Page 1

INSTRUCTIONS

309XXX

KEEP FOR REFERENCE.

Read this and all related manuals for

important warnings and instructions.

INSTRUCTIONS

First choice when

quality counts.

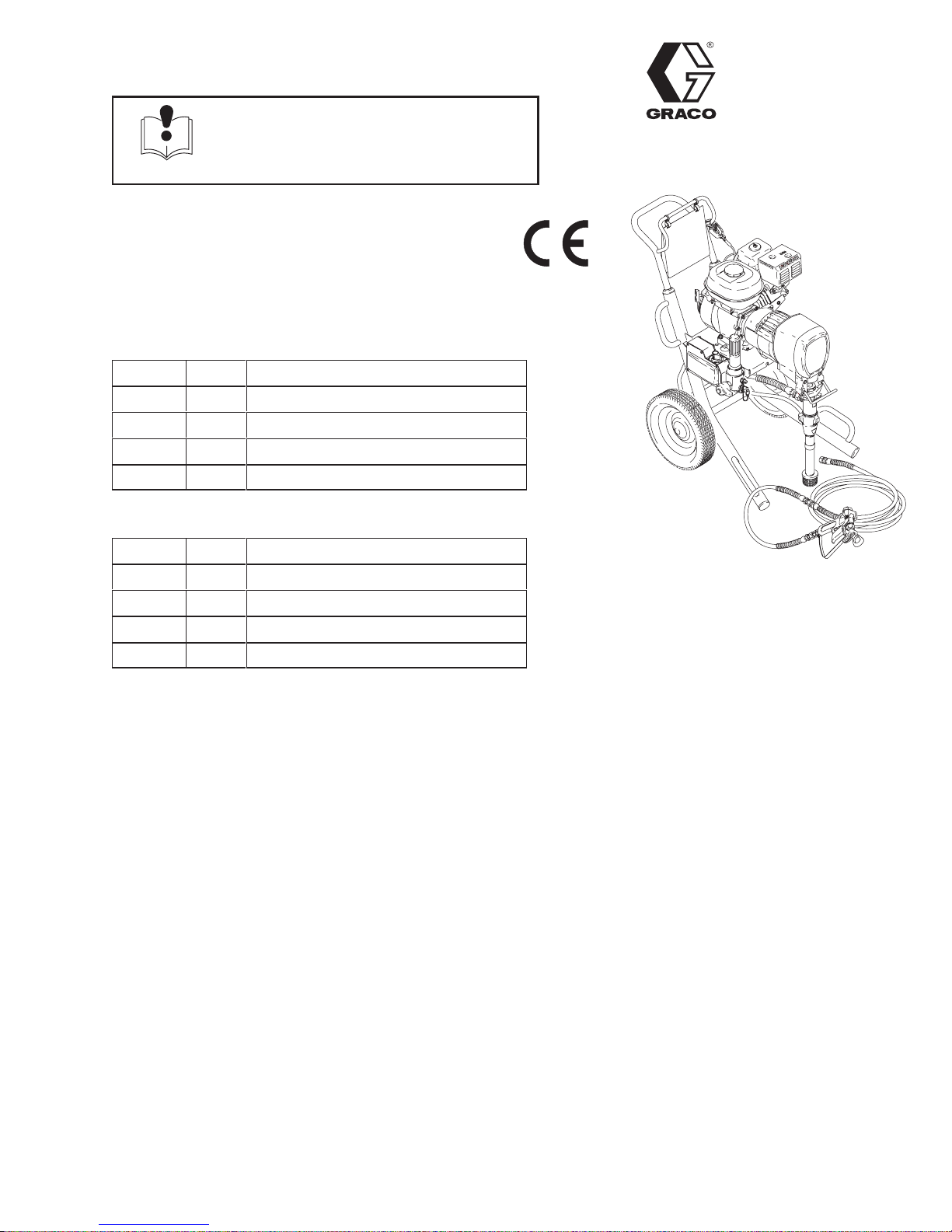

GMaxr 3900, 5900, 5900HD, 7900

Airless Paint Sprayers

3300 psi (227 bar, 22.7 MPa ) Maximum Working Pressure

Table of Manuals

Operation 308867. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displacement Pump 308798. . . . . . . . . . . . . . . . . . . . . .

Spray Gun 307614. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spray Tip 308644. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PC Board 308919. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drain Valve Kit 308961. . . . . . . . . . . . . . . . . . . . . . . . . . .

Rev. A

t

Model 232621

8695A

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

ECOPYRIGHT 1999, GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001

Page 2

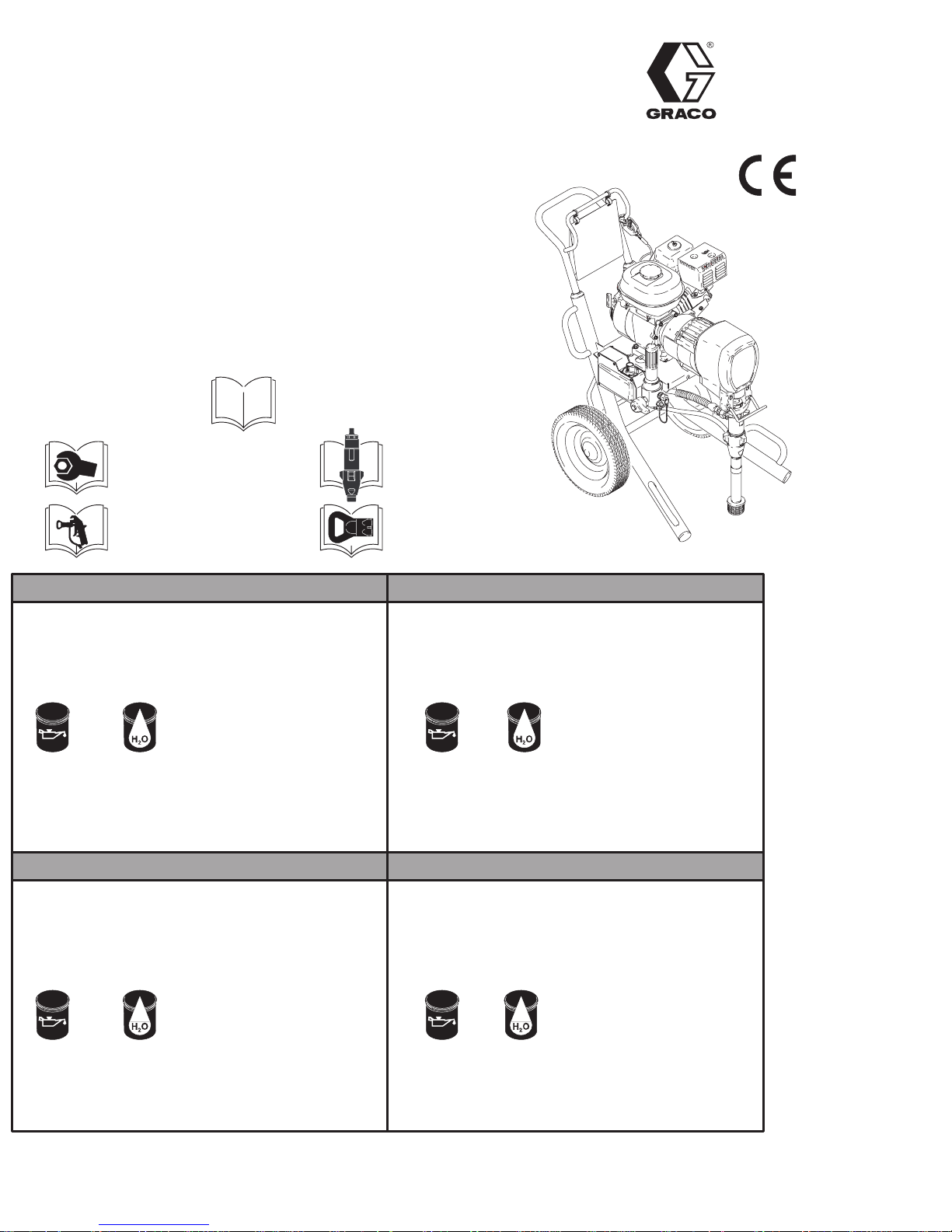

OPERATION – UTILIZAÇÃO

308867

FONCTIONNEMENT –FUNCIONAMIENTO

GMaxr 3900, 5900, 5900HD, 7900

3300 psi (228 bar, 22.8 MPa) Maximum Working Pressure

Pressão Máxima De Trabalho De 3300 psi (228 bar , 22,8 MPa)

Pression Maximale De Service 3300 lb/po2 (228 bar, 22.8 MPa)

3300 psi (228 bar, 22,8 MPa) Presión Máxima De Operación

232610, 232611, 232612, 232613*

232620, 232621, 232622, 232623, 232627, 232628*

232630, 232631, 232632, 232633{

All models not available in all countries

Nem todos os modelos existem à disposição em todos os países

T ous les modèles ne sont pas disponibles dans tous les pays

Hay modelos que no se distribuyen en todos los países

Related manuals

Manuais associados

Manuels afférents

Manuales relacionados

*308868. . . . . . .

{308870. . . . . . .

307614. . . . . . .

308798. . . . . . .

308644. . . . . . .

Rev. C

232620

INSTRUCTIONS

READ ALL INSTRUCTION AND WARNINGS

BEFORE SETTING UP OR OPERATING THIS UNIT.

You need:

S two adjustable wrenches

S two 5 gallon (20 liters) metal pails

S Compatible cleaning fluids

LatexOil Base

Clothing:

S respirator

S safety glasses

Fuel & oil specifications:

S Unleaded gasoline octane

86 or higher

S Do not use gasolines

containing methanol.

S SAE 10W–40

Operating Consideration:

S Always keep sprayer upright

while operating or transporting

INSTRUCTIONS

LIRE TOUTES LES INSTRUCTIONS ET A VERTISSEMENTS

AVANT DE PRÉPARER OU F AIRE FONCTIONNER CET

Matériel requis:

S Deux clés à molette

S Deux seaux métalliques de 5 gallons

(20 litres)

S Nettoyants liquides compatibles

APPAREIL.

Spécifications des carburants

et des huiles:

S Essence sans plomb, indice

d’octane 86 et supérieur

S Ne pas utiliser d’essences

contenant du méthanol

S SAE 10W–40

INSTRUÇÕES

LEIA TODAS AS INSTRUÇÕES E ADVERTÊNCIAS

ANTES MONT AR OU UTILIZAR EST A UNIDADE.

Você precisa de:

S Duas chaves inglesas

S Dois baldes metálicos de 20 litros

S Líquidos de limpeza compatíveis

À base de óleo Látex

Vestuário:

S Máscara de respiração

S Óculos protetores

Especificações do combustível

e óleo:

S Gasolina sem chumbo de

86 octanas ou mais

S Não use gasolina contendo

metanol

S SAE 10W–40

Conselho para a operação:

S Mantenha o pulverizador sempre

na vertical quando o estiver

utilizando ou transportando

INSTRUCCIONES

LEA TODAS LAS INSTRUCCIONES Y ADVERTENCIAS

ANTES DE PREP ARAR U OPERAR ESTA UNIDAD.

Necesita:

S Dos llaves ajustables

S Dos recipientes metálicos de

20 litros (5 galones)

S Fluidos de limpieza compatibles

Especificaciones de combustible

y aceite:

S Gasolina sin plomo de octanaje

86 o superior

S No use gasolina que

contengan metanol

S SAE 10W–40

Émail (base d’huile)

Protection personnelle:

S Respirateur

S Lunettes de protection

Latex

Précautions:

S T oujours maintenir le bec

pulvérisateur vers le haut

pendant le fonctionnement

ou le transport

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

Graco Inc. is registered to I.S. EN ISO 9001

Óleo Látex

Vestuario:

S Mascarilla

S Gafas de seguridad

Consideraciones para la operación:

S Mantenga siempre el pulverizador

en posición vertical mientras lo

opere o transporte

Page 3

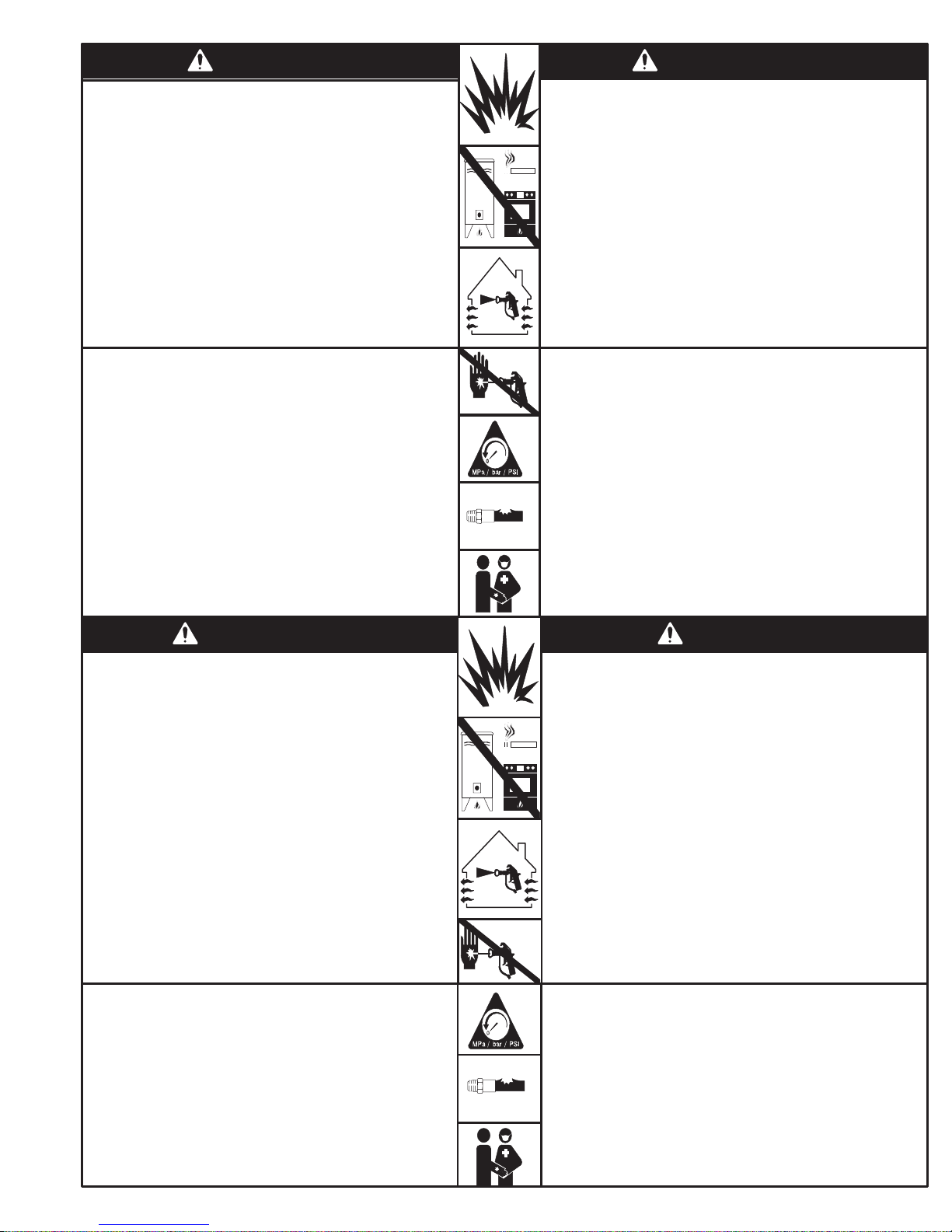

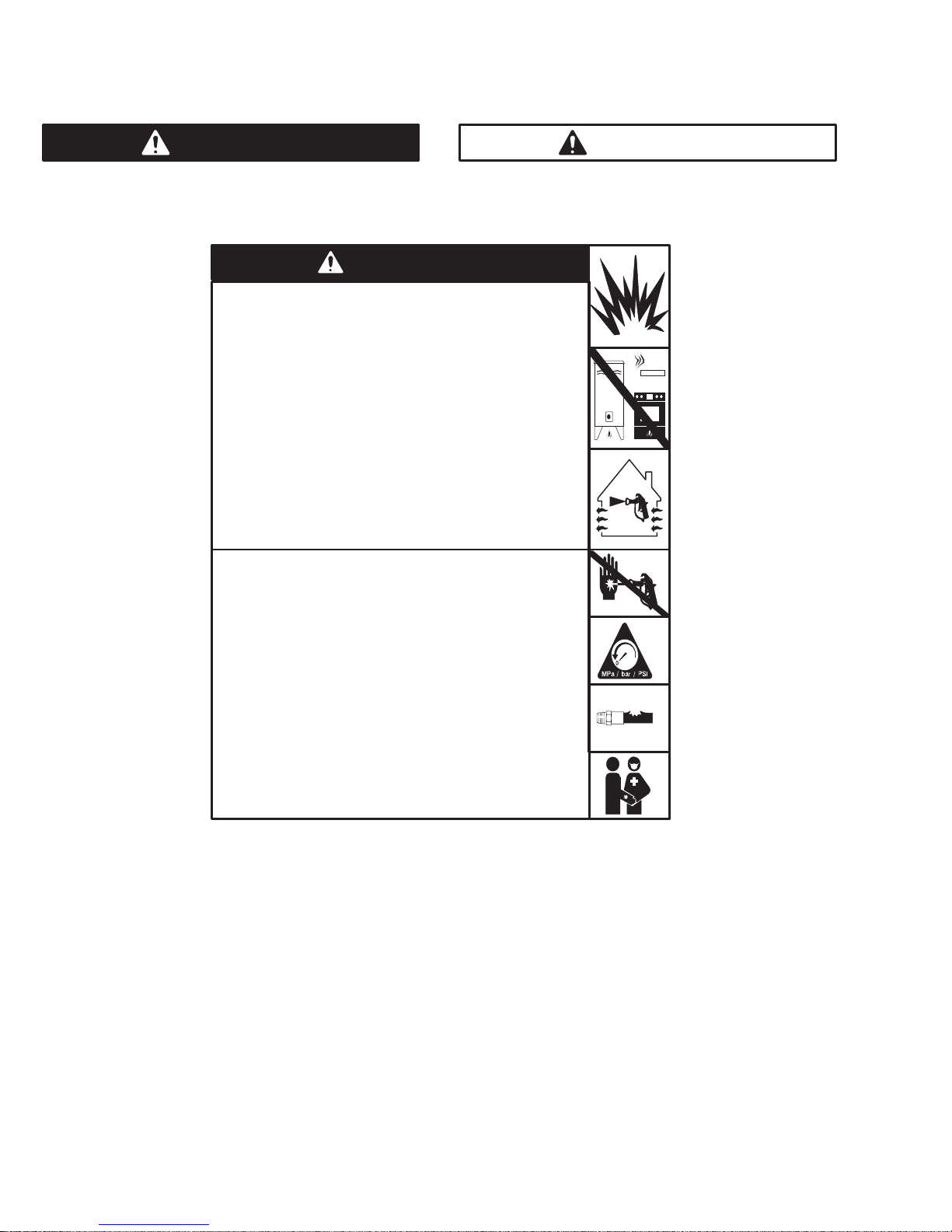

WARNING

Fire and explosion can occur when spraying or flushing flammable

fluid in an area where air circulation is poor and flammable vapors

can be ignited by an open flame or sparks.

To help prevent a fire and explosion:

Use outdoors or in an extremely well ventilated area.

Do not use 1,1,1–trichloroethane, methylene chloride, other

halogenated hydrocarbon solvents or fluids containing such

solvents in pressurized aluminum equipment. Such use could

result in a chemical reaction, with the possibility of explosion.

Remove, extinguish or unplug all ignition sources;

tape wall switches. Do not smoke in spray area.

Never fill fuel tank while the engine is running or hot.

Ground Sprayer, object being sprayed, paint and solvent pails.

Hold gun firmly to side of a grounded pail when triggering into pail.

Use only conductive airless paint hose.

Never run engine in inclosed area.

ADVERTÊNCIA

Poderá ocorrer incêndio e explosão quando for pulverizado ou injetado

líquido inflamável numa área onde houver má circulação de ar; vapores

inflamáveis poderão incendiar-se a partir de uma chama ou fagulhas a

descoberto.

Para ajudar a evitar incêndio e explosão:

Utilize no exterior ou numa área muito bem ventilada.

Não utilize 1,1,1–tricloroetano, cloreto de metileno, outros solventes de

hidrocarbonetos halogenados ou líquidos contendo tais solventes em

equipamento de alumínio pressurizado. Tal utilização poderá resultar

numa reação química, com possibilidade de explosão.

Retire, elimine ou desligue todas as fontes de ignição; coloque fita

adesiva na tomada da parede. Não fume na área de pulverização.

Nunca abasteça o depósito de combustível com o motor em funciona-

mento ou quente.

Ponha em contato com a terra o pulverizador, o objeto a ser pulveriza-

do, e os baldes de tinta e de solventes.

Segure a pistola firmemente de encontro ao lado de um balde em contato

com a terra, quando estiver descarregando para dentro do mesmo.

Utilize somente tubos flexíveis condutores para pintura a alta pressão.

Nunca faça funcionar o motor numa área fechada.

Fluid injection is a serious injury! If high pressure fluid pierces

your skin, the injury might look like “just a cut”. But it is a serious

wound! Get immediate medical attention.

To help prevent injection, always:

Engage trigger safety latch when not spraying.

Point gun away from yourself or anyone else.

Relieve pressure before checking or repairing any leak.

Relieve pressure when you turn off the sprayer or stop spraying.

Do not use components rated less than system

Working Pressu re

Never allow children to use this unit. If you are injured using this

equipment, get immediate medical treatment.

Maximum

MISE EN GARDE

Risque d’incendie et d’explosion imminent pendant la pulvérisation

ou le rinçage à pression de fluides inflammables dans une zone à mauvaise circulation d’air et en présence de gaz inflammables pouvant

s’allumer par une flamme nue ou des étincelles.

Pour éviter les risques d’incendie et d’explosion:

Manipuler les fluides à l’air libre ou dans une zone extrêmement

bien aérée.

Ne jamais utiliser de trichloroéthane 1,1,1, de chlorure de méthylène,

d’autres solvants à base d’hydrocarbures halogénés, ni de produits

contenant de tels solvants dans un équipement sous pression en

aluminium. Cela pourrait provoquer une réaction chimique avec risque

d’explosion.

Retirer, éteindre ou déboucher toute source d’inflammation, recouvrir

tout interrupteur mural avec du ruban adhésif. Ne pas fumer dans la

zone de pulvérisation.

Ne jamais remplir le réservoir d’essence lorsque le moteur est chaud

ou en marche.

Mettre à la terre le pulvérisateur, l’objet à pulvériser ainsi que les

seaux de peinture et de solvants.

Tenir le pistolet fermement contre la paroi d’un seau mis à la

terre lorsqu’on pulvérise dans le seau.

N’utiliser qu’un flexible pour peinture pulvérisée sans air.

Ne jamais mettre en marche un moteur dans une zone fermée.

A injeção de líquido é um ferimento grave! Se o líquido a alta pressão penetrar na sua pele, o ferimento poderá parecer “simplesmente

um corte”. Mas é um ferimento grave! Procure o médico imediatamente.

Para ajudar a evitar injeção de líquido, faça sempre o seguinte:

Engate o trinco de segurança do gatilho quando não estiver pulveri-

zando.

Sempre aponte a pistola para longe de você mesmo(a) ou de outras

pessoas.

Alivie a pressão antes de verificar ou reparar qualquer vazamento.

Alivie a pressão quando desligar o pulverizador ou parar de pulverizar.

Não utilize componentes classificados para uma pressão nominal

inferior à pressão máxima de trabalho dos sistemas.

Nunca permita que crianças utilizem esta unidade. Se sofrer algum

ferimento durante a utilização deste equipamento, procure o médico

imediatamente.

ADVERTENCIA

Pueden ocurrir incendios y explosiones cuando se pulveriza fluido inflamable o cuando se lava con este tipo de fluido en un área donde la

circulación de aire es deficiente y los vapores inflamables se pueden encender al contacto con el fuego o chispas.

Para prevenir incendios y explosiones:

Use en espacios abiertos o en un área muy bien ventilada.

No utilice nunca tricloretano–1,1,1, cloruro de metileno, u otros di-

solventes a base de hidrocarburos halógenos o fluidos que contengan

tales disolventes en un equipo a presión de aluminio. El uso de estas

sustancias puede provocar una intensa reacción química, con riesgos

de explosión.

Retire, apague o desconecte todas las fuentes de ignición; asegure el

interruptor de la pared con cinta. No fume en el área de pulverización.

Nunca llene el estanque de combustible mientras el motor esté en

marcha o caliente.

Ponga a tierra el pulverizador, el objeto que recibe el chorro pulverizado,

las cubetas de pintura y disolvente.

Sostenga firmemente la pistola a un lado de la cubeta puesta a

tierra cuando dispare dentro de ella.

Use solamente mangueras para pintura conductora sin aire.

Nunca haga andar el motor dentro de un área cerrada.

L’injection de fluide constitue une lésion grave! Si un fluide haute

pression perce la peau, la blessure peut paraître comme une

«simple coupure». Mais i l s’agit bien d’une lés i on grave! Consul t er

immédiatement un médecin.

Pour éviter les risques d’injection, toujours:

Bloquer le loquet de sécurité de la gâchette à la fin de la pulvérisation.

Pointer le pistolet loin de soi-même et toute autre personne à proximité

Décharger la pression avant de vérifier ou réparer une fuite.

Décharger la pression après la mise hors tension du pulvérisateur ou

à la fin de la pulvérisation.

Ne pas utiliser de composants dont la pression nominale est inférieure

à la pression maximale de service du système.

Ne jamais permettre aux enfants d’utiliser cet appareil. En cas de blessure pour avoir utilisé cet appareil, consulter immédiatement un médecin.

¡La inyección de fluido en la piel es una lesión seria! Si fluido de

alta presión le penetra la piel, la lesión podría parecer “sólo un

corte”. ¡Es una lesión seria! Consulte de inmediato al médico.

Para prevenir la inyección en la piel, siempre:

Enganche el seguro del gatillo cuando no use el pulverizador.

No apunte la pistola ni a sí mismo ni a los demás.

Alivie la presión antes de inspeccionar o reparar cualquier filtración.

Alivie la presión cuando apague el pulverizador o deje de usarlo.

No use componentes cuya capacidad nominal sea inferior a la

presión máxima de operación del sistema.

No permita que niños usen esta unidad. Si se lesiona usando este

equipo, sométase de inmediato a tratamiento médico.

3308867

Page 4

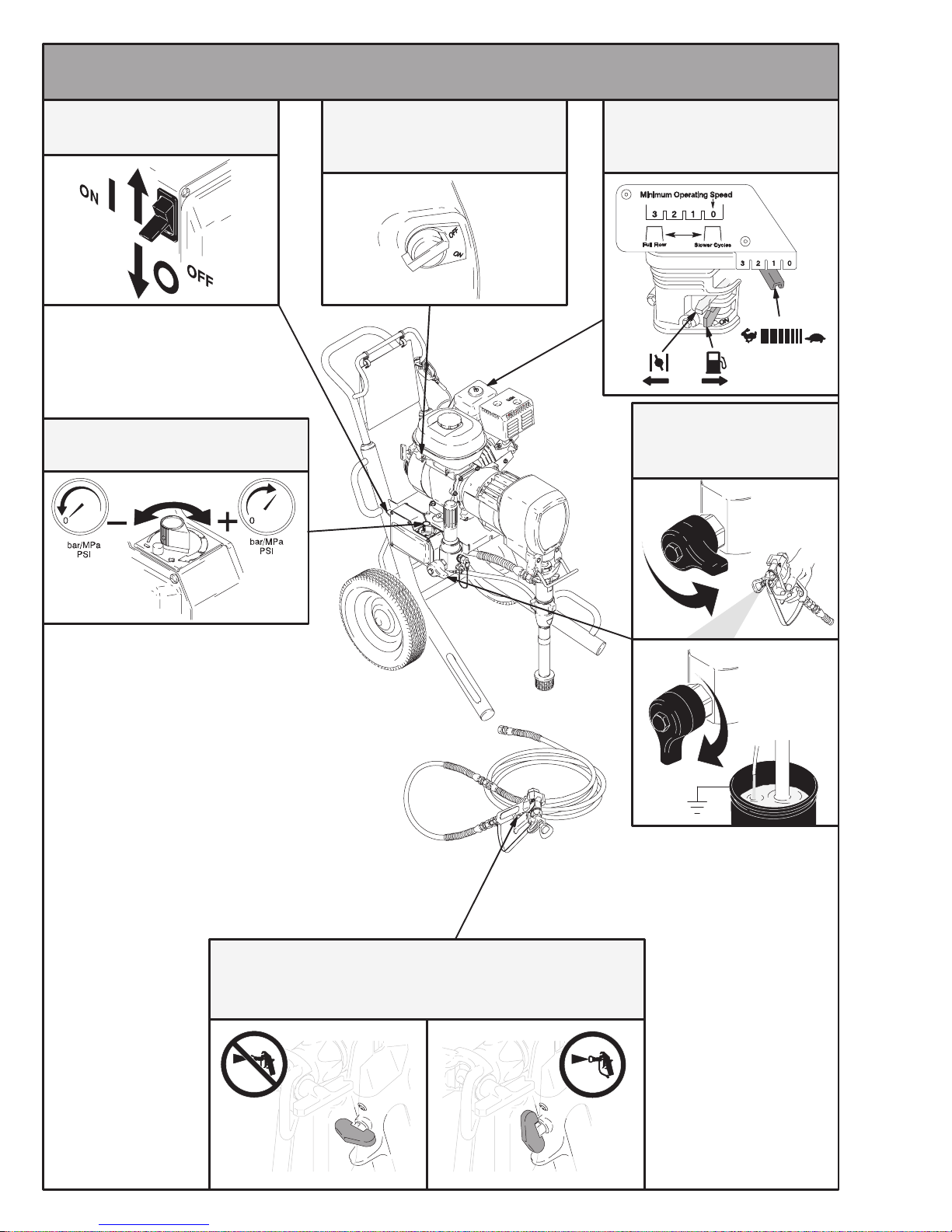

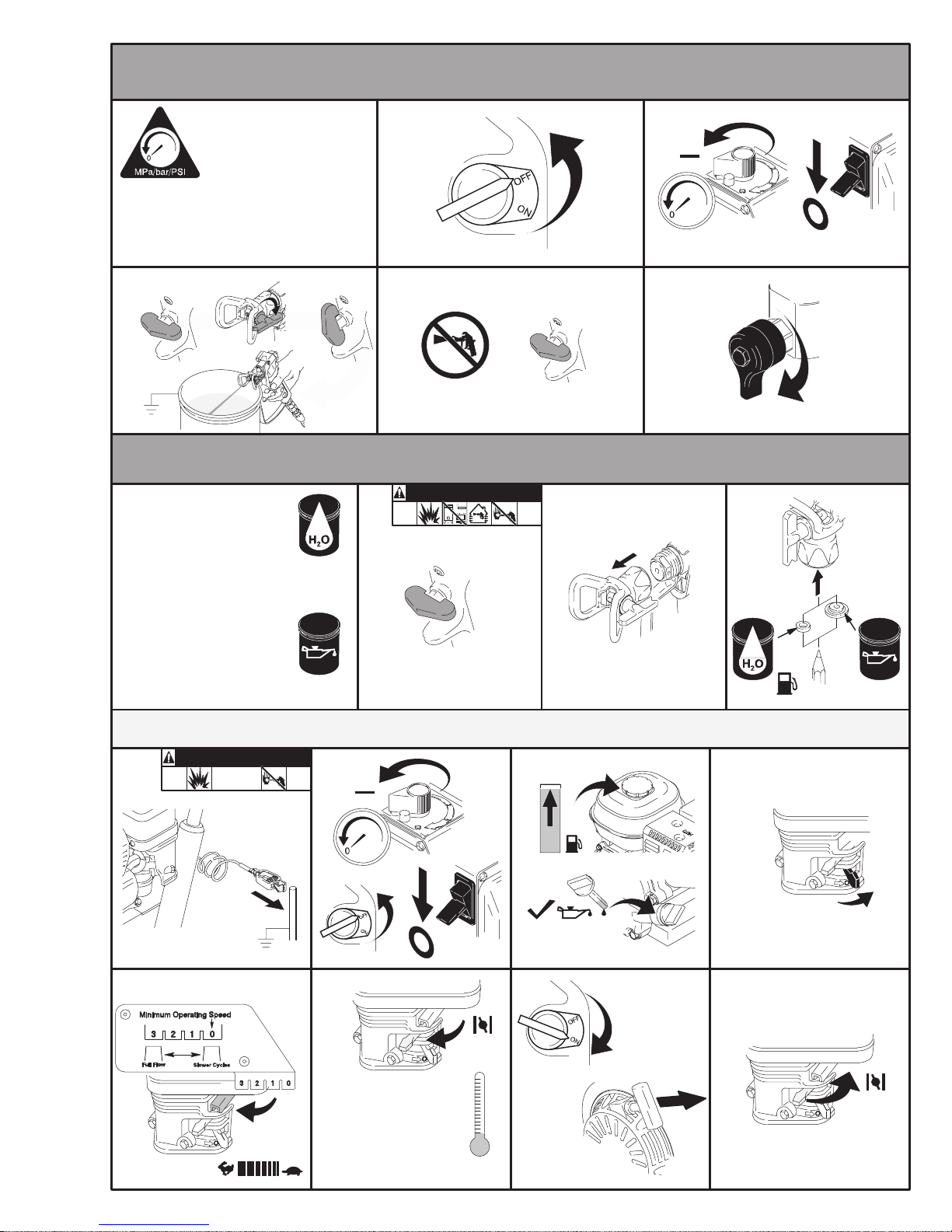

CONTROLS / CONTROLES / COMMANDES / CONTROLES

On/Off Switch Aan/Uit Schakelaar

Interrupteur Marche/Arrêt

Ein-Aus-Schalter

Pressure Control / Controle da pressão /

Système de contrôle de la pression /

Dispositivo de control de la presión

On/Off Switch

Interruptor de ligar e desligar

Interrupteur marche/arrêt

Interruptor de encendido/apagado

Engine Controls

Controles do motor

Commandes de moteur

Controles del motor

Drain V alve

Válvula de drenagem

Vidange

Válvula de vaciado

Trigger Lock

Fecho do gatilho

Loquet de sécurité

Seguro del gatillo

4 308867

8695A

Page 5

PRESSURE RELIEF / ALÍVIO DE PRESSÃO / DÉCHARGE DE PRESSION /

ALIVIO DE LA PRESIÓN 1→5

Follow 1–5 when you

stop spraying.

Siga os passos de 1–5

quando parar de pulverizar.

Suivre les étapes 1 à 5 lorsqu’on arrête

de pulvériser.

Siga los pasos 1–5 cuando deje de usar

el pulverizador.

3

12

54

STARTUP / P ARTIDA / DÉMARRAGE / PUESTA EN MARCHA 1→24

WARNING ADVERTÊNCIA

Flush with warm soapy water.

Faça a descarga com água

morma e sabão dissolvido.

Rincer avec de l’eau tiède

savonneuse.

Enjuague con agua tibia con

jabón.

1

MISE EN GARDE ADVERTENCIA

2

3

Flush with mineral spirits.

Faça a descarga com

álcool mineral.

Rincer avec une eseence

minérale.

Enjuague con alcohol

mineral.

Start Engine / Partida do motor / Démarrage / Partida del motor 4→11

WARNING ADVERTÊNCIA

MISE EN GARDE ADVERTENCIA

8

54 6

9

10

7

11

Cold Engine Starts

Partida do motor a frio

Démarrages à froid

Partida del motor en frío

5308867

Page 6

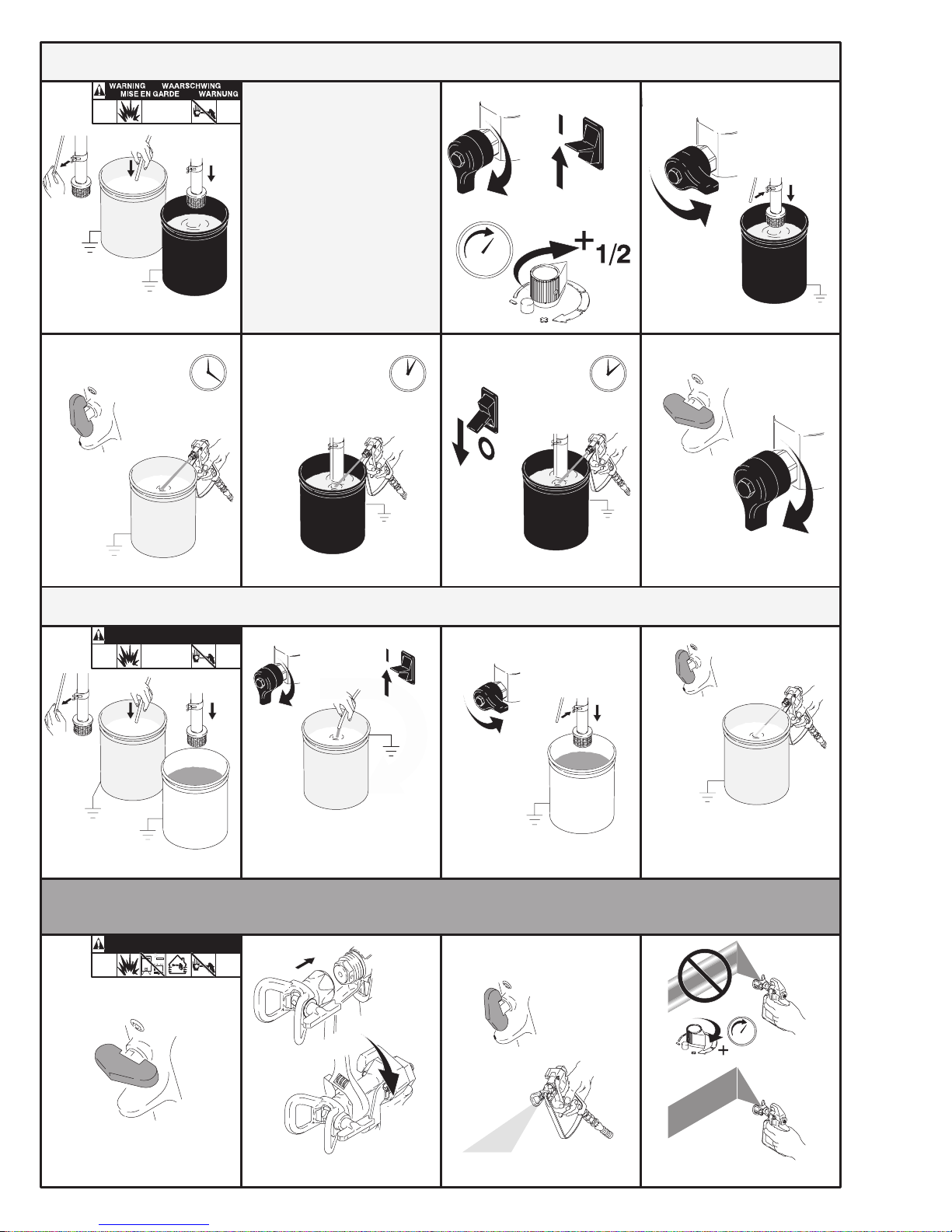

Flush / Descarga / Vidange / Enjuague 12→19

12

16

WASTE

RESÍDUOS

À JETER

DESECHO

RESÍDUOS

À JETER

DESECHO

WASTE

FLUSH

DESCARGA

VIDANGE

ENJUAGUE

20 SEC.

13

Start Engine

Partida do motor

Démarrage

Partida del motor

17

FLUSH

DESCARGA

VIDANGE

ENJUAGUE

1 MIN.

14

18

FLUSH

DESCARGA

VIDANGE

ENJUAGUE

10 SEC.

15

19

FLUSH

DESCARGA

VIDANGE

ENJUAGUE

Prime / Preparação / Amorçage / Cebado 20→23

WARNING ADVERTÊNCIA

MISE EN GARDE ADVERTENCIA

WASTE

AFVAL

REBUT

ABFAL

PAINT

TINTA

PEINTURE

PINTURA

21 2220

WASTE

AFVAL

REBUT

ABFAL

Watch for paint

Cuidado com a tinta

Vérifier l’arrivée de la peinture

Observe cuando salga pintura

PAINT

TINTA

PEINTURE

PINTURA

23

WASTE

AFVAL

REBUT

ABFAL

Watch for paint

Cuidado com a tinta

Vérifier l’arrivée de la peinture

Observe cuando salga pintura

SPRAY / PULVERIZAÇÃO / PULVÉRISATION / PULVERISACIÓN 1→4

WARNING ADVERTÊNCIA

1234

MISE EN GARDE ADVERTENCIA

6 308867

Page 7

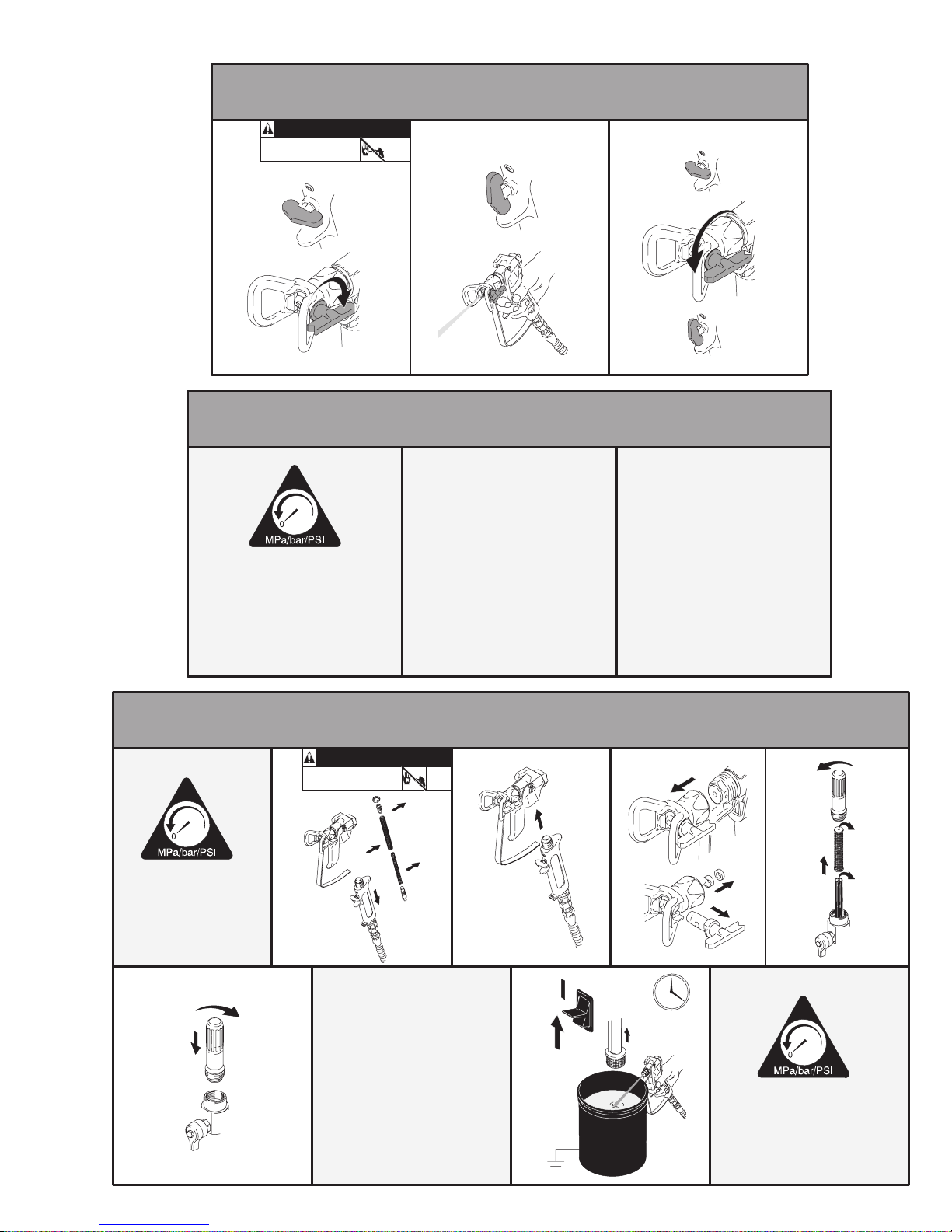

CLEAR CLOG / DESOBSTRUÇÃO / DÉCRASSEMENT /

DESTAPAR

WARNING ADVERTÊNCIA

1 23

MISE EN GARDE ADVERTENCIA

CHANGE P AINT / TROCA DE TINTA / CHANGEMENT

DE PEINTURE / CAMBIAR PINTURA

231

Flush

Descarga

Pressure Relief

Alívio de pressão

Vidange

Décharge de pression

Alivio de la presión

Enguaje

SHUTDOWN / DESATIVAÇÃO / ARRÊT / PARADA

WARNING ADVERTÊNCIA

MISE EN GARDE ADVERTENCIA

1

Pressure Relief

Alívio de pressão

Décharge de pression

Alivio de la presión

2534

Prime

Preparação

Amorçage

Cebado

6

7

Flush

Descarga

Vidange

Enguaje

FLUSH

DESCARGA

VIDANGE

ENJUAGUE

98

20 SEC.

Pressure Relief

Alívio de pressão

Décharge de pression

Alivio de la presión

7308867

Page 8

10 1 1 12

FLUSH

FLUSH

DESCARGA

SPOELEN

VIDANGE

RINÇAGE

ENJUAGUE

SPÜLUNG

13

14 16

18

Pressure Relief

Alívio de pressão

Décharge de pression

Alivio de la presión

19 20 21

Mineral Spirits

Álcool mineral

Essence minérale

Alcohol mineral

Mineral Spirits

White spirit

Lösungsbenzin

Thinner

1715

20 SEC.

WASTE

RESÍDUOS

À JETER

DESECHO

8 308867

Page 9

Graco Standard W arranty Garantia Standard da Graco

Garantie standard de Graco Garantía estándar Graco

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in material and

workmanship on the date of sale by an authorized Graco distributor to the original purchaser for use. With the exception of any special, extended, or

limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined

by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty installation,

misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non–Graco component

parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of the

claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned to the

original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will be made at a

reasonable charge, which charges may include the costs of parts, labor , and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER W ARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED T O

WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy (including,

but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or consequential loss)

shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED W ARRANTIES OF MERCHANTABILITY AND FITNESS FOR A P ARTICULAR

PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT MANUFACTURED BY

GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any , of their

manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder , or the

furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the negligence of

Graco, or otherwise.

PARA CLIENTES BRASILEIROS DA GRACO

As partes confirmam que solicitaram que o presente documento, assim como todos os demais documentos, notas e processos legais inseridos, atribuídos ou instituídos de acordo com o mesmo ou relacionados direta ou indiretamente com o este documento, sejam redigidos em inglês.

AUX CLIENTS DE GRACO AU CANADA

Les parties conviennent avoir demandé que le présent document, ainsi que tout autre document, avis et procédures judiciaires inclus, donnés dans les

présentes ou institués en vertu des présentes, ou en relation directe ou indirecte aux présentes, soient rédigés en anglais.

PARA CLIENTES DE GRACO EN COLOMBIA

Las partes reconocen que han solicitado que el presente documento, como asimismo todos los documentos, notificaciones y compromisos legales que

se suscriban, presentados o instituidos por el presente o relacionados directa e indirectamente con éste, sean redactados en inglés.

ADDITIONAL WARRANTY COVERAGE / COBERTURA DE GARANTIA ADICIONAL / GARANTIE PROLONGÉE /

COBERTURA ADICIONAL DE LA GARANTÍA /

Graco does provide extended warranty and wear warranty for products described in the “Graco Contractor Equipment Warranty Program”.

A Graco fornece prorrogação de garantia e garantia de desgaste para os produtos descritos no “Graco Contractor Equipment Warranty Program”

(Programa de garantia de equipamento do empreiteiro da Graco).

Graco n’offre pas de garantie prolongée ni de garantie contre l’usure pour les produits décrits dans le “Programme de garantie des équipements pour

entrepreneur de Graco”.

Graco ofrece una garantía extendida y una garantía de desgaste para los productos consignados en el “Programa de Garantía de Equipo Graco para

Contratistas”.

TO PLACE AN ORDER OR FOR SERVICE

PARA EFETUAR ENCOMENDAS OU PARA ASSISTÊNCIA TÉCNICA

POUR PLACER UNE COMMANDE OU DEMANDER DU SERVICE

PARA REMITIR UN PEDIDO O SOLICITAR SERVICIO

, contact your Graco distributor.

, contate o seu distribuidor da Graco.

, contactez votre distributeur Graco.

, póngase en contacto con el distribuidor de Graco.

All written and visual data contained in this document reflects the latest product information available at the time of publication. Graco reserves the

T odos os dados escritos e visuais contidos neste documento refletem as mais recentes informações sobre o produto disponíveis na época da

T oute information écrite et graphique incluse dans ce document reflète les caractéristiques les plus récentes des produits au moment d’aller sous

T oda la información escrita y visual contenida en este documento refleja la información de producto más reciente manejada al momento de la

publicação. A Graco reserva-se o direito de efetuar alterações em qualquer momento sem aviso prévio.

presse. Graco se réserve le droit d’apporter des modifications en tout temps sans avis.

publicación. Graco se reserva el derecho de introducir cambios en cualquier momento sin aviso.

Foreign Offices: Belgium, England, Korea, France, Germany, Hong Kong, Japan

Escritórios estrangeiros: Bélgica, Inglaterra, Coréia, França, Alemanha, Hong Kong, Japão

International: Belgique, Angleterre, Corée, France, Allemagne, Hong Kong, Japon

Oficinas internacionales: Bélgica, Inglaterra, Corea, Francia, Alemania, Hong Kong, Japón

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

right to make changes at any time without notice.

Sales Offices: Minneapolis, Detroit

Escritórios de Vendas: Minneapolis, Detroit

Bureaux des ventes: Minneapolis, Détroit

Oficina de ventas: Minneapolis, Detroit

http://www.graco.com

PRINTED IN USA 308867 November 1998, Revised March 1999

9308867

Page 10

INSTRUCTIONS-REPAIR

308868

KEEP FOR REFERENCE.

Read this and all related manuals for

important warnings and instructions.

INSTRUCTIONS

GMaxr 3900 and 5900

Airless Paint Sprayers

3300 psi (227 bar, 22.7 MPa ) Maximum Working Pressure

GMax 3900

Model Series Description

232610 A Hi-Boy

232611 A Hi-Boy with RAC IV tip, gun and hose

232612 A Lo-Boy

232613 A Lo-Boy with RAC IV tip, gun and hose

GMax 5900

Model Series Description

232620 A Hi-Boy

232621 A Hi-Boy with RAC IV tip, gun and hose

232622 A Lo-Boy

232623 A Lo-Boy with RAC IV tip, gun and hose

Rev. A

First choice when

quality counts.

Model 232621

All models are not available in all countries

U.S. PATENT NO. 4,323,741; 4,397,610 PATENTED

1983, CANADA AND OTHER P ATENTS PENDING

t

8695A

Related Manuals

Operation 308867. . . . . . . . . . . . . . . . . . . . . . . . . .

Displacement Pump 308798. . . . . . . . . . . . . . . . .

Spray Gun 307614. . . . . . . . . . . . . . . . . . . . . . . . .

Spray Tip 308644. . . . . . . . . . . . . . . . . . . . . . . . . . .

PC Board 308816. . . . . . . . . . . . . . . . . . . . . . . . . .

Drain Valve Kit 308961. . . . . . . . . . . . . . . . . . . . . .

Warnings and Cautions 2. . . . . . . . . . . . . . . . . . . . . . . . .

Component Identification and Function 3. . . . . . . . . . . .

Maintenance 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repair

Bearing Housing & Connecting Rod 7. . . . . . . . . . . . .

Drive Housing 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pinion Assembly/Rotor/Field/Shaft/Clutch 9. . . . . . . .

Clamp 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch Housing 1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine 1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pressure Control 12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

Table of Contents

Displacement Pump 14. . . . . . . . . . . . . . . . . . . . . . . . .

Parts

GMax 3900 & GMax 5900 Hi-Boy Sprayers 15. . . . .

Pinion Assembly 17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

GMax 3900 & GMax 5900 Lo-Boy Sprayers 18. . . . .

Complete Sprayers 20. . . . . . . . . . . . . . . . . . . . . . . . . .

Pressure Control 21. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Phone Number 23. . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Warranty 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ECOPYRIGHT 1999, GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001

Page 11

Warnings and Cautions

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

WARNING

Fire and explosion can occur when spraying or flushing flammable

fluid in an area where air circulation is poor and flammable vapors

can be ignited by an open flame or sparks.

To help prevent a fire and explosion:

Use outdoors or in an extremely well ventilated area.

Do not use 1,1,1–trichloroethane, methylene chloride, other

halogenated hydrocarbon solvents or fluids containing such

solvents in pressurized aluminum equipment. Such use could

result in a chemical reaction, with the possibility of explosion.

Remove, extinguish or unplug all ignition sources;

tape wall switch. Do not smoke in spray area.

Never fill fuel tank while the engine is running or hot.

Ground Sprayer, object being sprayed, paint and solvent pails.

Hold gun firmly to side of a grounded pail when triggering into pail.

Use only conductive airless paint hose.

Never run engine in inclosed area.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

Fluid injection is a serious injury! If high pressure fluid pierces

your skin, the injury might look like “just a cut”. But it is a serious

wound! Get immediate medical attention.

To help prevent injection, always:

Engage trigger safety latch when not spraying.

Point gun away from yourself or anyone else.

Relieve pressure before checking or repairing any leak.

Relieve pressure when you turn off the sprayer or stop spraying.

Do not use components rated less than system

Working Pressu re

Never allow children to use this unit. If you are injured using this

equipment, get immediate medical treatment.

Maximum

3088682

Page 12

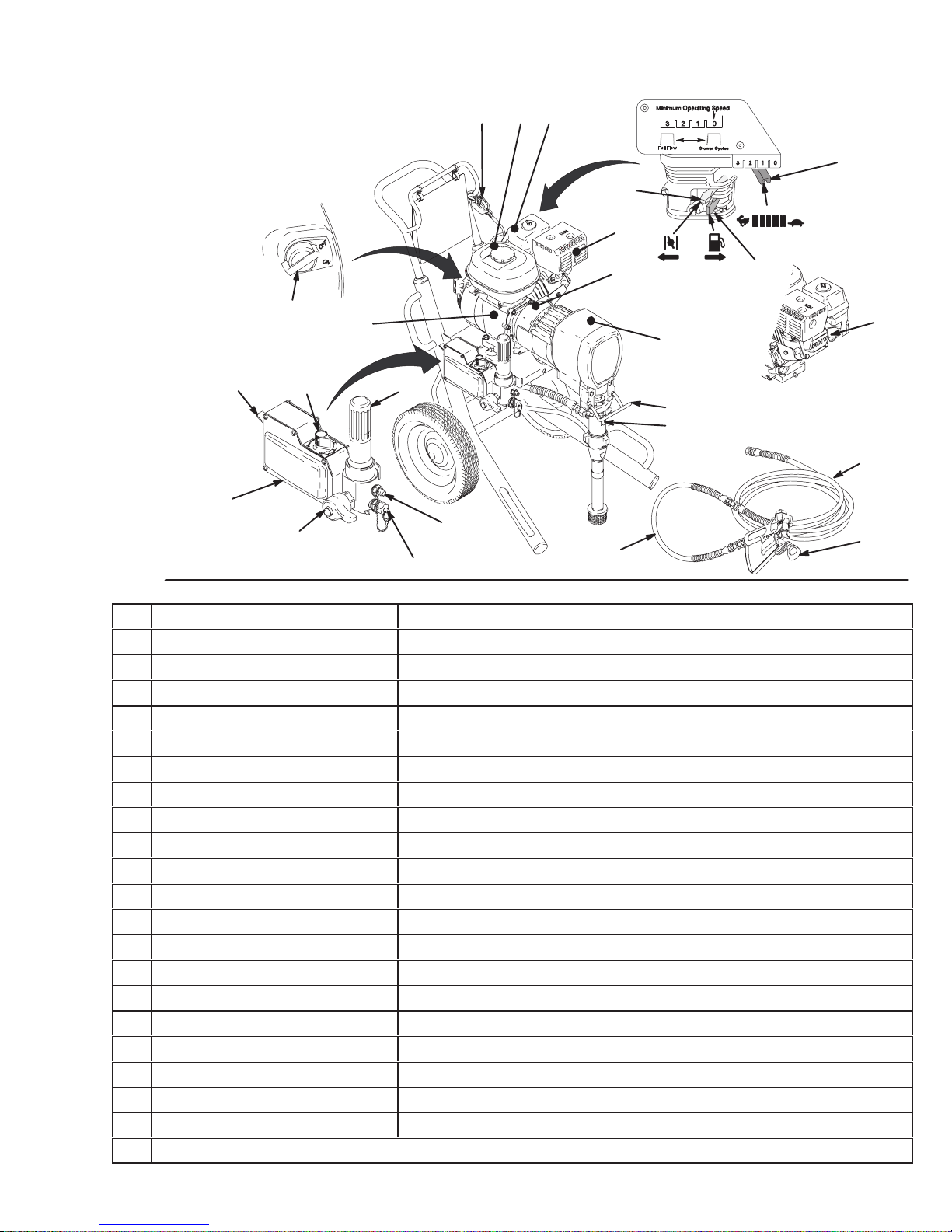

Component Identification and Function

202Main hose

203Whip end hose

204Contractor gun with RAC IV

DripLess tip guard and 517 size SwitchTip

K

A

M

X

Fig. 1

V

P

B

U

N

L

C

D

J

H

E

R

S

W

T

203

G

F

Model 232611

202

204

8696A

A Pressure Control Switch ON/OFF, enables/disables clutch function and pressure control

B Pressure Adjusting Knob Controls fluid outlet pressure

C Air Cleaner* Filters air entering the carburetor

D Fuel Tank* Uses 86 octane unleaded gasoline

E Muffler* Reduces noise of internal combustion

F Spark Plug Cable* Routes electrical current to spark plug

G Fuel Shutoff Lever* On/off lever to regulate fuel flow from gasoline tank to carburetor

H Choke* Enriches air/gasoline mixture for cold starting

J Throttle Lever* Adjusts engine speed for large or small orifice spray tips

K Engine Switch* Enables/disables engine operation

L Secondary Fluid Outlet Second hose and spray gun is connected here

M Pressure Control Controls clutch cycling to maintain fluid pressure.

N Primary Fluid Outlet Hose and spray gun is connected here

P Engine* 4–cycle gasoline engine

R Clutch Housing Transfers power from engine to drive assembly

S Drive Housing Transfers power from clutch to displacement pump

T Displacement Pump Provides fluid to be sprayed through spray gun

U Fluid Filter Filters fluid between source and spray gun

V Grounding Clamp and Wire Grounds sprayer system

W Pail Hanger Provides a hanger for paint pail

X Pressure Drain Valve Relieves fluid pressure when open

* For more detailed explanations of these controls, refer to the Honda Engines Owner’s Manual; supplied

Page 13

Maintenance

WARNING

INJECTION HAZARD

The system pressure must be manually

relieved to prevent the system from

starting or spraying accidentally. Fluid

under high pressure can be injected through the

skin and cause serious injury. To reduce the risk of

an injury from injection, splashing fluid, or moving

parts, follow the Pressure Relief Procedure

whenever you:

are instructed to relieve the pressure,

stop spraying,

check or service any of the system equipment,

or install or clean the spray tip.

Pressure Relief Procedure

1. Lock gun trigger safety.

2. Turn engine ON/OFF switch to OFF.

3. Move pressure control switch to OFF and turn

pressure control knob fully counterclockwise.

CAUTION

For detailed engine maintenance and specifications,

refer to separate Honda Engines Owner’s Manual,

supplied.

DAILY: Check engine oil level and fill as necessary.

DAILY: Check hose for wear and damage.

DAILY: Check gun safety for proper operation.

DAILY: Check pressure drain valve for proper opera-

tion.

DAILY: Check and fill the gas tank.

AFTER THE FIRST 20 HOURS OF OPERATION

Drain engine oil and refill with clean oil. Reference

Honda Engines Owner’s Manual for correct oil viscosity.

WEEKLY: Remove air filter cover and clean element.

Replace element, if necessary. If operating in an

unusually dusty environment: check filter daily and

replace, if necessary.

4. Unlock trigger safety. Hold metal part of gun firmly

to side of grounded metal pail, and trigger gun to

relieve pressure.

5. Lock gun trigger safety.

6. Open pressure drain valve. Leave valve open until

ready to spray again.

If you suspect that the spray tip or hose is completely

clogged, or that pressure has not been fully relieved

after following the steps above,

loosen tip guard retaining nut or hose end coupling to

relieve pressure gradually, then loosen completely.

Now clear tip or hose.

VERY SLOWLY

Replacement elements can be purchased from your

local HONDA dealer.

WEEKLY: Check level of TSL in displacement pump

packing nut. Fill nut, if necessary. Keep TSL in nut to

help prevent fluid buildup on piston rod and premature

wear of packings.

AFTER EACH 100 HOURS OF OPERATION:

Change engine oil. Reference Honda Engines Owner’s

Manual for correct oil viscosity.

SPARK PLUG: Use only BPR6ES (NGK) or

W20EPR–U (NIPPONDENSO) plug. Gap plug to

0.028 to 0.031 in. (0.7 to 0.8 mm). Use spark plug

wrench when installing and removing plug.

3088684

Page 14

Troubleshooting

WARNING

INJECTION HAZARD

To reduce risk of serious injury, including fluid injection or splashing in eyes or on skin, or injury from

moving parts, always follow Pressure Relief Procedure Warning, page 4, before checking, adjusting, cleaning or shutting down sprayer.

Check everything in chart before disassembling sprayer.

PROBLEM CAUSE SOLUTION

Engine won’t start

Engine operates, but disp

placement pump does not

operate

p

p

Engine switch is OFF Turn engine switch ON

Engine is out of gas Refill gas tank. Honda Engines Owner’s Manual.

Engine oil level is low Try to start engine. Replenish oil, if necessary.

Spark plug cable is disconnected or damaged Connect spark plug cable or replace spark

Cold engine Use choke

Fuel shutoff lever is OFF Move lever to ON position

Oil is seeping into combustion chamber Remove spark plug. Pull starter rope 3 or 4

Pressure control switch is OFF Turn pressure control switch ON.

Pressure setting is too low Turn pressure adjusting knob clockwise to

Fluid filter (318) is dirty Clean filter. Page 21.

Tip or tip filter is clogged Clean tip or tip filter. Manual 307614.

Displacement pump piston rod is stuck due to

dried paint

Honda Engines Owner’s Manual.

plug

times. Clean or replace spark plug. Try to start

engine. Keep sprayer upright to avoid oil seepage.

increase pressure.

Repair pump. Manual 308798.

Connecting rod is worn or damaged Replace connecting rod. Page 7.

Drive housing is worn or damaged Replace drive housing. Page 8.

Electrical power is not energizing clutch field Check wiring connections. Page 11.

Clutch is worn, damaged, or incorrectly

positioned

Pinion assembly is worn or damaged Repair or replace pinion assembly. Page 9.

Reference control board diagnostics. Page 13.

With pressure control switch ON and pressure

turned to MAXIMUM, use a test light to check

for power between clutch terminals on control

board.

Remove black clutch wires from control board

and measure resistance across wires. At 70 F,

the resistance must be between 1.2 0.2Ω

(GMax3900); 1.7 0.2Ω (GMax 5900); if not,

replace pinion housing.

Check control board fuse. If blown, replace

with equivalent automotive fuse.

Have pressure control checked by authorized

Graco dealer.

Replace clutch. Page 9.

308868 5

Page 15

PROBLEM CAUSE SOLUTION

Pump output is low

Excessive paint leakage into

throat packing nut

Strainer (31) is clogged Clean strainer

Piston ball (25) is not seating Service piston ball. Manual 308798.

Piston packings are worn or damaged Replace packings. Manual 308798.

O-ring (227) in displacement pump is worn or

damaged

Intake valve ball is not seating properly Clean intake valve. manual 308798.

Engine speed is too low Increase throttle setting. Manual 308867.

Clutch is worn or damaged Replace clutch. Page 9.

Pressure setting is too low Increase pressure. Manual 308867.

Fluid filter (318), tip filter or tip is clogged or

dirty

Large pressure drop in hose with heavy

materials

Throat packing nut is loose Remove throat packing nut spacer. Tighten

Throat packings are worn or damaged Replace packings. Manual 308798.

Replace o-ring. Manual 308798.

Clean filter. Manual 308867 or 307614.

Use larger diameter hose and/or reduce overall

length of hose. Use of more than 100 ft of 1/4

in. hose significantly reduces performance of

sprayer. Use 3/8 in. hose for optimum performance (50 ft minimum).

throat packing nut just enough to stop leakage.

Fluid is spitting from gun

Pump is difficult to prime

Displacement rod is worn or damaged Replace rod. Manual 308798.

Air in pump or hose Check and tighten all fluid connections.

Reprime pump. Manual 308867.

Tip is partially clogged Clear tip. Manual 307614.

Fluid supply is low or empty Refill fluid supply . Prime pump. Manual

308867. Check fluid supply often to prevent

running pump dry .

Air in pump or hose Check and tighten all fluid connections.

Reduce engine speed and cycle pump as

slowly as possible during priming.

Intake valve is leaking Clean intake valve. Be sure ball seat is not

nicked or worn and that ball seats well. Reas-

semble valve.

Pump packings are worn Replace pump packings. Manual 308798.

Paint is too thick Thin the paint according to the supplier’s

recommendations

Engine speed is too high Decrease throttle setting before priming pump.

Manual 308867.

Page 16

Bearing Housing and Connecting Rod

NOTE: The item numbers referenced are for the

Hi-Boy models. The Lo-Boy models models may have

different item numbers. Use the Hi-Boy item number

and part to find the corresponding Lo-Boy part and

item number.

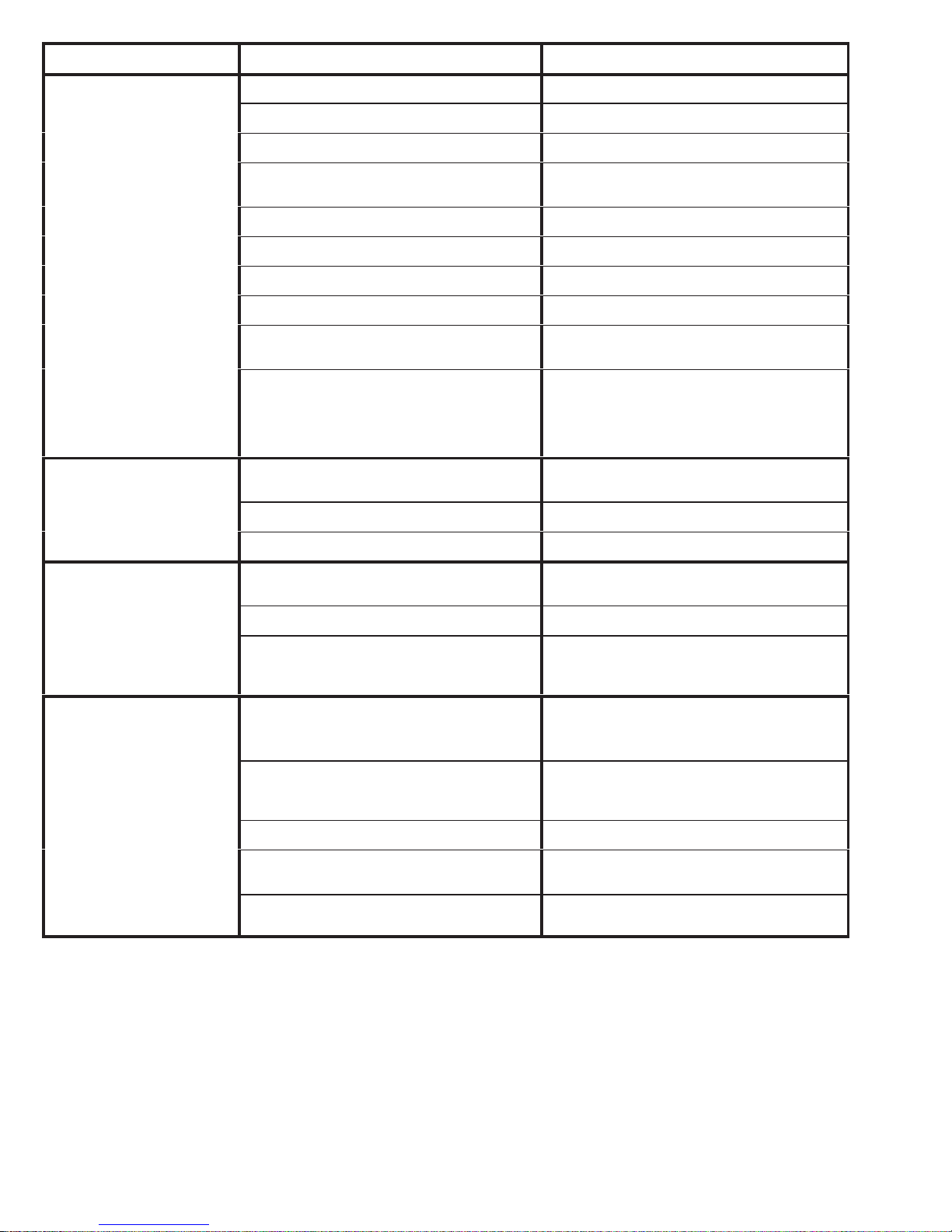

Removal

1.

Relieve pressure; page 4.

2. Fig. 3. Remove screws (14) and front cover (23).

3. For Hi-Boy models; remove spring clip (32) and

drain hose (54). Unscrew suction tube (30) from

pump, hold wrench on pump intake valve (A) to

keep pump from loosening. For Lo-Boy models;

unscrew swivel union (30aa) from pump.

4. Disconnect pump outlet hose (33) from displace-

ment pump outlet nipple (62).

5. Fig. 2. Use screwdriver to push up retaining spring

(26) at top of pump. Push out pin (29).

2. Assemble connecting rod (22) and bearing housing

(21).

3. Clean mating surfaces of bearing and drive housings.

4. Align connecting rod with crank (B) and carefully

align locating pins (F) in drive housing (20) with

holes in bearing housing (21). Push bearing housing onto drive housing or tap into place with plastic

mallet.

CAUTION

DO NOT use bearing housing screws (13) to align

or seat bearing housing with drive housing. Align

these parts with locating pins (F), to avoid premature bearing wear.

5. Install screws (13) and lockwashers (12) on bearing housing. Torque evenly to note 3 value in Fig. 3.

29

Fig. 2

26

7675B

6. Fig. 3. Loosen retaining nut (34). Unscrew and

remove displacement pump (28).

7. Remove four screws (13) and lockwashers (12)

from bearing housing (21).

8. Pull connecting rod (22) and lightly tap lower rear

of bearing housing (21) with plastic mallet to

loosen from drive housing (20). Pull bearing housing and connecting rod assembly (22) off drive

housing.

9. Inspect crank (B) for excessive wear and replace

parts as needed.

Installation

1. Evenly lubricate inside of bronze bearing (C) in

bearing housing (21) with high-quality motor oil.

Liberally pack top roller bearing (E), lower bearing

(D) inside connecting rod assembly (22) with

bearing grease.

6. Refer to Displacement Pump, Installation, page 14.

2

C

1

E

2

D

22

12, 13

B

3

23

20

14

29

26

F

33

62

21

28

A

34

32

54

1

Oil

2

Pack with bearing grease 114819

3

GMax 3900: Torque to 200 in-lb (22.6 Nm)

GMax 5900: Torque to 25 ft-lb (34 Nm)

Fig. 3

Model 232610 shown

30

8697A

308868 7

Page 17

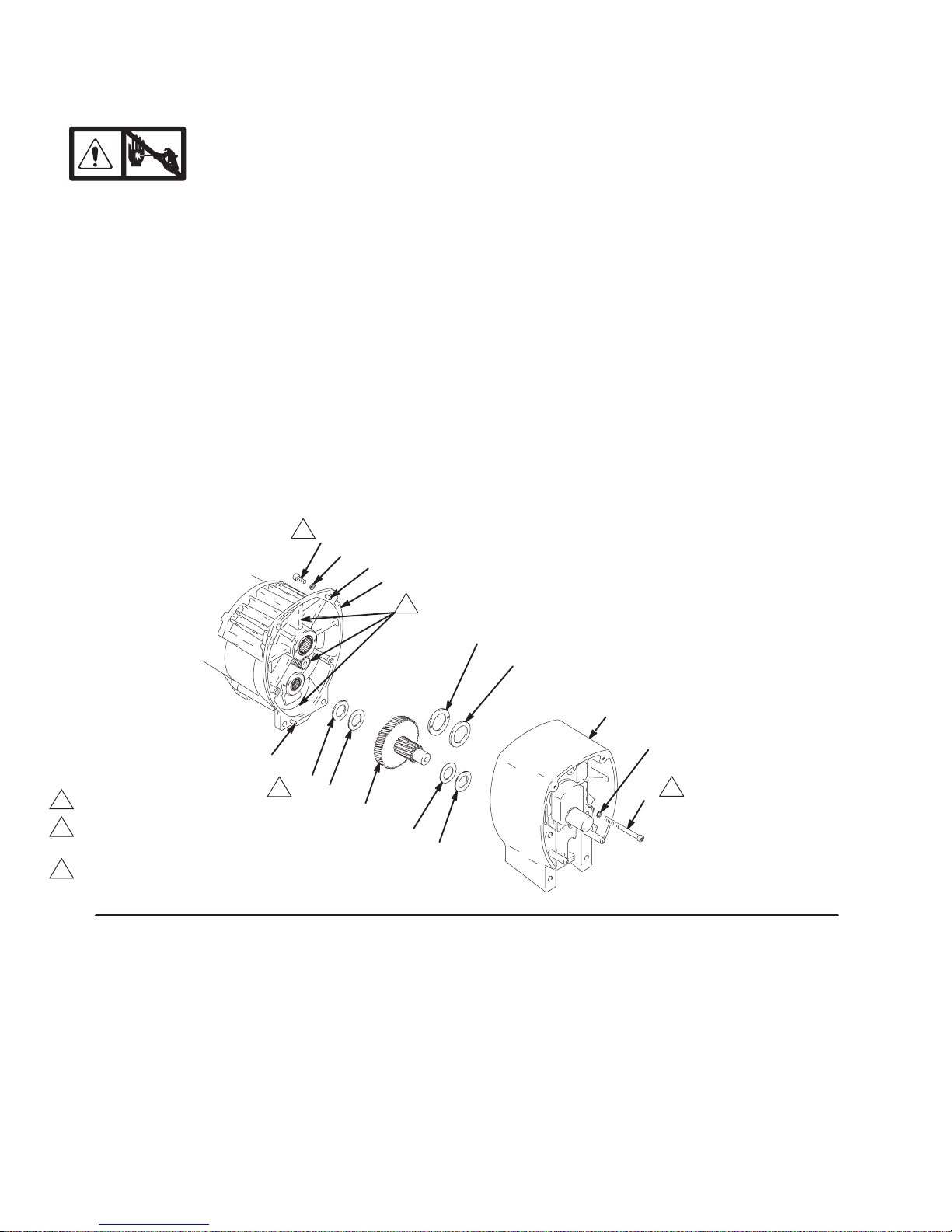

Drive Housing

Removal

1.

Relieve pressure; page 4.

2. Fig. 4. Remove bearing housing. Do 1. through 8.

of Bearing Housing and Connecting Rod procedure on page 7.

3. Remove two screws (81) and lockwashers (17).

4. Remove four screws (10) and lockwashers (17)

from pinion housing (19).

5. Lightly tap around drive housing (20) to loosen

drive housing. Pull drive housing straight off pinion

housing. Be prepared to support gear cluster (18),

which may also come out.

2

10

17

B

19

Installation

1. Liberally apply bearing grease (supplied with

replacement gear cluster) to gear cluster (18) and

to areas called out by note 3. Use full 0.62 pint

(0.29 liter) of grease for GMax 3900 and 0.68 pint

(0.32 liter) of grease for GMax 5900.

2. Place bronze colored washer (20g) on shaft protruding from large shaft of drive housing (20).

Place silver colored washer (20h) on pins on pinion

housing. Align gears and push new drive housing

straight onto pinion housing and locating pins (B).

3. Install four screws (10) and lockwashers (17) from

pinion housing (19).

4. Install two screws (81) and lockwashers (17).

5. Fig. 3. Install bearing housing. Do 1. through 6. of

Bearing Housing and Connecting Rod procedure on page 7.

B

1

GMax 3900 only

2

Torque to 125 in-lb – GMax 3900

Torque to 200 in-lb – GMax 5900

3

Apply remaining grease to these areas

Fig. 4

3

20h

20g

20

17

91

1

91

81

2

18

92

91

8698A

Page 18

Pinion Assembly/Rotor/Field/Shaft/Clutch

Removal

If pinion assembly (19) is not removed from clutch

housing (5), do 1. through 4. Otherwise, start at 5.

6. Fig. 8. Remove retaining ring (Z).

7. Tap pinion shaft (A) out with plastic mallet.

1.

Relieve pressure; page 4.

2. Disconnect field cable (X) from pressure control.

X

Bottom View

Fig. 5

8699A

3. Fig. 6. Remove five screws (10) and lockwashers

(17) and pinion assembly (19).

10

17

19

Z

A

Fig. 8

8703A

8. Fig.9. Use an impact wrench or wedge something

between armature (4a) and clutch housing to hold

engine shaft during removal.

9. Remove four screws (16) and lockwashers (17).

10. Remove armature (4a).

4a

16

17

10

Fig. 6

17

8700A

4. Fig. 7. Place pinion assembly (19) on bench with

rotor side up.

5. Remove four screws (72) and lockwashers (17).

Install two screws in threaded holes (E) in rotor.

Alternately tighten screws until rotor comes off.

72

17

E

Fig. 7

8701A

Fig. 9

8704A

308868 9

Page 19

Pinion Assembly/Rotor/Field/Shaft/Clutch

Installation

1. Fig. 10. Lay two stacks of two dimes on smooth

6. Fig. 8. Tap pinion shaft (A) in with plastic mallet.

bench surface.

2. Lay armature (4a) on two stacks of dimes.

7. Install retaining ring (Z) with beveled side facing

field (Y).

3. Press center of clutch down on bench surface.

8. Fig. 7. Place pinion assembly on bench with rotor

4a

0.12 ±.01 in. (3.0 ±.25 mm)

side up.

9. Apply locktite to screws. Install four screws (16)

and lockwashers (17). Alternately torque screws

to 125 in-lb until rotor is secure. Use threaded

Fig. 10

4. Install armature (4a) on engine drive shaft.

8705A

holes to hold rotor.

10. Fig. 6. Install pinion assembly (19) with five screws

(10) and lockwashers (17).

5. Install four screws (16) and lockwashers (17) with

torque of 125 in-lb.

11. Fig. 5. Connect field cable (X) to pressure control.

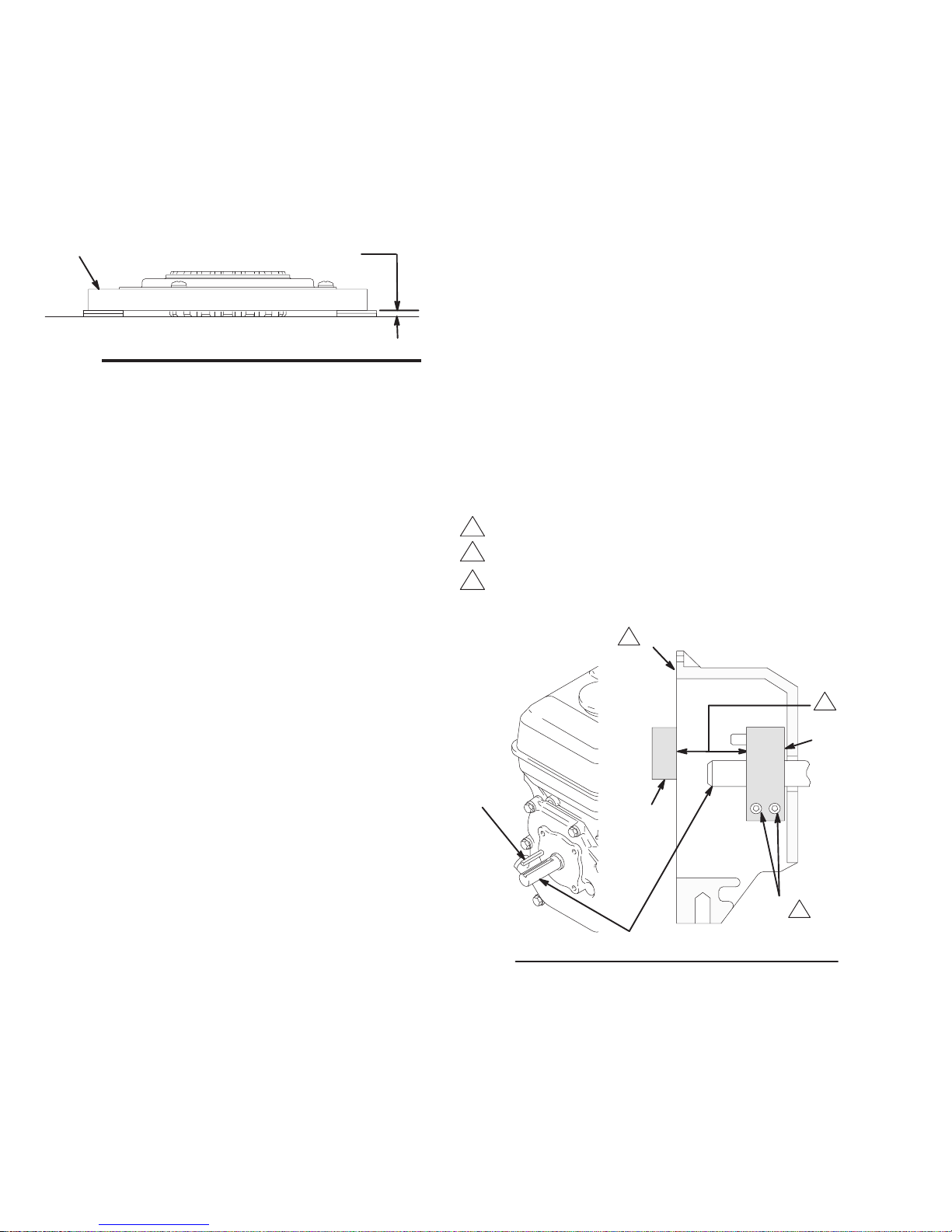

Clamp

Removal

1. Fig. 11. Loosen two screws (16) on clamp (8),

2. Push screwdriver into slot in clamp (8) and remove

clamp.

Installation

1. Fig. 11. Install engine shaft key (7).

2. Tap clamp (8) on engine shaft (A) with plastic

mallet.

3. Press clamp (8) onto engine shaft (A). Maintain

dimension shown note 2 in Fig. 11.

Check dimension: Place rigid, straight steel bar (B)

across face of clutch housing (5). Use accurate

measuring device to measure distance between

bar and face of clamp. Adjust clamp as necessary.

Torque two screws (16) to 125 ±10 in-lb (14 ±1.1

Nm).

1

Face of clutch housing

1.550 ±.010 in. (39.37 ±.25 mm); GMax 3900

2

1.812 ±.010 in. (46.02 ±.25 mm); GMax 5900

3

T orque to 125 ±.10 in-lb (14 ±1.1 Nm)

1

5

7

B

Fig. 11

A

16

2

8

3

03483

30886810

Page 20

Clutch Housing

Removal

1. Fig. 12. Remove four capscrews (75) and lockwashers (77) which hold clutch housing (5) to

engine.

2. Remove screw (15) from under mounting plate (D).

3. Remove engine key (7).

4. Pull off clutch housing (5).

Installation

1. Fig. 12. Push on clutch housing (5).

2. Install four capscrews (75) and lockwashers (77)

and secure clutch housing (5) to engine. Torque to

200 in-lb (22.6 Nm).

3. Install capscrew (15) from beneath mounting

plate (D). Torque to 26 ft-lb (35.2 Nm).

Engine

Fig. 12

7

D

15

5

77

75

8708A

Removal

1. Remove Pinion Assembly/Rotor/Field/Pinion/

Clutch, Clamp and Clutch Housing, as in-

structed on pages 7, 9 and 10.

2. Fig. 13. Disconnect all necessary wiring.

3. Fig. 14. Remove two locknuts (71) and screws

(70) from base of engine.

4. Lift engine carefully and place on work bench.

NOTE: All service to the engine must be performed by

an authorized HONDA dealer.

1

T o the field

2

T o the engine

2

Green

1

70

71

Fig. 14

Installation

1. Lift engine carefully and place on cart.

8710A

Fig. 13

GMax 5900 only

Black

2. Fig. 14. Install two screws (70) in base of engine

and secure with locknuts (71). Torque to 200 in-lb

(22.6 Nm).

3. Fig. 13. Connect all necessary wiring.

2

8709A

4. Install Pinion Assembly/Rotor/Field/Pinion/

Clutch, Clamp and Clutch Housing, as

instructed on pages 8, 9 and 10.

308868 11

Page 21

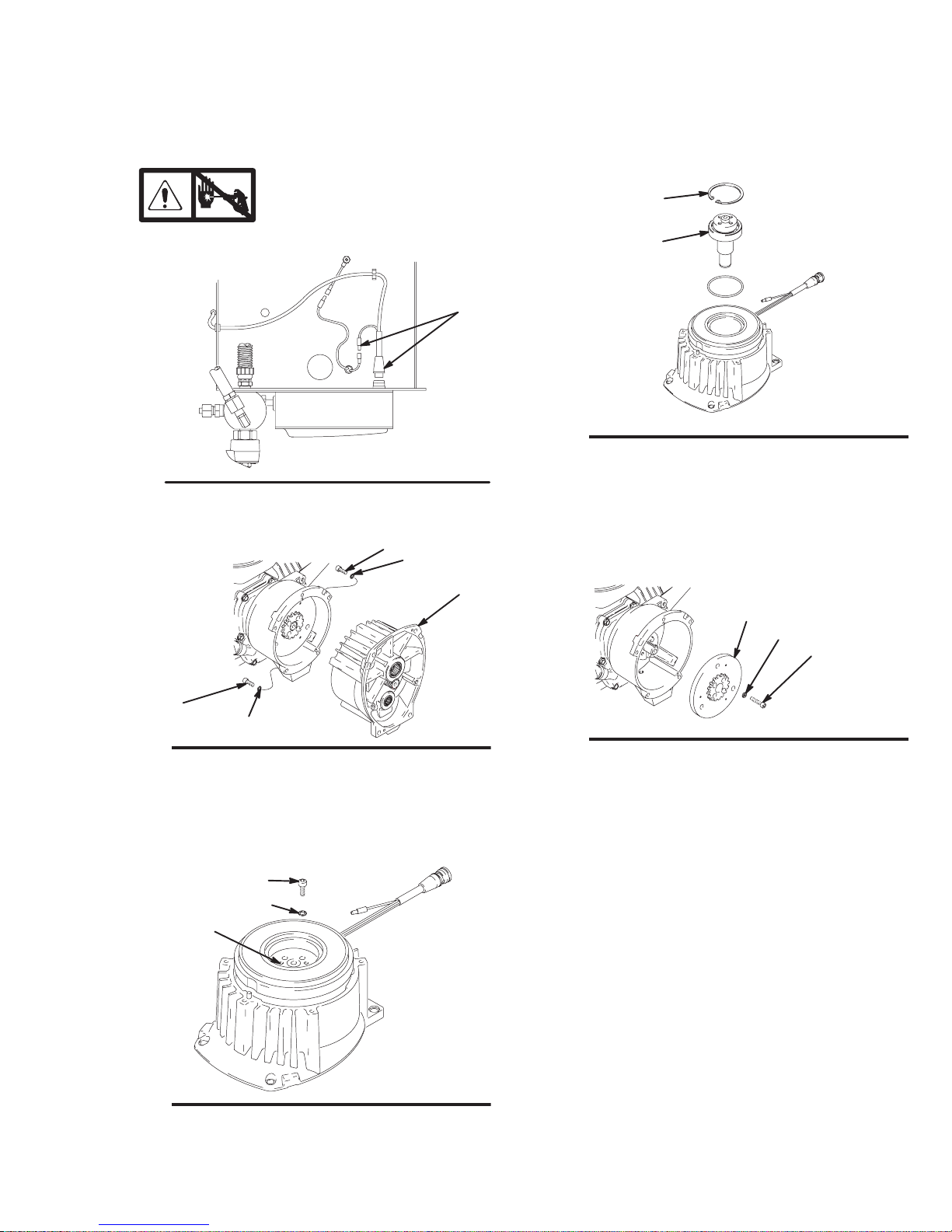

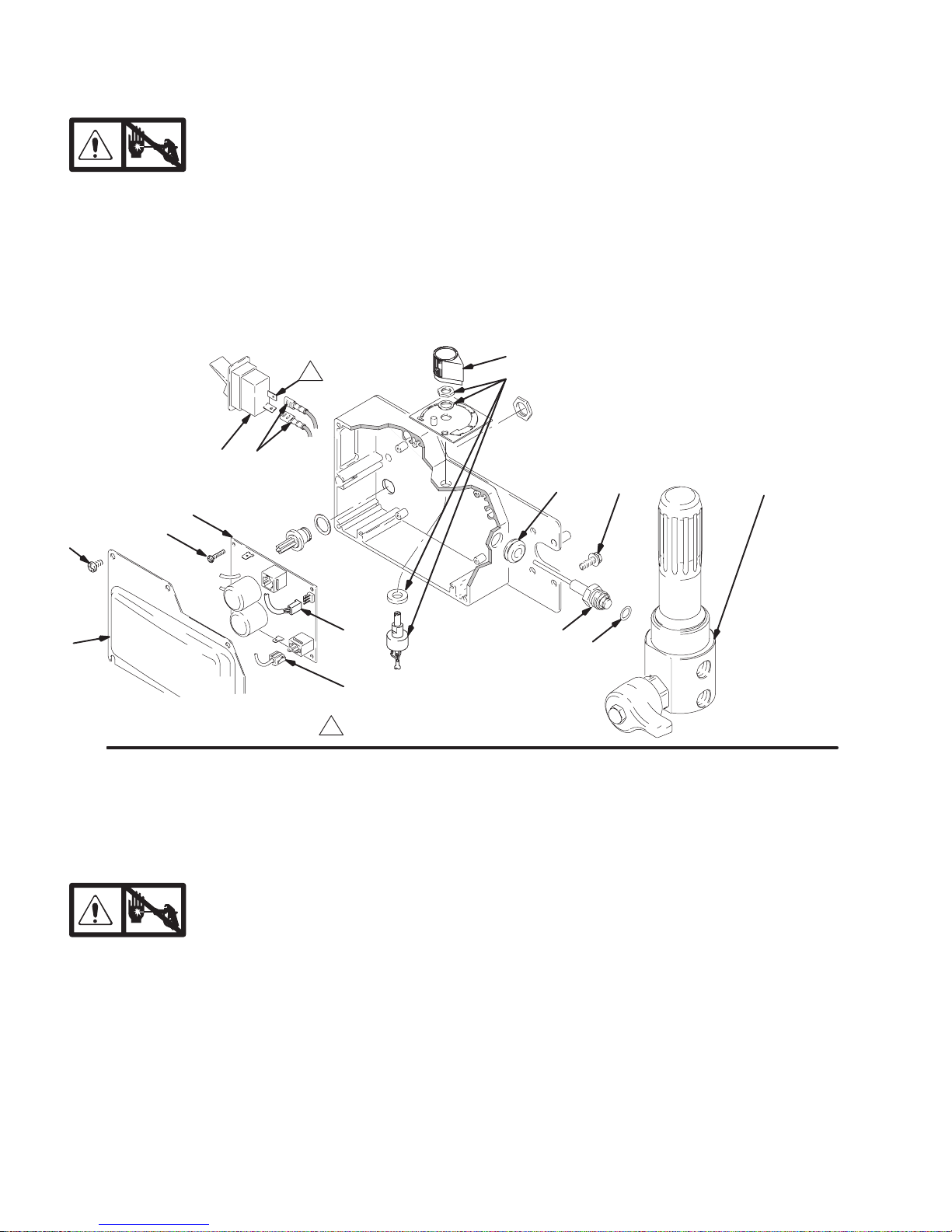

On/Off Switch

Removal

1.

2. Fig. 15. Remove five screws (307) and

cover (322).

3. Disconnect two wires (A) from ON/OFF

switch (309).

4. Press in on two retaining tabs on each side of

ON/OFF switch (309) and remove switch.

307

303

Relieve pressure; page 4.

A309

302

Installation

1. Install new ON/OFF switch (309) so tabs of switch

snap into place on inside of pressure control

housing.

2. Connect two wires (A) to ON/OFF switch.

3. Install pressure control cover (322) with five

screws (307).

313

310

315 319

318a

322

Fig. 15

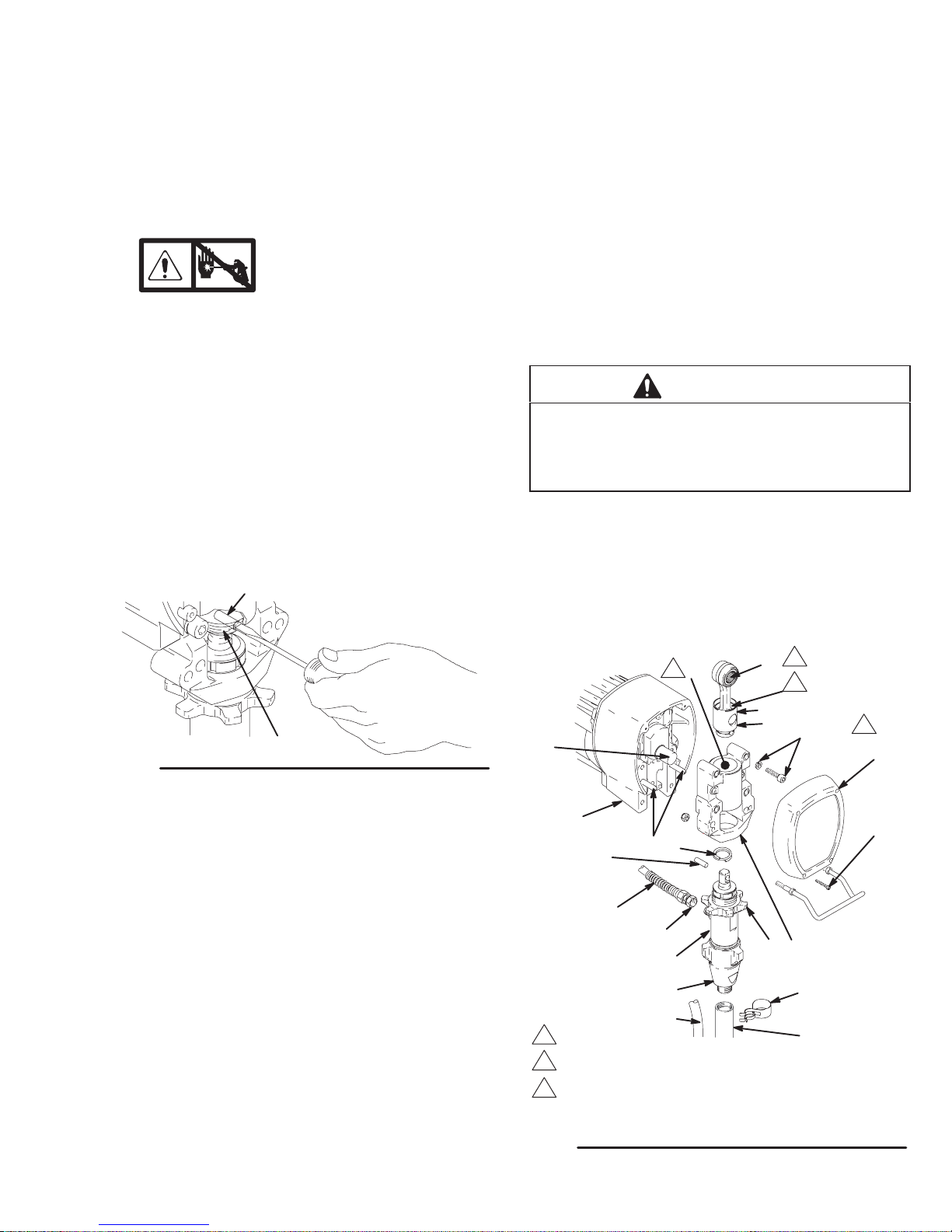

Pressure Control

Removal

1.

2. Fig. 15. Remove five screws (307) and

cover (322).

3. Fig. 22. Disconnect at control board (302):

Four clutch leads: two violet and two black.

Lead (D) from potentiometer.

Lead (E) from transducer.

Relieve pressure; page 4.

D

E

Locate switch terminals as shown

318z

Control Board

Installation

When installing replacement control board, follow

instructions with control board to set model type.

1. Fig. 15. Install green ground wire and control

board (302) with five screws (303).

2. Fig. 22. Connect to control board (302):

Two red leads (A) to ON/OFF switch (309).

Lead (E) to transducer.

318aa

Two red leads (A) to ON/OFF switch (309).

4. Fig. 15. Remove five screws (303), green ground

wire and control board (302).

30886812

Lead (D) to potentiometer.

Four clutch leads: two violet and two black.

3. Fig. 15. Install cover (322) with five screws (307).

Page 22

Pressure Control Transducer

Removal

1.

2. Fig. 15. Remove five screws (307) and

cover (322).

3. Disconnect lead (E) from control board (302).

4. Remove three screws (319) and fluid filter (318)

from control plate (301). Carefully pull transducer

connector through rubber grommet (315).

Relieve pressure; page 4.

Pressure Adjust Potentiometer

Removal

1.

2. Fig. 15. Remove five screws (307) and

cover (322).

3. Disconnect lead (D) from control board (302).

4. Loosen set screws on potentiometer knob (313)

and remove knob, shaft nut, lockwasher (310) and

pressure adjust potentiometer (310).

5. Remove seal (311) from potentiometer (310).

Relieve pressure; page 4.

5. Remove pressure control transducer (318z) and

packing o-ring (318aa) from filter housing (318a).

Installation

1. Fig. 15. Install packing o-ring (318aa) and pressure control transducer (318z) in filter

housing (318a). Torque to 30–35 ft-lb.

2. Carefully feed transducer connector through

rubber grommet (315). Install fluid filter (318) on

control plate (301) with three screws (319).

3. Connect lead (E) to motor control board (302).

4. Install cover (322) with five screws (307).

Installation

1. Install seal (311) on potentiometer (310).

2. Fig. 15. Install pressure adjust potentiometer

(310), shaft nut, lockwasher (310) and potentiometer knob (313).

a. Turn potentiometer shaft (310) clockwise to

internal stop. Assemble potentiometer knob

(313) to strike pin on plate (312) and have

bottom of knob clear plate by .040 to .060 in.

b. After adjustment of step a., tighten both set

screws in knob 1/4 to 3/8 turn after contact

with shaft.

3. Connect lead (D) to control board (302).

4. Install cover (322) with five screws (307).

Control Board Diagnostics

1. Fig. 15. Remove five screws (307) and

cover (322).

2. Start sprayer.

LED

BLINKS

Two times

repeatedly

Three

times repeatedly

Four times

repeatedly

Five times

repeatedly

SPRAYER OPERATION INDICATES WHAT TO DO

Sprayer shuts down and LED continues to blink two times repeatedly

Sprayer shuts down and LED continues to blink three times repeatedly

Sprayer shuts down and LED continues to blink four times repeatedly

Sprayer shuts down and LED continues to blink five times repeatedly

3. Turn ON/OFF switch ON.

4. Observe LED operation and reference following

table:

Run away pressure.

Pressure greater than

4500 psi (310 bar, 31

MPa).

Pressure transducer is

faulty or missing

Generator voltage is

low

High clutch current 1. Check clutch 5-pin bulkhead con-

1. Check pressure transducer connection at control board

2. Replace pressure transducer

3. Replace control board

1. Check pressure transducer connection at control board

2. Replace pressure transducer

3. Replace control board

1. Increase engine throttle

2. Check wiring connections

3. Service Honda engine alternator

nector. Clean contacts.

2. Measure 1.2 0.2Ω

(GMax3900); 1.7 0.2Ω (GMax

5900) across clutch field at 70F

3. Replace clutch field assembly

Six times

repeatedly

Sprayer shuts down and LED continues to blink six times repeatedly

High clutch temperature Replace clutch armature and rotor

308868 13

Page 23

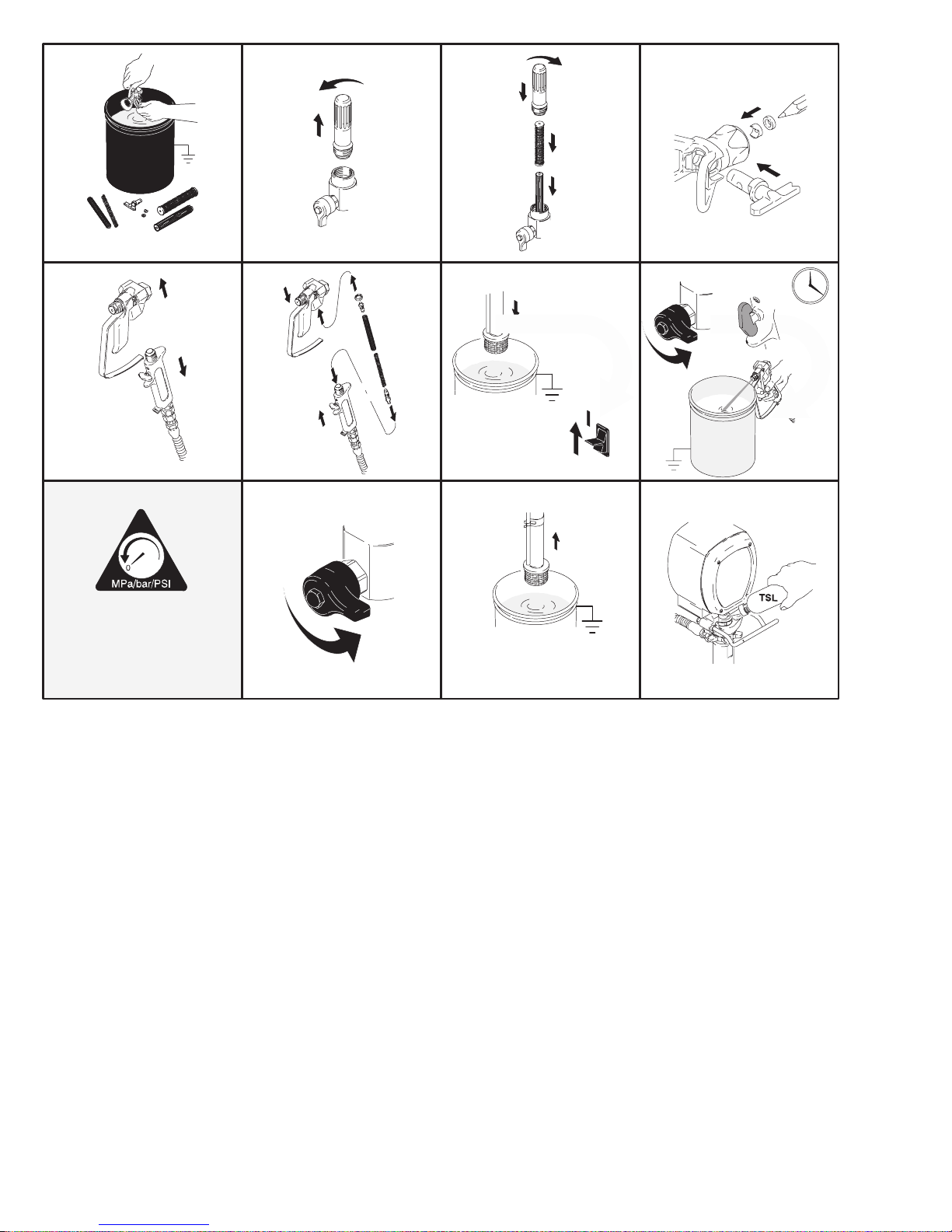

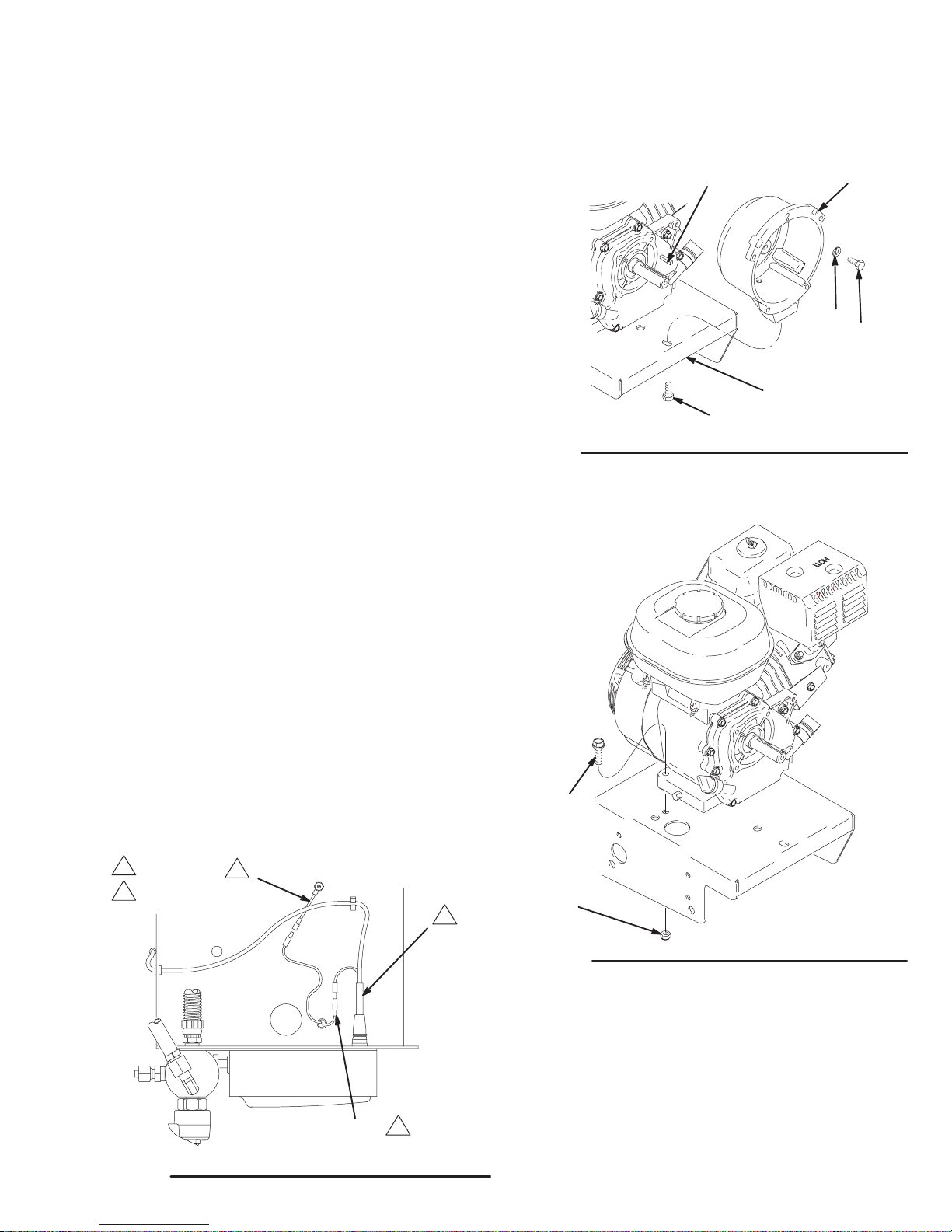

Removal

Displacement Pump

1. Flush pump.

2.

3. Fig. 16. Cycle pump with piston rod (222) in its

lowest position.

4. Fig. 16. Remove suction tube (30) and hose (33).

33

Fig. 16

Relieve pressure; page 4.

222

30

7672B

Repair

5. Fig. 17. Use screwdriver: push retaining spring up

and push out pin (29).

29

Fig. 17

6. Fig. 18. Loosen locknut by hitting firmly with a

20 oz (maximum) hammer. Unscrew pump.

Fig. 18

7675B

7673B

See manual 308798 for pump repair instructions.

Installation

WARNING

If pin works loose, parts could break off due to

force of pumping action. Parts could project

through the air and result in serious injury or property damage. Make sure pin and retaining spring

are properly installed.

CAUTION

If the pump locknut loosens during operation, the

threads of the bearing housing will be damaged.

Make sure locknut is properly tightened.

1. Fig. 19. Pull piston rod out 1.5 in. Screw in pump

until holes in bearing cross link and piston rod

align.

2. Fig. 17. Push pin (29) into hole. And push retaining

spring into groove all the way around connecting

rod.

Fig. 20. Screw jam nut down onto pump until stops.

Screw pump up into bearing housing until it is stopped

by jam nut. Back off pump and jam nut to align pump

outlet to back. Tighten jam nut by hand, then tap 1/8 to

1/4 turn with a 20 oz (maximum) hammer to approximately 75" 5 ft–lb (102 Nm).

Fig. 20

Fig. 21. Fill packing nut with Graco TSL until fluid flows

onto the top of seal.

7673B

1.5 in.

Fig. 19

30886814

7676B

Fig. 21

7677B

Page 24

Parts Drawing – GMax 3900 and GMax 5900 Hi-Boy Sprayers

Models 232610 and 232620

Ref 11

40

45

3

2

11

DETAIL A

49

35

47

DETAIL A

37

38

51

Ref 35

56

1

1

Label

2

See page 17 for the parts.

3

See manual 308798

for the parts.

4

See page 21 for the parts.

5

Used on GMax 5900, Model 232620

Used on GMax 3900, Model 232610

6

10

72

17

4b

6

10

17

5

7

8

91

17

18

16

17

92

4a

19

55

2

20h

91

33

68

26

29

2

20g

62

54

78

8699A

Bottom View

87

5

2

2

20

17

81

61

22

12

13

23

21

34

67

28

3

14

70

61

71

41

44

5

42

43

15

77

51

50

75

80

17

16

90

30

31

71

33(Ref)

53

4

53

88

89

54(Ref)

8712A

308868 15

Page 25

Parts List – GMax 3900 and GMax 5900 Hi-Boy Sprayers

Models 232610 and 232620

Ref

No. Part No. Description Qty

1 ENGINE

108879 GMax 3900, Model 232610 1

114530 GMax 5900, Model 232620 1

2 1 13084 RIVET , blind 2

3 192014 PLATE, indicator 1

4 CLUTCH ASSEMBL Y ,

includes 4a, 4b, 16, 17, 80

241 109 GMax 3900, Model 232610 1

241 113 GMax 5900, Model 232620 1

4a .ARMA TURE, clutch, 4 in., 1

GMax 3900, Model 232610

.ARMA TURE, clutch, 5 in., 1

GMax 5900, Model 232620

4b .ROTOR

4 in., GMax 3900, Model 232610 1

5 in., GMax 5900, Model 232620 1

5 CLUTCH HOUSING

193540 GMax 3900, Model 232610 1

193531 GMax 5900, Model 232620 1

7 183401 KEY , parallel 1

8 193680 CLAMP 1

10 CAPSCREW , socket head, 1/4–20 x 3/4 in.

100644 GMax 3900, Model 232610 9

101864 GMax 5900, Model 232620 4

11 239998 CART HANDLE & HOSE RACK 1

12 106115 LOCKWASHER, spring, 3/8 in. 4

13 CAPSCREW , socket head,

107210 GMax 3900, Model 232610; 3/8–16 x 1.5 in. 4

114666 GMax 5900, Model 232620; 3/8–16 x 2.25 in.4

14 114418 SCREW, self–tap, fil hd, 8–32 x 1 in. 4

15 113802 SCREW, flange, hex hd, 3/8–16 x 5/8 in. 1

16 108803 CAPSCREW, sch, 1/4–2 x 1 in. 6

17 LOCKWASHER, spring, 1/4 in.

105510 GMax 3900, Model 232610 21

105510 GMax 5900, Model 232620 11

18 GEAR COMBINATION

241439 GMax 3900, Model 232610 1

241440 GMax 5900, Model 232620 1

19 PINION ASSEMBL Y; Parts, page 17

241 108 GMax 3900, Model 232610 1

241 112 GMax 5900, Model 232620 1

20 DRIVE HOUSING; Parts, page 17

241007 GMax 3900, Model 232610 1

24101 1 GMax 5900, Model 232620 1

21 BEARING HOUSING

240523 GMax 3900, Model 232610 1

241015 GMax 5900, Model 232620 1

22 CONNECTING ROD

241008 GMax 3900, Model 232610 1

241012 GMax 5900, Model 232620 1

23 COVER, HOUSING, DRIVE

179899 GMax 3900, Model 232610 1

241308 GMax 5900, Model 232620 1

26 SPRING, retaining

176817 GMax 3900, Model 232610 1

183169 GMax 5900, Model 232620 1

28 DISPLACEMENT PUMP

Parts, manual 308798

239923 GMax 3900, Model 232610 1

240291 GMax 5900, Model 232620 1

29 PIN, straight

176818 GMax 3900, Model 232610 1

183210 GMax 5900, Model 232620 1

30 TUBE, intake

192641 GMax 3900, Model 232610 1

193097 GMax 5900, Model 232620 1

Ref

No. Part No. Description Qty

31 STRAINER

32 194194 CLIP , spring 1

33 240795 HOSE, coupled 1

34 NUT , retaining

35 CART FRAME

37 183350 WASHER, plain 2

38 110243 RING, retaining 2

39 108795 SCREW, mch, pn hd, 10–32 x 5/16 in. 4

40 SLEEVE

41 WHEEL, semi–pneumatic

42 101242 RING, retaining 2

43 104811 HUBCAP 2

44 154636 WASHER, GMax 5900, Model 232620 only 2

45 112827 BUTTON, snap 2

47 237686 GROUNDING CLAMP & WIRE 1

49 112798 SCREW, hex washer hd,, No. 8 x 3/8 in 1.

50 193700 PLUG, tubing; GMax 3900, Model 232610 2

51 109032 SCREW, mch, pn hd; 6

53 164672 ADAPTER 2

54 194178 HOSE, drain 1

55 194125 LABEL, danger 1

56 194126 LABEL, warning 1

61 114678 BUSHING, strain relief 1

62 NIPPLE, 3/8–18 npsm(m) x 1/4 npt(m)

67 192719 HANGER, pail 1

68 112746 LOCKNUT , 5/16–18 2

70 110837 SCREW, flng, hex hd, 5/16–18 x 1–1/2 in. 2

71 110838 LOCKNUT , heavy hex, 5/16–18 6

72 101682 SCREW, cap, sch 4

73 SCREW , cap, sch 4

75 109031 SCREW, cap, sch 4

76 101864 SCREW, cap, sch 4

77 WASHER, lock, spring

78 114687 CLIP , retainer 1

80 HUB, armature 1

81 107218 SCREW 2

82 206994 THROAT SEAL LIQUID; not shown 1

87 240997 CONDUCTOR, ground 1

88 110249 ADAPTER, male elbow, 90 1

89 240131 PLUG, packless 1

90 194195 DEFLECTOR 1

91 WASHER

92 114699 WASHER 1

181072 GMax 3900, Model, 232610 1

189920 GMax 5900, Model, 232620 1

192723 GMax 3900, Model 232610 1

193031 GMax 5900, Model 232620 1

240696 GMax 3900, Model 232610 1

240726 GMax 5900, Model 232620 1

192027 GMax 3900, Model 232610 2

191084 GMax 5900, Model 232620 2

106062 GMax 3900, Model 232610 2

17981 1 GMax 5900, Model 232620 2

193682 CAP , end; GMax 5900, Model 232620 2

GMax 3900, Model 232610 only

183461 GMax 3900, Model 232610 1

162485 GMax 5900, Model 232620 1

109031 GMax 3900, Model 232610 4

108842 GMax 5900, Model 232620 4

104008 GMax 3900, Model 232610 4

100214 GMax 5900, Model 232620 4

114672 GMax 3900, Model 232610 3

114672 GMax 5900, Model 232620 2

Danger & Warning labels, tags, and cards are free.

30886816

Page 26

Parts List & Drawing – Pinion Assembly

Ref No. 19 and 20

Ref No. 19: Pinion Housing Assembly 241108 for

GMax 3900; Pinion Housing Assembly 241112 for

GMax 5900

Ref

No. Part No. Description Qty

19 PINION HOUSING 1

19b 105489 PIN 2

19d* PINION SHAFT

241110 GMax 3900, Model 232610 1

241114 GMax 5900, Model 232620 1

19e* RETAINING RING, large

1 13094 GMax 3900, Model 232610 1

1 12770 GMax 5900, Model 232620 1

*Must be ordered separately ..

19e

19d

19b

10 (Ref)

17 (Ref)

Ref No. 20: Drive Housing Assembly 241007 for

GMax 3900; Drive Housing Assembly 241011 for

GMax 5900

Ref

No. Part No. Description Qty

20 DRIVE HOUSING ASSEMBL Y

20g* W ASHER

194173 GMax 3900, Model 232610 1

107089 GMax 5900, Model 232620 1

20h* WASHER

194172 GMax 3900, Model 232610 1

194411 GMax 5900, Model 232620 1

*Must be ordered separately ..

19

20h

20g

91 (Ref)

1

18 (Ref)

1

Only used on GMax 3900, Models 232610 and 232612

91 (Ref)

92 (Ref)

20

17 (Ref)

81 (Ref)

8715A

308868 17

Page 27

Parts Drawing – GMax 3900 and GMax 5900 Lo-Boy Sprayers

Models 232612 and 232622

Ref 11

40

45

3

2

11

DETAIL A

49

DETAIL A

37

38

51

Ref 35

56

70

1

Label

2

See page 17 for the parts.

3

See manual 308798

for the parts.

4

See page 21 for the parts.

5

Used on GMax 5900, Model 232622 only

6

Used on GMax 3900, Model 232612 only

5

76

10

6

72

17

4b

17

5

77

6

2

19

20h

2

20g

2

2

20

91

87

5

17

Bottom View

81

22

78

8699A

61

12

13

1

91

6

18

21

23

92

10

17

5

55

26

29

7

8

17

16

33

62

34

14

35

47

71

41

44

5

42

43

30886818

15

51

77

75

6

50

80

17

4

30d

30b (Ref)

16

4a

30aa

30a

30b

30e

30f

30ae

30ad

53

89

30c

30g

30ab

28

3

30

8713A

Page 28

Parts List – GMax 3900 and GMax 5900 Lo–Boy Sprayers

Models 232612 and 232622

Ref

No. Part No. Description Qty

1 ENGINE

108879 GMax 3900, Model 232612 1

114530 GMax 5900, Model 232622 1

2 1 13084 RIVET , blind 2

3 192014 PLATE, indicator 1

4 CLUTCH ASSEMBL Y ,

includes 4a, 4b, 16, 17, 80

241 109 GMax 3900, Model 232612 1

241 113 GMax 5900, Model 232622 1

4a .ARMA TURE, clutch, 4 in., 1

GMax 3900, Model 232612

.ARMA TURE, clutch, 5 in., 1

GMax 5900, Model 232622

4b .ROTOR

4 in., GMax 3900, Model 232612 1

5 in., GMax 5900, Model 232622 1

5 CLUTCH HOUSING

193540 GMax 3900, Model 232612 1

193531 GMax 5900, Model 232622 1

7 183401 KEY , parallel 1

8 193680 COLLAR, shaft 1

10 CAPSCREW , socket head, 1/4–20 x 3/4 in.

100644 GMax 3900, Model 232612 9

101864 GMax 5900, Model 232622 4

11 239998 CART HANDLE & HOSE RACK 1

12 106115 LOCKWASHER, spring, 3/8 in. 4

13 CAPSCREW , socket head,

107210 GMax 3900, Model 232612; 3/8–16 x 1.5 in. 4

114666 GMax 5900, Model 232622; 3/8–16 x 2.25 in.4

14 114418 SCREW, self–tap, fil hd, 8–32 x 1 in. 4

15 113802 SCREW, flange, hex hd,, 3/8–16 x 5/8 in. 1

16 108803 CAPSCREW, sch, 1/4–2 x 1 in. 6

17 LOCKWASHER, spring, 1/4 in.

105510 GMax 3900, Model 232612 21

105510 GMax 5900, Model 232622 11

18 GEAR COMBINATION

241439 GMax 3900, Model 232612 1

241440 GMax 5900, Model 232622 1

19 PINION ASSEMBL Y; Parts, page 17

241 108 GMax 3900, Model 232612 1

241 112 GMax 5900, Model 232622 1

20 DRIVE HOUSING

241007 GMax 3900, Model 232612 1

24101 1 GMax 5900, Model 232622 1

21 BEARING HOUSING

240014 GMax 3900, Model 232612 1

240724 GMax 5900, Model 232622 1

22 CONNECTING ROD

241008 GMax 3900, Model 232612 1

241012 GMax 5900, Model 232622 1

23 COVER, HOUSING, DRIVE

179899 GMax 3900, Model 232612 1

241308 GMax 5900, Model 232622 1

26 SPRING, retaining

176817 GMax 3900, Model 232612 1

183169 GMax 5900, Model 232622 1

28 DISPLACEMENT PUMP , Manual 308798

239923 GMax 3900, Model 232612 1

240291 GMax 5900, Model 232622 1

29 PIN, straight

176818 GMax 3900, Model 232612 1

183210 GMax 5900, Model 232622 1

30 241287 ASSEMBLY, tube, suction

30a 241 124 .TUBE, suction, 5 gallon (20 liter) 1

30aa 240513 ..SWIVEL, tube, inlet 1

30ab 176450 ..GUARD, hose 1

Ref

No. Part No. Description Qty

30ac 194306 ..HOSE, fluid 1

30ad 101818 ..CLAMP , hose 2

30ae 170957 ..TUBE, suction 1

30b 194180 .HOSE, drain 1

30c 194191 .CLIP , spring 1

30d 162453 .NIPPLE 1

30e 194195 .DEFLECTOR 1

30f 187147 .STRAINER 1

30g 144958 .STRAP, tie 1

33 240795 HOSE, coupled 1

34 NUT , retaining

35 CART FRAME

37 183350 WASHER, plain 2

38 110243 RING, retaining 2

39 108795 SCREW, mch, pn hd, 10–32 x 5/16 in. 6

40 SLEEVE

41 WHEEL, semi-pneumatic

42 101242 RING, retaining 2

43 104811 HUBCAP 2

44 154636 WASHER, GMax 5900, Model 232622 only 2

45 112827 BUTTON, snap 2

46 108068 PIN, spring, straight, 3/16 x 1–1/4 in. 2

47 237686 GROUNDING CLAMP & WIRE 1

49 112798 SCREW, hex washer hd, No. 8 x 3/8 in 1.

50 193700 PLUG, tubing; GMax 3900, Model 232612 2

51 109032 SCREW, GMax 3900, Model 232612 only 6

52 100020 WASHER, GMax 3900, Model 232612 only 4

53 164672 ADAPTER 2

55 194125 LABEL, danger 1

56 194126 LABEL, warning 1

61 114678 BUSHING, strain relief 1

62 NIPPLE, 3/8–18 npsm(m) x 1/4 npt(m)

70 110837 SCREW, flng, hex hd, 5/16–18 x 1–1/2 in. 2

71 110838 LOCKNUT , heavy hex, 5/16–18 6

72 101682 SCREW, cap, sch 4

73 SCREW , cap, sch 4

75 109031 SCREW, cap, sch 4

77 WASHER, lock, spring

78 114687 CLIP , retainer 1

80 HUB, armature 1

81 107218 SCREW 2

82 206994 THROAT SEAL LIQUID; not shown 1

87 240997 CONDUCTOR, ground 1

89 240131 PLUG, packless 1

89 Washer

92 114699 WASHER 1

192723 GMax 3900, Model 232612 1

193031 GMax 5900, Model 232622 1

240728 GMax 3900, Model 232612 1

240727 GMax 5900, Model 232622 1

192027 GMax 3900, Model 232612 2

191084 GMax 5900, Model 232622 2

106062 GMax 3900, Model 232612 2

17981 1 GMax 5900, Model 232622 2

193682 CAP , end; GMax 5900, Model 232622 2

183461 GMax 3900, Model 232612 1

162485 GMax 5900, Model 232622 1

109031 GMax 3900, Model 232612 4

108842 GMax 5900, Model 232622 4

104008 GMax 3900, Model 232612 4

100214 GMax 5900, Model 232622 4

114672 GMax 3900, Model 232612 3

114699 GMax 5900, Model 232622 2

Danger & Warning labels, tags, and cards are free.

308868 19

Page 29

Parts List & Drawing – Complete Sprayers

Models 232611, 232613, 232621, 232623

GMax 3900 and GMax 5900 Airless Paint Sprayers

Includes items 201 to 204

Ref

No. Part No. Description Qty

201 232611 GM3900 Hi-Boy Sprayer 1

See parts list on page 15

232621 GM5900 Hi-Boy Sprayer 1

See parts list on page 15

232613 GM3900 Lo-Boy Sprayer 1

See parts list on page 19

232623 GM5900 Lo-Boy Sprayer 1

See parts list on page 19

202 240794 HOSE, grounded, nylon; 1/4 in. ID; 1

cpld 1/4 npsm(fbe); 50 foot (15 m);

spring guards both ends

3300 psi (227 bar, 27.7 MPa)

203 238358 HOSE, grounded, nylon; 3/16 in. ID;

cpld 1/4 npsm(m) x 1/4 npsm(f) swivel;

3 foot (0.9 m); spring guards both ends 1

204 220955 CONTRACTOR SPRAY GUN

Includes RAC IV

and 517–size SwitchTip

See 307614 for parts 1

DripLess Tip Guard

Accessories

202

204

203

0160

DANGER LABELS

An English language DANGER label is on your

sprayer. If you have painters who do not read English, order one of the following labels to apply to

your sprayer. The drawing shows the best placement of these labels for good visibility.

Order the labels from your Graco distributor.

Apply other

language here

French 185956

Spanish 185961

German 186041

Greek 186045

Korean 186049

English 194125

Displacement Pump Repair Kits

Packing repair kits.

GMax 3900 239928

GMax 5900 240248

03497A

30886820

Page 30

Parts Drawing – Sprayer

GMax 3900 and 5900 Sprayers

Models 232610 through 232613 and 232619

Models 232620 through 232623 and 232629

309

308

320

314

313

310

312

321

301

305

304

306

302

303

315

307

318f

304

318e

319

318d

318b

318c

318z

307

322

305

311

310

318aa

318a

318g

318h

318m

318n

318l

318j

318k

8716A

308868 21

Page 31

Parts List – Sprayer

Models 232610 through 232613 and 232619; 232620 through 232623 and 232629

REF

NO. PART NO. DESCRIPTION QTY

301 193653 PLATE, control 1

302 241093 BOARD, PC 1

303 111839 SCREW, mch pan, 6–32 x 1/2 in. 5

304 240776 HARNESS, wiring. 1

305 193497 GASKET, control 2

306 193652 HOUSING, control box 1

307 114631 SCREW, mch, pan hd 10

308 193052 PLATE, instruction 1

309 114277 SWITCH, rocker , (spst) 1

310 241443 POTENTIOMETER, pressure control 1

311 193657 GASKET, potentiometer 1

312 193654 PLATE, instruction 1

313 114273 KNOB, potentiometer 1

314 193072 LABEL, control 1

315 114629 GROMMET, transducer 1

318 240777 FILTER, fluid 1

318a 193651 HOUSING, filter 1

318b 104361 O-RING 1

318c 186075 SUPPORT, filter 1

318d 167025 STRAINER, mesh, 60 1

REF

NO. PART NO. DESCRIPTION QTY

318e 171941 SPRING, compression 1

318f 192706 BOWL, filter 1

318g 193710* SEAL, valve 1

318h 193709* SEAT, valve 1

318j 194102* HANDLE, valve 1

318k 1 14688* NUT, cap, hex hd 1

318l 114708* SPRING, compression 1

318m 114797* GASKET 1

318n 240914* VALVE 1

318z 240314 TRANSDUCER, pressure control 1

318aa111457 O-RING 1

319 110997 SCREW, flange, hex 3

320 114532 TIE, wire, twist 1

189246 LABEL, warning 1

321

322 241444 COVER, pressure control 1

* Drain valve replacement kit 241276 available; includes

318g through 318n

Replacement warning labels may be ordered free of charge

includes 318aa

309

(Ref)

304

(Ref)

Fig. 22

Green

Black

Red

Red (+)

Violet

Wiring Diagram

310

D

E

A

318z

(Ref)

302

(Ref)

(Ref)

Potentiometer

Pressure

transducer

318aa

(Ref)

30886822

Page 32

Technical Data

PTFE

PTF

Honda GX120 Engine

Power Rating @ 3700 rpm

ANSI 4.0 Horsepower. . . . . . . . . . . . . . . . . . . . . . .

DIN 6270B/DIN 6271

NA 2.1 Kw – 2.8 Ps. . . . . . . . . . . . . . . . . . . . . .

NB 2.6 Kw – 3.6 Ps. . . . . . . . . . . . . . . . . . . . . .

Honda GX160 Engine

Power Rating @ 3700 rpm

ANSI 5.5 Horsepower. . . . . . . . . . . . . . . . . . . . . . .

DIN 6270B/DIN 6271

NA 2.9 Kw – 4.0 Ps. . . . . . . . . . . . . . . . . . . . . .

NB 3.6 Kw – 4.9 Ps. . . . . . . . . . . . . . . . . . . . . .

Maximum working pressure 3300 psi . . . . . . . . . . . . . . .

(227 bar, 22.7 MPa

Noise Level

Sound power 105 dBa. . . . . . . . . . . . . . . . . . . . . . . . .

per ISO 3744

Sound pressure 96 dBa. . . . . . . . . . . . . . . . . . . . . . . .

measured at 3.1 feet (1 m)

Cycles/gallon (liter)

GMax3900 182 (48). . . . . . . . . . . . . . . . . . . . . . . . . . .

GMax5900 93 (25). . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum delivery rating

GMax3900 1.15 gpm (4.4 liter/min). . . . . . . . . . . . .

GMax5900 1.5 gpm (5.7 liter/min). . . . . . . . . . . . . . .

Maximum tip size

GMax3900 1 gun with 0. 034 in. tip. . . . . . . . . . . . .

2 guns with 0.024 in. tip

3 guns with 0. 017 in. tip

GMax5900 1 gun with 0. 041 in. tip. . . . . . . . . . . . .

2 guns with 0.028 in. tip

3 guns with 0. 022 in. tip

4 guns with 0. 019 in. tip

Inlet paint strainer 16 mesh (1190 micron). . . . . . . . . . .

stainless steel screen, reusable

Outlet paint filter 60 mesh (250 micron). . . . . . . . . . . . .

stainless steel screen, reusable

)

Pump inlet size 3/4 in. npt (m). . . . . . . . . . . . . . . . . . . . . .

Fluid outlet size 1/4 npsm from fluid filter. . . . . . . . . . . .

Wetted parts zinc-plated carbon steel,

Viton, Delrin, leather, aluminum, tungsten car-

bide,nickle-plated carbon steel, stainless steel,

chrome plating

NOTE: Delrin, , Viton are trademarks

. . . . . . . . . . . . . .

, Nylon, polyurethane, UHMW polyethylene,

Model 232610

Hi-Boy without hose or gun

Weight (dry, without packaging) 110 lb (49.9 kg). . . . .

Height 40 in. (101.6 cm). . . . . . . . . . . . . . . . . . . . . . . . . .

Length 37 in. (94 cm). . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Width 22 in. (55.9 cm). . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model 232620

Hi-Boy without hose or gun

Weight (dry, without packaging) 150 lb (68 kg). . . . . . .

Height 41 in. (104.1 cm). . . . . . . . . . . . . . . . . . . . . . . . . .

Length 39 in. (99.1 cm). . . . . . . . . . . . . . . . . . . . . . . . . . .

Width 22 in. (55.9 cm). . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Phone Number

Dimensions

GMax 3900

Model 232612

Lo-Boy Cart without hose or gun

Weight (dry, without packaging) 110 lb (49.9 kg). . . . .

Height 40 in. (101.6 cm). . . . . . . . . . . . . . . . . . . . . . . . . .

Length 37 in. (94 cm). . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Width 22 in. (55.9 cm). . . . . . . . . . . . . . . . . . . . . . . . . . . .

GMax 5900

Model 232622

Lo-Boy without hose or gun