Page 1

Repair - Parts

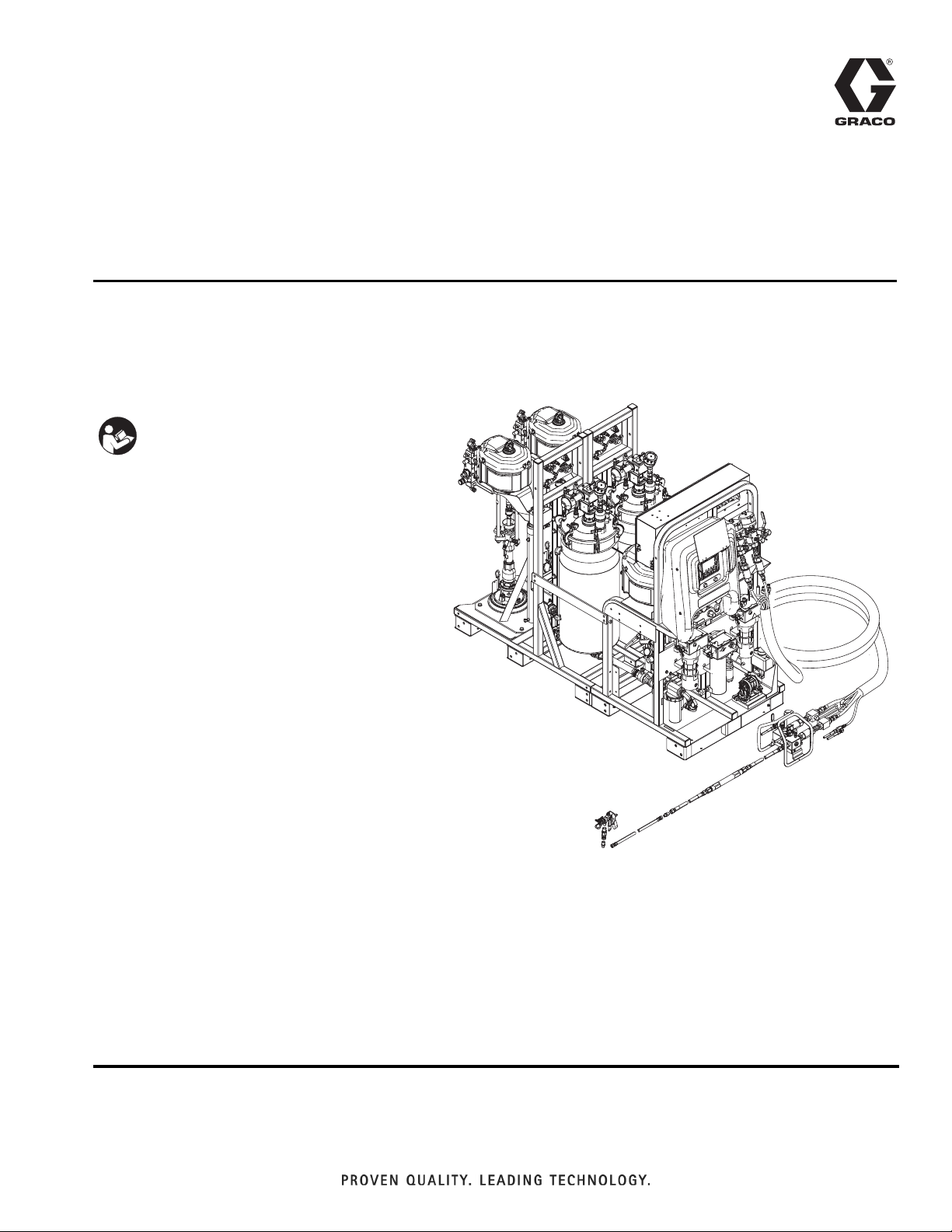

XM PFP

For spraying two-component intumescent epoxies. For professional use only.

Not for use in explosive atmospheres or hazardous locations.

Important Safety Instructions

Read all warnings and instructions in all

supplied manuals. Save all instructions.

See page 3 for model information, including

maximum working pressure and approvals.

3A2989G

EN

WLD

Page 2

Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Keep Components A and B Separate . . . . . . . . 6

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . 6

Components A and B . . . . . . . . . . . . . . . . . . . . . 6

Component Identification . . . . . . . . . . . . . . . . . . . . 6

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . 7

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Replace Air Filter Element . . . . . . . . . . . . . . . . . 9

User Interface/Control Box . . . . . . . . . . . . . . . . 10

Junction Box . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Air Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Dosing Valve Assembly . . . . . . . . . . . . . . . . . . 19

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Pump Assembly (System Module) . . . . . . . . . . 21

Pail Feed RAM Pump Assembly (Feed Module) 22

Solvent Pump . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Replace Radar Level Sensor . . . . . . . . . . . . . . 24

Set Up a New Guided Radar Level Sensor . . . 25

Electrical Schematics . . . . . . . . . . . . . . . . . . . . . . 27

Simplified Electrical Schematic . . . . . . . . . . . . . 27

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

XM PFP System (262869, 24W626) . . . . . . . . . 32

Base System (262878, 24W648) Subassemblies 44

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 62

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . 62

2 3A2989G

Page 3

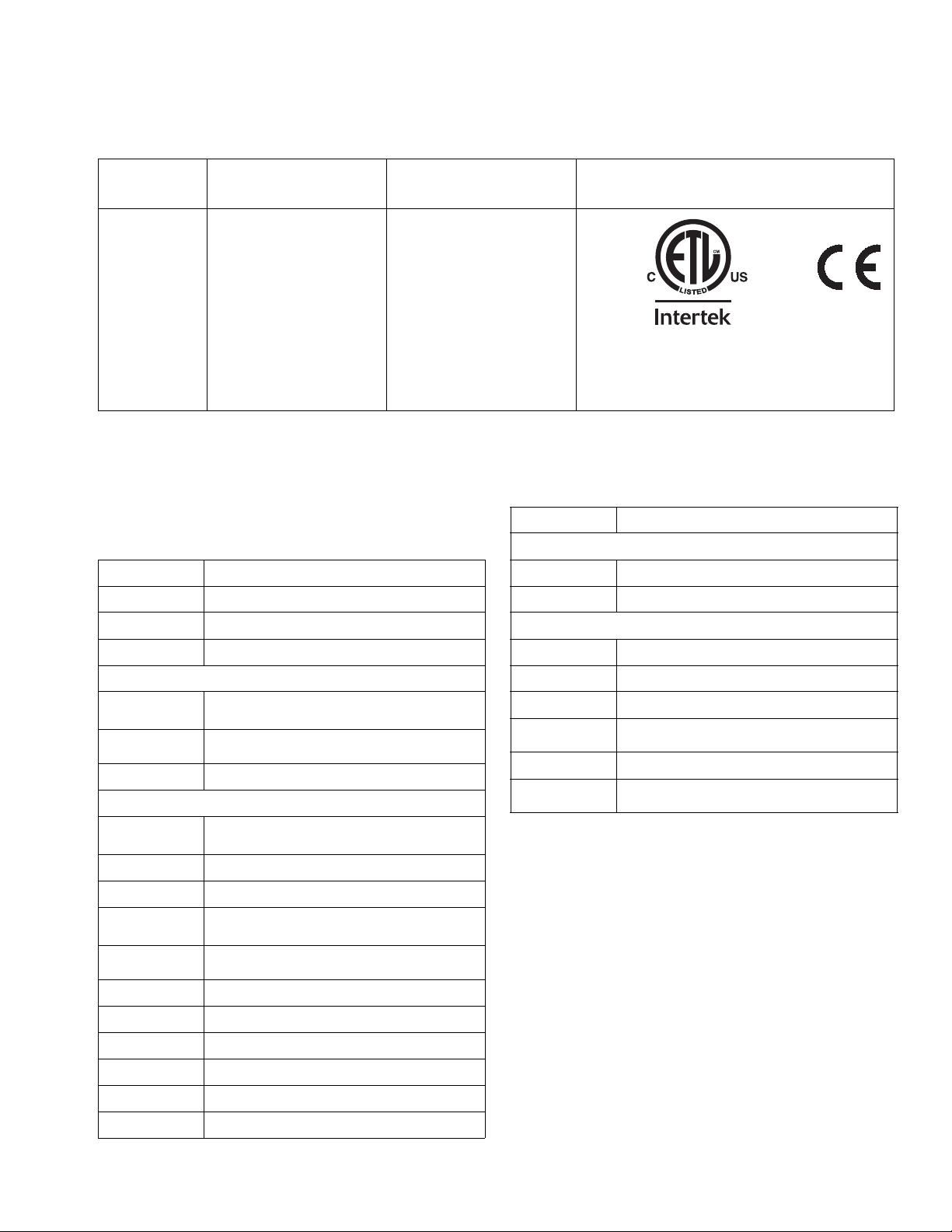

Models

Models

Models

Maximum Fluid

Working Pressure

Maximum Air Working

Pressure Approvals

A and B Materials:

6000 psi

(41 MPa, 414 bar)

Supply: 150 psi

262869

24W626

Flushing Fluid:

4500 psi

(31 MPa, 310 bar)

(1.0 MPa, 10.3 bar)

Max. Setpoint: 100 psi

(0.7 MPa, 7 bar)

Heating Fluid:

100 psi

(0.7 MPa, 7 bar)

Related Manuals

Manuals are available at www.graco.com. Component

manuals in English:

Manual Description

3A2776 XM PFP Setup - Operation

3A2988 XM PFP Mix Manifold Instructions - Parts

3A2799 XHF Spray Gun

Certified to CAN/CSA C22.2 No. 88

9902471

Conforms to

UL 499

Manual Description

Accessories

332073 Hot Water Flush Kit Instructions

3A2987 Air Dryer Kit Instructions

Other

313342 Dosing Valve Instructions - Parts

Heaters

®

309524

3A2954

3A2824 Viscon LT Fluid Heater Instructions - Parts

Pumps, Motors, Supply Systems

308652

311238

311762

312375

312376

312792

312794 Merkur Pump Assembly Instructions - Parts

312796 NXT Air Motor Instructions - Parts

313526 Supply Systems Operation

313527 Supply Systems Repair - Parts

312374 Air Control Instructions - Parts

Viscon

Instructions - Parts

Viscon HF High Flow, High Pressure Fluid

Heater Instructions - Parts

Husky

Pumps Instructions - Parts

NXT

Xtreme

Check-Mate® Displacement Pumps

Instructions - Parts

Check-Mate Pump Packages Instructions Parts

Merkur® Pump Repair - Parts

HP High Pressure Fluid Heater

™

205 Air-Operated Diaphragm

®

Air Motor Instructions - Parts

®

Lowers Instructions - Parts

306861 Ball Valves Instructions - Parts

307005 High Pressure Swivel Instructions - Parts

308169

407061 Simulation XM PFP Display Module

3A1244

Air Filters, Lubricators, and Kits Instructions

- Parts

Graco Control Architecture Module Programming

3A2989G 3

Page 4

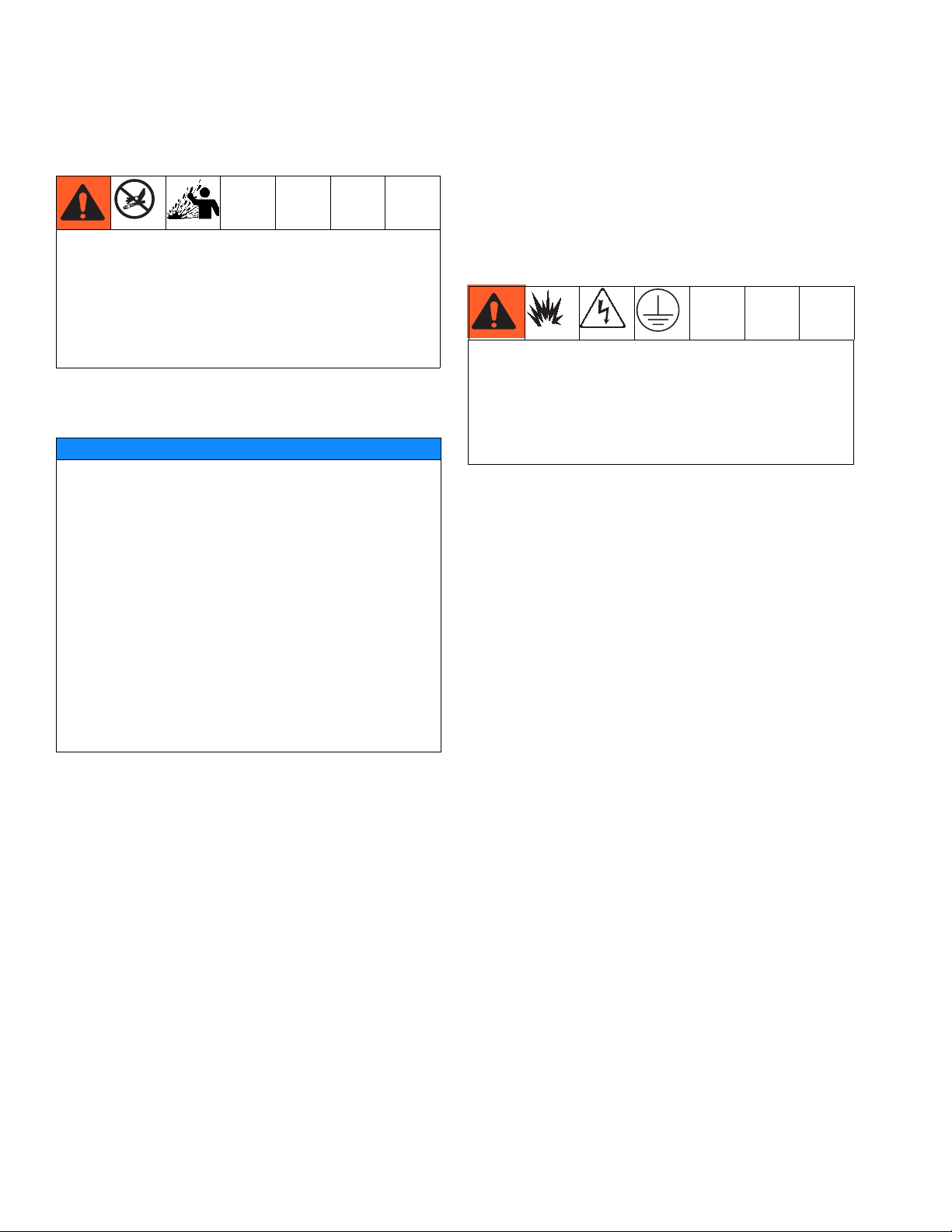

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

WARNING

WARNINGWARNINGWARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause

electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

or installing equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

•Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless they

are antistatic or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns:

• Do not touch hot fluid or equipment.

4 3A2989G

Page 5

Warnings

WARNING

WARNINGWARNINGWARNING

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure and disconnect all power sources.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes but is

not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer

SPLATTER HAZARD

Hot or toxic fluid can cause serious injury if splashed in the eyes or on skin. During blow off of platen,

splatter may occur.

• Use minimum air pressure when removing platen from drum.

3A2989G 5

Page 6

Component Identification

Keep Components A and B Separate

Cross-contamination can result in cured material in

fluid lines which could cause serious injury or damage

equipment. To prevent cross-contamination:

• Never interchange component A and component

B wetted parts.

• Never use solvent on one side if it has been contaminated from the other side.

Changing Materials

NOTICE

Changing the material types used in your equipment

requires special attention to avoid equipment damage

and downtime.

• When changing materials, flush the equipment multiple times to ensure it is thoroughly clean.

Component Identification

See XM PFP Operation manual for component identification.

Grounding

The equipment must be grounded to reduce the risk

of static sparking and electric shock. Electric or static

sparking can cause fumes to ignite or explode.

Improper grounding can cause electric shock.

Grounding provides an escape wire for the electric

current.

Ground the electrical connection properly according to

local codes.

• Always clean any fluid inlet strainers after flushing.

• Check with your material manufacturer for chemical

compatibility.

• When changing between epoxies and urethanes or

polyureas, disassemble and clean all fluid components and change hoses. Epoxies often have

amines on the B (hardener) side. Polyureas often

have amines on the B (resin) side.

Components A and B

IMPORTANT!

Material suppliers can vary in how they refer to plural

component materials.

Be aware that in this manual:

Component A refers to resin or major volume.

Component B refers to the hardener or minor volume.

This equipment doses the B component into the A component flow. An integration hose must always be used

after the mix manifold and before the static mixer.

6 3A2989G

Page 7

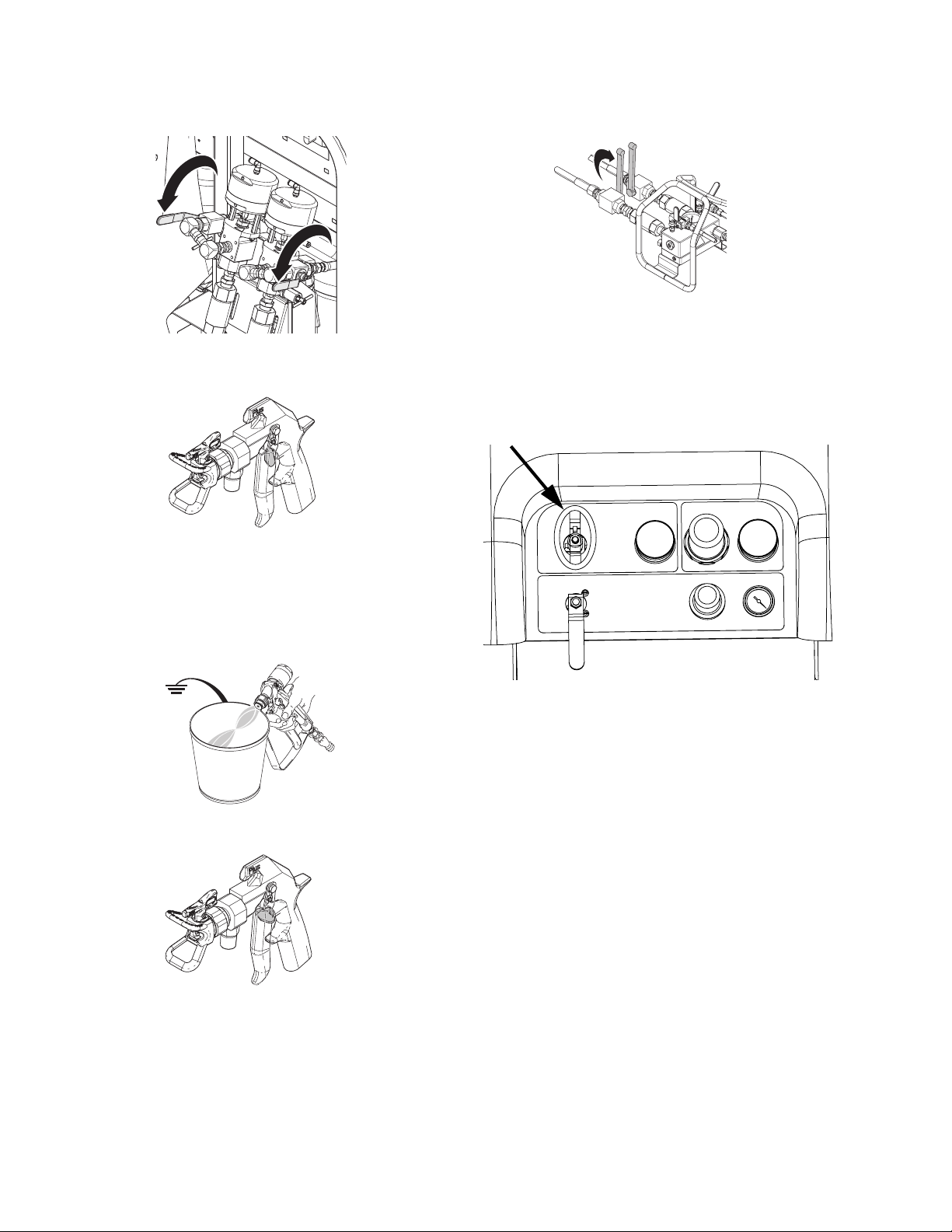

Pressure Relief Procedure

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the Pressure

Relief Procedure when you stop spraying and before

cleaning, checking, or servicing the equipment.

1. Engage trigger lock.

TI19265a2

2. If the system will be shut down for more than a few

hours, perform Park Fluid Pump Rods procedure

in XM PFP Operation manual to prevent fluid hardening on the pump shaft.

NOTICE

The material may expand when air pressure is

removed. This can cause the tank to overfill and

damage the parts attached to the tank lid. To prevent overfilling the tank, never relieve air pressure

in the tank unless the tank is less than half full.

Verify tank material level on the user interface, see

Appendix A - User Interface Display section in

XM PFP Operation manual.

5. If necessary to relieve tank air pressure: close both

feed system air control ball valves and back out the

air pressure regulator. Open the brass valves on the

tank lids for full tank de-pressurization. Pressure

gauge should read 0 psi.

FEED PUMP

BYPASS

ti20127a

3. Press (Stop button).

4. Slide the feed pump air supply valve (DF) and director valve air supply valve (DA) to the OFF position.

DF

DD

DA

F

IG

. 1: Feed Pump Controls

ti20104a

DE

DC

DB

F

IG

. 2

6. Open mix manifold ball valves.

ti20128a

3A2989G 7

Page 8

Troubleshooting

7. Open recirculation ball valves.

WLD

8. Disengage trigger lock.

TI19265a1

9. Hold a metal part of the gun firmly to a grounded

metal pail. Trigger gun to relieve pressure in material hoses. Use a pail lid with a hole to dispense

through. Seal around hole and gun with a rag to prevent splash back.

11. Close mix manifold material ball valves.

ti20129a

12. Perform Flush Mixed Material procedure in XM

PFP Operation manual to prevent mixed material

curing in the system and to relieve pressure in the

solvent lines.

13. Close metering pump air supply ball valve.

10. Engage trigger lock.

TI1953a

TI19265a2

14. If the system will be shutdown for more than a few

hours, fill pump A and B packing nuts with throat

seal liquid (TSL

™

).

NOTE: Fluid pressure in the system is now relieved.

Troubleshooting

See XM PFP Operation manual 3A2776 for troubleshooting details.

8 3A2989G

Page 9

Repair

Repair

NOTICE

Do not use air motor lift rings to lift the entire

assembly. This will damage the system. The system must be lifted from the bottom.

Follow Pressure Relief Procedure on page 7 if service

time may exceed pot life time, before servicing fluid

components, and before transporting sprayer.

Replace Air Filter Element

There are two air filters on the system: the inlet air regulator filter on the air controls and the main air inlet manifold filter. Check filters weekly and replace element as

needed.

3. Unscrew filter bowl from inlet air regulator (601d).

4. Remove and replace element.

601d

Filter Bowl

and Element

r_312359_313289_15

5. Screw filter bowl on securely.

6. Replace front and rear shrouds (19, 20) using four

nuts (21).

Main Air Inlet Manifold Filter

2. Unscrew filter bowl collar from main air inlet

filter (14).

To reduce the risk of serious injury, do not service air

filter until air line is depressurized. Removing a pressurized air filter bowl could cause serious injury.

Both Filters

1. Close main air shutoff valve on air supply line and

on system. Depressurize air line.

Control Air Regulator Filter

2. Remove four nuts (21) and then remove front and

rear shrouds (19, 20).

21

20

19

14

ti199526a1

3. Remove and replace filter element (701a). See Air

Filter (24P899), page 49.

4. Reassemble filter bowl.

ti19926a1

3A2989G 9

Page 10

Repair

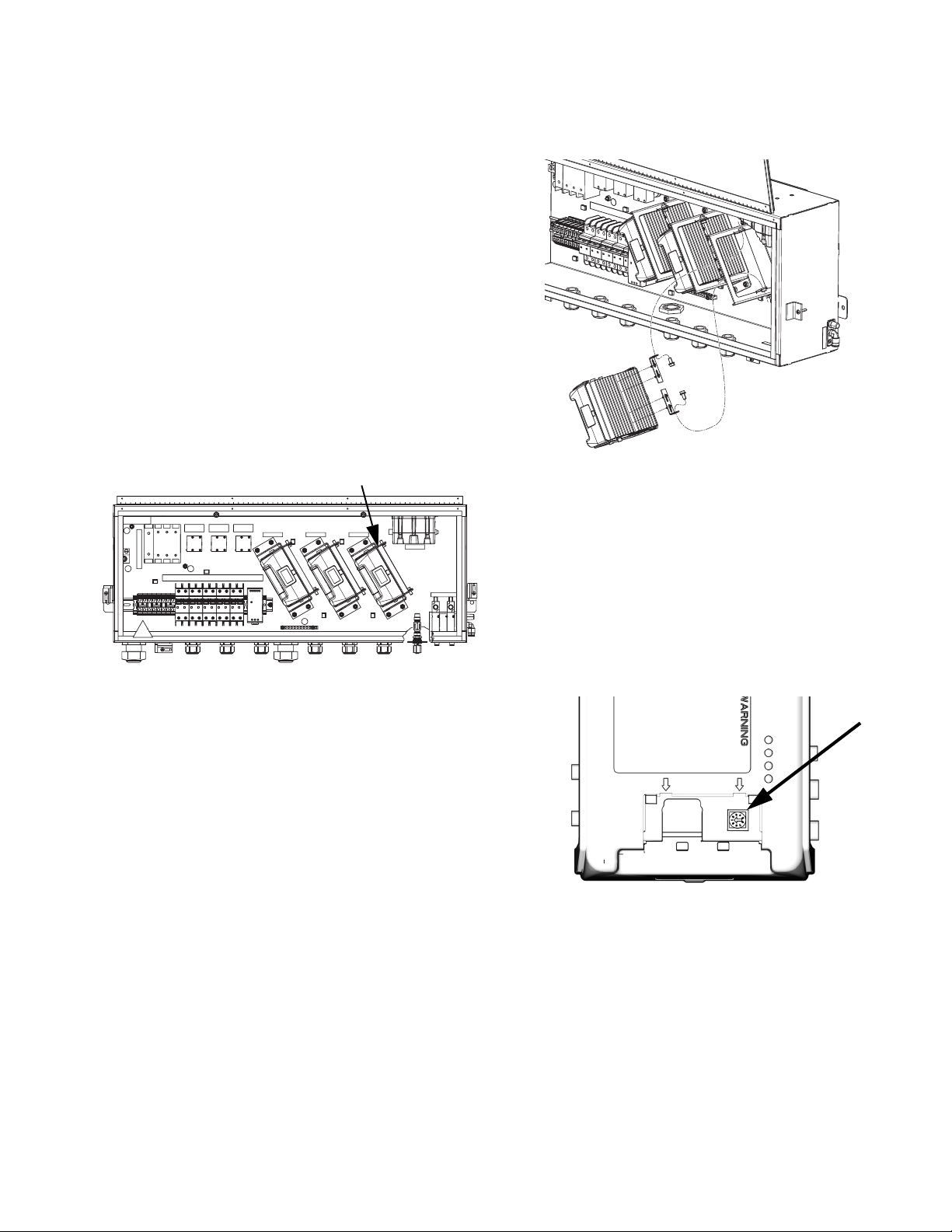

User Interface/Control Box

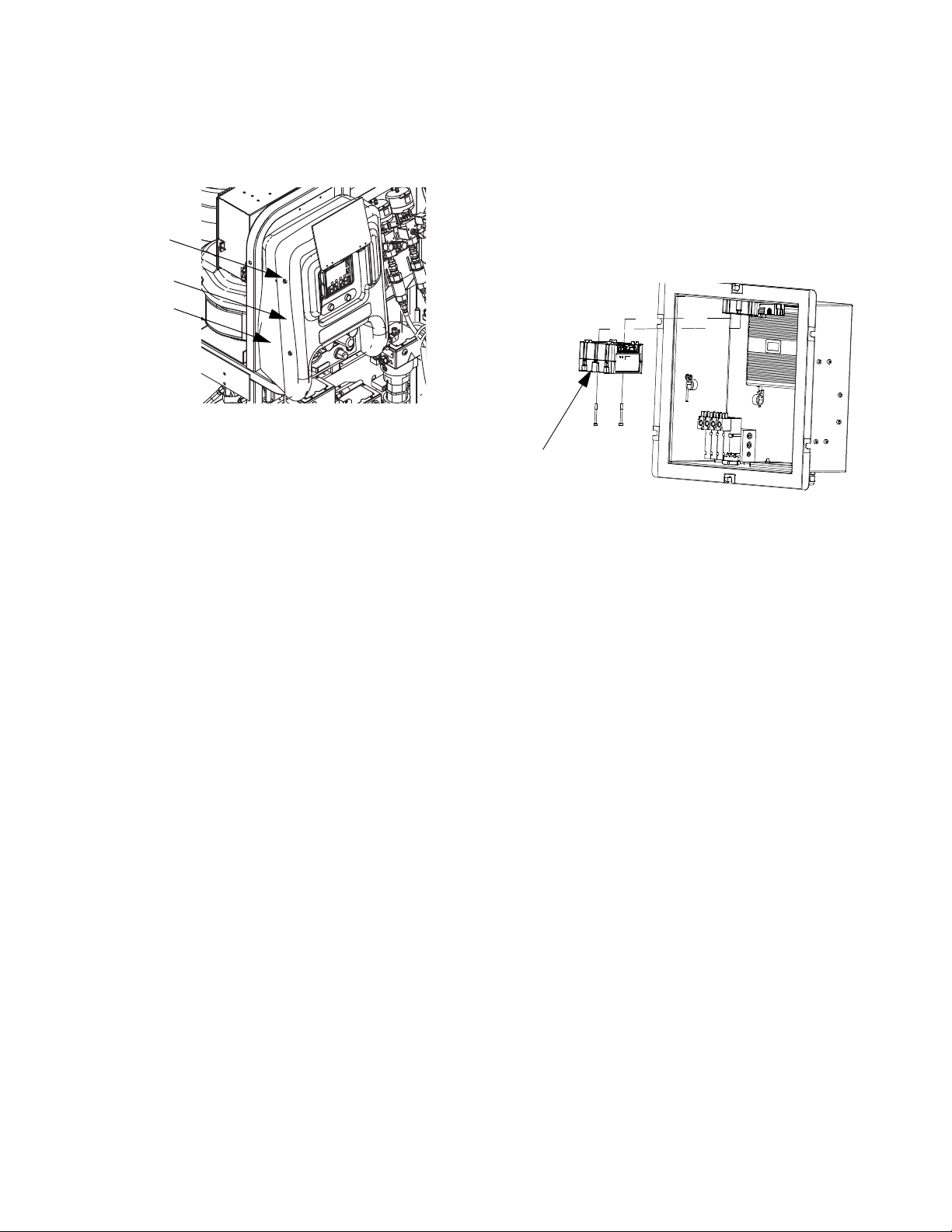

Remove Shroud and Front Panel of Control

Box

1. Close main air shutoff valve on air supply line and

on system. Depressurize air line.

2. Remove four nuts (21) and then remove front and

rear shrouds (19, 20).

21

20

19

2. Disconnect solenoid cable connector (542) from the

solenoid (509a) being replaced.

3. Remove two screws (509b) from the solenoid being

replaced then remove solenoid (509a). See F

IG

. 4.

509b

r_xm1a00_312359_313289_9_3

509a

FIG. 4

4. Use screws (509b) to install new solenoid (509a).

ti19926a1

3. Disconnect power.

4. Remove four nuts (17); leave two nuts on left side of

panel tight. Open front panel of control box (16).

See F

IG

. 3.

17

16

ti20158b1

IG

. 3

F

5. Reconnect solenoid cable connectors (542). See

Control Box (255771) on page 47.

NOTE:

From left to right, solenoid functions are as follows:

• Dosing valve A (DVA) (normally open)

• Dosing valve B (DVB) (normally open)

• Pump A (PA) (normally closed)

• Pump B (PA) (normally closed)

DVA

DVB

PA

PB

r_xm1a00_312359_313289_9_3

Replace Single Solenoid Module

1. Remove Shroud and Front Panel of Control Box,

see page 10.

10 3A2989G

Page 11

Repair

Update USB Module Software

1. Remove four nuts (21) and then remove front and

rear shrouds (19, 20).

21

20

19

ti19926a1

2. Use software token 16P644. See Graco Control

Architecture

instructions.

NOTE: Upgrade all modules in the system to the

software version on the token, even if you are

replacing only one or two modules. Different software versions may not be compatible.

All data in the module may be reset to factory

default settings. Record all settings and user preferences before the upgrade, for ease of restoring

them following the upgrade.

™

Module Programming manual for

Replace USB Module

1. Remove Shroud and Front Panel of Control Box,

see page 10.

2. Disconnect CAN cables and USB cable from USB

module (519).

3. Remove two mounting screws from USB module

and remove module from base.

r_312359_313289_23a

519

4. Follow steps in reverse order to install new USB

module.

5. Load software. See Update USB Module Soft-

ware.

The latest software version for each system can be

found at Tech Support at www.graco.com.

3A2989G 11

Page 12

Repair

Update Fluid Control Module (FCM)

Software

1. Remove four nuts (21) and then remove front and

rear shrouds (19, 20).

21

20

19

ti19926a1

2. Use software token 16P644. See Graco Control

Architecture

instructions.

NOTE: Upgrade all modules in the system to the

software version on the token, even if you are

replacing only one or two modules. Different software versions may not be compatible.

All data in the module may be reset to factory

default settings. Record all settings and user preferences before the upgrade, for ease of restoring

them following the upgrade.

™

Module Programming manual for

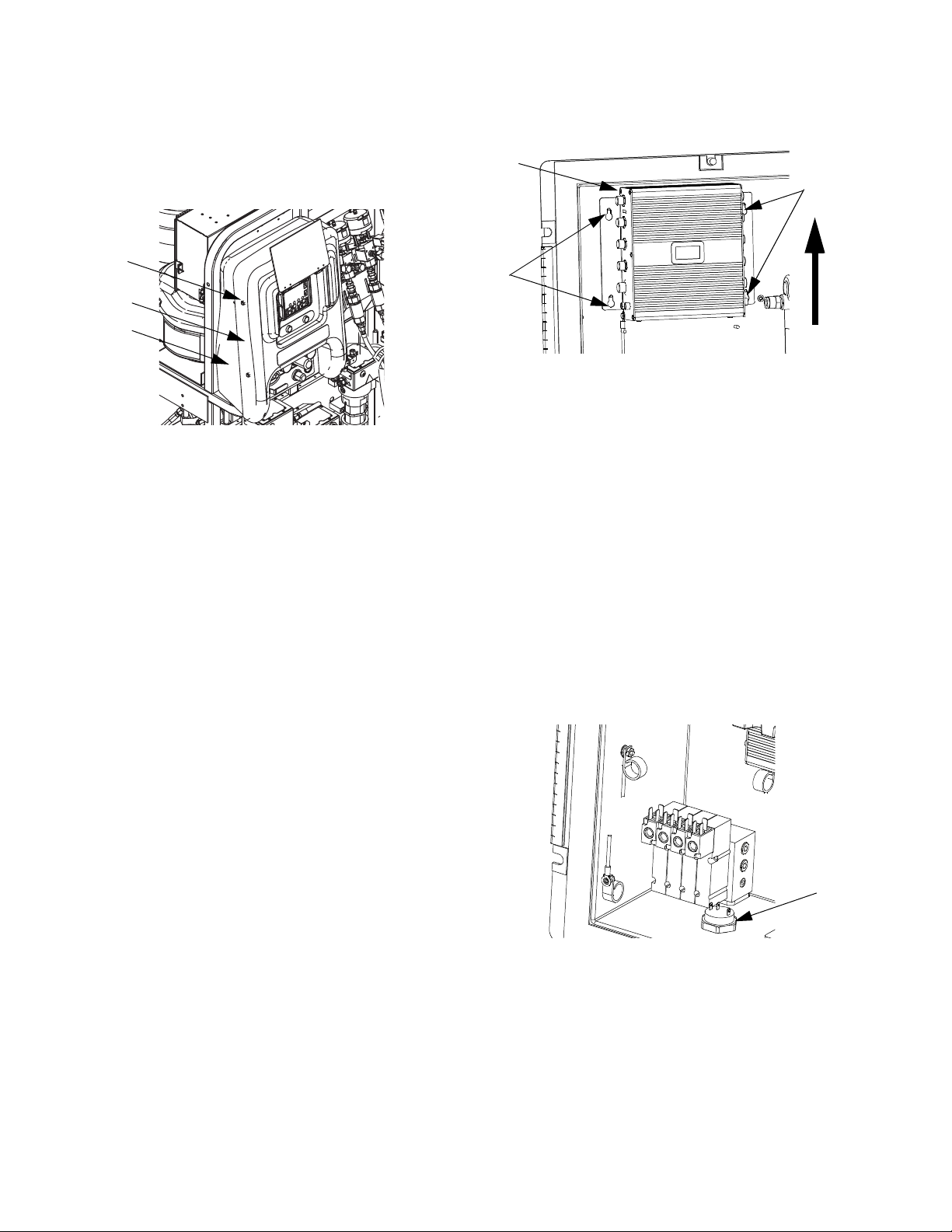

3. Loosen four mounting screws (535).

r_312359_313289_26

518

535

535

4. Slide FCM up and out of keyhole slots.

5. Follow steps in reverse order to install new FCM.

6. Load software. See Update Fluid Control Module

(FCM) Software.

7. Most of the system configuration is stored in the

FCM. Use the display to change the configuration to

the values in the old FCM. See XM PFP operation

manual for instructions.

Replace Alarm

1. Remove Shroud and Front Panel of Control Box,

see page 10.

2. Disconnect alarm wires from alarm (517).

The latest software version for each system can be

found at Tech Support at www.graco.com.

Replace Fluid Control Module (FCM)

NOTE:

The USB module does not need to be removed prior to

replacing the FCM.

1. Remove Shroud and Front Panel of Control Box,

see page 10.

2. Remove all cables from FCM (518). Take note of

cable locations.

3. Unscrew alarm (517) and replace.

r_312359_313289_22

517

4. Screw in new alarm. Reconnect alarm wires.

5. Reinstall front panel of control box and reinstall

shrouds.

12 3A2989G

Page 13

Repair

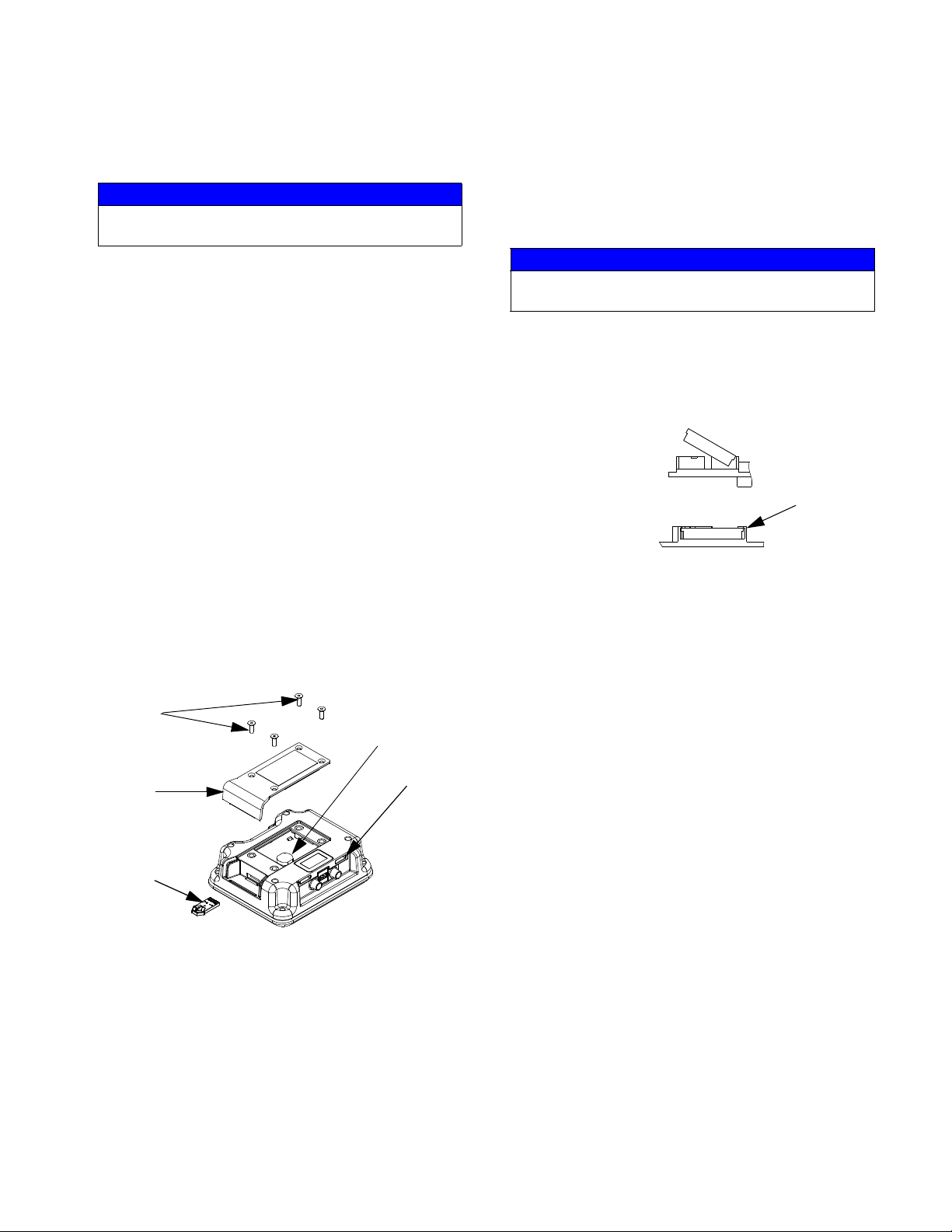

Display

Upgrade Software

NOTICE

To avoid damaging circuit board, wear a grounding

strap.

Use software token 16P644. See Graco Control Architecture

NOTE: Upgrade all modules in the system to the

software version on the token, even if you are

replacing only one or two modules. Different software versions may not be compatible.

All data in the module may be reset to factory

default settings. Record all settings and user preferences before the upgrade, for ease of restoring

them following the upgrade.

The latest software version for each system can be

found at Tech Support at www.graco.com.

™

Module Programming manual for instructions.

6. Turn power off.

7. Remove token (T).

8. Use screws (512) to install access cover (511).

Replace Display Battery

NOTICE

To avoid damaging circuit board, wear a grounding

strap.

1. Perform steps 1-2 in the Upgrade Software section

on page 13.

2. Use a flat head screwdriver to pry out old battery.

Remove Old Battery

Connector

Insert New Battery

r_xm1a00_312359_313289_9_8a

Tabs

1. Remove Shroud and Front Panel of Control Box,

see page 10.

2. Remove four screws (512) then remove access

cover (511).

512

Battery

L

511

T

r_xm1a00_312359_313289_2a

3. Insert and press token (T) firmly into slot.

NOTE:

There is no preferred orientation of token.

3. Replace with new battery. Ensure battery fits under

connector tabs before snapping other end in place.

NOTE:

Use only Panasonic CR2032 batteries for replacement.

4. Use screws (512) to install access cover (511).

4. Turn power on.

5. The red indicator light (L) will flash until new software is completely loaded.

3A2989G 13

Page 14

Repair

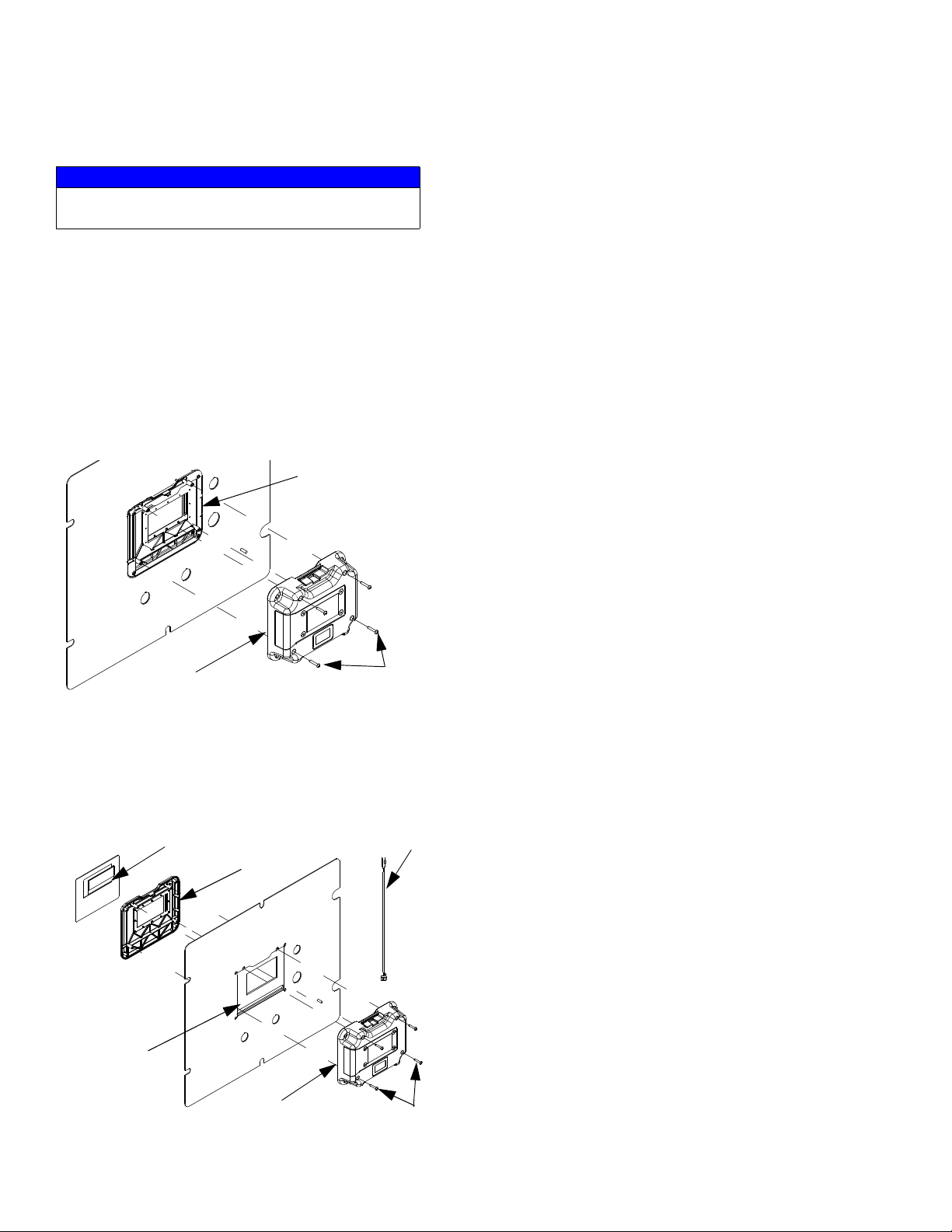

Replace Display

NOTE: Order display kit 257484 for replacement.

NOTICE

To avoid damaging circuit board, wear a grounding

strap.

1. Remove Control Box Shrouds, see page 17.

2. Disconnect CAN cable from display module.

3. Remove four screws (505) from rear display panel

(506) while holding front display panel (507) in

place.

NOTE:

To ease removal use clear tape to hold front display

panel (507) in place.

507

6. Discard old display assembly.

7. Place new front display panel (507) and

gasket (513) on front panel of control box (16).

NOTE:

To ease installation use clear tape to hold front display

panel in place.

8. Carefully connect display cables and key switch

cable to new circuit board.

9. Install new rear display panel (506) and secure with

four screws (505). Ensure key switch cable protrudes from opening in top of display module.

10. Install access cover and screws. Apply warning

label to access cover.

11. Reconnect CAN cable to display module.

12. Reconnect power.

13. Load software. See Upgrade Software, page 13.

14. Replace shroud.

r_312359_313289_24a

15. Configure system settings as they were set on old

display. See XM PFP Operation manual for instructions.

506

505

4. Remove rear display panel (505) and disconnect

display cable and key switch cable (539) from circuit

board.

5. Remove front display panel (507) and gasket (513).

Display Cable

539

507

513

r_xm1a00_312359_313289_25a

506

505

Replace Front Panel

See Replace Display, page 14, for instructions.

14 3A2989G

Page 15

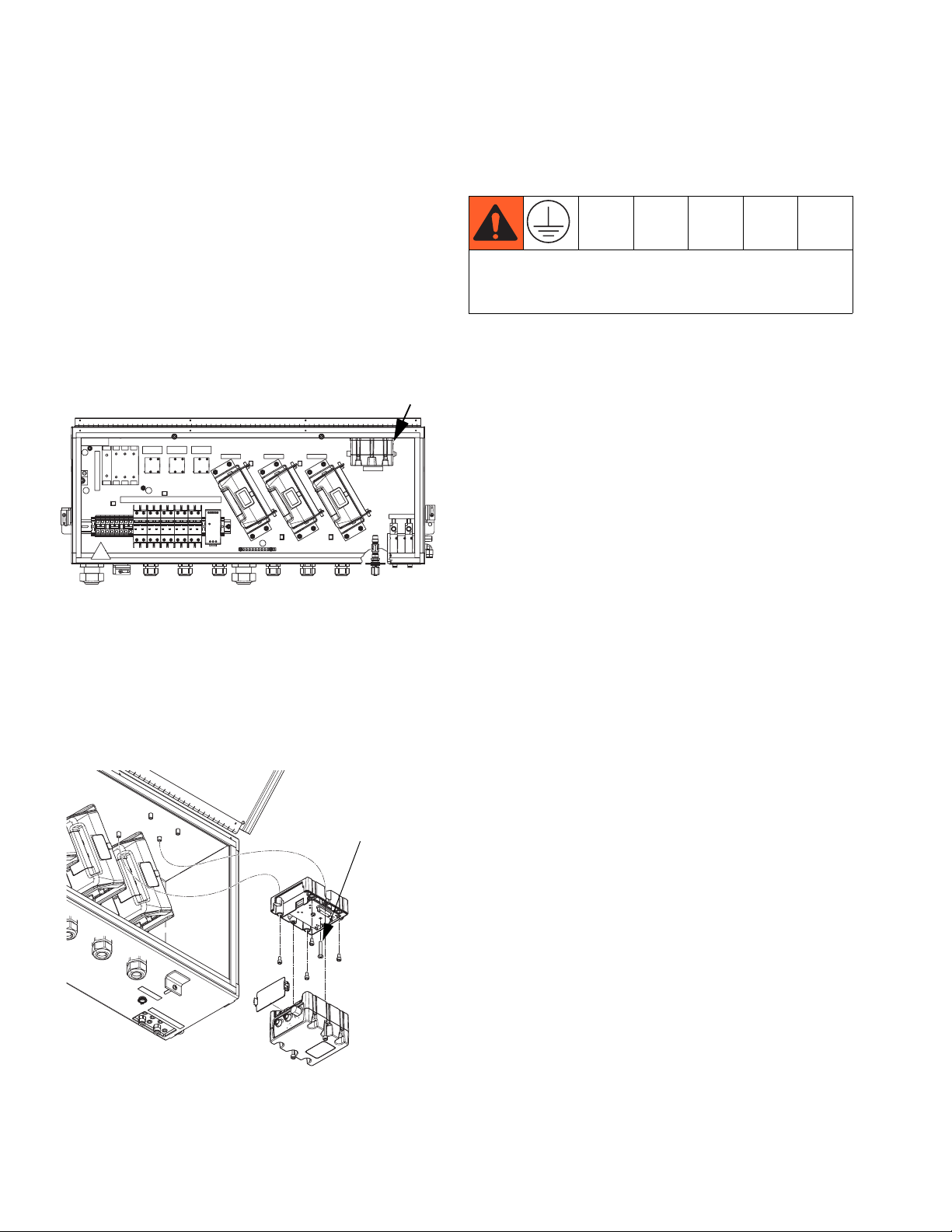

Repair

Junction Box

Update High Power Temperature Control

Module (HPTCM, ref. 404) Software

NOTE: Upgrade all modules in the system to the

software version on the token, even if you are

replacing only one or two modules. Different software versions may not be compatible.

All data in the module may be reset to factory

default settings. Record all settings and user preferences before the upgrade, for ease of restoring

them following the upgrade.

The latest software version for each system can be

found at Tech Support at www.graco.com.

1. Open junction box.

404

B HOSE A

Replace High Power Temperature Control

Module (HPTCM, ref. 404)

ti21595a

1. Turn system main power switch OFF.

2. Open junction box.

3. Unplug all connections on the HPTCM.

ti20155a

2. Use software token 16P644. See Graco Control

Architecture

™

Module Programming manual for

instructions.

4. Remove screws securing HPTCM then remove

HPTCM.

5. Remove access door on new HPTCM. Set rotary

switches to the same number as the old module.

B module = 1. Hose module = 2. A module = 0.

ti12360a

6. Use screws to install HPTCM.

7. Reattach HPTCM connections.

8. Close junction box.

3A2989G 15

Page 16

Repair

Update Fluid Control Module Cube (FCM3,

ref. 415) Software

NOTE: Upgrade all modules in the system to the

software version on the token, even if you are

replacing only one or two modules. Different software versions may not be compatible.

All data in the module may be reset to factory

default settings. Record all settings and user preferences before the upgrade, for ease of restoring

them following the upgrade.

The latest software version for each system can be

found at Tech Support at www.graco.com.

415

B HOSE A

3. Unplug all connections on the FCM3.

4. Remove two screws securing FCM3 then remove

FCM3.

Center ground screw in the Fluid Control Module

Cube must be used to avoid serious injury due to

electric shock.

5. Use screws to install FCM3.

6. Reattach FCM3 connections.

7. Perform Update Fluid Control Module Cube

(FCM3, ref. 415) Software on page 16.

8. Close junction box.

ti20155a

1. Open junction box.

2. Use software token 16P644. See Graco Control

Architecture

™

Module Programming manual for

instructions.

Replace Fluid Control Module Cube (FCM3,

ref. 415)

Ground screw

ti21594a

1. Turn system main power switch OFF.

2. Open junction box.

16 3A2989G

Page 17

Repair

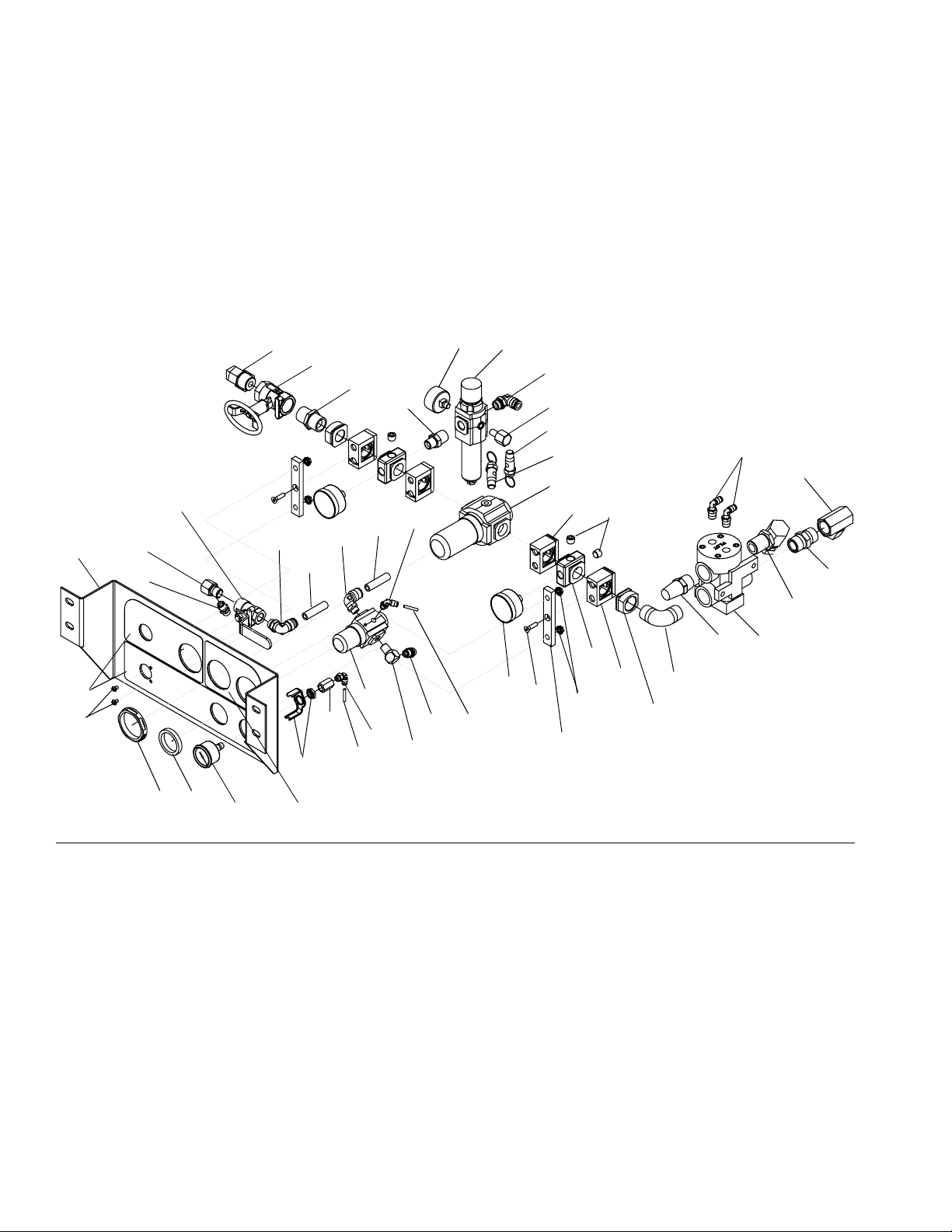

Air Controls

Remove Control Box Shrouds

1. Close main air shutoff valve on air supply line and

on system. Depressurize air line.

2. Remove four nuts (21) and then remove front and

rear shrouds (19, 20).

21

20

19

ti19926a1

Remove Air Control Assembly

1. Remove Control Box Shrouds.

2. Disconnect air motor air lines and system air line.

3. Remove four nuts (17) from front of air controls (18).

See page 36.

4. Pull out assembly.

5. Follow steps in reverse order to reinstall air control

assembly.

8. Follow steps in reverse order to reassemble.

Replace Solvent Air Regulator

1. Remove Control Box Shrouds.

2. Disconnect air motor air lines and system air line.

3. Remove four nuts (17) from front of air controls (18).

See page 36.

4. Pull out assembly.

5. Remove regulator nut (631), and disconnect air

lines (632, 633) running to regulator (625). See F

5 on page 18.

6. Remove regulator assembly and replace with new.

See part number shown in the System Air Con-

trols Module (255761) section beginning on

page 44.

7. Follow steps in reverse order to reassemble.

IG

Replace System Air Regulator

1. Remove Control Box Shrouds.

2. Disconnect air motor air lines and system air line.

3. Remove four nuts (17) from front of air controls (18).

See page 36.

4. Pull out assembly.

5. Remove regulator nut (601h) and disconnect system air line.

.

Replace Solvent Pump Air Ball Valve

1. Remove Control Box Shrouds.

2. Disconnect air motor air lines and system air line.

3. Remove four nuts (17) from front of air controls (18).

See page 36.

4. Pull out assembly.

5. Remove two nuts (630) from front of air control

bracket (619). See F

6. Disconnect air line (632) running to ball valve

assembly (626).

7. Replace with new ball valve assembly. See part

number shown in the System Air Controls Module

(255761) section beginning on page 44.

3A2989G 17

IG

. 5 on page 18.

6. Remove screws from quick clamps and open

clamps (601f) at hinge.

7. Remove regulator assembly (601c) and replace with

new. See part number shown in the System Air

Controls Module (255761) section beginning on

page 44.

8. Follow steps in reverse order to reassemble.

Replace Solenoid Inlet Air Regulator

1. Remove Control Box Shrouds.

2. Disconnect air motor air lines and system air line.

3. Remove four nuts (17) from front of air controls (18).

See page 36.

4. Pull out assembly.

Page 18

Repair

5. Disconnect air line.

6. Remove gauge (606) from block (601e).

7. Remove screws from quick clamps (601f) holding

air regulator assembly (601c) in place.

8. Open clamps (601f) at hinge and pull apart from

block (601e).

617

607

613

603

626

629

632

619

638

636

637

632

635

9. Remove regulator assembly (601d) and replace

with new. See part number shown in the System

Air Controls Module (255761) section beginning

on page 44.

10. Follow steps in reverse order to reassemble.

11. Set new air pressure regulator to at least 80-85 psi

(0.55-0.58 MPa, 5.5-5.8 bar).

616

644

608

610

611

Ref. 27

645

642

612

609

615

617

613

618

630

F

IG

. 5

640

631

627

627

618

628

633

625

629

634

635

633

606

621

620

622

643

642

641

604

646

647

18 3A2989G

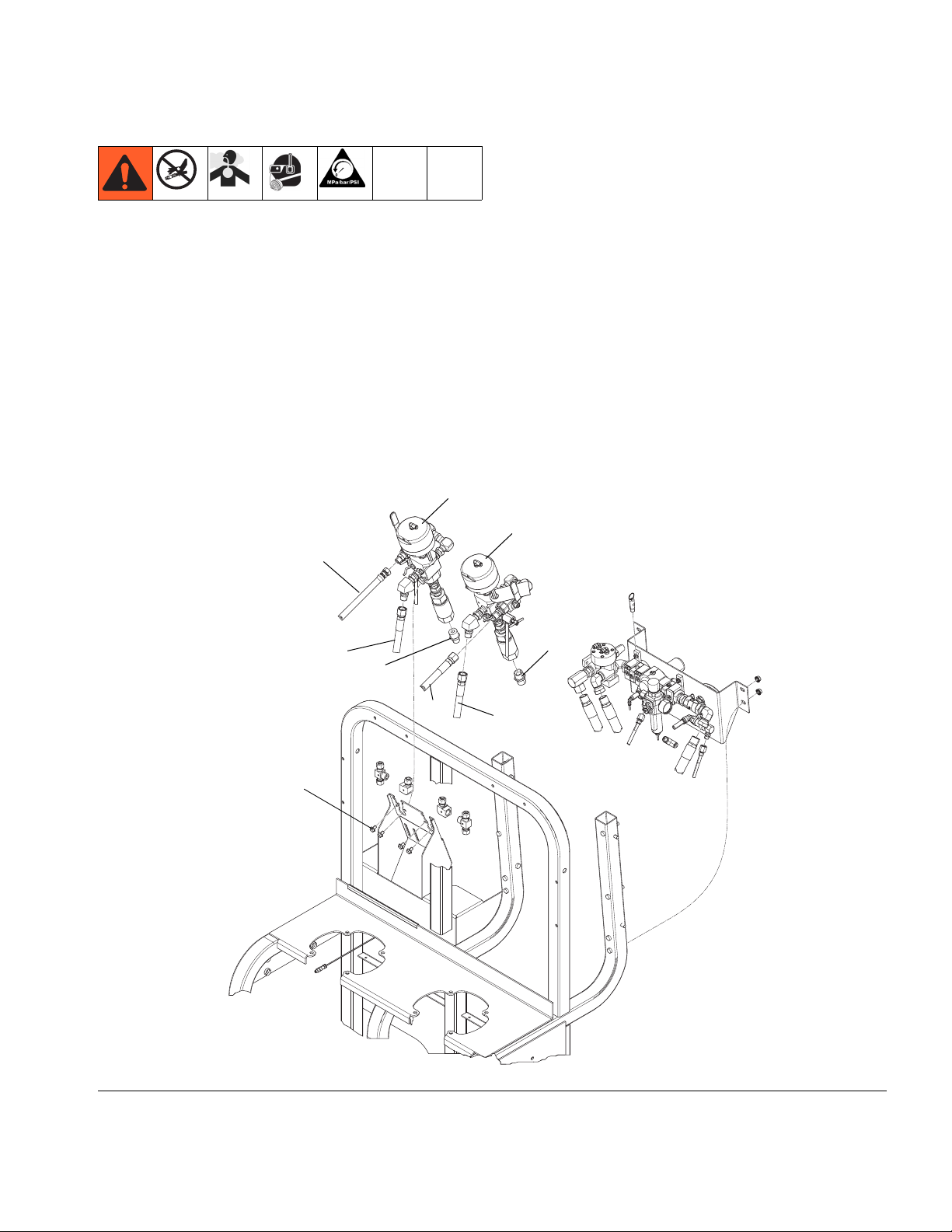

Page 19

Dosing Valve Assembly

Repair

1. Follow Pressure Relief Procedure, page 7.

2. Disconnect all fluid lines from dosing valves (28 or

IG

29). See F

3. Remove two bolts (31) securing dosing valve to

bracket.

4. Unscrew dosing valve nipple fitting (36 or 37) from

dosing valve outlet.

5. Disconnect pressure sensor (831) from dosing

valve. See page 50.

. 6.

29

55

85

36

6. Remove dosing valves.

7. See Ratio Control Valve Assemblies on page 50

for disassembly illustration.

8. Follow steps in reverse order to reassemble dosing

valve assembly. See Ratio Control Valve Assem-

blies on page 50 for assembly illustration and specifications.

28

37

FIG. 6

31

55

54

3A2989G 19

Page 20

Repair

Sensors

Replace Fluid Pressure Sensor

1. Close main air shutoff valve on air supply line and

on system.

2. Follow Pressure Relief Procedure, page 7.

3. Open control box cover. See User Interface/Con-

trol Box, page 10.

4. Disconnect pressure sensor (831) from dosing

valve. See Ratio Control Valve Assemblies on

page 50.

5. Disconnect other end of pressure sensor (831) from

FCM (518). See Control Box (255771) on page 47.

6. Replace with new fluid pressure sensor, and reconnect pressure sensor to FCM and dosing valve.

Hose Bundle Temperature Sensor (93)

1. Disconnect the M8 cable connection going into the

hose bundle.

2. Open up the hose bundle wrap and insulation until

sensor (93) can be removed easily without pulling

on cable.

3. Remove sensor.

4. Push new sensor fully into insulated portion of hose

bundle.

Replace Temperature (RTD) Sensors

This procedure applies to:

• Tank sensors mounted in the side of each tank near

the bottom (209).

• Glycol heater for hose outlet manifold sensor (100).

1. Close main air shutoff valve on air supply line and

on system.

2. Follow Pressure Relief Procedure, page 7.

3. Disconnect the M8 cable connection.

4. Loosen the compression nut. Pull sensor straight

out of fitting.

5. Remove fitting (82 or 208).

NOTE: The compressed ferrule cannot be removed

from the sensor. A new compression fitting must be

used.

6. Apply thread sealant then replace compression

fitting (82 or 208). Tighten fitting in place.

7. Position sensor (100 or 209):

• Tank: Insert sensor, leaving 5/8 in. sheath out-

side fitting.

• Heater manifold: Insert sensor, leaving 1/8 in.

sheath outside fitting.

8. Install compression nut on sheath hand-tight then

tighten an additional 3/4 turn.

5. Close insulation and hose bundle wrap and re-tape.

Ensure there is no stress on the cable.

6. Reconnect M8 connector.

20 3A2989G

Page 21

Repair

Pump Assembly (System Module)

Prior to servicing the pump assembly you must first

remove either the entire pump assembly or the displacement pump and air motor individually.

Remove Pump Assembly

1. Follow Pressure Relief Procedure, page 7.

2. Close ball valve at metering pump inlet.

3. Disconnect fluid inlet line from the displacement

pump. Leave line connected to the tank.

4. Disconnect air motor.

a. Disconnect sensor cable, air line, and ground

wire from air motor.

b. Remove mounting screws (5) and washers (4)

holding air motor (2 or 3) to mounting bracket.

IG

See F

5. Use lift ring on air motor to remove pump assembly.

. 7 on page 22.

Remove Displacement Pump

Follow these instructions for removing only the displacement pump; the air motor will remain installed.

1. Follow Pressure Relief Procedure, page 7.

2. Close ball valve on tank outlet.

3. Disconnect fluid inlet line from the displacement

pump. Leave line connected to the tank.

4. Remove clip (2b), and slide coupling cover (2c) up

to remove coupling (2a).

2c

2a

2b

ti8264a

5. Use a wrench to hold the tie rod flats to keep the

rods from turning. Unscrew the nuts (2e) from the tie

rods (2d) and carefully remove the displacement

pump (2f).

2d

2f

To avoid serious injury from falling objects caused by

the lift ring breaking, do not lift pump assembly by the

lift ring when the total weight of the pump assembly

exceeds 550 lb (250 kg).

6. Refer to Xtreme Displacement Pump manual

311762 to service or repair the displacement pump.

Refer to NXT Air Motor manual 311238 to service or

repair the air motor.

7. Follow steps in reverse order to reinstall pump

assembly.

3A2989G 21

6. Refer to the Xtreme Displacement Pump manual

7. Follow steps in reverse order to reinstall displace-

2e

ti8301a

311762 to service or repair the displacement pump.

ment pump.

Page 22

Repair

Remove Air Motor

1. Follow Pressure Relief Procedure, page 7.

2. Disconnect displacement pump from air motor. See

steps 2 and 3 under Remove Displacement Pump,

page 21.

3. Disconnect sensor cable, air line, and ground wire

from air motor.

4. Remove mounting screws (5) and washers (4) holding air motor (2 or 3) to mounting bracket.

2 or 3

Bracket

Solvent Pump

1. Follow Pressure Relief Procedure, page 7.

2. Disconnect pump inlet line (154) and air lines (57,

60) from solvent pump.

3. Disconnect fluid outlet line.

4. Remove four screws (153) that attach solvent

pump (8) to bracket (152) and remove solvent

pump.

152

153

8

4

5

r__312359_313289_32

IG

. 7

F

5. Refer to NXT Air Motor manual 311238 to service or

repair the air motor.

6. Follow steps in reverse order to reinstall air motor.

Pail Feed RAM Pump Assembly (Feed Module)

NOTE: See Pail Feed RAM Pump assembly (227) in

parts breakdown beginning on page 40.

See Supply Systems manual 313527 for service and

repair instructions and parts.

57

60

154

5. Refer to Merkur Pump Assembly manual 312794 to

service or repair solvent pump 257463.

6. Follow steps in reverse order to reinstall solvent

pump.

22 3A2989G

Page 23

Repair

Heaters

NOTE:

See applicable heater manual for wiring, repair, and

parts information. See Related Manuals on page 3.

Service and Repair

1. Follow Pressure Relief Procedure, page 7.

2. Disconnect fluid lines and electrical wiring from fluid

heater.

3. Refer to heater manual to service or repair heater.

4. Reconnect fluid lines and electrical wiring.

Replace

1. Follow Pressure Relief Procedure, page 7.

2. Disconnect fluid lines and electrical wiring from fluid

heater.

3. System Module Heaters: See F

mounting screws, lock washers, and plain washers

on back of heater (12 or 13) that secure it to the system frame. Slide heater up and remove from mounting plate.

4. Feed Module Heaters: See page 41. Remove 2

screws (224) then remove heater (226) from feed

module frame.

5. Replace heater. Follow steps in reverse order to

install new heater.

IG

. 8. Loosen four

12

13

12

F

IG

. 8: Heaters on System Module

3A2989G 23

Page 24

Repair

Replace Radar Level Sensor

NOTE: Order radar level sensor kit 24T052. See Feed

Module (24P883) on page 40 for kit contents.

NOTE: Tank level sensors changed in 2014. The old

sensors were red. The new sensors are blue. The blue

sensors can be used as direct replacements for the red

sensors.

1. With the tank empty, close the tank air supply ball

valve then open brass valve on tank lid to de-pressurize the tank. See F

IG

. 9.

Tank Air

Supply Ball

Valve location

(on other side

of panel)

8. Use a wrench to hold the 3/8 in. flats on the sensor

rod.

9. Tighten to approximately 25 - 30 in-lb (2.8 - 3.4

N•m). Do not over-tighten.

10. Reconnect sensor cable.

11. See Set Up a New Guided Level Sensor, page 25.

WLD

Valve

FIG. 9: Level Sensor Installation

2. Disconnect cable at the bottom of the feed module.

NOTE: Always use the new cable supplied with the

sensor. It has different connections than the old

sensor.

3. Disconnect 3/4 in. union that holds the level sensor

on top of the tank.

4. Pull the old sensor straight up out of the tank.

5. Remove plugs from new sensor and discard plugs.

Move fittings from old sensor to new sensor.

6. If the sensor rod was removed for shipping, apply

blue thread-lock to the threads in the end of the rod.

7. Feed the rod into the sensor head and screw the

threaded end into the sensor head.

24 3A2989G

Page 25

Repair

Set Up a New Guided Radar Level Sensor

Level sensors need to have three settings setup after installing on the tank of the PFP machine. The tank must be

empty, or the level needs to be at least below the bottom of the installed probe with the tank cover closed.

1. Open the sensor head cover over the display:

a. Loosen the securing clamp with an Allen wrench (if clamp is present).

b. Unscrew the round cover and pull away.

ti24380a

Use the operating keys to navigate within the operating menu and to select options from a list.

Key Meaning

“Minus” Key

• In a selection list, this key will move the selection bar upward.

• In an input matrix, this key will move the selection bar backward.

“Plus” Key

• In a selection list, this key will move the selection bar downward.

• In an input matrix, this key will move the selection bar forward.

“Enter” Key

• Opens the marked sub-menu or parameter.

E

+

2. Turn power on the machine. Set EMPTY CAL, then FULL CAL, then do a mapping of the Empty Tank.

3. Set EMPTY CAL to .939 meters:

a. Press E, then +, +, to get to Set Up. Then press E to get to EMPTY CAL, then press E.

• Confirms a changed parameter value.

“Escape” Key combination (press keys simultaneously)

• Closes a parameter without accepting the changes.

• Quits the current menu layer and returns to the next higher layer.

b. Press + until decimal point (.) appears, then press E.

c. Press + until 9 appears, then press E.

d. Press + until 3 appears, then press E.

e. Press + until 9 appears, then press E.

f. Press and hold E until the hourglass appears, then release.

3A2989G 25

Page 26

Repair

4. Set FULL CAL to .691 meters.

a. Press + to get to FULL CAL, then press E.

b. Press + until decimal point (.) appears, then press E.

c. Press + until 6 appears, then press E.

d. Press + until 9 appears, then press E.

e. Press + until 1 appears, then press E.

f. Press and hold E until the hourglass appears, then release.

5. Map EMPTY TANK.

a. Press + to get to MAPPING, then press E.

b. Press E to get to CONFIRM DISTANCE.

c. Press + until TANK EMPTY appears, then press E.

d. Press + under the check mark to confirm, END OF SEQUENCE will appear. Press and hold E until the hour-

glass appears, then release.

e. You are now finished. Press + and - together until the hourglass appears, then release.

6. The transmitter display should show nothing in the tank. Check the level display on the PFP machine control. It

should also show the tank as empty.

7. These settings can now be locked from display control so they will not be inadvertently changed.

8. Set display to lock ON:

a. Turn display counter-clockwise to release it as shown below (2).

b. Set the dip switch to the lock position as shown below (3).

c. Replace display (4).

d. Replace screw on lid (5).

e. Engage cover securing clamp.

26 3A2989G

Page 27

Electrical Schematics

Electrical Schematics

Simplified Electrical Schematic

Page 1 of 3

DISC1

Switch - 123969

th

pole - 123968

4

L3

FIELD

WIRE

SIDE

L2

L1

N

GRACO

WIRE

SIDE

GND-3

PS1

BLACK -V

RED

+V

CB5-3

CB5-1

CB4-3

CB4-1

CB3-3

CB3-1

CB2-3

CB2-1

CB1-3

CB1-1

TB8-1

+

+

Din rail

24VDC

Power Supply

-

3

1

3

1

3

1

3

1

3

1

CB5

30A

126130

CB4

20A

126128

CB3

30A

126130

CB2

20A

126128

CB1

25A

126129

TB8

TB7

16T147

L

N

GND

4

2

4

2

4

2

4

2

4

2

CB5-4

CB5-2

CB4-4

CB4-2

CB3-4

CB3-2

CB2-4

CB2-2

CB1-4

CB1-2

TB8-2

TB8-2

TB7-2

TB7-2

24VDC

POWER

L

N

GND-2

TCMA-5L2

TCMA-5L1

TCMH-5L2

TCMH5L1

TCMB-5L2

TCMB-5L1

SW3-3

SW1-3

SW3-1

SW1-1

SW2-3

SW2-1

KEY:

230VAC

DELTA

JUMPER

POSITIONS

380VAC

WYE

JUMPER

POSITIONS

TB5-1

TB3-1

TB1-1

TB6

TB5

TB4

TB3

TB2

TB1

TB6-2

TB5-2

TB5-2

TB4-2

TB4-2

TB3-2

TB2-2

TB2-2

TB1-2

TB1-2

3A2989G 27

Page 28

Electrical Schematics

Page 2 of 3

24VDC

POWER

GND-2

TCMA-5L2

TCMA-5L1

TCMH-5L2

TCMH5L1

TCMB-5L2

TCMB-5L1

SW3-3

SW1-3

SW3-1

SW1-1

SW2-3

SW2-1

Power

Distribution

Enclosure

16T147

1

-

SW1

15U423

SW1

Switch -

2

-

SW1

CK

LA

B

NEMA

L6-20R

3

1

W

S

3

1

2

15U423

SW

Switch -

4

2

4

1

W

S

ITE

WH

GND-2 GND-2

1

-

SW2

1

2

2

-

W2

S

CK

LA

B

NEMA

L6-30R

6

B

M

TC

TCMH-5L2

GND-2

TCMH-6

Splitter

125806

5

66

TCMH

255774

125357

1

2

TCMH-5L1

TCMB-5L2

GND-2

TCMB-5L1

3

2

W

S

3

4

4

2

W

S

E

T

I

H

W

3

SW

1

3

W

S

15U423

tch -

i

Sw

2

3

W

S

K

C

LA

B

NEMA

L6-20R

3

-

SW3

3

1

4

2

4

3

W

S

ITE

H

W

GND-2

6

5

TCMB

255774

126511

6

TCMB-6

Cable

125789

2

3

2

1

L

L

3

3

-

B

B

M

M

TC

TC

CK

ITE

LA

WH

B

GND-2

1

L

3

MHTC

K

C

LA

B

26

32

TCMA-5L2

TCMA-5L1

TCMH-6

Cable

125789

2

L

3

MHTC

ITE

WH

GND-2

GND-2

TCMA-6

5

66

TCMA

1

L

3

A

M

TC

K

C

A

L

B

32

TCMA-6

2

L

3

MATC

ITE

H

W

GND-2

255774

126511

CAN

NEMA

L6-20P

TER

A

E

ANK H

BT

W

75K

.

1

16T525

NEMA

L6-30P

TER

A

E

W

H

5K

H

S

LU

F

16T859

NEMA

L6-20P

TER

A

W

E

H

75K

K

.

1

N

A

T

A

16T525

TER

A

E

H

ID

LU

F

B

W

K

4

.

5

262853

24P242

126427

TER

A

E

W

H

K

4

OSE

H

245869

TER

A

E

H

ID

LU

F

A

KW

4

.

5

262853

28 3A2989G

Page 29

Page 3 of 3

CAN

Power

Distribution

Enclosure

FCM1

Base - 289697

FCM - 289696

1

1

M

M

C

FC

F

16T072

126496

5

7

1

2

121806

121806

B

oleno id

S

Manifold

Electrical Schematics

126495

124273

leno id A

o

S

126494

126494

Control Enclosure

Buzzer - 122000

Start - 121618

Manifold

Dose A

Motor A

256555

15M669

975

15M

15M977

15U542

16T123

Base - 289899

USB - 289900

15V778

A BLUE B

1

2

3

4

5

121683

USB1

AFCM

255920

GREEN

DISPLAY SHIELD

15M483

DISPLAY

FRONT

DISPLAY LCD

288997

15V779

15R324

15M976

1

977

15M

2

3

15U542

4

5

121683

255727

USB

SETUP

KEY

15M974

Stop - 121619

Manifold

256555

15M669

121617

Dose B

Motor B

127172

OR

S

N

SE

L

E

24T052

V

E

L

B

127172

SOR

N

SE

L

24T052

EVE

L

A

Air Motor Junction Box

NXT411

Linear Sensor - 256893

Reed Switch

RTD

ank

T

126381

A

RTD

ank

BT

Air Motor Junction Box

Linear Sensor - 256893

126381

Reed Switch

NXT411

3A2989G 29

Page 30

Electrical Schematics

XM PFP Air Logic Schematic

%

3803

$

3803

SLORW

YDOYH

;0'XDO

+LJK3UHVVXUH

0HWHULQJ3XPSV

9DOYHV

'RVLQJ

SVLOLPLW

(;+

3XPS

0LFURQ

)LOWHU5HJ

0DLQ

YDOYH

FRQWURO

5HJ

SVL

OLPLW

(;+

)OXVK

3XPS

%R[

6ROHQRLGV

;0&RQWURO

7R

&LUF

+RVH

3XPS

7R

SVL

%

OLPLW

)HHG

0RGXOH

7R

7R3QHXPDWLF

5DPSXPSSLORW$

$

)HHG

0RGXOH

7R3QHXPDWLF

5DPSXPSSLORW%

%R[

-XQFWLRQ

6ROHQRLGV

9DOYH

6\VWHP

{ರ

$872

PLFURQ

1”

30 3A2989G

Page 31

Feed Module Air Controls Schematic

3DLO

)HHG

3XPS

5$0

5HGKRVH

3XPS

3DLO

3LORW

%ORZRII

3XPS

2))21

~

:KLWH

3XPS

5HJ

83

'2:1

5DP

35(6685(

5(*8/$725

5DP

2))21

WRWDQN

'U\$LU

LINLWLVXVHG

Electrical Schematics

%ODFN

3XVK

3XPS

2YHULGH

~ 5HGKRVH

212))

&LUF$JLWDWRU

%ODFN

%XWWRQ

From

Level

J-Box

212))

Solenoid

~

5HG

KRVH

7DQN

3UHVVXUH

6SHHG

&RQWURO

~ 5HGKRVH

%ODFN

$LU

0RWRU

9HQW

~ 5HGKRVH

$JLWDWRU

5HGKRVH

0DQLIROG

7DQN/LG

7DQN

'U\$LU

2SWLRQDO

$LU)URP

ೀ5HGKRVH

3URSRUWLRQHU

3UHV

9DOYH

5HOLHI

6SHHG

&RQWURO

~

7DQN

3XPS

:DWHU

7XEH

+HDW

0RWRU

$JLWDWRU

/XEULFDWRU

3A2989G 31

Page 32

Parts

Parts

XM PFP System (262869, 24W626)

Ref. Part Description Qty.

1 SYSTEM MODULE AND MIX LINE 1

262878 Model 262869

24W648 Model 24W626

2 FEED MODULES ASSEMBLY 1

24P202 Model 262869

24W628 Model 24W626

2a 24P883 FEED MODULE 2

2b* C20461 NIPPLE, reducing 1

2c‡ 100505 BUSHING 1

2d‡ 156849 NIPPLE 1

2f◆ 15U654 LABEL, A/B Identification 1

Ref. Part Description Qty.

2g◆ 061134 HOSE, nylon 2.5

2h◆ --- CABLE TIE 8

3 HEATED HOSE BUNDLE 1

16T121 Model 262869

16T122 Model 24W626

--- Not for sale.

◆ Not shown.

‡ Not required for model 24W626.

* Qty. 2 required for 24W626.

1

2a

‡

2c

‡

2d

1

3

2a

*2b

32 3A2989G

ti20491a

Page 33

XM PFP System (262869, 24W626) Subassemblies

Base System (262878, 24W648)

Page 1 of 5

Parts

46

Heated Hose Bundle 16T121. Not included with assemblies 262878 and 262869.

Shown for reference only.

Heated Hose Bundle 16T122 not included with assembly 24W648 and 24W626.

Shown for reference only.

85

95

96

61

97

99

98

61

ti20154a

NOTE: Apply pipe sealant to all non-swiveling pipe threads.

3A2989G 33

Page 34

Parts

Base System (262878, 24W648) page 2 of 5

43

140

144

143

145

146

147

140a

67

10

45, 11

32

104

103

35

38

102

61

33

39

61

Set air regulator to 85 psi

(590 kPa, 5.9 bar)

101

30

67

57

36

44

54

8

151

154

148

152

2

153

4, 5

150

9

60

149

11

140

67

6

7

43

1

94

41

44

54

36

3

ti20156a

155

34 3A2989G

Page 35

Base System (262878, 24W648) page 3 of 5

56

Parts

29

28

27

31

120

85

36

55

54

37

67

60

118

105

67

59

ti20157a

3A2989G 35

Page 36

Parts

Base System (262878, 24W648) page 4 of 5

40

52

19

16

17

133

114

116

115

117

132

113

86

114

15

112

110

109

111

108

9

23

25

26

21

20

17

36 3A2989G

18

22 24

ti20158b

Page 37

Base System (262878, 24W648) page 5 of 5

Parts

107

12

15

54

78

79

127

120

9

132

133

87

106

13

34

82

100

12

54

85

93

64

100

ti20159b

3A2989G 37

Page 38

Parts

Base System (262878, 24W648)

Ref Part Description Qty

1 --- FRAME 1

2 L180C9 PUMP; B side lower 1

3 L220C9 PUMP; A side lower 1

4 100133 WASHER, lock, 3/8 8

5 100101 SCREW, cap, hex head 8

6 256169 PLATE, solvent pump 1

7 121488 SCREW, hex head, flanged 2

8 W30CAS PUMP, solvent, 6.0 in, 75 cc; see

312794

9 112395 SCREW, cap, flange head 8

10 24N598 JUNCTION BOX; see page 45 1

11 113796 SCREW, flanged, hex head 6

12 262853 HEATER, Viscon HF 2

13 245869 HEATER, Viscon HP 1

14 24P899 FILTER, air, 1-1/4, assembly 1

15 126899 FITTING, compression, straight 2

16 255771 BOX, control, air/electric 1

17 112958 NUT, hex, flanged 10

18 255761 MODULE, air controls, upper 1

19 --- COVER, shroud, rear 1

20 256177 COVER, shroud, front 1

21 117623 NUT, cap, 3/8-16 4

22 --- LABEL, XM PFP 1

23 15T567 NUT, backup plate, hinge 4

24 15T568 DOOR, control shroud 1

25 121471 HINGE, friction, positioning 2

26 112380 SCREW, mach, pan head 8

27 113498 VALVE, safety, 110 psi 1

28 --- VALVE, ratio control, left; see

page 50

29 --- VALVE, ratio control, right; see

page 50

30 C19024 FITTING, elbow, swivel 1

31 111801 SCREW, cap, hex head 8

32 217430 FITTING, swivel, union, 90 degree 1

33 15T536 REGULATOR, air, 3/8 npt 1

34 100329 BUSHING, pipe 1

35 116504 FITTING, tee, run 1

36 C20461 FITTING, nipple, reducing, hex

Model 262878 3

Model 24W648 2

37 160032 FITTING, nipple

Model 262878 2

Model 24W648 4

38 116643 VALVE, safety, relief, air 1

39 101689 GAUGE, press, air 1

40 121688 CONNECTOR, 3/8 npti x 3/8 tube

ptc

41 115313 PLUG, tube 8

42 160327 FITTING, union adapter, 90

degree

Ref Part Description Qty

43 15J277 CONTROL, de-ice, assembly 2

44 15M987 FITTING, elbow, 60 degree 2

45 117666 TERMINAL, ground 1

46 262893 MANIFOLD, mix; see manual

3A2988

47 --- SEALANT, pipe, stainless steel 1

48 --- LUBRICANT, thread 1

49 --- SEALANT, anaerobic 1

50 206995 FLUID, TSL, 1 qt. 1

1

52 108636 MUFFLER 1

53▲ 15X393 LABEL, warning, USB, all

languages

54 H75003 HOSE, coupled, 7250 psi,

0.50 in. ID, 3 ft

55 H75004 HOSE, coupled, 7250 psi,

0.50 in. ID, 4 ft

Model 262878 3

Model 24W648 5

56 H73806 HOSE, coupled, 7250 psi,

0.375 in. ID, 6 ft

(Model 262878 only)

57 H42506 HOSE, coupled, 4500 psi,

0.25 in. ID, 6 ft

58 205418 HOSE, coupled, air, 1/2 x 6 ft 2

59 16P244 HOSE, coupled, air, 5/16 x 3 ft 2

60 248208 HOSE, coupled, air, 5/16 x 4 ft 1

61◆ 159239 FITTING, nipple, pipe, reducing 4

62 16A004 FLASH DRIVE, USB, 2.0 1

63 121456 CONNECTOR, power, male, 3 pin 1

64 125806 CABLE, splitter, M8, 4-pin,

1

female/female/male, 1.5 m

65 126511 CABLE, GCA, M8, 4-pin, 1.5 m,

1

male/female

66 16T123 CABLE, GCA, CAN, male/female,

1.0 m

67 240900 HOSE, coupled, air, 30 in. x 3/4 in. 3

68 054172 TUBE, nylon, round, black, 1/4 in. 26.5

69 054175 TUBE, nylon, round, natural,

1/4 in.

70 551390 SIGHTGLASS, beaker, graduated 10

71 --- STRAP, tie 20

73 238909 WIRE, grounding assembly 1

74 C12508 TUBING, nylon, round, black,

3/8 in.

76 109025 TERMINAL, ring 1

79 16P856 LABEL, codes, alerts; all

languages

80 125357 CABLE, M8, 4-pin, male/female,

1

1 meter

81 126494 CABLE, M12, 5p, 4-wire with drain 2

82 126351 FITTING, compression,

2

thermocouple

1

1

3

1

1

1

2

1

8.5

4.7

1

1

1

38 3A2989G

Page 39

Parts

Ref Part Description Qty

85◆ H75002 HOSE, coupled, 7250 psi, 0.5 in.

(12 mm) ID, 2 ft

86 --- TUBE, 0.375 in. (9.5mm) ID blue

nylon

87 --- TUBE, 0.375 in. (12 mm) ID red

1.5

nylon

88 114601 CONDUIT, flexible, non-metallic 3.5

92 15T258 TOOL, wrench, Xtreme, 145/290 1

93 24P242 SENSOR, RTD, 1k ohm, insulated 1

94 158586 FITTING, bushing 1

95◆ 16T316 MIXER, static, assembly 1

96◆ H75010 HOSE, coupled, 7250 psi, 0.50 ID,

10 ft

97◆ H73803 HOSE, coupled, 7250 psi, 0.375

ID, 3 ft

98◆ 24P834 SWIVEL, straight 1

99◆ 262854 GUN, spray 1

100 126427 SENSOR, RTD, 1K ohm, 4 pin,

8in.

101 158990 MANIFOLD, air 1

102 165198 FITTING, nipple, reducing 1

103 121858 FITTING, elbow, 3/8 npte x 1/4

npte

104 101754 PLUG, pipe 1

105 119798 CONNECTOR, tee, push-tube 1

106 126896 FITTING, elbow, tube 1

107 121603 GRIP, cord, 0.51-0.71, 3/4 1

108 16T745 BRACKET, water circulation,

mount

109 16R871 BOTTLE, overflow, 1/2npt 1

110 113161 SCREW, flange, hex head 2

111 108126 FITTING, tee, street 1

112 126898 FITTING, elbow 1

113 D11021 PUMP, diaphragm 1

114 126897 FITTING, elbow 2

115 206264 VALVE, needle 1

116 151519 FITTING, nipple, reducing 1

117 15R472 FASTENER, hex head, flanged,

1/4 x 1

118 054760 TUBE, polyurethane, round, black 5

119 100028 WASHER, lock 1

120 115901 TRIM, edge, protection 2

121 16T171 STRAP, frame connector 2

122 100679 SCREW, cap, hex head 8

123 115211 SCREW, cap, hex head 2

124 --- SCREW, hex head with serrated

face flange base, 1/2-13

125 109570 WASHER, plain 20

126 112731 NUT, hex, flanged 10

127▲ 15W598 LABEL, warning 1

128 15U654 LABEL, identification, A/B 1

129 --- FLUID, ethylene glycol/water 2

Ref Part Description Qty

2

131 16F366 FITTING, 1/4 in. x 1/4 in. push to

connect

6

132 126346 FITTING, tee, tube x tube x nptm 2

133 126345 FITTING, elbow, tube x nptf 2

135 121683 CABLE, M8, 4-pin, male/female,

3 meter

136 122032 NUT, wire 2

137 15V778 CABLE, CAN, female-female,

20 in.

138 15V779 CABLE, CAN, female-female,

34 in.

1

140 257055 MOTOR, 6500 with sensor 2

140a 256893 LINEAR SENSOR ASSEMBLY

1

141 100133 WASHER, lock 8

142 100101 SCREW 8

143 257150 ROD, tie 6

144 197340 COVER, coupler 2

145 15H392 ROD, adapter 2

1

146 244820 CLIP, hairpin lanyard 2

147 244819 COUPLING, assembly rod 2

148 101712 NUT, nyloc 6

149 157350 ADAPTER, 3/8 x 1/4 1

1

150 100081 BUSHING 1

151 116395 UNION, 90 degree, 1/4 male x 3/8

swivel

152 256561 PLATE, mount, pump 1

153 111799 SCREW, M8 x 1.25 x 16 mm 4

154 256421 HOSE, siphon 1

1

155 181073 STRAINER, inlet 1

--- Not for sale.

▲ Replacement Danger and Warning labels, tags and

cards are available at no cost.

◆ Included in mix line and gun kit 24P833.

4

8

2

2

1

1

1

3A2989G 39

Page 40

Parts

Feed Module (24P883)

Page 1 of 2

246

217

298

297

243

208

247

216

201

209

207

213

212

213

211

210

218

272

202

254

219

219

273

215

267

266

265

268, 215

219a

300

269

230

270

213

211

206

253

233

254

271

252

252

251

Turns clockwise

WLF

as viewed from

the top

222220

40 3A2989G

Page 41

Page 2 of 2

Parts

225

250

249

250

224

223

224

227

261

260

259

258

257

231

262

227a

213

227c

277

226

229

228

224

276

227b

ti20161c

3A2989G 41

Page 42

Parts

Feed Module (24P883)

Ref Part Description Qty

201 --- FRAME 1

202 24M683 TANK, pressure, assembly 1

203 --- BOLT, hex head, 3.25 in. long,

5/8-11

204 111841 WASHER, plain 5/8 8

205 --- NUT, self-locking hex, nylon

206 16R869 COVER, tank wrap 1

207 --- BUSHING, pipe, hex head,

208 126351 FITTING, compression, thermo-

209 126381 SENSOR, RTD, 1k ohm, 4 pin,

210 126898 FITTING, elbow 2

211 295847 FITTING, elbow, 90, 3/4 mpt 2

212 16T481 VALVE, check (see page 57) 1

213 157785 FITTING, swivel 4

215 171988 GASKET, inspection cap 1

216 16T619 FITTING, nipple, thread on one

217 24P885 AGITATOR, assembly, air (see

218 --- MANIFOLD, assembly, air (see

219 24T052 SENSOR ASSEMBLY, level 1

220 D11021 PUMP, diaphragm 1

221 100016 WASHER, lock 4

222 102040 NUT, lock, hex 4

223 262860 PANEL, assembly, air 1

224 113796 SCREW, flanged, hex head 8

225 16R871 BOTTLE, overflow, 1/2 npt 1

226 16T525 HEATER, fluid, 240V, Viscon LT 1

227◆ 262868 SUPPLY UNIT, 40:1, 0 volt, S20,

227a P40DCS PUMP AND MOTOR, see man-

227b 257620 S20 RAM, see 313527 1

227c 257727 PLATEN, pail, see 313527 1

228 GC2041 WASHER, flat, std, 1/2 4

229 100017 SCREW, cap, hex head 4

230 117426 INSERT, tube 6

231 104633 VALVE, pilot 1

232 --- SEALANT, pipe, stainless steel 1

233 103475 FITTING, tee, pipe 1

234 --- TUBE, 0.375 in. (9.5mm) ID red

235 --- TUBE, 0.375 in. (9.5mm) ID blue

236 205418 HOSE, coupled 1

237 109130 HOSE, coupled, 48 in. 1

238 16P244 HOSE, coupled, 3 feet 3

239 15B772 HOSE, air, 18 inch 3

240 054172 TUBE, nylon, round 12

241 054753 TUBE, nylon, round, black 8

242 --- TUBE, 0.275 in. ID black nylon 5.5

243 115313 PLUG, tube 6

246 215241 HOSE, 3/4 in. x 6 ft, 6000 psi

247 16T244 VALVE, pressure relief, 3/4 in.

insert, 5/8-11

3/4 npt x 1/8 npt, steel

couple

3in.

end

page 51)

page 53)

20L

ual 312376

3.8

nylon

4.2

nylon

(41 MPa, 410 bar)

female npt

Ref Part Description Qty

248 --- TIE, cable, 14 in. 20

249 108126 FITTING, tee, street 1

250 126899 FITTING, compression, straight 2

251 112782 ELBOW, swivel, 90 degree 1

4

252 126897 FITTING, elbow 2

253 115764 FITTING, elbow, 90 degree 1

254 190451 UNION, adapter 2

255 --- LABEL, part description 1

4

257 116395 FITTING, swivel, elbow 1

258 103656 FITTING, pipe, hex 1

259 198171 FITTING, elbow 1

1

260 593538 VALVE, shuttle 1/8 nptf 1

261 112781 ELBOW, swivel, 90 degree 1

1

262 24K976 MUFFLER, 1/4 npt 1

263 100505 BUSHING, pipe 1

1

264 155665 UNION, adapter 1

265 16R985 FITTING, nipple, 2 npt 1

266 16R983 FITTING, adapter, 2 npt to

267 24P837 GASKET, agitator 1

268 210575 CAP, filler 1

269 16T245 COUPLING, shaft, one piece

1

270 16T396 SHAFT, agitator, lower 1

1

271 257604 BLADE ASSEMBLY 1

272 102726 PLUG, pipe headless 1

1

273 109212 SCREW, socket cap head 1

274 115219 FITTING, tee, 1/4 npt 1

275 262820 KIT, fluid outlet, flexible 1

276 126900 CONNECTOR, male 1

277 126692 CONNECTOR, male 1

296 156172 FITTING, union, swivel 1

297 260067 FITTING, strain relief 1

298★ 127172 CABLE, M12, 5-pin, 4-wire 1

299 102726 PLUG, pipe, headless 1

300 117571 GASKET, santoprene 1

1

1

--- Not for sale.

◆ See Supply Systems manuals 313526 and 313527

for detailed instructions and parts list for the S20

Supply Unit (262868).

★ Included in radar level sensor kit 24T052. See

Replace Radar Level Sensor on page 24.

NOTE: 24T052 Level sensor with the blue head

replaces the 24P884 sensor with the red head.

24T052 includes #298

1

1

3/4 npt

clamp

1

1

42 3A2989G

Page 43

Heated Hose Bundle

16T121 - 3/4 in. x 1/2 in. (included in model 262869)

16T122 - 3/4 in. x 3/4 in. (included in model 24W626)

Parts

305

310a

304

302

308

303

306

305 (blue)

307

310b

310c

302 (red)

303

309

301

Ref Part Description Qty

301 H67550 HOSE, coupled, 3/4 in., 6500 psi;

Model 16T121 - Qty 1

Model 16T122 - Qty 2

302 16X027 KIT, tube, 0.375 (9.5mm) ID red

nylon

303 H42550 HOSE, coupled, 4500 psi, 1/4 in. ID,

50 ft (15.2 m)

304 --- LABEL, identification 1

305 16X028 KIT, tube, 0.375 in. (9.5mm) ID blue

nylon

306 --- TAPE, electrical 1

307 --- TUBE, insulation, 2-5/8 in. ID, 50 ft

(15.2 m)

308 H75050 HOSE, coupled, 7250 psi, 1/2 in. ID,

50 ft (15.2 m); Model 16T121 only

309 16T138 JACKET, scuff, 50 ft (15.2 m) 1

310 16U666 KIT, tube fittings 1

310a 126894 UNION, 1/2 in. tube x 1/2 in. tube 4

310b 126898 ELBOW, 1/2 in. tube x 1/2 nptm 2

ti20243a

Ref Part Description Qty

310c 126896 ELBOW, 1/2 in. tube x 1/2 nptf 2

311◆ 16U111 KIT, fittings, hose connection 1

311a◆ C20487 NIPPLE, hex 2

311b◆ 158491 NIPPLE 1

2

311c◆ 156823 UNION, swivel 2

311d◆ 156971 NIPPLE, short 1

1

--- Not for sale.

2

◆ Not shown.

1

1

3A2989G 43

Page 44

Parts

Base System (262878, 24W648) Subassemblies

System Air Controls Module (255761)

NOTE: For Feed Module Air Panel (262860) parts, see page 55.

619

638

635

626

617

636

632

607

637

613

632

616

603

629

644

608

610

611

Ref. 27

645

642

609

615

612

613

617

618

630

628

627

631

640

Ref. Part Description Qty.

603 157350 NIPPLE, pipe; 1/2 x 3/8 npt 1

604 108307 ELBOW, pipe, male 1

606 101689 GAUGE, press, air 2

607 117346 VALVE, ball, vented 1

608 114316 ELBOW, male, swivel 1

609* 114109 ELBOW, male, swivel; 1/4 OD tube 2

610 158962 ELBOW, street; 1/4(f) x 1/8(m) 1

611 116643 VALVE, safety, relief, air 1

612 100721 PLUG, pipe 3

613 119992 PIPE, nipple; 3/4 x 3/4 npt 2

615 156589 ADAPTER, union; 90 deg. 1

616 113911 GAUGE, pressure, air 1

617 160327 ADAPTER, union; 90 deg. 2

618 15T119 LABEL, control 1

619 --- BRACKET, air controls 1

620 15R437 BRACKET, adapter, air controls 2

621 121432 SCREW, machine, hex flat head 2

622 115942 NUT, hex, flange head 4

625 116513 REGULATOR, air 1

626 121457 VALVE, ball, air, panel mounted 1

627 121424 GAUGE, pressure, panel mount, 1.5 in. 1

628 100451 COUPLING 1

629 114151 ELBOW, male, swivel 2

630 100264 SCREW, machine, pan head 2

631 116514 NUT, regulator 1

627

618

633

625

635

629

634

646

647

643

604

641

633

606

621

642

622

620

Ref. Part Description Qty.

632 054760 TUBE, polyurethane, round, black; 1.25

633 --- TUBE, polyurethane, round; 0.6 ft. 634 100840 ELBOW, street 1

635 162453 FITTING; 1/4 npsm x 1/4 npt 2

636 114114 ELBOW, male, swivel 1

637 114128 ELBOW, male, swivel 1

638 164259 ELBOW, street 1

640★ 122336 NUT, panel, regulator 1

641★ 113440 ADAPTER 2

642★ 113431 CLAMP, quick 4

643★ 113442 BLOCK, porting 2

644★ 15R488 REGULATOR 1

644a 123454 FILTER, element; 5 micron 1

645★ 15R487 REGULATOR 1

646★ 15R486 MUFFLER 1

647★ 15R485 VALVE, dual pilot 1

★ Parts included in Air Controls Kit 255772 (purchase sepa-

rately).

--- Not for sale.

in.

-

44 3A2989G

Page 45

Junction Box (24N598)

412

411

403, 446

418, 419, 423

4

404

402

403

Parts

413, 414, 443

415, 445

416

417,

444

405

405a

407, 408

B HOSE A

405b 406 403 407 420

405f 405c

405e

409

410

421

425

442

442

422,

439

ti20155a

426, 427

401

4

Set High Power Temperature Control Module zone addresses on dial

under cover when installing modules (404). Addresses: B Module =1,

Hose Module = 2, A Module = 0.

NOTE: See Electrical Schematics beginning on page 27 for cable

identification.

3A2989G 45

Page 46

Parts

Junction Box (24N598)

Ref Part Description Qty

401 --- ENCLOSURE 1

402 --- BRACKET, module 3

403 114231 NUT, lock, hex 16

404◆ 255774 MODULE, GCA, HPTCM 3

405 --- MODULE, breaker 1

405a 126382 BLOCK, terminal 8

405b 126129 BREAKER, 25A 1

405c 126130 BREAKER, 30A 2

405d 126684 JUMPER, red 3

405e 126453 POWER SUPPLY, 24V 1

405f 126128 BREAKER, 20A 2

406 121603 GRIP, cord, 0.51-0.71, 3/4 6

407 255047 BUSHING, strain relief, M40

thread

408 255048 NUT, strain relief, M40 thread 2

409 15U423 SWITCH, 2p, 25a 3

410 123967 KNOB, operator disconnect 1

411 123968 SWITCH, disconnect, 100 amp 1

412 123969 SWITCH, disconnect, 100 amp 1

413† 289697 MODULE, GCA, cube, base 1

414 104371 SCREW, cap sch 10 x 0.375 4

415z† 289696 MODULE, GCA, cube, FCM 1

416 117666 TERMINAL, ground 1

417 115942 NUT, hex, flange head 1

418 15U651 BRACKET, high power, GCA 6

419 117831 SCREW, machine, pan head 12

420 --- BAR, ground 1

421 109466 NUT, lock, hex 2

422 104387 SCREW, machine, pan head 4

423 113161 SCREW, flange, hex head 6

425 126496 CONNECTOR, thru, M12, male x

female, reverse key

426 --- MODULE, solenoid 1

426a 121636 VALVE, solenoid 2

426b 15A798 GASKET, outlet 1

426c 15A799 GASKET, inlet 1

427 106084 SCREW, machine, pan head 2

428 125789 CABLE, CAN, female / female,

0.5 m

429 123422 CABLE, CAN, 5-pin, female /

female, 0.4 m

430 121615 HARNESS, splitter, M8, 4-pin,

female/female/male, 3 m

432 126495 CABLE, splitter, 4-20ma, 2 circuit 1

433 124273 CONNECTOR, splitter 1

434 --- STRAP, tie 14

435 126494 CABLE, M12, 5p, 4wire with drain 2

436 121806 CABLE, solenoid 2

437 --- STRIP, foam, neoprene 10

438 16T147 CABLE, can power, M12 female,

pigtail

439 16P626 LATCH, enclosure 4

Ref Part Description Qty

440▲ 16T278 LABEL, multi-purpose; including

warnings text, shock arrow,

ground symbol, and various informational stickers

442 16T072 ADAPTER, cable, CAN 1

443 126687 SCREW, machine, pan head 1

444 558685 WASHER, lock, external type, 1/4 1

445† 277674 ENCLOSURE, cube door 1

446 555629 WASHER, lock, external type, #10 2

--- Not for sale.

▲ Replacement Danger and Warning labels, tags and

2

1

2

2

1

1

cards are available at no cost.

z Base electronic components do not have

XM PFP-specific software installed. Therefore, use

software upgrade token (506) to install software

before use.

† Parts available in Fluid Control Module Cube Kit

24R902. Kit includes items 413, 415, 445, software

token (506), and instructions.

◆ Parts available in High Power Temperature Control

Module Kit 24R903. Kit includes items 404, software

token (506), and instructions.

1

46 3A2989G

Page 47

Control Box (255771)

543

532

538

539

504b

Parts

504f

504g

504a, 504d

514

536

523

551

503

520

502

522

535

542

509

502

507

501

527

543

532

526

541

521

537

538

540

544

504h

504e

504c

545

508

526

528

501

529

543

530

515

510

519c

Qty

Ref. Part Description

501 --- BOX, control 1

502 --- LABEL, control display 1

503† 24R899 KIT, replacement, USB; includes

519 and 506

504z 257484 MODULE, display, kit

504a 15M483 SHIELD, membrane, display (qty.

10)

504b --- SCREW, pan head; #6 x 7/8 in. 4

z504c 288997 CASE, rear, display module, IS

version

504d 255727 CASE, front, data module 1

504e 277463 COVER, access, low level display 1

504f 113768 SCREW, socket, flat head 4

504g 15R458 GASKET, control, front panel 1

▲504h 15W958 LABEL, warning, battery 1

534

517

526

546

ti18050a

542

533

Ref. Part Description

.

505† 24R897 KIt, replacement, display; includes

504 and 506

1