Page 1

INSTRUCTIONS-PARTS LIST

This

manual contalns IMPORTANT

WARNINGS AND INSTRUCTIONS

READ AND RETAIN

FOR

REFERENCE

GM3500

SPRAYER

3000

psi

(2

10

bar)

MAXIMUM WORKING

PRESSURE

Model

231-078

Complete Sprayer,

with Stainless Steel Displacement

Pump

307-893

ORACO

Rev.

A

1

GRACO INC.

P.O.

BOX

1441 MINNEAPOLIS. MN 55440-1444

COPYRIGHT

1988,

GRACO INC.

Page 2

TABLE

OF

CONTENTS

Introduction

...............................

2

Warnings

Fueling

...................................

7

Startup

...................................

8

Maintenance

.......................I.....

10

Flushing Guidelines

.......................

11

Troubleshooting Guide

....................

13

Repair

Pressure Control

.......................

15

Pressure Control Calibration

..............

17

Bearing Housing and Connecting Rod

.......

18

Drive Housing

..........................

20

Pinion, Clutch, Field, Clamp, Engine

Pinion Housing Removal

..............

21

Setup

....................................

6

Repairing the Pinion

..................

22

Clutch

.............................

24

Engine

.............................

25

Field and Wiring Harness

..............

26

Clamp

.............................

27

Clutch Housing

......................

27

Reassembly

........................

28

Complete Sprayer, 231-078

...............

30

Pinion Assembly

........................

33

Pressure Control Assembly

................

34

Accessories

..............................

35

Dlmensions

...............................

35

TechnicalData

............................

35

Warranty

.........................

Back Cover

Parts Lists and Drawings

..

INTRODUCTION

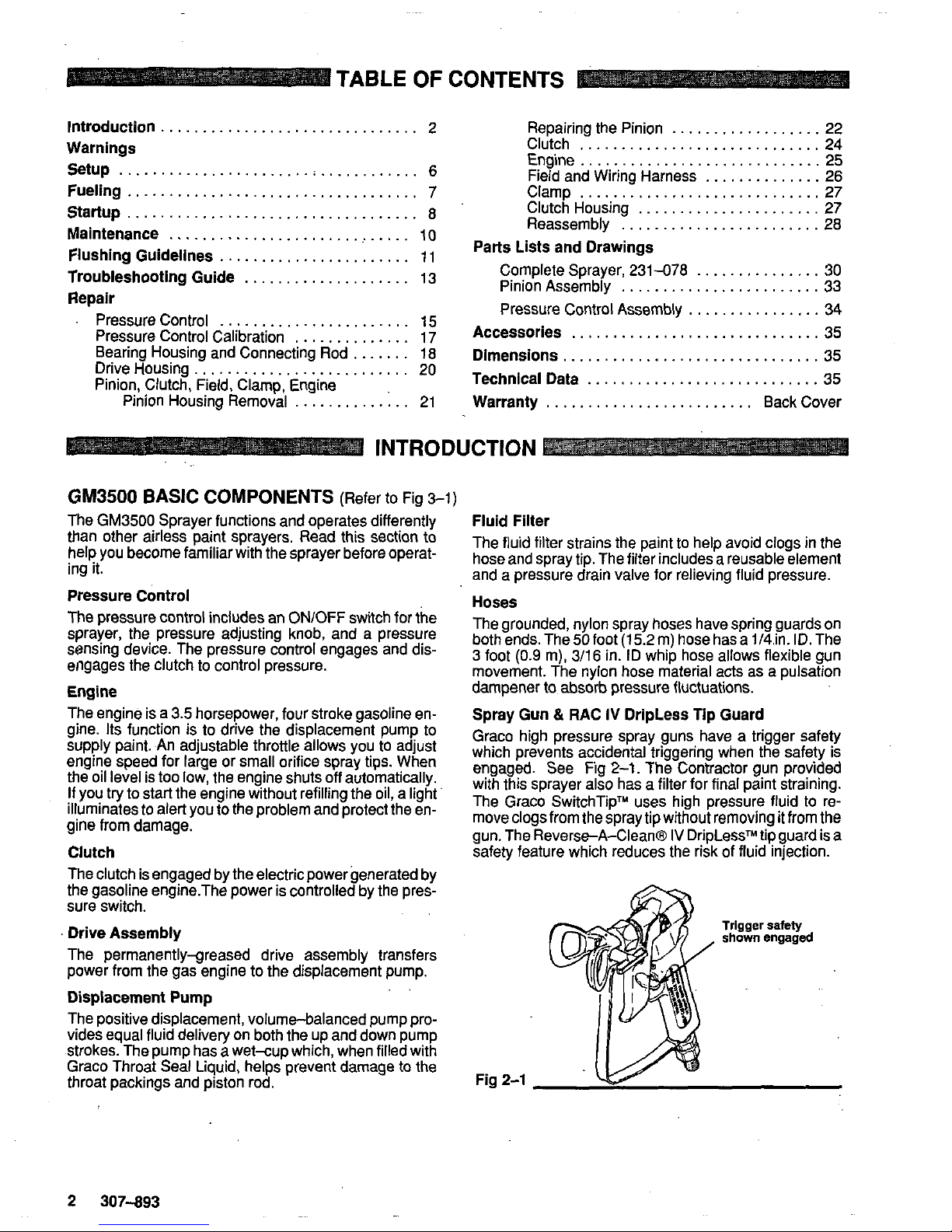

GM3500

BASIC

COMPONENTS

(Refer to Fig

3-1)

The GM3500 Sprayer functions and operates differently

than other airless paint sprayers. Read this section to

help you become familiar with the sprayer beforeoperating it.

Pressure Control

The pressure control includes an ONlOFF switch for the

sprayer, the pressure adjusting knob, and a pressure

sensing device. The pressure control engages and disengages the clutch to control pressure.

Engine

The engine is a 3.5 horsepower, four stroke gasoline en-

supply paint. An adjustable throttle allows you to adjust

gine. Its function is

to

drive the displacement pump to

engine speed for large or small orifice spray tips. When

the oil level is too low, the engine shuts

off

automatically.

illuminates to alert you to the problem and protect the en-

If

you try to start the engine without refilling the oil, a light

gine from damage.

Clutch

The clutch is engaged by the electric power generated by

the gasoline engine.The power is controlled by the pres-

sure switch.

Drive

Assembly

The permanently-greased drive assembly transfers

power from the gas engine to the displacement pump.

Displacement Pump

The positive displacement, volume-balanced pump provides equal fluid delivery

on

both the up and down pump

strokes. The pump has a wet-cup which, when filled with

Graco Throat Seal Liquid, helps prevent damage to the

throat packings and piston rod.

..

Fluid Filter

The fluid filter strains the paint to help avoid clogs in the

hose and spray tip. The filter includes a reusable element

and a pressure drain valve for relieving fluid pressure.

Hoses

The grounded, nylon spray hoses have spring guards on

bothends.The50foot(15.2m)hosehasa1/4,in.ID.The

3

foot

(0.9

m), 3/16 in.

ID

whip hose allows flexible gun

movement. The nylon hose material acts as a pulsation

dampener

to

absorb pressure fluctuations.

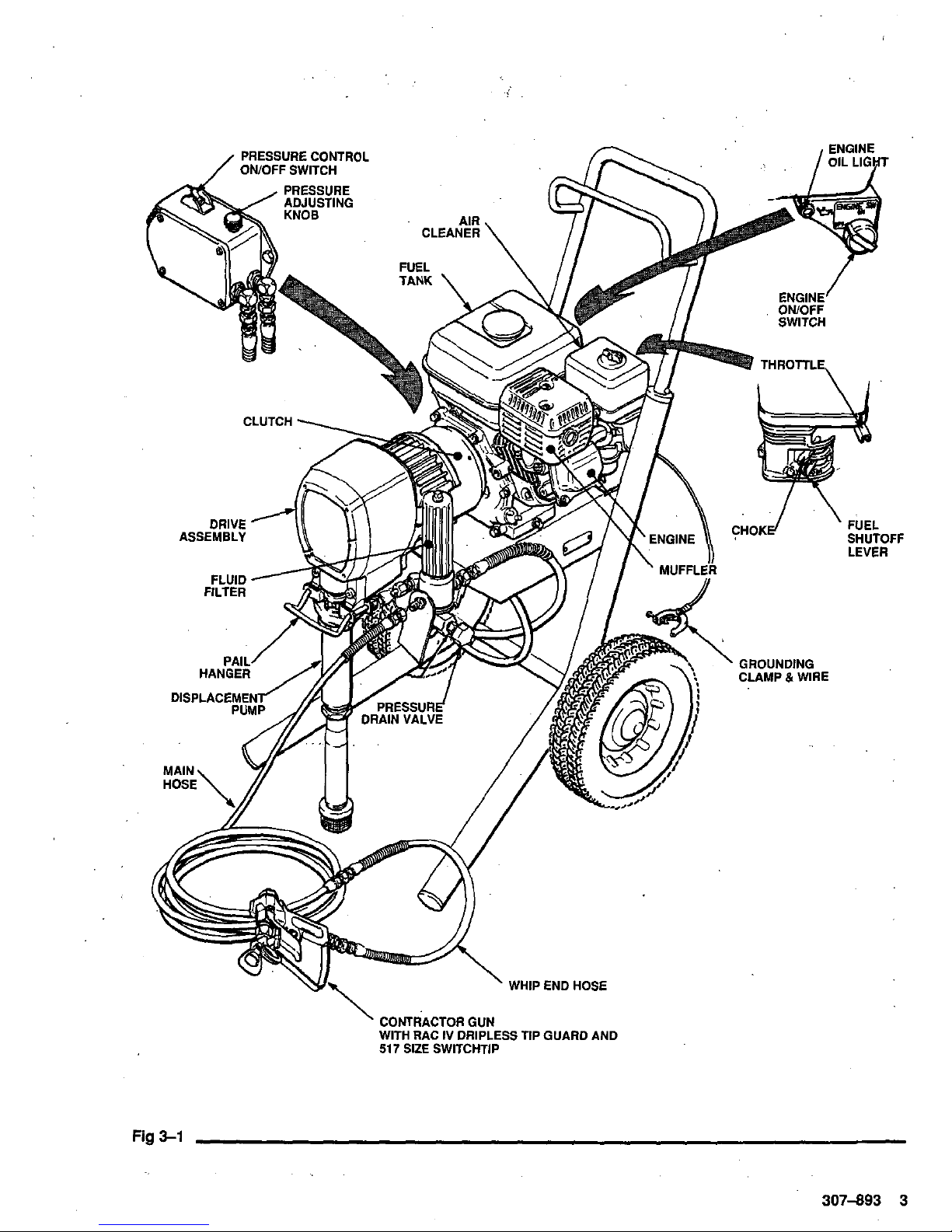

Spray Gun & RAC

IV

DripLess Tip Guard

Graco high pressure spray guns have a trigger safety

which prevents accidental triggering when the safety is

engaged. See Fig

2-1.

The Contractor gun provided

with this sprayer also has a filter for final paint straining.

The Graco SwitchTipTU uses high pressure fluid to re-

gun. The Revers+A-Clean@

IV

DripLessTM tip guard is

a

move clogs from the spray tip without removing it from the

safety feature which reduces the risk of fluid injection.

Trigger

safety

shown

engaged

Fig

2-1

2

307-893

Page 3

Fig

3-1

307-893

3

Page 4

SAFETY

WARNINGS

HIGH PRESSURE SPRAY CAN CAUSE SERIOUS INJURY.

FOR

PROFESSIONAL USE ONLY. OBSERVE ALL WARNINGS

Read and understand

all

instruction manuals before operating equipment.

FLUID.lNJECTlON HAZARD

General Safety

This equipment generates very high fluid pressure. Spray 6om

the gun, leaks or ruptured components can inject fluid through

yourskin and into your body and causeextremely serious bodily

injury, including the need for amputation. Also, fluid injected or

age.

splashed into the eyes or on the skin can cause serious dam-

NEVER put hand or fingers over the spray tip. NEVER try to

NEVER point the spray gun at anyone or at any part of the body.

"blow back paint; this is NOT an air spray system.

ALWAYS have the tip guard in place on the spray gun when

ALWAYS follow the

Pressure Relief Procedure.

below.before

spraying.

cleaning or removing the spray tip or servicing any system

equipment.

NEVER

try

to

stop or deflect leaks with your hand or body.

Be

sure equipment safety devices are operating properly before

each use.

Medical Alert-Airless Sarav

Wounds

~~ ~~~

MEDICAL

CARE AT 8NCE. DO NOT TREAT AS A SIMPLE

If

any fluid appears to enetrate

your skin,

getEMERGENCY

-r~-,

~~

CUT.

Tell the doctor exactly what fluid was injected.

Note

to

Physician: Injection in the skin is atraumaticinjury.

It

isimportanttotreattheinjurysurgicallyassoonaspossible.

Do

not delay treatment

to

research toxicity. Toxicity is a con-

cern with some exotic coatings injected directly into the

constructive hand surgeon may be

advisable.

blood stream. Consultation with a plastic surgeon or re-

Spray Gun Safety Devices

Be

sure all gun safety devices are operating properly before

cause a malfunction and result in serious bodily injury.

each use.

Do

not

remove or modify any part

of

the gun; this can

Safety Latch

Wheneveryoustopspraying,evenforamoment,alwayssetthe

gun safety latch in the closed or "safe" position. making the gun

tal triggering of the

gun.

inoperative. Failure

to set the safety latch can result in acciden-

Diffuser

The gun diffuser breaks up spray and reduces the risk of fluid

injection when the tip

is

not installed. Check diffuser operation

regularly. Follow the

Pressure Relief Procedure.

below, then

gunfirmlytothe pail. Using the lowest

possiblepressure,trigger

remove the spray tip. Aim the gun into a metal pail, holding the

the gun.

If

the fluid emitted

is

not diffused into an irregular

stream, replace the diffuser immediately.

Tip Guard

ALWAYS have the tip guard in place

on

the spray gun while

spraying. The tip guard alerts you

to

the fluid injection hazard

and helps reduce, but does

not

prevent,

the

risk of accidentally

placing your fingers

or

any part of your body close

to

the spray

tip.

Trigger Guard

Always have the trigger guard in place

on

the gun when spray.

ing

to

reduce the risk of accidentally triggering the gun

if

it is

dropped or bumped.

Spray Tip Safety

the spray tip clogs while spraying, engage thegun safety fkch

Use extreme caution when cleaning or changing spray

ti

s

If

and then remove the spray tip to clean

it.

immediately. ALWAYS follow the

Pressure Relief Procedure

fully relieved and the gun safety latch is engaged.

NEVER wipe

off

build-up around the spray tip until pressure is

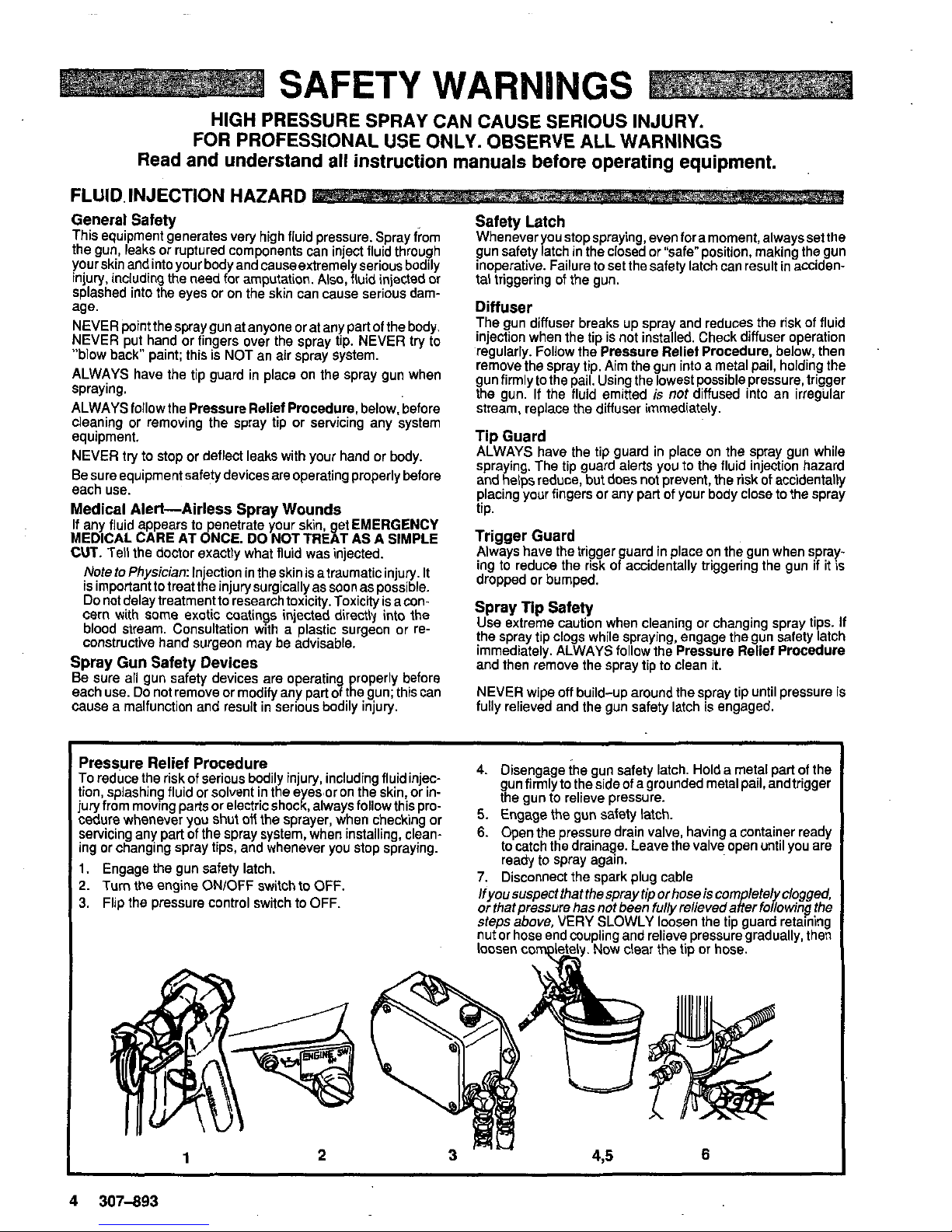

To reduce the risk of serious bodily injury, including fluidinjec-

Pressure Relief Procedure

tion, splashing fluid or solvent in the

e

es

oron the skin, or injury from moving parts or electric shod, always follow this procedure whenever you shut

ofl

the sprayer,

when

checking or

servicing any part

of

the spray system, when installing. clean-

ing or changing spray tips, and whenever you stop spraying.

2.

Turn the engine ON/OFF switch to OFF.

1.

Engage the gun safety latch.

3.

Flip the pressure control switch to OFF.

4.

Disengage the gun safety latch. Hold a metal part of the

the gun to relieve pressure.

gunfirmlytothesideofagroundedmetalpai1,andtrigger

5.

Engage the gun safety latch.

6.

Open the pressure drain valve, having a container ready

to catch the drainage. Leave the valve open until you are

ready to spray again.

7.

Disconnect the spark plug cable

lfyoo suspect that the spray tip orhose is corn lefel clogged,

or thatpressure has not been

fully

relieveda~er fo~o~i"~ the

steps above. VERY SLOWLY loosen the tip guard

retaining

nut or hose end coupling and relieve pressure gradually, then

loosen

completely. Now clear the tip or hose.

1

2

4

307-893

Page 5

MOVING PARTS HAZARD

Moving parts can pinch or amputate your fingers or other body

the sprayer. Follow the Pressure Relief Procedure on page

4

parts. KEEP CLEAR of moving parts when starting or operating

beforechecking orservicing any partofthesprayer. toprevent it

from starting accidentally.

EQUIPMENT MISUSE HAZARD

General

Safety

Any misuse of the spray equipment or accessories, such as

overpressurizing. modifying parts, using incompatible chemi-

cals and fluids, or using worn or damaged parts, can cause

them to ruoture and result in fluid iniection. solashino in the eves

or on the skin, or other serious bodily inju&,'orfire. Explosioi or

property damage.

NEVER alter or modify any part of this equipment: doing

so

could cause

it

to malfunction.

CHECK all spray equipment regularly and repair or replace

worn or damaged parts immediately.

Always wear protective eyewear, gloves, clothing and respira-

tor as recommended by the fluid and solvent manufacturer.

System

Pressure

This sprayer can develop 3000 psi

(210

bar) MAXIMUM

WORKING PRESSURE. Be sure that all spray equipment and

accessories used are rated to withstand this pressure.

DO

NOT

exceed the maximum working pressure of any component or

accessory used in the system.

Fluid

and

Solvent Compatibility

BE SURE that all fluids and solvents used are chemically compatible with the wetted parts shown in iheTECHNlCAL DATA

on

page 35. Always read the fluid and solvent manufacturer's

literature before using them in this sprayer.

HOSE SAFETY

High pressure fluid in the hoses can be very dangerous.

If

the

damage or misuse, the high pressure spray emitted from

it

can

hose develops

a

leak, split or rupture due to any kind

of

wear,

cause a fluid injection injury or other serious bodily injury or

property damage..

ALL FLUID HOSES MUST HAVE SPRING GUARDS ON

BOTH ENDS! The spring guards help protect the hose from

kinks or bends at or close

to

the coupling which can result in

hose rupture.

TIGHTEN all fluid connections securely before each use. High

pressure fluid can dislodge a loose coupling or allow high pressure spray

to

be emitted from the coupling.

tire hose forcuts, leaks, abrasion, bulging cover, or damageor

NEVER use a damaged hose. Before each use, check the en-

movement of the hose couplings.

If

any of these conditions

ex-

ist, replace the hose immediately. DO NOT try

to

recouple high

pressure hose or mend

it

with tape or any other device. A re-

paired hose cannot contain the high pressure fluid.

HANDLE AND ROUTE HOSES CAREFULLY.

Do

not pull on

hoses

to

move equipment. Keep hoses clear of moving parts

and hot surfaces of the pump and gas engine. Do not use fluids

or solvents which are not compatible with the inner tube and

coverofthe hose. DO NOTexpose Graco hose to temperatures

above

180'

F

(82''

C)

or below

-40°

F

(40'

C).

Hose Grounding Continuity

grounded spray system. Check the electrical resistance

of

your

Proper hose grounding continuity is essential to maintaining a

fluid hoses at least once a week.

If

your hose does not have a

tag on it which specifies the maximum electrical resistance,

contact the hose supplier or,manufacturer for the maximum resistance limits. Use a resistance meter in the appropriate range

for your hose to check the resistance. lfthe resistance exceeds

the recommended limits, replace

it

immediately. An un-

grounded or poorly grounded hose can make your system hazardous. Also read FIRE

OR

EXPLOSION HAZARD.

FIRE'OR

EXPLOSION

HAZARD

Static electricity is created by the flow of fluid through the pump

2.

Fluid

hoses: use only grounded hoses with a maximum of

and hose.

If

every part of the spray equipment is not properly

500feet(l50m)combinedhoselen

thtoensuregrounding

grounded, sparking may occur, and the system may become

continuity. See Hose Grounding

8

ontlnuity.

hazardous. Sparking may also occur when plugging in or un-

3. Spraygun:obtain grounding through connection to a prop-

plugging a power supply cord or using a gasoline engine.

Sparks can ignite fumes from solvents and the fluid being

erly grounded fluid hose and sprayer.

sprayed, dust particles and other flammable substances,

4.

Object being sprayed: according to local code.

fire orexplosion and serious bodily injury and property damage.

whether you are spraying indoors oroutdoors, and can cause a

5,

Fluid

supp~y

conta;ner:

to

local

code.

6.

All solvent pails used when flushing, according to local

If

you experience any static sparking or even a slight shock

while using this equipment,

STOP

SPRAYING IMMEDI-

code. Use only metal pails, which are conductive. Do not

ATELY. Check the entire system for proper grounding. Do not

place the pail on a non-conductive surface, such as paper

use the system again until the problem has been identified and

7,

To

conti.;iru

when

orrelieving

or cardboard, which interrupts the grounding continuity.

corrected.

pressure, always hold a metal part of the gun firmly to the

Grounding

side of a grounded metal pail, then trigger the gun.

To reduce the risk of static sparking, ground the sprayer and all

Flushing

safety

other spray equipment used or located in the spray area.

tions

for

your

area

and

type

of

equipment,

BE

SURE

to

ground

splashing by following theflushlng procedure given

on

Page

10

CHEcKyour

localelectricalcodefordetailedgrounding

inStluC-

Reduce the risk of fluid injection Wry, static sparking, or

all of this spray equipment:

of this manual. FollowthePressure Relief Procedureon page

4,

and remove the spray tip before flushing. Hold ametal part of

1.

Sprayer: connect a ground wire and clamp (supplied) to a the gun firmly

to

the side of a grounded metal pail and use the

true earth ground. lowest possible fluid pressure during flushing.

GASOLINE ENGINE HAZARD

NEVER

fill

the fuel tank while the engine is running

or

hot. fuel NEVER operate the engine in a closed building unless the en-

spilled

on

a hot surface can ionite and cause a fire. cline exhaust is DiDed outside. The exhaust contalns carbon

307-893

5

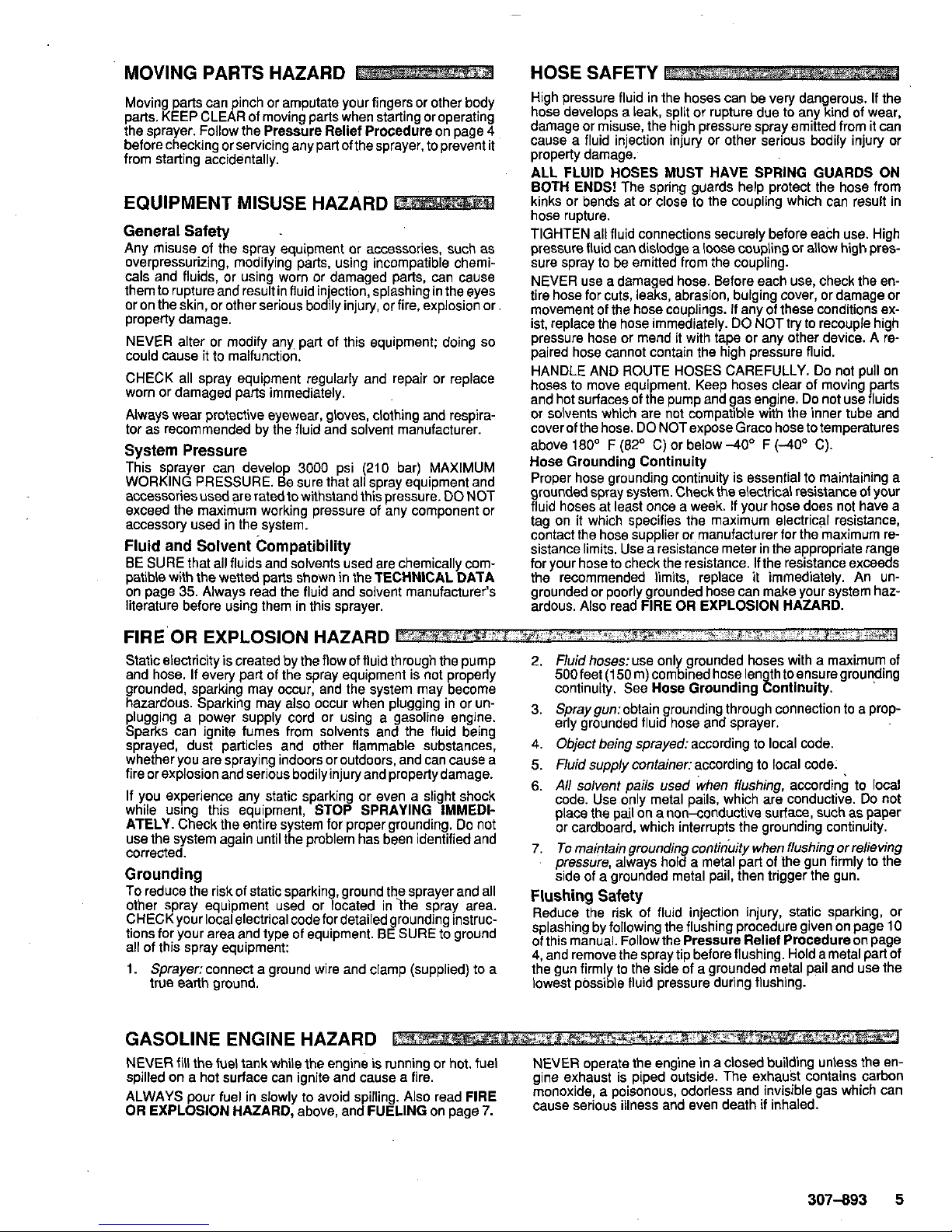

Page 6

SETUP

1.

Connect Hose

and

Gun.

Refer

to

Fig

6-1.

a. Remove the plastic cap plug from the filter outlet

nipple and screw the

50

ft.

(15.2

m) main fluid

hose onto the nipple.

b. Connect the whip end hose between the fluid

hose and the gun inlet connection.

c. Don't use thread sealant; and don't install the

spray tip yet!

WARNING

be sure the hoses are electrically conductive. That

If

you are supplying your own hoses and spray gun,

the gun has a tip guard and that each part is rated for

at least

3000psi(210

bar) Working Pressure. This is

to

reduce the risk of serious bodily injury caused by

static sparking, fluid injection or over-pressurization

and rupture of the hose or gun.

~~ ~ ~~ ~ ~

2.

Two

Gun Hookup.

Refer to Fig

6-1.

Remove the

cap from the secondary hose outlet and attach an accessory hose and gun to the

114

npsm(m) nipple.

CAUTION

To

avoid damaging the pressure control, which may

result in poor equipment performance and component Clamage, follow these precautions:

1.

Always use nylon spray hose at least

50

ft.

2.

Never use awire braid hose as it is

too

rigid

to

act

3.

Never install any shutoff device between the fil-

4.

Always use the main filter outlet for one gun

op-

(15.2

m) long.

as a pulsation dampener.

ter and the main hose. See Fig

6-1.

eration. Never plug this outlet.

3.

Fill Packing Nuwet-Cup.

Refer to Fig

6-1.

Fill the

packing nuffwet-cup

1/3

full with Graco Throat Seal

Liquid (TSL), supplied.

4.

Check the engine

oil

level.

Refer

to

the Honda engine manual, supplied. This is a summary of the information: Remove one of the oil fill plugs; the oil

should be almost overflowing. See Fig

7-1.

Add oil

as necessary.

tergent oil, SAE

1

OW-40,

classified "FOR SERVICE

Recommended lubricatiqn oil. Use a high quality de-

SE

or

SF",

for regular use and for the breaking-in

of

a new engine.

"

PRESSURE CONTROL

ONlOFF

SWITCH

SECONDARY

H

OUTLET

1/4

NP

WHIP END HOSE

Fig

6-1

6

307-893

Page 7

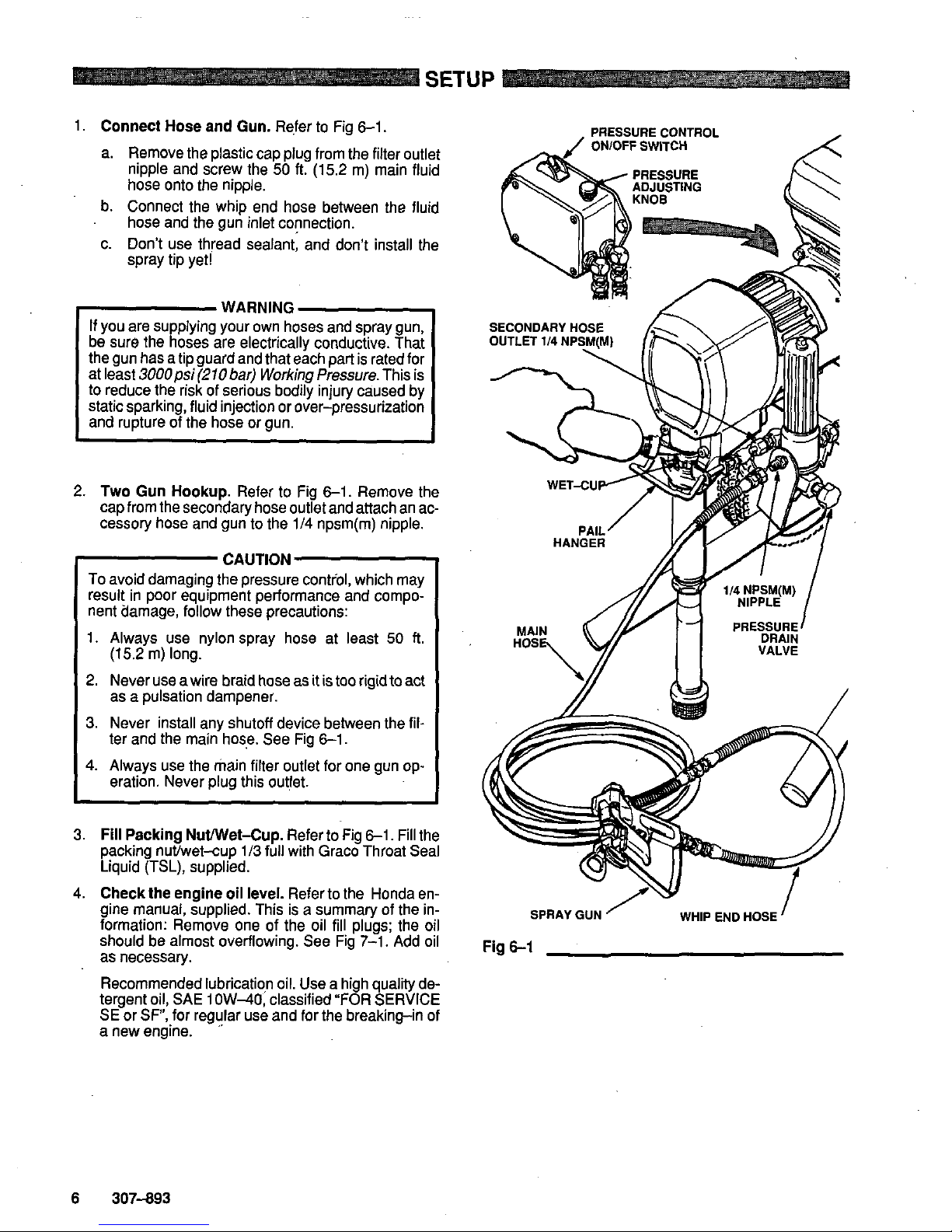

SETUP

5.

Be sure your system is properly grounded

be-

fore operating it.

Read and follow the warning sec-

tion,

FIRE

OR

EXPLOSION HAZARD,

on

page

5.

6.

Fill the gas tank.

See the

FUELING

section, below.

7.

Flush the pump

to

remove the lightweight oil which

was left in

to

protect pump parts after factory testing.

a. Before using water-base paint, flush with

mineral spirits followed by soapy water, and

then a clean water flush.

b. Before using oil-base paint, flush with mineral

c. See

FLUSHING GUIDELINES

on page 11 for

8. Prepare the paint

according

to

the manufacturer's

spirits only.

the flushing procedure.

recommendations.

a. Remove any skin that may have formed.

b. Stir the paint to mix pigments.

c.

Strain the paint through a fine nylon mesh

bag (available at most paint dealers) to

spray tip. This is probably the most important

remove particles that could clog the filter or

step toward trouble-free spray painting.

9.

Keep the sprayer uprlght and level

during opera-

tion and whenever it

is

being moved.

\

/

MUFFLER

//

Fig

7-1

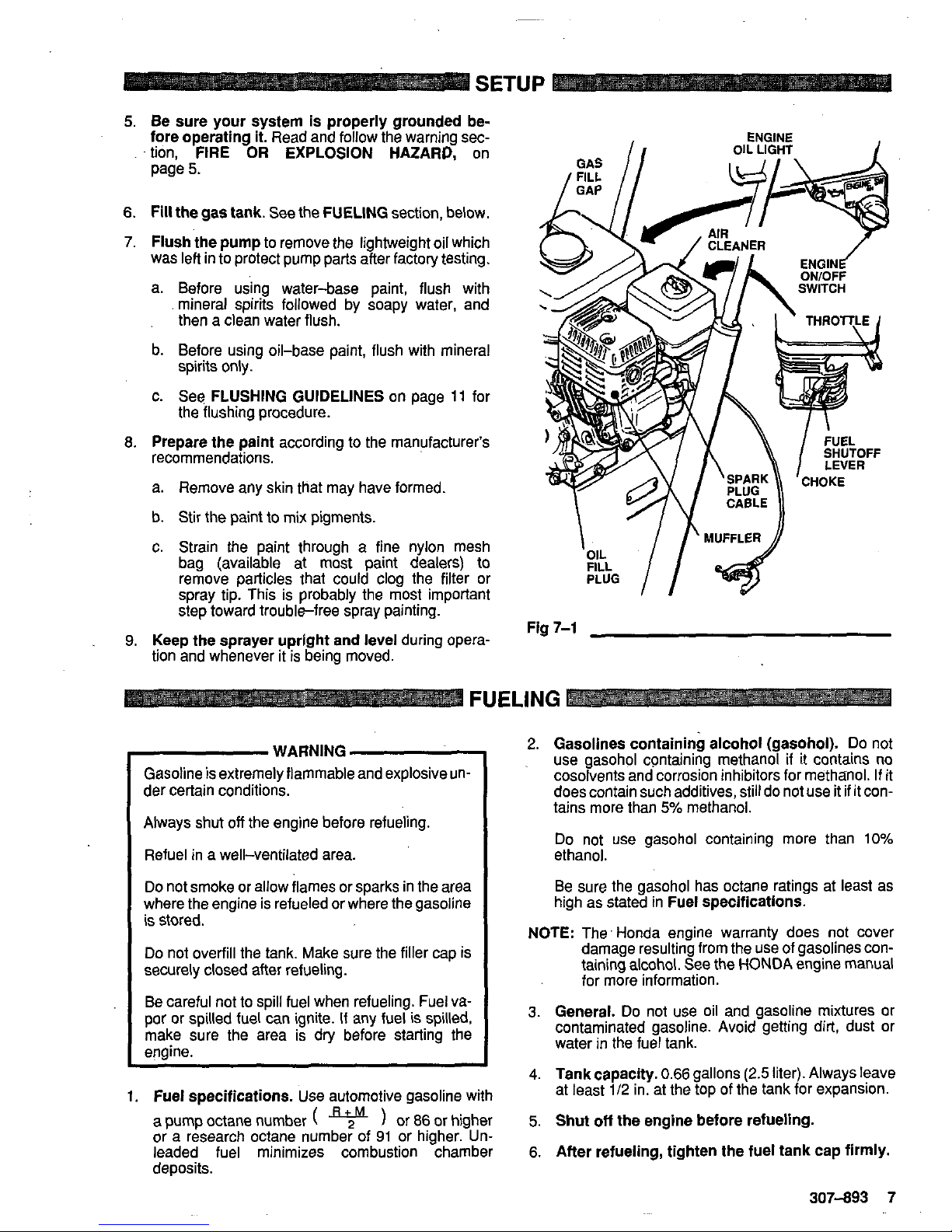

FUELING

-

WARNING

Gasoline

is

extremely flammable and explosive un-

der certain conditions.

Always shut

off

the engine before refueling.

Refuel in a well-ventilated area.

Do

not smoke or allow flames or sparks in the area

where the engine is refueled or where the gasoline

is

stored.

securely closed after refueling.

Do

not overfill the tank. Make sure the filler cap is

por or spilled fuel can ignite.

If

any fuel is spilled,

Be careful

not

to spill fuel when refueling. Fuel va-

engine.

make sure the area is dry before starting the

1.

Fuel specifications.

Use automotive gasoline with

a

pump octane number

(

or

86

or higher

or a research octane number of 91 or higher. Un-

deposits.

leaded fuel minimizes combustion chamber

2.

Gasolines containing alcohol (gasohol).

Do not

use gasohol containing methanol

if

it contains

no

cosolvents and corrosion inhibitors for methanol. If it

does contain such additives, still do not use it

if

it con-

tains more than

5%

methanol.

Do not use gasohol containing more than

10%

ethanol.

high as stated in

Fuel specifications.

Be sure the gasohol has octane ratings at least as

NOTE:

The' Honda engine warranty does not cover

damage resulting from the use of gasolines containing alcohol. See the

HONOA

engine manual

for more information.

3.

General.

Do

not

use oil and gasoline mixtures or

contaminated gasoline. Avoid getting dirt, dust or

water in the fuel tank.

4.

Tank capacity. 0.66

gallons

(2.5

liter). Always leave

5.

Shut

off

the engine before refueling.

6. After refueling, tighten the fuel tank cap flrmly.

at least

1/2

in. at the top of the tank for expansion.

307-893 7

~~

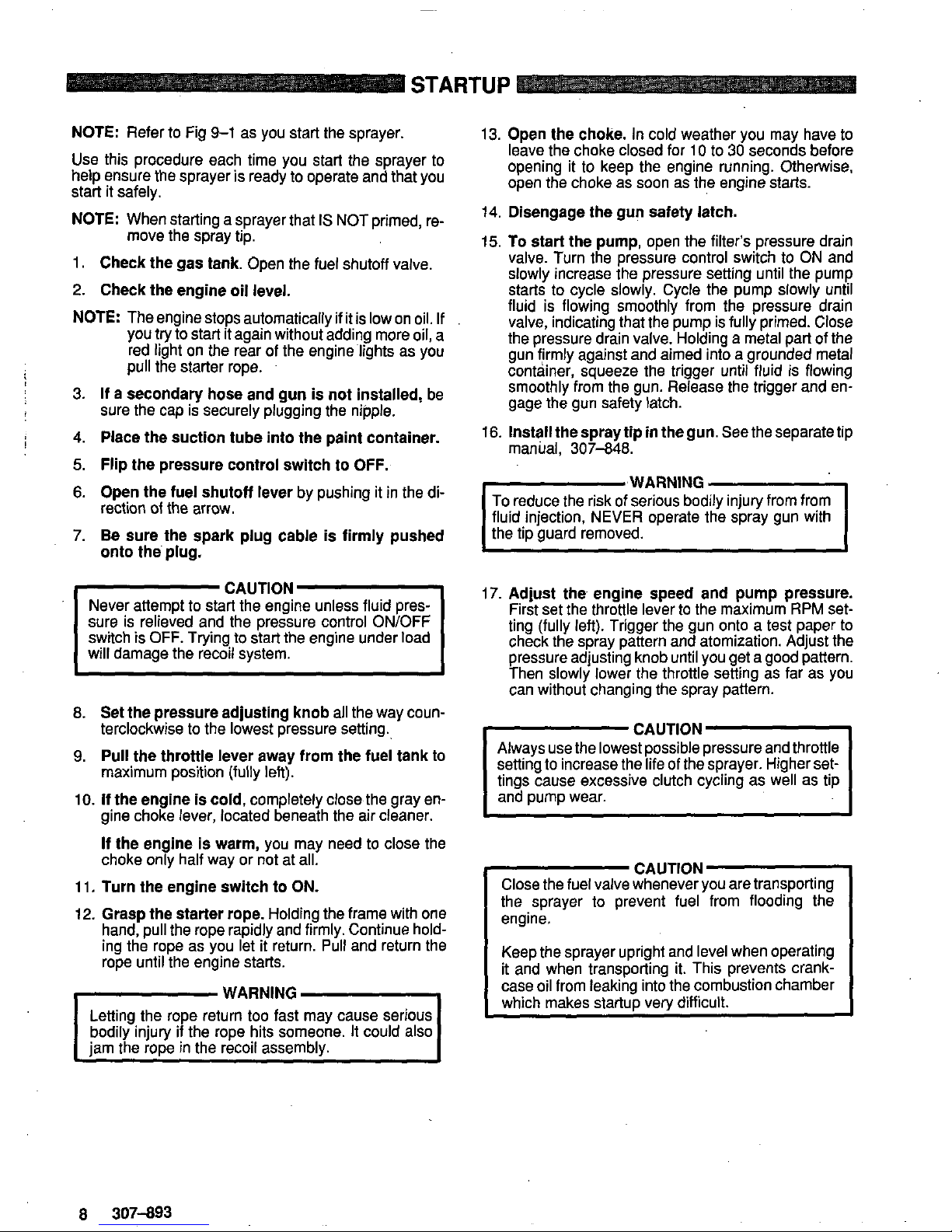

Page 8

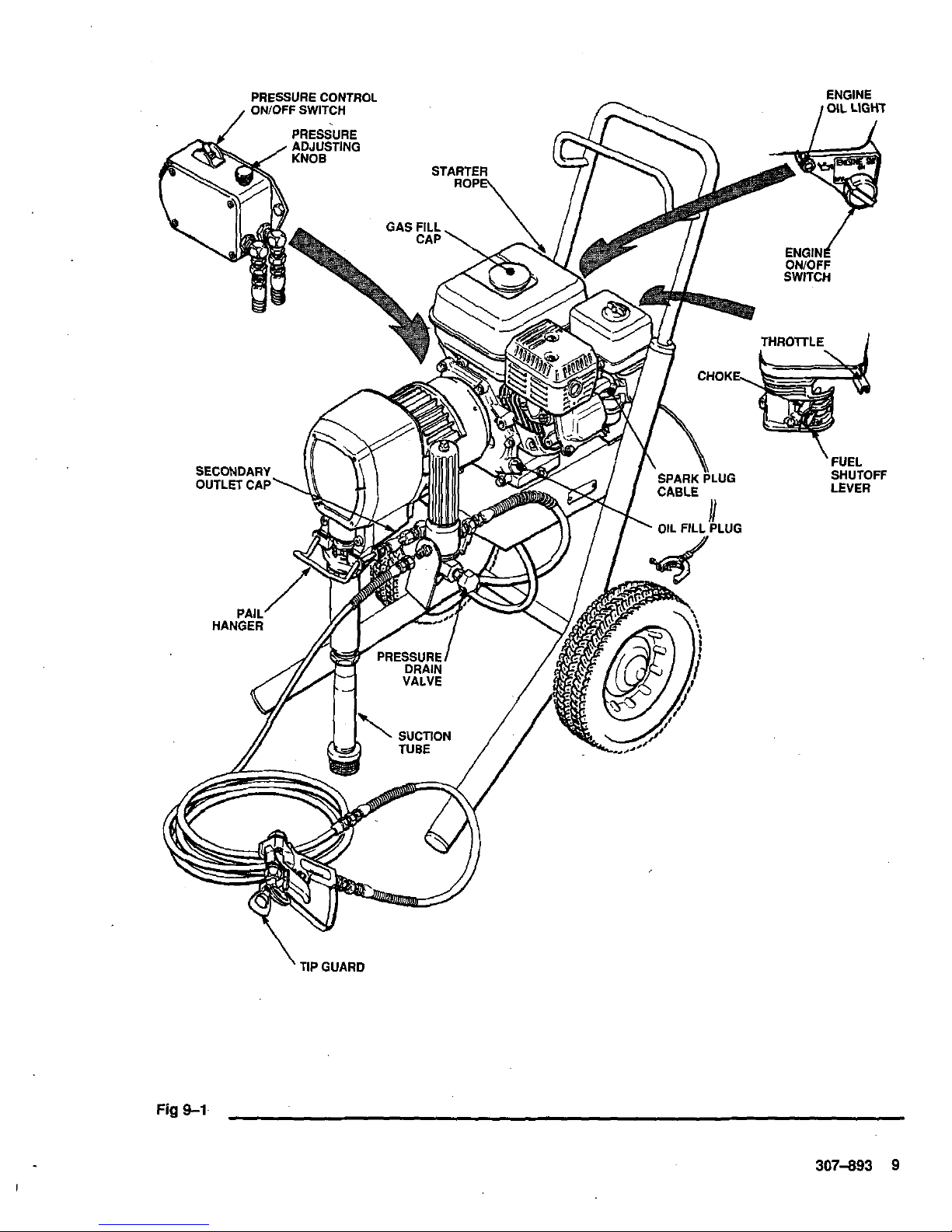

NOTE:

Refer to Fig

9-1

as you start the sprayer.

Use this procedure each time you start the sprayer to

help ensure the sprayer is ready to operate and that you

start it safely.

NOTE:

When starting a sprayer that

IS

NOT primed, re-

move the spray tip.

1.

Check the gas tank.

Open the fuel shutoff valve.

2.

Check the engine oil level.

NOTE:

The engine stops automatically if it is low on oil. If

you try to start it again without adding more oil, a

red light on the rear of the engine'lights as you

pull the starter rope.

3.

If

a

secondary hose and gun is not installed,

be

4.

Place the suction tube into the paint container.

5.

Flip the pressure control switch to OFF.

6.

Open the fuel shutoff lever

by pushing it in the di-

7.

Be sure the spark plug cable is firmly pushed

sure the cap is securely plugging the nipple.

!

rection

of

the arrow.

onto the'plug.

Never attempt to start the engine unless fluid pres-

sure is relieved and the pressure control ON/OFF

switch

is

OFF. Trying to stat? the engine under load

will damage the recoil system.

IcAuT1oNl

8.

Set the pressure adjusting knob

all the way coun-

terclockwise to the lowest pressure setting.

9.

Pull the throttle lever away from the fuel tank

to

maximum position (fully left).

10.

If

the engine is cold,

completely close the gray en-

gine choke lever, located beneath the air cleaner.

If

the engine is warm,

you may need to close the

choke only half way or not at all.

11.

Turn the engine switch to ON.

12.

Grasp the starter rope.

Holding the frame with one

hand, pull the rope rapidly and firmly. Continue holding the rope as you let it return.

Pull

and return the

rope until the engine starts.

WARNING

Letting the rope return too fast may cause serious

bodily injury

if

the rope hits someone. It could

also

jam the rope in the recoil assembly.

~

13.

Open the choke.

In cold weather you may have to

opening it to keep the engine running. Otherwise,

leave the choke closed for

10

to

30

seconds before

open the choke as soon as the engine starts.

14.

Disengage the gun safety latch.

15.

To start the pump,

open the filter's pressure drain

valve. Turn the pressure control switch to

ON

and

slowly increase the pressure setting until the pump

starts to cycle slowly. Cycle the pump slowly until

fluid is flowing smoothly from the pressure drain

valve, indicating that the pump is fully primed. Close

the pressure drain valve. Holding a metal part of the

gun firmly against and aimed into a grounded metal

container, squeeze the trigger until fluid is flowing

smoothly from the gun. Release the trigger and engage the gun safety latch.

16.

Install the spray tip in the gun.

See the separate tip

manual,

307-848.

I'wARN'NGl

To

reduce the risk of serious bodily injury from from

the tip guard removed.

fluid injection,

NEVER

operate the spray gun with

17.

Adjust the engine speed and pump pressure.

First set the throttle lever to the maximum

RPM

setting (fully left). Trigger the gun onto a test paper to

check the spray pattern and atomization. Adjust the

pressure adjusting knob until you get a good pattern.

Then slowly lower the throttle setting as far as you

can without changing the spray pattern.

CAUTION

Always use the lowest possible pressure and throttle

setting to increase the life of the sprayer. Higher settings cause excessive clutch cycling as well as tip

and pump wear.

Close

the fuel valve whenever you are transporting

CAUTION

the sprayer to prevent fuel from flooding the

engine.

Keep the sprayer upright and level when operating

case oil from leaking into the combustion chamber

it and when transporting it. This prevents crank-

which makes startuD verv difficult.

8

307-893

Page 9

Fig

9-1-

307-893

9

Page 10

MAINTENANCE

-WARNING

I

To

reduce the risk

of

serious bodily injury, including

fluid injection or splashing in the eyes or on the skin,

or injury from moving parts, always follow the

Pres-

sure Relief Procedure Warning

on page

11

before

checking, adjusting, cleaning and shutting down the

sDraver. Disconnect the SDark DIua.

CAUTION

tions, refer to the separate engine manual, supplied.

For detailed engine maintenance and specifica-

DAILY:

Checkthe engine

oil

level and

fill

as necessary.

WEEKLY:

Check the level of the

TSL

in the displace-

DAILY:

Check and

fill

the gas tank.

ment pump packing nut. Fill it

if

necessary. Keeping

TSL

in the nut helps lubricate the packings.

AFTER THE

FIRST

20

HOURS

OF

OPERA-

TION:

Drain the oil and refill with clean oil.

the element. Replace the element

if

necessary.

If

operat-

WEEKLY:

Remove the cover of the air filter and clean the

Oil.

ing in an unusually dusty environment, check the filter

daily and replace

if

necessary.

SPARK PLUG:

Use only a (NGK)

BPGES

or

BPR6ES

plug. Gap the plug to

0.025-0.030

in.

(0.7-0.8

mm). Be

Replacement elements can be purchased from your

lo-

sure to use a spark plug wrench when installing and re-

tal

Honda dealer. moving the plug.

AFTER EACH

100

HOURS

OF

OPERATION:

Change

10

307-893

Page 11

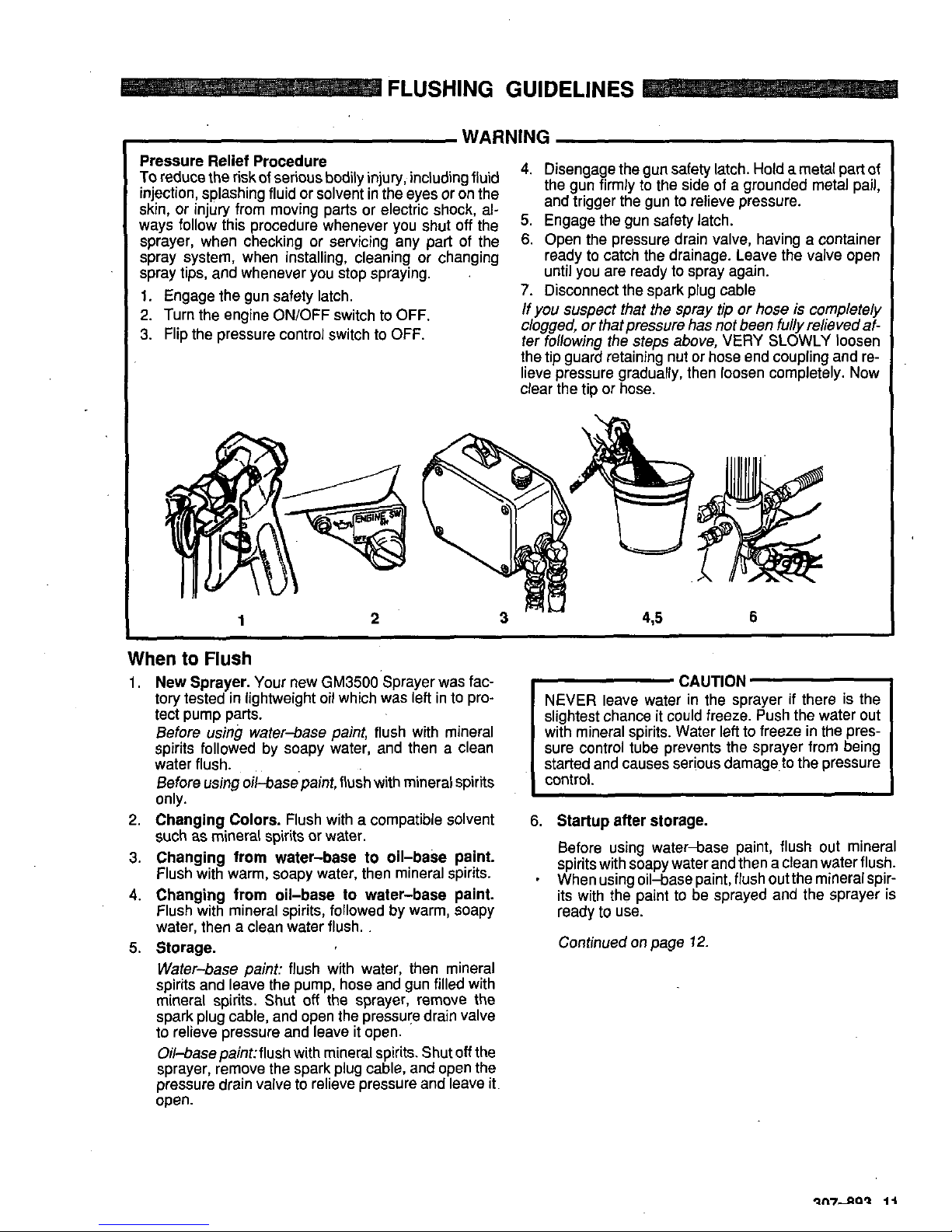

FLUSHING GUIDELINES

I

WARNING

Pressure Relief Procedure

Toreduce the riskof serious bodily injury, including Ruid

the

gun

firmly

to

the

side

of

a

grounded

metal

pail,

4.

Disengage the gun safety latch. Hold a metal part of

skin, or injury from moving parts or electric shock, al-

injection, splashing fluid or solvent in the eyes or on the

and

trigger

the

gun

to

relieve

pressure,

ways follow this procedure whenever you shut

off

the

5.

Engage

the

gun

latch.

sprayer, when checking or servicing any pari of the

6.

Open the pressure drain valve, having a container

spray system, when installing, cleaning or changing

ready to catch the drainage. Leave the valve open

spray tips, and whenever you stop spraying.

.

until you are ready to spray again.

1.

Engage the gun safety latch.

7.

Disconnect the spark plug cable

2.

Turn the engine ON/OFF switch to OFF.

If

you suspect that the spray tip or hose

is

completely

3. Flip the pressure control switch to OFF.

clogged, or that pressure has not been

fully

relieved

af-

ter fobwing the steps above,

VERY

SLOWLY loosen

the tip guard retaining nut or hose end coupling and re-

clear the tip or

hose.

lieve pressure

gradually, then loosen completely. Now

1

2

When to Flush

1.

New Sprayer.

Your new GM3500'Sprayer was fac-

tory

tested in lightweight oil which was left in to pro-

tect pump parts.

Before

using

water-base paint, flush with mineral

water flush.

spirits followed by soapy water, and then a clean

only.

Before using oil-basepaint, flush with mineral spirits

2.

Changing Colors.

Flush with a compatible solvent

such

as

mineral spirits or water.

3.

Changing from water-base to oil-base paint.

Flush with warm, soapy water, then mineral spirits.

4.

Changing from oil-base to water-base paint.

Flush with mineral spirits, followed by warm, soapy

water, then a clean water flush.

Water-base paint: flush with water, then mineral

spirits and leave the pump, hose and gun filled with

mineral spirits.

Shut

off

the sprayer, remove the

spark plug cable, and open the pressure drain valve

to relieve pressure and leave it open.

Oil4asepaint:flush with mineral spirits. Shut

off

the

sprayer, remove the spark plug cable, and open the

pressure drain valve to relieve pressure and leave it.

open.

5.

Storage.

-

CAUTION

NEVER leave water in the sprayer

if

there is the

slightest chance it could freeze. Push the water out

with mineral spirits. Water left to freeze in the pressure control tube prevents the sprayer from being

started and causes serious damage to the pressure

control.

6.

Startup after storage.

spirits with soapy water and

then a

clean water flush.

Before using water-base

paint,

flush

out mineral

*

When using oil-base paint, flush out the mineralspir-

its with the paint to be sprayed and the sprayer is

ready

to

use.

Continued on page

12.

Page 12

FLUSHING

GUIDELINES

How

to

Flush

1.

Follow the Pressure Relief Procedure Warning on

6.

Disengage the gun safety latch. Point the spray gun

page

1

1.

into a metal waste container and with a metal part of

the gun firmly touching the metal container, squeeze

the gun trigger. See Fig

12-2.

This procedure helps

reduce the risk of static sparking and splashing. Start

the sprayer, trigger the gun and slowly turn the pressure adjusting knob clockwise just until the pump

starts. Keep the gun triggered until clean solvent

comes from the nozzle. Release the trigger and engage the gun safety latch.

2.

Remove the filter bowl and screen; see manual

307-273, supplied. Clean the screen separately and

install the bowl without the screen to flush it. See Fig

12-1.

FILTER

BOWL

SCREEN

'

FILTER

SUPPORT

PRESSURE

DRAIN VALVE

Fig

12-1

7. Check all fluid connections for leaks.

If

anyJeak, first

follow the Pressure Relief Procedure Warning on

page

11.

Now tighten the connections, start the

sprayer, and recheck the connections for leaks.

8.

Remove the suction tube from the pail. Disengage

the gun safety and trigger the gun to force solvent

from the hose.

Do

not let the pump run dry for more

than

30

seconds to avoid damaging the pump packings! Then follow the Pressure Relief Procedure

Warning on page

11.

9.

Leave the pressure drain valve open until

you

are

bowl and reinstall the clean screen. Reinstall the

ready

to

use the sprayer again. Unscrew the filter

bowl, hand tight only.

IO.

If

you flushed with mineral spirits and are going

to

use a water-base paint, flush with soapy water fol-

sure Rellef Procedure Warning on page

11.

lowed by a clean water flush. Then follow the Pres-

3. Close the filter's pressure drain valve.

4.

Pour one-half gallon

(2

liters) of compatible solvent

into a grounded metal pail. Put the suction tube

in

the

pail.

5.

Remove the spray tip from the gun.

-1

Fig

1

To

reduce the risk of static sparking and splashing,

always remove the spray tip form the gun, and hold

a metal part of the gun firmly to the side

of

and aimed

into

a

grounded metal pail when flushing.

METAL

TO

META

CONTACT WHEN

FLUSHING

12

307-893

Page 13

I

WARNING

To reduce the risk of serious bodily injury, including fluid

5.

Engage the gun safety latch.

Pressure Relief Procedure

from

moving

always

follow

this when-

6.

Open the fluid pressure drain valve and leave

it

injection, splashing in the eyes or on the skin, or injury

you shut

off

the sprayer, checking, adjust or clean the open until you start the sprayer again.

system, or change spray tips.

7.

Disconnect the spark

plug

cable.

1. Engage the gun safety latch.

lfyou

suspect that the hose or

tip

is

completely clogged

2. Turn the engine ON/OFF switch to OFF. or that pressure

is not

fully

relieved affer

following

the

3.

Flip the pressure control switch to OFF.

stepsabove, VERY SLOWLY loosen a hose end fitting

or the tip guard retaining nut and relieve pressure

4.

Disengage the gun safety latch. Holding a metal part

gradually. Now clear the tip or hose.

trigger the gun.

of the gun firmly to the side of agrounded metal pail,

Check everything in the guide before disassembling the sprayer.

JROBLEM

fnginekprayer won't start

3ngine won't pull over.

?as engine operates but

jisplacement pump doesn't

)perate

CAUSE

I

SOLUTION

Engine switch not

ON

I

Turn on.

Engine

oil

level low

Try starting engine.

If

light on rear of

engine glows, replenish oil..

Spark plug cable disconnected or Connect cable on top of engine or respark plug bad place spark plug.

Out

of gas

Water frozen in pressure control.

Replenish

Graco dealer for

rep-:?

Return

pressure

control to authorized

Oil seepage into combustion

Remove spark plug. Pull engine over

chamber.

3

or 4 times. Clean and replace plug.

Try to start. Keep sprayer upright to

avoid seepage.

-,

Pressure control switch turned OFF

Clean filter.

Displacement pump outlet filter dirty

Increase pressure.

Pressure setting too low

Turn on.

or clogged

Tip or tip filter clogged Clean tip or tip filter.

Displacement pump rod seized by dry

Service pump. See

307-806.

paint

I

Connecting rod worn or damaged

Check wiring connections. See page

Electrical power not energizing

field

Replace. See page

20.

Driie housing worn or damaged

Replace. See page

18.

15.

With pressure control switch ON and

test light to check continuity across

pressure turned to

MAXIMUM,

use a

black and wire wires from pressure

control.

Have pressure control checked by

authorized Graco dealer.

Clutch worn or damaged

Service. See page

21.

Pinion assembly worn

or

damaged

Service. See page

24.

'

Continued on page

14

307-893 13

Page 14

TROUBLESHOOTING

GUIDE

PROBLEM

Displacement

.

pump outpu

low on upstroke

low on downstroke or bot1

Displacement pump outpu

strokes

Paint leaks into wetcup

Low fluid delivery

Spitting from gun

CAUSE

Pump inlet screen clogged

Piston ball check not seating

Piston packings worn or damaged

Displacement pump sleeve gasket

worn or damaged

Pump inlet screen clogged

Piston packings worn or damaged

properly

Intake valve ball check not seating

Engine RPM too low

~~~ ~

Clutch worn or damaged

Loose wet-cup

Throat packings worn or damaged

damaged

Displacement rod worn or

Pump inlet screen clogged

Pressure setting

too

low

Engine RPM

too

low

Dirty outlet filter, tip filter or tip

Large pressure drop in hose

Air in fluid pump or hose

Tip partially clogged

Fluid supply is low or empty

SOLUTION

Clean.

Service piston ball check.

Replace packings,

Replace.

Clean.

Replace packings.

Clean and service.

Increase throttle setting. See Startup,

Step 17, page

8.

Replace. See page

24.

Tighten just enough to stop leakage.

Replace packings. See 307-793.

Replace. See 307-793.

Clean.

Increase pressure. See Startup, Step

17, page

8.

Increase throttle setting. See Startup,

Step 17, page

8.

Clean.

Use larger diameter hose.

Check for loose connections at intake

and tiohten. Then mime the

ix.mD.

See STaiup, page

8:

Clear,

Refill and reprime the pump. See

Startup, page

8.

Check fluid supply

often to Drevent running dry.

,.

14

307-893

Page 15

REPAIR

Pressure Control Replacement

WARNING

To

reduce the risk

of

serious bodily injury, including

fluid injection or splashing in the eyes or on the skin,

or injury from moving parts, always follow the

Pres-

sure.Relief Procedure Warning

on

page 13 before

checking, adjusting, cleaning and shutting down the

sprayer. Disconnect the spark plug cable.

1. Disconnect both hoses at the pressure control (63),

holding the elbows firmly. See the

CAUTION

below.

Take note

of

the original location of each hose

to

be

sure you reassemble them correctly at the end of this

procedure. See Fig 15-1,

CAUTION

DO

NOTallow the elbow (314)

to

turn when remov-

ing or connecting the hoses. Turning the elbows can

2.

Working under the engine mounting plate

of

the cart,

disconnect the red, black and white wires. Then remove the three nuts (61) and lockwashers

(9)

from

the capscrews

(62)

which hold the pressure control

trol. See Fig

15-2.

bracket

(67)

to

the cart. Remove the pressure con-

3. Remove the pressure control cover and screws

(76,64) and the four screws

(65)

holding bracket

(67)

Fig

15-1

to the pressure control. See Fig 15-1.

trol wires. See Fig

15-2.

(see

page

17)

4. Remove the wire clamp

(32)

from the pressure con-

procedure

continued

on

newt

page

VIEW

FROM

UNDER ENGINE MOUNTING

PLATE

Fig

15-2

307-893

15

Page 16

~

REPAIR

5.

Disconnect the wires from the rectifier

(307).

Re-

9.

Reassemble

in

the reverse order. Be Sure

to

reinstall

move the screw

(311),

nut

(306)

and lockwasher

(305).

See Fig

16-1,

the wire clamp

(32)

on the new pressure control

wires. Fasten both clamps to the cart with the

6.

Unscrew the connector

(313)

from the box, pulling

the wires out with it.

same screws, lockwashers and nuts

(62,9,61)

which

hold the bracket

(67)

to the cart. See Fig

15-2.

7.

Holding the hex of the adapters

(A)

at the control box

with a wrench, remove the elbows

(314).

8.

Removethescrew(310)andiockwashers(305)from

10.

Perform the Pressure

Control Calibration

proce-

the ground wire

(308).

dure on the next page before regular operation of the

sprayer.

31 1,305,306

RED

RECTIFIER

(307)

CONNECTIONS

Fig

16-1

16

307-893

Page 17

REPAIR

Pressure

Control Calibration

(See

Fig

17-1)

L

WARNING

USE EXTREME CAUTION WHEN PERFORMING THIS CALIBRATION PROCEDURE

to reduce the risk of a fluid

injection injury or other serious bodily injury which can result from component rupture, electric shock, fire, explosion,

or moving parts.

This procedure sets the sprayer to 182-210 bar

MAXIMUM WORKING PRESSURE.

This procedure must be performed whenever the

pressure control assembly is removed and reinstalled

or replaced to be sure the sprayer is properly cali-

brated.

Improper calibration can cause the sprayer

to

over-

pressurize and result in component rupture, fire or ex-

plosion. It may also prevent the sprayer from obtaining

sprayer performance.

the maximum working pressure, resulting in poor

NEVER attempt

to

increase the fluid outlet pressure

by performing these calibrations in any other way.

NEVER EXCEED 210 bar MAXIMUM WORKING

PRESSURE. Normal. operation

of

the sprayer at

fire or explosion.

higher pressures could result in component rupture,

ALWAYS use a new 15.2 m spray hose rated for at

when performing this procedure.

A

used, under-rated

least 210 bar MAXIMUM WORKING PRESSURE

hose could develop a high pressure leak or rupture.

AVOID touching the wire in the pressure control assembly when the control box cover is removed, to reduce the risk of electric shock.

Service Tools Needed:

NEW 15.2 m, 231 bar flexible, nylon airless spray

hose, Part No. 21C-541

New 0.023 size spray tip.

0-350 bar fluid-filled pressure gauge, Part No.

20 liter pail and water

Mineral spirits

1.

Follow

the

Pressure Relief Procedure Warning

on

page 13.

2. Install the new 15.2 m spray hose to the sprayeroutlet. On the other end of the hose, install the gun and a

gauge in the top port

(6

-

See

fig

15-1)

of the fluid

new ,023 size tip. Install the fluid-filled pressure

filter. Remove the pressure control cover.

3. With the gun safety latch engaged, start the engine

(only). Using a 318” ignition wrench, turn the pressure

adjustment nut

(E)

clockwise

two

full turns. See Fig

the minimum setting, turn the sprayer switch

ON.

17-1. With the pressure control knob (D) turned to

THE DISPLACEMENT PUMP SHOULD NOT CYCLE

If

if

does

cycle,

shut the sprayer switch OFF, disengage the gun safety latch, trigger the gun into a

grounded waste container until pressure is relieved,

and engage the latch again. Turn the nut

(E)

a little

further clockwise. Turn the sprayer on again to be

sure

THE

PUMP

DOES

NOT

CYCLE.

4.

Increase the throttle setting and then the pressure

control setting to the maximum while triggering the

gun. Keep the gun triggered while observing the

pressure at which the pump stalls, which should be

approximately 210 bar.

NOTE:

When the gun trigger is released, it is normal for

the stall pressure

to

be 21 7 to 238 bar, during this

procedure.

/f

the

pressure

is

not

210

bar, turn the adjusting nut

clockwise

to increase pressure to obtain exactly

(E)

clockwise

to reduce pressure and

counter-

21

0

bar pressure.

102-81

4

fore the pressure starts to rise again.

Then note the pressure to which the gauge drops be-

entia1 wheel

(A)

clockwise

to bring the pressure to

IffhepressuredropstobeIow18Zbar,turnthediffer-

182 bar.

the differential wheel (A)

counterclockwise

to de-

If

the pressure stops

dropping

before

182

bar, turn

crease the pressure.

5. Follow the

Pressure Relief Procedure Warning

on

page

13.

Install the pressure control cover. Flush the

water out with mineral spirits, relieve pressure again,

and then

remove

all

the

test

equipment.

A\

/D

Fig

17-1

307-893

17

Page 18

REPAIR

Bearing

Housing

&

Connecting

Rod

WARNING

To

reduce the risk of serious bodily injury, including

fluid injection, splashing fluid in the eyes or on the

skin, or injury from moving parts, always follow the

Pressure Relief Procedure

Warnins on page 13

before repairing any part of the sprayer. Disconnect

the soark

Dlua

cable.

NOTE:

Steps 1

to

13 refer

to

Fig 18-1.

1. Remove the front cover and screws (23’68).

2.

Unscrew the suction tube (30) from the pump, hold-

pump from loosening.

ing a wrench on the pump intake valve

(B)

to

keep the

3. Disconnect the pump outlet hose (59) from the displacement pump outlet nipple (87).

4.

Use a screwdriver

to

push aside the retaining spring

(26) at the top of the pump. Push the pin (25)

out

the

rear.

5.

Loosen the jam nut (27) with an adjustable wrench.

Unscrew and remove the displacement pump.

6.

Use a hex key wrench to remove the four screws (73)

and lockwashers (74) from the bearing housing.

7. While pulling the connecting rod (22) with one hand,

with a plastic mallet to loosen it from the drive hous-

lightly tap the lower rear

of

the bearing housing (21)

ing (20).

Pull

the bearing housing and the connecting

rod assembly (22)

off

the drive housing.

8.

Inspect the crank

(A)

for excessive wear and replace

parts as needed.

9.

Evenly lubricate the inside of the bronze bearing

(F)

in !he bearing housing (21.) and the inside of the con-

ally pack the roller bearing

(E)

in the connecting rod

necting rod link (D) with high quality motor oil. Liber-

assembly (22) with bearing grease.

10.

Assemble the connecting rod (22) and bearing housing (21).

11.

Clean the mating surfaces of the bearing and drive

housings.

12. Align the connecting rod with the crank

(A)

and care-

fully align the locating pins

(C)

in the drive housing

the bearing housing onto the drive housing or tap it

(20) with the holes in the bearing housing

(21).

Push

into place with a plastic mallet.

CAUTION

13. Install the screws (73) and lockwashers

(74)

on the

bearing housing and tighten evenly to 125-145 in-lb

(14-16

Nm).

18

307-893

Page 19

REPAIR

NOTE:

Refer to Fig

19-1

for Step

14.

14.

Screw the displacement pump about

3/4

of the way

into the bearing housing

(21).

Hold the pin

(25)

up to

the pin hole in the connecting rod assembly

(22)

and

continue screwing in the pump until the pin slides

easily into the hole. Back

off

the pump until the top

threads of the pump cylinder are flush with the face

of

the bearing housing and the outlet nipple

(87)

is fac-

groove all

the

way

around the connecting rod.

ing back. Push the

retaining spring

(26)

into

the

Tighten the locknut

(27)

very tight - about.65 to

75

ft-lb

(90

to

100

N.m) -with a

2-1/4

in. open end

wrench and a light hammer.

WARNING

To reduce the risk of the pin

(25)

being projected into

the air and resulting in serious bodily injury, including

injury

to

the eyes, or property damage, including

damage to the pump connecting rod or bearing

housing:

Be sure the retaining spring

(26)

is firmly in the

groove all the way around, to prevent the pin

(25)

from working loose due to vibration.

If

the pin works loose, it or other parts could break

off

due to the force of the pump action. These parts

could be projected through the air.

15.

Reinstall the front cover and screw

(23,68).

Recon-

See Fig

18-1.

nect the suction tube

(30)

and pump outlet hose

(59).

Fig

19-1

307-893

19

Page 20

REPAIR

Drive

Housing

WARNING

To reduce the risk of serious bodily injury, including

fluid injection, splashing fluid in the eyes or on the

skin, or injury from moving parts, always follow the

before repairing any part of the sprayer. Discon-

Pressure Relief Procedure Warning

on

page

13

nect the spark plug cable.

NOTE: Refer to Fig 20-1 for this procedure.

1.

Remove the front cover and screws

(23,68)

2.

Disconnect the pump outlet hose (59) from the dis-

placement pump nipple

(57).

3.

Use a hex key wrench to remove the two screws

(I

0)

and lockwashers (1

1)

from the bottom front of the

pinion housing (1911). Then remove the top

two

screws

(IO)

and lockwashers

(1

1).

4.

Working from the front

of

the drive housing, remove

the two screws

(73)

and lockwashers

(74).

5.

Lightly tap around the drive housing with a plastic

mallet to loosen it from the pinion housing.

6.

While holding the connecting rod

(22)

with one hand,

lightly tap the back of the bearing housing

(21)

to

loosen the drive housing. Then pull the drive housing

straight

off

the pinion housing.

CAUTION

moving the drive housing

(20).

It iseasily damaged

DO NOT allow the gear cluster

(1

8)

to fall when re-

if

dropped. The gear may stay engaged in either the

drive housing or pinion housing.

each end of the gear cluster, or allow them to fall be-

DO

NOT lose the thrust balls (2Oc or 19j) located at

tween gears. The ball, which is heavily covered with

grease, usually stays in the shaft recesses, but

could be dislodged.

If

caught between gears and

not removed, the balls will seriously damage the

drive housing.

If

the balls are not in place, the bear-

ings will wear prematurely.

7.

Liberally apply bearing grease (ZOd, supplied) to the

gear cluster

(18).

Check

to

be sure the thrust balls

(20c

and 19j) are in place.

8.

Placethe bronze-colored washer (2Oa) and then the

silver-colored washer (20b) on the shaft protruding

from the big bearing of the drive housing

(20).

Align

the gears and push the new drive housing straight

onto the pinion housing and locating pins.

9. Starling at Step

6

and working backwards, continue

to

reassemble the sprayer. Or, move ahead to the

next section in this manual

if

further service is

needed.

Page 21

REPAIR

Pinion, Clutch, Clamp, Field and Engine

Disassembly of these parts can start from the pinion

housing, or from the clutch

if

no pinion service

is

needed.

If

starting from the pinion housing,

first follow Steps

1

to 6 of

Drive Housing.on

page 20, then continue below.

If starting from the clutch,

see page 24.

Pinion Housing Removal

WARNING

To

reduce the risk of serious bodily injury, including

fluid injection, splashing fluid in the eyes or

on

the

skin, or injury from moving parts. always follow the

Pressure Relief Procedure Warning on

page

13

before repairing any part of the sprayer. Disconnect

the spark plug cable.

NOTE:

Refer to Fig 21-1 for Steps 1 to

3,

except where

1. Remove the

two

bottom screws (IO) and lock-

washers

(1

1) first, and then remove the three screws

(IO)

and lockwashers (1

1)

holding the pinion hous-

ing (19n) to the clutch housing (2).

2.

Pull the pinion housing away from the clutch hous-

ing. The armature (4a) will come with it.

3.

Pull the armature (4a)

off

the hub (19f - see Fig

23-1) of the pinion housing.

noted.

Do not lose the thrust ball (19j). Refer to the

CAUTION

on

page 20 for more information.

NOTE:

To

disassemble the pinion,

go

to page 22.

To

disassemble more

of

the sprayer, go

to

page

24.

To

reassemble the sprayer from this point, skip

ahead to

Reassembly,

page 29, Step

7.

19j

Fig

21-1

307-893

21

Page 22

REPAIR

Repairing

the

Pinion

WARNING

If

you

havepurchasedpartsseparately,

use the following

To reduce the risk of serious bodily injury, including

instructions, disassembling only

as

far

as

needed for the

fluid injection, splashing fluid in the eyes oron the

parts being replaced.

skin, or injury from moving parts, always follow the

Pressure

Relief

Procedure Warning

on page 13

NOTE:

The old large bearing (19d) will be damaged

before repairing any part of the sprayer. Disconnect

when removed. Have an extra one on hand

if

you

the spark plug cable.

need to remove it for any reason.

1.

If

replacing the small bearing (I~c), press the old one

out of the pinion housing (19n).

NOTE:

Refer to Fig 23-1 unless otherwise instructed. 2. Remove the small ring (19e) from the hub and the

NOTE:

A hydraulic press is required for disassembly

large ring (19k) from the bearing recess.

and reassembly

if

you

purchase the

pinion

parts

3.

Push on the front

of

the shaft

(1

9b) to force the bear-

individually. If you do not have such a press, use ing and hub assembly out of the housing.

bearings pre-assembled and lubricated.

RePairKit221-043, which includestheshaft and 4.

using a hydraulic press,

place pieces of Steel bar

lfyouareusing the RepairKit,

221-043,

follow Steps 1 to

4,

below.

-

stock on the inner race of the large bearing (19d) and

press the shaft through the hub and bearing. See Fig

23-2.

1.

2.

3.

4.

6.

7.

Remove the small ring (19e) from the hub and the

large ring (19k) from the bearing recess.

ing and hub assembly out of the housing.

Push on the front of the shaft

(1

9b) to force the bear-

Press the mail bearing (19c) out of the pinion hous-

ing

(1

9n). Remove the new bearing from the shaft of

the kit and press it into the housing. See

DETAIL

A in

Fig

23-1.

shoulder of the housing (19n).

Install the shaft assembly (19a), pushing

it

to the

Install the rings (19e and 19k).

Skip ahead to

Reassembly,

page 29, Step

7,

or con-

tinue at the next section.

5.

Apply lubricant to the parts as shown in Fig 23-1.

6.

Press fit the following parts:

0

Small bearing (19c) into rear of housing

(19n). See DETAIL

A

in Fig 23-1.

Large bearing (19d) to shoulder of shaft (19b).

Hub (19f) onto the shaft (19b) all the way

to the large bearing (19d).

7.

Install the shaft assembly (19a), pushing it to the

shoulder

of

the housing (19n).

8.

Install the rings (19e and 19k).

9. Skip ahead to

Reassembly,

page29, Step

7,

orcontinue at the next section.

22

307-893

Page 23

REPAIR

ROUND STEE

BAR TO PUSH

19n

DETAIL

A

I

CUTAWAY VIEW OF PINION HOUSING

SHOWING PLACEMENT OF SMALL

BEARING (19c)

PRESS FIT

SMALL

BEARING

(19c) HERE

PRESS PLATFORM

PLACEMENT OF STEEL BLOCKS AND

BAR STOCK WHEN PRESSING OFF

LARGE BEARING

194

I

I

19e

Lubricate inner and

outer diameters

Lubricate teeth

Lubricate Inner

and outer diameters

Lubricate exterior

307-893

23

Page 24

REPAIR

Clutch

Assembly

NOTE:

The clutch assembly (4) includes the armature

5.

The armature (4a) was removed when pulling

off

the

(4a) and rotor (4b). The armature and rotor must

be replaced together

so

that they wear evenly.

pinion housing. Remove the armature from the pinion shaft.

from the clutch housing, follow Steps

1

to 4. Oth-

ewise, start at Step

5.

NOTE:

If

the pinion assembly (19) is not yet separated

6.

There are

two

ways to remove the rotor (4b).

a. Remove the four socket head capscrews

(16)

and lockwashers (11). Install

two

of the

1.

2.

3.

4.

Follow the

Pressure Relief Procedure Warning

on

page 13.

pump.

Disconnect the hose (59) from the displacement

Removing the bottom

two

screws first, remove the

five screws

(10)

and lockwashers

(1

1)

from the front

of

the clutch housing (2).

Tap lightly on the back

of

the bearing housing (21)

with a plastic mallet

to

loosen the assembly

(D)

from

the clutch housing.

Pull

the assembly away.

7.

Alternately tighten the screws until the rotor

screws' in the threaded holes in the rotor.

comes

off.

See Fig 24-1.

b.

You

can use a standard steering wheel puller.

However, you need

to

provide

two

screws

(B),

size

1/4-28

x

3

or 4 in. long. Install the

four

screws and lockwashers

(6)

of

the tool

the

capscrew

(C)

of the

tool

until the rotor

(A)

in the threaded

holes

of

the

rotor. Tighten

comes

off.

See the detail in Fig 24-1.

Skip ahead

to

Reassembly,

page 29, Step

6,

or con-

tinue on the next page.

Page 25

REPAIR

Engine

NOTE:

The engine must be removed before the

Field, Clamp or Clutch Housing can be re-

A

moved.

1.

Working under the mounting plate (A)

of

the cart,

remove the screw

(15),

lockwasher

(80)

and

washer

(34)

holding the clutch housing

(2)

to the

cart. See Fig

25-1.

TO

ENGINE

2.

Stillworking underthe mounting plate, remove the

two

nuts

(61)

and lockwashers

(9),

and then pull

the screws

(14)

out of the base of the engine. Dis-

connectthe red wire from the engine lead

(B).

Dis-

connect the black and white wires from the field.

Pull

the wires carefully through the grommets

(66)

before removing the engine. See Fig

25-1

and

25-2.

3.

Lift the engine carefully and place it on a work

bench.

4.

Remove the

Field and Wiring Harness, Clamp

and

Clutch Housing.

See pages

26

and

27.

5.

Skip ahead to

Reassembly,

page

28,

Step

1.

NOTE:

All service to the engine must be performed

by an authorized HONDA dealer.

VIEW

FROM

UNDER ENGINE MOUNTING PLATE

Fig

25-2

A

Fig

25-1

307-893

25

~~

~~

Page 26

REPAIR

Field and Wiring Harness

NOTE:

Refer to Fig

26-1.

1.

Remove the engine from the cart. See page

29.

2.

Loosen the four setscrews

(1

2)

holding the field

(6)

to

the clutch housing

(2)

and pull out the field.

3.

Pull the plastic caps

(6)

off

the wire screws

(33)

in

both places on the field. Loosen the screws and release the wires.

4.

Skip ahead to

Reassembly,

page

28,

Step

4.

Fig

26-1

26

307-893

Page 27

REPAIR

Clamp

Clutch

Housing

NOTE:

Removing the clamp requires a standard steer-

NOTE:

Refer

to

Fig

27-2.

vide

two

screws

(B),

size 1/4-28 x 3 or 4

inches

ing wheeipuller.

However,

you

will

need

to

pro-

long.

NOTE:

Refer

to

Fig 27-1,

2.

1.

2.

3.

Loosen the

two

screws (16) on the clamp (7), work- 3.

ing through the

slot

at the bottom

of

the clutch hous-

4,

ing (2)..

Install

two

screws

(B)

of the

tool

(A)

in

two

of the

5.

threaded holes in the clamp. Tighten the screw

(C)

until the clamp comes

off.

Skip ahead

to

Reassembly, page 28, Step 3, or con-

tinue

to

the right.

Remove the four capscrews (8) and lockwashers

(9)

holding the clutch housing

(2)

to the engine.

washer (34) from below the mounting plate

(D).

Remove the capscrew (15), lockwasher (80) and

Remove the engine key

(1

3).

Pull

off

the clutch housing (2).

Skip ahead

to

Reassembly, page 28, Step 1, or con-

tinue on the next page.

Fig

27-1

Fig

27-2

307-893

27

Page 28

REASSEMBLY

1.

2.

3.

4.

Install the

clutch housing

(2),

capscrews

(8)

and

lockwashers (9) on the engine. See Fig 2&1.

Install the engine shaft

key

(13).

See Fig 28-1,

sure you

maintain the 1.41 in.

+/-

0.01

(35.8

mm) di-

Slide the

clamp

(3)

onto

the

engine

shaft,

making

mension shown in Fig 28-2.

To

check the dimension, place a rigid, straight steel

bar

(B)

across the face of the clutch housing (2).

Us-

ing an accurate measuring device, check the distance between the bar and the face of the clamp. Ad-

just the clamp as necessary, and then torque the two

screws to 115-125 in-lb.(l3-15 Nm).

Connect the wires

(29).

to the screws (33) in both

snapoverthescrews. Guide the wires ofthe harness

places on the field.

Pull

the plastic caps

(C)

up and

field

(6)

in the clutch housing

(2).

Make sure the

(96) through the slot in the clutch housing. Slide the

setscrew holes in the field and the clutch housing (2)

align, and then tighten the setscrews (12) oppositely

and evenly, torquing to 25-30 in-lb (2.9 to 3.4

Nm).

See Fig 28-1.

CONNECT WIRING HARNESS

(29)

HERE BEFORE SLIDING FIELD

(6)

INTO HOUSING

(2)

Fig

28-1

SIDE CUTAWAY VIEW OF

Fig

28-2

CLUTCH HOUSING

28

307-893

Page 29

REASSEMBLY

5.

Place the'engine

(1)

assembly on the cart, aligning

the mounting holes, and carefully guiding the engine

through theappropriategrommets (66) in the mount-

wire

(D)

and wiring harness (29) from the field,

ing plate

(E).

Secure the engine with the capscrews

clutch housing

(2)

with the capscrews (15), lock-

(14), lockwashers (9) and nuts (61). Secure the

washer

(80)

and washer (34). Under the mounting

plate, connect the engine wire

to

the red wire and

connect the black and white wires. See Fig 29-1.

6. Making sure the face of the rotor (4b) and the field is

free of all oil and contaminants, install the rotor,

lockwashers (11) and capscrews (16). Torque the

capscrews to 6.5 to

7.5

ft-lb

(8.8

to 10 Nm). See

Fig 29-1.

After installing the rotor (4b), pull the engine recoil

rope to assure that the engine turns over and there is

no friction between the rotor (4b) and the field (6).

If

there is friction, recheck the clamp dimension. See

Step 3

on

page

29.

7.

Making sure the face of the armature (4a) is clean,

assemble the armature to the shaft in the pinion

housing (1 9n) until the armature contacts the ring

(19k). See Fig 29-1.

8.

Assemble the pinion

(19)

to the clutch housing using

capscrews (10) and lockwashers (1 1). See Fig 29-1.

It

VIEW

FROM

UNDERSIDE

OF

ENGINE

MOUNTING PLATE

Fig

29-1

.-

307-893 29

Page 30

Page 31

PARTS

LIST

Model

231478,

Series

A

GM3500 Sprayer with Upright

Cart

Includes

items

1

to

96

REF

NO.

PART

NO.

DESCRIPTION

QTY

NO. PART

NO.

DESCRIPTION

QTY

2

183-512

HOUSING, CLUTCH

1 ' 108479

ENGINE,

GASOLINE, 3.5 HP

1

40 183-194 SLEEVE

3 183-517

CLAMP, MOUNTING, ROTOR

1

42 101-242 RING, RETAINING

4 221-044

CLUTCH KIT

43 104-811 HUBCAP

REF

1

41 106062 WHEEL

2.

2

2

2

4a

INCLUDES ITEMS 4a

&

4b

.ARMATURE

1

44 154-636 WASHER, 5/8" SIZE; 16GA

1

45 179-777 BUTTON. SNAP

2

2

4b .ROTOR

1

46 108-068 PIN. SPRING. STRAIGHT. 3/16

2

~

"

~

~.

~

~-~

-

6 183-513

FIELD

7 108400

PIN, DOWEL: 5/16 X

1"

1

47 222-011

CLAMP,

GROUNDING;

25

FT

1

17.6

MI

WIRE 1

8 109-031 CAPSCREW,'1/4 SCH;

I

49 100-078 SCREW. HEX WASHER HD:

9

10

11

13

12

14

100-21 4

100-644

105-51

0

loa801

183-401

102-547

100-469

108-803

179-885

221442

5/16-24X

1

"

LOCKWASHER, 5/16

CAPSCREW, SCH; 1/4-20

LOCKWASHER. SPRING: 1/4"

UNC3A X .75

4

157-021

214-570

181-867'

222-198

178-034'

MACH;

NO.

6-32 X 0.38"

LOCKWASHER, INTERNAL

FLUID FILTER

SEE 307-273 FOR PARTS

LABEL,WARNING

PRESSURE DRAIN VALVE

TAG, WARNING

CAP

NIPPLE. HEX: 114 NPSM X

5 50

51

11

17

,4

52

53

1

54

SETSCREW, 1/4

KEY, PARALLEL; 3/16

SO

X 7/8"

CAPSCREW, HEX HD; 5/16-18

UNG2A X ,875"

CAPSCREW, HEX HD;

3/8-16 UNG2A X .75

56

2

57

22C-285

162453

15

114 NPT, 1-3/16" LONG

ELBOW, STR,

1/4-18

NPT (M X F)

HOSE, FLUID, GROUNDED, NYLON;

MM); SPRING GRDS BOTH ENDS

1/4"

ID CPLD 1/4 NPSM(F);

29

(715

NUT. HEX. 5/16-18

6

1

58

59

1

1

61

1

62

1

1~

63

1

1

64

100-840

21 8-083

16

17

SCREW, HEX SOC HD

LABEL, WARNING, HP

GEARREDUCER

PINION & PINION HOUSING

SEE PARTS LIST ON PAGE 33

DRIVE HOUSING

INCLUDES ITEMS 20a - 2Oc

.WASHER, BRONZE

.WASHER. SILVER

18

19

20

100-188

101-344

221-039

106075

109-099

183-392

107-209

183-519

102-556

183-037

108-662

107-21

0

106-115

179-959

1

83-51

8

100-016

206-994

100-1 33

164-672

183-035

177-762

CAPSCREW. HEX HD; 5/16-18

UNC-2A

X'.625

PRESSURE CONTROL SWITCH

SEE PARTS LIST ON PAGE 34

SCREW, MACH, OVHD, THD

FRMG; NO 6-24 X

1/2",TYPE

"C"

BUSHING, SNAP

BRACKET, MOUNTING

SCREW, MACH, FILH;

NO. E32 X

1"

LABEL,

ID,

GM3500, FRONT

RIVET.BLIND

HANGAR, PAIL

CAPSCREW, SCH; 3/6-16

NUT, RETAINER

UNQA X 1-1/2"

LOCKWASHER, SPRING; 3/8"

COVER, PRESSURE CONTROL

LABEL, ID, GM3500. SIDE

LOCKWASHER, SPRING, 114"

LOCKWASHER, SPRING; ,375

THROAT SEAL LIQUID,8

OZ.

ADAPTER, 1/4-18 NPSM X 318 NF

222-203

178-967

107-089

107-327

21 8-035

21

8-034

179-899

1

07-21 8

176-81

8

176-817

218-347

176-941

20a

20b

2oc

21

22

23

24

25

.GREASE,

10

02

TUBE

BEARING HOUSING

1

1

66

67

2

1

COVER, HOUSING

CAPSCREW. SCH:

1/4-20

X 2.75"

1

68

2

4

1

2

2

1

4

4

1

1

2

PIN

1

69

1

70

1

71

72

73

1

1

1

74

76

1

2

.

79

77

2

86

80

1 87

.

,,

.

SPRING, RETAINING

NUT. HEX

26

27

28

D~SPLACEMENT PUMP

SEE 307-793 FOR PARTS

SEE PAGE 35 FOR REPAIR KIT

CONDUCTOR, ELECTRICAL

TUBE, SUCTION,5 GAL.;3/4" PIPE

STRAINER

29

221-183

181472

180-573

108-868

109-033

108-851

30

31

32

33

34

CLAMP

SCREW, MACH, SLOTTED,

BDGH: 6-32 X 311

6

WASHER, PLAIN; TYPE."8";3/8"

CART

HANDLE

&

HOSE RACK

WASHER, PLAIN, 0.90"

'T

35

36

222-01

8

220-91

8

1

1

88

92

2

BRACKET'

LABEL, WARNING

37 183-350

38 108-691 PLUG, TUBING

39 109-032 SCREW, MACH, TYPE

11;

2

RECESS PNH; SELF-TAP

"F

NO. 10-24 X

1

/4

4 'Extra warning labels available free

of

charge.

Parts List & Drawing continued

on

the next page.

307-893

31

Page 32

PARTS LIST & DRAWING

REF

NO. PART

NO.

DESCRIPTION QTY

94 214-701

HOSE,

GROUNDED, NYLON;3/16"

ID;

CPLD 1/4 NPSMIFI: 3 FT

10.9

MI:

95 210-541

HOSE,

GROUNDED, NYLON; 1/4"

ID;

CPLD 1/4 NPSM(FBE);

50

FT

(15

M);

SPRING GUARDS BOTH

ENDS

1

GUARD AND 517 SIZE SWITCHTIP.

INCLUDES RAC

IV

DRIPLESS TIP

SEE 307-614

FOR

PARTS 1

SPRING

GUARDS'BOTH

ENDS"

1

96

220-9955