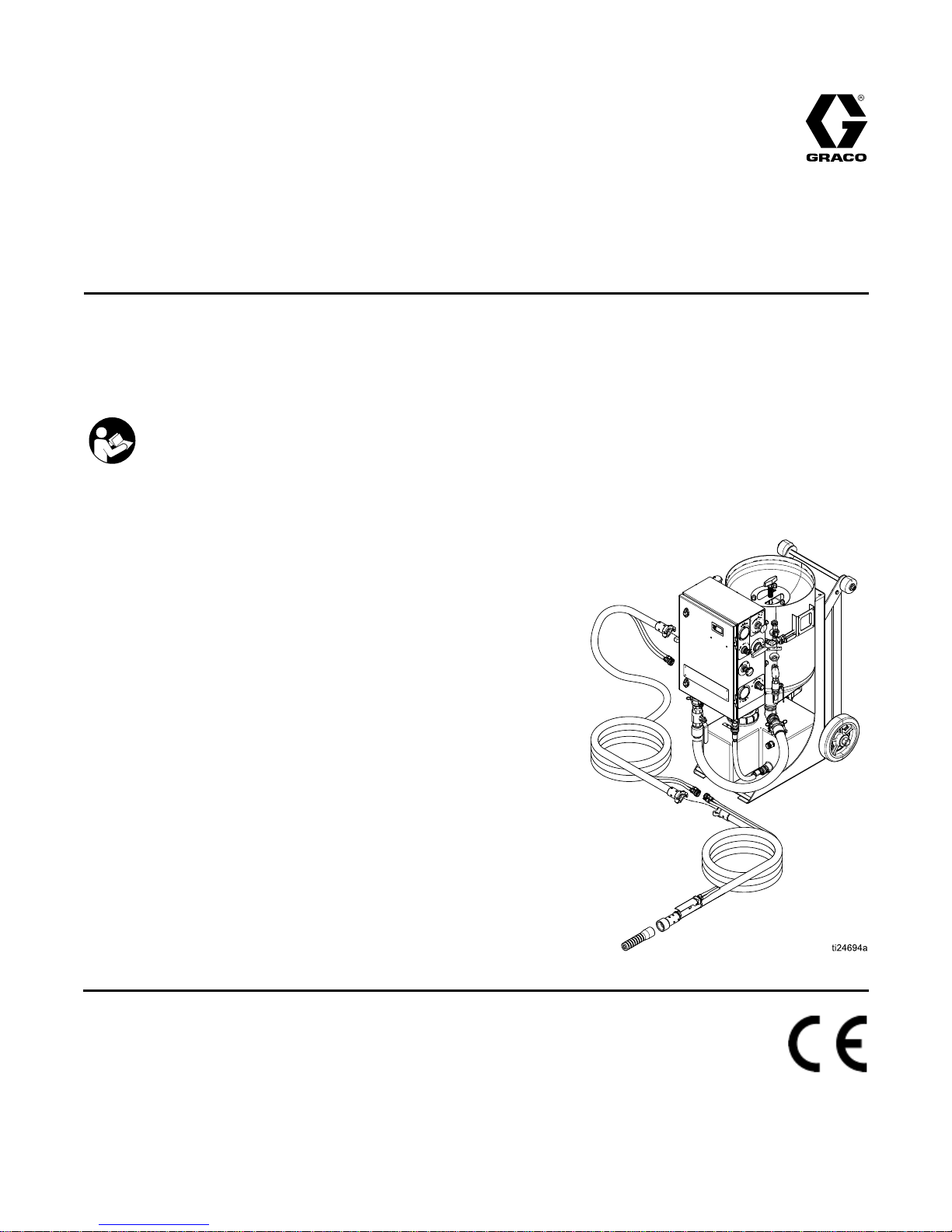

Graco EcoQuip, EcoQuip EQ300S, EcoQuip EQ600S, EcoQuip EQ30XS, EcoQuip EQ60XS Operation, Repair, And Parts

Page 1

Operation,Repair,andParts

EcoQuip EcoQuip

EcoQuip

Vapor Vapor

Vapor

Abrasive Abrasive

Abrasive

Blast Blast

Blast

System System

System

334142F

EN

Vapor Vapor

Vapor

abrasive abrasive

abrasive

blast blast

blast

system. system.

system.

For For

For

professional professional

professional

use use

use

only. only.

only.

Important Important

Important

Safety Safety

Safety

Instructions Instructions

Instructions

Readallwarningsandinstructionsinthismanual.Savethese

instructions.

125psi(8.6bar,0.86MPa)Maximum

WorkingPressure

Seepage3forModelinformation.

PROVENQUALITY.LEADINGTECHNOLOGY.

Page 2

Contents Contents

Contents

Models...............................................................3

RelatedManuals................................................3

Warnings...........................................................4

Notes.................................................................7

SystemComponentIdentication.........................8

EQ100M......................................................8

DataTrakControls........................................9

PressureReliefProcedure..................................10

Grounding(ATEXSystemsonly).........................10

Operation...........................................................11

ImportantNote.............................................11

ChecklistBeforeStarting..............................11

LiftingtheSystem........................................11

ConnectingtheBlastHoseandAir

Hose..............................................12

SettingUptheEquipment.............................13

BlastingTips................................................17

UsingtheWashFeature...............................19

RellingthePotwithAbrasive.......................20

ShuttingDown.............................................21

WinterizingtheEquipment............................23

Troubleshooting..................................................24

TroubleshootingExamples...........................27

Repair................................................................29

RepairingtheMainAirRegulator..................29

FlushingtheDiaphragmValve......................30

RepairingtheDiaphragmValve.....................31

CleaningtheAuto-VentValve.......................32

ReplacingtheDataTrakBattery....................33

ReplacingtheDataTrakFuse.......................34

Notes.................................................................35

Parts..................................................................36

EQ100MParts.............................................36

Enclosure....................................................38

PressurePot................................................40

BlastHoses.................................................41

HoseSchematic.................................................42

VaporAbrasiveBlastSystemsand

Accessories..........................................43

EcoQuipSystemCongurator.......................43

ModelSeries...............................................44

BlastHoseswithControlHose/Cables...........45

BlastHoseswithoutControl

Hose/Cables..................................45

BlastControlHoses/Cables..........................46

Nozzles.......................................................46

OtherAccessories........................................46

CommonSpareParts...................................47

Dimensions........................................................48

TechnicalSpecications......................................49

GracoExtendedWarrantyforEcoQuip™

Components.........................................50

2

334142F

Page 3

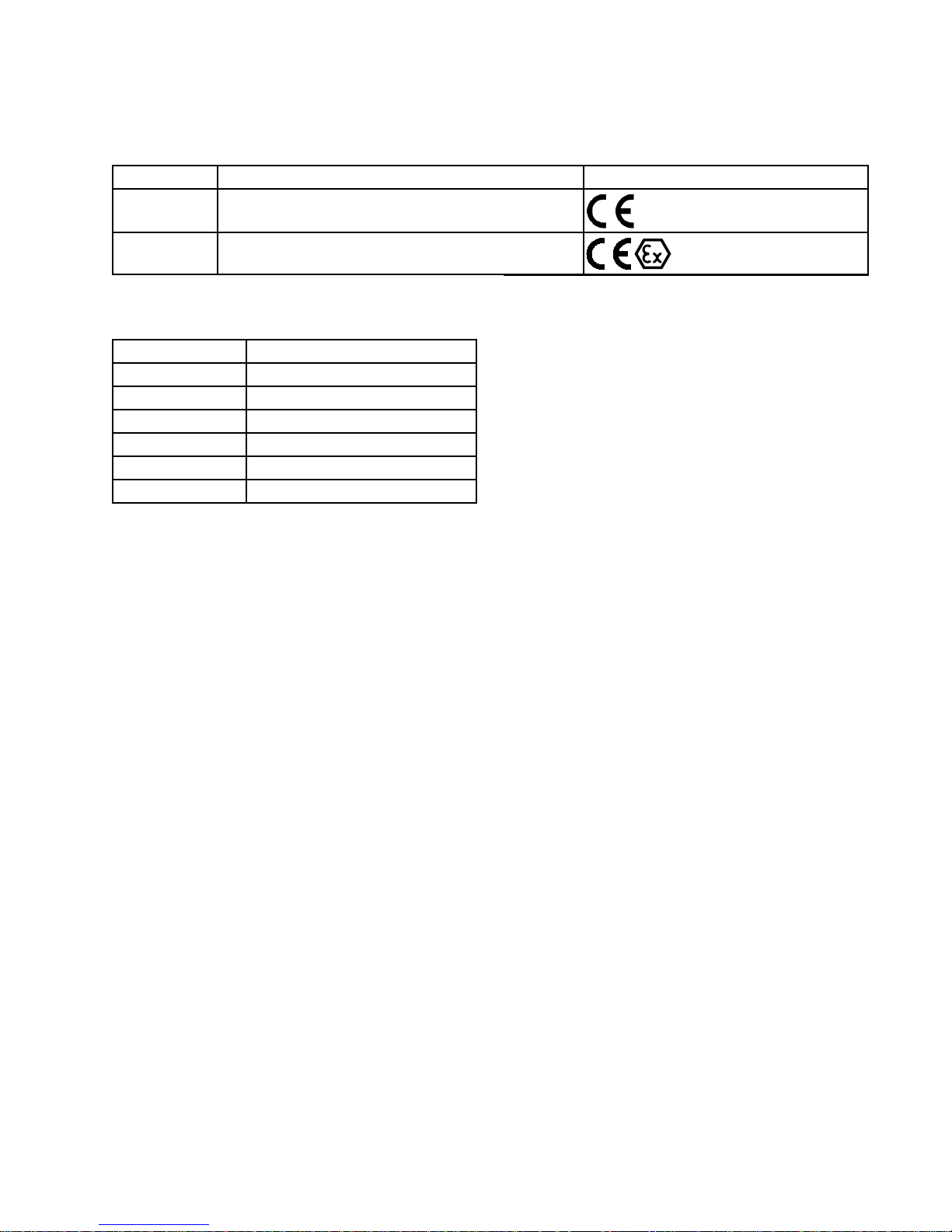

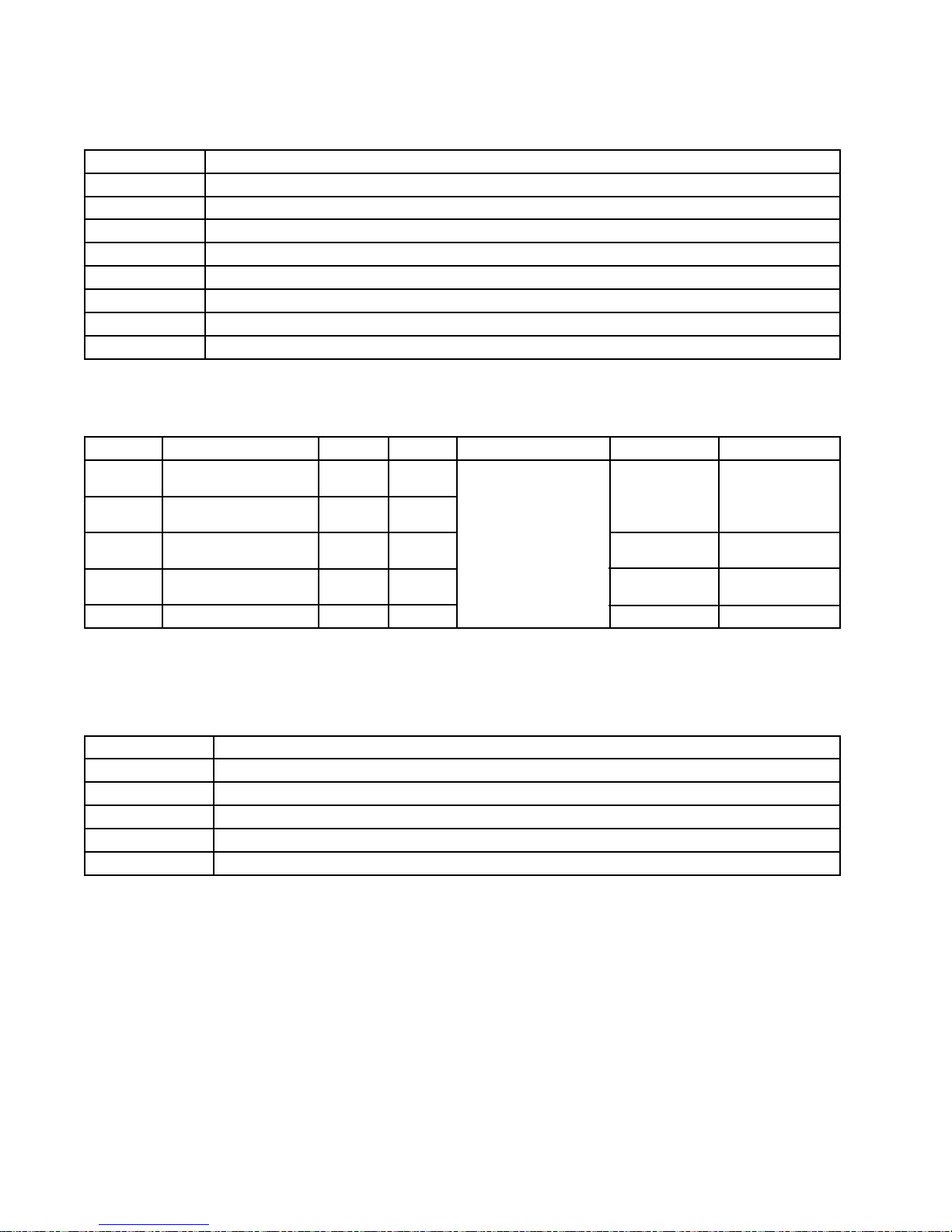

Models

Models Models

Models

Model Model

Model

Description Description

Description

Approvals Approvals

Approvals

EQ100MEcoQuip100VaporBlastSystem

EQ10XMEcoQuip100VaporBlastSystemATEXApproved

II 2G c ia IIA T3 X

Related Related

Related

Manuals Manuals

Manuals

Manual Manual

Manual

Number Number

Number

Product Product

Product

313840DataTrak

333397Pump

335035AirInletKit

334143

EQ300S,EQ600S

334666

EQ200T,EQ400T

334667

EQ300C,EQ600C

334142F3

Page 4

Warnings

Warnings Warnings

Warnings

Thefollowingwarningsareforthesetup,use,grounding,maintenance,andrepairofthisequipment.The

exclamationpointsymbolalertsyoutoageneralwarningandthehazardsymbolsrefertoprocedure-specic

risks.Whenthesesymbolsappearinthebodyofthismanualoronwarninglabels,referbacktothese

Warnings.Product-specichazardsymbolsandwarningsnotcoveredinthissectionmayappearthroughout

thebodyofthismanualwhereapplicable.

WARNING WARNING

WARNING

SPECIAL SPECIAL

SPECIAL

CONDITIONS CONDITIONS

CONDITIONS

FOR FOR

FOR

SAFE SAFE

SAFE

USE USE

USE

•Groundallequipmentintheworkarea.SeeGrounding Grounding

Grounding

Instructions Instructions

Instructions

.

•Alllabelandmarkingmaterialmustbecleanedwithadampcloth(orequivalent).

DUST DUST

DUST

AND AND

AND

DEBRIS DEBRIS

DEBRIS

HAZARD HAZARD

HAZARD

Useofthisequipmentcanresultinthereleaseofpotentiallyharmfuldustortoxicsubstances

fromtheabrasivebeingused,thecoatingsbeingremoved,andthebaseobjectbeingblasted.

•Foruseonlybysophisticatedusersfamiliarwithapplicablegovernmentalsafetyandindustrial

hygieneregulators.

•Useequipmentonlyinawell-ventilatedarea.

•Wearaproperlyt-testedandgovernmentapprovedrespiratorsuitableforthedustconditions.

•Followlocalordinancesand/orregulationsfordisposaloftoxicsubstancesanddebris.

4

334142F

Page 5

Warnings

WARNING WARNING

WARNING

EQUIPMENT EQUIPMENT

EQUIPMENT

MISUSE MISUSE

MISUSE

HAZARD HAZARD

HAZARD

Misusecancausedeathorseriousinjury.

•Donotoperatetheunitwhenfatiguedorundertheinuenceofdrugsoralcohol.

•Donotexceedthemaximumworkingpressureortemperatureratingofthelowestrated

systemcomponent.SeeTechnical Technical

Technical

Data Data

Data

inallequipmentmanuals.

•Donotusethisequipmentwithouthoserestraintsandcouplerpinsinstalledonallairand

blasthosecouplings.

•Donotblastunstableobjects.Thehighamountofuidowfromthenozzlecanpotentially

moveheavyobjects.

•Donotexceedloadratingoflifteyes.

•Donotoperateequipmentonorstandonanunstablesupport.Keepeffectivefootingand

balanceatalltimes.

•Useuidsandsolventsthatarecompatiblewithequipmentwettedparts.SeeTechnicalData

inallequipmentmanuals.Readuidandsolventmanufacturer’swarnings.Forcomplete

informationaboutyourmaterial,requestMSDSfromdistributororretailer.

•Donotleavetheworkareawhileequipmentisenergizedorunderpressure.

•TurnoffallequipmentandfollowthePressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

whenequipmentisnotinuse.

•Checkequipmentdaily.Repairorreplacewornordamagedpartsimmediatelywithgenuine

manufacturer’sreplacementpartsonly.

•Donotalterormodifyequipment.Alterationsormodicationsmayvoidagencyapprovals

andcreatesafetyhazards.

•Makesureallequipmentisratedandapprovedfortheenvironmentinwhichyouareusingit.

•Useequipmentonlyforitsintendedpurpose.Callyourdistributorforinformation.

•Routehosesandcablesawayfromtrafcareas,sharpedges,movingparts,andhotsurfaces.

•Donotkinkoroverbendhosesorusehosestopullequipment.

•Keepchildrenandanimalsawayfromworkarea.

•Complywithallapplicablesafetyregulations.

BURN BURN

BURN

HAZARD HAZARD

HAZARD

Equipmentsurfacesanduidthatisheatedcanbecomeveryhotduringoperation.Toavoid

severeburns:

•Donottouchhotuidorequipment.

FIRE FIRE

FIRE

AND AND

AND

EXPLOSION EXPLOSION

EXPLOSION

HAZARD HAZARD

HAZARD

Flammablefumes,suchassolvent,inwork work

work

area area

area

canigniteorexplode.Tohelppreventre

andexplosion:

•Useequipmentonlyinwellventilatedarea.

•Abrasivematerialexitingblastnozzlecangeneratesparks.Whenammableliquidsareused

neartheblastnozzleorforushingorcleaning,keeptheblastnozzleatleast20feet(6

meters)awayfromexplosivevapors.

•Keepworkareafreeofdebris,includingsolvent,ragsandgasoline.

•Keepaworkingreextinguisherintheworkarea.

334142F5

Page 6

Warnings

WARNING WARNING

WARNING

PERSONAL PERSONAL

PERSONAL

PROTECTIVE PROTECTIVE

PROTECTIVE

EQUIPMENT EQUIPMENT

EQUIPMENT

Wearappropriateprotectiveequipmentwhenintheworkareatohelppreventseriousinjury,

includingeyeinjury,hearingloss,inhalationoftoxicfumes,andburns.Protectiveequipment

includesbutisnotlimitedto:

•Protectiveeyewearandhearingprotection

•Protectiveclothing,shoes,andgloves

•Properlyt-testedandgovernmentapprovedrespiratorsuitableforthedustconditions

RECOIL RECOIL

RECOIL

HAZARD HAZARD

HAZARD

Blastnozzlemayrecoilwhentriggered.Ifyouarenotstandingsecurely,youcouldfalland

beseriouslyinjured.

6334142F

Page 7

Notes

Notes Notes

Notes

334142F

7

Page 8

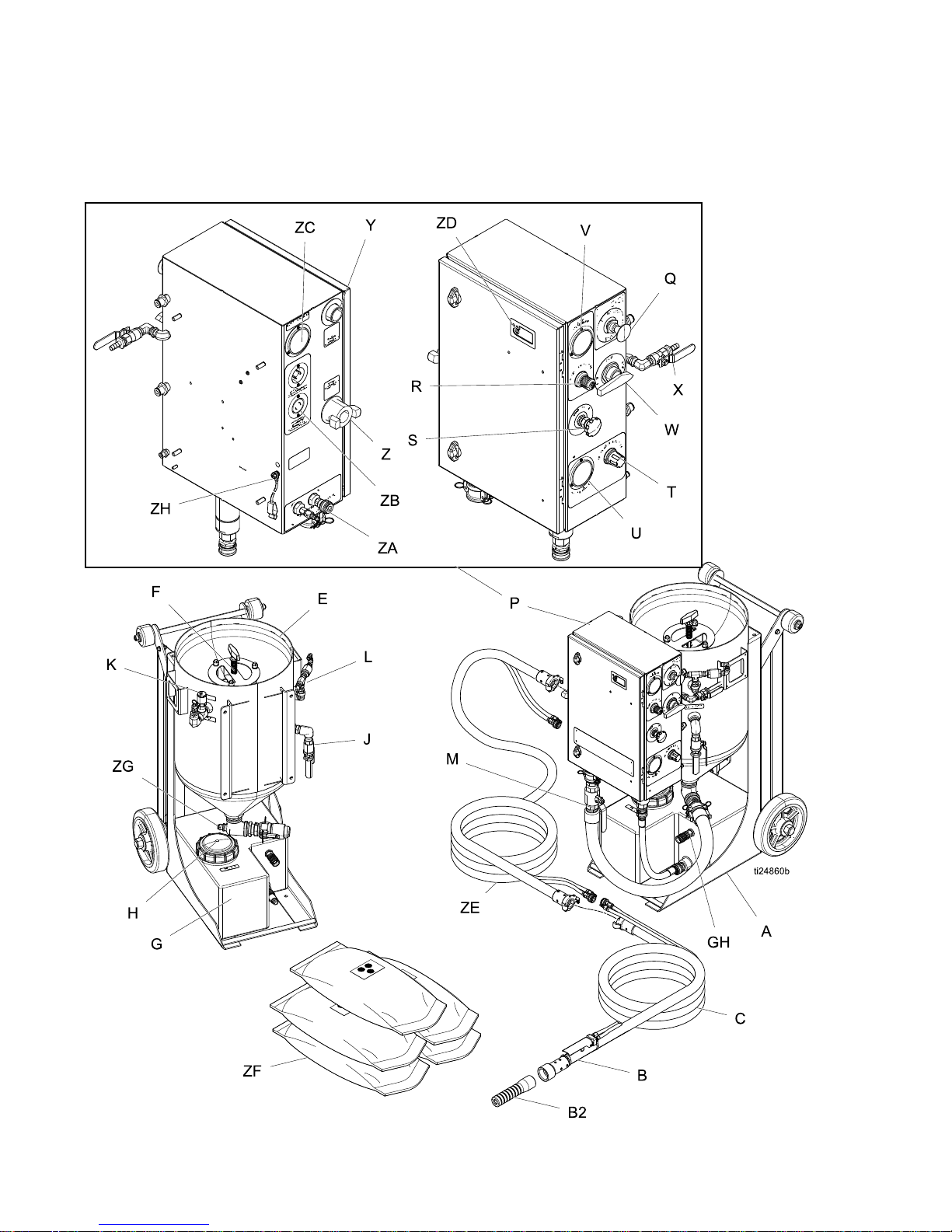

SystemComponentIdentication

System System

System

Component Component

Component

Identication Identication

Identication

EQ100M EQ100M

EQ100M

8334142F

Page 9

SystemComponentIdentication

Key: Key:

Key:

A

Cart

B

BlastControlSwitch

B2BlastNozzle

C

BlastHose

EPot

FPop-upPin

G

WaterTank

HWaterTankLid

JPotDumpValve

KAutoVentValve

L

BlastCheckValve

MAbrasiveBallValve

P

ControlBox

QEmergencyStop

RBlastAirRegulator

S

AbrasiveMeteringValve

TPotPressureRegulator

Key: Key:

Key:

U

PotPressureGauge

V

BlastAirPressureGauge

W

SelectorValve

XRinseBallValve

Y

AirSupplyConnection

Z

BlastConnection

ZA

PneumaticControlConnection

ZB

ElectricControlConnection(non-ATEX

systemsonly)

ZCSupplyAirPressureGauge

ZD

DataTrak(seeDataTrakControls,page9)

ZEAccessoryExtensionhose

ZFAbrasiveMaterial

ZG

FillPort

ZH

GroundWireandClamp(ATEXSystems

only)

GHGardenHoseConnection

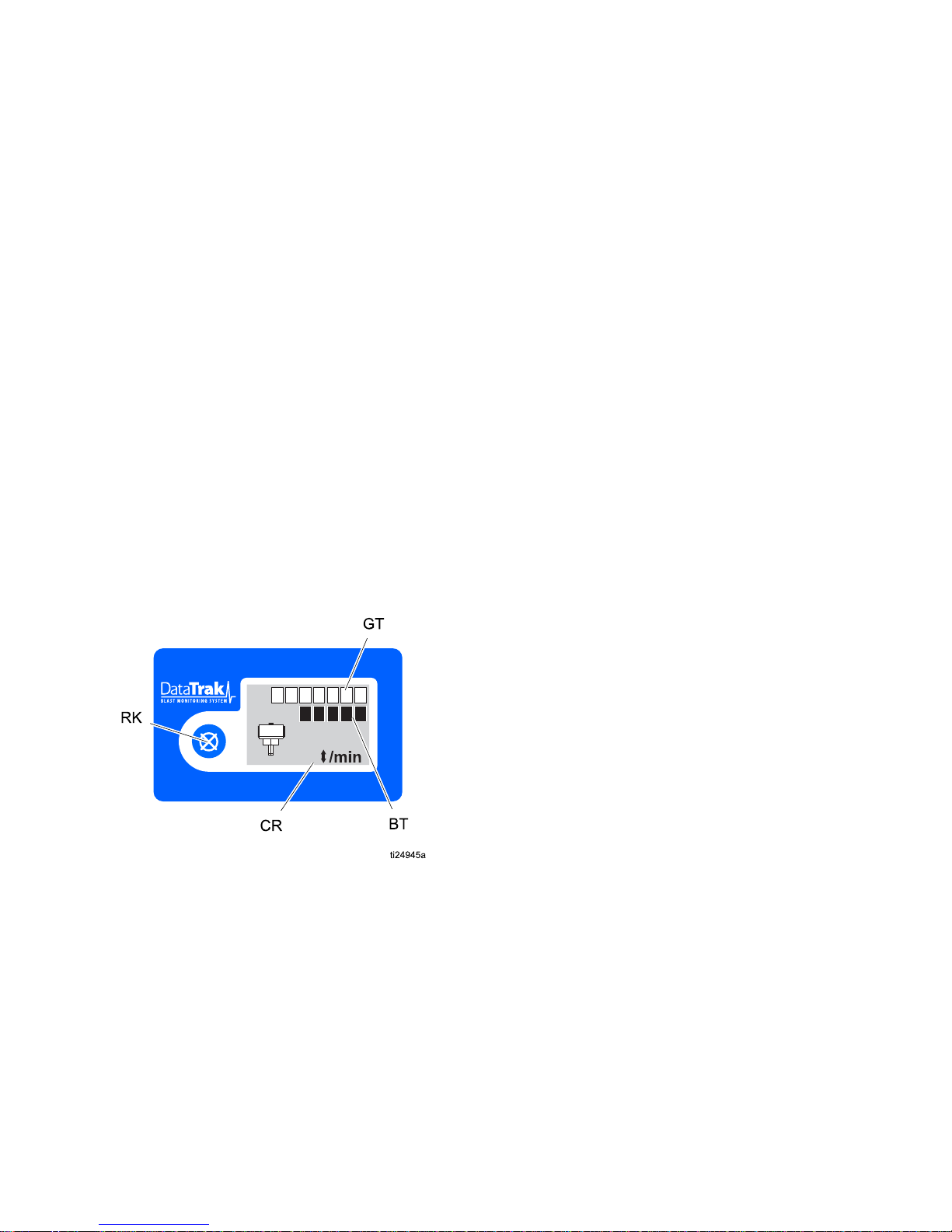

DataTrak DataTrak

DataTrak

Controls Controls

Controls

8800000

83000

9

Key: Key:

Key:

RK

ResetKey—Resultsinfaults.Pressand

holdforthreesecondstoclearthebatch

totalizer.

CRCycle/Rate

BTBatchTotalizer

GTGrandTotalizer

334142F9

Page 10

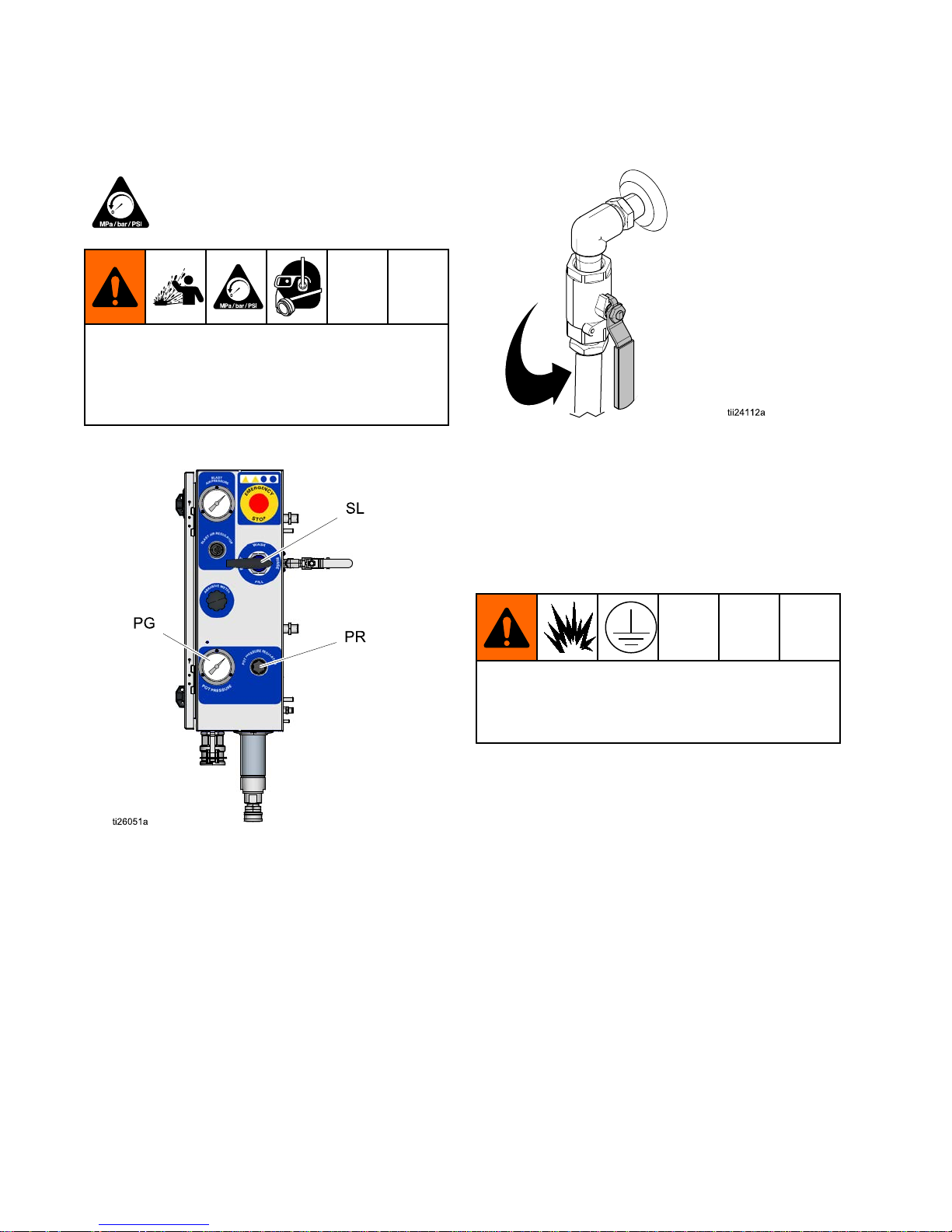

PressureReliefProcedure

Pressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

FollowthePressureReliefProcedure

wheneveryouseethissymbol.

Thisequipmentstayspressurizeduntilpressure

ismanuallyrelieved.Tohelppreventserious

injuryfrompressurizeduid,suchassplashing

uid,followthePressureReliefProcedurewhen

instructed.

1.Turnthepotpressureregulator(PR)off.

2.Closetheabrasiveballvalve.

3.Turnthecompressoroff.Closethecompressor

supplyairvalve.

4.Engagetheblastcontrolswitchtorelieve

pressureinthesystem.

5.Verifythatthesupplyairpressuregaugereads

0psi,thendisconnecttheairinlethosefromthe

system.

6.Turntheselectorvalve(SL)toFILL.

7.Openthedumpvalve.

8.Verifythatthepotpressuregauge(PG)displays

zeropressure.

Grounding Grounding

Grounding

(ATEX (ATEX

(ATEX

Systems Systems

Systems

only) only)

only)

Theequipmentmustbegroundedtoreducethe

riskofstaticsparking.Staticsparkingcancause

fumestoigniteorexplode.Groundingprovidesan

escapewirefortheelectriccurrent.

Systems: Systems:

Systems:

Usesuppliedgroundwireandclamp

(237686).

Air Air

Air

and and

and

uid uid

uid

hoses: hoses:

hoses:

UseonlygenuineGracoATEX

rated,conductivehoseswithamaximumof150ft

(45m)combinedhoselengthtoensuregrounding

continuity.Checktheelectricalresistanceofthe

hoses.Ifthetotalresistancetogroundexceeds29

megaohms,replacethehoseimmediately.

Air Air

Air

compressor: compressor:

compressor:

followmanufacturer’s

recommendations.

10334142F

Page 11

Operation

Operation Operation

Operation

Important Important

Important

Note Note

Note

Topreventfreezing,thisequipmentisshippedfrom

thefactorywithbluewindshieldwasheruidinside

thesystem.Itisnotnecessarytodrainbefore

using.Disposeoftheuidinaccordancewithlocal

regulations.

Checklist Checklist

Checklist

Before Before

Before

Starting Starting

Starting

•Checkthecompressedairsupplyaccordingtoits

operatormanual.Makesuretheairbeingsupplied

iscleanandrelativelyfreeofmoistureandoil

topreventwatercontaminationoftheaircontrol

components.

•Makesureairdeliveryvalvesareclosedbeforethe

airsupplycompressorisstarted.

•Makesureallrequiredhoserestraintsandcoupler

pinsareinworkingconditionandproperlyinstalled.

•Makesuretheequipmentissituatedonlevel

ground.Failuretokeeptheunitonlevelground

willmakeitdifcultorimpossibletopurgeallofthe

airfromthepressurevessel.

•Makesuretheequipmentisproperlysupportedon

asurfacethatcanholditstotalweight.Theweight

ofallpersonnel,thematerialbeingblasted,and

anyabrasivebeingstoredmustalsobeconsidered

(seeTechnicalSpecications,page49).

•Makesurethewatertankwillremainfullysupplied

withcleanwatertoavoidanypossibilityofthe

pumprunningdryduringblasting.

•Makesurethatthepotiscleanandfreeofany

internaldebris.

•Makesuretousethecorrecttypeofblastcontrol.

Anelectricorpneumaticblastcontrolswitchcan

beusedwithhoselengthslessthan150ft(45m).

Blastingwith150ft(45m)ormoreofblasthose

requirestheuseofanelectricblastcontrolswitch.

•Makesuretheblasthoseislaidoutasstraightas

possiblebetweentheequipmentandtheworksite

(acoiledblasthosewilluncoilunderpressure).

NOTICE NOTICE

NOTICE

Sharpbendsintheblasthosecouldcausethe

abrasivetowearthroughthehoseandcause

prematurefailureofthehose.

•Makesuretherubbergasketineachhosecoupler

isinworkingcondition.

Lifting Lifting

Lifting

the the

the

System System

System

•Liftthesystemwithaliftapparatusrated

appropriatelyfortheweightofthesystem(see

TechnicalSpecications,page49).

•Thesystemcanbeliftedusingtheliftringonthe

potorthecarthandle.

334142F

11

Page 12

Operation

Connecting Connecting

Connecting

the the

the

Blast Blast

Blast

Hose Hose

Hose

and and

and

Air Air

Air

Hose Hose

Hose

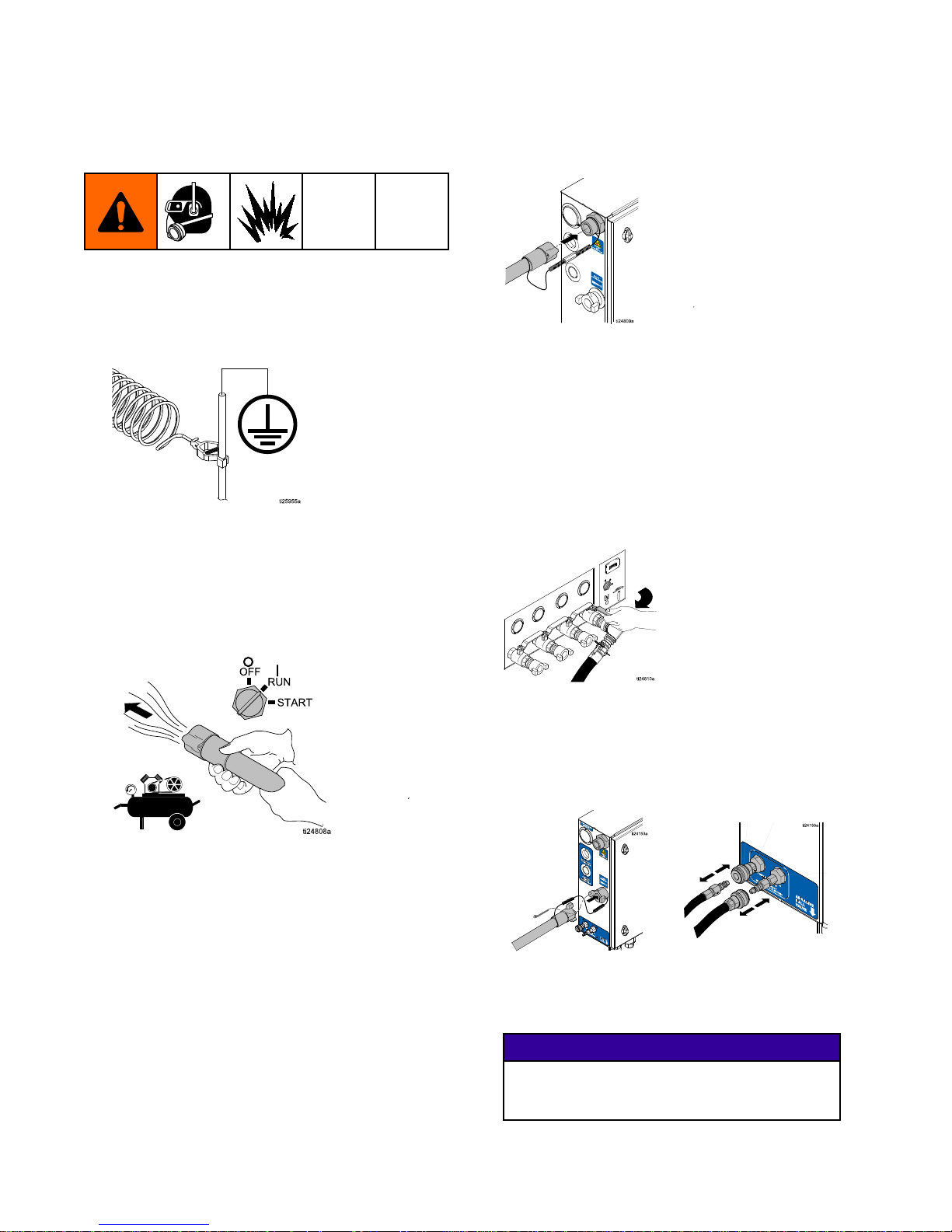

1.EQ10XM EQ10XM

EQ10XM

Models Models

Models

only: only:

only:

Connectthegrounding

cabletotheexternalgroundstud(ZH)onthe

enclosure,thenconnecttheclamptoatrueearth

ground.

2.Alwayspurgetheairsupplyhose15–20seconds

beforeconnectingtheairsupplyhosefromthe

compressor(oron-sitecompressedairsource)

tothepanel.Makesurealldebrisisclearedfrom

thehose.

3.Connectanappropriatelysizedair

supplyhosetotheairinlet.See

TechnicalSpecications,page49.

NOTE: NOTE:

NOTE:

Makesuretoproperlyinstallhose

restraintsandcouplerpinstothequick-coupler

andtheairline.Iftheholesonthequick-coupler

donotalign,thereissomethingwrongandthe

twocouplersarenotcompatible.DO DO

DO

NOT NOT

NOT

TURN TURN

TURN

ON ON

ON

THE THE

THE

AIR AIR

AIR

.Seekhelptogetthesituation

resolved.

4.Opentheairsupplyvalve(125psi,8.6Bar,0.86

MPamaximum).Ifnecessary,usearegulatorin

thesupplyairlinetomeetthesespecications.

OFF

START

RUN

NOTE: NOTE:

NOTE:

Makesuretheairsupplymeets

theappropriate appropriate

appropriate

air air

air

ow ow

ow

requirements. requirements.

requirements.

See

TechnicalSpecications,page49.

5.Connecttheblasthose,hoserestraints,control

hoses,andcouplerpins.

NOTE: NOTE:

NOTE:

Ifyouareusinganelectricblastcontrol,

checkalloftheelectricalconnectionsfromthe

paneltotheblastcontrol.

NOTICE NOTICE

NOTICE

Makesurenoelectricalconnectionswillbeexposed

towater.Exposuretowatercouldcauseashort

circuitanddamagetheequipment.

12

334142F

Page 13

Operation

Setting Setting

Setting

Up Up

Up

the the

the

Equipment Equipment

Equipment

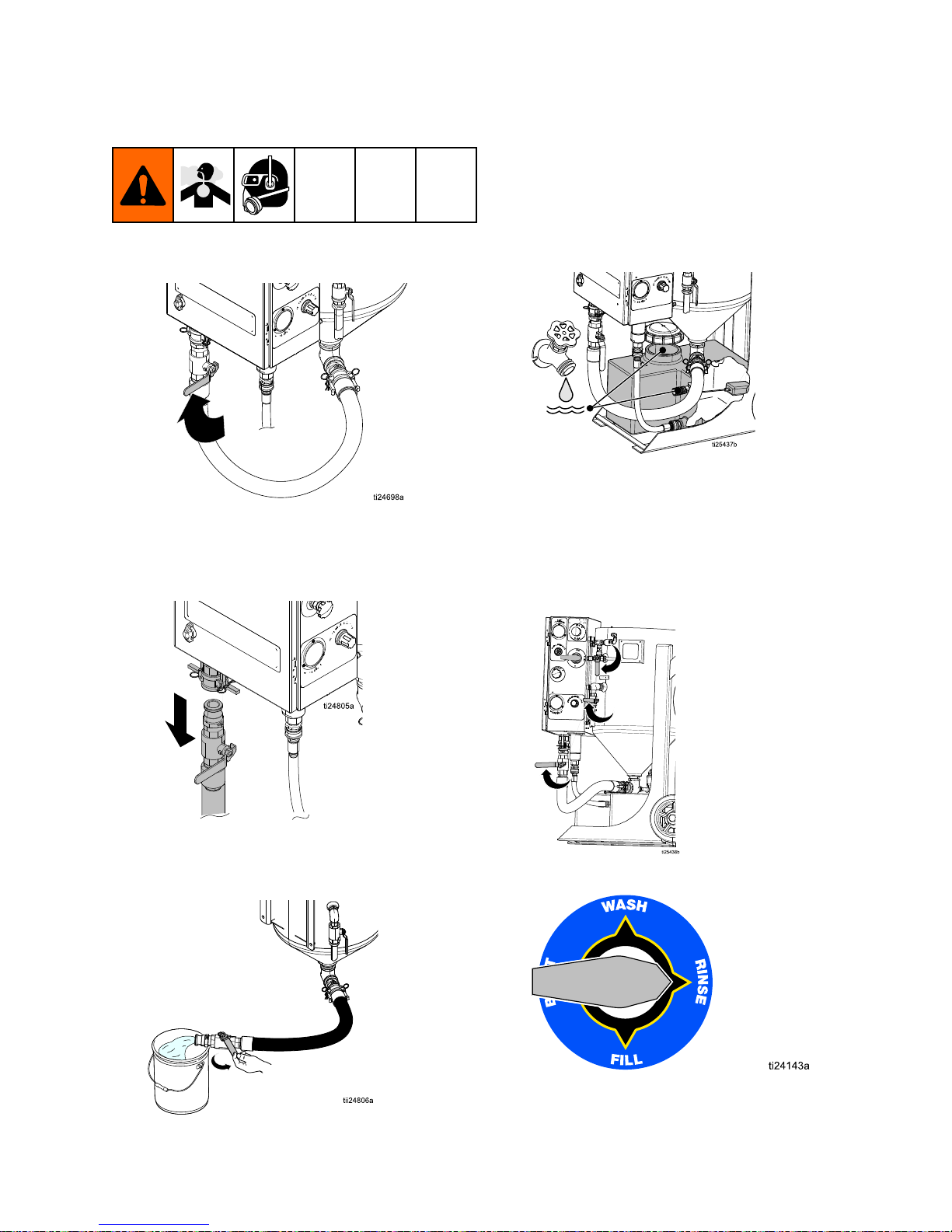

1.Disconnecttheabrasivehoseatthecamand

groovewiththeabrasiveballvalveclosed.

NOTE: NOTE:

NOTE:

Ifthepotcontainswaterandabrasive

(especiallyunderpressure),disconnectingthe

cam-lockwiththeballvalveopenwillcausean

unintentionalreleaseofabrasive.

2.Flushwaterthroughthepotandoutofthe

disconnectedabrasiveballvalvebeforellingthe

potwithwaterandabrasive.

3.Reconnecttheabrasivehose.

4.Disconnectthepumpinlethoseandushthe

watertanktoremoveanyremainingdebris.

Reconnectthepumpinlethose.

5.Fillthewatertankonlywithfreshwater.Connect

hosewithatleasta3/4in.(19mm)IDfromwater

supplyto3/4in.gardenhoseinletonwatertank.

NOTE: NOTE:

NOTE:

Themaximumwatersupplypressureis

100psi(6.8bar,.068MPa).Useauidregulator

ifnecessary.

NOTE: NOTE:

NOTE:

Theminimumowrequirementis3gpm

(11lpm).

6.Closetherinse,dump,andabrasiveballvalves.

7.TurntheselectorvalvetoRINSE.

334142F13

Page 14

Operation

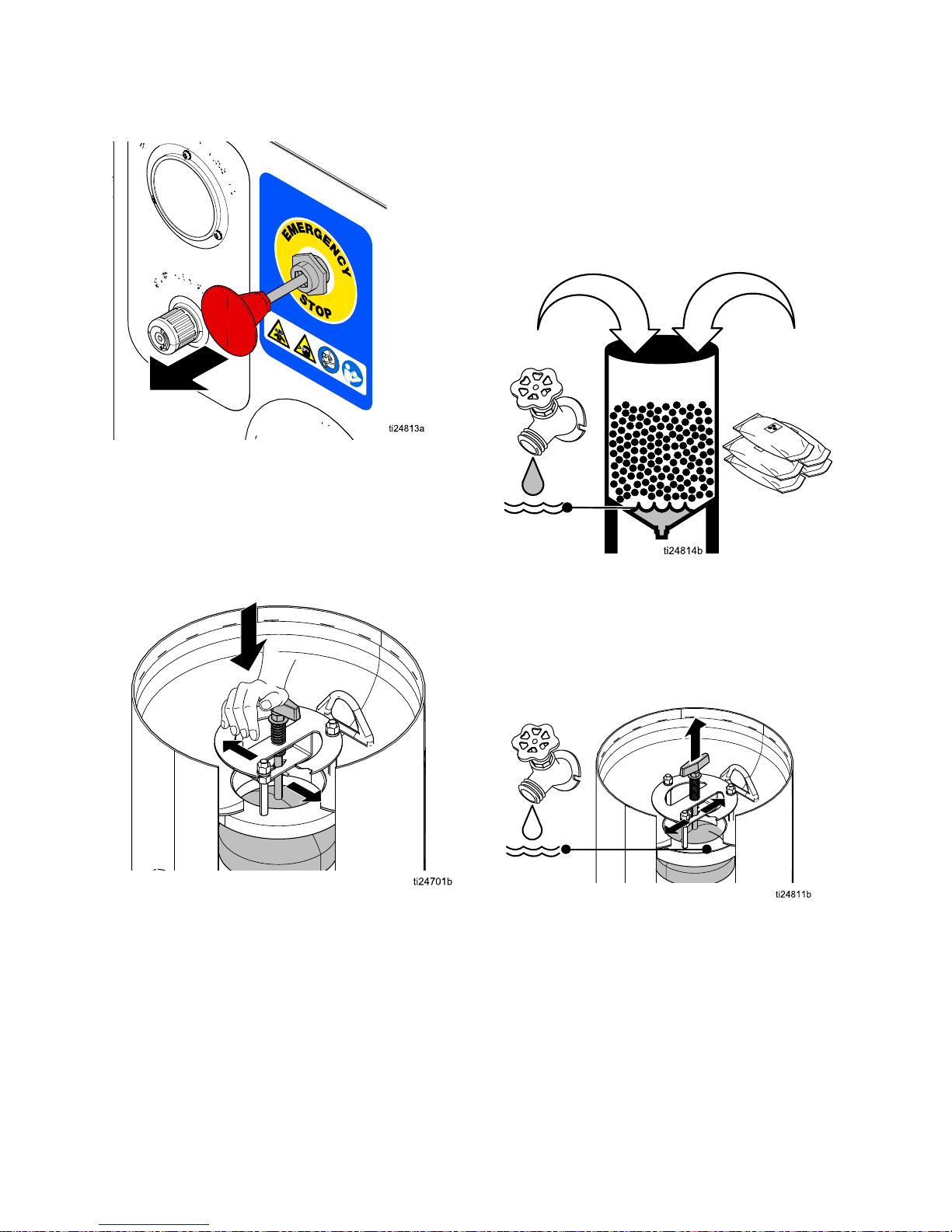

8.DisengagetheEmergencyStop.

NOTE: NOTE:

NOTE:

Thewaterpumpwillnotworkunlessthe

EmergencyStopisdisengaged.

9.Alignthepop-uphandlewiththepinslot,and

thenrmlypushandturnthehandle90°afterthe

pinisbelowthebracketslot.Properengagement

ofthepinwillholdthepop-updownuntilitis

released.

10.Add10gallons(30liters)offreshwaterto

thepot.Wearappropriatepersonalprotective

equipment,includingaproperlyt-tested

governmentapprovedrespiratorsuitableforthe

dustconditions.Addabrasivematerial(minimum

threebags,maximumve50lb(23kg)bagsof

high-massabrasive,orfour50lb(23kg)bags

oflowmassabrasive).

1

2

10 gal

(30 L)

150-250 lb

(68-113 kg)

11.Useagardenhoseortherinsehosetowashthe

abrasiveintothepotandclearanyabrasivefrom

thepop-upandgasket.

12.Whenthewaterlevelreachesthepop-upgasket,

rotatethehandletoreleasethepop-uppin.

NOTE: NOTE:

NOTE:

Makesurethepop-upgasketiscleanof

alldebris.

14

334142F

Page 15

Operation

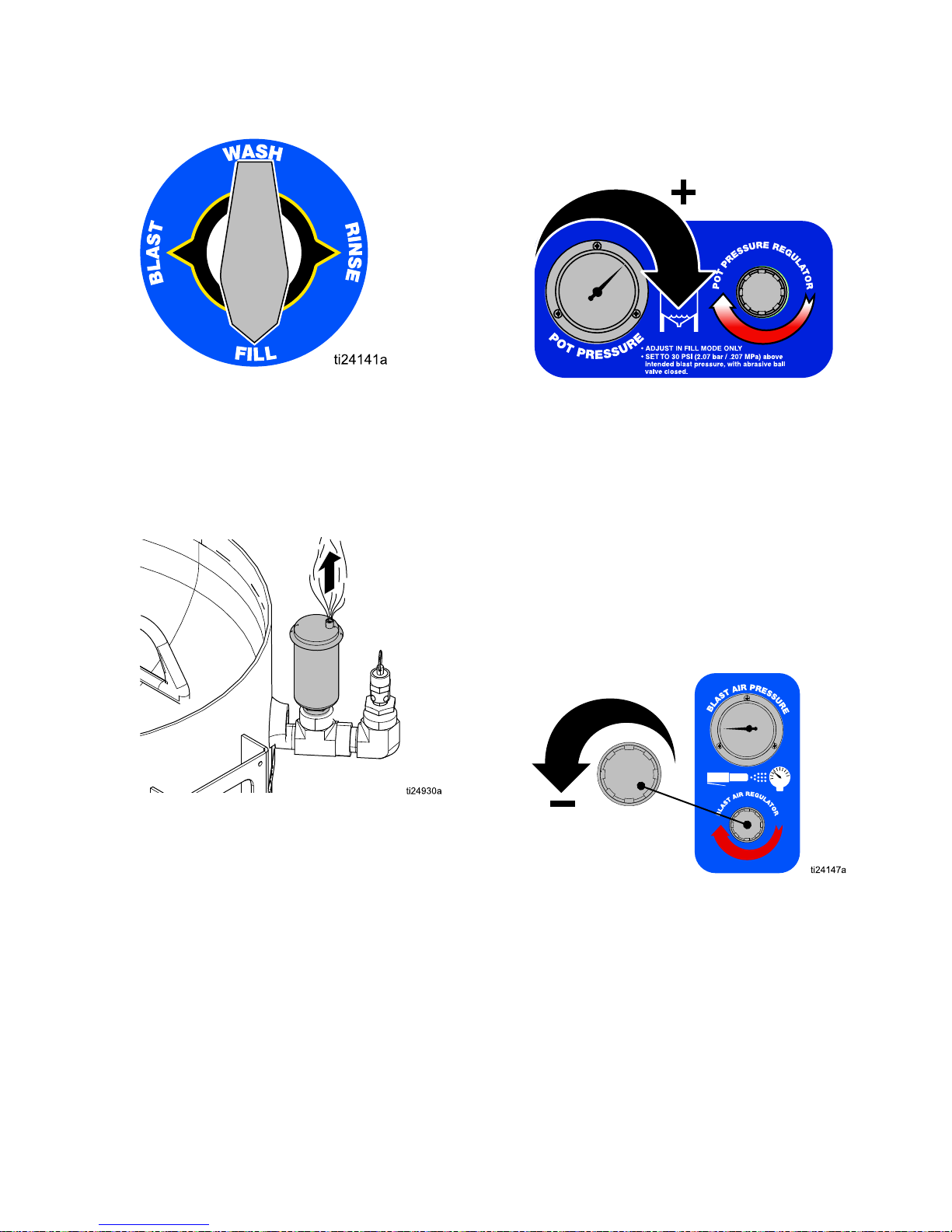

13.TurntheselectorvalvetoFILL.

NOTE: NOTE:

NOTE:

Thewaterpumpshouldbegincycling.If

not,openthepotpressureregulatorenoughto

causethepumptorunat60cpm.

NOTE: NOTE:

NOTE:

Theautovent/purgevalvewillallowall

oftheairtrappedinthetopofthepottovent.

Whenairstopsventing,thepotpressuregauge

willstarttoregisterpressure.

14.Waitforpotpressuretoincrease.

NOTE: NOTE:

NOTE:

Itcantakeuptoseveralminutesforthe

pottopressurize.

ti24824a

NOTE: NOTE:

NOTE:

Thepop-upcannotbepusheddown

unlessallofthepressureinthepotisreleased

byopeningthedumpvalve.

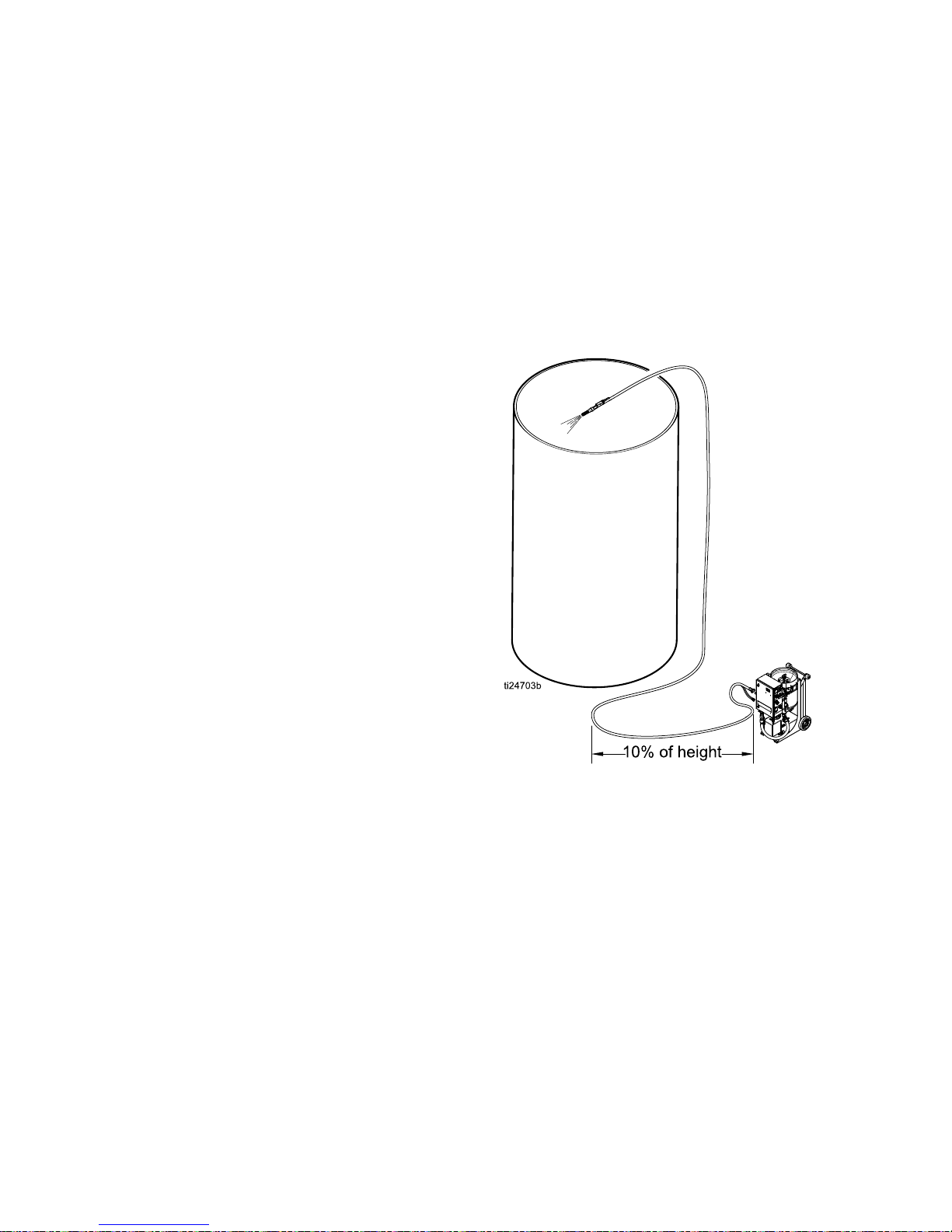

15.Setthepotpressure30psi(2.0Bar,0.2MPa)

higherthantheintendedblastpressure.Open

andclosethedumpvalveafterthepumpstalls.

Relievepotpressureto40psi(2.7Bar,0.27

MPa)beforeclosingthedumpvalve.Repeat

untilpotpressureisconsistent.

16.TurntheselectorvalvetoWASH.

17.Settheblastairpressure30psi(2.0Bar,0.2

MPa)lowerthanthepotpressurewhileblasting.

NOTE: NOTE:

NOTE:

Inordertoadjusttheblastpressure,

theblastcontrolswitchmustbeengaged.For

theinitialsetting,leavetheabrasiveballvalve

closed.

NOTE: NOTE:

NOTE:

Engageandreleasetheblastcontrol

switcheachtimetheblastregulatorisadjusted.

18.TurntheselectorvalvetoBLAST.

334142F15

Page 16

Operation

19.Opentheabrasiveballvalve.

NOTE: NOTE:

NOTE:

Makesurethepotpressurereturnstothe

initialsetting(itwillnotreturntotheinitialsetting

iftheabrasivemeteringvalveisclosed).

20.Engagetheblastcontrolswitchandbegin

blasting.

NOTE: NOTE:

NOTE:

Youmayhavetowait1–2minutesforthe

abrasivematerialtoreachthenozzle.

NOTE: NOTE:

NOTE:

Potpressureandblastpressureshould

equalizeduringblasting.Onlysetpotpressure

withtheabrasiveballvalveclosed.Neveradjust

potpressurewhileblasting.

21.Slowlyadjusttheabrasivemetervalvewhilethe

abrasiveisblastingfromthenozzle.Typical

adjustmentrangesfrom1/8to1/4turnopen.

NOTE: NOTE:

NOTE:

TheDataTrakcanbeusedtoassistin

settingthepumpcyclerate.Optimalabrasive

mediaconsumptiontypicallyoccurswiththe

cycleratesetat7–10cyclesperminute.

8800000

83000

9

NOTE: NOTE:

NOTE:

Useapieceoftestmaterialsimilarto

whatyouwillbeblasting.

NOTE: NOTE:

NOTE:

Alwaysstartasgentlyaspossibleand

thenincreasetheblastforceasnecessaryto

cleanwithoutdoinganydamagetothesubstrate.

Whenproperlyset,thepumpshouldcycle7-10

timesperminute.Highproductionrateusers

mayneedtoincreasecyclerateabove10cycles

perminute.

NOTE: NOTE:

NOTE:

Closetheabrasiveballvalvewhenever

youstopblastingformorethan20-30minutes.

Thiswillhelptoextendtheservicelifeofthe

diaphragmvalve.

16334142F

Page 17

Operation

Blasting Blasting

Blasting

Tips Tips

Tips

Whenrstlearningtheeffectsoftheblaster,geta

betterunderstandingoftheresultsbystartingata

shallowangle(closerto0°thanto90°)andkeep

thenozzleapproximately16in.(40cm)fromthe

application.Observetheresults,thenreducethe

distance,steepentheangle,andadjusttheblast

regulator.

Astheblastpressureisincreased,slowlyadjustthe

abrasivemeteringvalveandwatchtheDataTrak

toachieve7-10pumpcyclesperminute.See

DataTrakControls,page9.

NOTE: NOTE:

NOTE:

Theheavierandsmallertheabrasiveparticle

(i.e.80-grit),themoreaggressivetheresults.

Blasting Blasting

Blasting

on on

on

Higher Higher

Higher

Surfaces Surfaces

Surfaces

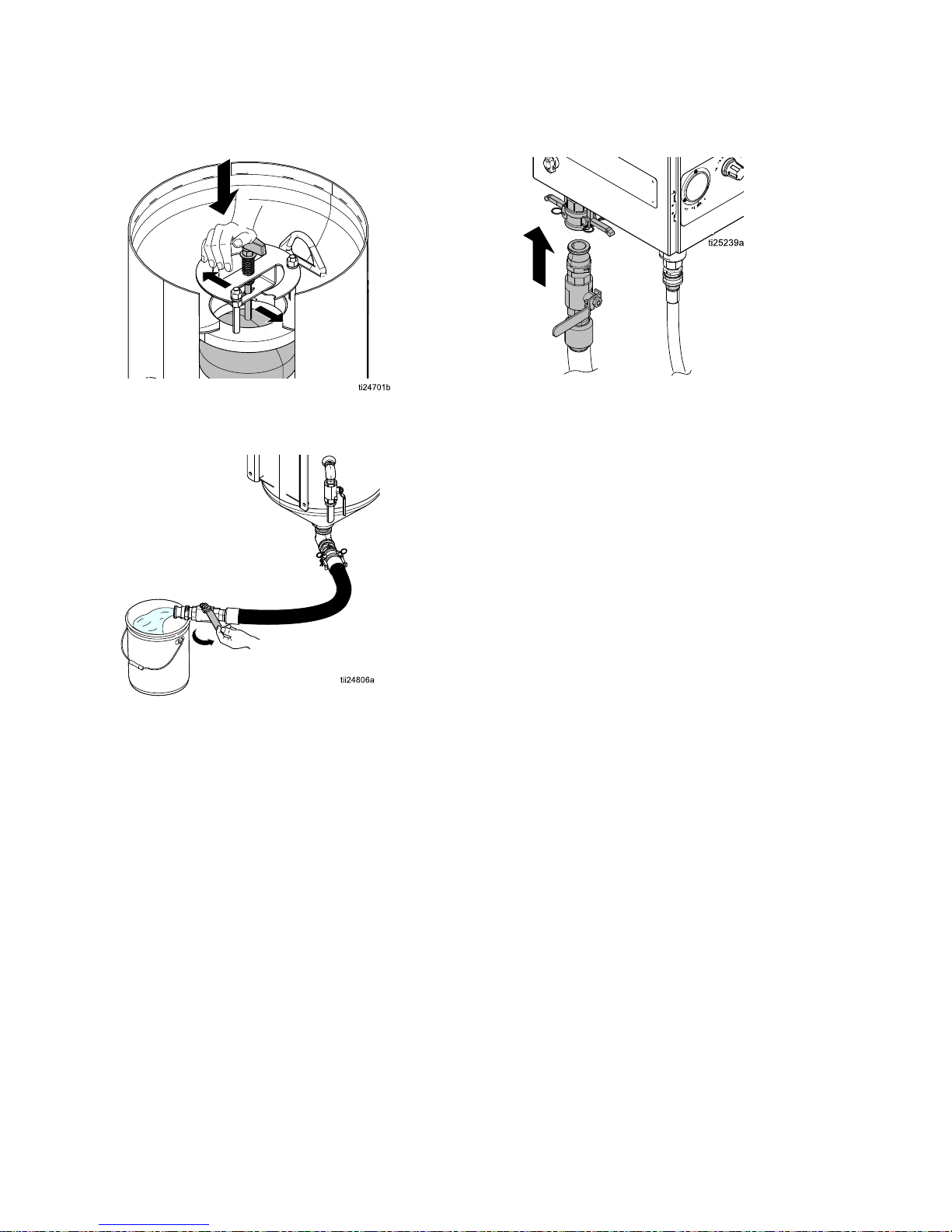

Whenblastingonasurfacehigherthanthe

equipment,makesurethatthereisalengthofblast

hoseonthegroundequalto10-20%oftheheight.

Thehoseonthegroundpreventsunspentabrasive

inthehosefromback-llingtheinternalplumbingof

thepanel.

Forexample:Whenblasting50feet(15m)straight

up,useatleast10feet(3m)ofblasthoseonthe

groundbeforetheblasthosegoesuptotheblasting

height.

334142F

17

Page 18

Operation

Abrasive Abrasive

Abrasive

Metering Metering

Metering

Valve Valve

Valve

Settings Settings

Settings

Thereisnoxedformulaforwhatworksbestineachapplication.Theinformationbelowworksbestforthe

majorityofthetime.Fromthisinitialsetting,adjustmentscanbemadeupordowntogetthefastestremoval

rateswithoutdamagetothesurface.

Normalsettingsare:110psi(7.5Bar,0.75MPa)initialpotsetting,lessthan1/2turnopenmeteringvalve,

blastingpressureat80psi(5.5Bar,0.55MPa).Forapplicationsrequiringhigherperformance,use

high-performanceabrasive(theheaviestmass@80grit)suchasGarnet,andthehighestpressuresthe

systemcansupport.Theinitialpotpressureshouldalwaysbe30psi(2.0Bar,0.2MPa)abovetheintended

blastpressure.

Graduallymakeadjustmentstomeetthespecicrequirementsforeachapplication.Makeadjustments(see

DataTrakControls,page9)toachieve7-10cyclesperminutetobethemostefcient(cutatthefastestrate

whileusingtheleastamountofabrasive).Blastingpressurescanrangebetween30-120psimax(2.0Bar,

0.2MPa–8.2Bar,0.82MPa).

Unlikeconventionalsandblasting,higherpressuresdonotnecessarilymeanbettercleaning.Nozzledistance

andtheangletothesurfacehasaneffectonperformance,asdoestheblastpressure.Choiceofabrasive

alsohasagreateffect.High-performanceabrasiveproducesthebestperformanceandcansaveenough

timetomakeupthedifferenceincost.

NOTE: NOTE:

NOTE:

Blastingwith150ft(45m)ormoreblasthoserequirestheuseofanelectricblastcontrol.

Grit Grit

Grit

Size Size

Size

Blast Blast

Blast

Pressure Pressure

Pressure

Abrasive Abrasive

Abrasive

Metering Metering

Metering

Valve Valve

Valve

Blast Blast

Blast

Angle Angle

Angle

Notes Notes

Notes

General General

General

40/70crushed

glass

60-80psi(4.1Bar,

0.41MPa-5.5Bar,

0.55MPa)

10cyclesper

minute

35°-65°

None

Wood Wood

Wood

80(usingalow

massabrasive

likecrushedglass

orwalnut)

40-50psi(2.7Bar,

0.27MPa-3.4Bar,

0.34MPa)

8cyclesper

minute

15°-30°

Donotwash,asit

mayraisethewood

grain.Brushoff

excessabrasiveafter

thewooddries.

Steel Steel

Steel

60–80(using

ahigh-mass

abrasivelike

Garnet)

100-120psi(6.8Bar,

0.68MPa-8.2Bar,

0.82MPa)

10–12cyclesper

minute

45°-65˚

None

Fiberglass Fiberglass

Fiberglass

40-70lowmass

45-65psi(3.1Bar,

0.31MPa-4.4Bar,

0.44MPa)

8cyclesper

minute

35°-45˚

None

NOTE: NOTE:

NOTE:

Adjustmentinblastpressurerequiresanadjustmentoftheabrasivemeteringvalve.

18334142F

Page 19

Operation

Using Using

Using

the the

the

Wash Wash

Wash

Feature Feature

Feature

Thewashfeaturecausesair-drivenwater(without

abrasive)torinseareasthathavealreadybeen

blastedwithabrasive.Itisalsoaconvenientfeature

forushingabrasivefromtheblasthose.

NOTICE NOTICE

NOTICE

Therewillalwaysbesomeresidualabrasivein

theblasthose.Neverusethewashfeatureon

anysurfaceotherthanwhereyouhaveblasted,or

intendtoblast.Itwillaffect/dullthesurface.

NOTICE NOTICE

NOTICE

Donotusethewashfeatureonwoodthathas

beenblasted.Itcoulddamagethewoodandcause

thegraintorise.Waitforthewoodtodryandthen

useabroom,brush,orvacuumtoremoveany

residualabrasive.

1.Closetheabrasiveballvalve.

2.TurntheselectorvalvetoWASH.

3.Blast1to2minutesuntiltheabrasiveiscleared

fromthehose.

4.Theequipmentisnowreadytowashany

previouslyblastedsurfaces.

334142F19

Page 20

Operation

Relling Relling

Relling

the the

the

Pot Pot

Pot

with with

with

Abrasive Abrasive

Abrasive

1.Closetheabrasiveballvalve.

2.TurntheselectorvalvetoRINSE.

3.Openthedumpvalveslowlytorelievethewater

pressureinthepot.

NOTE: NOTE:

NOTE:

Bepreparedtocapturethewaterthat

willbedrainedfromthepot.Alldisposalsmust

complywithnational,state,andlocalregulations.

4.Afterallofthepressureinthepothasbeen

relieved,engagethepop-uppinbycompressing

thespringandturningthehandle90°toholdthe

pop-upintheopenposition.

5.Addtheabrasive(minimumthreebags,

maximumve50lb(23kg)bagsofhigh-mass

abrasiveorfour50lb(23kg)bagsoflow-mass

abrasive)andcontinuetheproceduresfrom

SettingUptheEquipment,page13.

NOTE: NOTE:

NOTE:

Morewatermayneedtobedrainedfrom

thepottoallowadditionalabrasivetobeadded.

20334142F

Page 21

Operation

Shutting Shutting

Shutting

Down Down

Down

1.Whenyouhavenishedblasting,performwash

untilalloftheabrasiveisushedfromtheblast

hose.SeeUsingtheWashFeature,page19.

2.TurntheselectorvalvetoRINSE,andwiththe

abrasiveballvalveclosed,continuetoblastuntil

waterisclearedfromthehose.Thisistodrythe

insideofthehoseforstorage.

3.Opentheabrasiveballvalve,thenopenthe

dumpvalveuntilthepotpressuregaugereads

0psi.Closetheabrasiveballvalveanddump

valve.Turnoffwatersupply.

NOTE: NOTE:

NOTE:

Short-termshutdownisnowcomplete.

Iftheuntilwillbeshutdownformorethan24

hours,proceedtothenextstep.

4.Disconnecttheabrasiveballvalvecam-lockby

removingthecouplerpinsandpullingtherings

outanduptopullthetwocamsawayfromthe

groove.

5.Holdabucketunderthecam-lockcoupler,then

turntheselectorvalvetoWASH.Thiswillclean

debrisfromthecam-lockcouplerandgasket.

NOTE: NOTE:

NOTE:

Makesurethegasketiscleanandin

placeaftertheprocedure.

NOTE: NOTE:

NOTE:

Besuretocatchtheunspentabrasive

thatwillbewashedoutofthepanelplumbing.

6.TurntheselectorvalvetoFILL.Thiswillhelp

pushtheabrasiveoutthroughtheabrasivehose.

7.Placeabucketundertheabrasivehose.Slowly

openandclosetheabrasiveballvalvetoush

abrasivematerialfromthepot.Repeatseveral

times.Oncenoabrasivematerialowsfromthe

hose,closetheabrasiveballvalve.

NOTE: NOTE:

NOTE:

Estimatethata5gallonpailwillbe

neededforeachbagofabrasivestillinthepot.

Coverthebucketsduringstoragesodebrisdoes

notcontaminatetheabrasive.

334142F

21

Page 22

Operation

8.Engagethepop-uppintoholdthepop-upopen

andallowairtoenter.

9.Opentheabrasiveballvalveandushthepotof

anyremainingabrasivematerial.

10.Closethepotpop-upandreconnecttheabrasive

hose.

NOTE: NOTE:

NOTE:

Thesystemmustbewinterizedifitwillbe

exposedtotemperaturesbelowfreezing.See

WinterizingtheEquipment,page23.

11.Turnoffthewatersupplyanddisconnect

thegardenhose.Relievepressure

tocompletesystemshutdown(see

PressureReliefProcedure,page10).

22

334142F

Page 23

Operation

Winterizing Winterizing

Winterizing

the the

the

Equipment Equipment

Equipment

Vapor-AbrasiveBlastersmustbewinterized

wheneverthereisapossibilityoffreezing

temperaturesduringstorage.Itisimperativethat

youanticipatethepossibilityofafreezeandalways

protecttheunitduringfallandwinterseasons,evenif

beingstoredonlyovernight.

1.Makesureallofthewaterhasbeendrained

fromthepot.Reconnecttheabrasivehoseafter

drainingthepot.

2.Makesurethepotpop-upisintheclosed

position.Thiswillpreventdebrisfromentering

thepotduringstorage.

3.Drainthewatertankbydisconnectingthepump

inlethose.Reconnectthepumpinlethoseafter

allwaterisdrainedfromthetank.

NOTE: NOTE:

NOTE:

Alldisposalsmustcomplywithnational,

state,andlocalregulations.Inaddition,ifthe

watercontainsarustinhibitor,youmaywantto

retainandpreservethewaterduetotheexpense

oftheinhibitor.

4.Chooseawindshieldwashwitharatingthat

willprotecttheequipmentforthelowest

temperaturesinyourarea.Addatleast2gallons

(7.5liters)ofwindshieldwashtothewatertank.

5.TurntheselectorvalvetoRINSEandopenthe

rinseball-valve.Whileholdingtherinsehose

overthepot,runthepumpuntilwindshieldwash

comesoutoftherinsehose.

6.Movetheselectorvalveintotheotherthree

positions(WASH,BLAST,andFILL).Conrm

thattheinternalwatertubingllswithwindshield

washbeforeturningtheselectorvalvetothenext

position.

NOTE: NOTE:

NOTE:

All3/8in.tubingshouldbelledwith

windshieldwashforfullprotection.

7.EngagetheE-stop.

8.Makesurethattherinseball-valveandthedrain

ball-valveareleftopen.

NOTICE NOTICE

NOTICE

Wheniceformsbehindtheseals,thesealscan

becomedamaged.Duringstorage,positionall

ball-valvesintheopenposition.

334142F23

Page 24

Troubleshooting

Troubleshooting Troubleshooting

Troubleshooting

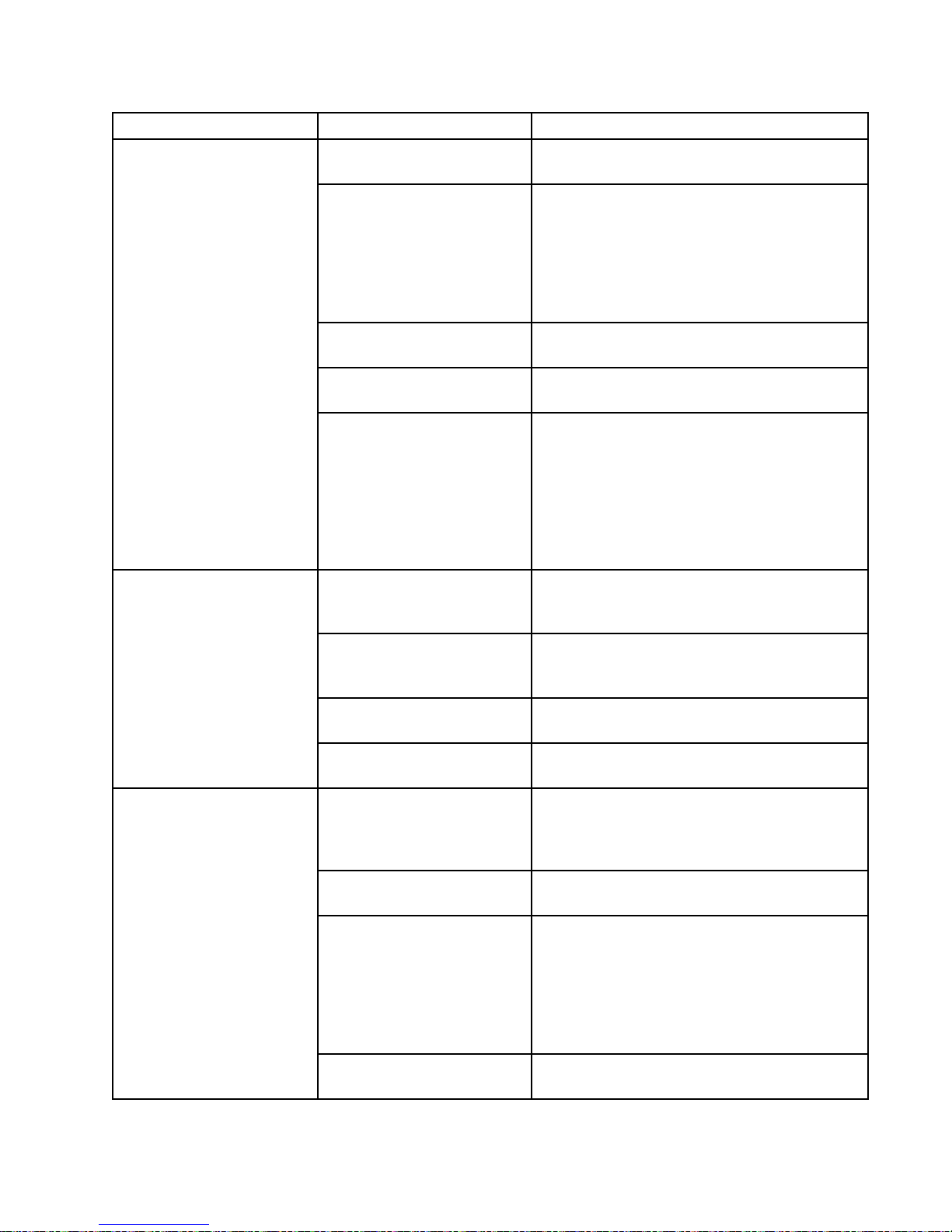

Problem Problem

Problem

Cause Cause

Cause

Solution Solution

Solution

Theairsupplyisinadequate.Makesuretheairinletpressuregaugereads

100-125psi(6.8–8.6bar,0.68–0.86MPa).If

thegaugedoesnotread100–125psicheck

theaircompressorforpropersetup.

TheEmergencyStopis

engaged.

DisengagetheEmergencyStop.

Inadequatewatersupplyto

thepump.

Makesurethewatertankisfullandtheinlet

ballvalveisopen.

Thepotpressureregulatoris

settoolow.

Increasethesettingonpotpressureregulator.

Thepotpop-upcannotseal

properly.

Cleanallabrasivefromthepop-upandgasket.

Makesurethepop-upspringisliftingandthe

pop-upisrmlyagainsttheseal.Ifcleaning

doesnotsolveissue,replacepop-upgasket.

TheAuto-Ventvalvewillnot

seal.

SeeCleaningtheAuto-VentValve,page32.

Thepotpressurereliefvalve

isdischargingwater.

Decreasethepotpressureto145psi(10.3

bar,1.03MPa)orless.Ifthevalveweepsor

relievesat145psi,replacevalve.

Thepotorpumpisleaking

pressure.

Makesuretheabrasiveballvalveandthe

dumpvalveareclosed.Ifpotpressure

gaugestillcreepsdownward.See

CheckingforLeaks,page27.

Thepotwillnotproperly

pressurize.

Thepotpressureregulatoris

malfunctioning.

Replacethepotpressureregulatorassembly.

Theairsupplyisinadequate.Makesuretheairinletpressuregaugereads

100-125psi(6.8–8.6bar,0.68–0.86MPa).If

thegaugedoesnotread100–125psi,check

theaircompressorforpropersetup.

Theblastairregulatoris

malfunctioning.

Replacetheblastairregulator.

Theblastpressurewillnot

reachthedesiredsetpoint.

Themainairregulatoris

malfunctioning.

SeeRepairingtheMainAirRegulator,page29.

24

334142F

Page 25

Troubleshooting

Problem Problem

Problem

Cause Cause

Cause

Solution Solution

Solution

Thepotdoesnothavea

sufcientamountofabrasive.

SeeRellingthePotwithAbrasive,page20.

Thesystemisnotproperly

setup.

SeeSettingUptheEquipment,page13.

Makesurethepotpressureisproperlyset.

Thepotpressuremustbeset30psi(2bar,

0.2MPa)abovetheblastpressure.Make

suretheselectorvalveissettoBLAST.The

abrasiveballvalvemustbeopen.Theabrasive

meteringvalvemustbeatleast1/8turnopen.

Thereisanobstructioninthe

mediacircuit.

SeeFlushingtheDiaphragmValve,page30.

Thediaphragmvalveisnot

working.

SeeRepairingtheDiaphragmValve,page31.

Noabrasiveowsfromthe

nozzleduringblastmode.

Thereisblockageinsidethe

potorinsidetheabrasive

hosebetweenthepotand

thepanel.

Makesuretheballvalveisclosed,then

disconnectthecam-lockcoupler.Openthe

abrasiveballvalveslightlyandmakesure

abrasiveisowingfromtheabrasivehose.

Ifnot,followtheshutdownprocedure(see

ShuttingDown,page21).Thoroughlyushthe

potandthemediahoseafterdrainingmedia

andwater.

Theblastregulatorisnot

adjustedtothecorrect

pressure.

Adjusttheblastregulatortothedesired

pressurewhiletheblastcontrolisengaged.

Thetubingtothemainair

regulatorisnotproperly

connected.

Conrmthatthetubingfromtheblastregulator

tothemainairregulatorisintact.See

HoseSchematic,page42.

Theblastairregulatoris

malfunctioning.

Replacetheblastairregulator.

Noblastairowwhenthe

blastcontrolisengaged.

Thewaterpumpcycles

whiletheblastcontrol

engaged.

Themainairregulatoris

malfunctioning.

SeeRepairingtheMainAirRegulator,page29.

Theairsupplyisinadequate.Makesuretheairinletpressuregaugereads

100-125psi(6.8–8.6bar,0.68–0.86MPa).If

thegaugedoesnotread100–125psi,check

theaircompressorforpropersetup.

TheEmergencyStopis

engaged.

DisengagetheEmergencyStop.

Theelectricblastcontrol

circuitismalfunctioning.

Inspectthehosecablefordamagedorshorted

wiring.Checkthebatteryandcontrolpanel

connections.MakesuretheDCpowersource

is12V.Checkthe3Afuseinsidethecontrol

panel,andreplaceitifnecessary.Checkthe

currentowinthecircuit.Ifcurrentexists,

replacetherelay.

Noblastairowwhenthe

blastcontrolisengaged.

Thewaterpumpdoes does

does

not not

not

cyclewhiletheblastcontrol

engaged.

Thepneumaticblastcontrol

circuitismalfunctioning.

SeePneumaticBlastControlCircuit,page28.

334142F25

Page 26

Troubleshooting

Problem Problem

Problem

Cause Cause

Cause

Solution Solution

Solution

Themainairregulatoris

stuckopen.

SeeRepairingtheMainAirRegulator,page29.

Theblastcontroltubingis

notconnectedproperly.

Ensureairtubingisroutedandconnected

properly.SeeHoseSchematic,page42.

Electricblastcontrolcircuitis

malfunctioning.

Inspecthosecablefordamagedorshorted

wiring.Checkbatteryandcontrolpanel

connections.EnsureDCpowersourceis12V.

Check3Afuseinsidecontrolpanelandreplace

itifnecessary.Checkcurrentowincircuit,if

currentexists,replacerelay.

Theblastcontrolisnot

engagedbutblastingstill

occurs.

Pneumaticblastcontrol

circuitismalfunctioning.

SeePneumaticBlastControlCircuit,page28.

Incorrectabrasiveisbeing

used.

Usethecorrectabrasive.See

AbrasiveMeteringValveSettings,page18.

Thepotdoesnothavea

sufcientamountofabrasive.

Rellthepotwithabrasive.See

RellingthePotwithAbrasive,page20.

Thepotpressuresettingis

incorrect.

Performthepressurereliefprocedure(see

PressureReliefProcedure,page10)

andresetpotpressure(see

SettingUptheEquipment,page13).

TheAuto-Ventvalvedoes

notventairwhenthepotis

lled.

MakesuretheAuto-Ventvalveisworking.

PerformtheAuto-Ventcleaningprocedure

(seeCleaningtheAuto-VentValve,page32).

Thediaphragmvalveis

malfunctioning.

Performthediaphragmushprocedure(see

FlushingtheDiaphragmValve,page30).

Ifushingdoesnotsolveproblem,see

RepairingtheDiaphragmValve,page31.

Theblastspraypatternis

irregular.

Thereisblockageinsidethe

potorinsidetheabrasive

hosebetweenthepotand

thepanel.

Makesuretheballvalveisclosed,then

disconnectthecam-lockcoupler.Openthe

abrasiveballvalveslightlyandmakesure

abrasiveisowingfromtheabrasivehose.

Ifnot,followtheshutdownprocedure(see

ShuttingDown,page21).Thoroughlyushthe

potandthemediahoseafterdrainingmedia

andwater.

Theunitisnotonalevel

surface.

Placetheunitonalevelsurface.Ifthisis

impossible,theAuto-Ventmustbeonthe

highersideoftheunit.

Theinitialpotpressureisnot

setcorrectly.

Conrmthattheauto-ventvalveisworking

andsetinitialpotpressure30psi(2.0bar,0.2

MPa)abovetheblastpressure.

TheAuto-Ventis

malfunctioning.

Performauto-ventcleaningprocedure(see

CleaningtheAuto-VentValve,page32).

Astronghoserecoiloccurs

frequentlywhentheblast

controlswitchisengaged.

Thediaphragmneedstobe

ushed.

Performthediaphragmushprocedure(see

FlushingtheDiaphragmValve,page30).

Ifushingdoesnotsolvetheproblem,see

RepairingtheDiaphragmValve,page31.

26334142F

Page 27

Troubleshooting

Troubleshooting Troubleshooting

Troubleshooting

Examples Examples

Examples

Checking Checking

Checking

for for

for

Leaks Leaks

Leaks

1.Openthedumpvalve.Checkpotpressure

gauge,thenclosethedumpvalve.

Lookatthepressuregaugetoconrmthatall

pressurehasbeenrelievedfromthepot.

ti24825a

2.Disconnectthetubingattheblastcheckvalve(L)

andatthellportcheckvalve(ZG).

3.Makesurethepop-upisclosed.Turntheselector

valvetoWASH,thenopentheabrasiveballvalve

topressurizethepot.Setthepotpressureto145

psi(9.9Bar,0.99MPa).

4.Checkthewaterpumptoconrmthatnowater

isleakingfromtheTSLllport.

NOTE: NOTE:

NOTE:

Thepumpshouldstallafterthepot

pressurizes.Ifthepumpdoesnotstall,replace

theseals.Refertothepumpmanualforrepair

information.

5.Checkforanywaterleakingfromeithercheck

valve.Ifacheckvalveisleaking,itmustbe

repairedorreplaced.Ifthevalvesaredamaged,

thepotwillnotbeabletomaintainpressure.

Also,checkthepotpressurereliefvalve.Ifthe

valveisweepingatpotpressuresof145psior

less,itneedstobereplaced.

6.Closetheabrasiveballvalve,thenclosetheair

inletballvalve.Engagetheblastcontrolswitch

torelievepressureintheblastcircuit.Conrm

thatthesupplyairpressuregaugereads0psi.

7.Disconnectthequickcouplerandconrmthatthe

ballvalveisnotleaking.Replacetheabrasive

ballvalveifitisleaking.

334142F

27

Page 28

Troubleshooting

Pneumatic Pneumatic

Pneumatic

Blast Blast

Blast

Control Control

Control

Circuit Circuit

Circuit

1.AttheAir-Relay,disconnectthepush-to-connect

tubingandcheckthetriggercircuit(fromtheblast

controlhandle).

2.Withtheblastcontrolswitchactivated,conrm

thatthereisairowingfromthedisconnected

tube.

NOTE: NOTE:

NOTE:

Theairowshouldbeatsupplyair

pressurebuttheairvolumeisreduceddueto

thesizeofthettingsandtubing.Ifyoudonot

getsupplyairpressure,checktheblastcontrol

switchforproperoperation,andchecktheblast

controlhosestomakesuretheyarenotkinked

orinternallyblocked.

3.Checkthein-linelterattheindustrialinterchange

nippleconnectiononthesideofthepanel(where

youattachtheblastcontrolhose).

4.Ifthepreviousstepsdonotxtheissue,replace

theairrelay.

Pneumatic Pneumatic

Pneumatic

Blast Blast

Blast

Control Control

Control

— —

—

ATEX ATEX

ATEX

Approved Approved

Approved

Electric/Pneumatic Electric/Pneumatic

Electric/Pneumatic

Blast Blast

Blast

Control Control

Control

28334142F

Page 29

Repair

Repair Repair

Repair

Repairing Repairing

Repairing

the the

the

Main Main

Main

Air Air

Air

Regulator Regulator

Regulator

SeeEnclosurePartsList,page39forrepairkits.

1.PerformPressureReliefProcedure,page10.

2.Makesurealloftheairpressureisrelievedinthe

unit.Ifnecessary,removetheairlterforaccess

totheairregulator.

3.Removethepistoncover.

NOTE: NOTE:

NOTE:

Thereisaspringinsidethiscover.

4.Removethediaphragmcoverforaccesstothe

diaphragmandtotheendofthepistonshaft.

5.Removethediaphragmandinspectforany

cracksortears.Replacethediaphragmif

necessary.

6.Carefullyremovethespringandpistonassembly,

thencleanoutanydebrisinthebodyofthe

regulator.Makesurethewiremeshisfreeof

debris.

7.Inspectthepistonanditssealforanyforeign

matterthatmayhavebeenthecauseforthe

pistontostayopen.

8.Inspectforanydamagetothepistonshaftwhere

itinteractswiththediaphragmcup.Replace

componentswithexcessivewear.

334142F29

Page 30

Repair

Flushing Flushing

Flushing

the the

the

Diaphragm Diaphragm

Diaphragm

Valve Valve

Valve

Thisprocedurecanbeperformedwiththecomponent

stillmountedinthepanel.

Iflarge-gritabrasiveorotherforeignmatterbecomes

lodgedinthediaphragmvalve,itwillbecome

necessarytoushthevalve.Thisisasimple

procedure;however,itdoescausethereleaseofa

largevolumeofairtoescapethroughthereleased

quickcoupling.Youneedtobepreparedforthe

releaseofairbypullingthequickcouplergrommet

outofitsgroovesothatitdoesnotgetlost.

1.OperatetheunitinWASH(see

UsingtheWashFeature,page19)until

allabrasiveclearsfromtheblasthose.

2.Closetheabrasiveballvalve,thenturnthe

selectorvalvetoRINSE.Blastuntilthehoseis

clearofabrasiveandwater.

3.Disconnectthequickcouplingattheabrasive

ballvalve(notatthebottomofthepot).

4.TurntheselectorvalvetoWASH.Remainin

WASHuntilalldebrisisclear.Removethe

grommetintheguidecoupler.

5.Makesurenothingisinthepathoftheopen

quickcoupler,thenengagetheblastcontrol

switchbrieyandseveraltimes.

NOTE: NOTE:

NOTE:

Highowairshouldescapethroughthe

cam-lockcoupling.Ifthisdoesnotoccur,the

diaphragmvalveismalfunctioning.Replace

entirediaphragmcanister.

NOTE: NOTE:

NOTE:

Donotdisassemblethecanister.

6.Holdthemaleendofthequickcouplerupto

thewatercomingfromthecam-lockendofthe

coupler.Cleanoffanydirtorabrasive.

7.TurntheselectorvalvetoRINSEtostoptheow

ofwater.

8.Re-insertthegrommetintoitsinternalgroove

insidethecam-lock.

9.Reconnectthequickcoupler.Ifproperlycleaned

andconnected,thereshouldbenoleaksatthe

couplerduringoperation.

30334142F

Page 31

Repair

Repairing Repairing

Repairing

the the

the

Diaphragm Diaphragm

Diaphragm

Valve Valve

Valve

SeeEnclosurePartsList,page39forrepairkits.

NOTE: NOTE:

NOTE:

Thediaphragmcanbereplacedwithout

removingtheassemblyfromthepanel.Youwillneed

a6mmAllenwrench.

1.PerformthePressureReliefProcedure,page10.

2.Applymorethan80psi(5.5Bar,MPa)air

pressuretotheregulatorinlettocausethepiston

toretract.

3.Loosenall4Allen-headcap-boltsevenlyand

thenremovethemcompletelywhilesupporting

thecanisterofthediaphragmvalve.

NOTE: NOTE:

NOTE:

Donotdisassemblethecanister.

4.Replacethediaphragm(naturalrubber

compound)andhand-tighten(onlyasfaras

necessary)toestablishthealignmentwiththe

canister.

NOTE: NOTE:

NOTE:

Thereisoneshimbetweenthediaphragm

andtheactuator.Keeptheshimandreuseit(it

doesnotcomewiththereplacementdiaphragm).

Donotcauseanypre-loadortorqueonthe

diaphragmbyover-tighteningitinamisaligned

position.

5.Insertall4Allen-headcapboltsandhand-tighten.

6.Tightenthecap-boltsinanalternatingpattern

(seeimagebelow)to80+/-8in-lb(9+/-0.9N•m).

Thiswillcauseaslightbulgeinthediaphragm

betweenthecanisterandthestainlesssteel

casting.

1

2

3

4

7.Relievethepressureappliedinstep2.

8.Testandconrmthattheunitisworkingproperly.

NOTE: NOTE:

NOTE:

Thiscanbedoneusingonlywaterto

chargetheequipment–thereisnoneedtouse

abrasiveforthistest.

334142F31

Page 32

Repair

Cleaning Cleaning

Cleaning

the the

the

Auto Auto

Auto

- --Vent Vent

Vent

Valve Valve

Valve

Afterthepop-uphasbeenclosedwhilellingthepot,

theauto-ventvalveshouldreleaseair(youshouldbe

abletoheartheairventing).

Thepotpressuregaugewillnotshowpressureuntil

theauto-ventvalvehasbledalloftheairandsealed.

Iftheauto-ventvalvedoesnotreleaseair,orifwater

leaksfromthestemduringthellprocess,thestem

valvemaybecloggedorfaulty.

Performthefollowingproceduretocleanaclogged

auto-ventvalve.

1.Trytopushandquicklyreleasethevalvewith

yournger.Ifthatdoesnotcausethevalveto

seal,openthedumpvalvetoreleaseallofthe

pressureinthepot.

2.Openthedumpvalvetorelievepotpressure.

Openthepop-upanddrainthepotuntilthewater

levelisbelowthepop-up.

3.TurntheselectorvalvetoRINSE.

4.Usetherinsehosetoforcewaterbackwardsinto

thevalvestem.

NOTE: NOTE:

NOTE:

Ifthepreviousstepsfailtoresolvethe

issue,replacethewholevalveassembly.

NOTICE NOTICE

NOTICE

Thevalvestemitselfisinternallyattachedtothe

oatanditisnoteld-serviceable.Donottryto

removethevalvestem.Damagetotheequipment

willoccur.

32334142F

Page 33

Repair

Replacing Replacing

Replacing

the the

the

DataTrak DataTrak

DataTrak

Battery Battery

Battery

FIRE FIRE

FIRE

AND AND

AND

EXPLOSION EXPLOSION

EXPLOSION

HAZARD HAZARD

HAZARD

Toreducetheriskofreandexplosion,thebattery

mustbereplacedinanon-hazardouslocation.

Useonlyanapprovedreplacementbattery(see

table).Useofanunapprovedbatterywillvoid

Graco’swarranty.

Replace Replace

Replace

Battery Battery

Battery

1.Unscrewcablefromthebackofthereedswitch

assembly.

2.Removethecablefromthetwocableclips.

3.RemovetheDataTrakmodulefromthebracket.

Takethemoduleandattachedcabletoa

non-hazardouslocation.

4.Removethetwoscrewsonthebackofthe

moduletoaccessthebattery.

5.Disconnecttheusedbatteryandreplaceitwith

anapprovedbattery.

Approved Approved

Approved

Batteries Batteries

Batteries

Energizeralkaline#522

Vartaalkaline#4922

Ultralifelithium#U9VL

Duracellalkaline#MN1604

334142F33

Page 34

Repair

Replacing Replacing

Replacing

the the

the

DataTrak DataTrak

DataTrak

Fuse Fuse

Fuse

FIRE FIRE

FIRE

AND AND

AND

EXPLOSION EXPLOSION

EXPLOSION

HAZARD HAZARD

HAZARD

Toreducetheriskofreandexplosion,thefuse

mustbereplacedinanon-hazardouslocation.

Useonlyanapprovedreplacementfuse(see

table).UseofanunapprovedfusewillvoidGraco’s

warranty.

Replace Replace

Replace

Fuse Fuse

Fuse

1.Removethescrew,metalstrap,andplastic

holder.

2.Pullthefuseawayfromtheboard

3.Replacewithanapprovedfuse.

Approved Approved

Approved

Fuses Fuses

Fuses

DataTrak DataTrak

DataTrak

Part Part

Part

Number Number

Number

*Series *Series

*Series

Letter Letter

Letter

Fuse Fuse

Fuse

Required Required

Required

AorB

24C580

289822

Candlater

24V216

A

24C580

Allotherpart

numbers

Bandlater24V216

34334142F

Page 35

Notes

Notes Notes

Notes

334142F35

Page 36

Parts

Parts Parts

Parts

EQ100M EQ100M

EQ100M

Parts Parts

Parts

9

Applyanti-seizetostuds.Torqueto25–30ft-lb(34–40N•m).

36334142F

Page 37

Parts

EQ100M EQ100M

EQ100M

Parts Parts

Parts

List List

List

Ref. Ref.

Ref.

Part Part

Part

Description Description

Description

Qty. Qty.

Qty.

2

EQ1840HOSE,clear,braided,

3/8in.ID

5ft

424X773KIT,replacement,

watertankassembly

1

5*EQ1907CAP,ventedwater

tanklid

1

6*

24X775

KIT,oatvalve

assembly

1

7*

128193

WASHER,ber

1

8*EQ1846COUPLER,

interchange,

straight-thr

1

10

17C032HOSE,inlet,water

1

11

–––––

PRESSUREPOT,

assy,2.0cf

1

12

EQ5183CABLE,battery,

electricblastcontrol

1

13

EQ1943HOSE,abrasive

media,1–1/4in.ID

1

14128226

NUT,ange,3/8–16

sst

4

15*

128194NUT,lock,1/2NPT,

brass

1

16*

128192

COUPLER,swivel,3/4

FGHTx1/2NPT

1

17*

128191

ADAPTER,QDset,

gardenhose

1

Ref. Ref.

Ref.

Part Part

Part

Description Description

Description

Qty. Qty.

Qty.

19

–––––

ENCLOSURE,blast,1

in.npt

1

2017D786KIT,replacement,hose

restraint

1

25123002

FITTING

1

26

EQ1931

ADAPTER,cam

groove,typeF,ss

1

28

EQ1273HOSE,tubing,natural,

3/8in.OD

4ft

33

EQ1881HOSE,tubing,natural,

1/4in.OD

1ft

35

–––––

LABEL,EQ100M,

branding

1

41206994

FLUID,TSL,8oz.

bottle

1

43

EQ5149

VALVE,abrasive

media,1–1/4in.

1

4417D787KIT,replacement,

couplerpin

1

▲4517F870LABEL,warning1

46

EQ1866FITTING,groundboss,

spud,1–1/4in.

1

*

Includedinassembly4.

▲

ReplacementDangerandWarninglabelsare

availableatnocost.

334142F37

Page 38

Parts

Enclosure Enclosure

Enclosure

12

Torquettingto35–40ft-lb(47–54N•m).

38334142F

Page 39

Parts

Enclosure Enclosure

Enclosure

Parts Parts

Parts

List List

List

Ref. Ref.

Ref.

Part Part

Part

Description Description

Description

Qty. Qty.

Qty.

1

17C132

KIT,repair,regulator,air1

2

17C133

KIT,gauge,airreulator3

3

17C625

KIT,regulator,blast1

4

EQ5178

KIT,e-stop,1/4npt1

5

EQ5179□

RELAY,airpilot,electric/pneumatic

blastcontrol

1

EQ7199♦

RELAY,airpilot,pneumaticblast

control

1

6

EQ5163KIT,manifold

1

7

EQ5112

KIT,blastcontrol,return1

8

EQ5113

KIT,blastcontrol,output1

9

EQ5181

VALVE,selector,5–way1

10

EQ5160

VALVE,needle,dose1

11125420

FITTING,bulkhead,M14x1/4in.tube

1

12

EQ1115

BULKHEAD,connector,union3/8in.2

14111639

SCREW,cap,hex,hd

4

15127918

NUT,ange,serrated,M5

4

▲16

17F870

LABEL,safety

1

17127917

NUT,ange,serrated,1/4–20,ss

5

18

–––––

ENCLOSURE,ssel,24in.x16in.x

8in.

1

19

EQ1527□FITTING,holder,fuse,atmtype

1

20

EQ1844□FUSE,atm,bladetype,3amp

1

22127929□

SCREW,sems,#6–32,3/8in.,sst

22

127929♦

SCREW,sems,#6–32,3/8in.,sst

18

23127932

SCREW,sems,#10–32,1–1/2in.,sst

2

24127908

NUT,ange,serrated,#10–32,ss

4

25

EQ1790□PLUG,angedinlet,twistlock

1

128142♦

PLUG,hole,snap-in,1–3/4in.

1

26

EQ1791□CONNECTOR,twist-lock,anged,2P,

F

1

128142♦

PLUG,hole,snap-in,1–3/4in.

1

33

EQ1121FITTING,elbow,stem1/4in.

5

37121022

FITTING,elbow,male,1/4innpt

1

38

–––––

KIT,blast,plumbing,1in.npt1

39

EQ1846COUPLER,interchange,straight-thr

1

41

–––––

GASKET,enclosure

2

42

–––––

GASKET,100,enclosure

2

Ref. Ref.

Ref.

Part Part

Part

Description Description

Description

Qty. Qty.

Qty.

4317B912

GROMMET,pump,mounting

1

44

EQ1840HOSE,clear,braided,3/8in.ID2ft

4517H164KIT,spacer,bc,1001

4717D685KIT,replacement,doorlatch2

49

–––––

BRACKET,DataTrak

1

50

–––––

GASKET,DataTrak

1

5124A592KIT,DataTrak,smarts,cyclecount

only

1

53

–––––

FITTING,nipple,reducing,sst

1

55

EQ1335COUPLER,sandblast,tank,brass,

1–1/4in.

1

56

EQ1867COUPLER,camlocktypeD,ss1–1/4

1

59111799

SCREW,cap,hex,hd

2

60

EQ5175KIT,airlter,1/4in.tube,withlter

1

6124V672PUMP,sst,3:11

62

–––––

BRACKET,pump

1

63127846

FITTING,elbow,push-to-connect,1/2

in.

1

66

–––––

FITTING,adapter

1

67

–––––

SPACER,washer,shim,ss

AR

68

EQ5119REGULATOR,xed,80psi

1

69

–––––

SPACER,washer,shim,ss

AR

70

EQ5223

KIT,washvalveassembly1

72100985♦

WASHER,lockext

1

73194337♦WIRE,grounding,door1

▲75

186620♦LABEL,groundsymbol3

76237686♦WIRE,groundassemblywithclamp1

77

555629♦

WASHER,#10externaltoothlock

2

7816P265♦LABEL,warning,explosion1

80

–––––

REGULATOR,air

1

17C129

KIT,repair,major

81

–––––

VALVE,diaphragm1

17C127

KIT,repair

17F505KIT,canister

□Fornon-ATEXapprovedsystems

♦ForATEXapprovedsystems

▲

ReplacementDangerandWarninglabelsareavailableatno

cost.

334142F39

Page 40

Parts

Pressure Pressure

Pressure

Pot Pot

Pot

Pressure Pressure

Pressure

Pot Pot

Pot

Parts Parts

Parts

List List

List

Ref. Ref.

Ref.

Part Part

Part

Description Description

Description

Qty. Qty.

Qty.

125A056

PRESSUREPOT,blast,

2.0cubicft.

1

224X765KIT,pressurepot,check

valve

1

324X766KIT,pressurepot,dump

valve

1

424X767KIT,pressurepot,

auto-vent

1

5

16G247FITTING,1/2nptx3/8in.

tube

1

6

EQ5148

KIT,pressurepot,unequal

tee

1

7

EQ1360HOSE,clear,braided,3/4

in.ID

3ft

8#

17D790KIT,replacement,

handwaygasket

1

9#

24X764KIT,replacement,pop-up

head,6in.

1

10#

17F065KIT,replacement,pop-up

gasket,6in.skirt

1

Ref. Ref.

Ref.

Part Part

Part

Description Description

Description

Qty. Qty.

Qty.

11#

24X768KIT,replacement,

alignmentbracket

1

12#

24X770KIT,replacement,pop-up

T-handle

1

13*EQ1860

VALVE,auto-vent,3/4npt1

14*

127699

VALVE,safety,150psi

1

15†

EQ1034

VALVE,check,3/8in.sst1

16†127852

FITTING,elbow,swivel,

push-to-connect

1

17‡

EQ1003

VALVE,ball,3/4npt,sst1

#

Includedinassembly1

†

Includedinassembly2

‡

Includedinassembly3

*

Includedinassembly4.

1

Applysealanttopipethreads.

40334142F

Page 41

Parts

Blast Blast

Blast

Hoses Hoses

Hoses

EQ5234 EQ5234

EQ5234

EQ5235 EQ5235

EQ5235

EQ5236 EQ5236

EQ5236

EQ5237 EQ5237

EQ5237

Ref. Ref.

Ref.

Part Part

Part

Description Description

Description

Qty. Qty.

Qty.

1

EQ1843*HOLDER,nozzle,nylon

1

128616

HOLDER,nozzle,brass

1

2

EQ1842*COUPLER,blasthose,

nylon

1

128617

COUPLER,blasthose,

brass

1

3

17D791*

HANDLE,blast,control

switch,electric

1

17D788HANDLE,blast,control

switch,pneumatic

1

4

-----

(seeBlastControlHoses/Cables,

page46)

5

-----

(seeBlastHoseswithControl

Hose/Cables,page45)

617H239

KIT,screws,fh,sst,8pk

1

7

17H240KIT,cableties,6pk1

8

17C459*GASKET,nylonblast

coupler

1

17C124GASKET,brassblast

coupler

1

917D786KIT,replacement,

whipcheck

1

1017D787KIT,replacement,hairpin,

hose

1

*

Non-ATEXsystemsonly

334142F

41

Page 42

HoseSchematic

Hose Hose

Hose

Schematic Schematic

Schematic

Ref. Ref.

Ref.

Part Part

Part

Color, Color,

Color,

Tube Tube

Tube

Size Size

Size

Cut Cut

Cut

Length Length

Length

1

EQ1296Orange,1/4in.OD

7.0in.

2

EQ1882Red,1/4in.OD

3.0in.

3

EQ1273Natural,3/8in.OD

6.0in.

4

EQ1273Natural,3/8in.OD

1.5in.

5

EQ1273Natural,3/8in.OD

3.0in.

6

EQ1273Natural,3/8in.OD

22.0in.

7

EQ1882Red,1/4in.OD

16.0in.

8

EQ1882Red,1/4in.OD

18.0in.

9

EQ1881Natural,1/4in.OD

21.0in.

Ref. Ref.

Ref.

Part Part

Part

Color, Color,

Color,

Tube Tube

Tube

Size Size

Size

Cut Cut

Cut

Length Length

Length

10

EQ1883Blue,1/4in.OD

15.0in.

11

EQ1883Blue,1/4in.OD

18.0in.

12

EQ1884Green,1/4in.OD

9.0in.

13

EQ1884Green,1/4in.OD

4.0in.

14

EQ1884Green,1/4in.OD

14.0in.

15

EQ1884Green,1/4in.OD

16.0in.

16

EQ1885Yellow,1/4in.OD

14.0in.

17

EQ1885Yellow,1/4in.OD

7.0in.

18

EQ1275Natural,1/2in.OD

14.0in.

42

334142F

Page 43

VaporAbrasiveBlastSystemsandAccessories

Vapor Vapor

Vapor

Abrasive Abrasive

Abrasive

Blast Blast

Blast

Systems Systems

Systems

and and

and

Accessories Accessories

Accessories

EcoQuip EcoQuip

EcoQuip

System System

System

Congurator Congurator

Congurator

Model Model

Model

Series Series

Series

Trailer Trailer

Trailer

Option Option

Option

Package Package

Package

(blast (blast

(blast

hose hose

hose

and and

and

nozzle) nozzle)

nozzle)

Conguration Conguration

Conguration

EQ EQ

EQ

3 3

3

0 0

0

X X

X

S S

S

EQ

1=100

0=Non-Trailer(100,

300,600Series)

0=Barepackage(noblasthoseor

nozzle)

3=Tier3compliant

compressor(400Series)

2=200E=Electricbrakes

(200,400Series)

E=Completepackage,electricblast

control,includes15m(50ft)blast

hoseandnozzle

4=Tiercompliantcompressor

(200,400Series)

3=300H=Hydraulicbrakes

(200Series)

P=Completepackage,pneumatic

blastcontrol,includes15m(50ft)

blasthoseandnozzle

C=Nocrashframeorwater

tank(300,600Series)

4=400

X=Completepackage,ATEX

approved,includes15m(50ft)blast

hoseandnozzle(100,300,600

Series)

M=Mobileunit(100Series)

6=600

S=Skidunit(300,600Series)

Accessory: Accessory:

Accessory:

Air Air

Air

Inlet Inlet

Inlet

Ball Ball

Ball

Valve/Strainer Valve/Strainer

Valve/Strainer

Kit Kit

Kit

24X419–1.25in.kit(100,300series)

24X420–1.50in.kit(600series)

*Includedinrepairkit17G019.

334142F43

Page 44

VaporAbrasiveBlastSystemsandAccessories

Model Model

Model

Series Series

Series

Part Part

Part

Description Description

Description

100 100

100

Series Series

Series

EQ100M

Barepackage,mobileunit

EQ10EMCompletepackage,electricblastcontrol,mobileunit

EQ10PMCompletepackage,pneumaticblastcontrol,mobileunit

EQ10XMCompletepackage,pneumaticblastcontrol,ATEXapproved,mobileunit

300 300

300

Series Series

Series

EQ300SBarepackage,skid/crashframeandwatertank

EQ300CBarepackage,noskid/crashframeorwatertank

EQ30ESCompletepackage,electricblastcontrol,skid/crashframeandwatertank

EQ30ECCompletepackage,electricblastcontrol,noskid/crashframeorwatertank

EQ30PSCompletepackage,pneumaticblastcontrol,skid/crashframeandwatertank

EQ30PCCompletepackage,pneumaticblastcontrol,noskid/crashframeandwatertank

EQ30XSCompletepackage,pneumaticblastcontrol,ATEXapproved,skid/crashframeandwatertank

EQ30XCCompletepackage,pneumaticblastcontrol,ATEXapproved,noskid/crashframeandwatertank

600 600

600

Series Series

Series

EQ600SBarepackage,skid/crashframeandwatertank

EQ600CBarepackage,noskid/crashframeorwatertank

EQ60ESCompletepackage,electricblastcontrol,skid/crashframeandwatertank

EQ60ECCompletepackage,electricblastcontrol,noskid/crashframeorwatertank

EQ60PSCompletepackage,pneumaticblastcontrol,skid/crashframeandwatertank

EQ60PCCompletepackage,pneumaticblastcontrol,noskid/crashframeandwatertank

EQ60XSCompletepackage,pneumaticblastcontrol,ATEXapproved,skid/crashframeandwatertank

EQ60XCCompletepackage,pneumaticblastcontrol,ATEXapproved,noskid/crashframeandwatertank

200 200

200

Series Series

Series

Trailers Trailers

Trailers

EQ2E04

Barepackage,electricbrakes,Tier4i

EQ2EE4Completepackage,electricblastcontrol,electricbrakes,Tier4i

EQ2EP4Completepackage,pneumaticblastcontrol,electricbrakes,Tier4i

EQ2H04

Barepackage,hydraulicbrakes,Tier4i

EQ2HE4Completepackage,electricblastcontrol,hydraulicbrakes,Tier4i

EQ2HP4Completepackage,pneumaticblastcontrol,hydraulicbrakes,Tier4i

400 400

400

Series Series

Series

Trailers Trailers

Trailers

EQ4E03

Barepackage,electricbrakes,Tier3

EQ4EE3Completepackage,electricblastcontrol,electricbrakes,Tier3

EQ4EP3Completepackage,pneumaticblastcontrol,electricbrakes,Tier3

EQ4E04

Barepackage,electricbrakes,Tier4i

EQ4EE4Completepackage,electricblastcontrol,electricbrakes,Tier4i

EQ4EP4Completepackage,pneumaticblastcontrol,electricbrakes,Tier4i

100,200,300Seriescompletepackagesinclude1.0in.ID4–plyhoseand#7standardnozzle.

400,600Seriescompletepackagesinclude1.25in.ID2–plyhoseand#8performancenozzle.

44

334142F

Page 45

VaporAbrasiveBlastSystemsandAccessories

Blast Blast

Blast

Hoses Hoses

Hoses

with with

with

Control Control

Control

Hose/Cables Hose/Cables

Hose/Cables

Part Part

Part

ID ID

ID

Blast Blast

Blast

Control Control

Control

Coupler Coupler

Coupler

1 1

1

Coupler Coupler

Coupler

2 2

2

Length Length

Length

Models Models

Models

ATEX ATEX

ATEX

Approved Approved

Approved

EQ5237

1.0in.Pneumatic2–Prongcoupler,nylon2–Prongcoupler,nylon

15m(50ft)

No

EQ5235

1.0in.Electric2–Prongcoupler,nylon2–Prongcoupler,nylon

15m(50ft)

No

EQ5236

1.0in.PneumaticNozzleholder,nylon2–Prongcoupler,nylon

15m(50ft)

No

EQ5234

1.0in.ElectricNozzleholder,nylon2–Prongcoupler,nylon

15m(50ft)

EQ100M,

EQ200T,

EQ300C,

EQ300S

No

24X6731.0in.PneumaticNozzleholder,brass2–Prongcoupler,brass

15m(50ft)

Yes

24X6761.0in.Pneumatic2–Prongcoupler,brass2–Prongcoupler,brass

15m(50ft)

EQ10XM,

EQ30XC,

EQ30XS

Yes

EQ5077

1.25in.Pneumatic2–Prongcoupler,nylon2–Prongcoupler,nylon

30m(100ft)

No

EQ5084

1.25in.Electric2–Prongcoupler,nylon2–Prongcoupler,nylon

30m(100ft)

No

EQ5082

1.25in.Electric2–Prongcoupler,nylon2–Prongcoupler,nylon

15m(50ft)

No

EQ5073

1.25in.Pneumatic2–Prongcoupler,nylon2–Prongcoupler,nylon

15m(50ft)

No

EQ5071

1.25in.PneumaticNozzleholder,nylon2–Prongcoupler,nylon

15m(50ft)

No

EQ5080

1.25in.ElectricNozzleholder,nylon2–Prongcoupler,nylon

15m(50ft)

EQ400T,

EQ600C,

EQ600S

No

24X6721.25in.PneumaticNozzleholder,brass2–Prongcoupler,brass

15m(50ft)

Yes

24X6741.25in.Pneumatic2–Prongcoupler,brass2–Prongcoupler,brass

15m(50ft)

Yes

24X6751.25in.Pneumatic2–Prongcoupler,brass2–Prongcoupler,brass

30m(100ft)

EQ60XC,

EQ60XS

Yes

100,200,300Seriescompletepackagesinclude1.0in.ID4–plyhoseand#7standardnozzle.

400,600Seriescompletepackagesinclude1.25in.ID2–plyhoseand#8performancenozzle.

Blast Blast

Blast

Hoses Hoses

Hoses

without without

without

Control Control

Control

Hose/Cables Hose/Cables

Hose/Cables

Part Part

Part

ID ID

ID

Blast Blast

Blast

Control Control

Control

Coupler Coupler

Coupler

1 1

1

Coupler Coupler

Coupler

2 2

2

Length Length

Length

Models Models

Models

ATEX ATEX

ATEX

Approved Approved

Approved

17F4961.0in.NoneNozzleholder,nylon2–Prongcoupler,nylon

15m(50ft)

No

17F4981.0in.None2–Prongcoupler,nylon2–Prongcoupler,nylon

15m(50ft)

EQ100M,

EQ200T,

EQ300C,

EQ300S

No

24X7271.0in.NoneNozzleholder,brass2–Prongcoupler,brass

15m(50ft)

Yes

24X7291.0in.None2–Prongcoupler,brass2–Prongcoupler,brass

15m(50ft)

EQ10XM,

EQ30XC,

EQ30XS

Yes

17F4971.25in.NoneNozzleholder,nylon2–Prongcoupler,nylon

15m(50ft)

No

17F4991.25in.None2–Prongcoupler,nylon2–Prongcoupler,nylon

15m(50ft)

No

17F5001.25in.None2–Prongcoupler,nylon2–Prongcoupler,nylon

30m(100ft)

EQ400T,

EQ600C,

EQ600S

No

24X7281.25in.NoneNozzleholder,brass2–Prongcoupler,brass

15m(50ft)

Yes

24X7301.25in.None2–Prongcoupler,brass2–Prongcoupler,brass

15m(50ft)

Yes

24X7311.25in.None2–Prongcoupler,brass2–Prongcoupler,brass

30m(100ft)

EQ60XC,

EQ60XS

Yes

100,200,300Seriescompletepackagesinclude1.0in.ID4–plyhoseand#7standardnozzle.

400,600Seriescompletepackagesinclude1.25in.ID2–plyhoseand#8performancenozzle.

334142F45

Page 46

VaporAbrasiveBlastSystemsandAccessories

Blast Blast

Blast

Control Control

Control

Hoses/Cables Hoses/Cables

Hoses/Cables

Part Part

Part

Description Description

Description

17F501

Blastcontrolhose,pneumatictwinline,55ft

24X746

Blastcontrolhose,pneumatictwinline,55ft,ATEXapproved

17F502

Blastcontrolhose,pneumatictwinline,55ft,extension

24X744

Blastcontrolhose,pneumatictwinline,55ft.extension,ATEXapproved

17F503

Blastcontrolhose,pneumatictwinline,110ft,extension

24X745

Blastcontrolhose,pneumatictwinline,110ft,extension,ATEXapproved

17F506

Blastcontrolcable,electric,55ft

17F507

Blastcontrolcable,electric,105ft

Nozzles Nozzles

Nozzles

Part Part

Part

Description Description

Description

Inlet Inlet

Inlet

Size Size

Size

Length Length

Length

Thread Thread

Thread

Size Size

Size

Sleeve Sleeve

Sleeve

Material Material

Material

Insert Insert

Insert

Material Material

Material

EQ1710Standard#7

(100,200,300Series)

1.25in.7.95in.

EQ1711Standard#8

(400,600Series)

1.25in.9.0in.

Polyurethane

BP200Sialon

EQ7073*Highperformance#7

(100,300Series)

1.25in.12.0in.

EQ7074*Highperformance#8

(400,600Series)

1.25in.

13.75 in.

BP200Sialon

EQ5166

Nozzleextension,24in.1.25in.24.0in.

50mmContractor

(2in.4–1/2UNC-2A)

Aluminum

NA

*Performancenozzlesrequire100psi(7bar,0.7MPa)ormoreairpressureatnozzle.

Other Other

Other

Accessories Accessories

Accessories

Part Part

Part

Description Description

Description

17C126PumpRetrotKit

24A592

DataTrakModuleandReedSwitch

24X419

Airinletballvalvestrainerkit(100,300Series)

24X420

Airinletballvalvestrainerkit(600Series)

17G019

Airinletballvalvestrainerrepairkit

46334142F

Aluminum

Aluminum

Boron Carbide

Page 47

VaporAbrasiveBlastSystemsandAccessories

Common Common

Common

Spare Spare

Spare

Parts Parts

Parts

Part Part

Part

Description Description

Description

17B186Pumprepairkit

17C459

Blasthosecouplergasket,nyloncouplers

17C124

Blasthosecouplergasket,brasscouplers

17C125Gasket,abrasiveballvalvecam-lock—1.25in.ID(100,200,300Series)

17C453Gasket,abrasiveballvalvecam-lock—1.5in.ID(400,600,Series)

17C127Diaphragmvalverepairkit(100,200,300Series)

17C128Diaphragmvalverepairkit(400,600Series)

17F504

Diaphragmvalvereplacementcanister(400,600Series)

17F505

Diaphragmvalvereplacementcanister(100,200,300Series)

17C129AirRegulatormajorrepairkit(100,200,300Series)

17C131AirRegulatordiaphragmrepairkit(400,600Series)

17F535

AirRegulatorpistonrepairkit(400,600Series)

17F536

AirRegulatoro-ringrepairkit(400,600Series)

17D790Handwaygasket

17D789Auto-ventvalve

17D785

Pressurereliefvalve

17D786Hoserestraint

17D787

Couplerpinkit(6pack)

206994

ThroatLiquidSeal

17F065Pop-upgasket

EQ1051

Nozzlegasket

EQ5183Batterycable(100,300,600Series)

17D788Replacementhandle,pneumaticblastcontrol

17D791

Replacementhandle,electricblastcontrol(notforATEXapprovedunits)

EQ1818

Filterelement,replacement

EQ1830Filteroat,replacement

EQ1842*

Blasthosecoupler,nylon

EQ1843*

Nozzleholder,nylon

*Reusestainlesssteelscrewsfromblasthoseassemblywhenreplacing.

334142F

47

Page 48

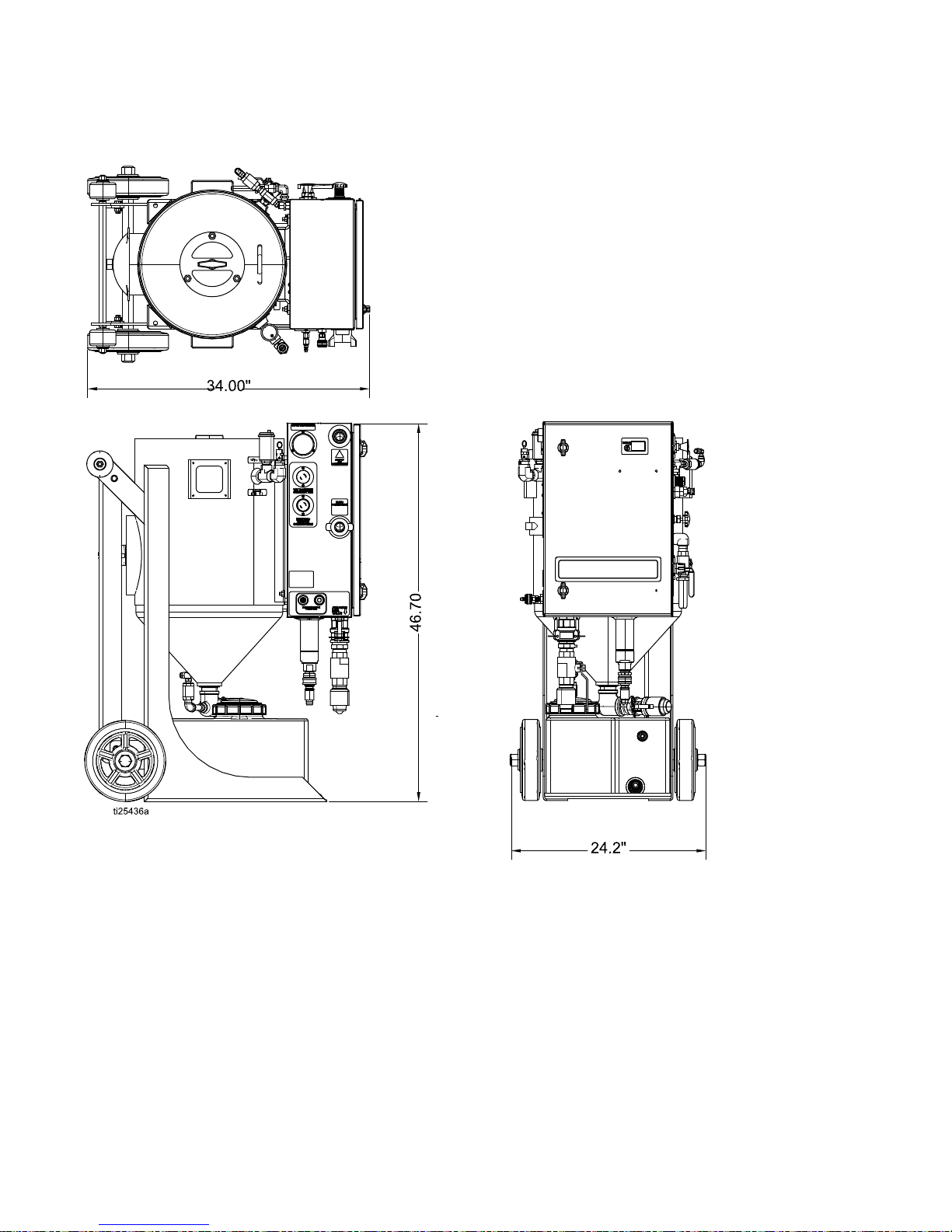

Dimensions

Dimensions Dimensions

Dimensions

48334142F

Page 49

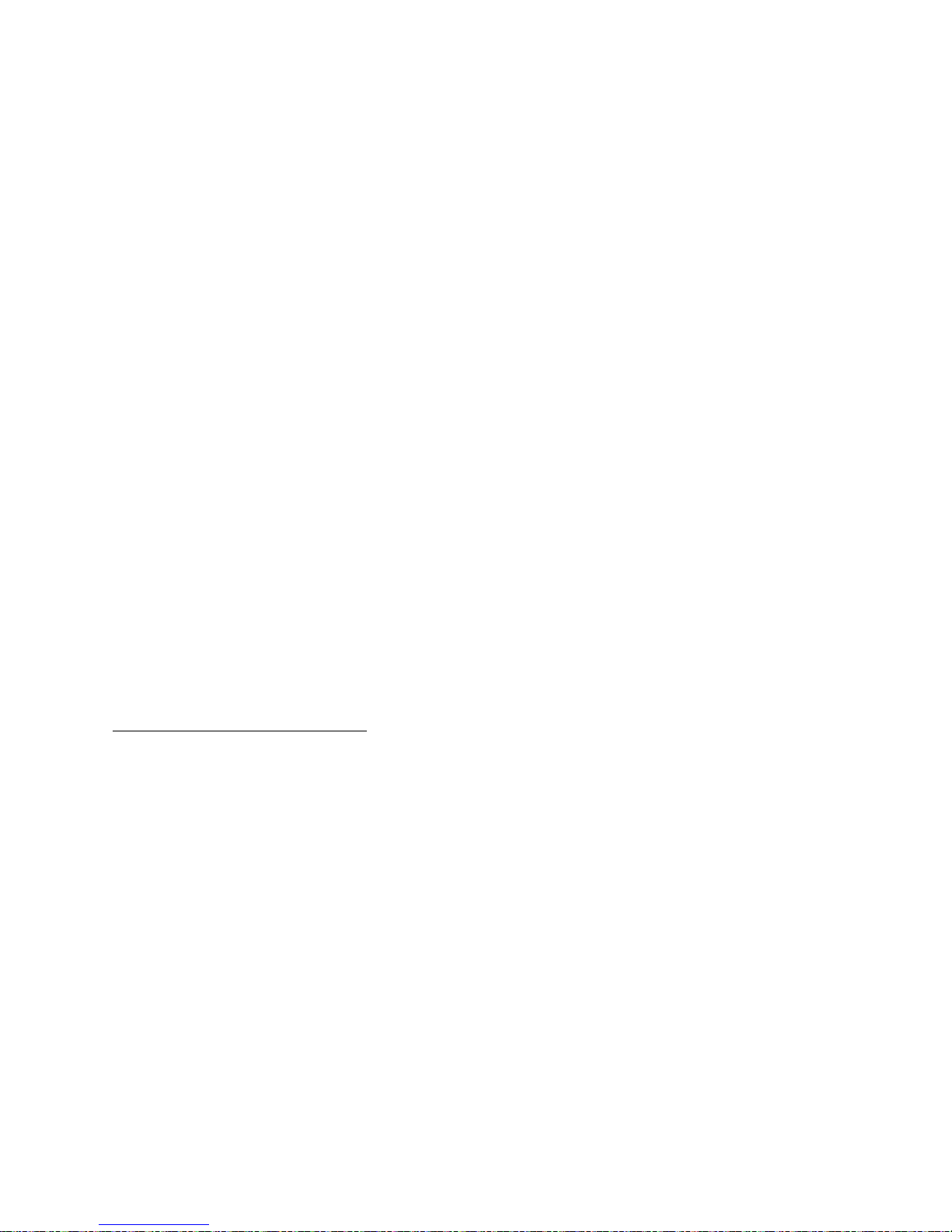

TechnicalSpecications

Technical Technical

Technical

Specications Specications

Specications

EQ100M EQ100M

EQ100M

U.S. U.S.

U.S.

Metric Metric

Metric

MaximumWorkingPressure125psi8.6bar,0.86MPa

OperatingTemperature35°–110°F1.6°–43.3°C

RecommendedCompressor185–375cfm

5.23–10.62m^3/min

BlastHoseSize

1in.ID25.4mmID

AbrasiveCapacity

100–250lb45–114kg

DryWeight360lb164kg

WetWeight900lb400kg

PressurePotVolume

2.0cubicfeet

57liters

WaterTankVolume10gallon38liters

Air Air

Air

Supply Supply

Supply

Hose Hose

Hose

Minimum Minimum

Minimum

ID ID

ID

185–600cfmcompressorandlessthan100ft

hoselength

1.5in.ID38mmID

Over600cfmcompressororgreaterthan

100ft.hoselength

2in.ID51mmID

Sound Sound

Sound

Data* Data*

Data*

SoundPressureLevel133dB(A)133dB(A)

SoundPowerLevel139dB(A)139dB(A)

InstantaneousSoundPressureLevel131dB(C)131dB(C)

*Allreadingsweretakenatthemaximumsystemblastpressure125psi(8.6bar,0.86MPa)fromtheoperator

position.Theabrasiveusedwasgarnetandthesubstratewassteel.TestedinaccordancewithISO9614–2.

334142F49

Page 50

Graco Graco

Graco

Extended Extended

Extended

Warranty Warranty

Warranty

for for

for

EcoQuip EcoQuip

EcoQuip

™ ™

™

Components Components

Components