Page 1

Instructions – Parts List

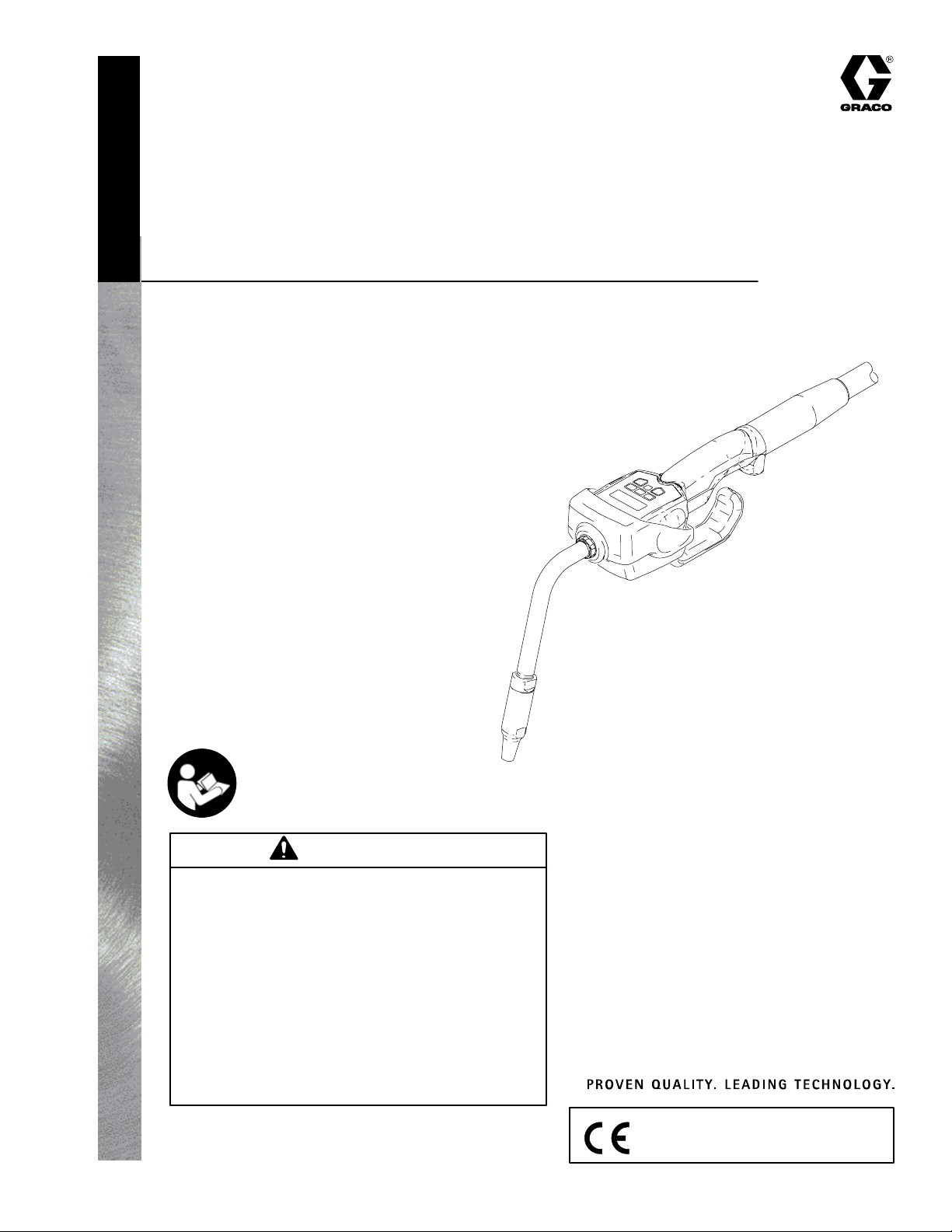

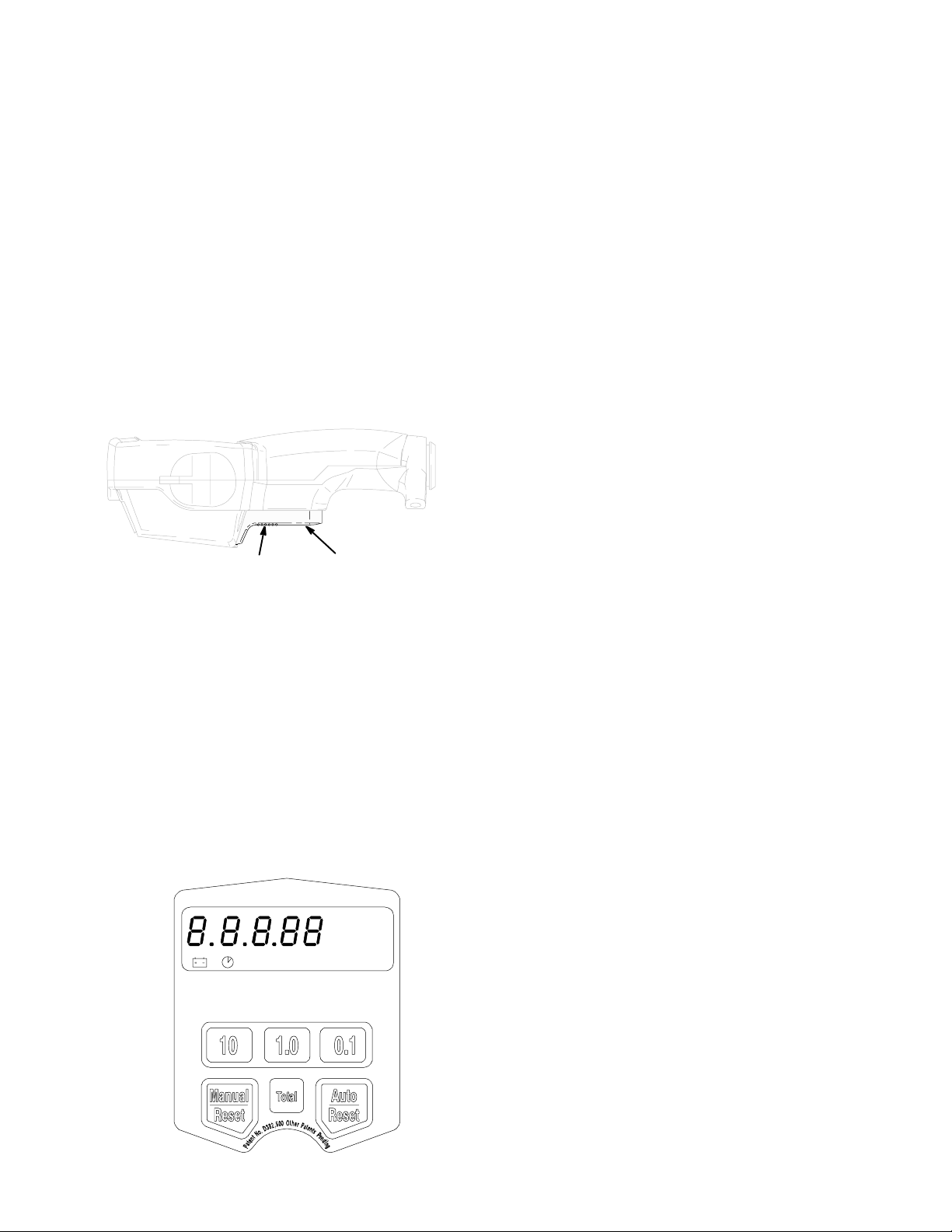

PRESET

PM5t Electronic

Metered Dispense Valves

For pre–set metered dispense of oils and antifreeze.

1000 psi (7 MPa, 69 bar) Maximum Working Pressure

5 gpm (18.9 lpm) Maximum Flow Rate

Model 238511 75_ bend 3/8–in. rigid tube

Model 238512 3/8–in. coupled flexible hose

Model 238515 90_ offset

Patent Nos.

4,883,199 DE3834454C2

D382,500 1025804

6,357,300 ZL97102971.7

6,047,906 187760

77664 13742

Model 238511 shown

309377E

TI0327

Important Safety instructions

Read all warnings and instructions in this manual.

Save these instructions.

CAUTION

D This dispense valve is designed to dispense

petroleum-based lubricants and antifreeze only.

Do not dispense windshield washer solvent with

this dispense valve.

D This dispense valve is designed for indoor use

only.

D This dispense valve is not designed for in-line

installation. Do not install with a shutoff valve on

the outlet side of the meter. Such installation

could result in damage to the meter housing

cover.

GRACO INC.ąP.O. BOX 1441ąMINNEAPOLIS, MNą55440-1441

Copyright 2001, Graco Inc. is registered to I.S. EN ISO 9001

Page 2

Table of Contents

Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts List 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Drawing 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensional Drawing 21. . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Standard Warranty 22. . . . . . . . . . . . . . . . . . . . . .

Graco Information 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARNINGWARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

INSTRUCTIONS

D This equipment is for professional use only.

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

D Read all instruction manuals, tags, and labels before you operate this equipment.

D Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor

for assistance.

D Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

D Do not leave this dispense valve unattended while it is dispensing.

D Check equipment daily. Repair or replace worn or damaged parts immediately.

D Do not exceed the maximum working pressure of the lowest rated system component. See the

Technical Data on page 20 for the maximum working pressure of this component.

D Use fluids and solvents that are compatible with the equipment wetted parts. See the Technical

Data section of all equipment manuals. Read the fluid and solvent manufacturer’s warnings.

D Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not

expose Graco hoses to temperatures above 180_ F (82_ C) or below –40_ F (–40_ C).

D Comply with all applicable local, state, and national fire, electrical, and safety regulations.

D Do not point the dispense valve at anyone or at any part of the body.

D Do not put your hand or fingers over the end of the dispense valve.

D Do not stop or deflect leaks with your hand, body, glove, or rag.

D Use only extensions and nozzles that are designed for use with this dispense valve.

D Follow the Pressure Relief Procedure on page 5 before you clean, check, or service this

D Tighten all fluid connections before you operate this equipment.

D Check the hoses, tubes, and couplings daily. Replace worn or damaged parts immediately. Do

2 309377

equipment.

not repair high pressure couplings; you must replace the entire hose.

Page 3

WARNINGWARNING

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames, or sparks can cause a hazardous condition and

result in a fire or explosion and serious injury.

D Be sure the entire fluid system is properly grounded. Refer to your pump instruction manual for

complete details. See Grounding on page 6.

D If there is any static sparking or you feel an electric shock while using this equipment, stop

dispensing immediately. Do not use the equipment until you identify and correct the problem.

D Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being dispensed.

D Keep the dispensing area free of debris, including solvent, rags, and spilled gasoline.

D Do not smoke while flammable fluids or fumes are in the dispensing area.

3309377

Page 4

Installation

Typical Installations

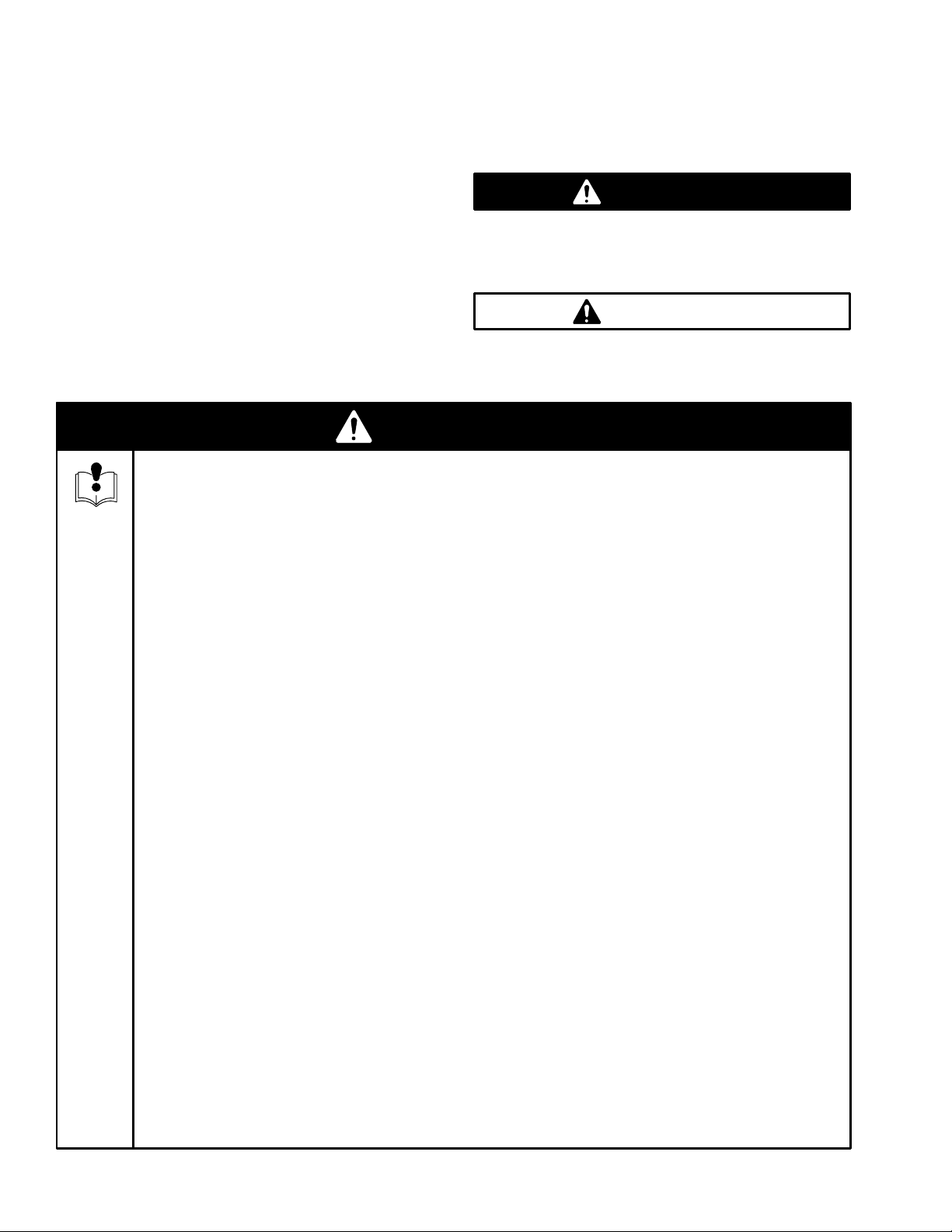

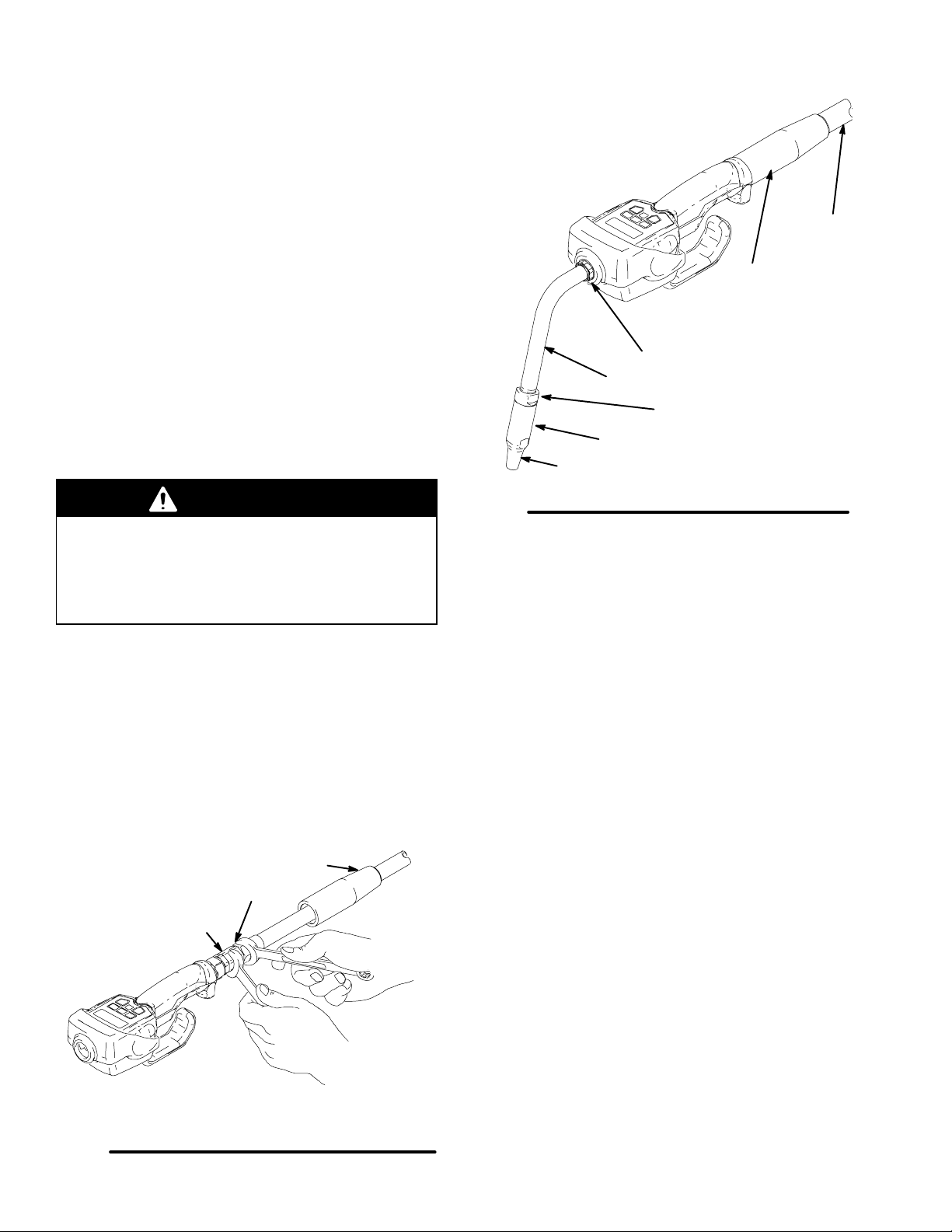

Fig. 1 shows a typical hose reel installation. These

dispense valves can also be installed on a console, as

shown in Fig. 2.

CAUTION

Do not use this dispense valve on non-Graco

consoles. Such use could result in the trigger

becoming inadvertently pressed while the dispense valve is stowed.

J

L

H

The typical installation shown in Fig. 1 is only a guide.

The components shown are typical; however, it is not a

complete system design. Contact your Graco distributor for assistance in designing a system to suit your

particular needs.

CAUTION

This dispense valve is not designed for in-line

installation. Do not install with a shut-off valve

on the outlet side of the meter. Such installation

could result in damage to the meter housing

cover.

Mounting Bracket

Mounting bracket 196471 is available for resting a PM5

dispense valve on a console. See Fig. 2.

CAUTION

Do not obstruct the trigger of this dispense

valve, and do not set the unit down resting on its

trigger, or it might not stop dispensing.

M

K

N

Fig. 1

KEY DESCRIPTION

H Thermal relief kit (required) Part No. 235998

Install downstream from pump.

J Fluid shut-off valve

K Hose

L Hose reel fluid inlet hose

M Hose reel

N PM5 electronic metered dispense valve

4 309377

06174B

mounting bracket

196471

Fig. 2

TI0334

Page 5

Installation

WARNING

PRESSURIZED EQUIPMENT HAZARD

The equipment stays pressurized until pressure is

manually relieved. To reduce the risk of serious

injury from pressurized fluid, accidental spray from

the dispense valve, or splashing fluid, follow the

Pressure Relief Procedure when you

D Are instructed to relieve pressure

D Check, clean, or service any system equipment

D Install or clean fluid nozzles or filter

Pressure Relief Procedure

1. Turn off the power supply to the pump.

2. Trigger the dispense valve into a waste container

to relieve pressure.

3. Open any bleed-type master air valves and fluid

drain valves in the system.

4. Leave the drain valve open until you are ready to

pressurize the system.

WARNING

FIRE AND EXPLOSION HAZARD

The movement of fluids through the

dispensing system generates static

electricity. The static electricity can

cause volatile fumes to ignite, resulting in explosion

and fire. The dispensing system must grounded.

See Grounding on page 6.

Installation Procedure

CAUTION

If this is a new installation, or if the fluid in the

lines is contaminated, flush the lines before you

install the metered valve. Contaminated lines

could cause the valve to leak.

1. If this is an existing installation, go to step 7.

Steps 2 through 6 are the Flushing Procedure.

2. Close the fluid shut-off valve (J) at each dispense

position.

3. Make sure the main fluid outlet valve at the pump

is closed, the air pressure to the pump motor is

adjusted, and the air valve is open. Slowly open

the main fluid valve.

4. Place the hose end (with no dispense valve connected) into a container for waste oil. Secure the

hose in the container so it will not come out during

flushing. If you have multiple dispense positions,

first flush the dispense position farthest from the

pump, and work your way toward the pump.

5. Slowly open the shut-off valve (J) at the dispense

position. Flush out a sufficient amount of oil to

ensure that the entire system is clean, and close

the valve.

6. Repeat step 5 at all other dispense positions.

7. Relieve the pressure.

Pre-Installation Procedure

1. Relieve the pressure.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure above.

2. Close the shut-off valve (item J in Fig. 1).

3. Ground the hose and reel or console. See

Grounding on page 6. Leave a minimum two

engaged threads bare when using PTFE tape. The

bare threads ensure a ground is maintained.

WARNING

To reduce the risk of serious injury, whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure at left.

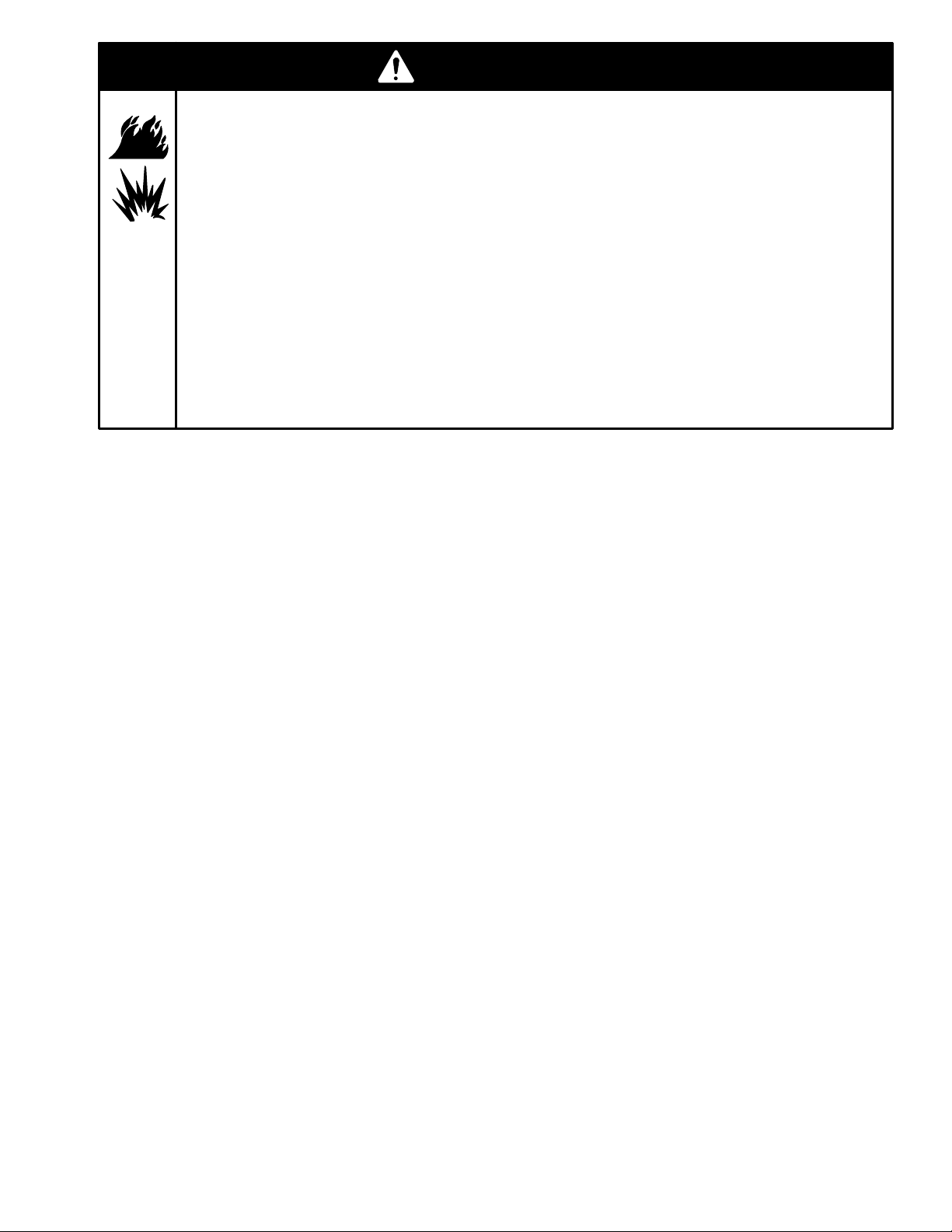

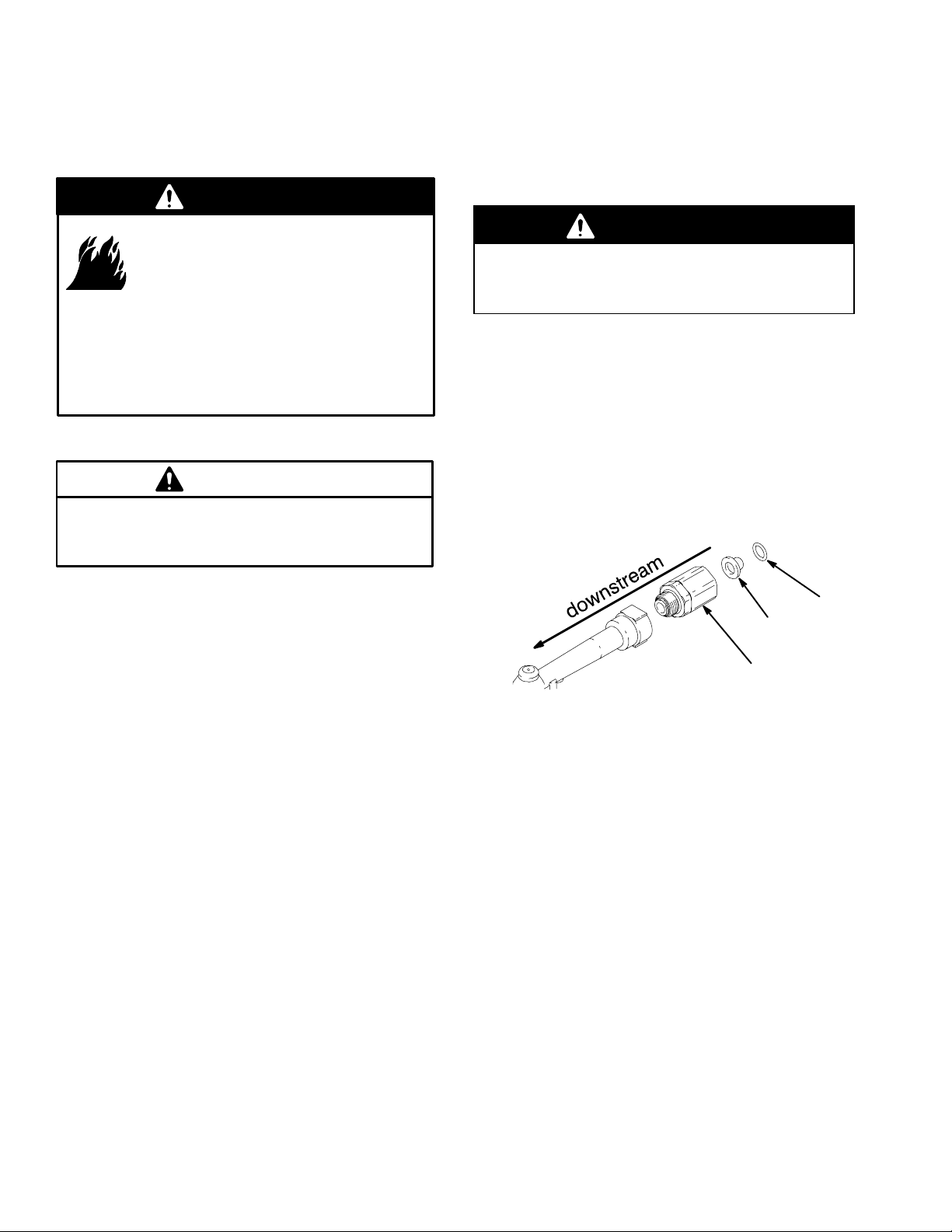

8. Slide the swivel cover (4) of the PM5 onto the

hose, small end first. See Fig. 3.

9. Apply thread sealant to the male threads of the

hose fitting, thread the hose fitting into the swivel

(3) of the PM5, and tighten it firmly. See Fig. 3.

NOTE: Make sure you let the sealant cure to the

manufacturer’s recommendations before you let

fluid into the system.

5309377

Page 6

Installation

10. Thread the sealing nut (5c, 6c, or 7c) onto the

extension (5a) or street elbow (6d or 7d), thread

the extension or elbow in at least three full turns,

position it for proper alignment, and tighten the

sealing nut. The PTFE seal on the sealing nut

must face the valve housing. See Fig. 4.

NOTE: The flexible extension (6a) can also be

threaded directly into the meter outlet without the

street elbow or sealing nut. See the note in the

Parts Drawing on page 19.

11. Thread the new nozzle (5b, 6b, or 7b) onto the

extension, and, with an open-end adjustable

wrench, tighten it firmly. See Fig. 4.

NOTE: Only tighten the nozzle with the wrench

on the flats of the nozzle bushing. Do not disas-

semble the bushing from the nozzle. Disassembly will affect the performance of the nozzle.

WARNING

Model shown has

75_ bend rigid

extension

5b

Fig. 4

hose

4

5c

5a

nozzle bushing

Nozzle is not serviceable.

TI0327

Do not use Graco’s old nozzle (Part No. 203655) or

any other manual shut-off nozzle on the PM5

extension. You must use the new automatic nozzle

that is provided with the PM5, or the meter could

be damaged. Do not use any sealant material.

12. Open all dispense position shut-off valves, and

start the pump to pressurize the system. See the

Operation section for proper operation of meter.

13. To ensure dispensing accuracy, purge all air from

the fluid lines and dispense valve before you use

it. Set the system flow to the desired flow rate,

which is typically 1.5 gpm. Do not exceed a 5-gpm

flow rate.

Slide onto

hose before

connecting.

hose fitting

3

4

Grounding

Proper grounding is an essential part of maintaining a

safe system.

To reduce the risk of static sparking, ground all system

components according to local and national electrical

codes. Refer to the user manuals for the pump and

other system components, and ground the following:

D Pump: Follow the manufacturer’s recommend-

ations.

D Air and Fluid hoses: Use only grounded hoses.

D Air compressor: Follow the manufacturer’s recom-

mendations.

Fig. 3

6 309377

TI0328

D Fluid supply container: Follow the local code.

To maintain grounding continuity when flushing or

relieving pressure, always hold a metal part of the

valve firmly to the side of a grounded metal pail, then

trigger the valve.

Page 7

Setup

Terms

The following terms are shown on the display and/or

used often in this instruction manual.

D R–TOTAL: resettable total

Displayed to show the cumulative amount that the

dispense valve has dispensed in all modes. It can

be reset to zero.

D TOTAL: non-resettable total

Displayed to show the cumulative amount that the

dispense valve has dispensed in all modes for the

history of the unit. It cannot be reset.

D MANUAL mode

Dispense mode in which the display counts up from

zero to show the dispensed amount. In this mode,

you may lock the trigger, but you must manually

unlock it when the desired amount is dispensed.

Memory setting also unlocks the trigger.

D AUTO mode

Dispense mode in which a preset, user-entered

amount is dispensed. When the preset amount is

dispensed, a beep sounds, the trigger unlocks to

stop the unit from dispensing, and the amount

dispensed is displayed. At this point, you may

dispense more by pulling back the trigger, and the

display resumes counting up in Manual mode.

D Asleep / Awake

Asleep is a battery-saving mode in which the display goes blank after 45 seconds of inactivity during

normal operation and 2 minutes when in the options

menu. The display comes awake from sleep mode

when you press the Manual/Reset or Auto/Reset

button, but not when you squeeze the trigger to

dispense fluid. The unit does keep track of the

amount dispensed while the display is asleep.

NOTE: If the unit falls asleep after any dispense

cycle, and you do wake it up by pressing the Auto/

Reset button, the previously dispensed amount is

cleared, and the Auto mode dispense amount

stored in memory is displayed. You will be at the

beginning of an Auto mode dispense cycle.

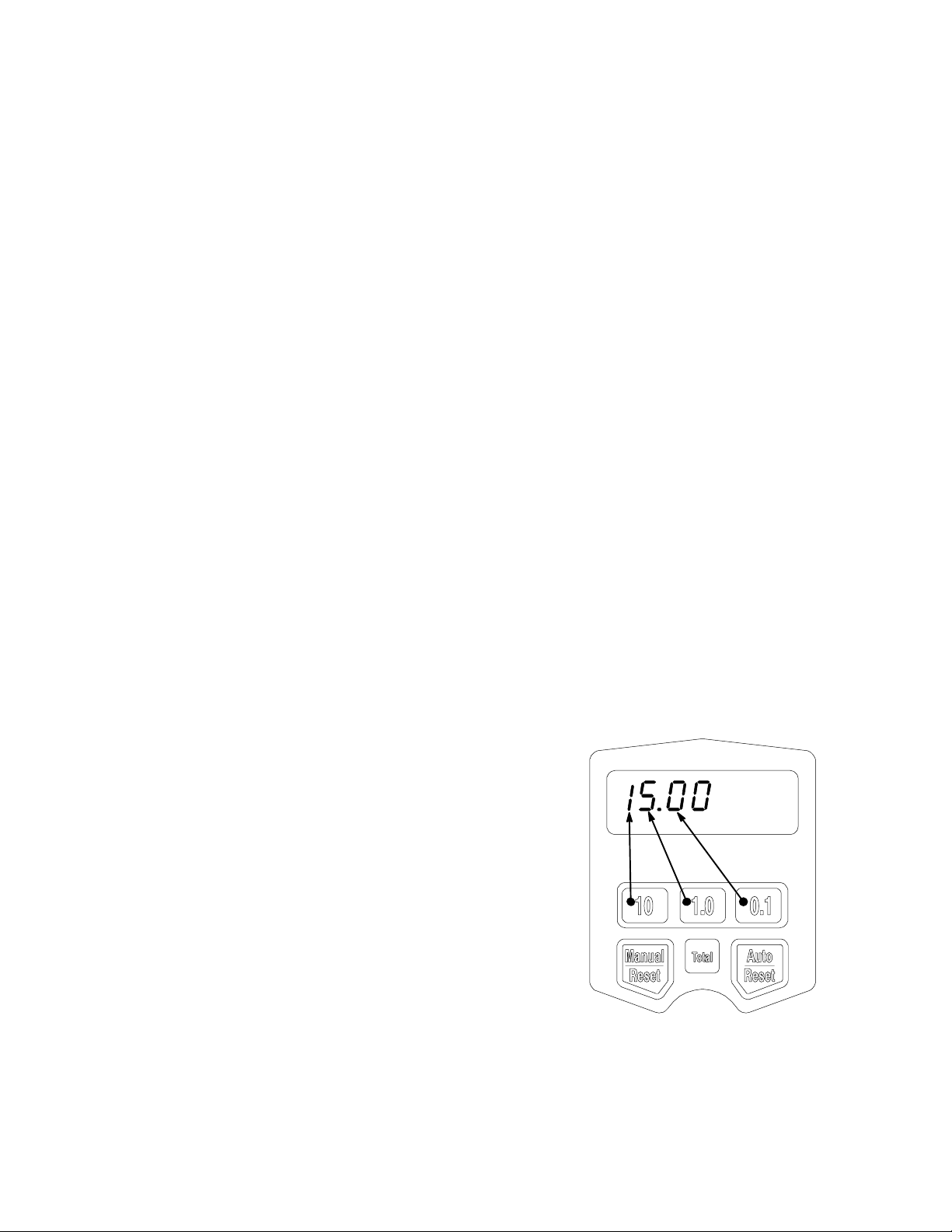

Keypad Buttons

The buttons on the keypad and their functions are as

follows (see the figure below):

D 10, 1.0, and 0.1

Used in Auto mode and during setup to enter

dispense amounts.

D MANUAL / RESET and AUTO / RESET

Used individually to select Manual mode and Auto

mode. Used together (pressed simultaneously) to

access the setup menus.

For both of these buttons, the first push selects the

mode, and the second push resets the display to

zero.

D TOTAL

Used in any mode to see the resettable total and

the non-resettable total.

NOTE: All buttons are disabled while fluid is being

dispensed.

GAL

AUTO

If the unit falls asleep after any dispense cycle, and

you do not wake it up by pressing the Manual/Reset or Auto/Reset button, it will default to manual

mode. When dispensing begins you will be at the

beginning of a manual mode dispense cycle.

06044A

7309377

Page 8

Setup

Selecting Dispensing Options

This is the procedure for setting or changing the resettable total, units of measurement, calibration factor, auto

preset amount, and shut-off default amount:

1. If the display is asleep, wake it up by pressing the Manual/Reset or Auto/Reset button.

2. To enter the dispensing options menus from any mode, press and hold the Manual/Reset and Auto/Reset

buttons simultaneously for four seconds.

The first menu is the Resettable Total menu, which is described in the first subsection below. You can advance

through the menus by pressing the Auto/Reset button. You will know which menu you are in, because a menu

indicator will be blinking in the display. The value that is displayed when you leave each menu and advance to

the next is the value that gets stored.

Resettable Total

In this menu, you can reset the resettable total to zero

or leave it unchanged. The resettable total accumulates until the next time it is manually reset.

1. If you have not already entered the dispensing

options menus, do steps 1 and 2 in Selecting

Dispensing Options above.

2. With R–TOTAL blinking and the current resettable

total displayed, as shown below, do ONE of the

following two options:

D Press the Manual/Reset button.

The resettable total is set to zero, and 0 GAL or 0

LITERS is displayed.

You can press the Manual/Reset button again to toggle

between zero and the previously displayed resettable

total. To lock in the displayed value and advance to

the Units of Measurement menu, press the Auto/Reset

button.

OR

D Press the Auto/Reset button.

The currently displayed value is stored, and the display

advances to the Units of Measurement menu.

Units of Measurement

In this menu, you can set the units of measurement to

quarts, gallons, pints, or liters.

1. If you have not already entered the dispensing

options menus, do steps 1 and 2 in Selecting

Dispensing Options above.

2. Press the Auto/Reset button repeatedly until QTS,

GAL, LITERS, or PTS blinks to indicate that you

are in the Units-of Measurement menu.

3. With QTS, GAL, LITERS, or PTS blinking, as

shown below, do ONE of the following two options:

D Press the Manual/Reset button.

Each time you press the Manual/Reset button, the

display scrolls to the next unit of measurement. To

lock in the new unit of measurement and advance to

the Calibration Factor menu, press the Auto/Reset

button.

OR

D Press the Auto/Reset button.

The displayed unit of measurement is retained, and

the display advances to the Calibration Factor menu.

D Do not obstruct the trigger

D Do not leave unattended

8 309377

GAL

R-TOTAL

! CAUTION

To prevent overfills and spills

D Do not operate below 32_ F (0_ C)

Maximum Working Pressure 7 MPa (70 bar, 1000 PSI)

D Read instruction manual

06044A

! CAUTION

D Do not obstruct the trigger

D Do not leave unattended

To prevent overfills and spills

D Do not operate below 32_ F (0_ C)

Maximum Working Pressure 7 MPa (70 bar, 1000 PSI)

D Read instruction manual

GAL

06044A

Page 9

Setup

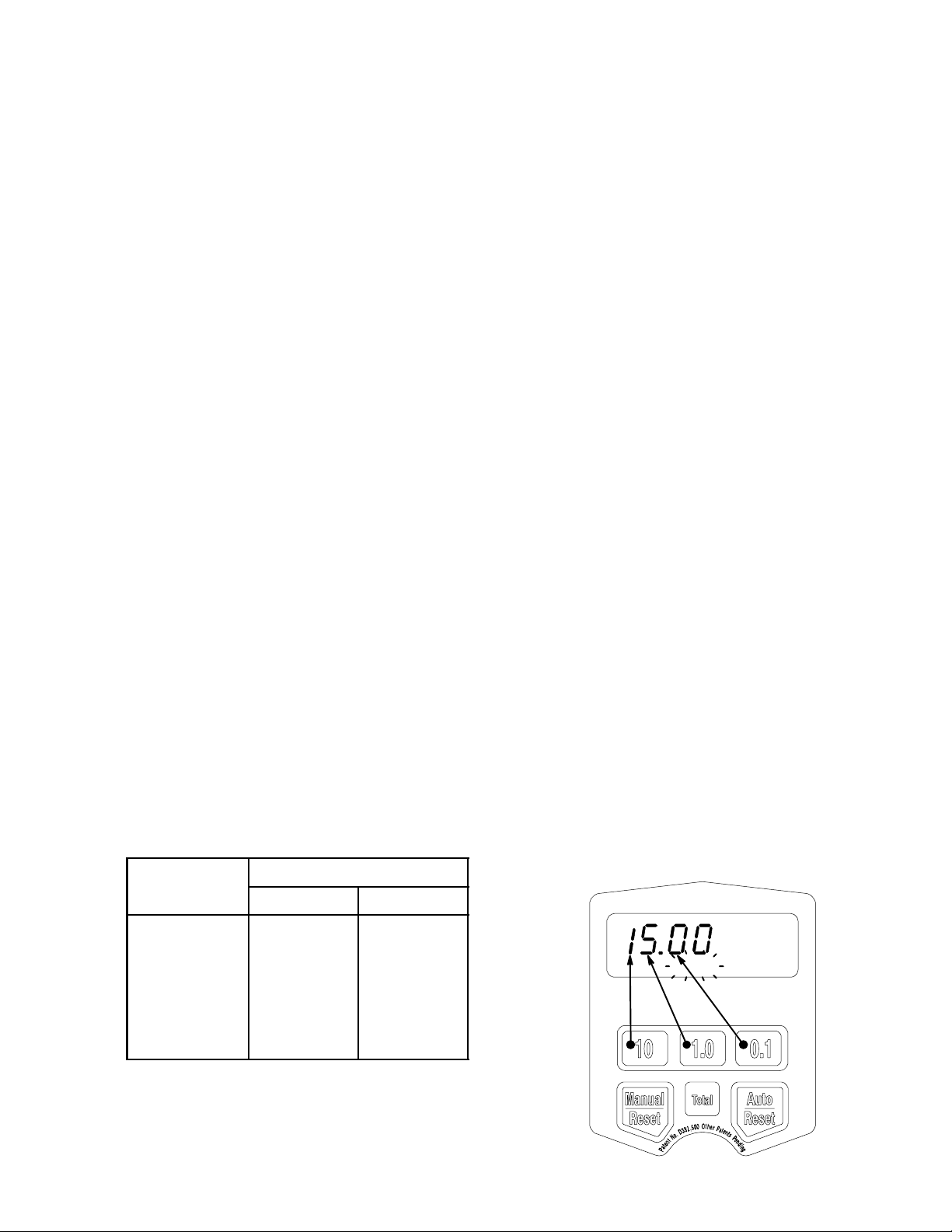

Calibration Factor

In this menu, you can recalibrate the meter for different

fluids.

1. If you have not already entered the dispensing

options menus, do steps 1 and 2 in Selecting

Dispensing Options on page 8.

2. Press the Auto/Reset button repeatedly until CAL

blinks and the current calibration factor is displayed to indicate that you are in the Calibration

menu.

3. With CAL blinking, you can press the Auto/Reset

button and choose not to change the calibration

factor, which advances to the Auto Preset Amount

menu.

OR

You can recalibrate the meter as follows:

3a. If the unit of measurement is liters, dispense

exactly one liter of fluid into a calibrated

1-liter container. If the unit of measurement

is gallons, pints, or quarts, dispense exactly

one quart of fluid into a calibrated 1-quart

container. For proper calibration, you must

dispense the exact amount, according to the

markings on the container.

After dispensing, the displayed number is the

new calibration factor. The new calibration

factor must be within 20 percent of the factory default value [in the range of 294–442

quarts (310–467 liters)], or it will not be

accepted.

The following table lists approximate calibration factors for different fluids. Your calibration number may vary slightly due to temperature or flow rate.

Calibration Number

Fluid

Quarts Liters

Auto Preset Amount

In this menu, you can specify an amount to be displayed when you enter the Auto dispense mode.

Typically, you would enter the amount you most frequently dispense.

1. If you have not already entered the dispensing

options menus, do steps 1 and 2 in Selecting

Dispensing Options on page 8.

2. Press the Auto/Reset button repeatedly until

AUTO blinks and the auto preset amount in

memory is displayed to indicate that you are in the

Auto Preset Amount menu. This is the amount

that is displayed when the Auto/Reset button is

pressed during normal operation.

3. With AUTO blinking and the stored auto preset

amount displayed, as shown below, do ONE of the

following two options:

D Enter a new auto preset amount by pressing

the 10 button to change the 10s digit,

the 1.0 button to change the 1s digit, and

the 0.1 button the change the first decimal

digit.

In the figure below, the arrows point from the numbered buttons on the keypad to the corresponding

digits in the display.

NOTE: If you press and hold the 10, 1.0, or 0.1 buttons, the digits advance rapidly.

To store the displayed auto preset amount in memory

and advance to the Shut-Off Default Amount menu,

press the Auto/Reset button.

OR

D Press the Auto/Reset button.

The currently displayed auto preset amount is

retained, and the display advances to the Shut-Off

Default Amount menu.

oil (10W–30) 368 389

gear lube 368 389

automatic

368 389

transmission

fluid

antifreeze 347 367

Calibration factors at 70_ F (21_ C) at 2.0 gpm (7.6 lpm).

3b. Press the Auto/Reset button to store the new

calibration factor and advance to the Auto

Preset Amount menu.

AUTO

! CAUTION

D Do not obstruct the trigger

D Do not leave unattended

To prevent overfills and spills

D Do not operate below 32_ F (0_ C)

Maximum Working Pressure 7 MPa (70 bar, 1000 PSI)

D Read instruction manual

GAL

06044A

9309377

Page 10

Shut-Off Default Amount

Setup

The shut-off default amount is for preventing accidental overfills when dispensing with the trigger locked in

Manual mode. The shut-off default amount is factory

preset at 5 quarts.

In this menu, you can change the shut-off default

amount.

1. If you have not already entered the dispensing

options menus, do steps 1 and 2 in Selecting

Dispensing Options on page 8.

2. Press the Auto/Reset button repeatedly until the

clock icon blinks, and the stored shut-off default

amount is displayed to indicate that you are in the

Shut-off Default Amount menu.

3. With the clock icon blinking and the stored shut-off

default amount displayed, as shown below, do

ONE of the following two options:

D Enter a new shut-off default amount by press-

ing the 10 button to change the 10s digit,

the 1.0 button to change the 1s digit, and

the 0.1 button the change the first decimal

digit. You cannot enter zero. To lock in the

new shut-off default amount and exit the

dispensing options menus, press the Auto/Reset button.

The PM5 beeps and returns to the Manual dispense

mode to indicate that you have exited the dispensing

options menus.

OR

D Press the Auto/Reset button.

The PM5 beeps and returns to the Manual dispense

mode to indicate that you have exited the dispensing

options menus.

QTS

! CAUTION

D Do not obstruct the trigger

D Do not leave unattended

To prevent overfills and spills

D Do not operate below 32_ F (0_ C)

Maximum Working Pressure 7 MPa (70 bar, 1000 PSI)

D Read instruction manual

06044A

10 309377

Page 11

Operation

Locking and Unlocking the Trigger

The trigger on this dispense valve has a locking mechanism. In Auto mode, the unit stops dispensing when

the entered amount has been dispensed. In Manual

mode, the trigger does not automatically unlock; you

must unlock it manually.

To lock the trigger, press on the part of the trigger

that has the textured grip (see below) until you feel it

click into the locked position.

To unlock the trigger, press on the smooth part of

the trigger (see below) until you feel it click out of the

locked position. When you release the trigger, fluid

flow stops.

Press here

to lock.

Press here

to unlock.

06227A

Dispensing Fluid in Manual Mode

1. Press the Manual/Reset button.

If the display was asleep, it wakes up and displays

the amount that was displayed before it fell asleep.

If the display was awake, and the meter is in the

Manual dispense mode, the meter beeps, and the

display clears to 0.00.

If the display was awake, and the unit is in the Viewing Totals mode or the Auto dispense mode, the meter

switches to the Manual dispense mode.

2. When the display is awake, you can dispense from

zero or from the displayed amount by doing one of

the following:

D Press the Manual/Reset button again to clear

the display to 0.00 if it is not already at 0.00.

Then go to step 3.

Checking Segments in the Display

When you press the Manual/Reset button or the

Auto/Reset button when the display is awake and in

the Manual or Auto dispense mode, the Segment

Check is displayed briefly. This display allows you to

check for burned out segments in the display. Press

the Manual/Reset or Auto/Reset button repeatedly to

get a good look at each segment in the display. The

Segment Check should show all of the segments

shown below.

QTS

PTS

CAL

GAL

LITERS

R-TOTAL

,, ,

AUTO

! CAUTION

D Do not obstruct the trigger

D Do not leave unattended

To prevent overfills and spills

D Do not operate below 32_ F (0_ C)

Maximum Working Pressure 7 MPa (70 bar, 1000 PSI)

D Read instruction manual

OR

D Go straight to step 3 to dispense from the

displayed amount.

3. Squeeze the trigger. You may lock it. See Lock-

ing and Unlocking the Trigger at left.

Fluid flows, and the amount displayed counts up from

zero or the previously dispensed amount.

4. Release/unlock the trigger when you have dispensed the desired amount of fluid.

Fluid flow stops, and the amount you have dispensed

is displayed.

You may press the Manual/Reset button again to reset

the displayed amount to zero.

06044A

NOTE: When the trigger is released, the automatic

nozzle prevents the fluid in the extension from running

out.

11309377

Page 12

Operation

Dispensing Fluid in Auto Mode

CAUTION

Before you begin a preset dispense cycle, make

sure AUTO is displayed. If you do not see

AUTO on the display, you are not in the Auto

dispense mode, and fluid flow will not stop when

the auto preset amount is dispensed.

1. Press the Auto/Reset button.

The display wakes up if it was asleep, and AUTO and

the stored preset dispense amount are displayed. The

factory default is 0.00.

NOTE: To change the stored preset dispense

amount, see Auto Preset Amount on page 9.

2. You can dispense or change the displayed preset

amount by doing one of the following:

D Go straight to step 3 to dispense the displayed

preset amount.

Viewing Totals

This is the procedure for viewing the non-resettable

and resettable totals. To change the resettable total,

see Resettable Total on page 8.

1. If the display is blank, press the Manual/Reset or

Auto/Reset button to wake it up.

2. Press the Total button to view the non-resettable

total amount.

If the unit of measurement is gallons, quarts, or pints,

the total is displayed in gallons, as shown below. If the

unit of measurement is liters, the total is displayed in

liters.

GAL

TOTAL

! CAUTION

D Do not obstruct the trigger

D Do not leave unattended

To prevent overfills and spills

D Do not operate below 32_ F (0_ C)

Maximum Working Pressure 7 MPa (70 bar, 1000 PSI)

D Read instruction manual

OR

D To change the displayed preset amount, you

can set the display to zero by pressing the

Auto/Reset button, then press the10 button to

change the 10s digit, press the 1.0 button to

change the 1s digit, and press the 0.1 button

the change the first decimal digit. Then go to

step 3.

3. Lock the trigger. See Locking and Unlocking

the Trigger on page 11.

Fluid flows, and the displayed dispensed amount

counts up from zero. When the preset amount is

dispensed, the unit beeps, the trigger unlocks, fluid

flow stops, the dispensed amount is displayed, and

the meter switches to the Manual dispense mode.

If you want to stop fluid flow before the preset amount

is dispensed, manually unlock the trigger. To continue

the dispense, lock the trigger, and the dispensed

amount resumes counting toward the preset amount.

If you want to continue dispensing after the trigger

unlocks at the preset dispense amount, squeeze the

trigger, and the dispensed amount resumes counting in

the Manual dispense mode until you release the trigger.

NOTE: When the trigger unlocks, the automatic

nozzle prevents the fluid in the extension from running

out.

12 309377

06044A

3. Press the Total button again to view the resettable

total amount.

If the unit of measurement is gallons, quarts, or pints,

the resettable total is displayed in gallons, as shown

below. If the unit of measurement is liters, the resettable total is displayed in liters.

GAL

R-TOTAL

! CAUTION

D Do not obstruct the trigger

D Do not leave unattended

To prevent overfills and spills

D Do not operate below 32_ F (0_ C)

Maximum Working Pressure 7 MPa (70 bar, 1000 PSI)

D Read instruction manual

06044A

Pressing the Total button repeatedly toggles between

the non-resettable and resettable total.

4. Press the Manual/Reset or Auto/Reset button to

return to the Manual or Auto dispensing mode.

Page 13

Troubleshooting

Relieve the pressure before you check or repair the

meter. Be sure all other valves and controls and the

pump are operating properly.

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 5.

Problem Cause Solution

Battery icon is displayed. Battery is low. Replace the battery. See Replacing

WARNING

the Battery on page 16.

Battery icon is blinking, and

bAtt is blinking.

Display does not activate. Battery is defective or dead.

Slow or no fluid flow Filter is clogged.

Battery is dead. Replace the battery. See Replacing

Electronic control is malfunctioning.

A dispense mode has not been

selected.

Pump pressure is low.

Shut-off valve is not fully open.

Foreign material is jammed in the

meter housing.

the Battery on page 16.

Replace the battery. See Replacing

the Battery on page 16.

Replace the electronic control

(clamshell).

Select a dispense mode by pressing

the Manual/Reset button or the

Auto/Reset button.

1. Relieve the pressure.

2. Clean or replace the filter. See

Replacing the Filter on page 16.

3. If the problem remains, contact

your Graco distributor for repair

or replacement.

Turn up pump pressure.

Fully open shut-off valve.

Contact your Graco distributor for

repair or replacement.

Displayed dispensed amount

is not accurate.

Unit needs to be calibrated for the

fluid that is being dispensed.

Calibrate the meter for the fluid that is

being dispensed. See Calibration

Factor on page 9.

continued

13309377

Page 14

Problem Cause Solution

Meter leaks from:

Troubleshooting

Cover/Control Poor swivel (3)/hose connection.

Meter leaks from:

Automatic

nozzle

NOTE: It is important to distinguish between the two

causes of this problem. A

new nozzle will not correct a

fluid leak caused by a faulty

valve.

Poor swivel (3)/meter housing

connection.

Damaged valve stem (16) assembly.

Poor seal at meter housing plate.

NOTE: Place a straight edge along

meter housing plate. If flat, plate and

seal are ok. If plate is not flat, meter

is damaged.

Automatic nozzle (5b, 6b, or 7b) has

a damaged seal.

Valve (16) has damaged or

obstructed seals.

Apply PTFE tape (leave minimum 2

engaged threads uncovered for

electrical continuity) or sealant to

threads of hose and tighten the

connection. See step 9 in

Installation Procedure.

Torque the fitting to 20–25 ft.lb.

Replace or clean valve stem and

O–rings. See Servicing the Valve.

Contact your Graco distributor for

repairs or replacement.

Replace the nozzle. See Replacing

the Automatic Nozzle on page 17.

Replace or clean valve stem and

o-rings. See Servicing the Valve on

page 17.

Meter leaks from:

Swivel

Unit does not stop dispensing

when assumed auto amount

is dispensed.

Poor swivel (3)/hose connection

Poor swivel (3)/meter housing

connection.

Auto amount was not entered.

Trigger is obstructed, or unit has

been set down resting on its trigger.

Apply PTFE tape (leave minimum 2

engaged threads uncovered for electrical continuity) or sealant to threads

of hose and tighten the connection.

See step 9 in Installation Proce-

dure.

Torque the fitting to 20–25 ft.lb.

Enter a preset dispense amount in

the Auto dispense mode. AUTO

must be displayed below the amount.

Never set the unit down resting on its

trigger.

14 309377

Page 15

Troubleshooting

Error Codes

Error codes are listed below. Even in an error condition, the unit keeps track of the amount dispensed.

With any error code displayed, as shown at right, you

can

D Press the Manual/Reset button.

Error code is cleared, unit switches into Manual

mode, and dispensed amount is displayed.

D Press the Auto/Reset button.

Error code is cleared, unit switches into Auto mode,

and the preset amount is displayed.

Error Code Cause Solution

! CAUTION

D Do not obstruct the trigger

D Do not leave unattended

To prevent overfills and spills

D Do not operate below 32_ F (0_ C)

Maximum Working Pressure 7 MPa (70 bar, 1000 PSI)

D Read instruction manual

06044A

Err 1 Flow rate is higher than 5 gpm.

or

Air was pumped through the line.

Err 2 Switch Error: Error occurred with

pick-up in internal gear.

or

Unit was dropped or unit encountered excessive vibration during

shipping.

Err 4 Flow has continued after it should

have shut off.

Err 5 The unit has dispensed the shut-off

default amount and has stopped

fluid flow.

Err 6 A preset dispense amount of zero

was entered for the dispense or is

stored as the default, and a Preset

dispense was attempted.

Adjust the flow rate so it is not higher

than 5 gpm.

Purge air from the line.

Ensure that your flow rate is not

higher than 5 gpm. For further assistance, contact your Graco distributor.

Press the Manual/Reset button at

start-up.

Check if the unit is resting on the

trigger or if an obstruction is pressing

the trigger. The unit checks for flow

every two seconds, and it beeps and

repeats the error code until the

trigger is released and the error code

cleared.

Press the Manual/Reset button, and

dispense again. To change the

shut-off default amount, see the

Shut-off Default Amount section

on page 10.

Enter an amount that is not zero.

See the Auto Preset Amount

section on page 9.

15309377

Page 16

Service

Replacing the Battery

WARNING

FIRE AND EXPLOSION HAZARD

Only replace the battery in a

non-hazardous location, away from

flammable fluids or fumes.

You may order battery Part No. 113716 separately.

Battery required to meet safety approvals:

Duracell alkaline MN1604, PC1604

or

Eveready alkaline EN22, 522

CAUTION

Before you replace the battery, press the Manual/

Reset button, which clears the dispensed amount

to zero. This saves everything to memory.

Replacing the Filter

The filter (25) is replaceable. To replace the filter, do

the following:

1. Relieve the pressure.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 5.

2. Unscrew the hose from the swivel (3).

3. Remove the o-ring (27), and remove the old filter

(25) from its seat in the swivel (3) with an o-ring

pick.

4. Push the new filter (25) into the swivel (3), and

make sure it is properly seated. Replace the

o-ring (27).

NOTE: Orient the new filter (25) so the concave side

of the screen points downstream, as shown below.

The low-battery and dead-battery displays are

explained in the Troubleshooting chart on page 13.

To change the battery, press the Manual/Reset button,

remove the impact guard (28), remove the battery

cover (2), and put in a new battery.

27

25

3

5. Screw the hose back into the swivel (3).

16 309377

Page 17

Service

Servicing the Valve

Valve Repair Kit 240453 is available and can be

ordered separately. See the Parts List on page 18

and the Parts Drawing on page 19. The parts with

asterisks next to their reference numbers are available

in the Valve Repair Kit.

When you are repairing the valve with new parts from

the Valve Repair Kit, use all of the new parts. To

replace the parts, do the following:

1. Relieve the pressure.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 5.

2. Remove the six screws (21) that hold the cover (1)

together, and open the cover.

Replacing the Automatic Nozzle

The automatic nozzle (5b, 6b, or 7b) is not serviceable.

If it leaks, replace it as follows:

1. Relieve the pressure.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 5.

2. Remove the old nozzle from the extension with an

open-end adjustable wrench on the flats of the

nozzle bushing. See below.

3. Remove the trigger (15) from the valve stem

(16b*).

4. Unscrew the valve seat (16e*), remove the valve

seat and valve stem assembly (16b*) from the

meter housing, and pull the valve stem assembly

out of the valve seat.

5. Discard the old valve stem assembly (16b*) and

the spring (16a*).

6. Apply lubricant to all new parts. Place the new

spring (16a*) in the new valve stem assembly

(16b*), push the new valve stem assembly back

into the valve seat (16e*), place the valve stem

assembly, seat and spring into the meter housing,

thread the valve seat into the meter housing, and

torque to 140 to 150 in-lb (16 to 17 N.m).

NOTE: Take care that the spring (16a*) does not

get pinched when you install the valve stem

assembly (16) into the meter housing.

7. Place the trigger (15) on the valve stem assembly

(16b*), put the cover (1) together, thread in the six

screws that hold the cover together, and torque to

7 to 10 in-lb (0.8 to 1.1 N.m).

nozzle bushing

TI0327

3. Thread the new nozzle (5b, 6b, or 7b) onto the

extension, and tighten it firmly with an open-end

adjustable wrench.

NOTE: Only tighten the nozzle with the wrench

on the flats of the nozzle bushing. Do not disassemble the bushing from the nozzle. Disassembly

will affect the performance of the nozzle.

WARNING

Do not use the old Graco nozzle (Part No. 203655)

or any other manual shut-off nozzle on the PM5

extension. You must use the new automatic nozzle

that is provided with the PM5, or the meter could

be damaged. Do not use any sealant material.

17309377

Page 18

Parts List

Ref.

No. Part No. Description Qty.

1 238554 COVER, electronics

(does not include 6 screws

(item 21/PN 113412) which may

be ordered separately) 1

2 191351 COVER, battery

(included with 238554) 1

3 240416 SWIVEL, straight 1

4 191286 SWIVEL COVER, black

191287 SWIVEL COVER, red

191288 SWIVEL COVER, blue

191289 SWIVEL COVER, green

191290 SWIVEL COVER, yellow 1

5 239949 NOZZLE ASSEMBLY

For Model 238511

(includes 5a through 5c)

5a 191036 .TUBE; 75_ bend 1

5b 239829 .NOZZLE, automatic 1

5c 113419 .NUT, seal; 3/8 in.–18 NPT 1

6 239951 NOZZLE ASSEMBLY

For Model 238512

(includes 6a through 6d)

6a 238370 .HOSE, flexible; 3/8 in. coupled 1

6b 239829 .NOZZLE, automatic 1

6c 113419 .NUT, seal; 3/8 in.–18 NPT 1

6d 155699 .ELBOW, street 1

7 239950 NOZZLE ASSEMBLY

For Model 238515

(includes 7a through 7d) 1

7a 191038 .TUBE, 15_ bend; 3/8 in. 1

7b 239829 .NOZZLE, automatic 1

7c 113419 .NUT, seal; 3/8 in.–18 NPT 2

7d 155699 .ELBOW, street 1

Ref.

No. Part No. Description Qty.

8 113716 BATTERY; standard 9V, alkaline 1

15 191046 TRIGGER 1

16 240453 KIT, valve repair

(includes 16a to 16e, 25, and 27)

16a* SPRING, compression 1

16b* VALVE STEM ASSEMBLY 1

16c* O-RING, packing 1

16d* O-RING, packing 1

16e* SEAT, valve 1

21 113412 SCREW, pan-head; 6–19x3/4 6

24 196829 LABEL 1

25* 114017 FILTER 1

27* 109018 O-RING 1

28 243758 GUARD, impact 1

* These parts are included in Valve Repair Kit

240453, which can be ordered separately.

Y Extra Warning labels are available for free.

18 309377

Page 19

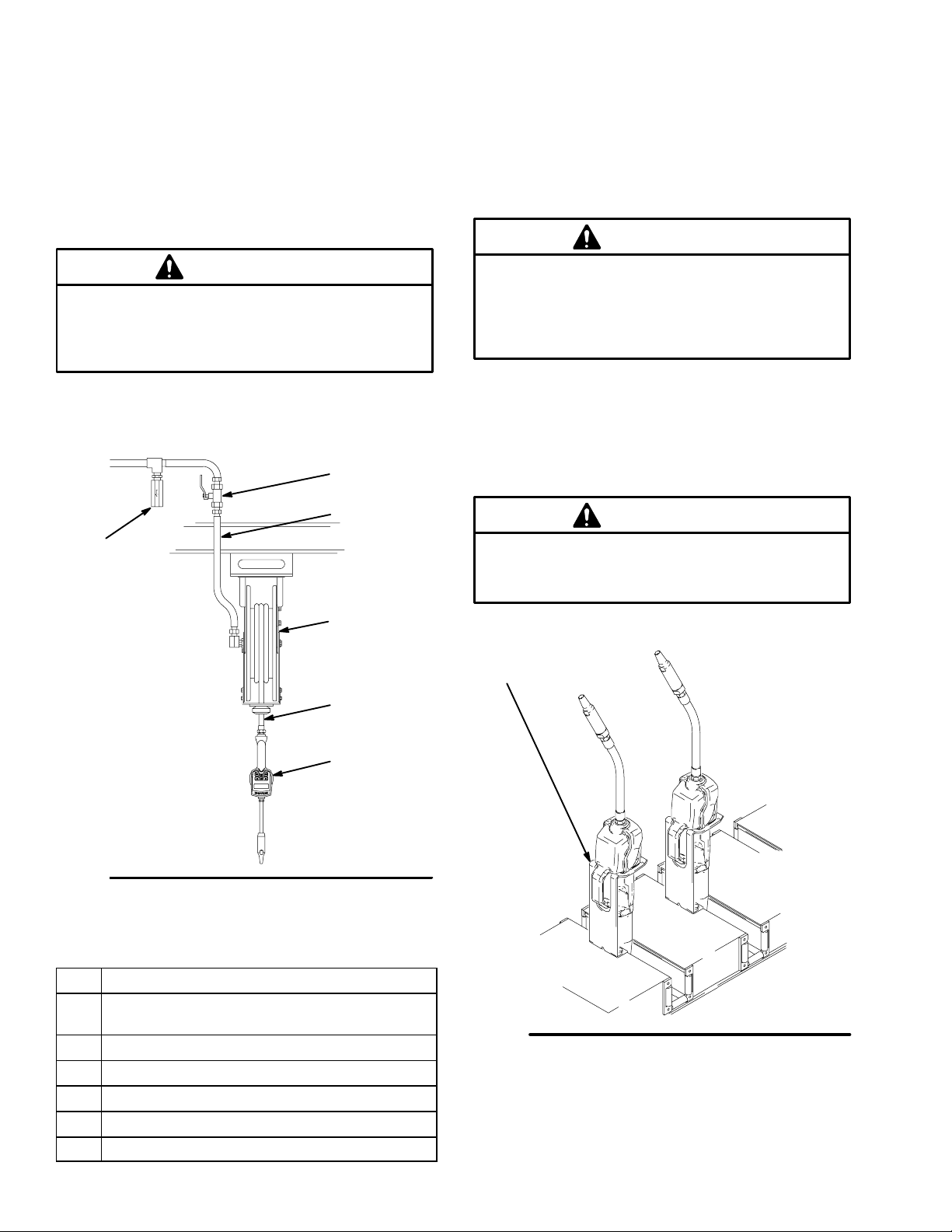

1

Torque to 7 to 10 in-lb (0.8 to 1.1 N.m).

2

Torque to 140 to 150 in-lb (16 to 17 N.m).

3

Apply lubricant when reassembling.

4

Torque to 20 to 25 ft-lb (27 to 34 N.m).

* These parts are included in Valve Repair Kit

240453, which can be ordered separately.

Parts Drawing

1

3

4

27*

25*

4

7b

7c

7a

7d

5a

7c

5c

5b

6d

6c

28

solenoid

(not available

for sale)

6a

24

meter housing

(not available for sale)

*16a

*16b

16

3

*16c

*16d

*16e

2

15

1

1

7119B

21

8

6b

2

This flexible extension can also

be threaded directly into the

meter outlet without the street

elbow (6d) or sealing nut (6c).

19309377

Page 20

Technical Data

Flow range* 0.26 to 5 gpm (1 to 18.9 lpm). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating pressure range 45 to 1000 psi (0.29 to 7 MPa, 2.9 to 69 bar). . . . . . . . . . . . . . . . . . . . . . . .

Weight 3 lb (1.36 kg). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Units of measurement factory-set in quarts or liters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

maximum totalizer amount = 99999 gallons or liters

maximum recorded dispensed volume = 999.99 units

maximum preset volume = 99.9 units

Inlet 1/2 npt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Outlet 3/8 npt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating temperature range 32_ F to 120_ F (0_ C to 49_ C). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range –30_ F to 120_ F (–34_ C to 49_ C). . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery** standard 9 volt alkaline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Expected battery life in typical shop environment 6 months. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wetted parts zinc, stainless steel #304, LCP,. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

carbon steel, polyurethane, nitrile rubber

Fluid compatibility lubricating oils, antifreeze mixtures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Meter valve assembly pressure loss

at 1.5 gpm (5.7 lpm) with 30-weight oil at 70_ F (21_ C) 17 psi (117 kPa, 1.2 bar). . . . . . . . . . . . . . .

Accuracy

Repeatability

* Tested in No. 10 motor oil. Flow rates vary with fluid pressure and viscosity.

{

}

+/– 0.5 percent. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

+/– 0.15 percent. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

** Battery required to meet safety approvals: DuracellR MN1604 or EvereadyR EN22, 522

{

At 2.5 gpm (9.5 lpm), at 70_ F (21_ C), with 10-weight oil, and 1 gallon dispensed. May require

calibration; out-of-box accuracy is +/– 1.25 percent.

}

At 2.5 gpm (9.5 lpm), at 70_ F (21_ C), with 10-weight oil, and 1 gallon dispensed.

DuracellR is a registered trademark of Duracell Inc.

PanasonicR is a registered trademark of Panasonic Industrial Co.

20 309377

Page 21

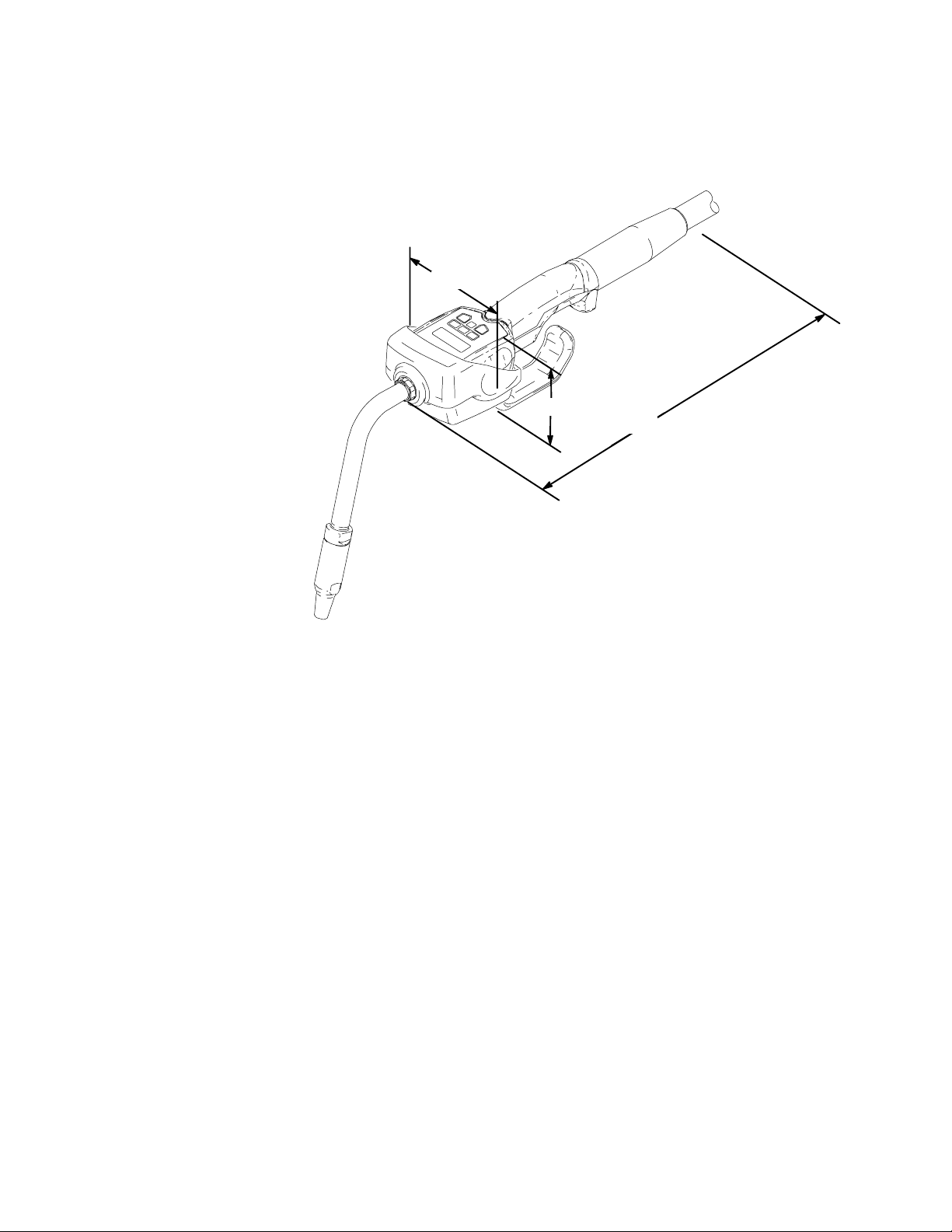

Dimensional Drawing

14.0 in. (356 mm) outlet to end of swivel cover

A

BC3.75 in. (95 mm) widest cross section (including impact guard)

3.10 in. (79 mm) keypad to bottom of impact guard

B

C

A

TI0327

21309377

Page 22

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by Graco,

Graco will, for a period of two (2) years from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective, including defects in the electronic meter control, which will be repaired or replaced for two (2) years from the date of sale.

This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within three (3) years of

the date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor, or call one of the following numbers

to identify the distributor closest to you:

1–800–533–9655 Toll Free

612–623–6928

612–378–3590 Fax

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

International Offices: Belgium, Korea, China, Japan

Graco Headquarters: Minneapolis

GRACO INC.ąP.O. BOX 1441ąMINNEAPOLIS, MNą55440-1441

MM 309377

www.graco.com

309377 06/2001, Revised 04/2006

22 309377

Loading...

Loading...