Page 1

Installation

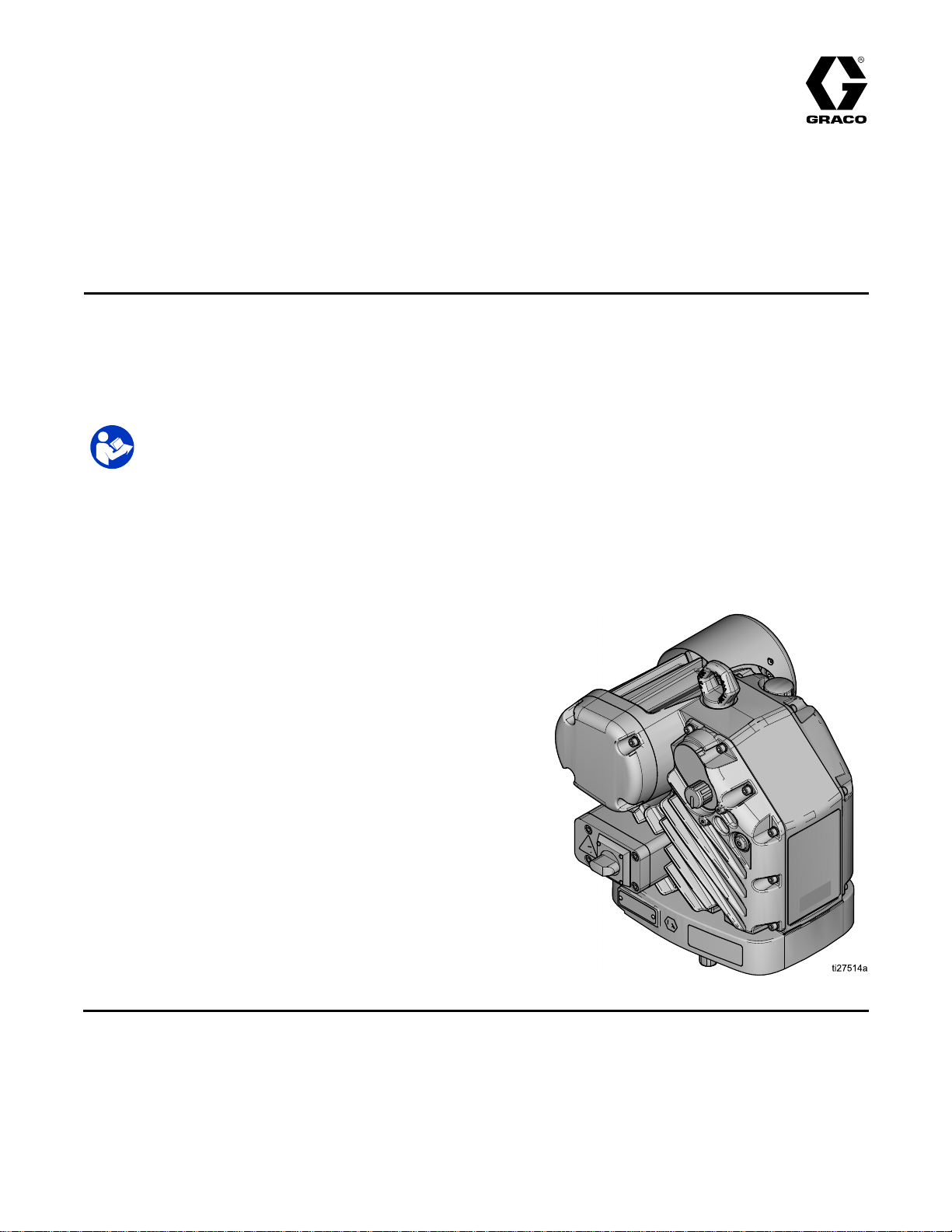

E60/E50 KingTM Electric Driver

Electric

Electric Electric

For

For For

Seepages3formodelandapprovals

information.

driver

driver driver

professional

professional professional

Important

Important Important

Readallwarningsandinstructionsinthismanualandthesystem

manualbeforeusingtheequipment.Saveallinstructions.

for

for for

3A8119A

EN

application

application application

use

only.

use use

only. only.

Safety

Safety Safety

of

nishing

of of

nishing nishing

Instructions

Instructions Instructions

materials

materials materials

and

protective

and and

protective protective

coatings

coatings coatings

using

King

using using

Sprayers.

King King

Sprayers. Sprayers.

PROVENQUALITY.LEADINGTECHNOLOGY.

Page 2

Contents

Contents Contents

ModelInformation...............................................3

DriverModel................................................3

RelatedManuals................................................3

Warnings...........................................................4

ComponentIdentication.....................................7

Installation..........................................................8

PowerRequirements....................................8

HazardousAreaCablingandConduit

Requirements.................................8

Grounding...................................................9

ConnectPower............................................10

GeneralRepairInformation.................................11

GracoInformation...............................................12

2

3A8119A

Page 3

ModelInformation

Model

Model Model

Driver

Driver Driver

Part

Part Part

24X960AKingDriver

List

List List

•IEC60079–0

•IEC60079–1

•EN60079–0

•EN60079–1

•ANSI/ISA60079–0

•ANSI/UL60079–1

•FM3600

•FM3615

•FM3810

•CSAC22.2No.0.4

•CSAC22.2No.0.5

•CSAC22.2No.30

•CAN/CSAC22.260079–0

•CAN/CSAC22.260079–1

•CAN/CSAC22.2No.61010.1

Standards

of ofofStandards Standards

Information

Information Information

Model

Model Model

Series

Series Series

2575

2575 2575

ExdbIIAT4Gb–5˚C≤Ta≤50C˚

FM15ATEX0060X

IECExFMG15.0035X

Description

Description Description

II2G

Related

Related Related

Manual

Manual Manual

English

English English

3A8124KingE60/E50ElectricDriver

3A8126

311619PumpMountingKitManual

in

in in

Weight

Weight Weight

110lb(50kg)

Explosionproof.ForClass1,Div1,GroupDT4.

Zone1,AExdbIIAT4Gb–5˚C≤Ta≤50C˚

ExdbIIAT4Gb–5˚C≤Ta≤50C˚

FM20CA0054X

Manuals

Manuals Manuals

Description

Description Description

Operation,RepairandTroubleshooting

KingE60/E50ElectricSprayer

3A8119A 3

Page 4

Warnings

Warnings

Warnings Warnings

Thefollowingwarningsareforthesetup,use,grounding,maintenance,andrepairofthisequipment.The

exclamationpointsymbolalertsyoutoageneralwarningandthehazardsymbolsrefertoprocedure-specic

risks.Whenthesesymbolsappearinthebodyofthismanualoronwarninglabels,referbacktothese

Warnings.Product-specichazardsymbolsandwarningsnotcoveredinthissectionmayappearthroughout

thebodyofthismanualwhereapplicable.

WARNING

WARNING WARNING

FIRE

AND

FIRE FIRE

Flammablefumes,suchassolventandpaintfumes,inwork work

Paintorsolventowingthroughtheequipmentcancausestaticsparking.Tohelpprevent

reandexplosion:

•Useequipmentonlyinwellventilatedarea.

•Eliminateallignitionsources;suchaspilotlights,cigarettes,portableelectriclamps,

andplasticdropcloths(potentialstaticsparking).

•Groundallequipmentintheworkarea.SeeGrounding Grounding

•Neversprayorushsolventathighpressure.

•Keepworkareafreeofdebris,includingsolvent,ragsandgasoline.

•Donotplugorunplugpowercords,orturnpowerorlightswitchesonoroffwhen

ammablefumesarepresent.

•Useonlygroundedhoses.

•Holdgunrmlytosideofgroundedpailwhentriggeringintopail.Donotusepailliners

unlesstheyareanti-staticorconductive.

Stop

•Stop Stop

equipmentuntilyouidentifyandcorrecttheproblem.

•Keepaworkingreextinguisherintheworkarea.

EXPLOSION

AND AND

EXPLOSION EXPLOSION

operation

operation operation

immediately

immediately immediately

HAZARD

HAZARD HAZARD

work

area

area area

canigniteorexplode.

Grounding

ifstaticsparkingoccursoryoufeelashock.Donotuse

instructions.

Staticchargemaybuilduponplasticpartsduringcleaningandcoulddischargeandignite

ammablevapors.Tohelppreventreandexplosion:

•Cleanplasticpartsonlyinwellventilatedarea.

•Donotcleanwithadrycloth.

•Donotoperateelectrostaticgunsinequipmentworkarea.

SPECIAL

SPECIAL SPECIAL

•Topreventtheriskofelectrostaticsparking,theequipment’snon-metallicpartsshould

becleanedonlywithadampcloth.

•Thealuminumhousingmaysparkuponimpactorcontactwithmovingparts,whichmay

causereorexplosion.Takeprecautionstoavoidsuchimpactorcontact.

•Allameproofjointsarecriticaltotheintegrityofthedriverasapprovedforhazardous

locationsandarenotrepairableifdamaged.Damagedpartsmustbereplacedonlywith

genuineGracopartswithnosubstitutions.

•ConsultGracoTechnicalAssistanceoryourGracodistributorifdimensionalinformation

ontheameproofjointsisnecessary.

•ConsultGracoTechnicalAssistanceoryourGracodistributorforgenuinereplacement

fasteners.M8x30socket-headcapscrewsofClass12.9steelorbetterwithaminimum

yieldstrengthof1100MPa(160,000psi)areacceptablealternatives.Allsocket-head

capscrewcoverfastenersmustbetorquedto15ft-lb(20.3N•m).

CONDITIONS

CONDITIONS CONDITIONS

FOR

SAFE

FOR FOR

USE

SAFE SAFE

USE USE

4

3A8119A

Page 5

Warnings

WARNING

WARNING WARNING

ELECTRIC

ELECTRIC ELECTRIC

Thisequipmentmustbegrounded.Impropergrounding,setup,orusageofthesystem

cancauseelectricshock.

•Turnoffanddisconnectpoweratmainswitchbeforedisconnectinganycablesand

beforeservicingorinstallingequipment.

•Connectonlytogroundedpowersource.

•Allelectricalwiringmustbedonebyaqualiedelectricianandcomplywithalllocal

codesandregulations.

•Donotexposetorain.Storeindoors.

•Waitveminutesbeforeservicingafterpowerisremoved.

BURN

BURN BURN

Equipmentsurfacesanduidthatisheatedcanbecomeveryhotduringoperation.To

avoidsevereburns:

•Donottouchhotuidorequipment.

MOVING

MOVING MOVING

Movingpartscanpinch,cutoramputatengersandotherbodyparts.

SHOCK

SHOCK SHOCK

HAZARD

HAZARD HAZARD

PARTS

PARTS PARTS

HAZARD

HAZARD HAZARD

HAZARD

HAZARD HAZARD

•Keepclearofmovingparts.

•Donotoperateequipmentwithprotectiveguardsorcoversremoved.

•Pressurizedequipmentcanstartwithoutwarning.Beforechecking,moving,orservicing

equipment,followthePressure Pressure

SKIN

INJECTION

SKIN SKIN

INJECTION INJECTION

High-pressureuidfromgun,hoseleaks,orrupturedcomponentswillpierceskin.This

maylooklikejustacut,butitisaseriousinjurythatcanresultinamputation.Get Get

immediate

immediate immediate

•Donotspraywithouttipguardandtriggerguardinstalled.

•Engagetriggerlockwhennotspraying.

•Donotpointgunatanyoneoratanypartofthebody.

•Donotputyourhandoverthespraytip.

•Donotstopordeectleakswithyourhand,body,glove,orrag.

•FollowthePressure Pressure

checking,orservicingequipment.

•Tightenalluidconnectionsbeforeoperatingtheequipment.

•Checkhosesandcouplingsdaily.Replacewornordamagedpartsimmediately.

surgical

surgical surgical

Pressure

Pressure

HAZARD

HAZARD HAZARD

treatment.

treatment. treatment.

Relief

Relief Relief

Relief

Procedure

Relief Relief

Procedure Procedure

Procedure

Procedure Procedure

whenyoustopsprayingandbeforecleaning,

anddisconnectallpowersources.

Get

3A8119A 5

Page 6

Warnings

WARNING

WARNING WARNING

TOXIC

TOXIC TOXIC

Toxicuidsorfumescancauseseriousinjuryordeathifsplashedintheeyesoron

skin,inhaled,orswallowed.

•ReadSafetyDataSheets(SDSs)toknowthespecichazardsoftheuidsyouare

•Storehazardousuidinapprovedcontainers,anddisposeofitaccordingtoapplicable

PERSONAL

PERSONAL PERSONAL

Wearappropriateprotectiveequipmentwhenintheworkareatohelppreventserious

injury,includingeyeinjury,hearingloss,inhalationoftoxicfumes,andburns.Protective

equipmentincludesbutisnotlimitedto:

•Protectiveeyewear,andhearingprotection.

•Respirators,protectiveclothing,andglovesasrecommendedbytheuidandsolvent

EQUIPMENT

EQUIPMENT EQUIPMENT

Misusecancausedeathorseriousinjury.

FLUID

FLUID FLUID

using.

guidelines.

manufacturer.

OR

FUMES

OR OR

FUMES FUMES

PROTECTIVE

PROTECTIVE PROTECTIVE

MISUSE

MISUSE MISUSE

EQUIPMENT

EQUIPMENT EQUIPMENT

HAZARD

HAZARD HAZARD

•Donotoperatetheunitwhenfatiguedorundertheinuenceofdrugsoralcohol.

•Donotexceedthemaximumworkingpressureortemperatureratingofthelowestrated

systemcomponent.SeeTechnical Technical

•Useuidsandsolventsthatarecompatiblewithequipmentwettedparts.SeeTechnical Technical

Specications

Specications Specications

warnings.Forcompleteinformationaboutyourmaterial,requestSafetyDataSheets

(SDSs)fromdistributororretailer.

•Donotleavetheworkareawhileequipmentisenergizedorunderpressure.

•TurnoffallequipmentandfollowthePressure Pressure

isnotinuse.

•Checkequipmentdaily.Repairorreplacewornordamagedpartsimmediatelywith

genuinemanufacturer’sreplacementpartsonly.

•Donotalterormodifyequipment.Alterationsormodicationsmayvoidagency

approvalsandcreatesafetyhazards.

•Makesureallequipmentisratedandapprovedfortheenvironmentinwhichyouare

usingit.

•Useequipmentonlyforitsintendedpurpose.Callyourdistributorforinformation.

•Routehosesandcablesawayfromtrafcareas,sharpedges,movingparts,andhot

surfaces.

•Donotkinkoroverbendhosesorusehosestopullequipment.

•Keepchildrenandanimalsawayfromworkarea.

•Complywithallapplicablesafetyregulations.

inallequipmentmanuals.Readuidandsolventmanufacturer’s

Technical

Specications

Specications Specications

Pressure

inallequipmentmanuals.

Relief

Relief Relief

Procedure

Procedure Procedure

whenequipment

Technical

6 3A8119A

Page 7

ComponentIdentication

Component

Component Component

Identication

Identication Identication

Ref.

Ref. Ref.

ADriver

CLiftRing

GOilDrainPlug

H

K

L

N

P

SPowerSwitch(Lock-outtag-outequipped)

YElectricalJunctionBox

X

Z

ZZ

Description

Description Description

DriverOutputShaft

OilSightGlass

StatusIndicatorLight(LED)

PressureControlKnob

OilFillCap(vented)

ConduitEntry

ElectricalJunctionBoxCover

GroundScrews

3A8119A

7

Page 8

Installation

Installation

Installation Installation

Installationofthisequipmentinvolvespotentially

hazardousprocedures.Onlytrainedandqualied

personnelwhohavereadandwhounderstand

theinformationinthismanualshouldinstallthis

equipment.

NOTE:

NOTE: NOTE:

information,seeDriverOperationmanual.

Power

Power Power

ForcompleteTechnicalSpecication

Requirements

Requirements Requirements

Improperwiringmaycauseelectricshockorother

seriousinjuryifworkisnotperformedproperly.

Haveaqualiedelectricianperformanyelectrical

work.Besureyourinstallationcomplieswithall

Localcodesandregulations.

Hazardous

Hazardous Hazardous

Requirements

Requirements Requirements

Explosion

Explosion Explosion

Allelectricalwiringinthehazardousareamustbe

encasedinClassI,DivisionI,GroupDapproved

explosion-proofconduit.FollowallNational,State,

andLocalelectriccodes.

Aconduitsealisrequiredwithin18in.(457

mm)ofthedriverfortheUSandCanada.See

ConnectPower,page10.

Allcablesmustberated70°Cminimum.

Flame

Flame Flame

Useappropriateconduit,connectors,andcable

glandsratedforATEXII2G.FollowallLocalcodes

andregulations.

Allcableglandsandcablesmustberated70°C

minimum.

Proof

Proof Proof

Area

Area Area

Proof

Proof Proof

(ATEX)

(ATEX) (ATEX)

Cabling

Cabling Cabling

and

Conduit

and and

Conduit Conduit

Seethetablebelowforpowersupplyrequirements.

Thedriverrequiresadedicatedcircuitprotectedwith

acircuitbreaker.

Model

Model Model

Theprotectiveearthinggroundconductormustbe

equaltothephaseconductors.

Voltage

Voltage Voltage

200–240Vac150/6015A 24X960

100–120Vac150/6025A

Phase

Phase Phase

Hz

Hz Hz

Amperage

Amperage Amperage

8 3A8119A

Page 9

Grounding

Grounding Grounding

Thisequipmentmustbegroundedtoreducethe

riskofstaticsparkingandelectricshock.Electric

orstaticsparkingcancausefumestoigniteor

explode.Impropergroundingcancauseelectric

shock.Groundingprovidesanescapewireforthe

electriccurrent.

Driver:

Driver: Driver:

Thedriverisgroundedthroughthepowercord.

Installation

Driver

Driver Driver

PumpGroundWire–Twogroundterminalsare

providediflocalcoderequiresredundantgrounding

connections.

Loosenthegroundscrew(ZZ)andattachaground

wire(Gracopart244524–notsupplied).Tightenthe

groundscrewsecurely.Connecttheotherendofthe

groundwiretoatrueearthground.

(optional

(optional (optional

secondary):

secondary): secondary):

3A8119A 9

Page 10

Installation

1

2

3

4

Connect

Connect Connect

Power

Power Power

Improperwiringmaycauseelectricshock,re

andexplosion,orotherseriousinjuryifwork

isnotperformedproperly.Haveaqualied

electricianperformanyelectricalwork.Besure

yourinstallationcomplieswithallNational,State

andLocalsafetyandrecodes.

1.Shutoffthefusedsafetyswitch(B)andfollow

theappropriatelock-out/tag-outprocedures.

Typicalxedinstallationforwallmounted

systemsshownbelow:

4.Installincomingpowerwiresintothedisconnect

terminalslabeled2T1and4T2,andtorqueto7

in-lb(0.8N•m).

5.Reinstalljunctionboxcover(Z)andscrews(J).

Torquescrewsto15–20ft-lb(21–27N•m).

NOTE:

NOTE: NOTE:

Onewireisinstalledinterminals1L1and

3L2.

Makesurewiresarenotpinchedwhen

re-installingcovers.Wireswillbedamaged

andcreateanelectricalhazardand/orreand

explosionhazardifpinched.

Disconnect

Disconnect Disconnect

2.Toinstallwiring,locatetheelectricaljunctionbox

(Y).Removefourscrews(J)andjunctionbox

cover(Z).Wireswillalreadybeinstalledinthe

frontsideofthedisconnectinterminalslabeled

Block

Terminals

Block Block

Terminals Terminals

Tightendisconnectblockterminalsto7in-lb

(0.8N•m).Donotover-tighten.

Tightencoverscrewsto15ft-lb(20.3N•m).

Aconduitseal(D)isrequiredwithin18in.

(457mm)ofthedriverfortheUSandCanada.

15in-lbmaximum(terminalbushings)

†Conduitnotsupplied.

‡Powercordnotsupplied.

1L1and3L2.

3.Connectthegroundwiretothelabeledground

screwinthebackofthejunctionbox.See

Grounding,page9.

10 3A8119A

Page 11

GeneralRepairInformation

General

General General

Information

Information Information

NOTE:

NOTE: NOTE:

instructions.

SeeDriverRepairmanualforspecic

Toavoidelectricshock,reandexplosionhazard,

and/orinjuryfrommovingpartshazard,turnoff

equipmentpowerandshutoffpoweratthemain

circuitbreakerbeforerepairing.Wearappropriate

protectiveequipmentwheninworkarea.Waitve

minutesbeforeservicing.

Makesurewiresarenotpinchedwhenre-installing

covers.Wireswillbedamagedandcreatean

electricalhazardand/orreandexplosionhazard

ifpinched.

Repair

Repair Repair

NOTE:

NOTE: NOTE:

Gracodistributorforgenuinereplacementfasteners.

M8x30socket-headcapscrewsofClass12.9steel

orbetterwithaminimumyieldstrengthof1100

MPa(160,000psi)areacceptablealternatives.All

socket-headcapscrewcoverfastenersmustbe

torquedto15ft-lb(20.3N•m).

ConsultGracoTechnicalAssistanceoryour

3A8119A

11

Page 12

Graco

Graco Graco

NOTE:

NOTE: NOTE:

ForthelatestinformationaboutGracoproducts,visitwww.graco.com.Forpatentinformation,seewww.graco.com/patents.

To

place

To To

place place

1-800-328-0211Fax: Fax:

Allwrittenandvisualdatacontainedinthisdocumentreectsthelatestproductinformationavailableatthetimeofpublication.

Gracoreservestherighttomakechangesatanytimewithoutnotice.OriginalInstructions.ThismanualcontainsEnglish.MM3A8119 3A8119

Information

Information Information

ForGracoWarrantyinformationseeDriverOperationmanual.

order,

an ananorder, order,

contactyourGracoDistributororcalltoidentifythenearestdistributor.Phone: Phone:

Fax:

612-378-3505

Graco

Headquarters:

Graco Graco

Headquarters: Headquarters:

GRACO

GRACO GRACO

INC.

AND

INC. INC.

AND AND

Copyright

Copyright Copyright

2020,

2020, 2020,

MinneapolisInternational International

SUBSIDIARIES

SUBSIDIARIES SUBSIDIARIES

Graco

Inc.

Graco Graco

All

Inc. Inc.

All All

International

P.O.

BOX

• ••P.O. P.O.

BOX BOX

Graco

manufacturing

Graco Graco

manufacturing manufacturing

www.graco.com

RevisionA–October2020

Phone:

612-623-6921or ororToll Toll

Ofces:

Ofces: Ofces:

1441

1441 1441

Belgium,China,Japan,Korea

MINNEAPOLIS

• ••MINNEAPOLIS MINNEAPOLIS

locations

locations locations

MN

55440-1441

MN MN

55440-1441 55440-1441

are

registered

are are

registered registered

to totoISO ISO

USA

• ••USA USA

ISO

9001.

9001. 9001.

Toll

Free:

Free: Free:

3A8119

Loading...

Loading...