Page 1

Instructions - Parts

Level Detection Module

3A2806C

and Drum Feed Kit

Installation kit to provide low level sensors in both chemical sides of an HFRL or HFRS

plural-component proportioner being fed from 55 gallon (208 liter) drums. Not for use with

standard configured HFR units. For professional use only.

Not approved for use in explosive atmospheres or hazardous locations.

Important Safety Instructions

Read all warnings and instructions in the HFRL and HFRS

Setup-Operations manual. Save all instructions.

EN

See page 3 for model information.

125 psi (0.86 MPa, 8.6 bar) Maximum Fluid Working Pressure

125 psi (0.86 MPa, 8.6 bar) Maximum Air Input Pressure

ti19596a

Page 2

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Component Identification . . . . . . . . . . . . . . . . . . . . 4

Complete Feed System . . . . . . . . . . . . . . . . . . . . 4

Electrical Panel Components . . . . . . . . . . . . . . . 5

Fluid Control Module (FCM) . . . . . . . . . . . . . . . . 6

Light Tower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Flush Pumps Before Using . . . . . . . . . . . . . . . . . . . 8

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Install 4 Drum Rack (Optional) . . . . . . . . . . . . . . 9

Refer to 4 Drum Rack, 01/0955/25 (Optional) on

page 30 for visual clarity. . . . . . . . . . . . . . . . 9

Position Drums . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Install Drum Feed Kit . . . . . . . . . . . . . . . . . . . . . . 9

Connect Feed Pump . . . . . . . . . . . . . . . . . . . . . . 9

Install Electrical Panel . . . . . . . . . . . . . . . . . . . . 10

Install Level Sensors . . . . . . . . . . . . . . . . . . . . . 12

Install Light Tower . . . . . . . . . . . . . . . . . . . . . . . 13

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Calibrate Barrel Style Level Sensors . . . . . . . . . 14

Set the ADM to Recognize the Feed System Kit 14

Set the ADM to Recognize which Level Sensors are

to Operate . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Set the Level Sensors Output Function . . . . . . 15

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 16

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Drum Feed Kit - Air Dryer . . . . . . . . . . . . . . . . . 16

Drum Feed Kit, Pump . . . . . . . . . . . . . . . . . . . . 17

Drum Feed Kit, Changing Top Drums . . . . . . . . 17

Install Upgrade Tokens . . . . . . . . . . . . . . . . . . . 18

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Level Sensor and Well . . . . . . . . . . . . . . . . . . . . 20

Electrical Schematics . . . . . . . . . . . . . . . . . . . . . . 21

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Drum Feed System, 24N816 . . . . . . . . . . . . . . . 22

Drum Feed Kit, 24N767 . . . . . . . . . . . . . . . . . . . 24

Electric Panel, 24N804 . . . . . . . . . . . . . . . . . . . 26

4 Drum Rack, 01/0955/25 (Optional) . . . . . . . . . 30

Appendix A - ADM Setup Screens Overview . . . . 32

Appendix B - ADM Run Screens Overview . . . . . 35

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 38

2 3A2806C

Page 3

Related Manuals

Component manuals in English. Manuals are available

at www.graco.com.

Manual No. Description

3A2175 HFRL and HFRS, Setup-Operations

3A2176 HFRL and HFRS, Repair-Parts

312877 Husky 1050 Air-Operated Diaphragm Pump, Operation

3A0235 Feed Supply Kits, Instructions-Parts

406987 GCA CAN Cables, Reference (Extension Cables)

Models

NOTE: Not for use with standard HFR units.

Related Manuals

Part

24N816

24N767

01/0955/25 4 Drum rack (Optional)

Description

KIT, low level, stack light, HFRL (Required):

- (2) low level sensors - (1) sensor per chemical side

- (1) control panel for level sensors

- (1) indicator stack light

Carbon steel drum feed kit with Husky pump (Optional):

- Kit is to add a drum feed to (1) chemical side

3A2806C 3

Page 4

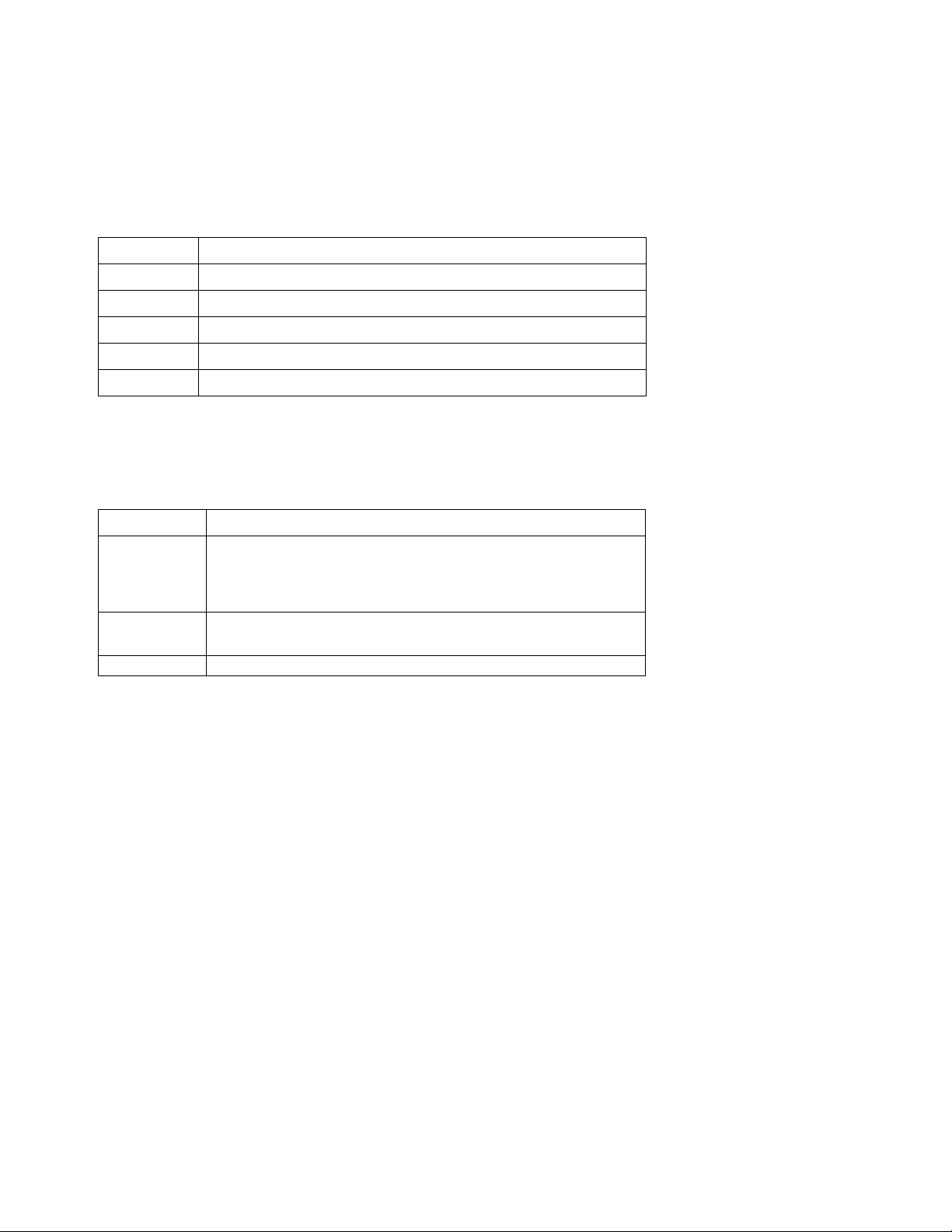

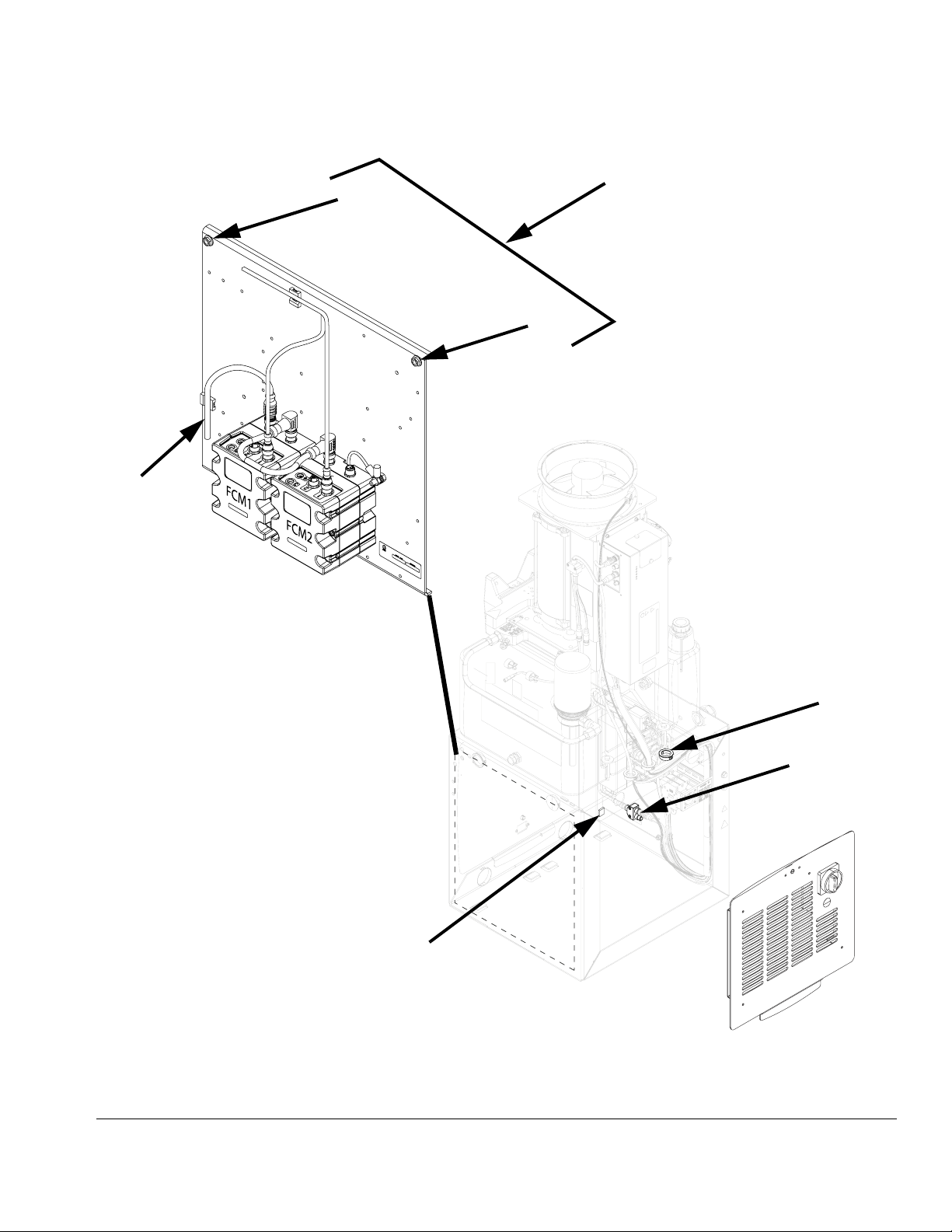

Component Identification

Component Identification

Complete Feed System

Figure Shown With:

(1) Level Kit

(2) Drum Feed Kit Options

(1) 4 Drum Rack Option

G

F

D

E

B

C

A

ti19596a

KJ H

FIG. 1: Component Identification - Feed System

Key:

A Auxiliary Control Panel (Mounted in Machine Base)

Refer to F

B Level Sensor - Low Level Indication

C Level Sensor - Empty Indication

D Indicator Stack Light

E Drum Feed / Pump Kit for One Chemical (Optional)

F 4 Drum Rack (Optional)

G Upper to Lower Drum Feed Hose

4 3A2806C

IG. 2

H Drum to Pump Feed Hose, 6 ft (1.8 m)

J Husky Pump

K HFR Supply Hose

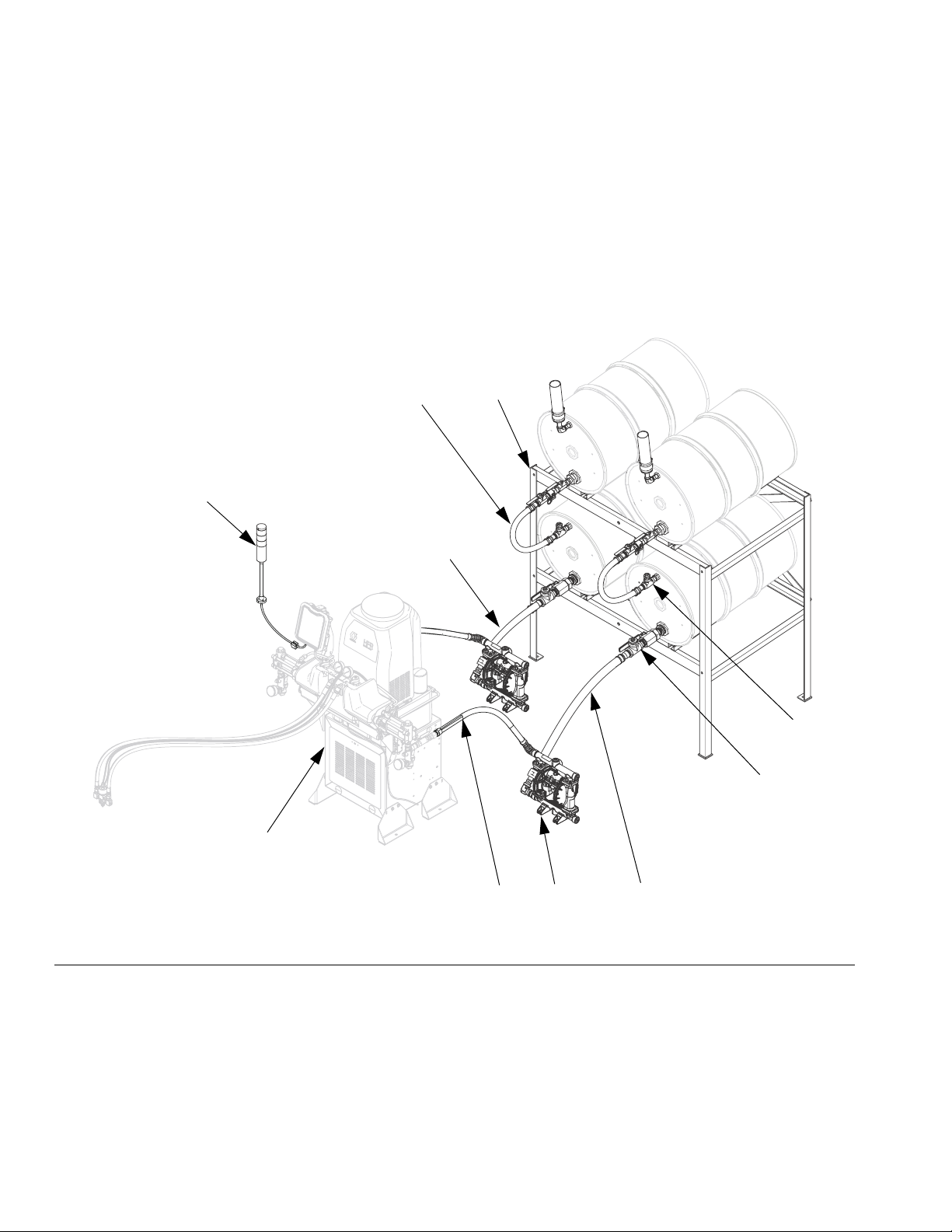

Page 5

Electrical Panel Components

Component Identification

The electrical panel will be located on the inside of the

HFRL stand enclosure, and includes two fluid control

modules.

AF

AD

Software is loaded on Fluid Control Modules (FCM).

Program token 16G584 is also provided.

AE

AA

FIG. 2: Component Identification - Electrical Panel

Key:

AA Fluid Control Module - A (Red) Tank

AB Fluid Control Module - B (Blue) Tank

AC Ground Cable

AD CAN Cable

AE Flanged Hex Nuts (3x)

AF Wire Tie Anchor

AC

AB

r_24n804

3A2806C 5

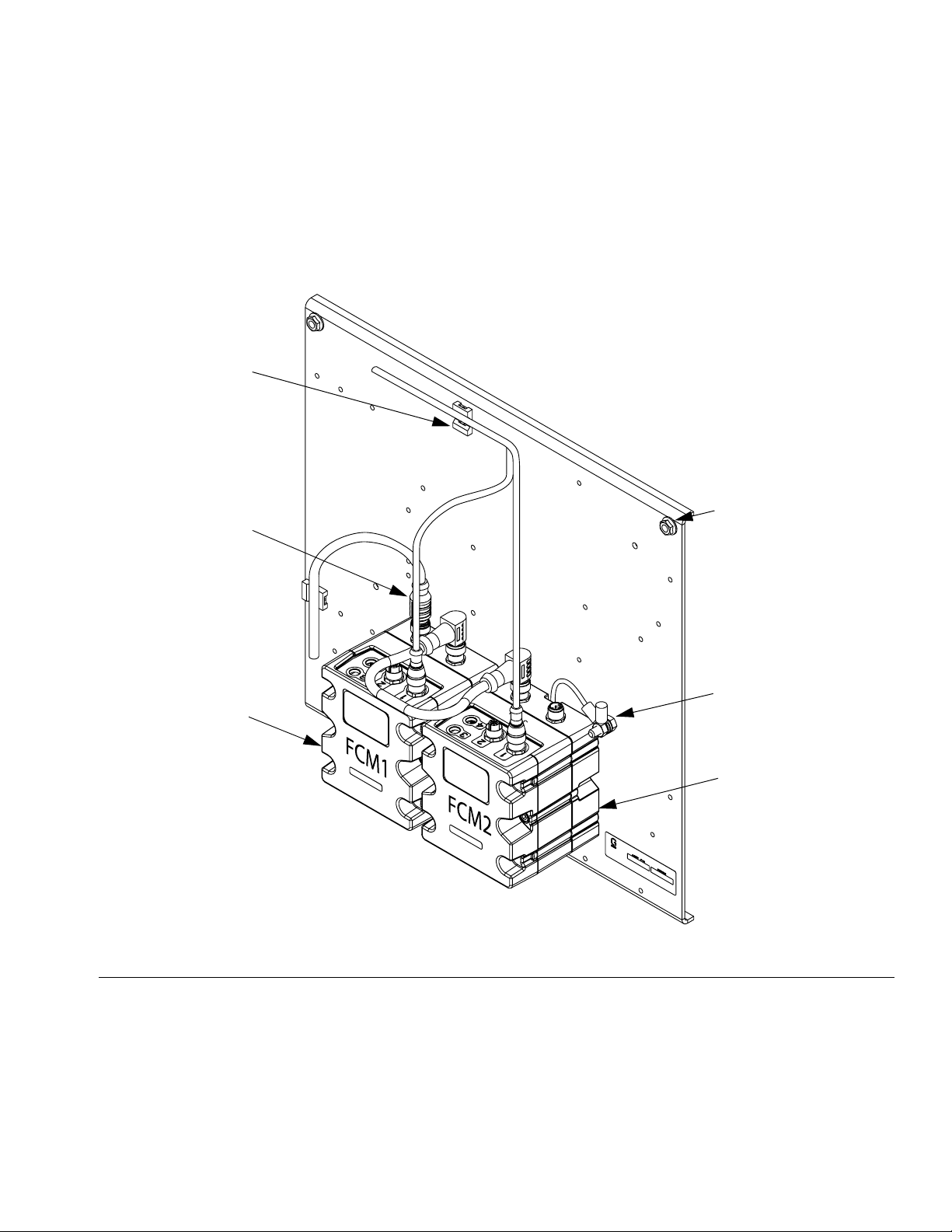

Page 6

Component Identification

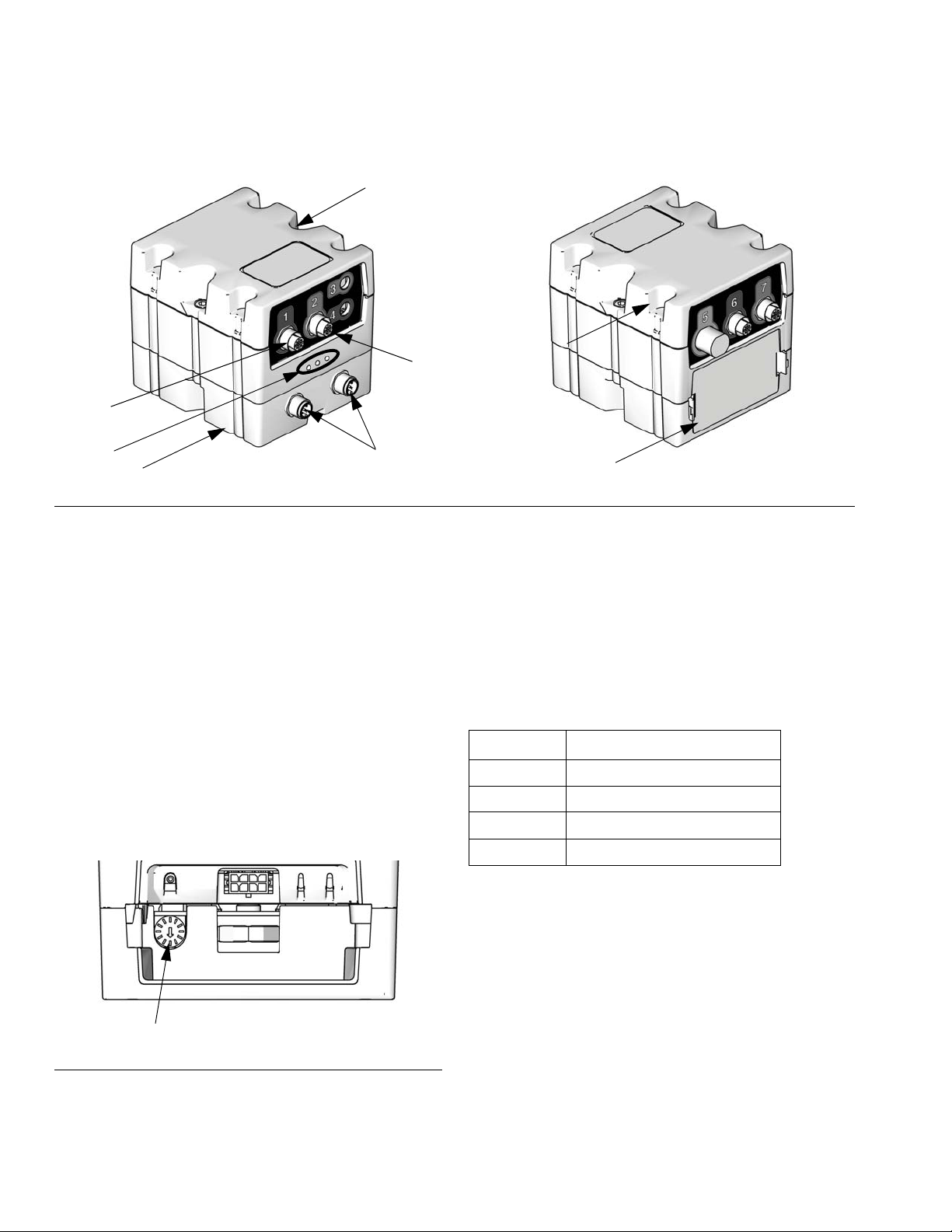

Fluid Control Module (FCM)

BA

BC

BH

BG

BE

ti12337a

BF

BB

FIG. 3: Component Identification - FCM

Key:

BA Fluid Control Module (FCM)

BB Base

BC Module Connection Screws

BD Access Cover

BE Module Status LEDs

BF CAN Connectors

BG Level Sensor Input

BH Fill Solenoid Signal

Adjust Rotary Switch

The rotary switch setting indicates which zone the fluid

control module will control in the system. The FCM uses

a 16-position rotary switch to make selections.

Set the rotary switch to the specific selection according

to the settings listed in the following table.

ti12336a

BD

Setting Zone

0 through 2 Not Used

3 B (Blue) Tank Level

4 A (Red) Tank Level

5 through F Not Used

Rotary Switch

ti12361a

FIG. 4: Adjust Rotary Switch

6 3A2806C

Page 7

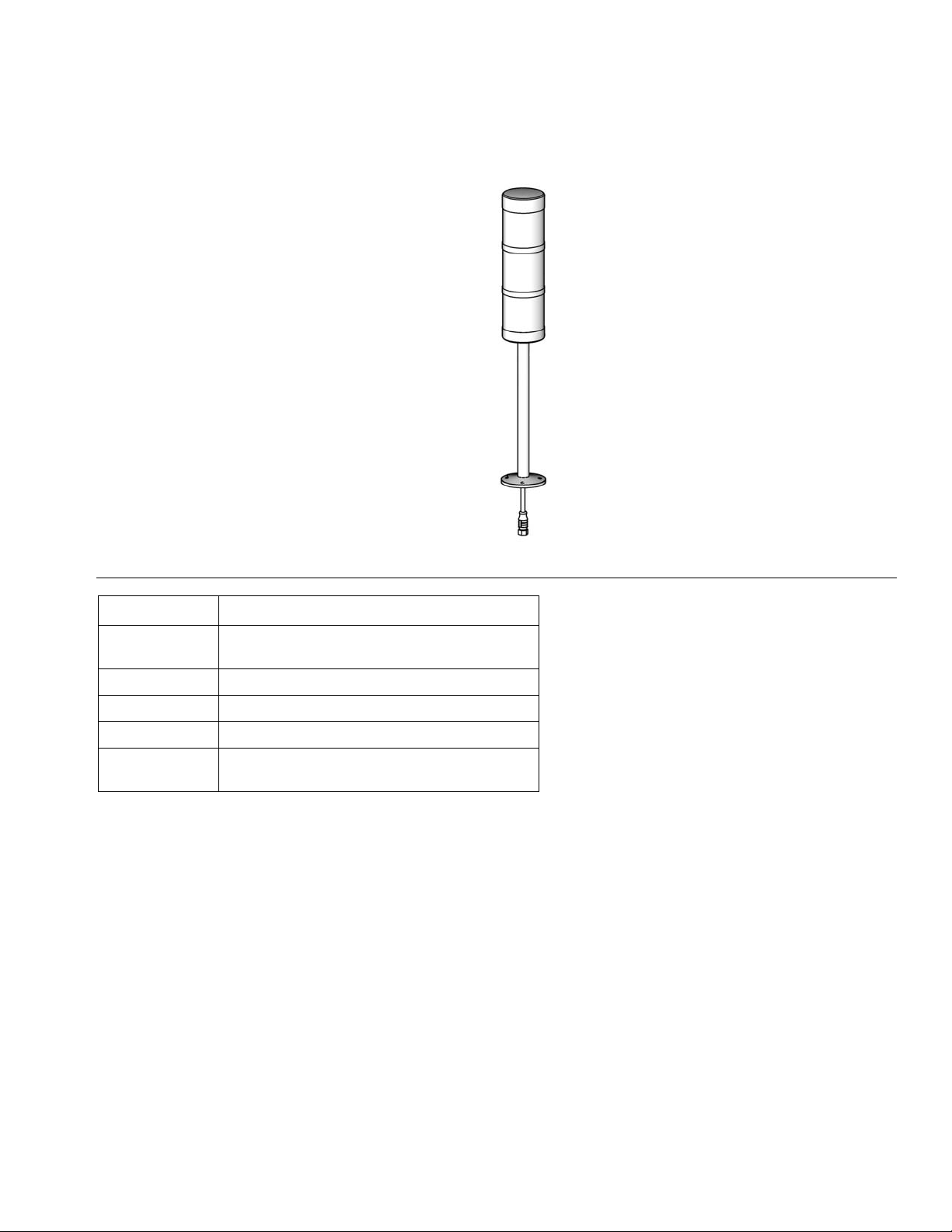

Light Tower

Component Identification

FIG. 5: Component Identification - Light Tower

Signal Description

Green on only System is powered up and there are no error con-

ditions present

Yellow on An advisory exists

Yellow flashing Material is at a low level condition

Red flashing A deviation exists

Red on The system is shut down due to an alarm occur-

ring.

Errors include advisories, deviations, or alarms, so

green will only be on when none of these occur. A yellow

light can be on at the same time as red (flashing or solid

on) when an advisory exists at the same time as a deviation or alarm.

Messaging will be viewable on the ADM to determine

the specific error code.

tower

3A2806C 7

Page 8

Grounding

Grounding

The equipment must be grounded. Grounding reduces

the risk of static and electric shock by providing an

escape wire for the electrical current due to static build

up or in the event of a short circuit.

Pump: follow instructions in separate feed pump manual, supplied.

HFR: see operation manual.

Fluid supply container: follow local code.

Solvent pails used when flushing: follow local code.

Use only conductive metal pails, placed on a grounded

surface. Do not place the pail on a nonconductive surface, such as paper or cardboard, which interrupts

grounding continuity.

To maintain grounding continuity when flushing or

relieving pressure: hold metal part of the spray gun or

dispense valve firmly to the side of a grounded metal

pail, then trigger the gun or valve.

Flush Pumps Before

Using

Flush equipment only in a well-ventilated area. Do

not spray flammable fluids.

NOTICE

Diaphragm pumps are factory tested with water.

Thoroughly flush pumps before using to prevent

moisture contamination when pumping moisture

sensitive materials.

8 3A2806C

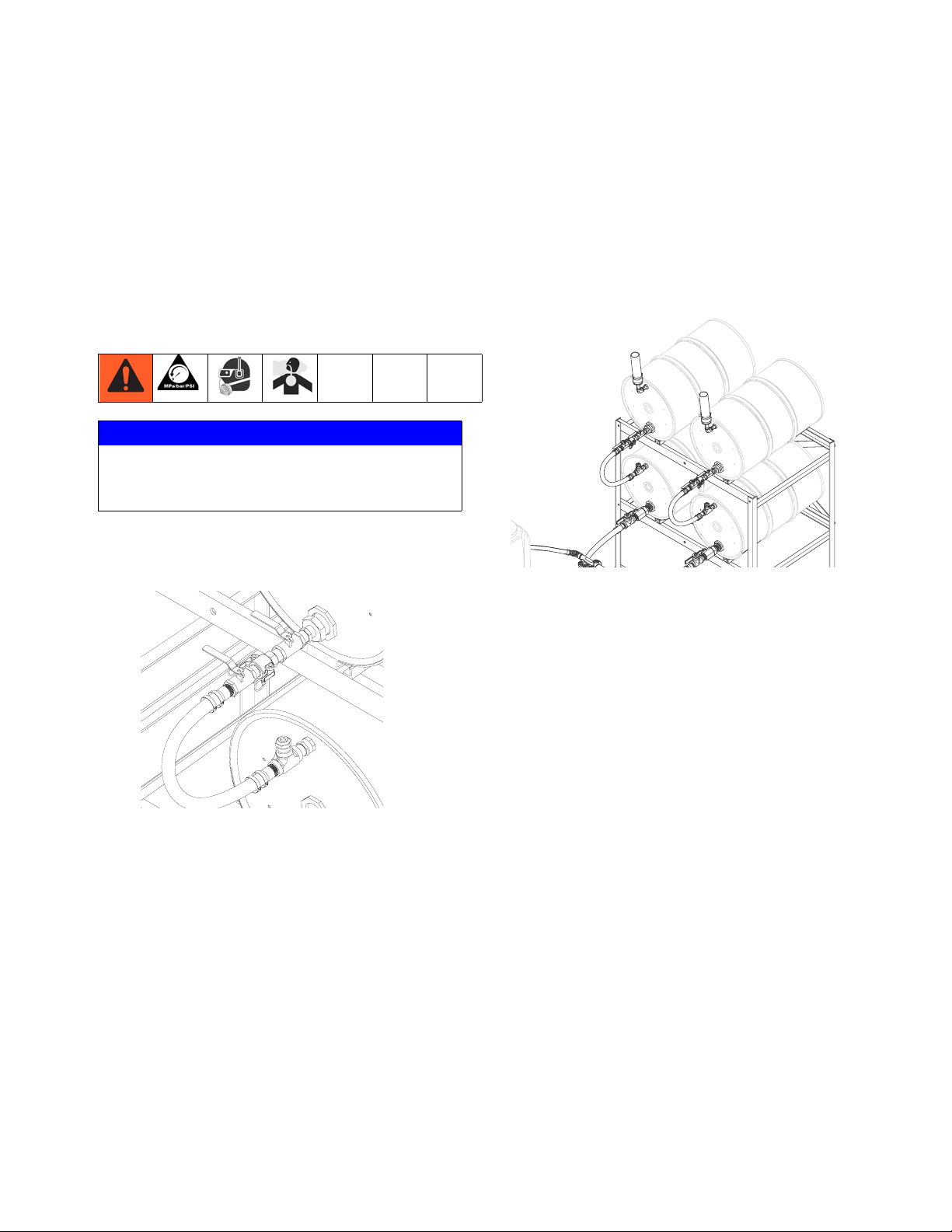

Page 9

Installation

Installation

Install 4 Drum Rack (Optional)

NOTICE

To avoid machine damage or personal injury,

anchor the rack to the floor with (4) 1/2” bolts (provided by customer) and verify all bolt assemblies

are tightened before loading the drums onto the

rack.

Refer to 4 Drum Rack, 01/0955/25 (Optional) on

page 30 for visual clarity.

Position Drums

Place component A (red) and component B (blue)

drums as desired. Air hose connecting feed pumps is

15 ft (4.57 m) long.

Fluid hose connecting feed pumps to systems are

10 ft (3.05 m) long.

4. Tighten all connections.

Connect Feed Pump

1. Supply clean, dry, filtered air to feed pumps.

NOTE: Air supply components are not included.

2. Refer to Husky 1050 Air-Operated Diaphragm

Pump, Operation manual for instructions.

Install Drum Feed Kit

NOTICE

To avoid machine damage or personal injury, do not

supply pressure to drums.

1. Complete Setup instructions in the pump manual

before installing in drum feed kit.

NOTICE

To avoid improper operation, the diaphragm pump

must be floor mounted.

2. If applicable, locate drum rack to allow access for

top drum change.

3. Dry fit all hose and fitting components to ensure

components are located properly and will reach the

HFRL. Refer to F

NOTE: Drum to pump feed hose length can be reduced

if necessary. Refer to F

IG. 1, page 4.

IG. 1, page 4, item H.

3A2806C 9

Page 10

Installation

Install Electrical Panel

1. Perform HFR shutdown procedure. See HFRL operation manual for detailed instructions.

2. Disconnect the power supply to the machine.

3. Turn the disconnect switch on the rear base cover of

the machine to the “OFF” position

4. Remove the cover to allow access into the base

cube.

5. Install the pre-assembled panel on the left side of

the cube, directly opposite of the main control panel.

Note the locations of the 3 studs; One in each top

corner, and one in the bottom center.

a. Orient the panel so the mounting holes match

the stud locations of the cube.

b. Insert the panel into the base cube.

8. Remove one of the hole plugs located on the top of

the base cube directly over the disconnect panel

that was just removed.

NOTE: There are three holes on the top edge of the

base cube. The plug can be easily pushed out from

inside the cube.

9. Replace the removed plug with the provided plastic

edge bushing

a. The bushing will snap into place by aligning the

smaller diameter end of the bushing on top of

the hole and pressing the bushing down through

the hole from outside the cube.

10. Insert the male ends of the sensor cords labeled

FCM1A and FCM2B through the bushing and into

the base cube.

11. Connect the cord labeled FCM1A to port “1” (Refer

to F

IG. 2, page 5) on the FCM labeled FCM1.

12. Connect the cord labeled FCM2B to port “1” (Refer

to F

IG. 2, page 5) on the FCM labeled FCM2.

c. Orient the top of the panel such that the studs in

the cube wall extend through the holes in the

top corners of the panel.

d. Fasten the panel to the studs with the (3)

flanged hex nuts provided. Tighten the nuts.

6. Connect the cable (labeled 121002) extending from

the panel to the yellow cable splitter located on the

lower left side of the main machine control panel.

a. Remove the two screws to free the splitter from

the panel.

b. Insert the cable end into the open port on the

splitter and tighten. Note that the plug is keyed

and only fits in the splitter in one orientation.

c. Reattach the splitter to the panel.

7. If there is no available connection on the splitter, an

alternate CAN connection will need to be used. The

alternate location may require a different gendered

cord (122487 is provided for this purpose). Consult

the system manual in finding an alternate connection location.

13. Attached the wire anchor to the inside face of the

base by inserting the provided screw through the

anchor and the weld nut indicated in F

IG. 6. Secure

in place by tightening the hex nut on the screw from

the outside of the base.

14. Secure the cords to the panel and the base cube by

using wire ties (not provided) and the installed plastic anchors.

10 3A2806C

Page 11

Step 6

Step 5

Installation

NOTE: Mounting location for panel is

only available on HFRL and HFRS

models. This location is used for

other control components on standard HFR models.

Step 5

r_24n804

Panel view is shown rotated 180°

from the installed position.

Step 13

Step 8,

Step 9

Step 6

Panel Install

FIG. 6: Install Electrical Panel

3A2806C 11

Page 12

Installation

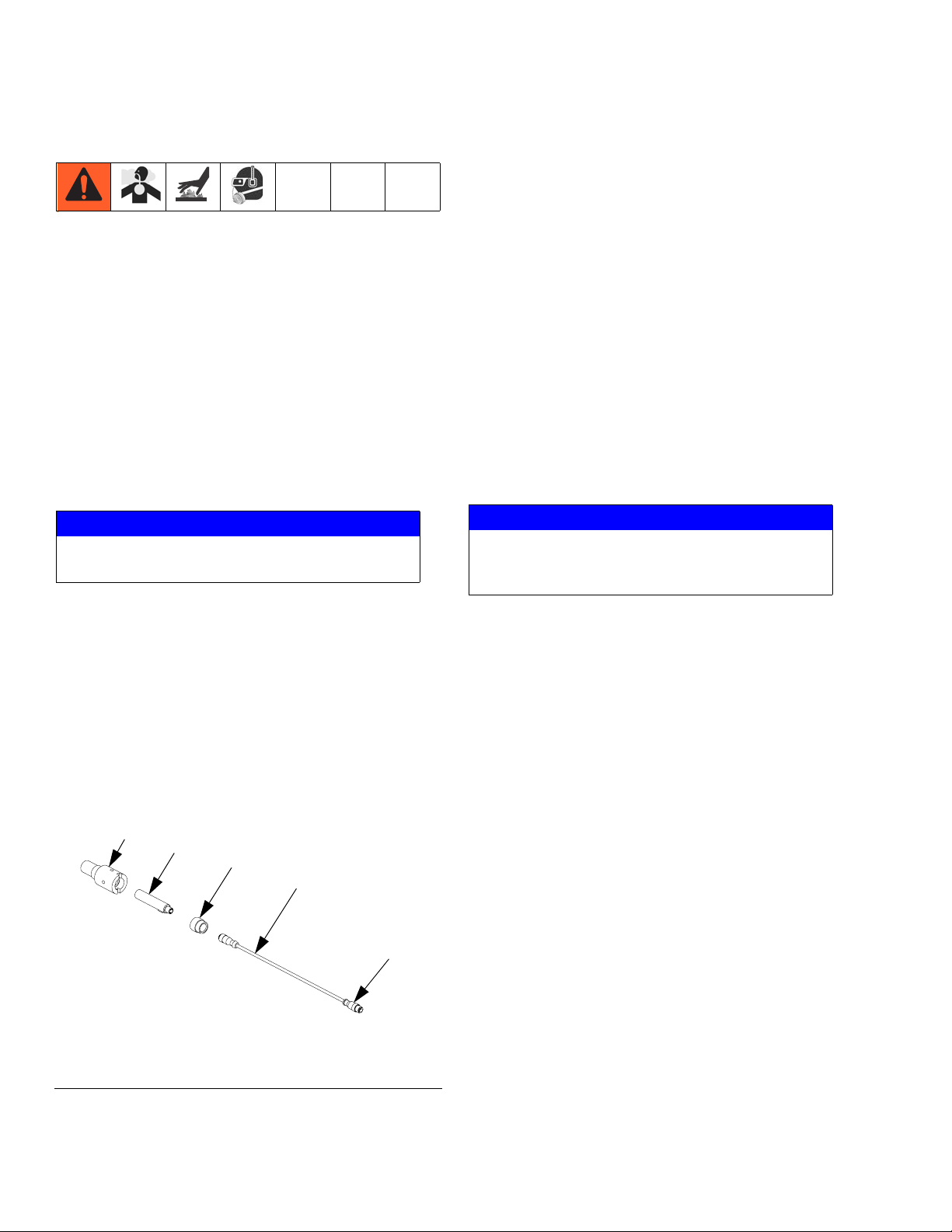

Install Level Sensors

NOTE: Lower drum hardware must be installed in an

empty drum and then installed on the lower drum rack.

The drum can then be filled from the cascade feed hose

from a full upper drum.

NOTE: There are two possible locations for the low level

sensor, depending on desired function. Install both sensors in the same location on each chemical side.

• Low Level Indication: Located in the upper to

lower drum feed hose

• Empty Indication: Located in the drum to pump

feed hose.

NOTICE

Do avoid machine damage, install one sensor on

each chemical side only.

where the well is inserted. Note these measurements as they will be need later.

5. Being careful to not cross-threads, thread assembled level sensor (CB) into well housing until it bottoms out against the bottom of the well. The bottom

of the level sensor will be slightly visible through the

bottom of the well.

NOTE: In the following step, do not allow PTFE

paste or tape to cover the tip of the level sensor

well. If paste comes in contact with the tip of the

level sensor well, thoroughly wipe it clean.

6. Apply PTFE paste and PTFE tape to the male

threads of the level sensor well housing.

7. Being careful to not cross-threads, thread the level

sensor well (CA) into the corresponding drum feed

port and lightly tighten with a crescent wrench.

NOTICE

Do not pressurize tank with level sensor removed

from sensor well. Doing so will rupture the level sensor well.

1. Turn main power off.

2. Drain drums below the lowest level sensor well.

NOTE: For proper level sensor function, the tip of

the level sensor well must protrude at least 1/8 in.

into the tank.

3. Route the level sensor wire through the corresponding well nut (CC). See F

IG. 7 for level sensor assem-

bly view.

CA

CB

CC

Wire

CD

8. The protrusion length must be at least 1/8 in.

(3.2 mm). If not, remove the level sensor well and

restart at step 4.

9. Rotate level sensor such that the cord is pointing

vertical and the sensing face is pointing down.

10. Plug the sensor connector (CD) into the level sensors.

a. Route the sensor wires from the control panel

through the bushing that was installed with the

level sensor panel (steps 8 and 9).

11. Plug the sensor connector into the connector on the

FCM.

12. Calibrate the sensor. See Calibrate Barrel Style

Level Sensors, page 14.

r_24b969_3A0395a_7a-2

FIG. 7: Level Sensor Assembly

4. Measure the length of the level sensor well housing,

and then measure the depth of the hole in the fitting

12 3A2806C

Page 13

Install Light Tower

NOTE: Install the light tower in a suitable location for

clear viewing.

1. Create the hole pattern below to match the light

tower base.

Ø 1.57

Bolt Circle

Ø 0.90

3x 8-32 UNC 2B

Equally Spaced

Mount Pattern

Installation

2. Use the provided screws to attach the light tower to

the mounting bracket.

3. Route the light tower cord as needed towards the

ADM.

NOTICE

To prevent damage to the cord, ensure it will not be

pinched during normal machine operation after

routing.

4. Connect the cable to the port labeled “1” on the

base of the ADM. Refer to F

IG. 1, page 4.

NOTE: A 5 m (16 ft) cable is provided with the level control kit. If extension cables are necessary, refer to GCA

CAN Cables - Reference manual.

3A2806C 13

Page 14

Setup

Setup

Calibrate Barrel Style Level

Sensors

1. Locate the calibration button on the sensor (11)

closest to the electrical connector through one of

the four holes of the sensor well housing (CA).

2. If the calibration button cannot be seen through one

of the four holes in the sensor well, rotate the sensor.

a. Loosen the sensor well nut (CC).

b. Rotate sensor until the calibration button can be

seen through one of the four holes in the sensor

well housing.

c. Tighten sensor well nut.

Set the ADM to Recognize the

Feed System Kit

1. Navigate to the ADM Supply Screen.

2. Press .

3. For the appropriate chemical side, select “Monitor”

within the Refill Setting selection box.

NOTE: Select “Disabled” if the level system is not being

used.

d. Press and hold the button down with the ball

end of an allen wrench for two seconds. The

light will flash slowly and then go out.

3. Test for proper sensor function.

a. Loosen the sensor well nut.

b. Back the sensor out of the well. The sensor

should sense the housing wall.

14 3A2806C

Page 15

Setup

Set the ADM to Recognize which

Level Sensors are to Operate

NOTE: Two sensors must be selected for each material

with a level sensor, regardless if there is only one low

level sensor installed.

1. Remain within the ADM Refill Screen.

2. For the appropriate chemical side, select and check

the middle sensor.

3. For the appropriate chemical side, select and check

the bottom sensor.

3. If it is desired to stop dispensing when a low level is

sensed, select and check “Low Material Disables

Dispense”.

NOTE: Setting this option initiates a deviation condition

and disables the machine from operation when there is

a low level condition. When a low level is sensed, the

machine will not cycle until the sensor see material. A

pop-up screen on the ADM alerts the operator of the

specific level condition.

4. If it is not desired to stop dispense, verify Low Mate-

rial Disables Dispense” is unchecked.

NOTE: This option is the default setting of the system

and is set as a deviation condition. When a deviation is

issued, the machine will continue to cycle and will not be

affected by the deviation.

NOTE: A low level condition generates a pop-up message on the ADM that can only be cleared by the operator. If the “Low Material Disables Dispense” option is

selected, dispensing can resume with a remote start

signal when material is replenished and the sensor sees

material. It is not necessary to clear the ADM to initiate a

start unless the ADM is used as the start device.

4. Press .

Set the Level Sensors Output

Function

1. Navigate to the ADM Advanced Screen 4.

2. Press .

5. Press .

3A2806C 15

Page 16

Startup

Startup

1. See Load fluid with feed pumps in HFR operation

manual.

2. Open feed pump air regulator.

3. Open feed pump bleed-type master air valve.

4. Adjust air to feed pump with needle valve.

NOTE:

• Cold, viscous material may be difficult to prime.

Use needle valve to reduce air flow to motor.

• Do not plug or shut off pump fluid outlet when

priming. Fluid must be free to flow through

pump to prime.

• To increase pump flow rate and reduce icing,

remove pump muffler. This will increase exhaust

noise.

5. Never let pump run when drum is empty. A dry

pump can accelerate and damage itself. If pump is

running too fast, stop it immediately. Check and refill

fluid supply, or flush with compatible solvent. Always

prime entire system to remove any air. Do not let

material harden in pump.

Shutdown

See Shutdown in system operation manual. Close feed

pump bleed-type master air valve.

Pressure Relief

Procedure

1. If the optional drum feed kit is being used, remove

the air pressure from the Husky pump.

2. See Pressure Relief Procedure in system operation manual.

Maintenance

Drum Feed Kit - Air Dryer

Replace silica gel units when the desiccant color or

moisture indicator has changed color from Blue (meaning dry) to Pink (meaning wet).

There is a sight window on the side of the canister to

allow viewing of the desiccant color.

1. Loosen the clamp ring and remove the desiccant

canister from the rubber housing.

2. Apply tape over the both ends of the canister.

3. Discard used canister.

4. Remove sticky tabs from the ends of the new canister to allow airflow.

5. Install canister into the rubber housing to allow viewing of the sight window.

NOTE: Make sure the arrows found on the canister point

into the rubber housing.

6. Tighten the clamp ring.

16 3A2806C

Page 17

Maintenance

Drum Feed Kit, Pump

NOTE: See supplied pump manual for maintenance,

repair, and parts information.

Tighten pump clamps and external fasteners periodically. See pump manual.

Drum Feed Kit, Changing Top

Drums

NOTICE

To prevent cross-contamination of fluid when

changing drums, complete changing one component before changing second component.

1. See Shutdown, page 16.

2. Close ball valves on top drum outlet assembly.

10. Install dryer assembly.

NOTE: To prevent contamination of the desiccant in the

dryer canister caused by sloshing material, it is recommended that the tape is temporarily placed over the air

inlet on the dryer canister. The tape should be removed

after the drum is installed.

11. Place drum on top rack and orient it so that the air

dryer assembly is on top and outlet is on the bottom.

ti19596a

12. Perform Drum Feed Kit - Air Dryer, page 16, as

required.

closed_ballvalves

3. Place a container underneath the CAM lock fitting to

catch chemicals.

4. Disconnect the CAM lock fitting from the system.

5. Remove the empty drum from the rack (if applicable) and place it vertically on the floor.

6. Remove the air dryer assembly ball valve assembly

from the empty drum.

7. Inspect and clean the threads of the full drum and

removed fitting assemblies.

8. Apply thread sealant to threads of the removed

assemblies.

13. Connect CAM lock fittings from lower drum securely

to ball valve assembly on upper drum and lock in

place.

NOTE: CAM levers on either side of female CAM receptacle should be perpendicular to the receptacle to mate

and parallel to body to lock.

14. Open both ball valves on top drum outlet assembly

to fill bottom the drum.

See Load fluid with feed pumps in GMS operation

manual.

9. Install the ball valve assembly.

3A2806C 17

Page 18

Maintenance

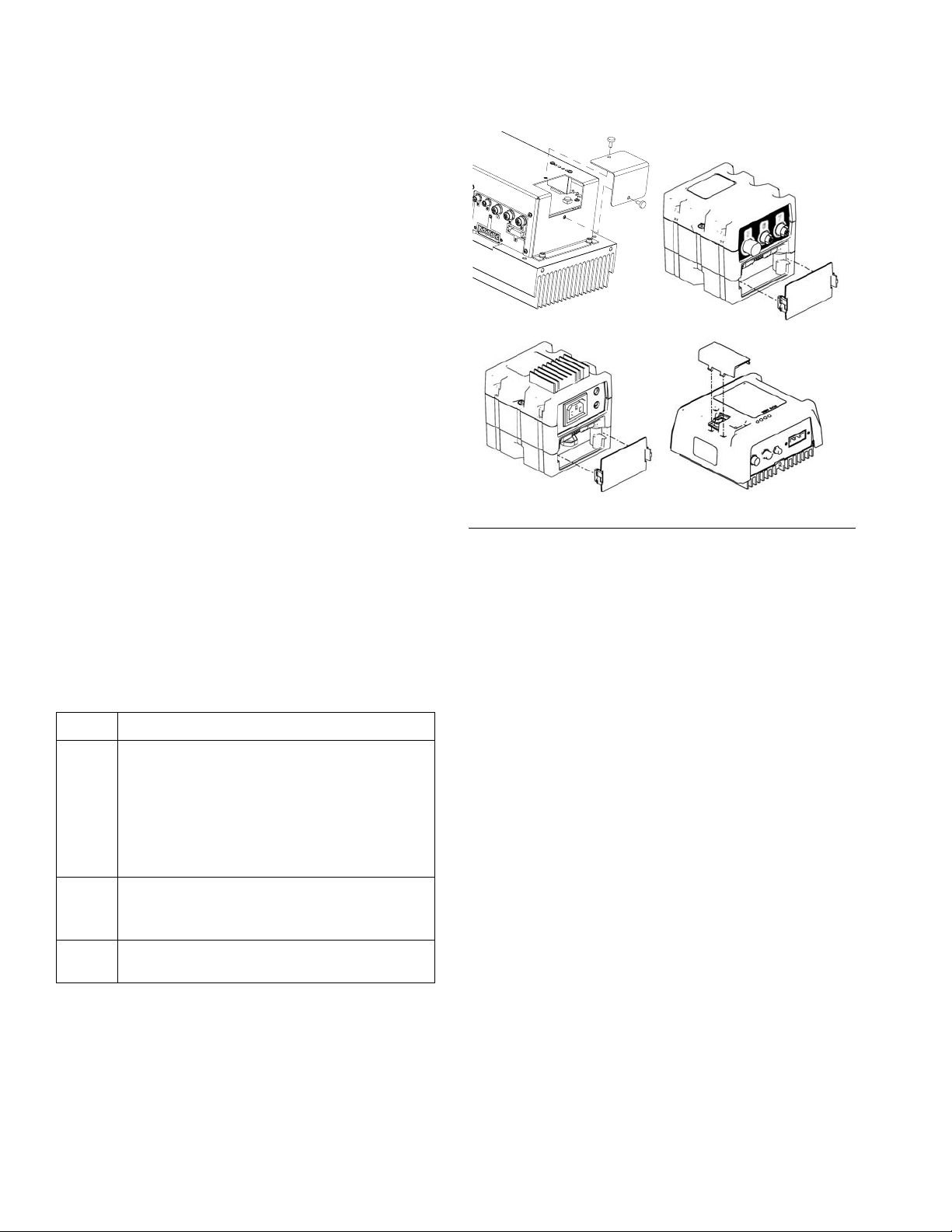

Install Upgrade Tokens

NOTE: The Motor Control Module, Fluid Control Mod-

ule, and Temperature Control Module connection to the

system is temporarily disabled during the installation of

upgrade tokens.

To install software upgrades:

1. Use correct software token stated in the table. See

Graco Control Architecture

™

Module Programming

manual for instructions.

NOTE: Upgrade all modules in the system to the

software version on the token, even if you are

replacing only one or two modules. Different software versions may not be compatible.

All data in the module (System Settings, USB Logs,

Recipes, Maintenance Counters) may be reset to

factory default settings. Download all settings and

user preferences to a USB before the upgrade, for

ease of restoring them following the upgrade.

See manuals for locations of specific GCA components.

The software version history for each system can be

viewed in the technical support section at

www.graco.com.

Token Application

16H821 HFR:

- Advanced Display Module

- Motor Control Module

- High Power Temperature Control Module

- Fluid Control Module (AC Power Pack)

- Discrete Gateway Module

- Communication Gateway Module

16G584 Tank Stand:

- Fluid Control Module

- Low Power Temperature Control Module

16G407 Ratio Monitoring (Flow Meters):

- Fluid Control Module

r_257396_3b9905_04b

ti12358a1

FIG. 8: Remove Access Cover

ti12334a1

ti12354a1

18 3A2806C

Page 19

Troubleshooting

Problem Cause Solution

Troubleshooting

Level sensor is not sensing

material when material is

present.

Level sensor is sensing

material when material is

not present.

Level sensors out of calibration. Calibrate level sensor.

Replace level sensor.

Intermittent electrical connections. Ensure the system main power is ON.

Ensure all electrical connections to the level

sensor are secure. See electrical schematic

in either the HFR or VRM Repair-Parts manual.

FCM errors. Check FCM. A red LED indicates a problem

with the module. See electrical schematic in

either the HFR or VRM Repair-Parts manual.

Replace FCM.

Level sensors out of calibration. Calibrate level sensor.

Replace level sensor.

Level sensors blocked inside reservoir.

Check inside reservoir to ensure there is

nothing blocking the level sensor.

Intermittent electrical connections. Ensure the system main power is ON.

Ensure all electrical connections to the level

sensor are secure. See electrical schematic

in either the HFR Repair-Parts manual.

FCM errors. Check FCM circuit breaker in base cube to

see if it has tripped. See electrical schematic in either the HFR or VRM

Repair-Parts manual.

Check FCM. A red LED indicates a problem

with the module. See electrical schematic in

either the HFR or VRM Repair-Parts manual.

Replace FCM.

3A2806C 19

Page 20

Repair

Repair

Level Sensor and Well

NOTE: For proper level sensor function, the tip of

the level sensor well must protrude at least 1/8 in.

into the reservoir.

CA

CB

CC

CD

r_24b969_3A0395a_7a-2

FIG. 9: Level Sensor Assembly

1. Turn main power off.

NOTE: In the following step, do not allow PTFE

paste or tape to cover the tip of the level sensor

well. If paste comes in contact with the tip of the

level sensor well, thoroughly wipe it clean.

9. Apply PTFE paste and PTFE tape to the male

threads of the level sensor well housing.

10. Being careful to not cross-threads, thread the level

sensor well into the tank (C) and lightly tighten with

a crescent wrench.

11. Measure the amount of the level sensor well housing that is visible beyond the day tank hole, then

perform the following equation:

P = L1 - (L2 + L3)

P = Protrusion length (inside of day tank)

L1 = Length of level sensor well (A10)

L2 = Visible length of level sensor well

L3 = Length of well threads in fitting

2. Close ball valves on the drum outlets.

3. Drain drums to below level sensor well.

4. Unscrew level sensor harness cable (CD) from level

sensor well housing (CA).

5. Use a crescent wrench to remove level sensor

well housing from tank (C).

6. Remove the old level sensor (CB) from well housing.

7. Measure the length of the level sensor well housing,

and then measure the depth of the hole in the fitting

where the well is inserted. Note these measurements as they will be needed later.

8. Being careful to not cross-threads, thread assembled level sensor (CB) into well housing until it bottoms out against the bottom of the well. The bottom

of the level sensor will be slightly visible through the

bottom of the well.

12. The protrusion length must be at least 1/8 in.

(3.2 mm). If not, remove the level sensor well and

restart at step 7.

NOTICE

Level sensor must be oriented with the sensing face

pointing down. Alternate orientations could result in

material pooling on the sensor face, resulting in a

false reading.

20 3A2806C

Page 21

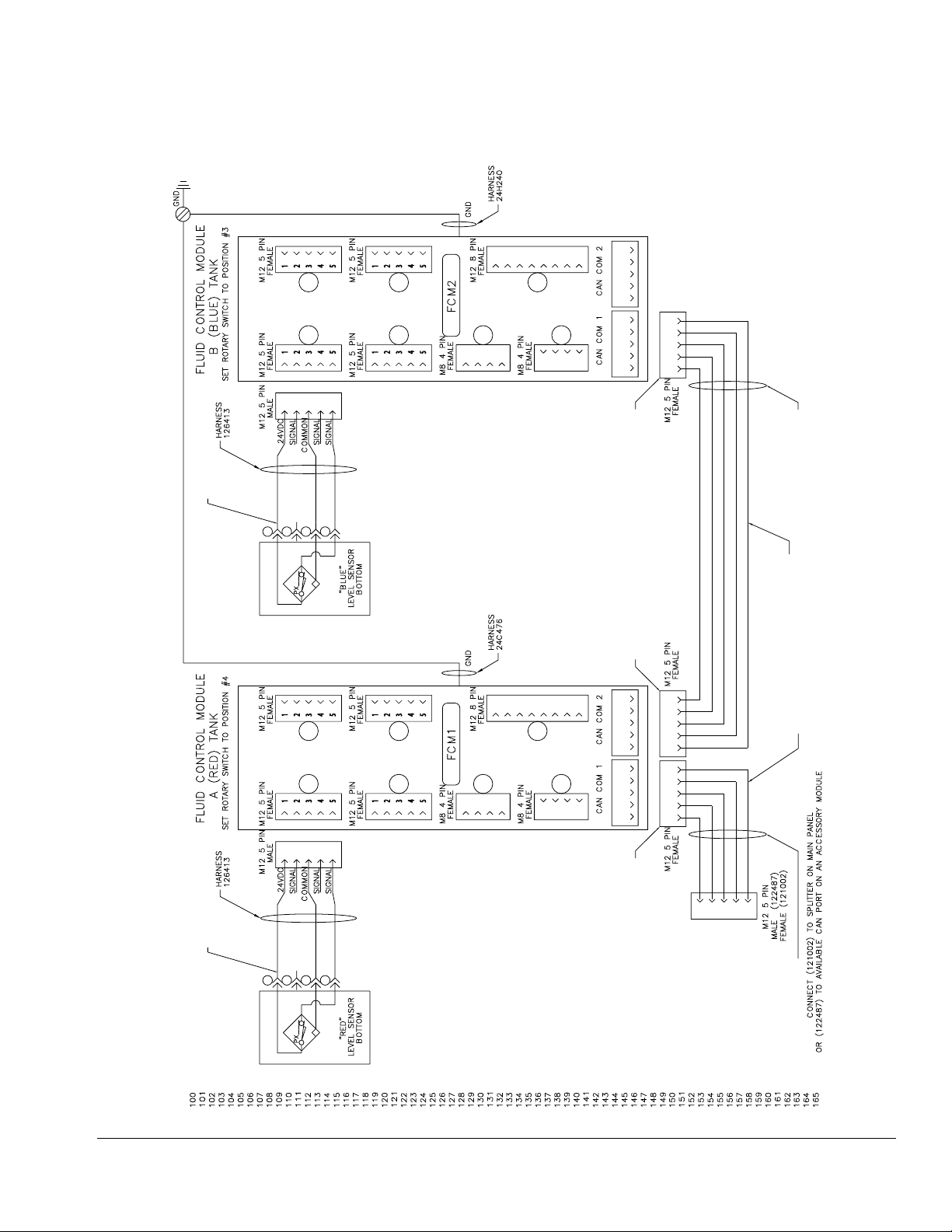

Electrical Schematics

GND

432

1

FEMALE

M12 5 PIN

5

1

FEMALE

M12 5 PIN

7

6

Electrical Schematics

24H24O

HARNESS

GND

54321

432

5

FEMALE

M12 8 PIN

876

5

1

B (BLUE) TANK

FEMALE

M12 5 PIN

SET ROTARY SWITCH TO POSITION #3

FLUID CONTROL MODULE

54321

54321

MALE

M12 5 PIN

HARNESS

126413

LABEL FCM2B

BOTH ENDS

A (RED) TANK

SET ROTARY SWITCH TO POSITION #4

FLUID CONTROL MODULE

HARNESS

126413

LABEL FCM1A

BOTH ENDS

24VDC

SIGNAL

1

2

1

FEMALE

M12 5 PIN

FEMALE

M12 5 PIN

MALE

M12 5 PIN

24VDC

SIGNAL

COMMON

3

PX___

7

1

COMMON

SIGNAL

SIGNAL

4

432

SIGNAL

SIGNAL

"BLUE"

5

54321

54321

FEMALE

M12 5 PIN

BOTTOM

LEVEL SENSOR

1

FEMALE

M12 5 PIN

FEMALE

M12 5 PIN

43215 43215

CAN COM 1 CAN COM 2

432

CAN COM 1

CAN COM 2

876

123451234512345

FEMALE

M12 5 PIN

FEMALE

M12 5 PIN

121597

HARNESS

BOTH ENDS

LABEL CAN1

LABEL CAN2

(2 CABLES)

1

FEMALE

M8 4 PIN

GND

3

432

24C476

HARNESS

FEMALE

M12 8 PIN

1

FEMALE

M8 4 PIN

54321

5

4

2

54321

432

5

6

FCM1 FCM2

43215 43215

CAN COM 1 CAN COM 2

432

CAN COM 1

FEMALE

M12 5 PIN

432

1

5

M12 5 PIN

MALE (122487)

FEMALE (121002)

1

FEMALE

M8 4 PIN

3

432

1

FEMALE

M8 4 PIN

4

2

54321

1

2

3

ti16632b

100

101

102

103

104

105

106

107

108

109

110

PX___

111

112

113

4

114

"RED"

BOTTOM

LEVEL SENSOR

118

116

115

117

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

HARNESS

CONNECT (121002) TO SPLITTER ON MAIN PANEL

122487 OR 121002

OR (122487) TO AVAILABLE CAN PORT ON AN ACCESSORY MODULE

162

160

161

165

163

164

FIG. 10: Drum Feed Kit 24N813

3A2806C 21

Page 22

Parts

Parts

Drum Feed System, 24N816

003

006

005

004

001

005

22 3A2806C

Page 23

Ref Part Description Quantity

001 24N804 PANEL, assy, fluid control, HFRL

(Inside Enclosure - Refer to F

IG. 2,

1

page 5)

003 255468 KIT, acc., light tower, TC ram 1

004 124003 CABLE, CAN, male-female, 5.0m 1

005* 24N767 KIT, drum feed, carbon (Optional) 1

006* 01/0955/25 RACK, 4 drum (Optional) 1

* Items are optional. Shown for clarity.

Replacement Danger and Warning labels, tags, and

cards are available at no cost.

Parts

3A2806C 23

Page 24

Parts

Drum Feed Kit, 24N767

100

121

116

117

118

119

118

115

102

103

101

102

104

105,

130

106

128

124

124

128

106

112

108

111

122

125

108

109

125

110

120

129,

130

126

107

114

115

127

r_24n767_parts

127

123

24 3A2806C

Page 25

Ref Part Description Quantity

101 109505 BUSHING 1

102 108209 NIPPLE, pipe close 2

103 94/0906-R2/99 VALVE, ball, 2w, 1-1/2npt, f, 1500ps 1

104 121443 FITTING, tee, 1 1/2npt 1

105 94/1045-M/99 BUSHING, 1.5nptx3/4npt, mf, ms, prox 1

106 94/0910/98 FITTING, barb, 1-1/2x1-1/2npt, m, ss 2

107 647673 PUMP, 1050a, ss/ss/pt/a 1

108 94/0398/99 FITTING, elbw, strt, 90, 1npt, mf, ms, 2 2

109 160022 FITTING, union, adapter 1

110 94/0758/99 FITTING, npl, hex, 1"x3/4npt, mm, ms, 2k 1

111 94/0433/99 FITTING, nipple, hex, 1npt, mm, 4.5k 1

112 123250 FITTING, coupling, 1.5nptx1npt, cs 1

114 123890 FITTING, tee, 1nptx1nptx1nptf, fff, c 1

115 94/0909/99 FITTING, nipple, barb, 1"x1"npt, m, ms 2

116 94/0459/99 BUSHING, 2nptx1npt, mf, blk, 150# 1

117 94/0456/99 FITTING, nipple, 1npt, mm, blk, sch40 1

118 94/0904-R2/99 VALVE, bal, 2w, 1''npt, f, 2000psi, ms 2

119 94/0912/99 FITTING, qd, 1''npt, m, cam, dfk, ms 1

120 94/0915/99 FITTING, qd, 1''npt, f, cam, dfk, ms 1

121 247616 DRYER, desiccant, option 1

122 94/0550/99 SWIVEL, 3/4npsx1npt, fm, ms, 4k 1

123 61/0055/88 HOSE, hose, chem, pe, 1", 200psi 6

124 61/0056/88 HOSE, chem, pe, 1-1/2 6

125 217382 HOSE, coupled, 10 ft 1

126 104969 BUSHING, reducing 1

127 94/0451-2/99 CLAMP, hose, 1-3/4"-3/4", ms 4

128 94/0414/99 CLAMP, hose, 2-1/4"-1-5/16", ms 4

129 94/0397-M/99 BUSHING, 1nptx3/4npt, mf, ms, prox 1

130* 102726 PLUG, pipe headles 2

Parts

Replacement Danger and Warning labels, tags, and

cards are available at no cost.

* Either the upper or lower plug can be removed and

replaced with a level sensor assembly.

- Only one sensor per chemical side can be used

- Both material sides should utilize the same (upper

or lower) sensor position.

3A2806C 25

Page 26

Parts

Electric Panel, 24N804

210

211

212

204

212

202

201

224

or

225

213

214

219

220

211

212

215

203

215

204

204,

215

205

206

208,

209

26 3A2806C

220

208,

209

207

233,

234

r_24n804_parts1

Page 27

222

221

Parts

223

220

218

214

225

224

213

216

217

r_24n804_parts2

3A2806C 27

Page 28

Parts

Ref Part Description Quantity

201 15Y917 PANEL, electric, heat 1

202 115942 NUT, hex, flange head 3

203 289697 MODULE, GCA, cube, base 2

204 24C476 HARNESS, wire, ground, term 1

205 102063 WASHER, lock, ext 2

206 114993 SCREW, mach, pan wash hd 2

207 102598 SCREW, cap, socket head 8

208 289696 MODULE, GCA, cube, FCM 2

209 277674 ENCLOSURE, cube door 2

210 100021 SCREW, cap hex hd 1

211 100015 NUT, hex mscr 2

212 100028 WASHER, lock 3

213 123452 HOLDER, anchor, wire tie, nylon 3

214 116610 SCREW, mach, phil, pan, #10 3

215 24H240 HARNESS, wire, ground, term, 9" 1

216 100020 WASHER, lock 1

217 100166 NUT, full hex 1

218 123679 BUSHING, wire protector, 1 3/8 od 1

219 121597 CABLE, CAN, 90 female/90 female 1

220 126413 HARNESS, m12xm12, 5px4p, mxf, 10m 2

221 121511 SENSOR, capacitive, 18mm, qck disc 2

222 16A511 HOUSING, well, prox, efector 2

223 15U978 CAP, well, prox, PR70 2

224 121002 CABLE, CAN, female / female 1.5m 1

225 122487 CABLE, CAN, male-female, 1.5m 1

226 16D656 LABEL, identification, electronics 1

227 070408 SEALANT, pipe, sst 1

228 16H821 TOKEN, GCA, upgrade, ADM32 1

229 16E530 SOFTWARE, GCA, tank stand 1

230 24N813 CONTROL, panel, HFRL, low levels 1

233 15A721 LABEL, designation 1

Replacement Danger and Warning labels, tags, and

cards are available at no cost.

28 3A2806C

Page 29

Parts

3A2806C 29

Page 30

Parts

4 Drum Rack, 01/0955/25

(Optional)

(Typical Installation - 9 Places)

305

305

305

303

301

304

305

305

A

F

302

D

C

305

E

B

Rack Dimensions:

A (Height): 60-1/2 in. (154 cm)

B (Length): 36-1/2 in. (93 cm)

C (Width): 60-1/2 in. (154 cm)

Anchor Locations:

D (Width): 57-1/2 in. (146 cm)

E (Length): 33-1/2 in. (85 cm)

F (Diameter): Ø 0.56 in. (1.4 cm)

30 3A2806C

To avoid machine damage or personal injury,

anchor the rack to the floor with (4) 1/2” bolts (provided by customer) and verify all bolt assemblies

are tightened before loading the drums onto the

rack.

01_0955_25

NOTICE

Page 31

Ref Part Description Quantity

301 01/0955-A/99 SHELF, rack, 4 drum 2

302 01/0955-B/99 SUPPORT, shelf, rack, 2/4 drum, right 1

303 01/0955-C/99 SUPPORT, shelf, rack, 2/4 drum, left 1

304 01/0955-D/99 STRAP, stabilizer, rack, 4 drum 2

305 01/0955/50 RACK, 2/4 drum, seal, hardware 1

Parts

3A2806C 31

Page 32

Appendix A - ADM Setup Screens Overview

Appendix A - ADM Setup Screens Overview

For other screen not mentioned, refer to the HFRL and

HFRS, Setup-Operations manual.

Supply Screen

This screen allows the user to specify the operating

parameters for off-board, integrated tanks and indicate

which positions have level sensors installed.

Activate at least 2 level sensors for each reservoir or the

level sensor functions will be disabled.

For a single low sensor in each drum feed, configure as

shown below. (Activate mid and low sensors, and set

refill setting to monitor).

Advanced Screen 1

This screen allows the user to set the language, date

format, current date, time, setup screens password,

screen saver delay, and turn on or off silent mode.

• Time: formatted in 24 hour time.

• Password: Enables the setup screens to be pass-

word protected. Entering “0000” disables the feature.

• Screen Saver: Enter the amount of time until the

backlight turns off. Entering “0” leave it constantly

on.

• Silent Mode: Check this box to turn off the buzzer

for key presses.

Advanced Screen 2

This screen allows the user to set the units of measure.

32 3A2806C

Page 33

Appendix A - ADM Setup Screens Overview

Advanced Screen 3

This screen allows the user to control the availability of

some key system features.

• Disable Dispensing From Display: Check this box

to disable dispensing from the ADM. A footswitch,

dispense valve trigger, or other external signal will

be the only way to initiate a dispense.

• Disable Modifying Temp Setpoint: Check this box

to disable modifying temperature setpoints from the

Run screens. This is only applicable if temperature

control items are installed and enabled.

• Disable Operator Mode Adjustments: When this

box is checked, the user will not be able to adjust

the dispense settings in Operator Mode.

• Dispense from Home Position: When this box is

checked, the machine will be required to reach a

defined home position before dispensing in shot or

sequence mode.

Advanced Screen 4

This screen is for enabling the optional ADM screens,

enabling USB log downloading, and erasing USB logs.

To enable the machine to automatically stop dispensing

when a reservoir is low: place an “X” beside the “Low

Material Disables Dispense” check box. When this feature is active, the machine will not cycle unless material

is present in the monitored reservoirs.

• Temperature Alarm Disables Dispense: When

this box is checked, the system will reject dispense

requests when any enabled heat/chiller zones are

below/above their setpoint.

• Enable Operator Mode Cavitation Alarm: Check

this box to enable cavitation alarms in Operator

Mode. Clear this box to disable cavitation alarms in

Operator Mode.

• Complete Dispense with Setpoint Error: When

this box is checked, the shot will continue dispensing even if the system never reaches the desired

setpoint.

• Enable Shot Aborted Notification: When this box

is checked, a pop-up notification will be displayed

when a shot is aborted.

• 2x Trigger For Dispense: When this box is

checked, the machine will require a double trigger

pull to initiate dispensing in shot or sequence mode.

3A2806C 33

Page 34

Appendix A - ADM Setup Screens Overview

Advanced Screen 5

This screen displays software information.

If the level controls are present but not active, the tank

monitor program will not appear in the advanced 5

screen as shown below.

34 3A2806C

Page 35

Appendix B - ADM Run Screens Overview

Appendix B - ADM Run Screens Overview

For other screen not mentioned, refer to the HFRL and

HFRS, Setup-Operations manual.

Home Screen, Refill Disabled

If refill is Disabled, the home screen will not show a

graphic display of the reservoirs.

Home Screen, Refill Enabled

Home Screen, Low Level - A (Red) Side

When a low level on the RED side is sensed, the pop up

error code appears and the active error display reads

“Red Low Material Level”. The light stack will flash yellow, and the audible alarm will sound. When this error

occurs, the machine will continue to dispense when a

start is initiated, unless the “Low Material Disables Dispense” flag is set.

Refer to Advanced Screen 3 to configure the machine

to stop dispensing when a low level sensor is triggered.

When the level sensors are active and both reservoirs

have material, the display looks as above. The stack

light will illuminate a solid green (Unless another error is

present).

When the level condition is acknowledged by the operator (by hitting the enter key), but not cleared; the audible

alarm will stop, and the pop up window will disappear.

The active error display will still indicate a low level condition, and the stack light will continue to flash yellow,

unless the low level condition has been corrected.

3A2806C 35

Page 36

Appendix B - ADM Run Screens Overview

Home Screen, Low Level - B (Blue) Side

When a low level on the BLUE side is sensed, the pop

up error code appears and the active error display reads

“Red Low Material Level”. The light stack will flash yellow, and the audible alarm will sound. When this error

occurs, the machine will continue to dispense when a

start is initiated, unless the “Low Material Disables Dispense” flag is set.

Refer to Advanced Screen 3 to configure the machine

to stop dispensing when a low level sensor is triggered.

When the level condition is acknowledged by the operator (by hitting the enter key), but not cleared; the audible

alarm will stop, and the pop up window will disappear.

The active error display will still indicate a low level condition, and the stack light will continue to flash yellow,

unless the low level condition has been corrected.

36 3A2806C

Page 37

Technical Data

Technical Data

Level Detection Module and Drum Feed Kit

US Metric

Maximum fluid working pressure 125 psi 0.86 MPa, 8.6 bar

Maximum air input pressure 125 psi 0.86 MPa, 8.6 bar

Noise (dBa)

Maximum sound pressure

Maximum sound power

Inlet/Outlet Sizes

Air inlet size

Materials of Construction

Wetted materials Carbon steel, PTFE, Stainless Steel, PE, Aluminum, Nylon

Weight

24N816 16 lb 7.3 kg

24N767 (Optional) 69 lb 31 kg

01/0955/25 (Optional) 209 lb 95 kg

Notes

† For additional technical data regarding the HFRL and HFRS systems, refer to manual.

For additional technical data regarding the Husky 1050 Air-Operated Diaphragm Pump, refer to manual.

†

†

1/2 NPTF

3A2806C 37

Page 38

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-746-1334 Fax: 330-966-3006

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2012, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original Instructions. This manual contains English. MM 3A2806

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised November 2013

Loading...

Loading...