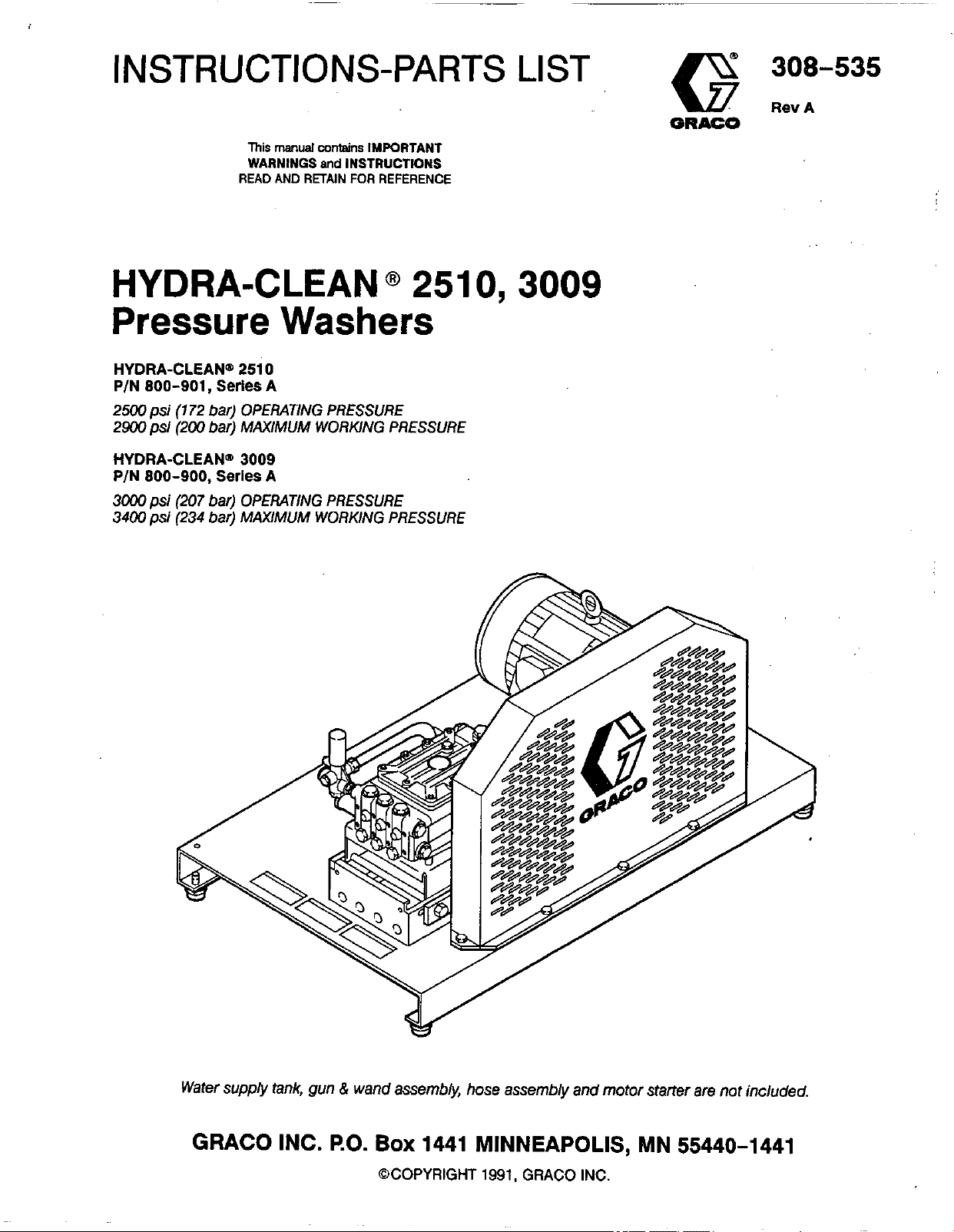

Graco Inc Hydra-Clean 308-535, Hydra-Clean 2510, Hydra-Clean 800-901, Hydra-Clean 3009, Hydra-Clean 800-900 User Manual

Page 1

INSTRUCTIONS-PARTS

This

manual

wntains

WARNINGS

READ AND RETAIN

and

IMPORTANT

INSTRUCTIONS

FOR

REFERENCE

LIST

CDRACO

HYDRA-CLEAN

@

251

Pressure Washers

HYDRA-CLEAN"

P/N

800-901,

2500psi

2900

HYDRA-CLEAN"

P/N

3000

3400

(172

psi

(200 bar) MAXIMUM WORKING PRESSURE

800-900,

psi

(207

psi

(234 bar) MAXIMUM WORKING PRESSURE

2510

Series A

bar) OPERATING PRESSURE

3009

Series

bar) OPERATING PRESSURE

A

0,3009

Water

supply

tank, gun & wand assembM, hose assembly and motor starter are not included.

GRACO INC.

RO.

Box

1441 MINNEAPOLIS, MN 55440-1441

@COPYRIGHT

1991.

GRACO

INC.

Page 2

~A~~~~~

HIGH PRESSURE SPRAY CAN CAUSE SERIOUS INJURY.

FOR

PROFESSIONAL

Read and understand all instruction manuals before operating equipment.

USE

ONLY.

OBSERVE

ALL WARNINGS.

FLUlD

1NJECTlON

HAZARD

General Safety

This pressure washer generates very high fluid

pressure. Spray from the gun, leaks or tuptured

components can inject fluid through your skin and into

your body and cause extremely

including the need for amputation. Also, fluid injected or

splashed into the eyes or on the skin can

damage.

NNER

part of the body.

spray tip.

ALWAYS

cleaning or servicing any part of the sprayer.

NNER

body.

Be sure equipment safety devices are operating

properly before each

point the spray gun or wand at anyone or at any

NNER

follow the

try

to

stop or deflect leaks with your hand or

put

Pressure Relief Procedure,

use.

serious

hand or fingers over the

bodily injury

cause

serious

before

Medical Treatment

If

any fluid appears to penetrate your skin, get

EMERGENCY MEDICALTREATMENTATONCE.

NOT TREAT AS A SIMPLE CUT.

what fluid was injected.

Tell

the

doctor exactly

DO

Pressure Relief Procedure

To

reduce the risk of serious bodily injury, including fluid

injection and splashing

always follow this procedure whenever you stop

spraying for more than

and before checking or repairing any part of the system.

1.

Engage the trigger safety latch.

2.

Thm

the sprayer

3.

Disconnect the electrical supply.

4.

Shut

off

the water supply.

5.

Disengage the trigger safety latch and trigger the

gun to relieve pressure, and then engage the trigger

safety latch again.

6.

Before long-term (ovemighi) storage, disconnect

the water supply and disconnect the electricity.

in

the eyes or on the skin,

10

minutes, when shutting down,

off.

Spray Gun Safety Devices

Be

sure

all gun safety devices are operating properly

use.

before each

the gun; this can cause a malfunction and result in

serious bodily injury.

Do not remove or modity any part of

NOTE

traumatic

surgically as

treatment

concern

direct& into

plastic

may be advisable.

TO

PHYSICIAN

injug It

soon

to

research toxiciv. Toxicify

with

.some

the

surgeon

bloodstream. Consultation

or

injection

Is

Important to

as possible.

exotic- coatings injected

reconstructive

in

the

treat the

Do

not delay

hand

skin

is

a

InJury

is

a

wirb

a

surgeon

SAFEIY

moment, always set the gun safety latch in the engaged

or"safe" position, making thegun inoperative. Failureto

properly

triggering of the gun.

SPRAY

cleaning or changing spray tips. If a spray tip clogs

while spraying, engage the gun safety latch

immediately.

Procedure

LATCH:

set

TIP

Whenever you stop spraying for a

the safety latch can result in accidental

SAFm.

ALWAYS

and then remove the spray tip to clean it.

Use

extreme caution when

follow the

Pressure

Relief

2

308-535

Page 3

GROUNDING INSTRUCTIONS

This product must be grounded. If it should malfunction

or break down, grounding provides a path of least

resistance for electric current to reduce the risk of

electric shock. This equipment is equipped with a cord

having an equipment-grounding conductor and a

The

grounding plug.

appropriate outlet that is properly installed and

&dunbed in accordance wiih

ordinances.

plug must be plugged into an

all

local codes and

Improper connection of the equipment- grounding

conductor can result in the risk of electrocution.

Check with a qualified electrician or service

GROUND FAULT CIRCUIT INTERRUPTER PROTECTION

To

comply with the National Electrical Code

and to provide additional protection from the risk of

electric shock, connect this pressure washer to a circuit

that is protected by a ground-fault circuit-interrupter

(GFCI).

(NFPA

70)

EQUIPMENT MISUSE HAZARD

General Safety

Any misuse of the pressure washer or accessories,

such as overpressurizing, modifying parts, using

incompatible chemicals and fluids, or using worn or

damaged parts, can cause them to rupture and result in

fluid injection, splashing in the eyes or on the skin, or

other serious bodily injury, fire, explosion or property

damage.

System Pressure

This sprayer can develop high operating pressure. Be

sure that all spray equipment and accessories are rated

to.withstand the maximum working pressure of this

sprayer.

pressure of any component or accessory used

system.

DO

Chemical Compatibility

NNER

so

CHECK

replace worn or damaged parts immediately.

ALWAYS

clothing.

the chemical manufacturer's literature for

recommendations

such as a respirator.

alter or modify any part of this equipment; doing

could cause it to malfunction.

all

spray equipment regularly and repair or

wear protective eyewear and appropriate

If

using a chemical injector, read and follow

on

additional protective equipment,

BE

SURE

injector are compatible with the wetted parts

hose, gun, wand and tip, as given in the Technical Data

(inside back cover). Always read the chemical

manufacturer's literature before using any chemical in

this pressure washer.

DANGER

NOT

exceed the maximum working

that all chemicals

-1

used

in

the chemical

in

of

the

the

308-535

3

Page 4

HOSE

SAFETY

High pressure fluid in the hoses can be very dangerous.

If

the hose develops a leak, split or rupture due

to

any

kind of wear, damage or misuse, the high pressure

spray emitted from it can cause a fluid injection injury or

other

serious

bodily injury or property damage.

NNER

entire hose for cuts, leaks, abrasion, bulging cover, or

damage or movement of the hose couplings.

these conditions exist, replace the hose immediately.

DO

use a damaged hose. Before each use, check

NOT

try

with tape or any other device. A repaired hose cannot

ALL

FLUID

BOTH

from kinks or bends at or close

can result in hose rupture.

HOSES

ENDS.

MUST

HAVE

STRAIN'REUEFS

ON

The strain reliefs help protect the hose

to

the coupling, which

contain the high pressure fluid.

HANDLEAND

on hoses

chemicals which are not compatible with the inner tube

TlGHTfN

use. High pressure fluid can dislodge a

or allow high pressure spray

all fluid connections securely before each

loose

coupling

to

be emitted from the

and cover

temperatures above

(-400

C).

coupling.

MOVING

Moving parts can pinch

body parts.

PARTS

KEEP

CLEAR

HAZARD

or

amputate fingers or other

of moving

parts

when starting

..

Pressure Rellef Procedure before checking

servicing the pressure washer

or operating the pressure washer. high pressure fluid from the gun.

NNER

operate

the

pressure washer without all guards

and interlocks installed and functioning. Follow the

TERMS

to

recouple high pressure hose or mend it

ROUTEHOSES CAREFULLY

to

move the pressure washer.

of

the hose.

DO

NOT

expose Graco hose

DO

Do

200" F (93O C) or below

to

prevent discharging

,

.

.

If

any of

not pull

not use

to

-40'

or

F

WARNING

or

DANGER

Alerts user

to

avoid or correct

NOTE

Identifies helpful procedures and information.

conditions that could cause bodily injury.

CAUTION

that could cause damage

Alerts user

to

avoid or correct conditions

to

the equipment.

IMPORTANT

United States Government safety standards have been adopted under the Occupational Safety and Health Act. These

standards-particularly the General Standards, Part 1910, and the Construction Standards. Part 1926-should be

consulted.

4

308-535

Page 5

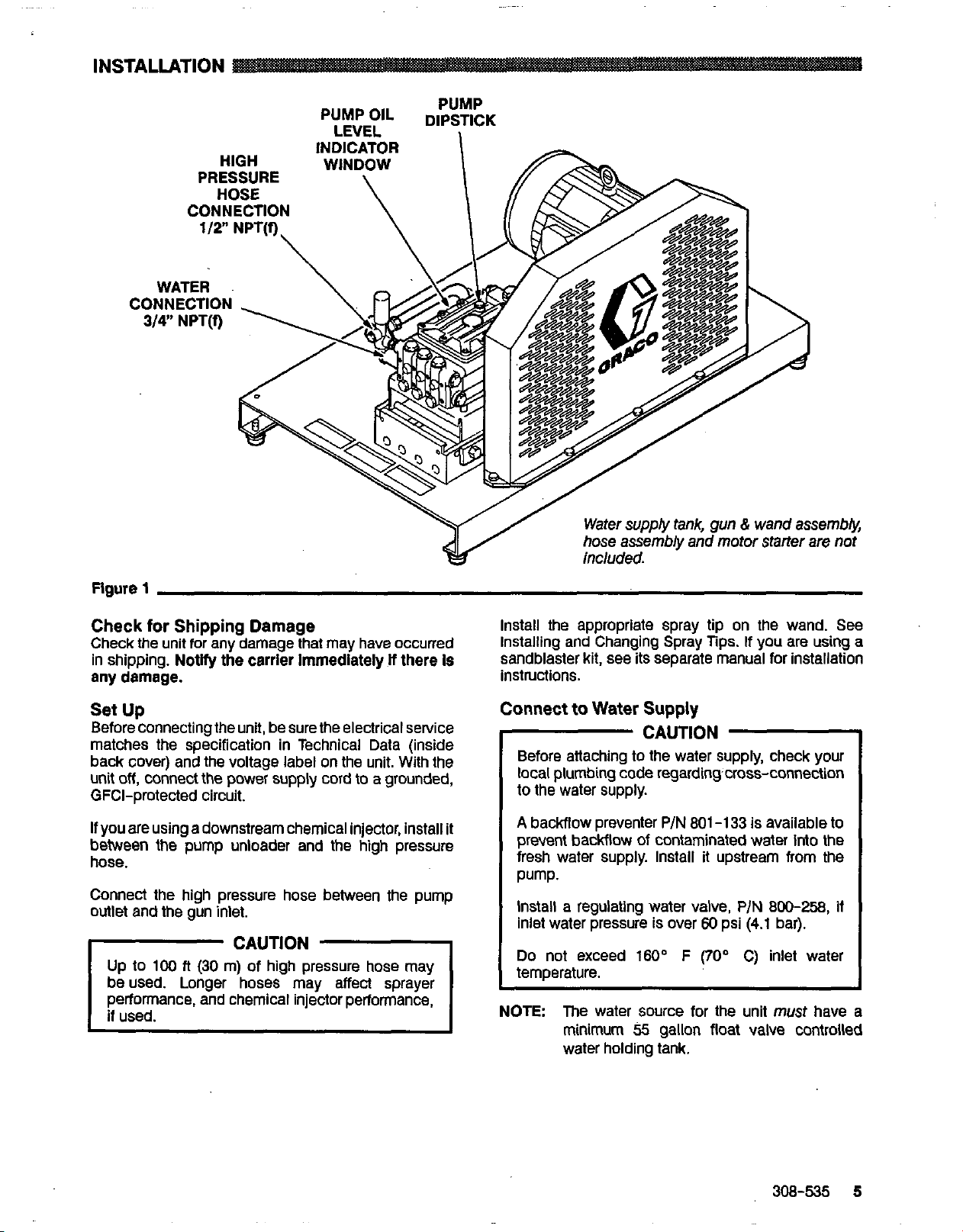

INSTALLATION

OIL DIPSTICK

LEVEL

PUMP

Figure

Check

Check the unit for any damage that may have occurred

in shipping.

any damage.

Set

Before connecting the unit, be sure the electrical setvice

matches the specification in Technical Data (inside

back cover) and the voltage label on the unit.

unit

GFCI-protected circuit.

If

between the pump unloader and

hose.

Connect the high pressure hose between the pump

outlet and me gun inlet.

1

for

Shipping Damage

Notify

the carrier Immediately

If

there

Is

Up

With

the

off,

connect the power supply cord to a grounded,

you are using a downstream chemical injector, install it

the

high pressure

Up

to

100

fi

(30

m)

of high pressure hose may

beused. Longer hoses may affect sprayer

performance, and chemical injector performance,

Install the appropriate spray tip on the wand. See

Installing and Changing Spray Tips.

sandblaster kit, see

instructions.

Connect

NOTE:

If

you are using a

its

separate manual for installation

to

Water

Before attaching to the water supply, check your

local plumbing code regardingcross-connection

to the water supply.

A

backflow preventer

prevent backflow

fresh water supply. Install

Pump.

Install a regulating water valve,

inlet water pressure is over

Do not exceed

temperature.

The water source for the unit

minimum

water holding tank.

Supply

CAUTION

P/N

801-133

of

contaminated water

it

60

160'

F

(70'

55

gallon float valve controlled

is

available to

into

upstream from the

P/N

800-258,

psi

(4.1

bar).

C) inlet water

must

the

if

have

a

308-535

5

Page 6

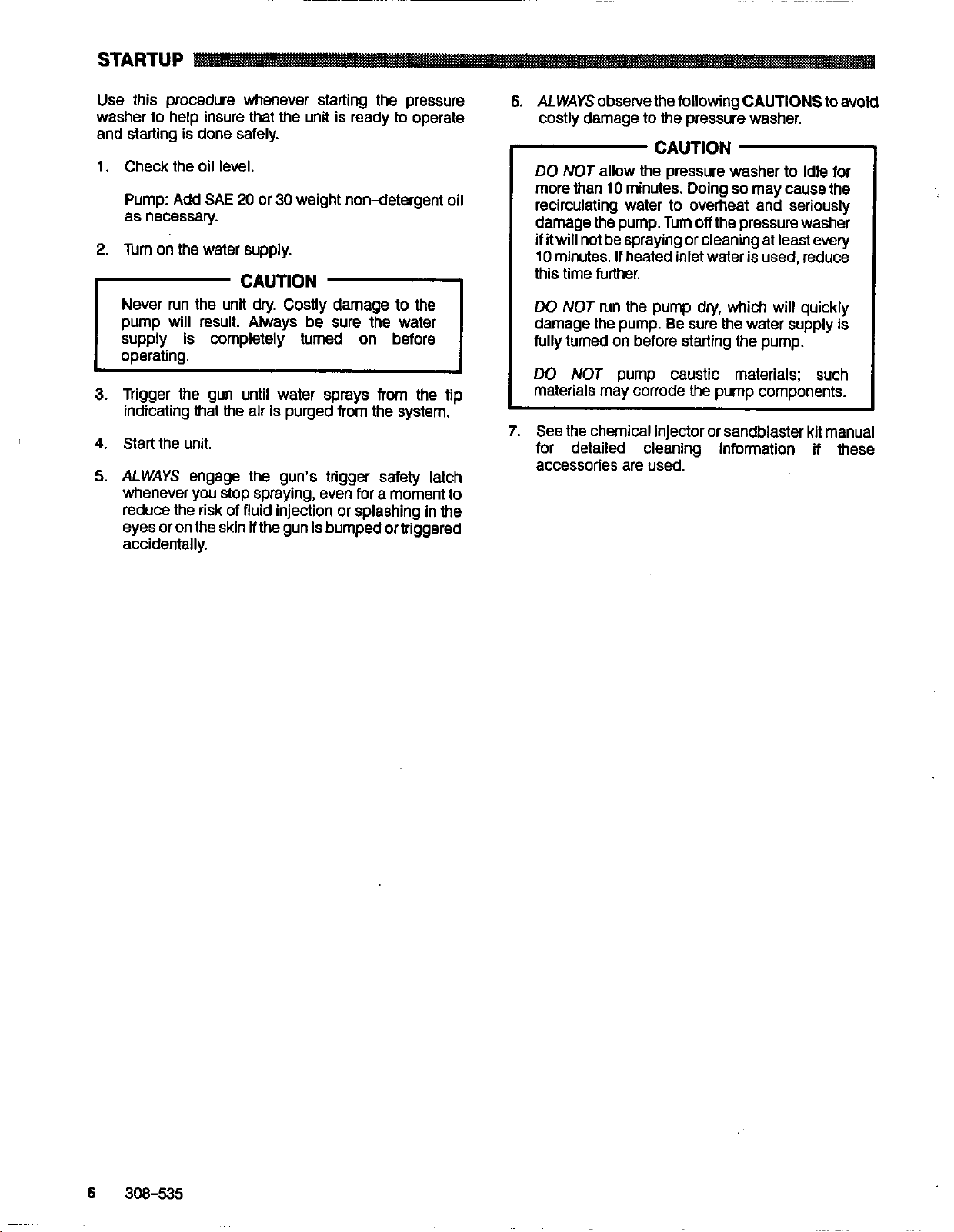

Use this procedure whenever starting the pressure

to

washer

and starting is done safely.

1.

2.

Tum on the water supply.

help insure that the unit is ready

Check the oil level.

Pump: Add SAE

as necessary.

20

or

30

weight non-detergent oil

to

operate

CAUTION

Never run the unit dry. Costly damage

pump will result. Always be sure the water

supply is completely tumed on before

operating.

3.

Trigger the gun until water sprays tom the tip

indicating that the air is purged tom the system.

4.

Start the unit.

5.

ALWAYS

whenever you stop spraying, even for a moment

reduce the risk of fluid injection or splashing in the

eyes or on the skin

accidentally.

engage the gun’s trigger safety latch

if

the gun is bumped or triggered

to

the

to

6.

ALWAYS

costly damage

observe the following

to

the pressure washer.

CAUTIONS

CAUTION

DO

NOT

allow the pressure washer

more than

recirculating water

damage the pump.

if it will not be spraying or cleaning at least every

10

minutes.

this time further.

DO

damage the pump. Be sure the water supply is

fully tumed on before starting the pump.

DO

materials may corrode the pump components.

7.

See the chemical injector or sandblaster

for detailed cleaning information

accessories are used.

10

minutes. Doing

to

Turn

If

heated inlet water is used, reduce

NOT

run the pump dry, which will quickly

NOT

pump caustic materials: such

so

overheat and seriously

off

the pressure washer

to

idle for

may cause the

kit

to

avoid

manual

if

these

Page 7

Trigger Safety Latch

Installing

and

Changing Spray

Tips

WARNING

To

reduce the risk

including fluid injection, splashing in the eyes or

on the skin,

latch whenever spraying stops, even for

moment.

In the engaged position, the trigger safety latch

prevents the gun from being triggered

accidentally by hand or

bumped.

when engaging

from being triggered. See Figure

ALWAYS

Be

sure the latch is pushed fully down

of

serious bodily injury,

engage the trigger safety

If

it

is dropped or

it

or

it

cannot prevent the gun

2.

a

WARNING

To

reduce the risk

including fluid injection or splashing in the eyes

or onto the skin, use extreme caution when

changing spray tips.

procedure below.

1.

Follow the

2.

Point the gun and wand away

anyone else.

3.

Without holding your hand over the spray tip

pull back the quick coupler ring

and then release the ring.

4.

Be sure the tip is secure before starting to spray

again.

5.

lip holding holes are provided on the chassis,

To

avoid blowing the O-ring

coupler, due to the high pressure In the system,

never operate the pressure washer without a tip

securely mounted in the quick coupler.

Pressure Rellef Procedure.

of

serious bodily injury,

ALWAYS

See

follow the

from

(B),

remove the tip

Figure

out

of

the quick

yourself and

3.

(A),

TRIGGER SAFETY LATCH SHOWN ENGAGED

TRIGGER SAFETY LATCH SHOWN DISENGAGED

Figure

2

Flgure

3

308-535

7

Page 8

SHUTDOWN, FLUSHING AND STORAGE

WARNING

PRESSURE RELIEF PROCEDURE

To

reduce the risk of serious bodily injury,

including fluid injection and splashing in the

eyes, or on the skin, always follow this

procedure whenever you stop spraying for more

than 10 minutes, when shutting down, and

before checking or repairing any part of the

system.

1.

Engage the trigger safety latch.

2.

Tum the sprayer

3.

Disconnect the electrical supply.

4.

Shut

off

the water supply.

5.

Disengage the trigger safety latch and

trigger the gun

engage the trigger safety latch again.

off.

to

relieve pressure, and then

~

1.

If the pressure washer will

temperatures, drain all water

must be stored in freezing temperatures, flush the

50%

unit with a

pressure. Flush the pressure washer before using it

to

again

remove the anti-freeze.

anti-freeze solution. Relieve

be

exposed

out

of the pump. If it

to

freezing

CAUTION

If

water does freeze

thaw it in a warm room before trying

DO

NOT

pour hot water on or into the pump; it

2.

After each use, wipe all surfaces of the pressure

washer with a clean, damp cloth.

3.

Perform the appropriate maintenance. See the

maintenance chart.

in

the pressure washer,

to

D

start it.

6.

Before long-term . (overnight) storage,

disconnect the water supply and

disconnect the electriclty.

MAINTENANCE

Observing regular maintenance intervals helps ensure

you

that

pressure washer.

There is a break-in period for the pump. After changing

the

longer.

get maximum performance and life from the

oil

initially, the interval between required changes is

To

reduce the risk of serious bodily injury,

including fluid injection, splashing in the eyes or

on the skin or injury from moving parts, always

follow the Pressure Relief Procedure

before proceeding.

Warning

I

Interval

Daily

hours of

otteration

I

500

Each

of operation or

6

months

hours

What to

Clean water inlet screen and

filter. Check pump oil level.

as

SAE

Change pump oil. Use

30

do

necessary.

20

or

30

non-detergent oil.

non-detergent oil.

SAE

Fill

20

I

or

8

308-535

Page 9

TROUBLESHOOTING CHART

io

reduce

inlury

the

risk

Of

serious

from

moving parts, always follow

bodily injury,

WARNING

including

the

Pressure Rellef Procedure Warning before

fluid injection, splashing

in

the

eyes

or

on

the

skin,

procaeding.

or

PROBLEM

ow

pressure and/or

ump runs rough

later leakage

nder pump manifold

later in pump

requent

remature failure

18

packlngs

:rong surging at the

let and low pressure

1

the discharge side

lit

will

from

or

of

not start

CAUSE

Worn

or wrong size tip.

Inlet filter clogged.

Worn

packlngs, abrasives in water or

natural

Belt slippage.

Fouled or

Even a small particle can cause the valve

lo stick.

Restricted Inlet.

wear.

Inadequate water supply.

dirty

Inlet or discharge valves.

Worn

inlet or discharge valves.

Leaking high pressure hose.

Worn

packlngs.

Yumld air condensing inside crankcase.

Nom

packlngs.

3ii

seals

leaking.

bred, damaged or worn plungers.

ibrasive material In the fluid being pumped.

nlet water temperature

hrpressurlzing pump.

3cessive pressure due

)r damaged tip.

'ump running

tw

too

high.

to

partially plugged

long without spraying.

Replace with tip

Clean. Check more frequently.

Check filter. Replace packlngs.

Check water flow rate to pump. Unit must have

minimum

tank.

TlgMen or replace.

Clean inlet and discharge valve assemblleg.

filter.

Check garden

Replace worn valves.

Replace high pressure

install new packings.

Change oil

Install new packlngs.

Install new oil

nstall new plungers.

nstall proper filtration on pump Inlet plumbing.

:heck water temperature; mav

lo

EQUIPMEN

:lean

rips.

Uever run pump more than

Io

3unnlng pump dry.

:orelgn particles in the Inlet or discharge

alve or worn inlet and/or discharge valves.

Init not plugged In.

ilectrlcal service off/GFCI activated.

hermal overload has tripped.

:lean or replace valves.

:heck power cord.

:heck fuse/clrcult breaker. Check for proper

iroundlng.

'ress

top button

of

proper size.

55

gallon float valve controlled water holding

hose,

may

hcse.

See

as

specified In MAINTENANCE.

See

seals.

See

See

not modi any

or replace tip.

Mt

run pump without water.

reset

button on

factory-set

r

MISUSE

on

the

HAZARD.

See

motof

motor starter for 3 phase units.

SOLUTION

See

PUMP SERVICE.

a

Check

be

collapsed or kinked.

PUMP SERVICE.

PUMP SERVICE.

PUMP SERVICE.

PUMP SERVICE.

not

exceed

adjustments.

Installing and Changing Spra)

10

minutes without spraylnc

See

PUMP SERVICE.

fur 1 phase units. Press

160°F.

See

308-535

B

Page 10

PARTS

DRAWING

800-900 Hydra-Clean@ 3009 Pressure Washer

800-901 Hydra-Clean@ 25lO~Pressure Washer

10

308-535

Page 11

~ ~~~

~~~

PARTS

800-900

800-901

REF

NO.

10

11

12

13

14

15

16

17

18

19

PART

NO.

1

800-643 CHASSIS

2

803-788 BELT GUARD

801-941

3

4

100-214

5

100-023 WASHER, Flat, 5/16

801-817

6

7

804-340 SCREW, Cap, hex hd.,

802-784 WASHER, Lock, 112

8

9

803-591 WASHER, Flat, 1/2

100-321 NUT, Hex, 1/2-13

803-799 SHEAVE. Motor

803-798

803-823

803-809

803-806

803-796

803-814

803-790 PUMP, 10 GPM (for 800-901

803-517 LABEL, Keep From Freezing

802-084 NIPPLE, 3/4

801-787

DRAWING

Hydra-Cleans

Hydra-Cleans

DESCRIPTION

SCREW, Cap, hex hd.,

5/16-18

WASHER; Lock, 5/16

MOTOR,

3 phase

1/2-13

Jfor 8C&900 only)

S

EAVE. Motor

only) See page 15

only) See page 12

TEE, 3/4

3009

2510

x

1

20

hp. TEFC.

.

X

2

X

2

Pressure Washer

Pressure Washer

QTY

1

1

6

6

6

1

4

6

10

6

1

1

1

2

1

1

-900

1

1

1

1

1

REF

NO.

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

PART

~~~~~~

NO.

DESCRIPTION

802-096 BUSHING, Hex, 1/2 x 3/4

803-141 HOSE, B ass

802-534 NIPPLE.

~~ ~~

803-872

155-665

803-396

803-790

800-720

LABEL, Graco G

SWIVEL, 3/8 NPSM x 3/8

LABEL, Warning

CAP, 1/2

UNLOADER. 3000 PSI

(for

r

ex

112 NPSM

SOO-Q~O

X

112

only)

NPT

800-721 UNLOADER. 2500 PSI

(for 800-901 only)

803-791

159-239

803-787

803-781

176-250

800-642

803-817

100-307

CAP, 3/4

NIPPLE, Hex 1/2

X

3/8

BRACKET, Pump

SUPPORT, Pump Bracket

LABEL, Warning, chassis

BRACKET, Rail Stiffener

BOLT, Eye

NUT. Hex 3/8-16

~

100-133 WASHER,-LOCk3/8

100-132 WASHER, Flat 3/8

802-845 FOOT, Rubber

172-981 LABEL. Wamina. chassis

~f/,

Square 3/Bx 2-112

NF

QTY

1

1

1

1

'T 1

1

1

1

1

1

1

.1

2

1

1

2

2

2

6

4

1

1

20

hp

Wrlng Diagram

230

Volt,

3

Phase

20

hp

Wring Dlagram

460

Volt,

3

Phase

308-535

11

Page 12

PARTS

801-790

DRAWING

Pump

Assem

16

20

\

13

12

4i

308-535

Page 13

PARTS

801-790

LIST

Pump Assembly,

2500

psi

REF

NO. NO. DESCRIPTION

10

11 Kit4 CAP

12 803-419 COVER, Crankcase

13 803-273 SCREW, Cap, socket hd

14 803-424 GASKET, Cover

15 803-433 BEARING, Tapered roller

16

17 803-421 COVER, Crankcase

18

19

20

21 803-414 CRANKCASE

22

23 803-430 O-RING

24 802-345 GAUGE, Sight 1

25 803-437 SCREW, Cap, socket hd

26 803-435 WASHER, Lock

27 803-427 YOKE, Crankshaft

28 803-416

29

30 803-434 BEARING, Ball

31 802-357 RING, Snap

PART

1 801.-781 MANIFOLD

2

801-468 SCREW, Cap, hex

3 801-469 WASHER, Lock

4 Kit

5 Kit 1

6 Kit

7 Kit

8

9 Kit 1 VALVE ASSEMBLY

1

1

1

Kit

1

Kit 4 O-RING

803-423 GASKET, Cover

802-793

801-488

801-782 DIPSTICK

803-429 O-RING

803-436 PIN, Wrist

O-RING

SEAT, Valve 36 803-415 CRANKSHAFT

PLATE, Valve 37 803-426 RING, Connecting rod

SPRING, Valve

GUIDE, Valve 39 Kit

CAP

O-RING

ROD,

Connecting

.

hd

REF PART

QTY

2

16

16 34

1

32

1

1

1

1 49 801-783 PLUNGER, Ceramic

1

1

1

1

4

4

6

6 57 Kit 6 SCREW, Piston

6

3

6

1

1

NO. NO. DESCRIPTION

32

'

33

35 803-428 SEAL, Oil

38 803-432 KM

40

41 803-425 COVER, Crankcase

42 803-422 GASKET, Cover

44

45

46

47 Kit 24 SEAL, Oil

48

50

51 Kit

52 Kit

53

54

55

56 Kit 6 O-RING

58

59

60

61 801-485 WASHER, Flat

62 Kit

803-418 COVER, Crankcase

803-283

803-420 GASKET, Cover

6

803-417 GUIDE, Piston

802-304 WASHER, Lock

803-438

803-431

Kit 6 WASHER, Flinger

Kit29

29

29

Kit29or PACKING

12

Kit

29

Kit 6 RING, Backup

801-482 CAP

801-483 WASHER, Flat

801-484

29

SCREW, Cap, socket

WASHER, Fiat

SCREW, Cap, socket

BUSHING

O-RING

RETAINER, O-ring

RING, Intermediate

RING, Head

CAP

RING, Long life

hd

hd

QTY

1

4

1

1

1

6

1

6

1

1

4

4

6

6

6

4

4

3

3

KI

Repalr

No. Part No.

I

Kil

Ref

No. Description

I

308-535

13

Page 14

PARTS

803-814

DRAWING

Pump

Assem

20

14

41

308-535

Page 15

PARTS

803-814

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

803-414 CRANKCASE

803-429 O-RING

803-436 PIN, Wrist

803-434 BEARING, Ball

802-357

LIST

Pump

.

-...

NO. DESCRIPTION

801-781 MANIFOLD

801-468 SCREW, Cap, hex

801-469 WASHER. Lock

Kit 1

Kit 1

Kit 1 PLATE, valve

Kit

1

Kit 1

Kit 1

Kit 4 O-RING

Kit 4 CAP

803-419

803-273

803-424

803-433

803-423

803-421

802-793 CAP

801-488 O-RING

801-782

~ ~ ~~~

~-

O-RING

SEAT. Valve

SPRING. Valve

GUIDE,

VALVE ASSEMBLY

COVER, Crankcase

SCREW, Cap, socket hd

GASKET, Cover

BEARING, Tapered roller

GASKET, Cover

COVER. Crankcase

DIPSTICK

-

O-RING

GAUGE. Sioht

~~

SCREW, Cap, socket hd

WASHER. Lock

YOKE,

ROD,

RING, Snap

~'

valve

. .

. .

.

-

.

.~,

Crankshart

Connecting

~

hd

QTY

2

16

16

1

32

1

'1

1

1

1.

1

1

1

4

4

1

6

6

6

3

6

1

1

REF

NO.

32

33

34

35

36

.37

38

39

40

41

42

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

PART

NO.

803-41

803-283

803-420

803-428

803-415

803-426

803-432

Kit 6

803-417

803-425

803-422

802-304

803-438

803-431

Kit 24

Kit 6

801

Kit

28

Kit 28

Kit 28

Kit

28

17

Kit

28

Kit 6 RING, Backup

Kit 6

Kit 6 SCREW, Piston

801-482 CAP

801-483 WASHER, Flat

801-484 CAP

801-485 WASHER, Flat

Kit

28

DESCRIPTION

8

COVER, Crankcase

SCREW, Cap, socket

GASKET, Cover

SEAL, Oil

CRANKSHAFT

RING, Connecting rod

KFV

WASHER, Flat

GUIDE, Piston

COVER, Crankcase

GASKET, Cover

WASHER, Lock

SCREW, Cap, socket hd

BUSHING

SEAL, Oil

WASHER, Flinger

PLUNGER, Ceramic

-490

O-RING

RETAINER, O-ring

RING, Intermediate

or

PACKING

RING, Head

O-RING

RING, Long life

hd

QTY

1

4

1

1

1

6

1

6

1

1

4

4

6

6

6

4

4

3

3

Repair

Parl

801-472

Valve

802-306

Valve Cap

801 -474

Plunger

Repair

801-486

Packing

801 -779

Oil Seal

801 -487

Packing

Retainer

KI

No.

&

-

Ret

No.

TI

-

-

-

-

Descrlptlon

4

O-RING

5

6

7

SPRING

GUIDE, Valve

8

VALVE ASSEMBLY

9

O-RING

10

11

39

WASHER, Flat

48

WASHER, Flinger

55

RING, Backup

O-RING

56

SCREW, Piston

57

PACKING

53

-

47

SEAL, Oil

-

50

51

52

lnlerniediate

PACKING

53

RING, Head

54

RING, Lona life 3

62

-

131

6

6

308-535 15

Page 16

PUMP

SERVICE

WARNING

To

reduce the risk of serious bodily injury,

including fluid injection, splashing in the eyes or

on the skin, or injury from moving parts, always

follow the Pressure Relief Procedure Warnlng

before proceeding.

NOTE:

NOTE

The following metric wrenches are needed:

M10, Mi3 and M30. Repair kits are available.

Refer

to

pump parts page formore details. For the best

results, use all parts in the kits.

There are

servicing the pump. P/N 800-298 is used

ease installation of packings. P/N 800-271

includes the items

in the removal of packing retainers.

the individual repair sections and the

two

different

1

tool

in

800-298

kits

and

to

tools

aid

in

to

to aid

Valves

NOTE:

1.

2. Examine the O-ring under the hex

3. Remove the valve assembly from the cavity; the

4.

NOTE

For a

set

of six valves, order

Remove the hex plug from the manifold using an

M30 wench.

if

it

is cut or distorted.

it

assembly may come apart.

Install the new valve. instail the O-ring and hex plug;

torque

to

75

fl-lb

(103

Nm).

Retorque the plug afler 5 hours of operation.

P/N

801

plug

and replace

-472.

Servicing

NOTE

1. Loosen the plunger retaining screw five

using an MI0 wrench. Push the plunger towards

crankcase

screw.

2.

Remove the screw from the plunger and examine

the O-ring, backup ring and copper bearindgasket

washer. Replace these parts, if necessary, using kit

801

3.

Remove the plunger and flinger from the plunger

shafl. Clean, examine and replace parts as

necessary.

4.

Inspect the plunger shaft for oil leakage from the

crankcase. if leaking is obvious, replace the oil

seals. Otherwise,

they cannot be reused.

replace the seals.

5.

Lightly grease the flinger and oil seal,

replaced and replace them on the plunger snafl.

Then install the plunger.

6.

Lightly grease the retaining screw and the outer end

of the plunger. Place the washer, O-ring and backup

ring around

the plunger. Torque

NOTE:

the

Plungers

Plunger repair kit, P/N 801-474 is available

replace retainers, O-rings, washers and

backup rings for three cylinders.

to

six tums,

to

separate the plunger and retaining

-474.

DO

NOT remove these seals as.

An

oil seal kit is available

if

it is being

the

screw

and

instail

the

screw through

to

14.4 fl-lb (19.5 Nrn).

if you pian

Servicing the V-Packings.

to

replace the packings, refer

to

the

to

to

Pumping Section

1.

Remove the eight capscrews and lockwashers from

the manifold using an Mi3 wrench.

2.

Carefully separate the manifold from the crankcase.

NOTE:

it may be necessaryto tap the manifold lightly

with a sofl mallet

to

loosen.

CAUTION

Keep the manifold properly aligned with the

ceramic plungers when removing

damage

3. Carefully examine each plunger for any scoring or

cracking and replace as necessary.

to

the plunger or seals.

to

avoid

7.

Lubricate the outside of each plunger. Slide the

manifold onto the crankcase, being careful not

damage the seals.

8.

Install

Torque the screws

tightening pattern (Figure

may cause the manifold

Figure

4

the

capscrews and washers finger-tight.

to

21.7 fl-lb

to

(29

Nm) following the

4).

Uneven tightening

bind

or jam.

I

3

2

6

1

I

to

16

308-535

Page 17

Servicing the V-Packings

NOTE:

1.

2.

3.

4.

There are

packings only, the other includes the

packings, rings and retainers.

Remove the manifold as outlined in the Pumping

Section.

Carefully pull the packing retainer from the

manifold. Examine the O-ring and replace it

cut or damaged.

Remove the v-packing and head ring.

intermediate retainer ring. Remove the second

v-packing and second head ring.

Inspect all parts and replace as necessary.

two

types of packing kits: one is

Pull

ACCESSORIES

(Must

be

purchased separately)

if

out

it is

the

5.

Thoroughly clean the packing cavities and examine

and

for debris

6.

Lightly grease the packing cavities and then

replace the packings in the following order: head

ring, v-packing, intermediate

v-packing and packing retainer with the O-ring

installed in the retainer groove.

Install the parts in the proper order and facing the

correct direction. Improperly installed parts will

cause a malfunction.

I

7.

Reassemble the manifold as instructed In Servicing

the Plungers.

damage.

ring,

head ring,

1

DOWNSTREAM CHEMICAL INJECTOR KIT

800-1 17 BRASS UP TO 5.5 GPM (21 LPM)

800-425 BRASS 5.6 TO

LPM)

800-649 STAINLESS STEEL UP TO

(21 LPM) 800-392

For injecting harsh cleaning chemicals downstream Includes

from the pump.

HOSE

800-375

3/8

coupled hose with

couplers.

ASSEMBLY WITH QUICK COUPLERS 800-398

diameterx 5ofoot x

801

4OOO

-568

10.8

GPM (21 TO

psi

(276

and

801

41

5.5

GPM GUN

bar) permanently

-569

3/8

quick

BACKFLOW PREVENTOR 801-133

Prevent back-up of contaminated water into fresh-.

supply. lnstaii upstream of pump.

couplers for hose and spray tip connections.

Includes

stainless steel spray wand and stainless steel threaded

connections

&

WAND ASSEMBLY

8WJ-350

803-222

for

hose

spray gun,

stainless steel spray gun,

and

32"

spray wand and quick

'pray

tip.

32

308-535

17

Page 18

TECHNICAL DATA

PTFE

PTFE

PTFE

PTFE

PTFE

PTFE

PTFE

PTFE

PTFE

Motor (totally enclosed

Electrical

Se~i~e

Water Pump Maximum Working Pressure

Water Pumo Maximum

Dimensions

Length

Width

Height

Maximum Inlet Water Temperature

wetted

parts

High Pressure

Bypass

Pressure Washer (including fittings)

fan

Flow

Hose

cooled)

Model

800-901

20

HP,

3

phase

2%

voIff50

460

voIff.25

amp13 phase

2500

psi

(172

bar)

(38

NPT

(261 kg)

mm)

rnm)

F

(70'

IPm)

(9

C)

10 gpm

314"

Ibs

48"

(1219 mm)

30"

(762

25"

(635

160

*

Acrylonitrile and Buna-N cover

amp/3 phase

or

~

and

tube

20

HP,

230

VOWXI

460

mlff25 amp/3 phase

3OOO

9

gpm

3/4"

575

Ibs

48"

(1219 rnm)

30'

(762

25"

(635

160' F (70'

Synthetic yarn and EPDM

Anodized aluminum, Aluminum or bronze

alloys,

composite, Ceramic, Buna-N, Wo olic,

steel,

Polymide-12 thermoplastic, Carbon

yellow chromate plate

is a reaistered trademark

of

the DuPont

Model

800-900

3

phase

amp13 phase or

psi

(207

bar)

(34

Ipm)

NPT

(9

(261 kg) 575

mm)

rnm)

C)

Bras Copper, Nylon-

303,304,

Comoanv.

and 316 Stainless

steel,

Zinc

with

or without

18

308-535

Page 19

THE GRACO WARRANTY

WARRANTY AND DISCLAIMERS

Graoawarmntsallequipmentmanufactursdby~andbearingitsnametobefreefmmdefectslnmaterial

and

workmanship

Aspurohaser'ssolemmedyforbreachofthiswarranty,Gramwill,foraperiodoltwentyfourmonthsfmm

dateofsale,repairorrepiaceanypartdtheequipmentprovende~~.Thiswarr~appliesonlywhen

the

equipment

recommendations.

This

warranty does not cover, and Gram shall nd

by fauity installation. misapplication, abrasion, conusion. inadequate or improper maintenance.

negligence. accident, tampering, or subsmution of non-Gm wmponent park. Nor Shall Graw

liableformalfunction,damageorwearcausedbytheinwmpatibilitywithGramequipmentof~chlres.

accessories. equipment or materials not supplied by Graw. or

instaliaton, operator!

Graw.

on

the

date of

sale

Is

installed. operated

or

maintenance

by

an

authorized

and

of

structms.

Graw distributor

maintained in

be

liable for, any malfunction. damage or wear

acmssories.

to

the

original purchaSErfor

accordance

the

Improper design, manufacture.

equipment or materials

with

Graco's written

not

supplied

Use.

caused

be

by

This warranty is conditioned upon

examination by Gram to vet@

replace

free

transportation prepaid. if inspection of

wo~manship,repairswiilbemadeatareesonablecharge,whichchargesmayincludethecosSofpark.

labor and transporhtion.

nlLPl

DAMAGES

LIABILITY EXCEED THE AMOUNT OF THE PURCHASE PRICE. ANY ACTION FOR BREACH OF

WARRANTY MUST BE BROUGHT WITHIN THREE

EQUIPMENT NOT

GRACOMAKESNOWARRANPIANDDlSCLAlMSALLlMPLlEDWARRAMlESOFMERCHANTABlLlTY

AND FITNESS FOR A PARTICULAR PURPOSE, WITH RESPECT TO ACCESSORIES, EQUIPMENT.

MATERIALS

manufactured

not

any.

of

for breach of

of charge any defech

AIMFRS

Mi

ANn

I

IUITATlnNP

OR

LOSS

IS

COVERED

OR

COMPONENTS SOLD

by

Gram (such

manufacturer.

these

warranties.

EXPRESSLY

Gram will provide

the

the

prepaid

claimed defect

patts.

EXCWDED

BY

GRACO

Btrr

as

electtic motor. switches, hose,

return

If

The

the

WARRANTY

NOT MANUFACTURED

purchaser

me

equipment will

equipment does not disclose any defect

AND

(3)

YEARS OF THE DATE OF SALE.

d

the

equipment claimed

claimed defect is

be

returned to

DENIED.

By

with

etc.)

reasanaide

verified.

IN

NO

GRACO.

are

assistance

to

be

Gm will repair or

the

original purchaser

in

CASE

SHALL GRACO'S

These

subject

items

to

the

in

making any

defscthre for

material or

Sold.

but

warranty,

it

dah

IMPORTANT PHONE NUMBERS

TO PUCE AN

distributor closest

ORDER,

to

you:

contact

your Graco

1-800-328-021 1

.distributor,

Toll

Free

or

call

this

number

to

identify the

FOR

TECHNICAL ASSISTANCE,

application

Factory

Subsldlav and

GRACO

of

Graw

Branches:

AIRllata

INC.

equipment:

Atlanta.

Companies: Canada: England: Swik3riand: France; Germany: Hong

RO.

1-800-543-0339

Chicago. Dallas.

BOX

1441 MINNEAPOLIS, MN 55440-1441

PRINTED IN U.S.A.

service

repair

Oet'oit.

308-535

information

Toll

cos

or

Free

Angeles. West Caldweil (N.J.)

4/91

assistance

regarding

the

brig:

~apan;

Loading...

Loading...