Page 1

Quick Start Guide for Protective Coating Handheld Sprayers

ATTENTION -

Maximum setting may not give the best or suitable fan pattern. Please read Quick Start Guide for details.

The pressure setting for this handheld sprayer is adjusted in a different manner than larger sprayers.

WARNING

This guide is intended as a quick reference. See Operation manual provided with your sprayer for full instructions on proper use and all safety warnings.

To help prevent fire and explosion: Always connect the ground wire provided when spraying flammable materials or static-producing oil-based materials.

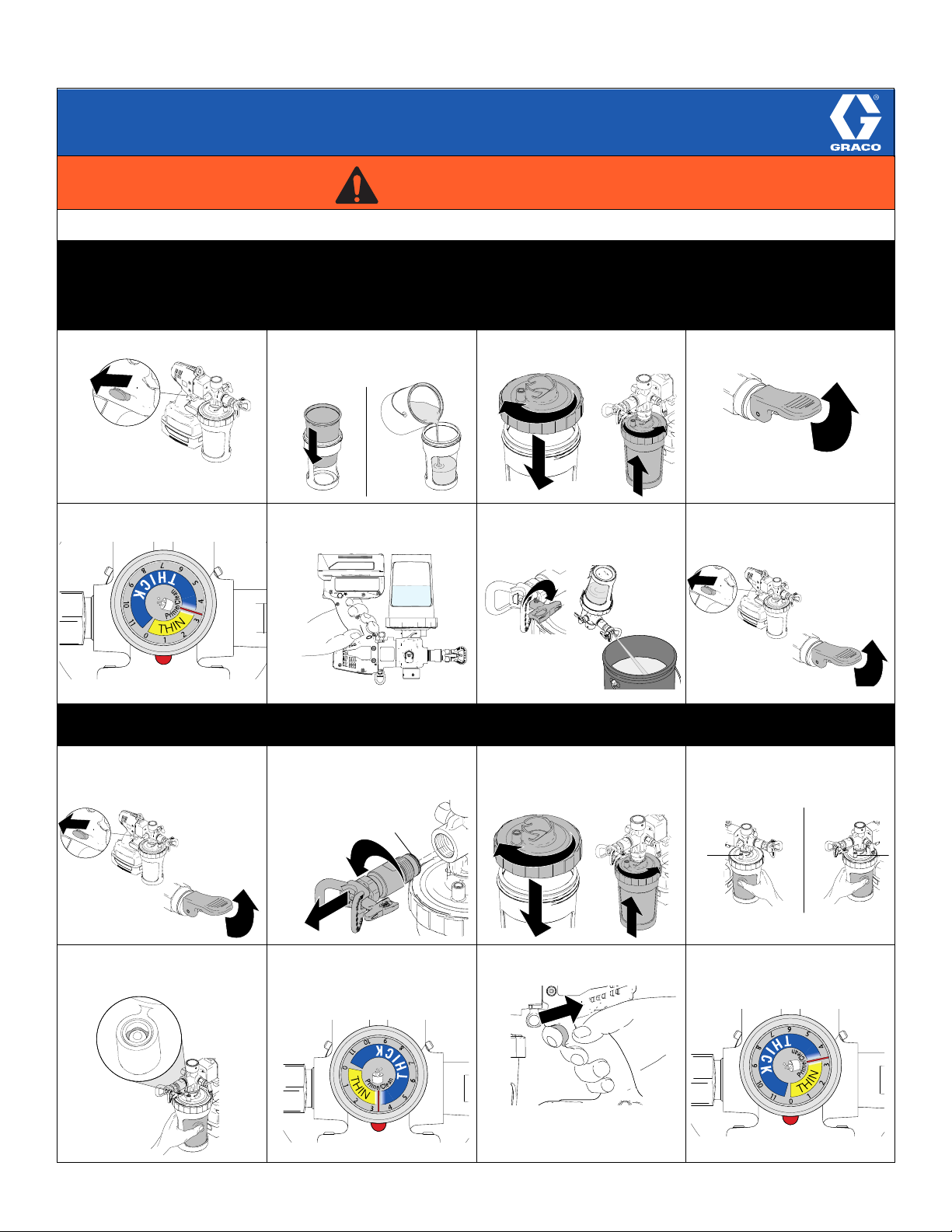

EVERY STARTUP -

FLUSHING OUT STORAGE MATERIAL

NOTE: Spraying water, solvents, and thin materials (low viscosity materials) at high pressure (setting “2” or higher with

yellow light flashing) can result in temporary pump leaking. To avoid, read and follow instructions (Quick Guide or Manual) on

how to properly adjust pressure.

1. Engage trigger lock. 2. Install and fill liner 1/2 full with

MUST

5. You

to setting “1”.

set pressure control

appropriate cleaning fluid for

material about to be sprayed.

6. Disengage trigger lock, turn

sprayer upside-down and

trigger for 10 seconds.

3. Thread lid onto cup and

connect cup to sprayer.

7. Reverse tip to UNCLOG

position. Put prime/pressure

relief valve to spray position

and trigger for 5 seconds.

4. Put prime/pressure relief valve

in UP position.

8. Engage trigger lock and put

prime/pressure relief valve UP

to release pressure. Remove

and dispose material cup.

LOADING SPRAY MATERIAL

1. Engage trigger lock and put

prime/pressure relief valve UP

to release pressure. Remove

and dispose material cup.

5. Squeeze liner to purge air

through check valve until

material reaches check valve.

3A2961C Copyright 2012, Graco Inc.

2. Unthread front valve housing

from sprayer, install filter if

needed, then reassemble.

6. You

MUST

relief valve UP to priming position. Turn pressure control

knob to prime/clean position in

line with red indicator dot.

Filter

put prime/pressure

3. Install liner into material cup

and fill with material. Thread lid

onto material cup and connect

cup to sprayer.

7. Disengage trigger lock and

trigger sprayer for 3 seconds.

4. To purge the maximum amount

of air out of the liner, slightly tilt

the sprayer so the check valve

is the highest point.

8. Turn pressure control knob

counter-clockwise to lowest

position. Put prime/relief valve

to DOWN position to spray.

Page 2

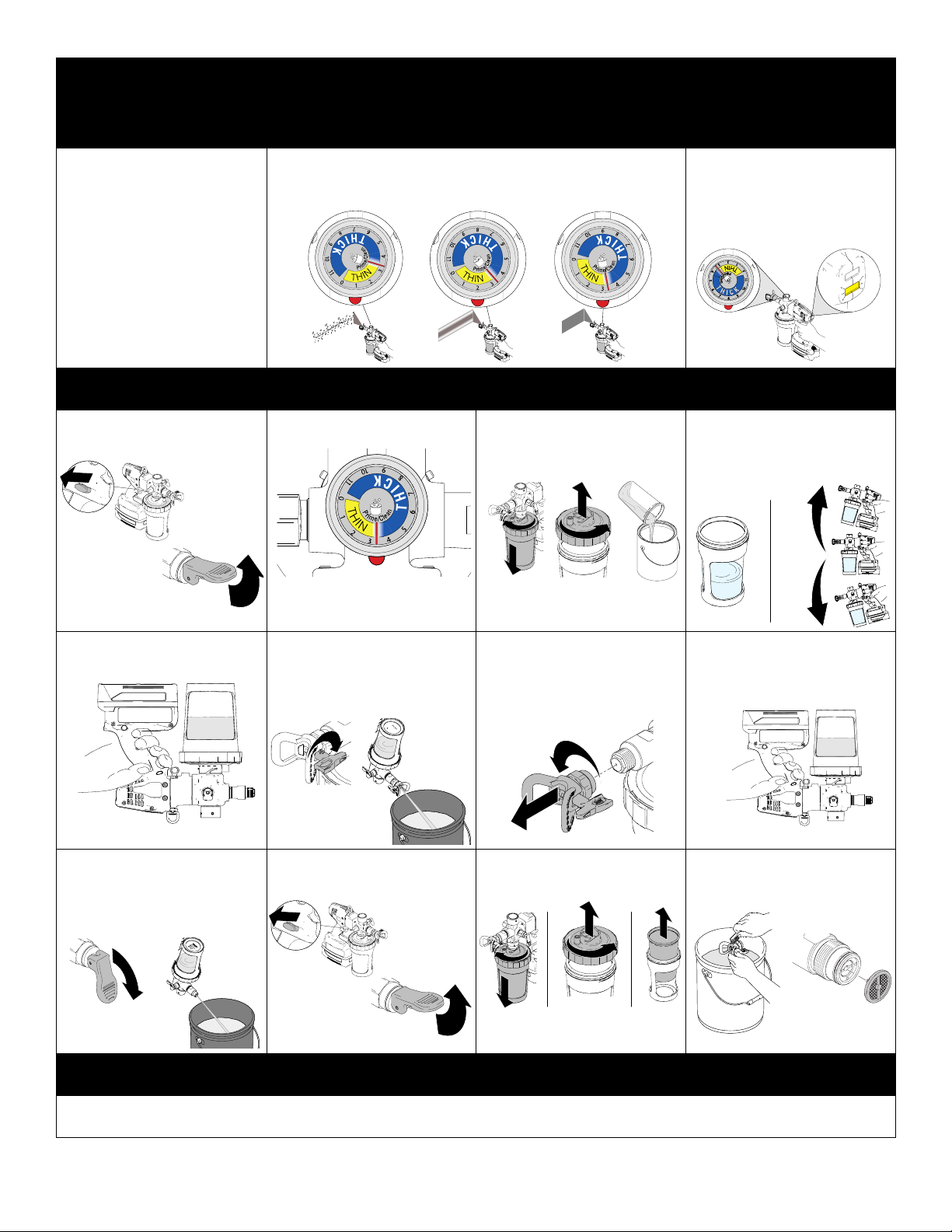

ADJUSTING PRESSURE

(Maximum pressure is NOT proper for all materials)

NOTE: Spraying water, solvents, and thin materials (low viscosity materials) at high pressure (setting “2” or higher with

yellow light flashing) can result in temporary pump leaking. To avoid, read and follow instructions (Quick Guide or Manual) on

how to properly adjust pressure.

1. To reduce overspray and

extend battery life, always

spray at lowest pressure that

produces desired spray

pattern.

CLEAN UP

1. Engage trigger lock and put

prime/pressure relief valve UP

to release pressure.

MUST

2. You

of “1” or less until desired spray pattern is achieved. Put pressure

relief handle in UP position to turn pressure control knob, then return

handle to DOWN position to spray.

2. Turn pressure control knob to

prime/clean position.

start with dial at “1” and gradually increase by increments

3.

Remove cup from sprayer and

lid from cup. Remove material

liner and lid. Properly dispose

lid and any excess material.

3. If yellow light is flashing while

triggering, pressure is set too

high. You

pressure until yellow light no

longer flashes, increase tip

size, or do not thin material as

much.

4. Insert a new liner into cup and

fill 1/3 full with appropriate

flushing fluid. Screw on lid and

attach cup to sprayer. Shake

sprayer to clean.

MUST

turn down

5. Disengage trigger lock, turn

sprayer upside-down and

trigger for 15 seconds.

9. Put prime/pressure relief valve

DOWN to spray position. Spray

remaining amount of fluid

through front of sprayer. If

sprayer is not completely clean,

repeat steps 8 and 9.

STORAGE

6. Reverse tip to UNCLOG position. Put prime/pressure relief

valve DOWN to spray position,

turn sprayer upside down, and

trigger sprayer for 2 seconds

only.

10. Engage trigger lock and put

prime/pressure relief valve UP

to release pressure.

7. Engage trigger lock. Put

prime/pressure relief valve in

UP position. Unthread

tip/guard from sprayer and

soak in flushing fluid. Remove

cup and properly dispose fluid.

11. Remove material liner and lid

and properly dispose. Properly

dispose used fluid.

8. Refill liner 1/3 full. Disengage

trigger lock, turn sprayer

upside-down and trigger

sprayer for approximately 15

seconds to recirculate material.

12. Clean Spray Tip/Guard

assembly with clean flushing

fluid. Use a soft brush if

needed. Remove material filter.

For storage, fill material cup 1/3 full with mineral spirits or dilute a 4 oz. bottle of Pump Armor concentrate with 4 oz. of water in material cup and

run through pump. Properly dispose storage fluid.

3A2961C Copyright 2012, Graco Inc.

Loading...

Loading...