fluid

3a

3b

3c

3d Spacer

3e

3f

3g O-Ring

11 Spring

Fig

Packing Rod

Assembly

Packing Housing

Fluid Rod

Packing Nut

Rod Packing

Fluid Packing

22

3b

3e

3f

3h

3a

3d

3g

(Item 11 not included with

Fluid Packing Rod Assembly)

11E

3c

3

03224

308-08423

Page 24

SERVICE

Fluid Packing Rod Removal and Repair

(continued)

8. Place the fluid packing (3f), rod packing (3e), and

housing

9. Lightly

is

force

bly

as

10. Lubricate

housing (3a).

(3a) on

tighten the packing nut (3c). The packing nut

properly tightened when there is 2 lbs. (9 N) of drag

when sliding the packing housing (3a) assem

along the shaft. T

needed.

the fluid rod (3b) as shown in Fig 22 .

ighten

or loosen the packing nut

the o-ring (3h) on the outside of the packing

11. Install

12. Make

-

7. Install the electrode, nozzle and resistor stud

8. Install

the fluid packing rod assembly (3) into the gun

barrel.

Using the 9 mm hex nut driver (45), tighten the

assembly

fluid rod.

shown

assembly and the air cap assembly as described in

Electrode

assembled

page 22.

until just snug, then

sure the spring (1

in Fig 22 .

Replacement

the arm

(29) and jam nut (25), with the jam nut

flush to the end of the rod. See Fig 20 ,

1) is installed on the nut (E)

check the drag on the

.

as

Page 25

SERVICE

KEY

F 3-wire

G Potentiometer

10

13

27 Alternator

27a O-Ring

27b Cushion

39

40

40a Gasket

40b Pad

40c Pad

40d Seal

40e Cushion

Connector

Gun Barrel

Retainer Ring

Gun Body

Power Supply

40a

40

40d

10

Fig

23

Power Supply Removal and Replacement

REPAIR

1. Remove

2.

3. Inspect the power supply for any physical damage.

4. Lubricate

5. Install

NOTES:

a. T

o avoid a loss in electrostatic performance,

inspect the gun handle’

s power supply cavity

for dirt or moisture. Clean the cavity with a

clean, dry rag.

b.

Do not expose the seal (40d) or o-ring (27a) to

solvents as solvents will damage them.

the barrel as described in

Barrel Removal

Grasp the power supply (40) with your hand. With a

gentle

side-to-side motion, being careful not to dam

the power supply

age

the

gun handle (39), then pull it straight out.

Check

the electrical

, pull the power supply free

resistance as instructed in

from

Test

Power Supply Resistance. If needed, replace the

power

supply

.

Before installing the power supply, inspect the seal

(40d) for any damage or swelling; replace if necessary. Also, make sure the gaskets/pads (40a–40e)

are

in place.

the

o-ring (27a) and insert the power sup

in the gun handle.

ply

the barrel on the handle as

described in

Barrel

Installation.

40b

G

.

-

-

40e

13

39

40c

F

27a

27b

27

0450

Power Supply Adjustment

The KV HI/LO switch, on the back of the gun manifold,

enables you to switch between full voltage and a lower

voltage

but

output. The lower voltage is factory set at 60 kV

can be adjusted between 45 and 80 kV

.

To adjust the low voltage setting, use a small blade end

screw driver to turn the potentiometer (G), clockwise

increase

fully

the voltage or counterclockwise to decrease it;

clockwise is 80 kV

, fully counterclockwise is 45 kV

to

Turbine Alternator Removal and

Replacement

NOTE: Replace turbine bearings after 2,000 hours of

operation.

1. Remove the power supply from the gun handle as

2. Squeeze the two ends of the retaining ring (13)

3. Use an ohmmeter to test the turbine alternator coil.

4. Connect

See your authorized Graco representative.

described

at left.

together and carefully pull the alternator (27) away

from the power supply (40) until the wire connector

disengages. See Fig 23 .

(F)

Measure

the resistance between the two outer termi

nals of the 3-wire connector (F). Resistance should

be

3 to 5 ohms. If the

replace

the alternator

reading varies from this value,

.

the 3-wire connector to the 3 prongs in the

power

supply

. Push the alternator (27) onto the pow

er supply (40) until the retaining ring (13) engages

with

the alternator

.

,

.

-

-

5. Install the power supply in the gun handle as

described

at left.

308-08425

Page 26

ighten

Nozzle

T

turn past hand tight

SPRAY GUN SERVICE NOTES

Lubricate

1/8 to 1/4

T

ighten

Stud

10 in-lbs (1.15 N

Resistor

into nozzle to

m)

CAUTION: Do not

damage Needle

wire during

trode

assy

. or disassy

Elec

-

.

Apply

ple)

equivalent to threads

Lubricate

low strength

Loctite or

(pur-

CAUTION:

tighten Capscrews

18

in-lbs (2 Nm) MAXIMUM

(about

half turn past snug), us

DO NOT over

wrench provided.

ing

. T

ighten to

Lubricate

-

T

orque

Fitting

(2.8–4.0 N

Install

grooves

to 25–35 in-lbs

m)

into

internal

in fitting

WARNING: DO

NOT remove

contact ring

Lubricate

Fits between

flared tube

and fitting

Stretch o-ring to start

it over fitting threads,

then thread it into

Install

flush to

end

of rod

place

Apply

high strength

(red)

Loctite or

equivalent to threads.

Lubricate

Apply

PTFE paste

to threads

Lubricate

0433

Page 27

Concave side

toward manifold

MANIFOLD SERVICE NOTES

Press

fit

Apply low strength

(purple)

Loctite or

equivalent

T

orque to

25 in-lb

(2.8 N

T

orque to

25 in-lb

(2.8 N

Apply low strength

(purple)

Loctite

or equivalent

m)

m)

Left-hand

threads

Lubricate

Must be

clean

Press fit

T

ighten until

hex bottoms

against manifold

0434

This end 8.5-8.9”

(215-225 mm) from

manifold surface when

properly assembled

Standard o-ring is V

Optional EPR o-ring is

provided with the man

for compatibility with

ifold

ketone

solvents.

iton.

-

Lubricate

orque to

T

25 in-lb

(2.8 N

m)

0434

308-08427

Page 28

SPRAY GUN P

ARTS DRA

WING

REF

NO. 3

Includes items 3a–3h

DETAIL A

3e

3a

3h

0601

43

12

6

3f

3d

16

3g

3c

See

Detail A

28

31

2

3

3b

14

9

27a

27

40e

27b

13

40b

18

40c

25

10

29

REF

15

3

7

36

11

20

REF 19

30

19

21a

21b

21

40

40d

40a

22

42

23

32

8

24

4

1

17

36

41d

39

41f

41a

41h

41j

41c

41b

41i

41g

41e

5

41

0433

Page 29

SPRAY GUN PARTS LIST

Part No. 224–224 Automatic

Electrostatic Air Spray Gun, without shroud

Includes items 1–17, 19–52

Part No. 235–893, Series A

Air Spray Gun, with standard shroud

Includes items 1–52

REF

NO. PART NO. DESCRIPTION QTY

1 186–762 PISTON, valve

2 223–977 STUD, resistor 1

3 224–747 PACKING ROD ASSY

Includes items 3a–3h

3a 185–495

3b 223–981

3c 185–488

3d* 186–069

3e* 178–763

3f* 178–409

3g* 111–504

3h* 111–316

4 186–763 COVER, piston 1

5 111–177 CAP SCREW

6 186–764 RING, air cap 1

7 102–025 NUT

8 100–518 SCREW

9 176–930

10 223–940

11 185–111 SPRING, compression

12{ 110–492 O-RING, PTFE r 1

13 185–114

14 185–158

15 185–096 SCREW

16 177–033

17{ 181–039 PACKING, u-cup, UHMWPE 1

186–770 SHROUD, standard;

188–699 SHROUD, slotted;

19 186–958

20 186–765 ROD, actuator 1

21 187–319 CONNECT

21a* 111–285

21b* 111–286

22 186–818

{ 185–113 GASKET

23

24 181–178 CAP

25 101–324 NUT

27 222–319 ALTERNAT

{ 110–073 SO-RING, Vitonr 1

27a

27b 185–124

28 185–107

29 186–766

30* 102–982 O-RING; PTFE

31* 111–507

32 111–182 SPRING, compression 1

{* 111–450

36

SHOUSING, packing 1

S

ROD, fluid

SNUT

, packing

SSPACER, packing 1

SPACKING, rod 1

SP

ACKING, fluid

S

O-RING, fluoroelastomer

S

O-RING, fluoroelastomer

, button hd; 1/4-20 x 0.5”

, hex; 1/4”-20

, mach, pnh; 6–32 x 3/8”

RING, retaining

BARREL, gun

RING, retainer

NOZZLE, fluid, See Manual 307–803

for available nozzles

AIR CAP; See Manual 307–803 for

available air caps

, alternator

, cap, relieved; M5 x 0.8

included with

Part No. 235–893 only

included with

Part No. 235–894 only

TUBE, flared;

OD tubing; Includes items 21a & 21b

SFERRULE 1

SFERRULE 1

FITTING, fluid; 5/8-20

, retainer

, hex, jam; 1/4”-20

Includes items 27a & 27b

SCUSHION 1

NEEDLE, electrode

ARM, actuator

O-RING; fluoroelastomer

O-RING; fluoroelastomer

PTFE 1

OR, male; 1/8 npt; for 1/4”

, manifold; polyethylene

, spring

OR, turbine

r 1

Part No. 235–894, Series A

Air Spray Gun, with slotted shroud

Includes items 1–52

REF

NO. PART NO. DESCRIPTION QTY

1

1

1

39 224–095 BODY

40 224–093 POWER SUPPLY ASSY

1

1

1

1

1

1

1

1

4

1

1

1

1

3

1

1

1

{ 186–840 SGASKET

40a

40b 185–099

40c 185–145

{ 186–637 SSEAL 1

40d

40e 185–141

41 224–340 CHECK VALVE ASSY

41a 187–264

41b 108–046

41c 101–435

41d 186–980

41e 186–981

41f 186–982

41g 186–983

41h 186–984

41i 186–985

41j 103–337

42* 103–337 O-RING; Viton 2

{ 186–848 GASKET

43

44** 179–791 T

45 110–087

46 107–460 WRENCH, barrel

47 185–123 WRENCH, electrode

48 187–421 WRENCH, nozzle

49** 180–060

50 187–343 COVER, gun

51 110–088

52 105–749 BRUSH 1

* The

replacements for these parts are available in Fluid Seal

Repair

Kit 237–786. Purchase the kit separately

** Additional warning tags and signs available at no charge.

French,

1

1

1

1

1

able. See ACCESSORIES section.

{

The replacements for these parts are available in Air Seal

Repair

When

German,

Kit 224–636. Purchase the kit separately

servicing use only genuine Graco replacement

and Spanish warning signs are also avail

parts. Use of other parts or any modification of the

could alter the grounding continuity of

1

1

1

2

gun

cause

parts to rupture and result in serious injury

explosion,

electrostatic shock or property damage.

, gun

; 85 KV

Includes items 40a–40e

, power supply

SPAD 1

SPAD 1

SCUSHION 1

Includes items 41a-41j

SMUFFLER/FLAME ARRESTOR 1

SBEARING, ball 1

SBEARING, ball 1

SFITTING, check valve; 5/16-18 1

SSCREW, check valve; M4 x 0.7 1

SBODY, check valve; 3/4-16 1

SNUT, check valve; 3/4-16 1

SSEAT, check valve 1

SVALVE, check, body 1

SO-RING; Viton 2

, air cap nut

AG, warning

DRIVER, hex nut; 9 mm

(not shown)

(not shown)

(not shown)

(not shown)

(not shown)

SIGN, warning, English

(not shown)

(not shown)

WRENCH, allen; 8 mm

.

.

WARNING

the gun or

, fire,

1

1

1

1

1

1

1

1

1

1

1

1

1

-

308-08429

Page 30

111

114

MANIFOLD P

110

106

ARTS DRA

WING

122

117d

117c

117h

116

118

117b

117g

104

117e

117f

104

103

107

113

115

MANIFOLD PARTS LIST

124

112

121

101

109

108

0434

Part No. 224–094 Gun Manifold

Includes items 101–124

REF

NO. P

101 111–224 LENSE

103* 106–167

104 110–078

106 186–846 BOLT

107 186–820 MANIFOLD 1

108 183–822

109

110 186–844

111 186–845

112

113 186–779

114 107–107

115 111–157

116 111–237

117 224–143

117a 186–809

117b 186–808

117c 186–810

117d 111–165

117e 224–577

ART NO.

{ 105–668 O-RING; Vitonr 4

{ 105–796 O-RING, Viton 1

DESCRIPTION QTY

O-RING; perfluoroelastomer

FITTING, tube; for 3/8” OD tube

, manifold; M5 x 0.8

SLEEVE, o-ring

FITTING, flow-washer; M16 x 1.5 LH

FITTING, turbine; 1/4-18 npsm LH

FITTING, fiber optic cable; 7/16-20

DISK, regulator

FITTING, tube; for 1/4” OD tube

FITTING, barb

SWITCH, voltage

Includes items 17a-17h

SCYLINDER 1

SPISTON 1

S

FITTING, plug

S

FITTING, male

SMAGNET 1

REF

NO. P

1

117f 111–208 SSPRING, compression 1

2

117g 111–295

2

117h 111–294

3

118 185–819

121 186–847

4

122

123 111–333 O-RING; EPR 1

1

124 224–548 TUBE 1

1

*

1

1

{

1

1

1

1

1

ART NO.

{ 111–180 O-RING; Viton 1

The replacements for these parts are available in Fluid Seal