Page 1

GENUINE GRACO PARTS AND ACCESSORIES

563933 MSP Bubble Tight

Inlet Shut-Off Valve Repair Kit

Important Safety Instructions

Read all warnings and instructions in manual. Save

these instructions.

406684B

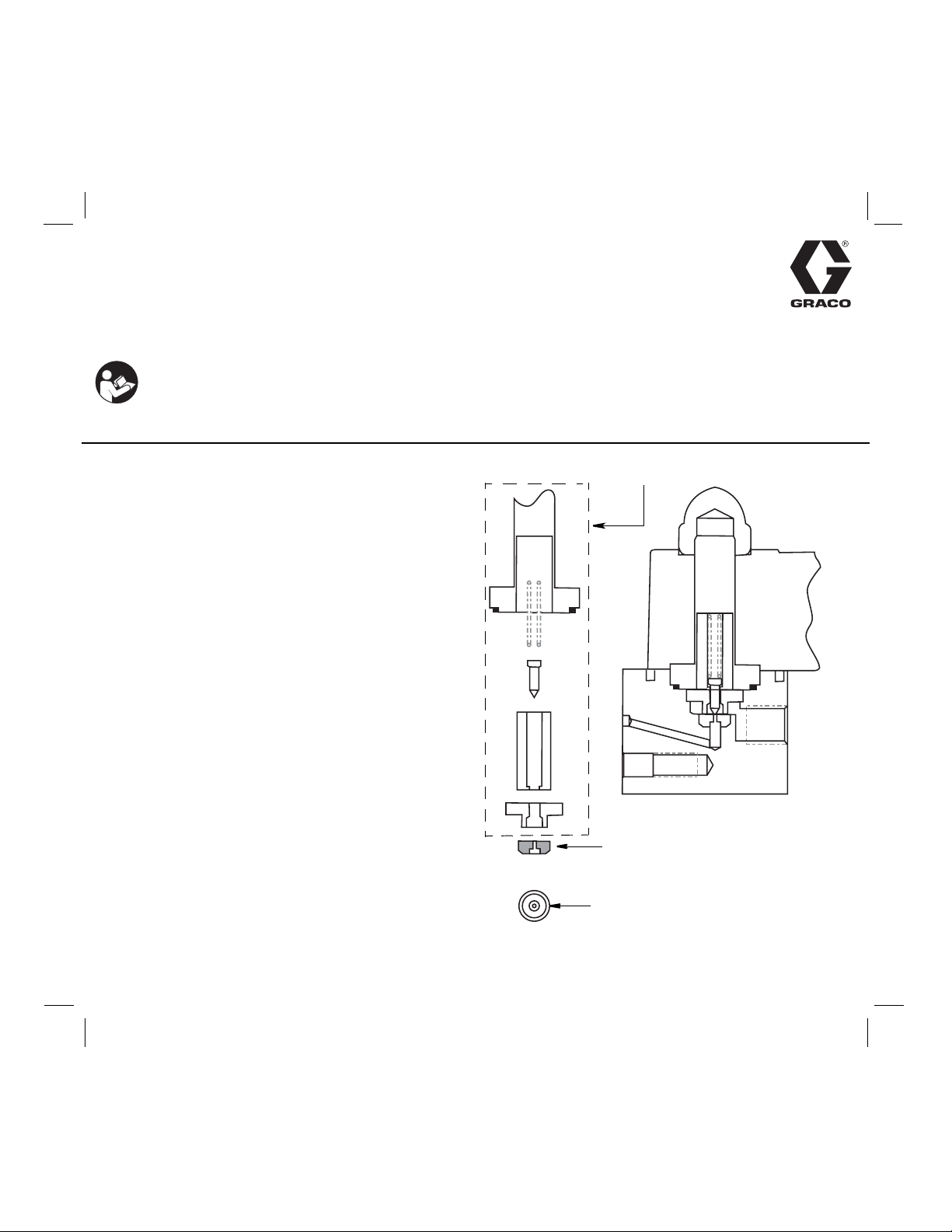

Included in Kit 1

Ref. Description Qty.

1 KIT, solenoid 1

2 SEAT, nylon 1

3 NUT, wrench (not shown) 1

4 SCREW, 1 1/4-6 flat head (not

shown)

1

Graco Inc. P.O. Box 1441 Minneapolis, MN 55440-1441

406684 Rev, B 06/2009

Copyright 2007, Graco Inc. is registered to ISO 9001

2

Nylon seat (2) face down

ti10990a

Page 2

Repair Instructions

Disassembly

1. Remove the 1/2-20 acorn nut at the top of the

solenoid coil and pull the coil off.

2. Slip the spanner nut (3, not shown) over rod.

Insert into the two holes in the retaining disc.

Loosen with a wrench.

3. Carefully remove the poppet valve components

including the metal poppet guide disc below and

inside the o-ring to expose the nylon valve seat.

Put aside all parts in order of their removal and

with a proper orientation to each other to serve as

a guide for reassembly of parts removed.

4. Insert a 1-1/4 x 6 (4, not shown) all purpose screw

into the end of a slide hammer (user provided) or

similar device. Place the screw tip into the small

hole in the center of the nylon seat and turn it

approximately two turns into the seat.

CAUTION: The nylon seat is only 0.150 inch deep.

Do not turn the screw in more than 1/8

inch in order to avoid damage to the valve

body below the nylon seat.

5. Apply the slide-hammer action several times until

the nylon seat is pulled completely free of the

seat-well. Remove the used nylon seat and

discard.

Reassembly

1. Place a new nylon seat (2) with its chamfered hole

downward over the nylon seat-well with its axis as

vertical as possible.

2. Place the metal poppet-guide disc on top of the

nylon seat and then a 0.600-0.660 inch O.D. metal

cylinder (e.g., a 1/4 inch drive ratchet-wrench,

7/16 inch socket) on top of the disc. Tap the metal

cylinder with a nylon hammer until the nylon seat

is fully inserted into the well. Remove the metalpoppet guide disc to verify.

3. Reinstall the metal poppet-guide disc and the new

valve components provided in the solenoid kit (1).

Use the disassembly orientation from Step 3 as a

reference. Discard used components when

complete.

4. Tighten the poppet valve’s retaining disc with the

spanner nut (3) to 8-10 ft-lbs torque. Remove

spanner nut.

5. Reinstall solenoid coil onto the valve rod and

secure with the acorn nut tightened to 30-55 in-lbs

torque.

Loading...

Loading...