Page 1

WARNING

WARNING

Repair Kit Instructions

Control and Pump Kits for SaniSpray

™

HP

65 Portable Hopper Sprayer

Use these instructions when replacing the control board or pump components for the

SaniSpray HP 65 Portable Hopper Sprayer.

Important Safety Instructions

Read all warnings and instructions in this manual and in Operations manual before using

the equipment. Be familiar with the controls and the proper usage of the equipment. Save

all instructions.

Includes:

Control Board Replacement, page 8

Pump Cartridge Replacement, page 10

Pump Inlet Valve Replacement, page 11

Prime Valve and Knob Replacement, page 11

Pressure Control Replacement, page 13

ELECTRIC SHOCK HAZARD: To avoid

serious injury, turn off and disconnect

power cord before servicing the

equipment.

Pressure Relief Procedure

Before servicing the sprayer, pump pressure

must be relieved.

SKIN INJECTION HAZARD: This

equipment stays pressurized until

pressure is manually relieved. To help

prevent serious injury from pressurized

fluid, such as skin injection or splashing

fluid, follow the Pressure Relief

Procedure whenever sprayer is stopped

and before sprayer is cleaned or

checked, and before equipment is

serviced.

1. Turn ON/OFF switch to the OFF position.

25T416, 25T417

25T418

25T403

25T415

25T402

2. Engage the trigger lock. Always engage

the trigger lock when sprayer is stopped to

prevent the gun from being triggered

accidentally.

3. Turn Pressure Control Knob to the lowest

setting.

4. Put drain tube into a pail and turn

Prime/Spray Valve to PRIME position to

relieve pressure.

Hold a metal part of the Spray Gun firmly to a

5.

grounded metal pail. Point Spray Gun into

pail. Disengage the Trigger Lock and trigger

the Spray Gun to relieve pressure

6. Engage the trigger lock.

7. If you suspect the spray tip or hose is

clogged or that pressure had not been fully

relieved:

a. VERY SLOWLY loosen the spray tip

guard retaining nut or the airless

hose end coupling to relieve pressure

gradually.

b. Loosen the nut or coupling

completely

c. Clear airless hose or spray tip

obstruction.

3A7936A

.

EN

Use only genuine Graco replacement parts.

The use of non-Graco replacement parts may void warranty.

Page 2

Torque to 110-120 in-lb

(12.5-13.6 N•m)

Torque to 30-36 in-lb

(3.4-4.0 N•m)

1

2

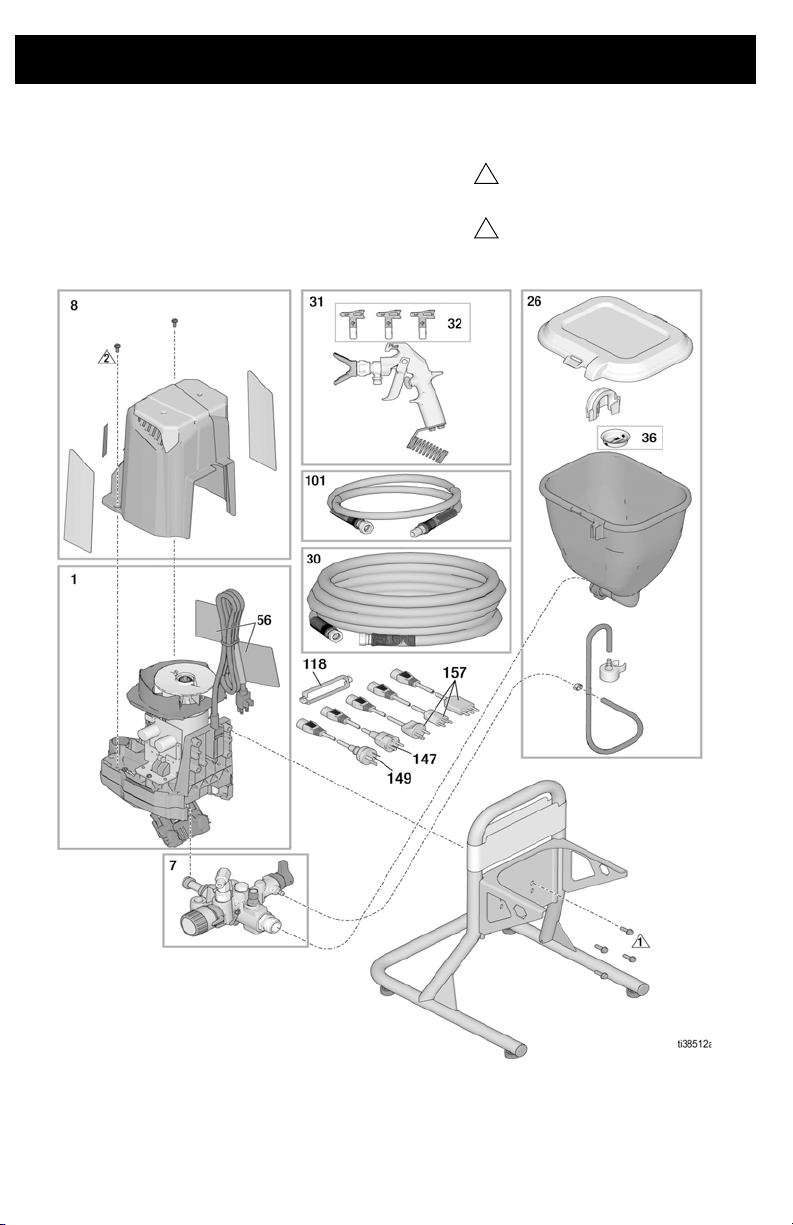

Parts - SaniSpray HP 65 (Quick Repair)

2 3A7936A

Page 3

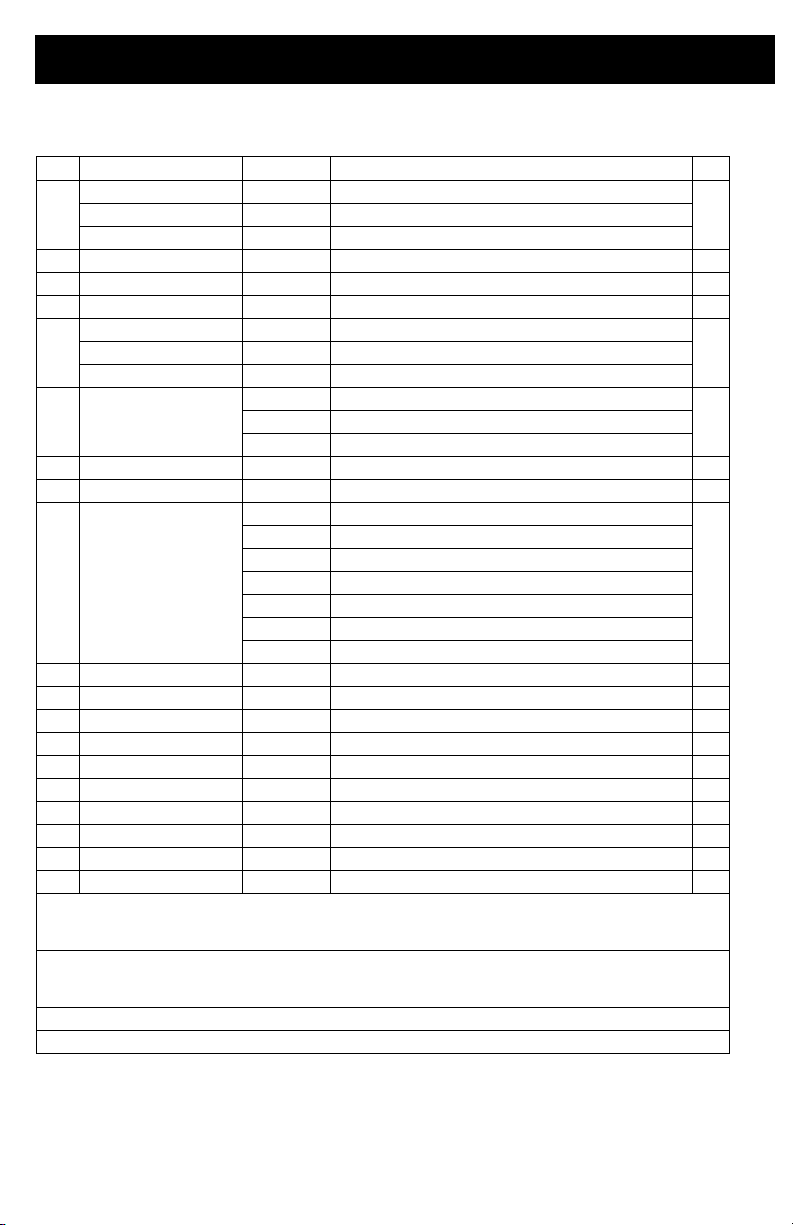

Parts List - SaniSpray HP 65 (Quick Repair)

Ref. Sprayer Model Part Description Qty.

25R972, 25R962 25R921 KIT, motor, drive, HP65, 120V, includes 56

1

25R948, 25R954 25T292 KIT, motor, drive, 230V, multi, includes 56

7 All 25R920 KIT, pump 1

8 All 25R922 KIT, enclosure 1

26 All 25R923 KIT, hopper 1

25R792 25R874 GUN, SaniSpray, HP, NA

31†

25R954, 25R962 25T290 GUN, SaniSpray, HP, AP

LP617 TIP, LP617

32 All

LP621 TIP, LP621

36 All 112133 SCREEN, hopper 1

56 All 25T410 KIT, warning labels, cord 1

CARD, medical alert (not shown)

222385 English, Spanish, French

17F690 Dutch, German, Italian

60 All

98 All 25T282 EXTENSION, 15 in. (not shown) 1

99* All 25R872 TIPSEAL, 5-pack (not shown) 1

101 All 25C828 HOSE, 1/8 in. x 4-1/2 ft. 1

118 25R948, 25R954 195551 PLUG, retaining 1

144 25R962 244285 CORDSET, Japan (not shown) 1

146 25R954 17N232 CORDSET, India (not shown) 1

147 25R948, 25R954 242001 CORDSET, EU Schuko 1

149 25R954 242005 CORDSET, ANZ 1

157 25R948 287121 CORDSET, Italy, Denmark, Switzerland 1

158 25R948 17J242 CORDSET, UK (not shown) 1

Motor/Drive Kit 25R921 does not include cordset adapter for Japan. Cordset adapter must

be ordered separate (see Ref. 144). Control Kit 25T292 does not include cordset adapter.

Cordset adapter must be ordered separate (see Ref. 146-158).

* Two extra TipSeals (polymer spray tip seals) are included with the sprayer. For disinfectant

applications, use TipSeal (polymer spray tip seal) instead of the OneSeal (metal seal) that

is included with the replacement spray tips.

† SaniSpray HP Gun includes LP619 Spray Tip.

Replacement safety labels, tags, and cards are available at no cost.

17A134 English, Chinese, Korean

17R476 English, Spanish, Portuguese (Brazil)

26A997 English, Indonesian, Hindi

26A998 English, Chinese, Japanese

125R946 25T291 KIT, motor, drive, 230V, CEE, includes 56

125R946, 25R948 25T289 GUN, SaniSpray, HP, EU

1LP619 † TIP, LP619

1

3A7936A 3

Page 4

Torque to 110-120 in-lb

(12.5-13.6 N•m)

Torque to 30-36 in-lb

(3.4-4.0 N•m)

1

2

5

Parts - SaniSpray HP 65 (Extended Repair)

Ref. Sprayer Model Part Description Qty.

25R792, 25R962 17J173 CORD, power, USA

3

25R948, 25R954 17L301 CORD, power, Multicord

15

15a

39 All 17K336 TUBE, drain, assembly 1

56 All 25T410 KIT, warning labels, cord 1

Replacement safety labels, tags, and cards are available at no cost.

4 3A7936A

25R792, 25R962 25T416 BOARD, control, 100-120V, includes 15a

25R946, 25R948,

25R954

25R792, 25R962 119276 FUSE, 12.5A slow blow, 100-120V

25R946, 25R948,

25R954

25T417 BOARD, control, 220-240V, includes 15a

129882 FUSE, 6.3A slow blow, 220-240V

125R946 17J175 CORD, power, EU Schuko

1

1

Page 5

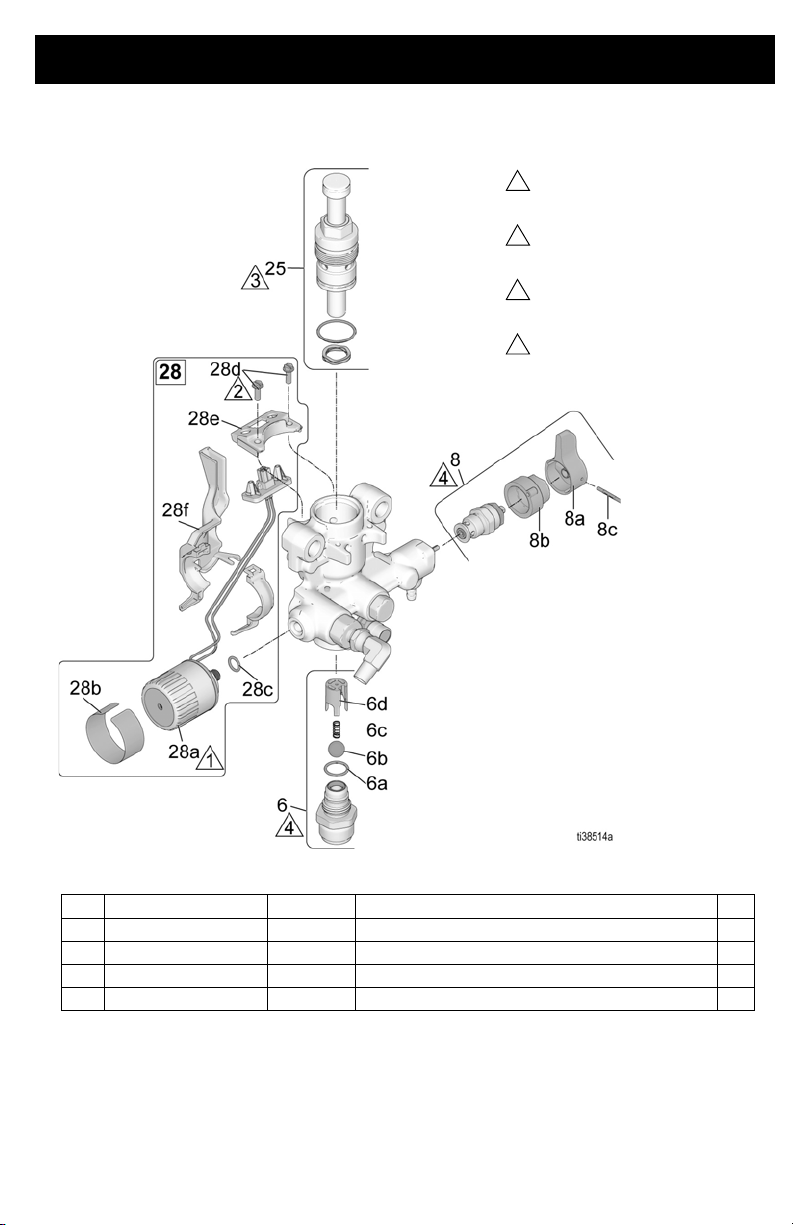

Parts - SaniSpray HP 65 (Pump Repair)

Torque to 140-160 in-lb

(16-18 N•m)

Torque to 270-330 in-lb

(30-37 N•m)

Torque to 30-35 ft-lb

(40-48 N•m)

Torque to 220-250 in-lb

(25-28 N•m)

123

4

Ref. Sprayer Model Part Description Qty.

6 All 25T403 KIT, inlet valve assembly 1

8 All 25T415 KIT, prime valve 1

25 All 25T418 KIT, pump cartridge 1

28 All 25T402 KIT, control, pressure 1

3A7936A 5

Page 6

1

3

ti27463a

2

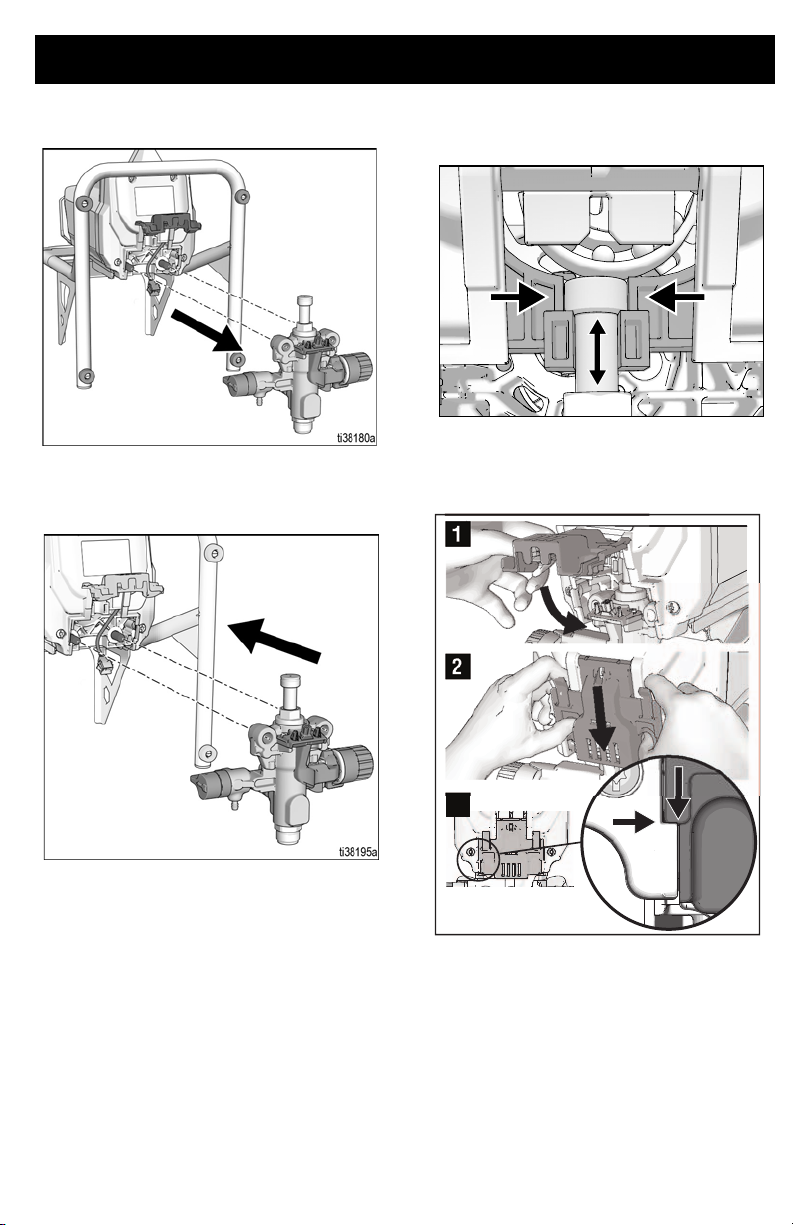

Motor Shield Removal/Installation

Disassembly

1. Perform Pressure Relief Procedure,

page 1.

2. Disconnect power cord.

Remove Motor Shield

3. Remove two machine screws and motor

shield (8).

Install Motor Shield

1. Install motor shield (8) using the two

screws removed earlier. Make sure the

motor shield slides into the switch bracket.

Be careful not to pinch cable when

installing the motor shield.

Pump Removal/ Installation

Remove Pump

1. Perform Pressure Relief Procedure,

page 1.

2. Disconnect power cord.

3. Remove the hopper.

4. Remove airless hose, if attached.

5. Re-position sprayer to access the easy

access door.

Open Easy Access Door

6. Pull tabs on sides of the easy access door

towards you while pushing the entire door

away from the inlet end of the pump.

7. Now lift the easy access door so it swivels

out of the way.

6 3A7936A

Page 7

8. Slide pump assembly off the mounting

1

ti27478a

2

3

pins.

2. Move pump displacement rod up or down

until cap is level with the opening in the

yoke.

ti27037a

Install Pump

1. Slide pump assembly onto the mounting

pins.

Close Easy Access Door

3. Swing easy access door closed and push

down to latch into pump.

NOTE: Door must be fully closed and latched

before sprayer will operate.

4. Install hopper and the hoses removed

earlier.

5. Perform Assembly Verification, page 13.

3A7936A 7

Page 8

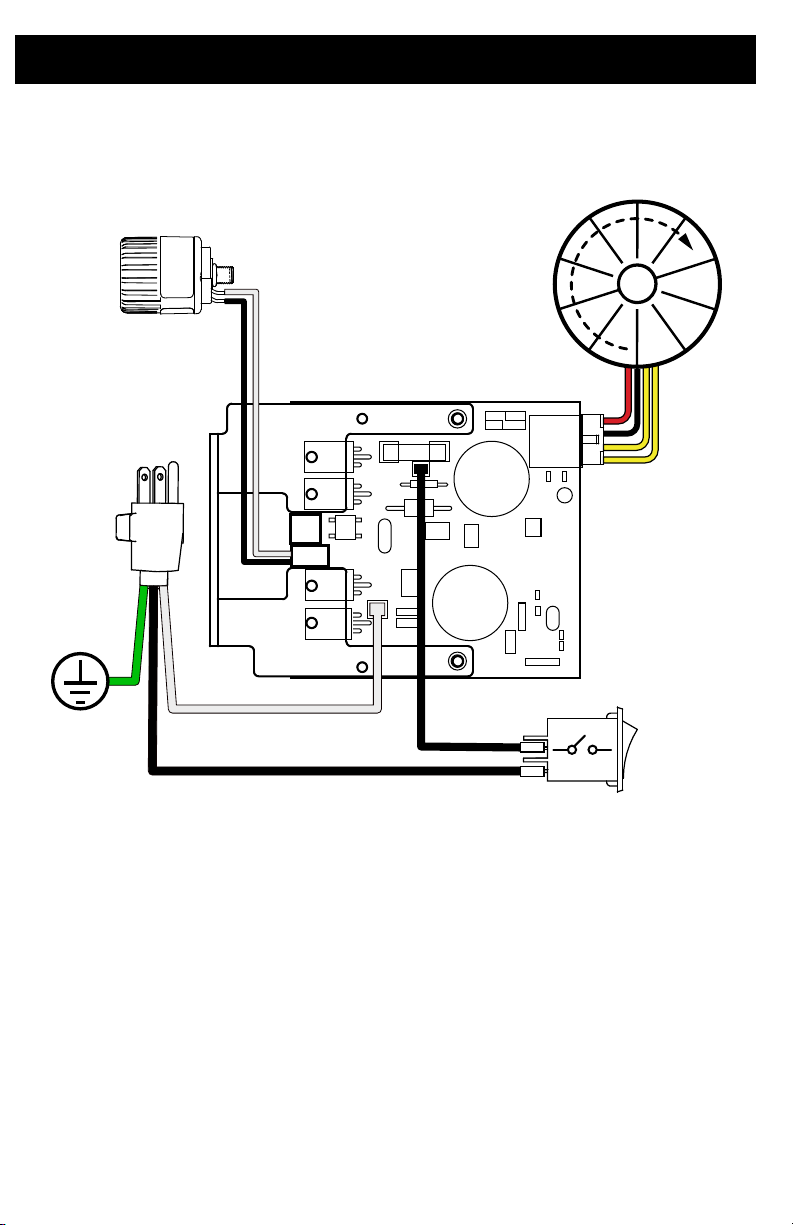

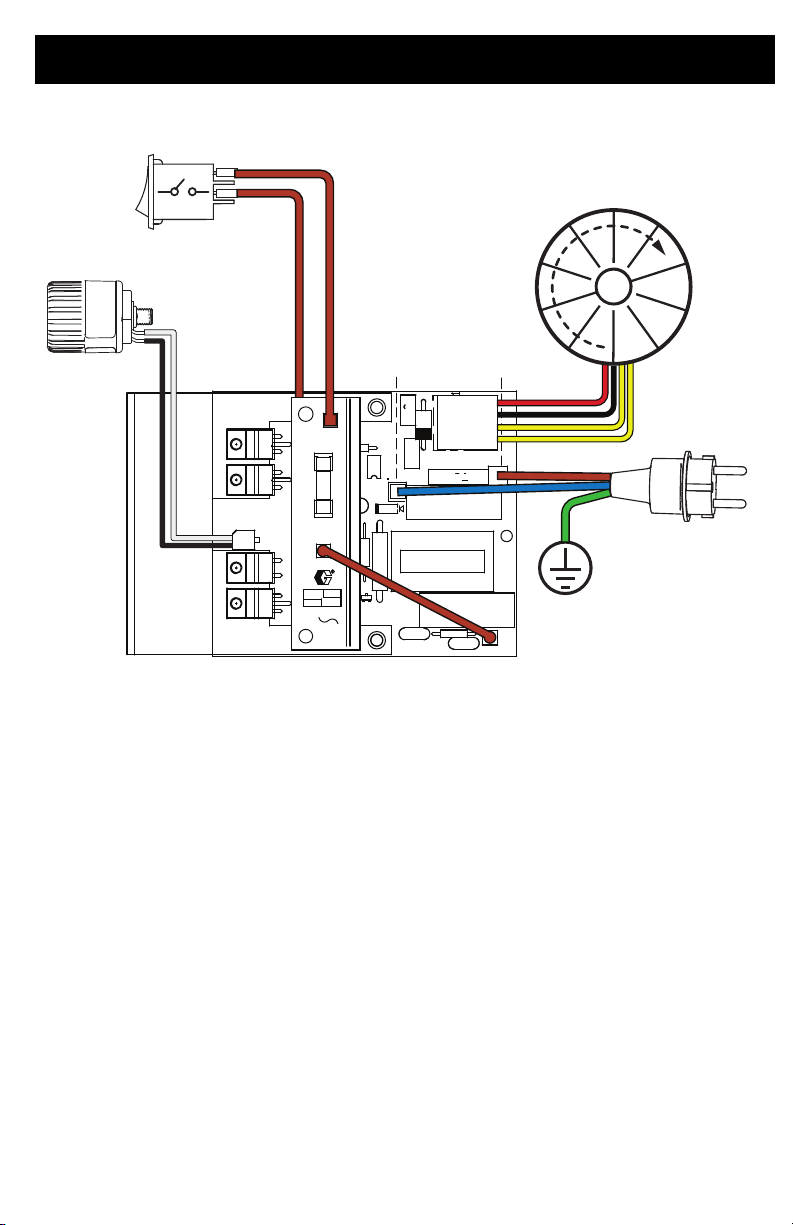

Control Board Replacement

Refer to Wiring Diagrams, pages 14 and 15.

Note color and location of all wires connected to

the control board before you start the control

board replacement.

Removal

1. Perform Pressure Relief Procedure,

page 1.

2. Disconnect power cord.

3. Remove Motor Shield, page 6.

4. Disconnect pressure switch and motor

connector from control board (15).

5. Disconnect ON/OFF switch and power

cord (3) connectors from control board (15)

leads.

6. Remove screw securing control board (15)

to drive housing.

Installation

1. Carefully slide new control board (15) into

place on the side of the driving housing.

Secure the screw and torque. See Parts -

SaniSpray HP 65 (Extended Repair),

page 4.

8 3A7936A

Page 9

2. Reconnect ON/OFF Switch and power

cord (3) connectors to the control board

(15) leads.

3. Reattach pressure switch and motor

connector to control board (15).

Fuse Replacement

If fuse is blown, check for:

• Pinched or shorted wires

• A defective motor

• A locked or frozen pump

1. Perform Pressure Relief Procedure,

page 1.

2. Disconnect power cord.

3. Remove Motor Shield, page 6.

4. Remove fuse (15a) from control board

(15).

5. Install new fuse (15a) on control board

(15).

6. Install Motor Shield, page 6.

7. Perform Assembly Verification, page 13.

4. Install Motor Shield, page 6.

5. Perform Assembly Verification, page 13.

3A7936A 9

Page 10

ti26947a

ti26954a

Pump Cartridge Replacement

Disassembly

1. Remove Hopper and Pump from sprayer.

See Remove Pump, page 6.

2. Insert hex end of pump into hex tool in the

sprayer frame and turn counterclockwise

to loosen assembly.

Assembly

1. On the new pump cartridge, remove

protective cap from the end of the piston

rod.

NOTICE

Be careful not to lose the packing spring that is

installed on the pump rod. Operation without the

packing spring will cause early pump failure.

2. While holding the pump body upside down,

start threading the new packing assembly

in by hand.

3. Remove entire packing assembly from

pump housing including the packing

spring.

3. Insert hex end of pump into hex tool in the

sprayer frame and tighten. Recommended

torque is 300 in-lb (35 N•m).

4. Install Pump onto sprayer, see page 7.

5. Perform Assembly Verification, page 13.

10 3A7936A

Page 11

Pump Inlet Valve

Prime Valve and Knob

Replacement

See Parts - SaniSpray HP 65 (Pump Repair),

page 5, for pump assembly diagram.

Disassembly

1. Perform Pressure Relief Procedure,

page 1.

2. Disconnect power cord.

3. Remove the hopper.

4. Remove inlet valve fitting (6) from pump

housing and discard. Make certain inlet ball

(6b), spring (6c), and ball guide (6d) are

removed from pump housing.

5. Clean all dried residue from around pump

inlet sealing area in pump housing.

Assembly

1. Assemble ball guide (6d), spring (6c), and

ball (6b) into pump housing (1).

a. The ball guide (6d) is keyed for

proper alignment.

b. Make certain the bump on the ball

guide (6d) is aligned with the slot in

the pump housing. Slide ball guide

(6d) into pump housing.

c. Install spring (6c) over ball stop pin in

the ball guide (6d).

d. Install ball (6b) into ball guide (6d).

2. Make certain o-ring (6a) is installed on inlet

valve housing (6).

3. Thread new inlet valve housing into pump

housing and torque. See Parts -

SaniSpray HP 65 (Pump Repair), page 5,

for torque.

4. Use a pencil or similar object to push on the

ball (6b) through the inlet valve intake to

make sure the ball moves freely.

5. Re-install the hopper.

6. Perform Assembly Verification, page 13.

Replacement

1. Perform Pressure Relief Procedure,

page 1.

2. Disconnect power cord.

3. Turn knob (8a) up to SPRAY position.

4. Remove pin (8c) with pin punch and

hammer.

5. Remove knob (8a) and base (8b).

3A7936A 11

Page 12

6. Remove valve stem assembly (8) from

pump housing. Make certain gasket (X)

and seat (Z) do not stay in pump housing.

Assembly

7. Apply sealant (provided in kit) to valve

threads. Install valve stem assembly in

pump manifold and torque. See Parts -

SaniSpray HP 65 (Pump Repair), page 5,

for torque.

8. Install base (8b) on valve, aligning pin (E)

in base (8b) with hole on pump housing.

9. Rotate valve stem with a pin punch until

hole is horizontal.

10. Install knob (8a) over base (8b).

11. Place knob in SPRAY position.

12. Insert end of pin punch through hole in

knob (8a), to make sure knob and valve

stem are aligned.

13. Apply small amount of grease to pin. Install

pin (8c) through hole in knob (8a). Tap pin

through knob with hammer. End of pin will

be flush with knob when correctly installed.

14. Perform Assembly Verification, page 13.

12 3A7936A

Page 13

Pressure Control Replacement

See Parts - SaniSpray HP 65 (Pump Repair),

page 5, for pump assembly diagram.

Disassembly

1. Remove Pump from sprayer, see page 6.

2. Remove wire shield (28f).

• Unsnap the wire shield.

• Remove retaining screw from pump

housing.

• Note wire routing, wires on new

pressure control will be routed the

same way.

• Save wire shield.

3. Remove the two screws (28d) from

electrical connector bracket (28e). Save

the screws.

4. Turn Pressure Control Knob fully

counterclockwise to expose the wrench

flats. Remove pressure control (28a) with

wire and electrical connector bracket

(28e). Verify the o-ring (28c) has been

removed from the pump housing.

Assembly

1. Examine pressure control (28a) to verify

the o-ring (28c) is on the pressure control.

If o-ring is not installed on pressure control,

install o-ring.

2. Apply one or two drops of thread locking

adhesive (included in kit) to threads of

pressure control (28a). Assemble pressure

control (28a) into pump housing and

torque. See Parts - SaniSpray HP 65

(Pump Repair), page 5, for torque.

3. Route wire from pressure control (28a) with

electrical connector bracket (28e) along

pump housing to mounting location.

4. Secure electrical connector bracket (28e)

to pump housing with two screws removed

earlier and torque. See Parts - SaniSpray

HP 65 (Pump Repair), page 5, for torque.

5. Install wire shield (28f).

• Make certain wire is under wire shield

(28f).

• Snap the wire shield around the pump

housing.

• Install retaining screw for wire shield

into pump housing.

6. Turn Pressure Control Knob clockwise as

far as it will go. Apply pressure control label

(28b) to knob. To position label correctly,

see note below:

NOTE: When properly positioned, the function

indicator (fi) and (+) position symbol on the

pressure control label (28b) are aligned.

7. Install Pump onto sprayer, see page 7.

8. Perform Assembly Verification, page 13.

Assembly Verification

After assembly is complete, perform the

following steps to verify proper operation. If

sprayer fails one of the steps, repeat sprayer

repair procedures.

• Rotate Prime/Spray Valve to make sure

it rotates forward to the spray position

and down to the prime pump position.

• Fill cup assembly with water and verify

sprayer primes and sprays. Follow setup

instructions in sprayer operation manual

for proper priming and spraying

procedure.

3A7936A 13

Page 14

Wiring Diagrams

ti27233a

M

Wiring Diagrams

100-120V

14 3A7936A

Page 15

220-240V

ti27485a

M

Wiring Diagrams

3A7936A 15

Page 16

www.graco.com/techsupport

?? ??

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call

distributor.

1-800-690-2894 to identify the nearest

All written and visual data contained in this document reflects the latest product information available at

the time of publication. Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A7936

International Offices: Belgium, China, Japan, Korea

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2020, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco Headquarters: Minneapolis

www.graco.com

Revision A, July 2020

Loading...

Loading...