Page 1

Instructions - Parts

®

Viscon

LT

3A2824B

Fluid Heater

For variable heating of fluids.

Not approved for use in explosive atmospheres or hazardous locations.

Model No. 16T525

1750 W; 7.3 A; 240VAC; 50/60Hz, 1 Phase

2000 psi (14 MPa, 138 bar) Maximum Working Pressure

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

EN

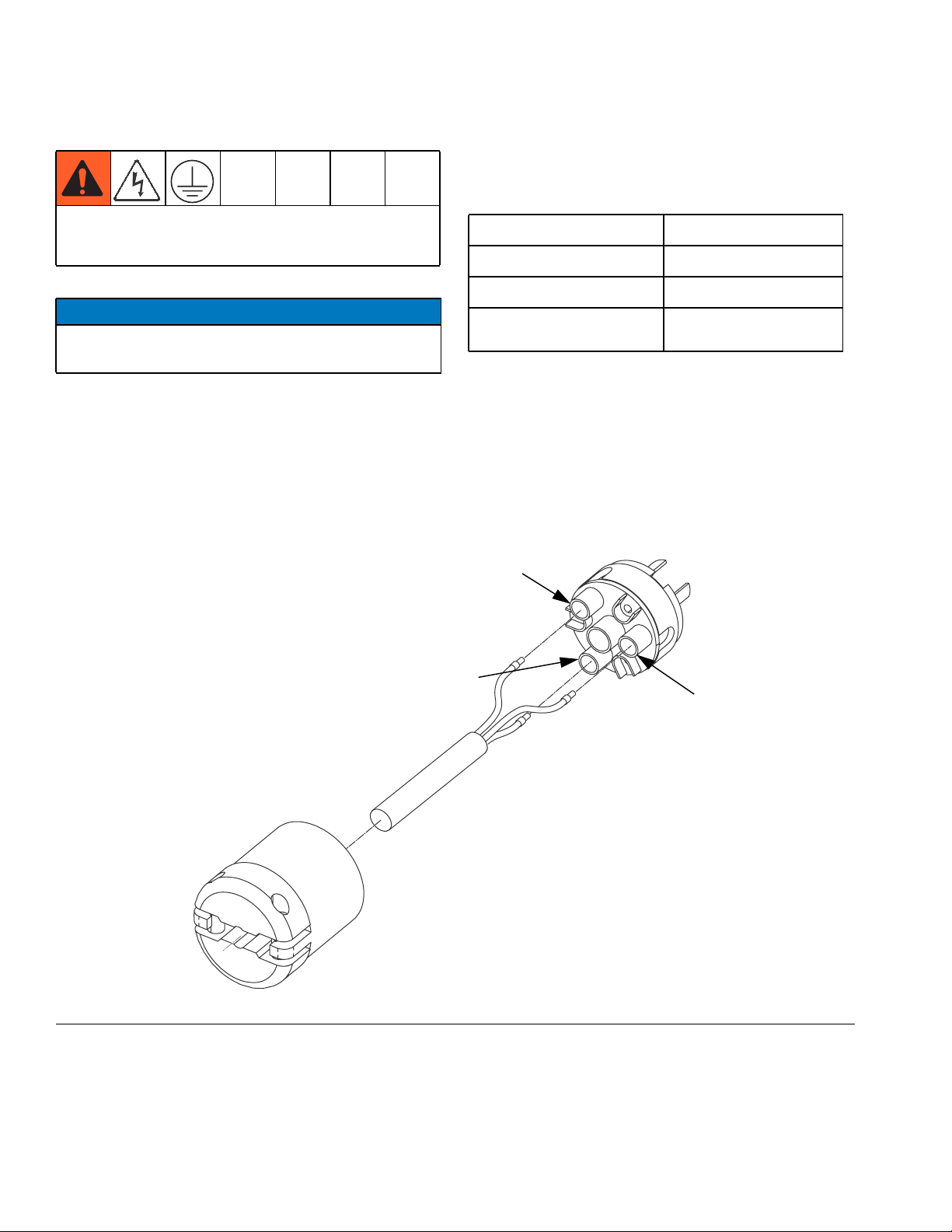

TI19998a

9902471

Conforms to

UL Std. 499

CSA Std. 22.2 No. 88

Page 2

Contents

Warnings .................................3

Installation ................................ 5

TypicalInstallationDrawing ................ 5

Component Identification ....................6

General Information ......................7

SelectingTubing .........................7

Mounting Heater .........................8

Fluid Connections and Accessories ..........9

Electrical Connections ................... 10

Operation ................................11

Pressure Relief Procedure ................11

Initial Flushing .........................11

Priming System .........................11

Setting Heater Control ................... 12

Troubleshooting .........................13

Repair ................................... 13

Before Beginning Repair ..................13

Heater Temperature Controls .............. 14

Parts ....................................18

Accessories .............................. 19

TechnicalData ............................ 20

Schematic Diagram ...................... 20

Dimensions ............................ 21

Graco Standard Warranty ................... 22

GracoInformation ........................ 22

2 3A2824B

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

WARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power cord before servicing equipment.

• Connect only to grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on power and extension cords.

• Do not expose to rain. Store indoors

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns:

• Do not touch hot fluid or equipment.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless they

are antistatic or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

3A2824B 3

Page 4

Warnings

WARNING

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes but is

not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical

reaction and equipment rupture. Failure to follow this warning can result in death, serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier for compatibility.

THERMAL EXPANSION HAZARD

Fluids subjected to heat in confined spaces, including hoses, can create a rapid rise in pressure due to

the thermal expansion. Over-pressurization can result in equipment rupture and serious injury.

• Open a valve to relieve the fluid expansion during heating.

• Replace hoses proactively at regular intervals based on your operating conditions.

4 3A2824B

Page 5

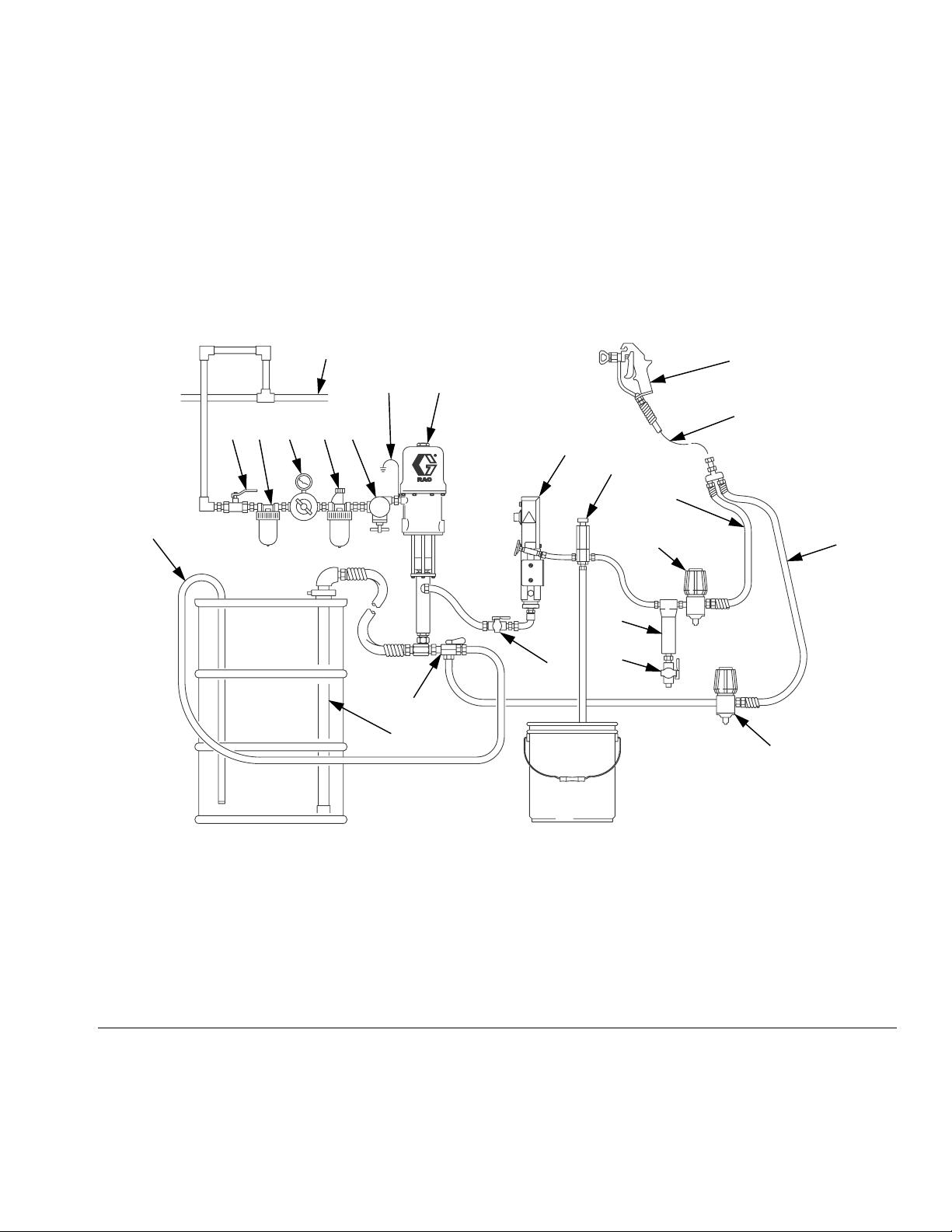

Installation

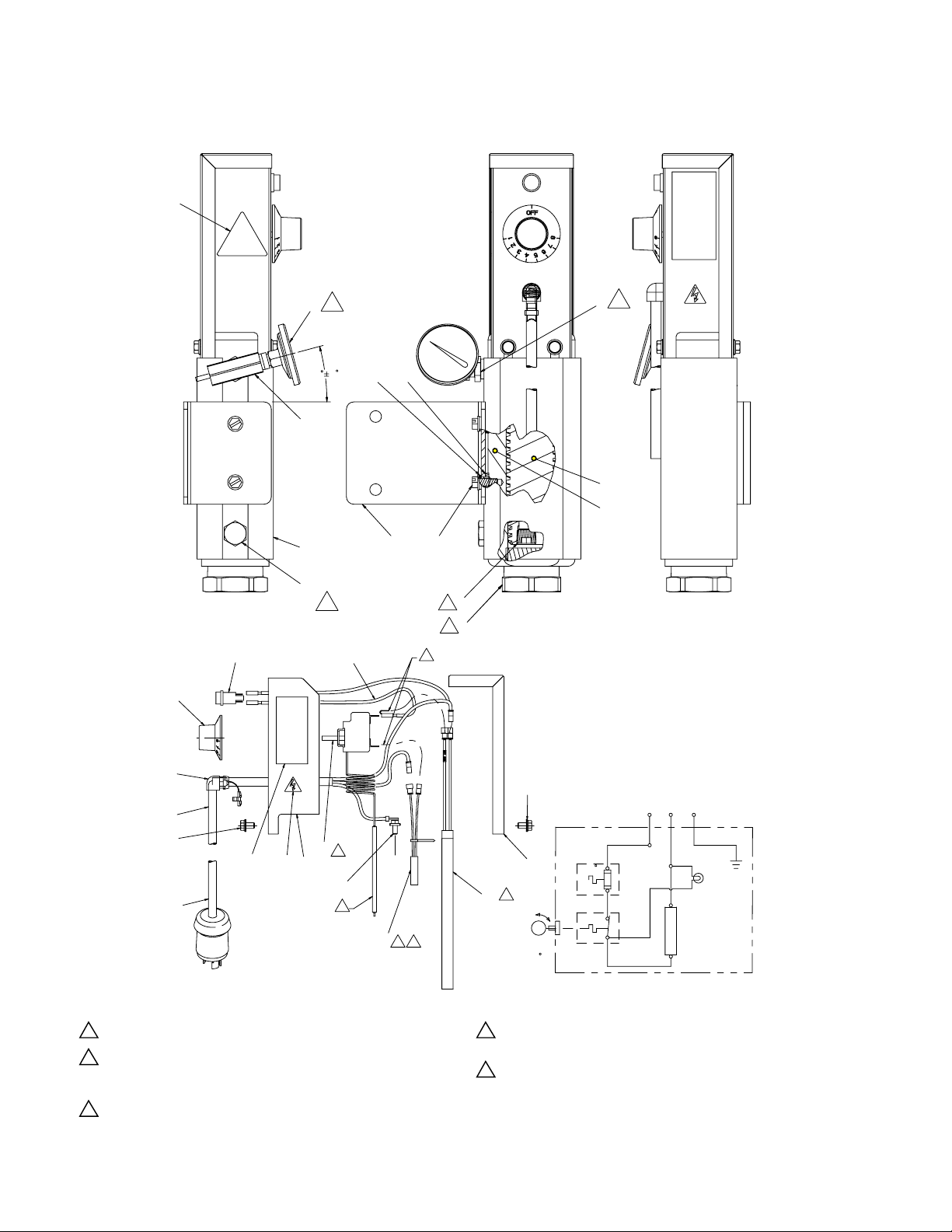

Typical Installation Drawing

The typical installation drawing is only a guide. Your Graco distributor can assist in designing your system.

Installation

Z

Q

GF

Y

EDCBA

K

X

P

V

N

R

L

M

T

U

W

S

ti19999a

Key:

A Bleed-type Master Air Valve

B Air Filter

C Air Regulator and Gauge

D Air Line Lubricator

E Pump Runaway Valve

F Ground Wire

G Pump

K Heater

L Fluid Filter

M Drain Valve

N Fluid Pressure Regulator

P Fluid Supply Line

Q Spray Gun

R Fluid Return Line

S Back Pressure Valve

T Fluid Shutoff Valve

U Director Valve

V Drain Back Tube

W Suction Tube

X Pressure Relief Valve

Y Whip End Hose

Z Air Supply Line

FIG. 1: Typical Installation – Heated Circulating System

3A2824B 5

Page 6

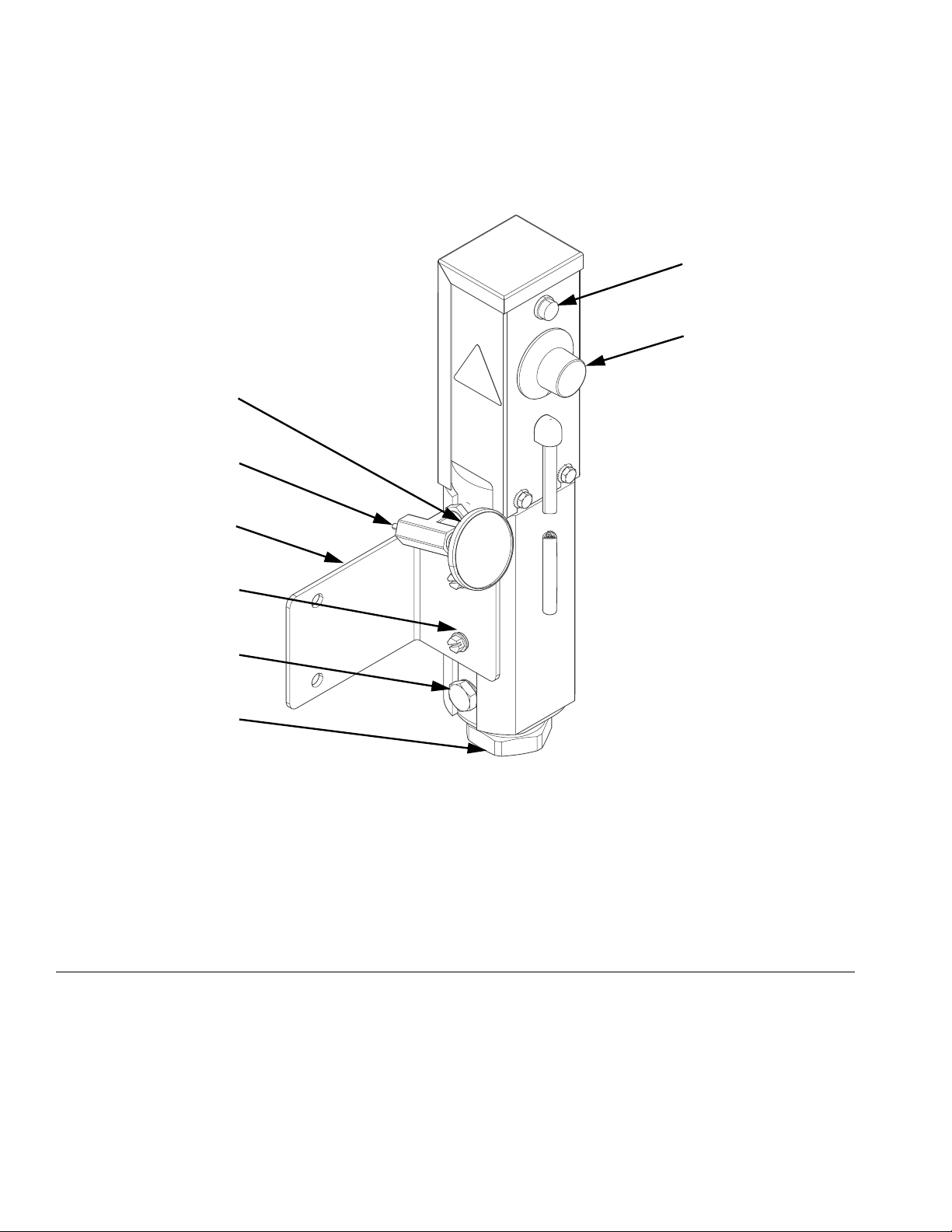

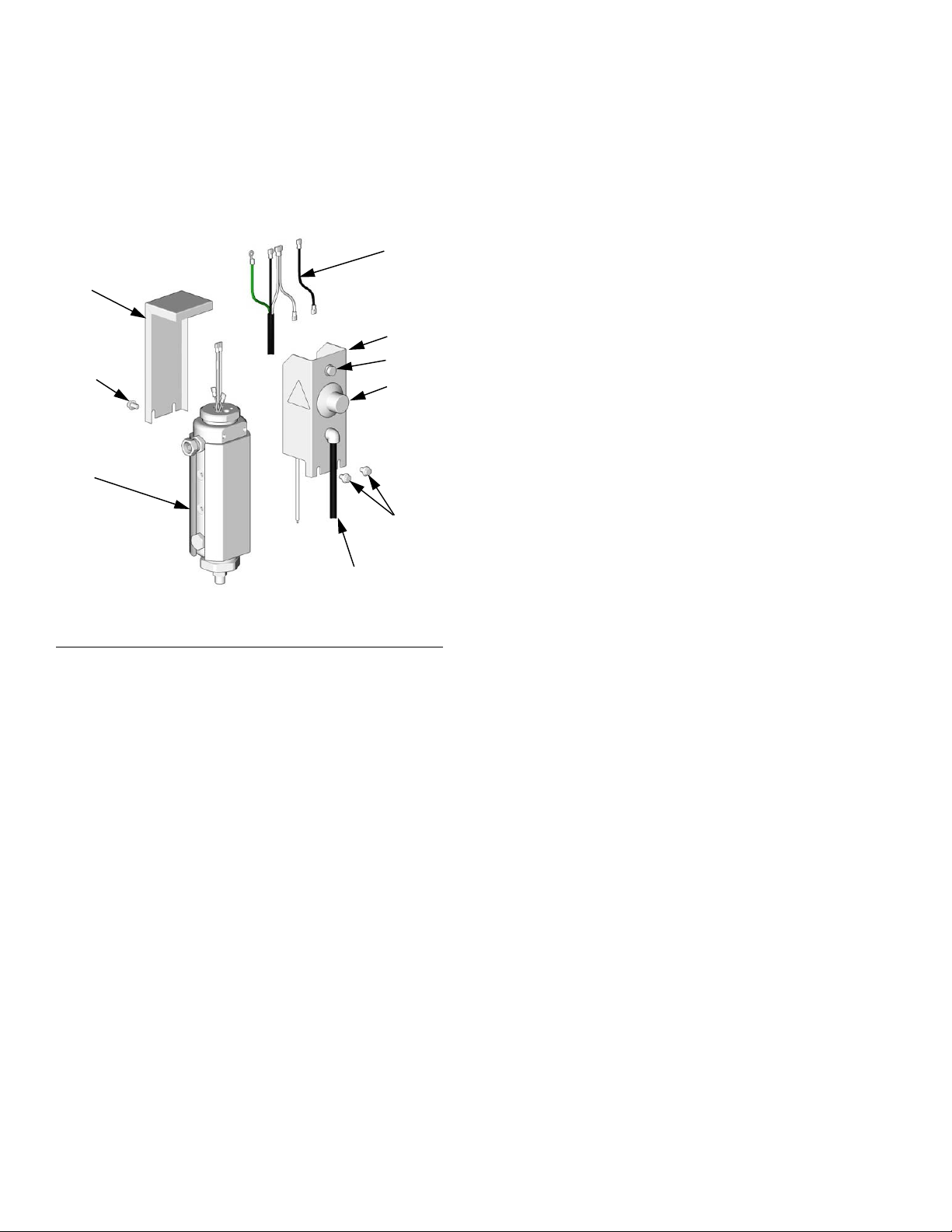

Component Identification

Component Identification

AE

AD

AB

AA

AF

AH

AG

AC

Key:

AA Temperature control

AB Heater light (illuminated while

heating)

AC Heater inlet, 3/8 npt(f)

AD Heater outlet, 1/4 npt(f)

FIG. 2: Typical Installation – Heated Circulating System

ti19998a

AE Outlet thermometer

AF Mounting bracket

AG Heater plug

AH Insulating washers

6 3A2824B

Page 7

Component Identification

General Information

• Select system components that meet temperature

and pressure ratings listed in Technical Data,

page 20. The heater’s normal output range is

adjustable from 84-180°F (29-82°C).

• To prevent fire and explosion, locate heater away

from all flammable materials and where operators

will not come in contact with hot metal surfaces.

• To avoid burns, insulate and/or label lines and

components exiting heater that may become hot.

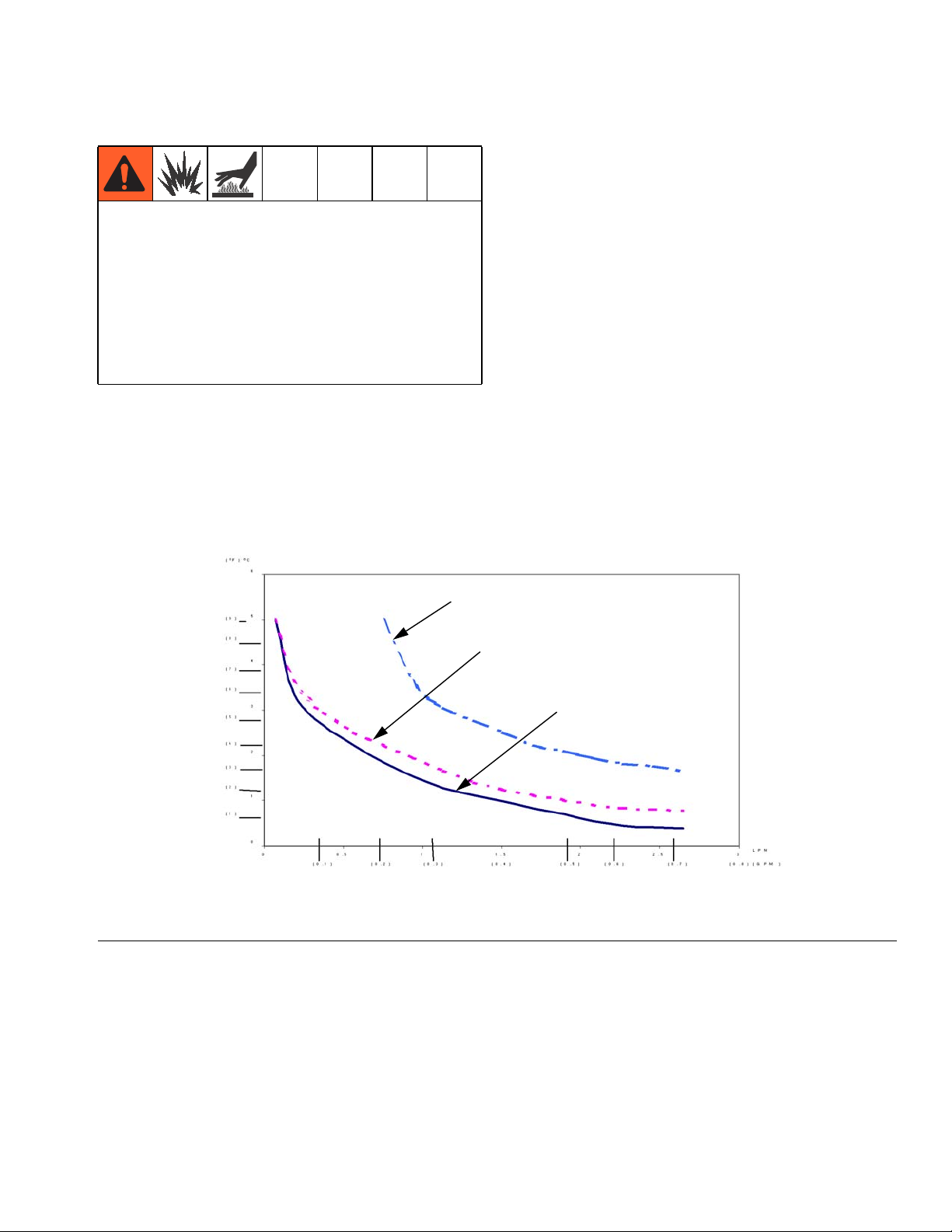

Heat Loss Curve: 70°F (21°C) Ambient

Selecting Tubing

Fluid loses some heat through the tubing or hose

between the heater and spray gun. Locate heater close

to the spray area to minimize heat loss through plumbing.

The chart in F

mon types of tubing.

Chart Notes:

• Higher flow rates have less heat loss.

• Foam-insulated steel tubing and high pressure airless paint hose retain heat best. Insulated tubing

and hose are more expensive, but higher costs are

commonly offset by lower operating costs.

IG. 3 shows a heat loss curve for 3 com-

Typical Fluid Temperature Drop

FIG. 3: Typical Temperature Drop

(20 ft.) 6.1 m steel tube

Fluid: (130° F) 54° C

(20 ft.) 6.1 m steel tube

(3/8 in.) 9 mm foam insulation

Fluid: (110° F) 43° C

(20 ft.) 6.1 m airless paint hose

Fluid: (110° F) 43° C

Flow Rate

3A2824B 7

Page 8

Component Identification

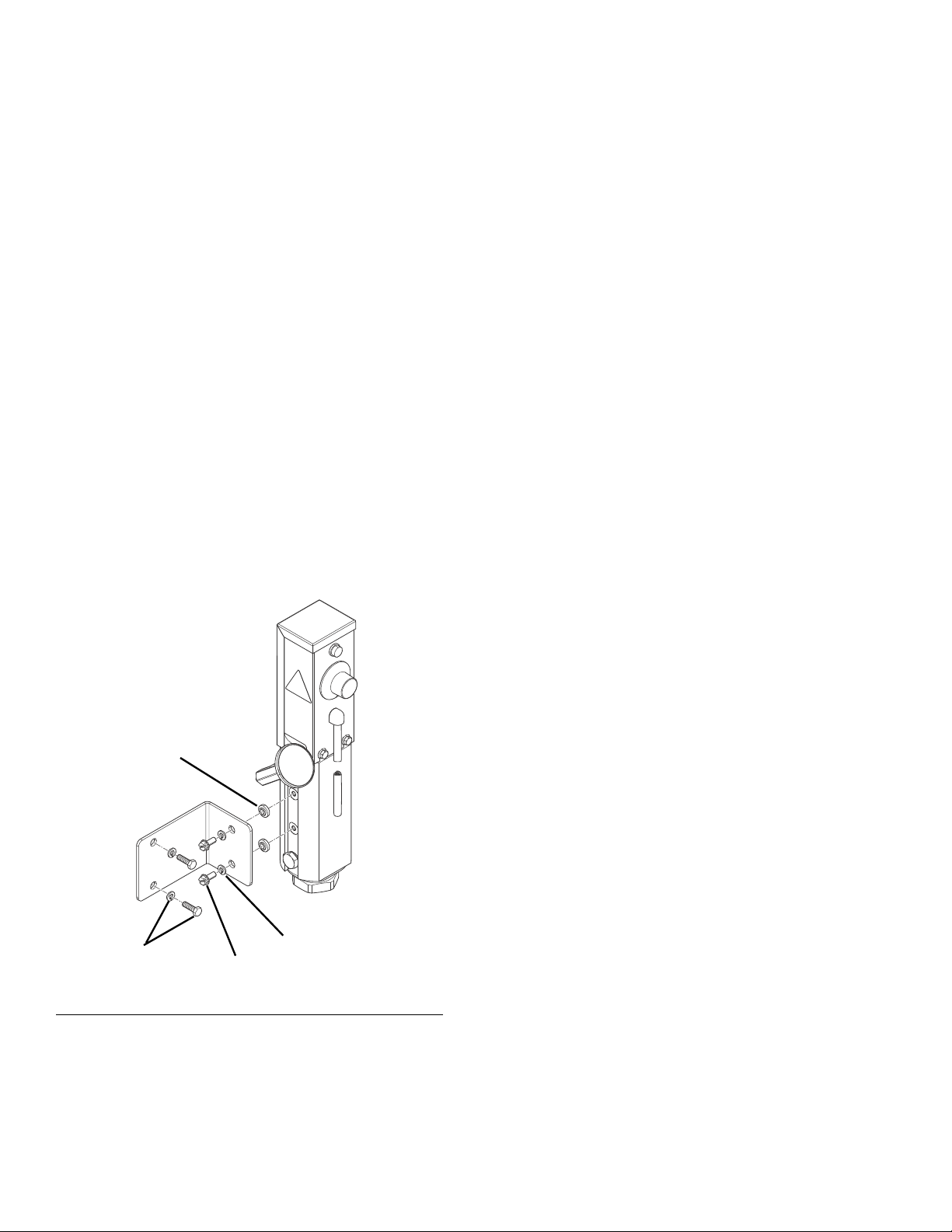

Mounting Heater

Heater controls must be easily accessible.

The mounting surface must be able to support the

weight of the heater and fluid, and any stress caused

during operation.

Wall Mounting

Use included wall bracket 16R988 and insulating

washers (29), part number 167002, quantity 2. See FIG.

4.

Use wall bracket as a template to mark bolt holes.

Bracket 16R988

(FIG.4)

1. Use 1/4 in. bolts of appropriate length and

lock-washer (CC), not supplied, to mount bracket.

2. Use two screws (32) and washers (31) to install

heater onto bracket.

29

ti20000a

CC

32

31

FIG.4:

8 3A2824B

Page 9

Fluid Connections and Accessories

To prevent serious injury caused by component or

equipment rupture:

• Never install a shutoff device between the heater

and gun as this will trap the heated fluid and not

allow for expansion.

• Never use a fluid regulator as a shutoff device if it

is installed between the heater and gun

• Provide a means for adequately handling fluid

expansion caused by heat.

To handle fluid expansion caused by heat:

Component Identification

• Use flexible hoses between heater and gun.

• Install a properly sized accumulator down-

stream from the heater.

• Install a pressure relief valve (X) pre-set to

relieve pressure when it exceeds the system

maximum working pressure.

3A2824B 9

Page 10

Component Identification

Electrical Connections

This equipment must be grounded. All electrical wiring

must be done by a qualified electrician and comply with

all local codes and regulations.

NOTICE

To help prevent heater damage, avoid spilling liquids

onto electrical components.

Requirements For All Installations

• The user must provide external over-current protection. For installations in the United States and Canada, a branch circuit breaker must be used for

over-current protection. The maximum recommended circuit breaker size is 15 amps.

Green or Green/Yellow

Power Cable Connections

The heater power cable uses a 3 conductor cable and a

NEMA L6-20P twist lock connector. If another connector

is used, follow the table below for correct wiring.

Cable Color Code Function

Black or Brown

White or Blue

Green or Green/Yellow

Line (Mains)

Neutral

Protective

Ground/Earth

FIG. 5: Connector

White or Blue

Black or Brown

ti20030a

10 3A2824B

Page 11

Operation

Operation

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, splashing

fluid and moving parts, follow the Pressure Relief

Procedure when you stop spraying and before

cleaning, checking, or servicing the equipment.

Follow Pressure Relief Procedure when you stop

spraying, and before cleaning, checking, or servicing

equipment.

1. Engage the gun trigger lock.

2. Shut off main power to the heater.

3. Circulate fluid for at least 10 minutes to cool the

heated fluid and heater.

4. Shut off all air and fluid supplies.

5. Disengage the gun trigger lock.

6. Hold a metal part of the gun firmly to a grounded

metal pail, and trigger the gun to relieve pressure.

7. Engage the gun trigger lock.

Initial Flushing

To avoid skin injection, do not point gun at anyone or

at any part of the body. To avoid fire and explosion,

ensure main power is off and heater is cool before

flushing. Do not turn on heater until fluid lines are

clear of solvent.

The heater was tested with lightweight oil, which needs

to be flushed out before using the equipment. Use a

compatible solvent, and follow flushing instructions in

your fluid supply and spray gun manual.

Priming System

(Refer to FIG.1,page5)

1. Do not turn on the heater yet.

2. If using an airless spray gun, do not install a spray

tip yet.

3. Start the pump according to the instructions supplied with it.

4. Turn the system director valve (U) to circulate, and

circulate fluid for several minutes.

5. Open the spray gun (Q) at the last outlet to prime

the line. Repeat for all gun stations.

6. Engage the gun trigger lock.

7. Shut off the air supply to the pump.

8. Perform Pressure Relief Procedure.

9. Install the gun spray tip.

3A2824B 11

Page 12

Operation

Setting Heater Control

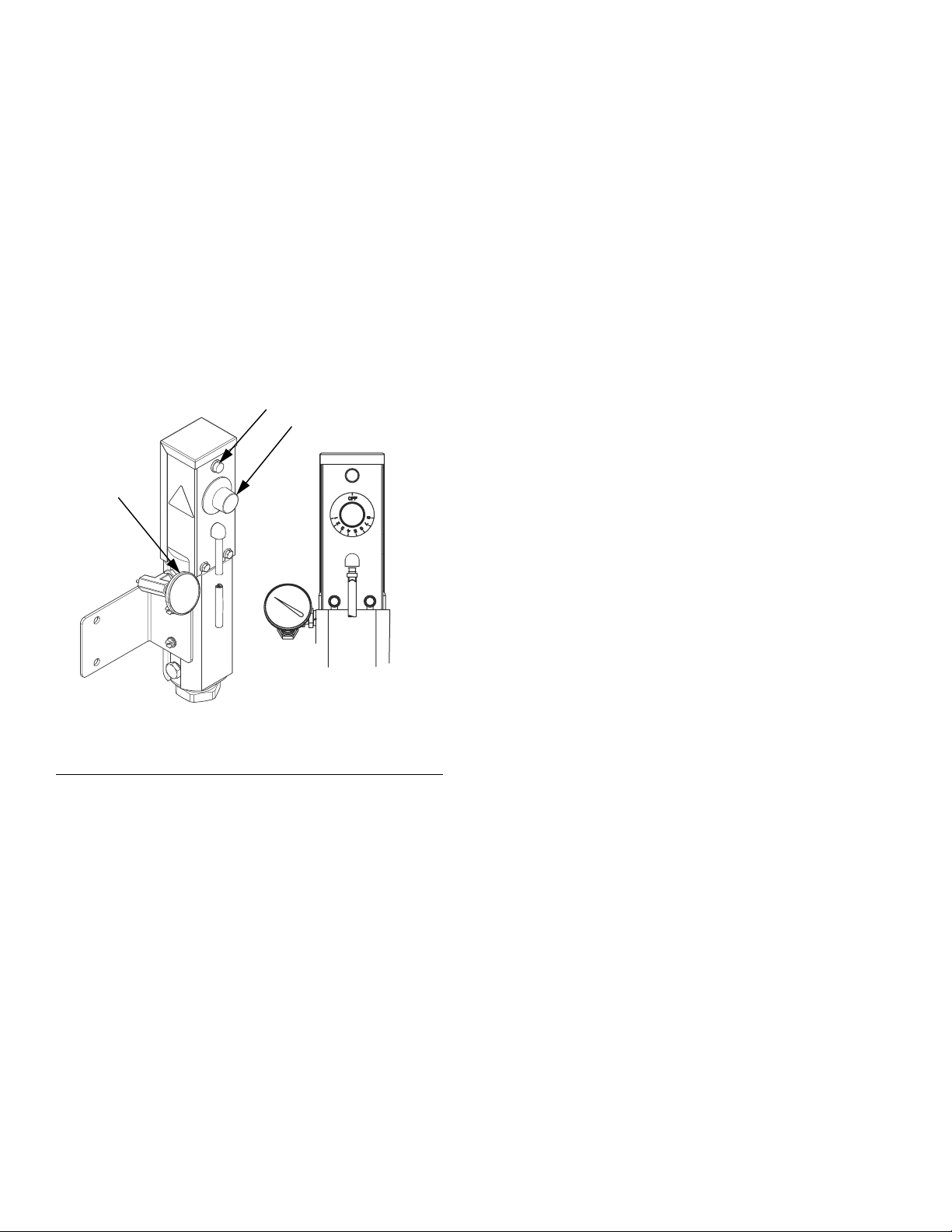

(Refer to FIG.6)

1. Set the heater control knob (9) to a trial setpoint of 4

or 5.

2. Start the pump and circulate fluid through the system at a very low flow rate of about 10-12 oz/min

(0.30-0.35 liter/min).

3. After the red heater light (AB) turns off, read the

temperature on the thermometer (38). If it does not

match the desired temperature, adjust the setpoint.

AB

9

35

F

IG. 6: Setting Heater Control

ti20002a

12 3A2824B

Page 13

Troubleshooting

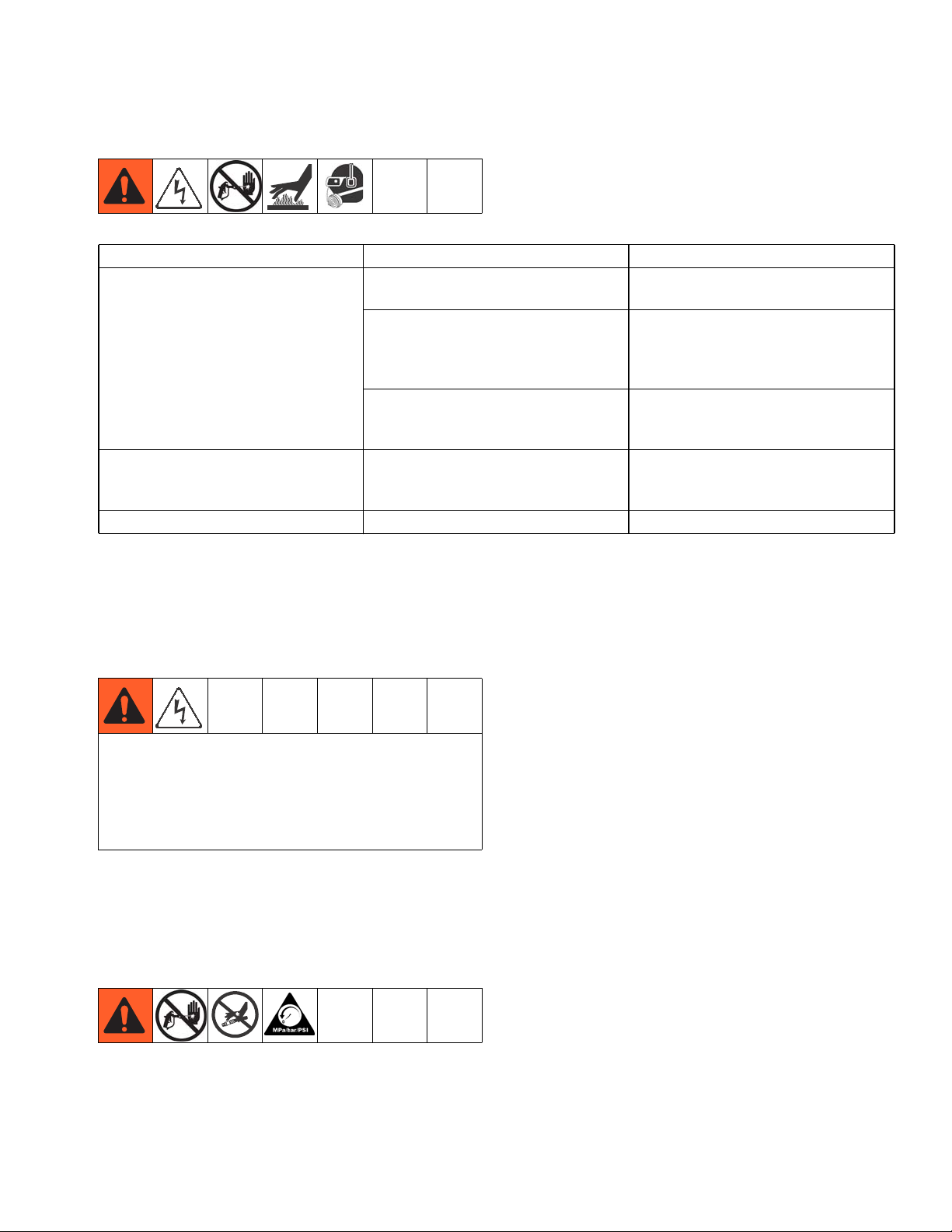

Troubleshooting

PROBLEM CAUSE SOLUTION

No heat and heater indicator light is

off.

No heat but heater indicator light is

on.

Heat but heater indicator light is off. Bad light. Check connections. Replace lamp.

Heater power off or circuit breaker

tripped.

Bad thermostat (17). With power on, check for continuity

Bad overtemperature sensor (19).

This is a high temperature limit fuse

and must be replaced if blown.

Bad heater cartridge (20). With power OFF, check for continuity

Turn heater power on or reset circuit

breaker.

on/off at clicks when turning the

heater control knob. To replace thermostat, see page 16.

With power on, check for continuity at

overtemperature sensor. To replace

sensor, see page 15.

at heater cartridge connections which

should be 29-36 ohms.

Repair

Before Beginning Repair

Repairing this equipment requires access to parts

which may cause electric shock or other serious injury

if work is not performed properly. Have a qualified

electrician connect power and ground to main power

switch terminals. Be sure to shut off all power to the

equipment before repairing.

1. Flush if necessary.

2. Shut off all power to equipment.

3. Perform Pressure Relief Procedure, page 11.

3A2824B 13

Page 14

Repair

Heater Temperature Controls

See FIG. 7. Control knob (9) sets temperature of heater.

Indicator light (8) turns on when thermostat is heating

and off when heater reaches setpoint.

22

21

17

12

1

8

9

F

IG.7

ti7008b

12

Power in

14 3A2824B

Page 15

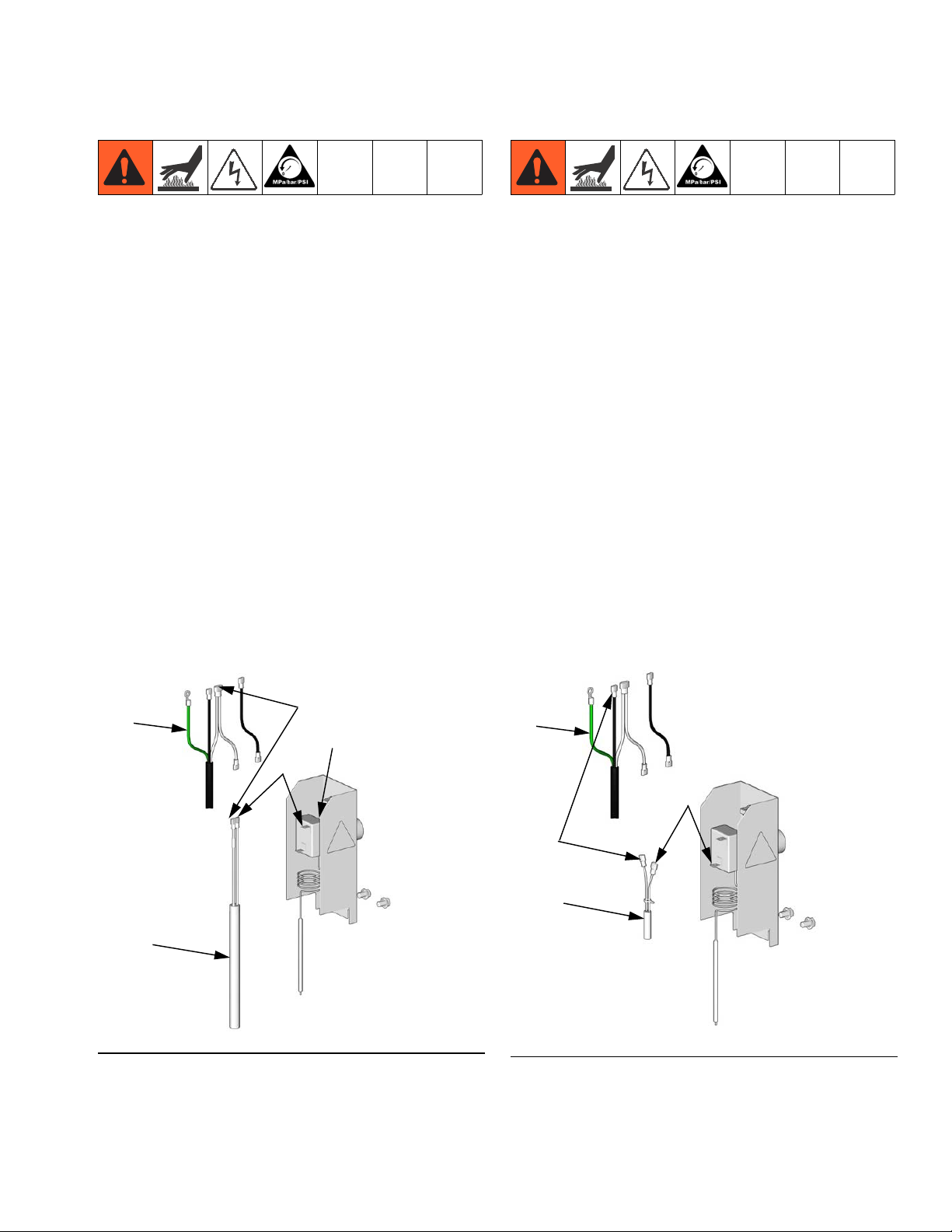

Repair

Heater Cartridge

1. See Before Beginning Repair, page 14. Relieve

pressure.

2. Wait for heaters to cool.

3. Testing: Use a multimeter to check resistance

across cartridge leads per the Technical Data

chart. Also check that neither lead has continuity to

the cartridge case.

4. See FIG. 7 and Parts illustration on page 18.

Loosen all four screws (12) from bracket (16) and

shield (21). Pull bracket assembly away from heater

housing (1) to remove heater cartridge (20) from

core. If necessary, plug (4) can be removed from the

bottom of core (2) so that cartridge can be pushed

out from underneath.

5. Disconnect heater cartridge from jumper

wires (22, CC) and heater thermostat switch (17,

HH). See FIG.8.

6. Connect new heater cartridge to jumper wire (CC)

and thermostat heater switch (H), then reassemble

heater in reverse order of disassembly.

Thermal Limit Sensor

1. See Before Beginning Repair, page 14. Relieve

pressure.

2. Wait for heaters to cool.

3. Testing: Check that you have continuity across the

two leads. If circuit is open, replace thermal limit

sensor (19). See FIG.9

4. See FIG. 7. Loosen all four screws (12) from

bracket (16) and shield (21). Pull bracket assembly

away from heater housing (1). To remove thermal

limit sensor (19) from core (2) pull upward with a

steady force.

5. Disconnect thermal limit sensor from jumper

wire (23, BB) and heater thermostat switch (17,

GG). See FIG.9.

6. Connect new thermal limit sensor to jumper

wire (BB) and thermostat switch (GG), then reassemble heater in reverse order of disassembly.

NOTE: Apply a thin film of heat sink compound 110009

to thermal limit sensor (19).

22

FIG.8

20

HH

CC

17

TI7009a

23

GG

BB

19

TI7010a

FIG.9

3A2824B 15

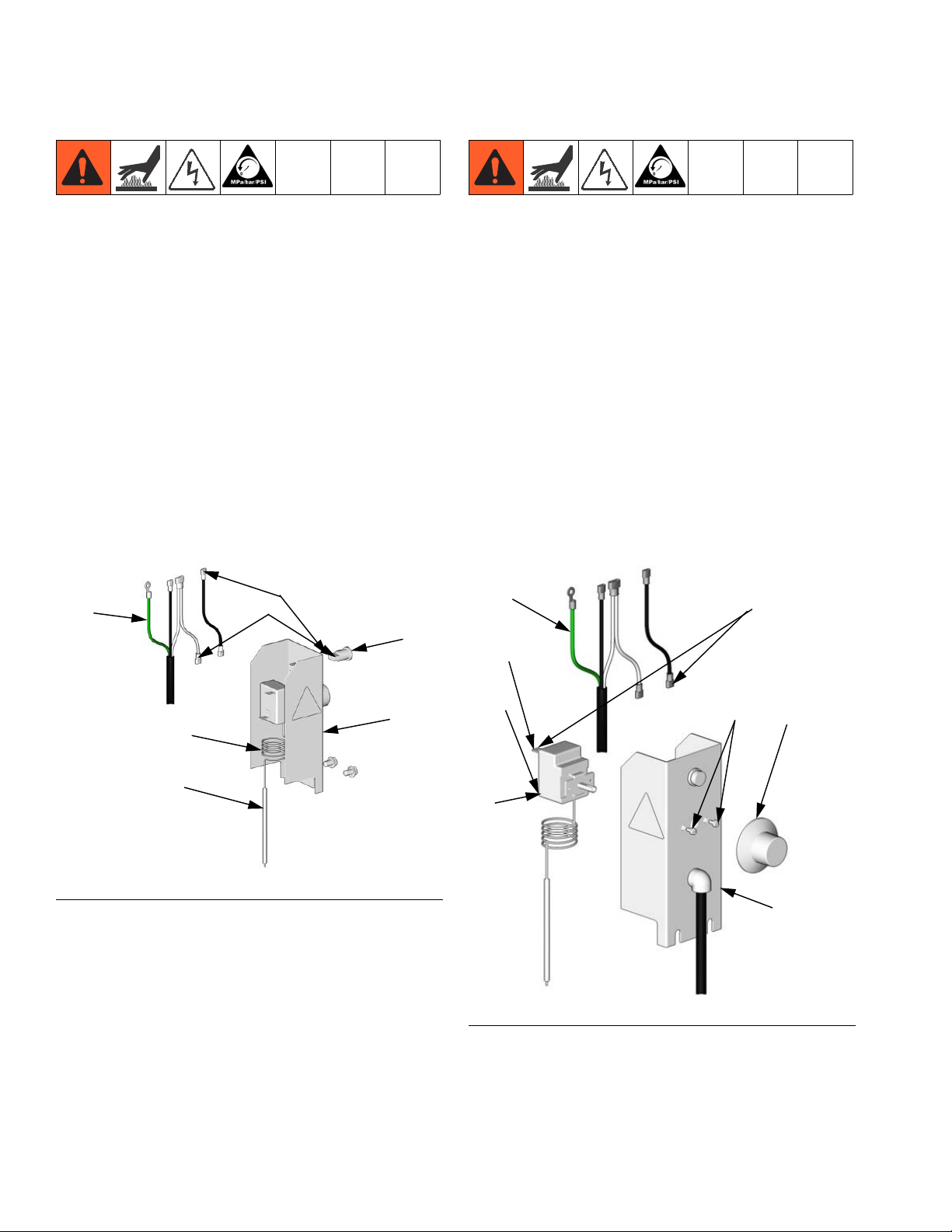

Page 16

Repair

Indicator Light

1. See Before Beginning Repair, page 14. Relieve

pressure.

2. Wait for heaters to cool.

3. See FIG. 7. Loosen two screws (12) and remove

shield (21).

4. Disconnect jumper wires (23, DD, EE) from back of

indicator light (9), then push light out through the

front face of the control bracket (17) by depressing

the prongs on the sides of the light. See FIG.10.

5. Press new light into control bracket (16) until prongs

lock in place.

6. Connect jumper wires (DD, EE) and reassemble

heater in reverse order of disassembly.

Heater Thermostat Switch

1. See Before Beginning Repair, page 14. Relieve

pressure.

2. Wait for heaters to cool.

3. Testing: See FIG. 10. With thermostat probe (JJ)

above 75°F (24°C), and below 160°F (71°C), the

continuity across the contacts should open when

turned off, and close when turned up toward 8. You

should hear the switch click open and closed.

4. See FIG. 7. Loosen two screws (12) and remove

shield (20).

5. See FIG. 11. Detach the two push on connectors

from thermostat switch (17). One is from thermal

limit sensor (19) at GG, and dual connector HH and

FF is from heater cartridge (21) and light (8).

22

FIG.10

KK

JJ

DD

EE

8

16

TI7011a

22

HH

GG

17

FIG.11

25

FF

9

16

TI7012a

6. Pull heater control knob (9) off of heater control

bracket (16) face.

7. Using a phillips head screwdriver, remove

screws (25) on control bracket face to release ther-

16 3A2824B

Page 17

Repair

mostat switch from bracket. Pull thermostat

probe (JJ) slowly out of heater core (2).

8. Insert new thermostat probe into core with heat sink

compound 110009. Use screws (25) to install new

thermostat switch behind bracket face and install

control knob.

9. Reattach jumper wires (22) and reassemble heater

in reverse order of disassembly.

• Stretch thermostat probe coils (KK) down to

contact top of core. Route wires from thermal

limit switch (19), heater cartridge (20), and

ground wire through center of coils.

• Bend tabs on thermostat away from each other

after installing wire connectors so they do not

interfere with shield (21).

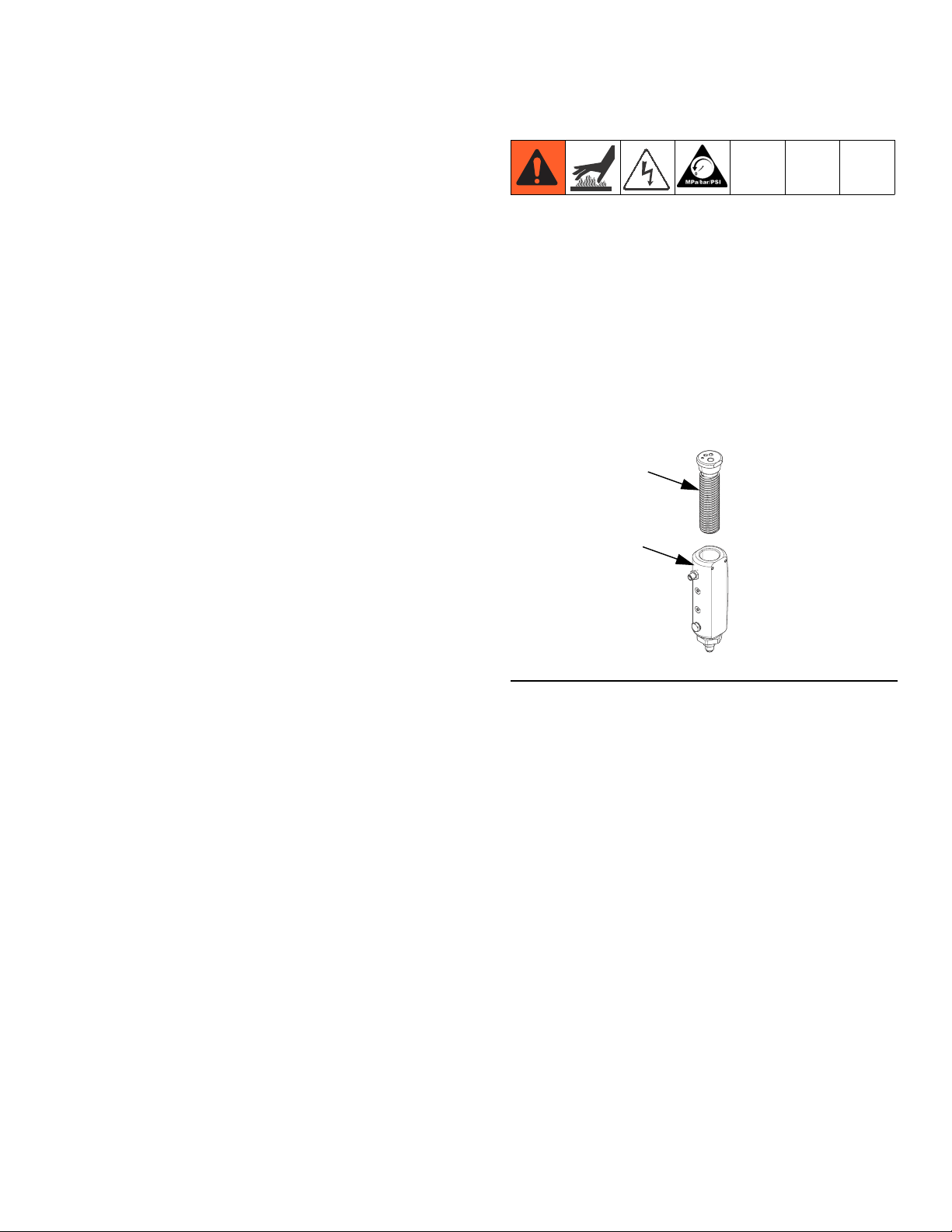

Cleaning Heater Core

1. See Before Beginning Repair, page 14. Relieve

pressure.

2. Wait for heaters to cool.

3. Loosen four screws (12) then pull control section up

out of the way.

4. See FIG. 12. Unscrew core (2) from housing (1).

Use wire brush to clean core then re-install in housing.

2

1

FIG.12

ti20004a

3A2824B 17

Page 18

Parts

Parts

;

;

;

723

..

Green/

Yellow

;

1

Apply a thin film of heatsink compound (26).

2

Stretch capillary coils (KK) down to contact top of core (2).

Route wires from thermal limit switch (19), heater

cartridge (20) and ground wire through center of coils.

7

Apply both tape (27) and sealant (28) to all pipe threads.

Brown

Blue

;

Power from

Control Box

OFF

&

9

Bend tabs on thermostat away from each other after installing

wire connectors so cover cannot contact wires.

12

Apply lubricant to o-ring (40).

&

Brown

)

Blue

Green/

Yellow

240 V

Lamp

5

240 V

1750 Watt

18 3A2824B

Page 19

Accessories

Ref Part Description Qty

1 24K987 HOUSING, heater 1

2 24K988 CORE, heater, spiral 1

3 24K992 INSULATOR, heater 1

4 101754 PLUG, pipe 1

5 24K991 BUSHING, reducing, 1-1/5 x 3/8 1

7 166863 FITTING, nipple, reducing 1

8 114286 LIGHT, indicator, 240V 1

9 24K979 KNOB, control, heater 1

10 119924 BUSHING, strain relief, 90 degree 1

11 16T187 HARNESS, power, heater 1

12 --- SCREW, machine, hex serrated 4

13 --- LABEL, identification 1

15▲ 189930 LABEL, electric shock, triangular 1

16 249521 BRACKET, heater control 1

17 24K978 SWITCH, thermostat, heater 1

18 116343 SCREW, ground 1

19 24K980 SENSOR, thermal limit, 152C, QD 1

20 16T173 CARTRIDGE, heater, 1750W,

240V

21 249520 SHIELD, heater control 1

22 119858 WIRE, jumper, heater 1

23▲ 189285 LABEL, burn hazard, triangular 1

24 172953 LABEL, designation 1

25 195874 SCREW, machine, phillips pan

head

26 110009 LUBRICANT, thermal, 1 oz tube 1

29 167002 INSULATOR, heat 2

30 16R989 BRACKET, heater 1

31 100016 WASHER, lock 2

32 108296 SCREW, machine, hex washer

head

33 113914 FITTING, tee, 1/4 npt, female 1

35 102124 THERMOMETER, dial 1

39 198241 PLUG, port, pressure 1

40 111457 O-RING 1

99 16T174 PLUG, electrical, locking, L6-20P 1

Accessories

110009 Heat sink compound, 1 oz. tube

1

2

2

--- Not for sale.

▲ Replacement Danger and Warning labels, tags and

cards are available at no cost.

◆ Not shown.

3A2824B 19

Page 20

Technical Data

Technical Data

Maximum Working Pressure ...................... 2000 psi (140 bar, 14 MPa)

Maximum Amps ................................ 7.3A

Maximum Fluid Temperature ...................... 180°F (82°C)

Voltage....................................... 240VAC,1750 Watts

Heater Resistance .............................. 29to36ohms

Heated Core Area ..............................

68 in.

2

(438 cm

FluidPath..................................... 3parallelpaths,40in.each

Pressure Drop ................................. Equivalent to 40 in. of 1/4 in. (6.3 mm) ID hose

Inlet ......................................... 3/8npt(f)

Outlet........................................ 1/4npt(f)

Weight ....................................... 9.0lb(4.1kg)

WettedParts .................................. Anodized aluminum, zinc-plated steel, stainless

steel, PTFE

Schematic Diagram

Power from

Control Box

Brown

Blue

2)

Green/

Yellow

OFF

90°C

127°C

R1

120 Volt

850 Watt

Or

240 Volt

1000 Watt

120V or

240V Lamp

F

20 3A2824B

Page 21

Dimensions

Technical Data

1/4 npsm Fluid Outlet

2.9 in.

(7.3 cm)

2.5 in.

(6.35 cm)

15.3 in.

(38.7 cm)

70 in. (178 cm) SJTO cable

with NEMA L6-20P twist

lock connector

3/8 npt(f) Fluid Inlet

ti19998a

3A2824B 21

Page 22

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2012, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

2ULJLQDOLQVWUXFWLRQV This manual contains English. MM 3A2824

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised February 2013

Loading...

Loading...