Page 1

Operation, Parts, Repair

Contractor PC Gun

Contractor PC Compact Gun

3A6285H

Contractor PC Spray Guns

For the application of architectural paints and coatings. For professional use only.

3600 psi (24.8 MPa, 248 bar) Maximum Working Pressure

See page 2 for additional model information.

Important Safety Instructions

Read all warnings and instructions in this manual. Refer to your sprayer instruction

manual for Pressure Relief, priming and spray instructions. Save these instructions.

Important Medical Information

Read the medical alert card provided with the gun. It contains injection injury treatment

information for a doctor. Keep it with you when operating the equipment.

EN

II 2 G Ex h IIB T6 Gb

Page 2

Contents

Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Gun Trigger Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Trigger Adjustment (Contractor PC Gun only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Install Tip and Tip Guard on Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Connect Gun to Sprayer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Aligning Spray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Spraying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Clear Spray Tip Clog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Tip and Guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Cleaning/Replacing Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Repair/Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Replacing Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Aligning Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

California Proposition 65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

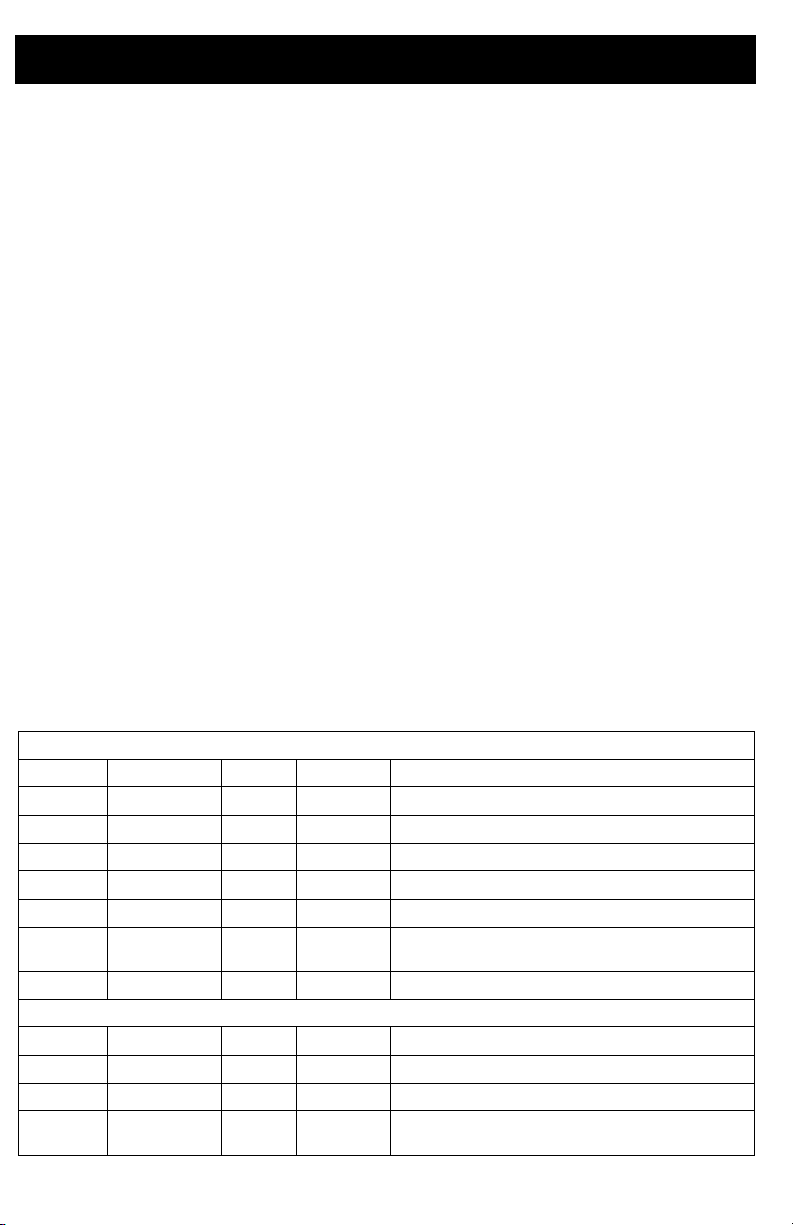

Models

Contractor PC Gun Models

Part No. Tip(s) Guard Filter Language Translation Included

17Y042 LTX517 RAC X 60 Mesh English, French, Spanish

17Y043 LP517 RAC X 60 Mesh English, French, Spanish, German

17Y044 LTX517 RAC X 60 Mesh English, Chinese, Japanese, Korean

17Y045 None RAC X 60 Mesh English, French, Spanish, German

17Y470 FFLP210 RAC X 100 Mesh English, French, Spanish

826252 LTX517 +

17Z644 LTX515 RAC X 60 Mesh English, French, Spanish

19Y349 LTX517 RAC X 60 Mesh English, French, Spanish

19Y350 LP517 RAC X 60 Mesh English, French, Spanish, German

19Y443 FFLP210 RAC X 100 Mesh English, French, Spanish, German

826261 LTX517 +

LP517

LP517

2 3A6285H

RAC X 60 Mesh English, French, Spanish

Contractor PC Compact Gun Models

RACX 60 Mesh English, French, Spanish

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this

equipment. The exclamation point symbol alerts you to a general warning and the hazard

symbols refer to procedure-specific risks. When these symbols appear in the body of this

manual or on warning labels, refer back to these Warnings. Product-specific hazard symbols

and warnings not covered in this section may appear throughout the body of this manual where

applicable.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Get immediate

surgical treatment.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop spraying and before cleaning,

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. Paint

or solvent flowing through the equipment can cause static sparking. To help prevent fire and

explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and

plastic drop cloths (potential static sparking).

• Ground all equipment in the work area. See Grounding instructions.

• Never spray or flush solvent at high pressure.

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off w hen flammable

fumes are present.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners

unless they are anti-static or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use

equipment until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

3A6285H 3

Page 4

Warnings

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Always wear appropriate gloves, eye protection, and a respirator or mask when painting.

• Do not operate or spray near children. Keep children away from equipment at all times.

• Do not overreach or stand on an unstable support. Keep effective footing and balance at

all times.

• Stay alert and watch what you are doing.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not kink or over-bend the hose.

• Do not expose the hose to temperatures or to pressures in excess of those specified by

Graco.

• Do not use the hose as a strength member to pull or lift the equipment.

• Do not spray with a hose shorter than 25 feet.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals

and create safety hazards.

•

Make sure all equipment is rated and approved for the environment in which you are using it.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious

chemical reaction and equipment rupture. Failure to follow this warning can result in death,

serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon

solvents or fluids containing such solvents.

• Do not use chlorine bleach.

• Many other fluids may contain chemicals that can react with aluminum. Contact your

material supplier for compatibility.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury,

including eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective

equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent

manufacturer.

4 3A6285H

Page 5

Setup

Setup

Pressure Relief Procedure

Follow the Pressure Relief

Procedure whenever you see this

symbol.

This equipment stays pressurized until

pressure is manually relieved. To help

prevent serious injury from pressurized

fluid, such as skin injection or splashed

fluid, follow the Pressure Relief

Procedure whenever sprayer is stopped

and before sprayer is cleaned or checked,

and before equipment is serviced.

1. Turn sprayer OFF.

2. Engage the trigger lock. Always engage

the trigger lock when sprayer is stopped

to prevent the gun from being triggered

accidentally.

3. Turn pressure control knob to lowest

setting.

4. Put drain tube into a waste pail and turn

Prime/Spray valve in PRIME position

(drain) to relieve pressure.

5. Hold the gun firmly to a pail. Point gun

into pail. Disengage the trigger lock and

trigger the gun to relieve pressure.

7. If you suspect the spray tip or hose is

clogged or that pressure has not been

fully relieved:

a. VERY SLOWLY loosen the tip

guard retaining nut or the hose end

coupling to relieve pressure

gradually.

b. Loosen the nut or coupling

completely.

c. Clear airless hose or spray tip

obstruction. See Clear Spray Tip

Clog, page 8.

Gun Trigger Lock

To prevent injury when the gun is not in

use, always engage the gun’s trigger lock

if unit is being shut down or left

unattended.

6. Engage the trigger lock.

3A6285H 5

Page 6

Setup

PUSH OR

PULL

HERE

Trigger Adjustment (Contractor PC Gun only)

The trigger can be adjusted to different

lengths depending upon user preference.

1. Relieve pressure. See Pressure Relief

Procedure, page 5.

2. Loosen adjustment knob (13c). Use a

flat blade screwdriver or coin if the knob

(13c) cannot be loosened by hand.

Complete one full turn to loosen the

adjustment knob. Three full turns could

result in the adjustment knob falling out.

3. Hold end of trigger (13b) and slide to

desired position.

NOTE: Hold trigger in location shown when

adjusting.

NOTE: If trigger is too difficult to slide, use a

flat blade screwdriver to slide it down and

apply grease to the location shown.

4. Tighten adjustment knob (13c) firmly.

6 3A6285H

Page 7

Setup

ti29141a

ti29140a

SPRAY

TIP

RUBBER

GASKET/METAL

SEAL

RETAINING NUT

TIP

GUARD

(26)

(25)

(24)

SPRAY

TIP

RUBBER

GASKET/METAL

SEAL

TIP

GUARD

RETAINING NUT

Install Tip and Tip Guard on Gun

To avoid serious injury from skin injection

do not put your hand in front of the spray tip

when installing or removing the spray tip

and tip guard.

NO YES

To prevent spray tip leaks make certain spray

tip and tip guard are installed properly.

1. Relieve pressure. See Pressure Relief

Procedure, page 5. Engage trigger lock

(15).

2. Use spray tip (26) to align gasket and

seal (24) in the tip guard (25).

4. Verify spray tip and tip guard parts are

assembled in the order shown.

5. Install guard (25) over end of gun (1).

Hand tighten retaining nut.

Connect Gun to Sprayer

Make sure sprayer is turned off and

unplugged from power source. Refer to your

sprayer instruction manual for priming and

spray instructions.

1. Attach supply hose to sprayer fluid

outlet.

2. Attach other end of supply hose to gun

swivel (7). Use two wrenches (one on

the swivel (7) and one on the hose), to

tighten all connections securely.

3. Refer to sprayer instruction manual for

priming instructions.

3. Insert tip (26) in guard (25).

3A6285H 7

Page 8

Operation

Operation

Aligning Spray

1. Relieve pressure. See Pressure Relief

Procedure, page 5. Engage trigger lock

(15).

2. Loosen guard (25) retaining nut.

3. Align guard (25) horizontally to spray a

horizontal pattern or vertically to spray a

vertical pattern.

4. Hand tighten guard (25) retaining nut

when you have adjusted to desired setting.

Spraying

1. Disengage trigger lock (15).

2. Be sure the arrow shaped tip (26) faces

forward (spray).

3. Hold gun perpendicular and approximately 12 inches (304 mm) from surface. Move gun first, then pull gun

trigger (13) to spray a test pattern.

4. Slowly increase pump pressure until

coverage is uniform and even (see

sprayer instruction manual for additional

information).

Clear Spray Tip Clog

In the event that particles or debris clog the

spray tip, this gun is designed with a

reversible spray tip that quickly and easily

clears the particles without disassembling the

sprayer.

1. Engage trigger lock (15). Rotate spray tip

(26) to unclog position. Disengage

trigger lock (15). Trigger gun at waste

area to clear clog.

NOTE: If spray tip (26) is difficult to rotate

when turning to the unclog position, perform

Pressure Relief Procedure, page 5, then

turn Prime/Spray valve to spray position and

repeat step 1.

2. Engage trigger lock (15). Rotate spray

tip (26) back to spray position. Disengage trigger lock (15) and continue

spraying.

Cleanup

Flush gun, clean filter (see

Cleaning/Replacing Filter on page 11) and

clean paint off the outside after each work

shift. Store in a dry location. Refer to your

sprayer manual for flushing instructions. Do

not leave the gun or any parts in water or

cleaning solvents.

NOTICE

To prevent damage to the gun parts, do not

leave the gun or any parts, except the tip, in

water or cleaning solvents. The gun is NOT

compatible with cleaning solvents that

contain methylene chloride.

8 3A6285H

Page 9

Parts

Contractor PC

Contractor PC Compact

Parts

Ref. Part Description Qty

1 17X496 HOUSING, assy 1

2 17Y297 KIT, repair, cartridge, includes

2a 17W752 PACKING, o-ring 1

2b 16H931 PACKING, o-ring 1

3a 17T073 TUBE, handle, Contractor PC 1

3b 19Y272 TUBE, handle, Compact 1

4 120776 PACKING, o-ring 1

5a 17V395 GUARD, trigger, Contractor PC1

5b 19Y270 GUARD, trigger, Compact 1

6 120733 O-RING, urethane, clear 1

7 288811 SWIVEL, assy, gun 1

8a FILTER, gun, Contractor PC 1

287032 60 mesh

287033 100 mesh

287034 60 and 100 mesh combo

8b FILTER, gun, Compact 1

19Y355 60 mesh

19Y356 100 mesh

19Y358 60 and 100 mesh combo

9 17Y226 SCREW, set 1

10a 17T030 HANDLE, gun, Contractor PC 1

10b 19Y376 HANDLE, gun, Compact 1

Includes 15, 16

2a, 2b

Ref. Part Description Qty

11 17V288 PIN, trigger 2

12 17V766 SPRING, compression 1

13 17Y466 TRIGGER, Contractor PC,

1

assy includes 11, 12, 13a,

19Y440 TRIGGER, Compact, assy

13a TRIGGER, upper 1

13b TRIGGER, lower 1

13c KNOB, adjustment 1

13d CLIP, trigger 1

13e SCREW, set 1

14 17Z690 TRIGGER, Contractor PC,

19Y512 TRIGGER, Compact, repair

15 17V767 LOCK, trigger 1

16 17Y024 PIN, spring 1

20 119799 BRUSH, cleaning (not shown) 1

21 222385 CARD, medical alert (not

Replacement Warning labels, tags and cards

are available at no cost.

13b, 13c, 13d

includes 11, 12, 13a, 13b, 13e

repair includes 13b, 13c, 13d

includes 13b, 13e

shown)

1

1

1

1

1

3A6285H 9

Page 10

Parts

Tip and Guard

Ref.Part Description Qty

24 246453

248936 KIT, SOLVENT, RAC X 1

17P501 OneSeal™, FFLP

17P502 KIT, SOLVENT, FFLP 1

25 246215 GUARD, RAC X 1

26† TIP, spray 1

LTX517 TIP, spray 517, RAC X 1

LTX515 TIP, spray 515, RAC X 1

10 3A6285H

OneSeal™, RAC X

(5-pack)

(5-pack)

Models: 17Y042,

17Y044, 826252

Model: 17Z644

1

1

Ref.Part Description Qty

LP517 TIP, spray 517, LP 1

Models: 17Y043,

826252

FFLP210 TIP, spray, 210 FFLP 1

Models: 17Y470

† For a list of all available tip sizes, talk to

your local distributor or visit

www.graco.com.

Page 11

Maintenance

To avoid injury always read all

warnings in this manual and the

sprayer manual, before performing

any maintenance on the gun.

Cleaning/Replacing Filter

A plugged filter reduces gun

performance. Clean filter after each

use.

1. Relieve pressure. See

Relief Procedure

2. Disconnect fluid hose from gun at

swivel (7).

3. Disconnect trigger guard (5) from

housing (1) as shown.

4. Engage trigger lock (15).

5. Contractor PC: Unscrew handle

(10) from housing (1).

Pressure

, page 5.

Maintenance

Contractor PC Compact: Unscrew handle

(10) from housing (1) using guard (5).

6. Remove filter (8) through top of

handle (10).

7. Clean filter (8). Use a soft brush to

loosen and remove excess debris.

8. Inspect filter (8) for damage to the

filter mesh. Replace the filter if the

filter mesh has holes or voids.

9. Inspect handle tube (3) for

damage. Replace if it is corroded or

pitted and check material for

compatibility with aluminum.

10. Inspect o-ring (4) and replace if

necessary.

11. Insert clean filter (8) into handle (10).

12. Reattach handle (10) to housing

(1). Tighten securely.

13. Disengage trigger lock (15).

14. Reconnect trigger guard (5) into the

slot in the housing (1) as shown.

15. Engage trigger lock.

3A6285H 11

Page 12

Repair/Replacement

Repair/Replacement

To avoid injury always read all

warnings in this manual and the

sprayer manual, before performing

any repairs on the gun.

Replacing Cartridge

Replace cartridge if the assembly is

leaking or if there is a loss in spray

performance that cannot be resolved by

flushing the gun.

1. Relieve pressure. See Pressure

Relief Procedure, page 5.

2. Engage trigger lock (15).

3. Remove tip (26) and guard (25)

from gun (1).

4. Disengage trigger lock (15).

5. Depress 2 pins (11) and pull trigger

assembly (13) up into repair

position as shown.

6. Unscrew cartridge (2) from front of

gun (1).

NOTE: If it is too difficult to remove by

hand, use a 1/8” allen wrench or 5/8

wrench (if your cartridge has flats) to

break loose as shown.

NOTICE

Never attempt to remove the cartridge

unless the trigger assembly (13) is in

the repair position --- cartridge will not

come out. If cartridge is left partially

removed, the gun will not operate

properly.

7. Use a soft brush to clean out

internal passages of gun.

12 3A6285H

Page 13

Repair/Replacement

No Gap (a)

8. Install new cartridge (2) into the

gun and torque to 150 in-lbs (17.0

N-m). There should be no gap in

the indicated area below (a).

9. Push trigger assembly (13) back

down into spray position. The push

pins (11) should snap back out to

normal position when trigger

assembly (13) is fully engaged.

Verify the cartridge is installed

correctly by making sure the trigger

assembly (13) can wiggle back and

forth.

Aligning Handle

If when tightened securely, handle no

longer matches up with housing, realign

handle.

1. Relieve pressure. See Pressure

Relief Procedure, page 5. Engage

trigger lock (15).

2. Tighten handle (10) securely.

3. Loosen set screw (9) using a 1/8”

allen wrench.

4. Rotate handle (10) so it is aligned

with housing (1).

5. Tighten set screw (9) securely.

NOTE: Do not operate the gun if the

cartridge is not installed correctly.

10. Reinstall tip (26) and guard (25).

3A6285H 13

Page 14

Technical Specifications

Technical Specifications

Maximum working pressure 3600 psi (248 bar, 24.8 MPa)

Fluid orifice size 0.120 in. (3.05 mm)

Inlet 1/4 NPSM swivel

Maximum material temperature 120° F (49° C)

Wetted Parts Stainless steel, aluminum, tungsten carbide, solvent

resistant elastomer, UHMwpE, acetal

Weight

Gun Without Tip and Guard With Tip and Guard

Contractor 21.2 oz (601 g) 23.8 oz (675 g)

Contractor PC - A 17.4 oz (493 g) 20.0 oz (567 g)

Contractor PC - B 18.8 oz (533 g) 21.4 oz (607 g)

Contractor PC Compact 16.1 oz (456 g) 18.7 oz (530 g)

Noise Level*

Sound power 87 dBa

Sound pressure 78 dBa

* Measured at 3.1 feet (1m) while spraying water-based paint, specific gravity 1.36, through a

517 tip at 3000 psi (207 bar, 20.7 MPa) per ISO 3744.

California Proposition 65

CALIFORNIA RESIDENTS

WARNING: Cancer and reproductive harm –

www.P65warnings.ca.gov.

Translated Manuals

3A6289 Spanish 3A6303 Latvian

3A6290 French 3A6304 Lithuanian

3A6291 Dutch 3A6305 Polish

3A6292 Italian 3A6306 Hungarian

3A6293 Turkish 3A6307 Czech

3A6294 Greek 3A6308 Slovakian

3A6295 Croatian 3A6309 Slovenian

3A6296 Portuguese 3A6310 Romanian

3A6297 Danish 3A6311 Bulgarian

3A6298 Finnish 3A6312 Chinese

3A6299 Swedish 3A6313 Japanese

3A6300 Norwegian 3A6314 Korean

3A6301 Russian 3A6318 German

3A6302 Estonian

Translated manuals can be requested through a distributor or at www.graco.com.

14 3A6285H

Page 15

Graco Standard Warranty

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing

its name to be free from defects in material and workmanship on the date of sale to the original purchaser

for use. With the exception of any special, extended, or limited warranty published by Graco, Graco will,

for a period of twelve months from the date of sale, repair or replace any part of the equipment

determined by Graco to be defective. This warranty applies only when the equipment is installed,

operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction,

damage or wear caused by faulty installation, misapplication, abrasion, corrosion, inadequate or

improper maintenance, negligence, accident, tampering, or substitution of non-Graco component parts.

Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco

equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper

design, manufacture, installation, operation or maintenance of structures, accessories, equipment or

materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an

authorized Graco distributor for verification of the claimed defect. If the claimed defect is verified, Graco

will repair or replace free of charge any defective parts. The equipment will be returned to the original

purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material

or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of

parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING BUT NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY

OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above.

The buyer agrees that no other remedy (including, but not limited to, incidental or consequential

damages for lost profits, lost sales, injury to person or property, or any other incidental or consequential

loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, IN CONNECTION WITH

ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT MANUFACTURED

BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose,

etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide purchaser with

reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from

Graco supplying equipment hereunder, or the furnishing, performance, or use of any products or other

goods sold hereto, whether due to a breach of contract, breach of warranty, the negligence of Graco, or

otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents,

notices and legal proceedings entered into, given or instituted pursuant hereto or relating directly or

indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du

présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés,

donnés ou intentés, à la suite de ou en rapport, directement ou indirectement, avec les procédures

concernées.

3A6285H 15

Page 16

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest

distributor.

All written and visual data contained in this document reflects the latest product information available at

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A6285

the time of publication.

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2018, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

www.graco.com

Revision H, September 2020

Loading...

Loading...