Page 1

Instructions-Parts

E

Flo®

E E

- --Flo® Flo®

DC

DC DC

User

User User

For

For For

Control

Control Control

Interface

Interface Interface

professional

professional professional

Module

Module Module

for

Flo®

DC

for for

E EE- --Flo® Flo®

use

only.

use use

only. only.

Pumps

DC DC

Pumps Pumps

Kit

Kit Kit

with

an

with with

Advanced

an an

Advanced Advanced

Motor.

Motor. Motor.

EN

3A2527L

Important

Important Important

Readallwarningsandinstructionsinthismanual,thesupplied

ADCMmanual,andtheE-FloDCmanualsbeforeusingthe

equipment.Save Save

See manual 332013 (supplied) for

complete warnings and approvals for

24L097 Advanced Display Control

Module (ADCM).

Safety

Safety Safety

Instructions

Instructions Instructions

Save

these

these these

instructions.

instructions. instructions.

PROVENQUALITY.LEADINGTECHNOLOGY.

Page 2

Contents

Contents Contents

RelatedManuals................................................3

Models...............................................................3

ControlModule...................................................4

Installation..........................................................4

InstalltheControlModule.............................4

CableConnection........................................5

Operation...........................................................6

ModuleScreens...........................................6

ModuleKeys................................................6

ScreenNavigationandEditing......................8

InitialSetup.................................................8

RunScreens......................................................9

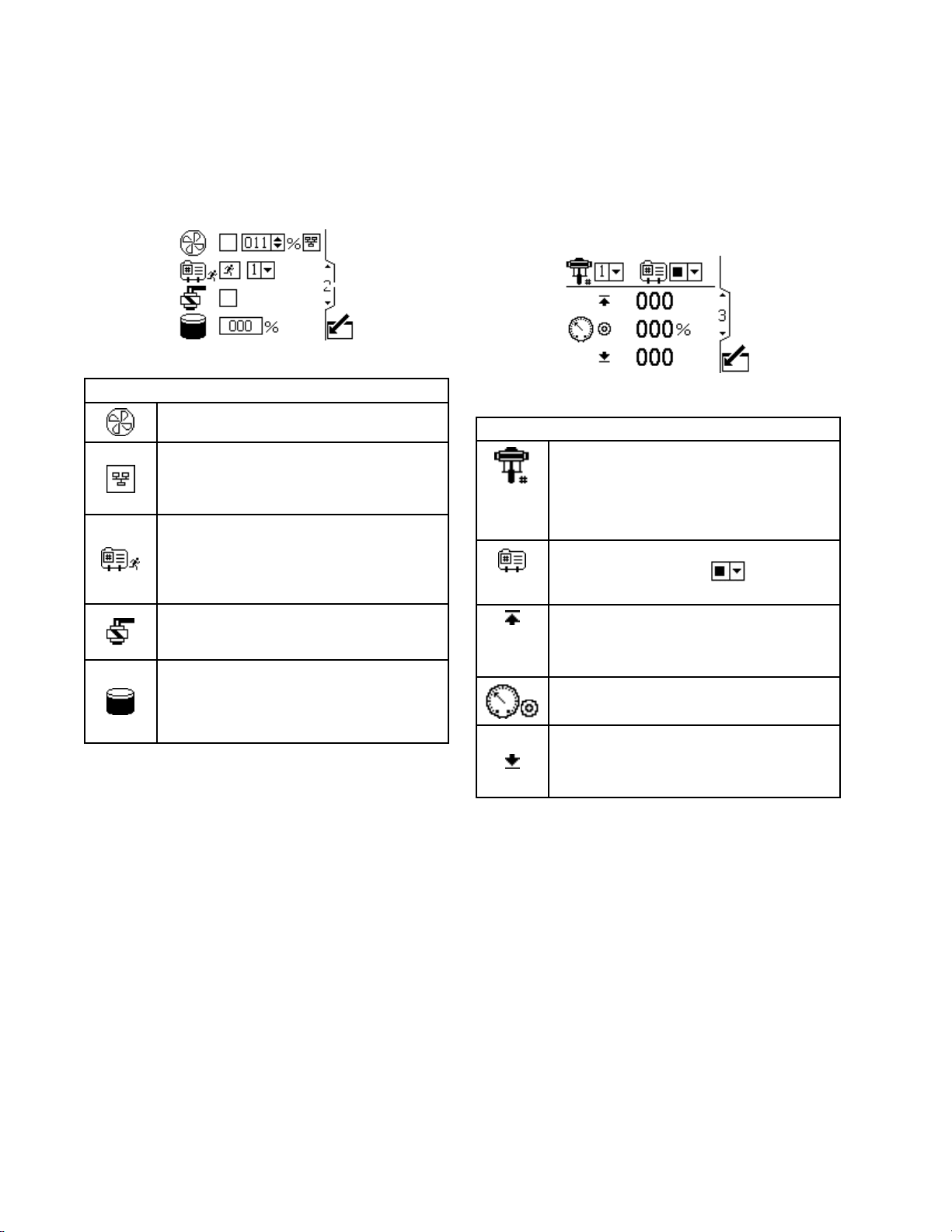

RunScreen1..............................................9

RunScreen2..............................................10

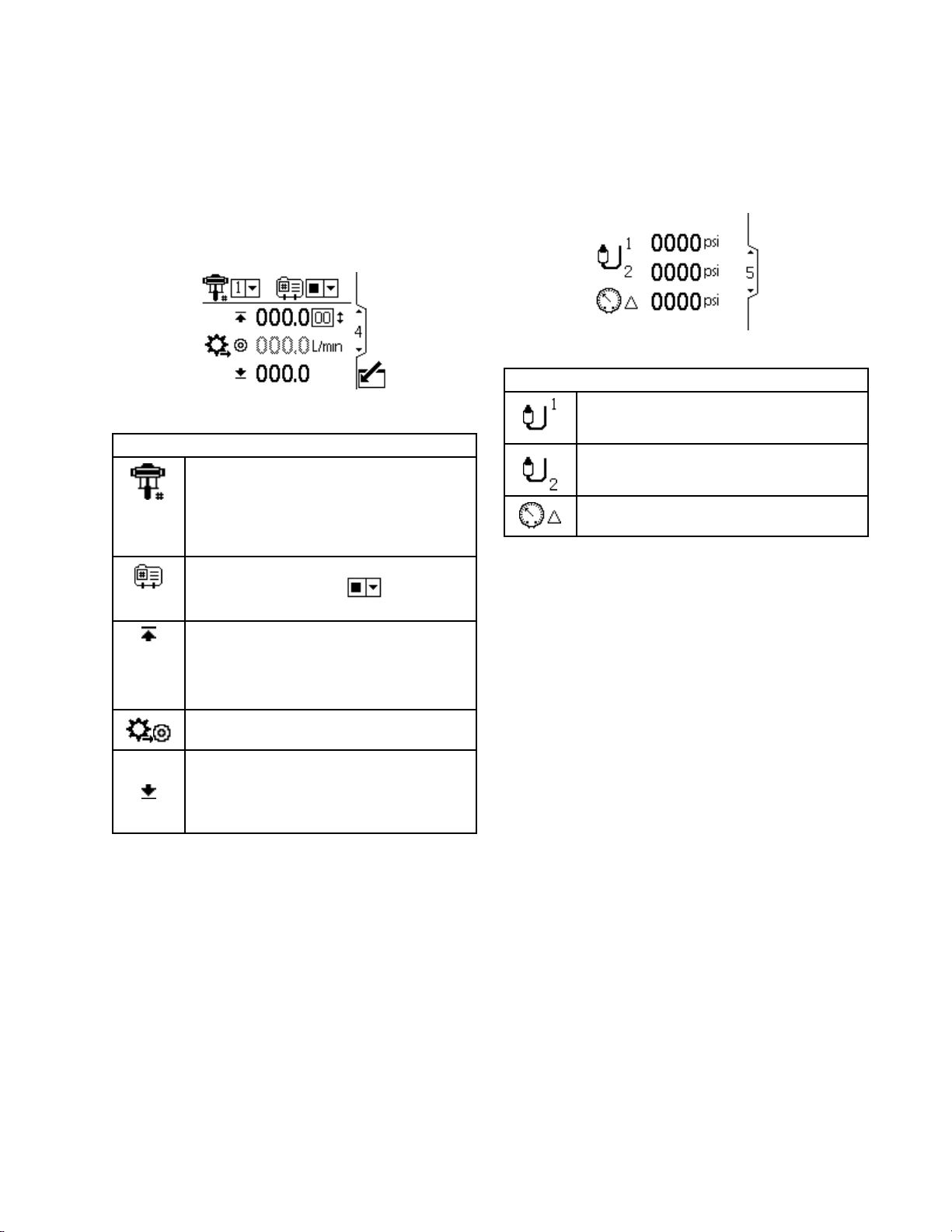

RunScreen3..............................................10

RunScreen4..............................................11

RunScreen5..............................................11

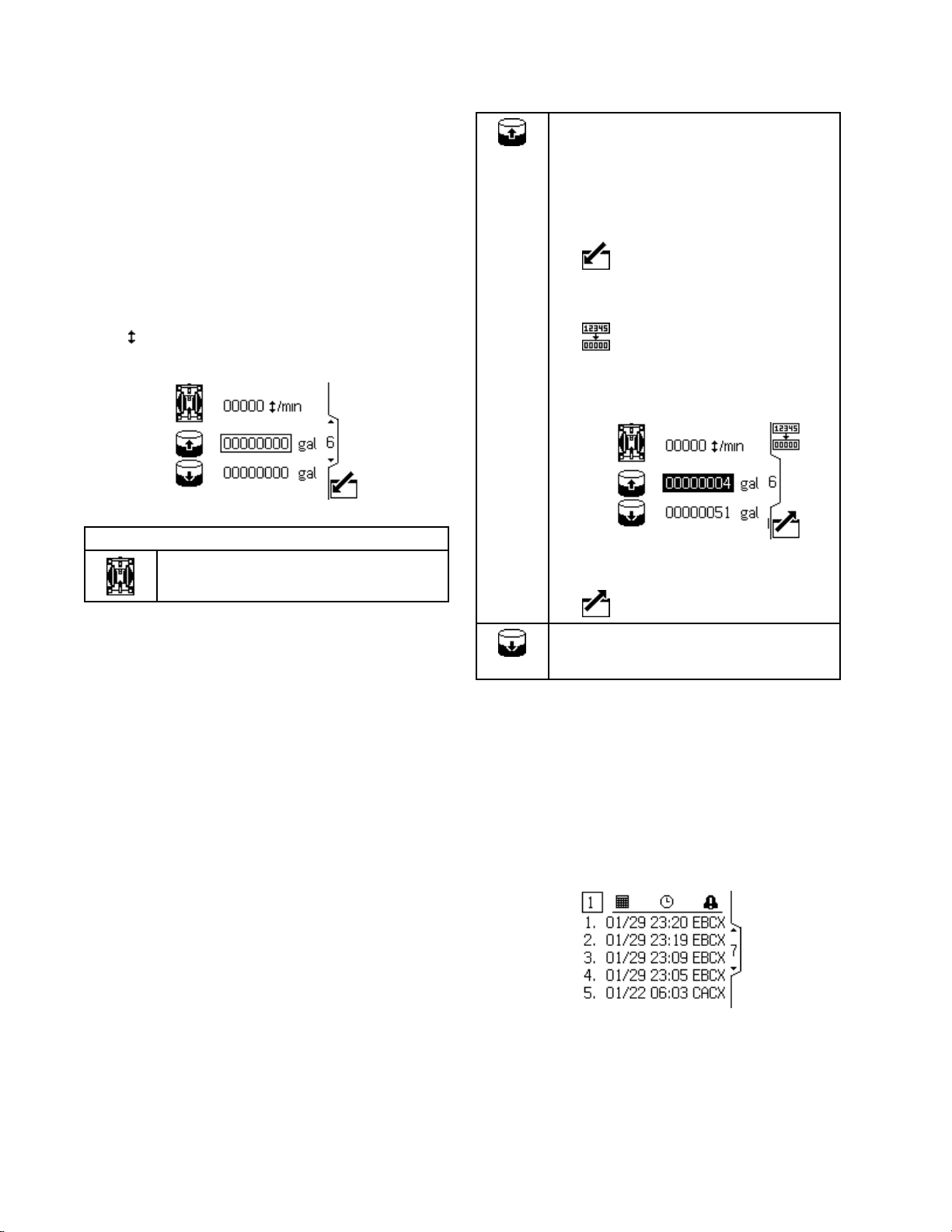

RunScreen6..............................................12

RunScreens7–10.......................................12

SetupScreens....................................................13

SetupScreen1............................................13

SetupScreen2............................................14

SetupScreen3............................................14

SetupScreen4............................................15

SetupScreen5............................................16

SetupScreen6............................................16

SetupScreen7............................................16

SetupScreen8............................................17

SetupScreen9............................................17

SetupScreen10..........................................18

SetupScreens11and12.............................18

SetupScreens13and14.............................18

SetupScreen15..........................................19

SetupScreen16..........................................19

SetupScreen17..........................................20

SetupScreen18..........................................21

SetupScreen19..........................................21

SetupScreen20..........................................22

SetupScreen21..........................................22

SetupScreen22..........................................23

SetupScreen23..........................................23

SetupScreen24..........................................24

SetupScreen25..........................................24

ErrorCodeTroubleshooting................................25

Parts..................................................................29

Accessories........................................................31

BPRControllerKit24V001...........................31

Run/StopSwitchKit16U729.........................32

PressureTransducerKitfor4-ballpumps

24R050,PressureTransducerKit

for2-ballpumps24Y245.................33

AppendixA-ModbusVariableMap.....................34

AppendixB-PumpControlfromaPLC...............51

AppendixC-ControlModuleProgramming...........54

CaliforniaProposition65.....................................55

2

3A2527L

Page 3

RelatedManuals

Related

Related Related

Manual

Manual Manual

English

English English

3A2526

3A2096

332013

3A0539Instructions-PartsManual,4–BallLowers

334359

3A4030Instructions,IntelligentPaintKitchen

Models

Models Models

24P821BDisplayonly

24P822B

in

in in

Part

Part Part

Manuals

Manuals Manuals

Description

Description Description

Instructions-PartsManual,E-FloDCMotor

Instructions-PartsManual,E-FloDC4-BallPistonPumps

Instructions-PartsManual,forAdvancedDisplayControlModule(ADCM)

Instructions-PartsManual,E-FloDC2000,3000,and4000CirculationPumps

No.

No. No.

Series

Series Series

Singlephase

Description

Description Description

24X599B

17V232BThreephase

17V233B

Singlephase(forusewithmotormodelsEM0014andEM0024only)

ThreePhase(EM1014andEM1024only)

3A2527L 3

Page 4

ControlModule

Control

Control Control

TheControlModuleprovidestheinterfaceforuserstoenterselectionsandviewinformationrelatedtosetup

andoperation.

Thescreenbacklightisfactorysettoremainon,evenwithoutscreenactivity.SeeSetupScreen19,page21to

setthebrightnessandbacklighttimer.Pressanykeytorestorethesettings.

Keysareusedtoinputnumericaldata,entersetupscreens,navigatewithinascreen,scrollthroughscreens,

andselectsetupvalues.

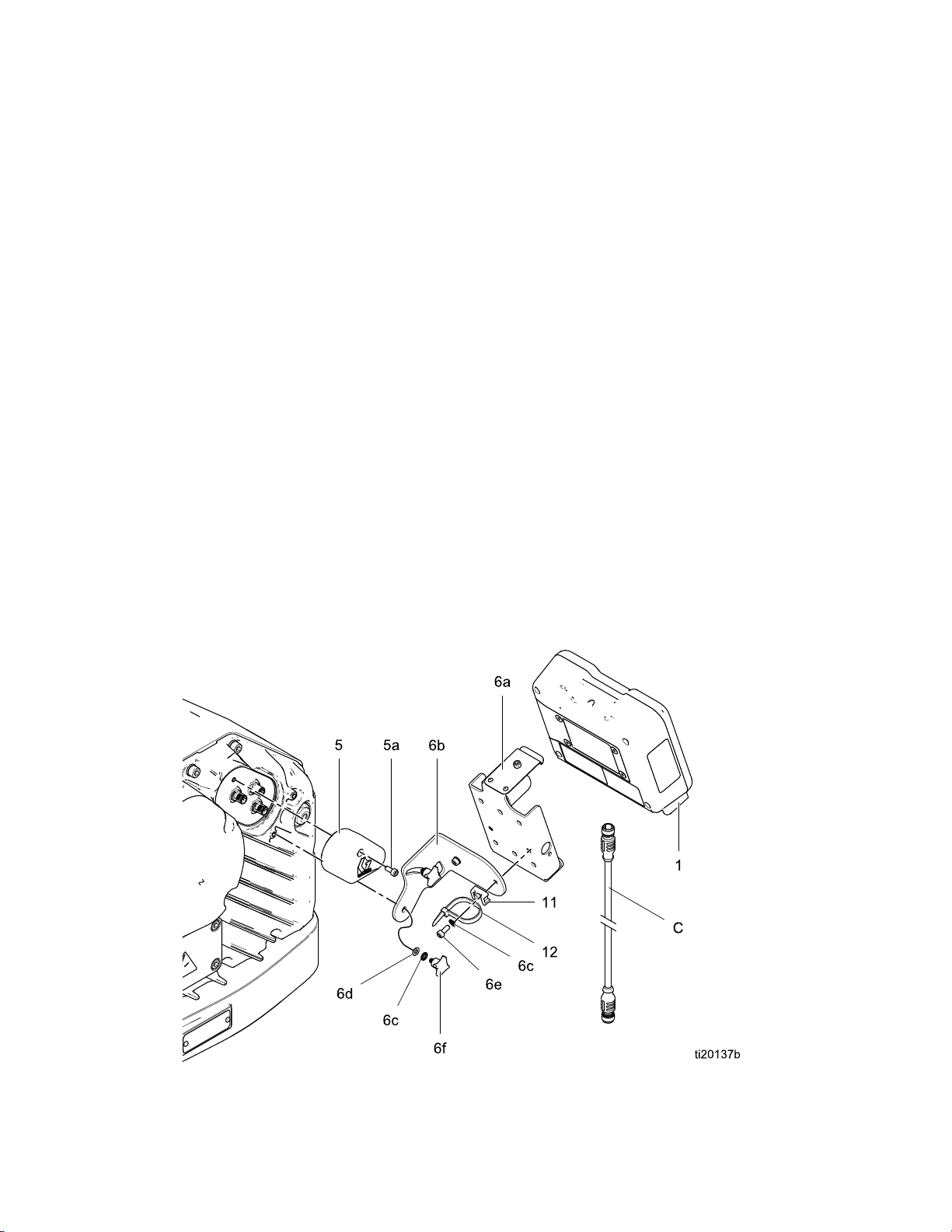

Installation

Installation Installation

Install

Install Install

1.Shutoffandlockoutpowertothemotor.

2.Forsinglephasemodelsonly,installthejumper

the

the the

connector(5)overthetoptwoterminalsofthe

motor,usingthescrew(5a).Threephasemodels

donothaveajumperconnector.

NOTE:

NOTE: NOTE:

seeAppendixAintheE-FloDCMotorManual

(3A2526),wherethecontrolmoduleisthe

referencedintrinsicallysafe(IS)apparatus.

Module

Module Module

Control

Control Control

Toconnectupto8motorstogether,

Module

Module Module

3.Assemblethebracketkit(6a-6f)andtheholder

andtie(11,12)asshown.

4.Installthemodule(1)inthebracket(6a),making

surethetabsatthebottomofthebracketengage

theslotsinthemodule,andthelipatthetopof

thebracketholdsthemodulesecurelyinplace.

5.Connecttheaccessorycable(C),usingthe

tie(12)asastrainreliefasshown.See

CableConnection,page5.

6.Restorepowertothemotor.

NOTE:

NOTE: NOTE:

differentmulti-unittopologies.

SeeAppendixCforinformationabout

Figure1InstalltheControlModule(SinglePhaseModelShown)

4

3A2527L

Page 5

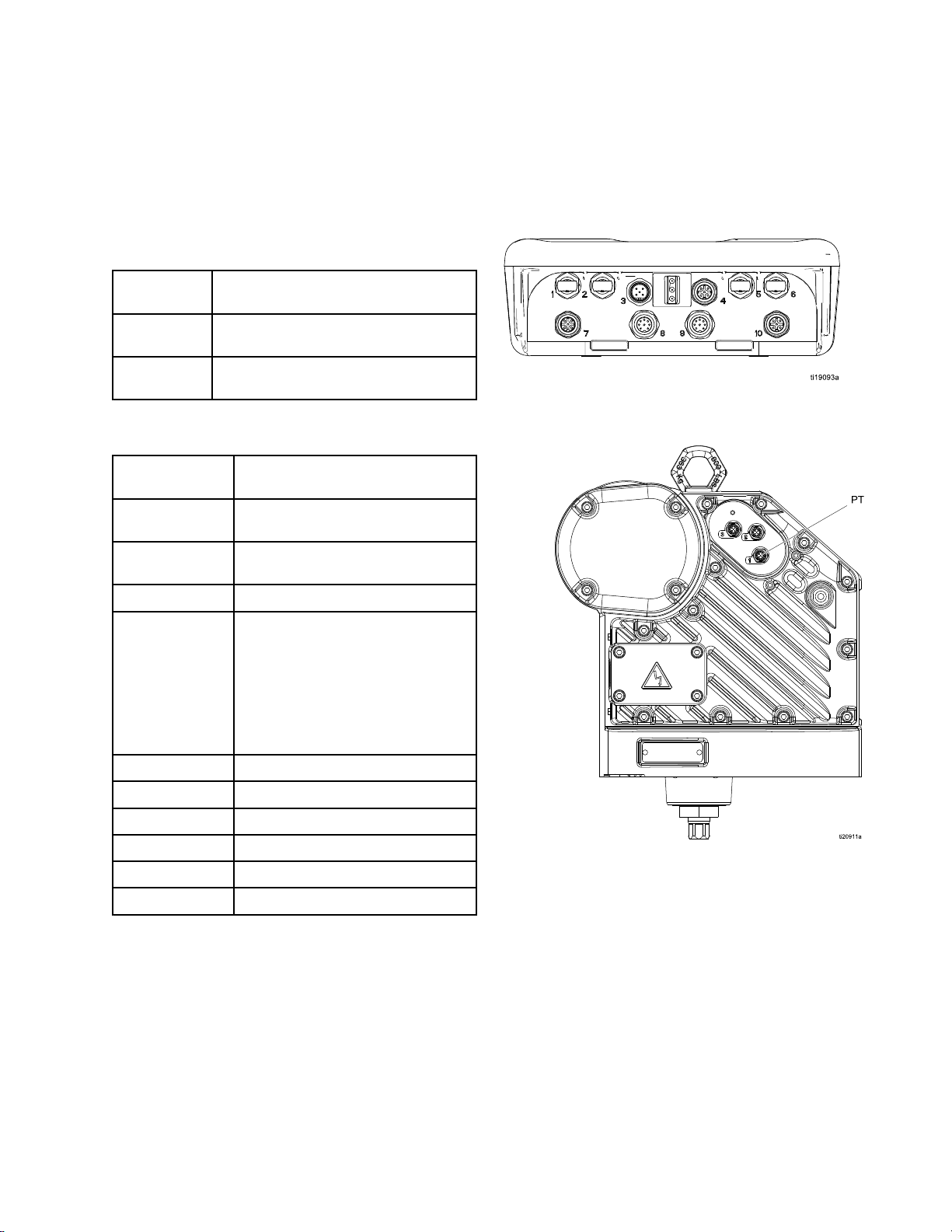

Installation

Cable

Cable Cable

Orderanaccessorycable(C)fromTable1.ConnectthecabletoPort3onthebottomofthecontrolmodule

(seeFig.2).Connecttheotherendtothepowerterminal(PT)onthemotor(seeFig.3).Connectother

cablesasdescribedinTable2.

Table

Table Table

Cable

Cable Cable

No.

No. No.

16P911

16P912

Table

Table Table

ADCM

ADCM ADCM

Number

Number Number

1

2

Connection

Connection Connection

CAN

1 11CAN CAN

2 22ADCM ADCM

Cables

Cables Cables

Part

Part Part

ADCM

Port

Port Port

Description

Description Description

IntrinsicallysafeCANcable,female

xfemale,3ft(1m)

IntrinsicallysafeCANcable,female

xfemale,25ft(8m)

Cable

Connections

Cable Cable

Connections Connections

Connector

Connector Connector

FiberOpticRX-toFiberOptic

ConverterModule

FiberOpticTX-toFiberOptic

ConverterModule

Purpose

Purpose Purpose

Figure2ADCMConnectors

3

4

5

6

7

8BPRcontrol4-20mAoutput

9PrimaryTankLevelMonitor

10Pressuretransducer2

PowerandCANcommunication

•Start/Stopinput(pin2)

•Fillpumpoutput(pin3)

•Reedswitchinput(pin4)

•Agitatorhaltinput(pin4)

•Tankhighoutput(pin4)

•Tanklowoutput(pin4)

•Auxiliaryoutput(pin4)

FiberOpticRX-tonextADCM

FiberOpticTX-tonextADCM

Pressuretransducer1

Figure3MotorPowerTerminal

3A2527L 5

Page 6

Operation

Operation

Operation Operation

Module

Module Module

TheControlModulehastwosetsofscreens:

RunandSetup.Fordetailedinformationsee

RunScreens,page9,andSetupScreens,page13.

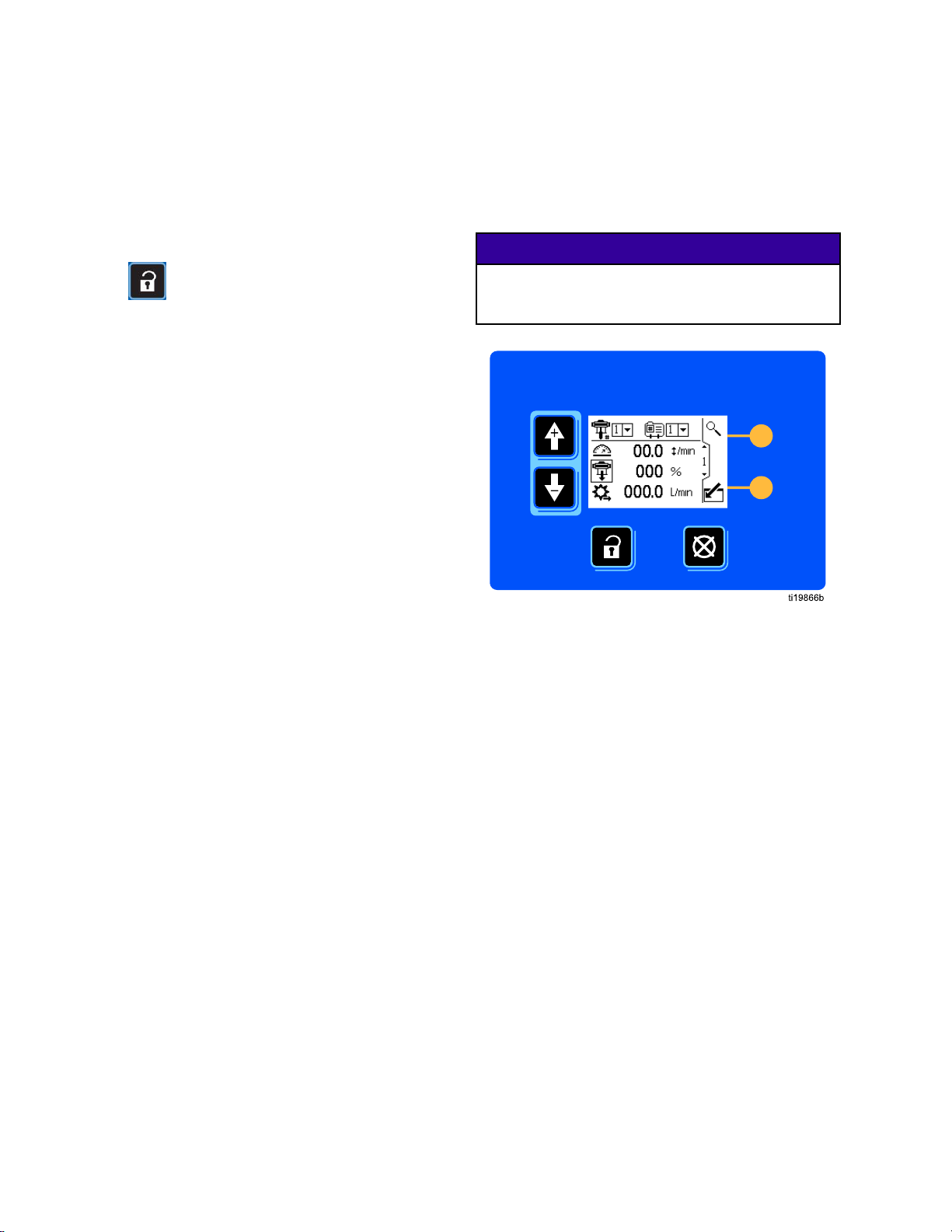

PresstotogglebetweentheRunscreensand

theSetupscreens.

InformationdisplayedontheRunandSteup

screenscorrespondstotheModbusRegisters.See

AppendixA-ModbusVariableMap,page34.

NOTE:

NOTE: NOTE:

loadrequirements.

Module

Module Module

Figure4isaviewofthecontrolmoduledisplayand

keys.Table2explainsthefunctionofthemembrane

keysonthecontrolmodule.Asyoumovethrough

thescreens,youwillnoticethatmostinformation

iscommunicatedusingiconsratherthanwords

tosimplifyglobalcommunication.Thedetailed

screendescriptionsinRunScreens,page9,and

SetupScreens,page13,explainwhateachicon

Screens

Screens Screens

Thescreenautomaticallydimsbasedonthe

Keys

Keys Keys

represents.Thetwosoftkeysaremembranebuttons

whosefunctioncorrelateswiththescreencontentto

theimmediateleftofthebutton.

NOTICE

NOTICE NOTICE

Topreventdamagetothesoftkeybuttons,donot

pressthebuttonswithsharpobjectssuchaspens,

plasticcards,orngernails.

Figure4ControlModuleKeypadandDisplay

6 3A2527L

Page 7

Operation

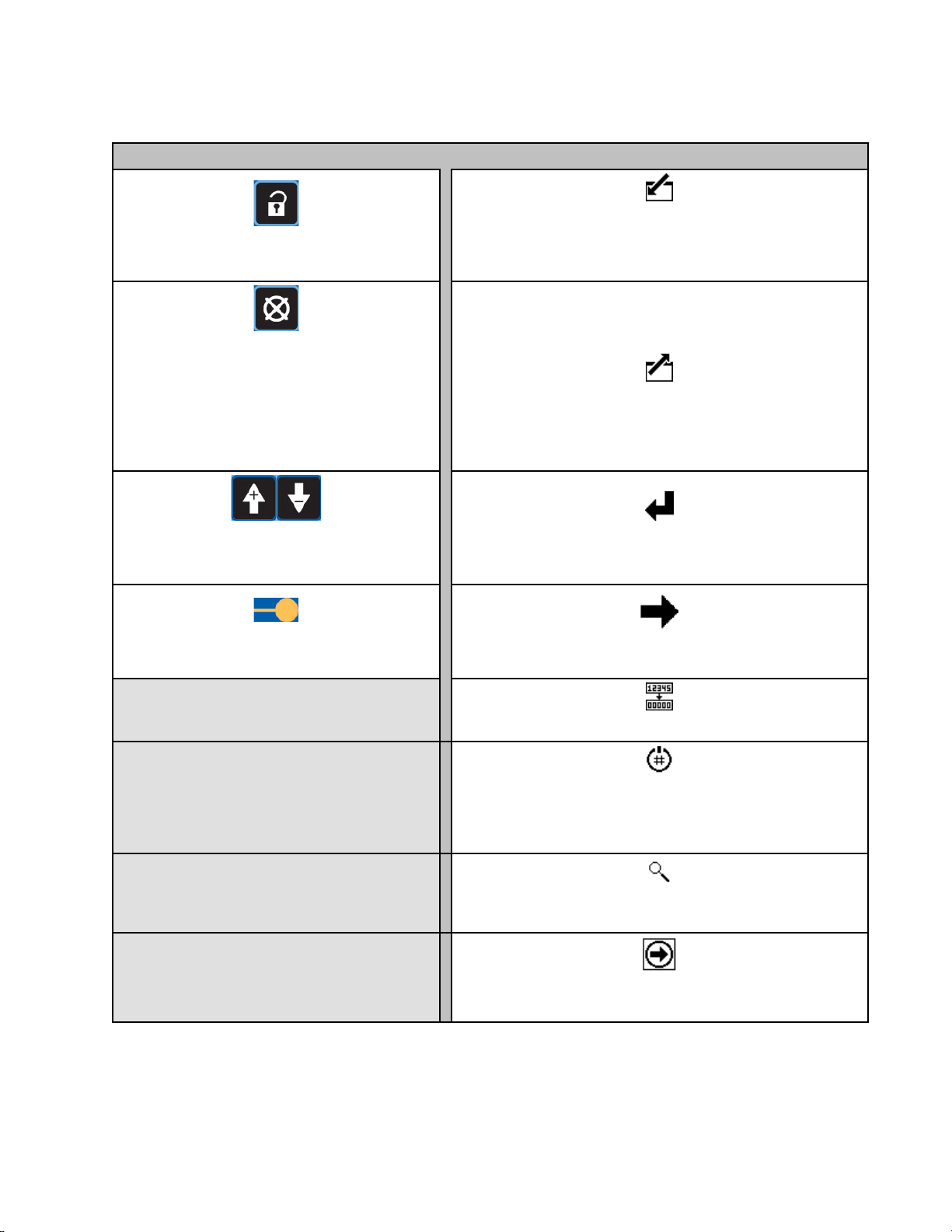

Table

Table Table

alarmtoclear,thiskeysetstheactivepump’s

eldsonascreen,ortoincreaseordecrease

thenumericvaluesinaeldthatcanbeedited.

Module

3 33Module Module

Toggle:

Toggle: Toggle:

Cancel/Error

Cancel/Error Cancel/Error

thecausehasbeenxed.Whenthereisno

proletoStop.Alsousedtocancelthedata

enteredandreturntotheoriginaldata.

NOTE:

NOTE: NOTE:

disabledinSetupScreen16.

Up/Down

Up/Down Up/Down

Keys

Keys Keys

Membrane

Membrane Membrane

TogglebetweentheRunscreens

andSetupscreens.

Reset:

Reset: Reset:

Thepumpstopfunctioncanbe

Arrows:

Arrows: Arrows:

Movebetweenscreensor

Keys

Keys Keys

Clearthealarmafter

Softkeys

Softkeys Softkeys

Enter

Screen:

Enter Enter

Screen: Screen:

AlsochangesthefunctionoftheUp/Downarrows

sotheymovebetweendataeldsonthescreen,

Enter:

Enter: Enter:

Presstoactivateaeldforeditingortoaccept

thehighlightedselectiononamenu.

Highlightdatathatcanbeedited.

ratherthanbetweenscreens.

Exit

Screen:

Exit Exit

Screen: Screen:

Exitdataediting.

Softkeys:

Softkeys: Softkeys:

Softkeyscolumnsatright.

Variesbyscreen.Seethe

Right:

Right: Right:

Movetotherightwheneditingnumberelds.Press

againtoaccepttheentrywhenalldigitsarecorrect.

Reset:

Reset: Reset:

Activate

Activate Activate

andonlyappearsonSetupScreens1–4iftheProle Prole

Lock

Lock Lock

Search:

Search: Search:

Acknowledge:

Acknowledge: Acknowledge:

Prole:

Prole: Prole:

boxischeckedonSetupScreen25,page24.

Presstoactivatetheprolejustedited.

PressinRunScreen1tomaketheactive

Resettotalizertozero.

Thissoftkeyisdisabledbydefault,

pumpblinkforidentication.

Presstoacknowledgethatasoftware

updatehasconcluded.

Prole

3A2527L

7

Page 8

Operation

Screen

Screen Screen

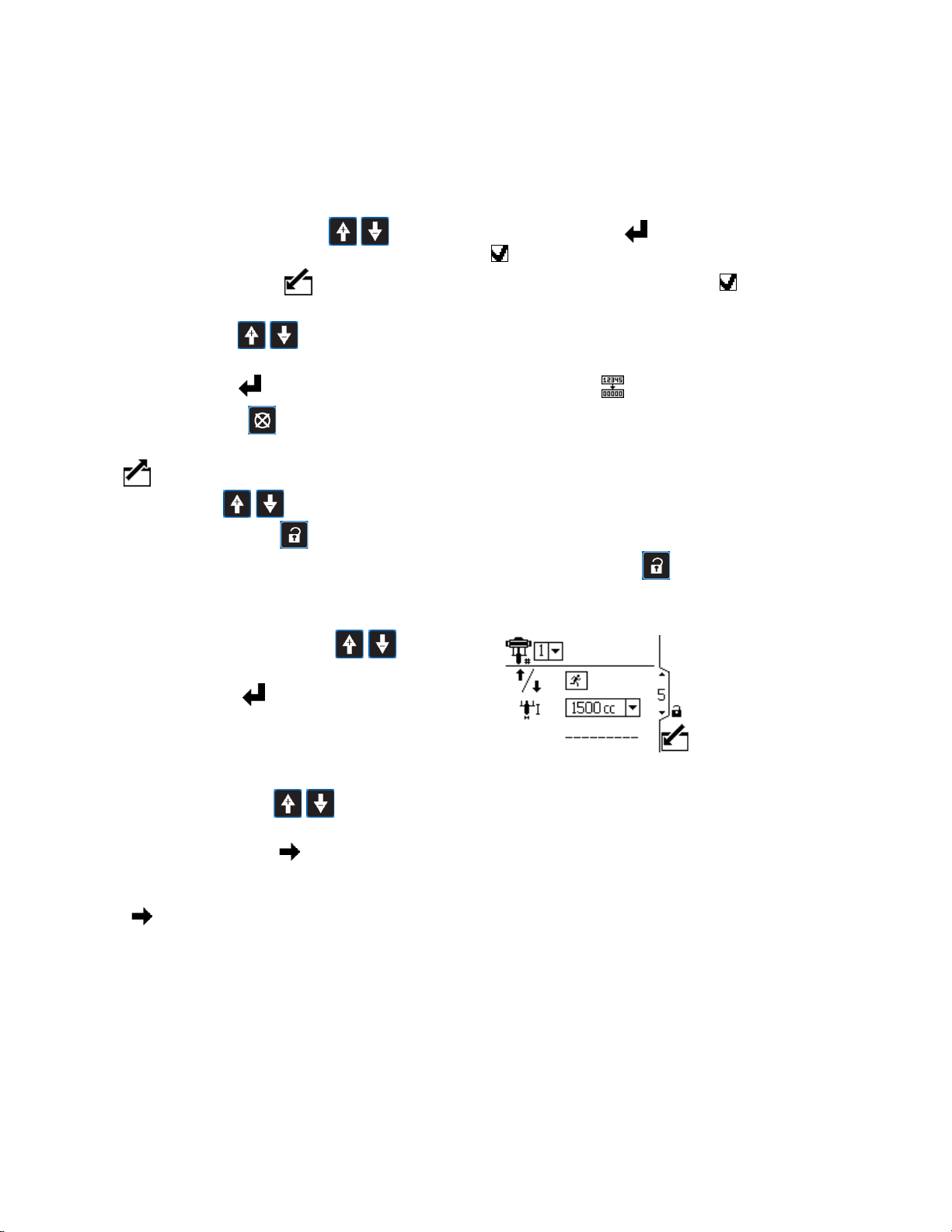

Refertothissectionforinstructionsonnavigating

screens,enteringinformation,andmakingselections.

All

Screens

All All

Screens Screens

•Usetheupanddownarrowkeystomove

betweenscreens.

•Presstheenterscreenkey

Therstdataeldonthescreenishighlighted.

•Usethearrowkeys

thatyouwanttochange.

•Presstheenterkey

•Pressthecancelkey

•Whenalldataiscorrect,presstheexitscreen

key

downarrowkeys

screen,orthetoggleicon

SetupscreensandRunscreens.

Menu

Menu Menu

Navigation

Navigation Navigation

toexitthescreen.Thenusetheupand

Fields

Fields Fields

and

and and

toedit.

tocancel.

tomovetoanew

tohighlightthedata

Editing

Editing Editing

tomovebetween

toenterascreen.

Check

Check Check

Acheckboxeldisusedtoenableordisablefeatures

inthesoftware.

•Presstheenterkey

•Thefeatureisenabledifacheck

Reset

Reset Reset

Thereseteldisusedfortotalizers.Pressthe

totalizerresetkey

Initial

Initial Initial

NOTE:

NOTE: NOTE:

Screens1through4,youmustsetupthesystem

parametersinSetupScreens5through25,as

follows.

1.Pressthelockicon

2.ScrolltoSetupScreen5.

Box

Fields

Box Box

Fields Fields

totogglebetweenacheck

andanemptybox.

Field

Field Field

toresettheeldtozero.

Setup

Setup Setup

BeforecreatingthepumpprolesinSetup

toentertheSetup

screens.SetupScreen1appears.

isinthebox.

•Usetheupanddownarrowkeys

highlightthecorrectchoicefromthemenu.

•Presstheentericon

Number

Number Number

•Therstdigitintheeldishighlighted.Usethe

•Presstherightarrowkey

•Whenalldigitsarecorrect,presstherightarrow

Fields

Fields Fields

upanddownarrowkeys

number.

digit.

key

againtoaccept.

toselect.

tochangethe

tomovetothenext

to

3.SeeSetupScreen5,page16,andselectthe

lowerusedinyoursystem.

4.Continuesettingthesystemparameters

onSetupScreen6,page16through

SetupScreen25,page24.

5.ScrolltoSetupScreen1.Establish

theprolesforeachpump.See

SetupScreen1,page13through

SetupScreen4,page15.

8 3A2527L

Page 9

RunScreens

Run

Run Run

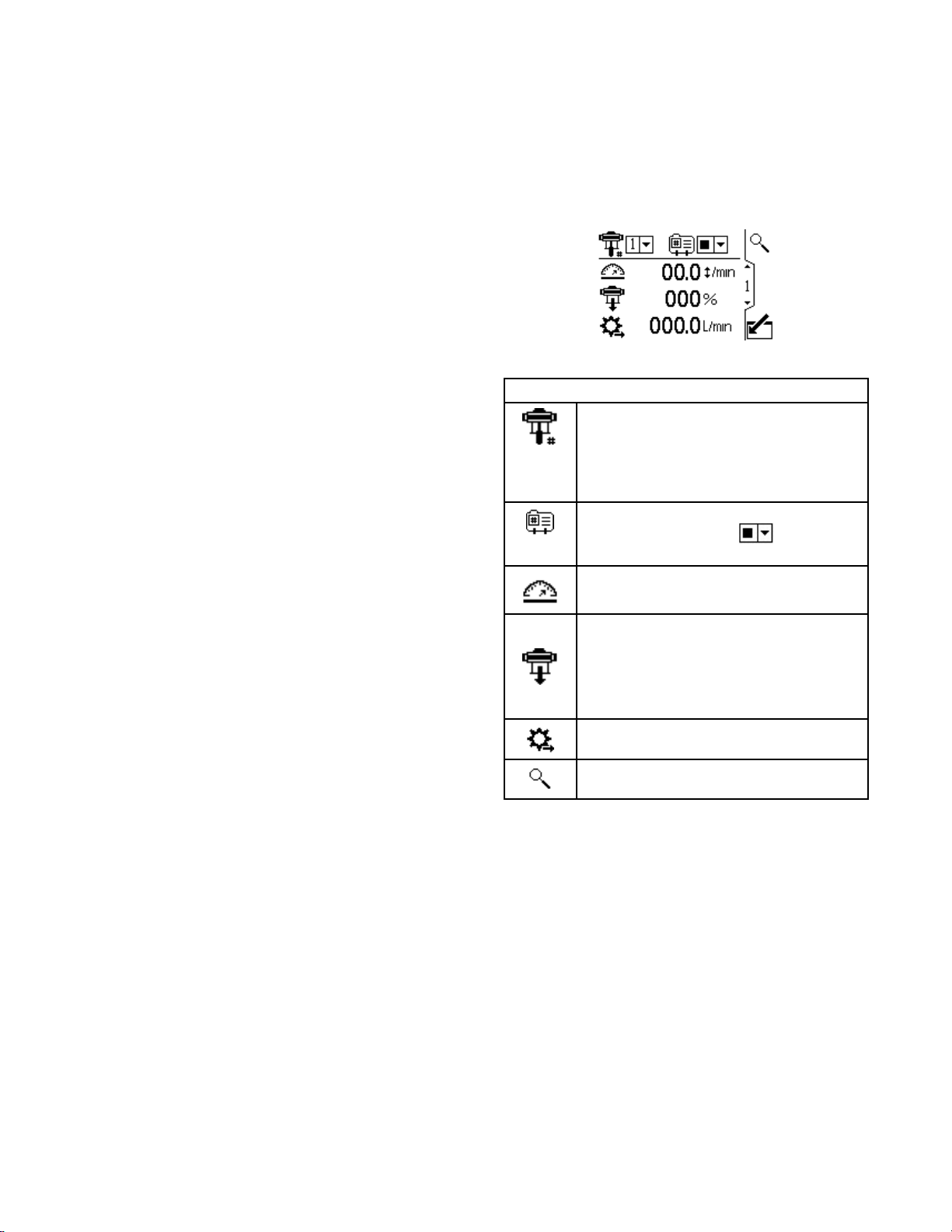

TheRunscreensdisplaycurrenttargetvaluesand

performanceforaselectedpumpandprole.Any

alarmsdisplayinthesidebarattherightofthe

screen.Screens7–10and11–14displayalogofthe

last20alarmsfortheactivepump.

TheactivepumpandprolemaybechangedinRun

Screens1,2,and3.

Screens

Screens Screens

Run

Run Run

Thisscreendisplaysinformationforaselected

pumpandprole.Aboxaroundaniconindicates

whichmodetheactivepumpandproleisrunning

(pressureorow).

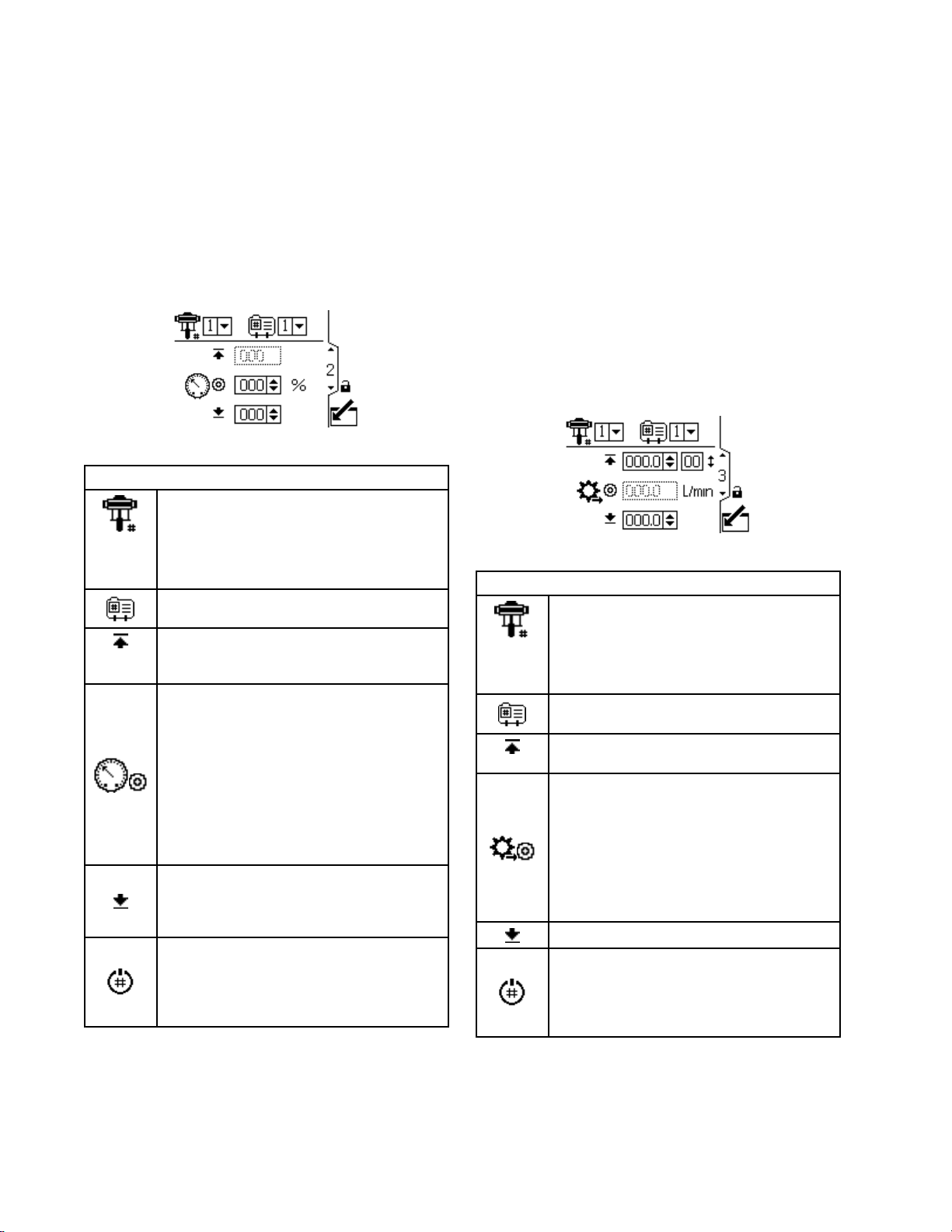

Figure5RunScreen1

Screen

Screen Screen

1

1 1

Run

Screen

Run Run

Screen Screen

Forsystemswithmultiplepumpsand

onedisplay,selectthepump(1to8)

fromthemenu.

NOTE:

NOTE: NOTE:

supportmultiplepumps.

Selecttheprole(1to4)fromthemenu.

Selectthestopoption

menutostopthepump.

Displaysthecurrentpumpspeedin

cyclesperminute.

Threephasesystemsdonot

Key

1 11Key Key

fromthe

Displaysthecurrentpumppressureas

apercentage.Ifatransducerisused,

thisiconisreplacedbythepressure

icon.Tosetupapressuretransducer,

seeSetupScreen8,page17and

SetupScreen9,page17.

Displayscurrentowrateinunitsas

selectedinSetupScreen18,page21.

Signalstheactivepumptoblinkcode9

foridentication.

3A2527L 9

Page 10

RunScreens

Run

Run Run

Thisscreendisplaysinformationforcontrollingan

electricagitatorusingthesupervisortopasson

thecontrolsetpointtoaVariableFrequencyDrive

(VFD),alsoknownasaninverter.

Figure6RunScreen2

Screen

Screen Screen

2

2 2

Run

Screen

Run Run

Screen Screen

Selectthisboxandsetthespeed

setpointfortheagitatorfrom0–100%.

Selectthisboxtoputagitator

controlinlocalonlymode.Setpoint

andEnable/Disablerequestsfrom

PLC/Supervisorwillbeignored.

Selectthisboxandholdthesoftkeyto

manuallyrunthepumpintheselected

prole.Thisfeatureallowstheuserto

runthemotorpastthetanklevellow

alarmtoemptythetank.

Selectthisboxandholdthesoftkey

buttontomanuallycontrolthellpump

solenoidoutput.

Currentprimarytankvolumeinpercent.

Theeldispopulatedwithdataonly

whenthetanksensorisenabled.See

SetupScreen19,page21.

Key

2 22Key Key

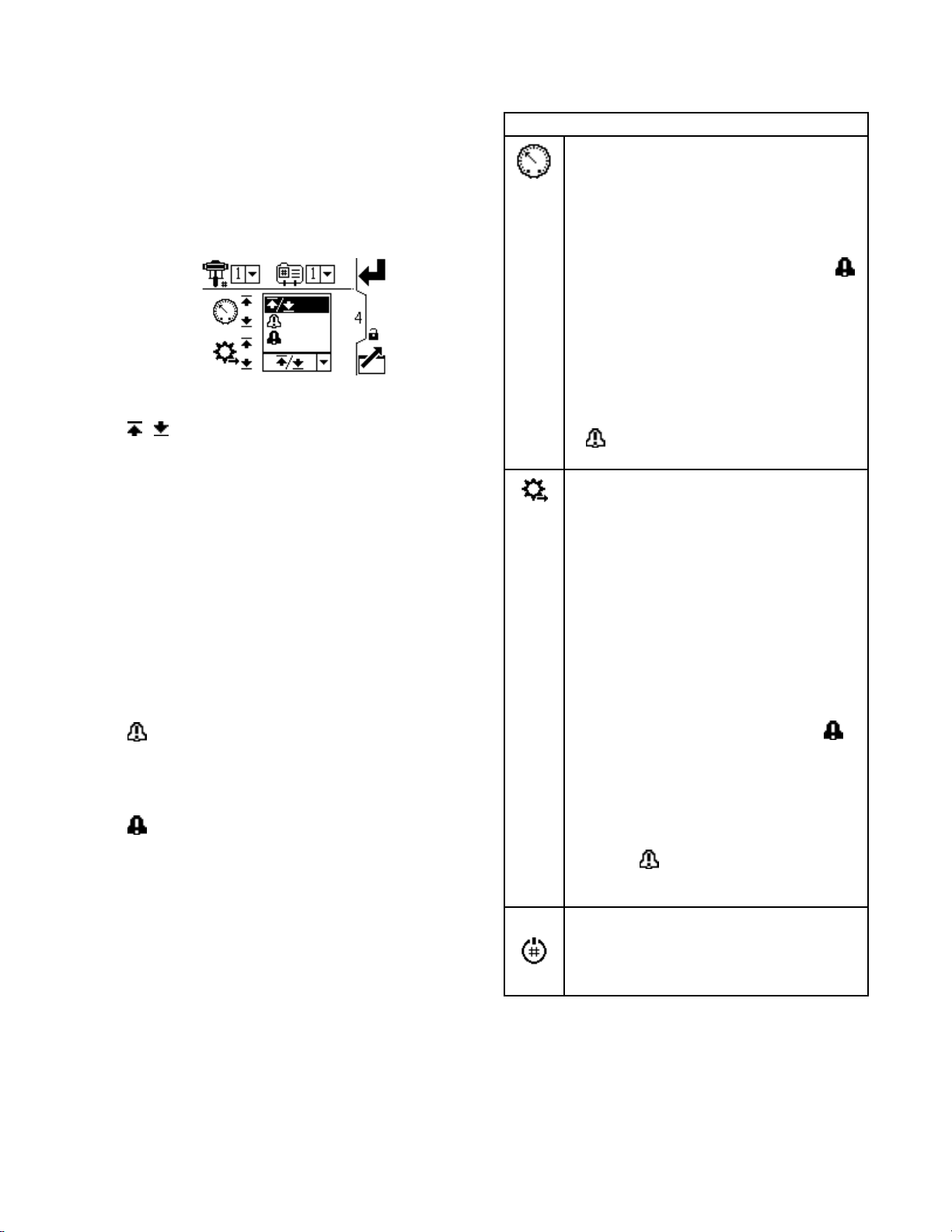

Run

Run Run

Thisscreendisplayspressuresettingsfortheactive

pumpandprole.Pressurecanbemeasuredinpsi,

bar,andMPa.

NOTE:

NOTE: NOTE:

setupselections.

Figure7RunScreen3,ShowninPressureMode

Screen

Screen Screen

Someeldsaregrayedout,dependingon

3

3 3

Run

Screen

Run Run

Screen Screen

Forsystemswithmultiplepumpsand

onedisplay,selectthepump(1to8)

fromthemenu.

NOTE:

NOTE: NOTE:

supportmultiplepumps.

Selecttheprole(1to4)fromthemenu.

Selectthestopoption

menutostopthepump.

Displaysthemaximumuidpressureas

selectedinSetupScreen2,page14.

SeeSetupScreen4,page15tosetor

disablethepressurealarms.

Displaysthetargetpressureasselected

inSetupScreen2,page14.

Displaystheminimumuidpressureas

selectedinSetupScreen2,page14.

SeeSetupScreen4,page15tosetor

disablethepressurealarms.

Threephasesystemsdonot

Key

3 33Key Key

fromthe

10 3A2527L

Page 11

RunScreens

Run

Run Run

Thisscreendisplaysuidowsettingsfortheactive

pumpandprole.Fluidowcanbemeasuresinliters

perminute,gallonsperminute,ccperminute,ozper

minute,orcyclesperminute.

NOTE:

NOTE: NOTE:

setupselections.

Figure8RunScreen4,ShowninPressureMode

Screen

Screen Screen

Someeldsaregrayedout,dependingon

4

4 4

Run

Screen

Run Run

Screen Screen

Forsystemswithmultiplepumpsand

onedisplay,selectthepump(1to8)

fromthemenu.

NOTE:

NOTE: NOTE:

supportmultiplepumps.

Selecttheprole(1to4)fromthemenu.

Selectthestopoption

menutostopthepump.

Displaysthemaximumowrateand

maximumcyclerateasselected

inSetupScreen3,page14.See

SetupScreen4,page15tosetor

disabletheowalarms.

Displaysthetargetowrateasselected

inSetupScreen3,page14.

Displaystheminimumowrateas

selectedinSetupScreen3,page14.

Threephasesystemsdonot

Key

4 44Key Key

fromthe

Run

Run Run

Thisscreendisplaysthecurrentpressurereadingsof

transducers1and2.Pressurecanbedisplayedas

psi,bar,orMPa.SeeSetupScreen23,page23.

Figure9RunScreen5

Screen

Screen Screen

5

5 5

Run

Screen

Run Run

Screen Screen

Displaysthepressureoftransducer1.

Displaysthepressureoftransducer2.

Displaysthepressuredifference

betweentransducer1andtransducer2.

Key

5 55Key Key

SeeSetupScreen4,page15tosetor

disabletheowalarms.

3A2527L

11

Page 12

RunScreens

Run

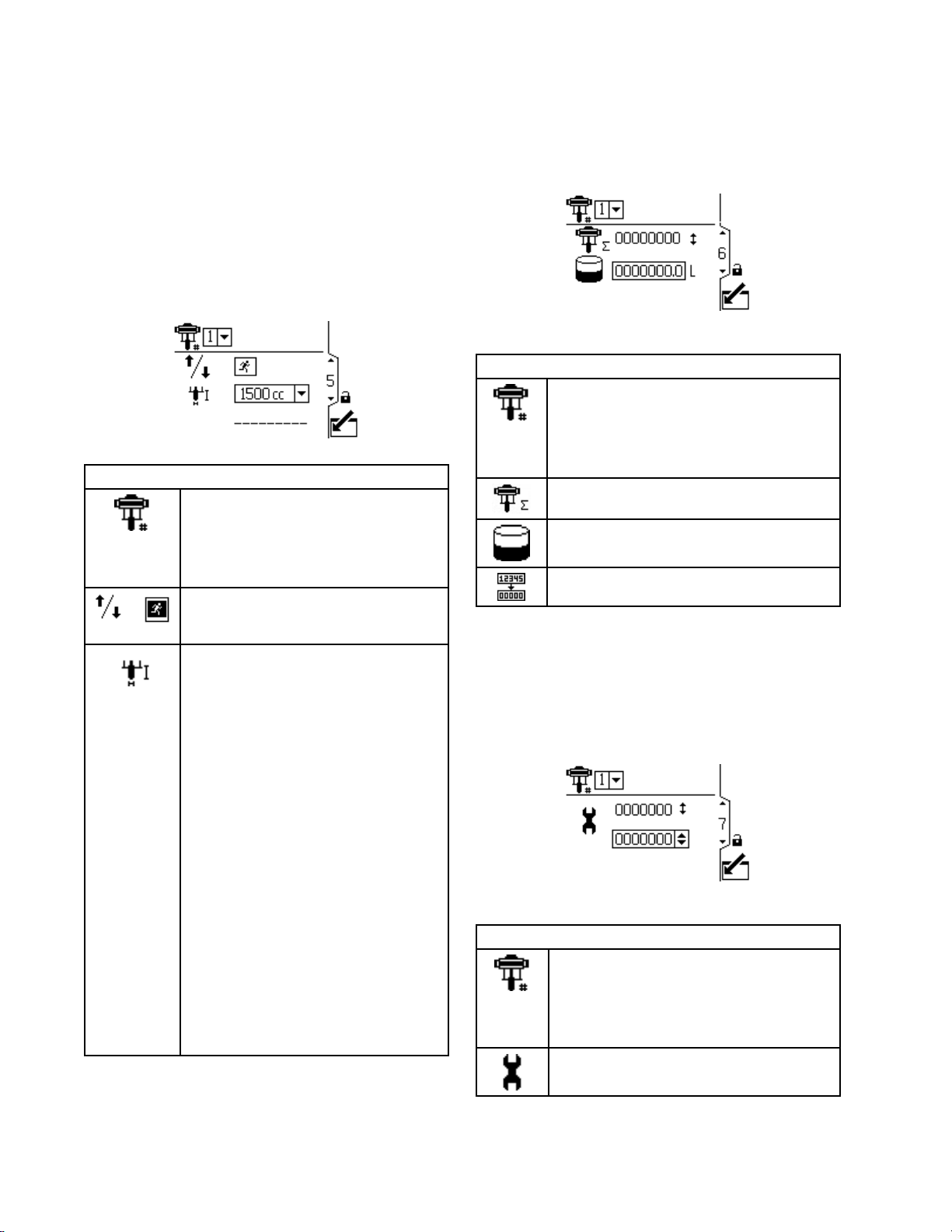

Run Run

Thisscreendisplaysvolumeinformationaboutthe

tank:thevolumedispensedandtheremaining

volume.Thevolumecanbedisplayedaslitersor

gallons.SeeSetupScreen25,page24.

NOTES:

NOTES: NOTES:

•Thescreennumbermaydiffer,dependingonthe

•Thisscreenappearsonlywhentheauxiliaryinput

Figure10RunScreen6

Screen

Screen Screen

featuresthatareenabled.

isconguredforthereedswitchonSetupScreen

19:

SeeSetupScreen19,page21.

6

6 6

Run

Screen

Run Run

Screen Screen

Displaysthecurrentcyclerate.

6 66Key Key

Key

Displaysanestimateofthevolume

dispensedoutofthistanksincethelast

resetevent.

Toresetthevolumedispensed:

1.Pressthebottomrightsoftkeyto

enterthescreen:

2.Pressthetoprightsoftkeytoreset

thevolumedispensedto0:

Thevolumeremainingsetstothe

volumeenteredonSetupScreen16.

(SeeSetupScreen16,page19.)

3.Pressthebottomrightsoftkeytoexit

thescreen:

Displaysanestimateoftheremaining

volumeinthesecondarytank,basedon

thelastresetevent.

Run

Run Run

RunScreens7–10displayalogofthelast20alarms,

withdateandtime.

Thecurrentlyactivepumpisdisplayedinaboxat

thetopleftofthescreen.

Forerrorcodes,see

ErrorCodeTroubleshooting,page25.

Figure11RunScreen7

Screens

Screens Screens

7–10

7–10 7–10

12

3A2527L

Page 13

SetupScreens

Setup

Setup Setup

UsetheSetupscreensforpumpsettingsandaccessoryfeatures.See

ScreenNavigationandEditing,page8forinformationonhowtomakeselectionsandenterdata.

Inactiveeldsaregrayedoutonascreen.

NOTE:

NOTE: NOTE:

1–4,performtheinitialsetuponSetupScreens5–25

Setup

Setup Setup

Usethisscreentosettheoperatingmodefora

selectedpumpandprole.

Figure12SetupScreen1

Screens

Screens Screens

BeforesettingupprolesonSetupScreens

Screen

Screen Screen

Forsystemswithmultiplepumpsand

onedisplay,selectthepump(1to8)

fromthemenu.

NOTE:

NOTE: NOTE:

supportmultiplepumps.

Selecttheprole(1to4)fromthemenu.

1

1 1

Setup

Setup Setup

Screen

Screen Screen

Threephasesystemsdonot

Key

1 11Key Key

toestablishthecongurationforyoursystemand

affectthedisplayeddata.

Selecttheoperatingmode

(force/pressureorow)fromthe

menu.

•Inforce/pressuremode,themotor

adjuststhepumpspeedtomaintain

theuidpressurepercentageseton

SetupScreen2.Iftheowlimitis

reachedbeforethetargetpressure,

theunitstopsdrivingtothepressure

(ifsetasanalarm).

•Inowmode,themotormaintains

aconstantspeedtomaintainthe

targetowratesetonSetupScreen

3,regardlessoftheuidpressure,

uptothepump’smaximumworking

pressure.

NOTE:

NOTE: NOTE:

onthreephasemotorsystems.

Ifthesystemisequippedwithaback

pressureregulator(BPR),setthetarget

airpressuretotheBPRfrom0to100

percent(approximately1to100psi).

Leavetheeldsetto000forasystem

withnoBPR.Thisvaluerepresentsthe

percentagethatisclosedontheBPR.If

thevalueisgreaterthanzerobutthere

isnoBPRsystem,theL6CAerrorcode

appears.

Thissoftkeyisdisabledbydefault,and

onlyappearsiftheProle Prole

checkedonSetupScreen25,page24.

Presstoactivatetheprolethatyoujust

edited.

Thisselectionisonlyavailable

Prole

Lock

Lock Lock

boxis

3A2527L 13

Page 14

SetupScreens

Setup

Setup Setup

Usethisscreentosetthemaximum,target,and

minimumforce/uidpressureforaselectedpump

andprole.Inforce/pressuremode,youcanset

atargetforce/uidpressure.Inowmode,you

cansetamaximumforce/uidpressure.Ineither

force/pressureorowmode,youcansetaminimum

pressure.SeeSetupScreen4,page15,tospecify

howthesystemwillrespondifthepumpbeginsto

operateoutsideofthesetboundaries.

Figure13SetupScreen2

Screen

Screen Screen

Forsystemswithmultiplepumpsand

onedisplay,selectthepump(1to8)

fromthemenu.

NOTE:

NOTE: NOTE:

supportmultiplepumps.

Selecttheprole(1to4)fromthemenu.

Setthemaximumpumpuid

force/pressure,asapercentageof

themaximumpressureofyourpump.

Inforce/pressuremode,settheforce/uid

pressuretargetasapercentageofthe

maximumpressureofyourpump.This

eldisnotusedinowmode.

NOTE:

NOTE: NOTE:

enabled,thetargetpressureisdisplayed

asapressurevalue(psi,bar,MPa)rather

thanapercentageofmaximumpressure.

SeeSetupScreen8,page17toenable

closedlooppressurecontrol.

Optionally,setaminimumpump

force/uidpressure,asapercentageof

themaximumforce/uidpressureofyour

pump.

Thissoftkeyisdisabledbydefault,and

onlyappearsiftheProle Prole

checkedonSetupScreen25,page24.

Presstoactivatetheprolethatyoujust

edited.

2

2 2

Setup

Setup Setup

Screen

Screen Screen

Threephasesystemsdonot

Ifclosedlooppressureis

Key

2 22Key Key

Prole

Lock

Lock Lock

boxis

Setup

Setup Setup

Usethisscreentosetyourowratesettingsfora

selectedpumpandprole.Inpressuremode,you

willsetamaximumowrate.Inowmode,youwill

setatargetowrate.Ineitherpressureorowmode,

aminimumowratemaybeset.SeeSetupScreen

4tospecifyhowthesystemwillrespondifthepump

beginstooperateoutsideofthesetboundaries.

NOTE:

NOTE: NOTE:

valuethatcanbedisplayedis9999.Iftheeld

displays####,thesavedvalueisoutofrange.Go

toSetupScreen18,page21andchangetheow

ratetoalargerunit.Returntothisscreenandreduce

thesettingtoalowervaluethatwillbewithinthe

display’srange,thenresettheowrateunitsto

cc/min.

Figure14SetupScreen3

Screen

Screen Screen

Withowrateunitsofcc/min,themaximum

Forsystemswithmultiplepumpsand

onedisplay,selectthepump(1to8)

fromthemenu.

NOTE:

NOTE: NOTE:

supportmultiplepumps.

Selecttheprole(1to4)fromthemenu.

Inowmode,setatargetowrate.This

eldisnotusedinpressuremode.

Inpressuremode,setthemaximumow

rate.Thesoftwarecalculatesthenumber

ofpumpcyclesneededtoachievethat

owrate.Thiseldisnotusedinow

mode.

NOTE:

NOTE: NOTE:

maximumowratesetting,themotorwill

notrunanderrorcodeWSC_appears.

Optionally,setaminimumowrate.

Thissoftkeyisdisabledbydefault,and

onlyappearsiftheProle Prole

checkedonSetupScreen25,page24.

Presstoactivatetheprolethatyoujust

edited.

3

3 3

Setup

Setup Setup

Screen

Screen Screen

Threephasesystemsdonot

Iftheproledoesnothavea

Key

3 33Key Key

Prole

Lock

Lock Lock

boxis

14

3A2527L

Page 15

SetupScreens

Setup

Setup Setup

Usethisscreentospecifyhowthesystemresponds

ifthepumpbeginstooperateoutsideofthepressure

andowsettingsestablishedonSetupScreen2and

SetupScreen3.Theoperatingmode(pressureor

ow,setonSetupScreen1)determineswhichelds

areactive.

Figure15AlarmPreferenceMenu

•/Limit: Limit:

noalert.

–MaximumpressuresettoLimit:Thesystem

–MaximumowsettoLimit:Thesystemreduces

–MinimumpressureorowsettoLimit:The

–PressurelimiterrorsincludeP1I_,P2I_,P3I_,

–FlowrateerrorsincludeK1D_,K2D_,K3D_,and

•

problem,butthepumpmaycontinuetorunpast

themaximumorminimumsettingsforveseconds

untilthesystem’sabsolutepressureorow

boundariesarereached.

•

causeandshutsdownthepump.

NOTE:

NOTE: NOTE:

activemeasurementsarefromtheirsetlimits.

Screen

Screen Screen

Limit:

reducestheowifnecessarytopreventthe

pressurefromexceedingthelimit.

thepressureifnecessarytopreventtheow

fromexceedingthelimit.

systemtakesnoaction.Usethissettingforno

minimumpressureorowsetting.

andP4I_.

K4D_.

Deviation:

Deviation: Deviation:

Alarm:

Alarm: Alarm:

Thesystemalertsyoutothealarm

Alerttriggertimevariesbasedonhowfar

4

4 4

Thepumpcontinuestorunandissues

Thesystemalertsyoutothe

Setup

Setup Setup

Toenablethepressurealarm:

•Line1(PressureMaximum):Select

Limit

Limit Limit

Forrunawaycontrol,setthemaximum

owtoAlarm Alarm

themaximumenteredonSetupScreen

3forveseconds,analarmsymbol

appearsonthescreenandthepump

shutsdown.

•Line2(PressureMinimum):Select

Limit

Limit Limit

Todetectapluggedlterorpipe,setthe

minimumowtoDeviation Deviation

ratedropsbelowtheminimumentered

onSetupScreen3,adeviationsymbol

appearsonthescreentowarnyouto

takeaction.Thepumpcontinuestorun.

Toenabletheowratealarm:

•Line3(FlowMaximum):SelectLimit Limit

Deviation

Deviation Deviation

Topreventtheconnectedequipment

fromexcessivepressure,setthe

maximumpressuretoLimit.

•Line4(FlowMinimum):SelectLimit Limit

Deviation

Deviation Deviation

Forrunawaycontrol,settheminimum

pressuretoAlarm Alarm

pumpdoesnotchangespeed,butthe

backpressurefalls.Whenthepressure

fallsbelowtheminimumenteredon

SetupScreen2,anAlarmsymbol

appearsonthescreenandthepump

shutsdown.

Todetectapluggedlterorpipe,setthe

maximumpressuretoDeviation Deviation

thepressureexceedsthemaximum

enteredonSetupScreen2,aDeviation

symbol

warnyoutotakeaction.Thepump

continuestorun.

Thissoftkeyisdisabledbydefault,and

onlyappearsiftheProle Prole

checkedonSetupScreen23,page23.

Presstoactivatetheprolethatyoujust

edited.

Screen

Screen Screen

Deviation

,Deviation Deviation

Alarm

Deviation

,Deviation Deviation

,orAlarm Alarm

.Iftheowrateexceeds

,orAlarm Alarm

Deviation

Alarm

,orAlarm Alarm

Alarm

,orAlarm Alarm

Alarm

.Ifahosebursts,the

appearsonthescreento

Prole

Key

4 44Key Key

Alarm

.

Alarm

.

.Iftheow

Limit

.

Limit

.

Deviation

Lock

Lock Lock

.When

boxis

,

,

3A2527L 15

Page 16

SetupScreens

Setup

Setup Setup

Usethisscreentosetthelowerpumpsize(cc)of

eachpump.Thedefaultisblank;selectthecorrect

lowersize,orcustom.Ifcustomisselected,enterthe

sizeofthelowerincc.Thisscreenalsoactivatesjog

mode,allowingyoutopositionthemotor/pumpshaft

forconnectionordisconnection.

NOTE:

NOTE: NOTE:

theselectedloweris750cc,topreventexceedingthe

pressureratingofthelower.

Figure16SetupScreen5

Screen

Screen Screen

Themotorwilllimititspressureoutputwhen

5

5 5

Setup

Setup Setup

Forsystemswithmultiplepumpsand

onedisplay,selectthepump(1to8)

fromthemenu.

NOTE:

NOTE: NOTE:

supportmultiplepumps.

Selecttoenablejogmode.Usethe

arrowkeystomovethemotoror

pumpshaftupordown.

Selectthecorrectpumplowersize

fromthemenu.Thedefaultisblank.

Ifcustomisselected,aeldopens

foryoutoinputthesizeofthelower

incc.

•Supplypumps

Screen

Screen Screen

Threephasesystemsdonot

Key

5 55Key Key

Setup

Setup Setup

Usethisscreentoviewthegrandtotalizervalueand

tosetorresetthebatchtotalizer.

Figure17SetupScreen6

Setup

Setup Setup

Usethisscreentosetthemaintenanceinterval(in

cycles)foreachpump.Thescreenalsodisplaysthe

currentcyclecount.ErrorcodeMND_appearswhen

thecounterreaches0(zero).

Screen

Screen Screen

Forsystemswithmultiplepumpsand

onedisplay,selectthepump(1to8)

fromthemenu.

NOTE:

NOTE: NOTE:

supportmultiplepumps.

Displaysthecurrentgrandtotalofpump

cycles.Thiseldcannotbereset.

Displaysthebatchtotalinselected

volumeunits.

Resetsthebatchtotalizertozero.

Screen

Screen Screen

6

6 6

Setup

Setup Setup

Screen

Screen Screen

Threephasesystemsdonot

7

7 7

Key

6 66Key Key

–145cc

–180cc

–220cc

–290cc

•Circpumps

–750cc*

–1000cc

–1500cc

–2000cc

–2500cc

*When750ccisselected,the

maximumforceiscappedto75%

topreventoverpressurizingthe

pump.

16 3A2527L

Figure18SetupScreen7

Setup

Setup Setup

Forsystemswithmultiplepumpsand

onedisplay,selectthepump(1to8)

fromthemenu.

NOTE:

NOTE: NOTE:

supportmultiplepumps.

Setthemaintenanceinterval(incycles)

foreachpump.

Threephasesystemsdonot

Screen

Screen Screen

7 77Key Key

Key

Page 17

SetupScreens

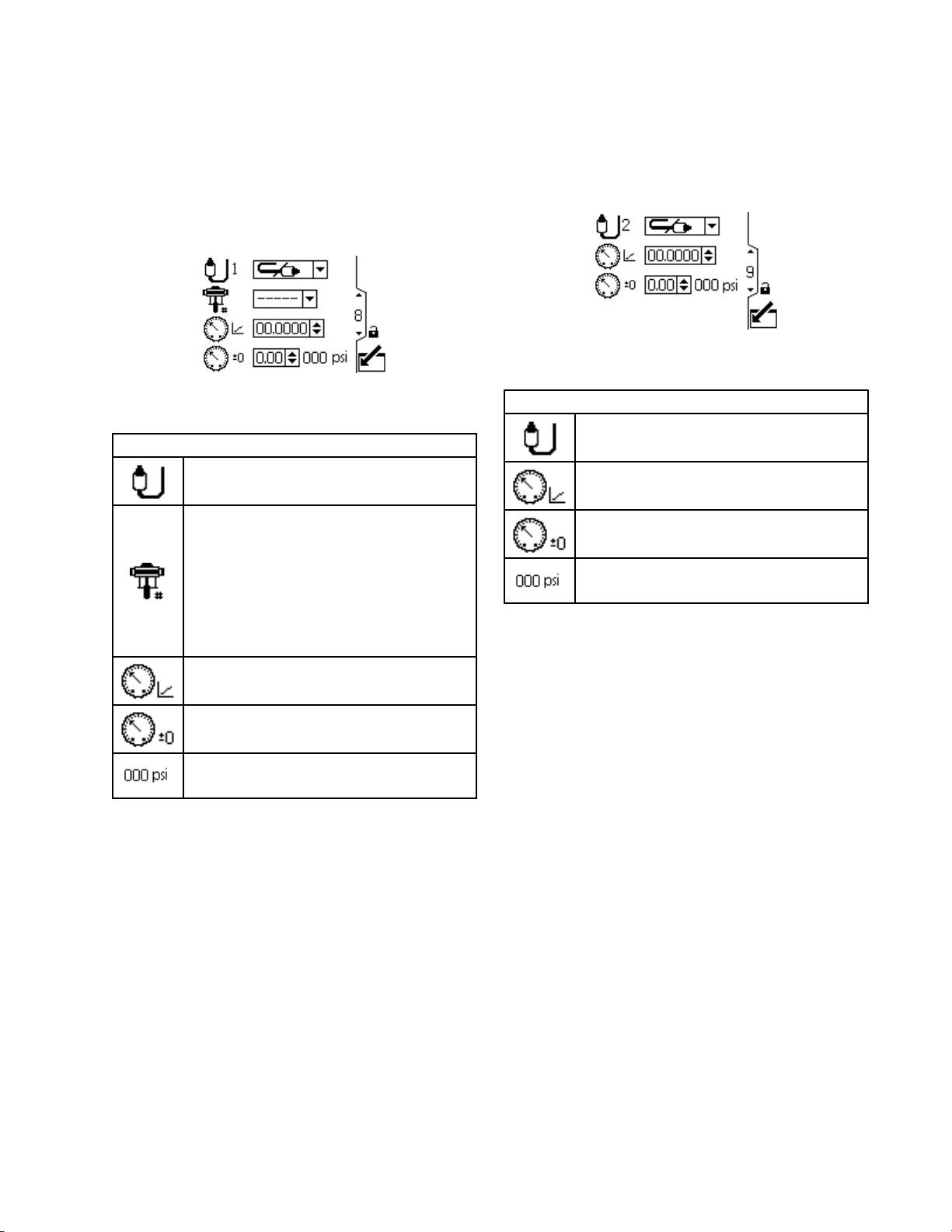

Setup

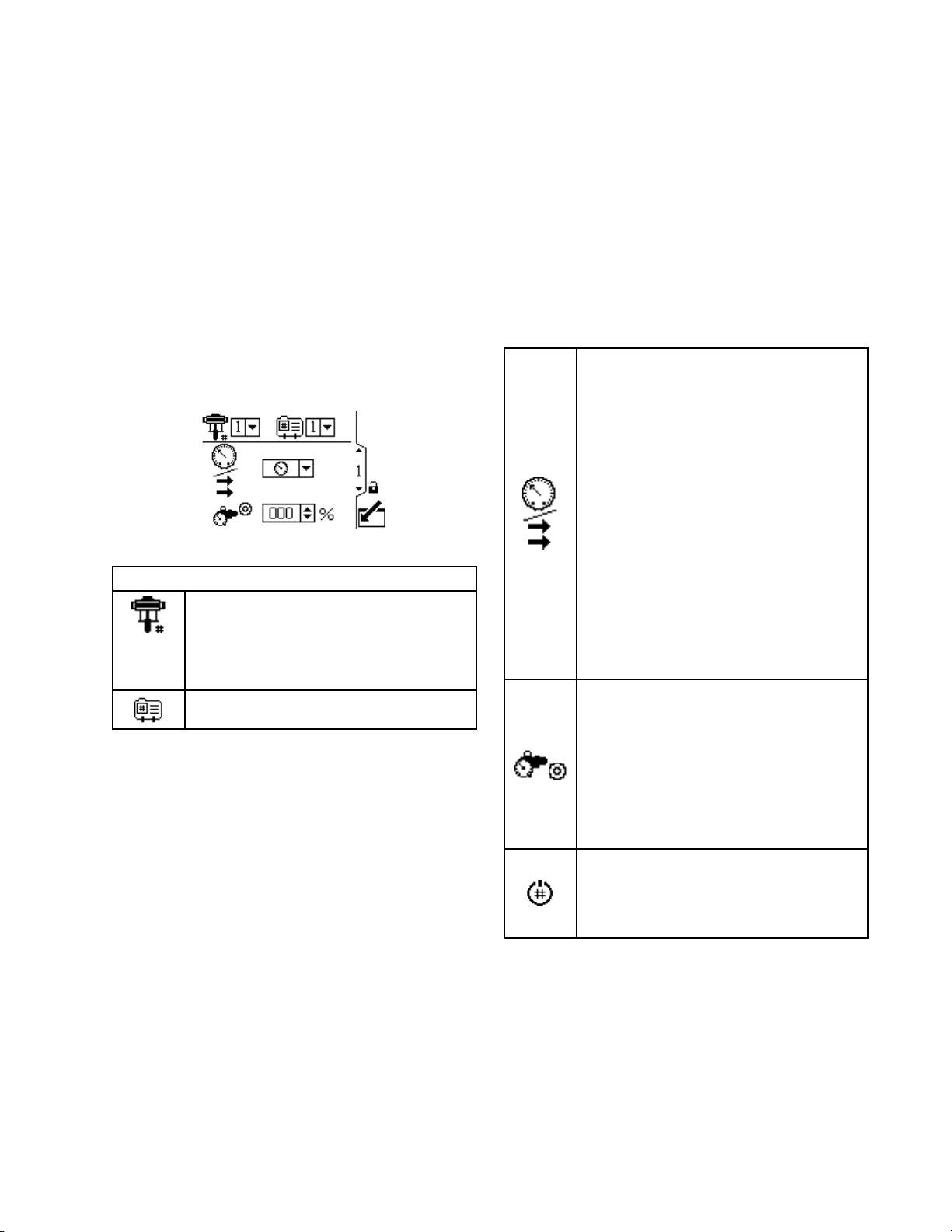

Setup Setup

Usethisscreentosetupthepressurefor

transducer1.Selectingatransducerandapump

activatesclosedlooppressurecontrol.

NOTE:

NOTE: NOTE:

transducertobeinstallednearthepumpoutlet.

Figure19SetupScreen8

Screen

Screen Screen

Closedlooppressurecontrolrequiresthe

Selectfromthemenuoptions(500psior

5000psi)toenablethetransducer.

Thisoptionenablesclosedlooppressure

controlandassignsthetransducertoa

pump.

•Forsystemswithmultiplepumpsand

onedisplay,selectthepump(1to8)

fromthemenu.

•Forthreephasepumps,selectpump

1.

Enterthecalibrationscalefactorfromthe

transducerlabel.

8

8 8

Setup

Setup Setup

Screen

Screen Screen

Key

8 88Key Key

Setup

Setup Setup

Usethisscreentosetupthepressurefortransducer

2.ThetypicalapplicationismonitoringBPRuid

pressure.

Figure20SetupScreen9

Screen

Screen Screen

Selectfromthemenuoptions(500psior

5000psi)toenablethetransducer.

Enterthecalibrationscalefactorfromthe

transducerlabel.

Enterthecalibrationoffsetvaluefromthe

transducerlabel.

Displaysthecurrenttransducerreading.

9

9 9

Setup

Setup Setup

Screen

Screen Screen

Key

9 99Key Key

Enterthecalibrationoffsetvaluefromthe

transducerlabel.

Displaysthecurrenttransducerreading.

3A2527L

17

Page 18

SetupScreens

Setup

Setup Setup

Usethisscreentospecifyhowthesystemresponds

ifthesystempressurebeginstooperateoutsideof

thesystemsettings.

Pressuretransducer2monitorsthepressureatthe

BPR.

Deltapressuremonitorsthedifferencebetweenthe

pumpoutletandtheBPR.

Figure21SetupScreen10

Thefollowingeventscanappear:

•

issuesnoalert.

•Deviation: Deviation:

theproblem,butthepumpmaycontinuetorun

pastthemaximumorminimumsettingsforve

secondsuntilthesystem’sabsolutepressureor

owboundariesarereached.

•

causeandshutsdownthepump.

Screen

Screen Screen

No

event:

No No

event: event:

Deviation:

Alarm:

Alarm: Alarm:

Thesystemalertsyoutothealarm

10

10 10

Thepumpcontinuestorunand

Thesystemalertstheuserto

Setup

Setup Setup

Thesescreensareauto-populatedbythesoftware.

Screen11displaystheserialnumbersofmotors1–4,

andScreen12displaystheserialnumbersofmotors

5–8.

NOTES:

NOTES: NOTES:

•Thescreennumbersmaydiffer,dependingonthe

featuresthatareenabled.

•Changingthepumporderwillshifteveryother

pumpuponeposition.Forexample,ifAD00001

ischangedtobepump4,AD00002willbecome

pump1,AD00003willbecomepump2,andsoon.

Figure22SetupScreens11and12(Screen11

shown)

Setup

Setup Setup

Thesescreensareauto-populatedbythesoftware.

Screen13displaysthesoftwareversionnumbers

ofmotors1–4,andScreen14displaysthesoftware

versionnumbersofmotors5–8.

Screens

Screens Screens

Screens

Screens Screens

11

and

11 11

13

13 13

12

and and

12 12

and

14

and and

14 14

NOTE:

Setup

Setup Setup

Screen

Screen Screen

10

Key

10 10

Key Key

Maximumandminimum

pressure.

Canbeconguredasno

event,deviation,oralarm.

Pressuredifference

betweentransducer1

and2.

NOTE: NOTE:

onthefeaturesthatareenabled.

Figure23SetupScreens13and14(Screen13

shown)

Thescreennumbersmaydiffer,depending

18 3A2527L

Page 19

SetupScreens

Setup

Setup Setup

Usethisscreentosetyourmodbuspreferences.

NOTES:

NOTES: NOTES:

•Thescreennumbermaydiffer,dependingonthe

featuresthatareenabled.

•Thefollowingarexedmodbussettings,which

cannotbesetorchangedbytheuser:DataBits:

8,StopBits:2,Parity:None

Figure24SetupScreen15

Screen

Screen Screen

Forsystemswithmultiplepumpsand

onedisplay,selectthepump(1to8)

fromthemenu.

NOTE:

NOTE: NOTE:

supportmultiplepumps.

Selectlocalorremotefrom

themenu.Thissettingappliestothe

selectedpumponly.

Localmodeallowsyoutoviewchanges

overthemodbusnetwork,butyoucannot

makechangesoverthemodbusnetwork.

Remotemodeallowsyoutobothview

andchangeinformationoverthemodbus

network.

EnterorchangetheModbusnodeID.

Thevalueisbetween1and246.Each

pumprequiresauniquenodeID,which

identiesthatpumpifmorethanone

pumpisconnectedtothedisplay.

Selecttheserialportbaudratefromthe

menu.Thisisasystem-widesetting.

15

15 15

Setup

Setup Setup

Screen

Screen Screen

Threephasesystemsdonot

15

15 15

Key

Key Key

Setup

Setup Setup

Usethisscreentocongureandcontrolthetankll

featureandIntelligentPaintKitchenperipherals.

NOTES:

NOTES: NOTES:

•Thescreennumbermaydiffer,dependingonthe

featuresthatareenabled.

•Thealerttriggertimevariesbasedonhowfar

activemeasurementsarefromtheirsetlimits.

Figure25SetupScreen16

Screen

Screen Screen

Selectthisboxtomanuallyactivatethe

llsolenoidoutputonport4,pin3.

Selectthisboxtoenablethetankto

automaticallyll.Youcanthensetthe

lllevels.

Congurethelowllpumpow

noticationforadeviationoranalarm

andsetthetime-outvalueinseconds.

Ifa1%levelchangeisnotdetected

withthetimeoutperiodinseconds,the

systemtakesactionbasedontheevent

type.

16

16 16

Setup

Setup Setup

Screen

Screen Screen

Whenthetanklevelreachesthis

level,thellsolenoidturnsoff.

Thisvaluecannotbehigherthan

thelevelbelow.

Whenthetanklevelreachesthis

level,thellsolenoidturnson.

Thisvaluecannotbelowerthan

thelevelabove.

16

Key

16 16

Key Key

•38400kbps

•57600kbps(default)

•115200kbps

3A2527L 19

Page 20

SetupScreens

Setup

Setup Setup

Usethisscreentomonitor,setup,andcontroltheIntelligentPaintKitchenperipherals.Formoreinformation,

seetheSetUpPeripheralssectionoftheIntelligentPaintKitchenmanual3A4030.

NOTES:

NOTES: NOTES:

•Thescreennumbermaydiffer,dependingonthefeaturesthatareenabled.

•Thesecondeldvaries,dependingonthemenuselectioninthersteld.

Figure26SetupScreen17,ReedSwitchOption

Shown

Screen

Screen Screen

Selecttheconnectedperipheralfromthemenu.

17

17 17

ConguresPort4pin4asaninputtoallowareedswitchtobeconnected.

Thecurrentreedswitchcyclerateappearsnexttothecyclerateicon

perminute.

Figure27SetupScreen17,ManualControlOption

Shown

Setup

Setup Setup

Screen

Screen Screen

17

Key

17 17

Key Key

incycles

ConguresPort4pin4asaninputtoallowapressureswitchtobeconnected.Ifthe

drumcoverisliftedwhilethiscongurationisproperlyconnected,theagitatorshutsdown.

Thecurrentinputstatusappearsintheagitatorstatuseld

NOTE:

NOTE: NOTE:

ConguresPort4pin4asanoutputtoallowfortheconnecteddevicetoreceiveanalarm

whenthelevelofthePrimaryTankisabovethevaluethatisdenedinthePrimary

TankHigheld.

ThisvalueisapercentageofthetotallevelofthePrimaryTank.

ConguresPort4pin4asanoutputtoallowfortheconnecteddevicetoreceiveanalarm

whenthelevelofthePrimaryTankisbelowthevaluethatisdenedinthePrimary

TankLoweld

ThisvalueisapercentageofthetotallevelofthePrimaryTank

ConguresPort4pin4asanoutputtoallowforanothersolenoidtobeconnectedand

controlledfromthedevice.

Selectthemanualoutputbox

solenoidmanually.Afteryoureleasethebutton,themanualactivationisterminated.

TheExternalTankFilloptionconguresPort4pin4asanoutputthesameastheone

ASupervisorModuleisrequiredforthisfunction.

.

andholdthebuttontocontroltheauxiliary

.

above.ThisoptionalsotiestheTankHighAlarm

outputsuchthattheADCMleavesitaloneforexternalcontroluntilthetanklevelgoes

abovethesetpoint.Afterthetanklevelisabovethesetpoint,theoutputisforcedoff.

,asconguredbelow,tothis

20 3A2527L

Page 21

SetupScreens

TheTankHighAlarmallowsfortheconnecteddevicetoreceiveanalarmwhenthelevelofthe

primarytankisabovethevaluethatisdenedinthiseld.Ifthevalueissetto0,theeventis

disabled.

TheTankLowAlarmallowsfortheconnecteddevicetoreceiveanalarmwhenthelevelofthe

primarytankisbelowthevaluethatisdenedinthiseld.Ifthevalueissetto0,theeventis

disabled.

Aneventcanbeconguredasadeviationoranalarm.Intheeventofanalarm,thepumpshutsoff

andtheagitatorturnsoff.

Setup

Setup Setup

Usethisscreentosetthestrokedisplacement

volumeandowrateunitsofthellpumpthatis

connectedtothecycleswitchinput.

NOTE:

NOTE: NOTE:

auxiliaryinputisselectedonSetupScreen17.See

SetupScreen17,page20.

Figure28SetupScreen18

Screen

Screen Screen

Thisscreenisgrayedoutunlessthe

Thestrokedisplacement:enterthe

volumepercycleincubiccentimeters.

Selecttheowrateunitstodisplayon

therunscreen:

•cycles/min

•cc/min

•liters/min

•gallons/min

18

18 18

Setup

Setup Setup

Screen

Screen Screen

18

Key

18 18

Key Key

Setup

Setup Setup

Usethisscreentocongurethefullvolumeofthe

secondarytank,andthepointsatwhichtheuseris

notiedthatthetankisnearingemptyandempty.

NOTE:

NOTE: NOTE:

auxiliaryinputisselectedonSetupScreen17.See

SetupScreen17,page20.

Figure29SetupScreen19

Screen

Screen Screen

Thisscreenisgrayedoutunlessthe

Enterthefulluidvolumeofthe

secondarytank.

Entertheuidvolumeatwhichpointthe

userisnotiedthatthesecondarytankis

nearingempty.

Whenthecurrentvolumeislessthanor

equaltothisvalue,thesystemgenerates

anL2B0event.

Entertheuidvolumeatwhichpointthe

userisnotiedthatthesecondarytank

isempty.

19

19 19

Setup

Setup Setup

Screen

Screen Screen

19

Key

19 19

Key Key

Whenthecurrentvolumeislessthanor

equaltothisvalue,thesystemgenerates

anL1B0event.

3A2527L

21

Page 22

SetupScreens

Setup

Setup Setup

Usethisscreentosetuptheinputscaling(radarlevel

sensor)for4–20mAdevicesandturnonthecurrent

loop(Port8andPort9oftheADCM).

NOTE:

NOTE: NOTE:

thefeaturesthatareenabled.

Figure30SetupScreen20

Screen

Screen Screen

Thescreennumbermaydiffer,dependingon

MonitorthebackpressureregulatormA

output.

SetthevalueforP9(Port9)between4

and20.

Selectthisboxtoturnonthe4-20mA

supply.Setthenumericalvaluesforthe

scalingceilingfor4-20mAsignal.

Setthetankleakagesetpoint.When

thepumpisputintooffproduction,the

systemcapturesthecurrenttanklevel.

If,atanytime,thecurrenttanklevel

dropsbythepercentageindicatedhere,

aleakagealarmwilltriggerandstop

thepump.Ifthevalueissetto0%,the

leakagealarmisdisabled.

20

20 20

Setup

Setup Setup

Screen

Screen Screen

20

Key

20 20

Key Key

Setup

Setup Setup

Thisscreenisforenablingamodbuscommunications

alarmanddisablingtheStopPumpfunctionofthe

Cancelkey.

NOTE:

NOTE: NOTE:

thefeaturesthatareenabled.

Figure31SetupScreen21

Screen

Screen Screen

Thescreennumbermaydiffer,dependingon

Selectthemodbusalarmtype:

SelectthisboxtomakeCAN

communicationadeviationthat

doesnotshutdownthepump.

SelectthisboxtodisabletheStopPump

functionoftheReset/Cancelkey.

Enableordisablethebacklightandset

thetime-outvalueinminutes.

21

21 21

Setup

Screen

Setup Setup

Screen Screen

None

Deviation

Alarm

21

Key

21 21

Key Key

SeeSetupScreen22,page23.

22

3A2527L

Page 23

SetupScreens

Setup

Setup Setup

Usethisscreentoenableordisabletherun/stop

switchandautorestart.

NOTE:

NOTE: NOTE:

thefeaturesthatareenabled.

Figure32SetupScreen22

Screen

Screen Screen

Thescreennumbermaydiffer,dependingon

Enableordisabletherun/stopswitch.The

defaultsettingisdisabled.SeeRun/Stop

SwitchKitinAccessories,page31.

Whenenabled,thiscongurationallows

therun/stopswitchtopausethepump

whileinaprole.Whentherun/stopswitch

isactive,thefollowingpop-upappears:

22

22 22

Setup

Setup Setup

Screen

Screen Screen

22

22 22

Enableordisableautorestart.Thedefault

settingisdisabled.Ifenabled,theunit

resumesoperationattheprolethatwas

setbeforetheunitwasturnedoff.

Enabletheoffproductionprolemode.

Thisfeatureturnsprole4intotheoff

productionprole.Whenprole4isactive,

thellpumpisdisabledandthecurrent

primarytanklevelisrecorded.Ifthe

primarytankleveldropsmorethanthe

congurableleakagelevelpercentage,the

systemtriggersthealarmandshutsoffthe

pump.

Thetankleakagesetpointis

conguredinSetupScreen20.(See

Key

Key Key

Setup

Setup Setup

Usethisscreentosettheunitsforpressure,totals,

andow.

SetupScreen20,page22.)

Screen

Screen Screen

23

23 23

Disabletheremotestartfunctionover

modbus.

Whenenabledalongwiththerun/stop

switch,youmusttoggletherun/stopswitch

whengoingfromprole0(stopped)to

runbeforethepumpcanstart.Whenthe

run/stopswitchisactive,thefollowing

pop-upappears:

Figure33SetupScreen23

Setup

Setup Setup

Selectthepressureunits:

•psi

•bar(default)

•MPa

Selectthevolumeunits:

•liters(default)

•gallons

•cc

Selecttheowrateunits:

•L/min(default)

•gpm

•cc/min

•oz/min

•cycles/min

Selectthesystemmode(singleorx2).

Ifyouareinsinglemodebutconnected

tox2orinx2modebutconnectedto

single,errorcodeWNNXappears.

Screen

Screen Screen

23

Key

23 23

Key Key

3A2527L 23

Page 24

SetupScreens

Setup

Setup Setup

Usethisscreentosetyourdateformat,date,time,

orforcearestartofthesystemwhenupdatingthe

software(updatetokeninsertedintothedisplay).

Afterthesoftwareupdateiscompletedsuccessfully,

thetokenmustberemovedpriortoselectingthe

Acknowledgekeyorpowercyclingthedisplay.Ifan

updatewasconcludedandthetokenisnotremoved,

pressingtheAcknowledgekeyrestartstheupdate

process.

NOTES:

NOTES: NOTES:

•Thescreennumbermaydiffer,dependingonthe

featuresthatareenabled.

•RefertoAppendixC-ControlModule

Programming,page54forinstructionsonsoftware

updating.Softwareupdateisdisruptivetoall

pumpsconnectedtothedisplay.Allpumps

attachedtothedisplaymustnotbepumping

materialwhenthesoftwareupdateisinitiated.

Screen

Screen Screen

24

24 24

Setup

Setup Setup

Usethisscreentoenterapasswordthatwillbe

requiredtoaccesstheSetupscreens.Thisscreen

alsodisplaysthesoftwareversion.

NOTE:

NOTE: NOTE:

thefeaturesthatareenabled.

Figure35SetupScreen25

Screen

Screen Screen

Thescreennumbermaydiffer,dependingon

Enterthe4–digitpassword.

Checktheboxtolockouttheagitator

eldintheRunscreens.

Checktheboxtolockouttheproleeld

ontheRunscreens.

25

25 25

Setup

Screen

Setup Setup

Screen Screen

25

Key

25 25

Key Key

Figure34SetupScreen24

Setup

Setup Setup

Selectyourpreferreddateformatfrom

themenu.

•MM/DD/YY

•DD/MM/YY(default)

•YY/MM/DD

Setthecorrectdate.

Setthecorrecttime.

Performasoftrestartofthesystem.

Screen

Screen Screen

24

Key

24 24

Key Key

24

3A2527L

Page 25

ErrorCodeTroubleshooting

Error

Error Error

Errorcodescantakethreeforms:

•Alarm:alertsyoutothealarmcauseandshuts

downthepump.

•Deviation

maycontinuetorunpastthesetlimitsuntilthe

system’sabsolutelimitsarereached.

•Advisory:informationonly.Pumpwillcontinue

tooperate.

Display

Display Display

Code

Code Code

NoneBasic6Alarm

Code

Code Code

:alertsyoutotheproblem,butpump

Applicable

Applicable Applicable

Motor

Motor Motor

Troubleshooting

Troubleshooting Troubleshooting

Blink

Blink Blink

Code

Code Code

Alarm

Alarm Alarm

Deviation

Deviation Deviation

Notes

about

Notes Notes

about about

•OnAdvancedmotors,ow(Kcodes)andpressure

(Pcodes)canbedesignatedasalarmsor

deviations.SeeSetupScreen4,page15.

•“X”meansthecodeisassociatedwiththedisplay

only.

•“_”inthecodeisaplaceholderforthenumberof

thepumpwheretheeventoccurred.

•Theblinkcodeisdisplayedusingthepower

indicatoronthemotor.Theblinkcodegivenbelow

indicatesthesequence.Forexample,blinkcode

1–2indicates1blink,then2blinks;thesequence

thenrepeats.

•Ablinkcodeof9isnotanerrorcode,butan

indicatorofwhichpumpisactive(

beenpushed,seeRunScreen1,page9).

or

or or

TheModeSelectknobissetbetweenPressure

.Settheknobtothemodeyouwant.

the

following

the the

following following

Description

Description Description

error

codes:

error error

codes: codes:

softkeyhas

andFlow

None

A4N_

A4N_ A4N_

A5N_

A5N_ A5N_

CAC_

CAC_ CAC_

CAD_

CAD_ CAD_

C3G_

C3G_ C3G_

C4G_

C4G_ C4G_

CBN_

CBN_ CBN_

CCC_

CCC_ CCC_

CCN_

CCN_ CCN_

Basicand

Advanced

Basicand

Advanced

Basicand

Advanced

AdvancedNoneAlarm

Advanced2–3Alarm

AdvancedNoneDeviation

AdvancedNoneAlarm

Basicand

Advanced

Advanced3–7Alarm

Basicand

Advanced

9None

6Alarm

4–6Alarm

2–4Deviation

3–6Alarm

Ablinkcodeof9isnotanerrorcode,butanindicatorof

whichpumpisactive.

Themotorcurrentexceeded13Aorthehardwareovercurrent

trippedat20A.

Internalhardwarecurrentcalibration.Replaceelectronics.

NOTE:

NOTE: NOTE:

DisplaydetectsalossofCANcommunication.Flashing

alarmappearsonthedisplay,andtheblinkcodeoccurs.

UnitdetectsalossofCANcommunication.Thisalarmisonly

logged.Noashingalarmappearsonthedisplay,butthe

blinkcodedoesoccur.

Displaydetectsalossofmodbuscommunicationwhen

modbusdeviationisenabledonSetupScreen16.

Displaydetectsalossofmodbuscommunicationwhen

modbusalarmisenabledonSetupScreen16.

Temporarycircuitboardcommunicationfailure.

Nodisplaywasdetectedatstartup.

NOTE:

NOTE: NOTE:

Circuitboardcommunicationfailure.

3phasemotoronly.

3phasemotoronly.

END_

END_ END_

3A2527L 25

Basicand

Advanced

5–6Advisory

Acalibrationoftheencoderandstrokerangeisinprogress.

Page 26

ErrorCodeTroubleshooting

Alarm

Display

Display Display

Code

Code Code

Applicable

Applicable Applicable

Motor

Motor Motor

Blink

Blink Blink

Code

Code Code

Alarm Alarm

Deviation

Deviation Deviation

or

or or

Description

Description Description

ENDC

ENDC ENDC

ENN_

ENN_ ENN_

E5D_

E5D_ E5D_

E5F_

E5F_ E5F_

E5N_

E5N_ E5N_

E5S_

E5S_ E5S_

E5U_

E5U_ E5U_

EBC_

EBC_ EBC_

ELD_

ELD_ ELD_

ELI_

ELI_ ELI_

ERR_

ERR_ ERR_

F1F0

F1F0 F1F0

AdvancedNoneAdvisory

AdvancedNoneAdvisory

Basicand

Advanced

AdvancedNoneAdvisory

Basicand

Advanced

AdvancedNoneAdvisory

AdvancedNoneAdvisory

AdvancedNoneAdvisory

Basicand

Advanced

Basicand

Advanced

Basicand

Advanced

AdvancedNoneAlarm

1–7Deviation

2–7Deviation

4–7Advisory

4–5Deviation

2–5Deviation

Calibrationoftheencoderandstrokerangewassuccessfully

completed.

Duallowersystemcalibrationcompletedsuccessfully.

Calibrateencoderfailure.

Duallowersystemcalibrationerror.Systemrunningtoo

rapidlytoperformcalibration.

Calibratestrokefailed.

Duallowersystemcalibrationstoppedorinterrupted.

Duallowersystemcalibrationunsteady.Systemcouldnot

determineoptimumsetting.

Run/StopswitchinStopposition(closed).

Startupeventrecord.

Deviationhotboardreset.

Deviationsoftwareerror.

Fillpumpownotdetected.Theprimarytanklevelhasnot

increasedwiththenoowtimeoutwindowandthenoow

timeouteventissettoalarm.

Fillpumpownotdetected.Theprimarytanklevelhasnot

F2F0

F2F0 F2F0

K1D_

K1D_ K1D_

K2D_

K2D_ K2D_

K3D_

K3D_ K3D_

K4D_

K4D_ K4D_

L1A0

L1A0 L1A0

L1AF

L1AF L1AF

L1BX

L1BX L1BX

L2A0

L2A0 L2A0

AdvancedNoneDeviation

Advanced1–2Alarm

AdvancedNoneDeviation

AdvancedNoneDeviation

Basicand

Advanced

AdvancedNoneAlarm

AdvancedNoneAlarm

AdvancedNoneAlarm

AdvancedNoneDeviation

1Alarm

increasedwiththenoowtimeoutwindowandthenoow

timeouteventissettodeviation.

Flowisbelowminimumlimit.

Flowisbelowminimumlimit.

Flowexceedsmaximumtarget;alsoindicatespumprunaway

conditionexists.

Flowexceedsmaximumtarget;alsoindicatespumprunaway

conditionexists.

Primarytankcurrentlevelisbelowtheprimarytankalarm

setpoint.

Whilethesystemwasinoffproductionmode,thecurrent

tankleveldroppedbelowtheleakagealarmpercentage.

Theestimatedremainingvolumeinthesecondarytank

isbelowthealarmlevel.Thevalueiscalculatedastotal

tankvolumesubtractedfromllpumpcountercalculated

dispensedvolume.

Theprimarytankcurrentlevelisbelowtheprimarytank

deviationsetpoint.

26 3A2527L

Page 27

ErrorCodeTroubleshooting

Alarm

Display

Display Display

Code

Code Code

L2BX

L2BX L2BX

Applicable

Applicable Applicable

Motor

Motor Motor

AdvancedNoneDeviation

Blink

Blink Blink

Code

Code Code

Deviation

Deviation Deviation

or

Alarm Alarm

or or

Theestimatedremainingvolumeinthesecondarytankis

belowthedeviationlevel.Thevalueiscalculatedastotal

tankvolumesubtractedfromllpumpcountercalculated

dispensedvolume.

Description

Description Description

L3A0

L3A0 L3A0

L4A0

L4A0 L4A0

L6CA

L6CA L6CA

L6CB

L6CB L6CB

MND_

MND_ MND_

P1CB

P1CB P1CB

P1D_

P1D_ P1D_

P9D_

P9D_ P9D_

P1I_

P1I_ P1I_

P2I_

P2I_ P2I_

P2CB

P2CB P2CB

AdvancedNoneDeviation

AdvancedNoneAlarm

AdvancedNoneDeviation

AdvancedNoneDeviation

AdvancedNoneAdvisory

AdvancedNoneAlarm

AdvancedNoneDeviation

AdvancedNoneDeviation

Advanced1–3Alarm

AdvancedNoneDeviation

AdvancedNoneDeviation

Theprimarytankcurrentlevelisabovetheprimarytank

deviationsetpoint.

Theprimarytanklevelisabovetheprimarytanklevelhigh

alarmsetpoint.

Port8isenabledandthecurrentdrawislessthan4mA.

TheBPRisrequestingavaluegreaterthan0%.Verifythat

thedeviceisconnected.

Port9isenabledandthecurrentdrawislessthan4mA.

Verifythatthedeviceisconnected.

Maintenancecounterisenabledandcountdownreached

zero(0).

Pressuretransducer2pressureisbelowthealarmsetpoint.

Unbalancedload.DualLowersystem—P1D1=Motor1is

requiringlessforcetoholdspeed;pumplowermayneed

service.P1D2=Motor2isrequiringlessforcethanmotor

1toholdspeed.

Majorunbalancedload—seeP1D_(P9D_ishigher

magnitude)

Pressureisbelowminimumlimit.

Pressureisbelowminimumlimit.

Pressuretransducer2pressureisbelowthedeviationset

point.

P3CB

P3CB P3CB

P3I_

P3I_ P3I_

P4CB

P4CB P4CB

P4I_

P4I_ P4I_

P5DX

P5DX P5DX

P6CA

P6CA P6CA

P6CB

P6CB P6CB

P6D_

P6D_ P6D_

P7C_

P7C_ P7C_

P9C_

P9C_ P9C_

T2D_

T2D_ T2D_

3A2527L

AdvancedNoneDeviation

AdvancedNoneDeviation

AdvancedNoneAlarm

Advanced1–4Alarm

AdvancedNoneDeviation

or

AdvancedNoneDeviation

Advanced1–6Alarm

AdvancedNoneDeviation

AdvancedNoneAlarm

Basicand

Advanced

3–5Alarm

Pressuretransducer2pressureisabovethedeviationset

point.

Pressureexceedsmaximumtarget.

Pressuretransducer2pressureisabovethealarmsetpoint.

Pressureexceedsmaximumtarget.

Morethanonepumpisassignedtoatransducer.The

assignmentforthattransducerisautomaticallyclearedunder

thiscondition.Usermustreassign.

Forunitswithoutclosedlooppressurecontrol:Transducer

(AorB)isenabledbutnotdetected.

Forunitswithclosedlooppressurecontrol:Transduceris

enabledbutnotdetected.

Pressuredifferencebetweentransducer1andtransducer2

isgreaterthanthedeviationsetpoint.

Pressuredifferencebetweentransducer1andtransducer2

isgreaterthanthealarmsetpoint.

Internalthermistordisconnectedormotortemperatureis

below0°C(32°F).

27

Page 28

ErrorCodeTroubleshooting

Alarm

Display

Display Display

Code

Code Code

Applicable

Applicable Applicable

Motor

Motor Motor

Blink

Blink Blink

Code

Code Code

Alarm Alarm

Deviation

Deviation Deviation

or

or or

Description

Description Description

T3D_

T3D_ T3D_

T4D_

T4D_ T4D_

V1I_

V1I_ V1I_

V2I_

V2I_ V2I_

V1M_

V1M_ V1M_

V3I_

V3I_ V3I_

V4I_

V4I_ V4I_

V9M_

V9M_ V9M_

WCW_

WCW_ WCW_

WMC_

WMC_ WMC_

Basicand

Advanced

Basicand

Advanced

Basicand

Advanced

Basicand

Advanced

Basicand

Advanced

Basicand

Advanced

Basicand

Advanced

Basicand

Advanced

AdvancedNoneAlarm

Basicand

Advanced

4–6Alarm

NoneDeviation

2–6Alarm

NoneDeviation

4–5Alarm

5

2Alarm

3Alarm

7

Deviation

Alarm

Motorovertemperature.Motorwillthrottleitselftostaybelow

85°C(185°F)internally.

Motorovertemperature.Motorwillthrottleitselftostaybelow

85°C(185°F)internally.

Brownout;voltagesuppliedtomotoristoolow.

Brownout;voltagesuppliedtomotoristoolow.

ACpowerislost.

Voltagesuppliedtomotoristoohigh.

Voltagesuppliedtomotoristoohigh.

Lowsupplyvoltagedetectedatstartup.

Systemtypemismatch;motorisanE-FloDCduallower

systemandthedisplaycongurationdoesnotmatch.

Changethedisplay’ssystemtypeontheSetupUnitsscreen

(screen15).

Internalsoftwareerror.

WNC_

WNC_ WNC_

WNN_

WNN_ WNN_

WSC_

WSC_ WSC_

WSD_

WSD_ WSD_

WXD_

WXD_ WXD_

Basicand

Advanced

AdvancedNoneAlarm

AdvancedNoneDeviation

Advanced1–5Alarm

Basicand

Advanced

3–4Alarm

4Alarm

Softwareversionsdonotmatch.

Systemtypemismatch;motorisanE-FloDCsinglelower

systemandthedisplaycongurationdoesnotmatch.

Changethedisplay’ssystemtypeontheSetupUnitsscreen

(screen12induallowermode).

Proleissetto0pressureor0ow.

Invalidlowersize;occursiftheunitisoperatedbeforesetting

upthelowersize.

Aninternalcircuitboardhardwarefailureisdetected.

28 3A2527L

Page 29

Parts

Parts

Parts Parts

24P822

24P822 24P822

Ref

Ref Ref

124P821

1a▲16P265LABEL,warning,

1b▲16P265LABEL,warning,

1c▲16P265LABEL,warning,

5

5a

624P823

Part

Part Part

24N910

———

Control

Control Control

Module

Module Module

Description

Description Description

DISPLAYKIT,control

module;includes

item1a;seemanual

332013forapprovals

informationaboutthe

bareADCMmodule

English

French

Spanish(shipped

loose)

CONNECTOR,

jumper;includes

item5a

SCREW,cap,socket

head;M5x40mm

BRACKETKIT,

controlmodule;

includesitems6a-6f

Kit

Kit Kit

(Single

(Single (Single

Phase,

Phase, Phase,

Qty

Qty Qty

1

1

1

1

1

1

1

Side

Side Side

Ref

Ref Ref

6a

6b

6c

6d

6e

6f

11

12

▲ReplacementDangerandWarninglabels,tags,

andcardsareavailableatnocost.

Itemsmarked———arenotavailableseparately.

Cable(C)isshownforreferencebutisnotincluded

inthekit.Orderspeciedlengthseparately.See

CableConnection,page5.

Part

Part Part

———

———

———

———

———

———

———

———

Mount)

Mount) Mount)

Description

Description Description

BRACKET,control

module

BRACKET,mounting

LOCKWASHER,

externaltooth;M5

WASHER;M5

SCREW,cap,socket

head;M5x12mm

KNOB;M5x0.8

HOLDER,tie

STRAP,tie

Qty

Qty Qty

1

1

4

2

2

2

1

1

3A2527L 29

Page 30

Parts

17V232

17V232 17V232

Ref

Ref Ref

1

1a▲

1b▲16P265LABEL,warning,

624P823

6a*

6b

6c

Part

Part Part

———

———

———

———

———

Control

Control Control

Module

Module Module

Description

Description Description

DISPLAYKIT,control

module;includes

item1a;seemanual

332013forapprovals

informationaboutthe

bareADCMmodule

LABEL1

French

BRACKETKIT,

controlmodule;

includesitems6a-6f

BRACKET,control

module

BRACKET,mounting

LOCKWASHER,

externaltooth;M5

Kit

(Three

Kit Kit

(Three (Three

Phase,

Phase, Phase,

Qty

Qty Qty

1

1

1

1

1

4

Side

Side Side

Ref

Ref Ref

6d

6e

6f

11

12

17

▲ReplacementDangerandWarninglabels,tags,

andcardsareavailableatnocost.

Itemsmarked———arenotavailableseparately.

Cable(C)isshownforreferencebutisnotincluded

inthekit.Orderspeciedlengthseparately.See

CableConnection,page5.

Part

Part Part

———

———

———

———

———

———

Mount)

Mount) Mount)

Description

Description Description

WASHER;M5

SCREW,cap,socket

head;M5x12mm

KNOB;M5x0.8

STRAP,tiewiring

HOLDER,tie

TOKEN,GCA,

upgrade,E-FloDC

(notshown)

Qty

Qty Qty

2

2

2

1

1

1

17W754

17W754 17W754

30 3A2527L

Top

Mount

Top Top

Mount Mount

Bracket

Bracket Bracket

Kit

Kit Kit

Page 31

Accessories

Accessories

Accessories Accessories

NOTE:

NOTE: NOTE:

soldseparately.

Partsforkitsinthefollowingtablearenot

Part

Part Part

25D293

25D294

17S640AuxiliarySolenoidKit

24Z671TankFillKit

241405

24A032

17B160

17T898

Kit

Kit Kit

RadarSensorKit

ReedSwitchCounterKit

FiberOpticCablesKM172

FiberOpticCablesKM173

BPR

BPR BPR

Ref

Ref Ref

101

102

103110436

104100030

105198178

106110207

107

108198171

———

Controller

Controller Controller

Part

Part Part

———

———

C19466

Parts not sold separately.

Kit

24V001

Kit Kit

24V001 24V001

Description

Description Description

TRANSDUCER,

miniature

CABLE,F/C,I.S.,8M

GAUGE,pressure,air

BUSHING

ELBOW

ELBOW

TEE1

ELBOW

Qty

Qty Qty

1

1

1

1

1

1

1

3A2527L 31

Page 32

Accessories

Run/Stop

Run/Stop Run/Stop

Technical

Technical Technical

Switch

Switch Switch

Specications

Specications Specications

Kit

16U729

Kit Kit

16U729 16U729

for

16U729

for for

16U729 16U729

Run/Stop

Run/Stop Run/Stop

Switch

Switch Switch

Voltage

Current

Power240Wmaximum

AmbientTemperature

EX

EX EX

Classication"SimpleApparatus"inaccordancewithUL/EN/IEC

ParametersUi=17.9V

Switch

Switch Switch

Ratings:

Ratings: Ratings:

Ratings:

Ratings: Ratings:

Kit

16U729

Kit Kit

16U729 16U729

US

US US

24VDC

10A

–13°-122°F–25°-50°C

60079-11,clause5.7

ClassI,Div1:GroupDT4

II

1

II II

1 1

ExiaIIAT4Ga

Ii=217mA

Pi=937mW

Ci=1200pF

Metric

Metric Metric

G

G G

Li=6.8uH

Li/Ri=7.4uH/Ohm

32 3A2527L

Page 33

Accessories

Pressure

Pressure Pressure

2 22- --ball ball

Technical

Technical Technical

ball

Ref

Ref Ref

101ADAPTER,

102

103

———

pumps

pumps pumps

Description

Description Description

tting,

pressure

sensor

PACKING,

o-ring

SENSOR,

pressure,uid

outlet

Transducer

Transducer Transducer

Parts not sold separately.

Specications

Specications Specications

Kit

Kit Kit

24Y245

24Y245 24Y245

24R050

24R050 24R050

Part

Part Part

16U4401

1193481

16P28915M6691

for

for for

for

for for

24R050

24R050 24R050

ball

4 44- --ball ball

24Y245

24Y245 24Y245

Part

Part Part

pumps

pumps pumps

Qty

Qty Qty

and

24Y245

and and

24Y245 24Y245

24R050,

24R050, 24R050,

Pressure

Pressure Pressure

Transducer

Transducer Transducer

Kit

for

Kit Kit

for for

Pressure

Pressure Pressure

Electrical

Electrical Electrical

Voltage

FullScalesensitivity

SpanAtMaxpressure

AmbientTemperature

EX

EX EX

Classication"SimpleApparatus"inaccordancewithUL/EN/IEC

ParametersUi=17.9V

Transducer

Transducer Transducer

Ratings:

Ratings: Ratings:

Ratings:

Ratings: Ratings:

Kits

24R050,

Kits Kits

24R050, 24R050,

24Y245

24Y245 24Y245

US

US US

5VDC

20.00mV/V

100mV

32°-140°F0°-60°C

60079-11,clause5.7

ClassI,Div1:GroupDT4

II

1

II II

1 1

ExiaIIAT4Ga

Ii=73mA

Pi=1.3W

Ci=900pF

Metric

Metric Metric

G

G G

Li=1.7uH

Li/Ri=6.6uH/Ohm

3A2527L 33

Page 34

AppendixA-ModbusVariableMap

Appendix

Appendix Appendix

TocommunicatethroughberopticswiththeE-Flo

DCControlModule,referencetheappropriate

hardwareasshowninmanual332356.That

manualindicatesvariousoptionsforconnecting

beropticcablesfromthecontrolmoduletothe

non-hazardousarea.Thefollowingtablelists

ModbusregistersavailabletoaPCorPLClocatedin

thenon-hazardousarea.

Table

Table Table

Modbus

Modbus Modbus

Register

Register Register

DateTimeReadOnly

403100Hour

403101Minute

403102

403103Year

403104Month

Modbus

4 44Modbus Modbus

A

A A

Registers

Registers Registers

Variable

Variable Variable

SecondReadOnly

Modbus

- --Modbus Modbus

Variable

Variable Variable

Map

Map Map

Table4showstheregistersneededforbasic

operation,monitoring,andalarmcontrolfeatures.

Tables5and6providebitdenitionsasneededfor

certainregisters.Table7showstheunitsandhowto

converttheregistervaluetoaunitvalue.

ReferencetheModbuscommunicationsettings

selectedinSetupScreen15,page19.

Register

Register Register

Access

Access Access

ReadOnly

ReadOnly

ReadOnly

ReadOnly

Size

Size Size

16Bit0-23

16Bit

16Bit

16Bit00-99

16Bit1-12

Notes/Units

Notes/Units Notes/Units

0-59

403105Day

DisplayAlarmsReadOnly

403106DisplayAlarmsUpperWord

403107DisplayAlarmsLowerWord

DisplayConguration

403200HourRead/Write16Bit0-23

403201MinuteRead/Write16Bit

403202

403203YearRead/Write16Bit00-99

403204MonthRead/Write16Bit1-12

403205DayRead/Write16Bit1-31

403206DisplayPasswordRead/Write16Bit0000-9999

403207DisplayDateFormatRead/Write16Bit0=MM/DD/YY

403208PressureUnitsRead/Write16Bit0=Psi

Second

ReadOnly

ReadOnly

ReadOnly

Read/Write16Bit

16Bit1-31

16Bit

16Bit

SeeTable5forbitdenitions.

0-59

1=DD/MM/YY

2=YY/MM/DD

1=bar

2=Mpa

34 3A2527L

Page 35

AppendixA-ModbusVariableMap

Modbus

Modbus Modbus

Register

Register Register

403209VolumeUnitsRead/Write16Bit0=Liters

403210FlowUnitsRead/Write16Bit0=Liter/min

403211

403212Transducer1TypeRead/Write16Bit0=None

403213Transducer1AssignedRead/Write16Bit0-1

403214Read/Write

403215

Variable

Variable Variable

ProleLock

Transducer1Scale

Register

Register Register

Access

Access Access

Read/Write16Bit

(Reads

ignored)

Read/Write

(Reads

ignored)

Size

Size Size

16Bit

16Bit

Notes/Units

Notes/Units Notes/Units

1=Gallons

1=Gallons/min

2=cc/min

3=oz/min4=Cycles/min

0=DisableProleLock

1=EnableProleLock

1=500psi(34.4Bar,3.44

MPa)

2=5000psi(344.7Bar,34.74

MPa)

IntegerValue(0-65535)

DecimalValue(0-65535)

403216Read/Write

(Reads

403217

Transducer1Offset

403218Transducer2TypeRead/Write16Bit0=None

403219ReservedRead/Write16Bit

403220Read/Write

Transducer2Scale

403221

ignored)

Read/Write

(Reads

ignored)

(Reads

ignored)

Read/Write

(Reads

ignored)

16Bit

16Bit

16Bit

16Bit

IntegerValue(0-65535)

DecimalValue(0-65535)

1=500psi(34.4Bar,3.44

MPa)

2=5000psi(344.7Bar,34.74

MPa)

IntegerValue(0-65535)

DecimalValue(0-65535)

3A2527L 35

Page 36

AppendixA-ModbusVariableMap

Modbus

Modbus Modbus

Register

Register Register

403222Read/Write

403223

403224

403225

403226

403227

403228ReservedRead/Write16Bit

403229ReservedRead/Write16Bit

403230ReservedRead/Write

403231PrimaryTankLevelRead/Write

403232

Variable

Variable Variable

Transducer2Offset

RemoteStartEnable

FillSolenoidOut

FillSolenoidOutKeepAlive

ReedSwitchCount

CongurableIOType

Register

Register Register

Access

Access Access

(Reads

ignored)

Read/Write

(Reads

ignored)

Read/Write16Bit

Read/Write16Bit

Read/Write16BitWriteanyvaluetoactivate.

Read/Write16Bit

(Reads

ignored)

(Reads

ignored)

Read/Write16Bit

Size

Size Size

16Bit

16Bit

16Bit

16Bit

Notes/Units

Notes/Units Notes/Units

IntegerValue(0-65535)

DecimalValue(0-65535)

0=Disabled

1=Enabled

0-65535Cyclecount

0-100%

0=ReedSwitchCount(AuxIn)

1=AgitatorHalt(AuxIn)

2=HighLevelPrimary(Aux

Out)

3=LowLevelPrimary(Aux

Out)

4=PLC(AuxOut)

5=PLCExternalFill(AuxOut)

L3A0/L4A0automaticallyturn

offAuxOut

403233

403234

AgitatorHaltStatus

AccessorySolenoidOut

Read/Write

(Reads

ignored)

Read/Write16Bit0=Disabled,1=Enabled

16Bit

0=AgitatorHaltSwitchNot

Active

1=AgitatorHaltSwitchActive

36 3A2527L

Page 37

AppendixA-ModbusVariableMap

Modbus

Modbus Modbus

Register

Register Register

PumpStatus

404100

Variable

Variable Variable

PumpStatusBits

Register

Register Register

Access

Access Access

Read/Write16Bitbit0=Pumptryingtomove

Size

Size Size

Notes/Units

Notes/Units Notes/Units

bit1=Pumpactuallymoving

bit2=ActiveAlarm

bit3=ActiveDeviation

bit4=ActiveAdvisory

bit5=SetupModied

(Registers6141-6159)

bit6=Reserved/unused

bit7=RunStatus

bit8=Prole1Modied

bit9=Prole2Modied

bit10=Prole3Modied

bit11=Prole4Modied

bit12=TankEvents

404101

404102

404103

404104

404105

404106BatchTotalHighWord

404107BatchTotalLowWord

404108

404109

404110MaintenanceTotalHighWord

404111MaintenanceTotalLowWord

404112PumpEvents1—HighWord

404113PumpEvents1—LowWord

CurrentSpeedReadOnly

CurrentFlowRateReadOnly

CurrentForceReadOnly

CurrentPumpOutletPressureReadOnly

CurrentBPRPressureReadOnly

GrandTotalHighWordReadOnly

GrandTotalLowWordReadOnly

16Bit10=1.0cycle/min

16Bit10=1.0L/Min

10=1.0Gal/Min

1=1cc/min

1=1oz/min

10=1.0CPM

16Bit

16Bit

16Bit

ReadOnly

ReadOnly

ReadOnly

ReadOnly

ReadOnly

ReadOnly

16Bit

16Bit

16Bit

16Bit

16Bit

16Bit

16Bit

16Bit