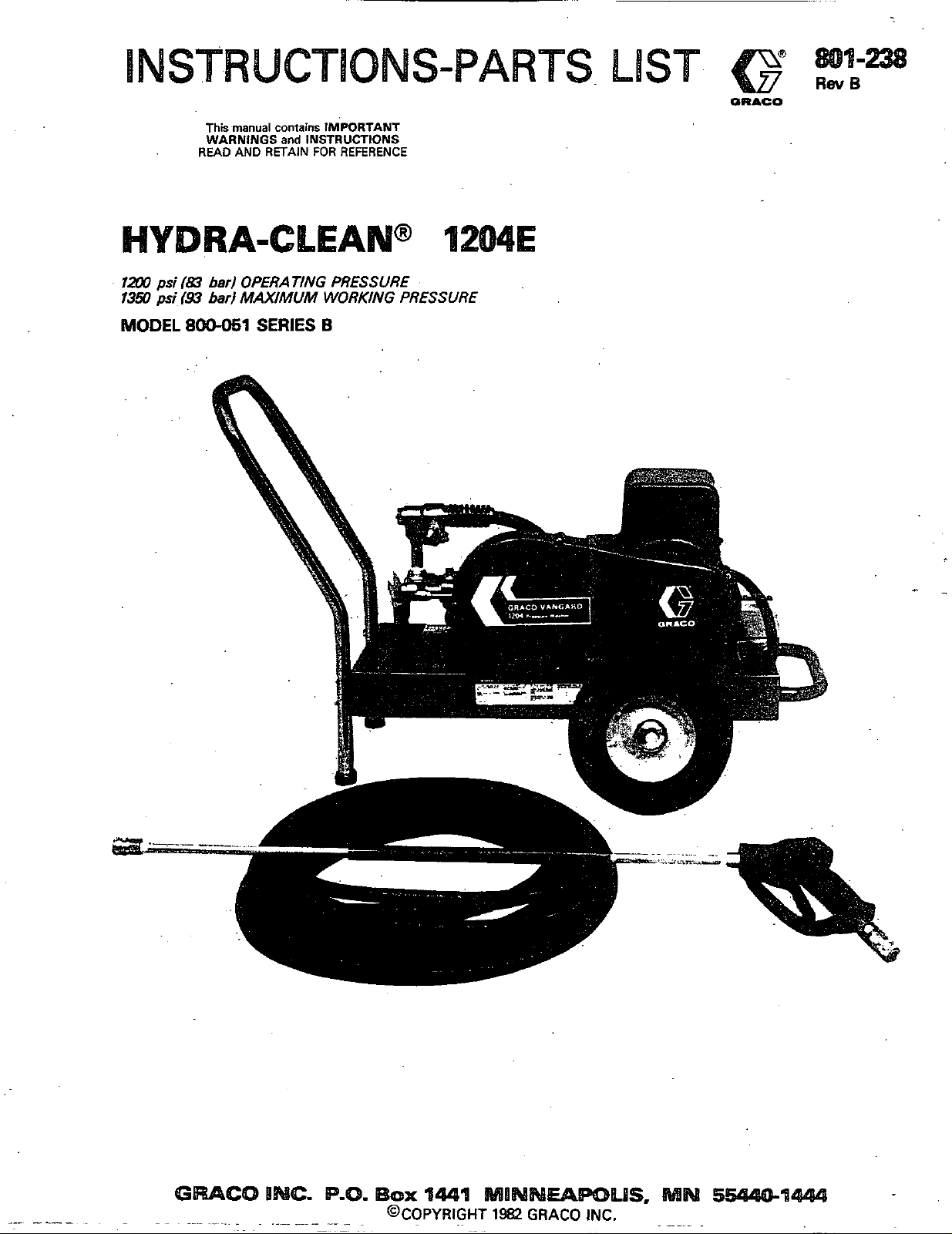

Page 1

1200

1350

psi

psi

TK~

WARNINGS

READ

(83

bed

(9.3

bad

manual

contains

AND RETAIN

IM'PORTANT

and

INSTRUCTIONS

FOR

REFERENCE

OPERATING PRESSURE

MAXIMUM WORKING PRESSURE

MODEL

8OO-051

SERIES

B

Page 2

HIGH

PRESSURE SPRAY

FOR

PROFESSIONAL

CAN

CAUSE

USE

SERIOUS

ONLY.

INJURY.

OBSERVE

Read and understand all instruction manuals before operating equipment.

IN

JECTlON

fluids under high pressure from spray or leaks can

penetrate

including the need for amputation.

NNER

body.

NNER

NNER

body.

ALWAYS

MEDICAL TREATMENT&~;T:",'?

If

any fluid appears to penetrate your skin, get

Tell the doctor exactlv what fluld

treatment instructions have your doctor

AVOID COMPONENT

Even after you shut

pressure in the pump, hose and gun until

by triggering the gun.

or servicing the unit, ahys shut

the gun to release pressure.

Be sure that

ponents will withstand the pressure developed.

.exceed the pressure rating of any component in system.

NNER

safety, as well as the function of the equipment,

stake.

Before each

ed conditions caused by traffic, sharp corners, pinching

or kinking. Tighten

each

the

skin and cause extremely serious injury,

point the spray gun

at

anyone or any part of the

put hand or fingers over the spray tip.

try

to

stop or deflect leaks with your hand or

have the tip guard in place when spraying.

''<?.X

EMERGENCY

BO

NOT TREAT AS A S!MPLE CUT.

MEDICAL

CARE

was

AT ONCE.

miected. For

Cali

the

NATIONAL POISON CENTER NETWORK

(412)681-6669

RUPTURE"~~,-:r_',":;i.'.

off

the electric motor, there is high

So

before removing the spray tip

off

all

accessory items and system com-

you

relieve

the unit and trigger

NNER

alter or modify equipment-your personal

use,

check hose for weak, worn

all

fluid connections securely before

use.

Replace any damaged hose.

or

damag-

is

at

ALL WARNINGS.

FIRE

Do

not spray flammable liquids.

where combustible fumes or dust may be present.

GENERAL

NNER

run the unit with the belt guard removed. Keep

clear of moving parts when

Observe detergent manufacturer's safety precautions.

Avoid getting detergent or other liquids in your eyes.

Follow the directions on the container regarding contact

with eyes, nose, and skin, breathing fumes, etc. Always

wear full goggles to protect your eyes from the spray as

well

as

any debris dislodged by the spray. If necessary,

wear gloves or other protective clothing. If antidotes or

treatment are recommended, be prepared

DON'T

spray toxic chemicals such

weed killer.

This unit has

from electric shock.

perly grounded outlet that will accept the 3-prong plug.

Do

not remove

The green

unit chassis and motor frame and the other

it

are connected to the motor switch for grounding

continuity.

The electric motor has an overload protection device

which automatically shuts

So,

before examining or working on a motor which has

stopped, shut

the electrical plug. This will avoid the hazard of the

motor starting unexpectedly.

ALWAYS CHECK to be sure the switch

the hoses and electric cord are clear

before plugging in the power cord.

~. ~. . .

:..

.~

,

' '

,..

,

.

.",.

.. .

,

. . .

.

the

;~..._il_x_~**"~.

.

,,,:

,

>,

...

i

~~.<,.,

i.-:

*.'.

Do

not operate the unit

-

,

.

.,

..

,,..,I

,

,,

..

.:,

:k;k'

unit is running.

to

as

insecticide or

a

3-prong grounding plug to protect you

Be

sure to plug the unit into a pro-

the

third

prong.

wire

of the electric cord

off

off

the unit, relieve pressure and pull out

is

connected to the

the motor if

is

OFF

of

moving parts

it

.,-.'i

,

,*.,.

.,.._

,,..

,,,*+

_c.

,

. .

1.

~~ . .

>

,,.!$.,,>~.

..

:.

.:

use them.

two

wires

overheats.

and that

,

Do

not

use

chemicals or agents which are not compati-

ble with Buna-N and PVC or neoprene cover of hose.

Do

not leave a pressurized unit unattended. Shut

off

the

unit and relieve pressure before leaving.

IMPORTANT

United States Government safety standards have been adopted under the Occupational Safety and Health

standards

consulted in connection with your

2,

-

801-238

particularly the General Standards, Part

use

of airless spray equipment.

1910,

and the Construction Standards, Part 1926 - should be

Act.

These

."

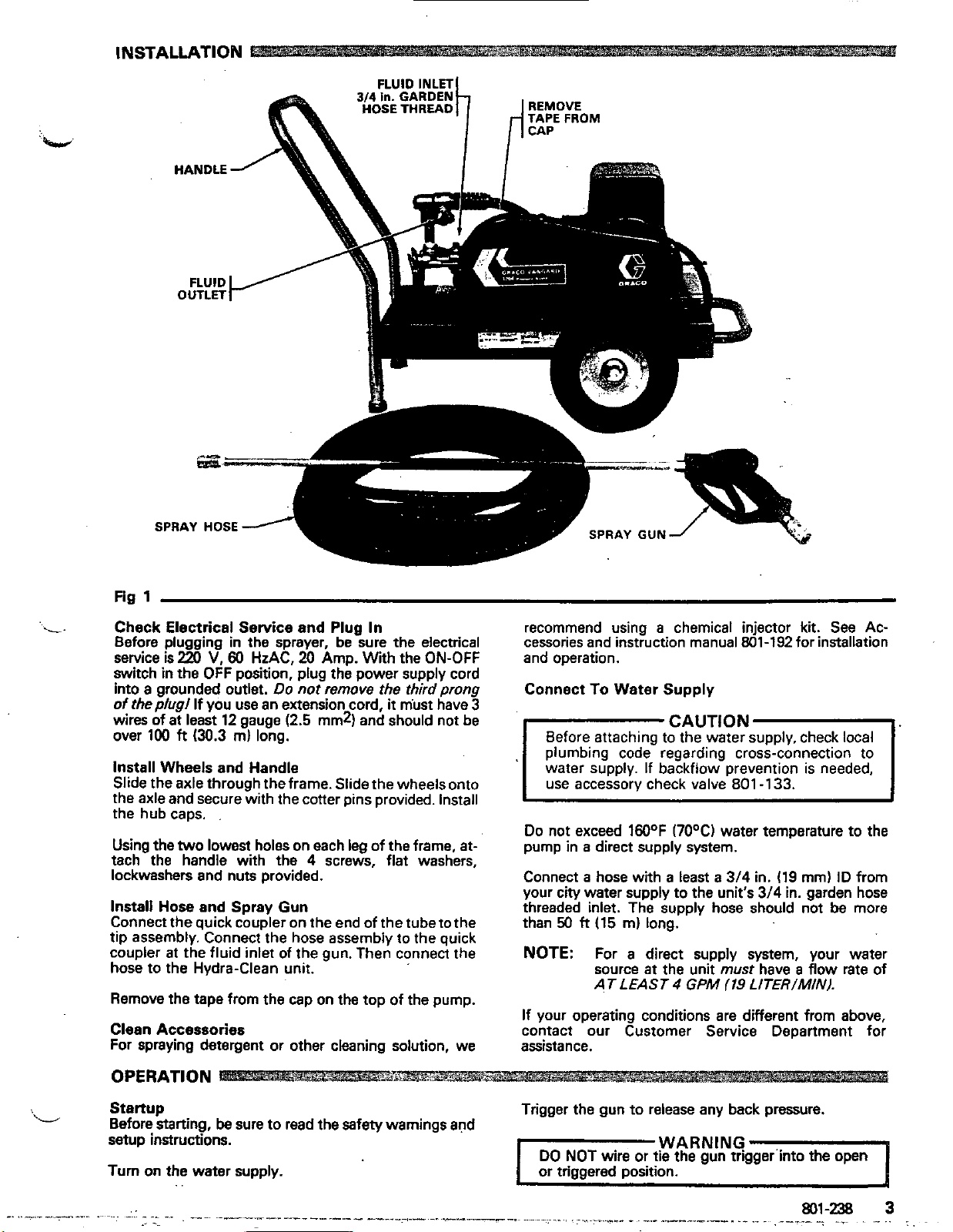

Page 3

IN

s1

Check Electrical Service and

Before plugging in the sprayer, be sure the electrical

service is

switch in the OFF position, plug the power supply cord

into a grounded outlet.

of

wires of

over 100

Install Wheels and Handle

Slide the axle through the frame. Slide the wheels onto

the axle and secure kith the cotter pins provided. Install

the hub caps.

Using the

tach the handle with the

lockwashers and nuts provided.

Install Hose and Spray Gun

Connect the quick coupler on the end of the tube tothe

tip assembly. Connect the hose assembly to the quick

coupler at the fluid inlet of the gun. Then connect the

hose to the Hydra-Clean unit.

Remove

Clean Accessories

For spraying detergent or other cleaning solution, we

220

V,

60

HzAC,

Do

the

plug1

If you

use

an extension cord,

at

least 12 gauge

ft

(30.3

m)

long.

two

lowest

the tape from the cap on the top of the pump.

holes on each leg of the frame,

Plug

In

20

Amp. With the ON-OFF

not remove the

it

mist have 3

(2.5

mm2)

and should not be

4

screws, flat washers,

third

prong

at-

recommend using

cessories and instruction manual 801-192 for installation

and operation.

Connect

l"-AUT'oNl~

Do not exceed 160OF

pump in

Connect

your city water supply to the unit's

threaded inlet. The supply hose should not

than

NOTE:

If your operating conditions are different from above,

contact our Customer Service Department for

assistance.

To

Before attaching to the water supply, check local

plumbing code regarding cross-connection to

water supply. If backflow prevention

use accessory check valve 801 -133.

a

direct supply system.

a

hose with a least

50

ft

(15

For a direct supply system, your water

source

AT LEAST

a

chemical injector kit. See Ac-

Water Supply

(7OoC)

m)

long.

at

the unit

4

GPM

is

needed,

water temperature to the

a

3/4

in. (19

must

(19

LITER/MIN).

mm)

3/4

in. garden hose

have

a

flow

ID from

be more

rate of

OPERATION

Startup

Before starting,

setup instructions.

Turn

on the water supply. or triggered position.

..

be

sure to read the safety warnings and

Trigger the gun to release any back pressure.

WARNING

DO

NOT

wire

or tie the gun trlgger'into the open

Page 4

CAUTION

unit

Never run the cleaning

the pump will result. Always be sure the water

supply is completely turned on before operating.

Inspect all connections for any leaks. Tighten if

necessary.

Cleaning

For cleaning

jector Kit manual

For cleaning

need to hold the spray nozzle from the surface on a

scrap piece of similar material. For soft surfaces such as

wood, hold the nozzle about

face and gradually bring

high

pressure spray is damaging the surface. Always

hold the nozzle

off

the

the

unit

with

harsh chemicals,

801-192.

with

clear water, test the distance

at

an angle to the surface and "chisel"

dirt.

When you have finished cleaning, shut

and trigger the spray gun to relieve pressure.

dry. Costly damage to

see

the Chemical

3

ft

(1

mm) from the sur-

it

closer, checking to

you

see

In-

will

if the

off

WARNING

Follow these precautions when removing and

stalling nozzles:

1.

Shut

off

to relieve pressure. Engage the trigger safety.

the cleaning unit and trigger the

in-

gun

B

Check the filter screen

often as necessary, at least

unit with the inlet and filter screen removed.

DO

NOT

try

engine speed. Changing these settings may cause

cessive pressure, intermittent unloader operation,

wasted fuel and increased wear on parts and

the warranty.

THE

PUMP

drained of water before exposure to freezing

temperatures.

subjected to freezing temperatures. If water does freeze

in

the unit, thaw before trying to start.

freeze solution may be pumped prior to cold weather

storage.

Use

only spray tips that are matched to the unit to avoid

excessive cycling and wear of the unloader valve.

ACCESSORIES.

pour hot water on a frozen pump.

temperature change may crack .the ceramic

plungers.

I

Do

not pump caustic materials.

to adjust the unloader valve or change the

MUST NOT BE RUN

Use

in

the water inlet connection as

daily.

Do

not operate the

DRY

and store the unit where

ex-

will

void

and must be

it

will not be

A

50%

anti-

See

A

sudden

I

2.

Keep the nozzle and the tube pointed away

from you and everyone

3.

Do

not put your hand over the tip to push the

nozzle into place. Grasp

keep your fingers away from the

4.

Do

not let anyone

while you are changing nozzles.

5.

Be

sure the slip ring is pushed forward to lock

the nozzle in place before triggering the spray

gun.

else.

it

from the side and

tip.

else

touch the spray valve

1

Shutdown

When the unit is not

When shuning down for the day or weekend, shut

the unit, shut

gun

to relieve pressure. Wipe

rag.

and Care of

off

the water supply valve, and trigger the

in

Unit

use,

turn

off

off

the water supply.

the

unit

with a damp

off

Before extended storage, flush the pump with light oil.

Avoid dragging hose over an abrasive surface such as

cement. This causes~excessive wear and shorter hose

life.

Clean the intake line strainer daily.

Lubrication and Care

Fill the pump crankcase to the dot on the oil gauge window with

or equivalent

and

50

hours of operation'and then every 3 months or at

hour intervals.

NEVER

Altering or adjusting unloader

25

oz

(0.75

liters) of crankcase oil

SAE

40

weight hydraulic oil with antiwear

rust

inhibitor additives. Change the oil after the first

alter adjustment or modify the unloader

wi//

erformance of

unit.

not

(801-144)

500

increase'

4

801-238

"

""

""

-- - ---

-~-

Page 5

DISCHARGE VALVES & VALVE SEATS

Disassembly

1.

Loosen the

2.

Then remove the

3.

Grasp the discharge manifold

underside and tap

4.

Valve assemblies will remain with the manifold. Invert manifold and discharge valve assemblies should

fall out.

5.

Inspect discharge valves for wear of ridges. (Spherical valves must be replaced when worn.)

Reassembly

1.

Place retainer

2.

Next insert spring into center of retainer

3.

Place valve over spring

4.

Next insert the valve seat

5.

Position manifold back onto pump.

2

(M8)

locking nuts about one turn.

2

(M8)

with

in

manifold chamber.

with

flange nuts.

with

a

soft

3 fingers on the

mallet to remove.

spherical side down.

NOTE: Exercise caution when inserting cylinders

6.

Replace flange nuts on studs and hand tighten both

sides. Then torque each side to

7.

Hand tighten locking nut.

-

When restarting the pump, checkto see that there

is no cylinder motion as this

failure of the cylinder O-rings. Center cylinder

motion can beeliminated byswitchingwith oneof

the end cylinders.

PUMPING SECTION

Disassembly

1.

Remove discharge manifold as described above.

2.

Slip cylinders out of inlet manifold.

NOTE: Identify cylinders

3.

Remove cotter pin, nut, and washer.

into manifold to avoid damaging cylinder

O-rings.

125

in-lb.

CAUTION

will

cause premature

1

BE2

so

they

will

be replaced

in

their original position. (Front to back.)

4.

Next

remove piston retainer, spacer, and piston

assembly.

5.

Remove inlet valve

Page 6

Reassembly

1.

Examine inlet valve surface and reverse if damaged.

(Both sides are lap surfaces.)

2.

Examine piston assembly for clean inlet surface.

damaged, replace and lubricate.

NOTE: CUP INSTALLATION

3.

Next replace piston spacer and retainer.

4.

Slip washer onto rod, screw on

in-lb.

5.

Examine cylinder wallsfor scoring oretching.These

conditions

assemblies. Replace if worn or damaged.

6.

Lubricate cylinder and replace O-rings and backup

rings (if defective).

Wipe

cup inserter lightly

ring onto piston. Force cup over inserter and

square

tion causes premature failure.

ALWAYS USE NEW COTTER PIN.

with

all surfaces. Faulty cup installa-

will

cause premature wear of piston

with

oil. Slip backup

nut

and torque to

If

60

SEALS AND

Disassembly

1.

Remove discharge manifold and piston assemblies

as described.

2.

Remove both

3.

With soft mallet, tap inlet manifold loosefromcrankcase.

4.

Place inlet manifold on pair of clearance blocks

crankcase side down, and drive out seals.

5.

Invert inlet manifold

6.

Lubricate circumference of new Prrrrrm-A-Lube

seals, position

DOWN and drive into place.

7.

Examine sleeves for scoring or other damage before'

removing.

8.

If worn, grasp sleeve

SLEEVES

(ME)

locking nuts from studs

with

CRANKCASE

in

manifold with GARTER

with

pliers and pull off.

SIDE

UP.

SPRING

with

7.

Position cylinders

chambers and carefully slip over rod ends onto the

pump.

8.

Replace flange nuts on studs and hand tighten both

sides. Then torque each side to

9.

Hand tighten locking nuts.

PUMPING SECTION CUTAWAY

in

their original order into manifold

125

in-lb.

NOTE: This procedure will marthesleeveso use

only if sleeve is

9.

Remove O-ring and backup rings from piston rod.

Reassembly

1.

Place barrier slinger on rod

2.

Lubricate new o:rings and backup rings. Install first

O-ring

in

backup ring against the shoulder

O-ring, then the second O-ring. Be careful to avoid

damaging the O-rings when slipping them over the

piston rod threaded ends.

3.

Immerse sleeve

rod. (Machined counter bore end first.)

4.

Replace seal retainers.

5.

Be careful when replacing inlet manifold,

let seals are not damaged by the threaded rod ends.

6.

Replace locking nuts on studs.

7.

Reassemble piston assemblies and discharge mani-

fold as described.

Consult factory for your local distributor for crank-

case servicing.

the O-ring groove on the piston rod. Position

in

oil, carefully twist and push onto

to

be replaced.

in

front of the first

so

the

in-

PROBLEM

Low

pressure

DIAGNOSIS AND MAINTENANCE

PROBABLE CAUSE

Worn nozzle.

Belt slippage.

Inlet suction strainer clogged.

in

Worn plunger cups. Abrasives

fluid or severe cavitation. Inadequate

water supply.

pumped

SOLUTION

Replace nozzle, of proper size.

Tighten or replace; use correct belt.

Clean. Check more frequently.

Install proper filter.

..

Page 7

SOLUTION

Low pressure

Pump

rough,

low

Cylinder O-rings blown

next to discharge

manifold

Leakage

0-Rings

discharge manifold and

black, powdery

substance

of

Water leakage from Worn inlet manifold seals.

under the inlet

manifold.

runs

pressure very

the 0-Rings.

(Cont.)

extremely

at the cylinder

at the

in

the 'area

Fouled or dirty inlet or discharge valves.

Worn inlet or discharge valves. Leaky

discharge hose.

Inlet restriction andlor air leaks. Damaged cup or stuck inlet or discharge valve.

Worn inlet manifold seals.

Pressures

Warped manifold.

Loose cylinders. Cylinder motion caused

by improper shimming of the discharge

manifold.

Leaking sleeve 0-Ring.

in

excess of rated PSI.

Clean inlet and discharge valve

assemblies.

Replace worn valves, valve seats and/c

discharge hose.

Replace worn cup or cups, clean out

foreign material, replace worn valves.

Replace worn seals.

Check for plugged nozzle. closed valve!

or improperly adjusted by-pass valve.

Replace manifold.

~~

Exchange middle andoutboardcylinder,

Install new seals. If piston rod sleeves

are scored, replace sleeves and sleeve

0-Ring.

0-Rings,

Oil leak between Worn crankcase piston rod seals.

crankcase and

ing

section

Oil leaking

of

crankcase

Excessive

end of the

pulley

Water

Oil leakage from under May

side

Dil leaking at'tha rear Damaged or improperly installed oil gauge

portion

xankcase

3il leakage from drain

,lug

in

of

crankcase wick lubricators.

of

-

pump-

in

the area

in

play

crankcase tension to drive

crankcase May be caused by humid air condensing

the

the

Worn crankcase seal or improperly install.

oil

seal retainer packing.

ed

Bad bearing.

Worn main

into water inside the crankcase.

Leakage of manifold inlet seals and/or

piston rod sleeve 0-Ring.

be

Worn crankcase piston rod seals.

or crankcase rear cover 0-Ring, and drain

I

~lua

0-Ring.

Loose

I

0-Ring.

ball

bearing from excessive

belt.

:

caused by excessive oiling of the

drain plug or worn drain plug

.

Replace crankcase piston rod seals

Remove oil seal retainer and replace

damaged gasket and/or seals.

Replace bearing.

Replace ball bearing. Properly tension

belt. Check shaft shims.

Change'oil every month or

Replace seals, sleeve and 0-Rings.

Wipe free of oil.

for

a

short period. If leakage continues,

replace the crankcase piston rod seals.

Replace oil gauge or cover 0-Ring, and

drain

plug 0-R,ing.

righten drain plug or replace 0-Ring.

Do

200

hours.

not oil lubricators

.oud

knocking noise

lump

hquent

ailure

nanifold seals

lhort

of

cup

in

Pulley

loose

on crankshaft.

Broken or worn bearing.

or

premature Scored rods or sleeves.

the inlet

I

Overpressure to inlet manifold.

life

Damaged or worn chrome plating of the

cvlinders.

I

:heck key and tighten set screw.

3eplace bearings.

3eplace rods and sleeves.

3educe inlet pressure per instructions.

3eplace the cylinders.

Page 8

DIAGNOSIS AND MAINTENANCE CONT

I

PROBLEM

Short

cup life

Strong surging a the

inlet and

on

the discharge side.

low

(Cont.)

pressure

PROBABLE CAUSE

Abrasive material

pumped.

Excessive pressure and/or temperature of

fluid being pumped.

Improper installation of cups.

Overpressure of pumps.

Running pump dry.

Front edge of piston sharp.

Chrome plating of cylinders damaged

causing excessive wear of cups. May be

caused

Foreign particles

valve or worn inlet and/or discharge

valves.

bv

Dumping acid solution.

in

the fluid being

in

the inlet or discharge

SOLUTION

Install proper filtration of pump inlet

plumbing.

Check pressures and fluid inlet

temperature; be sure they are within

specified range.

Properly install

groove on the

stalled, the cup

piston. Piston will run eccentric;

premature failure will result.

Reduce pressure.

Do

not run pump without water.

Replace with new piston.

Install new cups and cylinders. Pump

only fluid compatible with chrome.

:heck for smooth lap surfaces on inlet

and discharge valve seats. Discharge

valve seats and inlet valve seats.

Discharge valve seats and inlet valve

seats may be lapped on a very fine oil

stone; damaged cups and discharge

valves cannot be lapped but must be

.eplaced.

lip of new cup into

piston. If not properly in.

will

be extruded past th

Water leaking

valve stem

Short piston seal life.

from

I

I

Electric motor

I

run'

Electric motor stops

while spraying

won't

Norn piston seal.

-oose cleanout port

-eak

in

discharge hose.

.oose

stuffing box.

scored piston sleeve.

in

4brasives

'ower cord unplugged, or building circuit

use

blown.

lverload switch has opened.

'ower cord unplugged, or building circuit

use

blown.

lverload breaker has opened.

Ixtension cord.

-ip plugged.

water.

nut.

~ ~~~

3eplace seal assembly.

righten nut.

3eplace hose.

righten.

3eplace piston sleeve.

:lush

with

clean water.

:heck, replace.

Jnplug power cord', decrease pressure.

:heck, replace.

Jnplug power cord', relieve~pressure-

IllOW

to cool.

Ion't

use

more

than

100

h

of

12

ga ex-

ension cord.

lemove and clean.

Electric motor

Electric

when starting; blows

fuses

'This

30

to

motor

unit

60

runs,

labors

has an overload breaker

minutes. Also, try to correct the cause of overheating. Always

)isplacement pump frozen or gear train

lamage.

:aDacitor failure.

built

into the switch assembly. If

it

.haw

leplace capacitor.

opens, unplug power cord and let sprayer cool for

use

the lowest pressure setting needed.

Page 9

i

trv

PARTS

Gun and

14

5

A

DRAWING

Hose

Assembly

3

L

L

QTV

1

for

Repair Kit

Includes items

801083

A,

B,

C.

D,

E

and

F

SERVICE

1.

Remove the 8 screws from the body halves

(41.

See

the Parts Drawing. Separate the body

halves.

2.

Remove

the valve body

3.

Remove the snap ring

seat

4.

Remove

actuator rod

5.

After installing the

ball

between the ball and seat.

6.

Reassemble

new parts from the repair

(C)

and o-ring

lightly

the

plug

(14),

spring

15)

and

(GI.

(6).

Then remove the valve

(D).

the

sleeve

(F).

with

in

nut

(11)

and o-ring

new

seat

IC)

a

hammer

and ball

to

assure a proper seating

reverse order, using the remaining

kit.

ball

(E)

(AI,

(3)

and

(A)

from

with the

tap the

REF

.

NO. NO.

1

2

3

4 801-245

5

6

7

8

9 801-261

10

11

12

13 801-263

14

15 801-264

16 801-265

17

..

18 801-029

19 "801-009

20

21 801473

22

23

24 801474

25

26

27

28

Order

which

PART DESCRIPTION

801-007

800-017

801-244

801-249

801-254

801-256

801-262

~~ ~~

801-247

801.253

. 801-246

801-250

ml-1.34

".

."

'801-090

*801-374

'801-373

801-076

801477

801-103

'801491

parts

by

are

name

ordering.

you

SPRAY HOSE,

I15

m)

Ig

SPRAY GUN, lreplaceable

include items

.

HANDLE,

. HANDLE,

. SPRING

3/8"

3-16)

left

right

ID,

50

fl.

parts

. LEVER

. NEEDLE

. HEX PLUG

.

DISCHARGE FITTING

' '

. VALVE BODY

. GUIDE SLEEVE

. TUBE

. INLET FITTING

.

CAP

. SCREW

. SCREW

32"

TUBE,

GRIP

COUPLER, female

COUPLER,

HOUSING,

TIP, blasting;

TIP, cleaning;

GUARD, tip

PLATE, warning

RIVET

NIPPLE,

hex;

COUPLER, male auick disconnect

and

series

quick

male

quick disconnect

nozzle

0'

15"

1/4

x

3/8"

lener

disconnect

npt; brass

of the assembly

Wecommended "tool

**Replacement 0-Ring for Coupler

".

..~

-

.."

~~

"

.

".

,

.,.

....

~

,,

.._,_

"

_.

.

".

~

".

."

-

-. ~ .-

box"

.

. .

spare

.

pam.

Pen

.

"

..

No.

__

801-202.

801-238

.,

I

9

-.

. ..

-

.

. .

Page 10

T91

Ts

11

T4

T8-

MOTOR

POWER

1213

-

-

-

COR0

-

GRN

STARTER SWITCH

BLK

b

OFF

ON

SWITCH

BLK

WHT

BLK

Page 11

PARTS DRAWING

21

PARTS

REF PART DESCRIPTION

NO. NO.

LIST

an

REF

NO. NO.

PART

Piston

(Includes Ref. No's. 7-12, 18)

Valve

(Includes Ref. No's.

Cup

(Includes Ref. No's.

DESCRIPTION

kit

kit

kit

801-321

801 -322

801 -1

96

13-1

8,

12.

8)

18)

20

21

P

23

24

25

26

27

28

29

30

31

.~

32

33

34

35

36

37

38

..

42

43

44

45

46

47

50

51

52

53

1

800-016 MOTOR, 3

2

8ooM)9

801-270

3

4

801-198

5

801428

6

801-356 ..STUD

801-273 . HOSE, cpld 112 nptlmbe), 19 long

801-181

801-1 11 . NUT, brass, garden hose adapter

801-112

801-106

801-105

801-178

801-269

801-090

801-108

801-182

801-203

801-045

801

801-047

801-048 .. BALL

801-049

801-050

800013

801-143

801453

801-060

801-061

801-062

801-063 ..PLUG

801-068

801-069

801070

mo1-071

"

. - . .

801-176 BASE, belt guard

801-375 BELT, drive

801-300 PULLEY, pump

801-299 PULLEY, motor

PUMP ASSEMBLY. includes items

3-49

. PUMP, Ref No. 4-6 are replaceable

parts. Ref No. 7-19 are sold in kits

""I"

-...,

..

CAP

.. O-RING

. PROTECTOR,

. SCREEN, inlet, 112"

. TEE, brass, 112 npt

.

NIPPLE, straight, brass, 1/2 npt

3-1

.

ELBOW, street,

. PLUG, hex, brass, 3/8 npt

. COUPLER, male quick disconnect

. BUSHING. hex reducina brass. 114

x

112 npt

. NIPPLE, straight, steel, 112 npt

2.112"

-

.

ADAPTER,

. UNLOADER, includes items

.. CAGE, valve

.. O-RING

-046

.. SPRING

..

SEAT

.. O-RING

._ UNLOADER

..

TAG

.. O-RING

.. HOUSING

.. CYLINDER

.. GASKET

..

HOUSING, valve

..

SPRING

__

VALVE

SFAT

.

.

-

_.

12"

.

,

hp

112"

shaft

9O0,

garden hose

1/2 npt

I

x

x

33-49

54

55

56

57

58

59

60

61

62

63

64

65

66

67

1

2

2

1

1

1

1

1

1

2

68

69

70

n

73

74

..

75

76

77

2

1

1

1

1

1

1

2

1

1

1

Order

which

800"

800414

801012

801413

€fO-O15

".

801-231

801-240

801-293

801-241

801-214

801-291

801

801-023

801-024

801025

801

801-363

801-177

801-139

801-170

801-137

801-173

801-087

801415

801-132

801-130 LABEL, warning

801-129 LABEL, warning

801-141 LABEL. warning

801-204 LABEL. identification

801-008 LABEL. identification

801-242 CAP, hub

811-292 SCREW, self-tpg, flat hd, 6-32

801-235 WASHER.

61-% PIN,-cotter

801-225 STRAIN RELIEF

801-296 CONNECTOR, flexible conduit

801-294 CORD, power

801-295 SWITCH, starter

801-290 BOLT. carriage, 5/16-18

801-376

parts by name and series letter of the assembly for

'

you are ordering.

SPRAY GUN ASSEMBLY, see parts

on page

CHASSIS

GROMMET

HANDLE

FOOT

. ".

LABEL. caution

AXLE

TENSIONER, belt

WHEEL

BOLT, hex

BOLT, carriage, 5/16-18

ai2

SCREW, hex hd, 5/16-18

WASHER, flat, 1/4"

NUT, hex, 5/16

LOCKWASHER, 5/16

-298

BOLT. hex hd. 5/16-18

WASHER, lock, 3/8

COVER, belt guard

LOCKWASHER,

SCREW, hex hd mach, M6 x 25

KEY, pulley

KEY, pulley

SCREW, mach. cros recessed,

1

14-20

WASHER, flat, 5/16

RIVET

HUB.

9

x

1-3/4"

pulley

hd.

3/8-16 x 1-3/4"

1/4"

flat

~~

x

x

x

x

3"

3.5

1-3/4

2-1/2"

x

mm

112

A

12

6

8

5

4

2

1

2

2

2

-

2

1

1

1

1

1

1

A

1

Page 12

ACCESSORIES (Must

be

purchased

separately)

CHECK VALVE

Prevents

supply.

back

Install

801-133

up

of

upstream

contaminated

from

pump.

water

into

fresh

TECHNICAL DATA

ELECTRIC MOTOR

WATER PUMP: 1200 PSI

WElTED PARTS :Stainless

WEIGHT:

OVERALL DIMENSION

CHEMICAL INJECTOR KIT

For

injecting

from

pump.

:

max.

(15 litarlmin)

Phenolic Plastic, Nitrile Rubber

Steel,

165

Ib

:

Length: 30"

Width:

28"

Height:

25.5

pressure:

4

GPM

Aluminum.

1810

(710

mml

(650

harsh

mm)

mm)

cleaning

800-102

chemicals

downstream

MAX.

WATER

INLET HOSE CONNECTION

TEMPERATURE:

1W

(70°C)

:3/4"

garden hose

(f)

LIMITED WARRANTY

We wamnty each new machine sold by us to

Wring

defects in normal

mencing with deliwry of the machine to the original owner.

Our

obligation under this warranty

to

the

replacement or repair

or

a

Minmta

aa

iMpection

doas not

(including

service

shall disclose to have been defective. This warranty

nwlv

to defects caused

i&re

service

for a period

is

facili ddgnated

to

provide reasonable and

at

bv

expressly limited

while in the won of the consumer.

TO

NOT APPLY

WE SHALL NOT BE LIABLE

ANY THING, including but not limited

tranbpomtion charges in connection with the replacement or repair of

defective

We

make

THE WATER NOZZLE

pam.

no warranty

FOR

CONSEOUENTIAL DAMAGES

with

respect to trade accessories.

subject m the warranties of their manufacturers.

be

free from manuiac-

of

one

(0

war

at

Vangard Mfg., Minneapolis,

by

us, of such

damaoe

to,

or

nacessarv

THIS

WARRANTY DOES

OR

V-BELTS.

consequential labor costs

our option,

pan

unreasonable

maintenance)

or

They

com-

pam

use

OF

or

nre

Sub.ldt.y

FrntoryB-

and

GRACO

AflUlata

INC.

-Atlama.

Dallas.

Detroit.

Loa

Angel-.

Weat

Caldwdi

IN.J.1

Campnk.:Canada: England: Swttzarland France: Germany: Hone Kong: Japan

P.

0.

Box

1441

PRINTED

MINNEAPOLIS,

IN

U.SA

801

-238

5/82

MN

5"1444

"

lblmxB

Loading...

Loading...