Page 1

PIN

1200

This

WARNINGS

READ

800-233

psi

(82

bar)

manual

contains

AND RETAIN

and

IPAPQRTANT

1NSTRUCTIONS

FOR

REFERENCE

er

SERIES

OPERATING PRESSURE

"A"

..

.

GWACQ

BNC.

P.O.

BOX

1441

OCOPYRIGHT

MWINNEAPOILUS,

1987

GRACO

INC.

WWM 554404

Page 2

Gesaeual

Safety

This pressure washer generates very high fluid

pressure. Spray from the gun. leaks

or

ruptured

components can inject fluid through your skin and

into your body and cause extremely serious bodily

injury, including the need for amputation. Also, fluid

injected or splashed into the eyes or on the skin can

cause serious damage. In addition, some cleaning

solutions may be toxic and can cause chemical burns,

skin irritations, and allergic reactions if inhaled or

if

they come in contact with the body or eyes. Always

follow these precautions when operating your

pressure washing system to reduce the risk

of

serious bodily injury.

NEVERpointthespraygunatanyoneoratanypartof

the body. NEVER use the spray gun without the

wand. NEVER put hand or fingers over the spray tip.

NEVER try to stop or deflect leaks with your hand

or

body.

ALWAYS be sure equipment safety devices are

operating properly before each use.

Use this pump only for pumping water and waterdiluted cleaning solutions. NEVER use the pump for

paint or any other coatings.

ALWAYS wear protective eyewear and appropriate

clothing to protect yourself from the overspray and

as

the debris that is removed

you clean.

Read and follow the cleaning chemical

manufacturer's recommendations on preparation

use

and

of the cleaning solution,

and

the use of

breathing apparatus and proper ventilation.

Pressure

Relief

Procedure

To reduce the risk of serious bodily injury, including

fluid injection and splashing in the eyes, or on the

skin,

shut

always

off

follow this

the

pump, when

procedure whenever

checking or servicing

you

any

part of the system, when installing or changing spray

tips, and whenever you stop spraying for more than

IO

minutes.

1.

Engage the gun trigger safety latch.

2.

Turn pressure washer OFF.

3.

Remove the power cord from outlet.

4.

Shut

off

the water supply.

5.

Disengage the trigger safety latch and trigger the

gun to relieve pressure, and engage the latch

again.

Spray

Do

cause

Gun

Safety

not remove or modify any part of the gun; this can

a

malfunction and result

in

serious bodily

injury.

Safety Latch

ALWAYS engage the gun safety latch whenever you

stopcleaning,evenforamoment.ThelatchMUSTBE

pushed fully down

Failure to properly set the safety latch can result

accidental triggering of the gun. See Figure

Spray

Tip

Safety

to

make

the

gun inoperative.

2,

page

in

6.

Use extreme caution when cleaning or changing

spray tips. If the spray tip clogs while spraying,

engage the gun safety latch immediately. ALWAYS

follow the Pressure Relief Procedure and then

remove the spray tip to clean

it.

MEDICAL

TREATMENT

If any fluid appears to penetrate your skin, get

EMERGENCY

MOT

TREAT

MEDICAL

~ ~ ~ ~~

AS

A

.§IMFW

CARE

AT

~~

CUT.

Tell the doctor

ONCE.

DO

"

exactly what fluid was injected.

Note

To

Physician: Injection

traumatic injury.

It

injury surgically as

is important to treat the

soon

in

the skin is a

as possible.

Do

not

delay treatment to research toxicity. Toxicity is a

concern with some exotic coatings injected

into

directly

the bloodstream. Consultation with

a plastic surgeon or reconstructive hand

surgeon may~be advisable.

2

802-777

.. .

..

.:.

.

..

.,

.':.~,

...

~ .

..

..

.

,

,.

.

.

.

..

.

.

Page 3

,.

~~~~~~~~~~n~~$~

HAZARD

eapleoai

Any misuse of the pressure washer or accessories,

such as overpressurizing, modifying parts, using

incompatible chemicals and fluids, or using worn or

damaged parts, can cause them to rupture and result

in fluid injection, splashing in the eyesor ontheskin,

or other serious bodily injury or property damage.

NEVER alter or modify any part of this equipment,

doing

CHECK all cleaning equipment regularlyand repairor

replace worn or damaged parts immediately.

Safeuy

so

could cause

it

to malfunction.

NEVER use

entire hose for cuts, leaks, abrasion,

damage or movement of the hose couplings.

these conditions exist, replace the hose immediately.

DO

NOT try to recouple high pressure hose or mend

with tape or any other device. A repaired hosecannot

contain the high pressure fluid.

HANDLE AND ROUTE HOSES CAREFULLY.

on

pull

use chemicals which are not com.patible with the

inner tube and cover of the hose.

Graco hose to temperatures above 200OF (94OC) or

below

a

damaged hose. Before

hoses to move the pressure washer.

-4OOF

(-4OoCJ.

each use, check

bulging cover, or

DO

NOT expose

If

any of

Do

Do

it

not

not

a

If using

chemical manufacturer's literatureregarding the use

of protective eyewear, clothing and equipment.

$yStWDl

This sprayer can develop

MAXIMUM

spray equipment and accessories are rated to

withstand the maximum working pressure of this

sprayer. DO NOT exceed the maximum working

pressure of any component or accessory used in the

system.

Chemical

BE

SURE that

injector are compatible with the wetted parts of the

hose, gun, wand and

Data

manufacturer's literature before using any chemical

in this pressure washer.

High pressure fluid in the hoses can be very

dangerous. If the hose develops

rupture due to any

the high pressure spray emitted from it can cause a

fluid injection injury or other serious bodily injury or

property damage.

TIGHTEN

use.Highpressurefluidcandislodgealoosecoupling

or allow high pressure spray to be emitted from the

coupling.

chemical injector, read and follow the

Pl'eSSM6e

WORKING

1800

PRESSURE.

psi

(123

Be sure that

Compatibility

all

chemicals used in the chemical

tip,

as

given

in

the Technical

on

the back cover. Always read the chemical

a

leak,.split or

kind

of wear, damage or misuse,

all

fluid connections securely before each

bar)

all

~~~~~~~~A~

NEVER operate the pressure washerwithouttheunit

being properly grounded. This includes internal

on

wiring

building wiring. Because water

conductor, it

ground circuit to avoid serious bodily injury if

equipment should fail.

Moving parts can pinch or amputate your fingers or

other body parts. KEEP CLEAR of moving parts when

starting or operating the pressure washer. Followthe

Pressure Relief Procedure, page

or servicing the pressure washer to prevent

discharging high pressure fluid from the gun.

unit, plug (ground plug

is

~~~A~5

must

be intact), and

is

a

natural

very important to provide a good

2,

before checking

IMPORPAMB

United States Government safety standards have

been adopted under the, Occupational Safety and

Health Act. These standards-particularly the

Part

191

0,

General Standards,

Standards, Part 1926-should be consulted.

TERMS

WVAi~bJukG:

conditions that could cause bodily injury.

CAUTION:

conditions that could cause damage to or destruction

of equipment.

Alerts user to avoid or correct

Alerts user to avoid or correct

and the Construction

NOTE:

information.

Identifies helpful procedures and

802-777

3

>..

s.

..

Page 4

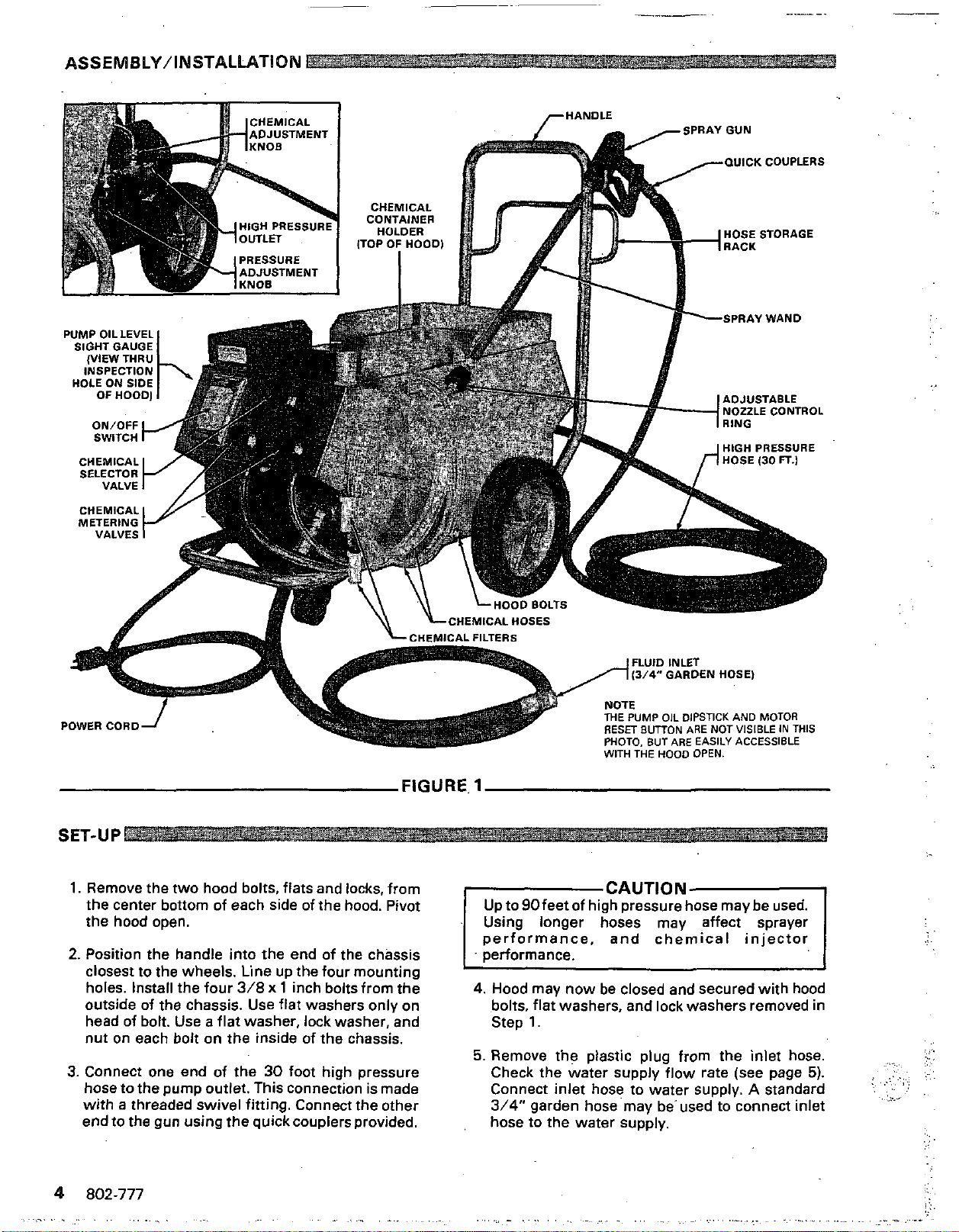

,.

1.

Remove the two hood bolts, flats and locks, from

the center bottom of each side of the hood. Pivot

the hood open.

2.

Position the handle into the end of the chassis

closest to the wheels. Line up the four mounting

holes. Install the four

318

x 1 inch bolts from the

outside of the chassis. Use flat washers only

head of bolt. Use a flat washer, lock washer, and

on

nut

3.

Connect one end of the

each bolt on

the

inside

of

the chassis.

30

foot high pressure

hose to the pump outlet. This connection is made

a

with

threaded swivel fitting. Connect the other

end to the gun using the quickcouplers provided,

4

002-777

. . ..

..

. ..

.

,

on

performance, and chemical injector

performance.

4.

Hood may

now

be closed and secured with hood

bolts, flat washers, and lock washers removed in

1.

Steu

5.

Remove the plastic plug from the inlet hose.

Check the water supply flow rate (see page

Connect inlet hose to water supply. A standard

3/4"

garden hose may be-used to connect inlet

hose to the water supply.

5).

..

~. .

,.

.

....

..

..'

. ..

..

..

.

i..

.>

,

.

:

,.:

.

Page 5

Water

Supply

CAUTION

Before connecting the water supply to the

pump, check your local plumbing code

regarding cross-connection to thewater supply.

A backflow preventor. Part No. 801-133, is

available to prevent the back flow of

contaminated water intothefreshwatersupply.

Install upstream from the pump.

DO

NOT exceed 160°F (7OOC) inlet water

temperature.

Higher’ temperatures

packings.

will

damage the pump

START-UP

A.

Check flow rate of the water supply.

be

at

least 4 gpm or the pressure washer

not develop full pressure.

6.

To check flow rate, time how long

fill a standard five gallon pail;

1

60

Hz

No.

minute and

AC,

20

it

must have a ground

12

gage wire. Extension

100

feet long.

no longer than

Electrical

7.

Connect electrical cord to the proper power

supply. The electrical service required is single

phase,

service must include a ground wire. If an

extension cord is used,

wire and be at least

cord must not be over

Supply

230V.

it

it

should take

15

seconds.

Amp. Electrical

It

must

will

takes to

Use this procedure each time you start the pressure

washer to help ensure the pressure washer

to operate and that you start

1.

Check pump oil level. Look at oil level indicator

window through inspection hole

hood.’ Pump also has a dipstick located under

hood on top of pump. Oil level should be up to dot

on oil level indicator window and

notch on dipstick. Add SAE

detergent oil as necessary. (SAE 30-weight nondetergent oil is preferred.)

2.

Connect pressure washer to water supply and to

proper electrical service as described

3.

Turn water supply

water sprays from the tip and all air is purged

from the system.

4.

Turn switch on control panel

5.

Always engage the gun’s trigger safety latch

whenever you stop spraying. even for a moment,

to reduce the risk of fluid injection or splashing

the eyes or on the

triggered accidentally.

6.

Most pressure washer spraying is done at full

pressure. If a reduced pressure

special application, there are two methods to

reduce the maximum output from the pressure

washer.

a. Turn the pressure control knob on the

unloader counterclockwise, as needed. This

method is best if you are operating

consistently at a reduced pressure.

on

skin

it

safely.

20

or 30-weight non-

and trigger the gun

to

“ON”

if the

gun

is

is

ready

in

side of the

within

in

the

set-up.

until

in

is bumped or

desired for a

b. Turn chemical selector valve to the

position, then open the adjustable nozzle on

the end of the spray wand, as needed. This

method is best to quickly reduce pressure for

a

special application.

DO

NOT attempt to adjust the adjustable nozzle

the

when

safety latch on the gun is in the

before adjusting to avoid seriousbodilyinjuryor

7.

Always observe the following cautions to help

avoid costly damage to your pressure washer.

,spray gun is

in

use. Be sure that the

“ON”

“OFF”

position

CAUTION

DO

NOT allow the pressure washer to idle for

10

more than

with

a thermal relief valve to help avoid the

recirculating water from becoming too hot and

seriously damaging the pump, but

idea to turn the pressure washer

not spraying or cleaning at least every

minutes.

DO

NOT

damage the pump. Be sure the water supply is

fully turned on before starting the pump.

DO

NOT operate the pressure washer

inlet screen removed. This screen helps keep

abrasive sediment out of the pump, which could

clog or scratch the pump.

DO

NOTpumpcaustic materials; such materials

may corrode and damage the pump components.

minutes. The

run the pump dry, which

unit

is equipped

it

off

will

is a good

if you are

10

quickly

with

the

Page 6

Chemical

8.

Be

open

Injector

sure

that the control ring

two

full turns from the closed position. To

Operation

on

the injector is

check this, the hood must be opened. Once the

it

control ring is open,

chemical mixture

may be left alone. The

is

controlled by the chemical

metering valves on the control panel.

9.

Place the chemical strainer@) and chemical

line(s) into your chemical container(s).

10.

Select which chemical you want to use

chemical selector valve

11.

To

apply the cleaning chemical to the work

the

surface,

adjustable

on

the control panel.

nozzle

on the end of

with

spray wand must be open. The chemical(s) can

only

be drawn into the water stream, and applied

in

to the work surface

a low pressure situation.

By opening the adjustable nozzle you create low

pressure. Closing it produces high pressure for

rinsing and pre-chemical flushing or nochemical

cleaning. One chemical may

turned

off

be

at the gun by using the adjustable nozzle as

described above.

WARNING

when the spray gun is

safety latch on the gun is

before adjusting to avoid serious bodily injuryor

in

use.

in

the

Be

sure that the

"ON"

position

and

the

the

on

12.

Adjust the chemical mixture(s)

with

the chemical

metering valve(s) on the control panel. Once the

chemical metering valve(s) are adjusted to the

desired setting, they may be left there for future

chemical applications.

13.

To change to the other chemical, turn the

chemical selector valve to the other chemical.

shut off chemical, turn the chemical selector

valve to the

"OFF"

position, or close the

adjustable nozzle. The chemical metering

valve(s) do

off

chemical supply.

have to be closed to change

or

not

CAUTION

the wetted parts shown

the end of this manual to avoid serious damage

Trigger

-

Safety

Latch

WARNING

To

reduce the risk of serious bodily injury,

including fluid injection, splashing

or on the skin, ALWAYS engage the trigger

safety latch whenever you stop spraying, even

for a moment.

In

the engage position, the trigger safety latch

prevents the gun from being triggered

accidentally by hand or if

bumped. Be sure the latch isfullyseated inslot

in

handle or

triggered.

being

it

cannot prevent the

See Figure

in

the technical data at

in

the eyes

it

is dropped

gun

2.

from

To

shut

or

...

..,~.

-. , .. . ~. . . .

6

802-777

,.

.

FIGURE

. .

..

-. .

.~

2

.

.

... . ~

,,

. ..

..~,

. . .

...

.

.. . . , ...

Page 7

~~~~U~~

Pwssure Relief Procedure

To reduce the risk of serious bodily injury,

including fluid injection and splashing in the

eyes, or on the skin, ALWAYS follow

procedure whenever you shut

when checking or servicing any

system, when installing or changing spray tips,

and whenever you stop spraying for more than

10

minutes.

1. Engage the gumtrigger safety latch.

2.

Turn the pressure washer

3.

Remove the power cord from the outlet,

4.

Shut

off

water supply.

5.

Disengage the trigger safety latch and trigger

the gun to relieve pressure, and engage latch

again.

1. After using the chemical injector system,

should be flushed out with water or

antifreeze solution if unit will be exposed to

freezing temperatures. This is best done by

replacing the chemical container@)

a

of water or

pressure washer as described

water or antifreeze solution into both chemical

lines until it passes through the injector.

flushing the chemical injector system,

help avoid unnecessary wear and prolong the life

of components.

50% antifreeze solution. Operate

off

the pump,

part of the

off.

with

in

start-up. Draw

this

a

50%

a

bucket

you

By

will

2.

If

the pressure washerwill beexposedtofreezing

temperatures, drain

you must store the pressure washer in freezing

temperatures, flush

solution. This can be done by placing the end of

the inlet hose into

solution. Start the pressure washer. Trigger the

10

gun for

seconds. Trigger and release about

seconds, release the trigger for

all

water out of the pump. If

it

with a

a

bucket of

50%

50%

antifreeze

antifreeze

10

times

10

or

untilthe5046antifreezesolutioncomesoutofthe

spray tip.

CAUTION

thaw it in a warm room before trying to start it.

Do not pour hot water

3.

it

After each use, wipe all surfaces

washer with a clean, damp cloth.

4.

Perform the appropriate maintenance. See the

chart ompage 7.

on

the pump;

it

may crack

of

the pressure

MAINTENANCE

Observing regular maintenance intervals helps

ensure that you get maximum performance and life

from your pressure washer.

is

There

changing the oil after the pump's break-in period, the

interval between required changes

If you are operating in dusty conditions, these

maintenance checks should be made more often.

a break-in period for the pump. After

is

longer,

INTERVAL

Daily

After first

50

hours of

operation.

Each 500 hours

of operation or

3

months.

OIL

Pump

*SAE 30-weight non-detergent oil is preferred.

15.2

1.45 liters) Non-Detergent*

WHAT

TO

DO

Clean water inlet screen.

Check pump oil level.

Fill as necessary.

Change pump break-in

Use SAE 20W or

non-detergent oil*.

Change pump oil.

Use SAE 20W or

non-detergent oil*.

CAPACITY TYPE

Oz.

SAE 20W or

30W

30W

oil.

30W

..

802-777

..

7

Page 8

TROUBLESHOOTING CHART.

To

reduce

the

risk of serious bodily injury, including fluid injection, splashing in the eyes or on the skin, or

~A~~~~~

injury from moving parts, always follow the Pressure Relief Procedure Warning on page

PROBLEM

Low Pressure

CAUSE

Worn noale.

Coupling slippage.

in

Air leak

inlet plumbing.

SOLUTION

Replace with noale of proper size.

Tighten or replace.

Disassemble, reseal, replace bad parts,

and reassemble.

Inlet filter clogged.

Clean. Use adequate size. Check more

frequently.

Worn packing. Abrasives

in

pumped fluid or severe cavita-

Install proper filter. Check flow available to

pump. Replace packings.

tion. Inadequate water supply.

Fouled or dirty inlet or dis-

Clean inlet and discharge valve assemblies.

charge valves.

Worn inlet or discharge valves.

Leaky discharge hose.

Pressure adjustment set down.

Replace worn valves, valve seats and/or

discharge hose.

Turn adjustment knob

pressure.

Pump runs exiremely

rough, pressure low.

Restricted inlet or air

entering the inlet plumbing.

Inlet restrictions and/or air

eaks. Stuck inlet or discharge

Proper size inlet plumbing; check for air

tight seal.

Clean out foreign material, replace worn

valves.

ilalve.

Replace seals.

Check flow available to oumo.

Replace packings

Water leakage from under

Leaking high pressure seals.

nadeouate water'suoolv.

aorn packings.

the manifold.

Water

in

pump crankcase.

Norn packings.

3il seal leaking.

May be caused by humid air

Replace packings.

Replace oil seals.

Change oil at

3

month or

:ondensing into water inside

he crankcase.

Frequent or premature

failure

of

the packing.

scored, damaged, or worn

hngers.

Urasive material in the water

Xeplace plungers.

nstall proper inlet filter.

)eing pumped.

nlet water temperature too

ligh.

Iver pressurizing pump.

:heck inlet water temperature; be

1

iure not to exceed

Jo

not modify any factory-set

6OoF.

tdjustments.

Strong surging at the inlet

and low pressure on the

discharge side.

Unit will not start.

Chemical injection system

doesn't work.

ixcessive pressure due to

lartially plugged or damaged

'ump running too long

vithout spraying or cleaning.

iunning pump dry.

breign particles in the inlet or

,ischarge valve, or worn inlet

nd/or discharge valves.

hit

not plugged in.

'lectric motor overheated

lectric service

off.

:hemica1 injector clogged.

>djustable noale completely

Iosed.

3w chemical level.

:lean or replace tip.

tip

Uever run pump more than

ninutes without spraying or cleaning.

10

not run pump without water.

leplace or clean valves.

:heck power cord.

.et motor cool and push reset bunon

In

motor.

:heck fuse/circuit breaker panel.

)isassemble chemical valve and clean.

:heck and clean chemical hose and filter.

'urn control ring on noale clockwise

1

cause drop

in

pressure:

:heck level of chemical.

7

before proceeding.

in

to increase

500

hour intervals.

10

8

802-777

....

~~

~

,.

~

..,....

,,

.,,

.,

...

-. . . .. . .

..

~~~

..

.

Page 9

PUMP

SERVICE

..

To

~A~~O~~

reduce the risk of serious bodily injury, including fluid injection, splashing in the eyes or on the skin, or

injury from moving parts, always follow the Pressure Relief Procedure Warning on page 7 before

proceeding.

NOTE:

Valves

1. Remove the hex plug (205) from the manifold

2.

3.

4.

Pumping Section

The following metric wrenches are needed: M6 Allen wrench, M10, and M30.

A pump repair tool kit, P/N 800-271,

Repair kits are available. Refer to the individual repairsections, and the parts pagefor more details. For

all

the best results, use

NOTE:

(206) using an M30 wrench..

Examine the O-ring (204) under the plug and

replace

Remove the valve assembly(203)from thecavity;

the assembly may come apart.

Install a new valve (203). Install the O-ring (204)

and plug (205) and torque'to 75 ft-lb (10.3 Nm).

NOTE:

To replace valves, order kit part no. 801

472.

it

if it is cut or distorted.

Retorque the plug after 5 hours of

operation.

the parts in the kit.

is

available. It includes packing, extraction and insertion tools

-

2.

Carefullypull the packing retainer(214)from the

manifold. Examine the O-ring (21 5) and replace it

is

cut or damaged.

if it

3. Remove the v-packing (212)and head ring (21 1).

Pull

out the intermediate retainer ring (213).

Remove the v-packing (21 2) and head ring (21 1).

4.

Inspect

5.Thoroughly clean the packing cavities and

examine.

6. Lightly grease. the packing cavities and then

replace the packings in the following order: head

ring (211). v-packing (212). intermediate ring

all

parts and replace as necessary.

(213),headring(211),packing(212),andpacking

retainer(214). with the O-ring (215) installed into

the retainer groove.

..

,

.

.

:

. ..

,.,

;:

:

,_

..

1. Remove the eight Allen head cap screws (201)

and lockwasher (202) from the manifold (206)

using

a

M6 Allen wrench.

2. Carefully separate the manifold from the

crankcase. It may be necessry to tapthe manifold

a

lightly with

rubber mallet.

CAUTION

To

avoid damaging

the manifold properly aligned with the ceramic

plungers when removing

3.

Carefully examine each plunger (221) and

replace

Servicing

NOTE: To replace just the v-packings, use kit

1. If the manifold is not already removed, follow

Steps 1 and 2

it

if there is any scoring.

The

part

entire pump.

-To replace the v-packings, rings and

retainers, orderthree ofkit part no. 801

664 to service the entire pump.

the

plungers or seals, keep

V-Packings

no.

801 -662 which

of

pumping section.

it.

will

service the

-

-

order and facing the correct direction. See

4.

Figure

malfunction.

7.

Reassemble the manifold as instructed in Steps 7

and

Servicing

NOTE:

1.

Loosen the plunger retaining screws (21 7). 5 to 6

turns, using an M10 wrench. Push the plunger

(221) toward the crankcase to separate the

plunger and retaining screw.

2. Remove the screw (217) from the plunger and

examine the

copper bearing/gasket washer (218). Replace

these parts, if necessary, using kit part no.

474.

3.

Remove the plunger (221) and flinger (222)from

the plunger shaft. Clean, examine and replace

parts as necessary.

Improperly installed parts will cause

8

of Servicing The Plungers.

The

Plungers

Plunger repair kit, part no. 801-474,

available to service all the plungers.

O-ring

(21

9).

backup ring (220) and

a

801

is

-

802-777

9

Page 10

4.

Inspect the plunger shaft for oil leakage from the

crankcase. If leaking is obvious, replace the oil

.seals (216). Otherwise,

seals as they cannot

NOTE:

Oil Seal .Kit, part

be

DO

NOT remove these

reused.

no.

801-658, is

available to replace all three seals.

5.

Lightly grease the oil seal (if

and the flinger, and replace them

it

is being replaced)

on

the plunger

shaft. Then install the plunger.

6. Lightly grease the retaining screw (217) and the

outer end of the plunger. Place the washer(218).

(220)

O-ring (214) and backup ring

around the

screw and install the screw through the plunger.

(2

Torque to 14.4 ft-lb

Nrn).

8. Install the eight Allen head cap screws(20l)and

washers (202)finger tight. Torque the screws to

15.9 ft-lb (2.2 Nm) following the tightening

in

Figure

3.

pattern

Uneven tightening maycause

the manifold to bind or jam.

NOTE:

If you plan to replace the packings, go to

Servicing the V-Packings.

7. Lubricate the outside of each plunger. Slide the

manifold onto the crankcase, being careful notto

damage the seals.

FIGURE

3

..

,.....

”.

. .

..

. .. ~.

.....

~

.,

FIGURE

10’

802-777

_i

. , ..

~.

.~

....

..

.~ .

.... . .

-

.......

4

~

. . ~

.

..

Page 11

PARTS

DRAWING

Hydra-Clean

1235,

P/M

800-233

.... . ..

(Continued)

..

802-777

.

.

11

Page 12

PARTS DRAWING

Hydra-Clean 1235

WIRING DIAGRAM PARTS LIST

Hydra-Clean

REF.

NO.

1 802-760 COVER, Switch

2 801-892 CORD W/PLUG, 12/3

4

5

6 802-980

7

8

9

10

11 802-664

12 801 -883 TIP

13 802-751

14 800-1 18

15 801-957

16 801-129

17 801-386

18 601-935

19 802-699

20 801-103

.~. . .

~~

.. . .

..

....

~.,

,

..

-

1235,

P/N 800-233

PART

NO.

DESCRIPTION

x

8'

801-223 SWITCH 1

801-894 SCREW, Ground

801-931 GRIP.

802-153

802-685

CORD

PLATE.

Cord

,

~~~~

(12/3)

Ins.

lPB1D

,.

-

.

-,

plug)

' '

BOX.

Switch

(with

801-417 LABEL, Relieve Pressure

HOOD

(1

5065)

PANEL. End

NOZZG, Adjustable

SLEEVE. Safetv

LABEL Warniig

LABEL, Warning, Ground

WAND

. .

. . .

.

-

GUN

NIPPLE, 3/8

x

1

/4

(Continued)

.

..

. . .

.

..

. .. ..

...

. . . . .

.

..

.

.

.

. . .

..

..

.

ON.

1

1

1

1

2

-

36"

1

1

1

1

1

1

1

1

1

1

1

1

.

.

.

.,.

.

Page 13

.~

REF.

.,

':

REF. PART

NO. NO.

21

801-009

22 801-090

23 801-967

24 801-605

25 801-875

27 801-546

28 801-015

29 801-363

30

801:214

31 801-813

33 801-025

34 801-023

35 802-729

36 801-878

37 801-818

38

801.879

39 801-235

40 801-880

41 801-857

42 802-648

43 801-024

44

801-940

45 802-703

46 800-247

47 802-730

48 801:910

49 801-112

50 802-735

51 801-683

52 801-501

53 800-246

54 802-669

55

802-683

56

801-937

57 802-636

58 802-843

59 802-733

60.

802-731

61 802-732

62 801-547

63 802.292

DESCRIPTION

QUICK COUPLER. Female

(Includes

801-202

0-Ring)

QUICK COUPLER, Male

30

HOSE,

SCREW,

LOCK,

BOLT,

FLAT,

LOCK,

BOLT,

TUBING,

LOCK,

FLAT,

10-24 x 3/4

#lo

3/8-16

5/16

3/8

3/8-16

1/4

5/16

1

/4

x

x

I.D.

1-1

1

-3/4

/4,

HANDLE

30-1

NUT,

BOLT.

6

3/8-18

x

1

WHEEL

518

FLAT,

COTTER PIN

AXLE

PIVOT

NUT,

5/16-18

BOLT,

5/16-18 x 3/4,

CASTER

BRACKET. Caster

BUMPER

PLUG, Plastic

FILTEWWASHER

HOSE, Inlet

STRAINER, Chemical

LABEL Serial No.

CHASSIS

HOSE BARB,

1

/8

x

1

/4

VALVE, Metering

LOCKNUT,

1/2

Electrical

PANEL, End, Control

LABEL Knob

SCREW,

LOCK.

FLAT,

FLAT,

FLAT,

6-32 x 1/2

#6

#6

3/4

#10

"G5'

"G5"

QN.

1

1

1

10

10

2

16

14

2

16'

4

4

1

4

10

2

4

2

1

2

4

4

1

1

1

1

1

1

2

1

1

4

2

1

1

2

4

4

4

1

A

PART

NO.

No.

64 802-684

65

801-733

66

802-686

67 801-221

68

801-305

69 802-052

70 800.248

71 802-625

72 802-783

73 802-698

74 801-887

75 802-633

76 802-785

77 802-786

78 802-784

79 801-139

80

802-629

81 800-115

82 801-622

83 801.178

84 801-523

85

802-086

86 801-891

87 801-890

88

802-842

89 800-138

90 801-900

91 802-752

92 801-881

93 801-620

94 801-866

95 801-524

96 801-905

97 801-907

98 801-709

DESCRIPTION

VALVE,

HOSE BARB,

3-Way

1/4 x 114

LABEL Control Panel

CONNECTOR, Crimp

WIRE NUT.

Yellow

WIRE NUT; Red

PUMP/MOTOR ASSEMBLY

item

71-80)

"C

72)

(Includes items

MOTOR. 3HP. TEFC.

(Includes

KEY

COUPLING (Includes item

SWDER

HOUSING (Includes items

BOLT,

1/2-13

BOLT, M6

LOCKWASHER.

LOCKWASHER.

x

1-1/4"

x

16

mm

SHCS

1/2

1/4

PUMP

1/2

1/2

"

x

318

3/8

Temo.

2"

'

1

/2 x 90°

3/8 x 45'

NPT(M)

NPT(M)

VALVE. Relief.

CROSS,

ELBOW, Street,

NIPPLE,

ELBOW. Street.

COUPLING,

3/8

NPSIM)

COUPLING,

3/8

NPSIFI

UNLOADER, Replacement

(Includes item

98)

INJECTOR, Chemical

GROMMET

~ . ~~~~

SUPPORT, Unloader

3/8

NPTlFI

COUPLING.

1

/4

NPSIF)

ELBOW, Street,

HOSE,

By-Pass

(Includes

802-627

..

1

/4 x 90"

Adapter)

x

LABEL Pump

3/8

ADAPTOR.

NPT

WASHER, Aluminum

1/4

PLUG,

NPT

Face

74)

76-79)

SHCS

x

x

QN.

1

3

1

3

4

1

1

1

1

1

1

1

4

4

4

1

1

1

1

1

2

1

'1

1

1

1

1

1

1

1

1

1

1

1

HOW

1.

To

TO

ORDER

be

sure

REPLACEMENT'PARTS

you receive the correct replacement

parts, kit or accessories, always give all

information requested

2.

Check the

number;

3.

Order

parts

do not

all

use the

parts from your nearest Graco

list

in

the chart below.

to

identify

ref

no.

the

when

distributor.

of

the

correct part

ordering.

6

digit

PART

NUMBER

OTY

PART

DESCRIPTION

802-777

-

13

Page 14

PARTS

Pump,

DRAWING

802-629

205

I

2044

203

20;

PARTS LIST

Pump,

t

t

$204

$205

,206

207

208

209

210

*211

t*212

*213

*214

*215

+**

21

**217

-218

*f

219

**

220

221

222

223

See page

REF.

NO.

201

202

203

6

802-629

PART

NO.

801-651

801-652

801 -470

802-319

801-485

801

801 -482

801 -483

801

801-660

801-659

13

484

-661

for

WASHER

318

1

SEAL

. . .

.

-

Order

NPT

/2

NPT

Replacement Parts"

CAP,

CAP,

WASHER

".

HEAD RING

PACKING

INTERMEDIATE RING

PACKING RETAINER

O-RING

OIL

PLUNGER RETAINING SCREW

WASHER

O-RING

-

.

BACK-UP RING

PLUNGER

FLINGER

OIL DIPSTICK

"How

To

6

6

3

3

-

3

3

3

3

7

-

3

3

3

1

REPAIR

OIL

801

Includes:

REF.

NO.

216

VALVE KIT

801

Includes:

KITS

.*x

SEAL KIT

-658

QTY.

3

tt

-472

*

PACKING & RETAIN.

ER KIT 801

I

(Three kits needed for

entire

pump)

Includes:

REF.

NO.

21 1

-664

QTY.

2

+

Includes:

REF.

NO.

21

2

VALVE CAP KIT

802-306

Includes:

REF.

NO.

204

205

PLUNGER REPAIR

KIT 801

Includes:

REF.

NO.

21

7

218

219

220

an.

6

$

QTY

6

6

*I

-474

QTY.

3

3

3

3

,,

..

.,

.,

.

.;..

.,:

14

..~~

~~.~

802-777

,

.

,

..

.

.

. . .. , . . . .~

. . . .

..

..

.

..~ ........ . ..

..

~,

. .

..

.

...

.

Page 15

PARTS DRAWING

PTFE

PTFE

PTFE

PTFE

PTFE

PTFE

PTFE

PTFE

PTFE

PTFE

PTFE

Chemical Injector,

1

I1

I

I

k12

I

800-138

11

PARTS LIST

Chemical Injector,

REF.

PART

NO.

NO.

1 801-684 NIPPLE, Hex,

2 801-685 O-RING

3 801-687 NOZZLE NO. 2. (16-21

4 801-688 O-RING

5 801-689 CHEMJET BODY

6 801-690 SPRING, cone

7 801-784 BALL

8

801-692

9 801-693

10 801-694 VALVESEAT

11 801-695 SPRING

12 801-696 O-RING

'13 801-697 NEEDLE/HOSE

14 801-698 ADJUSTMENT KNOB

15 '801-682 SPRING,

800-138

DESCRIPTION

brass,

O-iNG

O-RING

.~~

retaining

MRB

~.

3/8 NPT

I/min)

QTY.

1

1

1

1

1

1

1

I

I

I

i

TECHNICAL DATA

*If an extremely harsh chemical is to be injected,orif

corrosion problems exist, the standard brass

needle/hose barb (ref.

a

stainless steel needle/hose barb, pan

no.

13)

may be replaced with

969.

See page

MOTOR 3 hp. single phase 230

WATER PUMP: 1200 psi (83 bar) measured at pump

WmED PARTS: High Pressure Hose: Acrylonitrilie and Buna-N cover and tube

3.5'GPM 113.3 liter/min)

Bypass

Hose: Synthetic yarn, EPDM

Pressure

Aluminum, Aluminum

Nylon- composite. Ceramic. Buna-N.

Cotton Phenolic. 316, 303, & 304 Stainless

Steel, Polymide-12 Thermo-plastic.

Carbon Steel. zinc

Washer

13

far "Haw Ta Order Replacement Parts"

V.

60

Hz, 20 Amp, TEFC

(including fitting): Anodized

or

Bronze alloys. Brass, Copper,

or

yellow chromate plate

no.

801

-

UNIT WEIGHT 150 Ib.

OVERALL DIMENSION Length: 38 in. (965 mm)

MAX. INLET WATER TEMPERATURE: 1 60°F

INLET HOSE CONNECTION 3/4" garden hose

PUMP OIL CAPACITY 15.2

'

is

a registered trademark of the DuPont Company

168

kg)

Width: 19 in. 1482

Height: 33 in. 1838 mm)

(700

02.

(.45

mm)

c)

(f)

liters)

802-777

15

Page 16

THE

GRACO

WARRANTY

Gram warrants

material and workmanship

purchaser

twelve months

warranty applies only when the equipment is installed. operated and maintained in accordance

Graco's written recommendations.

This~rrantydoesnOtcover,andGracoshalln~tbeliablefo~,a~~malf~nction,damagearwearcau~~

by faulty installation. misapplication. abrasion, corrosion. inadequate

negligence. accident. tampering. or Substitution of non-Graco component pans..Nor shall

liable for malfunction. damage

structures. aCCeSSOri85. equipment or materials not supplied

manufacture. installation. operation or maintenance of structures, accessories. equipment or materials

not supplied

This Warranty is conditioned upon the prepaid return

examination by Graco to verify the claimed defect

replace free

transportation prepaid. If inspaction

workmanship. repairs

pans. labor and transportation.

DlSCLPIlMERS AND LIMITATIONS

THE

TERMS~OFTHlSW~RRANfiCOkTITUTE

ARE IN LIEU OF ANY OTHER WARRMIES (EXPRESS OR IMPLIED). INCLUDING WARRANTY'OF

MERCHANTABILITY

CONTRACTUALUABILITIES, INCLUDING PRODUCTLIABILITIES. BASEDON NEGUGENCEORSTRICT

LIABILITY. EVERY FORM OF LIABILITY FOR DIRECT, SPECIAL

LOSS

IS

AMOUNT OFTHE PURCHASE PRICE. ANY ACTION FOR BREACH OFWARRANTYMUSTBE BROUGHT

WITHIN

EQUIPMENT NOT

GFIACO

ITY

MATERIALS.

not manufactured bv Gram (such as electric motor. switches. hose, etc.1. are subject to the warranty, if

any.

claim

EXPRESSLY EXCLUDED AND DENIED. IN NO CASE SHALL GRACO'S UABlLllY EXCEED THE

TWO

MAKES

AND FITNESS FOR A PARTICULAR PURPOSE, WiTH RESPECTTO ACCESSORIES, EOUIPMENT.

of

their manufacturer. Graco will provide purchaser with reasonable assistance

for

all

equipment manufactured by it and bearing

on

for

use.

As

purchaser's

from

the date of sale. repair

by Graco.

of

chaw

any

Will

OR

(2)

YEARS OF THE DATE OF SALE.

COVERED

NO

WARRAN~.AN~D~~~~~MSA~~~M~LIED

OR

COMPONENTS SOLD BUT NOT MANUFACTURED BY GRACO. These items sold, but

breach of these warranties.

the date of sale by an authorized Graco distributor to the original

sole

remedy for breach

or

wear caused by the incompatibilify

defective

be made at a reasonable charge, which charges may include the costs

WARRANTY OF FiTNESS FOR A PARTICULAR PURPDSE.AND OF ANY NON-

pans.

of

the equipment does not disclose any defect

BY

GRACO WARRANTY

WARRANTY

is

name to be free from defects

of

or

replace any pan

If

the claimed defect is verified, Graco

The equipment will

PURCHASER'S SOLE AND EXCLUSIVE REMEDY AND

this warranty, Graco

of

the equipment proven defective. This

or

by

Graco. or -the improper design.

of

the equipment claimed to

be

returned to the original purchaser

OR

CONSEOUENllAL DAMAGES

WARRAMIES

will,

for a period

improper maintenance,

with

Graco equipment of

be

defenive for

will

in

material or

OF

MERCHANTABIL-

in

making any

with

G~~~~

repair or

OR

in

of

be

of

Subsidiary and Affiliate Companies:

Factory

GRACO

INC.

Branches:

P.Q.

Atlanta. Dallas. Detroit.

BOX

PRINTED IN U.S.A. 802-776 10/87

10s

Canada: England: Switzerland: Francs: Germany:

1441

MINNEAPOLIS,

Angeles. West Caldwell IN.J.1

MN

55440-1444

Hong

KO~~:

J~~~~

Loading...

Loading...