Page 1

INSTRUCTIONS-PARTS

This manual contains

WARNINGS

READ

AND

RETAIN

PORTABLE, AIRLESS

IMPORTANT

and

INSTRUCTIONS

FOR

REFERENCE

LIST

GRACO

307-293

Rev.

N

SUPERSEDES M

GH

3000

psi

(210 bar)

433

PAINT

MAXIMUM

WORKING PRESSURE

SPRAYER

Model 215-433, Series G

Includes Sprayer 231-005, Hose, Gun, Tip Guard and

Spray Tip

of

Choice.

Model 231-005, Series A

Sprayer only

INDEX

Warnings

Installation

Flushing Guidelines

Operation

Regular Maintenance

Troubleshooting

Repair

Parts Drawings

Accessories

How

Technical Data

Warranty ... ,

....................................

..................................

....................................

......................................

to

Order Replacement Parts

.......................

.......................

.............................

& List

...................................

......

...................

...................

'"

..... , ....

, ... Back Cover

2, 3

4, 5

6,

8, 9

10

11

12-15

16-19

20

........

Back Cover

21

7

~--------------------------------------WARNING-------------------------------------.

Aluminum and Zinc Material Hazard

Never

use

such solvents in this equipment.

plosion, which

Consult your

1,1, 1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids containing

could cause death, serious bodily injury

fluid suppliers

GRACO

INC.

Such

use

could result in a serious chemical reaction, with the possibility

to

ensure that the fluids being used are compatible

P.O.

BOX

©COPYRIGHT

1441

and/or

substantial property damage.

MINNEAPOLIS,

1985

GRACO INC.

with

aluminum and zinc parts.

MN

55440-1444

of

ex-

Page 2

WARNING

HIGH PRESSURE

all

warnings.

SPRAY

Read

and

CAN

CAUSE SERIOUS

understand

all

instruction

FLUID INJECTION HAZARD

General

This equipment generates very high fluid pressure. Spray from

the gun,

through your skin and into your body and

serious bodily injury, including the need for amputation. Fluid

injected or splashed into the

serious damage.

NEVER

body.

try

ALWAYS have the tip guard on the spray

ALWAYS

Safety

leaks or ruptured components

eyes

or on the skin can cause

point the spray gun at anyone or at any part

to

NEVER

"blow

put hand or fingers over the spray tip.

back"

paint; this

follow

the Pressure Relief Procedure, below,

is

NOT

an

air spray system.

gu

can

inject fluid

cause

extremely

of

the

NEVER

n when spraying.

before cleaning or removing the spray tip or servicing any

system equipment.

NEVER

Be

before each use.

Medical

If

MEDICAL

SIMPLE CUT. Tell the doctor exactly what fluid was injected.

try

to

stop or deflect leaks with your hand

sure equipment safety devices

any fluid appears

Note

It

possible.

Alert-Airless

to

Phys/cilln:

is

important

CARE

Do

not

Spray

to

penetrate your skin, get EMERGENCY

AT

ONCE. DO

Injection in the skin is a traumatic injury.

to

treat

the

delay treatment to research toxicity. Tox-

Wound

injury

are

operating properly

NOT

TREAT

surgically

8S

or

soon

body.

AS

A

as

icity is a concern with some exotic coatings injected directly

into the blood stream. Consultation with a plastic surgeon or

reconstructive hand surgeon

Spray Gun

Be

sure all gun safety devices

each

can cause a malfunction and

use.

Safety

Do

Devices

not

remove or modify any part

may

be

advisable.

are

operating properly before

result in serious bodily injury.

of

the gun; this

INJURY.

manuals

For

professional

before

operating

use

only.

equipment.

Observe

Safety Latch

Whenever you stop spraying,

the gun safety

the gun inoperative.

accidental triggering

latch

in

Failure to set the safety latch

of

even

the closed or

the gun.

for a moment, always set

"safe"

position, making

can

result in

Diffuser

The gun diffuser breaks up spray and reduces the risk

injection when the tip

regularly. Follow the Pressure Relief

then remove the spray tip. Aim the gun into a metal pail,

holding

pressure, trigger the gun.

to

Tip

ALWAYS

spraying. The tip guard alerts you

and

your fingers

the gun firmly to the pail. Using the lowest possible

an

irregular stream, replace the diffuser immediately.

Guard

have the tip guard

helps reduce, but does not prevent, accidentally placing

or

is

any part

not

installed. Check diffuser operation

If

the fluid emitted is

in

place on the spray gun while

of

your body close

Procedure,

not

to

the fluid injection hazard

to

of

fluid

below,

diffused in-

the spray tip.

Trigger Guard

Always have the trigger guard in place on the gun when spray-

to

reduce the risk

ing

dropped or bumped.

Spray

Tip

Use

the spray tip clogs while spraying, engage the gun safety latch

immediately.

cedure

NEVER

fully relieved

Safety

extreme caution when cleaning or changing spray tips. If

ALWAYS

and then remove the spray tip

wipe

off

and

of

accidentally triggering the gun

follow the Pressure

build-up around the spray tip until pressure

the gun safety latch is engaged.

to

clean it.

Relief

if

Pro-

it

is

is

Relief

Pressure

To reduce the risk

always follow this procedure whenever you shut

parts,

installing, cleaning or changing spray tips, and whenever you stop spraying.

when

bypass

valve.

metal part

ty

latch. (7) Open the drain valve, having a container ready

ready to spray again.

If

you

suspect

steps above,

completely.

Procedure

of

serious bodily injury, including fluid injection, splashing in the

(3)

Depress the engine stop button.

of

the gun firmly

to

the side of-a grounded metal pail, and trigger the gun

off

the sprayer, when checking or servicing any part

(4)

Close the fuel shutoff valve.

to

catch the drainage.

that the spray tip or hose is completely clogged, or that pressure has

VERY SLOWLY loosen the tip guard retaining

Now

clear the tip

or

hose.

/4

nut

or hose end coupling and relieve pressure gradually, then loosen

eyes

or on the skin, or injury from moving

(1)

Engage the gun safety latch.

(5)

Disengage the gun safety latch and hold a

to

relieve pressure.

(8)

Leave

the drain valve open until you

not

been

fully

5

of

the spray system,

(2)

Open the

(6)

Engage the gun safe-

relieved after following the

are

2 307-293

Page 3

EQUIPMENT MISUSE

General

Any

overpressurizing, modifying parts, using incompatible

chemicals and fluids, or using worn or damaged parts,

cause

serious bodily injury,

NEVER

could cause

CHECK

worn or damaged parts immediately.

Read

regarding the use

System

This sprayer

WORKING

accessories

pressure

ing pressure

system.

Fluid

BE

patible with the wetted parts shown

the back cover. Always

turer's literature before using them

HOSE

High pressure fluid in the hoses

hose develops a

damage or misuse, the high pressure spray emitted from

cause a fluid injection injury or other serious bodily injury or

property damage.

ALL

BOTH ENDSI

kinks or bends at or close

hose rupture.

TIGHTEN

pressure fluid can dislodge a loose coupling or

pressure spray

NEVER

hose

movement

exist, replace the hose immediately.

high pressure hose or mend

repaired hose cannot contain the high pressure fluid.

HANDLE AND

hoses

are

DO

or

Hose

Proper hose grounding continuity

grounded spray system. Check the electrical resistance

air and fluid hoses at least once a week.

have a tag on it which specifies the maximum electrical

resistance, contact the hose supplier or manufacturer

maximum resistance limits. Use a

propriate range for your hose to check the resistance.

resistance exceeds the recommended limits, replace

mediately. An ungrounded

your system hazardous. Also

HAZARD,

Safety

misuse

of

the spray equipment or accessories, such

them

to

rupture and result in fluid injection or other

alter

or

modify any part

it

to

all

spray equipment regularly and repair

and follow the fluid and solvent manufacturer's literature

Preb Jure

can

PRESSURE.

are

of

Compatibility

SURE

rated

this sprayer.

of

that all fluids and solvents

SAFETY

leak, split or rupture due

FLUID HOSES

for

to

not

NOT expose the hose to temperatures above 180°F (82°C)

below

Grounding

The spring guards help protect the hose from

all

fluid connections securely before

to

use a damaged hose.

cuts, leaks, abrasion, bulging cover, or damage or

of

the hose couplings.

ROUTE HOSES CAREFULLY.

move equipment. Do not

compatible

-40°F (-40°C).

to the right.

HAZARD

fire, explosion or property damage.

of

malfunction.

of

protective clothing and equipment.

develop 3000

Be

sure that

to

withstand the maximum working

DO

any component or accessory used

read

MUST

to

be emitted from the coupling.

it

with

the inner tube and cover

Continuity

or

this equipment; doing

or

psi

(210 bar)

all

spray equipment and

NOT exceed the maximum work-

used

are

in

the fluid and solvent manufac-

HAVE

the coupling which

Befo.re

with tape or any other device. A

poorly grounded hose

the Technical Data on

in

this sprayer.

can

be

very dangerous. If the

to

SPRING

each use, check entire

If

any

DO

NOT try

use

fluids

is

essential

If your hose does

voltage 'meter in the ap-

read

FIRE OR EXPLOSION

MAXIMUM

chemically com-

any kind

GUARDS

can

each

use. High

allow high

of

these conditions

to

Do

not pull on

or

solvents which

of

the hose.

to

maintaining a

can

as

can

so

replace

in

the

of

wear,

it

can

ON

result in

recouple

of

your

not

for

the

If

the

it

im-

make

MOVING PARTS HAZARD

Moving parts can pinch or amputate your fingers or other

body parts.

operating the sprayer.

on page 2 before checking or servicing the sprayer to prevent

it

from starting accidentally.

KEEP

CLEAR

of

Follow the Pressure

moving parts when starting or

Relief

Procedure

,," IMPORTANT

United States Government' safety standards have been

adopted under the

standards-particularly the General

the Construction Standards, Part

Occupational Safety and Health Act. These

Standards, Part

1926-should

1910,

be

consulted.

and

FIRE

OR

EXPLOSION

Static electricity

through the pump and hose.

ment

is

system may become hazardous. Sparking may also occur

when plugging

can

dust particles and other flammable substances, whether you

are

plosion and serious bodily injury and property damage.

Always locate the sprayer at least

spray area.

the spray

in the air.

If

while using this equipment,

MEDIATELY.

ding.

identified and corrected.

Grounding

To reduce the risk

all

CHECK

structions

ground

1.

not

ignite fumes from solvents and the fluid being sprayed,

spraying indoors or outdoors, and

you experience any static sparking or even a slight shock

Do

not

other spray equipment used or located in the spray area.

your local electrical code

all

Sprayer: connect the ground wire and clamp (provided) to

a true earth ground.

is

properly grounded, sparking may occur, and the

in

Do

not

area

when there

Check the entire system for positive groun-

use

the system again until the problem

for

your

of

this spray equipment:

HAZARD

created by the high velocity

or

unplugging a power supply cord. Sparks

plug in or unplug any power supply cords in

of

static sparking, ground the sprayer and

area

If

every part

is

any chance

and type

See

Fig

can

20

feet

(6

of

STOP

for

detailed grounding in-

of

equipment.

1.

flow

of

of

the spray equip-

cause a fire

m) away from the

igniting fumes still

SPRAYING

BE

fluid

or

IM-

has

been

SURE to

ex-

o

o

o

Fig 1

2.

Fluid hoses:

500

feet

ing continuity. Refer to the section Hose

tinuity.

3.

Spray gun: obtain grounding through connection

perly grounded fluid hose and sprayer.

4. Object being sprayed: according to local code.

5.

Fluid supply container: according

6.

All

solvent pails

code.

place the pail on a non-conductive surface, such

or cardboard, which interrupts the grounding continuity.

7.

To

maintain grounding continuity when flushing

ing pressure,

the side

Flushing

Reduce the risk

splashing by

on page 6

cedure

Hold a metal part

pail and use the lowest possible fluid pressure during

metal

flushing.

GAS

ENGINE HAZARDS

NEVER

Fuel

spilled on a hot surface can ignite and

AL

WA

YS pour fuel

NEVER operate the engine in a closed building unless the

engine exhaust

monoxide, a poisonous, odorless and invisible

cause

serious illness and

NEVER alter the throttle setting which

maximum

with this

use

(150

Use

of

Safety

of

on page 2, and remove the spray tip before flushing.

fill the fuel tank while the engine

full load engine

can

only grounded hoses with a maximum

m)

combined hose length to ensure ground-

used

only

always hold a metal part

a

grounded

of

following the specific flushing procedure given

this manual. Follow the Pressure

of

is

piped outside. The exhaust contains carbon

damage the sprayer and will void the warranty.

when flushing, according

metal

pails, which are conductive.

metal pail, then trigger the gun.

fluid injection injury, static sparking, or

the gun firmly to the side

in

slowly to avoid spilling.

even

death

speed

of

Grounding

to

local code.

of

the gun firmly to

of

is

running or hot.

if

2800

gas

inhaled.

is

factory set at the

RPM. Tampering

Relief

a grounded

cause

which

to

to

as

or

Con-

a pro-

local

Do

not

paper

reliev-

Pro-

a fire.

can

of

307-293

3

Page 4

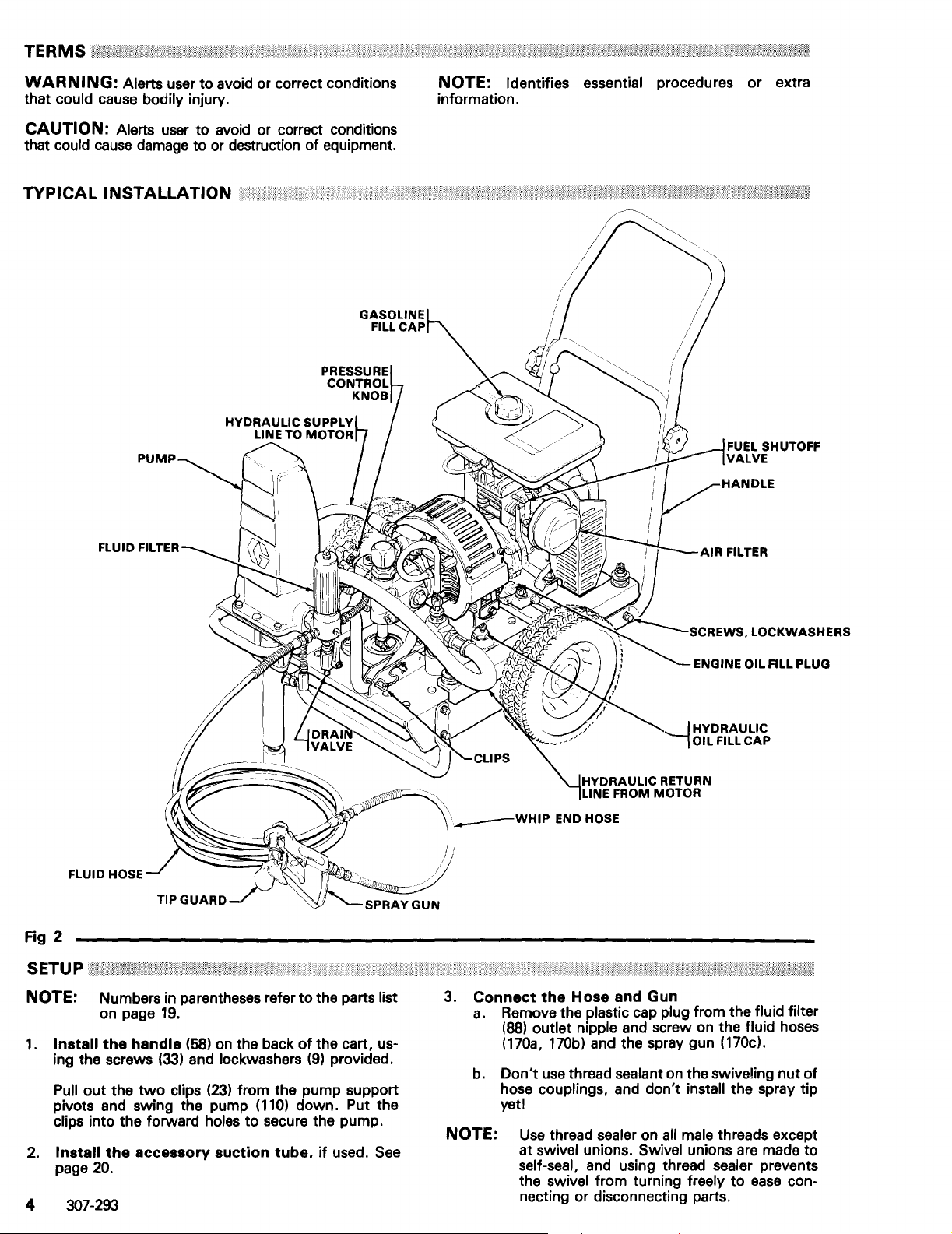

TERMS

WARNING:

that

could cause bodily injury.

Alerts user to avoid or correct conditions

CAUTION: Alerts user

that

could

cause

damage to or destruction

TYPICAL

INSTALLATION

to

avoid or correct conditions

of

equipment.

NOTE: Identifies essential procedures or extra

information.

FUEL SHUTOFF

VALVE

FLUID HOSE

Fig 2

SETU P

U;;ti/'WH:nA

NOTE: Numbers in parentheses refer

on page

1.

Install

the

ing the screws

out

Pull

the

pivots and swing the pump

clips into the forward

2.

Install

page

the

20.

4 307-293

19.

handle

two

(58)

(33)

and lockwashers

clips

accessory

on

the back

(23)

from the pump support

(110)

holes

to

secure the pump.

suction

tube,

to

the parts list

of

the cart, us-

(9)

provided.

down. Put the

if

used.

See

'

___

)

I

3.

Connect

a.

b.

NOTE:

~

IHYDRAULIC

--,

WHIP

HYDRAULIC RETURN

FROM MOTOR

LINE

END HOSE

the

Hose

and

OIL FILL

Gun

CAP

Remove the plastic cap plug from the fluid filter

(88)

outlet nipple and screw on the fluid hoses

(170a,

170b) and the spray gun (170cl.

Don't

use thread sealant on the swiveling

nut

of

hose couplings, and don't install the spray tip

yeti

Use

thread sealer on

swivel unions. Swivel unions

at

all

male threads except

are

made

to

self-seal, and using thread sealer prevents

swivel from turning freely

the

to

ease

con-

necting or disconnecting parts.

Page 5

4. Fill

5.

the

Packing

the

Seal

Hydraulic

to

it

in the hole, but do not thread

oil should

Graco Throat

Check

a.

Unscrew the oil fill cap.

is

attached

and set

place. The

Nut/Wet

Cup

Liquid nsu, supplied.

Oil Level

See

the cap. Wipe

be

up

dipstick.

------CAUTION

To prevent damage

hydraulic pump,

part no. 169-236

207-428

oil

b. Add

(1

gaI.l3.8Iiter).

may damage the hydraulic components.

oil

as

pletely full hydraulic system contains about

2-1/2 gallons (9.5 liter)

to

the cooling

use

only Graco Hydraulic

(5

gal.l20

Other types

needed

to

the proper level. A com-

of

(141)

1/4

Fig

3.

The dipstick

off

the dipstick

to

the full line on the

------..,

syster:n

liter) or part

of

hydraulic

oil.

full with

it

in

a~d

011,

nc.>.

6.

Check

a.

b.

the

Engine

Oil Level

Unscrew the oil fill plug.

is

dipstick

Without

attached

threading the plug into place, check

be sure the oil

is

to

up

to

See

Fig

the plug.

the

top

3 and 4. The

mark on the

dipstick.

If oil

is

c.

needed,

recommended

RECOMMENDED ENGINE

detergent

regular use and

SEASON

Spring, Summer,

7.

oil classified "FOR SERVICE

for

GRADE

OR

TEMPERATURE

30°F

to

Winter

Crankcase capacity:

Fill

the

Fuel

Tank

see

the chart below

oil type and weight.

OIL:

Use

the breaking-in

OF

ENGINE

OIL CHART

Autumn

0°

1-1/4 pints (0.6 liters)

a high quality,

SO

of

a new engine.

GRADE

SAE

SAE 10W-30

.-------WARNING-----

Fuel

spilled on a

plosion and cause serious bodily injury and pro-

perty

damage. Always shut

it

cool before filling the tank, and carefully follow

steps 7.a.

fuel.

any

hot

surface

to

7.c., below, being sure not

can

cause a fire or ex-

off

the engine and let

or

for

SE",

OF

30

to

to

the

for

OIL

...

spill

Fig 3

_______________

@

Fig 4

_______________

HYDRAULIC

OIL

FILL

CAP

ENGINE OIL

PLUG

FILL

100

IN PLACE TO

CHECK

NOT THREAD

LEVEll

a. Close the fuel shutoff valve.

b.

Use

only clean, fresh well-known brands

unleaded regular grade gasoline. The

octane requirements are 86 octane

U.S.A.

c. Remove the

which

Be

_

8.

so

the cap.

Grounding

and 96 octane elsewhere.

gasoline fill cap and fill the tank,

holds about 1 gallon (3.8 liters)

sure the air vent in the fill cap

fuel can

flow

See

to

the carburetor, then replace

Fig

2.

WARNING-----

To reduce the risk

of

static sparking, fire or explo-

See

Fig

3.

mi~imum

of

is

not

plugged

In

of

the

fuel.

...

sion which can result in serious bodily injury and

property damage, always ground the

~prayer

and

system components, and the object being sprayed

as

instructed under FIRE OR EXPLOSION

HAZARD

9.

Flush

in the pump after factory testing

pump from corrosion.

_

on page

on page

the

6.

sprayer

3.

to

remove the oil which was left

See

"Flushing Guidelines"

to

protect the

307-293 5

Page 6

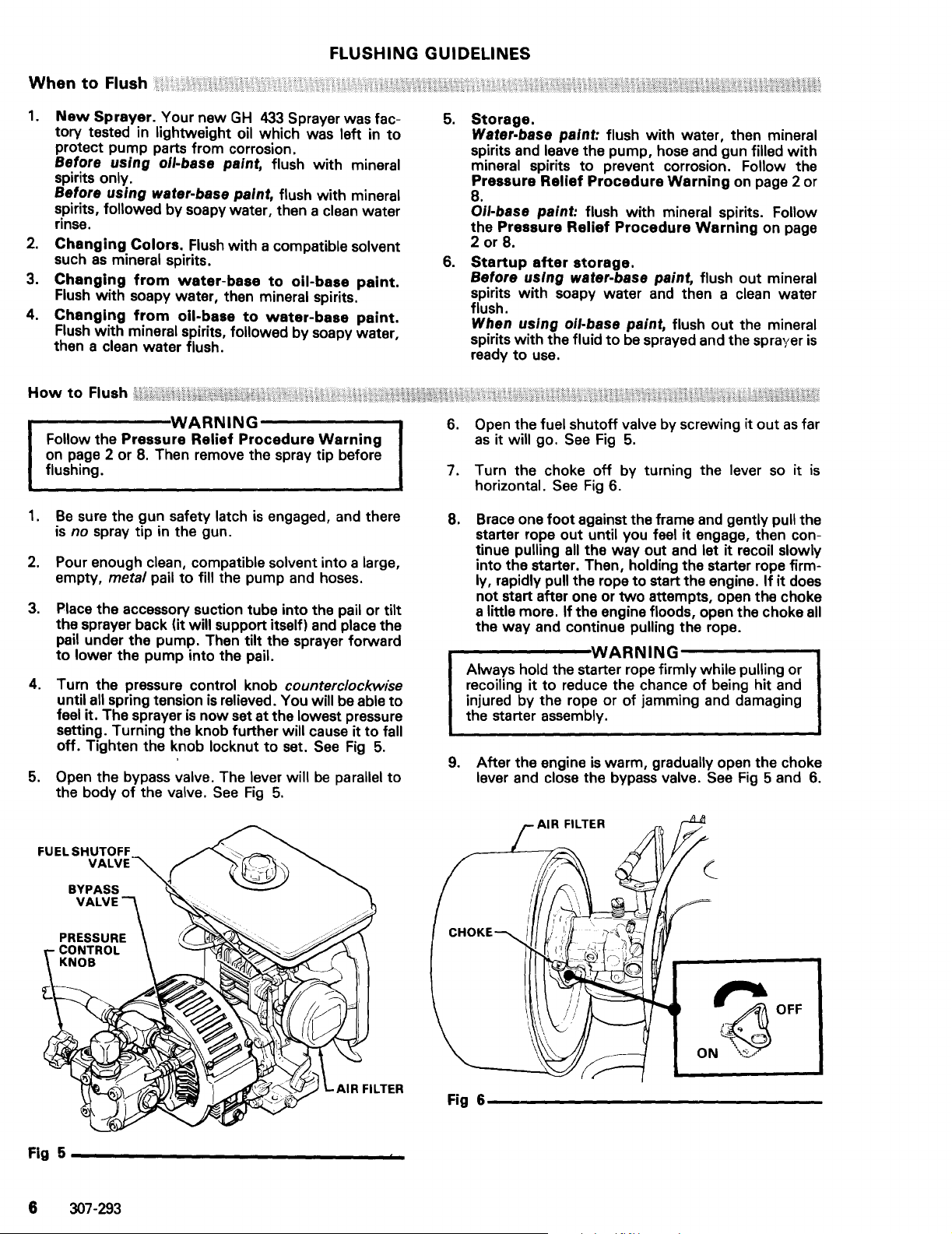

FLUSHING GUIDELINES

When

1.

to

Flush

New

Sprayer. Your new

tory tested in lightweight oil which was left in

protect pump parts from corrosion.

GH

433

Sprayer was fac-

to

Before using oil-base paint, flush with mineral

spirits only.

Before

spirits,

rinse.

2.

Changing

such

3.

Changing

Flush

4.

Changing

Flush

then a clean water flush.

How

------------WARNING----------~

Follow the Pressure

on page 2 or

flushing.

1.

Be

is

2.

Pour enough clean, compatible solvent into a large,

empty,

using water-base paint, flush with mineral

followed by soapy water, then a clean water

Colors.

as

mineral spirits.

from

with

soapy water, then mineral spirits.

from

with

mineral spirits, followed by soapy water,

to

Flush

B.

sure the gun safety latch

Flush with a compatible solvent

water-base

oil-base

Relief

Then remove the spray tip before

to

oil-base

to

water-base

Procedure

is

engaged, and there

Warning

no spray tip in the gun.

metal pail

to

fill the pump and hoses.

paint.

paint.

3. Place the accessory suction tube into the pail or tilt

the sprayer back (it will support itself) and place the

pail under the pump. Then tilt the sprayer forward

to

lower the pump into the pail.

4. Turn the pressure control knob counterclockwise

until all spring tension

feel it. The sprayer

setting. Turning the knob further will cause it

off. Tighten the knob locknut

5. Open the bypass valve. The lever will

the body

of

the valve.

is

relieved. You will

is

now

set at the lowest pressure

to

set.

See

Fig

5.

See

be

be

able

to

Fig

5.

parallel

fall

to

to

5.

Storage.

Water-base paint: flush with water, then mineral

spirits and leave the pump, hose and gun filled

mineral spirits

Pressure

Relief

to

prevent corrosion. Follow the

Procedure

Warning

on page 2 or

B.

Oil-base paint: flush with mineral spirits. Follow

the Pressure

2 or

B.

6.

Startup

Before using water-base paint, flush out mineral

spirits with soapy water and then a clean water

flush.

When using oil-base paint, flush out the mineral

spirits with the fluid

ready

to

6. Open the fuel shutoff valve by screwing it

as

it will go.

7. T urn the choke

horizontal.

B.

Brace one

starter rope

tinue pulling

into the starter. Then, holding the starter rope firmly, rapidly pull the rope

not start after one or

little more.

a

the way and continue pulling the rope.

---------WARNING-------..

Always hold the starter rope firmly while pulling or

recoiling

injured by the rope or

the starter assembly.

9.

After the engine

lever and close the bypass valve.

Relief

Procedure

after

storage.

to

use.

See

See

foot

out

all the way out and let

If

the engine floods, open the choke all

it

to

reduce the chance

be

Fig

5.

off

by turning the lever

Fig

6.

against the frame and gently pull the

until you feel

to

two

of

is

warm, gradually open the choke

Warning

sprayed and the sprayer

it

engage, then con-

it

recoil slowly

start the engine.

attempts, open the choke

of

jamming and damaging

being hit and

See

Fig

with

on page

out

as

so

it

If

it

does

5 and 6.

is

far

is

Fig 5

______________

6

307-293

....

CHOKE

ON~

Fig

6-----------------

~~OFF

Page 7

10.

Point the gun into the metal pail and hold a metal

of

part

..-----~WARNING-----..,

To reduce the risk

cause fire or explosion, always

the gun firmly against the pail.

of

static sparking, which can

hold a metal part

See

the gun firmly against a grounded metal pail when

flushing. This

also reduces splashing.

Fig

of

7.

11.

Disengage the gun safety latch and squeeze the

gun trigger.

pressure control knob clockwise just enough

start the pump. See

A"ow

12.

At

the pump

the same time, slowly turn the

to

Fig

5.

to

operate until clean solvent

comes from the gun.

13. Release the trigger and engage the gun safety

latch.

Fig 7

-----------------

MAINTAIN

METAL

CONTACT WHEN

FLUSHING

TO

FIRM

METAL

14.

If

you

are

going

to

start

spraying,

place the

pump or accessory suction tube into the supply

container.

Release

the gun safety latch and trigger

the gun into another empty, metal container,

of

holding a metal part

the gun firmly against the

metal pail, and force the solvent from the pump and

hose. Engage the gun safety latch until you are

to

15.

ready

If

you

prime the pump

are

going

to

(see

store

Step 3, page 9).

the

sprayer,

the accessory suction tube or pump from the sol-

of

vent pail, holding a metal part

the gun firmly

against the metal pail, and force the solvent from

the pump and hose. Engage the gun safety latch.

to

the

Refer

"When

16.

Whenever

Pressure

"Storage"

To Flush",

you

shut

Relief

Procedure

procedure in the section

see

page 6.

off

the

sprayer,

Warning,

follow the

on page 2

or 8.

remove

307-293 7

Page 8

Pressure

To reduce the risk

from moving parts, always

any part

Engage the gun safety latch. (2) Open the bypass valve. (3) Depress the engine stop button. (4) Close the fuel

shutoff valve.

metal pail, and trigger the gun

a container ready

If

you suspect

following the steps sbove, VERY SLOWLY loosen the tip guard retaining nut or hose end coupling and relieve

pressure gradually, then loosen completely.

of

;/

""

~'\../

Relief

/\

Procedure

of

serious bodily injury, including fluid injection, splashing in the eyes or on the skin, or injury

follow this procedure whenever you shut

the spray system, when installing, cleaning or changing spray tips, and whenever you stop spraying. (1)

(5) Disengage the gun safety latch and hold a metal part

to

catch the drainage. (8)

thst

the sprsy tip

/\

to

relieve pressure. (6) Engage the gun safety latch. (7) Open the drain valve, having

or

hose is completely clogged,

~

WARNING

Lea(ve

the drain valve open until you are ready

Now

clear the tip or hose. 5

./3

--------------~

off

the sprayer, when checking or servicing

of

or

the gun firmly

thst

pressure hss

\_

,"

c~

to

the side

to

spray again.

not

been fully relieved

of

a grounded

sfter

~~\1.'\~

"/

1. Prepare

a.

Prepare the fluid according

manufacturer's recommendations.

b. Place the pump or accessory suction tube into

the fluid container.

2.

Starting

a.

Open the bypass valve to make startup easier.

In

the open position, the valve lever

to

the body

the filter drain valve.

b. Turn the pressure control knob

wise

be

able

lowest pressure setting. Turning the knob further

c.

Open the fuel shutoff valve

tion.

d.

If

the engine

the lever in the direction of the arrow.

e.

Brace one

pull the starter rope until you feel

then continue pulling

recoil slowly into the starter. Then, holding the

starter rope

the engine.

attempts, open the choke a little more. If the

engine

continue pulling the rope.

1

the

Fluid

the

Sprayer

of

the valve. Refer

until all spring tension

to

feel it. The sprayer is

will cause

See

floods, open the choke all the way and

it

to

fall off.

Fig

8.

is

cold, close the choke by turning

foot

against the frame and gently

all the way out and let

firmly, rapidly pull the rope

If

it

does not start after one or

~

to

the fluid

is

to

Fig

counterclock-

is

relieved. You will

now

set at the

to

a vertical posi-

See

it

parallel

8. Close

Fig

9.

engage,

to

start

two

it

FUEL

Fig 8

SHUTOFF

VALVE

_______________

7

_

r--~----WARNING

Always hold the starter rope firmly while pulling or

recoiling it

injured by the rope or of jamming and damaging

the starter assembly.

8

307-293

to

reduce the chance

-------.

of

being hit and

Fig 9

______________

~~

OFF

ON~

_

Page 9

f. After the engine is warm, gradually open the

choke lever and close the

8 and

9.

NOTE: In cold weather, run the engine

minutes with the bypass valve open before

starting the displacement pump

hydraulic motor stalling.

avoid

g. Follow the Pressure

Ing,

on page 8,

to

Relief

shut

off

bypase valve.

for

Procedure

the sprayer.

-------WARNING------

To

stop

the

engine

the engine STOP button. Close the bypass valve

possible. See Fig 8. Then relieve the fluid pressure

in the pump and hose

sure

Relief

3.

Prime

a.

Be

b. Don't

c.

If

procedure in

d. Disengage the gun safety latch.

e.

Point the gun into a metal pail and hold a metal

part

10.

f. Squeeze the trigger and slowly turn the

pressure control knob

start the pump.

g.

Operate the pump until all air

pump and hoses and fluid is flowing freely from

the gun.

h. Release the trigger and engage the gun safety

latch.

L Turn the pressure control knob counterclock-

wise

be

lowest pressure setting. Turning the knob further will cause it

j.

Follow the Pressure

ing

gun

instruction

Procedure

the

Pump

sure the gun safety latch

install the spray tip yeti

the engine has not been started, follow the

of

the gun firmly against the pail.

until all spring tension

able

to

on page

as

instructed in your separate gun or nozzle

-------CAUTION

DO

NOT move the sprayer while the engine is

operating. Tilting the sprayer during operation will

cause lubrication problems.

in

an

emergency,

as

instructed in the Pres-

Step

Warning,

2,

page

on page

is

8.

engaged.

clockwise just enough

See

Fig

8.

is

purged from the

is

feel it. The sprayer

to

fall off.

8.

manual.

Relief

Then install the spray tip in the

relieved. You will

is

now

Procedure

------

MAINTAIN

METAL

CONTACT WHEN

FLUSHING

TO

depress

See

Fig

about

15

to

help

Warn-

if

8.

See

Fig

to

set at the

Warn-

FIRM

METAL

4.

Adjusting

a.

Turn the pressure control knob clockwise

crease and

pressure. Tighten the knob locknut

b. Always use the lowest pressure necessary

completely atomize the fluid.

-------CAUTION

Operating the sprayer at a higher pressure than

needed wastes fluid, causes early tip wear, and

shortens sprayer life.

c.

If

rather than increasing the pressure.

d. Check the spray pattern. The tip

determine the pattern width and

Refer

ed

-------CAUTION

The engine throttle

2800 RPM. The sprayer warranty will

and the

justment

5.

Cleaning a Clogged

---~-.-..;WARNING------

To reduce the risk

NEVER

the spray tip when cleaning or checking

cleared tip. Always point the gun toward the

ground or into a waste container when checking

see

to

clearing tip.

a.

Follow the Pressure

ing

b. Clean the front

day

the tip. To clean, and

while

nozzle instruction

cedure.

6.

When

a.

Whenever you stop spraying, even

( break,

Warning

b.

Clean the

separate gun instruction

c. Flush the sprayer at the end

the fluid you are spraying

could harden in the sprayer overnight.

vent

an

d.

the

Pressure

counterclockwise

to

to

-----

more coverage is needed,

to

the separate instruction manual receiv-

with

your gun.

use

a larger tip

size

flow

-----

has

been set and locked at

hydraulic pump life shortened

is

changed.

Tip

of

a fluid injection injury,

hold your hand, body, or rag in front

if

the tip was cleared or when using a self-

Relief

on page

to

spraying, refer

Shutting

"Flushing"

to

oil-based solvent such

help prevent pump corrosion. Be

relieve

with

mineral

For

long term shutdown or storage, always fill

the sprayer

corrosion. Be

pump

8.

of

keep fluid from building up and clogging

follow the Pressure

on page 8.

tip

flush, then fill the pump and hoses with

pressure

after

the tip frequently during the

to

clear a tip

to

your separate gun or

manual for the proper pro-

Off

the

Sprayer

and gun

on page

with

sure

filling

as

recommended

manual.

6.

Use a compatible sol-

in

spiritsl

the

mineral spirits

to

relieve

it

with

is

be

if

this ad-

Procedure

Relief

of

water-based

as

pump

mineral

for

Procedure

each work day

mineral spirits

after

to

prevent pump

pressure

to

in-

decrease

set.

to

.......

and angle

rate.

....

voided

of

for

a

Warn-

if

it clogs

a short

by

your

or

if

See

to

sure

to

filling

in

the

spirits/

if

it

Fig

10

________________

_

307-293 9

Page 10

1.

Always

stroke

day. This

and damaging the packings.

2.

Keep

nut/wet-cup

helps

3.

Check

should be tight enough to stop leakage,

tighter. Overtightening will damage the packings.

stop

the

when you take a break and at the end

helps keep fluid from drying on the rod

the

protect the packings and rod.

the

tightness

pump a the

displacement

1/4

full

of

TSL at

of

the

bottom

pump

all

times. The TSL

packing

nut

packing

------CAUTION------

Proper engine and hydraulic oil level

to prevent

as

often

4.

Check

must be up

only Graco Hydraulic Oil,

5.

Check

oil must

the fill cap unthreaded.

more than one ounce

Consult the engine manual, supplied, for additional

recommended maintenance.

costly damage

as

recommended

tha

hydraulic

to

the top mark on the dipstick (25).

the

engine

be

up

to

to

the sprayer. Check it

in

Steps 4 and 5, below.

oil

level

see

oil

level

the top mark on the dipstick with

The

engine should not

of

oil per hour

is

important

weekly.

ACCESSORIES.

at

least

weekly.

of

operation.

of

of

the

daily.

but

The oil

Use

The

use

Its

It

no

8.

To

change

a.

Follow the Pressure Relief

Ing,

ceeding.

Place a waste container under the drain plug (7)

b.

of

the

plug before proceeding.

c.

Remove the nuts (4) and reservoir (66).

d. Remove the return line filter (55) and install a

new filter assembly.

e. Inspect the inlet filter (21)

f. Install the reservoir and nuts. Then pour

2-1/2

through the dipstick hole (25),

stall

the

hydraulic

on

page 8. Allow the oil to cool before pro-

the hydraulic reservoir.

plug, and drain the reservoir. Reinstall the

gallons (9.5 liters)

the dipstick.

oil:

Procedure

See

Fig

11. Unscrew

and

replace

of

Graco Hydraulic

See

Fig

Warn-

if

needed.

11. In-

in

Oil

6.

Inspect

clogging. Replace it after every

tion or every six months, whichever comes first. A

clogged or worn

and will damage the hydraulic pump.

7.

Change

of

first. For continuous operation in temperatures

above 85°F (30°C), change the oil after every 1000

hours or six months

cedure.

------CAUTION

Cleanliness

hydraulic system.

ting dust or dirt into the hydraulic system to prevent damage to the

the

return

out

the

operation or every

hydraulic

is

essential when servicing the

Use

hydraulic components.

line

filter. (65)

filter reduces filter capability

oil

after

12

months, whichever comes

of

use.

Refer to Step 8

frequently

500

hours

every

2000 hours

-----

special care

to

avoid get-

of

for

for

opera-

pro-

.......

Fig

11

_______________

_

10 307-293

Page 11

~-----------------------------WARNING------------------------------~

To reduce the risk

from moving parts,

troubleshooting

of

serious bodily injury, including fluid injection, splashing in the eyes or on the skin, or injury

always

or

repairing your sprayer.

follow

the Pressure Relief Procedure Warning

as

given on page 2

or

8 before

Check everything in the Troubleshooting Chart before disassembling the sprayer.

TROUBLESHOOTING

PROBLEM

Gas

engine doesn't work properly.

Gas

engine operates,

ment pump doesn't operate.

Displacement pump operates, but Piston

output

is

low

on upstroke.

Displacement pump operates but out- Piston packings worn or damaged.

put

is

low

both strokes.

Paint leaks into wet-cup.

Excessive

motor piston rod wiper.

Fluid delivery

on downstroke

leakage around hydraulic Piston rod or

is

low.

but

displace-

and/or

on

CAUSE

motor

Hydraulic

Pressure setting

Displacement pump outlet filter (if Clean the filter.

used) dirty

Tip or tip filter (if used) clogged.

Hydraulic fluid

Hydraulic pump worn or damaged.

Hydraulic motor worn or damaged. Return sprayer

Displacement pump rod seized

dried paint.

ball check not seating properly. Service piston ball check.

Piston packings worn or damaged.

Intake valve ball check

properly.

Loose wet-cup.

Throat packings worn or damaged.

Pressure

Displacement pump

used)

Hydraulic pump worn or damaged.

Hydraulic motor wom or damaged. Return sprayer for

Large

setting too low.

dirty or clogged.

pressure drop

stalled. See

too

low.

or

clogged.

too

low. Shut

not

seating Service intake valve ball check. See

seal

worn or damaged.

outlet filter (if

in

fluid hose.

by

SOLUTION

Consult

Increase

Remove tip

mediately. *

page

Tighten just enough to stop

engine manual, supplied.

"Starting

off

Return sprayer

Service pump. See page

Replace packings. See page

Replace packings.

13.

Replace

Replace

the Sprayer;' page 8.

pressure.

sprayer and add fluid im-

packings.

these parts.

and/or

See

page

for

for

See

See

page

filter and clean.

5.

repair.

repair.

13.

See

page

page

See

manual

306-98l.

Increase

Clean

Return sprayer for

Use

pressure.

filter.

larger diameter

repair.

repair.

hose.

9.

See

page

13.

13.

leakage.

13.

13.

Spitting from gun.

*Check the hydraulic fluid

Use

only Graco approved hydraulic fluid;

level

often.

Air entrained

Fluid

supply

Do

not allow it to become too low.

see

page

in

fluid pump or

is

low

5.

or empty.

hose.

Check for loose connections on suction

assembly, tighten, then reprime pump.

supply container.

Refill

307-293

11

Page 12

Disconnect

1.

Solvent flush the displacement pump

Stop the pump on the down stroke.

the

Displacement

Pump

if

possible.

2. Follow the Pressure Relief

on page 8.

3.

Remove the accessory suction tube,

remove the fluid hose from the displacement pump.

Procedure

if

Warning

used, and

4. Unscrew the three tie rod locknuts (114).

5. Remove the lower cotter

6.

Unscrew the displacement rod from the connecting

rod.

7. Pull the pump

Displacement

NOTE:

Packing Repair Kit No. 208-919

for

page

parts in the kit.

off

the tie rods (116).

Pump

servicing the displacement pump.

18.

For the best results,

pin

Service

(1121.

use

is

all

available

See

the new

12 307-293

Fig

12

------

_________

_

Page 13

Intake

1.

2.

Valve

Unscrew the extension (62),

the retaining ring

tension. Clean the parts

(See Fig

(52) and strainer

13)

in

solvent.

if

Screw the intake valve housing

used, and remove

(51)

from the ex-

(138)

out

pump housing (140).

3. Remove the

(125)

and o-ring (133)from the intake valve housing.

4.

Clean

damage, replacing parts

5.

If no further pump service is needed, reassemble

valve and screw

the

quing

Piston,

1.

Cylinder,

Screw the intake valve housing

ball stop pin (132), ball guide (136), ball

all the parts and inspect them

as

needed.

it

to

65

to

75

or

into the pump housing, tor-

ft-Ib (88

Displacement

to

102

N·m).

Rod (See Fig

out

for

of

housing.

2.

Loosen the packing nut

ment rod

3. Secure the rod

(139)

4.

Remove the ball (124), retainer (130), glands (137,

135)

(142)

down and out

in

out

of

the displacement rod.

and packings

(141)

and push the displace-

of

the housing.

a vise and screw the piston stud

(127,

131).

of

the

wear or

13)

the pump

USE WRENCHES

ON FLATS ONLY

135

31

LIPS

.~~-----=:::...<-...,

OFTHE

V-PACKINGS

MUST

FACE

DOWN

137

THROAT

PACKINGS

124

30

127

LIPS

OF

THE

FACE UP

a---'~'

V-PACKINGS

MUST

35

139

TORQUE TO

66-76 ft-Ib

(88-102 N·m)

5.

Clean

all parts and inspect them carefully

or damage. Inspect the outside

inside

of

these parts

if

needed. A worn rod or cylinder will

cause premature wear

Stack a female gland (135), one PTFE v-packing

6.

(131)

and four leather v-packings (127), male gland

(137)

and packing retainer

Be

sure the lips

7.

the cvlinder

Grease

(124)

Torque

NOTE:

the outside

on the piston, and install the piston in the rod.

to

65

to

If

you

are

for

of

of

the v-packings face UP.

of

the packings, place a ball

75 ft-Ib (88

installing a new sleeve, be sure

of

the rod and the

scoring or wear. Replace

the packings.

(130)

on

the piston stud.

to

102

N·m).

for

wear

to

install it with the tapered end down and

(128)

place a new gasket

and housing.

If

the old sleeve cannot be

between the sleeve

removed easily, contact your nearest Graco

Factory Branch or

Service Depot.

8. Slide the displacement rod up into the housing from

it

the bottom until

protrudes from the packing nut.

Reinstall the intake valve.

Throat

1.

Packings

(See Fig

13)

Screw the intake valve housing out

of

the pump

housing.

2. Remove the piston and rod

as

explained above.

INTAKE

VALVE

Fig

13-------

6.

Loosely install the packing nut/wet-cup (141).

7.

Reinstall the displacement rod and intake valve.

Reassembly

1.

Secure the displacement rod to the motor

(See

Fig

_______

12)

cotter pin (112).

2. Secure the pump housing

and tighten the tie rod locknuts

50 ft-Ib

(47

to

68 N·m).

(140)

to the tie rods

(114)

evenly

3. Tighten the packing nut just enough

leakage,

with

TSL.

but

no

tighter.

Fill

the wet-cup

PISTON

VALVE

with

to

to

1/4

_

(116)

35

to

stop

full

a

(131,

127)

3. Remove the pac kings

137)

from the throat

4.

Clean

the throat.

5. Grease the inside

of

of

the pump housing (140),

the packings, then install the

and glands (135,

male gland (137), four leather v-packings (127), one

PTFE v-packing

(131)

and the female gland

(135), one at a time into the throat, being sure they

"nest"

face

properly.

DOWN.

Be

sure the lips

of

the v-packings

4.

Install the extension

(62)

assembly or accessory

suction tube.

5.

Start the pump and operate it slowly to check the

tie rods

necessary,

6.

Reinstall the pump in its mounting.

for

binding. Adjust the tie rod locknuts,

to

eliminate binding.

if

7. Before operating the pump, reconnect the sprayer

ground wire

if

it

was disconnected during repair.

307-293

1~

Page 14

Replacing the Hydraulic Pump

1.

Follow the Pressure Relief Procedure Warning

on page 8. Let the hydraulic system cool before

beginning the service procedure.

9.

Be

sure the new hydraulic pump

as

number

stamped on the pumps

the old one. Check the numbers

to

verify them.

has

the same part

2. Unscrew the reservoir drain

tainer ready

3.

Disconnect the hydraulic inlet hose

swivel

4. Disconnect the bypass

(84).

5.

Remove the four nuts

on the reservoir cover (90).

6.

Remove the

washers (98)

7.

Pull the pump away and loosen the setscrews (38a)

on the pump half

8.

Raise

(21)

filter

to

catch the draining fluid.

union

(45)

at the motor and from the tee (54).

two

screws (8), lockwashers

holding the hydraulic pump (70).

of

the pump and turn

which

is

in the oil reservoir.

plug (7), having a con-

(92)

hose

(85)

from the ball valve

(27)

from the seal plate

the coupler (38).

it

to

unthread the inlet

from the 90°

(11)

(160)

and

10.

Remove all fittings from the old pump and install

them on the new pump in the same order.

11.

Install the new pump, being sure

let filter

12.

Check Dimension A

dimension is correct, tighten the setscrews (38a).

(21)

to

the bottom

as

shown in

r-------CAUTION

The correct coupling dimension

improper

spider which will damage the coupler and make

the sprayer

13.

Reconnect the hoses. Reinstall the reservoir plug

(7),

approved

coupler engagement

inoperable.

and refill the reservoir with clean, Graco-

hydraulic oil.

to

of

the pump.

Fig

------.,

is

critical

to

connect the in-

15.

When the

to

the coupler

76

avoid

Fig

90

14

__________________________________

65

_

14

307-293

Page 15

Drive

Unit

1.

Disconnect the hydraulic inlet hose

paint pump's

2. Loosen the coupling

90°

swivel union (45),

disconnect the hydraulic oil drain hose

oil cooler inlet elbow

(See Figs 14 and

Disconnect the bypass hose (85) from the bypass

3.

4.

(84).

valve

Remove the oiler cooler

cooler retaining screw

(2).

drain hose

nut

(42).

Loosen the cooler drain connector

Pull the cooler up, out

5. Remove the locknuts

15)

nut

of

the elbow (41) and

(41).

(69),

the fan guard (76), the

(40) and clamp

of

(27)

from the

(92)

(2) from the

(68),

the housing.

four

mounts (31).

6.

Remove the four locknuts

(160) screws.

plate

(27)

from the filter seal

from the

and the

engine

9.

Insert a hex socket wrench between the blades

the fan wheel (75) and loosen the coupling setscrew

(38a) so you can remove the flexible coupling

and key (38b). Loosen the fan wheel setscrew (X)

and remove the fan wheel (75).

10.

Unscrew the

adapter plate

11. Unscrew the

mounting screws

mounting plate

12.

Replace parts

order

of

four

capscrews

(64) from the engine.

four

locknuts (20) from the engine

(3) and

(65).

as

needed and reassemble in reverse

(34)

lift

the engine

and remove the

disassembly with special attention

following:

NOTE: Set the gap between the

flexible

coupling

(38)

two

halves

at 1/32 in. (0.8 mm)

and tighten the setscrews firmly. See Fig

off

to

of

of

(38)

the

the

the

15.

7. Lift up the entire drive assembly (engine, fan, and

tilt

it

hydraulic pump) and

8. Remove the

(60)

housing

hydraulic pump

to

four

screws

the adapter plate (64) and take the

(70) and cooler housing

forward.

(12)

holding the cooler

off

of

the

engine (32).

X

Fig15

TOP

CUTAWAY

OF

COUPLINGS

VIEW

(38)

INSIDE COOLER HOUSING

(60)

________________________________________________________________________

307-293

__

15

Page 16

-

--------;;--;-;::;-----

NO

TE:

and tubing

Corresp~md~nJ1nnections"

" bold letters (A)

re

fer

to

hose

110

el

215-433, Series G

Includes I

Mod "tems2-171

Model

Includes Item

006 Series A

~1-

s 2-169,

41

171

17-"

.....

'j

i"'ll.

69

90

(ref)

78

6

307-293

Page 17

64

Model

Includes Items

433

2~5-

Series G

2-171

Model

Includes Items

006

~1-

Series A

2-169,

171

27

160 --____

102

....

58

307-293

11

Page 18

Ref

No

No.

110

171

123

Includes items

111-142,

Ref

Includes items

124-142

.

,.?--111

117

./'"115

118

(see

306-980

for parts)

142

~

U~130

122

18

140

128~~.

~

129

~

~

307-293

Torque

U

I

Torque

I

to

65-75

(88-102

to

(88-102

~.-=~

137

®'

114

127

..

~

135~.

~::~

ft-Ib~

N'm)

134

133~

136~~132

125~

138~

65-75

ft-lb::C~,_

N'm):

~

td

208-919

(Ord~r

Consists of:

*Use extra packin (

if

Pump

separately).

Ref

No.

124

125

127*

131

133

135

137

stacking

Repair P

Qty.

1

1

6

2

1

2

2

is

loo~e.

arts

ref no.

Kit

127)

in piston

Page 19

PARTS LIST

Model 215-433, Series G

Includes items

REF

PART

NO. NO.

2 215-969

3

100-003 CAPSCREW, hex

4

104-858

6

100-028 LOCKWASHER,

100-040

7

B

100-101

9

100-186

100-188

10

11

100-133

12

100-575

13

160-032 NIPPLE, pipe;

14

100-467

15

100-615

16

100-896 BUSHING, pipe;

17

104-869 SCREW, pnh, seIf·tapping, 10-24 x

18

101-242

19 178-392

20

101-566

21

In-267

23 102-801 CLIP, retaining

25

215-971

27

103-450

28

104-120 CAPSCREW, hex hd;

30

104-761

31

104-766

32

104-788

33

100-001

34 105-180 CAPSCREW, hex hd;

161-401

35

36

104-772 BOLT, carriage;

37

102-782 WASHER, plain;

105-793 COUPLING, flexible 1

38

40

100-014

41

105-457 ELBOW, union; 3/8-18 (fbe) 1

42

104-782

43

100-187

44

154-636 WASHER,

165-470 UNION, 90° adapter;

45

46

156-971

47

158-556

48 160-327

50

104-832 PIN, clevis 2

51

164-717 STRAINER,

164-718

52

53

165-198 NIPPLE, hex reducing;

54

168-466 TEE, pipe;

167-748 FILTER, fluid

55

58 174-019 HANDLE,

174-020

59

177-266

60

61

174-028 SUPPORT, frame 1

62

174-029 HOUSING, screen 1

63

174-032 FITTING, pump;

64

174-035 PLATE, adapter

66 174-038

214-607

66

67

174-040

174-041

68

177-270

69

70 177-269 PUMP, hyd., 950 psi (66.5 bar) max., 6

71

219-099 KNOB,

72

73 179-811

74

174-066 SPACER,

174-066

75

76

174-076

172-809 GUARD, fan 1

T!

78 174-079 GUARD, fan,

79 174-077

81

208-994

84

210-667

86 214-638

157-676 .UNION,

86

88 214-570 FLUID FILTER, see instruction manual 307-273 1

89

214-580 SUPPORT,

90

215-970 COVER, reaervoir 1

214-596 HOSE,

91

214-601 HOSE,

92

93

104-781 SLEEVE, compression 1

94 172-532 LABEL, warning

167-812

95

150-707

97

98

100-731

2-171

DESCRIPTION

HOSE,

3/8"

3/8"

NUT,

PLUG, pipe;

CAPSCREW, hex hd; 3/8-16 x

LOCKWASHER,

NUT,

LOCKWASHER;

CAPS CREW,

ELBOW,

BUSHING,

RING, retaining,

CLIP, retaining 2

LOCKNUT,

FILTER, hydraulic fluid 1

INDICATOR, hydraulic oil level

LOCKNUT,

KNOB, removable 2

MOUNT,

ENGINE, gasoline;

CAPSCREW,

PLATE, support, diaphragm 4

CAPSCREW,

NUT, compression

NUT,

swivel

NIPPLE, short;

NIPPLE,

UNION, 90°; adapter

swivel 1

RING,

HANDLE, upper

HOUSING, cooler 1

PLATE,

RESERVOIR

GASKET,

CLAMP, pad

COOLER

KEY,

WHEEL, semi·pneumatic 2

WHEEL,

GUARD,

PAD,

THROAT

BALL

HOSE, static free airless;

cpld

wlspring

swivel 1

EMBLEM, Graco

PLATE, designation

WASHER,

ID; Buna·N'" tube, cpld

npt(f),

90° swivel

flange; 1/4-20 24

3/8

hex; 5/16" 3

street;

pipe;

nylon insert; 3/8-16 4

hex; 5/16-18 8

engine 4

hex; 5/16-24 1

flat

hex reducing;

pump

retaining 1

3/4

lower

mounting

reservoir 1

pump

parallel; 0.187" square; 1.875" long 1

wheel

blower

fan

cooler

SEAL

VALVE, see 306-861

1/4"

npt(mxf);

guards; includes item 86 2

90°

adapter; 1/4"(f) x

pump

3/4"

10, cpld

1/2"

ID, cpld

flat

w/o·ring;

hd;

3/8-16x

int

tooth;

npt

int

tooth;

3/B"

hex hd;

3/8-16x5/8"

3/4

npt

x 1-3/8" 1

1"

npt

3/4x

1/4

3/4x

1/2

ext. 2

5/16-18x

4.6 hf,

hex hd; 5 16-18 x

5/16-24x3/4"

5/16-18x2"

1/4"

hex hd; 1/4-20 x

1/2

1/4

npt

1"

3/4

3/B x 1/4

npt(f)

3/4

npt(ml

lower

L10UID, 1

14"

3/4

1/2

1

ft

Ig. 1

1-1/2"

1/4"

l'

5/16"

npt

npt

3/8"

1"

5/8"

1-1/4"

npt(m) x

1/2

npsm(f)

x

3/4

npt

npt(m)

x

3/4

npt(f)

npt

x

1/4

npt(m)

gpm

max. 1 both ends

pint

for

parts 2

1/4"

ID nylon tube,

Ig (350

mm),

1/4

npsm(f)

npt(mbe) 1

npt(mbe) 1

Model 231-005, Series A

Includes items 2-169,

REF

OTV

4

1 Includes items

1

2

15

4

4

1

2

1

12

2

1 123

3

1

B

4 130

2

2

1

1

6

1

2

2

1

1

1

1

1

1 includes items

1

1

1

1 l70c 217-593

2 See 307-321

1

1

1

2 "Recommended

1

1

1

1

1

6

PART

NO.

NO.

100 101-846

101

102

103

104

105 102-302

110

111

112

113

114

115

116

117

118

119

120

122

124

125

127

128

129

131

132

133

134 165-279

135

136

137

138

139

140

141

142

144

145

146

156

157

159

180

161

162

163

164

168

167

188

169

170

1708

170b

170d

171

XXi

103-181

103-538

208-950

065-136 .WIRE, electrical

214-605

Series A includes items 111-142,

l00-07B . SCREW, rd

"100-103 .PIN, cotter;

101-330

101-566

102-360

168-221

169-453 .SHIELD

169-455

167-817

169-933 .LABEL, hydraulic inlat

208-666

Series C

208-916 .DISPLACEMENT PUMP

Series A includes items 123-142

""100-066 ..

""100-084 ..

""164-477

"164-480

164-481

164-484 .. RETAINER, piston packing

"·164-862

165-049

""165-052 .. SEAL, o·ring; PTFE 1

""165-895 ..

170-257

""171-146 ..

205-981 .. HOUSING, intake valve

208-345 .. SEAT, piston valve

207-420

207-731

210-041

208-755 CABLE

104-811 CAP, hub

102-472

156-823

176-680 SEAL, flange

168-590 ELBOW, street; 3/4-14

176-681 PLATE, seal

103-927 CLAMP, hose

177-661

510-161

105-972 CLIP, retaining

158-223

105-429

176-140 LABEL, identification

176-139 LABEL, warning

218-918

210-541

214-701

21S-001

154-771

& 307 Numbers in description refer to separate instruction manuals.

"tool

""Supplied in repair

See

"How

kit

To

Order Replecement Parts"

171

DESCRIPTION

SCREW, self·tapping; type

LOCKWASHER,

CLAMP,

CONDUCTOR,

.TERMINAL,

VISCOUNT

.SCREW,

.LOCKNUT,

.WASHER,

.ROD,

tie; 5-3/4" (146

.PLATE, designation

.CAP

.VISCOUNT HYDRAULIC MOTOR

see 306-980

BALL,

chrome alloy;

BALL,

chrome alloy; 112" dia

.. V·PACKING. leather

.. GASKET, PTFE

.. SLEEVE,

.. V·PACKING, PTFE

.. PIN, ball stop

.. RETAINER, o·ring

GLAND,

.. GUIDE, ball

GLAND,

..

HOUSING, displacement

.. NUT, packing;

.. DISPLACEMENT ROD

RIVET, blind

UNION,

straight adapter;

GUARD, muffler

FASTENER, screw,

WASHER,

NUT,

seal 1

HOSE & GUN KIT

.HOSE,

1/4"

m)long;

(15

.HOSE,

3/16"

1/4

npt(m);

.AIRLESS SPRAY GUN

See 307-614

.SPRAY

O·RING; Buna·N

box"

spare parts.

208-919.

ext

ground

ground

104

& 105

ring

3000 Pump Assy,

hd

mach; 8-32 x

1/8x

1-1/2"

drive; type

3/8-16 screw size

flat

for

parts

hOUSing

packing; female

packing; male

w/lubricant

3/4"

special;

9/32"

170e-17Od

ID; nylon, cpld

spring guards

ID; nylon, cpld

3

ft

(0.9

for

parts

TIP KIT

for

garts

Keep

on

"f",

tooth;

"U",

m)long;

page

6-32x3/8"

no. 6

171

1"

No.

2x

1/4"

mm)

ASSY,

5/16"

dia

pump

cup 1

1/4

npt(m

x

fl

npt

(mbe) 1

Ig

1/4

npsm(f); 50

both

ends

1/4

npsm(fl

spring guards

on hand to

reduca

21.

ft

x

down

25

time.

OTV

1

ft

1

1

3

1

2

3

3

3

1

1

1

1

1

1

1

6

1

1

1

2

1

1

2

1

2

1

1

1

1

2

2

2

1

1

1

1

1

2

2

2

1

1

307-293 19

Page 20

ACCESSORIES

(Must

be

purchased separately)

FLUID GAUGE 102-814

5000

psi

(350 bar)

WORKING PRESSURE

Install to

hydraulic

KEEP

read

fluid system.

DIRT OUT

SELECT-A-FAN

3000

psi

(210 bar)

WORKING PRESSURE

MAXIMUM

pressure in

OF

SYSTEM

(with

MAXIMUM

tips)

206-310

Fits the fan pattern to both wide and

narrow

surfaces and clears

tip

stoppages.

DIRECTIONAL

ADAPTER

(less

tips) 206-235

3000

psi

WORKING PRESSURE

(210 bar)

Adjustable

MAXIMUM

1800 swiveling nozzle

permits changing the spray pattern

direction

DUAL

3000

WORKING PRESSURE

Two spray tips controlled

gun-used

to

satisfy work piece demands.

ADAPTER

psi

(210 bar)

(less tips)

MAXIMUM

where one tip does not pro-

206-238

by

one spray

vide sufficiently wide spray pattern or

work piece demands

angled

in

opposite directions.

two

spray patterns

.if.·

~

,

.

:.-

STATIC

3000

Part No.

psi

214-701

210-540

210-541

214-703

214-705

FREE

(207 bar)

FLUID HOSE (Nylon)

3/16 in.14.8 m)

1/4

in.16.4 mm)

1/4

in.(6.4 mm)

3/8

in.{S.5 mm)

3/8

in.(S.5 mm)

MAXIMUM

10

WORKING PRESSURE

Length Thd. Size

3

ftlO.S

m)

1/4

nptlm x

1/4

25

50

25

50

ft17.6

ft{15.2

ft{7.6

ft(15.2

m)

m)

m)

m)

1/4

3/8

3/8

npsm(f)

npsm(f)

npt{m)

nptlm)

f)

BALL VALVE 210-657-FOR 2-GUN HOOKUP

5000 psi (350 bar)

HYDRA-CLEAN® CONVERSION KIT

Converts

GH

MAXIMUM

433

from

WORKING PRESSURE

214-664

an

airless paint sprayer to

an

airless pressure washer. Includes:

208-508

214-665

208-571

307-297

55-GAL

Displacement Pump Kit

Gun

and

Hose

Kit

Suction Kit

Instruction Manual

SUCTION TUBE

207-485

REVERSE-A-CLEAN

5000

psi

Clears

5 GAL.

REF

NO. NO.

1

2

3

4

5

6

(350 bar)

tip stoppages by paint pressure.

(19

PART

101-818

160-327

170-705

170-706

170-957

181-072

MAXIMUM

liter)

SUCTION TUBE

DESCRIPTION

CLAMP,

UNION, 90° swivel;

ADAPTER, intake

HOSE,

TUBE, suction

STRAINER

III

216-001

WORKING PRESSURE

hose

1"

ID x 48"; nylon tube

KIT

3/4

208-920

nptlmxf)

QTY

1-1/2"

HYDRAULIC

169-238

207-428

5 gallons

1 gallon (3.8 liters)

21

....

,

3/4

156-591

r

NPT::::.l]

156-593-~

156-592~W

176-684~

2"

NPT

NPT

1oo-220~

159-100~

100-279

159-101-~

FLUID (approved

(20

liters)

type)

20

307-293

Page 21

SERVICE

INFORMATION

Listed below by the assembly changed are OLD, NEW,

ADDED and DELETED parts.

ASSEMBLY

CHANGED

215-433 and

231-005** NEW

Sprayers

214-605

Viscount

Pump

PART

STATUS

OLD 100-063

DELETED

DELETED

ADDED

REF

NO.

19

96

148

171

PART

NO.

178-392

102-816

208-920

154-nl

NAME

Cotter Pin

Retaining

Cap

Suction Kit*

O-Ring

Clip

INTERCHANGEABILITY NOTE: NEW parts replace the

OLD parts listed directly above them.

*Now

available

as

an

accessory;

see

page 20.

**Model 231-005 Sprayer replaces obsolete Model

215-436.

HOW

1.

TO ORDER REPLACEMENT PARTS

To

be

sure you receive the correct replacement parts,

kit or accessories, always give

all

of

the information

requested in the chart below.

2.

Check the parts list

do

not

use the ref. no. when ordering.

3.

Order

all

parts from your nearest Graco distributor.

to

identify the correct part number;

6 digit

PART

NUMBER QTY

PART DESCRIPTION

307-293

21

Page 22

TECHNICAL

DATA

Engine

Gasoline Tank

Hydraulic Pump

Hydraulic

Fluid Sump

Hydraulic Pump Suction Filter

Hydraulic

Oil Return Filter

Fluid

Filter

Displacement Pump

Wetted Parts

Weight

Noise Level

Wisconsin Robin, Model

cylinder, air cooled, 4.6

single

EY

laW,

HP

4 cycle,

(3.43 kW)

1 gallon capacity

4 gpm

(15Iiter/min)

maximum volume; 600-900 psi

(41-62 bar) pressure range

2-1/2 gallons (9.5 liters) operating level

100

mesh

(149

(1190

microns) monel wire cloth

microns) monel wire cloth backup; reusable type.

(2580

cm2)

400 sq. in.

surface area;

with

16

25

micron filtration;

disposable type

60

mesh

(250

screen

with

microns).

3/8

npt(f) inlets and

18

sq. in.

(116

cm2)

1/4

npt(f) outlets;

stainless steel

reusable type

3000

psi

(210