Page 1

Instructions-Parts

G-Chem Beam

3A6349C

Pump

Lever-driven pump for injecting chemicals at well sites. For professional use only.

See page 3 for model information, including maximum working pressure.

Important Safety Instructions

Read all warnings and instructions in this manual

before using the equipment. Save all instructions.

EN

Page 2

Contents

Models and Approvals . . . . . . . . . . . . . . . . . . . . . . 3

G-Chem Beam Pumps . . . . . . . . . . . . . . . . . . . . 3

Fluid Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Configuration Number Matrix . . . . . . . . . . . . . . . . . 4

G-Chem Beam Pump Assembly Configuration Code

4

Fluid Module Configuration Code . . . . . . . . . . . . 5

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Flush Before Using Equipment . . . . . . . . . . . . . . 8

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . 8

Pumpjack Connections . . . . . . . . . . . . . . . . . . . 10

Fluid Connections . . . . . . . . . . . . . . . . . . . . . . . 11

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pressure Relief Procedure . . . . . . . . . . . . . . . . 12

Flush the Equipment . . . . . . . . . . . . . . . . . . . . . 12

Prime the Pump . . . . . . . . . . . . . . . . . . . . . . . . 13

Calibrate Chemical Dosage . . . . . . . . . . . . . . . 13

Adjust the Pump Stroke . . . . . . . . . . . . . . . . . . 14

Preventive Maintenance Schedule . . . . . . . . . . 17

Tighten Threaded Connections . . . . . . . . . . . . . 17

Tighten Packings . . . . . . . . . . . . . . . . . . . . . . . 17

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Pump Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

G-Chem Beam Drive Module . . . . . . . . . . . . . . 21

G-Chem Beam Fluid Module . . . . . . . . . . . . . . 23

Kits and Accessories . . . . . . . . . . . . . . . . . . . . . . 25

G-Chem Beam Pump . . . . . . . . . . . . . . . . . . . . 25

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

G-Chem Beam Pump Dimensions . . . . . . . . . . 26

Technical Specifications . . . . . . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

California Proposition 65 . . . . . . . . . . . . . . . . . . . 27

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 28

2 3A6349C

Page 3

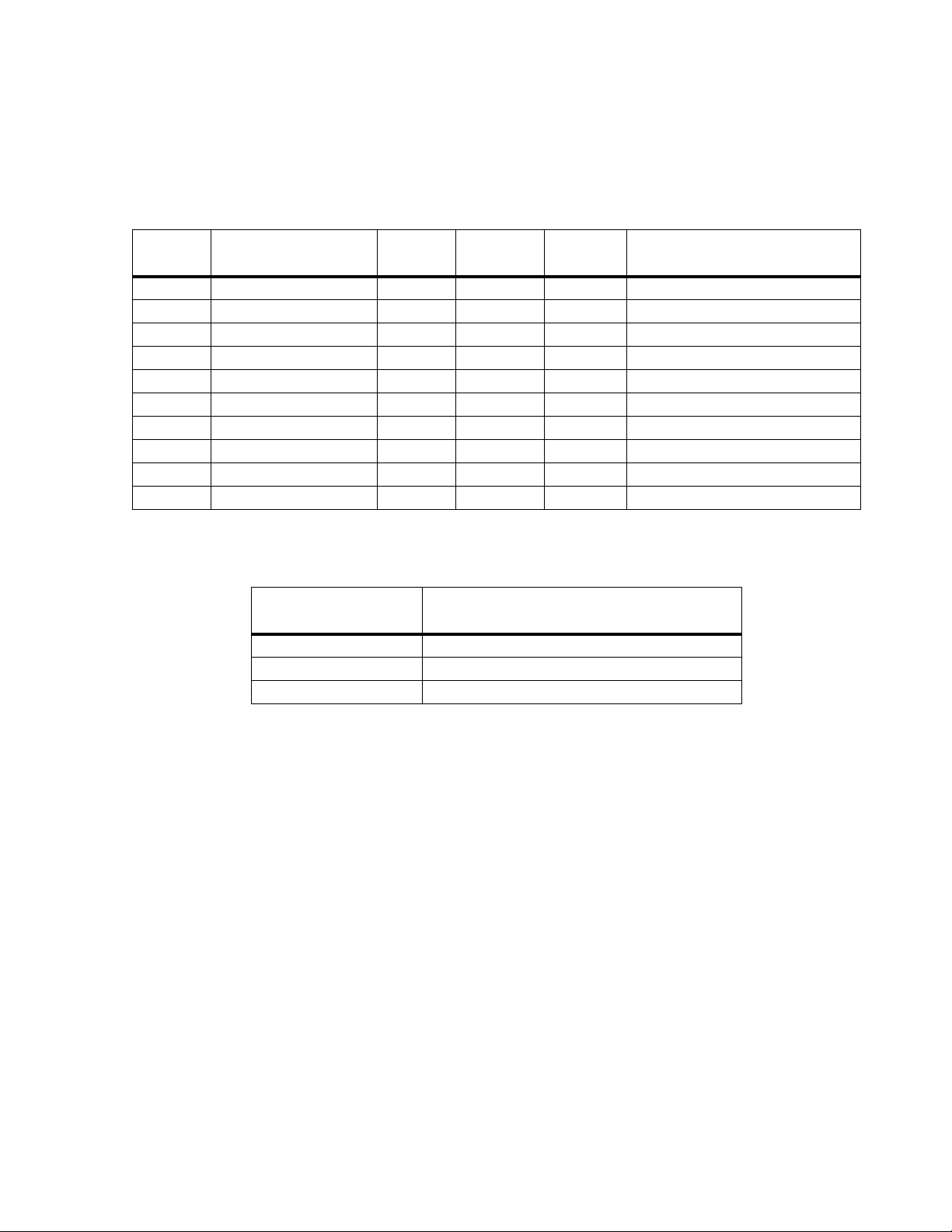

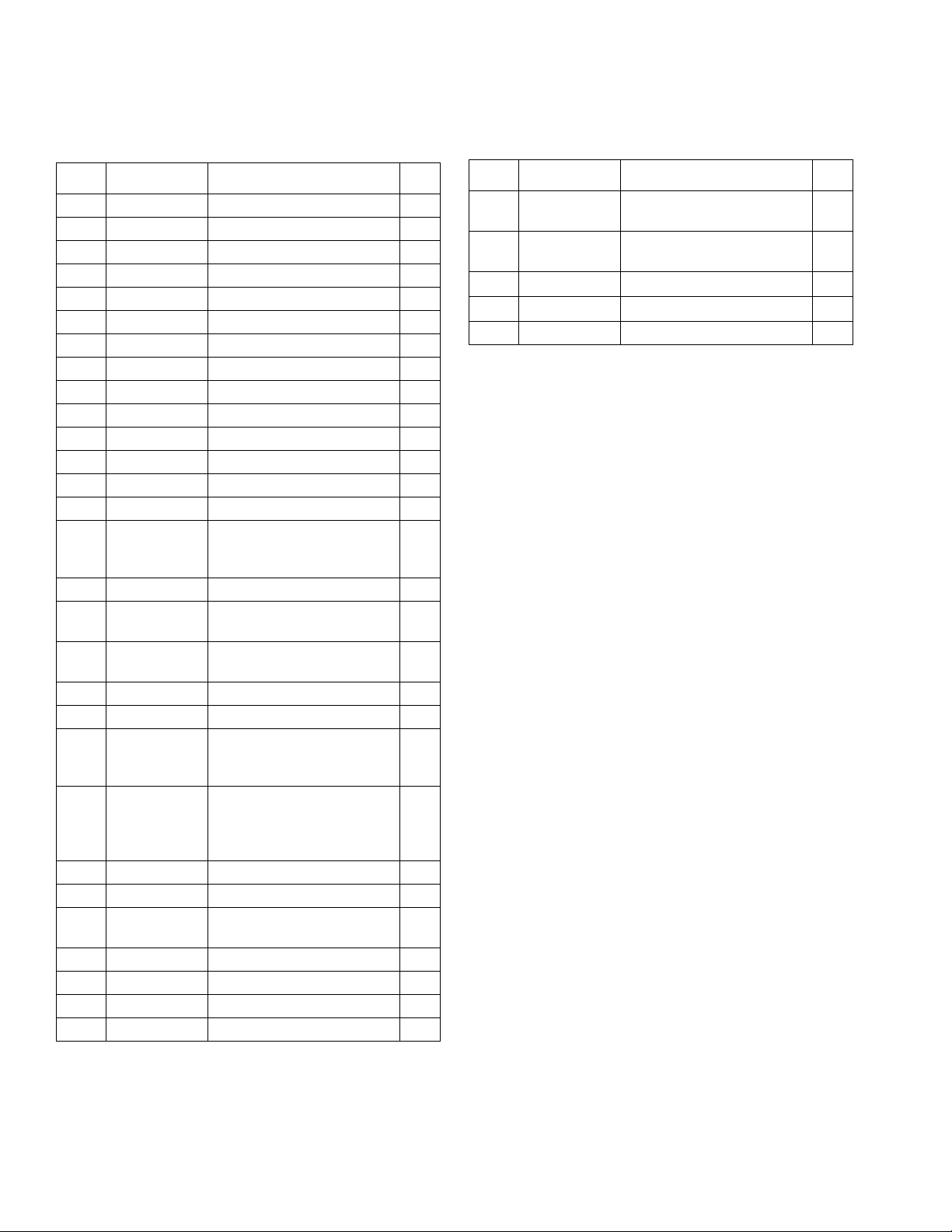

Models and Approvals

G-Chem Beam Pumps

Models and Approvals

Models Configuration Number

A23000 CI-NAO-2XF-000-0 1/4 in. Simplex FKM 2500 (17.2, 172)

A23001 CI-NAO-3XF-000-0 3/8 in. Simplex FKM 1500 (10.3, 103)

A23002 CI-NAO-5XF-000-0 1/2 in. Simplex FKM 800 (5.5, 55)

A23003 CI-NAO-2XG-000-0 1/4 in. Simplex HNBR 2500 (17.2, 172)

A23004 CI-NAO-3XG-000-0 3/8 in. Simplex HNBR 1500 (10.3, 103)

A23005 CI-NAO-5XG-000-0 1/2 in. Simplex HNBR 800 (5.5, 55)

A23006 CI-NAO-2XH-000-0 1/4 in. Simplex TFE/P 2500 (17.2, 172)

A23007 CI-NAO-3XH-000-0 3/8 in. Simplex TFE/P 1500 (10.3, 103)

A23008 CI-NAO-5XH-000-0 1/2 in. Simplex TFE/P 800 (5.5, 55)

A23009 CI-NAO-2XJ-000-0 1/4 in. Simplex PTFE 500 (3.4, 34)

Fluid Modules

Plunger

Size

Plunger Size

1/4 in. 2500 (17.2, 172)

3/8 in. 1500 (10.3, 103)

1/2 in. 800 (5.5, 55)

Number of

Pumps

Maximum Working Pressure

Seal

Material

psi (MPa, bar)

Maximum Working Pressure

psi (MPa, bar)

3A6349C 3

Page 4

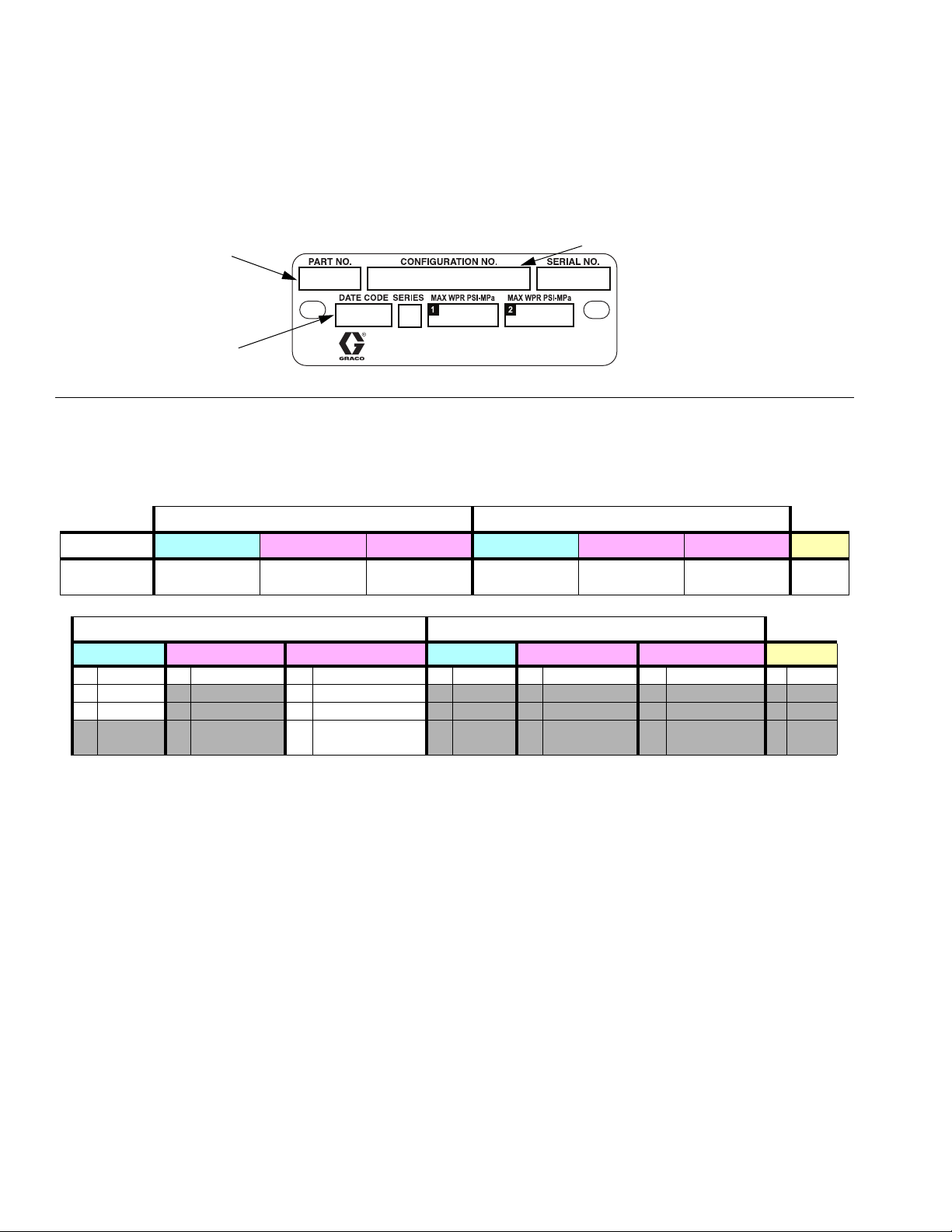

Configuration Number Matrix

A23000 CI-2XF-000-0 ########

A 2500(17

)

# ####

Graco Inc., P.O. Box 1441

Mpls, MN 55440 USA

Model Number

Configuration Number

Date Code

Configuration Number Matrix

Check the identification plate (ID) for the 12-digit Configuration Number of your pump. Use the following matrix to

define the components of your pump.

FIG. 1 Example of the G-Chem Assembly Identification Plate

G-Chem Beam Pump Assembly Configuration Code

Sample Configuration Number: CI-12E-2XF-000-0

Side 1 Side 2

CI 2 X F 0 0 0 0

Chemical

Injection

Plunger Size Plunger Coating Seal Material Plunger Size Plunger Coating Seal Material Qualifier

Side 1 Side 2

Plunger Size Plunger Coating Seal Material Plunger Size Plunger Coating Seal Material Qualifier

2 1/4” X Chromex F FKM 0 None 0 None 0 None 0 None

33/8”

51/2” HTFE/P

GHNBR

J PTFE w/FFKM

checks

4 3A6349C

Page 5

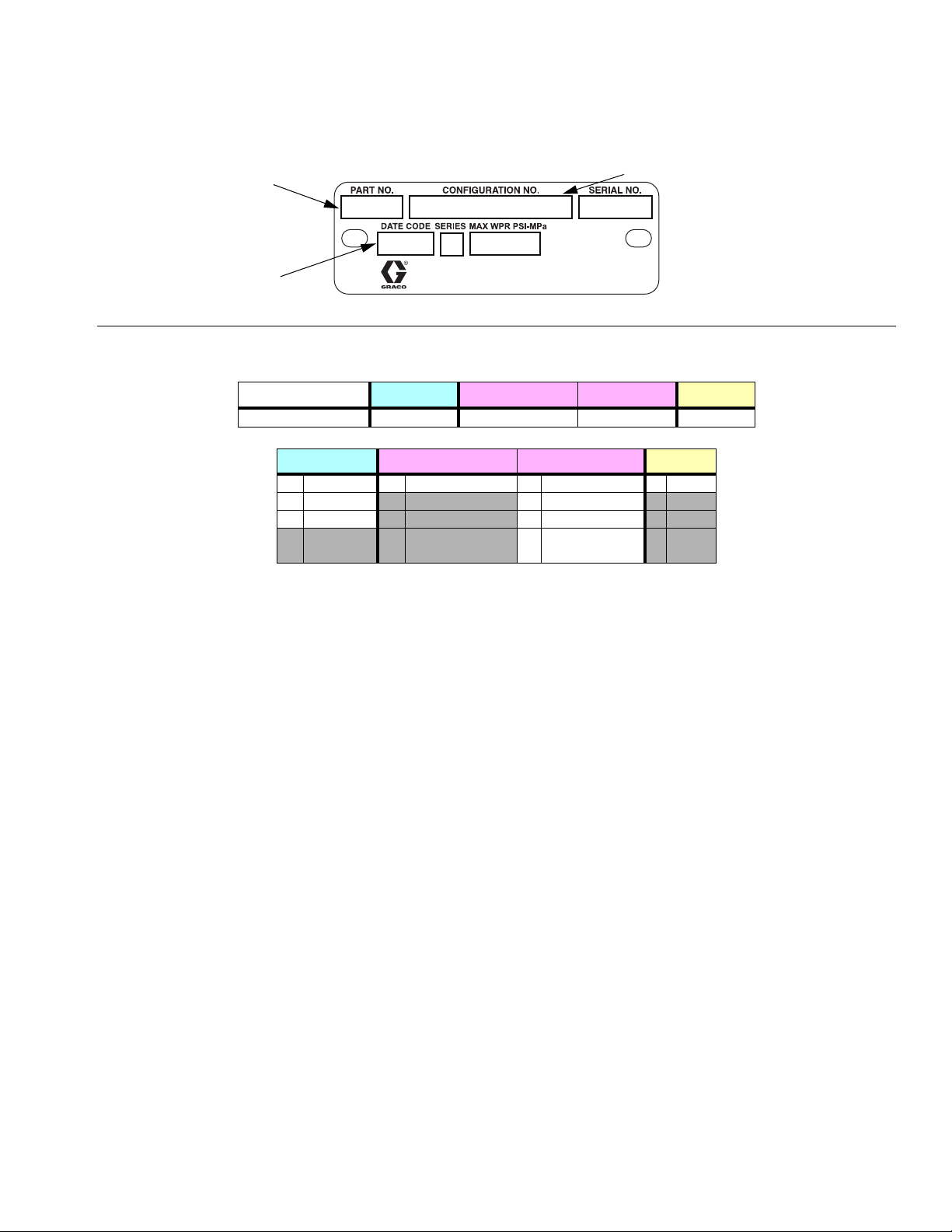

Fluid Module Configuration Code

A30970 ########

A 2500(17

)

# ####

Graco Inc., P.O. Box 1441

Mpls, MN 55440 USA

CI-25-XF-0

Model Number

Configuration Number

Date Code

FIG. 2 Example of the Fluid Module Identification Plate

Sample Configuration Number: CI-25-XF-0

CI 25 X F 0

Chemical Injection Plunger Size Plunger Coating Seal Material Qualifier

Plunger Size Plunger Coating Seal Material Qualifier

25 1/4” X Chromex F FKM 0 None

38 3/8” G HNBR

50 1/2” HTFE/P

Configuration Number Matrix

J PTFE w/FFKM

checks

3A6349C 5

Page 6

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area be aware that flammable fumes can ignite or

explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Ground all equipment in the work area.

• Keep work area free of debris, including rags and spilled or open containers of solvent.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Use only grounded hoses.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment until

you identify and correct the problem.

• Keep a working fire extinguisher in the wor k ar ea .

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or da m age d pa rt s imm ed ia tely .

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Befo re checking, moving, or servicing equ ipment,

follow the Pressure Relief Procedure and disconnect all power sources.

6 3A6349C

Page 7

Warnings

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read Safety Data Sheet (SDS) to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. Protective equipment includes but is not

limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by th e fluid and solvent manufacturer.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See Technical Specifications in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Specifica-

tions in all equipment manuals. Read fluid and solve nt manufacturer’s warnings. Fo r complete information about your material, request Safety Data Sheets (SDSs) from distributor or retailer.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment regularly. Repair or replace wo rn or damaged parts immediately with genuine man ufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

3A6349C 7

Page 8

Installation

Installation

To avoid injury due to unexpected moving parts,

remove power to the pumpjack and wait for the walking beam to stop moving before performing any task

on the G-Chem pump. The G-Chem pump is directly

influenced by the motion of the pumpjack’s walking

beam, and the pump is inactive only when the walking

beam is unable to move.

Grounding

The equipment must be grounded to reduce the risk

of static sparking. Static sparking can caus e fum es t o

ignite or explode. Grounding provides an escape wire

for the electric current.

Pump: grounded through fluid lines.

Fluid lines: use only electrically conductive lines.

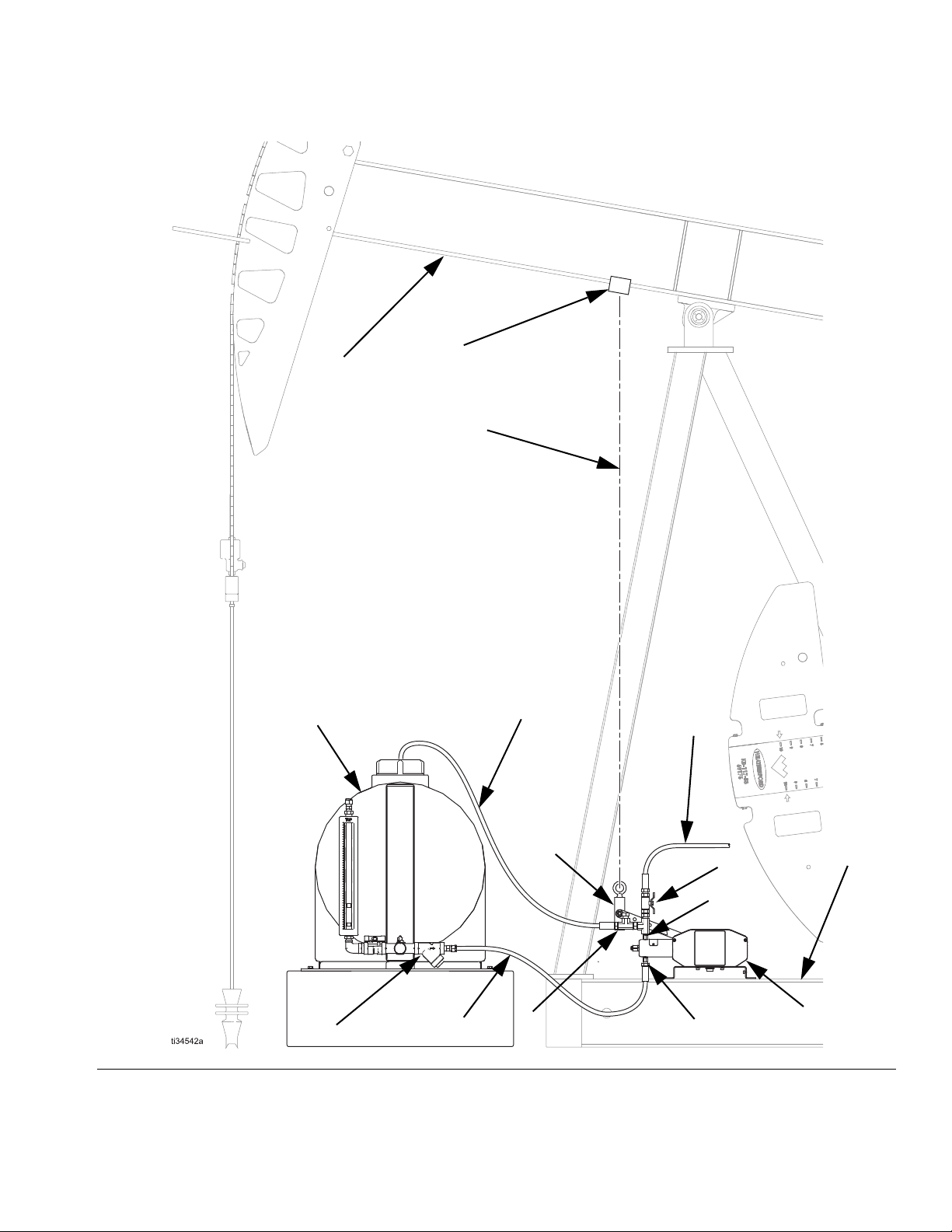

Typical Installation

FIG. 3 is an example of an installation with a G-Chem

chemical injection beam pump. Your installation may differ from what is shown here. (See Accessories on

page 8.) The G-Chem beam pump (A) and the swivel

block (B) are the only components in F

Graco. All other components are supplied by customer.

Key:

A G-Chem Beam Pump

B Swivel Block and Eye Bolt

CTank

D Pressure Relief Valve (Required)

E Inlet Line

F Outlet Line

G Pressure Relief Line

H Inlet Port

JOutlet Port

K Manifold Assembly (includes y-strainer and fluid shutoff

valve (L))

L Fluid Shutoff Valve (inlet & outlet) (Required)

M Pumpjack Base (I-Beam)

N Cable/Rod/Pipe

P Walking Beam

R Beam Clamp

IG. 3 supplied by

Fluid supply container: follow local code.

Accessories

Install the following required accessories in the order

shown in a typical installation (see F

using adapters as necessary.

• Fluid filter (Y-Strainer) (included in K): with a 60

mesh (250 micron) stainless steel element to filter

particles from the fluid before in reaches the pump.

• Fluid shutoff valves (L): shuts off fluid flow.

• Pressure relief valve (D): overload protection.

IG. 3 on page 9)

Flush Before Using Equipment

The equipment was tested with lightweight oil, which is

left in the fluid passages to protect parts. To avoid contaminating your fluid with oil, flush the equipment with a

compatible solvent before using the equipment. See

Flush the Equipment, page 12.

8 3A6349C

Page 9

Installation

A

B

F

E

G

C

D

H

J

N

K

L

M

R

P

FIG. 3 Typical G-Chem beam pump installation with pumpjack

3A6349C 9

Page 10

Installation

21 in.

6 in.

122

A

8

Pumpjack Connections

1. Remove power to the pumpjack and wait for the

pumpjack to stop moving.

2. Attach a cable (N) to the walking beam (P) using a

beam clamp (R) or other connection method (both

user-supplied).

• Place the beam clamp (R) on the walking beam

(P) where the vertical travel is, at most, 21 in.

(53.34 cm), which is the maximum travel of the

G-Chem pump’s lever arm.

4. Securely clamp or bolt the G-Chem pump (A) to the

pumpjack base (M) using the pump’s supplied

base (112).

• The G-Chem pump (A) is shipped with the sup-

plied base (112) already attached.

5. Connect the lever arm (122) to the walking beam

(P) by routing the end of the cable (N) through the

eye bolt (8) on the supplied swivel block (B).

6. Ensure there is no slack in the cable (R) when the

G-Chem pump (A) is maximum stroke (setting “1”

on the lever arm (122) and “Full” on the stroke

adjust). Refer to Adjust the Pump Stroke on

page 14.

FIG. 4 Lever arm range of travel

3. Position the G-Chem pump (A) on the pumpjack

base (M) so that the walking beam (P) provides a

straight upward pull as it rises.

• The lever arm (122) must be able to travel 6 in.

below the base of the G-Chem pump (A) to

achieve maximum flow.

10 3A6349C

Page 11

Fluid Connections

201

215

210, 211

216

122

112

101

7

8

Installation

1. With the pumpjack off, r emove and discard the caps

on the check valves (215 and 216).

FIG. 5 G-Chem Beam Pump Components

Key:

7 Swivel Block

8Eye Bolt

101 Drive Housing

112 Mounting Panel

122 Lever Arm

201 Fluid Cylinder

210 Bleed Valve

211 Bleed Needle

215 Inlet Check Valve

216 Outlet Che ck Valve

3. Install a pressure relief valve (D) on the outlet side

of the pump. See F

IG. 3 on page 9.

In the event of a fluid line blockage, to reduce the risk

of skin injection and damage to the pump, ensure the

pressure relief valve is set at or below the maximum

working pressure of the pump.

4. Set the pressure relief valve at or below the maximum working pressure of the pump.

5. Connect a 1/4 npt(f) fluid line from the outlet check

valve (J) to the injection point.

2. Connect a 1/4 npt(f) fluid line fro m the fluid source to

the inlet check valve (215).

3A6349C 11

Page 12

Operation

Operation

To avoid injury due to unexpected moving parts,

remove power to the pumpjack and wait for the walking beam to stop moving before performing any task

on the G-Chem pump. The G-Chem pump is directly

influenced by the motion of the pumpjack’s walking

beam, and the pump is inactive only when the walking

beam is unable to move.

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

Flush the Equipment

To avoid fire and explosion, always ground equip ment

and waste container. To avoid static sparking and

injury from splashing, always flush at the lowest possible pressure.

• Check fittings for leaks and tighten as necessary.

• Flush with a fluid that is compatible with the fluid

being dispensed and the equipment’s wetted parts.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection and splashing

fluid, follow the Pressure Relief Procedure when

you stop dispensing and before cleaning, checking, or

servicing the equipment.

NOTE: Always discharge fluid into an approved container or location.

1. Remove power to the pumpjack and wait for the

pumpjack to stop moving.

2. Shut off the inlet (E) and outlet (F) lines using shutoff valves (L). See F

3. Slowly loosen the fitting connected to the outlet

check valve (216) to relieve downstream fluid pressure. See F

4. Open the bleed needle (211) on the end of the

pump cylinder (201) to relieve internal pump pressure.

IG. 3 on page 8.

IG. 3 on page 9.

1. Follow the Pressure Relief Procedure.

2. Disconnect lever arm (122) from the pumpjack.

3. Connect the inlet check valve (215) to the supply

source of the flushing fluid. See F

4. Connect the outlet check valve (216) to a waste reservoir.

5. Operate the lever arm (122) by hand until the dispensed fluid is predominantly flushing fluid.

6. Follow the Pressure Relief Procedure.

7. Reconnect the lever arm (122) to the pumpjack.

Refer to Pumpjack Connections, page 10.

IG. 3 on page 8.

5. Disconnect and cap the inlet (E) and outlet (F) fluid

lines.

12 3A6349C

Page 13

Operation

Prime the Pump

NOTICE

To avoid potential damage to equipment, verify that all

system valves are open before priming the pump.

1. Remove power to the pumpjack and wait for the

pumpjack to stop moving.

2. Disconnect lever arm (122) from the pumpjack.

3. Verify all connections and fluid lines are tight.

4. Verify only the inlet valve (215) is open.

5. Place a chemical compatible bucket under the bleed

valve (210).

6. In order to prime the pu mp, turn the bleed needle

(211) counterclockwise.

7. Operate the lever arm (122) by hand to prime the

pump.

8. The pump is prime d when discharge from the bleed

valve (210) has transitioned from air, to bubbly liquid

chemical, to pure liquid chemical.

Calibrate Chemical Dosage

1. With the pumpjack turned off, set the stroke adjustment of the pump to an estimated setting for the

desired flow rate. Refer to Adjust the Pump

Stroke, page 14, and Baseline Chemical Dosage

Settings, page 16.

2. Follow the instr uctions provided with your calibration

gauge.

3. Adjust the stroke adjustment accordingly after the

test is performed. Increasing the stroke adjustment

of the pump will increase the pump flow rate.

4. If a slower flow is desired, slow the pumping rate of

the pumpjack, or adjust the orientation of the lever

arm by removing the retaining clip (123) at the base

of the lever arm (122) and rotating the handle to a

different position on the octagonal shaft. This will

lengthen or shorten the lever arm stroke.

5. Repeat the instructions provided with your calibration gauge to verify changes.

6. Repeat steps 3 - 5, as necessary, until the desired

flow rate is achieved.

9. Turn the bleed ne edle (211) clockwise until tight and

verify that fluid has stopped draining from the port.

10. Reconnect the lever arm (122) to the pumpjack.

Refer to Pumpjack Connections, page 10.

3A6349C 13

Page 14

Operation

128

127

3/4

Full

1/2

209

121

Stroke holes

Adjust the Pump Stroke

The stroke of the G-Chem pump can be adjusted by a

combination of a pin in the pump and the lever arm.

Stroke Adjustment with Pin Settings

The pump has three defined stroke adjustment positions.

1. Follow the Pressure Relief Procedure on page 12.

2. Disconnect the G-Chem pump (A) from the pumpjack by removing the swivel block (B) from the lever

arm (122).

3. Expose the drive shaft by loosening the fasteners

(128) and removing the guard (127). The fasteners

are captive and will remain with the guard.

6. Align the desired stroke hole (1/2, 3/4, or Full) with

hole in the fluid plunger (209). Use a screwdriver to

push in the pin (120).

FIG. 7 Stroke adjustment - pin positions

7. Push the split ring (121) into place to cover the

pin (120).

FIG. 6 Expose the drive shaft

4. Push the split ring (121) left or right to expose the

dowel pin (120) in one of the stroke holes.

5. Push out the pin (120) using a screwdriver or punch.

8. Replace the gu ard (127) and tighten the fasteners

(128).

9. Reconnect the G-Chem pump (A) to the pumpjack

by reattaching the swivel block (B) to the level

arm (122).

14 3A6349C

Page 15

Stroke Adjustment with Lever Arm Settings

123

122

105

The handle has two defined stroke adjustment positions.

1. Follow the Pressure Relief Procedure on page 12.

2. Disconnect the G-Chem pump (A) from the pumpjack by removing the swivel block (B) from the lever

arm (122).

3. Remove the retaining clip (123) from the lever

arm (122) using a flat-blade screwdriver.

4. Remove the lever arm (122) from the shaft (105).

5. Reorient the lever arm ( 122) so the arrow on the

lever arm lines up with either “1” or “2” on the

shaft (105).

Operation

FIG. 8 Stroke adjustment - lever arm positions

6. Reinstall the lever arm (122) in the desired orientation.

7. Reinstall the retaining clip (123) onto the shaft using

your fingers or a pair of pliers.

8. Reconnect the G-Chem pump (A) to the pumpjack

by reattaching the swivel block (B) to the level

arm (122).

3A6349C 15

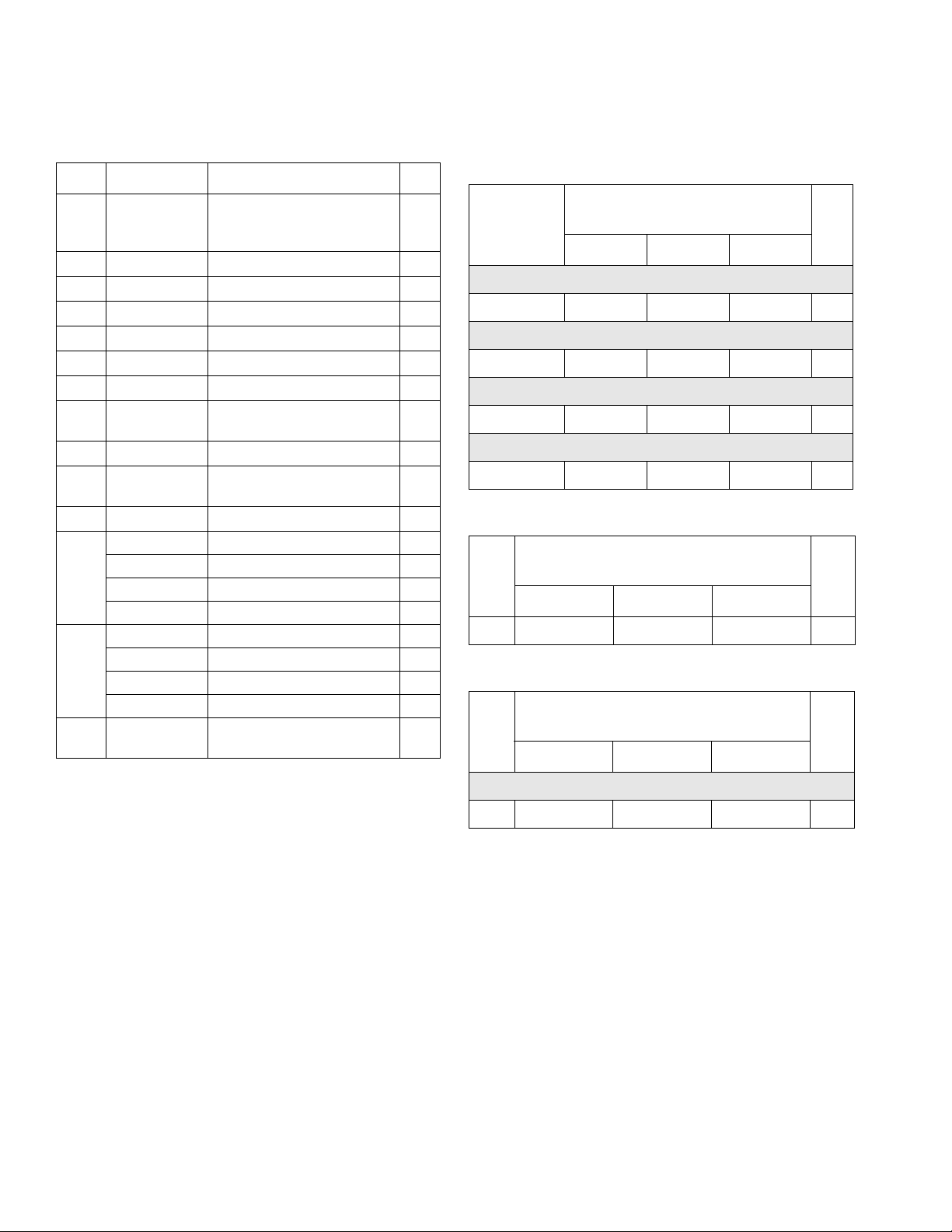

Page 16

Operation

Baseline Chemical Dosage Settings

See Adjust the Pump Stroke, page 14, to adjust stroke settings. CPM (cycles per minute) is determined by the

pumpjack speed. To use these charts, find the desired flow rate for the plunger size and adjust the pin and lever arm

as necessary.

1/4 in. Plunger 3/8 in. Plunger 1/2 in. Plunger

CPM

5

10

15

Pin

Setting

3/4 2 0.3 (1.1) 3/4 2 0.7 (2.6) 3/4 2 1.2 (4.5)

1/2 1 0.5 (1.9) 1/2 1 1.1 (4.2) 1/2 1 1.8 (6.8)

Full 2 0.6 (2.3) Full 2 1.5 (5.7) Full 2 2.6 (9.8)

3/4 1 0.7 (2.6) 3/4 1 1.6 (6.1) 3/4 1 3.2 (12.1)

Full 1 1.2 (4.5) Full 1 2.8 (10.6) Full 1 5.0 (18.9)

3/4 2 0.5 (1.9) 3/4 2 1.3 (4.9) 3/4 2 2.3 (8.7)

1/2 1 1.0 (3.8) 1/2 1 2.2 (8.3) 1/2 1 3.6 (13.6)

Full 2 1.2 (4.5) Full 2 2.9 (11.0) Full 2 5.1 (19.3)

3/4 1 1.5 (5.7) 3/4 1 3.2 (12.1) 3/4 1 6.5 (24.6)

Full 1 2.5 (9.5) Full 1 5.7 (12.6) Full 1 10.0 (37.9)

3/4 2 0.8 (3.0) 3/4 2 2.0 (7.6) 3/4 2 3.5 (13.2)

1/2 1 1.4 (5.3) 1/2 1 3.3 (12.5) 1/2 1 5.4 (20.4)

Full 2 1.8 (6.8) Full 2 4.4 (16.7) Full 2 7.7 (29.1)

3/4 1 2.2 (8.3) 3/4 1 4.8 (18.2) 3/4 1 9.7 (36.7)

Full 1 3.7 (14.0) Full 1 8.5 (32.2) Full 1 15.0 (56.8)

Lever

Setting

Approximate

Flow Rate

[GPD (LPD)]

Pin

Setting

Lever

Setting

Approximate

Flow Rate

[GPD (LPD)]

Pin

Setting

Lever

Setting

Approximate

Flow Rate

[GPD (LPD)]

NOTE: Not all stroke adjustment combinations are pos-

sible.

16 3A6349C

Page 17

Maintenance

Preventive Maintenance

Schedule

The operating conditions of your particular pump determines how often maintenance is required. Establish a

preventive maintenance schedule by recording when

and what kind of maintenance is needed, and then

determine a regular schedule for checking your pump.

Tighten Threaded Connections

Check that all threaded connections are tight at routine

intervals.

Tighten Packings

Operation

The packings included in your pump have the ability to

be adjusted to stop leaks that develop when the seals

are worn. If a leak develops in the pump’s fluid section,

tighten the packing nut clockwise by 1/16th of a turn, or

lower, until the leak is eliminated. The life of the packing

can be affected by over-tightening the packings. If the

packing nut needs to be tightened repeatedly after short

intervals, replace the packing.

Storage

If the pump is going to be stored for long periods, it is

recommended that the pump be flushed with a

light-weight oil or rust prohibiter to protect pump components. Store the pump with protective fluid inside whenever possible.

3A6349C 17

Page 18

Troubleshooting

Troubleshooting

1. Follow Pressure Relief Procedure, pa ge 12,

before checking or repairing the pump.

Problem Cause Solution

Air bubbles in fluid Suction line is loose Tighten suction line

Fluid leaking Loose fittings Tighten fittings

Worn or damaged seals and/or packing

Lever arm moving, but fluid not moving

Pump stalled Check pump for contamination

Air in pump Prime pump

Worn or damaged check valve seals Replace inlet and outlet check valves

2. Check all possible problems and causes be fore disassembling the pump.

Adjust or tighten seals and/or packing. If leak persists, replace seals

and/or packing.

18 3A6349C

Page 19

Repair

128

127

3

201

209

101

120

201

Packing

Stack

207

206

204

205

204

205

203

202

Pump Repair

1. Remove power to the pumpjack and wait for the

pumpjack to stop moving.

2. Follow the Pressure Relief Procedure.

3. Disconnect lever arm (122) from the pumpjack.

Repair

4. Expose the drive shaft by loosening the fasteners

(128) and removing the guard (127). The fasteners

are captive and will remain with the guard.

FIG. 9 Expose the drive shaft

5. Remove the screws (3) and slide the fluid cylinder

away from the drive housing (101).

NOTE: The plunger (209) will stay within the drive

housing (101) unless the dowel pin (120) is

removed. The dowel pin is held in place by a split

ring that can be push aside to free the pin. It is not

necessary to remove the plunger (209) unless it is

damaged and needs to be replaced.

FIG. 10 Disconnect the fluid cylinder

6. Remove packing nut (207) from fluid cylinder (201).

3A6349C 19

FIG. 11 G-Chem Pump Repair

Page 20

Repair

7. Carefully remove the packing stack (203-206) and

the spacer (202) from the fluid cylinder (201).

8. Replace the packing stack (203-206). Inspect the

spacer (202) and replace, if necessary. Lubricate

prior to reassembly.

9. Replace the packing nut (207) assembly into fluid

cylinder. Tighten until hand tight and the flange of

the packing nut (207) is below the surface of the

fluid cylinder (201).

10. Slide the fluid cylinder (201) onto the plunger (209)

and use the screws (3) to attach the fluid cylinder

(201) to the drive housing (101).

NOTE: Install the plunger (209) first if it was

removed, and secure it with the dowel pi n (120) and

split ring (121). Refer to Stroke Adjustment with

Pin Settings, on page 14, for specific placement of

the pin (120) and ring (121).

11. Replace the guard (127) and tighten the fasteners

(128).

20 3A6349C

Page 21

Parts

6

8

9

7

130

123

102

103

105

112

113

114

119

121

109

120

128

3

133

127

129

131

101

125

130

106

115

118

116

117

108

110

107

6

6

5

6

5

122

Fluid Module,

see page 23.

G-Chem Beam Drive Module

Configuration CI-2XF-000-0 shown

Parts

3A6349C 21

Page 22

Parts

G-Chem Drive Module Parts List

Ref. Part Description Qty

3 100644 Screw, socket head cap 3

5 -- Nut, hex 2

6 -- Washer, flat 4

7 -- Block, swivel 1

8 -- Bolt, eye 1

9 -- Screw, hex head cap 1

101 -- Housing, drive 1

102 -- Bearing, retainer 1

103 -- Bearing, sleeve 1

105 -- Shaft 1

106 B32708 Bearing, CIP carriage 1

107 -- Carriage, plunger return 1

108 B32711 Block, plunger return 1

109 -- Adjuster, stroke 1

110 15B588 Screw, socket head cap;

included with plunger return

block (ref 108)

112 B32949 Panel, mounting 1

113 115814 Washer, flat; included with

mounting panel (ref 112)

114 -- Fastener, SCHS; included

with mounting panel (ref 112)

115 -- Washer, plastic shaft 1

116 B32708 Cam, eccentric, CIP 1

117 -- Deep Groove Ball Bearing,

included with CIP eccentric

cam (ref 116)

118 -- Key, square; included with

CIP carriage bearing

(ref 106) and CIP eccentric

cam (ref 116)

119 -- Screw, set 1

120 B32268 Pin, dowel 1

121 -- Ring, split; included with

dowel pin (ref 120)

122 -- Arm, shaft lever 1

123 -- Clip, shaft retaining 1

125 -- Plug, Simplex 1

127 B32787 Guard 1

4

4

4

1

1

1

Ref. Part Description Qty

128 -- Screw, captive; included with

guard (ref 127)

129 -- Label, branding ; included

with guard (ref 127)

130

131

133 -- Cap Plug, threaded 2

15H108 Label, pinch warning safety 3

17G318 Label, multiple warning safety 1

2

1

Replacement Danger and Warning labels, tags, and

cards are available at no cost.

22 3A6349C

Page 23

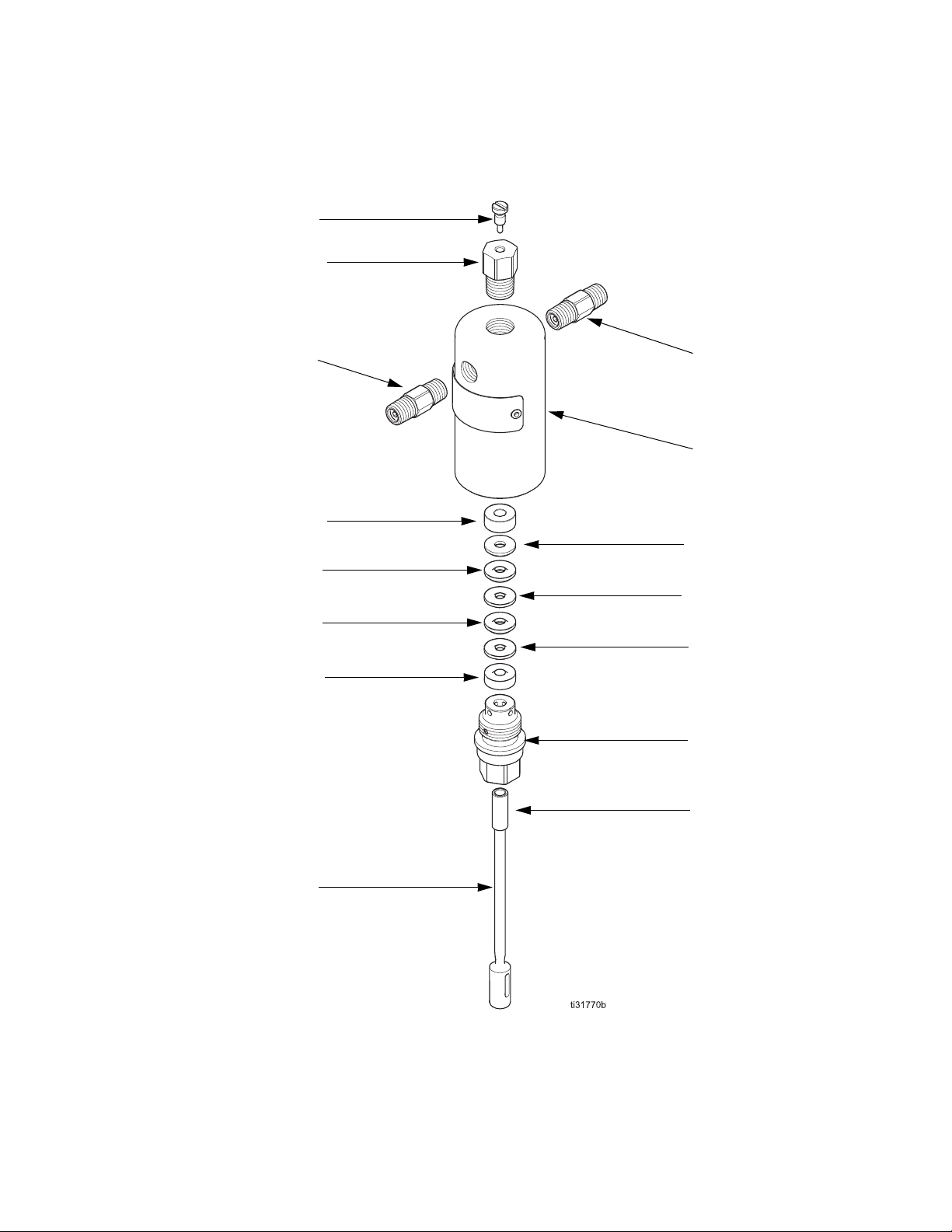

G-Chem Beam Fluid Module

211

215

210

216

202

205

205

206

201

209

203

204

204

208

207

Parts

3A6349C 23

Page 24

Parts

G-Chem Fluid Module Parts List

Ref. Part Description Qty

201 See Kits and

Accessories,

page 25

202

203

204

205

206

207

208

209

210

211

215

216

217

-- Spacer, packing nut 1

See Table 1 Adapter, male, vee stack 1

See Table 1 Packing, vee, plastic 2

See Table 1 Packing, vee, rubber 2

See Table 1 Adapter, female, vee stack 1

See Table 2 Nut, packing 1

-- Bearing, sleeve; included

See Table 3 Plunger 1

B32872 Valve, bleed; includes bleed

17F572 Needle, bleed 1

B32733 Valve, inlet check; FKM 1

B32735 Valve, inlet check; HNBR 1

B32857 Valve, inlet check; TFE/P 1

B32279 Valve, inlet check; FFKM 1

B32734 Valve, outlet check; FKM 1

B32736 Valve, outlet check; HNBR 1

B32858 Valve, outlet check; TFE/P 1

B32280 Valve, outlet check; FFKM 1

-- Nylon Ball, included with

Cylinder, fluid 1

1

with packing nut (ref 207)

1

needle (ref 211)

1

packing nut (207)

Table 1: Packing Kit (includes ref. 203 - 206)

Part Numbers by Fluid Plunger

Size Diameter

Ref

FKM

203 - 206 B32784 B32782 B32780

HNBR

203 - 206 B32785 B32783 B32781

TFE/P

203 - 206 B32854 B32855 B32856

PTFE

203 - 206 B32978 -- --

Table 2: Packing Nut

Part Numbers by Fluid Plunger Size

Diameter

Ref

207 B32776 B32775 B32774

Table 3: Fluid Plunger

Part Numbers by Fluid Plunger Size

Diameter

Ref

Qty.1/4 in. 3/8 in. 1/2 in.

1

1

1

1

Qty.1/4 in. 3/8 in. 1/2 in.

1

Qty.1/4 in. 3/ 8 in . 1/2 in.

Chromex-Coated 17-4 Stainless Steel

209 B32779 B32778 B32777

24 3A6349C

1

Page 25

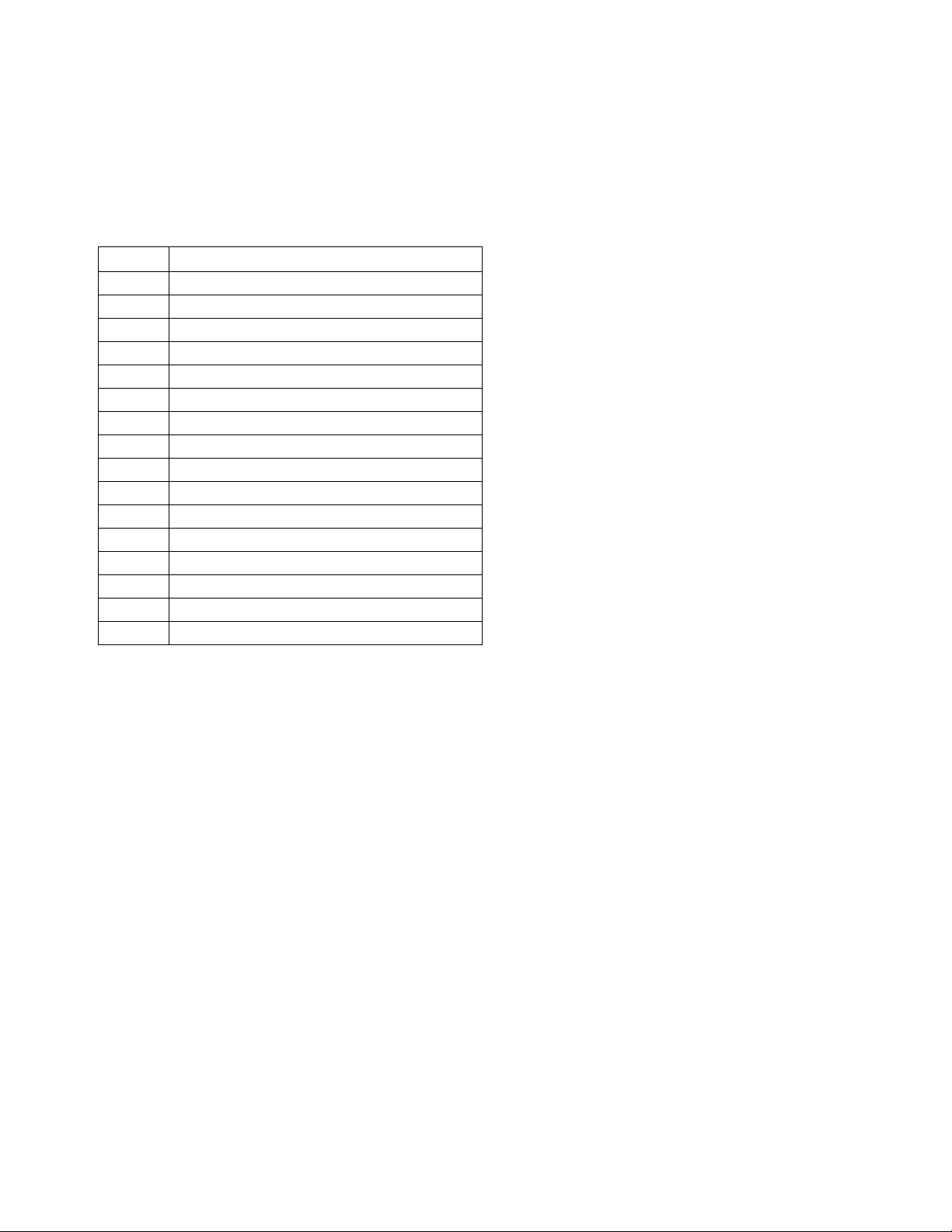

Kits and Accessories

G-Chem Beam Pump

Part No. Description

B32045 225-750 PSI Pressure Relief Valve Kit

B32046 750-1500 PSI Pressure Relief Valve Kit

B32047 1500-2250 PSI Pressure Relief Valve Kit

B32048 2250-3000 PSI Pressure Relief Valve Kit

A30970 1/4” FKM: Chromex Fluid Module*

A30971 1/4” HNBR: Chromex Fluid Module*

A30980 3/8” FKM: Chromex Fluid Module*

A30981 3/8” HNBR: Chromex Fluid Module*

A30990 1/2” FKM: Chromex Fluid Module*

A30991 1/2” HNBR: Chromex Fluid Module*

A30973 1/4” PTFE: Chromex Fluid Module*

B32983 Shaft Kit (includes ref. 115, 105, and 122)

B32984 Lever Arm Kit (includes ref. 122, 123, and 130)

B32985 Counterweight Kit (includes ref. 5, 6, 7, 8, and 9)

B33072 Beam Attachment Kit (includes ref. R and 8)

B33066 Extra weight kit (includes ref. 5,6,7, and 9)F

Kits and Accessories

* Includes ref. 6, 201-211, 215, and 216

3A6349C 25

Page 26

Dimensions

Dimensions

G-Chem Beam Pump Dimensions

FIG. 12 G-Chem Pump Dimensions

A B C D E F G

13.8 in.

(35.1 cm)

26 3A6349C

9.3 in.

(23.6 cm)

4.6 in.

(11.7 cm)

7.4 in.

(18.8 cm)

18.4 in.

(46.7 cm)

3.3 in.

(8.4 cm)

12.7 in.

(32.3 cm)

Page 27

Technical Specifications

Technical Specifications

G-Chem Chemical Injection Pump

US Metric

Maximum fluid working pressure Varies by model. See Models and Approvals on page 3.

Environmental temperature range, ordinary location -40°–131°F -40°–55°C

Noise (dBa)

Maximum sound pressure

Inlet/Outlet Sizes

Fluid inlet size 1/4 in. npt(m)

Fluid outlet size 1/4 in. npt(m)

Materials of Construction

Pump/Check Valve Seal Material

Wetted Parts

Weight

G-Chem,1 pump 14.8 lb. 6.7 kg

See Configuration Chart on page 4 for seal material. All other packing

materials are UHMWPE and PTFE unless otherwise noted.

See Configuration Chart on page 4 for plunger material. All other

materials are 303 and 316 stainless steel unless otherwise noted.

<70 dBa

California Proposition 65

CALIFORNIA RESIDENTS

WARNING: Cancer and reproductive harm. – www.P65warnings.ca.gov.

3A6349C 27

Page 28

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the neares t distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2017, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A6349

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revision C, June 2020

Loading...

Loading...