Page 1

Installation - Parts

®

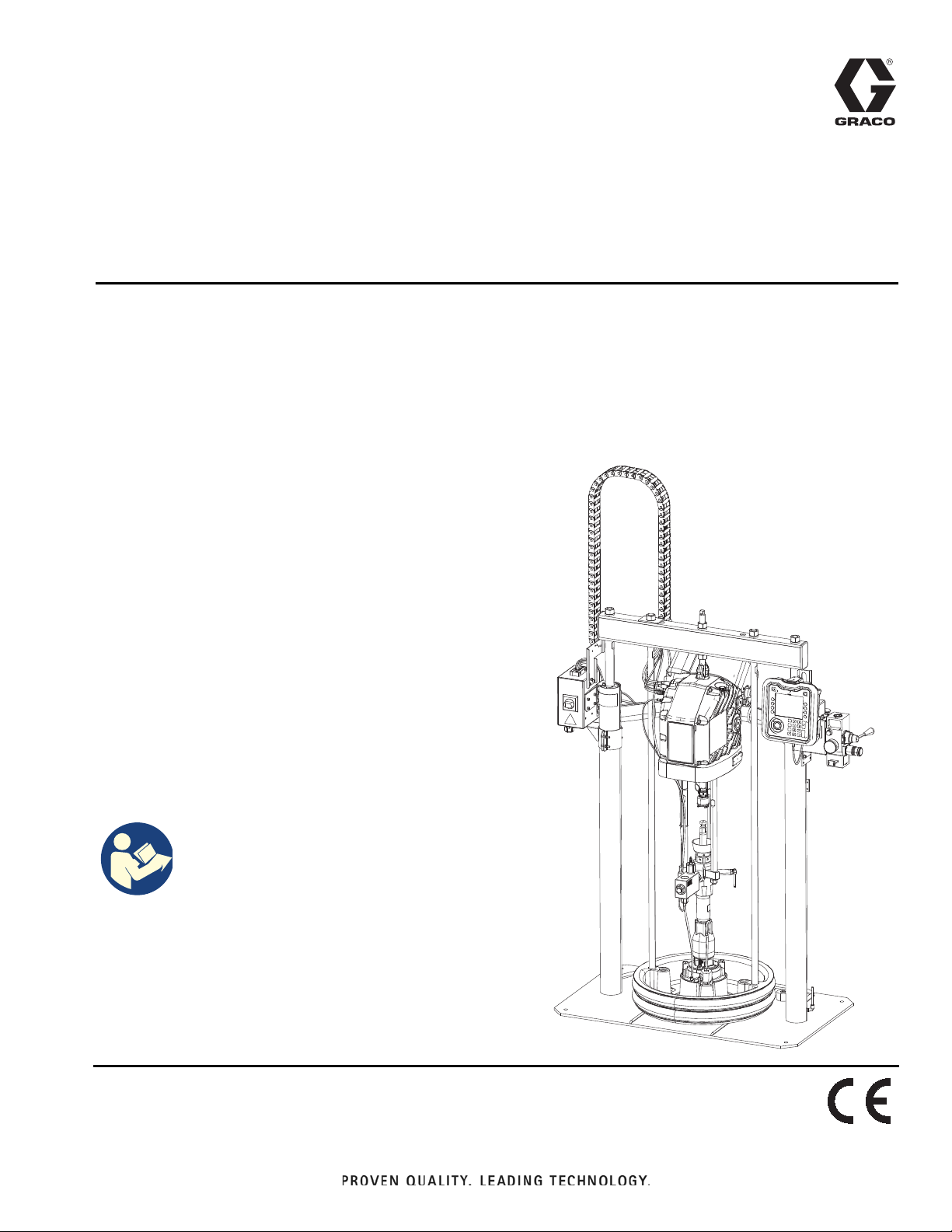

E-Flo

SP

3A6331G

Supply Systems

For transferring or dispensing sealants, adhesives, or other medium to high viscosity

fluids. For professional use only.

Not approved for use in explosive atmospheres or hazardous locations.

D60 3 inch dual post

20 liter (5 gallon), 30 liter (8 gallon),

60 liter (16 gallon) sizes

150 psi (1.0 MPa, 10 bar) Maximum Air Inlet Pressure

EN

D200 3 inch dual post

200 liter (55 gallon) size

150 psi (1.0 MPa, 10 bar) Maximum Air Inlet Pressure

D200S 6.5 inch dual post

200 liter (55 gallon) size

125 psi (0.9 MPa, 9 bar) Maximum Air Inlet Pressure

See page 4 for model information, including maximum

working pressure and approvals.

The Graco Control Architecture Electric Components

are Listed in Intertek’s Directory of Listed Products.

Important Safety Instructions

Read all warnings and instructions in this

manual and in related manuals before

using the equipment. Save all

instructions.

Page 2

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

System Pressure . . . . . . . . . . . . . . . . . . . . . . . . . 6

Tandem Ram . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Component Identification . . . . . . . . . . . . . . . . . . . 11

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . 11

Integrated Air Control Module . . . . . . . . . . . . . . 12

Integrated Air Line Accessories . . . . . . . . . . . . . 12

Advanced Display Module (ADM) . . . . . . . . . . . 13

Platen Component Identification . . . . . . . . . . . . 14

Junction Box Connections . . . . . . . . . . . . . . . . . 15

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Power Requirements . . . . . . . . . . . . . . . . . . . . . 17

Connect Power . . . . . . . . . . . . . . . . . . . . . . . . . 17

Attach Drum Stops. . . . . . . . . . . . . . . . . . . . . . . 18

Fluid Hose and Air Line Connections. . . . . . . . . 18

Install Vented Oil Cap Before Using Equipment. 18

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Wet Cup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Flush the Pump . . . . . . . . . . . . . . . . . . . . . . . . . 20

Start and Adjust the Ram. . . . . . . . . . . . . . . . . . 21

Start and Adjust the Pump . . . . . . . . . . . . . . . . . 21

Pressure Relief Procedure. . . . . . . . . . . . . . . . . . . 22

Shutdown and Care of the Pump . . . . . . . . . . . . . 23

Change Drums. . . . . . . . . . . . . . . . . . . . . . . . . . 23

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Driver Maintenance . . . . . . . . . . . . . . . . . . . . . . 24

Platen Maintenance . . . . . . . . . . . . . . . . . . . . . . 25

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Disconnect Pump from Platen . . . . . . . . . . . . . . 30

Connect Platen . . . . . . . . . . . . . . . . . . . . . . . . . 31

Remove Wipers . . . . . . . . . . . . . . . . . . . . . . . . . 31

Install Wipers . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Remove Displacement Pump. . . . . . . . . . . . . . . 31

Install Displacement Pump . . . . . . . . . . . . . . . . 32

Remove Driver . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Install Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Supply Unit Repair . . . . . . . . . . . . . . . . . . . . . . . 34

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

D200s 6.5 in. Supply Units . . . . . . . . . . . . . . . . . 38

D200 3 in. Supply Units . . . . . . . . . . . . . . . . . . . 40

D60 3 in. Supply Units . . . . . . . . . . . . . . . . . . . . 42

D200s and D200 Pump Mounts for 55 Gallon (200

Liter) Platen . . . . . . . . . . . . . . . . . . . . . . . . . 44

D60 Pump Mount 257624 for 5 Gallon (20 Liter)

Platen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Cable Track . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

55 Gallon Platen . . . . . . . . . . . . . . . . . . . . . . . . . 49

20 Liter (5 Gallon), 30 Liter (8 Gallon), and 60 Liter

(16 Gallon) Platens . . . . . . . . . . . . . . . . . . . 50

Kits and Accessories . . . . . . . . . . . . . . . . . . . . . . . 55

Drum Roller Kits for D200 and D200S Supply Units,

255627 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Drum Position Clamp Set for D200 Supply Units,

206537 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Drum Position Clamp for D200S Supply Units . . 55

Enclosed Wet Cup Recirculation Kit. . . . . . . . . . 55

200 Liter (55 Gallon) Platen Cover Kits, 255691 55

Light Tower Kit, 255468 . . . . . . . . . . . . . . . . . . . 55

ADM Kit, 25E437 . . . . . . . . . . . . . . . . . . . . . . . . 55

CAN Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

I/O Cable, 122029 . . . . . . . . . . . . . . . . . . . . . . . 55

Communication Gateway Module (CGM) Kits . . 56

Low Level Sensor Kit, 25E447 . . . . . . . . . . . . . . 58

Tandem Connection Kit, 25E595 . . . . . . . . . . . . 59

Tandem Depressurization/Recirculation Kit, 25E618

(carbon steel), 25E619 (stainless steel). . . . 60

Tandem Fluid Filter Kit, 25E620 . . . . . . . . . . . . . 64

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

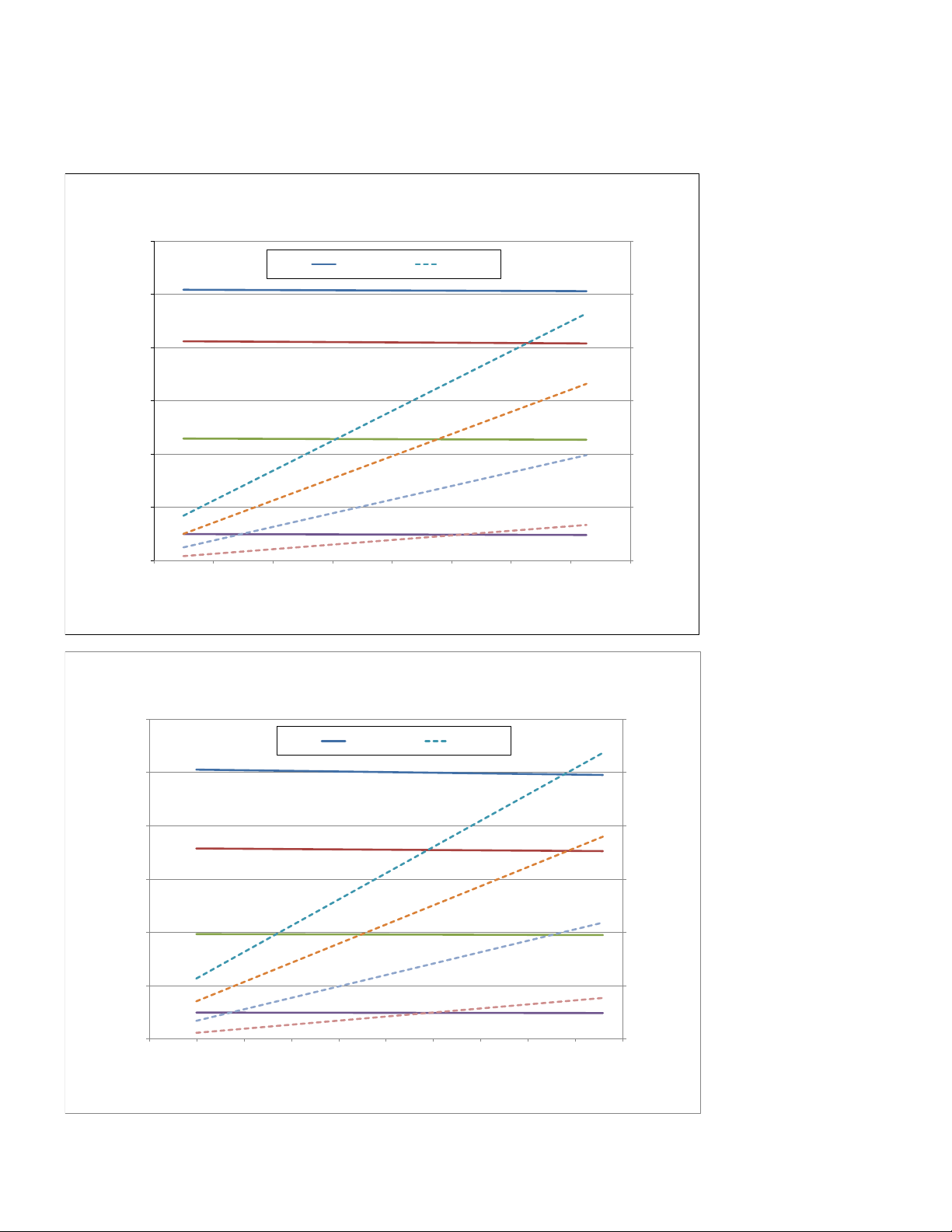

Pump Performance . . . . . . . . . . . . . . . . . . . . . . . . . 69

E-Flo SP Performance Charts . . . . . . . . . . . . . . 70

Technical Specifications . . . . . . . . . . . . . . . . . . . . 76

California Proposition 65 . . . . . . . . . . . . . . . . . . . . 77

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 78

Graco Information 78

2 3A6331G

Page 3

Related Manuals

Manual Description

3A6586

3A6724 E-Flo SP Software Instructions

313526 Supply Systems Operation

E-Flo SP Electric Pump Instructions Parts

Related Manuals

312375

311827

311825

311717

312889

312467

312468

312469

312470

312374 Air Controls Instructions-Parts

312491 Pump Fluid Purge Kit Instructions - Parts

312492 Drum Roller Kit Instructions

312493 Light Tower Kit Instructions

312494

406681 Platen Cover Kit

Check-Mate® Displacement Pumps

Instructions-Parts

™

Dura-Flo

180cc, 220cc, 290cc) Instructions-Parts

Dura-Flo

580cc) Instructions-Parts

Carbon Steel Displacement Pump

(1000cc) Instructions-Parts

60 cc Check-Mate Displacement Pump

Repair Parts

100 cc Check-Mate Displacement Pump

Repair Parts

200 cc Check-Mate Displacement Pump

Repair Parts

250 cc Check-Mate Displacement Pump

Repair Parts

500 cc Check-Mate Displacement Pump

Repair Parts

Enclosed Wetcup Recirculation Kit

Instructions - Parts

Displacement Pumps (145cc,

™

Displacement Pumps (430cc,

334048 EPDM Hose Wiper Kit Instructions - Parts

3A6321

3A6482

3A6331G 3

ADM Token In-System Programming

Instructions

APD20 Advanced Precision Driver

Instructions

Page 4

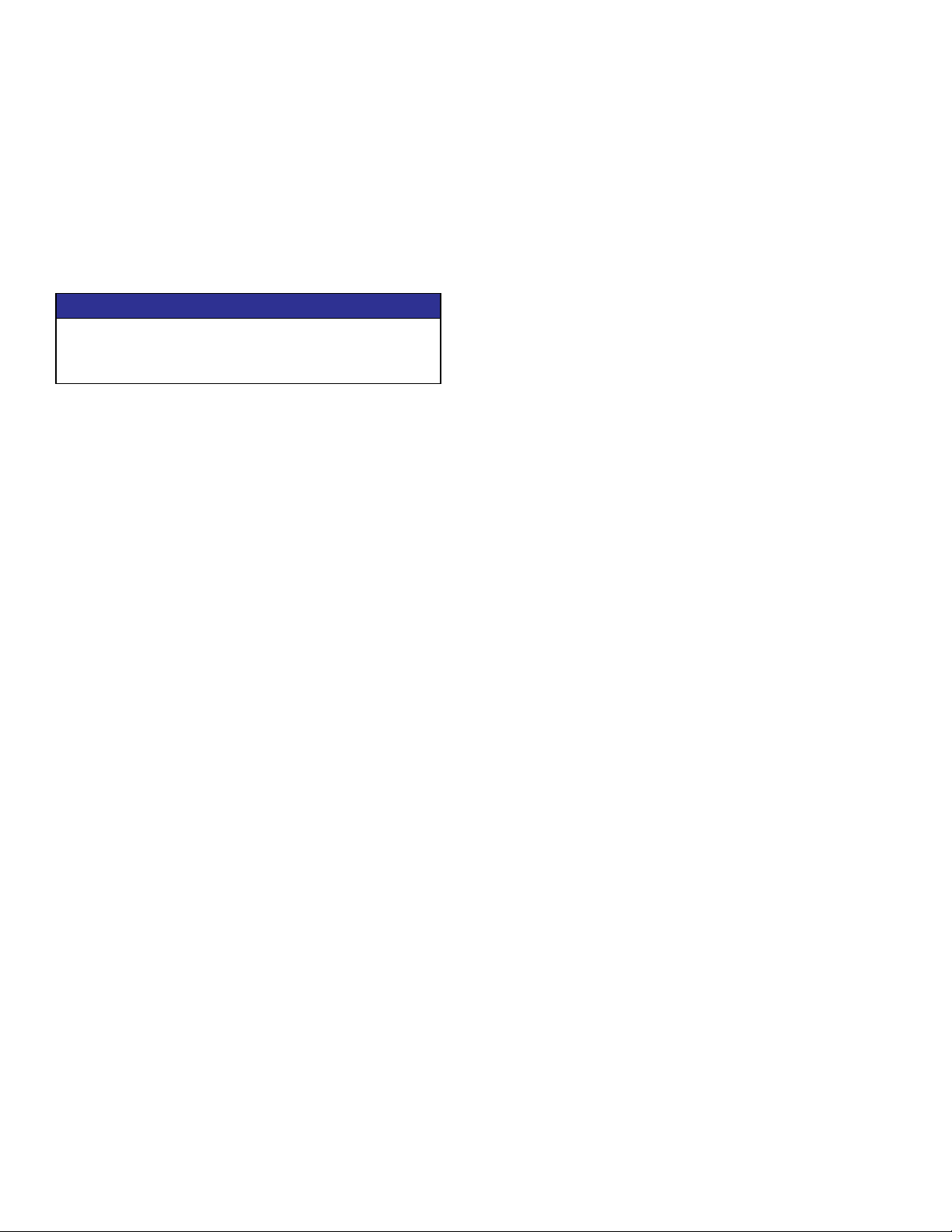

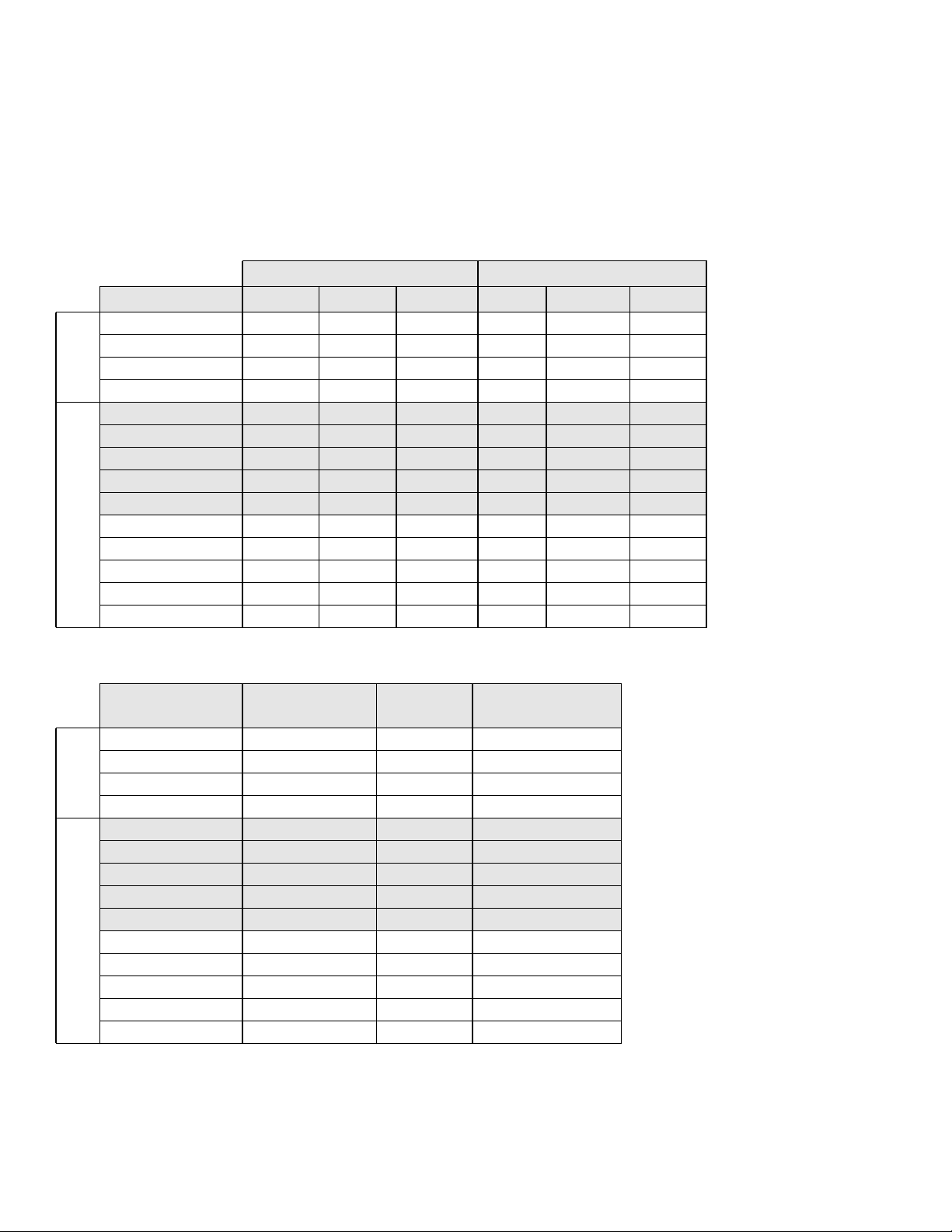

Models

Models

Check the identification plate (ID) for the 7-digit part number of the supply system. Use the following matrix to define

the construction of the supply system, based on the seven digits. For example, Part No. EMC1121 represents an

electric supply system (EM), a carbon steel Check-Mate 100 Severe Duty displacement pump with an electric driver

(C1), a 3 in. dual post ram with integrated air controls (1), a 5-gallon platen with a nitrile seal (2), and 240 VAC power

(1).

NOTICE

To prevent damage to DataTrak soft key buttons, do

not press the buttons with sharp objects such as pens,

plastic cards, or fingernails.

NOTE: Systems with the EMD as the first and second digits are Dura-Flo supply systems.

The digits in the matrix on the next page do not correspond to the Ref. Nos. in the Parts drawings and lists.

4 3A6331G

Page 5

Models

EM C1 1

First

and

Second

Digit

EM

(Electric

Supply

System)

Third and

Fourth

Digit Fifth Digit

Ram Options

Pump

Code

(See Table

1: for 2-digit

Check-Mate

Pump

Code)

(See Table

1: for 2-digit

Dura-Flo

Pump

Code)

Size Style

1 3 in. D60

2 3 in. D200

3 6.5 in. D200s

21

Sixth Digit Seventh Digit

Platen and Seal Options

Drum

Size

20 L

(5 Gal) INT 1 No Platen 1 None 240 VAC

200 L

(55 Gal) INT 2

200 L

(55 Gal) INT 3

Air

Controls

Platen

(5 Gal) F, SW CS Nitrile D60 2 None 480 VAC

(5 Gal) F, SW CS

4

(5 Gal) F, DW CS Nitrile D60 4 ADM 480 VAC

5

(5 Gal) F, DW CS

6

(5 Gal) F, SW SS

200 L

7

(55 Gal) DR

200 L

8

(55 Gal) DR AL EPDM

200 L

9

(55 Gal) DR AL Neoprene

200 L

A

(55 Gal) DR AL

Size

20 L

20 L

20 L

20 L

20 L

Platen

Style

Platen

Material

PTFE

Coated

AL EPDM

Seal

Material

Polyure-

thane D60 3 ADM 240 VAC

Polyure-

thane D60

PTFE

coated D60

EPDM

Hose

Ram

Compati-

bility Interface Power

D200,

D200s

D200,

D200s

D200,

D200s

D200,

D200s

Interface and Power

Options

KEY:

INT = Integrated air controls SW = Single wiper CS = Carbon Steel Severe Duty

F = Flat DW = Double wiper SS = Stainless Steel Severe Duty SM = Stainless Steel MaxLife

DR = Dual o-ring AL = Aluminum

CM = Carbon Steel MaxLife

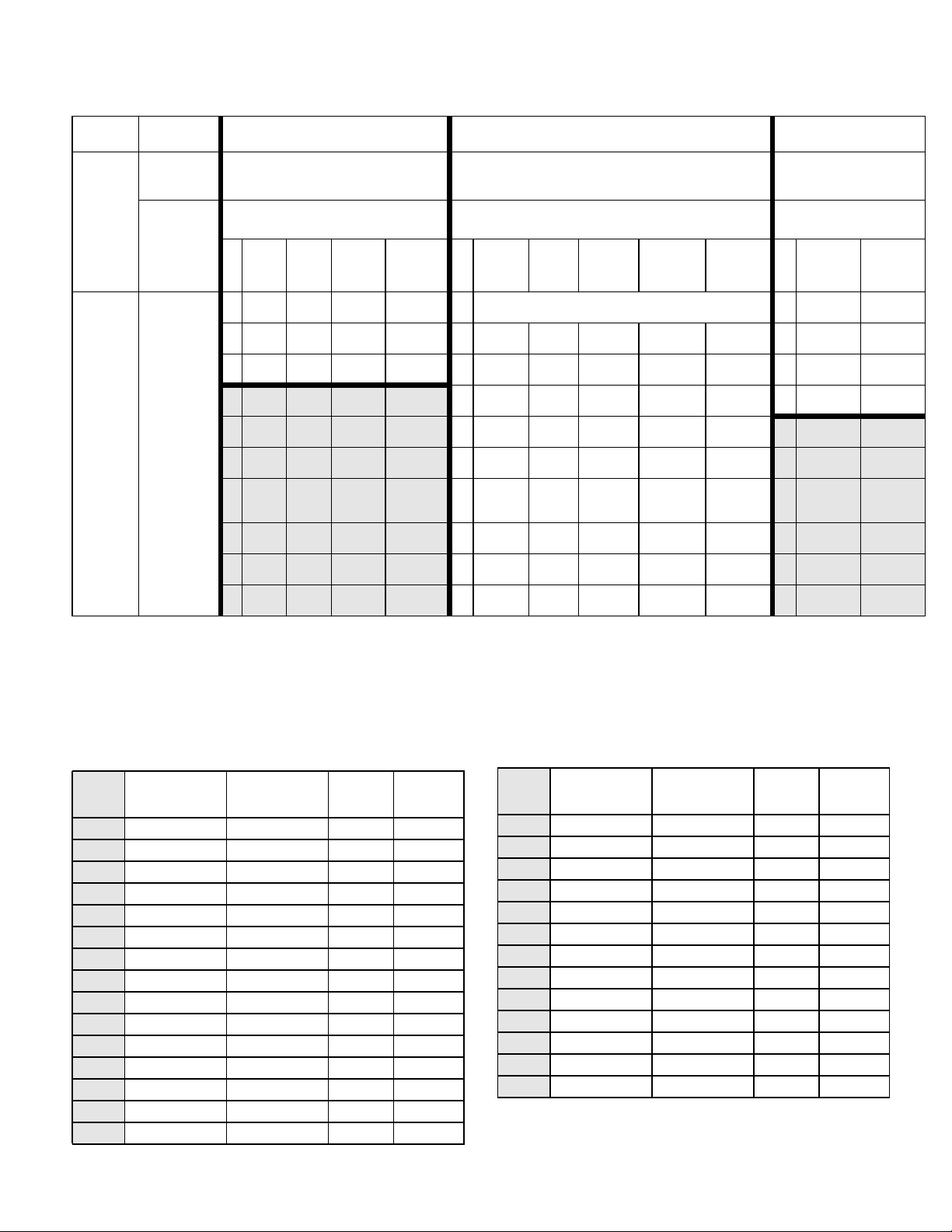

Table 1: Pump Code Index

Pump

Code Part No. Pump Type

Pump

Size

Pump

Material

C1 EC100CS1 Check-Mate 100cc CS

C2 EC100CM1 Check-Mate 100cc CM

C3 EC100SS1 Check-Mate 100cc SS

C4 EC100SM1 Check-Mate 100cc SM

C5 EC200CS1 Check-Mate 200cc CS

C6 EC200CM1 Check-Mate 200cc CM

C7 EC200SS1 Check-Mate 200cc SS

C8 EC200SM1 Check-Mate 200cc SM

C9 EC250CS1 Check-Mate 250cc CS

CA EC250CM1 Check-Mate 250cc CM

CB EC250SS1 Check-Mate 250cc SS

CC EC250SM1 Check-Mate 250cc SM

CD EC500CS1 Check-Mate 500cc CS

CE EC500CM1 Check-Mate 500cc CM

CF EC500SS1 Check-Mate 500cc SS

Pump

Code Part No. Pump Type

CG EC500SM1 Check-Mate 500cc SM

D1 ED115CS1 Dura-Flo 115cc CS

D2 ED145CS1 Dura-Flo 145cc CS

D3 ED145SS1 Dura-Flo 145cc SS

D4 ED180CS1 Dura-Flo 180cc CS

D5 ED180SS1 Dura-Flo 180cc SS

D6 ED220CS1 Dura-Flo 220cc CS

D7 ED220SS1 Dura-Flo 220cc SS

D8 ED290CS1 Dura-Flo 290cc CS

D9 ED290SS1 Dura-Flo 290cc SS

DA ED430CS1 Dura-Flo 430cc CS

DB ED430SS1 Dura-Flo 430cc SS

DC ED430SM1 Dura-Flo 430cc SM

NOTE: See the E-Flo SP Electric Pump Instructions-Parts

manual for a complete parts list.

Pump

Size

Pump

Material

®

3A6331G 5

Page 6

Models

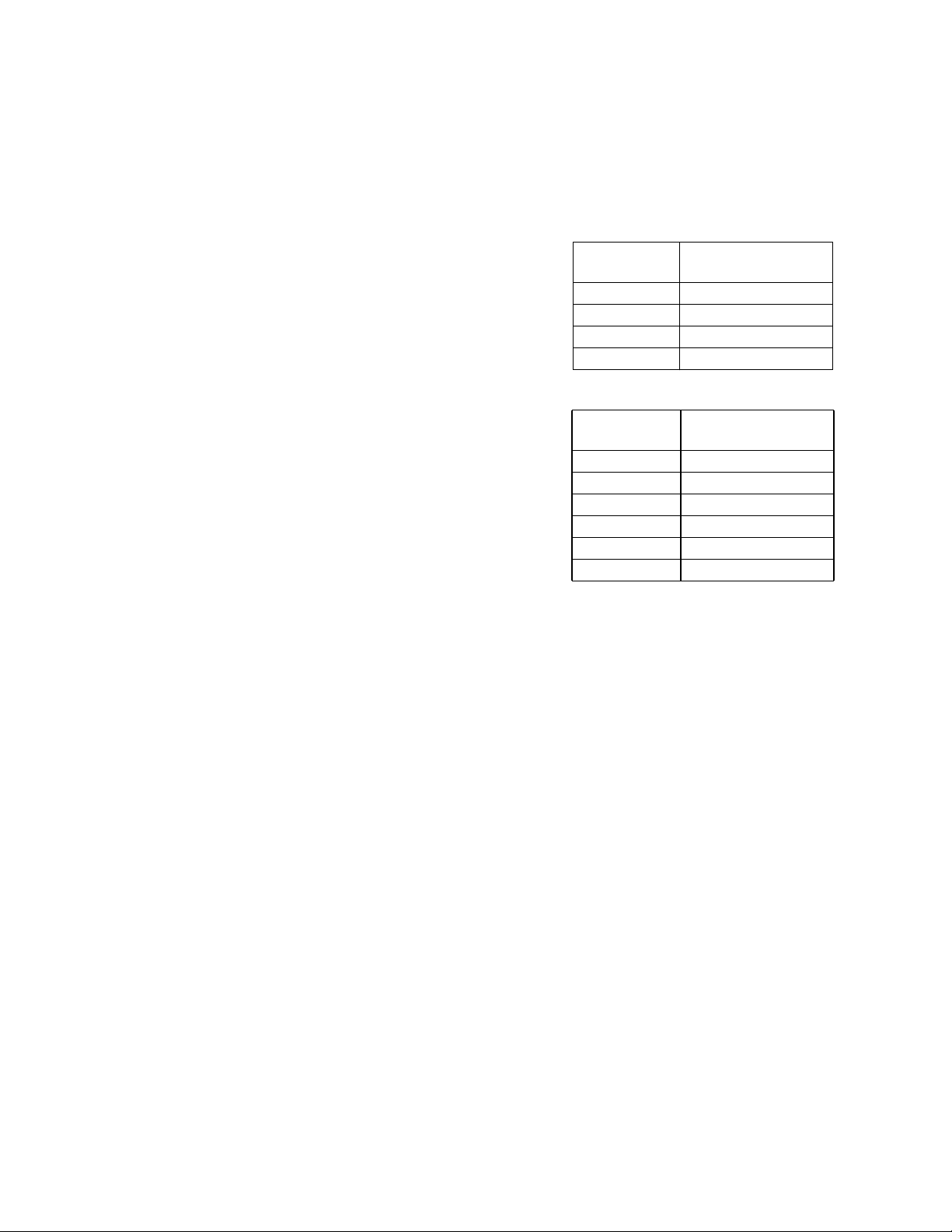

System Pressure

Due to factors such as the dispensing system design,

the material being pumped, and the flow rate, the

dynamic pressure will not reach the rated working (stall)

pressure of the system.

Pump Working (Stall) Pressure Max Dynamic (Run) Pressure

Lower Size psi bar MPa psi bar MPa

100CS/CM/SS/SM

200CS/CM/SS/SM

250CS/CM/SS/SM

500CS/CM/SS/SM

Check-Mate

145SS

180SS

220SS

290SS

430CS/SS/SM

115CS

Dura-Flow

145CS

180CS

220CS

290CS

6,000 414 41.4 6,000 414 41.4

4,200 290 29.0 3,905 269 26.9

3,400 234 23.4 3,122 215 21.5

1,600 110 11.0 1,487 103 10.3

5,600 386 38.6 5,204 359 35.9

4,500 310 31.0 4,164 287 28.7

3,700 255 25.5 3,470 239 23.9

2,800 193 19.3 2,602 179 17.9

1,900 131 13.1 1,735 120 12.0

6,000 414 41.4 6,000 414 41.4

5,600 386 38.6 5,204 359 35.9

4,500 310 31.0 4,164 287 28.7

3,700 255 25.5 3,472 239 23.9

2,800 193 19.3 2,602 179 17.9

Flow Rate Table

Lower Size

100CS/CM/SS/SM

200CS/CM/SS/SM

250CS/CM/SS/SM

500CS/CM/SS/SM

Check-Mate

145SS

180SS

220SS

290SS

430CS/SS/SM

115CS

Dura-Flow

145CS

180CS

220CS

290CS

Flow Rate

(cc/min)

2,500 0.66 1 in. NPT female

5,000 1.32 1 in. NPT female

6,250 1.65 1 in. NPT female

12,500 3.30 1-1/2 in. NPT female

3,625 0.96 1 in. NPT female

4,500 1.19 1 in. NPT female

5,500 1.45 1 in. NPT female

7,250 1.92 1 in. NPT female

10,750 2.84 1-1/2 in. NPT female

2,875 0.76 1 in. NPT female

3,625 0.96 1 in. NPT female

4,500 1.19 1 in. NPT female

5,500 1.45 1 in. NPT female

7,250 1.92 1 in. NPT female

Flow Rate

(gpm) Outlet Fitting Size

6 3A6331G

Page 7

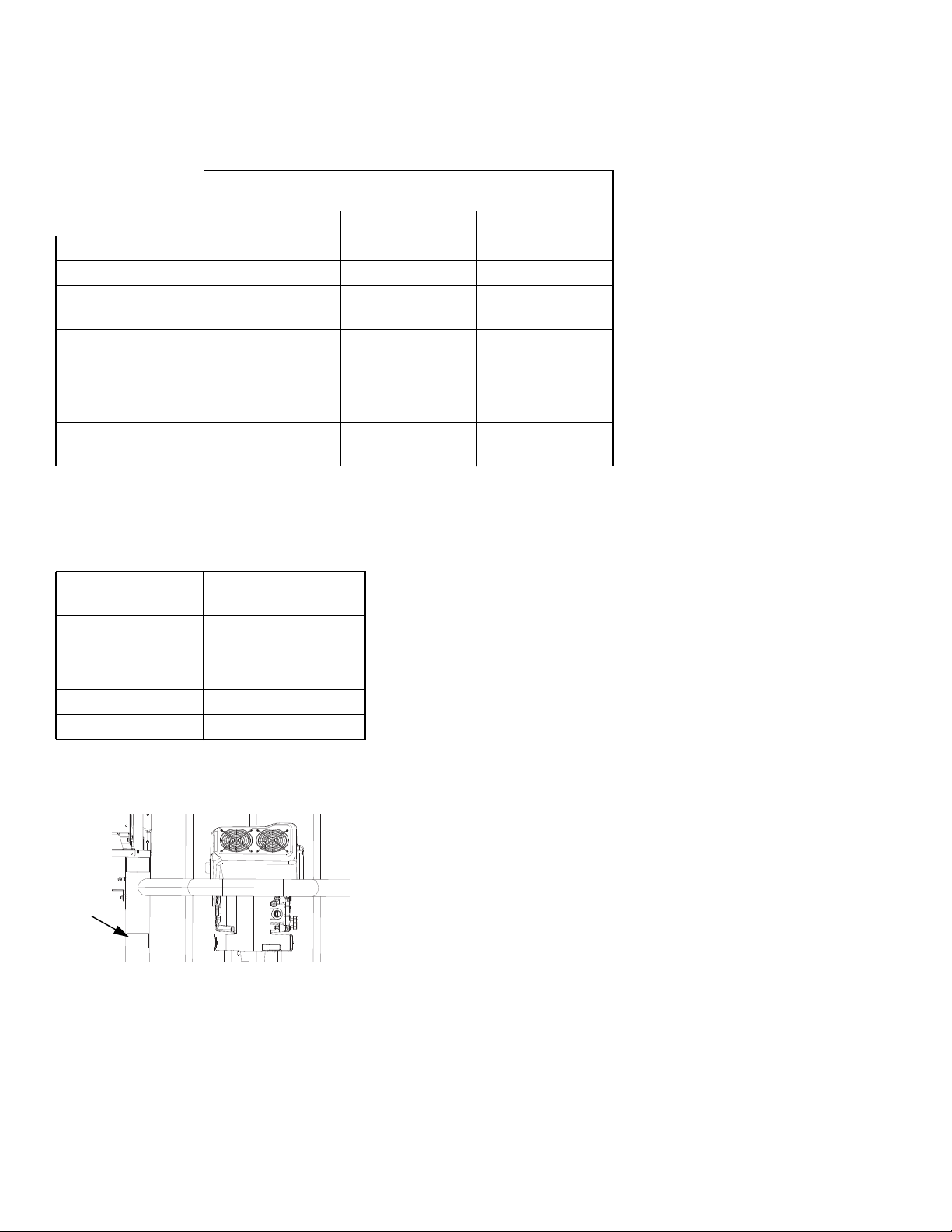

Tandem Ram

Models

How to Buy

1. Configure Tandem Ram “A” - E-Flo SP Ram with an

ADM (Quantity 1 per Tandem System).

- Example: EMC1283 – D200 Ram, Electric

Pump with Check-Mate 100 CS Lower, 200L

EPDM Platen, 240V, with ADM.

2. Configure Tandem Ram “B” - E-Flo SP Ram without

an ADM (Quantity 1 per Tandem System).

- Example: EMC1281 – D200 Ram, Electric

Pump with Check-Mate 100 CS Lower, 200L

EPDM Platen, 240V, without ADM.

3. Purchase Tandem Connection Kit, 25E595

(Quantity 1 per Tandem System).

4. Purchase Accessories.

- Depressurization/Recirculation Kit (Quantity 1

per Ram)

25E618: for Carbon Steel Pump Lowers

25E619: for Stainless Steel Pump Lowers

5. Purchase hoses for the system.

- For Check-Mate Pumps:

Pump Lower

Size

100cc 6000 psi

200cc 4200 psi

250cc 3400 psi

500cc 1600 psi

- For Dura-Flo Pumps:

Pump Lower

Size

115cc 6000 psi

145cc 5600 psi

180cc 4500 psi

220cc 3700 psi

290cc 2800 psi

430cc 1900 psi

Max. Pressure

Rating

Max. Pressure

Rating

- Fluid Filter Kit, 25E620 (Quantity 1 per Tandem

System)

- Extension Cables for Fluid Filter Monitoring

Pressure Transducers (Quantity 1 per Ram)

124943: 1 meter

122497: 2 meters

124409: 3 meters

17H363: 7.5 meters

17H364: 16 meters

- Low Level Sensor Kit, 25E447 (Quantity 1 per

Ram)

NOTE: Rams come with Empty Level Sensors

already installed.

3A6331G 7

Page 8

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The

exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks.

When these symbols appear in the body of this manual or on warning labels, refer back to these Warnings.

Product-specific hazard symbols and warnings not covered in this section may appear throughout the body of this

manual where applicable.

DANGER

SEVERE ELECTRIC SHOCK HAZARD

This equipment can be powered by more than 240 V. Contact with this voltage will cause death or

serious injury.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• This equipment must be grounded. Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Equipment can start without warning. Before checking, moving, or servicing equipment, follow the

Pressure Relief Procedure and disconnect all power sources.

8 3A6331G

Page 9

Warnings

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. Paint or

solvent flowing through the equipment can cause static sparking. To help prevent fire and explosion:

• Use equipment only in well-ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static sparking).

• Ground all equipment in the work area. See Grounding instructions.

• Never spray or flush solvent at high pressure.

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless they

are anti-static or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment until

you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Specifications in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical

Specifications in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For

complete information about your material, request Safety Data Sheets (SDSs) from distributor or

retailer.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

SPLATTER HAZARD

Hot or toxic fluid can cause serious injury if splashed in the eyes or on skin. During blow off of platen,

splatter may occur.

• Use minimum air pressure when removing platen from drum.

3A6331G 9

Page 10

Warnings

WARNING

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read Safety Data Sheets (SDSs) to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. Protective equipment includes but is not

limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

10 3A6331G

Page 11

Component Identification

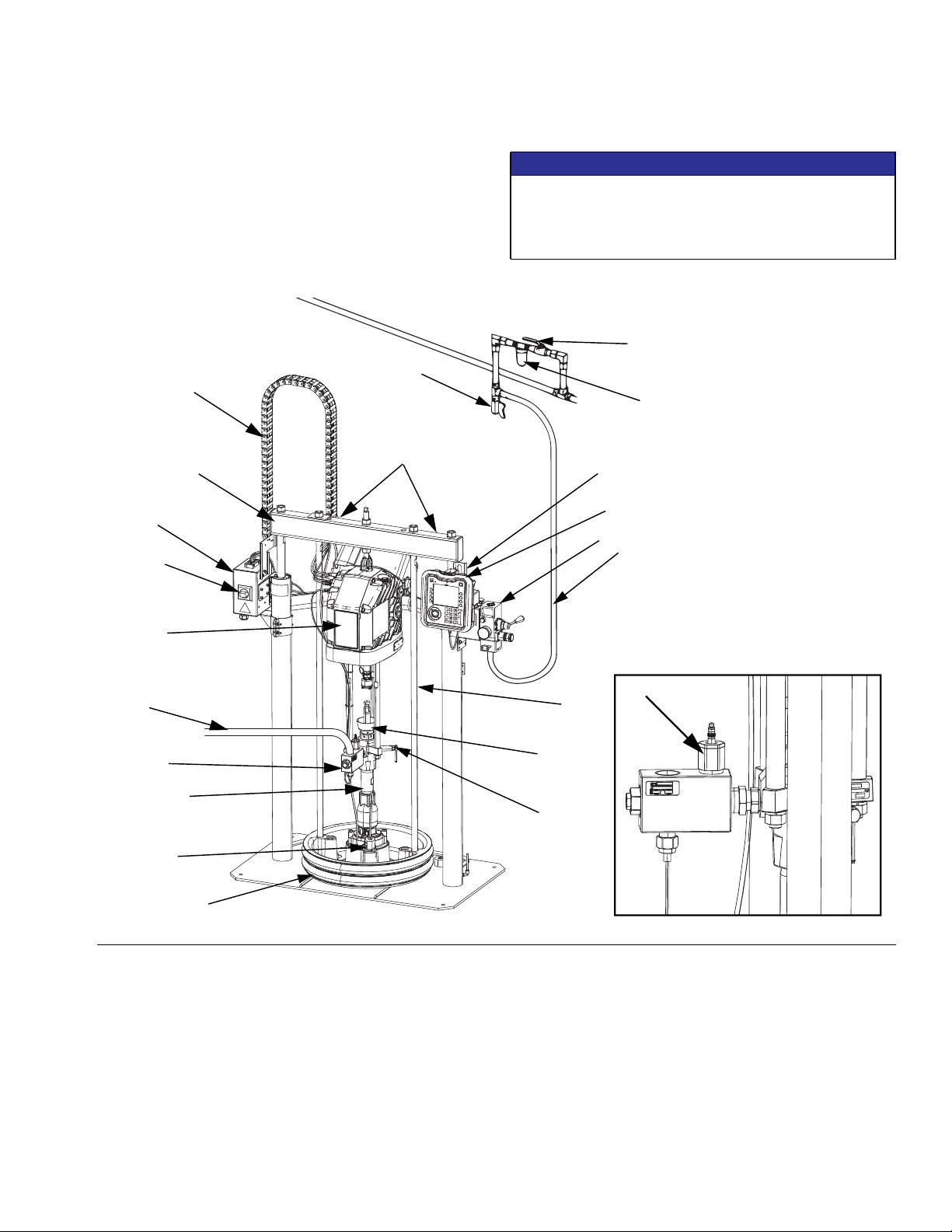

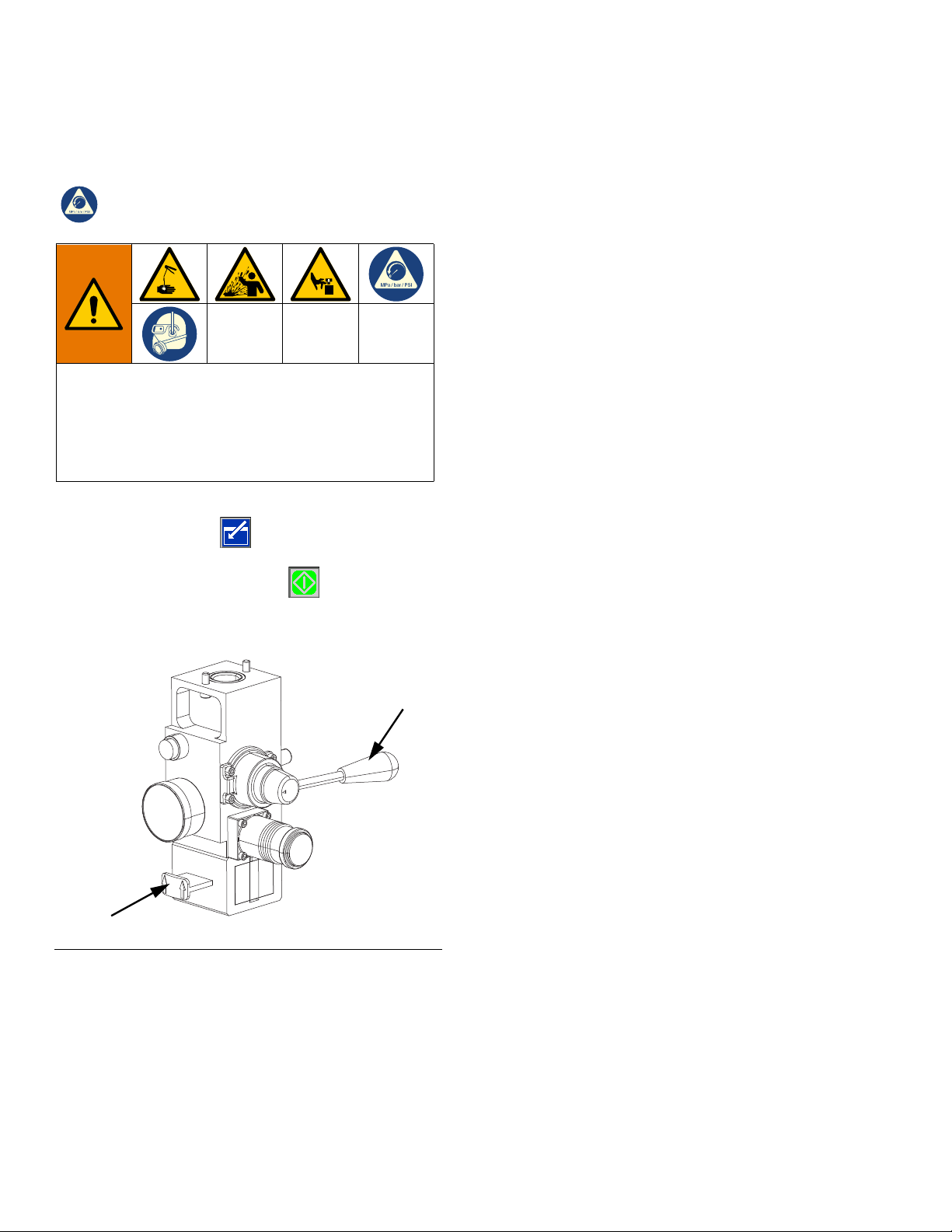

Component Identification

Typical Installation

D200 3 in. and D200s 6.5 in. Dual Post

EMC1223 Model

Shown

U

E

Lift Locations

A

K

M

B

NOTICE

Always lift the supply system at the proper lift locations

(see FIG. 1). Do not lift in any other way. Failure to lift

at the proper lift locations can result in damage to the

supply system.

W

V

X

F

G

T

NOTE: The Outlet Pressure Relief

Valve is used on Check-Mate 100cc

pumps only. See the E-Flo SP Electric

Pump Instructions-Parts manual for a

complete parts list.

S

Y

C

J

D

FIG. 1: Typical Installation

Key:

A Ram Assembly

B Electric Driver

C Displacement Pump

D Platen

E Cable Track

F Advanced Display Module (ADM)

G Integrated Air Controls (see F

J Platen Bleed Port

K Power Junction Box

M Disconnect Switch

IG. 2)

N

Z

R

P

N Platen Lift Rod

P Pump Bleed Valve

R Enclosed Wet Cup

S Fluid Line (not supplied)

T Air Line (not supplied)

U Air Line Drain Valve (not supplied)

V Air Filter (not supplied)

W Bleed Type Air Shutoff Valve (required) (not supplied)

X Level Sensors

Y Outlet Pressure Transducer

Z Outlet Pressure Relief Valve (Check-Mate 100 only)

3A6331G 11

Page 12

Component Identification

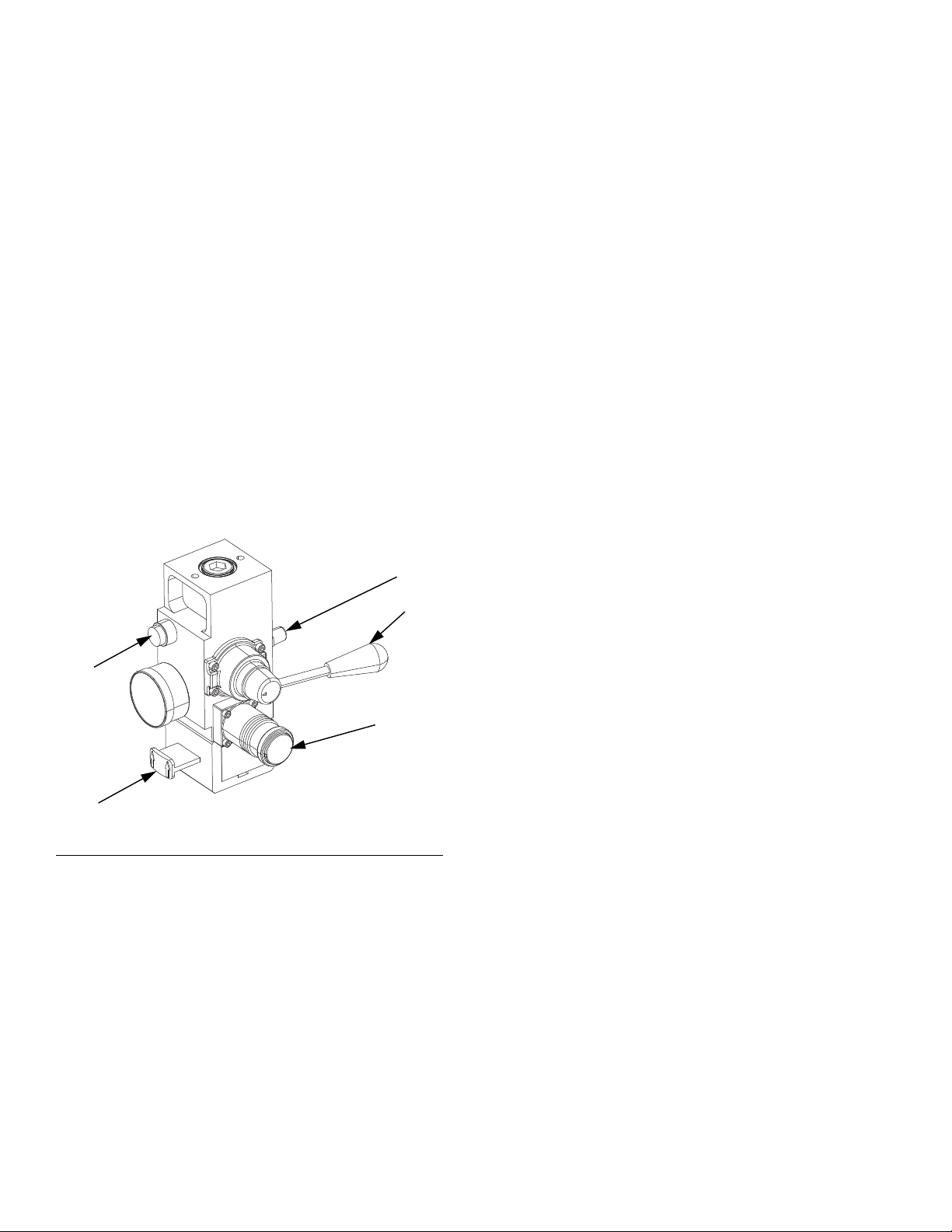

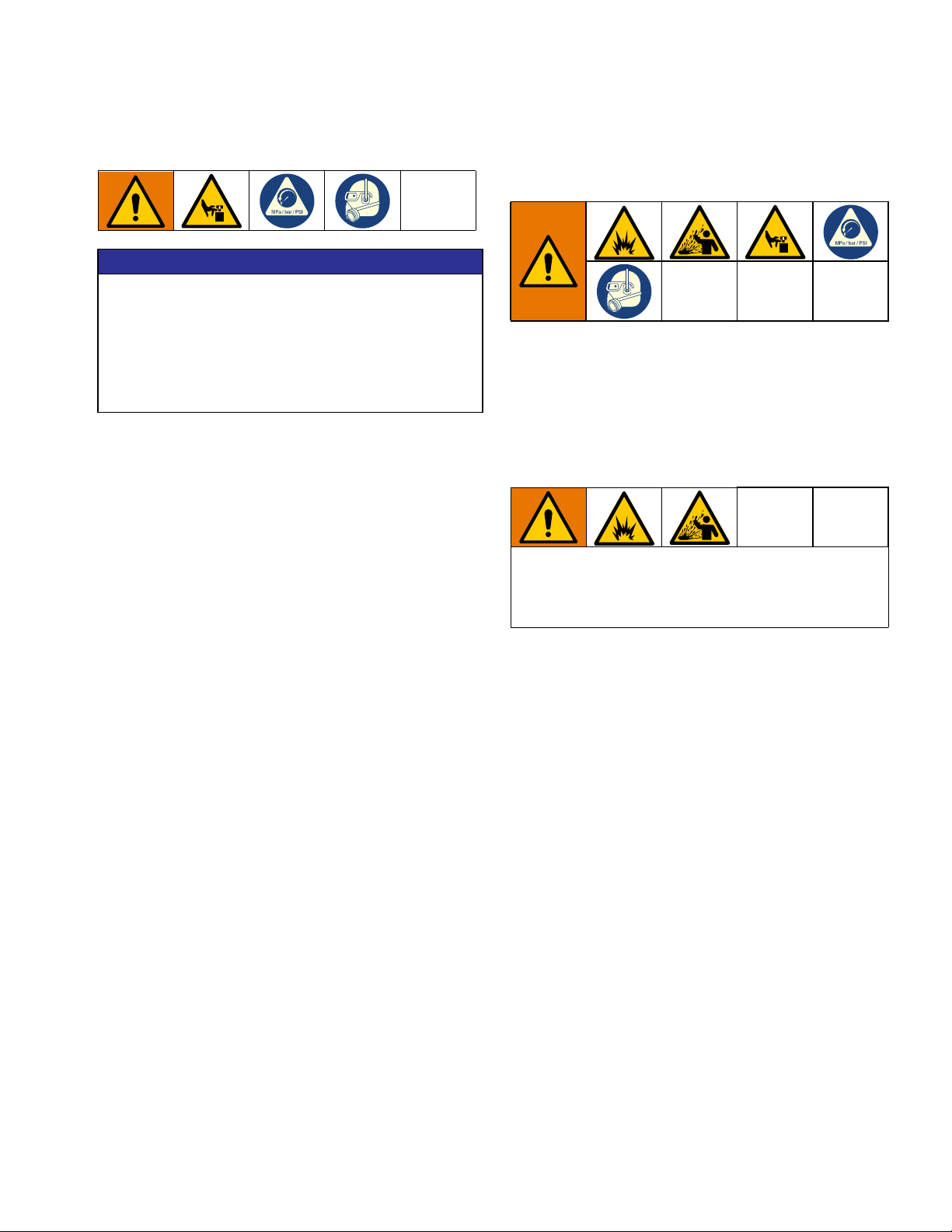

Integrated Air Control Module

D200, D200s, and D60 Models

The integrated air controls include:

• Main air slider valve (AA): turns air on and off to

the system. When closed, the valve relieves pressure downstream.

• Ram air regulator (AB): controls ram up and down

pressure and blowoff pressure.

• Ram director valve (AC): controls ram direction.

• Exhaust port with muffler (AD)

• Blowoff button (AE): turns air on and off to push

the platen out of an empty drum.

Integrated Air Line Accessories

See FIG. 1.

• Air line drain valve (U).

• Air line filter (V): removes harmful dirt and mois-

ture from compressed air supply.

• Second bleed-type air valve (W) (required): iso-

lates air line accessories for servicing. Locate

upstream from all other air line accessories.

• Air relief valve (required) (not visible):

automatically relieves excessive pressure.

AE

AA

FIG. 2. Integrated Air Control Module

AD

AC

AB

12 3A6331G

Page 13

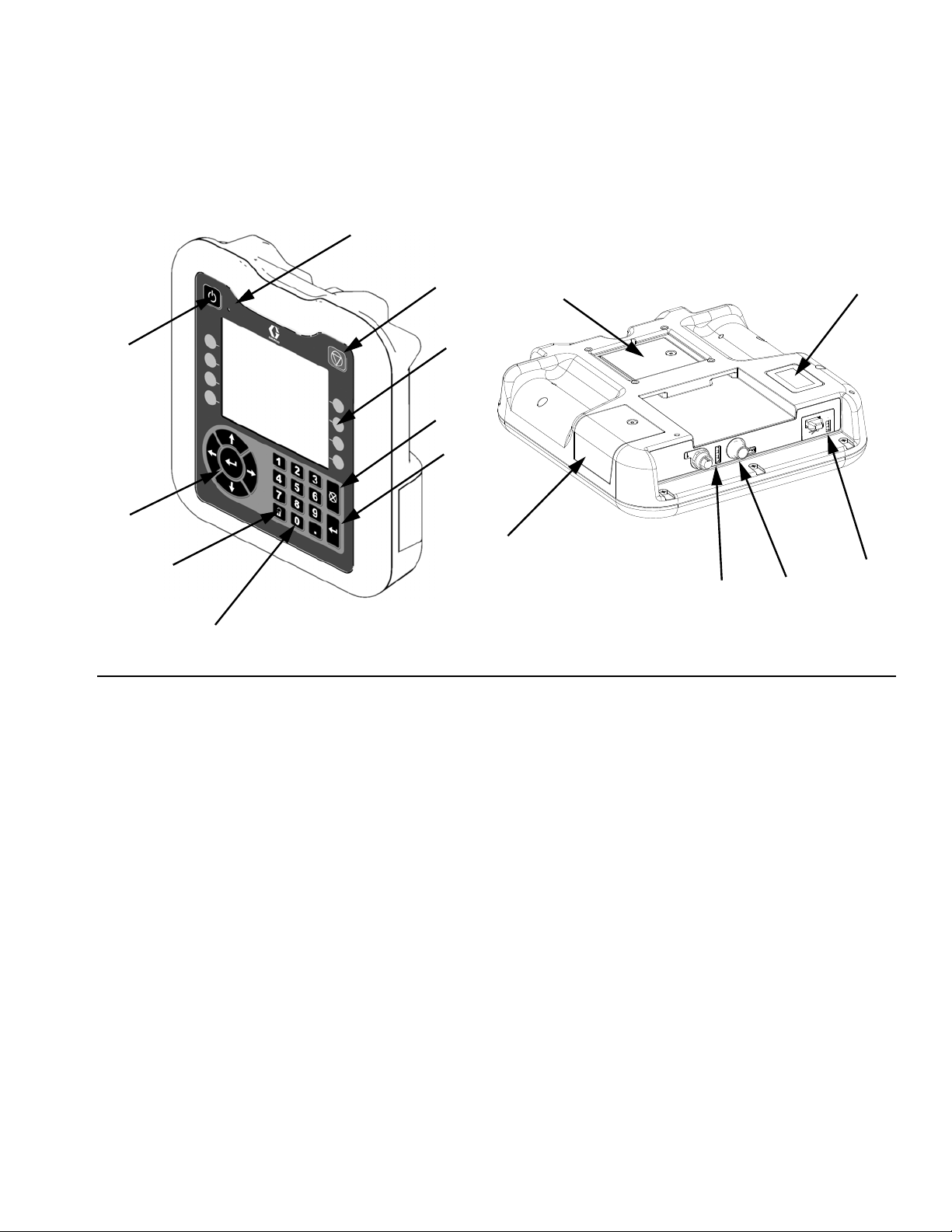

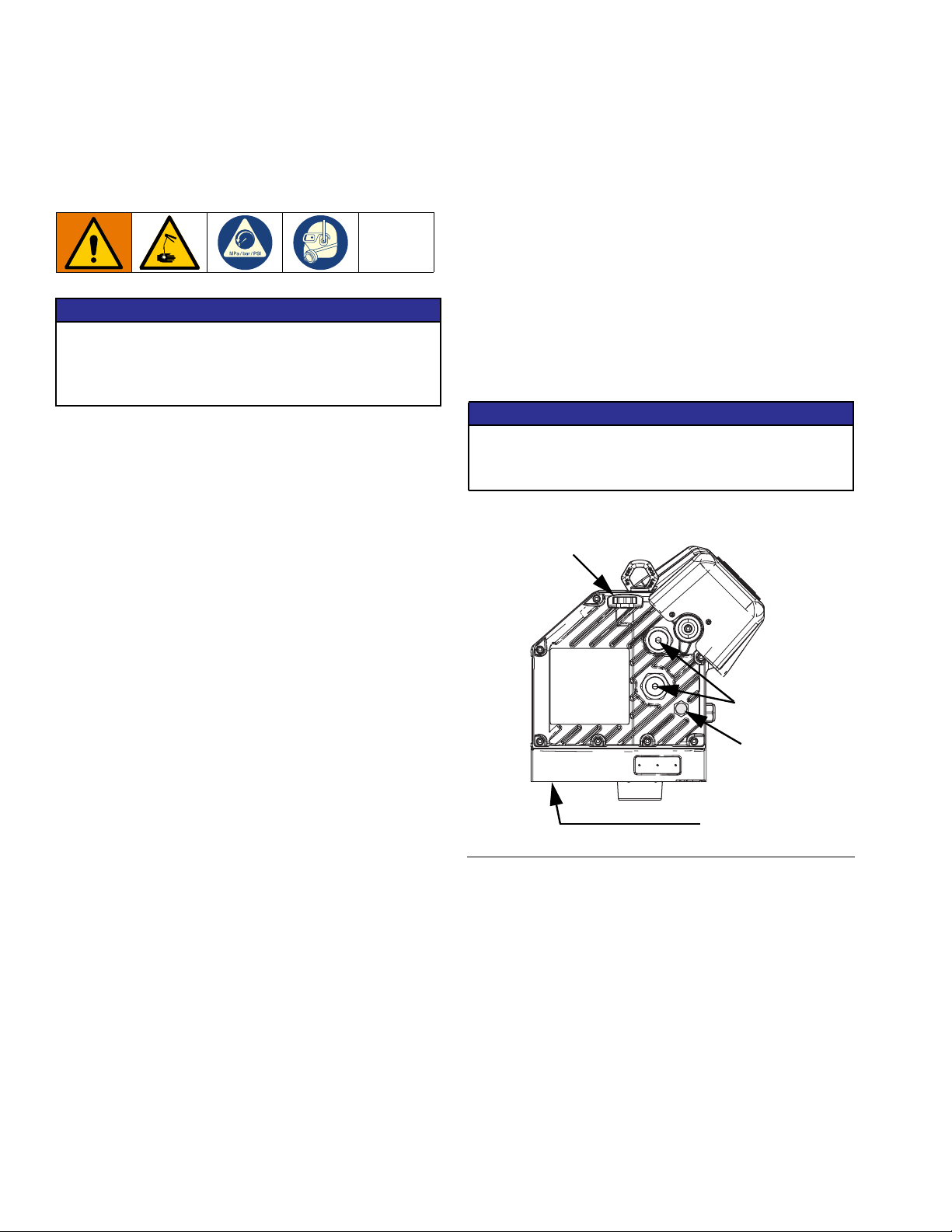

Advanced Display Module (ADM)

Front and Rear Views

BB

Component Identification

BA

BH

BG

BJ

FIG. 3: ADM Component Identification

Key:

BA Pump Enable

Enables the pump. Toggles between Active and

System Off.

BB Pump Status Indicator Light

BC Pump Soft Stop

Stops all pump processes and disables the pump.

BD Soft Keys

Defined by the icon on the screen next to the soft

key.

BE Cancel

Cancel a selection or number entry while in the

process of entering a number or making a selection.

Cancels the pump processes.

BF Enter

Accept change, acknowledge error, select item, and

toggle selected item.

BC

BE

BF

BD

BR

BP

BN

BG Lock/Setup

Toggle between run and setup screens.

BH Directional Keypad

Navigate within a screen or to a new screen.

BJ Numeric Keypad

BK Part Number Identification Label

BL USB Interface

BM CAN Cable Connection

Power and communication.

BN Module Status LEDs

Visual indicators to show the status of the ADM.

BP Token Access Cover

Access cover for software token.

BR Battery Access Cover

BK

BL

BM

3A6331G 13

Page 14

Component Identification

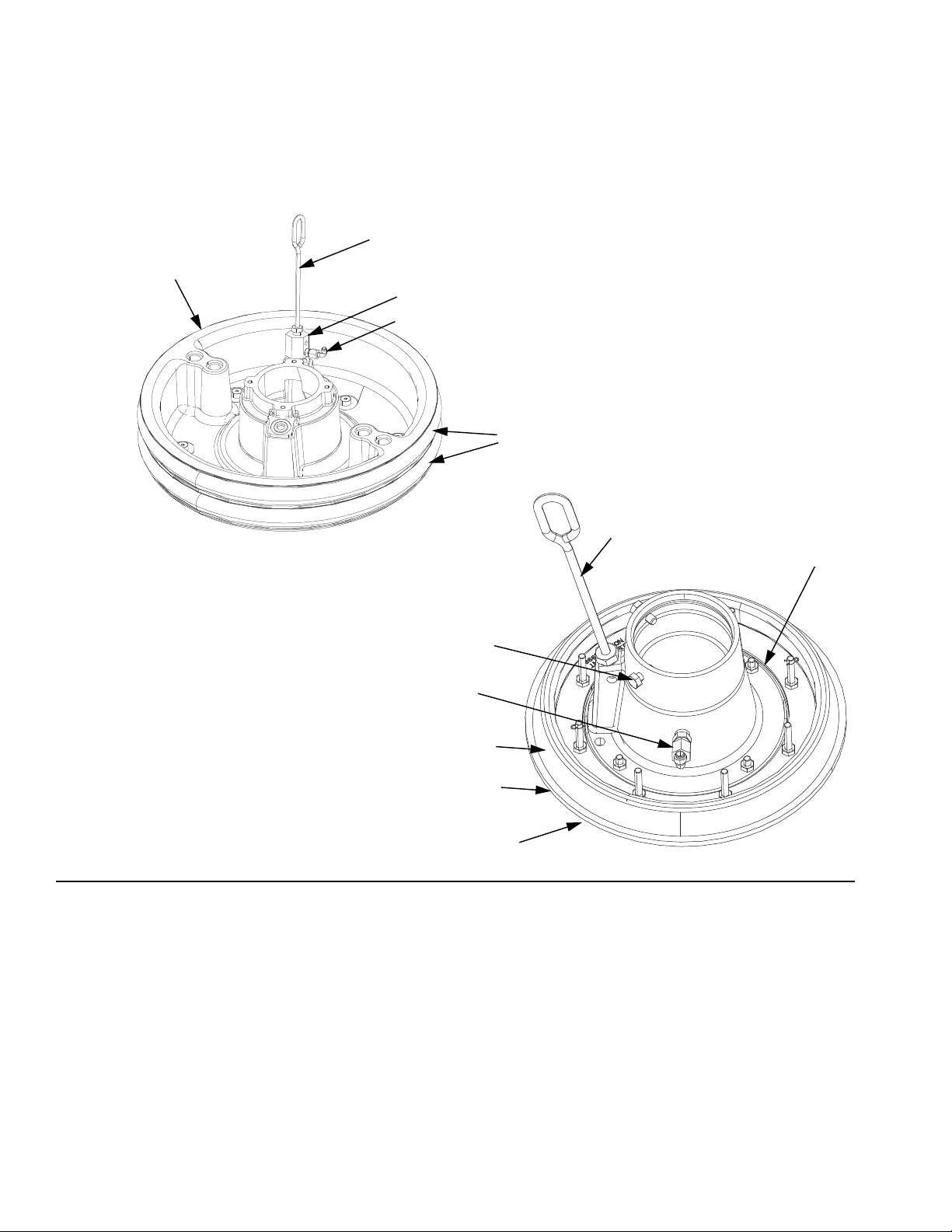

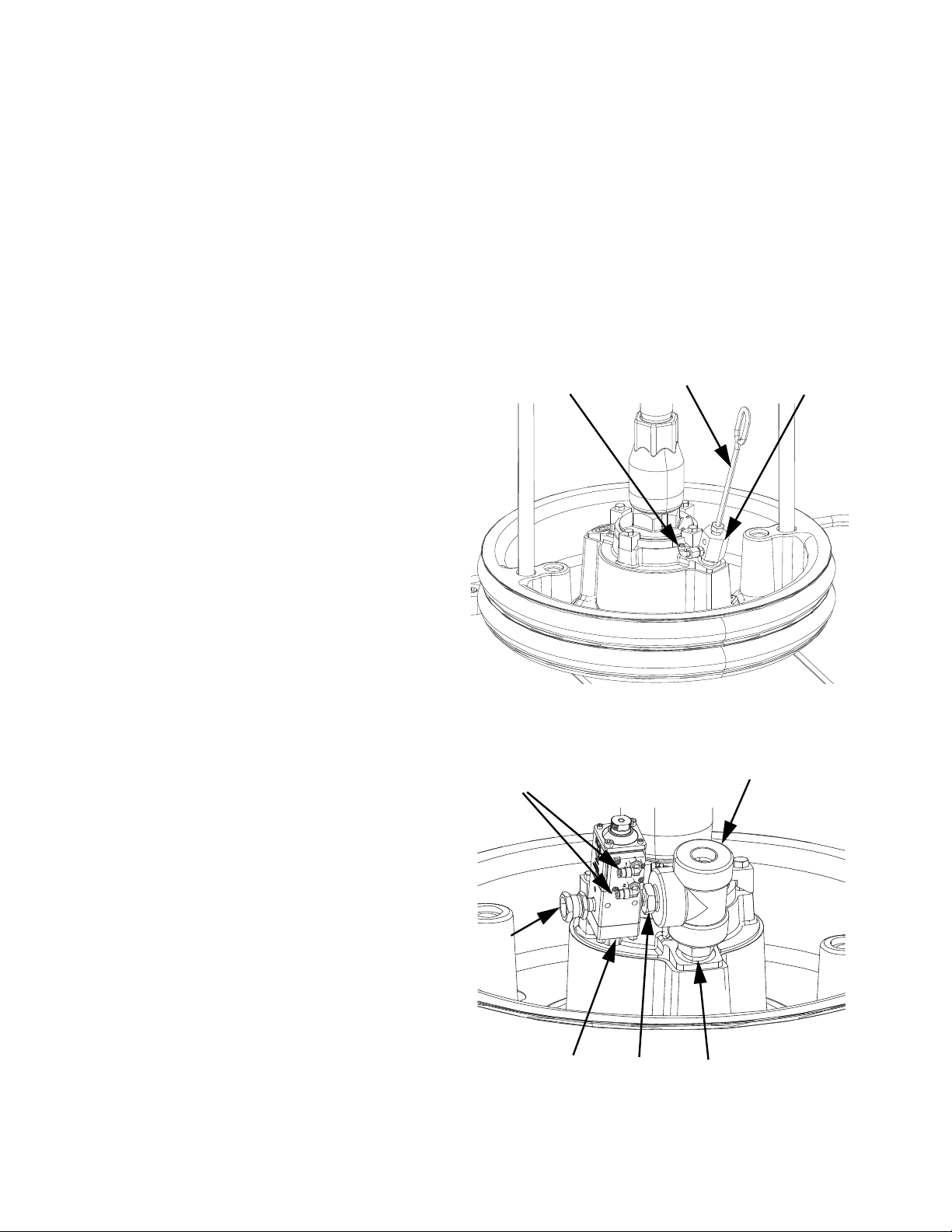

Platen Component Identification

Model 255319, 200 liter (55 gallon)

EF

EA

EG

EH

FIG. 4

EB

Model 256742 and 256745,

20 liter (5 gallon)

EF

EA

ED

EH

EC

EB

EJ

Key:

EA Plate

EB Wipers

EC Spacer

ED Cap Screws

EE Clamps (not shown)

EF Bleed Stick

EG Bleed Port

EH Air Assist Body Check Valve

EJ Wiper Plate (under wiper)

EK O-ring Seal (not shown)

14 3A6331G

Page 15

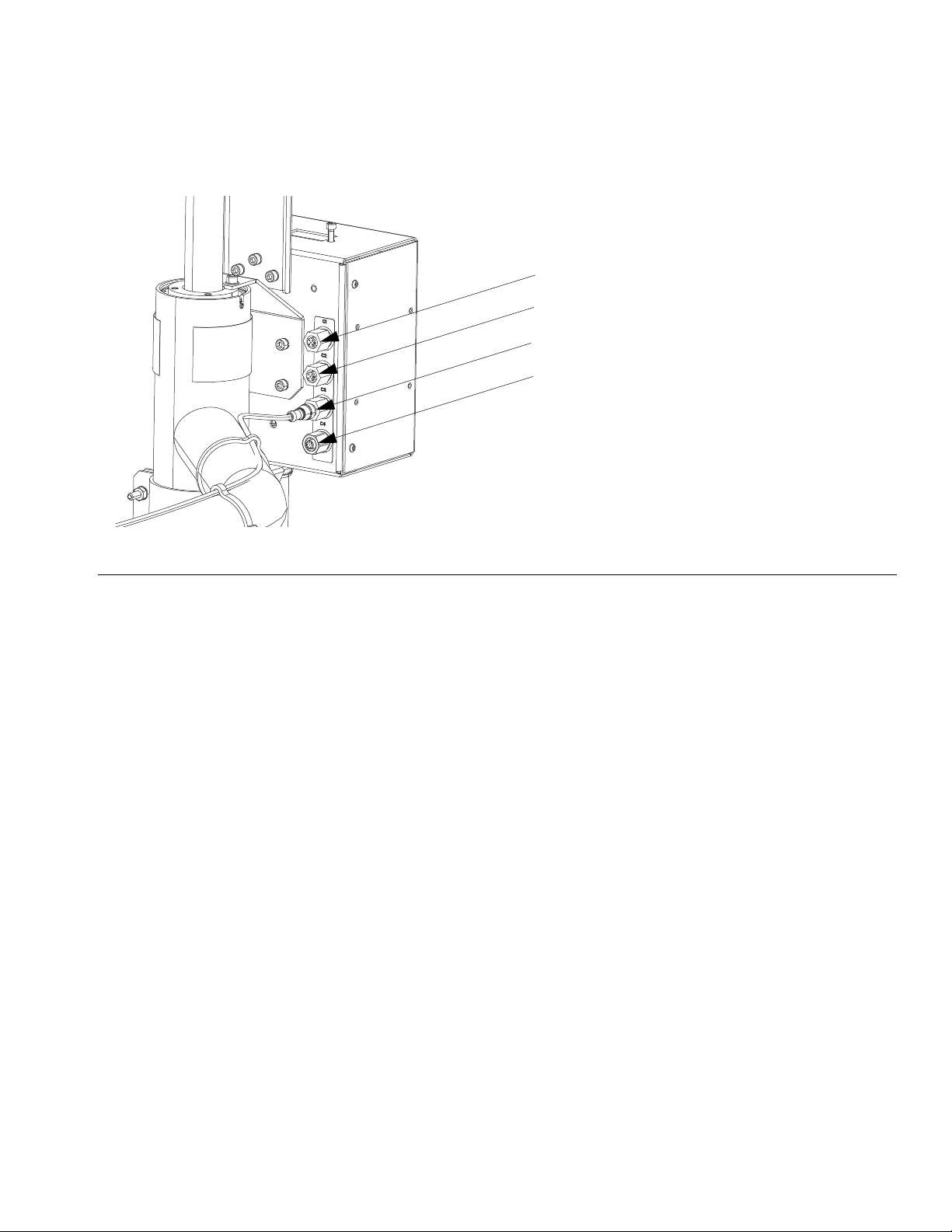

Junction Box Connections

Component Identification

C1

C2

C3

C4

FIG. 5

Key:

C1 CGA CAN Port

C2 GCA CAN Port

C3 Low and Empty Level Sensor Input

C4 Fluid Filter Solenoid Input

NOTE: See the E-Flo SP Software Instructions manual

for all I/O descriptions.

3A6331G 15

Page 16

Installation

Installation

All electrical wiring must be done by a qualified electrician and comply with all local codes and regulations.

Location

To properly locate and anchor the supply system, refer

to Dimensions on page 67.

NOTICE

Always lift the supply system at the proper lift locations

(see FIG. 1). Do not lift in any other way. Failure to lift

at the proper lift locations can result in damage to the

supply system.

Attach a lifting sling at the proper lift locations. Lift off the

pallet using a crane or a forklift.

NOTE: The lift ring on the driver is only to be used for

replacing the driver. Do not use it to lift the entire system.

Grounding

The equipment must be grounded to reduce the risk

of static sparking and electric shock. Electric or static

sparking can cause fumes to ignite or explode.

Improper grounding can cause electric shock.

Grounding provides an escape wire for the electric

current.

Electric pump: the pump is grounded through the

power cord.

Ram: the ram is grounded through the power cord.

Air and fluid hoses: use only electrically conductive

hoses with a maximum of 500 ft. (150 m) combined

hose length to ensure grounding continuity. Check the

electrical resistance of the hoses. If the total resistance

to ground exceeds 29 megaohms, replace the hose

immediately.

Air compressor: follow manufacturer’s recommendations.

Dispense valve: ground through connection to a prop-

erly grounded fluid hose and pump.

Position the ram so the driver, disconnect switch, air

controls, and ADM are easily accessible. Ensure that

there is enough space overhead for the ram to raise

fully.

Using the holes in the ram base as a guide, drill holes

for 1/2 in. (13 mm) anchors.

Ensure that the ram base is level in all directions. If necessary, level the base using metal shims. Secure the

base to the floor using 1/2 in. (13 mm) anchors that are

long enough to prevent the ram from tipping.

Fluid supply container: follow local code.

Solvent pails used when flushing: follow local code.

Use only conductive metal pails, placed on a grounded

surface. Do not place the pail on a non-conductive surface, such as paper or cardboard, which interrupts the

grounding continuity.

To maintain grounding continuity when flushing or

relieving pressure: hold a metal part of the dispense

valve firmly to the side of a grounded metal pail, then

trigger the valve.

16 3A6331G

Page 17

Installation

Power Requirements

The system requires a dedicated circuit protected with a

circuit breaker.

Voltage Phase Hz Current

200-240 VAC 1 50/60 20 A

400-480 VAC 1 50/60 10 A

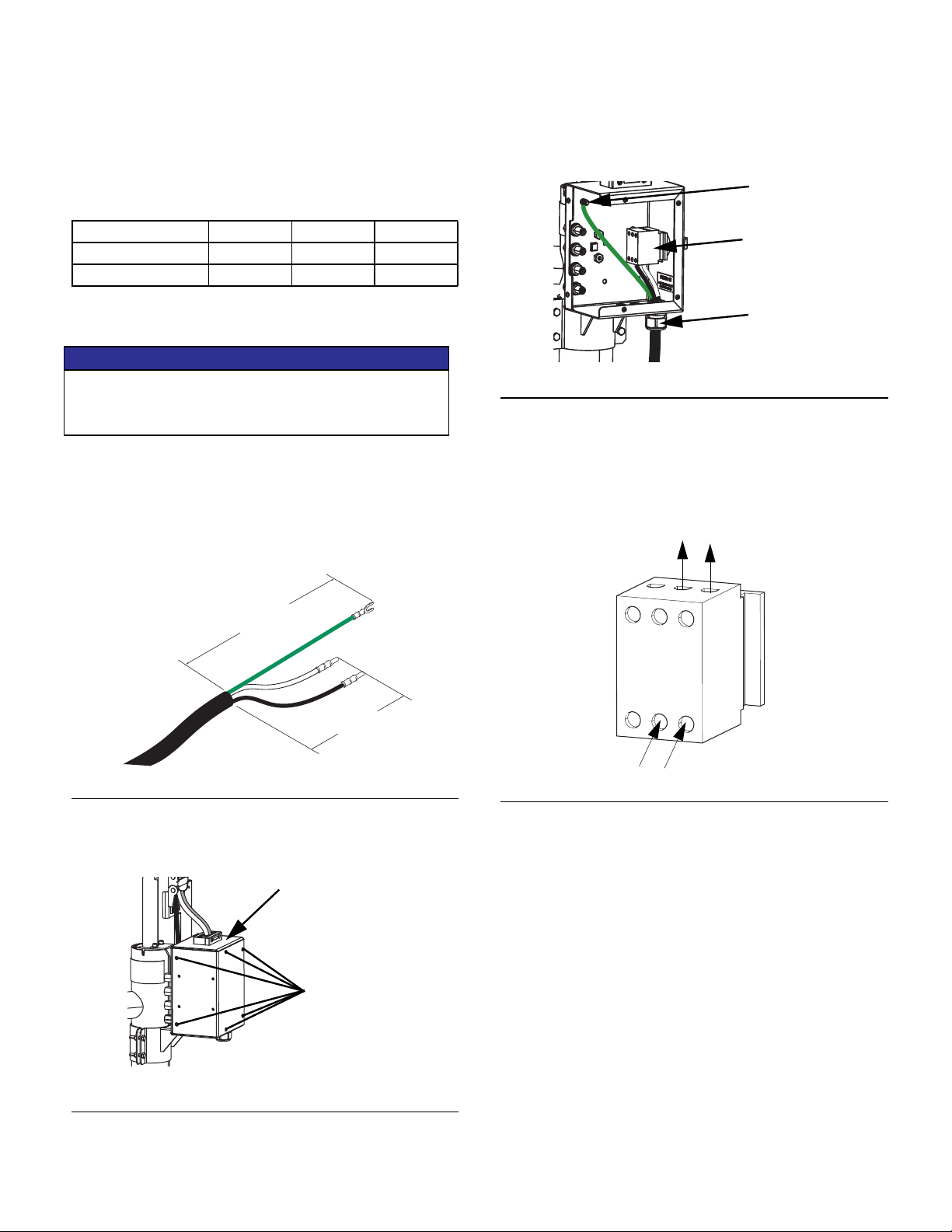

Connect Power

NOTICE

To avoid equipment damage, route and secure a

power cord that is long enough to allow the full range

of movement for the ram.

6. Cut power cord wires to the following lengths:

• Ground wire - 6.5 inches (16.5 cm)

• Power wires - 3.0 inches (7.6 cm)

• Add ferrules as necessary. See FIG. 6.

8. Insert the power cord through the cord grip and into

the junction box (K).

Ground Stud

Disconnect Switch

Terminal Block

Cord Grip

FIG. 8: Power Connection

9. Attach the ground wire to the ground stud inside the

junction box (K).

10. Refer to FIG. 9 and connect the wires from the power

cord into terminals 4T2 and 6T3 on the disconnect

switch terminal block.

LQ

LQ

FIG. 6: Power Cord

7. Remove the six screws holding the cover of the junction box (K), then remove the junction box cover.

K

Screws

1L1

3L2

5L2

2T1

4T2

6T3

FIG. 9: Disconnect Switch Terminal Block

11. Tighten the cord grip to securely hold the power cord

to the junction box (K).

12. Replace the junction box cover and secure it with the

six screws that were removed in step 2.

FIG. 7: Remove the Junction Box Cover

3A6331G 17

Page 18

Installation

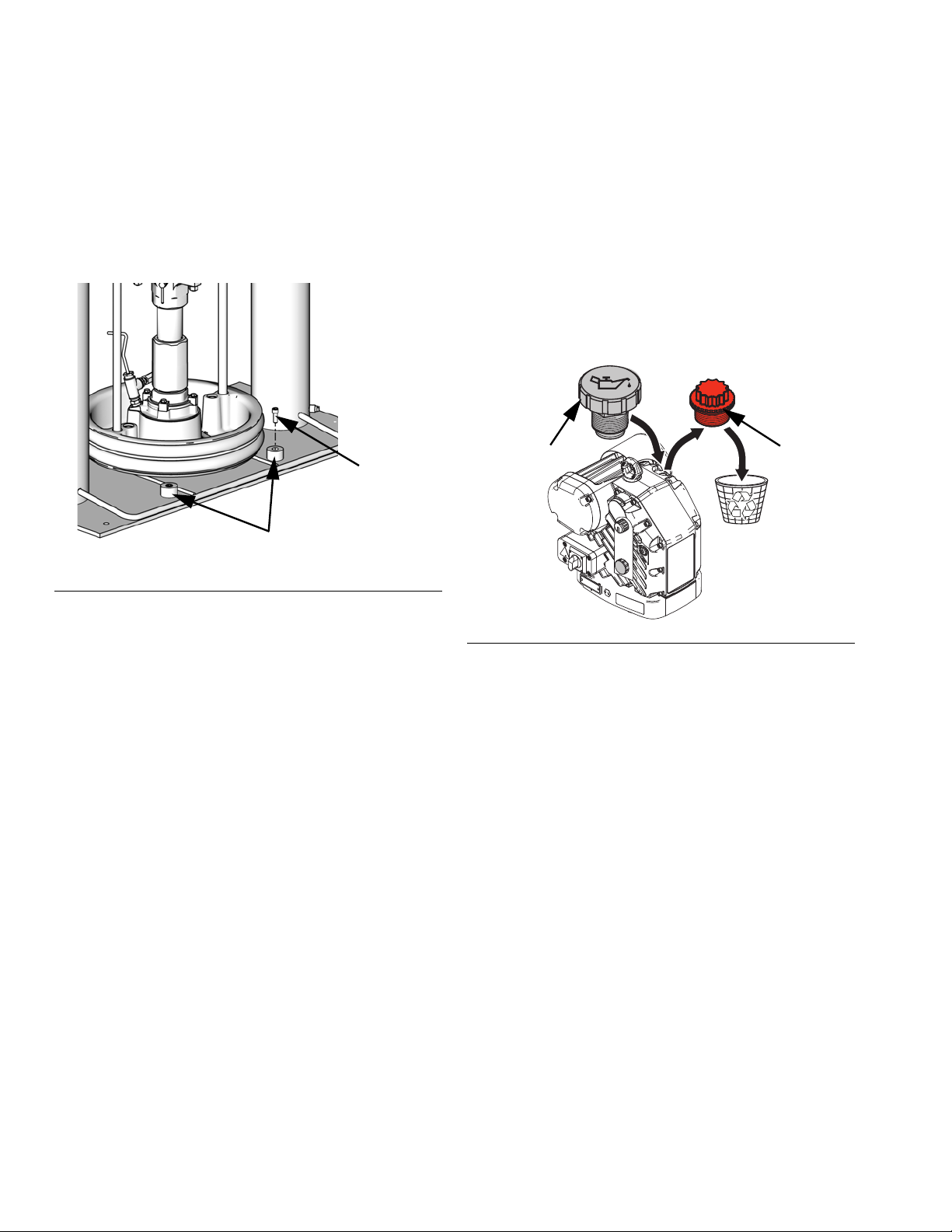

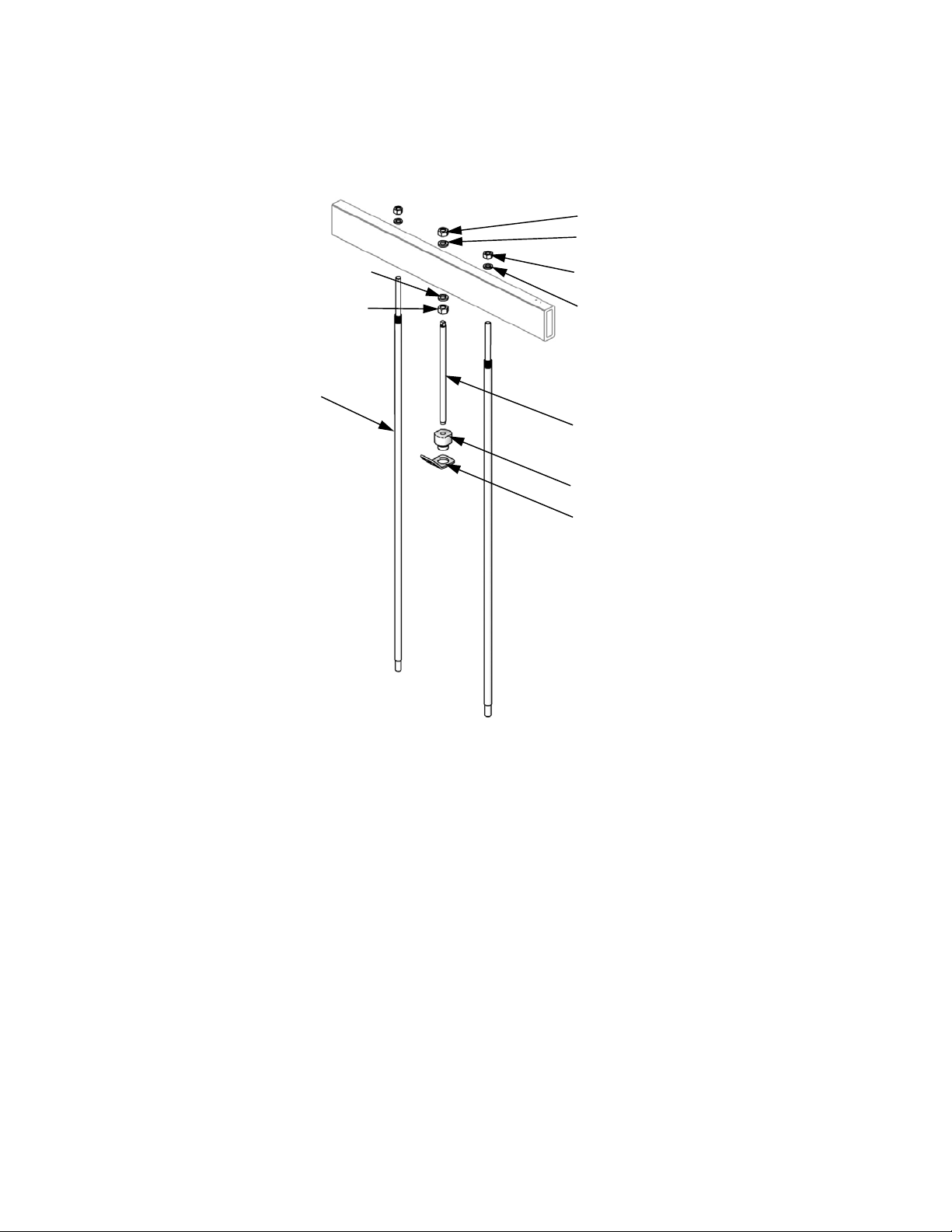

Attach Drum Stops

The electric supply systems are shipped with drum

stops in place to help position the drum on the ram. For

replacement parts, order Kit 255477. The kit includes 2

each of capscrews, lock washers (not shown), and drum

stops.

Capscrews

Drum Stops

FIG. 10: Drum Stop Installation

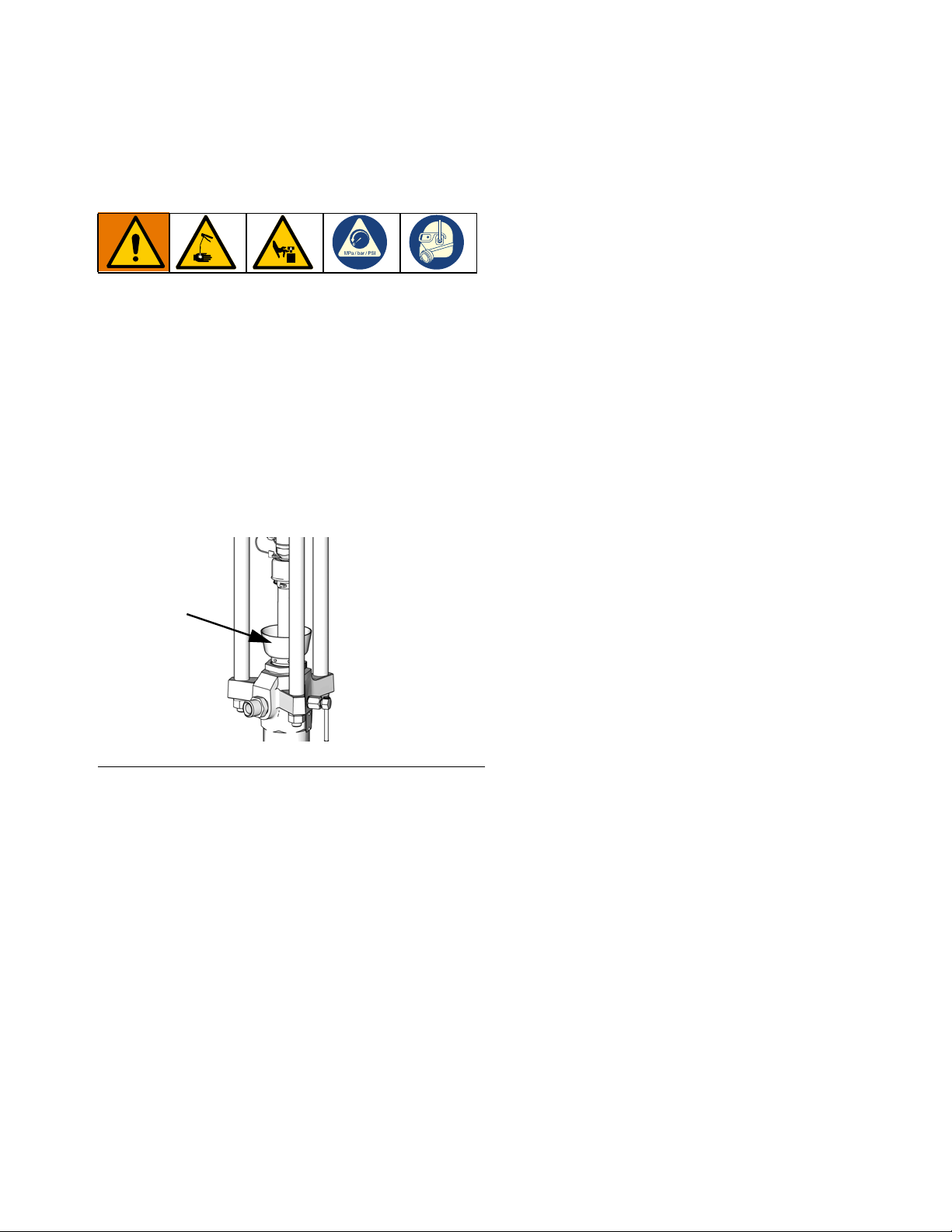

Install Vented Oil Cap Before Using Equipment.

The driver gear-box is shipped from the factory pre-filled

with oil. The temporary unvented cap prevents oil leaks

during shipment. This temporary cap must be replaced

with the vented oil cap supplied with the equipment,

before use.

NOTE: Prior to use, check oil level. Oil level should be

half way up the sight glass.

Vented Cap

Unvented

Cap

1. Locate the correct set of mounting holes on the ram

base.

2. Using the capscrews and lock washers, attach the

drum stops to the ram base.

Fluid Hose and Air Line Connections

Refer to FIG. 1 on page 11 for a typical installation.

Attach the fluid hose (not supplied) to the Outlet Check

Valve (E) connection.

Attach the air line (not supplied) to the bottom of the

Integrated Air Control (G) at the 3/4 in. NPT connection.

NOTE: Be sure all components are adequately sized

and pressure rated to meet the system’s requirements.

FIG. 11: Unvented and Vented Oil Caps

18 3A6331G

Page 19

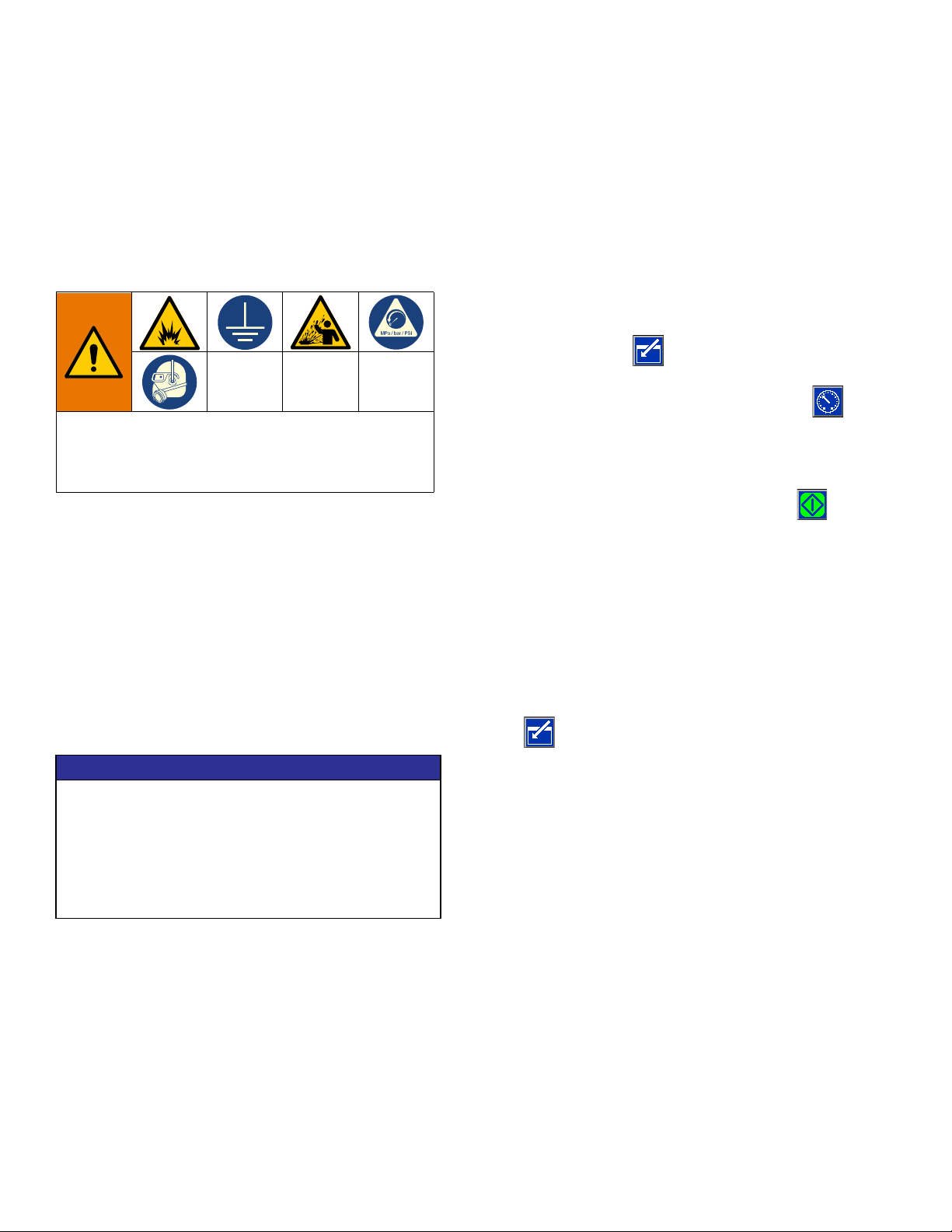

Setup

Wet Cup

Before starting, fill the wet cup (L) 1/3 full with Graco

Throat Seal Liquid (TSL) or a compatible solvent.

Torque the Wet Cup

The wet cup is torqued at the factory; however, throat

packing seals on Severe Duty pumps may relax over

time. Check wet cup torque frequently after initial

start-up and periodically after the first week of production. Maintaining proper wet cup torque is important to

extending seal life.

Setup

R

FIG. 12: Wet Cup

NOTE: MaxLife pumps use a special u-cup throat seal

that is non-adjustable and does not require periodic

torquing.

1. Follow the Pressure Relief Procedure on page 22.

2. Torque the wet cup (R) 95-115 ft-lbs (128-155 N•m)

using the packing nut wrench (supplied) whenever

necessary. Do not overtighten the wet cup. See the

table below for torque values.

3A6331G 19

Page 20

Startup

Startup

Letters in parenthesis are used in this section for reference to callouts in the Component Identification section starting on page 11.

Flush the Pump

To avoid fire and explosion, always ground the equipment and the waste container. To avoid static sparking and injury from splashing, always flush at the

lowest possible pressure.

NOTE: The pump is tested with lightweight oil, which is

left in to protect the pump parts. If the fluid you are using

may be contaminated by the oil, flush it out with a compatible solvent before using the pump.

Always flush at the lowest pressure possible. Check

connectors for leaks and tighten as necessary. Flush

with a fluid that is compatible with the fluid being dispensed and the equipment wetted parts.

3. Turn the disconnect switch (M) ON.

4. At the ADM (F), use the ADM’s arrow keys to select

the pump you want to flush from the Menu Bar.

NOTE: If multiple pumps are connected together, there

can be up to six pumps listed in the Menu Bar.

5. Enter the Edit screen for that pump by pressing the

soft key next to the icon.

6. Press the soft key next to the Pressure Mode

icon.

7. Enter 100 psi (0.69 MPa, 6.9 bar) as the pressure.

8. Press the soft key next to the Pump On/Off

icon to turn on the pump.

9. Adjust pressure as necessary.

10. Hold a metal part of the dispense valve firmly to the

side of a grounded metal pail.

11. Open the dispense valve and flush the system until

clear solvent flows from the gun/valve.

NOTE: Check with your fluid manufacturer or supplier

for recommended flushing fluids and flushing frequency.

NOTICE

To prevent damage to the pump from rust, never

leave water or water-based fluid in a carbon steel

pump overnight. If you are pumping a water-based

fluid, flush with water first. Then flush with a rust

inhibitor, such as mineral spirits. Relieve pressure,

but leave the rust inhibitor in the pump to protect

parts from corrosion.

NOTE: Refer to the E-Flo SP Software Instructions

manual for additional information about using the

software features of the ADM. See Related Manuals on

page 3.

1. Follow the Pressure Relief Procedure on page 22.

2. Place a pail of compatible solvent in the ram. See

Grounding instructions for solvent pails on page

16.

12. Exit the Edit screen by pressing the soft key next to

the icon.

13. Repeat steps 3 through 11 for each pump you want

to flush.

14. Follow the Pressure Relief Procedure on page 22.

15. Remove the solvent pail from the ram.

20 3A6331G

Page 21

Startup

Start and Adjust the Ram

1. Turn the disconnect switch (M) OFF.

2. Raise the Ram by opening the main air slider valve

(AA) and setting the ram air regulator (AB) to 40 psi

(0.28 MPa, 2.8 bar).

3. Set the ram director valve handle (AC) to UP and let

the ram rise to its full height.

4. Set the ram director valve handle (AC) to neutral.

5. Lubricate the platen wiper (EB) with grease or other

lubricant compatible with the fluid you will pump.

6. Put a full drum/pail on the ram base and center it

under the platen (D).

7. Remove the drum/pail cover and smooth the surface of the fluid with a straightedge. To prevent air

from being trapped under the platen, scoop fluid

from the center of the pail to the sides, to make the

surface concave.

8. Adjust the drum/pail to be sure it is aligned with the

platen, and remove the platen bleed stick to open

the platen bleed port.

9. With hands away from the drum/pail and the platen,

push down on the ram director valve (AC) handle,

and lower the ram until the platen rests on the lip of

the drum/pail. Move the ram director valve handle to

the horizontal position (neutral).

10. Lower the ram:

a. Set the ram director valve (AC) to DOWN and

continue to lower the ram until fluid appears at

the platen bleed port.

b. Set the ram director valve to neutral, replace the

platen bleed stick, and tighten it securely.

Start and Adjust the Pump

1. With the disconnect switch (M) OFF, set the ram air

regulator (AB) to about 50 psi (0.35 MPa, 3.5 bar).

Set the ram director valve (AC) to DOWN.

2. Turn the driver disconnect switch (M) ON.

3. Start the pump. See the E-Flo SP Software Instructions manual for instructions on operating the system.

D60

Platen Bleed Stick

EB

4. Keep the ram director valve (AC) set to DOWN

while the pump is operating.

NOTE: Increase air pressure to the ram if the pump

does not prime properly with more viscous fluids.

Decrease air pressure if fluid is forced out around the

top seal or platen.

D200

Platen Bleed Stick

EB

3A6331G 21

Page 22

Pressure Relief Procedure

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, splashing

fluid and moving parts, follow the Pressure Relief Procedure when you stop spraying and before cleaning,

checking, or servicing the equipment.

1. At the ADM, enter manual mode by pressing the

soft key next to the icon.

2. Press the soft key next to the icon to stop the

pump.

7. Hold a metal part of the dispense valve firmly to the

side of a grounded metal pail, and open the dispense valve to relieve pressure.

8. Open your system’s fluid line drain valve and open

the pump bleed valve (P). Have a container ready to

catch the drainage.

9. Leave the pump bleed valve (P) open until ready to

dispense again.

3. Turn the disconnect switch (M) OFF.

AC

AA

FIG. 13: Air Control for Pressure Relief

4. Close the main air slider valve (AA).

5. Set the ram director valve (AC) to DOWN. The ram

will slowly drop.

6. Once the ram is completely down, jog the ram director valve up and down to bleed air from the ram cylinders.

22 3A6331G

Page 23

Shutdown and Care of the Pump

Change Drums

NOTICE

To prevent damage to the pump from rust, never

leave water or water-based fluid in a carbon steel

pump overnight. If you are pumping a water-based

fluid, flush with water first. Then flush with a rust

inhibitor, such as mineral spirits. Relieve pressure,

but leave the rust inhibitor in the pump to protect

parts from corrosion.

1. Set the ram director valve (AC) to DOWN, and lower

the ram to the desired position for shutdown.

2. Set the ram director valve (AC) to neutral.

1. Stop the pump.

2. Set the ram director valve (AC) to UP to raise the

platen, and immediately press and hold the blowoff

air button (AE) until the platen is completely out of

the drum. Use the minimum amount of air pressure

necessary to push the platen out of the drum.

Shutdown and Care of the Pump

3. Stop the pump at the bottom of the stroke to prevent

fluid from drying on the exposed displacement rod

and damaging the throat packings. See the E-Flo

SP Software Instructions manual for information

about jogging the pump. See Related Manuals on

page 3.

4. Always flush the pump before the fluid dries on the

displacement rod. Follow steps to Flush the Pump

on page 20.

Excessive air pressure in the material drum could

cause the drum to rupture, causing serious injury. The

platen must be free to move out of the drum. Never

use drum blowoff air with a damaged drum.

3. Release the blowoff air button (AE) and allow the

ram to rise to its full height.

4. Remove the empty drum.

5. Inspect the platen and, if necessary, remove any

remaining material or material build–up.

3A6331G 23

Page 24

Maintenance

Maintenance

Driver Maintenance

NOTICE

Do not open/remove the gear cover. The gear side is

not intended to be serviced. Opening the gear cover

may alter the factory set bearing pre-load and may

reduce the product life.

Preventative Maintenance Schedule

The operating conditions of your particular system

determine how often maintenance is required. Establish

a preventative maintenance schedule by recording

when and what kind of maintenance is needed, and

then determine a regular schedule for checking your

system.

Change the Oil

NOTE: Change the oil after a break-in period of 200,000

to 300,000 cycles. After the break-in period, change the

oil once per year.

Check Oil Level

Refer to FIG. 14 below. Check the oil level in the sight

glass on a regular basis. The oil level should be near the

halfway point of the sight glass when the driver is not

running. If the oil is low, open the fill cap and add Graco

Part No. 16W645 ISO 220 silicone-free synthetic EP

gear oil.

The oil capacity is approximately 1.0 - 1.2 quarts (0.9 -

1.1 liters). Do not overfill.

NOTICE

Only use oil with Graco part number 16W645. Any

other oil may not lubricate properly and can cause

damage to the drive train.

Fill Cap

1. Follow the Pressure Relief Procedure on page 22.

2. Place a minimum 2 quart (1.9 liter) container under

the oil drain port.

3. Remove the oil drain plug. See FIG. 14 for the loca-

tion of the drain plug. Allow all oil to drain from the

driver.

4. Reinstall the oil drain plug. Torque to 18-23 ft-lb

(25-30 N•m).

5. Open the fill cap and add Graco Part 16W645 ISO

220 silicone-free synthetic EP gear oil. Check the oil

level in the sight glass. Fill until the oil level is near

the halfway point of the sight glass. The oil capacity

is approximately 1.0 - 1.2 quarts (0.9 - 1.1 liters). Do

not overfill.

6. Reinstall the fill cap.

Bearing Pre-loads

Sight Glass

Oil Drain Plug

FIG. 14: Sight Glass and Oil Fill Cap

Bearing Pre-Load

The bearing pre-loads are factory set and are not user

adjustable. Do not adjust the bearing pre-loads. See

APD20 Advanced Precision Driver Instructions-Parts

manual for maintenance information.

24 3A6331G

Page 25

Maintenance

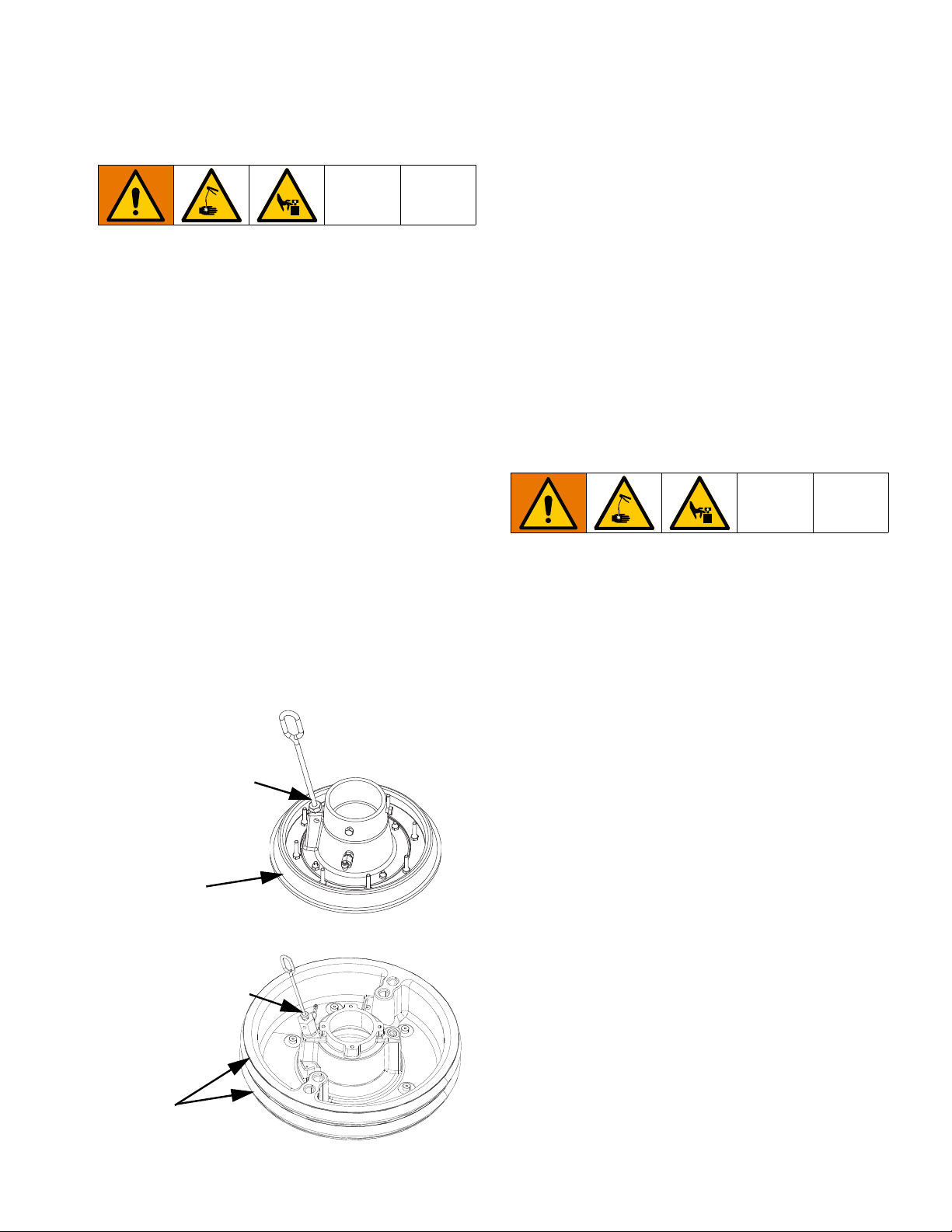

Platen Maintenance

See FIG. 15. If the platen does not come out of the pail

easily when the pump is being raised, the air assist tube

(F) or check valve may be plugged. A plugged valve

prevents air from reaching the underside of the plate to

assist in raising it from the pail.

1. Follow the Pressure Relief Procedure on page 22.

2. Refer to parts illustration on page 50 and

disassemble air assist valve as shown.

3. Clear air assist tube (AT) in platen. Clean all parts of

valve and reassemble.

4. Remove bleed stick (EF) from platen. Push bleed

stick through bleed relieve ports to remove material

residue.

Adjust Spacers

Tapered and Straight Sided Pails

The platen is supplied for use with 20 liter (5 gallon), 30

liter (8 gallon), and 60 liter (16 gallon) straight sided

pails, but only single wiper platens can be easily

modified for use with tapered pails.

Platen with Tapered Pails

1. Follow the Pressure Relief Procedure on page 22.

2. Working from the bottom, use screwdriver to pry

spacer (EC) loose. Work spacer upward completely

above the flange of the platen. See FIG. 16.

3. By hand, angle spacer (EC) and work it off the plate,

pulling it down over the flange and bottom wipers

(EB). See FIG. 17.

4. Save spacer (EC), as it is required for other applications.

EF

FIG. 15

1

To use Model 255745 platens

with tapered pails, the spacer

(EC) must be removed.

AT

r_255468_313527_33a

EC

FIG. 16

EB

EC

r_255468_313527_30a

3A6331G 25

Page 26

Maintenance

Platen with straight sided pail

1. Follow the Pressure Relief Procedure on page 22.

2. Ensure large diameter of spacer (EC) is facing

down. Work spacer (EC) up over the platen by

hand completely above the flange of the platen. See

FIG. 17.

3. Working from the top, use screwdriver to position

spacer (EC) between flange and wipers (EB). See

FIG. 18.

EC

EB

r_255468_313527_30a

FIG. 17: Sliding spacer

Remove and Reinstall Wipers

Disassemble 20, 30, and 60 Liter Wiper Assemblies

1. Follow the Pressure Relief Procedure on page 22.

2. Remove wiper assembly; see FIG. 35 on page 50:

a. For all single wiper platens: Remove two clips

(470) with needle nose pliers and remove platen

cover (469).

b. Remove eight nuts (459) that hold wiper assem-

bly to platen casting (451) and remove wiper

assembly.

c. See Reassemble 20, 30, and 60 Liter Wiper

Assemblies to change wiper sizes, styles, or a

complete wiper assembly.

3. Remove eight nuts (459) on wiper assembly.

4. Separate top plate (457), spacer (452), wiper(s)

(453), wiper support (454), and bottom plate (455).

5. Clean, inspect, and replace worn components.

Reassemble 20, 30, and 60 Liter Wiper Assemblies

EC

EB

FIG. 18: Installing Spacer

r_255468_313527_32a

1. Assemble wiper assembly; see FIG. 35 on page 50:

a. For single wiper assemblies with carbon steel

platens: Place bottom plate (455) on flat surface. Place wiper support (454), wiper (453),

spacer (452), and top plate (457) on bottom

plate (455).

b. For single wiper assemblies with SST platens:

Place bottom plate (455) on flat surface. Place

wiper support (454), wiper (453), flowered wiper

support (460), PTFE spacer (452), and top plate

(457) on bottom plate (455).

c. For double wiper assemblies: Place bottom

plate (455) on flat surface. Place wiper support

(454), wiper (453), spacer (452), wiper (453)

and top plate (457) on bottom plate (455).

2. Install eight nuts (459) on outer ring. Torque to 45

in-lbs (61 N•m).

3. Replace o-ring (456), or install new o-ring under

platen casting (451). Use lubricant to hold in place.

26 3A6331G

Page 27

4. Install platen casting (451). Tighten with four nuts

(459).

Remove 55 Gallon Platen Wipers

Maintenance

1. Follow the Pressure Relief Procedure on page 22.

2. Turn the disconnect switch (M) to OFF.

3. To replace worn or damaged wipers (EB), raise

platen up out of drum. Remove drum from base.

Wipe fluid off of platen.

4. Cut top and bottom wipers with knife and remove

from platen. See FIG. 19.

EB

TI10613A

FIG. 19

Reinstall 55 Gallon Platen Wipers

1. Using a wooden or plastic tool to prevent damage to

the wiper (EB), clean all material from seal grooves.

EB

TI10614A

FIG. 20

Remove 55 Gallon Platen Hose Wipers

1. Follow the Pressure Relief Procedure on page 22.

2. Turn the disconnect switch (M) to OFF.

3. To replace worn or damaged wipers (EB), raise

platen up out of drum. Remove drum from base.

Wipe fluid off of platen.

4. Loosen ends of banding (410) with jack screw. See

FIG. 21.

2. Working from the bottom, angle one wiper (EB) over

back of platen. See FIG. 20.

3. Insert wiper (EB) in top groove and run front of wiper

into groove.

4. Insert second wiper (EB) in lower groove and run

front of wiper into groove.

5. Lubricate outside of wiper with lubricant compatible

with material being pumped. Check with material

supplier.

410

WLD

FIG. 21

3A6331G 27

Page 28

Maintenance

Reinstall 55 Gallon Plate Hose Wipers

1. Clean all material from the seal grooves. Lubricate

ram plate grooves before assembly.

2. Assemble two bands (410) together. Align one end

of band about 9 in. from jack screw and tape

attached band. Install screw jack in slot.

410

3. Insert jack screw end of band (410) into hose (408

or 409) and push completely through hose.

WLD

410

408, 409

NOTE: To prevent material from potentially leaking past

both hoses, ensure hose (408,409) seams are 90°-180°

apart, and not on top of each other.

408

409

410 (x2)

WLD

WLD

4. Lubricate outside of hoses (408,409) and place on

upper or lower groove on plate. Adjust hose and

band so that the angled ends of hose press against

each other. Tighten two ends of banding (410)

together with jack screw.

410

WLD

5. Work hose to completely close gap at the ends.

28 3A6331G

Page 29

Troubleshooting

Troubleshooting

2. Check all possible problems and causes before

disassembling the ram, pump, or platen.

NOTE: Refer to Supply Unit Operation manual for

descriptions of DataTrak diagnostic codes.

NOTE: Refer to your pump package manual for pump

1. Follow Pressure Relief Procedure, page 22,

before checking or repairing the ram, pump, or

platen.

Problem Cause Solution

Ram will not raise or lower. Closed air valve or clogged air line. Open, clear.

Not enough air pressure. Increase.

Worn or damaged piston. Replace. See Supply Unit Repair on

Hand valve closed or clogged. Open, clear.

Ram raises and lowers too fast. Air pressure is too high. Decrease.

Air leaks around cylinder rod. Worn rod seal. Replace. See Supply Unit Repair on

Fluid squeezes past ram plate wipers.

Pump will not prime properly or

pumps air.

Air assist valve will not hold drum

down or push plate up.

Air pressure too high. Decrease.

Worn or damaged wipers. Replace. See Remove and Rein-

Not enough pressure. Increase pressure setting.

Worn or damaged piston. Replace. See pump manual.

Hand valve closed or clogged. Open, clear. See Platen Mainte-

Hand valve is dirty, worn, or damaged.

Closed air valve or clogged air line. Open, clear. See Platen Mainte-

Not enough air pressure. Increase.

Valve passage clogged. Clean. See Platen Maintenance on

troubleshooting.

page 34.

page 34.

stall Wipers on page 26.

nance on page 25.

Clean, service.

nance on page 25.

page 25.

3A6331G 29

Page 30

Repair

Repair

Disconnect Pump from Platen

4. Carefully pull pump away to prevent damage to

pump inlet and remove o-ring (428).

20, 30, and 60 Liter Platen

1. Follow the Pressure Relief Procedure on page 22.

The pump is mounted to the platens by different mounting kits. See the Repair Kits on page 55.

55 Gallon Platen

1. Follow the Pressure Relief Procedure on page 22.

2. Turn the disconnect switch (M) to OFF.

3. Remove four hex screws (426), four clamps (427),

and washers (425).

428

426

425

427

428

2. Turn the disconnect switch (M) to OFF.

3. Loosen two 5/16 in. screws (462) from platen.

4. Carefully pull pump away to prevent damage to

pump inlet. If using a pump with intake adapter,

remove screws (472), adapter (471), and o-rings

(463) from pump inlet.

428

426

425

427

426

425

427

TI10422A

Check-Mate Mounting

FIG. 22: 55 Gallon Mounting Kit

463

462

r_255648_313527_35a

Check-Mate Mounting

FIG. 23: 20, 30, and 60 liter mounting kit

30 3A6331G

Dura-Flo SS Mounting

471

462

Dura-Flo SS Mounting

472

463

Dura-Flo CS Mounting

471

462

Dura-Flo CS Mounting

472

463

Page 31

Repair

Connect Platen

55 Gallon Platen

1. Place o-ring (428) from mounting kit on the platen. If

attached to plate, place displacement pump onto

platen. See FIG. 22.

2. Secure pump’s intake flange to plate with screws

(426), washers (425), and clamps (427) included in

mounting kit 255392.

20, 30, and 60 Liter Platen

NOTE: Before installing the 20, 30, or 60 liter platen to a

pump with an intake adapter, install adapter and o-ring

from mounting kit using the two set screws. See FIG. 23.

1. Place o-ring (463) from mounting kit on pump

intake. Loosen the pump intake flange screws (462)

and carefully lower pump onto o-ring (463) and

platen.

2. Secure pump’s intake flange to plate with screws

(462).

Remove Displacement Pump

The procedure for removing your displacement pump

depends on which driver and platen your unit uses. Find

your ram unit, driver, and platen below to remove the

displacement pump. Refer to your displacement pump

manual to repair the displacement pump.

If the driver does not require servicing, leave it attached

to its mounting. If the driver does need to be removed,

see Remove Driver on page 33.

D200 3 in. and D200s 6.5 in. Supply Units

1. Follow the Pressure Relief Procedure on page 22.

2. Turn the disconnect switch (M) to OFF.

3. See Disconnect Displacement Pump in your

pump package manual.

4. Open the main air slider valve (AA).

Remove Wipers

See Remove and Reinstall Wipers on page 26.

Install Wipers

See Remove and Reinstall Wipers on page 26.

5. Raise the driver:

a. Loosen nut (105a) under ram bar and thread it

down the threaded rod (106) to the lift ring

adapter (107) holding the driver. Use wrench on

nut (105) on top of ram bar to raise driver.

106

105

105a

107

FIG. 24

3A6331G 31

Page 32

Repair

b. For driver with smaller platens and all supply

units: See procedure for D60 3 in. Dual Post

Supply Units on page 32.

6. See Disconnect Pump from Platen on page 30 to

disconnect the platen from the displacement pump.

7. Use two people to lift out the displacement pump.

Install Displacement Pump

D200 3 in. and D200s 6.5 in. Supply Units

1. Insert displacement pump on platen. Follow Connect Platen steps on page 31.

2. See Reconnect Displacement Pump in your pump

package manual.

3. Connect driver:

a. Use wrench on nut (105) on top of ram bar to

lower driver onto displacement pump. See FIG.

24 on page 31. Thread nut (105) up and tighten

it under ram bar. Tighten nut (105) below the

crossbar to 25 ft-lb (34 N•m) maximum.

D60 3 in. Dual Post Supply Units

1. Raise ram to install displacement pump to platen.

2. Insert displacement pump on platen. Follow Con-

nect Platen steps on page 31.

FIG. 25

D60 3 in. Dual Post Supply Units

1. Follow the Pressure Relief Procedure on page 22.

2. Turn the disconnect switch (M) to OFF.

3. See Disconnect Displacement Pump in your

pump packages manual.

4. See Disconnect Pump from Platen on page 30 to

disconnect the platen from the displacement pump.

5. Open the main air slider valve (AA).

6. Raise the ram assembly to lift the driver away from

the displacement pump.

3. See Reconnect Displacement Pump in your pump

packages manual.

7. Remove displacement pump and service as

needed.

32 3A6331G

Page 33

Remove Driver

To avoid serious injury when installing and removing

the driver, make sure the driver is supported at all

times.

Repair

1. Follow the Pressure Relief Procedure on page 22.

2. Turn the disconnect switch (M) OFF.

3. See Disconnect Displacement Pump in your

pump package manual.

4. Disconnect power from the driver:

a. Remove the driver housing cover (HC).

b. Disconnect the wires inside the driver housing.

c. Loosen the cord grip (CG).

d. Remove wires from driver housing by pulling

them through the cord grip (CG).

e. Disconnect the cables connected to ports 1-6

on the side of the driver, shown in FIG. 27.

HC

FIG. 27

5. Disconnect driver:

a. D200 3 in. and D200s 6.5 in. supply units:

Loosen nut (125) below crossbar. Use wrench

to hold lift ring adapter (127) in place and loosen

threaded rod (126) above crossbar with another

wrench. See FIG. 28.

126

125

125

127

FIG. 28: 55 Gallon Platen

b. D60 3 in. supply units: Remove screws (255)

CG

FIG. 26

FIG. 29: D60 with Ram

3A6331G 33

and washers (256) from mounting plate (259).

Using a secure hoist, lift the driver from the

mounting plate (259). See FIG. 29.

259

256

255

Page 34

Repair

Install Driver

To avoid serious injury when installing and removing

the driver, make sure the driver is supported at all

times.

D200 3 in. and D200s 6.5 in. Supply Units

55 gallon platen:

1. Using a capable hoist, insert tie rods into displacement pump and secure driver to pump.

a. See Reconnect Displacement Pump in your

pump package manual.

b. Install threaded rod (126) through center hole in

the crossbar. Install lock washers (124) and

nuts (125) onto threaded rod (126), both above

and below crossbar. Use wrench to hold lift ring

adapter (127) and tighten threaded rod (106)

into lift ring adapter (127) using another wrench.

See FIG. 30.

c. Tighten nut (125) below crossbar to 25 ft-lb (34

N•m) maximum.

2. Connect power to the driver. Follow a-e of step 4 on

page 33 in reverse.

3. Turn the disconnect switch (M) ON.

D60 3 in. Dual Post Supply Unit

1. Using a secure hoist, attach driver to mounting plate

(259) with screws (255) and washers (256). See

FIG. 29 on page 33.

2. See Reconnect Displacement Pump in your pump

package manual.

3. Connect power to the driver. Follow a-e of step 4 on

page 33 in reverse.

Supply Unit Repair

To reduce the risk of serious injury whenever you are

instructed to relieve pressure always follow the

Pressure Relief Procedure on page 22. Do not use

pressurized air to remove the guide sleeve or the

piston.

D200s 6.5 in. Ram Piston Rods

d. Tighten nut (125) above crossbar to lock driver

in place.

126

125

124

125

FIG. 30

Always service both cylinders at the same time. When

you service the lift rod always install new o-rings in the

piston rod seal and ram piston.

Disassemble Piston Rod Seal

1. Follow the Pressure Relief Procedure on page 22.

2. Turn the disconnect switch (M) OFF.

3. Remove the nuts (123) and lockwashers (122) holding the tie bar (219) to the piston rods (132). See

parts illustration on page 38.

4. Remove nuts (303, 305) and washers (302, 304).

See parts illustration on page 44.

127

5. Lift tie bar (219) off of rods.

6. Remove retaining ring (136) by gripping the ring tab

with a pair of pliers and rotating the ring out of its

groove.

7. Remove snap ring (134) and rod wiper (133).

8. Remove guide sleeve (135) by sliding it off of rod

(132). Four 1/4 in -20 holes are provided to ease

removal of the guide sleeve.

34 3A6331G

Page 35

Repair

9. Inspect parts for wear or damage.

134

136

137

133

142

135

132

TI10784A

FIG. 31: 6.5 in. Piston Rod Seal

Assemble Piston Rod Seal

1. Install new o-rings (137,142), rod wiper (133), and

snap ring (134). Lubricate packings with o-ring lubricant.

2. Slide guide sleeve (135) onto rod (132) and push it

into cylinder. Replace retaining ring (136) by feeding

it around the guide sleeve groove.

7. Remove guide sleeve (135) and slide it off piston

rod (132).

NOTICE

Do not tilt the piston rod to one side when removing it

from the base or when installing it. Such movement

can damage the piston or inside surface of the base

cylinder.

8. Carefully lay piston (141) and rod (132) down so rod

will not be bent. Remove bottom retaining ring (138)

and o-ring (139). Remove piston guide band (140).

Slide piston (141) off piston rod (132).

132

139

138

137

141

140

3. Reinstall tie bar (219) using nuts (123) and lockwashers (122). Torque to 40 ft-lb (54 N•m).

4. Reinstall washers (302, 304) and nuts (303, 305).

Disassemble Ram Piston

1. Follow the Pressure Relief Procedure on page 22.

2. Turn the disconnect switch (M) OFF.

3. Remove nuts (123) and lockwashers (122) holding

the tie bar (219) to the piston rods (132). See page

38.

4. Remove nuts (303, 305) and washers (302, 304).

See parts illustration on page 44.

5. Lift tie bar (219) off rods.

6. Remove retaining ring (136) by gripping the ring tab

with a pair of pliers and rotating the ring out of its

groove.

TI10785A

FIG. 32: 6.5 in. Ram Piston

Assemble Ram Piston

1. Install new o-rings (139, 137) on piston rod (132)

and piston (141). Lubricate the piston (141) and

o-rings (139, 137). Reinstall piston (141) and lower

retaining ring (138) onto piston rod (132). Install piston guide band (140) onto piston (141).

2. Carefully insert piston (141) into cylinder and push

rod (132) straight down into cylinder. Add three

ounces of lubricant to each cylinder after inserting

the piston (141).

3. Slide guide sleeve (135) onto piston rod (132).

4. Install retaining ring (134) and tie bar (219). Perform

steps to Disassemble Ram Piston in reverse

order.

3A6331G 35

Page 36

Repair

D200 and D60 3 in. Ram Piston Rods

Always service both cylinders at the same time. When

you service the piston rod always install new o-rings in

the piston rod seal and ram piston.

Disassemble Piston Rod Seal and Bearing

1. Follow the Pressure Relief Procedure on page 22.

2. Access piston rod seal and bearing.

a. For D200 3 in. Ram: Remove nuts (125) and

lockwashers (124) holding the tie bar (219) to

the piston rods (246). Remove nuts (305) and

washers (304). Remove tie bar (219). Refer to

parts illustration on page 40.

b. For D60 3 in. Ram: Ensure ram is in lowest

position. Remove nuts (125) and lockwashers

(254) from piston rods (261). Remove entire

pump package, including the mounting plate

(259) off of the piston rods (261). Secure pump

package so pump and platen will not fall. See

page 45.

D200 and D60 3 in. Rams

245

241

238

243

244

261,

246

WLD

FIG. 33: 3 in. Piston Rod Seal

Assemble Piston Rod Seal and Bearing

218

240

242

3. Remove retaining ring (218).

4. Remove piston rod seal and bearing.

a. Slide end cap (241), pin (238), o-ring (245), and

spring (244) up off of the piston rod (261, 246).

Remove retaining ring (242) and bearing (243)

from end cap (241) and remove o-ring (240).

5. Inspect parts for wear or damage. Replace as necessary.

NOTE: Do not reinstall end cap assembly if the ram

piston (247) needs to be removed from the piston rod.

See the next page for ram piston repair instructions.

See FIG. 33 on page 36.

1. Lubricate o-ring (240) and bottom bearing (243).

a. Install o-ring (240), bottom bearing (243), and

retaining ring (242) into end cap (241).

b. Install new o-ring (245) and pin (238) on end

cap (241). Lubricate o-ring (245) and end cap

(241).

c. Slide spring (244) and end cap (241) on piston

rod (261, 246).

2. Install retaining ring (218).

3. For D200 3 in Ram: Install tie bar (219), washers

(124), and nuts (125).

4. For D60 3 in. Ram: Remount mounting plate (259)

and attach nuts (255) and lockwashers (256).

Torque to 40 ft-lb (54 N•m).

36 3A6331G

Page 37

Repair

Disassemble Ram Piston

1. Complete steps 1-4 from Disassemble Piston Rod

Seal and Bearing to remove the end cap from the

piston rod.

NOTICE

Do not tilt the piston rod to one side when removing it

from the base or when installing it. Such movement

can damage the piston or inside surface of the base

cylinder.

2. Carefully lay piston (247) and rod (261, 246) down

so piston rod will not be bent. Remove nut (125),

washer (124), piston (247), outer o-ring (245), and

inner o-ring (239).

3. Inspect parts for wear or damage. Replace as necessary.

261, 246

245

Assemble Ram Piston

1. Install new o-rings (245, 239) and lubricate piston

(247) and o-rings.

2. Apply medium strength thread sealant. Install piston

(247), washer (124), and nut (125) on piston rod

(261, 246).

3. Carefully insert piston (247) into cylinder and push

piston rod (261, 246) straight down into cylinder.

4. Slide spring (244) and end cap (241) onto piston rod

(261, 246).

5. For D200 3 in. Rams: Install retaining ring (218), tie

bar (219), washers (124), and nuts (125).

6. For D60 3 in. Rams: Install retaining ring (218) and

install mounting plate (259) with nuts (255) and

washers (256) with pump package and platen.

239

FIG. 34: 3 in. Ram Piston

247

124

125

TI10521A

3A6331G 37

Page 38

Parts

Parts

D200s 6.5 in. Supply Units

Model 25E201 Shown

141

145

146

148

150

149

147

134

142

105

125

126

124

123

121

122

108

107

143

108

107

115

101

131

110

104

Detail A

114

112

144

149

116

135

152

153

152

136

111

155

154

117

119

118

136

106

160

106

134

132

107,108

Detail B

106

103,

113

102,

109

133

130

131

38 3A6331G

Page 39

D200s 6.5 in. Supply Units, 25E201

Parts

Ref. Part Description Qty.

101 102040 NUT, lock, hex 1

102 110755 WASHER, plain 1

103 117017 WASHER 1

104 15V954 LABEL, valve, shutoff, air control 1

105 16W583 LABEL, cross bar 1

106 C12509 TUBE, nylon, rnd 15

107 100016 WASHER, lock 15

108 121112 SCREW, cap, socket head 15

109 121250 SCREW, shch 1

110 255375 BRACKET, mounting, painted 1

111 255438 RAM, 6.5 in. 1

112 255633 BRACKET, pendant pivot, painted 1

113 121253 KNOB, display adj., ram pkgs 1

114 255639 BRACKET, mounting, assembly 1

115 24C264 CONTROL, air, ram, hyd driver 1

116 25E207 JUNCTION BOX, ram mounted,

e-drive

117 C19853 SCREW, cap, socket hd 2

118 C32467 STOP, drum 2

119 C38185 WASHER, lock 2

120 070408 SEALANT, pipe, sst 1

121 15M531 ROD, follower 2

122 101015 WASHER, lock 2

123 C19187 NUT, nex 2

124 101533 WASHER, spring lock 2

125 101535 NUT, full hex 2

126 15J992 ROD, threaded 1

127 15J991 ADAPTER, lift ring 1

128 15J993 RING, lift, plate 1

129 073028 LUBRICANT, anti-seize 1

130 130787

PKG

131 123656 CABLE, spin, male/female 1

SENSOR, barrel, m18 x 1, pnp, nc 1

Ref. Part Description Qty.

132 24D006 ACTUATOR, sensor, low/empty,

wmmlt, pt

133 17Y704

PKG

134 114958 STRAP, tie 7

135 196548 LABEL, caution (Junction Box) 1

136 15J074 LABEL, safety, crush & pinch 4

141 113939 NUT, jam, hex 2

142 113933 WASHER, lock, helical 2

143 15M538 BEAM, tie, 6.5 in. ram 1

144 C32401 ROD 2

145* C03043 RING, snap 2

146* C31001 WIPER, rod 2

147 25T845 SLEEVE, guide 2

148* C32409 RING, retaining 2

1

149* C38132 PACKING, o-ring 4

150* C02073 PACKING, quad ring 2

152* C20417 RING, retaining 4

153* 158776 PACKING, o-ring 2

154* C32408 BAND, guide 2

155 C32405 PISTON, elevator air 2

157 100040 PLUG, pipe 2

160 114153 FITTING, elbow, male, swivel 2

Replacement safety labels, tags, and cards are

available at no cost.

* Parts included in Supply Units Repair Kit 918432

(purchase separately).

Not shown.

BRACKET, lvl sensor, dual,

d200s. pnt

1

1

3A6331G 39

Page 40

Parts

D200 3 in. Supply Units

Model 25E200 Shown

108

107

115

218

245

246

116

245

240

243

242

238

241

244

225

135

224

220

125

124

201,

213,

107

219

107,

108

205,

217

226

105

125

124

126

252

108

107

208

101

106

107,108

136

112

133

104

Detail A

114

102,

109

103,113

107,108

221

106

Detail B

132

247

239

124

125

40 3A6331G

117

119

118

106

223

131

130

134

Page 41

D200 3 in. Supply Units, 25E200

Parts

Ref. Part Description Qty.

101 102040 NUT, lock, hex 1

102 110755 WASHER, plain 1

103 117017 WASHER 1

104 15V954 LABEL, valve, shutoff, air control 1

105 16W583 LABEL, cross bar 1

106 C12509 TUBE, nylon, rnd 15

107 100016 WASHER, lock 16

108 121112 SCREW, cap, socket head 12

109 121250 SCREW, shcs 1

112 255633 BRACKET, pendant pivot, painted 1

113 121253 KNOB, display adj., ram pkgs 1

114 255639 BRACKET, mounting, assembly 1

115 24C264 CONTROL, air, ram, hyd driver 1

116 25E207 JUNCTION BOX, ram mounted,

e-drive

117 C19853 SCREW, cap, socket hd 2

118 C32467 STOP, drum 2

119 C38185 WASHER, lock 2

120 070408 SEALANT, pipe, sst 1

124* 101533 WASHER, spring lock 6

125* 101535 NUT, full hex 6

126 15J992 ROD, threaded 1

127 15J991 ADAPTER, lift ring 1

128 15J993 RING, lift, plate 1

129 073028 LUBRICANT, anti-seize 1

130 130787

PKG

131 123656 CABLE, spin, male/female 1

132 255381 ACTUATOR, sensor, low/empty,

133 17Y702

PKG

134 114958 STRAP, tie 7

135 196548 LABEL, caution (Junction Box) 1

136 15J074 LABEL, safety, crush & pinch 4

SENSOR, barrel, m18 x 1, pnp, nc 1

painted

BRACKET, lvl sensor, dual, d200,

pnt

Ref. Part Description Qty.

201 100014 SCREW, cap, hex hd 4

205 108050 WASHER, lock, spring 6

208 189559 CAP, end 2

213 100015 NUT, hex mscr 4

217 121518 SCREW, cap, shc 6

218* 127510 RING, retaining, internal 2

219 167646 BEAM, tie 1

220 255286 RAM, weldment, 3” 1

221 255296 BRACKET, mounted, painted 1

223 128863 FITTING, elbow 2

224 15W703 BRACKET, mounting, btm 1

225 16A314 BRACKET, mounting, acc. box 1

226 16A566 BRACKET, mounting, ram 1

1

1

1

234 070303 LUBRICANT, grease 1

235 073021 LUBRICANT, oil 1

237 070615 SEALANT, thread, med strength 1

238* 121259 BEARING, ram end cap 1

239* 156401 PACKING, o-ring 1

240* 156698 PACKING, o-ring 1

241* 15F453 RETAINER, retaining ring 1

242 15M295 BEARING, ram end cap 1

243 15U979 PIN, spring, straight 1

244* 160138 SPRING, compression 1

245* 160258 PACKING, o-ring, buna-n 2

246 167651 ROD, piston ram 1

247 183943 PISTON 1

251 C20987 PACKING, o-ring 1

252 167652 ROD, tie ram 2

Replacement safety labels, tags, and cards are

available at no cost.

* Parts included in Supply Units Repair Kit 255687 (pur-

chase separately).

Not shown.

3A6331G 41

Page 42

Parts

D60 3 in. Supply Units

Model 25E199 Shown

218

245

240

243

242

260

238

241

244

107,108

225

256

255

108

125

254

259

114

107

101

106

112

136

Detail A

254,125

108

107

221

115

104

102,

109

261

245

116

247

239

125

205,

217

124

135

224

201,107,

213

257

226

117

119

118

258

106

223

107,108

106

132

223

Detail B

133

103,113

107,108

134

130

131

134

107,108

42 3A6331G

Page 43

D60 3 in. Supply Units, 25E199

Parts

Ref. Part Description Qty.

101 102040 NUT, lock, hex 1

102 110755 WASHER, plain 1

103 117017 WASHER 1

104 15V954 LABEL, valve, shutoff, air control 1

106 C12509 TUBE, nylon, rnd 2

107 100016 WASHER, lock 18

108 121112 SCREW, cap, socket head 14

109 121250 SCREW, shch 1

112 255633 BRACKET, pendant pivot, painted 1

113 121253 KNOB, display adj., ram pkgs 1

114 255639 BRACKET, mounting, assembly 1

115 24C264 CONTROL, air, ram, hyd driver 1

116 25E207 JUNCTION BOX, ram mounted,

E-drive

117 C19853 SCREW, cap, socket hd 2

118 C32467 STOP, drum 2

119 C38185 WASHER, lock 2

120 070408 SEALANT, pipe, sst 1

124* 101533 WASHER, spring lock 1

125* 101535 NUT, full hex 3

130 130787

SENSOR, barrel, m18 x 1, pnp, nc 1

PKG

1313 123673 HARNESS 1

132 255381 ACTUATOR, sensor, low/empty,

painted

133 17Y702

PKG

BRACKET, lvl sensor, dual, D200,

pnt

134 114958 STRAP, tie 4

135 196548 LABEL, caution (Junction Box) 1

136 15J074 LABEL, safety, crush & pinch 4

201 100014 SCREW, cap, hex hd 4

205 108050 WASHER, lock, spring 6

213 100015 NUT, hex mscr 4

217 121518 SCREW, cap, shc 6

Ref. Part Description Qty.

218* 127510 RING, retaining, internal 2

221 255296 BRACKET, mounted, painted 1

223 128863 FITTING, elbow 2

224 15W703 BRACKET, mounting, btm 1

225 16A314 BRACKET, mounting, acc. box 1

226 16A566 BRACKET, mounting, ram 1

234 070303 LUBRICANT, grease 1

235 073021 LUBRICANT, oil 1

237 070615 SEALANT, thread, med strength 1

238* 121259 BEARING, ram end cap 1

239* 156401 PACKING, o-ring 1

240* 156698 PACKING, o-ring 1

241* 15F453 RETAINER, retaining ring 1

1

242 15M295 BEARING, ram end cap 1

243 15U979 PIN, spring, straight 1

244* 160138 SPRING, compression 1

245* 160258 PACKING, o-ring, buna-n 2

247 183943 PISTON 1

254 104395 WASHER, lock, tooth, external 2

255 110141 SCREW, cap, sch 4

256 100133 WASHER, lock, 3/8 4

257 256734 RAM, dp, weldment 1

258 16T421 ADAPTER, pipe hex 1

259 17L703 BRACKET, shelf, D60, 3400/6500 1

1

1

17X806

260

PKG

BRACKET, cable track, D60 ram 1