Graco EFR Instructions - Parts Manual

Instructions - Parts

EFR

3A6165A

Electric Fixed-Ratio Proportioner

For use with two-component sealant and adhesive materials. For professional use only.

Not approved for use in explosive atmospheres or hazardous locations.

2000 psi (13.8 MPa, 138 bar) Maximum Fluid Inlet Pressure

3500 psi (24.1 MPa, 241 bar) Maximum Fluid Outlet Pressure

See page 3 for model information.

Important Safety Instructions

Read all warnings and instructions in this

manual and in related manuals before

using the equipment. Save these instructions.

EN

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Keep Components A (Red) and

B (Blue) Separate . . . . . . . . . . . . . . . . . . . . . . . . 7

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . 7

A (Red) and B (Blue) Components . . . . . . . . . . . 7

Component Identification . . . . . . . . . . . . . . . . . . . . 8

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . 9

Advanced Display Module (ADM) . . . . . . . . . . . 10

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Power Requirements . . . . . . . . . . . . . . . . . . . . 12

Connect Power . . . . . . . . . . . . . . . . . . . . . . . . . 12

Install Vented Oil Cap Before Using Equipment 14

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Motor Position . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Pressure Relief Procedure . . . . . . . . . . . . . . . . 19

Adjust Material Inlet Pressure . . . . . . . . . . . . . . 20

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Preventative Maintenance Schedule . . . . . . . . 21

Check Oil Level . . . . . . . . . . . . . . . . . . . . . . . . . 21

Change the Oil . . . . . . . . . . . . . . . . . . . . . . . . . 22

Bearing Pre-Load . . . . . . . . . . . . . . . . . . . . . . . 22

ADM - Battery Replacement and

Screen Cleaning . . . . . . . . . . . . . . . . . . . . . . . . 22

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

EFR Common System Parts . . . . . . . . . . . . . . . 25

Fluid Section . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Driver and Yoke Assembly . . . . . . . . . . . . . . . . 27

Electrical Assembly . . . . . . . . . . . . . . . . . . . . . . 29

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Applicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Dispense Valve Interface Kit . . . . . . . . . . . . . . . 30

Inlet Regulator Kits . . . . . . . . . . . . . . . . . . . . . . 30

Inlet Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Outlet Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Additional Accessories . . . . . . . . . . . . . . . . . . . 30

Advanced Display Module (ADM) Operation . . . . 31

ADM Screen Overview . . . . . . . . . . . . . . . . . . . . . . 32

Home Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Index Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

I/O Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Technical Specifications . . . . . . . . . . . . . . . . . . . . 45

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 46

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 46

Related Manuals

Manual Description

3A0019

3A6482

312185 MD2 Valve Instructions-Parts

3A6338

2 3A6165A

Z-Series Chemical Pumps Instructions-Parts

APD20 Advanced Precision Driver

Instructions

Communications Gateway Module Installation Kit Instructions-Parts

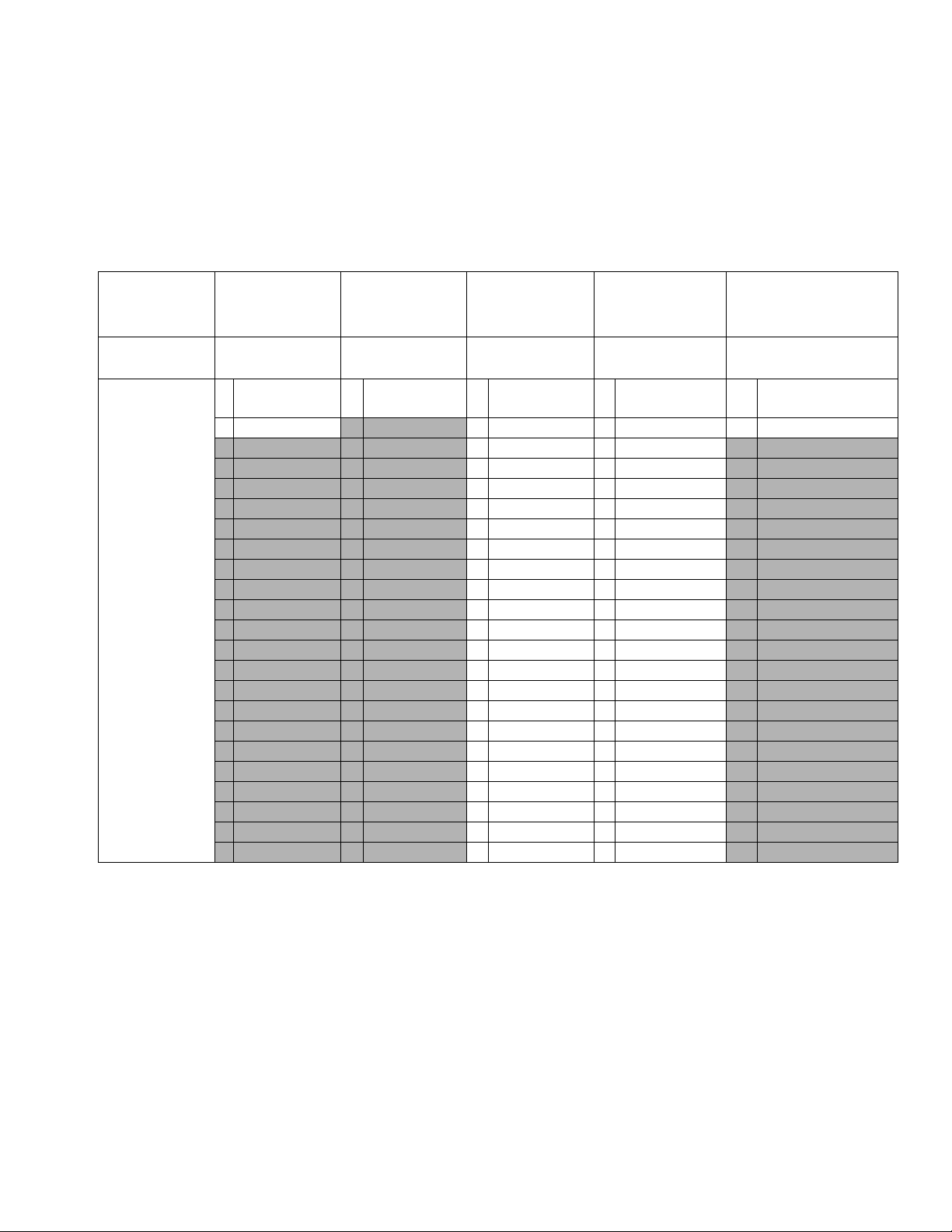

Models

Models

Use the following matrix to determine the 8-digit system part number.

NOTE: To order replacement parts, see the Parts section on page 25. The digits in the matrix do not correspond to

the Ref. Nos. in the Parts drawings and lists.

EFR

(First, Second

and Third Digits)

System

Designator

EFR

(Electric

Fixed-Ratio

Proportioner)

Digit 4 Digit 5 Digit 6 Digit 7 Digit 8

Voltage Options Control Options A Side Pump B Side Pump Material Options

2

4 480V

240V A ADM A 5 cc A 5 cc C

B 10 cc B 10 cc S Stainless Steel

C 15 cc C 15 cc

D 20 cc D 20 cc

E 25 cc E 25 cc

F 30 cc F 30 cc

G 35 cc G 35 cc

H 40 cc H 40 cc

I 45 cc I 45 cc

J 50 cc J 50 cc

K 60 cc K 60 cc

L 65 cc L 65 cc

M 70 cc M 70 cc

N 75 cc N 75 cc

O 80 cc O 80 cc

P 86 cc P 86 cc

Q 90 cc Q 90 cc

R 100 cc R 100 cc

S 105 cc S 105 cc

T 120 cc T 120 cc

U 140 cc U 140 cc

V 150 cc V 150 cc

W 160 cc W 160 cc

Carbon and Stain-

less Steel

3A6165A 3

Warnings

DANGER

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

SEVERE ELECTRIC SHOCK HAZARD

This equipment can be powered by more than 240 V. Contact with this voltage will cause death or

serious injury.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• This equipment must be grounded. Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

4 3A6165A

Warnings

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. Paint or

solvent flowing through the equipment can cause static sparking. To help prevent fire and explosion:

• Use equipment only in well-ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static sparking).

• Ground all equipment in the work area. See Grounding instructions.

• Never spray or flush solvent at high pressure.

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Use only grounded hoses.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment until

you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read Safety Data Sheets (SDSs) to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

3A6165A 5

Warnings

WARNING

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Equipment can start without warning. Before checking, moving, or servicing equipment, follow the

Pressure Relief Procedure and disconnect all power sources.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Specifications in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical

Specifications in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For

complete information about your material, request Safety Data Sheets (SDSs) from distributor or

retailer.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. Protective equipment includes but is not

limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

6 3A6165A

Warnings

Keep Components A (Red) and B (Blue) Separate

Cross-contamination can result in cured material in

fluid lines which could cause serious injury or damage

equipment. To prevent cross-contamination:

• Never interchange component A (red) and

component B (Blue) wetted parts.

• Never use solvent on one side if it has been

contaminated from the other side.

Changing Materials

NOTICE

Changing the material types used in your equipment

requires special attention to avoid equipment damage

and downtime.

• When changing materials, flush the equipment

multiple times to ensure it is thoroughly clean.

• Check with your material manufacturer for

chemical compatibility.

A (Red) and B (Blue) Components

NOTE: Material suppliers can vary in how they refer to

plural component materials.

For all machines:

• The A (Red) side is intended for hardeners and

catalysts.

• The B (Blue) side is intended for polyols, resins, and

bases. Regardless of the configuration of material

used, the high volume material must be in the B

(Blue) side.

3A6165A 7

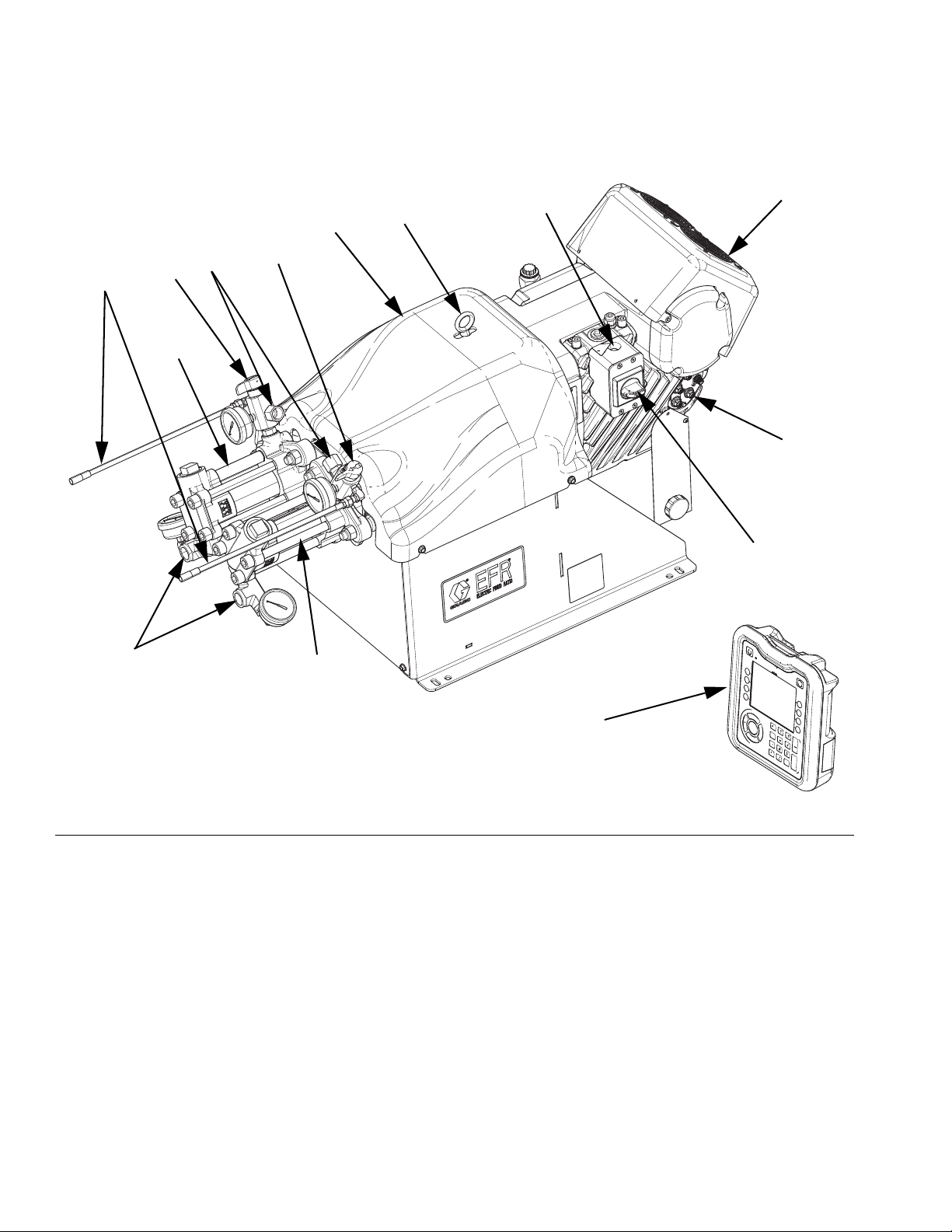

Component Identification

F

G

H

C

M

A

S

B

D

K

J

N

P

R

Component Identification

FIG. 1: Component Identification

Key:

AA Pump

BB Pump

C Power Disconnect Switch

D Advanced Display Module (ADM)

F Pump Yoke Shroud

G Electric Driver

H Incoming Power Connection

J Pump Inlets

K Pump Outlets

M Driver Communication and I/O Connectors

N Lift Ring

P Pressure Relief Drain Tubes

R A-Side Outlet Drain Valve

S B-Side Outlet Drain Valve

8 3A6165A

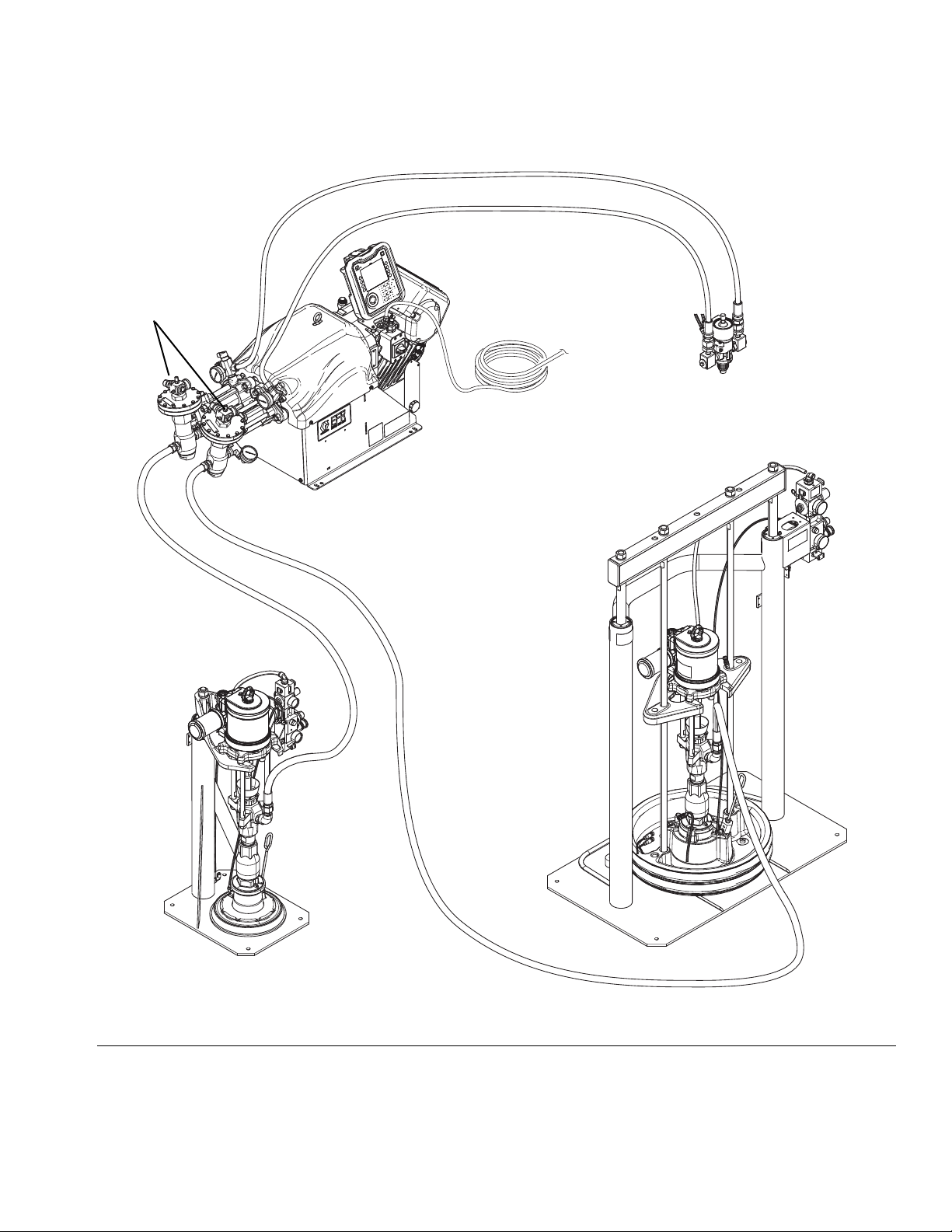

Typical Installation

WLD

Dispense Valve*

A Supply System*

B Supply System*

Power Cord with User

Supplied Dedicated

Circuit Protection

Inlet Regulators

EFR Proportioner

Component Identification

FIG. 2: Typical Installation

* Required accessories not supplied with the proportioner.

Optional accessories not supplied with the proportioner.

3A6165A 9

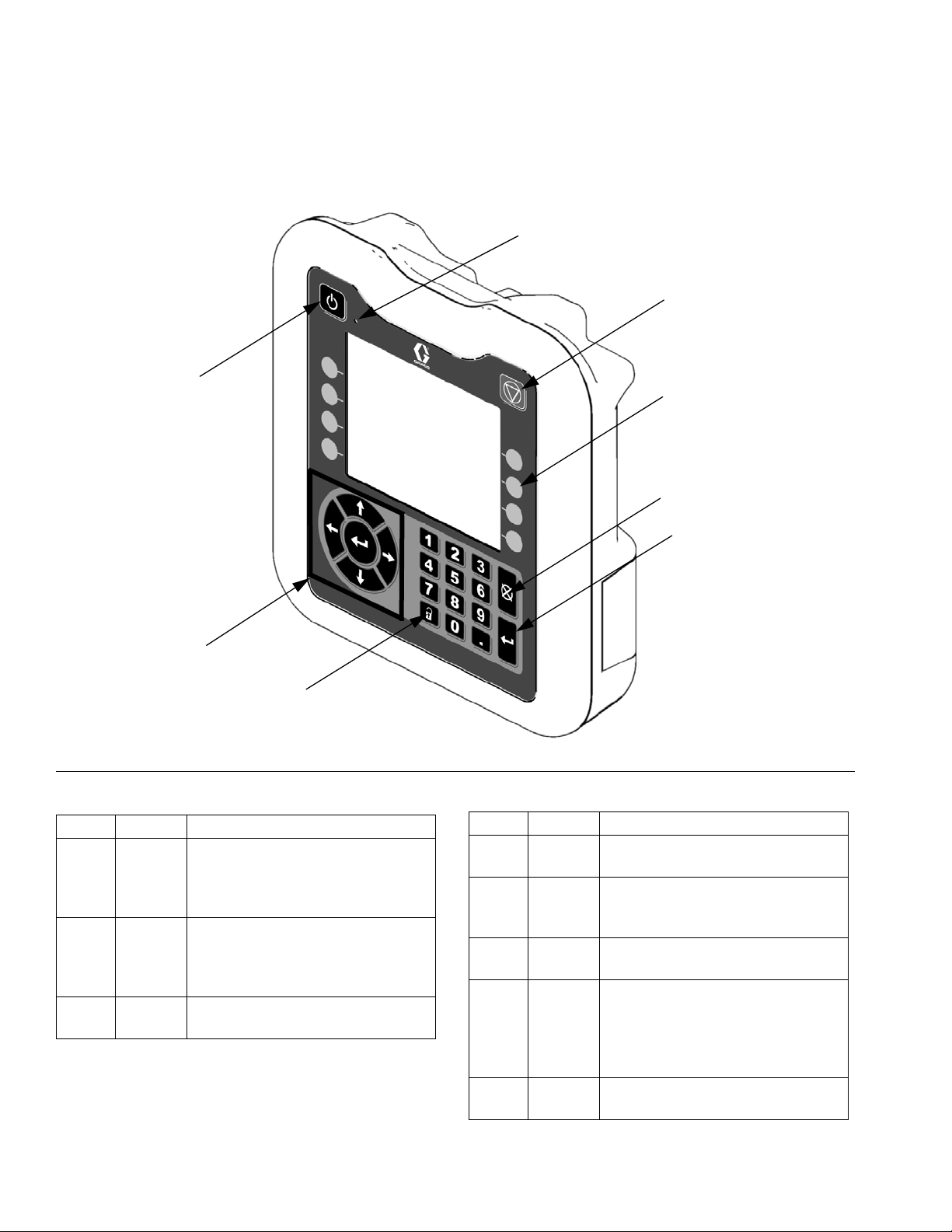

Component Identification

TI12362a1

AA

AB

AC

AE

AH

AG

AF

AD

Advanced Display Module (ADM)

User Interface

FIG. 3: ADM Component Identification - Front

Buttons

Callout Button Function

AA System

enable/

disable

AB System

Status

Indicator

Light

AC Stop Stop all system processes. Is not a

Enables/disables system. When

system is disabled, temperature

control and dispense operation are

disabled.

Displays system status. See Sys-

tem Status Indicator (AB) Conditions on page 11 for details.

safety or emergency stop.

Callout Button Function

AD Soft

Defined by application using ADM.

Keys

AE Cancel Cancel a selection or number entry

while in the process of entering a

number or making a selection.

AF Enter Acknowledge changing a value or

making a selection.

AG Lock/SetupToggle between run and setup

screens. If setup screens are password protected, button toggles

between run and password entry

screen.

AH Naviga-

tion

Navigate within a screen or to a

new screen.

10 3A6165A

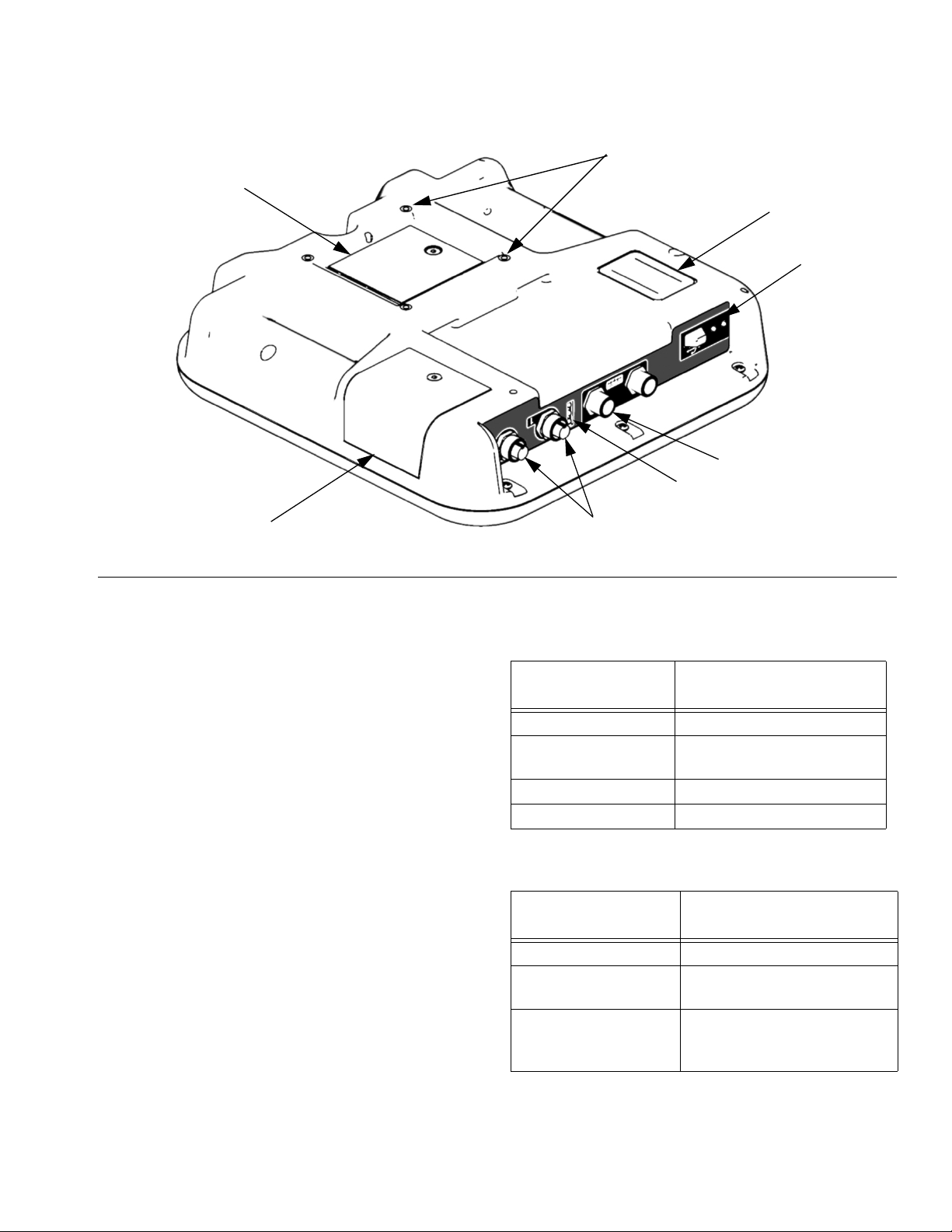

Component Identification

AR

AK

AJ

AL

AP

AN

AM

AS

ti12363a1

FIG. 4: ADM Component Identification - Rear

Key:

AJ Flat Panel Mount

AK Model Number

AL USB Module Interface

AM CAN Cable Connections

AN Module Status LEDs

AP Accessory Cable Connections

AR Token Access Cover

AS Battery Access Cover

System Status Indicator (AB) Conditions

Green Solid - Run Mode, System On

Green Flashing - Setup Mode, System On

Yellow Solid - Run Mode, System Off

Yellow Flashing - Setup Mode, System Off

ADM Module Status LEDs (AN) Conditions

Module Status LED

Signal Description

Green on System is powered up.

Yellow on Communication in prog-

ress.

Red solid ADM hardware failure.

Red flashing Uploading software.

USB Module Status LEDs (AL) Conditions

Module Status LED

Signal Description

Green flashing System is powered up.

Yellow on Downloading information to

Green/Yellow Flashing

USB

ADM is busy, USB cannot

transfer information when in

this mode

3A6165A 11

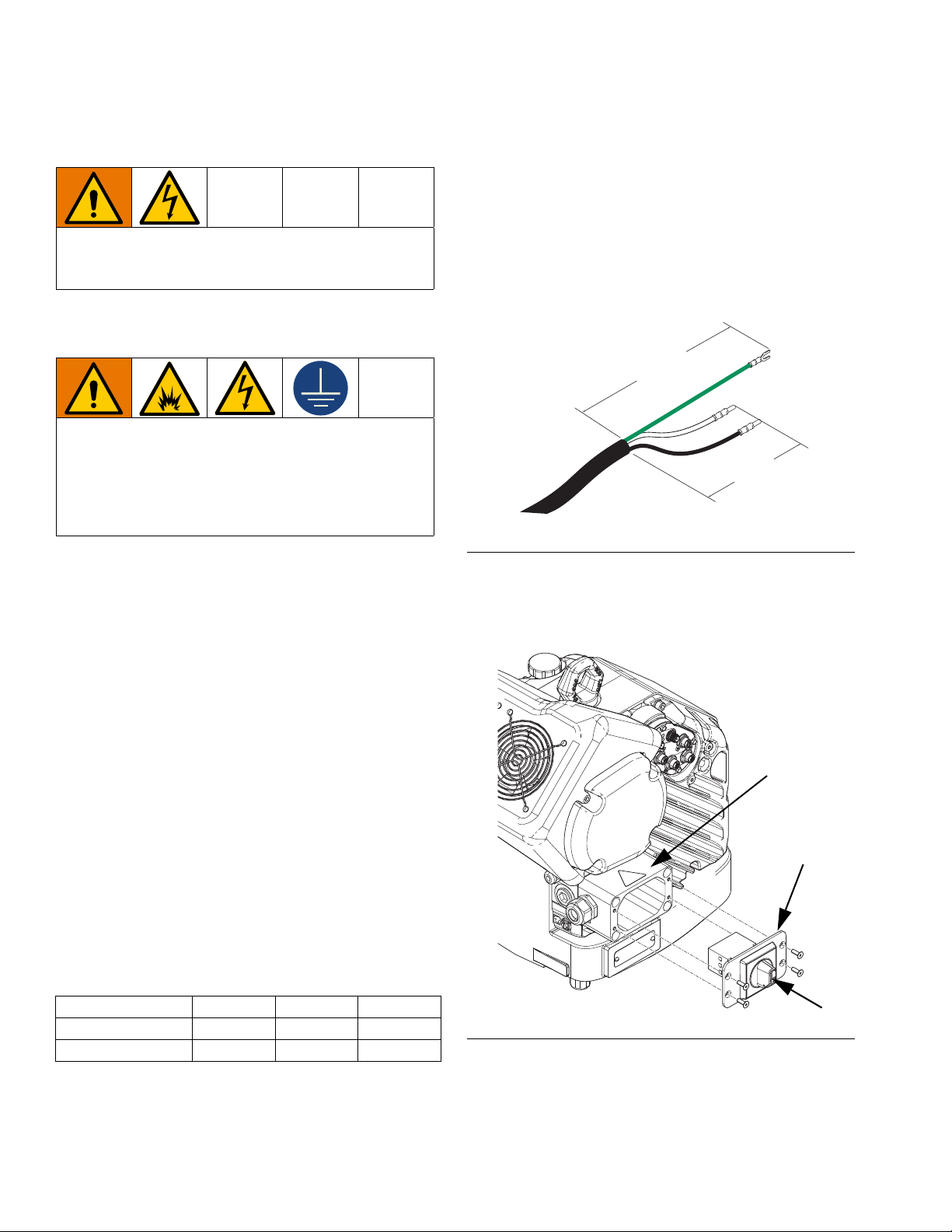

Installation

LQ

LQ

WLD

BB

BA

C

Installation

All electrical wiring must be done by a qualified electrician and comply with all local codes and regulations.

Grounding

The equipment must be grounded to reduce the risk

of static sparking and electric shock. Electric or static

sparking can cause fumes to ignite or explode.

Improper grounding can cause electric shock.

Grounding provides an escape wire for the electric

current.

EFR: grounded through the power cord (customer supplied).

Fluid supply containers: follow local code.

Connect Power

1. Cut power cord wires to the following lengths:

• Ground wire - 6.5 inches (16.5 cm)

• Power wires - 3.0 inches (7.6 cm)

• Add ferrules as necessary. See F

FIG. 5: Power Cord

2. Remove the four screws to separate the junction

box cover (BA) and disconnect switch (C) from the

junction box (BB) on the electrical driver.

IG. 5.

Object being dispensed: follow local code.

Solvent pails used when flushing: follow local code.

Use only conductive metal pails, placed on a grounded

surface. Do not place the pail on a nonconductive

surface, such as paper or cardboard, which interrupts

grounding continuity.

To maintain grounding continuity when flushing or

relieving pressure: hold metal part of the dispense

valve firmly to the side of a grounded metal pail, then

trigger the dispense valve.

Power Requirements

The system requires a dedicated circuit protected with a

circuit breaker.

Voltage Phase Hz Current

200-240 VAC 1 50/60 20 A

400-480 VAC 1 50/60 10 A

FIG. 6: Remove Junction Box Cover

12 3A6165A

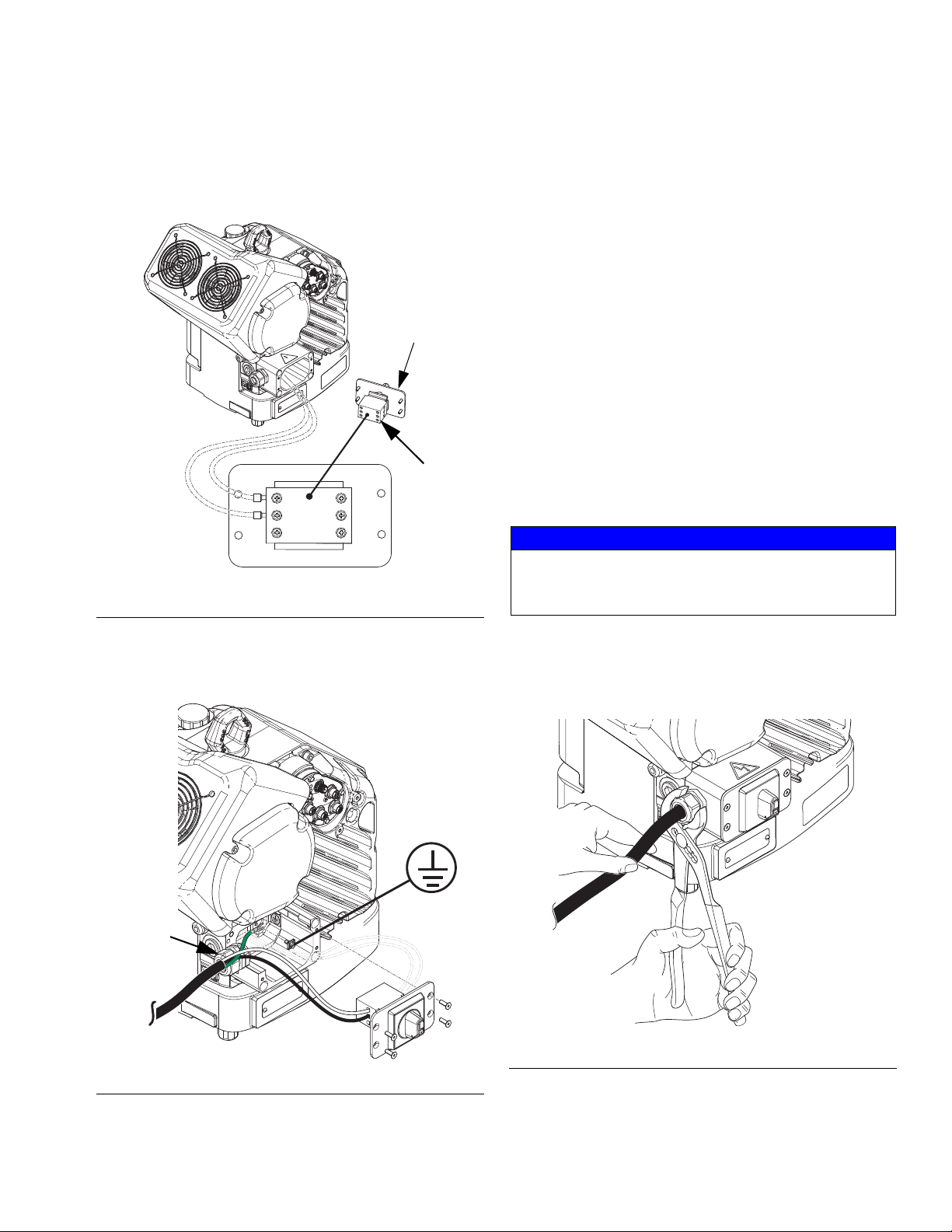

Installation

WLE

/

/

/

7

7

7

BA

C

WLD

Cord Grip

WLD

NOTE: Inside the junction box, power wires are

pre-installed to terminals 2T1 and 4T2 on the disconnect

block. Refer to F

IG. 7 for the terminal locations.

WLD

FIG. 7: Terminal Connections

4. Attach the ground wire to the ground terminal inside

the junction box as shown in F

5. Refer to F

IG. 7 and connect the wires from the

IG. 8.

power cord into terminals 1L1 and 2L2.

NOTE: For 480V systems, a step-down transformer is

factory-installed between the power disconnect switch

and the electric driver. See Wiring Diagrams on page

43.

NOTE: Do not attach the ground wire to the grounding

lug locknut on the outside of the electric driver. See

Grounding on page 12.

6. Place the power wires into the open area on either

side of the power disconnect switch (C) as space

permits.

7. Reinstall the junction box cover (BA) and disconnect

switch (C) using the four screws removed in step 2.

NOTICE

Make sure all wires are routed correctly before installation. If wires get pinched when the screws are tightened, damage will occur.

3. Insert the power cord through the cord grip and into

the junction box.

FIG. 8: Connect Power

8. Tighten the cord grip to securely hold the power

cord in the junction box.

FIG. 9: Tighten Cord Grip

3A6165A 13

Installation

PX

PY

Install Vented Oil Cap Before Using Equipment

The driver gear-box is shipped from the factory pre-filled

with oil. The temporary unvented cap (PX) prevents oil

leaks during shipment. This temporary cap must be

replaced with the vented oil cap (PY), supplied with the

equipment, before use.

NOTE: Prior to use, check oil level. Oil level should be

half way up the sight glass.

FIG. 10: Unvented and Vented Oil Caps

14 3A6165A

Loading...

Loading...