Page 1

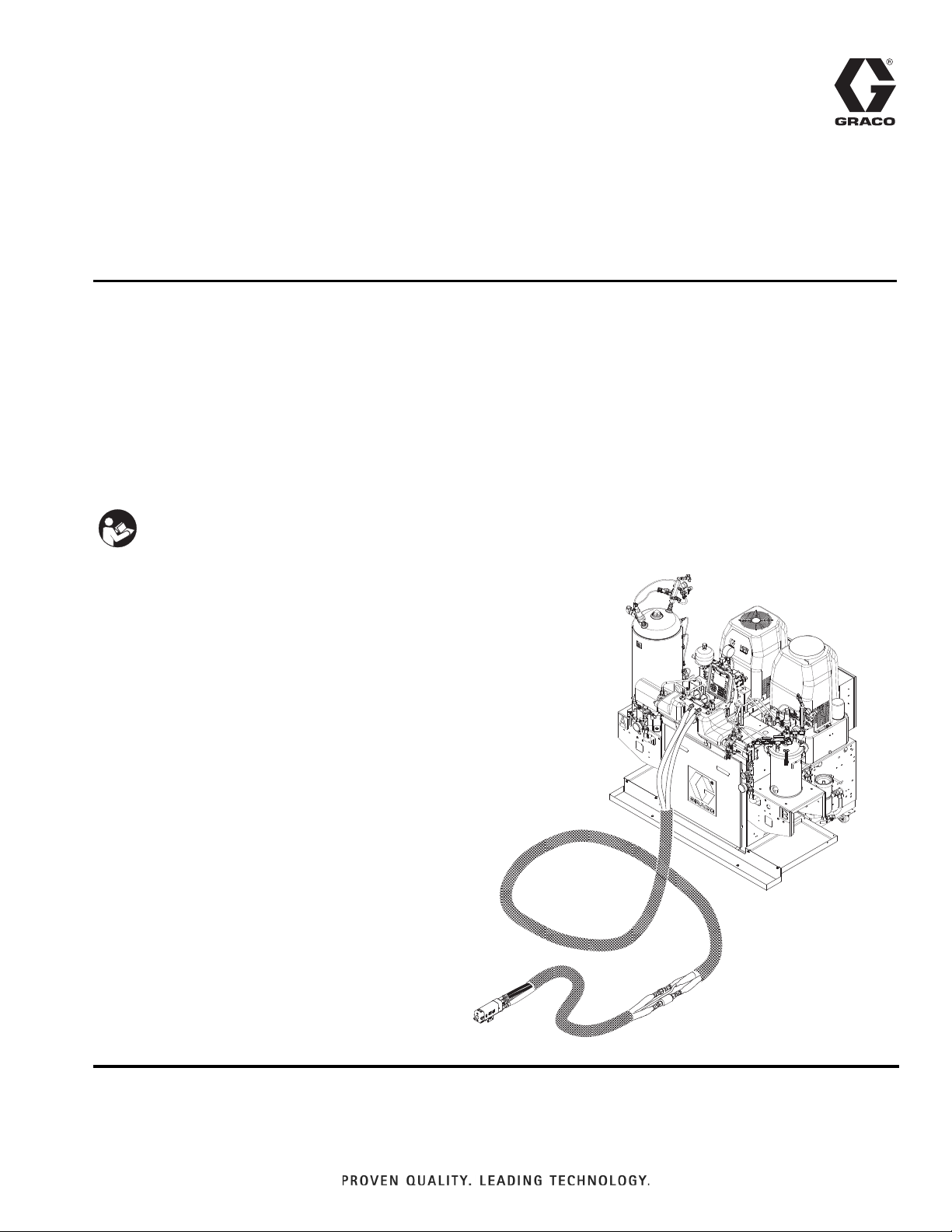

Setup - Operation

ti19507a

™

HFR

for NVH

3A2797G

Foam - Cart

Hydraulic, Plural-Component, Fixed-Ratio Proportioner.

For dispensing NVH foam.

For professional use only. Not approved for use in explosive atmospheres or hazardous

locations.

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

EN

See page 4 for model information and maximum

working pressure.

Patents Pending

Page 2

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Applicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

GX-16 Orifices . . . . . . . . . . . . . . . . . . . . . . . . . . 6

B (Blue) and A (Red) Feed Tanks . . . . . . . . . . . 6

AC Power Pack . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Refill Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

GX-16 Shutoff Valve Kit . . . . . . . . . . . . . . . . . . . 6

Additional Accessories . . . . . . . . . . . . . . . . . . . . 7

Communications Gateway Module (CGM) . . . . . 7

Bag Filter Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

GX-16 Fitting Kits . . . . . . . . . . . . . . . . . . . . . . . . 7

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Important Two-Component Material Information 11

Isocyanate Conditions . . . . . . . . . . . . . . . . . . . . 11

Material Self-ignition . . . . . . . . . . . . . . . . . . . . . 11

Keep Components A (Red) and B (Blue) Separate

11

Moisture Sensitivity of Isocyanates . . . . . . . . . . 11

Foam Resins with 245 fa Blowing Agents . . . . . 11

Changing Materials . . . . . . . . . . . . . . . . . . . . . . 12

A (Red) and B (Blue) Components . . . . . . . . . . . . 12

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . . 13

Component Identification . . . . . . . . . . . . . . . . . . . 14

HFR Hydraulic Power Pack . . . . . . . . . . . . . . . . 17

Motor Control Module (MCM) . . . . . . . . . . . . . . 18

Advanced Display Module (ADM) . . . . . . . . . . . 20

Fluid Control Module (FCM) . . . . . . . . . . . . . . . 23

Temperature Control Module . . . . . . . . . . . . . . . 24

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 44

Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Install Upgrade Tokens . . . . . . . . . . . . . . . . . . . 47

IsoGuard Select™ System . . . . . . . . . . . . . . . . 48

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Light Tower (Optional) . . . . . . . . . . . . . . . . . . . . 49

Appendix A - ADM Icons Overview . . . . . . . . . . . 52

Setup Screen Icons . . . . . . . . . . . . . . . . . . . . . . 52

Run Screen Icons . . . . . . . . . . . . . . . . . . . . . . . 53

Appendix B - ADM Setup Screens Overview . . . 54

Appendix C - ADM Run Screens Overview . . . . . 69

Appendix D - ADM Error Codes . . . . . . . . . . . . . . 75

Appendix E - System Events . . . . . . . . . . . . . . . . 87

Appendix F - USB Operation . . . . . . . . . . . . . . . . . 89

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

USB Options . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Download Log Files . . . . . . . . . . . . . . . . . . . . . . 89

Log Files, Folder Structure . . . . . . . . . . . . . . . . 90

Transfer System Settings . . . . . . . . . . . . . . . . . . 92

Update Custom Language . . . . . . . . . . . . . . . . . 93

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Motor Control Module Technical Data . . . . . . . . 96

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 98

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 98

2 3A2797G

Page 3

Related Manuals

Manuals are available at www.graco.com. Component

manuals below are in English:

System Manuals

313998 HFR Repair-Parts

Power Distribution Box Manual

3A0239 Power Distribution Boxes Instruc-

tions-Parts

Pumpline Manuals

3A0019 Z-Series Chemical Pumps Instruc-

tions-Parts

3A0020 HFR Hydraulic Actuator Instruc-

tions-Parts

Feed System Manuals

3A0238 AC Hydraulic Power Pack Instruc-

tions-Parts

3A0235 Feed Supply Kits

Instructions-Parts

3A0395 Stainless Steel Tank Feed Sys-

tems Instructions-Parts

3A1299 Carbon Steel Tank Feed Systems

Instructions-Parts

3A0237 Heated Hoses and Applicator Kits,

Instructions-Parts

308495

Viscon® Heater Kit Manual

Related Manuals

Dispense Valve Manuals

313536 GX-16, Operation

Accessory Manuals

3A1149 HFR Discrete Gateway Module

Kits Manual

312864 HFR Communications Gateway

Module Instructions-Parts

3A1936 Agitator Kit

Instructions-Parts

3A1962 Agitator Kit with Heat Blanket

Instructions-Parts

3A1657 HFR Flow Meter Kits

Instructions-Parts

332544 HFR for NVH Prepoly Refresh Kit

Instructions-Parts

3A2797G 3

Page 4

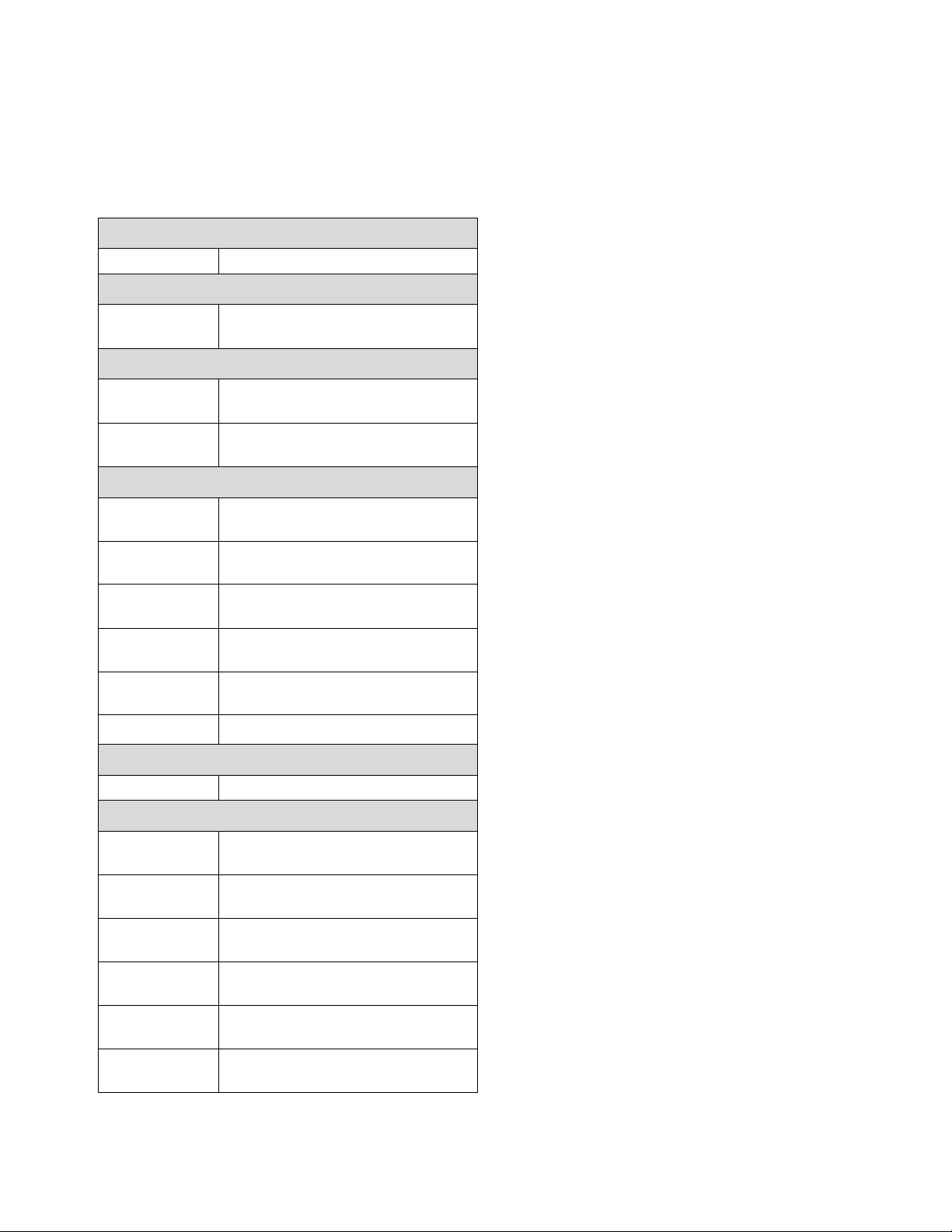

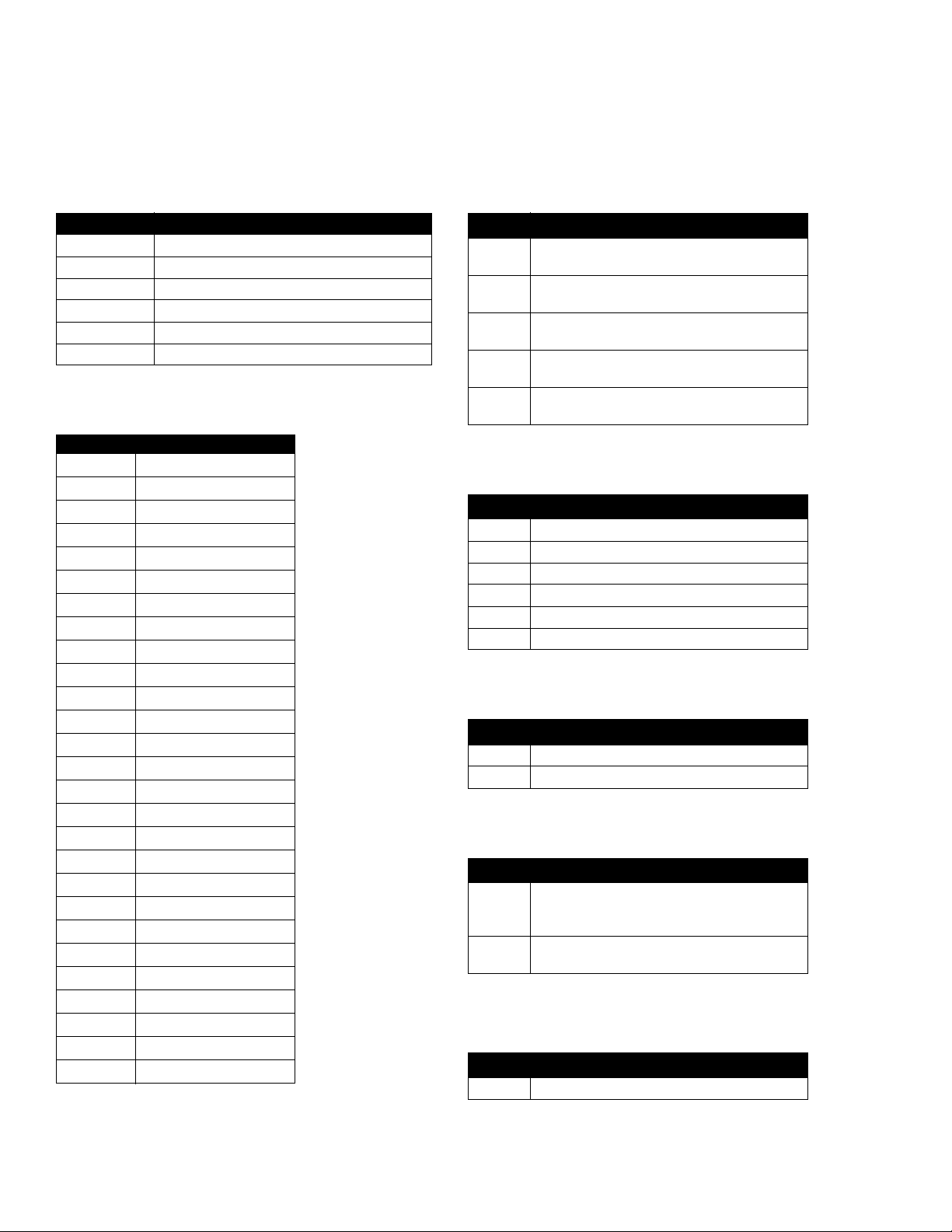

Models

Models

Full Load

System

Peak Amps

Per Phase*

Voltage

(phase)

24N569 90 230V (3)

24N570 ★✖ 68 400V (3)

24N571 90 230V (3)

24N572 ★✖ 68 400V (3)

24N573 90 230V (3)

24N574 ★✖ 68 400V (3)

24N575 90 230V (3)

24N576 ★✖ 68 400V (3)

System

Material

Ratio

(A:B)

A (Red)

Pump

Size

B (Blue)

24N569

24:1 120 5 .061 .011

24N570 ★

24N571

16:1 160 10 .057 .014

24N572 ★

Pump

Size

Primary

Heater

Watts

A (Red)

6,000

A (Red)

Orifice

Primary

Heater

Watts

B (Blue)

Max Flow

Rate◆

lb/min

(kg/min)

Approximate

Output per

Cycle (A+B)

gal. (liter)

Hydraulic

Pressure

Ratio

18 (8.2) 0.033 (0.125) 1.9:1

4,000

24 (11) 0.045 (0.170) 1.4:1

6,000 17 (7.7) 0.032 (0.121) 3.7:1

4,000 18 (8.2) 0.033 (0.125) 1.9:1

B (Blue)

Orifice

25’ (7.6 m)

Chemical

Hose Bundle

10’ (3 m)

Chemical

Hose Bundle

24J290 24J316

Maximum

Fluid Working

Pressure ‡

psi (MPa, bar)

2000

(14, 138)

24N573

24N574 ★

24N575

24N576 ★

System

24N569

24N570 ★

24N571

24N572 ★

24N573

24N574 ★

24N575

24N576 ★

1:1 60 60 .039 .039 24N287 24N289

24:1 120 5 .085 .013 24K681

27.5’ (8.4 m)

Hydraulic

Hose Bundle

10’ (3 m)

Hydraulic

Hose Bundle

24V197 24J177

4 3A2797G

Page 5

Models

* Full load amps with all devices operating at maximum capabilities. Fuse requirements at various flow rates and

mix chamber sizes may be less.

◆ Flow rate is independent of frequency 50/60 Hz.

★ approved.

‡ The maximum fluid working pressure for the base machine without hoses is 3000 psi (20.7 MPa, 207 bar). If

hoses rated at less than 3000 psi are installed, the system maximum fluid working pressure becomes the rating of

the hoses. If 2000 psi hoses were purchased and installed by Graco, the working pressure for the machine is

already setup for the lower 2000 psi (13.8 MPa, 138 bar) working pressure by Graco. If the machine was purchased without hoses and aftermarket hoses rated at or above 3000 psi are to be installed, see instruction manual 313998 for the procedure to setup the machine for higher rated hoses. The change in working pressure is

made by changing a rotary switch setting in the Motor Control Module. The minimum pressure rating for hoses is

2000 psi. Do not install hoses with a pressure rating lower than 2000 psi.

✖ See 400 V Power Requirements.

400 V Power Requirements

• 400 V systems are intended for International voltage

requirements. Not for voltage requirements in North

America.

• If a 400 volt configuration is operated in North America, a special transformer rated for 400 V (“Y” configuration (4 wire)) may be required.

• North America mostly employs a 3 wire or Delta

configuration. The two configurations are not interchangeable.

3A2797G 5

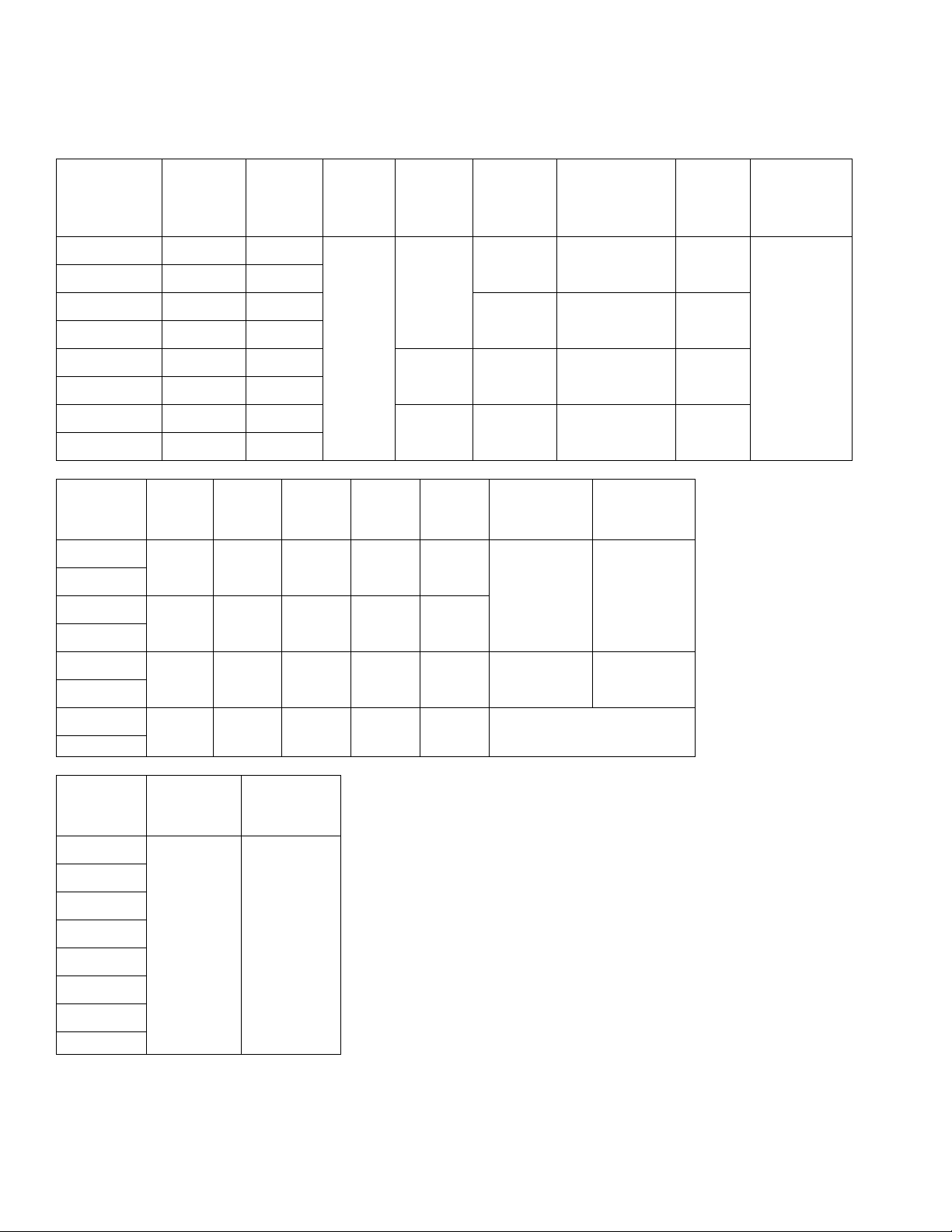

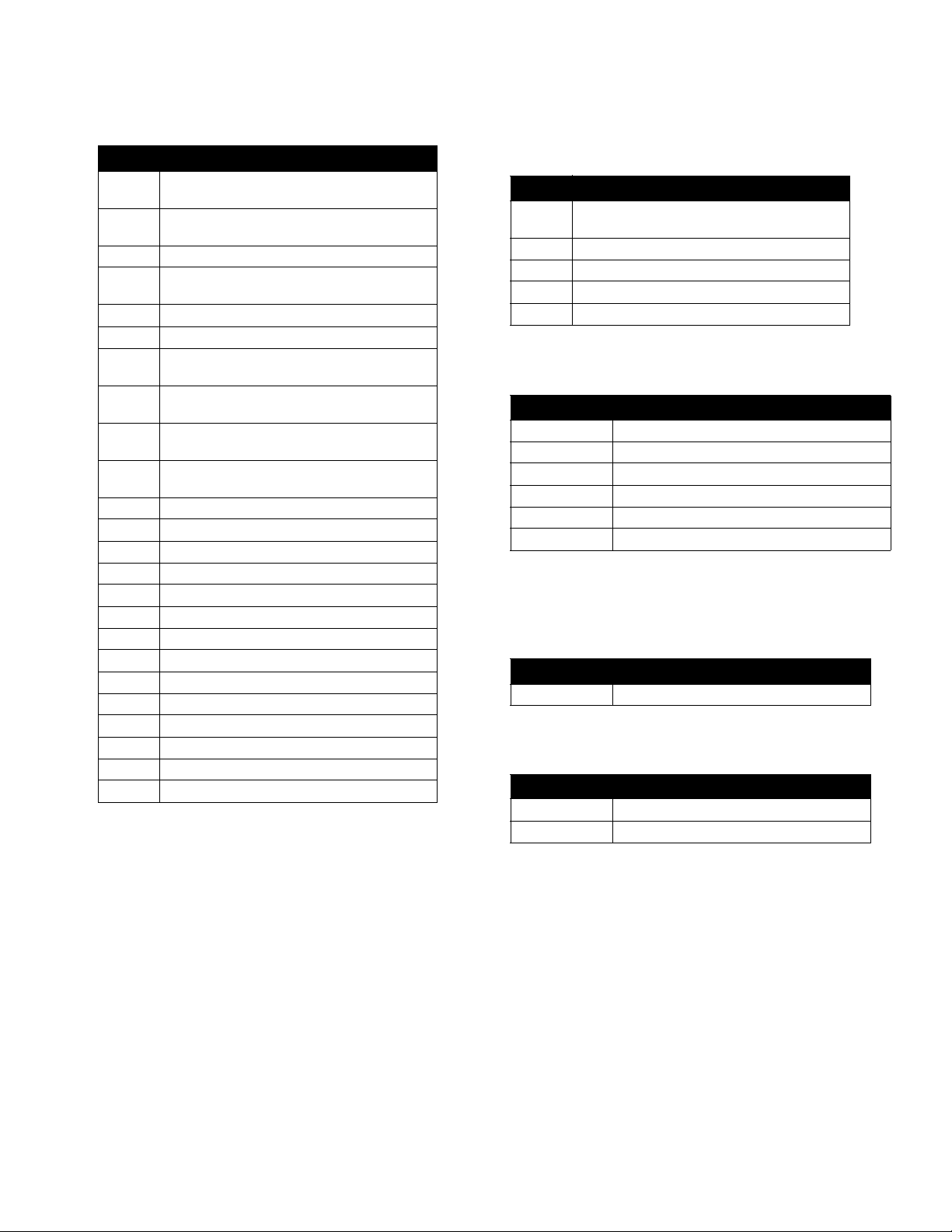

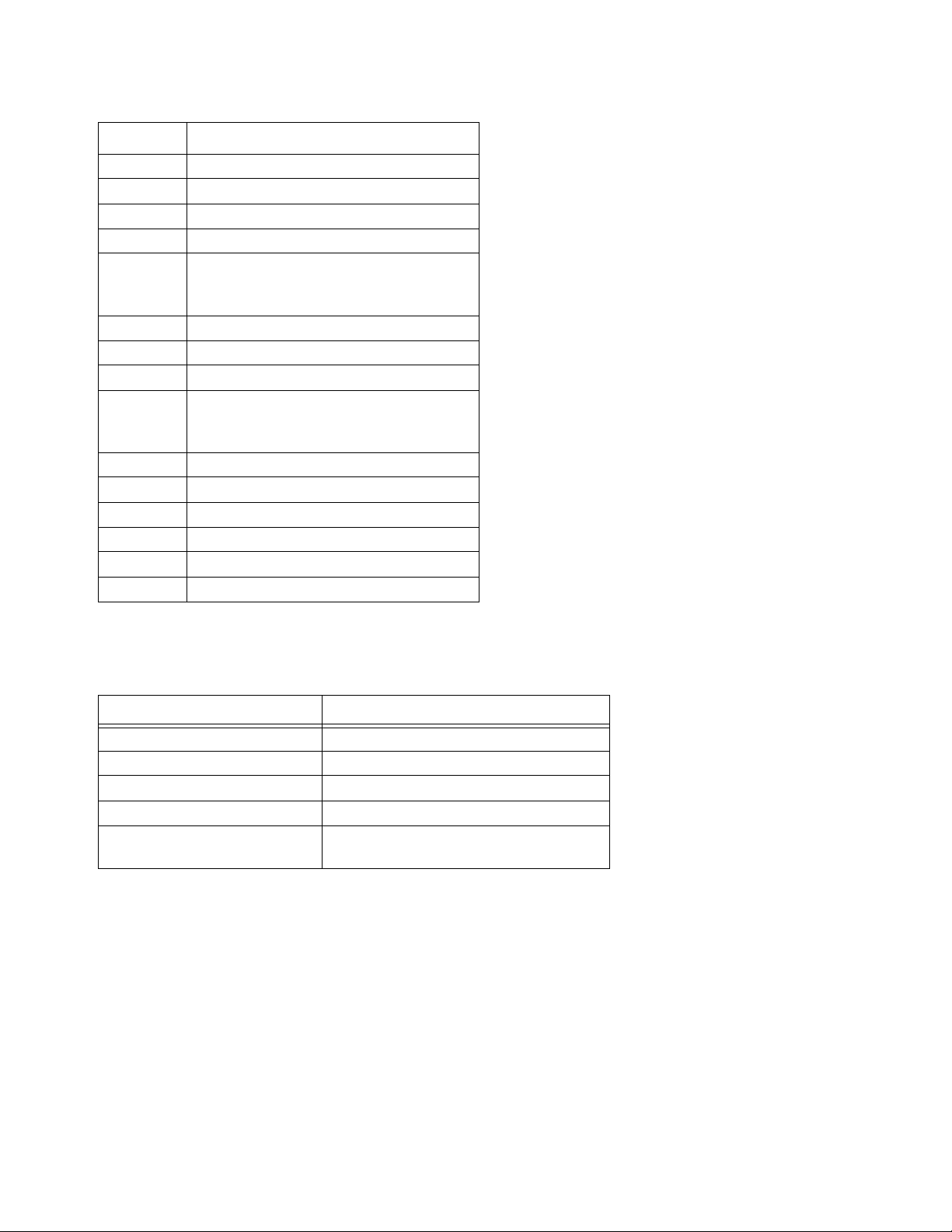

Page 6

Accessories

Accessories

Applicator

Part Description

24J187 GX-16, 24:1, Straight, Machine Mount

24K233 GX-16, 24:1, Left, Machine Mount

24K234 GX-16, No Orifice, Left, Machine Mount

24E876 GX-16, No Orifice, Straight, Machine Mount

24E877 GX-16, 24:1, Right, Machine Mount

24E878 GX-16, No Orifice, Right, Machine Mount

GX-16 Orifices

Part Description

257701 0.011 in. Orifice

257702 0.013 in. Orifice

24N158 0.014 in. Orifice

257703 0.016 in. Orifice

257704 0.018 in. Orifice

257705 0.020 in. Orifice

257706 0.022 in. Orifice

257707 0.023 in. Orifice

257708 0.024 in. Orifice

257709 0.025 in. Orifice

257710 0.026 in. Orifice

257711 0.028 in. Orifice

257712 0.029 in. Orifice

257713 0.032 in. Orifice

257714 0.035 in. Orifice

257715 0.036 in. Orifice

257716 0.038 in. Orifice

257717 0.039 in. Orifice

257718 0.040 in. Orifice

257719 0.042 in. Orifice

257720 0.043 in. Orifice

257721 0.044 in. Orifice

257722 0.049 in. Orifice

257723 0.052 in. Orifice

24N159 0.057 in. Orifice

257724 0.061 in. Orifice

24K682 0.085 in. Orifice

B (Blue) and A (Red) Feed Tanks

Part Description

24N594 20 gal. (75 l) Stainless Steel Tank, No Agitation,

Insulation, 3 Level Sensors, A-Side

24N595 20 gal. (75 l) Stainless Steel Tank, No Agitation,

Insulation, 3 Level Sensors, B-Side

24N578 20 gal. (75 l) Carbon Steel Tank, No Agitation, 3

Level Sensors, A-Side

24N597 20 gal. (75 l) Carbon Steel Tank, No Agitation, 3

Level Sensors, B-Side

24N579 2 gal. (8 l) Stainless Steel Tank, No Agitation, 1

Level Sensor, B-Side

AC Power Pack

Part Description

24J912 230V, AC Power Pack

24J913 400V, AC Power Pack

24E347 Hydraulic Power Pack Level Sensor Kit

24C872 Hydraulic Power Pack Pressure Gauge Kit

24E348 Hydraulic Power Pack Temperature Sensor

124217 Power Pack Accumulator Charging Kit

Refill Kits

Part Description

24M418 Low Volume, 2 gal. (7.6 l) tank

24M419 High Volume, 20 gal. (76 l) tank

GX-16 Shutoff Valve Kit

Part Description

24M596 GX-16 Shutoff Valve Kit

For use with: 24N569, 24N570, 24N571, 24N572,

24N573, 24N574

24M368 GX-16 Shutoff Valve Kit

For use with: 24N575, 24N576

GX-16 Proximity Kit

Part Description

24K659 GX-16 Proximity Kit

6 3A2797G

Page 7

Accessories

Additional Accessories

Part Description

24C871 Hydraulic Power Pack Hydraulic Tank Fluid Level

Sensor

24C873 Hydraulic Power Pack Manifold Oil Temperature

Sensor

24F516 IsoGuard Select fluid, 6 quar ts

121728 Extension Cable for Advanced Display Module,

4 meter,

255468 Light Tower

255244 Foot Switch with Guard and 4 meter Cable

24G389 Pneumatic Agitator for 20 gal. (75 l) Carbon Steel

Tank, No Heat

24K344 Pneumatic Agitator for 20 gal. (75 l) Carbon Steel

Tank, Heat

24K348 Pneumatic Agitator for 20 gal. (75 l) Stainless

Steel Tank, No Heat

24K346 Pneumatic Agitator for 20 gal. (75 l) Stainless

Steel Tank, Heat

24K223 Isolated Pistol Grip Adapter

123694 Straight Gun Cover

123226 90° Gun Cover

123695 12 ft (3.7 m) Hose Cover

125236 Z-Series Pump Cover

125113 Gun Cover Handle Hole Cover

248280 3 oz. Quik Shot Grease Tube (10 Pack)

117792 3 oz. Grease Gun

0553-6 14 oz. Synthetic Grease Tube

255468 Light Tower Kit

24T182* Flow Meter Kit, NVH Cart, 24:1 and 16:1

24T183* Flow Meter Kit, NVH Cart, 1:1

24T180 PrePoly Refresh Kit, NVH Car t, with Autofill

24T181 PrePoly Refresh Kit, NVH Car t, without Autofill

* Flow meter electronics kit, 24J318, is required for flow meter kit

installation.

Communications Gateway Module (CGM)

Part Description

24J415 CGM Mounting Kit

(Required for all applications)

CGMDN0 GCA Gateway Module, DeviceNet Fieldbus

CGMEP0 GCA Gateway Module, EtherNet/IP Fieldbus

CGMPB0 GCA Gateway Module, PROFIBUS Fieldbus

CGMPN0 GCA Gateway Module, PROFINET Fieldbus

Bag Filter Kits

Part Description

24J312 High Volume Filter Kit (40 Mesh)

24P095 Low Volume Filter Kit (100 Mesh)

125147 40 Mesh Filter Replacement

125148 100 Mesh Filter Replacement

0135-4.30x.313 TEV O-Ring for Lid Seal

0131-4.30x.313 EP O-Ring for Lid Seal

GX-16 Fitting Kits

The following kit is for Models 24N575 and 24N576 only.

Part Description

24N435 Gun Fitting Kit

The following kits are for all other Models.

Part Description

24K672 Right Orientation, 90° Fitting Adapter Kit

24K674 Left Orientation, 90° Fitting Adapter Kit

3A2797G 7

Page 8

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and regulations.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear chemically impermeable gloves when spraying, dispensing, or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of toxic fumes, and burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispensing device at anyone or at any part of the body.

+

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking,

or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

8 3A2797G

Page 9

Warnings

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic

drop cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical

reaction and equipment rupture. Failure to follow this warning can result in death, serious injury, or

property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material

supplier for compatibility.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and

cause serious injury.

• Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

3A2797G 9

Page 10

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment

and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, follow the Pressure Relief Procedure and disconnect all power sources.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns:

• Do not touch hot fluid or equipment.

10 3A2797G

Page 11

Important Two-Component Material Information

Important Two-Component Material Information

Isocyanate Conditions

Spraying or dispensing materials containing isocyanates creates potentially harmful mists, vapors, and

atomized particulates.

Read material manufacturer’s warnings and material

MSDS to know specific hazards and precautions

related to isocyanates.

Prevent inhalation of isocyanate mists, vapors, and

atomized particulates by providing sufficient ventilation in the work area. If sufficient ventilation is not

available, a supplied-air respirator is required for

everyone in the work area.

To prevent contact with isocyanates, appropriate personal protective equipment, including chemically

impermeable gloves, boots, aprons, and goggles, is

also required for everyone in the work area.

Material Self-ignition

Some materials may become self-igniting if applied

too thickly. Read material manufacturer’s warnings

and material MSDS.

Keep Components A (Red) and

Moisture Sensitivity of Isocyanates

Isocyanates (ISO) are catalysts used in two component

foam and polyurea coatings. ISO will react with moisture

(such as humidity) to form small, hard, abrasive crystals,

which become suspended in the fluid. Eventually a film

will form on the surface and the ISO will begin to gel,

increasing in viscosity. If used, this partially cured ISO

will reduce performance and the life of all wetted parts.

NOTE: The amount of film formation and rate of crystallization varies depending on the blend of ISO, the

humidity, and the temperature.

To prevent exposing ISO to moisture:

• Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere. Never

store ISO in an open container.

• Keep the ISO lube pump reservoir (if installed) filled

with IsoGuard Select™, part 24F516. The lubricant

creates a barrier between the ISO and the atmosphere.

• Use moisture-proof hoses specifically designed for

ISO, such as those supplied with your system.

• Never use reclaimed solvents, which may contain

moisture. Always keep solvent containers closed

when not in use.

• Never use solvent on one side if it has been contaminated from the other side.

• Always lubricate threaded parts with ISO pump oil

or grease when reassembling.

B (Blue) Separate

Foam Resins with 245 fa Blowing Agents

Some foam blowing agents will froth at temperatures

Cross-contamination can result in cured material in

fluid lines which could cause serious injury or damage equipment. To prevent cross-contamination of

the equipment’s wetted parts, never interchange

component A (Red) and component B (Blue) parts.

3A2797G 11

above 90°F (33°C) when not under pressure, especially

if agitated. To reduce frothing, minimize preheating in a

circulation system.

Page 12

A (Red) and B (Blue) Components

Changing Materials

• When changing materials, flush the equipment multiple times to ensure it is thoroughly clean.

• Always clean the fluid inlet strainers after flushing.

• Check with your material manufacturer for chemical

compatibility.

• Most materials use ISO on the A (Red) side, but

some use ISO on the B (Blue) side. See the following section.

A (Red) and B (Blue) Components

IMPORTANT!

Material suppliers can vary in how they refer to plural

component materials.

Be aware that when standing in front of the manifold on

proportioner:

• Component A (Red) is on the left side.

• Component B (Blue) is on the right side.

For all machines:

• The A (Red) side is intended for ISO, hardeners,

and catalysts.

• If one of the materials being used is moisture-sensitive, that material should always be in the A (Red)

side.

• The B (Blue) side is intended for polyols, resins, and

bases.

12 3A2797G

Page 13

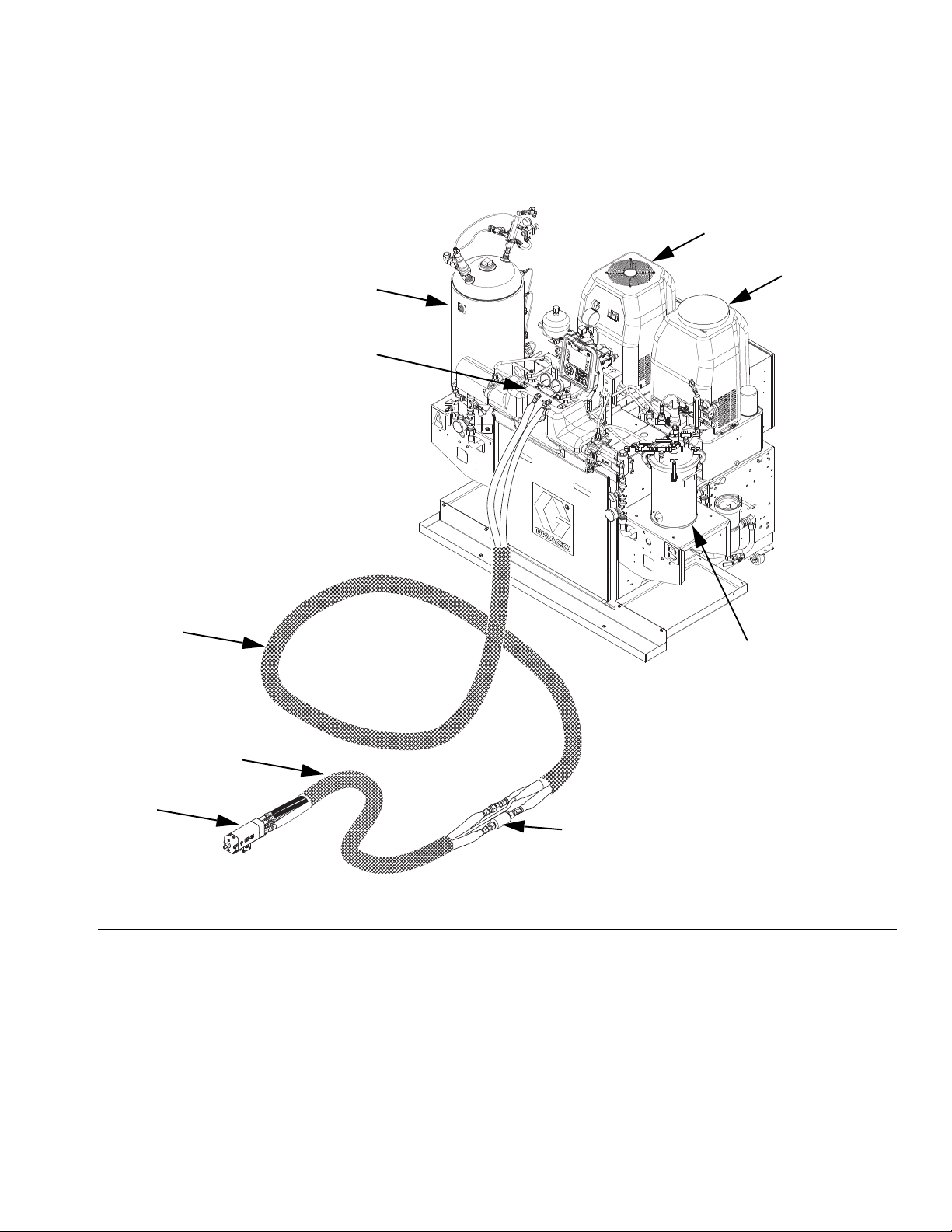

Typical Installation

* Shown exposed for clarity.

Wrap with tape during operation.

ti19507a

F*

A

H

E

J

D

C

B

G

Typical Installation

FIG. 1: Typical Installation

Key:

A Tank Stand - A (Red)

B Tank Stand - B (Blue)

C AC Power Pack

D HFR Power Pack

E Dispense Gun

F Fluid Temperature Sensor (FTS)

G Manifold

H Main Hose Bundle

J Whip Hose Bundle

3A2797G 13

Page 14

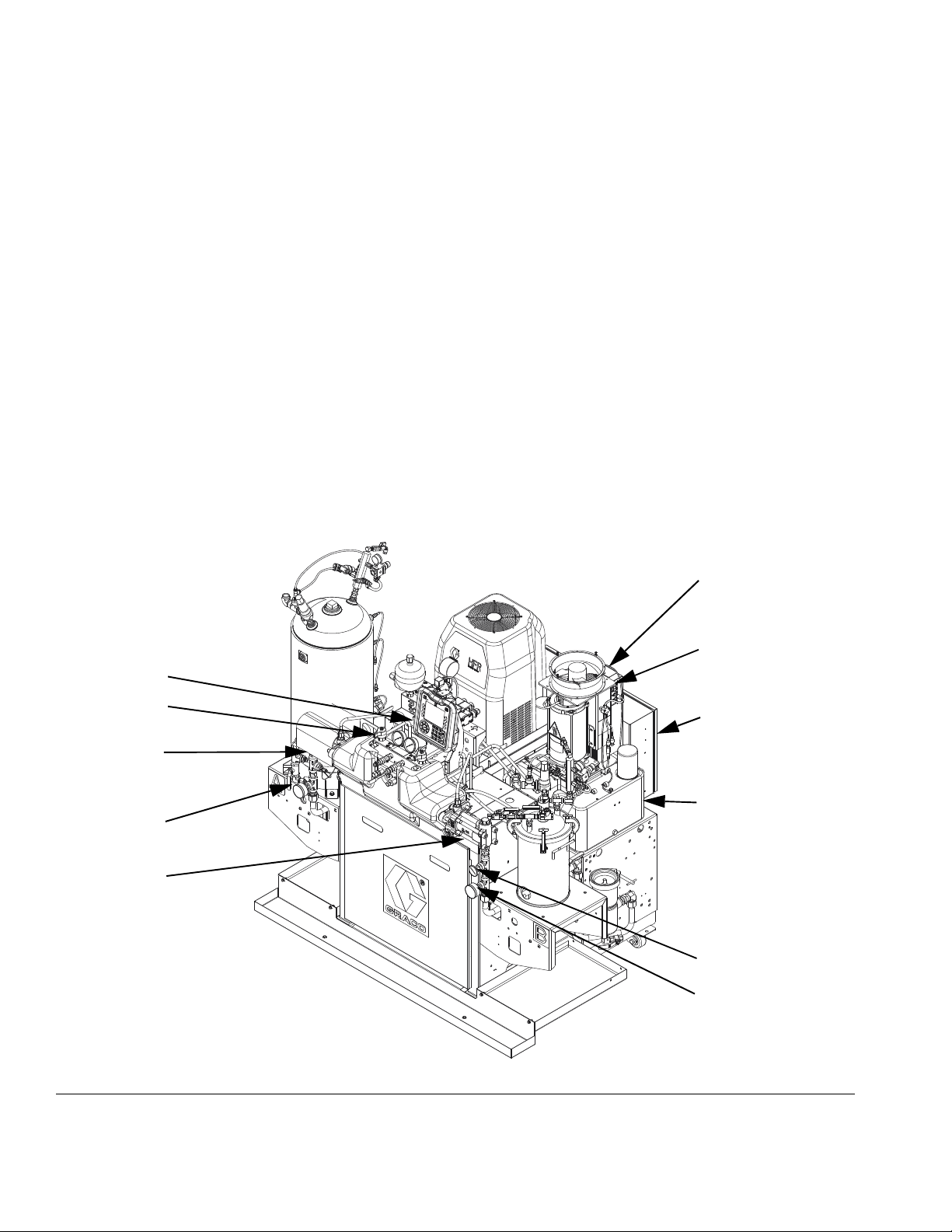

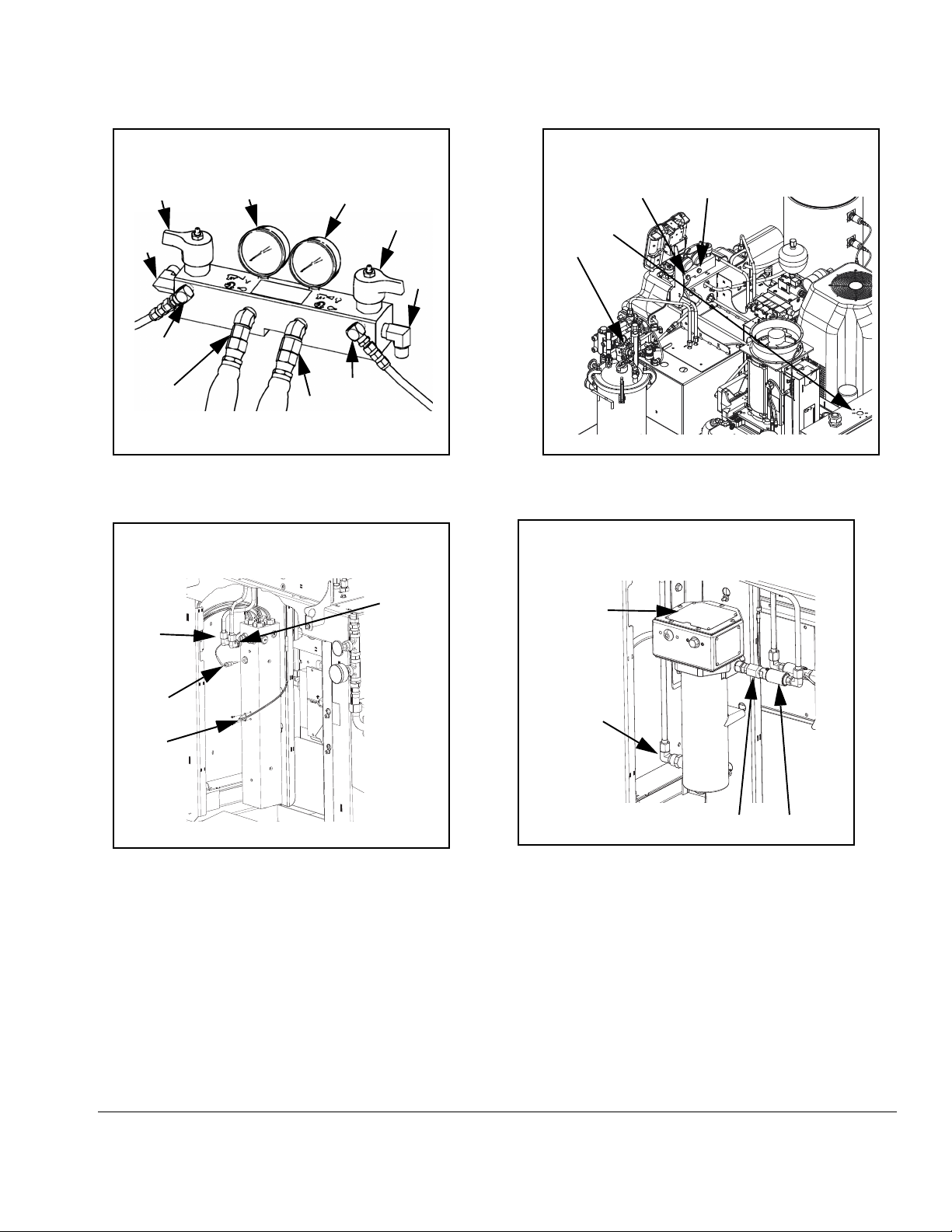

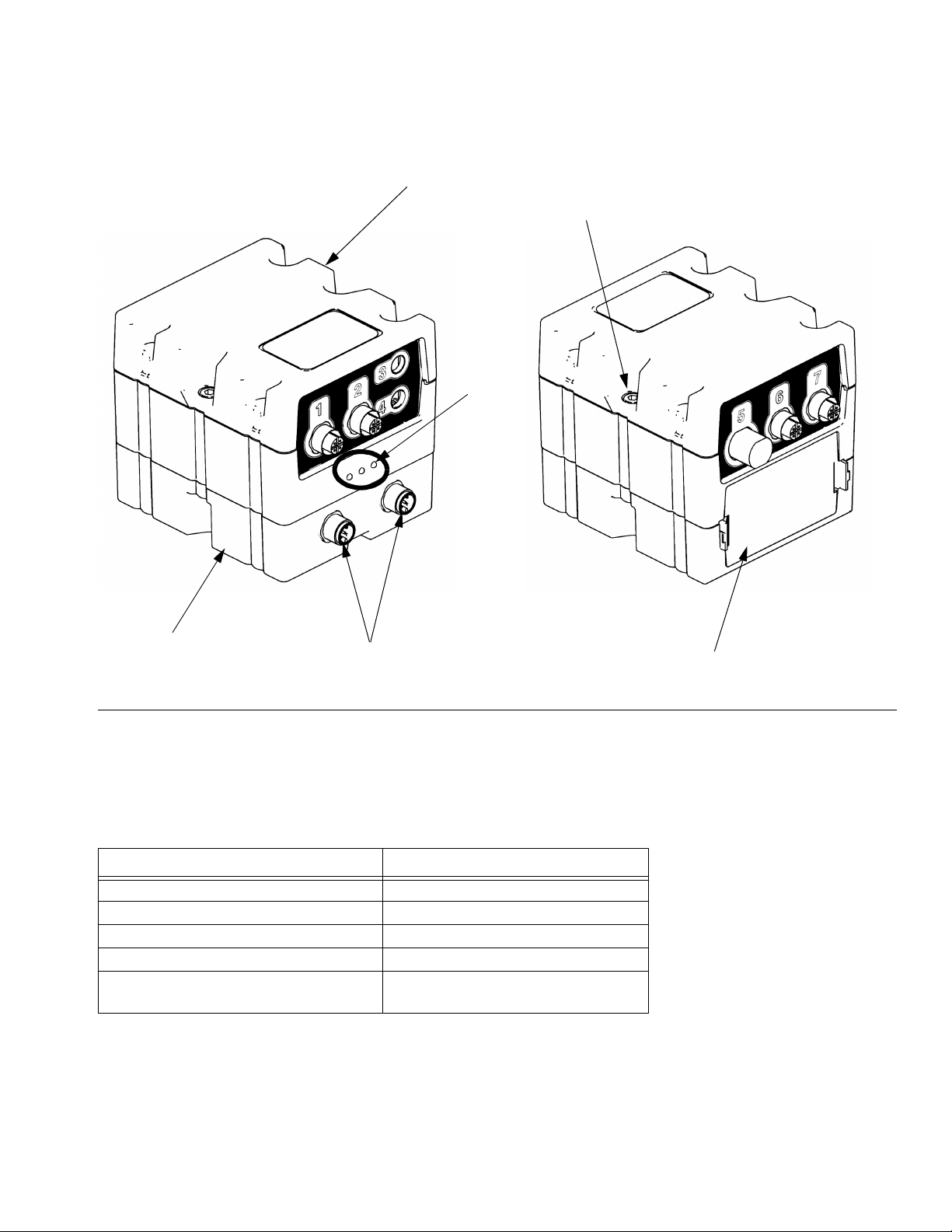

Component Identification

PA

PB

FP

AA

HP

FM

PD

HT

MA

FP

FT

ti19508a

Component Identification

Key for FIG. 2 and FIG. 3.

AA Advanced Display Module (see page 20)

BA Component A (Red) Pressure Relief Outlet

BB Component B (Blue) Pressure Relief Outlet

FA Component A (Red) Fluid Manifold Inlet (on left side of

manifold block)

FB Component B (Blue) Fluid Manifold Inlet

FM HFR Fluid Manifold

FP Feed Inlet Pressure Gauge

FT Feed Inlet Temperature Gauge

GA Component A (Red) Outlet Pressure Gauge

GB Component B (Blue) Outlet Pressure Gauge

HA Component A (Red) Hose Connection (from feed to gun

or mix head)

HB Component B (Blue) Hose Connection (from feed to gun

or mix head)

HP Hydraulic Power Pack Assembly

HT Hydraulic Tank

LS Pumpline Linear Sensor

MA Motor Control Module, see page 18

MP Main Power Switch

PA Component A (Red) Pump

PB Component B (Blue) Pump

PD Power Distribution Box

PHB Primary Heater - B Side

PHA Primary Heater - A Side

PI Primary Heater Fluid Inlet

PO Primary Heater Fluid Outlet

PR Primary Heater RTD

PS Primary Heater Overtemperature Switch

SA Component A (Red) PRESSURE RELIEF/DISPENSE

Valve

SB Component B (Blue) PRESSURE RELIEF/DISPENSE

Valve

TA Component A (Red) Pressure Transducer

TB Component B (Blue) Pressure Transducer

TC High Power Temperature Control Module (not shown, see

page 24)

FIG. 2: Component Identification, Heated Model shown with shrouds removed

14 3A2797G

Page 15

Component Identification

ti9880a1

GA

GB

SB

FB

BB

HB

HA

BA

FA

SA

Fluid Manifold (FM) Detail

LS

TB

TA

MP

Rear View

Primary Heater (PHA)

Detail, A (Red) side shown

ti19509a

ti19510a

PO

PR

PS

PI

Primary Heater (PHB)

Detail, B (Blue) side shown

ti19511a

PI

PO

PR

PS

(In Enclosure)

FIG. 3: Component Identification, Continued

3A2797G 15

Page 16

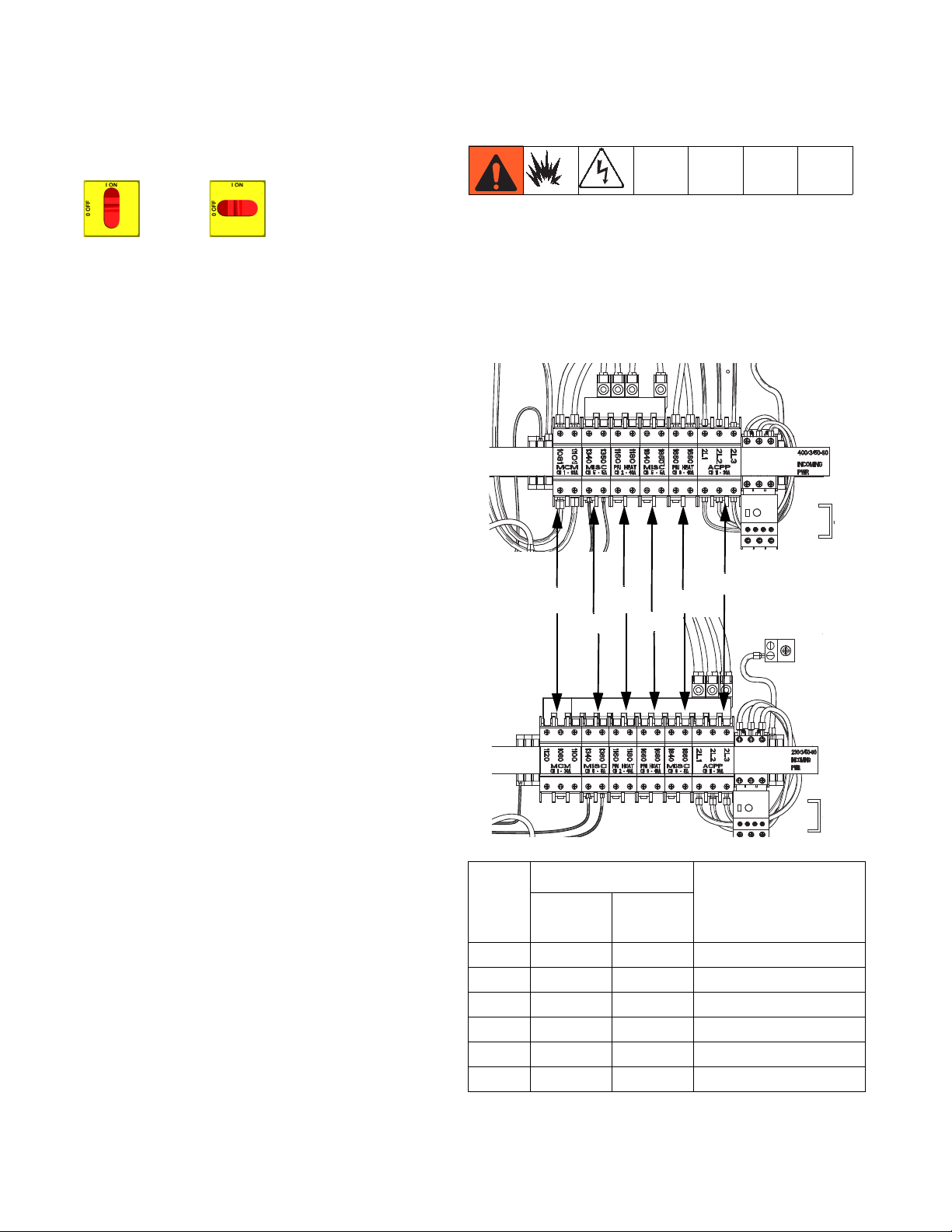

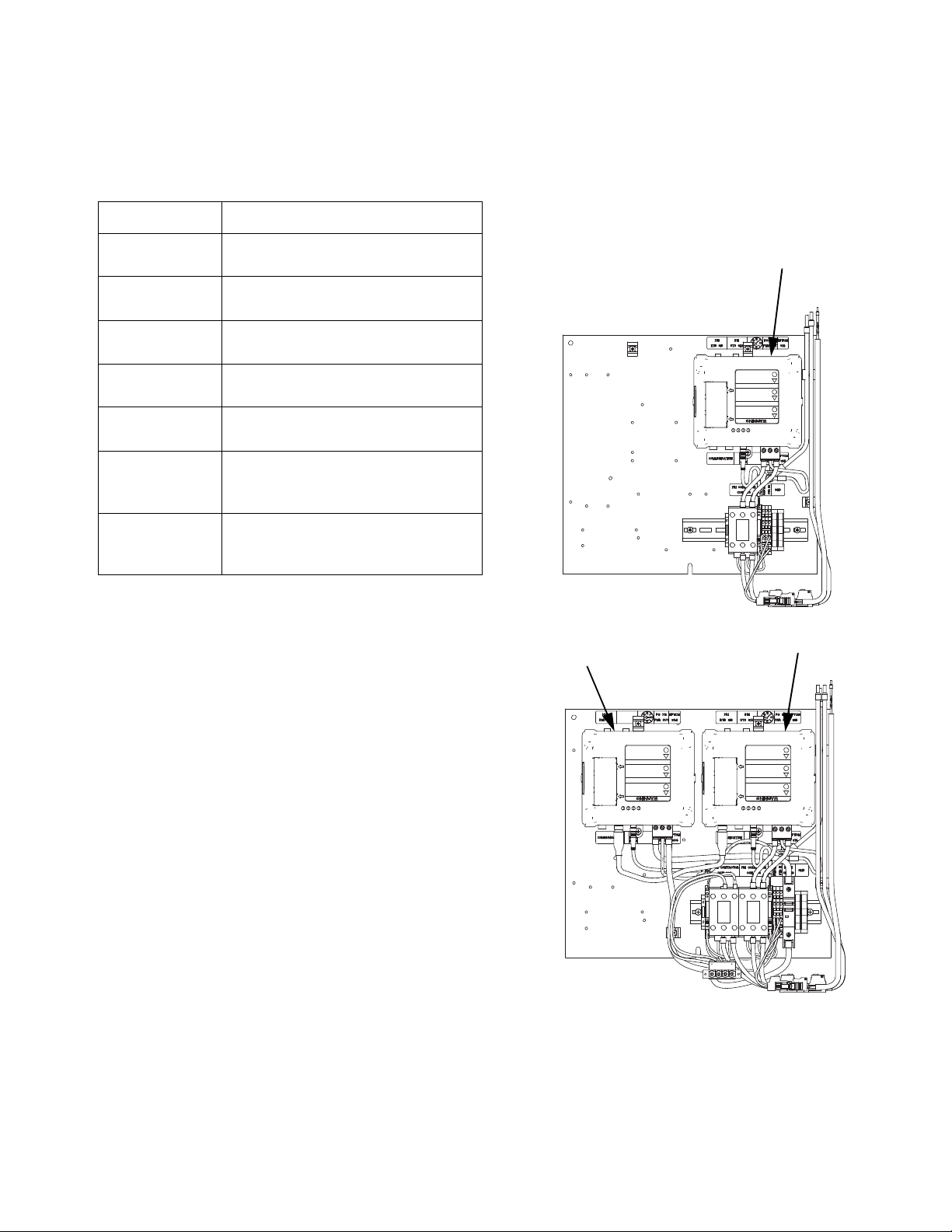

Component Identification

CB1

CB5

CB2

CB9

CB6

CB11

400V/ 3 phase

230V/ 3 phase

ti19512a

ti19513a

Main Power Switch

Located on top of the power distribution box, see

page14. The main power switch turns power

ON and OFF . The main power switch

does not turn pumps or heat zones on.

Circuit Breakers

Most circuit breakers are located inside the power distribution box. The main block of circuit breakers in the

power distribution box is shown below, with detailed

information in the following table. For more information

about items in the power distribution box, see power distribution box manual.

Size

400V/

Ref.

3 phase

CB1 63A 30A Motor Control Module

CB2 40A 40A Primary Heater A

CB5 5A 5A Miscellaneous

CB6 5A 5A Miscellaneous

230V/

3 phase

Component

CB9 40A 40A Primary Heater B

CB11 30A 30A AC Power Pack

16 3A2797G

Page 17

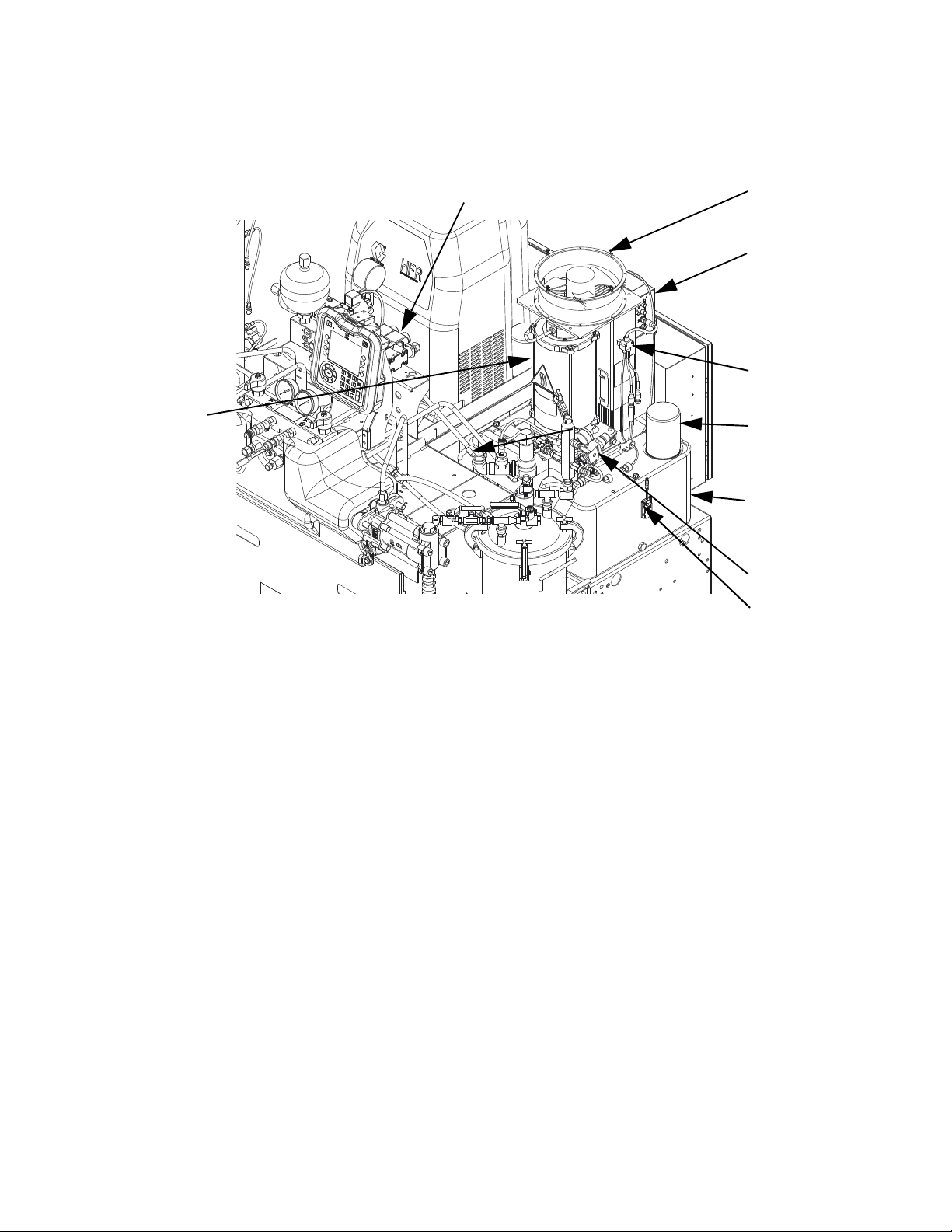

HFR Hydraulic Power Pack

ti19514a

DB

DE

DA

DG

DD

DH

DF

DK

DL

Component Identification

FIG. 4: HFR Hydraulic Power Pack

Key:

DA 9 Gallon Hydraulic Oil Reservoir (see Technical Data on

page 95 for specifications)

DB Electric Motor

DD Hydraulic Housing

DE Directional Valve

DF Motor Control Module (see page 18)

DG Fan

DH Oil Filter

DJ Shroud (not shown, removed for clarity)

DK 3 Way Splitter

DL Oil Level Sensor (Optional)

3A2797G 17

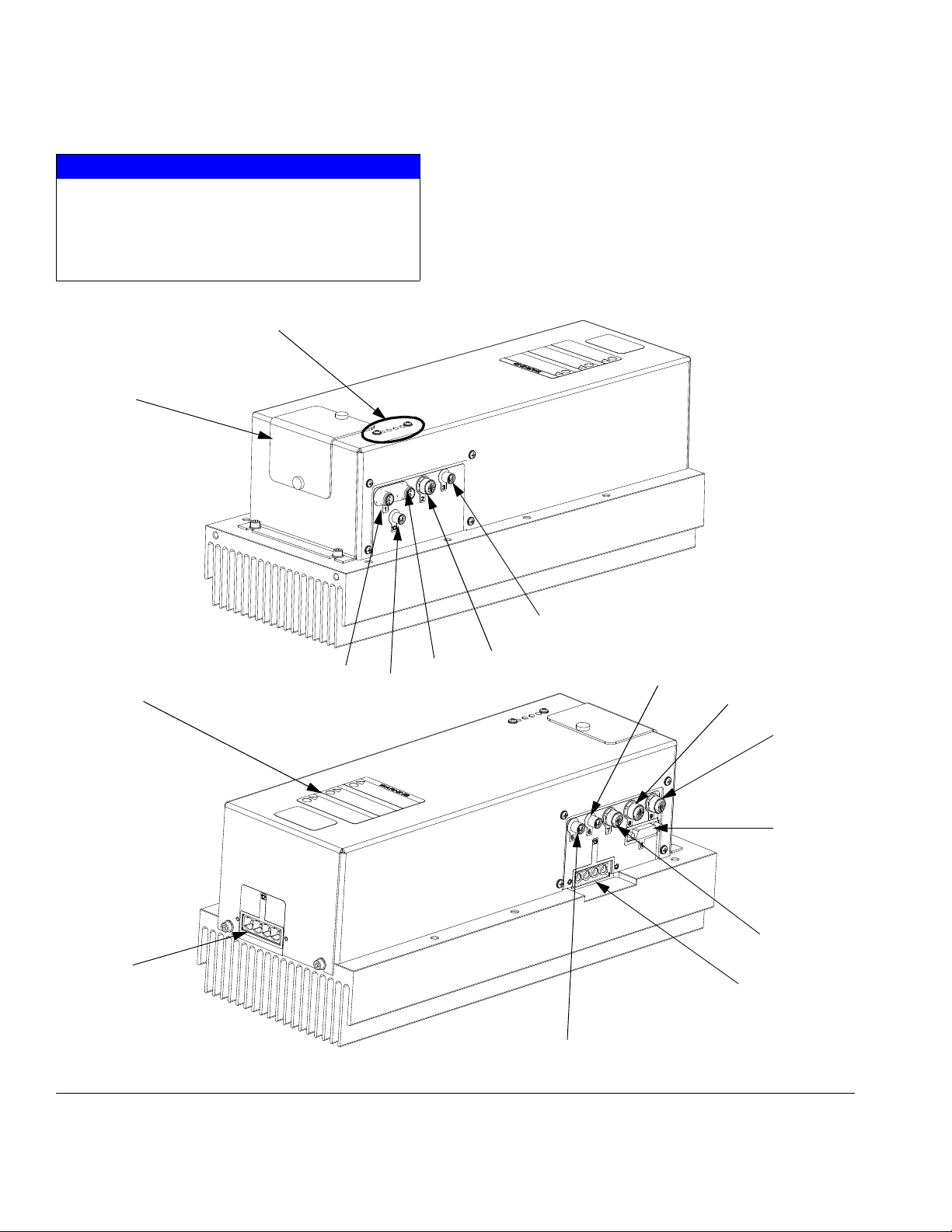

Page 18

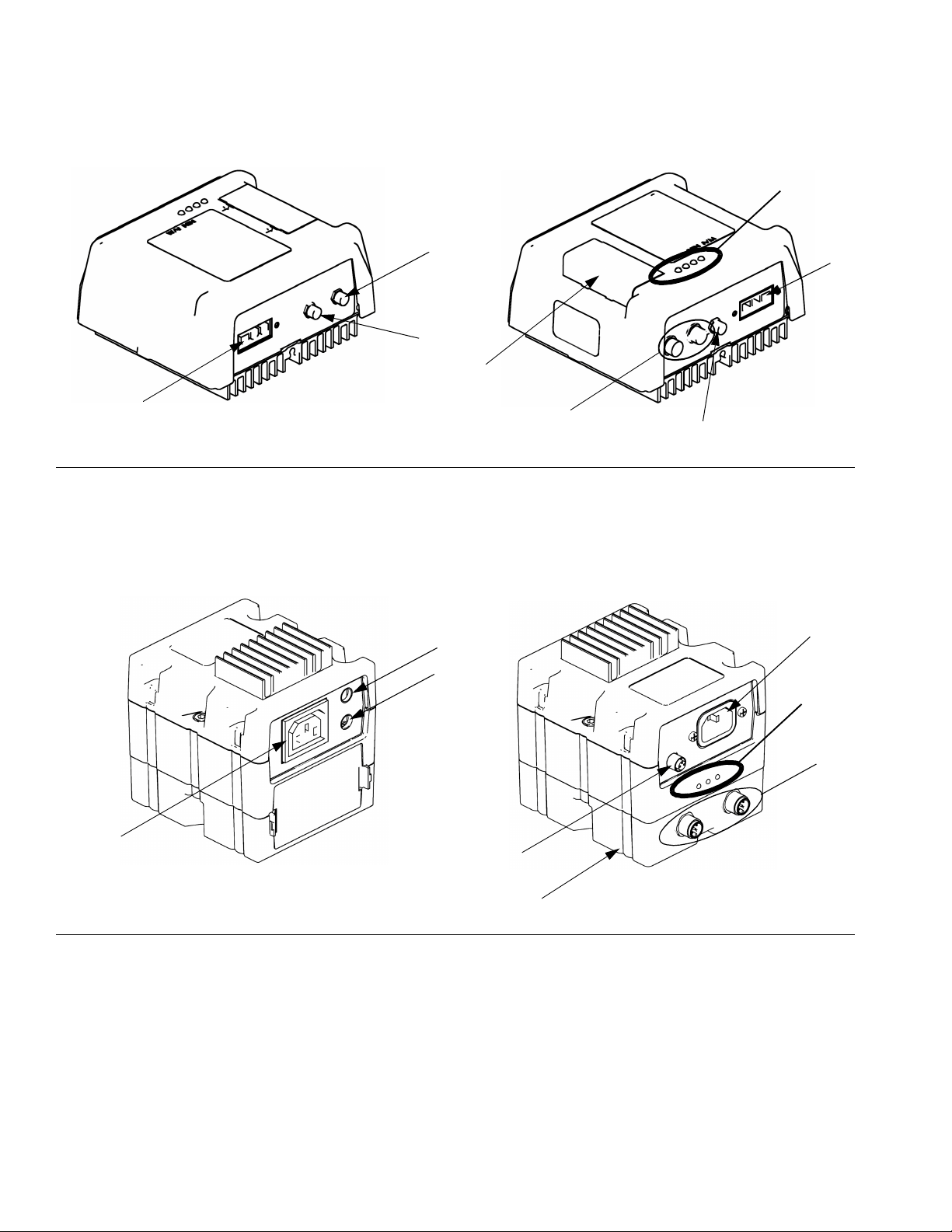

Component Identification

A

r_257396_3b9905_01b

r_257396_3b9905_03b

C

12

B

13

1A

11

1B

5

7

6

8

9

10

2

3

Motor Control Module (MCM)

NOTICE

If the Motor Control Module is replaced, the selector

switch must be set prior to initial startup of the

Motor Control Module or damage may occur. See

HFR Repair manual for details, see Related Manu-

als on page 3.

For MCM location, see reference MA in FIG. 2 on

page 14. When installed, the end of the MCM with the

power input connection (12) faces down and the end

with the access cover (A) faces up.

The Motor Control Module uses an 8-position selector

switch to set the system maximum working pressure.

FIG. 5: MCM Component Identification

18 3A2797G

Page 19

Ref Description

A Access Cover

B LEDs

C Warning Label

1A, 1B CAN Connections

2 Three-way Splitter to: Oil Low Level

Sensor, Dispense Valve Solenoid, and

Footswitch

3 Oil Temperature Sensor

5 Electric Motor Temperature Sensor

6 LVDT (Position Sensor)

7 Three-way Splitter to:

Hydraulic Directional Valve,

Oil Overtemperature Switch

8 Pressure Transducer B (Blue) side

9 Pressure Transducer A (Red) side

10 Not used

11 Motor Position Sensor

12 MCM Power Input Connection

13 Motor Power Connection

Component Identification

Diagnostic Information

7

Table 1: LED (Ref B) Status Signal

Module Status LED Signal Description

Green on System is powered up.

Yellow on Internal communication in progress.

Red solid MCM hardware failure. Replace MCM.

Red flashing fast Uploading software.

Red flashing slow Token error. Remove token and upload

software token again.

3A2797G 19

Page 20

Component Identification

TI12362a1

CA

CB

CC

CE

CH

CG

CF

CD

CF

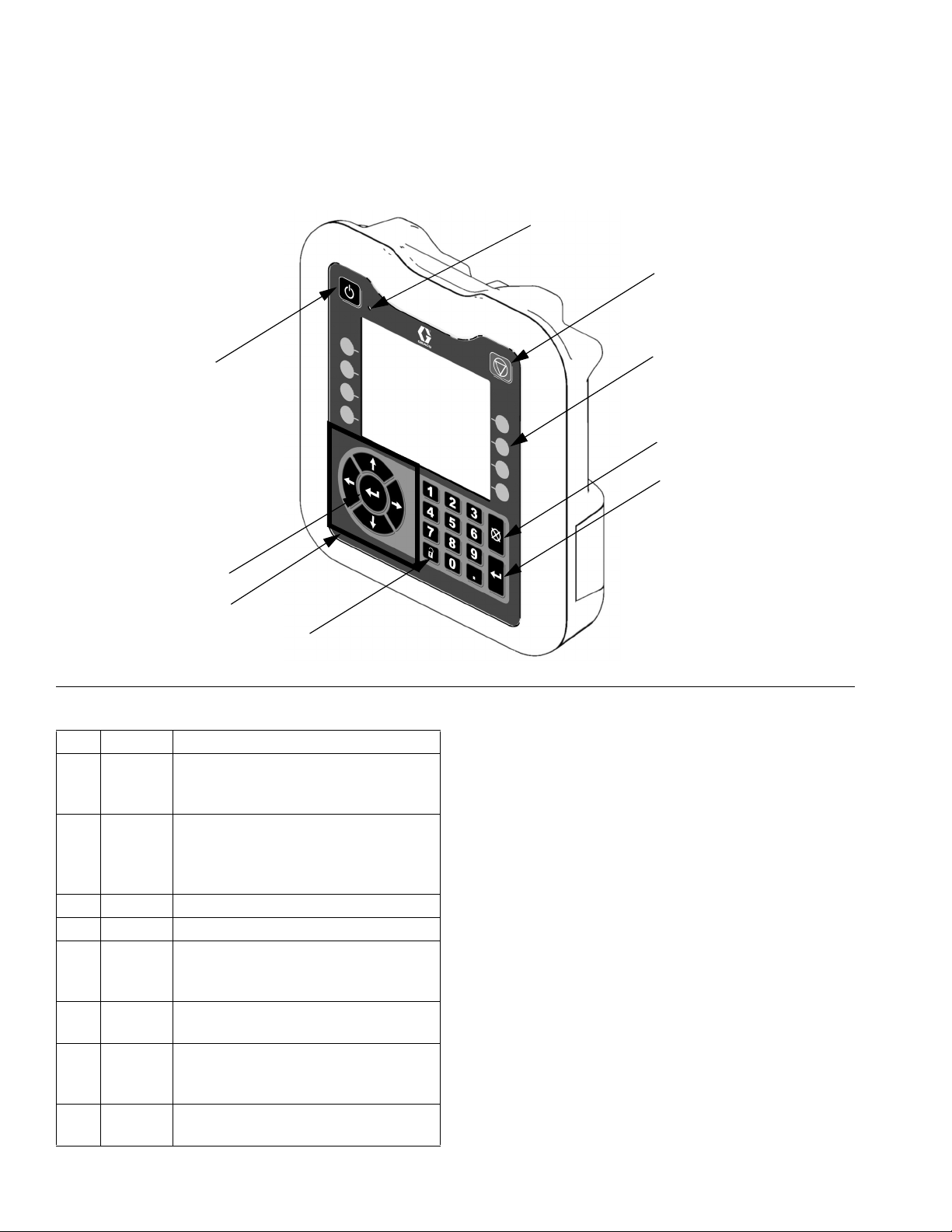

Advanced Display Module (ADM)

User Interface

FIG. 6: ADM Component Identification - Front

Buttons

Ref. Button Function

CA System

enable/

disable

CB System

Status

Indicator

Light

CC Stop Stop all system processes.

CD Soft Keys Defined by application using ADM.

CE Cancel Cancel a selection or number entry

CF Enter Acknowledge changing a value or

CG Setup Toggle between run and setup

CH Naviga-

tion

Enables/disables system. When system is disabled, temperature control

and dispense operation are disabled.

Displays system status. See System

Status Indicator (CB) Conditions on

page 20 for details.

while in the process of entering a

number or making a selection.

making a selection.

screens or password screen if setup

screens are password protected.

Navigate within a screen or to a new

screen.

System Status Indicator (CB) Conditions

Green Solid - Run Mode, System On

Green Flashing - Setup Mode, System On

Yellow Solid - Run Mode, System Off

20 3A2797G

Page 21

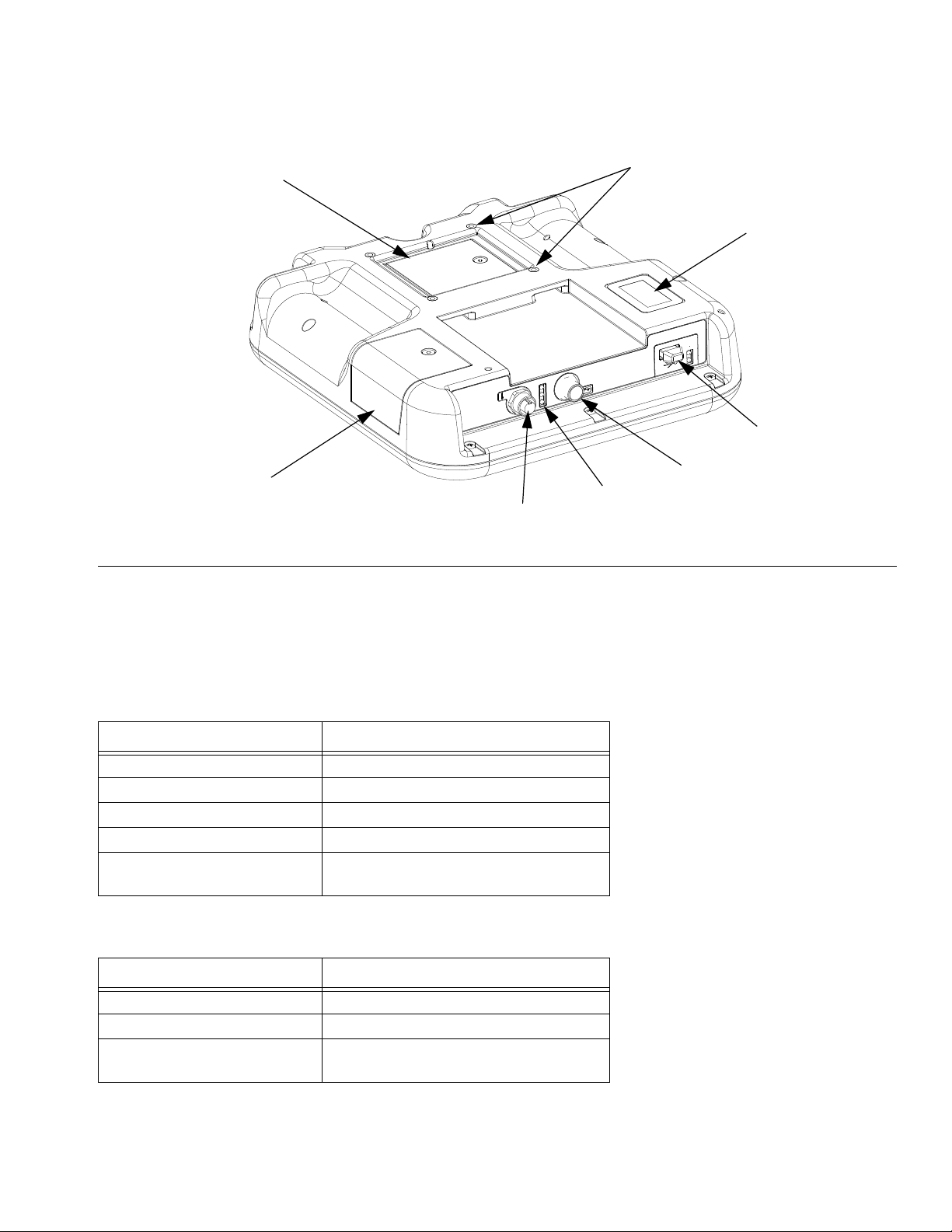

Component Identification

CR

CK

CJ

CL

CP

CN

CM

CS

r_24E451_3B9900_1a

FIG. 7: ADM Component Identification - Rear

Key:

CJ Flat Panel Mount

CK Model Number

CL USB Module Interface

CM CAN Cable Connections

CN Module Status LEDs

CP Accessory Cable Connections

CR Token Access Cover

CS Battery Access Cover

ADM Module Status LEDs (CN) Conditions

Module Status LED Signal Description

Green on System is powered up.

Yellow on Communication in progress.

Red solid ADM hardware failure.

Red flashing fast Uploading software.

Red flashing slow Token error. Remove token and upload

software token again.

USB Module Status LEDs (CL) Conditions

Module Status LED Signal Description

Green flashing System is powered up.

Yellow on Downloading information to USB

Green/Yellow Flashing ADM is busy, USB cannot transfer

information when in this mode

3A2797G 21

Page 22

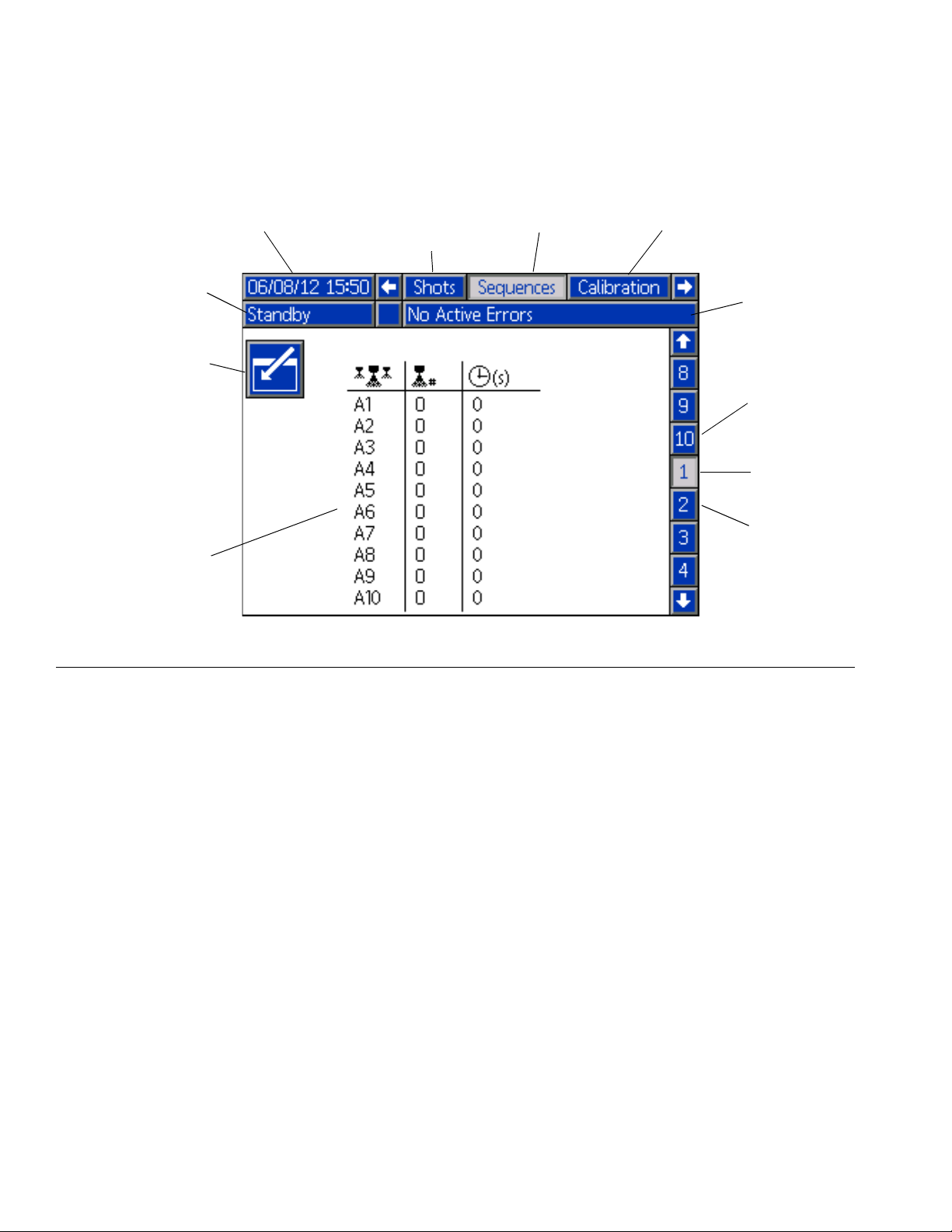

Component Identification

Current date and time Current chapter

Enter/Exit screen

Previous chapter

(Left Arrow)

Next chapter

(Right Arrow)

Function display

Current

page

Next

page

(Down Arrow)

Previous

page

(Up Arrow)

Mode

Faults, Status

Main Display Components

The following figure calls out the navigational, status, and general informational components of each screen. For

details regarding the user interface display see Shutdown, page 44.

FIG. 8: Main Display Components

22 3A2797G

Page 23

Fluid Control Module (FCM)

ti12337a1

ti12336a1

A

E

B

C

D

F

Component Identification

FIG. 9: Fluid Control Module (FCM)

Key:

A Fluid Control Module

B Base

C Module Connection Screws

D Access Cover

E Module Status LEDs

F CAN Connectors

Diagnostic Information

Module Status LED (Ref E) Signal Diagnosis

Green on System is powered up

Yellow Internal communication in progress

Red solid FCM hardware failure. Replace FCM.

Red flashing fast Uploading software.

Red flashing slow Token error. Remove token and

upload software token again.

3A2797G 23

Page 24

Component Identification

1

2

3

5

4

6

LED

Signals

7

ti12352a1

ti12353a1

1

2

3

4

5

6

7

ti12356a1

ti12357a1

LED

Signals

Temperature Control Module

FIG. 10: High Power Temperature Control Module Sensor Connections

Key:

1 Overtemperature Switch Connection (primary heaters

only)

2 RTD Temperature Sensor Connection

3 Output Power Connection

4 DC Output Connection

5 Input Power Connection

6 CAN Connections

7 Rotary Selector Switch, Token Access

FIG. 11: Low Power Temperature Control Module Cable Connections

1 Overtemperature Switch Connection

2 RTD Temperature Sensor Connection

3 Output Power Connection

4 DC Output Connection

5 Input Power Connection

6 CAN Connections

7 Base

24 3A2797G

Page 25

Component Identification

Primary Heater B (Blue)

Primary Heater A (Red)

Right Side from

Rear View

Left Side from

Rear View

ti17748a

ti17749a

Material Temperature

FTS - (Red)

Temperature Control Module Diagnostic

Information

Module Status LEDs

Signal Description

Green on Temperature control module is

powered up.

Yellow on Internal communication in prog-

ress.

Red solid Temperature control module failure.

See Troubleshooting table.

Red flashing

fast

Red flashing

slow

Blue light off

(High Power

Module only)

Blue flashing

(High Power

Module only)

Uploading software.

Token error. Remove token and

upload software token again.

Temperature control module is off.

See Troubleshooting table.

Length of flashes indicates amount

of power running through temperature control module.

Heat Control Zone Selection

The HFR unit supports four independent temperature

control zones and two independent temperature monitoring zones. The high power temperature control modules are located inside the frame below the hydraulic

power pack.

3A2797G 25

Page 26

Component Identification

High Power Module Rotary Switch Location

Low Power Module Rotary Switch Location

S

S

ti12360a

ti12361a

Adjust Rotary Switch

The rotary switch setting indicates which zone the temperature control module will control in the system. The

high power module uses an 8-position rotary switch. The

low power module uses a 16-position rotary switch.

Set the rotary switch (S) to the specific selection according to the settings listed in the following tables.

High Power Module Rotary Switch Settings

Setting Zone

0 Not Used

1 B (Blue) Primary Heat

2 B (Blue) Hose Heat

3 A (Red) Primary Heat

4 A (Red) Hose Heat

5 through 7 Not Used

Low Power Module Rotary Switch Settings

Setting Zone

0 through 4 Not Used

5 B (Blue) Tank Heater

6 A (Red) Tank Heater

7 B (Blue) Chiller

8 A (Red) Chiller

9 through F Not Used

FIG. 12: Rotary Switch

26 3A2797G

Page 27

Component Identification

3A2797G 27

Page 28

Setup

Setup

Perform this setup procedure to secure all necessary

machine connections for machine operation.

1.

Locate system.

a. Locate system on a level surface. See Dimen-

sions on page 97 for space requirements.

b. Do not expose system to rain.

2.

Electrical requirements. See Models on page 4

for detailed electrical requirements information.

Installing this equipment requires access to parts

which may cause electric shock or other serious injury

if work is not performed properly. Have a qualified

electrician connect power and ground to main power

switch terminals, see step 4 in this setup procedure.

All electrical wiring must be done by a qualified electrician and comply with all local codes and regulations.

3.

Ground system

This equipment must be grounded.

a. System: grounded through power cord. See

step 4 on page 28.

b. Fluid supply containers: follow your local code.

c. Object being dispensed into: follow your local

code.

d. Solvent pails used when flushing: follow your

local code. Use only metal pails, which are conductive, placed on a grounded surface. Do not

place pail on a nonconductive surface, such as

paper or cardboard, which interrupts grounding

continuity.

e. To maintain grounding continuity when flushing

or relieving pressure, hold a metal part of dispense gun firmly to the side of a grounded

metal pail, then trigger gun.

4.

Connect electrical cord to system.

NOTE: See Power Line Voltage Surges information on

page 29.

NOTE: Power cord is not supplied. See the following

table.

28 3A2797G

Page 29

Setup

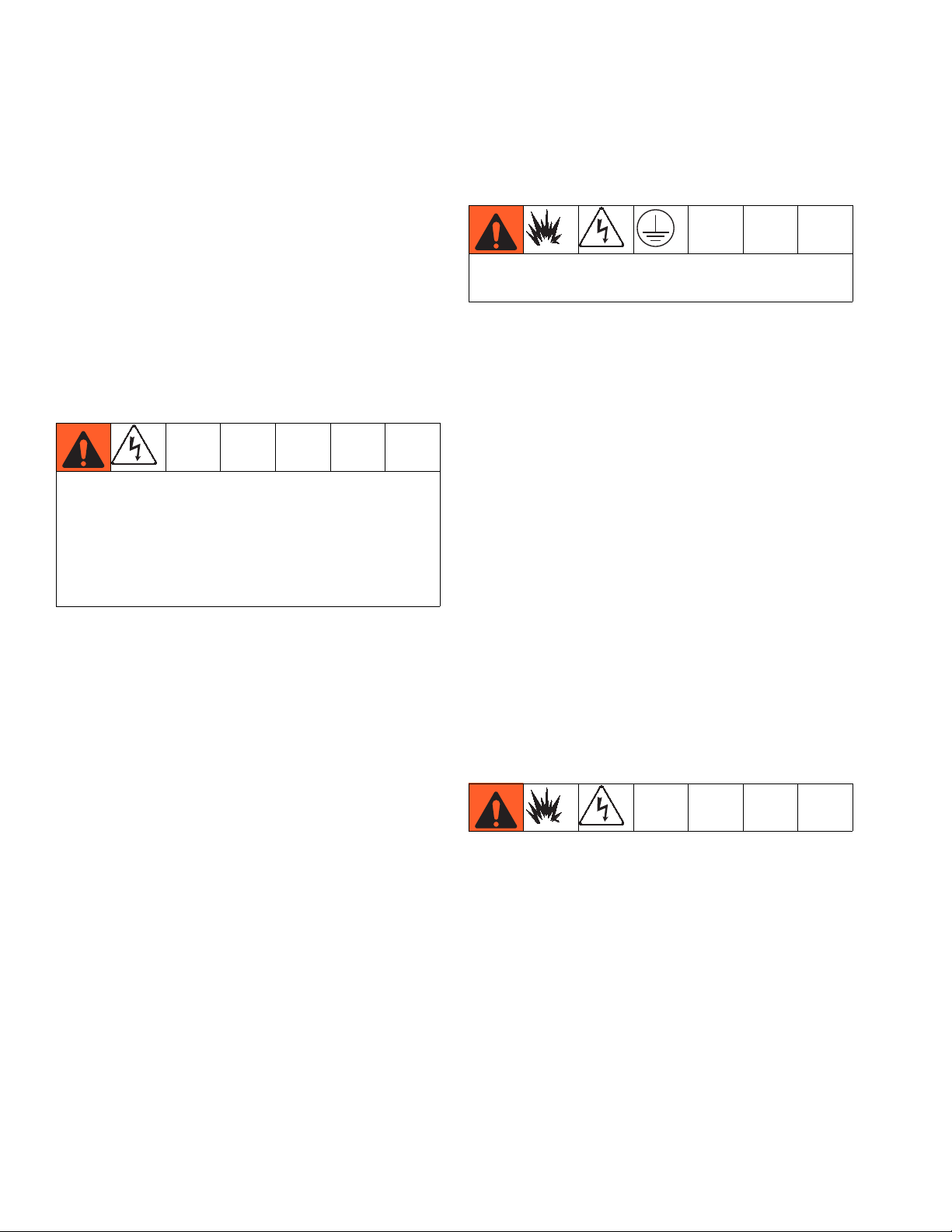

r_24C686_313998_1a

L1L2L3N

GND

Maximum Permissible Transient Voltage Surges

* Constructed from ITIC 1996 curve, referenced by IEC 61000-2-4

1200Vac, 1697Vdc

264Vac, 373Vdc

336Vac, 475Vdc

288Vac, 407Vdc

480Vac, 679Vdc

<--1 MW Max Surge Power

<--150 KW Max Surge Power

<--50 KW Max Surge Power

<--No Power Limit

0

200

400

600

800

1000

1200

1400

Time (seconds)

Voltage (Volts RMS)

Table 2: Power Cord Requirements

Cord Requirements

Model

Heated system,

4 (21.2), 3 wire + ground

AWG (mm2)

230V, 3 phase

Heated system,

4 (21.2), 4 wire + ground †

400V, 3 phase

† Residual Current Device (RCD) must be rated at

300 mA if installed.

Electrical Cord Wires by Model

230V, 3 phase: L1, L2, L3, GND

400V, 3 phase: L1, L2, L3, N, GND

Use 5/32 or 4 mm hex allen wrench to connect the three

power leads to L1, L2, L3, and Neutral (as required).

Connect green to ground (GND).

The MAX-HOLD feature on a multimeter can be used to

determine peak DC voltage on the line. DC is the proper

setting, as opposed to AC, because peak voltage is the

critical parameter that affects the DC voltage level

stored on the capacitive bus in power conversion equipment. Reading should not regularly exceed approximately 400VDC to avoid tripping the 420VDC alarm

level in the Motor Control Module. If power quality is suspect, power conditioning or isolation of the device(s)

causing poor power quality is recommended. Consult a

qualified electrician if there are any concerns about the

available power supply.

Power Line Test Steps with Multimeter

a. Set multimeter to “DC voltage”.

b. Connect multimeter probes to supplied power

line.

c. Press “Min Max” successively to show the peak

positive and negative DC voltages.

d. Confirm readings do not exceed 400VDC

(Motor Control Module alarm issued at

420VDC).

FIG. 13: 400V, 3 phase shown

Power Line Voltage Surges

Power conversion equipment can be sensitive to voltage

fluctuations on incoming power. The Motor Control Module falls under the category of power conversion equipment because energy is stored on a capacitive bus and

then modulated to control a brushless motor. Engineered design takes this into account and withstands a

wide range of conditions, but it is possible for supplied

power to occasionally fall outside the tolerable range in

industrial plants with high-amperage reactive pulsed

loads such as welding equipment. If the tolerable range

is exceeded, an overvoltage condition is flagged and the

system will shut down in an alarm state to protect itself

and alert the user of unstable power. Excessive or

repeated overvoltage may permanently damage hardware.

3A2797G 29

The chart below shows the permissible magnitude and

duration of temporary over-voltage events:

Page 30

Setup

B2

A2

ti19515a

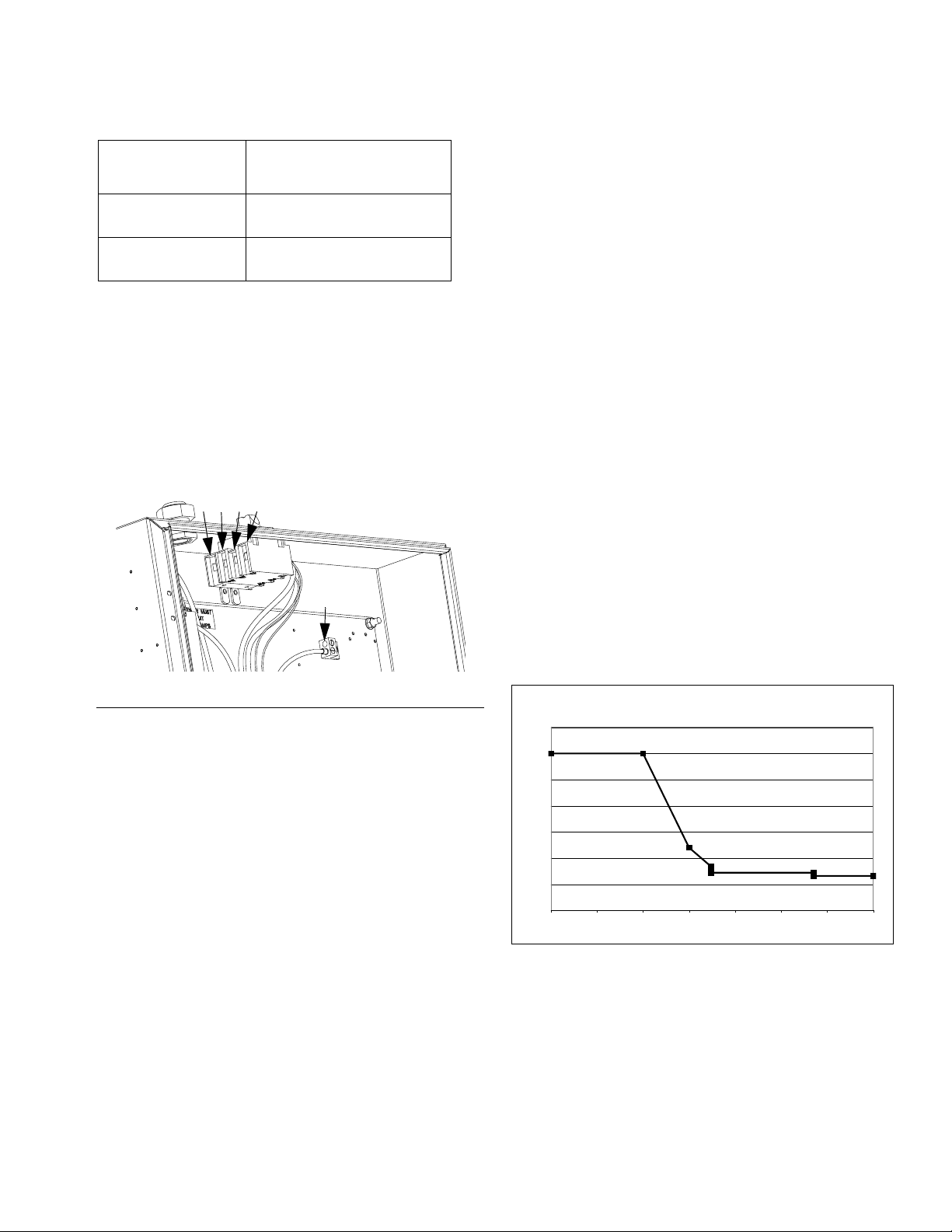

5.

Connect HFR Proximity Cables to the GX-16.

6.

Connect Hydraulic Lines to the system.

NOTE: Refer to the HFR and GX-16 manuals for more

details for the following procedures.

NOTE: The cable is indicated by a green stripe.

a. Connect the GX-16 proximity sensor to the

proximity cable.

b. Connect the 10 ft (3 m) hydraulic whip hose

cable to the 25 ft (7.6 m) chemical hose cable.

c. Connect the other end of the cable to the electri-

cal connector found near the fluid manifold on

the HFR.

NOTE: The electrical connector will be indicated by a

green stripe and labeled “PG-MPO”.

NOTICE

Damage can occur to the directional valve if the

hydraulic hose diameter is larger than 3/8 in.

(9.5 mm).

To prevent damage to the applicator or directional

valves, do not allow any dirt or foreign matter to

enter the lines, when connecting the hose kit to the

applicator and hydraulic power pack.

a. Connect the hydraulic hose to the hydraulic

hose fittings (A2 and B2) on the AC power pack.

Hydraulic

Hose Fitting

Hydraulic

Hoses

Hydraulic Hose

Color Markings

A2 Material close Green

B2 Material open Green/White

FIG. 14: Hydraulic Fittings on Hydraulic Housing

b. Hand tighten each fitting.

c. Tighten each fitting 1/4 turn past hand tight.

30 3A2797G

Page 31

7.

Install GX-16 Fitting Adapter Kit

(Models 24N575 and 24N576 Only).

a. Remove the chemical fittings from the back of

the GX-16.

b. Install JIC #4 fitting assembly into the B Supply

port.

c. Install JIC #6 fitting assembly into the B Return

port.

d. Install JIC #8 fitting assembly into both A Supply

and A Return ports.

Setup

8.

Install Flow Meter Kit (Optional).

Refer to HFR Flow Meter Kits, Instruction-Parts manual

for installation and setup instructions.

9.

Install PrePoly Refresh Kit (Optional).

Refer to HFR for NVH Prepoly Refresh Kit, Instructions-Parts for installation and setup instructions.

3A2797G 31

Page 32

Setup

ti19507a

Step 9g,

Step 9h

Step 9c,

Step 9d,

Step 9e,

Step 9f

Step 9i,

Step 9j

FIG. 15: Material Hose Connections

32 3A2797G

Page 33

Setup

HFR material

manifold

A

B

Remove

reducer

10.

Connect Material Hoses

NOTICE

Avoid routing hoses in walkway areas to prevent

operators from tripping on hoses running between

system components. This also prevents fittings from

leaking.

NOTE: Refer to FIG. 15 on page 32 for visual clarity of

the following steps.

a. Ensure main power is OFF .

b. Ensure A (Red) and B (Blue) inlet valves on the

HFR and the material supply ball valves on the

tanks are closed.

d. Remove reducer fitting from B (Blue) connection

of the HFR fluid manifold (Models 24N573,

24N574 only). Install the provided additional

spacers near the location of the FTS for the

remaining material lines. Refer to FIG. 15 and

FIG. 16.

FIG. 16: Material Manifold

e. Install ball valves (optional) between main hose

and whip hose. Connect the main hose bundle

to the whip hose bundle.

NOTE: The ball valve kit is designed to fit in one orientation only.

c. Remove reducer fitting from the A (Red) con-

nection of the HFR fluid manifold. Install FTS in

the A (Red) material supply line between main

hose and whip hose. Ensure the FTS is facing

toward the fluid flow of material after installation.

See Heated Hose manual for instructions. Refer

to FIG. 15 and FIG. 16.

NOTICE

If using the ball valve kit, ensure the FTS does not

go through the ball valve. Failure to do so will result

in damage to the FTS and the inability to close the

ball valve.

f. Assemble the hydraulic hose sections together

and place the assembled hose connection near

the FTS area. Refer to FIG. 15.

g. Connect A (Red) and B (Blue) hoses to A (Red)

and B (Blue) outlets on HFR fluid manifold (FM).

Hoses are color coded: solid red for component

A, solid blue for component B.

3A2797G 33

Page 34

Setup

Y

h. Connect cables (Y). Be sure cables have slack

when hose bends. Wrap cable and electrical

connections with electrical tape. See Heated

Hose manual for heated hose connection

details and illustrations for the various types of

heated hoses.

i. Connect the other end of the supply hoses

(solid color) to the applicator. See the applicator

manual for fluid inlet identification.

11.

Connect GX-16 Hydraulic Lines

a. Navigate to the System Screen 2 and set the

mode to run as straight head: prox dispense

valve.

Trapped air can cause the pump to cycle unexpectedly,

which could result in serious injury from splashing or

moving parts.

b. Verify the mixhead hydraulic power pack is not

active by verifying the gauge is at 0.

j. Connect A (Red) and B (Blue) return hoses

(solid with white stripe) to the applicator. See

the applicator manual for fluid outlet identification.

NOTE: The other end of the return hose will be connected in step n on page 39.

FIG. 17: Gauge

c. Check the hydraulic fluid level. See Technical

Data on page 95 for specifications.

d. Use the supplied 7/16 in. JIC male-male

adapter at the gun end to connect hoses

34 3A2797G

Page 35

Setup

ti14495a

ti14496a

ti14494a

together. This creates a hydraulic fluid circulation loop.

FIG. 18: Hydraulic Loop

e. Turn on the power pack by navigating to the

Home Screen, Standby Mode and press .

Circulate oil for 3 minutes to purge air from

hydraulic hoses.

NOTE: The hydraulic hose marked with both green and

white stripe is for the open port of the gun. The hydraulic

hose marked with only a green stripe is for the close

port of the gun.

FIG. 19: Hydraulic Connections

j. Attach trigger switch cable (if applicable) to gun

and HFR.

NOTE: Pressure should not increase while air is purged

from hoses.

f. Turn off the power pack by pressing . Look

at the gauge to verify no pressure exists in the

hydraulic hoses and the AC Power Pack.

g. Remove the 7/16 in. JIC male-male adapter

connecting the hydraulic hoses.

NOTICE

To prevent air from entering the hydraulic hoses, do

not spill oil while disassembling the adapter connection. If spilling occurs, replace the lost fluid by manually filling the hoses with hydraulic fluid.

h. Fill both open and close gun chambers with

hydraulic fluid.

i. Attach hydraulic hoses to the gun. Tighten each

fitting 1/4 turn past hand tight.

FIG. 20: Cable Connections

3A2797G 35

Page 36

Setup

12.

Setup the Advanced Display Module (ADM)

When main power is turned on by turning the main

power switch (MP) to the ON position, the splash screen

will be displayed until communication and initialization is

complete.

To begin using the ADM, the machine must be on and

enabled. To verify the machine is enabled, verify the

System Status Indicator Light (CB) is illuminated green,

see FIG. 6 on page 20. If the System Status Indicator

Light is not green, press the ADM Power On/Off (CA)

button . The System Status Indicator Light will illuminate yellow if the machine is disabled.

The blue token (24M560) must be installed to enable

cold start up, temperature monitor zones, and shot times

less than one second.

Perform the following tasks to fully setup your system.

Enter Setup Mode by pressing the button.

a. Define shots. See Shots Screen, page 55 for

more detail.

b. Define sequences. See Sequences Screen,

page 58 for more detail.

c. Calibrate HFR, page 37. See Calibration

Screen, Main, page 59 for more detail.

d. Define pump information. See

System Screen 1, page 60 for more detail.

e. Define dispense valve and other system set-

tings. See System Screen 2, page 60 for more

detail.

f. Define labels and other system settings. See

System Screen 3, page 61 for more detail.

g. If desired, view/reset counters. See Mainte-

nance Screen, page 62 for more detail.

h. Define level sensors and refill settings. See

Supply Screen, page 63 for more detail.

NOTICE

To ensure proper machine operation, the blue token

must remain installed in the ADM during operation.

If the machine is in the Disabled mode screen press

repeatedly to select standby mode.

Navigation

• Press or to navigate to new screens.

• Press or to navigate to new screens or

to move between fields.

• Press to activate the desired field or to acti-

vate/deactivate an option.

i. Enable/disable temperature conditioning com-

ponents. See Conditioning Screen 1, page 64

for more detail.

j. Define temperature conditioning setpoints. See

Conditioning Screen 2, page 64 for more

detail.

k. If Night mode will be used, define Night mode

settings. See Conditioning Screen 3, page 65

for more detail.

l. Set general system settings. See Advanced

Screen 1, page 67 for more detail.

m. Set units of measure. See Advanced Screen 2,

page 67 for more detail.

n. Enable/disable system features. See Advanced

Screen 3, page 67 for more detail.

36 3A2797G

Page 37

Setup

13.

Calibrate HFR

NOTE: Machine is calibrated from the factory. Only per-

form the following steps when changing or rebuilding

pumps.

The HFR calibration procedure is a two step process.

The first step, Learn Mode, must be performed whenever the pump line is rebuilt or if any other maintenance

is performed that may affect the mechanical tolerances

in the pump line. If the machine does not appear to be

utilizing the full extent of the pump stroke, or if the

machine appears to be contacting the end of the

hydraulic cylinder, follow the Learn Mode procedure.

The Learn Mode procedure will teach the system the

mechanical limits of travel.

• Learn Mode Procedure:

a. Ensure the dispense valve is set up as either

straight head or straight head prox.

b. Navigate to the Calibration screen.

• Set temperatures:

This equipment is used with heated fluid, which can

cause equipment surfaces to become very hot. To

avoid severe burns:

• Do not touch hot fluid or equipment.

• Allow equipment to cool completely before touching it.

• Wear gloves if fluid temperature exceeds 110°F

(43°C).

For detailed temperature adjustments, including alarm

levels, or upon initial machine configuration, see Condi-

tioning Screen 2 on page 64 for details. For minor

adjustments to the temperature setpoint once the

machine has been initially configured, see the Status

Screen on page 72.

• Set system control and dispense modes: See System Screen 1 on page 60.

c. Press

d. Press and then . The pump will travel to

the right most extreme position.

e. After the pump stops moving, press and

then press . The pump will travel to the left

most extreme position.

f. After the pump stops moving, press to

return to the main Calibration screen.

NOTE: During this process, the system learned the

mechanical limits of travel. If the pump did not reach

both the left and right extreme limits for any reason,

repeat the procedure.

• Set pump sizes: See System Screen 1 on page 60.

• Define Shot Recipes

a. Navigate to the Shots screen.

b. Press to enter the screen.

c. Use the directional keypad to navigate to the

shot detail column for the desired shot number.

d. Type the desired setting for that item then

press .

e. Repeat the previous two steps for all desired

shot numbers.

• Change pressure imbalance setting (optional)

The pressure imbalance function detects conditions that

can cause off-ratio dispense, such as loss of feed pressure/supply, pump seal failure, clogged fluid inlet filter, or

a fluid leak.

The pressure imbalance default is factory-set at 500 psi

(3.5 MPa, 35 bar). For tighter ratio error detection, select

a lower value. For looser detection or to avoid nuisance

alarms, input a higher value.

3A2797G 37

Page 38

Setup

a. Navigate to System Screen 3.

b. Press to enter the screen.

c. Navigate to the pressure imbalance field.

d. Type the desired pressure imbalance setting

then press .

e. Press and input the specific gravity (SG) of

each material into the ADM.

14.

Flush the System

NOTE: System components will contain testing oil from

the factory. Perform the following procedure when the

machine is initially installed. Both supply and pressure

relief must be flushed.

a. Close both A side (Red) and B side (Blue) feed

inlet valves on the system. See FIG. 2 on page

14.

b. Close A side (Red) and B side (Blue) material

return ball valves on the system.

c. Close both A side (Red) and B side (Blue) mate-

rial supply ball valves on the system.

d. Place the applicator return hoses into a con-

tainer.

NOTICE

To prevent cross contamination, keep components

A (Red) and B (Blue) in separate containers.

e. Fill tank A (Red) with approximately 5 gal. (19 l)

of material and tank B (Blue) with approximately

2 gal. (8 l) of material.

f. Pressurize both material tanks.

38 3A2797G

Page 39

NOTE: A minimum feed pressure of 50 psi (0.35 MPa,

FP

ti10006a1

ti9877a1

SA

SB

3.5 bar) is required at both feed inlet pressure gauges

(FP). Maximum feed pressure is 75 psi (

517 kPa, 5.2 bar)

Maintain A (Red) and B (Blue) feed pressures within

10% of each other.

g. Turn HFR main power ON .

h. Navigate to the System Setup Screen. Set the

low pressure dispense to 25%.

Setup

l. Stop dispensing by pushing from the

.

Standby Screen.

m. Close feed inlet valve and the material supply

ball valve on the system.

n. Connect the applicator return hose to the fluid

inlet fitting on the system.

NOTE: The following steps are referring to the B side

(Blue) components of the system.

i. Set PRESSURE RELIEF/DISPENSE valve (SA,

SB) to DISPENSE for the corresponding

material side.

j. Open feed inlet valve and the material supply

ball valve on the system.

k. Navigate to the Standby Screen and push

to start pumps.

FIG. 21: Return Lines

Do not install shutoffs downstream of the PRESSURE

RELIEF/DISPENSE valve outlets (BA, BB). The

valves function as overpressure relief valves when set

to DISPENSE . Lines must be open so valves

can automatically relieve pressure when machine is

operating.

If circulating fluid back to the supply drums, use high

pressure hose rated to withstand the maximum working pressure of this equipment.

o. Ensure all material hose connections are tight.

NOTE: Material will dispense into the container from the

applicator material hose at this time. Continue to dispense fluid until no material contamination is noticed.

stand.

q. Repeat steps j thru p for A side (Red).

NOTE: If necessary, navigate to Operator Mode to

adjust the flowrate

3A2797G 39

p. Open the RETURN ball valves on the tank

Page 40

Setup

ti17747a

Orifice

(A) Side

15.

Install GX-16 Orifices

16.

Pressure check hose

See hose manual. Pressure check for leaks. If no leaks,

wrap hose and electrical connections to protect from

damage.

a. Close both A side (Red) and B side (Blue) feed

inlet valves on the system. See FIG. 2 on page

14.

b. Close A side (Red) material return ball valves

on the material tank stand.

c. Follow Pressure Relief Procedure on page 44.

d. Remove plugs from GX-16.

e. Install orifices provided.

17.

Check hydraulic fluid level

Hydraulic reservoir is filled at the factory. Check fluid

level before operating the first time, and weekly thereafter. See Technical Data on page 95 for specifications.

FIG. 22: GX-16 Plug Location

40 3A2797G

Page 41

18.

LR

RB

24C352_313998_8e

r_24m419_3a1961_1a

IsoGuard Select Fluid System Setup

Component A (Red) Pump: Fill IsoGuard Select reser-

voir (LR) with IsoGuard Select fluid (provided by Graco).

a. Lift the reservoir (LR) out of the bracket (RB)

and remove the container from the cap.

19.I

nstall High Volume Fill Kit (Optional).

FIG. 23: High Volume Refill Kit

Setup

b. Fill with fresh fluid. Thread the reservoir onto

the cap assembly and place it in the

bracket (RB).

c. Push the supply tube approximately 1/3 of the

way into the reservoir. The supply tube is the

tube with the check valve with an arrow pointing

in the direction of flow towards the IsoGuard

Select fluid cylinder.

d. Push the return tube into the reservoir until it

reaches the bottom. The return tube is the tube

with the check valve with an arrow pointing in

the direction of flow away from the IsoGuard

Select fluid cylinder.

NOTE: The return tube must reach the bottom of the

reservoir to ensure that isocyanate crystals will settle to

the bottom and not be siphoned into the supply tube and

returned to the pump.

a. Perform Pressure Relief Procedure, page 44.

b. Close the ball valves located on the day tanks.

c. Insert the refill valve onto the ball valve.

d. Connect the air tube from the “open” port on the

refill valve to the fitting on the solenoid valve that

is located inside the tank stand base cube.

e. Remove the plug from other port on the sole-

noid valve and install the air tube fitting.

f. Connect the air tube from the “close” port on the

refill valve to the fitting installed in step e above.

3A2797G 41

Page 42

Setup

r_24m418_3a1961_1a

20.I

nstall Low Volume Fill Kit (Optional).

FIG. 24: Low Volume Refill Kit

a. Perform Pressure Relief Procedure, page 44.

b. Close the ball valves located on the day tanks.

c. Remove the swivel fitting from the day tank inlet

port ball valve.

d. Insert the refill valve onto the ball valve.

e. Install the swivel fitting onto the refill valve

assembly.

f. Remove the air tube fitting installed on the sole-

noid valve located inside the tank stand base

cube.

g. Install the air tube fitting provided with the kit

into the open port on the solenoid valve.

h. Install the air tube from the refill valve to the

solenoid valve.

42 3A2797G

Page 43

Startup

ti9877a1

SA

SB

ti10442a1

LOCKED

ti10441a1

UNLOCKED

To reduce the risk of personal injury, do not operate

HFR without all covers and shrouds in place.

Startup

1. Check that all machine connections are setup. See

Setup procedure, page 28.

2. Check level and condition of ISO lube daily, see

IsoGuard Select™ System on page 48.

3. Verify both PRESSURE RELIEF/DISPENSE valves

(SA, SB) are set to DISPENSE .

4. If dispense valve has a trigger safety lock, engage

the trigger safety lock.

6. Press to enable system. LED should be solid

green.

7. Navigate to Home Standby screen and press

to initiate auto startup.

8. Check that heat zones are on and temperatures are

on target. Check fluid pressure display. Refer to Sta-

tus Screen on page 72 for more details.

9. If dispense valve has a trigger safety lock, disengage the trigger safety lock.

i. Equipment is ready to dispense.

5. Open system fluid inlet valves and ball valves found

on the material tanks. As applicable, ball valves on

the material tanks include material supply, applicator return, and pressure relief. Check for leaks.

3A2797G 43

Page 44

Shutdown

ti9879a1

SA

SB

Shutdown

1. Park pumps.

a. From the Home screen, press and select

Standby mode.

b. Press . Material will not dispense. Pump

will park automatically. Once pump is parked,

pump will stop moving.

2. Press to disable the ADM.

3. Turn main power switch (MP) to OFF position.

4. Close A (Red) and B (Blue) fluid supply valves.

Pressure Relief Procedure

1. Press to disable the ADM.

2. Shut off feed pumps and agitator, if used.

3. Turn PRESSURE RELIEF/DISPENSE valves (SA,

SB) to PRESSURE RELIEF/CIRCULATION .

Route fluid to waste containers or supply tanks.

Ensure gauges drop to 0.

5. Perform Pressure Relief Procedure on page 44.

6. Shut down feed pumps as required. See feed pump

manual.

4. For models with a dispense valve with a safety

lock, engage gun safety lock.

5. Relieve pressure in dispense valve. See dispense

valve manual.

44 3A2797G

Page 45

Flushing

SA

SB

ti9880a1

N

N

Flush equipment only in a well-ventilated area. Do not

dispense flammable fluids. Do not turn on heaters

while flushing with flammable solvents. Heaters must

be off and cool when solvent is in the system.

• Flush out old fluid with new fluid, or flush out old

fluid with a compatible solvent before introducing

new fluid.

• Use the lowest possible pressure when flushing.

• All fluid components are compatible with common

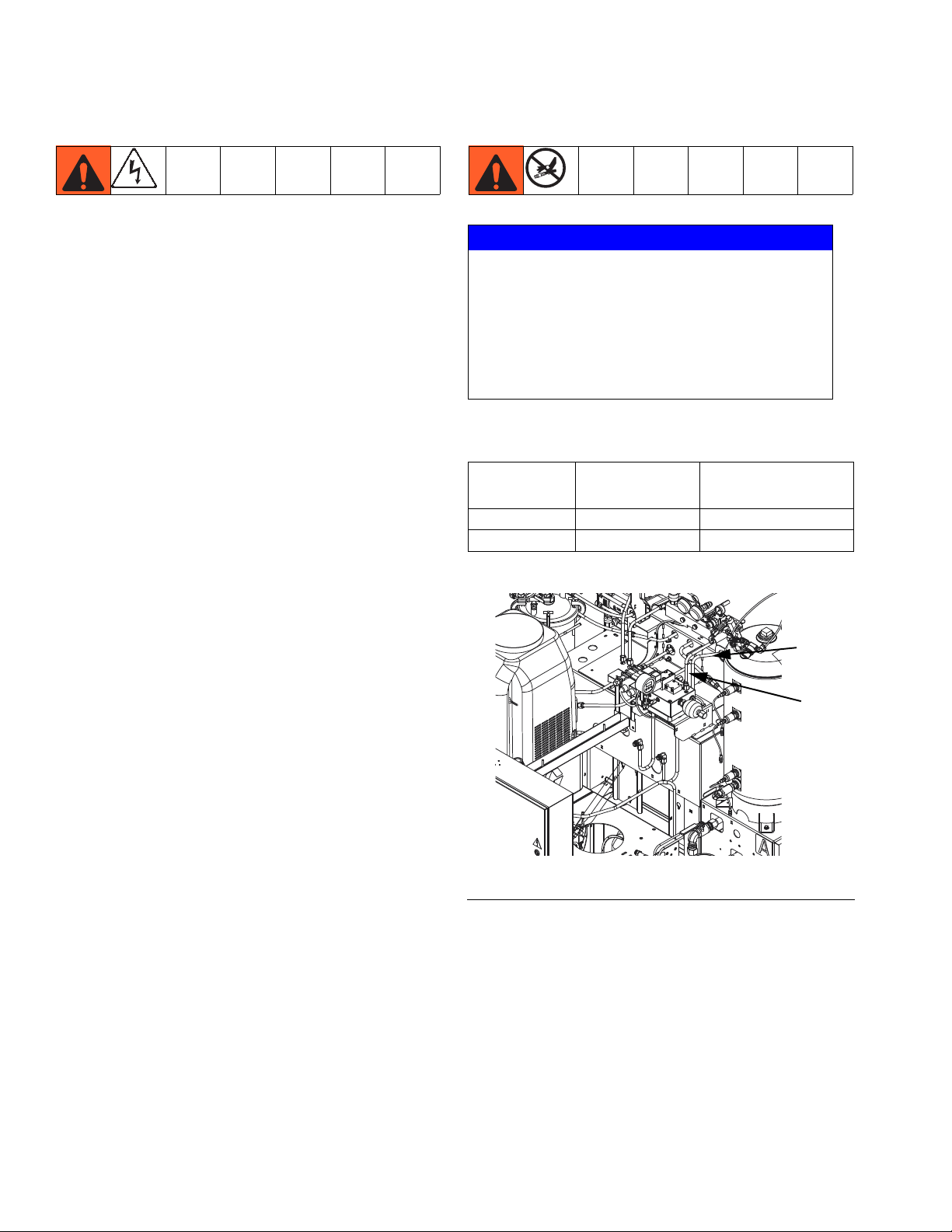

solvents. Use only moisture-free solvents. See Run

Screen Icons on page 53 for list of wetted components to verify compatibility of solvent with wetted

materials. See solvent manufacturers information for

material compatibility.

Flushing

• To maintain grounding continuity when flushing or

relieving pressure, hold a metal part of dispense

gun firmly to the side of a grounded metal pail, then

trigger gun.

• To flush feed hoses, pumps, and heaters separately

from heated hoses, set PRESSURE RELIEF/DISPENSE valves (SA, SB) to PRESSURE

RELIEF/CIRCULATION . Flush through bleed

lines (N).

• To flush entire system, circulate through gun fluid

manifold (with manifold removed from gun).

• To prevent moisture from reacting with isocyanate,

always leave the system dry or filled with a moisture-free plasticizer or oil. Do not use water. See

Important Two-Component Material Information

on page 11.

• Solvent pails used when flushing: follow your local

code. Use only metal pails, which are conductive,

placed on a grounded surface. Do not place pail on

a nonconductive surface, such as paper or cardboard, which interrupts grounding continuity.

3A2797G 45

Page 46

Maintenance

ti9879a1

IM

Maintenance

Task Schedule

Change break-in oil in a new unit After first 250

hours of opera-

tion or within 3

months, which-

ever comes first

Inspect hydraulic and fluid lines

for leaks

Inspect IsoGuard Select™ fluid

level and condition, refill or

replace as needed, page 48

Check hydraulic fluid level Weekly

Grease circulation valves with

Fusion® grease (117773)

Daily

Daily

Weekly

Task Schedule

Check hoses for wear Monthly

Check hydraulic fluid and filter 6 months

Grease (115982) high volume

refill valve, if equipped

Monthly

Change Break-in Oil

After initial break-in, see Table 5 for recommended frequency of oil changes.

Table 3: Frequency of Oil Changes

Ambient

Temperature

0 to 90°F

(-17 to 32°C)

90°F and above

(32°C and above)

Recommended

Frequency

1000 hours or 12 months,

whichever comes first

500 hours or 6 months,

whichever comes first

Verify operation of air drying system to prevent isocyanate crystallization

Verify vent holes on bottom of

electrical cabinet are clear and

unobstructed

Inspect air filter (part 24H018),

clean or replace as necessary,

Use compressed air to remove

dust buildup on control boards,

fan, motor (under shield), and

hydraulic oil coolers

Clean up all hydraulic leaks; identify and repair cause of leak

Inspect the gun, fluid lines, trigger

switch cable and proximity switch

cable for wear or damage

Grease (117773 or 0553-6) the

gun

Clean and service the orifices

and filters

Weekly

Weekly

Daily

Monthly

As needed

Daily

Weekly or every

15,000 shots

As Needed

Grease Circulation Valves With Fusion

Grease (117773)

Check Hydraulic Fluid Level

Check hydraulic fluid level on dipstick. Fluid level must

be between indent marks (IM) on dipstick. Refill as

required with approved hydraulic fluid; see Run Screen

Icons on page 53. If fluid is dark in color, change fluid

and filter.

Check Accumulator Pre-Charge Weekly

Check tightness of all clamps and

fittings

46 3A2797G

Weekly

Page 47

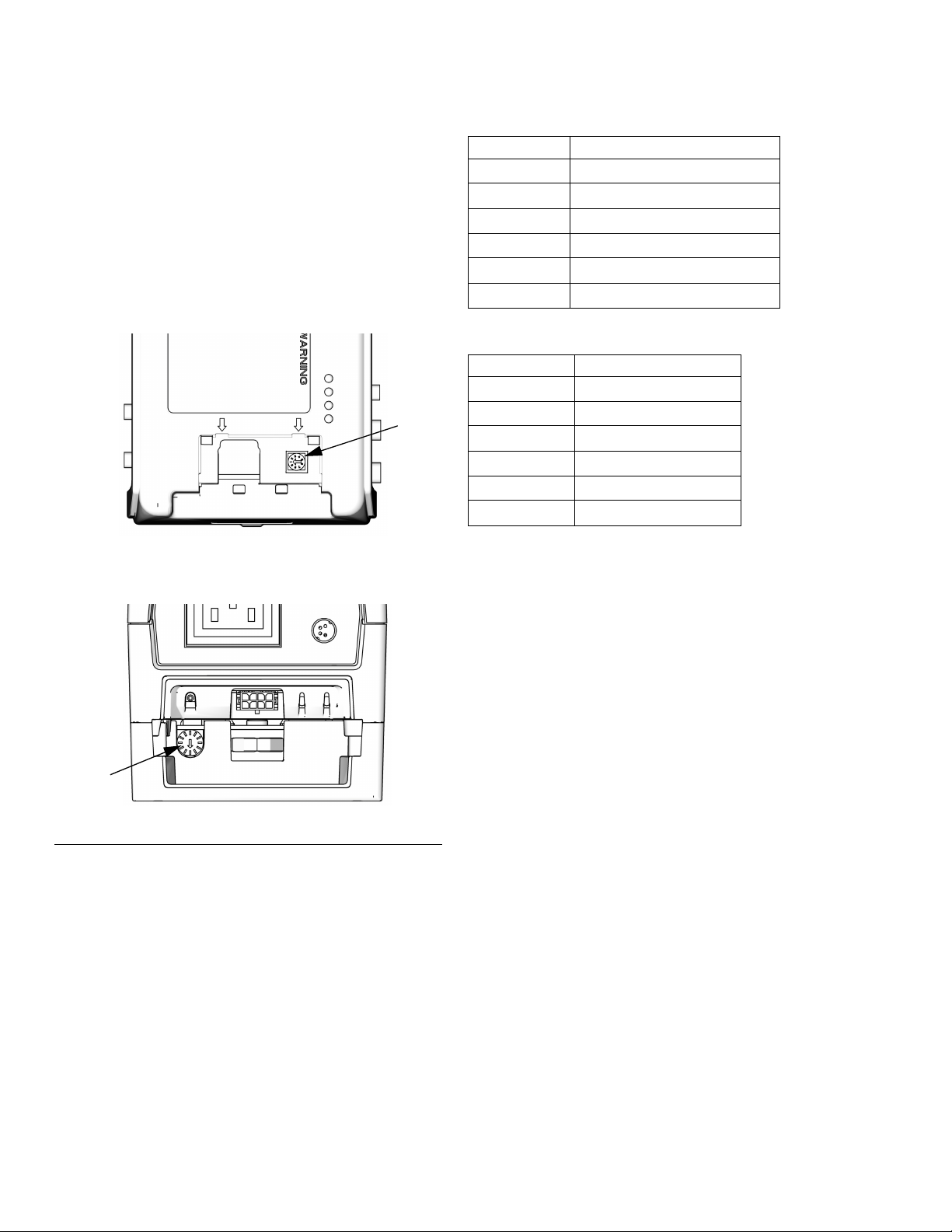

Install Upgrade Tokens

r_257396_3b9905_04b

ti12334a1

ti12358a1

ti12354a1

NOTE: The Motor Control Module, Fluid Control Module, and Temperature Control Module connection to the

system is temporarily disabled during the installation of

upgrade tokens.

To install software upgrades:

1. Use correct software token stated in the table. See

Graco Control Architecture™ Module Programming

manual for instructions.

NOTE: Upgrade all modules in the system to the

software version on the token, even if you are

replacing only one or two modules. Different software versions may not be compatible.

All data in the module (System Settings, USB Logs,

Recipes, Maintenance Counters) may be reset to

factory default settings. Download all settings and

user preferences to a USB before the upgrade, for

ease of restoring them following the upgrade.

Maintenance

See manuals for locations of specific GCA components.

The software version history for each system can be

viewed in the technical support section at

www.graco.com.

16H821 HFR:

16G584 Tank Stand:

16G407 Ratio Monitoring (Flow Meters):

FIG. 25: Remove Access Cover

Token Application

- Advanced Display Module

- Motor Control Module

- High Power Temperature Control Module

- Fluid Control Module (AC Power Pack)

- Discrete Gateway Module

- Communication Gateway Module

- Fluid Control Module

- Low Power Temperature Control Module

- Fluid Control Module

3A2797G 47

Page 48

Maintenance

24C352_313998_8e

IsoGuard Select™ System

Check the condition of the A (Red) pump IsoGuard

Select fluid daily. Change the fluid if it becomes a gel, its

color darkens, or it becomes diluted with isocyanate.

Gel formation is due to moisture absorption by the pump

IsoGuard Select fluid. The interval between changes

depends on the environment in which the equipment is

operating. The pump lubrication system minimizes

exposure to moisture, but some contamination is still

possible.

Fluid discoloration is due to continual seepage of small

amounts of isocyanate past the pump packings during

operation. If the packings are operating properly,

IsoGuard Select fluid replacement due to discoloration

should not be necessary more often than every 3 or 4

weeks.

9. Push the return tube into the reservoir until it

reaches the bottom.

NOTE:

The return tube must reach the bottom of the reservoir,

to ensure that isocyanate crystals will settle to the bottom and not be siphoned into the supply tube and

returned to the pump.

To change pump IsoGuard Select fluid:

1. Perform Pressure Relief Procedure on page 44.

2. Remove fittings from IsoGuard Select fluid cylinder

inlet and outlet ports. Keep supply tube, return tube,

and leak management tube connected to the fittings.

3. Carefully place ends of tubes with fittings still connected into an empty pail to drain IsoGuard Select

fluid.

4. Lift the IsoGuard Select fluid reservoir out of the

bracket and remove the container from the cap.

Holding the cap over a suitable container, remove

the inlet check valve and allow the IsoGuard Select

fluid to drain. Reattach the check valve to the inlet

hose. See FIG. 26.

5. Drain the reservoir and flush it with clean IsoGuard

Select fluid.

6. When the reservoir is flushed clean, fill with fresh

IsoGuard Select fluid.

FIG. 26: IsoGuard Select Fluid System

Prime IsoGuard Select Fluid Cylinder

Ensure that the IsoGuard Select fluid cylinder outlet

faces upward for air to exhaust.

1. Remove check valve from end of inlet tube.

2. Cut tip of IsoGuard bottle and fill the reservoir

through the tube.

3. With check valve arrow pointing towards the

IsoGuard Select fluid cylinder, install check valve in

end of inlet tube.

4. Install tubes into reservoir and install reservoir into

holder.

7. Thread the reservoir onto the cap assembly and

place it in the bracket.

8. Push the supply tube approximately 1/3 of the way

into the reservoir.

48 3A2797G

Page 49

Troubleshooting

Before performing any troubleshooting procedure:

1. Perform Pressure Relief Procedure on page 44.

2. Turn main power OFF.

3. Allow equipment to cool.

Try the recommended solutions in the order given for

each problem, to avoid unnecessary repairs. Also,

determine that all circuit breakers, switches, and controls are properly set and wiring is correct before assuming there is a problem.

Troubleshooting

Light Tower (Optional)

Signal Description

Green on only System is powered up and there are

no error conditions present

Yellow on An advisory exists

Red flashing A deviation exists

Red on The system is shut down due to an

alarm occurring.

Errors include advisories, deviations, or alarms, so

green will only be on when none of these occur. A yellow

light can be on at the same time as red (flashing or solid

on) when an advisory exists at the same time as a deviation or alarm.

PROBLEM CAUSE SOLUTION

General

Display Module completely

dark

No or incorrect amount of

material dispensed from

either side

Significant material leaking

from pump seal

Material dispensed not correct weight

A (Red) and B (Blue) Primary Heaters

Control of primary heat is

abnormal; high temperature

overshoots

Hose System

Material heats but heats

slower than usual or it does

not reach temperature

No Power Verify AC Power switch is ON

Thrown Breaker Check Machines Breakers and Reset

Loose Connection Tighten 5-pin cable on Advanced Display Module

Bad Display Module Replace Advanced Display Module

Ball Valve closed (if Installed) Open tank ball valve.

Tank Empty Add fluid

Tank Clogged Clean tank

Air In Material Prime the machine

Pump shaft worn and/or shaft seal

worn

Specific gravity of one or more of the

two materials has changed since calibration

Check valve malfunction Remove check valve; clean or replace as necessary

Piston worn or broken Replace Piston

Dirty RTD connection Unplug and re-plug RTD wires.

RTD not contacting heater element Loosen ferrule nut, push in RTD so tip contact heater

Failed heater element Replace

Signal failure from RTD Check connections

RTD wired incorrectly Check connections. Power up zones one at a time

Ambient temperature is too cold Use auxiliary hose system.

FTS failed or not installed correctly Check FTS

Remove pump shaft assembly and reinstall read

pump rebuild kit

Run calibration

element. Holding RTD tip against heater element,

tighten ferrule nut 1/4 turn past tight.

and verify that temperature for each zone rises.

3A2797G 49

Page 50

Troubleshooting

PROBLEM CAUSE SOLUTION

Material does not maintain

temperature while spraying

Material temperature

exceeds setpoint

Erratic material temperature Faulty RTD connection Verify that all FTS connections are snug and that pins

Material does not heat FTS failed or is not contacting cor-

Proportioning System

Proportioning pump does not

hold pressure when stalled

Ambient temperature is too cold Increase A (Red) and B (Blue) setpoints to increase

fluid temperature and keep it steady

Flow too high Use smaller mix chamber. Decrease pressure.

Faulty RTD connections Verify that all FTS connections are snug and that pins

of connectors are snug and that pins of connects are

clean. Examine connection of thermocouples to long

green plug on heater control board. Unplug and

re-plug RTD wires, cleaning off any debris. Unplug

and re-plug long green connector on heater control

board.

of connectors are clean. Examine connection of RTD

to long green plug on heater control board. Unplug

and re-plug RTD wires, cleaning off any debris.