Repair/Parts

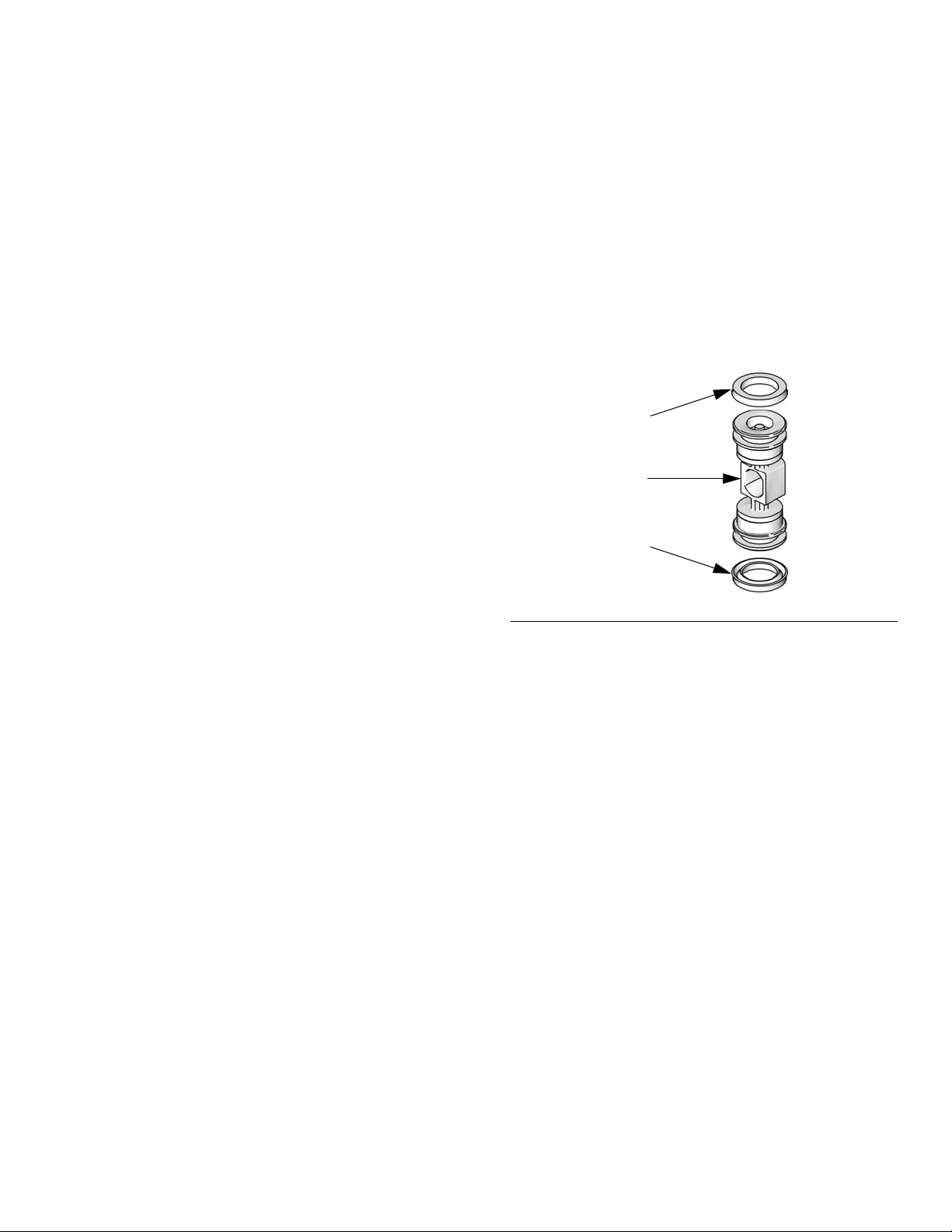

Center

Flange

ti13844a

ti13843a

End

Flange

1050P Polypropylene

1050C Conductive

Polypropylene

1050F PVDF

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

1050S Stainless Steel

1050H Hastelloy

ti14342a

1050A Aluminum

ti13946a

®

Husky

1050 Air-Operated

Diaphragm Pump

1-inch pump with modular air valve for fluid transfer applications.

For professional use only.

See page 4 for model information, including approvals.

125 psi (0.86 MPa, 8.6 bar) Maximum Fluid Working Pressure

125 psi (0.86 MPa, 8.6 bar) Maximum Air Input Pressure

313435ZAA

EN

Related Manuals

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

To Find Your Nearest Distributor . . . . . . . . . . . . . . 3

To Specify the Configuration of a New Pump . . . . 3

To Order Replacement Parts . . . . . . . . . . . . . . . . . 3

Distributor Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Pump Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ATEX Certifications . . . . . . . . . . . . . . . . . . . . . . . . . 5

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Pressure Relief Procedure . . . . . . . . . . . . . . . . 10

Repair or Replace Air Valve . . . . . . . . . . . . . . . 10

DataTrak . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Check Valve Repair . . . . . . . . . . . . . . . . . . . . . 14

Diaphragms and Center Section . . . . . . . . . . . . 15

Torque Instructions . . . . . . . . . . . . . . . . . . . . . . 18

Related Manuals

Manual Description

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Parts/Kits Quick Reference . . . . . . . . . . . . . . . . 21

Center Section . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Air Valve and Data Monitoring . . . . . . . . . . . . . . 24

Fluid Covers and Manifolds . . . . . . . . . . . . . . . . 26

Seats and Check Ball . . . . . . . . . . . . . . . . . . . . 28

Diaphragms . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Seat, Check Ball, and Diaphragm Kits . . . . . . . 31

Manifold O-Rings . . . . . . . . . . . . . . . . . . . . . . . . 32

DataTrak . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Graco Standard Husky Pump Warranty . . . . . . . . 36

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 36

312877

313597

313598

313840

406824

406825

406826

Husky 1050 Air-Operated Diaphragm Pump, Operation

Husky 1050A UL-Listed Diaphragm Pump, Operation

Husky 1050A CSA-Compliant Diaphragm Pumps, Operation

DataTrak, Instructions/Parts

Pulse Count Kits, Instructions

Reed Switch with Solenoid Kits, Instructions

Torque Instructions (Manifolds and Fluid Covers)

2 313435ZAA

To Find Your Nearest Distributor

To Find Your Nearest Distributor

1. Visit www.graco.com.

2. Click on Where to Buy and use the Distributor Locator.

To Specify the Configuration of a New Pump

Please call your distributor.

OR

Use the Online Diaphragm Pump Selector Tool at

www.graco.com.

To Order Replacement Parts

Please call your distributor.

Distributor Note

1. To find part numbers for new pumps or kits, use the Online Diaphragm Pump Selector Tool.

2. To find part numbers for replacement part s:

a. Use the configuration number from the ID plate on the pump. If you only have the Graco 6-digit part num-

ber, use the selector tool to find the corresponding configuration number.

b. Use the Configuration Number Matrix on the next page to understand which parts are described by each

digit.

c. Refer to the main Parts illustration and to the Parts/Kits Quick Reference. Follow the page references on

these two pages for further ordering information, as needed.

3. Please call Graco Customer Service to order.

313435ZAA 3

Pump Matrix

CONFIGURATION NO.PART NO. SERIAL NO.

SERIESDATE CODE

MAX WPR PSI-bar

MADE IN

ID

ti14103a

Pump Matrix

Check the identification plate (ID) for the Configuration Number of your

pump. Use the following matrix to define the components of your pump.

Sample Configuration Number: 1050A-PA01AA1SSBNBNPT

1050 A P A01A A1 SS BN BN PT

Pump

Size

Wetted

Section

Material

Drive

Identifier

Center

Section and

Air Valve

Fluid

Covers and

Manifolds

Seats Balls Diaphragms Manifold

O-Rings

Pump

Size

1050 A Aluminum P

1050 C Conductive

1050 F PVDF A01D Remote

1050 H‡ Hastelloy A01E Optional FKM Seals C2 Conductive polypropylene, end

1050 P Polypropylene AC1A CSA-Compliant

1050 S‡ Stainless Steel AU1A UL-Listed; Fuel

, ‡, or : See ATEX Certifications, on page 5.

Contains pressure relief valve

Wetted Section

Material

Polypropylene

Drive

Identifier

Pneumatic

Center Section and

Air Valve Material

A01A Standard A1 Aluminum, standard ports, inch

A01B Pulse Count A2 Aluminum, standard ports, metric

A01C DataTrak C1 Conductive polypropylene,

Aluminum

AU3A UL-Listed; Fuel

C01A Standard H1 Hastelloy, standard ports, inch

Conductive

Polypropylene

Polypropylene

C01B Pulse Count H2 Hastelloy, standard ports, metric

C01C DataTrak P1 Polypropylene , center flange

C01D Remote P2 Polypropylene, end flange

P01A Standard S1 Stainless steel, standard ports,

P01B Pulse Count

P01C DataTrak S2 Stainless steel, standard ports,

P01D Remote

Air

Valve/Monitoring

transfer

dispense

Fluid Covers and Manifolds

center flange

flange

F1 PVDF, center flange

F2 PVDF, end flange

inch

metric

Stainless steel, center flange,

S5-1

horizontal outlet port

Stainless steel, center flange,

S5-2

vertical outlet port

Check Valve Seats Check Valve Balls Diaphragm Manifold O-Rings

AC Acetal AC Acetal BN Buna-N — Models with

AL Aluminum BN Buna-N CO Polychloroprene Overmolded

BN Buna-N CR Polychloroprene Standard FK FKM Fluoroelastomer

FK FKM Fluoroelastomer CW Polychloroprene Weighted GE Geolast

GE

Geolast

®

FK FKM Fluoroelastomer PO PTFE/EPDM Overmolded

Buna-N, FKM

Fluoroelastomer or TPE

seats do not

use o-rings.

PP Polypropylene GE Geolast PS PTFE/Santoprene Two-Piece PT PTFE

PV PVDF PT PTFE PT PTFE/EPDM Two-Piece

SP

Santoprene

SS 316 Stainless Steel SS 316 Stainless Steel TP TPE

®

SP Santoprene SP Santoprene

TP TPE TP TPE

4 313435ZAA

ATEX Certifications

All 1050A (Aluminum) and

1050C (Conductive Polypropylene)

pumps are certified:

II 2 GD c IIC T4

‡ 1050S (Stainless Steel) and 1050H

(Hastelloy) pumps with aluminum or

conductive polypropylene centers are

certified:

II 2 GD c IIC T4

DataTrak and Pulse Count are

certified:

0359

II 1 G

Ex ia IIA T3 Ga

ITS13ATEX27862X

9902471

Class I, Div. 1,

Group D T3A

ATEX Certifications

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. When

these symbols appear in the body of this manual, refer back to these Warnings. Additional, product-specific warnings

may be found throughout the body of this manual where applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep wor k area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

Static charge may build up on plastic parts during cleaning and could discharge and ignite flammable

materials and gases. To help prevent fire and explosion:

• Clean plas tic parts in a well ventilated area.

• Do not clean with a dry cloth.

• Do not operate electrostatic guns in equipment work area.

313435ZAA 5

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment

and follow the Pressure Relief Procedure in this manual when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cable s away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and

cause serious injury.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

• Tighten all flu id connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

THERMAL EXPANSION HAZARD

Fluids subjected to heat in confined spaces, including hoses, can create a rapid rise in pressure due to

the thermal expansion. Over-pressurization can result in equipment rupture and serious injury.

• Open a valve to relieve the fluid expansion during heating.

• Replace hoses proactively at regular intervals based on your operating conditions.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical

reaction and equipment rupture. Failure to follow this warning can result in death, ser ious inj ury, or prop erty damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material

supplier for compatibility.

PLASTIC PARTS CLEANING SOLVENT HAZARD

Use only compatible water-based solvents to clean plastic structural or pressu re-conta ining parts. Many

solvents can degrade plastic parts and cause them to fail, which could cause serious injury or property

damage. See Technical Data in this and a ll other equipment instructio n manuals. Read fluid and so lvent

manufacturer’s warnings.

6 313435ZAA

Warnings

WARNING

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Route exhaust away from work area. If diaphragm ruptures, fluid may be exhausted with air.

• Store ha zardous fluid in approved containers, and dispose of it according to applicable guidelines.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns:

• Do not touch hot fluid or equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the oper ating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Cloth ing and respirator as recommended by the fluid and solvent manufacturer

• Protective eyewear, gloves, and hearing protection.

313435ZAA 7

Troubleshooting

Troubleshooting

Problem Cause Solution

Pump cycles but will not prime. Pump is running too fast, causing

cavitation before prime

Check valve ball severely worn or

wedged in seat or manifold.

Seat severely worn. Replace ball and seat . See pa g e 14 .

Outlet or inlet clogged. Unclog.

Inlet or outlet valve closed. Open.

Inlet fittings or manifolds loose. Tighten.

Manifold o-rings damaged. Replace o-rings. See page 14.

Pump cycles at stall or fails to hold

pressure at stall.

Pump will not cycle, or cycles once

and stops.

Pump operates erratically. Clogged suction line. Inspect; clear.

Worn check valve balls, seats, or

o-rings.

Air valve is stuck or dirty. Disassemble and clean air valve.

Check valve ball severely worn and

wedged in seat or manifold.

Pilot valve worn, damaged, or

plugged.

Air valve gasket damaged. Replace gasket. See page 10.

Check valve ball is wedged into seat

due to overpressurization.

Dispensing valve clogged. Relieve pressure and clear valve.

Air tubing is plugged

(remote air control models).

Sticky or leaking check valve balls. Clean or replace. See page 14.

Diaphragm (and backup) ruptured. Replace. See page 15.

Restricted exhaust. Remove restriction.

Pilot valves damaged or worn. Replace pilot valves. See page 15.

Air valve damaged. Replace air valve. See page 10.

Air valve gasket damaged. Replace air valve gasket. See

Air supply erratic. Repair air supply.

Exhaust muffler icing. Use drier air supply or use low ice

Lower air inlet pressure.

Replace ball and seat. See page 14.

Replace. See page 28.

See page 11. Use filtered air.

Replace ball and seat. See page 14.

Replace pilot valve. See page 15.

Install pressure relief kit. See Acces-

sories, page 32.

Clear tube.

page 10.

muffler (Graco part 102656).

8 313435ZAA

Troubleshooting

Problem Cause Solution

Air bubbles in fluid. Suction line is loose. Tighten.

Diaphragm (and backup) ruptured. Replace. See page 15.

Loose manifolds, damaged seats or

manifold o-rings.

Diaphragm shaft bolt o-ring dam-

Tighten manifold bolts or replace

seats or o-rings. See page 14.

Replace o-ring.

aged.

Pump cavitation. Reduce pump speed or suction lift.

Loose diaphragm shaft bolt. Tighten.

Exhaust air contains fluid being

pumped.

Diaphragm (and backup) ruptured. Replace. See page 15.

Loose diaphragm shaft bolt. Tighten or replace. See page 15.

Diaphragm shaft bolt o-ring dam-

Replace o-ring. See page 15.

aged.

Moisture in exhaust air. High inlet air humidity. Use drier air supply.

Pump exhausts excessive air at

stall*.

Worn air valve cup or plate. Replace cup and plate. See page 11.

Damaged air valve gasket. Replace gasket. See page 10.

Damaged pilot valve. Replace pilot valves. See page 15.

Worn shaft seals or bearings. Replace shaft seals or bearings. See

page 15.

Air tubing is damaged or loose

Replace tubing or secure connection.

(remote air control models).

Remote air pressure is higher than

pump air pressure (remote air control

Regulate remote pilot air pressure to

be equal to or less than main air.

models).

Pump leaks air externally. Air valve or fluid cover screws loose. Tighten.

Diaphragm damaged. Replace diaphragm. See page 15.

Air valve gasket damaged. Replace gasket. See page 10.

Remote air pressure is higher than

pump air pressure (remote air control

Regulate remote pilot air pressure to

be equal to or less than main air.

models).

Pump leaks fluid externally from

joints.

Loose manifold screws or fluid cover

screws.

Tighten manifold screws or fluid

cover screws. See page 18.

Manifold o-rings worn out. Replace o-rings. See page 14.

Pump leaks fluid externally through

manifold or fluid cover.

Excessive pump speed or inlet

starvation.

Replace manifold and reduce pump

speed or improve pump feed.

* A small amount of air will exhaust during stall if the pump is stopped while in the process of changing over. This is

normal. If desired, Valve Upgrade Kit 24K224 can be installed to minimize air exhausting.

313435ZAA 9

Repair

WARNINGWARNINGWARNING

WARNING

ti14094a

ti14095a

Aluminum Model

Shown

109

Repair

SPECIAL CONDITIONS FOR SAFE USE

Equipment must comply with the following

conditions to avoid a hazardous condition

which can cause fire or explosion.

• All label an d marking material must be

• The ele ctronic monitoring system is

cleaned with a damp cloth (or equivalent).

required to be grounded. See Grounding

instructions in your pump operation manual.

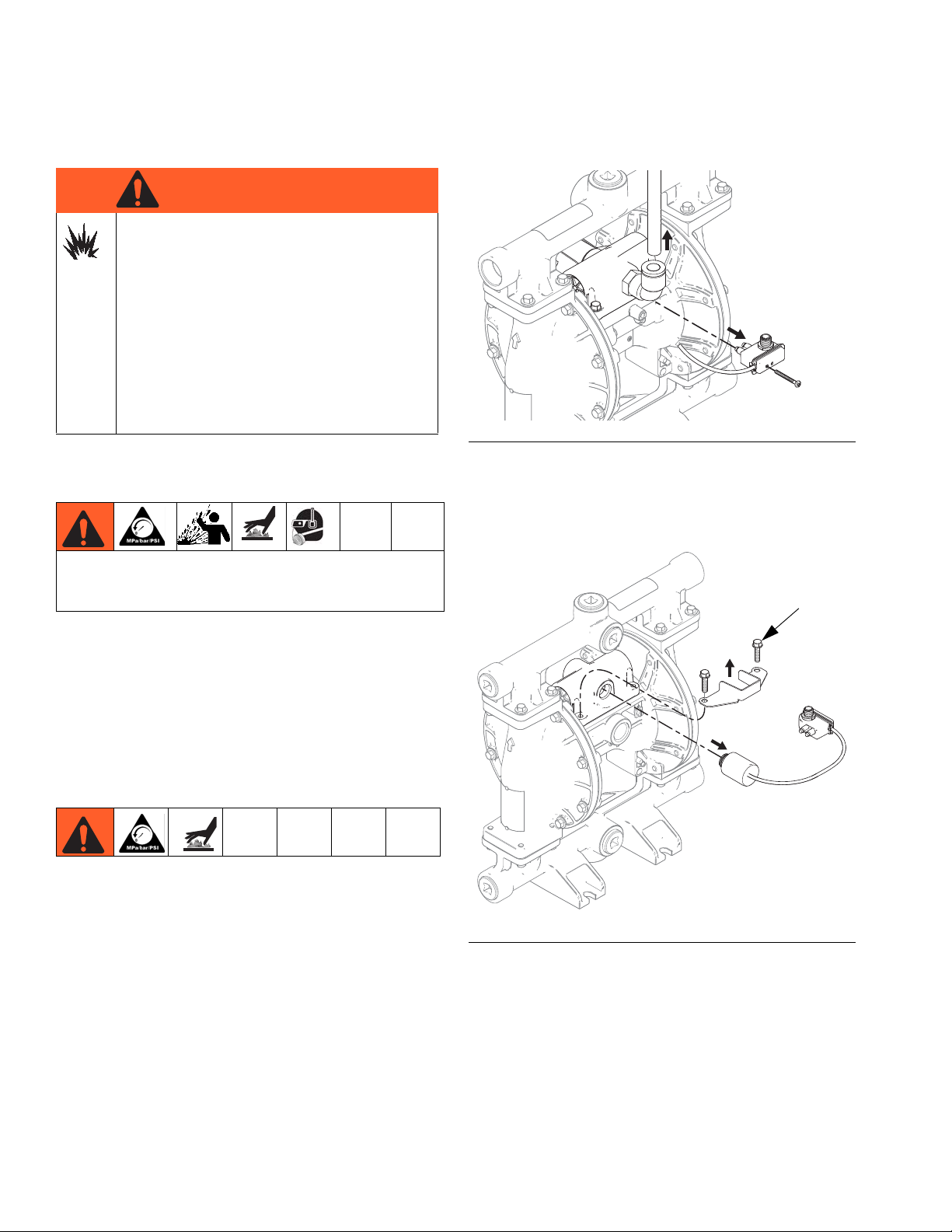

FIG. 1. Reed switch assembly and air line removal

Pressure Relief Procedure

Trapped air can cause the pump to cycle unexpectedly, which could result in serious injury from splashing.

1. Shut off the air supply to the pump.

2. Open the dispensing valve, if used.

3. Open the fluid drain valve to relieve fluid pressure.

Have a container ready to catch the drainage.

Repair or Replace Air Valve

Replace Complete Air Valve

1. Stop the pump. Relieve the pressure. See Pressure

Relief Procedure in previous section.

4. For motors with DataTrak: Remove two screws

and the solenoid bracket. Pull the solenoid out of

the air valve.

F

IG. 2. Solenoid removal

2. Disconnect the air line to the motor.

3. For motors with Pulse Count or DataTrak:

Remove screw to disconnect the reed switch

assembly from the air valve.

10 313435ZAA

5. Remove screws (109, metal pumps) or nuts (112,

plastic pumps). Remove the air valve and gasket

(108).

6. To repair the air valve, go to Disassemble the Air

Valve, step 1, in next section. To install a replacement air valve, continue with step 7.

7. Align the new air valve gasket (108) on the center

housing, then attach the air valve. See Torque

Instructions, page 18.

Repair

Lips face down

Lips face up

208†

208†

202

ti12754a

8. For motors with DataTrak: Remember to reattach

the solenoid bracket and the solenoid.

9. For motors with Pulse Count or DataTrak: Use

screw to attach the reed switch assembly to the new

air valve. Reconnect cable.

10. Reconnect the air line to the motor.

Replace Seals or Rebuild Air Valve

NOTE: Repair kits are available. See page 25 to order

the correct kit(s) for your pump. Air Valve Seal Kit parts

are marked with a †. Air Valve Repair Kit parts are

marked with a . Air Valve End Cap Kit parts are

marked with a .

Disassemble the Air Valve

1. Perform steps 1-5 under Replace Complete Air

Valve, page 10.

2. See F

IG. 4. Use a Torx screwdriver (T8 for alumi-

num centers, T9 for plastic centers) to remove two

screws (209). Remove the valve plate (205),

cup assembly (212-214), spring (211), and detent

assembly (203).

Reassemble the Air Valve

NOTE: Apply lithium-based grease whenever instructed

to grease.

1. Use all parts in the repair kits. Clean other parts and

inspect for damage. Replace as needed.

2. Grease the detent cam (204) and install into housing (201).

3. Grease the u-cups (208) and install on the piston

with lips facing toward the center of the piston.

3. Pull the cup (213) off of the base (212). Remove the

o-ring (214) from the cup.

4. See F

each end of the air valve. Use the piston (202) to

push the end caps (207, 217) out of the ends.

Remove end cap o-rings (206). If pump model is

equipped with a runaway protection solenoid, also

remove the solenoid release button (218) and

o-ring (219).

5. Remove the u-cup seals (208) from each end of the

piston (202), then remove the piston. Remove the

detent cam (204) from the air valve housing (201).

IG. 4. Remove the retaining ring (210) from

IG. 3. Air valve u-cup installation

F

4. Grease both ends of the piston (202) and install it in

the housing (201), with the flat side toward the cup

(212). Be careful not to tear u-cups (208) when sliding piston into housing.

5. Standard or Pulse Count models (no runaway

protection solenoid): Grease new o-rings (206)

and install on the end caps (207). Install the end

caps into the housing.

DataTrak models (with runaway protection solenoid): Orient the air valve so the air inlet faces for-

ward. Grease and install new o-ring (206) on

right-side end cap (207). Grease and install new

o-ring (206) and the solenoid release button (218)

and o-ring (219) on left-side end cap (217). Install

the end caps into the housing.

6. Install a retaining ring (210) on each end to hold end

caps in place.

313435ZAA 11

Loading...

Loading...