Page 1

Injecto-Flo EO-3

Electric Operated Pumps

DESCRIPTION

The EO-3 pump package includes a 115 or 230 VAC motor direct

coupled to a gear pump and mounted on a 3.6 liter (7.6 pint)

plastic reservoir. Each is equipped with a low level switch and

rated for service up to 24 bar (350 psi) . Timer equipped models

include a built in pressure switch. On/off cycles on remote control

models are programmed by a remote timer or from a machine's

PLC where available.

When electrical power is applied to the pump motor, lubricant fl ow

pressurizes the system mainlines causing the piston distributors

to dispense a measured volume of lubricant to the bearing points.

Making of the pressure switch contacts (pressure switch equipped

models) or expiration of the on time causes power to be shut off

from the motor. This stops fl ow and permits the internal vent valve

to release mainline pressure which allows the piston distributors to

re-prime in preparation for the next lube cycle.

SPECIFICATION

Motor Voltage 115 + 10% VAC, 50/60 Hz, 1 pH

230 + 10% VAC, 50-60 Hz, 1 pH

Current Consumption 3.8A in-rush, 1.8A running @ 115 VAC

1.9A in-rush, 0.9A running @ 230 VAC

Motor Power 1/18 hp

Motor Speed 1680 RPM @ 60 Hz

1340 RPM @ 50 Hz

3

Pump Flow Rate 8.5 in

Pressure Relief valve protected, 350 psi (24 bar),

Oil Viscosity ISO 50-1500 (SUS 250-5000)

Operating Temperature 14ºF to 120ºF (-10ºC to 49ºC)

Operation Intermittent, 20% duty cycle @ max

*Low Level Switch 10 watt @ 115/230 VAC

Suction Strainer 60 mesh screen

Pressure Gauge 0-850 psi (0-60 bar)

Electrical Connection Supplied with liquid tight cable

Reservoir 7.6 pint (3.6 liter) translucent nylon

Timer Equipped Models

Timer

On-Time 5-90 sec

Off-Time 2.5-1000 min or 1-21 hours (pre-lube-

/min (140 cm3/min)

Pressure switch set @ 320 psi (22 bar)

pressure (350 psi)

5 watt @ 24 VDC, N.C. Contacts

connector and screw terminals

selectable)

Pressure MonitorSelectable

Programming Via 2 Jumper Bars and 8 Dip Switches

One Fault Output SPDT

Three Indicator Lights Power on (GN), Operating (YL), Fault

Manual Run Push-button

320 psi (22 bar)

(Rd)

ORDERING INFORMATION

Description Part No. Old Part No.

115V, timer, manual run, indicator light,

pressure switch, low level switch

230V, timer, manual run, indicator light,

pressure switch, low level switch

115V, remote, manual run, pressure

switch, low level switch

Description Part No. Old Part No.

230V, remote, manual run, pressure

switch, low level switch

Replacement Outlet Nut, 6 mm tube 555732 435-702-466

Replacement Outlet Ferrule, 6 mm tube 555731 435-702-421

Outlet Adaptor, M12 x 1M) to 1/4 NPTF(F) Dis 435-702-471

562850 126-410-017

258294 126-410-018

562851 126-410-021

247669 126-410-026

Page 2

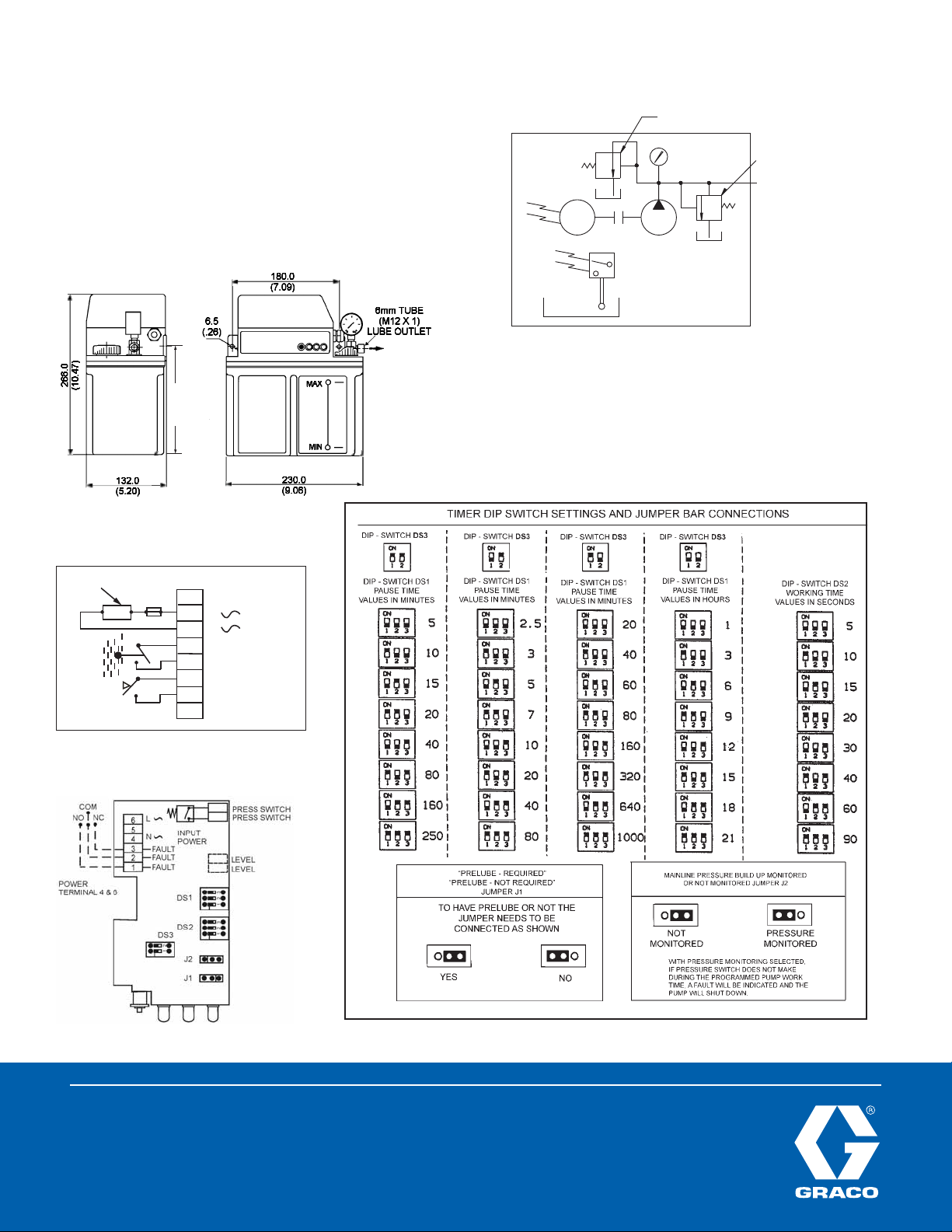

INSTALLATION DATA

System Schematic

Mounting

The entire pump package is installed with two 6mm (1/4 in)

screws that pass through holes in the mounting fl ange at the

top of the reservoir. Mounting dimensions are given in Figure 1.

Figure 2 is a simplifi ed schematic for the entire pumping unit.

DIMENSIONS

[mm/(inches)]

181.0

(7.12)

Figure 1

Remote Control

VENT VALVEVENT VALVE

PRESSURE

GAUGEGAUGEGAUGE

RELIEF

VALV E

LUBE

OUTLET

M

LOW LEVELLOW LEVELLOW LEVELLOW LEVEL

Figure 2

Electrical Hookup

Electrical hookups are shown in Figures 3 and 4. Timer dip switch

settings and jumper bar connections (timer equipped models) are

shown in Figure 5. All electrical connections should be made with

16 AWG stranded wire and insulation rated for 115/230 VAC and

105OC.

FUSE F 2.5A 250V

M

Time Control

0

1

2

3

4

5

6

7

Figure 3

Figure 4

N

INPUT

L

POWER

LEVEL

LEVEL

PRESSURE SWITCH

PRESSURE SWITCH

Figure 5

All written and visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice.

Contact us today!

To receive product information or talk with a Graco representative,

call 800-533-9655 or visit us online at www.graco.com.

©2006-2011 Graco Inc. Form No. L12606 Rev. C 4/11 Printed in U.S.A. All other brand names or marks are used for identification purposes and are trademarks of their respective owners. All written and

visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice.

Loading...

Loading...