Page 1

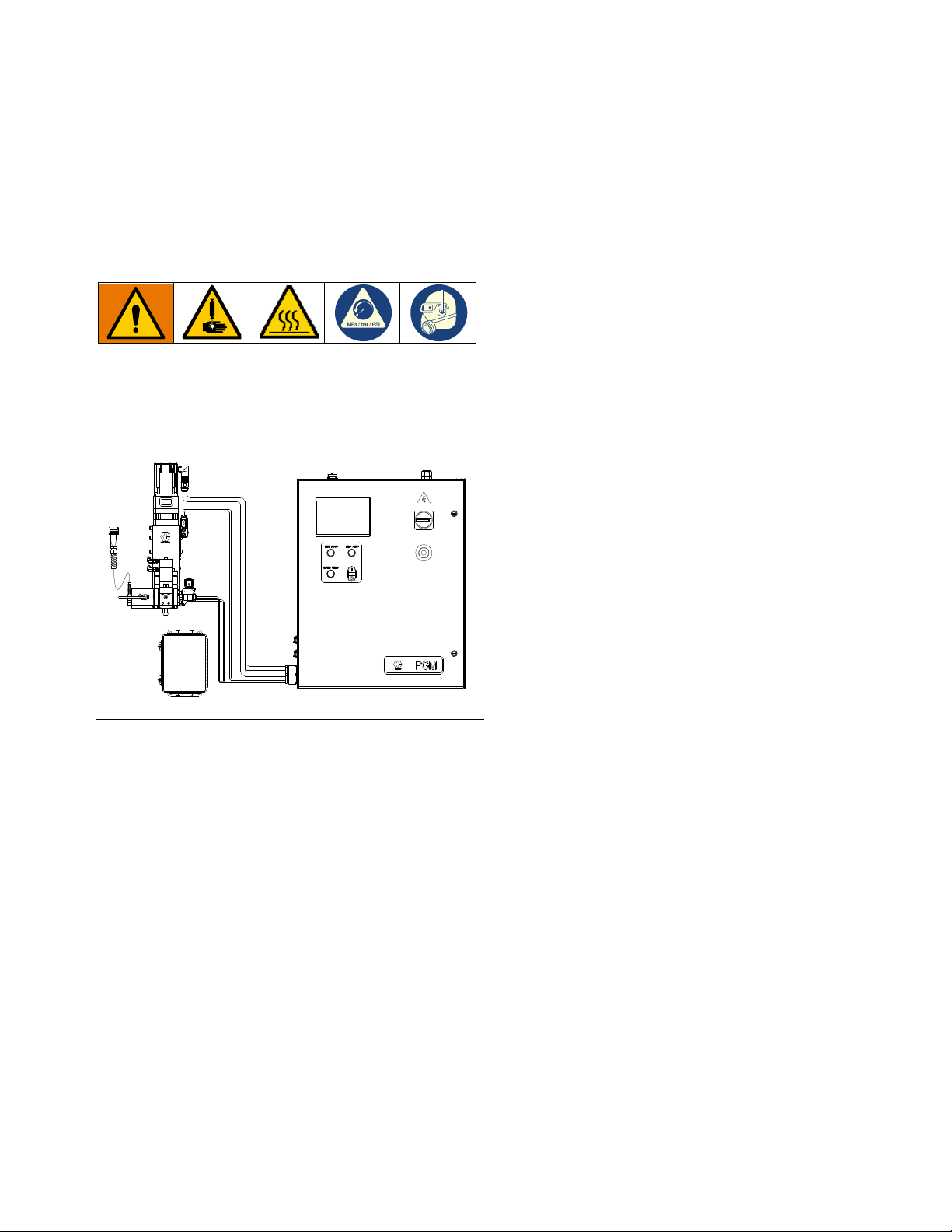

Instructions - Parts

™

PGM

Precision Gear Metering

For metering and dispensing ambient or high-temperature, high-viscosity

single-component materials. For professional use only.

Not approved for use in European explosive atmosphere locations.

2500 psi (17.2 MPa, 172 bar) Maximum Working Outlet Pressure

1500 psi (10.3 MPa, 103 bar) Maximum Working Inlet Pressure

See Technical Specifications on page 102 for temperature ranges

3A5185B

EN

See page 4 for model information.

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

Page 2

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Bulk Melt (Therm-O-Flow 20 + Therm-O-Flow 200)

and Ambient Hoses . . . . . . . . . . . . . . . . . . . 4

Remote Dispense Valves . . . . . . . . . . . . . . . . . . 5

Fixed Dispense Valves . . . . . . . . . . . . . . . . . . . . 5

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

System Configurations . . . . . . . . . . . . . . . . . . . . 8

Component Identification . . . . . . . . . . . . . . . . . 10

System Overview . . . . . . . . . . . . . . . . . . . . . . . 11

Typical Applications . . . . . . . . . . . . . . . . . . . . . 11

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Before Installation . . . . . . . . . . . . . . . . . . . . . . . 12

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Install Control Center . . . . . . . . . . . . . . . . . . . . 13

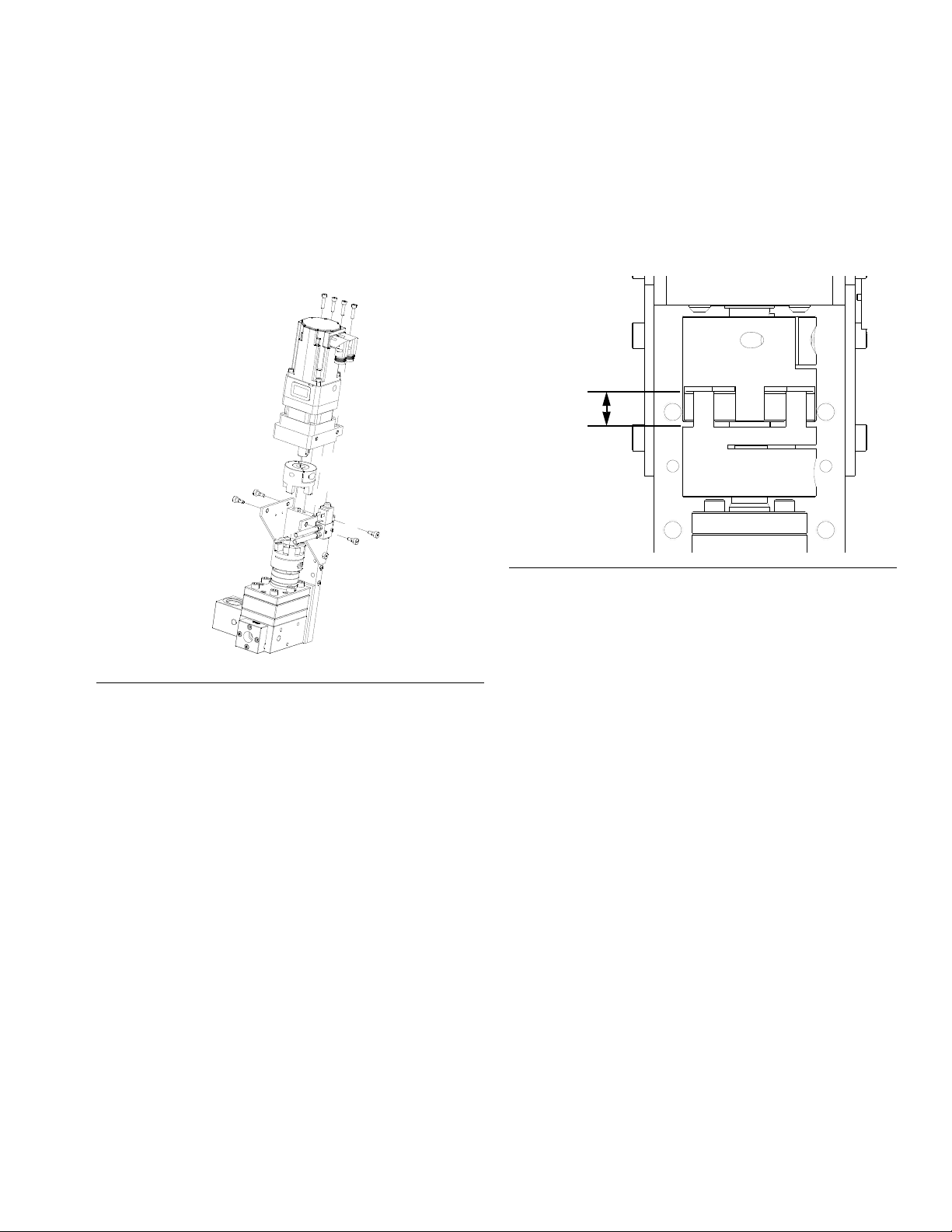

Install Gear Meter Assembly . . . . . . . . . . . . . . . 14

Install Cable Assemblies . . . . . . . . . . . . . . . . . . 17

System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Configure Control Settings . . . . . . . . . . . . . . . . 19

Configure Mode Settings . . . . . . . . . . . . . . . . . 19

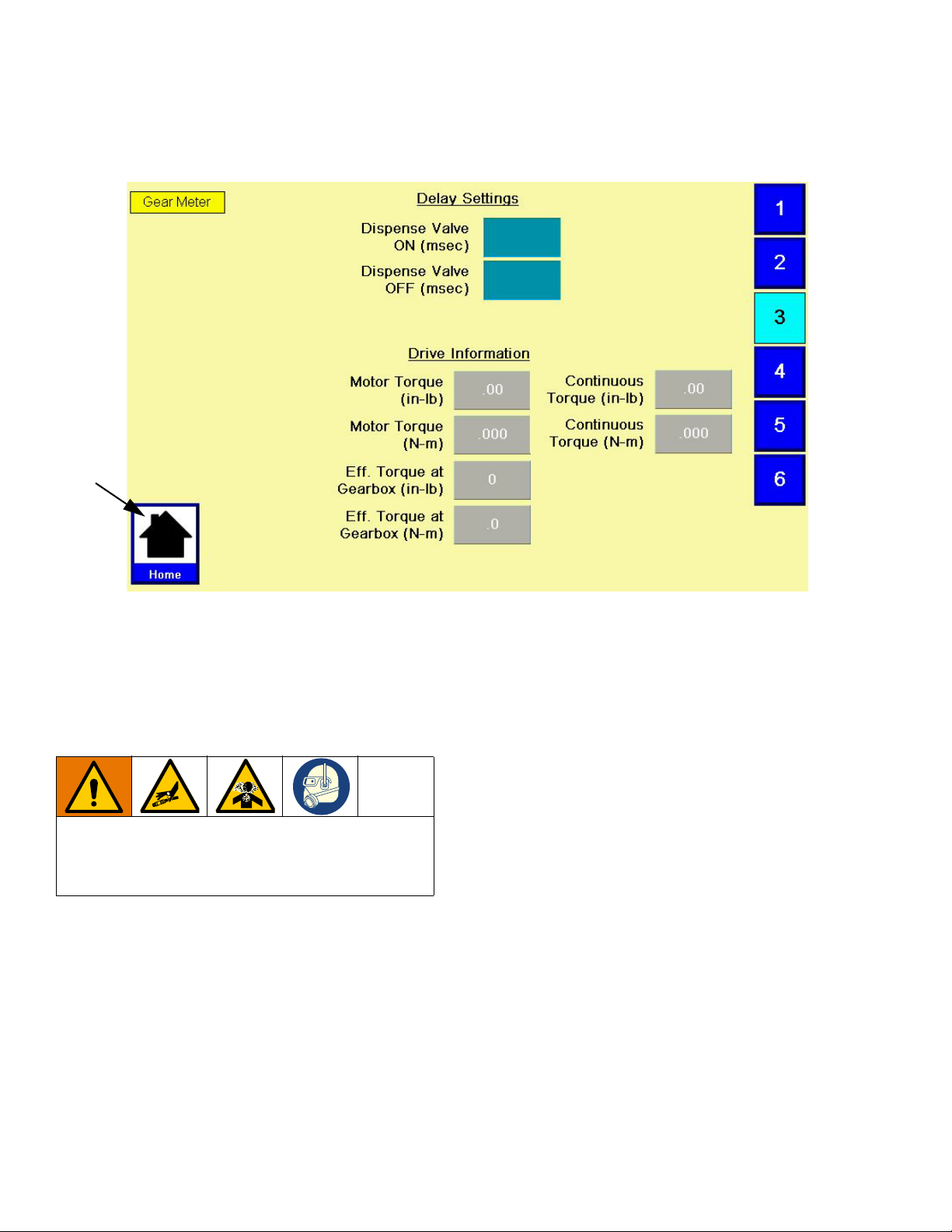

Configure Delay Settings . . . . . . . . . . . . . . . . . 20

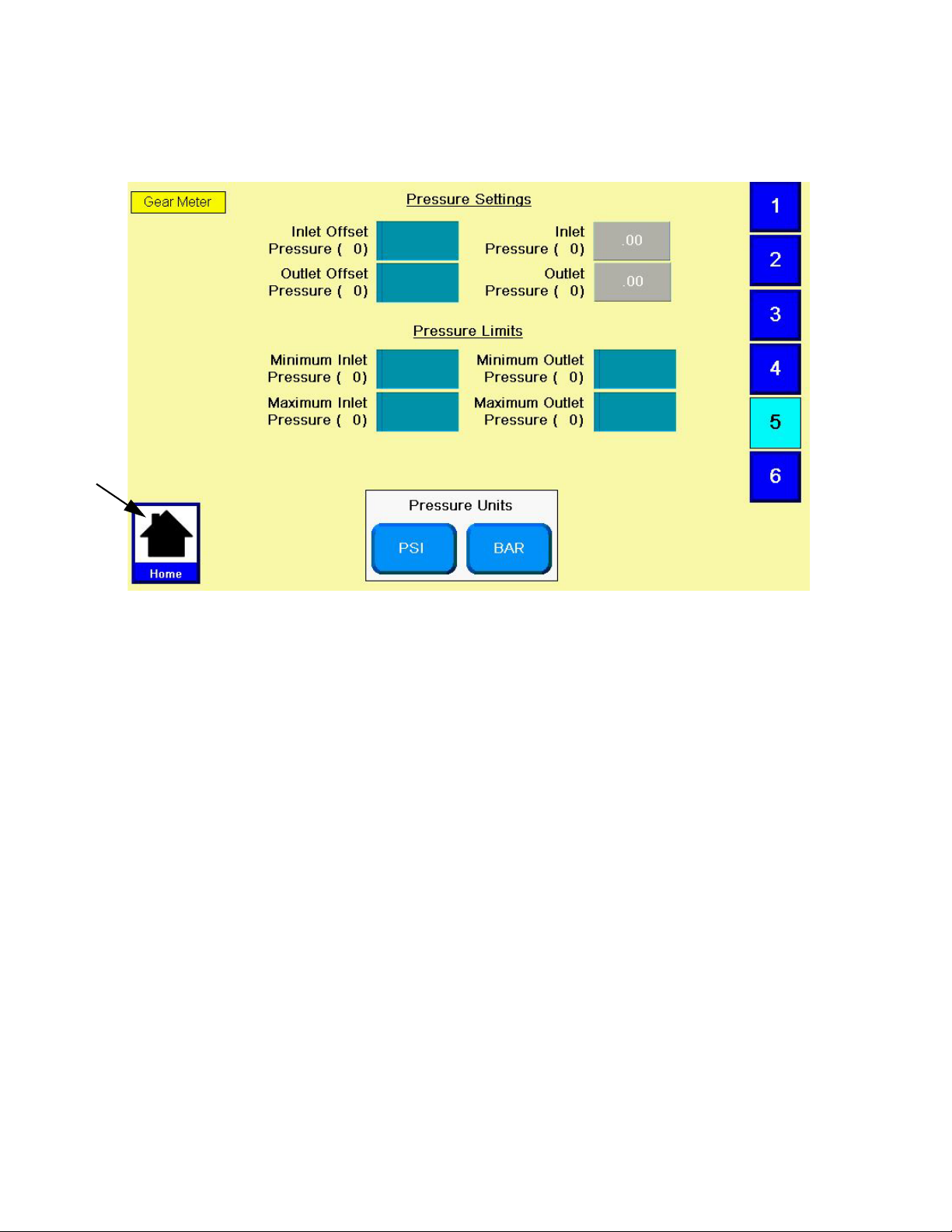

Adjust Pressure Sensors . . . . . . . . . . . . . . . . . 20

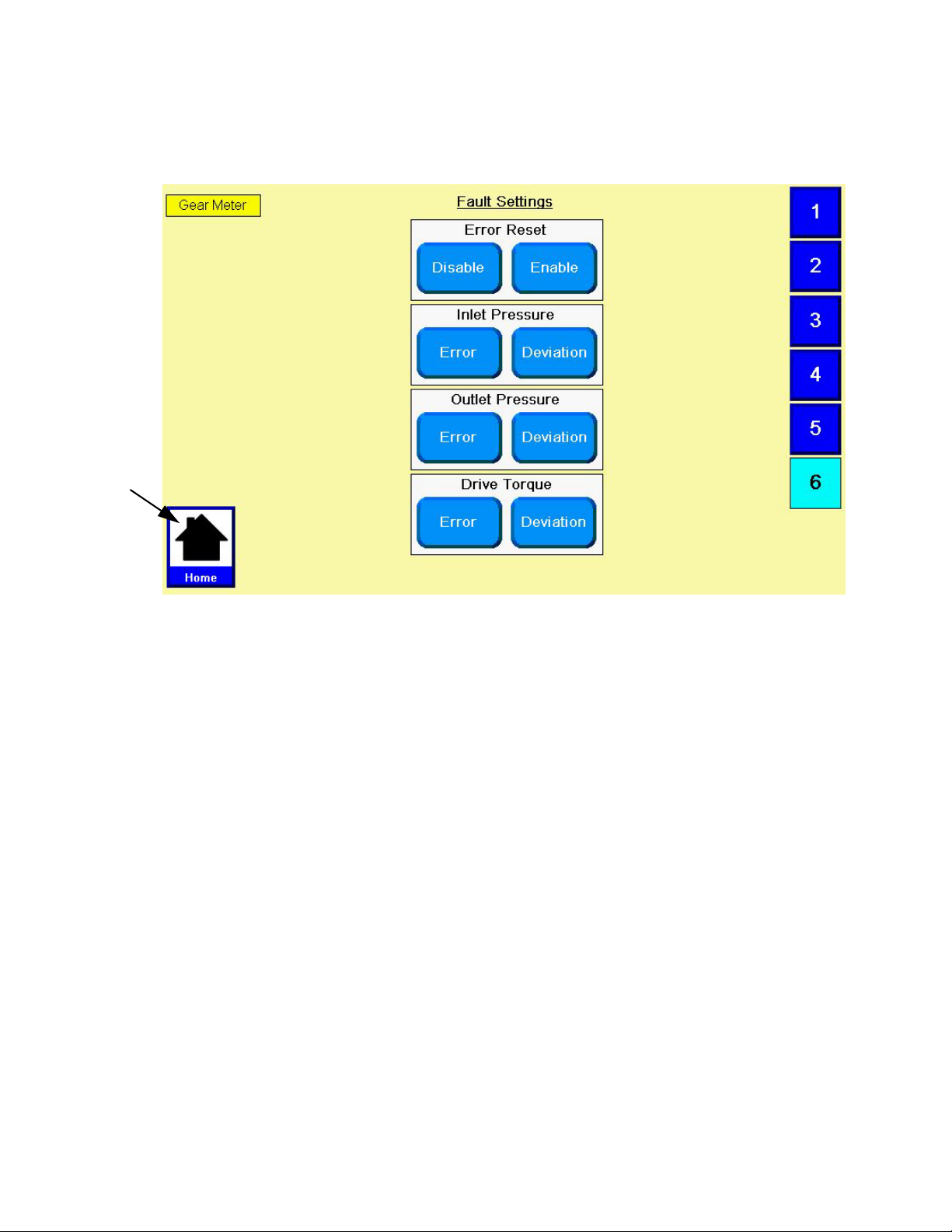

Configure Errors . . . . . . . . . . . . . . . . . . . . . . . . 21

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Load Material . . . . . . . . . . . . . . . . . . . . . . . . . . 22

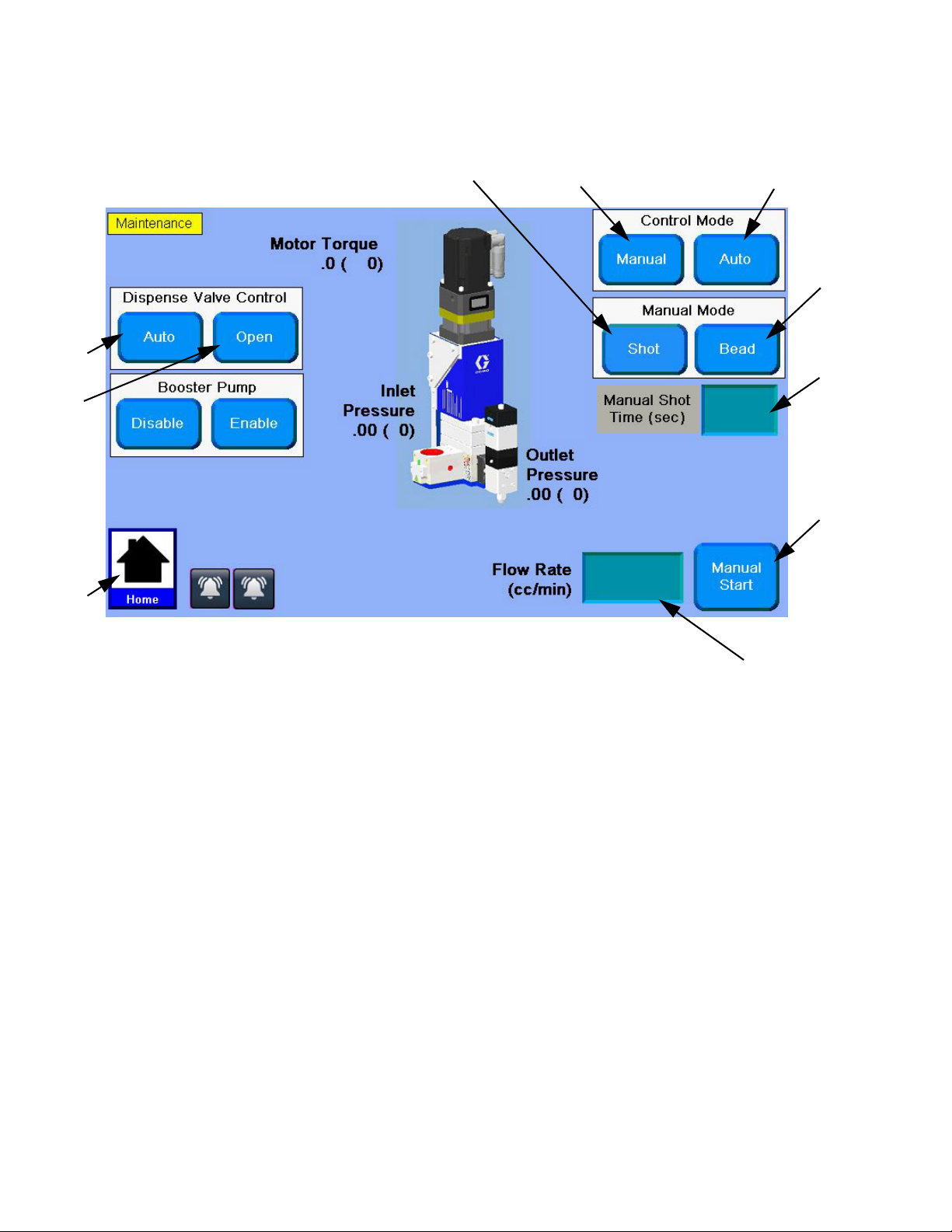

Maintenance Mode Operation . . . . . . . . . . . . . . 23

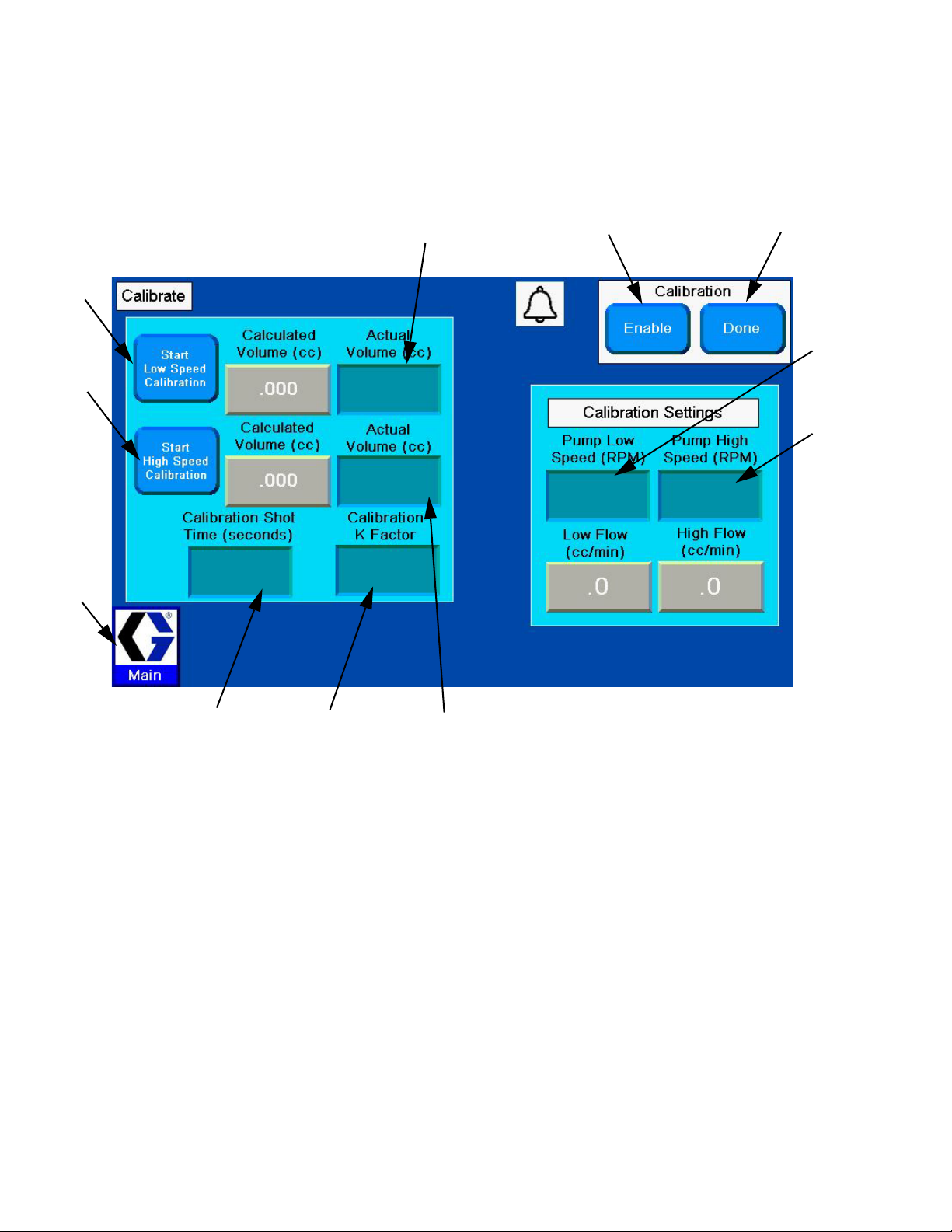

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Dispense from Maintenance Screen . . . . . . . . . 25

Automation Control (Normal) Operation . . . . . . 25

Typical Automation Cycle . . . . . . . . . . . . . . . . . 25

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 26

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Dispense Valves . . . . . . . . . . . . . . . . . . . . . . . . 30

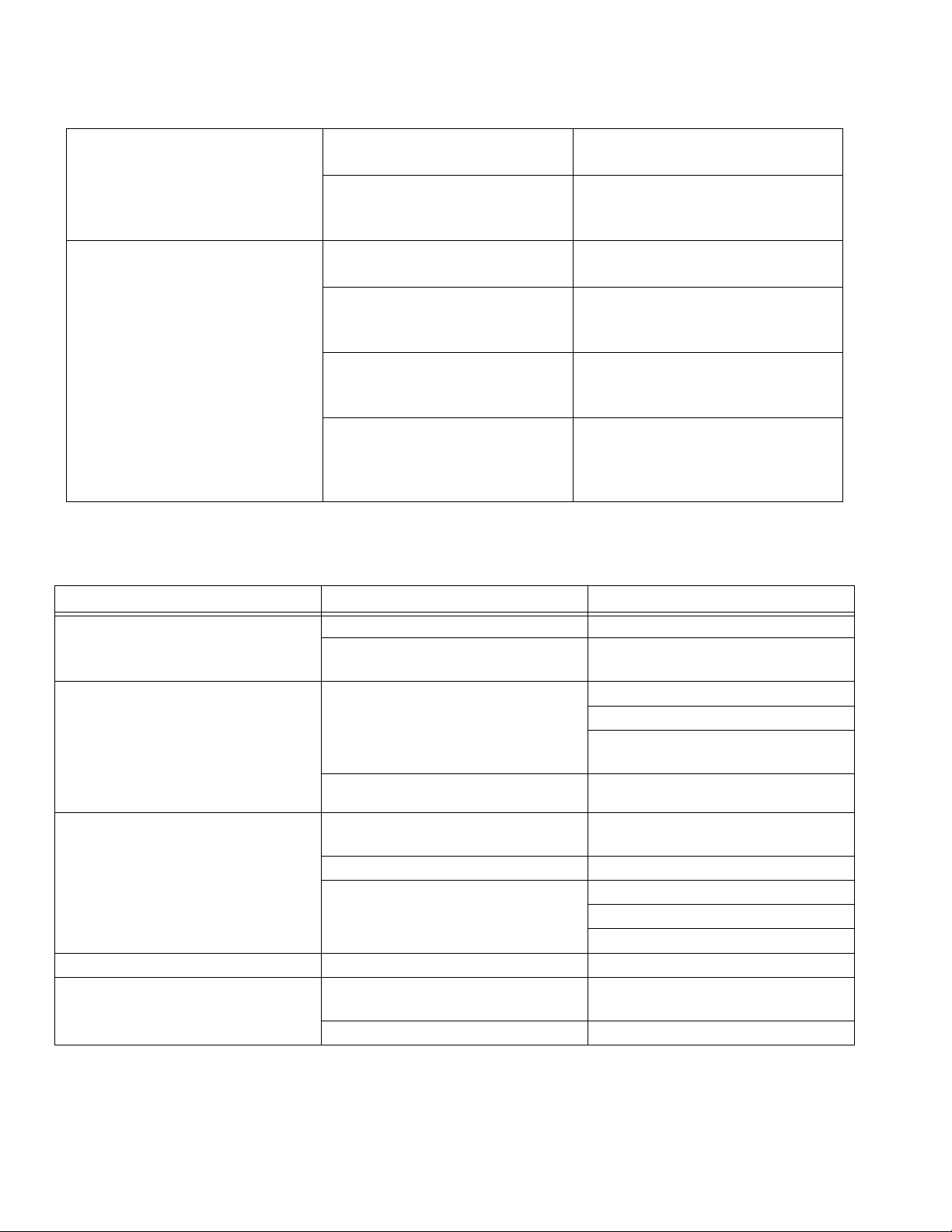

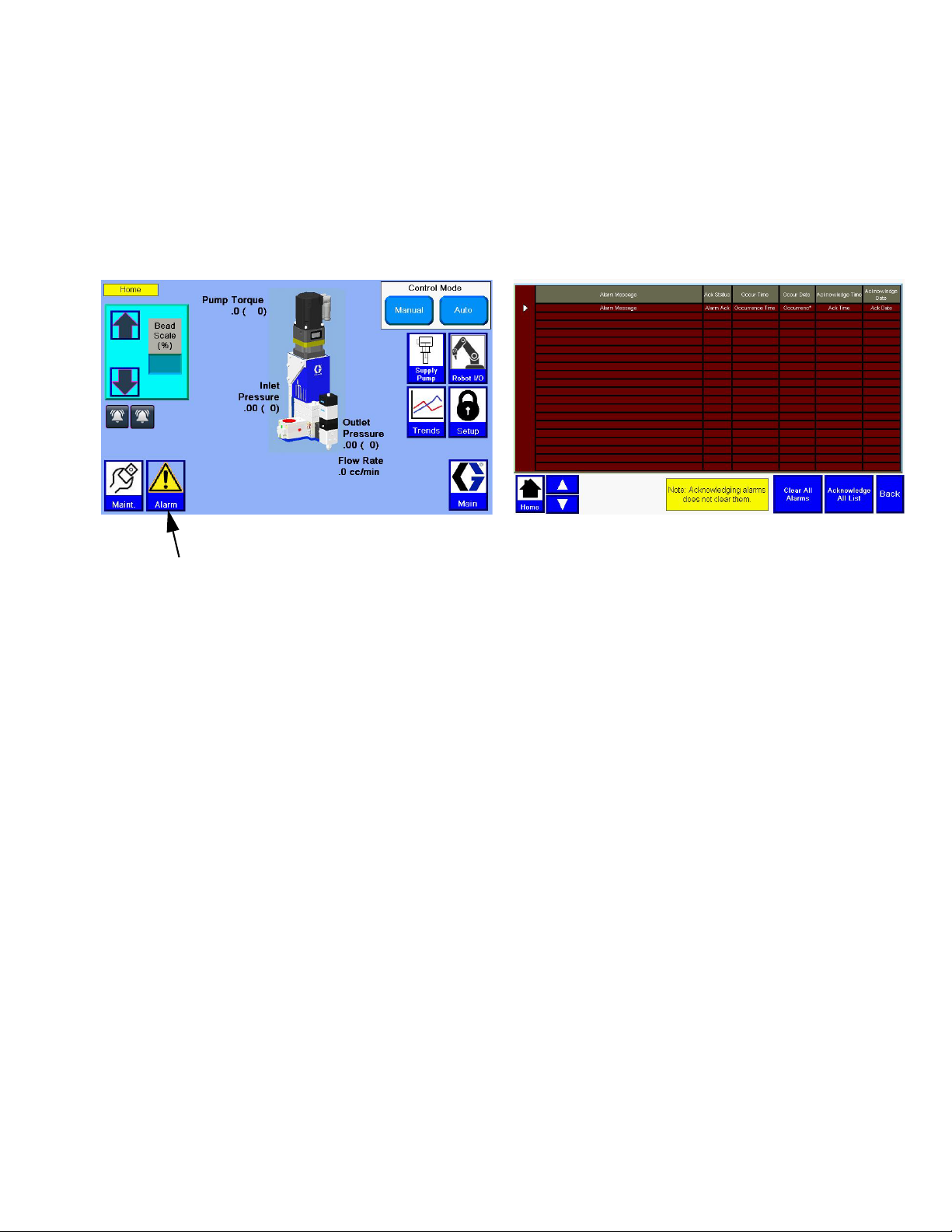

Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

View Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Diagnose Errors . . . . . . . . . . . . . . . . . . . . . . . . 31

Clear Errors and Reset Control Unit . . . . . . . . . 31

Error Codes and Troubleshooting . . . . . . . . . . . 32

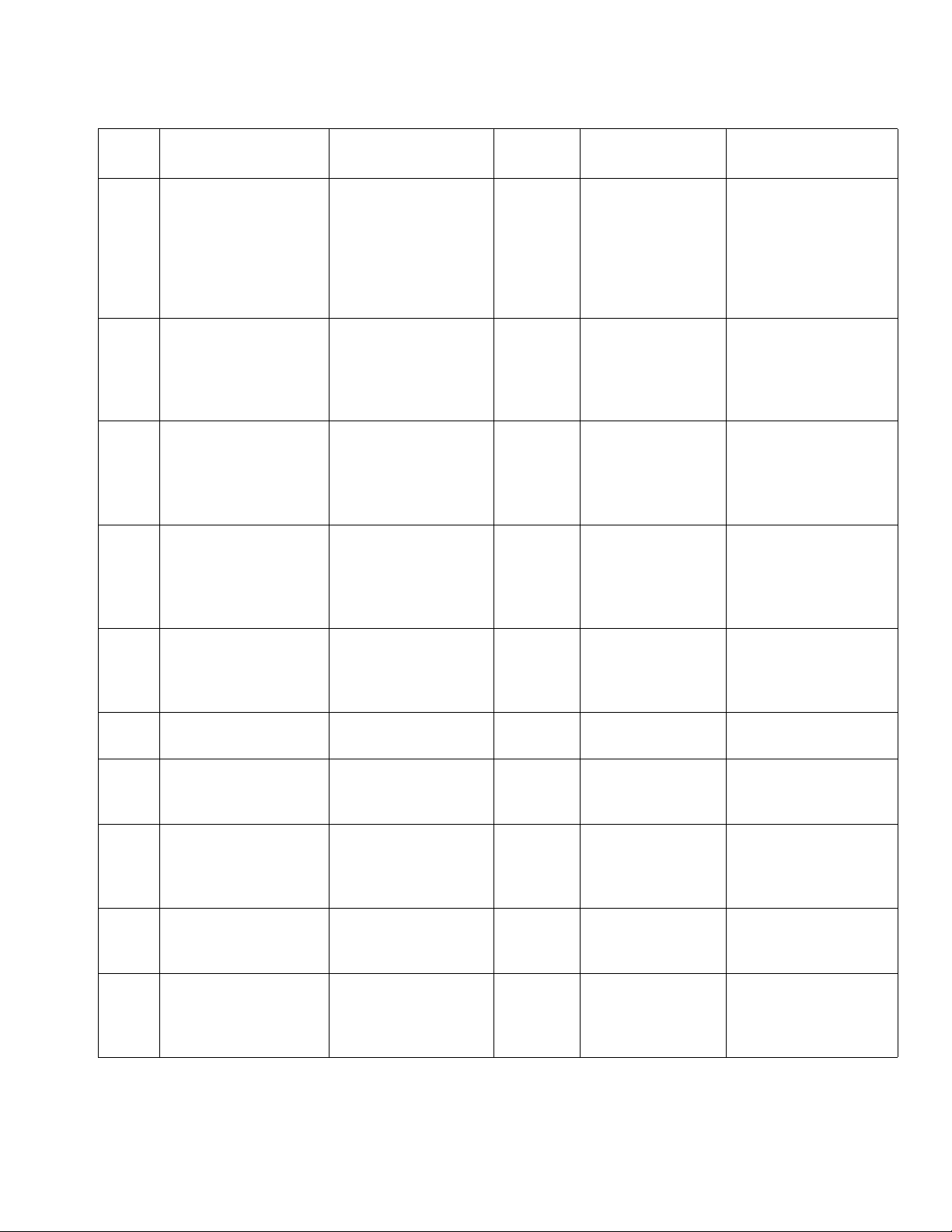

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Maintenance Schedule . . . . . . . . . . . . . . . . . . . 34

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

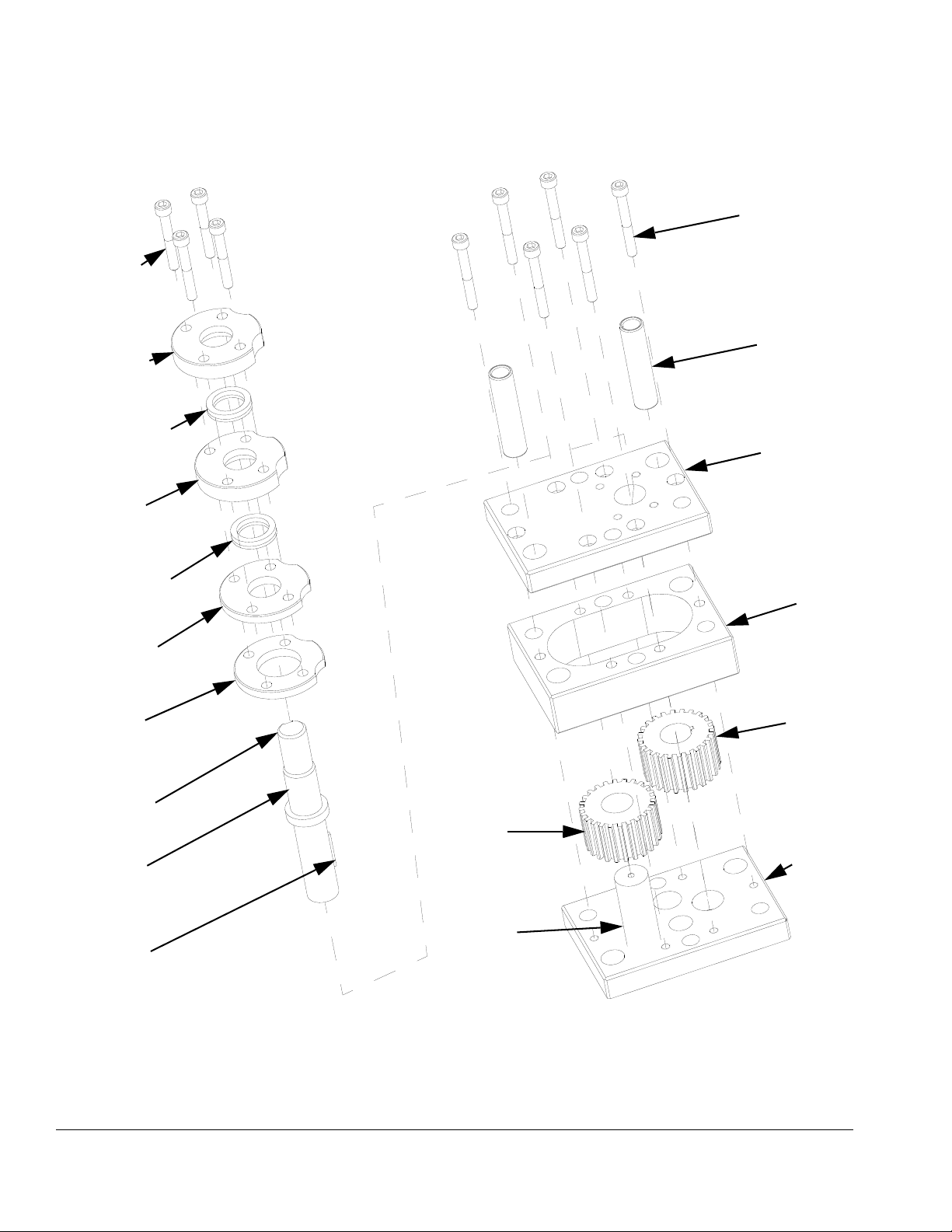

Gear Meter Assembly . . . . . . . . . . . . . . . . . . . . 35

PGM-6 Pump Repair . . . . . . . . . . . . . . . . . . . . . 40

PGM-20 Pump Repair . . . . . . . . . . . . . . . . . . . . 44

Gear Pump Maintenance Guide . . . . . . . . . . . . 47

Installing new heater units and RTD sensors . . 48

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

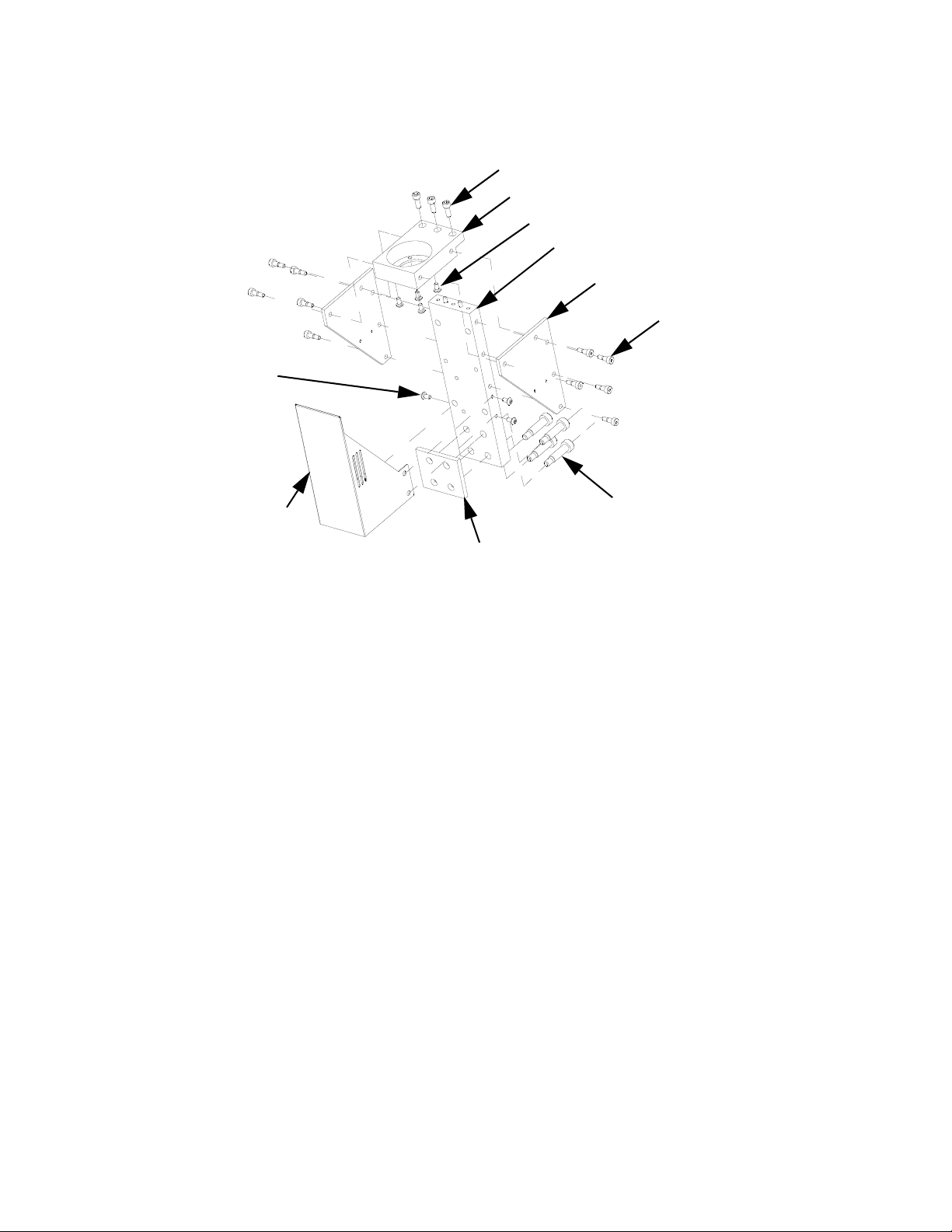

PGM-20 Mounting Frame . . . . . . . . . . . . . . . . . 49

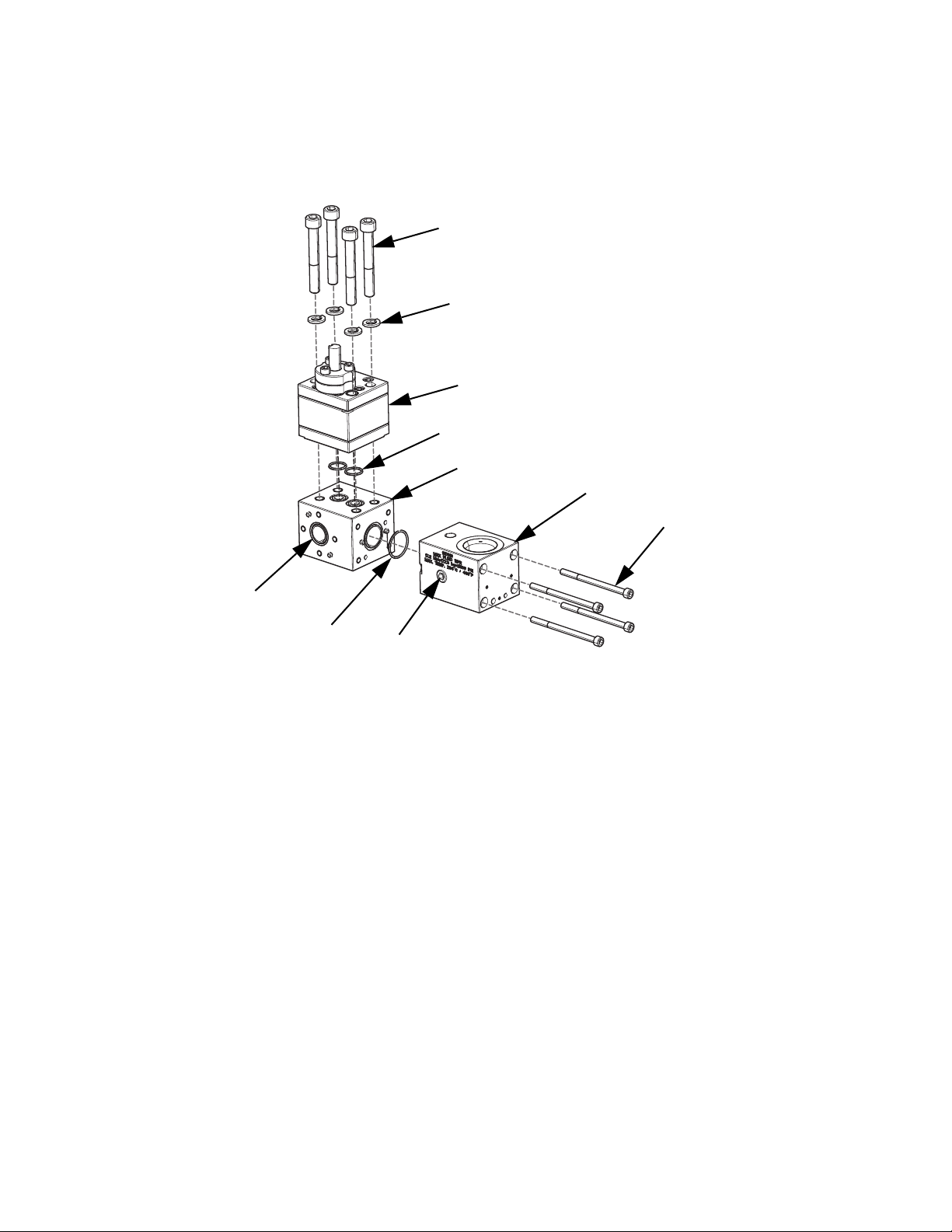

PGM-20 Lower Assembly Block . . . . . . . . . . . . 50

PGM-20 Pump Heat Kit . . . . . . . . . . . . . . . . . . . 51

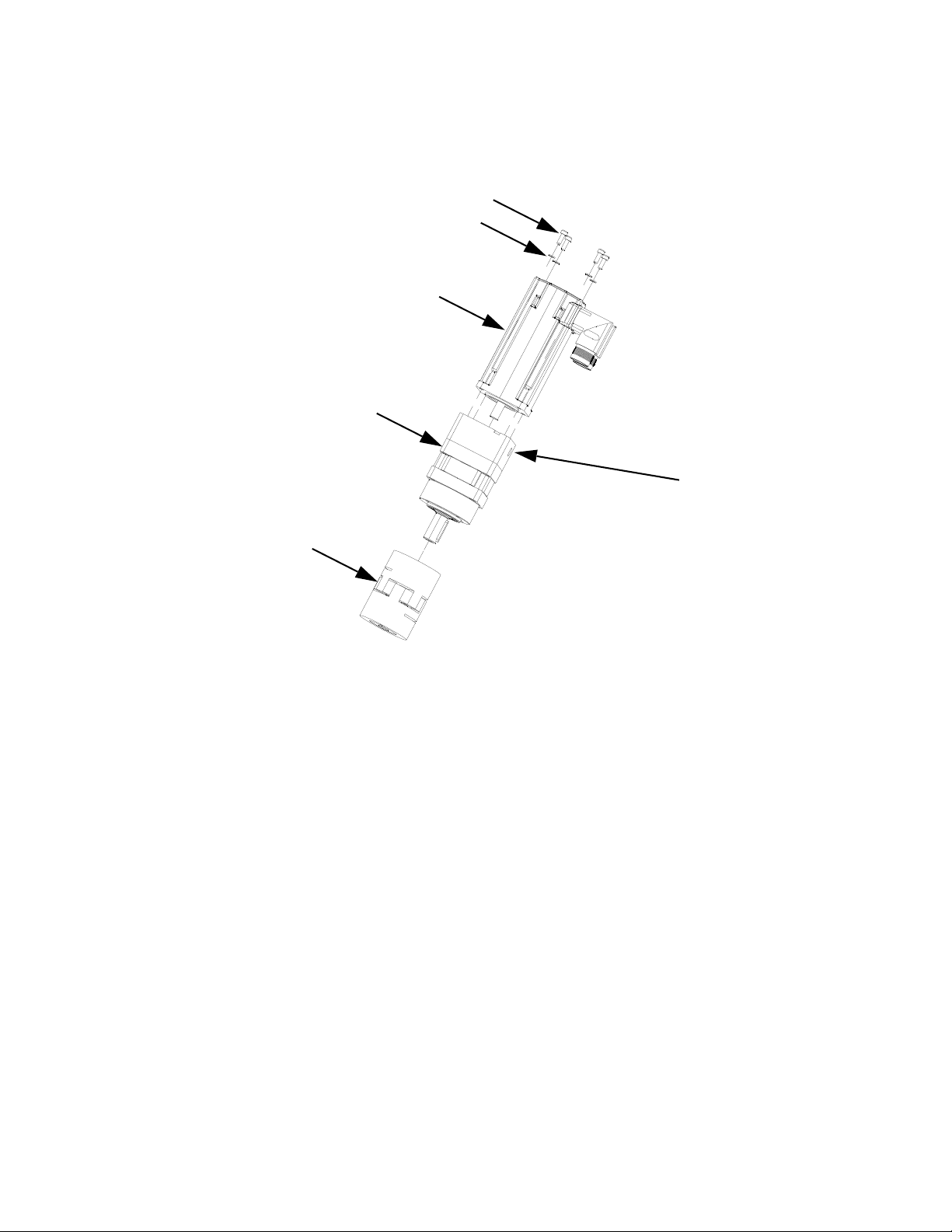

PGM Drive - 20 cc Pump . . . . . . . . . . . . . . . . . . 52

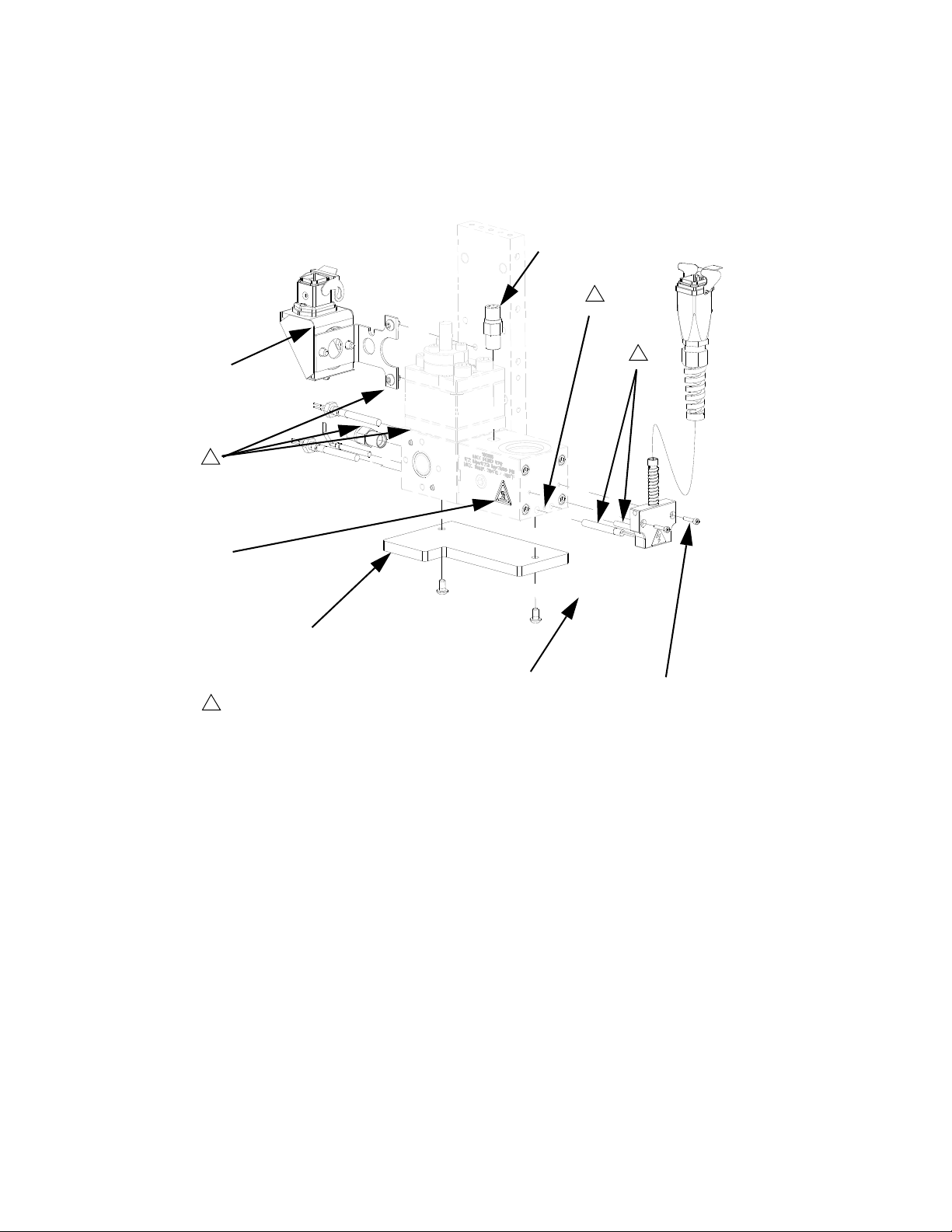

EnDure Dispense Valve Fix Mounted . . . . . . . . 53

Gear Meter Assembly Panel . . . . . . . . . . . . . . . 54

PGM Back Panel . . . . . . . . . . . . . . . . . . . . . . . . 56

Remote Mount Amplifiers . . . . . . . . . . . . . . . . . 57

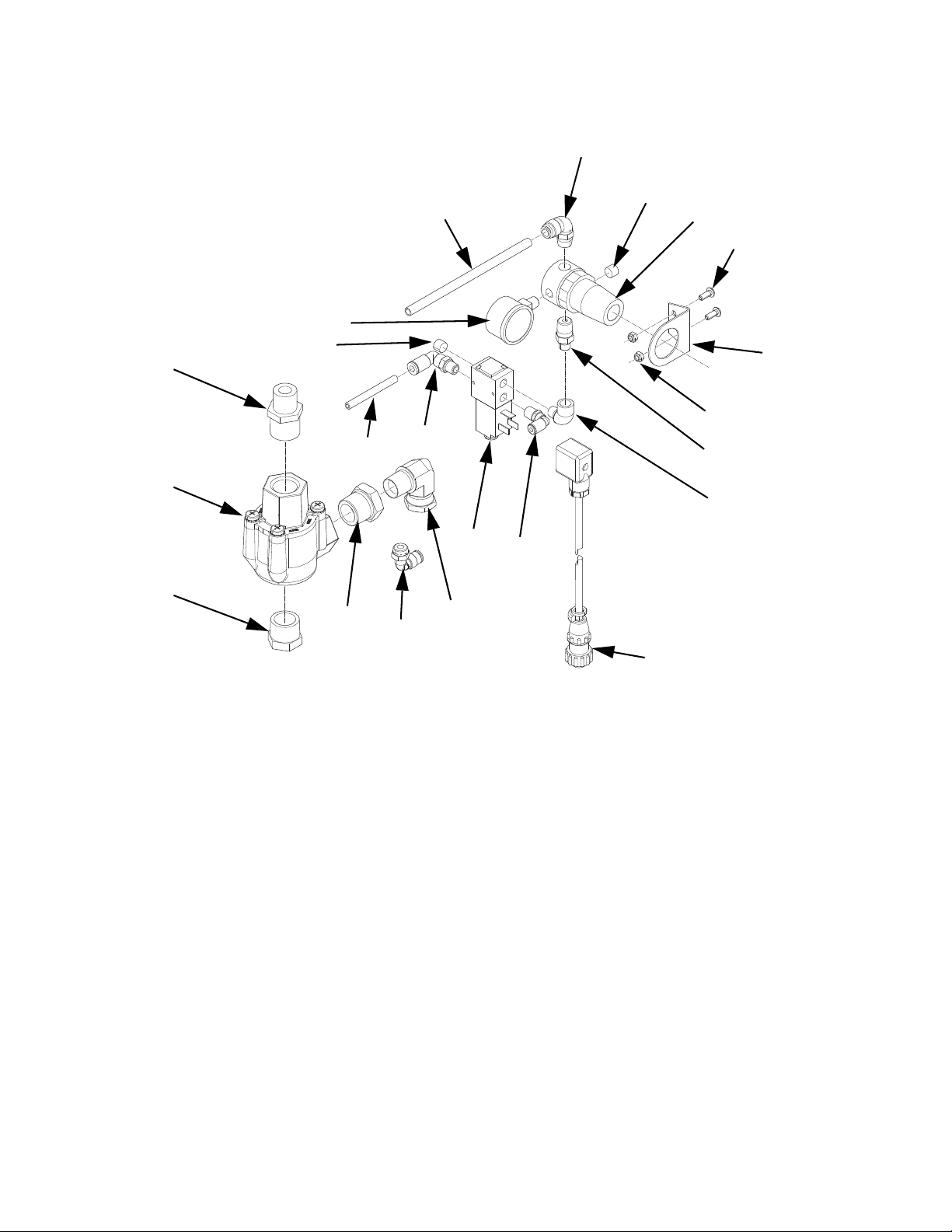

PGM Remote Dispense Valve . . . . . . . . . . . . . . 58

PGM Ambient Transducer . . . . . . . . . . . . . . . . . 59

PGM-6 Mounting Frame . . . . . . . . . . . . . . . . . . 60

PGM-6 Drive Kit . . . . . . . . . . . . . . . . . . . . . . . . . 61

PGM-6 Lower Assembly Block . . . . . . . . . . . . . 62

PGM-6 Pump Heat Kit . . . . . . . . . . . . . . . . . . . . 63

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

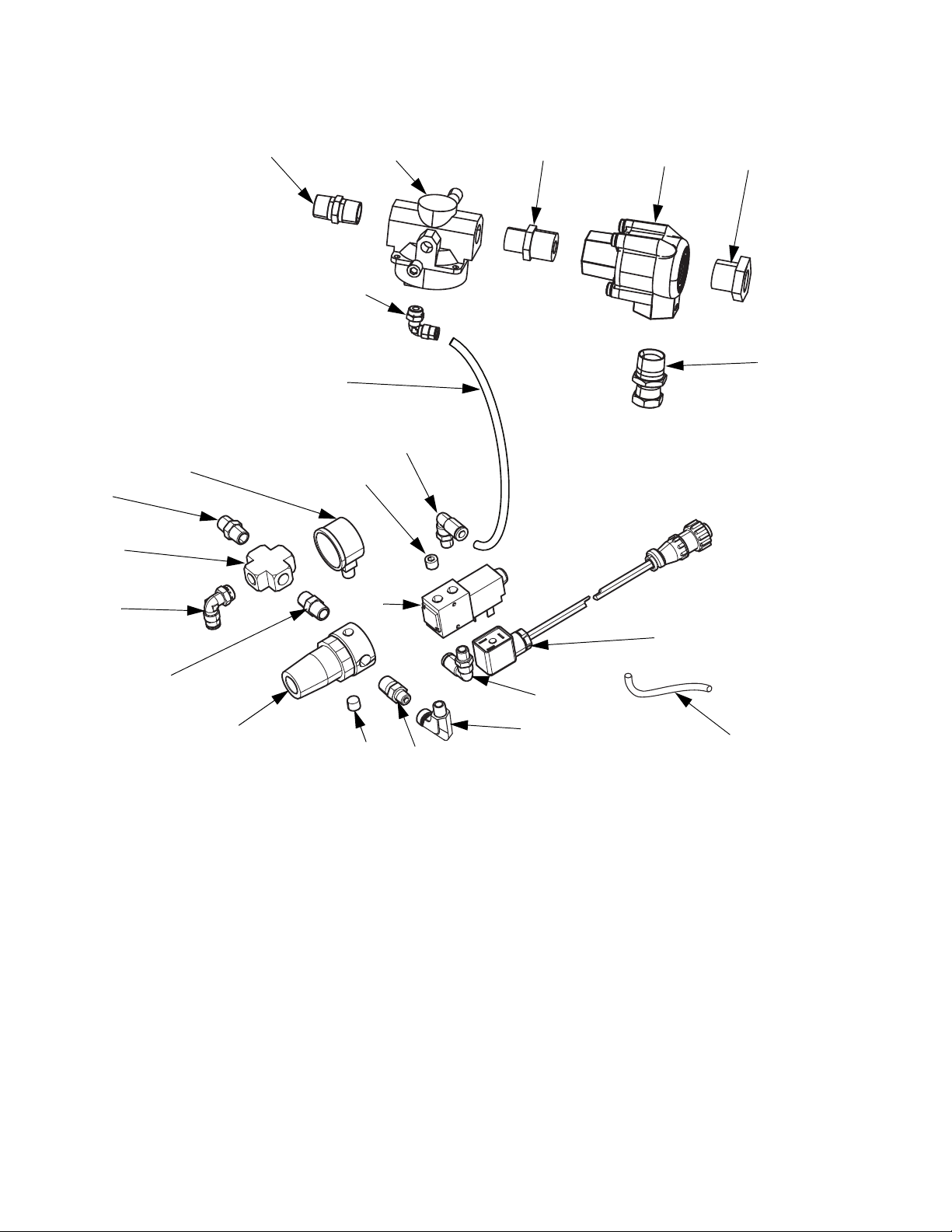

Accessory Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Automation Interface Cable Assembly . . . . . . . 74

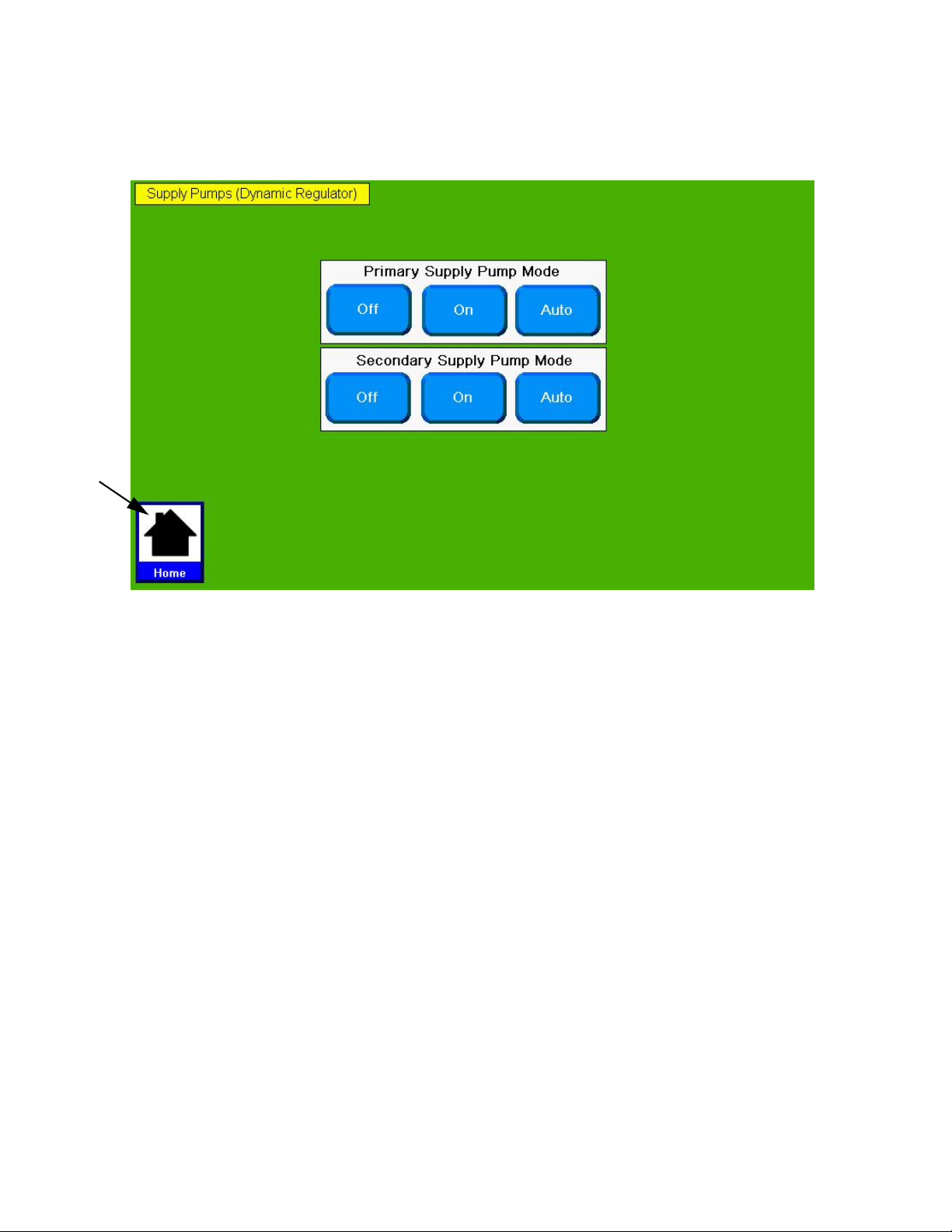

Dynamic Regulators (98****) . . . . . . . . . . . . . . . 75

EnDure Valve Nozzles . . . . . . . . . . . . . . . . . . . . 81

Heater Nests . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

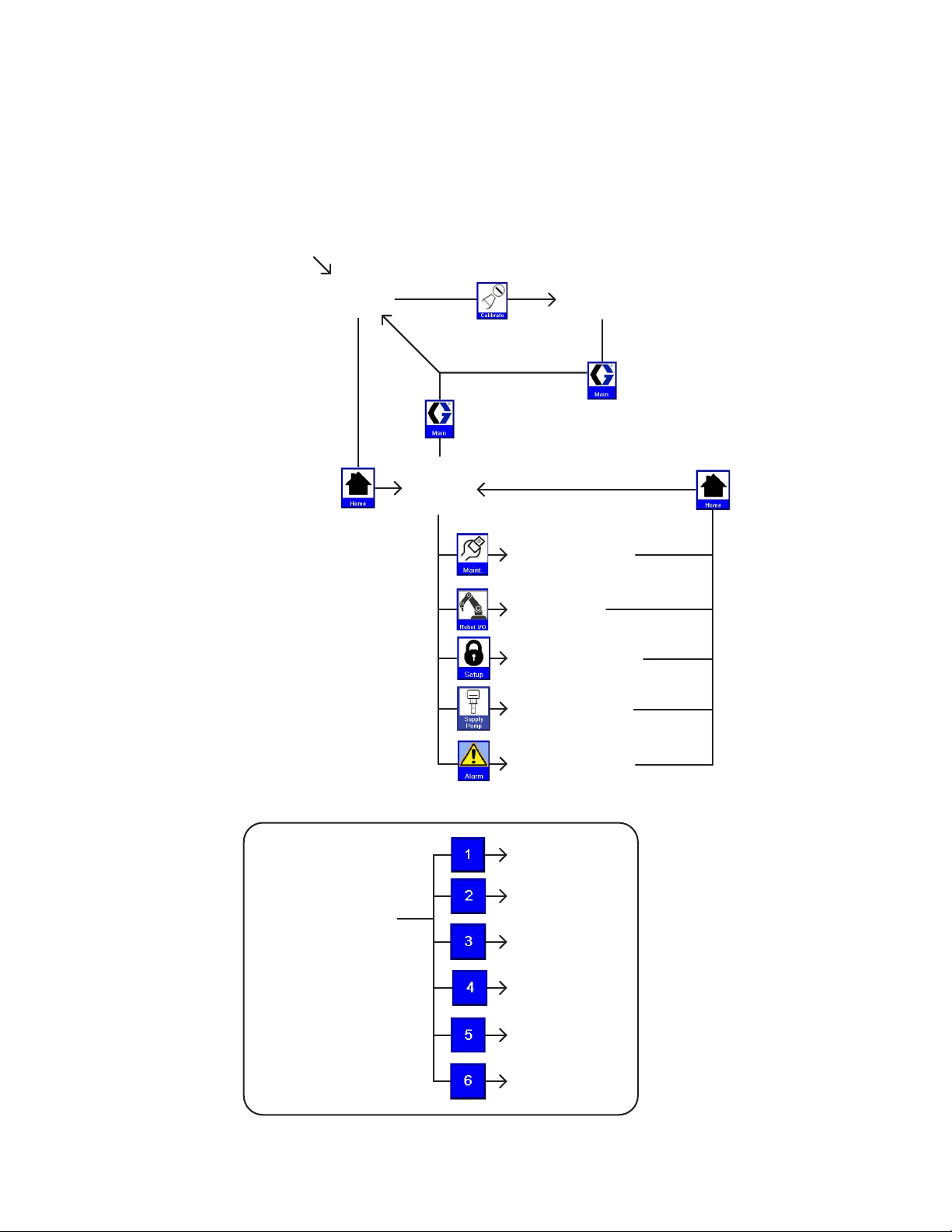

Appendix A - User Interface Display . . . . . . . . . . 82

Screen Navigation Diagram . . . . . . . . . . . . . . . . 82

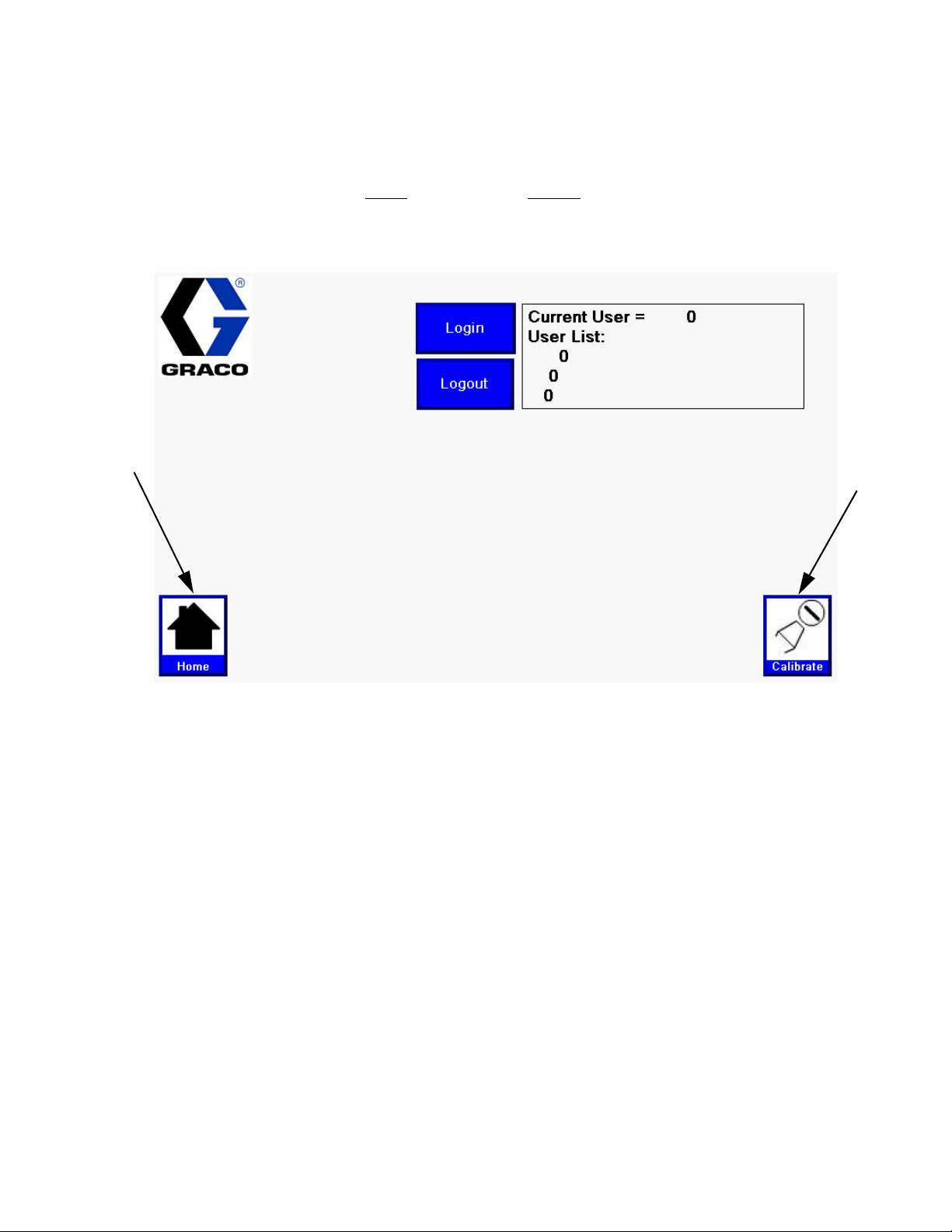

Main Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Calibrate Screen . . . . . . . . . . . . . . . . . . . . . . . . 84

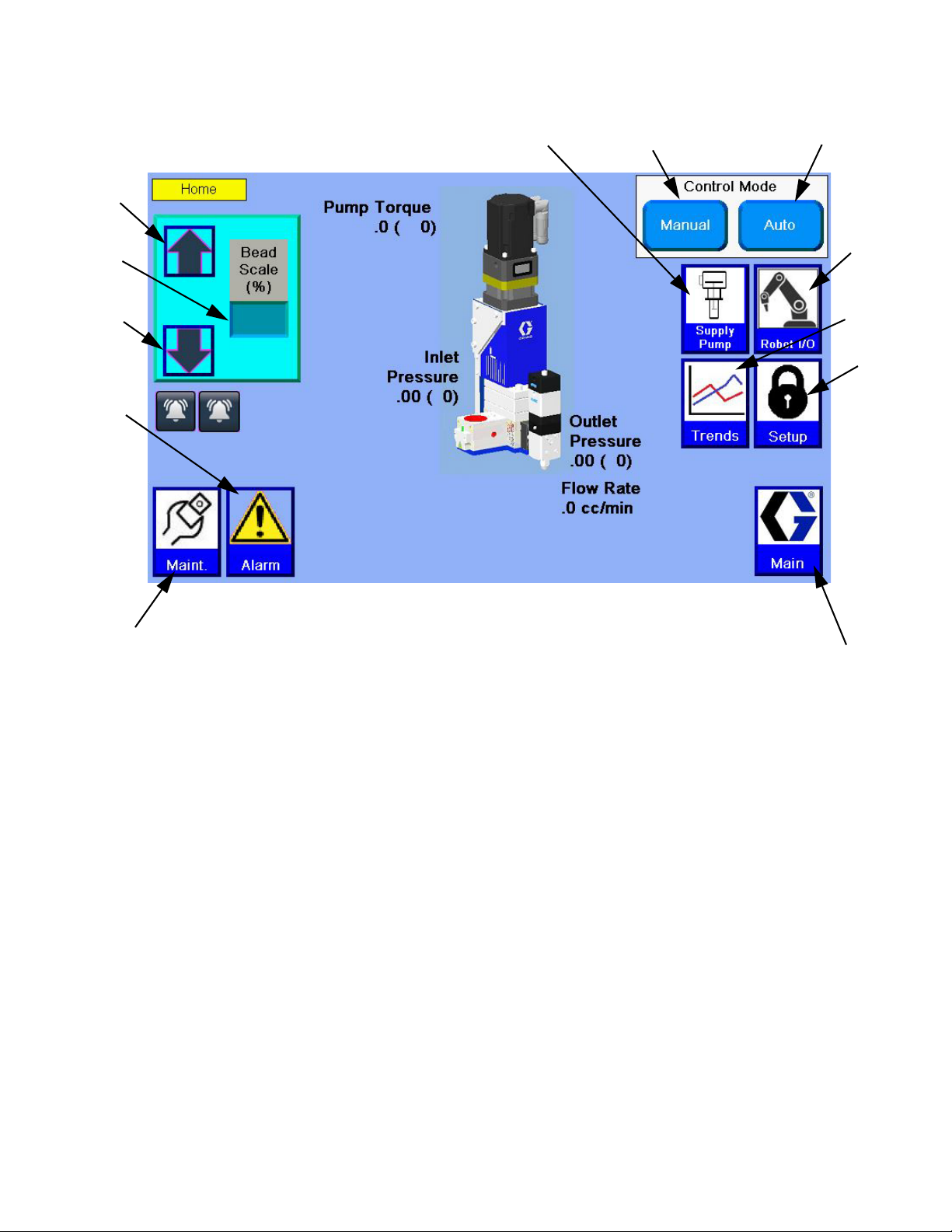

Home Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Maintenance Screen . . . . . . . . . . . . . . . . . . . . . 86

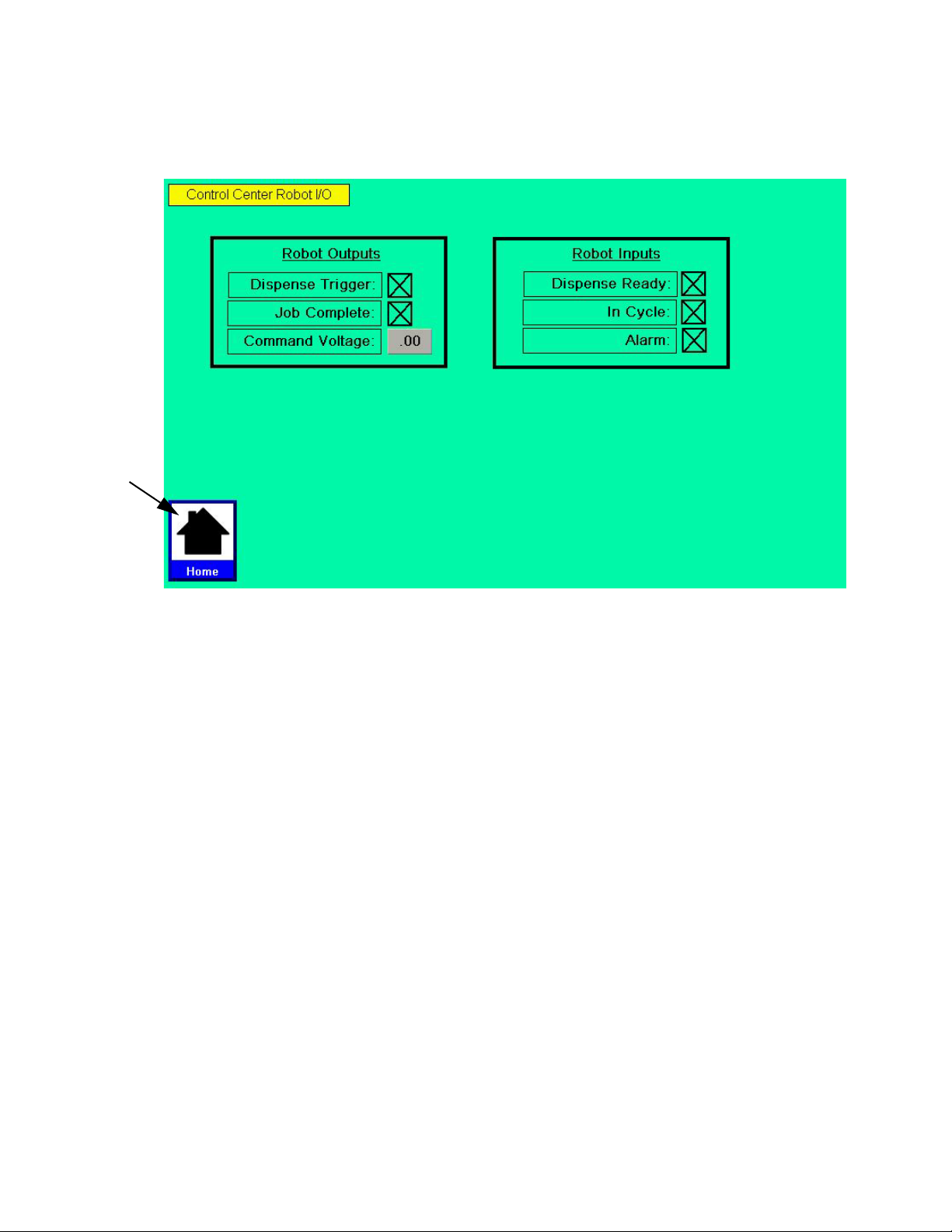

Robot I/O Screen . . . . . . . . . . . . . . . . . . . . . . . . 87

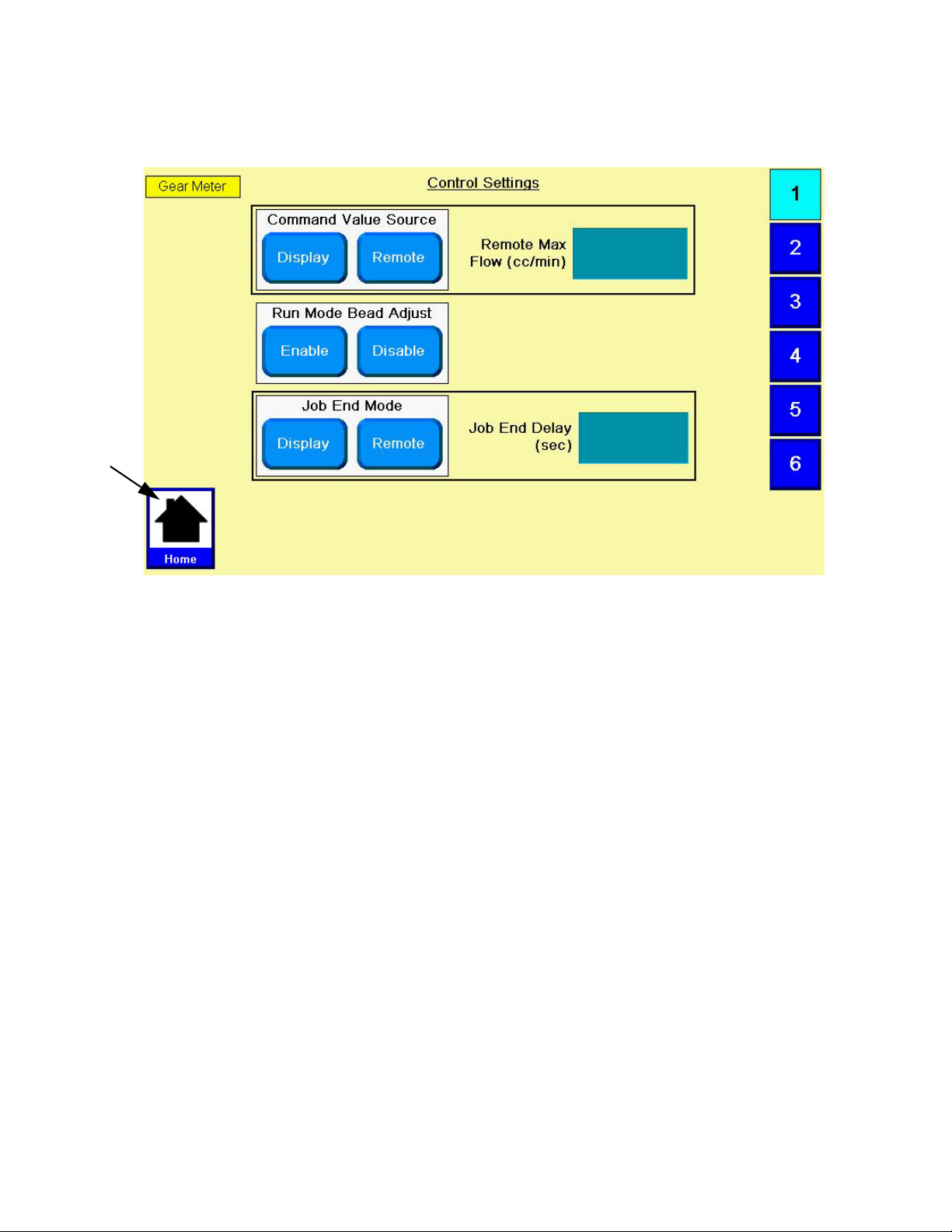

Setup #1 Screen . . . . . . . . . . . . . . . . . . . . . . . . 88

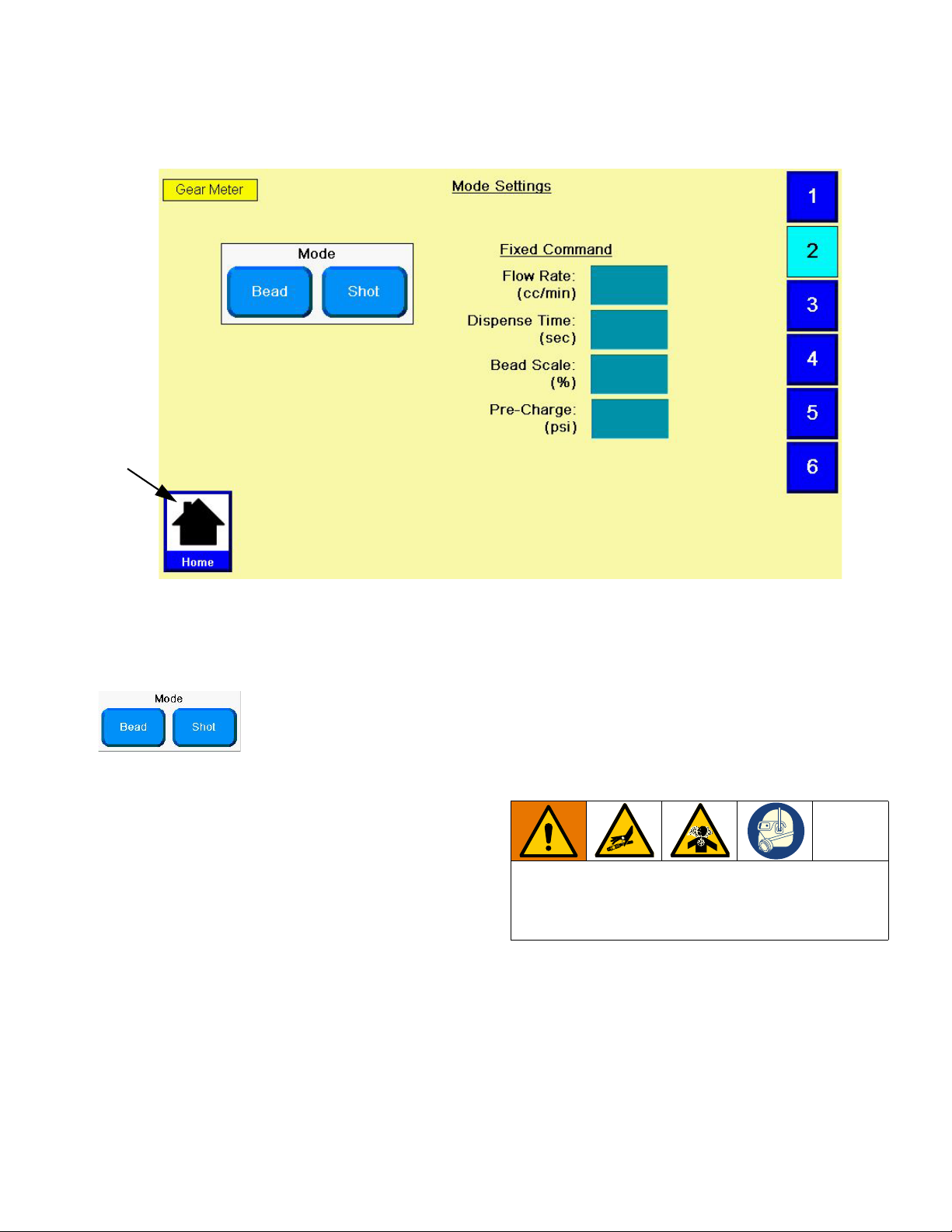

Setup #2 Screen . . . . . . . . . . . . . . . . . . . . . . . . 89

Setup #3 Screen . . . . . . . . . . . . . . . . . . . . . . . . 90

Setup #4 Screen . . . . . . . . . . . . . . . . . . . . . . . . 91

Setup #5 Screen . . . . . . . . . . . . . . . . . . . . . . . . 92

Setup #6 Screen . . . . . . . . . . . . . . . . . . . . . . . . 93

Supply Pump Screen . . . . . . . . . . . . . . . . . . . . . 94

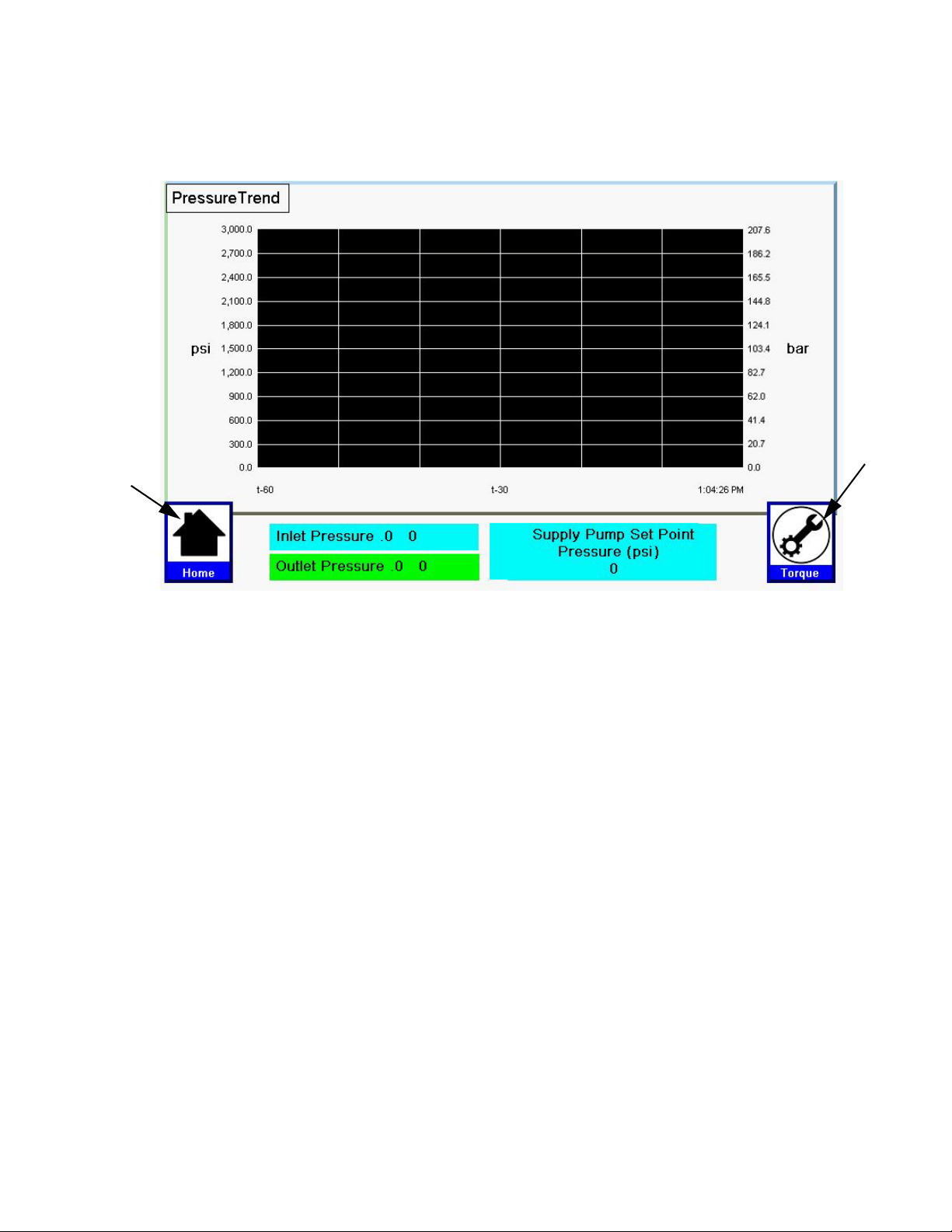

Pressure Trend Screen . . . . . . . . . . . . . . . . . . . 95

Torque Trend Screen . . . . . . . . . . . . . . . . . . . . 96

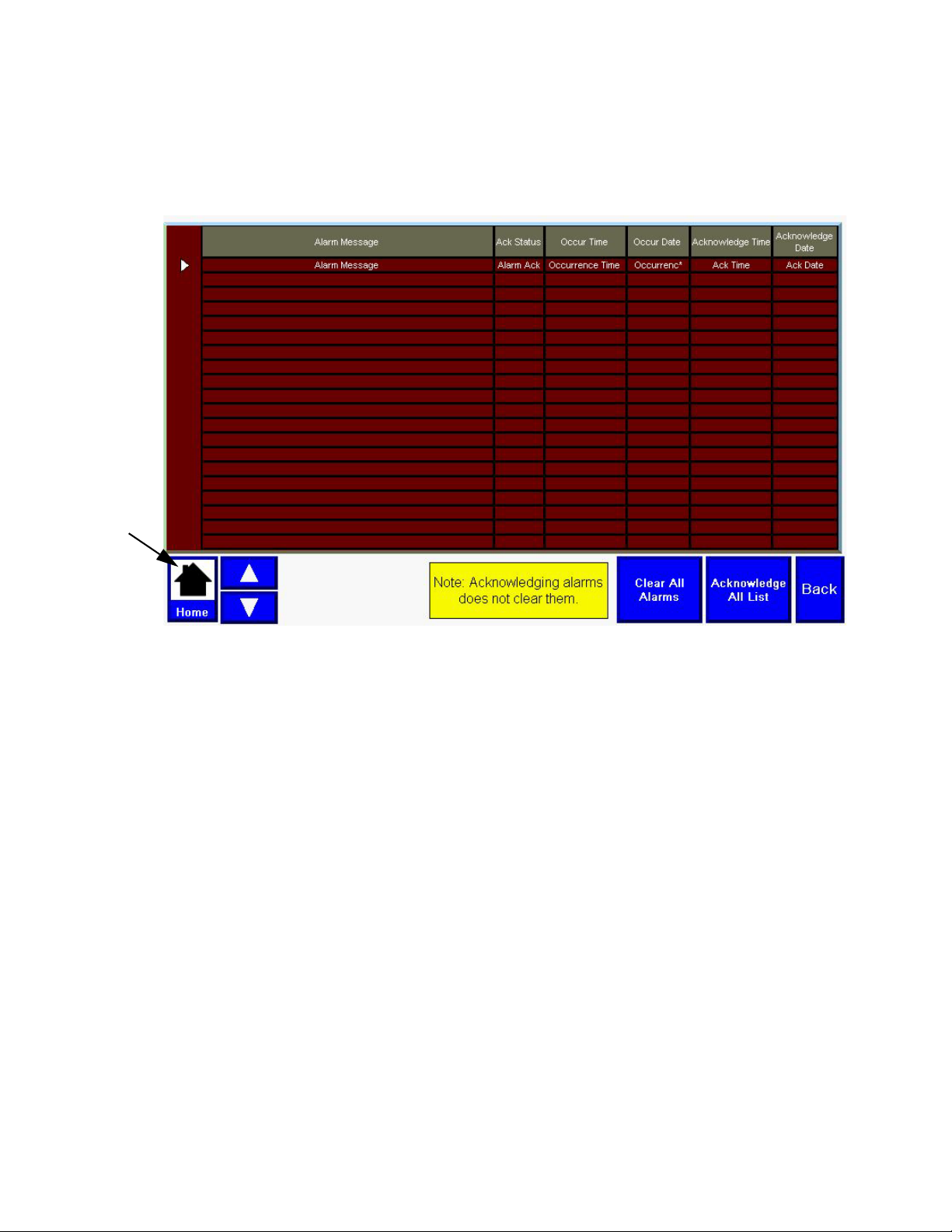

Alarm Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

2 3A5185B

Page 3

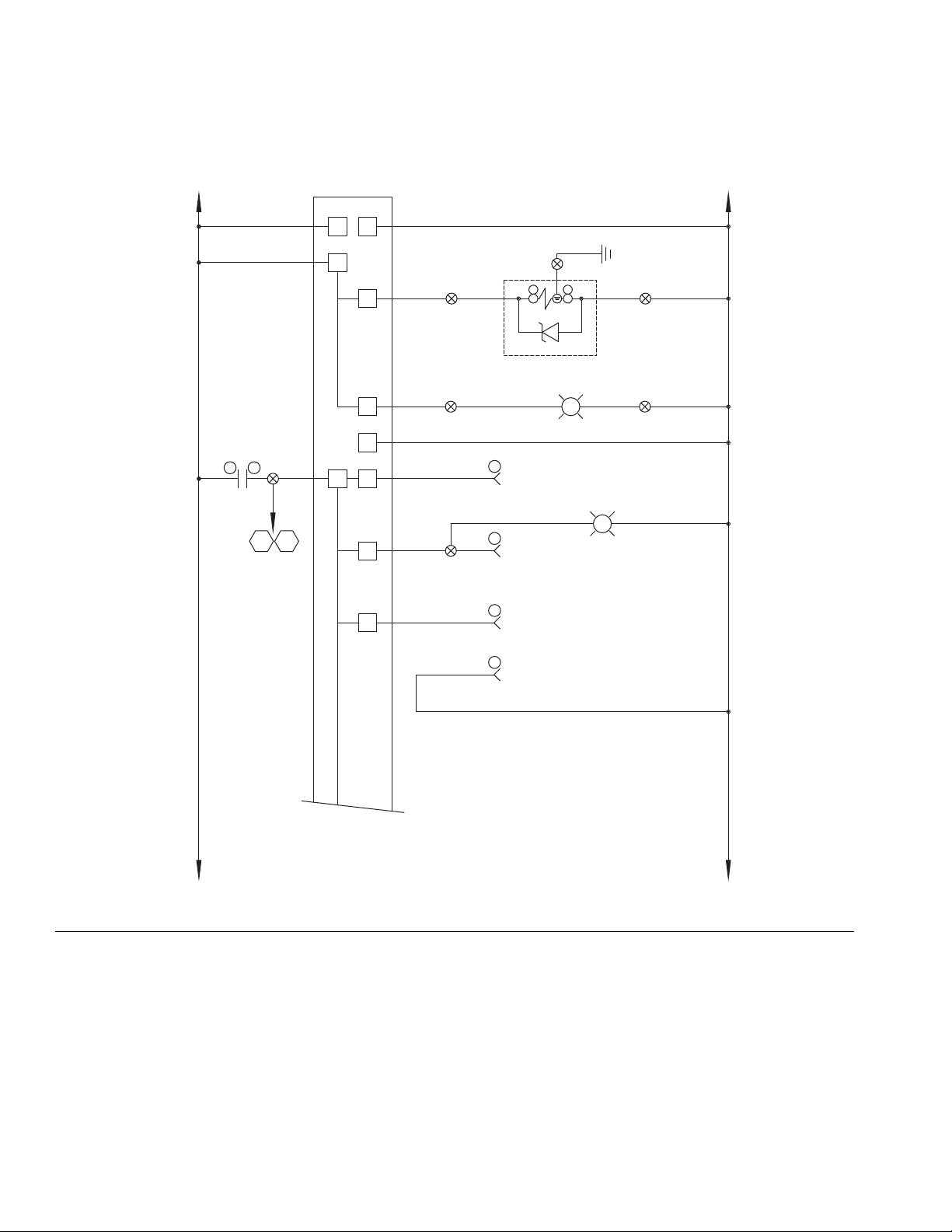

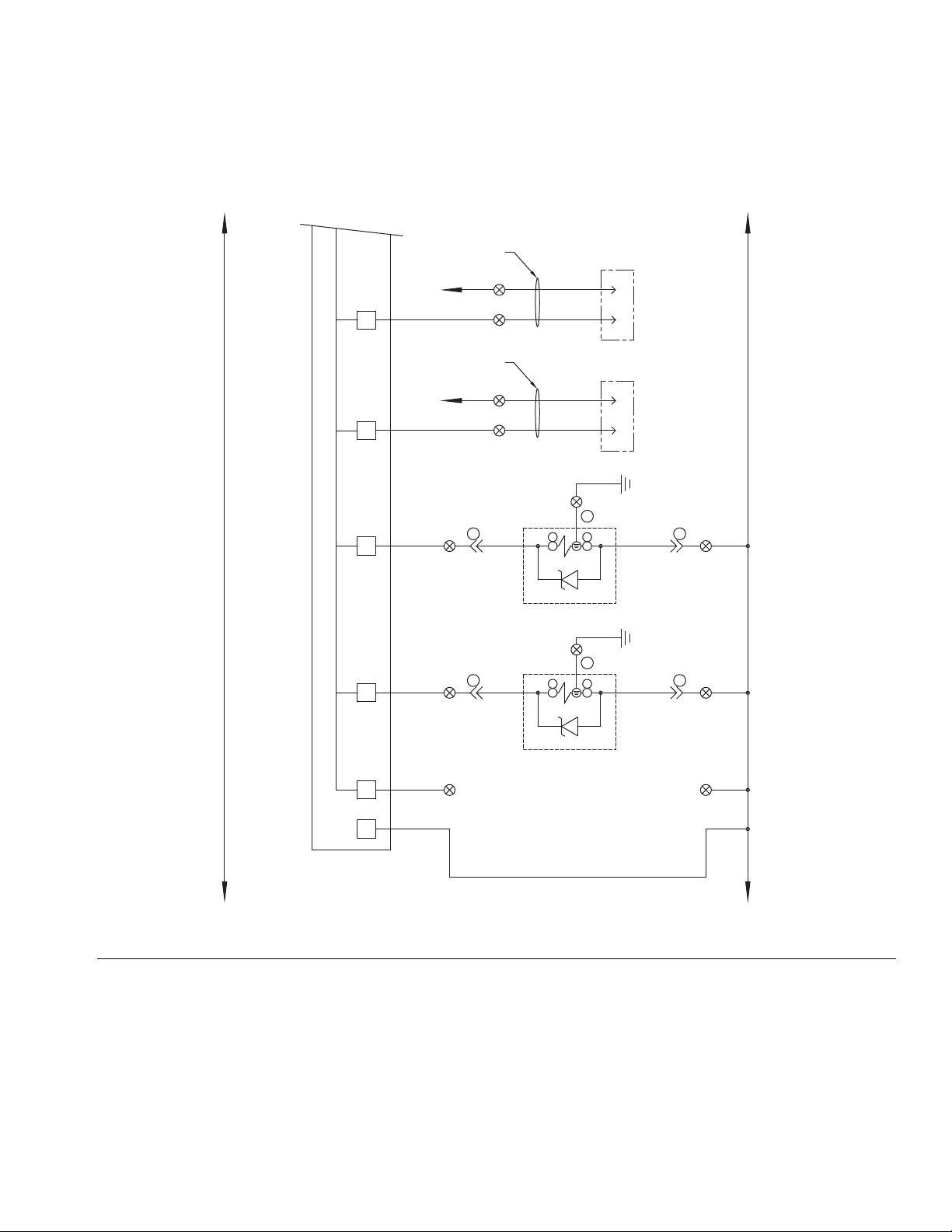

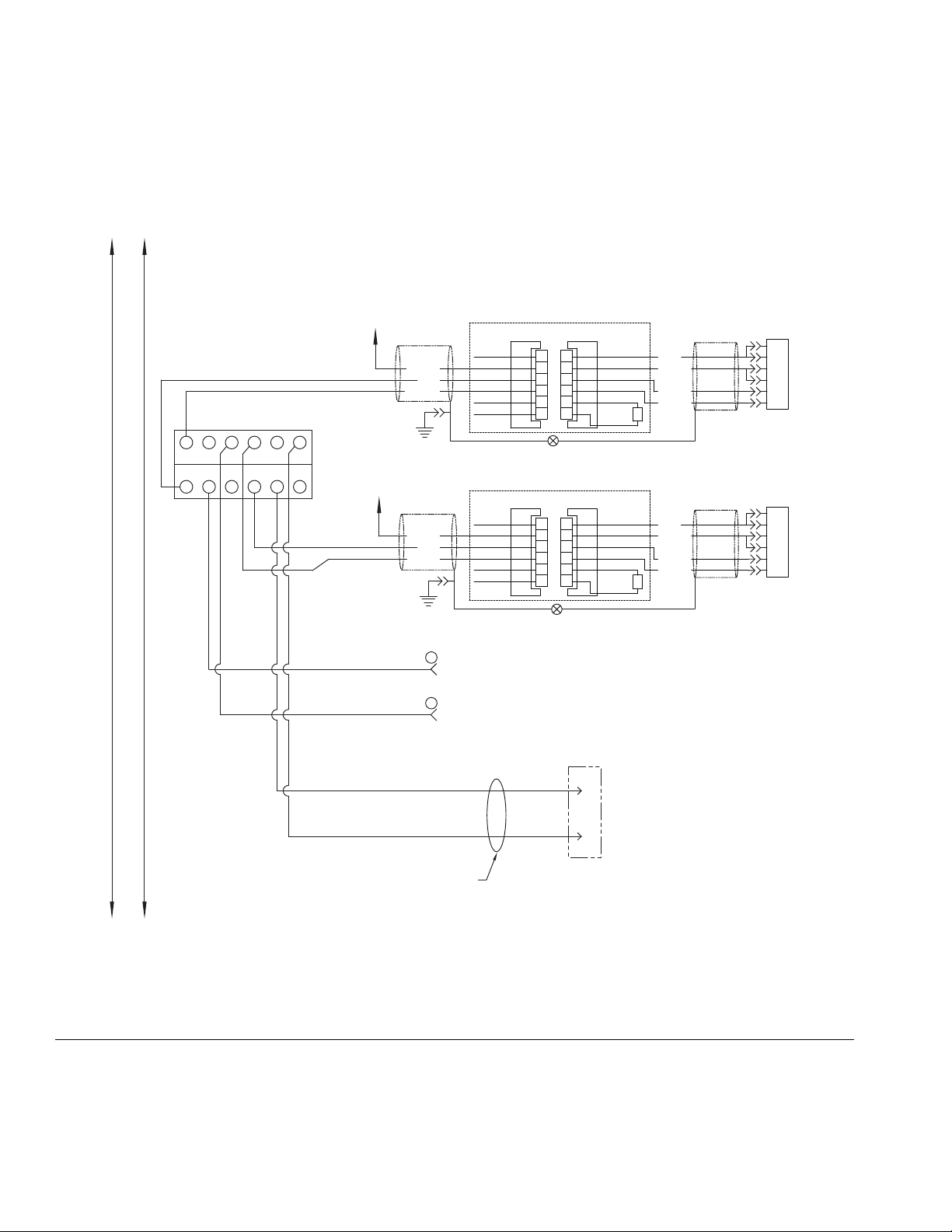

Appendix B - I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

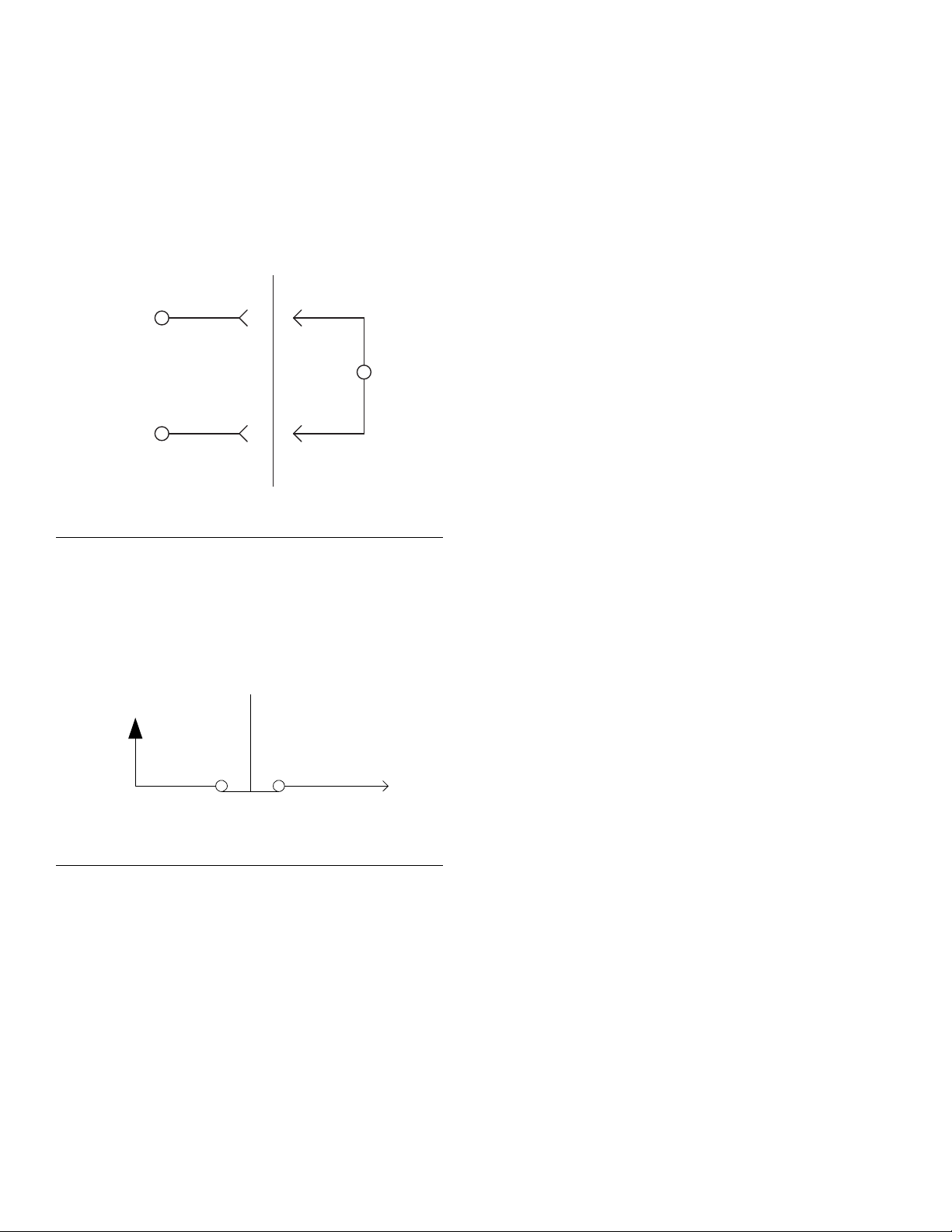

Using the PGM I/O . . . . . . . . . . . . . . . . . . . . . . 98

Appendix C - Theory of Operation . . . . . . . . . . . 101

Theory of Operation . . . . . . . . . . . . . . . . . . . . 101

Technical Specifications . . . . . . . . . . . . . . . . . . . 102

Graco Standard Warranty . . . . . . . . . . . . . . . . . . 104

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . 104

Related Manuals

Part Description

309376

310538

334130 Therm-O-Flow 200 (P/N UH****)

311208 Therm-O-Flow 200 (P/N 98****)

313296 Warm Melt Supply Systems

309213 Therm-O-Flow Accessory Heat Zone

EnDure

Instructions-Parts List

Therm-O-Flow

Valves Instructions-Parts List

Instructions-Parts

Instructions

Instructions-Parts

Controls Instructions-Parts List

®

Automatic Dispense Valves

®

Automatic Dispense

313526 Ambient Supply Systems Operation

3A5185B 3

Page 4

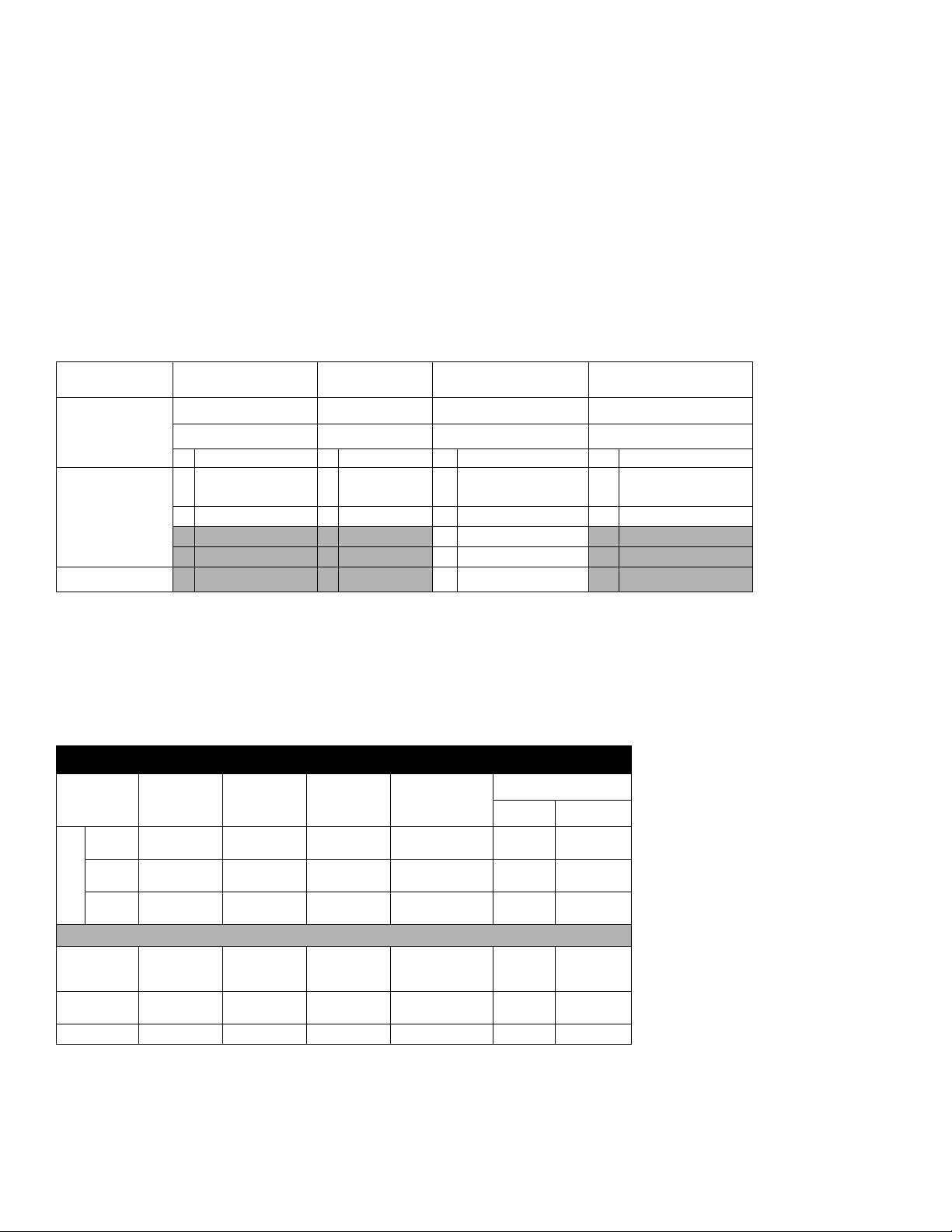

Models

Models

NOTE: This manual covers a series change to the PGM system. For systems built prior to 2016, refer to manual

3A0260.

Check the identification (ID) plate for the 6-digit part number of the fluid metering system. Use the following matrix to

define the construction of the system, based on the six digits. For example, Part PG0111 represents a PGM fluid

metering system (PG), with a 6cc system (0), unheated (1), with controls/3m (1), and an EnDure snuff-back (1).

NOTE: To order replacement parts, see Parts section in this manual. The digits in the matrix do not correspond to the Ref. Nos. in the Parts drawings and lists.

PG 0

First and

Second Digits

Third Digit

Size

1

Fourth Digit

Heat

1

Fifth Digit

Controls *

2

Sixth Digit

Valve

Description Description Description Description

PG

(Precision

Gear Meter)

0

2 20cc 2 Heated 1 Controls / 3m 6 Remote mount

6cc 1 Unheated 0 No controls 1 EnDure

snuff-back

2 Controls / 6m

3 Controls / 9m

4 Controls / 15m

* PGM Control Center does not include heat controls. Heat loads are configured to be controlled by Therm-O-Flow

Controllers.

Bulk Melt (Therm-O-Flow 20 + Therm-O-Flow 200) and Ambient

Hoses

Hose Diameter

- 8

3/4 in. - 16 JIC

6 ft None 19M404

10 ft 19M402

15 ft Non None None None 109165/

Hose Length

PGM Inlet

(-16 SAE)

PGM Outlet

(3/4 in. npt)

Valve Inlet 124287 C20768 107052 124288 158256 † 190451 †

17J652

None None 124238

124286 C20595 15M863 107127 124290 † 124289 †

- 10

7/8 in. - 14 JIC

17J654

19M405

17J655

- 12

1-1/16 in. - 12

JIC

None 19M416

19M412

17J662

Fittings

124235 (90°)

1-5/16 in. - 12 JIC

- 16

17J666

19M417

17J667

124239

124243 †

124236 (90°)

Non-Heated Hoses

3/8 in. 1/2 in.

109163 626720

None 215441

685602*

None None

(1/2 in. x 5 ft)

511381*

* Indicates PTFE hose, all others Buna-N.

† Indicates swivel.

Therm-O-Flow part number 98xxxx models.

4 3A5185B

Page 5

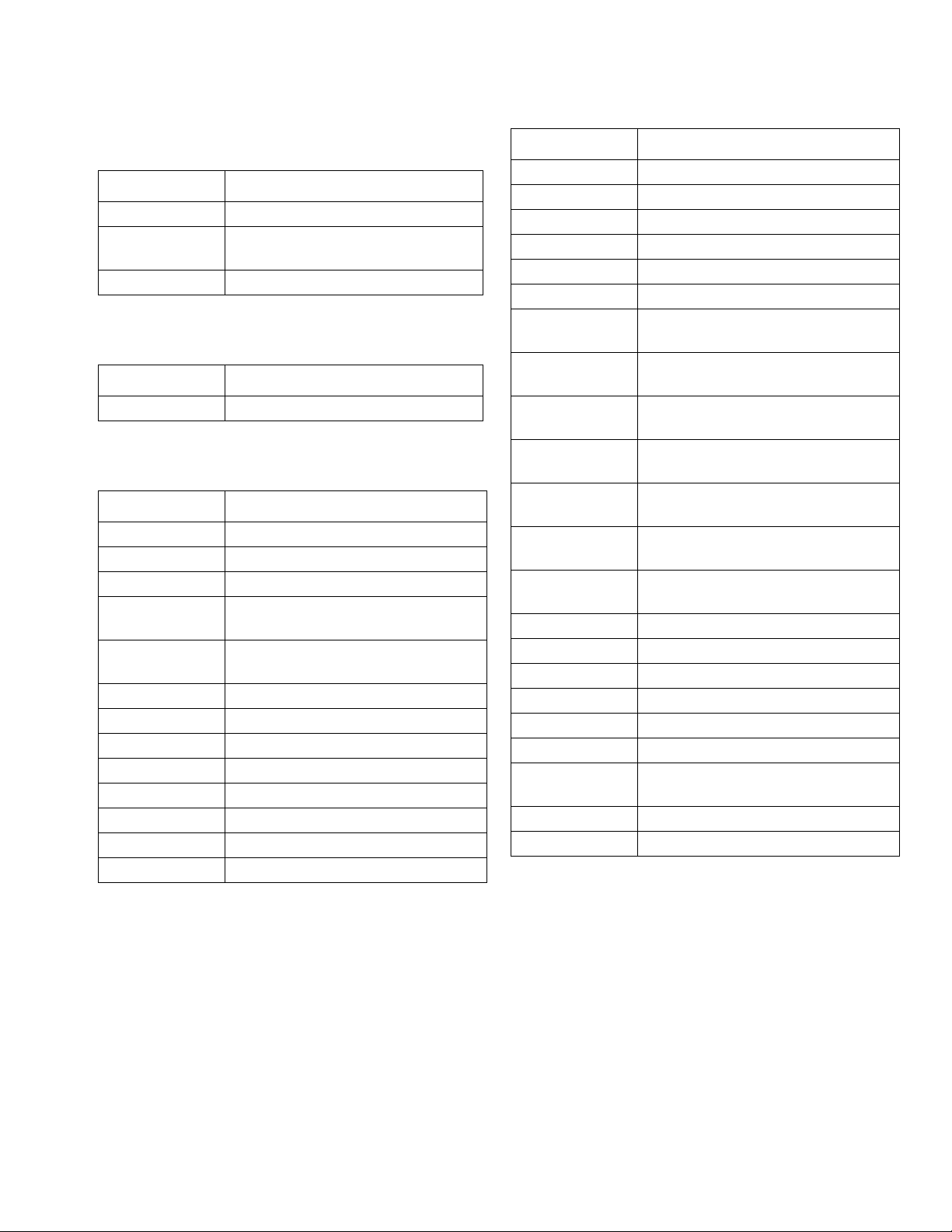

Models

Remote Dispense Valves

Part Description

243694 Heated Dispense Valve

244951 EnDure Valve, Heated,

1/2 in. npt male outlet

244909 EnDure Valve, Heated

Fixed Dispense Valves

Part Description

244907 EnDure Valve snuff-back

Accessories

Part Description

24D824 Automation I/O Cable

24E654 Ribbon Nozzle Kit, 10 x 1.5 mm

24E655 Bead Nozzle Kit, 3 mm dia.

25A055 Dynamic Air Regulator for

Therm-O-Flow (P/N UH****)

24E575 Dynamic Air Regulator for

Therm-O-Flow (P/N 98****)

24E607 Gear Pump Seals, 6 cc

24E619 Gear Pump Seals, 20 cc

24E677 O-ring Kit, 6 cc

24E626 O-ring Kit, 20 cc

24E678 Heated Nest, Pilot

24E679 Heated Nest, Ribbon or Bead

16E242 Nozzle Heater Insert

16E256 Ported Nozzle Heater Insert

Part Description

124267 Seal Housing, 6 cc

24E826 Gear Shaft Repair Kit, 6 cc

24E827 Seal Shaft Repair Kit, 6 cc

124266 Pump Seal Housing, 20 cc

24E824 Gear Shaft Repair Kit, 20 cc

24E825 Seal Shaft Repair Kit, 20 cc

124235 Elbow Fitting, 90 degree, 3/4 in.

tube x 16 SAE

124236 Elbow Fitting, 90 degree, 1 in. tube

x 16 SAE

124237 Elbow Fitting, 90 degree, 16 SAE x

20 JIC

124238 Adapter Fitting, 3/4 in. Tube x

16 SAE

124239 Adapter Fitting, 1 in. Tube x

16 SAE

124240 Adapter Fitting, 1-1/4 in. Tube x

16 SAE

124241 Adapter Fitting, 16 SAE x

1in.NPTF

124242 Swivel, 16 SAE x 1 in. NPTF

124243 Swivel, 16 SAE x 1 in. tube

124244 Swivel, 1/2 NPTM x 10 JIC

124245 Swivel, 1/2 NPTM x 1/2 NPTF

124286 Adapter Fitting, 3/4 NPTM x 8 JICM

124287 Adapter Fitting, 1/2 NPTM x 8 JICM

124288 Adapter Fitting, 1/2 NPTM x 16

JICM

124289 Swivel Fitting, 3/4 NPTM x 1/2 NPS

124290 Swivel Fitting, 3/4 NPTM x 3/8 NPS

3A5185B 5

Page 6

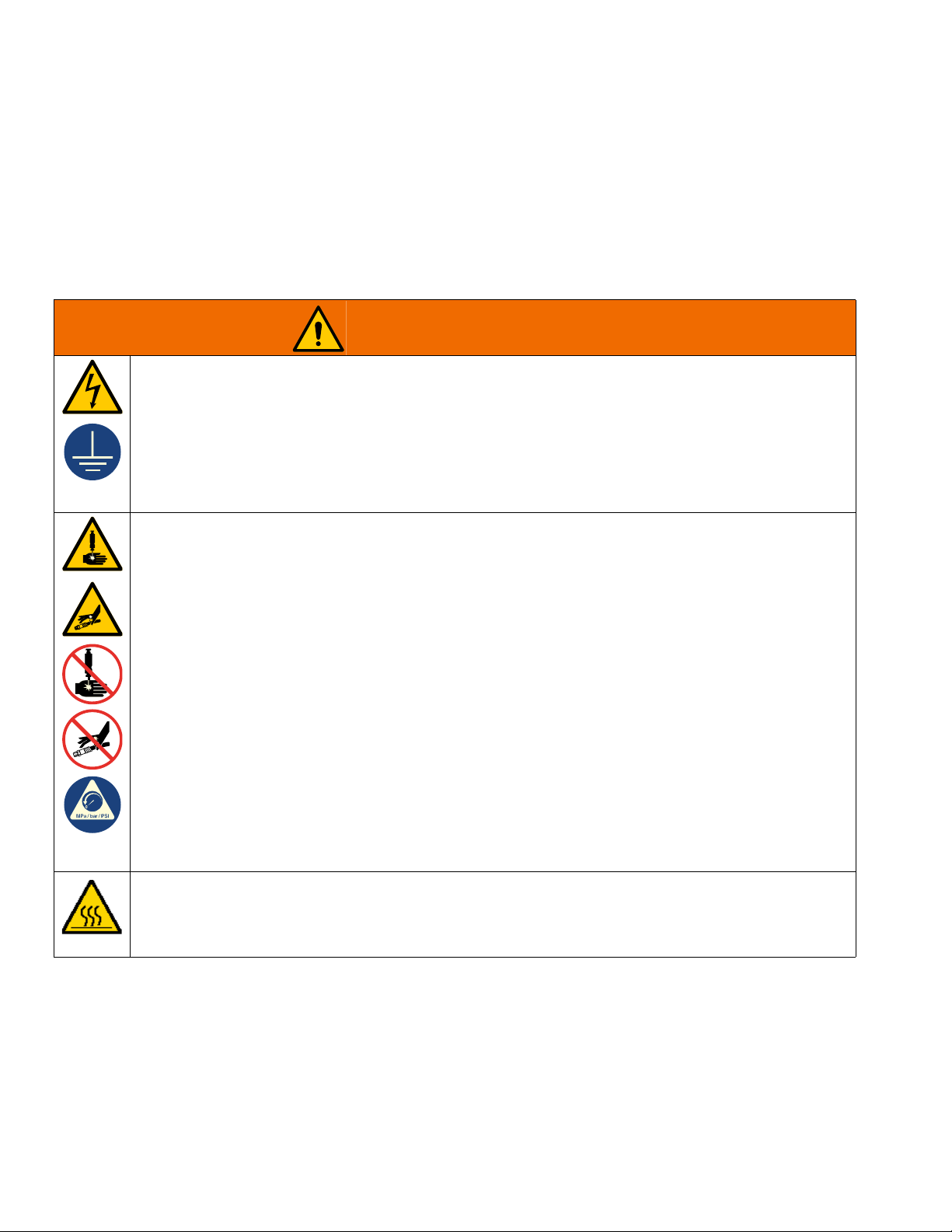

Warnings

WARNING

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric

shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing or

installing equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and regulations.

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Engage trigger lock when not dispensing.

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

BURN HAZARD

Equipment surfaces and fluid that is heated can become very hot during operation. To avoid severe

burns:

• Do not touch hot fluid or equipment.

6 3A5185B

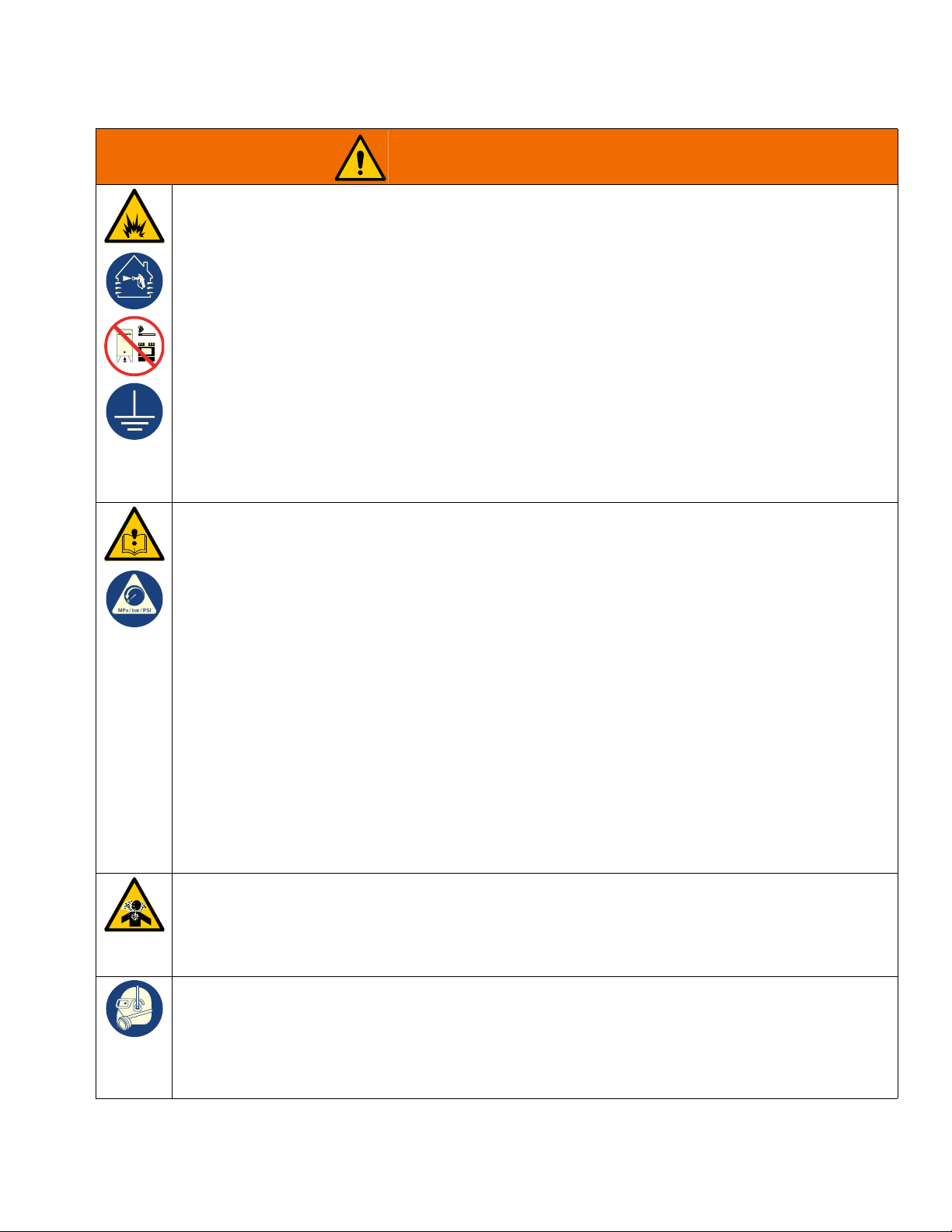

Page 7

Warnings

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. Paint or solvent

flowing through the equipment can cause static sparking. To help prevent fire and explosion:

• Use equipment only in well-ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static sparking).

• Ground all equipment in the work area. See Grounding instructions.

• Never spray or flush solvent at high pressure.

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes are

present.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless they are

anti-static or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment until

you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See Technical Specifications in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Specifications

in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request Safety Data Sheets (SDSs) from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read Safety Data Sheets (SDSs) to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. Protective equipment includes but is not

limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

3A5185B 7

Page 8

Overview

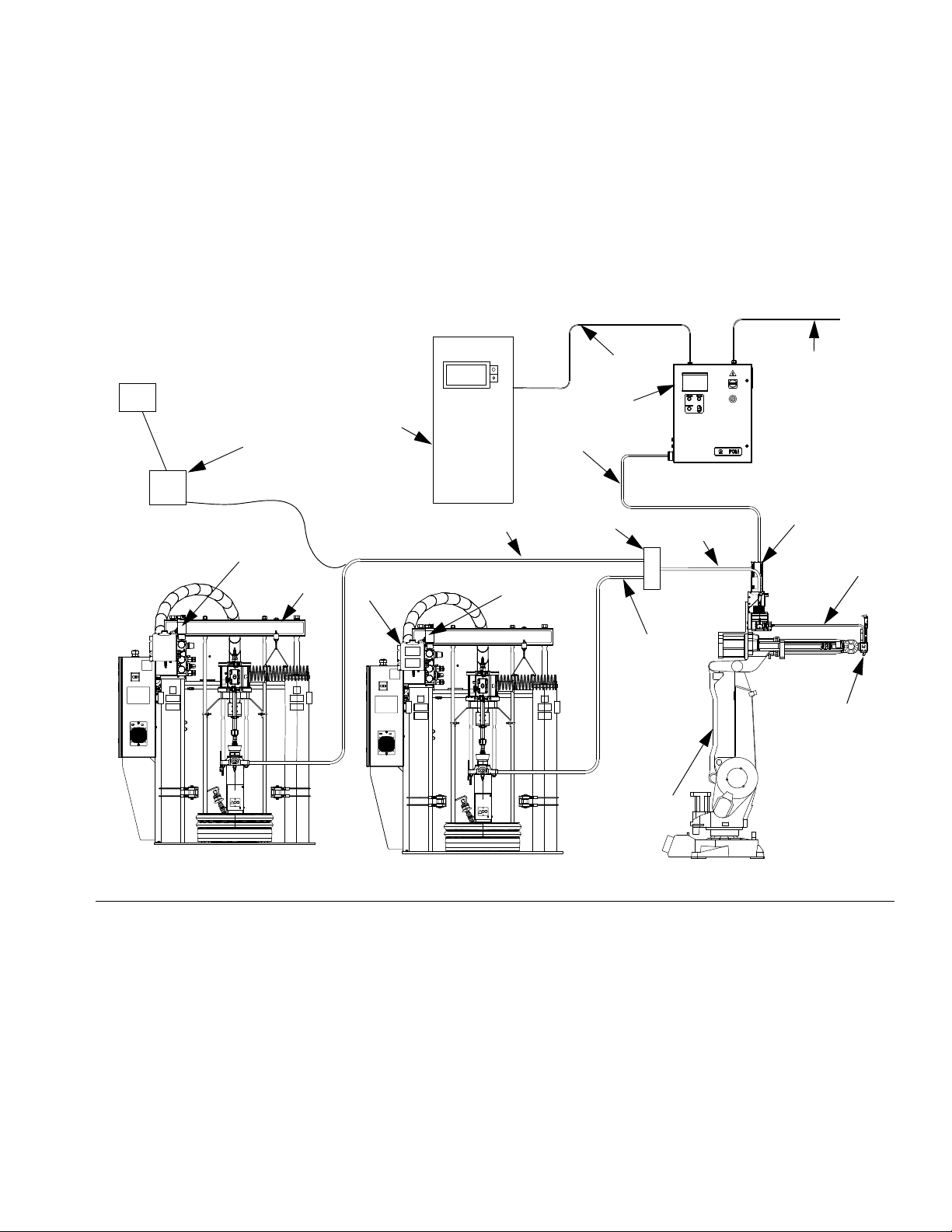

AD

AC

AH

AB*

AF*

AA*

AE

AK

AM

AG

Air Supply

Drop Site

AN

Power

AL

AJ

AH

AH

AO

AO

Overview

System Configurations

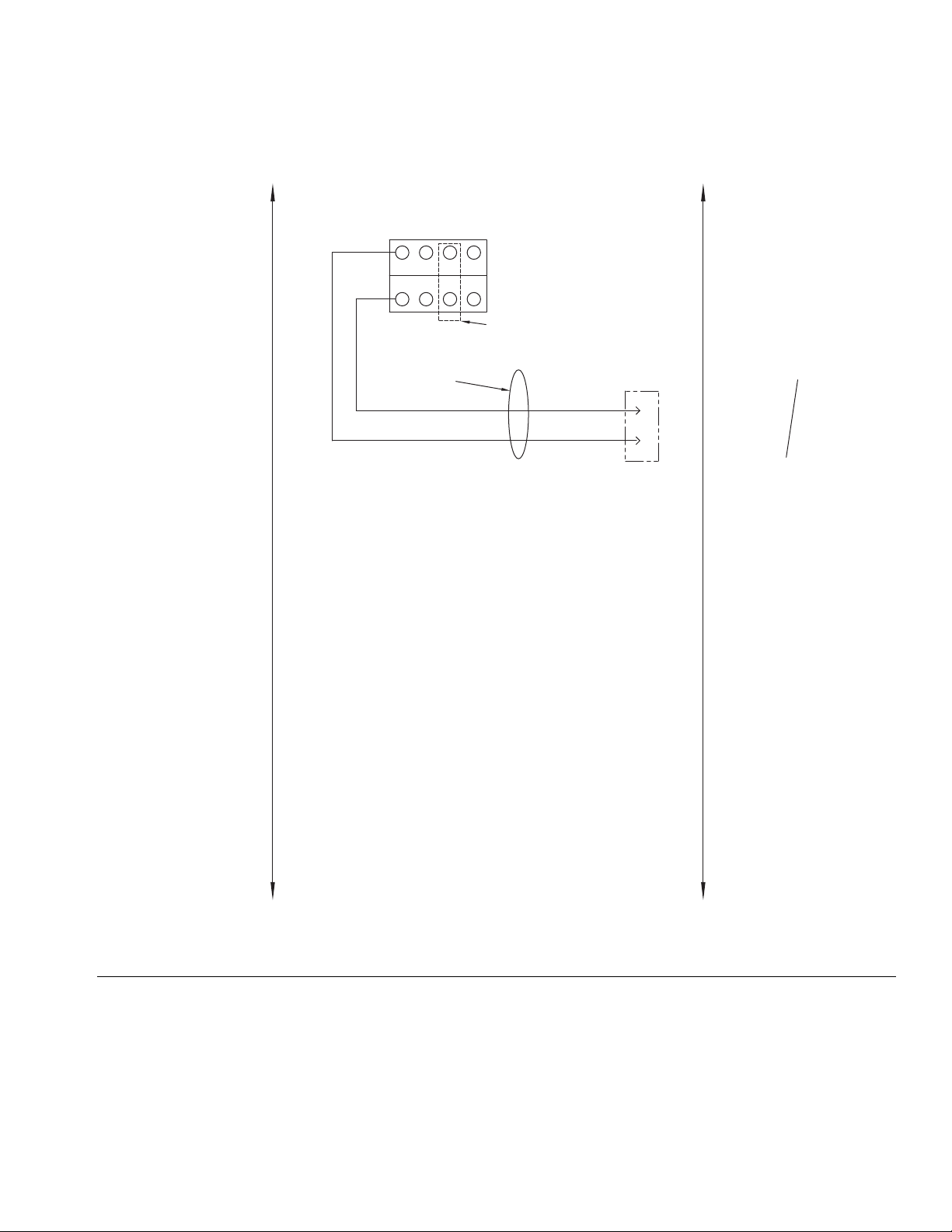

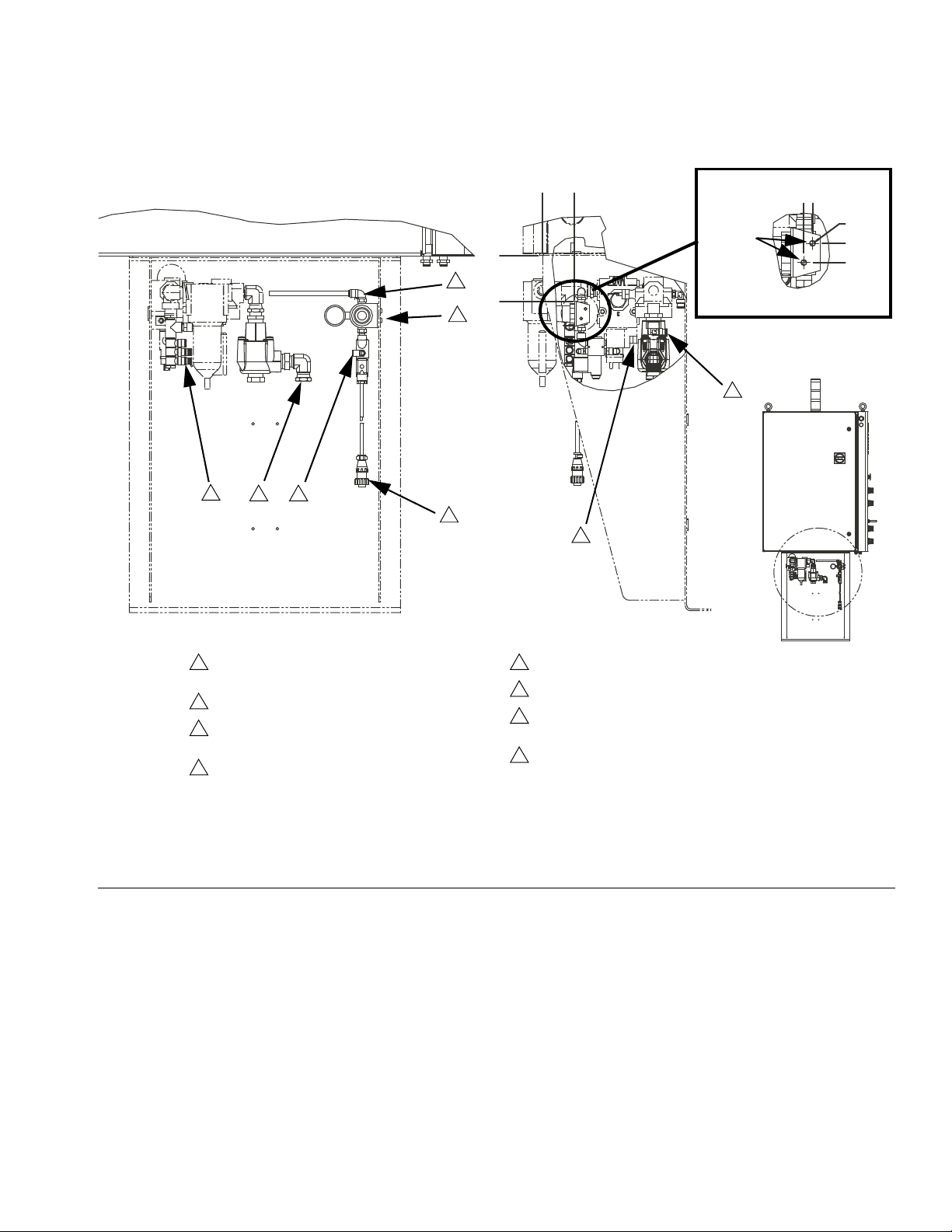

Typical Heated System Installation

F

IG. 1: Typical Heated System Installation

Key:

AA *Control Center (User Interface)

AB *Gear Meter Assembly

AC Applicator/Dispense Valve†

AD Automation Robot

AE Automation Interface Cable †

AF *Gear Meter Cables

AG Heated Fluid Supply System

AH Fluid Supply Hose

AJ Heat Control

AK Automation Controller

AL Air Filter Assembly

AM Remote Dispense Hose †

AN Heated Manifold

AO Dynamic Regulator †

*Included

† Accessory

8 3A5185B

Page 9

Typical Ambient System Installation

G

D

C*

F*

A*

E

H

J

Air Supply

Drop Site

K

Power

B*

Overview

F

IG. 2: Typical Ambient System Installation

Key:

A *Control Center (User Interface)

B *Gear Meter Assembly

C *Applicator/Dispense Valve

D Automation Robot

E Automation Interface Cable†

F *Gear Meter Cables

G Fluid Supply System

H Fluid Supply Hose

J Automation Controller

K Air Filter Assembly

* Included

† Accessory

3A5185B 9

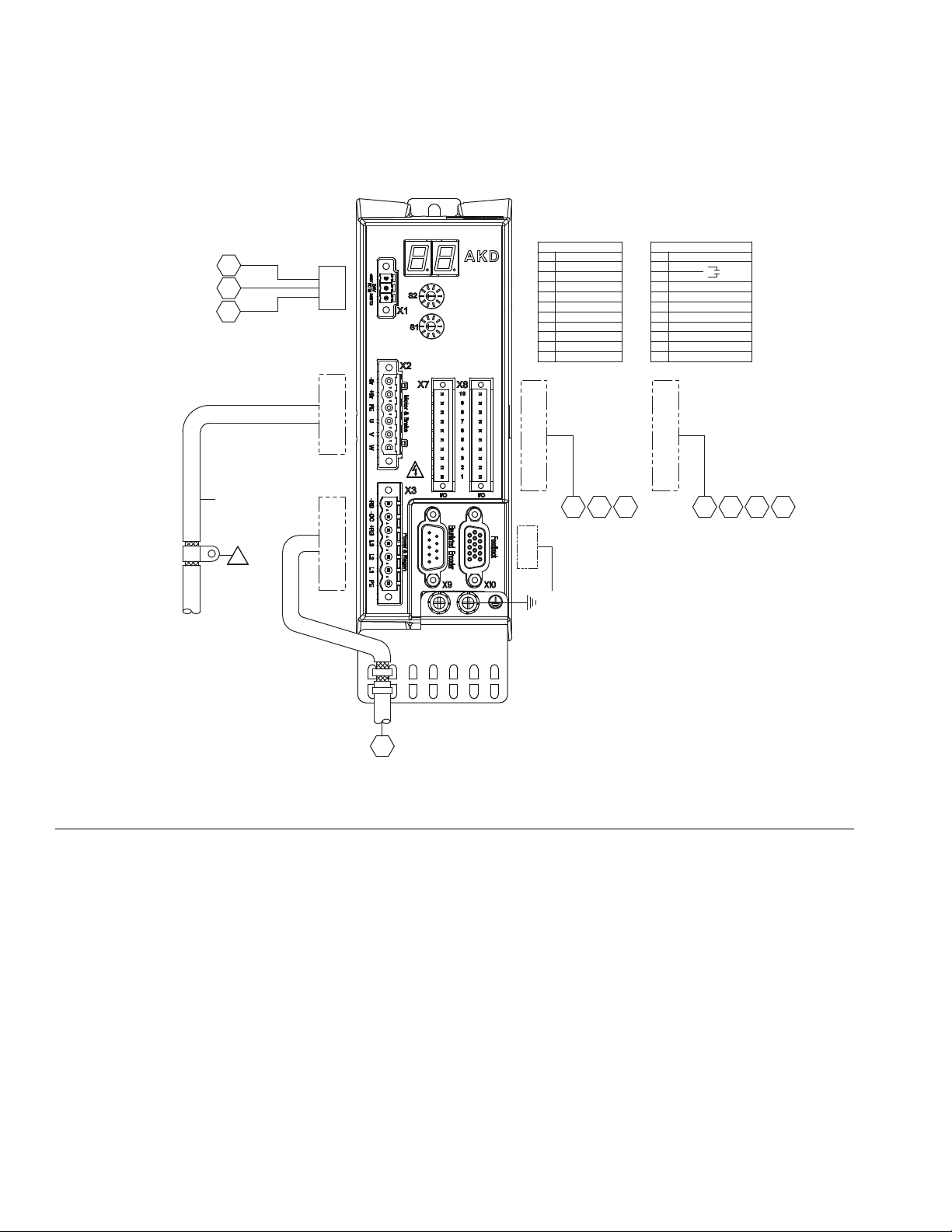

Page 10

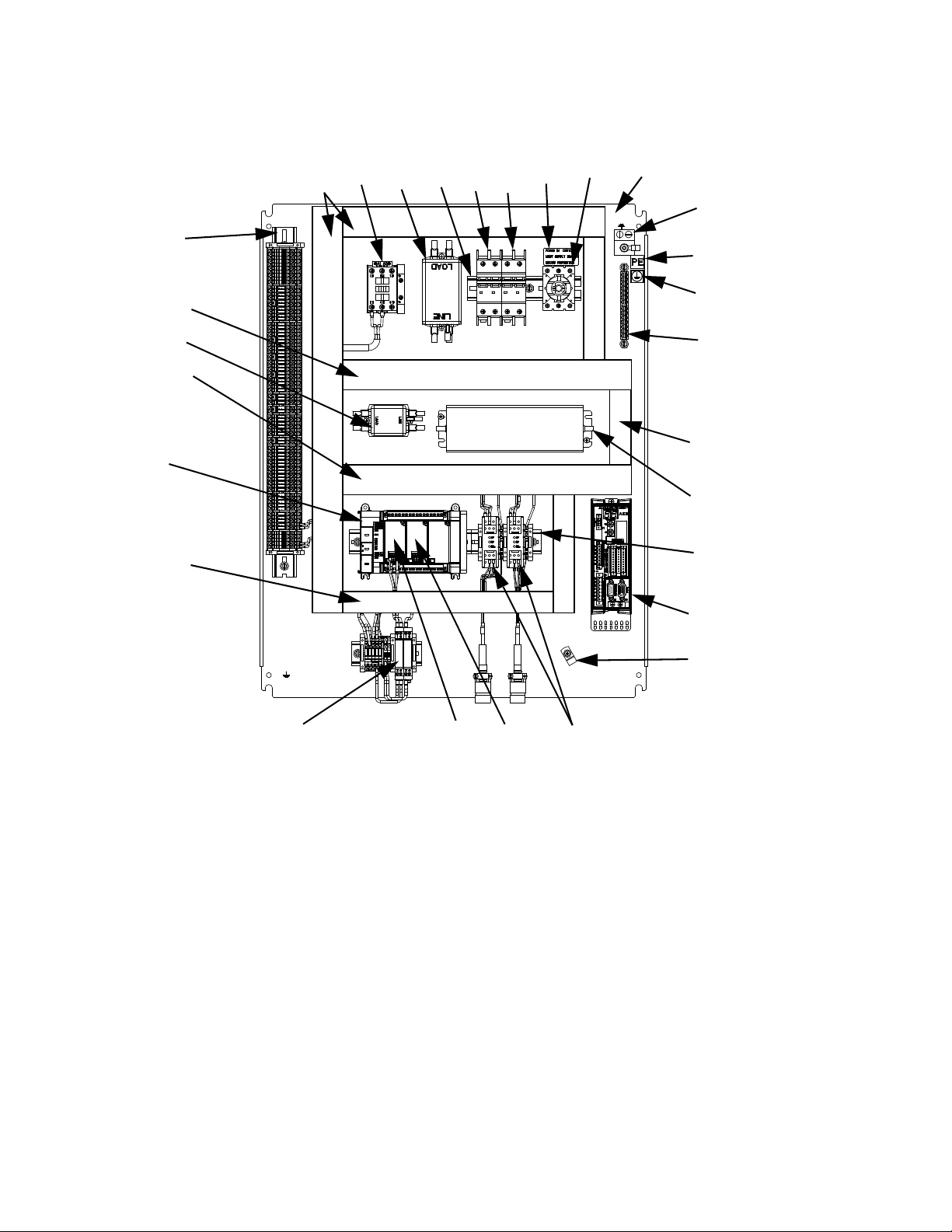

Overview

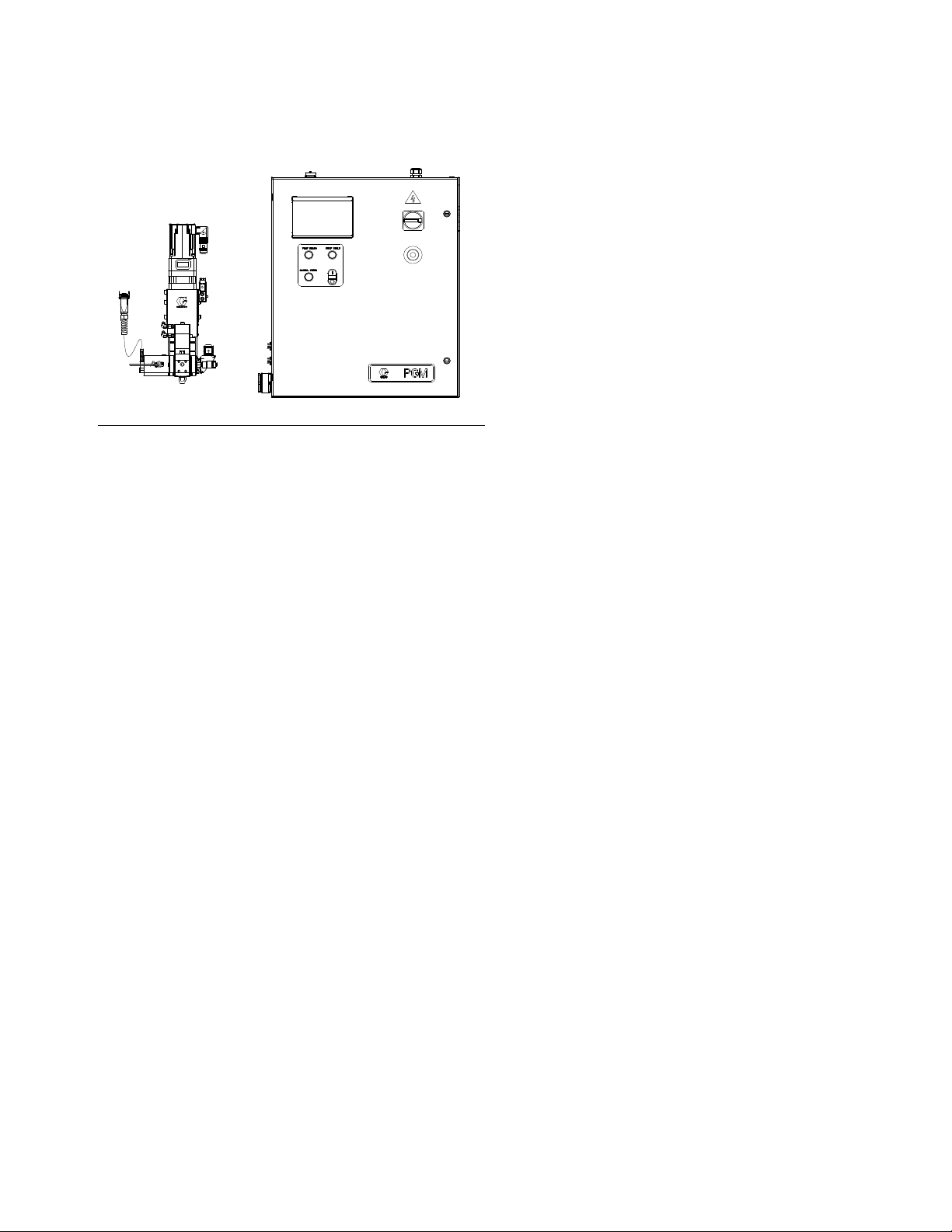

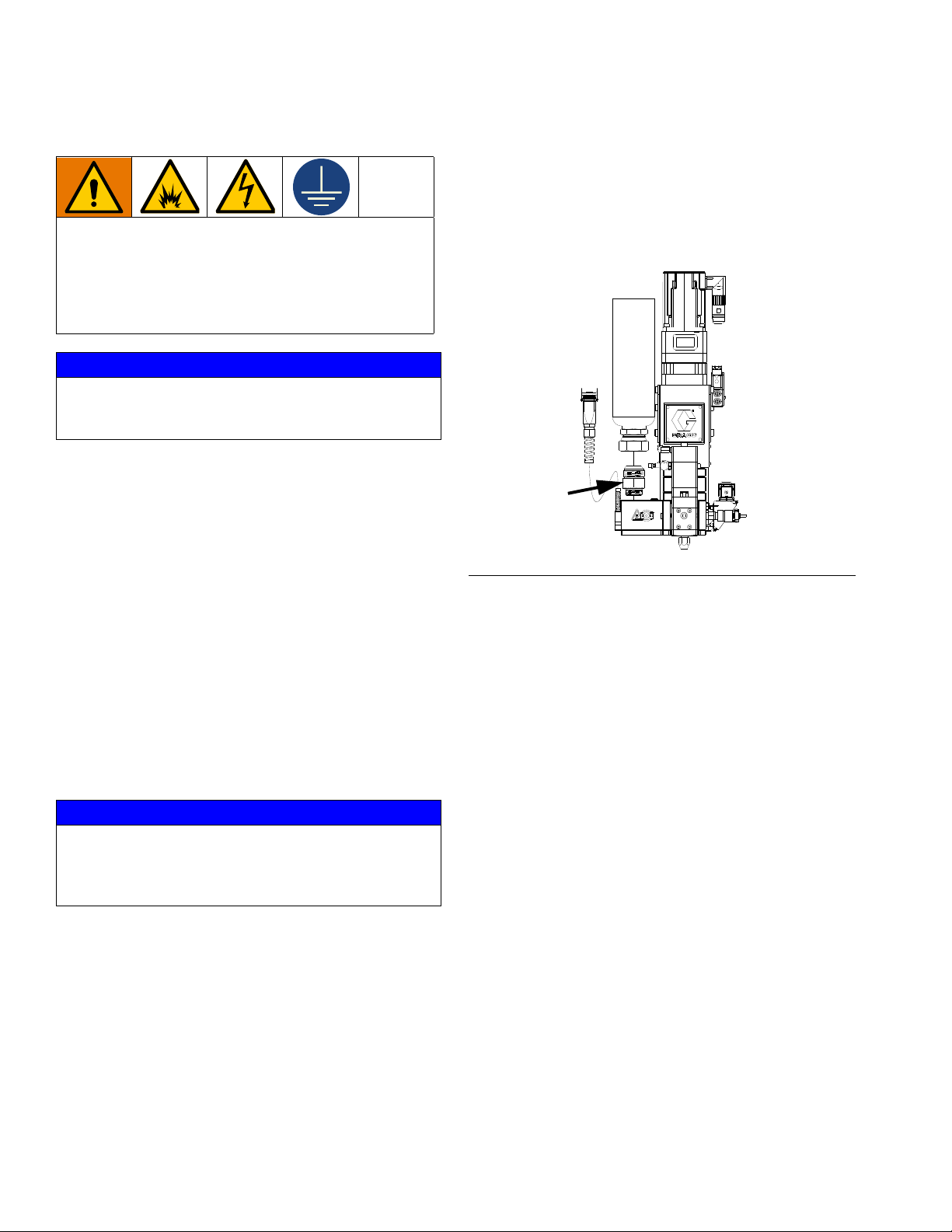

Key:

1 Gear Meter

2 System Controls Box

3 User-Interface Touch Display

4 External Control Interface

Connections

5 Power Input

6 Main Power Switch

7 Emergency Stop

8 Pump Fault Indicator Light

9 Control Power On/Off buttons

10 Pump Ready Light

11 Manual Purge Button

12 Dispense Valve

1

2

3

4

5

12

6

7

8

9

10

11

Component Identification

FIG. 3

10 3A5185B

Page 11

Overview

System Overview

F

IG. 4: Control Center Dimensions

The PGM system provides positive displacement metering for precision bead control. The control accepts automation signals to provide accurate and consistent output

flow. The gear meter can achieve high flow rates with

high viscosity materials.

Control Power On/Off

Typical Applications

• Solar Panel

• Perimeter Seal

• Desiccant

• Edge Seal

• Automotive Manufacturing

• Window and Door General Assembly

Control Power is the power for the signals to the gear

meter which control gear meter rotation. When Control

Power is off, the gear meter cannot rotate.

Pump Ready Light

The Pump Ready light displays when the pump is ready

for Automatic Mode dispensing. When Manual mode is

enabled, this light will not turn on.

Pump Fault Light

The Pump Fault light is illuminated whenever a pump

fault is active.

Manual Purge Button

The Manual Purge button initiates a shot.

3A5185B 11

Page 12

Installation

Installation

Before Installation

• Have all system and component documentation

available during installation.

• See component manuals for specific data on component requirements. Data presented here applies to

the PGM assemblies only.

• Be sure all accessories are adequately sized and

pressure-rated to meet system requirements.

• Use the PGM control center only with the PGM

metering assembly.

Overview

The basic steps to install a PGM system are shown

below. See the separate component manuals for

detailed information on supply systems and dispense

valves.

NOTICE

To avoid damaging the PGM system, use at least two

people to lift, move, or disconnect the system. The

system is too heavy for one person to lift or move.

Installation Steps

1. Mount control center.

2. Connect and ground control center.

3. Mount gear meter assembly.

4. Ground gear meter assembly.

5. Check ground continuity.

6. Connect fluid line between gear meter and dispense

valve. For remote mount dispense valves, connect fluid supply line and air supply to gear meter.

7. Plumb filter assembly near air drop site that will be

used for gear meter assembly.

8. Connect other fluid and air lines to additional system

components as instructed in their manuals.

9. Install cable assemblies.

12 3A5185B

Page 13

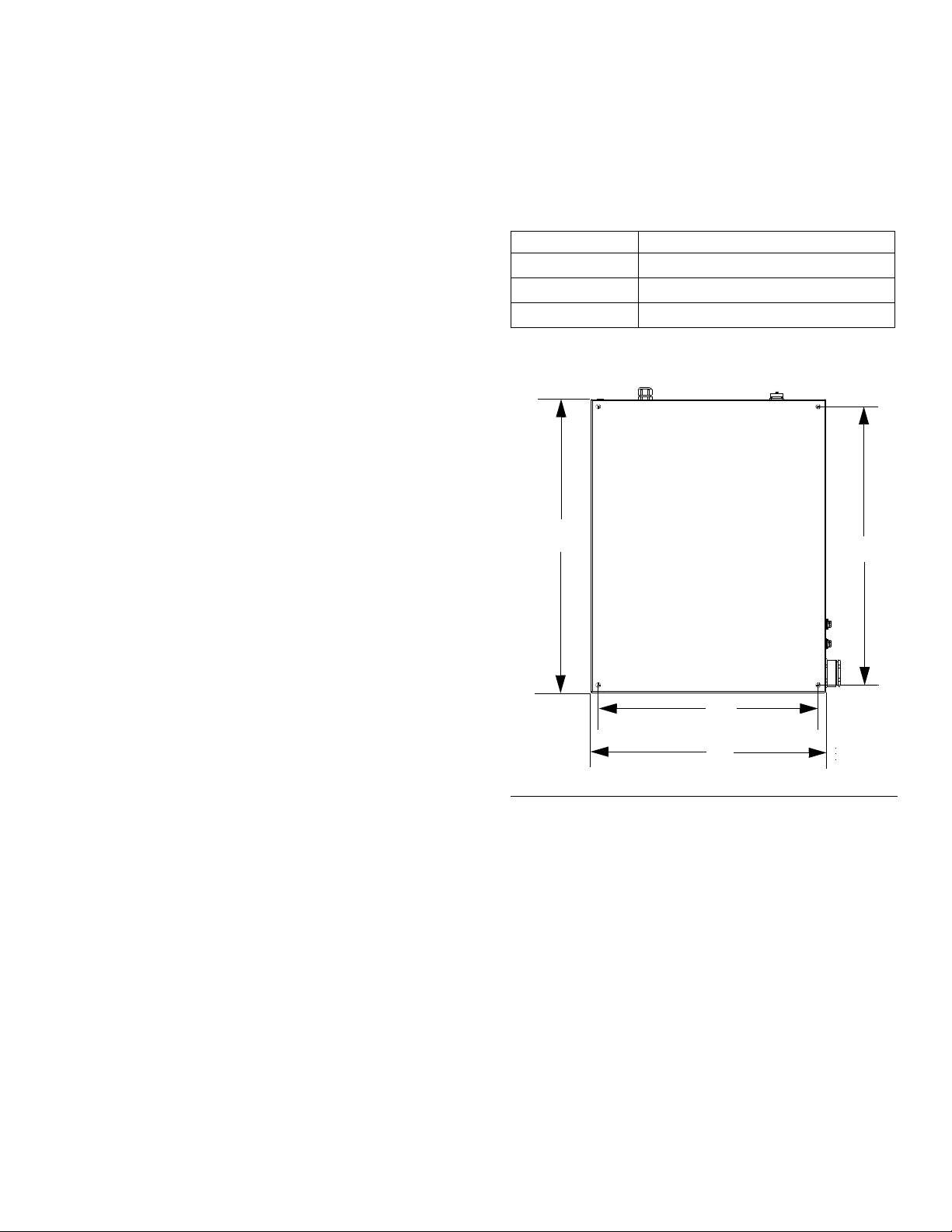

Installation

A

B

C

D

Install Control Center

Mount

Ensure the following criteria are met before mounting

the PGM control center:

• Select a location for the control center that allows

adequate space for installation, service, and use of

the equipment.

• For best viewing, the user interface should be

60-64 in. (152-163 cm) from the floor.

• Ensure there is sufficient clearance around the control unit to run cables to other components.

• Ensure there is easy access to an appropriate electrical power source. The National Electric Code

requires 3 ft. (0.91 m) of open space in front of the

control center.

• Ensure there is easy access to the power switch.

Secure the control center with appropriate size bolts

through the 0.50 in. (13 mm) diameter holes. See the

mounting dimensions in the following table and F

Control Center Assembly Measurement

A

B

C

D

24.0 in. (610 mm)

22.5 in. (572 mm)

30.0 in. (762 mm)

28.5 in. (724 mm)

IG. 5.

• Ensure the mounting surface can support the weight

of the control center and the cables attached to it.

F

IG. 5: Control Center Dimensions

3A5185B 13

Page 14

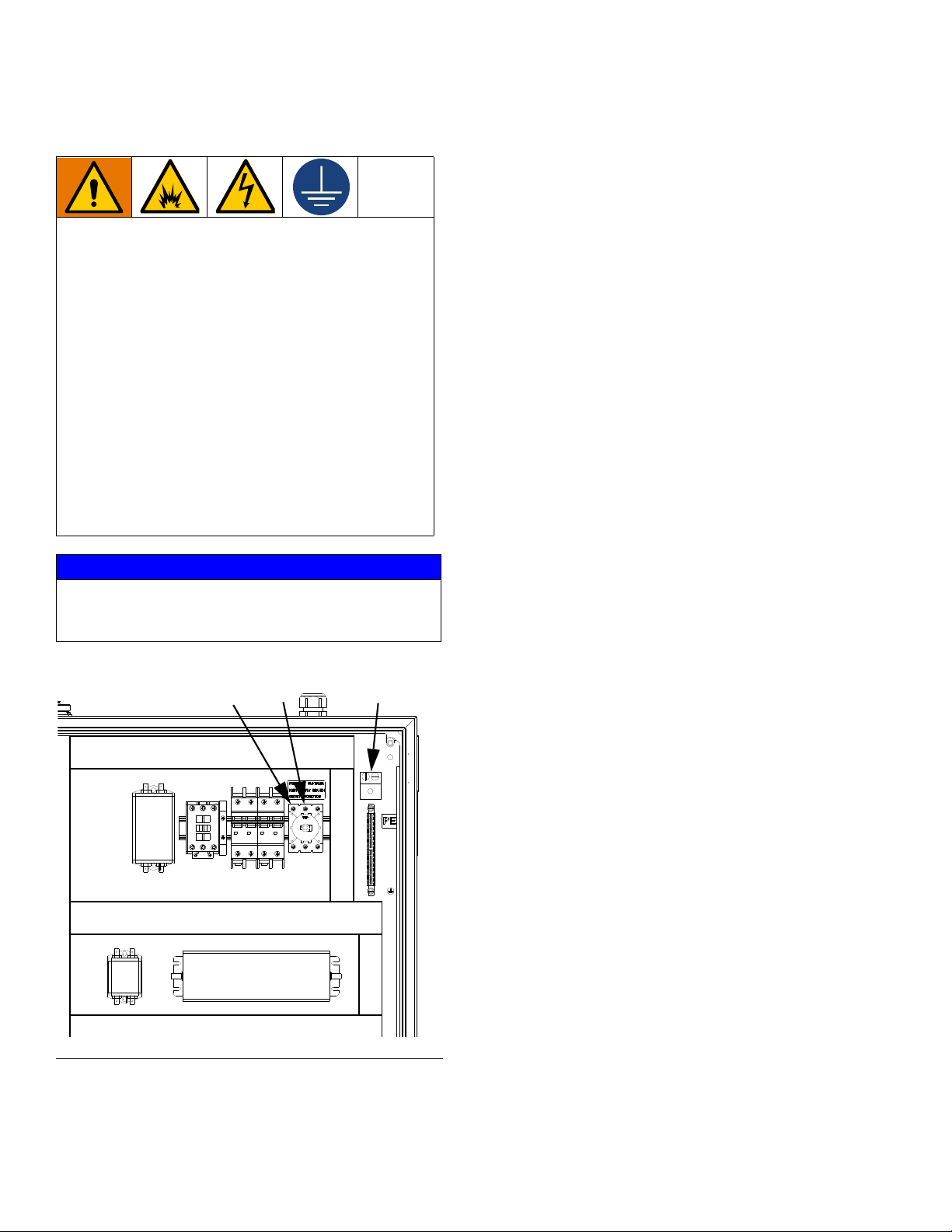

Installation

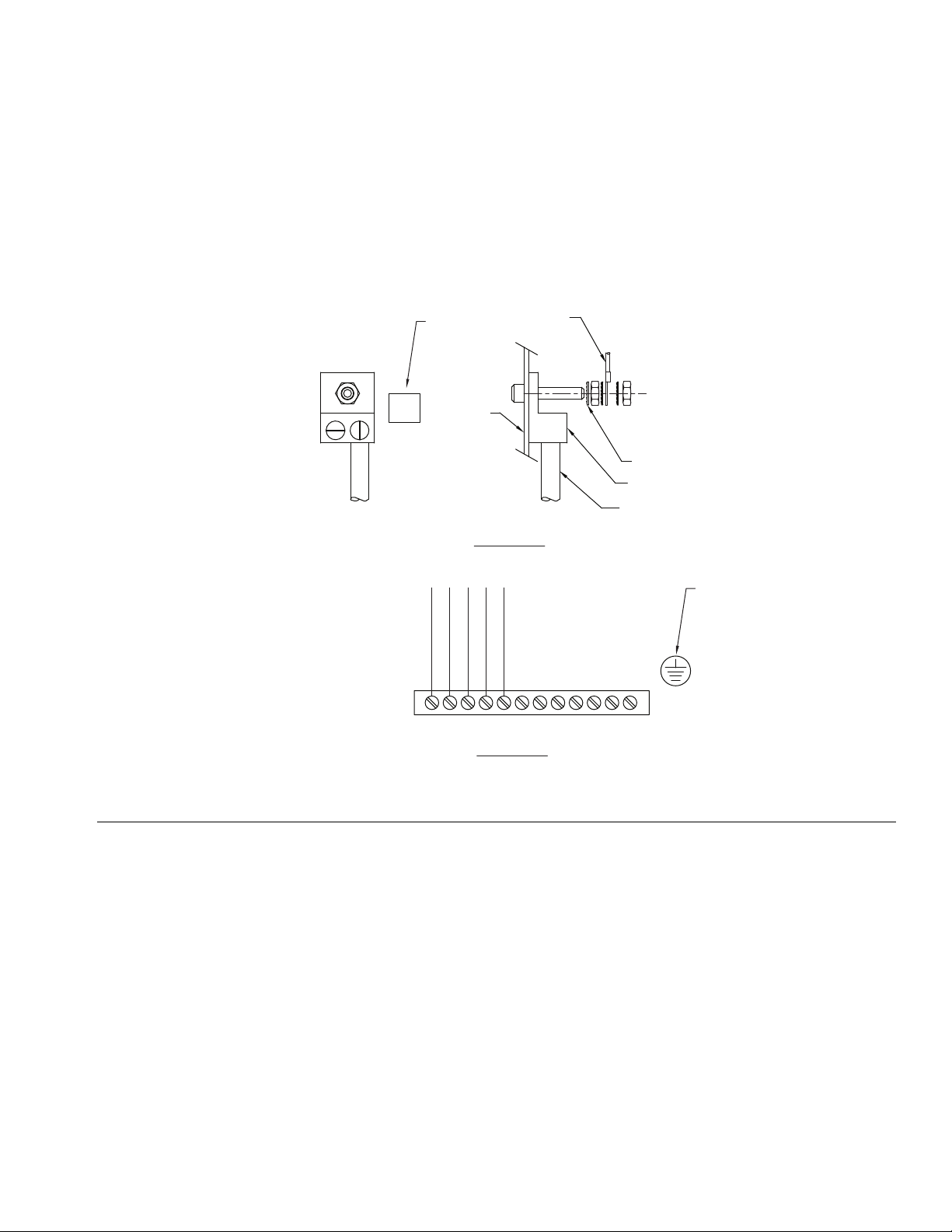

L2

L1

Ground

Electrical Connections

Follow these precautions when grounding, connecting cables, connecting to a power source or making

other electrical connections.

To reduce the risk of fire, explosion, or electric

shock:

• The control center must be electrically connected

to a true earth ground; the ground in the electrical

system may not be sufficient.

• A qualified electrician must complete all grounding and wiring connections.

• For wiring, refer to F

Refer to your local code for the requirements for a

“true earth ground” in your area.

If power and grounding connections are not done properly, the equipment will be damaged and the warranty

voided.

IG. 6.

NOTICE

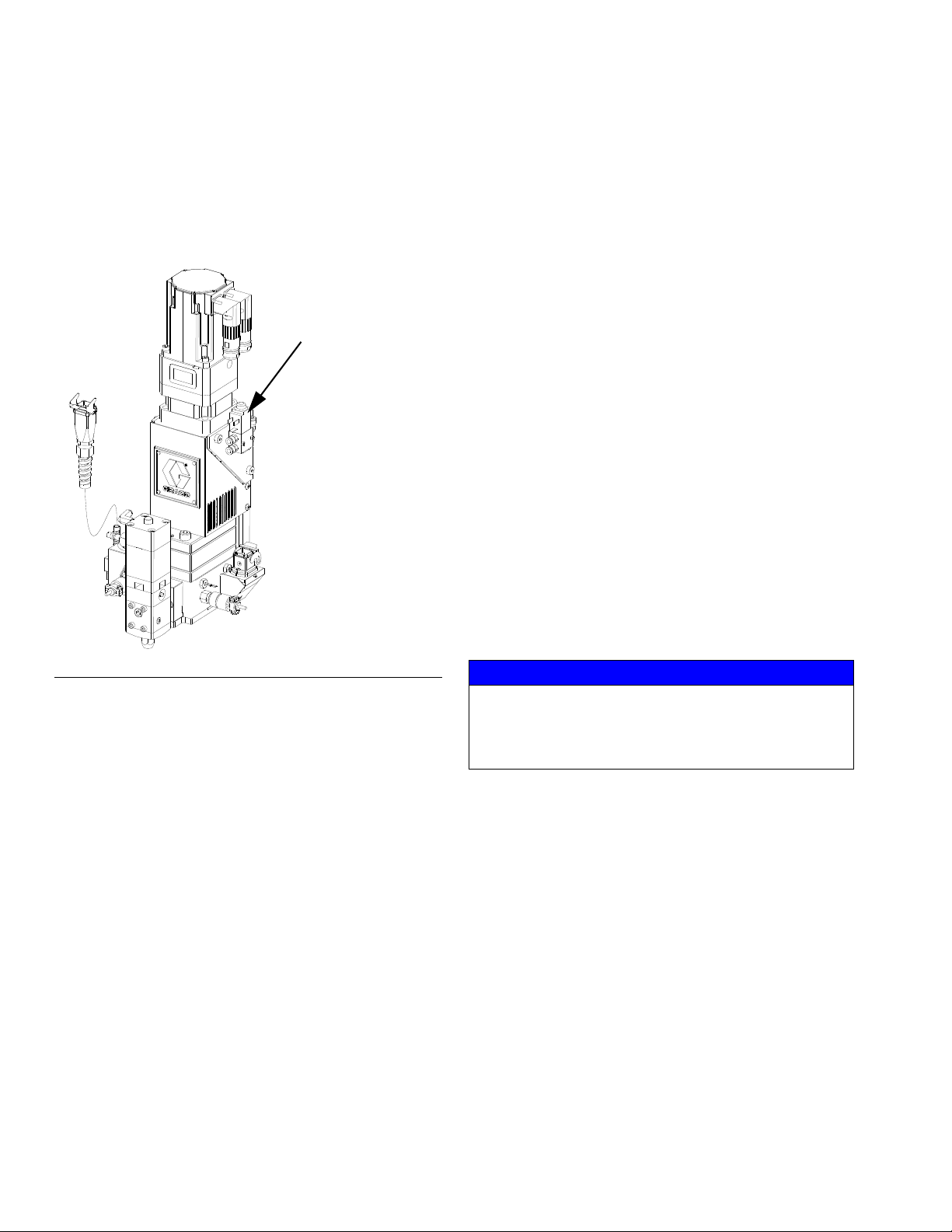

Install Gear Meter Assembly

To install the PGM metering assembly:

• Mount the gear meter assembly.

• Ground gear meter assembly.

• Connect the gear meter assembly to the control cen-

ter.

• Connect fluid lines and cables.

Mount

Before Mounting Assembly

• See component manuals for specific information on

component requirements. Information presented

here pertains to the PGM gear meter assembly only.

• Have all system and subassembly documentation

available during installation.

• Be sure all accessories are adequately sized and

pressure-rated to meet the system's requirements.

• Use only the Graco PGM gear meter assembly with

the Graco PGM control center.

Mount Assembly

F

IG. 6: 240 Vac Wiring

1. Select a location for the gear meter assembly. Keep

the following in mind:

• Allow sufficient space for installing the equipment.

• Make sure all fluid lines, cables and hoses easily reach the components to which they will be

connected.

• Make sure the gear meter assembly allows the

automation unit to move freely along all axis.

• Make sure the gear meter assembly provides

easy access for servicing its components.

14 3A5185B

Page 15

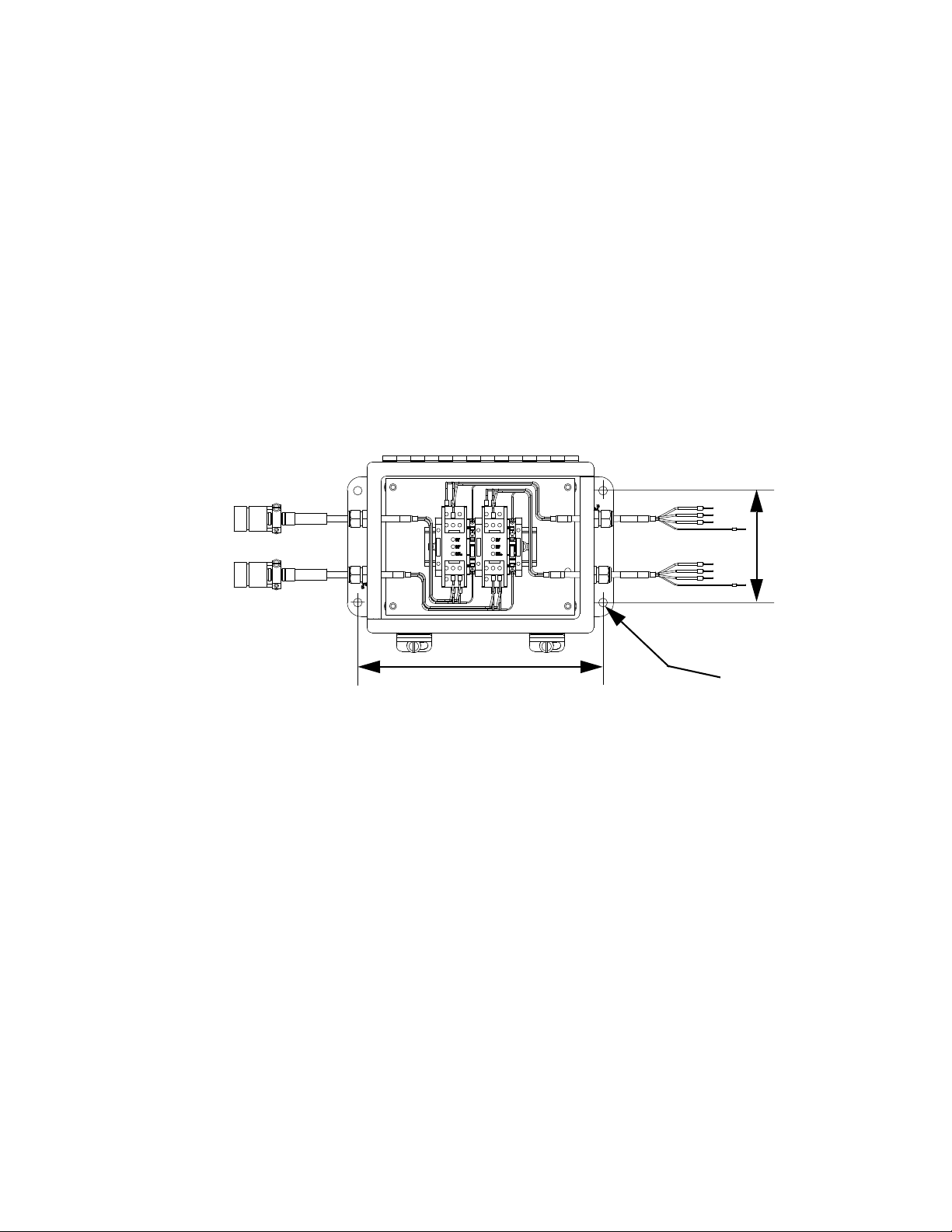

2. Mount and secure the gear meter assembly to the

C

B

6 cc Pump

20 cc Pump

A

A

D

C

B

0.238 in. (6.0 mm)

diameter

0.238 in. (6.0 mm)

diameter

automation unit (or other mounting surface) with

mounting plate. The mounting plate is tapped with

M10 x 1.5 bolts. Maximum bolt length through plate

is 0.75 in. (19 mm). See the mounting dimensions in

Table 4 and F

IG. 7.

Table 4: Gear Meter Assembly Measurement

6 cc Pump 20 cc Pump

Installation

A

B

C

D

2.00 in. (50.8 mm) 3.00 in. (76.2 mm)

5.00 in. (127 mm) 3.875 in. (98.43 mm)

2.375 in. (60.33 mm) 2.313 in. (58.75 mm)

NA 1.063 in. (27.00 mm)

F

IG. 7: Gear Meter Assembly Dimensions

3A5185B 15

Page 16

Installation

Grounding

The equipment must be grounded to reduce the risk

of static sparking and electric shock. Electric or static

sparking can cause fumes to ignite or explode.

Improper grounding can cause electric shock.

Grounding provides an escape wire for the electric

current.

NOTICE

If power and grounding connections are not done properly, the equipment will be damaged and the warranty

voided.

Gear Meter

Ground the gear meter assembly as instructed here and

in the individual component manuals. Make sure the

gear meter assembly and its components are installed

correctly to ensure proper grounding.

• For a remote mount dispense valve, connect a

fluid line between the gear meter outlet and the dispense valve. Shorter fluid lines (hoses) will provide

better fluid system response.

• See page 4 for list of inlet fittings.

FIG. 8: Inlet Fitting

Air and Fluid Hoses

For static dissipation, use only electrically conductive

hoses or ground the applicator / dispense valves.

Dispense Valve

Follow the grounding instructions in the dispense valve

manual.

Connect Fluid and Air Lines

NOTICE

Route all fluid and air lines carefully. Avoid pinching

and premature wear due to excessive flexing or rubbing. Hose life is directly related to how well they are

supported.

Follow the instructions in your separate component

manuals to connect air and fluid lines. The following are

only general guidelines.

• The PGM gear meter assembly should be installed

on the automation unit or in another appropriate

place, as close as practical to the dispense valve.

• Air must be clean and dry, between 60-100 psi

(0.41-0.68 MPa, 4.14-6.89 bar). Flush air line before

plumbing in air filter assembly (234967). Plumb in air

filter assembly near air drop site (upstream of PGM).

Adding an air regulator to this line will provide more

consistent dispense valve response times.

• Connect a 1/4 in. OD air supply line to the inlet port

on the PGM air supply inlet.

NOTE: To maximize system performance keep the

dispense hose length as short as the application

will allow.

16 3A5185B

Page 17

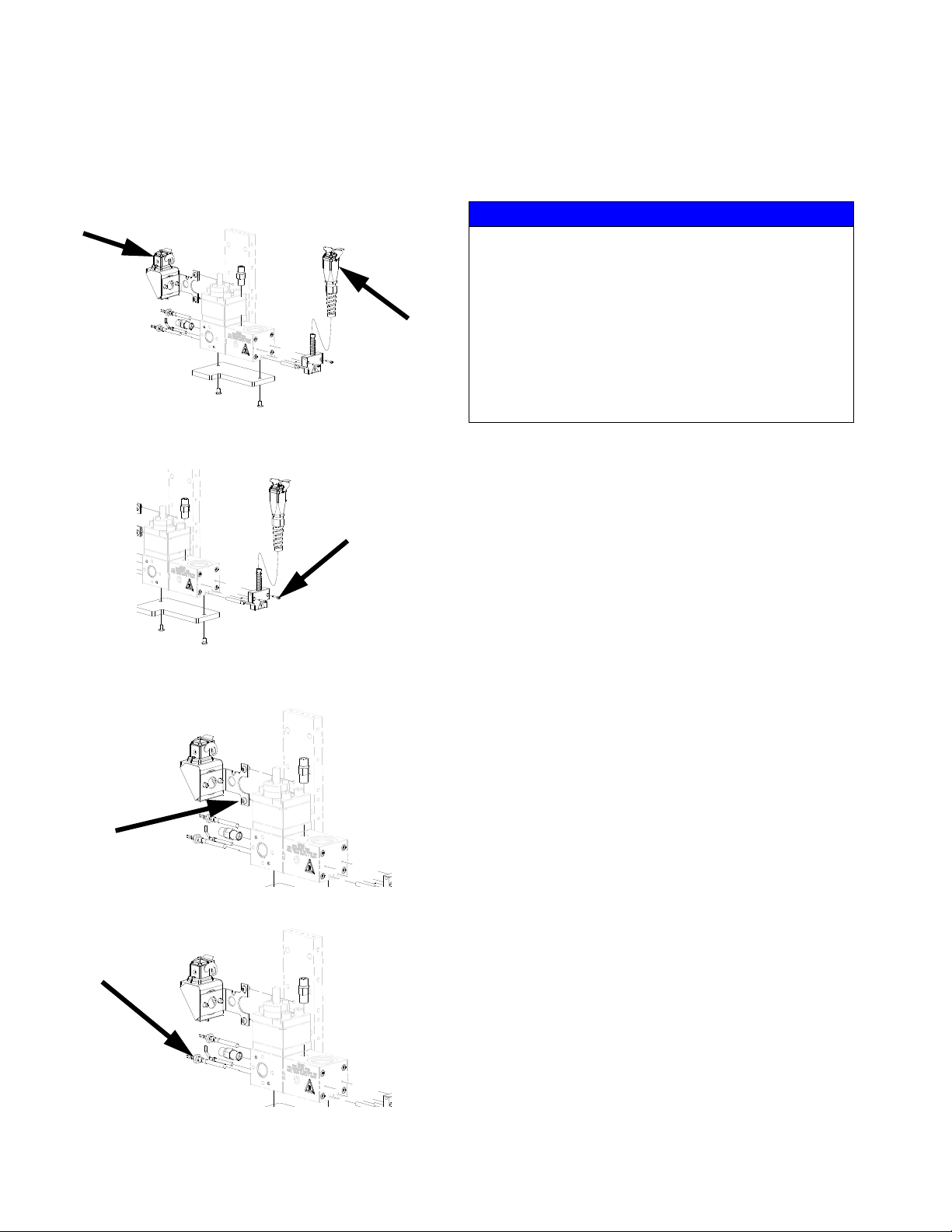

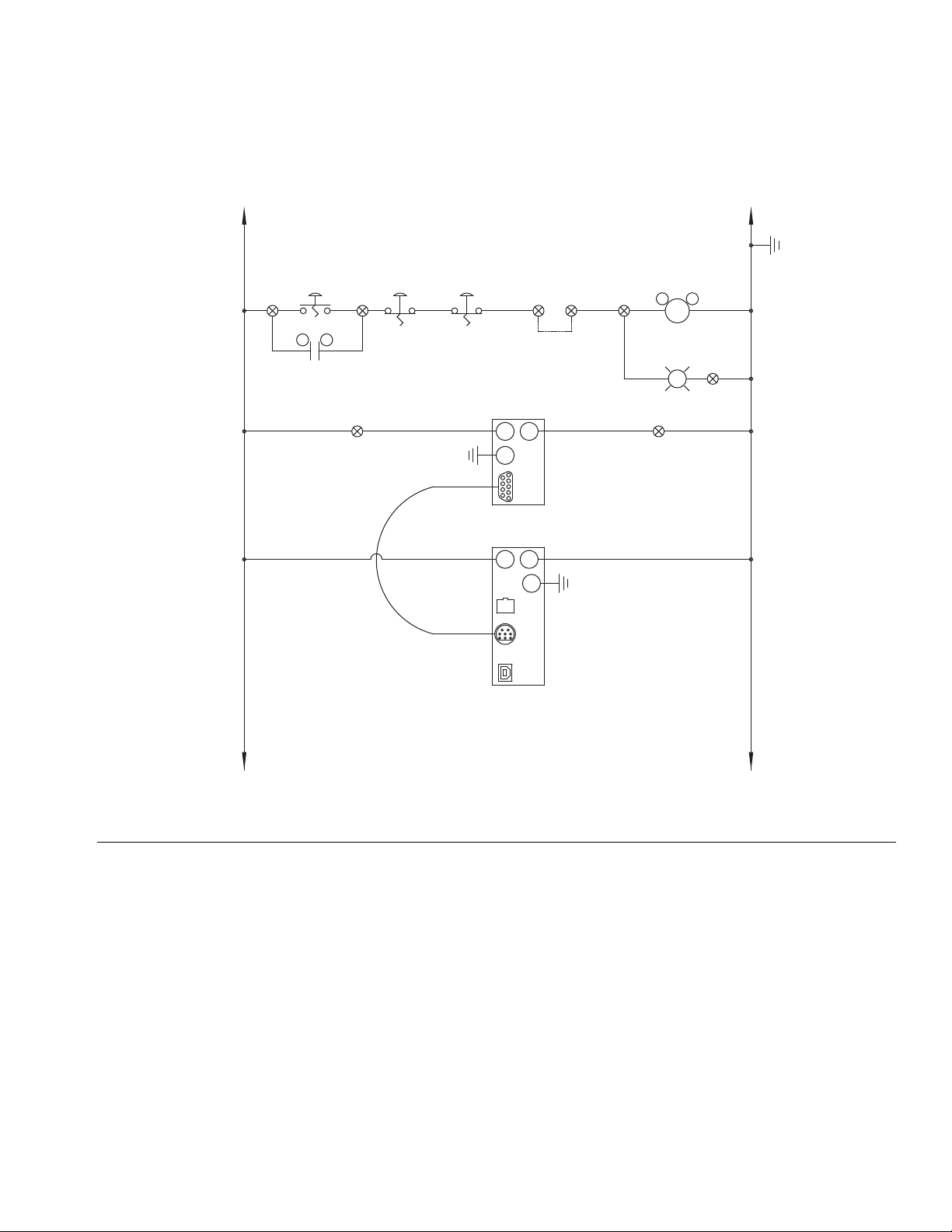

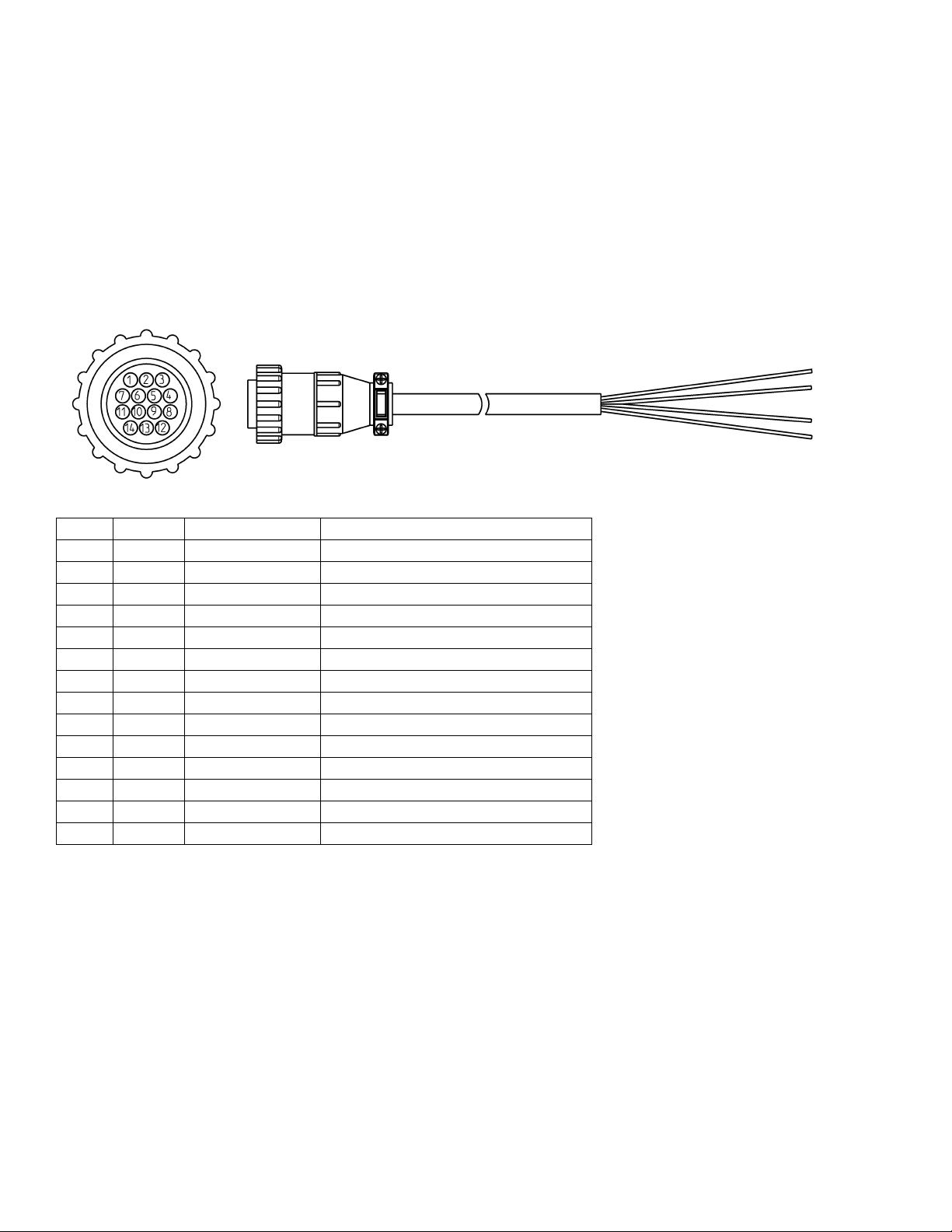

Install Cable Assemblies

NOTE: Models with

15 meter cables

include a remote

junction box to be

mounted in the field.

Installation

1. Connect servo motor power and feedback cables.

2. Connect pressure transducer cable.

3. Connect dispense valve solenoid cable.

4. Connect heat cables, if equipped, to Therm-O-Flow

controller.

F

IG. 9: Cable Installation Diagram

3A5185B 17

Page 18

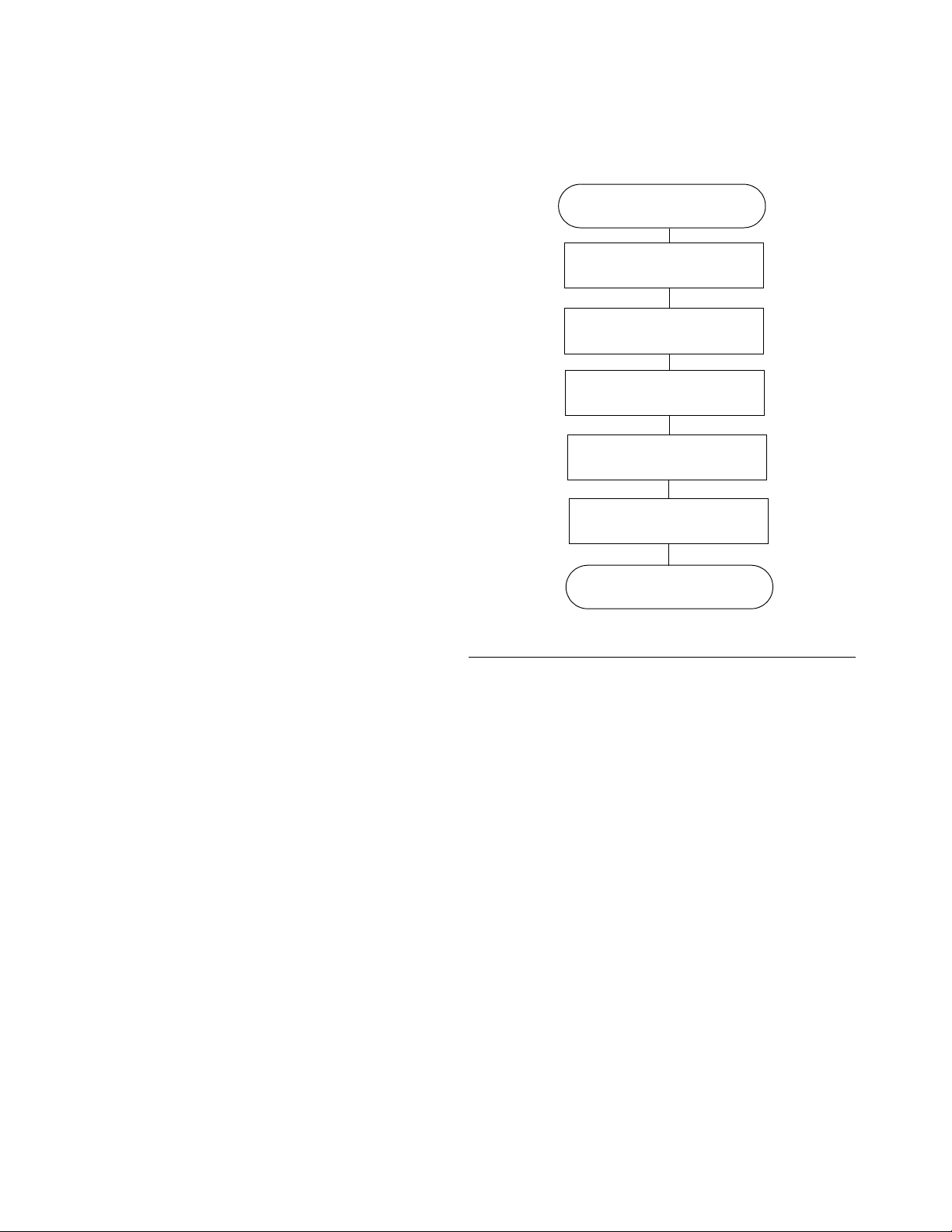

System Setup

System Setup

Configure Control Settings (page 19)

Configure Mode Settings (page 19)

Configure Delay Settings (page 20)

Adjust Pressure Sensors (page 20)

Configure Errors (page 21)

End System Setup

System Setup

Overview

The PGM system compensates for temperature, flow, or

pressure fluctuations. However, if there is a hardware

change on the supply system or the dispense material is

changed, the PGM system must be setup again.

After material is loaded into the supply system, set up

the PGM system using the Setup screens. F

shows the major system setup steps. The following subsections provide instructions to complete each setup

step. Once these steps are complete the module is

ready for operation.

NOTE: See Appendix A - User Interface Display on

page 82 for detailed operating instructions for each

user interface screen.

IG. 10

F

IG. 10

18 3A5185B

Page 19

System Setup

Configure Control Settings

Set the controls for the dispense source, how dispense

commands are sent, and auto mode settings.

1. From the Home screen, select the Setup icon

.

NOTE: The Setup screens are password protected.

Enter password “PGM17

screens.

”to access the following

Configure Mode Settings

Set the dispense mode (bead or shot). The bead scale

and pre-charge are also adjustable from the Mode Settings screen.

NOTE: See Appendix A - User Interface Display on

page 82 for a description of each feature.

1. With the system in setup mode,

igate to the Mode Settings screen.

press

to nav-

F

IG. 11

2. Select Display or Remote from the Command Value

Source Options.

3. If Command Value Source is set to Remote,

enter the Remote Max Flow (cc/min) for the 10 VDC

command source.

4. Select Enable or Disable for Run Mode Bead Adjust

Options. Default is Disable.

5. Select Display or Remote for Job End Mode

Options.

6. If Job End Mode is set to Display, press Job End

Delay Display field and enter desired delay time in

seconds.

FIG. 12

2. Select Bead or Shot for the Dispense Mode.

3. If Command Value Source is set to Display, enter

the flow rate in cc/min in the Fixed Command Flow

Rate. See Configure Control Settings for instructions to set the Command Value Source value.

4. If Shot Time is displayed, enter the Shot Time in

Seconds.

NOTE: Shot Time is only displayed if Dispense

Mode is set to Shot.

3A5185B 19

Page 20

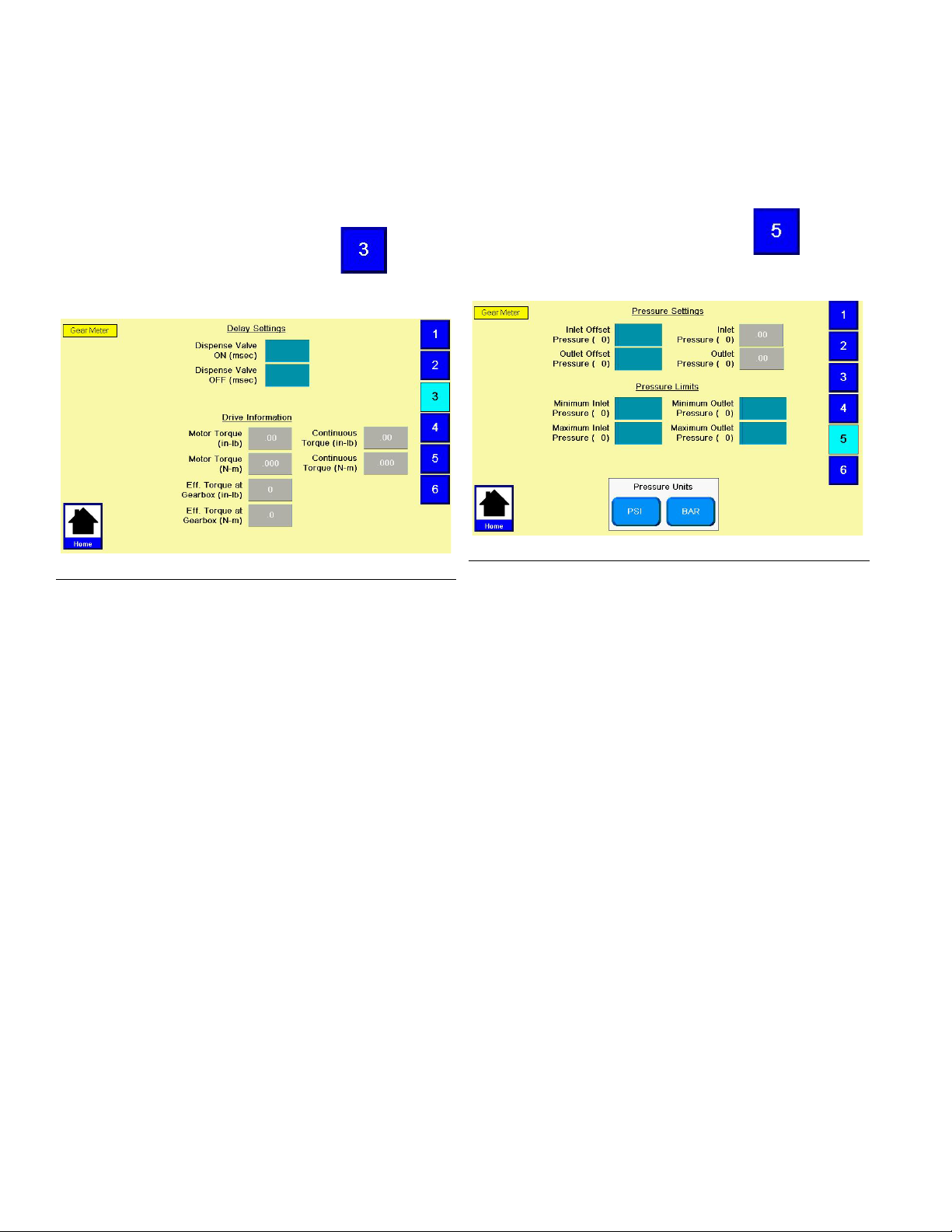

System Setup

Configure Delay Settings

Set on and off delays (in milliseconds) for the dispense

valve.

1. With the system in setup mode,

igate to the Delay Settings screen.

F

IG. 13

press

to nav-

Adjust Pressure Sensors

Set pressure offsets and pressure limits.

1. With the system in setup mode,

igate to the Pressure Sensor screen.

FIG. 14

press

to nav-

2. Press the On Delay field and enter a desired delay

value in milliseconds. Default is zero milliseconds.

3. Press the Off Delay field and enter e desired value

in milliseconds. Default is zero milliseconds.

2. Set the desired offset for the inlet and outlet pressures. Remove all pressure on the sensors, and

then adjust the offset so the measured value

reads 0.

NOTE: Offsets are set at the factory.

3. Set the desired minimum and maximum pressure

limits for the inlet and outlet.

NOTE: These values may need changed after the

system has gone through the Startup procedure.

20 3A5185B

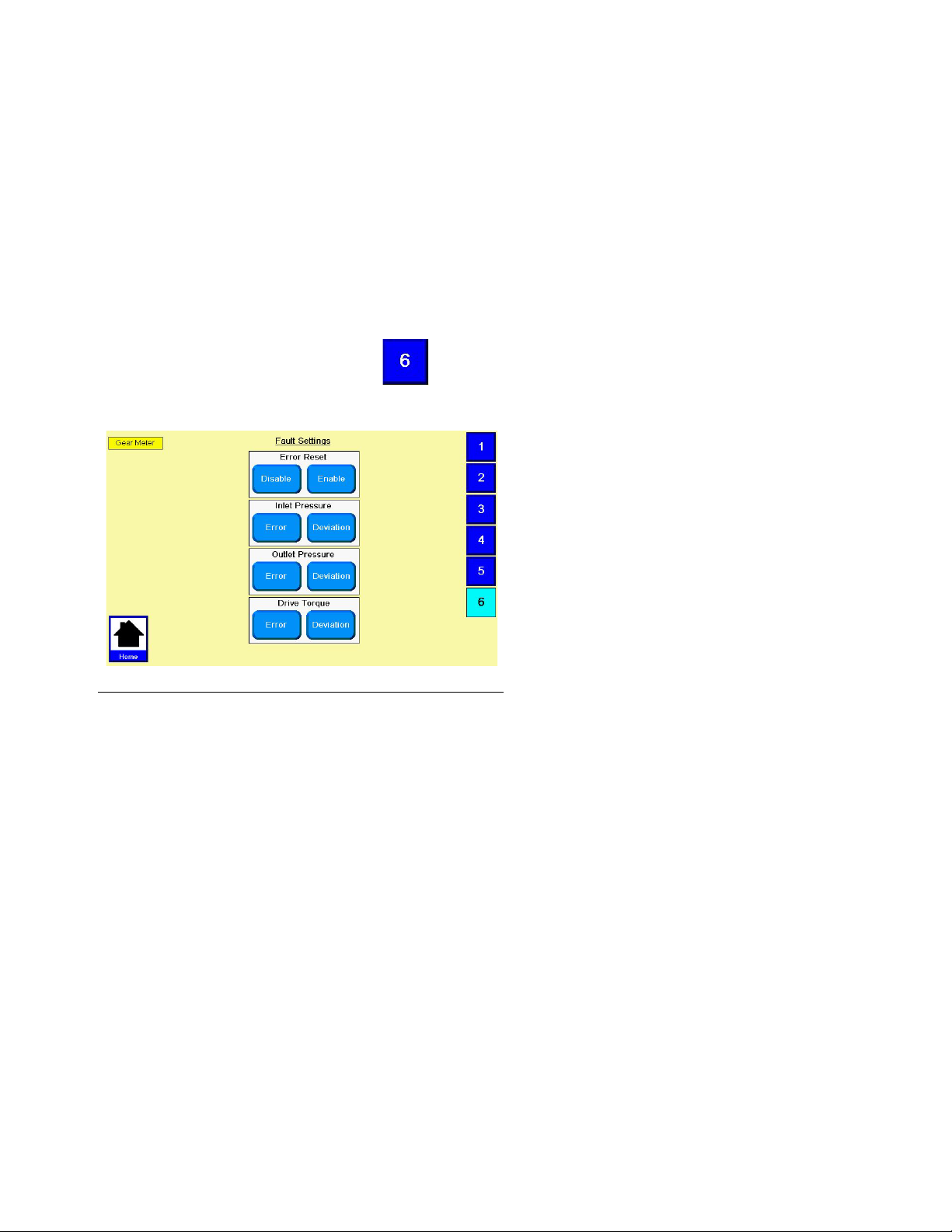

Page 21

Configure Errors

Set the error type (error or deviation) that will be issued

if the pressure or drive torque goes outside the set high

and/or low limits. See Appendix A - User Interface

Display on page 82 for information on the purpose of

each error type.

NOTE: When an alarm is set to Error the machine

will be disabled when the alarm occurs.

System Setup

1. With the system in setup mode,

igate to the Errors screen.

F

IG. 15

2. Select Enable or Disable for the Error Reset.

3. Select Error or Deviation for the Inlet Pressure.

4. Select Error or Deviation for the Outlet Pressure.

press

to nav-

5. Select Error or Deviation for the Drive Torque.

3A5185B 21

Page 22

Operation

Operation

Startup

Initial Startup

1. Ensure the PGM control enclosure and all of the

proper connections to and from the control enclosure have been made. Ensure fittings are tight.

2. Read and understand the Operation and User

Interface sections of this manual along with the

related manuals.

3. Continue startup with Step 2 in Standard Startup.

Standard Startup

1. Carefully inspect the entire system for signs of leakage or wear. Replace or repair any worn or leaking

components before operating the system.

2. Press the Stop button on the control enclosure.

3. Turn on air and electrical power to the system.

4. Turn on the main power to supply power to the

PGM.

Load Material

Before using the system, material must be loaded into

the supply system.

1. If this is a new installation, follow the Initial Startup

procedure. Otherwise, follow the Standard Startup

procedure.

2. Turn on the fluid supply pressure to the fluid inlet

block for the PGM.

3. Place the dispense valve over a waste container.

4. Navigate to the Maintenance screen. See Screen

Navigation Diagram on page 82 in the Appendix

A - User Interface Display section.

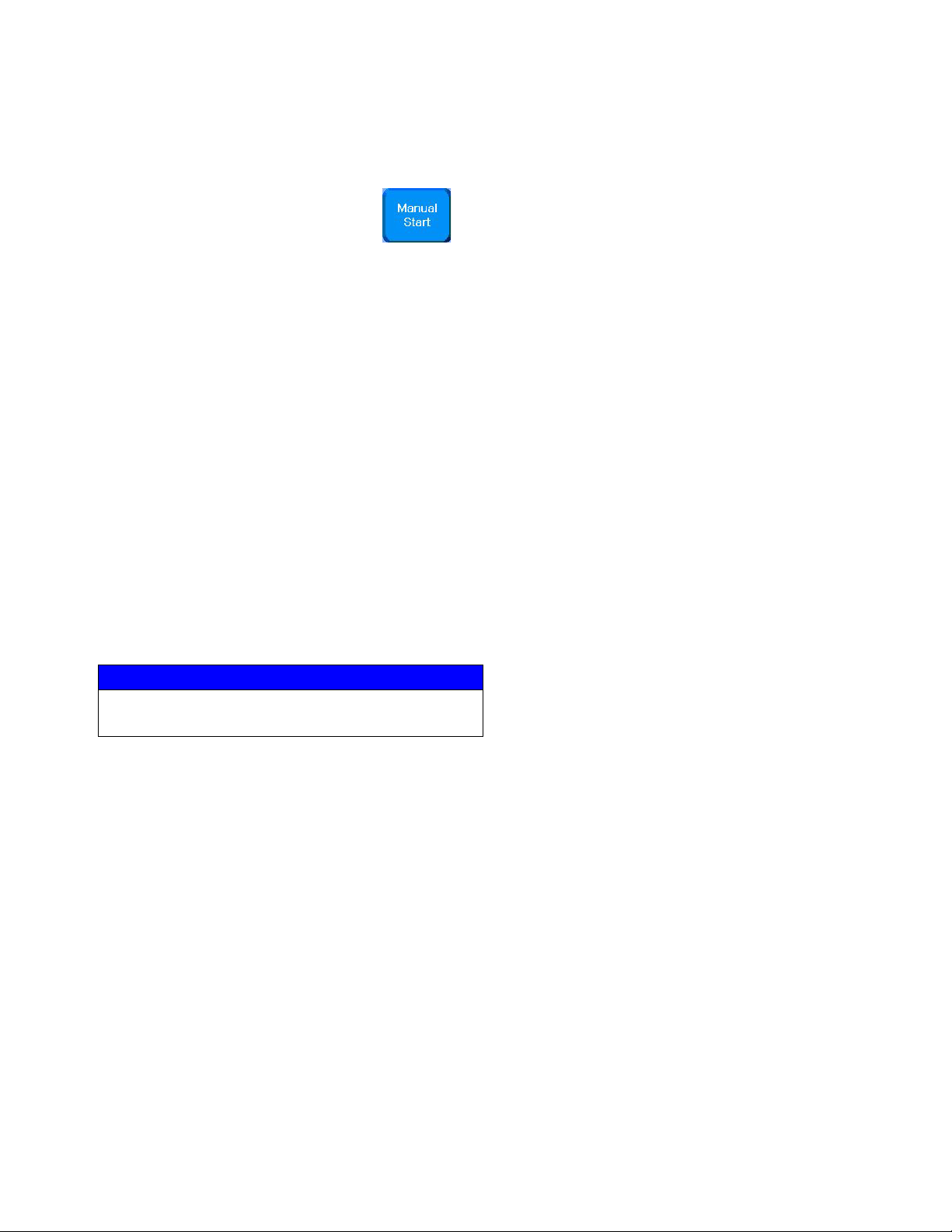

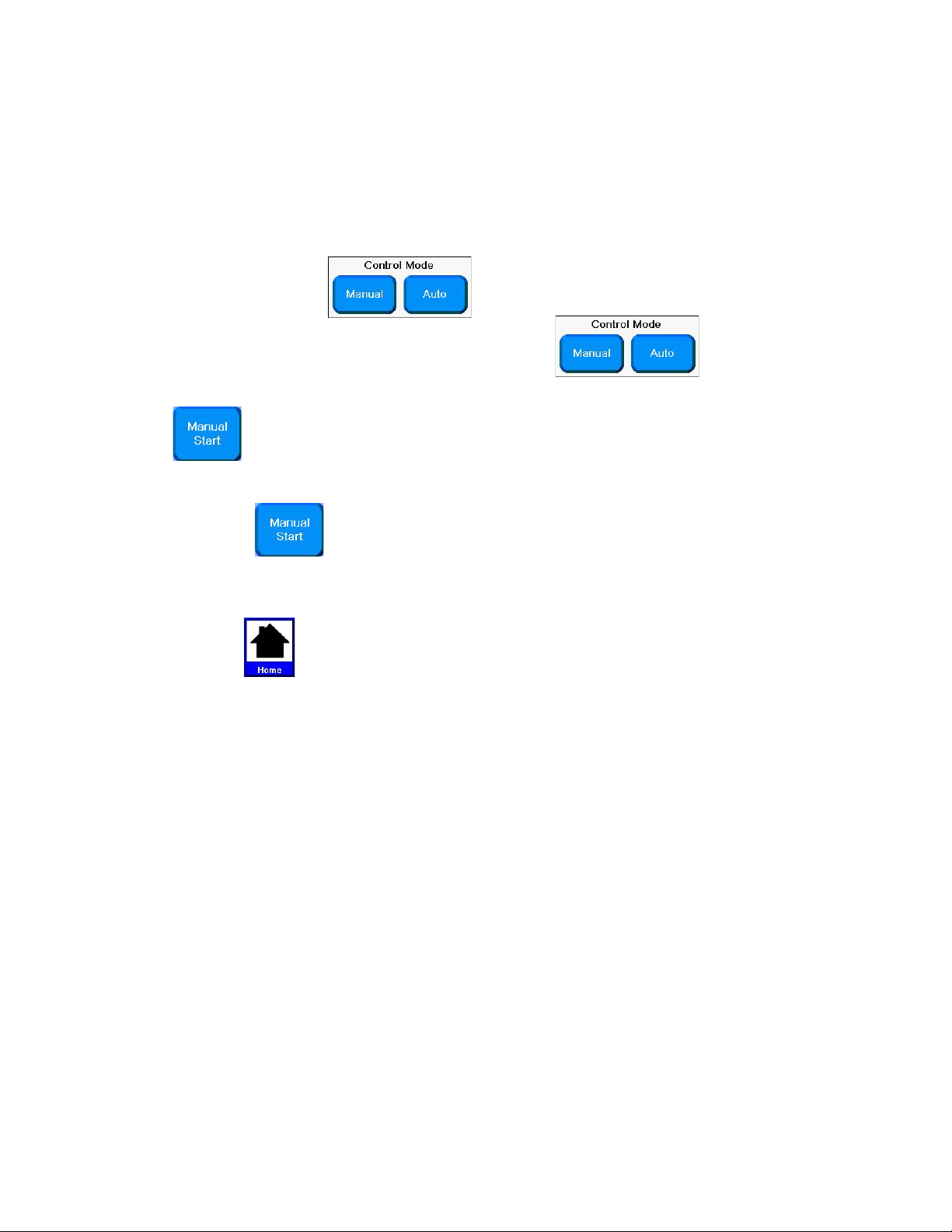

5. Select Manual Control Mode .

6. Enter the minimum flow rate to prime the system.

See the following table.

Pump Size

cc / revolution

612

20 40

Min Flow Rate

cc / minute

5. Check Interface Signals: If this is a new installation, power on each system input and verify that

each input is being received. See Appendix B - I/O

on page 98.

6. For heated systems, open the dispense valve over a

waste container while the system is heating up. This

will prevent a pressure build-up caused by fluids or

gases expanding from the heat.

7. Turn on the material supply system.

22 3A5185B

7. Press and hold the manual start button .

Dispense fluid until clean, air-free fluid flows from

the dispense valve.

NOTE: The manual purge button on the user-interface panel can be used to prime the system.

8. If desired, press to navigate to the Home

screen.

Page 23

Operation

Maintenance Mode Operation

Operating from maintenance mode enables the pump to

begin dispensing when the user presses .

Dispense parameters and duration depend on the

selected control.

Verify System Operation

Use maintenance mode to manually check the operation

of the PGM system components before switching over

to automation control (normal operation).

NOTE: Perform any of the following procedures

while in maintenance mode.

Set Inlet Pressure

The inlet pressure reading should be in the range of

300 psi (2.1 MPa, 21 bar) to 1500 psi (10.3 MPa,

103 bar). The recommended inlet pressure should be

500 psi (3.4 MPa, 34 bar) lower than the outlet pressure.

Dispense Weight Verification

1. From maintenance screen, select Shot mode.

2. Enter a 10 second shot time.

3. Enter the desired flow rate.

4. Record a minimum of 5 shot weights.

5. If shot weights are inconsistent check feed pressure

or reduce flow rate and repeat shot test.

NOTE: Regular weight checks are recommended to

ensure system is performing properly.

Follow steps in the supply system manual to set the inlet

pressure.

NOTICE

Excessive inlet pressure will cause accelerated wear

on the gear meter seals and the pump feed system.

Feed System Pressure Drop

During material flow, the PGM inlet pressure decreases.

The amount the pressure decreases is the amount of

pressure lost between the feed pump and the PGM inlet.

With high viscosity fluids, long line lengths, or small

diameter line sizes this pressure decrease can be thousands of psi (hundreds of bar). This means that the

static pump pressure is set much higher than the PGM

needs at its inlet. To prevent excessive static pressure

at the inlet of the PGM, a dynamic regulator is recommended on air motor supply air. During dispense the

normal pump regulator is active. During a stalled condition the dynamic regulator is active.

3A5185B 23

Page 24

Operation

Calibration

1. Perform Startup procedure, page 22. Verify all system components are at desired pressures and temperatures. Adjust as desired.

2. Navigate to the Calibrate screen. See Screen Navi-

gation Diagram on page 82 in the Appendix A User Interface Display section.

NOTE: PGM systems are calibrated at the factory. Per-

form calibration after pump maintenance or during troubleshooting (see page 29 for troubleshooting matrix).

3. Press the Enable Calibration button .

4. Weigh one disposable container and tare the scale.

5. Place container below dispense tip.

15. Enter the volume into the High Speed Calibration

Actual Volume input box .

16. Press the Done button .

17. If desired, press to navigate to the Main

screen.

6. Press the Start Low Speed Calibration

button .

7. Weigh the container.

8. Divide the weight of the dispensed material by the

specific gravity to determine the volume.

9. Enter the volume into the Low Speed Calibration

Actual Volume input box .

10. Weigh a second disposable container and tare the

scale.

11. Place container below dispense nozzle.

12. Press the Start High Speed Calibration

button .

13. Weigh the container.

14. Divide the weight of the dispensed material by the

specific gravity to determine the volume.

24 3A5185B

Page 25

Operation

Dispense from Maintenance Screen

1. Navigate to the Maintenance screen. See Screen

Navigation Diagram on page 82 in the Appendix

A - User Interface Display section.

2. Select Manual Control Mode .

3. Select Bead or Shot from the Manual Mode Option.

Manually Dispense Fluid

1. Press and verify the dispense valve

opens.

2. Continue to press as long as needed to

load or dispense material. Release to stop dispensing.

Automation Control (Normal) Operation

During automation control (normal operation) the PGM

automatically dispenses when it receives a command

from the automation unit.

NOTE: See Appendix B - I/O on page 98.

To enter Auto mode, select Auto (A) Control

Mode .

Typical Automation Cycle

In order for the system to run it must be in Auto mode.

Before a cycle begins the robot outputs should have the

following values:

• Job Complete: 0

• Dispense Trigger: 0

A typical cycle consists of the following dispensing

sequence.

3. If desired, press to navigate to the Home

screen.

1. The robot checks that Dispenser Ready signal is set

to On (High). If On, a cycle can begin.

2. If command source is set to Remote, robot sends

0-10 VDC Flow Rate signal.

NOTE: See Setup Screen 1 information in the

Appendix A - User Interface Display section beginning on page 82.

3. Robot turns on dispense trigger.

4. PGM turns on In Cycle.

5. Robot removes dispense trigger.

6. If Job Complete is set to Remote, robot turns on Job

Complete.

7. Robot removes Job Complete before starting the

next cycle.

NOTE: In the event of a deviation alarm, the Dispense Ready signal will remain on along with the

alarm signal. In the event of an error alarm, the Dispense Ready signal will turn off and the alarm signal

will remain on.

3A5185B 25

Page 26

Pressure Relief Procedure

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, follow the

Pressure Relief Procedure when you stop dispensing and before cleaning, checking, or servicing the

equipment.

1. Shut off the fluid supply to the PGM inlet block.

2. If equipped, place a waste container beneath the

fluid drain valve under the filter.

3. Place a waste container beneath the dispense

valve.

4. Slowly open the drain valve at each fluid filter to

relieve fluid pressure. Close valve when pressure

gauge reads zero.

5. Navigate to the Maintenance screen. See Screen

Navigation Diagram on page 82 in the Appendix

A - User Interface Display section.

6. Perform the following steps to perform a low flow

dispense:

a. From the Mode drop-down menu, select Bead

mode.

b. Enter the minimum flow rate for your system.

For example, 12 cc/min or 40 cc/min depending

on the size of the gear meter.

c. Press or the Purge button on the

control enclosure to begin the low flow dispense.

d. Continue to dispense until the inlet pressure on

the PGM is near zero.

e. Visually locate the plug installed at the back of

the inlet block.

f. Place a container under the plug and slowly

remove the plug to relieve remaining inlet pressure.

7. In maintenance mode, select Open Dispense Valve

Control mode , which opens

the dispense valve. Press the manual dispense but-

ton until fluid flow stops.

26 3A5185B

Page 27

Pressure Relief Procedure

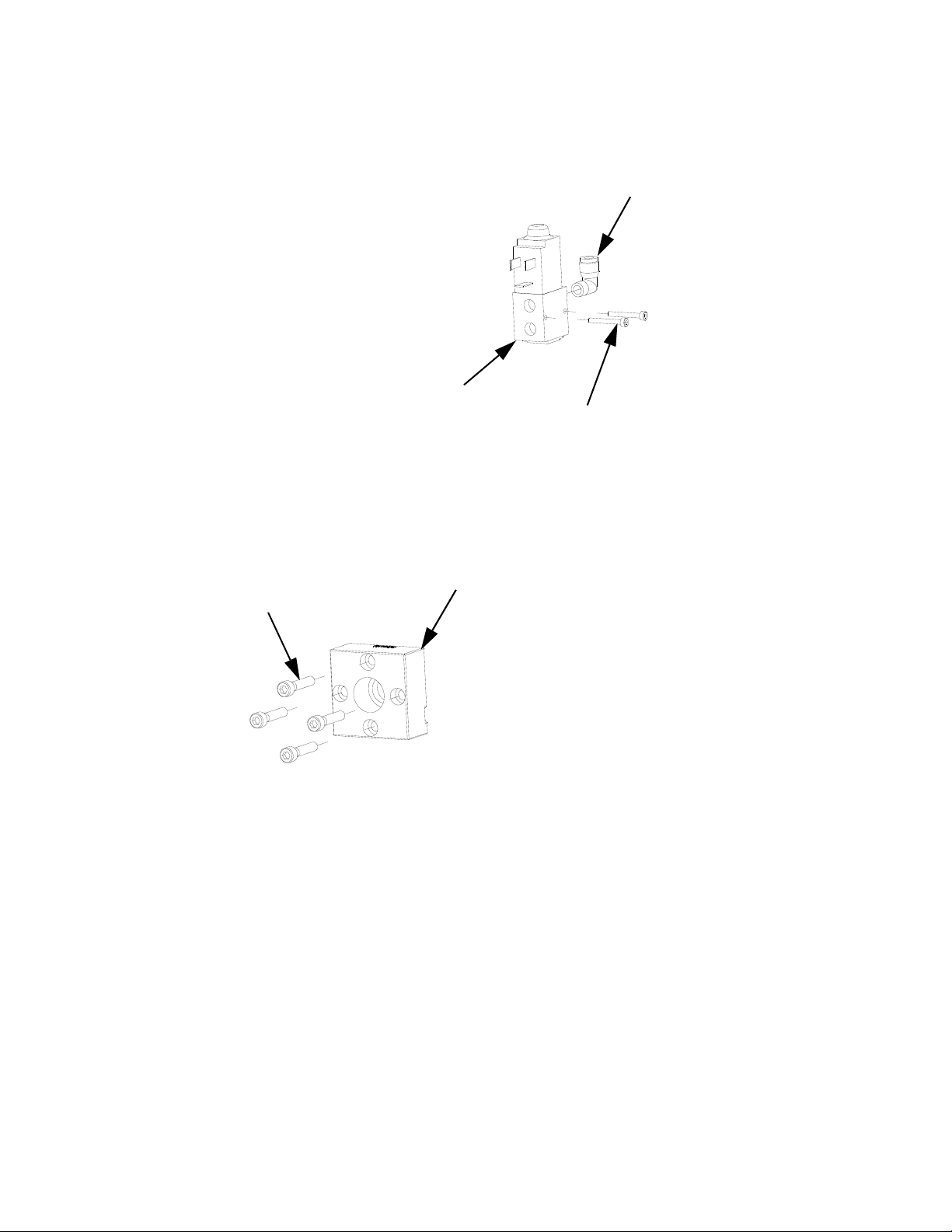

Dispense Valve

Air Solenoid

8. If the dispense device cannot be actuated from the

control center, refer to F

IG. 16 and perform the fol-

lowing steps to open the dispense valve and relieve

fluid pressure:

a. Manually actuate the plunger on the solenoid,

that opens the dispense valve to relieve fluid

pressure. Refer to F

IG. 16.

b. Continue actuating the plunger until all pressure

is purged from the system between the needle

and dispense valve before proceeding to the

next step.

9. If you suspect that a valve, hose, or dispense nozzle

is clogged or that pressure has not been fully

relieved:

a. Very slowly remove the dispense tip, clean the

orifice, and continue relieving pressure as

described in steps 6-8.

b. If this does not remove the obstruction, very

slowly loosen the hose end coupling to relieve

pressure gradually, then loosen the coupling

completely. Clear the valves or hose. Do not

pressurize the system until the blockage is

cleared.

10. Shut off power and air to the fluid supply system.

FIG. 16: Dispense Valve Air Solenoid

3A5185B 27

Page 28

Shutdown

Shutdown

1. Press the Stop button. See FIG. 17.

2. Shut off the material supply to the gear meter/meter.

3. Shut off heat to PGM. See related manuals section

for Therm-O-Flow manual and Accessory Heat Control.

4. For heated systems, open the dispense valve over a

waste container while the system is cooling down.

This will prevent a pressure build-up caused by fluids or gases expanding from the heat.

5. Shut off power and air to the fluid supply system.

6. Turn off the main power supply.

FIG. 17: Stop Button

28 3A5185B

Page 29

Troubleshooting

Troubleshooting

NOTE: Check all possible solutions in the chart

below before you disassemble the system.

Refer to Supply Systems manual for additional troubleshooting; refer to Related Manuals on page 3. Also

refer to Error Codes and Troubleshooting, page 32.

PGM Fluid Assembly

Problem Cause Solution

No Inlet Pressure No air pressure on supply system Verify supply system pressure

Leak in supply system Check supply lines and connections

False signal being sent to control Check inlet pressure sensor output;

verify that it corresponds to zero

pressure; replace sensor and/or

amplifier

Leak at PGM drive shaft Replace drive shaft seals

No Outlet Pressure Dispense motor not rotating Refer to Error code section of the

manual; Cycle power and perform

startup

Dispense Off delay set too long Verify Dispense valve delays in

setup screens

Dispense valve solenoid stuck

open

False signal being sent to control Check outlet pressure sensor out-

High Outlet Pressure Blocked dispense tip Replace dispense tip

Flow rate too high for application decrease flow rate

Dispense valve On delay set too

long

Dispense valve solenoid stuck

closed

3A5185B 29

Verify function of dispense valve

put; verify that it corresponds to zero

pressure; replace sensor and/or

amplifier

Verify Dispense valve delays in

setup screens

Verify function of dispense valve

Page 30

Troubleshooting

Dispense pattern too light Supply pressure too low Verify inlet pressure needed for flow

rate

Flow rate too high for application Perform dispense weight verifica-

tion, see Calibration procedure on

page 24; Lower flow rate and repeat

Measured flow does not match

command

Supply pressure too low Verify inlet pressure needed for flow

rate

Flow rate too high for application Perform dispense weight verifica-

tion, see Calibration procedure on

page 24; Lower flow rate and repeat

Gear meter is not calibrated Perform calibration; Perform weight

verification, see Calibration procedure on page 24

Gear meter is worn or damaged Perform weight verification, see Cal-

ibration procedure on page 24; if

weights are not repeatable repair or

replace gear meter

Dispense Valves

Problem Cause Solution

Valve not opening Air not getting to open port Verify air pressure solenoid

No Dispense Trigger signal from

automation unit

Valve not shutting off Air not getting to close port (except

AutoPlus valve)

Dispense Trigger signal from automation unit is on

Sluggish open/close Air pressure low Verify air pressure is above 60 psi

Needle/seat worn Rebuild valve; replace needle/seat

Pressurized material past the valve

shut-off is escaping

Material leaks from back of valve Shaft seal is worn Rebuild valve; replace seals

Air leaks from dispense valve Loose air connections Check air connections; tighten if

Worn piston o-ring Rebuild valve; replace piston o-ring

Check input from automation unit

Verify air pressure to solenoid

Verify solenoid operation

Verify air line routing and connections

Check input from automation unit

(0.4 MPa, 4 bar)

Reduce running pressure

Reduce nozzle length

Increase nozzle orifice size

necessary

30 3A5185B

Page 31

Errors

Access the Alarm

View screen

Errors

View Errors

Errors can be viewed from the Home screen or from the

Alarm View screen.

There are three levels of errors: alarms, deviations, and

advisories. Alarms are critical and require immediate

correction; therefore the system automatically shuts

down. Deviations are important and require attention but

not immediately. Advisories are not critical but still

require attention.

NOTE:

• Errors set the dispenser ready signal LOW.

Clear Errors and Reset Control Unit

From the Alarm View screen, perform the following

steps to clear an error before restarting the control unit:

1. Press Acknowledge All List

2. Press Clear All Alarms

NOTE: Acknowledging alarms does not clear them.

NOTE: See the Configure Errors section on page 21.

• Advisories and deviations do not set the dispenser

ready signal LOW.

Diagnose Errors

See Error Codes and Troubleshooting for valid error

codes, possible causes, and solutions.

3A5185B 31

Page 32

Errors

Error Codes and Troubleshooting

Error

No.

1 Control Power Off Control power has

2 Inlet Pressure Devia-

3 Inlet High Pressure

4 Inlet Low Pressure

5 Outlet Pressure Devi-

Error Name Error Description

PGM Control Errors

been removed

Inlet material pres-

tion

Error

Error

ation

sure outside limits

Inlet material pressure above max limit

Inlet material pressure below min limit

Outlet material pressure outside limits

Error

Type

Advisory Stop button or

Deviation Feed pressure set

Alarm Feed pressure too

Alarm Feed pressure too

Deviation Back pressure is

Cause Solution

E-stop

too high or too

low. Limits are not

set correctly

high. Limits are

not set correctly.

low. Limits are not

set correctly.

too high or too

low. Limits are not

set correctly.

Press Control Power

button

Verify pressure limits

in Setup Screen 5.

Verify supply pressures during dispense.

Verify pressure limits

in Setup Screen 5.

Verify supply pressures during dispense.

Verify pressure limits

in Setup Screen 5.

Verify supply pressures during dispense.

Verify pressure limits

in Setup Screen 5.

Verify outlet pressures during dispense.

6 Outlet High Pressure

Error

7 Outlet Low Pressure

Error

8 Inlet Max Pressure

Fault - Relieve Pressure and Cycle Power

Outlet material pressure above max limit

Outlet material pressure below min limit

Inlet material pressure exceeds max

rated pressure

Alarm Back pressure is

too high. Limits

are not set correctly.

Alarm Outlet pressure

too low. Limits are

not set correctly.

Alarm Feed system pres-

sure is set too

high. Pressure

sensor damaged.

Verify pressure limits

in Setup Screen 5.

Verify outlet pressures during dispense.

Verify pressure limits

in Setup Screen 5.

Verify outlet pressures during dispense.

Perform pressure

relief procedure.

Change inlet supply

pressure. Cycle

power; Verify Pressure sensor is working properly.

32 3A5185B

Page 33

Errors

Error

No.

9 Outlet Max Pressure

10 Drive Torque Devia-

Error Name Error Description

Outlet material presFault - Relieve Pressure and Cycle Power

sure exceeds max

rated pressure

Motor exceeds contion

tinuous rated torque

11 Drive Torque Error Motor exceeds con-

tinuous rated torque

12 Drive Peak Torque

Error - Drive disabled,

Motor exceeds peek

torque rating

Cycle Power

Error

Type

Cause Solution

Alarm Dispense valve

not opening. Flow

rate too high.

Material not at

temperature.

Deviation Flow rate too high.

Dispense Valve

not opening.

Material not at

temperature.

Alarm Flow rate too high.

Dispense Valve

not opening.

Material not at

temperature.

Alarm Flow rate too high.

Dispense Valve

not opening.

Material not at

temperature.

Perform pressure

relief procedure;

Cycle Power; Verify

Dispense valve function; Perform weight

check verification;

Reduce flow rate.

Lower flow rate;

reduce outlet pressure drop; Verify

material temperature.

Lower flow rate;

reduce outlet pressure drop; Verify

material temperature.

Cycle Power Lower

flow rate; reduce outlet pressure drop;

Verify material temperature.

13 Pre-Charge Timeout Pre-Charge Pressure

was not reached

after dispense

14 High Pressure Inter-

lock OFF

15 Dispense Valve Open

(Auto Default)

16 Calibration is enabled

complete calibration

Pressure limit is

bypassed

Dispense valve is

open

Calibration mode

enabled

procedure

17 Drive Fault, Cycle

Power

18 Calibration out of

range

Motor drive is dis-

abled

Calibration values

are out of range or

flow rate is too low

for current K factor

Advisory Pre-Charge value

not set correctly.

Advisory Pressure sensors

are disabled.

Advisory Dispense valve

open button has

been selected.

Advisory Calibration

enabled selected

from the calibrate

screen.

Alarm Various condi-

tions.

Advisory Improper calibra-

tion, flow rate too

low, or pump

wear.

Set Pre-Charge to

zero. Monitor outlet

pressure; Adjust

Pre-Charge pressure.

Contact Graco customer service.

From the Maintenance screen select

Dispense valve Auto.

Complete calibration

procedure.

Cycle Power verify

motor torque during

dispense.

Perform calibration

procedure.

3A5185B 33

Page 34

Maintenance

Maintenance

Prior to performing any maintenance procedures, follow

the Pressure Relief Procedure on page 26.

Maintenance Schedule

The following tables list the recommended maintenance procedures and frequencies to operate the equipment

safely. The maintenance is divided between mechanical and electrical tasks. Maintenance must be performed by

trained personnel per this schedule to assure safety and reliability of the equipment.

Mechanical

Operator Maintenance Person

Task Daily Weekly Monthly

Inspect system for leaks

Depressurize fluid, after opera-

tion

Remove heat from system,

after operation

Inspect filter (234967) bowls

and drain

Check hoses for wear

Check/tighten fluid connections

Check/tighten air connections

Lubricate dispense valves*

Replace gear meter seals

Rebuild dispense valve*

Replace air filter

Replace Solenoid

Replace gear meter drive shaft

Replace gear head

* Check component manual for more detailed maintenance information.

3-6

months

or

125,000

cycles

18-24

months

or

500,000

cycles

36-48

months

or

1,000,000

cycles

As

Required

Electrical

Task Weekly

Check cables for wear

Verify cable connections

Verify operation of “System Stop” button

* Check Component Manual for more detailed maintenance information.

34 3A5185B

Page 35

Repair

Repair

NOTE: Refer to Parts section beginning on page 49

for part reference number identification.

Gear Meter Assembly

This section describes how to remove and replace components on the gear meter assembly.

Prepare Gear Meter Assembly for Repair

Replace Servo Motor or Gear Head

Replacing either the Servo Motor or Gear Head requires

the following procedure.

Remove Servo Motor and Gearhead

1. Prepare Gear Meter Assembly for Repair,

page 35.

2. Remove support gussets (9, 1106).

3. Remove bolts (1, 1103) connecting top mounting

plate (8, 1105) to vertical mounting plate (10, 1107).

4. Remove servo motor, gear head, and top plate.

Coupling (303, 1203) will separate.

5. Remove coupling half.

6. Remove 4 screws (3, 1110) that mount to plate to

gear head.

7. Remove gear head coupling covers (302a, 1202a).

8. Loosen gearhead coupling on gearhead shaft.

FIG. 18

1. Perform Pressure Relief Procedure, page 26.

2. Disconnect main power at the control box.

3. If present, remove power from the heat control.

4. Remove servo power cable and servo feed back

cable. See gear meter assembly parts; see Parts

section starting on page 49.

5. Remove heat cables.

6. Remove pressure transducer cables and dispense

valve cable.

7. Remove supply air pressure from solenoid.

8. Remove front guard.

9. Remove material hoses if necessary.

9. Remove 4 bolts connecting servo motor to gearhead.

10. Remove servo motor from gear head.

3A5185B 35

Page 36

Repair

SEE DETAIL

A

DETAIL

A

SCALE

3/2

Install Servo Motor or Gearhead

1. Remove key from motor shaft.

NOTICE

Use caution when handling servo motor to prevent

damage. Do not use tools that could cause damage.

2. Slide the gear head. bushing into the drive coupling

and align slots in drive coupling and bushing. See

IG. 19.

F

FIG. 19

3. Rotate the drive coupling to align clamping bolts

with access holes.

4. Place motor on work surface with motor shaft facing

NOTE: Orient servo motor so that the motor connections do not interfere with material inlet hose.

9. Install gussets with shoulder bolts (5, 1104).

straight up then mount the gear head. Mounting the

gear head in any other orientation will usually lead

to misalignment and excessive noise.

Remove Coupling

1. Prepare Gear Meter Assembly for Repair,

5. Pre-torque drive coupling to 0.4 N•m (4 in-lb).

6. Bolt gear head to the motor with fasteners provided.

7. Final toque drive coupling to 8.5 N•m (76 in-lb) in

three steps increasing torque each time.

8. Do not tighten coupling to gear head output shaft

page 35.

2. Remove support gussets (9, 1106).

3. Remove bolts (1, 1103) connecting top mounting

plate (8, 1105) to vertical mounting plate (10, 1107).

4. Remove servo motor, gear head, and top plate.

until drive assembly is mounted in frame.

36 3A5185B

Page 37

Repair

Gap

5. Loosen clamping bolts on each side of coupling and

remove coupling.

NOTE: Pump shaft key may fall out during coupling

removal. Secure pump shaft key until coupling is

replaced.

Install Coupling

5. Separate coupling until proper gap is created. F

21. See the following table.

Pump Size

cc / revolution Gap (mm)

618

20 20

FIG. 21

IG.

FIG. 20

1. Slide coupling onto gear head output shaft. Tighten

coupling bolt just enough to hold it’s position.

2. Align pump shaft key and slide coupling onto pump

shaft. Tighten coupling bolt just enough to hold it’s

position.

3. Attach servo motor, gear head, and top plate to

pump assembly. See F

IG. 20.

4. Slide drive coupling so it is evenly spaced between

pump and gearhead. Both sides of coupling should

slide easily on each shaft. If coupling does not slide

freely, loosen pump bolts (103, 1303) and align

pump until coupling moves freely. Tighten pump to

pump block to 430-480 in-lb (48.58-54.23 N•m).

6. Tighten coupling bolts to the following torques:

Pump Size

cc / revolution

Torque,

in-lb (N•m)

6 132 (15)

20 309 (35)

7. Install gussets with shoulder bolts (5, 1104).

3A5185B 37

Page 38

Repair

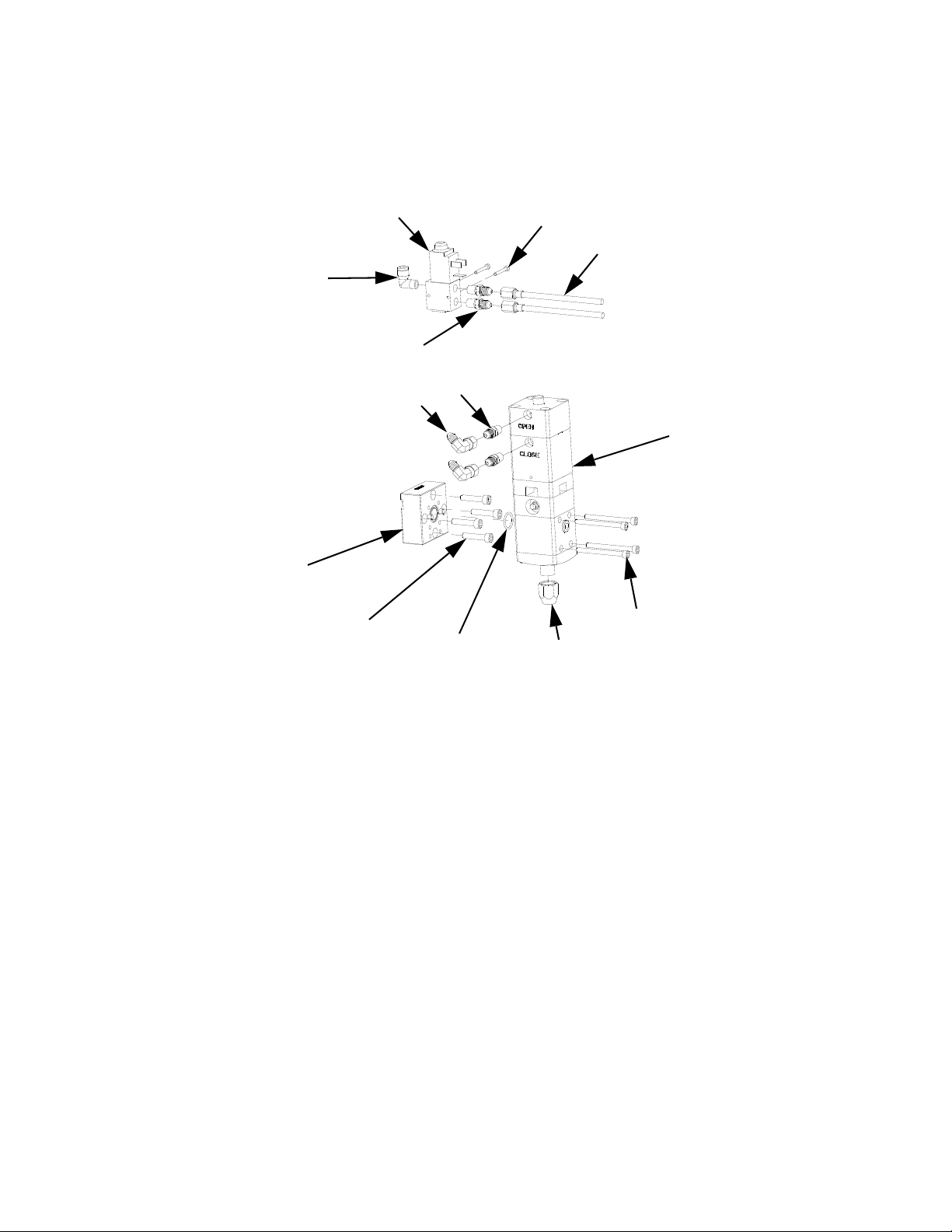

Dispense Valve

Air Solenoid

Remove Dispense Valve

1. Prepare Gear Meter Assembly for Repair,

page 35.

2. Manually actuate solenoid to ensure pressure has

been removed.

4. Connect air lines.

5. Apply air to the solenoid.

6. Manually shuttle solenoid, see F

pense valve is open when solenoid is depressed.

IG. 22. Verify dis-

Replace Solenoid

1. Prepare Gear Meter Assembly for Repair,

page 35.

2. Disconnect solenoid cable. Remove mating

screws (405) from gusset.

3. Remove the dispense valve solenoid (410) and

replace it with a new solenoid.

4. Reconnect solenoid cable.

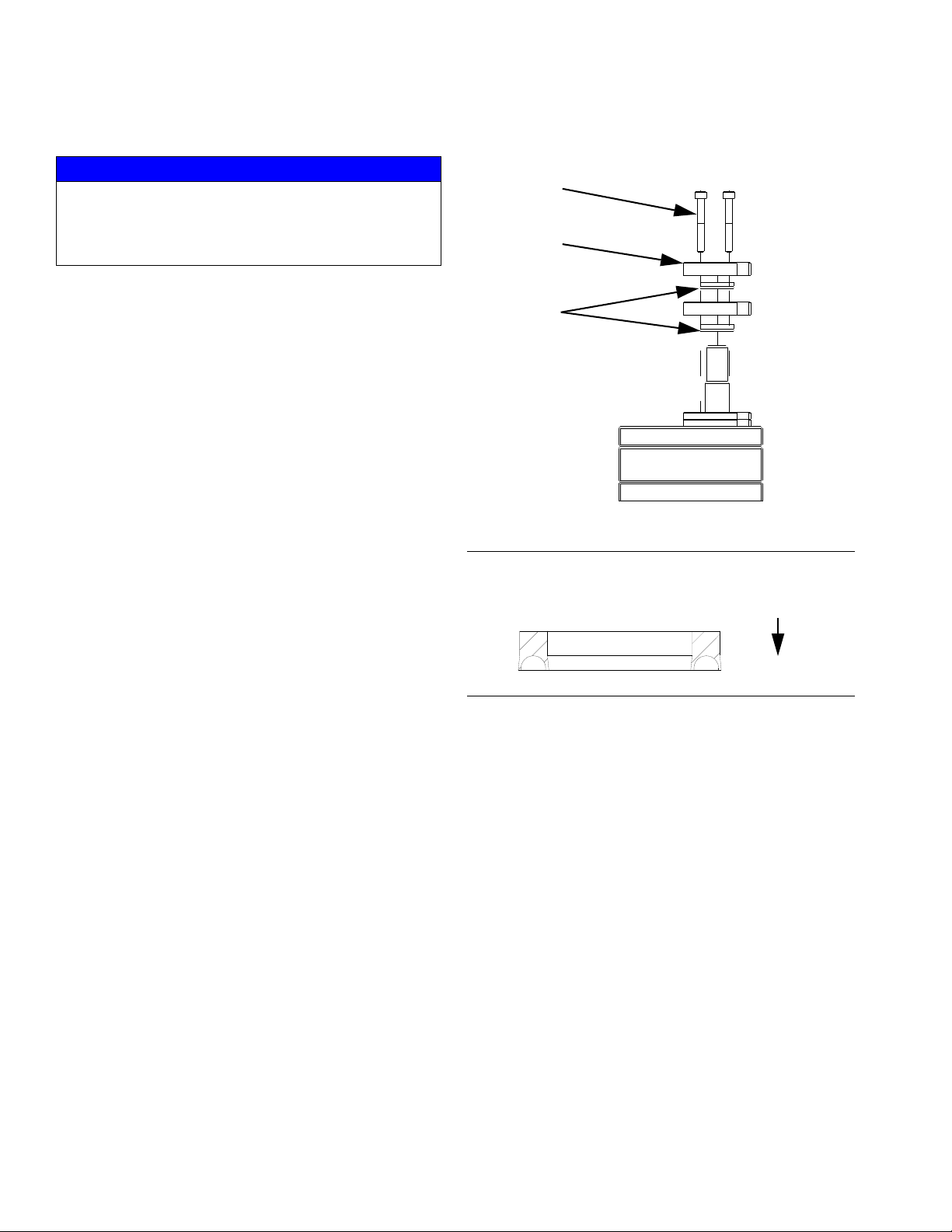

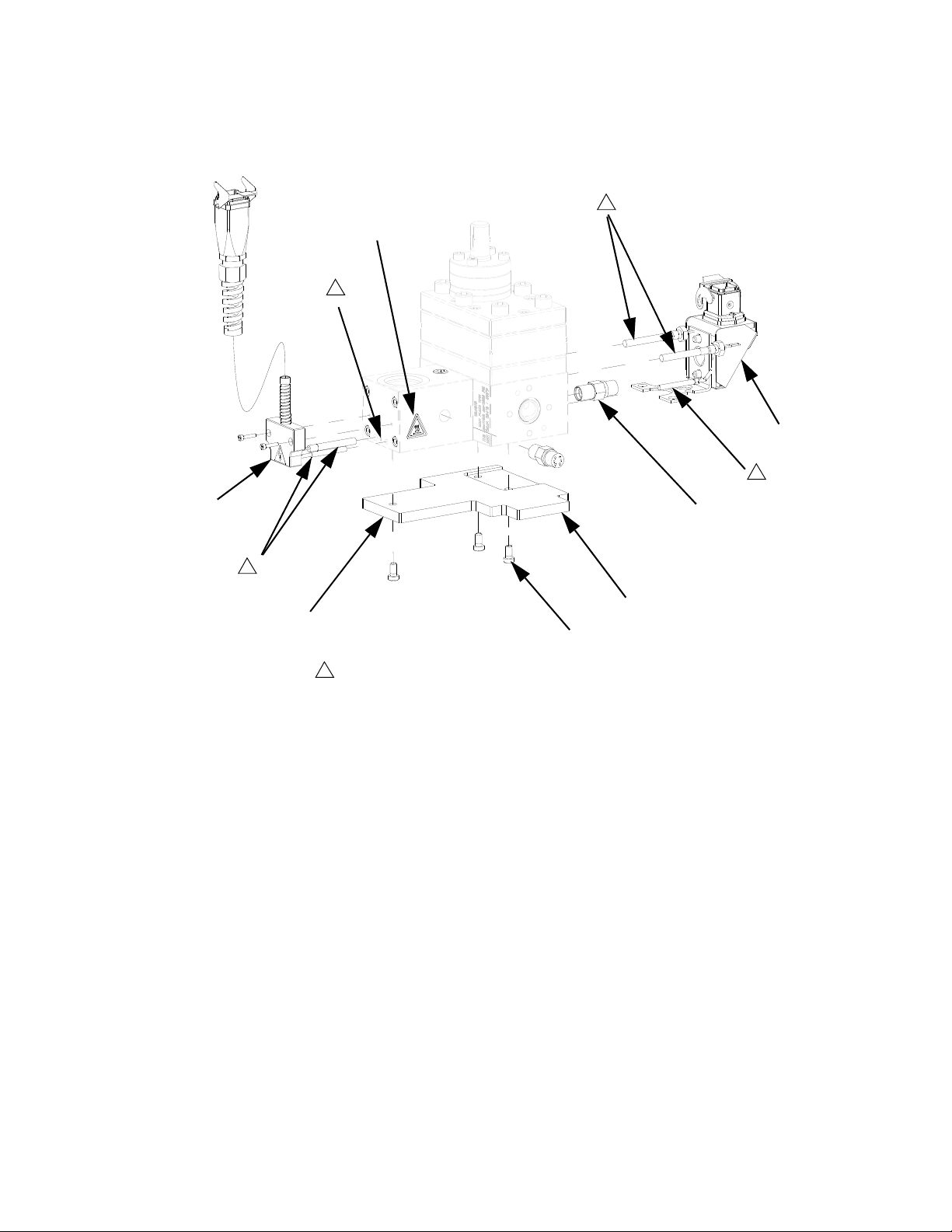

Gear Meter O-Ring Replacement

Refer to Parts section starting on page 49 for o-ring kits.

1. Prepare Gear Meter Assembly for Repair,

page 35.

FIG. 22: Dispense Valve Air Solenoid

3. Verify air supply is off.

4. Remove air lines from dispense valve.

5. Remove four dispense valve mounting bolts and

remove dispense valve.

NOTE: For remote mount dispense valves, remove

supply hose at inlet block of dispense valve.

6. Refer to dispense valve manual for complete dispense valve repair instructions; refer to Related

Manuals on page 3.

Install Dispense Valve

1. For direct mounted dispense valves, replace

o-ring (409) if necessary.

2. Align dispense valve with mounting pins on front

block.

2. Remove pump block shoulder bolts (4, 1102). See

F

IG. 23.

NOTICE

Pump section should be fully supported to prevent

damage being dropped. It is recommended that the

gear meter assembly be located on a work bench for

service.

3. Install four mounting bolts (408) torque to

50-60 in-lb (5.6-6.7 N•m).

38 3A5185B

Page 39

Repair

4, 1102

*107, 1306

105,

1305*

102, 1302

104, 1304

* Provided in o-ring kit 24E626.

103,

1303

106,

1304

109,

1308

412

407

108,

1309

3. Remove drive assembly. See FIG. 23.

12. Replace pump block o-rings (106, 104; 1304). See

F

IG. 24.

FIG. 23

4. Perform Remove Dispense Valve procedure.

5. Loosen 4 bolts (407) and remove front block (412).

6. Loosen 4 bolts and remove inlet block (110, 1302).

7. Loosen pump bolts (3, 1303) and remove

pump (108, 1309).

8. Replace front block o-ring (105, 1305).

9. Install front block (412) onto pump block (109,

1308).

10. Replace inlet block o-ring (107, 1306).

11. Install inlet block (102, 1302) onto pump block.

FIG. 24

13. Place pump (109, 1308) onto pump block. Install

bolts (103, 1303) and tighten to 430 in-lb (48.58

N•m).

14. Locate drive assembly on top of pump assembly.

15. Tighten pump block mounting shoulder bolts to

frame (4, 1102).

16. Replace all electrical connections and fluid connections before applying fluid pressure and power.

3A5185B 39

Page 40

1614

1611

1612†

1611

1612†

1613

1601

1602

1607

1608

1615

1605

1609

1604

1606

1603

1610

† Parts included in kit 24E607.

Parts included in kit 24E827.

Parts included in kit 24E826.

(P/N: 125657)

(P/N: 125656)

Repair

PGM-6 Pump Repair

FIG. 25: PGM-6

40 3A5185B

Page 41

Repair

PGM-6 Pump Disassembly

1. Prepare Gear Meter Assembly for Repair,

page 35.

2. Refer to Gear Pump Maintenance Guide on

page 47 for special notes regarding gear pump

repair.

3. Remove four pump block shoulder bolts (1102).

NOTICE

Pump section should be fully supported to prevent

damage being dropped. It is recommended that the

gear meter assembly be located on a work bench for

service.

4. Remove drive assembly. See F

NOTICE

IG. 23.

NOTE: Notches on the pump plates can be used to

separate the plates.

9. To remove the drive shaft (1605) from the bottom

plate (1603) press the shaft and gear from the bottom pump plate towards the coupling end.

10. To remove the drive gear (1607) from the drive shaft

(1605), support the drive gear at the lower end to

allow the shaft to be pressed through the gear from

the top or coupling end. Make sure to leave clearance for the drive key.

11. The stud (1606) for the driven gear (1608) is press

fit into the back plate (1603) and need not be

removed if not worn.

NOTICE

The PGM pump design relies on a lap fit between

components for performance and sealing. Be careful

not to drop the gears (1607, 1608) or damage the

mating surfaces of the pump plates (1601, 1603) and

gear case (1602). To prevent damage, do not use pliers or screwdrivers to remove the gears.

Thicker materials may require heating prior to disassembly. Do not expose the pump to thermal shock.

Raise temperature at a maximum rate of 180°F

(100°C) per hour. Do not exceed 400°F (204°C).

Exceeding this temperature could promote leakage in

the pump. Gradually cool the pump to room temperature.

5. Remove seal retainer fasteners (1614) and seal

retainers (1611).

6. Remove pump dowel pins (1610) using an arbor

press.

NOTICE

Do not use a hammer to remove dowel pins as this

will damage the pump.

7. Remove the pump plate screws (1613).

8. Separate the pump front plate (1601), gear case

(1602) and back plate (1603).

12. Clean all components thoroughly before reassembly. The use of an ultrasonic cleaner is recommended.

3A5185B 41

Page 42

Repair

1515,

1614

1512,

1611

*1513,

1612

Pump Body

PGM-6 Pump Assembly

NOTICE

Do not hammer or force components together or damage may occur. Parts will drop into place if properly

cleaned and aligned. Use of a compatible oil is recommended during assembly.

1. Place the back plate (1603) on a table inside facing

up.

2. Place the driven gear (1608) on its stud (1606).

3. Place gear case (1602) onto back plate (1603).

Check orientation of dowel pin holes to assure they

align with the ones in the back plate.

4. Slide drive gear (1607) onto drive shaft (1605). Verify shaft key (1609) is installed properly.

5. Install drive gear (1607) and drive shaft (1605) into

back plate (1603).

6. Position top plate (1601) over drive shaft (1605) and

place onto gear case (1602).

12. Install new seals (1612). See F

FIG. 26: Seal Locations

IG. 26 and FIG. 27.

7. Rotate the gears several times to ensure free rotation.

8. Insert the dowel pins (1610) and rotate the gears

several times to ensure free rotation.

NOTE: Dowel pins are not a press fit and may be

installed using a plastic hammer if necessary.

9. Install pump plate screws (1613) and tighten to

85-105 in-lb (9.6-11.8 N•m).

10. Rotate the gears several times to ensure free rotation.

11. Apply a heat resistant, non-evaporating lubricant to

the seal area of the drive shaft (1605).

FIG. 27: Seal Orientation

13. Install seal retainers (1611) and seal retainer

screws (1614). Tighten screws to 85-105 in-lb

(9.6-11.8 N•m).

14. Align pump shaft key and slide coupling onto pump

shaft. Tighten coupling bolt just enough to hold it’s

position.

15. Attach servo motor, gear head, and top plate to

pump assembly. See F

IG. 20.

16. Separate coupling until proper gap is created. See

F

IG. 21.

17. Tighten pump block mounting shoulder bolts to

frame (1102).

18. Replace all electrical connections and fluid connections before applying fluid pressure and power.

42 3A5185B

Page 43

Repair

3A5185B 43

Page 44

Repair

1515

1512

1513†

1512

1513†

1511

1510

1504

1508

1516

1514

1509

1501

1502

1506

1503

1507

1505

† Parts included in kit 24E619.

Parts included in kit 24E825.

Parts included in kit 24E824.

(P/N: 125655)

(P/N: 125654)

PGM-20 Pump Repair

FIG. 28: PGM-20

44 3A5185B

Page 45

Repair

PGM-20 Pump Disassembly

1. Prepare Gear Meter Assembly for Repair,

page 35.

2. Refer to Gear Pump Maintenance Guide on

page 47 for special notes regarding gear pump

repair.

3. Remove six pump block shoulder bolts (4).

NOTICE

Pump section should be fully supported to prevent

damage being dropped. It is recommended that the

gear meter assembly be located on a work bench for

service.

4. Remove drive assembly. See F

NOTICE

IG. 23.

be needed. These will provide clearance for the

drive shaft key (1508) and the top plate (1501).

10. Support pump top plate (1501) and press drive shaft

(1504) through drive gear (1506). Stop when there

is enough clearance between the drive gear (1506)

and top plate (1501) to insert one spacer. Be sure to

allow clearance for drive key (1508).

11. Continue pressing the drive shaft (1504) and inserting spacers until the shaft is free from the drive gear

(1506).

12. The stud (1505) for the driven gear (1507) is press

fit into the back plate (1503) and need not be

removed if not worn.

NOTICE

The PGM pump design relies on a lap fit between

components for performance and sealing. Be careful

not to drop the gears (1607, 1608) or damage the

mating surfaces of the pump plates (1601, 1603) and

gear case (1602). To prevent damage, do not use pliers or screwdrivers to remove the gears.

Thicker materials may require heating prior to disassembly. Do not expose the pump to thermal shock.

Raise temperature at a maximum rate of 180°F

(100°C) per hour. Do not exceed 400°F (204°C).

Exceeding this temperature could promote leakage in

the pump. Gradually cool the pump to room temperature.

5. Remove seal retainer fasteners (1515) seal retainers (1512), spacers (1510) and (1511).

6. Remove pump dowels (1509) using an arbor press.

NOTICE

Do not use a hammer to remove dowel pins as this

will damage the pump.

7. Remove the pump plate screws (1514).

8. Separate the pump front plate (1501), gear case

(1502) and back plate (1503).

NOTE: Notches on the pump plates can be used to

separate the plates.

13. Clean all components thoroughly before reassembly. The use of an ultrasonic cleaner is recommended.

9. To remove drive shaft (1504) from the drive gear

(1506) several flat spacers 1/8 in. (3 mm) thick will

3A5185B 45

Page 46

Repair

PGM-20 Pump Assembly

NOTICE

Do not hammer or force components together, or

damage may occur. Parts will drop into place if properly cleaned and aligned. Use of a compatible oil is

recommended during assembly.

1. Place back plate (1503) on a table inside face up.

2. Install the driven gear (1507) on stud (1505).

3. Place gear case (1502) onto back plate (1503).

Check orientation of dowel pin holes to assure they

align with the ones in the back plate.

4. Place the top plate (1501) on its edge on a table.

Pass the drive shaft (1504) through the top plate

from the seal side so that the boss on the shaft rests

on the top plate.

5. Rotate the drive shaft (1504) to position the drive

key slot at the top. Insert the drive key (1508) and

driven gear (1506).

14. Align pump shaft key and slide coupling onto pump

shaft. Tighten coupling bolt just enough to hold it’s

position.

15. Attach servo motor, gear head, and top plate to

pump assembly. See F

IG. 20.

16. Separate coupling until proper gap is created. See

F

IG. 21.

17. Tighten pump block mounting shoulder bolts to

frame (4).

18. Replace all electrical connections and fluid connections before applying fluid pressure and power.

6. Grasp the top plate (1501), drive shaft (1504) and

driven gear (1506) to prevent them from separating

and carefully lower them into position onto the gear

case (1502).

7. Rotate the gears several times to ensure free rotation.

8. Insert the dowel pins (1509) and check again for

free rotation.

NOTE: Dowel pins are not a press fit and may be

installed using a plastic hammer if necessary.

9. Install pump plate screws (1514) and tighten to

85-105 in-lb (9.6-11.8 N•m).

10. Rotate the gears several times to ensure free rotation.

11. Apply a heat resistant, non-evaporating lubricant to

the seal area of the drive shaft (1504).

12. Install new seals (1513). See F

IG. 26 and FIG. 27.

13. Install spacers (1510, 1511), seal retainers, (1512)

and seal retainer screws (1515). Tighten screws to

85-105 in-lb (9.6-11.8 N•m).

46 3A5185B

Page 47

Gear Pump Maintenance Guide

Review these guidelines prior to performing any maintenance on the pumps.

• Do not run pump dry.

• Do not pull from a vacuum or negative suction head.

• Do not flush with water or other non-lubricating fluid.

• Do not pump corrosives, abrasives and/or fluids carrying particles that may harm the pump.

• Do not heat or cool pump faster than 180°F (100°C)

per hour.

• Do not drop disassembled parts on a hard surfaces

and do not let parts knock together.

• Never strike the pump parts with an iron hammer.

The parts are designed to drop in place if properly

aligned. Use arbor press to insert or remove press

fit components.

Repair

• Do not use pliers to lift the gears.

• Never use a screwdriver to pry the gears upward.

• Apply clean oil or compatible fluid during assembly.

3A5185B 47

Page 48

Repair

Installing new heater units and RTD sensors

1.Prepare Gear Meter Assembly for Repair, page 35.

2. Disconnect the power cables from the heaters.

3. Remove two M3 screws to remove the kit from the

inlet block.

6. Remove the heaters and sensor from the block.

NOTICE

The heaters may be difficult to remove and removal

depends on the system type. To ensure proper heat

transfer and to avoid premature heater failure,

System with through hole:

Press out the heater element using an 0.125” (3 mm)

diameter pin.

System without through hole:

Drill out the heater element using a 5mm (0.203 in.)

drill bit. Do not increase the hole diameter.

7. Clean any residue from both heater and sensor

ports.

8. Installation is the reverse of removal.

4. Remove two M6 screws to remove the kit from the

pump block.

5. Remove the two M8 heater nuts and M6 sensor nut.

48 3A5185B

Page 49

Parts

12

11

10

9

3

8

1

4

2

5

ti21285a

PGM-20 Mounting Frame

Parts

Ref Part Description Qty

1 124164 SCREW, shcs, M6-1.0 x 25 4

2 124165 SCREW, bhcs, M5-0.6 x 10 4

3 124166 SCREW, bhcs, M6-1.0 x 10 4

4 124167 SCREW, shoulder, 10x30, M8-1.25 6

5 124168 SCREW, shoulder, 8 x 6, M6-1.0 8

8 16D840 PLATE, mounting 1

9 16D841 GUSSET 2

10 16D842 PLATE 1

11 16D843 INSULATOR 1

12 16V444 GUARD, drive 1

3A5185B 49

Page 50

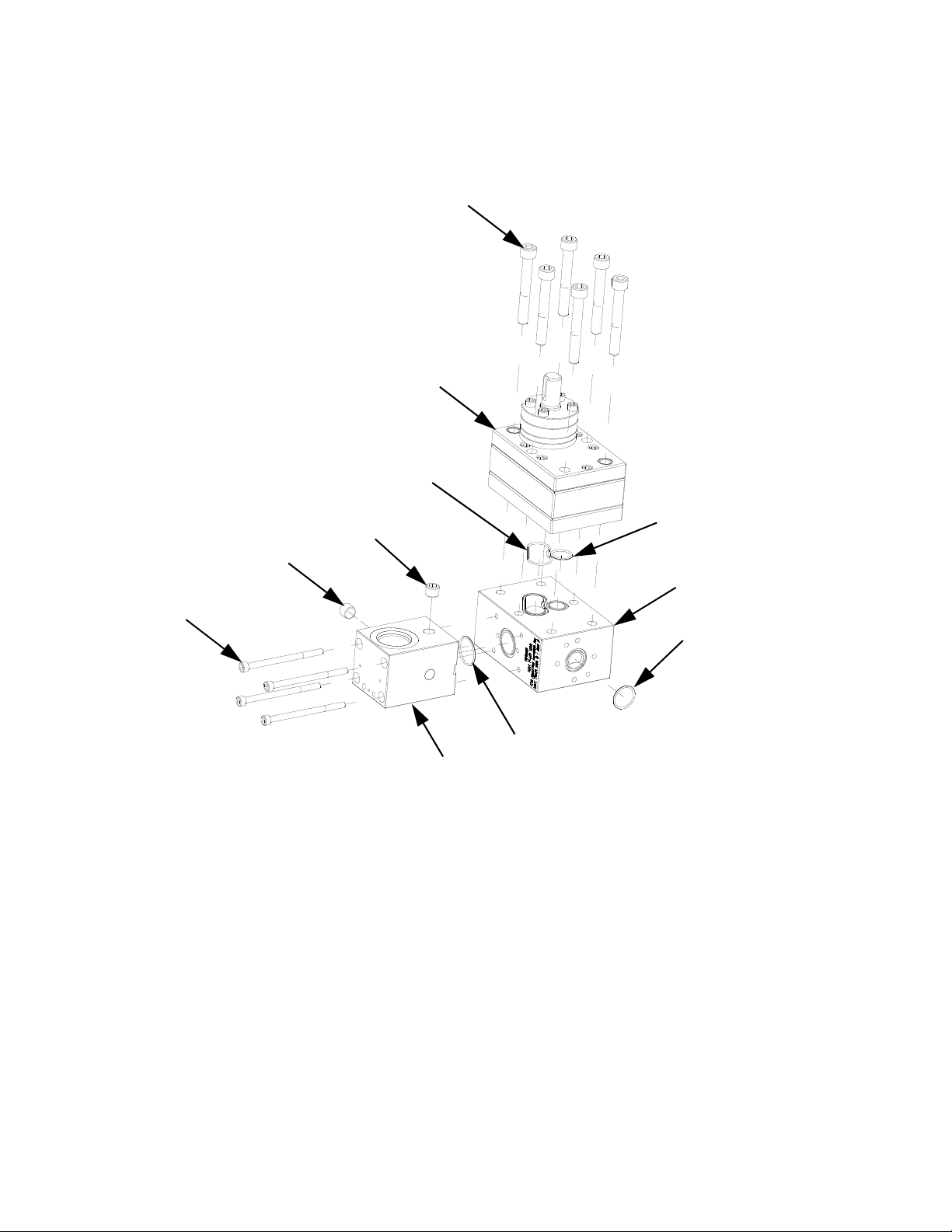

Parts

103

108

104

101

101

102

105

109

106

107

110

PGM-20 Lower Assembly Block

Ref Part Description Qty

101 101970 PLUG, pipe, headless 2

102 124173 SCREW, M6-1.0 x 90 4

103 124174 SCREW, M10-1.5 x 75 6