Graco Inc Hydra-Clean A, Hydra-Clean 1020, Hydra-Clean 800-902, Hydra-Clean 308-533, 720 User Manual

...Page 1

INSTRUCTIONS-PARTS

This

rnanulll

mntains

WARNINGS

READ AND RETAIN

and

IMPORTANT

INSTRUCTIONS

FOR

REFERENCE

LIST

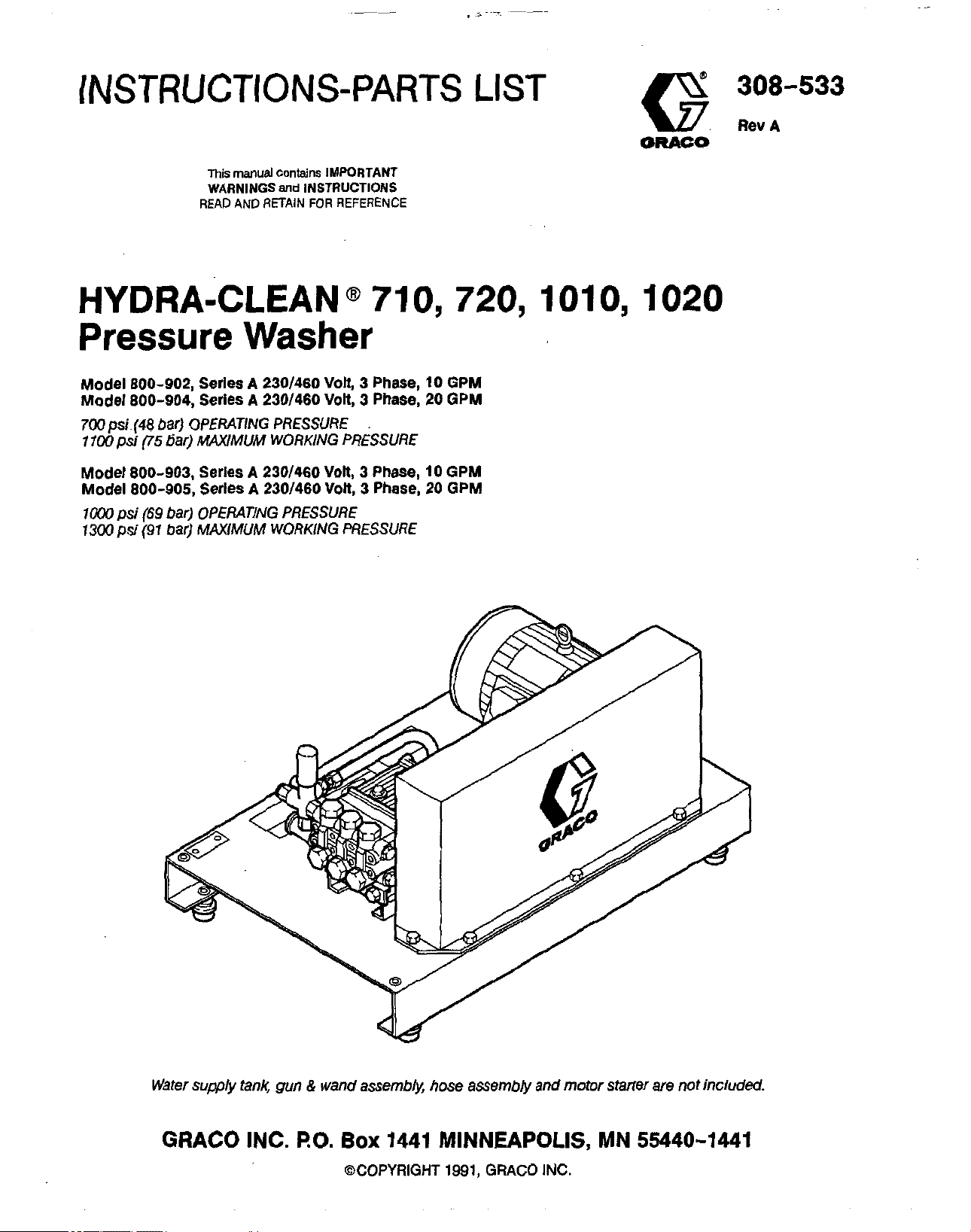

HYDRA-CLEAN

~~

8

71

Pressure Washer

Model 800-902, Series A 230/460

A

Model 800-904, Series

700psi.(48

1100

Model 800-903, Serles A 230/460

Model 800-905, Serles

10oO

1300

psi

psi

psi

(75

(69

(91

bar)

OPERATING PRESSURE

bar)

MAXIMUM

bar)

OPERATING PRESSURE

bar)

MAXlMUM

230/460

WORKING

A

230/460

WORKlNG PRESSURE

Volt,

3 Phase,

Volt,

3

Phase, 20 GPM

.

PRESSURE

Volt,

3 Phase,

Volt,

3 Phase, 20 GPM

0,720,

10

GPM

10

GPM

I

01

0,1020

Water supply tank,

GRACO

gun

INC.

&

wand assembly,

RO.

Box

@COPYRIGHT

hose

assembly and motor starler are not included.

1441 MINNEAPOLIS, MN 55440-1441

1991,

GRAGO

INC.

Page 2

HIGH

PRESSURE SPRAY CAN CAUSE SERIOUS INJURY

FOR PROFESSIONAL

USE

ONLY. OBSERVE ALL WARNINGS.

Read and understand

all

instruction manuals before operating equipment.

FLUID INJECTION HAZARD

General Safety

mis pressure washer generates very high

pressure. Spray from the gun, leaks or ruptured

components can inject fluid through your skin and into

your body and cause extremely serious bodily injury

including the need for amputation. Also,fluid injectedor

skin

splashed into the eyes or on the

damage.

NNER

part of the body.

spray tip.

ALWAYSfollow the Pressure Relief Procedure, before

cleaning or servicing any part of the sprayer.

NNER

body.

Be sure equipment safety devices are operating

properly before each use.

point the spray gun or wand at anyone or at any

try

to

NNER

stop

put hand or fingers over the

or

deflect leaks with your hand or

can cause serious

fluid

Pressure Relief Procedure

To

reduce the risk of serious bodily injury, including fluid

injection and splashing in the eyes or on the skin,

always follow this procedure whenever you stop

10

spraying for more than

and before checking

1.

Engage the trigger safety latch.

2.

Tum the sprayer

3.

Disconnect the electrical supply.

4.

Shut

off

the water supply.

5.

Disengage the trigger safety latch and trigger the

gun

io

relieve pressure, and then engage the trigger

safety latch again.

6.

Before long-term (overnight) storage, disconnect

the water supply and disconnect the electricity.

minutes, when shutting down,

01

repairing any part ofthe system.

off.

Medical Treatment

If

any fluid appears

EMERGENCY MEDICALTREATMENTATONCE.

NOT TREAT

what fluid was injected.

NOTE TO PHYSICIAN lnjection

traumatic injur,! It

surglcaily as soon as possible.

treatment to research toxicity Toxicity is a

concern

direct& into the bloodstream. Consultation

plastic surgeon or reconstructive

may be advisable.

AS

with

A

to

penetrate your skin, get

SIMPLE

some exotic coatings injected

CUT. Tell the doctor exactly

in

the skin is a

Is

Important to treat the injury

Do

not delay

with

hand

surgeon

DO

a

Spray Gun Safety Devices

all

Be sure

before each use.

the gun; this can cause a malfunction and result in

serious bodily injury.

SAFETY

moment, always set the gun Safety latch in

or "safe" position, making the gun inoperative. Failureto

properly

triggering

SPRAY TIP SAFEPI: Use extreme caution when

cleaning or changing spray tips.

while spraying, engage the gun safety latch

immediately.

Procedure and then remove the spray tip

gun safety devices are operating properly

Do

not remove or modify any part

LATCH:

set

of

Whenever you stop spraying

the

the safety latch can result in accidental

the gun.

If

a spray tip clogs

ALWAYS

follow the Pressure Rellet

for

engaged

to clean it.

of

a

Page 3

GROUNDING INSTRUCTIONS

mis Droduct must be grounded. If it should malfunction

or

bieak

resistance

electric shock. This equipment is equipped with a cord

having an equipment-grounding conductor and a

grounding plug. The plug must be plugged into an

aooromiate outlet that is DroDerlv installed and

giunded in accordance

ordinances.

down,

grounding provides a path

for

electric current

to

reduce the risk

with

ail lbcal codes and

of

least

of

1-

improper connection

conductor can result In the risk

Check with a qualified electrician or service

if

person

Is

you are in doubt as to whether the outlet

properly grounded.

GROUND FAULT CIRCUIT INTERRUPTER PROTECTION

To

comply with the National Electrical Code (NFPA

and

to

provide additional protection from the risk of

electric shock, connect this pressure washer

is

that

(GFCI).

protected by a ground-fauit circuit-intempter

to

70)

a circuit

EQUIPMENT MISUSE HAZARD

General Safety

Any misuse of the pressure washer or accessories,

such as overpressurizing, modifying parts, using

incompatible chemicals and fluids, or using wom or

to

damaged parts, can cause them

fluid injection, splashing in the eyes

other serious bodily injury, fire, explosion or property

damage.

NEVER

so

CHECK

replace wom or damaged parts immediately.

ALWAYS

clothing.

the chemical manufacturer’s literature for

recommendations on additional protective equipment,

such

alter

or modify any part of this equipment; doing

could cause

ail spray equipment regularly and repair or

as

a respirator,

it

to

malfunction.

wear protective eyewear and appropriate

If

using a chemical injector, read and follow

rupture and resun in

or

on the skin, or

System Pressure

This

sprayer can develop high operating pressure. Be

sure that all spray equipment and accessories are rated

to

withstand the maximum working pressure of this

sprayer.

pressure of any component or accessory used in the

system.

DO

Chemical Compatibility

BE

SURE

injector are compatible with the wetted parts of the

hose, gun, wand and tip, as given

(inside back cover). Always read the chemical

manufacturer’s literature before using any chemical in

this pressure washer.

that ail chemicals used in the chemical

DANGER

of

the equipment- grounding

of

electrocution.

NOT

exceed the maximum working

in the Technical Data

..

308-533

3

Page 4

HOSE

SAFETY

High pressure fluid in the hoses can be very dangerous.

If

the

hose develops a leak, split or rupture

kind of wear, damage or misuse, the high pressure

spray emitted from it can cause a fluid injection injury or

other serious bodily injury or property damage.

ALL

FLUID HOSES

BOTH

from kinks or bends at or close

can result

TlGHTEN

use. High pressure fluid can dislodge a

or ailow high pressure spray

coupling.

MOVING

Moving parts can pinch or amputate fingers or other

body parts.

or

NNER

and interlocks installed and functioning. Follow the

ENDS.

in

hose rupture.

all fluid connections securely before each

PARTS

K€€P

operating the pressure washer.

operate the pressure washer without all guards

MUST

HAVE STRAlN RELIEFS ON

The strain reliefs help protect the hose

to

the coupling, which

to

be emitted from the

HAZARD

CLEAR

of moving parts when starting

due

loose

to

any

coupling

TERMS

NNER

entire hose

damage or movement of the hose couplings.

these conditions exist, replace

DO

with

contain

HANDLEAND ROUTE

on hoses

chemicals which are not compatible with the inner tube

and cover of

temperatures above

(-400

Pressure

servicing the pressure washer to prevent discharging

high pressure fluid from the gun.

use a damaged hose. Before each use,'check

for

cuts, leaks, abrasion, bulging cwer,

If

the

hose immediately.

NOT

try

to recouple high pressure hose or mend it

tape

or any other device. A repaired hose cannot

the

high pressure fluid.

C).

HOS€S

to

move the pressure washer. Do not use

the

hose.

DO

200"

Relief

Procedure

WFFULLY

NOT

expose Graco hose

F

(93'

C) or below

before checking or

DO not pull

-40'

or

any of

to

F

WARNING

conditions that could cause bodily injury.

CAUTION: Alerts user

that could cause damage

or

DANGER Alerts user

to

avoid or correct conditions

to

the equipment.

to

avoid or correct NOTE Identifies helpful procedures and information.

IMPORTANT

United States Government safety standards have been adopted under the Occupational Safety and Health Act. These

standards-particularly the General Standards, Part 1910, and the Construction Standards, Part 1926-should be

consulted.

4

308-533

Page 5

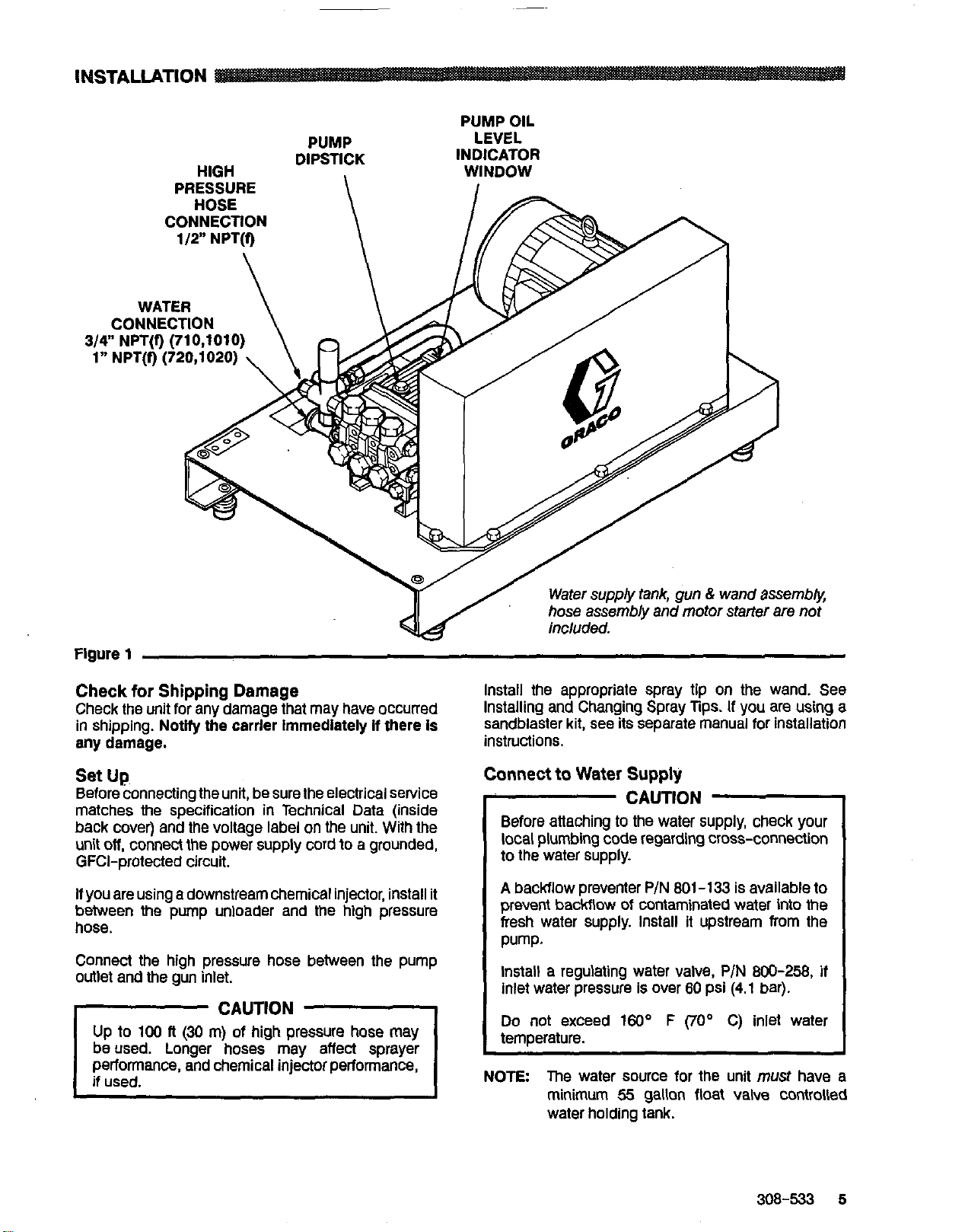

INSTALLATION

PUMP

OIL

for

Check

Check

in shipping. Notify the

any

damage.

UP.

Set

Before connectingthe unit, be sure the electrical sewice

matches the specification in Technical Data (inside

back cover) and the voltage label on the unit. With the

off,

unit

GFCI-protected circuit.

If you are using a downstream chemical injector, install it

between the pump unloader and the high pressure

hose.

Connect the high pressure hose between the pump

outlet

Shipping Damage

the

unit for any damage that may have occurred

carrler

connect the power supply cord to a grounded,

and the gun inlet.

Immediately If there

Is

CAUTION

Up

to

100

ft

(30 m) of high pressure hose may

beused. Longer hoses may affect sprayer

performance, and chemical injector performance,

if

used.

Install the appropriate spray tip on the wand. See

If

Installing and Changing Spray Tips.

sandblaster kit, see

instructions.

Connect

to

its

separate manual for installation

Water Supply

you are using a

CAUTION

Before attaching

local plumbing code regarding cross-connection

to the water supply.

A

backflow preventer P/N 801-133 is available to

prevent bacMlow

fresh water supply.

Pump.

Install a regulating water valve,

inlet water pressure is Over

Do

not exceed

temperature.

NOTE The water source for the unit

minimum 55 gallon float valve controlled

water holding tank.

to

the water supply, check your

of

contaminated water into the

Install

160"

F

it

60

(70'

upstream

P/N

800-258,

psi

(4.1

bar).

C) inlet water

from

must

the

if

have a

308-533

5

Page 6

STARTUP

Use

this procedure whenever starting the pressure

washer

and starting is done safely.

1.

2.

to

help insure that the unit is ready

Check the oil level.

Pump: Add SA€

as necessary.

lhm on the water supply.

20

or

30

weight non-detergent

to

operate

CAUTION

Never run the unit dry. Costly damage

pump will result. Always

supply is completely tumed on before

3.

Trigger the gun until water sprays from the

indicating that the air

4.

Start the unit.

5.

ALWAYS

vhenever you stop spraying, even for a moment

reduce the risk of fluid injection or splashing in

eyes or on the skin if the gun

accidentally.

engage the gun’s trigger safety latch

be

sure the water

is

purged from the system.

is

bumped or triggered

to

the

oil

tip

to

the

6.

ALWAYS

costly damage

observe

the following

to the pressure washer.

CAUTIONS

CAUTION

DO

NOT

allow the pressure washer

than

10

more

recirculating water

damage the pump. Tum

if

it will not be spraying

10

minutes. If heated inlet water is used, reduce

this time further.

DO NOT

damage the pump.

fully tumed on before starting the pump.

DO

NOT

materials may corrode the pump components.

7.

See

the chemical injector or sandblaster kit manual

for detailed cleaning information

accessories

minutes. Doing

to

or

run

the pump

Be

pump caustic materials; such

are

used.

so

overheat and seriously

off

the pressure washer

cleaning at least every

dly.

which will quickly

sure the water supply is

to

idle for

may cause

if

to

avoid

the

these

6

308-533

Page 7

Trigger

Safety

Latch

Installing

and

Changing Spray Tips

WARNING

To

reduce the risk of serious bodily injury,

including

on the skin,

latch whenever spraying stops, even for a

moment.

in the engaged position, the trigger safety latch

prevents the gun from being triggered

accidentally by hand or if it is dropped or

bumped.

when engaging it

from being triggered. See Figure

fluid

injection, splashing

ALWAYS

Be

sure

engage the trigger safely

the

latch is pushed fully down

or

it cannot prevent the gun

in

the eyes or

2.

WARNING

To

reduce the risk of serious bodily injury,

including fluid injection or splashing

or

onto

the skin,

changing spray tips.

procedure below.

1.

Follow the Pressure Relief Procedure.

2.

Point the gun and wand away from yourself and

anyone

3.

Without holding your hand

pull back the quick coupler ring

and then release the ring. See Figure

4.

Be sure the tip is secure before starting

again.

5.

Tip holding holes are provided on

To

coupler, due

never operate the pressure washer without a tip

securely mounted in the quick coupler.

else.

avoid blowing the O-ring out of the quick

use

extreme caution when

ALWAYS

Over

to

the high pressure in the system,

in

the eyes

follow the

the spray tip

(B),

remove the tip

3.

to

the

chassis

(A),

spray

TRIGGER SAFETY LATCH

TRIGGER SAFETY LATCH SHOWN DISENGAGED

Figure

2

SHOWN

ENGAGED

Flgure

3

308-533

7

Page 8

~ ~~~~~

SHUTDOWN, FLUSHING AND STORAGE

WARNING

PRESSURE RELIEF PROCEDURE

To

reduce

including fluid injection and splashing

eyes, or on the skin, always follow this

procedure whenever you stop sprayingformore

than

before checking or repairing any part of the

system.

1.

Engage the trigger safely latch.

2.

TUm the sprayer

3.

Disconnect the electrical supply.

4. Shut

5.

Disengage the trigger safety latch and

trigger the gun to relieve pressure, and then

engage the trigger safely latch again.

the

risk of serious bodily injury,

in

the

10 minutes, when shutting down, and

off.

off

the water supply.

-

1.

If

the pressure washer will be exposed to freezing

temperatures, drain all water out

must

be stored in freezing temperatures, flush the

unit with a

pressure. Flush the pressure washer before using

again to remove the anti-freeze.

~~

50% anti-freeze solution. Relieve

.~

of

the pump. If it

it

CAUTION

If

water does freeze in the pressure washer,

thaw it in a warm room before trying to start

DO

NOT

pour hot water on or into the pump; it

2.

After each

washer with a clean, damp

3.

Perform the appropriate maintenance.

maintenance chart.

use,

wipe all surfaces of the pressure

cloth.

it.

See

the

6.

Before long-term (overnight) storage,

disconnect the water supply and

the

disconnect

electricity.

MAINTENANCE

Observing regular maintenance intervals helps ensure

that

you

get maximum performance and life from the

pressure washer.

There

is

a break-in period

the oil initially, the interval between required changes

longer.

for

the pump. After changing

is

WARNING

To

reduce the risk of serious bodily injury,

including fluid injection, splashing in the eyes or

on the skin or injury from moving parts, always

follow the Pressure Rellef Procedure

before proceeding.

Wamlng

.

Interval

Daily

After first

hours of SAE

operation

Each

of operation or

6

months

50

500

hours Change pump oil.

What

to

do

inlet

Clean water

filter. Check pump oil level. Fill

as necessary.

Change pump break-in oil.

20

or

30

30

non-detergent

screen and

non-detergent

Use

SAE

oil.

Use

oil.

20

or

Page 9

TROUBLESHOOTING

To

reduce

injury from

the

risk

moving

of

serious

parts,

CHART

bodily

always follow

WARNING

injury, Including fluid injection, splashing

the

Pressure Relief Procedure Warning before

in

the eyes

or

on

the

skin,

proceeding.

or

PROBLEM

I

Low pressure andlor Wom or wrong size

I

pump

NnS

rough Inlet filter clogged.

Water leakage from

under

wmo manifold

~

"

v-

r

Water in pump

Frequent or

premature fai'ure

the packings

Strong surging at the

inlet and low pressure

on the discharge side

I

Unit will

not

start

~ ~~

I

Worn

packings,

natural wear.

Inadequate water supply.

Belt

slippage.

Fouled or

Even

to stick.

Restricted inlet.

Worn inlet or discharge valves.

1

Leaking high pressure hose.

Wom packings.

Humid air condensing inside crankcase.

Worn packings.

Oil

Scored.

Of

Abrasive material

Inlet water temperature

I

Overpressurizing pump.

Excessive pressure due

or damaged

I

Pump

Running pump dry.

Foreign particles

valve or wom Inlet and/or discharge valves.

Unit not plugged in.

Electrical sewice off/GFCi activated.

Thermal overload has tripped.

dirty

a

small particle can

seals

leakino.

damaged or wom plungers.

tip.

running

too

CAUSE

tip.

abrasives

inlet or discharge valves.

in

long

in

in

water

M

cause

the valve

. . .

the

fluid

being pumped.

too

high.

to

parilally plugged or replace

without

the inlet M discharge

spraylng.

SOLUTION

Replace wiih

Clean. Check more frequently.

Check fitter.

Check water flow rate

mlnimum

tank.

Tighten or replace.

Clean

filter.

Check garden hose, may

Replace wom valves.

ReDlace hioh DreSSure hose.

Install new packings.

Change oil

Install new packings.

Install

instali new plungers.

Install proper flltraiion on pump inlet plumbing.

Check water temperature; may not

Do

not modify any faciory-set adJusimenis.

I

EQUIPMENT MISUSE

Never

Do not run pump without water.

Clean

Check power

Check fuse/clrcuiI breaker. Check for proper

grounding.

Press reset bmn

stop button on the mdor siarter for

tip

of proper size.

Replace

55

gallon float valve controlled water holding

inlet

and discharge valve assemblies. Check

packings.

to

See

PUMP SERVICE.

pump. Unit must have

be collapsed or kinked.

-.

See

PUMP SERVICE.

as specified

new

oil

seals.

run

pump

or replace valves.

wrd.

See

tip.

See

more

on

in

MAINTENANCE.

See

PUMP SERVICE.

PUMP SERVICE.

~ee

PUMP

SERVICE.

HAZARD.

Installing

than

10

minutes wiihout sprayin(

See

PUMP SERVICE.

motor

for

1

phase units. Press

~~~~

exceed

and

3

1W"

Changlng Spra)

phase unih.

a

See

308-533

9

Page 10

PUMP

SERVICE

Servicing the Plungers

To

reduce the risk

including fluid injection, splashing in the eyes or replace retainers, O-rings. washers and

on the skin, or injury from moving parts, always backup rings for three cylinders.

follow the Pressure Relief Procedure

before proceeding.

NOTE The following metric wrenches are needed:

M10, M13 and M30. Repair kits are available.

to

Refer

pump parts

results, use

NOTE: There are

servicing the pump. P/N

ease installation

includes the items in

in the removal of packing retainers.

the individual repair sections and the

Valves

NOTE: For a

set

803-666.

1.

Remove

M30 wrench.

2.

Examine the O-ring under the hex plug and replace

if

it

Remove the valve assembly from the cavity; the

3.

assembly may come apart.

the

hex

it is cut or distorted.

of

serious bodily injury, NOTE Plunger repair kit, P/N

Warnlng

page for more details. For the best

all parts in the kits.

Wo different

tool

kits to aid

800-298

of

packings. P/N

800-298

of six valves, order P/N

plug from

the

and

manifold

-

is used to

800-271

tools

to

803-664

using

in

aid

or

an

803-677

1.

Loosen the plunger retaining screw five

using

an

MlOwrench. Push the plungertowards the

to

crankcase

screw.

2.

Remove the screw from ihe plunger and examine

the O-ring, backup ring and copper bearing/gasket

washer. Replace these parts,

separate the plunger and retaining

if

is available

to

necessary, using kit

801-474.

3. Remove the plunger and flinger from the plunger

shaft. Clean, examine and replace parts as

necessary.

Inspect the plunger shaft for oil leakage from the

4.

If

crankcase.

seals. Otherwise,

they cannot be reused. An oil seal kit is available

replace the seals.

5.

Lightly grease the oil seal,

and the flinger and replace them on the plunger

shaft. Then install the plunger.

6.

Lightly grease the retaining screw and the outer end

oiihephger. Place the wisher, O-ring and backup

ring around the screw and install the screw through

the plunger. Torque

leaking is obvious, replace the oil

DO

NOT remove these seals

if

it

is being replaced,

to

14.4

ft-lb

(19.5

Nm).

4.

to

six tums,

as

to

NOTE: Retorque the plug after

5

hours of operation.

Pumping Section

1.

Remove the eight capscrews and lockwashers from

the manifold using an M13 wrench.

2.

Carefully separate the manifold from the crankcase.

NOTE:

It

may be necessary to tap the manifold lightly

soft

with a

mallet to loosen.

CAUTION

Keep the manifold properly aligned with the

ceramic plungers when removing to avoid

damage

3. Carefully examine each plunger for any scoring or

cracking and replace as necessary.

to

the plunger or seals.

7.

Lubricate. the outside of each plunger. Slide the

manifold onto the crankcase, being careful not

damage the seals.

8.

Install the capscrews and washers finger-tight.

Torquethescrewsto21.7ft-lb(29Nm)followingthe

4).

tightening pattern (Figure

may cause the manifold

Figure

4

Uneven tightening

to

bind or jam.

I

to

10

308-533

Page 11

Servicing the V-Psckings

NOTE:

1.

mere are

two

types

of packing kits: one is

packings only, the other includes the

packings, rings and retainers.

Remove the manifold as outlined in the Pumping

Section.

5. moroughly clean the packing cavities and examine

for

debris and damage.

6.

Lightly grease the packing cavities and then

replace the packings in the following order: head

'

ring, v-packing, intermediate

ring, head ring,

v-packing and packing retainer with the O-ring

installed in the retainer groove.

2.

Carefully pull the packing retainer from the

manifold. Examine the O-ring and replace it

cut or damaged.

3.

Remove the v-packing and head ring. Pull

intermediate retainer ring. Remove the second

v-packing and second head ring.

4.

inspect

all

parts and replace as necessary.

if

out

it is

the

CAUTION

the

install

the correct direction. Improperly installed parts

will

7.

Reassemble the manifold

the Plungers.

parts in the proper order and facing

cause a malfunction.

as

instructed in Servicing

308-533

11

Page 12

PARTS DRAWING

710

800-902 Hydra-Clean@

800-903 Hydra-Clean@

For wiring diagrams, see pages 13 and

Pressure Washer

I010

Pressure Washer

15

12

308-533

9’

7

Page 13

PARTS

800-902

800-903

LIST

Hydra-Clean@

Hydra-Clean@

710

Pressure Washer

1010

Pressure Washer

REF

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

PART

NO.

803-566

801 -940

100-21 4

100-527

800-447

177-144

800-444

803-m

802-845

801

-020

172-981

176-250

803-560

801 -376

803-576

803-769

801-91 1

803-575

803-574

803-770

803-088

803-517

100-21

100-1 33

4

DESCRIPTION

BELT GUARD

SCREW. CaD. hex

WASHER, Lock, 5/16

WASHER, Flat, 5/16

CHASSIS

LABEL, Warning. belt guard 1

BRACKET, Rail Stiffener 1

SCREW, Cap, hex

FOOT, Rubber 4

NUT. Lock 1/2-13

LABEL, Waming,~chassis

LABEL, Warning, chassis

BRACKET, Rail Stiffener

HUB. Motor. 5 hD

Afor 800-902 only) 1

H

B, Motor, 7-1/2 hp

(for 800-903 only)

SHEAVE, Motor

(for 800-902 only)

SHEAVE, Motor

(for 800-903 only)

HUB, Pump

(for 800-902 only)

HUB, Pump

Afor 800-903 only)

S

EAVE, Pump

(for 800-902 only)

SHEAVE, Pump

(for 800-903 only)

LABEL, Keep From Freezing 1

WASHER, Lock, 5/16

W

r

SHER,

800-902

(for 800-903 only) 4

Lock, 3y8

hd.

hd,

)

3/8-16x5

QTY

1

5

5

1

2

2

~

1

1

1

1

1

1

1

1

1

1

4

REF

NO.

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

PART

NO.

100-527

100-023

803-579

803-580

801

803-593

100-023

100-133

803-761

803-762

802-784

803-591

803-396

800-445

803-577

802-084

801 -787

803-791

803-599

800-687

800-688

159-239

803-141

803-142

801 -274

803-872

802-096

DESCRIPTION

WASHER, Flat, 5/16

WASHER, Flat, 3/8

M

MOTOR, 7-1/2

SCREW, Cap, hex hd

-941

SCRW,

WASHER, Flat, 3/8

WASHER, Lock, 318

BELT, Drive (for 800-902 only

BELT, Drive (for 800-903 on14

WASHER, Lock, 1/2

WASHER, Flat, 112

DECAL, WamingKaution

BRACKET, Pump Support

PUMP, 10 GPM (see page 16)

NIPPLE, 3/4x2

TEE, 314

PLUG, Plastic, 3/4

PLUG, Plastic, 1/2

UNLOADER,

UNLOADER, lo00 PSI

NIPPLE, Hex 3/8x1

NIPPLE,

BUSHING, Hex, 3/8x1/4

LABEL, Graco G

BUSHING, Hex, 1/2x3/4

(for 800-902 only)

IY

TOR,

800-903

5hp,TEF

Only

,

3 phase (for 800-902 only)

hp,

700

TEFC,

PSI

2

3 phase (for 800-903 only)

(for 800-902 only)

Cap, hex hd

(for 800-903 only)

(for 800-902 only)

(for 800-903 only

Br=

ex

112 NPSM x 318 NPT

QTY

4

4

1

1

4

4

2

2

2

2

2

2

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

5

hp

230

Wlrlng

Volt,

Diagram

3

Phase

308-533

13

Page 14

PARTS

800-904

800-905

For wiring diagrams, see pages

DRAWING

Hydra-Clean@

Hydra-Clean@

720

Pressure Washer

1020

Pressure Washer

13

and

15

I

\

40

I

I

I

I

14

308-533

Page 15

PARTS

800-904

800-905

LIST

Hydra-Cleans

Hydra-Clean@

720

Pressure

1020

Pressure Washer

Washer

REF

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

PART

NO.

803-566

801

-940

100-21 4

100-527

800-447

177-144

8w-444

803-777

802-845

801

-020

172-981

176-250

803-560

603-767

801 -623

803-878

803-879

803-575

803-574

603-880

803-776

803-517

100-133

802-784

DESCRIPTION

BELT GUARD

SCREW, Cap, hex

5/16-18X3/4

WASHER, Lock, 5/16

WASHER, Flat, 5/16

CHASSIS

LABEL, Warning, belt guard

BRACKET, Rail Stiffener

SCREW,

FOOT. Rubber

NUT,

LABEL. Wamina. chassis

LABEL; Warnin& chassis

BRACKET. Rail Stiffener

HUB, Motor, 10

(for 800-904 only)

HUB, Motor, 15 hp

(for 800-905 only)

SHEAVE, Motor

SHEAVE, Motor

HUB, Pump

HUB, Pump

SHEAVE, Pump

SHEAVE. Pumo

LABEL, Keep From Freezing

WASHER, Lock, 3/8

WASHER, Lock,

Cap, hex hd, 3/8-16X5

Lock

1/2-13

(for 800-904 only)

(for 800-905 only)

(for 800-904 only)

(for 800-905 only)

(for 800-904 only)

(for 606-905 only)

(lor

800-004

(for 800-905 only)

hp

on1

hd,

)

1&

QTY

1

5

5

5

1

1

1

2

4

2

'1

1

1

1

1

1

1

1

1

1

1

1

4

6

REF

NO.

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

PART

NO.

100-023

803-591

803-581

803-582

803-593

803-592

100-023

100-133

803-677

802-784

803-591

803-396

800-446

803-578

803-585

803-586

803-791

803-599

800-687

800-688

168-595

21 4-956

202-965

157-191

803-872

DESCRIPTION

WASHER, Flat, 3/8

(for 800-904 only)

WASHER, Flat, 1/2

S,,

800-905 Only)

M TOR, 10 hp, TEFC,

3 phase (for 800-904 only)

MOTOR, 15 hp, TEFC,

3 phase (for 800-905 only)

SCREW, Cap, hex hd

(for 800-904 only)

SCREW, Cap, hex hd

(for 800-905 only)

WASHER, Flat, 3/8

WASHER, Lock, 3/8

BELT, Drive

WASHER, Lock, 1/2

WASHER, Flat, 1/2

DECAL, Warning/Caution

BRACKET, Pump Support

PUMP,

NIPPLE, Hex, 1

TEE, 1

PLUG, Plastic,

PLUG, Plastic, 1/2

UNLOADER, 700 PSI

UNLOADER, loo0 PSI

ADAPTER, Hex 3/4X1/2

HOSE, Bypass

SWIVEL, 1x3/4

NIPPLE, Hex, 1/2x3/4

LABEL, Graco

20

GPM (see page 18)

1

(for 800-904 only)

(lor 800-905 only)

G

QTY

4

4

1

1

4

4

2

2

2

2

2

1

2

1

1

1

1

1

1

1

1

1

1

1

1

7.5,

Wring

230

10

Diagram

Volt,

&

15

3

hp

Phase

308-533

15

Page 16

PARTS

803-577

DRAWING

Pump

Assembly,

10

GPM

16

308-533

Page 17

REF

NO.

1

2

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

PART

NO.

803-657 SCREW, Cap, socket hd.

803-639 WASHER, Lock 16

KIT 62 VALVE ASSEMBLY

803-630

803-61 6 COVER, Valve

803-655

37

KTT

803-606

801-475 DIPSTICK

803-615 GASKET, Cover

KIT 74 SCREW, Piston

KIT74

KIT 74

KIT74 WASHER, Flat

803-609

803-607

803-612 COVER, Crankcase

803-608

801-652 WASHER, Lock

803-294 SCREW, Cap, socket hd.

802-344 O-RING

802-345 GAUGE, Sight

801-484 PLUG, Hex hd.

803-651

803-645 PIN, Wrist

DESCRIPTION

O-RING

SCREW, Cap, socket

SEAL, Oil

CRANKCASE

O-RING

RING, Backup

PISTON

CRANKSHAFT

ROD,

Connecting 3

SCREW, Cap, socket hd. 9

hd.

QTY

8

6

6

2

8

3

1

1

1 42

3

3

3

3

3

1

1

6

6

1

1

2

3

REF

NO.

31

33

34

35

36

37

38

39

41

43

44

45

46

47

48

49

50

51

52

53

54

55

PART

NO.

803-610 GUIDE, Piston

803-641 WASHER, Flinger

803-653

803-605

803-613 SPACER

KIT 32 SEAL, Oil

803-632 O-RING

803-638

803-633

802-317 WASHER, Lock 4

802-305 SCREW, Cap, socket hd. 4

803-647 PLUG, Hex hd. 1

803-643

803-289 WASHER, Flat 1

803-61 1 HEAD, Pump

KIT 39 O-RING

KIT 39 RETAINER, Packing

KIT 38,39 PACKING 6

KIT 39 RING, Head

KIT 39 RING, Intermediate

803-635

802-357 RING, Retaining 1

803-614 SPACER

DESCRIPTION

SCREW, Cap, hex hd.

COVER, Crankcase

BEARING, Ball

BUSHING

WASHER, Flat

KCI

am

3

3

a

2

1

1

2

2

3

1

1

6

6

6

3

1

1

Repair

Part

803-660

Seal

Oil Seal

Packina

Packing

Retainer

Valve

Plunger O-RING

Repair

Kit

No. No.

&

Ref

37 SEAL. Oil

I I

W.

Description Incl.

2

RETAINER,

Packing

PACKING

RING. Head

SCREW, Piston

RING, Back-up

308-533

17

Page 18

PARTS DRAWING

803-578

Pump

Assembly,

20

GPM

18

308-533

/-

/-

/-

22

27

Page 19

PARTS

LIST

803-578

Pump

Assembly,

20

GPM

REF

NO.

1

2

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

PART

NO.

803-659

803-640 WASHER, Lock

KIT43

803-631 O-RING

803-650 CAI? Valve

803-624 COVER, Crankcase

44

KIT

803-617 CRANKCASE

803-648

803-627

KIT 74

KIT 74 O-RING

KIT 74

KIT 74

803-621

803-618 CRANKSHAFT

803-625 COVER, Crankcase

803-620

803-639 WASHER, Lock

803-656 SCREW, Cap, socket hd.

802-344 O-RING

802-345 GAUGE, Sight

801-484 PLUG, Hex hd.

803-652 SCREW, Cap, socket hd.

DESCRIPTION

SCREW, Cap, socket hd.

'

VALVE ASSEMBLY

SEAL, Oil

DIPSTICK

GASKET, Cover

SCREW, Piston

RING, Backup

WASHER, Flat

PISTON

ROD, Connecting

QTY

8

12

6

6

6

1

3

1

'1

1

3

3

3

3

3

1

1

3

6

6

2

1

2

10

REF

NO.

30

31

32

33

34

35

36

37

38

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

PART

NO. DESCRIPTION

803-646 PIN, Wrist

803-629 GUIDE, Piston

KIT 79,80 RING, Backup

803-641 WASHER, Flinger

803-654 SCREW, Cap, hex hd.

803-623 COVER, Crankcase

803-628

802-353

803-637 BEARING, Tapered Roller

803-634 BUSHING

803-658 SCREW, Cap, socket

803-649 PLUG, Hex

803-647 PLUG, Hex hd.

803-644 WASHER, Flat

803-643

803-622 HEAD, Pump

80

KIT

KIT 80 RETAINER, Packing

KIT 79,80 PACKING

80

KIT

80 RING, Intermediate

KIT

803-636 KEY

802-357

KIT 32 SEAL, Oil

SHIM

O-RING

hd.

hd.

WASHER, Flat

O-RING

RING, Head

RING, Snap

QTY

3

3

3

3

8

1

2

2

2

3

4

1

1

1

1

1

3

3

6

6

3

1

1

1

Repair

Part

No.

803-660

Oil Seal

803-664

Valve

803-665

Oil Seal

803-667

Plunger

Repair

803-668

Packing

803-669

Packing

Retainer

KR

&

-

Ret

No.

-

54

-

8

-

12

-

16

17

RING, Back-up

18

WASHER. Flat

19

-

RING, Back-up

32

PACKING

49

-

RING, Back-up

32

O-RING

47

RETAINER,

48

Packing

PACKING

49

RING. Head

50

RING,

51

Intermediate

1; 1

~

I: I

I1 I

I

I

308-533 19

Page 20

ACCESSORIES

PTFE

PTFE

PTFE

PTFE

PTFE

PTFE

PTFE

PTFE

PTFE

(Must

DOWNSTREAM CHEMICAL INJECTOR KIT BACKFLOW PREVENTOR 801-133

800-117 BRASS UP TO

800-425 BRASS 5.6 TO 10.8 GPM (21 TO 41

be

purchased

separately)

5.5

GPM (21 LPM)

Prevent back-up

supply. Install upstream of pump.

of

contaminated water

into

fresh

INLET PRESSURE REGULATOR 800-258

to

60

psi

Regulates inlet water pressure

maximum.

HOSE

ASSEMBLY WITH QUICK COUPLERS

(4

800-375

x

50

foot

x

4OOO

psi

(276

3/8” diameter

coupled hose with

couplers.

TECHNICAL

Motor (Totally Enclosed

:an Cooled)

Ilectrical Service 230

DATA

801-568

and 801-569 3/8” quick

Model

5.0

3

phaseor

bar) permanently

800-902

hp, 3 phase

v011/20

amp/ 230

Includes 803-350 spray gun, 32 spray wand, quick

bar)

coupler for hose connection and adjustable nozzle.

800-042

Includes

stainless steel spray

connections for hose and spray tip.

Model 800-903 Model 800-904 Model

7.5

hp. 3 phase 10.0 hp,

volV20

amp/

3

phase

or

800-222

230 volt/30 amp/

3 phase

stainless

wand

and stainless steel threaded

3

phase 15.0 hp.

M

steel

230

3 phase

spray gun, 32

800-905

3

phase

voItl40

amp/

or

Bypass

Pressure Washer

(including fittings)

Hose

Acrylonitrile and Buna-N wver and

Synthetic yam and EPDM

Anodized aluminum, Aluminum

Ceramic. Buna- on Phenolic, 303,304, and 316 Stainless Steel, P de-12

Thermoplastic. Carbon Steel, Zinc with

is

a registered trademark

tube

or Bronze alloys, Brass, Copper, Nylon- composite.

or

without Yellow Chromate Plate

of

the

DuPont

Companfl

Loading...

Loading...