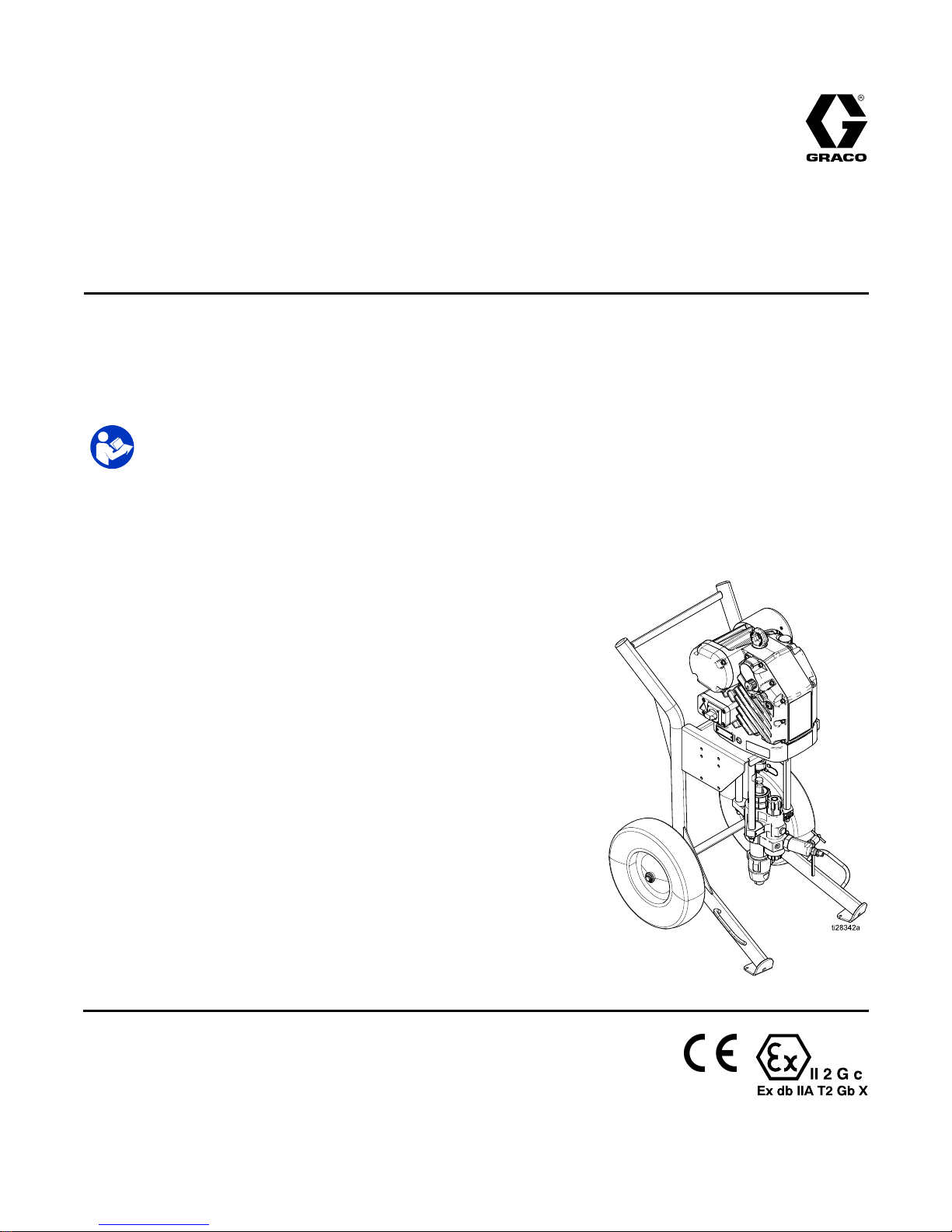

Graco e-Xtreme Operation, Repair, And Parts

Operation,Repair,andParts

e e

e

- --Xtreme® Xtreme®

Xtreme®

Sprayer Sprayer

Sprayer

3A3164D

EN

Electric Electric

Electric

high high

high

pressure pressure

pressure

sprayer sprayer

sprayer

packages packages

packages

for for

for

application application

application

of of

of

protective protective

protective

coatings. coatings.

coatings.

For For

For

professional professional

professional

use use

use

only. only.

only.

Important Important

Important

Safety Safety

Safety

Instructions Instructions

Instructions

Readallwarningsandinstructionsinthismanualandinthee-Xtreme

Drivermanuals.Save Save

Save

all all

all

instructions. instructions.

instructions.

See page 3 for model information. See

Technical Specications for maximum

working pressure.

II 2 G c

Ex db IIA T2 Gb X

PROVENQUALITY.LEADINGTECHNOLOGY.

Contents Contents

Contents

RelatedManuals................................................2

ModelInformation...............................................3

Warnings...........................................................4

ComponentIdentication.....................................7

Installation..........................................................8

PowerSupplyRequirements.........................8

ConnectthePowerSupply...........................8

Grounding...................................................8

InstallVentedOilCapBeforeUsing

Equipment......................................9

FlushBeforeUsingEquipment......................9

Setup.................................................................10

PressureReliefProcedure............................12

TriggerLock................................................12

Prime/Flush.................................................13

Spray.................................................................15

Shutdown...........................................................16

Maintenance......................................................16

PreventiveMaintenanceSchedule................16

ChangetheOil.............................................16

DailyMaintenance.......................................16

CheckOilLevel...........................................17

CorrosionProtection....................................17

Flushing......................................................17

CartMaintenance.........................................17

Troubleshooting..................................................18

ErrorCodeTroubleshooting..........................20

StandbyMode.............................................20

ErrorCodesTable........................................20

Repair................................................................22

XtremeLowerRemoval................................22

DisconnectandReconnectLower.................22

OutletCheckValves.....................................23

Parts..................................................................24

PartsDrawing..............................................24

OutletCheckValvesParts............................27

Dimensions........................................................29

TechnicalSpecications......................................32

GracoStandardWarranty....................................34

Related Related

Related

Manuals Manuals

Manuals

Part Part

Part

Description Description

Description

3A3165e-XtremeDriverInstallation

3A5124

e-XtremeDriverOperation,RepairandParts

311619PumpMountingKitManual

311762XtremeLowerManual

312145

XTRGunManual

2

3A3164D

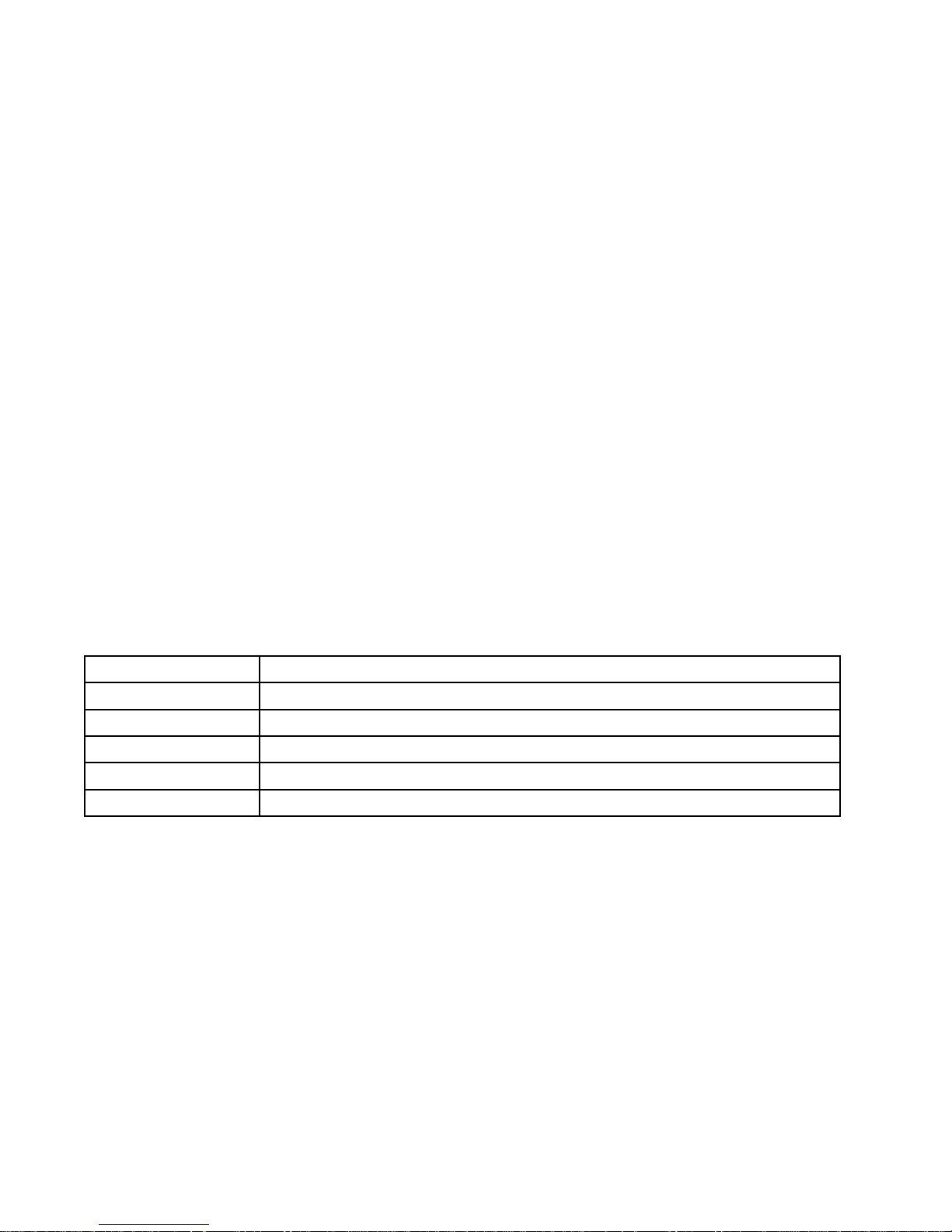

ModelInformation

Model Model

Model

Information Information

Information

Package Package

Package

Filter Filter

Filter

Model Model

Model

Description Description

Description

Complete* Complete*

Complete*

(Hose (Hose

(Hose

and and

and

Gun) Gun)

Gun)

MaximumFluid

Tempterature:

160°F(71°C)

Bare Bare

Bare

(No (No

(No

Hose Hose

Hose

or ororGun) Gun)

Gun)

MaximumFluid

Temperature:

180°F(82°C)

Integrated Integrated

Integrated

Filter Filter

Filter

No No

No

Filter Filter

Filter

Lower Lower

Lower

Pump Pump

Pump

24Y901*e-XtremeEx45,Cart*

✔✔

24Y902

e-XtremeEx45,Cart

✔✔

24Y903*e-XtremeEx45,Cart

✔✔

24Y904

e-XtremeEx45,Cart

✔✔

24Y905*e-XtremeEx45,Cart

withHopper

✔✔

24Y906

e-XtremeEx45,Cart

withHopper

✔✔

24Y907*e-XtremeEx45,Cart

withHopper

✔✔

24Y908

e-XtremeEx45,Cart

withHopper

✔✔

24Y909*

e-XtremeEx45,WallMount

✔✔

24Y910e-XtremeEx45,WallMount

✔✔

24Y911*

e-XtremeEx45,WallMount

✔✔

24Y912e-XtremeEx45,WallMount

✔✔

145cc

24Z901*e-XtremeEx35,Cart

✔✔

24Z902

e-XtremeEx35,Cart

✔✔

24Z903*e-XtremeEx35,Cart

✔✔

24Z904

e-XtremeEx35,Cart

✔✔

24Z905*e-XtremeEx35,Cart

withHopper

✔✔

24Z906

e-XtremeEx35,Cart

withHopper

✔✔

24Z907*e-XtremeEx35,Cart

withHopper

✔✔

24Z908

e-XtremeEx35,Cart

withHopper

✔✔

24Z909*

e-XtremeEx35,WallMount

✔✔

24Z910e-XtremeEx35,WallMount

✔✔

24Z911*

e-XtremeEx35,WallMount

✔✔

24Z912e-XtremeEx35,WallMount

✔✔

180cc

Formaximumworkingpressure,seeTechnicalSpecications,page32.

*LowerFluidtemperatureduetoXTR5gun.

NOTE: NOTE:

NOTE:

Seethee-XtremeDriverInstallationmanualfordriverapprovalsinformation.

3A3164D 3

Warnings

Warnings Warnings

Warnings

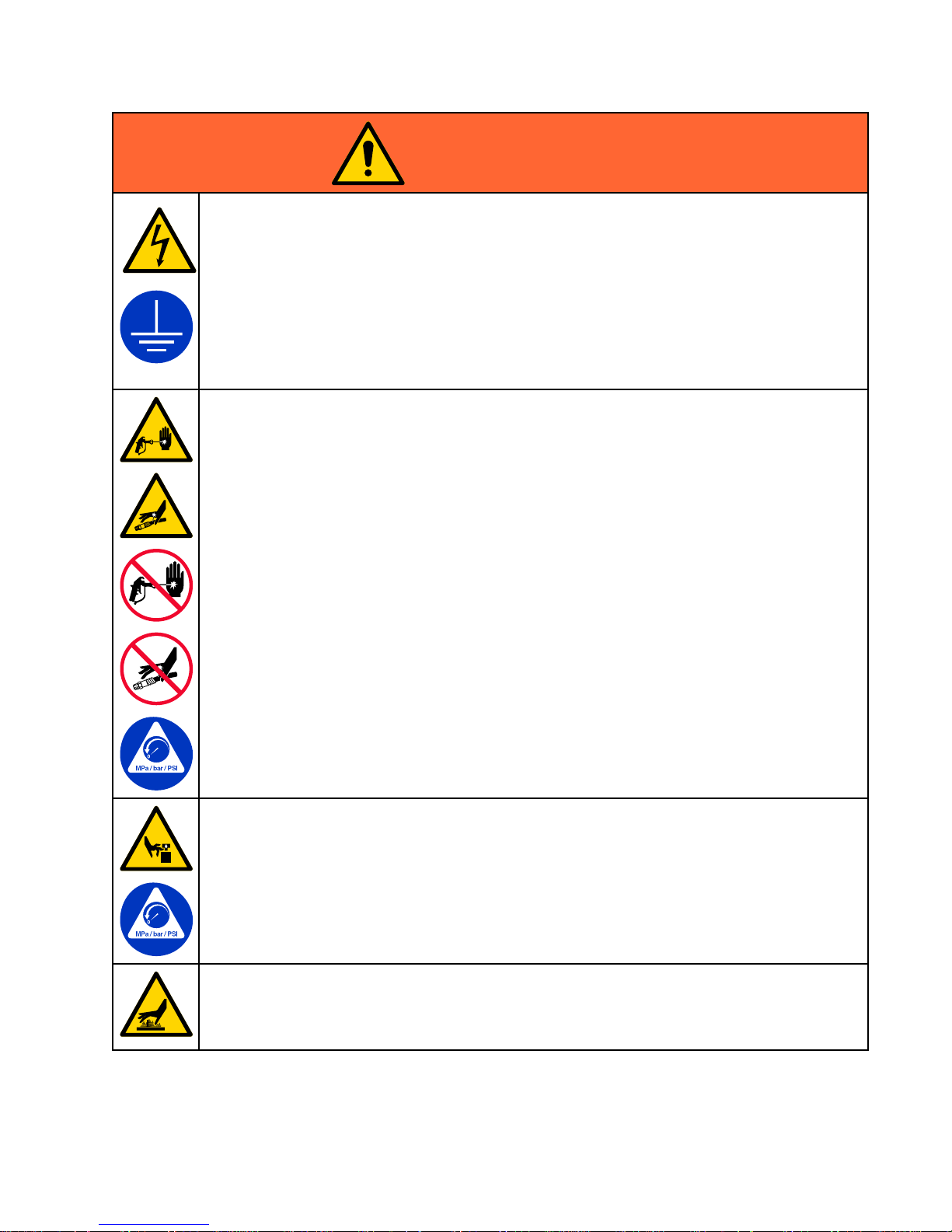

Thefollowingwarningsareforthesetup,use,grounding,maintenance,andrepairofthisequipment.The

exclamationpointsymbolalertsyoutoageneralwarningandthehazardsymbolsrefertoprocedure-specic

risks.Whenthesesymbolsappearinthebodyofthismanualoronwarninglabels,referbacktothese

Warnings.Product-specichazardsymbolsandwarningsnotcoveredinthissectionmayappearthroughout

thebodyofthismanualwhereapplicable.

WARNING WARNING

WARNING

FIRE FIRE

FIRE

AND AND

AND

EXPLOSION EXPLOSION

EXPLOSION

HAZARD HAZARD

HAZARD

Flammablefumes,suchassolventandpaintfumes,inwork work

work

area area

area

canigniteorexplode.Paint

orsolventowingthroughtheequipmentcancausestaticsparking.Tohelppreventreand

explosion:

•Useequipmentonlyinwellventilatedarea.

•Eliminateallignitionsources;suchaspilotlights,cigarettes,portableelectriclamps,and

plasticdropcloths(potentialstaticsparking).

•Groundallequipmentintheworkarea.SeeGrounding Grounding

Grounding

instructions.

•Neversprayorushsolventathighpressure.

•Keepworkareafreeofdebris,includingsolvent,ragsandgasoline.

•Donotplugorunplugpowercords,orturnpowerorlightswitchesonoroffwhenammable

fumesarepresent.

•Useonlygroundedhoses.

•Holdgunrmlytosideofgroundedpailwhentriggeringintopail.Donotusepaillinersunless

theyareantistaticorconductive.

•Stop Stop

Stop

operation operation

operation

immediately immediately

immediately

ifstaticsparkingoccursoryoufeelashock. ..Donotuse

equipmentuntilyouidentifyandcorrecttheproblem.

•Keepaworkingreextinguisherintheworkarea.

Staticchargemaybuilduponplasticpartsduringcleaningandcoulddischargeandignite

ammablevapors.Tohelppreventreandexplosion.

•Cleanplasticpartsonlyinwellventilatedareas.

•Donotcleanwithadrycloth.

•Donotoperateelectrostaticgunsinequipmentworkarea.

SPECIAL SPECIAL

SPECIAL

CONDITIONS CONDITIONS

CONDITIONS

FOR FOR

FOR

SAFE SAFE

SAFE

USE USE

USE

•Topreventtheriskofelectrostaticsparking,theequipment’snon-metallicpartsshouldbe

cleanedonlywithadampcloth.

•Thealuminumhousingmaysparkuponimpactorcontactwithmovingparts,whichmay

causereorexplosion.Takeprecautionstoavoidsuchimpactorcontact.

•Allameproofjointsarecriticaltotheintegrityofthedriverasapprovedforhazardous

locationsandarenotrepairableifdamaged.Damagedpartsmustbereplacedonlywith

genuineGracopartswithnosubstitutions.

4

3A3164D

Warnings

WARNING WARNING

WARNING

ELECTRIC ELECTRIC

ELECTRIC

SHOCK SHOCK

SHOCK

HAZARD HAZARD

HAZARD

Thisequipmentmustbegrounded.Impropergrounding,setup,orusageofthesystemcan

causeelectricshock.

•Turnoffanddisconnectpoweratmainswitchbeforedisconnectinganycablesandbefore

servicingorinstallingequipment.

•Connectonlytogroundedpowersource.

•Allelectricalwiringmustbedonebyaqualiedelectricianandcomplywithalllocalcodes

andregulations.

•Donotexposetorain.Storeindoors.

•Waitveminutesbeforeservicingafterpowerisremoved.

SKIN SKIN

SKIN

INJECTION INJECTION

INJECTION

HAZARD HAZARD

HAZARD

High-pressureuidfromgun,hoseleaks,orrupturedcomponentswillpierceskin.Thismay

looklikejustacut,butitisaseriousinjurythatcanresultinamputation.Get Get

Get

immediate immediate

immediate

surgical surgical

surgical

treatment. treatment.

treatment.

•Donotspraywithouttipguardandtriggerguardinstalled.

•Engagetriggerlockwhennotspraying.

•Donotpointgunatanyoneoratanypartofthebody.

•Donotputyourhandoverthespraytip.

•Donotstopordeectleakswithyourhand,body,glove,orrag.

•FollowthePressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

whenyoustopsprayingandbeforecleaning,checking,

orservicingequipment.

•Tightenalluidconnectionsbeforeoperatingtheequipment.

•Checkhosesandcouplingsdaily.Replacewornordamagedpartsimmediately.

MOVING MOVING

MOVING

PARTS PARTS

PARTS

HAZARD HAZARD

HAZARD

Movingpartscanpinch,cutoramputatengersandotherbodyparts.

•Keepclearofmovingparts.

•Donotoperateequipmentwithprotectiveguardsorcoversremoved.

•Pressurizedequipmentcanstartwithoutwarning.Beforechecking,moving,orservicing

equipment,followthePressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

anddisconnectallpowersources.

BURN BURN

BURN

HAZARD HAZARD

HAZARD

Equipmentsurfacesanduidthatisheatedcanbecomeveryhotduringoperation.Toavoid

severeburns:

•Donottouchhotuidorequipment.

3A3164D 5

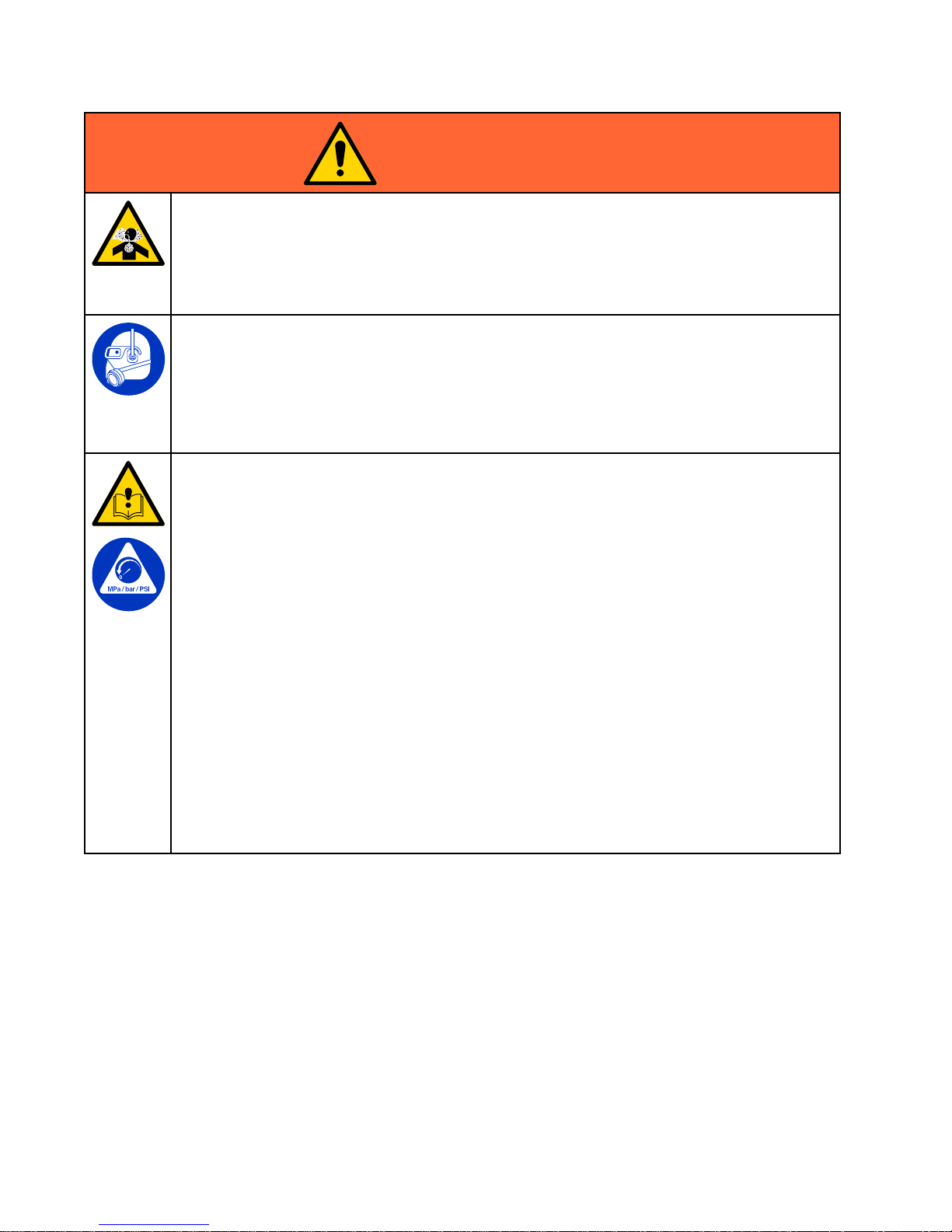

Warnings

WARNING WARNING

WARNING

TOXIC TOXIC

TOXIC

FLUID FLUID

FLUID

OR OR

OR

FUMES FUMES

FUMES

Toxicuidsorfumescancauseseriousinjuryordeathifsplashedintheeyesoronskin,

inhaled,orswallowed.

•ReadSafetyDataSheets(SDSs)toknowthespecichazardsoftheuidsyouareusing.

•Storehazardousuidinapprovedcontainers,anddisposeofitaccordingtoapplicable

guidelines.

PERSONAL PERSONAL

PERSONAL

PROTECTIVE PROTECTIVE

PROTECTIVE

EQUIPMENT EQUIPMENT

EQUIPMENT

Wearappropriateprotectiveequipmentwhenintheworkareatohelppreventseriousinjury,

includingeyeinjury,hearingloss,inhalationoftoxicfumes,andburns.Thisequipmentincludes

butisnotlimitedto:

•Protectiveeyewear,andhearingprotection.

•Respirators,protectiveclothing,andglovesasrecommendedbytheuidandsolvent

manufacturer.

EQUIPMENT EQUIPMENT

EQUIPMENT

MISUSE MISUSE

MISUSE

HAZARD HAZARD

HAZARD

Misusecancausedeathorseriousinjury.

•Donotoperatetheunitwhenfatiguedorundertheinuenceofdrugsoralcohol.

•Donotexceedthemaximumworkingpressureortemperatureratingofthelowestrated

systemcomponent.SeeTechnical Technical

Technical

Data Data

Data

inallequipmentmanuals.

•Useuidsandsolventsthatarecompatiblewithequipmentwettedparts.SeeTechnical Technical

Technical

Data Data

Data

inallequipmentmanuals.Readuidandsolventmanufacturer’swarnings.Forcomplete

informationaboutyourmaterial,requestSafetyDataSheets(SDSs)fromdistributoror

retailer.

•Donotleavetheworkareawhileequipmentisenergizedorunderpressure.

•TurnoffallequipmentandfollowthePressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

whenequipmentisnotinuse.

•Checkequipmentdaily.Repairorreplacewornordamagedpartsimmediatelywithgenuine

manufacturer’sreplacementpartsonly.

•Donotalterormodifyequipment.Alterationsormodicationsmayvoidagencyapprovals

andcreatesafetyhazards.

•Makesureallequipmentisratedandapprovedfortheenvironmentinwhichyouareusingit.

•Useequipmentonlyforitsintendedpurpose.Callyourdistributorforinformation.

•Routehosesandcablesawayfromtrafcareas,sharpedges,movingparts,andhotsurfaces.

•Donotkinkoroverbendhosesorusehosestopullequipment.

•Keepchildrenandanimalsawayfromworkarea.

•Complywithallapplicablesafetyregulations.

6 3A3164D

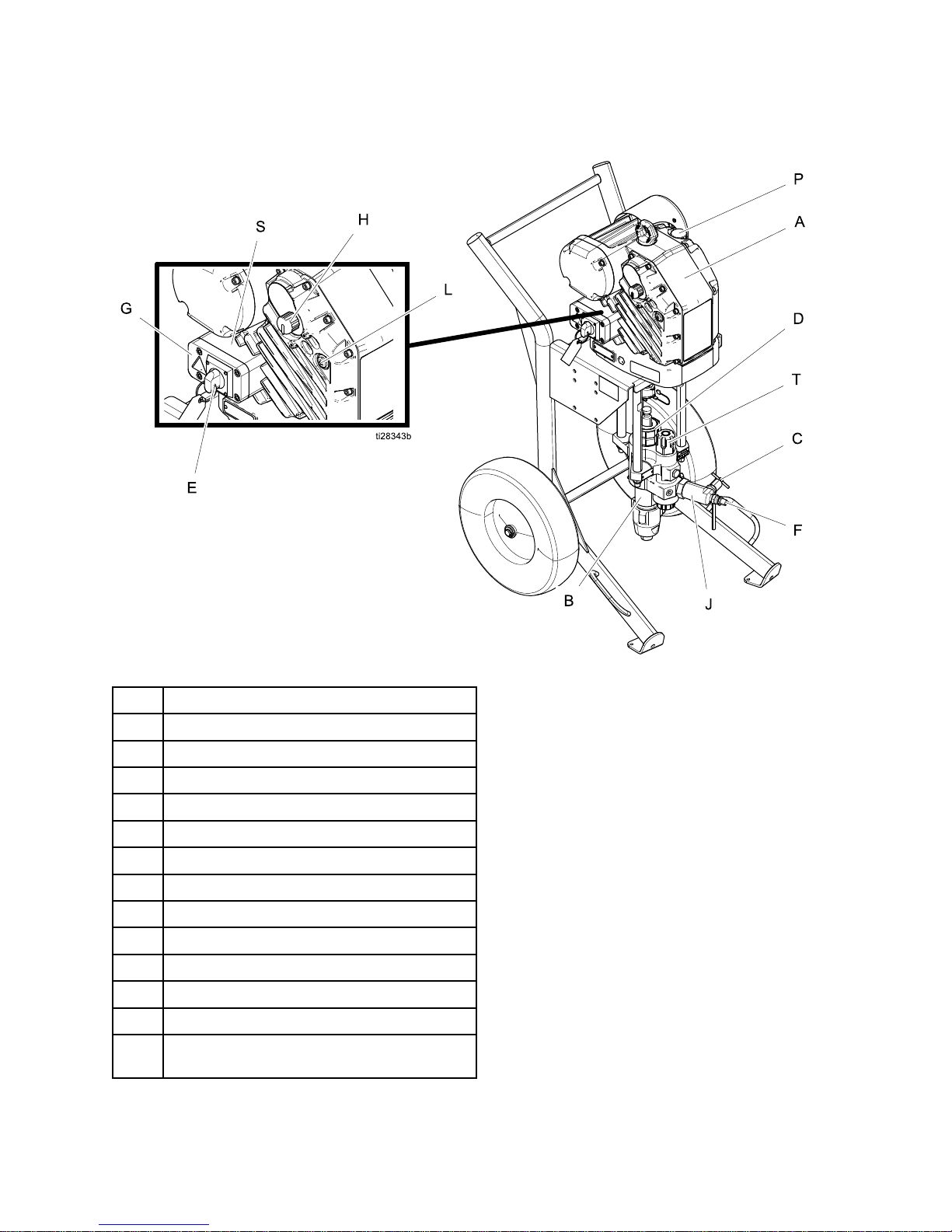

ComponentIdentication

Component Component

Component

Identication Identication

Identication

Ref. Ref.

Ref.

Description Description

Description

AElectricDriver

BPumpLower

C

FluidDrain/PurgeValve

DPackingNut

E

PowerSwitch

F

FluidOutlet

GJunctionBoxCover

HPressureAdjustmentKnob

J

OutletCheckValve

L

StatusIndicatorLight(LED)

P

OilFillCap(vented)

S

JunctionBox

T

FilterCap(modelsequippedwithintegrated

lteronly)

NOTE: NOTE:

NOTE:

Seethee-XtremeDriverOperation/Repair

manualforwarninglabelinformation.

3A3164D

7

Installation

Installation Installation

Installation

Toreducetheriskofelectricshock,reand

explosion,allelectricalwiringmustbedonebya

qualiedelectricianandcomplywithalllocalcodes

andregulations.

Power Power

Power

Supply Supply

Supply

Requirements Requirements

Requirements

SeeDriverInstallationmanualforinstructionsfor

powersupplyrequirements.

Connect Connect

Connect

the the

the

Power Power

Power

Supply Supply

Supply

SeeDriverInstallationmanualforinstructionsto

connectthepowersupply.

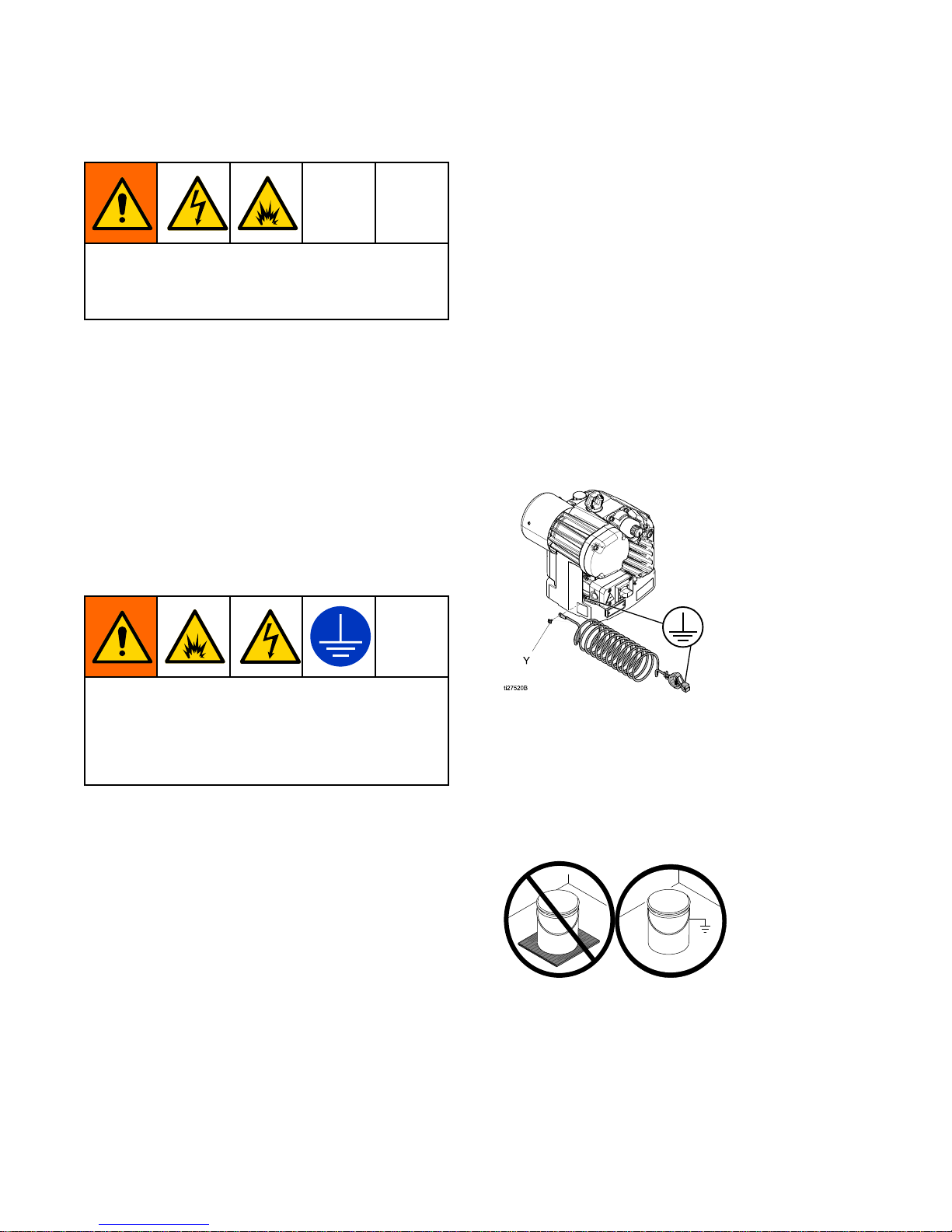

Grounding Grounding

Grounding

Thisequipmentmustbegroundedtoreducethe

riskofstaticsparkingandelectricshock.Electric

orstaticsparkingcancausefumestoigniteor

explode.Impropergroundingcancauseelectric

shock.Groundingprovidesanescapewireforthe

electriccurrent.

Sprayer: Sprayer:

Sprayer:

Systemisgroundedthroughthepower

cord.

Fluid Fluid

Fluid

hoses: hoses:

hoses:

Useonlyelectricallyconductivehoses

withamaximumof210ft.(64m)combinedhose

lengthtoensuregroundingcontinuity.Check

electricalresistanceofhoses.Iftotalresistance

togroundexceeds25megaohms,replacehose

immediately.

Spray Spray

Spray

gun: gun:

gun:

Groundthroughconnectiontoaproperly

groundeduidhoseandpump.

Fluid Fluid

Fluid

supply supply

supply

container: container:

container:

Followlocalcode.

Object Object

Object

being being

being

sprayed: sprayed:

sprayed:

Followlocalcode.

Solvent Solvent

Solvent

pails pails

pails

used used

used

when when

when

ushing: ushing:

ushing:

Followlocal

code.Useonlyconductivemetalpails,placedon

agroundedsurface.Donotplacethepailona

non-conductivesurface,suchaspaperorcardboard,

whichinterruptsgroundingcontinuity.

To To

To

maintain maintain

maintain

grounding grounding

grounding

continuity continuity

continuity

when when

when

ushing ushing

ushing

or or

or

relieving relieving

relieving

pressure: pressure:

pressure:

Holdthemetalpartofthespray

gun/dispensevalvermlytothesideofagrounded

metalpail,thentriggerthegun/valve.

Tools Tools

Tools

Required: Required:

Required:

•Groundingwiresandclampsforpails(Gracopart

244524–notsupplied)

•Two5gallon(19liter)metalpails(Gracopart

101108–notsupplied)

1.Connectthegroundwire(Y)toagroundstudon

thebackofthemotor.

2.Groundtheobjectbeingsprayed,uidsupply

container,andallotherequipmentinthe

workarea.Followyourlocalcode.Useonly

electricallyconductiveairanduidhoses.

3.Groundallsolventpails.Useonlymetalpails,

whichareconductive,placedonagrounded

surface.Donotplacepailonanon-conductive

surface,suchaspaperorcardboard,which

interruptsgroundingcontinuity.

8 3A3164D

Installation

Install Install

Install

Vented Vented

Vented

Oil Oil

Oil

Cap Cap

Cap

Before Before

Before

Using Using

Using

Equipment Equipment

Equipment

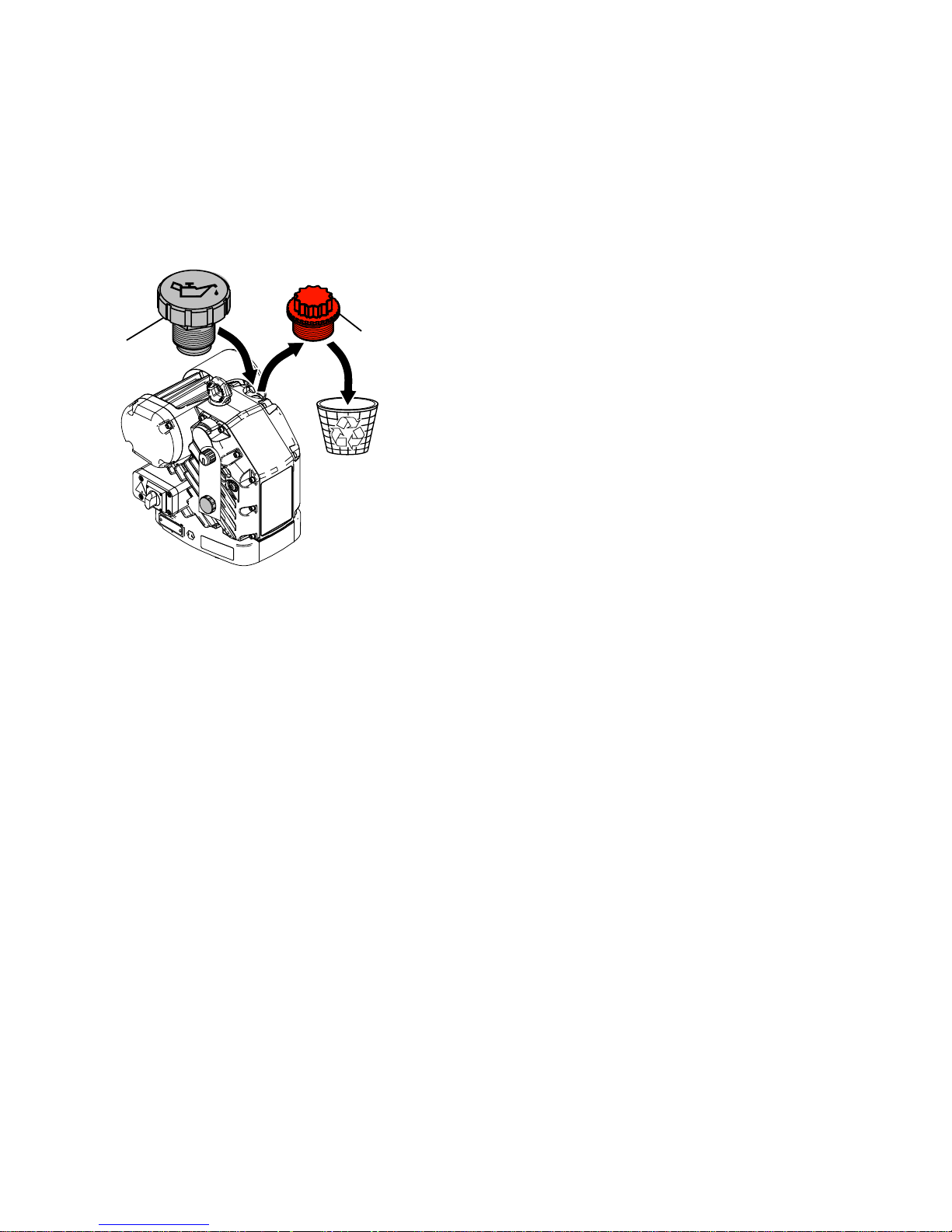

Thedrivergearboxisshippedfromthefactory

pre-lledwithoil.Thetemporaryunventedcap(PX)

preventsoilleaksduringshipment.Thistemporary

capmustbereplacedwiththesuppliedventedoil

cap(P)beforeuse.

PX

P

ti31010a

Flush Flush

Flush

Before Before

Before

Using Using

Using

Equipment Equipment

Equipment

Thepumpuidsectionwastestedwithlightweight

oil,whichisleftintheuidpassagestoprotectparts.

Toavoidcontaminatingyouruidwithoil,ushthe

equipmentwithacompatiblesolventbeforeusing

theequipment.

SeePrime/Flush,page13.

3A3164D 9

Setup

Setup Setup

Setup

Toavoidtipover,makesurecartisonaatand

levelsurface.Failuretodosocouldresultininjury.

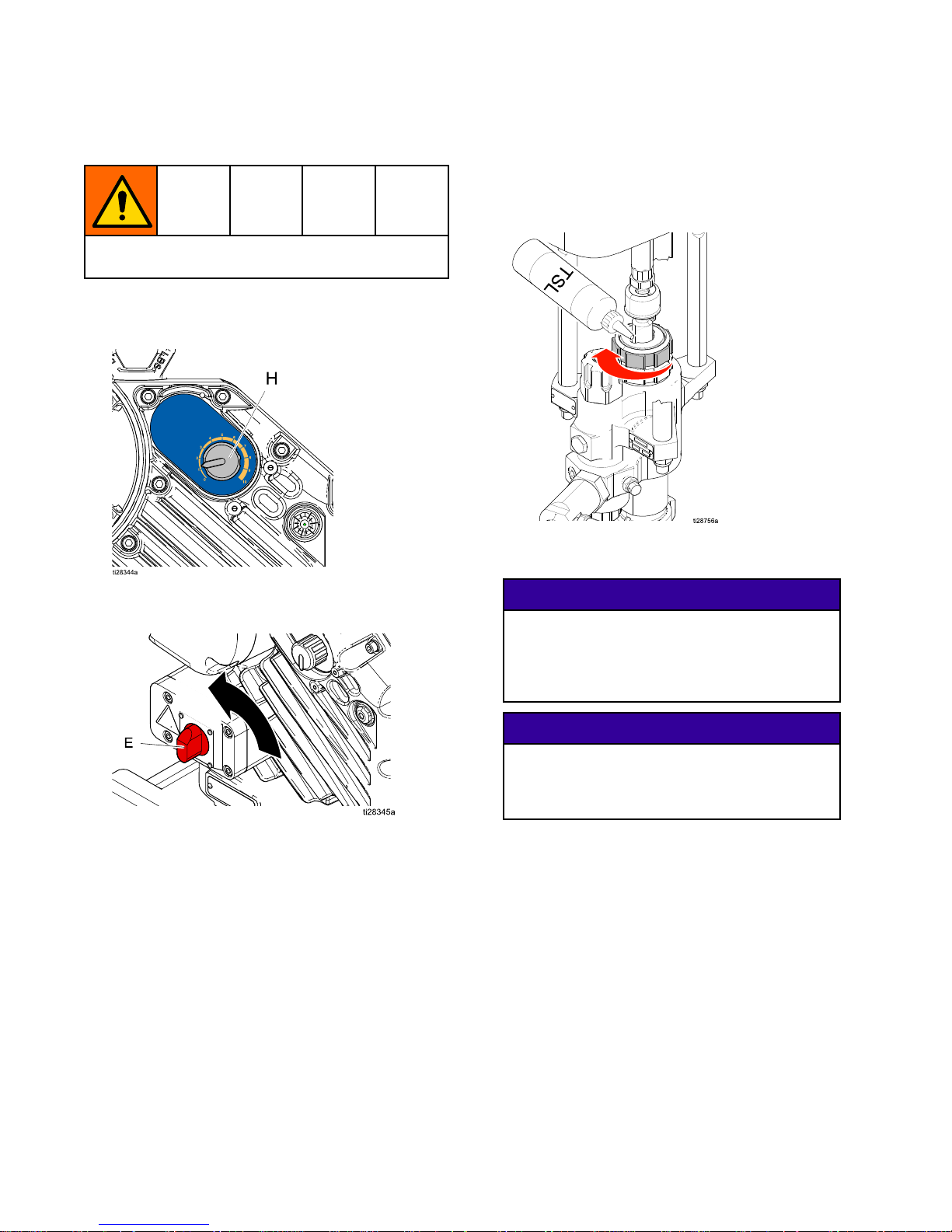

1.Pullpressureadjustmentknob(H)outandturn

counterclockwiseuntilitstops.Pushtheknob

intolock.

2.Turnpowerswitch(E)OFF.Connectunitto

powersource.

OFF

3.Checkpackingnut(D).SeeXtremelowerpump

manual311762forpackingnuttorque.Fillwith

ThroatSealLiquid(TSL

TM

).

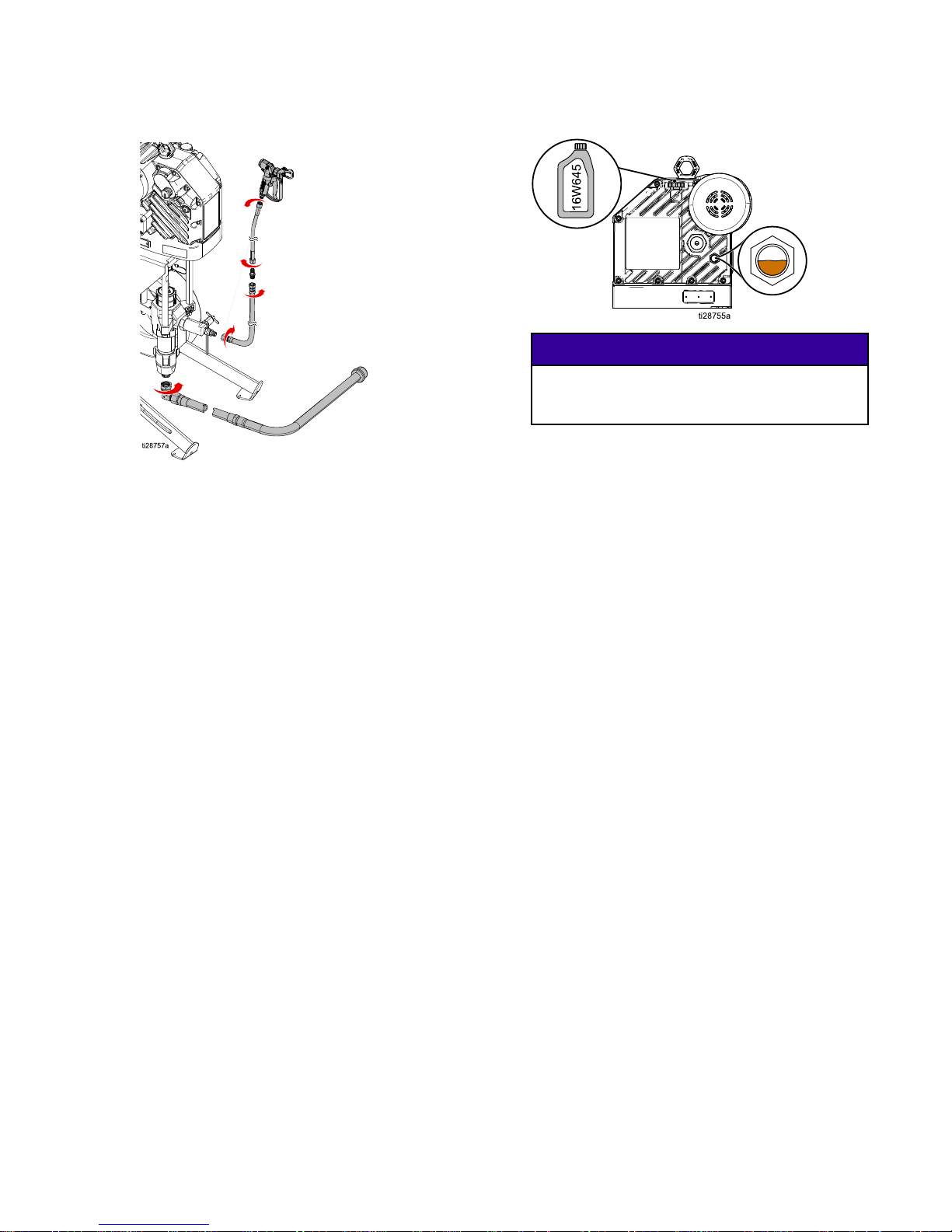

4.Attachelectricallyconductiveuidhosetopump

loweroutletviaoutletcheckvalveandtighten.

NOTICE NOTICE

NOTICE

Attachingthehosedirectlytothelowerpump

canresultindamagetothesprayerduring

cavitation,orwhenthesprayerrunsoutof

material.Useanoutletcheckvalvebetween

thelowerpumpandhosetoavoiddamage.

NOTICE NOTICE

NOTICE

Theminimumhosesizeallowableis3/8in.

IDx50ft(10mmx15m).Smallerhoses

cancausehighpressurespikesandresultin

damagetothesprayer.

5.Attachhosetogunandtighten.

10 3A3164D

Setup

6.Attachmaterialsupplyinlethosetopumplower.

NOTE: NOTE:

NOTE:

Maximumsuggestedlengthis6ft(1.8

m),minimumsuggestedinnerdiameteris1in.

(2.5cm).

7.Checkoillevel.

NOTICE NOTICE

NOTICE

OnlyuseoilwithGracopartnumber16W645.

Anyotheroilmaynotlubricateproperlyand

cancausedamagetothedrivetrain.

8.Alwaysushandprimesprayerbeforeeachuse

(seePrime/Flush,page13).

3A3164D

11

Loading...

Loading...