Graco HVLP EDGE II, 17P481, 17P484, HVLP EDGE II Plus, 17P653 Operation - Repair - Parts

...

3A4980B

EN

Operation/Repair/Parts

HVLP EDGE II™/EDGE II Plus Gun

For the application of architectural paints and coatings. The HVLP Edge II Gun is not

intended to be used on an external compressor. For professional use only.

Models: 17P481, 17P483, 17P484, 17P653, 17P654

10 psi (0.07 MPa, 0.7 bar) Maximum Air Working Pressure

50 psi (0.35 MPa, 3.5 bar) Maximum Fluid Working Pressure

Important Safety Instructions

Read all warnings and instructions in this manual and your sprayer instruction

manual. Be familiar with the controls and the proper usage of the equipment.

Save these instructions.

Related Manuals:

3A4967 Graco FinishPro

HVLP Sprayer

ti30935a

www.graco.com/techsupport

?? ??

Table of Contents

2 3A4980B

Table of Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Key Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Know Your Spray Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

EDGE II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

EDGE II Plus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Fluid and Work Piece Preparation . . . . . . . . . . . . . . . . . . . . . 9

Fluid Set Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Fluid Set Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Fill FlexLiner System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Fill Siphon Cup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

How to Spray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Adjust Spray Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Adjust Flow and Pattern Size . . . . . . . . . . . . . . . . . . . . . . . . 16

Spray Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Triggering Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Aiming Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Refilling FlexLiner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Refilling Siphon Cup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

EDGE II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Parts List - EDGE II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

EDGE II Plus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Parts List - EDGE II Plus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

FlexLiner System & Siphon Cup Assembly . . . . . . . . . . . . . 32

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

FlexLiner System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Siphon Cup Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Models

3A4980B 3

Models

Key Features

*Configured for use with remote cup (sold separately)

Edge II

• Combines fluid and air flow into one simple control.

• Optimized to spray the majority of fine finish applications.

• Quick adjustment and indicator for repeatable spray setting.

Edge II Plus

• Ultimate control for customized fine finish applications.

• Independent fluid and air flow controls.

• Additional pattern size control.

• Compatible with SmartStart feature on Graco FinishPro HVLP ProContractor and

ProComp sprayers

FlexLiner System

• Allows user to spray gun at any angle without cup adjustment.

• Reduces cleaning time with disposable liner and no siphon tube.

• Quick change cup connection.

Siphon Cup

• Traditional metal HVLP fluid cup.

Provided with:

Model

FlexLiner System

Siphon Cup

No cup*

Edge II 17P481 17P653

Edge II Plus 17P483 17P484 17P654

ti31026a

ti31027a

Warnings

4 3A4980B

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this

equipment. The exclamation point symbol alerts you to a general warning and the hazard

symbols refer to procedure-specific risks. When these symbols appear in the body of this

manual or on warning labels, refer back to these Warnings. Product-specific hazard symbols

and warnings not covered in this section may appear throughout the body of this manual

where applicable.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help

prevent fire and explosion:

• Do not spray flammable or combustible materials near an open flame or sources of ignition

such as cigarettes, motors, electrical equipment, and plastic drop cloths (potential static

sparking).

•

Turbine motor generates sparks. Keep sprayer in a well ventilated area at least 20 feet (6 m)

from the spray area when spraying, flushing, cleaning, or servicing. Do not spray pump

assembly.

• Connect to a grounded outlet and use grounded extensions cords. Do not use a 3-to-2

adapter.

• Do not use a paint or a solvent containing halogenated hydrocarbons.

• Do not spray flammable or combustible liquids in a confined area.

• Keep spray area well-ventilated. Keep a good supply of fresh air moving through the area.

• Do not smoke in the spray area or spray where sparks or flame is present.

• Do not operate light switches, engines, or similar spark producing products in the spray

area.

• Keep area clean and free of paint or solvent containers, rags, and other flammable

materials.

• Know the contents of the paints and solvents being sprayed. Read all Safety Data Sheets

(SDSs) and container labels provided with the paints and solvents. Follow the paint and

solvents manufacturer’s safety instructions.

• Keep a working fire extinguisher in the work area.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the equipment, leaks, or ruptured components can splash in the eyes or on skin and

cause serious injury.

• Follow the Pressure Relief Procedure when you stop spraying/dispensing and before

cleaning, checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

Warnings

3A4980B 5

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Always wear appropriate gloves, eye protection, and a respirator or mask when painting.

• Do not operate or spray near children. Keep children away from equipment at all times.

• Do not overreach or stand on an unstable support. Keep effective footing and balance at

all times.

• Stay alert and watch what you are doing.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not kink or over-bend the hose.

• Do not expose the hose to temperatures or to pressures in excess of those specified by

Graco.

• Do not use the hose as a strength member to pull or lift the equipment.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals

and create safety hazards.

•

Make sure all equipment is rated and approved for the environment in which you are using it.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious

chemical reaction and equipment rupture. Failure to follow this warning can result in death,

serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon

solvents or fluids containing such solvents.

• Do not use chlorine bleach.

• Many other fluids may contain chemicals that can react with aluminum. Contact your

material supplier for compatibility.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin,

inhaled, or swallowed.

• Read SDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable

guidelines.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury,

including eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective

equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent

manufacturer.

CALIFORNIA PROPOSITION 65

This product contains a chemical known to the State of California to cause cancer, birth defects

or other reproductive harm. Wash hands after handling.

Know Your Spray Gun

6 3A4980B

Know Your Spray Gun

EDGE II

R

Y

H

A B C D

M

L

Q

P

X

G

K

S

N

E

ti30936a

Z

T

V

U

Y

S

W

R

A Edge II Air Cap

B Retaining Ring

C Fluid Nozzle

D Fluid Needle

E Fluid / Air Flow Control Knob

G EasyGlide™ Trigger

H Trigger Slide

KAir Inlet

L FlexLiner System

M FlexLiner Cup

N FlexLiner

P FlexLiner Cover

Q FlexLiner Ring

R Cup Fitting

S Material Strainer

T Siphon Cup

U Quick Clean Check Valve

V Latch

W Swivel Tube

X Packing Nut

Y Spray Gun Tubing

Z Siphon Cup Assembly

Know Your Spray Gun

3A4980B 7

EDGE II Plus

R

H

A

B

C J D

M

Q

P

X

G

K

N

E

F

ti30937a

L

S

Y

Z

T

V

U

Y

S

W

R

A Edge II Air Cap

B Retaining Ring / Pattern Size Control

C Fluid Nozzle

D Fluid Needle

E Fluid Flow Control Knob

F Air Flow Control Knob

G EasyGlide™ Trigger

H Trigger Slide

J Air Cap Guide

KAir Inlet

L FlexLiner System

M FlexLiner Cup

NFlexLiner

P FlexLiner Cover

Q FlexLiner Ring

R Cup Fitting

S Material Strainer

T Siphon Cup

U Quick Clean Check Valve

V Latch

W Swivel Tube

X Packing Nut

Y Spray Gun Tubing

Z Siphon Cup Assembly

Pressure Relief Procedure

8 3A4980B

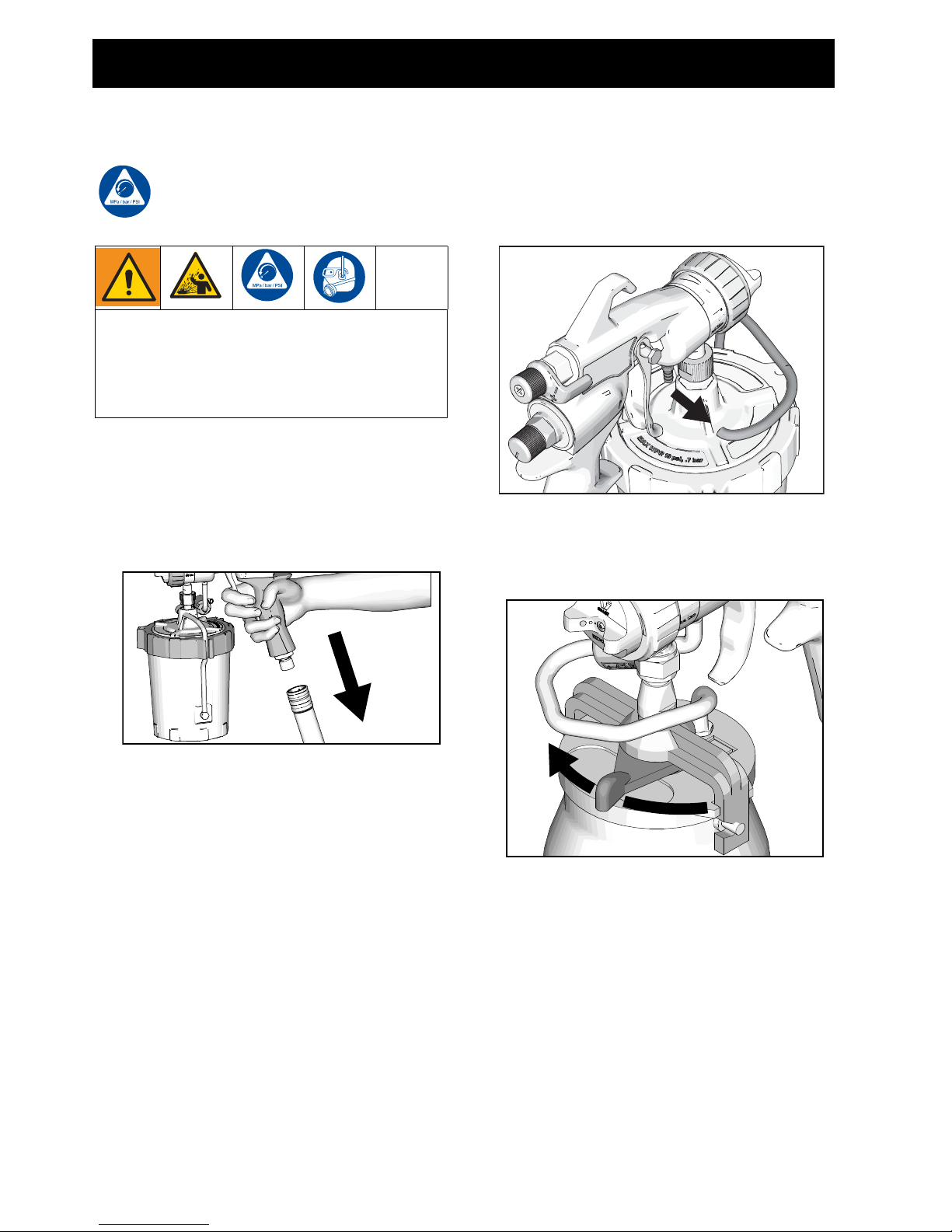

Pressure Relief Procedure

Follow the Pressure Relief

Procedure whenever you see this

symbol.

1. Turn the HVLP sprayer ON/OFF switch

to OFF position.

2. Unplug power cord to disconnect power

from the HVLP sprayer.

3. Disconnect spray gun from air hose.

NOTE: If using a remote cup, refer to manual

provided with cup. If using with a Graco

FinishPro HVLP ProComp sprayer,

reference sprayer manual.

4. If using a FlexLiner System:

Disconnect tubing from gun to relieve

pressure in the cup.

5. If using a metal siphon cup:

Unlatch cup cover, loosen or remove cup

from cover to relieve pressure.

The spray gun cup is pressurized. To

reduce the risk of splashing from

pressurized fluid, always follow the

Pressure Relief Procedure before

removing cup.

ti30757a

ti30627a

ti30628a

Setup

3A4980B 9

Setup

Fluid and Work Piece

Preparation

• Strain fluids before spraying. This

includes colors, reducers and

hardeners.

• Use a slower drying reducer or thinner to

compensate for the faster drying time

caused by the warm air of the turbine. Do

not over reduce.

• Spray performance varies with the

viscosity of the material sprayed, HVLP

sprayer, and length of hose.

• Most material manufacturers provide

recommendations for their materials.

Follow these recommendations.

• For proper adhesion, ensure surface of

work piece is completely clean.

Fluid Set Selection

For best spray performance, select proper

fluid set for fluid being sprayed. Reference

the Fluid Set Selection Guide for the fluid

set recommended for your application. Fluid

set numbers are marked on fluid needles and

nozzles.

FLUID SET SELECTION GUIDE

Material Fluid Set #2 Fluid Set #3 Fluid Set #4 Fluid Set #5 Fluid Set #6 Fluid Set #7

17P485 17P486 17P487 17P488 17P489 17P490

Dye

Ink

Non-wiping Stain

Automotive Finish

Lacquer

Stain

Enamel

Epoxy

Urethane

Varnish

Primer

Industrial Finishes

Latex

Multi-Spec

Butyrate

Nitrate Dope

Oil Wall Paint

ti30938a

Setup

10 3A4980B

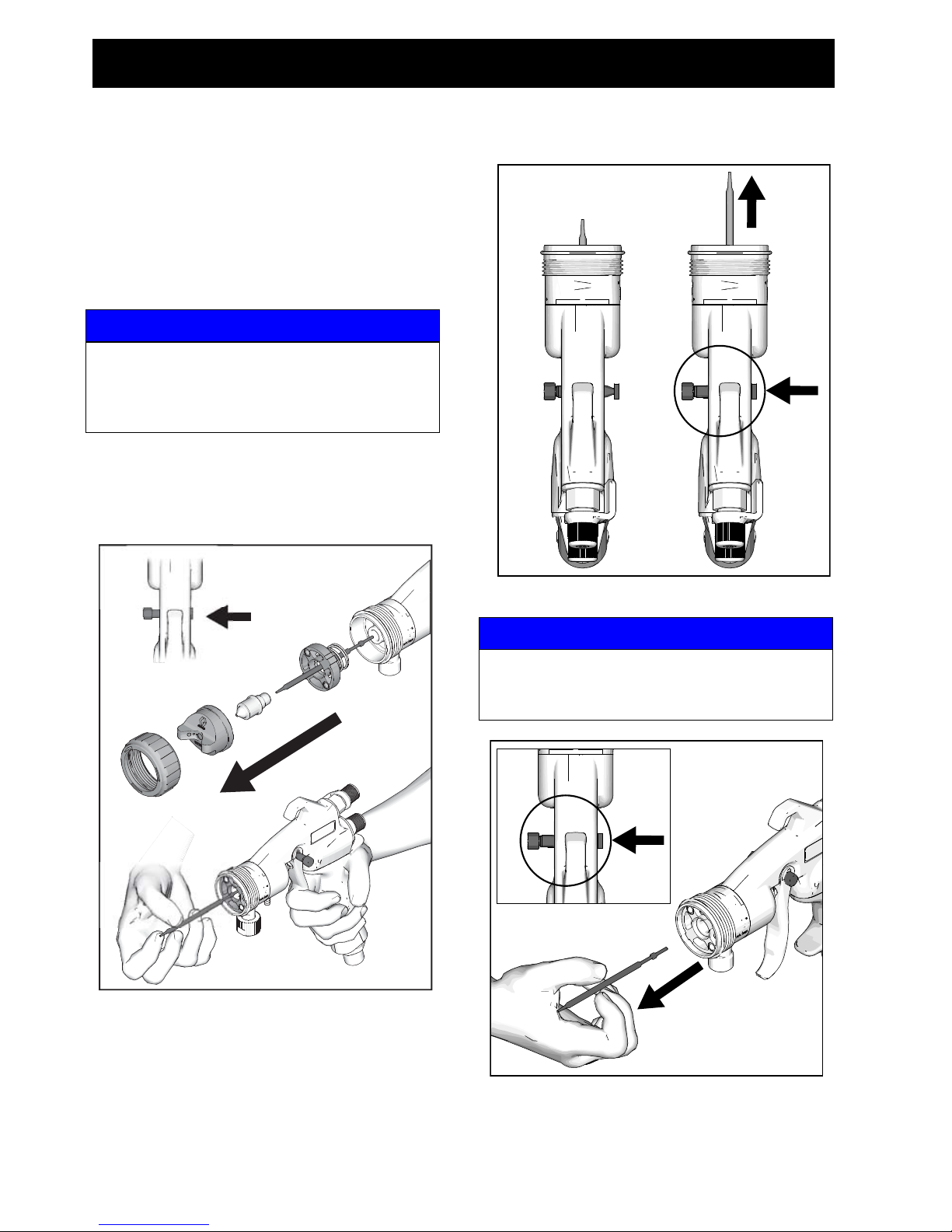

Fluid Set Replacement

Removal

1. Perform Pressure Relief Procedure,

page 8.

2. Remove retaining ring and air cap.

3. Trigger the gun and remove fluid nozzle.

NOTE: Edge II Plus guns contain air cap

guide and spring held in place by fluid nozzle.

Upon removal of fluid nozzle, set aside air cap

guide and spring.

4. Move trigger slide from SPRAY position

(A) to NEEDLE REMOVAL position (B).

5. Remove needle from front of gun.

NOTICE

Trigger the gun whenever removing or

installing the fluid nozzle. This prevents the

fluid nozzle and needle seating surfaces

from being damaged.

ti30850a

NOTICE

Do not use a pliers to remove needle.

Damage to the needle tip will cause leaking

at the fluid nozzle.

ti30851a

SPRAY

Position

NEEDLE

REMOVAL

Position

A

B

ti30852a

Setup

3A4980B 11

Installation

1. Insert needle and move trigger slide from

NEEDLE REMOVAL position (B) to

SPRAY position (A).

2. Trigger the gun and install air cap guide

with spring (Edge II Plus only), and fluid

nozzle.

3. Install air cap and retaining ring.

ti30939a

ti30940a

Loading...

Loading...