Operation, Repair and Parts

InvisiPac®

334784G

Pattern Controller

To control fluid dispense valves of adhesive supply equipment. For professional use only.

Not approved for use in explosive atmospheres or hazardous locations.

See page 3 for model information and Agency approvals.

Important Safety Instructions

Read all warnings and instructions in this manual

and related manuals. Save these instructions.

EN

WLD

Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Component Identification (Internal Models - HM25c)

8

Component Identification

(Internal Models - HM25 and HM50) . . . . . . . . . 9

Component Identification (External Models) . . . 10

Installation - Internal Models (HM25c) . . . . . . . . . 11

Connect Pattern Control Board . . . . . . . . . . . . . 11

Installation - Internal Models (HM25 and HM50) . 12

Connect Pattern Control Board . . . . . . . . . . . . . 12

Connect Power Supply and Advanced Display

Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Install Control Board into InvisiPac System . . . 14

Installation - External Models . . . . . . . . . . . . . . . . 15

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Connect Advanced Display Module (ADM) . . . . 15

Connect Pattern Control Board . . . . . . . . . . . . . 16

Connect Electrical Cord . . . . . . . . . . . . . . . . . . 17

Wire Pattern Control Board . . . . . . . . . . . . . . . . . 18

Valve Installation . . . . . . . . . . . . . . . . . . . . . . . . 18

Trigger Installation . . . . . . . . . . . . . . . . . . . . . . 18

PLC Inputs and Outputs Installation (optional) . 19

Encoder Installation

(PC-8e only) . . . . . . . . . . . . . . . . . . . . . . . . 20

Run Up Installation (PC-8e only) . . . . . . . . . . . 20

Initial Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Software Update . . . . . . . . . . . . . . . . . . . . . . . . 21

Key Token . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Screen Maps . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

HMI Interface . . . . . . . . . . . . . . . . . . . . . . . . . . 23

PC Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Advanced Screens . . . . . . . . . . . . . . . . . . . . . . 35

Stitching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Random Length Bead Mode . . . . . . . . . . . . . . . . . 38

Mirror Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Gun Compensation (optional) . . . . . . . . . . . . . . 40

Line Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Run Up Control (PC-8e only) . . . . . . . . . . . . . . . 42

Modulated Bead (PC-8e Only) . . . . . . . . . . . . . 43

Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Triggers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Run Up Control . . . . . . . . . . . . . . . . . . . . . . . . . 44

PLC Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Run Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

PLC Inputs and Outputs . . . . . . . . . . . . . . . . . . 48

Software Update Procedure . . . . . . . . . . . . . . . . . 49

USB Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Download Procedure . . . . . . . . . . . . . . . . . . . . . 50

Accessing Files . . . . . . . . . . . . . . . . . . . . . . . . . 50

USB Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

External Models . . . . . . . . . . . . . . . . . . . . . . . . . 51

Internal Models (HM25c) . . . . . . . . . . . . . . . . . . . . 53

Internal Models (HM25 and HM50) . . . . . . . . . . 54

Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Internal Pattern Controller (HM25 and HM50

Systems with AWB) . . . . . . . . . . . . . . . . . . 58

Internal Pattern Controller (HM25 Systems with DIN

Rail) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

External Models . . . . . . . . . . . . . . . . . . . . . . . . . 60

Dimensioned Drawings . . . . . . . . . . . . . . . . . . . . . 61

Technical Specifications . . . . . . . . . . . . . . . . . . . . 64

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 66

2 334784G

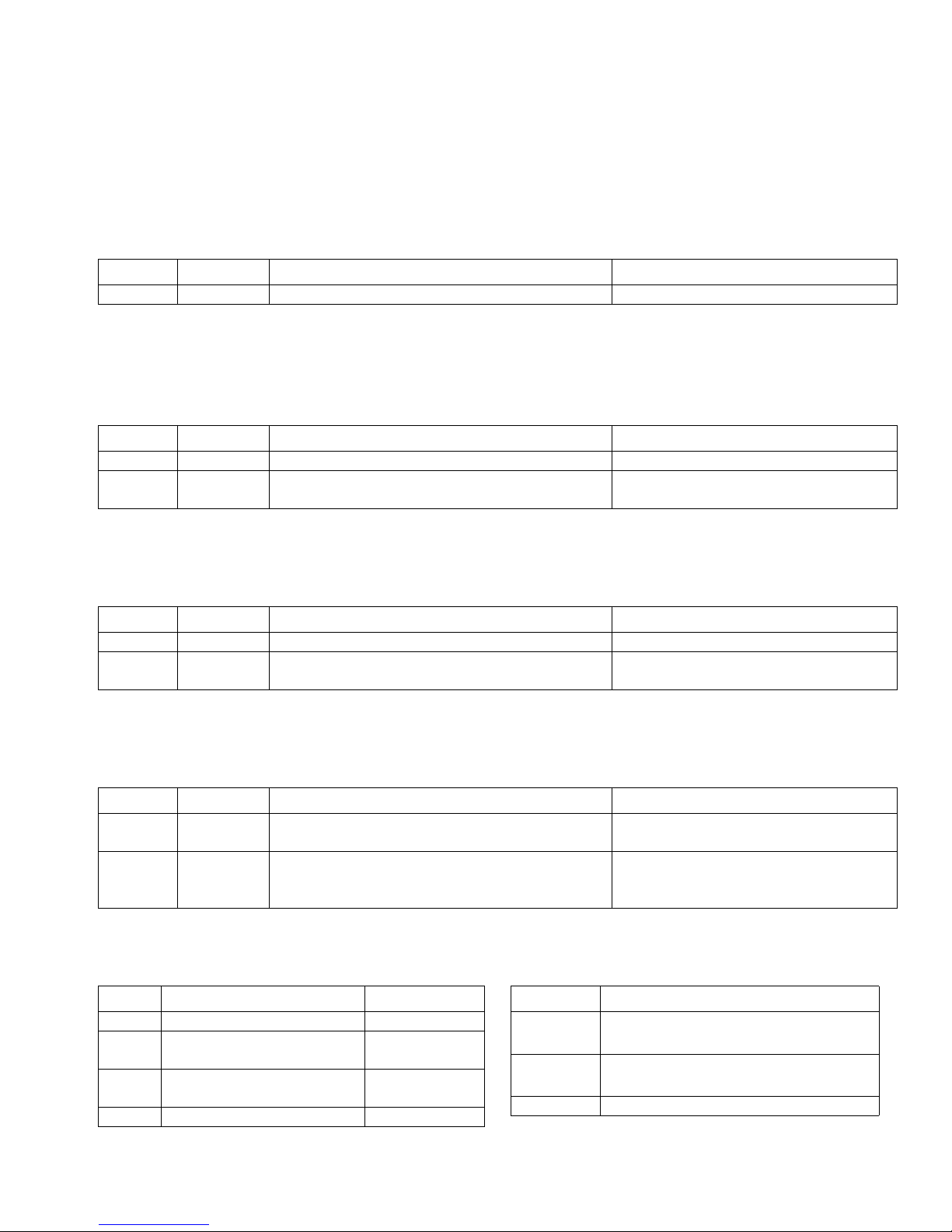

Models

Internal Models (HM25c)

Used to upgrade InvisiPac HM25c systems to include pattern control.

Part Type Description Contents

25M526 PC-8* Time or distance mode, no encoder Pattern controller

* Order kit 17F712 to upgrade to PC-8e.

Internal Models (HM25 and HM50)

Used to upgrade InvisiPac HM25 and HM50 systems to include pattern control.

Part Type Description Contents

24X640 PC-8 Time or distance mode, no encoder Internal pattern controller

24X641 PC-8e Time or distance mode, with or without encoder

Run up control (optional)

Internal pattern controller

Key token for encoder and run up

Models

External Integrated Models

Used to connect a separate pattern control enclosure to an InvisiPac system (compatible with all InvisiPac systems)

Part Type Description Contents

24X523 PC-8 Time or distance mode, no encoder Pattern controller

24X524 PC-8e Time or distance mode, with or without encoder

Run up control (optional)

Pattern controller

Key token for encoder and run up

External Stand Alone Models

Used for applications without an InvisiPac system

Part Type Description Contents

24X525 PC-8 Time or distance mode, no encoder Pattern controller

Advanced display module

24X526 PC-8e Time or distance mode, with or without encoder

Run up control (optional)

Pattern controller

Advanced display module

Key token for encoder and run up

Approvals Related Manuals

Part Description Approvals

127971 External pattern controller CE, ETL, cETL

24W293 Internal pattern controller

(HM25c)

24X521 Internal pattern controller

(HM25 and HM50)

24E451 Advanced display module CE, ETL, cETL

CE, ETL, cETL

CE, ETL, cETL

Part Description

3A4938

333347

334934 Run Up Pressure Kit

InvisiPac HM25c Tank-Free

Delivery System

InvisiPac HM25 and HM50 Tank-Free

Hot Melt Delivery System

™

Hot Melt

™

334784G 3

Warnings

WARNING

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause

electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before

servicing or installing equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Specifications in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Specifi-

cations in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete

information about your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

• manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

BURN HAZARD

Equipment surfaces and fluid that is heated can become very hot during operation. To avoid severe

burns.

• Do not touch hot fluid or equipment.

4 334784G

Warnings

WARNING

SKIN JECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgi-

cal treatment.

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking,

or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Equipment can start without warning. Before checking, moving, or servicing equipment, follow the

Pressure Relief Procedure and disconnect all power sources.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire and explosion:

• Do not use solvent-based adhesives that can create an explosive atmosphere when processed.

• Use equipment only in well-ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic

drop cloths (potential static sparking).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

334784G 5

Warnings

WARNING

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read Safety Data Sheets (SDSs) to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury,

including eye injury, hearing loss, inhalation of toxic fumes, and burns. Protective equipment includes

but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent

manufacturer.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious

chemical reaction and equipment rupture. Failure to follow this warning can result in death, serious

injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents.

• Do not use chlorine bleach.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material

supplier for compatibility.

6 334784G

Overview

Overview

InvisiPac pattern control systems can be integrated with InvisiPac systems or stand alone with any other equipment.

For all installations, the advanced display module (ADM) is used to make programming easy.

PC-8 controllers operate in time or distance mode without an encoder. Up to 8 guns and 4 independent triggers are

supported.

PC-8e controllers include the same features as PC-8 with the addition of distance based control using an encoder,

and run up control using an I/P or V/P pressure regulator.

Features of the PC-8 and PC-8e:

Feature

Gun outputs

Trigger inputs

Encoder

Run up control

Program storage

PLC enable / disable

PLC alarm output

PLC program select

Password protection

Integrated power supply

For more information, see Technical Specifications,

page 64.

8

4

2 (PC-8e only)

2 (PC-8e only)

50

Yes

Yes

Yes

Yes

Yes

Details

334784G 7

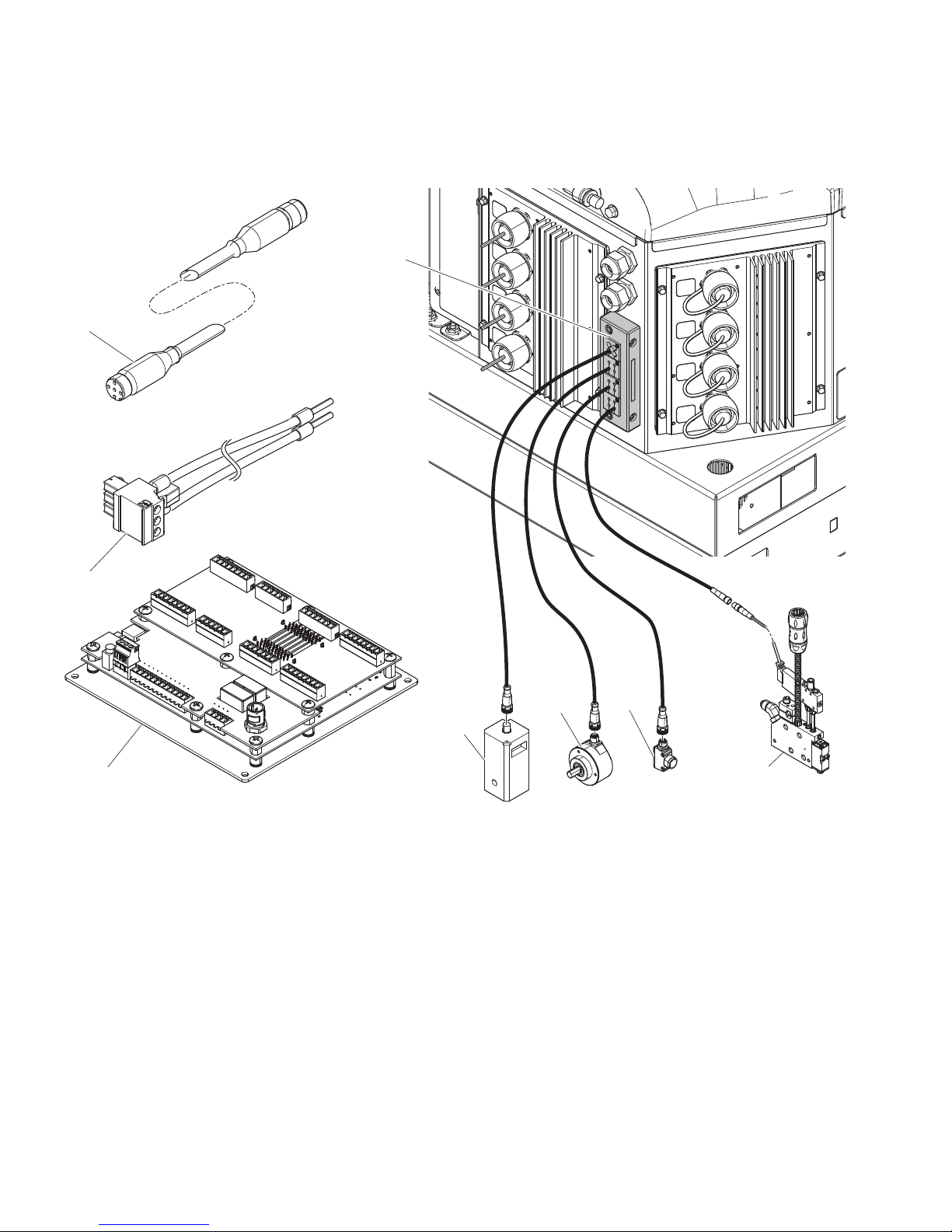

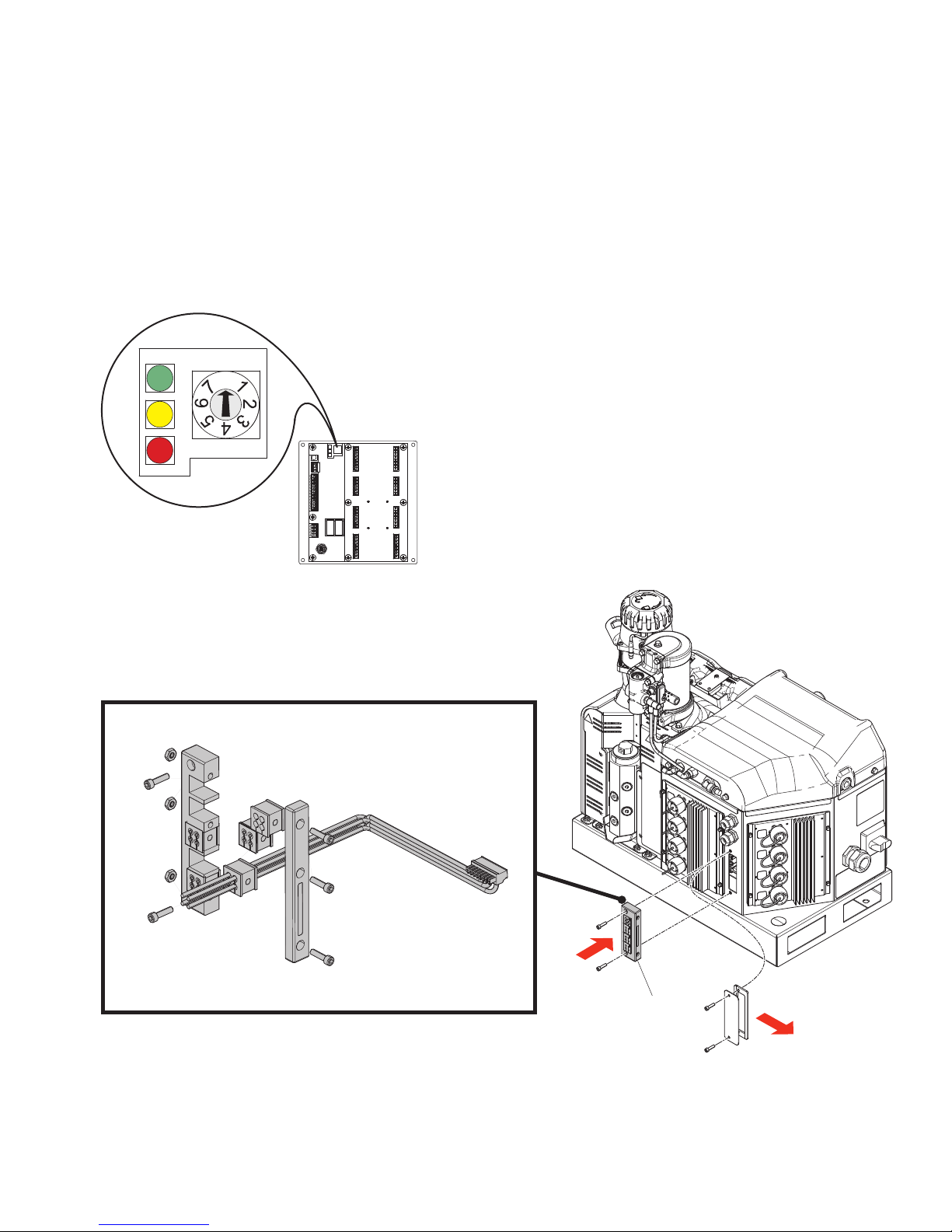

Component Identification (Internal Models - HM25c)

/

.

-

+

WLE

6

3

&

7

Installed onto InvisiPac System

Component Identification (Internal Models - HM25c)

Key

C Communication cable

HValve

J Trigger

K Encoder

Key

L Run up

P Power harness

S Control board

T Cord grip

8 334784G

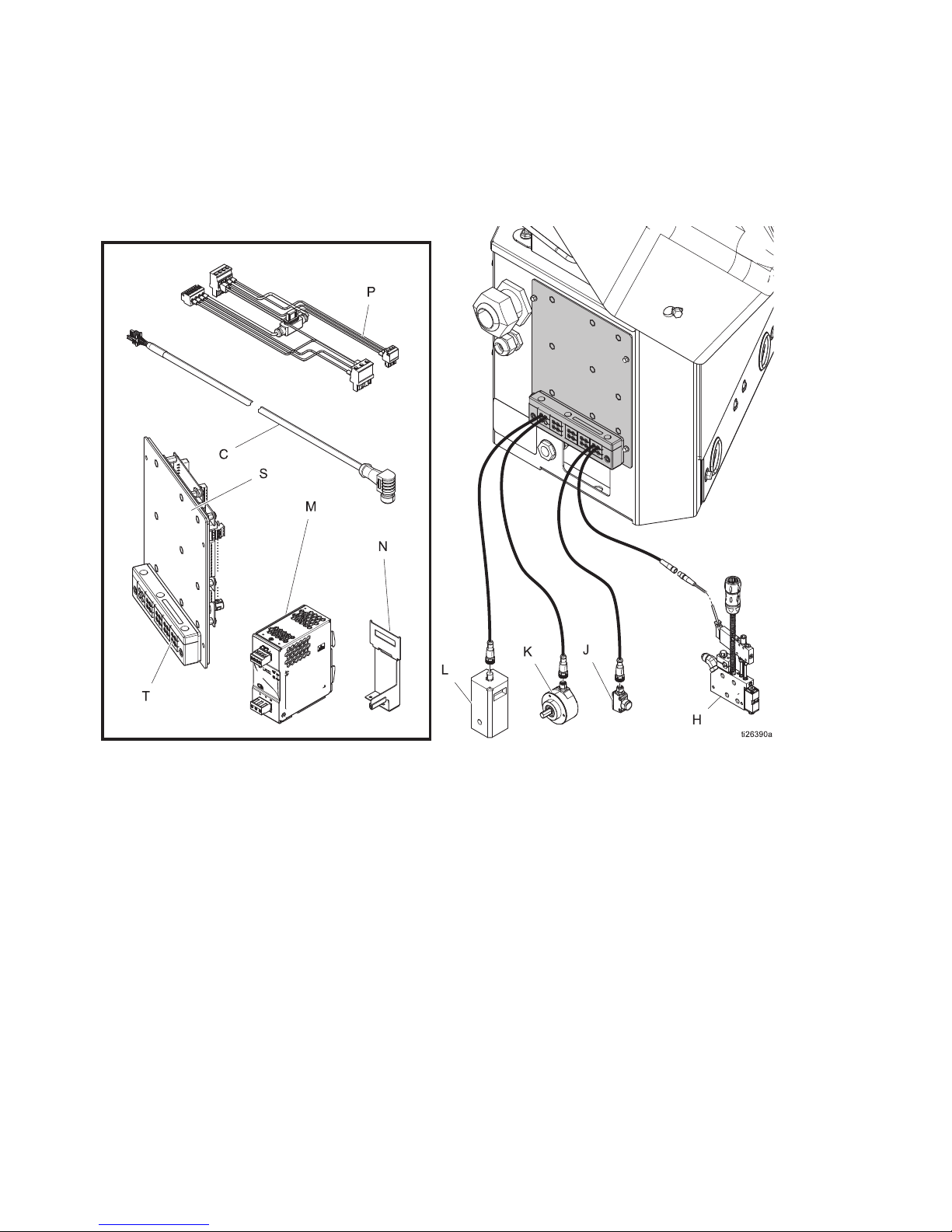

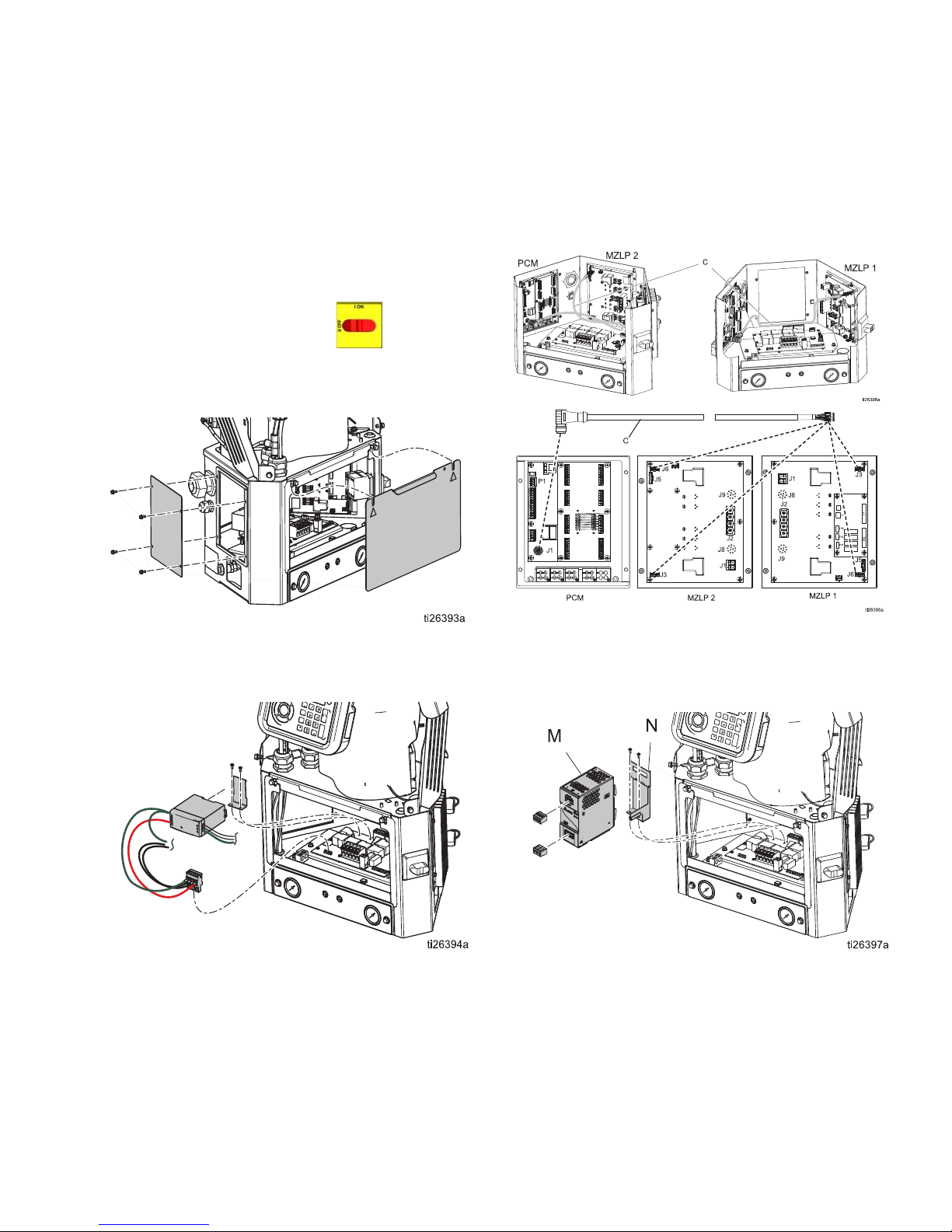

Component Identification (Internal Models - HM25 and HM50)

Installed onto InvisiPac System

Component Identification

(Internal Models - HM25 and HM50)

Key

C

H

J

K

L

334784G 9

Communication cable

Valve

Trigger

Encoder

Run Up

Key

M

N

P

S

T

Power supply

Power supply bracket

Power harness

Control board

Cord grip

Component Identification (External Models)

7

7

7

3

6

%

'

&

1

/

.

-

+

$

0

WLE

(

Component Identification (External Models)

Key

A

B

C

D

E

H

J

Pattern controller

Power switch

Communication cable

ADM

USB port

Valve

Trigger

Key

K

L

M

N

P

S

T

Encoder

Run up

Inside view of pattern controller

Customer power board (not included)

Ground terminal

Control board

Cord grips (I/O x2 power)

10 334784G

Installation - Internal Models (HM25c)

WLD

0

WLD

7

Installation - Internal Models (HM25c)

Connect Pattern Control Board

1. Set pattern control system type selector switch to 0.

NOTE: The system must be powered off for a

change in system type to have an effect.

2. Remove cord grip assembly (T) from back of InvisiPac system and remove inserts. Inserts with grip

tightly on most M8 and M12 cables and expand and

compress to accept cables larger than the apparent

hole size.

3. Install valve signal wires, trigger signal wires, PLC

wires (optional). See Wire Pattern Control Board,

page 18.

4. Route cables through the opening in the back of the

InvisiPac enclosure as shown.

5. Apply cord grip inserts over cables and replace into

frame. Replace frame onto back of InvisiPac enclosure.

6. Remove excess slack from the cables but do not

pull tight. Tighten cord grip frame on inserts to

secure.

334784G 11

Installation - Internal Models (HM25 and HM50)

0

Installation - Internal Models (HM25 and HM50)

Connect Pattern Control Board

1. Set pattern control system type selector switch to 0.

NOTE: The system must be powered off for a

change in system type to have an effect.

WLD

2. Remove cord grip assembly (T) from pattern control

board (S) and remove inserts. Inserts will grip tightly

on most M8 and M12 cables and will expand and

compress to accept cables larger than the apparent

hole size.

3. Install valve signal wires, trigger signal wires, PLC

wires (optional) and encoder and run up wires

(PC-8e only). See Wire Pattern Control Board,

page 18.

4. Route cables through the opening in the pattern

control board back panel as shown.

5. Apply cord grip inserts over cables and replace into

frame. Replace frame onto pattern control panel.

6. Remove excess slack from cables but do not pull

tight. Tighten cord grip frame on inserts to secure.

12 334784G

Installation - Internal Models (HM25 and HM50)

Connect Power Supply and Advanced Display Module

NOTE: If the internal pattern controller is being installed

into a first generation HM25 with DIN rail writing, additional connections must be made.

Install Kit 24Y171 has the necessary components and

instructions to perform this installation. See Kits, page

55.

1. Turn main power switch OFF.

2. Remove panel door, then remove blanking plate

from left-hand side of system electrical enclosure.

4. Connect communication cable (C) to open J3 connector (or J6, if J3 is used) on MZLP board. If connecting to MZLP #2, loop extra cable length along

edge of electrical enclosure.

3. Remove connector from AWB terminal pins J1 and

remove the power supply and harness from mounting bracket. Unscrew mounting bracket from AWB.

5. Remove blue connectors from terminals of power

supply W and discard or set aside. Install new

power supply bracket (N) onto AWB and clip new

power supply (M) into place.

334784G 13

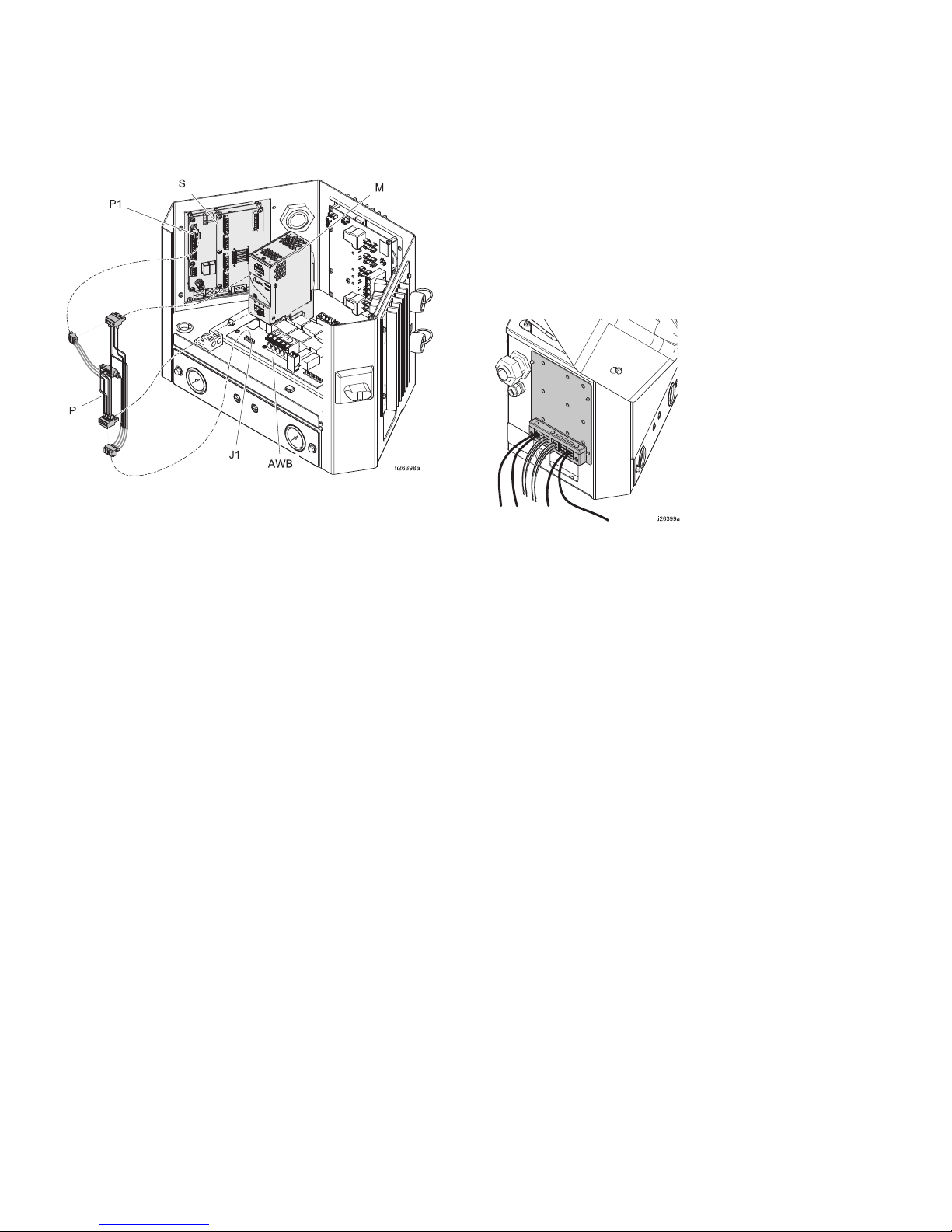

Installation - Internal Models (HM25 and HM50)

6. Connect power harness (P) to AWB terminal pins J1

and the input and output terminals of power supply.

Install Control Board into

InvisiPac System

1. Mount board into open space on left-hand side of

electrical enclosure. Use serrated-flange screws.

2. Connect power harness to power control board terminal P1, and connect communication cable to pattern control board terminal P4.

3. Replace system electrical enclosure door.

14 334784G

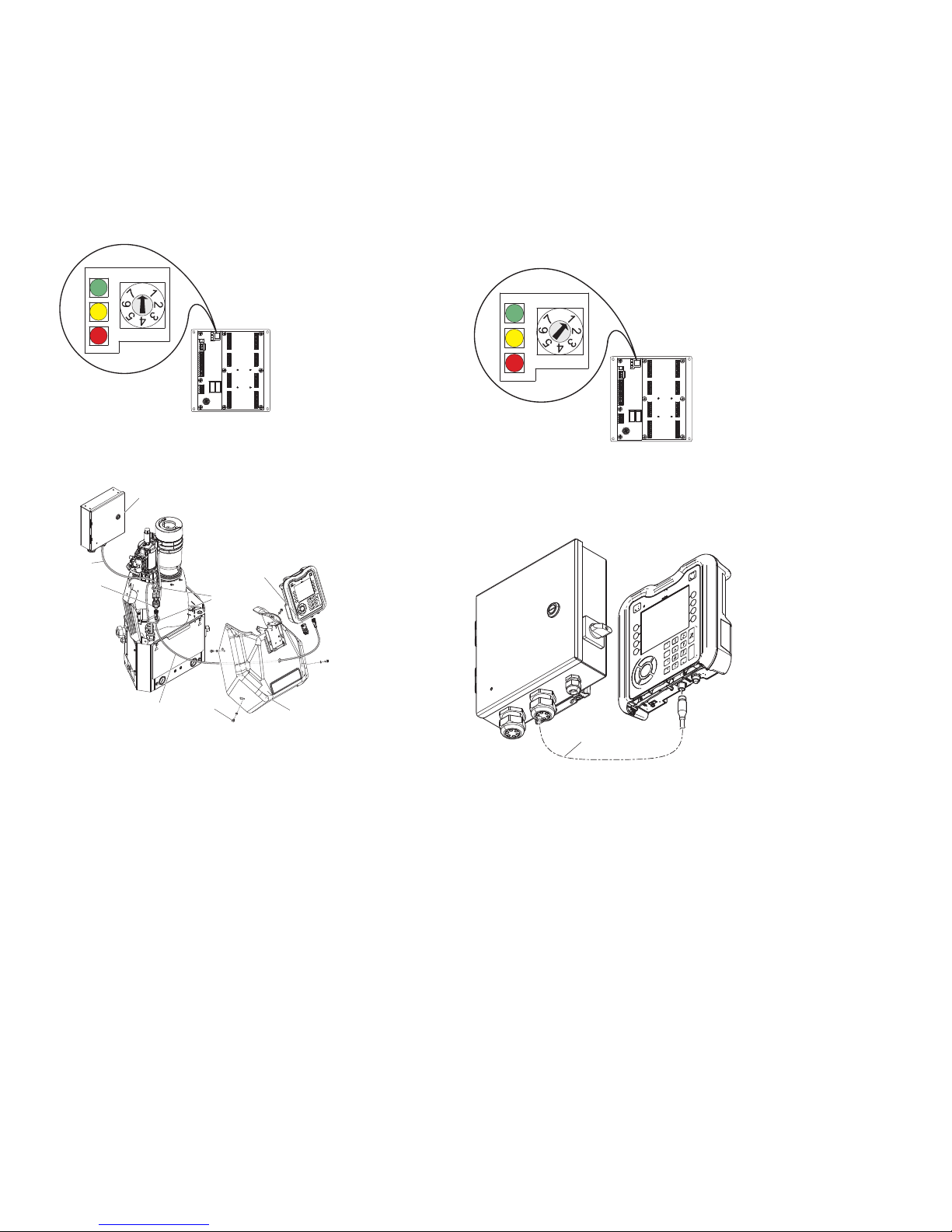

Installation - External Models

WLF

13 in (330.2 mm)

Clearance

WLD

0

$

'

%

Installation - External Models

Mounting

The pattern controller and ADM can be mounted using

the included VESA-compatible brackets and mounting

software.

1. Unscrew the two lower screws to uncouple the

“wall” portion of the bracket.

2. Securely mount the bracket in the desired location.

3. Slide the controller onto the bracket and tighten the

two screws for permanent fastening.

ALTERNATIVE METHOD: Remove mounting hardware

and mount directly to any surface.

NOTE: Make sure at least 13 in. of clearance is available above the top of the mounting bracket in order to

slide the enclosure in and out of the wall mount.

Connect Advanced Display

Module (ADM)

Integrate with InvisiPac HM25c

1. Set pattern control system type selector switch to 0.

NOTE: The system must be powered off for a

change in system type to have an effect.

2. Disconnect the CAN cable from the ADM (D) and

connect it to one of the male ends of the splitter (2).

NOTE: To make repairing the system easier, locate the

system so that it is easily accessible and has sufficient

lighting.

334784G 15

WLE

3. Connect the CAN cable from the pattern controller

enclosure (A) to the other male end of the splitter

(2).

4. Connect the male end of the short CAN cable contained in the pattern controller kit (3) to the female

end of the splitter (2).

5. Connect female end of the short CAN cable (3) to

the ADM.

6. Use zip ties to attach the CAN cables and splitter to

the ADM bracket (B).

Installation - External Models

WLD

0

WLD

0

&

WLD

Integrate with InvisiPac (HM25 or HM50)

1. Set pattern control system type selector switch to 0.

NOTE: The system must be powered off for a

change in system type to have an effect.

2. Disconnect the CAN cable from the ADM (D), push

the cable through the plastic shroud (B), the remove

the shroud from the system.

$

Stand Alone

1. Set the pattern control system type selector switch

to 1.

NOTE: The system must be powered off for a

change in system type to have an effect.

2. Mount the ADM using the provided bracket

3. Connect the CAN cable (C) between the pattern

controller and the ADM

&

%

WLD

3. Connect the CAN cable from the ADM (D) to one of

the male ends of the splitter (2).

4. Connect the CAN cable from the pattern controller

(A) to the other male end of the splitter (2).

5. Connect the male end of the short CAN cable contained in pattern controller kit (3) to the female end

of the splitter.

6. Push the free end of the short CAN cable (3)

through the shroud and connect the female end to

the ADM.

7. Use zip ties (4) to attach the CAN cable bundle to

the other vertical bundle of cables.

Connect Pattern Control Board

See Wire Pattern Control Board, page 18.

1. Install triggers and valves

2. Install PLC inputs and outputs (optional)

3. Install encoder (PC-8e only)

4. Install run up (optional, PC-8e only)

16 334784G

Connect Electrical Cord

Improper wiring may cause electric shock or other

serious injury if work is not performed properly.

Have a qualified electrician perform any electrical

work. Be sure your installation complies with all

National, State, and Local safety and fire codes.

The equipment must be grounded to reduce the

risk of electric shock. Improper grounding can

cause electric shock. Grounding provides an

escape wire for the electric current.

The pattern controller system is equipped with a ground

terminal. Have a qualified electrician ground the system

using this terminal.

Electrical power enters through the smaller cord grip on

the right side of the enclosure (see figure). The power

cord can be further secured inside the enclosure with

the provided zip-tie and tie mount.

Installation - External Models

2. Connect earth ground to the grounding terminal.

3. Verify that the cord grip securely tightens around the

power cord. Use a wrench to tighten, if necessary.

1. Install power wires (L1/L2 or L/N) into terminals 2

and 4 on the disconnect switch. The switch accepts

solid or stranded 12 AWG and 14 AWG wire. For

ratings, see Technical Specifications, page 64.

NOTE: The power switch housing can be removed

for easy wiring using the red tab on top of the

switch.

334784G 17

Wire Pattern Control Board

Wire Pattern Control Board

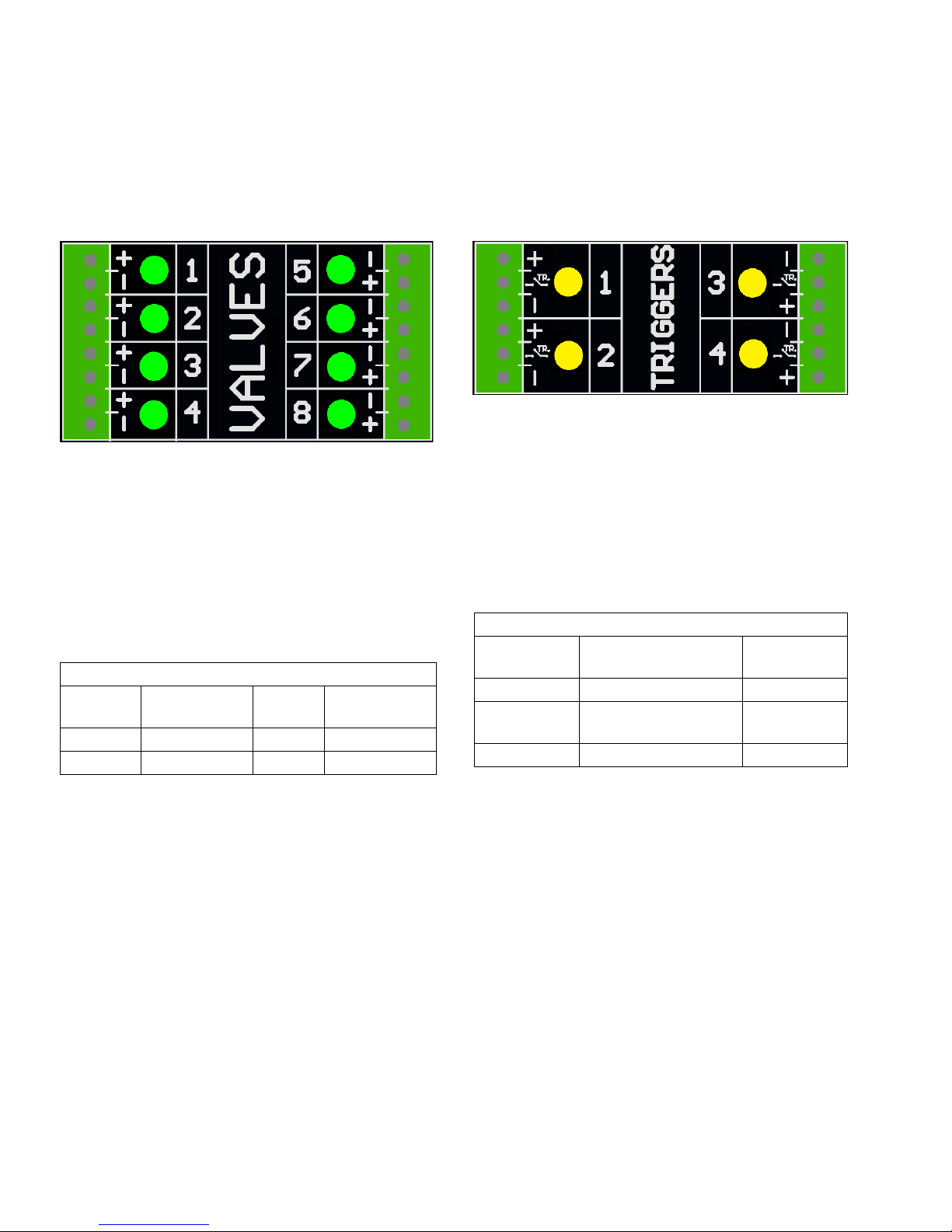

Valve Installation

1. Connect up to 8 valves.

NOTE: Control voltage is 24 VDC with a limit of 1

amp per output and 6 amps total.

NOTE: Green LEDs indicate the status of each

valve.

NOTE: DIN cable black wires are labeled 1 and 2. 1

is plus and 2 is minus.

Standard Wiring Colors

Terminal

Cable

Plus (+) 24V Supply Brown Black 1

Minus (-) Return Blue Black 2

Function M8

Cable

DIN Cable

Trigger Installation

1. Connect up to 4 NPN, PNP, or dry contact triggers.

NOTE: Supplied voltage (+) is 24 VDC

2. Connect the two wires between TR and minus (-) to

install a dry contact.

NOTE: Yellow LEDs indicate the status of each trigger. Polarity can be inverted if needed. See Trigger

Setup, page 31.

Standard Wiring Colors

Terminal Function M8 or M12

Cable

Plus (+) 24V Supply Brown

TR NPN, PNP, or dry con-

tact

Minus (-) Return (or dry contact) Blue

Black or white

18 334784G

PLC Inputs and Outputs Installation (optional)

PCM PLC Output

Customer Input

24 VDC, 240VAC, 2A

Max

To Customer Input

PCM PLC Input

Customer Output

Vin (no polarity)

30 VDC Max

Dry Contact

(customer supplied)

Customer

PCM

(Jumper Wire)

“+”

(24 VDC)

“-”

(GND)

Functions:

Type Function Description

Input ENABLE Turns the controller on and off (rising edge enables, falling edge disables).

Integrated systems: Turn the heat on/off using the InvisiPac PLC input

(instead of this input). The pattern controller will be turned on by the InvisiPac

system once the InvisiPac goes inactive.

DISABLE Disables the pattern controller (pull high to disable)

NOTE: DISABLE polarity can be changed with the invert disable input setting.

See General Setup (Screen 4), page 32.

PROGRAM

SELECT

Output ALARM 1 Relay opens for active alarm(s) on Line 1

ALARM 2 Relay opens for active alarm(s) on Line 2

Specifications

Inputs Outputs

• Bipolar Input • Dry contact output

• Electrically isolated • 0-24 VDC or 0-240 VAC

• 0-30 VDC • 2A max

• Min. 10 VDC to assert

• Sinks 10 mA at 24 VDC

Bits select a program to run (1-15) i.e. 1010 selects program #10

NOTE: 0000 disables PLC selection (local program selection ADM)

Wire Pattern Control Board

NOTE: To connect a dry contact signal, route GND to

one terminal and connect 24 VDC signal through the dry

contact to the other terminal (see image below).

334784G 19

Alarms indicated by output relays. See Troubleshooting Error Codes, page 45 for more details.

Code Description

A40P Over-current on accessory

power supply output

A4XP Over-current on communication

cable output

A4_P Over-current on valve output “_”

K4_P Encoder “_” pulse rate exceeds

maximum limit

Wire Pattern Control Board

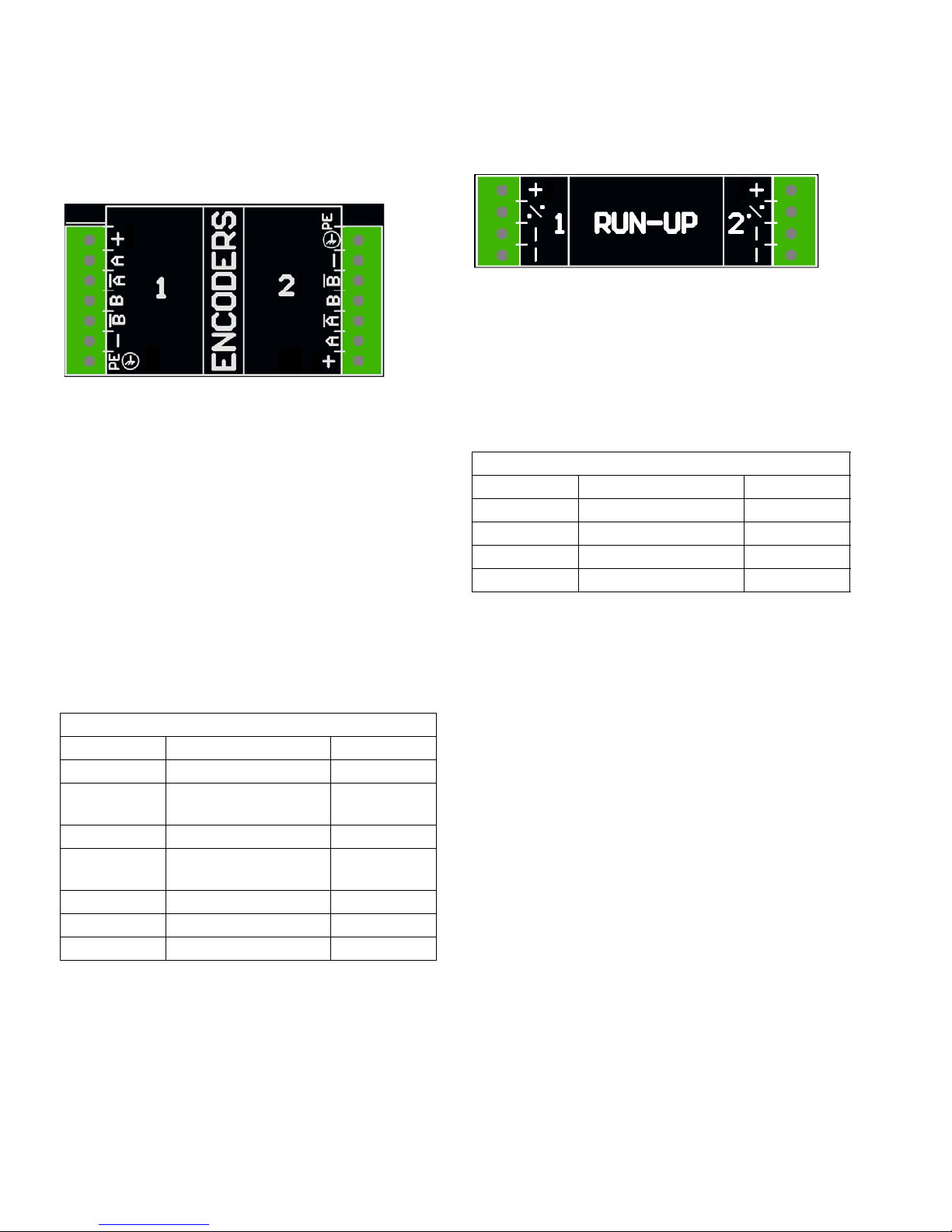

Encoder Installation

(PC-8e only)

1. Connect up to two encoders to monitor line speed.

NOTE: Line 1 and line 2 on the ADM.

NOTE: Encoder type must be quadrature differential

line driver (RS422). Scaling is entered in the

encoder setup screen using the live calibration feature.

NOTE: Some encoders have Z and Z’ connections.

These are not used and do not need to be connected.

Run Up Installation (PC-8e only)

1. Connect up to two “I/P” or “V/P” run-up air pressure

regulators to vary pump pressure based on line

speed. Hardware automatically detects whether an

I2P or V2P is connected.

NOTE: Pressure vs. line speed settings are entered

on the run-up setup screen. See Run Up Control,

page 42.

Standard Wire Colors

Terminal Function M12 Cable

Plus (+) 24V Supply Brown

% Output to run-up Black

Minus (-) Return Blue

Minus (-) Return White

NOTE: Encoder direction can be reversed by swapping A and A’ with B and B’. Do this is the line speed

reads negative on the ADM.

Graco Encoder Wiring Diagram

Terminal Function Wire Color

Plus 15V Supply Red

A Phase A signal

(RS422)

A’ Phase A signal return White

B Phase B signal

(RS422)

B’ Phase B signal return Green

Minus (-) Return Blue

PE Shield Bare

Brown

Yellow

20 334784G

Initial Startup

Initial Startup

Software Update

When integrating into an InvisiPac system, the system

may require a software update in order to be compatible

with the pattern controller. Follow Software Update

Procedure, page 49.

Key Token

For PC-8e models only, a key token is required to

enable encoder and run up use.

1. Remove token access panel on back of ADM.

2. Insert blue key token 24X626 and press firmly into

slot.

3. Replace cover, leaving key token inside.

334784G 21

Screens

PC Home Events ErrorsPC Control

1. Program Storage

- Purge

2. Pattern Definition

- Pattern

Preview

Press to switch between Run and Setup

PC Setup

1. Event Map

2. Line Mode

3. Trigger Setup

4. General

5. Gun Setup

6. Run Up 1

7. Run up 2

Advanced

1. Display

2. Units

3. USB Settings

4. Software

Screens

Navigate through each screen to set up the pattern controller interface.

• Run screens include the home page and pattern definition.

• Setup screens contain configurable settings for each accessory.

Screen Maps

NOTE: On integrated InvisiPac system, additional chapters are present for hot melt HMI.

Run Screens

Setup Screens

22 334784G

HMI Interface

WLLD

1 2 3

4 5 6

7 8 9

0 .

1 2 3

4 5 6

7 8 9

0 .

%&

%'

%(

%)

%*

%+

%$

WLD

Screens

Key Function

BA Controller enable/disable

BC Stop all system processes

BD Defined by icon next to soft key

BE Abort current operation

BF Accept change, acknowledge error,

select item, toggle selected item

BG Toggle between run and setup

screens

BH Navigate within a screen or to a new

screen

NOTICE

To prevent damage to soft key buttons, do not

press the buttons with sharp objects such as pens,

plastic cards, or fingernails.

334784G 23

Screens

A

B

C

D

%

PC Screens

Home

Read-only view of pattern controller inputs and outputs:

1. Status of guns , triggers , and PLC signals.

2. Production rate , and units completed .

3. Material dispensed per product .

A - Gun states

B - Trigger states

C - Line information

D - PLC signals

Icon Name Description

Gun Gun status: active (green), enabled (gray), disabled (crossed out)

Trigger Trigger status: active (bright yellow), inactive (dark yellow)

Line number Line number for other display values in row

Line speed Current line speed (or fixed line speed setting)

Run up

output

Production

rate

Product count Total products completed. To configure and reset, see Trigger Setup (Screen 3), page 31.

Glue rate Amount of glue per product (integrated InvisiPac systems only). NOTE: For best results,

PLC enable State of enable signal from PLC

PLC

disable

Active

program

PLC alarm Alarm status to the PLC (on line 1 or 2)

Percentage of run up pressure range being output (PC-8e only)

Number of product per minute

enter the appropriate specific gravity value for the adhesive material in use (see the InvisiPac system manual).

State of disable signal from PLC

Displays the active program chosen by the PLC (displays dashes if the PLC is not selecting

a program)

24 334784G

Screens

PB

A

C

D

E

F

G

H

J

Program Storage (Screen 1)

1. Select program to load.

2. Copy program , erase program , or rename program .

3. Purge guns .

4. Lock/unlock controller for maintenance .

NOTE: Copy, erase, and rename capabilities are disabled if “Lock Pattern Definition” is enabled. See General

Setup, page 32.

A - Enter screen

B - Maintenance lock/unlock

C - To purge screen

D - Active program

P - Screen number (Screen 1)

Icon Name Description

Maintenance lock Press to disable pattern controller (without disabling the InvisiPac pump and heaters)

Maintenance lock Press to enable pattern controller

E - Exit screen

F - Copy selected

G - Erase selected

H - Rename selected

J - Press to select active program

334784G 25

Screens

A

B

Gun Purge

1. Purge individual guns .

2. Purge all guns by pressing enter .

NOTE: Only guns with assigned triggers will purge.

NOTE: Guns may only be purged when the system is active or within 5 minutes of the system being active.

A - Press to purge

B - Disabled guns will not purge

Icon Name Description

Purge Purge specific gun

Enter Purge all enabled guns

Return/cancel Exit screen

26 334784G

Screens

A

B

D

P

E

C

F

H

G

J

Pattern Definition (Screen 2)

1. Enter start point and length of beads.

2. Enable or disable stitching for each bead.

3. Preview this pattern.

NOTE: To clone the pattern from gun A to gun B, navigate to any bead on gun B and press/hold the number key for

gun A.

NOTE: Enter the screen and scroll down to see valves 5-8. Add beads and continue to scroll right to access beads

6-24.

A - Enter screen

B - Pattern preview

C - Dots = stitched

Solid = solid bead

D - Current program*

E - Start of bead

Bead length

P - Screen number (Screen 2)

F - Exit screen

G - Confirm changes

H - Cancel changes

J - Stitch bead

Icon Name Description

Bead offset Distance from the edge of the product to the start of the bead

Bead length Length of the bead

Stitch bead Enable or disable stitching of this bead

* Current program indicator signifies that changes to the setting on this page will only affect the current program.

334784G 27

Screens

A

B

Pattern Preview

Read-only display of bead pattern.

A - Endpoint of last bead

B - Exit preview

- Gun number

- Trigger number

NOTE: Dotted pattern shows stitching. The actual number of stitched bead sis not represented.

NOTE: A red pattern indicates that the gun does not have a trigger selected. See Event Map, page 29.

28 334784G

Event Map (Screen 1)

A

B

C

D

E

F

G

P

H

J

Enter configuration settings for this pattern:

1. Assign trigger to each gun.

2. Enter gun trigger offset.

3. Enter minimum product length (if false trigger pickup is a concern).

4. Enable pattern mirroring.

5. Enter stitch percentage and interval.

A - Enter screen

B - Gun number

C - Trigger for gun

D - Gun trigger offset

E - Minimum product length

F - Current program*

G - Stitch interval

H - Stitch savings

J - Mirror mode

P - Screen number (Screen 1)

Screens

Icon Name Description

Trigger Trigger associated with this gun

Gun trigger offset The physical distance or time between the trigger and the gun

Minimum product length Blocks triggers from activating a second pattern within the minimum product

length

Mirror mode Mirrors beads from the leading edge of the box to the trailing edge of the box.

NOTE: If mirror mode is selected, the gun-to-trigger offset must be at least half

the length of the box. See Mirror Mode, page 39.

Stitch savings Percentage of glue saved by stitching. Set to 0 to disable stitching. NOTE: Stitch-

ing must also be enabled/disabled for each bead. See Stitching, page 37.

Stitch interval The distance between the start of each stitch

* Current program indicator signifies that changes to the settings on this page will only affect the current program.

334784G 29

Screens

A

P

B

Line Mode (Screen 2)

1. Select mode:

a. Time based.

b. Distance mode without encoder (uses fixed line

speed).

c. Distance mode with encoder.

2. For time mode, there are no additional settings.

3. For distance mode without encoder:

a. Pass one product by the trigger at normal

speed.

NOTE: See trigger setup section if product is

not tripping the trigger properly.

A - Enter screen

B - Last box length

P - Screen number (Screen 2)

b. Adjust line speed setting until length of last

product is correct.

4. For distance mode with encoder:

a. Verify positive line speed when line is moving

forward. If speed is negative, swap A and A’

with B and B’ wires at the encoder connector on

the pattern controller.

b. Pass one product by the trigger.

c. Adjust encoder pulses per mm until

length of last product is correct.

Icon Name Description

Time based Time mode select In time mode, programs settings are in units of milliseconds

Line number Line number for other settings/value sin a row

Length of last product Length of the last product seen by a trigger on the line.

Mode Select if encoder is to be used

Encoder pulses per mm Pulses encoder generates per mm of line travel.

Low line speed alarm Outputs will not fire when the line is below this speed.

High line speed alarm Read-only: maximum line speed allowed.

30 334784G

Line speed • If encoder enabled: view current line speed

NOTE: Value adjusts for changes in encoder/speed settings.

NOTE: 1000 ppr encoder, 300 mm wheel = 3.333 pulses/min.

NOTE: A value of 0 disables this alarm.

NOTE: The value is calculated from the encoder pulses per mm.

• If encoder disabled: enter fixed line speed

Trigger Setup (Screen 3)

A

B

C

D

G

E

P

F

1. Select trigger polarity :

a. Trigger should show bright yellow when

product is present and dark yellow for no product.

b. If polarity is backwards, use the drop-down

to invert the detection.

2. Select trigger line number (PC-8e only):

a. If product runs past all triggers at the same

speed, select line 1.

A - Enter screen

B - Trigger polarity

C - Line 1 or 2

D - Reset selected counter

E - Lifetime trigger count

F - Resettable trigger count

G - Include in product count

P - Screen number (Screen 3)

Screens

b. Where two line speed settings are required,

select line 1 for triggers sensing from the first

line speed and line 2 for the second.

3. Trigger cycle counters:

a. View current and lifetime cycle counts of each

trigger.

b. Press soft key to reset current cycle count

of selected trigger.

Icon Name Description

Trigger polarity Toggle polarity to invert state of trigger signal

Select line Select which line the trigger is sensing on (PC-8e only)

Reset counter Reset trigger cycle count. NOTE: Resetting the first trigger on a given line will reset the

product counter on the PC home screen for the given lion.

Include in product

count

Checked - Include trigger cycles in product counter.

Unchecked - Do not include trigger cycles in product counter (see table below).

Line Configuration Diagram Trigger Setup PC Home

Single line

Multi-unit line

Multi-line

abled (gray) check box.

NOTE: To reset the PC Home product count for each line, reset the current trigger count for the trigger with the dis-

334784G 31

Screens

A

P

General Setup (Screen 4)

1. Lock pattern definition (optional) — Protects pattern

from accidental changes. Operator must enter a

password to change patterns, and copy, delete, or

rename programs.

NOTE: This setting will only take effect if run

screens are also locked. See Advanced Screens,

page 35.

2. Invert disable input (optional):

• Used to invert the polarity of the PLC disable input

signal. See PLC Inputs and Outputs Installa-

tion, page 19.

• If selected, disable signal must be pulled high to

allow the pattern controller to dispense.

• If not selected (default), disable signal must be

pulled high to disable the pattern controller from

dispensing.

3. Enable pressure compensation (optional PC-8e

only):

• Used to maintain consistent glue output with vari-

able line speed.

• With run-up kit installed, this feature adjusts pump

pressure according to the output vs. speed curve.

For run-up settings, see Run Up Control, page

34.

4. Enable modulated bead (optional, PC-8e only):

• Used to maintain consistent glue output with variable line speed.

• Adjusts output by stitching beads according to the

output vs. speed curve.

• When pressure compensation is enabled, modulated bead becomes active below the minimum

output percentage.

• When pressure compensation is disabled, modulated bead follows the output vs. speed curve. For

run-up settings, see Run Up Control, page 42.

5. On stop (PC-8e only):

• Clear queue (default): Products in process stop

when the line stops and do not continue when the

line restarts. Products queued between the trigger

and gun will also be cleared when the line stops.

• Keep queue: Products in process stop when the

line stops and do not continue when the line

restarts. Products queued between the trigger

and gun are kept when the line stops and processed when the line restarts. Products in the

queue can be manually cleared by turning the

system off and back on using the power button.

• Pause: Products in process pause when the line

stops and continue when the line restarts. Products queued between the trigger and gun are kept

when the line stops and processed when the line

restarts. Products in process and in the queue

can be manually cleared by turning the system off

and back on using the power button.

A - Enter screen

P - Screen number (Screen 4)

32 334784G

Gun Setup (Screen 5)

A

B

C

D

P

E

Screens

1. Gun compensation see Calibration - Gun Com-

pensation, page 40:

• Enter gun open compensation .

• Enter gun close compensation .

A - Enter screen

B - Gun open compensation

C - Gun close compensation

D - Lifetime gun cycles x 1000

E - Resettable gun cycles x 1000

P - Screen number (Screen 5)

Icon Name Description

Open compensation Mechanical delay between electrical signal to gun and physical open-

ing of gun

Close compensation Mechanical delay between electrical signal to gun and physical closing

of gun

Reset counter Reset gun cycle count

2. Gun cycle counters:

• View current and lifetime cycle counts of each

gun,

• Press soft key to reset current cycle counter of

selected gun.

334784G 33

Screens

A

B

D

P

E

C

Run Up Control (Screens 6-7, PC-8e only)

Enter run up output settings. See Calibration - Run Up Control, page 34.

A - Enter screen

B - Minimum output

C - Maximum output

D - High calibration point

E - Low calibration point

P - Screen number (Screen 6)

Icon Name Description

Output pressure

percentage

Line speed Upper and lower line speed points

Enter minimum and maximum pressure for run up control.

Enter corresponding pressure points for entered line speed points to set run up curve.

Run up pressure

to line speed

Curve is set by two points which are defined by the user. Upper and lower limits

define bounds over which run-up will function linearly.

curve

NOTE: % output refers to the percentage of the run up controller full scale setting, not the percentage of the inlet high

pressure.

34 334784G

Advanced Screens

Screens

Advanced - Display

General display settings including language, time, and

password protection.

Name Description

Language Select the display language

Date format Select the display format

Date Enter display date

Time Enter display time

Password Enter password to restrict access to

Setup screens. NOTE: A value of

“0000” does not require a password for

access to setup screens.

Screen

saver

Silent mode If selected, disables the display been

Lock run

screens

Enter time-out for the display screen

saver. NOTE: A value of “0” disables

screen saver.

functionality

If selected, operators will not be able to

change most run screen settings

NOTE: In order for this setting to have

any effect, a password other than

“0000” must be entered above.

NOTE: When referring to the run set of

screens from the setup screens, the

operator will have two minutes to make

changes before the screens lock.

Advanced - Units

Select the system units to be used on the display.

Name Description

Temperature Select the system temperature units

(integrated systems only)

Mass units Select the system mass units (inte-

grated systems only)

Distance units Select the system distance units.

NOTE: This setting applies to all pattern control distance values except

when time based mode is selected on

PC Setup - Line Mode (distance units

become time units of milliseconds).

334784G 35

Screens

Advanced - USB Downloads Settings

Select USB download settings.

Name Description

Disable USB downloads/uploads

Disable USB log

errors

Download depth Sets the length of the data logs

Disables USB port from transmitting data to/from a USB drive

Disables USB log advisory

to be downloaded (affects the

download time)

Advanced - System Software

Read only display of system software.

Name Description

Module Name of module in system

Software part # Part number of software installed

on module

Software version Version of software installed on

module

NOTE: If software versions or part numbers do not

match the expected values, see Software Update Pro-

cedure, page 49.

36 334784G

Stitching

Stitching is used to reduce adhesive consumption while maintaining bond strength.

Definitions

Sub-Bead -

One dispense cycle of a stitched bead.

Stitch Interval -

The distance between the starts of the adjacent sub-beads.

Stitch Savings -

Stitching

The percentage of adhesive saved.

Anchor Beads

An anchor bead is a sub-bead placed at the end of the stitched bead that guarantees the stitched bead ends at the

same location as the original (non-stitched) bead.

Setup

In order to stitch any bead, perform the following steps:

1. Navigate to Event Map, page 29.

2. Enter the desired stitch interval and stitch

3. Navigate to Pattern Definition, page 27.

4. Stitch individual beads be selecting the stitch bead

option within each bead entry box.

NOTE: Not all beads for a specific gun must be

stitched (some can be stitched while others are

solid).

savings for the desired gun.

NOTE: Stitching can be disabled by setting stitch

savings to “0”.

334784G 37

Random Length Bead Mode

Random Length Bead Mode

For handling products of various lengths with one pattern.

To use random length bead mode, perform the following steps:

1. Navigate to Event Map, page 29.

2. Verify the appropriate gun-trigger offset for

the selected gun.

NOTE: Gun-trigger offset must be greater than or

equal to the leading margin.

3. Enable mirror mode for the desired gun.

4. Navigate to Pattern Definition, page 27.

5. Enter the leading margin (LM) in the bead 1 offset

box.

NOTE: The leading margin is equal to the trailing

margin.

6. Enter the length of the longest random bead (LRB)

that may be needed in the bead 1 length box.

7. Enable or disable stitching for bead 1.

38 334784G

Mirror Mode

For symmetrical patterns, including products with varying lengths.

To use mirror mode, perform the following steps:

Mirror Mode

1. Navigate to Event Map, page 29.

2. Verify gun-trigger offset for the selected gun is greater than or equal to the end of the final bead (final

bead offset + length).

3. Enable mirror mode for the desired gun.

4. Navigate to Pattern Definition, page 27.

5. Enter bead information for the first half of the product.

6. Enable or disable stitching for each bead.

Material Tracking

The material tracking feature can be used on pattern controllers that are connected to an InvisiPac (internal and integrated systems). See the material tracking section in manual 333347 for more details.

334784G 39

Calibration

Adjustment (ms) =

5000 x Measured offset distance (in.)

Line speed (ft/min)

Adjustment (ms) =

60 x Measured offset distance (mm)

Line speed (m/min.)

Standard units:

Metric units:

Calibration

Gun Compensation (optional)

For high speed and precision applications.

NOTE: Before entering gun compensation values, make

sure the gun-trigger offset has been entered on Event

Map, page 29.

Gun compensation ensures higher accuracy of bead

placement. Begin with Recommended Values below

and adjust according to Calibration Routine.

Gun Compensation Adjustment Guide:

Edge Leading Edge Trailing Edge

Relative Position

Desired:

Lagging Leading Lagging Leading

Recommended Values

GM-100: 5-10 ms

GS-35: 10-20 ms

Unknown, other: 10 ms

Calibration Routine

1. Navigate to Gun Setup, page 33.

2. Dispense desired pattern (program contained within

the pattern controller).

3. Measure the error distance between the dispensed

pattern on the product and the desired pattern.

4. Adjust open/close compensation values according

to the following Gun Compensation Table and

Gun Compensation Formula below.

5. Repeat steps 2-3 until desired pattern achieved.

vs.

Dispensed:

Adjustment Increase Decrease Increase Decrease

Gun Compensation Formula:

Determine the gun compensation adjustment amount in milliseconds.

Bead offset distance in inches (mm) as a function of Gun Compensation and Line Speed

Gun

Compensation

(ms)

5

10

20

50 ft/min

15.24 (m/min)

0.05 in.

1.27 (mm)

0.1 in.

2.54 (mm)

0.2 in.

5.08 (mm)

100 ft/min

30.48 (m/min)

0.1 in.

2.54 (mm)

0.2 in.

5.08 (mm)

0.4 in.

10.16 (mm)

Line Speed

200 ft/min

60.96 (m/min)

0.2 in.

5.08 (mm)

0.4 in.

10.16 (mm)

0.8 in.

20.32 (mm)

500 ft/min

154.24 (m/min)

0.5 in.

12.7 (mm)

1.0 in.

25.4 (mm)

2.0 in.

50.8 (mm)

1000 ft/min

304.8 (m/min)

1.0 in.

25.4 (mm)

2.0 in.

50.8 (mm)

4.0 in.

101.6 (mm)

40 334784G

Line Speed

Calibration

1. Make sure the pattern controller is “inactive” or

“locked”. Press the power butting to toggle the status (if necessary).

2. Pass a product of known length past the trigger in

use.

3. Once the product has passed the trigger, note the

value displayed in the Last Product Length

indicator.

a. On encoder systems (PC-8e only), adjust

Encoder Pulses per mm until the last

product length value matches the expected

length.

Actual Pulses per mm = current pulses per mm

x distance observed (On ADM) / distance measured

NOTE: A minimum of 0.25 pulse/mm is required

to achieve 1 mm distance precision.

NOTE: The value is the length of the part of the

product that passes below the trigger in use, not

necessarily the overall length of the product.

Last Product Length displayed for trigger is 18.00 inches

long.

4. Adjust settings:

NOTE: Last product length indicator will update

according to the changes made in settings above

(step 2 only needs to be performed once).

b. On fixed line speed systems (both versions),

adjust Fixed Line Speed until the Last

Product Length value matches the expected

length.

Actual Speed = current speed x distance mea-

sured / distance observed (on ADM)

334784G 41

Calibration

Run Up Control (PC-8e only)

Run up control is used to adjust fluid pressure according

to line speed.

NOTE: The Graco run up controller is calibrated for the

procedure below. When using a non-Graco run up controller, make sure the controller settings are set to 0 psi

offset and 100 psi span.

1. Change units on regulator from BAR to PSI (using

buttons on front of regulator):

2. Disable the pressure compensation.

NOTE: This is required to determine the settings.

4. Use the dial and gauge on the InvisiPac system to

adjust the pump pressure until the desired glue output is achieved.

5. Enter the pressure displayed on the run up controller in the highlighted boxes below.

6. Reduce the line speed to the minimum speed and

enter the line speed in the highlighted box below.

7. Reduce the pump pressure, then use the dial and

gauge on the InvisiPac system to adjust the pump

pressure until the desired glue outputs is achieved.

3. Turn the system ON at maximum speed and enter

the line speed into the highlighted box below.

42 334784G

NOTE: InvisiPac pump pressure must be at least 20

psi.

8. Enter the pressure displayed on the regular in the

highlighted boxes below

Calibration

Low Output =

Minimum Speed

Maximum Speed

* 100

9. Return the pressure on the InvisiPac pump pressure

gauge to the position from step 3.

10. Enable the pressure compensation.

Modulated Bead (PC-8e Only)

NOTE: A value of “100” will ensure that a solid bead

is dispensed at speeds above maximum line speed.

3. Enter the minimum and maximum line speed.

NOTE: The maximum line speed is the speed at

which beads will go from solid to stitched.

Modulated bead is used to adjust fluid output according

to line speed without a pressure regulator (using stitching).

NOTE: Modulated beads use the same stitch interval as

a normal stitched bead. See Event Map, page 29.

1. Enable modulated bead.

2. Enter “100” for both high and output values.

4. Enter the low output values.

334784G 43

Verification

Verification

This section verifies proper installation of the InvisiPac

pattern control system. For further assistance, see

Troubleshooting, page 45.

Valves

1. To verify glue can be dispensed, turn system ON

and attempt a purge on each installed valve, then

verify the valve is actuated (glue has been dispensed from the appropriate valve).

2. To verify the electrical signal, disconnect the cable

from the solenoid and attempt a purge on each

installed valve and verify the signal is actuated (via

the LED on the valve connector).

Triggers

1. Navigate to Home, page 24.

2. Without product in front of the trigger, verify the trigger indicator LED is OFF.

3. With product in front of the trigger, verify the trigger

indicator LED is ON.

3. Run the line at various speeds and verify the appropriate run up output is displayed on the ADM. Verify

the run-up output pressure correctly follows.

4. If the percentage/pressure displayed does not

match the expected value, see Run Up Control,

page 44.

PLC Inputs

1. Navigate to Home, page 24.

2. Actuate the PLC input remotely and verify the

expected result is indicate din the PLC IO section in

the upper right corner of the display.

Action Icon Expected Out-

come

Turn on line from PLC.

NOTE: on integrated systems, use InvisiPac PLC IO

to turn on/off InvisiPac. Pattern controller will be in

standby until InvisiPac

becomes active.

Turn off line from PLC

Encoder

1. Navigate to Home, page 24.

2. Verify the line speed displayed in the current line

speed indicator is positive and varies for different line speeds.

3. If the line speed shown does not match the

known/expected value, see Calibration, page 40.

Run Up Control

1. Navigate to Home, page 24.

2. Turn the system ON and wait for the pattern controller to become ACTIVE.

Create safety fault (open

door)

Remove safety fault (close

door)

Select program from PLC Program #

De-select program from PLC

Create an alarm.

NOTE: on integrated systems, turn off pattern control

box (will generate CAXP

alarm).

Clear the alarm.

NOTE: on integrated systems, turn on pattern control

box.

---

PLC detects

alarm

PLC alarm

clears

44 334784G

Troubleshooting

Troubleshooting

Error Codes

When errors occur, press to acknowledge each error. After being acknowledged, the error will clear automati-

cally when the condition that caused it is corrected. Active errors scroll on the menu bar.

Alarms shut down the pattern controller and activate the dry contact PLC output. Advisories and deviation are informational only and do not shut the system down.

Alarms (shut the system down)

Code Description Cause Solution

CAXP Communication error ADM unable to communi-

cate with pattern controller

A40P Over-current Over-current on trigger

and/or run up power supply output (pins identified

by "+" on control board)

A4XP Over-current Over-current on commu-

nication cable output (P3

on control board)

A4_P Over-current Over-current on valve

output “_”

K4_P High pulse rate Encoder “_” pulse rate

exceeds maximum limit

Check for green power light on the pattern controller

Check communicating cabling

Check accessory cabling for short circuit.

Check ADM CAN cabling for short circuit

Replace display (ADM)

Check wiring for short circuit

Verify valve resistance is higher than 24 ohms

Select encoder with lower pulse rate

Reduce line speed or gearing ratio

Advisories and Deviation (do not shut the system down)

Code Description Cause Solution

V1_P

or

V2_P

V3_P

or

V4_P

K1_P Low line

EBTX PC-8e token

334784G 45

Low voltage Power supply voltage below 18

VDC

High voltage Power supply voltage above 28

VDC

Poor encoder coupling on line

speed

removed

“_”

Line speed is less than low line

speed alarm level on line “_”

Missing or loose PC-8e token If missing, re-insert PC-8e token. If present, check for loose

To check for overloaded power supply, measure the voltage

with all valves off, and then with all valves on (purging)

To check for overheated power supply, allow the unit to cool

and recheck voltage

Adjust voltage to 24 Vis possible, or replace the power supply

Adjust voltage to 24 V if possible or replace the power supply

Check to ensure proper coupling between line and encoder.

Verify pattern controller is reading appropriate line speed.

See Line Mode, page 30.

Increase line speed or decrease low line speed alarm level.

See Line Mode, page 30.

connection.

Troubleshooting

/

Display

Problem Cause Solution

Display does not turn on Select dial on pattern control board set

to wrong position

Power not turned on Check for green light on pattern control

Communication cable disconnected Verify pattern control board is connected to

Pattern control screens not

present

Run up control screens not

present

Encoder settings not present

Selector dial on pattern control board

set to wrong position

Software version mismatch Perform software update process with lat-

PC-8e key token not inserted in ADM Obtain PC-8e key token (comes with

Integrated systems: set to 0

Stand-alone systems: set 1

board and display

display

Integrated systems: set to 0

Stand-alone systems: set to 1

est version of software. See Software

Update Procedure, page 49.

PC-8e versions of InvisiPac pattern control

system)

Pattern

Problem Cause Solution

No pattern dispensed

Pattern dispenses

too early/late

Pattern measurement units are in

distance/time

Valve not associated with correct trigger (or not assigned to any trigger)

Physical problem with valve See “No Glue Dispensed” troubleshooting help within

Improper stitch settings

Wrong/empty programs selected Ensure proper program is selected on PC Control -

Pattern controller not ACTIVE Turn on pattern controller. Stand-alone systems will go

Improper gun-triggered offset entered

Improper valve open/close compensa-

tion entered

Improper line mode selected Select appropriate line mode setting on PC Setup -

Ensure valve has appropriate trigger selected

Valve section

Stitch Interval too short or Stitch Savings

too high

Program Storage (see Program Storage, page 25)

and PC Control - Pattern Preview (see Pattern Pre-

view, page 28) contains a pattern

ACTIVE immediately, whereas Integrated systems will

go ACTIVE once the InvisiPac system has gone

ACTIVE

Ensure appropriate Gun-Trigger Offset is

entered on PC Setup - Event Map. See Event Map,

page 29.

Perform calibration routine found in Calibration - Gun

Compensation. See Calibration, page 40.

Line Mode. See Line Mode, page 30.

46 334784G

Troubleshooting

Valve

Problem Cause Solution

System reset when guns

fire

No glue dispensed Solenoid shorted Ensure proper wiring between solenoid and pat-

Current draw from combined valves

exceeds power supply rating (150 W)

Wrong type of valve in use Pattern controller is only compatible with 24 VDC

Ensure current draw is below 6A total between all

simultaneously firing valves

tern controller. If no shorts found, consider replacing solenoid.

solenoids (no electric valves or AC solenoids)

Trigger

Problem Cause Solution

Trigger always on/off Sensor is covered/misaligned Clear any sensor obstruction and verify sensor

changes states with object present/absent

Polarity is backwards Change Trigger Polarity in PC Setup - Trigger

Setup. See Trigger Setup, page 31

Improper sensor type/installation See Installation - Trigger Installation for proper sen-

sor selection/installation

Trigger detects multiple

times on one box

Trigger sensor turned off

(no 24VDC present)

Trigger not adjusted properly or artifacts on the object being sensed

cause false detection

Excessive current drawn from

24VDC supply on

Set Minimum Product Length in PC Setup -

Event Map. See Event Map, page 29.

Perform power cycle to reset power to 24 VDC pins

If error persists, remove components and power

cycle until component with excessive current draw

is discovered

Encoder

Problem Cause Solution

Encoder speed is negative Encoder travel direction is

reversed

Encoder speed varies significantly

Encoder reads wrong

speed

Encoder does not read line

speed

Line speed is fixed Fixed line speed mode selected

334784G 47

Encoder coupling is slipping Improve encoder coupling to line by using different

Encoder is improperly scaled Perform calibration routine found in Calibration - Line

Encoder movement not proportionately scaled to path of product

Improper senor type/installation See Installation - Encoder Installation for proper sen-

Wrong line mode selected Select encoder line mode setting on PC Setup - Line

Exchange A and A’ wires with B and B’ wires

Flip encoder to spin the opposite direction

bracket, mounting, coupling, etc.

Speed. See Calibration, page 40

Remount encoder to ensure ratio between encoder

movement and product movement is always a fixed

proportion

sor selection/installation

Mode. See Line Mode, page 30

Select encoder line mode setting on PC Setup -

Line Mode. See Line Mode, page 30

Troubleshooting

Run Up

Problem Cause Solution

Run up controller reads 0

psi

Run up controller produces

undesired results

Integrated systems: InvisiPac systems

is INACTIVE

Stand-alone systems: PC system is

INACTIVE

No pressure to inlet of run up controller Ensure pressure is being supplied to the inlet

Improper user settings entered Perform calibration routine found in Calibra-

Output pressure desired is greater

than inlet pressure

Integrated systems: Turn system ON, run up

will be active once system is ACTIVE (pump

will turn on)

Stand-alone systems: Turn system ON, run up

controller will be active immediately

of run up controller (check for valves and

shut-offs upstream of controller)

tion - Run Up Control. See Calibration, page

40

Ensure enough pressure is being supplied to

the inlet of the run up controller (standard calibration routine calls for 100 psi)

PLC Inputs and Outputs

Problem Cause Solution

Input from PLC not read by pattern controller

Output form pattern controller

not read by PLC

Improper input signal from PLC See PLC Inputs and Outputs Installation

Broken wire Check wiring between pattern controller and

Improper interface to PLC See PLC Inputs and Outputs Installation

Broken wire Check wiring between pattern controller and

(optional), page 19

PLC

(optional) for specifications and proper

installation

PLC

48 334784G

Software Update Procedure

ti31552a

Software Update Procedure

When software is updated on the ADM the software is

then automatically updated on all connected GCA components. A status screen is shown while software is

updating to indicate progress.

1. Turn system main power switch OFF.

2. Remove ADM from bracket.

3. Remove token access panel.

4. Insert and press InvisiPac software upgrade token

(part no. 24R324) firmly into slot.

NOTE: There is no preferred orientation of token.

First:

Software is checking which GCA modules will take the

available updates.

Second:

Status of the update

with the approximate time until completion.

Third:

Updates are complete. Icon indicates

update success/failure. See the following Icon table.

Icon Description

Update successful

5. Install ADM into bracket.

6. Turn system main power switch ON.

NOTICE

A status is shown while software is updating to indicate

progress. To prevent corrupting the software load, do

not remove token until the status screen disappears.

NOTE: When the screen turns on, you will see the following screens:

Update unsuccessful

Update complete, no changes

necessary

Update was successful/complete but one or more GCA modules did not have a CAN

boot-loader so software was not

updated on that module

7. Remove token (T).

8. Replace token access panel.

9. Press to continue to the InvisiPac operation

screens.

334784G 49

USB Download

USB

ti31550a

USB Download

The system can store 250,000 entries in its logs and

adds a new entry every 15 seconds. This means the

system stores 655 hours of system operation data, or 27

days of around-the-clock operation. Once full, th system

will overwrite the oldest data.

NOTE: To prevent losing any data, never go more than

27 days without downloading the logs.

Download Procedure

NOTICE

Uploading an edited system configuration file can damage the system. Never put a modified SETTINGS.TXT

file in the UPLOAD folder on the flash drive.

1. Insert USB flash drive into USB port.

NOTE: Flash drive must be 8 GB or smaller.

Accessing Files

All files downloaded from the USB are put in a DOWNLOAD folder on the stick drive. For example:

“E:\GRACO\12345678\DOWNLOAD\”. The 8-digit

numeric folder name matches the 8-digit ADM serial

number, which is located on the back of the ADM. When

downloading from multiple ADMs, there will be one

sub-folder in the GRACO folder for each ADM.

The log files should be opened in a spreadsheet program.

NOTE: If emailing the files, zip (compress them to minimize file size.

USB Logs

During operation, InvisiPac stores system and performance related information to memory in the form of log

files. InvisiPac maintains the events, data, GCA, black

box, and diagnostics logs. Follow the Download Proce-

dure to retrieve log files.

2. The menu bar and USB indicator lights indicate that

the USB is downloading files. Wait for USB activity

to complete. A pop-up will be present until the transfer is complete if it is not acknowledged.

NOTE: If the pop-up screen does not appear, the

flash drive is not compatible with the ADM. Try a different flash drive.

NOTE: The system can log up to 45 MB of additional data per week depending on system operation.

Events Log

The event log (1-EVENT.CSV) maintains a record of the

last 175,000 events. Each event record in the log file

contains the date and time the event occurred, the event

type, event code, and event description.

Data Log

The data log (2-DATA.CSV) tracks the setpoint and

actual temperatures every 15 seconds. This log can

store up to 250,000 lines of data. The system stores

1041 hours of system operation data, or 43 days of

around-the-clock operation. Once full, the system will

overwrite the oldest data.

NOTE: To prevent losing any data, never go more than

43 days without downloading the logs.

GCA Log

This log (3-GCA.CSV) lists the installed GCA modules

and their respective software versions.

Black Box, Diagnostic Logs

50 334784G

These logs (4-BLACKB.CSV, 5-DIAGN.CSV) are

designed to provide useful information to Graco when

calling for technical assistance.

Parts

WLD

External Models

Parts

334784G 51

Parts

Parts List

Ref. Part Description Qty.

1 - - - - - ENCLOSURE, PC, painted 1

2 - - - - - FOAM, gasket 2

3 - - - - - LABEL, pattern controller 1

4 186620 LABEL, symbol ground 1

5 127886 GROMMET, pattern control-

ler

6 126881 BUSHING, strain relief 2

7 126891 NUT, bushing 2

8 114421 BUSHING, strain relief 1

11 - - - - - FASTENER, hex, standoff 4

12 - - - - - TOOL, screwdriver 1

13 127939 BLOCK, ground 1

15 - - - - - WASHER, lock, ext 2

16 - - - - - NUT, #8-32 hex 2

17 17E019 MODULE, GCA, pattern con-

trol

19 - - - - - SCREW, machine, ph, 8 x

3/8 in.

20 - - - - - WASHER, lock 1

21 - - - - - NUT, hex 1

22 - - - - - WASHER, lock 4

23 - - - - - LATCH, tool, secured 1

24 - - - - - LATCH, cam 1

25 - - - - - SCREW, cap, hex hd 4

26 - - - - - BLANK, label kit 1

Ref. Part Description Qty.

29 116772 CONNECTOR, plug, 3.81

mm, 4 position

30 119162 CONNECTOR, plug, 6 posi-

tion

31+ 128156 BRACKET, mounting,

2

slide-on

32* 128147 CONNECTOR, plug, 3.81

mm, 8 position

33 128117 CONNECTOR, plug, 3.81

mm, 12 position

35 127768 CABLE, can female, 1.5 m 1

37 - - - - - TIE, cable, 7.5 in. 1

38 128116 CONNECTOR, plug, 3.81

mm, 7 position (PC-8e only)

40 24X626 KIT, token, GCA, key, PC-8e

1

(PC-8e only)

41 124654 CONNECTOR, splitter

4

(externally integrated models

only)

42 121226 CABLE, can, male/female,

0.4 m (externally integrated

models only)

43 24P860 KIT, replacement, ADM

(stand-alone models only)

+ Qty. 2 for Stand-Alone models

* Qty. 4 for PC-8e

Replacement Danger and Warning labels are available at no cost.

1

2

1

2

1

2

1

1

1

1

52 334784G

Internal Models (HM25c)

WLD

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

Internal Models (HM25c)

Parts List

Ref. Part Description Qty.

201 17E019 MODULE, GCA, pattern control 1

202 17M504 HARNESS, PC-8 internal 1

203 FRAME, cord grip, 4-position 1

204 125856 SCREW, 8-32, serrated flange 4

205 121000 CABLE, can female/female 0.5m 1

206 128117 CONNECTOR, plug, 3.81mm, 12-position 1

207 128147 CONNECTOR, plug, 3.81mm, 8-position 2

208 129538 CONNECTOR, plug, 3.81mm, 4-position 1

209 129540 CONNECTOR, plug, 3.81mm, 6-position 2

334784G 53

Internal Models (HM25c)

Internal Models (HM25 and HM50)

Parts List

Ref. Part Description Qty.

101 24X521 MODULE, GCA, PC-8e, internal 1

101b 128176 FRAME, cable grip, 5 position 1

101c 128177 INSERT, rubber, cable grip 4 x 6

mm

101d - - - - - PIN, 0.250 in. 4

101e 128178 INSERT, rubber, cable grip, 4 x 3

mm

101f - - - - - PIN, 0.125 in. 16

101g - - - - - SCREW, #10-32 x 0.750 2

102 128180 POWER SUPPLY, 120 W 1

103 128443 BRACKET, power supply, PC-8e

internal

104 128183 HARNESS, power, PC-8e inter-

nal, AWB

105 128182 CABLE, can, female/male 1

106 125856 SCREW, 8-32, serrated flange 4

Ref. Part Description Qty.

129 116772 CONNECTOR, plug, 3.81 mm, 4

position

130 119162 CONNECTOR, plug, 3.81 mm, 6

1

132+ 128147 CONNECTOR, plug, 3.81 mm, 8

4

133 128117 CONNECTOR, plug, 3.81 mm, 12

138* 128116 CONNECTOR, plug, 3.81 mm, 7

140* 24X626 KIT, token, GCA, key, PC-8e

1

1

+ Qty. 4 for PC-8e

* PC-8e only

position

position

position

position

FUSE, automotive, 4A, 32V, mini

(not shown)