Page 1

Instructions - Parts

®

VISCON

High Flow, High Pressure Fluid Heater

For variable heating of viscous fluids.

Not approved for use in explosive atmospheres or hazardous locations.

7250 psi (50 MPa, 500 bar) Maximum Working Pressure

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

HF

3A2954D

EN

See page 2 for model numbers, descriptions, and approvals

information.

Externally Controlled, RTD

Feedback Model

Thermostat

Controlled

ti20051a

Page 2

Models

Contents

Models ...................................2

Warnings .................................3

Installation ................................ 5

TypicalInstallationDrawing ................ 5

Component Identification ....................6

General Information ...................... 7

SelectingTubing .........................7

Mounting Heater .........................8

Fluid Connections and Accessories ..........9

Electrical Connections ...................10

RTD Temperature Connection .............10

Grounding ............................. 10

Operation ................................11

Pressure Relief Procedure ................11

Initial Flushing .........................11

Priming System .........................11

Setting Heater Control ...................12

AdjustingforSpraying .................... 12

Maintenance ..............................13

Flushing ..............................13

Drain the Heater ........................ 13

Troubleshooting ...........................14

Repair ...................................16

Primary Thermostat & Probe ...............16

Overtemperature Switch ..................16

Control Knob ...........................18

Heater Core Removal and Fluid Passage

Unclogging .........................19

Heater Cartridges .......................20

RTD Sensor and Fitting Replacement ........21

Parts ....................................22

24P016 ...............................22

262853 ...............................24

Accessories ..............................26

TechnicalData ............................27

Performance Charts .....................28

Dimensions ............................29

Graco Standard Warranty ...................30

GracoInformation .........................30

Models

VAC (50/60 Hz single phase) /

Model Series Description

24P016 C Thermostat Control 240 / 5400 / 22.5

262853 C

RTD, For Use With

External Digital Control

Watts / Amps

240 / 5400 / 22.5

Approvals

9902471

Conforms to

UL Std. 499

CSA Std. 22.2 No. 88

2 3A2954D

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

WARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric

shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

or installing equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe burns:

• Do not touch hot fluid or equipment.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless they

are antistatic or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

3A2954D 3

Page 4

Warnings

WARNING

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes but is not

limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about

your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical

reaction and equipment rupture. Failure to follow this warning can result in death, serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier for compatibility.

THERMAL EXPANSION HAZARD

Fluids subjected to heat in confined spaces, including hoses, can create a rapid rise in pressure due to

the thermal expansion. Over-pressurization can result in equipment rupture and serious injury.

• Open a valve to relieve the fluid expansion during heating.

• Replace hoses proactively at regular intervals based on your operating conditions.

4 3A2954D

Page 5

Installation

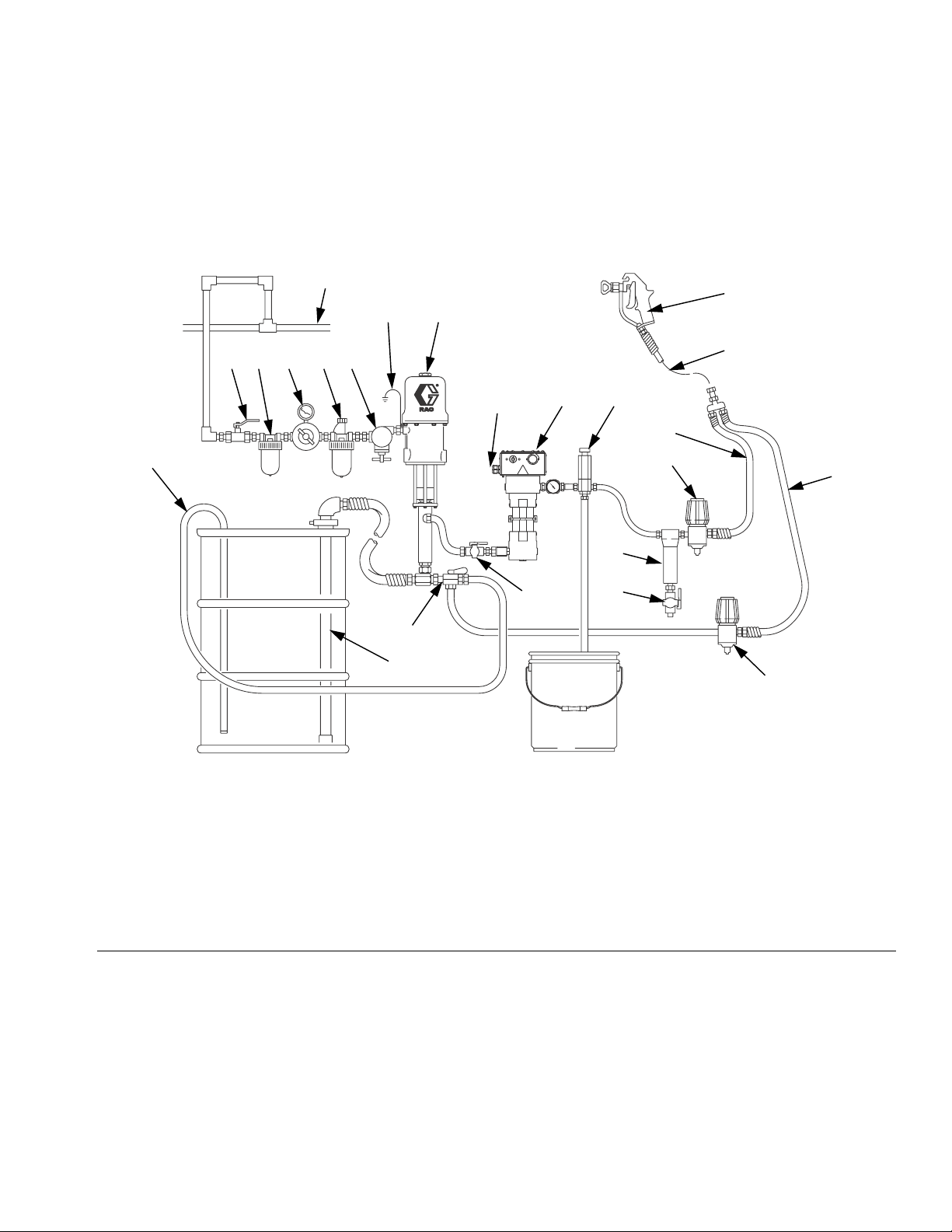

Typical Installation Drawing

The typical installation drawing is only a guide. Your Graco distributor can assist in designing your system.

Installation

Z

Q

GF

Y

EDCBA

J

XK

P

V

N

R

L

T

M

U

W

S

05486-524

Key:

A Bleed-type Master Air Valve

B Air Filter

C Air Regulator and Gauge

D Air Line Lubricator

E Pump Runaway Valve

F Ground Wire

G Pump

J Power Cable (not shown)

K Heater

L Fluid Filter

M Drain Valve

N Fluid Pressure Regulator

P Fluid Supply Line

Q Spray Gun

R Fluid Return Line

S Back Pressure Valve

T Fluid Shutoff Valve

U Director Valve

V Drain Back Tube

W Suction Tube

X Pressure Relief Valve

Y Whip End Hose

Z Air Supply Line

FIG. 1: Typical Installation – Heated Circulating System

3A2954D 5

Page 6

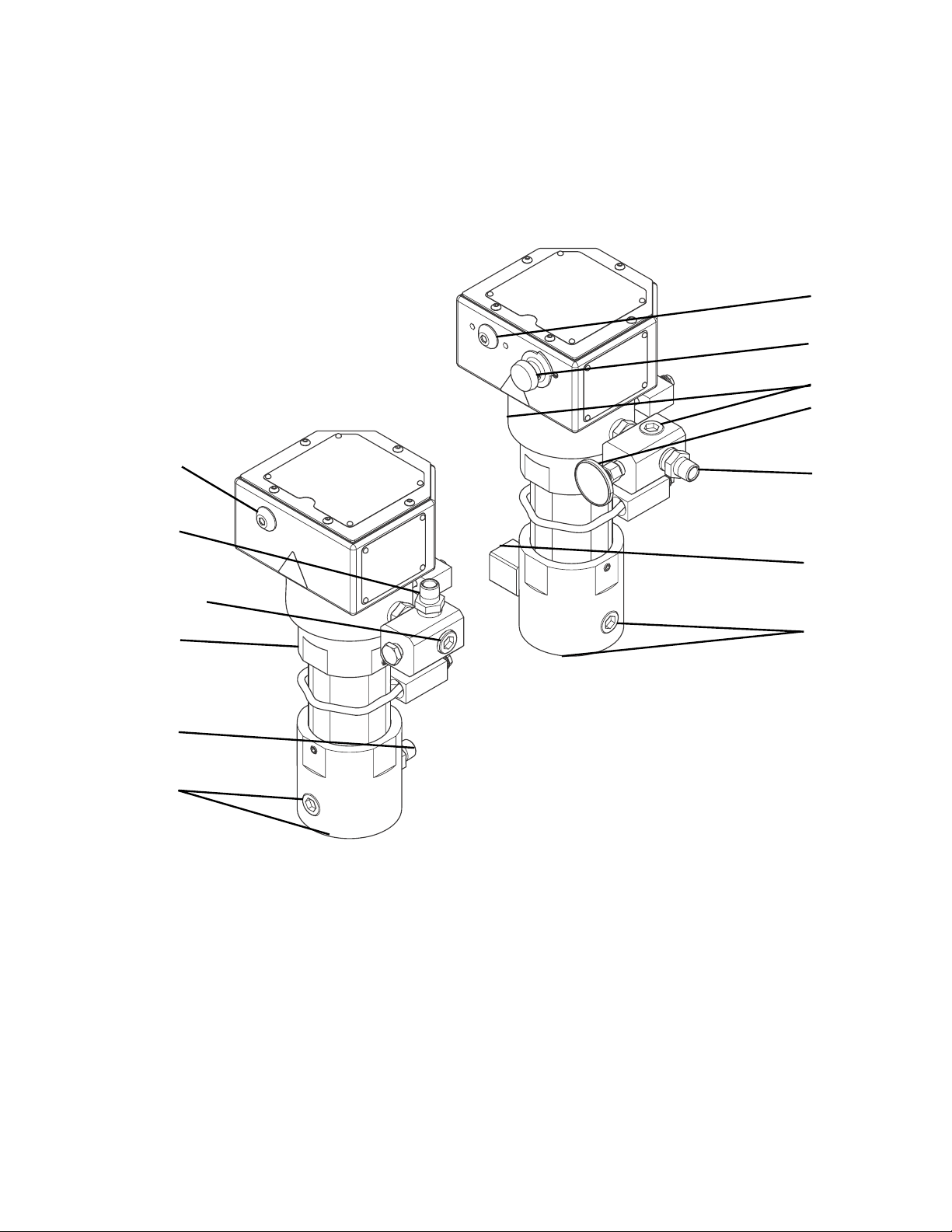

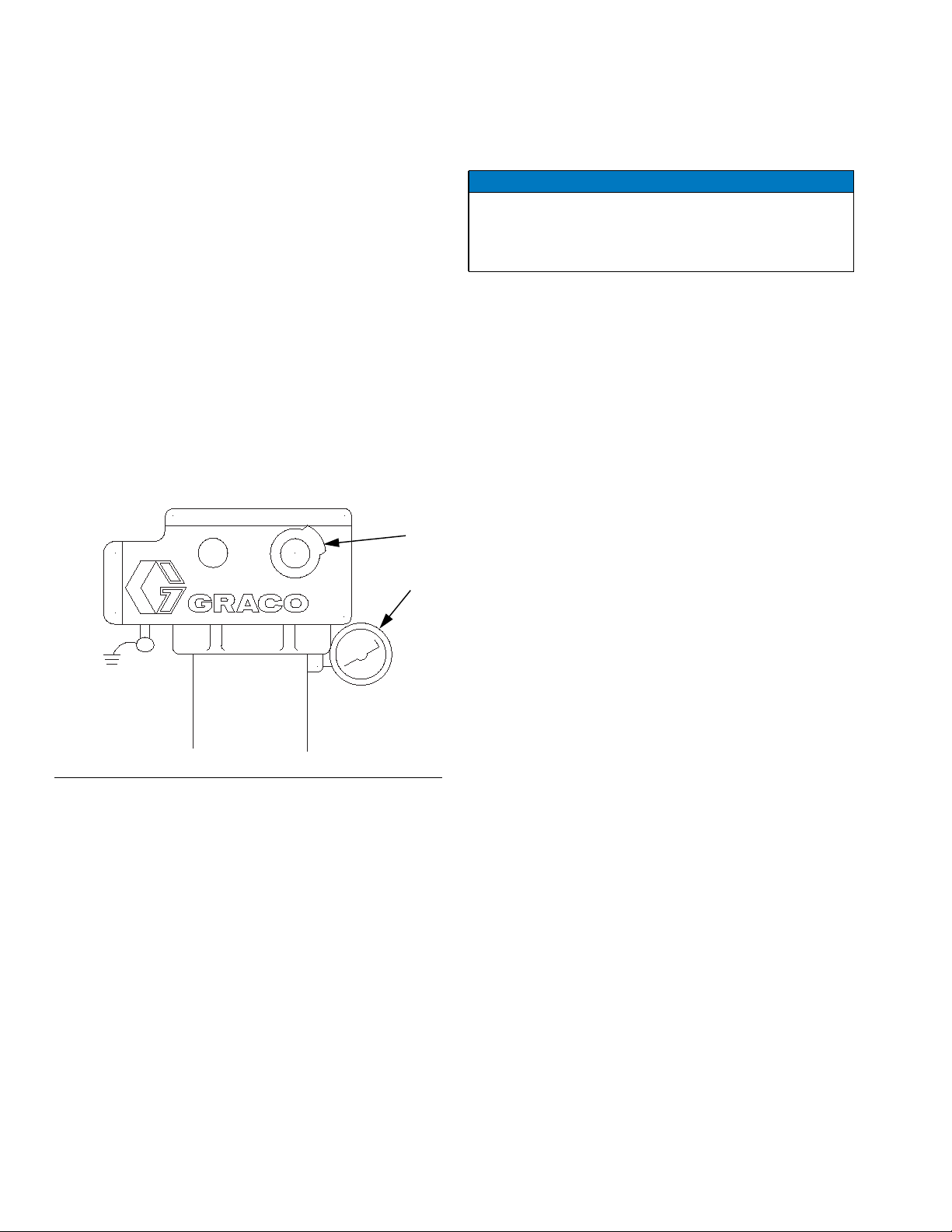

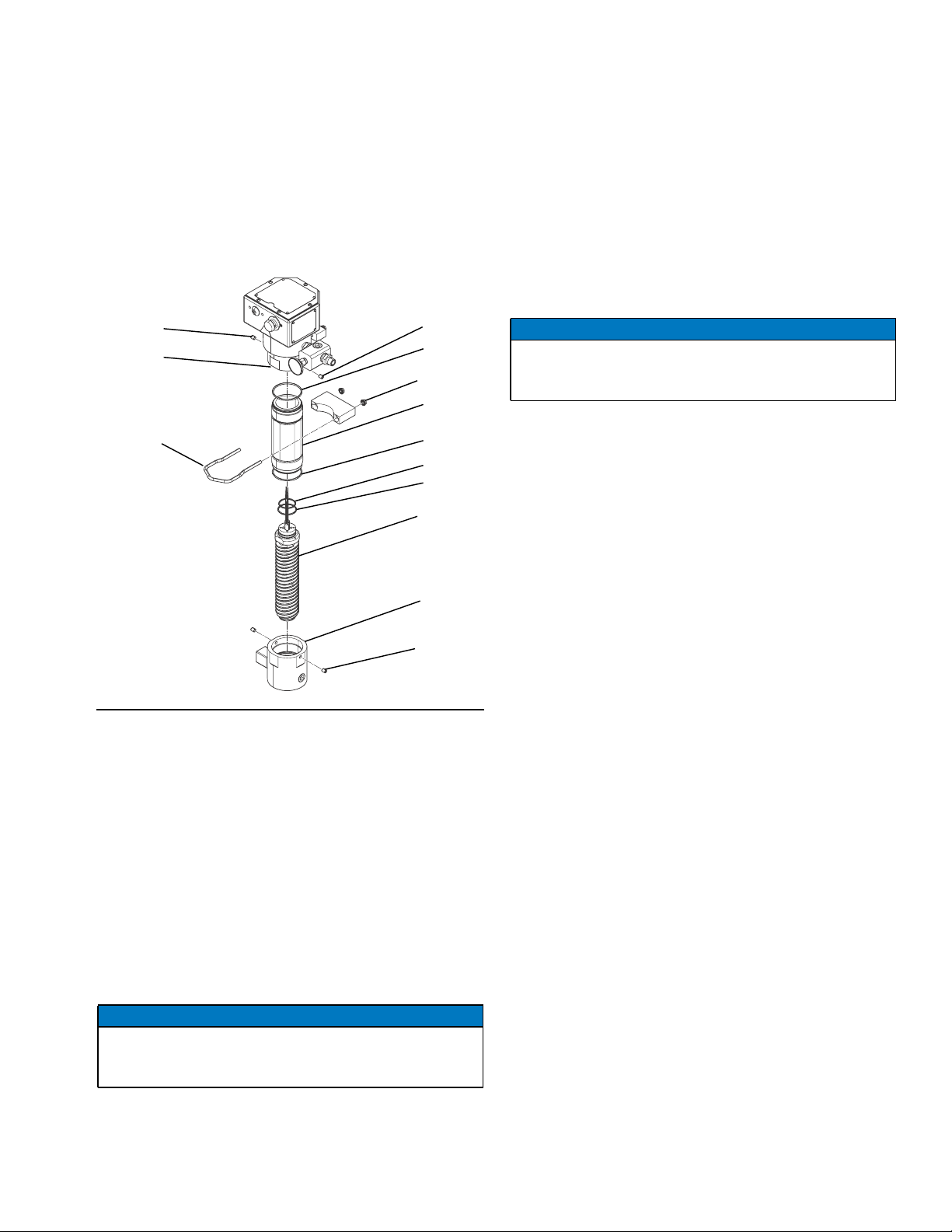

Component Identification

Component Identification

Thermostat

Controlled Model

A3

A4

A3

A2

A6, A8

A8

A1

A7

Externally Controlled, RTD

Feedback Model

A8

A5

A2

A1

A7

ti20051a

Key:

A1 Fluid Inlet

A2 Fluid Outlet

A3 Heater ON Indicator Light

A4 Temperature Control Knob (24P016 Only)

A5 Temperature Gauge (24P016 Only)

A6 Optional External RTD Feedback Port (262853 Only)

A7 Optional Inlet Ports (front and bottom)

A8 Optional Outlet Ports (one on outlet manifold and one on

opposite side of heater)

6 3A2954D

Page 7

General Information Selecting Tubing

Fluid loses some heat through the tubing or hose

between the heater and spray gun. Locate heater close

to the spray area to minimize heat loss through plumb-

• Select system components that meet temperature

and pressure ratings listed in Technical Data,

page 27. The heater’s normal output range is

adjustable from 84-220°F (29-104°C).

• To prevent fire and explosion, locate heater away

from all flammable materials and where operators

will not come in contact with hot metal surfaces.

• To avoid burns, insulate and/or label lines and

components exiting heater that may become hot.

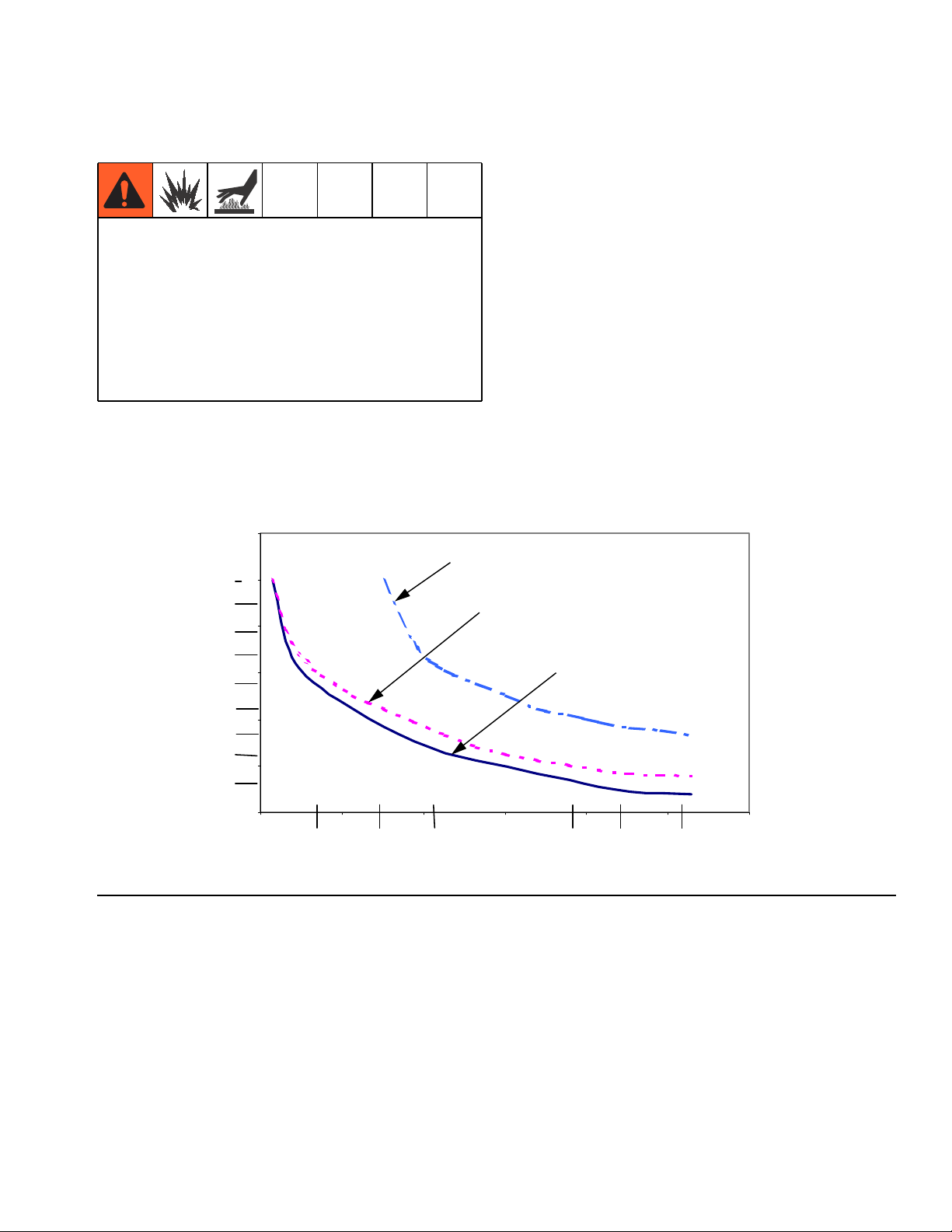

Heat Loss Curve: 70°F (21°C) Ambient

(°F) °C

6

5

(9)

(8)

4

(7)

(6)

3

(5)

(20 ft.) 6.1 m steel tube

Fluid: (130° F) 54° C

ing.

The chart in FIG. 2 shows a heat loss curve for 3 common types of tubing.

Chart Notes:

• Higher flow rates have less heat loss.

• Foam-insulated steel tubing and high pressure airless paint hose retain heat best. Insulated tubing

and hose are more expensive, but higher costs are

commonly offset by lower operating costs.

(20 ft.) 6.1 m steel tube

(3/8 in.) 9 mm foam insulation

Fluid: (110° F) 43° C

(20 ft.) 6.1 m airless paint hose

Fluid: (110° F) 43° C

Component Identification

(4)

2

(3)

(2)

Typical Fluid Temperature Drop

1

(1)

0

0 0 .5 1 1.5 2 2 .5 3

(0.1) (0.2) (0.3) (0.4) (0.5) (0.6) (0.7) (0.8)

FIG. 2: Typical Temperature Drop

LPM

(GPM)

Flow Rate

3A2954D 7

Page 8

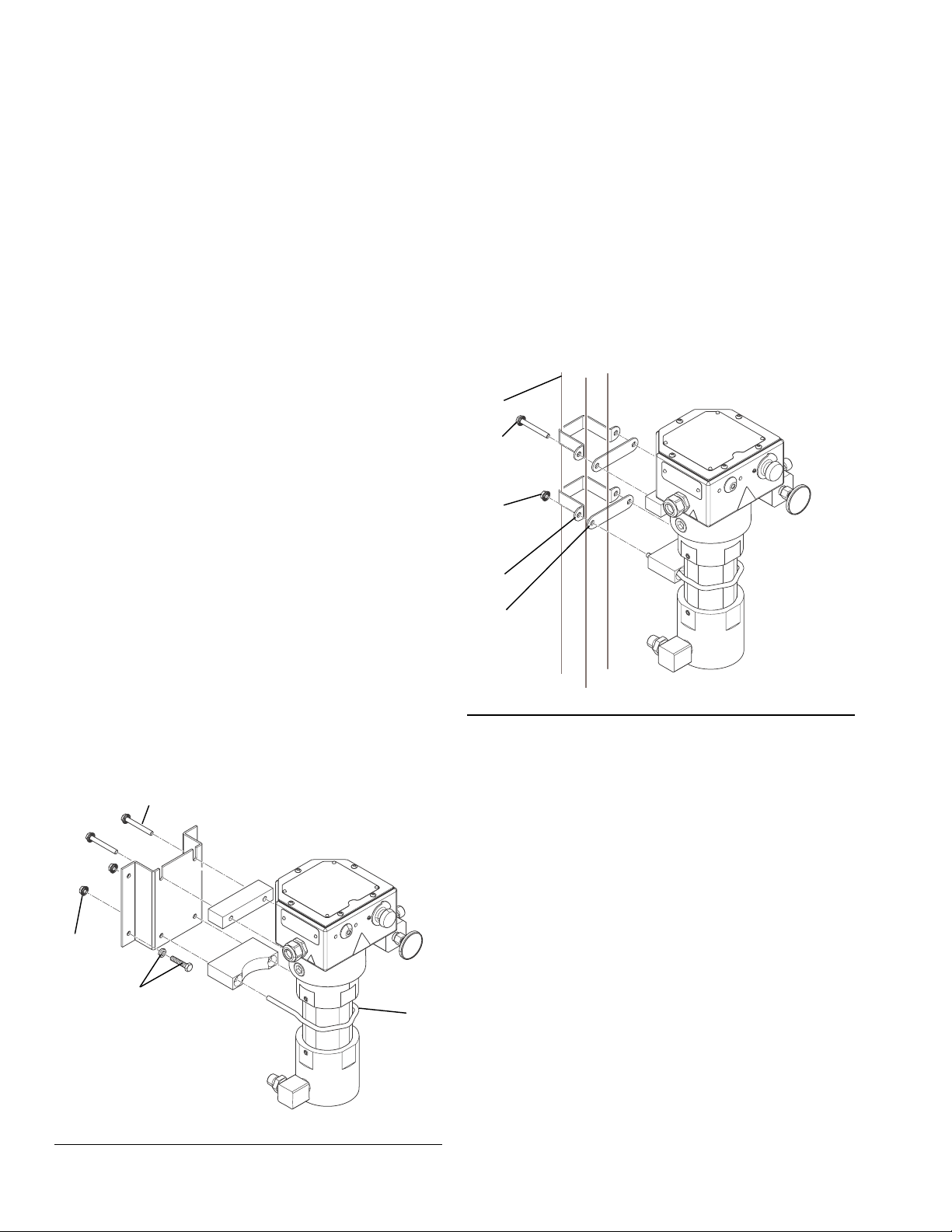

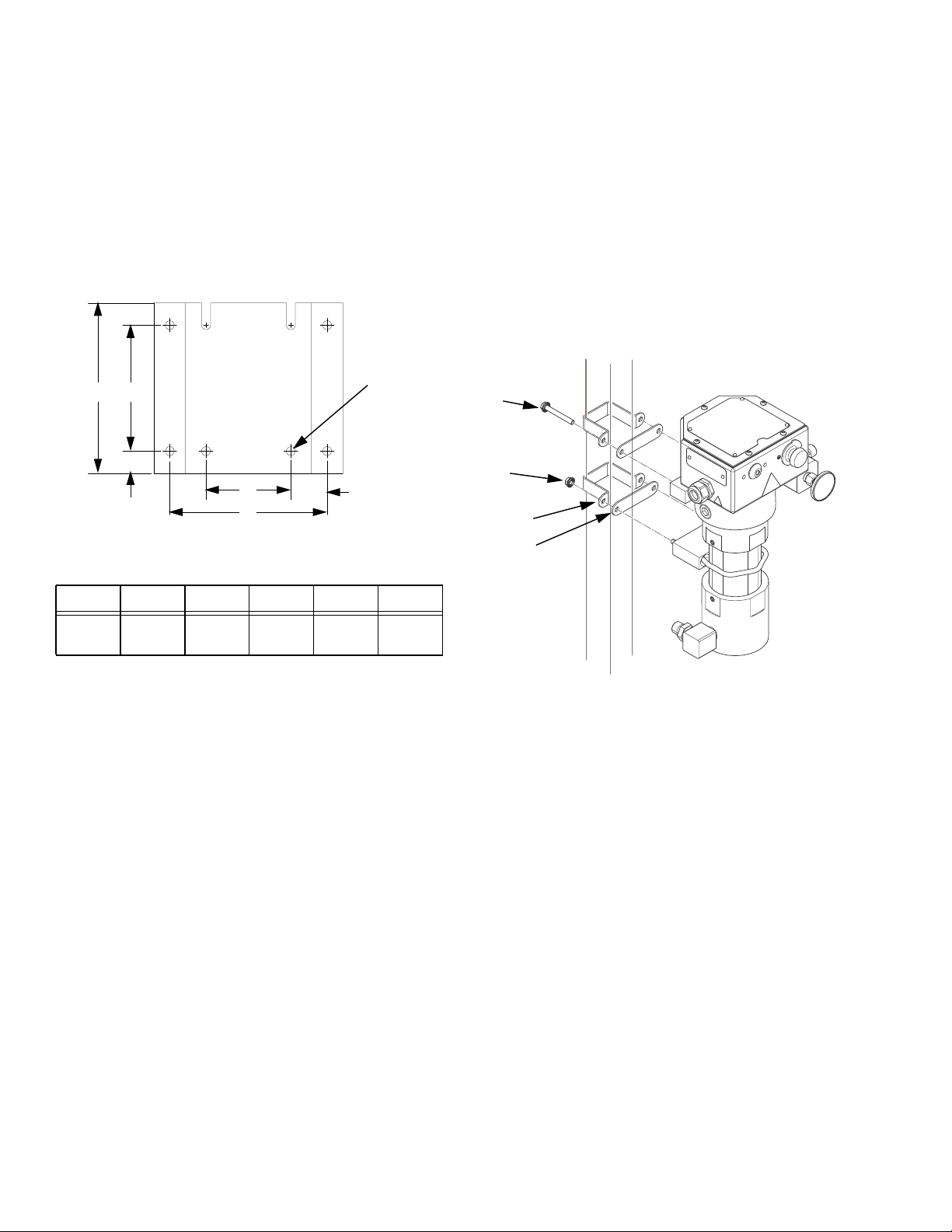

Component Identification

Mounting Heater

NOTE: The Viscon HF heaters will mount anywhere a

Viscon HP heater was previously mounted. See the

dimensions listed for accessory bracket 192585 on

page 26 and the heater dimensions shown on page 29.

NOTE: Heater controls must be easily accessible.

NOTE: The mounting surface must be able to support

the weight of the heater and fluid and any stress caused

during operation.

Wall Mounting

NOTE: Use wall bracket as a template to mark bolt

holes.

Accessory Bracket 192585

(FIG.3)

1. Use lockwashers and M8 bolts (AA) of appropriate

length, not supplied, to mount bracket.

2. Install two screws (74) through spacer block and

into top two heater mounting holes until they are

about 1/8 in. (3 mm) from fully installed.

3. Lift heater and slide two screw heads into bracket

slots.

4. Install u-bracket (78) around heater and install

remaining 2 nuts (90). Tighten all nuts and bolts.

Cart Mounting

(FIG.4)

NOTE: For a 2.5 in. square tube frame cart you need to

have 2 each of cart mounting bar 183485 (CC) and

clamp 183484 (BB). See Accessories, page 26, to

order.

Place clamps (BB) around the cart vertical post (DD)

and secure to the heater mounting bars (CC) with bolts

(74) and nuts (90).

DD

74

90

BB

CC

ti20055a

FIG.4

74

90

AA

FIG. 3: Accessory Bracket 192585

8 3A2954D

78

ti20054a

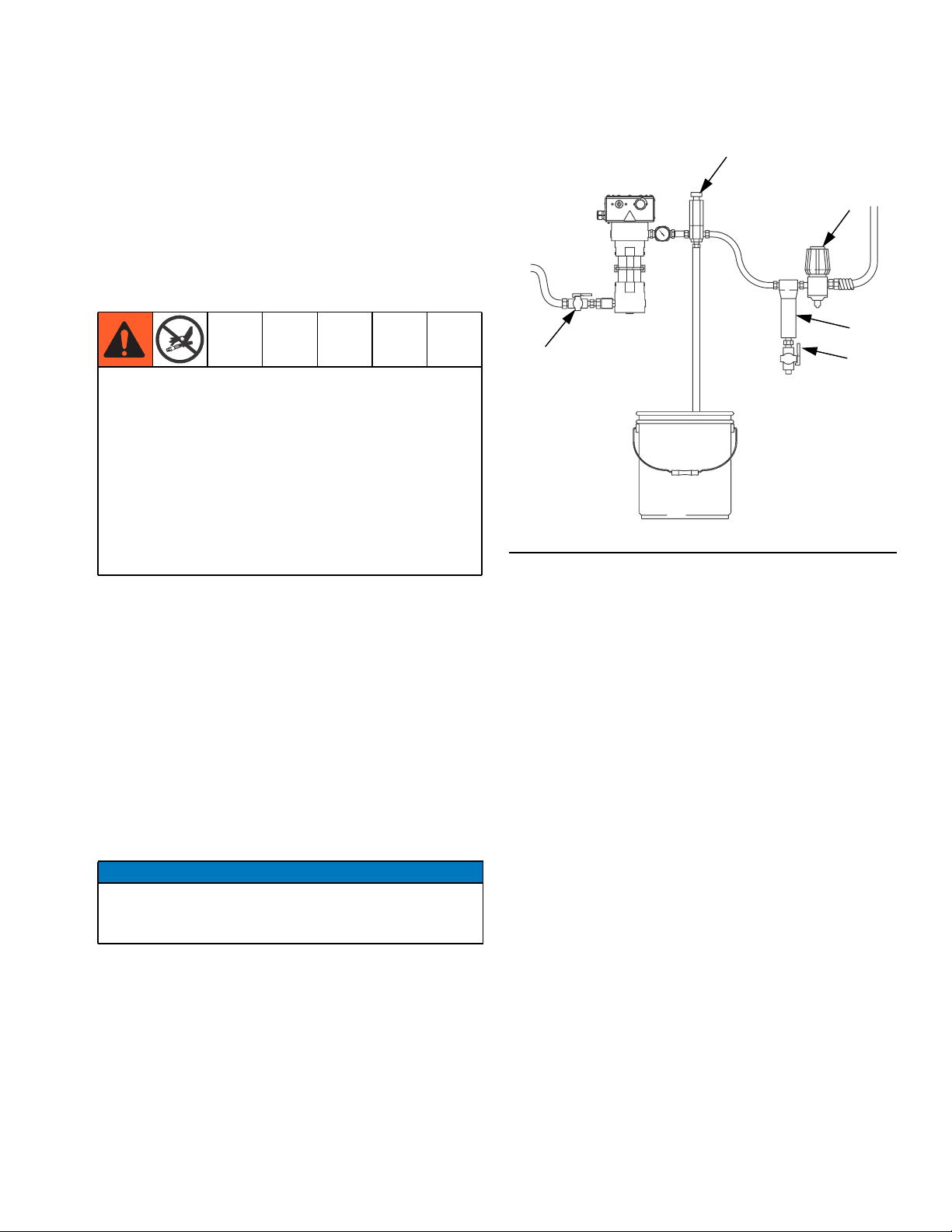

Page 9

Component Identification

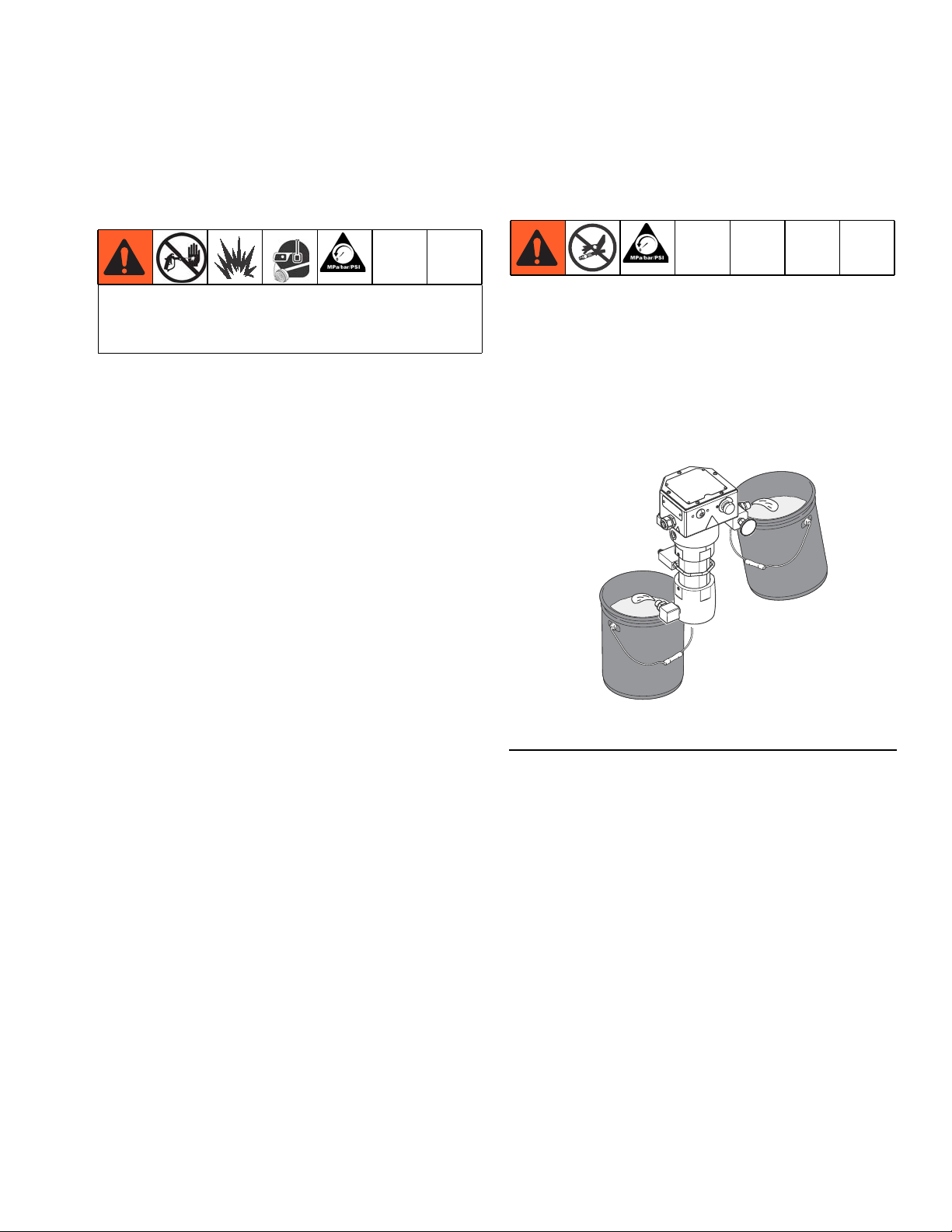

Fluid Connections and Accessories

(FIG.5)

1. Install a fluid shutoff valve (T) in the heater’s

3/4 in. npt(m) fluid inlet. Do not overtighten. Connect

the fluid supply line to the valve.

To prevent serious injury caused by component or

equipment rupture:

• Never install a shutoff device between the heater

and gun as this will trap the heated fluid and not

allow for expansion.

• Never use a fluid regulator as a shutoff device if it

is installed between the heater and gun

• Provide a means for adequately handling fluid

expansion caused by heat.

X

T

FIG. 5: Fluid Connections and Accessories

N

L

M

ti20056a

To handle fluid expansion caused by heat:

• Use flexible hoses between heater and gun.

• Install a properly sized accumulator down-

stream from the heater.

• Install a pressure relief valve (X) pre-set to

relieve pressure when it exceeds the system

maximum working pressure.

2. If feeding an airless spray gun, install a fluid

filter (L), drain valve (M), and fluid pressure regulator (N) near the heater’s 3/4-14 npt(f) fluid outlet.

Then connect the fluid outlet line.

NOTICE

The RTD sensor must always be mounted on the outlet side of housing (67). If you plumb the outlet to the

left side, swap position of sensor (88) and plug (82).

3A2954D 9

Page 10

Component Identification

Electrical Connections

Heater installation must be in compliance with all

applicable local codes and regulations. This equipment must be grounded. Improper grounding, setup,

or usage of the system can cause electric shock. All

electrical wiring must be done by a qualified electrician and comply with all local codes and regulations.

NOTICE

To help prevent damage, avoid spilling liquids onto

electrical components and never operate with the

cover removed or screws missing.

Requirements For All Installations

• The power supply must not exceed heater voltage

and amperage. See Models, page 2.

• Conductors used for supply connection must be

suitable for at least 221°F (105°C). An intermediate

Type “e” junction may be required.

Grounding

The equipment must be grounded to reduce the risk

of static sparking and electric shock. Electric or static

sparking can cause fumes to ignite or explode.

Improper grounding can cause electric shock.

Grounding provides an escape wire for the electric

current.

Wire the heater to a properly grounded power supply

through the electrical connections and grounding

screw (8). In a mobile installation, also ground the truck

or trailer to a true earth ground.

• Branch circuit breaker over-current protection must

be used. The recommended branch circuit breaker

size is 30 amps.

• Connections are made through the strain relief cord

grip (87). It will accept cords with an outside diameter of 0.51-0.71 in. (13-18 mm).

• Make your ground connection to the green ground

lug inside the control head.

• Make your power connections to the single white

and black wires which have loose ends in the control

head. Refer to the applicable schematic on page 15.

RTD Temperature Connection

(Model 262853 Only)

A separate smaller cord grip is provided to bring a cable

and connector into the M8 4-pin connection inside the

heater. Refer to the applicable schematic on page 15

and the Technical Data on page 27.

10 3A2954D

Page 11

Operation

Operation

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, splashing

fluid and moving parts, follow the Pressure Relief

Procedure when you stop spraying and before

cleaning, checking, or servicing the equipment.

Follow Pressure Relief Procedure when you stop

spraying, and before cleaning, checking, or servicing

equipment.

1. Engage the gun trigger lock.

2. Shut off main power to the heater.

3. Circulate fluid for at least 10 minutes to cool the

heated fluid and heater.

Initial Flushing

To avoid skin injection, do not point gun at anyone or

at any part of the body. To avoid fire and explosion,

ensure main power is off and heater is cool before

flushing. Do not turn on heater until fluid lines are

clear of solvent.

The heater was tested with lightweight oil, which needs

to be flushed out before using the equipment. Use a

compatible solvent, and follow flushing instructions in

your fluid supply and spray gun manual.

Priming System

(Refer to FIG.1,page5)

1. Do not turn on the heater yet.

2. If using an airless spray gun, do not install a spray

tip yet.

4. Shut off all air and fluid supplies.

5. Disengage the gun trigger lock.

6. Hold a metal part of the gun firmly to a grounded

metal pail, and trigger the gun to relieve pressure.

7. Engage the gun trigger lock.

3. Start the pump according to the instructions supplied with it.

4. Turn the system director valve (U) to circulate, and

circulate fluid for several minutes.

5. Open the spray gun (Q) at the last outlet to prime

the line. Repeat for all gun stations.

6. Engage the gun trigger lock.

7. Shut off the air supply to the pump.

8. Perform Pressure Relief Procedure.

9. Install the gun spray tip.

3A2954D 11

Page 12

Operation

Setting Heater Control

(Refer to FIG.6)

This procedure applies to model 24P016 only. Heater

262853 with RTD control has no adjustments to make

on the heater, it requires use of an external temperature

controller.

1. Set the heater control knob (33) to a trial setpoint of

4or5.

2. Start the pump and circulate fluid through the system at a very low flow rate of about 10-12 oz/min

(0.30-0.35 liter/min).

3. After the indicator light turns off: read the temperature on the thermometer (2). If it does not match the

desired temperature, adjust the setpoint.

33

2

Adjusting for Spraying

NOTICE

Operating the heater at its highest setting of over

180°F (82°C) for long periods of time decreases the

heater life and can cause fluid to dry out which can

cause heater clogging and a poor spray pattern.

1. Adjust pump pressure and heater setpoint to the

lowest settings needed for good fluid atomization.

2. Set all system back pressure valves (S - FIG.1on

page 5) to maintain even fluid pressure at all gun

stations.

05549-524

FIG. 6: Setting Heater Control

12 3A2954D

Page 13

Maintenance

Maintenance

Flushing

To avoid fire and explosion, ensure main power is off

and heater is cool before flushing. Do not turn on

heater until fluid lines are clear of solvent.

Clogged fluid passages reduce heating efficiency, flow

rate, and pressure. Flush or clean whenever a change in

heating efficiency, flow rate, or pressure is noticed.

1. Follow Pressure Relief Procedure, page 11.

2. Ensure main power is off and heater is cool before

flushing. Use a compatible solvent, and follow flushing instructions in your fluid supply and spray gun

manual. Do not turn on heater until fluid lines are

clear of solvent.

Drain the Heater

(FIG.7)

1. Follow Pressure Relief Procedure, page 11.

2. Remove heater inlet and outlet fittings or pipe plugs.

Have a container ready to catch the fluid.

Outlet

Inlet

FIG. 7: Drain the Heater

ti20057a

3A2954D 13

Page 14

Troubleshooting

Troubleshooting

Problem Cause Solution

Heater will not heat. No current. Check circuit and fuses.

Overtemperature switch (10) tripped. • Check continuity of

overtemperature switch. If

circuit is open, press red reset

switch and re-check.

Determine why switch opened

before restarting.

• Model 24P016 only: check that

the thermostat (24) is open

when the knob is turned to the

left and closed when turned to

the right.

Burned out heater cartridges (81). Replace cartridges.

Temperature too low. Fluid requires more warm-up time. Increase warm-up time.

Wrong temperature setting. Adjust setting, page 12.

Flow rate too high. Reduce flow rate or use 2 heaters.

Clogged fluid passages. Heater Core Removal and Fluid

Passage Unclogging, page 19.

One of the two heater cartridges (81)

failed.

Temperature too high. Wrong temperature setting. Adjust setting, page 12.

Failed primary thermostat (24). Replace, page 16.

High fluctuating temperatures, about

220-250°F (104-120°C) at 0.1 GPM.

Too much pressure drop or fluid will

not flow.

Heater fittings leak. Loose or damaged fittings. Tighten or replace fittings.

Heater temperature rises far beyond

the setpoint temperature during heating

Primary thermostat (24) contacts

sticking.

Flow rate too high. Reduce flow rate or use 2 heaters.

Clogged fluid passages. Flush or clean, page 13.

Model 262853 only: RTD sensor (88)

is installed too far into fluid path. Sensor does not sense aluminum core.

Heater core is dirty or has baked on

material.

Check each cartridge for a resistance

of approximately 21 ohms. The pair

in parallel should have a resistance

of approximately 10.7 ohms. See

Heater Cartridges on page 20.

Replace thermostat (24), page 16.

Replace sensor (88) and compression fitting (72). See page 21.

Disassemble and clean all parts that

come in contact with material.

14 3A2954D

Page 15

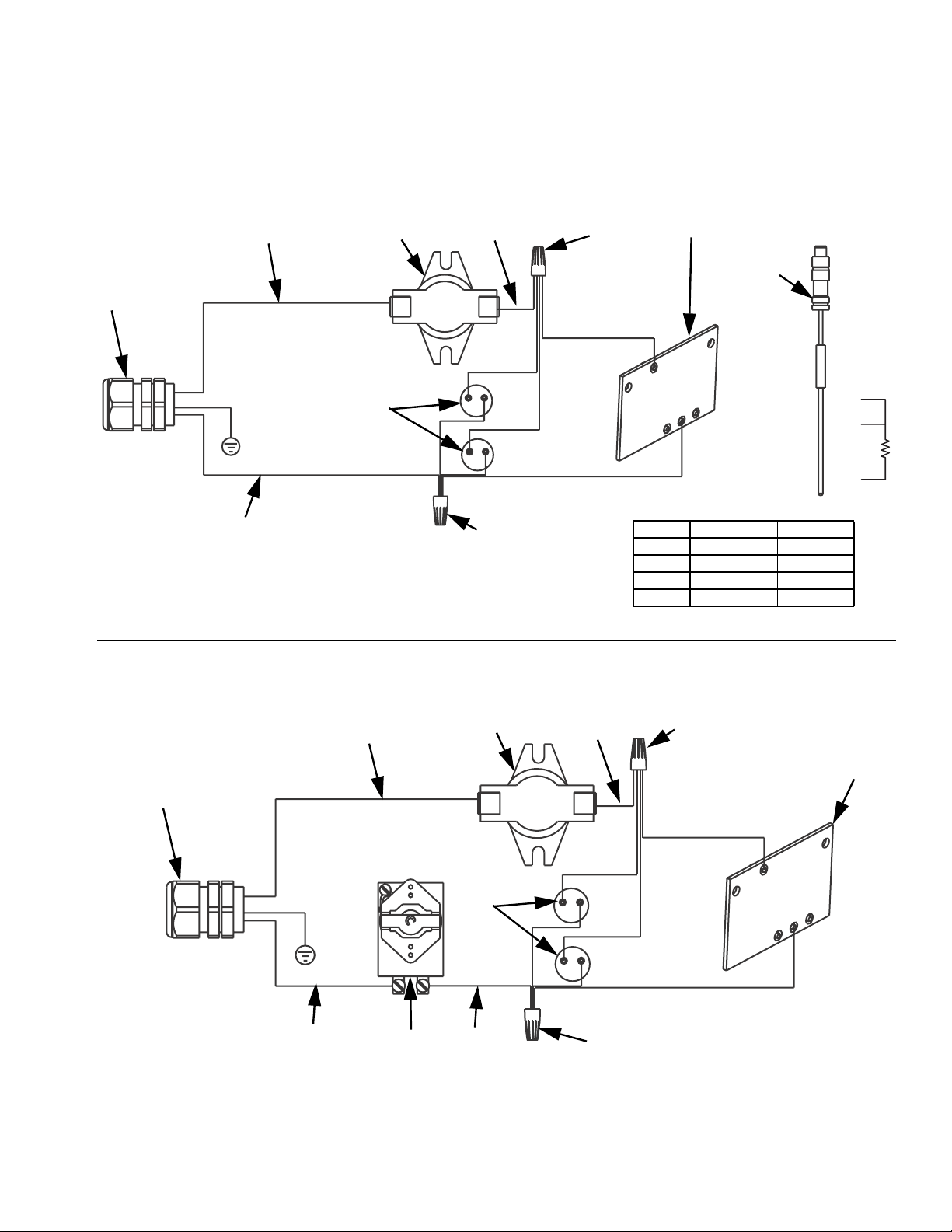

NOTE: See the Parts illustration that applies to your heater on page 22 or 24.

37

10

37

89

WHITE

87

260°F

53

Troubleshooting

RTD Sensor

(1000 ohm)

42, 88

81

BLACK

96

ti20062a

FIG. 8: Electrical Schematic - 262853 Heater with RTD

98

87

WHITE

89

10

260°F

98

4

1

3

RTD Pin Wire Color Signal

1 Red Excitation

2 --- ---

3 White RTD Element

4 Red Lead Ohms

89

53

81

BLACK

ti20063a

24

9737

89

FIG. 9: Electrical Schematic - 24P016 Heater with Thermostat

3A2954D 15

Page 16

Repair

Repair

To avoid burns, electric shock, and skin injection,

make sure the main power is OFF, heater is cool, and

pressure is relieved before repairing.

Overtemperature Switch

NOTE: This switch is a manual reset type. Press the red

button to reset the switch. Check for continuity across

the contacts. If the switch tripped, always determine the

cause before returning the heater to service.

1. Follow Pressure Relief Procedure, page 11.

Primary Thermostat & Probe

(Model 24P016 Only, see FIG.10onpage17)

1. Perform Pressure Relief Procedure, page 11.

2. Remove screws (52) then remove housing

cover (18).

3. Loosen screws (25) that secure thermostat in place.

4. Remove wires from the primary thermostat terminals (FF).

5. Loosen setscrew (26) in switch shaft (28)

6. Pull thermostat probe (EE) out of heater block.

7. Remove thermostat (24) from housing (1).

8. Remove screw standoff (35) with washer (27).

9. Remove bracket from thermostat (24) and secure to

new thermostat.

NOTICE

To avoid damaging capillary tube (GG) of the thermostat, which can cause heater malfunction, do not kink

or nick the tube.

2. Remove screws (52) then remove housing

cover (18).

3. Unplug wires from tabs (HH) on switch.

4. Remove the two screws (16) securing the switch

then remove the switch (10).

5. Liberally apply thermal lubricant (part no. 110009) to

the bottom of the thermostat switch and reinstall it in

reverse order of disassembly.

Reassembly Notes

• Refer to FIG.8orFIG. 9 for wiring connections.

• Make sure gasket (47) is installed and aligned with

electrical housing screw holes.

• Secure cover (18) with screws (52). Torque screws

to 89 in-lb (10 N•m).

To avoid shorting out the heater, do not allow capillary

tube to contact the terminals on switch (10) or

thermostat (24). Follow step 10, below.

10. Liberally apply thermal lubricant (part no. 110009) to

probe (EE) of new thermostat (24). Loop capillary

tube (GG) several times and wrap the loops with tie

strap (42-not shown). Insert probe in the heater

block.

11. Continue reassembling in reverse order of disassembly. See the following Reassembly Notes section.

16 3A2954D

Page 17

Repair

10

16

52

18

47

25

EE

81

FIG. 10: Thermostat Repair - 24P016

54

24

GG

FF (not visible in current view)

27

35

26

28

29

25

51

50

48

20

33

JJ

HH

24

3030

12

52

18

47

10

16

88

72

25

54

HH

1

51

50

48

20

FIG. 11: Sensor Repair - 262853

3A2954D 17

Page 18

Repair

Control Knob

This procedure applies to heater 24P016 only. See the

Parts illustration on page 22.

1. Follow Pressure Relief Procedure, page 11.

2. Turn control knob (33) to setpoint 1.

3. Loosen the control knob setscrew (30).

4. Remove control knob.

5. Remove adjusting knob (12) from the control knob

and press fit it onto the new control knob. Check the

grommet (29) and replace if worn.

6. Position new knob so setpoint 1 aligns with the

12 o’clock position and the knob is about 1/16 in.

(1 mm) away from the housing. Install and tighten

setscrew (30).

18 3A2954D

Page 19

Repair

Heater Core Removal and Fluid Passage Unclogging

The heater core (68) can be removed for thorough

cleaning or replacement. See the Parts illustration that

applies to your heater on page 22 or 24.

83

67

78

83

76

90

66

76

79

70

68

65

9. Remove screws (52) then remove cover (18).

10. On model 262853 only, remove RTD sensor (88).

Loosen nut on compression fitting (72). Pull nut and

sensor straight up out of heater.

11. Remove 4 screws (71) from top of plate (69).

12. Disconnect heater cartridge (81) wire leads from

wire nuts (89).

NOTICE

To prevent damage to sensors and wiring, do not turn

core (68). The core pushes straight down out of

housing (67).

13. Pull heater core straight down out of the upper

housing (67).

14. Use a wire brush to clean outside fluid passages

until bare aluminum is visible.

NOTE: Model 24P016 Only: The capillary bulb/tube

from the thermostat (24) will slowly pull out of its hole in

the core (68). The heater core wires will pull down

through plate (69).

83

ti20065a

FIG.12

1. Follow Pressure Relief Procedure, page 11.

2. Disconnect power.

3. Drain the Heater, page 13.

4. Loosen set screws (83) from bottom inlet housing

witha3/16in.hexkey.

5. Unscrew bottom inlet housing (65).

6. Remove nuts (90) then remove cylinder u-bolt

clamp (78).

7. Loosen set screws (83) on upper fluid housing (67).

NOTICE

On model 262853 only, to prevent damaging the RTD

sensor (72), do not rotate the core (68) when performing the following step.

Reassembly Notes

• Always replace o-rings (70, 76, and 79).

• Refer to FIG.10orFIG. 11 on page 17 for wiring

connections.

• Model 262853 only: Make sure the core (68) is

aligned with the plug (82) pin in housing (67).

• Make sure gasket (47) is installed and aligned with

electrical housing screw holes.

• Secure cover (18) with screws (52). Torque screws

to 85-90 in-lb (10 N•m).

8. Unscrew cylinder (66). Pull down to remove.

3A2954D 19

Page 20

Repair

Heater Cartridges

See Parts illustration that applies to your heater on

page 22 or 24.

1. Follow Pressure Relief Procedure, page 11.

2. Disconnect power.

3. Drain the Heater, page 13.

4. Perform Heater Core Removal and Fluid Passage

Unclogging procedure on page 19. This includes

removing the inlet housing (65).

5. With the inlet housing removed, remove 5

screws (52) and cover (18).

6. Disconnect wires from heater cartridges (81).

7. Remove pipe plug (95) and springs (31) from bottom of core (68).

8. Use a 3/8 in. (10 mm) rod to push each cartridge out

of the top of the core.

9. Wire new cartridges per FIG.8orFIG. 9, page 15.

20 3A2954D

Page 21

Repair

RTD Sensor and Fitting Replacement

(Model 262853 Only)

1. Follow Pressure Relief Procedure, page 11.

2. Disconnect power.

3. Remove screws (52) then remove cover (18).

4. Disconnect M8 cable connection for sensor (88).

5. Loosen nut on compression fitting (72) and pull the

sensor (88) straight up and out.

6. Remove compression fitting.

Reassembly

NOTICE

Sensor (88) position cannot be changed once a compression fitting (72) has been tightened. A new sensor

(88) and a new compression fitting (72) must be used

if the position is wrong.

1/8 in. (1.6 to 3.2 mm) into fluid outlet, when looking

into the outlet. See FIG.13.

M8 Plug

1/16-1/8 in.

(1.6-3.2 mm)

ti20209a

FIG.13

NOTE: Sensor (88) and fitting (72) must be replaced

together.

1. Install new compression fitting (72) into

housing (67).

NOTICE

The RTD sensor must always be mounted on the outlet side of housing (67). If you plumb the outlet to the

left side, swap position of sensor (88) and plug (82).

2. Position sensor through housing (67) so it sticks

through the aluminum shoulder on core (68) 1/16 to

3. Tighten compression nut on fitting (72) 3/4 turn after

it holds sensor tight.

4. Connect M8 plug.

5. Install cover.

3A2954D 21

Page 22

Parts

Parts

24P016

48

20

12

7

13

12

14

4

36

87

5150

33

53

25

92

5

64

4

54

30

43

14

57

15

8

52

18

47

9

1

5

24

5

14

17

91

27

35

25

28,

26

4

29

16

10

75

2

74

5

83

84

67

14

3

83

90

5

77

78

16

9

11

66

17

76

1

79

70

81

68

6

69

82

2

2

Apply sealant (39) and tape (44).

3

Torque to 7-11 ft-lb (10-15 N•m).

4

Loosen setscrew (26). Turn shaft (28)

clockwise and re-tighten setscrew (26).

Turn shaft counter-clockwise. Install

knob (33) with “1” at 12 o’clock

position. Tighten knob setscrew (30).

5

Apply sealant (34).

6

Apply thermal lubricant (38) to bottom

of flange (10).

7

Press fit onto knob (33).

71

5

83

5

7

14

2

67

16

75

2

32

93

2

49

2

2

9

9

Apply thermal lubricant (38) completely

covering probe before inserting.

11

Wrap capillary tube of thermostat (24)

and attach strap (42).

nick tube. Position wrapped

capillary tube between

thermostat (24) and wall of

enclosure (1) maintaining at least

0.6 in. from heating element.

12

Connect appropriate wire (240V) and

terminal end (part of item 53) to heater

terminal.

13

Apply adhesive (56) if required.

13

Do not kink or

96

73

73

2

31

95

2

65

17

83

2

ti20061a

14

Apply spray adhesive as necessary on

gasket.

15

Locate on wall of housing near (8).

16

Assemble sleeve (66) to housing (67).

After bottoming parts together loosen

between 0 and 90 degrees to align set

screws (83) to sleeve flats (66).

17

Assemble housing (65) to sleeve (66).

After bottoming parts together loosen

between 0 and 180 degrees to align set

screws (83) to sleeve flats (66).

18

Cut wires from board.

75

2

22 3A2954D

Page 23

24P016

Ref Part Description Qty

1 --- ENCLOSURE, controls, heater 1

2 102124 THERMOMETER, dial 1

5 107542 WASHER, lock, spring 6

7 15A990 GASKET, heater 1

8 116343 SCREW, ground 1

9 117367 SCREW, socket head cap,

M8 x 18

10 24P291 THERMOSTAT SWITCH 1

12 177969 KNOB, adjusting 1

13▲ 177922 TAG, warning 1

14 100055 SCREW, drive, #6 10

16 105676 SCREW, machine, pan head 2

17 --- LABEL, brand 1

18 15A810 COVER, heater controls, top 1

20 15B828 HOUSING, light, heater 1

24 108676 THERMOSTAT 1

25 100032 SCREW, machine, pan head 4

26 105672 SCREW, set, socket cap head 1

27 114027 WASHER, flat 2

28 183068 SHAFT, switch 1

29 112738 GROMMET 1

30 101366 SCREW, set, socket cap head 1

31† 16A240 SPRING, compression 2

32 16R930 FITTING, tee, thermometer, 3/4 1

33 177968 KNOB, control 1

34 --- SEALANT, anaerobic 1

35 117526 SPACER, standoff, threaded 2

36▲ 15B623 LABEL, electric shock warning 1

37 246346 WIRE, assy 1

38† 110009 LUBRICANT, thermal, 1 oz tube 1

39† --- SEALANT, pipe, stainless steel 1

42 --- STRAP, tie wiring 1

43▲ 15B625 LABEL, multiple warnings, English 1

44 --- TAPE, tfe, sealant 1

47 15A991 GASKET, heater 1

48 15B827 LENS, light, glass 1

49 15D757 HOUSING, thermometer 1

50 103338 PACKING, o-ring 1

51 117483 SCREW, jam, socket 1

52 111962 SCREW, cap, button head 5

53 246014 BOARD, circuit, heater indicator

light assembly

54 106216 NUT, lock 1

56 --- SEALANT, anaerobic 1

57▲ 172953 LABEL, grounding symbol, round 1

60▲◆ 15B819 LABEL, multiple warnings,

multi-language

64 111307 WASHER, lock, external 1

Ref Part Description Qty

65 24P019 HOUSING, inlet, heater 1

66 24P021 SLEEVE, center, heater 1

67 24P020 HOUSING, outlet, heater 1

68† --- CORE, spiral, heater 1

69 16P607 PLATE, mounting, heater 1

70† 164891 PACKING, o-ring 1

71† 103374 SCREW, machine, round head 4

6

73 16R883 FITTING, nipple, reducing, 3/4 x

1/2

74 --- SCREW, machine, serrated hex

head; 5/16-18 x 2.5 in.

75 102726 PLUG, pipe headless, 3/4 in. 4

76† 126396 PACKING, o-ring, PTFE, 235 2

77 16P609 CLAMP, mounting, bottom, heater 1

78 16P610 CLAMP, u-bolt, heater 1

79† 102930 PACKING, o-ring 1

81 16P821 CARTRIDGE, heater, 2700W,

240V

82 556410 PLUG, steel 1/8 pipe hex head 2

83 101679 SCREW, set, socket cap 4

84 16P608 CLAMP, mounting, top, heater 1

87 121603 GRIP, cord, 0.51-0.71, 3/4 1

89◆ 122032 NUT, wire 3

90 110996 NUT, hex, flange head 2

91▲ 189285 LABEL, burn hazard, triangular 1

92▲ 189930 LABEL, shock hazard, triangular 1

93 16R882 FITTING, nipple, 3/4 1

95† 105325 PLUG, pipe 1

96 166590 FITTING, elbow, street, high

pressure

97 16T515 WIRE, assembly, ring x quick

connect

98 16T502 WIRE, assembly 1

--- Not for sale.

▲ Replacement Danger and Warning labels, tags and

cards are available at no cost.

◆ Not shown.

† Parts included in Heater Core (68) Replacement Kit

1

1

24P022.

Parts

2

2

2

1

1

3A2954D 23

Page 24

Parts

262853

36

86,85

87

48

20

14

50

25

25

51

64

54

43

75

2

74

14

84

52

8

18

47

14

3

9

78

5

1

67

83

90

77

66

76

21

21

79

70

14

81

17

68

91

7

10

69

67

73

14

6

21

31

95

83

2

21

16

2

82

1

71

24

6

82

88

20

2

72

83

21

2

93

2

94

1

Apply medium strength, thread-locking fluid.

2

Apply sealant (39) and tape (44).

3

Torque to 7-11 ft-lb (10-15 N•m).

6

Apply thermal lubricant (38) to bottom of flange (10) and

plate (82) and top of core (68).

12

Connect appropriate wire (240V) and terminal end (part of item

53) to heater terminal.

14

Apply spray adhesive as necessary on gasket.

32

2

75

13

18

Cut wires from board. Cut ring terminals from white wire and

240V black wire. Strip wire for connection to wire nuts (89).

19

Power cord is user supplied.

20

Secure RTD connector (88) with tie strap (42) to RTD stem (88).

21

Assemble sleeve (66) to housing (67). After bottoming parts

together loosen between 0 and 90 degrees to align set

screws (83) to sleeve flats (66).

24

Tighten screws adequately to compress o-ring (70). Plate (69)

and core (68) must be tight against each other.

75

73

65

2

2

21

ti20060a

24 3A2954D

Page 25

Parts

262853

Ref Part Description Qty

1 --- ENCLOSURE, controls, heater 1

5 107542 WASHER, lock, spring 6

7 15A990 GASKET, heater 1

8 116343 SCREW, ground 1

9 117367 SCREW, shcs, m8x18 6

10 24P291 THERMOSTAT SWITCH 1

13▲ 177922 TAG, warning 1

14 100055 SCREW, drive, #6 10

16 105676 SCREW, machine, pan head 2

17 --- LABEL, brand 1

18 15A810 COVER, heater controls, top 1

20 15B828 HOUSING, light, heater, viscon

hp

25 100032 SCREW, machine, pan head 2

31† 16A240 SPRING, compression 2

32 16R930 FITTING, tee, thermometer, 3/4 1

36▲ 15B623 LABEL, electric shock warning 1

37 16T502 WIRE, assembly 2

38† 110009 LUBRICANT, thermal, 1 oz tube 1

39† --- SEALANT, pipe, stainless steel 1

42 --- STRAP, tie wiring 2

43▲ 15B625 LABEL, multiple warnings,

English

44 --- TAPE, tfe, sealant 1

47 15A991 GASKET, heater 1

48 15B827 LENS, light, glass 1

50 103338 PACKING, o-ring 1

51 117483 SCREW, jam, socket 1

52 111962 SCREW, cap, button head 5

53 246014 BOARD, circuit, heater indicator

light assembly

54 106216 NUT, lock 1

57▲ 172953 LABEL, grounding symbol, round 1

60▲◆ 15B819 LABEL, multiple warnings,

multi-language

64 111307 WASHER, lock, external 1

65 24P019 HOUSING, inlet, heater 1

66 24P021 SLEEVE, center, heater 1

67 24P020 HOUSING, outlet, heater 1

68† --- CORE, spiral, heater 1

69 16P607 PLATE, mounting, heater 1

70† 164891 PACKING, o-ring, PTFE, #135 1

71† 103374 SCREW, machine, round head 4

72 126351 FITTING, compression,

thermocouple

73 16R883 FITTING, nipple, reducing, 3/4 x

1/2

74 126669 SCREW, machine, serrated hex

head; 5/16-18 x 2.5 in.

75 102726 PLUG, pipe headless, 3/4 in. 4

Ref Part Description Qty

76† 126396 PACKING, o-ring, PTFE, 235 2

77 16P609 CLAMP, mounting, bottom,

heater

78 16P610 CLAMP, u-bolt, heater 1

79† 102930 PACKING, o-ring 1

81 16P821 CARTRIDGE, heater, 2700W,

240V

82 16V591 PLUG, steel locator 1

83 101679 SCREW, set, socket cap 4

84 16P608 CLAMP, mounting, top, heater 1

85 260067 FITTING, strain relief, 1/2 npt 1

86 117625 NUT, locking 1

87 121603 GRIP, cord, 0.51-0.71, 3/4 1

1

88 126381 SENSOR, RTD, 1k ohm, 4 pin 1

89◆ 122032 NUT, wire 3

90 110996 NUT, hex, flange head 2

91▲ 189285 LABEL, burn hazard, triangular 1

92▲ 189930 LABEL, shock hazard, triangular 1

93 16R882 FITTING, nipple, 3/4 1

94 198292 PLUG, pipe, 3/8 npt 1

95† 105325 PLUG, pipe 1

1

--- Not for sale.

▲ Replacement Danger and Warning labels, tags and

cards are available at no cost.

◆ Not shown.

† Parts included in Heater Core (68) Replacement Kit

24P022.

1

1

1

2

2

1

2

3A2954D 25

Page 26

Accessories

Accessories

Mounting Bracket

192585

AB

D

C

E

Dimensions – inches (mm)

A B C (4x) D E F (2x)

5.0

(127)

6.76

(172)

0.88

(22.4)

3.37

(85.6)

F

6.25

(158.8)

M8

7761a

1.44

(36.6)

Cart Bracket

For mounting heaters to 2.5 in. (63 mm) square tube

frames. Order 2 each of the following.

183484: Clamp

183485: Mounting bar

74

90

183484

183485

ti20055a

74 & 90 screw and nut included with heater

Thermal Lubricant

110009: 1 fluid ounce tube

26 3A2954D

Page 27

Technical Data

Technical Data

The heater can be used in the following environmental conditions: indoor use, 99% maximum relative humidity, pollution degree 2, installation category II, maximum ambient temperature 135° F (57° C).

Maximum Working Pressure ...................... 7250 psi (50 MPa, 500 bar)

Voltage/Wattage/Current*...................... SeeModels on page 2.

Fluid Passage Heat Transfer Area .................

Fluid Passage Dimensions (3 parallel paths) ......... Height: 0.41 in.

Fluid Passage Equivalent Diameter................. 0.72in.(18.3mm)

Thermometer Range ............................ 64-250°F (18 - 121°C)

WettedParts .................................. StainlessSteel,Anodized Aluminum, Electroless

Temperature Operating Range .................... 84-219°F (29 - 104°C)

Weight....................................... 51lb(23.2kg)

RTD (Model 262853 only) ........................ 1000 ohm, class B, 3-wire

* Main supply fluctuation not to exceed 10%.

210 in.2(1355 cm2)

Width: 0.32 in.

Length: 3x48in.

Nickel-Plated Steel, PTFE

Connector: M8, 4-pin male

3A2954D 27

Page 28

Technical Data

Performance Charts

Outlet Temperature versus Flow Rate (at each knob setting)

170

166

9

160

150

143

140

8

Viscon HF Heater with 70°F Test Oil

138

105

88.1

121

112

128

96

108

101

86.4

122

115

93

120

112

105

99

92

86

130

120

110

100

Maximum Temperature Rise (°F)

90

80

0.00 0.25 0.50 0.75 1.0 0 1.25 1.50 1.7 5

128

7

6

115

103

5

128

118

109

99

4

91

89.5

Flow Rate (gpm)

Temperature Rise versus Flow Rate (at each knob setting)

100

93

90

80

70

60

50

40

30

20

Maximum Temperature Rise (°F)

10

0

0.00 0.2 5 0.50 0.75 1.0 0 1.25 1.50 1.75

9

64

8

50.9

7

37.1

6

24.6

5

14.2

4

Viscon HF Heater with 72°F Test Oil

70.1

60

53.3

45.8

40.5

27.6

19.9

10.7

33.4

22.9

16.2

7.7

Flow Rate (gpm)

5.6

41.1

30.1

19.7

13.6

53.2

49.9

38.7

28.1

18.1

17.1

11.7

3.7

119

111

104

98

92

86

49

37.8

27.2

10.8

3

28 3A2954D

Page 29

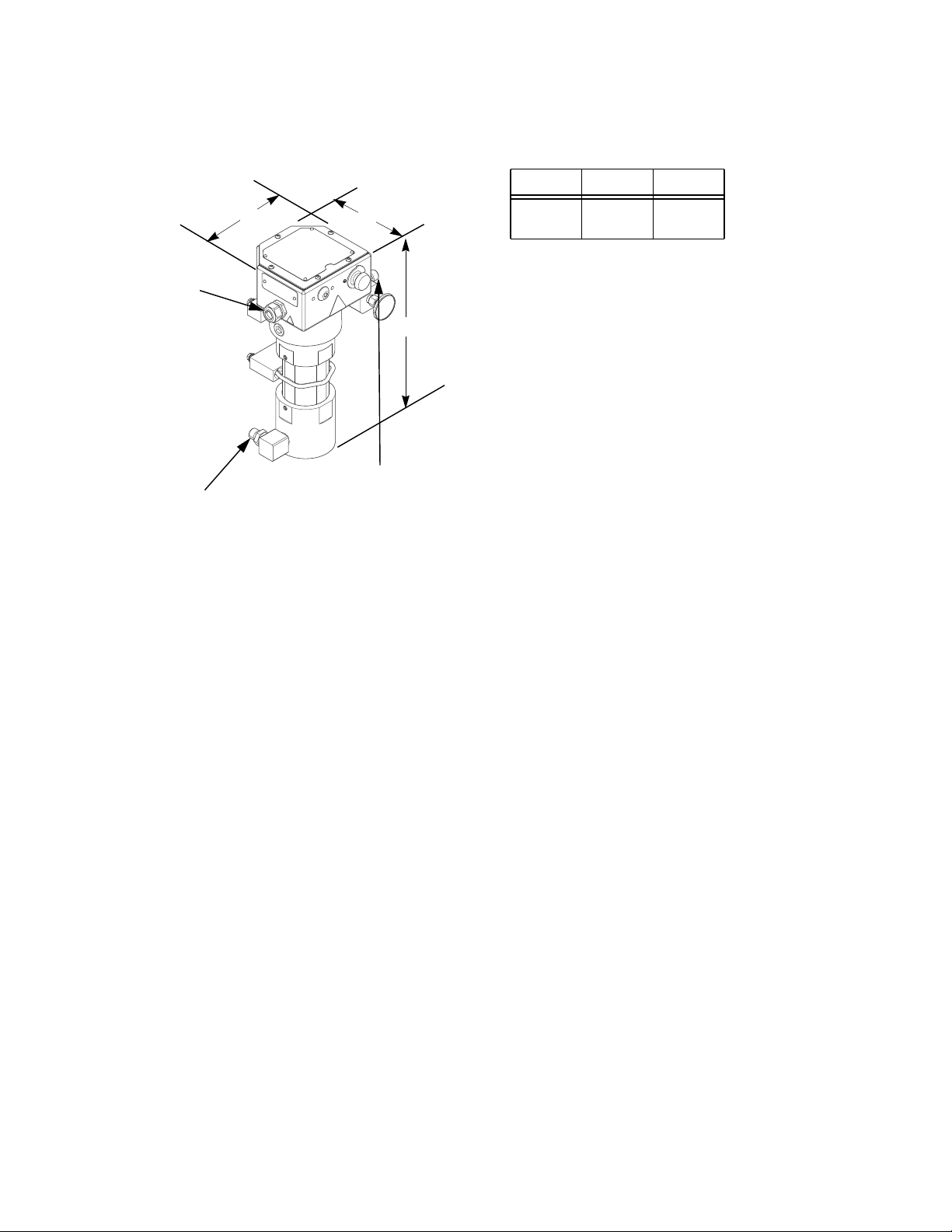

Technical Data

Dimensions

Stain Relief

in 3/4 npt(f)

Electrical

Conduit Port

1/2 in. npt(m)

Fluid Inlet shown

Model 24P016 shown

A

ti20064a

B

C

3/4-14 npt(f)

Fluid Outlet

with a 3/4 x

1/2 nipple

Measurements – inches (mm)

ABC

7.25

(184)

7.0

(178)

17.75

(451)

NOTE:

• 24P016 comes with a 3/4 in. street elbow and a 3/4

x 1/2 inlet nipple.

• 262853 comes with a 3/4 x 1/2 inlet nipple pointing

to the back.

• Lower inlet housing can be turned to face the front,

back, left, or right.

3A2954D 29

Page 30

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2012, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

)RUSDWHQWLQIRUPDWLRQVHHZZZJUDFRFRPSDWHQWV

2ULJLQDOLQVWUXFWLRQV This manual contains English. MM 3A2954

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised May 2013

Loading...

Loading...