Page 1

.I

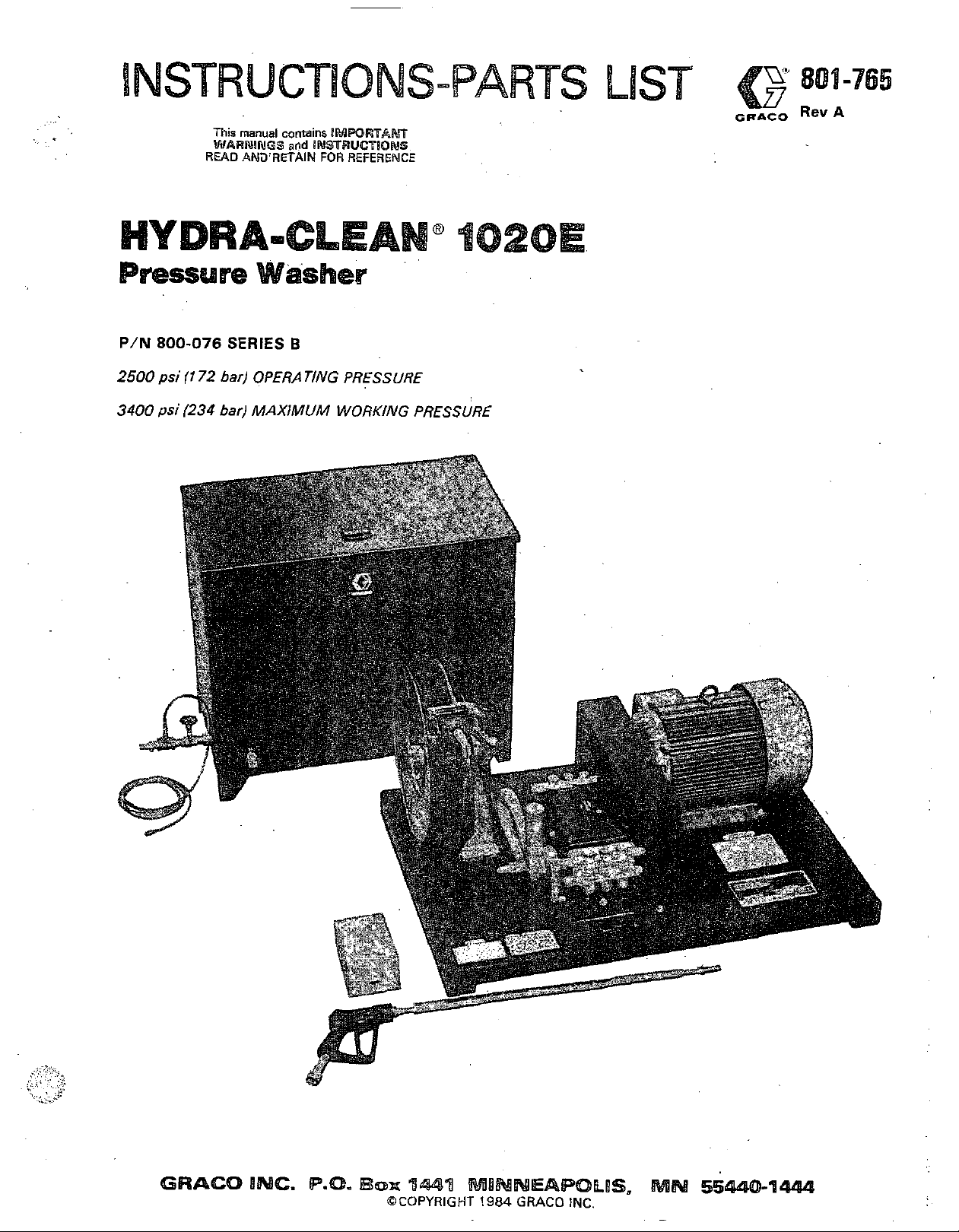

P/N

800-076

2500

psi

3400

psi

This

manual

WARMLNES

READ

contains

AND'RETAIM

SERIES

(1

72

bar) OPERATING PRESSURE

(234 bar)

MAXIMUM

IRAPORTA,MB

and

lMSTWUCPlQMS

FOR

B

WORKING PRESSURE

REFERENCE

Page 2

OMJECTOGPN

E-iaARD

Fluids under high pressure from spray or leaks can

penetrate the skin and cause extremely serious

injury, including the need for amputation.

NEVER

the body.

NEVER

NEVER

body.

MEDlCAL

If

Tell the doctor exactly what fluid was injected. For

treatment instructions have our doctor call the

AVOOD

Even after you shut

high pressure

relieve

the spray tip

unit

Be sure that all accessory items and system

components

NEVER

in

personal safety, as well as the function of 'the

equipment, is at stake.

point the spray gun at anyone or any part of

put hand or fingers over the spray tip.

try to Stop or deflect leaks

with

your hand or

~REA~~E~T

an fluid a ears to enetrate your skin, get

E&Effi:QG&Y

DO

NOT

~A~UO~A~

C~~~O~~~~

it

by triggering the gun.

or

and

trigger the gun to release pressure.

will

exceed the pressure rating of any component

system.

NEVER

MEDU8AWa.

PREAU

POISON

(412)

689-6669

CARE

AS

A

SUMRE

CdUEBa

AB

ONCG.

CMU.

NETWORK

RUPTURE

off

the electric motor, there is

in

the pump, hose and gun until you

So

before removing

servicing the unit, always shut

withstand the pressure developed,

alter or modify equipment-your

off

the

for

Before each use, check hose

damaged conditions caused by traffic, sharp corners,

pinching or kinking. Tighten all fluid connections

'securely before each use. Replace any damaged

hose.

Do

not use chemicals or agents which are not

compatible

cover of hose.

Do

not leave a pressurized

unit

the

with

Buna-N. Viton, PVC, or neoprene

unit

and relieve pressure before leaving.

weak, worn or

unattended. Shut

off

FURE

Do not spray flammable liquids.

unit

where combustible fumes

present.

Do

not operate the

or

dust may be

GENERAL

NEVER

Keep clear of moving parts when the unit is running.

Observe detergent- manufacturer's safety

precautions. Avoid getting detergent or other liquids

in

regarding contact with eyes. nose, and .skin,

breathing fumes, etc. Always wear full goggles

protect your eyes from the spray as well as any debris

dislodged by the 'spray. If necessary, wear gloves or

other protective clothing. If. antidotes or treatment

are recommended, be prepared

Don't spray toxic chemicals such as insecticide or

weed killer.

run the

your eyes. Follow the directions

unit

with

the belt guard removed.

to

on

the container

use them.

to

2-

801-765

Page 3

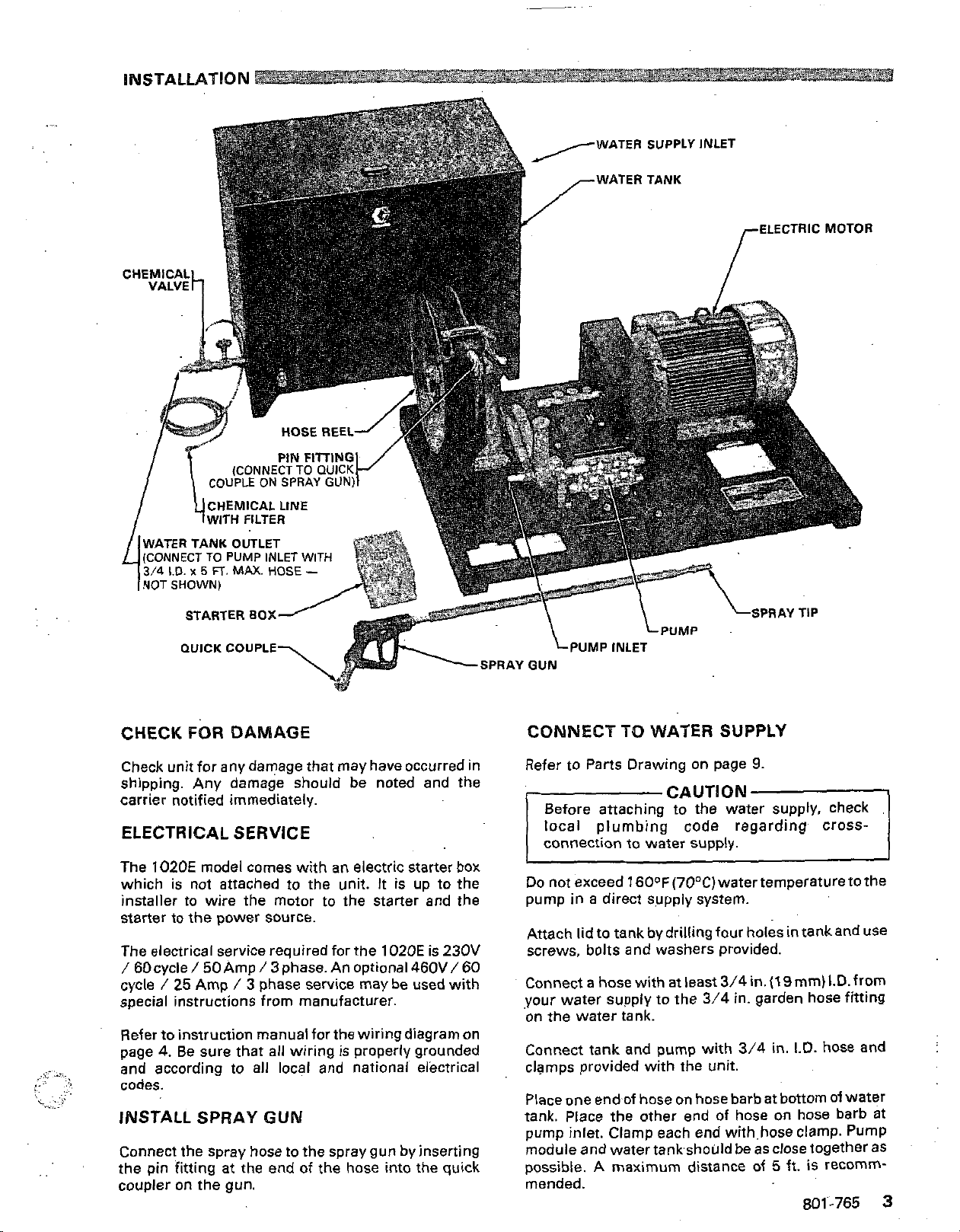

INSTALLATION

..

-

.

ii,

..*.

..

'

:'>,

,..

,.

..

,.

.

'i

CHECK FOR

Check unit for any damage that may have occurred

shipping. Any damage should be noted and the

carrier notified immediately.

DAMAGE

in

Refer to Parts Drawing on page

ELECTRICAL SERVICE

The

1020E

which is not attached to the

installer to wire the motor to the starter and the

starter to the power source.

The electrical service required for the

/

6Ocycle / 50Amp / 3 phase. An optional 460V/

cycle

special instructions from manufacturer.

Refer to instrucfion manual for the wiring diagram on

page

and according to all local and national electrical

codes.

INSTALL SPRAY

Connect the spray hose to the spray gun by inserting

the pin fitting at the end

coupler on the gun.

model comes

with

an electric starter box

unit.

It

is up to the

1020E

/

25

Amp / 3 phase service may be used with

4.

Be sure

that

all wiring is properly grounded

GUN

of

the hose into the quick

is 230V

60

Connectahosewithatleast3/4in.(ISmm)l.D.frOm

your water supply to the 3/4 in. garden hose fitting

on the water tank.

Connect tank and pump

clamps provided

Place one end of hose on hose barb at

tank. Place the other end

pump inlet. Clamp each end with,hose clamp. Pump

module and water tankshould be asclose together as

possible. A maximum distance

CONNECT

TO

WATER

SUPPLY

9.

connection to water supply.

Do

not exceed

pump

in

Attach lid

screws, bolts and washers provided.

mended.

16O0F(7O0C)watertemperaturetothe

a

direct supply system.

to

tank by drilling four holes

with

3/4

with

the

unit.

of

hose on hose barb

of

in

tank and use

in.

I.D.

hose and

bottom

5

of

ft.

is recomm-

801-765

water

at

3

Page 4

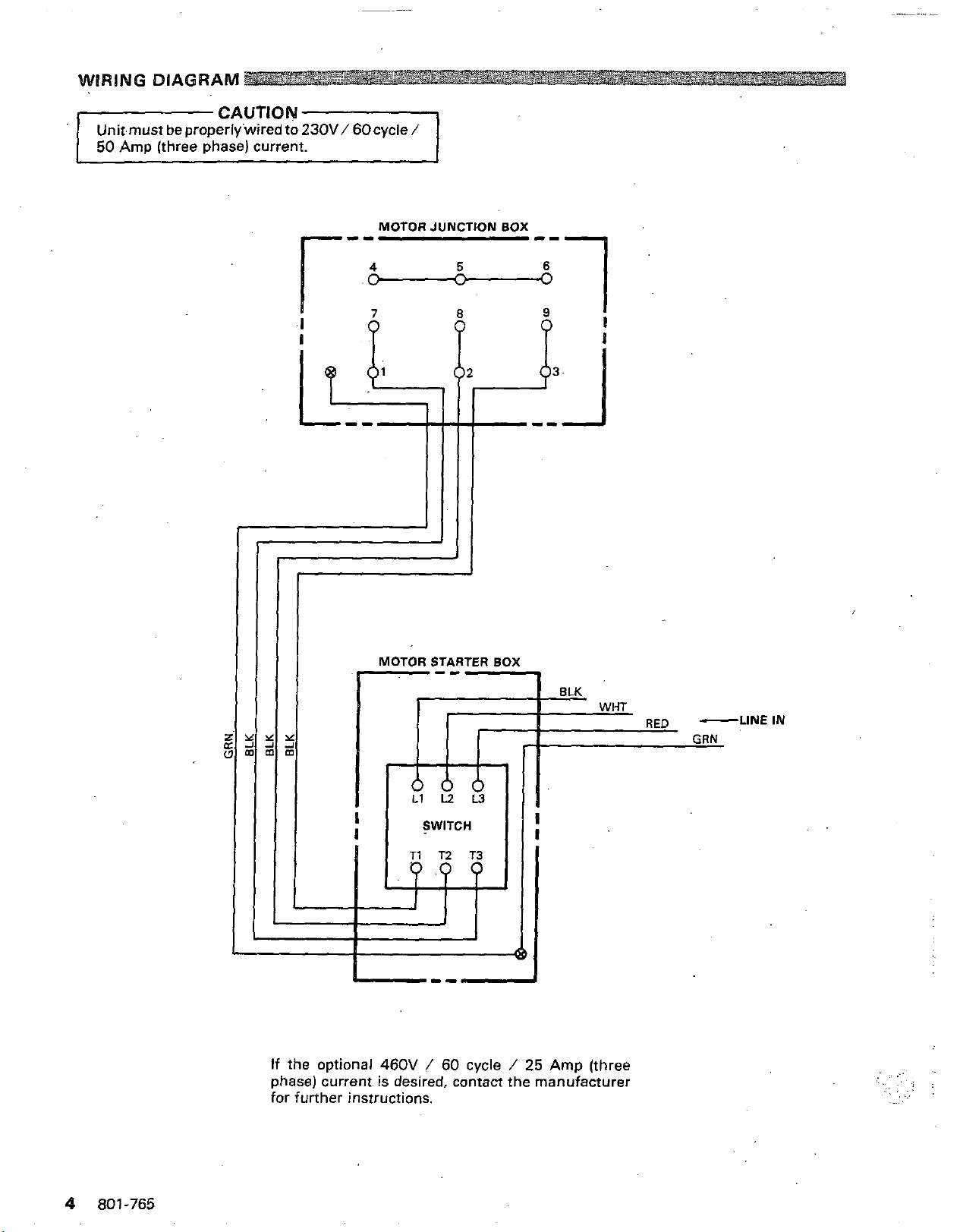

WIRING

DIAGRAM

CAUTION

Unit must

50

Amp (three phase) current.

be

properlywired to

230V/

60cycle

/

MOTOR

JUNCTION

BOX

4

801-765

I

I

If the optional

phase) current is desired, contact the manufacturer

for further instructions.

460V / 60

cycle

/

25

Amp

(three

Page 5

OPERATION

STARTUP SHUTDOWN AND CARE

Before'starting, be sure to read the safety warnings

and installation instructions.

Check oil level in pump

Turn on the water supply.

water supply is completely turned on and that

the water tank is full before operating.

all

Inspect

necessary.

Trigger the gun to release any back-pressure.

connections for any leaks. Tighten if

WARNUNG

DO

NOT wire or tie the gun trigger into the open

or triggered position.

Push starter switch to ON position.

CLEANING

The

1020E

injector system. See photo on page

the chemical injector insert plasticchemical linewith

filter into chemical container. Close large gate valve

at water tank outlet

factory installed sleeve. Open needle valve, directly

connected to the gate valve.

comes

with

an upstream chemical

3. When using

until

valve bottoms out against

OF

UNIT

When the unit is not

When shutting down for the day or weekend, shut

the unit, shut

the gun to relieve pressure. Wipe

damp rag.

off

in

use, turn off.the watersupply.

off

the water supply valve, and trigger

off

the unit

with

CAUTION

spraying, for longer pump life. The pump

overheat if left running for over

without spraying.

Check filter on inside

least once a month. If filter is plugged, remove from

tank and disassemble filter. Rinse parts

reassemble filter and replace

If water surges occur while using unit, this is

indication that the.filter might need cleaning.

THE PUMP MUST NOT

drained of water before exposure to freezing

temperatures. Use and store the unit where

be subjected. to freezing temperatures. If water does

freeze

antifreeze solution may be pumped prior to cold

weather storage.

in

the unit,

of

water tank at the outlet at

in

BE

RUN DRY and must be

thaw

before trying to start.

10

water tank.

will

minutes

it

will

A

50%

off,

an

not

CAUTION

pour

hot

water on a frozen pump.

temperature change may crack the ceramic

plungers.

A

sudden

a

to

The needle valve may be used

flow.

If chemical does not come up chemical hose, check

chemical filter on the end of hose.

will

Check the distance you

from surface by test.spraying on a scrap of similar

material. For soft surfaces, such as wood, hold nozzle

about 3 ft.

closer, check to see

damaging the surface.

Mist-wet surface

briefly, then use spray rinse to "chisel"

nozzle

determined to be best for surface. If some dirt

remains, repeat procedure, letting

longer. Protect surfaces that might be damaged by

cleaning solution or high pressure spray. and rinse

solution before

When you have finished cleaning, shut off

trigger spray gun to relieve pressure.

For abrasive cleaning, see the Water Sandblaster

Tank Manual,

(1

m) from surface

with

at

an

angle to surface, and at distance you

it

dries.

801 -767.

need to hold spray nozzle

if

the high pressure spray

cleaning solution. Let

adjust chemical

and

gradually bring

off

it

soak a little

dirt.

unit

it

soak

Keep

and

it

is

Do not pump caustic materials.

with

Before extended storage, flush the pump

Avoid dragging hoseover an abrasivesurfacesuch as

cement, This causes excessive wear and shorter

hose life.

Lubrication

Fill pump crankcase to dot on oil gauge window

54

oz.

or equivalent SA€

antiwear and rust inhibitor additives. Change initial

fill after

months or at

'N€V€/?

Altering or adjusting unloader

performance of

Service

by qualified service personnel.

and

Care

(1.6

liters)

of

crankcase oil (part no.

40

weight hydraulic oil

50

hour running period. Change oil every

500

hour intervals.

alter adjustment or modify the unloader

willnot

unit.

of

the unloader must.be performed only

light oil.

with

801 -144)

with

increase

3

801-765

5

Page 6

PARTS

Pressure

DRAWING

Washer

Assembly,

800-076

NOTE

6

Item

1,

801-765

Water Tank

Assembly,

is

not

shown:

see

page

..

9.

Page 7

PARTS

LIST

Pressure Washer Assembly, 800-076

REF. PART

NO.

NO.

1

800-148

2

800-150

3 800.144

4 800-145

5 801-814

6 801-247

7 801-316

8

801-815

9 801-129

10

801-130

1 1 801-388

12 801-816

13 801-817

. 801.818

14

15 801-214

16 801.819

17 801-015

18

801-363

'

801-020

19

20

801-830

21

801-831

22

801.808

23 801-809

24 801-810

25 801-81

26 801-316

REF.

PART

NO.

DESCRIPTION

WATER TANK ASSEMBLY,

Not

Shown, see page

CHASSIS WELDMENT ASSY.

PUMP ASSEMBLY. see

parts drawing/list. page

SPRAY GUN ASSEMBLY,

see parts drawing/list, page

DRIVE BELT,

BUSHING. HP.

ELBOW,

LABEL, warning

LABEL, warning, multi-language

LABEL warning

LABEL, grounding

LABEL, serial

MOTOR,

SCREW,

SCREW,

SCREW,

WASHER, flat,

WASHER, lock,

NUT, hex, 1/2-13-NC,

HOSE, HP.

HOSE, HP,

HOSE REEL ASSEMBLY,

(replaceable parts include

items

23-26)

.

BUMPER. hose

.

GUIDE, arm

1

SWIVEL STEM

.

STREET ELBOW,

8x46

street,

no.

electric

3/8-16 x 1"

hex,

hex,

3/8-16

3/8-16 x 3"

hex,

5/16

50 ft.

34'in.

9

1/2" x 3/8

900

HP,

112

x

1

3/8

lock

StoD

1/2

NPT

11

-3/4

8

NPT

QTY

1

1

3

1

1

1

1

1

1

1

1

4

8

1

15

13

2

1

1

1

1

NO. DESCRIPTION

27 801 -822

28

801-823

29 '801.567

30 '801-566

31 801-825

32 801-612

33 801-820

34 801-023

35 801-139

36 801-082

37 801 -826

38 801

39

40

41

42

43

44

45

46

47

Order pans by name

which

*

Recommended "tool box" spare parts,

-008

801-128

801 -417

'801 -758.

801 -603

801 -827

801

-828

801

-829

801 -821

801 -824

you

are ordering.

PULLEY. motor,

BUSHING. oullev.

(includes

QUICK COUPLE, female,

34".

QUICK COUPLE, male,

3/8.

WELDMENT, beltguard

WASHER, flat,

BOLT. hex,

8".

WASHER. flat.

WASHER; lock,

BOLT. hex.

BELTGUARD PLATE

LABEL. Graco "G"

LABEL warning, cover

LABEL starting

TIP,

NIPPLE, hex brass,

STARTER BOX

HEATER ELEMENT

START-STOP KIT

PULLEY, pump,

HUE, pump, QI-32mm (includes

key and bolts)

and

key

and bolts)

brass

steel

1/2-13

grade

5

M6

1513, 1 /4

series letter

3TE-58

P1-1-5/8

7/16

NC

1/4

1/4

x

30mm

meg

3/8

3TB-94

of

the assembly

x

NPT

0

.ow

".

1

1

1

1

1

4

2

2

-

2

2

~

1

1

1

1

1

3

1

1

1

for

PARTS DRAWING

Unloader Assembly,

Unloader Assembly, 800-1

REF. PART

NO. NO.

1

800-044

2 801-045

3 801-046

4 801-047 .

7 801-050

8

800-123

9 801-059

10 601-412

11 801-432

12 801-062

13 801-063

.

...

,

.

..

14 801-068

15 801-069

16 801-070

17 801-071

18 801-465

Order pans by name and series letter

which

you

are ordering.

DESCRIPTION

SLEEVE ASSEMBLY

CAGE, valve

O-RING

SPRING

O-RING

UNLOADER SUB-ASSEMBLY

O-RING

HOUSING

CYLINDER

O-RING

HOUSING VALVE

SPRING

VALVE

SEAT

SCREW, button hd.,

#6-32

NC

22

x

5/16 2

of

the assembly for

QN

1

1

2

1

2

1

1

1

1

1

1

1

1

1

Page 8

PARTS

DRAWING

Gun Assembly,

800-1

45

SERVICE

Gun, Cartridge Replacement

1.

Pressaccesspin(12)fromgunhandleandremove

access plate (14) by sliding plate backwards.

Remove cartridge

19

mm socket wrench.

2.

Check inside housing to be sure all O-rings came

out when cartridge was removed. If O-ring can be

seen inside the housing. remove

not

to

damage internal threads in housing.

3.

Throw away old cartridge and install new cartridge

using a small amount

Besuretotightencartridgefirmlyagainsthousing.

4.

Slide access plate intoplaceandinstall access pin.

8

801-765

(5)

from housing

of

pipe sealant on threads.

(6)

by using a

it,

being careful

PARTS

Gun Assembly,

REF.

NO.

1

2

3

4 801-638 SPRAY GUN, (replaceable

5

6

7

8 801-256 . TRIGGER PIN

9

10

11 801-673

12 801-428

13 801-419

14 801-427

15 801-420

16 801-423

Order parts by name and series letter

which

LIST

800-1

PART

NO.

801-134 TUBE.

801-674

801-1 17 TIP ADAPTOR

801-639

801-671

801-670 .

801-424

801-672 .

DESCRIPTION

GRIP 1

parts

include

.

CARTRIDGE

.

HOUSING

HEX PLUG

.

TRIGGER

OUTLET

. PIN COVER

ACCESS PIN

.

.

HANDLE

ACCESS PLATE

.

TUBE

.

.

INLET FITTING 1

you are ordering.

45

32”

items 5-16)

of

the assembly

ON

1

1

1

1

1

1

1

1

for

Page 9

_..

..

.~

.

..

.

...

..

,.

,,..

..

\_".

PARTS

Water Tank

REF

NO.

1 801 -793 NIPPLE, brass, low pressure,

PART REF PART

NO.

LIST

Assembly,

800-148

DESCRIPTION

3/4

npt

x

1-3/8" long

QTY

NO.

NO.

13 801-366

2 14 801 -803 TUBING, spacer,

2 801-794 BUSHING. brass, low

1"

3

pressure,

801.796 PLUG, brass, low pressure,

npt x 3/4 npt

3/4 npt 1

3

15 801-804 VALVE, needle

16 801 -805 VALVE, 3/4 npt 2

17 801 -806 VALVE, float

4 801.797 TEE, brass, low pressure, 18 801-807

3/4 npt

5

801-733 HOSE BARB. brass,

1

6 801 -798 HOSE BARB. brass.

3/4 hose

7 801-799

ELBOW, street, brass, low

pressure, 3/4 npt

8

801-1 10 ADAPTER, garden hose

9

801-111

10

801-1 12 FILTER. garden hose

11

801-800

COUPLING, garden hose

FILTER

12 801-801 TANK, water

/4 hose

x

1

/4 npt

x

1/4

3/4

90°

npt

npt

x

x

1

19 801.802

20 801-310

1

21 801-023 WASHER, flat, 1/4"

22 801 -139 WASHER, lock. 1/4 4

1 23

801-795

24 801.812 CHEMICAL STRAINER 1

1 25

1

1 27

801

26 801-123 HOSE, clamp, 1-1/4" 2

801-570

1 28 BO1

1

1

Order

which

parts

you

-81 3

-008

DESCRIPTION

BOLT,

,350

BALL.

LID,

NUT, 1/4-20

BUSHING, hex, 1 /2 x 3/4

TUBING,

HOSE, 3/4

LABEL. Graco "G':

by

name

and

are ordering.

1

/4-20 NC x 1"

ID

x

.55

OD

float

tank

NC

1

/4

ID

ID x 2

series letter

x

x

8

ft.

of

.6

in. long

ft.

the assembly

801-765

QTY

4

1

1

1

1

1

4

8

1

1

1

1

for

9

Page 10

SERVICE

Pump

(Refer to Parts Drawing, Page 11)

NOTE:

Valves:

1.

2.

3. Remove valve unit and o-ring (14) from cavity.

4.

5.

NOTE:

Pumping Section:

Removethe16capscrews(l2)fromthemanifolds

1.

using the M13 wrench.

2. Carefully separate the manifolds from the

crankcase.

NOTE:

Three .sizes of metric wrenches are

necessary for servicing the pump; M13,

M30.

and M10.

Remove the hex plug (1 6) from manifold (1 7) using

M30 wrench.

Examine o-ring

or distortion exist.

NOTE:

Replace valves with Kit

Replace hex plug and torque to 75

K/m).

Hex plug should be re-torqued after

hours operation.

It

lightly

(1

Valve

removal.

may

with

5)

under plug and replace if cuts

unit

may come apart during

No.

801

-472 if necessary.

ft.

Ibs.

(10.3

be

necessary to tap manifold

mallet to loosen.

5

7.

Install retaining screw assembly into plunger and

torque to 14.4 ft. Ibs. (2 K/m).

8.

Lubricate each plunger and carefully slide

manifolds onto crankcase.

9.

Replace the 16 capscrews and snug them up.

ft.

Torque to 21.7

NOTE:

Servicing V-Packings:

NOTE:

1.

After removing the 16 capscrews and the

manifolds carefully pull packing retainer (30)from

the manifold. Examine o-ring (21) and replace if

necessary.

2. Rem'ove low pressure packing (19) and head ring

(1

8).

3.

Pull

Remove long life ring

(1 9) and head ring (1 8).

4.

Inspect all parts and replace if necessary.

The eight capscrews on each manifold

must be torqued evenly to apply equal

pressure on the manifold

properly and doesn't bind or jam. This is

best done by torquing bolts closest to the

center of the manifold first and then

working out from those bolts.

Use

packing repair 'kit

intermediate retainer ring (31 1 from manifold.

Ibs. (3 K/m).

P/N

(20).

high pressure packing

so

801

that

-769.

it

seats

Keep manifold properly aligned with ceramic

plungers or seals.

r-CAuT'oN7

plungers when removing

3.

Carefully examine each plunger (27) for any

scoring and replace if necessary.

Servicing Plungers:

1. Loosen plunger retaining screw

using

crankcase. This

retaining screw.

2.

Remove retaining screw from plunger and

examine o-ring (29) back-up ring (28) and copper

bearing/gasket washer (24). Replace if necessary

using plunger repair kit P/N 801-474.

3. Remove plunger from plunger rod and remove

copper flinger (26). Clean or replace if necessary.

"10

wrench.

'

will

to

avoid damage

(23)

Push

separate plunger and

plunger towards

to

5-6 turns,

NOTE:

5.

Thoroughly clean packing cavity

examine. Lightly grease packing cavity.

6:Replace packing assembly

head ring

intermediate ring (31

packing retainer (30) and o-ring (21).

Carefully study the location of each part and the

position of the seals to assure proper

reassembly and operation.

7.

Lubricate each plunger and carefully slide

manifold onto crankcase.

NOTE:

4.

Lightly grease flingerand replace

5. Replace plunger.

6.

Lightly grease retaining screw assembly to avoid

cutting o-ring;Lightlygrease outer endof plunger.

it

on plungerrod.

8.

Replace the 16 capscrews

tighten as previously described (step 9 under

servicing plungers).

If just the packings are needed

801-769. If rings or retainers need

replacement use kit 801-770.

in

in

the following order:

(18).

packing

(19).

long life ring

),

head ring (1 8). packing(19).

use

kit

manifold and

(20).

CAUTION

When replacing the manifold onto .. .

plungers, extreme caution should be

exercised to avoid damage to the seals. .~

in

the manifolds and

I

16

801-765

Page 11

. .~

. .

..

. . ..

..

.

.,..

....

PART

REF

NO.

NO.

1 800-122

2 801-416

3 801-316

4

801-786

5 801-787

6

801-788

7 801-121

8

801-789

9 801-123

10

801-570

11 801-790

12 801-468

13 801-469

14 801-852 . VALVE UNIT

15 801-470

16 801.648

17 801-781

18 801-774

DESCRIPTION

UNLOADER ASSEMBLY,

parts drawing/list, page

BUSHING. 3/8 NPT

ELBOW.

NIPPLE,

TEE, LP,

BARB, 1

BARB. 3/4 NPT

BRACKET.

CLAMP-HOSE, 1-1/4

HOSE, LP, 314

PUMP, T1631, 2500 PSI,

(replaceable parts include

items

.

SCREW,

.

WASHER

. O-RING

.

HEXPLUG.MZ4x2x16 12

. MANIFOLD 2

. HEADRING

street,

brass,

brass,

/2

mounting

12-35)

M8

REF

PART

see

an

7

x

3/4 NPT 1

HP, 1/2 NPT

3/4 x 3 1

3/4 NPT

NPT x 3/4

x

3/4 2 26 801-489 FLINGER

ID

x

70

mrn

24"

16

16

12

12

12

1

1

1

1

2

2

NO.

NO.

19 801-776

20 801.775

21 801-476

22 801-780

23 801 -493 . PLUNGER RETAINING SCREW

24 801-492

25 801-782

~~ . ~

27 801-783 . PLUNGER

28

801-491 . BACK-UP RING

29 801488

30 801-772

31 801-773

32 801-484

33 801-482

34 801-483

35

801-485

Order

parts

by

name and series letter of the assembly for

which

you

are ordering.

DESCRIPTION

.

PACKING

.

LONG LIFE RING

. O-RING

.

OILSEAL

. BEARING/GASKET WASHER

.

OIL DIPSTICK.

,

O-RING

. PACKING RETAINER

.

INTERMEDIATE

RING

. CAP, 3/8 NPT

. CAP, 1/2 NPT

. WASHER 4

. WASHER 3

QTY

801-765

12

6

6

6

6

6

6

3

4

11

Page 12

SERVICE

TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

Low Pressure Worn nozzle.

Belt slippage.

Air leak

Relief valve stuck, partially

plugged or improperly

adjusted; valve seat worn.

Tank outlet filter clogged.

Worn packing. Abrasives

pumped fluid or

tion. Inadequate

I

Fouled or dirty inlet or discharge

valves.

1

Worn inlet or discharge valve.

Leaky discharge hose.

Restricted inlet or air entering

the inlet plumbing.

Inlet restrictions and/or

leaks. Stuck inlet or discharge

valve.

Leaking high pressure seals.

Water leabge.from under

the manifold.

Water

in

pump crankcase.

t-"

Worn packing

May be caused by humid air

condensing into water inside the

crankcase.

in

inlet plumbing.

severe cavitawater

in

supply.

air

with

Replace

Xghten or replace;

all three at

Disassemble, reseal, and reassemble.

Clean, and adjust relief valve; check

and dirty valve seats. Kit available.

Clean. Check more frequently.

Install proper filter. Check flow available to

pump.

Clean inlet and discharge valve assemblies

Replace worn valves, valve seats and/or

discharge hose.

Proper size inlet plumbing; check for

seal.

Clean out foreign material, replace worn valves.

Replace seals

new

Install

Change oil at 3rnonth or500Hour intervalsusing

Crankcase Oil (other approved oil every month or

200

hours1 P/N 801-144.

nozzle of proper size.

use

correct belts and replan

the

same time.

packing

for

air

worn

tight

Strong surging at the inlet

and

low

discharge side.

Electric motor stops while

spraying.

pressure on the

I

Electric

starting;

motor labors when

blows fuses.

Scored plungers.

Over pressure to inlet manifold.

Damaged or worn plungers.

in

Abrasive material

being pumped.

Excessive pressure and/or

temperature of fluid being

pumped.

Over pressure of pumps.

Running pump dry.

Foreign particles in the inlet or

discharge valve, or worn inlet

and/or discharge valves.

Building circuit fuse blown.

Overload switch has opened.

Building circuit fuse blown.

Overload switch has opened.

Tip plugged.

Not wired properly,

the fluid

Replace plungers.

Reduce inlet pressure.

Replace plungers.

Install proper filtration on pump inlet plumbing.

Check pressures and fluid inlet temperature; be

sure

they are within specified range. Pump

overheat if run for over

spraying.

Check tip size.

Do

not

run

Check for smooth lap surfaces on inlet and .

discharge valve seats. Discharge valve seats and

inlet valve.seats may be lapped on

stone.

Check, replace or reset.

unit

Shut

:heck, replace or reset.

Shut unit

:o

cool.

qemove and clean.

3eplace capacitor.

See

wiring diagram.

Use

Dum0

off,

hold gun open, restart.

off,

relieve

10

minutes without

only proper tip.

without water.

.,

pressure-allow

a

veryfine

will

011

12

801-765

Page 13

ACCESSORIES

(Must

be

purchased

separately)

WATER

For

SANDBLASTER

abrasive cleaning

TANK

of

stubborn dirt and paint

800-149

ELECTRLCAL SERVICE

WETTED PARTS

TOTAL UNIT WEIGHT

OVERALL DIMENSION:

TECHNICAL DATA

20

MOTOR:

WATERTANK:

WATER PUMP

(Empty Tank)

hp Gould Century

230'4160

65

gallon

25W

psi

10

GPM

Stainless

Phenolic Plastic. Ceramic

Liners. Nitrile Rubber

650

Ib.

1295

Water

Tank

Length:

Width:

35.5

Height:

30

Hr/50

Ampl3 phase

I246

liters)

(172

bar) max.

(38

liter/min)

Steel, Aluminum,

kg)

21.5

in.

(546

in.

1902

(762

mm)

mml

in.

mm)

MAXIMUM INLET

WATER TEMPERATURE:

INLET HOSE CONNECTION:

Pump

Modula

Length:

Width:

3/4

34

in.

(864

47

in.

Height:

160°

11194 mm)

26

in.

(660

170°

C)

garden hose to water tank

mml

mm)

,801

-765

13

Page 14

THE

GRACO

Graco Inc. warrants all equipment manufactured

material and workmanship under normal use and service. This warranty enends to the original

purchaser for

installed and operated

cover damage

corrosion, negligence. accident, substitution

This

warranty is conditioned upon the prepaid return

examination by Graco to verily the claimed defect. If the claimed defect is verified..Graco will repair

replace free

transportation prepaid. If inspection

material, repairs will be made

a

period of

or

of

charge. any defective parts. The equipment will be returned to the Original purchaser

12

months from the date of purchase and applies only when the equipment

in

accordance with written factory recommendations. This warranty does

wear which,

in

the reasonable judgment of Graco. arises from misuse, abrasion,

of

the equipment does not disclose any defect

ai

a

reasonable charge and return transportation

WARRANTY

by

it and bearing

of

non-Graco pans, fauhy installation or tampering.

of

the equipment claimed to be defective for

its

name to

be

free from defects

in

workmanship or

will

be charged.

nor

in

is

or

EOUIPMENTNOTCOVERED

Graco that are not manufactured

the warranty. if any.

making such claims.

BY

of

their manufacturer. Graco will provide purchaserwith reasonable assistance in

GRACO WARRANPI. Accessories or components ofequipment sold by

by

Graco (such as electric motors, switches, hose, etc.) are subjectto

:

Subsidiary and Affiliate

Factory Branches:

6RACQ

. .

..

INC.

P.8.

Atlanta.

BOX

Compenies:

Dallas.

Canada; England: Switzerland;

Detroit.

14411

PRINTED 1N.U.S.A.

Los

MUNNEAPOUS.

801-765

Angelsr. West Caldwell

France:

Germany; Hong Kong; Japan

WIN

8/84

IN.J.1

55440-1444

45-10069

REV A

Loading...

Loading...