Page 1

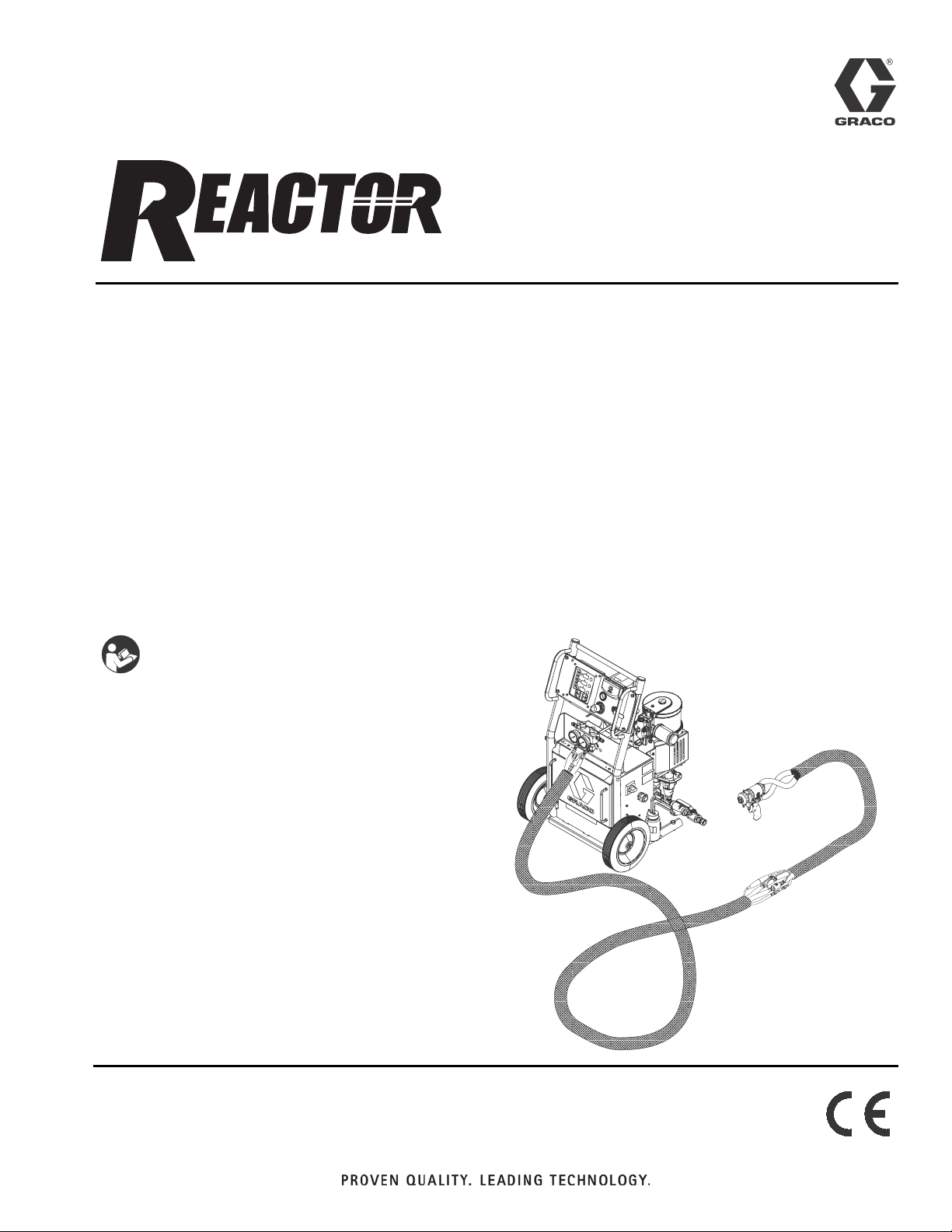

Repair-Parts

®

A-25

PLURAL COMPONENT PROPORTIONER

3A1570A

Air operated, electrically heated, plural component proportioner

For spraying or dispensing 1:1 ratio polyurethane foam formulations and other 1:1 fast

setting materials.

Not for use in explosive atmospheres or hazardous locations.

This model is field-configurable to the following supply voltages:

230 V, 1 Phase

230 V, 3 Phase

380 V, 3 Phase

2000 psi (14 MPa, 138 bar) Maximum Fluid Working Pressure

80 psi (550 kPa, 5.5 bar) Maximum Air Working Pressure

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

EN

See page 3 for model information, including maximum

working pressure and approvals.

ti16811a

Page 2

Contents

Proportioner Models . . . . . . . . . . . . . . . . . . . . . . . . 3

Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Important Two-Component Material Information . 7

Isocyanate Conditions . . . . . . . . . . . . . . . . . . . . . 7

Material Self-ignition . . . . . . . . . . . . . . . . . . . . . . 7

Keep Components A and B Separate . . . . . . . . . 7

Moisture Sensitivity of Isocyanates . . . . . . . . . . . 7

Foam Resins with 245 fa Blowing Agents . . . . . . 7

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . 8

DataTrak Diagnostic Codes . . . . . . . . . . . . . . . . . 9

Temperature Control Diagnostic Codes . . . . . . . 9

E01: High fluid temperature . . . . . . . . . . . . . . . 10

E02: High zone current . . . . . . . . . . . . . . . . . . . 11

E03: No zone current . . . . . . . . . . . . . . . . . . . . 11

E04: Fluid Temperature Sensor (FTS) or

thermocouple disconnected . . . . . . . . . . . . 11

E05: Control board over temperature . . . . . . . . 12

E06: Communication cable unplugged . . . . . . . 12

Communication Diagnostic Codes . . . . . . . . . . 12

E30: Momentary loss of communication . . . . . . 12

E99: Loss of communication . . . . . . . . . . . . . . . 12

Before Beginning Repair . . . . . . . . . . . . . . . . . . . 13

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 13

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Park . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pumps and Pressures . . . . . . . . . . . . . . . . . . . . 15

Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Hose Heat System . . . . . . . . . . . . . . . . . . . . . . 20

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Disconnect Pump . . . . . . . . . . . . . . . . . . . . . . . 22

Connect Pump . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Remove Air Motor . . . . . . . . . . . . . . . . . . . . . . . 24

Install Air Motor . . . . . . . . . . . . . . . . . . . . . . . . . 24

Recirculation / Over Pressure Relief Block . . . . 25

Air Inlet Filter / Water Separator (Auto Drain) . . 25

Temperature Control Module . . . . . . . . . . . . . . . 26

Primary Heater . . . . . . . . . . . . . . . . . . . . . . . . . 28

Heated Hose . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Fluid Temperature Sensor (FTS) . . . . . . . . . . . . 32

Pump Lubrication System . . . . . . . . . . . . . . . . . 35

Fluid Inlet Strainer Screen . . . . . . . . . . . . . . . . . 36

Temperature Display . . . . . . . . . . . . . . . . . . . . . 36

Replace DataTrak Battery or Fuse . . . . . . . . . . 38

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Recommended Spare Parts . . . . . . . . . . . . . . . . . 39

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Control Panel, 262575 . . . . . . . . . . . . . . . . . . . . 44

Temperature Control . . . . . . . . . . . . . . . . . . . . . 45

Wheel Kit, 262695 . . . . . . . . . . . . . . . . . . . . . . . 45

Fluid Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Fluid Inlet Kit, 262695 . . . . . . . . . . . . . . . . . . . . 46

6 kw Dual Zone Heater, 24J788 . . . . . . . . . . . . 47

A-25 Air Motor Pump Assembly, 262573 . . . . . . 48

Air Tubing Connections . . . . . . . . . . . . . . . . . . . 49

Breaker Module, 262576 . . . . . . . . . . . . . . . . . . 50

Reactor A-25 Wiring Schematic . . . . . . . . . . . . . . 51

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 56

2 3A1570A

Page 3

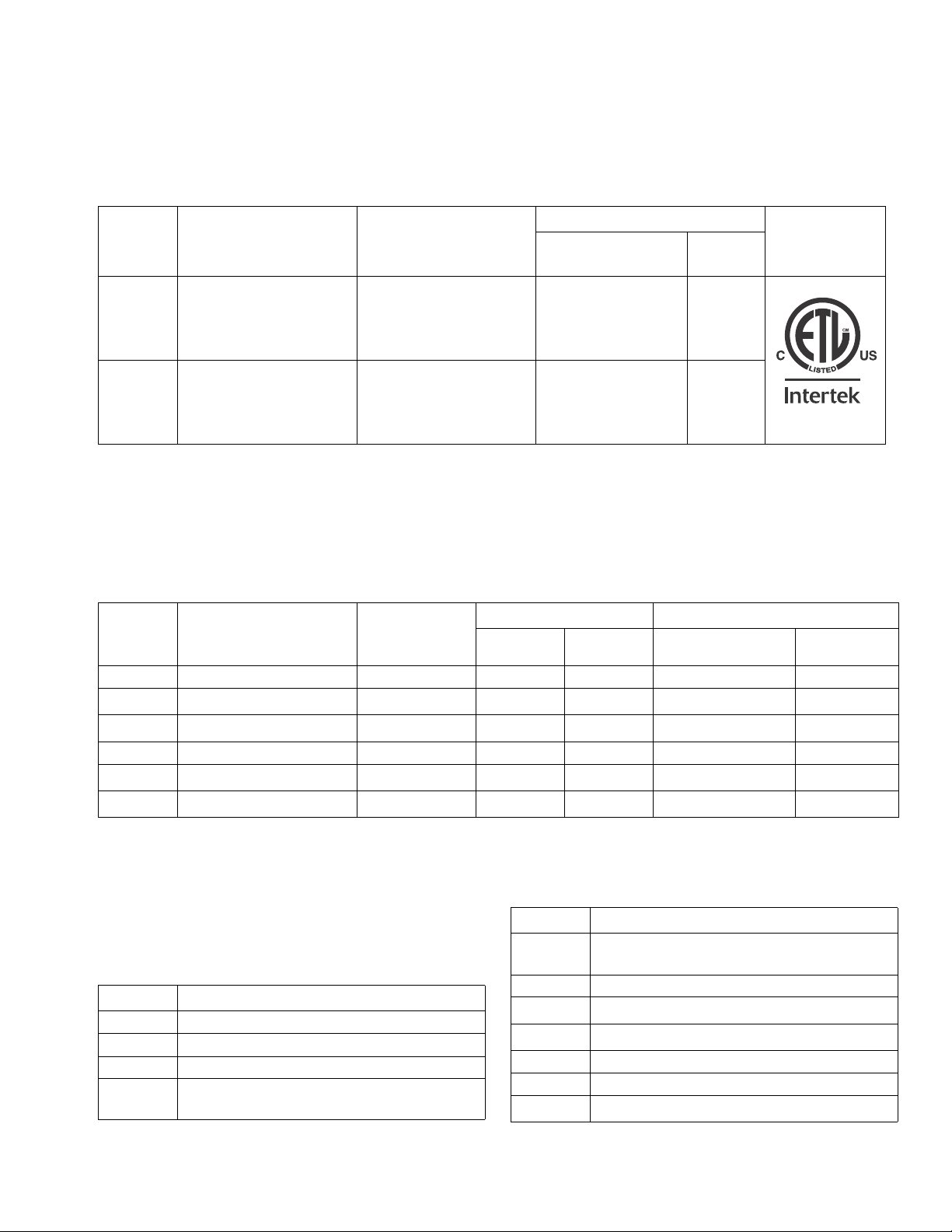

Proportioner Models

All proportioners can be configured to operate on 380V (4 wire), 230V (3 wire), or 230V 1Ø.

Proportioner Models

Maximum Fluid Working

Pressure

Part No.

262572 2000 psi (14, 138) 80 psi (550, 5.5) --- ---

262614 2000 psi (14, 138) 80 psi (550, 5.5) 24A592

Only available in Asia.

psi (MPa, bar)

Maximum Air Working

Set Pressure

psi (kPa, bar)

Includes:

DataTrak

(cycle count only)

Wheels

Systems

All systems include a proportioner, spray gun, and 60 ft (18.3 m) of heated hose.

Part

P22614

AP2614

CS2614

P22572

AP2572

CS2572

Maximum Working

Pressure

psi (MPa, bar)

2000 (14, 138)

2000 (14, 138)

2000 (14, 138)

2000 (14, 138)

2000 (14, 138)

2000 (14, 138)

Proportioner

262614

262614

262614

262572

262572

262572

Heated Hose Gun

50 ft (15 m) 10 ft (3 m) Model Part

246678 246050

246678 246050

246678 246050

246678 246050

246678 246050

246678 246050

Probler P2 GCP2R1

Fusion

Fusion

Probler P2 GCP2R1

Fusion

Fusion

™

™

™

™

AP

CS

AP

CS

Approvals

3172585

246101

CS01RD

246101

CS01RD

Related Manuals

Manuals are available at www.graco.com.

Component manuals in English:

Manual Description

3A1569

309577

309815

309827

3A1570A 3

Reactor A-25 Proportioner, Operation

Proportioning Pump, Repair-Parts

Feed Pump Kit, Instructions-Parts

Feed Pump Air Supply KIt, Instruc-

tions-Parts

Manual Description

309852

309572

309550

312666

313213

313541

312796

Circulation and Return Tube Kit, Instructions-Parts

Heated Hose, Instructions-Parts

Fusion

Fusion

Probler P2 Spray Gun, Instructions-Parts

DataTrak Kits, Installation-Parts

NXT

™

AP Spray Gun, Instructions-Parts

™

CS Spray Gun, Instructions-Parts

®

Air Motor, Instructions-Parts

Page 4

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and

warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric

shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing or

installing equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear chemically impermeable gloves when spraying, dispensing, or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area

of the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of

toxic fumes, and burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe burns:

• Do not touch hot fluid or equipment.

4 3A1570A

Page 5

Warnings

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes are

present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment until

you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Engage trigger lock when not spraying.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

3A1570A 5

Page 6

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about

your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment and

follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical

reaction and equipment rupture. Failure to follow this warning can result in death, serious injury, or

property damage.

• Do not use 1,1,1-trichloroethylene, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier

for compatibility.

THERMAL EXPANSION HAZARD

Fluids subjected to heat in confined spaces, including hoses, can create a rapid rise in pressure due to

the thermal expansion. Over-pressurization can result in equipment rupture and serious injury.

• Open a valve to relieve the fluid expansion during heating.

• Replace hoses proactively at regular intervals based on your operating conditions.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure and disconnect all power sources.

6 3A1570A

Page 7

Important Two-Component Material Information

Important Two-Component Material Information

Isocyanate Conditions

Spraying or dispensing materials containing

isocyanates creates potentially harmful mists, vapors,

and atomized particulates.

Read material manufacturer’s warnings and material

MSDS to know specific hazards and precautions

related to isocyanates.

Prevent inhalation of isocyanate mists, vapors, and

atomized particulates by providing sufficient

ventilation in the work area. If sufficient ventilation is

not available, a supplied-air respirator is required for

everyone in the work area.

To prevent contact with isocyanates, appropriate

personal protective equipment, including chemically

impermeable gloves, boots, aprons, and goggles, is

also required for everyone in the work area.

Material Self-ignition

Some materials may become self-igniting if applied

too thickly. Read material manufacturer’s warnings

and material MSDS.

Moisture Sensitivity of Isocyanates

Isocyanates (ISO) are catalysts used in two component

foam and polyurea coatings. ISO will react with moisture

(such as humidity) to form small, hard, abrasive crystals,

which become suspended in the fluid. Eventually a film

will form on the surface and the ISO will begin to gel,

increasing in viscosity. If used, this partially cured ISO

will reduce performance and the life of all wetted parts.

NOTE: The amount of film formation and rate of crystallization varies depending on the blend of ISO, the

humidity, and the temperature.

To prevent exposing ISO to moisture:

• Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere. Never

store ISO in an open container.

• Keep the ISO lube pump reservoir (if installed) filled

with Graco Throat Seal Liquid (TSL), Part 206995.

The lubricant creates a barrier between the ISO and

the atmosphere.

• Use moisture-proof hoses specifically designed for

ISO, such as those supplied with your system.

• Never use reclaimed solvents, which may contain

moisture. Always keep solvent containers closed

when not in use.

• Always lubricate threaded parts with ISO pump oil

or grease when reassembling.

Keep Components A and B Separate

Cross-contamination can result in cured material in

fluid lines which could cause serious injury or

damage equipment. To prevent cross-contamination

of the equipment’s wetted parts, never interchange

component A (isocyanate) and component B (resin)

parts.

3A1570A 7

Foam Resins with 245 fa Blowing Agents

Some foam blowing agents will froth at temperatures

above 90°F (33°C) when not under pressure, especially

if agitated. To reduce frothing, minimize preheating in a

circulation system.

Page 8

Important Two-Component Material Information

Changing Materials

Changing the material types used in your equipment

requires special attention to avoid equipment damage

and downtime.

• When changing materials, flush the equipment multiple times to ensure it is thoroughly clean.

• Always clean the fluid inlet strainers after flushing.

• Check with your material manufacturer for chemical

compatibility.

• When changing between epoxies and urethanes or

polyureas, disassemble and clean all fluid components and change hoses. Epoxies often have

amines on the B (hardener) side. Polyureas often

have amines on the B (resin) side.

8 3A1570A

Page 9

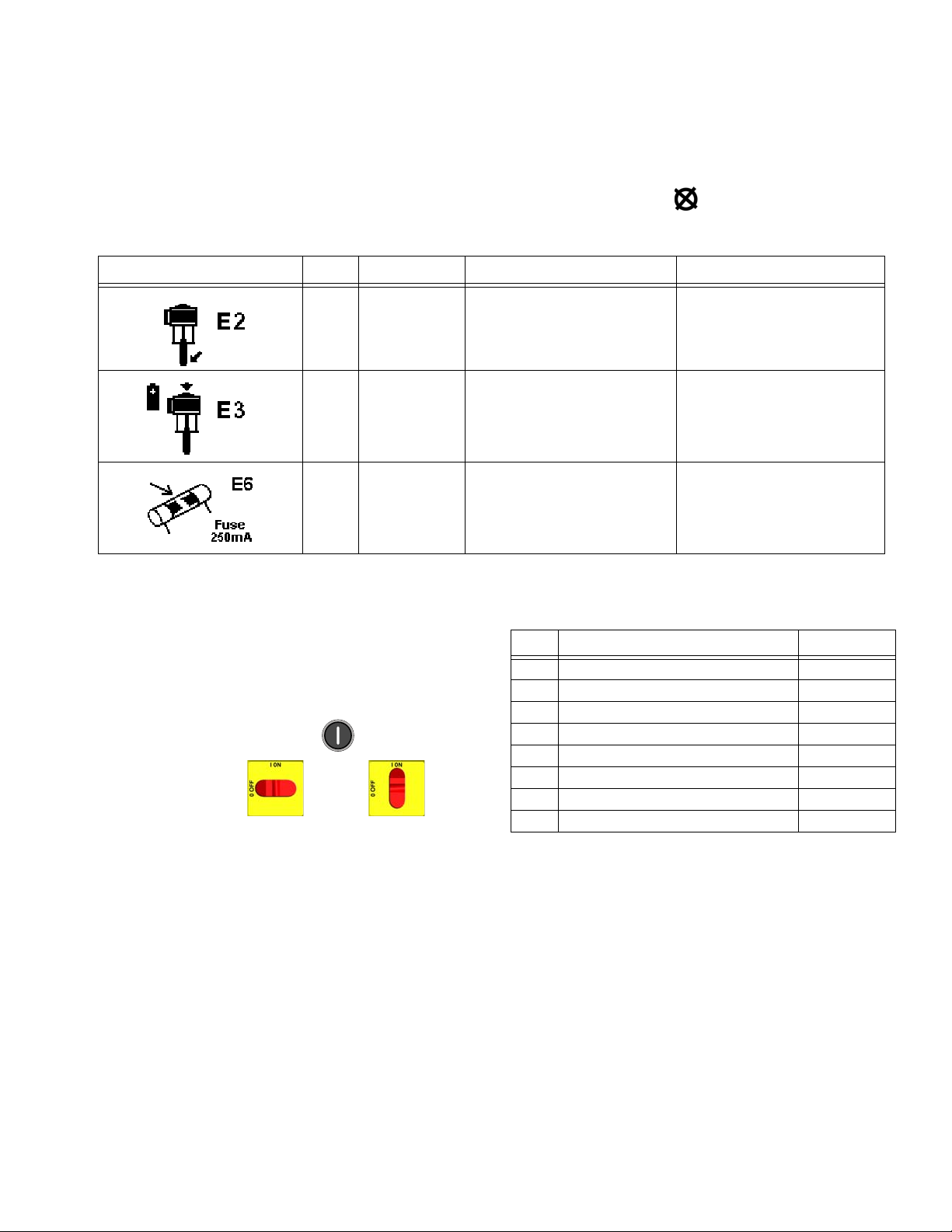

DataTrak Diagnostic Codes

Important Two-Component Material Information

DataTrak can diagnose several problems with the pump.

When the monitor detects a problem, the LED will flash

and a diagnostic code will appear on the display.

To acknowledge the diagnosis and return to the normal

operating screen, press once to wake up the display,

and once more to clear the diagnostic code screen.

Symbol Code Code Name Diagnosis Cause

E-2 Diving Down Leak during downstroke. Worn intake valve.

E-3 Low Battery Battery voltage too low to stop

runaway.

E-6 Blown Fuse Fuse is blown. Replace fuse;

see page 38.

Temperature Control Diagnostic Codes

Low battery. Replace battery;

see page 38.

• Faulty solenoid or solenoid

wiring.

• Extreme temperatures

(above 140°F [60°C]).

Temperature control diagnostic codes appear on temperature display.

These alarms turn off heat. E99 clears automatically

when communication is regained. Codes E03 through

E06 can be cleared by pressing . For other codes,

turn main power OFF then ON to clear.

Code Code Name Alarm Zone

01 High fluid temperature Individual

02 High zone current Individual

03 No zone current Individual

04 FTS or thermocouple disconnected Individual

05 Control board over temperature Individual

06 Communication cable unplugged Individual

30 Momentary loss of communication All

99 Loss of communication All

NOTE: For hose zone only, if FTS is disconnected at

startup, display will show hose current 0A.

3A1570A 9

Page 10

Important Two-Component Material Information

E01: High fluid temperature

Causes of E01 Errors

• Thermocouple A or B (361) senses a fluid temperature above 230°F (110°C).

• Fluid temperature sensor (FTS) senses a fluid temperature above 230°F (110°C).

• Overtemperature switch (359) senses a fluid temperature above 230°F (110°C) and opens. At 190°F

(87°C) the switch closes again.

• Thermocouple A or B (361) fails, is damaged, is not

touching the heater element (358), or has a poor

connection to the temperature control module.

• Overtemperature switch (359) fails in the open position.

• The temperature control module fails to turn off any

heat zone.

• Zone power wires or thermocouples are switched

from one zone to another.

• Failed heater element where thermocouple is

installed.

• Loose wire

between temperature control module and thermocouples A and B (361) or FTS (21) [depending on

which zone is displaying E01]. See Table 2, page

26. Ensure that all wires are securely connected to

connector B.

4. Remove connector B from temperature control module, and check continuity of overtemperature switch,

thermocouples A and B, or FTS by measuring resistance across the pins on the plug end; see Table 1.

Table 1: Sensor Connector Continuity Checks

Pins Description Reading

1 & 2 OT switch nearly 0 ohms

3 & 4 Jumpered nearly 0 ohms

5 & 6 Thermocouple A 4-6 ohms

8 & 9 Thermocouple B 4-6 ohms

11 & 12 FTS approximately 35

ohms per 50 ft (15.2

m) of hose, plus

approximately 10

ohms for FTS at 70°F

(21°C)

10 & 12 FTS open

• Jumper wire covered in heat shrink in the wiring harness near the single over temperature switch connectors on the heater, is loose or incorrectly wired

Checks

Troubleshooting this equipment requires access to

parts that may cause electric shock or other serious

injury if work is not performed properly. Have a

qualified electrician perform all electrical

troubleshooting. Be sure to shut off all power to the

equipment before repairing.

Check which zone is displaying the E01 error.

1. Check that connector B is firmly plugged into temperature control module (see F

2. Clean and re-plug connections.

3. Check connections between the temperature control

module and overtemperature switch (359), and

IG. 6, page 26).

NOTE: Before doing the following checks, note which

zone (A, B, FTS, or all) has high fluid temperature.

5. Verify fluid temperature, using an external temperature sensing device.

• If temperature is too high (sensor reading is

229°F [109°C] or above):

6. Check if thermocouples A and B are damaged, or

not contacting the heater element, page 30.

7. To test that temperature control module turns off

when equipment reaches temperature setpoint:

a. Set temperature setpoints far below displayed

temperature.

b. Turn zone on. If temperature rises steadily,

power module is failing.

c. Verify by swapping with another power module.

See Replacing Temperature Control Assem-

bly Modules, page 27.

10 3A1570A

Page 11

Important Two-Component Material Information

d. If the swapped module does not fix the problem,

the power module is not the cause.

8. Verify continuity of heater elements with an ohmmeter, see page 28.

E02: High zone current

1. Turn main power OFF .

2. Relieve pressure, page 13.

NOTE: Disconnect whip hose.

3. Disconnect hose connector (D) at Reactor.

4. Using an ohmmeter, check between the two terminals of the connector (D). There should be no continuity.

5. Exchange zone module with another one. Turn zone

on and check for error (see page 27). If error disappears, replace faulty module.

b. Perform Transformer Primary Check and

Transformer Secondary Check, starting on

page 33.

NOTE: When a no current error occurs, the LED on this

specific zone’s module turns red when the error is displayed.

E04: Fluid Temperature Sensor (FTS) or thermocouple disconnected

1. Check temperature sensor connections to long

green connector (B) on temperature control module,

page 26. Unplug and re-plug sensor wires.

2. Test fluid temperature sensor continuity with ohmmeter, page 10.

3. If an error occurred for the hose zone, check FTS

connections at each section of hose.

4. If an error occurred for the hose zone, test FTS by

plugging directly into machine.

For hose zone: If error still occurs, perform Transformer

Primary Check and Transformer Secondary Check,

starting on page 33.

NOTE: When there is a high current error, the LED on

that zone’s module will turn red while the error is displayed.

E03: No zone current

1. Check for tripped circuit breaker inside electrical

cabinet or at power source for that zone. Replace

circuit breaker if it trips habitually.

2. Check for loose or broken connection at that zone.

3. Exchange zone module with another one. Turn zone

on and check for error (see page 27). If error disappears, replace faulty module.

4. If E03 occurs for all zones, the 238CR contactor

may not be closing. Verify wiring from heater control

to contactor coil.

a. Hose zone: test hose continuity, page 31.

F

D

ti17788a

5. To verify heater control module is not causing the

problem, use a wire to short-circuit the two pins corresponding to the FTS (red and yellow for A or B

zone, red and purple for hose). The display will

show the control heater module temperature.

6. If an error occurred for the hose zone, temporarily

use the current control mode. Refer to Reactor

Operation manual.

3A1570A 11

Page 12

Important Two-Component Material Information

E05: Control board over temperature

NOTE: Each module has an on-board temperature sen-

sor. Heat is turned off if module temperature exceeds

185°F (85°C) within the heater module.

1. Check that fan above electrical cabinet is operating.

2. Check that electrical cabinet door is properly

installed.

3. Check for obstructions blocking cooling holes in bottom of electrical cabinet.

4. Clean heatsink fins behind heater control modules.

5. Ambient temperature may be too high. Allow Reactor to cool by moving to a cooler location.

E06: Communication cable unplugged

1. Unplug and re-plug cable that connects heater control module to heater module.

2. Replace communication cable if problem persists.

Communication Diagnostic Codes

E30: Momentary loss of communication

Communications between the display and the motor

control board or the temperature control module have

been momentarily lost. Normally, when communication

is lost, the corresponding display will show E99. The

corresponding control board will register E30 (The red

LED will flash 30 times). If communications are reconnected, the display can show the E30 for a small time

(no more than about two seconds). It should not be possible for E30 to be shown continuously, unless there is a

loose connection causing the display and the board to

continuously loose and regain communication.

Check all wiring between the display and the control

board.

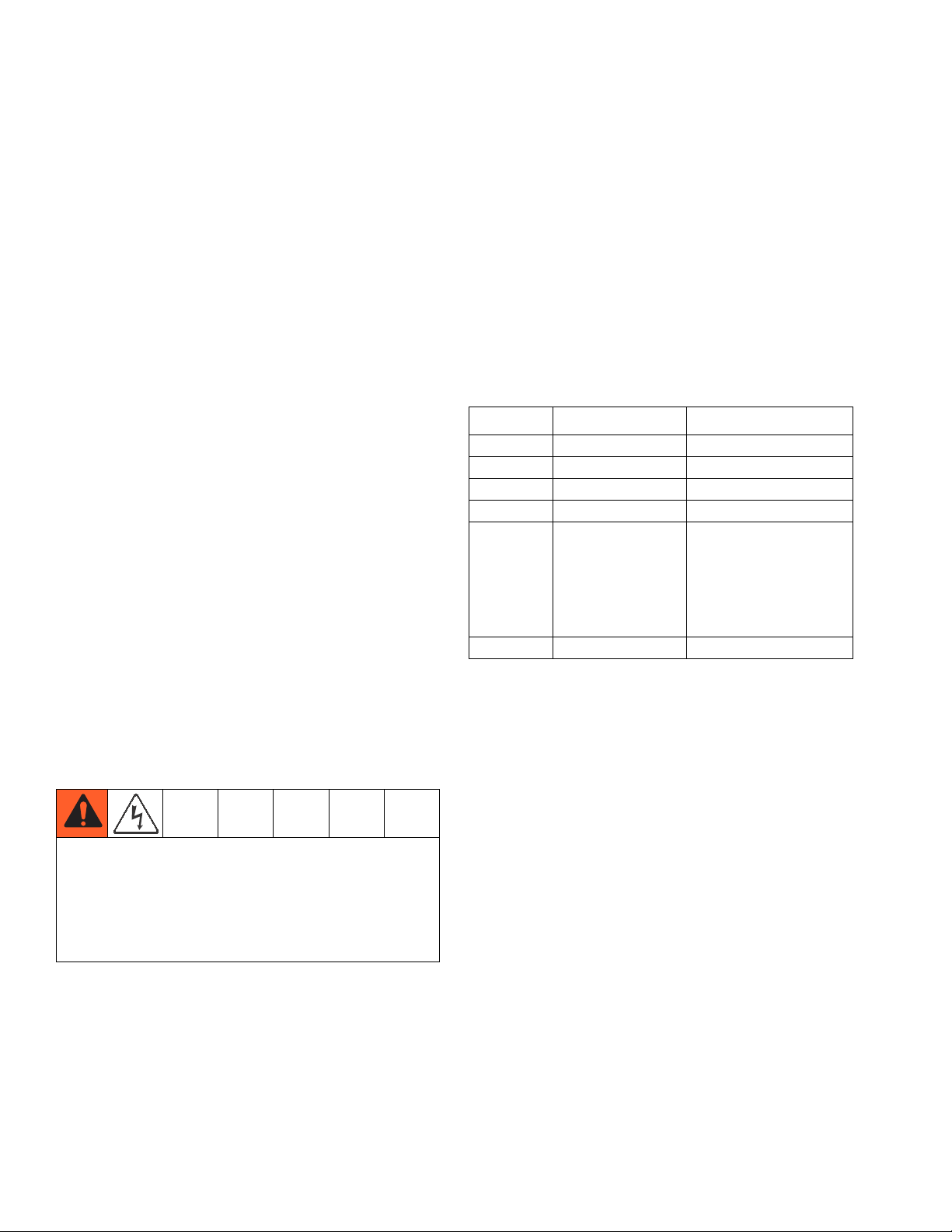

E99: Loss of communication

Communications between the display and the temperature control module has been lost. When communication

is lost, the display will show E99.

1. Check all wiring between the display and the temperature control module. Pay close attention to the

wire crimping on plug J13 for temperature display

and connector for control module.

Step 2 measures line voltage and should be done by

a qualified electrician. If work is not performed

properly it may cause electric shock or other serious

injury.

2. Measure the incoming voltage to the module (it

should be ~ 230Vac).

3. If it was only receiving 1 leg of the 230Vac the board

may light up, and still not function properly. Correct

the incoming voltage problem.

12 3A1570A

Page 13

Before Beginning Repair

Before Beginning Repair

Repairing this equipment requires access to parts

that may cause electric shock or other serious injury

if work is not performed properly. Electrical

troubleshooting must be done by a qualified

electrician. Be sure to shut off all power to equipment

and lock out power at the source before repairing.

1. Flush if necessary. See Flushing, page 14.

2. Turn main heater power OFF .

3. Relieve pressure. See Pressure Relief Procedure.

Pressure Relief

5. Close gun fluid inlet valves A and B.

ti2421a

6. Close pump inlet supply valves.

ti17716a

Procedure

The Fusion AP gun is shown.

1. Turn off feed pumps and agitator if used.

2. Park component A pump. Follow Park; see page 14.

3. Close the air inlet valve.

4. Engage gun piston safety lock.

ti2409a

Shutdown

1. Turn main heater power OFF .

2. Follow Park.

3. Check and fill wet-cups (AK, Z).

AK

Z

4. Follow gun shutdown procedure. See gun manual.

3A1570A 13

ti16974a

Page 14

Park

Park

Park the pumps at the end of the day to cycle component A pump to home position, submerging displacement rod.

1. Open the park valve.

Open

2. Trigger the gun until pumps stops at the bottom and

relieves pressure.

3. Close the air motor shutoff valve.

4. Close the park valve.

Close

Flushing

Flush equipment only in a well-ventilated area. Do

not spray flammable fluids. Do not turn on heaters

while flushing with flammable solvents.

• Flush out old fluid with new fluid, or flush out old

fluid with a compatible solvent, such as toluene,

naptha, or mineral spirits before introducing new

fluid.

• Use lowest possible pressure when flushing.

• To flush feed hoses, pumps, and the heater separately from the heated hoses, set PRESSURE

RELIEF/SPRAY valves (SA, SB) to PRESSURE

RELIEF/CIRCULATION. Flush through bleed lines

(N).

N

SA

SB

N

ti8441a

• To flush entire system, circulate through gun fluid

manifold (with manifold removed from gun).

• Always leave hydraulic oil or a non-water based,

non-water absorbent fluid in system. Do not use

water.

Only use flush solvents that are compatible with

Fluoroelastomer seals. Non-compatible solvents will

damage seals and cause hazardous conditions, such

as high pressure leaks and pressure switch failure.

14 3A1570A

Page 15

Troubleshooting

Problems

Try the recommended solutions in the order given for

Before performing any troubleshooting procedures:

1. Relieve pressure, page 13.

2. Turn main power OFF .

3. Allow equipment to cool.

Power

PROBLEM CAUSE SOLUTION

Heat zones do not operate No power Connect power cord

Power cord not connected properly Check connections

No power when disconnect switch is

turned on; using 230V, 1 phase or

230V, 3 phase power

External main supply power circuit

breaker trips and Reactor disconnect

switch fails when switch is turned on.

No temperature display lights at

startup

Power terminal jumper still at 380V, 3

phase position, as shipped from factory

Power terminal jumper was left in

230V, 1 phase position. When using

230V, 3 phase or 380V, 3 phase

power

No power Connect power cord

Control power fuses blown Check and replace fuses on long ter-

each problem, to avoid unnecessary repairs. Also,

determine that all circuit breakers, switches, and controls are properly set and wiring is correct before assuming there is a problem.

Turn Main Disconnect Switch ON

Place jumpers in correct position; see

Operation manual and label inside

front lower cabinet.

Place jumpers in correct position; see

Operation manual. Replace main

power disconnect switch; see page

40.

Turn Main Disconnect Switch ON

minal strip

Troubleshooting

Pumps and Pressures

PROBLEM CAUSE SOLUTION

Pump does not run up and down Motor control valve closed Open air motor shutoff valve

No air supply Air supply line not connected

Open inlet air ball valve

Air pressure regulators set at 0 psi Turn up air pressure regulators

Air motor shuttle valve is centered. Push button on top of air motor shut-

tle valve.

Pump runs but no fluid pressure Fluid inlet ball valves closed Open fluid inlet ball valves

3A1570A 15

Page 16

Troubleshooting

PROBLEM CAUSE SOLUTION

Fluid pressure low or dropping Air supply pressure low when spray-

ing

Increase inlet air pressure

Increase air compressor size to meet

flow requirements

Remove airline quick disconnects

Use 3/8 in. (0.95 cm) ID or larger air

supply hose. Use 1/2 in. (12.7 mm) if

longer than 25 ft (7.6 m).

Icing in air motor exhausts or mufflers Check inlet filter water separator; see

page 25. Stop spraying while ice

melts.

Pump output low, but pressure is normal

One pressure gauge drops when

pumps are stalled on both the

upstroke and the downstroke

Obstructed gun impingement ports or

Flush and clean gun; see gun manual

filters

Leaking pump throat Repair pump; see 309577

Leak between pump and gun Check fluid tubes, heater, and hoses

Pressure Relief/Spray valve leaking

back to supply

Spray gun is leaking on one side or

Clean and repair spray gun

plugged on the other side

One pressure gauge drops when

pumps are stalled on the downstroke,

Inlet ball check not sealing Clean or replace; see 309577

Inlet check seat o-ring not sealing Repair pump; see 309577

but not the upstroke

One pressure gauge drops when

pumps are stalled on the upstroke,

but not the downstroke

Piston check ball not sealing Repair pump; see 309577

Piston packing not sealing Repair pump; see 309577

Loose piston stud in pump Repair pump; see 309577

Bad inside sleeve seal Repair o-ring; see 309577

A side rich; lack of B side A side gauge is low B side restriction downstream of

gauge. Check gun check valve

screen, mix module, or mix manifold

restrictor.

A side impingement port is worn.

B side gauge is low B side material supply problem.

Check B side inlet strainer and pump

intake valve.

B side rich; lack of A side A side gauge is low A side material supply problem.

Check A side inlet strainer and pump

intake valve.

B side gauge is low A side restriction downstream of

gauge. Check gun check valve

screen, mix module, or mix manifold

restrictor.

B side impingement port is worn.

16 3A1570A

Page 17

Troubleshooting

PROBLEM CAUSE SOLUTION

Fluid pressures not balanced

between A and B side

Pump does not reverse direction Obstruction of air motor or pumps Check and clear obstruction

Unequal fluid pressure between

UP/DOWN stroke

Air motor doesn’t move with air pres-

sure applied

Pump movement speed is erratic Worn air motor seals Replace seals. See Air Motor man-

Fluid viscosities not equal Adjust A and B temperature settings

to balance viscosity. Sometimes nor-

mal if pressure offset is below 200 psi

(14 bar)

Preheat material in drums by recircu-

lating; see Operation manual

Inlet Y-strainer screen plugged on low

pressure side

Gun port or filter plugged on high

pressure side

Pump inlet ball not seating or sticking Clean seating; see pump manual

Drum fluid outlet supply hose too

small

Low side feed pump not working Turn on or repair feed pump

Pressure Relief/Spray valve leaking

back to supply

Feed pumps boost pressure on up

stroke.

Damaged air valve Replace or service air valve. See Air

Damaged pilot valve Replace valve. See Air Motor manPark valve left open or leaking

Worn pump seals Replace seals; see Pump manual.

Clean inlet filter screen

Clean or replace; see gun manual

Use 3/4 in. (1.9 cm) ID hose with

short length

Reduce feed pump pressures

Motor manual.

ual.

ual.

Electronics

Problem Cause Solution

Plug in power cord.

No power.

Display does not illuminate.

Low voltage. Ensure input voltage is within specifi-

Loose wire. Check connections, page 36.

Display disconnected. Check cable connections, page 36.

Display disconnected. Check cable connections, page 36.

Display cable damaged or corroded. Clean connections; replace cable if is

Temperature display does not

illuminate.

3A1570A 17

Turn disconnect ON .

cations, page 36.

damaged.

Page 18

Troubleshooting

Problem Cause Solution

Low voltage. Ensure input voltage is within specifi-

cations, page 36.

Poor display connection. Check cable connections, page 36.

Erratic display; display turns on and

off.

Display cable damaged or corroded. Clean connections; replace cable if is

Replace damaged cable.

damaged.

Display cable not grounded. Ground cable, page 37.

Display extension cable too long. Must not exceed 100 ft (30.5 m)

Hose display reads OA at startup. FTS disconnected or not installed. Verify proper installation of FTS (see

Operation manual), or adjust FTS to

desired current setting.

Poor display connection. Check cable connections, page 36.

Replace damaged cable.

Display does not respond properly to

button pushes.

Display cable damaged or corroded. Clean connections; replace cable if is

damaged.

Ribbon cable on display circuit board

Connect cable (page 36) or replace.

disconnected or broken.

Broken display button. Replace, page 36.

No hose heat. Loose hose electrical connections. Check connections. Repair as neces-

sary.

Circuit breakers tripped. Reset breakers (CB1 or CB2), page

34.

Hose zone not turned on.

Press zone key.

A and B temperature setpoints too

low.

Failed temperature control module. Open cabinet. Check if board LED is

Low hose heat. A and B temperature setpoints too

low.

Hose temperature setpoint too low. Check. Increase if necessary to

Flow too high. Use smaller mix chamber. Decrease

Low current; FTS not installed. Install FTS, see operation manual.

Hose heat zone not turned on long

enough.

Loose hose electrical connections. Check connections. Repair as neces-

Check. Increase if necessary.

blinking. If not, check power wiring

connections to ensure module has

power. If board has power and LED is

not blinking, replace module, page

26.

Increase A and B setpoints. Hose

designed to maintain temperature,

not increase temperature.

maintain heat.

pressure.

Allow hose to heat up, or preheat

fluid.

sary.

18 3A1570A

Page 19

Heater

PROBLEM CAUSE SOLUTION

Primary heater(s) does not heat.

Control of primary heat is abnormal;

high temperature overshoots or E01

error occurs intermittently.

Troubleshooting

Heat turned off.

Press or zone

keys.

Temperature control alarm. Check temperature display for diag-

nostic code, page 9.

Signal failure from thermocouple. See E04: Fluid Temperature Sen-

sor (FTS) or thermocouple disconnected, page 11.

Dirty thermocouple connections. Examine connection of thermocou-

ples to long green plug on heater

control board. Unplug and re-plug

thermocouple wires, cleaning off any

debris. Unplug and re-plug long

green connector.

A

B

Thermocouple not contacting heater

element.

Failed heater element. See Primary Heater, page 28.

Signal failure from thermocouple. See E04: Fluid Temperature Sen-

Thermocouple wired incorrectly. See E04: Fluid Temperature Sen-

Loosen ferrule nut (N), push in thermocouple (361) so tip (T) contacts

heater element (358). Holding thermocouple tip (T) against heater element, tighten ferrule nut (N) 1/4 turn

past tight. See page 30 for illustration.

sor (FTS) or thermocouple disconnected, page 11.

sor (FTS) or thermocouple disconnected, page 11. Power up zones

one at a time and verify that temperature for each zone rises.

3A1570A 19

Page 20

Troubleshooting

Hose Heat System

PROBLEM CAUSE SOLUTION

Ambient temperature is too cold. Use auxiliary hose heat system.

Hose heats but heats slower than

usual or it does not reach temperature.

Hose does not maintain temperature

while spraying.

FTS failed or not installed correctly. Check FTS, page 11.

Low supply voltage. Verify line voltage. Low line voltage

significantly reduces power available

to hose heat system, affecting longer

hose lengths.

A and B setpoints too low. Increase A and B setpoints. Hose is

designed to maintain temperature,

not to increase it.

Ambient temperature is too cold. Increase A and B setpoints to

increase fluid temperature and keep

it steady.

Flow too high. Use smaller mix chamber. Decrease

pressure.

Hose was not fully preheated. Wait for hose to heat to correct tem-

perature before spraying.

Low supply voltage. Verify line voltage. Low line voltage

significantly reduces power available

to hose heat system, affecting longer

hose lengths.

A and/or B heaters are overheating

material.

Check primary heaters for either a

thermocouple problem or a failed ele-

ment attached to thermocouple, page

11.

Faulty thermocouple connections. Verify that all FTS connections are

Hose temperature exceeds setpoint.

Faulty thermocouple connections. Verify that all FTS connections are

Erratic hose temperature.

FTS not installed correctly. FTS should be installed close to end

20 3A1570A

snug and that pins of connectors are

clean. Examine connection of ther-

mocouples to long green plug on

heater control board. Unplug and

re-plug thermocouple wires, cleaning

off any debris. Unplug and re-plug

long green connector on heater con-

trol board.

snug and that pins of connectors are

clean. Examine connection of ther-

mocouples to long green plug on

heater control board. Unplug and

re-plug thermocouple wires, cleaning

off any debris. Unplug and re-plug

long green connector.

of hose in same environment as gun.

Verify FTS installation, page 32.

Page 21

PROBLEM CAUSE SOLUTION

Troubleshooting

Hose does not heat.

Hoses near Reactor are warm, but

hoses downstream are cold.

FTS failed or is not contacting

Check FTS, page 11.

correctly.

FTS not installed correctly. FTS should be installed close to end

of hose in same environment as gun.

Verify FTS installation, page 32.

Temperature control alarm. Check temperature display or diag-

nostic code, page 32.

Shorted connection or failed hose

heating element.

With hose heat on and temperature

setpoint above displayed hose zone

temperature, verify voltage between

connectors at each section of hose.

Voltage should drop incrementally for

each section of hose further from

Reactor. Use safety precautions

when hose heat is turned on.

3A1570A 21

Page 22

Repair

Repair

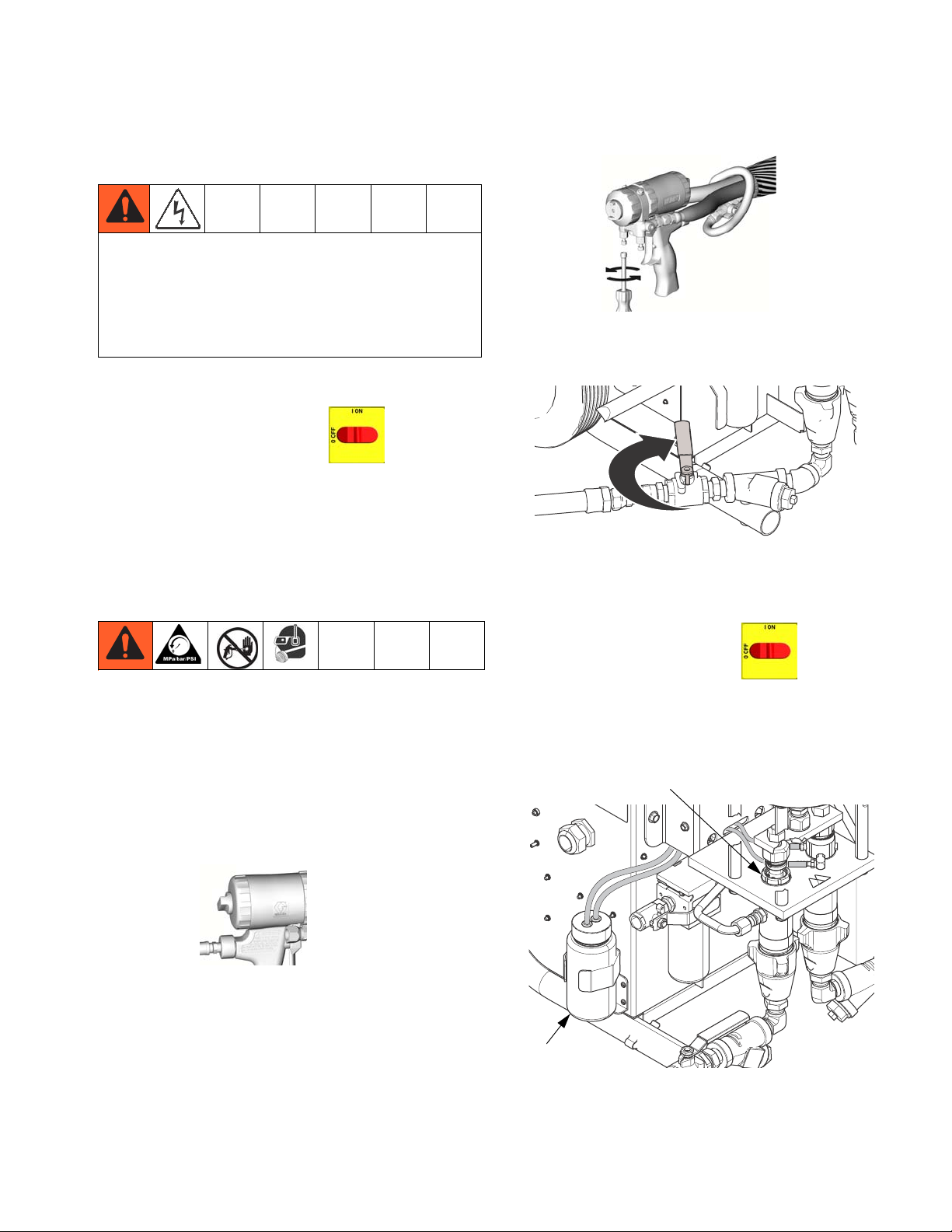

6. Shut off inlet air ball valve (G)

Unless otherwise noted, all repair procedures must

be completed with incoming power switched OFF

and locked out at the source. Any electrical repair or

troubleshooting required beyond the scope of this

manual must be performed by a qualified electrician.

Shut off air inlet ball valve and shut off all air supply

pressure.

Disconnect Pump

Air motor shaft, yoke, pump rod and connecting rod

move during operation. Moving parts can cause

serious injury such as pinching or amputation. Keep

hands and fingers away from connecting rod during

operation.

NOTE: See manual 309577 for pump repair instructions.

1. Turn main heater power OFF .

7. Remove screws (13, 15) and pump covers (63).

13

63

63

13

15

8. Disconnect A side (21) and B side (23) steel outlet

tubes from adapters (312).

23

312

M

15

ti17989a

M

2. Follow Flushing, page 14.

3. Follow Pressure Relief Procedure, page 13.

4. Follow Park instructions, page 14.

5. Shut off both feed pumps and close both inlet supply

valves (F).

F

G

22 3A1570A

F

ti17988a

318

317

9. Remove adapter (312) from fluid outlet (M).

10. For A Side pump, disconnect barb fitting (318),

elbow fitting (317), and two pipe plugs (324).

NOTE: It is not necessary to cut tubes connected to

barb fittings.

312

324

21

ti17990a

Page 23

Repair

11. Push retaining wire clip (307) up. Push retaining pin

(306) out.

307

306

12. Loosen lock nut (302) by hitting firmly with a

301

302

304

non-sparking hammer.

303

ti17991a

5. For Iso A pump only:

a. Install two pipe plugs (324).

b. Reconnect two tubing lines (N) from ISO Pump

Lube reservoir. Flush and refill reservoir with

TSL 206995.

6. Refill Resin B pump wet cup with TSL 206995.

13. Unscrew pump out of pump mounting plate (301).

14. See pump manual for repair procedures and

replacement parts.

Connect Pump

1. Ensure locknut (302) is screwed on pump with flat

side up. Grease pump mounting threads in plate

and pump cylinders (303, 304) with lithium grease.

Screw pump into pump mounting plate (301) until

top of pump thread is above mounting plate 1/2 to 1

1/2 threads above flush.

NOTE: Pump rod connecting links (302) should be positioned so that pins (306) are in line with each other.

2. Align pump rod hole with link hole. Push retaining

pin (306) in. Pull retaining wire clip (307) down to

cover pin ends.

3. Tighten locknut (302) by hitting firmly with a

non-sparking hammer.

4. Install adapter (312) in fluid outlet. Connect A side

(21) and B side (23) steel outlet tubes.

3A1570A 23

Page 24

Repair

Remove Air Motor

1. Press in tube fitting ferrules and pull out tubing (65)

to disconnect air line.

2. Disconnect DataTrak communication cable, if

installed.

3. Place wrench on adapter (315) and a another

wrench on lock nut (313). Remove lock nut (313).

315

313

ti17992a

FIG. 1

4. Remove four nuts (310) from tie rods (309).

6. Lay air motor on a clean flat work space. Place a

wrench on the tie rod flats (309) and hold one of

other tie rods with your hand to keep the air motor

(308) in place. Remove the tie rods from the air

motor.

309

308

ti17994a

FIG. 3

309

314

301

310

ti17993a

FIG. 2

5. Loosen two screws (314) behind air motor bracket.

Carefully lift air motor and tie rods away from the

proportioner frame and plate (301).

7. Use a wrench to hold the piston rod in place and

remove the adapter (315) with another wrench. See

F

IG. 1.

8. See air motor manual for repair instructions.

Install Air Motor

1. Apply medium blue thread lock on adapter (315).

Use a wrench to hold the piston rod in place and

install the adapter (315) with another wrench.

Torque to 32-38 ft-lbs (43-51 N•m). See F

2. Install tie rods (309) in the bottom of the air motor

(308). See F

IG. 3.

3. Install tie rods through plate (301). Ensure screws

(314) fit in the bracket slots (311). Install screws

(314). See F

IG. 2.

4. Tighten nut (313) to 32-38 ft-lbs (43-51 N•m).

5. Evenly torque four tie rod nuts (310) in small increments to 27-32 ft-lbs (37-43N•m). See F

IG. 1.

IG. 2.

24 3A1570A

Page 25

Repair

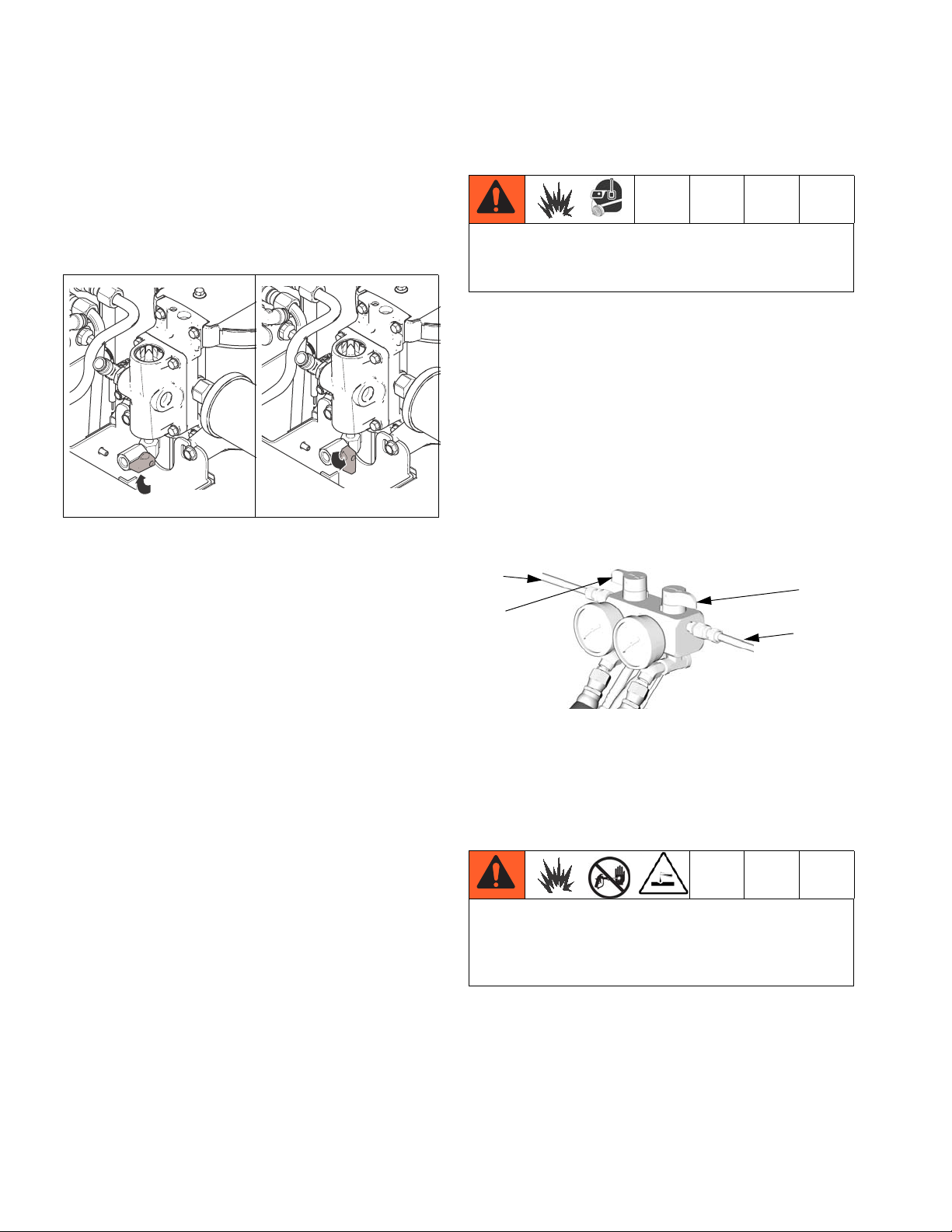

Recirculation / Over Pressure Relief Block

Valves can be serviced with the block on the machine

(see page 46 for parts view). For thorough cleaning,

remove the block assembly as follows.

1. Disconnect two fluid tubes connected to back of

recirculation block (3).

2. Loosen and remove two screws (10) in back of recirculation block.

10

3

ti17995a

FIG. 4

3. See Fluid Manifold, page 46. Clean and inspect all

parts for damage. Ensure that the seat (8a) and

gasket (8b) are positioned inside each valve cartridge (8).

4. Apply PTFE pipe sealant to all tapered pipe threads

before reassembling.

5. Reassemble in reverse order, following all notes on

page 46.

Air Inlet Filter / Water Separator (Auto Drain)

Air Filter Element Removal

1. Close air inlet valve (302) on filter (301).

2. Hold in metal spring clip and twist black cover counterclockwise to remove.

302 301

FIG. 5

3. Unscrew clear drain cover by hand.

4. Unscrew black filter element retainer to remove element.

5. Inspect filter element. Clean or replace.

Air Filter Element Installation

1. Insert cleaned or replacement filter (114228).

2. Hand-screw filter retainer into place.

ti17996a

3. Hand-screw clear drain cover until tight.

4. Reposition black cover and turn. Make sure it

“snaps” back into place.

3A1570A 25

Page 26

Repair

Temperature Control Module

Table 2: Temperature Control Module Connections

Connector Description

DATA (A) Data reporting

PIN

HOSE T/C P; FTS (purple)

12

11 HOSE T/C R; FTS (red)

10 HOSE T/C S; FTS (silver

(unshielded bare wire))

9 HEATER T/C B, Y;

SENSOR (B)

DISPLAY (C) Display

COMMUNICATION (D) Communication to power

PROGRAM (E) Software programming

BOOT (F) Software bootloader

POWER/RELAY (G) Circuit board power input and

Thermocouple (yellow)

8 HEATER T/C B, R;

Thermocouple (red)

7 Not used

6 HEATER T/C A, Y;

Thermocouple (yellow)

5 HEATER T/C A, R;

Thermocouple (red)

4, 3 OVERTEMPERATURE B;

Overtemperature switch B

2, 1 OVERTEMPERATURE A;

Overtemperature switch A

boards

contactor control output

A

B

C

H

ti17997a

D

E

F

G

ti9843a1

Right Side of

Control Heater Module

Table 3: Temperature Control Module Connections

J

Connector Description

COMMUNICATION

(H)

POWER (J) Power to heater

Communication to control

board

ti9843a4

Bottom of Power Modules

FIG. 6: Temperature Control Module Connections

26 3A1570A

Page 27

Repair

Test SCR Circuit

1. Test the SCR circuit in the on position:

a. Make sure everything is connected, including

the hose.

b. Turn main power ON .

c. Adjust the hose heat setpoint above the ambi-

ent hose temperature.

d. Turn on heat zone by pressing .

e. Hold down to view electrical current.

Hose current should ramp up to 45A. If there is

no hose current, see E03: No zone current,

page 11. If hose current exceeds 45A, see E02:

High zone current, page 11. If hose current

stays several amps below 45A, hose is too long

or voltage is too low.

2. Test the SCR circuit in the off position:

Replacing Temperature Control Assembly

Modules

NOTICE

Before handling assembly, put on static conductive

wrist strap to protect against static discharge which

can damage assembly. Follow instructions provided

with wrist strap.

1. Turn main power off . Disconnect power

supply.

2. Relieve pressure, page 13.

3. Refer to electrical diagrams. See Reactor A-25 Wir-

ing Schematic, page 51. Temperature control

assembly is on left side inside cabinet.

4. Remove bolts that secure transformer assembly and

slide assembly to side in cabinet.

5. Put on static conductive wrist strap.

6. Disconnect all cables and connectors from assembly. See Temperature Control Module, page 26.

a. Make sure everything is connected, including

the hose.

b. Turn main power ON .

c. Adjust the hose heat setpoint below the ambi-

ent hose temperature.

d. Turn on heat zone by pressing .

Using a voltmeter, carefully measure the voltage at the

hose connector. You should not get a voltage reading. If

you do, the SCR on the temperature control module is

bad. Replace the temperature control assembly.

7. Remove nuts and take entire temperature control

assembly to workbench.

8. Replace defective module.

9. Install assembly in reverse order.

3A1570A 27

Page 28

Repair

Primary Heater

Read Warnings on page 4. Wait for heater to cool

before repairing.

Heater Element

1. Turn main power OFF . Disconnect power

supply.

2. Relieve pressure, page 13.

3. Wait for heaters to cool.

4. Remove heater shroud.

5. See F

Heater Rod

IG. 7. Disconnect heater element wires from

heater wire connector. Test with ohmmeter.

Element

Wattage Ohms

Line Voltage

The primary heaters output their rated wattage at 230

Vac. Low line voltage will reduce power available and

the heaters will not perform at full capability.

1500 30-35

6. To remove heater element, first remove thermocouple (361) to avoid damage, see step 7, page 30.

7. Remove heater element (358) from housing (351).

Be careful not to spill any fluid left in housing.

8. Inspect element. It should be relatively smooth and

shiny. If there is a crusted, burnt, ash-like material

adhered to element or sheath shows pitting marks,

replace element.

9. Install new heater element (358), holding mixer

(360) so it does not block thermocouple port (P).

10. Reinstall thermocouple, page 30.

11. Reconnect heater element leadwires to heater wire

connector.

12. Replace heater shroud.

28 3A1570A

Page 29

2 5

355

351

353

1 6

5

361

362

359

356

357

354

Repair

6

3 6 7

352

1

Torque to 120 ft-lbs (163 N•m).

2

Torque to 23 ft-lbs (31 N•m).

3

Torque to 40 ft-lbs (54 N•m).

4

Apply 110009 thermal heatsink compound.

5

Apply sealant and PTFE tape to all non swiveling

and threads without o-rings.

6

Apply lubricant to o-rings.

7

Orient rupture disc housing (369) with exhaust

hole pointing towards the bottom of the heater.

FIG. 7. 6 kW Dual Zone Heater

6

360

1

358

ti17998a

3A1570A 29

Page 30

Repair

Thermocouple

Read Warnings on page 4. Wait for heater to cool

before repairing.

1. Turn main power OFF . Disconnect power

supply.

2. Relieve pressure, page 13.

3. Wait for heaters to cool.

4. Remove heater shroud.

5. Disconnect thermocouple wires from B on temperature control module. See Table 2, page 26 and F

IG.

6, page 26.

6. Feed thermocouple wires out of cabinet. Note path

as wires must be replaced in the same way.

7. See F

IG. 8. Loosen ferrule nut (N). Remove thermo-

couple (361) from heater housing (351), then

remove thermocouple housing (H). Do not remove

the thermocouple adapter (356) unless necessary. If

adapter must be removed, ensure that mixer (360)

is out of the way when replacing the adapter.

8. Replace thermocouple, F

IG. 8.

a. Remove protective tape from thermocouple tip

(T).

b. Apply PTFE tape and thread sealant to male

threads and tighten thermocouple housing (H)

into adapter (356).

c. Push in thermocouple (361) so tip (T) contacts

heater element (358).

d. Holding thermocouple (T) against heater ele-

ment, tighten ferrule nut (N) 1/4 turn past tight.

9. Route wires (S) into cabinet and thread into bundle

as before. Reconnect wires to board.

10. Replace heater shroud.

11. Turn on heaters A and B simultaneously to test.

Temperatures should rise at same rate. If one

heater is low, loosen ferrule nut (N) and tighten thermocouple housing (H) to ensure thermocouple tip

(T) contacts element (358).

1

Apply PTFE tape and thread sealant.

S

361

2

Apply 110009 thermal heatsink compound.

N

H

1

356

301

358

2

359

T

360

ti7924a

FIG. 8. Thermocouple

30 3A1570A

Page 31

Repair

Overtemperature Switch

Read Warnings on page 4. Wait for heater to cool

before repairing.

1. Turn main power OFF . Disconnect power

supply.

2. Relieve pressure, page 13.

3. Wait for heaters to cool.

4. Remove heater shroud.

5. Disconnect one leadwire from overtemperature

switch (359), F

ter. Resistance must be approximately 0 ohms.

6. If switch fails test, remove wires and screws. Discard failed switch. Apply thermal compound

110009, install new switch in same location on

housing (351), and secure with screws (311).

Reconnect wires.

NOTE: If wires need replacement, disconnect temperature control module. See Table 2, page 26 and F

page 26

IG. 8. Test across switch with ohmme-

IG. 6,

5. If hose fails test, retest at each length of hose,

including whip hose, until failure is isolated.

Check FTS Cables

1. Turn main power OFF . Disconnect power

supply.

2. Relieve pressure, page 13.

3. Disconnect FTS cable (F) at Reactor, FIG. 9.

F

D

ti17788a

FIG. 9. Heated Hose

4. Test with ohmmeter between pins of cable connector.

Heated Hose

Refer to the heated hose manual for hose replacement

parts.

Pins Result

1 to 2 approximately 35 ohms per 50 ft (15.2 m) of

hose, plus approximately 10 ohms for FTS

1 to 3 infinity

Check Hose Connectors

5. If cable fails test, retest at FTS, page 32.

1. Turn main power OFF . Disconnect power

supply.

2. Relieve pressure, page 13.

NOTE: Whip hose must be connected.

3. Disconnect hose connector (D) at Reactor, F

4. Using an ohmmeter, check between the two terminals of the connector (D). There should be continuity.

3A1570A 31

IG. 9.

Page 32

Repair

Fluid Temperature Sensor (FTS)

Test/Removal

1. Turn main power OFF . Disconnect power

supply.

2. Relieve pressure, page 13.

3. Remove tape and protective covering from FTS.

Disconnect hose cable (F). Test with ohmmeter

between pins of cable connector.

Pins Result

1 to 2 approximately 10 ohms

1 to 3 infinity

3 to FTS groundscrew 0 ohms

1 to FTS component A

fitting (ISO)

infinity

4. If FTS fails any test, replace FTS.

5. Disconnect air hoses (C, L), and electrical connectors (D).

6. Disconnect FTS from whip hose (W) and fluid hoses

(A, B).

7. Remove ground wire (K) from ground screw on

underside of FTS.

8. Remove FTS probe (H) from component A (ISO)

side of hose.

Installation

The Fluid Temperature Sensor (FTS) is supplied. Install

FTS between main hose and whip hose. See Heated

Hose manual 309572 for instructions.

D

K

F

ISO

B

A

H

C

B

W

A

L

ti9581c

FIG. 10: Fluid Temperature Sensor and Heated Hoses

32 3A1570A

Page 33

Repair

Transformer Primary Check

1. Turn main power OFF .

2. Locate the two smaller (10 AWG) wires coming out

of transformer. Trace these wires back to contactor

and circuit breaker (911). Use an ohmmeter to test

for continuity between two wires; there should be

continuity.

Transformer Secondary Check

1. Turn main power OFF .

2. Locate the two larger (6 AWG) wires coming out of

transformer. Trace these wires back to large green

connector under hose control module and circuit

breaker (909). Use an ohmmeter to test for continuity between two wires; there should be continuity.

If you are not sure which wire in green plug under

hose module connects to transformer, test both

wires. One wire should have continuity with the

other transformer wire in breaker (909) and the

other wire should not.

3. To verify transformer voltage, turn on hose zone.

Measure voltage from 178CB-2 to HPOD-1; see

Reactor A-25 Wiring Schematic, page 51.

Model Secondary Voltage

310 ft. 90 Vac*

210 ft. 62 Vac*

* For 230 Vac line voltage.

Replace Transformer

1. Turn main power OFF . Disconnect power

supply.

2. Open Reactor cabinet.

3. Remove bolts holding transformer to cabinet floor.

Slide transformer forward.

4. Disconnect the transformer wires; see Reactor

A-25 Wiring Schematic, page 51.

909

911

F

IG. 11: Circuit Breaker Module

5. Remove transformer from cabinet.

6. Install new transformer in reverse order.

ti17999a

3A1570A 33

Page 34

Repair

Replace Circuit Breaker Module

1. Turn main power OFF . Disconnect power

supply. Turn circuit breakers on to test.

2. Relieve pressure, page 13.

3. Using an ohmmeter, check for continuity across circuit breaker (top to bottom). If no continuity, trip

breaker, reset, and retest. If still no continuity,

replace breaker as follows:

a. Refer to electrical diagrams and table below.

Disconnect wires and remove bad breaker.

NOTE: To reference cables and connectors, see the

electrical diagrams and parts drawings on page 49 and

51.

b. Install new breaker and reconnect wires.

Ref. Size Component

CB1 50 A Hose Secondary (single)

CB2 40 A Hose Primary (double)

CB3 25 A Heater A (double)

CB4 25 A Heater B (double)

CB1

CB2

CB3 CB4

ti17569a

FIG. 12

34 3A1570A

Page 35

Pump Lubrication System

Check the condition of the ISO pump lubricant daily.

Change the lubricant if it becomes a gel, its color darkens, or it becomes diluted with isocyanate.

Repair

ST

Gel formation is due to moisture absorption by the pump

lubricant. The interval between changes depends on the

environment in which the equipment is operating. The

pump lubrication system minimizes exposure to moisture, but some contamination is still possible.

Lubricant discoloration is due to continual seepage of

small amounts of isocyanate past the pump packings

during operation. If the packings are operating properly,

lubricant replacement due to discoloration should not be

necessary more often than every 3 or 4 weeks.

To change pump lubricant:

1. Relieve pressure, page 13.

2. Lift the lubricant reservoir (LR) out of the bracket

(RB) and remove the container from the cap. Holding the cap over a suitable container, remove the

check valve and allow the lubricant to drain. Reattach the check valve to the inlet hose (ST). See F

IG.

13.

3. Drain the reservoir and flush it with clean lubricant.

RT

LR

RB

ST

FIG. 13. Pump Lubrication System

RT

ti18001a

4. When the reservoir is flushed clean, fill with fresh

lubricant.

5. Thread the reservoir onto the cap assembly and

place it in the bracket.

6. The lubrication system is ready for operation. No

priming is required.

3A1570A 35

Page 36

Repair

Fluid Inlet Strainer Screen

The inlet strainers filter out particles that can plug the

pump inlet check valves. Inspect the screens daily as

part of the startup routine, and clean as required.

Isocyanate can crystallize from moisture contamination

or from freezing. If the chemicals used are clean and

proper storage, transfer, and operating procedures are

followed, there should be minimal contamination of the

A-side screen.

NOTE: Clean the A-side screen only during daily

startup. This minimizes moisture contamination by

immediately flushing out any isocyanate residue at the

start of dispensing operations.

1. Close the fluid inlet valve at the pump inlet and shut

off the appropriate feed pump. This prevents material from being pumped while cleaning the screen.

2. Place a container under the strainer base to catch

drain off when removing the strainer plug (C).

Temperature Display

NOTICE

Before handling board, put on static conductive

wrist strap to protect against static discharge which

can damage assembly. Follow instructions provided

with wrist strap.

1. Turn main power OFF . Disconnect power

supply.

2. Relieve pressure, page 13.

3. Refer to Reactor A-25 Wiring Schematic, page 51.

4. Put on static conductive wrist strap.

5. Disconnect main display cable (106) at lower left

corner of display module; see F

6. Remove screws (116) and cover (105); see F

IG. 15.

IG. 15.

3. Remove the screen (A) from the strainer manifold.

Thoroughly flush the screen with compatible solvent

and shake it dry. Inspect the screen. No more than

25% of the mesh should be restricted. If more than

25% of the mesh is blocked, replace the screen.

Inspect the gasket (B) and replace as required.

4. Ensure the pipe plug (D) is screwed into the strainer

plug (C). Install the strainer plug with the screen (A)

and gasket (B) in place and tighten. Do not overtighten. Let the gasket make the seal.

5. Open the fluid inlet valve, ensure that there are no

leaks, and wipe the equipment clean. Proceed with

operation.

A

B

C

D

Ti10974a

FIG. 14. Fluid Inlet Strainer

7. Disconnect cable connector from back of temperature display (102). See F

IG. 15.

8. Disconnect ribbon cable(s) (R) from back of display;

see F

IG. 15.

9. Remove nuts (103) and plate (101).

10. Disassemble display, see detail in F

IG. 15.

11. Replace board (102a) or membrane switch (102b)

as necessary.

12. Reassemble in reverse order, see F

IG. 15. Apply

medium strength thread sealant where shown. Be

sure display cable ground wire (G) is secured

between cable bushing and cover (105) with screws

(107).

36 3A1570A

Page 37

102

Repair

116

119

G

106

105

107

104

103

Detail of Membrane Switches and Temperature Display Board

Temperature Display

102b

ti18026a

102a

102c

1

R

ti18003a

FIG. 15. Display Module

3A1570A 37

Page 38

Repair

Replace DataTrak Battery or Fuse

4. Remove two screws on back of module to access

battery.

The battery and fuse must be replaced in a

non-hazardous location.

Use only the following approved replacement batteries. Use of an unapproved battery will void Graco’s

warranty and FM and Ex approvals.

• Ultralife lithium # U9VL

• Duracell alkaline # MN1604

• Energizer alkaline # 522

• Varta alkaline # 4922

Use only a Graco-approved replacement fuse. Order

Part 24C580.

Replace Battery

1. Unscrew cable from the back of the reed switch

assembly. See F

2. Remove the cable from the two cable clips.

IG. 16.

5. Disconnect the used battery and replace with an

approved battery. See F

IG. 18.

Replace Fuse

1. Remove the screw, metal strap, and plastic holder.

2. Pull the fuse away from the board.

3. Replace with a new fuse.

Solenoid Cable

Connection

Fuse

Sensor Cable

Connection

ti11992a

F

IG. 16. Disconnect DataTrak

3. Remove DataTrak module from bracket. See F

17. Take module and attached cable to a non-hazardous location.

IG.

Battery

ti11994a

FIG. 18. DataTrak Battery and Fuse Location

ti18004a

F

IG. 17. Remove DataTrak

38 3A1570A

Page 39

Accessories

Accessories

Feed Pump Kits

Pumps, hoses, and mounting hardware to supply fluids

to Reactor. Includes 246483 Air Supply Kit. See 309815.

246483 Air Supply Kit

Hoses and fittings to supply air to feed pumps, agitator,

and gun air hose. Included in feed pump kits. See

309827.

246978 Circulation Kit

Return hoses and fittings to make circulation system.

Includes two 246477 Return Tube Kits. See 309852.

246477 Return Tube Kit

Desiccant dryer, return tube, and fittings for one drum.

Two included in 246978 Circulation Kit. See 309852.

TSL (Throat Seal Liquid)

206995 1 qt (1 liter) bottle

206996 1 gal. (3.8 liter) container

P2 Spray Gun

Probler P2 Gun available in round or flat pattern. See

313213.

Y-Strainer Screen

Replacement strainer screen for fluid Y-strainer; 20

mesh.

Part Description

180199 20 mesh; as shipped

255082 80 mesh (2 pack)

255083 80 mesh (10 pack)

114228 Air Filter Element

Replacement air filter element; 5 micron.

262695 Wheel Kit

All hardware and wheels to convert model 262572.

Recommended Spare

24A592 DataTrak with Cycle Count Only Kit

DataTrack and reed switch for NXT Air Motor. See manual 313541.

Heated Hoses

50 ft (15.2 m) and 25 ft (7.6 m) lengths, 1/4 in. (6 mm),

3/8 in. (10 mm), or 1/2 in. (13 mm) diameter, 2000 psi

(14 MPa, 140 bar) or 3500 psi (24 MPa, 241 bar). See

309572.

Heated Whip Hoses

10 ft (3 m) whip hose, 1/4 in. (6 mm) or 3/8 in. (10 mm)

diameter, 2000 psi (14 MPa, 140 bar) or 3500 psi (24

MPa, 241 bar). See 309572.

Fusion Spray Gun

Air Purge Gun available in round or flat pattern. See

309550. Mechanical Purge Gun available in round or flat

pattern. See manual 309856. Clear Shot Gun available

in round or flat patter. See manual 312666.

Parts

Keep the following spare parts on hand to reduce downtime.

Part No. Description

262648 Pump, Resin (B) side

246421 Resin (B) Pump Repair Kit for 262648

pump

262647 Pump, ISO (A) side

15C851 ISO (A) Pump Repair Kit for 262647

pump

246963 Wet Cup Kit for 262647 pump

206995 TSL bottle, 1 qt (1 liter)

101078 Y-Strainer; includes 180199 element

180199 Element, Y-Strainer, 20 mesh

114228 Element, air filter, 5 micron

239914 Valve, recirc/spray; includes seat and

gasket

3A1570A 39

Page 40

Parts

Parts

262572, Bare Reactor A-25

262614, Reactor A-25 with DataTrak and Wheels

66

67

6

14 (x4)

1

79

50

20

57

10

58

20

18

3

4

84

57

83

62

51

11

11 (x6)

7

62

8

52

9 (x4)

59

100 (x4)

88

16

56 (x4)

38

35

17

85

26

13

91, 92

ti18023a

15 15

40 3A1570A

19

89

90 (x6)

Page 41

Parts

5

25 (x2)

93

15

13 (x2)

63

61

24

7

2

68

69

23

22

3

1

94

1

Torque pump locking nuts to 66-74 ft-lbs (90-100 N•m).

2

Apply anaerobic polyacrylate pipe sealant to all non-swiveling pipe threads.

3

Torque tube ends to 212-265 in-lbs (24-30 N•m).

4

Connect ground wire (94) from motor lug to ground lug in cabinet.

3A1570A 41

9 (x4)

15

63

13 (x2)

21

ti18024a

Page 42

Parts

34

60

49

98

33

37

13 (x4)

49

12

5

262572, Bare Reactor A-25

262614, Reactor A-25 with DataTrak and Wheels

Ref Part Description Qty.

1---CART 1

2 262573 PUMP; see page 48 1

3 262577 MANIFOLD, relief; see page 46 1

4 --- PANEL, control, heater;

see page 45

5 24J788 HEATER, system, (6.0kw,

230v); see page 47

6 262575 PANEL, control; see page 44 1

7 262576 MODULE, breaker; see page 50 1

8 24M177 TRANSFORMER, 2790va,

230/62

1

1

1

ti18025a

10

13 (x4)

83

30

27

29

31

28

32

80

ti18007a

9 111799 SCREW, cap, hex hd; M8 x 1.25 8

10 108296 SCREW, mach, hex wash hd;

1/4-20 UNC-2A

11 125621 SCREW, machine, hex washer,

hd; M6 x 1

12 16G917 BRACKET, heater 1

13 114182 SCREW, mach, hex flange; M6

x 1

14 117623 NUT, cap, 3/8-16 4

15 106084 SCREW, mach, pan hd; M5 x

0.8

16 117682 BUSHING, strain relief 1

4

6

13

2

42 3A1570A

Page 43

Parts

17 123970 SWITCH, disconnect, 40a 1

18 123971 KNOB, disconnect, operator 1

19 123972 SWITCH, fourth pole 1

20 205447 COUPLING, hose 2

21 16G921 TUBE, fluid, A, heater, inlet 1

22 16G922 TUBE, fluid, A, heater, outlet 1

23 16G923 TUBE, fluid, B, heater, inlet 1

24 16G924 TUBE, fluid, B, heater, outlet 1

25 112125 PLUG, tube 2

26 117666 TERMINAL, ground 1

27 15D795 FILTER, air, 40 micron 1

28 107128 TEE, service 1

29 114110 ELBOW, male, swivel 1

30 162449 NIPPLE, reducing 1

31 158491 NIPPLE 1

32 262660 VALVE, ball, 1/2 npt x 1/2 npt 1

33 114269 GROMMET, rubber 4

34 16G918 COVER, heater 1

35 246995 BOTTLE, assembly, complete 1

36 234366 KIT, fluid inlet, pair; see page 46 1

37† 262695 KIT, wheel; see page 51 2

38 16M152 BRACKET, lube, reservoir 1

44‡ 247791 HARNESS, wire, hose 1

45‡ 261669 KIT, fluid temp sensor, coupler 1

49 167002 INSULATOR, heat 2

50 16J433 HARNESS, wire, display, ext. 1

51 16J434 HARNESS, over temp, a-side,

b-side

52 261821 CONNECTOR, wire, 6awg 1

53‡ --- FLUID, oxide inhibitor 1

54‡ 206994 FLUID, TSL, 8 oz. bottle 1

55‡ 206995 FLUID, TSL, 1 qt. 1

56 186494 CLIP, spring 4

57 --- HOSE, PTFE; 5 ft (1.5 m), 0.25

in. (6.35 mm) ID

58 15G280 LABEL, warning 1

59 189930 LABEL, caution 1

60 189285 LABEL, caution 3

61 15H108 LABEL, pinch point 1

62 15B380 CABLE, hose, control 1

63 16G952 COVER, pump 2

64 --- TUBE, polyethylene, rnd; 3/4

OD; 0.75 ft (0.2 m); see page 49

65 --- TUBE, polyurethane, rnd, black;

5.12 ft (1.56 m); see page 49

66 --- INSERT, control panel 2

67† 24B563 KIT, DataTrak 1

68† 24B659 SWITCH, reed assy 1

69† --- FASTENER, screw, pan head,

1

m4 x 35mm

79 262581 COVER, electrical, assembly 1

80 --- SCREW, shcs, m5x60 2

83 248208 HOSE, coupled, 4 feet 1

82‡ 15H187 WIRE, jumper, w/quick discon-

1

nect

84 --- LABEL, product 1

85 16J808 LABEL, warning, disconnect

1

wiring

88 195874 SCREW, phillips, pan hd; M4 x 8 1

89 16K669 FILTER, electrical 3

90 115266 SCREW, cap, socket hd; M5 x 106

91 --- SCREW, pan hd; M5 x 16 1

92 --- WASHER, #10, external tooth

1

lock

93 --- TUBE, pe, spiral, wrapping; 1.2

1

ft (0.4 m)

94 16M086 WIRE, ground, pump 1

95‡ 114601 CONDUIT, flexible, non-metallic 1

96‡ --- SLEEVE, heat-shrink, 2:1; 0.75

1

ft, 1/2 in. ID, 1/4 in. OD

97‡ 120573 BRIDGE, plug-in, jumper 4

98 16M088 LABEL, error codes 1

99‡ 114958 STAP, tie 10

100 105676 SCREW, pan hd 4

1

Replacement Danger and Warning labels, tags, and

cards are available at no cost.

† Only used with 262614.

Only used with 262572.

Included in Reed Switch Kit 24B659.

1

‡Not shown.

1

1

3A1570A 43

Page 44

Parts

Control Panel, 262575

116105

102

101

103

1

108

112

104

1

115

121

109

110

107

113