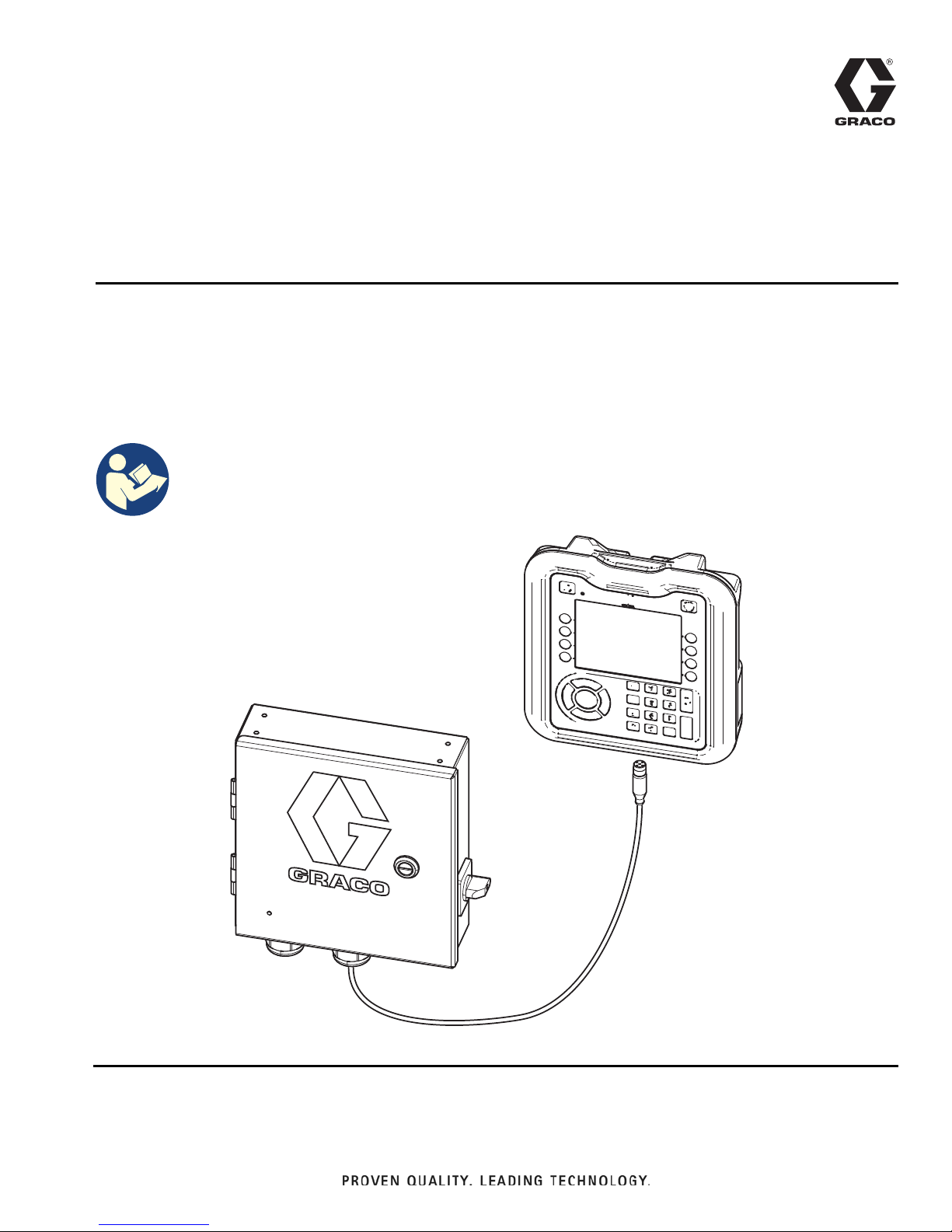

Graco InvisiPac HM25, InvisiPac HM25c, InvisiPac HM50 Operation, Repair, And Parts

Operation, Repair and Parts

InvisiPac®

334784G

Pattern Controller

To control fluid dispense valves of adhesive supply equipment. For professional use only.

Not approved for use in explosive atmospheres or hazardous locations.

See page 3 for model information and Agency approvals.

Important Safety Instructions

Read all warnings and instructions in this manual

and related manuals. Save these instructions.

EN

WLD

Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Component Identification (Internal Models - HM25c)

8

Component Identification

(Internal Models - HM25 and HM50) . . . . . . . . . 9

Component Identification (External Models) . . . 10

Installation - Internal Models (HM25c) . . . . . . . . . 11

Connect Pattern Control Board . . . . . . . . . . . . . 11

Installation - Internal Models (HM25 and HM50) . 12

Connect Pattern Control Board . . . . . . . . . . . . . 12

Connect Power Supply and Advanced Display

Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Install Control Board into InvisiPac System . . . 14

Installation - External Models . . . . . . . . . . . . . . . . 15

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Connect Advanced Display Module (ADM) . . . . 15

Connect Pattern Control Board . . . . . . . . . . . . . 16

Connect Electrical Cord . . . . . . . . . . . . . . . . . . 17

Wire Pattern Control Board . . . . . . . . . . . . . . . . . 18

Valve Installation . . . . . . . . . . . . . . . . . . . . . . . . 18

Trigger Installation . . . . . . . . . . . . . . . . . . . . . . 18

PLC Inputs and Outputs Installation (optional) . 19

Encoder Installation

(PC-8e only) . . . . . . . . . . . . . . . . . . . . . . . . 20

Run Up Installation (PC-8e only) . . . . . . . . . . . 20

Initial Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Software Update . . . . . . . . . . . . . . . . . . . . . . . . 21

Key Token . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Screen Maps . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

HMI Interface . . . . . . . . . . . . . . . . . . . . . . . . . . 23

PC Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Advanced Screens . . . . . . . . . . . . . . . . . . . . . . 35

Stitching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Random Length Bead Mode . . . . . . . . . . . . . . . . . 38

Mirror Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Gun Compensation (optional) . . . . . . . . . . . . . . 40

Line Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Run Up Control (PC-8e only) . . . . . . . . . . . . . . . 42

Modulated Bead (PC-8e Only) . . . . . . . . . . . . . 43

Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Triggers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Run Up Control . . . . . . . . . . . . . . . . . . . . . . . . . 44

PLC Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Run Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

PLC Inputs and Outputs . . . . . . . . . . . . . . . . . . 48

Software Update Procedure . . . . . . . . . . . . . . . . . 49

USB Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Download Procedure . . . . . . . . . . . . . . . . . . . . . 50

Accessing Files . . . . . . . . . . . . . . . . . . . . . . . . . 50

USB Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

External Models . . . . . . . . . . . . . . . . . . . . . . . . . 51

Internal Models (HM25c) . . . . . . . . . . . . . . . . . . . . 53

Internal Models (HM25 and HM50) . . . . . . . . . . 54

Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Internal Pattern Controller (HM25 and HM50

Systems with AWB) . . . . . . . . . . . . . . . . . . 58

Internal Pattern Controller (HM25 Systems with DIN

Rail) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

External Models . . . . . . . . . . . . . . . . . . . . . . . . . 60

Dimensioned Drawings . . . . . . . . . . . . . . . . . . . . . 61

Technical Specifications . . . . . . . . . . . . . . . . . . . . 64

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 66

2 334784G

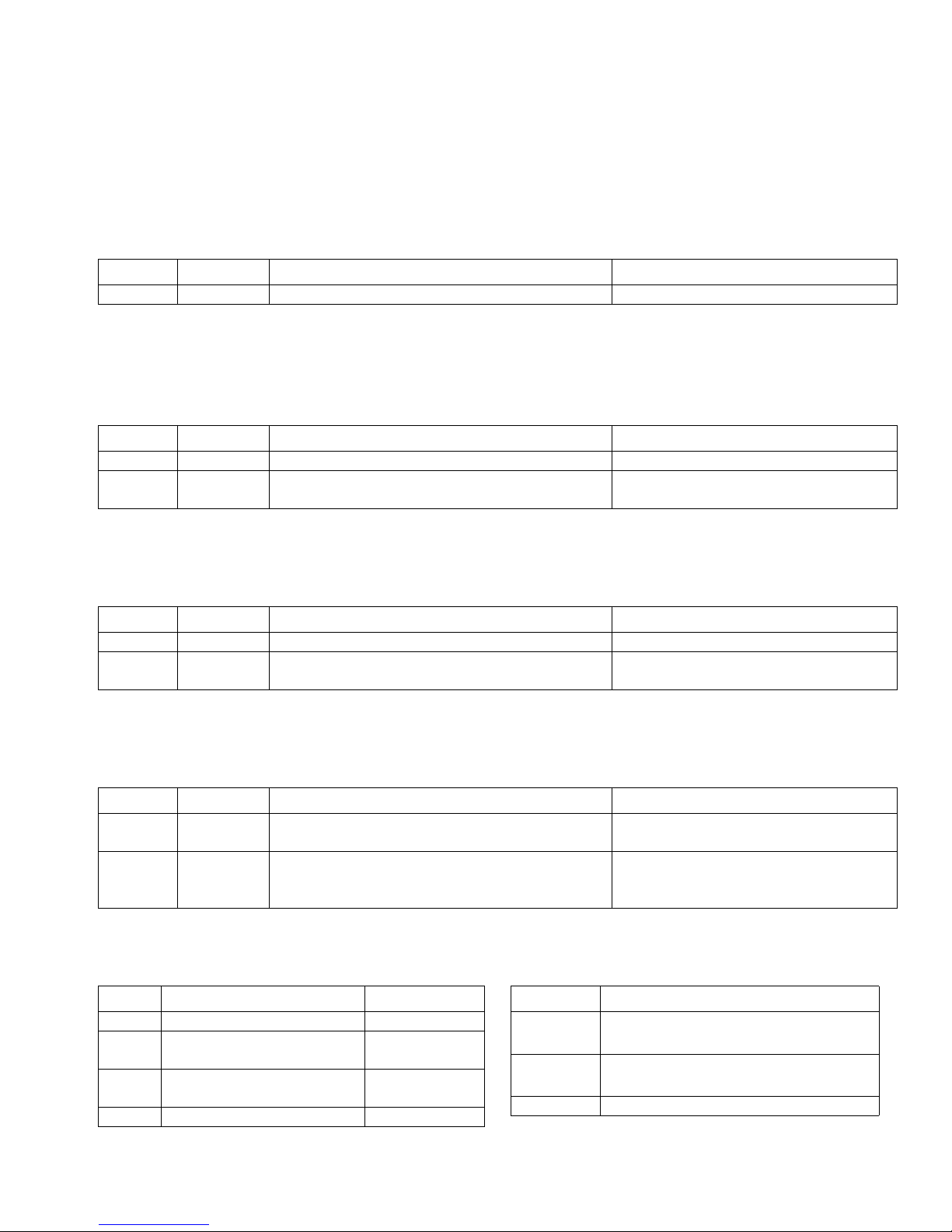

Models

Internal Models (HM25c)

Used to upgrade InvisiPac HM25c systems to include pattern control.

Part Type Description Contents

25M526 PC-8* Time or distance mode, no encoder Pattern controller

* Order kit 17F712 to upgrade to PC-8e.

Internal Models (HM25 and HM50)

Used to upgrade InvisiPac HM25 and HM50 systems to include pattern control.

Part Type Description Contents

24X640 PC-8 Time or distance mode, no encoder Internal pattern controller

24X641 PC-8e Time or distance mode, with or without encoder

Run up control (optional)

Internal pattern controller

Key token for encoder and run up

Models

External Integrated Models

Used to connect a separate pattern control enclosure to an InvisiPac system (compatible with all InvisiPac systems)

Part Type Description Contents

24X523 PC-8 Time or distance mode, no encoder Pattern controller

24X524 PC-8e Time or distance mode, with or without encoder

Run up control (optional)

Pattern controller

Key token for encoder and run up

External Stand Alone Models

Used for applications without an InvisiPac system

Part Type Description Contents

24X525 PC-8 Time or distance mode, no encoder Pattern controller

Advanced display module

24X526 PC-8e Time or distance mode, with or without encoder

Run up control (optional)

Pattern controller

Advanced display module

Key token for encoder and run up

Approvals Related Manuals

Part Description Approvals

127971 External pattern controller CE, ETL, cETL

24W293 Internal pattern controller

(HM25c)

24X521 Internal pattern controller

(HM25 and HM50)

24E451 Advanced display module CE, ETL, cETL

CE, ETL, cETL

CE, ETL, cETL

Part Description

3A4938

333347

334934 Run Up Pressure Kit

InvisiPac HM25c Tank-Free

Delivery System

InvisiPac HM25 and HM50 Tank-Free

Hot Melt Delivery System

™

Hot Melt

™

334784G 3

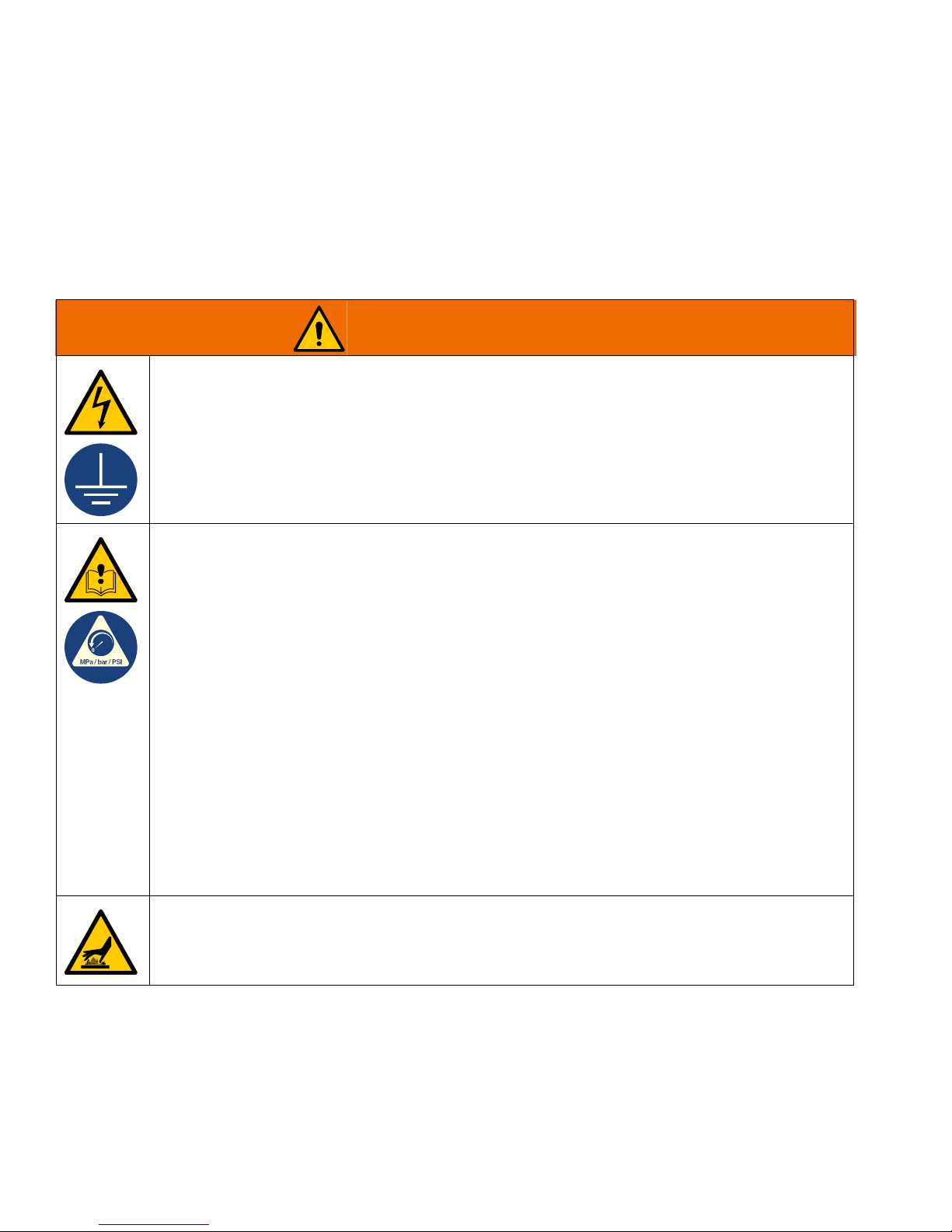

Warnings

WARNING

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause

electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before

servicing or installing equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Specifications in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Specifi-

cations in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete

information about your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

• manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

BURN HAZARD

Equipment surfaces and fluid that is heated can become very hot during operation. To avoid severe

burns.

• Do not touch hot fluid or equipment.

4 334784G

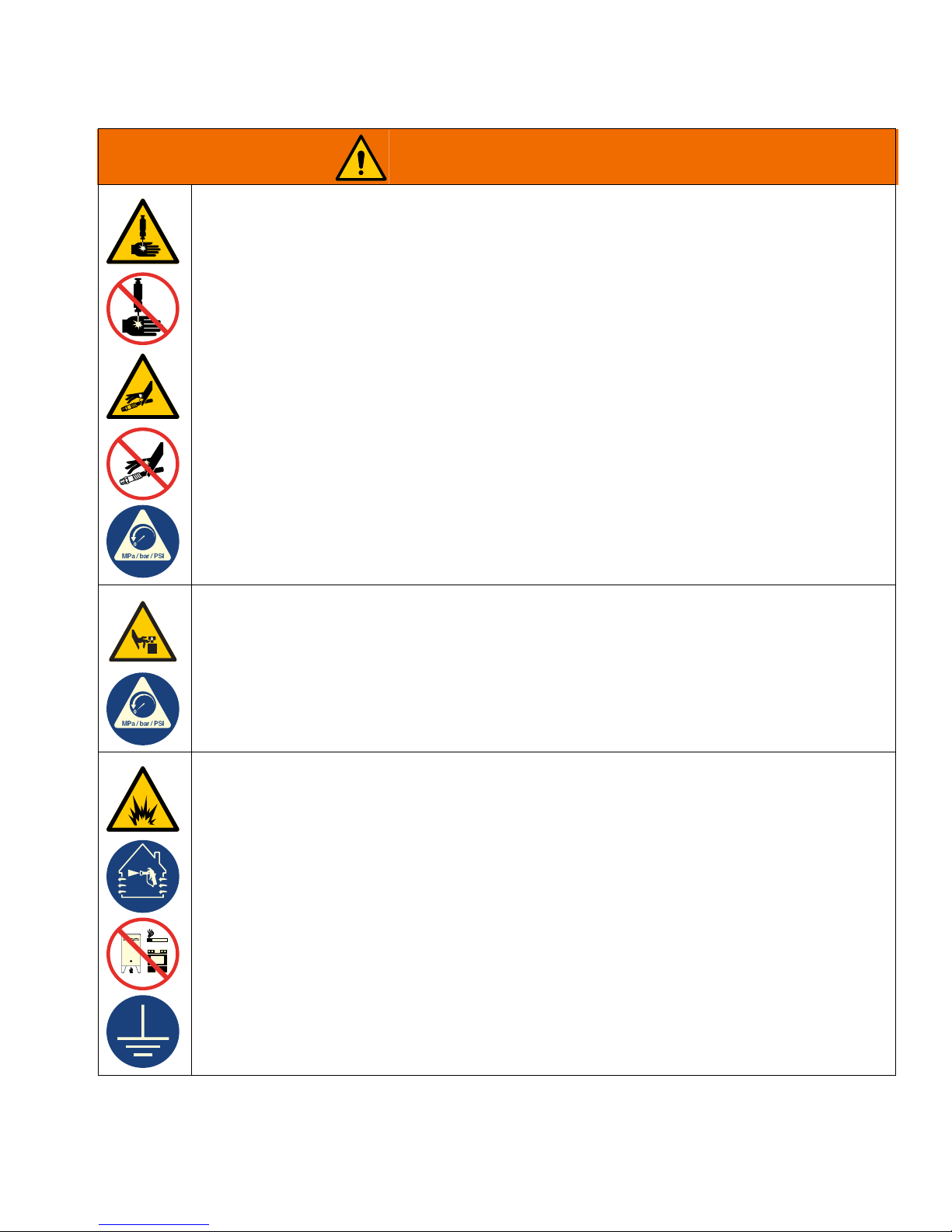

Warnings

WARNING

SKIN JECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgi-

cal treatment.

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking,

or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Equipment can start without warning. Before checking, moving, or servicing equipment, follow the

Pressure Relief Procedure and disconnect all power sources.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire and explosion:

• Do not use solvent-based adhesives that can create an explosive atmosphere when processed.

• Use equipment only in well-ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic

drop cloths (potential static sparking).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

334784G 5

Warnings

WARNING

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read Safety Data Sheets (SDSs) to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury,

including eye injury, hearing loss, inhalation of toxic fumes, and burns. Protective equipment includes

but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent

manufacturer.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious

chemical reaction and equipment rupture. Failure to follow this warning can result in death, serious

injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents.

• Do not use chlorine bleach.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material

supplier for compatibility.

6 334784G

Overview

Overview

InvisiPac pattern control systems can be integrated with InvisiPac systems or stand alone with any other equipment.

For all installations, the advanced display module (ADM) is used to make programming easy.

PC-8 controllers operate in time or distance mode without an encoder. Up to 8 guns and 4 independent triggers are

supported.

PC-8e controllers include the same features as PC-8 with the addition of distance based control using an encoder,

and run up control using an I/P or V/P pressure regulator.

Features of the PC-8 and PC-8e:

Feature

Gun outputs

Trigger inputs

Encoder

Run up control

Program storage

PLC enable / disable

PLC alarm output

PLC program select

Password protection

Integrated power supply

For more information, see Technical Specifications,

page 64.

8

4

2 (PC-8e only)

2 (PC-8e only)

50

Yes

Yes

Yes

Yes

Yes

Details

334784G 7

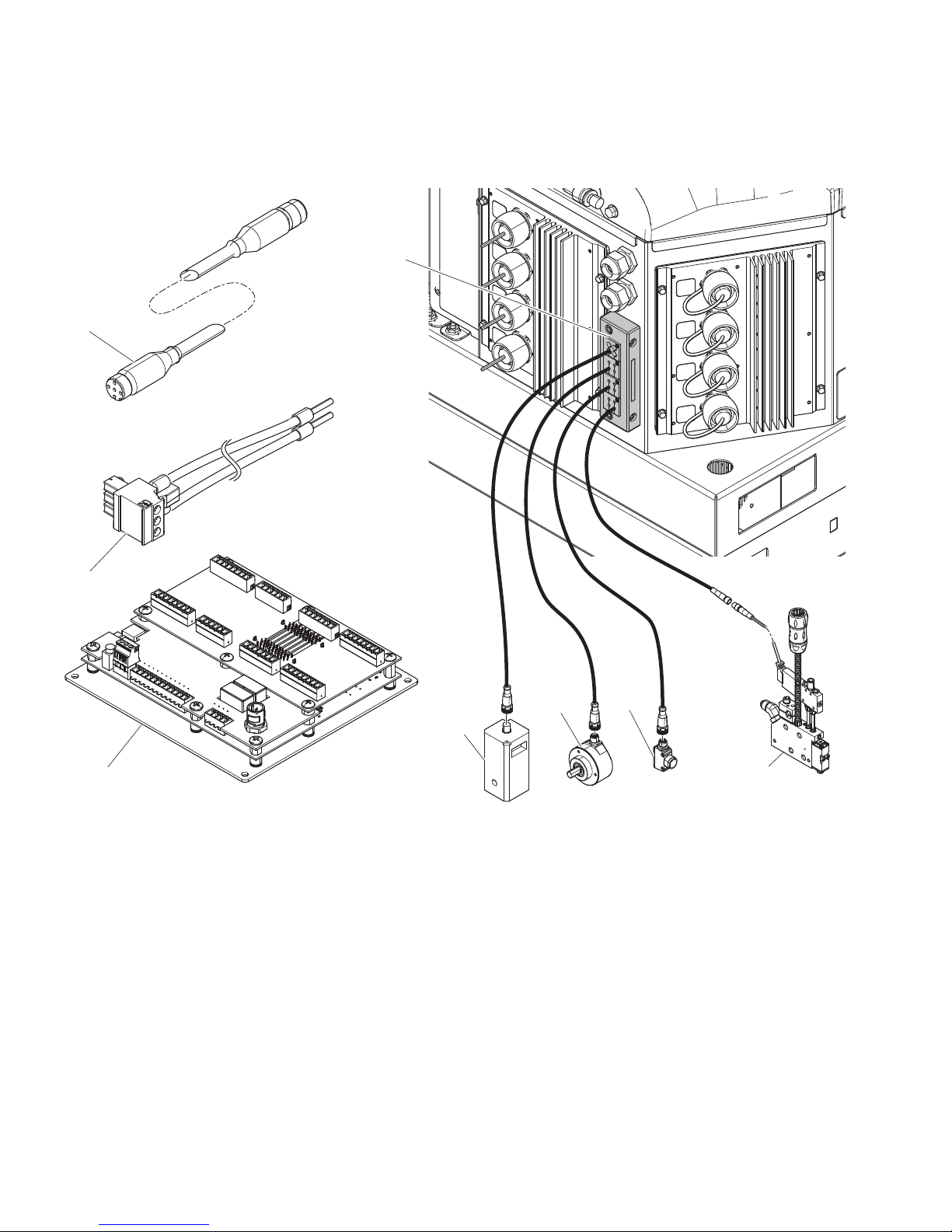

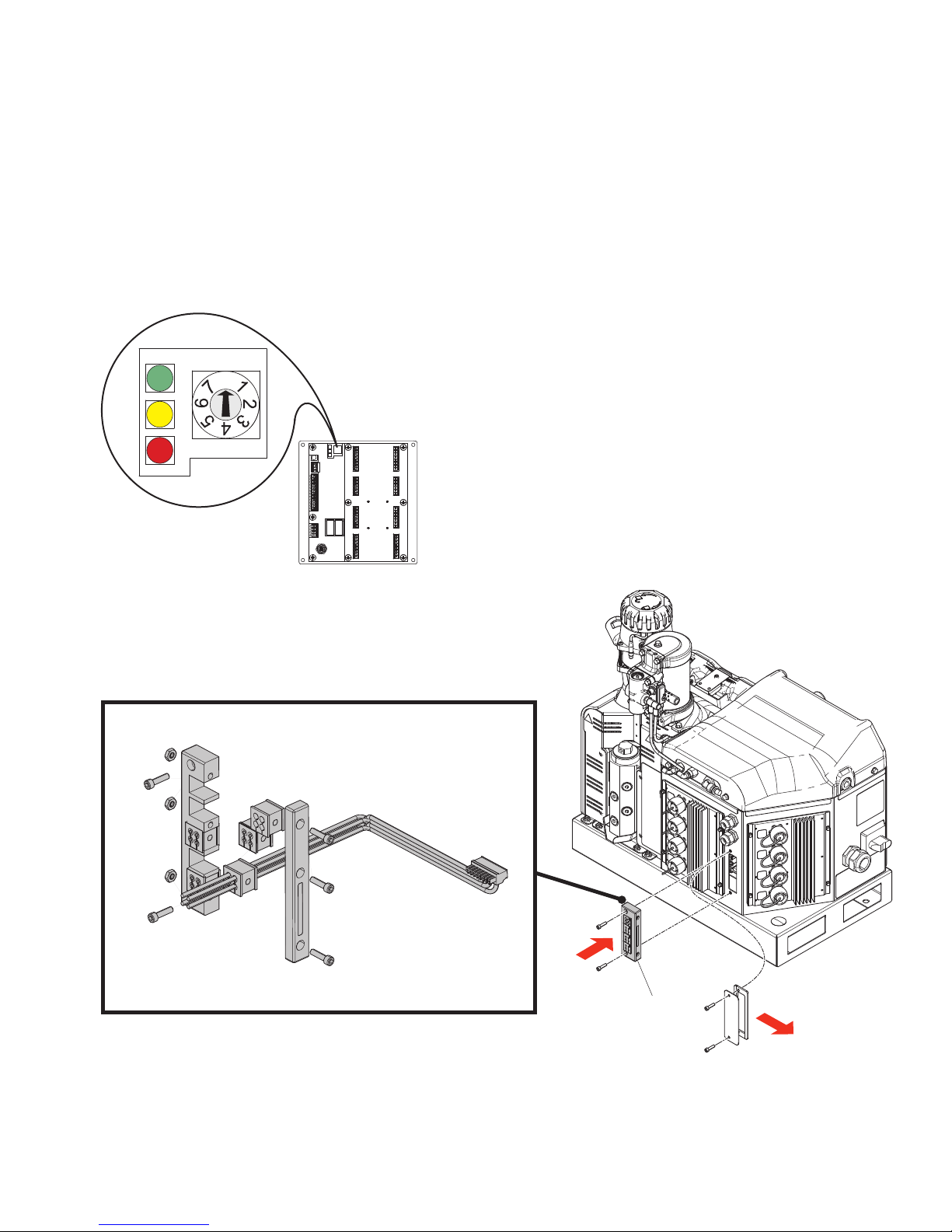

Component Identification (Internal Models - HM25c)

/

.

-

+

WLE

6

3

&

7

Installed onto InvisiPac System

Component Identification (Internal Models - HM25c)

Key

C Communication cable

HValve

J Trigger

K Encoder

Key

L Run up

P Power harness

S Control board

T Cord grip

8 334784G

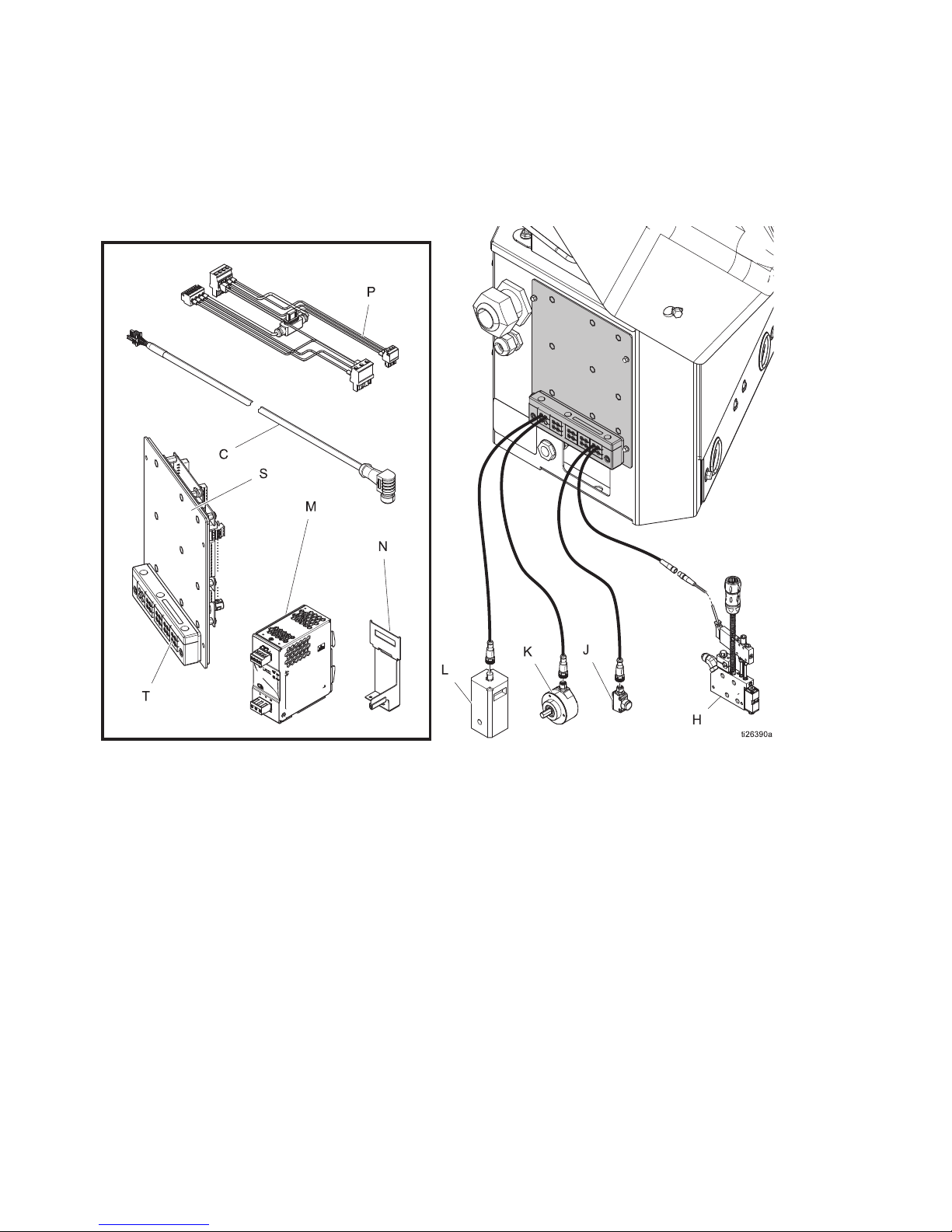

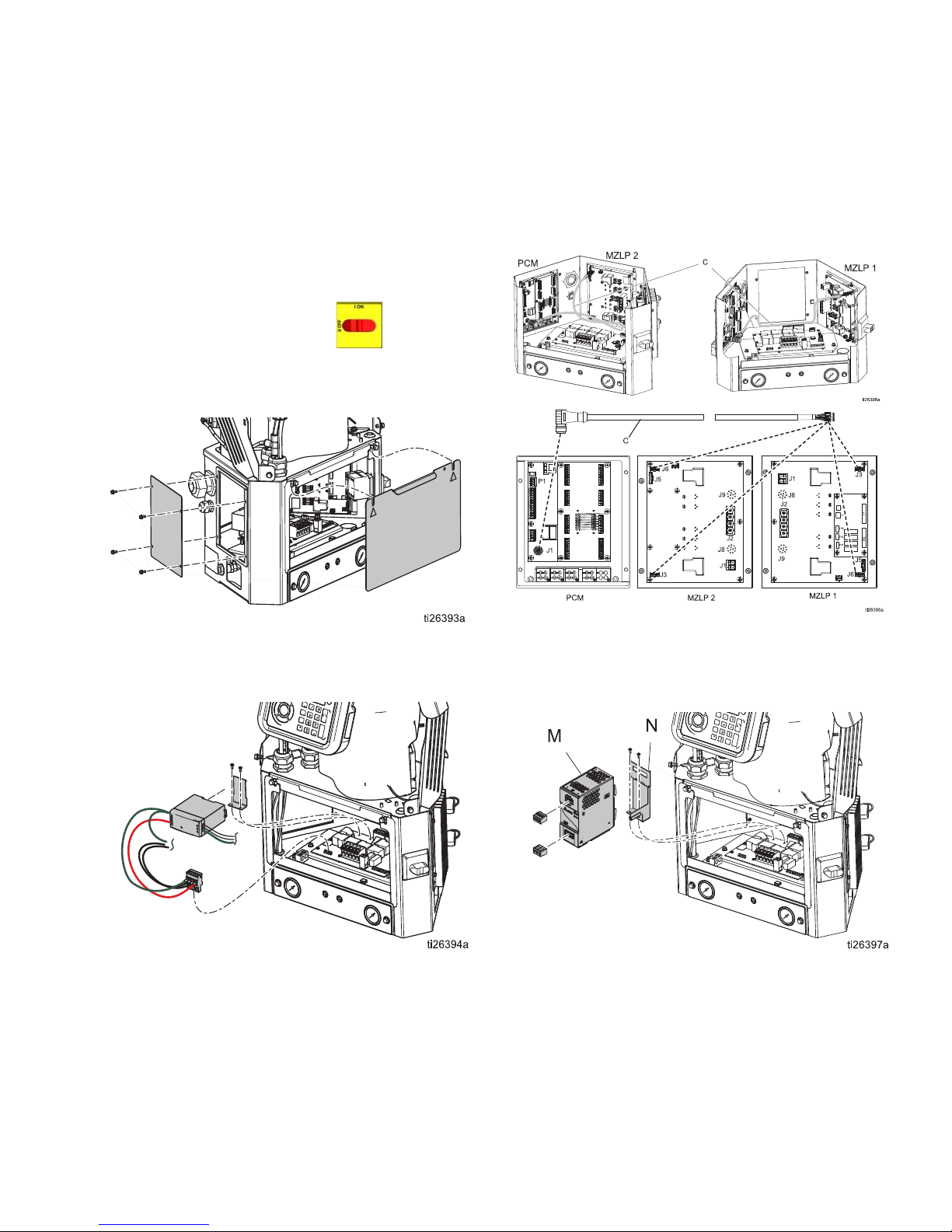

Component Identification (Internal Models - HM25 and HM50)

Installed onto InvisiPac System

Component Identification

(Internal Models - HM25 and HM50)

Key

C

H

J

K

L

334784G 9

Communication cable

Valve

Trigger

Encoder

Run Up

Key

M

N

P

S

T

Power supply

Power supply bracket

Power harness

Control board

Cord grip

Component Identification (External Models)

7

7

7

3

6

%

'

&

1

/

.

-

+

$

0

WLE

(

Component Identification (External Models)

Key

A

B

C

D

E

H

J

Pattern controller

Power switch

Communication cable

ADM

USB port

Valve

Trigger

Key

K

L

M

N

P

S

T

Encoder

Run up

Inside view of pattern controller

Customer power board (not included)

Ground terminal

Control board

Cord grips (I/O x2 power)

10 334784G

Installation - Internal Models (HM25c)

WLD

0

WLD

7

Installation - Internal Models (HM25c)

Connect Pattern Control Board

1. Set pattern control system type selector switch to 0.

NOTE: The system must be powered off for a

change in system type to have an effect.

2. Remove cord grip assembly (T) from back of InvisiPac system and remove inserts. Inserts with grip

tightly on most M8 and M12 cables and expand and

compress to accept cables larger than the apparent

hole size.

3. Install valve signal wires, trigger signal wires, PLC

wires (optional). See Wire Pattern Control Board,

page 18.

4. Route cables through the opening in the back of the

InvisiPac enclosure as shown.

5. Apply cord grip inserts over cables and replace into

frame. Replace frame onto back of InvisiPac enclosure.

6. Remove excess slack from the cables but do not

pull tight. Tighten cord grip frame on inserts to

secure.

334784G 11

Installation - Internal Models (HM25 and HM50)

0

Installation - Internal Models (HM25 and HM50)

Connect Pattern Control Board

1. Set pattern control system type selector switch to 0.

NOTE: The system must be powered off for a

change in system type to have an effect.

WLD

2. Remove cord grip assembly (T) from pattern control

board (S) and remove inserts. Inserts will grip tightly

on most M8 and M12 cables and will expand and

compress to accept cables larger than the apparent

hole size.

3. Install valve signal wires, trigger signal wires, PLC

wires (optional) and encoder and run up wires

(PC-8e only). See Wire Pattern Control Board,

page 18.

4. Route cables through the opening in the pattern

control board back panel as shown.

5. Apply cord grip inserts over cables and replace into

frame. Replace frame onto pattern control panel.

6. Remove excess slack from cables but do not pull

tight. Tighten cord grip frame on inserts to secure.

12 334784G

Installation - Internal Models (HM25 and HM50)

Connect Power Supply and Advanced Display Module

NOTE: If the internal pattern controller is being installed

into a first generation HM25 with DIN rail writing, additional connections must be made.

Install Kit 24Y171 has the necessary components and

instructions to perform this installation. See Kits, page

55.

1. Turn main power switch OFF.

2. Remove panel door, then remove blanking plate

from left-hand side of system electrical enclosure.

4. Connect communication cable (C) to open J3 connector (or J6, if J3 is used) on MZLP board. If connecting to MZLP #2, loop extra cable length along

edge of electrical enclosure.

3. Remove connector from AWB terminal pins J1 and

remove the power supply and harness from mounting bracket. Unscrew mounting bracket from AWB.

5. Remove blue connectors from terminals of power

supply W and discard or set aside. Install new

power supply bracket (N) onto AWB and clip new

power supply (M) into place.

334784G 13

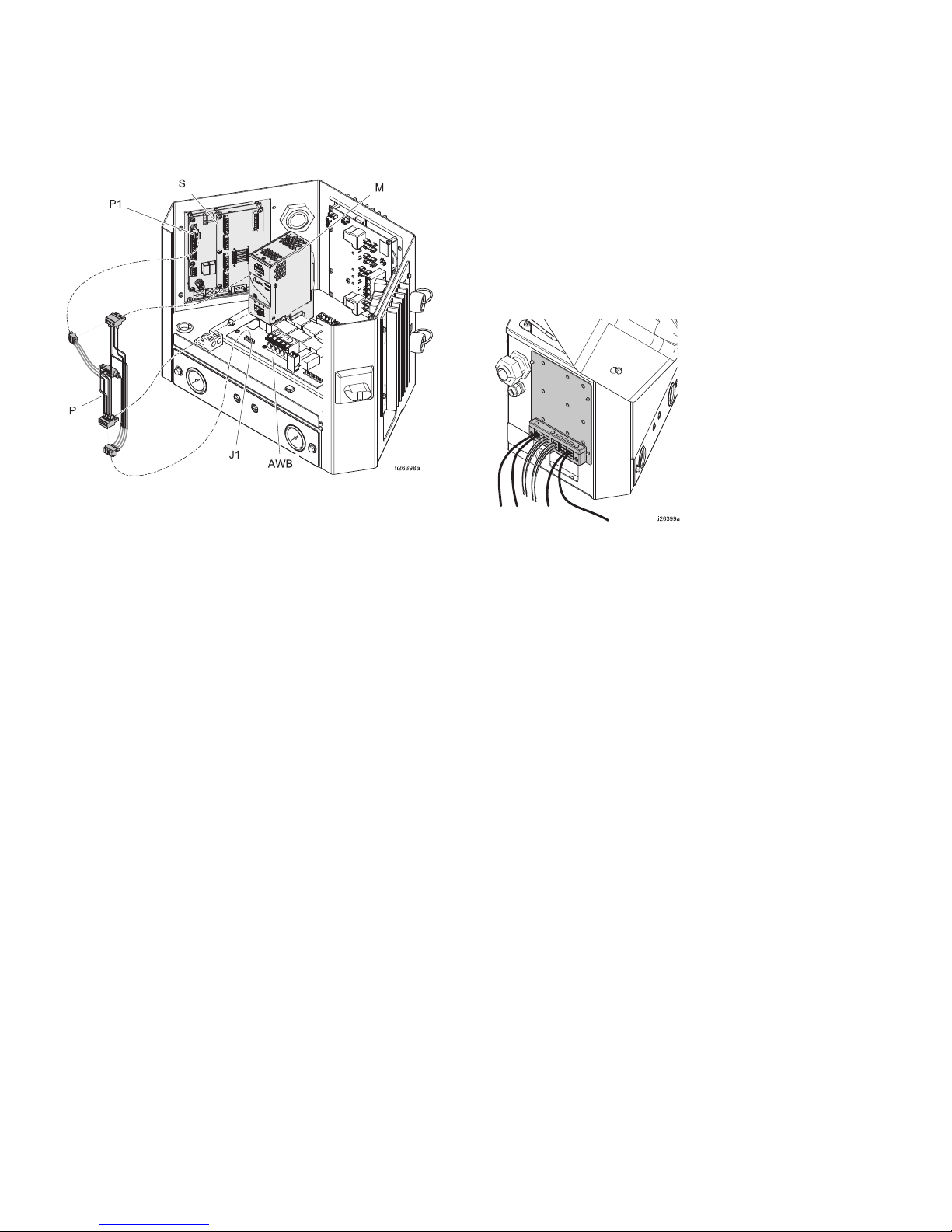

Installation - Internal Models (HM25 and HM50)

6. Connect power harness (P) to AWB terminal pins J1

and the input and output terminals of power supply.

Install Control Board into

InvisiPac System

1. Mount board into open space on left-hand side of

electrical enclosure. Use serrated-flange screws.

2. Connect power harness to power control board terminal P1, and connect communication cable to pattern control board terminal P4.

3. Replace system electrical enclosure door.

14 334784G

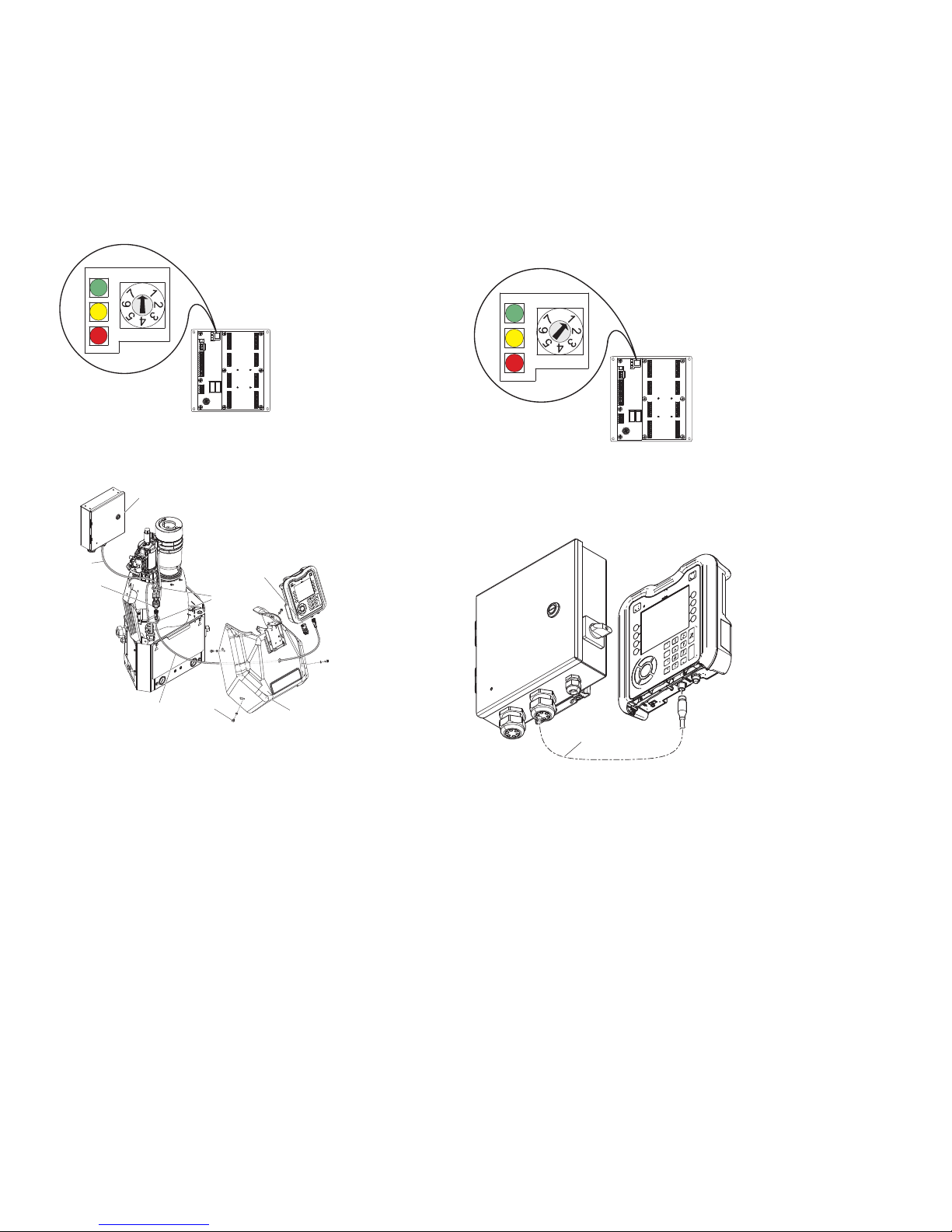

Installation - External Models

WLF

13 in (330.2 mm)

Clearance

WLD

0

$

'

%

Installation - External Models

Mounting

The pattern controller and ADM can be mounted using

the included VESA-compatible brackets and mounting

software.

1. Unscrew the two lower screws to uncouple the

“wall” portion of the bracket.

2. Securely mount the bracket in the desired location.

3. Slide the controller onto the bracket and tighten the

two screws for permanent fastening.

ALTERNATIVE METHOD: Remove mounting hardware

and mount directly to any surface.

NOTE: Make sure at least 13 in. of clearance is available above the top of the mounting bracket in order to

slide the enclosure in and out of the wall mount.

Connect Advanced Display

Module (ADM)

Integrate with InvisiPac HM25c

1. Set pattern control system type selector switch to 0.

NOTE: The system must be powered off for a

change in system type to have an effect.

2. Disconnect the CAN cable from the ADM (D) and

connect it to one of the male ends of the splitter (2).

NOTE: To make repairing the system easier, locate the

system so that it is easily accessible and has sufficient

lighting.

334784G 15

WLE

3. Connect the CAN cable from the pattern controller

enclosure (A) to the other male end of the splitter

(2).

4. Connect the male end of the short CAN cable contained in the pattern controller kit (3) to the female

end of the splitter (2).

5. Connect female end of the short CAN cable (3) to

the ADM.

6. Use zip ties to attach the CAN cables and splitter to

the ADM bracket (B).

Installation - External Models

WLD

0

WLD

0

&

WLD

Integrate with InvisiPac (HM25 or HM50)

1. Set pattern control system type selector switch to 0.

NOTE: The system must be powered off for a

change in system type to have an effect.

2. Disconnect the CAN cable from the ADM (D), push

the cable through the plastic shroud (B), the remove

the shroud from the system.

$

Stand Alone

1. Set the pattern control system type selector switch

to 1.

NOTE: The system must be powered off for a

change in system type to have an effect.

2. Mount the ADM using the provided bracket

3. Connect the CAN cable (C) between the pattern

controller and the ADM

&

%

WLD

3. Connect the CAN cable from the ADM (D) to one of

the male ends of the splitter (2).

4. Connect the CAN cable from the pattern controller

(A) to the other male end of the splitter (2).

5. Connect the male end of the short CAN cable contained in pattern controller kit (3) to the female end

of the splitter.

6. Push the free end of the short CAN cable (3)

through the shroud and connect the female end to

the ADM.

7. Use zip ties (4) to attach the CAN cable bundle to

the other vertical bundle of cables.

Connect Pattern Control Board

See Wire Pattern Control Board, page 18.

1. Install triggers and valves

2. Install PLC inputs and outputs (optional)

3. Install encoder (PC-8e only)

4. Install run up (optional, PC-8e only)

16 334784G

Connect Electrical Cord

Improper wiring may cause electric shock or other

serious injury if work is not performed properly.

Have a qualified electrician perform any electrical

work. Be sure your installation complies with all

National, State, and Local safety and fire codes.

The equipment must be grounded to reduce the

risk of electric shock. Improper grounding can

cause electric shock. Grounding provides an

escape wire for the electric current.

The pattern controller system is equipped with a ground

terminal. Have a qualified electrician ground the system

using this terminal.

Electrical power enters through the smaller cord grip on

the right side of the enclosure (see figure). The power

cord can be further secured inside the enclosure with

the provided zip-tie and tie mount.

Installation - External Models

2. Connect earth ground to the grounding terminal.

3. Verify that the cord grip securely tightens around the

power cord. Use a wrench to tighten, if necessary.

1. Install power wires (L1/L2 or L/N) into terminals 2

and 4 on the disconnect switch. The switch accepts

solid or stranded 12 AWG and 14 AWG wire. For

ratings, see Technical Specifications, page 64.

NOTE: The power switch housing can be removed

for easy wiring using the red tab on top of the

switch.

334784G 17

Wire Pattern Control Board

Wire Pattern Control Board

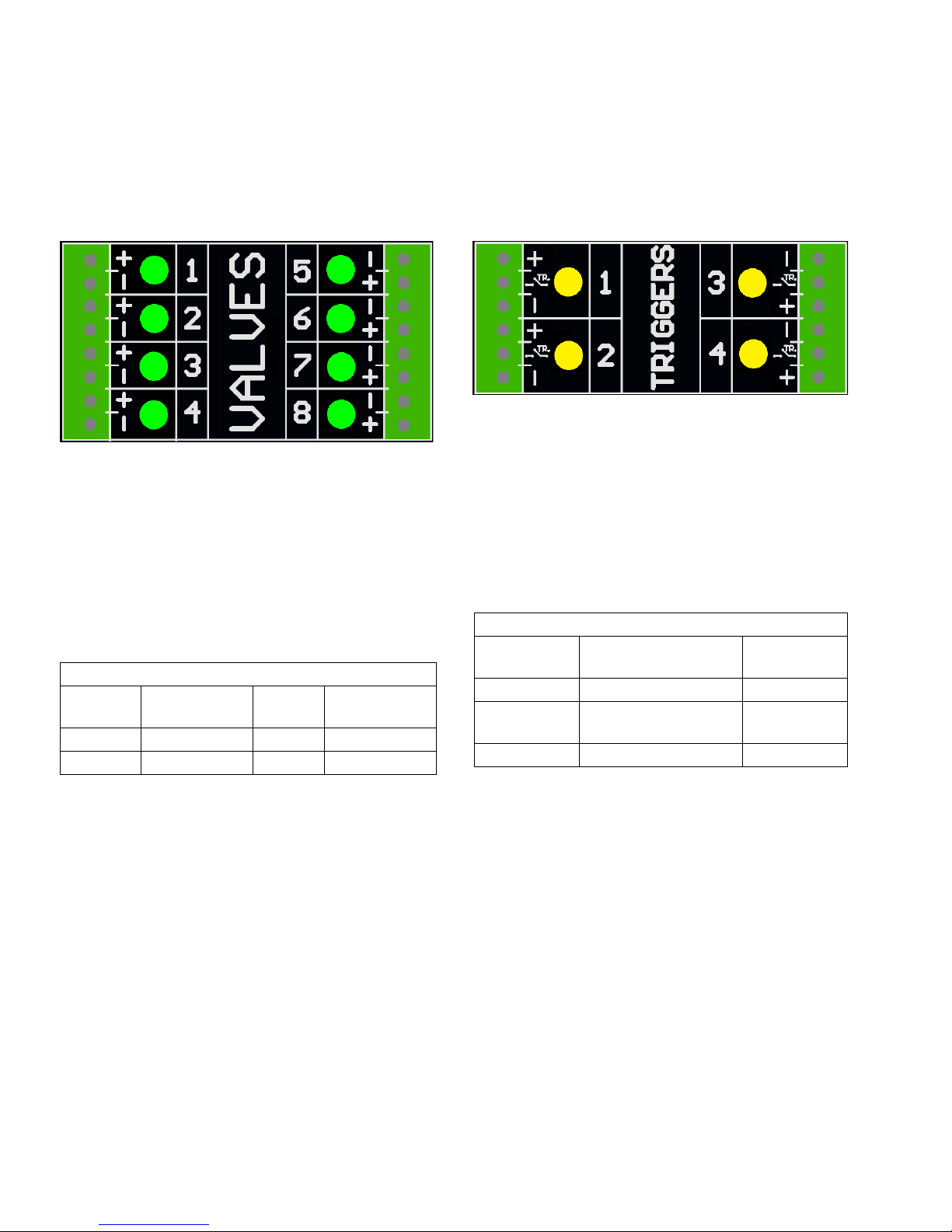

Valve Installation

1. Connect up to 8 valves.

NOTE: Control voltage is 24 VDC with a limit of 1

amp per output and 6 amps total.

NOTE: Green LEDs indicate the status of each

valve.

NOTE: DIN cable black wires are labeled 1 and 2. 1

is plus and 2 is minus.

Standard Wiring Colors

Terminal

Cable

Plus (+) 24V Supply Brown Black 1

Minus (-) Return Blue Black 2

Function M8

Cable

DIN Cable

Trigger Installation

1. Connect up to 4 NPN, PNP, or dry contact triggers.

NOTE: Supplied voltage (+) is 24 VDC

2. Connect the two wires between TR and minus (-) to

install a dry contact.

NOTE: Yellow LEDs indicate the status of each trigger. Polarity can be inverted if needed. See Trigger

Setup, page 31.

Standard Wiring Colors

Terminal Function M8 or M12

Cable

Plus (+) 24V Supply Brown

TR NPN, PNP, or dry con-

tact

Minus (-) Return (or dry contact) Blue

Black or white

18 334784G

PLC Inputs and Outputs Installation (optional)

PCM PLC Output

Customer Input

24 VDC, 240VAC, 2A

Max

To Customer Input

PCM PLC Input

Customer Output

Vin (no polarity)

30 VDC Max

Dry Contact

(customer supplied)

Customer

PCM

(Jumper Wire)

“+”

(24 VDC)

“-”

(GND)

Functions:

Type Function Description

Input ENABLE Turns the controller on and off (rising edge enables, falling edge disables).

Integrated systems: Turn the heat on/off using the InvisiPac PLC input

(instead of this input). The pattern controller will be turned on by the InvisiPac

system once the InvisiPac goes inactive.

DISABLE Disables the pattern controller (pull high to disable)

NOTE: DISABLE polarity can be changed with the invert disable input setting.

See General Setup (Screen 4), page 32.

PROGRAM

SELECT

Output ALARM 1 Relay opens for active alarm(s) on Line 1

ALARM 2 Relay opens for active alarm(s) on Line 2

Specifications

Inputs Outputs

• Bipolar Input • Dry contact output

• Electrically isolated • 0-24 VDC or 0-240 VAC

• 0-30 VDC • 2A max

• Min. 10 VDC to assert

• Sinks 10 mA at 24 VDC

Bits select a program to run (1-15) i.e. 1010 selects program #10

NOTE: 0000 disables PLC selection (local program selection ADM)

Wire Pattern Control Board

NOTE: To connect a dry contact signal, route GND to

one terminal and connect 24 VDC signal through the dry

contact to the other terminal (see image below).

334784G 19

Alarms indicated by output relays. See Troubleshooting Error Codes, page 45 for more details.

Code Description

A40P Over-current on accessory

power supply output

A4XP Over-current on communication

cable output

A4_P Over-current on valve output “_”

K4_P Encoder “_” pulse rate exceeds

maximum limit

Wire Pattern Control Board

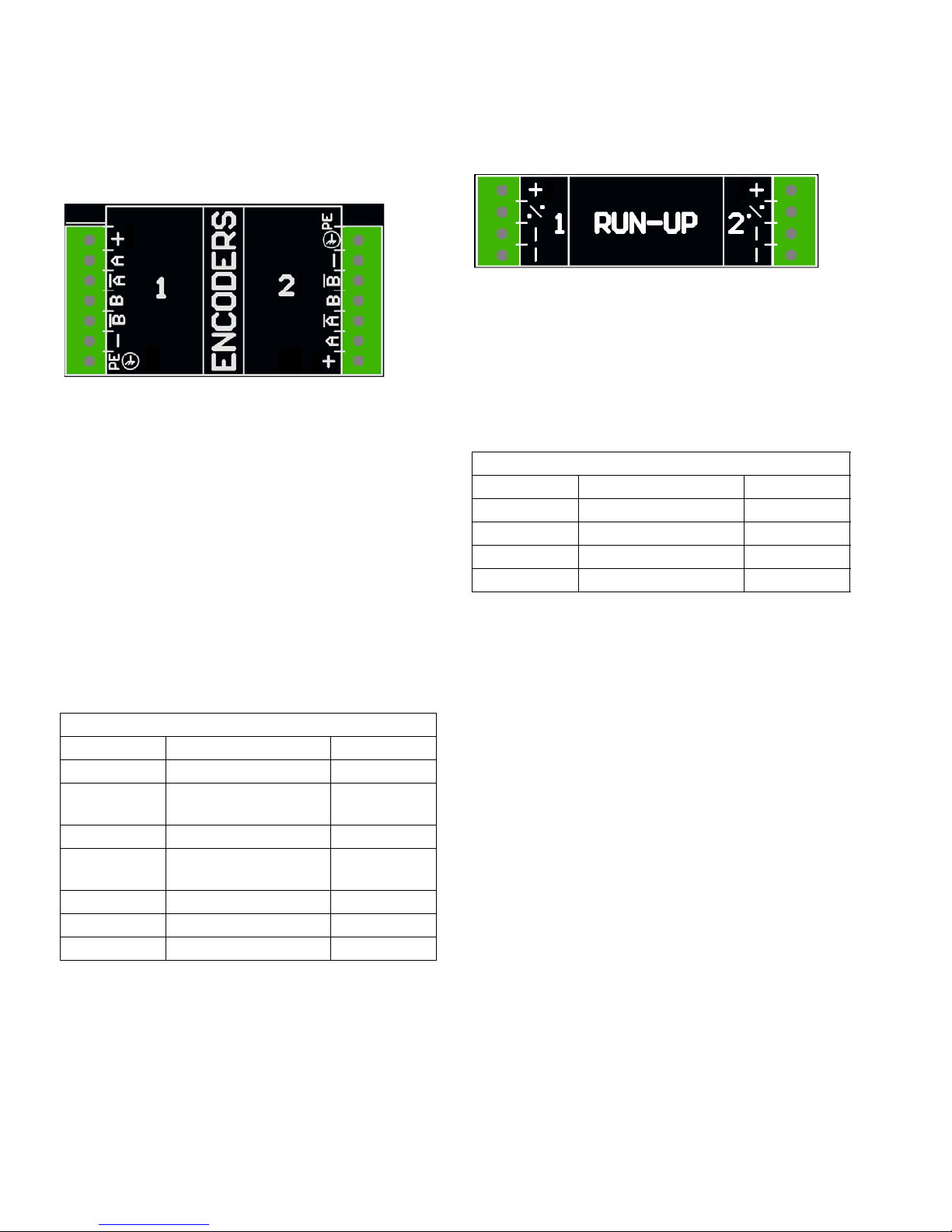

Encoder Installation

(PC-8e only)

1. Connect up to two encoders to monitor line speed.

NOTE: Line 1 and line 2 on the ADM.

NOTE: Encoder type must be quadrature differential

line driver (RS422). Scaling is entered in the

encoder setup screen using the live calibration feature.

NOTE: Some encoders have Z and Z’ connections.

These are not used and do not need to be connected.

Run Up Installation (PC-8e only)

1. Connect up to two “I/P” or “V/P” run-up air pressure

regulators to vary pump pressure based on line

speed. Hardware automatically detects whether an

I2P or V2P is connected.

NOTE: Pressure vs. line speed settings are entered

on the run-up setup screen. See Run Up Control,

page 42.

Standard Wire Colors

Terminal Function M12 Cable

Plus (+) 24V Supply Brown

% Output to run-up Black

Minus (-) Return Blue

Minus (-) Return White

NOTE: Encoder direction can be reversed by swapping A and A’ with B and B’. Do this is the line speed

reads negative on the ADM.

Graco Encoder Wiring Diagram

Terminal Function Wire Color

Plus 15V Supply Red

A Phase A signal

(RS422)

A’ Phase A signal return White

B Phase B signal

(RS422)

B’ Phase B signal return Green

Minus (-) Return Blue

PE Shield Bare

Brown

Yellow

20 334784G

Loading...

Loading...