Graco ChemSafe 515 Instructions - Parts Manual

Instructions-Parts

ChemSafe™ 515

Air-Operated

1/2–inch hig

Not approved for use in European explosive atmosphere locations.

100 psi (0.7 MPa, 7.0 bar) Maximum Air

Supply Pressure

100 psi (0.7 MPa, 7.0 bar) Maximum

Fluid Working Pressure

h purity pump for industrial applications. For professional use only.

Important

Read all warnings and instructions in this manual. Save these

instructions.

Safety Instructions

Diaphragm Pump

334794E

EN

PROVEN QUALITY. LEADING TECHNOLOGY.

Contents

Warnings ........................................................... 3

Configuration Number Matrix............................... 6

Installation.......................................................... 8

General Information ..................................... 8

Tighten Bolts ............................................... 8

Tips to Reduce Cavitation............................. 8

Mount The Pump ......................................... 9

Ground The System..................................... 10

Air Lines...................................................... 10

Air Exhaust Ventilation ................................. 11

Fluid Supply Line ......................................... 12

Fluid Outlet Line........................................... 12

Operation........................................................... 13

Tighten Bolts ............................................... 13

Flush the Pump Before First Use .................. 13

Start and Adjust the Pump............................ 13

Pressure Relief Procedure............................ 14

Pump Shutdown .......................................... 14

Maintena

nce ...................................................... 15

Maintenance Schedule................................. 15

Lubrication................................................... 15

Tighten Threaded Connections..................... 15

Flushing and Storage ................................... 15

Troubleshooting.................................................. 16

Repair................................................................ 18

Disassembl

Disassembl

Replace the

Reassemble

Reassemble

Torque Instructions............................................. 23

Parts.................................................................. 24

Kits.................................................................... 27

Dimensions ........................................................ 28

Performance Charts............................................ 29

Technica

l Data ................................................... 31

e the Fluid Section...................... 18

e the Center Section ................... 19

Air Motor................................... 19

the Center Section.................... 20

the Fluid Section....................... 21

2

334794E

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The

exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific

risks. When these symbols appear in the body of this manual or on warning labels, refer back to these

Warnings. Product-specific hazard symbols and warnings not covered in this section may appear throughout

the body of this manual where applicable.

WARNING

FIRE AND EX

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help

prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and

plastic drop cloths (potential static arc).

•Keepwork

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable

fumes are present.

• Ground all equipment in the work area. See Grounding instructions.

•Useonly

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless

they are antistatic or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use

equipment until you identify and correct the problem.

• Keepaw

• Route exhaust away from all ignition sources. If diaphragm ruptures, fluid may be exhausted

with air.

c charge may build up on plastic parts during cleaning and could discharge and ignite

Stati

flamma

• Clean plastic parts only in well ventilated area.

• Do not

• Do not operate electrostatic guns in equipment work area.

ble vapors. To help prevent fire and explosion:

PLOSION HAZARD

area free of debris, including solvent, rags and gasoline.

grounded hoses.

orking fire extinguisher in the work area.

cleanwithadrycloth.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the equipment, leaks, or ruptured components can splash in the eyes or on skin

and cause serious injury.

low the Pressure Relief Procedure when you stop spraying/dispensing and before

•Fol

aning, checking, or servicing equipment.

cle

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

334794E 3

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can ca

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed

system compo

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data

in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete

information about your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

•Turnoffall

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals

and create safety hazards.

•Makesure

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kin

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

THERMAL

Fluids subjected to heat in confined spaces, including hoses, can create a rapid rise in pressure

due to the thermal expansion. Over-pressurization can result in equipment rupture and serious

injury.

use death or serious injury.

the maximum working pressure or temperature rating of the lowest rated

nent. See Technical Data in all equipment manuals.

equipment and follow the Pressure Relief Procedure when equipment is not in use.

all equipment is rated and approved for the environment in which you are using it.

k or over bend hoses or use hoses to pull equipment.

EXPANSION HAZARD

• Open a valve to relieve the fluid expansion during heating.

• Replace hoses proactively at regular intervals based on your operating conditions.

TIC PARTS CLEANING SOLVENT HAZARD

PLAS

Many solvents can degrade plastic parts and cause them to fail, which could cause serious

injury or property damage.

• Use only compatible water-based solvents to clean plastic structural or pressure-containing

parts.

•SeeTechnical Data in this and all other equipment instruction manuals. Read fluid and

solvent manufacturer’s MSDSs and recommendations.

4

334794E

WARNING

TOXIC FLUID OR FUMES HAZARD

Warnings

Toxic fluids o

inhaled, or s

• Read MSDSs to know the specific hazards of the fluids you are using.

• Route exhaus

the air.

• Store hazardous fluid in approved containers, and dispose of it according to applicable

guidelines.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid

severe burns:

• Do not touch hot fluid or equipment.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury,

including eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective

equipment includes but is not limited to:

•Protect

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent

manufacturer.

r fumes can cause serious injury or death if splashed in the eyes or on skin,

wallowed.

t away from work area. If diaphragm ruptures, fluid may be exhausted into

ive eyewear, and hearing protection.

334794E 5

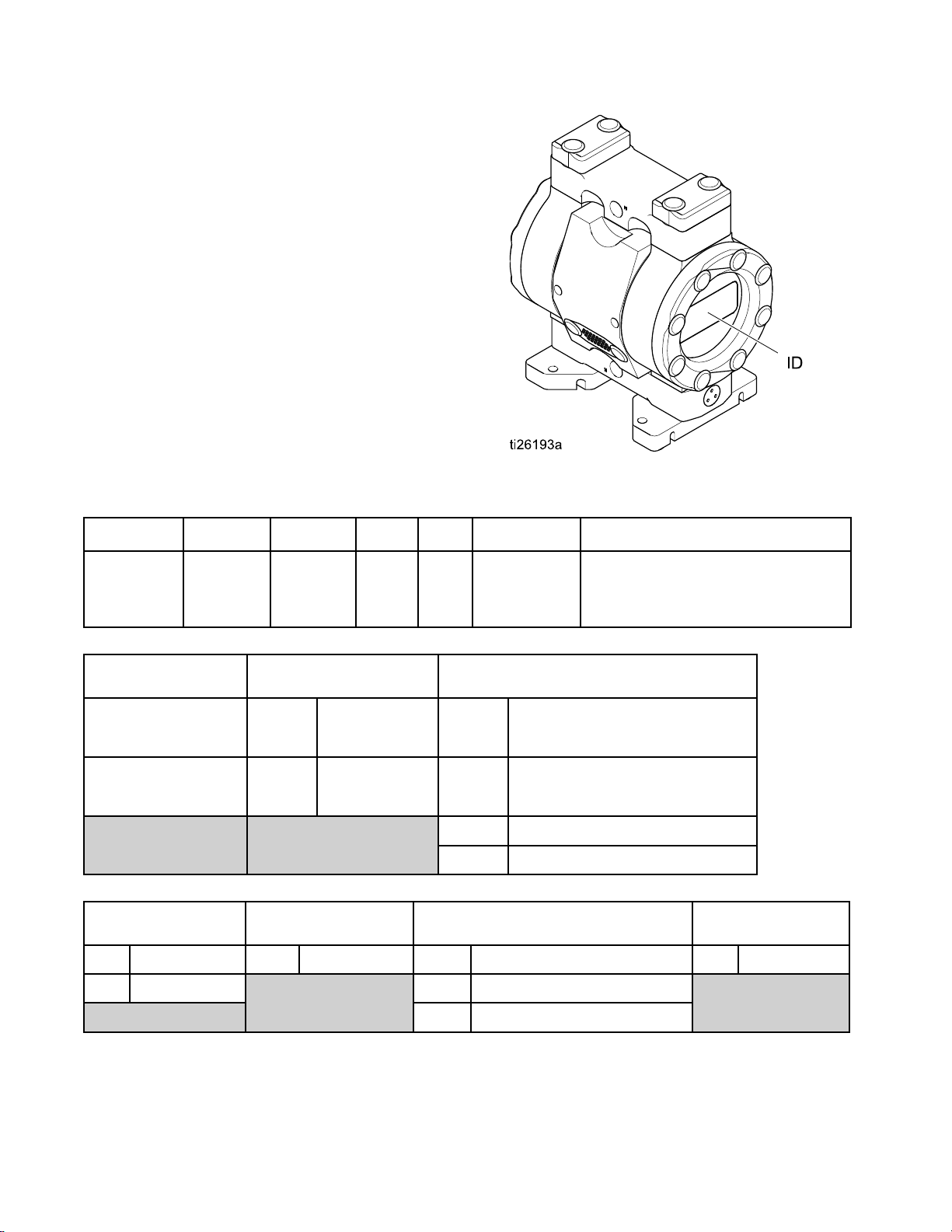

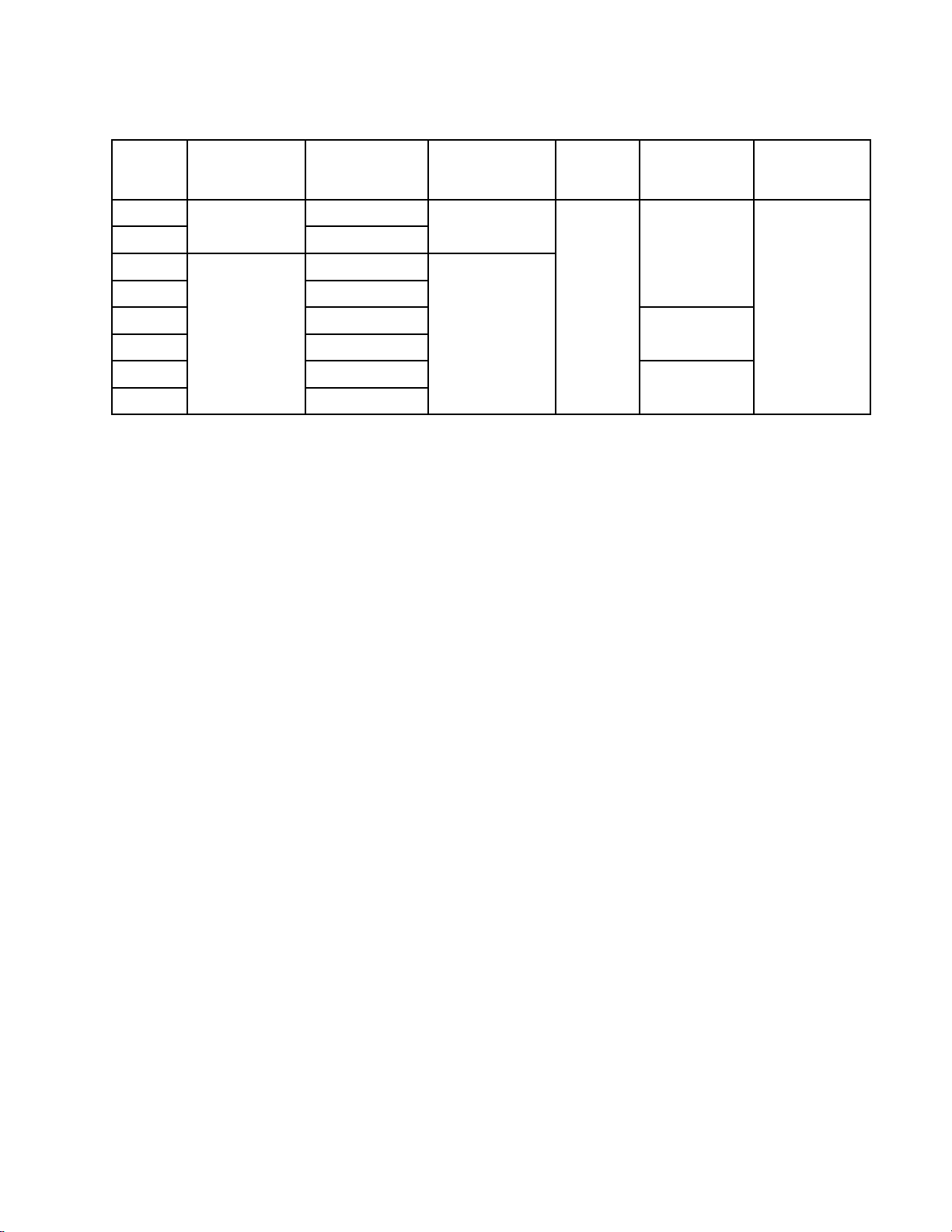

Configuration Nu

mber Matrix

Configuration

Number

Matrix

Check the iden

Configuratio

following ma

pump.

Sample Configuration Number: 515PT-P01APT3PTPTPOPT

515PT P01A PT3

Pump

Model

tification plate (ID) for the

n Number of your pump. Use the

trix to define the components of your

PT PT

Center

Section

and Air

Valve

Fluid

Covers

and

Manifolds

Seats

PO

Balls Diaphragms

PT

Manifold and Seat Seals

Pump

515 PT

1/2 in.

PTFE

515 UH

1/2 in. UHMWPE

Material

Seat

PTFE

PT

UHMWPE

UH

Center Section and Air

Valve Material

opylene

P01A

P03A

Ball Material Diaphragm Material

PT

Polypr

center

air inl

Polypropylene

center with

bspt air inlet

PTFE

with npt

et

Fluid Covers and Manifolds

PT3

PT4

UH3

UH4

BN

EP

PO

PTFE, n

PTFE, bspt

UHMW, npt

UHMW

Buna N

EPDM

PTFE/EPDM Overmolded

pt

,bspt

fold and Seat

Mani

Material

Seal

PTFE

PT

6 334794E

Models

Configuration Nu

mber Matrix

Model Pump

24X426

24X425

24X498

24X497

24X540

24X541

24X496

24X495

1/2 in. PTFE

1/2 in.

UHMWPE

Air & Fluid

Connection

Threads

bspt

npt

bspt

npt

bspt

npt

bspt

npt

Fluid Covers,

Seats, &

Manifolds

PTFE

UHMW

Balls Diaphragm

PTFE/EPDM

Overmolded

PTFE

EPDM

Buna N

Manifold Seal

PTFE

334794E

7

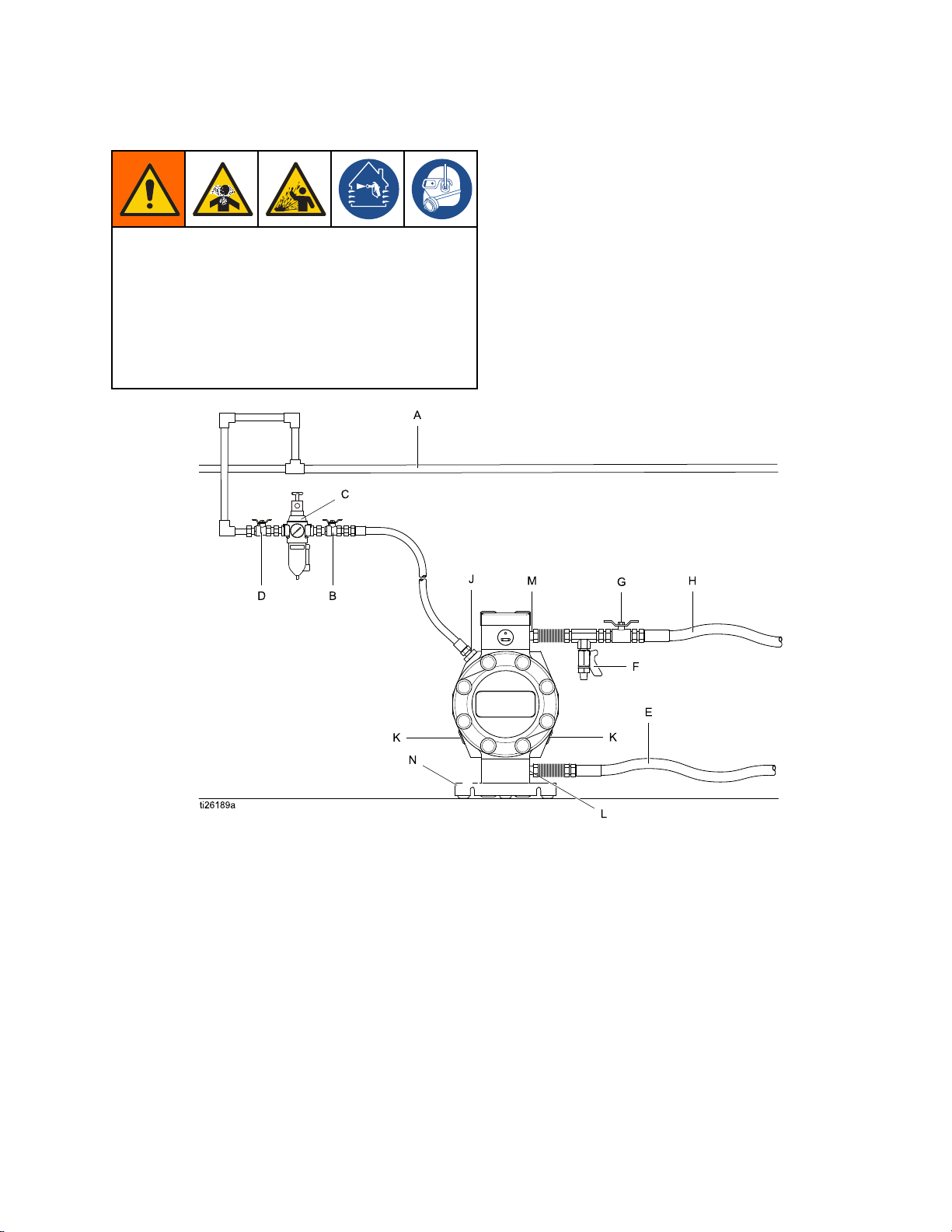

Installation

Installation

General Information

The Typical I

selecting an

your Graco di

system to sui

Graco Parts

are adequat

system’s re

Reference letters in the text, for example (A), refer to

the callouts in the figures.

Variations in color between the plastic components

of this pump are normal. Color variation does not

affect the performance of the pump.

Storage: P

upon deli

Flushing

nstallation shown is only a guide for

d installing system components. Contact

stributor for assistance in planning a

t your needs. Always use Genuine

and accessories. Be sure all accessories

ely sized and pressure rated to meet the

quirements.

umps that are not put into operation

very must be stored appropriately. See

and Storage, page 15.

Tighten Bolts

Before m

first tim

Remove

Torque

Replac

operat

pump ha

in ther

or if t

tempe

ounting and using the pump for the

e, check and retorque all external bolts.

all protective bolt covers (37). Follow

Instructions, page 23, to tighten all bolts.

e the bolt covers (37). After the first day of

ion, retorque the bolts. Retorque the bolts if the

s been idle for an extended time, been used

mal cycling applications, been disassembled,

here is a large difference between environmental

ratures and fluid temperatures.

Tips to Reduce Cavitation

Cavitation i

collapse of b

or excessive

including pi

balls, and s

the pump. Ca

both result

Cavitation depends on the vapor pressure of the

pumped liquid, the system suction pressure, and the

velocity pressure. It can be reduced by changing any

of these factors.

1. Reduce vapor pressure: Decrease the

temperature of the pumped liquid.

2. Increase suction pressure:

a. Lower the

b. Reduce t

c. Increas

3. Reduce

the pum

Pumped liquid viscosity is also very important but

normally is controlled by factors that are process

dependent and cannot be changed to reduce

cavitation. Viscous liquids are more difficult to pump

and more prone to cavitation.

n an AODD pump is the formation and

ubbles in the pumped liquid. Frequent

cavitation can cause serious damage,

tting and early wear of fluid chambers,

eats. It may result in reduced efficiency of

vitation damage and reduced efficiency

in increased operating costs.

installed position of the pump

relative

piping.

length t

fittings

to the liquid level in the supply.

he friction length of the suction

Remember that fittings add friction

o the piping. Reduce the number of

to reduce the friction length.

e the size of the suction piping.

liquid velocity: Slow the cyclic rate of

p.

Graco recommends taking all the above factors

into account in system design. To maintain pump

efficiency, supply only enough air pressure to the

pump to achieve the required flow.

o distributors can supply site specific

Grac

estions to improve pump performance and

sugg

ce operating costs.

redu

8 334794E

Mount The Pump

To avoid serious injury from toxic fluid or fumes:

• Ventilate to a remote area. The pump

exhaust air may contain contaminants. See

Air Exhaust Ventilation, page 11.

• Never move or lift a pump under pressure. If

dropped, the fluid section may rupture. Always

follow the Pressure Relief Procedure, page 14,

before moving or lifting the pump.

Installation

1. Be sure the mounting surface can support the

weight of the pump, hoses, and accessories, as

well as the stress caused during operation.

2. For all mountings, be sure the pump is secured

with screws through the mounting feet. Always

mount the pump upright.

3. Make sure the surface is flat and that the pump

doesn’t wobble.

4. For ease of operation and service, mount the

pump so air valve, air inlet, fluid inlet and fluid

outlet ports are easily accessible.

Accessories/Components Not Supplied System Components

A Air supply line J

B

C Air filter/regulator assembly

D

E

F

G Fluid shutoff valve

H

Bleed-type master air valve (required

for your pump)

Master air valve (to isolate the

filter/regulator for service)

Grounded flexible fluid supply line

Fluid drain valve (required for your

pump)

Grounded, flexible fluid outlet line

K

L Fluid inlet port

M Fluid outlet port

N

Air inlet port (not visible)

Exhaust port and muffler

Mounting feet

334794E 9

Installation

Ground The Sys

The equipment must be grounded to reduce the

risk of static sparking. Static sparking can cause

fumes to ignite or explode. Grounding provides an

escape wire for the electrical current.

• Always ground the entire fluid system as

described below.

• The pumps are not conductive. Any system

used to pump flammable fluids must be properly

grounded.

• Follow your local fire codes.

Before operating the pump, ground the system as

explained below.

• Pump: Always ground the entire fluid system by

making sure the fluid has an electrical path to a

true earth ground.

• Air and fluid hoses: Use only flexible grounded

hoses with a maximum of 500 ft. (150 m) combined

hose length to ensure grounding continuity.

• Air compressor: Follow manufacturer’s

recommendations.

• Fluid supply container: Follow local code.

• Solvent pails used when flushing: Follow local

code. Use only conductive metal pails, placed

on a grounded surface. Do not place the pail

on a nonconductive surface, such as paper or

cardboard, which interrupts grounding continuity.

tem

Air Lines

1. Install an air

the fluid press

thesameasthe

2. Locate a bleed

the pump and u

sure the valv

and located d

Trapped air can cause the pump to cycle

unexpectedly, which could result in serious

injury from splashing.

3. Locate ano

from all a

them duri

4. An air lin

moisture

5. Install a

the acce

pump air

ID.Ifah

use a lar

regulator and gauge (C) to control

ure. The fluid stall pressure will be

setting of the air regulator.

-typemasterairvalve(B)closeto

se it to relieve trapped air. Be

e is easily accessible from the pump

ownstream from the regulator.

ther master air valve (D) upstream

ir line accessories and use it to isolate

ng cleaning and repair.

e filter (C) removes harmful dirt and

from the compressed air supply.

grounded, flexible air hose (A) between

ssories and the 1/4 npt(f) or 1/4 bspt

inlet. Use a hose with a minimum 1/4 in.

ose longer than 10 ft. (3 m) is required,

ger diameter hose.

Check your system electrical continuity after the

initial installation, and then set up a regular schedule

for checking continuity to be sure proper grounding

is maintained.

10 334794E

Loading...

Loading...