Page 1

Dyna-Star® 10:1

Dyna-Star® 10:1

High Ratio Hydraulically-Powered Lubrication Pump

Available Electronically Only

Long-lasting, fl exible design saves money and is easy to use and install

• Achieve full pressure performance by safely tapping low pressure hydraulics

• Pre-packaged modules ready-to-work with both injector and divider valve systems

• Multiple pump and accessory options for use with refi nery drum and custom tank installations

• Self-lubricating for long life and reliable operation

• Ultra-quiet hydraulic motor—no need for add-on muffl ers

• High effi ciency motor design uses less hydraulic oil

Page 2

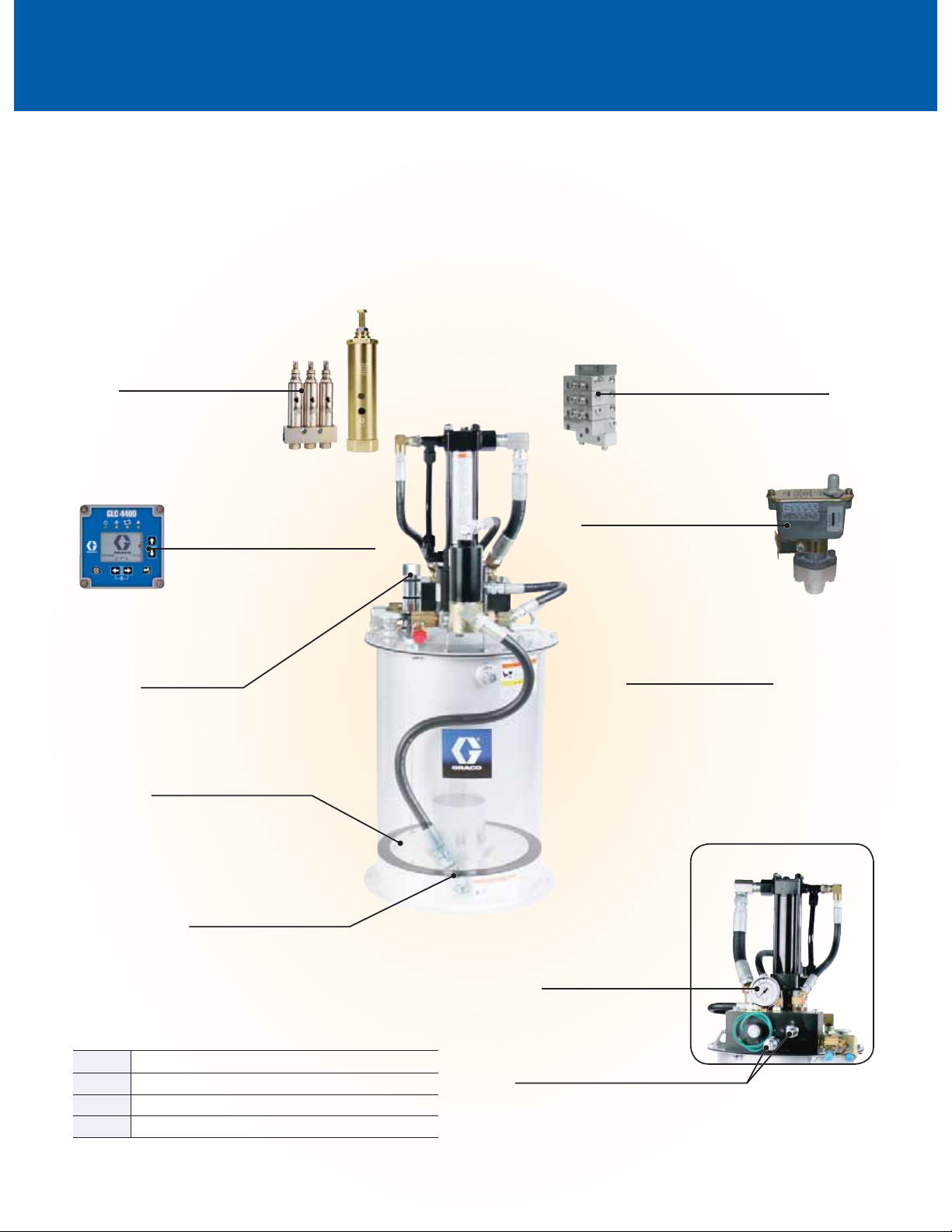

Graco® Quality by Design

Superior System Performance

Heavy-duty construction and mining equipment rely on fresh lubricant to fl ush contaminants from critical pivot points.

An automatic lubrication system from Graco provides constant lube replenishment, preventing expensive and catastrophic

component failures. Divider valves and injectors accurately distribute lubricant to multiple lube points and are designed to

accept a variety of system accessories which include electronic controllers, pressure switches and level indicators.

GL-1 and Gl-11 Injectors

• Exclusive seal design for up to

30% longer life

• Field adjustable output for most

every application

Rugged Digital Controller

Full featured performance—time- or

pressure-based control to monitor reservoir

levels and system pressure

Level Indicator

• Positive, at-a-glance indication of

reservoir lubrication level

• Auto shut-down when low level

is reached

Follower Plate

Innovative design forces grease into

the pump for consistent operation

Trabon® Divider Valve Assembly

• Accurately meters lubrication to each point

• Add performance indicators to ensure vital

components have been lubricated

Pressure Switch

Lets the controller know when optimum

system pressure is reached ensuring

complete lubrication cycle

Field-Proven Graco Fire-Ball®

Grease Pump Lower

Double-acting piston design—the industry

standard for long life

For optimal system performance

NLGI #1 grease is recommended

Center-Feed

Vent and Refill Port

Located below follower plate for

trouble-free venting and refilling

Module and Kit Accessories

247700 Follower plate for 60 lb (27 kg) and 90 lb (41 kg) modules

244023 Level indicator for 60 lb (27 kg) and 90 lb (41 kg) modules*

24B591 GLC 4400, 12/24 VDC controller

115124 Pressure switch

* Follower plate 247700 required for level indicator 244023 to function

Detail of back side of module assembly.

Built-In Gauge

Conveniently monitor hydraulic

output pressure

Pressure and Flow Control

Ability to adjust pressure and flow puts

you in control

Page 3

Typical Applications

Ordering Information

Mobile

• Front-end loaders - 12 cu. yd. or higher

• Mining trucks - 100 ton capacity or higher

• Shovel fronts

• Drag lines

• Bucket wheel excavators

Stationary

• Cement plant

• Jaw and gyratory crushers

• Grinding mill seals

• Mineral sizers

• Ship loaders - slew bearings

• Sludge pumps

DYNA-STAR 10:1 MODULES AND KITS

247574 Dyna-Star 10:1 60 lb (27 kg) Pump Module - Injector - Overall height 35.15 in (842mm).

247706 Dyna-Star 10:1 60 lb (27 kg) Pump Kit - Divider Valve (DV) - Overall height 35.15 in (842mm).

247444 Dyna-Star 10:1 90 lb (41 kg) Pump Module - Injector - Overall height 42.75 in (1086 mm).

247707 Dyna-Star 10:1 90 lb (41 kg) Pump Kit - DV - Overall height 42.75 in (1086 mm). Includes

247902 Pressure relief kit for 247706 and 247707

312349 Manual for 247574, 247706, 247444, 247707

Includes pump (247540), reservoir assembly (247575), hydraulic control assembly (247538)

and vent valve assembly (243170) fully assembled.

Includes pump (247540), reservoir assembly (247575) and hydraulic control assembly

(247538) not assembled.

Includes pump (247443), reservoir assembly (241486), hydraulic control assembly (247538)

and vent valve assembly (243170) fully assembled.

pump (247443), reservoir assembly (241486) and hydraulic control assembly (247538) not

assembled.

Maximum fl uid output for modules and kits = 3,500 PSI (241 bar)

DYNA-STAR 10:1 REFINERY DRUM AND CUSTOM TANK APPLICATIONS

Description Refi nery Drums Custom Tank Applications

Weight lbs (kg) 120 (55) 400 (180) 60 (27) 60 (27) 120 (55) 120 (55) 400 (180) 400 (180)

Divider Valve (DV) or

Injector Based

Pump 247443 247450 247540 247540 247443 247443 247450 247450

Hydraulic Control (1) 247705 247705 247538 247538 247538 247538 247538 247538

Vent Valve 243170 243170 243170

Cover 247703 247704

Follower Plate 247701 247702

Pump Gasket 15M442 15M442 15M442 15M442 15M442 15M442 15M442 15M442

Custom Tank Kit (2) 247970 247456 247457

(1) Hydraulic control assembly (247705) includes longer hoses to enable remote mounting.

(2) Kits include pump (24750, 247443 or 247450), hydraulic control assembly (247538), vent valve (243170) and pump gasket (15M442).

DV DV Injector DV Injector DV Injector DV

GL INJECTORS

114901 One GL-1 injector and manifold

114902 Two GL-1 injectors and manifold

114903 Three GL-1 injectors and manifold

114904 Four GL-1 injectors and manifold

114905 Five GL-1 injectors and manifold

114909 Replacement GL-1 injector

24A918 GL-11 injector

FIREBALL 300 AND DYNA-STAR 5:1 MODULES & ACCESSORIES

241573 Fireball 300, 50:1 90 lb (41 kg) Pump Module. Includes pump (239887), reservoir assembly

241485 Follower plate (fi ts 241573).

243159 Dyna-Star 5:1 90 lb (41 kg) Pump Module. Includes pump (224751), reservoir assembly

243191 Follower plate (fi ts 243159).

See Lubrication Equipment Buyer’s Guide section 14 for more information.

(241486) and vent valve assembly (241572).

(241486), hydraulic control assembly (243501) and vent valve assembly (243170).

Page 4

Technical Specifi cations

8000

(552)

6000

(414)

4000

(276)

2000

(138)

0

1.5

(1.1)

2.0

(1.5)

1.0

(0.7)

0.5

(0.4)

0.0

0.25 0.50 0.75 1.00 1.25

(0.11) (0.23) (0.34) (0.45) (0.57)

cycles/min

Pressure - PSI (bar)

Input Hydraulic Horsepower (kw)

60 0153045

B

C

D

A

Test Fluid: NLGI #1 grade grease

Flowrate–lb per min (kg per min)

600 psi hydraulic inlet pressure

A

300 psi hydraulic inlet pressure

B

Hp (600 psi hydraulic input)

C

Hp (300 psi hydraulic input)

D

DYNA-STAR 10:1 PUMPS

Part Number 247540 247443 247450

Drum Size 60 lb (27 kg) 120 lb (55 kg) 400 lb (180 kg)

Overall Pump Length 33.9 in (861 mm) 41.5 in (1054 mm) 48.5 in (1232 mm)

Pump Lower Length 19.75 in (501 mm) 26.75 in (679 mm) 33.75 in (857 mm)

Maximum Hydraulic

Input Pressure

Maximum Hydraulic

Fluid Input Volume

Maximum Flow

Output Rate

Maximum CPM 60 60 60

Maximum Fluid

Output Pressure

Hydraulic Supply Inlet 3/4"–16 JIC (37º Flare) 3/4"–16 JIC (37º Flare) 3/4"–16 JIC (37º Flare)

Hydraulic Return

Outlet

Fluid Outlet 1/2" npt 1/2" npt 1/2" npt

Maximum Incoming

Hydraulic Fluid Temp.

312350 Manual for 247540, 247443, 247450

600 psi (41 bar) 600 psi (41 bar) 600 psi (41 bar)

3 gpm (11.4 lpm) 3 gpm (11.4 lpm) 3 gpm (11.4 lpm)

1.1 lb/min (0.5 kg/min) 1.1 lb/min (0.5 kg/min) 1.1 lb/min (0.5 kg/min)

7500 psi (517 bar) 7500 psi (517 bar) 7500 psi (517 bar)

3/4" npt 3/4" npt 3/4" npt

200ºF (93ºC) 200ºF (93ºC) 200ºF (93ºC)

ABOUT GRACO

Founded in 1926, Graco is a world leader

in fl uid handling systems and components.

Graco products move, measure, control,

dispense and apply a wide range of

fl uids and viscous materials used in

vehicle lubrication, commercial and

industrial settings.

The company’s success is based on its

unwavering commitment to technical

excellence, world-class manufacturing and

unparalleled customer service. Working

closely with qualifi ed distributors, Graco

offers systems, products and technology

that set the quality standard in a wide

range of fl uid handling solutions.

Graco provides equipment for spray fi nishing,

protective coating, paint circulation,

lubrication, and dispensing sealants and

adhesives, along with power application

equipment for the contractor industry.

Graco’s ongoing investment in fl uid

management and control will continue to

provide innovative solutions to a diverse

global market.

TYPICAL PUMP PERFORMANCE

Call today for product information or talk to a Graco

representative at 1.800.533.9655 or visit us online at

www.graco.com.

©2008-2010 Graco Inc. 338973 Rev. C 1/00. All other brand names or marks are used for identifi cation purposes and are trademarks of their

respective owners. All written and visual data contained in this document are based on the latest product information available at the time of

publication. Graco reserves the right to make changes at any time without notice.

Loading...

Loading...