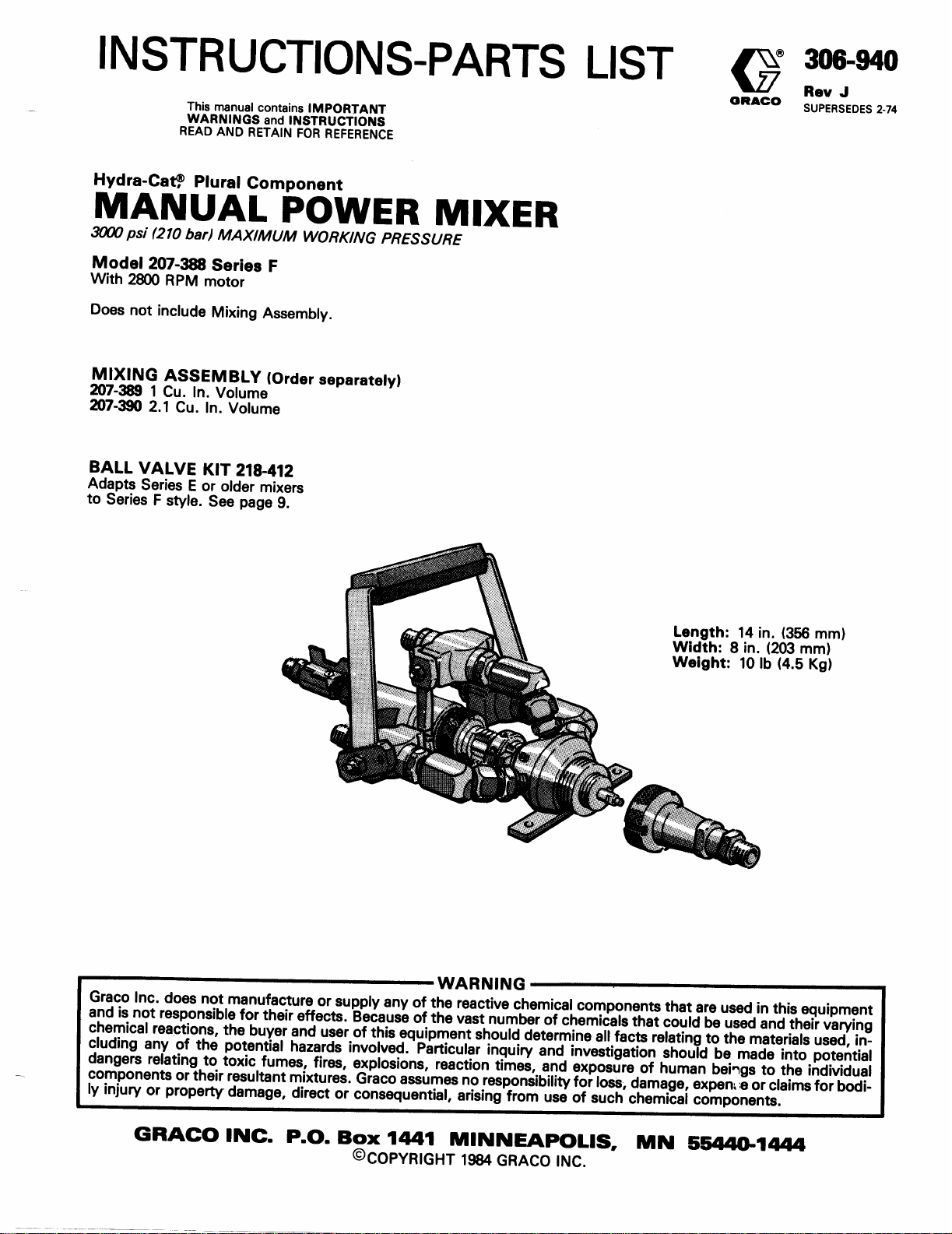

Page 1

Parts

Page 2

General Safety

This equipment generates very high fluid pressure. Spray from

the gun, leaks or ruptured components can inject fluid

through your skin and into your body and cause extremely

serious bodily injury, including the need for amputation. Also,

fluid injected or splashed into the eyes can cause serious

damage.

NEVER point the spray gun or dispensing valve at anyone or at

any part of the body. NEVER put hand or fingers over the

spray tip or nozzle. NEVER try to “blow back” fluid; this is

NOT an air spray system.

ALWAYS follow the Pressure Relief Procedure, below,

before

cleaning or removing the spray tip or nozzle or servicing

any system equipment.

NEVER try to stop or deflect leaks with your hand or body.

Be sure equipment safety devices are operating properly

before each use.

Medical Treatment

If any fluid appears to penetrate your skin, get

EMERGENCY

Tell the doctor exactly what fluid was injected. For treatment

instructions, have your doctor call the

DO NOT TREAT AS A SIMPLE CUT.

MEDICAL CARE AT ONCE .

NATIONAL POISON CENTER NETWORK

(412)681-6869

Pressure Relief Procedure

To reduce the risk of serious bodily injury, including injection,

always follow this procedure whenever the pump is shut off,

when checking or servicing any part of the system, when installing or changing spray tips, and whenever you stop spraying.

1.

Close the mixer material valves.

2.

Open the solvent flush valve(s) and flush until clean.

Spray Gun or Dispensing Valve Safety Devices

Be sure all gun safety devices are operating properly before

each use. Do not remove or modify any part of the gun; this

can cause a malfunction and result in serious bodily injury.

Safety Latch (If your gun is equipped with one)

Whenever you stop spraying, even for a moment, always set

the gun safety latch in the closed or “safe” position, making

the gun inoperative. Failure to set the safety latch can result in

accidental triggering of the gun.

Diffuser (If your gun is equipped with one)

The diffuser breaks up spray and reduces the risk of injection

when the tip is not installed. Check diffuser operation regular-

ly. Follow the Pressure Relief Procedure, below, then

remove the spray tip. Aim the gun into a metal pail, holding

the gun firmly to the pail. Using the lowest possible pressure,

trigger the gun. If the fluid emitted is

regular stream, replace the diffuser immediately.

fip Guard (If your gun is equipped with one)

ALWAYS have the tip guard in place on the spray gun while

spraying. The tip guard alerts you to the injection hazard and

helps prevent accidentally placing your fingers or any part of

your body close to the spray tip.

Trigger Guard (If your gun is equipped with one)

NEVER

guard helps prevent the gun from triggering accidentally if it is

dropped.

Spray Tip or Nozzle Safety

Use

nozzle. If the spray tip or nozzle clogs while spraying, engage

the gun safety latch immediately. ALWAYS follow the

Pressure Relief Procedure and then remove the spray tip to

clean it.

NEVER

pressure is fully relieved and the gun safety latch is engaged.

not

diffused into an ir-

operate the gun with the trigger guard removed. The

extreme caution when cleaning or changing spray tips or

wipe off build up around the spray tip or nozzle until

3.

Shut off the material and solvent pumps.

4. Open the spray gun or dispensing valve to relieve

pressure.

5.

If material has hardened in the hose or mixer, close the

material valve, shut off the material and solvent pumps,

and slow/y loosen the material inlet hose(s) to relieve

pressure, then remove the dispensing hose.

“~%**?.Y” <+ ‘9.y +*i

EQUIPMENT

M/S(JSE

HAZARD ~~~~~~~~~~~~~~~,~;.:-

y+J~~ “‘X :q+&.&&,>:

General Safety

Any misuse of the spray equipment or accessories, such as

overpressurizing, modifying parts, using incompatible

chemicals and materials, or using worn or damaged parts, can

cause them to rupture and result in injection or other serious

bodily injury, fire, explosion or property damage.

NEVER alter or modify any part of this equipment; doing so

could cause it to malfunction.

CHECK all spray equipment regularly and repair or replace

worn or damaged parts immediately.

2

306-940

,:,,~.~~i;:‘::,~~,,~,.,~;,:~:

:;,:~.I:~.‘.~;:~~:,~~,‘,~:.‘,

:., :‘.I:.

< ., .:

‘:$;<I.ty:,;I;;, :‘,.. ‘.;.‘-,“‘.-;:;;~

System Pressure

Never exceed the maximum working pressure of the lowest

rated equipment in your spray system. This manifold has a

3cKx)

psi (210 bar) MAXIMUM WORKING PRESSURE. Be

sure that all fluid and air accessories you add to the spray

system are properly rated to withstand the maximum air and

fluid working pressures of this system.

Material Compatibility

BE SURE that all materials and solvents used are chemically

compatible with the wetted parts shown in the Technical Data

on the back cover. Always read the material and solvent

manufacturer’s literature before using them in this sprayer.

Page 3

HOSE

SAFETY

,;

.,/ .‘y_‘;. :.: ,..: .,‘..:<:.’ y:::’

y: ;,

‘;..;; ,,,.., :K:

Static electricity is created by the high velocity flow of fluid

through the pump and hose. If every part of the spray equip-

ment is not properly grounded, sparking may occur, and the

system may become hazardous. Sparking may also occur

when plugging in or unplugging a power supply cord. Sparks

High pressure fluid in the hoses can be very dangerous. If the

hose develops a pinhole leak, split or rupture due to any kind

of wear, damage or misuse, the high pressure spray emitted

from it can cause an injection injury or other serious bodily injury or property damage.

can ignite fumes from solvents and the fluid being sprayed,

dust particles and other flammable substances, whether you

are spraying indoors or outdoors, and can cause a fire or ex-

plosion and serious bodily injury and property damage. Do not

ALL FLUID HOSES MUST HAVE SPRING GUA’RDSI The

spring guards help protect the hose from kinks or bends at or

close to the coupling which can result in hose rupture.

plug in or unplug any power supply cords in the spray area

when there is any chance of igniting fumes still in the air.

TIGHTEN all fluid connections securely before each use. High

pressure fluid can dislodge a loose coupling or allow high

Grounding

pressure spray to be emitted from the coupling.

To reduce the risk of static sparking, ground the sprayer and

all other spray equipment used or located in the spray area.

CHECK your local electrical code for detailed grounding in-

structions for your area and type of equipment. BE SURE to

ground all of this spray equipment:

NEVER use a damaged hose. Before each use, check entire

hose for cuts, leaks, abrasion, bulging cover, or damage or

movement of the hose couplings. If any of these conditions

exist, replace the hose immediately. DO NOT try to recouple

high pressure hose or mend it with tape or any other device. A

1.

Pump:

use a ground wire and clamp as instructed in your

repaired hose cannot contain the high pressure fluid.

pump instruction manual.

HANDLE AND ROUTE HOSES CAREFULLY. Do not pull on

2.

Fluid hoses:

of 500 feet

grounding continuity. Refer also to Hose Grounding

Continuity.

3.

Spray gun, manifold or dispensing valve: obtain groun-

ding through connection to a properly grounded fluid

hose and sprayer.

use only grounded hoses with a maximum

(150 m)

combined hose length to ensure

hoses to move equipment. Do not use materials or solvents

which are not compatible with the inner tube and cover of the

hose. DO NOT expose the hose to temperatures above

(62OC)

Hose Grounding Continuity

Grace fluid hoses have electrically conductive material on the

surface of the center core of the hose. Other hoses on the

market may have a ground wire extending the length of the

4.

Object being sprayed:

according to local code.

hose. The ground wire can break in use which will destroy the

electrical grounding of the hose.

5.

All

solvent pails

code.

Use on/y

place the pail on a non-conductive surface, such as paper

or cardboard, which interrupts the grounding continuity.

used when flushing, according to local

metalpaik,

which are conductive. Do not

To be sure of continuity, check electrical resistance at least

once a week. Check overall resistance when using multiple

hose assemblies. If the resistance exceeds 29 megohms,

replace it immediately. Ground wire hose may have different

6.

To maintain grounding continuity when flushing or reliev-

ing pressure,

the side of a

always hold a metal part of the gun firmly to

metal

pail, then trigger the gun.

resistance; check supplier.

MOVING PARTS HAZARD

Flushing Safety

Reduce the risk of injection injury, static sparking, or splashing

by following the specific flushing procedure given on page 5 of

this manual. Follow the Pressure Relief Procedure on page

2, and remove the spray tip before flushing. Hold a metal part

of the gun firmly to the side of a

metal

pail and use the lowest

possible fluid pressure during flushing.

Moving parts can pinch or amputate your fingers or other

body parts. KEEP CLEAR of moving parts when starting or

operating the sprayer. Unplug the sprayer and relieve pressure

before checking or servicing the sprayer to prevent it from

starting accidentally.

or below

-4OOF (-4OOC).

16OOF

.

IMPORTANT

United States Government safety standards have been adopted under the Occupational Safety and Health Act. These standards-par-

ticularly the General Standards, Part 1910, and the Construction Standards, Part 1926-should be consulted.

306-W

3

Page 4

INSTALLATION

*_~I.

,;: ,.

, :

~ . .

:.

. .

For assistance in setting up a plural component system,

you should contact

Belmont, Chicago, Illinois 60121-2891, (3121678-7200.

This will help ensure that you select the proper type and

size of equipment for your job.

All inlet connections on this mixer have l/4

threads.

Grace

Fluid Systems, 9451 West

npt(m)

Use an air regulator to control the mixer motor speed.

Install a bleed-type master air valve on the air line to

shut off and relieve air to the mixer motor.

Start and prime the solvent pump and check the

flushing system before connecting the material hoses.

OPERATION i

Determine Motor Air Pressure Setting

Pull the actuating lever (29) back to close the inlet

valves. Then refer to the separate operating instructions

for your proportioning pump, and start the system.

Set the air pressure to the mixer motor at about 30 psi

(2.5 bar). Place a small waste container under the mixer

outlet (A). Open the air valve to start the mixer motor,

then open the material inlet valves. When the container

is full, close the valves.

Increase the air pressure slightly and dispense another

sample. Repeat this procedure five or six times, record-

ing the air pressure setting for each sample. Place

another waste container under the mixer outlet, start

the mixer motor, and open the solvent valve. When

clean solvent comes form the outlet, close and the solvent valve then stop the mixer motor.

Let all samples “cure”,

each one for proper cure. Select the sample which

cured properly at the lowest air pressure and use that

pressure for the mixer air supply. Repeat the test if none

of the samples cured properly.

or harden, completely. Examine

CAUTION

Always use the lowest possible air pressure as this

produces the least amount. of heat created by fric-

tion of the mixing shaft with the motor.

r

4

306-940

I i

Determine Material Pot Life

To test the pot life, use a cup with approximately the

same shape and size as the mixing assembly chamber; 1

cubic inch for Model 207389, or 2.1 cubic inch for

Model 207-390. Start the mixer motor and open the

material valves to fill the container. Close the material

valves and starting timing the reaction.

Flush the mixing chamber with solvent to remove the

mixer material.

When the material starts to gel, check how long the

reaction has taken. This is the operating pot life of your

material. Reduce that time by at least 10% to determine

how long your system can remain idle without flushing

or dispensing material. For example, if the pot life is 11

minutes, then 9 minutes is the maximum time that mixed material should be left in the mixing chamber and

hoses before dispensing or flushing.

NOTE:

ASSEMBLY

If the material pot life is 10 minutes or less,

use the Grace Automatic Power Mixer.

Page 5

a,rarcup

Start the mixer motor before opening the material

valves. Then close the valves before stopping the

motor.

rwsnmg

When you stop dispensing for a short time, close the

mixer material valves and open the solvent flush valve.

Leave the motor running. Point the material outlet into a

waste container, open the dispensing valve and flush

When you stop dispensing for 10 minutes or longer,

stop the mixer motor to prevent heat build up caused by

friction. Do not allow the system to stand idle for more

until the solvent is clean. Close the solvent valve, stop

the motor and open the dispensing valve to relieve

pressure.

than the mixed material pot life.

For longer shutdowns, solvent flush as above, follow

For the most consistent results, always fully open the

actuating lever when dispensing. If a dispensing valve is

used, you can leave the mixer material valves open until

you are ready to flush.

the Pressure Relief Procedure on page 6, then discon-

nect the dispensing hose and equipment from the mixer. Unscrew the adapter (201) from the mixing chamber

and remove the mixing shaft (204). Soak and clean

parts with clean solvent and a stiff brush. Rinse and

Lubrication

blow dry with air. Clean all material off the mixer

chamber. Do not reassemble until you are ready to use

the mixer again.

Solvent may channel through viscous materials and

leave a coating of mixed material on the inner tube of

For automatic mixer motor lubrication, install an air line

lubricator ahead of the motor. For manual lubrication,

your hose. Be sure all material is thoroughly flushed

from the hose after each use.

remove the plug in the air motor head and place 10 to 15

drops of oil into the motor each day. Use only

lightweight machine oil.

Disassemble all other dispensing equipment, as

necessary, and clean thoroughly.

BE SURE AIR

MOTOR IS

LUBRICATED

PROPERLY

204,

306-940

5

Page 6

TROUBLESHOOTING GUIDE

WARNING

To reduce the risk of serious bodily injury,

eluding

checking. or repairing any parts and whenever you

shut down the sytem.

2. Open the solvent flush valve and flush until

3.

4. Shut off the material pumps and solvent

I

injection, follow this procedure before

1

1.. Close the mixer material valves.

clean.

Shut off the air to the mixer motor.

pump.

Open the dispensing valve to relieve pressure.

5.

6. Open any drain valves.

in-

Check all possible causes and solutions before

disassembling the mixer for repair. If problem is still not

corrected, refer to the troubleshooting sections in the

separate manuals supplied with each component in

your system.

PROBLEM

Air motor won’t run

Little or no Part A (Resin) coming

out

Little or no Part B (Catalyst) com- Material supply container

ing out.

Air motor runs but material not

mixed properly.

CAUSE

Not enough air pressure or

volume.

Closed or clogged air valves (42)

or lines.

Hardened material in mixing

chamber.

Material supply container

empty.

Plugged material inlet or check

valve.

Air motor (7) malfunction. Replace.

empn/.

Plugged material inlet (31) or

check (15) valve.

Not enough air pressure or

volume.

Plugged material inlet (31) or

check (15) valve.

SOLUTION

Check. Requires 25 to 30 CFM

at

106

psi (7 bar) for con-

tinuous operation.

Open, clear.

See last section of Service,

page 7. Observe pot life.

Refill, prime system

Clean. Refer to Service.

Refill, prime system.

Clean, refer to Service.

Check, adjust.

Clean. Refer to Service.

Drive shaft (18) broken.

Worn or damaged spline shaft

(B).

Broken or damaged mixing shaft

Replace. Refer to Service.

Replace. Refer to Service.

Replace. Refer to Service.

(204).

Air motor (7) malfunction.

Mixed material won’t flush out. Hardened material in mixing

chamber (202).

Solvent supply container empty.

Solvent not compatible with

material.

Material leaks around packing re- Worn or damaged drive shaft

tainer (16). packings (17).

*Be sure to read and observe the material manufacturer’s literature before using any material In this system.

Replace.

See last section of Service

Observe pot life.

Fill and prime.

Check, correct”

Replace. Refer to Service.

*. . .

6 306-94-o

Page 7

To Inspect or Replace Drive Spline or Mixing Shaft

If mixer motor runs but material is not mixed properly:

Use a spanner wrench to unscrew the connecting hous-

ing retainer nut (23) CLOCKWISE off the air motor-it

has left hand threads. Inspect the spline shaft (B) for

wear or damage and replace if necessary. Also check

the thrust spring (14) and replace if it is weak or broken.

See Fig 4.

Screw the mixing assembly retaining nut (11) COUNT-

ERCLOCKWISE off the head (24) and remove the mix-

ing assembly. Remove the mixing shaft (204) from the

chamber (202). See Figures 5 and 6. Place parts in solvent and clean thoroughly. Inspect parts for wear or

damage. Replace the entire mixing assembly if the mix-

ing chamber is nicked or scored. Check the o-ring (6) in

place on the head (24) and replace if necessary.

To inspect or replace the drive shaft

(18),

clean all

material off the shaft, then loosen the packing nut (19)

and pull the shaft through the back of the connecting

housing. If the shaft is damaged in any way, replace it.

Check the packing contact area for burrs or scratches

which will cause premature packing wear.

To reassemble, install one or two washers (27) between

the spline shaft and air motor to obtain a 0.347 to 0.437

in. (8.8 to 11 .l mm) dimension. Refer to Detail in Fig 4.

Leave the packing nut (19) loose until the mixer is

assembled, then tighten.

Replace Packings

If material leaks around the packing retainer (161, and

tightening the packing nut (19) does not stop it:

Disassemble the mixer as explained above. Turn the

packing nut all the way up against the housing retaining

nut (23). Remove the packing retainer (16). See Fig 5.

Remove the packings carefully, using a suitable hooked

tool. Be careful not to scratch the housing (43). Inspect

the packing retainer gland end. If it is damaged, replace

the retainer.

Insert a new male gland (22) into the housing, then install new packings (17) one at a time, pushing each all

the way into the housing. Install the packing retainer in

the housing (43). Reassemble the mixer, then tighten

the packing nut (19) snugly, just enough to stop

leakage.

0.347” to 0.437”

(8.8 to 11.1 mm)

Fig 5

42’

306-940

7

Page 8

Cleaning and Servicing Inlet or Check Valves

If either the inlet or check valve seems plugged or

damaged:

Remove the actuating lever. Remove and disassemble

the plugged valve. Clean all parts and inspect for wear

or damage, replacing parts as necessary. Lubricate

parts with a light grease and reassemble the valve. Align

the hole in the ball (35) with the hole through the body

MO). Refer to the Parts Drawing.

Unscrew the swivel (30) from the check valve and screw

the check valve seat (15) out of the mixer head (24).

Disassemble the valve and clean all parts. Also clean the

passageway in the head. Check the valve seat (15) for

nicks and replace parts as necessary. Replace the

gasket (26) reassemble and screw into the mixer. Refer

to mixing assembly.

Install the swivel and actuating lever.

If Material Hardens in the Mixing Chamber

Shut off air to the solvent and material supply pumps.

Close the mixer inlet valves and

material inlet hoses to relieve pressure. Then remove

the mixing assembly retaining nut and disconnect the

dispensing hose.

slow/y

loosen the

Tap on the mixing chamber (202) with a piece of wood

or a plastic hammer to break it loose, then pry it off.

Knock out the mixing shaft, if possible, and place parts

in a pail of compatible solvent. If the mixing shaft (204)

will not come out, and there is no solvent available that

will dissolve the material without damaging the parts,

install a complete new mixing assembly. Refer to mixing

assembly .

Completely disassemble the mixer and clean it

thoroughly. Reassemble, using new packings, glands

and any other parts, as necessary. Be sure that no

hardened material remains on any part of the mixer.

FcAuT’oNI

Fig 6,

Be sure to check and then observe the mixed

material

ing in the mixer and resulting in costly damage.

pot life to prevent

material

from harden-

201

0

306-940

Page 9

Model 207-388 Power Mixer

Series F Includes items l-43

42

213-040

MATERIAL INLET

(SEE DETAIL A)

l/4

h

MATERIAL INLET

NPTl

33

BALL VALVE

f

REF PART

NO. NO.

“101823

102-207

“102-310

102-410

102556

“102595

102597

102598

150-707

158-485

164548

167-124

167-125

167-731

167-743

* 167-745

* 167-746

* 167-747

167-761

* 167-762

167-763

* 167-764

DESCRIPTION

BALL, sst; 5/16” dia.; check valve

SETSCREW,

thd sz; l/4” long

CAPNUT, hex; No.

nylon insert

CAPSCREW,

size;

3/8”

RIVET

O-RING, PTFE

MOTOR, air; 2800 RPM

CAPSCREW,

size;

l/2”

PLATE, serial

GASKET, copper

NUT, plain knurled; l-5/8”-18 UNEF

thd size

GRIP, hand; lower, nylon

GRIP, hand; upper, nylon

SPRING, helical compression

SEAT, check valve

RETAINER, packing, female gland

V-PACKING, PTFE

SHAFT, mixer drive

NUT, plain round; l-l/8”-12 UNF-2

thd size; packing nut

GUIDE, spring; check valve

BRACKET, mounting

GLAND, packing; male

sot

hd cup pt; l/4-20

sot

long

long

hd; No. 6-32 thd

sot

hd; No.

lo-32

thd sz;

lo-32

thd

QTY

3

2

3

2

2

1

2

1

1

2

:

i

r,

1

;

1

1

REF PART DESCRIPTION

NO. NO,

167-765

167-766

* 167-770

“168492

170-786

178-747

217561

207-411

213-040

Series B

104893

104892

164-900

178-746

165-274

165-964

178-745

172-094

178-743

165-599

208390

167-767

*Recommended ‘tool box” spare parts. Keep on hand to

reduce down time.

NUT, plain knurled; l-7/16” thd

HEAD, power mixer

SPRING, helical compression, check

valve

GASKET, copper; 7/8” dia.

WASHER, l/2” dia.

SOLVENT VALVE LEVER

ACTUATING LEVER

ADAPTER, swivel union,

3/8

npt(f)

BALL VALVE

Includes items 32-41

.O-RING, PTFE

.O-RING, PTFE

. WASH ER, acetal homopolymer

. BALL, valve

.NIPPLE,

.NUT, stem packing

.STEM,

. SEAT, ball

.HOUSING,

.STEM

BALL VALVE (see 307-068 for parts)

HOUSING, mixer head

adapter, 1/4x

valve

valve

45O;

11/16

thd

QTY

sz

3ow4o

1

z

2

:

3

3

1

z

:

1

2

1

1

1

9

Page 10

4000 RPM AIR MOTOR 102-584

For materials which are more difficult to mix

MIXING ASSEMBLIES

207-389 1 Cu. In. Volume

207-390 2.1 Cu. In. Volume

Includes items 201-205

BALL VALVE KIT 218-412

Adapts Series E and older power mixers to new style

ball valve and actuating lever style. If your mixer is

Series E or older, the material ball valves must be replaced together and a new lever installed as the old parts are

not interchangeable. Kit includes two ball valves,

213-040 and one actuating lever 217561.

201 167-738

202

-f

167-739

167-753

203 167-953

r207-395

205

207494

Model 207-389

Model 207-390

ADAPTER,

3/8

npt(m)

CHAMBER,

CHAMBER, mixing (Model

GASKET, copper

MIXING SHAFT. 2 blade

(Model-267-389)’

MIXING SHAFT, 3 blade

(Model 207-390)

BEARING, end thrust

pipe; 7/8-14(f) to

thd size

mixing (Model 207-389)

~

207-390)

10

204

306-940

Page 11

Page 12

TECHNICAL DATA

All inlets : l/4

Material Outlet :

Air Motor :

Air Requirements :

Wetted Parts :

npt(m)

3/8

npt(m), or

7/8-14-UNF

1 HP; 2800 RPM maximum

25 to 30 CFM at 100 psi (7 bar) continuous operation

Stainless steel, steel, carbon steel; PTFE, Nylon,

Viton

SERVICE INFORMATION

Listed below by the assembly changed are ADDED and

DELETED parts.

ASSEMBLY PART

CHANGED STATUS

I

207-388

Mixer to

Series F

DELETED

ADDED

DELETED

ADDED

DELETED

ADDED

FIEF

PART

NO. NO. NAME

205-643 Lever

28

170-747 Lever

207-394 Lever

29

217-561 Lever

207-875 Valve

31

213-040 Valve

NOTE: ADDED parts are NOT interchangeable with

DELETED parts.

*When ordering replacement ball valve on Series E or

earlier mixers, order Kit No. 217-412 which includes

two new style ball valves and new style actuating

lever.

Grace Inc. warrants all equipment manufactured by it and bearing its

name to be free from defects in material and workmanship under

normal use and service. This warranty extends to the original

purchaser for a period of 12 months from the date of purchase and applies only when the equipment is installed and operated in

accordance with written factory recommendations. This warranty

I

does not cover damage or wear which, in the reasonable judgment of

Grace, arises from misuse, abrasion, corrosion, negligence, accident,

substitution of non-Grace parts, faulty installation or tampering.

This warranty is conditioned upon the prepaid return of the equipment

claimed to be defective for examination by Grace to verify the claimed

defect. If the claimed defect is verified,

free of charge, any defective parts. The equipment will be returned to

the original purchaser transportation prepaid. If inspection of the

equipment does not disclose any defect in workmanship or material,

repairs will be made at a reasonable charge and return transportation

will be charged.

THIS LIMITED WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF

ANY OTHER WARRANTIES (EXPRESS OR IMPLIED) INCLUDING

WARRANTY OF MERCHANTABILITY OR WARRANTY OF

FITNESS FOR A PARTICULAR PURPOSE AND OF ANY NON-

CONTRACTUAL LIABILITIES INCLUDING PRODUCT LIABILITIES

BASED ON NEGLIGENCE OR STRICT LIABILITY. EVERY FORM OF

LIABILITY FOR DIRECT, SPECIAL OR CONSEQUENTIAL

DAMAGES OR LOSS IS EXPRESSLY EXCLUDED AND DENIED.

EQUIPMENT NOT COVERED BY GRACO WARRANTY. Accessories

or components of equipment sold by Grace that are not manufactured

by

the warranty, if any, of their manufacturer.

purchaser with reasonable assistance in making such claims.

with outlet adapter removed

THE GRACO WARRANTY

Grace

will repair or replace

Grace

(such as electric motors, switches, hose, etc.) are subject to

Grace

will provide

Subsidiary and Affiliate Ccmpanier:Canada; England; Switzerland; France; Germany; Hong Kong; Japan

Factory BranchesAtlanta, Dallas, Detroit, Los Angeles, West Caldwell

(N.J.1

GRACO INC. P. 0. Box 1441 MINNEAPOLIS, MN 5544011444

PRINTED IN U.S.A. 30&940 4-67 Revised 5-84

Loading...

Loading...