Page 1

INSTRUCTIONS-PART.S LIST

This

manual contains

WARNINGS

READ AND RETAIN

AND

IMPORTANT

INSTRUCTIONS

FOR

REFERENCE

ORACO

307-670

Rev

Supersedes

G

D

ELECTRIC,

ULTRA@

207

bar

Model.226-998, Series

Complete sprayer with hose, gun, RAC

DripLessTM Tip Guard and SwitchTipTM.

U.S.

PATENT NO. 4,323,741, 4,397,610

PATENTED 1983, CANADA

AND OTHER PATENTS PENDING

NOTE: See Index on page

230

VAC

MAXIMUM

WORKING PRESSURE

433

E

2

AIRLESS PAINT SPRAYER

lV@,

n

.

Hazard

Never use 1 ,1, 1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluidscontaining

such solvents in this equipment. Such

sion, which could cause death, serious bodily injury and/or substantial property damage.

Consult your fluid suppliers to ensure that the fluids being used are compatible with aluminum and zinc parts.

Refer to the Technical Data on page 43 for more information.

of

Using

Fluids

GRACO INC. P.O.

Containing Halogenated Hydrocarbons

use

could result in a serious chemical reaction, with the possibility of explo-

BOX

COPYRIGHT 1983, GRACO INC.

WARNING

1:Ml

MINNEAPOLIS, MN

55440-1444

Page 2

TABLE

OF

CONTENTS

Introduction 2

Warnings 4

Setup

Operation

Shutdown

Flushing Guidelines

Troubleshooting Guide

Motor Won't Operate

Low Output

No

Excessive Pressure Fluctuations

Motor

Electrical Short

SpinTest

BridgeTest

Repair

List of Tools

General Repair Notes

Power Supply Cord Replacement

Filter Replacement

ON/OFF Switch Replacement

Microswitch Replacement

...............................

.................................

....................................

.................................

&

Care

.........................

.......................

....................

............................

Output

.............................

...........

Is

Hot and Runs Intermittently

........

.........................

.............................

............................

...........................

...................

........

-

.

......................

.............

................

6

8

10

11

13

16

17

17

18

18

19

20

21

21

22

22

23

23

INTRODUCTION

ULTRA@

Your new Ultra@ 433 Sprayer functions and operates dif

ferently than other airless paint sprayers. This section will

help you become familiar with the sprayer before operat

ing it.

Pressure Control

The pressure control includes an

sprayer, the pressure adjusting control knob and a pres

sure sensing device. Its function is to control the motor

speed

sure at the pump outlet.

Motor

The DC motor has sealed bearings and replaceable

tor brushes. Its function is to drive the displacement

pump at the rate needed to supply sufficient paint volume

at the selected pressure. Working together, the pressure

control and motor cause the pump to cycle whenever

there is fluid or pressure demand. When the pump is cy

cling, the motor sounds like an automobile starter crank

ing. When the pump

intermittently until the fluid pressure stabilizes, then the

motor will shut itself

to the sprayer and it will stay pressurized and ready to

use

unless you manually shut it off and relieve pressure.

433

BASIC COMPONENTS

ONlOFF switch for the

so

that the sprayer maintains constant fluid pres

is

not cycling, the motor may hum

off.

However, there will stili be power

-

-

-

-

mo-

-

-

Bridge.Rectifier Replacement

Choke Replacement

Varistor Replacement

Circuit Board Replacement

Pressure Control Replacement

Pressure Control Calibration

Bearing Housing

Conn. Rod

Drive Housing

Motor Brush Replacement

Capacitor Replacement

Motor Replacement

Parts Lists and Drawings

Complete Sprayer

Pressure Control Assembly

NOTE:

Accessories 42

Technical Data 43

Dimen.sions.. 43

Warranty Back Cover

Fluid Filter

The fluid filter strains the paint to help avoid clogs in the

hose and spray tip. The filter includes a reusable element

and a pressure drain valve for relieving fluid pressure.

Hoses

The grounded, nylon spray hoses have spring guards on

both ends.

3/16 in.

nylon hose material acts as a pulsation dampener to ab

sorb pressure fluctuations.

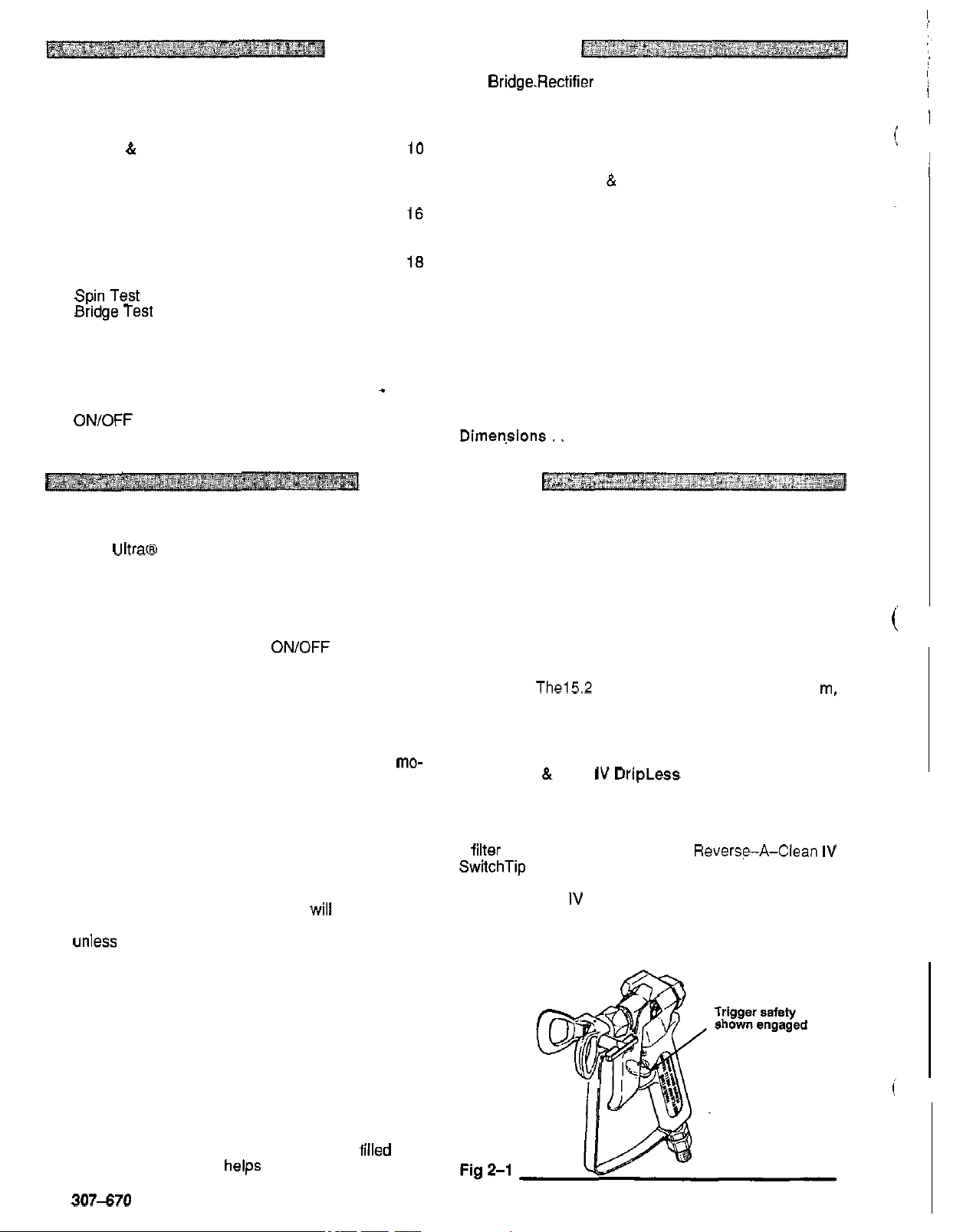

Spray Gun

Graco high pressure spray guns have a trigger safety

which prevents accidental triggering when it

See

a

SwitchTip uses high pressure fluid to remove clogs from

the spray tip without removing

verse

which helps reduce the risk of fluid injection injury.

See manual 307-793, supplied, for the displace

ment pump repair instructions and parts list.

.........................

The152 m hose has a 1/4 in.

ID

whip hose allows flexible gun movement. The

&

Fig Z-I.

filter for final paint straining. The ReverseA-Clean IV

-A-

Clean IV DripLess tip guard is a safety feature

Replacement 32

..............................

.............................

.............................

RAC

The gun provided with the sprayer also has

.....................

....................

&

Replacement, 30

...................... 35

.......................

IV

DripLess Tip Guard

..............

................

.............

...............

24

25

25

26

27

28

..............

...............

.................

...................

................

ID.

The

is

engaged.

it

from the gun. The Re

0.9

33

34

38

40

m,

-

-

-

Because the motor is DC, it

age or voltage fluctuations than an AC motor, and an ex

tension cord of up to 45 m can be used.

Drive Assembly

The sealed drive assembly transfers power from the DC

motor to the displacement pump.

Displacement Pump

The positive displacement, volume

vides equal fluid delivery on both the up and down pump

strokes. The pump has a wet

Graco Throat Seal Liquid,

throat packings and piston rod.

2

307-670

is

less sensitive to low volt

-

balanced pump pro-

-

cup which, when filled with

helps prevent damage to the

-

-

Page 3

Fig

3-1

\

CONTRACTOR GUN

WlTH

RAC

517 SIZE

'

IV

DRIPLESS

SWITCHTIP

WHIP

END HOSE

TIP

GUARD

AND

307470 3

Page 4

HIGH

FOR

Read and understand

PRESSURE SPRAY CAN CAUSE SERIOUS INJURY.

PROFESSIONAL USE ONLY. OBSERVE ALL WARNINGS

all

instruction manuals before operating equipment.

FLUID INJECTION HAZARD

General

This equipment generates very high fluid pressure. Spray from

the gun, leaks or ruptured components can inject fluid through gun safety latch in the closed or"safe"position, making the gun

yourskin and into your body and causeextremelyserious bodily inoperative. Failure

injury, including the need for amputation. Also, fluid injected or tal triggering of the gun.

splashed into the eyes or on the skin can cause serious dam

age.

NEVER pointthespray gunat anyoneorat any partofthe body,

NEVER put hand or fingers Over the spray tip. NEVER

"

blow back" paint; this is NOT an air spray system.

ALWAYS have the tip guard in place

spraying. the gun.

ALWAYSfollow the Pressure Relief Procedure,

cleaning or removing the spray tip or servicing any system

NEVER

Be sure equipment safety devices are operating properly before

each use.

Medical

. . . - -. - -.

If

any fluid appears

MEDICAL

CUT.

Note to Physician: Injection in the skin is a traumatic inju

important to treat the injury surgically as

not

with some exotic coatinos iniected directlv into the blood

stream. Consultation with

hand surgeon may be advisable.

Spray

Be sure all gun safety devices are operating properly before

each use. Do

cause a malfunction and result in serious bodily injury.

Safety

on

the spray gun when gunfirmlytothepail.

below;

try

to'stop or deflect leaks with your hand or body.

Alert-Airless Sarav Wounds

. .

.

-. . . . . . .

CARE

Tell the doctor exactly what fluid was injected.

delay treatment to research toxicity. Toxicity

Gun

Safety Devices

not

.

- -

to

AT ONCE.

remove or modify any part of the gun; this can

-,-~-,

penetrate your skin. get

DO

-

a plistic surgeon br reconstructive

NOT

~ ~~~~~~

TREAT

soon

EMERGENCY

AS

as possibr. Do

is

try

before

A

SIMPLE

It is

a concern

to

Safety

Wheneveryoustopspraying,evenforamoment,

-

Latch

to

set the safety latch can result in acciden

Diffuser

The gun diffuser breaks up spray and reduces the risk of fluid

injection when the tip is not installed. Check diffuser operation

regularly. Follow the Pressure Relief Procedure, below, then

remove the spray tip. Aim the gun into a metal pail, holding the

If

the fluid emitted is not diffused into an irregular

stream*

Tio

ALWAYS have the tip guard in place

spraying. The tip guard alerts you

and helps reduce, but does not prevent, the risk of accidentally

placing your fingers or any part of your body close

tip.

Trigger

Always have the trigger guard in place

ing

dropped or bumped.

Spray

Use extreme caution when cleaning or changing spray tips.

the spray tip clogs while spraying. engage the gun safety latch

immediately. ALWAYS foilow the Pressure Relief Procedure

and then remove the spray tip to clean

NEVER wipe

fully relieved and the gun safety latch is engaged.

replace

Guard

.~

~ ~

Guard

to

reduce the risk of accidentally triggering the gun

Tip Safety

Usingthelowestpossiblepressure,trigger

the

diffuser

off

buiid-up around the spray tip until pressure is

immediately'

to

the fluid injection hazard

on

the spray gun while

on

the gun when spray

it.

alwayssetthe

to

the spray

if

it

is

-

-

If

i

,

Pressure Relief

To reduce the risk of serious bodily injury, including fluid in

jection,splashingfluidorsolventintheeyesorontheskin,or

injury from moving Darts or electric shock, always follow this

procedure whenever

ingorservicinganypartofthespraysystem,wheninstalling,

cleaning

I

spraying.

1.

2.

4

307-670

or

Engage the gun safety latch.

Turn the ON/OFF switch

I

Procedure

YOU

shut

Off

the sprayer, when check-

changing spray tips, and whenever you stop

to

OFF,

9

3.

-

~

Disengage the gun safety latch. Hold a metal art of the

'

. gun firmly to the side of a grounded metal pair and trig-

ger the gun

4.

Enoage the aun safetv latch.

5.

OGnihepre&uredra-invalve,

to catch the drainage. Leave the valve

ready

If

you

suspect that the spray tip or hose

clogged,orthatpressurehasnotbeenful~relievedafterfol-

lowinqthestepsabove,VERYSLOWLYloosenthetiDauard

retai6n nut'or hose end coupling and relieve pi&sure

gradual

9

y,

to

relieve pressure.

having acontainerready

open

to

spray again.

then loosen completely. Now clear the tip or hose.

until you are

is

completely

I

I

I

Page 5

MOVING PARTS HAZARD

Moving parts can pinch or amputate your fingers or other body

pans. KEEP CLEAR of moving parts when starting or operating

the sprayer. Follow the Pressure Relief Procedure on page

beforechecking or servicing any part ofthe sprayer,

from starting accidentally.

to

prevent it

4

EQUIPMENT MISUSE HAZARD

General

Anv misuse of

ovirpressurizing, modi$ing'parts. using incompatible chemi

cals and fluids, or using worn or damaged parts, can cause

them

oron the skin, or other serious bodily injury, or fire, explosion or

property damage.

NEVER alter or modify any part of this equipment; doing

could cause it

CHECK all spray equipment regularly and repair or replace

worn or damaged parts immediately.

Always wear protective

tor as recommended by the fluid and solvent manufacturer.

S

Tlis sDraver can develoo

PRESSURE. Be sure that

used are rated

maximum working pressure of anv component or accessory

used in the system.

Fluid

BE

patible with the wetted parts shown in

on page

literature before using them in this sprayer.

Safet

t

1

e spray eauipment or accessories, such as

to

rupture and result in fluid injection, splashing in the eyes

to

malfunction.

-.

eyewear, gloves, clothing and respira

stem

Pressure

to

withstand this pressure.

and

SURE

Solvent Compatibility

that all fluids and solvents used are chemically com-

43.

Always read the fluid and solvent manufacturer's

207

all

bar MAXIMUM WORKING

spray equipment and accessories

DO

NOT exceed the

theTECHNlCAL DATA

so

HOSE SAFETY

High pressure fluid

hose develops a leak, split or rupture due

damage or misuse, the high pressure spray emitted from it can

cause a fluid injection injury or other serious bodily injury or

property damage.

ALL FLUID HOSES MUST HAVE SPRING GUARDS ON

BOTH

ENDS! The spring guards help protect the hose from

kinks or bends at or close

hose rupture.

TIGHTEN all

pressure fluid can dislodge a

sure spray

NEVER use a damaged hose. Before each use, check the en

tire hose for cuts, leaks, abrasion. bulging cover, or damage or

movement

ist, replace the hose immediately.

pressure hose or mend it with tape or any other device.

paired hose cannot contain the high pressure fluid.

HANDLE AND ROUTE HOSES CAREFULLY.

hoses

and hot surfaces of the pump and gas engine.

-

or solvents which are

coverofthe hose.

above

Hose

Proper hose grounding continuity is essential

groundedspriy system. Checkthe electrical resistanceof your

fluid hoses at least once a week.

tag on it which specifies the maximum electrical resistance,

conlact the hose supplier or manufacturer for the maximum re

sistance limits. Use a resistance meter in the appropriate range

for your hose

the recommended limits, replace it immediately. An un

grounded or poorly grounded hose can make your system haz

ardous.

lo

of

to

move equipment. Keep hoses clear of moving paris

62"

C or below -40' C.

Grounding

Also

in

the hoses can be very dangerous.

to

the coupling which can result in

fluid connections securely before each use. High

be emitted from the coupling.

the hose couplings.

loose coupling or allow high pres

If

DO

to

any kind of wear,

any of these conditions ex

NOT try

to

Do

not

DO NOTexposeGraco hosetotemperatures

compatible with the inner tube and

Do

Continuity

to

If

your hose does not have

to

check the resistance.

read FIRE

OR

EXPLOSION HAZARD.

If

the resistance exceeds

If

the

recouple high

no1 use fluids

maintaining a

A

re-

not pull on

a

-

-

-

-

-

-

FIRE OR EXPLOSION HAZARD

2.

Fluid

Static electricity is created by the flow of fluid through the pump

and hose.

grounded, sparking may occur, and the system may become

hazardous. Sparking may also occur when plugging in or

plugging a power supply cord or using a gasoline engine.

Sparks can ignite fumes from solvents and the fluid being

sprayed, dust particles and other flammable substances,

whether you are spraying indoors or outdoors, and can cause a

fireorexplosionandseriousbodilyinjuryandpropertydamage.

If

you experience any static sparking or even a slight shock

while using this equipment,

ATELY. Check the entire svstem for orooeroroundina.

use the system again until

corrected.

If

every pari of the spray equipment is not properly

STOP

the problem has b>en idenzfied and

SPRAYING IMMEDI-

Do

un-

not

Grounding

To reduce the risk of static sparking, ground the sprayer and all

other spray equipment used or located in the spray area.

CHECKyourlocalelectricalcodefordetailedgroundinginstruc-

tions for your area and type of equipment. BE SURE

all of this spray equipment:

1.

Sprayecconnect a ground wire and clamp (supplied)

true earth ground.

to

ground

to

a

3.

4.

5.

6.

7.

Flushing

Reduce the risk of fluid injection injury, static sparking, or

splashing by following the flushing procedure given on page 11

&

page

partofthegunfirmlytothesideofagroundedmetalpailanduse

the lowest possible fluid pressure during flushing.

hoses:use only grounded hoses with a maximum of

150 m combined hose length

ity. See Hose Grounding Continuity.

Spraygun: obtain grounding through connection

erly grounded fluid hose and sprayer.

Object

being

sprayed: according

Fluid

supply container: according

All solvent pails used when flushing, according

code. Use only metal pails, which are conductive. Do not

place the pail on a non

or cardboard, which interrupts the grounding continuity.

To

maintain grounding continuity when flushing orrelieving

pressure, always hold a metal part of the gun firmly

side of a grounded

Safety

12 of this manual. Follow the Pressure Relief Procedure

4.

and remove the spray tip before flushing. Hold a metal

metal pail, then trigger the gun.

to

ensure grounding continu-

to

a prop

to

local code.

to

local code.

to

local

-

conductive surface, such as paper

to

the

on

IMPORTANT

United States Government safety standards have been adopted under the Occupational Safety and Health Act. These standards-

particularly the General Standards, Part 1910, and the Construction Standards, Part 1926 - should be consulted.

-

307-670

5

Page 6

1.

Connect Hose and Gun.

Refer

to

Fig

SETUP

6-1

NOTE:

2.

When tightening fittings at the pressure control,

hold one wrench firmly on the hex of the pressure

control fitting to keep it from rotating. Use an

other wrench to tighten the mating fitting.

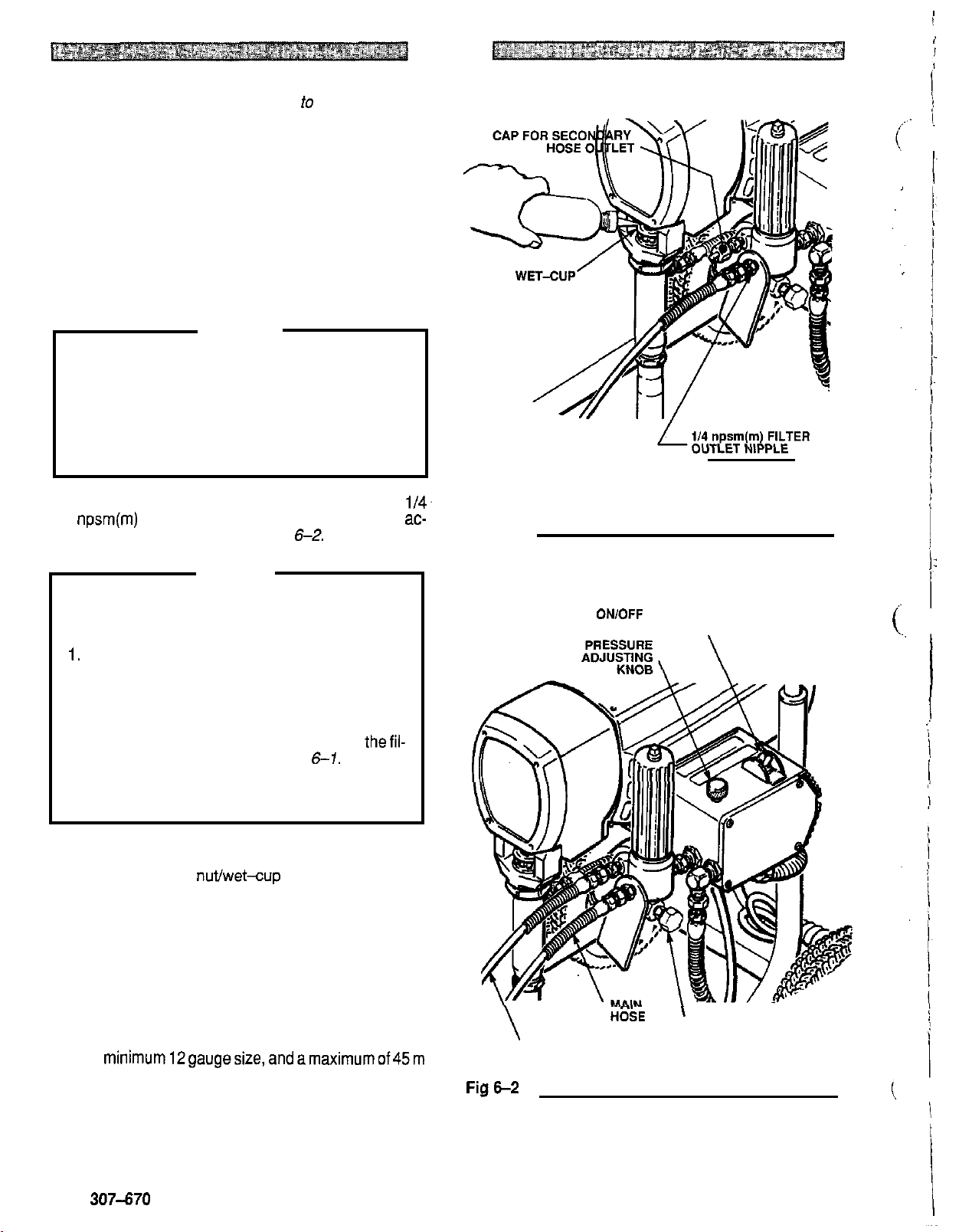

a. Remove the cap from the filter outlet nipple and

screw the

b. Connect the whip hose between the fluid hose

and the gun inlet connection.

c. Don't use thread sealant, and don't install the

spray tip yet!

If you are supplying your own hoses and spray

gun, be sure the hoses are electrically conduc

tive, that the gun has a tip guard and that each

part is rated for at least

sure. This is to reduce the risk of serious bodily

injury caused by static sparking, fluid injection or

over

-

pressurization and rupture of the hose or

gun.

Two Gun Hookup.

npsm(m) nipple - See

cessory hose and gun. See

To

avoid damaging the pressure control, which

may result in poor equipment performance and

component damage, follow these precautions:

1.

Always use nylon spray hose at least

long.

15.2

m main

WARNING

CAUTION

fluid

hose onto the nipple.

207

bar

Working

Remove the cap from the

Fig

6-1

-

and attach an ac-

Fig

6-2.

Pres

15.2

-

-

m

-

1/4.

Fig

6-1

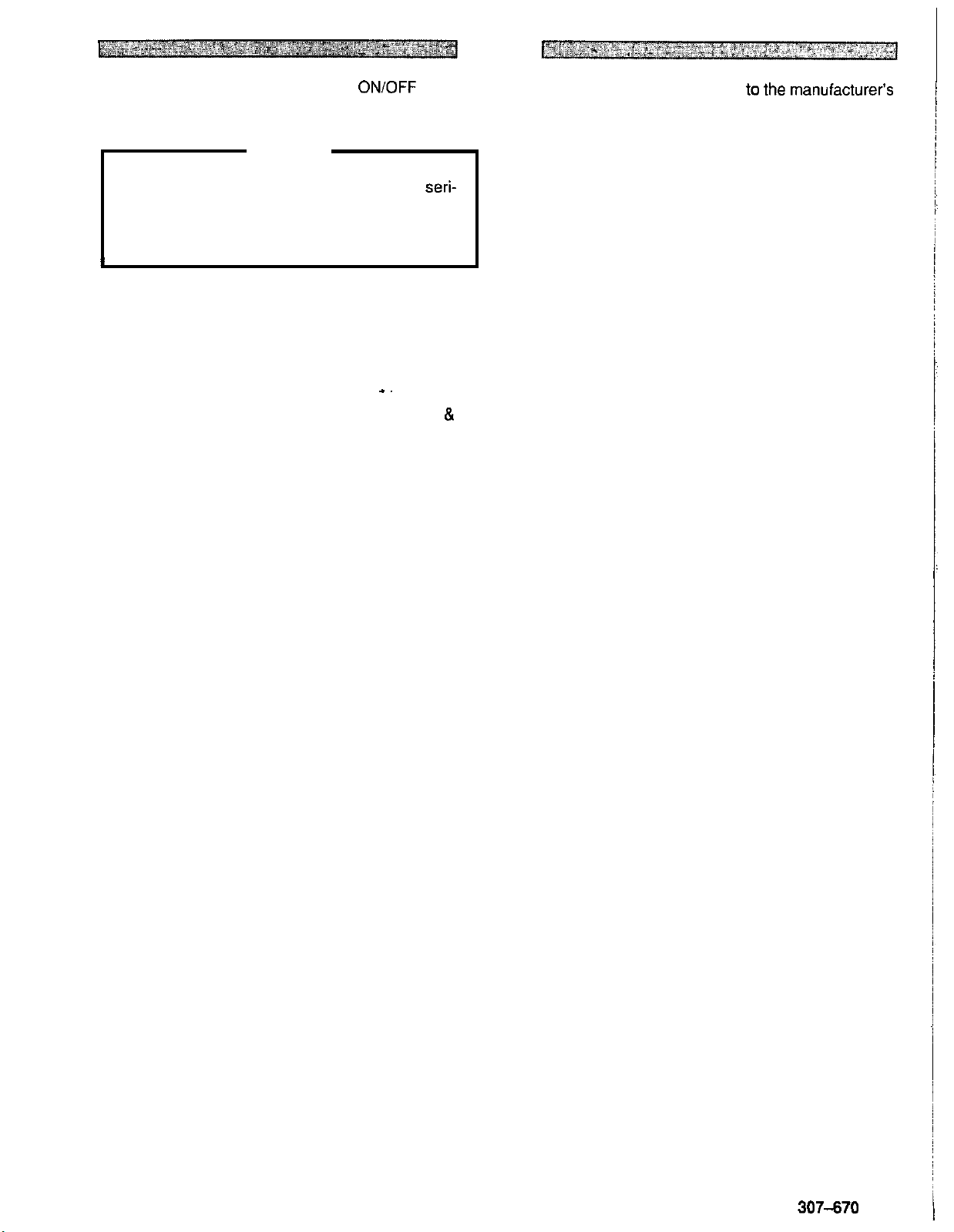

ON/OFF SWITCH

DO NOT INSTALL ANY

SHUTOFF DEVICE

HERE

\

2.

Never use a wire braid hose as it is

act

as

a pulsation dampener.

3.

Never install any shutoff device between thefil-

ter and the main hose. See

4.

Always use the main filter outlet for one gun op

eration. Never plug this outlet.

3. Fill Packing Nutwet-Cup.

Fill the packing nut/wet-cup

Throat Seal Liquid (TSL), supplied.

4.

Check the Electrical Service

a. Be sure the electrical service is properly rated for

your sprayer and that the outlet you use is prop

erly grounded.

b. Have a licensed electrician attach an appropri

ate plug

c. Use an extension cord which has

minimum12gaugesize,andamaximumof45m

long. Longer lengths may affect sprayer per

formance.

to

the power supply cord.

Fig

See

1/3

6-1.

Fig

full

too

6-1

with Graco

3

wires of a

rigid to

-

-

...

^.

.

-

\

SECONDARY HOSE

-

.

HOSE

'

PRESSURE

DRAIN VALVE

6

307-670

Page 7

5.

Plug

in

the Sprayer.

OFF.

Then plug the cord into a grounded electrical

outlet at least

6

Be sure the

ONlOFF

m away from the spray area.

WARNING

Proper electrical grounding is essential

to

reduce

the risk of fire or explosion which can result in seri-

ous

bodily injury and property damage. Refertothe

warning section

FIRE

OR

EXPLOSION HAZARD

on page 5 for more detailed grounding instructions.

f

6.

Flush the pump

was left in

to

a. Before using water

to remove the lightweight oil which

protect pump parts after factory testing.

-

base paint, flush with min

eral spirits followed by soapy water, and then a

clean water flush.

b. Before using oil

spirits only.

c. See

FLUSHING GUIDELINES

-

base paint, flush with mineral

-.

on page

for the flushing procedure.

SETUP

switch is

11

&

12

7.

Prepare the

paint

according

to

the manufacturer's

recommendations.

a. Remove any skin that may have formed.

b. Stir the paint

to

mix pigments.

c.. Strain the paint through a fine nylon mesh bag

(available at most paint dealers)

to

remove parti

cles that could clog the filter or spray tip. This is

probably the most important step toward

trouble

-

free spray painting.

I

-

307470

7

Page 8

'(

OPERATION

WARNING

Pressure Relief Procedure

To

reduce the risk of serious bodily injury, including

fluid injection, splashing fluid or solvent in the eyes

or on the skin, or injury from moving parts or electric

shock, always follow this procedure whenever you

shut off the sprayer, when checking or servicing

any part of the spray system, when installing,

cleaning or changing spray tips, and whenever you

stop spraying.

1.

Engage the gun safety latch.

2.

Turn the ONlOFF switch

3. Disengage the gun safety latch.

part of the gun firmly

metal pail, and trigger the gun

sure.

4. Engage the gun safety latch,

5.

Open the pressure drain valve, having a con

tainer ready

valve open until you are ready

lf you suspect

pletely clogged,

relievedaffer following

around the tip guard retaining nut or hose end cou-

pling and VERY SLOWLY loosen the part

lieve pressure gradually, then loosen completely.

Now clear the tip or hose.

to

catch the drainage. Leave the

that

the spray

or

that

to

OFF.

Hold a metal

to

the side of a grounded

to

relieve pres

to

spray again.

tip

or

hose

pressure

the

has

not been fully

steps above,

wrap a rag

is

*

com

to

re

-

-

-

-

the

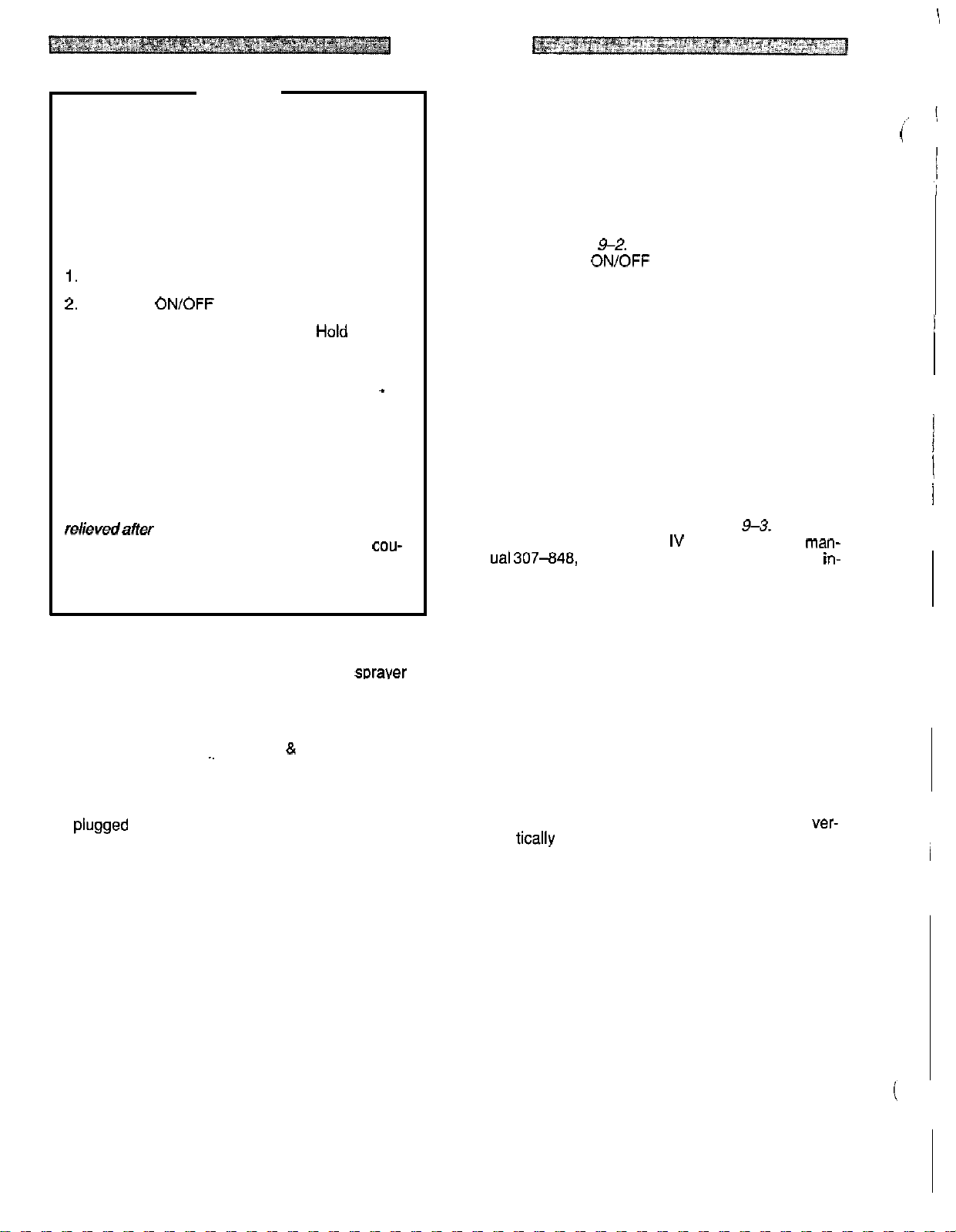

3. Put the suction tube into

4.

Lower the pressure setting

adjusting knob all the way counterclockwise. See

9-1.

5.

Disengage the gun safety latch.

6.

To prime the pump,

firmly against and aimed into a metal waste con

tainer.

open, turn the

crease the pressure setting until the sprayer starts.

Keep the gun triggered until all air is forced

system and the paint flows freely from the gun. Re

lease the trigger and engage the gun safety latch.

NOTE:

7. Check all fluid connections for leaks.

found, follow the

ing, to

8.

Install the Spray Tip and Tip Guard.

gun safety latch is engaged. See

spray tip.

ual307-848, supplied with the gun, for installation in-

structions.

9.

Adjust the Spray Pattern

See

Fig

9-2.

ON/OFF switch

If the pump is hard

under the pressure drain valve and open it.

When fluid comes from the valve, close it. Then

disengage the gun safety latch and proceed as in

Step

6,

above.

the left, before tightening connections.

If

using the

hold a metal part of the gun

Squeeze the trigger and hold it

to

Pressure Relief Procedure Warn

RAC

paint container.

by turning the pressure

See

Fig

to

ON, and slowly in

prime, place a container

If

Be sure the

Fig

9-3.

install the

IV tip guard, refer

9-3.

out

of the

any are

to

man-

Fig

-

-

i

i

i!

-

-

Startup

Use this procedure each time

help ensure the sprayer is ready

start it safely.

NOTE:

1.

2.

For the first time startup, be sure

sprayer first. See page

GUIDELINES.

Close the pressure drain valve.

stalled a secondary hose, be sure the nipple is firmly

plugged with the cap.

Don't install the spray tip yet!

.'

you

to

11

See Fig

start the sDraver

operate and that you

to

&

12

for

FLUSHING

If you have not in

9-1.

to

flush the

a. Increase the pressure adjusting knob setting just

until spray from the gun is completely atomized.

To avoid excessive overspray and fogging, and

to

decrease tip wear and extend the life of the

sprayer, always use the lowest possible pres

sure needed

b. If more coverage is needed, use a larger tip

rather than increasing the pressure.

c. Test the spray pattern. TO adjust the direction of

-

the spray pattern, engage the gun safety latch

and loosen the retaining nut. Position the tip

guard horizontally for a horizontal pattern or ver-

tically for a vertical pattern. Then tighten the re

taining nut.

to

get the desired results.

-

-

8

307-670

Page 9

OPERATION

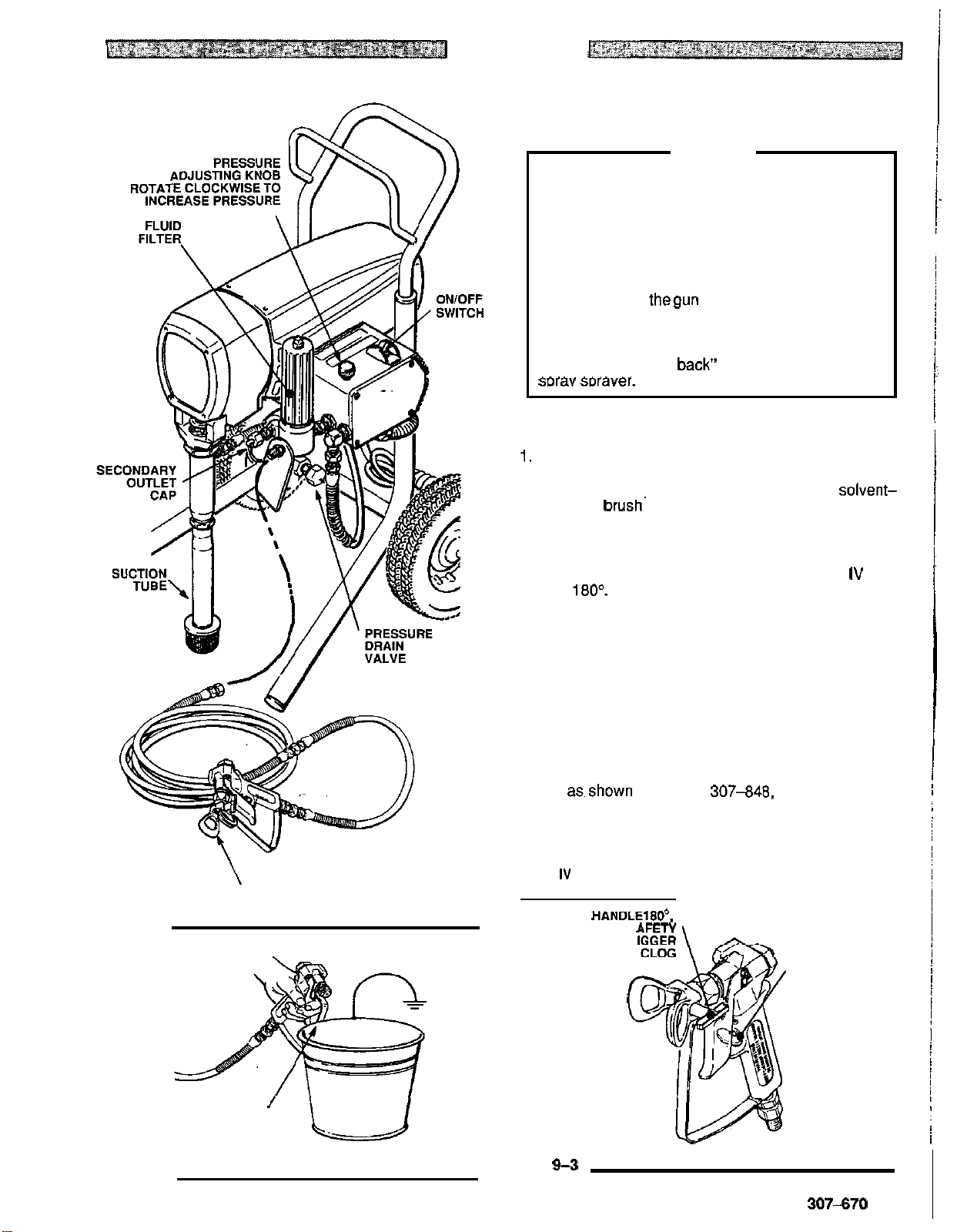

Cleaning a Clogged

Tip

WARNING

To reduce the risk of serious bodily injury from fluid

injection:

NEVER operate the spray gun with thetipguard re

moved.

DO

NOT hold your hand, body, or a rag in front of

the spray tip when cleaning or checking a clogged

tip. Always point

waste container when checking to see

thegun toward the ground or into a

if

the tip is

clear.

DO NOT

try

to "blow back" paint: this is NOT an air

mrav sDraver.

1.

Clean the front of the tip frequently during the day's

operation. First, follow the

dure Warning

soaked

brush^

on page 8. Then use a solvent-

to wipe-away fluid build-up, which

Pressure Relief Proce

helps prevent tip clogging.

-

-

Fig

9-1

NEVER OPERATE THE GUN

WITH THE TIP GUARD

REMOVED

2.

If the spray tip does clog, release the gun trigger, en

gage the gun safety latch, and rotate the RAC

dle

180".

See

Fig

9-3.

3.

Disengage the gun safety latch and trigger the gun

IV

han

into a waste container. Engage the gun safety latch

again.

4. Return the handle to the original position, disengage

the gun safety latch, and resume spraying,

5.

If the tip is still clogged, engage the gun safety latch,

shutoff and unplug the sprayer, and open the pres

sure drain valve to relieve pressure. Clean the spray

tip as.shown in manual 307-848, supplied with the

RAC IV.

RAC

IV

HANDLE SHOWN

IN SPRAYING POSITION,

HANDLElBO",

TURN

DISENGAGES

LATCH AND TR

GUN

TO

CLEAR

GUN

SAFETY

LATCH

SHOWN EN.

GAGED

-

-

-

MAINTAIN FIRM

METAL TO METAL

CONTACT WHEN

Fig

9-2

FLUSHING

1

Fig

9-3

307-670

9

Page 10

~~~

SHUTDOWN AND CARE

WARNING

To reduce the risk of serious bodily injury, including

on

fluid injection or splashing in the eyes or

or injury from moving parts, always follow the

sure Relief Procedure Warning

on page

checking, adjusting, cleaning and shutting down the

sprayer.

1

.

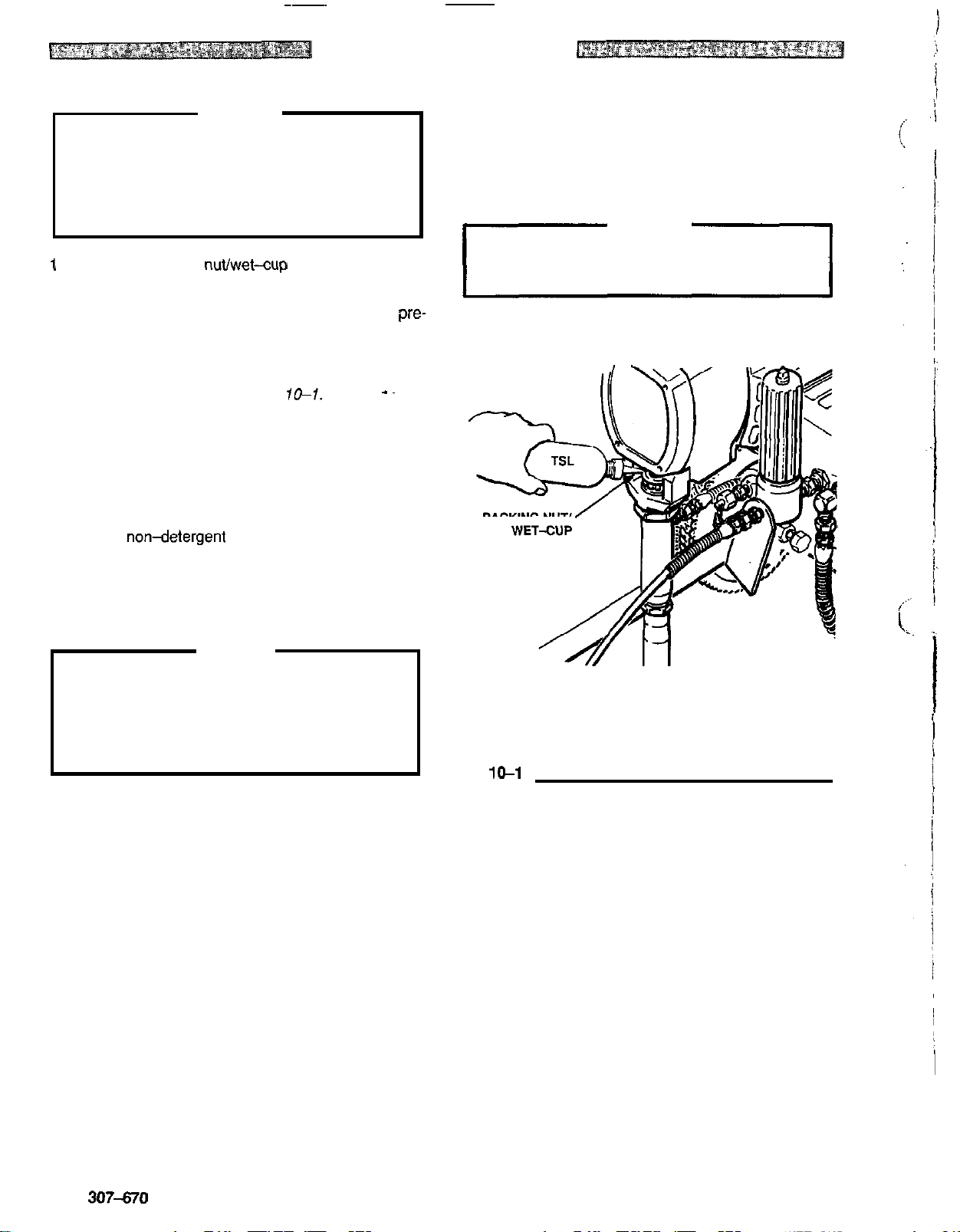

Check the packing nuvwet-cup daily. First follow the

Pressure Relief Procedure Warning

Be sure the wet-cup is 1/3 full of TSL at all times

help prevent fluid buildup

mature wear

tight enough

of packings. The packing

to

stop leakage, but no tighter. Over

on

the piston rod and pre-

tightening may cause binding and excessive packing

wear. Use a round punch or brass rod and light ham

mer

to

adjust the nut. See

Fig

10-1.

2. Clean the fluid filter often and whenever the sprayer

is stored. First follow the

dure Warning

307

-

273, supplied, for the cleaning procedure.

on

Pressure Relief Proce

page 11. Refer

the skin,

Pres

-

11

before

on page

11.

to

nut should be

-~

to

manual

__

5.

For very short shutoff periods, leave the suction tube

in the paint, follow the

Warning

6.

Coil the hose and hang it

on page 11, and clean the spray tip.

ing it, even for overnight,

Pressure Relief Procedure

on

the hose rack when stor

to

help protect the hose

-

from kinking, abrasion, coupling damage, etc.

WARNING

Refer

to

the warning section

page 5 for information on the hazard

HOSE SAFETY

of

using dam

on

-

aged hoses.

-

-

3. Lubricate the bearing housing after every 100 hours

of operation. Fill the connecting rod cavity with

No.

10 non-detergent oil.

4.

Flush the sprayer at the end of each work day and

it with mineral spirits

and freezing. See

page

11.

'To

prevent pump corrosion, and

chance of fluid freezing in the pump

to

help prevent pump corrosion

FLUSHING GUIDELINES

CAUTION

to

reduce the

or

pressure con

SAE

fill

on

trol in cold weather, never leave water or any type of

paint in the sprayer when it is

can seriously damage the sprayer or result in a

not

in use. Freezing

loss

of pressure or stalling.

I

I

PACKING

Fig

10-1

NUT/

10

307-670

Page 11

FLUSHING GUIDELINES

Pressure Relief Procedure

To reduce the risk of serious bodily injury, including

fluid injection, splashing fluid or solvent in the eyes or

on the skin, or injury from moving parts or electric

shock, always follow this procedure whenever you

shut off the sprayer, when checking or servicing any

part of the spray system, when installing, cleaning or

changing spray tips, and whenever you stop spraying.

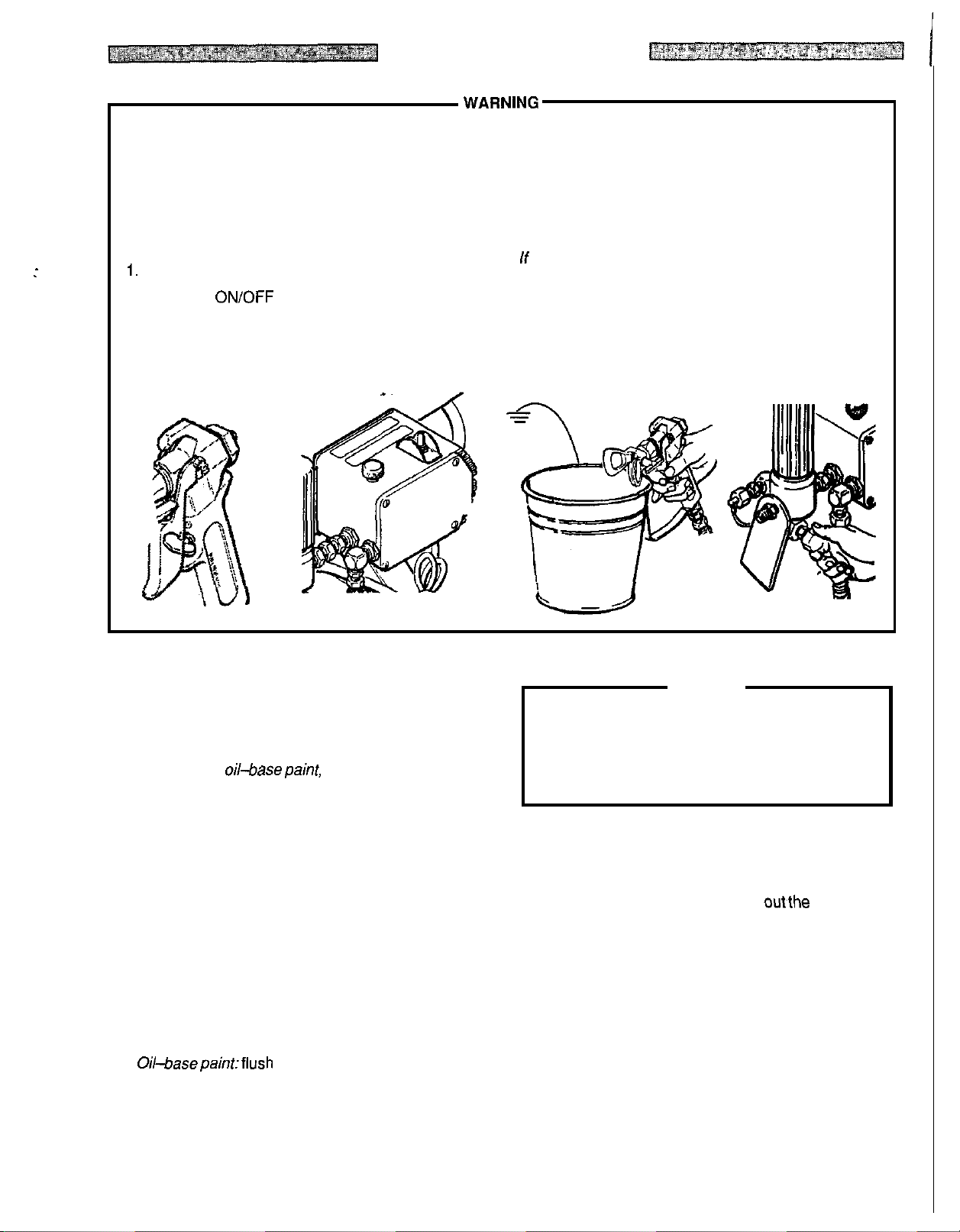

1.

Engage the gun safety latch.

2.

Turn the ON/OFF switch to

3.

Disengage the gun safety latch. Hold a metal part

of the gun firmly to the side of a grounded metal

pail, and trigger the gun to relieve pressure.

OFF,

4.

Engage the gun safety latch.

5.

Open the pressure drain valve, having acontainer

ready to catch the drainage. Leave the valve open

until you are ready to spray again.

If

you

suspect that the spray tip or hose

clogged, or that pressure

has

not

been

is

completely

fully

relieved

after following the steps above, wrap a rag around the

tip guard retaining nut or hose end coupling and

VERY SLOWLY loosen the part to relieve pressure

gradually, then loosen completely. Now clear the tip or

hose obstruction.

1

1.

New Sprayer. Your new sprayer was factory tested

2

in lightweight oil which was left in to protect pump

parts.

Before using water

-

base paint, flush with mineral

spirits followed by soapy water, and then a clean

water flush.

Before

using

oil-basepaint, flush with mineral spirits

only.

2.

Changing Colors. Flush with a compatible solvent

such

as

3.

Changing

mineral spirits

from

or

water.

water-base

to

oil-base paint.

Flush with warm, soapy water, then mineral spirits.

4.

Changing

from

oil-base to water-base paint.

Flush with mineral spirits, followed by warm, soapy

water, then a clean water flush.

5.

Storage.

3

4

CAUTION

NEVER leave water in the sprayer

if

there

is

slightest chance it could freeze. Push the water out

with mineral spirits. Water left to freeze in the pressure control tube prevents the sprayer from being

started and causes serious damage to the pressure

control.

6.

Startup after storage.

-

Before using water

base paint, flush out mineral

spirits with soapy water and then a clean water flush.

When using oil

-

base paint, flush outthe mineral spir-

its with the paint to be sprayed and the sprayer

ready to use.

the

is

Water

-

base paint: flush with water, then mineral

spirits and leave the pump, hose and gun filled with

mineral spirits. Shut off the sprayer, open the pres

sure drain valve to relieve pressure and leave it open.

Oil-basepainttfiush with mineral spirits. Shut

off

the

sprayer, open the pressure drain valve to relieve

pressure and leave

it

open.

-

Continued on page

12.

307-670

11

Page 12

~

How

to

Flush

~~

~~

FLUSHING GUIDELINES

1.

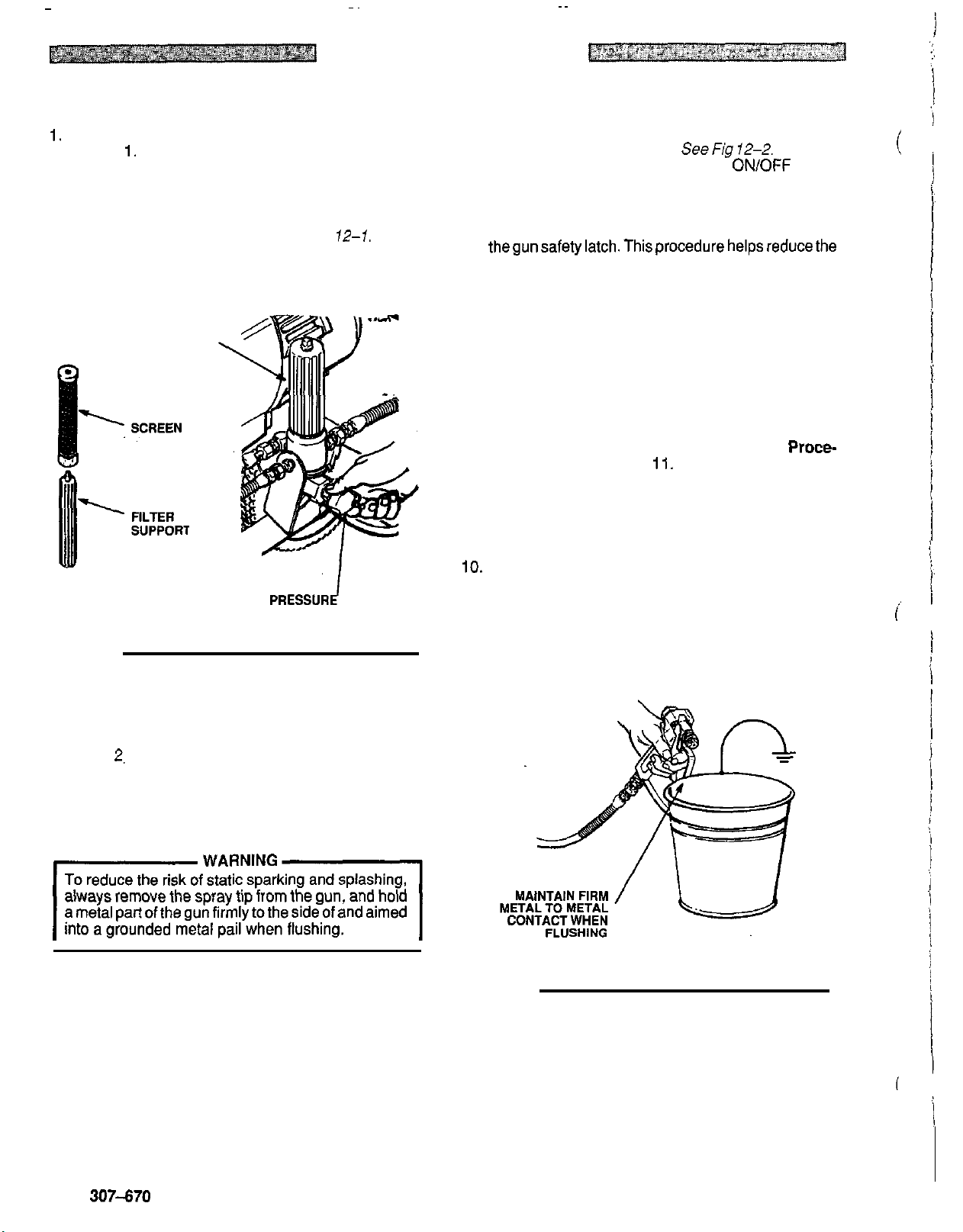

Follow the

page

2.

If

the sprayer has been used before, remove the filter

bowl and screen: see manual 307

Pressure Relief Procedure Warning

1

1.

-

273, supplied.

Clean the screen separately and install the bowl

without the screen to flush

FILTER

BOWL

it.

See

Fig

PRESSUR*

DRAIN VALVE

12-1.

on

7. Hold a metal part of the gun firmly against and aimed

into a metal wastecontainer.

the trigger and hold

to

ON,

and slowly increase the pressure setting until

it

open, turn the

SeeFig

12-2.

Squeeze

ON/OFF

switch

the sprayer starts. Keep the gun triggered until all air

is forced out

of

the system and the solvent flows

freely from the gun. Release the trigger and engage

thegunsafetylatch.Thisprocedurehelpsreducethe

risk of static sparking and splashing.

NOTE:

If the pump is hard to prime, place a container

under the pressure drain valve and open it.

When fluid comes from the valve, close it. Then

disengage the gun safety latch and proceed as in

Step 7, above.

8.

Remove the suction tube from the pail. Disengage

the gun safety latch and trigger the gun

vent from the hose.

Do

not let the pump run dry for

to

force

sol

more than 30 seconds to avoid damaging the pump

packings! Then follow the

dure Warning

9.

Leave the pressure drain valve open until you are

on page

ready to use the sprayer again.

Pressure Relief Proce-

11.

If

the screen was re

moved, unscrew the filter bowl and reinstall the clean

screen. Reinstall the bowl, hand tight only.

IO.

If

you flushed with mineral spirits and are going to

use a water

lowed by a clean water flush. Then follow the

sure Relief Procedure Warning

-

base paint, flush with soapy water fol

Pres

on page

11.

-

-

(

-

-

i

Fig 12-1

3. Close the pressure drain valve.

4.

Pour

2.

liters of compatible solvent into a grounded

metal pail. Put the suction tube in the pail.

5.

Remove the spray tip from the gun,

6.

Lower the pressure setting by turning the pressure

if

it

is installed.

adjusting knob all the way counterclockwise.

Fig

12-2

12

307-670

Page 13

TROUBLESHOOTING

Pressure

To

reduce

fluid

the

alwaysfollowthisprocedurewhenever

sprayer,

sDrav

sprajl

1.

2.

3.

4.

Relief

the risk

iniection.

eyes

svstem.

tips,

Engage

Turn the

Unplug

Disengage the

or

on

when

and

the

the

th'e ikin,

ON/OFF

iniuw

checking

when

whenever

gun

power supply

Procedure

of

serious bodily injury,

from

solashina

moving

installing,

or

sewicing

park

cleanina

yoistop

safety latch.

switch to

cord.

gun

safety

latch. obstruction.

fluid

or

spraying.

OFF.

or

electric

you

any

or

WARNING

'5.

Hold

including

solvent

in

shock,

shut

off

part

the

of

the

changing ready

"

grounded

oressure.

6,

ingage

7.

Open

8.

Leave

ready to spray

lf

you

clogged,

ter

following

auard retainina nut

SLOWLY

ally,

then

GUIDE

a

metal

part

metal

the

gun

the

Pressure

to

catch the drainage.

the

pressure

suspect

that

orthatpressure

the steps

loo&&

loosen

the

completely.

of

pail,

safety

drain

drain

again.

the

spray

above,

or

hose

part

the

gun

firmly

to

and

trigger

the

latch.

valve, having

valve

open

tip

or

has

to

hose

notbeen

wrap a rag around the

end

relieve pressure

Now

fullyrelievedaf

coudina

clear the tip

the

side

gun

to

a

Container

until

you

is

complete/y

and

or

of

a

relieve

are

tip

VERY

gradu

hose

-

-

:heck everything

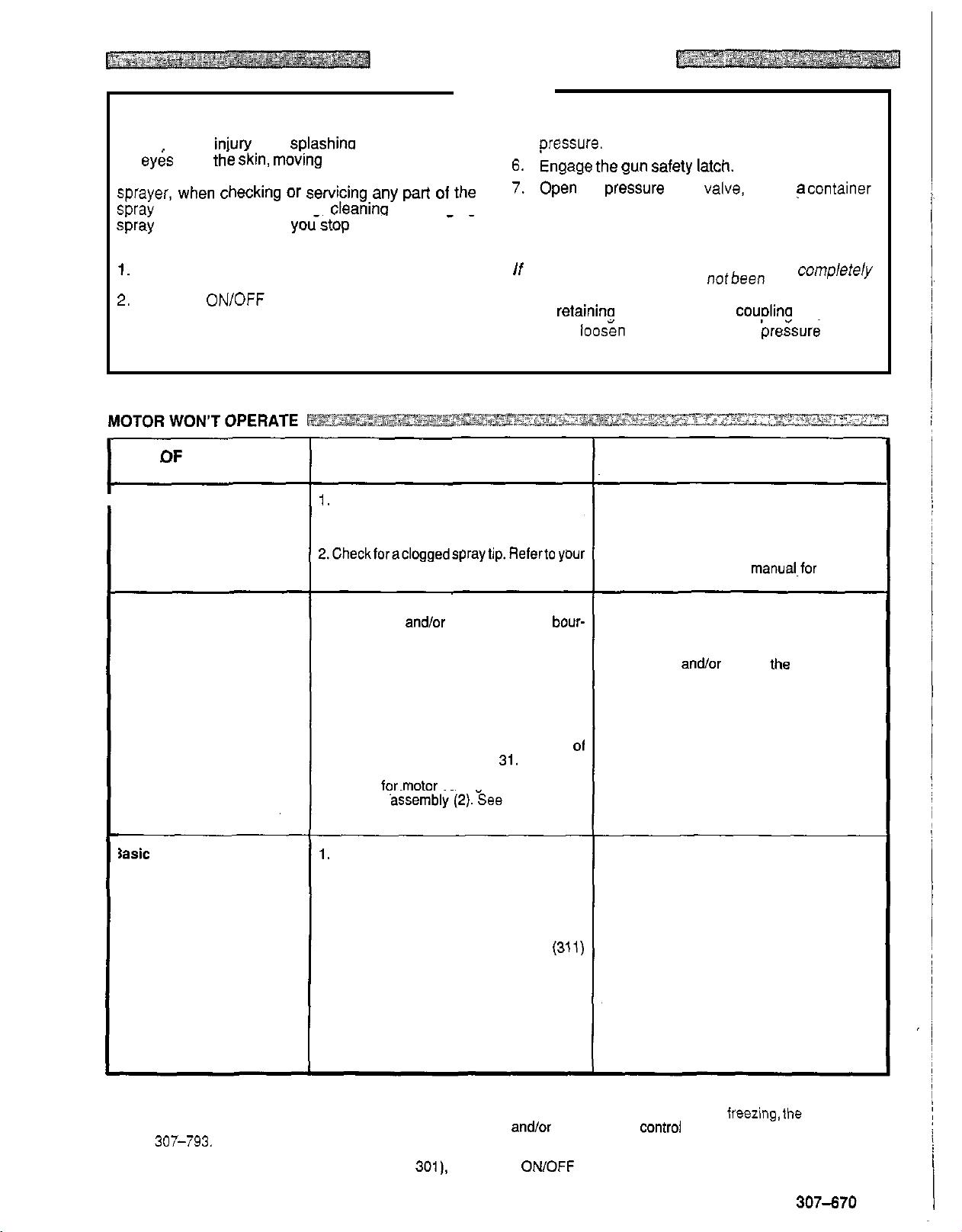

TYPE

OF

Basic Fluid Pressure

Problems

Basic Mechanical Problems

in

the

PROBLEM

guide

-

E

%ask Electrical Problems

before

disassembling

~ ~~

TO

WHAT

If

check

1.

Check the pressure control knob setting.

The motor

mum setting (fully counterclockwise).

2.Checkforacloggedspraytip.Refertoyour

separate gun or tip instruction manual.

1. Check for frozen or hardened paint in the

pump (39)

don tube. Using a screwdriver, carefully

try to rotate fan at back of motor by hand.

See page 19.

2.

Check displacement pump connecting

rod pin

into connecting rod

spring (35) should be firmly in groove

connecting rod. See page

3. Check for.motor damaae. Remove drive

housing

to rotate fan by hand.

1.

Check electrical supply with volt meter.

Meter should read 190

2.

Check extension cord for visible damage.

Use a volt meter or test lamp at extension

cord outlet to check.

3. Check sprayer power supply cord

for visible damage such as broken insula

tion or wires.

4.

Check motor brush leads. terminals and

brush length. Brush length should be

mm minimum. See page 33.

CHECK

is

OK,

will

andlor pressure control bour-

(20).

It must be completelypushed

assembly~(2). 3ee page

the

go

to

the next check.

not run

sprayer.

if

it

is at the mini

(3)

and retaining

31.

-

250 Volts.

32.

(3ql)

Try

14

WHAT

If

1.

-

2.

1.

2.

01

3. Replace motor

1. Reset building circuit breaker: replace

2.

3.

-

4.

TO

check

Slowly increase the pressure setting to

if

the motor starts.

Relieve pressure, refer to your separate

gun or tip instruction

ing.

Thaw. Plug in sprayer and turn

crease pressure setting to see

starts.

ment pump packings (see manual

307

control box (301). See page 27.

Push pin into place and secure with the re

taining spring.

building fuse. Try another electrical outlet.

Replace extension cord.

Replace power supply cord. See page

Tighten terminal screws; replace brushes.

See page 33.

DO

is

not

OK,

refer

to

this column.

manual.for tip clean

on.

If

it

doesn't, replace the displace

-

793) andlor replace the bare pressure

(1)

if

fan won't turn.

see

Slowly in

if

motor

22.

-

-

-

-

if

Thaw the sprayer

not try

to

start the sprayer until it has thawed completely.

If

operate.

manual

When replacing the bare pressure control box (item 301), remove the

and reinstall these parts in the bare box.

paint hardened (dried) in the sprayer, the pump packings andlor bare pressure control must bereplaced. See page

307-793.

water or water-based paint has frozen

in

it,

due to exposure to low temperatures, by placing it in a warm area.

If

the bourdon tube was not damaged by

OWOFF

the

freezing,the pump should

switch, bridge, circuit board and electrical hardware

27

Do

or

307-670 13

Page 14

‘YPE

OF

PROBLEM

WHAT TO CHECK

If

check

is

OK,

go

to the next check.

WHAT

If

TO

check is not

DO

OK,

refer to this column.

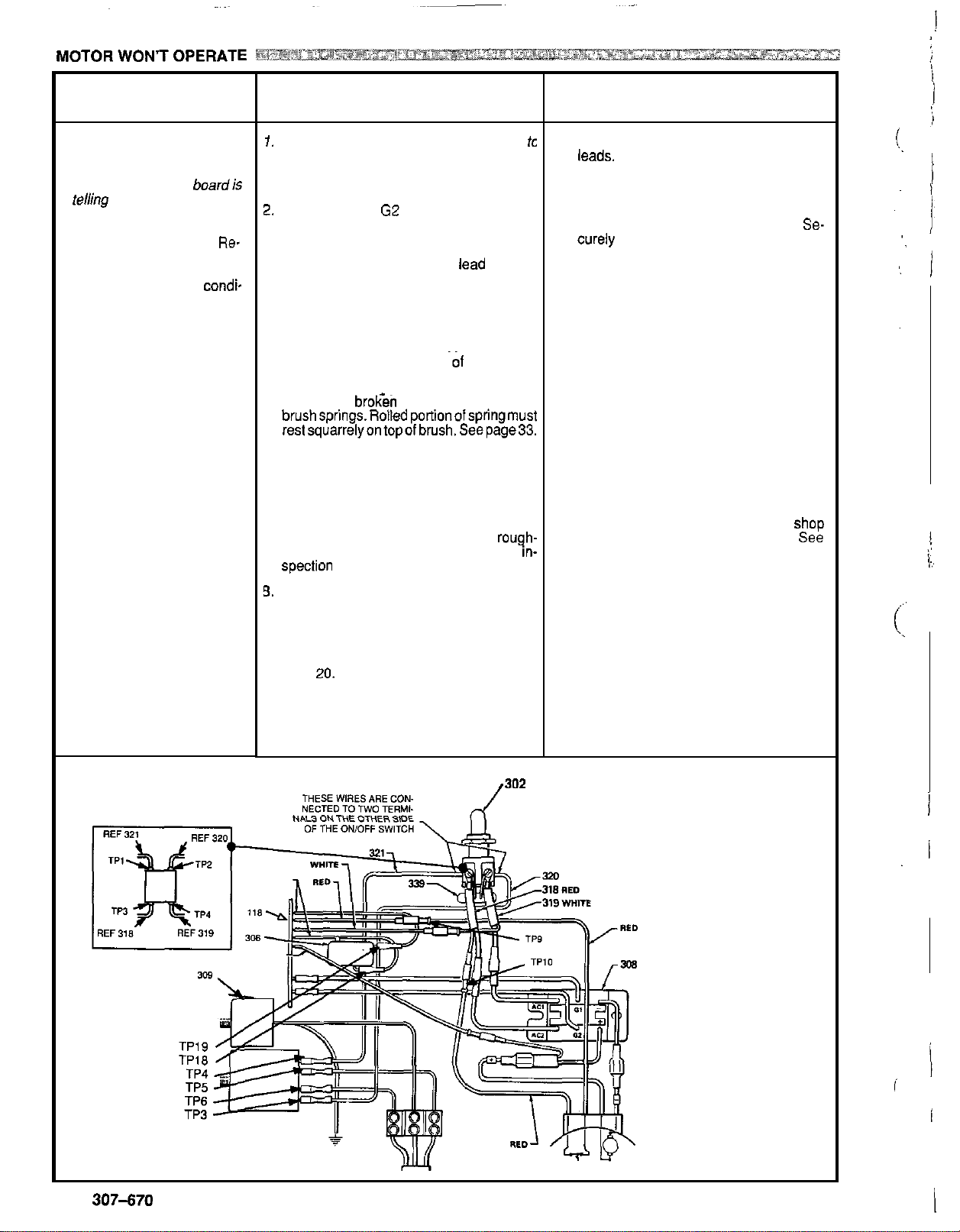

Diagnosing circuit board

indicator lamps. The nor

mal condition

clear lamp on when

telhg pump

Follow Pressure Relief

Procedure Warning.

move gun from hose. Re

move pressure control cover

and check for faulty

tion of circuit board lamps.

Condition

Both lamps on; pump

won’t operate and motor

is

not

is

to

A

running

red lamp on,

boardis

run.

Re-

condi-

1.

Check leads from bridge

be sure they are securely fastened ana

properly mated.

2.

Check

GI

and

circuit board (118) and bridge (308) for

damage or loose terminals.

-

3.

Check for loose motor brush lead connec

tions and terminals. See page 33.

4.

Checkbrush length which should be

minimum. See page 33.

NOTE:

same rate on both sides

Check both brushes.

5.

Check for brocen or misaligned motor

brushsprings.Rolledportionofspringmust

reslsquarrelyontopofbrush.Seepage33.

6.

Check motor brushes for binding in brush

holders. See page 33.

7.

Check motor armature commutator for

burn spots, gouges and extreme

ness. Remove motor cover and brush

spection plates

3.

Check motor armature for shorts using ar

mature tester (growler) or perform spin

test. See page 19.

3.

Check bridge (308) by substituting with a

good bridge or performing bridge test. See

page

CAUTION:

mature is determined to be good. A bad ar

mature

bridge.

The brushes do not wear at the

20.

Do

will

G2

to

not perform this check until ar

immediately burn out a good

(308)

connections between

of

check. See page 28.

to

motor tc

14

mm

the motor.

rough-

in-

1. Replace any loose terminals and crimp to

leads. Be sure male terminal blades are

straight and firmly connected to mating

part.

2.

Clean circuit board male terminals. Re

place loose or damaged terminals.

curely reconnect leads.

3. Tighten terminal screws. Replace

brushes

33.

4.

Replace brushes. See page 33.

5. Replace spring

with brush. See page 33.

6.

Clean brush holders. Remove carbon

with small cleaning brush.

leads with

free vertical brush movement.

7.

Remove motor and have motor ShOD

resurface commutator

page 35.

8. Replace motor. See page 35

-

9. Replace bridge. See page

-

-

if

leads are damaged. See page

if

broken. Realign spring

slot

in brush holder to assure

Align

if

possible. see

24

Se-

brush

-

!

WIRING DIAGRAM

14

307-670

I

302

Page 15

WPE

OF

PROBLEM

:ondition B (continued)

Both lamps

REFER

ING

off

TO

~

THE WIR-

-.

DIAGRA~J

PAGE 14 TO IDENTIFY

TP POINTS.

WHAT TO

If

check

1. Checkelectrical supply. Connectvoltmeter

to

190-250

2.

O

N

Check power supply

sprayer turned

TP1 and TP2. Meter should read 190-250

Volts.

CHECK

is

OK.

00

to the next check.

electrical outlet. Meter should read

Volts

to

ON.

See page 26.

circuit board with

Measure voltage at

WHAT TO

If

check

1.

Reset circuit breaker or replace outlet

is

DO

not

OK.

refer to this column.

fuse.lf circuit breaker or fuse continues

open, see "Electrical Short", page 18.

2. Unplug sprayer. Check continuity

polesofON/OFFswitch(302)fromTPlto

TP2 and

TP2

to

TP3. Replace switch

faulty.

of

to

both

if

:ondition

Red lamps

Clear lamp off

Unplug

C

on,

sprayer!

TP4 to TP6 and TP3

Check for any loose connections.

-.

3.

Check all terminals and wires for damage

or loose

4.

Checkmotorthermalcutoutswitch..Unplug

sprayer. Allow motor

motor thermal switch leads at

TP10. Use ohmmeter

fit.

to

cool. Disconnect

TP9 and

to

check continuity.

Switch should be closed when motor

3. Replace damaged terminals and recon

nect securely.

4.

close when motor is cool. See page 35.

is

cool.

5.

Check microswitch

pressure

in

the pressure control, discon

(306).

With no fluio

5.

nect wires TPlSandTP19. Checkcontinu-

ity across switch terminals with an ohmrne-

fer. Switch contact should be closed. De

press actuator button.

An

audible "clickin-

-

dicates the contacts have opened. Ohm-

6.

Check circuit board (118) by substituting

6. Replace circuit board. See page

with a aood board. See Daoe 26.

1.

Checkcircuit board

(1

18) by removing from

1. Replace circuit board. See page 26.

box withoutdisconnecting wires; see page

26 for removal procedure.

I

WARNING;

Removing the circuit board while still wired over-rides the

optical detector which could cause the sprayer to over

microswitch does

enough

to

check lamp condition, then shut off immediately.

WARNING:

~

only!

Do

not allow any metal objects

not

function properly. Turn the sprayer

To reduce the risk of electric shock, handle board by edges

to

come in contact with the board!

Check continuity of

RFI

filter (310) from

to TP5. Replace filter

if

faulty.

Check power supply cord (31 1) for

nuitv from TP5 to TP7 and TP6

Replace cord

Replace electric motor

if

faulty.

if

switch does

conti-

to

TP8.

not

Replace ihe microswitch. See page 23.

26.

-

pressurize,

on

if

the

ONLY long

-

on

Plug in and turn

should be

board over

ofi

and unplug the sprayer.

on

-

rides the optical detector.

2. Check bourdon tube flag and

sprayer. Clear lamp

now - removing the circuit

detectorposi-

tion. Reinstall circuit board (see page 26).

Turn pressure setting to maximum; flag

should extend less than half way into opti

cal detector

slot

from the bottom.

Turn

2. Calibrate pressure control to see

corrects problem. See page 28.

-

If

not, replace bare pressure control box

(301). See page

27.

307-670

if

that

15

Page 16

TYPE

OF

PROBLEM

TO

WHAT

If check

1.

Check for worn spray tip.

2. Check

tinue to stroke whbn gh trigger is re

leased. Plug in and turn on sprayer.

Primewith

ily, then release and engage safety

latch. Relieve pressure, turn

plug sprayer.

3. Check electrical supply with

Meter should read

4. Check extension cord size and length;

must be at least 12 gauge wire and no

longer than

5. Check

(308) to circuit board (1 18) for damage

or

page 26.

6.

Check stall pressure. Refer

tion Procedure on page 28.

7. Check bridge (308)

terminalstomotor. Inspect wiring insula

tion and terminals for signs of overheat

ing. See page 24.

8. Check for loose motor brush leads and

terminals. See page 33.

9.

Check for worn motor brushes which

should be 14 mm minimum. See page

33.

10.Checkfor broken and misaligned motor

brush springs. Rolled portion of spring

must rest squarely

11.Check motor brushes for binding in

brush holders. See page 33.

12.Checkcircuit board (1 18) by substituting

with a good circuit board. See page

13.Check motor armature for shorts by

ing an armature tester (growler) or per

form spin test. See page 19.

14,Checkbridge(308)bysubstitvtingwitha

good bridge or by performing the bridge

test. See page

CAUTION:

armature is determined

armature will immediately burn out a good

bridge.

CHECK

is

OK,

go to the next check.

to

see that Dum0 does

paint.Triggergun momentar

190-250

15,2 m .

G1

and G2 leads from bridge

loose

wires or connectors. Refer

+

on

top of brush.

20

or 24.

Do

not perform this check until

to

not

con

off

and

un

volt

meter.

Volts.

to

to

Calibra

and - leads and

26.

us

be good. A bad

-

-

-

-

-

-

-

-

-

WHAT

If

1.

2. Service pump. See manual 307

3. Reset building circuit breaker; replace

4. Replace with a correct, grounded exten

5. Clean circuit board male terminals. Re

6.

7.

8. Tighten terminal screws. Replace

9. Replace brushes. See page 33.

10.Replace spring

11.Clean brush holders, remove carbon

12.Replace circuit board.

13.Replace motor.

14.Replace bridge.

TO

check

Follow Pressure Relief Procedure

Warning then replace tip. See

separate gun or tip manual.

building fuse. Repair electrical

try

sion cord.

place loose or defective lead terminals.

Securely reconnect lead terminals to

board.

Calibrate pressure control. See page 28.

Be

tered and firmly connected

minals. Replace any

damaged wiring. Securely reconnect

wires to bridge.

brushes

33.

with brush. See page 33.

dust with small cleaning brush. Align

brush lead with slot in brush holder to as

sure free vertical brush movement.

DO

is

not

OK,

refer to this column.

you1

-

793.

another outlet.

sure male terminal blades are cen

loose

if

leads are damaged. See page

if

broken. Realign spring

See

See

page 35.

See

page 24.

outlet

to

female ter

terminal or

page

26.

or

-

-

-

-

-

16

307-670

Page 17

IO

OUTPUT

TYPE OF PROBLEM WHAT TO CHECK

If check

Is

OK,

go

to

the next check.

~~...~~

If

check

~

is

-

"

not

OK,

refer to this column.

Motor runs and pump

strokes

Motor runs but pump does

not

stroke

1. Check paint supply.

2. Check for clogged intake strainer.

loose

3. Check for

4.

Check

to

ton ball are seating properly.

ual 307-793.

5.

Check for leaking around throat packing

nut which may indicate worn or dam-

aged packings. See manual

1. Check displacement pump connecting

rodpin. See page 31.

2.

Checkconnectingrodassembiyfordam-

age.

I

3.

See

Be sure crank'in drive housing rotates;

plug in sprayer and turn

to

check. Turn

See

page 30.

suction tube or fittings.

see

if

intake valve ball and pis

page 30.

on

off

and unplug sprayer.

See

man

307-793.

momentarily

1.

Refill and reprime pump.

2. Remove and clean, ihen reinstall.

3. Tighten; use thread sealant or sealing

-

4.

-

5.

1. Replace pin

2. Replace connecting rod assembly.

3. Check drive housing assembly for dam

on

tape

Remove intake valve and clean. Check

balls and seats for nicks; replace

sary. See manual 307-793.

Replace packings.

Also

paint or nicks and replace

spring is fully

necting rod. See page

page 30.

age and replace

32.

threads

check piston valve seat for hardened

if

necessary.

See

manual 307-793.

if

necessary.

if

missing.

in

Be

groove all around con

sure retaining

31,

if

necessary. See page

if

neces

-

-

See

-

'YPE OF PROBLEM

spray pattern varlations.

WHAT TO CHECK

If

check Is

1.

Be sure both G1 and G2 leads from

bridge (308) to circuit board (118) are

firmly connected. See page 26.

2. Check stall pressure. Refer to Calibra

tion procedure on page 28.

3. Check bourdon tube flag and detector

position. Turn pressure setting to

mum; flag

tical detector slot of circuit board.

4.

Check circuit board

ing with a good board. See page 26.

5.

Check

16.

OK,

sho.uld

''\

LOW

go

to the next check.

not

drag or bind in

CIRCUIT

FLAG

(1

18)

OUTPUT

section on page

BOARD

by

substitut

maxi-

op-

WHAT TO

If check

1.

Reconnect securely.

-

2. Calibrate pressure control. See page

28.

3. Carefully bend flag into alignment with

detector

lem.

trol assembly (301). Calibrate pressure

control after reassembly.

-

4.

Replace circuit board.

DO

is

not

OK.

refer

to

See

slot

to see

if

If

not,

replace bare pressure con

that corrects prob

See

this column.

page 26.

page 26.

-

-

307-670

17

Page 18

~~ ~~

WHAT TO CHECK

If

check

is

OK,

go

to the next check.

1.

Check to see

ing at high pressure with small tips,

which causes low motor

sulk in excessive heat build up.

2. Check

where sprayer is located

32°Corifsprayerislocatedindirectsun.

if

sprayer has been operat-

to

see

if

ambient temperature

RPM

is

more than

and re-

~

~~ ~

WHAT TO

If

check is not

1.

Decrease pressure setting or increase tip

DO

OK.

refer to this column.

size.

2 Move sprayer

to shaded, cooler area

possible.

if

'YPE

OF

PROBLEM

Building circuit breaker opens a6

soon

as sprayer switch is turnec

on.

CAUTION

Any short in any part of the mot01

power circuit, which is connectec

to

the output side

will cause the bridge

immediately. Correctly diagnose

and repairallshorts

ing and replacing bridge.

of

the bridge

to

burn

ou

beforecheck-

3. Checkto see

stalled condition (sprayer turned

pressurized, but

if

sprayer has been left in a

not

operating) for long

on,

periods of time.

*

WHAT TO CHECK

If

check

is

OK,

go

to the next check.

1.

Check

all

electrical wirino for damaaed

insulation, and

all terminals for

or damage. Be sure to check wires

Ioos;

fit

be

tween pressure control and motor which

are encased in conduit (22). See page

35.

2. Check for missing inspection plate gas

ket (see Daoe

othermetaliomeialcontactpointswhich

could cause a short.

3.

Check motor armature for shorts by us-

ing an armature tester (growler) or

form spin test. See page

windings for burns.

4.

Checkbridge (308) by substituting with a

good bridge or by performing bridge test.

See page 20.

CAUTION:

armature is determined

armature will immediately burn out a good

bridge.

331.

bent terminal forks or

Do

not

perform this check until

to be good. A bad

19.

per-

Inspect

3. Turn off sprayer whenever you stop

spraying for a while and relieve fluid pres

sure.

WHAT TO

If

check

1.

Repair

DO

is

not

OK,

refer to this column.

or

replace any damaged wiring or

terminals. Securely reconnect all wires.

-

-

2.

Correct faulty conditions

3.

Replace motor.

4.

Replace bridge.

See

See

page 35.

page 24

-

Building circuit breaker opens

as

soon

as

sprayer is plugged

into outlet and sprayer is

turned

on.

L

18

307470

~~

NOT

1.

Check 'Basic Electrical Problems' on

page 13.

2. Check

ON/OFF switch (302). See page

23. Be sure the sprayer is unplugged!

Disconnect wires from switch and check

switch with ohm meter. The ohm meter

should read infinity with the

ON/OFF

switch OFF, and zero with the switch

ON.

CAUTION:

A

short in the motor circuit will

burn the bridge out immediately, which in

turn usually causes the

fail

in the closed mode.

ON/OFF switch to

2.

Replace ON/OFF switch. See page 23.

Page 19

SPIN

TEST

WARNING

Pressure Relief Procedure

To reduce the risk of serious bodily injury, including

fluid injection,

the eyes or on the skin, moving park or electric shock,

always follow this procedure whenever you shut

sprayer, when checking or servicing any

spray system, when installing, cleaning or changing ready to catch the drainage.

spray tips, and whenever

1.

Engage the gun safety latch.

2.

Turn the ON/OFF switch to OFF.

3.

Unplug the power supply cord.

4.

Disengage the gun safety latch.

injury from splashing fluid or solvent in

off

part of the

youstop spraying.

the

..

5.

Hold a metal part of the gun firmly

grounded metal pail, and trigger the

oressure.

6,

Engage

7.

Open the Pressure drain valve, having acontainer

8.

Leave the pressure drain valve open until you are

ready to spray again.

If

you suspect that the spray tip or hose

clogged,

ter following the steps above, wrap a rag around the tip

guard retaining nut or hose end coupling and VERY

SLOWLY loosen the

then loosen completely. Now clear the tip or hose

struction.

the

gun

safety

latch,

or

thatpressure has not been fullyrelievedaf-

partto relieve pressure gradually,

to

the side of a

gu.n to relieve

is

completely

ob

-

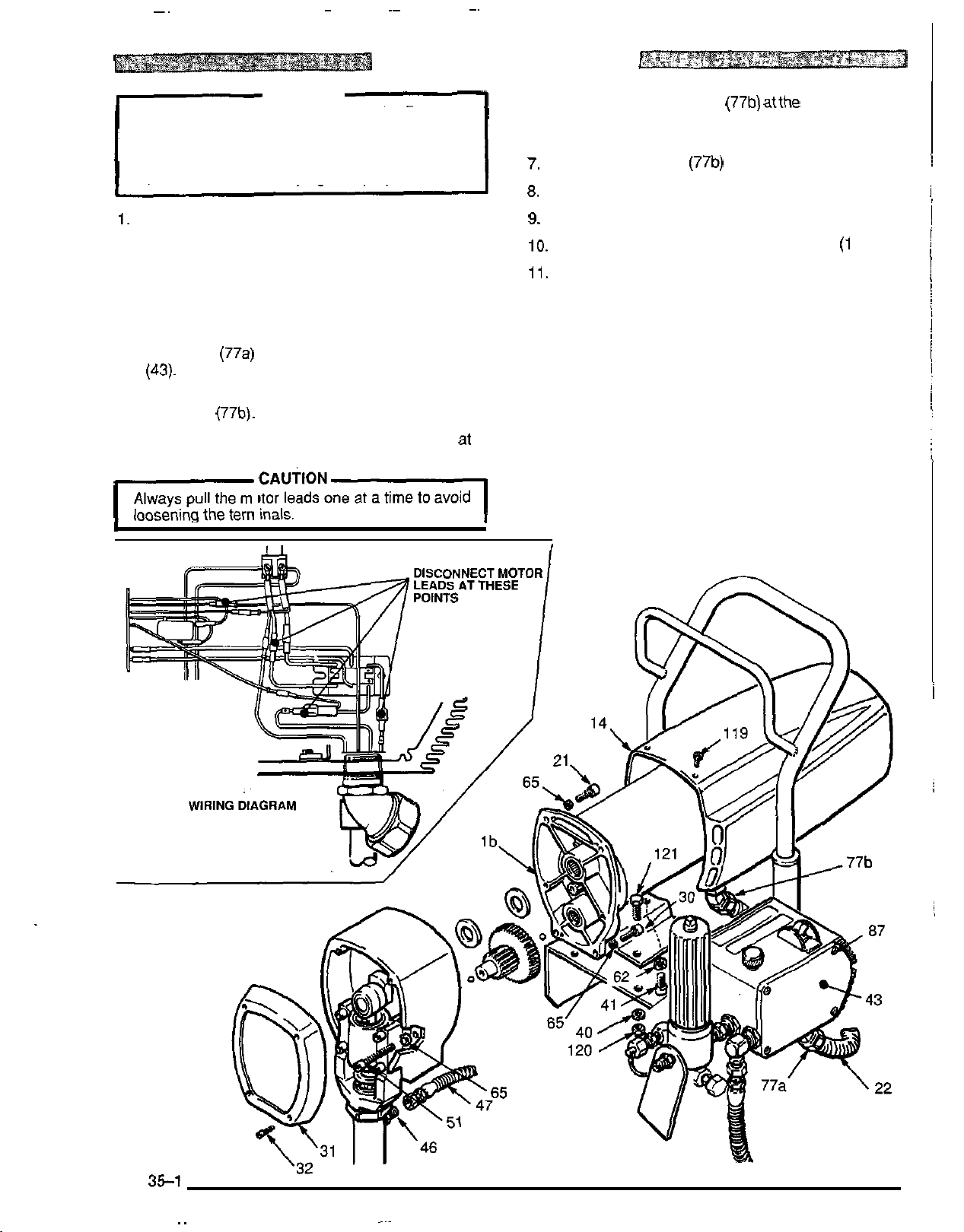

For checking armature, motor winding

cal continuity.

Setup

Remove the drive housing from the sprayer as described

in DRIVE

HOUSING

REPLACEMENT, Steps

Grid brush electri-

1-6,

page

32.

Remove the pressure control cover and screws, the mo-

tor cover, the fan cover (F), and the inspection covers

See

Fig

19-1.

Disconnect the

(308).

See

Armature Short Circuit Test

Quickly turn the motor fan by hand.

the motor will coast

ing

to

a complete stop.

If

the motor does not spin freely and resists rotation, the

armature

page

35.

Armature; Brushes, and Motor Wiring Open Circuit

Test (Continuity)

Connect the two black motor leads together with a test

lead.

Turn the motor fan by hand

second.

two

leads from the motor

fig

19-2.

If

two

or three revolutions before com-

is

shorted and the motor must be replaced. See

atabout

to

the bridge

there are no shorts,

two

revolutions per

(J).

Fig

19-1

If there

lowing and repair parts

a)

b) broken brush leads

c) loose brush terminal screws

d) worn brushes

e)

f) loose motor lead terminals

If

motor. See page

is

uneven or

broken brush springs

broken motor leads

there is still uneven or no turning resistance, replace the

no

turning resistance, check the

as

needed. See page

35.

33.

fol-

Fig

19-2

307-670

19

Page 20

BRIDGE

Remove the bridge from the pressure control box and

perform this test to determine

See

BRIDGE

Useacontinuitytester,suchasmulti-metersetonthexi

ohms scale.

All tests must be performed.

test, it must be replaced.

Fig 20

-

1 shows the position

Using the chart at the right, connect the meter wires as

indicated and then check

Fig

20-1

RECTIFIER REPLACEMENT,

if

the bridge is functional.

If

the bridge fails even one

of

the wires

the,continuity.

on

page 24.

the bridge.

TEST

Check For

1.

Line short

Connect meter + to bridge ACl

Connect meter - to

2. Diode 1

Connect meter

Connect meter

""""""""""__

Connect meter + to bridge ACI

Connect meter - to bridae

3.

Diode 2

Connect meter + to bridge

Connect meter - to bridge AC2

""""""""""""""""

Connect meter

Connect meter

4. Gate 1

Connect meter + to bridge

Connect meter

5.

Gate 2

Connect meter

Connect meter

5.

Diode

3

Connect meter

Connect meter

""""""""""""""""

Connect meter + to bridge

Connect meter

+

to

-

to

+

to bridge AC2

-

to

-

to bridge AC1

+to

bridge

-

to

bridge AC2

+to

bridge

-

to bridge

-

to bridge

bridge AC2

bridge

bridge ACl

-

-

I

-

bridge

-

+

+

+

+

-

Ohmmeter

Reading

No

continuib

Continuity

-

-

- -

- - -

No

continuity

Continuity

No

continuity

No

continuity

No

continuity

Continuity

No

continuity

-

20

307-670

Page 21

~

GENERAL REPAIR NOTES

WARNING

Pressure Relief Procedure

To reduce the risk of serious bodily injury, including

fluid injection, injury from splashing fluid or solvent

in the eyes or on the skin, moving parts or electric

shock, always follow this procedure whenever you

.shut off the sprayer, when checking or servicing any

part of

thespray system, when installing, cleaning or

changing spray tips, and whenever you stop spray

ing.

1. Engage the gun safety latch.

2. Turn the

3. Unplug the power supply cord.

4.

Disengage the gun safety latch.

5.

Holdametalpartofthegunfirmlytothesideofa

grounded metal pail, and trigger the gun to re

lieve pressure.

6.

Engage the gun safety latch.

7.

Open the pressure drain valve, having a con

tainer ready

8.

Leave the pressure drain valve open until you

are ready to spray again.

If

you

plete& clogged, or that pressure

relievedafter following the steps above, wrap a rag

around the tip guard retaining nut or hose end cou-

pling and VERY SLOWLY loosen the part to relieve

pressure gradually, then loosen completely. Now

clear the

'001

List

Phillips screwdriver

Small flat blade

screwdriver

Needle nose pliers

Plastic mallet' 1/2 open end wrench

Adjustable wrench

2 adjustable,

open

Torque wrench

ON/OFF switch to OFF.

to

catch the drainage.

suspect that the spray

ti0

or hose obstruction.

114"

311 6 hex key wrench

518"

318" open end wrench

3/4" open end wrench

718"

-

end wrench

High quality motor oil

Bearing grease

.~

tip

or hose

has

hex key wrench

socket wrench

open end wrench

is

not been

com

fu//y

CAUTION

be sure

on a wire to disconnect

2. Route wires in the pressure control assembly care

-

Improper wire routing can result in poor sprayer per

formance or damage to the pressure control.

-

3. Keep all screws, nuts, washers, gaskets, and electri

-

4. Test your repair before regular operation of the

-

1-

To reduce the risk of serious bodily injury, including

electric shock,

electrical parts with your fingers or a tool while

specting the repair.

Shut

complete the inspection.

Reinstall all covers, gaskets, screws and washers

before operating the sprayer.

Do

to avoid damaging the pump packings.

to

properly mate connectors, and never pull

it.

Pulling on a wire could

fully through the legs

This is

which moves as the pressure setting changes, and to

avoid pinching the wires between the pressure

trol box and cover.

cal fittings removed during repair procedures. These

parts are not normally provided with replacement as

semblies.

sprayer to be sure the problem is corrected.

If the sprayer does not operate properly, review the

repair procedure again to verify that everything was

done correctly.

Troubleshooting Guide, pages 13

tify other possible problems and solutions.

to avoid interfering with the bourdon tube,

DO

off

the sprayer and unplug it as soon as you

of

the U-shaped bourdon tube.

con-

CAUTION

If

necessary, refer to the

-

20, to help iden

WARNING

NOT touch any moving parts or

in-

-

1

CAUTION

not run the sprayer dry for more than

30

seconds

-

-

-

-

For

calibration procedure

3/8" ignition wrench Clean water

0.015"

High pressure. oil

5 gallon pail

.

spray tip Mineral spirits

-

filled NEW

lest gauge,

Part No. 102

When disconnecting wires in the pressure control as

sembly, use needle nose pliers to separate mating

connectors.

When reconnecting the wires, be

of the insulated male connector

wraparound blade of the female

-

814

on&:

207

bar hioh

pressure spray hose,

Part No.

214-915.

sure the flat blade

is centered in the

connector.

I

-

5.

Reinstall the motor cover before regular operation of

the sprayer and replace it

directs cooling air around the motor to help prevent

overheating. It can also help reduce the risk of burns,

fire or explosion: see the

WARNING

During operation, the motor becomes very hot and

could burn your skin

als spilled on the hot, bare motor could cause a fire

or explosion. Always have the motor cover in place

during regular operation to reduce the risk of burns,

fire or explosion.

if

it is damaged. The cover

WARNING,

if

touched. Flammable materi-

below.

307470

21

Page 22

POWER SUPPLY CORD REPLACEMENT

WARNING

Before doing this procedure, follow the

Relief Procedure Warning

the risk of a fluid injection injury, splashing in the

eyes or on the skin, injury from moving parts, or

electric shock.

Refer

to

Fig

22-f

and

22-2

1.

Use the 19 mm open end wrench to remove the nut

(337)

from the filter stud (31

2.

Use the 13 mm socket wrench

(44)

Screws

frame.

3.

Remove the pressure control mounting bracket

using a Phillips screwdriver.

4.

Disconnect the power supply cord wires

control box terminal strip (336) using a screwdriver.

5.

Install the new power supply cord

verse order of disassembly.

6.

Have a licensed electrician install a new plug on the

other end of the cord. Be sure

regarding the type of plug

holding the pressure control

on page 21 to reduce

0).

to

to

follow all local codes

to

use.

Pressure

remove the three

from

(31

1) in the re-

to

the

(89)

the

Fig

22-1

FILTER REPLACEMENT

Relief Procedure Warning

the risk of a fluid injection injury, splashing in the

eyes or on the skin, injury from moving parts, or

electric shock.

Refer

to

Fig

22-2

1. Remove the pressure control cover and screws.

2.

Use a needle nose pliers to remove the four wires

from

the

filter (310).

3.

Use the

lockwashers (337, 338) on the outside of the

pressure control box.

4.

Remove the old filter and install a new one in the

reverse order of disassembly.

M8

wrench

on

page 21

to

remove the lower nut and

to

reduce

Fig

22-2

w-\

i

311

22

307-670

Page 23