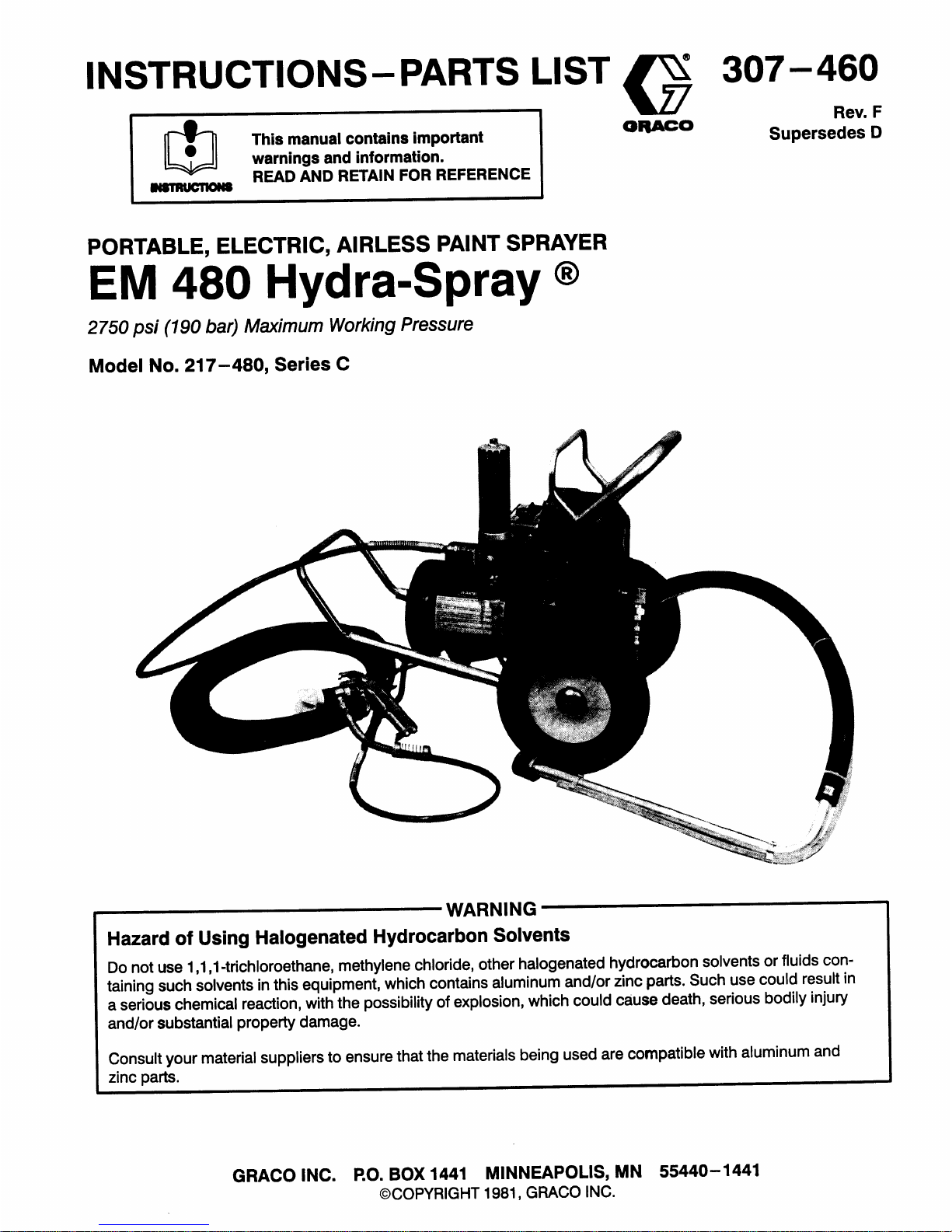

Page 1

Page 2

WARNING

HIGH PRESSURE SPRAY CAN CAUSE SERIOUS INJURY.

General Safety

This equipment generates very high fluid pressure. Spray from

the gun, leaks or ruptured components can inject fluid

through your skin and into your body and cause extremely

serious bodily injury, including the need for amputation. Also,

fluid injected or splashed into the eyes can cause serious

damage.

NEVER point the spray gun at anyone or at any part of the

body. NEVER put hand or fingers over the spray tip. NEVER

try to “blow back” paint; this is NOT an air spray system.

ALWAYS have the tip guard in place on the spray gun when

spraying.

Spray Gun Safety Devices

Be sure all gun safety devices are operating properly before

each use. Do not remove or modify any part of the gun; this

can cause a malfunction and result in serious bodily injury.

Safety Latch

Whenever you stop spraying, even for a moment, always set

the gun safety latch in the closed or “safe” position, making

the gun inoperative. Failure to set the safety latch can result in

accidental triggering of the gun.

Diffuser

The gun diffuser breaks up spray and reduces the risk of injection when the tio is not installed. Check diffuser operation

ALWAYS follow the Pressure Relief

Procedur?,

. below,

before cleaning or removing the spray tip or

servlcrng

any

system equipment.

NEVER

try to stop or deflect leaks with your hand or body.

regularly. Follow’ the Pressure Relief Procedure,’ below,

then remove the spray tip. Aim the gun into a metal pail,

holding the gun firmly to the pail. Using the lowest possible

pressure, trigger the gun. If the fluid emitted

Is

not diffused in-

to an irregular stream, replace the diffuser immediately.

Be sure equipment safety devices are operating properly

before each use.

Medical Treatment

If any fluid ap ears to enetrate our

skrh et

EMEhENCY hEDICAi

CAR6 &T ONCE.

DO NOT TREAT AS A SIMPLE CUT.

Tell the doctor exactly what fluid was injected. For treatment

instructions, have your doctor call the

NATIONAL POISON CENTEP NETWORK

(412)681-6668 .

Tip Guard

ALWAYS have the tip guard in place on the spray gun while

spraying. The tip guard alerts you to the injection hazard and

helps prevent accidentally placing your fingers or any part of

your body close to the spray tip.

Spray Tip Safety

Use extreme caution when cleaning or changing spray tips. If

the spray tip clogs while spraying, engage the gun safety latch

immediately. ALWAYS follow the Pressure Relief Procedure and then remove the spray tip to clean it.

,-

r

NEVER wipe off build up around the spray tip until pressure is

fully relieved and the gun safety latch is engaged.

Pressure Relief Procedure

To reduce the risk of serious bodily injury, including injection or injury from moving parts or electric shock, always follow this

procedure whenever you shut off the sprayer, when checking or servicing any part of the spray system, when installing, cleaning or changing spray tips, and whenever you stop spraying.

(1)

Engage the gun safety latch.

(2)

Turn the ON/OFF switch to

OFF.

(3)

Unplug the power supply cord.

(4)

Disengage the gun safety latch.

(5)

Hold a metal part of the gun firmly to the side of

a metal pail, and trigger the gun to relieve pressure.

(6)

Engage the gun safety latch. (7) Open the drain valve, having a container

ready to catch the drainage.

(8)

Leave the drain valve open until you are ready to spray again.

If you suspect that the spray tip or hose is completely clogged, or that pressure has not been fully relieved after following the

steps above, VERY SLOWLY loosen the tip guard retaining nut or hose end coupling and relieve pressure gradually, then loosen

completely. Now clear the tip or hose.

ENGAGE SAFETY TURN SWITCH TO OFF UNPLUG CORD

DISENGAGE SAFETY

AND TRIGGER GUN;

ENGAGE SAFETY AGAIN OPEN DRAIN VALVE

2 307460

Page 3

General Safety

Any misuse of the spray equipment or accessories, such as

overpressurizing, modifying parts, using incompatible

chemicals and materials, or using worn or damaged parts, can

cause them to rupture and result in injection or other serious

bodily injury, fire, explosion or property damage.

NEVER alter or modify any part

could cause it to malfunction.

of this equipment; doing

so

CHECK all spray equipment regularly

worn or damaged parts immediately.

and

repair

or

replace

System Pressure

This soraver can develoo 2750 osi

173J

bar) MAXIMUM

WORkINk

PRESSURE.

Be sure that ail spray equipment and

accessories are rated to withstand the maximum working

pressure of this sprayer. DO NOT exceed the maximum working pressure of any component or accessory used in the

system.

Material Corn

P

BE SURE that al

atibility

materials and solvents used are chemically

compatible with the wetted parts shown in the Technical Data

on the back cover. Always read the material and solvent

manufacturer’s literature before using them in this sprayer.

HOSE SAFETY

2.

High pressure fluid in the hoses can be very dangerous. If the

hose develops a pinhole leak, split or rupture due to any kind

of wear, damage or misuse, the high pressure spray emitted

from it can cause an injection injury or other serious bodily injury or property damage.

ALL FLUID HOSES MUST HAVE SPRING GUARDS! The

spring guards help protect the hose from kinks or bends at or

close to the coupling which can result in hose rupture.

TIGHTEN all fluid connections securely before each use. High

pressure fluid can dislodge a loose coupling or allow high

pressure spray to be emitted from the coupling.

NEVER use a damaged hose. Before each use, check entire

hose for cuts, leaks, abrasion, bulging cover, or damage or

movement of the hose couplings. If any of these conditions

exist, replace the hose immediately. DO NOT try to recouple

high pressure hose or mend it with tape or any other device. A

repaired hose cannot contain the high pressure fluid.

HANDLE AND ROUTE HOSES CAREFULLY. Do not pull on

hoses to move equipment. Do not use materials or solvents

which are not compatible with the inner tube and cover of the

hose. DO NOT expose the hose to temperatures above

WOOF

W°C) or below

-4OOF (-4OOC).

Hose Grounding Continuity

The fluid hoses provided with this sprayer have electrically

conductive material on the surface of the center core of the

hose. Other hoses on the market may have a ground wire ex-

tending the length of the hose. The ground wire can break in

use which will destroy the electrical grounding of the hose.

To be sure of continuity, check electrical resistance at least

once a week. Check overall resistance when using multiple

hose assemblies. If the resistance exceeds 29 megohms,

replace it immediately. Ground wire hose may have different

resistance; check supplier.

FIRE OR EXPLOSION HAZARD.

.‘- (.l

Static electricity is created by the high velocity flow of fluid

through the pump and hose. If every part of the spray equipment is not properly grounded, sparking may occur, and the

system may become hazardous. Sparking may also occur

when plugging in or unplugging a power supply cord. Sparks

can ignite fumes from solvents and the fluid being sprayed,

dust particles and other flammable substances, whether you

are spraying indoors or outdoors, and can cause a fire or explosion and serious bodily injury and property damage.

Always plug the sprayer into an outlet at least 20 feet (6

m)

away from the sprayer and the spray area. Do not plug in or

unplug any power supply cords in the spray area when there is

any chance of igniting fumes still in the air.

Groundin

f

To reduce te risk of static sparking, ground the sprayer and

all other spray equipment used or located in the spray area.

CHECK your local electrical code for detailed grounding instructions for your area and type of equipment. BE SURE to

ground all of this spray equipment:

1.

3.

4.

5.

6.

Sprayer:

plug the power supply cord, or extension cord,

each equipped with an undamaged three-prong plug, into

a properly grounded outlet. Do not use an adapter. All ex-

tension cords must have three wires and be rated for 15

amps.

Fluid hoses:

use only grounded hoses with a maximum of

500 feet

(150 m)

combined hose length to ensure ground-

ing continuity. Refer to Hose Grounding Continuity.

Spray gun: obtain grounding through connection to a

properly grounded fluid hose and sprayer.

Object being sprayed:

according to local code.

All solvent pails

used when flushing, according to local

code.

Use only

metalpails,

which are conductive. Do not

place the pail on a non-conductive surface, such as paper

or cardboard, which interrupts the grounding continuity.

To maintain grounding continuity when flushing or relieving pressure,

always hold a metal part of the gun firmly to

the side of a

metal

pail, then trigger the gun.

Flushin

Safety

i!Reduce te risk of injection injury, static sparking, or splashing

by following the specific flushing procedure given on page 9

of this manual. Follow the Pressure Relief Procedure on

page 2, and remove the spray tip before flushing. Hold a

metal part of the gun firmly to the side of a

metal

pail and use

the lowest possible fluid pressure during flushing.

MOVING PARTS HAZARD’

. .

Moving parts can pinch or amputate your fingers or other

body parts. KEEP CLEAR of moving parts when starting or

operating the sprayer. Unplug the sprayer and relieve pressure

before checking or servicing the sprayer to prevent it from

starting accidentally.

IMPORTANT

United States Government safety standards have been adopted under the Occupational Safety and Health Act. These standards-par-

ticularly the General Standards, Part 1910, and the Construction Standards, Part 1926-should be consulted.

307460

3

Page 4

A VERTISSEMENT

La pulv&isation A haute pression peut causer des blessures

tr&s

graves.

R6serv6 exclusivement & I’usage professionnel. Observer toutes

les

consignes de

s&wit&

Bien lire et bien comprendre tous

les

manuels d’instructions avant d’utiliser le mat6riel.

Consignes

g6n6rales

de

skuritd

Cet appareil produit un fluide 8 tres haute pression. Le fluide

pulverise par le pistolet ou le fluide sous pression provenant de

fuites ou de ruptures peut penetrer sous la peau ou a I’interieur

du corps et entrainer des blessures tres graves, voir

mQme

une

amputation. MQme sans Qtre sous pression, le fluide bclabous-

sant ou entrant dans les yeux peut aussi entrainer des

blessures graves.

NE JAMAIS pointer le pistolet vers quelqu’un ou vers une par-

tie quelconque du corps. NE JAMAIS mettre la main ou les

doigts sur I’ajutage du pulverisateur. NE JAMAIS essayer de

“refouler” la peinture. Cet appareil N’est PAS un compresseur

pneumatique.

TOUJOURS garder la protection de I’ajutage en place sur le

pistolet pendant la pulverisation.

TOUJOURS observer la March g Suivre pour

D6tendre

la

Pression

don&e plus loin, avant de nettoyer ou d’enlever

I’ajutage du pulverisateur, ou d’effectuer un travail

quelcon-

que sur une partie de I’appareil.

NE JAMAIS essayer

d’arrQter

ou de

devier

les fuites

avec

la

main ou le corps.

Avant chaque utilisation, bien s’assurer que les dispositifs de

securite fonctionnent correctement.

Soins mddicaux

En cas de pen&ration de fluide sous la peau:

DEMANDER IMMEDIATEMENT DES SOINS

MEDICAUX D’URGENCE.

NE PAS SOIGNER

CE7TE

BLESSURE COMME

UNE SIMPLE COUPURE.

Dire exactement au medecin quel type de liquide a 6te inject&

Pour avoir des instructions concernant le traitement

ap-

proprie, dire au medecin d’appeler le

CENTRE ANTI-POISON SUIVANT:

NATIONAL POISON CENTER NETWORK

(412)681-6669

enlever ni modifier une partie quelconque du pistolet; ceci

ris-

querait d’entrainer un mauvais fonctionnement et des

blessures graves.

Verrou de s&wit&

A chaque fois que I’on

s’arrkte

de

pulveriser, mQme

s’il s’agit

d’un court instant, toujours mettre le verrou de

securite

du

pistolet sur la position “fermee” ou “securite” (“safe”) pour

empkher le pistolet de fonctionner. Si le

verrou

de

securite

n’est pas mis, le pistolet peut se dtklencher accidentellement.

Diffuser

Le diffuseur du pistolet sert B diviser le jet et a reduire les

ris-

ques d’injection accidentelle quand I’ajutage n’est pas en

place. Verifier le fonctionnement du diffuseur regulierement.

Pour cette verification,

detendre

la

pression

en observant la

Marche a Suivre pour

Ddtendre

la

Pression donnee

plus

loin puis enlever I’ajutage du pulverisateur. Pointer le pistolet

dans un seau en metal, en le maintenant fermement contre le

seau. Puis, en utilisant la pression la plus faible possible, ap-

puyer sur la gachette du pistolet. Si le fluide projete

n’estpas

diffuse sous forme de jet irregulier, remplacer immediatement

le diffuseur.

Protection de l’aju tage

TOUJOURS maintenir la protection de I’ajutage en place sur fe

pistolet du pulverisateur pendant la pulverisation. La protection de I’ajutage attire I’attention sur les risques d’injection et

contribue B eviter que les doigts ou une partie quelconque du

corps ne passe accidentellement

B

proximite immediate de

I’ajutage du pulverisateur.

Consianes

de

skurit4

concernant I’ajutage du

pulvklsateur

Faire extramement attention B l’occasion du nettoyage ou du

remplacement des ajutages du pulverisateur. Si l’ajutage se

bouche

pendant la pulverisation, mettre immediatement le

verrou de

securite

du pistolet. TOUJOURS bien observer la

Marche g Suivre pour

Ddtendre

la

Pression

puis

enlever

I’ajutage du pulverisateur pour le nettoyer.

Avant chaque utilisation, bien s’assure que tous les dispositifs

de

securite

du pistolet fonctionnent correctement. Ne pas

NE JAMAIS essuyer ce qui s’est accumule autour de I’ajutage

du pulverisateur avant que la pression ne soit completement

tombee et que le verrou de securite du pistolet ne soit engage.

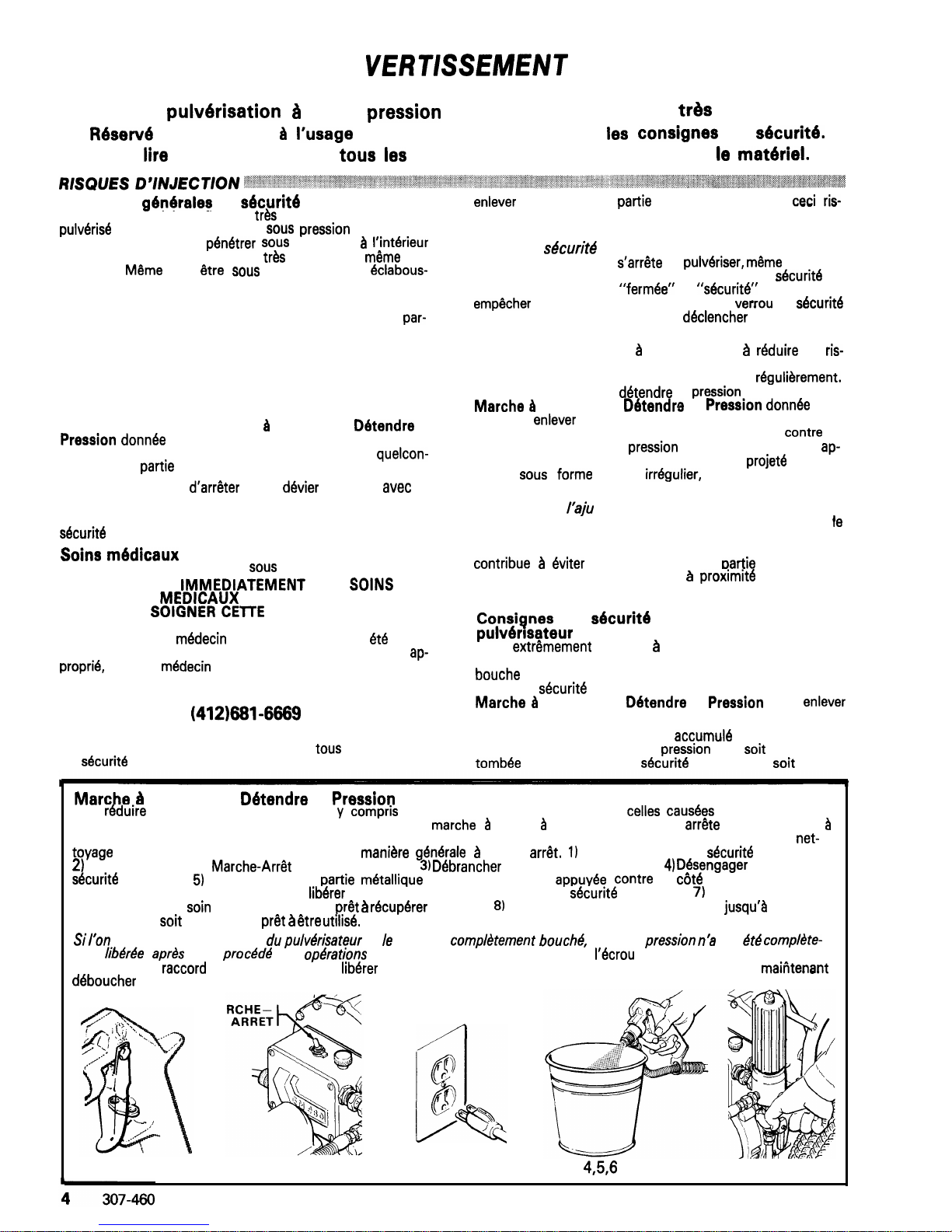

Marche A Suivre pour D6tendre la

Pression

Pour reduire les risques de blessures graves, y compris les blessures par injection de fluide ou celles causees par des pieces en

mouvement ou par electrocution, toujours bien observer cette marche a suivre B chaque fois que I’on arrQte le pulverisateur,

B

I’occasion de la verification ou de la reparation d’une piece de I’appareil de pulverisation, 8 I’occasion de I’installation, du net-

toyage ou du remplacement des ajutages et d’une

man&e

g&n&ale a chaque arr9t. 1) Engager le verrou de securite du pistolet.

2)

Mettre I’interrupteur

Marche-Arrat

sur ARRET (“OFF”). 3)

Debrancher

le cordon d’alimentation. 4)

Desengager

le verrou de

securite du pistolet. 5) En maintenant une partie metallique du pistolet fermement appuyee contre le

c&e

d’un seau en metal,

appuyer sur la gachette du pistolet pour liberer la pression. 6) Engager le verrou de securite du pistolet. 7) Ouvrir le robinet de

purge en prenant

soin

d’avoir un recipient

prQt B recuperer

le liquide. 8) Laisser le robinet de purge ouvert

jusqu’a

ce que le

pulverisateur

soit

de nouveau

prQt a

&re

utilise.

Sil’on soupconne que l’ajutage du pulvkisateur ou

le

tuvau est complktement bouchh, ou que la pression n’a pas

BttS

complkte-

ment

lib&&e

apr&s avoir

proc&d&

aux

opkrations

ci-dessus, desserrer TRES LENTEMENT l’ecrou de retenue de la protection de

I’ajutage ou le raccord du bout du tuyau et liberer progressivement la pression, puis terminer le desserrage. On peut maintenant

debaucher I’ajutage ou le tuyau.

MA

1

2 3

‘L&6

7

Page 5

RISQUES EN CAS DE MAUVAISE UTILISATION DU MATERIEL

Consignes g6n&ales de

skurit4

Toute utilisation anormale de I’appareil de pulverisation ou des

accessoires comme, par exemple, la mise sous une pression

excessive, les modifications de pieces, I’utilisation de produits

chimiques et de matieres incompatibles et I’utilisation de

pieces us&es ou abimees peut causer des deg&s B I’appareil ou

des ruptures de pieces et entrainer une injection de liquide ou

d’autres blessures serieuses, un incendie, une explosion ou

d’autres degats.

NE JAMAIS alterer ou modifier une piece de cet appareil; ceci

risquerait d’entrainer son mauvais fonctionnement.

VERIFIER regulierement tout I’appareil de pulverisation et ses

equipements et &parer ou remplacer immediatement les

pieces u&es ou abimees.

MESURES DE SECURITE CONCERNANT LES

Le fluide a haute pression circulant dans les tuyaux peut &re

tres dangereux. En cas de fuite sur le tuyau,

mQme

minuscule,

de fissure, dechirure ou rupture a la suite de I’usure, de degfits

ou d’une mauvaise utilisation, les projections de fluide haute

pression qui en proviennent peuvent entrainer des blessures

graves par penetration sous la peau ou par contact, ainsi que

des deggts materiels.

TOUS LES TUYAUX FLEXIBLES DOIVENT AVOIR DES

RESSORTS SPIRALE DE PROTECTION! Les spirales de

protection contribuent 8 eviter la formation de pliures, de

boucles ou de noeuds sur les tuyaux qui pourraient entrainer la

rupture du tuyau 8 I’endroit du raccord ou a son voisinage.

SERRER FERMEMENT tous les raccords avant chaque utilisa-

tion. Le fluide sous pression peut faire sauter un raccord

desserre ou produire un jet a haute pression s’echappant par le

raccord.

NE JAMAIS utiliser un tuyau endommage. Avant chaque

utilisation, verifier entierement chaque tuyau pour deceler les

coupures, fuites, abrasions, boursouflures de I’enveloppe ou

toute autre deterioration ou jeu des raccords. Si I’on constate

I’une de ces deteriorations, il faut remplacer le tuyau

immediatement. NE PAS essayer de refaire le raccord d’un tuyau

haute pression ni de reparer le tuyau avec du ruban adhesif ou

Pression

Ce pulverisateur peut produire une PRESS/ON MAXIMUM DE

TRAVAIL

l&W

bar 12750 lb/po.2). S’assurer que tous les

elements du pulverisateur et ses accessoires sont concus pour

resister a la pression maximum de travail de ce pulverisateur.

NE PAS depasser la pression maximum de travail d’aucun des

elements ou accessoires utilises avec cet appareil.

Compatibilit4 chimique des corps

BIEN

S’ASSURER que tous les corps des solvants utilises

sont chimiquement compatibles avec les parties mouilkes

indiquees dans les “Donnees techniques”, au dos de la couver-

ture. Toujours lire soigneusement les documents et brochures

du fabricant des mat&es et solvants utilises avant de s’en ser-

vir dans ce pulverisateur.

TUYAUX FLEXIBLES

par tout autre moyen. Un tuyau repare ne peut pas resister au

fluide sous pression.

MANIPULER LES TUYAUX AVEC PRECAUTION ET

CHOISIR SOIGNEUSEMENT LEUR CHEMIN. Ne pas deplacer

le materiel en tirant sur le tuyau. Ne pas utiliser de mat&es ou

de solvants qui ne sont pas compatibles avec I’enveloppe

in-

terieure ou exterieure du tuyau. NE PAS exposer le tuyau

a

des temperatures superieures a 82°C

(18OOF)

ou inferieures

a

-40°C

(-4OOF).

Continuitd du circuit de mise A la terre des tuyaux

Les tuyaux flexibles fournis avec ce pulverisateur ont une surface conductrice continue au coeur du tuyau. D’autres tuyaux

vendus dans le commerce cornportent un fil de mise a la terre

allant tout au long du tuyau. Ce fil de mise a la terre peut se

rompre a I’usage, ce qui supprime la mise a la terre du tuyau.

Pour

&re

certain de la continuite de la mise a la terre, il faut

verifier la resistance Blectrique des tuyaux au moins une fois

par semaine. Verifier aussi la resistance d’ensemble quand il y

a plusieurs tuyaux assembltk Si la resistance depasse 29

megohms, remplacer immediatement le tuyau. La resistance

des tuyaux mis a la terre par un fil peut Qtre differente; se

renseigner aupres du fournisseur.

RISQUES D’INCENDIE OU D’EXPLOSION

De l’electricite statique est produite par le passage du fluide

a

grande vitesse dans la pompe et dans les tuyaux. Si toutes les

pieces de I’appareil de pulverisation ne sont pas convenable-

ment

reliees a

la masse ou B la terre, des etincelles peuvent se

produire et I’appareil risque d’9tre dangereux. Des Btincelles

peuvent egalement se produire a I’occasion du branchement

ou du debranchement du cordon d’alimentation. Les etincelles

sont suffisantes pour allumer les vapeurs de solvants et le

fluide pulverise, les fines particules de poussiere ainsi que

d’autres substances inflammables, quand on pulverise a

I’in-

terieur ou 8 I’exterieur, et

elles

peuvent causer un incendie ou

une expiosion, ainsi que des blessures graves et des deggts

materiels. Toujours brancher le pulverisateur dans une prise se

trouvant a au moins 6 m

(20

pieds) de I’appareil et de I’endroit

oti se fait la pulverisation. Ne pas brancher ou debrancher un

cordon d’alimentation quel qu’il soit dans la zone ou se fait la

pulverisation quand il y a le moindre risque que des vapeurs

encore presentes dans I’air prennent feu.

Mise & la terre ou A la masse

Pour reduire les risques de production d’etincelles d’electricite

statique, le pulverisateur et tous les equipements utilises ou se

trouvant dans la zone de pulverisation doivent Qtre relies a la

terre ou a la masse. Pour connaitre le detail des instructions de

mise ZI la terre dans la region et le type particulier d’equipe-

ment, CONSULTER le code ou les reglementations electriques

locales. S’ASSURER que tous les equipements de pulverisa-

tion suivants sont bien relies a la terre:

2. Tuyaux

flexibles:

Afin d’assurer la continuite de la mise a la

terre, n’utiliser que des tuyaux comportant une mise a la terre

\ ;.

et ayant une longueur maximum combinee de 150 m

(1500

pieds). Se reporter egalement au paragraphe “Con-

tinuitb du circuit de mise A la

terre

des tuyaux”.

3. Pistolet: Realiser la mise 8 la terre en le raccordant a un

tuyau flexible et a un pulverisateur

deja

convenablement relies

a

la terre.

4. Objets, mattkiel ou surfaces recevant la pulv&isation:

observer le code ou les reglementations locales.

5. Tous /es seaux de so&ants utilises pour le rincage: observer

le code ou les reglementations locales. N’utiliser que des seaux

m&a//iques conducteurs de l’electricite. Ne pas mettre le seau

sur une surface non conductrice comme sur du papier ou du

carton car

cela

interromprait la continuite le la mise a la terre.

6. Pour conserver la continuith de la mise B la terre quand on

rince le

matkriel ou quand on lib&e la pression, toujours

maintenir une partie metallique du pistolet fermement appuyee

contre le cot& d’un seau en m&a/ puis appuyer sur la detente

du pistolet.

Mesures de Sdcurit4 concernant le

Rincage

Pour reduire les risques de blessures par penetration de la

peau et les risques dirs aux etincelles d’electricite statique ou

aux eclaboussures, observer la marche a suivre pour le rincage

donnee a la page 9 de ce manuel. Observer la “Marche

&

Suivre pour

Dbtendre

la Pression” donnee

a

la page 4 en

enlever

l’ajutage du pulv&isateur avant le

rincage.

Maintenir

une partie metallique du pistolet fermement appuyee contre le

tote d’un seau en m&al et utiliser la pression la plus faible

possible pendant le rincage.

1. Pulwkisateur: Brancher le cordon d’alimentation ou la

rallonge qui doivent Qtre equip& d’une prise 8 3 fiches en bon

&at, dans une prise de courant convenablement mise a la

terre. Ne pas utiliser d’adaptateur. Toutes les rallonges doivent

avoir 3 fils et

&re

prevues pour 15 amperes.

307460 5

Page 6

ADVERTENCIA

EL ROCIADO A ALTA

PRESION

PUEDE CAUSAR GRAVES

LESIONES.

SOLO PARA US0 PROFESIONAL. RESPETE LOS AVISOS DE ADVERTENCIA.

Lea y entienda todo el manual de instrucciones antes de manejar el equipo.

PEUGRO DE Iff YECCION DE FLUID0

Seguridad general

Este equip0 genera un fluid0 a una presion muy alta. El

rociado de la pistola,

10s

escapes de fluid0 o roturas de

10s

componentes pueden inyectar fluid0 en la piel y el cuerpo y

causar lesiones extremadamente graves, incluyendo a veces la

necesidad de amputacibn. Tambien, el fluid0 inyectado o

salpicado en

10s

ojos puede causar graves dafios.

NUNCA apuntar la pistola hacia alguien o alguna parte del

cuerpo. NUNCA colocar la mano o

10s

dedos encima de la bo-

quilla.

NUNCA tratar de “hater retornar la pintura”; este NO

es un sistema de rociado de

aire.

SIEMPRE tener colocado el protector de la boquilla en la

pistola mientras se esta pulverizando.

SIEMPRE seguir el procedimiento de descarga de presibn,

dado m& abjo, antes de limpiar o sacar la boquilla o de dar

servicio a cualiquier equip0 del sistema.

NUNCA tratar de parar o desviar

10s

escapes con la mano o el

cuerpo.

Asegurar que todos

10s

aparatos de seguridad del equip0

estan funcionando bien antes de cada uso.

Tratamiento

medico

Si pareciera que un poco de fluid0 penetro la piel, conseguir

TRATAMIENTO MEDICO DE

URGENCIA

DE

INMEDIATO.

NO TRATAR LA

HERIDA

COMO UN SIMPLE CORTE.

Decir al medico exactamente cua fluid0 fue. Para instruc-

ciones de tratamiento, pedir al medico que

llame

a la

CADENA DEL CENTRO

NACIONAL

DE

ENVENENAMIENTO

Aparatos de seguridad de la

pistola pulverizadora

Asegurar que todos

10s

aparatos protectores de la pistola

estan funcionando bien antes de cada uso. No sacar ni

modificar ninguna pieza de la pistola pues podria causar el

malfuncionamiento de la misma con

las

consiguientes lesiones

personales.

Pestillo

de

segut-idad

Cada

vez que se deje de pulverizar, aunque sea por un breve

momento, siempre colocar el pestillo de seguridad en la

position “cerrada”, lo que deja la pistola inoperante. El no

hacerlo puede llevar al disparo imprevisto de la pistola.

Difusor

El difusor de la pistola dispersa el chorro pulverizado y reduce

el riesgo de inyeccion cuando no esta instalada la boquilla.

Revisar con regularidad el funcionamiento del difusor. Seguir

el procedimiento de descarga de presibn, dado mas abajo,

y despues sacar la boquilla. Apuntar la pistola a un balde

metalico, sosteniendola bien firme contra

61.

Utilizando la

presion m&r bajo posible, disparar la pistola. Si el fluid0

emitido no sale

disperse

en un chorro irregular, reemplazar de

inmediato el difusor.

Protector de la boquilla

SIEMPRE tener el protector de ia boquilla colocado en la

pistola mientras se esta pulverizando. Este protector llama la

atencion contra el peligro de inyeccibn y ayuda a prevenir la

colocacion accidental de

10s

dedos o cualquier otra parte del

cuerpo cerca de la boquilla.

Seguridad de la boquilla pulverizadora

Tener mucho cuidado al limpiar o cambiar

las

boquillas. Si

llegara a obstruirse mientras esta pulverizando, enganchar

el

pestillo de la pistola de inmediato. SIEMPRE seguir el pro-

cedimiento de descarga de

presih

y despues sacar la bo-

quilla

para limpiarla.

NUNCA limpiar la acumulacion de pintura alrededor de la bo-

quilla

antes de que se haya descargado por complete la

presion y el pestillo este enganchado.

Procedimiento de descarga de

presih

Para reducir el riesgo de sufrir graves lesiones corporales, rncluyendo inyeccion o lesiones causadas por piezas en movimiento o

choque electrico, siempre seguir este procedimiento al apagar la maquina pulverizadora, al revisar o dar servicio a cualquier parte

del sistema de pulverizacibn, al instalar, limpiar o cambiar

las

boquillas, y cada vez que se deja de pulverizar.

(1)

Enganchar el

pestillo de la pistola.

(2)

Mover el interruptor electrico (ON/OFF) a la position OFF (apagado).

(3)

Desenchufar el cordon

ektrico.

(4) Desenganchar el pestillo de la pistola. (5) Sujetar una parte mettilica de la pistola bien firme contra un balde de

metal, y disparar la pistola para descargar la presibn.

(6)

Enganchar el pestillo de la pistola.

(7)

Abrir la valvula de drenaje y tener

listo un reclipiente para recibir la pintura.

(8)

Dejar la valvula de drenaje abierta hasta que se este nuevamente listo para

pulverizar.

Sise sospecha que la boquilla o la manguera est4 completamente obstruida, o que no se ha descargado por complete la presidn

despuh de haber seguido elprocedimiento anterior, aflojar MUY LENTAMENTE la tuerca de retention del protector de la bo-

quilla

o acoplamiento de la punta de la manguera y descargar gradualmente la presibn, despues, aflojarlo por complete. Luego,

despejar la boquilla o la manguera.

1

2 3

456

7

6

307460

Page 7

PELIGRO POR MAL US0 DEL EQUIP0

Seguridad eneral

Cualquier maBuso del equip0 pulverizador o

10s

accesorios, tal

coma sobrepresurizacion, modificacibn de piezas, uso de

materiales y productos quimicos incompatibles, o utilization

de piezas dafiadas o desgastadas, puede hacen que se rompan

y causen la inyeccion de fluid0 u otras lesiones corporales

graves, incendio, explosion o dafion a la propiedad.

NUNCA alterar o modificar ninguna

hacerlo podria causar una averia.

pieza

de este equipo; el

REVISAR con

regularidad el equip0 pulverizador y reparar o

reemplazar de inmediato

las

piezas dafiadas o desgastadas.

Presi6n

del

sistema

Esta pulverizadora puede desarrollar 190 barias

(2756

psi) de PRESION DE TRABAJO MAXIMA. Asegurar que todo

el equip0 pulverizador y sus accesorios tienen la capacidad

para aguantar la presibn maxima de trabajo de esta

pulverizadora. NO exceder la presion maxima de trabajo de

ningun componente o accesorio de este sistema.

Compatibilidad de material

ASEGURAR que todos

10s

materiales y solventes usados son

quimicamente compatibles con

las

piezas mojadas ilustradas

en la hoja de datos tecnicos en la contratapa. Siempre leer

las

instrucciones del fabricante del material y solvente antes de

usarlos en esta pulverizadora.

SEGURIDAD

EN EL US0 DE LAS MANGUERAS

El fluid0 que pasa a alta presion por

las

mangueras puede ser

muy peligroso. Si en la manguera se desarrolla un escape

pequefio, una rotura o rajadura debido a cualquier tipo de

desgaste, daiio o maltrato, el chorro a alta presion emitido por

alli

puede causar una lesion por inyeccion u otras lesiones cor-

porales graves o dafion a la propiedad.

iTODAS

LAS MANGUERAS PARA FLUIDOS TIENEN

QUE TENER

GUARDAS

DE RESORTE! Estas protegen

las

mangueras contra dobleces o retorceduras en

10s

acoplamien-

tos o cerca de ellos,

10s

que podrian traducirse en roturas de la

manguera.

Antes de usarlas, APRETAR bien firmes todas

las

conexiones.

El fluid0 a alta presion puede desalojar un acoplamiento suelto

o dejar que por &I escape un chorro a alta presibn.

NUNCA usar una manguera que esta daiiada. Siempre,

revisarla en busca de cortaduras, escapes, abrasion, cubierta

abultada, o acoplamientos sueltos o dafiados. Si llegara a

en-

contrarse cualquiera de estas condiciones, reemplazar de

inmediato la manguera. NO intentar reacoplar una manguera de

alta presion o enmendarla con cinta adhesiva u otro material

similar. Una manguera que ha sido remendada no aguante el

fluid0 a alta presion.

MANEJAR Y PASAR

CUIDADOSAMENTE

LAS

MANGUERAS. No tirar de

las

mangueras para mover el

equipo. No usar materiales o solventes que

Sean

incompatibles

con el tubo interno y la cubierta dela manguera. NO exponer

las

mangueras a temperaturas sobre 82°C (180°F) o bajo

-40°C (-40°F).

Continuidad a tierra de la manguera

Las mangueras para fluidos provistas con esta pulverizadora

tienen material electricamente conductive en la superficie del

nlicleo central. Otras mangueras a la venta tienen a veces un

alambre a tierra a todo el largo. Este alambre puede romperse

con el uso, destruyendose por lo tanto, la conexion a tierra de

la manguera.

Corn0 precaution, revisar por lo menos una vez a la semana la

resistencia electrica. Revisar la resistencia general al usar con-

juntos de mangueras multiples. Si excede de 29 megaohmios,

reemplazarla de inmediato. Las mangueras con alambre a

tierra tienen diferentes resistencias; consultar con el

proveedor.

PELIGRO DE INCENDIO 0 EXPLOSIOhl

El flujo a alta velocidad del fluid0 al pasar por la bomba y

manguera crea electricidad estatica. Si todas

las

partes del

equip0 pulverizador no tienen buena tierra, pueden ocurrir

chispas, convirtiendo al sistema en

algo

peligroso. Tambien,

pueden producirse chispas al enchufar o desenchufar el cordon electrico. Estas chispas pueden inflamar

10s

vapores de

10s

solventes y el chorro de fluid0 pulverizado, particulas de

polvo y otras sustancias inflamables, sea al aire libre o bajo

techo, lo que podria causar una explosion o incendio y graves

lesiones corporales y dafios a la propiedad. Enchufar siempre

la pulverizadora a un tomacorriente que se encuentre a por lo

menos 6 m

(20

pies) de la maquina y del area que se va a

rociar. No enchufar o desenchufar ningun cordon electrico en

el lugar donde se esta rociando cuando todavia exista la

posibilidad de que queden vapores inflamables en el

aire.

Puesta a tierra

Para reducir el riesgo de chispas estaticas, conectar a tierra la

pulverizadora y todo el otro equip0 de pulverizar que se use o

se encuentre en el lugar que se va a rociar. CONSULTAR el

cddigo electrico de la localidad para

las

instrucciones sobre

las

conexiones a tierra exigidas para la zona y tipo de equipo.

ASEGURAR de conectar a tierra todo este equip0

pulverizador:

1. Pulverizadora: enchufar el cordon electrico, o cable exten-

sor, cada uno con un enchuf de tres patas en buen estado, a

un tomacorriente con puesta a tierra apropiado. No usar un

adaptador. Totos

10s

cables extensores tienen que tener tres

hilos y una capacidad de 15 amperios.

2. Mangueras para fluidos: usar solamente mangueras con

puesta a tierra de una longitud combinada de 150 m

KiOO

pies), para asegurar buena continuidad a tierra. Referirse

tambien al parrafo sobre continuidad a tierra de la

manguera.

3.

Pistola:

hater la puesta a tierra conectandola a una

manguera de fluid0 y pulverizadora bien conectadas atierra.

4. Objet0

local.

que se

estA

rociando:deconformidad con el cbdigo

5. Todos

/OS

baldes de solvente usados durante el lavado, de

conformidad con el cbdigo local. Usar solamente baldes de

metal, que

Sean

conductivos. No colocar el balde en una

superficie no conductiva, coma papel o carton, que inter-

rumpe la continuidad a tierra.

6.

Para

mantener la continuidad a tierra durante ei lavado o

descarga de presih, siempre apoyar una parte metalica de la

pistola bien firme contra el costado del balde de metal,

despues apretar el gatillo.

Seguridad durante el lavado

Reducir el riesgo de lesiones por inyeccion, chispas electricas

o salpicaduras,

siguiendo el procedimiento de lavado

especifico dado en la pagina 9 de este manual. Seguir el pro-

cedimiento de descarga de presibn en la pagina 6, y quitar

la boquilla rociadora antes de lavar. Apoyar una parte metalica

de la pistola bien firme contra el costado de un balde de metal

y usar la presion mas baja posible de fluid0 durante el lavado.

PELIGRO DE LAS PIEZAS MOVILES

Las piezas en movimiento pueden pinchar o amputar dedos u

otras partes del cuerpo. MANTENERSE ALEJADO de

las

piezas en movimiento durante el arranque o funcionamiento

de la pulverizadora. Desenchufar la pulverizadora y descargar

la presion antes de revisarla o darle servicio, para impedir que

arranque inesperadamente.

IMPORTANT

Se han adoptado

las

normas de seguridad del gobierno de

10s

Estados Unidos de Norteamerica bajo el Acta de Seguridad y

Salud Ocupacional. Deberan consultarse estas normas, en

especial

las

Generales, Parte 1910, y

las

Normas de Construc-

cibn, Parte 1926.

307-460

7

Page 8

INS TALLATION

\

.’

.’

,

”

I.

.’ I

,. :.

:

.: I,:!.. .,,

,

r

ON/OFF switch

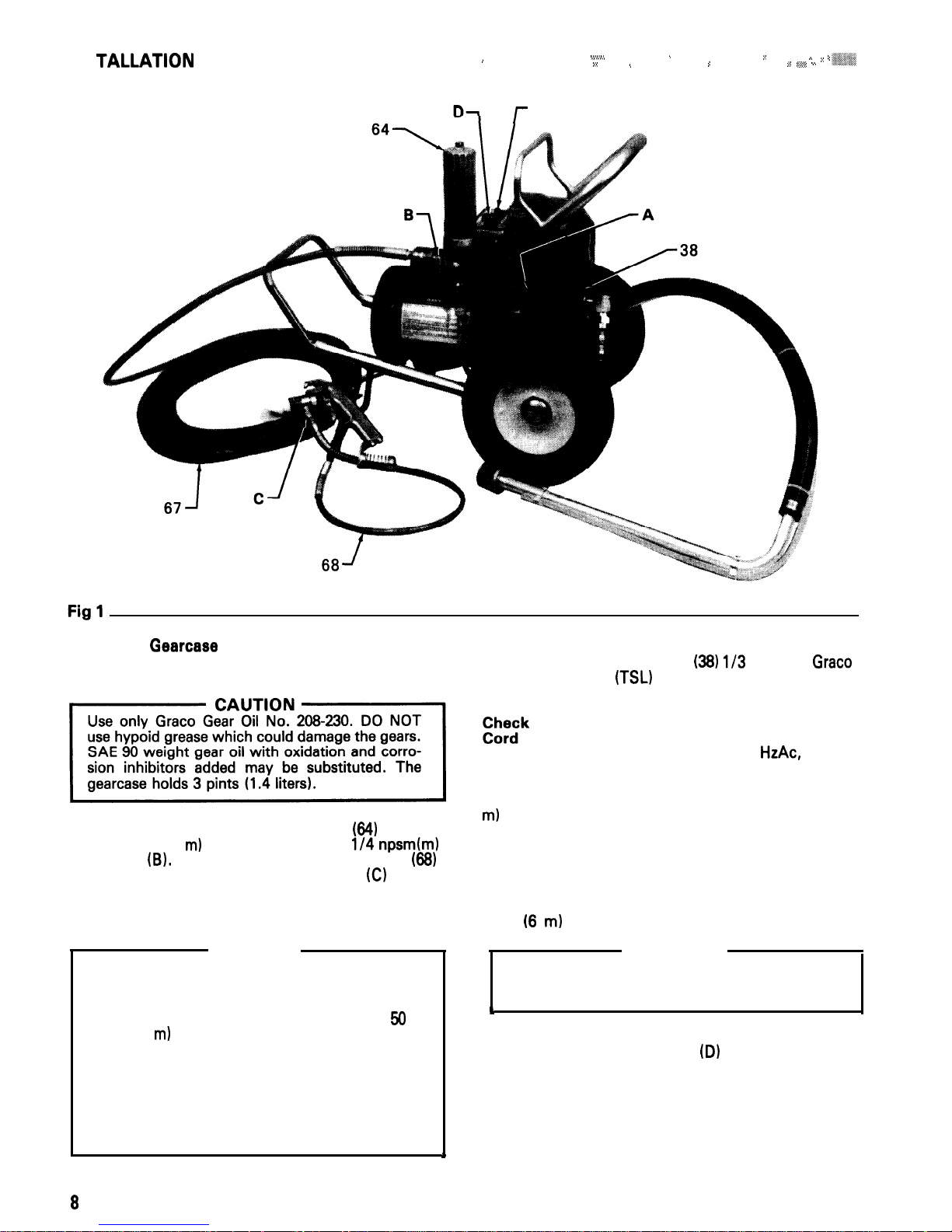

Check the Gearcase Oil

Remove the fill plug (A) and ensure that the oil level is

up to the fill plug opening. See Fig 1.

Connect the Gun

Remove the plastic cap plug from the filter (64) and connect the 50 ft (15 m) spray hose (67) to the

l/4

npsm(m)

filter outlet

(B).

Then connect the whip end hose (68)

between the spray hose and the fluid inlet (C) of the

gun. Do not use thread sealer. Do not install the spray

tip yet; wait until after flushing the sprayer. The longer

the spray hose, the lower the delivery rate.

To avoid damaging the pressure control, which

CAUTION

may result in poor sprayer performance, follow

these precautions:

1. Always use nylon spray hose at least 50 ft

(15.2 m) long.

2.

Never use wire braid hose at it is too rigid to

act as a pulsation dampener.

3.

Never install any shutoff device between the

filter and the main hose. See Fig 1.

4. Never plug the main filter outlet while the

sprayer is operating.

\

8

307460

Fill Packing Nut/Wet Cup

Fill the packing nut/wet cup

(38)

l/3 full with

Grace

Throat Seal Liquid (TSL) to help protect and prolong

the life of the pump’s throat packings.

Ei;;k

Electrical Service and Plug In Power Supply

Be sure the electrical service is 120 V, 60 HzAc, 15 Amp

(minimum) and that the outlet you use is properly

grounded. Use an extension cord which has 3 wires of

12 gauge (minimum) size and a maximum of 100 ft (30.3

m)

long. Longer lengths may affect sprayer perfor-

mance.

Plug in the Sprayer

Be sure the ON/OFF switch is OFF. Refer to Fig 1. Then

plug the cord into a grounded electrical outlet at least

20 ft (6 m) away from the spray area.

WARNING

To reduce the risk of static sparking, be sure to

read and follow the grounding instructions given

on page 3 of this manual.

4

Set Pressure Control

Turn the pressure control knob (D) counterclockwise to

the lowest setting each time before you start the sprayer

to help prolong the pump life.

Flush the Pump

An important part of the care and maintenance of your

EM 480 is proper flushing. See “Flushing Guidelines”

on page 9 for “When to Flush” and “How to Flush”.

Page 9

FLUSHING GUIDELINES

When To Flush .

1. Before using your new sprayer. Your new EM 480

was factory tested in No. 10 motor oil and the oil was

left in it to protect the parts.

Before using water-based paint: Flush out the oil

with mineral spirits, then flush out the mineral spirits

with soapy water followed by a clean water rinse.

Before using

o&based

paint: Flush out the oil with

mineral spirits only.

2. Whenever you change the color of your paint

supply. Flush with a compatible solvent such as

mineral spirits or water.

3. Whenever you change from water-based to oilbased paint. Flush with soapy water, then mineral

spirits.

4. Whenever you change from oil-based to water-

based paint. Flush with mineral spirits, then soapy

water, followed by a clean water rinse.

5.

Before you store your sprayer.

When using water-based paint: Flush with water,

then mineral spirits and leave the pump, hose, and

gun filled with mineral spirits.

When using o&based paint: Flush with mineral

spirits and leave the pump, hose, and gun filled with

mineral spirits.

6. Before you use your sprayer after storage.

Before using water-based paint: Flush out mineral

spirits with soapy water followed by a clean water

rinse.

Before using o&based paint: Flush the mineral spirits

out and the unit is ready to use.

How To Flush

. . .

.;

.’ :: <>

1. Follow the Pressure Relief Procedure Warning on

page 2, then remove the spray tip.

\

WARNING

To reduce the risk of an injection injury, always

remove the spray tip from the gun before flushing.

2. Remove the filter bowl and screen. See manual

307-273, supplied. If the bowl is tight, remove the

filter assembly from the sprayer first. Install the

bowl on the filter without the screen. Clean the

screen separately.

CAUTION

Using excessive force to remove the filter bowl

while still on the sprayer could rotate the pressure

control fittings and damage the bourdon tube.

\

3.

Pour

l/2

gallon (2 liters) of compatible solvent (see

“When to Flush”) into a bare metal pail. Put the

pump suction tube in the pail.

4. Be sure the pressure control knob is set at

minimum, then disengage the gun safety latch.

When you are flushing or relieving pressure,

ALWAYS hold a metal part of the gun firmly to a

the risk of static sparking, which can cause fire or

5.

Point the spray gun into the metal pail, squeeze the

trigger, turn the sprayer to ON, and slowly turn the

pressure control setting clockwise just until the

sprayer starts.

Always use the lowest possible

pressure.

6.

Keep the gun triggered until clean solvent comes

from the nozzle. Release the trigger. Then open the

filter drain valve, which is connected to a drain

valve, and flush again to remove paint from the

drain tube.

7. Release the trigger and engage the gun safety

latch. Close the drain valve.

Fig

8.

9.

10.

11.

12.

2

Check all fluid connections for leaks. If there are

any leaks, follow the Pressure Relief Procedure

Warning, above,

then tighten the connections.

Start the sprayer again and check to be sure the

leaking has stopped.

Remove the suction tube from the pail. Disengage

the gun safety latch and trigger the gun into a metal

pail to force solvent from the hose. Do not let the

pump run dry for more than 30 seconds to avoid

damaging the pump packings!

Engage the gun safety latch, turn the sprayer to

OFF, and unplug the sprayer. Open the drain valve.

Unscrew the filter bowl (F) and reinstall the screen

(G) so the stud of the filter support (H) protrudes

through the end of the screen. Install the spring (E)

on the stud, and reinstall the bowl, hand tight only.

Be careful not to rotate or jar the pressure control

fittings.

If you flushed with mineral spirits and are going to

use a water-based paint, you must flush again with

soapy water, followed by a clean water rinse.

307460 9

Page 10

Prepare the Paint

Prepare the paint as instructed by the manufacturer. If

the paint has been opened before, remove any skin that

has formed. Stir the paint thoroughly to dissolve any

hard pigments. Strain the paint through a fine nylon

mesh bag (available at most paint dealers) to remove

particles that might clog the filter or the spray tip. This is

probably the most important step toward trouble-free

spray painting.

Prime the Sprayer

Plug the power supply cord into a grounded, 3-prong

outlet. Close the drain valve. Put the paint suction tube

into the pail of paint. Don’t install the spray tip in the

gun yet! Disengage the gun safety latch and point the

gun into a metal waste container. Squeeze the gun trigger, turn the ON-OFF switch to the ON position and

let the sprayer operate until all air is forced out of the

system. Engage the gun safety latch.

NOTE: If the pump is hard to prime, turn on the

sprayer and open the drain valve. Let the

sprayer run until paint has filled the drain

tube (21). This method bleeds the air from

the pump. Then release the gun safety latch

and trigger the spray gun to prime the hose.

Engage the gun safety latch.

Install the Spray Tip and Tip Guard

Follow the Pressure Relief Procedure Warning, below.

Unscrew the retaining nut from the gun. Install the

Reverse-A-Clean III (90) spray housing with the tip installed (see instruction manual

307321

or the instruc-

tion label with the Reverse-A-Clean). Then tighten the

Reverse-A-Clean retaining nut by hand until snug. Final-

ly, use a wrench and tighten the retaining nut

l/4

turn.

This is essential to prevent leaking.

For information about your airless gun, see instruction

manual 307633.

Adjust the Spray Pattern

Adjust the pressure control knob

(D)

so the fluid

pressure completely atomizes the spray from the gun.

Always use the lowest possible pressure to get the

desired results. See Fig 3.

Now test the spray pattern on a piece of light colored

paper. The tip position determines the direction of the

pattern width. To adjust the pattern, engage the gun

safety latch and loosen the retaining nut to position the

tip so the groove is horizontal for a horizontal pattern or

vertical for a vertical pattern. Once positioned, tighten

the retaining nut.

Fig 3

/

10 307460

Xeaning

and Clearing the Spray Tip

WARNING

To reduce the risk of an injection injury, DO NOT

hold your hand, body, or a rag in front of the spray

tip when cleaning or checking a clogged tip.

Always point the gun toward the ground or into a

waste container when checking to see if the tip is

clear.

DO NOT try to “blow back” paint; this is NOT an

air spray sprayer.

DO NOT wipe build up off of the gun or tip until

pressure is relieved. See The Pressure Relief Pro-

cedure Warning, below.

Clean out the front of the spray tip frequently during the

day’s operation and at the end of the work day. Always

relieve pressure according to the Pressure Relief Procedure Warning, below. Then use a solvent soaked

brush to clean the spray tip and to keep material build

up from drying and clogging the spray tip.

If the spray tip clogs while spraying, release the spray

gun trigger, engage the gun safety latch, and turn the

Reverse-A-Clean handle

18OO.

See Fig 4. Disengage the

gun safety latch and trigger the gun. Fluid pressure

should force the obstruction from the spray tip. Release

the trigger, engage the gun safety latch, return the handle to the original position, and resume spraying.

ROTATE

HANDLE

180”

Fig 4

Shutdown and Care of the Sprayer

WARNING

Pressure Relief Procedure

To reduce the risk of serious bodily injury, including injection or injury from moving parts or

electric shock, always follow this procedure

whenever you shut off the sprayer, when checking or servicing any part of the spray system,

when installing, cleaning or changing spray tips,

and whenever you stop spraying.

1.

Engage the gun safety latch.

2.

Turn the ON/OFF switch to OFF.

3.

Unplug the power supply cord.

4.

Disengage the gun safety latch.

5.

Hold a metal part of the gun firmly to the side

of a metal pail, and trigger the gun to relieve

pressure.

6.

Engage the gun safety latch.

7. Open the drian valve, having a container

ready to catch the drainage.

8.

Leave the drain valve open until you are ready

to spray again.

If you suspect that the spray tip or hose is

com-

ple

tely

clogged, or that pressure has not been fully

relieved after following the steps above, VERY

SLOWLY loosen the tip guard retaining nut or

hose end coupling and relieve pressure gradually,

then loosen completely. Now clear the tip or hose

obstruction.

Page 11

Before each use, squirt one drop of oil onto the lower

pivot point (J) of the pump (33). See Fig 5.

For very short shutoff periods, relieve pressure, leave

the suction tube in the paint and clean the front of the

spray tip.

Check the packing nut/wet cup (38) before each use

and periodically when in use. Follow the Pressure Relief

Procedure Warning before checking or tightening. The

packing nut should only be tight enough to stop

leakage. Do not over tighten. Overtightening may cause

binding and excessive wear on the packings.

Clean the outlet filter often and whenever the sprayer is

stored. On the last workday of the week, flush all the

paint out of the sprayer. See “Flushing Guidelines,’ on

page 9. If you are using a paint that will dry overnight,

flush the sprayer daily at shutdow’h.

Always push the suction tube onto the clip (13) on the

side of the frame (6) and wrap the hose around the

sprayer when storing it, even if only overnight, to help

protect the hose from damage.

Do not store the sprayer with water in it. Even for over-

night storage, you should fill the sprayer with mineral

spirits. This prevents rust and greatly extends the life of

the sprayer.

CAUTION

Do not let water freeze in the pressure control or

pump in cold weather. Freezing could cause a

change in the pressure control calibration or stripping of gears, resulting in loss of pressure or

stallina.

Fig 5

Once a month, lubricate the needle bearing (36) in the

displacement rod (34); use a grease gun to apply the

grease to the grease fitting (35). See Fig 5.

Periodically, or if the motor overheats, unplug the

power supply cord, follow the Pressure Relief Procedure Warning on page 10, and clean all paint and dirt

off the motor. Change the gearcase oil at least once a

year, using Grace Gear Oil no. 206-230. The gearcase

holds 3 pints (1.4 liters). Don’t use hypoid grease.

307460 11

Page 12

This guide will help you identify the causes and solu-

tions to sprayer problems. If you cannot identify and

resolve the problem, or if “Return for repair” is in-

dicated, contact your nearest authorized service agency

for instructions on where and how to return the sprayer

for repair.

NOTE: Reference letters in parentheses in the

Troubleshooting Guide refer to the notes on

page 13.

PROBLEM

I. Electric motor won’t operate

Ii. Electric motor stops while spraying

II. Electric motor runs, but output low

(See Problem VII

also)

WARNING

Pressure Relief Procedure

To reduce the risk of serious bodily injury, including injection or injury from moving parts or

electric shock, always follow this procedure

whenever you shut off the sprayer, when check-

ing or servicing any part of the spray system,

when installing, cleaning or changing spray tips,

and whenever you stop spraying.

1.

Engage the gun safety latch.

2. Turn the ON/OFF switch to OFF.

3.

Unplug the power supply cord.

4. Disengage the gun safety latch.

5.

Hold a metal part of the gun firmly to the side

of a metal pail, and trigger the gun to relieve

pressure.

6.

Engage the gun safety latch.

7. Open the drain valve, having a container

ready to catch the drainage.

8.

Leave the drain valve open until you are ready

to spray again.

If

you suspect that the spray tip or hose is com-

pie tely clogged, or that pressure has not been fully

relieved after following the steps above, VERY

SLOWLY loosen the tip guard retaining nut or

hose end coupling and relieve pressure gradually,

then loosen completely. Now clear the tip or hose

obstruction.

CAUSE

1. Power cord unplugged or damaged,

or building circuit fuse blown

2. Motor thermal overload switch has

opened.

3. Pressure setting too low

4. Damaged extension cord

5. Motor capacitor failure

(b)

6. Pressure control damaged by freezing

(c)

or overpressurizing

(d)

7. Material or water hardened in

sprayer (cl.

8. Electric motor burned out

9. ON/OFF switch failure

lO.Triac failure

1. Power cord unplugged, or building

circuit fuse blown

2. Pressure setting too low

3. Tip or filter plugged

4. Pressure control, motor capacitor

(a), or motor failure

1. Piston ball check not seating

2. Piston packings worn or damaged

3. Intake valve ball check not seating

4. Displacement pump frozen

(c)

or

drive assembly damaged

5. Pressure control frozen

(c)

or

damaged by over-pressurization IdI

SOLUTION

1. Check, reset or replace.

2. Unplug sprayer; cool (a).

3. Increase.

4.

Replace.

5.

Replace. See page 15.

6.

Replace. See page 16.

7. Thaw, try to start; return for repair

if needed.

8.

Replace. See page 15.

9.

Replace.

10.

Replace.

1. Check, reset or replace.

2. Increase.

3. Remove and clean.

4. Repair or replace.

1.

Repair. See page 14.

2.

Replace. See page 14.

3.

Repair. See page 14.

4. Thaw; restart; return for repair if

needed.

5. Thaw; restart; return for repair if

needed.

12 307460

Page 13

PROBLEM

IV. Electric motor runs, but no output

and pump not stroking

CAUSE SOLUTION

1. Drive assembly damaged 1. Repair or replace.

V. Paint leaks into wet-cup

VI. Excessive surge (pulsing) at spray

gun

1. Packing nut too loose

2. Throat packings worn or damaged

3. Damaged or worn piston rod

1. Filter partially clogged

2. Spray tip too big or worn

3. Paint too thick

4. Wrong type hose

5. Displacement pump check balls dir-

ty

or sticking

6. Displacement pump check balls and

packings worn or damaged

7. Pressure control or motor damaged

or pressure control out of adjust-

ment

1. Tighten just enough to stop

leakage.

2. Replace (e). See page 14.

3. Replace (e). See page 14.

1. Remove and clean.

2. Change tip.

3. Thin per paint manufacturer’s

recommendations.

4. Use minimum 56 ft (15.2

ml

grounded nylon hose; do not use

wire braid hose.

5. Flush, then remove and clean if

needed.

6. Replace. See page 14.

7. Check pressure control calibration,

repair or replace.

VII. Not enough paint pressure (See

Problem III also)

VIII. Poor spray pattern.

1,

Pressure setting too low

2. Spray tip too big or worn

3. Pressure control or motor damaged

1. Clogged spray tip

2. Pressure setting too low

3. Outlet filter or hose partially clogged

4. Spray tip too big or worn

5. Paint supply low or pail empty

6. Paint too thick

1.

Increase.

2. Change tip; see manual 367-321.

3. Return for repair.

1. Clean. See manual 307-321.

2. Increase.

3. Clean; see manual 367-273.

4. Change tip; see manual 367-321.

5. Fill;

reprime

to remove air.

6. Thin per paint manufacturer’s

recommendations.

IX. Spitting from spray gun

X. Static sparking from gun

1. Paint supply low or pail empty

2. Sprayer sucking air or gun needle

not seating

1. Sprayer or work not grounded

1. Fill, reprime to remove air.

2. Tighten fittings; repair gun; see

manual 307633.

1. Check hose continuity and electrical

ground connection.

(a) When a capacitor fails, the motor hums for about one minute, then shuts off the sprayer.

(b)

The motor will not operate when the motor thermal switch has opened. Engage the gun safety latch, allow the sprayer to cool.

lf

the sprayer continues to shut off, try reducing the spraying pressure, use a larger spray tip or add an additional

56

ft (15.2 m) of

spray hose. If the problem is not corrected, return the sprayer for repair.

,

(c)

Never leave water or water-based material in the sprayer to prevent damage caused by freezing if the air temperature is below

freezing, and to help prevent corrosion. Always leave the sprayer filled with mineral spirits or a compatible oil-based solvent.

(d)

The pressure control can be over-pressurized by: (1) using less than

50

ft (15.2 m) of nylon spray hose; (2) using wire braid hose;

(3)

adding a shutoff device between the pump outlet and spray gun; (4) plugging the main fluid outlet of the filter;

(5)

using the

drain valve as a shutoff device; (6) clogged or incorrectly assembled fluid filter.

307-460 13

Page 14

WARNING

Always follow the Pressure Relief Procedure Warning on page 12 before checking or repairing any

parts.

Displacement Pump Removal and Replacement

Flush the pump if possible. Follow the Pressure Relief

Procedure Warning, on page 12. Be sure to unplug the

power supply cord.

Disconnect the suction (20) and fluid line (1) hoses and

open the pump shield (16). See Fig 6 and Parts Drawing. Remove the socket head screws (32), lockwashers

(311, and flat washer (29) and spacer (63) from the pivot

shaft, and the flat washer (30) and thrust washer (28)

from the crank. Be very careful to hold the pump as you

slide it off the shafts to avoid damaging the needle bearings. See Fig 6.

Repair Kit No. 208940 is available to repair the pump.

Use all of the new parts in the kit, even if the old parts

look good. Old parts wear faster and result in more frequent packing replacement.

Intake Valve Removal and Replacement

Screw the intake valve (51) housing out of the displacement cylinder (54). Remove the ball stop pin (531, guide

(47),

and ball (52). Clean and inspect for wear or

damage. Reassemble, using new parts from the repair

kit. Torque the intake valve housing to 50-150 ft-lb

(68-205

Nmm).

See Fig 7.

NOTE:

You can test the intake valve by filling it with

solvent and seeing if any leaks past the ball.

It should not leak. The valve must be clean

for this test; any dirt will hold the ball off the

seat and let solvent leak past.

Throat Packings, Displacement Rod and Piston

Removal and Replacement

Screw the packing nut (38) out of the displacement

cylinder (54). Carefully pull the displacement rod

assembly (34) and piston housing

(45)

out of the

cylinder. Wrap the rod end with tape to protect the

bearing (36) and clamp securely in a vise. Screw the

piston off the rod using a wrench on the hex of the

piston (if it’s too tight, heat it in boiling water to soften

the locking compound). Remove the ball (461, glands

(41,441 and packings

(42,43).

Slide the throat packings

(61, 62) and glands (39, 40) off the rod. Clean and inspect. Install the repair kit parts. Be sure to install the

PTFE and leather packings in the order shown. See

Fig 7 and the Parts Drawing.

Thoroughly clean and degrease the piston housing (45)

and displacement rod (37). Using locking compound,

screw the piston housing onto the displacement rod and

torque to 400-425 in-lb (45-48 N-m). If the packing bulge

makes it hard to insert the piston housing into the

displacement cylinder, loosen the piston housing, insert

it into the cylinder and torque again from the intake end

of the cylinder using a hex socket.

*21

832

DRAIN PLUGA

1

63

Fig 6

35

36

37

LIPS OF V-PACKINGS

3

\

e-61

-4’

4243

44

46

5

54

53

50-160

ft-lb

M8-206 Nmrnl

Fig 7

14 307460

Page 15

I

-__

_-__

-._-_

Always follow the Pressure Relief Procedure Warning on page 12 before checking or repairing any

parts.

I

Bearings Removal and Replacement

Use an arbor press to remove and install bearings (36,

50) in the displacement rod (37) end and in the intake

valve

(51)

housing. See Fig 7. When replacing the

displacement rod bearing, be sure the hole in the bearing lines up with the lubrication hole at the top of the

rod. See Fig 7. Soak the valve bearings in oil before installing. Grease the displacement rod bearing whenever

the pump is removed.

Motor Removal and Replacement

Disconnect hoses (1, 20) from the displacement pump

(33). Disconnect the hose (1) from the pressure control

(74). Disconnect hoses (21,671 from the fluid filter (64).

See Fig 8. Disconnect the conduit and wires (K) from

the motor. See Fig 9.

65

83

84

Remove the fluid pump from the gearcase. See

Displacement Pump Service on page (7). Remove the

four capscrews (87) along the bottom of the pump side

of the gearcase. Tip the sprayer forward onto the frame

handle so the gearcase is in a horizontal position. See

Fig 9. The gearcase must be kept horizontal as the cover

is removed to avoid spilling the gearcase oil.

Remove the three capscrews (78) holding the pressure

control to the gearcase cover, and remove the control.

Remove the remaining capscrews from the gearcase

cover. Then carefully lift the motor and cover assembly

straight up, off the gearcase. See Fig 9.

NOTE:

The motor is sold only as an assembly, installed on a gearcase cover with bearings in

place, and a new gasket. Don’t try to

remove the

gearcase

cover. Order part

number 217-086 for the replacement

assembly. Terminals (96, 97) are not included with a new motor. Order these separately

and crimp to motor leads as shown in

Fig 11.

To install the new motor assembly, clean all the

capscrews and the area around the screw holes on the

gearcase

cover with the primer provided with the

replacement assembly. Then apply sealant (also provid-

ed) to the bottom side of the screw heads. These two

steps are very important in preventing the gearcase oil

from leaking.

Secure the cover to the gearcase with the capscrews

(801, then put the pressure control in place and secure

with the three capscrews (78). Connect the conduit and

wires to the motor. Tip the sprayer back to its normal

position and install the capscrews

(87)

and tighten.

Connect the displacement pump and all the hoses.

Refer to Fig 6.

Motor Capacitor Removal and Replacement

If the motor won’t start, unplug the power supply cord,

check and/or replace the motor starting capacitor (105)

located under the capacitor cover

(L).

Remove the

screws holding the cover to the motor. Lift the cover

enough to turn it over, and use the tip of a screwdriver,

if necessary, to gently pry the capacitor out of the

cover. The wires and resistor are connected with quick

disconnect terminals. Unsnap the wires and resistor and

discard the old capacitor and resistor. Snap the wires

and resistor onto the new capacitor, making sure the

wires are located properly. See Fig 10. Install the

capacitor in the cover and screw the assembly onto the

motor.

Fig 10

Page 16

WARNING

Always follow the Pressure Relief Procedure Warning on page 12 before checking or repairing any

parts.

Pressure Control Removal and Replacement

WARNING

Do not alter the factory adjusted pressure switch

(M).

Changing the setting may cause unsafe high

pressure or poor performance.

\

CAUTION

/)

Never attempt to remove the swivel adapter (N) or

nipple (P) from the pressure control. Any twisting

or jarring of the pressure control fitting could alter

the factory setting of the control, or permanently

damage the control. When removing the fluid

filter (64) or fluid hose (11, hold the swivel adapter

(N) or nipple (P) secure with a wrench.

Remove the fluid hose (1) from the pressure control

(74). Disconnect the conduit (98) and wires (K) from the

motor

(Q).

Refer to Fig 11. Then remove the three

capscrews (78) holding the control to the gearcase.

Unless the cover plate (73) or mounting bracket (75) is

damaged, only the pressure control switch assembly

(74) needs to be replaced. In that case, remove the filter

and covers from the old assembly.

Use screws (76) to install the mounting bracket onto the

switch assembly, and use screws (79) to install the front

cover. Position the assembly onto the gearcase cover,

and use screws (78) to secure it. Connect the conduit

and wires to the motor, install the fluid filter, and recon-

nect the hoses. Calibrate the pressure control before

operating the sprayer. See page 15.

Circuit Board Removal and Replacement

If the circuit board (85) is all that needs to be replaced in

the pressure control, remove the screws (79) and the

front cover (73). See Fig 11. Pull the board out carefully,

just far enough to reach the wire terminals. Unsnap the

wires and finish removing the board.

Position the new card at the control so the wire connectors are at the top. Following the color coded diagram in

Fig 11, snap the wires onto the board. Carefully guide

the wires back into the control, making sure they don’t

get caught on anything, then slide the new board into

place. Calibrate the pressure control before operating

the sprayer. See page 15.

16 307460

Page 17

Pressure Control Calibration (See Fig

12)

WARNING

USE EXTREME CAUTION WHEN PERFORMING THIS CALIBRATION PROCEDURE to reduce the risk of

an injection injury or other serious bodily injury which can result from component rupture, electric shock, fire, explosion, or moving parts.

This procedure sets the sprayer to 2750 psi (190 bar)

MAXIMUM WORKING PRESSURE.

This procedure must be performed whenever a new

or used circuit board, microswitch, or pressure con-

trol assembly is removed and reinstalled or replaced

to be sure the sprayer is properly calibrated.

Improper calibration can cause the sprayer to overpressurize and result in component rupture, fire or

explosion. It may also prevent the sprayer from ob-

taining the maximum working pressure which would

result in poor sprayer performance.

NEVER attempt to increase the fluid outlet pressure

by performing these calibrations in any other way.

NEVER EXCEED 2756 psi

(190

bar) MAXIMUM

WORKING PRESSURE. Normal operation of the

sprayer at higher pressures could result in compo-

nent rupture, fire or explosion.

ALWAYS use a new 50 foot (15.2 m) spray hose

rated for

3000

psi (210 bar) MAXIMUM WORKING

PRESSURE when performing this procedure. A

us-

ed, under-rated hose could develop a high pressure

leak or rupture.

AVOID touching the wire in the pressure control

assembly when the control box cover is removed to

reduce the risk of electric shock.

ON/OFF SWITCH

Tools Needed:

NEW 50 ft (15.2 m) 3000 psi (210 bar) airless spray

hose, Part No. 210541

Needle Valve, Part No. 102-715 or 103-067

3/8”

open end wrench

Fluid-Filled Pressure Gauge, Part No. 102-814

5 gallon pail and water

Mineral Spirits (for flushing after test)

1.

2.

3.

Follow the Pressure Relief Procedure Warning on

page 12. Install a new 50 ft (15.2 m) spray hose to

the sprayer outlet, On the other end of the hose install a needle valve. Install a fluid-filled pressure

gauge in the top port of the fluid filter.

Open the needle valve slightly. Turn the pressure

control knob

(D)

to the minimum setting. Plug in

the sprayer and turn the switch ON. Increase the

pressure setting just enough to start the sprayer.

Prime the hose and pump with water, being sure to

eliminate all air from the system.

Open the needle valve a little more-enough to

allow the pump to run continuously-and turn the

pressure control knob to maximum. Now, ve/y

slow/y

start to close the needle valve, but don’t

close it all the way. Observe the pressure at which

the pump stalls, which should be approximately

2756 psi (190 bar).

NOTE: The slower the pressure is brought up, the

easier it is to note the exact stall pressure.

Closing the needle valve quickly causes the

pressure to rise too fast which gives a false

reading.

5. Now open the needle valve very slowly while

observing the pressure gauge. Check to see if the

pressure drops to approximately 2356 psi (164 bar)

before starting again.

/f the pressure is lower: unplug the sprayer and

relieve pressure. Use a

3/8”

open end wrench to

turn the pressure adjustment nut, at the bottom of

the pressure control knob shaft (RI, counterclock-

wise

l/8

turn or less, then repeat steps 2 and 3.

lf

the pressure is lower: shut off and unplug the

sprayer, but do not relieve pressure. Turn the differential wheel

(S)

counterclockwise just one notch

and repeat Steps 4 and 5. Check the pressure drop

again, and repeat if necessary.

NOTE: If you adjust the differential wheel, recheck

the stall pressure (steps 2 and 3) to be sure

the stall pressure has not changed.

lf

the pressure is higher: unplug the sprayer and 6. Follow the Pressure Relief Procedure, flush the

relieve pressure. Turn the pressure adjustment nut water out with mineral spirits, relieve pressure

clockwise

l/8

turn or less and repeat steps 2 and 3.

again, then remove the test hose, needle valve and

Repeat until the proper stall pressure is obtained.

pressure gauge.

R

(below)

Fig 12

4. Now check to see at what pressure the sprayer

starts to run again after stalling. Plug in the sprayer,

turn it on, close the needle valve, and set the

pressure at maximum. Allow the sprayer to run until

it stalls.

307460

17.

Page 18

'-28

18

307460

\-lo61

Page 19

REF PART

NO. NO.

DESCRIPTION

216-126

106-062

154-636

178-392

104-811

217506

102637

**172-981

103-l 17

178-566

169-377

* * 176-250

106-101

100-272

loo-032

177669

101-946

177-716

103-473

176-920

177-787

106-140

106-142

103-927

170-l 13

102-952

168521

164-055

159346

100-016

101-550

208-372

HOSE, nylon

cpld l/4 npsm(fbe);

swivel one end; 21.75” (554 mm) lg,

spring guard

WHEEL, semi-pneumatic

WASHER, flat

;;pP,

,sE;ng

FRAME, sprayer

CAPSCREW, hex hd;

3/8-16;

l-1/2”

(38

mm)

LABEL, WARNING

RING, retaining

SLEEVE, handle

HANDLE, frame

LABEL, WARNING

CLIP, component; suction tube

LOCKWASHER, shakeproof

SCREW,

math,

pnh; 6-32 x

1/4”(6 mm)

SHEILD, hinged

PIN, cotter

BRACKET, hinge

TIE, plastic

HOSE, suction, nylon; 3/4” ID; 30”

(762 mm) lg

TUBE, drain; polyethylene; 68” (1.7

m)

STUD, hose

CLAMP, hose

CLAMP, hose

TUBE, suction

STRAINER, inlet

WASHER, thrust

WASHER, spacer

WASHER, flat

LOCKWASHER, spring;

l/4”

screw

size

CAPSCREW,

sot

hd; l/4-20 x

l/2”

(13 mm)

DISPLACEMENT PUMP

Includes items 34-63. See page 21.

REF PART

NO. NO.

ifi

67

214-570

21 O-657

21 o-541

68 214-701

89

218-132

70 177-762

71 157-350

72

217-492

73

177668

74

217-085

75

177-569

76 106-078

106-170

100643

79 106-075

80

loo-021

81

E

172-412

loo-055

217-086

217-084

106-076

“105-679

102-876

100-721

PLUG, pipe; hdls;

l/4

npt

“21

~-XXX

SPRAY TIP of choice, see 307-321

216-001

Reverse-A-Clean III

DESCRIPTION

QN

FILTER, fluid; see 307-273 for parts

VALVE, ball; see 306861 for parts

HOSE, spray,

cpld l/4 npsmlfbe)

swivel one end; l/4” ID; 50 ft

(15 m)

Ig; spring guard one end; static free

HOSE, whip end;

3/16”

ID;

cpld

l/4 npt(m)

x

l/4 npsm(f);

static free;

36” (914 mm) Ig

SPRAY GUN, see 307633 for parts

LABEL, warning