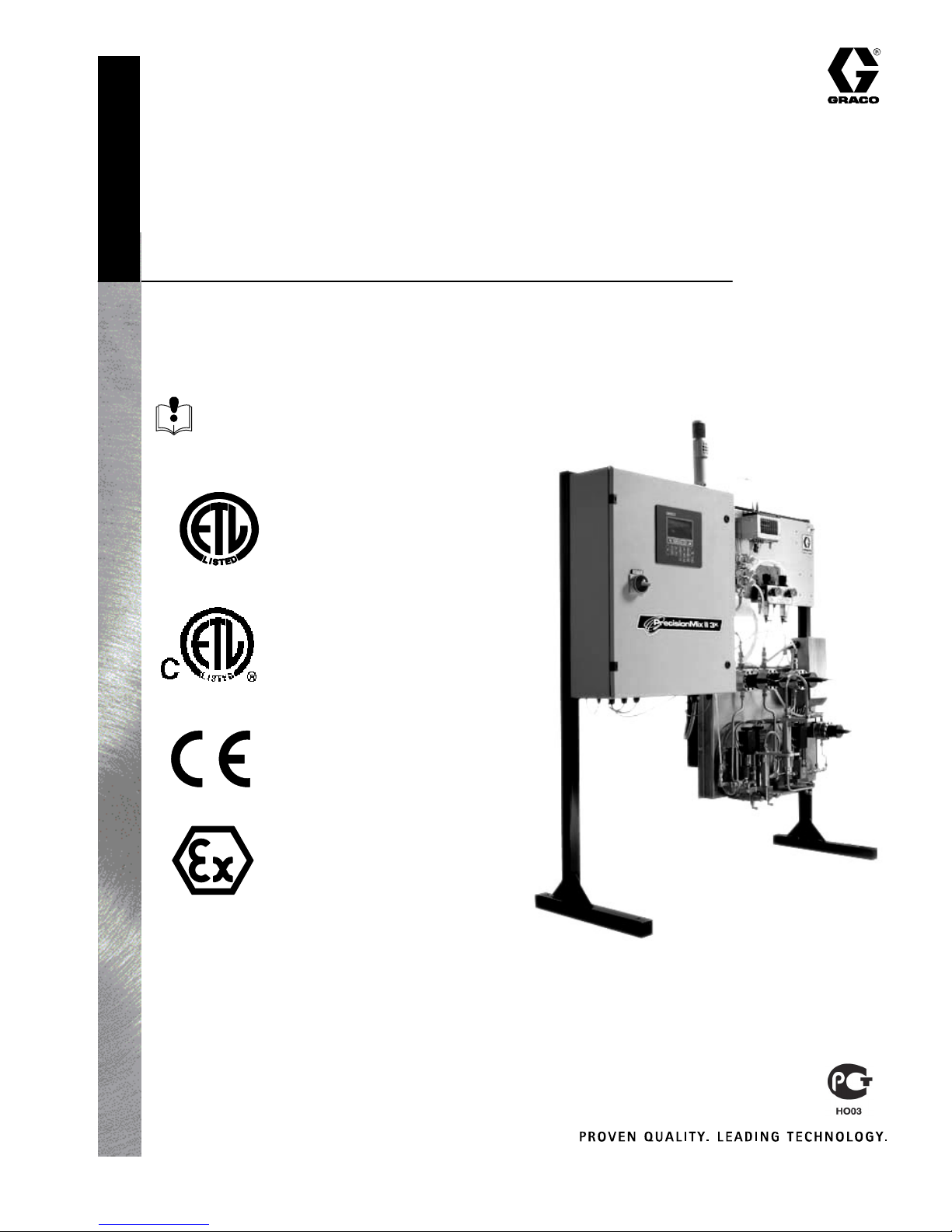

Page 1

Instructions – Parts List

PRECISIONMIX II

3K System

309107E

For Proportional Mixing of Two and Three Component Coatings

Patent No. 5,368,059

Read warnings and instructions.

See page 2 for the Table of Contents.

Conforms to ANSI/UL

standard 2279

Class 1 Zone 0

AExia II A T4

110474

Certified to CAN/CSA

22.2 No. E79–11

0359

II 2 G

EEXia II A T3

ITS03ATEX21382

GRACO INC.ąP.O. BOX 1441ąMINNEAPOLIS, MNą55440-1441

Copyright 2001, Graco Inc. is registered to I.S. EN ISO 9001

Page 2

Table of Contents

Warnings 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using this Manual 2–3. . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 2–4. . . . . . . . . . . . . . . . . . . . . .

How the PrecisionMix II 3K Works 2–6. . . . . . . . . .

Functional Diagrams 2–7. . . . . . . . . . . . . . . . . . .

Changing the Mixing Order 2–10. . . . . . . . . . . . . . . .

Flow Control Overview 2–12. . . . . . . . . . . . . . . . . . .

Flow Control Features 2–12. . . . . . . . . . . . . . . .

System Requirements 2–12. . . . . . . . . . . . . . . .

General Operation Sequence 2–12. . . . . . . . . .

One Gun Flow Control Using a Flow Meter

in the Mixed Material Line 2–13. . . . . . . . . .

Flow Control Components 2–14. . . . . . . . . . . . .

Flow Control Parameters 2–15. . . . . . . . . . . . . .

Using Recipes/Color Change 2–16. . . . . . . . . . . . . .

No Color Change 2–16. . . . . . . . . . . . . . . . . . . . .

Integrated Color Change 2–16. . . . . . . . . . . . . .

Integrated Color Change with Queue 2–17. . . .

Color Change Sequences 2–18. . . . . . . . . . . . .

Changing from One Color Change

Sequence to Another 2–19. . . . . . . . . . . . . .

Actual Valve Times 2–20. . . . . . . . . . . . . . . . . . .

Installation 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Typical Installation 3–3. . . . . . . . . . . . . . . . . . . . . . . .

Non-intrinsically Safe 3–4. . . . . . . . . . . . . . . . . .

Intrinsically Safe 3–5. . . . . . . . . . . . . . . . . . . . . .

Fluid Supply Requirements 3–6. . . . . . . . . . . . . . . . .

Mounting Components 3–7. . . . . . . . . . . . . . . . . . . .

For Wall Mounting 3–7. . . . . . . . . . . . . . . . . . . . .

Stand Mounting Kit 241501 3–9. . . . . . . . . . . . .

System Installation 3–10. . . . . . . . . . . . . . . . . . . . . . .

Install the Controller and User Interface 3–10.

Power Requirements 3–11. . . . . . . . . . . . . . . . .

Install the Fluid Panel with Fluid Meters 3–12.

Install the Air Control Kit 3–13. . . . . . . . . . . . . .

Install the Operator Station 3–13. . . . . . . . . . . .

Install the Color/Catalyst/Reducer

Change Valves and Solenoids 3–14. . . . . .

Install the Gun Flush Box and

Solenoid Box 3–16. . . . . . . . . . . . . . . . . . . . .

Install the Optional Flow Control 3–20. . . . . . . .

Fluid Connections 3–20. . . . . . . . . . . . . . . . . . . .

Pressure Test and Solvent Flush

the System 3–20. . . . . . . . . . . . . . . . . . . . . .

Digital Outputs 3–21. . . . . . . . . . . . . . . . . . . . . . .

Component Electrical Connections 3–22. . . . . . . . .

Controller Terminal Block 3–29. . . . . . . . . . . . . . . . .

Ground the System 3–30. . . . . . . . . . . . . . . . . . . . . .

Check the Resistance 3–31. . . . . . . . . . . . . . . . . . . .

Power-up Checklist 3–32. . . . . . . . . . . . . . . . . . . . . .

Checking Flow Control I/P Transducers 3–34.

Testing Flow Control External 4–20 mA Input

Signal 3–35. . . . . . . . . . . . . . . . . . . . . . . . . . .

Pressure Test and Solvent Flush Procedure 3–36.

Test Color Valve Operation 3–36. . . . . . . . . . . .

Pressure Test Component A 3–36. . . . . . . . . . .

Pressure Test Component B and C 3–36. . . . .

Pressure Test the Solvent Lines 3–36. . . . . . . .

Operation 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pressure Relief Procedure 4–3. . . . . . . . . . . . . . . . .

Operator Controls and Indicators 4–4. . . . . . . . . . . .

Operator Station 4–4. . . . . . . . . . . . . . . . . . . . . .

User Interface 4–6. . . . . . . . . . . . . . . . . . . . . . . .

Operating Checklist 4–7. . . . . . . . . . . . . . . . . . . . . . .

Mode Switch 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purging the Ratio Check Valves 4–8. . . . . . . . . . . . .

Purging the PrecisionMix II 3K System 4–10. . . . . .

Starting Production 4–12. . . . . . . . . . . . . . . . . . . . . . .

Stopping Production 4–14. . . . . . . . . . . . . . . . . . . . . .

Flow Control Operation 4–15. . . . . . . . . . . . . . . . . . .

Flow Control Tips 4–15. . . . . . . . . . . . . . . . . . . . . . . .

Integrated Color Change 4–16. . . . . . . . . . . . . . . . . .

Multiple Gun Flush Box Operation 4–16. . . . . . . . . .

Printer Reports 4–18. . . . . . . . . . . . . . . . . . . . . . . . . .

Run Mode Report 4–18. . . . . . . . . . . . . . . . . . . .

Recipe Report 4–19. . . . . . . . . . . . . . . . . . . . . . .

System Setup (Configuration) Report 4–20. . .

Job Totals Report 4–22. . . . . . . . . . . . . . . . . . . .

Batch Totals Report 4–22. . . . . . . . . . . . . . . . . .

Grand Totals Report 4–23. . . . . . . . . . . . . . . . . .

Alarm Report 4–23. . . . . . . . . . . . . . . . . . . . . . . .

Screen Map 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Run Monitor 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Home Screen 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Target/Actual 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flow Rate 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Potlife Timer 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flow Rate Setpoint 6–5. . . . . . . . . . . . . . . . . . . . . . . .

Enter New Setpoint 6–5. . . . . . . . . . . . . . . . . . . . . . .

Recipe Select 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm History 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Integrated Color Change with Queue 6–7. . . . . . . .

Modify Queue Screen 6–8. . . . . . . . . . . . . . . . . . . . .

Totalizers 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Home Screen 7–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Select Recipe and Totalizer Screen 7–3. . . . . . . . . .

Job Totals 7–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Batch Totals 7–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Grand Totals 7–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

Page 3

Table of Contents

System Configuration 8–1. . . . . . . . . . . . . . . . . . . . . . .

Home Screen 8–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Password Screen 8–3. . . . . . . . . . . . . . . . . . . . . . . . .

Menu Screen 8–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Language 8–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Station Number 8–5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Units of Measurement 8–6. . . . . . . . . . . . . .

Recipes 8–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Potlife Timer 8–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flow Rate Limits 8–7. . . . . . . . . . . . . . . . . . . . . . . . . .

Solvent Meter 8–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purge Sequence: Valves 8–8. . . . . . . . . . . . . . . . . . .

Purge Sequence: Purge Alarms 8–9. . . . . . . . . . . .

Mixed Load Volumes 8–10. . . . . . . . . . . . . . . . . . . . .

Guns Setup 8–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mix/Purge 8–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flow Control 8–11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Integrator Volume 8–12. . . . . . . . . . . . . . . . . . . . . . . .

Integrated Color Change 8–12. . . . . . . . . . . . . . . . . .

Password Selection 8–12. . . . . . . . . . . . . . . . . . . . . .

Time and Date Set 8–13. . . . . . . . . . . . . . . . . . . . . . .

Display Setup 8–14. . . . . . . . . . . . . . . . . . . . . . . . . . .

Print Setup 8–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air Flow Switch 8–15. . . . . . . . . . . . . . . . . . . . . . . . . .

Flow Control Setup 8–16. . . . . . . . . . . . . . . . . . . . . . .

Home Screen 8–16. . . . . . . . . . . . . . . . . . . . . . .

Password Screen 8–16. . . . . . . . . . . . . . . . . . . .

Menu Screen 8–16. . . . . . . . . . . . . . . . . . . . . . . .

Flow Control Options 8–17. . . . . . . . . . . . . . . . .

Flow Control Menu 8–17. . . . . . . . . . . . . . . . . . .

Source of Flow Control Data 8–18. . . . . . . . . . .

Flow Control Scaling 8–18. . . . . . . . . . . . . . . . . .

Flow Control Force Output 8–19. . . . . . . . . . . .

Flow Control Delay Time 8–19. . . . . . . . . . . . . .

Flow Control Meter Location 8–20. . . . . . . . . . .

Integrated Color Change Setup 8–21. . . . . . . . . . . .

Home Screen 8–21. . . . . . . . . . . . . . . . . . . . . . .

Password Screen 8–21. . . . . . . . . . . . . . . . . . . .

Menu Screen 8–21. . . . . . . . . . . . . . . . . . . . . . . .

Color Change Mode Screen 8–22. . . . . . . . . . .

Color Change Sequence 8–22. . . . . . . . . . . . . .

Color Change Graph Screen 8–23. . . . . . . . . . .

Purge and Mix Timer Values 8–23. . . . . . . . . . .

A Component Dump Timer Value 8–24. . . . . . .

A Component Solvent Timer Value 8–24. . . . .

B Component Dump Timer Value 8–25. . . . . . .

B Component Solvent Timer Value 8–25. . . . .

C Component Dump Timer Valve 8–26. . . . . . .

C Component Solvent Timer Valve 8–26. . . . .

Gun 1 Trigger Start/Duration Times 8–27. . . . .

Gun 2 Trigger Start/Duration Times 8–27. . . . .

Special 1, 2, 5, and 6

Trigger Start/Duration Times 8–28. . . . . . .

PrecisionMix II 3K Robotic Interface 8–29. . . . . . . .

Pressure Test and Solvent Flush

the System 8–29. . . . . . . . . . . . . . . . . . . . . .

PrecisionMix II 3K Robotic Applications 8–29.

Integrated Color Change 8–30. . . . . . . . . . . . . .

Non-integrated Color Change 8–31. . . . . . . . . .

Digital Inputs 8–32. . . . . . . . . . . . . . . . . . . . . . . .

Recipe Setup 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Home Screen 9–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Password Screen 9–3. . . . . . . . . . . . . . . . . . . . . . . . .

Recipe Selection 9–4. . . . . . . . . . . . . . . . . . . . . . . . . .

Setup Menu with Integrated Color Change On

and Flow Control On 9–5. . . . . . . . . . . . . . . . . . .

Setup Menu with Integrated Color Change

and Flow Control Off 9–5. . . . . . . . . . . . . . . . . . .

Mix Ratio and Tolerance 9–6. . . . . . . . . . . . . . . . . . .

Color Change Sequence 9–7. . . . . . . . . . . . . . . . . . .

Purge Sequence 9–8. . . . . . . . . . . . . . . . . . . . . . . . . .

System Alarms with Flow Control On and

Hand Gun Selected 9–9. . . . . . . . . . . . . . . . . . . .

System Alarms with Flow Control On and

Automatic Gun Selected 9–10. . . . . . . . . . . . . .

System Alarms with Flow Control Off 9–10. . . . . . .

Meter Calibration Tests 9–11. . . . . . . . . . . . . . . . . . .

Component A Flow Meter Calibration 9–12. . . . . . .

Component B Flow Meter Calibration 9–13. . . . . . .

Component C Flow Meter Calibration 9–13. . . . . . .

Solvent Flow Meter Calibration 9–14. . . . . . . . . . . .

Mixed Material Calibration Screen 9–14. . . . . . . . . .

Gun 1 Meter Calibration 9–15. . . . . . . . . . . . . . . . . .

Setup Flow Control 9–16. . . . . . . . . . . . . . . . . . . . . . .

Gain Factor Graphs 9–17. . . . . . . . . . . . . . . . . . . . . .

Flow Meter Calibration Procedure 9–18. . . . . . . . . .

Selection 1, 2, 3, or 4: Calibrating the

Meters Individually 9–18. . . . . . . . . . . . . . . .

Selection 6: Calibrating the Gun 1 Meter 9–20

Selection 5: Mixed Material Calibration 9–21. .

3

Page 4

Table of Contents

Troubleshooting 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision Number 10–2. . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Reference 10–3. . . . . . . . . . . . . . . .

Alarm Troubleshooting 10–7. . . . . . . . . . . . . . . . . . . .

To Clear the Alarm and

Restart the System 10–7. . . . . . . . . . . . . . .

Ratio Low or Ratio High 10–8. . . . . . . . . . . . . . .

Dose Time A, B, or C 10–9. . . . . . . . . . . . . . . . .

Overdose A, B, or C 10–9. . . . . . . . . . . . . . . . . .

Flow Rate Alarms for a System without

Flow Control 10–10. . . . . . . . . . . . . . . . . . .

Flow Too Low 10–10. . . . . . . . . . . . . . . . . .

Flow Too High 10–10. . . . . . . . . . . . . . . . . .

Flow Rate Alarms for a System with

Flow Control 10–10. . . . . . . . . . . . . . . . . . .

Gun #1 High/Low Flow 10–10. . . . . . . . . .

Gun # 2 High/Low Flow 10–10. . . . . . . . . .

Pot Life Exceeded 10–10. . . . . . . . . . . . . . . . . .

Purge/Load Interlock Not Ready 10–11. . . . . . .

Invalid Recipe 10–11. . . . . . . . . . . . . . . . . . . . . .

I/O Change 10–11. . . . . . . . . . . . . . . . . . . . . . . . .

Purge Not Completed 10–11. . . . . . . . . . . . . . . .

Purge Time Out 10–11. . . . . . . . . . . . . . . . . . . . .

Display Battery Low 10–12. . . . . . . . . . . . . . . .

Control Battery Low 10–12. . . . . . . . . . . . . . . .

Memory Failure 10–12. . . . . . . . . . . . . . . . . . . .

Communications Error 10–12. . . . . . . . . . . . . .

Invalid Guns From Input/Output Alarm 10–12

Air Flow Switch Alarm 10–12. . . . . . . . . . . . . .

Defaults Loaded 10–12. . . . . . . . . . . . . . . . . . .

Software Revision Alarm 10–12. . . . . . . . . . . .

Configuration Module Alarm 10–12. . . . . . . . .

External Alarms 10–12. . . . . . . . . . . . . . . . . . . .

Warnings 10–13. . . . . . . . . . . . . . . . . . . . . . . . . .

Job Total Rollover 10–13. . . . . . . . . . . . . . . . . .

Batch Total Rollover 10–13. . . . . . . . . . . . . . . .

Grand Total Rollover 10–13. . . . . . . . . . . . . . . .

Calibrate A Meter 10–13. . . . . . . . . . . . . . . . . .

Calibrate B Meter 10–13. . . . . . . . . . . . . . . . . .

Calibrate C Meter 10–13. . . . . . . . . . . . . . . . . .

Solenoid Box Troubleshooting 10–14. . . . . . . . . . .

Gun Flush Box Troubleshooting 10–16. . . . . . . . . .

Operator Station

with Color Change Troubleshooting 10–17. . .

Service 11–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the User Interface Battery 11–3. . . . . . .

Replacing the Controller Battery 11–4. . . . . . . . . . .

Replacing Isolation Barrier Fuses 11–5. . . . . . . . . .

Replacing the User Interface 11–5. . . . . . . . . . . . . .

Replacing the Power Supply 11–6. . . . . . . . . . . . . . .

Changing the Power Supply Voltage 11–6. . . . . . . .

Replacing Power Supply Fuses 11–6. . . . . . . . . . . .

Servicing the Operator Station 11–7. . . . . . . . . . . . .

Replacing Control Modules 11–8. . . . . . . . . . . . . . . .

Replacing Control Submodules 11–9. . . . . . . . . . . .

4

Parts 12–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controller with User Interface 12–3. . . . . . . . . . . . . .

Part No. 243540 12–3. . . . . . . . . . . . . . . . . . . . .

Part No. 243541 12–3. . . . . . . . . . . . . . . . . . . . .

Controller 12–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part No. 240834 12–4. . . . . . . . . . . . . . . . . . . . .

Flow Control 12–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

One Gun 12–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

One Gun with Flow Meter in

Mixed Material Line 12–6. . . . . . . . . . . . . . .

Communication Ports 12–8. . . . . . . . . . . . . . . . . . . .

Part No. 241379 12–8. . . . . . . . . . . . . . . . . . . . .

Part No. 241378 12–8. . . . . . . . . . . . . . . . . . . . .

Software Utilities Kit 12–8. . . . . . . . . . . . . . . . . . . . . .

Part No. 243546 12–8. . . . . . . . . . . . . . . . . . . . .

Fluid Panel 12–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Non-Intrinsically Safe 12–9. . . . . . . . . . . . . . . . .

Intrinsically Safe 12–9. . . . . . . . . . . . . . . . . . . . .

Fluid Panel Module 12–10. . . . . . . . . . . . . . . . . . . .

Part No. 243493 12–10. . . . . . . . . . . . . . . . . . .

Solenoid Module 12–12. . . . . . . . . . . . . . . . . . . . . . .

Part No. 552184 12–12. . . . . . . . . . . . . . . . . . .

Part No. 552186 12–12. . . . . . . . . . . . . . . . . . .

Fluid Meters 12–13. . . . . . . . . . . . . . . . . . . . . . . . . .

Part No. 243512 12–13. . . . . . . . . . . . . . . . . . .

Part No. 243513 12–13. . . . . . . . . . . . . . . . . . .

Part No. 243515 12–14. . . . . . . . . . . . . . . . . . .

Air Supply Station 12–16. . . . . . . . . . . . . . . . . . . . . .

Part No. 570122 12–16. . . . . . . . . . . . . . . . . . .

Operator Station 12–17. . . . . . . . . . . . . . . . . . . . . . .

Part No. 240835 12–17. . . . . . . . . . . . . . . . . . .

Part No. 240877 12–18. . . . . . . . . . . . . . . . . . .

Low Pressure Color Change Module 12–19. . . . .

Part No. 241386 12–19. . . . . . . . . . . . . . . . . . .

Part No. 242025 12–19. . . . . . . . . . . . . . . . . . .

Part No. 241387 12–20. . . . . . . . . . . . . . . . . . .

Part No. 242026 12–20. . . . . . . . . . . . . . . . . . .

High Pressure Color Change Module 12–22. . . . .

Part No. 241499 12–22. . . . . . . . . . . . . . . . . . .

Part No. 241500 12–23. . . . . . . . . . . . . . . . . . .

Part No. 907347 12–25. . . . . . . . . . . . . . . . . . .

Color Change Valve Assemblies 12–26. . . . . . . . .

Low Pressure Color Change Valves 12–26. . .

High Pressure Color Change Valves 12–26. .

Valve Bracket Changing Procedure 12–27. . .

Page 5

Table of Contents

Gun Flush Box 12–28. . . . . . . . . . . . . . . . . . . . . . . .

Part No. 241389 12–28. . . . . . . . . . . . . . . . . . .

Part No. 241394 12–28. . . . . . . . . . . . . . . . . . .

Gun Flush Solenoid Box 12–29. . . . . . . . . . . . . . . .

Part No. 115125 12–29. . . . . . . . . . . . . . . . . . . .

Gun Holders for Gun Flush Box 12–30. . . . . . . . . .

Cable Chart 12–31. . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote User Interface 12–32. . . . . . . . . . . . . . . . .

Part No. 240874 12–32. . . . . . . . . . . . . . . . . . .

Stand Mount 12–33. . . . . . . . . . . . . . . . . . . . . . . . . .

Part No. 241501 12–33. . . . . . . . . . . . . . . . . . .

Audio/Visual Alarm 12–33. . . . . . . . . . . . . . . . . . . . .

Part No. 241380 12–33. . . . . . . . . . . . . . . . . . .

Accessories 12–34. . . . . . . . . . . . . . . . . . . . . . . . . . .

Part No. 241647 Catalyst Change Kit 12–34.

Part No. 195048 Paint Shield 12–34. . . . . . . .

Part No. 195049 Paint Shield 12–34. . . . . . . .

Part No. 241263 Printer Kit 12–34. . . . . . . . . .

Printer Power Supply 12–34. . . . . . . . . . . . . . .

Part No. 514037 Printer Paper 12–34. . . . . . .

Manual Dump Valve Kits 12–35. . . . . . . . . . . .

2K Fluid Outlet Valves 12–35. . . . . . . . . . . . . .

Part No. 513052 Air Flow Switch 12–35. . . . .

Part No. 241962 Hydro-Softfeel

Material Application Kit 12–35. . . . . . . . . .

Cable Network PC AMR 12–35. . . . . . . . . . . . .

Catalyst Supply Modules 12–35. . . . . . . . . . . .

Utilities Software 13–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Utilities Overview 13–3. . . . . . . . . . . . . . . . . . . . . . . .

Connection Error 13–3. . . . . . . . . . . . . . . . . . . . . . . .

Mode Switch 13–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Backup PrecisionMix II 13–4. . . . . . . . . . . . . . . . . . .

Restore PrecisionMix II 13–7. . . . . . . . . . . . . . . . . . .

Update the Operating System 13–9. . . . . . . . . . . . .

Update PrecisionMix II Program 13–11. . . . . . . . . .

Connecting Utilities 13–12. . . . . . . . . . . . . . . . . . . .

Update User Interface Program 13–13. . . . . . . . . .

Reset PrecisionMix II Password 13–15. . . . . . . . .

Set PrecisionMix II Date and Time 13–16. . . . . . .

Open Graco Web Site 13–17. . . . . . . . . . . . . . . . . .

Edit Language 13–17. . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 14–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Standard Warranty 14–6. . . . . . . . . . . . . . . . . . .

Graco Phone Number 14–6. . . . . . . . . . . . . . . . . . . . . .

5

Page 6

6

Page 7

1

Warnings

1–1Warnings

Page 8

1–2 Warnings

Page 9

WARNING

FIRE, EXPLOSION, AND ELECTRIC SHOCK HAZARD

Improper grounding, poor air ventilation, open flames, or sparks can cause a hazardous condition and

result in fire or explosion and serious injury.

The PrecisionMix Controller must only be installed and serviced by a qualified electrician.

The PrecisionMix Controller is for use only in non-hazardous locations. The maximum applied relay

voltage shall not exceed +24 volts. Do not operate the controller in hazardous locations, as defined

in Article 500 of the National Electrical Code (USA).

Ground the equipment and the object being sprayed. See Ground the System on page 3–30.

Do not install non-intrinsically safe equipment in a hazardous area.

Provide fresh air ventilation to avoid the buildup of flammable vapors from solvent or the fluid being

sprayed.

Extinguish all the open flames or pilot lights in the spray area.

Keep the spray area free of debris, including solvent, rags, and gasoline.

Do not turn on or off any light switch in the spray area while operating or if fumes are present.

Do not smoke in the spray area.

Do not operate a gasoline engine in the spray area.

If there is any static sparking while using the equipment, stop spraying immediately. Identify and

correct the problem.

Keep liquids away from the electrical components.

Disconnect electrical power at the main switch before servicing the equipment.

The battery inside the PrecisionMix Controller may explode if mishandled. Do not recharge or

disassemble the battery. Do not expose the battery to fire or heat. The battery is intended for use

at normal temperatures, where high temperature cycles are not expected to exceed 212 F

(100 C).

TOXIC FLUID HAZARD

Hazardous fluids or toxic fumes can cause serious injury or death if splashed in the eyes or on the

skin, swallowed, or inhaled.

Know the specific hazards of the fluid you are using. Read the fluid manufacturer’s warnings.

Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state and national guidelines.

Wear the appropriate protective clothing, gloves, eyewear, and respirator.

1–3Warnings

Page 10

WARNING

INJECTION HAZARD

Spray from the gun, hose leaks, or ruptured components can inject fluid into your body and cause

extremely serious injury, including the need for amputation. Splashing fluid in the eyes or on the skin

can also cause serious injury.

Fluid injected into the skin might look like just a cut, but it is a serious injury. Get immediate medi-

cal attention.

Do not point the spray gun at anyone or at any part of the body.

Do not put hand or fingers over the spray tip.

Do not stop or deflect fluid leaks with your hand, body, glove, or rag.

Follow the Pressure Relief Procedure on page 4–3 whenever you: are instructed to relieve pres-

sure; stop spraying; clean, check, or service the equipment; or install or clean the spray tip.

Tighten all the fluid connections before operating the equipment.

Check the hoses, tubes, and couplings daily. Replace worn, damaged, or loose parts immediately.

Permanently coupled hoses cannot be repaired; replace the entire hose.

EQUIPMENT MISUSE HAZARD

INSTRUCTIONS

Equipment misuse can cause the equipment to rupture, malfunction, or start unexpectedly and result

in serious injury.

This equipment is for professional use only.

Read all instruction manuals, tags, and labels before operating the equipment.

Use the equipment only for its intended purpose. If you are uncertain about usage, call your Graco

distributor.

Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

Check the equipment daily. Repair or replace worn or damaged parts immediately.

Do not exceed the maximum working pressure of the lowest rated system component. See the

instruction manuals of the individual PrecisionMix components for their maximum working pressures.

Route the hoses away from the traffic areas, sharp edges, moving parts, and hot surfaces. Do not

expose Graco hoses to temperatures above 180F (82C) or below –40F (–40C).

Do not use the hoses to pull the equipment.

Do not move pressurized equipment.

Use fluids or solvents that are compatible with the equipment wetted parts. See the Technical

Data section of all the equipment manuals. Read the fluid and solvent manufacturer’s warnings.

Comply with all applicable local, state and national fire, electrical and other safety regulations.

1–4 Warnings

Page 11

2

Overview

Overview 2–1

Page 12

2–2

Overview

Page 13

Using this Manual

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

Special Note Symbol

This symbol precedes information that should

be taken special note of.

Screen Navigation Symbol

This symbol precedes information that tells you

how to enter information and navigate through

the User Interface screens.

Text that appears in grey on the screens in these

instructions indicates lines that may or may not appear

on your display, depending on previous selections that

have been made.

Text that appears in a grey box indicates a selection

that is being recommended or explained in that section of the instructions.

Manual Overview

The information is organized in the following way:

1. Warnings: Read this section for important safety

information.

2. Overview: This section provides information on

the instruction manuals and on PrecisionMix II 3K

Component ID and function.

3. Installation: This section provides information on

installing a configured PrecisionMix II 3K system.

After installation is complete, a startup checklist is

provided to verify the system is installed correctly

and ready to begin production. Portions of the

checklist will guide you to other procedures, such

as purging the system and configuring the software, to prepare the system for production.

4. Operation: The Pressure Relief Procedure and

miscellaneous operation procedures are in this

section.

5. Screen Map: The screen map shows the general

layout of all the User Interface screens and provides the page number to go to for more detailed

information on each screen.

6. Run Monitor: This section covers the use of the

Run Monitor screens.

7. Totalizer: This section covers the use of the

Totalizer screens.

8. System Configuration: This section covers how

to use the System Configuration screens. These

screens are used to configure how the system will

operate. Integrated color change and flow control

are part of the system configuration.

9. Recipe Setup: This section covers how to use the

Recipe Setup screens to setup recipes.

10. Troubleshooting: This section provides information on troubleshooting alarm conditions and some

system problems.

11. Parts: This section includes parts drawings and

lists for components of the PrecisionMix II 3K

system.

Overview 2–3

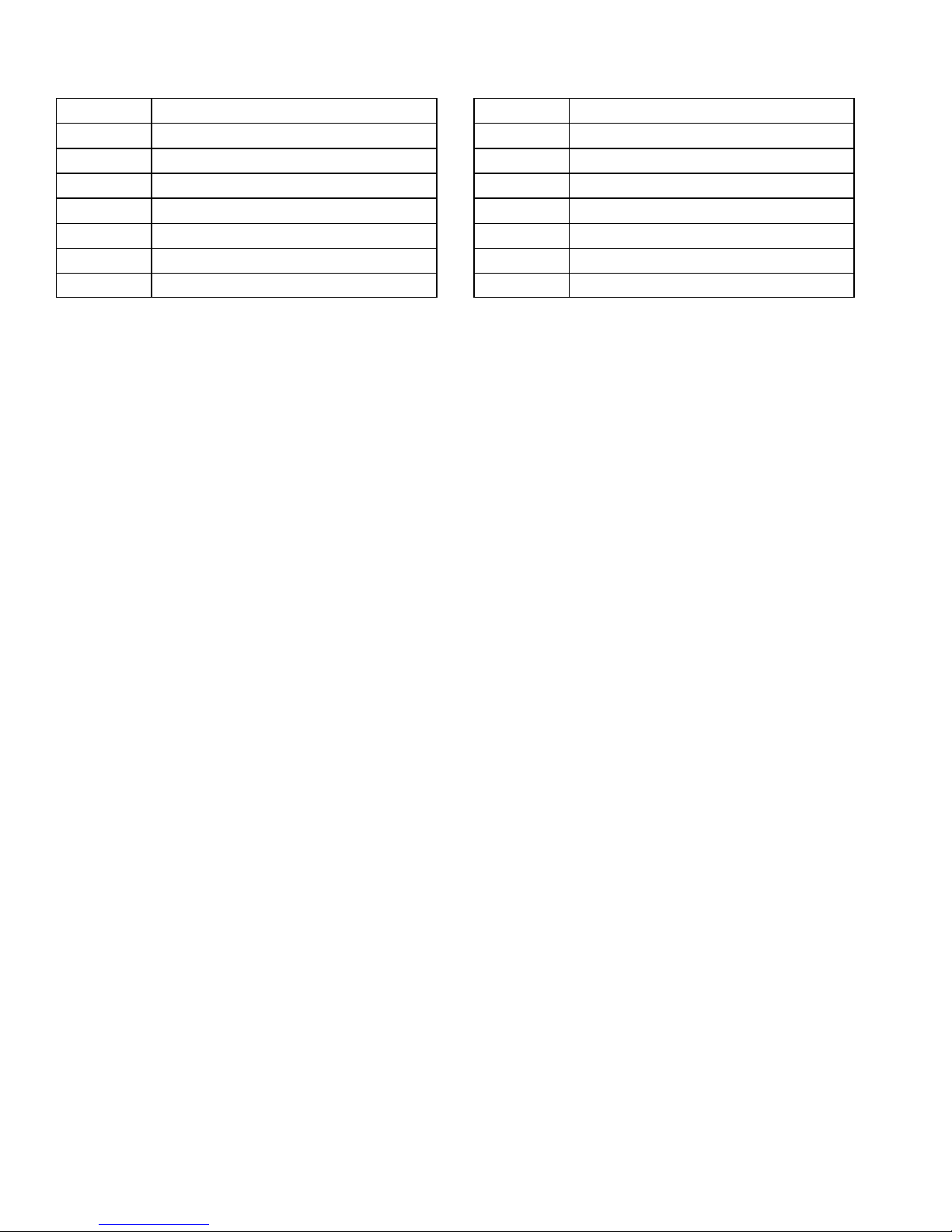

Page 14

Related Publications

Form No. Description

308288 Fluid Manifold Manual

308778 G3000 Meter Manual

309148 Piston Meter Manual

309149 Magnetic Meter Manual

307731 LP Color Change Valve Assy. Manual

307941 LP Color Change Valve Manual

308977 HP Color Change Valve Assy. Manual

Form No. Description

308291 HP Color Change Valve Manual

309227 Gun Flush Box Manual

308818 Printer Manual

308292 Fluid Pressure Regulator

309138 System Electrical Schematic

309158 System Configurator Schematic

309234 Coriolis Meter Manual

2–4

Overview

Page 15

Overview 2–5

Page 16

How the PrecisionMix II 3K Works

Usage

The standard Graco PrecisionMix II 3K can blend most

two and three component epoxy or polyurethane

paints. The PrecisionMix is not for use with “quick-setting” paints (those with a pot life of less than 15 minutes). For information on handling quick-setting paints

or abrasive fluids, contact your Graco distributor.

Fluid Supply

The system can be set up to mix components supplied

from pressure tanks or feed pumps. The materials can

be transferred from their original containers or from a

central paint recirculating line.

The standard PrecisionMix II 3K is designed to operate

an air spray or air-assisted system with a capacity of

up to 2000 cc/min.

Adaptive Overrun Correction

The actual volume of fluid dispensed each cycle can

vary slightly from the calculated target. However, the

controller monitors this variance and continuously

makes adjustments to keep the ratio of Component A

to Component B and the ratio of Component C to

Component B within the user specified tolerance.

Other inputs and outputs are provided to control the

purging process, signal an alarm, and interface with

the operator. Refer to Fig. 3.21, page 3–29.

The order in which the three components are mixed

depends on the characteristics of the materials being

used. In the standard configuration, Component A is

mixed with Component C first, then the blend of A and

C is mixed with Component B. The instructions in this

manual correspond with this mixing order.

To convert the PrecisionMix II 3K to a configuration

where Component A is mixed with Component B

before Component C is added, refer to Changing the

Mixing Order, on page 2–10.

The following is a typical ratio cycle:

Figures 2.2, 2.3, and 2.4 show the flow of fluid through

component lines A, B, and C during this cycle.

1. To begin operation, the operator enters the desired

ratio and other parameters through the User

Interface (BB) and turns the operator switch (AA)

to MIX .

Operating Cycle

The 3K fluid manifold consists of four separate fluid

supply lines for Component A, B, C, and the flushing

material. The Component A, B, and C supply lines

have the following parts to individually control the flow

of the three materials. Refer to Fig. 2.2.

Fluid filters (DA, DB, DC)

Check valves (EA, EB, EC)

Flow meters (FA, FB, FC)

Dispense valves (GA, GB, GC)

The dispense valves control the entry of the components into the integrator chambers. The flow meters

monitor the exact fluid volumes being dispensed and

send electrical pulses to the controller. The controller

monitors these pulses and signals the solenoids to turn

the dispense valves on or off accordingly (based on

the target volumes calculated by the controller).

Fig. 2.1

AA BB

2. When the operator triggers the spray gun, the

controller sends a signal to activate the solenoid

valve for the component A dispense valve (GA).

See Fig. 2.2.

3. The component A dispense valve (GA) opens and

Component A begins to flow into the first integrator

chamber (L). When the correct quantity is dispensed (based on the calculated target value), the

component A dispense valve closes. See Fig. 2.2.

2–6

Overview

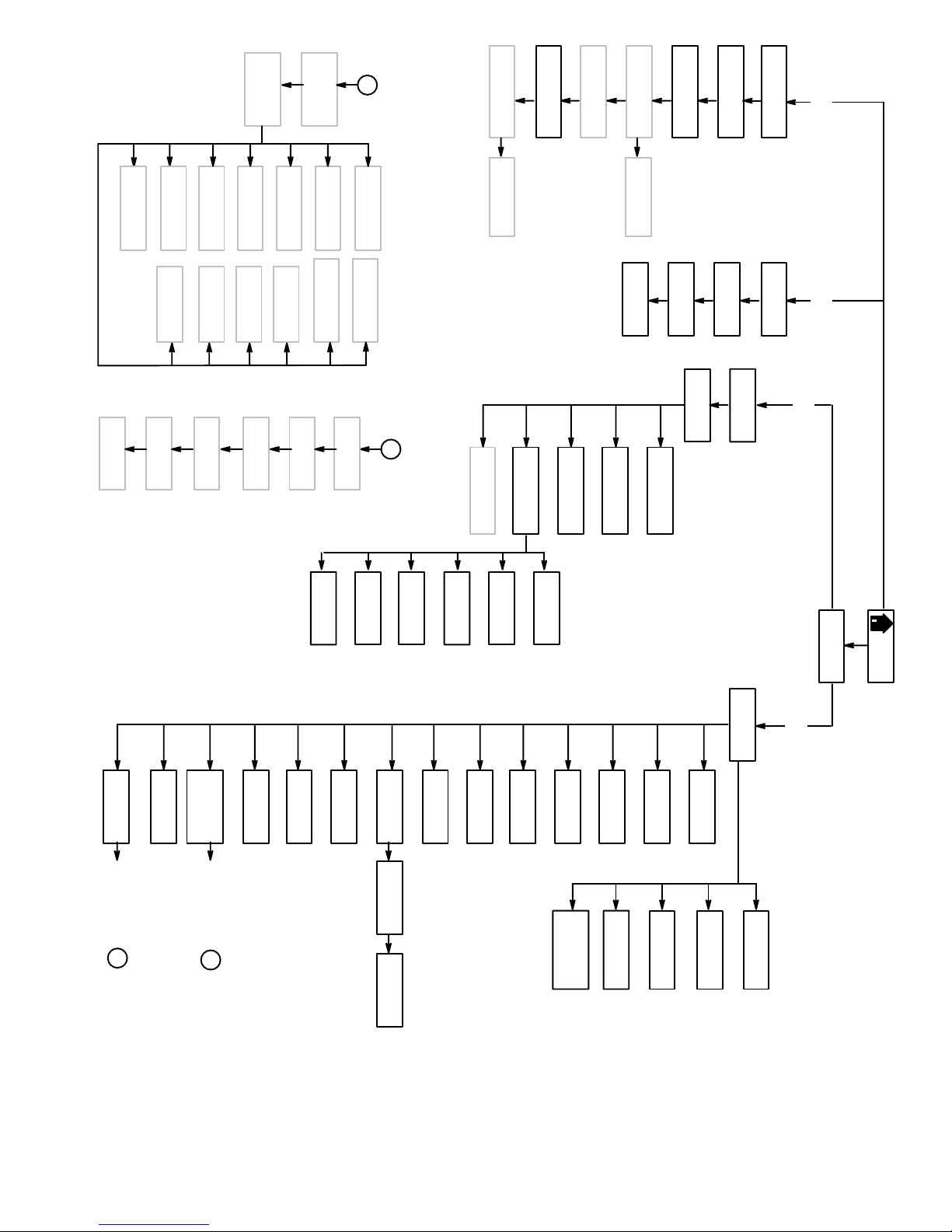

Page 17

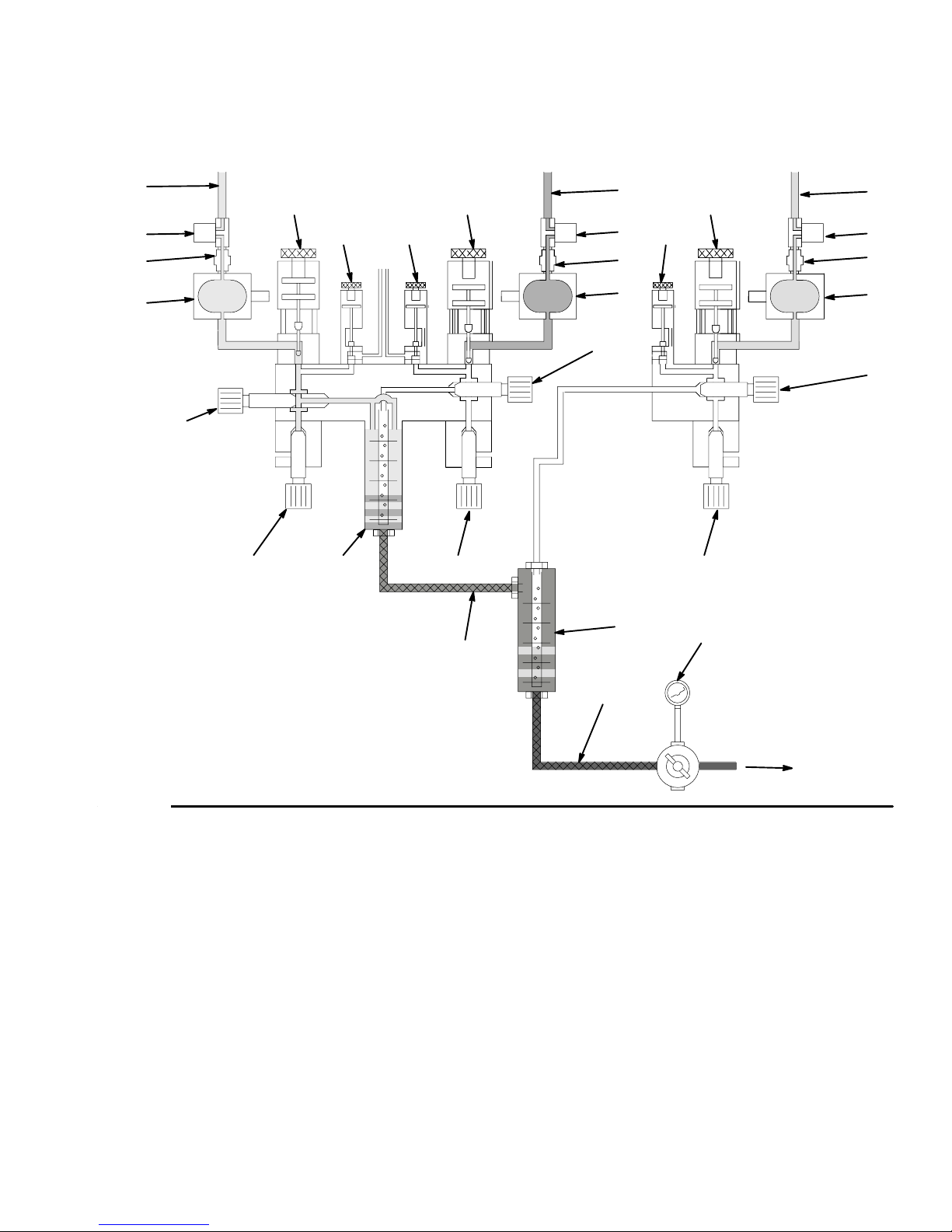

How the PrecisionMix II 3K Works

Functional Diagram – Component A Dispense

Component A Component BComponent C

A

A

G

A

D

A

E

A

F

A

J

A

K

A

H

C

H

L

C

G

C

K

C

C

D

H

C

E

C

F

C

J

N

B

G

B

B

K

Q

B

B

D

B

E

B

F

B

J

M

Fig. 2.2

KEY for Figs. 2.2, 2.3, and 2.4

Component A

A Supply Line, Component A

DAFluid Filter, Component A ,

100 mesh minimum

EACheck Valve, Component A

FAFlow Meter, Component A

GADispense Valve, Component A

HAPurge Valve (usually air), Component A

JAFluid Shut-off Valve, Component A

KARatio Check Valve, Component A

Component C

C Supply Line, Component C

DCFluid Filter, Component C,

100 mesh minimum

ECCheck Valve, Component C

FCFlow Meter, Component C

GCDispense Valve, Component C

HCPurge Valve (usually solvent),

Component C

JCFluid Shut-off Valve, Component C

KCRatio Check Valve, Component C

P

Component B

B Supply Line, Component B

DBFluid Filter, Component B,

100 mesh minimum

EBCheck Valve, Component B

FBFlow Meter, Component B

GBDispense Valve, Component B

HBPurge Valve (usually solvent),

Component B

JBFluid Shut-off Valve, Component B

KBRatio Check Valve, Component B

Other

L First Integrator

M First Static Mixer

N Second Integrator

P Second Static Mixer

Q Fluid Meter

R Fluid Supply to Gun

R

TI0085B

Overview 2–7

Page 18

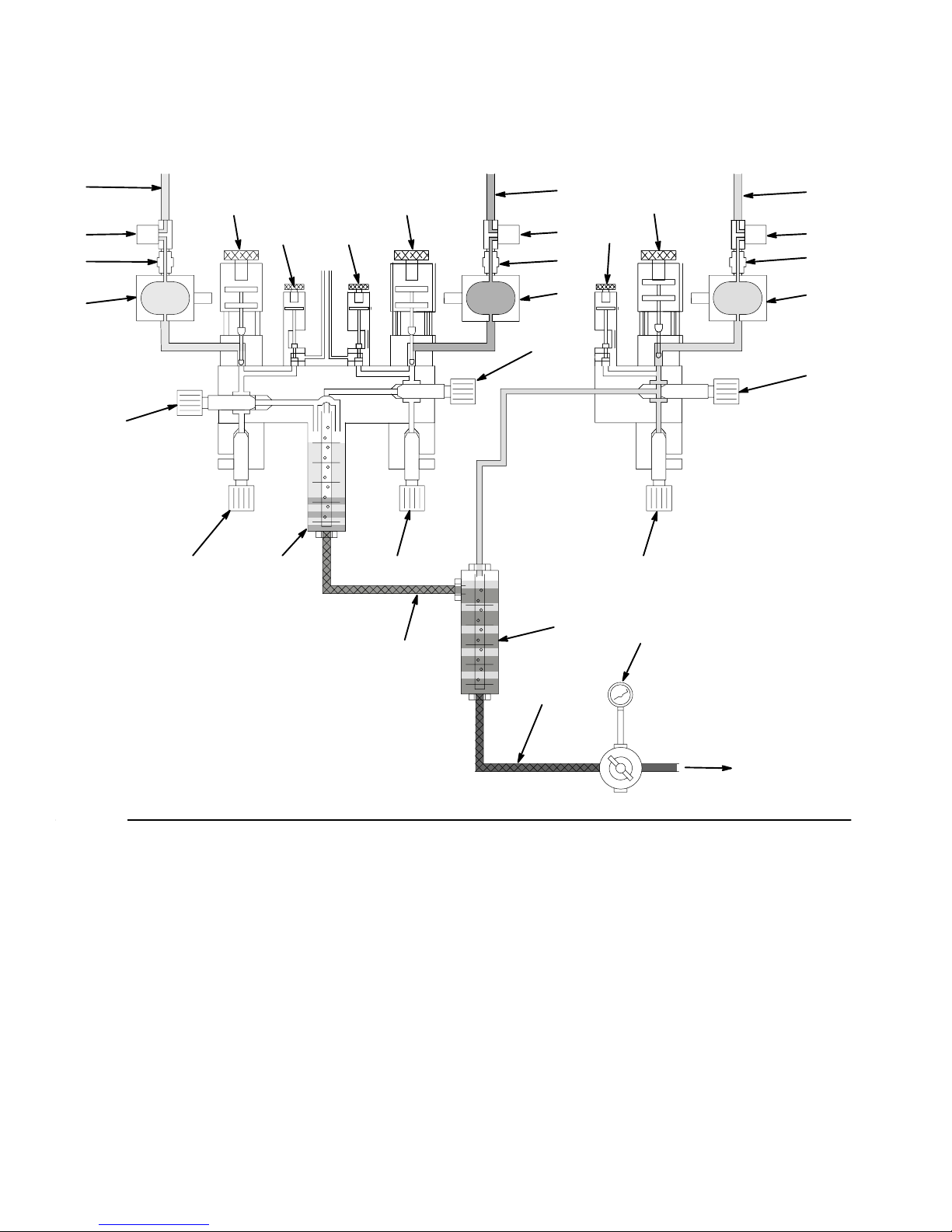

How the PrecisionMix II 3K Works

Functional Diagram – Component B Dispense

Component A Component BComponent C

A

A

G

A

D

A

E

A

F

A

J

A

K

A

H

C

H

L

C

G

C

K

C

C

D

H

C

E

C

F

C

J

N

B

G

B

B

K

Q

B

B

D

B

E

B

F

B

J

M

Fig. 2.3

4. The controller sends a signal to activate the solenoid valve for the component B dispense valve

(GB). See Fig. 2.3.

P

R

TI0087B

5. The component B dispense valve (GB) opens and

Component B flows into the second integrator

chamber (N). The fluid is lined up proportionately

with the previously-dispensed Component A and C

dose. The component B dispense valve closes

when the target volume for Component B is

reached. See Fig. 2.3.

2–8

Overview

Page 19

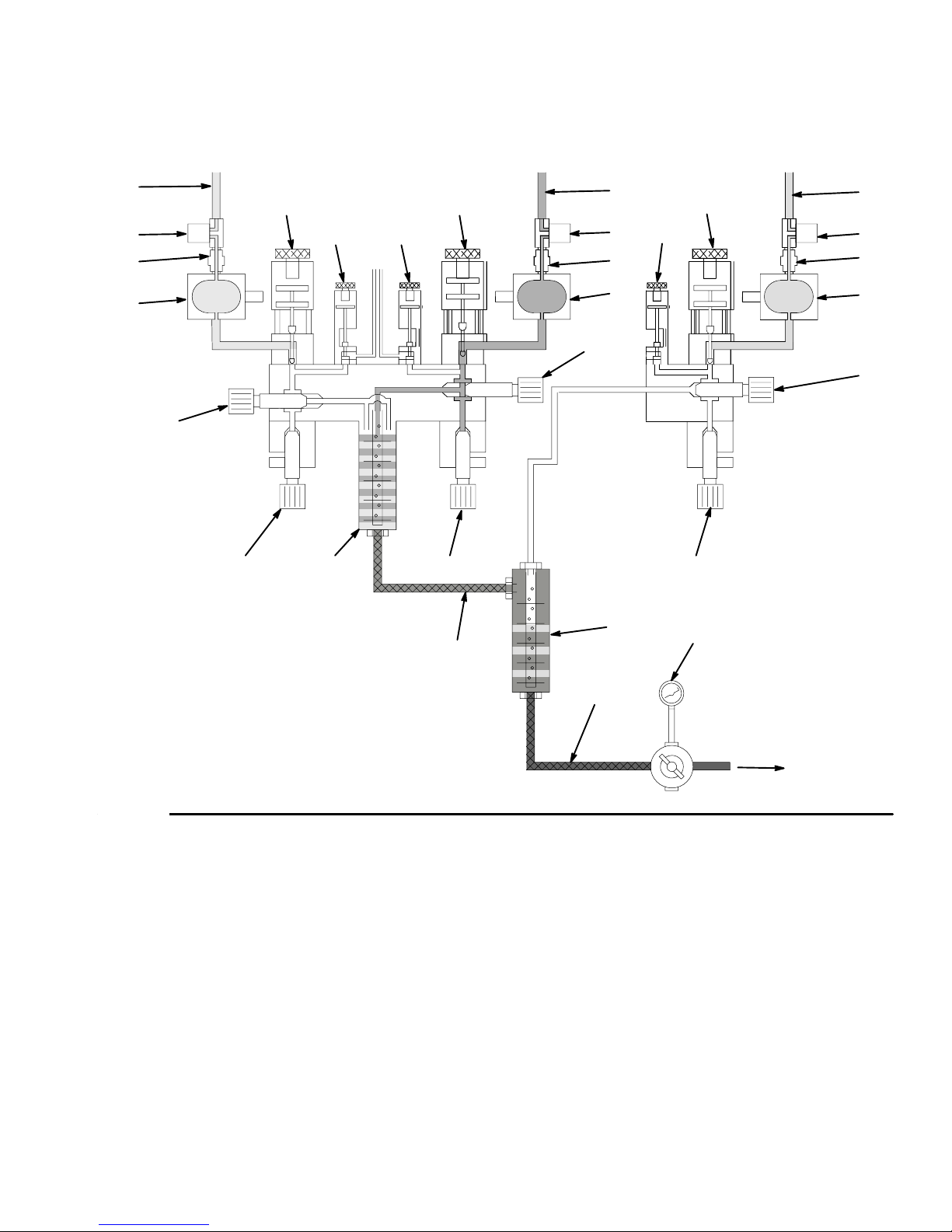

How the PrecisionMix II 3K Works

Functional Diagram – Component C Dispense

Component A Component BComponent C

A

A

G

A

D

A

E

A

F

A

J

A

K

A

H

C

H

L

C

G

C

K

C

C

D

H

C

E

C

F

C

J

N

B

G

B

B

K

Q

B

B

D

B

E

B

F

B

J

M

Fig. 2.4

6. The component C dispense valve (GC) opens and

Component C flows into the first integrator chamber. The fluid is lined up proportionately with

Components A and B. The component C dispense

valve closes when the target volume for Component C is reached. See Fig. 2.4.

7. Components A and C flow into a static mixer (M),

where they are mixed. The mixture then flows into

the second integrator chamber (N). See Fig. 2.4.

8. The three components are given a homogeneous

blending as they pass through a second static

mixer tube (P).

P

R

TI0086B

9. The three components continue to be alternately

fed into the integrators as long as the gun is triggered. Output from the mixer tube to the spray gun

may be controlled by a fluid pressure regulator (Q).

After the trigger is released, if the gun is not triggered again within four minutes, the system will go

to an idle mode, which closes off the mix manifold.

When the gun is triggered again, the system will

continue the process where it left off. Operation

can be stopped at any time by energizing the

standby input or shutting off the main power

switch.

Overview 2–9

Page 20

Changing the Mixing Order

The order in which the three components are mixed

depends on the characteristics of the materials being

used. In the standard configuration, Component A is

mixed with Component C first, then the blend of A and

C is mixed with Component B. The instructions in this

manual correspond with this mixing order.

To convert the PrecisionMix II 3K to a configuration

where Component A is mixed with Component B

before Component C is added, perform the following

steps.

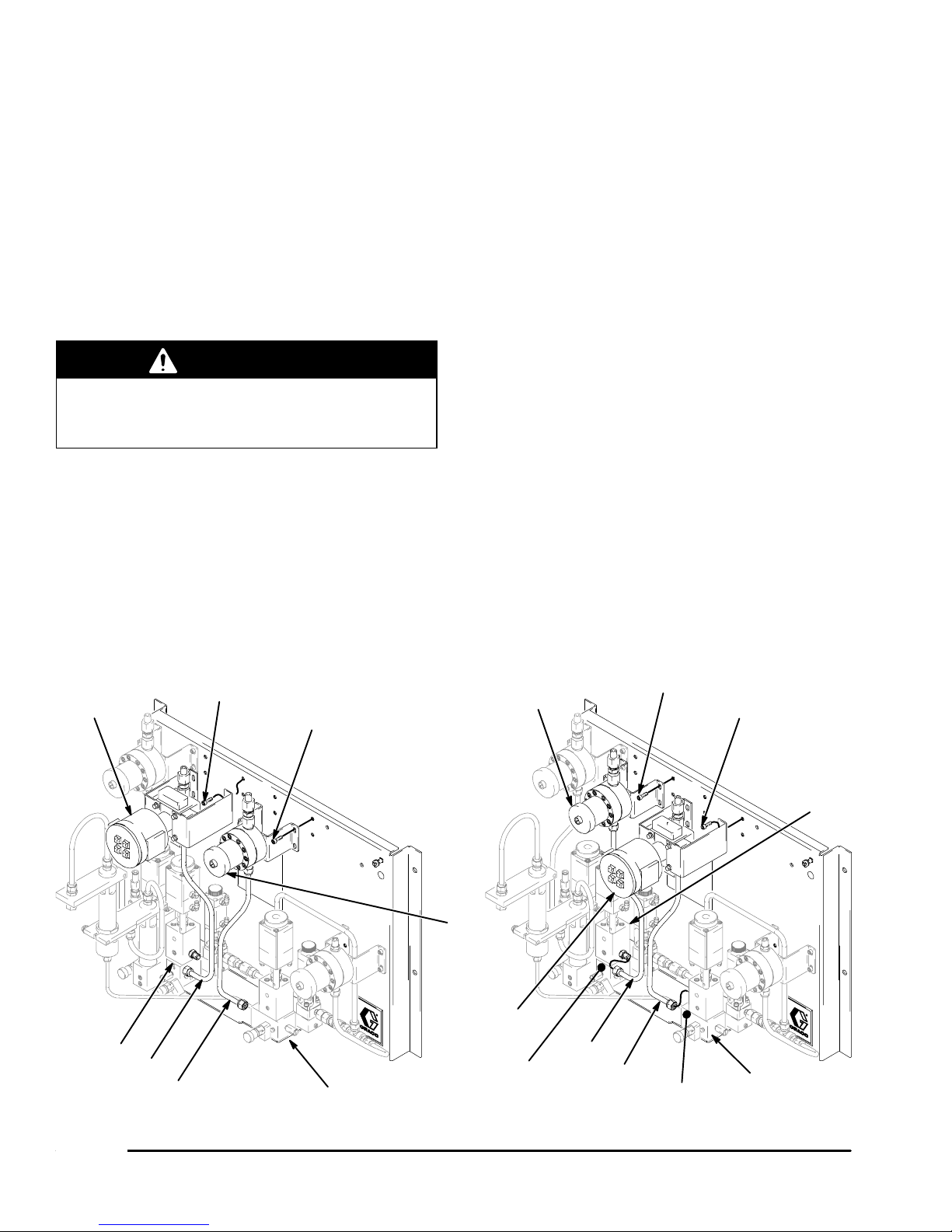

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 4–3.

1. Flush the system and relief the pressure.

2. Refer to Fig. 2.5. Unscrew the nut of the Component C tube (T) from the nipple at the dispense

valve (V).

4. Unscrew the nut of the Component B tube (W)

from the nipple at the dispense valve (Y).

5. Remove the screws (S) and take the Component

B meter (Z), bracket, and tube off the fluid panel.

6. Turn the tubes of both meters 180 so the nuts

face in the opposite direction.

7. Reinstall the Component B and C meters, in the

opposite locations.

8. Refer to Fig. 2.6. Disconnect the red air lines (R)

from the elbows at the Component B and C dispense valves and reconnect them to the opposite

dispense valve. Switch the green air lines (G) in

the same way.

9. Refer to Fig. 2.6. Disconnect the red air lines (R)

from the elbows at the Component B and C purge

valves and reconnect them to the opposite purge

valve. Switch the green air lines (G) in the same

way.

10. Using Part No. 196303 Label, relabel dispense

valve B to C and dispense valve C to B.

3. Remove the screws (S) and take the Component

C meter (U), bracket, and tube off the fluid panel.

S

U

V

T

W

Disassembly Reassembly

Fig. 2.5

S

Y

11. Reverse the wires on terminals 4271 and 4291.

Refer to Fig. 3.21, page 3–29.

Z

Z

U

W

Affix Label B Here

Affix Label C Here

2–10

S

S

T

V

Y

TI0223

Overview

Page 21

Changing the Mixing Order

AB

RGG GGG GRR RRR

Before Changing Component B and C Tubing Connections

CAP BPCP

AB

RGG GGG GRR RRR

After Changing Component B and C Tubing Connections

Fig. 2.6

CAP BP CP

ABCAPBPCP

GGGG G

RGRRR RR

Detail of Solenoid Box

TI0227

Overview 2–11

Page 22

Flow Control Overview

Flow Control is used to limit the flow of material to the

air spray gun to help avoid sags and runs in the finish

due to coatings being applied too thick or quickly and

to assure adequate coverage. Flow control can be

configured for use with a manual or automatic air spray

gun. Refer to Flow Control Setup, page 8–16.

The flow control module uses flow meters, fluid regulator, current to pressure (I/P) transducer, and the PrecisionMix II 3K controller to adjust and maintain the flow

of material to the air spray gun.

Flow control is an optional feature of the PrecisionMix 3K system. Your system must be

configured with flow control hardware and

software in order to use flow control. Detailed

information on using flow control is in other

sections of this manual.

Flow control is NOT for use with air-assisted or

airless spray guns.

System Requirements

The fluid feed system must have adequate volume and

pressure to supply the air spray gun. The Component

A, B and C fluid supply pressures need to be balanced. The fluid feed hose, gun nozzle and needle

size and travel must be sized and adjusted properly to

keep the flow control operating at its maximum efficiency.

General Operation Sequence

1. When the controller is first turned on, a pre-configured pilot air pressure is applied to the fluid regulator.

2. When the air spray gun is triggered, the controller

waits for the set delay time to elapse before it

starts monitoring the flow and making any necessary adjustments. The delay time is user selectable (typically 1–2 seconds) and helps assure the

fluid is moving at a normal rate before flow rate

adjustments occur.

3. When the fluid moves through the fluid lines, the

flow meter(s) monitors the flow and sends meter

pulses to the controller. These pulses are converted into flow measurements and checked

against the set values in the controller.

Flow Control Features

Ability to control one manual or automatic air

spray gun

Programmable maximum flow setpoint

Programmable lower flow control start value for

manual gun

Delayed activation of flow control after the gun is

triggered

Manual flow rate reset function, which can be

initiated from the in-booth Flow Control Station

An indicator light on the Flow Control Station to

show when the flow rate is resetting for manual gun

operation.

4. If the fluid flow falls outside the set values, the

controller sends a signal to adjust the fluid regulator to correct the flow. The flow is raised or lowered by the pilot air pressure from the current to

pressure (I/P) transducer. The greater the pilot air

pressure to the fluid regulator, the higher the fluid

pressure and the greater the fluid flow.

5. When the air spray gun is turned off, the flow

control holds the pilot air pressure value and does

not attempt to adjust fluid flow until the gun is

triggered again.

6. When the gun is triggered, the process of controlling the fluid flow continues.

2–12

Overview

Page 23

Flow Control Overview

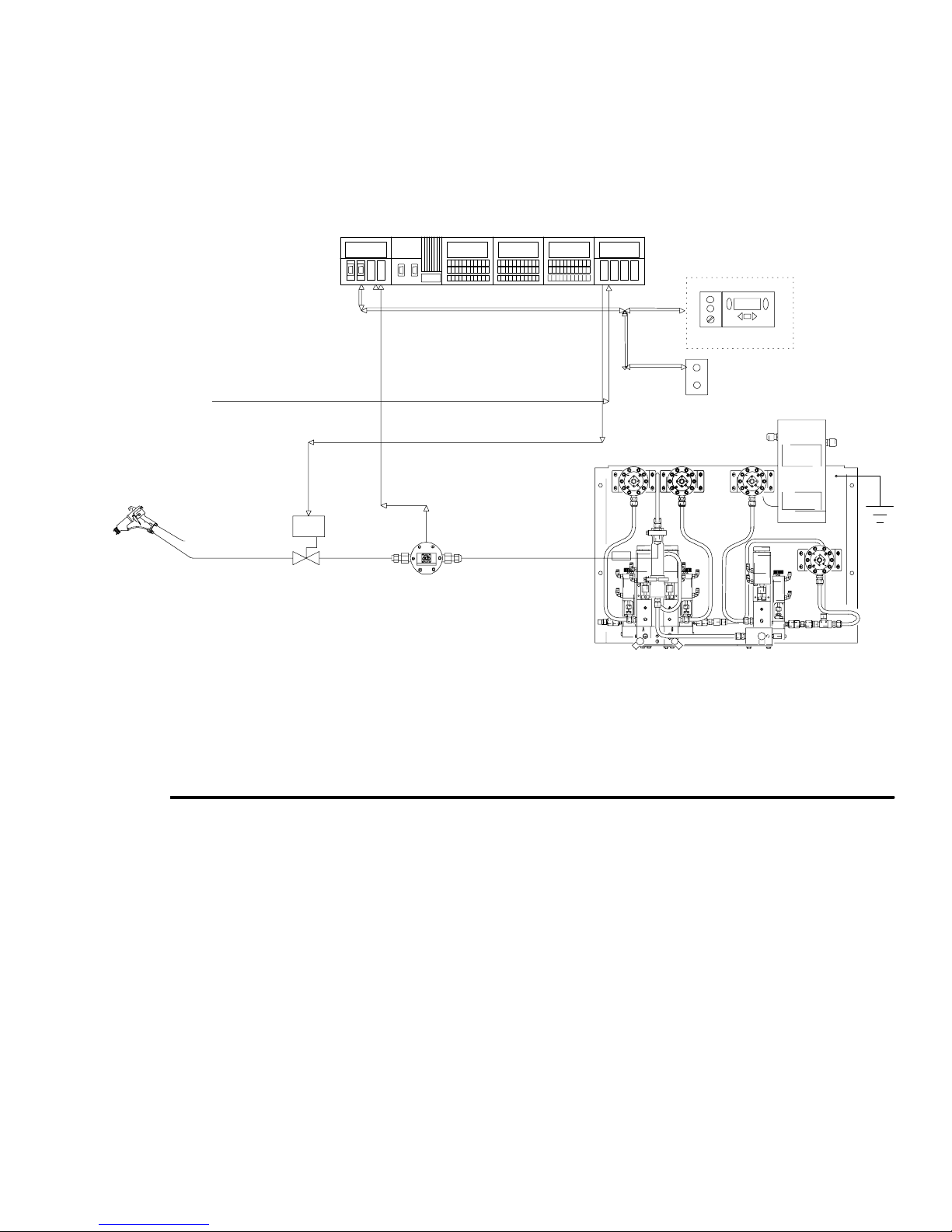

One Gun Flow Control Using a Flow Meter in the Mixed Material Line

Fig. 2.7 shows a one gun system that is using a flow meter, installed in the mixed material line, to monitor fluid flow

to the gun. Using a flow meter in the mixed material line, rather than monitoring fluid flow with the component A, B,

and C flow meters, provides a faster response to changes in the flow rate setpoint.

PrecisionMix II 3K Controller Panel

User Interface with

Color Change

RS–485

External Analog Setpoint

(use optional)

Current to

Pressure

Transducer

Fig. 2.7

Typical Installation of One Gun Flow Control Using a Flow Meter in the Mixed Material Line

4 to 20 mA Analog In

Flow Control Station

4 to 20 mA Analog Out

Flow Meter Signal

I/P

Fluid Regulator

Flow Meter

(Optional)

Fluid Panel

TI0162

Overview 2–13

Page 24

Flow Control Overview

Flow Control Components

(Refer to Fig. 2.7)

Flow Meter

Digital pulses are sent by the flow meters to the controller to provide fluid flow rate information.

Fluid Regulator

The flow control regulates the fluid flow to a pre-programmed flow rate by adjusting the fluid regulator. The

fluid regulator uses a pneumatic pilot pressure from a

current to pressure (I/P) transducer to open and close

the regulator needle.

Current to Pressure (I/P) Transducer

An adjustable pneumatic signal is required for the

controller to regulate the fluid flow. The current to

pressure transducer provides this signal. The controller

outputs an analog current signal that varies from 4

milli-amps to 20 milli-amps and the transducer

changes the milli-amp signal to a 1–100 psi (7–700

kPa, 0.1–7 bar) pneumatic signal. The pneumatic

pressure signal is applied to a fluid pressure regulator,

which controls the output fluid pressure to the air spray

gun.

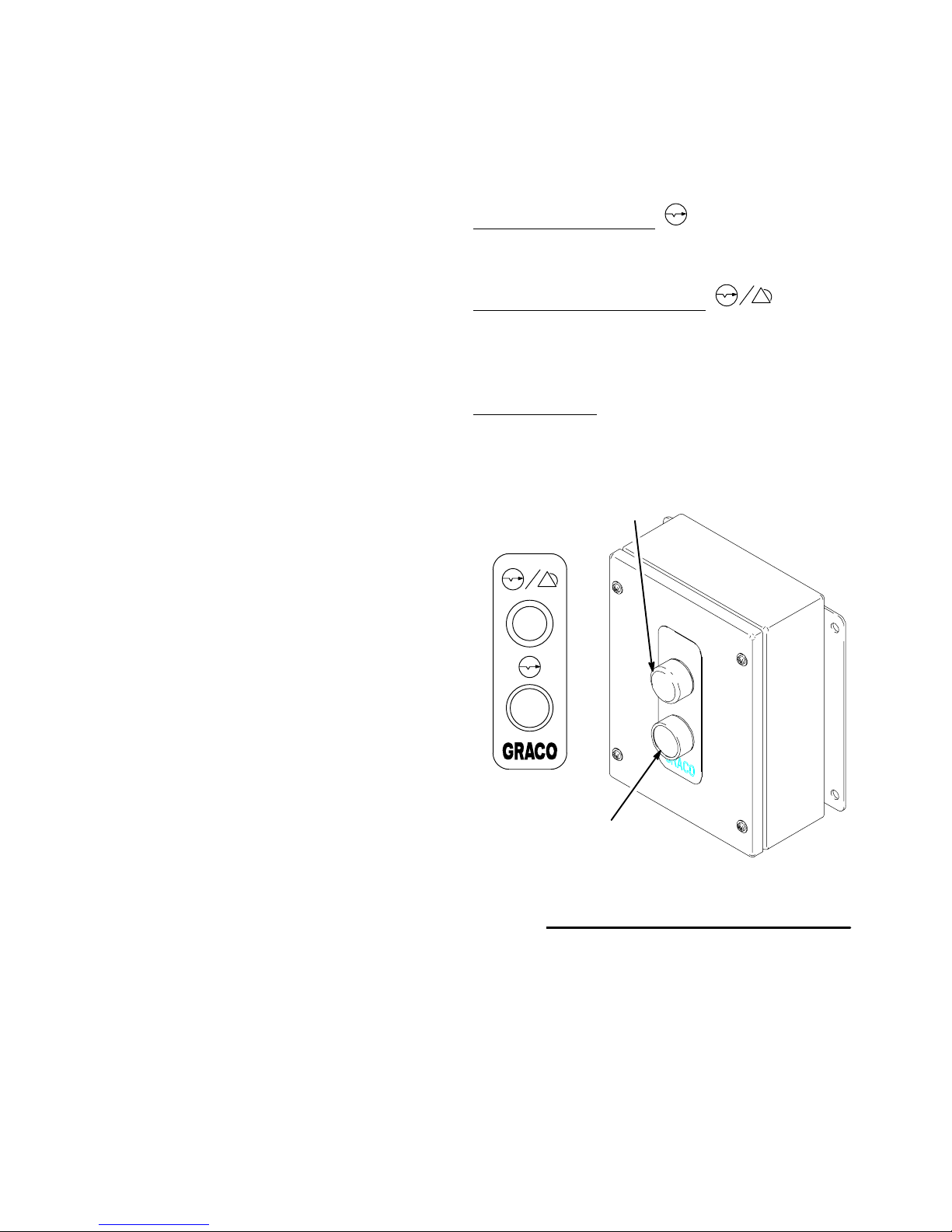

Flow Control Station

The Flow Control Station consists of a Flow Control

Reset/Warning light and Flow Control Reset button,

which are used with manual air spray guns to manually

initiate flow control reset.

Flow Control Reset Button

Pressing the reset button will cause the flow control

system to calibrate the flow rate to the current setpoint.

Flow Control Reset/Warning Light

The controller activates the Reset/Warning light when

the flow control system is resetting flow rate (solid

light) or when a flow control alarm condition occurs

(flashing light––flow rate is outside the set tolerance).

Flow Rate Alarms

Wait for the system to automatically calibrate the flow

rate or manually reset the flow rate by pressing the

reset button.

Flow Control Reset/

Warning Light

PrecisionMix II 3K Controller

The controller can be configured to control and display

the fluid control information, including setpoint, actual

flow, milli-amp output values to the I/P transducer,

system parameter, and I/O conditions. The controller

will indicate when the system is operating within flow

control tolerance and when it is not.

Fig. 2.8

Flow Control

Reset Button

Flow Control Station

9003A

2–14

Overview

Page 25

Flow Control Overview

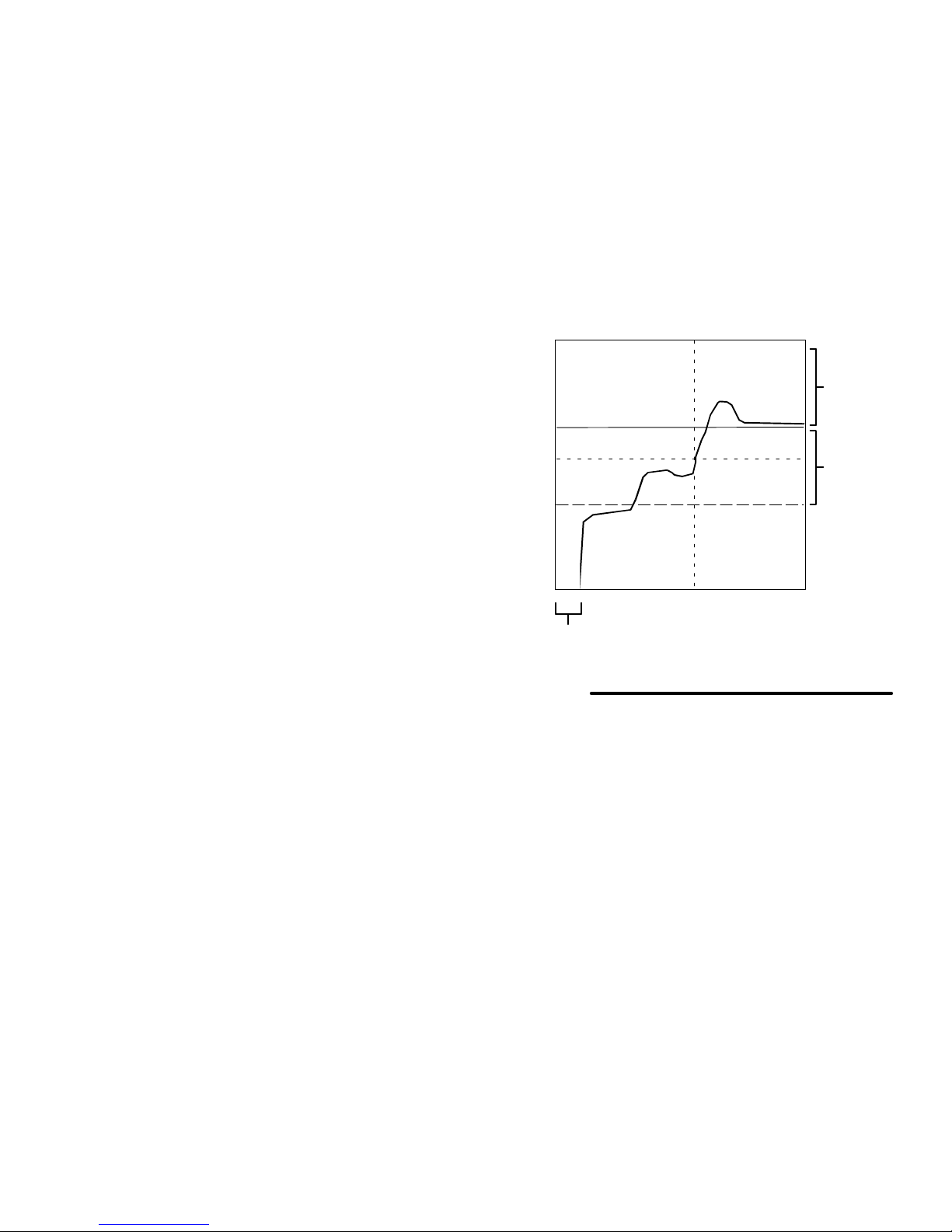

Flow Control Parameters (Refer to Fig. 2.9)

The following flow control parameters are entered from

either the User Interface or from digital input:

Setpoint Source – Specifies the source of the

flow limit value as User Interface, network or analog

input (refer to page 8–18).

Analog Scaling – If analog is the source of input,

the scaling for analog input must be set. The setting

is used to calculate the relationship between the

flow rate and a 4–20 mA input signal (refer to page

8–18).

Flow Rate Setpoint – Sets the value for the

desired flow rate. Flow control monitors and calibrates flow rate based on this value and the other

parameters (refer to page 9–9 or 9–16).

Delay Time – Sets the time that flow control waits

after the gun is triggered before starting to monitor

the flow rate. This allows time for the fluid to quickly

reach the setpoint and avoid unnecessary alarms or

corrections (refer to page 8–19).

Flow Control Low Limit – This value is only used

with manual guns and is always entered from the

User Interface (refer to page 9–9). The flow control

stops making adjustment if the flow rate falls below

the difference of setpoint and the “Low Limit”

volume. The warning alarm output will be on when

the actual flow rate falls out of this tolerance for 5

seconds. This helps the system allow for periodic

partial triggering (feathering) of a hand gun without

adjusting the flow rate.

If the setpoint is changed, the low limit will change

accordingly.

Example – If the setpoint is 500 cc/min. and the low

limit is 100 cc/min.:

The flow control will stop making adjustments

when the flow rate falls below 400 cc/min.

Changing the setpoint to 300 cc/min. will

change the low limit value to 200 cc/min.

Alarm

Tolerance

Flow Rate Setpoint

Flow

Delay Time

Fig. 2.9

Low Limit

Gun “feathered”,

No Flow Control

NOTE: Graph shown for hand gun flow control.

Full Flow Control

Time

Alarm

Tolerance

Overview 2–15

Page 26

Using Recipes/Color Change

There are three modes of operation relating to the

changing of recipes: No Color Change, Integrated

Color Change, and Integrated Color Change with

Queue. Refer to page 8–22. The controller logic

decides whether or not to allow a chosen recipe

change to occur. The criteria for allowing a recipe

change are as follows:

1. The new recipe must contain valid data for the

desired ratio, flow meter K-factors, tolerance, and

pot life times.

2. An active alarm must not exist in the system.

3. An Integrated Color Change can not already be in

progress.

4. The recipe number must not be greater than the

number of recipes configured to run on the system.

5. The input device used to change the recipe value

must be configured as the recipe input device

(User Interface, Network, I/O, or Operator Station).

6. When “No Color Change” is selected, the operator

switch on the Operator Station must be in the

A color change may be performed with the operator

switch in the Mix or Standby position. If the

operator switch is in the Mix position, the system

will be ready for immediate spraying after a color

change. The green light on the Operator Station will

blink while a color change is in operation. The green

light indicates that the system is busy and is not ready

for spraying.

Mix/Load Volumes

If mix/load volumes are configured for the system, the

fill portion of the color change may continue after the

color change has timed out. This feature may be used

in conjunction with a gun flush box to make sure that

the desired volume of material is loaded into the system. The system keeps track of the volume that is

mixed during the fill portion of the color change. If the

mix/load volume is not reached, then the system will

continue to fill until the volume is reached (the operator

switch needs to be in the Mix position for this to

occur automatically). Setting the mix/load volume to

zero will disable the mix/load volume feature.

Standby

position.

No Color Change

The system will boot up for the first time with color

change turned off. In this mode, color changes are

performed manually. The recipe number is changed

through the User Interface, Network, I/O, or Operator

Station. The operator must manually dump and purge

the old material from the system and then load the new

material into the system.

Integrated Color Change

The Integrated Color Change mode of operation

automatically performs the tasks necessary to execute

a color change. This is a time-based mode that is

configurable by the user. Refer to page 8–21. The

timing of the color change is configured in one of four

color change sequences. The color change

sequences contain start times and timer duration for

the devices that are controlled during a color change.

Each recipe is then assigned one of the four color

change sequences for its operation.

Recipe Zero

Recipe zero is considered the “Purge Down” recipe.

The purpose of this recipe is to allow the user to purge

out the material lines and the mixed material lines

without loading a new color. A typical use for recipe

zero is at the end of a shift. The operator performs a

color change to recipe zero and the lines are cleaned

out to prevent hardening of catalyzed material between

shifts. Multiple Purge Downs may also be performed if

the lines are not sufficiently clean. Another Purge

Down is triggered by pressing the Enter key on the

Operator Station or by setting the the color change bit

on the I/O high.

NOTE: Recipe 0 has a unique Purge Sequence 0 to

allow for end of shift or production shutdown. If you are

using a solvent meter, any additional solvent used in

the recipe 0 purge cycle will not be included in the

solvent totals. It is important to configure Purge Sequence 0 to flush all materials clean in one purge

cycle, to maintain accurate solvent use records.

Continued on the next page.

2–16

Overview

Page 27

Using Recipes/Color Change

Integrated Color Change – continued

The devices that are controlled by the Integrated Color

Change Sequences are as follows.

Purge Valves: The Integrated Color Change

Sequence typically starts by purging out the old mixed

material. The purge can be further defined by setting

the total purge time, the purge time for the first cycle,

the purge time for the last cycle, and the individual

purge times for the three possible purge valves. The

beginning of the purge can be delayed to allow time for

the gun triggers to activate. Refer to page 8–23.

Mix Valves: The sequence fills the hoses with the new

mixed material after the system has finished purging.

The target mix parameters are calculated after the

purge is completed, before the mix begins. The user

defines the mix (fill) time duration for the Color Change

Sequence. Refer to page 8–23.

Dump Valves: The dump valves open immediately

when the Color Change Sequence begins. The user

then configures how long these valves stay open. The

purpose of these valves is to allow the unmixed A, B,

and C component materials to dump from the system

before entering the mix manifold. Refer to page 8–24

and 8–26.

Special Outputs 1, 2, 5, and 6: The special outputs

are optional outputs that the user can configure for

their particular application. Each of these valves can

be turned on and off up to four times during a color

change sequence. Refer to page 8–28.

Specials 1 and 2 are pneumatic outputs, while Specials 5 and 6 are electrical outputs.

Integrated Color Change with Queue

The Integrated Color Change with Queue mode of

operation runs in a similar fashion to the standard

Integrated Color Change mode. The difference

between the two modes is that the Queue parameters

override the normal color change parameters during

the color change. Five data sets can be set up in a

queue and sent to the controller individually. Refer to

page 6–7. A queue data set consists of the following

five parameters.

1. Sequence Number – The number for the color

change sequence that will be used for the new

color.

2. Recipe Number – The recipe number that will be

used for the new color.

3. Color Valve Component A (Resin) – The number

corresponding to the component A color valve

chosen for the new color.

Solvent Valves: The Solvent valves open immediately

when the Color Change Sequence begins. The user

then configures how long these valves stay open. The

purpose of these valves is to push the unmixed A, B,

and C component materials through the dump valves

and clean the hoses for the next material. Refer to

page 8–24 and 8–26.

Gun Triggers 1–2: The gun triggers are electrical

outputs that can be configured to turn on and off up to

two times. These outputs are typically wired to the

spray guns triggers to allow automatic purging and

filling. Refer to page 8–27.

4. Color Valve Component B (Catalyst) – The

number corresponding to the component B color

valve chosen for the new color.

5. Color Valve Component C (Reducer) – The

number corresponding to the component C color

valve chosen for the new color.

A Queue Color Change is triggered by pressing the

Enter key on the Operator Station or by setting the

Color Change Bit on the I/O of the controller. The data

set values on the top of the queue will be used for the

Color Change. When color change is complete, the

top level of the queue is erased and all of the other

data sets move up one level on the queue.

Overview 2–17

Page 28

Using Recipes/Color Change

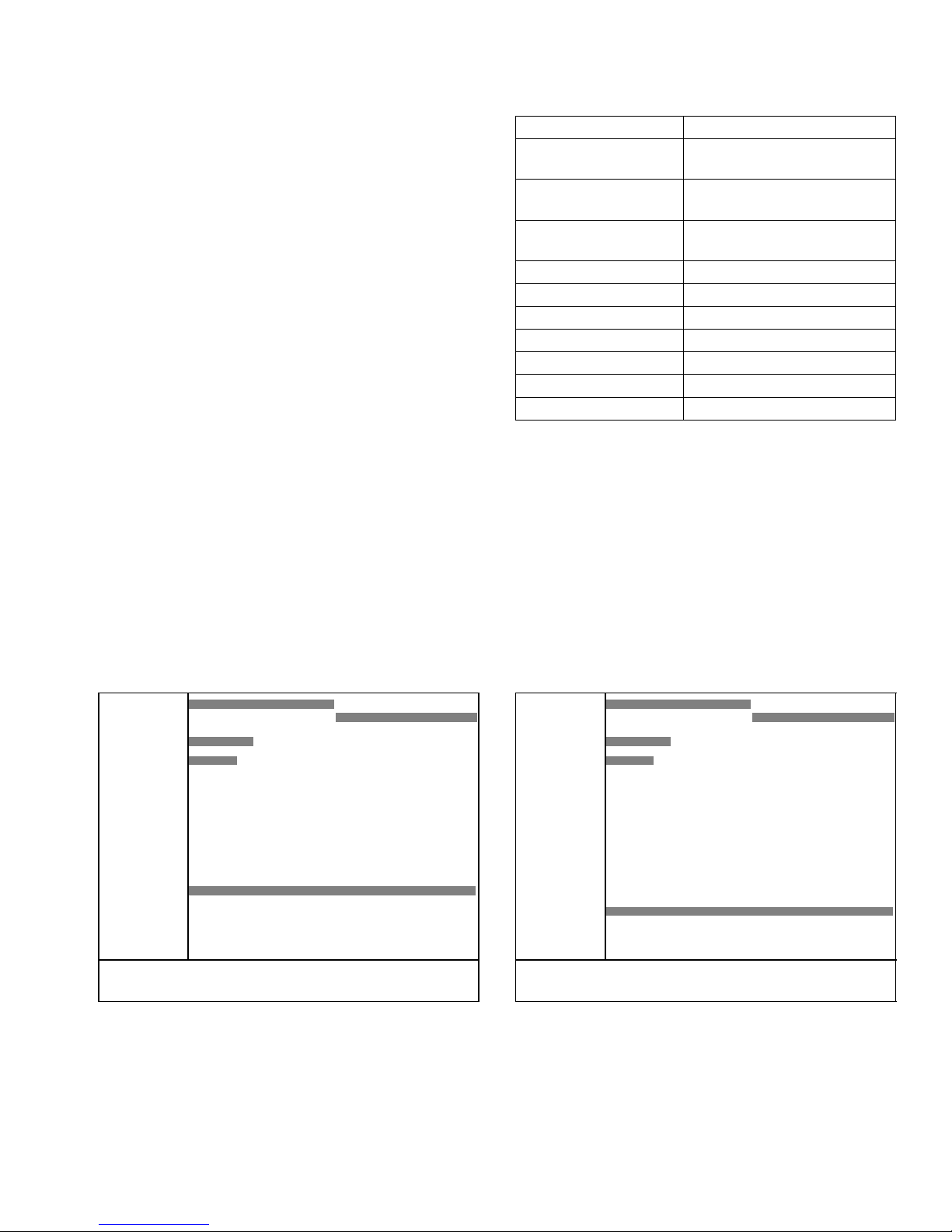

Color Change Sequences

There are four color change sequences that can be set

up to control how a color change will operate. These

sequences can be viewed on the User Interface in a

graphical fashion. A typical color change sequence

looks as follows.

Color Change Graph Screen

1. PURGE

MIX**

2. A DUMP

3. A SOLV

4. B DUMP

5. B SOLV

6. C DUMP

7. C SOLV

8. GUN1 TG

9. GUN2 TG

10.SPEC 1

11.SPEC 2

12.SPEC 5

13.SPEC 6

0 Sec 40.0

Color Chg Seq 1. Enter Function (1-13) 01

Sequence 1:

Purge time = 20 Seconds

Mix time = 20 seconds

Component A Dump time = 7 seconds

Component A Solvent time = 5 seconds

Gun 1 time = 40 seconds

Total Sequence Time = 40 seconds

The color change sequence begins by closing all of the

color change valves. Then the dump valve for Component A (resin) will immediately open, as well as the

solvent valve on the color stack. This will allow solvent

to flow into the fluid lines, through the flow meter, and

out through the dump valve.

The color change solvent valve stays open for 5 seconds, then it closes and the new color valve, associated with the new recipe, will open. The dump valve

remains open for two seconds after the new color

valve is opened, to allow the new color to fill the fluid

line and flush out the remaining solvent. The dump

valve is open for a total of 7 seconds.

In parallel with the dumping and filling of the fluid lines,

a purge is occurring through the mix manifold and

mixed material lines. The purge always starts at the

beginning of a color change sequence. The above

sequence triggers Gun 1 for the entire sequence. This

allows the purge to flush solvent through the mix

manifold and mixed material lines and out through the

gun. After 20 seconds, the purge is complete.

The system then begins to mix new material. The

system mixes for 20 seconds until the mix manifold

and the mixed material lines are full of new material.

This sequence is a 40 second long operation.

NOTE: When using automatic spray guns or gun flush

boxes, you must specify trigger times for each gun.

The screen shown above reflects the use of manually

triggered spray guns.

2–18

Overview

Page 29

Using Recipes/Color Change

Changing from One Color Change

Sequence to Another

It is possible to perform a color change from a recipe

associated with one color change sequence to a recipe

that is associated with another color change sequence.

In this case the system automatically uses the old

sequence for dumping and purging and the new

sequence for loading and mixing. This type of color

change is useful in applications where one material

tends to purge and load more quickly than another.

When switching from one sequence to another, there

are two transition points that determine which

sequence is being used at a given time. The first

transition point occurs when the solvent valve for the

color change stack closes. The second transition point

is when the purge is complete. The table at right lists

the outputs associated with the transition points.

An example of a color change from one sequence to another is as follows.

Transition Point Output

Color Stack Solvent

Component A Closes

Color Stack Solvent

Component B Closes

Color Stack Solvent

Component C Closes

Purge Ends Mix

Dump Valve Component A

Dump Valve Component B

Dump Valve Component C

Gun 1 Trigger

Gun 2 Trigger

Special 1

Special 2

Special 5

Special 6

Sequence 1:

Purge time = 20 Seconds

Mix time = 20 seconds

Component A Dump time = 7 seconds

Component A Solvent time = 5 seconds

Special 1 on time = 0 seconds

Special 1 time = 40 seconds

Total Sequence Time = 40 seconds

Color Change Graph Screen

1. PURGE

MIX**

2. A DUMP

3. A SOLV

4. B DUMP

5. B SOLV

6. C DUMP

7. C SOLV

8. GUN1 TG

9. GUN2 TG

10.SPEC 1

11.SPEC 2

12.SPEC 5

13.SPEC 6

0 Sec 40.0

Color Chg Seq 1. Enter Function (1-13) 01

Sequence 2:

Purge time = 40 Seconds

Mix time = 40 seconds

Component A Dump time = 13 seconds

Component A Solvent time = 10 seconds

Special 2 on time = 0 seconds

Special 2 time = 40 seconds

Total Sequence Time = 80 seconds

Color Change Graph Screen

1. PURGE

MIX**

2. A DUMP

3. A SOLV

4. B DUMP

5. B SOLV

6. C DUMP

7. C SOLV

8. GUN1 TG

9. GUN2 TG

10.SPEC 1

11.SPEC 2

12.SPEC 5

13.SPEC 6

0 Sec 80.0

Color Chg Seq 1. Enter Function (1-13) 01

Overview 2–19

Continued on the next page.

Page 30

Using Recipes/Color Change

Changing from One Color Change

Sequence to Another – continued

Actual valve times:

Purge time = 20 seconds

Mix time = 40 seconds

Component A Dump time = 8 seconds

Component A Solvent time = 5 seconds

Special 1 on time = 0 seconds

Special 1 time = 20 seconds

Special 2 on time = 20 seconds

Special 2 time = 40 seconds

Total Sequence Time = 60 seconds

Actual Valve Times

1. PURGE

MIX**

2. A DUMP

3. A SOLV

4. B DUMP

5. B SOLV

6. C DUMP

7. C SOLV

8. GUN1 TG

9. GUN2 TG

10.SPEC 1

11.SPEC 2

12.SPEC 5

13.SPEC 6

0 Sec 60.0

Color Chg Seq 1. Enter Function (1-13) 01

2–20

Overview

Page 31

3

Installation

Installation

3–1

Page 32

Installation3–2

Page 33

Typical Installation

WARNING

FIRE, EXPLOSION, AND ELECTRIC

SHOCK HAZARD

Installing and servicing this equipment

requires access to parts which could

cause an electric shock or other serious

injury if the work is not performed properly.

Do not install or service this equip-

ment or perform any of the following

installation and adjustment procedures unless you are trained and

qualified.

Comply with all applicable local, state, and

national fire, electrical, and other safety regulations.

WARNING

FLAMMABLE OR TOXIC

VAPOR HAZARD

Provide fresh air ventilation to avoid the

buildup of flammable or toxic vapors. Do

not operate the spray gun unless ventilation fans are operating. Follow all national, state, and local codes regarding air

exhaust velocity requirements.

NOTE:

Reference numbers and letters in parentheses in

this manual’s text refer to the numbers and letters

in the illustrations.

Be sure all accessories are adequately sized and

pressure-rated to meet the system’s requirements.

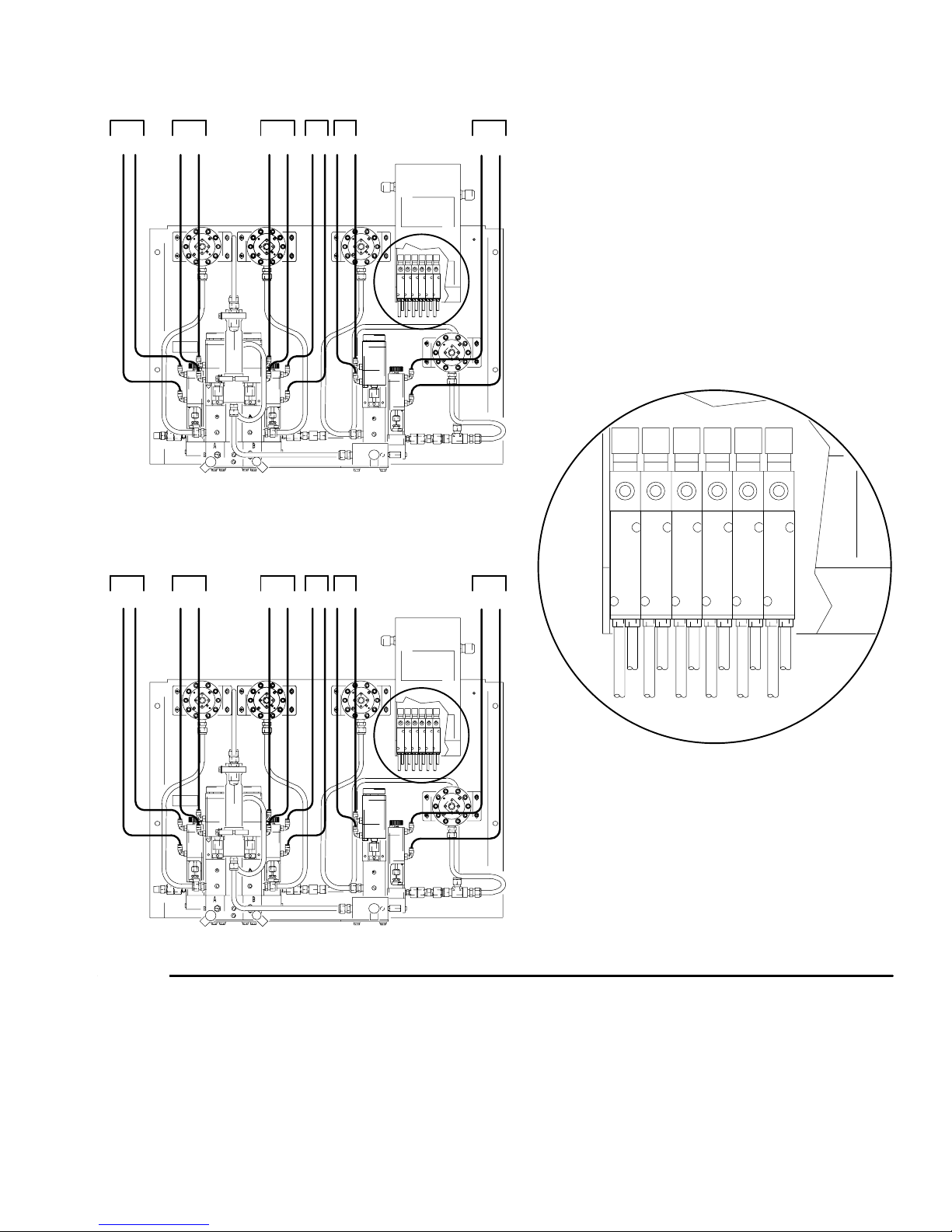

The Typical Installations shown in Figs. 3.1 and 3.2

are only a guideline for selecting and installing

system components and accessories, and are not

an actual system design. Contact your Graco

distributor for assistance.

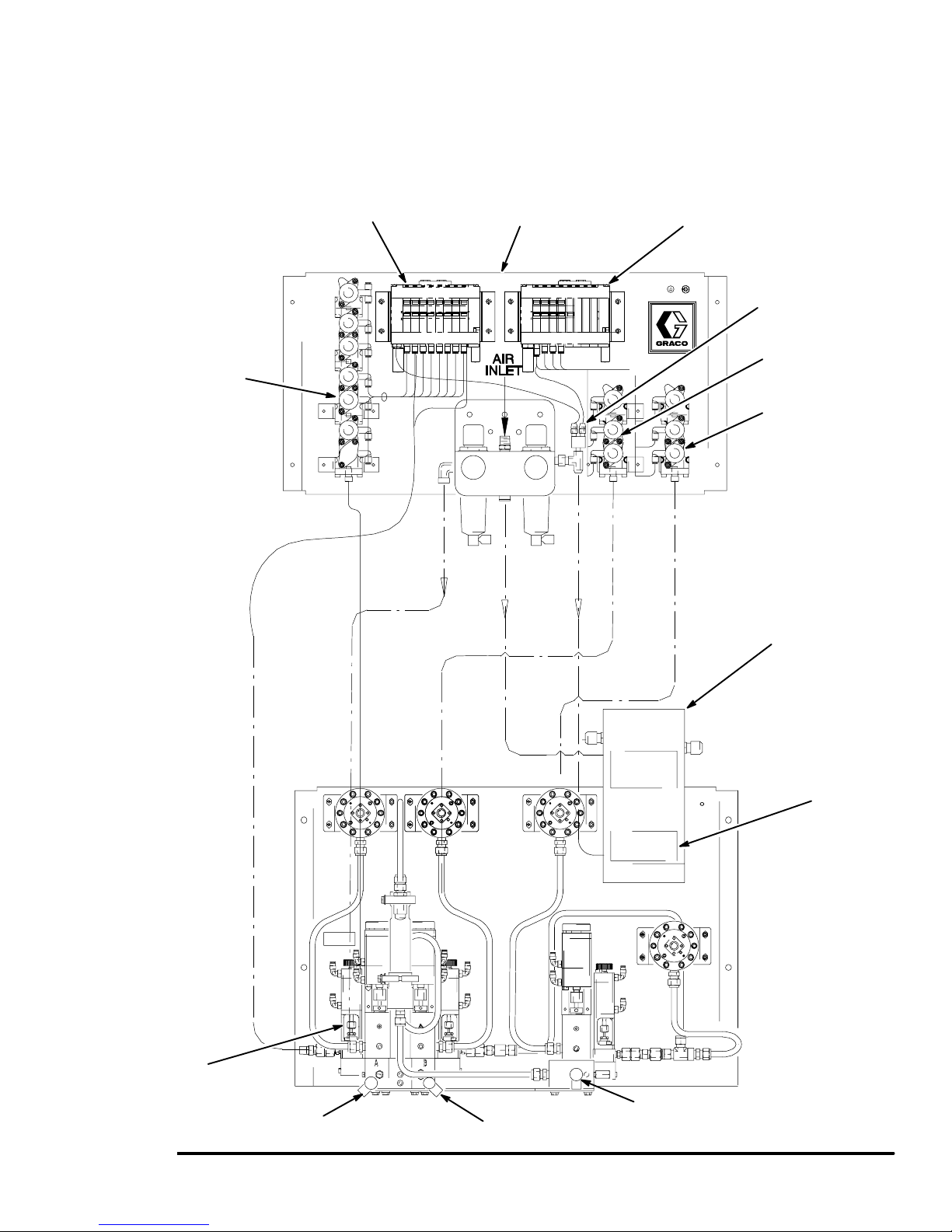

KEY for Figs. 3.1 and 3.2

NOTE: The typical installation drawings (Figs. 3.1 and 3.2) show all possible system options. Your system may not include all these options.

A Alarm

B Controller

C Solenoid Bank for color change, 8 or

16 valves

D Solenoid Bank for catalyst or reducer

change, 8 valves

E Air Regulators

F Transducer

G Solenoid Box for gun flush box,

1 & 2 guns

H Gun Flush Box

J Flow Control

K Fluid Regulator, air operated

L Atomizing Air Shutoff Valve, air piloted

M Color/Resin Change Valves

N Fluid Panel

P Solenoid Box for fluid panel

Q Operator Station

R Operator Station with color change

S Flow Control Station

T User Interface (also available as a

remote interface, see page 3–10)

U Catalyst Change Valve

Installation

3–3

Page 34

Typical Installation

NON-INTRINSICALLY SAFE

TI0172

H

Key

Electrical

Pneumatic

Fluid

NOTE: See page 3–3 for

key to letter references

Gun Flush Box Cable

Flow Control Meter Cable

D

C

User interface is also available

as a remote interface, see

page 3–10.

1

F

U

Flow Control I/P Cable

Air In

M

Fluid Line To Gun

Component B

Component C

Solenoid Air

Atomizing Air

Component A

Purge Air

Resin Dump

E

G

L

J

K

P

Fluid Hose

N

S

1

Solenoid Power Cable

Solenoid Network Cable

T

B

A

Fig. 3.1

Solenoid Box Cable

Connector

Network PC

or Printer Cable

HAZARDOUS AREA

NON-HAZARDOUS AREA

Operator Station Cable

R

Q

Installation3–4

Page 35

Typical Installation

INTRINSICALLY SAFE

TI0225

H

Key

Electrical

Pneumatic

Fluid

NOTE: See page 3–3 for

Gun Flush Box Cable

Flow Control Meter Cable

CD

key to letter references

User interface is also available

as a remote interface, see

page 3–10.

1

F

Flow Control I/P Cable

Fluid Line To Gun

G

L

K

J

U

Component B

Component C

Solenoid Air

Air In

Atomizing Air

Component A

Purge Air

P

Fluid Hose

N

S

Resin Dump

M

E

Solenoid Power Cable

Solenoid Network Cable

AB

Fig. 3.2

Installation

1

T

Solenoid Box Cable

HAZARDOUS AREA

NON-HAZARDOUS AREA

Operator Station Cable

Connector

Network PC

or Printer

Cable

R

Q

3–5

Page 36

Fluid Supply Requirements

Common fluid supplies include pressure tanks, circulating lines, and pail or drum pumps. The fluid supply

should be capable of supplying enough pressure to

deliver a flow rate 1.5 times the maximum desired flow

rate.

If the Flow Control system is installed, it is very important to balance the fluid pressures of the Component

A, B and C fluid supplies to be within 2 psi (14 kPa, 0.1

bar) of each other at the fluid outlet.

The fluid supply must be free of pressure spikes, which

are commonly caused by a pump stroke changeover.

If necessary, install pressure regulators on the fluid

inlets to the PrecisionMix II 3K to reduce the fluid

supply pressure. Contact your Graco distributor for

information on fluid pressure regulators.

Circulating Lines

For maintenance and safety, you must install a ball

valve between each supply line and the

PrecisionMix 3K.

Installation3–6

Page 37

Mounting Components

The controller, color change panel, and fluid panel can

be wall mounted or installed on Part No. 241501 Stand

Mounting Kit. If the Stand Mounting Kit was ordered

with the system, the parts were mounted to the stand

at Graco. The Gun Flush Box can be wall, stand, or

drum mounted in the spray booth.

NOTE:

Refer to Figs. 3.1 and 3.2 for non-hazardous versus

hazardous location equipment requirements.

Refer to Fig. 3.3 through 3.6 for dimensions and

mounting hole layouts.

For Wall Mounting

Mount the components to a wall, as follows:

1. Ensure that the wall and mounting hardware are

strong enough to support the weight of the equipment, fluid, hoses, and stress caused during

operation.

Operator Station

(without integrated color change)

Depth: 3.25 in.

(83 mm)

8 in.

(203 mm)

6 in.

(152 mm)

6.75 in.

(171 mm)

Operator Station

(with integrated color change)

Depth: 3 in.

(76 mm)

8 in.

(203 mm)

11 in.

(279 mm)

11.75 in.

(298 mm)

6 in.

(152 mm)

6 in.

(152 mm)

2. Mark the mounting holes on the wall at a convenient height for the operator, using the equipment

as a template.

Color Change Panel: In order to use the

standard supplied fluid hose, the color change

panel must be mounted within 12 in. (305 mm)

of the fluid panel. Contact your Graco distributor for other available fluid hoses.

Operator Station or Flow Control Station:

Mount the station(s) inside the spray booth, at

a convenient location for the operator to access and use.

Flow Control Station

Depth: 3.25 in.

(83 mm)

(203 mm)

Fig. 3.3

6 in.

(152 mm)

8 in.

6.75 in.

(171 mm)

6 in.

(152 mm)

Continued on the next page.

9042A

Installation

3–7

Page 38

Mounting Components

For Wall Mounting – continued

Remote User Interface: If a remote User

Interface is used, mount it at a convenient

location for the operator to view and use.

Gun Flush Box: Install the gun flush box in

the spray booth. Locate it as far away from the

spray or application point as possible to help

avoid getting over-spray on it.

Gun Flush Solenoid Box: Install the gun

flush solenoid box in the non-hazardous area,

within 25 ft. (7.6 m) of the gun flush box. 100

ft. (30.5 m) of cable is provided, which connects the solenoid box with the controller.

3. Drill the mounting holes in the wall and install

anchors as needed.

4. Bolt the equipment securely to the wall.

Controller

Depth: 9 in.

(229 mm)

24 in.

(610 mm)

30 in.

(762 mm)

Remote User Interface

Depth: 3.75 in.

(95 mm)

11 in.

(279 mm)

Gun Flush Box

Depth: 9 in.

(229 mm)

(229 mm)

Gun Flush Solenoid Box

Depth: 3.25 in.

(83 mm)

12 in.

(305 mm)

9 in.

(229 mm)

12.75 in.

(324 mm)

14 in.

(356 mm)

9 in.

8 in.

(203 mm)

Fig. 3.4

22.5 in.

(572 mm)

28.5 in.

(724 mm)

TI0165

Fig. 3.5

6 in.

(152 mm)

6.75 in.

(171 mm)

6 in.

(152 mm)

9042A

Installation3–8

Page 39

Mounting Components

Stand Mounting Kit 241501

1. Select the desired location for the mounting stand.

Be sure to leave sufficient space around the

equipment for operator access, routing of hoses

and cabling, and ventilation.

56 in.

(1422 mm)

22 in.

(559 mm)

55.25 in.

(1403 mm)

30 in.

(762 mm)

28.75 in.

(730 mm)

2. Drill holes in the floor, using the mounting stand

base as a template, and install anchors as needed.

3. Secure the mounting stand to the floor.

19 in.

(483 mm)

Color Change Panel

Depth: 9 in.

(229 mm)

Fig. 3.6

Fluid Panel

Depth: 17.4 in.

(442 mm)

28.75 in.

(730 mm)

Dimensions and Mounting Holes

11 in.

(279 mm)

10 in.

(254 mm)

15 in.

(381 mm)

20.56 in.

(522 mm)

70 in.

(1778 mm)

TI0170

Installation

3–9

Page 40

System Installation

NOTE:

All options ordered on configured systems are

electrically tested at the factory and shipped connected from Graco.

It is recommended that all cables routed in the

spray booth and high traffic areas be enclosed in

conduit to prevent damage from paint, solvent, and

traffic.

Refer to the Electrical Connection table and

diagram, page 3–29, for wiring connections.

Install the Controller and User Interface

(Code A)

The controller is available with a panel mount user

interface or a remote user interface.

1. If you are using a remote user interface (T), Part

No. 194372 standard cable (C1) is provided to

connect the remote interface (T) to the controller

(B). The 9-pin D-SUB cable is 50 ft. (15.2 m) long.

See Fig. 3.7.

B

T

C1

TI0165

Fig. 3.7

2. Provide power to the controller, using conduit to

protect the wiring.

3. Ground the controller to a true earth ground. See

Grounding the System on page 3–30.

Installation3–10

Page 41

System Installation

Power Requirements

The Precision Mix II control is designed to operate with

120 Vac or 220 Vac input power. See Fig. 3.8 for the

wiring connections.

It is possible for voltage brown out conditions to cause

the Precision Mix II control to go into a memory failure

mode. If the power being supplied to the system is not

free of excessive dips an uninterruptable power supply

(UPS) or a power conditioner will need to be supplied.

The Precision Mix II control is already equipped with a

surge suppressor, adding one will not be necessary.

The basic requirements for purchasing a UPS or

power condition are as follows:

L1 L2 or Common

Ground

1. Purchase one rated for the desired input voltage

(120 Vac or 220 Vac).

2. Purchase one with a minimum output current of

125 Watts.

3. Purchase one that is rated for industrial use and

the maximum temperature conditions of the installation site.

NOTE: It is not recommended to mount either a UPS

or power conditioner inside the Precision Mix II control.

Fig. 3.8

L1 L2

Installation

3–11

Page 42

System Installation

Install the Fluid Panel (Code E) with Fluid

Meters (Code F)

A non-intrinsically safe fluid panel (Code E–1) is available for installing in a non-hazardous area. Refer to the

typical installation drawing on page 3–4.

WARNING

FIRE AND EXPLOSION HAZARD

The controller must be configured with

the proper barriers for it to be used with

a fluid panel installed in a hazardous

area. A non-intrinsically safe system

must be installed as shown in Fig. 3.1,

page 3–4.

An intrinsically safe fluid panel (Code E–2) is available

for installing in a hazardous area. Refer to the typical

installation drawing on page 3–5.

NOTE:

The selected fluid meters (S1, S2, S3, S4) are

installed on the fluid panel at the factory.

2. In certain situations, the cable (C6) may need to

be disconnected and reconnected to route the

cable as desired. If this is necessary follow the

steps below and refer to the Electrical Connec-

tion table and diagram, page 3–29.

Non-intrinsically Safe Fluid Panel Cable Wiring

a. Connect the cable wires to the terminals in the