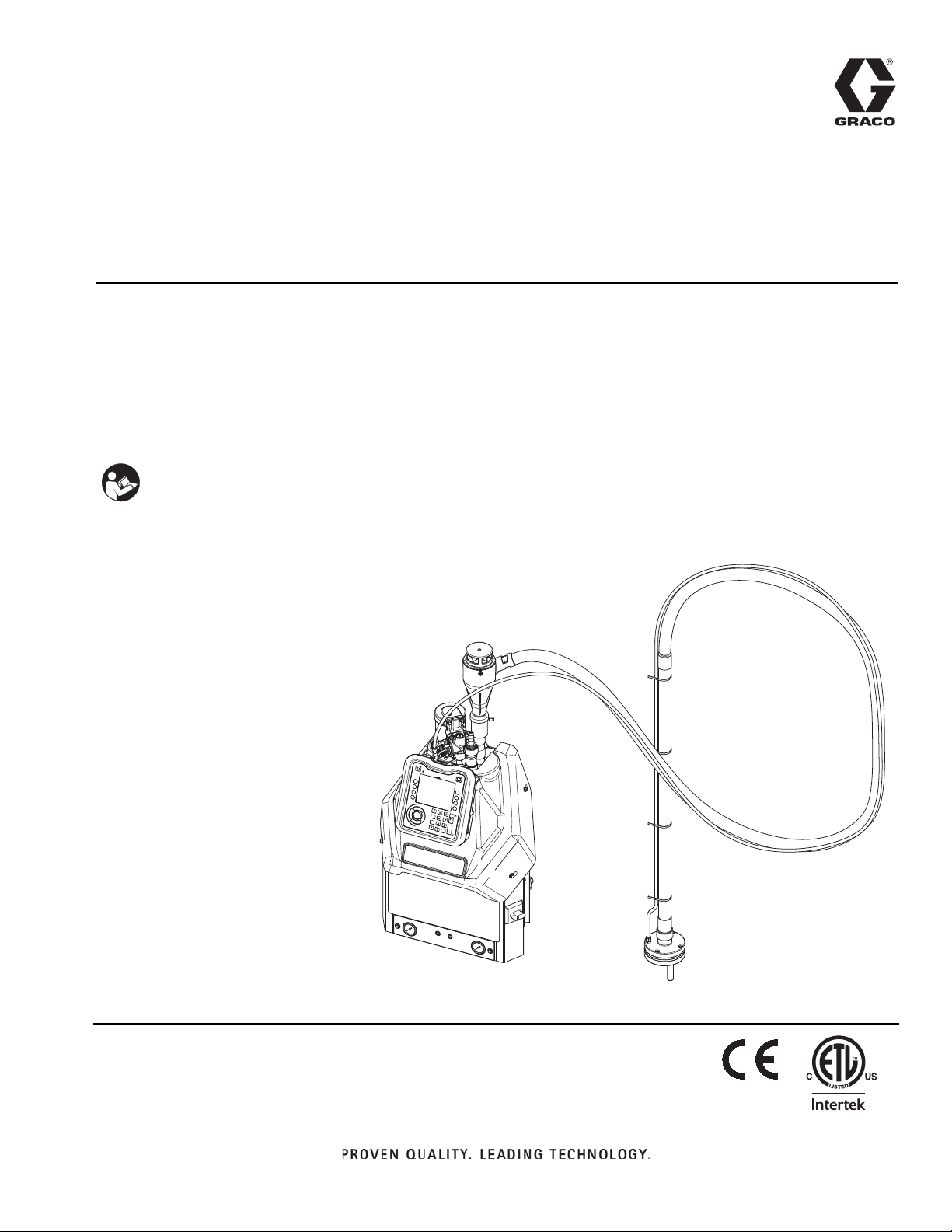

Graco InvisiPac Tank-Free HM25 Instructions - Parts Manual

Instructions - Parts

™

InvisiPac

™

HM25 Tank-Free

3A2347ZAA

Hot Melt Delivery System

For delivering and dispensing hot melt adhesive pellets. For professional use only.

Not approved for use in explosive atmospheres or hazardous locations.

1200 psi (8.3 MPa, 83 bar) Maximum Working Pressure

400°F (204°C) Maximum Fluid Operating Temperature

100 psi (0.7 MPa,7 bar) Maximum Air Inlet Pressure

Important Safety Instructions

Read all warnings and instructions in this

manual and in the gun and hose manuals.

Save all instructions.

EN

ti20440b

9902471

Certified to

CAN/CSA C22.2 No. 88

Conforms to

ANSI/UL 499

Contents

Related Manuals ...........................3

Required Tools ............................3

Models ...................................4

Warnings .................................5

Component Identification ...................8

Setup....................................13

Grounding ............................. 13

Location .............................. 13

Attach Components ..................... 13

Recommended Air Setup .................17

Connect Electrical Cord ..................18

480V Electrical Circuits ...................20

208V Electrical Circuits ...................20

SelectADMSettings ..................... 20

Guns .................................22

PLC Connection ........................23

Material Tracking ....................... 25

Operation ................................ 29

Overview ..............................29

Initial Startup and Prime .................. 29

Manual Refill ........................... 30

Automatic Refill .........................31

Dispense ..............................31

Shutdown ............................. 32

Schedule ..............................32

Pressure Relief Procedure ................33

Drain the System ....................... 33

Flush .................................34

Operation Tips to Minimize Charring.........36

Maintenance ..............................37

Replace Outlet Filter ..................... 37

Replace Inlet Filter ...................... 37

Replace Funnel Filter ....................38

Filter Maintenance Guidelines* .............39

Troubleshooting ..........................40

ADM Error Code Table ...................40

MZLP Troubleshooting ................... 53

Repair ................................... 54

Pump ................................. 54

Melter.................................58

Multi-Zone Low Power Temperature Control Module

(MZLP) ............................65

System ................................67

AirControls ............................69

AirMotor ..............................70

Software Update Procedure ...............74

Electrical Schematics ......................76

Incoming Power and Terminal Jumpers ......76

Typical Hose Applicator Wiring .............80

Parts ....................................81

Inlet Funnel Filter Kit, 24U701 ..............93

Accessories ..............................94

Preventive Maintenance Kit ................95

Complete Maintenance Kit ................95

Non-Graco Gun Adapter Cables ............96

Air Adjustment Lock, 24R084 ..............97

System Stand, 24R088 ...................98

Caster for Stand, 120302 .................98

Adapter Plate, 24R083 ...................98

30 Gallon Vibrating Hopper, 24R136 .........99

Light Tower Kit, 24R226 .................101

Air Reservoir Kit, 16W366 ................102

Air Metric Fitting Kit, 24W637 .............110

Material Tracking Kit, 24Y162 .............110

AppendixA-ADM ........................111

General Operation ......................111

Icon Identification .......................111

Appendix B - USB Downloading, Uploading . . . 117

Download Procedure ....................117

Accessing Files ........................117

Upload Procedure ......................117

USB Logs ............................118

System Settings File ....................118

System Language File ...................119

Technical Data ...........................120

Graco Extended Warranty ..................126

GracoInformation ........................126

2 3A2347ZAA

Related Manuals

Manuals are available at www.graco.com. Component

manuals in English:

Part Description

3A2805 InvisiPac GS35 Hot Melt Gun Instructions -

Parts

332072 InvisiPac Heated Hose Instructions - Parts

333348 MZLP Fuse Kit, Instructions

334784 InvisiPac Pattern Controller, Opera-

tions-Repair-Parts

335010 Dedicated Feed Sensor Air Kit

Required Tools

Related Manuals

• Standard allen wrench set

• Metric allen wrench set

• Various sizes of crescent wrenches

• 11/16 in. wrench

• 3/8 in. ratchet

• 3/8 in. socket

• 5/16 in. driver

• 7/16 in. socket

• 7/8 in. deep well socket

• 1 in. socket

• 13 mm socket

• 10 mm socket

• 1/2 in. ratchet

• Side cutter

• Phillips head screwdriver

• Flat head screwdriver

• Multimeter

• Tubing cutter

3A2347ZAA 3

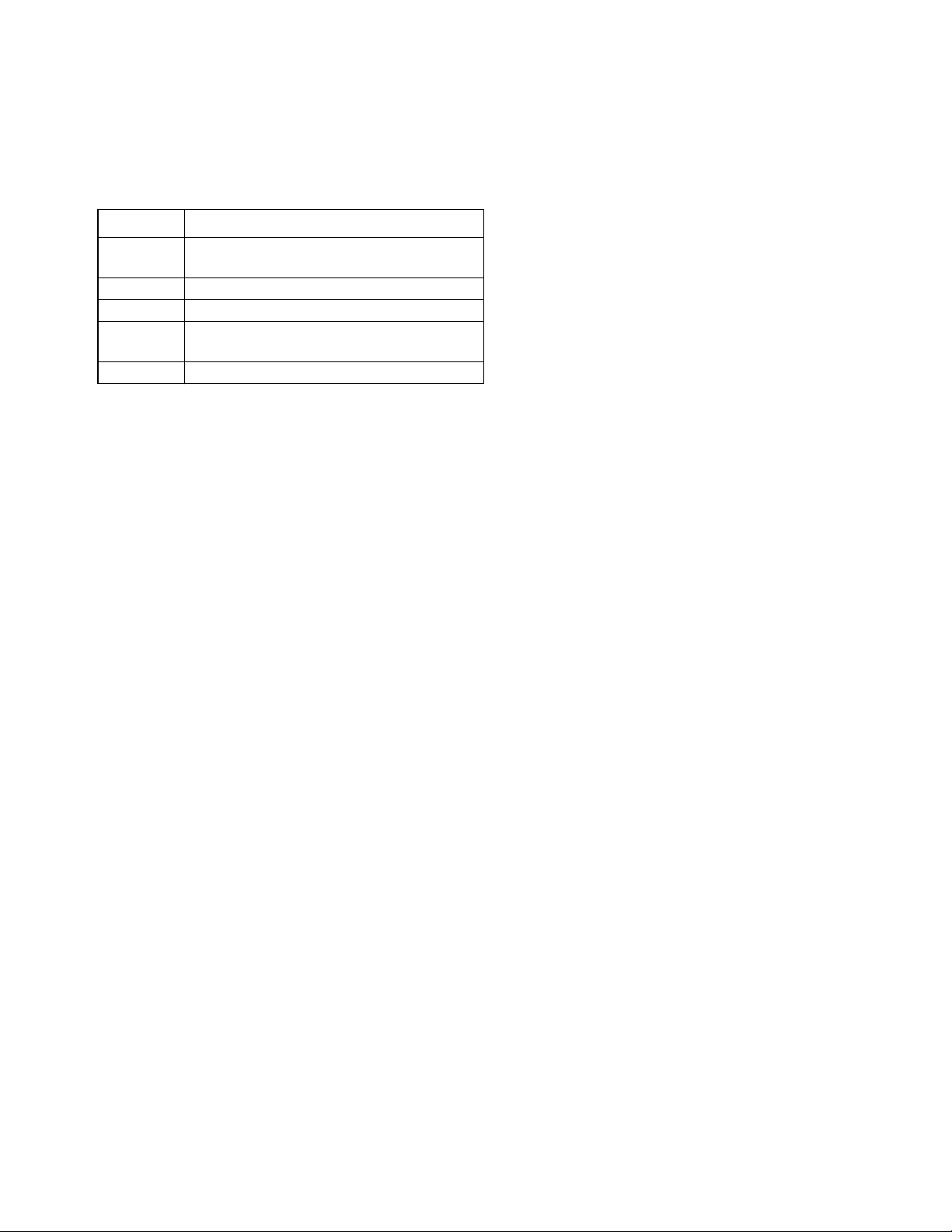

Models

Models

NOTICE

To prevent system damage, verify terminal jumpers

are installed correctly before applying power.

Model Channels Voltage ˓ Type Description Frequency

24P260 2 200-240VAC

24P261 4 200-240VAC

24P262 2 350-415VAC Y

24P263 4 350-415VAC Y

24P264 2

24P265 4

24U132 6 200-240VAC

24U133 6 350-415VAC Y

24U134 6

200-240VAC ˂

200-240VAC ˂

200-240VAC ˂

1˓ /PE

1˓ /PE

3˓ / Neutral / PE

3˓ / Neutral / PE

3˓ /PE

3˓ /PE

1˓ /PE

3˓ / Neutral / PE

3˓ /PE

• 1-Phase

• 200-240VAC

• 2 wire and PE

• 3-Phase with Neutral

• 350-415 VAC Line to

Line

• 200-240VAC Line to

Neutral

• 3 wire and Neutral and

PE

• 3-Phase without

Neutral

• 200-240 VAC Line to

Line

• 3 wire and PE

• 1-Phase

• 200-240VAC

• 2 wire and PE

• 3-Phase with Neutral

• 350-415 VAC Line to

Line

• 200-240VAC Line to

Neutral

• 3 wire and Neutral and

PE

• 3-Phase without

Neutral

• 200-240 VAC Line to

Line

• 3 wire and PE

50/60 Hz 32A

50/60 Hz 40A

50/60 Hz 16A

50/60 Hz 16A

50/60 Hz 27A

50/60 Hz 27A

50/60 Hz 40A

50/60 Hz 30A

50/60 Hz 40A

Max

Amps

4 3A2347ZAA

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

WARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause

electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

or installing equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns:

• Do not touch hot fluid or equipment.

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

+

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure and disconnect all power sources.

3A2347ZAA 5

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Do not use solvent-based adhesives that can create an explosive atmosphere when processed.

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

6 3A2347ZAA

Warnings

WARNING

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes but is

not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical

reaction and equipment rupture. Failure to follow this warning can result in death, serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier for compatibility.

3A2347ZAA 7

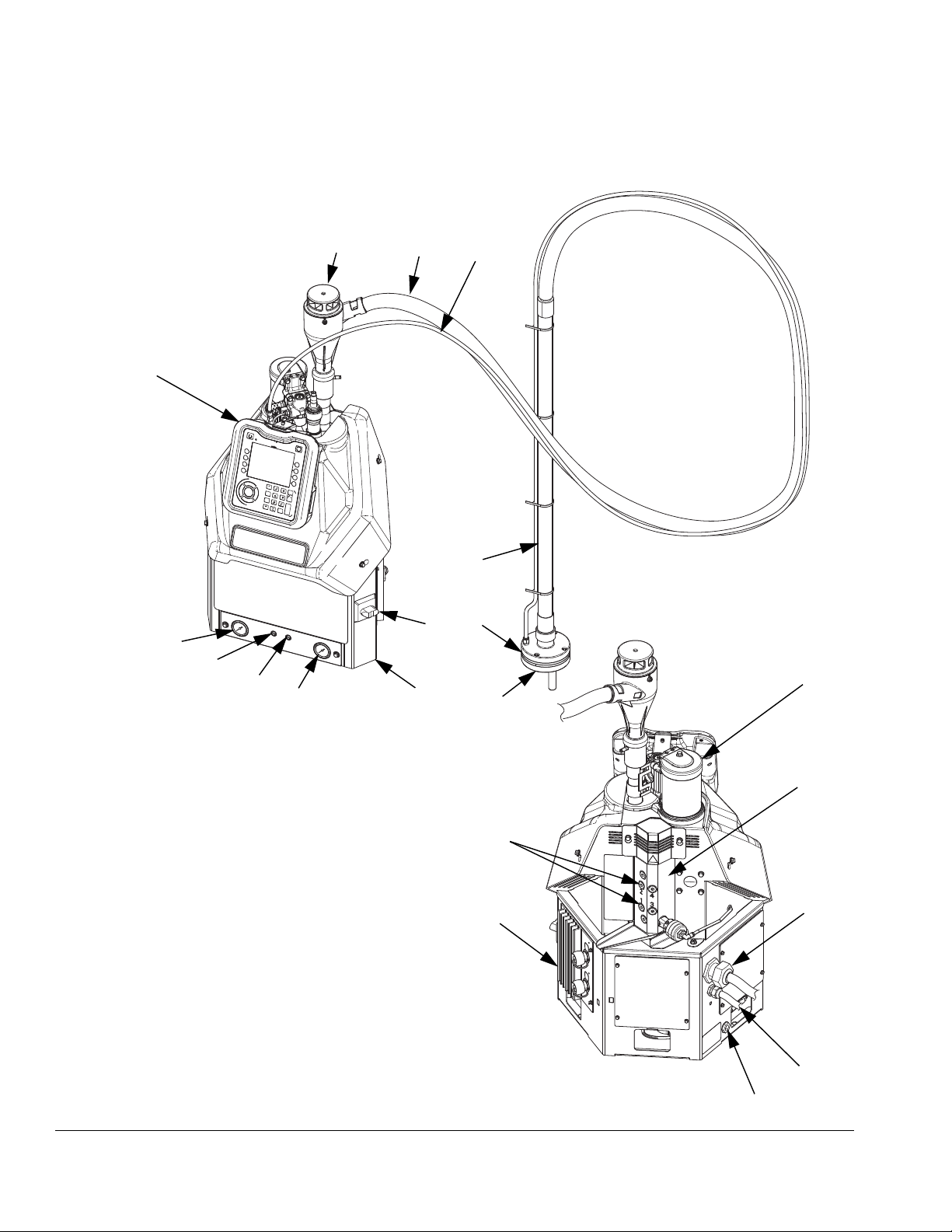

Component Identification

Component Identification

G3

G2

G4

A

G

G1

H

F

E

C

D

B

K

L

Key:

A Advanced Display Module (ADM)

B Electrical Enclosure

C Pump Air Pressure Regulator

D Pump Air Pressure Gauge

E Vacuum Transfer Air Pressure Regulator

F Vacuum Transfer Air Pressure Gauge

G Shaker Tube

G1 Shaker Head

G2 Vacuum Transfer Tube

G3 Vacuum Transfer Inlet Funnel

G4 Vacuum Transfer 3/8 in. OD Air Supply

H Main Power Switch

J System Air Inlet

K Vacuum Transfer (Shaker) Inlet

L Air Motor and Pump

M Incoming Power Strain Relief

N Heated Fluid Manifold (Melter)

P Multi-Zone Low Power Temperature Control Module (MZLP)

R Fluid Outlets for connection to Heated Hoses (numbered 1-4)

S Customer I/O Cable (optional)

R

P

ti20441b

N

M

S

J

FIG.1

8 3A2347ZAA

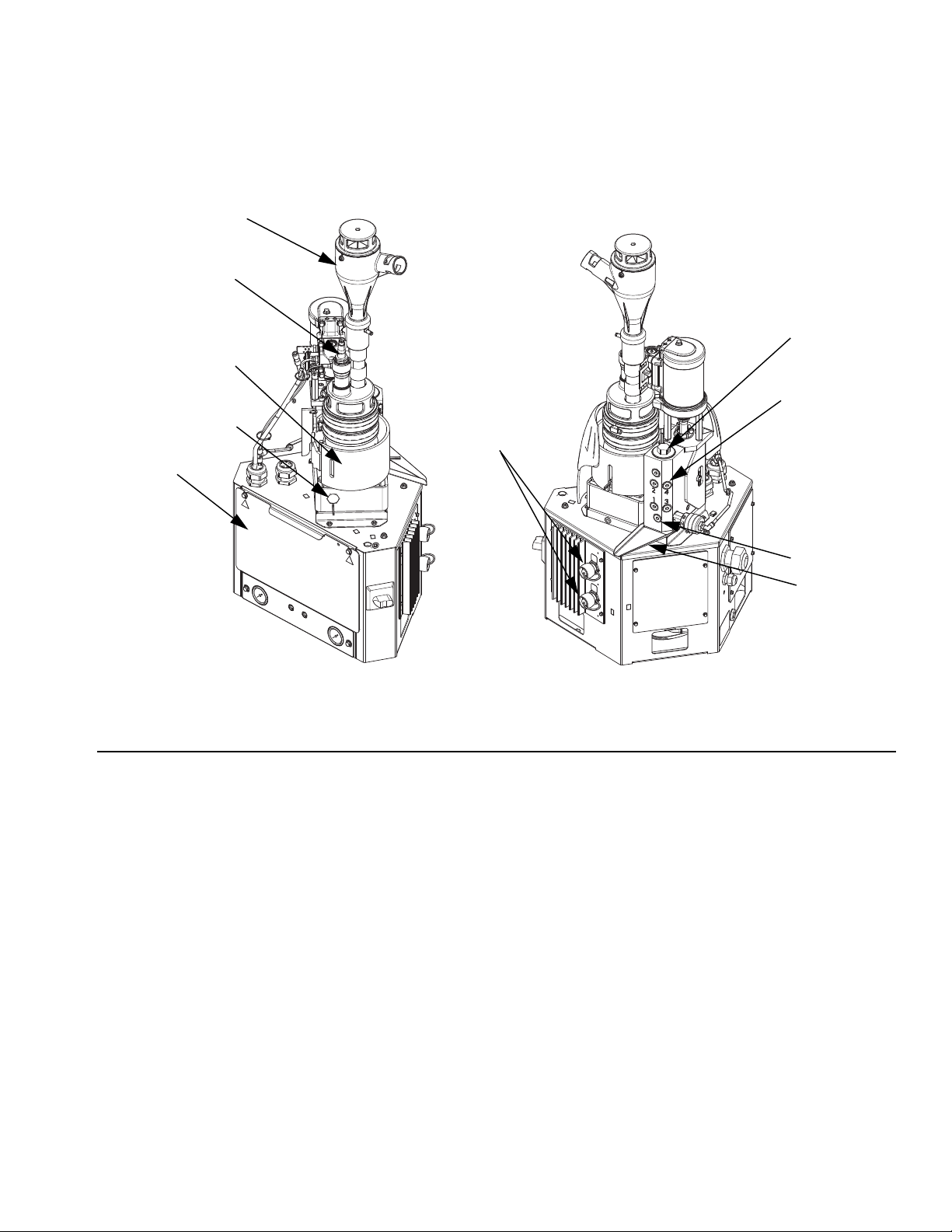

Heated Fluid Manifold

AB

Z

U

X

T

Component Identification

Y

R

AA

NOTE: System shown with plastic and metal shrouds removed.

FIG.2

Key:

T Electrical Enclosure Front Access Door

U Melter

W1 Drain Port

W2 Drain Tray

X Inlet Filter (Low Pressure - Before Pump)

Y Outlet Filter (High Pressure - After Pump)

W1

W2

ti20442b

Z Adhesive Pellets Level Sensor

AA Power and RTD Harness Connection to Heated Hose and

Gun (harness connects from system to heated hose then

from heated hose to gun)

AB Inlet Funnel Screen

3A2347ZAA 9

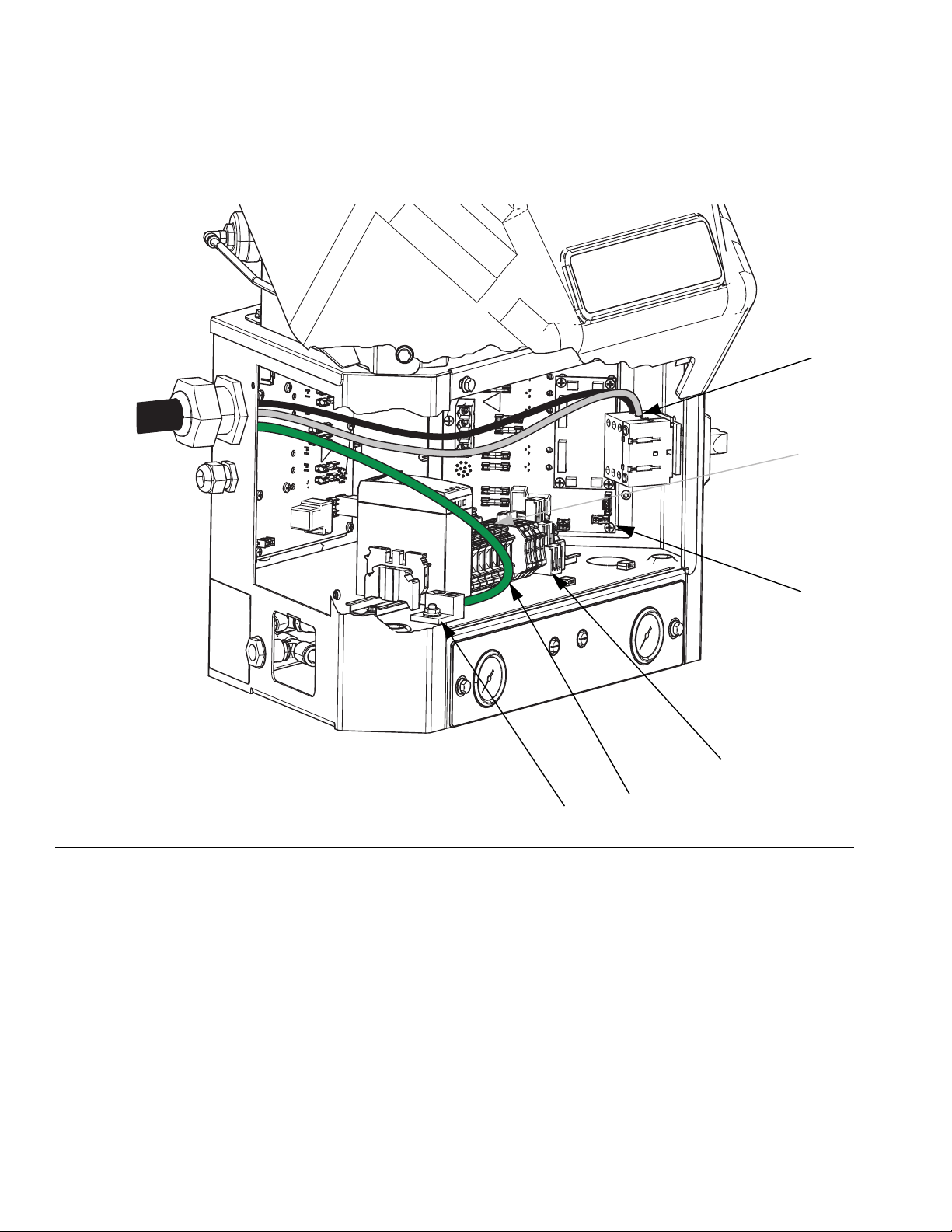

Component Identification

Electrical Enclosure

AC

AJ

FIG.3

Key:

P Multi-Zone Low Power Temperature Control Module

(MZLP)

AC Incoming Power Connection

AF Chassis Ground

P

ti20907b

AH

AG

AF

AG Terminal Blocks and Jumpers

AH Heater Relay

AJ Incoming Power Terminal Jumpers. See page 18.

10 3A2347ZAA

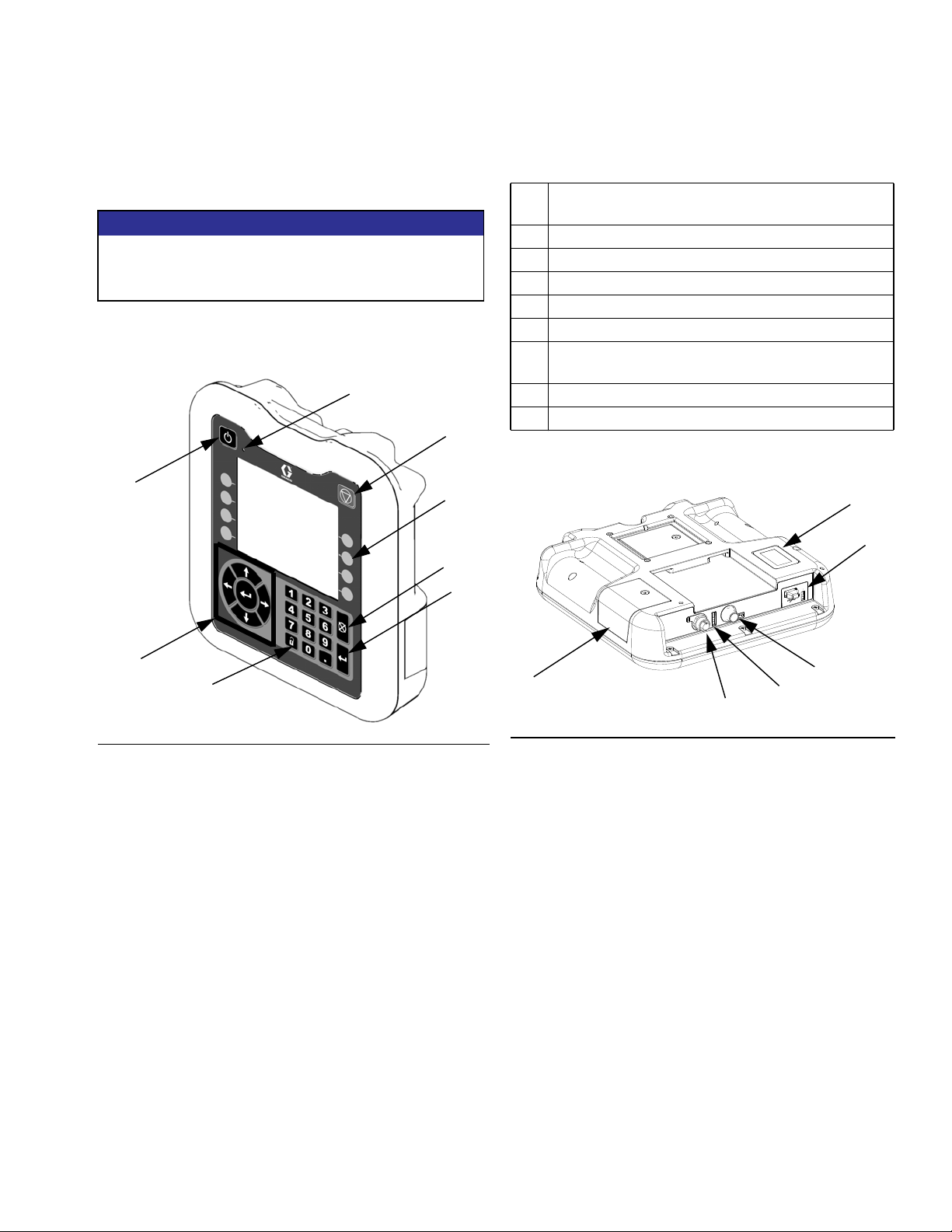

Advanced Display Module (ADM)

Component Identification

User Interface

NOTICE

To prevent damage to soft key buttons, do not press

the buttons with sharp objects such as pens, plastic

cards, or fingernails.

NOTE: See AppendixA-ADMon page 111 for complete ADM operation details.

BB

BC

BA

BD

BE

BF

B

Ke

y Function

BA Heating system and pump enable/disable

BB System status indicator (LED)

BC Stop all system processes

BD Defined by icon next to softkey

BE Abort current operation

BF Accept change, acknowledge error, select item,

toggle selected item

BG Toggle between Operation and Setup screens

BH Navigate within a screen or to a new screen

BK

BL

BH

FIG.4

BG

TI12362a1

BR

BM

BN

BP

FIG.5

Key:

BK Part Number Identification Label

BL USB Interface

BM CAN Cable Connection (Power Supply and Communica-

tion)

BN Module Status LEDs

BP (Not used)

BR Software Token Access Panel

3A2347ZAA 11

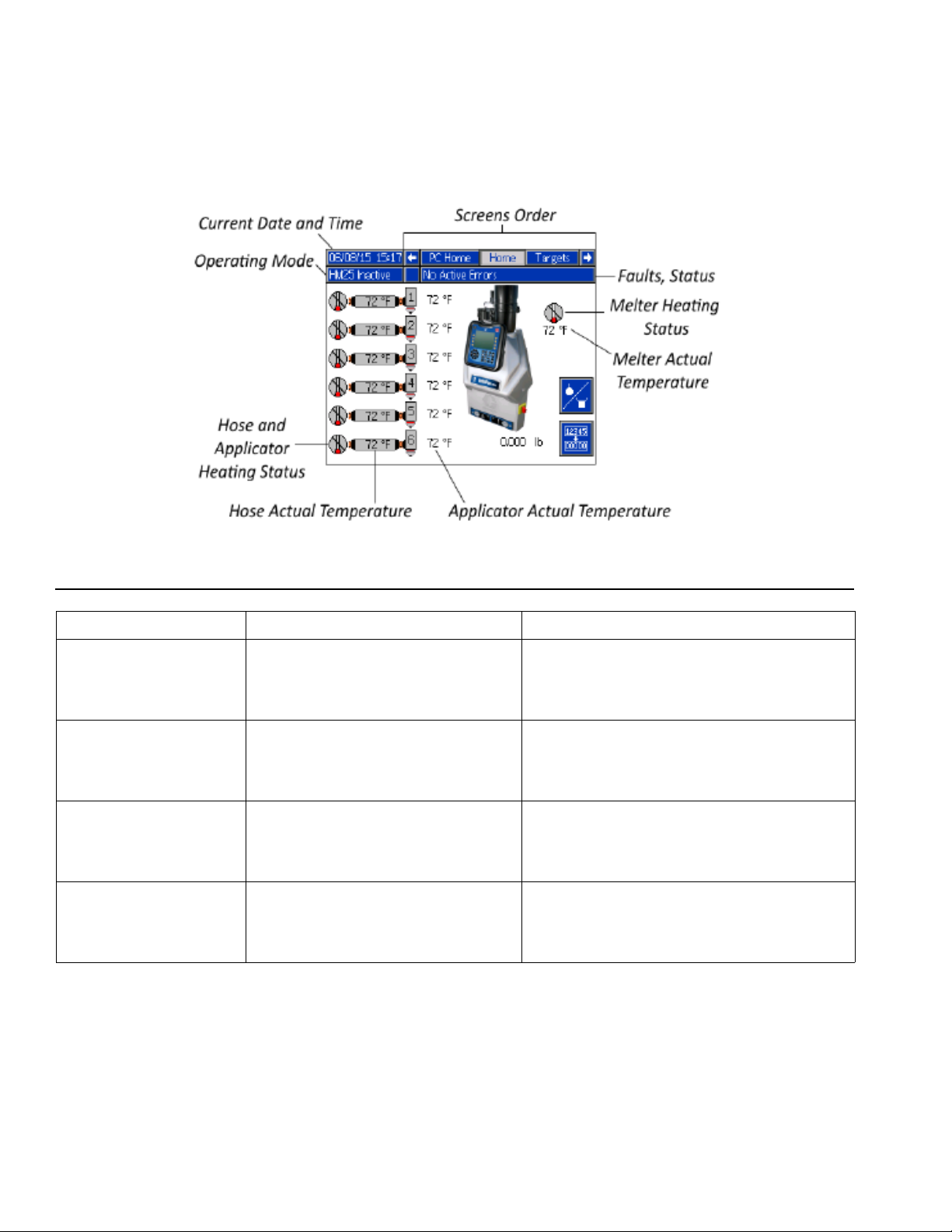

Component Identification

Screen Components

FIG. 6: Main Screen Components

Operating Mode Description Component Status

• No System Status Indicator LED on the

System Off

Inactive

Warm Up

Active

The system doesn’t have power.

The heating system and pumps are

disabled.

The system is increasing the material

to the set temperature.

The system is ready to dispense

material.

ADM

• No heat

• Pump is off

• Yellow system status indicator LED on the

ADM

• No heat

• Pump is off (manually changed)

• Flashing green system status indicator LED

on the ADM

• Heat is increasing to setpoint temperature

• Pump is off

• Solid green system status indicator LED on

the ADM

• Heat is at setpoint temperature

• Pump is on

12 3A2347ZAA

Setup

Setup

Grounding

The equipment must be grounded to reduce the risk

of electric shock. Improper grounding can cause

electric shock. Grounding provides an escape wire

for the electric current.

The InvisiPac system is equipped with a ground terminal. Have a qualified electrician ground the system

using this terminal. See Connect Electrical Cord on

page 18.

Location

Ambient temperature must be 32-120°F (0-49°C).

The supplied vacuum transfer hose length is 10 ft (3 m).

The maximum vacuum transfer hose length available is

30 ft (9.1 m). The adhesive pellets container must be

located within reach of the vacuum transfer hose and no

more than 30 ft (9.1 m).

The gun(s) must be located no more than 25 ft (7.6 m)

from the melter.

Place the base system on a surface that is eye-level for

easiest operation. Use System Stand, 24R088,to

install system at eye-level. See page 98.

If installing the system in place of a non-Graco hot melt

system, purchase Adapter Plate, 24R083. See

page 98.

Attach Components

To reduce the risk of electric shock, do not connect

electrical cord until after this Attach Components

procedure is complete.

1. Place the base system in the desired operating

location and orientation. See Location on this page.

• The bottom of the electrical enclosure has holes for

securing the InvisiPac system to a surface. The

holes are accessible through the bottom access

doors in the three rear walls of the electrical enclosure.

• To install the InvisiPac system in place of a

non-Graco hot melt system, purchase Adapter

Plate, 24R083. See installation instructions on

page 98.

• To raise the system to eye-level, purchase System

Stand, 24R088. See installation instructions on

page 98.

NOTE: Supplied vacuum transfer hose must reach from

the system to the adhesive pellets container. Supplied

heated hose must reach from system to gun(s).

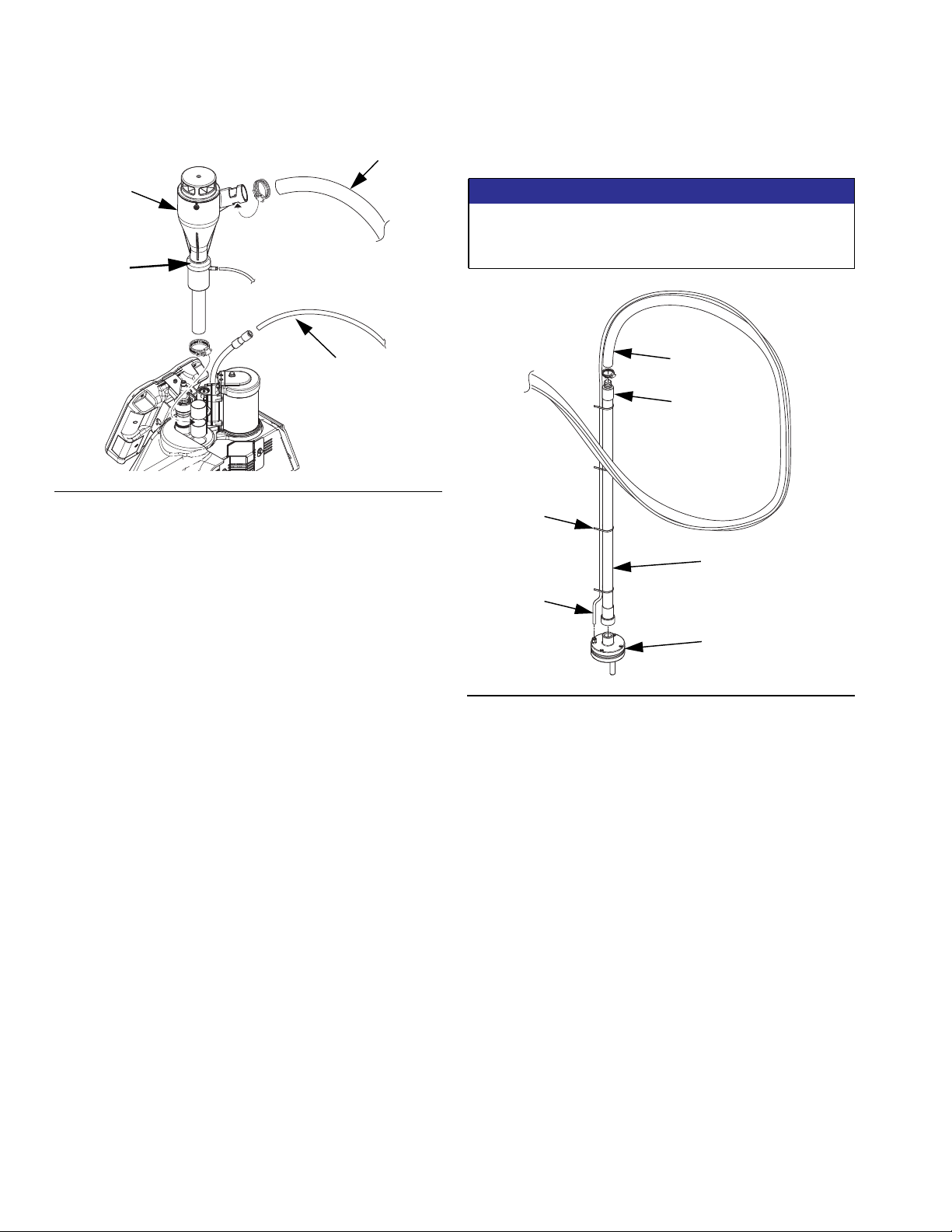

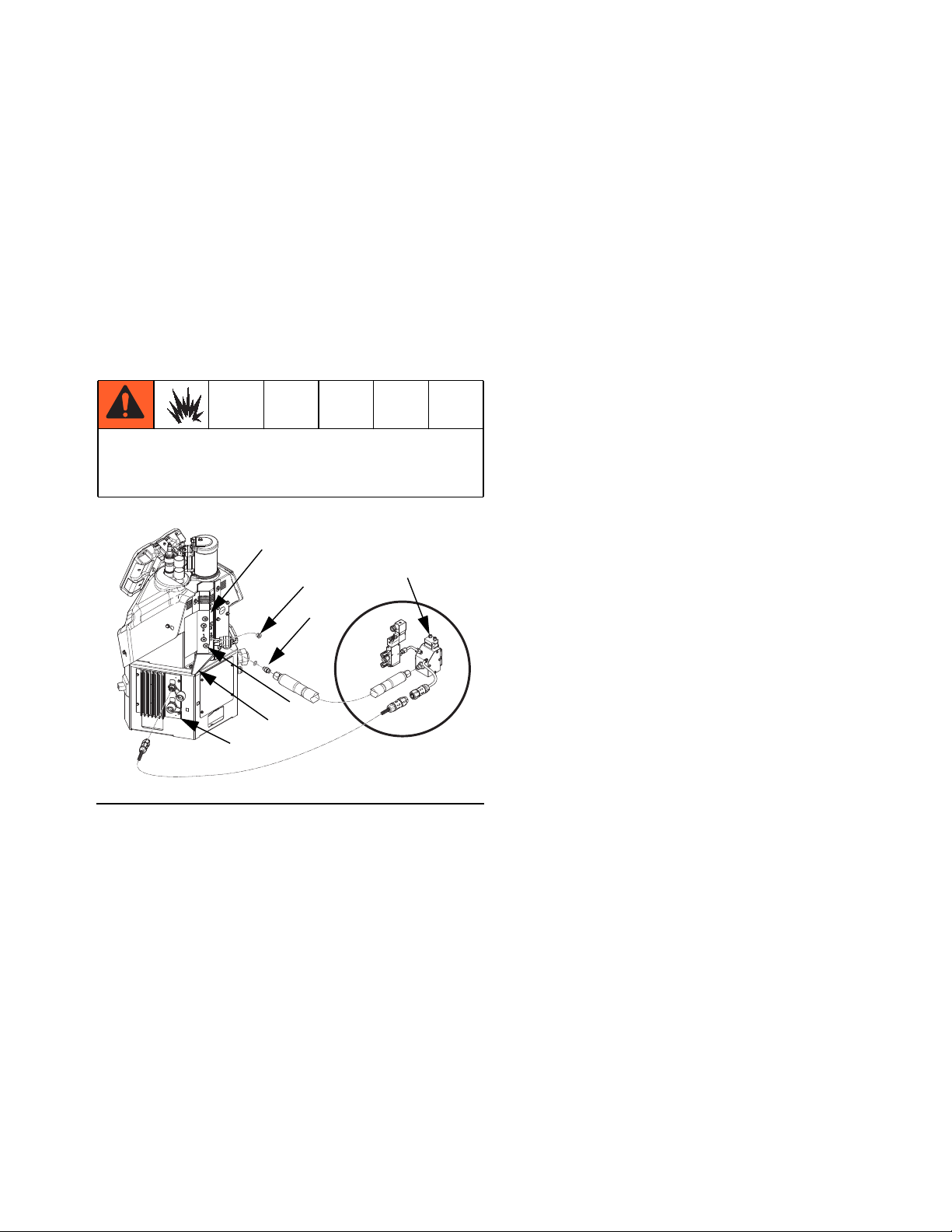

2. Install vacuum transfer inlet funnel (G3) onto system. See FIG.7.

a. Slide funnel through the bracket connected to

the air motor.

Optional 30 Gallon Vibrating Hopper, 24R136, available (purchase separately). See page 99.

To make repairing the system easier, locate the system

so that all sides are easily accessible and have sufficient

lighting.

3A2347ZAA 13

b. Position the funnel so the funnel inlet faces the

desired direction.

c. Connect 5/32 in. OD air line to funnel.

d. Install supplied hose clamp around the air motor

bracket and funnel base then tighten.

Setup

G2

6. Apply pipe sealant to threads then attach steel

shaker tube (G) to shaker head (G1). See FIG.8.

G3

G7

G4

ti21130b

FIG.7

3. Insert 1.3 in. (33 mm) OD clear vacuum transfer

hose (G2) into vacuum transfer funnel (G3) inlet and

secure with supplied hose clamp. See FIG.7.

4. Connect the long supplied 3/8 in. OD air line (G4) to

the 3/8 in. push-to-connect fitting on the air line from

the system. See FIG.7.

NOTE: To rotate funnel, loosen set screws (qty 4, G7)

1/4 turn each. Once funnel is aligned properly, hand

tighten screws back down.

NOTICE

To prevent shaker head (G1) galling to the shaker

tube (G), do not overtighten shaker head onto shaker

tube. These should be hand-tightened.

G2

G6

G5

G

G4

G1

ti21131a

FIG.8

NOTE: In the following steps, when routing the vacuum

transfer hose, ensure there are no tight coils, turns, or

dips in the vacuum hose. These will inhibit optimal functioning of the vacuum transfer system.

NOTE: Maximum vacuum hose length is 30 ft (9.1 m).

Use horizontal hose routing as much as possible. The

vacuum hose must not rise more than 10 ft (3.0 m),

measured from the vacuum inlet. Any vertical rise will

lower the maximum flow rate of the vacuum transfer

system.

5. Route the 1.3 in. (33 mm) OD clear vacuum transfer

hose from the system to the adhesive pellets container location.

7. Attach 1.3 in. (33 mm) clear vacuum transfer hose

(G2) to steel shaker tube (G) and secure with supplied hose clamp. See FIG.8.

8. Route the 3/8 in. OD air line (G4) alongside the

1.3 in. (33 mm) clear vacuum transfer hose (G2)

and secure at multiple points with the supplied zip

ties (G5). See FIG.8.

9. If desired, secure the 1.3 in. (33 mm) clear vacuum

transfer tube and 3/8 in. OD air line with zip ties to a

supporting structure at various points in the routing.

10. Attach the other end of the long 3/8 in. OD air line

(G4) to the 3/8 in. push-to-connect fitting on the

shaker head (G1).

11. Ensure the adhesive pellets container is in the

desired operating location. The location should be

chosen to make it easy to fill the container with pellets.

14 3A2347ZAA

Setup

12. Place shaker assembly in an empty adhesive pellets container then fill the container with adhesive

pellets.

NOTE: To promote optimal system performance, purchase 30 Gallon Vibrating Hopper, 24R136. See

installation instructions on page 99.

NOTE: If static buildup on feed tube (G) is excessive,

install optional feed tube ground kit 24R708 to feed tube

end (G6). See FIG.8.

13. Install heated hoses, see FIG.9:

To reduce the risk of fire and explosion, only use

Graco heated hoses with the InvisiPac system. Use

of non-Graco hoses will void agency approvals.

N

247

Gun

68

d. Remove plug (247) from the lowest numbered

outlet on the melter. Do not use the drain

plug (W1). See FIG.9.

NOTE: In the following step, the o-ring side of the

hydraulic fitting (68) faces the system. See FIG.9.

e. Install the supplied hydraulic fitting (68) with an

o-ring into the open port and tighten with an

11/16 in. wrench or socket.

f. Install hose onto hydraulic fitting (68) with male

electrical connector side toward the system.

Use 11/16 in. wrench to tighten hose onto

hydraulic fitting (68).

g. Locate MZLP (AA) connector marked with same

number as the hose fluid outlet port. Remove

that connector cover then install connector from

heated hose. See FIG.9.

h. Repeat the procedure for the remaining chan-

nels. Use the bottom melter ports first to ease

installation.

W1

W2

AA

ti21132a

FIG.9

a. Place a rag on the drain tray (W2) attached to

the melter. Residual oil may be in the system

from the factory. See FIG.9.

b. Use a 1/4 in. allen wrench to remove the drain

port plug (W1). See FIG.9.

NOTE: A 1/4 in. allen wrench is shipped loose with the

system.

c. When fluid stops draining, re-install drain port

plug (W1) then remove rag. See FIG.9.

i. Install cap on any unused MZLP electrical con-

nectors.

NOTE: Fluid outlet port 1 must be used and electrical

connector from that hose must be connected to MZLP

connector 1. The system will not operate unless a hose

is connected to MZLP connector 1. If a hose is not connected to connector 1, “Invalid Sensor - hose/gun” faults

will result.

14. Install gun(s), see FIG.9:

NOTE: Use of a Graco gun is not required with this system. However, all guns attached to the system must be

rated for 1200 psi (8.3 MPa, 83 bar), 400°F (204°C),

have an RTD type sensor, and use no more than 400W.

a. Connect heated hose fluid outlet to gun fluid

inlet. Use 11/16 in. wrench to tighten. See FIG.

9.

b. For Graco guns, attach gun electrical connector

to heated hose electrical connector. See FIG.9.

3A2347ZAA 15

Setup

c. For non-Graco guns, attach gun electrical con-

nector to adapter harness (16T916, 16T917, or

16Y828) then attach adapter harness connector

to heated hose connector. See Non-Graco

Gun Adapter Cables on page 96 to determine

which adapter cable to use with your valve.

d. Repeat for any additional guns.

15. If necessary, set up the valve controller to control

opening and close the gun. See gun manual.

NOTE: The system controls gun heating only. A separate gun controller must be set up to open and close the

guns.

16. Install the supplied air inlet bleeding ball valve and

air filter kit (Graco Part No. 24R707) at the 1/4 NPT

female system air inlet (J). See FIG.10.

17. If using the same air for the gun(s), make sure to

install the tee in the air line before the ball valve.

There should not be anything between the ball valve

and the system. See gun manual for gun air pressure requirements, and use a regulator before the

gun to decrease the air pressure, if necessary.

18. Close the ball valve.

WLE

ti21147a

FIG.11

19. Attach a 3/8 in. minimum air supply line to air filter.

See FIG.11.

J

WLE

ti21133a

FIG.10

NOTE: The system must have a bleed-type ball valve

that bleeds pressure downstream when closed. Otherwise, the supplied air will need to be disconnected from

the system whenever the pressure is relieved.

NOTE: The system must use an air filter with a minimum flow rate of 30 scfm.

NOTE: Air supply pressure must be between 80 psi

(550 kPa, 5.5 bar) and 100 psi (690 kPa, 6.9 bar). Recommended pressure is 100 psi (690 kPa, 6.9 bar). If air

pressure is expected to drop below 80 psi (0.5 MPa,

5 bar), there is an air reservoir kit that allows the system

to operate down to 60 psi (0.4 MPa, 4 bar). See Air

Reservoir Kit, 16W366, on page 102.

20. To lock access to the air pressure adjustments, purchase See Attach Components on page 13.. See

installation instructions on page 96.

21. To install a light tower that illuminates red when a

system error occurs, purchase Light Tower Kit,

24R226. See installation instructions on page 101.

22. To upgrade a 2 channel system to a 4 channel system, purchase 4 Channel Upgrade Kit, 24R237.

See installation instructions on page 103.

23. Install MZLP electrical connector caps on all unused

channels.

16 3A2347ZAA

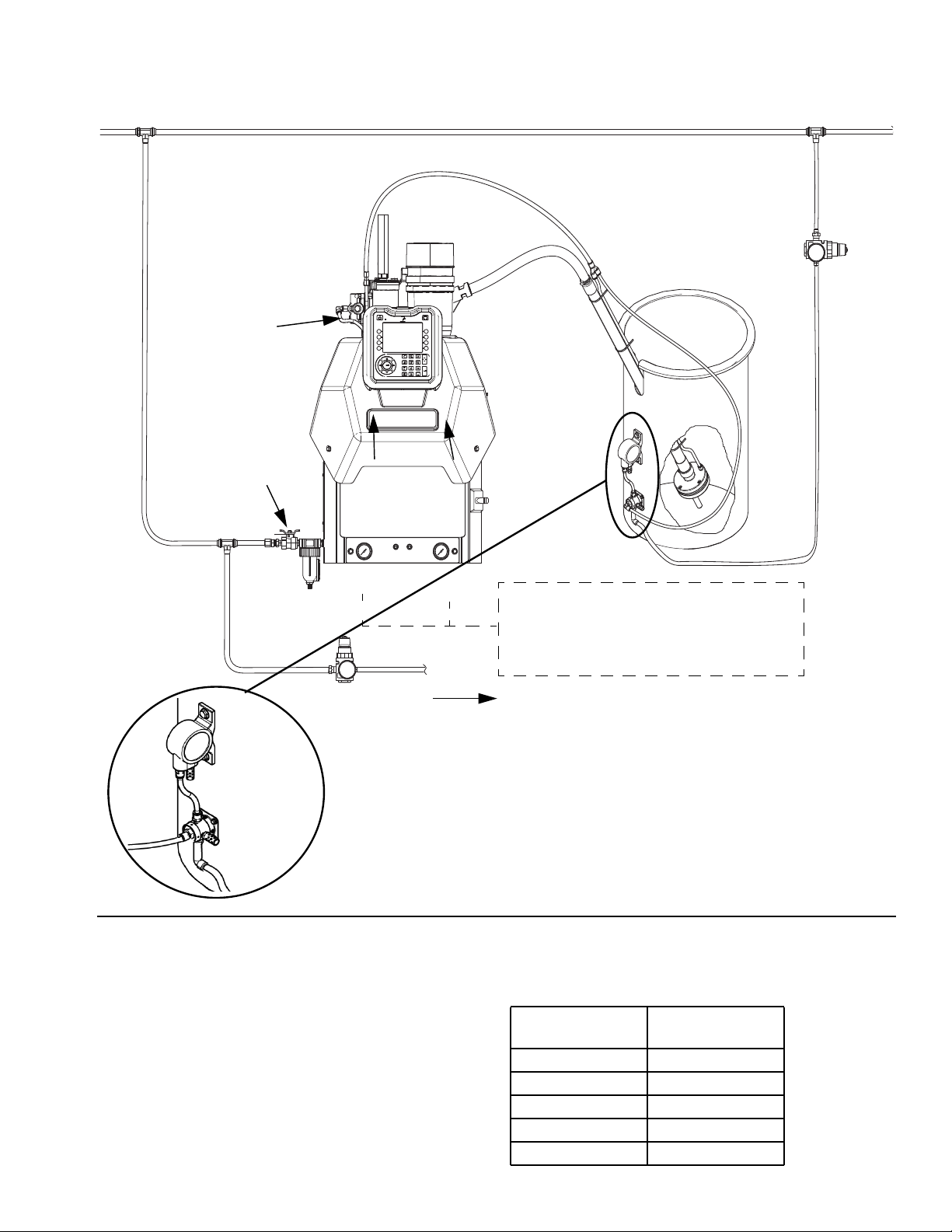

Recommended Air Setup

Main Air Line

Setup

Air In:

Less than 50 ft (15.2 m): 3/8 in.

More than 50 ft (15.2 m): 1/2 in.

80-100 psi

(5.5-6.8 bar, 0.55-6.8 MPa)

30 scfm capacity.

Ensure funnel air

is connected

Air Filter/Ball Valve at

System Air Inlet

(Graco Kit 24R707,

included)

Vacuum Pump

No dips in vacuum

transfer hose

40 - 80 psi (2.8-5.5 bar,

0.28-0.55 MPa);

Air In:

3/8 in.,

100 psi

(6.8 bar, 0.68 MPa),

30 scfm capacity

Regulator

Vacuum:

Pump:

20-100 psi

Regulator set to

70 psi

(4.8 bar, 0.48 MPa)

InvisiPac

Vacuum

Feed Air

Hopper

Shaker

Pilot

Valve

Plant Air

Supply

FIG.12

If plant air pressure is >90 psi, add air regulator kit to the

24H420 to the air supplying the hopper shaker. Regulate the shaker air according to the vacuum feed pressure according to the table below.

WLF

Air to applicators

NOTE: Using vacuum feed air pressure higher than

necessary may cause the melter to over fill and Interrupt

production.

Vacuum Feed air

pressure

Max air pressure

to hopper

40 psi (2.8 bar) 60 psi (4.1 bar)

50 psi (6.4 bar) 75 psi (5.2 bar)

60 psi (4.1 bar) 90 psi (6.2 bar)

70 psi (4.8 bar) 105 psi (7.2 bar)

80 psi (5.5 bar) 120 psi (8.3 bar)

3A2347ZAA 17

Setup

Connect Electrical Cord

NOTE: See Grounding section on page 13.

Improper wiring may cause electric shock or other

serious injury if work is not performed properly. Have

a qualified electrician perform any electrical work. Be

sure your installation complies with all National, State

and Local safety and fire codes.

To reduce the risk of electric shock, perform the

entire Attach Components procedure beginning on

page 13 prior to connecting electrical cord.

NOTE: The installed strain relief bushing (106) fits a

0.708-1.260 in. OD electrical cord. See FIG.14.If

needed, use a wrench to tighten the strain relief bushing

until it is snug on the cable.

NOTE: Tubing 17F777 and 17F779 is included for

smaller diameter electrical cord. Place around the power

cord and secure in the strain relief brushing (106).

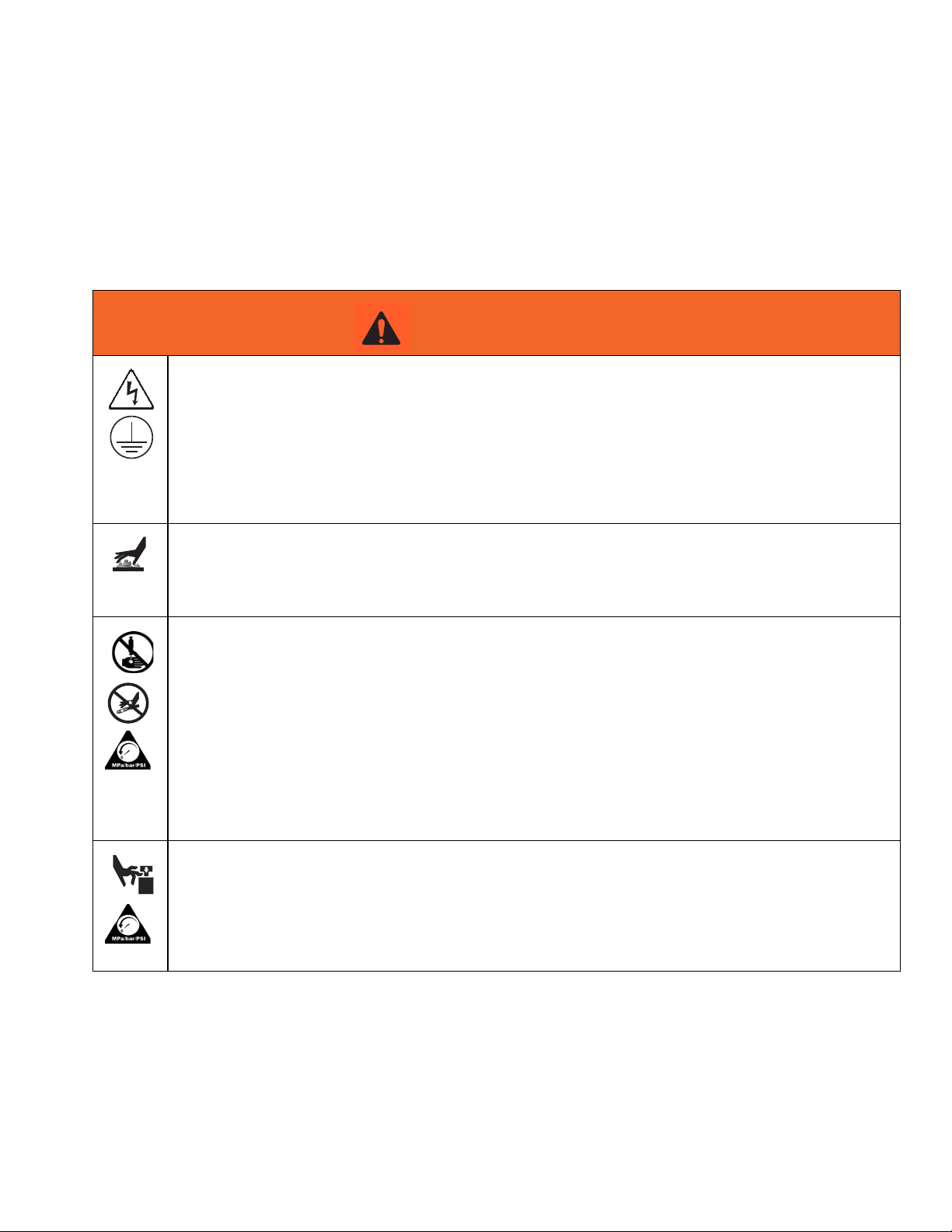

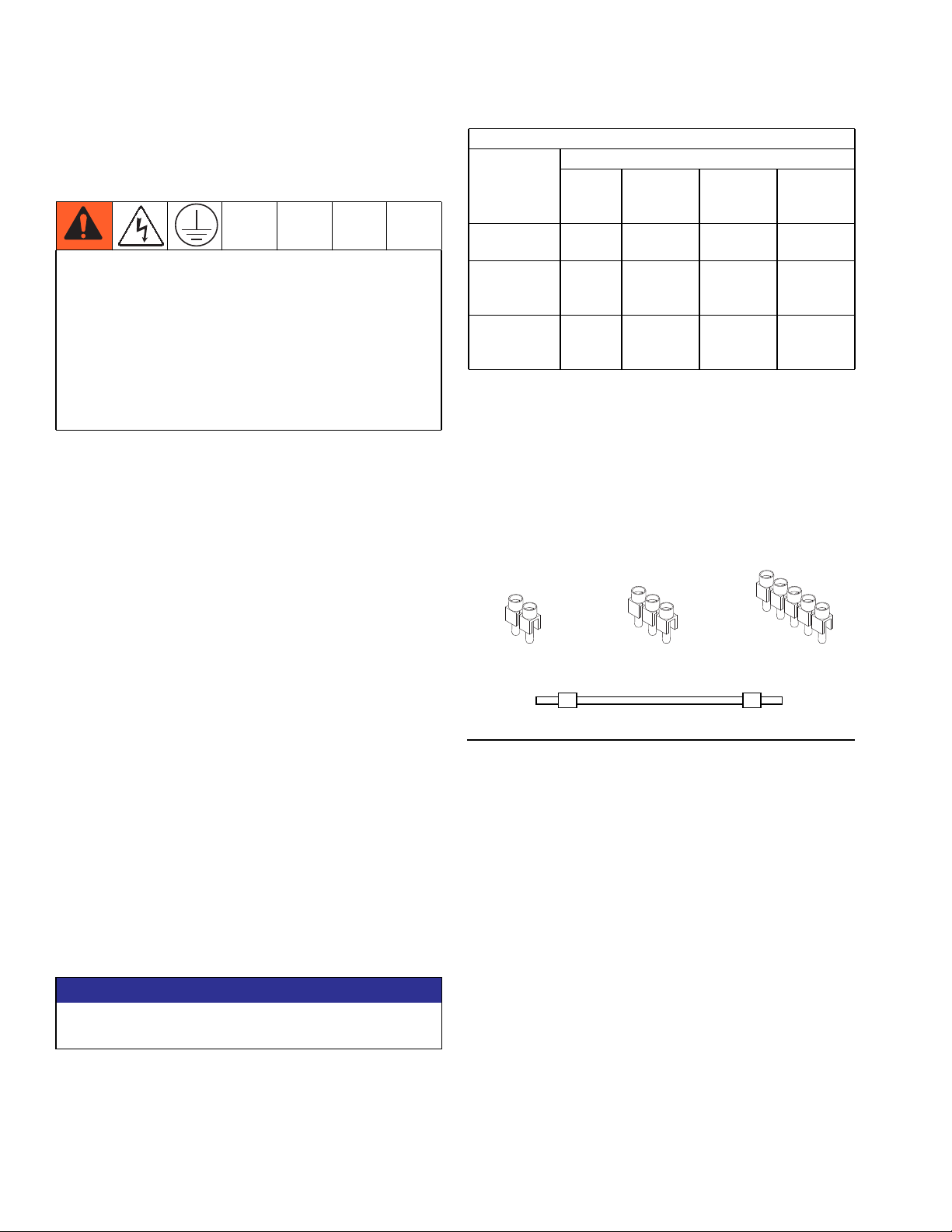

Terminal Block Jumper Installation Guide

Terminal Block Location

Voltage

200-240VAC,

1 phase

350-415VAC,

3 phase,

WYE

200-240VAC,

3 phase,

DELTA

Jumper

Wire

127201

Not used Not used 3-5 6-10

Not used

3-7

2-Terminal

Jumper

126814

5-6,

8-9

4-5,

9-10

3-Terminal

Jumper

126815

2-4 Not used

6-8 Not used

5-Terminal

Jumper

126816

NOTE: The jumpers only need to be changed if using a

different phase or voltage from what the system was

designed for at the factory.

NOTE: All necessary jumpers are supplied with the system in a bag located behind the electrical enclosure

front access panel. Keep unused jumpers in bag.

2-Terminal

126814

3-Terminal

126815

5-Terminal

126816

NOTE: The accessory strain relief bushing kit 24x190 is

available for smaller (0.512-1.024 in, 13-26 mm) OD

electrical cords. See Accessories, page 107.

For 480V Electrical Circuits, see page 20.

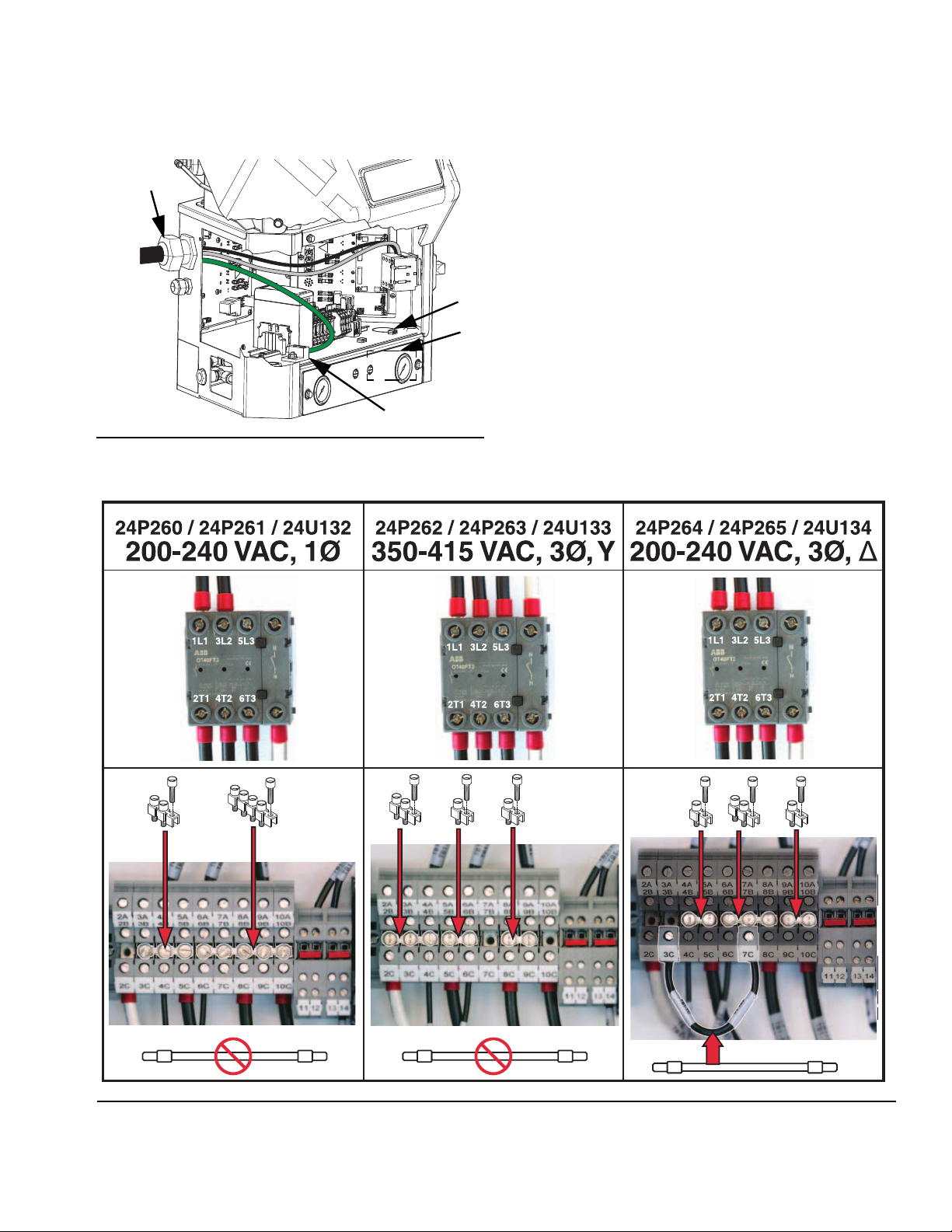

1. Turn main power switch OFF.

2. Disconnect cable from ADM, push cable through

plastic shroud, then remove plastic shroud from system.

3. Remove electrical enclosure access door (T). See

FIG. 2 on page 9.

4. Ensure the terminal block jumpers are in the correct

locations for the phase and voltage used. If necessary, change them to match FIG. 15 on page 19.

See the following table, FIG. 13, and FIG.15.

NOTICE

To prevent system damage, verify terminal jumpers are

installed correctly before going on to the next step.

ti21182a

Wire

127201

FIG. 13: Jumpers

NOTE: Use the supplied hard metal 2, 3, and 5 terminal

jumpers and jumper wire for terminals 2C-10C. Use the

red, plastic jumpers for terminals 11-14.

5. Insert electrical cord through electrical enclosure

strain relief bushing (106). See FIG. 14 on page 19.

a. Alternate electrical cord routing: using conduit,

run electrical cord from access port (X) through

hole (Y). Conduit is required when routing wires

near compressed air components.

18 3A2347ZAA

Setup

6. Attach insulated ferrules to the end of each wire. 7. Connect ground wire to chassis ground (AF). See

FIG.14.

106

8. Connect L1, L2, L3, and N as shown in FIG. 15. Not

all models use all 4 wires.

9. Use zip ties to secure the electrical cord to the

tie-downs located on the top of the inside of the

electrical enclosure.

Y

X

10. Tighten screw-terminals to at least 10 in-lb

(1.1 N•m).

11. Install electrical enclosure door.

FIG.14

AF

ti20907b

12. Perform Select ADM Settings on page 20 prior to

turning on heat.

FIG.15

3A2347ZAA 19

Setup

480V Electrical Circuits

For 480V electrical supply, a 480V to 240V step-down

transformer must be installed by a qualified electrician.

Transformer Sizing

For single-phase power, 480V to 240V transformer

24U169 (purchase separately) may be used. See Sin-

gle-Phase 480V to 240V Transformer, 24U169 on

page 107.

Minimum transformer rating can be calculated by taking

output voltage times the ADM setting.

Single Phase, 20A ADM Breaker Setting Example:

240 volts x 20 amps = 4800 watts

Three Phase, 20A ADM Breaker Setting Example:

240 volts x 20 amps x ෭ (3) = 8315 watts

208V Electrical Circuits

For 208V electrical supply, a qualified electrician can

install a 208V to 240V step-up transformer to improve

startup times.

Transformer Sizing

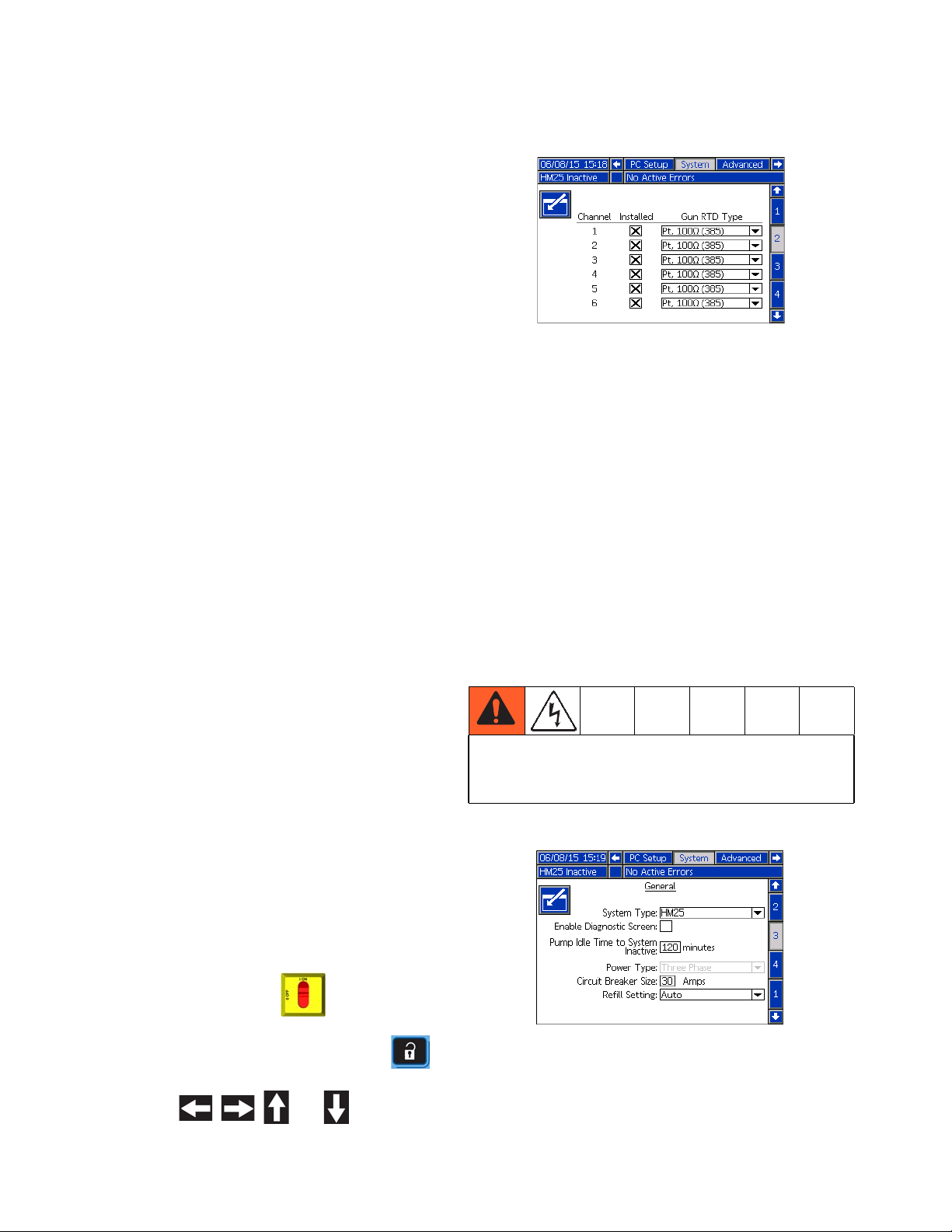

3. On the System 2 screen:

a. Check the box in the “Installed” column for each

channel that has a heated hose and gun

installed.

b. Select the RTD type used on each installed

gun. See gun manual.

NOTE: An incorrect RTD setting will cause the system

to be incapable of maintaining the temperature setting.

NOTE: The supported RTD types are Ni, 100 ohm; Ni,

120 ohm; NiFe, 604 ohm; Pt, 100 ohm (385), Pt,

100 ohm (392); and Pt, 1000 ohm. An “Auto” selection is

available but should only be used when the specific

RTD type cannot be identified. Using the “Auto” RTD

setting may result in inaccurate temperatures.

Minimum transformer rating can be calculated by taking

transformer output voltage times the ADM breaker setting.

Single Phase, 20A ADM Breaker Setting Example:

240 volts x 20 amps = 4800 watts

Three Phase, 20A ADM Breaker Setting Example:

240 volts x 20 amps x SQRT(3) = 8315 watts

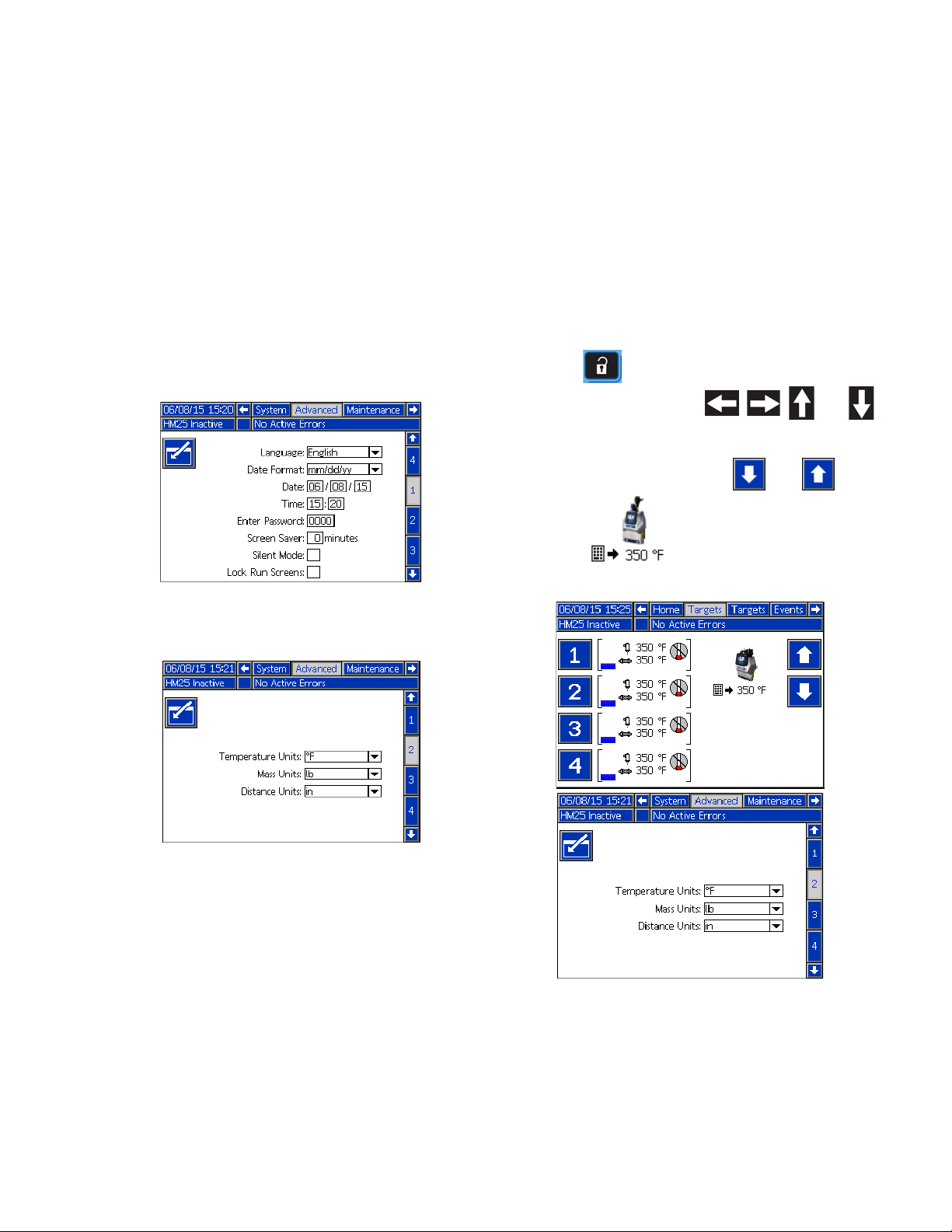

Select ADM Settings

NOTE: See AppendixA-ADMon page 111 for

detailed ADM information, including general operation.

1. Turn main power switch ON .

2. When the ADM is finished starting up, press

to switch from the Operation screens to the Setup

screens. Use , , , and to navigate

between screens.

To prevent fire and explosion, a qualified electrician

must determine the proper circuit breaker size to use

for the power supplied to the system.

4. On the System 3 screen:

a. Enter the main circuit breaker size used. This is

the circuit breaker installed external to the system for the system power supply.

20 3A2347ZAA

Setup

NOTE: If using a 480V to 240V transformer, the breaker

size entered will be two times the 480V rating. If using

transformer 24U169, the breaker size should be set to

30 amps and power type should be set to single phase.

NOTE: The InvisiPac system limits the amount of power

it pulls based on the input circuit breaker size. This

impacts the startup times because it affects the heating

energy used to warm up the materials.

b. Select the incoming power type.

5. On the Advanced 1 screen, set the system date and

time.

NOTE: The Schedule function enables the system to

automatically enable and disable heating at specified

times so that the system is already up to temperature

when a shift begins.

8. If desired, set any remaining settings in the Setup

screens before going on to the next steps that use

the Operation screens. These are not required for

system operation but include useful functions. See

AppendixA-ADM, beginning on page 111, for

detailed information about each setup item.

9. Press to switch from the Setup screens to the

Operation screens. Use , , , and to

navigate between screens.

10. On the Targets screen, use and , shown

next to , to adjust system melter setting.

Also, the desired temperature setting can be typed

in using the numeric keypad.

6. On the Advanced 2 screen, set the temperature and

mass units.

7. To setup the optional Schedule function, see

Schedule on page 32.

3A2347ZAA 21

Setup

11. On the Targets screen, adjust heated hose and gun

temperature settings:

NOTE: InvisiPac is a high powered tank-free system

that delivers heat faster than traditional tank systems.

Tanks are often run at a lower temperature than the

application temperature to avoid excessive adhesive

degradation since a large volume of adhesive sits at

temperature.

a. Press to select the channel.

b. Use and , shown next to , to

adjust gun temperature setting to the desired

setting for that channel.

NOTE: If a higher applicator temperature is desired,

adjust all zones to the higher temperature or adjust only

the applicator in small increments.

c. Use and , shown next to ,

to adjust heated hose temperature setting to the

desired setting for that channel.

NOTE: Alternatively, use the physical up and down

arrow push-buttons on the ADM keypad until is

next to the temperature setting to change then use the

numeric keypad to enter the desired temperature.

NOTICE

Set melter, hose, and gun to the same setpoint temperature for best performance. Do not set the hose

temperature higher than the melter. Running the hose

at a setpoint higher than the melter is unnecessary in

this tank-free system and could lead to adhesive degradation in the hose. Short adhesive residence time in

the melter eliminates the need to set the melter at a

lower setpoint than other zones. See Operation Tips

to Minimize Charring, page 36.

NOTE: Alternatively, use the physical up and down

arrow push-buttons on the ADM keypad until is

next to the temperature setting to change then use the

numeric keypad to enter the desired temperature.

Guns

Gun heating is controlled by the InvisiPac system. A

pattern controller is required to control the opening and

closing of guns. If using an InvisiPac Pattern Controller,

refer to manual 334784 - InvisiPac Pattern Controller for

details on wiring and setup.

22 3A2347ZAA

Setup

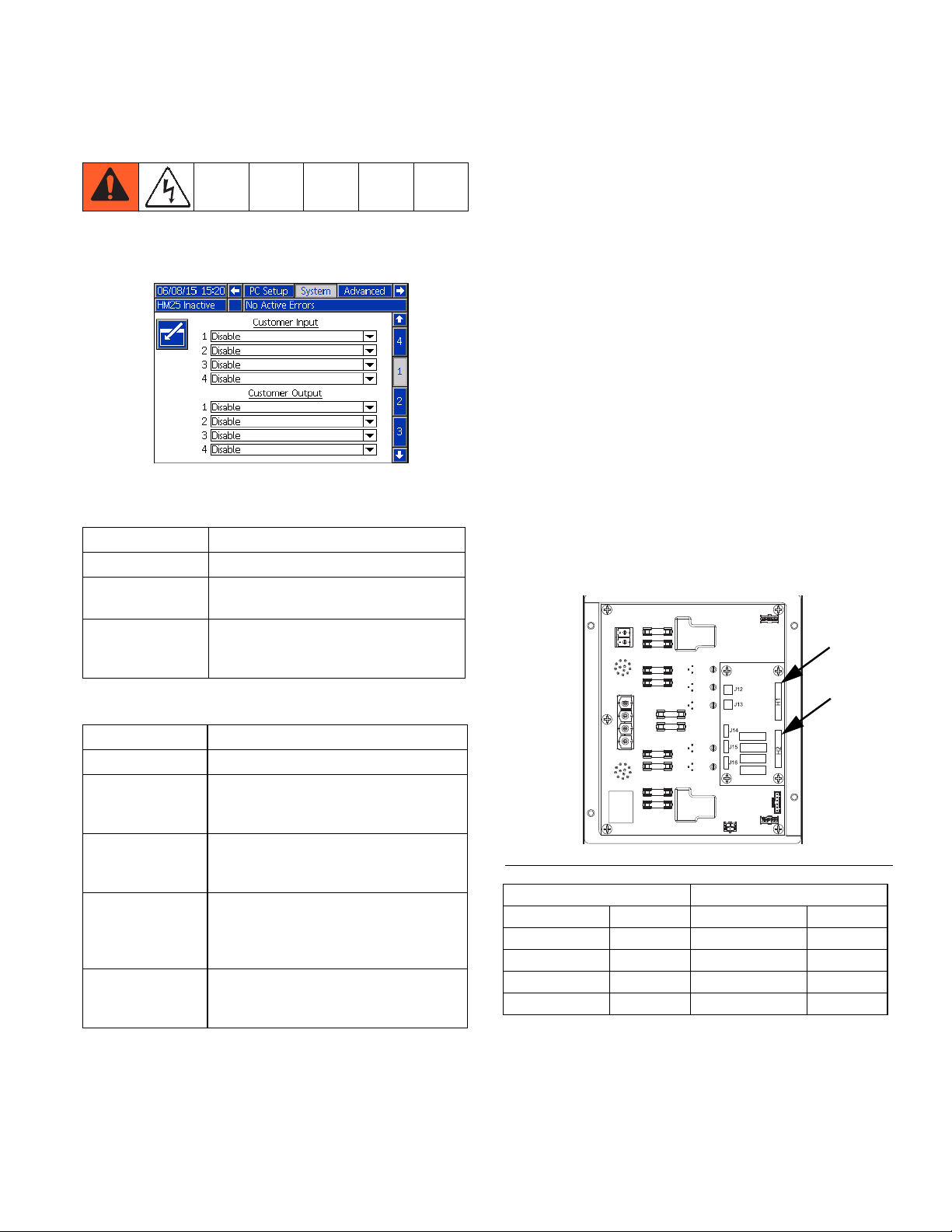

PLC Connection

A PLC can control and monitor all items shown in the

dropdown menus on the System 1 screen in the Setup

screens.

Customer Input Dropdown Options

Option Description

Disable Not used.

Heater On/Off Turn on or off the heating system and

pump.

Channel 1, 2, 3,

or 4 Enable/Disable

Customer Output Dropdown Options

Enable or disable hose and gun heating for that individual channel.

NOTE: The InvisiPac system ships with two

screw-terminal connectors that plug into MZLP

connectors H1 and H2. Connectors are located in a bag

on the inside of the electrical enclosure front access

door. To replace the connectors, order kit 24P176.

1. On the System 1 screen (in the Setup screens) select

the function of each input on MZLP connector H1 and

each output on MZLP connector H2.

2. Turn main power switch OFF.

3. Remove electrical enclosure front access door.

4. Route I/O cable through strain relief in electrical

enclosure. See Customer I/O Cable (S) in FIG.1on

page 8.

5. Remove power from PLC.

6. Connect the PLC to connectors H1 and H2.

NOTE: Each connector has four signals. The MZLP

board specifies the input range for each signal. See the

following table for pin assignments.

J1

J2

F1

F2

F3

F4

F5

J3

H1

H2

Option Description

Disable Not used.

System Ready Indicates when the system is up to tem-

perature and the pump is stalled at

pressure.

Error (Alarm) Indicates when there is an active alarm.

An active alarm will disable the heating

system and pump.

Error (Deviation/Advisory)

Maintenance Due Indicates when the maintenance total

Indicates when there is an active deviation or advisory. An active deviation or

advisory will NOT disable the heating

system and pump.

has reached the preset notification

value.

FIG. 16: MZLP Board

H1 - Customer Input H2 - Customer Output

Signal Pin Signal Pin

1 1,2 1 1,2

2 3,4 2 3,4

3 5,6 3 5,6

4 7,8 4 7,8

F7

F8

F9

F10

F6

J5

J6

J7

Inputs: High: 10-30 Vdc, Low: 0-5 Vdc. Inputs function

NOTE: All outputs are normally open when power is

OFF. For Error (Alarm) output, the contacts open when

an alarm occurs. For all others, contacts close.

without concern for polarity. Applying “high” voltage will

turn the heaters on and enable channels. Removing voltage will turn the heaters off and disable channels.

Outputs: 0-250 Vac, 0-30 Vdc, 2A.

3A2347ZAA 23

Setup

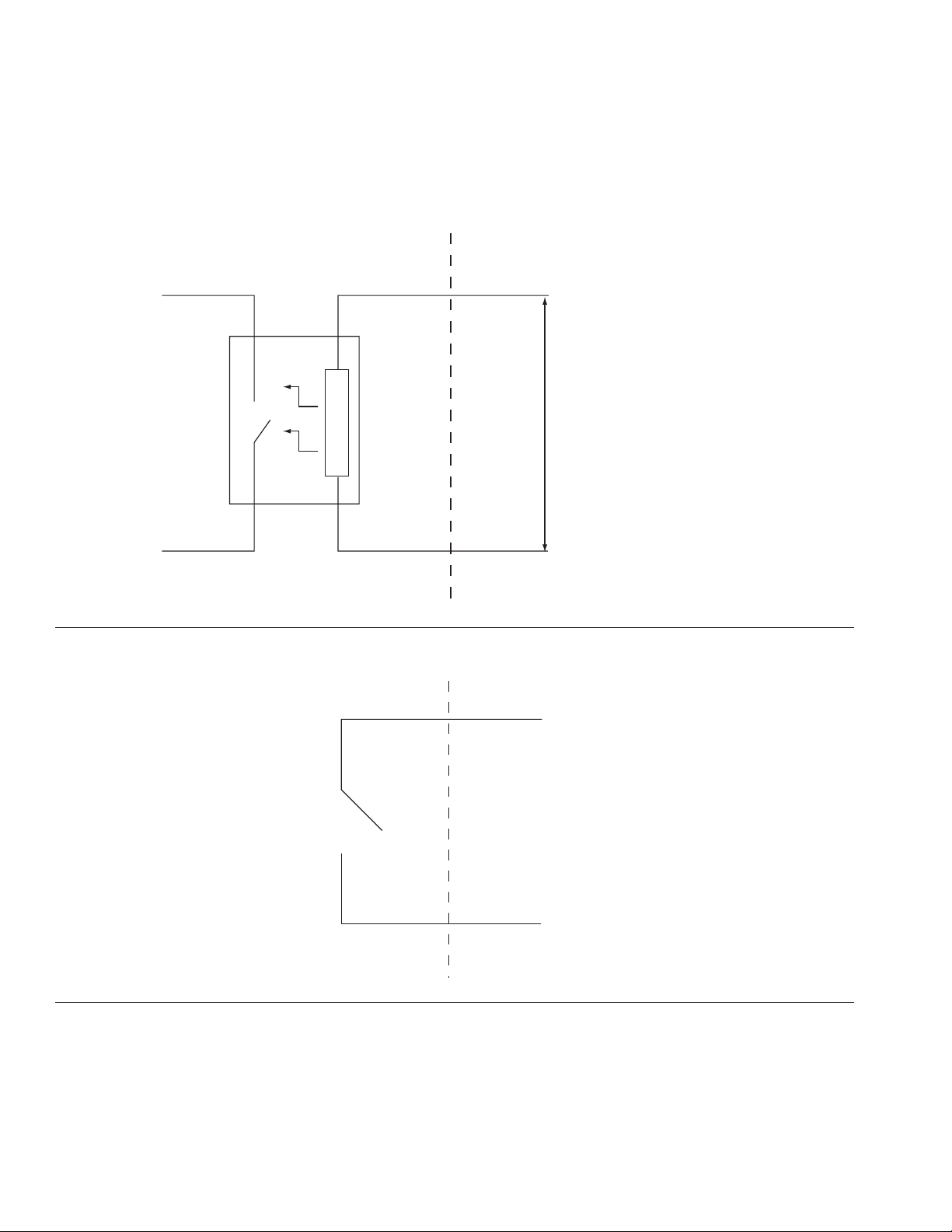

PLC Connection Block Diagrams

The following block diagrams show how to connect customer inputs and outputs to the InvisiPac MZLP. For convenience, each InvisiPac ships with connector kit 24P176. If a connector is lost or damaged, order kit 24P176 for

replacements.

FIG. 17: Customer Input

MZLP Customer In

MZLP Customer Out

Customer Output

Vin (no polarity)

30 VDC Max

Customer In

FIG. 18: Customer Output

250 VAC, 2A Max

To Customer Input

24 3A2347ZAA

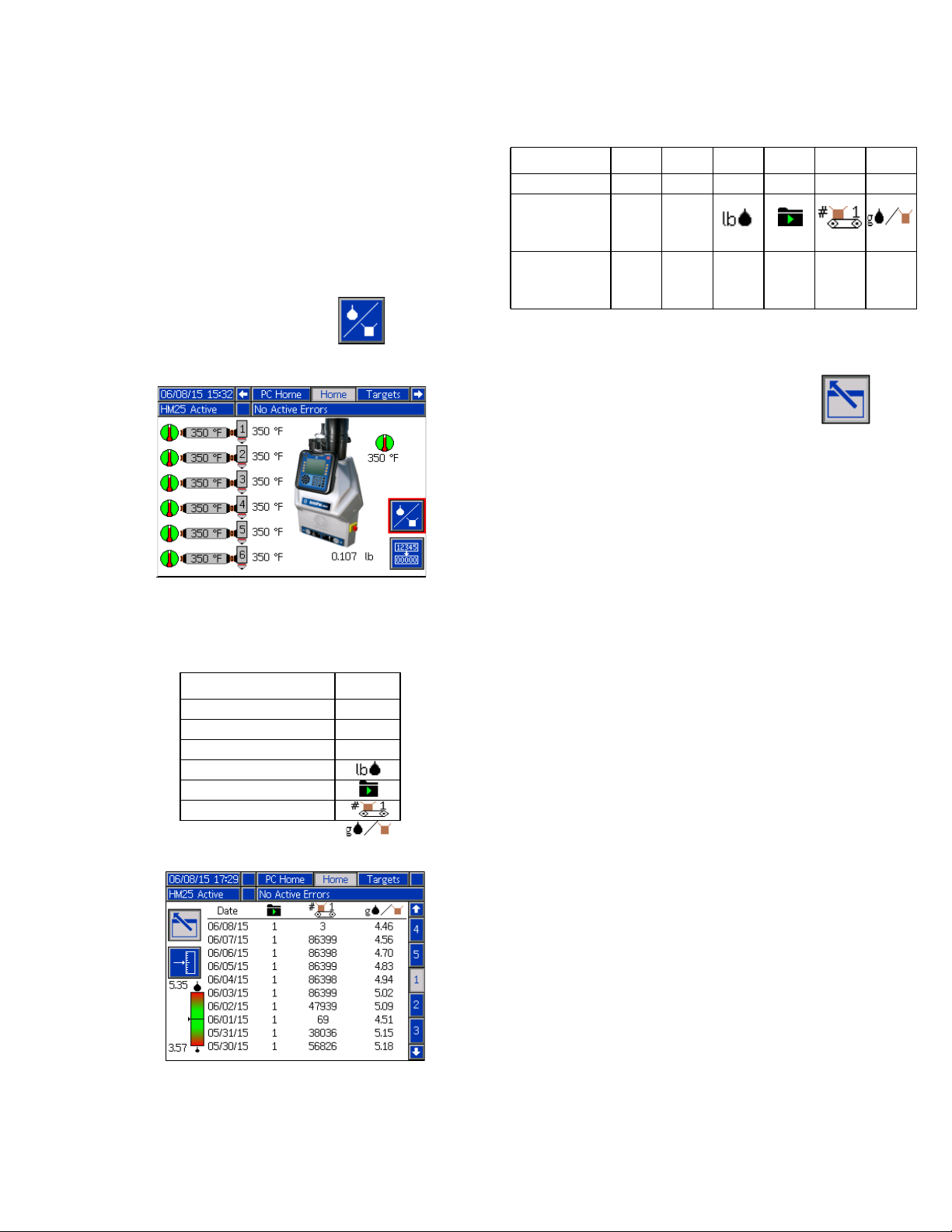

Material Tracking

The material tracking function allows the user to track

product counts and material usage for long term data

collection.

Viewing the Log

In order to view the log, navigate to the Home screen

System Type Date Cycles

InvisiPac XXX

InvisiPac w/

ADM Unit

Counter

InvisiPac w/

Pattern Con-

troller

XXX

XXX

Setup

X*

and press the material log softkey (see below).

Once inside the log (see below), use the up/down arrow

keys to view previous data. The log stores up to 200

rows of data including the following:

Item Icon

Date N/A

Cycles N/A

Material Used

Program

Products

Material per Product

* See Material Tracking Coverage for pattern Controller

Systems.

To exit the log, press the screen exit softkey .

Different system types will have different data shown in

the material log. The chart below outlines what data is

shown for each system type.

3A2347ZAA 25

Setup

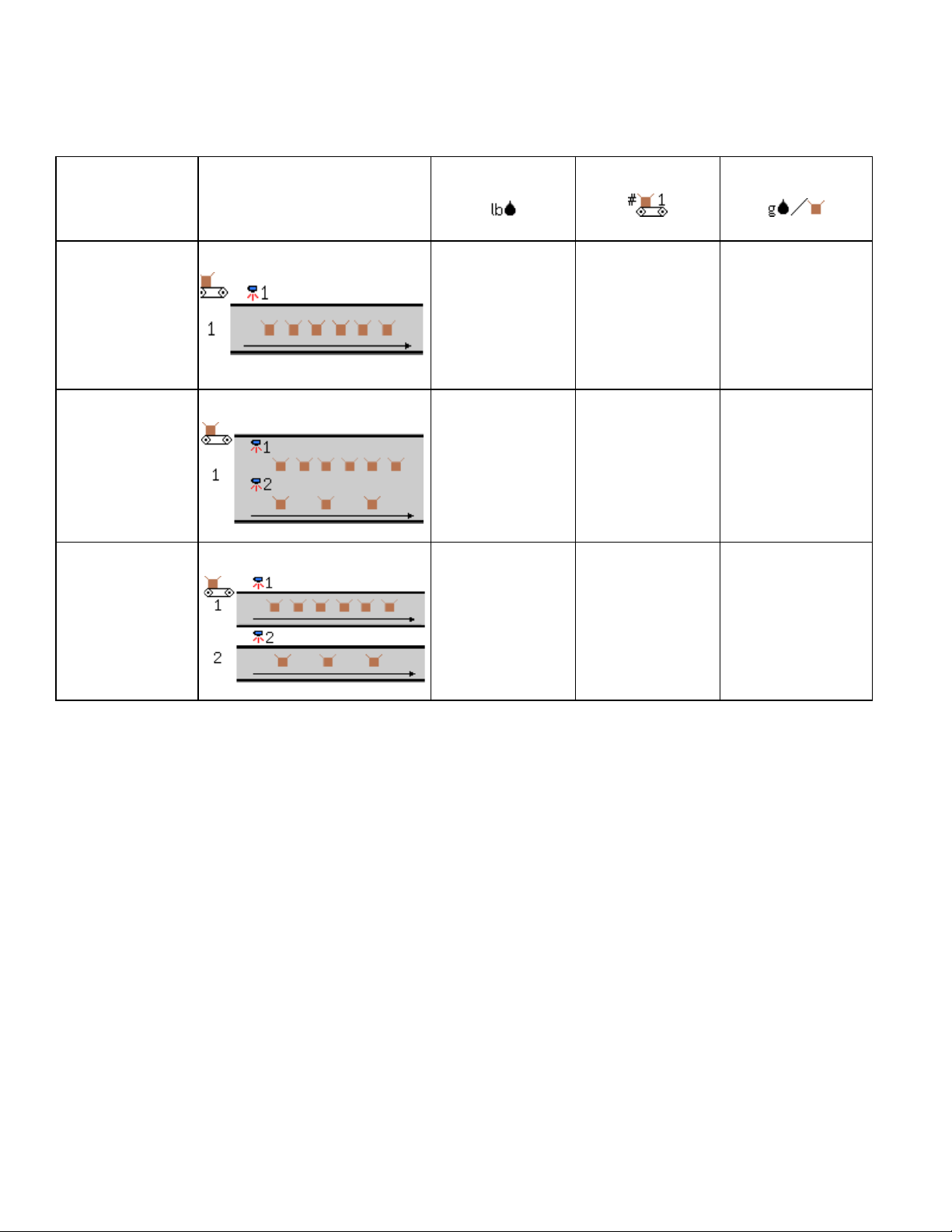

Material Tracking Coverage for Pattern Controller Systems

Material Used

Line Configuration Diagram

Single Line XX X

Multi-Unit Line XX

Multi-Line XX

()

Products per Line

()

Material per Product

( )

X*

**

* Products on both parts of the line must be the same in order to generate accurate material per product data.

** Accurate material per product data cannot be generated for multi-line configurations (assumes different products).

26 3A2347ZAA

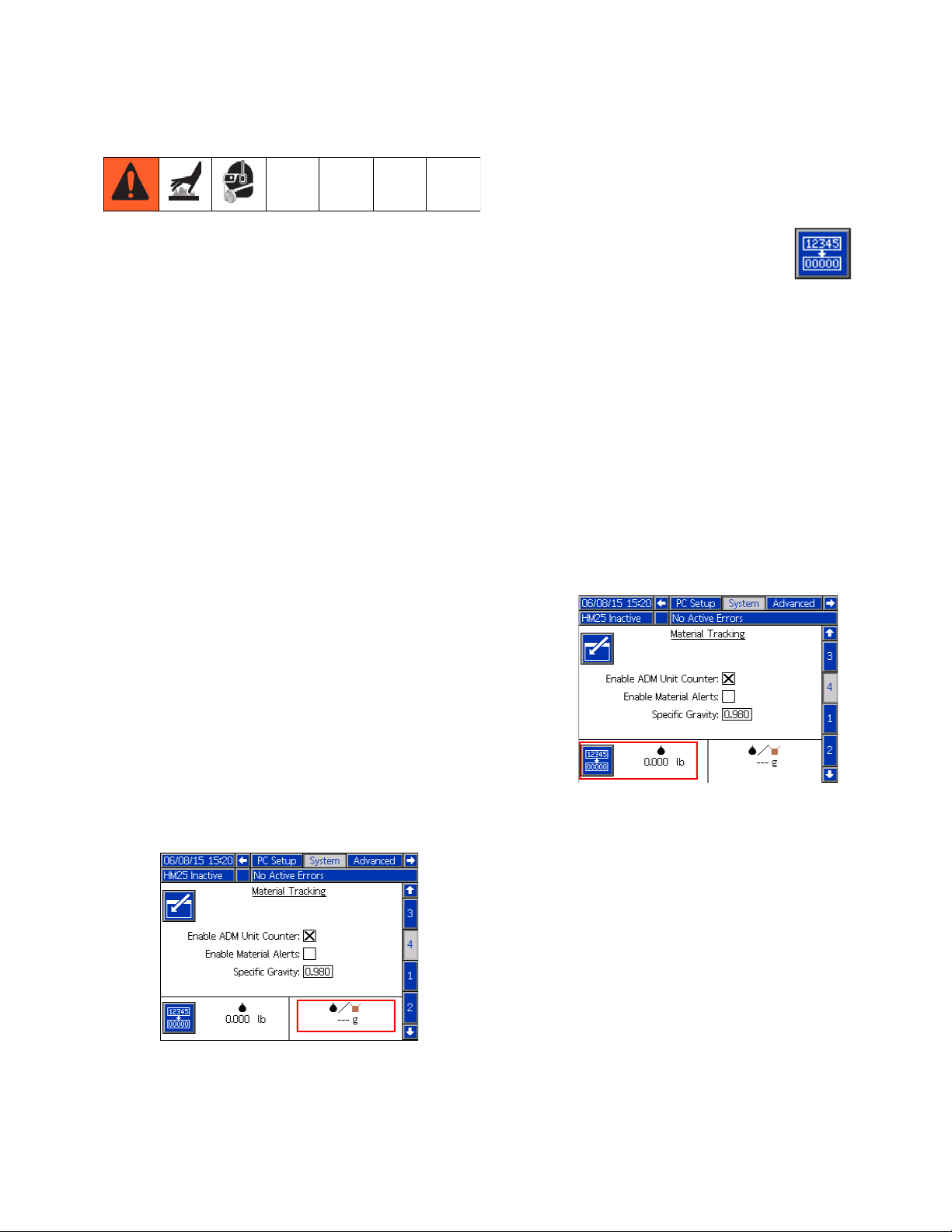

Setup

Calibration

Perform the following steps to calibrate the material

tracking function:

1. Navigate tj the material Tracking Screen (Screen 4

of the System chapter).

2. To calibrate using the tape and scrape method:

a. Obtain a scale.

b. Place tape on a procudt(s) in locations where

material is dispensed.

c. Run normal production (un-taped products) until

a value appears in the grams per product label

(this could take several minutes of production).

d. Run taped products(s) through line and allow

material to cool and harden on the tape.

3. To calibrate using the purge method:

a. Obtain a scale and a container.

b. Reset the calibration weight totalizer by press-

ing and holding the reset softkey .

c. Tare scale with empty container and purge at

least 1 lb. of material into the container.

d. Weigh container with material.

e. Adjust the specific gravity setting until the

weight displayed in the totalizer matches the

value measured by the scale using the following

formula:

New SG Value = Durrent SG Value x Measured Weight /

Displayed Weight

e. Scrape all material from product and place on

scale.

f. Adjust the specific gravity setting until the grams

per product displayed matches the value measured by the scale using the following formula:

New SG Value = Current SG Value x Measured Grams

per Product / Displayed Grams per Product

3A2347ZAA 27

Setup

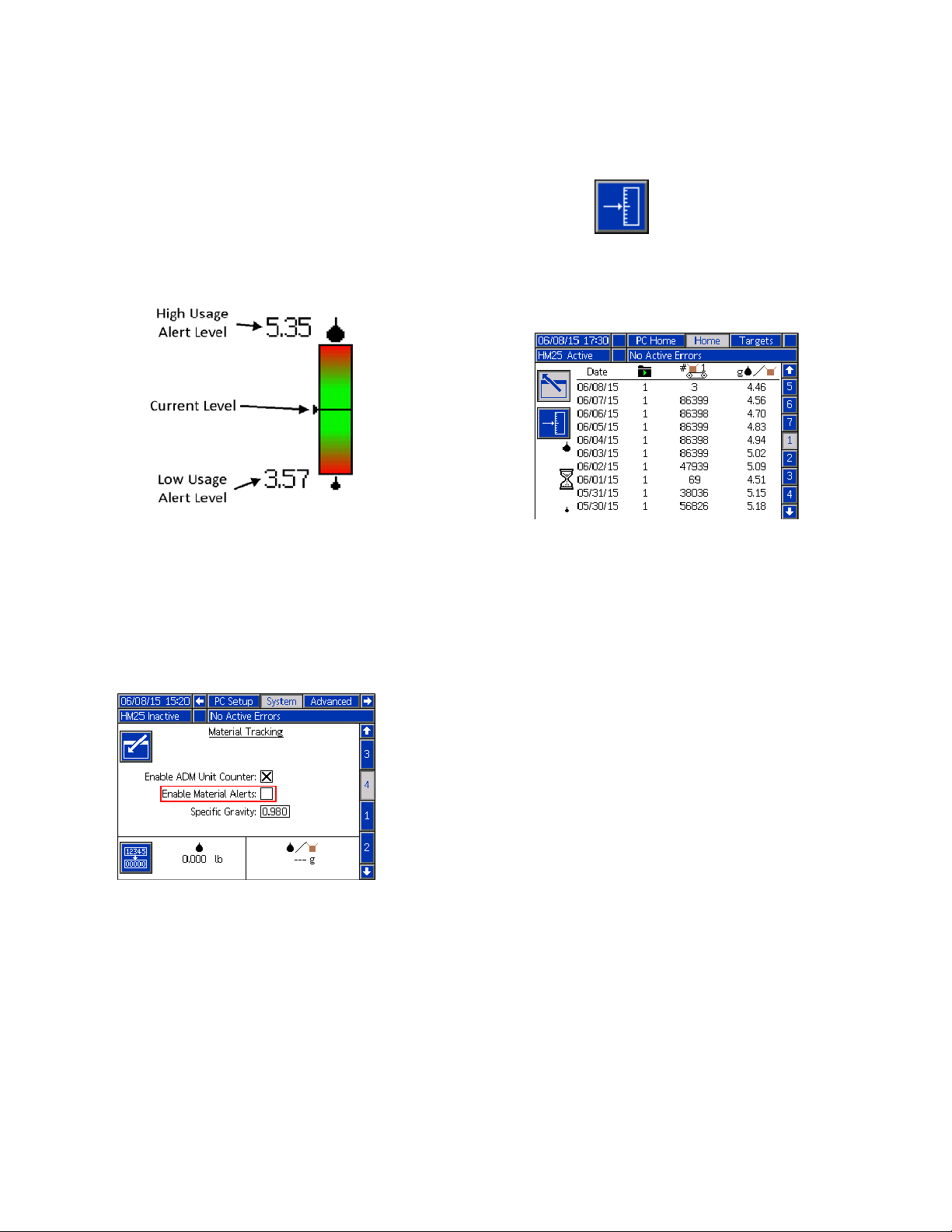

Material Alerts

This feature can be used ot monitor material usage

based on a target material per unit value. If material

alerts are enabled the system wil lrecord an event every

time the system deviates over 20% from the target. The

material alert information can be seen in the bottom left

corner of the material log (see image below).

Enable/Disable Material Alerts

To enable/disable material alerts, select/deselect the

Enable Material Alerts setting on the Material Tracking

Screen (Screen 4 of the System chapter).

Reset Material Target

To reset the material target value, press the reset mate-

rial target softkey . An hourglass will appear

indicating that the system is learning the new target

(current machine output).

NOTE: the material target will be automatically reset

whenever a Pattern Controller setting is changed (e.g.

switch from solid bead to stitched bead).

28 3A2347ZAA

Operation

Heating and dispensing hot melt adhesive may

create potentially harmful vapors. Read material

manufacturer’s warnings and material MSDS to know

specific hazards and precautions. Ventilation of the

work area may be required.

NOTE: See AppendixA-ADMon page 111 for

detailed ADM information.

Operation

Initial Startup and Prime

NOTE: All setup procedures must be completed prior to

initial startup. See Setup on page 13.

NOTE: Only 1/4 in. (6 mm) round hot melt adhesive pel-

lets can be used in the InvisiPac system. PSA-type

adhesive pellets will not work in the InvisiPac system.

NOTICE

To prevent damage to soft key buttons, do not press

the buttons with sharp objects such as pens, plastic

cards, or fingernails.

NOTE: See Appendix B - USB Downloading, Uploading on page 117 for detailed USB information.

Overview

The system includes a vacuum transfer system that

pulls the adhesive pellets into the system as needed.

Once melted, the adhesive enters the pump where it is

pumped into the heated hoses then to the heated guns.

The gun then briefly opens to dispense the desired

quantity of adhesive.

Even though the system rises to operating temperature

quickly, there is a Schedule function in the ADM that

eliminates waiting for the system to heat up. The Schedule function automatically enables the heating system at

the user-specified times so the system is ready to dispense when a shift begins. The Schedule function also

disables the heating system at user-specified times to

ensure the heating system is disabled when not being

used.

1. Direct the guns into an appropriate waste container.

2. Verify the shaker inlet is at the bottom of the empty

adhesive pellets container. Optional vibrating adhesive pellets container, part 24R136, is available.

See Accessories on page 94.

NOTE: The shaker inlet must be completely covered in

adhesive pellets to effectively pull pellets into the tube.

3. Fill adhesive pellets container with hot melt adhesive pellets.

4. Turn main power switch ON .

5. Open system air inlet ball valve.

WLE

6. Use pump air pressure regulator (C) to adjust pump

air pressure to 0. See F

3A2347ZAA 29

IG. 1 on page 8.

Operation

7. Use vacuum transfer air pressure regulator (E) to

adjust vacuum transfer air pressure setting to

40-100 psi (280-690 kPa, 2.8-6.9 bar). Recommended setting is 60 psi (414 kPa, 4.1 bar). See

FIG. 1 on page 8.

NOTE: Vacuum transfer will not begin operating until

pump reaches operating temperature.

To prevent fire and explosion, never exceed the

cleaning fluid’s rated temperature. If the system was

just flushed, residual cleaning fluid is still in the

system until the system is primed with adhesive. Do

not raise temperature above cleaning fluid rated

temperature until system is primed with adhesive.

NOTE: A new system may have residual oil due to testing at the factory prior to shipping. To prevent smoking,

make sure to perform the following step.

8. On new systems only: temporarily adjust the melter

temperature to 250°F (121°C). See Select ADM

Settings on page 20 for instructions.

12. With the guns open and the system up to temperature, slowly increase pump air pressure until the

pump begins to run very slowly. Approximately 20

psi (140 kPa, 1.4 bar) should be sufficient.

NOTE: Operation may be erratic below 20 psi (140 kPa,

1.4 bar).

13. Continue running the pump until clean, air-free

material is dispensed from each gun.

14. When each gun is fully primed, adjust pump to

desired pressure setting:

a. Adjust pump pressure to between 20-100 psi

(140-690 kPa, 1.4-6.9 bar).

b. Use separate gun controller to repeatedly open

and close each gun while inspecting the dispense pattern.

c. Repeat until desired dispense pattern is

achieved.

Manual Refill

9. Press to enable the heaters and pump.

NOTE: When system is up to temperature, the pump will

be activated automatically but will not start because

there is no air pressure supplied to the pump.

NOTE: When the melter is up to temperature, the

auto-fill function will initiate to fill the funnel with pellets.

10. On new systems only: After the melter has reached

250°F (121°C) and the funnel is filled with pellets,

set the melter temperature back to the desired operating temperature. See Select ADM Settings on

page 20 for instructions.

11. Use separate gun controller to open the guns and

keep them open.

NOTICE

In the following step, to prevent damage to the pump

due to pump cavitation, do not supply more than 20 psi

(140 kPa, 1.4 bar) air pressure to the pump until the

system is fully primed.

NOTE: Use Automatic Refill whenever possible. The

system uses Automatic Refill by default and must be

manually changed to Manual Refill. Only use Manual

Refill if the Automatic Refill system is not functioning

properly and cannot be fixed in a timely manner. Perform service to automatic feed system as soon as possible to limit debris buildup on feed cap.

It is recommended to maintain a minimum flow rate of

1.5 lb/hour to prevent material from melting within the

feed cap and funnel. If production rate is below

1.5 lb/hour or system sits at temperature without dispensing for extended periods of time, use manual refilling with caution. System flow rate can be monitored by

enabling the Diagnostic screen.

1. On the System 3 screen (in the Setup screens),

select “Manual” from the Refill mode dropdown.

2. Remove the phillips head screws then remove the

funnel cap from the funnel.

30 3A2347ZAA

Loading...

Loading...