Page 1

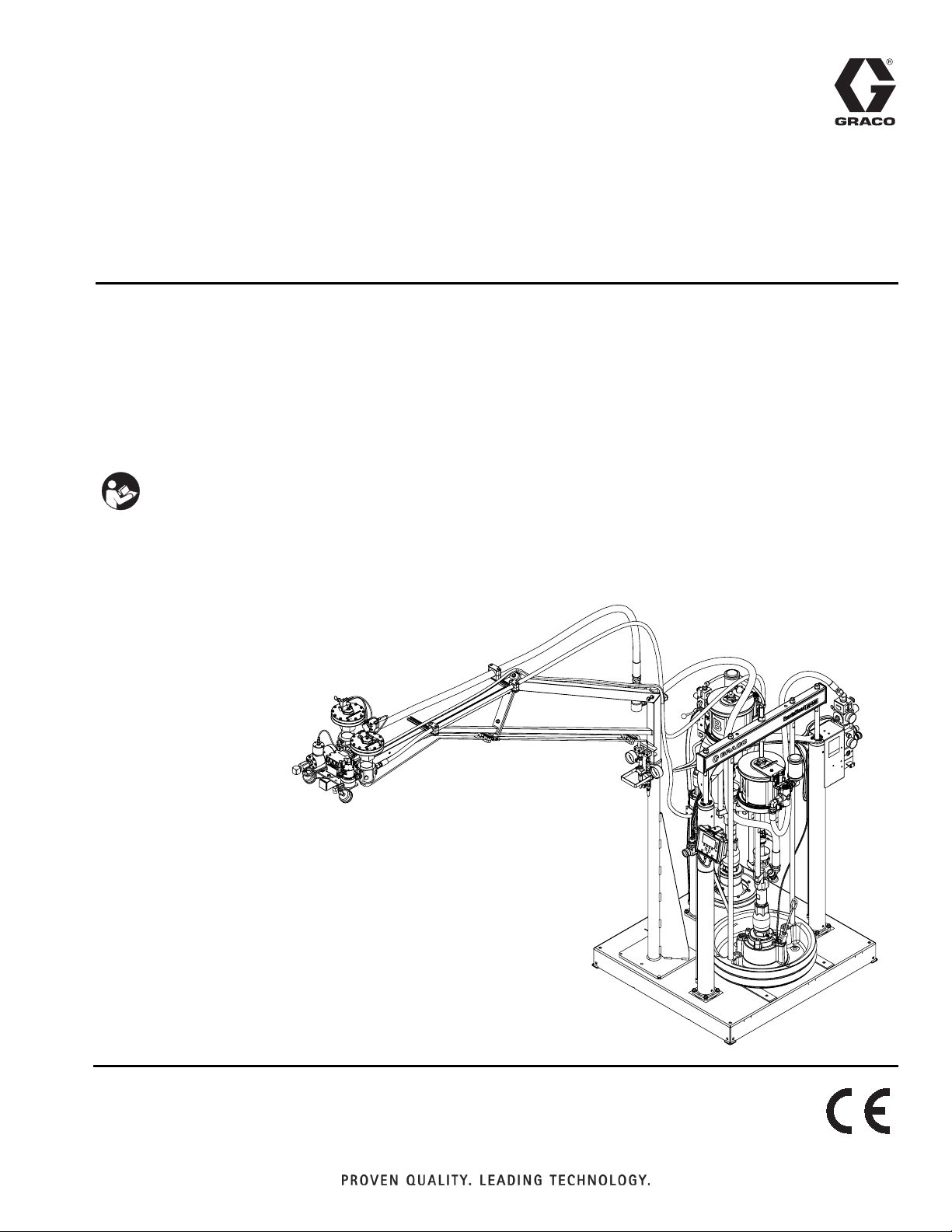

Setup-Operation

™

ExactaBlend

AGP

Advanced Glazing

Proportioner

For dispensing two component silicone, polysulfide, and urethane materials.

For professional use only.

Not approved for use in explosive atmospheres or hazardous locations.

See page 4 for model information, including maximum working pressure and approvals.

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

3A2894F

EN

S100 Shown

Page 2

Contents

Contents

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Base Machines . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Hose Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Dispense Valves . . . . . . . . . . . . . . . . . . . . . . . . . 5

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Important Isocyanate (ISO) Information . . . . . . . . 8

Isocyanate Conditions . . . . . . . . . . . . . . . . . . . . 8

Material Self-ignition . . . . . . . . . . . . . . . . . . . . . . 8

Keep Components A and B Separate . . . . . . . . . 8

Moisture Sensitivity of Isocyanates . . . . . . . . . . . 9

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . 9

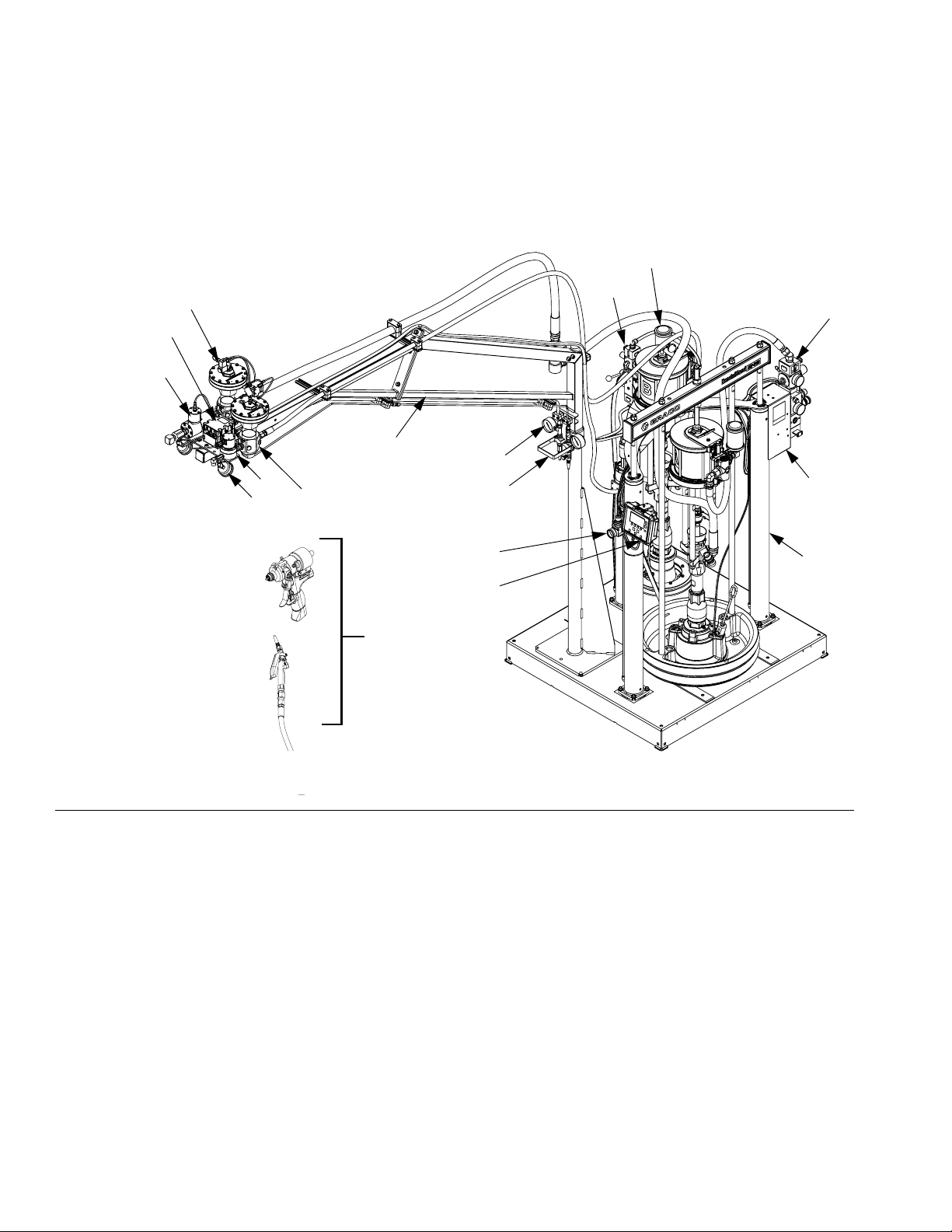

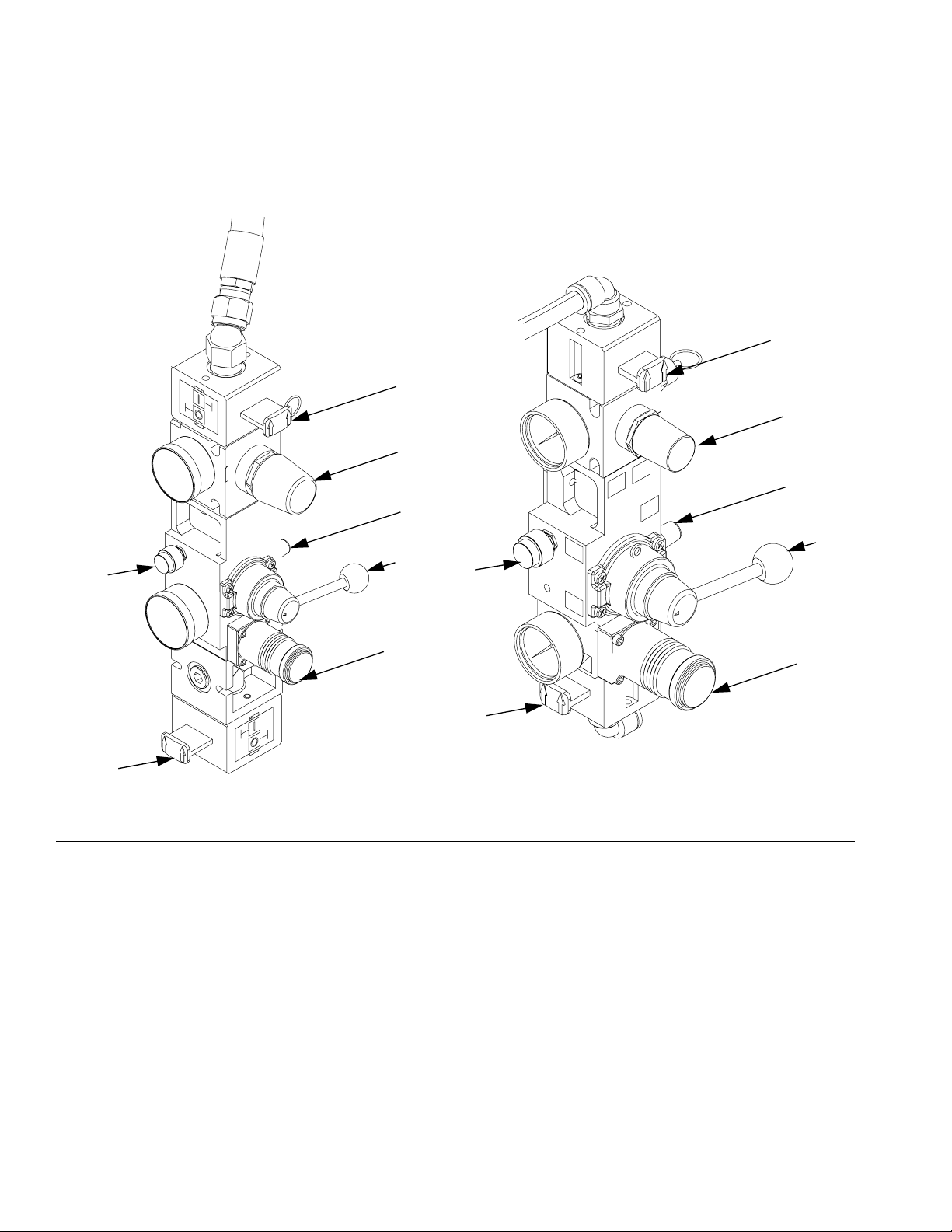

Component Identification . . . . . . . . . . . . . . . . . . . 10

S100 Models . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

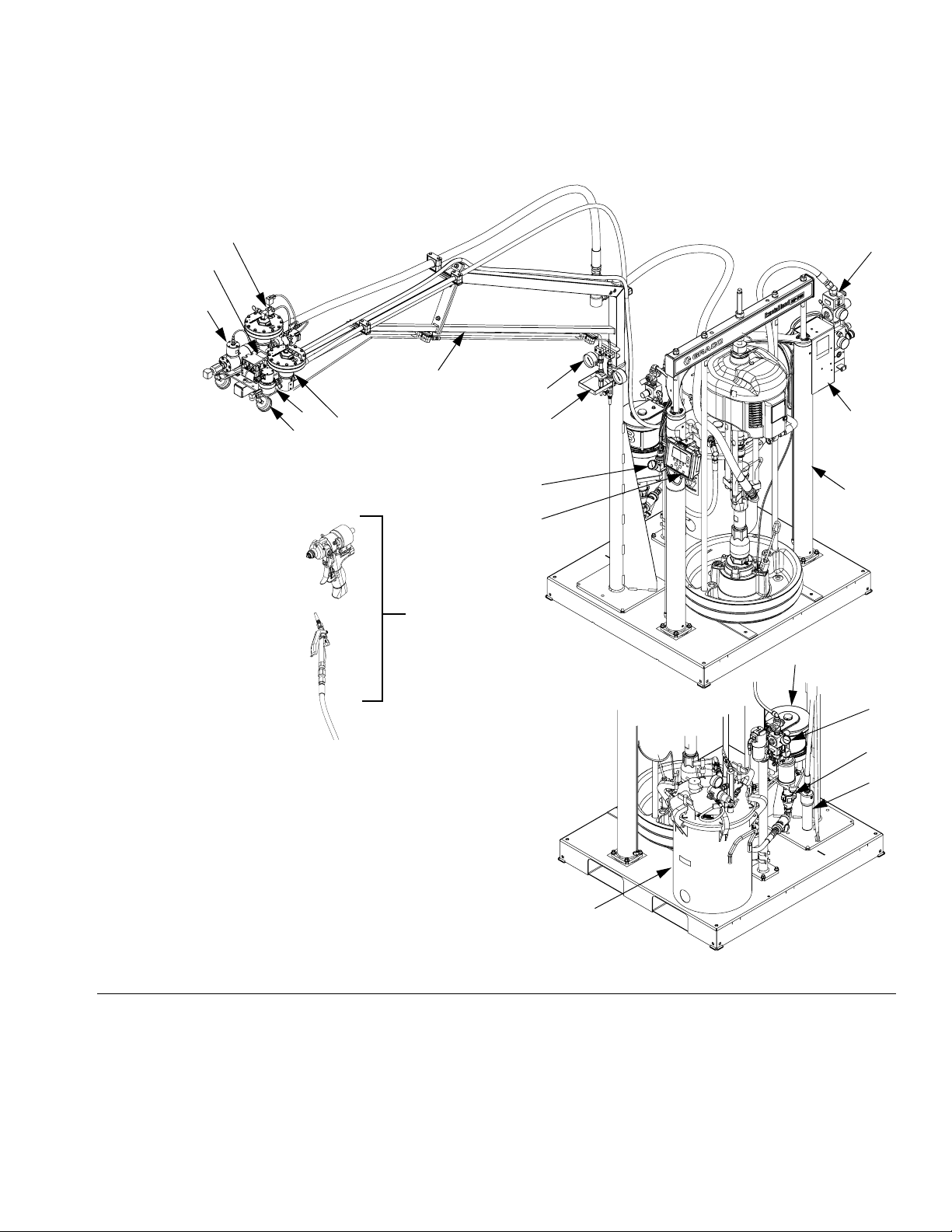

U100 Models . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

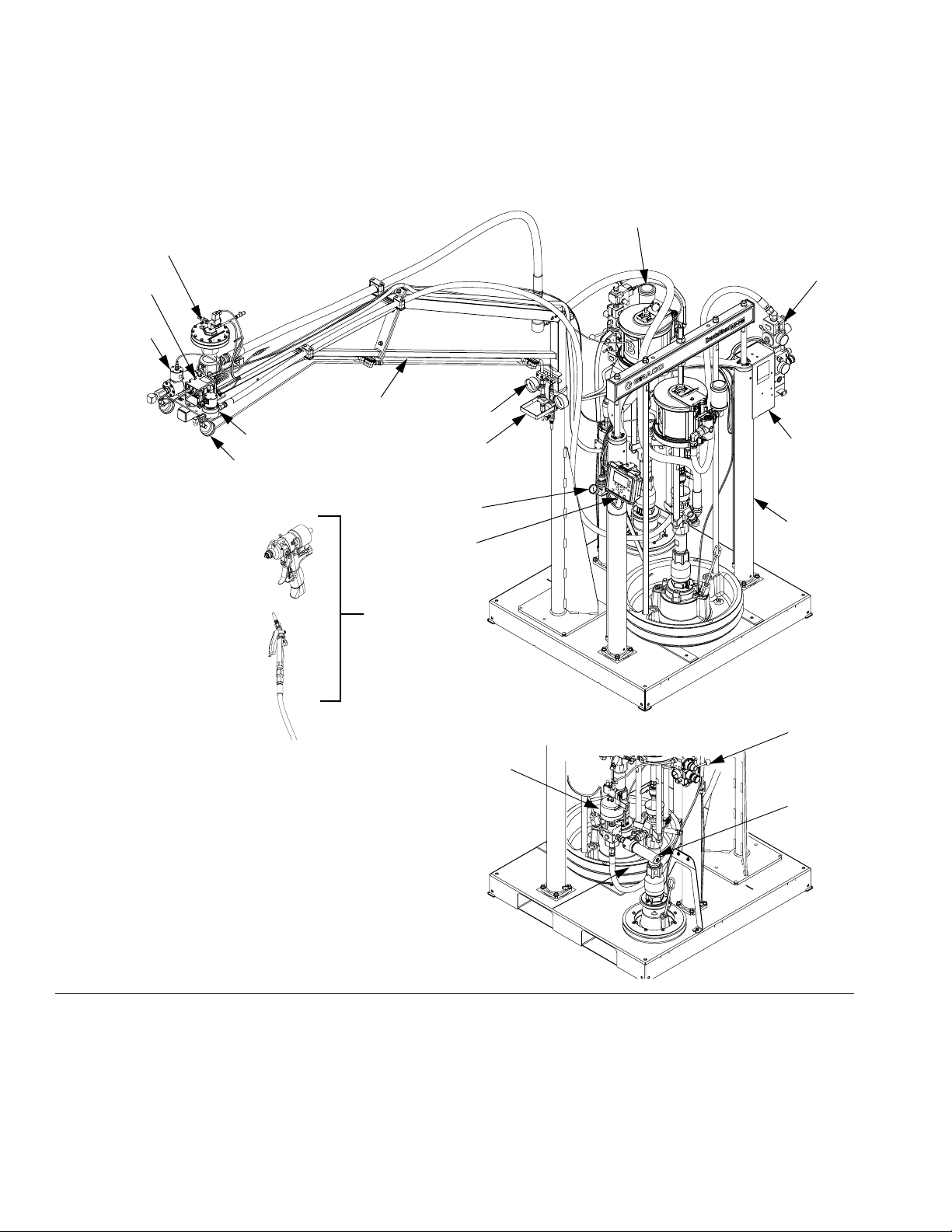

P100 Models . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Display Module (DM) . . . . . . . . . . . . . . . . . . . . . 14

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Electrical Enclosure . . . . . . . . . . . . . . . . . . . . . 17

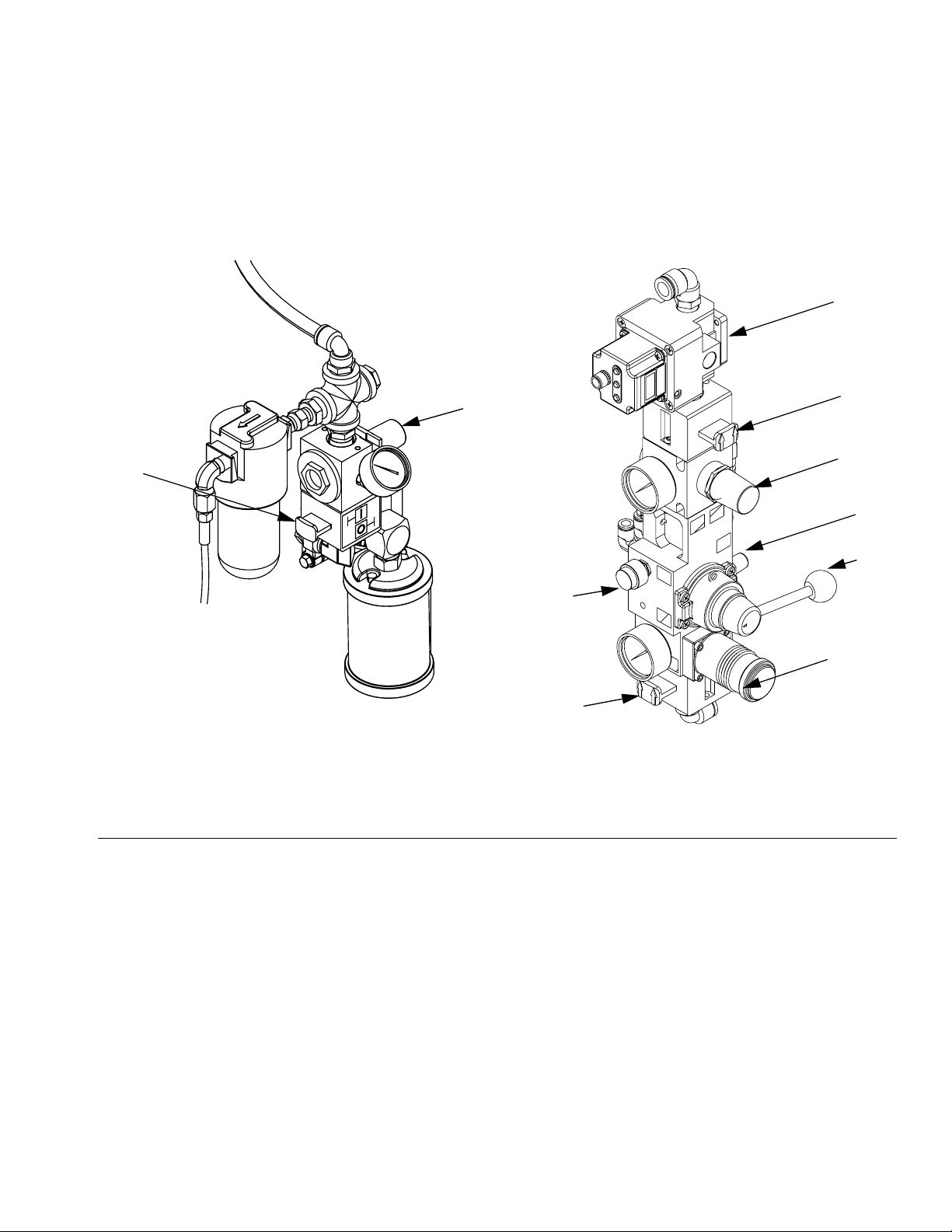

Integrated Air Controls . . . . . . . . . . . . . . . . . . . 18

Fluid Control Module (FCM) . . . . . . . . . . . . . . . 20

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Base Purge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 46

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Calibration Check . . . . . . . . . . . . . . . . . . . . . . . . . 49

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Adjust Packing Nuts . . . . . . . . . . . . . . . . . . . . . 52

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

DM - Battery Replacement and Screen Cleaning 53

Software Update Procedure . . . . . . . . . . . . . . . 54

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Mechanical and Electrical . . . . . . . . . . . . . . . . . 55

Display Module . . . . . . . . . . . . . . . . . . . . . . . . . 58

Accessories and Kits . . . . . . . . . . . . . . . . . . . . . . . 60

Light Tower 24R824 . . . . . . . . . . . . . . . . . . . . . . 60

Low Level Sensors, 24R935

(S100 and P100 only) . . . . . . . . . . . . . . . . . 60

USB Kit, 24R936 . . . . . . . . . . . . . . . . . . . . . . . . 61

MD2 Nose Pieces . . . . . . . . . . . . . . . . . . . . . . . 61

Catalyst (B) Hoses . . . . . . . . . . . . . . . . . . . . . . . 61

Restrictor Kit, 24R804 . . . . . . . . . . . . . . . . . . . . 61

Caster Kit, 24T091 . . . . . . . . . . . . . . . . . . . . . . . 62

Mixer Elements for MD2 . . . . . . . . . . . . . . . . . . 62

Appendix A - DM Icons Overview . . . . . . . . . . . . . 64

Setup Screen Icons . . . . . . . . . . . . . . . . . . . . . . 64

Run Screen Icons . . . . . . . . . . . . . . . . . . . . . . . 65

Appendix B - DM Setup Screens Overview . . . . . 66

Appendix C - DM Run Screens Overview . . . . . . 68

Appendix D - DM Error Codes . . . . . . . . . . . . . . . 70

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 78

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 78

2 3A2894F

Page 3

Related Manuals

Manuals are available at www.graco.com. Component manuals below are in English:

System Manuals

332452 ExactaBlend AGP Advanced Glazing Proportioner, Parts

332453 ExactaBlend AGP Advanced Glazing Proportioner - Accessory Kits, Kit Instructions

Ram Manuals

3A0233 Air-Powered Ram, Instructions-Parts

Pump Manuals

312375

Check-Mate

Air Motor Manuals

3A1211

311238

SaniForce

®

NXT

333007 ExactaBlend AGP Air Motor, Instructions-Parts

®

Displacement Pumps, Instructions-Parts

™

Air Motors, Instructions-Parts

Air Motor, Instructions-Parts

Related Manuals

Displacement Pump Manuals

309577 Displacement Pump, Repair-Parts

Dispense Valve Manuals

312185 MD2 Valve, Instructions-Parts

308253

Ultra-lite

™

Pistol Grip Flo-Gun, Instructions-Parts

Flow Meter Manuals

308778 Volumetric Fluid Flow Meter, Instructions-Parts

309834 Helical Gear Fluid Flow Meters, Instructions-Parts

Fluid Filters Manuals

307273 Fluid Outlet Filter, Instructions-Parts List

Fluid Regulators Manuals

307517 Mastic Fluid Regulators, Instructions-Parts List

308647 Fluid Pressure Regulators, Instructions-Parts List

Pressure Pot Manuals

308369 5-, 10-, and 15-Gallon Pressure Tanks, Instructions-Parts List

Heated Platen Manuals

332511 ExactaBlend AGP Advanced Glazing Proportioner - Heated Platen Kit, Kit Instructions

Reference Manuals

3A1244

Graco Control Architecture

™

Module Programming

Val ve Manua ls

313342 Dosing Valve, Instructions-Parts

3A2894F 3

Page 4

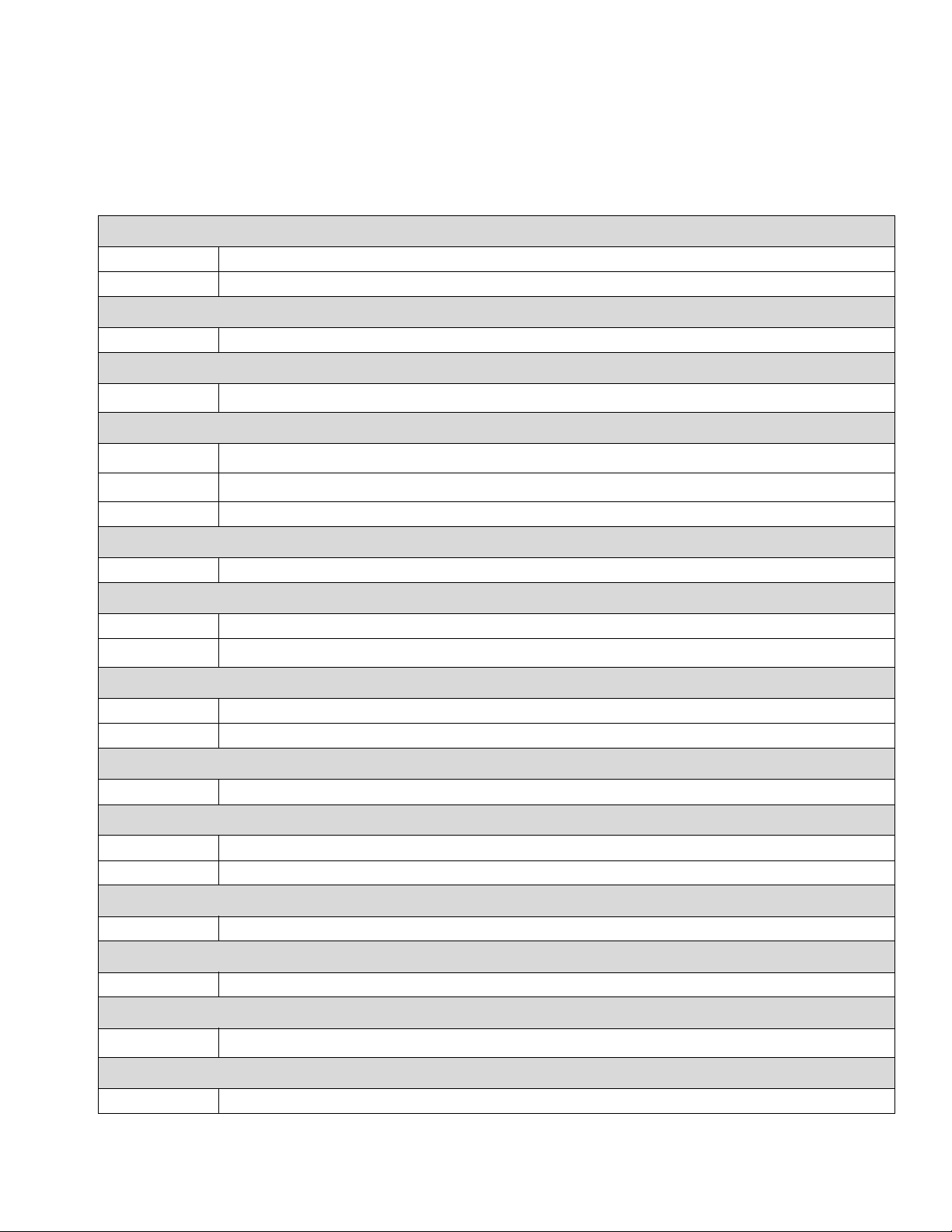

Models

Models

Base Machines

Chemical

Part No.

24R809

24R810

24R811

24R812

24R813

24R814

24R815

24R816

* An agitator is recommended for urethane applica-

tions utilizing a pressure pot. Set the agitator to

25-50 rpm.

Industry

Silicone

Urethane*

Polysulfide

Description

AGP-S100 System, 55 gallon/5 gallon

(200 liter/20 liter) machine with boom

AGP-S100 System, 55 gallon/5 gallon

(200 liter/20 liter) machine

AGP-U100 System, 55 gallon/5 gallon

(200 liter/20 liter) machine with boom

AGP-U100 System, 55 gallon/5 gallon

(200 liter/20 liter) machine

AGP-U100 System, 55 gallon/5 gallon

(200 liter/20 liter) machine with boom

and pressure pot

AGP-U100 System, 55 gallon/5 gallon

(200 liter/20 liter) machine with pressure pot

AGP-P100 System, 55 gallon/5 gallon

(200 liter/20 liter) machine with boom

AGP-P100 System, 55 gallon/5 gallon

(200 liter/20 liter) machine

Ratio

(by Weight)

6:1 to 14:1

Maximum Working Pressure

psi (MPa, bar)

MD2:

3000 (21, 207)

Ultra-lite with flexible hose mixer:

3000 (21, 207)

Ultra-lite with Tri-core mixer:

4000 (28, 276)

4 3A2894F

Page 5

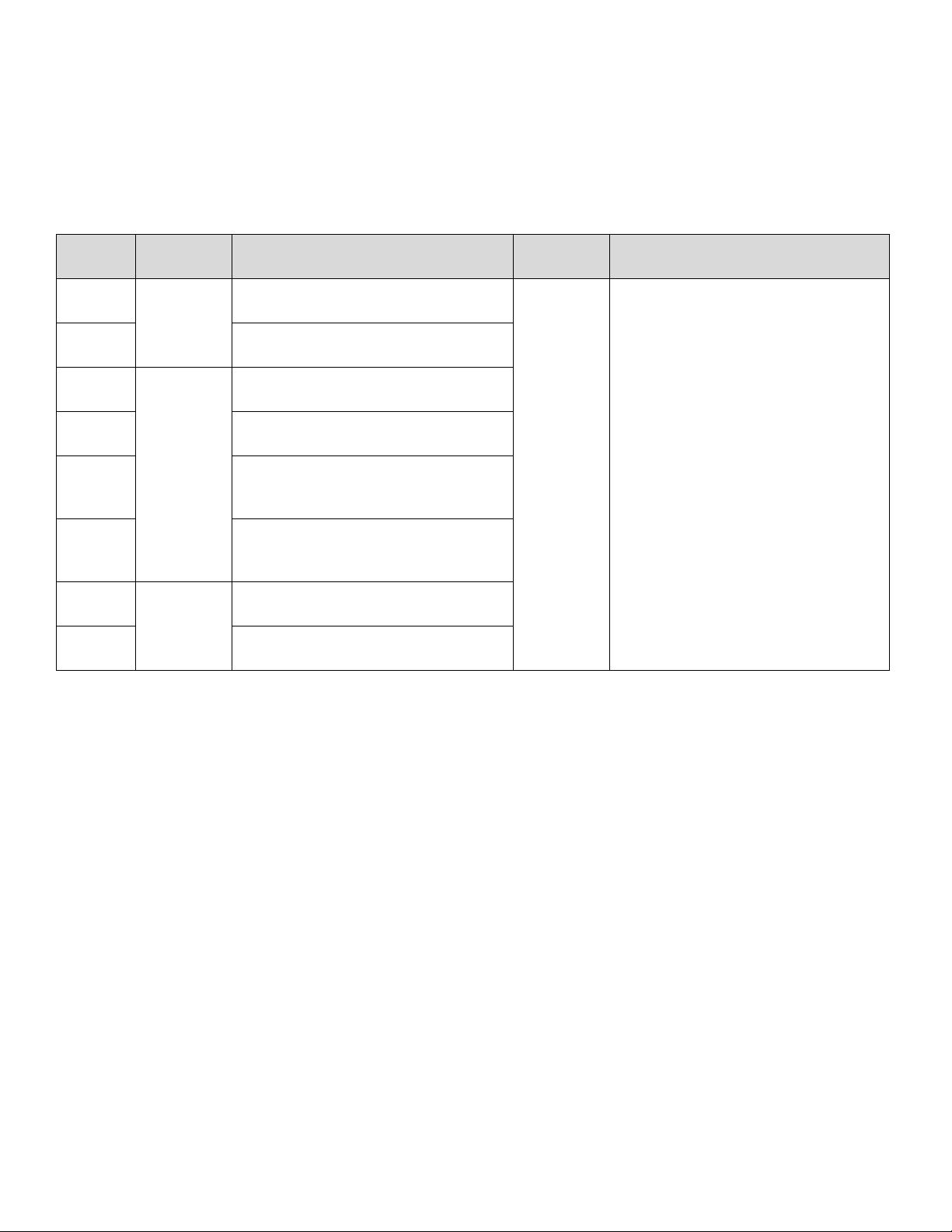

Hose Kits

Hose Kit

Reference

Part No.

24R832 #1

24R833 #2 1/4 x 60 (0.6 x 152) 1/8 x 60 (0.3 x 152)

24R834 #3 1/4 x 60 (0.6 x 152) 1/4 x 60 (0.6 x 152)

24T092 #4 3/8 x 60 (1.0 x 152) 1/4 x 60 (0.6 x 152)

24T093 #5 1/8 x 60 (0.3 x 152) 3/32 x 60 (0.2 x 152)

24T094 #6 1/2 x 60 (1.3 x 152) 3/8 x 60 (1.0 x 152)

24U253 #7 3/32 x 60 (0.2 x 152) 3/32 x 60 (0.2 x 152)

No.

Base Hose

in. (cm)

5/8 x 120 (1.6 x 305)

Catalyst Hose 1

in. (cm)

1/8 x 60 (0.3 x 152) 1/8 x 60 (0.3 x 152)

Catalyst Hose 2

in. (cm)

Dispense Valves

Part No. Description

24P217 MD2 dispense valve with handle

24P223 Ultra-lite 6000 with 36 element flexible hose mixer

24P221 Ultra-lite 6000 with 36 element Tri-core mixer

Models

3A2894F 5

Page 6

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and

warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

WARNINGWARNINGWARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power cord before servicing equipment.

• Connect only to grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on power and extension cords.

• Do not expose to rain. Store indoors

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure and disconnect all power sources.

6 3A2894F

Page 7

Warnings

WARNING

WARNINGWARNINGWARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless they

are antistatic or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Dat a in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Route exhaust away from work area. If diaphragm ruptures, fluid may be exhausted into the air.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes but is

not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer

3A2894F 7

Page 8

Important Isocyanate (ISO) Information

WARNING

WARNINGWARNINGWARNING

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical

reaction and equipment rupture. Failure to follow this warning can result in death, serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids containing such solvents.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier for compatibility.

Important Isocyanate (ISO) Information

Isocyanates (ISO) are catalysts used in some two component materials.

Isocyanate Conditions

Spraying or dispensing materials containing isocyanates creates potentially harmful mists, vapors, and

atomized particulates.

Read material manufacturer’s warnings and material

MSDS to know specific hazards and precautions

related to isocyanates.

Prevent inhalation of isocyanate mists, vapors, and

atomized particulates by providing sufficient ventilation in the work area. If sufficient ventilation is not

available, a supplied-air respirator is required for

everyone in the work area.

To prevent contact with isocyanates, appropriate personal protective equipment, including chemically

impermeable gloves, boots, aprons, and goggles, is

also required for everyone in the work area.

Material Self-ignition

Keep Components A and B Separate

Cross-contamination can result in cured material in

fluid lines which could cause serious injury or damage

equipment. To prevent cross-contamination:

• Never interchange component A and component

B wetted parts.

• Never use solvent on one side if it has been contaminated from the other side.

Some materials may become self-igniting if applied

too thick. Read material manufacturer’s warnings and

material MSDS.

8 3A2894F

Page 9

Moisture Sensitivity of Isocyanates

Exposure to moisture (such as humidity) will cause ISO

to partially cure; forming small, hard, abrasive crystals,

which become suspended in the fluid. Eventually a film

will form on the surface and the ISO will begin to gel,

increasing in viscosity.

NOTICE

Partially cured ISO will reduce performance and the

life of all wetted parts.

• Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere. Never

store ISO in an open container.

• Keep the ISO pump wet cup or reservoir (if

installed) filled with appropriate lubricant. The

lubricant creates a barrier between the ISO and

the atmosphere.

• Use only moisture-proof hoses compatible with

ISO.

• Never use reclaimed solvents, which may contain

moisture. Always keep solvent containers closed

when not in use.

• Always lubricate threaded parts with an appropriate lubricant when reassembling.

Important Isocyanate (ISO) Information

NOTE: The amount of film formation and rate of crystallization varies depending on the blend of ISO, the

humidity, and the temperature.

Changing Materials

NOTICE

Changing the material types used in your equipment

requires special attention to avoid equipment damage

and downtime.

• When changing materials, flush the equipment

multiple times to ensure it is thoroughly clean.

• Always clean the fluid inlet strainers after flushing.

• Check with your material manufacturer for chemical compatibility.

3A2894F 9

Page 10

Component Identification

Component Identification

S100 Models

J

L

H

B

H

M

J

M

D

F

F

K

G

FIG. 1: S100 Models

Key:

A Display Module (DM)

BBoom

C Ram - Base (A) Chemical*

D Ram - Catalyst (B) Chemical*

E Dispense Valve*

F Integrated Air Controls

G Electrical Enclosure

P

C

A

E

H Flow Meters*

J Fluid Regulator*

K Calibration Check Assembly

L Fluid Control Module (FCM)

M Material Pressure Gauges

N Catalyst (B) Filter

P Fluid Regulator Adjustment

Controls the pressure to the base (A) fluid regulator.

R Pressure Pot (U100 only)*

S Air Motor (U100 only)*

T Displacement Pump (U100 only)*

U Dosing Valve (P100 only)*

* Refer to specific component manual for more detailed

information.

10 3A2894F

Page 11

U100 Models

Component Identification

J

L

H

B

M

H

M

J

E

K

P

A

S

F

G

C

FIG. 2: U100 Models

NOTE: Refer to key found on page 10.

F

T

N

R

3A2894F 11

Page 12

Component Identification

P100 Models

J

L

H

D

F

M

B

H

E

M

K

P

A

U

G

C

F

N

R

FIG. 3: U100 Models

NOTE: Refer to key found on page 10.

12 3A2894F

Page 13

Component Identification

3A2894F 13

Page 14

Component Identification

Display Module (DM)

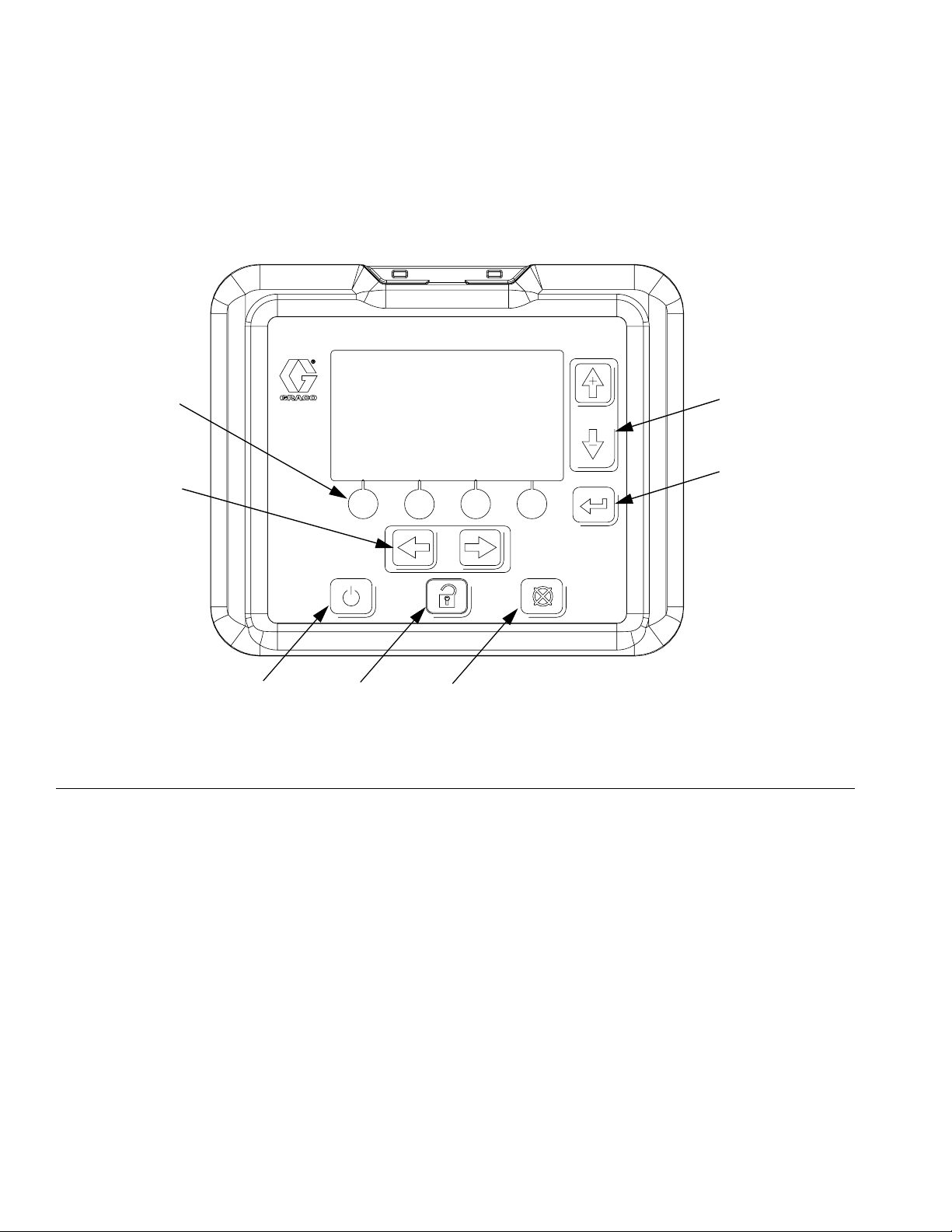

User Interface

BB

BF

BA

BE

FIG. 4: DM Component Identification - Front

Key:

BA System Enable/ Disable

Enables/disables the system. When the system is

disabled, dispense operation is disabled.

BB Soft Keys

Defined by application using the DM.

BC Cancel

Cancel a selection or number entry while in the process of

entering a number or making a selection.

BD Enter

Acknowledge changing a value or making a selection.

BE Lock/Setup

Toggle between run and setup screens. If setup screens

are password protected, button toggles between run and

password entry screen.

BF Field Selection

Navigate to another field when the DM is in setup mode.

These buttons have no function when the DM is in run

mode.

BG

BD

BC

BG Increase / Decrease / Field Selection

Increase or decrease the selected value. Navigate to

another field.

14 3A2894F

Page 15

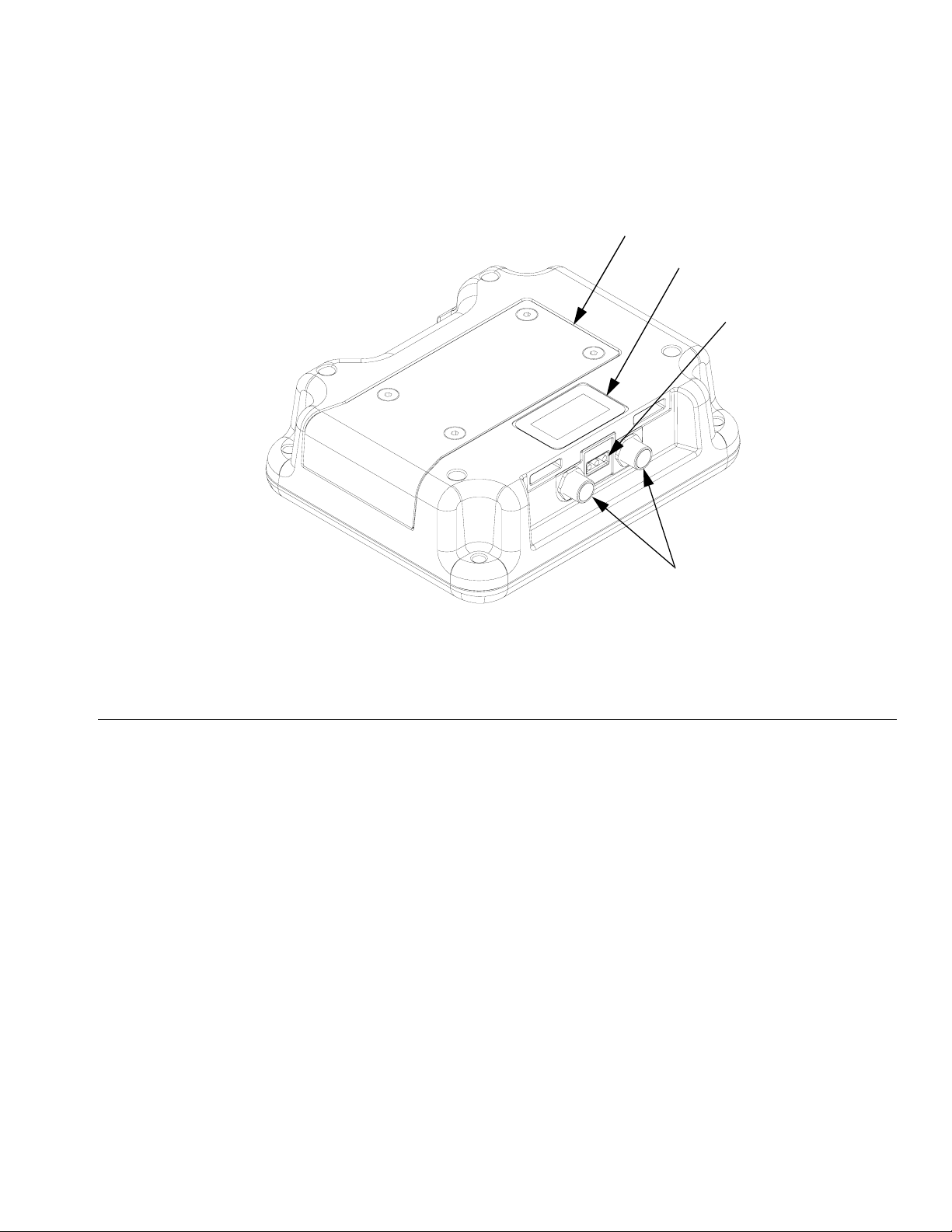

BL

Component Identification

BH

BK

FIG. 5: DM Component Identification - Rear

BH Model Number

Identification tag for the DM.

BJ CAN Cable Connections

Electrical connection for power and communication to

other GCA devices.

BK Module Status LEDs

Visual indicators to show the status of the DM:

Green Solid - Power provided.

Green Off - No power.

Yellow Flashing - Communication with other GCA

devices occurring.

Red Solid - Bad DM or machine is in critical status

Red Flashing - Wrong program uploaded.

BL Token/Battery Access Cover

Access cover for token and battery.

BJ

3A2894F 15

Page 16

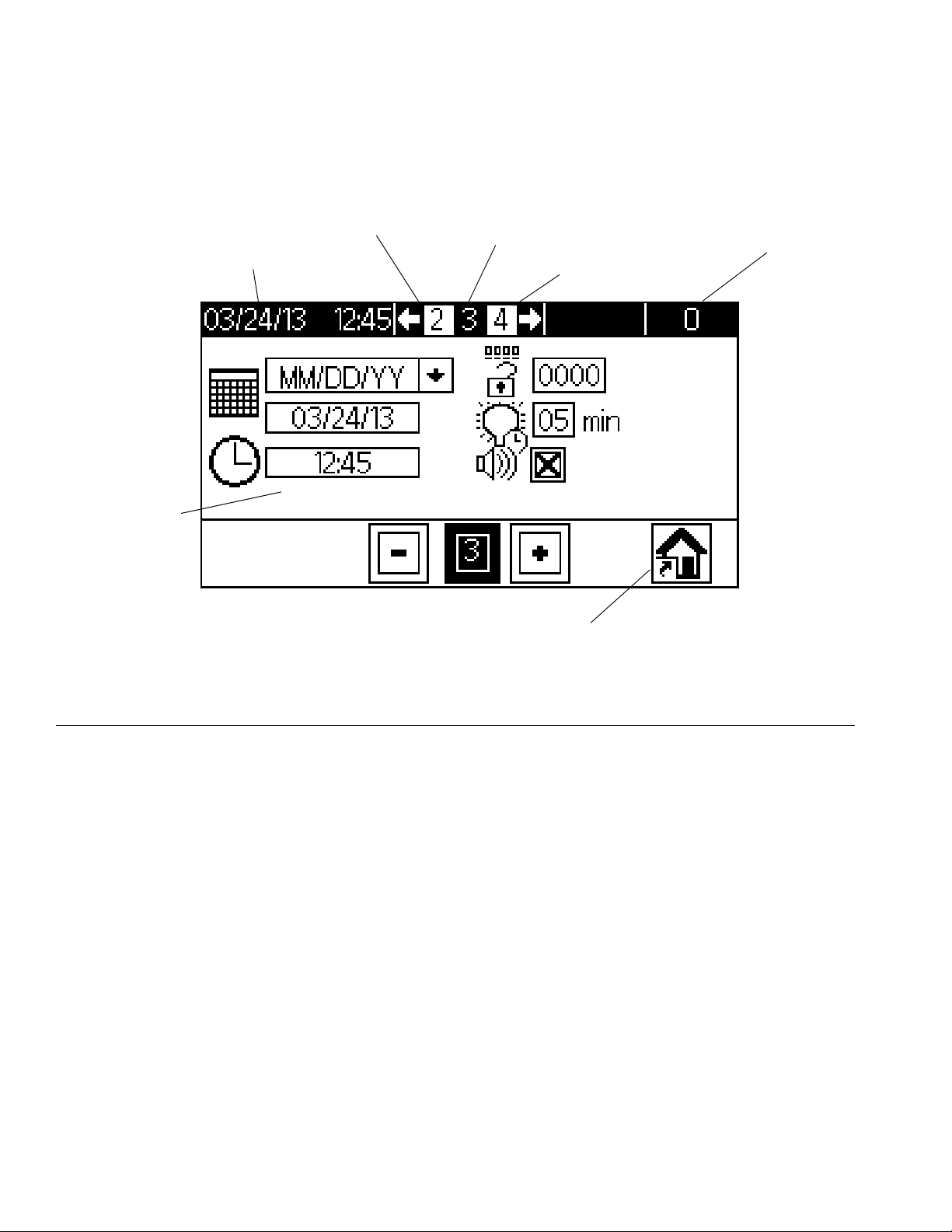

Component Identification

Main Display Components

The following figure calls out the navigational, status, and general informational components of each screen.

Current date and time

Function display

Previous screen

Current screen

Selection screen

Faults, Status

Next screen

F

IG. 6: Main Display Components

16 3A2894F

Page 17

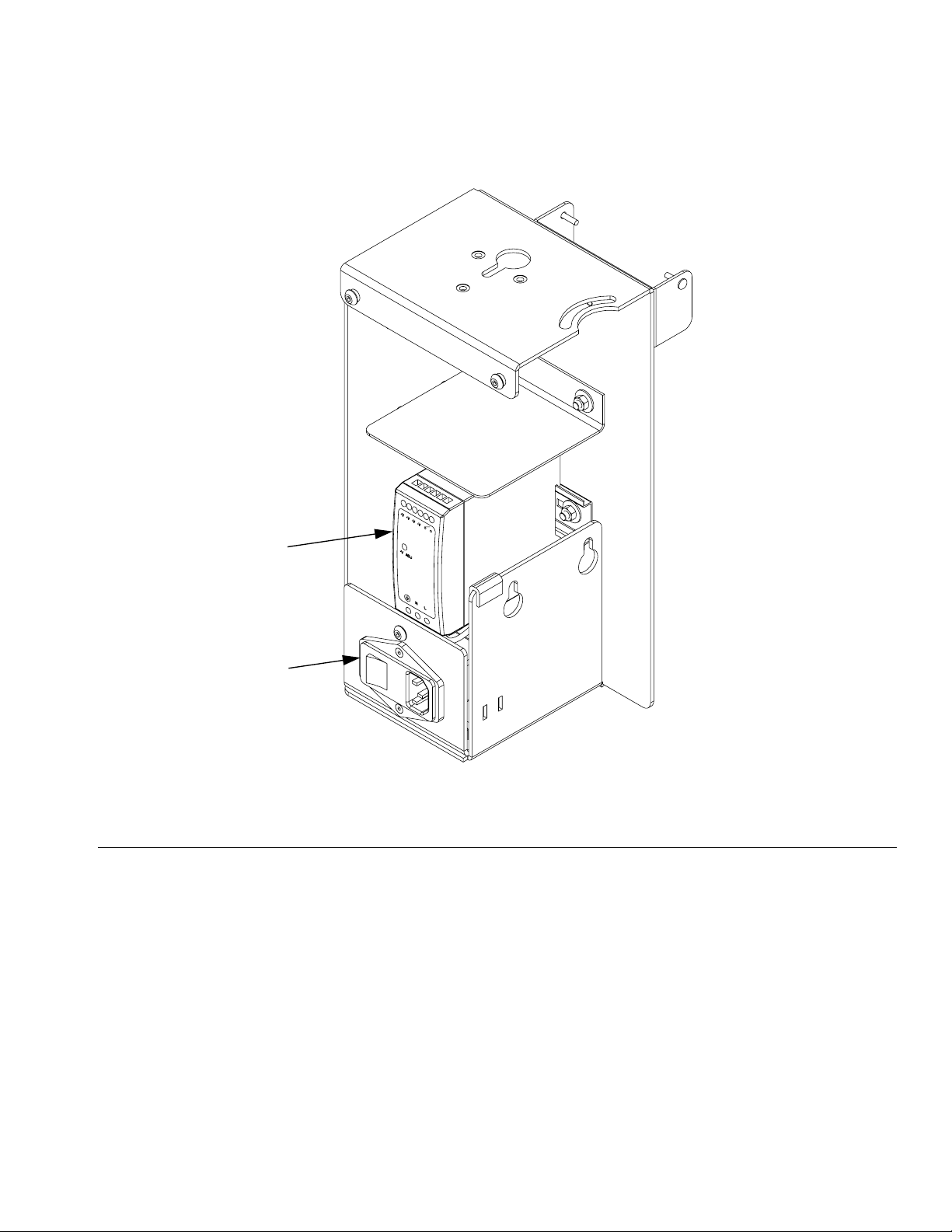

Electrical Enclosure

Component Identification

DB

DA

FIG. 7: Electrical Enclosure

Key:

DA Power Switch

Turns electrical power on or off.

DB 24VDC Power Supply

Converts input power to 24 VDC.

3A2894F 17

Page 18

Component Identification

Integrated Air Controls

CG

Base (A) Side

All Models

Catalyst (B) Side

S100 Models

CF

CF

CE

CE

CD

CD

CC

CC

CG

CA

FIG. 8: Integrated Air Controls

Key:

CA Main Air Slider Valve

Turns air on and off to the entire system. When closed,

the valve relieves pressure downstream.

CB Ram Air Regulator

Controls the ram up and down pressure and blowoff

pressure.

CC Ram Director Valve

Controls the ram direction.

CD Exhaust Port with Muffler

CE Air Motor Regulator

Controls the air pressure to the motor.

CF Air Motor Slider Valve

Turns air on and off to the air motor. When closed, the

valve relieves air trapped between it and the motor. Push

the valve in to shutoff.

CB

CB

CJ

CG Blowoff Button

Turns air on and off to push the platen out of an empty

drum.

CJ Catalyst Air Slider Valve

Turns air on and off to the catalyst motor only. When

closed, the valve relieves pressure down stream.

CK Voltage to Pneumatic Regulator (V/P)

Electrically controlled air regulator.

18 3A2894F

Page 19

Component Identification

CF

Catalyst (B) Side

U100 Models

CE

Catalyst (B) Side

P100 Models

CK

CF

CE

CD

CC

CG

IG. 9: Integrated Air Controls

F

NOTE: Refer to key found on page 18.

CB

CJ

3A2894F 19

Page 20

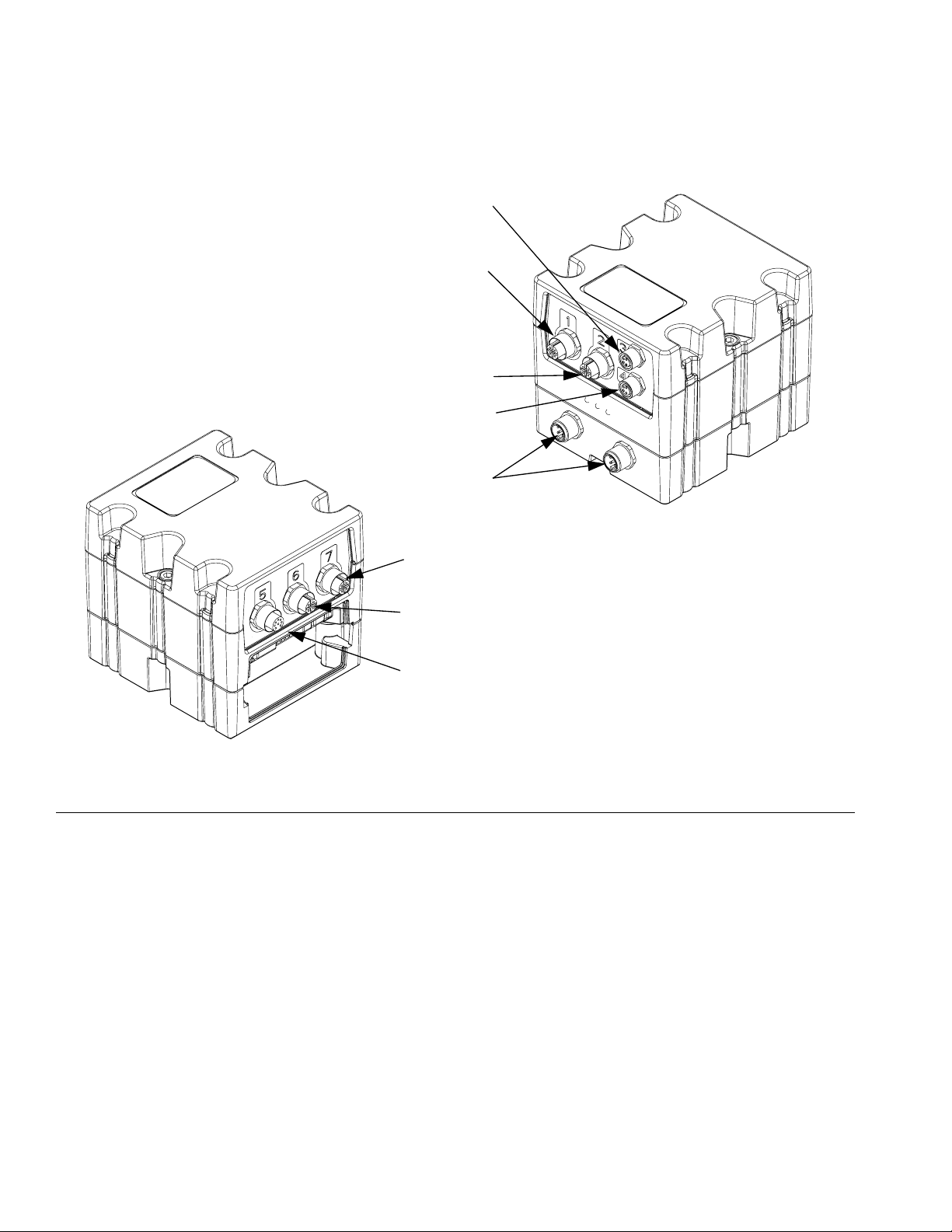

Component Identification

Fluid Control Module (FCM)

EC

EA

EB

ED

EH

FIG. 10: FCM

Key:

EA Port 1 - Air Shut off Valve

Controls the air to the base (A) material regulator.

Port 1 - Low Level Sensors (Optional)

Low level input for the both materials. Refer to

Accessories and Kits, page 60, for more details.

Includes splitter.

EB Port 2 - Flow Meters

Base (A) and Catalyst (B) flow meter input. Includes

splitter

EC Port 3 - Solenoid Valve (P100 only)

To open and close the dosing valve.

ED Port 4 - Voltage to Pneumatic (V/P) Regulator

Controls the air to the catalyst (B) material regulator.

EE Port 5 - Audible Light Tower (Optional)

Visual and audible indicator of machine status. Refer to

Accessories and Kits, page 60, for more details.

EF Port 6 - Not Used

EG Port 7 - Not Used

EG

EF

EE

EH CAN Connection

Supplies power and communication to GCA components.

20 3A2894F

Page 21

EA

Component Identification

Component Connection Reference from

FCM (S100 Model Shown)

ED

EB

EB

EA

EC

EE

FIG. 11: Component Connection Reference from FCM

3A2894F 21

Page 22

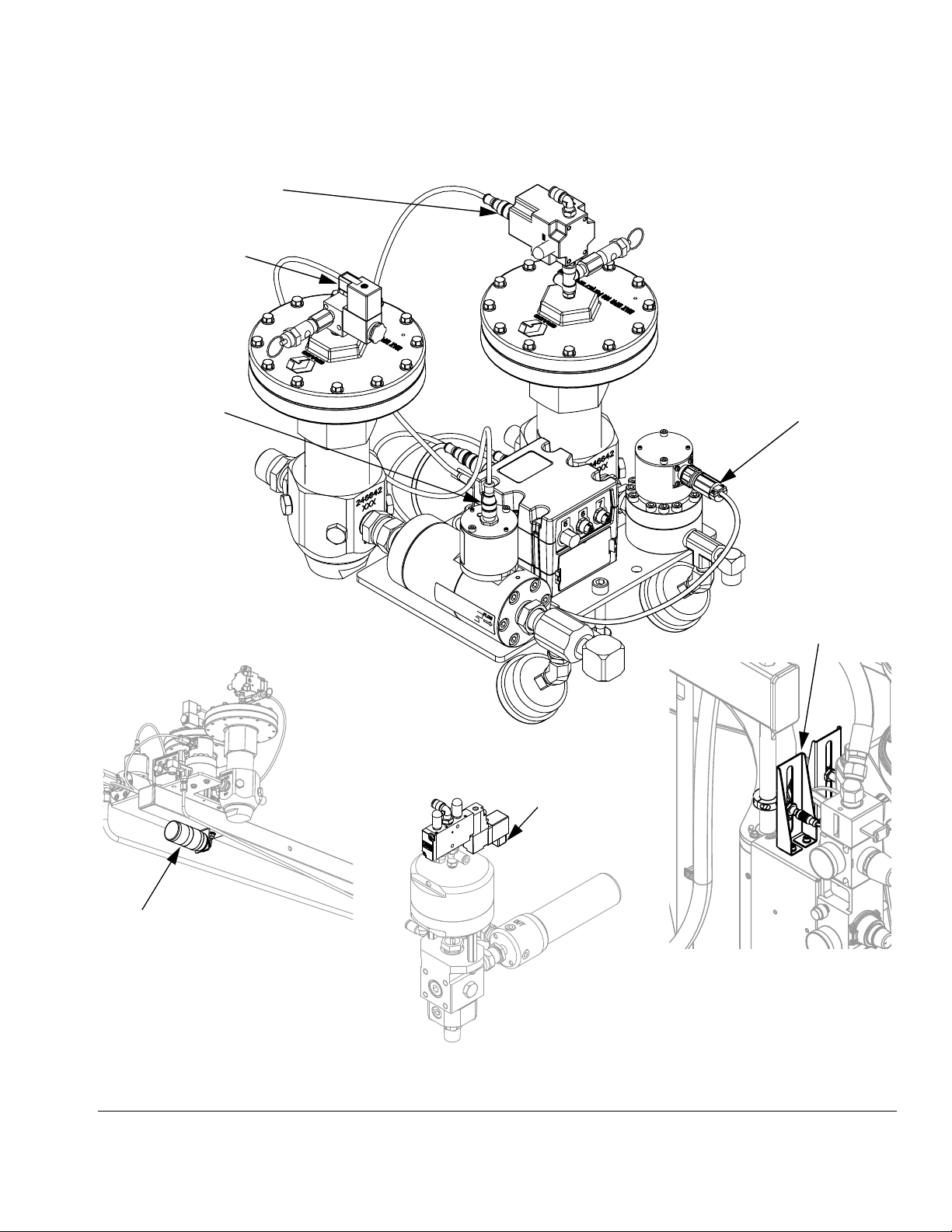

Installation

Installation

NOTICE

To avoid flow meter malfunction, do not use PTFE

tape on NPT threads. Only apply pipe sealant, Loc-

®

tite

#565 or equivalent, to all NPT threads when

installing.

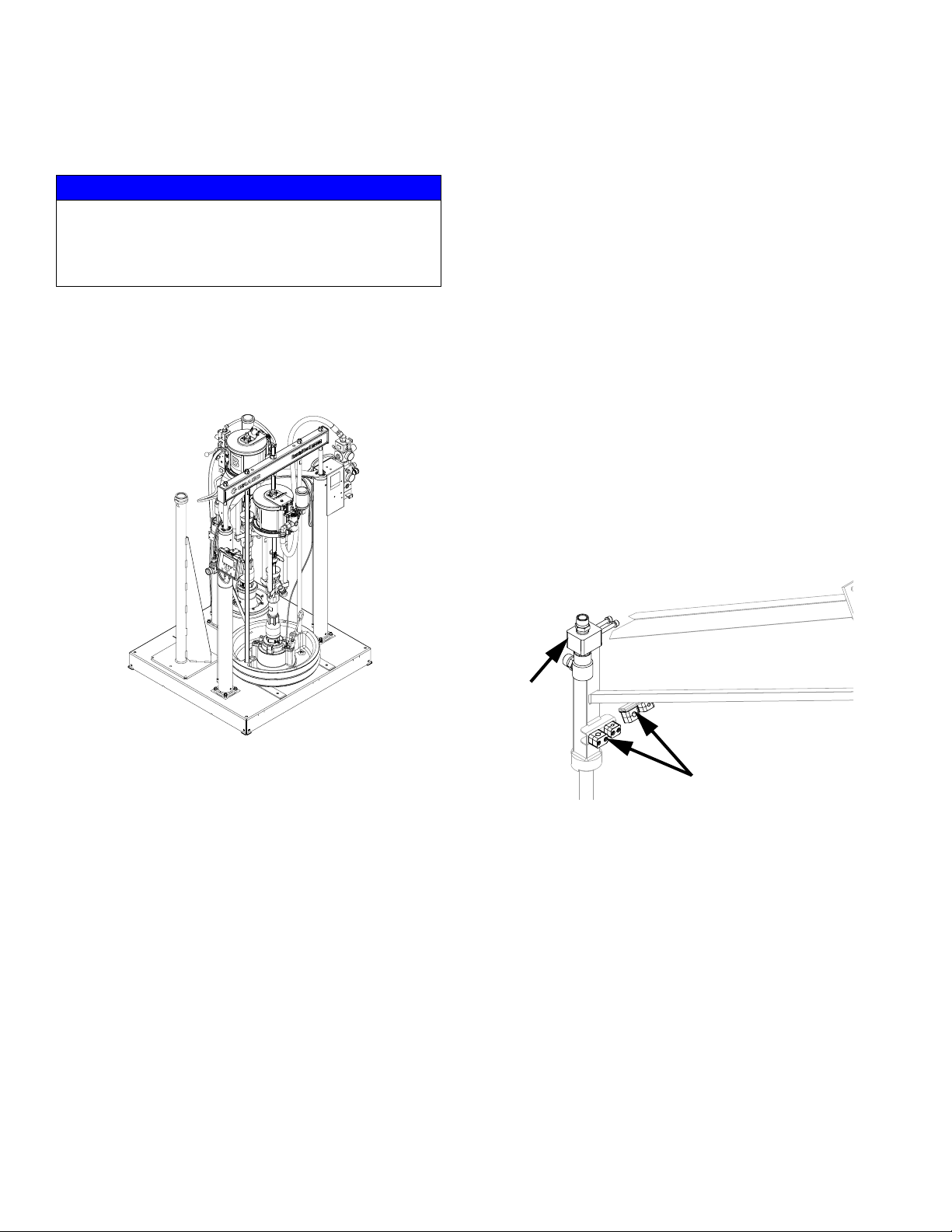

1. Locate the Machine Base.

Locate the machine on a level surface. Refer to Dimensions, page 76, for space requirements.

S100 Shown

2. Assemble the Hose Clamps

and Swivel Assembly onto

the Boom Base.

a. Torque the swivel assembly fasteners to 24 ft-lb

(33 N•m).

b. Hand tighten all hose clamps.

NOTE: Refer to steps 8 and 10 for visual clarity of hose

clamp placement.

Swivel

Assembly

Calibration Check only

22 3A2894F

Page 23

Installation

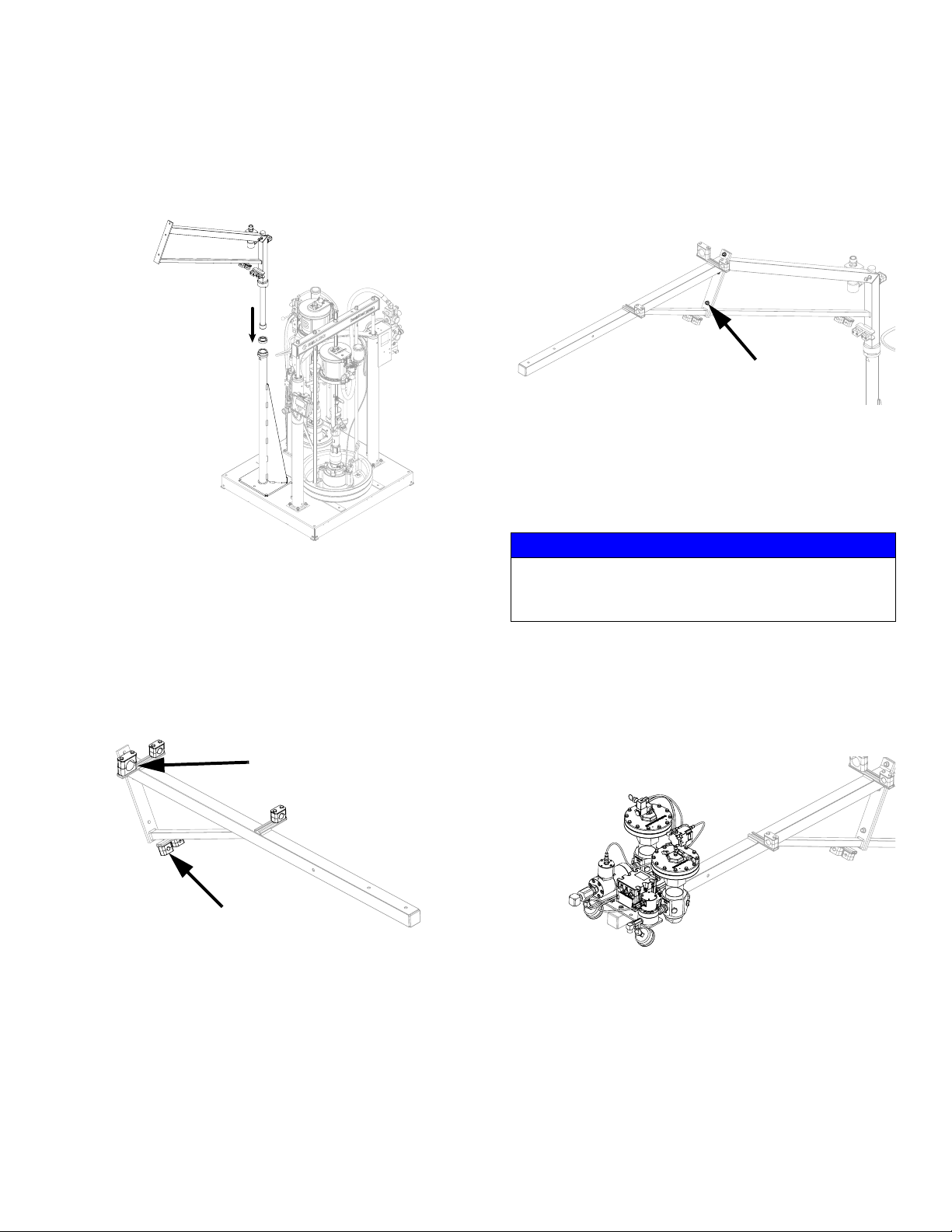

3. Install the Boom Base onto

the Machine Base.

Slide the boom base into the machine base mast.

4. Assemble the Hose Clamps

onto the Front Boom Arm.

5. Install the Front Boom Arm

onto the Boom Base.

Torque all fasteners to 24 ft-lb (33 N•m).

(3) Places

6. Install the Fluid Plate onto the

Front Boom Arm.

NOTICE

Injury may occur if the fluid plate is lifted by only one

person. Use a hoist, multiple people, or remove the

fluid regulators prior to installation.

Hand tighten all hose clamps.

NOTE: Refer to steps 8 and 10 for visual clarity of hose

clamp placement.

Resin Hose Clamp

Calibration check only

a. Torque the fluid plate fasteners to 24 ft-lb

(33 N•m).

b. Install the fluid regulators if removed for installa-

tion.

3A2894F 23

Page 24

Installation

7. Calibration Check Only:

Install the Calibration Check

Assembly and Material Tubes

onto the Boom Assembly.

a. Tighten all fittings to prevent leaking.

b. Tighten all hose clamps to secure material lines.

NOTE: For additional assembly details, refer to the

ExactaBlend AGP Advanced Glazing Proportioner Accessories, Instructions manual.

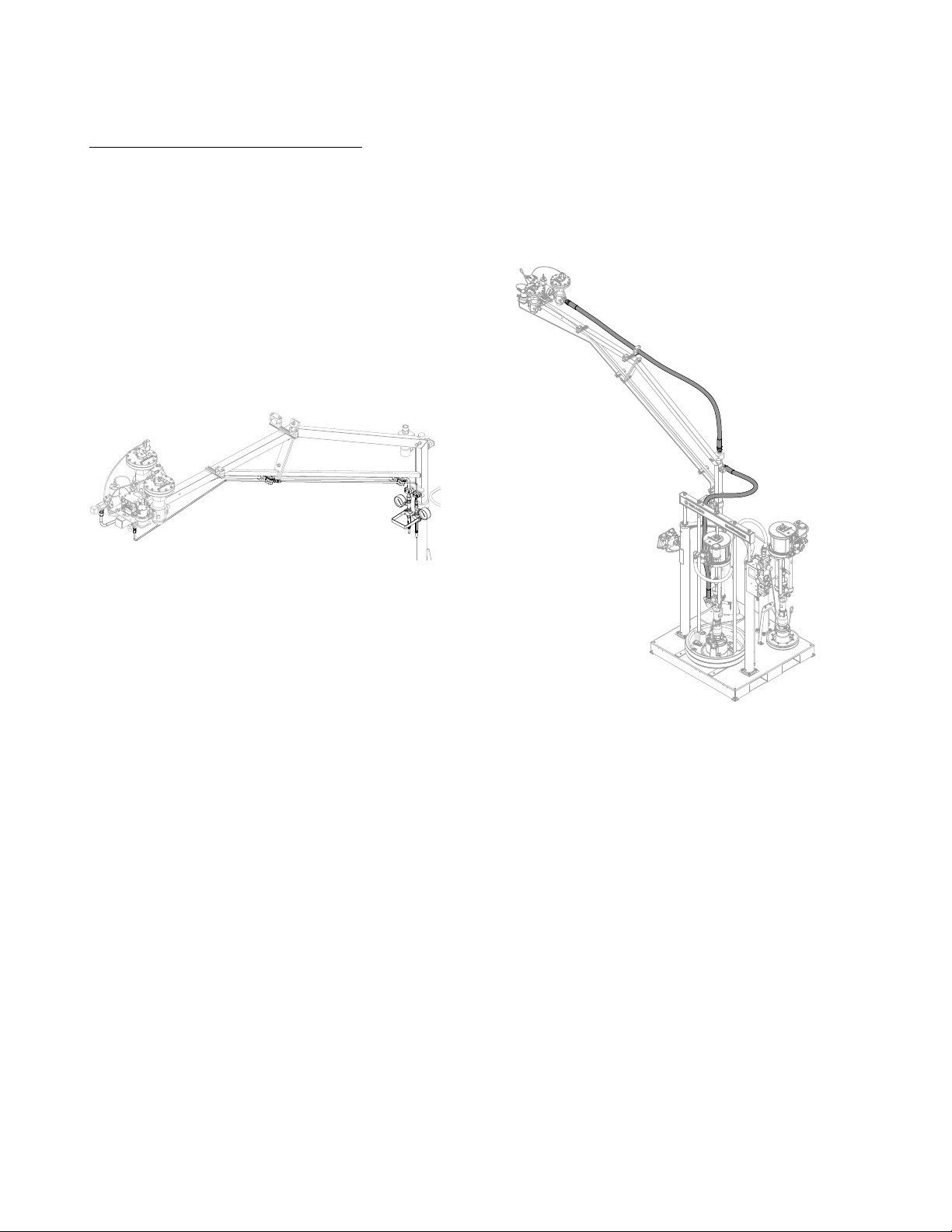

8. Route and Connect the

Base (A) Material Hoses.

a. Tighten all fittings to prevent leaking.

b. Tighten all hose clamps to secure material lines.

S100 Shown

24 3A2894F

Page 25

9. P100 Only: Install the Dosing

Valve.

a. Tighten all fittings to prevent leaking.

b. Install the air supply from the catalyst integrated

air controls.

c. Connect the solenoid cable from port “3” of the

FCM. Refer to Fluid Control Module (FCM),

page 20. Allow enough length for lifting the ram

out of material container.

Label “100”

Installation

3A2894F 25

Page 26

Installation

10.Route and Connect the Catalyst (B) Material Hose.

a. Tighten all fittings to prevent leaking.

b. Tighten all hose clamps to secure material lines.

U100 Shown

P100 Shown

S100 Shown

26 3A2894F

Page 27

Installation

11.Route and Connect the Air

Hoses and Electrical Lines.

Secure the electrical lines to the boom using electrical

tape or zip ties.

NOTE: Securing the ground cable to the fluid plate is

required for the proper grounding of the machine.

NOTE: S100 and U100 models are shown below. For

P100 models, the V/P is located on the catalyst air controls. Refer to Integrated Air Controls, page 18.

Label “102”

Label “103”

CAN Cable

Ground Cable

12.Assemble the Base (A) Material Whip Hose.

Tighten all fittings to prevent leaking.

Machine End

Dispense End

S100 Shown

3A2894F 27

Page 28

Installation

13.Assemble the Catalyst (B) Material Whip Hose.

Refer to PKE 2863 found at http://graco.custhelp.com/app/answers/detail/a_id/2863 or by utilizing the QR code below

for recommended hose size configurations, pin sizes, and calibration numbers. Tighten all fittings to prevent leaking.

NOTE: Refer to Restrictor Kit, 24R804, page 61, for purchase. Restrictor pin size is for typical applications and are

for reference only. It may be necessary to install other pins or configurations to obtain balanced pressures.

#1 = 0.094 in. (2.4 mm) • #2 = 0.098 in. (2.5 mm) • #3 = 0.102 in. (2.6 mm)

NOTE: Refer to Catalyst (B) Hoses, page 61, for additional hose sizes available.

a. Select the fluid plate to restrictor housing hose.

Install the adapter.

b. Select the restrictor pin or union.

U100 with MD2: Install the union to the fluid

plate to restrictor housing hose. If utilizing the

restrictor pin assembly, the restrictor pin assembly will be installed in step d.

All other Configurations: Install the restrictor

pin assembly or union to the fluid plate to

restrictor housing hose.

Note the orientation of

pin and pin housing.

c. Select the restrictor housing to dispense valve

hose. Install the restrictor housing to dispense

valve hose to the restrictor pin assembly or

union.

d. U100 with MD2: If utilizing the restrictor pin

assembly, replace the swivel union found on the

MD2 with the restrictor pin assembly.

28 3A2894F

Page 29

Installation

14.Connect the Catalyst (B) and

Base (A) Material Whip Hoses

to the Fluid Plate.

NOTICE

Damage to the moisture-lok hoses may result in

moisture sensitive material to cure within the hose. To

avoid machine damage, avoid damaging the protective coating on the moisture-lok hoses.

a. Tighten all fittings to prevent leaking.

c. MD2: Tape sleeve 8 in. (20 cm) behind the high

volume fitting to allow adequate movement of

the gun handle.

8 in. (20 cm)

Ultra-Lite: Tape sleeve just behind manifold

block.

Base

b. Slide protective sleeve over base and catalyst

hoses.

Catalyst

d. Pull the other end of the protective sleeve tightly

and secure with electrical tape.

3A2894F 29

Page 30

Installation

15.MD2 Only: Connect the Air

Fitting and Route the Air

Hose.

a. Remove the plug located on the catalyst (B) integrated air control.

S100 Shown U100 Shown P100 Shown

b. Install the air fitting if required. Use sealant on the threads and tighten to prevent leaking.

S100 Shown U100 Shown P100 Shown

c. Route the air line beside the other air hoses that were routed in step 11.

30 3A2894F

Page 31

Installation

16.Ultra-lite Tri-core Only:

Replace the Relief Valve on

Both Integrated Air Controls.

Replace the standard relief valve found on both the

base (A) and catalyst (B) integrated air controls with the

relief valve for the Ultra-lite Tri-core dispense valve.

S100 Shown

17.U100 Models Only: Locate

and Connect the Pressure

Pot

a. Locate the pressure pot on the machine base.

b. Connect the chemical line from the pressure pot

to the fluid filter inlet using fitting provided.

c. Connect the air line from the Base (A) Inte-

grated Air Controls to the pressure pot.

U100 Shown

3A2894F 31

Page 32

Installation

18.Install Accessories.

Refer to the ExactaBlend AGP Advanced Glazing Proportioner - Accessory Kits manual for details.

19.Connect Air to the Machine.

NOTE: Air inlet port size is 3/4 npt (f).

20.Connect Electrical Power to

Machine.

Connect the power cord to the electrical enclosure.

Grounding

The equipment must be grounded to reduce the risk

of static sparking and electric shock. Electric or static

sparking can cause fumes to ignite or explode.

Improper grounding can cause electric shock.

Grounding provides an escape wire for the electric

current.

Machine: Grounded through customer supplied power

cord.

Fluid supply container: follow local code.

Solvent pails used when flushing: follow local code.

Use only conductive metal pails, placed on a grounded

surface. Do not place the pail on a nonconductive surface, such as paper or cardboard, which interrupts

grounding continuity.

To maintain grounding continuity when flushing or

relieving pressure: hold metal part of the gun/dispense

valve firmly to the side of a grounded metal pail, then

trigger the gun/valve.

32 3A2894F

Page 33

Setup

NOTICE

To prevent damage to soft key buttons, do not press

the buttons with sharp objects such as pens, plastic

cards, or fingernails.

Setup

When software is updated on the DM, the software is

then automatically updated on all connected GCA components. A status screen is shown while the software is

updating to indicate the progress. When the status bar is

complete, press to continue.

When the main electrical power is turned on, the splash

screen will be displayed until communication and initialization is complete.

The DM will display an error message when initialization

is complete. This error occurs because the machine has

not been calibrated. Press to acknowledge the

error and continue with the setup procedure.

3A2894F 33

Page 34

Setup

1. Purge Material Lines.

To avoid personal injury or machine damage, adjust all

air regulators counter-clockwise prior to turning the

main air on.

a. Load material.

Ram: Perform the “Change Drums” procedure

in the Air-Powered Ram manual.

Pressure Pot: Perform “Filling the Tank” procedure in the 5-, 10-, and 15-Gallon Pressure

Tanks manual. An agitator is recommended for

urethane applications utilizing a pressure pot.

Set the agitator to 25-50 rpm.

b. Calibration Check Assembly Only: Close the

calibration check assembly.

d. Open the base (A) main air slider valve.

e. Set the base (A) air motor regulators to 10 psi

(70 kPa, 0.7 bar).

To avoid personal injury or machine damage, do not

exceed 25 psi on the base (A) material until a steady

flow of material has been established.

c. Close the base (A) air motor slider valve.

f. Set the fluid regulator adjustment to 40 psi

(280 kPa, 2.8 bar).

g. Place the base (A) hose end into a waste con-

tainer.

34 3A2894F

Page 35

Setup

h. Activate on the DM.

i. Open the base (A) air motor slider valve.

l. Deactivate on the DM.

m. Close the base (A) air motor slider valve.

j. Increase the base (A) air motor regulator as

required to have material flow out of the hose.

k. Dispense the material into the waste container

until the base (A) material hose is purged and

free of air.

n. Repeat steps a through m for the catalyst (B)

hose. Refer to Integrated Air Controls,

page 18, for visual clarity.

NOTE: Activate on the DM when prompted and all

slider valves refer to the catalyst (B) air controls.

3A2894F 35

Page 36

Setup

2. Connect the dispense applicator.

MD2:

a. Connect both base (A) and catalyst (B) material

hoses to the dispense applicator.

b. Activate both and on the DM.

c. Open the catalyst (B) ball valve and dispense

material into a waste container until the dispense valve has been purged and is free of air.

Ultra-lite:

a. Connect the base (A) hose to the base (A) inlet

fitting.

b. Connect the catalyst (B) hose to the catalyst (B)

inlet fitting.

d. Activate on the DM.

c. Open the catalyst (B) ball valve and dispense

material into a waste container until the dispense valve has been purged and is free of air.

d. Close the catalyst (B) ball valve and dispense

material into a waste container until only

base (A) is present.

36 3A2894F

Page 37

Setup

3. Calibration Check Assembly

Only: Purge material lines to

the calibration check assembly.

a. Open the base (A) and catalyst (B) air motor

slider valves.

b. Activate both and on the DM.

c. Place a waste container underneath the calibra-

tion check assembly.

d. Remove the JIC caps from the calibration check

assembly.

e. Open the calibration check assembly.

3A2894F 37

Page 38

Setup

f. Dispense the material into the waste container

until both the base (A) and catalyst (B) material

lines have been purged and are free of air.

g. Close the calibration check assembly.

h. Clean the nozzles of the calibration check

assembly and install the JIC caps.

i. Activate on the DM.

4. Calibrate the machine.

Perform the following procedure during initial setup of

the machine, if the flow meters were replaced, or if the

machine needs to be recalibrated.

a. Engage the trigger lock.

b. Open the base (A) and catalyst (B) air motor

slider valves.

c. Set the base (A) and catalyst (B) air motor regu-

lators.

MD2 or Ultra-lite with flexible hose:

70 psi (480 kPa, 4.8 bar).

Ultra-lite with Tri-core:

85 psi (586 kPa, 5.9 bar)

38 3A2894F

Page 39

Setup

d. Set the fluid regulator adjustment to 40 psi

(280 kPa, 2.8 bar).

e. Place two separate containers on two separate

scales and zero the scales. These containers

will be used in step j.

NOTE: Weight units of the scales are to be set as

grams.

f. Navigate to setup Screen 2.

g. Activate to signal the machine of the fol-

lowing calibration shot.

h. MD2: Install the calibration nozzle onto the dis-

pense applicator.

i. Disengage the trigger lock.

NOTE: Screen 2 is already shown if this procedure is

performed during the initial setup of the machine.

Screen 2 - Recalibration

Screen 2 - Initial Calibration

3A2894F 39

Page 40

Setup

j. Dispense the chemicals into two separate con-

tainers.

MD2: Chemical will be dispensed through the

applicator.

Ultra-lite: Chemical will be dispensed through

the calibration check assembly.

k. Continue to dispense the chemical into the con-

tainers until both status bars are complete.

l. Weigh both containers separately and input the

values of both chemicals into setup Screen 2.

NOTE: To change a value in a desired field, perform the

following.

• Press or to highlight the

desired field to be changed.

• Press to activate the desired field or to

activate/deactivate an option.

• Press or to change the value of the

selected field.

• Press to set the value.

NOTE: Weight units are in grams.

NOTE: If the light tower is installed, a green light will be

illuminated when the status bars are complete.

40 3A2894F

Page 41

Setup

m. Press to signal the machine that the cali-

bration procedure is complete. The machine will

automatically calculate the K factor of both

materials.

n. Engage the trigger lock.

o. MD2: Remove the calibration nozzle and install

a static mixer on the dispense valve.

p. Navigate to the Home screen.

5. Set the Display Module (DM).

Perform the following tasks to fully setup the DM. Refer

to Appendix A - DM Icons Overview, page 64, for clarity.

a. Define general system settings. See Screen 3,

page 66.

b. Define specific system settings. See Screen 1,

page 66.

c. P100 with Ultra-Lite Tri-core Mixer: Select the

85 psi (5.9 bar) option box. See Screen 1,

page 66.

3A2894F 41

Page 42

Startup

Startup

Do not operate machine without all covers and

shrouds in place.

1. Engage the trigger lock.

2. Install the static mixer or nozzle onto the dispense

applicator. See specific applicator manual for

details.

NOTE: Cutting more than two outlet steps on the static

mixer may increase the chance of the mixing elements

being pushed out of the static mixer.

NOTE: If using the mixer element kit 24T035, assemble

the sleeve onto the MD2 dispense applicator prior to fastening the 1/4 NPT outlet adapter. Hand tighten the 1/4

NPT outlet adapter.

3. Turn the power on at the electrical enclosure.

4. Open the base (A) and catalyst (B) main air slider

valves.

5. Open the base (A) and catalyst (B) air motor slider

valves.

42 3A2894F

Page 43

Startup

6. Verify the base (A) and catalyst (B) air motor regulators are set to the correct pressure.

MD2 or Ultra-lite with flexible hose:

70 psi (480 kPa, 4.8 bar).

Ultra-lite with Tri-core:

85 psi (586 kPa, 5.9 bar)

7. P100 with Ultra-Lite Tri-core Mixer: Verify that the

85 psi (5.9 bar) option box is selected. Refer to

Screen 1, page 66.

NOTE: The Home screen will indicate “Not OK” and the

light tower, if installed, will illuminate red until the next

step is completed.

10. Disengage the trigger lock.

NOTE: If a new static mixer has been installed, a base

purge is recommended to prevent side walling. Perform

Base Purge, page 44.

11. Hold a metal part of the gun firmly to a grounded

metal pail. Trigger the gun until the Display Module

shows “OK” and the light tower, if installed, illuminates green.

8. Verify the ram director valve is set to lower the ram.

9. The DM will show a standby screen when power is

first supplied to the machine. Press to go to

the Home screen.

r_255179_purge

NOTE: Additional dispensing may be required in order

to ensure a good mixture.

3A2894F 43

Page 44

Base Purge

Base Purge

Base purge results in the purging of the base (A) chemical through the dispense valve. Base purging prevents

mixed material within the dispense applicator from curing. The machine will remain pressurized and electrically connected.

1. Navigate to the Purge/Prime screen.

NOTE: Verify both pumps are activate.

2. Close the catalyst (B) ball valve located near the

dispense applicator.

3. Dispense material into a waste container until only

the base (A) chemical is present.

4. Engage the trigger lock.

44 3A2894F

Page 45

Base Purge

3A2894F 45

Page 46

Pressure Relief Procedure

Pressure Relief

Procedure

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, splashing

fluid and moving parts, follow the Pressure Relief

Procedure when you stop dispensing and before

cleaning, checking, or servicing the equipment.

1. If electrical power is supplied to the machine,

perform Base Purge, page 44.

If electrical power is not supplied to the

machine, continue to the next step.

2. S100 and P100: Close the base (A) and catalyst (B)

air motor slider valves.

U100: Close the base (A) air motor slider valve and

the supply ball valve on the pressure pot. Bleed the

air from the pressure pot by opening the manual

bleed valve.

MD2:

a. Remove the static mixer.

b. Open the catalyst (B) ball valve located near the

dispense applicator.

c. Disengage the trigger lock.

d. Trigger the gun to relieve pressure into a waste

container.

e. Verify the pressure gauges display “0”.

46 3A2894F

Page 47

Pressure Relief Procedure

f. Close the base (A) and catalyst (B) main air

slider valves.

g. If electrical power is not supplied to the

machine, place a waste container underneath

the pump bleed valves. Open the pump bleed

valves.

NOTE: For U100 systems, the catalyst bleed valve is

located on the pump outlet filter.

Ultra-lite:

a. Remove the JIC caps from the calibration check

assembly.

b. Place a waste container underneath the calibra-

tion check assembly.

c. Open the calibration check assembly to relieve

pressure into a waste container.

h. Clean the nose of the dispense valve or bleed

valve.

i. Install the night cap onto the MD2.

d. Verify the pressure gauges display “0”.

3A2894F 47

Page 48

Shutdown

e. Close the calibration check assembly.

f. Clean the nozzles of the calibration check

assembly and install the JIC caps.

g. Close the base (A) and catalyst (B) main air

slider valves.

Shutdown

1. Perform Pressure Relief Procedure, page 46.

2. Turn the power off at the electrical enclosure.

h. If electrical power is not supplied to the

machine, place a waste container underneath

the pump bleed valves. Open the pump bleed

valves. Clean the pump bleed valves once complete.

NOTE: For U100 systems, the catalyst bleed valve is

located on the pump outlet filter.

48 3A2894F

Page 49

Calibration Check

Calibration Check

Perform the calibration check procedure to verify the calibration of the flow meters are correct.

1. Perform Base Purge, page 44.

2. Navigate to the Home screen.

3. Activate on the DM.

5. MD2 Only: Install the calibration nozzle onto the

dispense applicator.

6. Open the catalyst (B) ball valve located near the dispense applicator.

4. Remove the static mixer.

3A2894F 49

Page 50

Calibration Check

7. Calibration Check Assembly Only: Dispense

material into a waste container at the calibration

check assembly to verify the V/P shown on the DM

is at the correct value.

NOTE: A restrictor pin for the catalyst (B) restrictor

housing may be required to obtain 5 psi (35 kPa,

0.3 bar) or above for the V/P shown on the DM.

9. Hold a metal part of the gun firmly to a grounded

metal pail. Trigger the gun until the Display Module

shows “OK”.

10. Place two separate containers on two separate

scales and zero the scales. These containers will be

used in step 11.

8. Disengage the trigger lock.

NOTE: Weight units of the scales are to be set as

grams.

50 3A2894F

Page 51

Calibration Check

11. Dispense the chemicals into two separate containers.

MD2: Chemical will be dispensed through the applicator.

Ultra-lite: Chemical will be dispensed through the

calibration check assembly.

12. Continue to dispense the chemical into the containers until a 400 gram shot has been dispensed.

13. Weigh both containers separately and calculate the

ratio (A/B) of the two chemicals.

14. Compare the ratio calculated from the weighed containers with the ratio shown on the DM.

15. If the ratio comparison is acceptable, acti-

vate on the DM or repeat steps 10 through 14

twice if more verification is required. Press to

clear all values if more than three samples are

required.

16. If the ratio comparison is unacceptable, perform

Calibrate the machine. page 38.

NOTE: A value will be shown on the DM when a dis-

pense is complete. This is the value the machine was

running at based on the flow meter values.

3A2894F 51

Page 52

Maintenance

Maintenance

Task Schedule

Refer to specific component manual for more detailed information.

Check catalyst (B) filter assembly

to prevent crystallization.

Verify calibration check assembly

outlets are clear and unobstructed.

Check desiccant. Weekly

Check restrictor housing and pin

assembly to prevent crystallization.

U100: Check iso lube bottle for

discoloration.

Perform Shutdown and install

nightcap.

Adjust packing nuts. When TSL has

As Required

Weekly

Weekly

Weekly

Daily

Daily

seeped through

the packing nut

Adjust Packing Nuts

5. After TSL is added, tighten dosing valve packing

nuts 1/4 turn after nut contacts packings; about

145-155 in-lb (16-18 N•m).

TSL

Filters

Once a week check, clean, and replace (if needed) the

following filters.

• S100 and U100 Models:

Catalyst pump outlet filter comes with a 60 mesh filter. Two pack 60 mesh filter replacement kit,

224459, is available.

NOTE: There must be no pressure when adjusting the

packing nuts. Air pressure in the feed tanks is too much.

1. Follow Pressure Relief Procedure, page 46,

including relieving air pressure in the tanks.

2. Fill metering pump packing nuts with throat seal liquid (TSL).

3. After TSL is added, torque metering pump packing

nuts to 50 ft-lb (67.5 N•m). Follow instructions in

Xtreme Lowers manual 311762.

4. Fill dosing valve packing nut with throat seal liquid

(TSL).

52 3A2894F

• P100 Models:

Catalyst pump outlet filter comes with a 30 mesh filter. Two pack 30 mesh filter replacement kit,

224458, is available.

Seals

Once a week, check and tighten throat seals on the

pumps and dosing valve.

Page 53

DM - Battery Replacement and Screen Cleaning

Maintenance

Battery Replacement

A lithium battery maintains the DM clock when power is

not connected.

To replace the battery:

1. Disconnect power to the DM.

NOTE: This can be done by removing the CAN cable

from the bottom of the DM.

2. Remove rear access panel.

3. Remove the old battery and replace with a new

CR2032 battery.

4. Properly dispose the old lithium battery according to

local codes.

5. Replace rear access panel.

6. Connect the power to the DM and reset the clock

through Screen 3. Refer to Appendix B - DM

Setup Screens Overview for more detail.

Cleaning

Use any alcohol-based household cleaner, such as

glass cleaner, to clean the DM. Spray on the rag then

wipe DM. Do not directly spray the DM. Replaceable

screen protectors, 15M483, are available.

3A2894F 53

Page 54

Maintenance

Software Update Procedure

When software is updated on the DM, the software is

then automatically updated on all connected GCA components. A status screen is shown while the software is

updating to indicate the progress.

Refer to PKE 2823 found at

http://graco.custhelp.com/app/answers/detail/a_id/2823/

or by utilizing the QR code below for software version

history.

1. Turn the power switch to OFF.

2. Remove the DM from the bracket.

3. Remove the token access panel.

6. Turn the power switch to ON.

NOTICE

A status is shown while software is updating to indicate progress. To prevent corrupting the software

load, do not remove token until the status screen disappears.

NOTE: When the screen turns on, the following screen

will appear.

Icon Description

F

IG. 12: Remove Access Cover

4. Insert and press software upgrade token (Token

part no.16V853) firmly into the slot.

5. Install the DM onto the bracket.

Update successful.

Update unsuccessful.

Update complete, no changes necessary

Update was successful/complete but one

or more GCA modules did not have a

CAN boot-loader, so the software was not

updated in that module.

7. Remove the token.

8. Replace the token access panel.

9. Press to continue.

54 3A2894F

Page 55

Troubleshooting

Troubleshooting

1. Follow Pressure Relief Procedure, page 46, before checking or repairing a dispense valve.

2. Check all possible problems and causes before disassembling the dispense valve.

Mechanical and Electrical

PROBLEM CAUSE SOLUTION

Dispense Applicator

No flow of catalyst (B). Clogged gun nose. Clean or replace the gun nose.

Clogged injector housing (Ultra-lite

only).

Clogged restrictor housing

Ball valve is closed. Open the ball valve.

V/P is off. Ensure the power is on.

No air to catalyst (B) pump. Turn air on.

No catalyst ram down pressure.

Dosing valve leaking at rod. Loose or worn packings.

Dosing valve between main

housing and outlet housing.

Dosing valve not cycling Bad cable. Replace the cable.

Dispense valve will not dispense

material.

Dispense valve will not stop

material dispense.

Bad o-ring. Replace both o-rings on the seat.

Bad power valve. Replace the power valve.

Trigger lock engaged. Disengage the trigger lock.

No air to MD2. Connect air to the MD2.

Clogged mixer. Clean or replace Tri-core or Flex mixer.

Ultra-lite has cured material in it. Clean or replace.

No air to MD2. Connect air to the MD2.

Bad seal in MD2.

Ultra-lite seal is worn Replace the seal.

Clean or replace the injector housing.

Clean or replace the restrictor housing

and pin.

Ensure the machine is in dispense

mode.

Ensure V/P is turned on when machine

enters Purge/Prime mode.

Ensure that there is pressure to the

catalyst ram and that the control lever

is in the down position.

Tighten packing nut. If leak continues,

replace the packings.

Turn on the air.

Turn on the air.

Repair the MD2. Refer to the MD2 for

more details

3A2894F 55

Page 56

Troubleshooting

PROBLEM CAUSE SOLUTION

No material flow. Material supply is off.

Clogged mixer. Replace the static mixer.

Clogged restrictor Clean or replace the restrictor.

Fluid Plate

V/P won't turn on.

Ensure the base (A) solenoid valve is

on and has pressure.

Ensure the catalyst (B) V/P is on and

has pressure.

Ensure the motor(s) have air pressure.

Ensure there is sufficient down pres-

sure and the control lever is in the

down position.

Clean or replace the Tri-core or hose

mixer.

NOTE: The V/P turns off after 30

seconds of no activity. It will turn

Bad cable. Replace the cable.

on during dispense or when

entering Purge/Prime mode.

Disconnected cable. Connect the cable.

V/P reads “0”. Air supply to V/P shut off. Turn on the air supply to the V/P.

V/P does not match information

on the information screen.

Air supply is restricted.

Replace with a minimum 3/4 in. ID

hose.

Faulty V/P. Replace V/P

V/P obtains 85 psi (586 kPa,

5.86 bar) and then alarms.

Flow rate is too high. Reduce the flow rate.

Too much restriction in the catalyst (B)

hose.

Resize the hoses to reduce restriction.

Flowmeter clogged. Clean or replace the flow meter.

Bad flowmeter. Replace the flowmeter.

Abnormal pressures during operation or after dispense

Catalyst (B) air motor pressure is too

low.

Clogged restrictor housing.

Pressures not balanced. Change catalyst hose size.

Ball/seat not seating properly in fluid

regulator(s).

Catalyst (B) air motor pressure is too

low.

Clean or replace restrictor housing and

pin.

Clean or replace ball/seat.

Use a fitting behind the restrictor hous-

Restrictor pin not seating in housing.

ing with an inner diameter that will not

allow the pin to back out.

56 3A2894F

Page 57

Troubleshooting

PROBLEM CAUSE SOLUTION

Pump

Abnormal pump pressures during operation.

Worn or damaged packings. Replace the packings.

Bad check valves. Clean or replace the check valves.

Pump moves during stall. Malfunctioning check valves. Clean or replace the check valves.

Pump does not run. No air supply to the pump.

Turn on the air or increase the air pres-

sure.

Catalyst (B) ball valve is closed. Open the ball valve.

Clogged mixer. Replace or clean the mixer.

Ultra-lite has cured material in it. Clean or replace.

Clogged restrictor Clean or replace the restrictor.

3A2894F 57

Page 58

Troubleshooting

Display Module

CODE PROBLEM CAUSE SOLUTION

F6A3-A Base Flow Meter Error Flow meter signal is not detected. Check the base flow-meter cable.

Flow meter is clogged. Replace sensor.

Flow rate is too low. Clean the flow meter.

F6B3-A Catalyst Flow Meter Error Flow meter signal is not detected. Check the catalyst flow-meter cable.

Flow meter is clogged. Replace sensor.

Flow rate is too low. Clean out the flow meter.

Increase system flow rate.

F5D0-A Machine not calibrated

F9D4-A System Flow Rate too Low

F9D5-A System Flow Rate too High

R4D0-A High Ratio Alarm Ratio is too high. Re-calibrate the machine.

R1D0-A Low Ratio Alarm Ratio is too low. Re-calibrate the machine.

R9CX-A

L1C1-D

N/A Purge Timer Expired Gel timer has expired. Use machine. (Normal operation).

Insufficient Restrictions /

Unbalanced Pressure

Check Pump Base/Catalyst Drum

Calibration sequence has not been

performed.

Flow rate is too low for accurate

measurement by flow meters.

Flow rate is too high for accurate

measurement.

Catalyst material line is plugged. Check the material supply.

The flow for the base is too high

and the flow for the catalyst is too

low.

Adjusted flowrate between dispenses.

Base flow rate is too low. Check the material supply.

Adjusted flowrate between dis-

penses.

The restrictor pin is missing or

under sized.

Hoses are not sized to properly

balance the pressures.

Low level drum.

Perform Calibration procedure or

enter known calibration values.

Increase the system flow rate.

Reduce the restriction in the catalyst

flow path.

Decrease the system flow rate.

Increase the restriction in the catalyst flow path.

The flow could be turned down or a

larger size hose could be used for

the catalyst.

Run until machine status states

“OK.”

Increase the base flow rate.

Run until machine status states

“OK.”

Install a restrictor pin of the correct

size.

Size the hoses so that the pressures

are balanced.

Check drum base or catalyst material level and replace if necessary.

Check the drum level sensor cable.

Dispense material into a waste container.

Base purge the machine.

58 3A2894F

Page 59

CODE PROBLEM CAUSE SOLUTION

CUCX-V Duplicate Node Found Unknown Software Error. Cycle the system power.

Unintended module plugged into

the system.

CACX-A FCM Missing FCM unplugged from CAN bus.

Verify that only necessary GCA modules are plugged into system.

Verify the FCM CAN cable is

plugged in.

Damaged FCM. Replace the FCM.

Damaged FCM Base. Replace the FCM base.

CAUX-A USB Disconnected USB unplugged from CAN bus.

Verify the USB CAN cable is plugged

in.

Damaged USB. Replace the USB.

Damaged USB Base. Replace the USB base.

Troubleshooting

3A2894F 59

Page 60

Accessories and Kits

Accessories and Kits

Light Tower 24R824

Visual and audible indicator of machine status.

Status Description

Red - Solid An error has occurred and

requires maintenance.

Red and Green - Solid Allows a dispense but notifies

the user of an uncleared error

(e.g. low level).

Green - Solid Machine is ready to dispense

Green - Flashing Machine is okay. Gel timer

has expired.

Low Level Sensors, 24R935 (S100 and P100 only)

Alerts the user when material drums are empty.

Calibration Check Assembly,

24R777

Allows the user to watch the DM while performing the

Calibration Check procedure. Kit is required for all

Ultra-lite dispense valve applications.

60 3A2894F

Page 61

Accessories and Kits

USB Kit, 24R936

Allows the user to monitor and download information of

the machine status.

MD2 Nose Pieces

204

202

201

Catalyst (B) Hoses

Allows the user to balance material pressure in the catalyst (B) line by changing the hose diameter.

Part Description

16W047

16V531

16V219

16V220

16V221

HOSE, assy, 3/32”x60”, 6k, nylon

HOSE, assy, 1/8”x60”, 6k, nylon

HOSE, assy, 1/4”x60”, 5k, ss, braid

HOSE, assy, 3/8”x60”, 5k, ss, braid

HOSE, assy, 1/2”x60”, 5k, ss, braid

Restrictor Kit, 24R804

Allows the user to balance material pressure in the catalyst (B) line by changing the pin size.

105

101

Ref Part Description

201 15V628 10:1 Nightcap

202 15K688 Retaining Nut

203 24P850 10:1 Ratio Check

204 256793 Assembly Tool

203

102,

103,

105

Ref Part Description

101 16V360 HOUSING, restrictor, 1/4npt

102 16V356 PIN, restrictor, #1, 0.094 in.

103 16V359 PIN, restrictor, #2, 0.098 in.

104 16V357 PIN, restrictor, #3, 0.102 in.

105 124961 FITTING, 04jic x 1/4npt

104

3A2894F 61

Page 62

Accessories and Kits

Caster Kit, 24T091

Includes four casters.

Mixer Elements for MD2

003

10 mm Mixer Elements

Ref Part Description

001

002

003

127160 MIXER, assy, 10mm x 12 element

24T250

24T251

16V841 SLEEVE, mixer, no front thread

24T035

MIXER, assy, 10mm x 12 element 25 count

MIXER, assy, 10mm x 12 element 50 count

SLEEVE, mixer, thread x 1/4 NPT

outlet

001

002

1/2 in. Mixer Elements

Ref Part Description

001

002

512288 MIXER, assy, 1/2 x 24 element

512289 MIXER, assy, 1/2 x 30 element

512286 MIXER, assy, 1/2 x 36 element

16T001 SLEEVE, mixer, 24 element

16T002 SLEEVE, mixer, 30 element

16T003 SLEEVE, mixer, 36 element

62 3A2894F

Page 63

Accessories and Kits

3A2894F 63

Page 64

Appendix A - DM Icons Overview

Appendix A - DM Icons Overview

Setup Screen Icons

Icon Description

Return to Home Screen

Left Navigation

Navigates to the previous

screen.

Right Navigation

Navigates to the next

screen.

Set Purge Timer

Allow the machine to

remind the operator to take

a shot before the chemical

hardens in the gun. Timer

starts once a dispense is

complete.

Lock Ratio Setpoint

Lock the current ratio setpoint. Ratio setpoint will not

be able to be adjusted

when activated. Icon shown

represents that it is not

locked.

Low Level Sensor Option

Toggle if a low level sensor

is installed or not installed

on the machine. Icon shown

represents not installed.

Icon Description

Calendar / Date

Set the date format and current date.

Time

Set the current time in 24

hour format.

Password

Set a password to lock system settings. Password

“0000” disables the lock.

Backlight Time

Set how long the screen will

illuminate when idle before

darkening. Entering “0” disables the timer.

Audible Alarm

Allow the machine to sound

an alarm when an error

occurs.

Download Depth

Set how many hours of data

the system will download.

Log Intervals

Set the time interval that the

system will record the

machine status.

Display Module

Base (A) Pump

Catalyst (B) Pump

Weight

System units are in grams

Flow Meter

Shows the calibration factor (K) after calibration has

been performed.

Start Calibration

Confirmation

64 3A2894F

Advanced Fluid Control

Module

Ultra-Lite Tri-core Mixer

(P100 Model Only)

Toggle if an ultra-lite tri-core

mixer is installed on a P100

machine.

Page 65

Run Screen Icons

Icon Description

Return to Home Screen

Navigate to Purge/Prime Screen

Navigate to Alarm Log Screen

Navigate to Information Screen

Calibration Check

Changes the machine status to not

okay in order to perform the calibration check procedure.

Calibration Reset

Clears all data and resets all samples to “0”.

Appendix A - DM Icons Overview

Purge Timer Counter

Visual indicator to show the user the

remaining idle time before another

shot needs to be taken. The timer

will begin to flash when expired.

Base (A) Pump Select

Icon will appear white when not activated, black when activated.

Catalyst (B) Pump Select

Icon will appear white when not activated, black when activated.

Error Number / Event Number

Date

Time

Error / Event Code

Navigate to Totalizer Screen

3A2894F 65

Page 66

Appendix B - DM Setup Screens Overview

Appendix B - DM Setup Screens Overview

If the DM is showing a Run screen, press to

access the Setup screens, which have a black header.

Screen 1

This screen allows the user to set the purge timer, lock

the ratio setpoint, toggle if low level sensors are

installed, and to toggle if an Ultra-lite with Tri-core mixer

is installed on a P100 machine.

S100 and U100 Models

Screen 2

This screen allows the user to calibrate the machine.

See Calibrate the machine. page 38, for more details.

Screen 3

This screen allows the user to format and set the current

date and time, reset the password, adjust the backlight

timer, and toggle sound/silent operation.

P100 Models

66 3A2894F

Page 67

Screen 4

This screen is only displayed when the USB option is

installed. The screen allows the user to enable downloading of USB logs, set log intervals, and set how many

hours of data to download.

Screen 5

This screen is displayed as Screen 4 when the USB

option is not installed. The screen displays information

of part numbers and software versions that are currently

found within the system. The USB information is only

displayed when the USB option is installed.

Appendix B - DM Setup Screens Overview

3A2894F 67

Page 68

Appendix C - DM Run Screens Overview

Appendix C - DM Run Screens Overview

If the DM is showing a Setup screen, press to

access the Run screens.

Home

This screen shows the current ratio and allows the user

to access other screens.

Purge/Prime

This screen allows the pumps to be run independently.

NOTE: All machine alarms are disabled when this

screen is displayed on the DM.

• Press the corresponding to deactivate or acti-

vate the desired pump for operation.

NOTE: The screen below shows only the catalyst (B)

pump selected.

• Press or to increase or decrease the

ratio.

• Press the corresponding to access another

screen or to toggle an option.

• Shows the current state of the machine (okay/not

okay).

68 3A2894F

Page 69

Appendix C - DM Run Screens Overview

Alarm Log

This screen displays the last 70 errors that have

occurred.

• Press or to show other errors.

Total i zer

This screen displays the total amount of material (in kilograms) dispensed for each pump.

Calibration Check

This screen displays the ratio after a calibration check

dispense.

NOTE: Production material cannot be dispensed

from this screen.

Information

This screen displays diagnostic information useful in

troubleshooting.

3A2894F 69

Page 70

Appendix D - DM Error Codes

Appendix D - DM Error Codes

Error Code Error Name Error Type

0000-0 No Active Errors Alarm

CA00-A Unrecognized Error Alarm

F6A3-A Pump A Check Flow Meter Alarm

F6B3-A Pump B Check Flow Meter Alarm

F5D0-A Machine has not been calibrated Alarm

F9D4-A System Flow Rate is too Low Alarm

F9D5-A System Flow Rate is too High Alarm

R4D0-A High Ratio Alarm Alarm

R1D0-A Low Ratio Alarm Alarm

L1C1-D Check Pump A Drum Deviation

EHD0-R Purge Timer Expired Record Only

E9D0-R System not ok for dispense Record Only

ELM0-R System Power On Record Only

EMM0-R System Power Off Record Only

ENB6-R Begin Flowmeter Calibration, Pump A Record Only

ENA6-R Begin Flowmeter Calibration, Pump B Record Only

ENB7-R End Flowmeter Calibration, Pump A Record Only

ENA7-R End Flowmeter Calibration, Pump B Record Only

ENB8-R Abort Flowmeter Calibration, Pump A Record Only

ENA8-R Abort Flowmeter Calibration, Pump B Record Only

EGC6-R Enter Purge/Prime Screen Record Only

EGB9-R Purge On, Pump A Record Only

EGBA-R Purge Off, Pump A Record Only

EGA9-R Purge On, Pump B Record Only

EGAA-R Purge Off, Pump B Record Only

EGC7-R Exit Purge/Prime Screen Record Only

ECCX-R Ratio Changed Record Only

EADX-R Start Dispense Record Only

EBDX-R End Dispense Record Only

CUCX-V Duplicate Node Found Advisory

CACX-A FCM Missing Alarm

CAUX-A USB Disconnected Alarm

ECB3-R Pump A K-factor Changed Record Only

ECA3-R Pump B k-factor Changed Record Only

ECDC-R Gel Timer Changed Record Only

ECFB-R Pressure Transducer Installed Record Only

EQU0-R USB Logs Downloaded Record Only

EQU0-D No Configuration Deviation

EQU8-D Disk Removed Too Early Deviation

R9CX-A Insufficient Restriction / Unbalanced Pressures Alarm

70 3A2894F

Page 71

Appendix D - DM Error Codes

3A2894F 71

Page 72

Schematics

Schematics

TO GROUND LUG

LABEL J2A

HARNESS

LABEL J2A

ON FLUID PLATE

TO GROUND LUG

HARNESS

ON RAM BOX

HARNESS

122030

126520

16U132

16V151

.5M

SPL335

1

ON FLUID PLATE

TO GROUND LUG

321

4

43215

43215

43215

FEMALE

M12 5 PIN

FEMALE

M12 5 PIN

MALE

M12 5 PIN

246652

HV FLOWMETER

5

1

2

SOL

43215

43215

1 1

43215

3

DV320

HV AIR DUMP

321

CBA

54321

127032

289814

LV FLOWMETER

43215

43215

2

LABEL J1

LABEL SOL410

LABEL J2B

.5M

HARNESS

16U014

LABEL J2B

FLUID CONTROL

1.5M

123395

HARNESS

MODULE FRONT VIEW

FCM232

FEMALE

4M

HARNESS

123657

M12 5 PIN

MALE

M12 5 PIN

POLYSULFIDE OPTION

FEMALE

M12 5 PIN

0.5M

126996

HARNESS

1

MALE

M8 4 PIN

1

FEMALE

M8 4 PIN

1

FEMALE

M8 4 PIN

1

MALE

M8 4 PIN

1

2

SOL

POLYSULFIDE OPTION

43215

43215

42315

BLK

423

432

1 1

432

LABEL

EP370

LABEL J4

FEMALE

M12 5 PIN

43215 43215

CAN COM 1 CAN COM 2

COMPLIANCE DOCUMENT

AGENCY: CE,ETL

SEE GRACO ENGINEERING STD. 2.7001

CHANGING THIS DOCUMENT MAY AFFECT

AGENCY APPROVAL AND/OR TECHNICAL FILE

432

LABEL J3

3

127356

PWR VALVE

HARNESS

LABEL SOLXM

4.5M

127399

220V/

1PH/

50-60HZ

100

101

4M

120952

FEMALE

M12 5 PIN

43215

43215 43215

24F493

DISPLAY MODULE

1

FCM SELECTOR SWITCH

TO GROUND

LUG

136

16V094

HARNESS

136

HARNESS

16V096

135

16V094

HARNESS

138

139

137

LUG

GRD

N

L

140

142

141

120V/240V INPUT

129

HARNESS

130

131

16V097

132

TO GROUND

134

135

133

FOR SILICONE MACHINES: 24R809 AND 24R810 SET DIAL TO "1"

FOR POLYURETHANE MACHINES: 24R811 AND 24R812 SET DIAL TO "2"

FOR POLYSULFIDE MACHINES: 24R815 AND 24R816 SET DIAL TO "3"

4A

FUSES

120910

113

GND

N

L

114

114835

128

126

124

127

125

123

122

120

118

116

121

119

115

117

107

(USA)

SW125

GND

N

L

112

108

111

109

110

CORDSET

121598

GND

N

L

106

104

102

105

103

PS148

143

126453

144

24VDC OUTPUT

147

145

146

CAN COM 1 CAN COM 2

V-

V-

V+

V+

149

148

150

43215 43215

M12 5 PIN

CAN CABLE

TO GROUND

LUG

HARNESS

16V096

155

152

151

154

153

157

158

156

BLK

RED

2.5M

16U012

HARNESS

161

160

159

160

165

162

161

164

163

72 3A2894F

Page 73

289900

USB MODULE

43215

43215

43215 43215

CAN COM 1 CAN COM 2

16T072

ADAPTER

FEMALE

M12 5 PIN

FEMALE

M12 5 PIN

43215

43215

120952

HARNESS

SPL335

126520

Schematics

TO J1

118

127137

43215

2

43215

43215

LABEL J1B

1

43215

HARNESS

24R936

OPTIONAL

USB ADAPTER

FEMALE

M12 5 PIN

FEMALE

M12 8 PIN

MALE

M12 8 PIN

43215

5

432

1

MALE

M12 5 PIN

LABEL J1BA

PX353

HV RAM

LOW LEVEL

DRUM SENSOR

24R935

SENSOR

OPTIONAL

LOW LEVEL

341

2

5

1 1

54321

876

FLUID CONTROL

MODULE BACK VIEW

432

1

876

5

J5

FEMALE

M12 5 PIN

1

54321

24315

PX353

43215

LV RAM

LOW LEVEL

DRUM SENSOR

LABEL J1BB

0.5M

127184

HARNESS

FEMALE

M12 4 PIN

MALE

M12 4 PIN

432

1

432

1

J5 J5

A

G

24R824

LIGHT TREE

210

208

206

209

204

202

200

201

207

205

203

R

234

232

230

228

211

215

213

221

219

217

226

229

227

225

223

224

222

220

218

214

216

212

235

233

231

236

238

237

244

242

240

243

241

239

250

248

246

249

247

245

256

254

252

251

257

255

253

258

264

262

260

265

263

261

259

3A2894F 73

Page 74

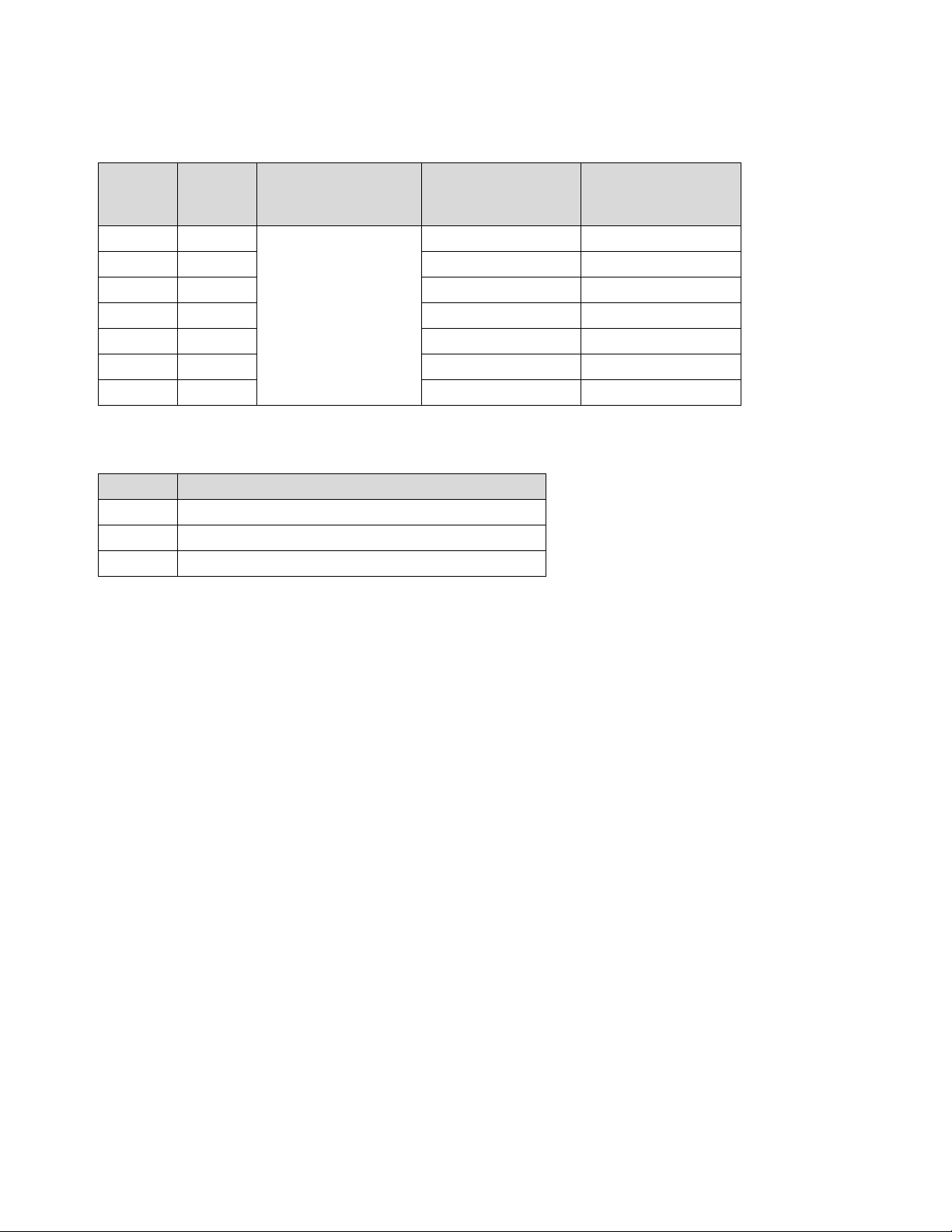

Schematics

HV RAM / PUMP (RED)

HV RAM CYLINDERS

RAM UP/DOWN

HV RAM PRESSURE

HV AIR MOTOR

SHUT-OFF

AIR MOTOR

SAFETY VALVE

100

HV FLUID REGULATOR

85 PSI

SAFETY VALVE

SOL320

QUICK

127415

EXHAUST

75 PSI FOR 3000 PSI SYSTEM

REGULATOR

102

90 PSI FOR 4000 PSI SYSTEM

HV AIR MOTOR

100

ON/OFF

REGULATOR

3-WAY VALVE

REGULATOR

HV MATERIAL

127032

LV RAM / PUMP (BLUE)

(DELETE THIS LINE FOR 6K GUN)

MD2 PNEUMATIC GUN

RAM UP/DOWN