Page 1

Instructions

Variable Frequency

Drive

Motor drive control for Graco E-Flo® Electric Circulation Pumps.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

See page 3 for approvals information.

Part No. 15J753, 200-240 Vac

UNIDRIVE SP Digital AC Drive

208/230VAC, 5HP, SP2201

Part No. 15J754, 380-480 Vac

UNIDRIVE SP Digital AC Drive

460VAC, 5HP, SP1405

UNIDRIVE Information

311596F

Unidrives are manufactured by Control Techniques

Corporation. Read all warnings and instructions

from Control Techniques (provided on a CD)

before beginning the installation or operation of

this equipment.

Related Graco Manuals

Manual Description

311592 E-Flo Installation Manual

311593 E-Flo Operation Manual

311594 E-Flo Repair-Parts Manual

311606 VFD/BPR Air Control Manual

311608 Power Module Manual

311612 Ethernet Upgrade Kit Manual

311690 High-Flo Lowers

ti9002a

Page 2

Warnings

Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

E-Flo Electric Circulation Pumps . . . . . . . . . . . . 3

Pump Operational Limits . . . . . . . . . . . . . . . . . . . 3

Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Glossary of Terms . . . . . . . . . . . . . . . . . . . . . . . . 3

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Variable Frequency Drive (VFD) Kits and Options 5

Repair Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Controls and Indicators . . . . . . . . . . . . . . . . . . . . . 6

Control Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Variable Frequency Drive (VFD) Keypad . . . . . . 7

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Ground the VFD . . . . . . . . . . . . . . . . . . . . . . . . . 8

Navigating the Keypad . . . . . . . . . . . . . . . . . . . . 8

E-Flo Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Calibrate and Autotune the Motor . . . . . . . . . . . . 9

Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . 12

SMARTCARD Defaults . . . . . . . . . . . . . . . . . . . 12

Complete System Reload . . . . . . . . . . . . . . . . . 13

E-Flo Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Back Pressure Regulator (BPR) Control . . . . . . 15

Cycle Counter . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Flow Rate Monitoring . . . . . . . . . . . . . . . . . . . . 16

Pressure Monitoring . . . . . . . . . . . . . . . . . . . . . 16

Operational Envelope Limit . . . . . . . . . . . . . . . . 21

Running the Pump . . . . . . . . . . . . . . . . . . . . . . . . . 21

Secure Disable . . . . . . . . . . . . . . . . . . . . . . . . . 21

Start/Stop Command . . . . . . . . . . . . . . . . . . . . . 22

Flow Control . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Drive Trip Codes and Diagnostic Procedures . . 24

Trips and Diagnostic Procedures . . . . . . . . . . . . 24

Resetting the System . . . . . . . . . . . . . . . . . . . . 24

Computer Control and Monitoring . . . . . . . . . . . . 27

Ethernet Upgrade Kit 15H885 . . . . . . . . . . . . . . 27

E-Flo Software Update . . . . . . . . . . . . . . . . . . . . . . 27

Configure the Ethernet Card . . . . . . . . . . . . . . . 30

Install the Computer Software . . . . . . . . . . . . . . 31

Connect the VFD to the PC . . . . . . . . . . . . . . . . 31

Run Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Advanced Options Screen . . . . . . . . . . . . . . . . . 35

BPR Production Flow Screen . . . . . . . . . . . . . . 36

Data Logging Screen . . . . . . . . . . . . . . . . . . . . . 39

Power Monitor Screen . . . . . . . . . . . . . . . . . . . . 40

Pressure Transducer Calibration Procedure . . . . 41

System Electrical Diagrams . . . . . . . . . . . . . . . . . 42

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Mounting Hole Diagrams . . . . . . . . . . . . . . . . . . . . 45

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 46

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 46

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

ELECTRIC SHOCK HAZARD

Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

2 311596F

Page 3

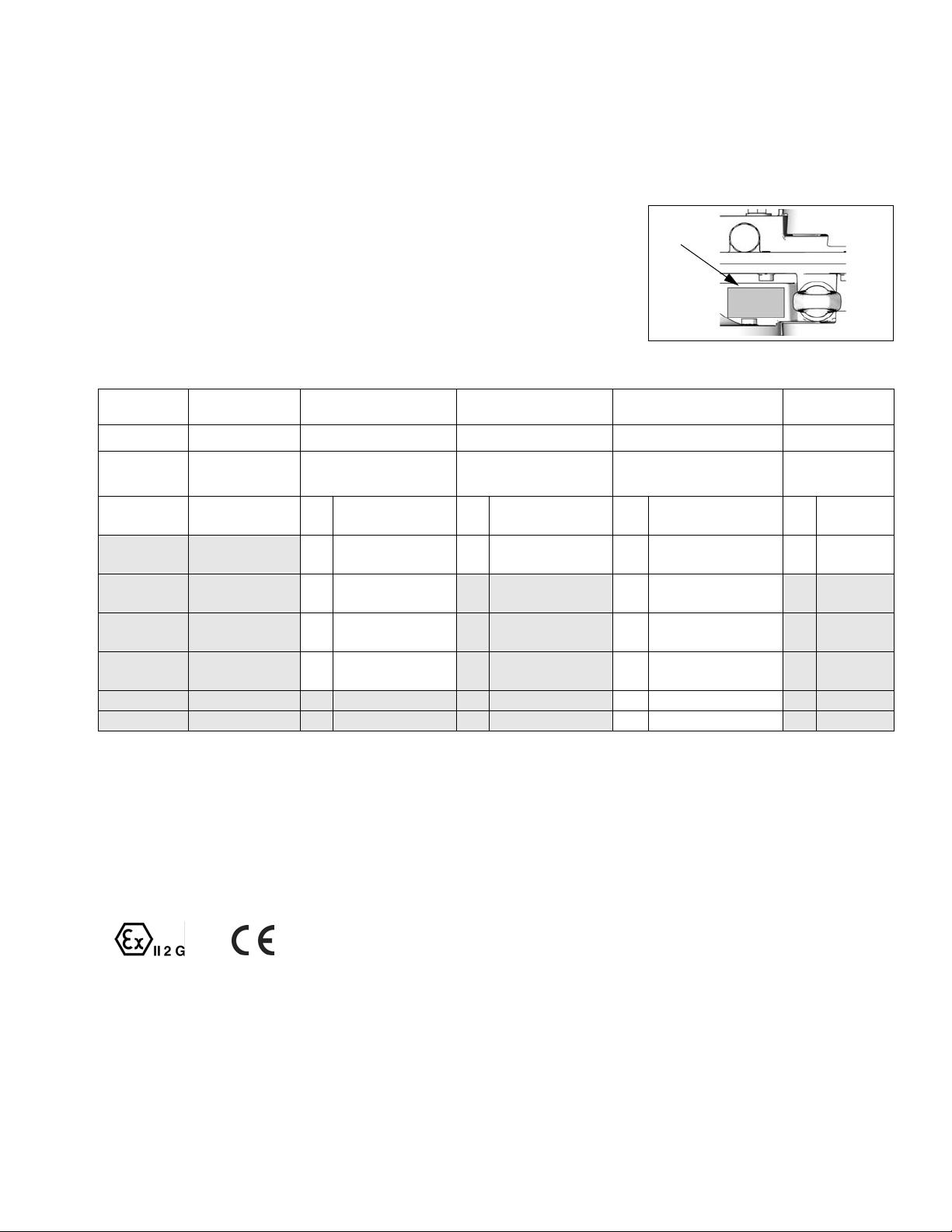

Models

E-Flo Electric Circulation Pumps

Check your pump’s identification plate (ID) for the 6-digit part number of your

pump. Use the following matrix to define the construction of your pump, based

on the six digits. For example, Pump Part No. EP2160 represents electric

power (E), pump (P), 230/460V motor (2), sensor circuit installed (1), 2000 cc

Maxlife lower (6), and no stand installed (0). To order replacement parts, see

the Repair-Parts manual 311594.

EP 2 1 6 0

First Digit Second Digit Third Digit Fourth Digit Fifth Digit Sixth Digit

Power

Source

E (electric) P (pump) 0 No motor 0 No circuit

Equipment

Style Motor Sensor Circuit Lower Size Stand Option

installed

1 230/400V, 5 HP,

AT EX

2 230/460V, 5 HP,

UL/CSA

3 230/400V, 3 HP,

AT EX

4 230/460V, 3 HP,

UL/CSA

1 Circuit installed 2 1500 cc Chromex 1 Stand

ID

ti8912a

ID Plate, Viewed from Above

1 1000 cc Chromex 0 No stand

installed

installed

3 2000 cc Chromex

4 1000 cc Maxlife

5 1500 cc Maxlife

6 2000 cc Maxlife

7 750 cc Chromex

Models

Pump Operational Limits

See Related Graco Manuals on the front cover.

Approvals

This equipment meets requirements of the following

approval agencies:

II2G EExdIIA T3

311596F 3

Glossary of Terms

Term Description

VFD Variable Frequency Drive

TDC Top Dead Center; measures position of pump

drive

I/O Input/output

Trip A condition which causes VFD to trip motor; see

page 24

PCB Printed Circuit Board

Pr Parameter

Run Set of commands enabling motor to run in desig-

nated direction

Stop Set of commands authorizing motor to stop run-

ning

Page 4

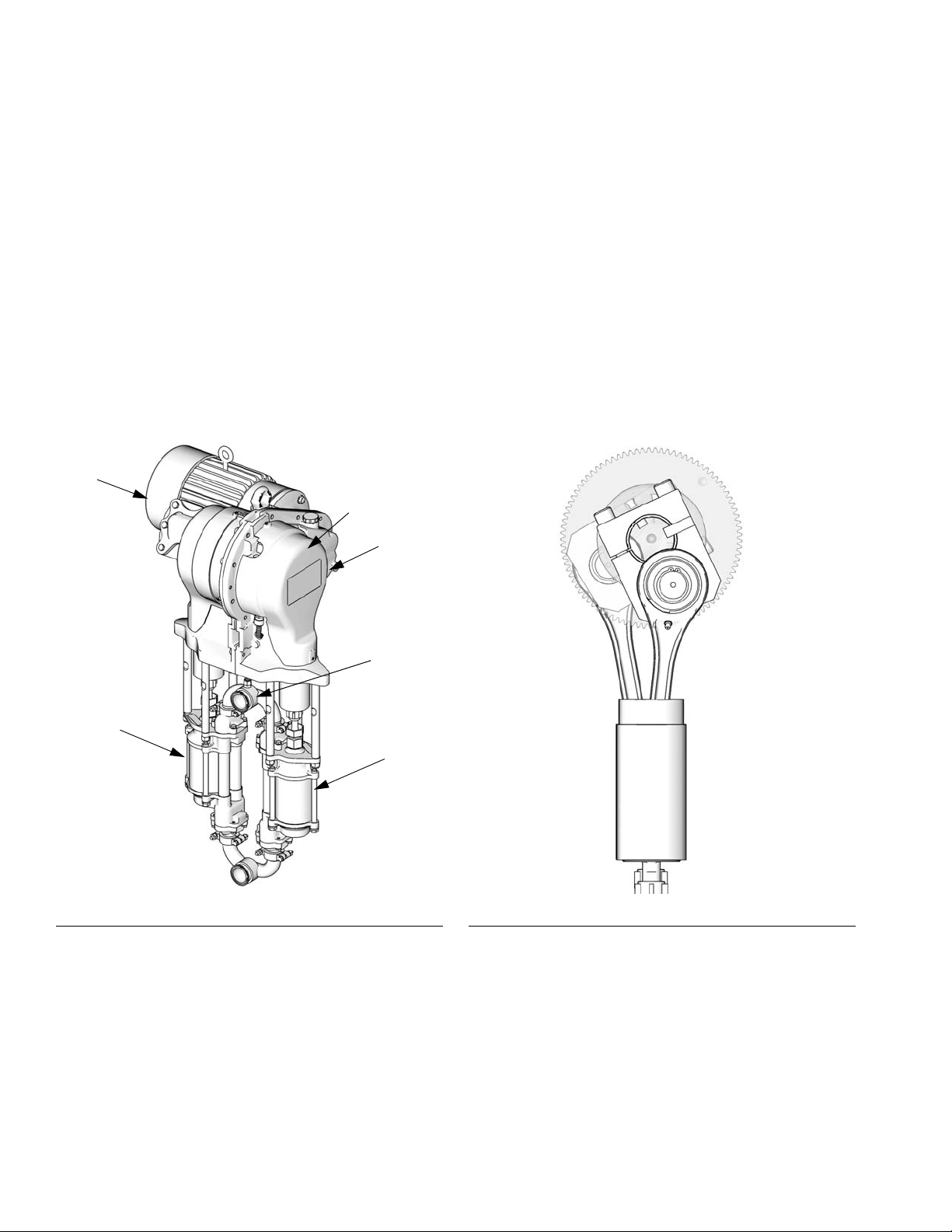

Overview

Overview

An electric motor (B) provides input to a 75:1 gear reducer (GR), which drives two fluid pumps (FP). See FIG. 1. The

stroke positions of the two pumps are offset to achieve consistent flow from the pump assembly. See F

The optional sensor circuit includes a top dead center (TDC) sensor which assists software in measuring motor

speed, and a pressure transducer (PT) with circuit board, which measures fluid pressure at the pump outlet. The

Graco VFD software mimics the effect of a camshaft, constantly adjusting motor speed to keep steady fluid flow and

achieve minimal pressure variation. The output shaft of the gearbox and the connecting rods experience the effect of

the imaginary camshaft by speeding up when the pressure drops (pump lower is at a changeover) and slowing down

when pressure increases (both lowers are pumping).

The VFD can be controlled by a local control box mounted in the hazardous area, via communication protocol (such

as modbus), or directly from the keypad.

IG. 2.

B

FP

F

IG. 1. Electric Circulation Pump

TDC (behind

cover)

GR

PT

FP

ti8317a

ti8321a

IG. 2. Cutaway Showing Offset Stroke Positions

F

4 311596F

Page 5

Variable Frequency Drive (VFD) Kits and Options

Variable Frequency Drive (VFD) Kits and Options

Kits and options can be ordered through your Graco Distributor.

Repair Kits

Transducer Kit P/N 15H876 - replaces the pressure

sensor and its circuit board. Note that pressure sensor

can be calibrated, and calibration procedure is included

in this manual.

Circuit Board Kit P/N 15H879 - replaces the sensor circuit board.

Top Dead Center Sensor Kit P/N 15H877 - replaces

top dead center (TDC) sensor.

Options

Ethernet Upgrade Kit P/N 15H885 - provides Ethernet

module for the VFD. Ethernet cable is not included.

Circuit System Kit P/N 15J755 - contains PCB and

sensors necessary to run Graco programmed VFD and

take advantage of low flow and pressure fluctuations

delivery by Graco software.

Local I/O Box P/N 120373 (UL/CSA) or 120991

(ATEX) - allows the operator to control the E-Flo locally

at the pump when performing maintenance or troubleshooting. The local I/O box has the following features:

• secure disable switch

• run/stop switch

• local/remote switch

• jog/park switch

•trip reset

Power Module P/N 288036- supplies necessary hardware to interface with the pump’s intrinsically safe (IS)

circuitry. The hardware includes IS barriers, transformer,

24 VDC power supply, fuses and terminal blocks for connectivity.

RFI Filter Module for 230 VAC VFD: P/N 120365

RFI Filter Module for 480 VAC VFD: P/N: 120366

VFD 200/240V Control Kit: P/N 15J753

VFD 380/480V Control Kit: P/N 15J754

311596F 5

Page 6

Controls and Indicators

Controls and Indicators

If Local mode of operation is an option for a given installation, use Graco Local I/O Explosion Proof Control Box

(see page 5).

Two Variable Frequency Drives are available and are

used for different voltages. Use the appropriate one for

your system. See front cover for part number information.

Control Modes

There are two ways to control or monitor the E-Flo Electric Circulation Pump.

• Locally

• Remotely (Keypad/Modbus)

The addition of a local control box allows the operator to

control the E-Flo at the unit. See Available Options on

page 5.

Starting, running, and stopping of the motor is controlled

by the Sequencer, which has been programmed to comply with E-Flo Local and Remote schemes. VFDs are

normally installed in electrical enclosures, away from

motors, which they control. Local mode refers to controls which are installed locally at the pump, or within

sight of the pump. Remote mode refers to controls

installed remotely, away from the pump.

More then one command is required to be active for

motor to operate. All of these are controlled by Graco

software. Do not try to reconfigure VFD parameters to

operate outside of the Graco design described in this

manual. Doing so can cause system malfunction.

Parameters are controlled by the program in the

AppsLite module and will be reset back to E-Flo defaults

at next reset. Reset occurs during each power-up.

Run command refers to a set of commands, enabling

motor to run in designated direction.

Stop command refers to a set of commands, authorizing

motor to stop running.

Local Control Mode

When Local mode is selected, motor can only be started

by a hardware switch. VFD terminal #27 is configured

for this operation (see System Electrical Diagrams,

page 42). Normally open position is Stop; closed posi-

tion is Run.

Common ground is available at VFD terminals #1,

3, 11, 21, 23, and 30.

Mode selection is performed by a hardware switch. Digital I/O #5 (VFD terminal #28) is configured for this operation (see System Electrical Diagrams, page 42).

Normally open position of the switch commands remote

mode; closed position commands local mode.

Common ground is available at VFD terminals #1,

3, 11, 21, 23, and 30.

6 311596F

Stop Command Via Keypad

To initiate the Stop command via the keypad, press the

Stop/Reset (red) button on a keypad display.

Remote Control Mode

When remote control mode is selected, control commands can be directly entered into the VFD by means of

a keypad or can be sent via modbus. Refer to SM Ethernet User Guide (Control Techniques) for more information on modbus control.

Page 7

Controls and Indicators

Variable Frequency Drive (VFD)

Keypad

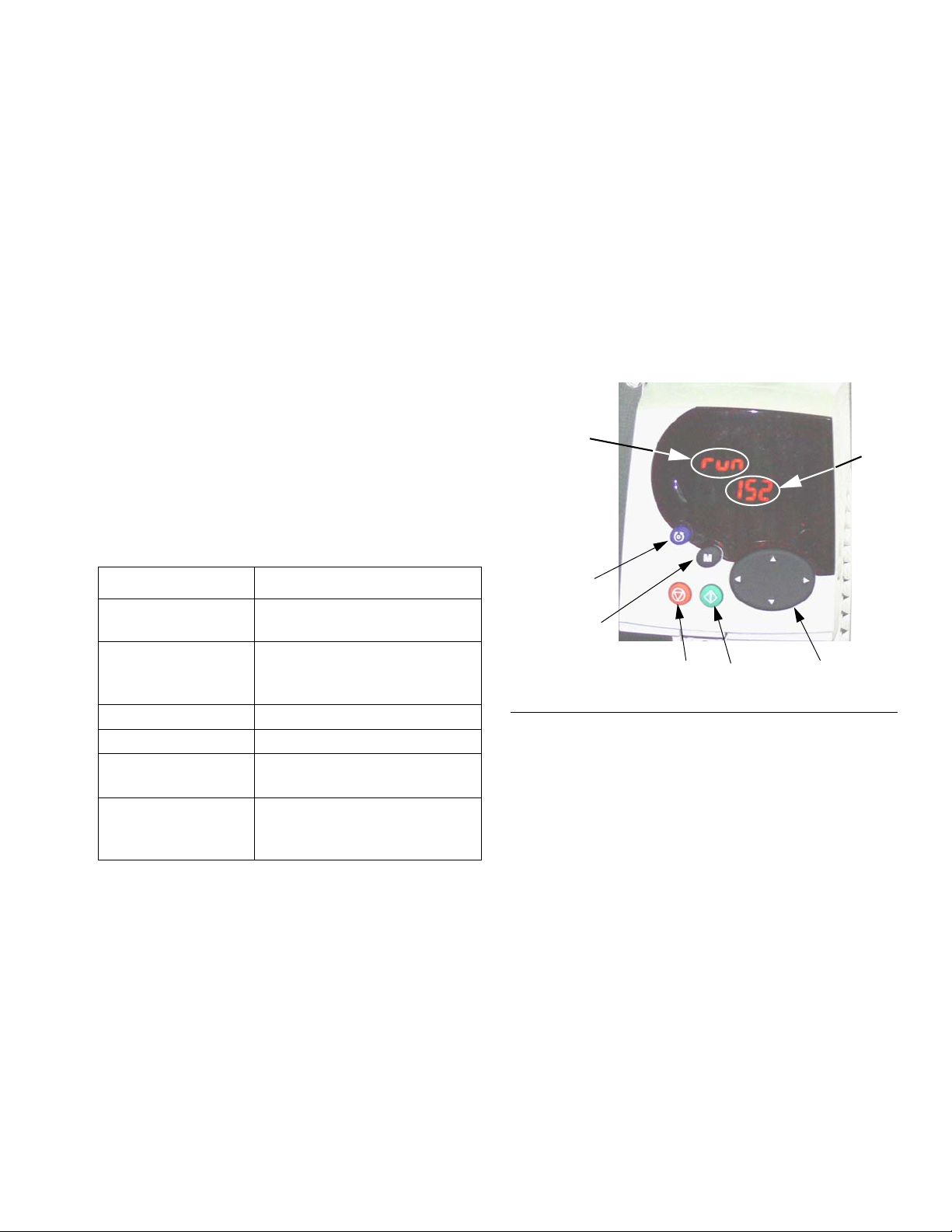

The VFD keypad consists of a display, four control buttons, and a joypad with four arrow keys. See F

VFD Display

The VFD display has two rows.

The upper row (A) displays either the drive status (run is

shown) or the parameter being viewed, in the format

XX.XX (for example, 20.05). In this manual, parameters

are referred to as Pr (for example Pr 20.05).

The lower row (B) displays the parameter value (152 is

shown) or a trip code.

Table 1 shows some examples of drive status codes.

Refer to the User’s Guide by Control Techniques for the

full list.

Table 1: Drive Status Examples

IG. 3.

VFD Control Buttons

• Fwd/Rev (U): not active in this application.

• Stop/Reset (V)

• Start (I, green): not active in this application.

• Mode (M, black): used to change between the display modes - parameter view, parameter edit, status.

• Joypad: used to navigate the parameter structure

and change parameter values. See page 8 for

details.

A

B

Display Code Definition

Auto tunE

(flashes alternately)

inh VFD is inhibited and will not

rdY Motor is ready to run.

run Motor is running.

triP VFD has tripped. Trip code

dEC Decelerating - motor speed is

Motor auto tune is in progress.

run because Secure Disable

is engaged.

appears in lower display.

ramping to zero following a

stop command.

U

M

V

FIG. 3: Variable Frequency Drive Keypad

I

Joypad

311596F 7

Page 8

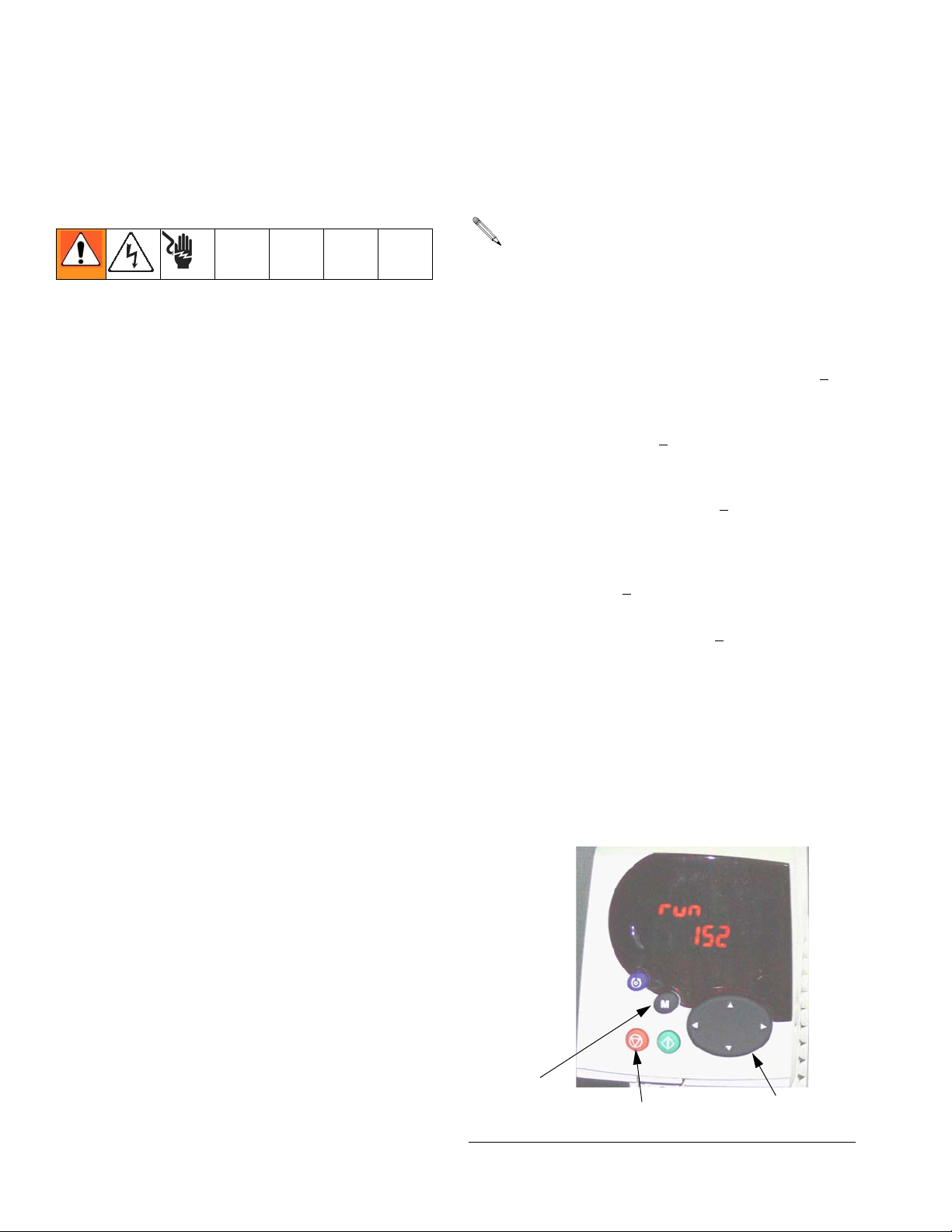

Setup

Setup

Ground the VFD

The equipment must be grounded. Grounding reduces

the risk of static and electric shock by providing an

escape wire for the electrical current due to static build

up or in the event of a short circuit. Ground the variable

frequency drive through a proper connection to a power

source. Refer to the Control Techniques manuals for

grounding instructions.

Navigating the Keypad

The Unidrive SP User Guide has a detailed explanation

of the Keypad operation and contains navigation procedures. The following is an example and is not intended

to explain in detail the complete operation of the Keypad. It is strongly recommended that the installer refer to

the Unidrive SP User Guide (provided on a CD) for

detailed instructions.

Calibration of lower size is chosen as an example to

explain the operation of the Keypad display. Graco

default setting for the lower size is 2000cc. In the following example, we will change the lower size to 1500cc.

2. Alter the value of Pr 20.03:

While number 20.03 is flashing on the upper row of

the screen, number 2000 is displayed on the lower

row of the screen, representing lower size of

2000cc.

a. Press the (M) key once. This will cause the cur-

sor to move to the bottom row of the display and

the least significant digit of the number 2000

(most right digit) should be flashing.

b. Press the Left arrow key to navigate to the third

digit from the right 20

to start flashing.

c. Press the Up arrow key to scroll to number 5.

This should cause number 25

screen with number 5 still flashing.

d. Press the Left arrow key to navigate to the next

digit on the left. This will cause number ‘2’ to

start flashing (2

e. Press the Down arrow key to change the num-

ber 2 to number 1. Number 1

played on a screen with number 1 flashing.

f. Press the (M) key once to move cursor from the

bottom row to the top row. This will cause number 20.03 on the top row to flash.

00. This will cause the digit

00 to display on a

500).

500 should be dis-

Each parameter consists of a menu number and submenu number. Lower size calibration value is located in

Pr 20.03: 20 refers to Menu 20; 03 refers to Submenu

03.

1. Navigate to Pr 20.03:

a. Pressing the Left and Right arrow keys will allow

you to navigate between menus 0 and 22.

b. Pressing the Up and Down arrow keys will allow

you to navigate within the submenus.

c. Press the Left or Right arrow keys until you

reach menu 20 (Number 20.00 should be flashing on a screen).

d. Press the Up or Down arrow keys until you

reach submenu 3 (Number 20.03 should be

flashing on a screen)

8 311596F

g. This completes the procedure of changing a

parameter value. In this case you have changed

Pr 20.03 from 2000 to 1500 (number 1500 will

show on lower row of display).

M

V

F

IG. 4: Variable Frequency Drive Keypad

Joypad

Page 9

E-Flo Calibration

CAUTION

The system must be calibrated before start-up. Failure

to calibrate will result in malfunction, alarm trips, and

decreased safety.

E-Flo Calibration

pressure performance for low flow settings (corresponding motor frequency of less than 12 Hz).

5. Continue with step 1. Pressure Sensor Calibration

on page 10.

Calibrate and Autotune the

Motor

IMPORTANT: Before installing the motor it must be

calibrated and autotuned. This allows the drive to

have better control of the motor.

Graco Motors

To calibrate and autotune motors purchased from

Graco, perform the following steps:

1. Motor Selection. Parameter Pr 20.37 is reserved

for the motor calibration information listed on the

pump’s identification plate. The value of Pr 20.37 is

determined as follows:

EP1XXX=> Pr 20.37 = 1

EP2XXX=> Pr 20.37 = 0

EP3XXX=> Pr 20.37 = 4

EP4XXX=> Pr 20.37 = 3

2. Load Graco Motor Defaults. Navigate to Pr 20.16

and set its value to 56. At this time the specific

Graco motor parameters will be loaded and the

number 56 will be replaced by 0 automatically.

3. Follow the instructions under Autotune the Motor,

page 10.

IMPORTANT: Autotuning the motor is especially

important if using a 3HP motor, or if a 5HP motor is

used on a system with a low flow setting (corresponding frequency of less than 12 Hz).

Non-Graco Motors

Graco does not support the use of the Graco VFD

CAM mode on motors not supplied by Graco.

Use only 1500 rpm or 1800 rpm rated motors.

To calibrate and autotune motors not purchased from

Graco, perform the following steps:

1. Motor Selection. Set Pr 20.37 to 2 (non-Graco

motor).

2. Set Motor Parameters. Navigate to menu #5. Refer

to your motor’s identification plate for necessary

information.

a. Pr 5.06 - Rated Frequency.

b. Pr 5.07 - Motor Rated Current.

c. Pr 5.08 - Rated Load RPM/Rated Speed.

d. Pr 5.09 - Rated Voltage.

e. Pr 5.10 - Rated Power Factor.

f. Pr 5.11 - Number of Motor Pole Pairs (4 pole

motor has 2 pairs).

3. Enter Motor Rated Current. Multiply motor rated

current found on motor’s identification plate by 10.

Enter resulting value into Pr 20.12.

4. Follow the instructions under Autotune the Motor,

page 10.

4. Pr 5.27 controls the Slip Compensation feature. It is

turned on by default for 3HP motors and turned off

for 5HP motors. Turning this feature on will improve

311596F 9

5. Continue with step 1. Pressure Sensor Calibration

on page 10.

Page 10

E-Flo Calibration

Autotune the Motor

IMPORTANT: Before installing the motor it must be

calibrated and autotuned. This allows the drive to

have better control of the motor.

Refer to the User’s Guide by Control Techniques for

complete autotuning instructions.

The motor shaft will rotate during autotuning. Keep

clear of moving parts.

1. Decouple motor from gearbox. Secure motor to prevent it from jumping during autotuning.

2. Apply power to motor. Motor will rotate during autotuning. Keep clear of motor shaft and moving parts.

3. Navigate to Pr 5.12 and set its value to 2.

4. Apply Run command, see page 22. Autotuning will

begin.

5. When motor stops turning, check that Pr 5.10

(Power Factor) and Pr 5.17 (Stator Resistance) are

set to non-zero values. This indicates that the autotune was successful.

To prevent accidental change of pressure sensor calibration parameters, they are locked by Pr 20.16. To

enter calibration parameters, perform the following

steps:

a. Set Pr 20.16 to 777, to unlock pressure sensor

parameters.

b. Select and set TDC and pressure transducer

function (software level 5.00.00 and later only):

• TDC: Pr 8.11. Select On (enable) or Off

(disable).

• Pressure Transducer: Pr 7.13. Select On

(enable) or Off (disable).

• Select Analog Signal Mode: Pr 7.11. Typi-

cally 4-20tr.

c. Enter calibration parameters Pr 20.34, 20.35,

and 20.36.

d. Set Pr 20.16 to 0 to lock parameters, then set

Pr 0.00 to 1001 to save parameters.

If pressure sensor is part of the system (EPX1XX –>

Fourth Digit = 1), calibration information is printed on the

label located on the circuit board cover. If the system

was purchased without a Circuit System Kit (Graco P/N:

15J755) but one was installed later, affix the label

(included with the kit) to the circuit board cover and

enter calibration information into the VFD.

6. To save motor parameters, navigate to Pr 5.00, set

its value to 1001, and press the red Stop/Reset button. The number 1001 will automatically change to

0, indicating that the parameters have been saved.

1. Pressure Sensor Calibration

IMPORTANT: Pressure sensor information for your

system is listed on the label attached to the pump

gearbox circuit board cover.

CAUTION

Pressure sensor calibration information must be

entered into the VFD. Failure to do so will result in

Pressure Sensor Calibration Trip (#50), nuisance

trips, or system malfunctions.

Pressure sensor information (Pr 20.34, 20.35, and

20.36) for your system must be keyed into the Vari-

able Frequency Drive before system start-up.

Calibration Parameters from the label:

Pr 20.34 – Zero Calibration

Pr 20.35 – Calibration Pressure

Pr 20.36 – High Calibration

2. Pump Lower Size Selection

Parameter Pr 20.03 is reserved for the Lower size calibration information listed on the unit’s identification

plate:

EPXX1X => Pr 20.03 = 1000

EPXX4X => Pr 20.03 = 1000

EPXX2X => Pr 20.03 = 1500

EPXX5X => Pr 20.03 = 1500

EPXX3X => Pr 20.03 = 2000

EPXX6X => Pr 20.03 = 2000

EPXX7X => Pr 20.03 = 750

If the pump lowers are changed to a different size

after purchase, the plate information is no longer

valid.

10 311596F

Page 11

E-Flo Calibration

3. Unit Selection

Select measuring units in parameter Pr 20.15. The

default is English.

English => Pr 20.15 = 0

Metric => Pr 20.15 = 1

Measurement unit summary:

Measurement English Metric

Pressure psi bar

Flow gpm lpm

The Keypad display does not show a decimal point.

T

ABLE 2 provides resolution values for measure-

ment setting parameters.

4. High Pressure Alarm Setting

The High Pressure Alarm setting is controlled by parameter Pr 20.09. The default unit is English and default setting is 300 psi. Refer to T

allowable setting for a given Lower size and units. The

High Pressure Alarm (#40) becomes active when system pressure reaches the pressure setting in Pr 20.09.

ABLE 2 to determine maximum

Low Pressure Alarm Disable => Pr 20.08 = 0

This feature is disabled by default.

6. Low Pressure Alarm Setting

The Low Pressure Alarm setting is controlled by parameter Pr 20.07. The default unit is English and default setting is 150 psi. Refer to T

allowable setting for a given Lower size and units. The

Low Pressure Alarm (#41) becomes active if it is

enabled (Pr 20.08 = 1) and system pressure drops lower

than the Low Pressure Alarm setting.

For metric units, multiply the desired pressure by

10 and enter the result into the VFD. The last digit

is a decimal.

System pressure must first rise above the Low

Pressure Alarm setting for the trip to start operating. This allows the system to build up to operating

pressure without shutting down due to Low Pressure Alarms.

ABLE 2 to determine maximum

7. System Ramp Rate Selection

For metric units, multiply the desired pressure by

10 and enter the result into the VFD. The last digit

is a decimal.

5. Low Pressure Alarm

Enable/Disable

Low Pressure is an adjustable feature. Parameter Pr

20.08 is used to enable and disable the feature:

Low Pressure Alarm Enable => Pr 20.08 = 1

Ramp rate controls the time it takes for the pump to

reach the preset rate. Units is English, measured in gallons per minute/minute (gpm/min). Note that a fast ramp

rate may cause the pump to rapidly build high system

pressure, causing system shutdown due to a High Pressure Trip (Alarm #40).

The Ramp Rate setting is controlled by parameter Pr

20.02. Ramp rate range is 10 – 1000 gpm/min. Any

number within this range can be selected. It is recommended that the default ramp rate be kept. The default

setting is 100gpm/min.

311596F 11

Page 12

E-Flo Calibration

8. Speed Potentiometer

Enable/Disable

Variable resistor (potentiometer) is used to control motor

frequency. Refer to Motor Speed Control, page 23, for

more information. Set Pr 20.38 to enable or disable the

speed potentiometer. Disable is the default.

• Speed Potentiometer Enable=> Pr 20.38 = 1

• Speed Potentiometer Disable=> Pr 20.38 = 0

9. Saving Calibration

The last step in the calibration procedure is to save all

calibration values.

a. Saving to the Drive/Program Module.

To ensure that all calibration values are permanently saved to the drive/program module:

1. Navigate to Pr 0.00 and set its value to

1001.

Factory Defaults

E-Flo System Specific Parameters (menu 20 parameters)

All of the E-Flo features are controlled by menu 20

parameters. VFDs are shipped with these parameters

set to default values (refer to Table 2 for more information). Factory defaults can be loaded as follows:

1. Disable the drive through Secure Disable (if a Graco

Local Control Box is used, press the red

mushroom-type Secure Disable button).

2. Navigate to Pr 20.16 and set its value to 1234. At

this time the program defaults will be loaded and

number 1234 will automatically be replaced by 0.

E-Flo Motor Specific Parameters

VFDs are shipped with all motor parameters defaulted to

UL/CSA motor. It is essential for system performance

that proper motor calibration parameters are entered

into the VFD. See page 9 for more information.

2. Press the red Stop/Reset button. The

number 1001 will automatically change to

0, indicating that all parameters have been

saved.

b. Saving to the SMARTCARD.

SMARTCARD is an excellent memory

backup for system-specific parameter calibrations. If system parameters are mistakenly

altered, using SMARTCARD can restore initial calibration.

1. Ensure that SMARTCARD is installed in

the VFD. (VFD is shipped with SMARTCARD already installed and Graco

defaults saved to memory location #101).

2. Navigate to Pr 0.00 and set its value to

4202 (memory location #202).

3. Press the red Stop/Reset button. Small

red dot on keypad display will start blinking, indicating that parameters are being

saved.

To restore factory defaults, set Pr 20.16 to 45.

SMARTCARD Defaults

Default Graco parameter values for menus 0 through 22

are saved on SMARTCARD in location #101, as differences from the drive defaults; see the Control Techniques manual for further information. Use Code 6101 to

load Graco defaults.

4. When dot stops blinking, the save is completed.

12 311596F

Page 13

E-Flo Calibration

Complete System Reload

A complete system reload may be necessary because

of an error in calibration or accidental parameter alteration.

1. Disconnect power to the VFD.

2. Remove all solutions modules. Reconnect power.

3. Navigate to Pr 0.00 and set its value to 1244.

4. Press the red Stop/Reset button. Number 1244 will

be automatically replaced by 0 as an indication that

all VFD parameters are reset to defaults.

5. Navigate to Pr 0.00, set its value to 1001, and press

red Stop/Reset button to save the changes. Number

1001 will be automatically replaced by 0.

6. Disconnect power from the VFD, reinstall all modules, and reconnect power. Reset any faults associated with solutions modules (VFD may not

recognize modules upon first power-up). Navigate to

Pr 0.00, set its value to 1001, and press red

Stop/Reset button.

7. Navigate to Pr 17.20 and set it to ON.

8. Navigate to Pr 17.21 and set it to ON.

9. Navigate to Pr 17.00, set its value to 1001, and

press red Stop/Reset button. Number 1001 will be

automatically reset to 0 as an indication that

changes have been saved.

10. Load system-specific calibration from the SMARTCARD (if saved at initial calibration).

a. Graco defaults are loaded as differences from

VFD defaults in memory location #101. Navigate to Pr 0.00, set its value to 6101, and press

red Stop/Reset button.

b. Recommended memory location for customer

calibration is #202. Navigate to Pr 0.00, set its

value to 6202, and press red Stop/Reset button.

11. If SMARTCARD is not available or if initial calibration was not saved to SMARTCARD, perform the following steps:

a. Load Graco system defaults - set Pr 20.16 to

1234.

Saving parameters will allow the VFD to retain

information associated with solutions modules.

b. Repeat E-Flo Calibration, beginning with Cali-

brate and Autotune the Motor on page 9 and

continuing with steps 1-9 of the calibration procedure (pages 10-12).

311596F 13

Page 14

E-Flo Features

E-Flo Features

Drive Active (System ON) Output

VFD Relay output is available at VFD terminals 41 and

42. The output can be mapped to most of the parameters. The most common is Drive Active. This relay output

will be closed when drive is active (there will be continuity between terminals 41 and 42). Pr 8.27 controls the

relay source. In case Drive Active is a desired source,

navigate to Pr 8.27 and set it to 10.02.

Pr 10.02 is a Drive Active indicator. See the Control

Techniques manual for further information.

Jog Mode

Jog mode allows the user to run the pump at the slow

speed and to stop it at a desired position. Note that park

angle allows easy access to the stand-side lower. Jog

mode can therefore be used to stop the pump at an

angle which will allow easy access to the motor-side

lower. Jog speed is equivalent to the following flow rates:

2000cc lowers: 2.7 gpm (10.2 lpm)

1500cc lowers: 1.9 gpm (7.3 lpm)

1000cc lowers: 1.4 gpm (5.4 lpm)

750cc lowers: 1.0 gpm (3.8 lpm)

Jog Mode in Local Control

Operation

To initiate Jog mode, press and hold the jog button. Jog

mode will stay active as long as the jog button is

pressed. When the jog button is released, the system

will stop.

Jog Mode - Keypad / Modbus Control

Parameter Pr 20.01 is allocated to control system

modes. Jog mode is mode #2. In order to initiate jogging, navigate to Pr 20.01 and set its value to 2. At this

time the system will enter the Jog mode.

When the pump has reached the desired position, stop

the system using one of the following methods:

• Put the system in Park by setting Pr 20.01 to 3, or

• Initiate the Stop command by using the red

Stop/Reset button or via Pr 20.25 (see Running the

Pump on page 21 for details).

IMPORTANT: Once system is stopped and jogging

is no longer required, change Pr 20.01 back to 0 to

revert to Cam mode.

Park Mode

Park mode allows you to park the pump in a position

allowing easy access to stand-side lower.

Hardware

Jog mode requires a momentary, normally open switch.

Graco offers a control box with jog switch installed. If

local control box is used and Local/Remote switch is set

to Local, jog mode can be initiated by pressing momentary “Jog” switch. Digital I/O #6 (VFD terminal #29) is

configured for the Jog mode (see System Electrical

Diagrams, page 42). Normally open (N.O.) position of

the switch disables jogging and closed position of the

switch (VFD terminal #29 connected to common)

enables jogging.

14 311596F

Park Mode in Local Control

Jog button has a dual function – Jog and Park. To

access the Park mode, press and release the switch in

less than 1 second.

Park Mode – Keypad / Modbus Control

Parameter Pr 20.01 is allocated to control system

modes. Park mode is mode #3. To initiate parking, navigate to parameter Pr 20.01 and set its value to 3. The

system will enter the Park mode. See Jog Mode instructions.

Page 15

E-Flo Features

Prime/Flush Mode

Prime/Flush mode allows system priming and flushing.

Once enabled, it commands the pump to run at the following flow rates for 2 minutes:

2000cc lower: 33.8 gpm (128.4 lpm)

1500cc lower: 24.3 gpm (92.3 lpm)

1000cc lower: 17.9 gpm (68.0 lpm)

Parameter Pr 20.40 enables and disables the

Prime/Flush mode.

Prime/Flush Enable => Pr 20.40 = 1 (Prime/Flush cycle

will start).

Prime/Flush Disable => Pr 20.40 = 0.

Notes:

1. Run the Prime/Flush mode with minimum flow

restriction.

2. Once Pr 20.40 is set to 1, the Prime/Flush cycle will

start and run for 2 minutes, at which time the pump

will stop. Pr 20.40 is automatically reset back to 0.

Back Pressure Regulator (BPR)

Control

BPR Production/Sleep modes – Keypad / Modbus

Control.

Digital I/O #3 (VFD terminal #26) is allocated for 24VDC,

0.5 W (maximum) solenoid.

Pr 20.18 enables and disables the solenoid output:

Pr 20.18 = 0: solenoid output disabled

Pr 20.18 = 1: solenoid output enabled

See System Electrical Diagrams on page 42 and

manual 311606 for wiring and installation details.

BPR Production/Sleep modes Graco E-Flo Control

The E-Flo program offers several BPR control features,

which are not available using the Keypad. See Com-

puter Control and Monitoring for more information.

311596F 15

Page 16

E-Flo Features

Cycle Counter

Two cycle counters are available: Grand Cycle counter

and Batch Cycle counter. Batch Cycle counter is a

resettable counter.

Grand Cycle Counter

Grand cycle counter is a non-resettable counter. First

four digits (XXXX9999) of the counter are located in

Pr 20.27. Next four digits (9999XXXX) are located in

parameter Pr 20.28.

Batch Cycle Counter

Batch cycle counter is a resettable counter. First four

digits (XXXX9999) of the counter are located in parameter Pr 20.29. Next four digits (9999XXXX) are located in

parameter Pr 20.30.

Batch Cycle Counter reset

Parameter Pr 20.26 resets Batch Cycle Counter when

set to 1.

Pr 20.26 resets to 0 automatically.

Pressure Monitoring

Average Pressure

Pr 20.31 displays average cycle pressure. It is a running

average of one full cycle. See T

tion.

For metric units, the last digit is a decimal.

Pressure Deviation

Pr 20.32 displays pressure deviation measured over one

full cycle. See T

For metric units, the last digit is a decimal.

ABLE 2 for more information.

ABLE 2 for more informa-

Flow Rate Monitoring

The average flow is displayed in Pr 20.17. Pr 20.15 is a

control parameter that allows the user to choose units

for measuring flow. If Pr 20.15 is set to 0, then units are

English and flow is displayed in gallons per minute

(gpm). If Pr 20.15 is set to 1, then units are Metric and

flow is displayed in liters per minute (lpm).

Pr 20.17 is an integer, and therefore it is not able to display decimal numbers. The last digit represents decimal

number. For example, if Pr 20.15 is set to 0 (English

units) and Pr 20.17 displays number 125, the flow

equals to 12.5 gpm (see T

Pump Displacement Volume

E-Flo Pump Volumes:

Lower Size

2000cc 4278 1.13

1500cc 3070 0.81

ABLE 2).

Volume per

Cycle (cc)

Volume per

Cycle (Gal)

1000cc 2263 0.60

750 cc 1537 0.41

16 311596F

Page 17

E-Flo Features

Yes

Load

Defaults ***Units

Mode)

0 (Cam

Default**

Pr

20.37 =

2

Pr

20.37 =

1 or 4

Pr

20.37

= 0 or

3

Pr

20.37 =

2

Pr

20.37

= 1 or

4

Low Limit High Limit

Pr

20.37

= 0 or

3

Res-

olu-

tion*

Units

Yes

100

[GPM/MIN]

Cus-

36.7 30.7

Cus-

3.8 6.1

LPM 0.1 N/A No

tomer

tomer

Pr

specific

Pr

Pr

specific

2

20.37 =

3,4

20.37 =

20.37

= 0, 1

150 [PSI] Yes

34.5 31.7 34.5

0

Bar 0.1

2

Pr

20.37 =

2

Pr

20.37

= 1 or

4

Pr

20.37

= 0 or

3

Pr

20.37 =

2

Table 2: E-Flo Calibration Parameters / Modbus Map

Pr

20.37

= 1 or

4

Low Limit High Limit

Pr

20.37 =

0 or 3

Reso-

lution*

English Units Metric Units

N/A N/A

0 = Cam

1 = Constant Speed

2 = Jog

Run Mode Selection

3 = Park

1 10 1000 N/A

MIN

GPM/

Ramp Rate

Selection

Lower Size

CC N/A 750 2000 CC N/A 750 2000 2000cc Yes

Selection (750cc,

1000cc, 1500cc,

2000cc)

Local/Remote

N/A N/A 0 (Local) 1(Remote) N/A N/A 0 (Local) 1(Remote) N/A N/A

Control Indicator

(Indicates position

of the Local/Remote

switch)

Flow Setting

Cus-

9.7 8.1

Cus-

1.0 1.6

1.4 2.4 14.3 11.9 5.3 9.1 54.1 45.0

GPM 0.1

750 cc Lowers

1000cc Lowers

tomer

specific

tomer

specific

1.9 3.2 19.4 16.2 7.2 12.1 73.4 61.3

2.7 4.5 27.1 22.6 10.2 17.0 102.6 85.6

1500cc Lowers

2000cc Lowers

Pr

Pr

Pr

20.37 =

= 3,4

20.37

20.37

= 0, 1

Low Pressure Alarm

Setting

500 460 500

0

PSI 1

1000cc Lowers 460 460 460 31.7 31.7 31.7

1500cc Lowers 350 350 350 24.1 24.1 24.1

2000cc Lowers 300 300 300 20.7 20.7 20.7

750cc Lowers

Low Pressure Alarm

Enable

N/A N/A 0 (Disable) 1 (Enable) N/A N/A 0 (Disable) 1 (Enable) 0 (Disable) Yes

0 = Disable

1 = Enable

20.02

Parame-

ter ID Function

20.01

20.03

20.04

20.05

20.07

20.08

311596F 17

Page 18

E-Flo Features

Load

Defaults ***Units

2

20.37 =

3,4

20.37 =

20.37

= 0, 1

2

20.37 =

= 3,4

20.37

300 [PSI] Yes

34.5 31.7 34.5

0

Bar 0.1

[A] 0.1 N/A No

N/A 0 N/A

Default**

20.37 =

2

20.37 =

1 or 4

= 0 or

3

20.37 =

2

= 1 or

4

= 0 or

3

olu-

tion*

Units

20.37 =

2

= 1 or

4

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

20.37

Pr

Pr

20.37

Low Limit High Limit

Pr

20.37

Res-

Pr

Pr

20.37

= 0 or

3

20.37 =

2

= 1 or

4

20.37 =

0 or 3

Reso-

lution*

Parame-

ter ID Function

Pr

Pr

20.37

Pr

Pr

20.37

Low Limit High Limit

Pr

English Units Metric Units

500 460 500

460 460 460 31.7 31.7 31.7

20.37

= 0, 1

High Pressure

Alarm Setting

350 350 350 24.1 24.1 24.1

0

PSI 1

1000cc Lowers

1500cc Lowers

750cc Lowers

20.09

300 300 300 20.7 20.7 20.7

2000cc Lowers

Motor Rated

Current x 10;

[A] 0.1

multiply motor rated

current listed on a

motor ID plate) by

10; for example,

I=6.5A, Pr20.12 =

20.12

08.8 08.8

0 15.5 0 15.5

N/A N/A N/A N/A N/A N/A 0 Yes

65

High Voltage Drive

Low Voltage Drive

Unit Selection (0 =

English, 1 = Metric)

Calibration (special

20.15

parameter)

1234 = Load

Defaults (resets

system related

menu 20

parameters to

Graco default

settings)

20.16

56 = Load Motor

Defaults (resets

motor related

parameters to

Graco default

settings)

777 = Unlock

pressure calibration

GPM 0.1 N/A LPM 0.1 N/A N/A N/A

parameters

20.17 Flow Indicator

18 311596F

Page 19

Pr

Pr

Load

Pr

20.37 =

Pr

20.37 =

20.37

= 0 or

Pr

20.37 =

20.37

= 1 or

E-Flo Features

Defaults ***Units

Default**

2

1 or 4

3

2

4

Low Limit High Limit

Pr

20.37

= 0 or

3

Res-

olu-

tion*

Units

Pr

20.37 =

2

Pr

20.37

= 1 or

4

Pr

20.37

= 0 or

3

Pr

20.37 =

2

Pr

20.37

= 1 or

4

Low Limit High Limit

Pr

20.37 =

0 or 3

Reso-

lution*

English Units Metric Units

N/A N/A 0 (Disable) 1 (Enable) N/A N/A 0 (Disable) 1 (Enable) 0 (Disable) Yes

CPM 0.1 N/A CPM 0.1 N/A N/A No

N/A N/A No

[A] 0.1 N/A [A] 0.1 N/A N/A N/A

N/A N/A 0 (Stop) 2 (Run) N/A N/A 0 (Stop) 2 (Run) 0 (Stop) Yes

N/A N/A 0 (Not Reset) 1 (Reset) N/A N/A 0 (Not Reset) 1 (Reset) N/A No

N/A 1 N/A N/A 1 N/A N/A N/A

N/A 1 N/A N/A 1 N/A N/A N/A

N/A 1 N/A N/A 1 N/A N/A N/A

PSI 1 N/A Bar 0.1 N/A N/A N/A

N/A 1 N/A N/A 1 N/A N/A N/A

BPR Valve Solenoid

Control

0 = Solenoid

Disable

1 = Solenoid Enable

Average Cycle Rate

Indicator

Graco defined

software version

major

Graco define

software version

minor

Average Motor

Current Indicator

(divide by 10)

Run/Stop

Command

0 = Stop

1 = Stop

2 = Run

Reset Batch Cycle

Counter

0 = Not Reset

1 = Reset

Grand Cycle Count -

First 4 places -

yyyy9999

Parame-

ter ID Function

20.18

20.19

20.20

20.21

20.24

20.25

20.26

20.27

Grand Cycle Count -

Next 4 places -

9999xxxx

20.28

Batch Cycle Count -

First 4 places -

yyyy9999

20.29

Batch Cycle Count -

Next 4 places -

9999xxxx

20.30

Average System

Pressure Indicator

20.31

311596F 19

Page 20

Pr

Pr

Load

Pr

20.37 =

Pr

20.37 =

20.37

= 0 or

Pr

20.37 =

20.37

= 1 or

Defaults ***Units

Default**

2

1 or 4

3

2

4

E-Flo Features

Yes

Motor)

0 (5 H.P. UL

Low Limit High Limit

Pr

20.37

= 0 or

3

Res-

olu-

tion*

Units

Pr

20.37 =

2

Pr

20.37

= 1 or

4

Pr

20.37

= 0 or

3

Pr

20.37 =

2

Pr

20.37

= 1 or

4

Low Limit High Limit

Pr

20.37 =

0 or 3

Reso-

lution*

English Units Metric Units

PSI 1 N/A Bar 0.1 N/A N/A N/A

N/A 1 N/A N/A 1 N/A N/A N/A

PSI 1 100 500 Use English Units to calibrate N/A N/A

N/A 1 0 N/A N/A 1 0 N/A N/A N/A

N/A 1 0 N/A N/A 1 0 N/A N/A N/A

N/A 1 0 4 N/A 1 0 1

N/A N/A 0 (Disable) 1 (Enable) N/A N/A 0 (Disable) 1 (Enable) 0 (Disable) Yes

N/A N/A 0 (Disable) 1 (Enable) N/A N/A 0 (Disable) 1 (Enable) N/A Yes

Control Enable

0 = Disable

1 = Enable

Prime/Flush Enable

(Special parameter,

returns to Disable

state once flushing

is complete)

0 = Disable

Pressure Sensor

Error Indicator

(used for

calibration)

Zero Point

Calibration

System Calibration

Pressure

High Point

Calibration

0 = 5 H.P. UL Motor

1 = 5 H.P. ATEX

Motor

2 = Customer Motor

3 = 3 H.P. UL Motor

4 = 3 H.P. ATEX

Motor

Motor Select

20.32 Pressure Range

Parame-

ter ID Function

20.33

20.34

20.35

20.36

20.37

Analog Input Speed

20.38

20.40

1 = Enable

Pr 20.17 is showing a number 157, while English units are selected. Last digit 7 is a decimal, which means that the flow is 15.7 GPM.

* Resolution: Note that the Keypad display does not utilize a decimal point. Last digit of a variable with a resolution of 0.1 is a decimal. For example, flow indicator

**Default: All calibration parameters have a default setting. Drives are shipped out from Graco with all calibrations set to their defaults. Use Pr 20.16 to reload default.

***Load Defaults: Yes indicates that a default value will be loaded if Load System Defaults is triggered (Pr 20.16 = 1234).

20 311596F

Page 21

Running the Pump

Operational Envelope Limit

Explosion-proof electric motors have constant torque

and variable torque limits. E-Flo system is a constant

torque application, and therefore the motor’s constant

torque limits must not be violated. The system is available with two motors: the UL/CSA explosion-proof motor

and the ATEX explosion-proof motor. To stay within the

allowed torque, flow and pressure limits are installed.

Flow Limit

Speed command is limited to 5:1 operation for ATEX

motors and 10:1 operation for UL/CSA motors. 5:1 dictates a frequency of 10 Hz minimum to 50 Hz maximum.

10:1 dictates a frequency of 6 Hz minimum to 60 Hz

maximum.

See T

ABLE 2 for flow limits (Pr 20.05).

Pressure Limits

Operating pressure limits are unique to the pump lower

sizes. If the system pressure is greater than the maximum allowed for a given pump lower size for longer than

30 seconds, system Trip #44 will shut the system down.

See T

ABLE 3 for system pressure limits.

Running the Pump

CAUTION

The drive has been programmed by Graco. Do not

attempt to recalibrate the Sequencer or Motor Control

as it can interfere with the Graco Program.

Secure Disable

According to Control Techniques Unidrive SP User

Guide, “Secure Disable (SD) function provides a means

for preventing the drive from generating torque in the

motor, with very high level of integrity”. This hardware

function controls enable/disable state of the drive.

Secure Disable/Drive enable hardware input (VFD terminal #31) is designed for positive logic input only. It

should be connected to internal 24VDC power supply

(VFD terminal #22). The SD is a fail-safe function; it

enables the drive when 24VDC is connected to SD

hardware input and disables (inhibits) the drive when SD

hardware input is open.

Pr 6.29 and Pr 8.09 can be used to monitor state of the

Hardware enable input.

Table 3: System Pressure Limits

Non-Graco

Lower

Size

(cc)

2000 250 17.2 250 17.2

1500 330 22.8 330 22.8

1000 460 31.7 460 31.7

750 425 (if set

Graco Motor

(Pr 20.37 = 0, 1, 3, or 4)

psi bar psi bar

29.3 (if set

to 3 or 4);

500 (if set

to 0 or 1)

to 3 or 4);

34.5 (if set

to 0 or 1)

Motor

(Pr 20.37 = 2)

500 34.5

Local I/O Box (see page 5) provides a normally closed

Secure Disable switch, which has a red mushroom-type

button (press to latch, pull to unlock). When latched,

switch opens SD circuit, therefore disabling (inhibiting)

the drive. When unlocked, switch closes SD circuit,

enabling the drive.

311596F 21

Page 22

Running the Pump

Start/Stop Command

Local Control Mode

When Local mode is selected, Run command can only

be initiated by means of Run/Stop hardware switch – set

Run/Stop switch to Run position.

Stop command can be initiated by one of the following:

1. Run/Stop switch:

Set Run/Stop switch to Stop position.

2. Stop/Reset button:

Press Stop/Reset (red) button on a VFD Keypad

display. Note that if Stop command was initiated by

pressing Stop/Reset button, one of the following two

actions will restart the pump:

a. Cycle the Run/Stop switch – Set it to Stop posi-

tion and then to ‘Run’ position.

b. Cycle Secure Disable circuit.

3. Secure Disable circuit:

Disable the drive by disconnecting SD circuit. Note

that if motor is stopped by means of SD circuit while

Run/Stop switch was in Run position, the Run command will be reapplied once SD circuit is reconnected.

Remote Control Mode

Run command can be varied via Keypad only if

Local/Remote switch is set to Remote.

To initiate Run command via Keypad, navigate to Pr

20.25 and set its value to 2.

Stop command can be initiated by one of the following:

1. Red Stop/Reset button on a keypad:

Press Stop/Reset (red) button on a VFD Keypad

display. If Stop command was initiated by pressing

Stop/Reset button, one of the following two actions

will restart the pump:

a. Set Pr 20.25 to 1 and then to 2.

b. Cycle SD circuit.

2. Navigate to Pr 20.25 and set its value to 1 or 0.

22 311596F

Page 23

Running the Pump

Flow Control

Motor Speed Control

Motor speed is set indirectly, by setting Pump Flow

Rate, which is then translated to motor speed by Graco

Software.

Motor Speed is set via Preset Reference 1. Refer to

Unidrive SP User Guide, Menu 1: Frequency / Speed

Reference Logic Diagram.

Local Mode

Resistance of 0 ohms corresponds to zero flow.

Increase in resistance causes increase in flow. Use Pr

5.01 to monitor instantaneous speed of the motor (in

Hz).

Hardware required – 5 k ohm Variable Resistor (Potentiometer). Refer to Control Technique Unidrive SP User

Guide for more details on electrical installation (also see

System Electrical Diagrams, page 42).

3. Enter the result into parameter Pr 20.05 (enter num-

ber 120).

See TABLE 2 for flow limits.

Speed Potentiometer control mode is available if the following conditions are valid:

1. Speed Potentiometer Enable = (Pr 20.38 = 1).

2. Control Mode = Local (Local/Remote switch in Local

position; Digital I/O #5 (VFD terminal #28) is

grounded (Common ground is available at VFD terminals #1, 3, 11, 21, 23, and 30).

Remote Mode

In this mode the speed potentiometer mode has no

effect even if enabled.

To have a remote control, the following condition must

be true:

VFD

Internal 10 VDC

Differential Analog Input (+)

Differential Analog Input (-)

Common Ground

IG. 5

F

4

5

6

1

RUN/STOP

SPEED POT

(5 k ohm)

If Speed Potentiometer is not installed, flow can be controlled directly from the Keypad. The following conditions

must be true:

1. Speed Potentiometer Enable = Disable (Pr 20.38 =

0).

2. Control Mode = Local (Local/Remote switch in Local

position; Digital I/O #5 (VFD terminal #28) is

grounded (Common ground is available at VFD terminals #1, 3, 11, 21, 23, and 30).

Enter desired flow into Pr 20.05 as follows (example

shown is in English units):

Control Mode = Remote (Local/Remote switch in

Remote position; Digital I/O #5 (VFD terminal #28) is

floating.

Flow is controlled by the Pr 20.05.

Multiply desired flow value by 10 (see Local Mode

above and T

ABLE 2 for more details).

1. Determine desired flow (for example, 12 gallons per

minute [gpm]).

2. Multiply desired flow by 10 (12gpm*10 = 120gpm).

311596F 23

Page 24

Diagnostics

Diagnostics

Drive Trip Codes and Diagnostic

Procedures

Drive status and trips are located in Menu 10. Drive trips

are stored in Pr 10.20 through Pr 10.29. For more information on trip and diagnostic procedures refer to Control Technique Unidrive SP Advance User Guide.

Trips and Diagnostic

Procedures

System trips with values in the range of #40 – 50, and

trip 100 are E-Flo specific.

Trips #40 – 50 will cause the system to shutdown upon

becoming active. Trip 100 is reserved for a system alarm

reset.

An external trip is also configured specifically for E-Flo;

its trip code is Et. This trip becomes active if one of the

following conditions is true:

• Power is applied to the motor while Secure Disable

circuit is connected (normally closed switch is

closed, indicating Drive Enable). It is therefore recommended to disable the drive by disconnecting the

Secure Disable circuit (normally closed switch is

open) before applying power to the motor.

• VFD/Apps module(s) reset is initiated while drive is

enabled (Secure Disable circuit is connected). It is

therefore recommended to disable the drive before

performing system reset,

Refer to the Control Technique User Guides for trip

codes which are not listed in T

ABLE 4.

Resetting the System

1. Stop the pump.

2. Disable the drive by disconnecting the Secure Disable circuit.

3. Navigate to Pr 0.00 and set its value to 1070. Press

the red (reset) button. Note that the system will reset

at this time. Value of Pr 0.00 will be reset back to 0

automatically.

24 311596F

Page 25

Table 4: Trips and Diagnostic Procedures

Trip

Code Trip Description Diagnostic

Diagnostics

40 High System Pressure

(System pressure is higher

than the allowed maximum)

41 Low System Pressure

(System pressure is lower

than the allowed minimum)

42 No TDC (Top Dead Center

Sensor is not detected)

43 High Motor Current

(Motor current has

exceeded the maximum for

the duration of 30 seconds)

1. Check High Pressure Alarm setting (Pr 20.09). Verify that system

desired operational pressure is lower then High Pressure Alarm setting.

2. Check for flow restrictions (closed valves, unexpected restrictions).

3. Check pump fluid section for proper operation (piston seals, ball

checks). Refer to pump maintenance manual for additional information.

1. Check Low Pressure Alarm setting (Pr 20.07). Verify that system

desired operational pressure is higher then Low Pressure Alarm setting.

2. Check fluid level. Low fluid level will cause system to run at low pressure.

3. Check fluid supply to the pump.

4. Check pump fluid section for proper operation (piston seals, ball

checks). Refer to pump maintenance manual for additional information.

1. Verify that output shaft is turning.

2. Check all of the wiring.

3. Verify that sensor is operational. Remove PCB cover and monitor LED

light on a top of the sensor. The light should be normally on and it

should be off for only short period of time when top dead center is

reached.

1. Check motor calibration Pr 20.37 (UL/CSA. motor is 0 and ATEX motor

is 1).

2. Check torque on both throat-packing nuts (see lower repair-parts manual 311690).

3. Flow/Pressure combination may be set too high for a given fluid/system.

44 Operational Envelope

(System has operated outside of operational window

for the duration of 30 seconds)

1. Check system pressure setting. Ensure that system pressure does not

exceed the allowed operational envelope. Refer to Operation Manual

311593 for Motor Speed and Flow Charts and to Operational Enve-

lope Limit on page 21.

2. Check pressure sensor calibration. If sensor needs to be recalibrated

follow instructions, page 41.

311596F 25

Page 26

Diagnostics

Table 4: Trips and Diagnostic Procedures

Trip

Code Trip Description Diagnostic

45 Motor Stalled This trip occurs when the motor is not able to develop torque, and therefore

cannot put the pump into motion.

1. Relieve system pressure.

2. Check lowers, slider cylinders, and output shaft with connecting rods for

visible damage. If no damage is visible, check for excessive heat which

is a sign of friction.

3. Check motor wiring.

4. Disconnect lowers and try running just the motor and gearbox.

49 Runtime Trip 1. Reset the system (see directions on page 24).

2. Cycle power.

3. Perform Complete System Reload, page 13.

50 Pressure Calibration Enter proper pressure sensor calibration parameters, page 9.

Et External Trip Open Secure Disable circuit and reset the trip.

CL2 Loss of Pressure Sensor 1. Ensure that pressure sensor wiring is installed as shown in F

2. Ensure that pressure sensor shield is grounded. Use PCB terminal J3-3

as shown in F

IG. 29. Do not ground the shield at both ends.

3. Check wiring and power to the barrier.

4. Check pressure transducer current (VFD terminal #7). The pressure

transducer current range should be 4-20 mA.

IG. 29.

26 311596F

Page 27

Computer Control and Monitoring

Computer Control and

Monitoring

To control or monitor the system using the supplied software with a computer (PC), the following components

are required:

• Graco VFD, Part No. 15J753 or 15J754

• Ethernet Upgrade Kit 15H885

• Category 5 Ethernet Cable

To control the pump using a computer, the system must

be in remote mode and the SECURE/DISABLE switch

must be disabled.

To monitor the pump from a computer, the system must

be in local mode.

Ethernet Upgrade Kit 15H885

The Ethernet Upgrade Kit includes a module which

allows a computer to monitor/communicate with the

VFD via Ethernet. See manual 311612 for installation

instructions.

2. Download Winflasher III from the Control Techniques website.

3. Connect CT COMM Cable to RJ45 serial interface

connector in the front of the VFD.

If the Ethernet module is installed it must be disabled to allow serial communication.

4. Disable the Ethernet Module (if installed) as follows.

a. Navigate to Pr 16.37 and set its value to OFF.

b. Save all parameters: Navigate to Pr 0.00, set its

value to 1001 and press the red Stop/Reset button. Wait until number 1001 changes to 0 automatically as an indication that changes have

been saved.

c. Cycle power to the VFD. This is necessary to

activate serial communication after the Ethernet

module has been disabled.

5. Update the software as follows:

a. Launch winflash.exe (Winflasher III program).

E-Flo Software Update

The following components are required to update E-Flo

software:

Hardware

• CT COMM Cable

Software

• CT SOFT and Winflasher

Installation Instructions

1. Connect to Control Techniques website and download CT SOFT (http://www.control techniques.com

CT SOFT is a free program, but must be registered

with Control Techniques.

).

F

IG. 6

311596F 27

Page 28

E-Flo Software Update

b. Read information in the Introduction window

and select Next.

F

IG. 7

c. Choose “Download a compiled program” option

and select Next.

d. Browse for a Graco software file and select

Next.

FIG. 9

e. Select the method for downloading: In the

“Select the method for downloading” window

under “Connection Protocol”, select CT-RTU

(Unidrive SP). Under “Settings” choose Slot 3.

Ensure that the correct communication port is

selected. Use the “Change Communications

Settings” button to change the port assignment.

Select Next.

IG. 8

F

IG. 10

F

28 311596F

Page 29

E-Flo Software Update

f. Read the Important Safety Warning and select

Next.

F

IG. 11

g. Press the red button to begin the download.

h. Wait for download to finish. Do not disconnect

power while downloading as it may cause damage to the equipment. When the download has

ended, select Finish to exit the program.

FIG. 13

If the Ethernet module is used it must be

re-enabled to allow serial communication.

6. Re-enable the Ethernet Module (if used) as follows.

a. Navigate to Pr 16.37 and set its value to ON.

b. Save all parameters: Navigate to Pr 0.00, set its

value to 1001 and press the red Stop/Reset button. Wait until number 1001 changes to 0 automatically as an indication that changes have

been saved.

IG. 12

F

311596F 29

Page 30

E-Flo Software Update

Configure the Ethernet Card

To configure the Ethernet card for proper access

manually set the IP address rather than allowing

the PC to automatically do so. These procedures

are written for a Windows XP operating system.

1. Go to Start>Control Panel.

2. Select Network Connections.

3. Select the icon for the network connection you will

be using to communicate with the VFD, right click on

the icon, and select properties. See F

IG. 14.

FIG. 15

F

IG. 14

4. The Local Area Connection Properties window will

open. Select Internet Protocol from the listed

options. Click on Properties. The Internet Protocol

Properties window will appear. See F

IG. 15.

30 311596F

Page 31

E-Flo Software Update

5. See FIG. 16. Select “Use the following IP address.”

The default Pump IP address is 192.168.1.100.

Enter a number which differs from the default

address in only the last set of numbers, for example:

192.168.1.10. This enables the computer to connect

to the VFD. Set Subnet mask to 255.255.255.0.

Install the Computer Software

Load the supplied CD into your computer and follow the

software installation instructions as they appear on the

screen.

Once the installation is complete, select E-Flo from the

Windows Start menu.

Graco uses a Visual Basic program to display the

run screen on the computer. This software and

program is not supported by Graco.

Connect the VFD to the PC

Use a CAT 5 Ethernet Cable (D) to connect the VFD

Ethernet Module (C) to the PC. See F

IG. 17.

IG. 16

F

6. Press OK.

It may take 30-60 seconds for the computer to

locate the address and establish the connection.

F

IG. 17

C

D

311596F 31

Page 32

E-Flo Software Update

Connecting to Multiple VFDs

Connecting to multiple VFDs requires that each VFD

must have an individual Ethernet upgrade kit. Furthermore, a router is probably necessary to allow one

instance of the Visual Basic software to control all

drives. The following steps describe the correct procedure to set up numerous connections:

1. Connect an Ethernet cable from each module to the

router and also from the router to PC.

2. Open the VB application and press Connect. See

F

IG. 18.

F

IG. 18

3. Click CONNECT. See F

appears. See F

IG. 22. The Network Setup window

will close when connection is made.

IG. 19. The Run screen

Multiple run windows should now appear. To connect to

each drive, the IP Address of each drive must be

unique. To accomplish this, navigate to drive parameter

#16.13 on each drive and increment this such that each

pump contains a different value. For example:

Drive 1: Par. #16.13 = 100

Drive 2: Par. #16.13 = 101

Drive 3: Par. #16.13 = 102

Drive 4: Par. #16.13 = 103

After doing this on each drive, each drive must be reset.

See Resetting the System, page 24, for instructions.

7. Repeat steps 2 and 3 for each additional IP address

you selected in step 5 on page 31.

At this point, go to the software again, and press the

Connect button on the main run window and then, in the

Network Address Setup window, enter the new IP

address.

4. In the main run window, go to Options>Add or

Change Pump Info.

5. Enter the new pump information. See F

IG. 20.

Check the boxes next to each connected drive.

Press Button to

Connect

IG. 19. Network Address Setup Window

F

Default Pump IP

Address

6. Select Save Settings and then select Open Selected

Pumps.

F

IG. 20 Multiple VFD Connections

32 311596F

Page 33

E-Flo Software Update

Run Screen

Speed Control

Graco uses a Visual Basic program to display the

run screen on the computer. This software and

program is not supported by Graco.

See FIG. 22. The sliding scale on the Run screen sets

the pump speed in units of flow.

To change units of measure (English/Metric), select

Options menu, then Advance Options screen (see

page 35).

In remote mode, the slider is active and can be controlled on the computer. Select the slider with the cursor

and move it to the desired value on the scale.

In local mode, the slider cannot be controlled on the

computer. It will independently move up and down the

scale, reflecting average flow as measured by the VFD.

• To stop the pump, press STOP. The button display

will change to STOPPED, and the RUNNING button

display will change to RUN.

PARK ON/OFF Button

• PARK ON sets the pumps to the park position.

• PARK OFF turns off the park feature and resumes

normal operation.

Trip Reset Button

Trip button becomes enabled (active) when Secure Disable is pressed.

Press to reset the pump if a trip occurs.

BPR Button

• BPR IN PRODUCTION: use in normal production

mode.

• BPR IN SLEEP: when no production.

Counters

See FIG. 22. The counters are active in both remote and

local mode.

Pressure - Displays fluid pressure reading from

pressure transducer.

Flow Rate - Displays flow per minute.

CPM Rate - Displays pump cycles per minute reading

from TDC sensor.

Batch Counter - Displays batch cycle count. User

resettable; see Reset Batch Counter, page 35.

Cycle Count - Displays total cycle count. Not resettable.

Control Buttons

See FIG. 22. In remote mode, the buttons are active and

may be used to control the pump.

RUN and STOP Status Buttons

The status buttons operate as a toggle switch to run or

stop the pump.

Set the speed (flow) to the desired level for sleep

mode and the system will slow down when BPR

OUT OF PRODUCTION button is pushed.

Access the Advanced Options Screens

From the Run screen (FIG. 21) go to the Options

pull-down menu. Select the Advanced Options Screen

(page 35). From the Advanced Screen the Data Log-

ging Screen (page 39), or Power Monitor Screen

(page 40) can be selected.

F

IG. 21

• To run the pump, press RUN. The button display will

change to RUNNING, and the STOPPED button display will change to STOP.

311596F 33

Page 34

E-Flo Software Update

Run Screen

To access

Advanced/Data Logging/

Power Monitor Screens

To reset Batch

Counter

Fluid Pressure

Flow Rate

CPM Rate

Batch Counter

Cycle Count

RUN Status Button

STOP Status Button

PARK ON/OFF Button

Trip Reset Button

BPR In Production

Button

Sliding Speed

Control

Record of trips

FIG. 22. Run Screen

34 311596F

Page 35

E-Flo Software Update

Advanced Options Screen

The advanced screen allows user changes to operating

parameters. This is only effective in the remote mode.

See F

IG. 24.

Units of Measure

Select desired units (English or Metric). See FIG. 24.

Values on Run screen will change accordingly.

Trips

• High Pressure Trip: Default is 300 psi. If measured

pressure is more than the set pressure, a high pressure trip will occur. See T

20.09.

• Low Pressure Trip: The low pressure trip is an

optional setting. To set, select the low pressure trip

box and input the desired value. If measured pressure is less than the set pressure, a low pressure

trip will occur.

ABLE 2 on page 17, Pr

Flow Calibration

Lower Size: Select size of pump lowers (750cc,

1000cc, 1500cc, or 2000cc).

Trend Timer

Trend timer is used for a timeline management for data

logging. Set desired trend time (1 to 5 seconds) or (1 to

5 minutes).

CAM

• CAM: CAM is the default. This setting utilizes the

E-Flo cam profile which eliminates pressure fluctuations by adjusting motor speed incrementally.

• Constant Speed: Sets motor to a constant speed,

which negates the cam profile and may result in

pressure fluctuations.

Reset Batch Counter

Press to reset batch counter on Run screen.

System pressure must first rise above the Low

Pressure Alarm setting for the trip to start operating. This allows the system to build up to operating

pressure without shutting down due to Low Pressure Alarms.

311596F 35

Page 36

E-Flo Software Update

Drive Status Messages

There are two groups of drive status messages:

• Drive Health

• Drive Warning Messages

An active status message will turn red. See T

page 38 for additional information.

ABLE 5 on

Prime/Flush

Prime/flush allows system priming and flushing. Once

enabled, the pump will ramp up to the following flow

rates for two minutes.

• 2000 cc lower: 33.8 gpm (128.4 lpm)

• 1500 cc lower: 24.3 gpm (92.3 lpm)

• 1000 cc lower: 17.9 gpm (68.0 lpm)

• 750 cc lower: 12.2 gpm (46.2 lpm)

BPR Production Flow Screen

BPR Production Flow Screen

is accessed from the options

menu in main screen

FIG. 23 BPR Production Flow Screen

36 311596F

Page 37

Advanced Options Screen

Selecting the Auto/Setup displays the BPR Screen shown in FIG. 25.

E-Flo Software Update

Set Trend Time

Set desired units

of measure

Set high and low

pressure limit,

and low pressure

trip, if desired

Set size of lower

Reset batch

counter

Record of Trips

FIG. 24

Set BPR

Auto Mode

Prime/Flush

Drive

Status

Messages

Return to Run

Screen

BPR Timer Screen

Select Production

Select (De)Activation

Times

Select Sleep Flow Rates

F

IG. 25

Days

311596F 37

Page 38

E-Flo Software Update

Direction Commanded True 10.13

Braking IGBT ActiveBraking 10.11

Running at or Below Min. Speed 10.04

Direction Running True 10.14

Over Temperature Alarm 10.18 Motor overtemperature switch activated.

Under Voltage Active 10.16

Braking Resistor Alarm 10.12

Output is at Current Limit 10.09

Table 5: Drive Status Messages

Message Parameter ID Description

DRIVE HEALTH MESSAGES

Drive Healthy 10.01 Drive is not tripped.

Drive Active 10.02 Drive is active.

At Speed 10.06 Motor is rotating.

Load Reached 10.08

Regenerating 10.10

Drive at Zero Speed 10.03

DRIVE WARNINGS MESSAGES

Drive Warning 10.19 There is an active drive alarm (10.18,

10.17, or 10.12).

Overload Alarm 10.17

Mains Loss 10.15 Loss of input power.

Above Set Speed 10.07 Unit is running faster than set speed

range.

Below Set Speed 10.05 Unit is running slower than set speed

range.

38 311596F

Page 39

E-Flo Software Update

Data Logging Screen

The data logging screen records pressures, speed,

time, and ranges.

1. Press Start Data Logging button.

Begin data logging

2. Default filename is LogFile.CSV. Enter the desired

filename.

3. Pressing Start Data Logging will begin logging, and

indicator will start moving.

4. Press Stop Data Logging to complete and close file.

Record of Trips

Return to Run Screen

F

IG. 26. Data Logging Screen

311596F 39

Page 40

E-Flo Software Update

Power Monitor Screen

The Power Monitor screen displays motor status in Hz, Amps, and horsepower.

To zoom in on the graphs, select one of the sliders on an axis and slide it toward the other on the same axis.

Press Clear button to restart graph information.

Motor Speed (Hz)

Record of Trips

Motor Power (HP or KW)

Motor Current (Amps)

Clear

F

IG. 27. Power Monitor Screen

40 311596F

Return to Run Screen

Page 41

Pressure Transducer Calibration Procedure

Pressure Transducer Calibration Procedure

E-Flo pressure sensor must be calibrated against an

instrument grade High Precision Pressure Transducer,

which should be installed near the E-Flo pressure sensor.

1. Ensure that the High Precision Pressure Transducer

calibration is up to date.

2. Set Pr 20.16 to 777, to unlock pressure sensor

parameters.

3. Calibrate Low Pressure Point as follows:

a. Ensure that system is not pressurized. Calibra-

tion instrument pressure reading should be 0

psi.

b. Use Keypad to navigate to Pr 20.33; monitor its

reading for 5 – 10 seconds to determine its

average value. Make a record of it.

c. Navigate to Pr 20.34 and enter the recorded

average value of Pr 20.33.

4. Calibrate the High Pressure Point as follows:

a. Pressurize the system to 250 – 275 psi.

5. Set Pr 20.16 to 0 to lock parameters, then set

Pr 0.00 to 1001 to save parameters.

6. Verify pressure calibration.

a. Relieve system pressure.

b. Navigate to Pr 20.31 and verify that its reading

is within the range of 0-3 psi.