Page 1

Injecto-Flo® II

Page 2

Trabon® Injecto-Flo® II

L12121

PISTON DISTRIBUTOR FOR OIL

AND FLUID GREASE

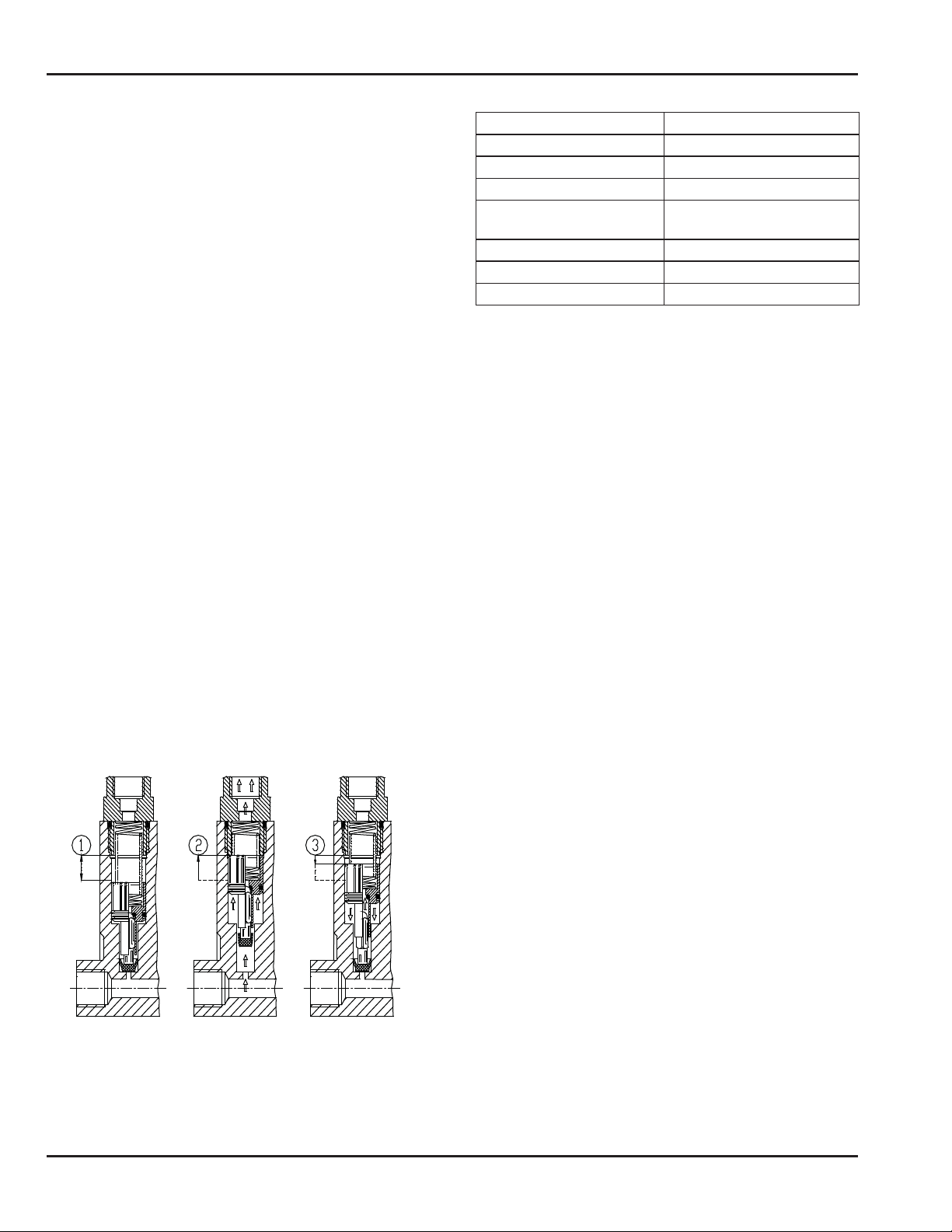

FUNCTION

Piston distributors meter out and distribute the lubricant delivered

by an intermittently actuated pump.

The quantities of lubricant for the individual lube points are

determined by exchangeable metering nipples. The metered

amount is indicated on the individual nipples. The amount needed

to cover the total oil demand can then be further regulated via the

lubricating frequency.

To meet the required quantities and comply with space constraints

it is possible to choose among four

distributor groups that differ in terms of their metering ranges and

sizes.

The functional principle of the groups is the same, but there are

differences in design. Different distributor groups can be used in

one installation.

Distributor for Oil group Quantity cm³

3400 0.01 0.03 0.06 0.1 0.16

3500 0.1 0.2 0.4 0.6

3900 0.2 0.4 0.6 1.0 1.5

Distributor for

fl uid grease group

3410 0.01 0.03 0.06 0.1

3510 0.1 0.2 0.3

3910 0.1 0.2 0.3

Quantity cm³

FUNCTION

1. The amount of lubricant intended for the lube point is stored in

front of the piston in the distributor.

2. When the central lubrication pump begins to deliver lubricant,

the piston moves and the lubricant in front of it is fed to the

lube point at a main line pressure of 10-45 bars.

3. When pump delivery stops and main line pressure is relieved,

the distributor’s piston returns to its initial position and

transfers a measured quantity of lubricant into the space in

front of it.

Page 2

Page 3

Trabon® Injecto-Flo® II

SINGLE-LINE LUBRICATION SYSTEM WITH PISTON DISTRIBUTOR FOR OIL OR FLUID GREASE

L12121

FUNCTION

A pump feeds the lubricant through the main line to the piston

distributors. From there it is directed to the lube points in precisely

metered quantities. This takes place in a time- or pulse-controlled

sequence.

PLANNING

1. Determine the type of drive to be used for the lube pump

(manual, electric, or pneumatic).

2. Select the lubricant. Then determine the pump unit and type

of distributors.

3. Determine the number of lube points and defi ne the amount

of lubricant required to meet the needs of each point.

Ascertain the total amount of lubricant needed per unit of

time or clock pulse. Then determine the reservoir size based

on total delivery volume and desired refi ll frequency.

CHOICE OF DISTRIBUTORS

Select the piston distributors on the basis of the

metered quantity and spatial constraints.

The ratio of the metered quantities in respect to each other should

be the same as the consumption of the individual lube points.

The total amount needed by the installation is then regulated by

the number of lube cycles per unit of time.

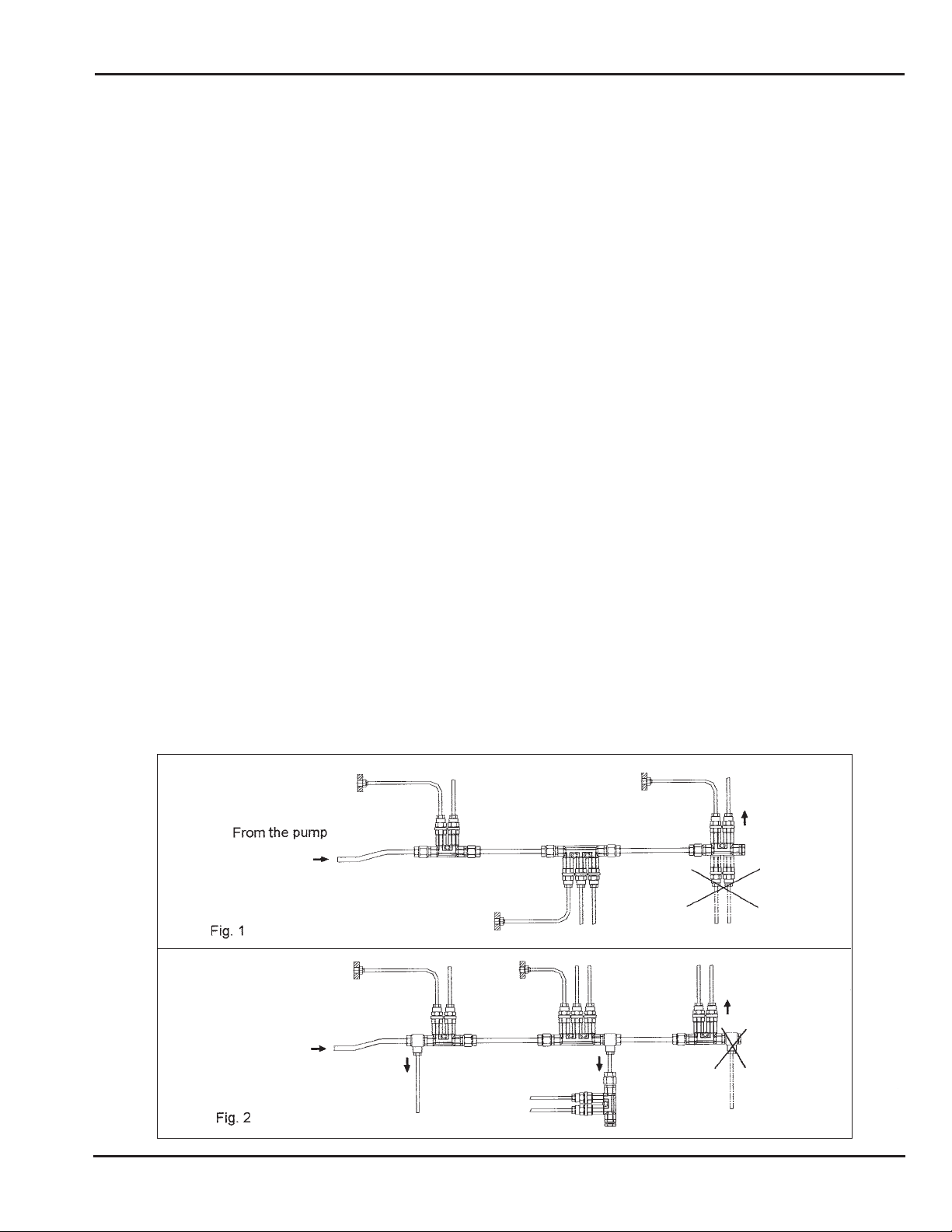

INSTALLATION LAYOUT

When installing a central lubrication system, route the main lines

and distributors in such a way that any air in the system can

escape on its own via the lube points.

To do so, mount the distributors at appropriate places and at the

end of the installation in such a way that the connections to the

lube points point upward (Fig. 1).

The main lines from the pump to the distributors should, if

possible, be installed with a rising gradient.

If lines have to be routed to distributors at lower

locations, proceed in accordance with Fig. 2.

Check the main-line resistance values, especially in regard to the

relief routine, with very large systems, ones with a large number

of branches or when highly viscous lubricants are used.

Each distributor port may be connected to only one lube point!

Do not connect the secondary line (distributor outlet connection)

to the lube point until bubble-free lubricant emerges at the line

end after repeated actuation of the pump. NOTE: It might be

necessary to pre-fi ll long secondary lines with lubricant.

If a secondary line becomes blocked or broken, it will not effect

the remaining lube points in the system.

Page 3

Page 4

Trabon® Injecto-Flo® II

35

110 110

35

2.5

182

Ø9

P

290

270

M14x1.5

Ø8

175

128

187.5

67.5

339.5

15

40

60

20

92

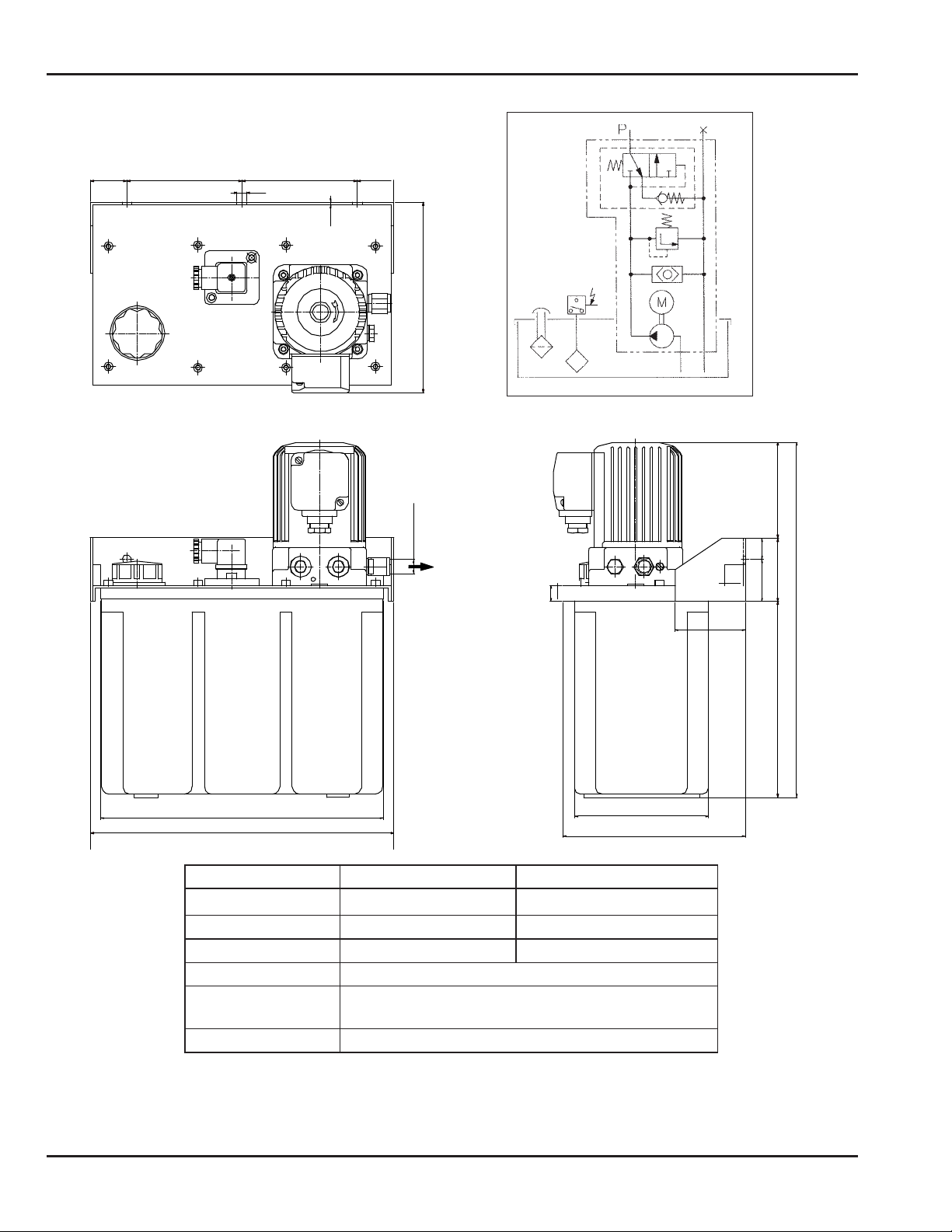

PUMP SPECIFICATIONS

L12121

Pump Specs 564138 (513-001-200) 122591– (513-002-201)

Lubricants Oil 50-1000 cSt Fluid Grease NLGI 000,00

3

Output 0.5 L/min (30 in

/min) 0.2 L/min (12 in3/min)

Pressure 25 bar (360 psi) 40 bar (580 psi)

Reservoir Capacity 6 Liter (1.6 gallon) plastic

Voltage, Current 230/400 VAC 50 Hz, 0.66 A /0.38A

276/480 VAC 60 Hz, 0.75A /0.43A

Low Level Switch Max. Voltage 250 VAC, 0.8A

Consult Graco factory for availability of electrical pumps for automotive specifi cations.

Page 4

Page 5

Trabon® Injecto-Flo® II

L12121

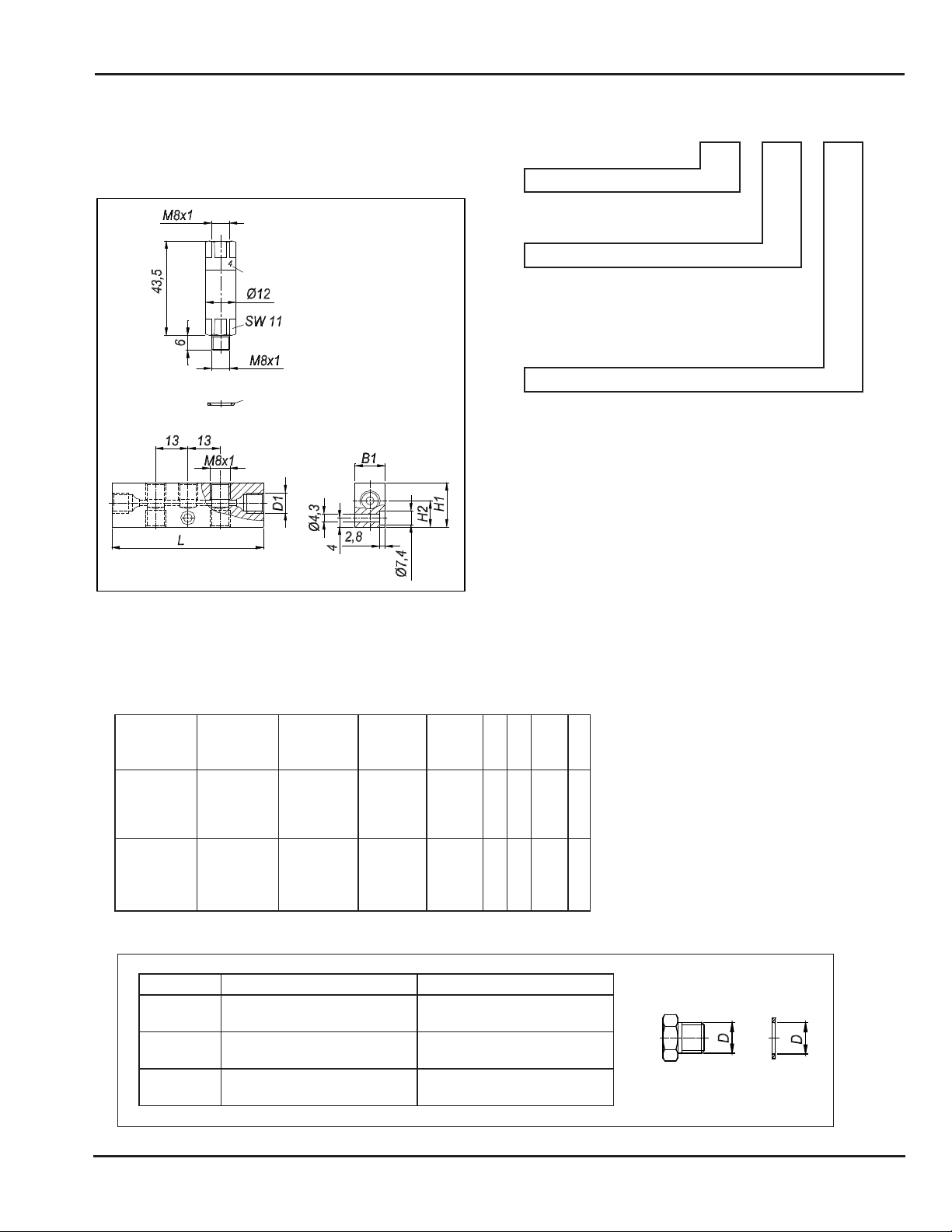

PISTON DISTRIBUTOR FOR OIL

GROUP 3200 0.01 – 0.16 CM³

tube 4

Metering Marking

washer

ORDER KEY:

320 - X-X-X

Number of Outlets

2 - Two

3 - Three

5 - Five

Metering

3

- outlet closed

0 - 0 cm

1 - 0.01 cm

2 - 0.03 cm

3 - 0.06 cm

4 - 0.10 cm

5 - 0.16 cm

Inlet Thread D1

B - M10x1

C - M14x1.5

Order Example:

Order Key: 3 4 2

Order Key: 320 3-342-B

3

3

3

3

3

Distributor group: 3200

with 3 outlets key: 3

marking from the left to the right: 0.06 - 0.10 - 0.03

Inlet Thread of the Distributor Manifold (M10x1)

Order Key: B

Specifi cations

Operating Pressure: 10 - 45 bar

Medium: Oil

Viscosity: 32 to 2000 cSt

Temperature Range: +0

Perm. Residual Pressure: Max. 1.5 bar

Manifold

Part No.

558333 513-000-100 2 52

558335 513-000-102 3 M10 x 1 6 13 17 10.5 65

558337 513-000-104 5 65

558334 513-000-101 2 61

558336 513-000-103 3 M14 X 1.5 8 18 20 11 74

558338 513-000-105 5 74

Thread Plug (Old Part No.) Washer (Old Part No.)

M8 x 1

M10 x 1

M14 x 1.5

Manifold

Old Part No.

Number of

lubrication

points

558151

(435-702-261)

558192

(435-702-361)

564139

(513-000-200)

Thread D1 Main line Ø B1 H1 H2 L

558153

(435-702-415)

558154

(435-702-416)

564140

(513-000-201)

O

C to + 70OC

Page 5

Page 6

Trabon® Injecto-Flo® II

L12121

PISTON DISTRIBUTOR FOR OIL

GROUP 3400 0.01 – 0.16 CM³

PISTON

DISTRIBUTOR

1-PORT

No. 3400-1X

PISTON

DISTRIBUTOR

2-PORT

NO. 3400-2XX

ORDER KEY:

3400 - X - X

Number of Outlets

1 - One

2 - Two

3 - Three

5 - Five

Metering

3

- outlet closed

0 - 0 cm

1 - 0.01 cm

2 - 0.03 cm

3 - 0.06 cm

4 - 0.10 cm

5 - 0.16 cm

3

3

3

3

3

Order Example:

Distributor group: 3400

with 3 outlets key: 3

marking from the left to the right: 0.06 - 0.10 - 0.03 cm

Order Key: 3 4 2

Order Key: 3400-3-342

Specifi cations

Operating Pressure: 10 - 45 bar

Medium: Oil

Viscosity: 32 to 2000 cSt

Temperature Range: +0

Perm. Residual Pressure: Max. 1.5 bar

Metering Nipple Part No. Old Part No.

.03 cc 558311 513-000-021

.06 cc 558312 513-000-022

.10 cc 558313 513-000-023

.16 cc 558314 513-000-024

O

C to + 70OC

3

PISTON

DISTRIBUTOR

3-PORT

NO. 3400-3XXX

Thread Plug (Old Part No.) Washer (Old Part No.)

M8 x 1

M10 x 1

PISTON

DISTRIBUTOR

5-PORT

NO. 3400-5XXXXX

558151

(435-702-261)

558192

(435-702-361)

588153

(435-702-415)

558154

(435-702-416)

Page 6

Page 7

Trabon® Injecto-Flo® II

L12121

PISTON DISTRIBUTOR FOR OIL

GROUP 3500 0.10 – 0.60 CM³

PISTON

DISTRIBUTOR

1-PORT

NO. 3500-1X

PISTON

DISTRIBUTOR

2-PORT

NO. 3500-2XX

ORDER KEY:

3500 - X - X

Number of Outlets

1 - One

2 - Two

3 - Three

5 - Five

Metering

3

- outlet closed

0 - 0 cm

4 - 0.10 cm

5 - 0.20 cm

6 - 0.40 cm

7 - 0.60 cm

3

3

3

3

Order Example:

Piston distributor group: 3500

with 3 outlets key: 3

marking from the left to the right: 0.60 - 0.20 - 0.40 cm

Order Key: 7 5 6

Order Key: 3500-3-756

Metering Nipple Part No. Old Part No.

.10 cc 558315 513-000-030

.20 cc 558316 513-000-031

.40 cc 558317 513-000-032

.60 cc 558318 513-000-033

3

PISTON

DISTRIBUTOR

3-PORT

NO. 3500-3XXX

Specifi cations

Operating Pressure: 10 - 45 bar

Medium: Oil

Viscosity: 32 to 2000 cSt

Temperature Range: +0

O

C to + 70OC

Perm. Residual Pressure: Max. 1.5 bar

Thread Plug (Old Part No.) Washer (Old Part No.)

M8 x 1

M12 x 1

558151

(435-702-261)

558152

(435-702-403)

PISTON

DISTRIBUTOR

5-PORT

NO. 3500-5XXXXX

(435-702-415)

(435-702-417)

588153

558155

Page 7

Page 8

Trabon® Injecto-Flo® II

L12121

PISTON DISTRIBUTOR FOR OIL

GROUP 3900 0.20 – 1.50 CM³

PISTON

DISTRIBUTOR

1-PORT

NO. 3900-1X

PISTON

DISTRIBUTOR

2-PORT

NO. 3900-2XX

ORDER KEY:

3500 - X - X

Number of Outlets

1 - One

2 - Two

3 - Three

Metering

3

- outlet closed

0 - 0 cm

5 - 0.20 cm

6 - 0.40 cm

7 - 0.60 cm

8 - 1.00 cm

9 - 1.50 cm

Order Example:

Order Key: 5 7 9

Order Key: 3900-3-579

Specifi cations

3

3

3

3

3

Metering Nipple Part No. Old Part No.

.20 cc 558319 513-000-040

.40 cc 558320 513-000-041

.60 cc 558321 513-000-042

1.00 cc 558322 513-000-043

1.50 cc 558323 513-000-044

Distributor group: 3900

with 3 outlets key: 3

marking from the left to the right: 0.20 - 0.60 - 1.50 cm

3

Operating Pressure: 10 – 45 bar

Medium: Oil

Viscosity: 32 to 2000 cSt

Temperature Range: +0°C to + 70°C

Perm. Residual Pressure: Max. 1.5 bar

Thread Plug (Old Part No.) Washer (Old Part No.)

M8 x 1

M12 x 1

558151

(435-702-261)

558152

(435-702-403)

588153

(435-702-415)

558155

(435-702-417)

PISTON DISTRIBUTOR 3-PORT NO. 3900-3XXX

Page 8

Page 9

Trabon® Injecto-Flo® II

L12121

PISTON DISTRIBUTOR FOR

FLUID GREASE NLGI 000, 00

GROUP 3410 0.01 – 0.10 CM³

PISTON

DISTRIBUTOR

1-PORT

NO. 3410-1X

PISTON

DISTRIBUTOR

2-PORT

NO. 3410-2XX

ORDER KEY:

3500 - X - X

Number of Outlets

1 - One

2 - Two

3 - Three

5 - Five

Metering

3

- outlet closed

0 - 0 cm

1 - 0.01 cm

2 - 0.03 cm

3 - 0.06 cm

4 - 0.10 cm

Order Example:

Order Key: 3 4 2

Order Key: 3410-3-342

Specifi cations

3

3

3

3

Metering Nipple Part No. Old Part No.

.03 cc 558324 513-000-051

.06 cc 558325 513-000-052

.10 cc 558326 513-000-053

Piston distributor group: 3400

with 3 outlets key: 3

marking from the left to the right: 0.06 - 0.10 - 0.03 cm

Operating Pressure: 10 - 45 bar

Medium: Grease NLGI 000, 00

Temperature Range: +0

O

C to + 60OC

Perm. Residual Pressure: Max. 1.5 bar

3

PISTON

DISTRIBUTOR

3-PORT

NO. 3410-3XXX

Thread Plug (Old Part No.) Washer (Old Part No.)

M8 x 1

M10 x 1

558151

(435-702-261)

558192

(435-702-361)

PISTON

DISTRIBUTOR

5-PORT

NO. 3410-5XXXXX

588153

(435-702-415)

558154

(435-702-416)

Page 9

Page 10

Trabon® Injecto-Flo® II

L12121

PISTON DISTRIBUTOR FOR

FLUID GREASE NLGI 000,00

GROUP 3510 0.10 – 0.30 CM³

PISTON

DISTRIBUTOR

1-PORT

NO. 3510-1X

PISTON

DISTRIBUTOR

2-PORT

NO. 3510-2XX

ORDER KEY:

3500 - X - X

Number of Outlets

1 - One

2 - Two

3 - Three

5 - Five

Metering

3

- outlet closed

0 - 0 cm

4 - 0.10 cm

5 - 0.20 cm

6 - 0.30 cm

3

3

3

Order Example:

Piston distributor group: 3510

with 3 outlets key: 3

marking from the left to the right: 0.20 - 0.10 - 0.03 cm

Order Key: 5 4 6

Order Key: 3510-3-546

Metering Nipple Part No. Old Part No.

.10 cc 558327 513-000-060

.20 cc 558328 513-000-061

.30 cc 558329 513-000-062

3

PISTON

DISTRIBUTOR

3-PORT

NO. 3510-3XXX

Specifi cations

Operating Pressure: 10 - 45 bar

Medium: Grease NLGI 000, 00

Temperature Range: +0

O

C to + 60OC

Perm. Residual Pressure: Max. 1.5 bar

Thread Plug (Old Part No.) Washer (Old Part No.)

M8 x 1

M12 x 1

PISTON

DISTRIBUTOR

5-PORT

NO. 3510-5XXXXX

558151

(435-702-261)

558152

(435-702-403)

588153

(435-702-415)

558155

(435-702-417)

Page 10

Page 11

Trabon® Injecto-Flo® II

L12121

PISTON DISTRIBUTOR FOR

FLUID GREASE NLGI 000,00,0

GROUP 3910 0.10 – 0.30 CM³

PISTON

DISTRIBUTOR

1-PORT

NO. 3910-1X

PISTON

DISTRIBUTOR

2-PORT

NO. 3910-2XX

ORDER KEY:

3500 - X - X

Number of Outlets

1 - One

2 - Two

3 - Three

Metering

3

- outlet closed

0 - 0 cm

4 - 0.10 cm

5 - 0.20 cm

6 - 0.30 cm

Order Example:

Order Key: 5 6

Order Key: 3910-3-56

Specifi cations

3

3

3

Metering Nipple Part No. Old Part No.

.10 cc 558330 513-000-070

.20 cc 558331 513-000-071

.30 cc 558332 513-000-072

Piston distributor group: 3910

with 3 outlets key: 3

marking from the left to the right: 0.20 - 0.30 cm

Operating Pressure: 10 - 45 bar

Medium: Grease NLGI 000,00,0

Temperature Range: +0

O

C to + 60OC

Perm. Residual Pressure: Max. 1.5 bar

3

Thread Plug (Old Part No.) Washer (Old Part No.)

M8 x 1

M12 x 1

558151

(435-702-261)

558152

(435-702-403)

PISTON

DISTRIBUTOR

3-PORT

NO. 3910-3XXX

588153

(435-702-415)

558155

(435-702-417)

Page 11

Page 12

Trabon® Injecto-Flo® II

Oil Pump - 3L Reservoir (no control)

Part No. Reservoir Size (L) Flow (lpm) Level Switch Refi ll Style

122545 3 0.2 None Screw cap

122546 3 0.2 None Straight Connector (10mm pipe)

122547 3 0.5 None Screw cap

122548 3 0.5 None Straight Connector (10mm pipe)

122549 3 0.2 Single w/DIN Screw cap

122550 3 0.2 Single w/DIN Straight Connector (10mm pipe)

122551 3 0.5 Single w/DIN Screw cap

122552 3 0.5 Single w/DIN Straight Connector (10mm pipe)

122553 3 0.2 Single w/M12 Top Screw cap

15U859 3 0.2 Single w/M12 Top Straight Connector (10mm pipe)

122554 3 0.5 Single w/M12 Top Screw cap

122555 3 0.5 Single w/M12 Top Straight Connector (10mm pipe)

122556 3 0.2 Dual w/DIN Screw cap

122557 3 0.2 Dual w/DIN Straight Connector (10mm pipe)

122558 3 0.5 Dual w/DIN Screw cap

122559 3 0.5 Dual w/DIN Straight Connector (10mm pipe)

122560 3 0.2 Dual w/M12 Top Screw cap

122561 3 0.2 Dual w/M12 Top Straight Connector (10mm pipe)

122562 3 0.5 Dual w/M12 Top Screw cap

15U858 3 0.5 Dual w/M12 Top Straight Connector (10mm pipe)

Oil Pump - 6L Reservoir (no control)

Part No. Reservoir Size (L) Flow (lpm) Level Switch Refi ll Style

122563 6 0.2 None Screw Cap

122564 6 0.2 None Straight Connector (10mm pipe)

122565 6 0.5 None Screw Cap

122566 6 0.5 None Straight Connector (10mm pipe)

122567 6 0.2 Single w/DIN Screw Cap

122568 6 0.2 Single w/DIN Straight Connector (10mm pipe)

564138 6 0.5 Single w/DIN Screw Cap

122569 6 0.5 Single w/DIN Straight Connector (10mm pipe)

122570 6 0.2 Single w/M12 Top Screw Cap

122571 6 0.2 Single w/M12 Top Straight Connector (10mm pipe)

122572 6 0.5 Single w/M12 Top Screw Cap

122573 6 0.5 Single w/M12 Top Straight Connector (10mm pipe)

122574 6 0.2 Dual w/DIN Screw Cap

122575 6 0.2 Dual w/DIN Straight Connector (10mm pipe)

122576 6 0.5 Dual w/DIN Screw Cap

122577 6 0.5 Dual w/DIN Straight Connector (10mm pipe)

122578 6 0.2 Dual w/M12 Top Screw Cap

122579 6 0.2 Dual w/M12 Top Straight Connector (10mm pipe)

122580 6 0.5 Dual w/M12 Top Screw Cap

15U860 6 0.5 Dual w/M12 Top Straight Connector (10mm pipe)

L12121

Page 12

Page 13

Trabon® Injecto-Flo® II

Fluid Grease Pump - 3L reservoir (no control)

Part No. Reservoir Size (L) Flow (lpm) Level Switch Refi ll Style

122581 3 0.2 None Screw Cap

563301 3 0.2 None Straight Connector (10mm pipe)

122582 3 0.2 Single w/DIN Screw Cap

122583 3 0.2 Single w/DIN Straight Connector (10mm pipe)

122584 3 0.2 Single w/M12 Top Screw Cap

122585 3 0.2 Single w/M12 Top Straight Connector (10mm pipe)

122586 3 0.2 Dual w/ DIN Screw Cap

122587 3 0.2 Dual w/ DIN Straight Connector (10mm pipe)

122588 3 0.2 Dual w/M12 Top Screw Cap

557547 3 0.2 Dual w/M12 Top Straight Connector (10mm pipe)

Fluid Grease Pump - 6L reservoir ( no control)

Part No. Reservoir Size (L) Flow (lpm) Level Switch Refi ll Style

122589 6 0.2 None Screw Cap

122590 6 0.2 None Straight Connector (10mm pipe)

122591 6 0.2 Single w/DIN Screw Cap

122592 6 0.2 Single w/DIN Straight Connector (10mm pipe)

122593 6 0.2 Single w/M12 Top Screw Cap

122594 6 0.2 Single w/M12 Top Straight Connector (10mm pipe)

122595 6 0.2 Dual w/DIN Screw Cap

122596 6 0.2 Dual w/DIN Straight Connector (10mm pipe)

122597 6 0.2 Dual w/M12 Top Screw Cap

122598 6 0.2 Dual w/M12 Top Straight Connector (10mm pipe)

L12121

Oil Pumps with Integrated Control

Part No. Reservoir Size (L) Flow (lpm) Voltage Control System Monitoring System System Refi ll

122897 6 0.2 230 VAC w/Time or Pulse Man Lube, Lvl Switch, Pres Gauge, Pres Switch, Green light,

red light

122898 6 0.5 230 VAC w/Time or Pulse Man Lube, Lvl Switch, Pres Gauge, Pres Switch, Green light,

red light

122895 3 0.2 230 VAC w/Time or Pulse Man Lube, Lvl Switch, Pres Gauge, Pres Switch, Green light,

red light

Fluid Grease Pump - with Integrated Control

Part No. Reservoir Size (L) Flow (lpm) Voltage Control System Monitoring System System Refi ll

122896 3 0.2 230 VAC w/Time or Pulse Man Lube, Lvl Switch, Pres Gauge, Pres Switch, Green light,

red light

122899 6 0.2 230 VAC w/Time or Pulse Man Lube, Lvl Switch, Pres Gauge, Pres Switch, Green light,

red light

Screw Cap

Screw Cap

Screw Cap

Screw Cap

Screw Cap

Page 13

Page 14

Trabon® Injecto-Flo® II

L12121

3400 Single Point Piston Distributors - Oil

3

558306 0.01 cm

558307 0.03 cm

558308 0.06 cm

558309 0.10 cm

558310 0.16 cm

122804 0.01 cm

122805 0.03 cm

122806 0.06 cm

122807 0.10 cm

122808 0.16 cm

M8x1

3

M8x1

3

M8x1

3

M8x1

3

M8x1

3

M10x1

3

M10x1

3

M10x1

3

M10x1

3

M10x1

3500 Single Point Piston Distributors - Oil

3

121658 0.1 cm

121659 0.2 cm

121660 0.4 cm

121661 0.6 cm

122813 0.1 cm

122814 0.2 cm

122815 0.4 cm

122816 0.6 cm

M10x1

3

M10x1

3

M10x1

3

M10x1

3

M12x1

3

M12x1

3

M12x1

3

M12x1

3900 Single Point Piston Distributors - Oil

121665 0.2 cm

121666 0.4 cm

121667 0.6 cm

121668 1.0 cm

121669 1.5 cm

122820 0.2 cm

122821 0.4 cm

122822 0.6 cm

122823 1.0 cm

122824 1.5 cm

3

M14x1.5

3

M14x1.5

3

M14x1.5

3

M14x1.5

3

M14x1.5

3

M12x1

3

M12x1

3

M12x1

3

M12x1

3

M12x1

3410 Single Point Piston Distributors - Grease

3

121654 0.01 cm

121655 0.03 cm

121656 0.06 cm

121657 0.10 cm

122809 0.01 cm

122810 0.03 cm

122811 0.06 cm

122812 0.10 cm

M8x1

3

M8x1

3

M8x1

3

M8x1

3

M10x1

3

M10x1

3

M10x1

3

M10x1

3510 Single Point Piston Distributors - Grease

3

121662 0.1 cm

121663 0.2 cm

121664 0.3 cm

M10x1

3

M10x1

3

M10x1

3510 Single Point Piston Distributors - Grease (continued)

3

122817 0.1 cm

122818 0.2 cm

122819 0.3 cm

M12x1

3

M12x1

3

M12x1

3910 Single Point Piston Distributors - Grease

3

121670 0.1 cm

121671 0.2 cm

121672 0.3 cm

122825 0.1 cm

122826 0.2 cm

122827 0.3 cm

M14x1.5

3

M14x1.5

3

M14x1.5

3

M12x1

3

M12x1

3

M12x1

3400/3410 Series Bar Manifolds

15X624 Tee M8/M8 - 1 Port

15X667 M10/M8 - 2 Port

15X668 M10/M8 - 3 Port

15X669 M10/M8 - 4 Port

15X670 M10/M8 - 5 Port

15X671 M10/M8 - 6 Port

15X672 M10/M8 - 7 Port

15X673 M10/M8 - 8 Port

15X674 M10/M8 - 10 Port

15X683 M14/M8 - 2 Port

15X684 M14/M8 - 3 Port

15X685 M14/M8 - 4 Port

15X686 M14/M8 - 5 Port

15X687 M14/M8 - 6 Port

15X688 M14/M8 - 7 Port

15X689 M14/M8 - 8 Port

15X690 M14/M8 - 10 Port

3500/3510 Series Bar Manifolds

15X625 Tee M10/M10 - 1 Port

15X675 M10/M10 - 2 Port

15X676 M10/M10 - 3 Port

15X677 M10/M10 - 4 Port

15X678 M10/M10 - 5 Port

15X679 M10/M10 - 6 Port

15X680 M10/M10 - 7 Port

15X681 M10/M10 - 8 Port

15X682 M10/M10 - 10 Port

15X691 M14/M10 - 2 Port

15X692 M14/M10 - 3 Port

15X693 M14/M10 - 4 Port

15X694 M14/M10 - 5 Port

15X695 M14/M10 - 6 Port

Page 14

Page 15

Trabon® Injecto-Flo® II

L12121

3500/3510 Series Bar Manifolds (continued)

15X696 M14/M10 - 7 Port

15X697 M14/M10 - 8 Port

15X698 M14/M10 - 10 Port

3900/3910 Series Bar Manifolds

15X626 Tee M14/M14 - 1 Port

15X699 M14/M14 - 2 Port

15X700 M14/M14 - 3 Port

15X701 M14/M14 - 4 Port

15X702 M14/M14 - 5 Port

15X703 M14/M14 - 6 Port

15X704 M14/M14 - 7 Port

15X705 M14/M14 - 8 Port

15X706 M14/M14 - 10 Port

3400 Dispensing Meters

122989 0.01 cm

558311 0.03 cm

558312 0.06 cm

558313 0.10 cm

558314 0.16 cm

3

3

3

3

3

3410 Dispensing Meters

122990 0.01 cm

558324 0.03 cm

558325 0.06 cm

558326 0.10 cm

3

3

3

3

3500 Dispensing Meters

558315 0.1 cm

558316 0.2 cm

558317 0.4 cm

558318 0.6 cm

3

3

3

3

3510 Dispensing Meters

558327 0.1 cm

558328 0.2 cm

558329 0.3 cm

3

3

3

3910 Dispensing Meters

558330 0.1 cm

558331 0.2 cm

558332 0.3 cm

3

3

3

3400/3410 Cast Manifolds

122841 2 Outlets, Oil PD, Red Plastic Cover

122861 3 Outlets, Oil PD, Red Plastic Cover

122862 5 Outlets, Oil PD, Red Plastic Cover

122863 2 Outlets, Grease PD, White Plastic Cover

122864 3 Outlets, Grease PD, White Plastic Cover

122865 5 Outlets, Grease PD, White Plastic Cover

3500/3510 Cast Manifolds

122866 2 Outlets, Oil PD, Red Plastic Cover

122868 3 Outlets, Oil PD, Red Plastic Cover

122869 5 Outlets, Oil PD, Red Plastic Cover

122885 2 Outlets, Grease PD, White Plastic Cover

122886 3 Outlets, Grease PD, White Plastic Cover

122887 5 Outlets, Grease PD, White Plastic Cover

3900/3910 Cast Manifolds

122888 2 Outlets, Oil PD, Red Plastic Cover

122889 3 Outlets, Oil PD, Red Plastic Cover

122890 2 Outlets, Grease PD, White Plastic Cover

122891 3 Outlets, Grease PD, White Plastic Cover

Direct-to-Bearing Piston Distributors

122789 To Fit Distributor M14/D4/0.03 cm

122790 To Fit Distributor M14/D4/0.06 cm

122791 To Fit Distributor M14/D4/0.1 cm

122792 To Fit Distributor M14/D6/0.03 cm

122793 To Fit Distributor M14/D6/0.06 cm

122794 To Fit Distributor M14/D6/0.1 cm

122795 Direct-to-Lube PD D10.35/0.03 cm

122796 Direct-to-Lube PD D10.35/0.06 cm

122797 Direct-to-Lube PD D10.35/0.1 cm

122798 Direct-to-Lube PD D13.5/0.1 cm

122799 Direct-to-Lube PD D13.5/0.2 cm

122800 Direct-to-Lube PD D13.5/0.3 cm

122801 Direct-to-Lube PD D13.5/0.4 cm

3

3

3

3

3

3

3

3

3

3

3

3

3

Page 15

Page 16

Look to Graco Inc. for all your Centralized Lubrication System needs.

Bulletins

Description Bulletin

Injecto-Flo Oil Pumps

AO-1 Air Operated Pumps L12601

EO-1 Electric Pumps L12605

EO-3 Electric Pumps L12606

Consult Graco Factory for availability of Electrical Pumps for automotive specifi cations.

Bulletins

Description Bulletin

LubriSystem

LubriSystem Pumps L12100

Note: LubriSystem pumps can also be used with oil or fl uid grease.

Bulletins

Description Bulletin

Electronic Pumps

Solid State Timer L14521

GLC 4400 340391

WMP II Maxi-Monitor L14750

Contact us today!

To receive product information or talk with a Graco representative,

call 800-533-9655 or visit us online at www.graco.com.

©2006-2009 Graco Inc. Form No. L12121 Rev. B 1/09 Printed in U.S.A. All other brand names or marks are used for identification purposes and are trademarks of their respective owners. All written and

visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice.

Loading...

Loading...