Page 1

Installation - Parts

®

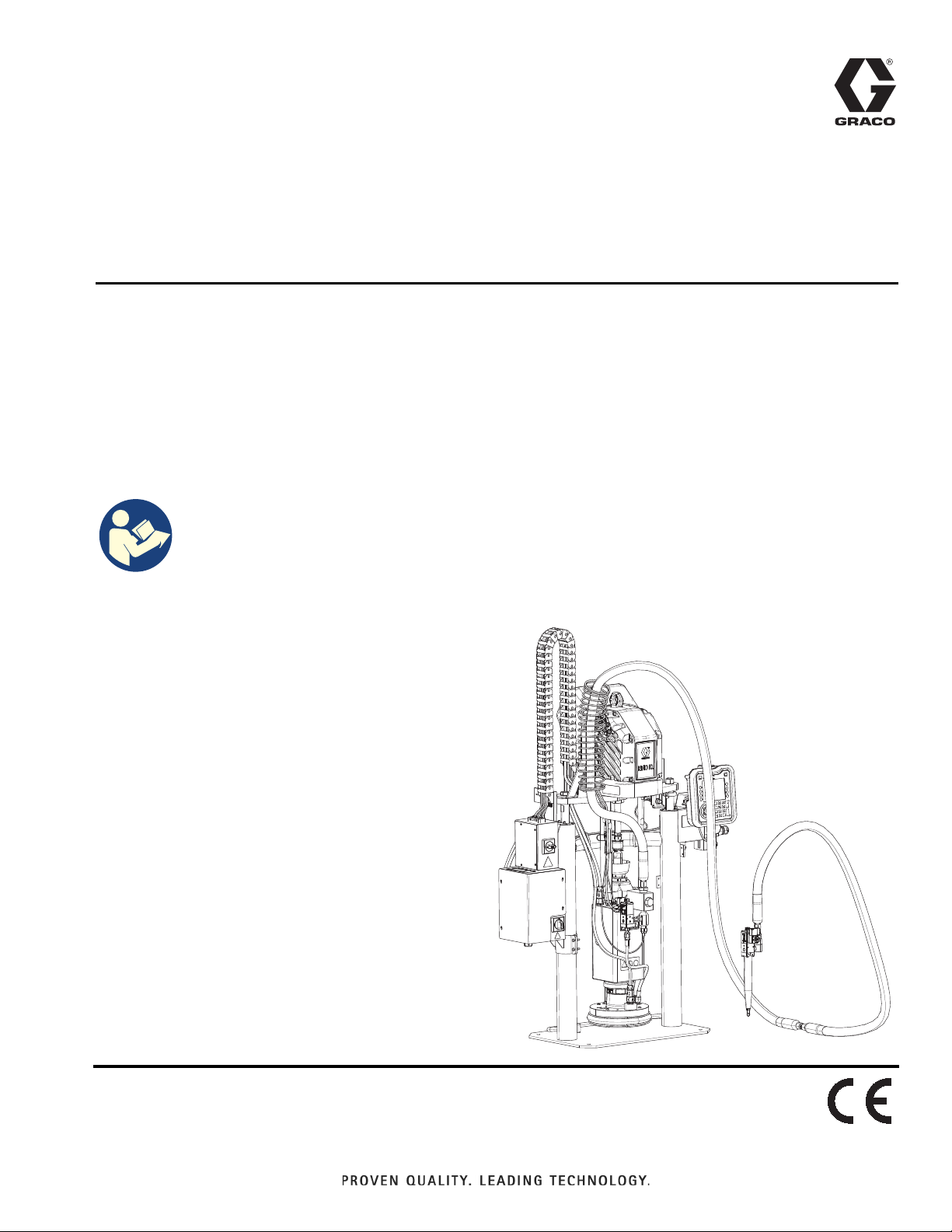

E-Flo

iQ Dispense

333586F

System

For dispensing and metering sealants, adhesives, and other medium to high viscosity

fluids. For professional use only.

Not approved for use in explosive atmospheres or hazardous (classified) locations.

See page 4 for system component information.

Important Safety Instructions

Read all warnings and instructions in this

manual and in related manuals before

using the equipment. Save all

instructions.

EN

Page 2

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Dispense System Configurator . . . . . . . . . . . . . . . . 4

Dispense System Components. . . . . . . . . . . . . . . . 5

iQ Ram Supply Units . . . . . . . . . . . . . . . . . . . . . . 5

iQ Dispense Valves . . . . . . . . . . . . . . . . . . . . . . . 6

Hose Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Dispense System Pressure . . . . . . . . . . . . . . . . . . . 7

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Dispense System Component Identification . . . . 11

Single Ram . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Tandem Ram . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Supply Unit Component Identification . . . . . . . . . 13

iQ Ram Supply Unit . . . . . . . . . . . . . . . . . . . . . . 13

Power Disconnect . . . . . . . . . . . . . . . . . . . . . . . 14

Integrated Air Controls (AG) . . . . . . . . . . . . . . . 15

Air Line Accessories . . . . . . . . . . . . . . . . . . . . . 15

Advanced Display Module (ADM) . . . . . . . . . . . 16

Platen (AD) Component Identification . . . . . . . . 17

Electric Driver Communication Connections . . . 18

Installing Tandem. . . . . . . . . . . . . . . . . . . . . . . . 20

Power Junction Box and Heat Control Box

Connections. . . . . . . . . . . . . . . . . . . . . . . . . 22

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Power Requirements . . . . . . . . . . . . . . . . . . . . . 25

Connect Power . . . . . . . . . . . . . . . . . . . . . . . . . 25

Attach Drum Stops . . . . . . . . . . . . . . . . . . . . . . . 27

Install Vented Oil Cap Before Using Equipment. 28

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Air Line Connections . . . . . . . . . . . . . . . . . . . . . 29

Hoses and Fittings . . . . . . . . . . . . . . . . . . . . . . . 29

Electrical Connections . . . . . . . . . . . . . . . . . . . . 31

Heat Connections (Hoses and Accessories) . . . 33

Wet Cup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Hose Care Guidelines . . . . . . . . . . . . . . . . . . . . . . 36

Flush Before Using Equipment . . . . . . . . . . . . . 36

Check Resistance (Heated Systems) . . . . . . . . . . 37

Check Sensor Resistance . . . . . . . . . . . . . . . . . 37

Check Heater Resistance . . . . . . . . . . . . . . . . . 37

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . 39

Shutdown and Care of the Pump . . . . . . . . . . . . . 41

Change Drums . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Driver Maintenance . . . . . . . . . . . . . . . . . . . . . . 43

Platen Maintenance . . . . . . . . . . . . . . . . . . . . . . 44

Recycling and Disposal . . . . . . . . . . . . . . . . . . . . . 45

End of Product Life . . . . . . . . . . . . . . . . . . . . . . . 45

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Supply Systems Troubleshooting . . . . . . . . . . . . 46

Heat Control Box Troubleshooting . . . . . . . . . . . 47

Platen Valve Kit Troubleshooting . . . . . . . . . . . . 47

Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Disconnect Pump from Platen . . . . . . . . . . . . . . 48

Connect Platen . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Remove Wipers . . . . . . . . . . . . . . . . . . . . . . . . . 50

Install Wipers . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Remove Displacement Pump. . . . . . . . . . . . . . . 50

Install Displacement Pump . . . . . . . . . . . . . . . . . 52

Remove Driver . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Install Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Ram Supply Unit Repair. . . . . . . . . . . . . . . . . . . 55

Replace Heat Control Box Electrical Component(s)

58

Replace Fuses in Harness (25R652) . . . . . . . . . 60

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

D200s 6.5 in. Ram Supply Units. . . . . . . . . . . . . 61

D200 3 in. Ram Supply Units . . . . . . . . . . . . . . . 63

D60 3 in. Ram Supply Units . . . . . . . . . . . . . . . . 65

D200, D200s Pump Mounts for 55 Gallon (200 Liter)

Platen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

D60 Pump Mount for 5 Gallon (20 Liter) Platen . 68

D200s Pump Mounts for 16 Gallon (60 Liter)

Platens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Power Junction Box . . . . . . . . . . . . . . . . . . . . . . 70

Heat Control Box, 25R454 . . . . . . . . . . . . . . . . . 72

Cable Track, 26A935 . . . . . . . . . . . . . . . . . . . . . 73

55 Gallon Platen . . . . . . . . . . . . . . . . . . . . . . . . . 74

20 Liter (5 Gallon) Platens . . . . . . . . . . . . . . . . . 75

60 Liter (16 Gallon) Platens . . . . . . . . . . . . . . . . 77

Tandem Block, 25R848, 25R849 . . . . . . . . . . . . 79

2 333586F

Page 3

Related Manuals

Kits and Accessories . . . . . . . . . . . . . . . . . . . . . . . 80

System Kits and Accessories . . . . . . . . . . . . . . . 80

Drum Kits and Accessories . . . . . . . . . . . . . . . . 81

CAN Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

I/O Integration Cable . . . . . . . . . . . . . . . . . . . . . 82

Integration Extension Cables . . . . . . . . . . . . . . . 82

Platen/Pump Heat Harness . . . . . . . . . . . . . . . . 82

Pressure Transducer Cables . . . . . . . . . . . . . . . 82

Solenoid Cables . . . . . . . . . . . . . . . . . . . . . . . . . 82

Heat Extension Cables . . . . . . . . . . . . . . . . . . . . 82

Cable Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Fitting Kits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Tandem Fitting Kits . . . . . . . . . . . . . . . . . . . . . . 83

Additional Accessories . . . . . . . . . . . . . . . . . . . . 83

Check-Mate 200 CS Pump Heater Kit, 25R450 . 84

Platen Heater Kit, 25R451 . . . . . . . . . . . . . . . . . 85

Communication Gateway Module (CGM) Kits . . 86

Platen Valve Kit, 25R452 . . . . . . . . . . . . . . . . . . 88

Platen Valve Kit, 25R453 . . . . . . . . . . . . . . . . . . 90

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Pump Performance . . . . . . . . . . . . . . . . . . . . . . . . . 95

E-Flo iQ Dispense System Performance Chart . 96

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Technical Specifications . . . . . . . . . . . . . . . . . . . 102

California Proposition 65 . . . . . . . . . . . . . . . . . . . 103

Graco Standard Warranty . . . . . . . . . . . . . . . . . . 104

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . 104

Related Manuals

Related Manuals in English:

Manual in

English

333587 E-Flo iQ Supply System Operation

312375

312468

312374 Air Controls Instructions-Parts

312491 Pump Fluid Purge Kit Instructions - Parts

312492 Drum Roller Kit Instructions

312493 Light Tower Kit Instructions

312494

406681 Platen Cover Kit

334048 EPDM Hose Wiper Kit Instructions - Parts

3A6321

3A6482

333585 iQ Dispense Valves, Instructions-Parts

3A1244 Graco Control Architecture Module

3A4241

Description

Check-Mate

Instructions-Parts

200 cc Check-Mate Displacement Pump

Repair Parts

Enclosed Wetcup Recirculation Kit

Instructions - Parts

ADM Token In-System Programming

Instructions

APD20 Advanced Precision Driver

Instructions

Hot Melt/Warm Melt Heated Hose

Instructions

®

Displacement Pumps

333586F 3

Page 4

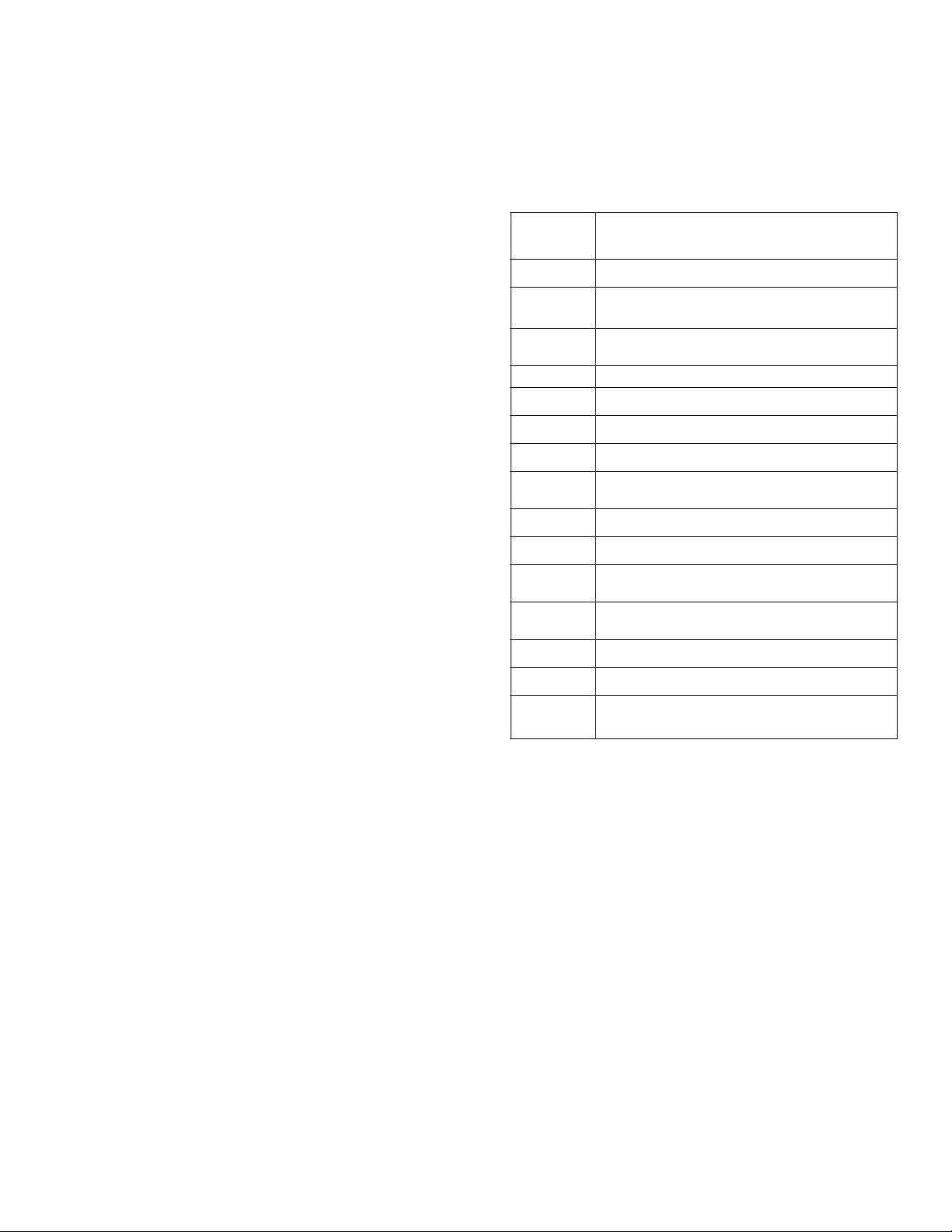

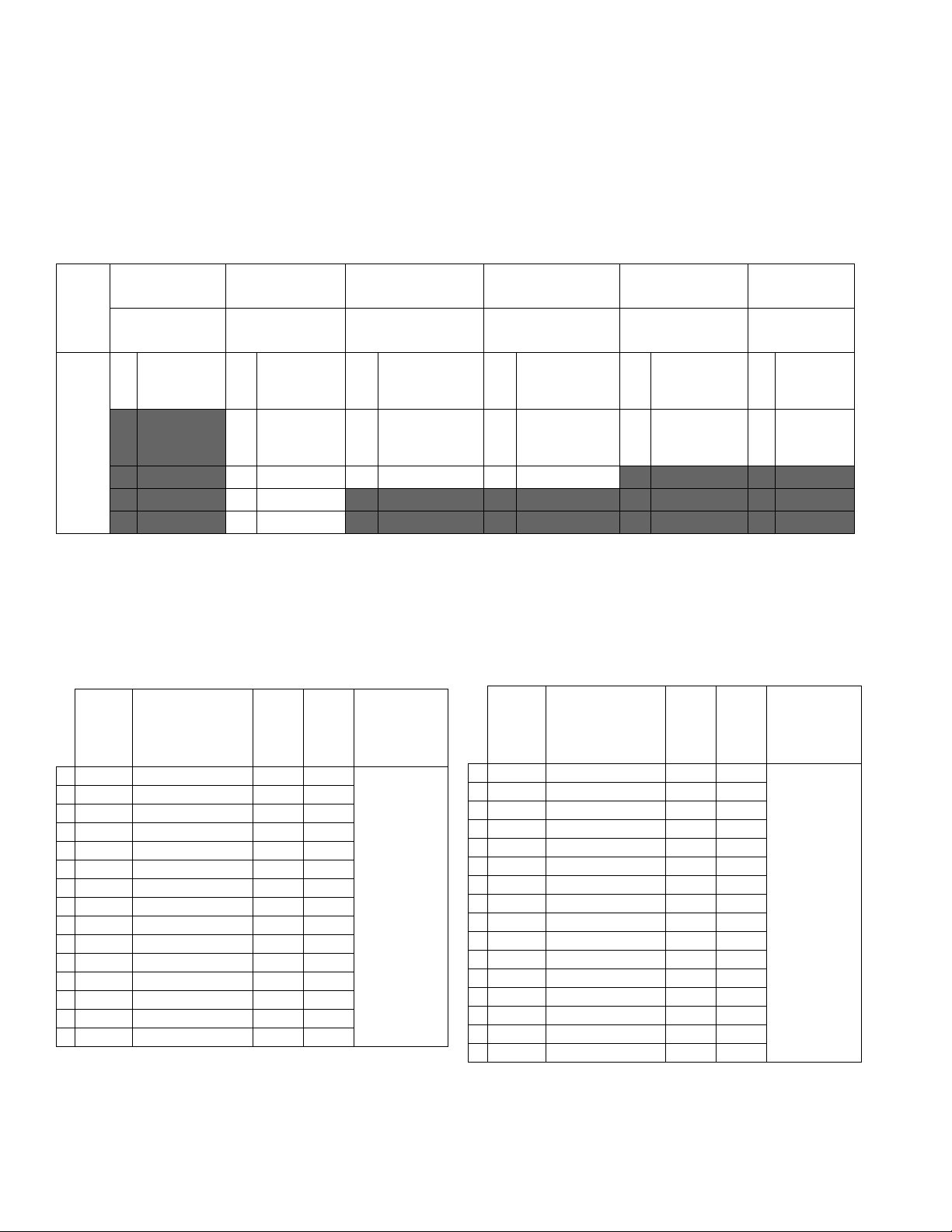

Dispense System Configurator

Dispense System Configurator

The E-Flo iQ dispense system provides the flexibility to configure a complete system to meet your specific needs.

This includes offering multiple combinations of the following components:

• iQ Ram Supply Units

• iQ Dispense Valves

• Hoses and connectors

For dispense system component information, see Dispense System Components on page 5.

First,

Second

and

Third

Digit

EQC

E-Flo iQ

System

Fourth

Digit

Revision

Fifth

Digit Sixth Digit

Seventh

Digit

Platen

Single or

Tandem

S Single H Heated Y Yes

T Tan-

dem

Heat

Option

A Ambient

Valve

Option

Eighth Digit

Ram Supply Unit Options

Size

A 3 in.

B 3 in.

C 3 in.

D 3 in.

F 3 in.

G 3 in.

H 3 in.

J 3 in.

K 6.5 in.

M 6.5 in.

N 6.5 in.

P 6.5 in.

R 6.5 in.

T 6.5 in.

Drum

Size

20 L

(5 Gal) CS EPDM

20 L

(5 Gal) CS

20 L

(5 Gal) CM EPDM

20 L

(5 Gal) CM

200 L

(55 Gal) CS EPDM

200 L

(55 Gal) CS

200 L

(55 Gal) CM EPDM

200 L

(55 Gal) CM

200 L

(55 Gal) CS EPDM

200 L

(55 Gal) CS

200 L

(55 Gal) CM EPDM

200 L

(55 Gal) CM

60 L (16

Gal) CS PTFE

60 L (16

Gal) CS PTFE

Pump

Material

Seal

Material

Neo-

prene

Neo-

prene

Neo-

prene

Neo-

prene

Neo-

prene

Neo-

prene

Ninth Digit

Fieldbus

Option

A Ether-

Net/IP

B PROF-

INET

C PROFI-

BUS

D Devi-

ceNet

N None

Digits Ten

through

Seventeen

Hose

Options for

Tandem

Hoses (Dig-

its 10-13)

and Supply

Hoses (Dig-

its 14-17)

(See Hose

Options on

page 6)

Digits

Eighteen

through

Twenty Seven

Valve Options

(See the iQ

Dispense

Valves Instruc-

tions - Parts

manual for

valve model

options)

KEY:

CS = Carbon Steel Severe Duty

CM = Carbon Steel MaxLife

®

®

4 333586F

Page 5

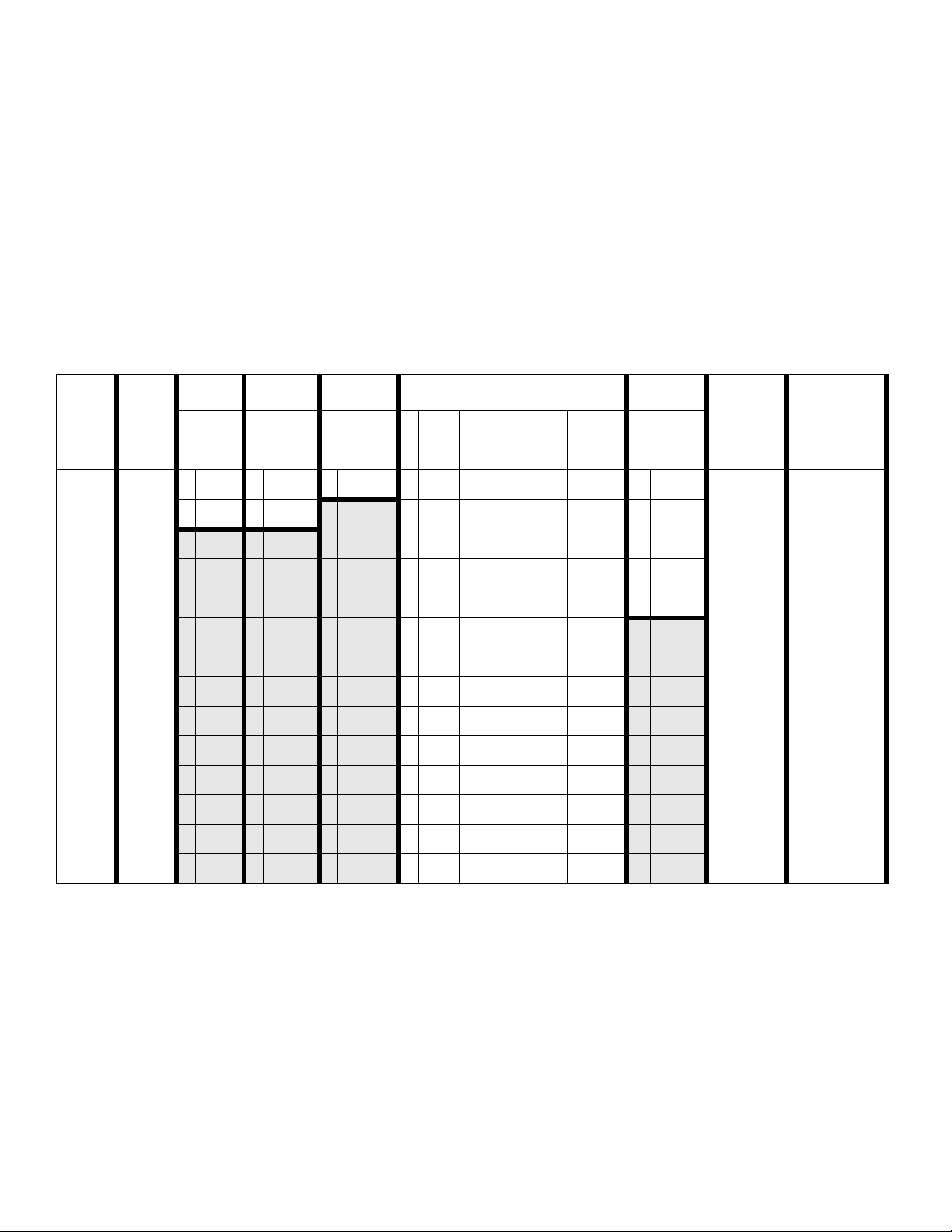

Dispense System Components

Dispense System Components

NOTE: The Heated option for the E-Flo iQ system is for warm melt applications with a maximum temperature of 70° C

(158° F).

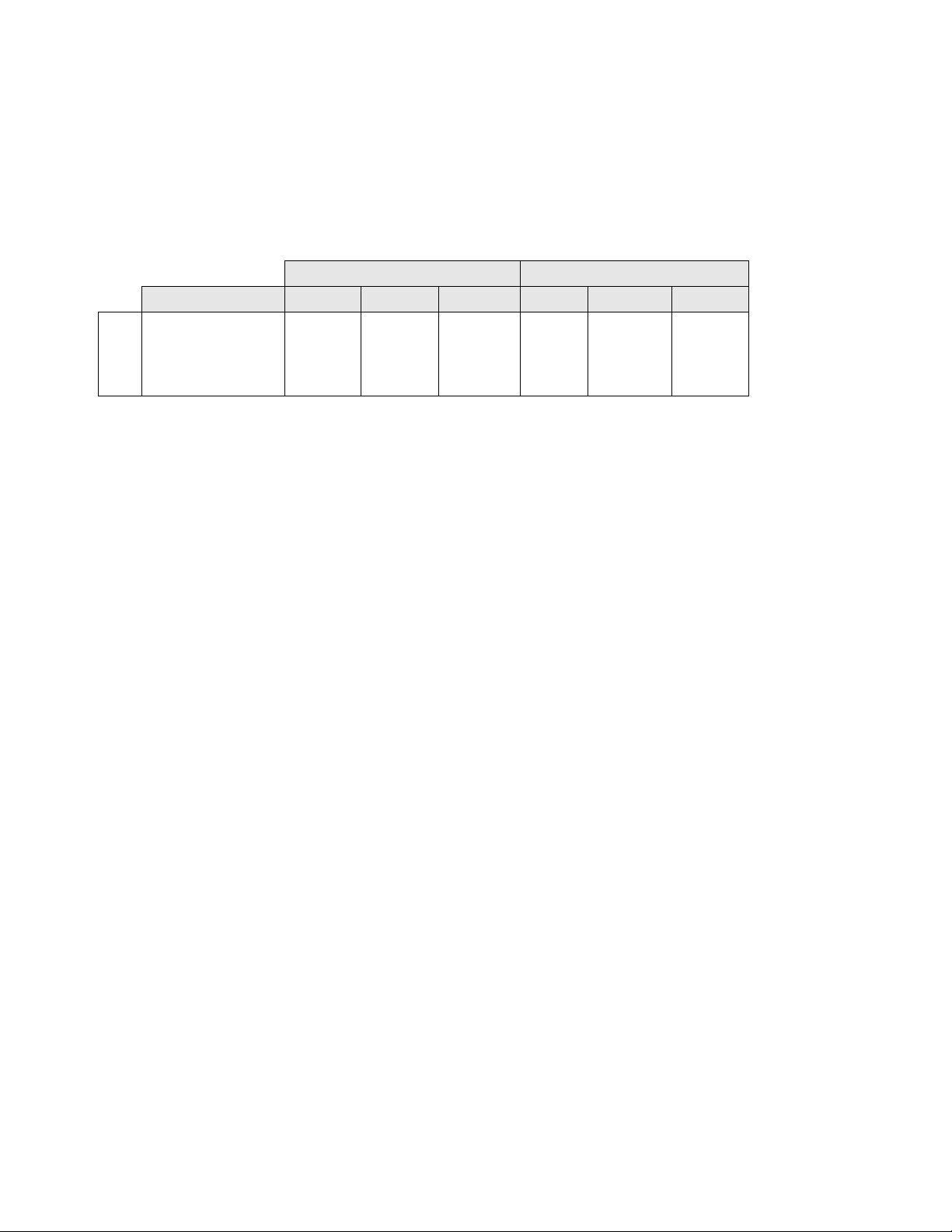

iQ Ram Supply Units

Check the identification plate (ID) on the back of the ram post near the Power Junction Box (AJ) for the seven-digit part

number of the iQ ram supply unit. Use the following matrix to define the construction of the unit, based on the seven digits.

For example, Part No. EZC2421 represents an electric supply unit (EZ), a carbon steel Check-Mate 200 Severe Duty dis-

placement pump (C2), a 3 in. ram (4), a 5-gallon platen with a neoprene seal (2), and an Advanced Display Module (ADM)

(2).

The digits in the following matrix do not correspond to the reference numbers in the Parts drawings and lists.

EZ C2 4

First

and

Second

Digit

EZ

(Electric

Supply

System)

Third and Fourth Digit Fifth Digit

Check-Mate Pump Options Ram Options

Pump

Size

Material

C1 200cc CS Ambient

C2 200cc CS Heated

C3 200cc CM Ambient

C4 200cc CM Heated

Heated/

Ambient

≤70° C

≤70° C 4 D60 3 in.

Name Size

1 D60 3 in.

2 D200 3 in.

3 D200s 6.5 in.

5 D200 3 in.

6 D200s 6.5 in.

Drum

Size Style

20 L

(5 Gal) Ambient 1

200 L

(55

Gal) Ambient 2

200 L

(55

Gal) Ambient 3

20 L

200 L

(55

Gal)

200 L

(55

Gal)

Heated

≤70° C 4

Heated

≤70° C 5

Heated

≤70° C 6

(5 Gal)

Sixth Digit

Platen and Seal Options

Platen

Size

(5 Gal) CST/AL Neoprene

(5 Gal) CST/AL Neoprene

(5 Gal) CST/AL EPDM

(5 Gal) CST/AL EPDM

200 L

200 L

200 L

7

200 L

8

9

A

Platen

Material

20 L

20 L

20 L

20 L

(55

Gal) AL Neoprene

(55

Gal) AL Neoprene

(55

Gal) AL EPDM

(55

Gal) AL EPDM

60 L

(16

Gal) CST/AL

60 L

(16

Gal) CST/AL

Material Wiper

22

Seventh

Digit

Interface

Options

Seal

PTFE

Coated

Nitrile

PTFE

Coated

Nitrile

Single

Single

Single

Single

Double

Double

Double

Double

Single

Single

Heated/

Ambient Interface

Ring Ambient 2ADM

Ring

Ring Ambient

Ring

Ring Ambient

Ring

Ring Ambient

Ring

Flat Ambient

Flat Heated

Heated

≤70° C 4 No ADM

Heated

≤70° C

Heated

≤70° C

Heated

≤70° C

KEY:

CS = Carbon Steel Severe Duty

CM = Carbon Steel MaxLife

CST/AL = Carbon Steel/Aluminum

AL = Aluminum

333586F 5

Page 6

Dispense System Components

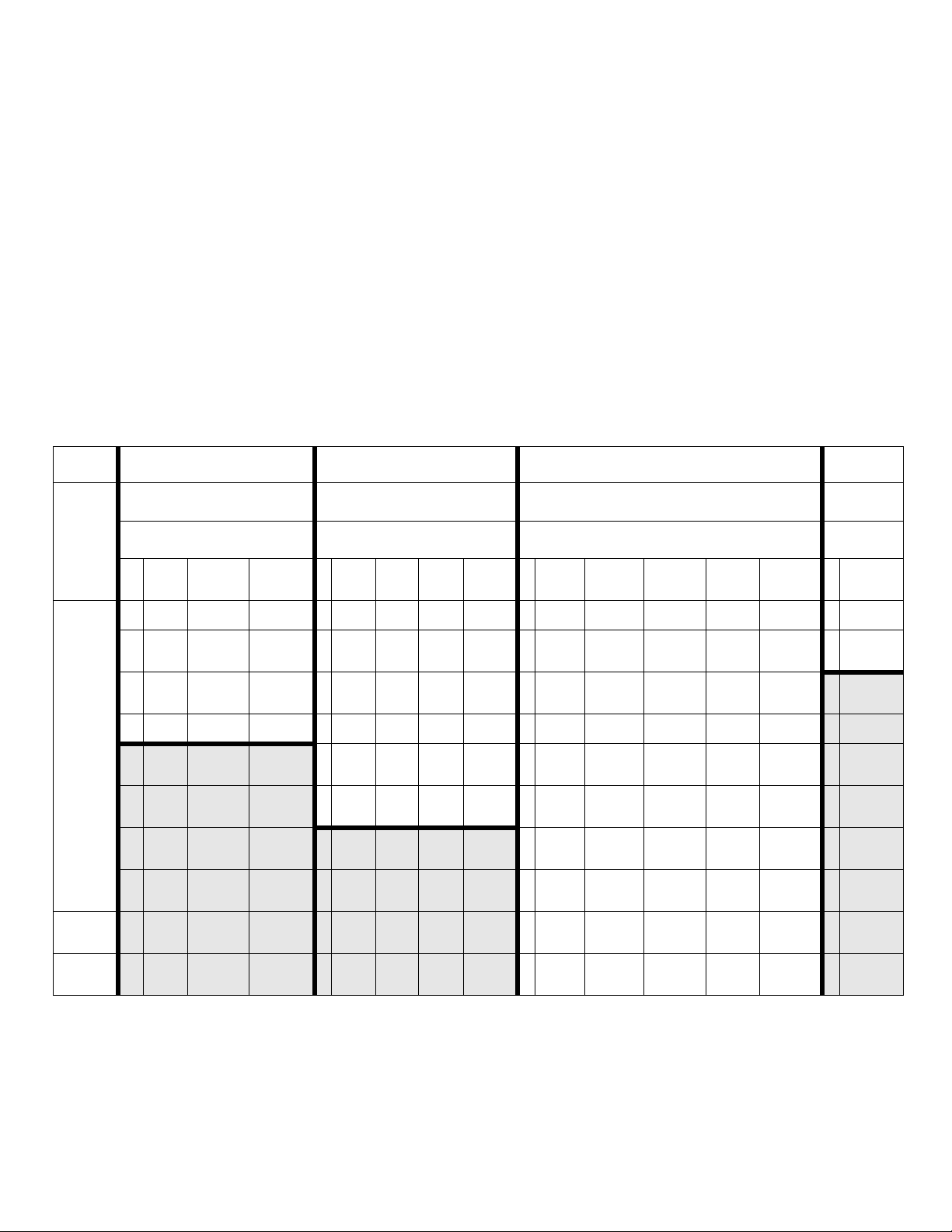

iQ Dispense Valves

Check the identification plate on the valve for the ten-digit part number of the iQ dispense valve. Use the following

matrix to define the construction of the valve, based on the ten digits. For example, Part No. V25AB060BA

represents a valve (V) with 1/4” NPT inlet ports (25), NPT tip size (A), ball/seat type (B), 60 mm outlet block length

(060), solenoid (B), with no heat (A).

First

Digit

Second and

Third Digit

Fourth Digit Fifth Digit

Size Tip Size Type

Sixth, Seventh,

and Eighth Digit

Outlet Block

Length

Ninth Digit Tenth Digit

Action Heat

Valve

25

1/4 in. NPT

A 1/4 in. NPT B Ball/Seat 000 NA B

Mounted

A None

Solenoid

60 mm

V

C 0.6 mm S Snuff-Back 060

D 1.0 mm T Tip Seal 200

200 mm

D

*Remote

Solenoid

Block

B

Heated

≤

70° C

F 1.3 mm

G 1.7 mm

* Remote solenoid supplied by customer.

NOTE: Refer to the iQ Dispense Valves Instructions-Parts manual for additional information about iQ Dispense

Valves. See Related Manuals on page 3.

Hose Options

Working

Pressure

Temperature

Rating

4000 psi (28

MPa, 276 bar)

at -65° F - 400°

F (101° C - 204°

Part No. JIC Dash Size Length Heat

04 19M404 -10 (5/8 in, 15.9 mm) 6 ft Heated

05 19M405 -10 (5/8 in, 15.9 mm) 10 ft Heated

06 19M406 -10 (5/8 in, 15.9 mm) 15 ft Heated

07 19M407 -10 (5/8 in, 15.9 mm) 20 ft Heated

08 19M408 -10 (5/8 in, 15.9 mm) 25 ft Heated

11 19M411 -12 (3/4 in, 19.0 mm) 6 ft Heated

12 19M412 -12 (3/4 in, 19.0 mm) 10 ft Heated

13 19M413 -12 (3/4 in, 19.0 mm) 15 ft Heated

14 19M414 -12 (3/4 in, 19.0 mm) 20 ft Heated

15 19M415 -12 (3/4 in, 19.0 mm) 25 ft Heated

16 19M416 -16 (1 in, 25.4 mm) 6 ft Heated

17 19M417 -16 (1 in, 25.4 mm) 10 ft Heated

18 19M418 -16 (1 in, 25.4 mm) 15 ft Heated

19 19M419 -16 (1 in, 25.4 mm) 20 ft Heated

20 19M420 -16 (1 in, 25.4 mm) 25 ft Heated

Working

Pressure

Temperature

Rating

4000 psi (28

MPa, 276 bar)

at -65° F - 212°

F (-54° C - 100°

C)

3000 psi (21

MPa, 207 bar)

at 213° F - 400°

F (101° C - 204°

C)

Part No. JIC Dash Size Length Heat

65 17K265 -10 (5/8 in, 15.9 mm) 6 ft Ambient

66 17K266 -10 (5/8 in, 15.9 mm) 10 ft Ambient

67 17K267 -10 (5/8 in, 15.9 mm) 15 ft Ambient

68 17K268 -10 (5/8 in, 15.9 mm) 20 ft Ambient

69 17K269 -10 (5/8 in, 15.9 mm) 25 ft Ambient

72 17K272 -12 (3/4 in, 19.0 mm) 6 ft Ambient

73 17K273 -12 (3/4 in, 19.0 mm) 10 ft Ambient

74 17K274 -12 (3/4 in, 19.0 mm) 15 ft Ambient

75 17K275 -12 (3/4 in, 19.0 mm) 20 ft Ambient

76 17K276 -12 (3/4 in, 19.0 mm) 25 ft Ambient

77 17K277 -16 (1 in, 25.4 mm) 6 ft Ambient

78 17K278 -16 (1 in, 25.4 mm) 10 ft Ambient

79 17K279 -16 (1 in, 25.4 mm) 15 ft Ambient

80 17K280 -16 (1 in, 25.4 mm) 20 ft Ambient

81 17K281 -16 (1 in, 25.4 mm) 25 ft Ambient

00 No Hose N/A N/A N/A

C)

6 333586F

Page 7

Dispense System Pressure

Due to factors such as the dispensing system design,

the material being pumped, and the flow rate, the

dynamic pressure will not reach the rated working (stall)

pressure of the system.

Pump Working (Stall) Pressure Max Dynamic (Run) Pressure

Lower Size psi bar MPa psi bar MPa

Dispense System Pressure

Check-Mate

200CS/CM

4,000 290 29.0 3,905 269 26.9

333586F 7

Page 8

Warnings

DANGER

WARNING

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The

exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks.

When these symbols appear in the body of this manual or on warning labels, refer back to these Warnings.

Product-specific hazard symbols and warnings not covered in this section may appear throughout the body of this

manual where applicable.

SEVERE ELECTRIC SHOCK HAZARD

This equipment can be powered by more than 240 V. Contact with this voltage will cause death or

serious injury.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• This equipment must be grounded. Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

8 333586F

Page 9

Warnings

WARNING

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Equipment can start without warning. Before checking, moving, or servicing equipment, follow the

Pressure Relief Procedure and disconnect all power sources.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. Paint or

solvent flowing through the equipment can cause static sparking. To help prevent fire and explosion:

• Use equipment only in well-ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static sparking).

• Ground all equipment in the work area. See Grounding instructions.

• Never spray or flush solvent at high pressure.

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless they

are anti-static or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment until

you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

333586F 9

Page 10

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Specifications in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical

Specifications in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For

complete information about your material, request Safety Data Sheets (SDSs) from distributor or

retailer.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

SPLATTER HAZARD

Hot or toxic fluid can cause serious injury if splashed in the eyes or on skin. During blow off of platen,

splatter may occur.

• Use minimum air pressure when removing platen from drum.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read Safety Data Sheets (SDSs) to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

BURN HAZARD

Equipment surfaces and fluid that is heated can become very hot during operation. To avoid severe

burns:

• Do not touch hot fluid or equipment.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. Protective equipment includes but is not

limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

10 333586F

Page 11

Dispense System Component Identification

A

B

C

D

E

H

G

J

F

*Circular

Electrical

Connection

*Square

Electrical

Connection

*Circular

Electrical

Connection

*Square

Electrical

Connection

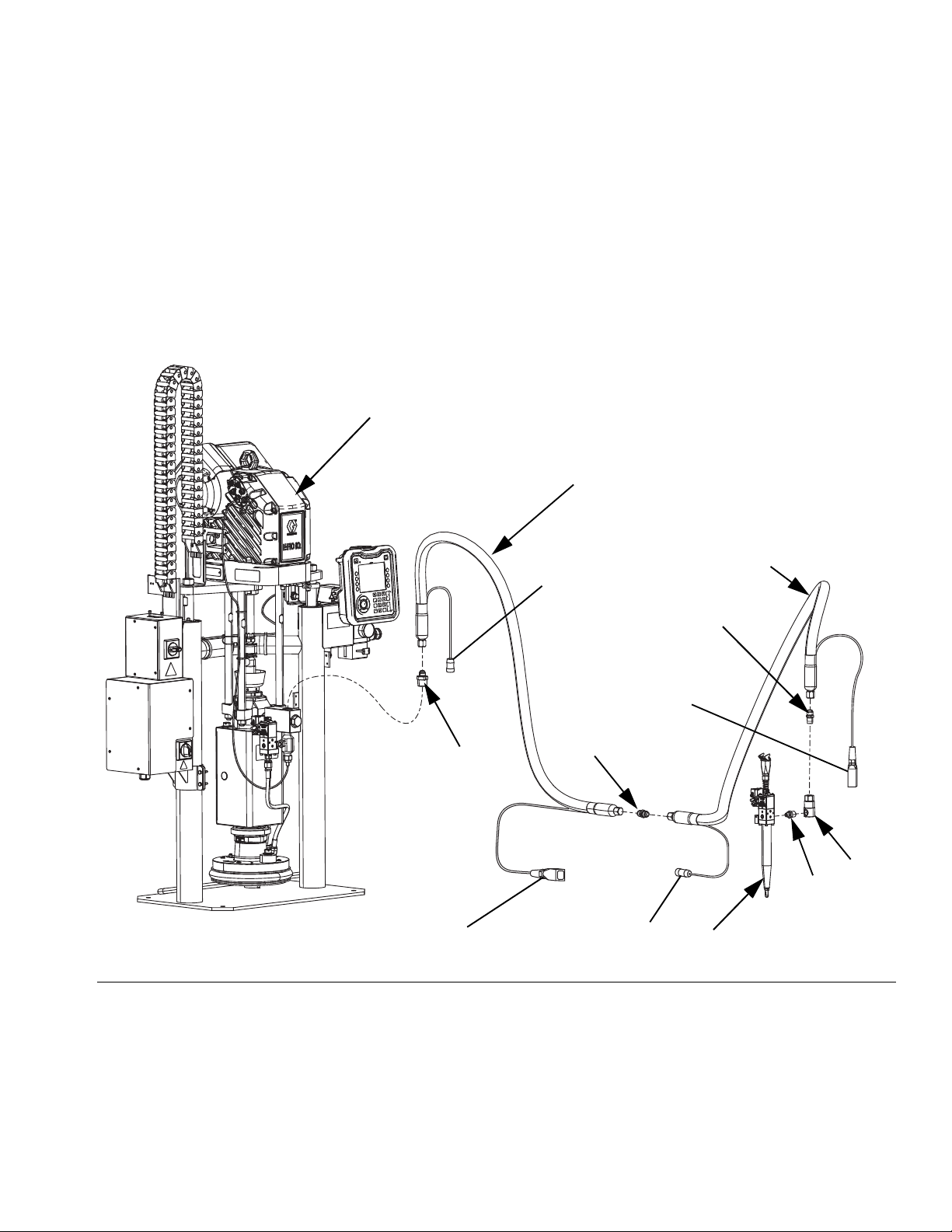

Dispense System Component Identification

Single Ram

NOTE: FIG. 1 shows a typical E-Flo iQ dispense system

installation with a single iQ ram supply unit, hoses,

connectors, and an iQ dispense valve. Some

installations may require only one hose depending on

the needs of the system.

FIG. 1: Single E-Flo iQ Dispense System

Key:

A iQ Ram Supply Unit

B iQ Dispense Valve

C Supply Hose 1

D Supply Hose 2

E Ram Supply System to Supply Hose 1 Fitting

F Supply Hose 1 to Supply Hose 2 Fitting

G Supply Hose 2 to Swivel Fitting

H Swivel Fitting

J Swivel to Valve Fitting

* Applies to heated hoses only.

333586F 11

Page 12

Dispense System Component Identification

A

B

M

D

F

G

H

J

K

L

R

C

E

N

P

*Circular

Electrical

Connection

*Square

Electrical

Connection

*Circular

Electrical

Connection

*Square

Electrical

Connection

*Circular

Electrical

Connection

S

S

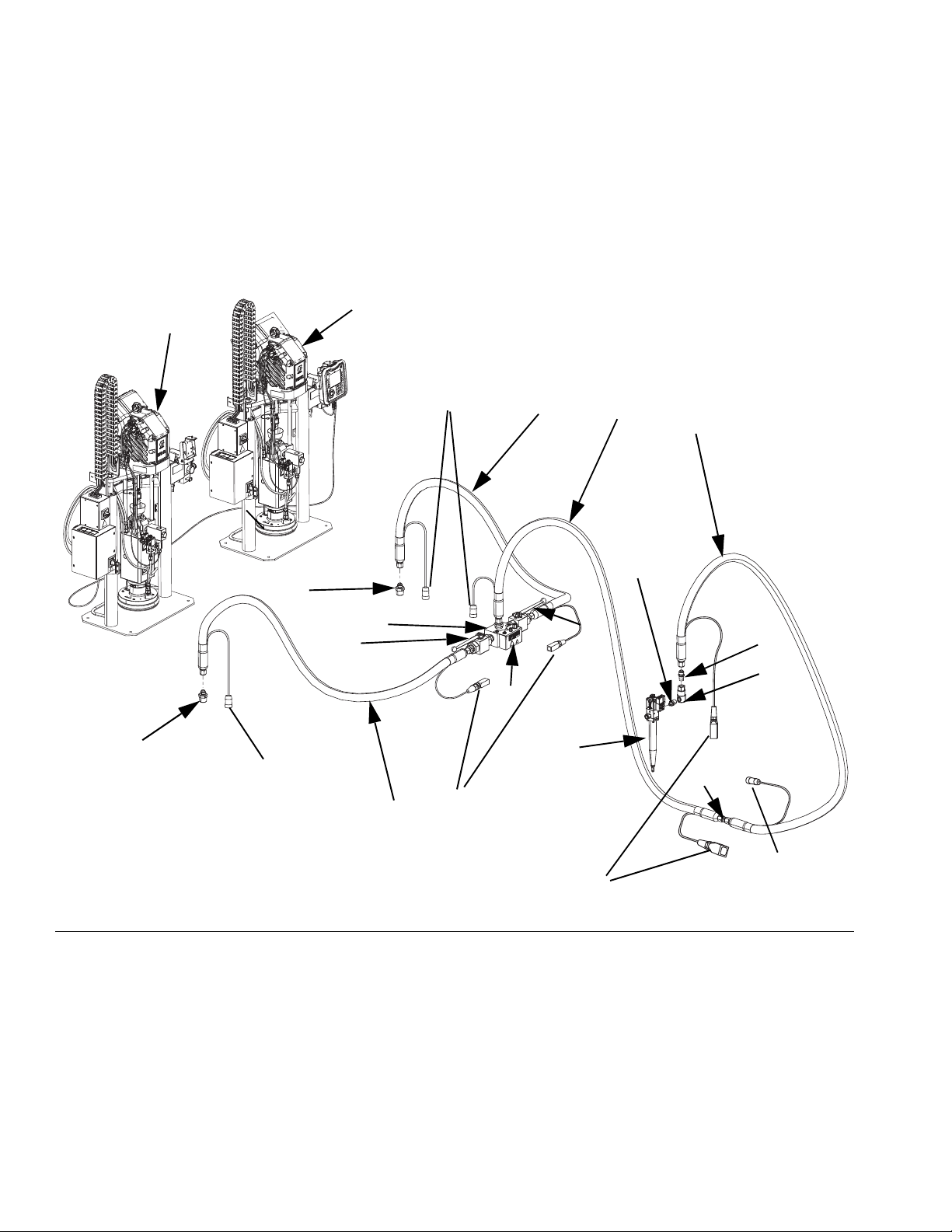

Tandem Ram

Tandem E-Flo iQ Dispense Systems consist of two

rams connected using a 3-way block with ball valves,

and are controlled by a single ADM.Tandem E-Flo iQ

Dispense Systems operate identically to Single E-Flo iQ

Dispense Systems, with the added benefit of dispensing

from the second ram when the first drum is empty.

NOTE: F

IG

. 2 shows a typical E-Flo iQ dispense system

installation with a tandem iQ ram supply unit, hoses,

connectors, and an iQ dispense valve. Some

installations may not require Supply Hose 2 (D) to iQ

Dispense Valve (B) depending on the needs of the

system.

FIG. 2: Tandem E-Flo iQ Dispense System

Key:

A iQ Ram Supply Unit 1

B iQ Dispense Valve

C Supply Hose 1

D Supply Hose 2

E Tandem Block to Supply Hose 1 Fitting

F Supply Hose 1 to Supply Hose 2 Fitting

G Supply Hose 2 to Swivel Fitting

H Swivel Fitting

J Swivel to Valve Fitting

K iQ Ram Supply Unit 2

L Tandem Hose 1

M Tandem Hose 2

N Ram Supply Unit 1 to Tandem Hose 1 Fitting

P Ram Supply Unit 2 to Tandem Hose 2 Fitting

R Tandem Block

S Ball Valve

* Applies to heated hoses only.

12 333586F

Page 13

Supply Unit Component Identification

Lift Locations

Ambient System

AZ

Heated System

AZ

AK

AU

AT

AS

AA

AB

AV

AF

AG

AR

AN

AM

AD

AJ

AK

*AX

AL

*ZA

AZ

AY

AC

AE

AW

ZB

AH

ZC

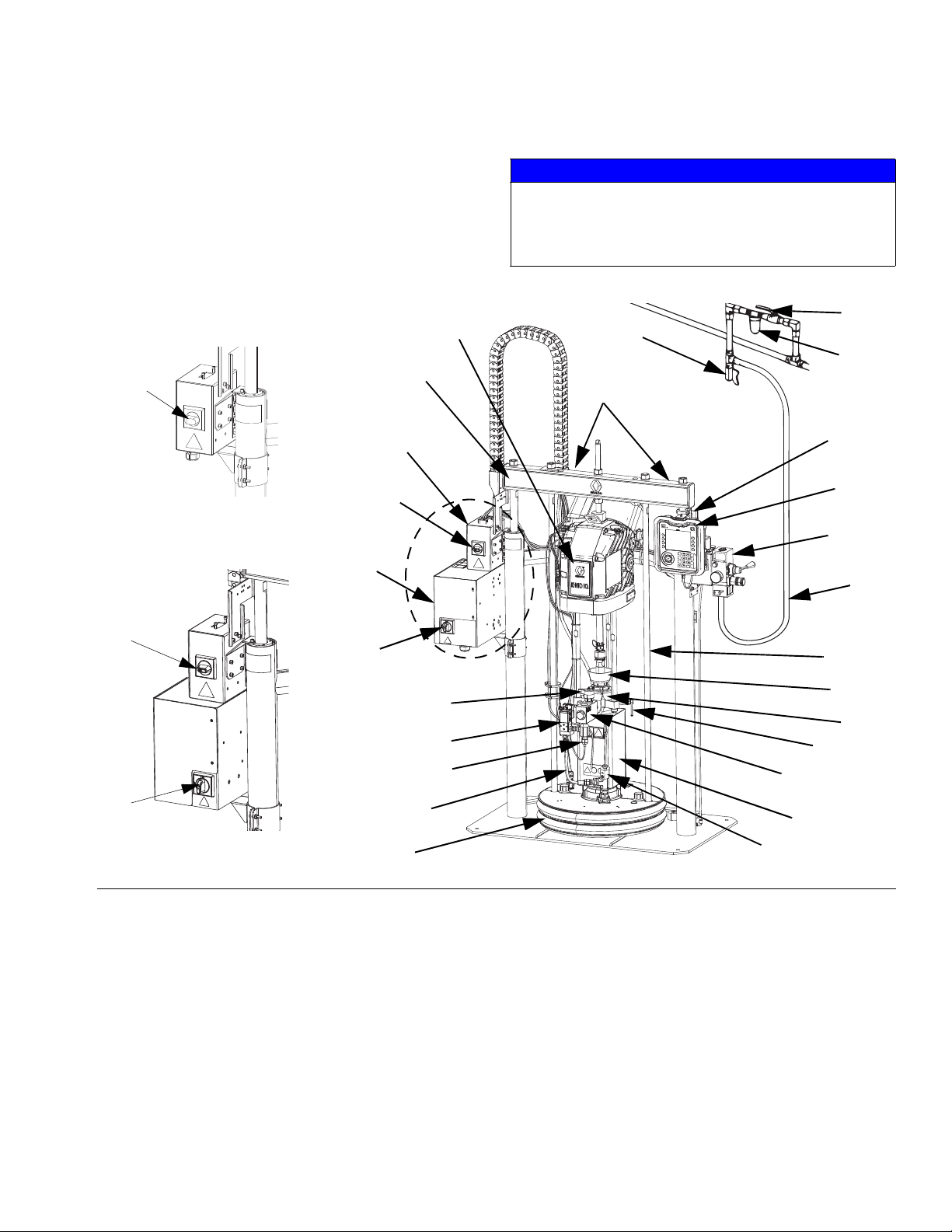

Supply Unit Component Identification

iQ Ram Supply Unit

D200 3 in. Dual Post

NOTICE

Always lift the iQ Ram Supply Unit at the proper lift

locations (see F

IG

. 3). Do not lift in any other way.

Failure to lift at the proper lift locations can result in

damage to the Supply System.

FIG. 3: iQ Ram Supply Unit

Key:

AA Ram Assembly

AB Electric Driver

AC Displacement Pump

AD Platen (see F

AE Fluid Check Valve

AF Advanced Display Module (ADM)

AG Integrated Air Controls (see F

AH Platen Bleed Port

AJ Power Junction Box

AK Power Junction Box Switch

AL Platen Lift Rod

AM Pump Bleed Valve

AN Wet Cup

333586F 13

IG

. 7)

IG

. 5)

AR Air Line (not supplied)

AS Air Line Drain Valve (not supplied)

AT Air Filter (not supplied)

AU Bleed Type Air Shutoff Valve (required) (not supplied)

AV Level Sensors

AW Outlet Pressure Transducer

AX *Heat Control Box

AY Platen Valve Kit (optional)

AZ Disconnect Switch (see Power Disconnect on page 14)

ZA *Pump Heater

ZB Recirculation Hose

ZC Pump Relief Valve

* Parts on heated systems only.

Page 14

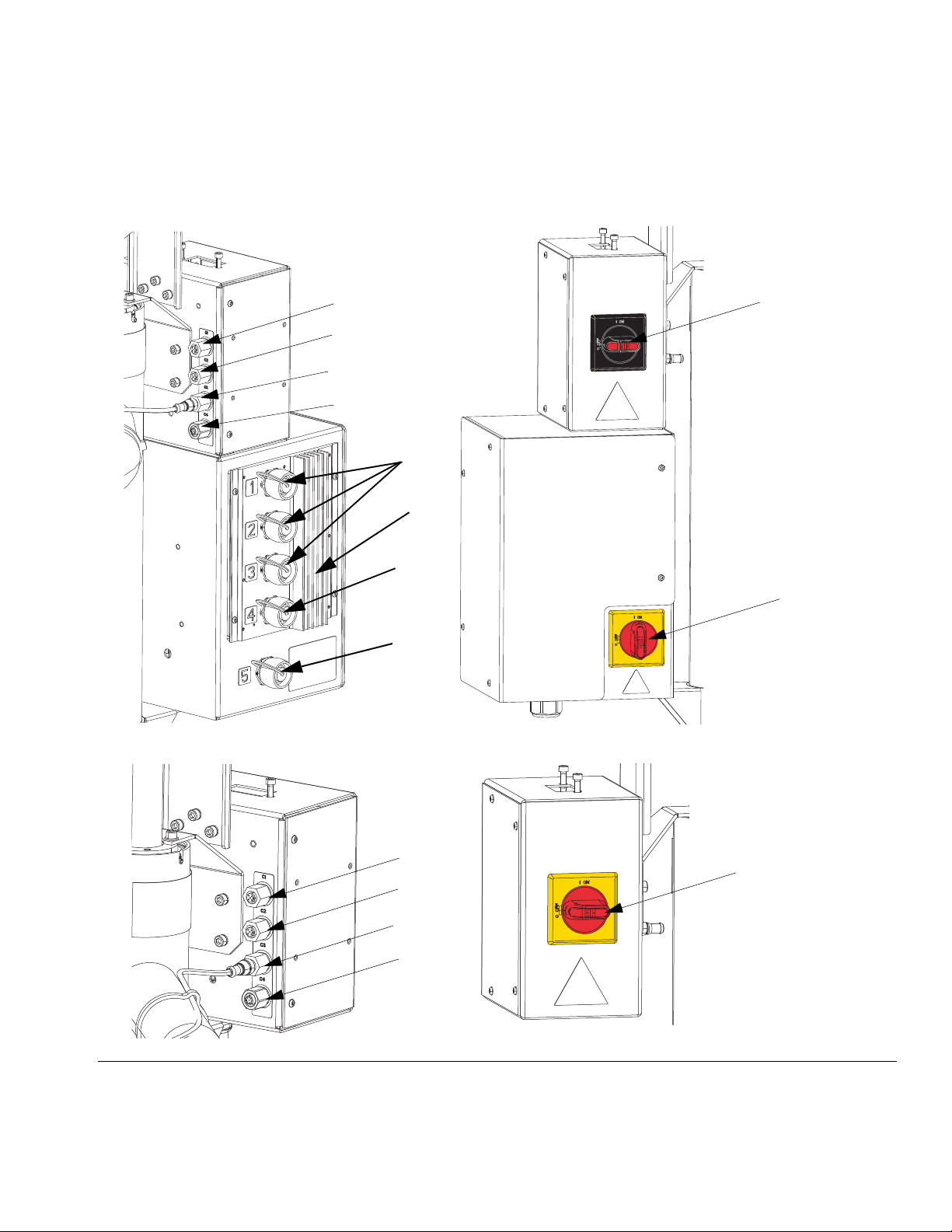

Supply Unit Component Identification

AK

AZ

Heated System

AZ

Ambient System

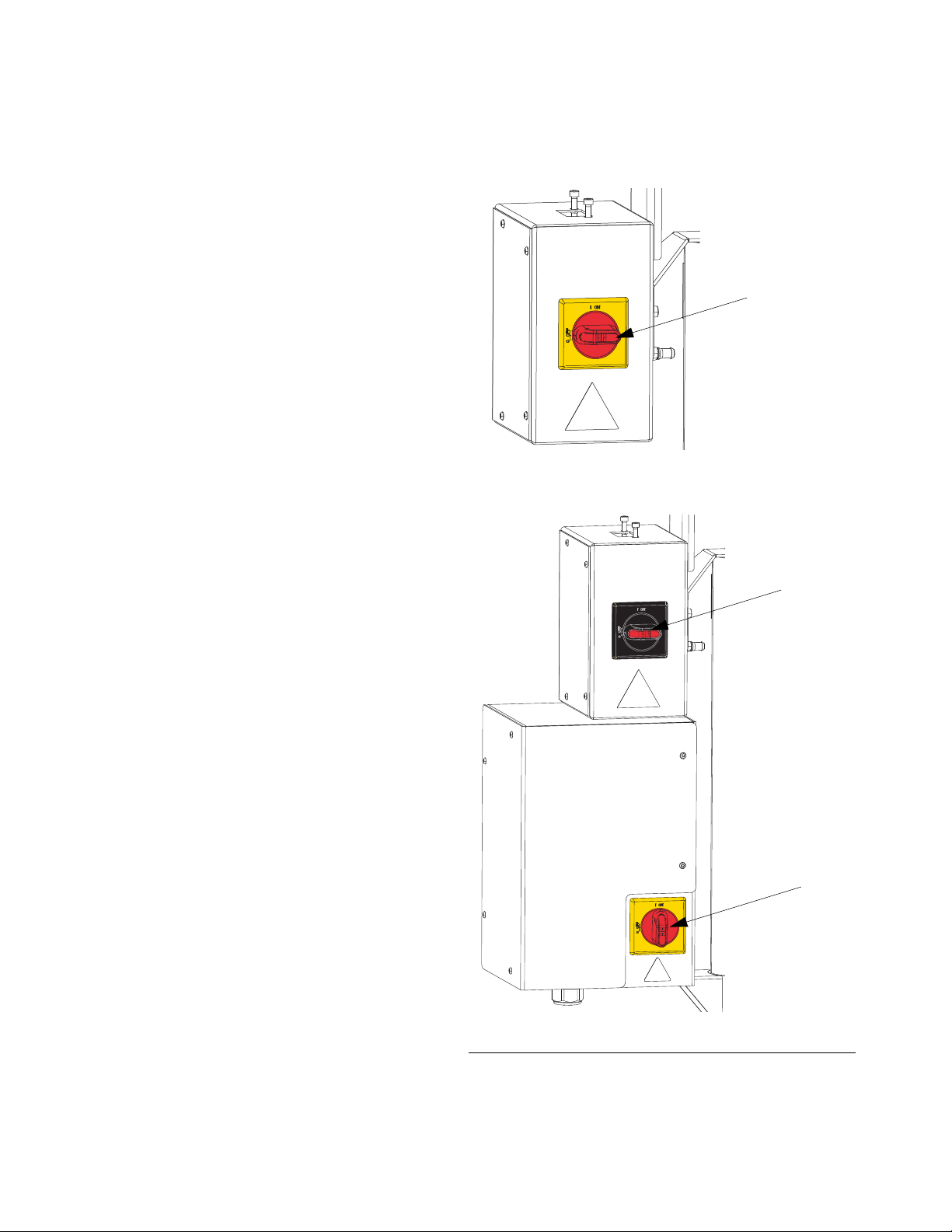

Power Disconnect

Every E-Flo iQ Dispense System has a red and yellow

Disconnect Switch which shuts off power to the entire

system. The location of the switch is different for

ambient and heated systems. See F

On ambient systems, the Disconnect Switch (AZ) is

located on the Power Junction Box (AJ).

On heated systems, the Disconnect Switch (AZ) is

located on the Heat Control Box (AX). Heated systems

also have a red and black Power junction Box Switch

(AK) located on the Power Junction Box (AJ). The

Power Junction Box Switch (AK) removes power to

everything EXCEPT heat. The Disconnect Switch (AZ)

removes power to the entire system, including heat.

IG

. 4.

F

IG

. 4. Power Disconnect

14 333586F

Page 15

Supply Unit Component Identification

BA

BB

BC

BE

BD

BD

1/4 NPT

Plug

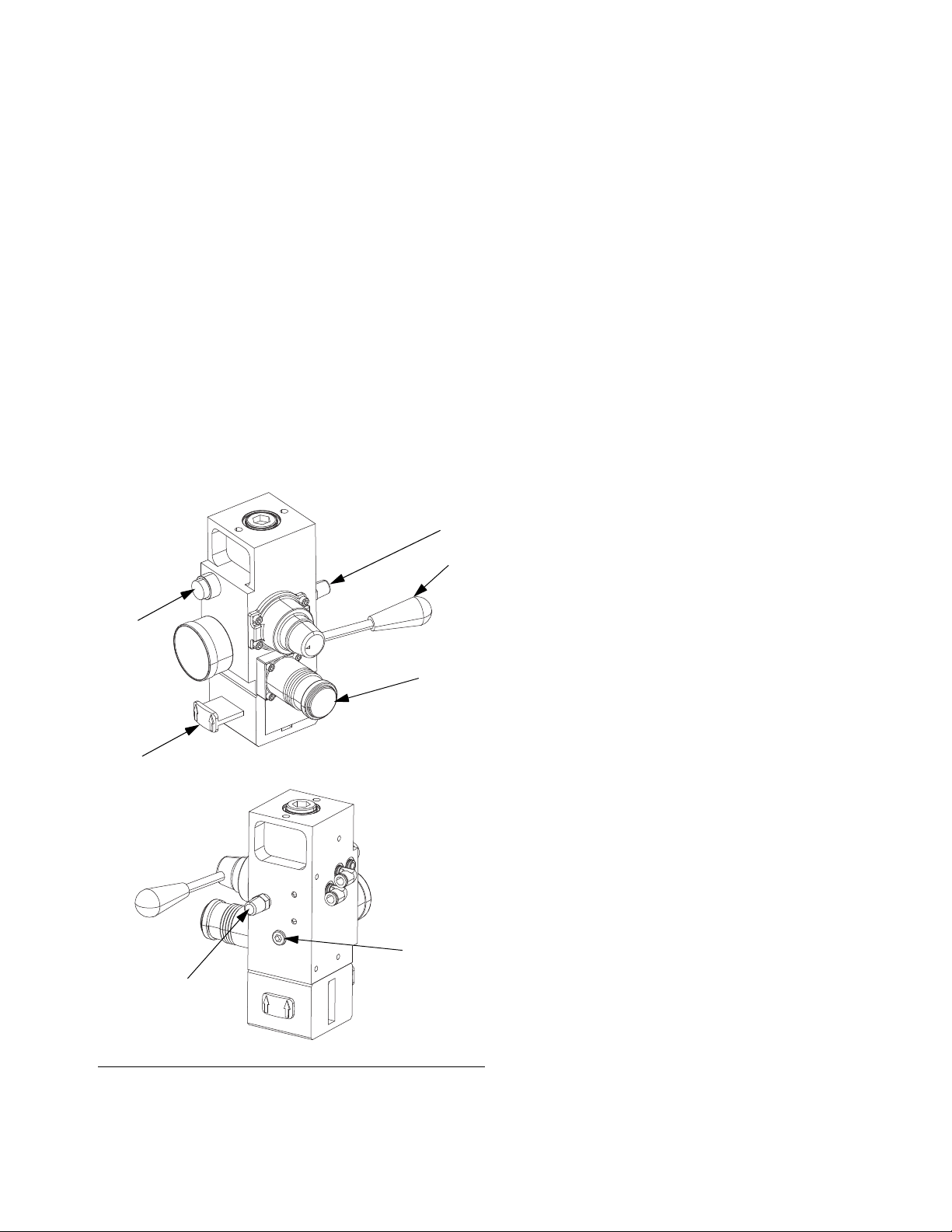

Integrated Air Controls (AG)

The integrated air controls include:

• Main Air Slider Valve (BA): turns the air on and off

to the iQ Ram Supply Unit. When closed, the valve

relieves all air pressure downstream.

• Ram Air Regulator (BB): controls the Ram Assem-

bly up and down pressure and the blowoff pressure.

• Ram Director Valve (BC): controls the Ram

Assembly direction.

• Exhaust Port with Muffler (BD)

• Blowoff Button (BE): turns the air on and off to

push the Platen (AD) out of an empty drum.

Air Line Accessories

See FIG. 3.

• Air Line Drain Valve (AS) (not supplied): removes

condensed water from air line.

• Air Line Filter (AT) (not supplied): removes harmful dirt and moisture from the compressed air sup-

ply.

• Second Bleed-type Air Valve (AU) (required) (not

supplied): isolates the Air Line accessories for ser-

vicing. Locate upstream from all other Air Line

accessories.

F

IG

. 5. Integrated Air Controls

333586F 15

Page 16

Supply Unit Component Identification

CA

CB

CC

CD

CE

CF

CG

CH

CP

CK

CN

CM

CL

CJ

CR

CS

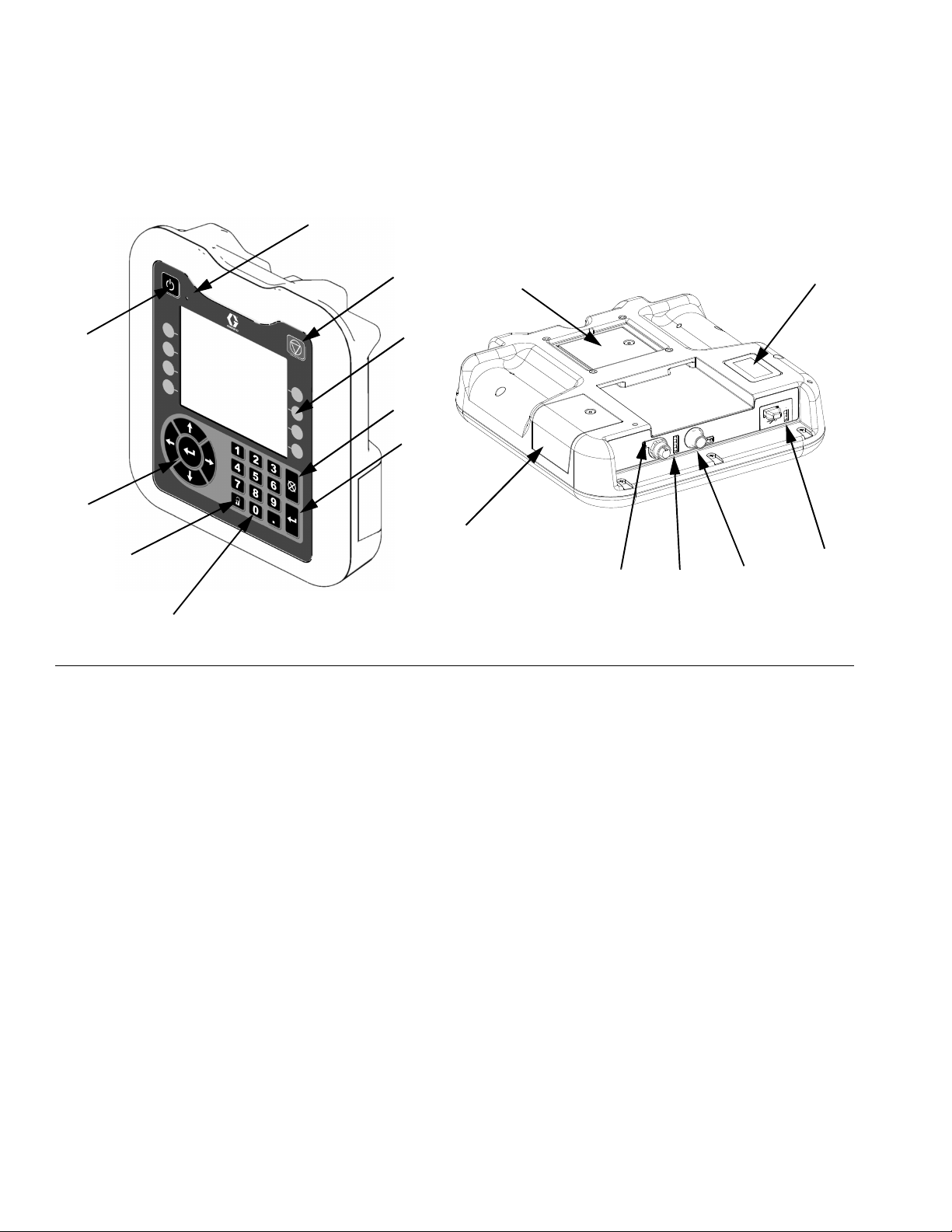

Advanced Display Module (ADM)

Front and Rear Views

FIG. 6: ADM Component Identification

Key:

CA Startup/Shutdown

Starts up or shuts down the system. Toggles

between Active and Inactive system.

CB System Status Indicator LED

CC Pump Soft Stop

Stops all pump processes and disables the pump.

Also stops all heating processes and disables the

heat. This is not a safety or emergency stop.

CD Soft Keys

Defined by the icon on the screen next to the soft

key. Performs the specific operation for that icon

when pressed.

CE Cancel

Cancels a selection or number entry while in the

process of entering a number or making a selection.

Cancels the pump processes. Exits a screen

without saving changes.

CF Enter

Select to update a field, accept a selection or value,

acknowledge an event, enter a screen, and toggle

selected items.

CG Lock/Setup

Toggles between Run screens and the iQ Menu.

CH Directional Keypad

Navigate within a screen or to a new screen.

CJ Numeric Keypad

Input numeric values.

CK Part Number Identification Label

CL USB Interface

CM CAN Cable Connection

Power and communication.

CN Module Status LEDs

Visual indicators to show the status of the ADM.

CP Token Access Cover

Access cover for blue software token.

CR Battery Access Cover

CS Light Tower Connection

NOTE: If using a tandem system, the ADM is only

included with the iQ Ram Supply Unit 1 (A).

16 333586F

Page 17

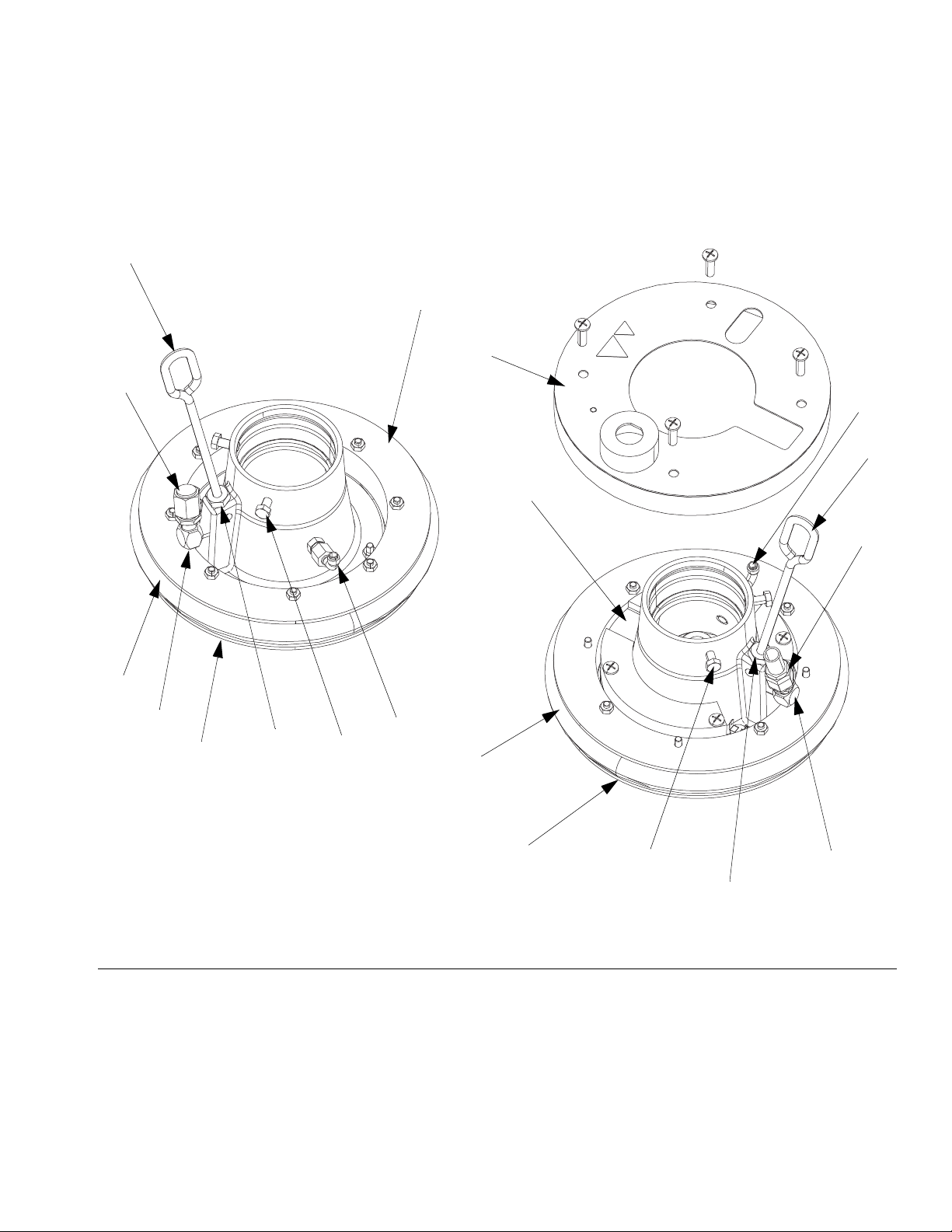

Platen (AD) Component Identification

Ambient

Heated

EF

EC

EB

EJ

ED

EH

EA

EA

EB

EF

EJ

EH

EG

EG

ED

EL

EL

EM

EM

Supply Unit Component Identification

F

IG

. 7

Key:

EA Plate

EB Wiper

EC Heater Cover

ED Cap Screws

EF Bleed Stick

EG Bleed Port

EH Air Assist Body Check Valve

EJ Wiper Plate (under wiper)

333586F 17

EK O-ring Seal (not shown)

EL Platen Valve Port

EM Platen Valve Cap

Page 18

Supply Unit Component Identification

Port 1

Port 2

Port 4

Port 6

Port 3

Port 5

Port 3 Connection

Port 4 Connection

Pump

Solenoid

Valve

(M8 4 pin)

Power

Junction Box

Port C3

(M12 5 pin)

Power

Junction Box

Port C4

(M12 8 pin)

Dispense

Valve

Solenoid

(M8 4 pin)

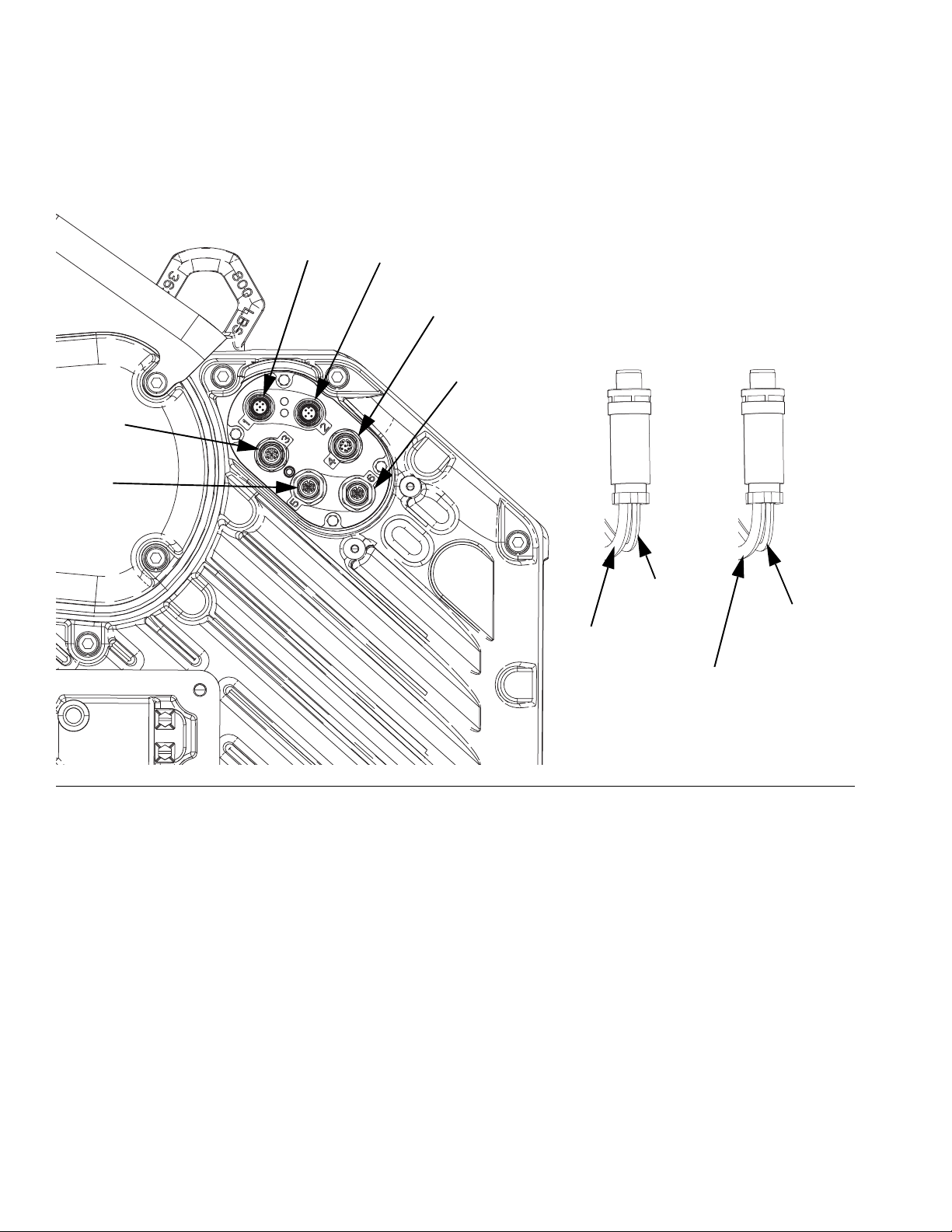

Electric Driver Communication Connections

Single Ram

F

IG

. 8

Key:

Port 1 Connects to port C1 on the Power Junction Box.

Port 2 Connects to port C2 on the Power Junction Box.

Port 3 Connects to port C3 on the Power Junction Box

(M12 5 pin), and to the pump solenoid valve (M8 4

pin).

Port 4 Connects to port C4 on the Power Junction Box

(M12 8 pin), and to the dispense valve solenoid (M8

4 pin).

Port 5 Connects to the pump pressure transducer.

Port 6 Connects to the valve pressure transducer.

18 333586F

Page 19

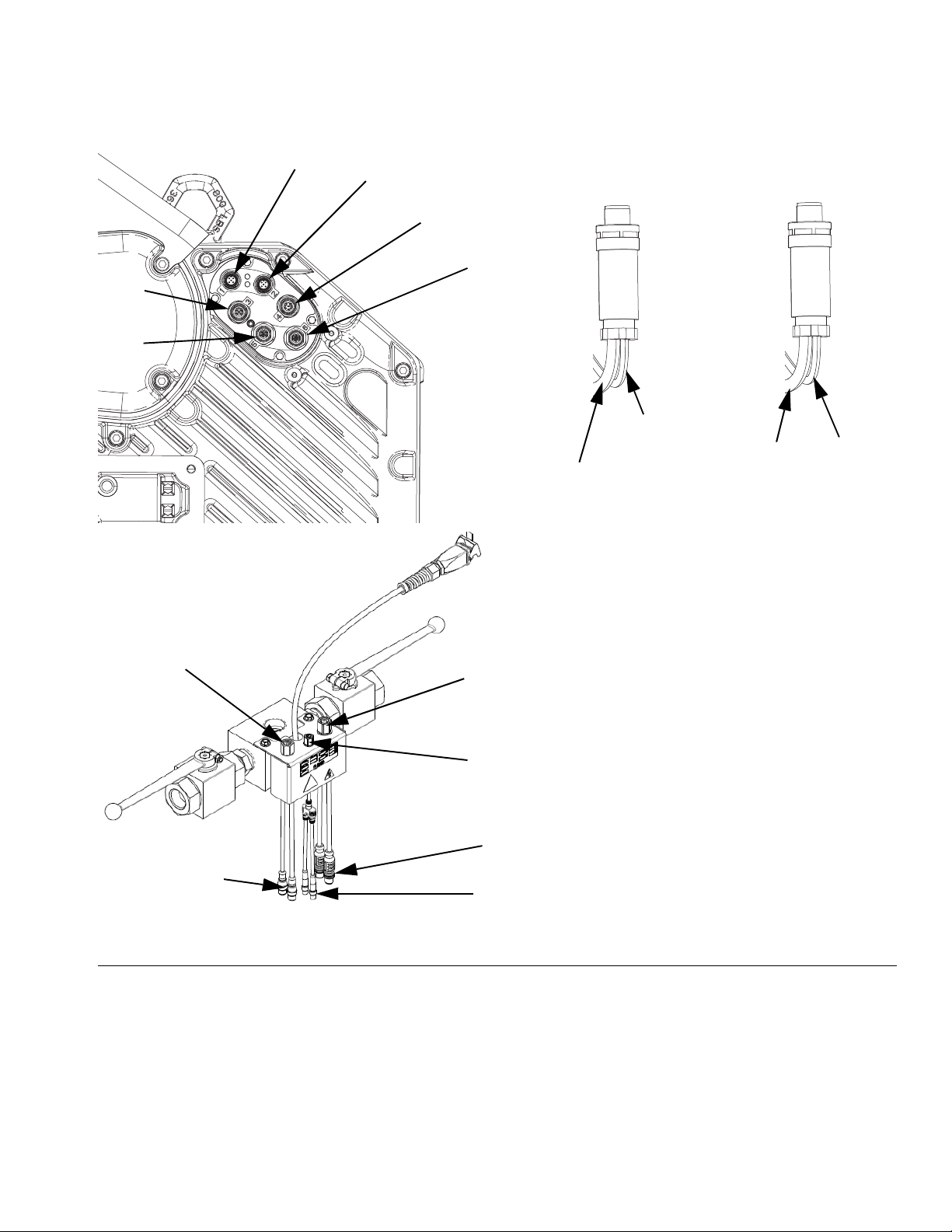

Tandem Ram

Port 1

Port 4

Port 6

Port 3

Port 5

Port 3 Connection

Port 4 Connection

Pump

Solenoid

Valve

(M8 4 pin)

Power

Junction Box

Port C3

(M12 5 pin)

Tandem

Block

discrete

Robot

connection

Splitter

Tandem

Block

dispense

valve

Solenoid

Splitter

(M8 4 pin)

Tandem Block

To Robot

Controller

To Dispense

Valve Solenoid

To Driver Port 6

To Power Junction Box Port C4

(Robot Controller Splitter M12 8 pin)

To Power Junction Box Port C4

(Solenoid Splitter M8 4 pin)

Pressure

Transducer

Port 2

Supply Unit Component Identification

FIG. 9

333586F 19

Page 20

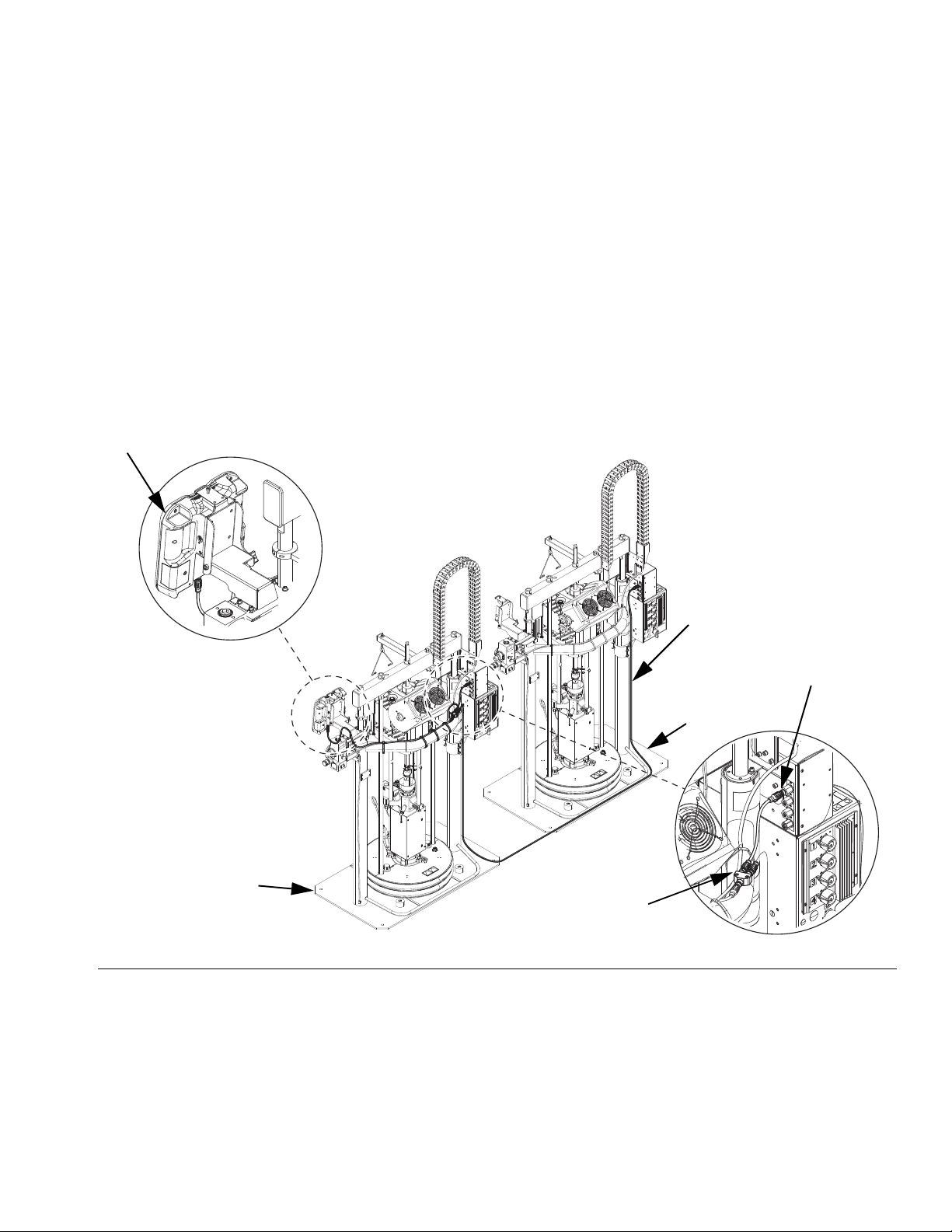

Supply Unit Component Identification

A

K

ADM

C1

Cable from Tandem Kit

Splitter from Tandem Block

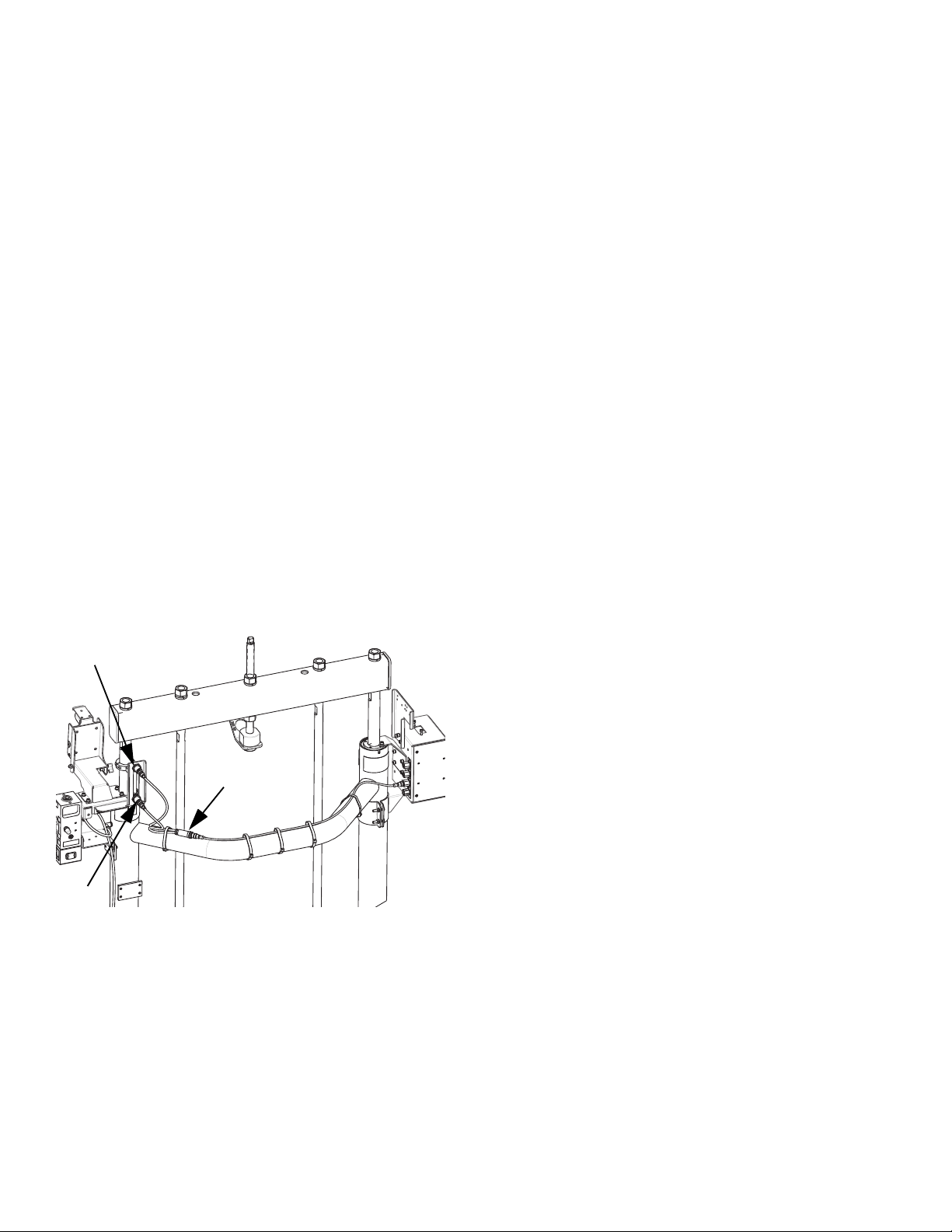

Installing Tandem

1. Remove cable from port C1 on ram 1 and plug into

female end of splitter. Splitter is included in tandem

kit.

2. Install 0.4 m cable (121226) included in tandem kit

from male end of splitter to part C1 on ram 1.

3. Install 5.0 m cable (124003) included in the tandem

kit, from male end of splitter and connect to part C1

of ram 2.

4. Use zip ties included in kit to secure cables to ram

frame. See F

NOTE: Ram 1 includes ADM, ram 2 has no ADM.

IG

. 10 for cable routing.

F

IG

. 10: Communication Connections

Key:

Port 1 Connects to port C1 on the Power Junction Box.

Port 2 Connects to port C2 on the Power Junction Box.

Port 3 Connects to port C3 on the Power Junction Box (M12 5 pin), and to the platen valve solenoid (M8 4 pin).

Port 4 Connects to port C4 on the Power Junction Box, and to the Tandem Block (R) solenoid splitter (M8 4 pin).

Port 5 Connects to the pump pressure transducer.

Port 6 Connects to the valve pressure transducer splitter on the Tandem Block (R).

20 333586F

Page 21

Low Level Sensor Kit, 25R439

LL

EL

SP

NOTE: The Low Level Sensor Kit is an optional

accessory for Single Ram Systems, and a required

accessory for Tandem Ram Systems.

To install the Low Level Sensor:

1. Turn the Disconnect Switch (AZ) OFF.

2. Disconnect cable from the empty level sensor (EL).

3. Mount the low level sensor (LL) on the mounting

bracket.

4. Connect the splitter cable (SP) to the previously

disconnected cable.

5. Connect the splitter cable (SP) lead labeled EMPTY

to the empty level sensor (EL).

6. Connect the splitter cable (SP) lead labeled LOW to

the low level sensor (LL).

Supply Unit Component Identification

7. Raise/lower the low level sensor (LL) to the desired

position to activate the sensor.

8. See the E-Flo iQ Supply System Operation manual

to set up the low level sensor.

333586F 21

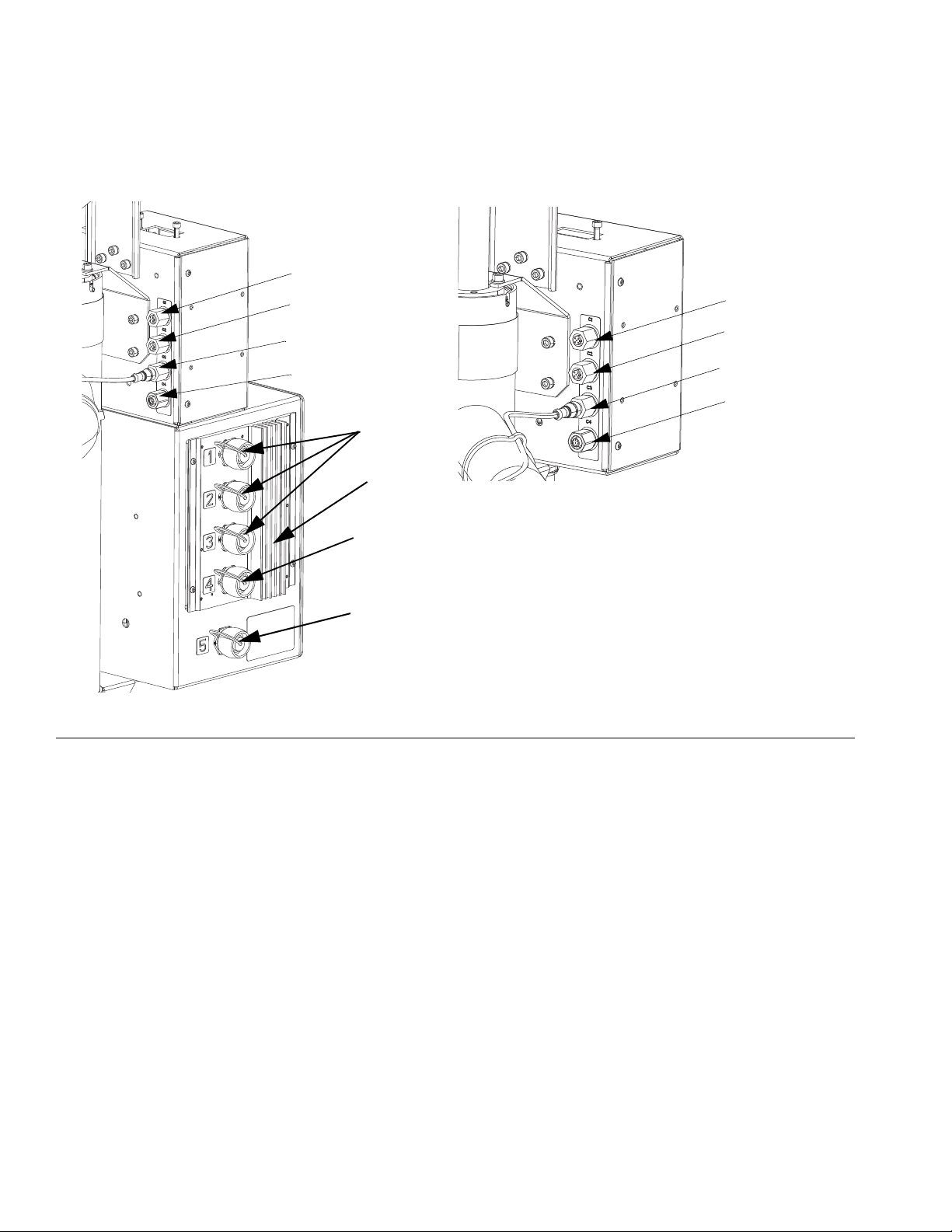

Page 22

Supply Unit Component Identification

C1

C2

C3

C4

Ambient

Heated

C1

C2

C3

C4

C5

C6

C7

AK

AZ

AZ

AMZ

Power Junction Box and Heat Control Box Connections

Single Ram

FIG. 11

Key:

C1 GCA CAN Port (to ADM)

C2 GCA CAN Port (to CGM)

C3 Low and Empty Level Sensor Input

C4 Discrete Integration Cable

22 333586F

C5 Heated Hose/Accessory Connec-

tion

C6 Heated Pump Connection

C7 Heated Platen Connection

AK Power Junction Box Switch

AZ Disconnect Switch

AMZ Auto Multi-Zone

Page 23

Tandem Ram

C1

C2

C3

C4

Ambient

Heated

C1

C2

C3

C4

C5

C6

C7

AMZ

Supply Unit Component Identification

FIG. 12

iQ Ram Supply Unit 1

Key:

C1 GCA CAN Port (to ADM splitter cable on Tandem Block

(R) using the supplied CAN cable (124003))

C2 GCA CAN Port (to CGM)

C3 Low and Empty Level Sensor Input

C4 Discrete Integration Cable (to robot splitter cable on tan-

dem block)

C5 Port 1, Port 2, Port 3: Heated Hose/Accessory Connec-

tion

C6 (Port 4) Pump

C7 (Port 5) Platen

AK Power Junction Box Switch (same as Single Ram on

page 22)

AZ Disconnect Switch (same as Single Ram on page 22)

AMZ Auto Multi-Zone

iQ Ram Supply Unit 2

Key:

C1 GCA CAN Port (to ADM splitter cable on Tandem Block

C2 GCA CAN Port (to CGM)

C3 Low and Empty Level Sensor Input

C4 Discrete Integration Cable (to robot splitter cable on TanC5 Port 1, Port 2, Port 3: Heated Hose/Accessory Connec-

C6 (Port 4) Pump

C7 (Port 5) Platen

AK Power Junction Box Switch (same as Single Ram on

AZ Disconnect Switch (same as Single Ram on page 22)

AMZ Auto Multi-Zone

(R) using the supplied CAN cable (124003))

dem Block (R))

tion

page 22)

333586F 23

Page 24

Installation

Installation

All electrical wiring must be done by a qualified electrician and comply with all local codes and regula-

tions.

The E-Flo iQ Dispense System is shipped in five to six

containers:

1. iQ Ram Supply Unit that includes the fully

assembled ram, electric driver, and pump.

2. iQ Dispense Valve

3. Hoses (shipped in one or two containers depending

on the number of hoses used)

4. Fittings

5. Cables and a pressure transducer

The E-Flo iQ Tandem Dispense System is shipped in

ten to eleven containers:

1. iQ Ram Supply Unit that includes the fully

assembled ram, electric driver, and pump.

2. Second iQ Ram Supply Unit that includes the fully

assembled ram, electric driver, and pump.

3. iQ Dispense Valve

4. Hoses (shipped in three or four containers

depending on the number of hoses used)

5. Fittings

6. Tandem fittings

7. Cables and a pressure transducer

8. Tandem Kit

Location

Remove the iQ Ram Supply Unit from its crate. Attach a

lifting sling at the proper lift locations (see F

of the pallet using a crane or a forklift.

To properly locate and anchor the iQ Ram Supply Unit

(A), see Dimensions on page 93.

NOTICE

Always lift the iQ Ram Supply Unit at the proper lift

locations (see F

Failure to lift at the proper lift locations can result in

damage to the system.

NOTE: The lift ring on the Driver (AB) is only to be used

for replacing the Driver. Do not use it to lift the entire

system.

Position the Ram Assembly (AA) so the Driver (AB),

Power Junction Box Switch (AK) and/or Disconnect

Switch (AZ), Integrated Air Controls (AG), and ADM

(AF) are easily accessible. Ensure that there is enough

space overhead for the Ram Assembly to raise fully.

Use the holes in the Ram Assembly base as a guide

and drill holes for 1/2 in. (13 mm) anchors.

Ensure that the Ram Assembly base is level in all direc-

tions. If necessary, level the base using metal shims.

Secure the base to the floor using 1/2 in. (13 mm)

anchors that are long enough to prevent the Ram

Assembly from tipping.

IG

. 3). Do not lift in any other way.

IG

. 3). Lift off

NOTE: Additional items including CGM and accessories

may be shipped in additional containers.

This section describes how to install and set up the

E-Flo iQ system and make all the necessary component

connections.

24 333586F

Page 25

Installation

LQ

LQ

Grounding

The equipment must be grounded to reduce the risk

of static sparking and electric shock. Electric or static

sparking can cause fumes to ignite or explode.

Improper grounding can cause electric shock.

Grounding provides an escape wire for the electric

current.

Ram Assembly: the iQ Ram Supply Unit is grounded

through the incoming power cord. See Connect Power

on page 25.

Air and fluid hoses: use only electrically conductive

hoses with a maximum of 500 ft. (150 m) combined

hose length to ensure grounding continuity. Check the

electrical resistance of the hoses. If the total resistance

to ground exceeds 29 megaohms, replace the hose

immediately.

Air compressor: follow the manufacturer’s recommen-

dations.

Power Requirements

Each iQ Ram Supply Unit requires a dedicated circuit

protected with a circuit breaker.

For Ambient Systems:

Voltage Phase Hz Current

200-240 VAC 1 50/60 20 A

For Heated Systems:

Voltage Phase Hz Current

200-240 VAC 1 50/60 60 A

200-240 VAC 3 50/60 38 A

380-420 VAC 3 (YN) 50/60 38 A

Connect Power

NOTICE

To avoid equipment damage, route and secure a

power cord that is long enough to allow the full range

of movement for the Ram.

Dispense valve: see the iQ Dispense Valves Instruc-

tions-Parts manual for grounding information.

Fluid supply container: follow local code.

Solvent pails used when flushing: follow local code.

Use only conductive metal pails, placed on a grounded

surface. Do not place the pail on a non-conductive sur-

face, such as paper or cardboard, which interrupts the

grounding continuity.

To maintain grounding continuity when flushing or

relieving pressure: hold a metal part of the dispense

valve firmly to the side of a grounded metal pail, then

trigger the valve.

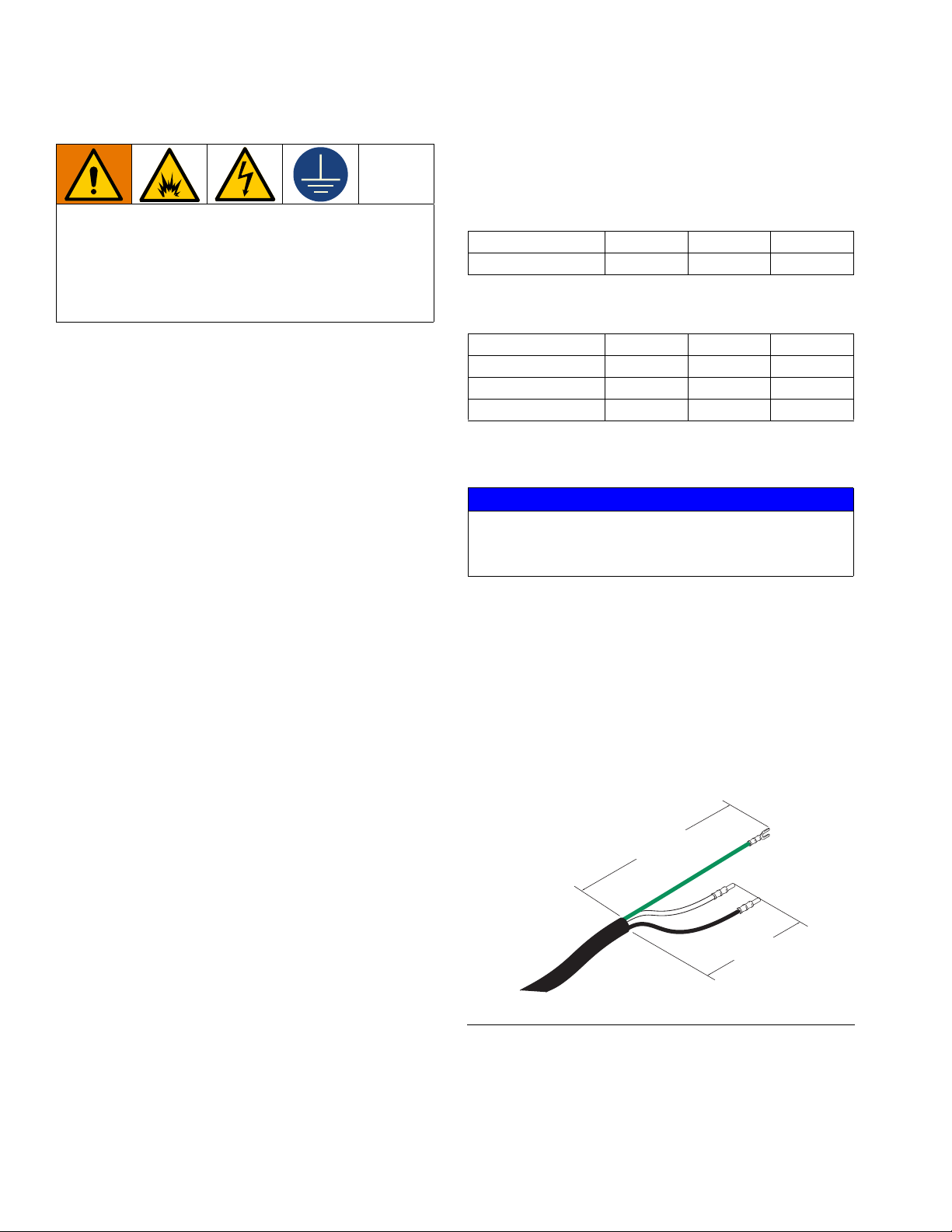

Ambient Systems

1. Turn the Disconnect Switch (AZ) OFF.

2. Cut power cord wires to the following lengths:

• Ground wire - 6.5 inches (16.5 cm)

• Power wires - 3.0 inches (7.6 cm)

• Add ferrules as necessary. See F

FIG. 13: Power Cord

3. Remove the six screws holding the cover of the

Power Junction Box (AJ), then remove the Power

Junction Box cover.

IG

. 13.

333586F 25

Page 26

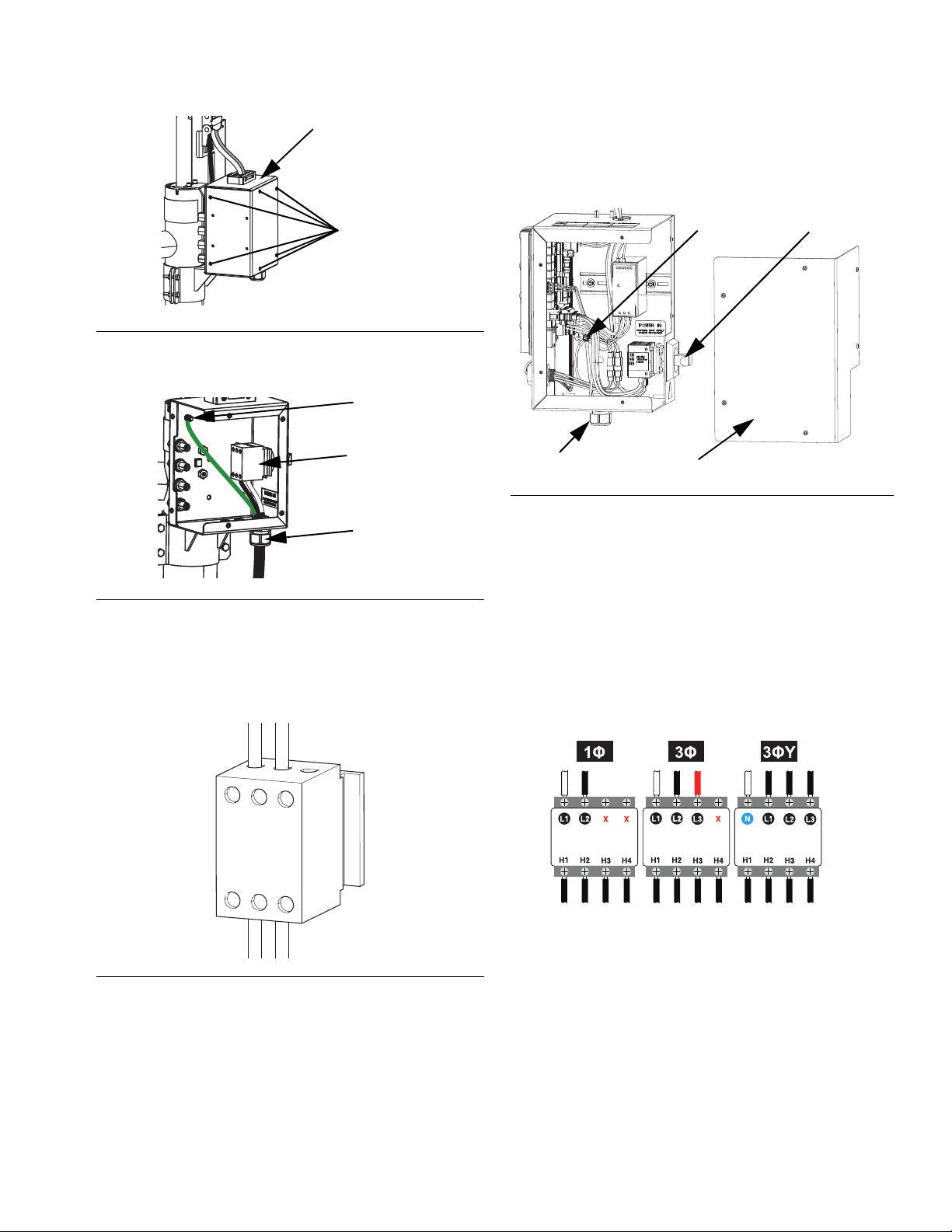

Installation

Screws

AJ

Ground Lug

Cord Grip

Disconnect Switch

Terminal Block

1L1

3L2

5L3

2T1

4T2

6T3

SR

350

GS

AZ

ti31214a

FIG. 14: Remove the Power Junction Box Cover

4. Insert the power cord through the cord grip and into

the Power Junction Box (AJ).

Heated Systems

1. Turn the Heat Control Box Disconnect Switch (AZ)

OFF.

FIG. 17

2. Loosen the screws and remove the cover (350) on

the Heat Control Box (AX).

FIG. 15: Power Connection

5. Attach the ground wire to the ground lug inside the

Power Junction Box (AJ).

6. Refer to F

IG

. 16 and connect the wires from the

power cord into terminals 4T2 and 6T3 on the Dis-

connect Switch terminal block.

3. Insert the electrical cord through the electrical

enclosure strain relief bushing (SR).

4. Attach insulated ferrules to the end of each wire.

5. Connect the ground wire to the ground stud (GS).

6. Connect power wires to the Heat Control Box Dis-

connect Switch (AZ) as shown below.

NOTE: Use a flat-head or Pozidriv screwdriver to tighten

the terminals to 7-10 in-lb (0.8-1.1 N•m).

FIG. 16: Disconnect Switch Terminal Block

NOTE: Use a flat-head or Pozidriv screwdriver to tighten

7. Tighten the strain relief bushing (SR) around the

electrical cord.

the terminals to 7-10 in-lb (0.8-1.1 N•m).

7. Tighten the cord grip to securely hold the power

cord to the Power Junction Box (AJ).

8. Replace the Power Junction Box cover and secure it

with the six screws that were removed in step 2.

26 333586F

8. Close the Heat Control Box door (350).

Page 27

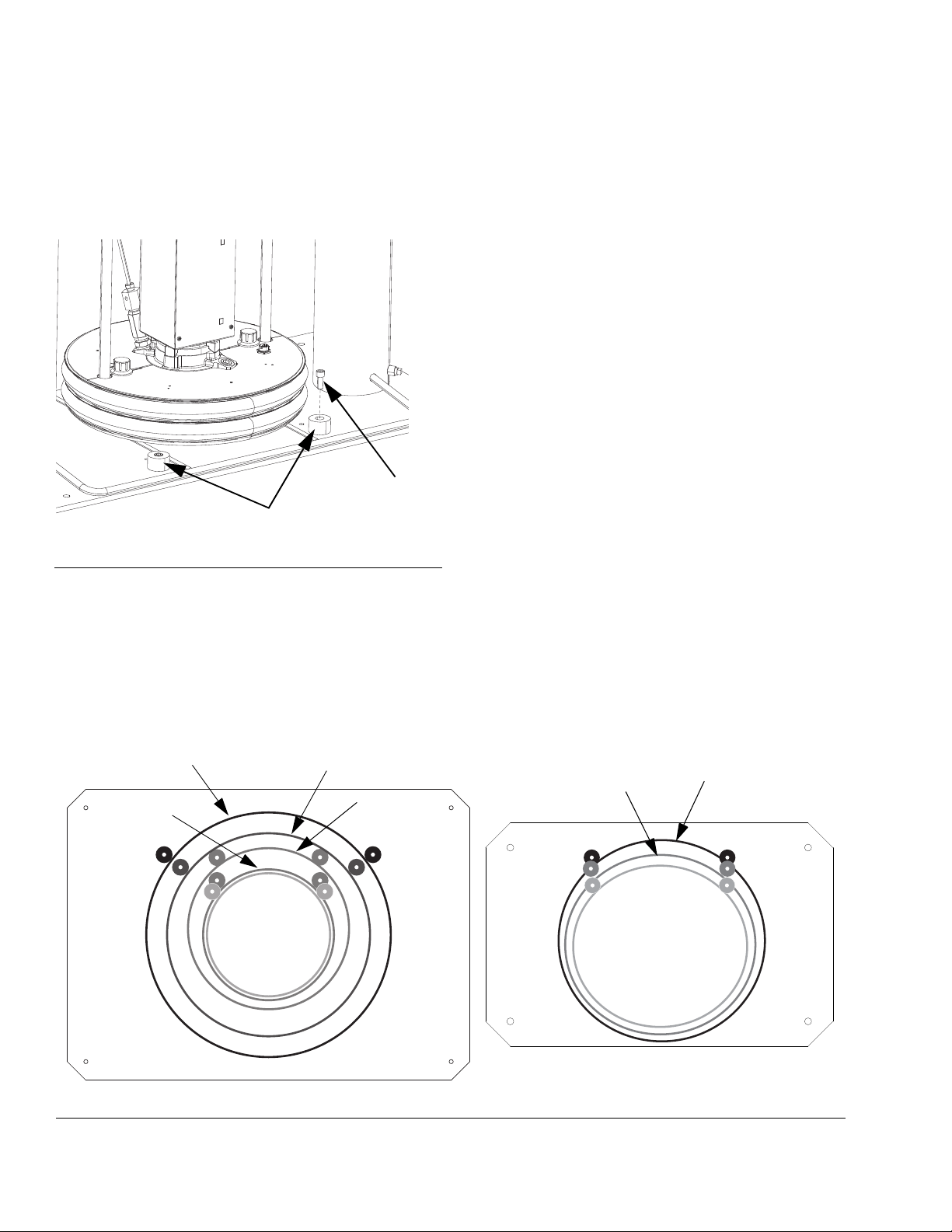

Attach Drum Stops

Drum Stops

Capscrews

55 gal (200 L)

30 gal (115 L)

8 gal (30 L)

5 gal (20 L)

D200 and D200s Base D60 Base

8 gal (30 L)

5 gal (20 L)

60 gal (16 L)

16 gal (60 L)

The iQ Ram Supply Units are shipped with drum stops

in place to help position the drum on the Ram Assembly

(AA). For replacement parts, order Kit 255477. The kit

includes 2 each of capscrews, lock washers (not

shown), and drum stops.

Installation

FIG. 18: Drum Stop Installation

1. Locate the correct set of mounting holes on the

Ram Assembly base. See F

2. Using the capscrews and lock washers, attach the

drum stops to the Ram Assembly base.

IG

. 19.

FIG. 19: Ram Base

333586F 27

Page 28

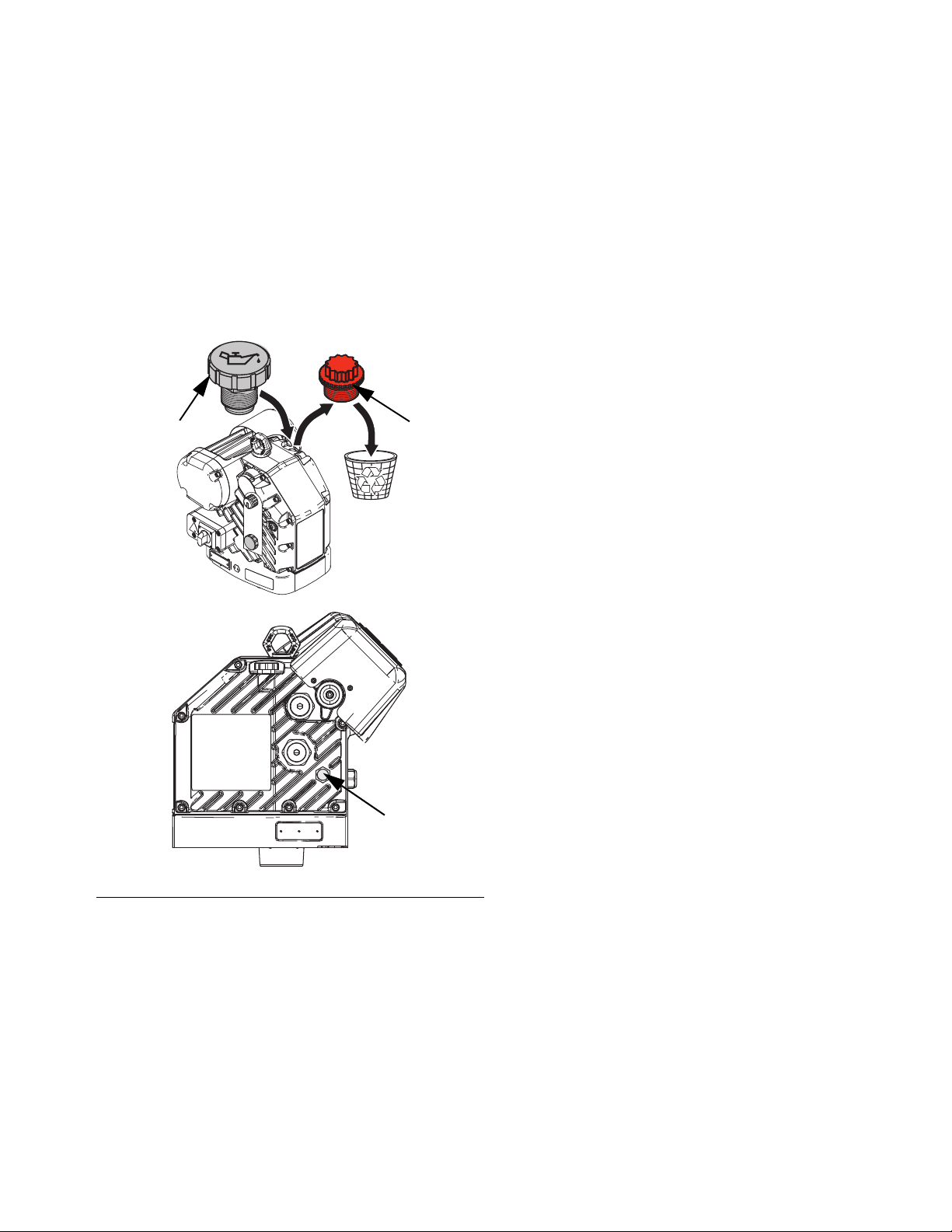

Installation

Unvented

Cap

Vented Cap

Sight Glass

Install Vented Oil Cap Before Using Equipment.

The Driver gear-box is shipped from the factory

pre-filled with oil. The temporary unvented cap prevents

oil leaks during shipment. Replace this temporary cap

with the vented oil cap supplied with the equipment

before use.

NOTE: Prior to use, check oil level. Oil level should be

half way up the sight glass.

28 333586F

FIG. 20: Unvented and Vented Oil Caps

Page 29

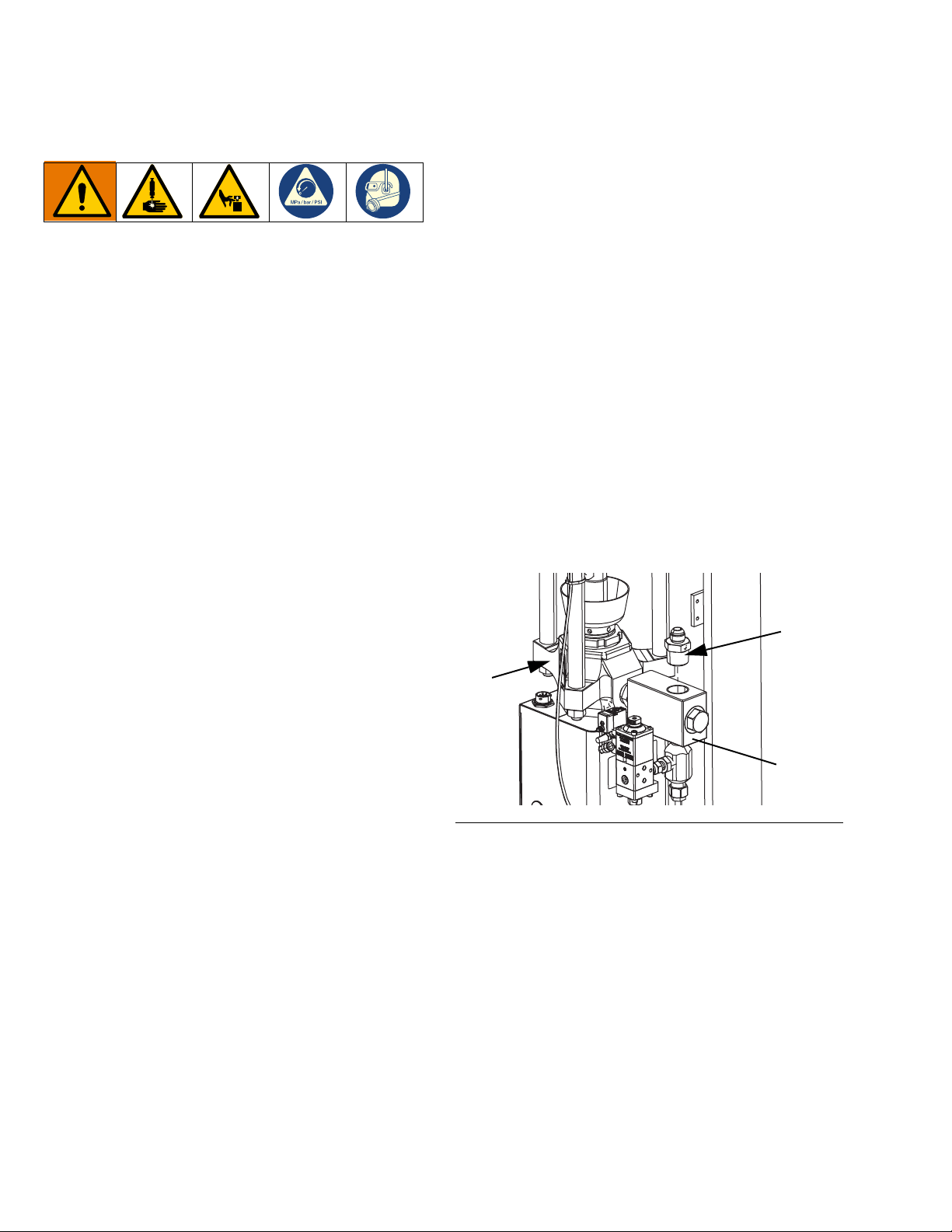

Setup

A, K

E, N, P

Fluid

Check

Valve

Setup

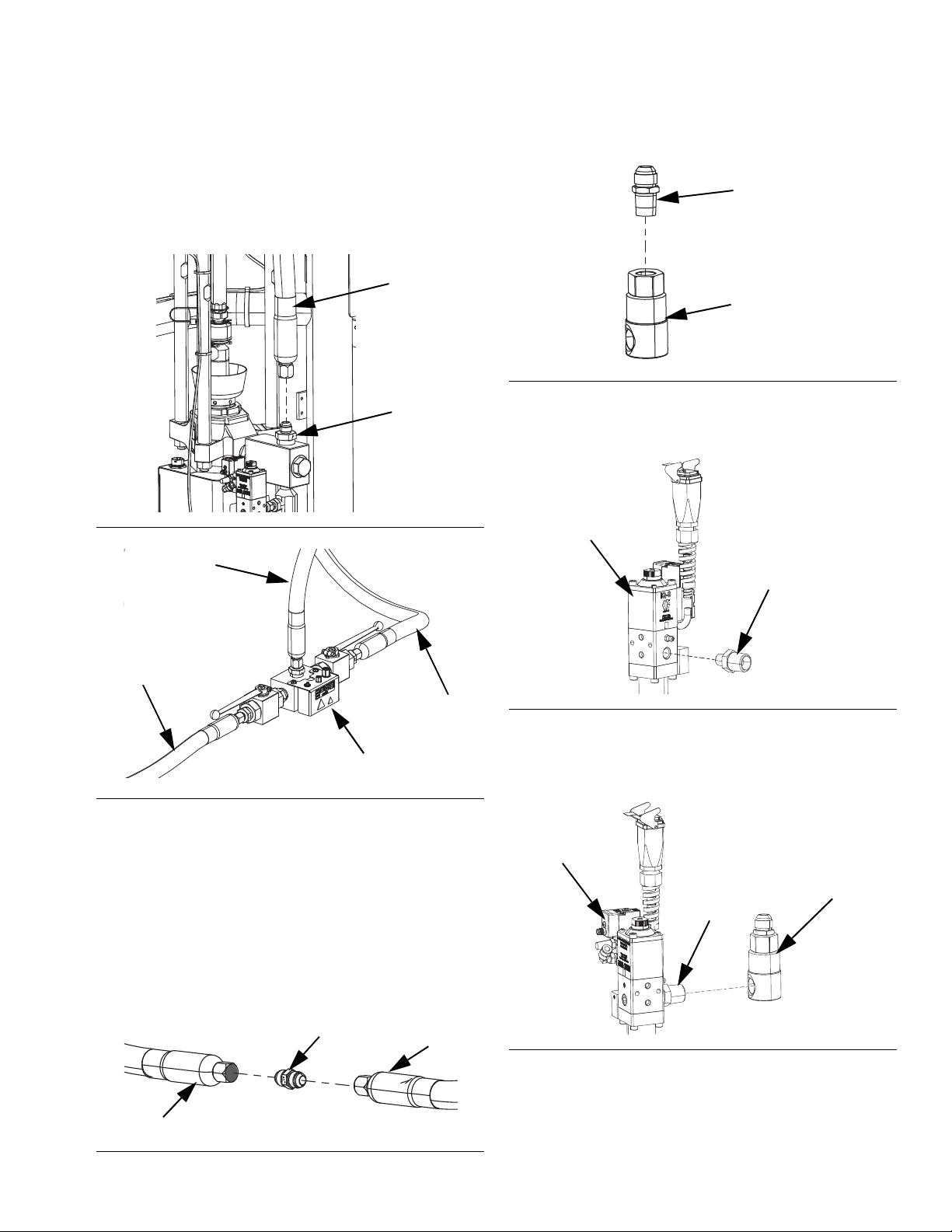

2. If using a Single iQ Ram Supply System, connect

the Ram Supply System to Supply Hose 1 Fitting

(E) to the fluid check valve (AE) on the iQ Ram

Supply Unit (A).

Remove the iQ Dispense Valve (B) from its packaging.

Refer to the iQ Dispense Valves Instructions-Parts

manual included with the valve for information about

installing the valve. See Related Manuals on page 3.

Air Line Connections

Refer to FIG. 3 on page 13 for a typical installation.

Attach the Air Line (AR) (not supplied) to the bottom of

the Integrated Air Control (AG) at the 3/4 in. NPT con-

nection.

NOTE: Be sure all components are adequately sized

and pressure rated to meet the system’s requirements.

Hoses and Fittings

NOTE: A number of options are available for fittings,

hoses, and cables for the E-Flo iQ Dispense System.

Yours may differ in appearance from those shown in

F

IG

. 1 on page 11 and FIG. 2 on page 12. However, the

steps for making the connections are the same.

3. If using a Tandem iQ Ram Supply System:

a. Connect the Ram Supply Unit 1 to Tandem

Hose 1 Fitting (N) to the fluid check valve (AE)

on iQ Ram Supply Unit 1 (A).

b. Connect the Ram Supply Unit 2 to Tandem

Hose 2 Fitting (P) to the fluid check valve (AE)

on the iQ Ram Supply Unit 2 (K).

NOTE: The Recirculation Hose (ZB) should not be

connected to the to the platen fitting at this time. See the

E-Flo iQ Dispense System Operation manual for more

information on when to connect the Recirculation Hose

(ZB).

See F

IG

. 1 on page 11 and FIG. 2 on page 12 to connect

the hoses and fittings to the iQ Ram Supply Unit(s) (A,

K) and the Dispense Valve (B).

NOTE: Do not connect any hoses if flushing the pump

for the first time. See the E-Flo iQ Dispense System

Operation manual for instructions on flushing the pump

and connecting hoses.

NOTE: To ensure the best crossover performance with

an E-Flo iQ Tandem System, Tandem Hose 1 and

Tandem Hose 2 must be the same inner diameter and

length.

1. Follow the Pressure Relief Procedure on page 39.

333586F 29

FIG. 21

4. If using a Single iQ Ram Supply System, connect

Supply Hose 1 (C) to the Ram Supply System to

Supply Hose 1 Fitting (E) as shown in F

F

IG

. 22.

5. If using a Tandem iQ Ram Supply System:

a. Connect Tandem Hose 1 (L) to the Ram Supply

Unit 1 to Tandem Hose 1 Fitting (N) as shown in

F

IG

. 2 and FIG. 22.

b. Connect Tandem Hose 2 (M) to the Ram

Supply Unit 2 to Tandem Hose 2 Fitting (P) as

IG

shown in F

. 2 and FIG. 22.

IG

. 1 and

Page 30

Setup

E, N, P

L, M, C

C

R

L

M

F

C

D

G

H

J

B

J

B

H

c. Connect Tandem Hose 1 (L) and Tandem Hose

2 (M) from the supply system to the Tandem

Block (R). See F

IG

. 23.

d. Connect Supply Hose 1 (C) to the Tandem

IG

Block (R). See F

. 23.

FIG. 22

7. Connect the Supply Hose 2 to Swivel Fitting (G) to

the Swivel Fitting (H).

FIG. 25

8. Connect the Swivel to Valve Fitting (J) to the

Dispense Valve (B) as shown in F

IG

. 26.

FIG. 26

9. Connect the Swivel Fitting (H) to the Dispense

Valve (B) at the Swivel to Valve Fitting (J) that was

connected in step 8.

FIG. 23

6. If you are using two supply hoses (C and D), use the

Supply Hose 1 to Supply Hose 2 Fitting (F) to

connect Supply Hose 1 (C) to Supply Hose 2 (D).

See F

IG

. 24.

NOTE: If using heated hoses, make sure the electrical

connections of each hose are oriented correctly, with

the circular electrical connector facing the Ram. See

F

IG

. 1 on page 11 for proper hose orientation on the

system.

FIG. 27

FIG. 24

30 333586F

Page 31

Setup

B

H

G

D

PC

PC

Pressure Transducer Cable

Connection (XX).

Discrete Robot Cable

Connection (SS).

Dispense Valve solenoid

Cable Connection (YY).

M12 8 pin Discrete Robot

Splitter (RR).

M8 4 Pin Dispense Valve

Solenoid Splitter (TT) to

Splitter Attached to Port 4

on Electric Drive (AB) on

Ram 1 and Ram 2. Pin

M12 5 Pin Pressure

Transducer Splitter

Cable (ZZ) to Port 6

on Electric Drive

(AB) on Ram 1 and

Ram 2..

R

(NN)

10. If two hoses are used, connect Supply Hose 2 (D) to

the Swivel Fitting (H) on the Dispense Valve (B)

using the Supply Hose 2 to Swivel Fitting (G). If only

one hose is used, connect Supply Hose 1 (C) to the

Swivel Fitting (H) on the Dispense Valve (B) using

the Supply Hose 2 to Swivel Fitting (G).

FIG. 28

11. Tighten all fittings until secure.

12. Connect the Air Line (AR) (not supplied) to the air

fitting (FT) on the dispense valve solenoid. See the

iQ Dispense Valves Instructions-Parts manual. See

F

IG

. 31.

Electrical Connections

Pressure Transducer

1. If using a Single iQ Ram Supply System, connect

the pressure transducer cable (PC) from dispense

valve (B) to Port 6 on the Electric Driver (AB). See

Electric Driver Communication Connections for

Single Rams on page 18.

2. If using a Tandem iQ Ram Supply System:

a. Connect the Pressure Transducer Cable (PC)

from the Dispense Valve (B) to the Tandem

Block Valve Pressure Transducer Splitter. See

F

IG

. 29.

b. Connect one male end of the M12 5 pin

Pressure Transducer Splitter cable (ZZ) on the

Tandem Block (R) to Port 6 on the Electric

Driver (AB) on Ram 1. The second male end

goes to Port 6 on Ram 2. See Electric Driver

Communication Connections for Tandem

Rams on page 19.

FIG. 29

333586F 31

Page 32

Setup

Solenoid Valve

Solenoid Valve

Cable

B

PA

PC

FT

VD

NN

VC

Dispense Valve Solenoid

3. If using a Single iQ Ram Supply System:

a. Connect the solenoid valve cable (VC) to the

M8 4 pin end of the splitter cable attached to

Port 4 on the Electric Driver (AB). See Electric

Driver Communication Connections for

Single Rams on page 18. See F

b. Connect the 90 degree end of the included M8 4

pin cable (VD) to the dispense valve, and the

straight end of the solenoid valve cable to (VC).

See F

IG

. 31.

4. If using an iQ Tandem Ram Supply System:

IG

. 31.

a. Connect the dispense valve solenoid cable to

the tandem dispense valve solenoid connector

(YY) on tandem block (R).

b. Connect the 90 degree end of the included M8 4

pin cable (15N040) to the dispense valve, and

the straight end of the solenoid valve cable to

(VC). See F

IG

. 31.

c. Connect one male end of the M8 4 pin splitter

(TT) on the tandem block (R) to the M8 4 pin

end of the splitter cable attached to Port 4 on

the Electric Driver (AB) for ram 1 and ram 2.

See Electric Driver Communication

Connections for Tandem Rams on page 19.

NOTE: Make sure the pins on the solenoid valve cable

are oriented as shown in F

IG

. 30 before the cable is

plugged into the solenoid valve.

FIG. 31

Robot Connection (if used)

5. If using a Single iQ Ram Supply System:

a. Connect the included M12 8 pin 4 meter I/O

integration cable with flying leads (128441) to

Port C4 of the power junction box (AJ)

b. Flying leads of the 4 meter I/O integration cable

(128441) connect to robot controller (not

included).

6. If using a Tandem iQ Ram Supply System:

a. Connect the included M12 8 pin 4 meter I/O

integration cable with flying leads (128441) to

discrete robot cable connector (SS) on tandem

block (R).

b. Connect M12 8 pin discrete robot splitter (RR)

to Port C4 of the power junction box (AJ) on ram

1 and ram 2.

c. Flying leads from the 4 meter I/O integration

cable (128441) connect to robot controller (not

included).

FIG. 30

NOTE: If the robot controller is located further away

from the unit than the 4 meter I/O integration cable

(128441) can reach, an integration extension cable can

be used to increase the length. See

32 333586F

Page 33

Setup

Hose 1

Circular electrical

connection

Hose 2 *

Circular electrical

connection

Square electrical

connection

Square electrical

connection

C5 - Port 1

C5 - Port 2

Single system includes:

• Two heated hoses

• One heated valve

Heat Connections (Hoses and Accessories)

1. Connect heated hoses (with circular electrical

connectors) to Heat Control Box Ports 1, Port 2 or

Port 3 (C5).

2. Connect heated accessories to the square electrical

connector end of each heated hose that is used.

Single System Example

Example 1: Single system with two heated

hoses and one heated dispense valve.

• Hose 1 - Circular electrical connection to Port 1

(C5).

• Hose 2 - Circular electrical connectors to Port 2

(C5). *

• Heated valve - Square electrical connections from

hose 2 to iQ dispense valve (B). See F

IG

. 32.

F

IG

. 32

Note: port 4 is always used for heated pump. Port 5 is

always used for heated platen.

* Requires Heat Extension Cables. See page 82.

333586F 33

Page 34

Setup

Tandem system includes:

• Four heated hoses

• One heated tandem block

• One heated valve

C5 - Port 1

C5 - Port 1

C5 - Port 2

C5 - Port 3

Ram 1

Ram 2

Ram 1

Ram 2

Hose 1

Circular electrical

connection

Hose 2

Square electrical

connection

Hose 3 *

Hose 4 *

Circular electrical

connection

Example 2: Tandem system with 4 heated

hoses, one heated tandem block and one

heated dispense valve.

• Hose 1 - To tandem block from pump 1 - circular

electrical connection to Port 1 (C5) of ram 1.

• Hose 2 - To tandem block from pump 2 - circular

electrical connector to Port 1 (C5) of ram 2. **

• Hose 3 - From tandem block - circular electrical

connector to part 2 (C5) of ram 1 or ram 2. *

• Hose 4 - From hose 3 to extend length of hose circular electrical connector to Port 3 (C5) of ram 1

or ram 2. *

• Heated Valve - Square electrical connection from

hose 4 to iQ dispense valve (B).

• Heated Tandem Block - Square electrical

connection from hose 1 or hose 2 to heated tandem

block (R). See F

IG

. 33

.

F

IG

. 33

Note: port 4 is always used for heated pump. Port 5 is

always used for heated platen.

* Requires Heat Extension Cables. See page 82.

** Heat extension cable included in tandem block kit

(25R848).

34 333586F

Page 35

Wet Cup

AN

Before starting, fill the Wet Cup (AN) 1/3 full with Graco

Throat Seal Liquid (TSL) or a compatible solvent.

Torque the Wet Cup

The Wet Cup (AN) is torqued at the factory; however,

throat packing seals on Severe Duty pumps may relax

over time. Check Wet Cup torque frequently after initial

start-up and periodically after the first week of produc-

tion. Maintaining proper Wet Cup torque is important to

extending seal life.

Setup

FIG. 34: Wet Cup

NOTE: MaxLife pumps use a special u-cup throat seal

that is non-adjustable and does not require periodic

torquing.

1. Follow the Pressure Relief Procedure on page 39.

2. Torque the Wet Cup (AN) 95-115 ft-lbs (128-155

N•m) using the packing nut wrench (supplied)

whenever necessary. Do not overtighten the Wet

Cup.

333586F 35

Page 36

Hose Care Guidelines

Hose Care Guidelines

Fluids subjected to heat in confined spaces can

create a rapid rise in pressure due to the thermal

expansion. Over-pressurization can result in equip-

ment rupture and serious injury.

• Open a valve to relieve the fluid expansion during

heating.

• Replace hoses pro actively at regular intervals

based on your operating conditions.

NOTE: Pressure check the hose assemblies. Refer to

the E-Flo iQ Supply System Operation manual for

instructions on priming the system. Check carefully for

leaks at the hose connections. If there are leaks, follow

the Pressure Relief Procedure on page 39.

Do not use hose to pull the equipment.

Use hose support spring.

Do not clamp, squeeze, or zip tie hose.

Minimum bend radius:

Use 2 wrenches to tighten. Torque to specification:

Do not tape or cover hose.

Do not flex hose when cold.

Do not bend or crimp hose.

Do not twist hose.

Use proper length hose.

Flush Before Using Equipment

The equipment was tested with lightweight oil, which is

left in the fluid passages to protect parts. To avoid

contaminating the fluid with oil, flush the equipment with

a compatible solvent before using the equipment. See

the E-Flo iQ Supply System Operation manual for

information about flushing the equipment. See Related

Manuals on page 3.

36 333586F

Page 37

Check Resistance (Heated Systems)

Check Resistance (Heated Systems)

Check Sensor Resistance

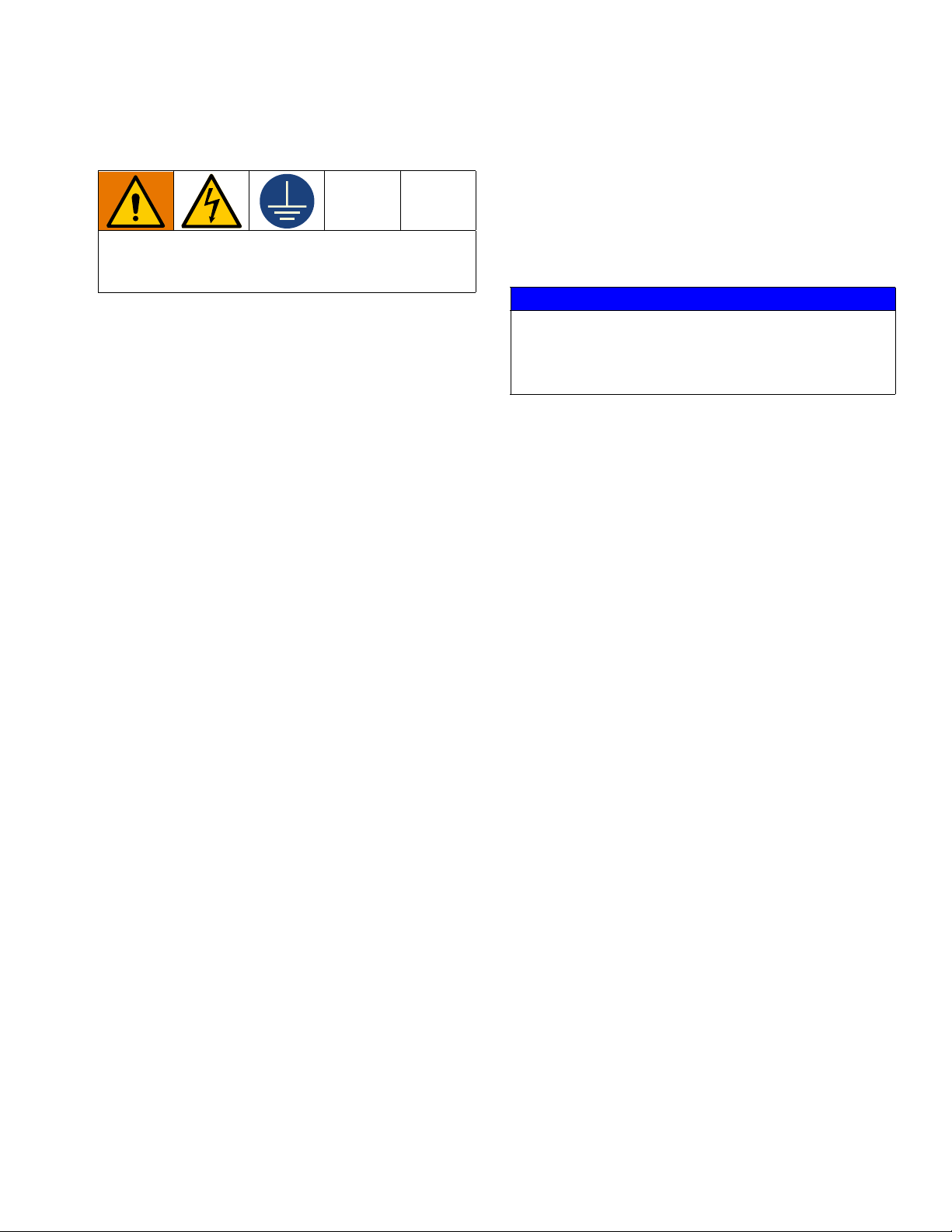

To reduce risk of injury or damage to equipment,

conduct these electrical checks with the Power

Junction Box Switch (AK) and the Disconnect Switch

(AZ) OFF.

NOTE: Instructions for checking sensor resistance

applies to heated systems only.

The package includes up to nine heat sensors and

controllers for each of the heated zones. To check

sensor resistance:

1. Turn the Power Junction Box Switch (AK) and the

Disconnect Switch (AZ) OFF.

2. Wait for components to cool down to ambient room

temperature 63°-77°F (17°-25°C). Check electrical

resistance for the components.

NOTE: Check resistance at ambient room temperature

63°-77°F (17°-25°C).

Check Heater Resistance

To reduce risk of injury or damage to equipment,

conduct these electrical checks with the Power

Junction Box Switch (AK) and the Disconnect Switch

(AZ) OFF.

NOTE: Instructions for checking heater resistance

applies to heated systems only.

1. Turn the Power Junction Box Switch (AK) and the

Disconnect Switch (AZ) OFF.

2. Make electrical resistance checks for the compo-

nents.

3. Replace any parts whose resistance readings do

not comply with the ranges listed in Table 1: Sen-

sors on page 38.

Circular Hose

AMZ Pins

First Heat Zone A, J

Second Heat Zone C, D

First RTD G, K

Second RTD M, K

Earth Ground B

3. Replace any parts whose resistance readings do

not comply with the ranges listed in Table 1: Sen-

sors on page 38.

Connector

333586F 37

Page 38

Check Resistance (Heated Systems)

Table 1: Sensors

Port Zone Component

1 Heated Hose 100 G, K See hose manual See hose manual

1

2

3

4

59

2 Heated Accessory 1 100 M, K See accessory manual

3 Heated Hose 100 G, K See hose manual See hose manual

4 Heated Accessory 2 100 M, K See accessory manual

5 Heated Hose 100 G, K See hose manual See hose manual

6 Heated Accessory 3 100 M, K See accessory manual

7 Not Used NA NA NA NA

8 Pump 1000 M, K 37 C, D

5 gallon platen 100 M, K 80 C, D

55 gallon platen 1000 M, K 15

RTD Range

(Ohms)

RTD Pin

Numbers

Heater Element

Resistance (Ohms)

Heater Pin

Numbers

See accessory

manual

See accessory

manual

See accessory

manual

C, D (#1)

A, J (#2)

38 333586F

Page 39

Pressure Relief Procedure

S

Pump

Pressures

Valve

Pressure

Pump

Pressure

Valve

Pressure

Single Unit Run Screen

Tandem Unit Run Screen

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, splashing

fluid and moving parts, follow the Pressure Relief Pro-

cedure when you stop spraying and before cleaning,

checking, or servicing the equipment.

NOTE: The ADM must be in Local control mode to

depressurize the system. See the See the E-Flo iQ

Supply System Operation manual.

NOTE: For iQ Tandem Ram Supply Systems, make

sure both Ball Valves (S) on the Tandem Block are open

to ensure pressure is fully relieved.

soft key to open the iQ Dispense Valve (B) allowing

the system to depressurize.

FIG. 35: Tandem Block Ball Valves

NOTE: To relieve pressure for the entire E-Flo iQ

Dispense System, follow steps 1 through 12. To relieve

pressure for the fluid side only, leaving air on to the ram

cylinder follow steps 1 through 9.

1. Ensure the control mode is set to Local. See Con-

trol Modes in the E-Flo iQ Supply System Opera-

tion manual.

2. At the ADM (AF) Run screen, press the soft

key for Valve Depressurization. Then press the

333586F 39

3. The current pump pressure and current dispense

valve pressure show the progress of the

depressurization on the Run screen.

4. When all of the pressure has been relieved in the

system, press the soft key to close the iQ

Dispense Valve (B).

5. Press the soft key to exit the valve

depressurization mode.

NOTE: If using a tandem system, perform steps 6-12 on

both units.

6. If using an ambient system, turn the Disconnect

Switch (AZ) OFF. If using a heated system, turn the

Page 40

Pressure Relief Procedure

BA

BC

Open

Close

Power Junction Box Switch (AK) and the Disconnect

Switch (AZ) OFF.

7. Open the Pump Bleed Valve (AM). Have a container

ready to catch the drainage.

8. Leave the Pump Bleed Valve (AM) open until ready

to dispense again.

9. If you suspect the dispense valve is clogged or that

pressure has not been fully relieved:

a. VERY SLOWLY loosen the hose end coupling to

relieve pressure gradually.

b. Loosen the coupling completely.

c. Clear the obstruction in the tip/nozzle of the

valve.

10. Close the Main Air Slider Valve (BA).

FIG. 36: Air Control for Pressure Relief

11. Set the Ram Director Valve (BC) to DOWN. The

Ram (AA) will slowly drop.

12. Once the Ram (AA) is completely down, jog the Ram

Director Valve (BC) up and down to bleed air from

the Ram (AA) cylinders.

40 333586F

Page 41

Shutdown and Care of the Pump

Change Drums

Shutdown and Care of the Pump

NOTICE

To prevent damage to the pump from rust, never

leave water or water-based fluid in a carbon steel

pump overnight. If you are pumping a water-based

fluid, flush with water first. Then flush with a rust

inhibitor, such as mineral spirits. Relieve pressure,

but leave the rust inhibitor in the pump to protect

parts from corrosion.

1. Follow the Pressure Relief Procedure on page 39.

2. Set the Ram Director Valve (BC) to DOWN, and

lower the Ram (AA) to the desired position for

shutdown. If using a tandem system, perform this

step on both units.

3. Set the Ram Director Valve (BC) to neutral.

4. Stop the Pump at the bottom of the stroke to prevent

fluid from drying on the exposed displacement rod

and damaging the throat packings. See the E-Flo iQ

Supply System Operation manual for information

about jogging the Pump. See Related Manuals on

page 3.

5. Always flush the Pump before the fluid dries on the

displacement rod. See the E-Flo iQ Supply System

Operation manual for steps to flush the pump.

Keep hands away from the pump inlet to prevent

serious injury from moving parts.

If the Platen (AD) does not come out of the pail easily

when the Pump is being raised, the air assist tube (AT)

or check valve (416) may be plugged. A plugged valve

prevents air from reaching the underside of the plate to

assist in raising it from the pail. See F

1. Turn off power to the Electric Driver (AB):

a. If using an ambient Single Ram Supply System,

turn the red Disconnect Switch (AZ) OFF. See

F

IG

. 37.

b. If using a heated Single Ram Supply System,

turn the black Power Junction Box Switch (AK)

OFF. See F

c. If using an ambient Tandem Ram Supply

System, turn the red Power Junction Box Switch

(AK) OFF on the Ram Supply Unit that requires

a drum change only. See F

d. If using a heated Tandem Ram Supply System,

turn the black Disconnect Switch (AZ) OFF on

the Ram Supply Unit that requires a drum

change only. See F

IG

. 37.

IG

. 37.

IG

. 40 on page 44.

IG

. 37.

333586F 41

Page 42

Shutdown and Care of the Pump

AK

AZ

Heated System

AZ

Ambient System

BB

BC

BE

2. Set the Ram Air Regulator (BB) to 0 psi.

3. Set the Ram Director Valve (BC) to UP.

4. Slowly increase the pressure on the Ram Air

Regulator until the Platen (AD) starts to raise, and

immediately press and hold the Blowoff Button (BE)

until the Platen is completely out of the drum.

Excessive air pressure in the material drum could

cause the drum to rupture, causing serious injury. The

Platen must be free to move out of the drum. Never

use drum blowoff air with a damaged drum.

5. Release the Blowoff Button (BE) and allow the Ram

to rise to its full height.

F

IG

. 38. Integrated Air Controls

6. Remove the empty drum.

F

IG

. 37. Power Disconnect

42 333586F

Page 43

Maintenance

Fill Cap

Sight Glass

Bearing Pre-loads

Oil Drain Plug

AB

Maintenance

Driver Maintenance

NOTICE

Do not open/remove the gear cover. The gear side is

not intended to be serviced. Opening the gear cover

may alter the factory set bearing pre-load and may

reduce the product life.

Preventative Maintenance Schedule

The operating conditions of your particular system determine how often maintenance is required. Establish a pre-

ventative maintenance schedule by recording when and

what kind of maintenance is needed, and then determine

a regular schedule for checking your system.

Change the Oil

NOTE: Change the oil after a break-in period of 200,000

to 300,000 cycles. After the break-in period, change the

oil once per year.

Check Oil Level

See FIG. 39 below. Check the oil level in the sight glass on

a regular basis. The oil level should be near the halfway

point of the sight glass when the Driver (AB) is not run-

ning. If the oil is low, open the fill cap and add Graco Part

No. 16W645 ISO 220 silicone-free synthetic EP gear oil.

The oil capacity is approximately 1.0 - 1.2 quarts (0.9 - 1.1

liters). Do not overfill.

NOTICE

Only use oil with Graco part number 16W645. Any

other oil may not lubricate properly and can cause

damage to the drive train.

1. Follow the Pressure Relief Procedure on page 39.

2. Place a minimum 2 quart (1.9 liter) container under

the oil drain port.

3. Remove the oil drain plug. See F

of the drain plug. Allow all oil to drain from the Driver

(AB).

4. Reinstall the oil drain plug. Torque to 18-23 ft-lb

(25-30 N•m).

5. Open the fill cap and add Graco Part 16W645 ISO

220 silicone-free synthetic EP gear oil. Check the oil

level in the sight glass. Fill until the oil level is near the

halfway point of the sight glass. The oil capacity is

approximately 1.0 - 1.2 quarts (0.9 - 1.1 liters). Do not

overfill.

6. Reinstall the fill cap.

IG

. 39 for the location

FIG. 39: Sight Glass and Oil Fill Cap

Bearing Pre-Load

The bearing pre-loads are factory set and are not user

adjustable. Do not adjust the bearing pre-loads. See

APD20 Advanced Precision Driver Instructions-Parts

manual for maintenance information.

333586F 43

Page 44

Maintenance

EC

AT

EF

EG

TI10613A

EB

EB

55 Gallon Platen

5 Gallon Platen

Platen Maintenance

1. Follow the steps to Change Drums on page 41.

2. Follow the Pressure Relief Procedure on page 39.

3. Refer to parts illustration on page 75 and remove

the platen check valve (449) as shown.

4. Clear air assist tube (AT) in Platen (AD).

5. Clean all parts of the platen check valve (449) and

replace if necessary.

6. Remove Bleed Stick (EF) from Platen (AD). Push

Bleed Stick through Bleed Relieve Ports (EG) to

remove material residue.

Remove and Reinstall Wipers

Remove Platen Wipers

NOTE: Five gallon Platens have a single Wiper that

must be removed, and 55 gallon Platens have a top and

bottom Wiper that must be removed.

1. Follow the Pressure Relief Procedure on page 39.

2. If using an ambient system, turn the Disconnect

Switch (AZ) OFF. If using a heated system, turn the

Power Junction Box Switch (AK) and the

Disconnect Switch (AZ) OFF.

3. To replace worn or damaged Wipers (EB), raise

Platen up out of drum. Remove drum from base.

Wipe fluid off of Platen.

4. Cut the Wiper(s) (EB) with knife and remove from

Platen. See F

IG

. 41.

FIG. 40

FIG. 41

44 333586F

Page 45

Maintenance

TI10614A

EB

55 Gallon Platen

5 Gallon Platen

EB

Reinstall Platen Wipers

NOTE: Five gallon Platens have a single Wiper that

must be reinstalled, and 55 gallon Platens have a top

and bottom Wiper that must be reinstalled.

1. Using a wooden or plastic tool to prevent damage to

the Wiper (EB), clean all material from the seal

grooves.

2. Working from the bottom, angle one Wiper (EB)

over the back of the Platen (AD). See F

3. Insert the Wiper (EB) in the top groove and run the

front of the Wiper into the groove.

4. If using a 55 gallon Platen, insert the second Wiper

(EB) in the lower groove and run the front of the

Wiper into the groove.

5. Lubricate the outside of the Wiper with lubricant

compatible with the material being pumped. Check

with the material supplier.

IG

. 42.

Recycling and Disposal

End of Product Life

At the end of the product’s useful life, dismantle and

recycle it in a responsible manner.

• Perform the Pressure Relief Procedure.

• Drain and dispose of fluids according to applicable

regulations. Refer to the material manufacturer’s

Safety Data Sheet.

• Remove motors, batteries, circuit boards, LCDs

(liquid crystal displays), and other electronic

components. Recycle according to applicable

regulations.

• Do not dispose of batteries or electronic

components with household or commercial waste.

F

IG

. 42

• Deliver remaining product to a recycling facility.

333586F 45

Page 46

Troubleshooting

Troubleshooting

2. Check all possible problems and causes before

disassembling the Ram, Pump, or Platen.

NOTE: Refer to Supply Unit Operation manual for

descriptions of ADM diagnostic codes.

NOTE: Refer to your Pump package manual for Pump

1. Follow Pressure Relief Procedure, page 39,

before checking or repairing the Ram, Pump, or

Platen.

Supply Systems Troubleshooting

Problem Cause Solution

System will not turn ON. No power to unit. Check main power breaker is turned

Ram will not raise or lower. Closed air valve or clogged air line. Open, clear.

Not enough air pressure. Increase.

Worn or damaged piston. Replace. See Ram Supply Unit

Hand valve closed or clogged. Open, clear.

Ram raises and lowers too fast. Air pressure is too high. Decrease.

Air leaks around cylinder rod. Worn rod seal. Replace. See Ram Supply Unit

Fluid squeezes past ram plate wip-

ers.

Pump will not prime properly or

pumps air.

Air assist valve will not hold drum

down or push plate up.

Air pressure too high. Decrease.

Worn or damaged wipers. Replace. See Remove and Rein-

Not enough pressure. Increase pressure setting.