Installation - Parts

®

E-Flo

SP

Electric Pumps

3A6586G

for Sealants and Adhesives

For use with single-component sealant and adhesive materials. For professional use only.

Not approved for use in explosive atmospheres or hazardous locations.

See page 3 for model information, including maximum working pressure and approvals.

Important Safety Instructions

Read all warnings and instructions in this

manual and in all related manuals before

using the equipment. Save all

instructions.

EN

Related Manuals

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

System Pressure . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Component Identification . . . . . . . . . . . . . . . . . . . . 7

Electric Pump with 100 cc Check-Mate CS

Lower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Advanced Display Module (ADM) . . . . . . . . . . . . 8

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Location and Mounting . . . . . . . . . . . . . . . . . . . . 9

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Power Requirements . . . . . . . . . . . . . . . . . . . . . 9

Connect Power . . . . . . . . . . . . . . . . . . . . . . . . . 10

Connect the Standalone Transformer . . . . . . . . 11

Install Vented Oil Cap Before Using

Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . 12

Fluid Hose Connection . . . . . . . . . . . . . . . . . . . 12

Connecting Multiple Pumps . . . . . . . . . . . . . . . 13

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Wet Cup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Flush the Pump . . . . . . . . . . . . . . . . . . . . . . . . . 14

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 16

Shutdown and Care of the Pump . . . . . . . . . . . . . 16

Driver Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 17

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Electric Pumps with Check-Mate Lowers . . . . . 18

Electric Pumps with Dura-Flo Lowers . . . . . . . . 22

Check Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Kits and Accessories . . . . . . . . . . . . . . . . . . . . . . . 28

Advanced Display Module Kit 25E439 . . . . . . . 28

Communication Gateway Module (CGM) Kits . . 29

Inlet Pressure Sensor Kit, 24Y245 . . . . . . . . . . 30

Pump Stand Frame, 253692 . . . . . . . . . . . . . . . 31

Wall Mount Bracket, 255143 . . . . . . . . . . . . . . . 31

Floor Mount Adapter, 223952 . . . . . . . . . . . . . . 32

CAN Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Light Tower Kit, 255468 . . . . . . . . . . . . . . . . . . . 32

I/O Cable, 122029 . . . . . . . . . . . . . . . . . . . . . . . 32

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

E-Flo SP Pump Dimensions . . . . . . . . . . . . . . . 33

Pump Stand Mounting Hole Diagram . . . . . . . . 34

Floor Stand Mounting Hole Diagram . . . . . . . . . 35

Electric Driver Mounting Hole Pattern . . . . . . . . 35

Transformer Mounting Hole Diagram . . . . . . . . 36

Pump Performance . . . . . . . . . . . . . . . . . . . . . . . . 37

E-Flo SP Performance Charts . . . . . . . . . . . . . . 38

Technical Specifications . . . . . . . . . . . . . . . . . . . . 43

California Proposition 65 . . . . . . . . . . . . . . . . . . . 44

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 46

Related Manuals

Manuals are available online at www.graco.com.

Manual in

English Description

3A6331 E-Flo SP Supply Systems Instructions-Parts

3A6724 E-Flo SP Software Instructions

3A6482 APD20 Driver Instructions-Parts

312375

311762

311827

311825

308148

3A6321 ADM Token In-System Programming

3A1244

311619 Pump Mounting Kits

307971 Floor Stand Accessory

2 3A6586G

Check-Mate

Dura-Flo

Dura-Flo

Dura-Flo

Dura-Flo

Graco Control Architecture™ Module Programming

®

100cc, 200cc, 250cc, 500cc CS/CM/SS/SM Lower Instructions-Parts List

™

145cc, 180cc, 220cc, 290cc CS Lower Instructions-Parts List

™

145cc, 180cc, 220cc, 290cc SS Lower Instructions-Parts List

™

430cc CS/SS/SM Lower Instructions-Parts List

™

1800 Pumps Instructions-Parts List

:

Models

Models

Check your pump package’s identification (ID) label

located on the side of the electric driver for the 8-digit

part number of your pump package. Use the following

matrix to identify the construction of your pump package

based on the eight digits.

For example: model EC100CS3 is an electric (E)

Check-Mate (C) 100 cc (100) pump with a carbon steel

(C) Severe Duty® (S) lower, an Advanced Display

Module (ADM), and 240 VAC power (3).

Pump Style Pump Type Pump Size Pump Material Interface / Power

1st Digit 2nd Digit 3rd, 4th & 5th Digit 6th Digit 7th Digit 8th Digit

E Electric Pump C Check-Mate 100 100 cc Check-Mate C Carbon Steel S Severe Duty 1 None 240 VAC

200 200 cc Check-Mate S Stainless Steel M MaxLife 2 None 480 VAC

250 250 cc Check-Mate 3 ADM 240 VAC

500 200 cc Check-Mate 4 ADM 480 VAC

E Electric Pump D Dura-Flo 115 115 cc Dura-Flo C Carbon Steel S Severe Duty 1 None 240 VAC

145 145 cc Dura-Flo C Carbon Steel S Severe Duty 3 ADM 240 VAC

180 180 cc Dura-Flo S Stainless Steel 4 ADM 480 VAC

220 220 cc Dura-Flo

290 290 cc Dura-Flo

430 430 cc Dura-Flo

NOTE: Each Check-Mate pump size is available in CS,

CM, SS, and SM pump materials. Dura-Flo pump

material combinations depend on the pump size. For

Dura-Flow pumps, MaxLife® is only available with the

430 cc stainless steel pump lower. Refer to the matrix

below.

To order replacement parts, see the Parts section

starting on page 18.

2 None 480 VAC

430 430 cc Dura-Flo S Stainless Steel M MaxLife

220 220 cc Dura-Flo

290 290 cc Dura-Flo

NOTE: A single electric pump must include an ADM. Up

to six pumps can be connected in a system and

controlled by a single ADM. See Connecting Multiple

Pumps on page 13.

Approvals

C

Carbon Steel

Severe Duty

T

UHMW PE/PTFE

3A6586G 3

Models

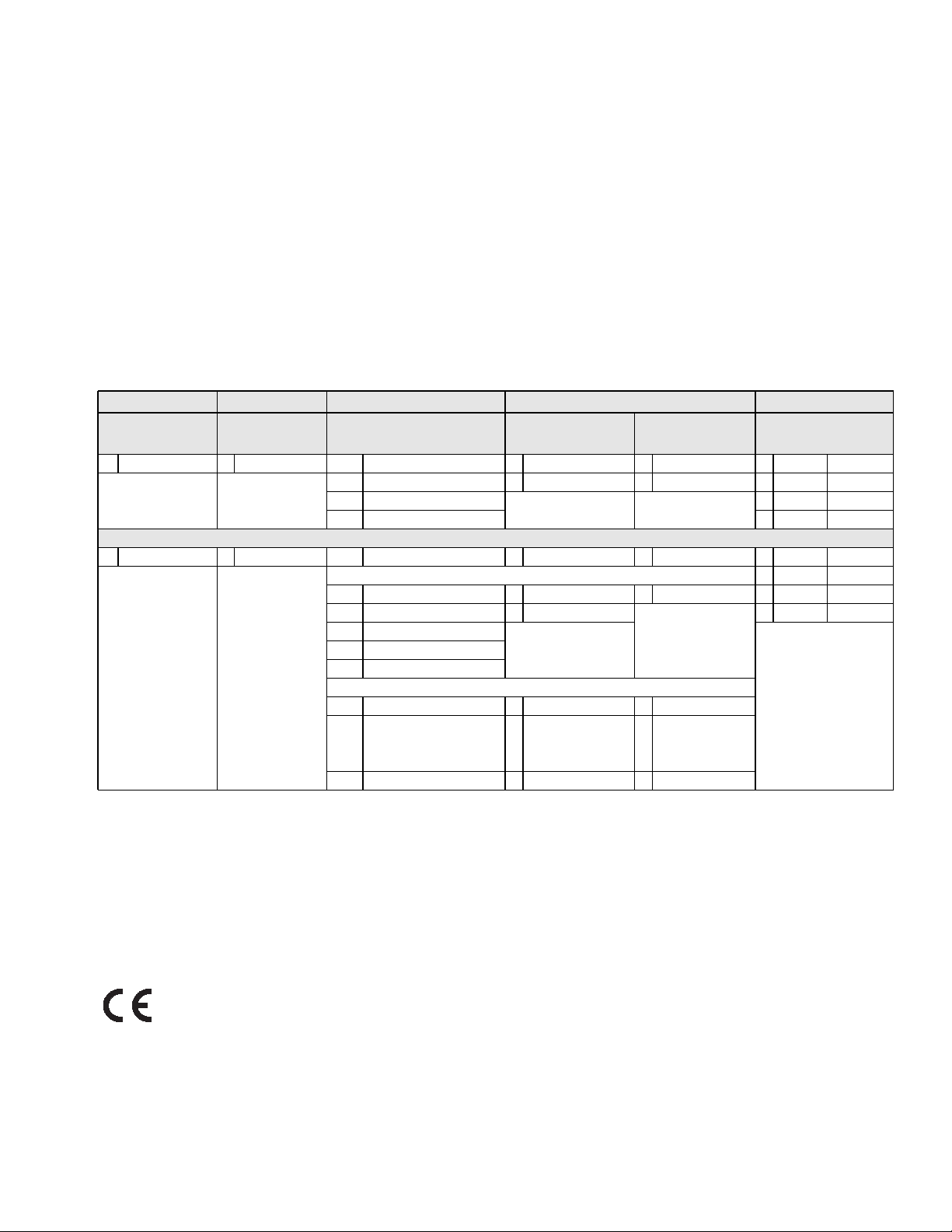

System Pressure

Due to factors such as the dispensing system design,

the material being pumped, and the flow rate, the

dynamic pressure will not reach the rated working (stall)

pressure of the system.

Pump Working (Stall) Pressure Max Dynamic (Run) Pressure

Lower Size psi bar MPa psi bar MPa

100CS/CM/SS/SM

200CS/CM/SS/SM

250CS/CM/SS/SM

500CS/CM/SS/SM

Check-Mate

145SS

180SS

220SS

290SS

430CS/SS/SM

115CS

Dura-Flow

145CS

180CS

220CS/CT

290CS/CT

6,000 414 41.4 6,000 414 41.4

4,200 290 29.0 3,905 269 26.9

3,400 234 23.4 3,122 215 21.5

1,600 110 11.0 1,487 103 10.3

5,600 386 38.6 5,204 359 35.9

4,500 310 31.0 4,164 287 28.7

3,700 255 25.5 3,470 239 23.9

2,800 193 19.3 2,602 179 17.9

1,900 131 13.1 1,735 120 12.0

6,000 414 41.4 6,000 414 41.4

5,600 386 38.6 5,204 359 35.9

4,500 310 31.0 4,164 287 28.7

3,700 255 25.5 3,472 239 23.9

2,800 193 19.3 2,602 179 17.9

Flow Rate Table

Lower Size

100CS/CM/SS/SM

100CS/CM/SS/SM

100CS/CM/SS/SM

100CS/CM/SS/SM

Check-Mate

145SS

180SS

220SS

290SS

430CS/SS/SM

115CS

Dura-Flow

145CS

180CS

220CS/CT

290CS/CT

Flow Rate

(cc/min)

2,500 0.66 1 in. NPT female

5,000 1.32 1 in. NPT female

6,250 1.65 1 in. NPT female

12,500 3.30 1-1/2 in. NPT female

3,625 0.96 1 in. NPT female

4,500 1.19 1 in. NPT female

5,500 1.45 1 in. NPT female

7,250 1.92 1 in. NPT female

10,750 2.84 1-1/2 in. NPT female

2,875 0.76 1 in. NPT female

3,625 0.96 1 in. NPT female

4,500 1.19 1 in. NPT female

5,500 1.45 1 in. NPT female

7,250 1.92 1 in. NPT female

Flow Rate

(gpm) Outlet Fitting Size

4 3A6586G

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The

exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks.

When these symbols appear in the body of this manual or on warning labels, refer back to these Warnings.

Product-specific hazard symbols and warnings not covered in this section may appear throughout the body of this

manual where applicable.

DANGER

SEVERE ELECTRIC SHOCK HAZARD

This equipment can be powered by more than 240 V. Contact with this voltage will cause death or

serious injury.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• This equipment must be grounded. Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure and disconnect all power sources.

3A6586G 5

Warnings

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. Paint or

solvent flowing through the equipment can cause static sparking. To help prevent fire and explosion:

• Use equipment only in well-ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static sparking).

• Ground all equipment in the work area. See Grounding instructions.

• Never spray or flush solvent at high pressure.

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless they

are anti-static or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read Safety Data Sheets (SDSs) to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Specifications in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical

Specifications in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For

complete information about your material, request Safety Data Sheets (SDSs) from distributor or

retailer.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. Protective equipment includes but is not

limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

6 3A6586G

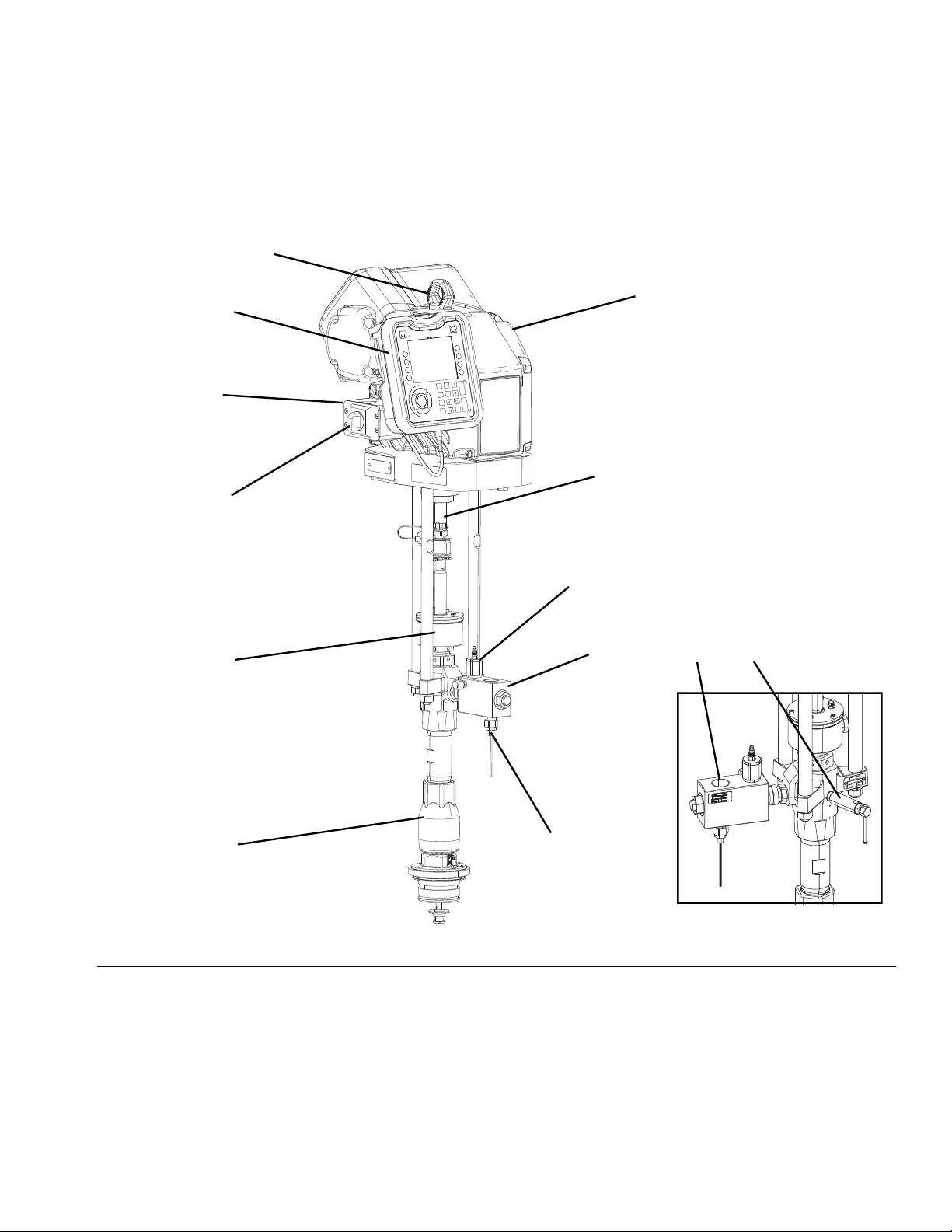

Component Identification

Electric Pump with 100 cc Check-Mate CS Lower

E

A

D

F

K

J

Component Identification

H

B

FIG. 1: E-Flo SP Components

Key:

A Electric Driver

B Displacement Pump

C Check Valve Block

D Advanced Display Module (ADM)

E Lift Ring

F Power Junction Box

G Pump Bleed Valve

N

C

M

H Wet Cup

J Disconnect Switch

K Driver Output Shaft

L Fluid Hose Connection

M Pressure Transducer Sensor

N Pressure Relief Valve (Model EC100xxx Only)

L

G

3A6586G 7

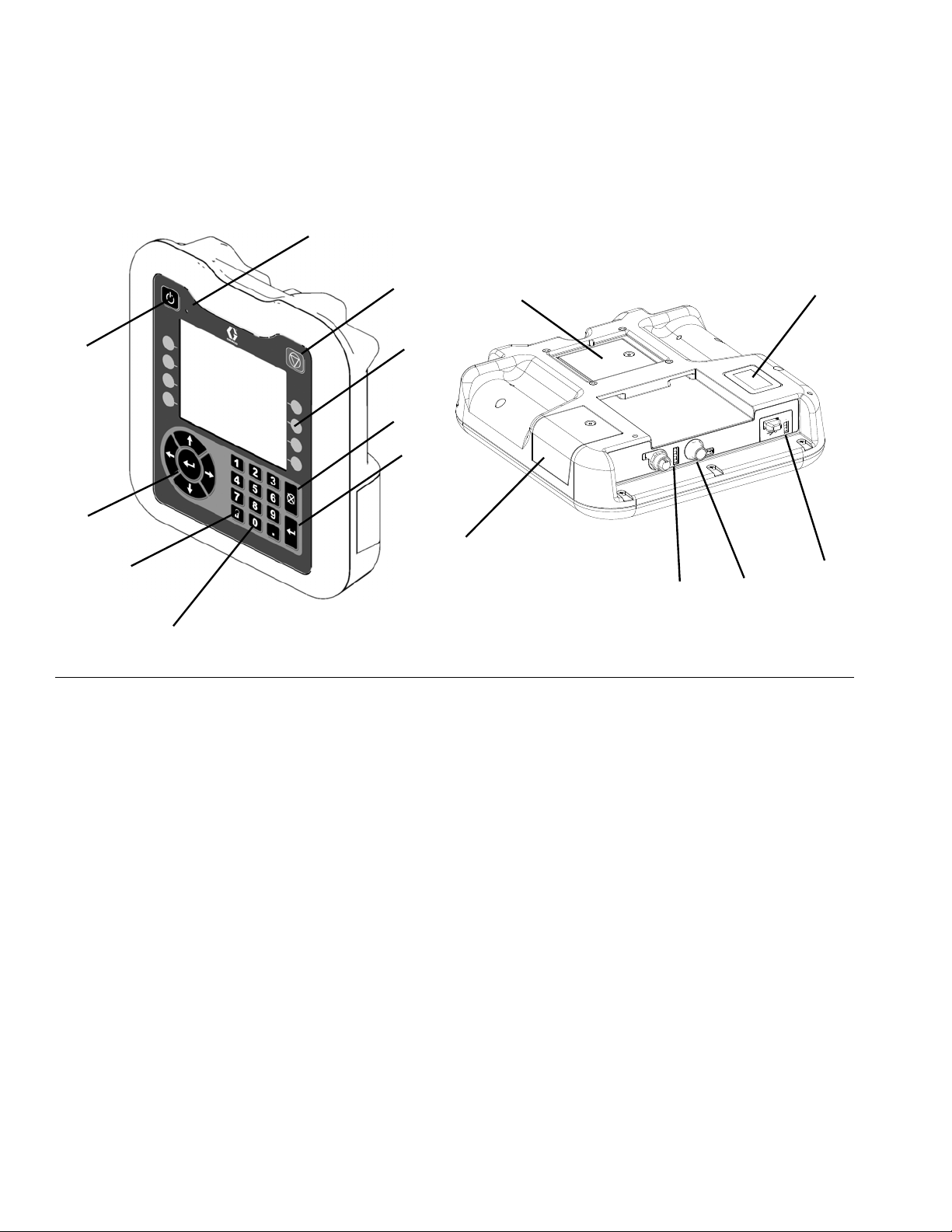

Component Identification

Advanced Display Module (ADM)

Front and Rear Views

BB

BA

BH

BG

BJ

FIG. 2: ADM Component Identification

Key:

BA Pump Enable

Enables the pump. Toggles between Active and System

Off.

BB Pump Status Indicator Light

BC Pump Soft Stop

Stops all pump processes and disables the pump.

BD Soft Keys

Defined by the icon on the screen next to the soft key.

BE Cancel

Cancel a selection or number entry while in the process of

entering a number or making a selection. Cancels the

pump processes.

BF Enter

Accept change, acknowledge error, select item, and

toggle selected item.

BC

BE

BF

BD

BR

BP

BG Lock/Setup

Toggle between run and setup screens.

BH Directional Keypad

Navigate within a screen or to a new screen.

BJ Numeric Keypad

BK Part Number Identification Label

BL USB Interface

BM CAN Cable Connection

Power and communication.

BN Module Status LEDs

Visual indicators to show the status of the ADM.

BP Token Access Cover

Access cover for software token.

BR Battery Access Cover

BN

BK

BL

BM

8 3A6586G

Installation

Installation

Accessories are available from Graco. Make certain

accessories such as hoses are adequately sized and

pressure-rated to meet the system’s requirements.

Location and Mounting

To properly locate and mount the pump, refer to

Dimensions starting on page 33. Always position the

pump so the driver, disconnect switch, and ADM are

easily accessible.

Attach a chain or hook at the proper lift location. Lift off

the pallet using a crane or a forklift. See the lift ring (E)

in Figure 1 on page 7.

NOTICE

Always lift the pump at the proper lift location (E). Do

not lift in any other way. Failure to lift at the proper lift

location can result in damage to the pump system.

Three pump mounting options are available from Graco:

a pump stand, a wall mount, and a floor mount adapter.

See Kits and Accessories starting on page 28 for

information about installing a pump using these

mounting options.

Always ensure the pump is level. If you are using the

pump stand, you can level the base using metal shims if

necessary. Secure the stand or floor mount using

anchors that are long enough to prevent the pump from

tipping.

Refer to the Electric Driver Mounting Hole Pattern on

page 35 to mount the driver to the stand or wall mount

once you have properly secured them to the floor or

wall.

Grounding

The equipment must be grounded to reduce the risk

of static sparking and electric shock. Electric or static

sparking can cause fumes to ignite or explode.

Improper grounding can cause electric shock.

Grounding provides an escape wire for the electric

current.

Electric pump: the pump is grounded through the

power cord.

Fluid hoses: use only electrically conductive hoses with

a maximum of 500 ft. (150 m) combined hose length to

ensure grounding continuity. Check the electrical

resistance of the hoses. If the total resistance to ground

exceeds 29 megaohms, replace the hose immediately.

Dispense valve: ground through connection to a

properly grounded fluid hose and pump.

Fluid supply container: follow local code.

Solvent pails used when flushing: follow local code.

Use only conductive metal pails, placed on a grounded

surface. Do not place the pail on a non-conductive

surface, such as paper or cardboard, which interrupts

the grounding continuity.

To maintain grounding continuity when flushing or

relieving pressure: hold a metal part of the dispense

valve firmly to the side of a grounded metal pail, then

trigger the valve.

Power Requirements

The system requires a dedicated circuit protected with a

circuit breaker.

Voltage Phase Hz Current

200-240 VAC 1 50/60 20 A

400-480 VAC 1 50/60 10 A

3A6586G 9

Installation

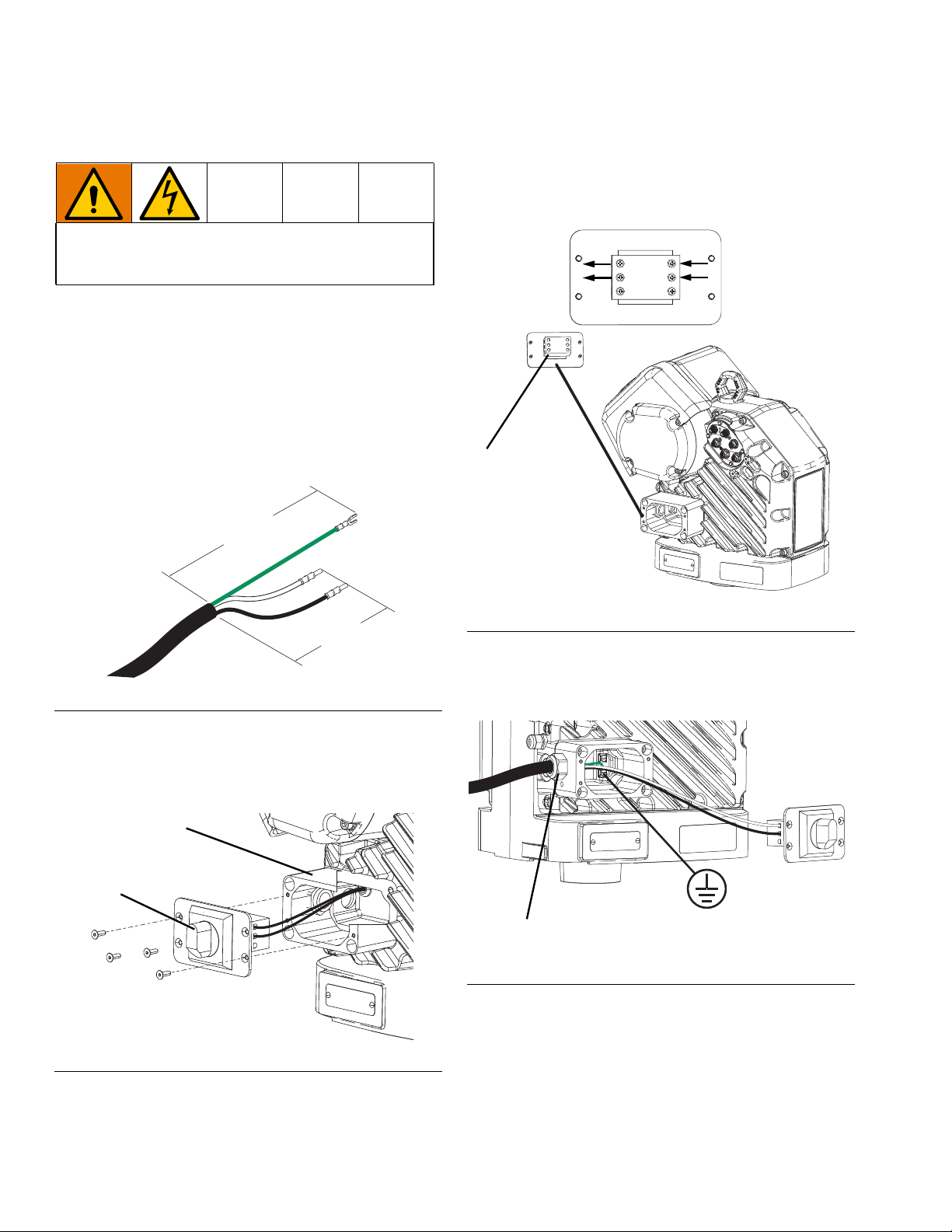

Connect Power

All electrical wiring must be done by a qualified

electrician and comply with all local codes and

regulations.

Letters in parenthesis are used in this section for

reference to callouts in the Component Identification

section starting on page 7.

1. Cut power cord wires to the following lengths:

• Ground wire - 6.5 inches (16.5 cm)

• Power wires - 3.0 inches (7.6 cm)

• Add ferrules as necessary. See Figure 3.

LQ

NOTE: Inside the junction box, power wires to the driver

are connected to terminals 3L2 and 5L3 on the

disconnect block. Refer to Figure 5 for the terminal

locations.

Power to

Driver

/

/

7

7

7

Incoming

Power

/

Disconnect

Block

LQ

FIG. 3: Power Cord

2. Remove the four screws to separate the junction

box cover and disconnect switch (J) from the

junction box (F) on the electric driver.

F

J

FIG. 4: Remove Junction Box Cover

FIG. 5: Terminal Connections

3. Insert the power cord through the cord grip and into

the junction box.

Cord Grip

For clarity, power wires to

the driver are not shown

FIG. 6: Connect Power

4. Refer to Figure 5 and connect the wires from the

power cord into terminals 4T2 and 6T3. Each wire

can be connected to either terminal.

5. Attach the ground wire to one of the two ground

terminals inside the junction box as shown in Figure

6.

10 3A6586G

Installation

NOTE: Do not attach the ground wire to the grounding

lug locknut located by the wiring cord grip on the outside

of the electric driver. The lug locknut should only be

used for other grounding purposes if needed.

6. Place the power wires into the open area on either

side of the disconnect block as space permits.

7. Reinstall the junction box cover and disconnect

switch (J) using the four screws removed in step 2.

NOTICE

If wires get pinched when the screws are tightened,

damage will occur. Make sure all wires are routed

correctly before installation.

8. Tighten the cord grip to securely hold the power

cord in the junction box.

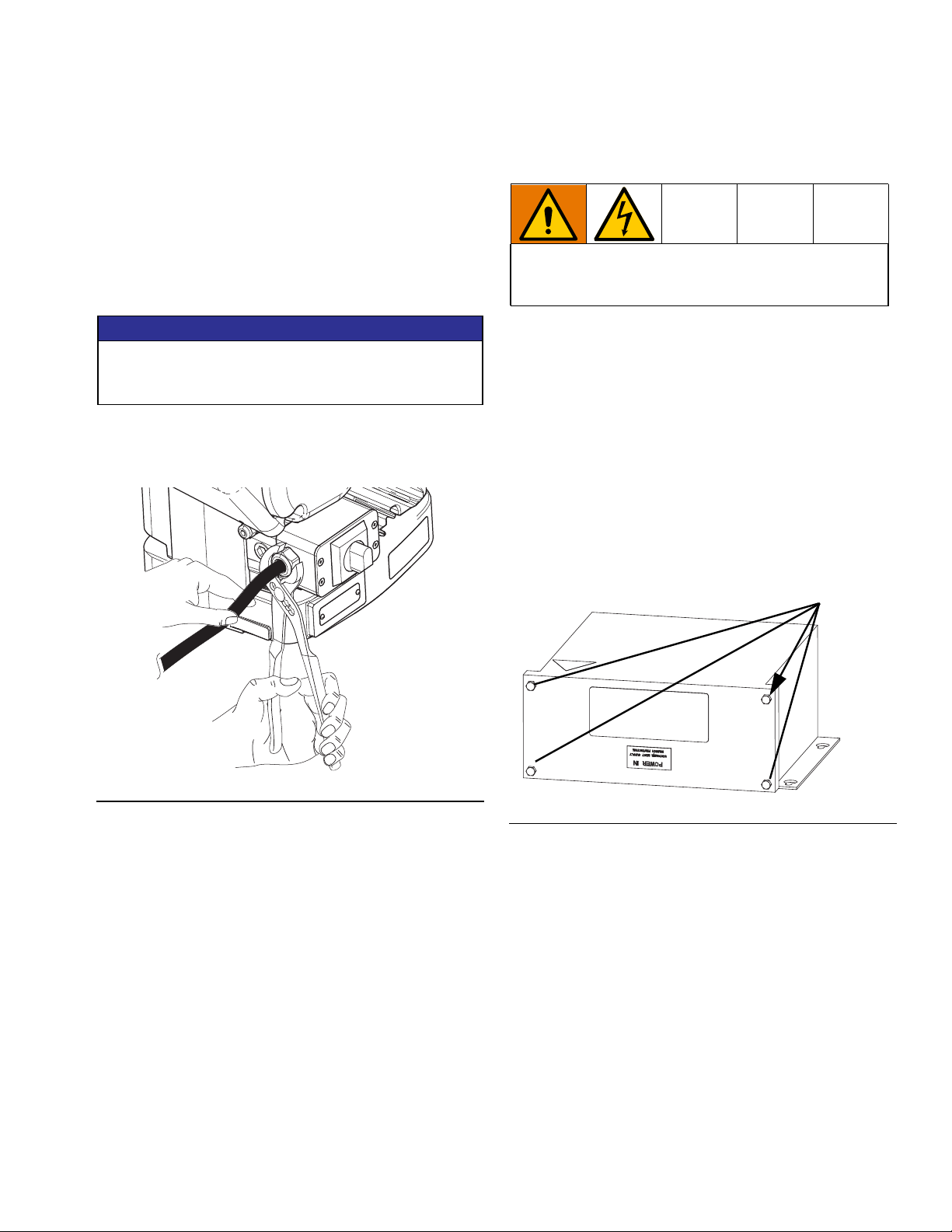

Connect the Standalone Transformer

All electrical wiring must be done by a qualified

electrician and comply with all local codes and

regulations.

Units rated 480 VAC are shipped with a standalone

transformer, part no. 25E268. Mount the transformer

near the pump in a secure location that prevents

damage to the transformer or the wiring to the pump.

1. Refer to the Transformer Mounting Hole Diagram

on page 36 and use the mounting holes as a guide

to drill holes for 1/4 in. (6 mm) screws.

2. Attach the transformer securely to the mounting

surface.

3. Remove the four screws on the transformer as

shown in Figure 8 and remove the front cover.

Remove

FIG. 7: Tighten Cord Grip

FIG. 8: Standalone Transformer

4. Insert the power cord (not included) through a

punch-out on the side of the transformer. A cord grip

or conduit connection (not included) must be used

where wiring passes through the punch-out.

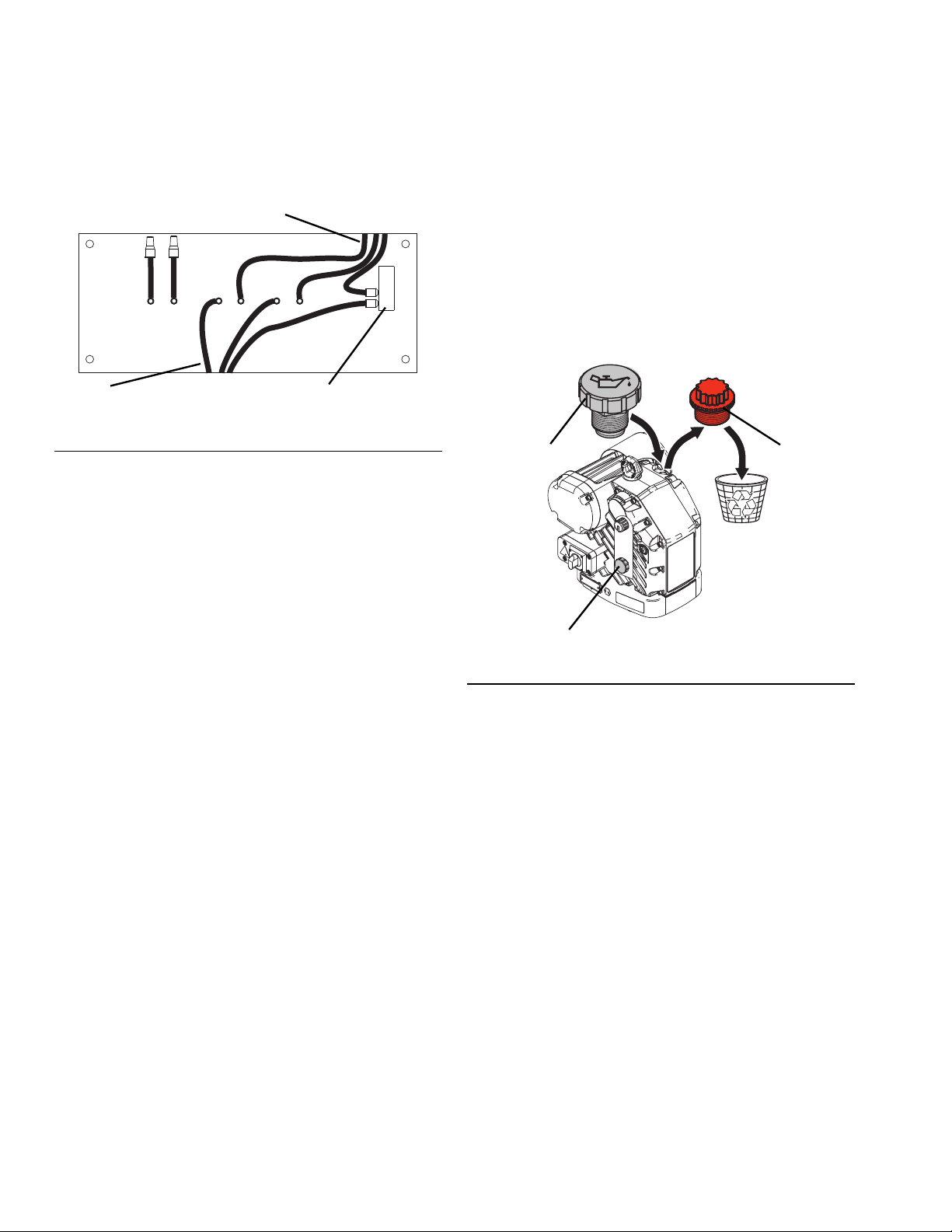

5. Refer to Figure 9 on page 12 and connect the wires

from the power cord to the wires marked H1 and H2

inside the transformer.

6. Connect the power cord ground wire to the

grounding bar inside the transformer as shown in

Figure 9 on page 12.

3A6586G 11

Installation

7. Connect wiring (not included) to X1 and X2 and a

ground wire to the grounding bar. This wiring is for

connection to the pump.

Connections to Pump

X2

H3 X3

H2

Connections from Power Supply

X1

H1

Grounding Bar

FIG. 9: Transformer Wiring Connections

NOTE: The other wires shown in Figure 9 (H3, X3) are

connected at the factory and are not required for

connecting the transformer to the pump.

8. Run the wiring to the pump out through one of the

punch-outs in the side of the transformer cover. A

cord grip or conduit connection (not included) must

be used where wiring passes through the

punch-out.

9. Reattach the front cover using the four screws

removed in step 3.

Install Vented Oil Cap Before Using Equipment.

The driver gear-box is shipped from the factory pre-filled

with oil. The temporary unvented cap prevents oil leaks

during shipment. Before use, this temporary cap must

be replaced with the vented oil cap supplied with the

equipment.

NOTE: Prior to use, check oil level. Oil level should be

half way up the sight glass.

Vented Cap

Vented cap attached here where shipped.

FIG. 10: Unvented and Vented Oil Caps

Unvented

Cap

10. Connect the wiring from the transformer into

terminals 4T2 and 6T3 inside the junction box and

attach the ground wire to one of the two ground

terminals inside the junction box as described in

Connect Power on page 10.

Fluid Hose Connection

Refer to Figure 1 on page 7.

Attach the fluid hose (not supplied) to the check valve

fluid hose connection (L).

NOTE: Be sure all components are adequately sized

and pressure rated to meet the system’s requirements.

12 3A6586G

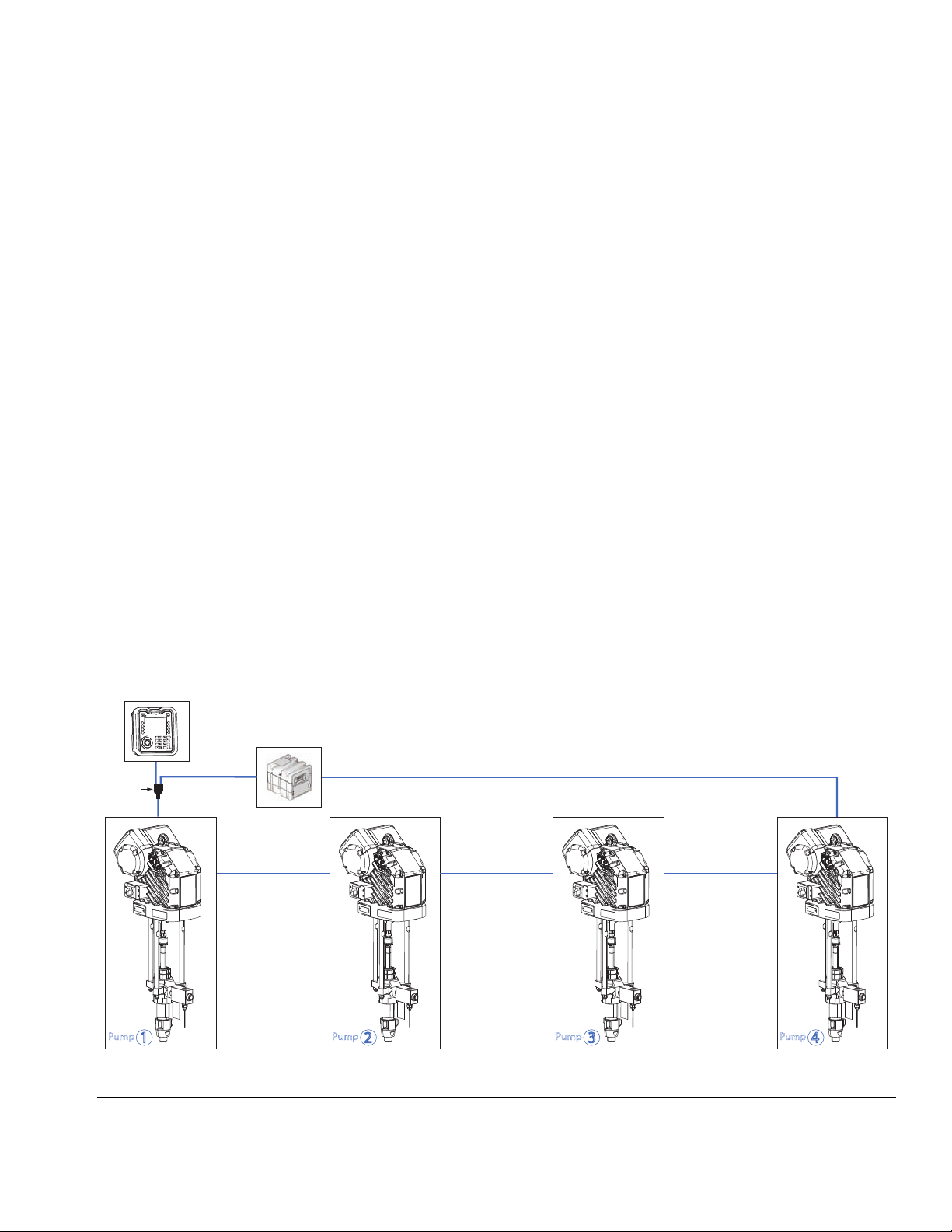

Connecting Multiple Pumps

Installation

Up to six E-Flo SP pumps can be connected together

and operated from one Advanced Display Module

(ADM). This can be configured with or without a

Communication Gateway Module (CGM).

The following components are required for connecting

the pumps, based on the configuration of your system:

• 1 pump with an ADM

• 1 to 5 additional pumps without an ADM

• 1 CAN cable for connecting each pump

• 1 splitter (part no. 121807)

• 1 CAN cable to connect the last pump to the splitter

(or CGM)

The following are optional for connecting the pumps:

• 1 CGM

• 1 cable to connect the CGM to the splitter

Connect the Pumps

NOTE: Refer to Figure 11 for the following steps.

Figure 11 shows four pumps connected. The ADM can

be mounted on the first pump or at a location separate

from the pump.

1. Connect a CAN cable from port 1 on the first pump

(shown as Pump 1 in Figure 11) to the splitter.

2. Connect a second CAN cable from the splitter to the

ADM.

3. Connect a third CAN cable to port 1 on the CGM.

NOTE: Figure 11 shows the configuration with a CGM.

If you are not using a CGM, the CAN cable from the last

pump is connected directly to the splitter.

4. Connect another CAN cable from port 2 on Pump 1

to port 1 on Pump 2.

5. Use additional CAN cables to make the same

connections between each pump.

6. Connect the last pump in the system from port 2 on

the pump to the CGM at port 2 or directly to the

splitter.

7. Refer to the E-Flo SP Software Instructions manual

for information about configuring and operating

multiple pumps. See Related Manuals on page 2.

NOTE: Refer to CAN Cables on page 32 for a listing of

available cables.

Optional

Optional

Splitter

From Port 1

Pump

1 2 43

To Port 1

From Port 2 To Port 1

To Port 2

From Port 2 To Port 1 From Port 2

Pump

FIG. 11: Multiple Pump Connections

NOTE: Four pumps shown. Can

connect up to six pumps.

From Port 2

To Port 1

Pump Pump

3A6586G 13

Setup

Setup

Letters in parenthesis are used in this section for

reference to callouts in the Component Identification

section starting on page 7.

NOTE: Refer to the E-Flo SP Software Instructions

manual for ADM setup instructions. See Related

Manuals on page 2.

Wet Cup

Before starting, fill the wet cup (H) 1/3 full with Graco

Throat Seal Liquid (TSL) or a compatible solvent.

Torque the Wet Cup

The wet cup is torqued at the factory; however, throat

packing seals on the pumps may relax over time. Check

wet cup torque frequently after initial start-up and

periodically after the first week of production.

Maintaining proper wet cup torque is important to

extending seal life.

Flush the Pump

To avoid fire and explosion, always ground the

equipment and the waste container. To avoid static

sparking and injury from splashing, always flush at

the lowest possible pressure.

NOTE: The pump is tested with lightweight oil, which is

left in to protect the pump parts. If the fluid you are using

may be contaminated by the oil, flush it out with a

compatible solvent before using the pump.

Always flush at the lowest pressure possible. Check

connectors for leaks and tighten as necessary. Flush

with a fluid that is compatible with the fluid being

dispensed and the equipment wetted parts.

NOTE: Check with your fluid manufacturer or supplier

for recommended flushing fluids and flushing frequency.

H

FIG. 12: Wet Cup

NOTICE

To prevent damage to the pump from rust, never

leave water or water-based fluid in a carbon steel

pump overnight. If you are pumping a water-based

fluid, flush with water first. Then flush with a rust

inhibitor, such as mineral spirits. Relieve pressure,

but leave the rust inhibitor in the pump to protect

parts from corrosion.

NOTE: Refer to the E-Flo SP Software Instructions

manual for information about using the software

features of the ADM. See Related Manuals on page 2.

1. Follow the Pressure Relief Procedure on page 16.

2. Turn the disconnect switch (J) ON.

3. At the ADM (D), use the ADM’s arrow keys to select

the pump you want to flush from the Menu Bar.

NOTE: If multiple pumps are connected together, there

can be up to six pumps shown in the Menu Bar.

14 3A6586G

Loading...

Loading...