Page 1

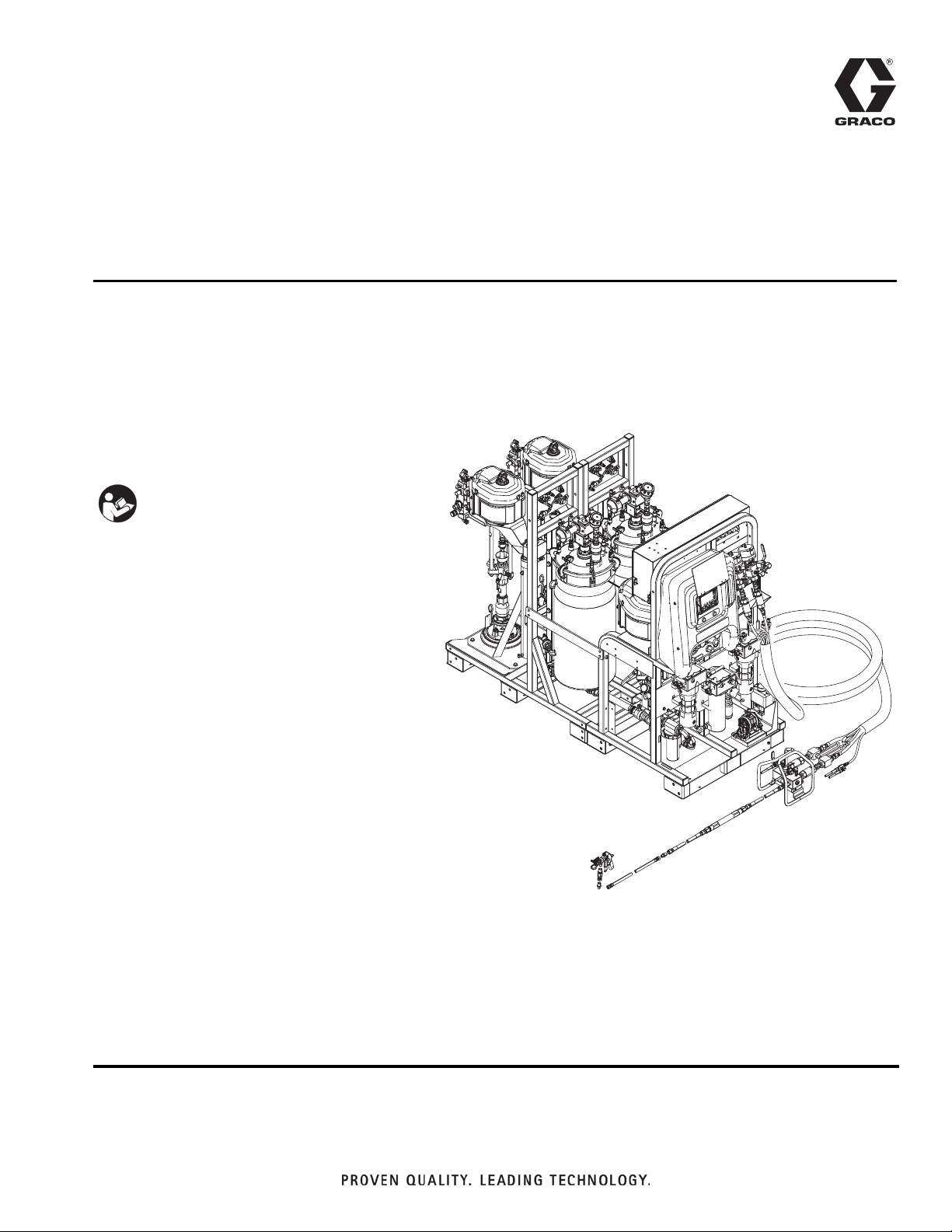

Setup - Operation

XM PFP

For spraying two-component intumescent epoxies. For professional use only.

Not for use in explosive atmospheres or hazardous locations.

Important Safety Instructions

Read all warnings and instructions in all

supplied manuals. Save all instructions.

3A2776D

EN

See page 3 for model information, including

maximum working pressure and approvals.

WLD

Page 2

Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Keep Components A and B Separate . . . . . . . . 6

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . 6

Components A and B . . . . . . . . . . . . . . . . . . . . . 6

Component Identification . . . . . . . . . . . . . . . . . . . . 7

Typical Setup (Front View) . . . . . . . . . . . . . . . . . 7

Typical Setup (Back View) . . . . . . . . . . . . . . . . . 8

Fluid Control Assembly . . . . . . . . . . . . . . . . . . . . 9

Main Power and Heater Controls . . . . . . . . . . . 10

Sprayer and Flush Pump Air Controls . . . . . . . 10

Feed Module Air Controls . . . . . . . . . . . . . . . . 11

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . 12

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Unboxing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Configuration Options . . . . . . . . . . . . . . . . . . . . 14

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Connect Power . . . . . . . . . . . . . . . . . . . . . . . . 16

Connect Air Supply . . . . . . . . . . . . . . . . . . . . . . 17

Connect Feed Module Lines to Sprayer Module 18

Install Level Sensor Probe . . . . . . . . . . . . . . . . 19

Check Level Sensor Calibration . . . . . . . . . . . . 19

Connect the Fluid Hose Bundle to the System . 20

Connect the Fluid Hose Bundle to the

Mix Manifold . . . . . . . . . . . . . . . . . . . . . . . . 21

Connect the Mix Manifold to the Gun . . . . . . . . 22

Prime Heated Fluid Circulation System . . . . . . 23

Initial Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Prime Solvent Flush Pump . . . . . . . . . . . . . . . . . . 29

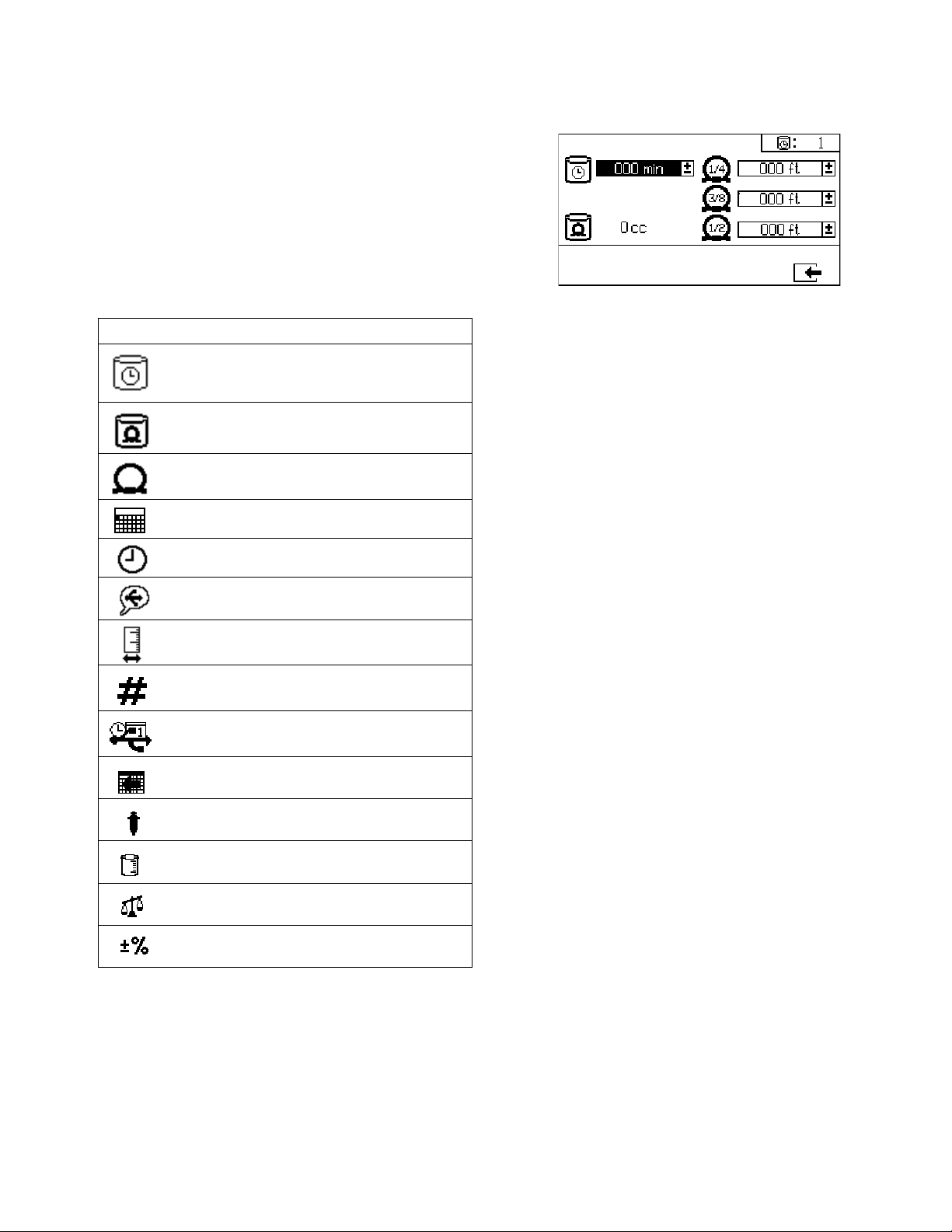

Adjust Ratio and System Settings . . . . . . . . . . . . 31

Temperature Settings . . . . . . . . . . . . . . . . . . . . . . 31

Spray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Flush Mixed Material . . . . . . . . . . . . . . . . . . . . . . 36

Park Metering Pump Rods . . . . . . . . . . . . . . . . . . 37

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 38

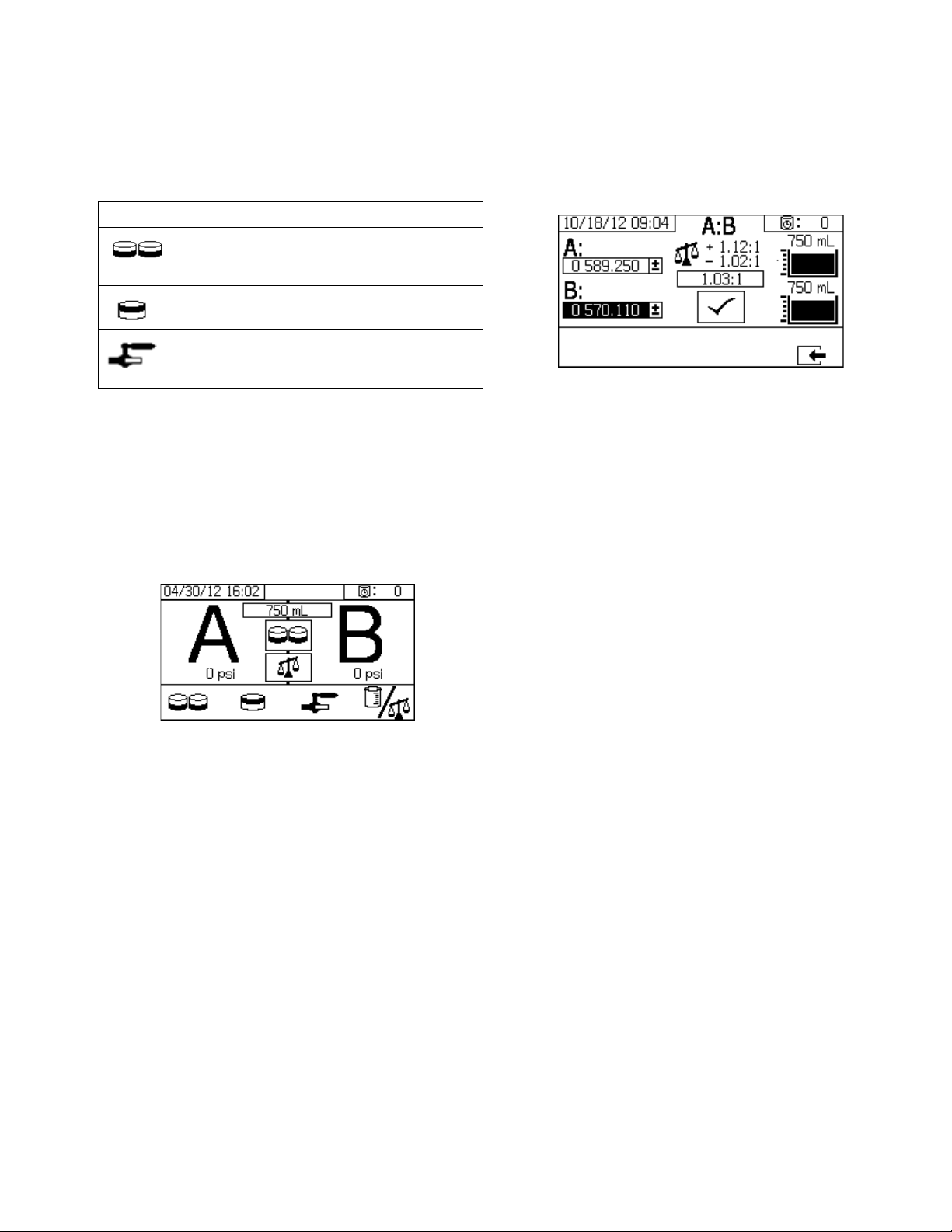

System Verification . . . . . . . . . . . . . . . . . . . . . . . . 40

Pump and Metering Test . . . . . . . . . . . . . . . . . . 40

Batch Dispense or Ratio Test . . . . . . . . . . . . . . 42

Down Stream Valve Leak Test . . . . . . . . . . . . . 43

Mix and Integration Tests . . . . . . . . . . . . . . . . . 44

Empty and Flush Entire System . . . . . . . . . . . . . . 45

Prepare Level Sensor for Shipping . . . . . . . . . . . 49

Download Data from USB . . . . . . . . . . . . . . . . . . . 50

USB Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Download Setup . . . . . . . . . . . . . . . . . . . . . . . . 50

Download Procedure . . . . . . . . . . . . . . . . . . . . . 50

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Adjust Packing Nuts . . . . . . . . . . . . . . . . . . . . . 52

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Clean the System . . . . . . . . . . . . . . . . . . . . . . . 53

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

General Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Individual Control Module LED Diagnostic

Information . . . . . . . . . . . . . . . . . . . . . . . . . 55

Troubleshooting Table . . . . . . . . . . . . . . . . . . . 55

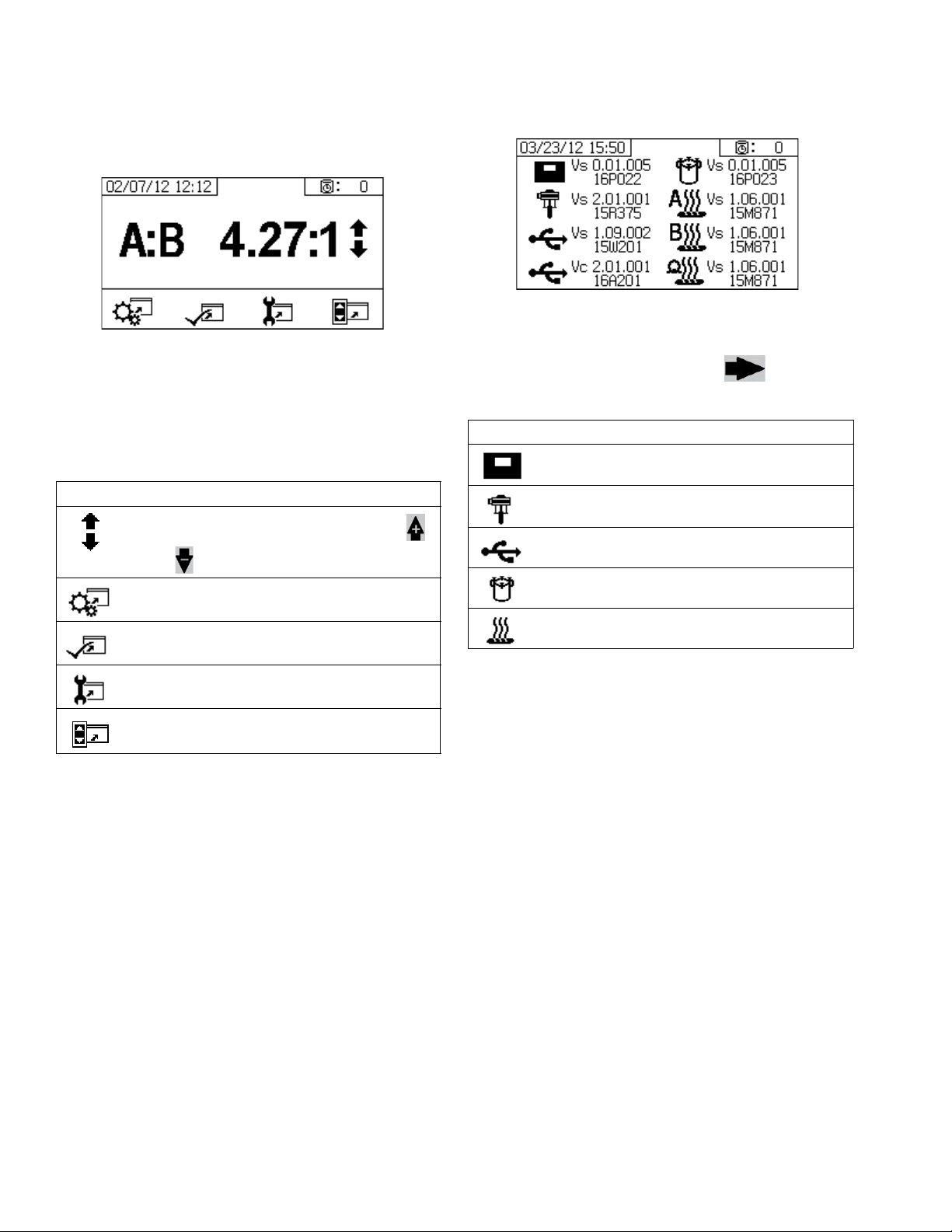

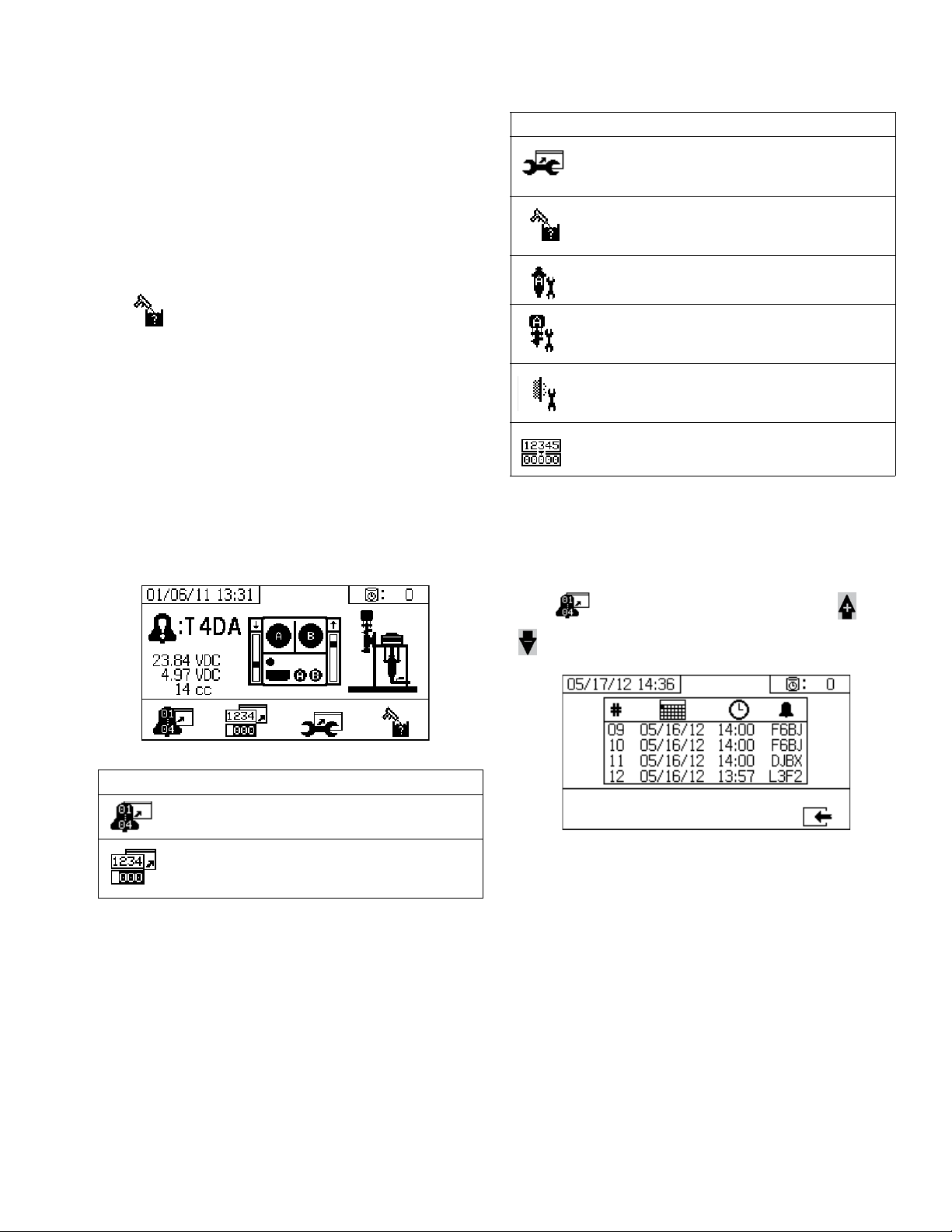

Appendix A - User Interface Display . . . . . . . . . . 58

Change a Setting . . . . . . . . . . . . . . . . . . . . . . . . 58

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Setup Mode Screens . . . . . . . . . . . . . . . . . . . . . 59

Operator Command Mode Screens . . . . . . . . . . 66

Automatically Displayed Screens . . . . . . . . . . . 73

Appendix B - Alarms . . . . . . . . . . . . . . . . . . . . . . . 75

Alarms Overview . . . . . . . . . . . . . . . . . . . . . . . . 75

Alarm Code Troubleshooting . . . . . . . . . . . . . . . 78

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 88

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 88

2 3A2776D

Page 3

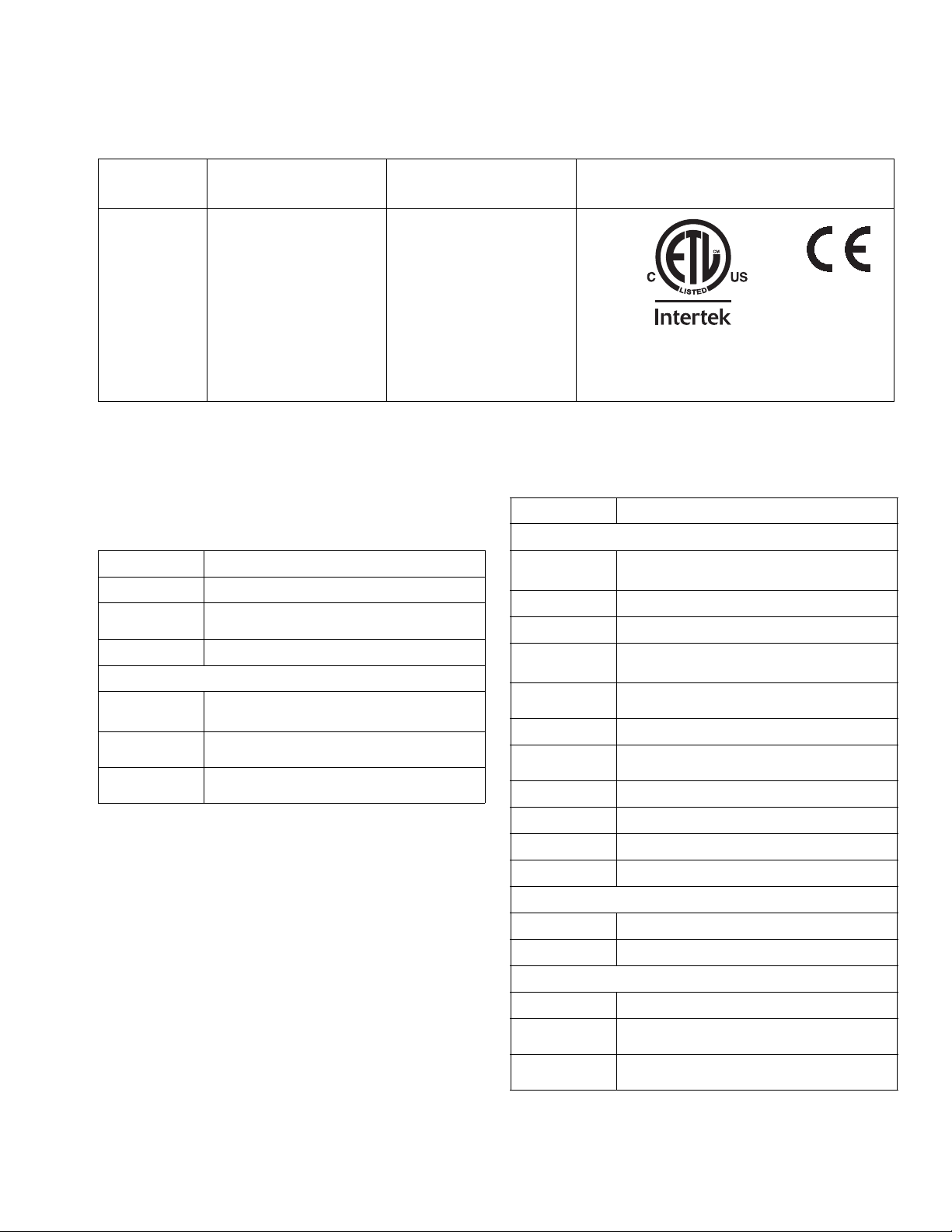

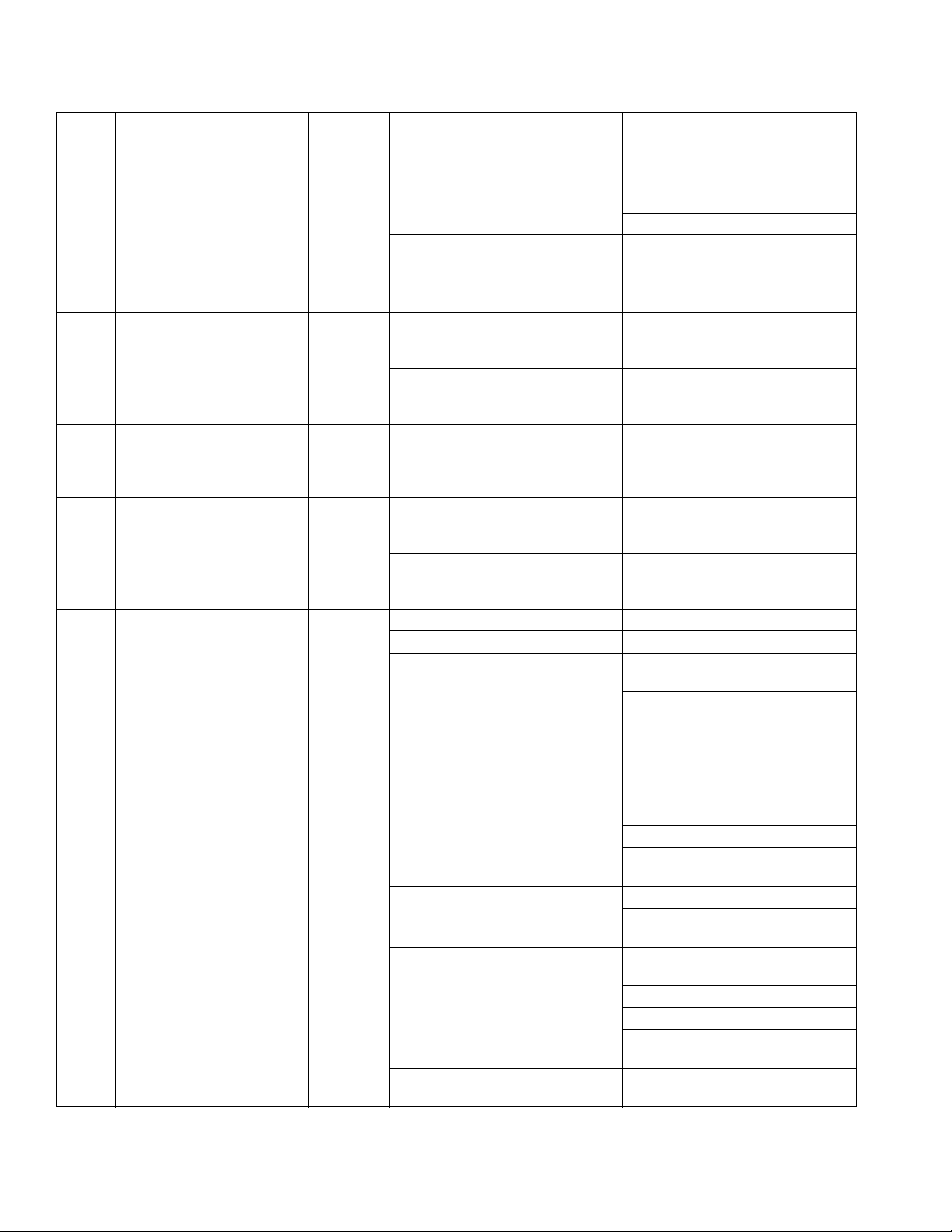

Models

Models

Models

Maximum Fluid

Working Pressure

Maximum Air Working

Pressure Approvals

A and B Materials:

6000 psi

(41 MPa, 414 bar)

Supply:

262869

24W626

Flushing Fluid:

4500 psi

(31 MPa, 310 bar)

(1.0 MPa, 10.3 bar)

Max. Setpoint:

(0.7 MPa, 7 bar)

Heating Fluid:

100 psi

(0.7 MPa, 7 bar)

Related Manuals

Manuals are available at www.graco.com. Component

manuals in English:

Manual Description

3A2989 XM PFP Repair

3A2988

3A2799 XHF Spray Gun

Heaters

309524

3A2954

3A2824

XM PFP Mix Manifold Instructions Parts

Viscon

®

HP High Pressure Fluid

Heater Instructions - Parts

Viscon HF High Flow, High Pressure

Fluid Heater Instructions - Parts

Viscon LT Fluid Heater Instructions -

Parts

150 psi

100 psi

Certified to CAN/CSA C22.2 No. 88

9902471

Conforms to

UL 499

Manual Description

Pumps, Motors, Supply Systems

™

308652

311238

311762

312375

312376

312792

312794

Husky

Pumps Instructions - Parts

NXT

Xtreme

Check-Mate

Instructions - Parts

Check-Mate Pump Packages Instructions - Parts

Merkur

Merkur Pump Assembly Instructions -

Parts

205 Air-Operated Diaphragm

®

Air Motor Instructions - Parts

®

®

312796 NXT Air Motor Instructions - Parts

Lowers Instructions - Parts

®

Displacement Pumps

Pump Repair - Parts

313526 Supply Systems Operation

313527 Supply Systems Repair - Parts

312374 Air Control Instructions - Parts

Accessories

332073 Hot Water Flush Kit Instructions

3A2987 Air Dryer Kit Instructions

Other

306861 Ball Valves Instructions - Parts

307005

308169

3A2776D 3

High Pressure Swivel Instructions Parts

Air Filters, Lubricators, and Kits

Instructions - Parts

Page 4

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

WARNING

WARNINGWARNINGWARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause

electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

or installing equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

•Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless they

are antistatic or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns:

• Do not touch hot fluid or equipment.

4 3A2776D

Page 5

Warnings

WARNING

WARNINGWARNINGWARNING

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure and disconnect all power sources.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes but is

not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer

SPLATTER HAZARD

Hot or toxic fluid can cause serious injury if splashed in the eyes or on skin. During blow off of platen,

splatter may occur.

• Use minimum air pressure when removing platen from drum.

3A2776D 5

Page 6

Warnings

Keep Components A and B Separate

Cross-contamination can result in cured material in

fluid lines which could cause serious injury or damage

equipment. To prevent cross-contamination:

• Never interchange component A and component

B wetted parts.

• Never use solvent on one side if it has been contaminated from the other side.

Changing Materials

NOTICE

Changing the material types used in your equipment

requires special attention to avoid equipment damage

and downtime.

• When changing materials, flush the equipment

multiple times to ensure it is thoroughly clean.

Components A and B

IMPORTANT!

Material suppliers can vary in how they refer to plural

component materials.

Be aware that in this manual:

Component A

Component B

This equipment doses the B component into the A component flow. An integration hose must always be used

after the mix manifold and before the static mixer.

refers to resin or major volume.

refers to the hardener or minor volume.

• Always clean any fluid inlet strainers after flushing.

• Check with your material manufacturer for chemical compatibility.

• When changing between epoxies and urethanes

or polyureas, disassemble and clean all fluid components and change hoses. Epoxies often have

amines on the B (hardener) side. Polyureas often

have amines on the B (resin) side

6 3A2776D

Page 7

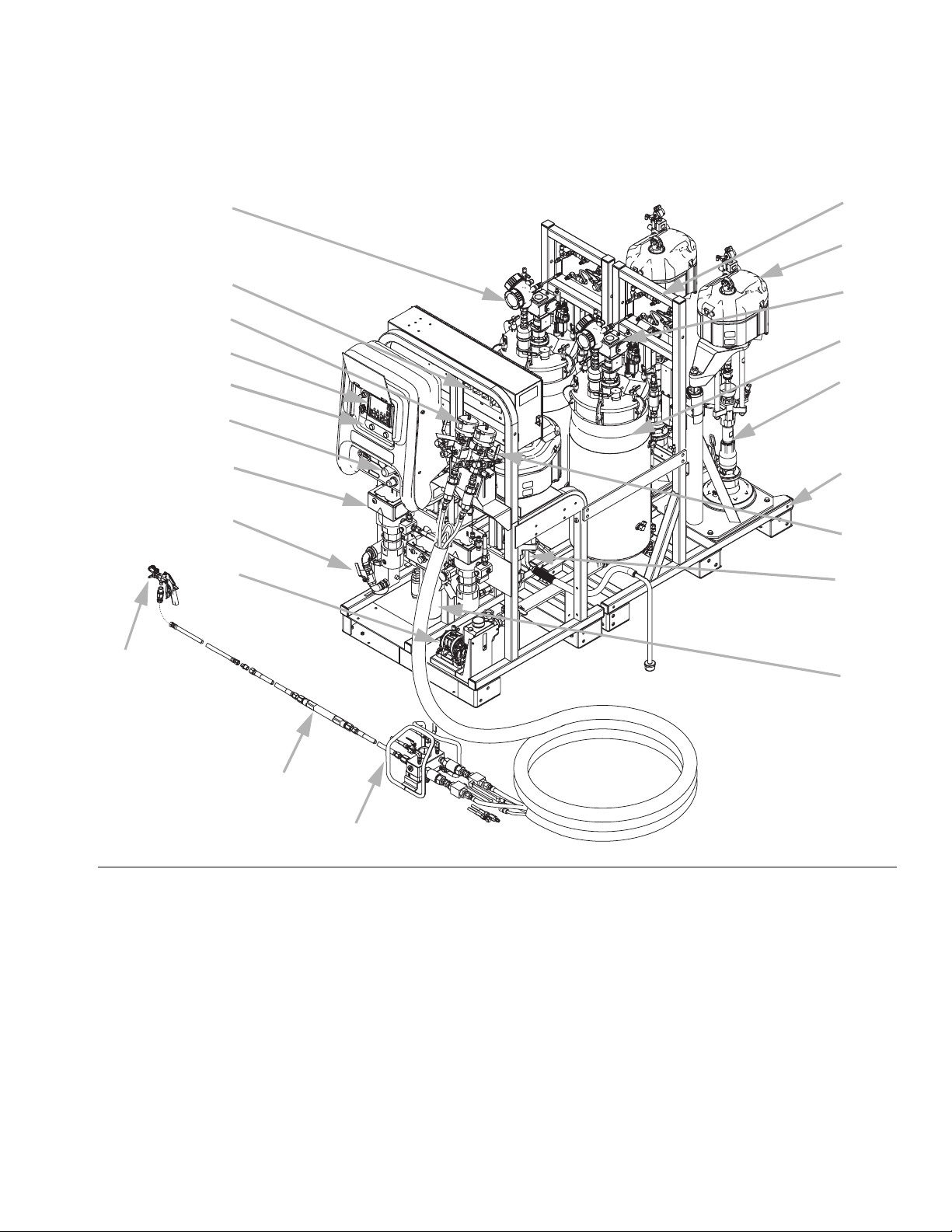

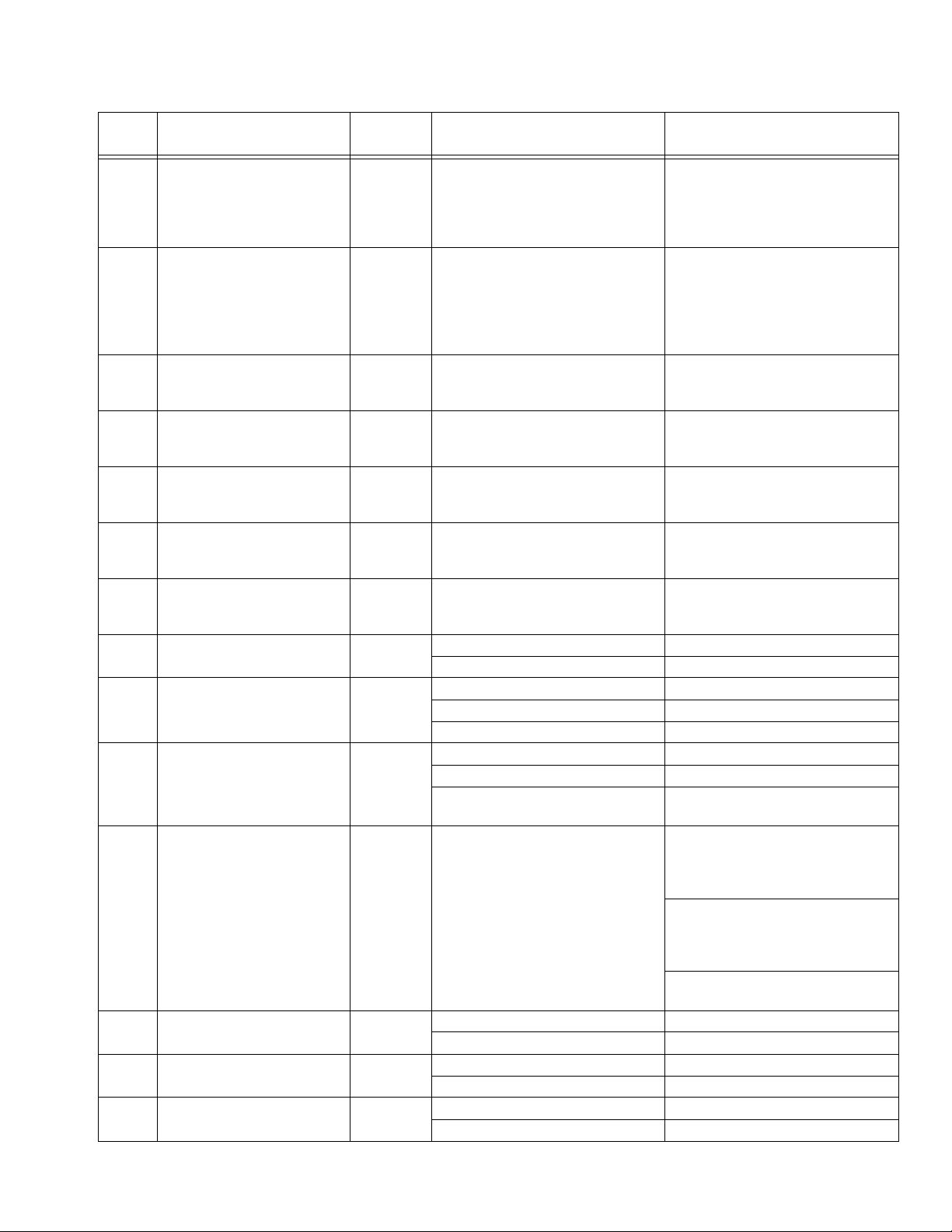

Component Identification

Typical Setup (Front View)

Y

Component Identification

V

U

J

B

C

D

G

K

E, F

C1

T

ti19927a

WLE

L

P

M

A

N

X

H

S

R

FIG. 1

Key:

AFrame

B Fluid Control Assembly

C GCA Control Display

D Metering Pumps Control On and Off Buttons

E Main Air Supply Shutoff Valve, 1 in. npt(f) Inlet

F Air Filter, 1-1/4 in.

G Air Controls for Sprayer and Flush Pump (see page 10)

H Viscon HP Heater for hose bundle

J Junction Box/Heater Controls (see page 10)

K Viscon HF Material Heater

L Air Powered Agitator with Lubricator

M Feed Pump

N Recirculation Control Valve

P Pressure Tank, Double-Wall Temperature Conditioned

3A2776D 7

R Remote Mix Manifold

S Static Mixer Assembly

T Spray Gun

U Air Motor

V Supply Controls (see page 11)

W High Pressure Fluid Metering Pump

X Solvent Flush Pump (Merkur Pump)

Y Radar Fluid Level Sensor

Z Air Regulator for Feed Tanks and Pumps

A1 Heated Tank Circulation Components (uses a Viscon LT)

B1 TSL Supply Bottle and Bracket

C1 Heated Fluid Circulation Pump for Hose Bundle

D1 Insulation Jacket

Page 8

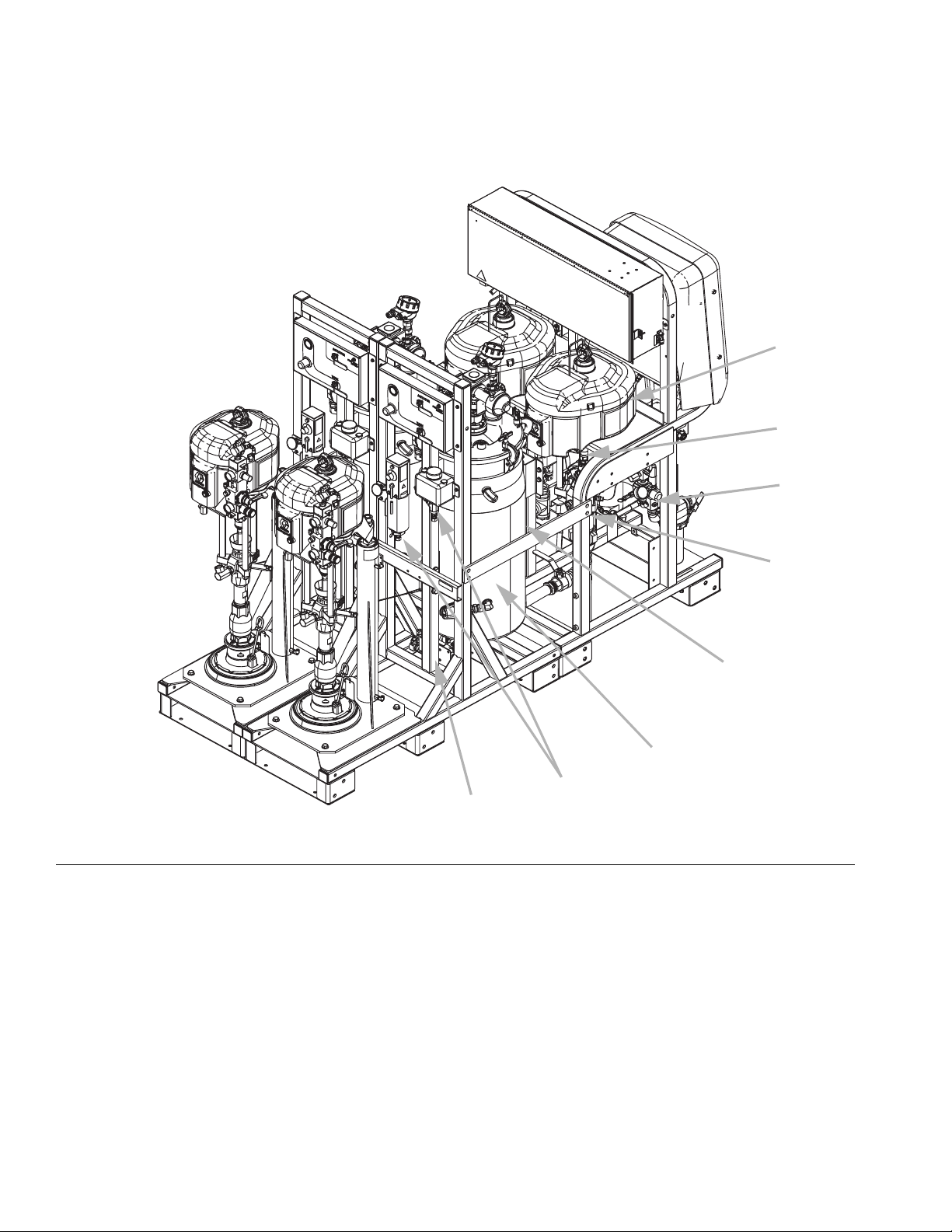

Component Identification

Typical Setup (Back View)

U

B1

Z

FIG. 2

C1, A1

A1

WLD

W

X (located between

metering pumps, not

visible in current view)

D1, A1

8 3A2776D

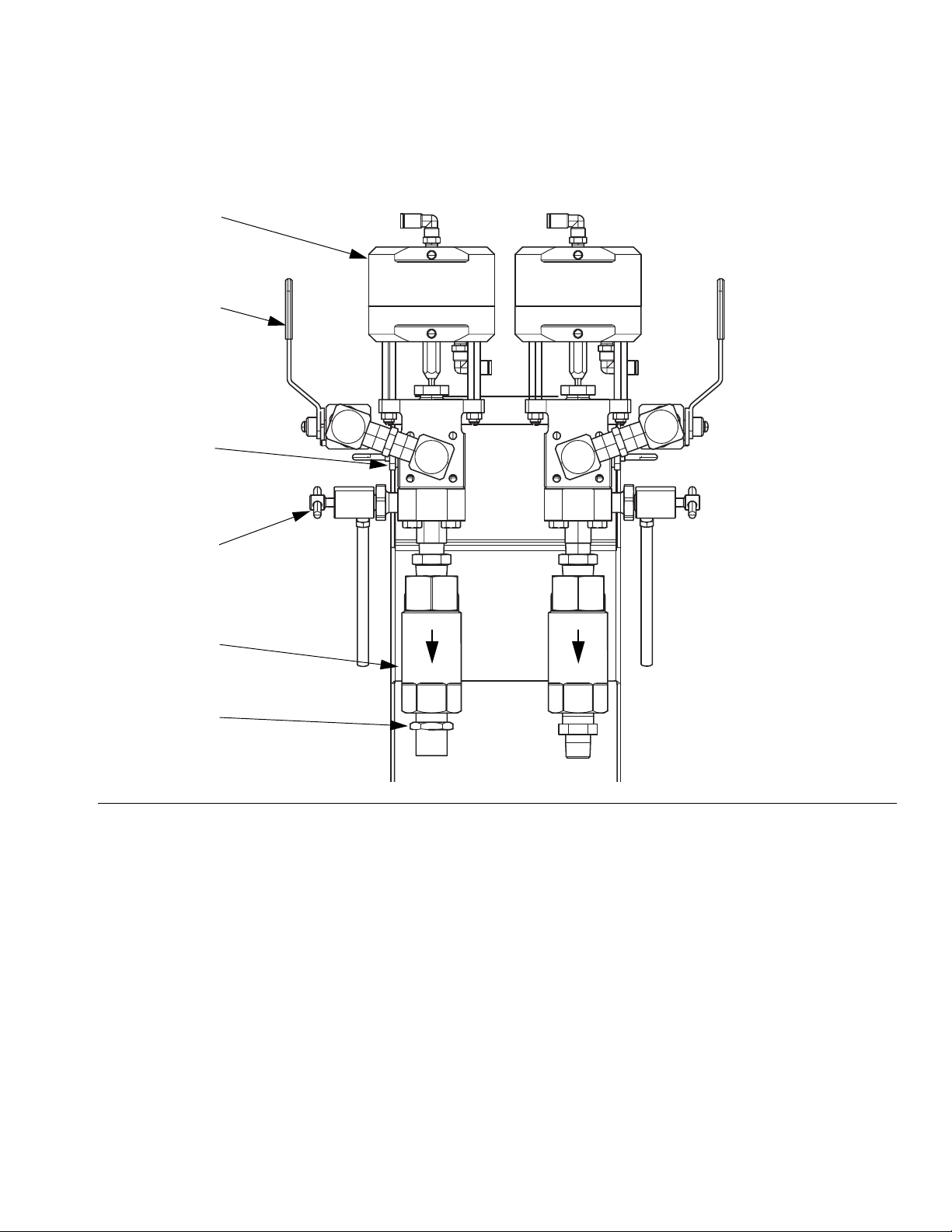

Page 9

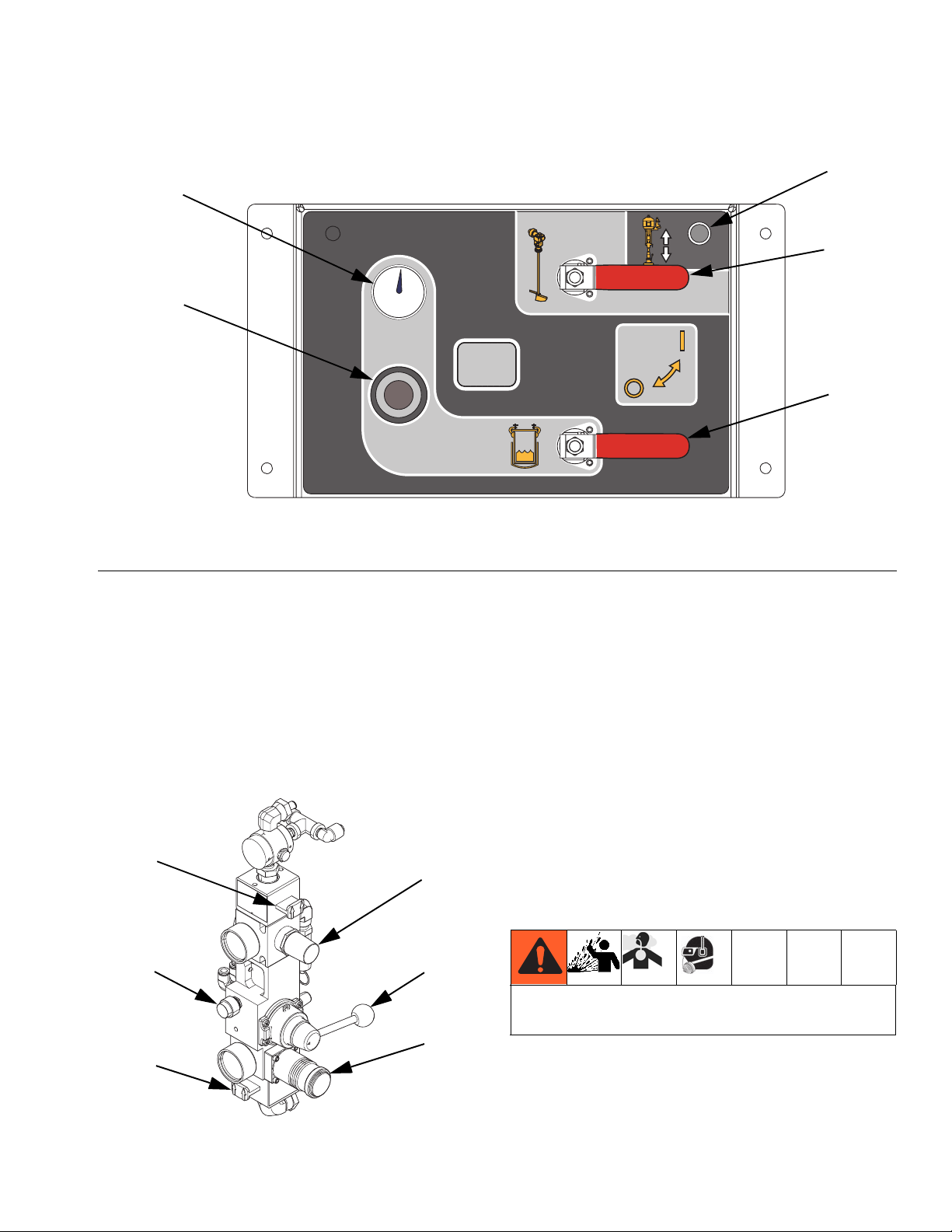

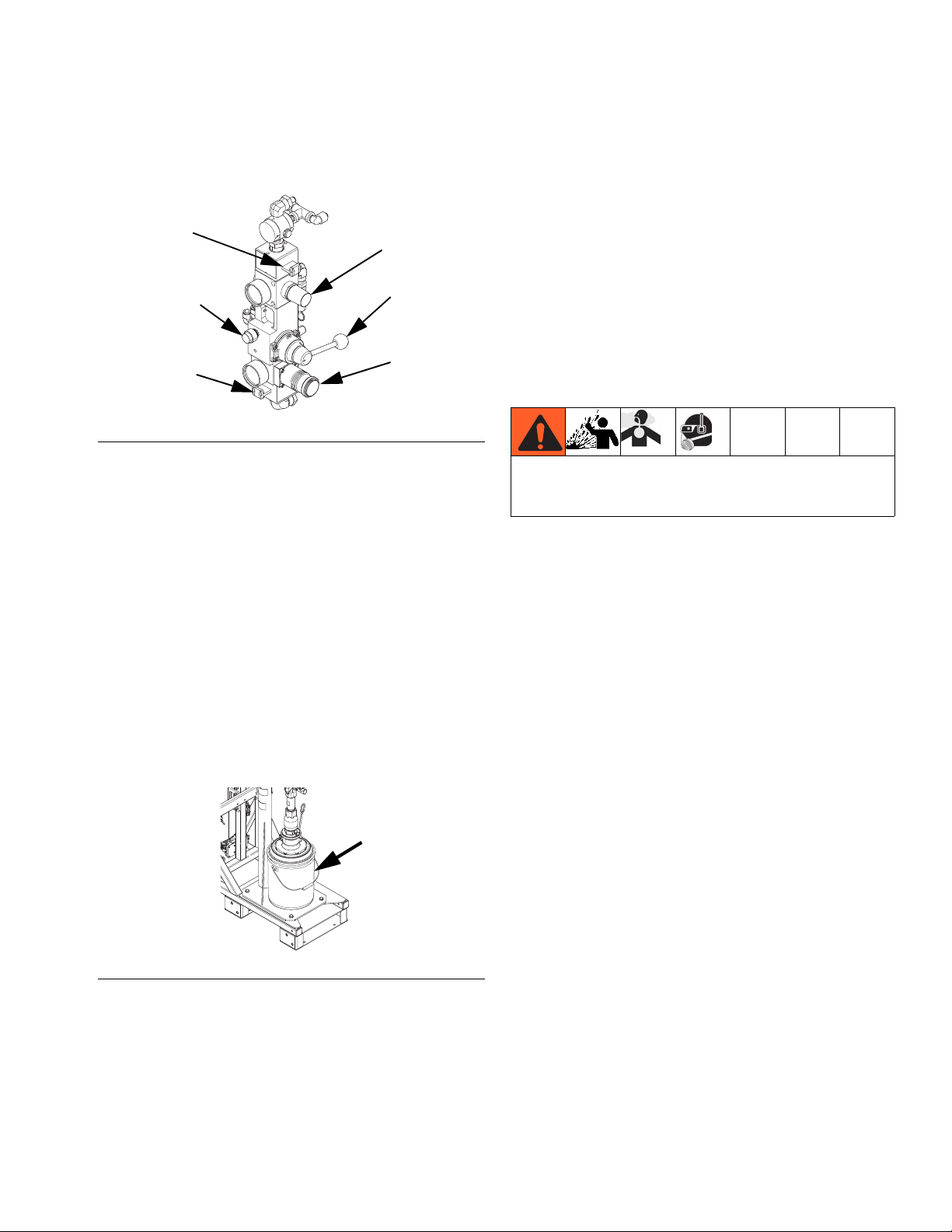

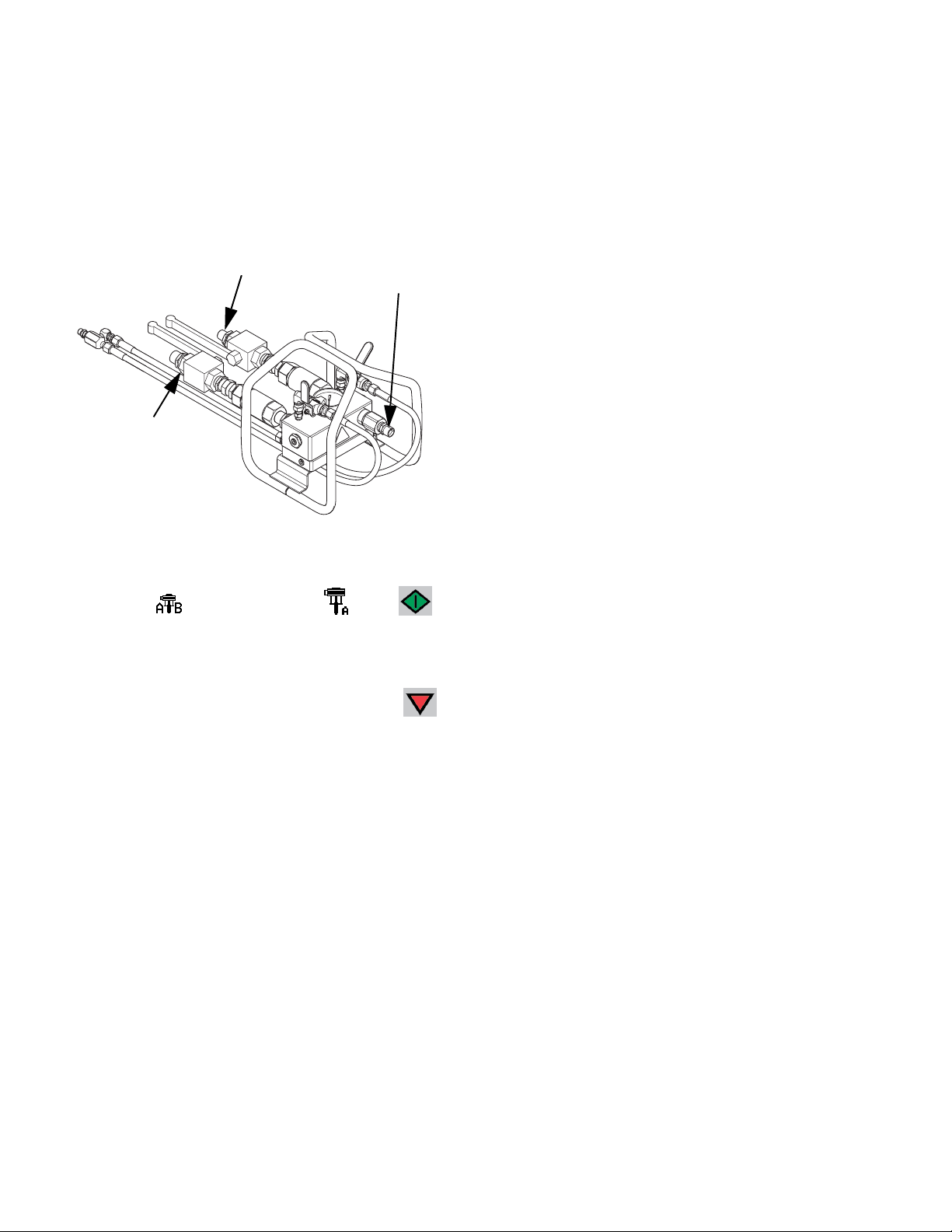

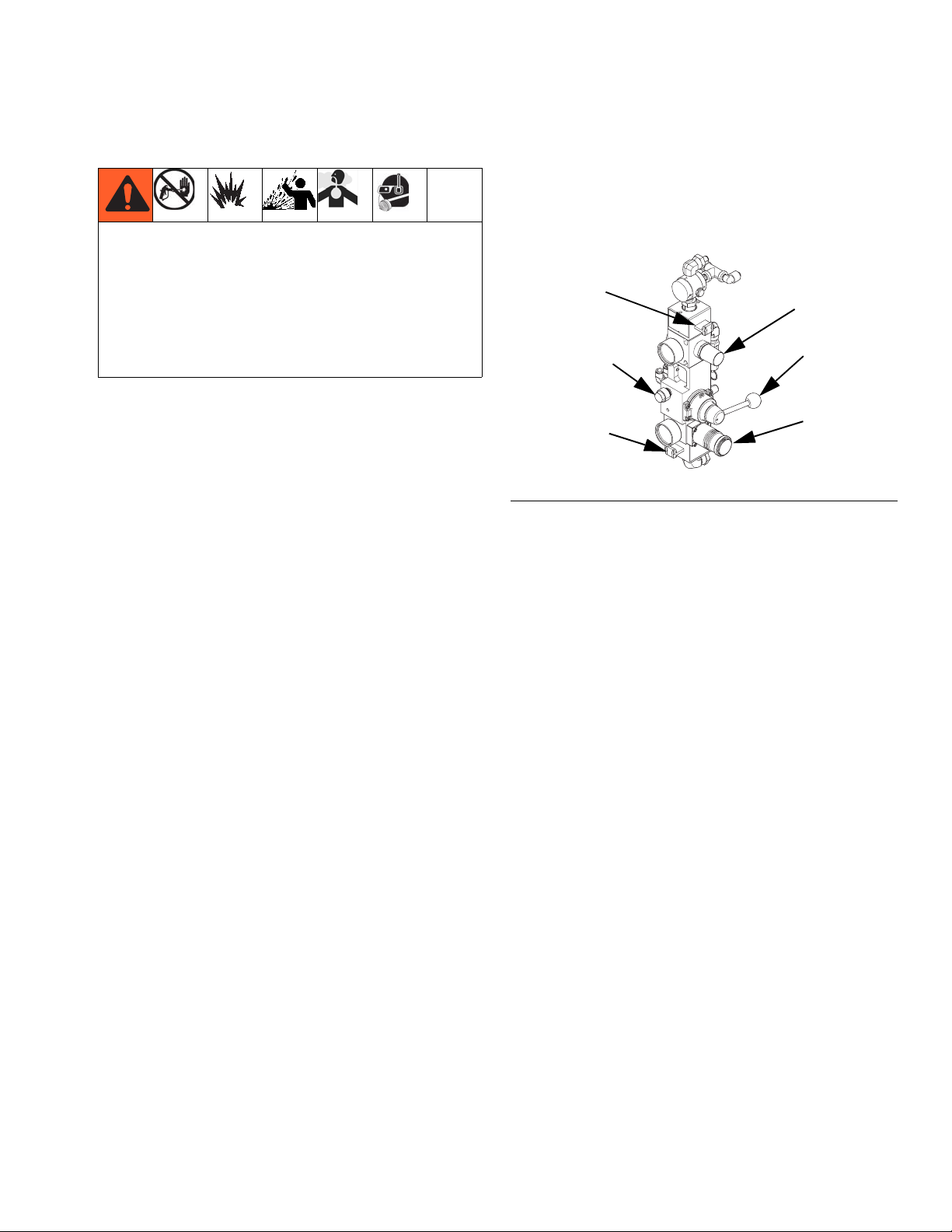

Fluid Control Assembly

AA

AC

AL

Component Identification

AE

AG

AJ

FIG. 3

AA Dosing Valve

AC Recirculation Valve

AE Sampling Valve

AG Outlet Check Valve

AJ Hose Connection (Model 262869) - A side: 3/4 npt(m); B side: 1/2 npt(m)

Hose Connection (Model 24W626) - A side: 3/4 npt(m); B side 3/4 npt(m)

AL Pressure Sensor

ti19928a

3A2776D 9

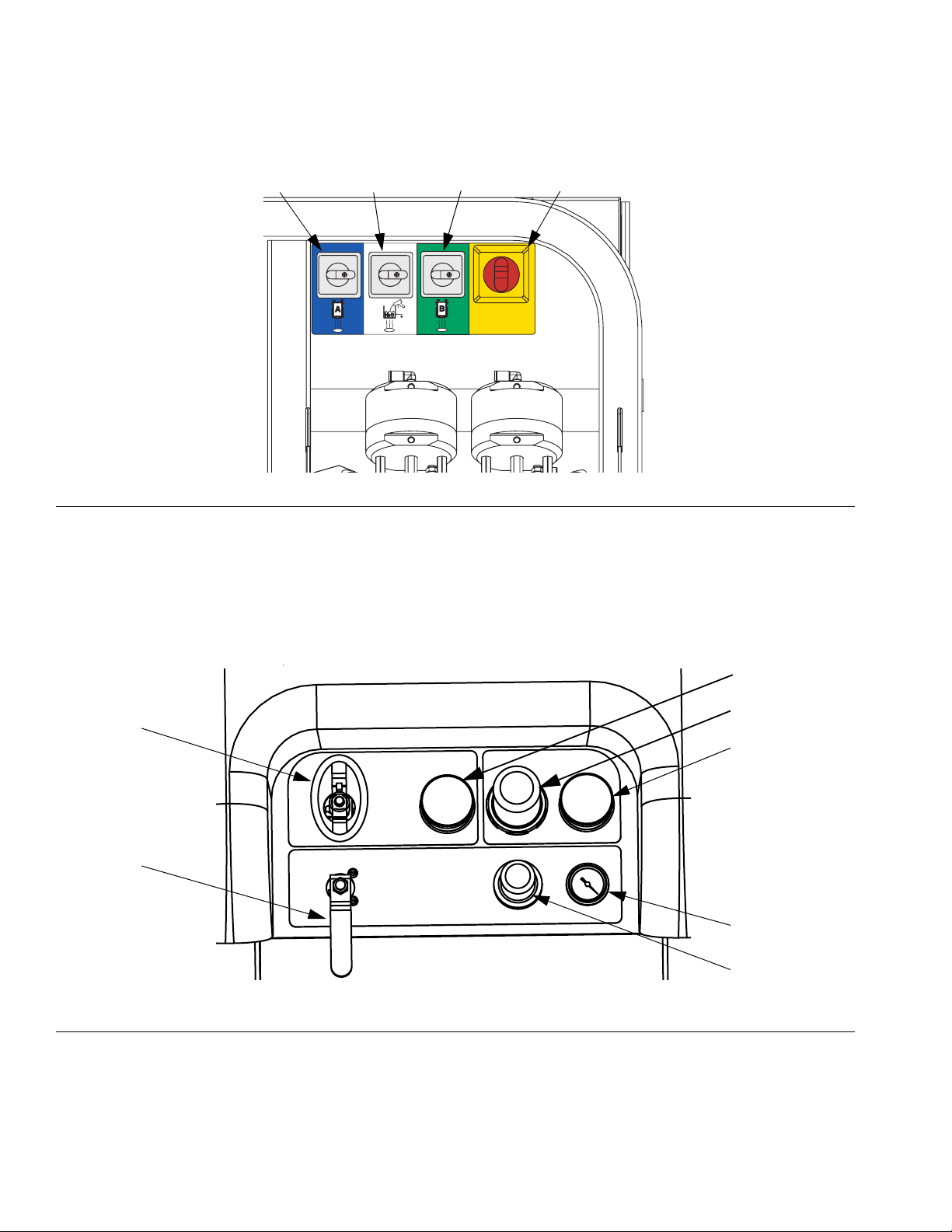

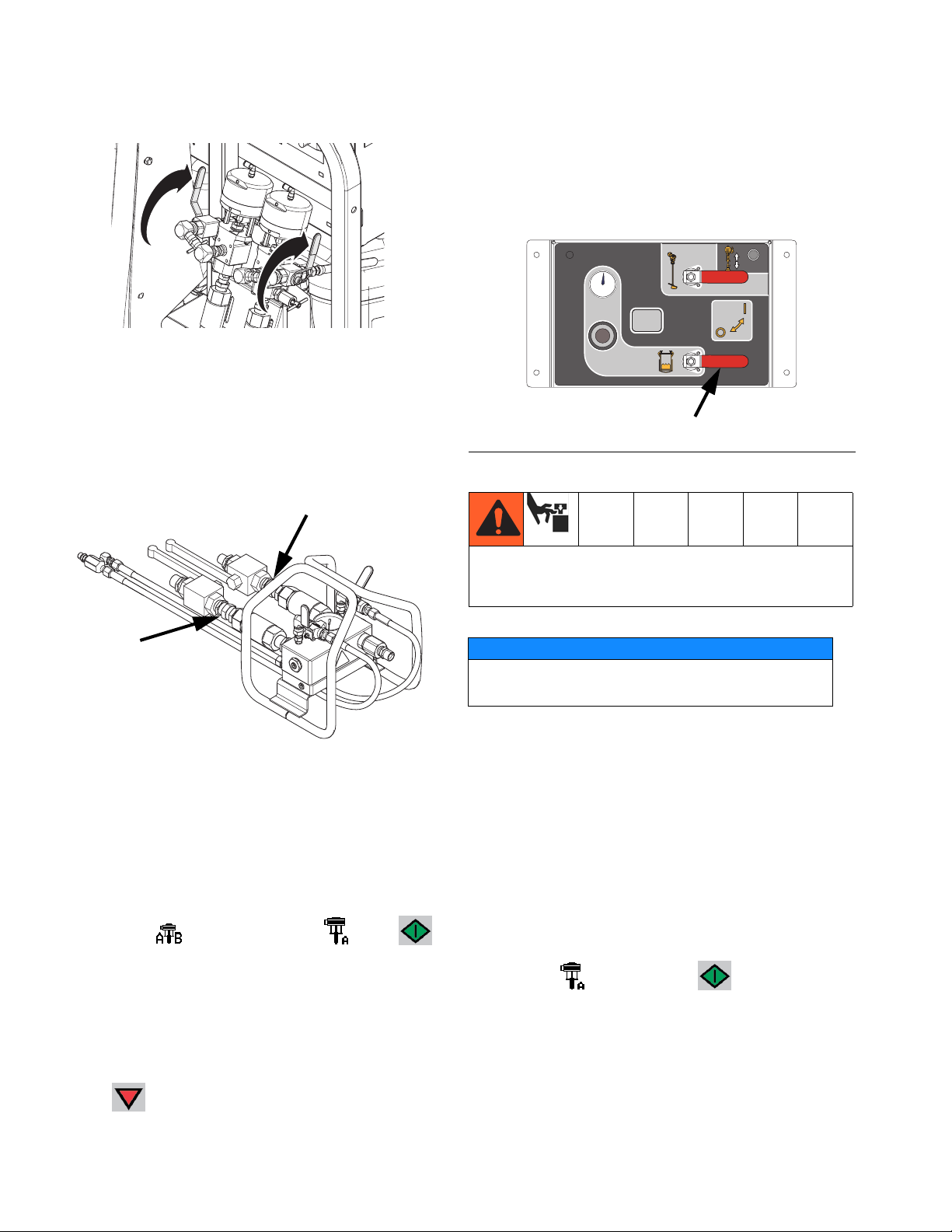

Page 10

Component Identification

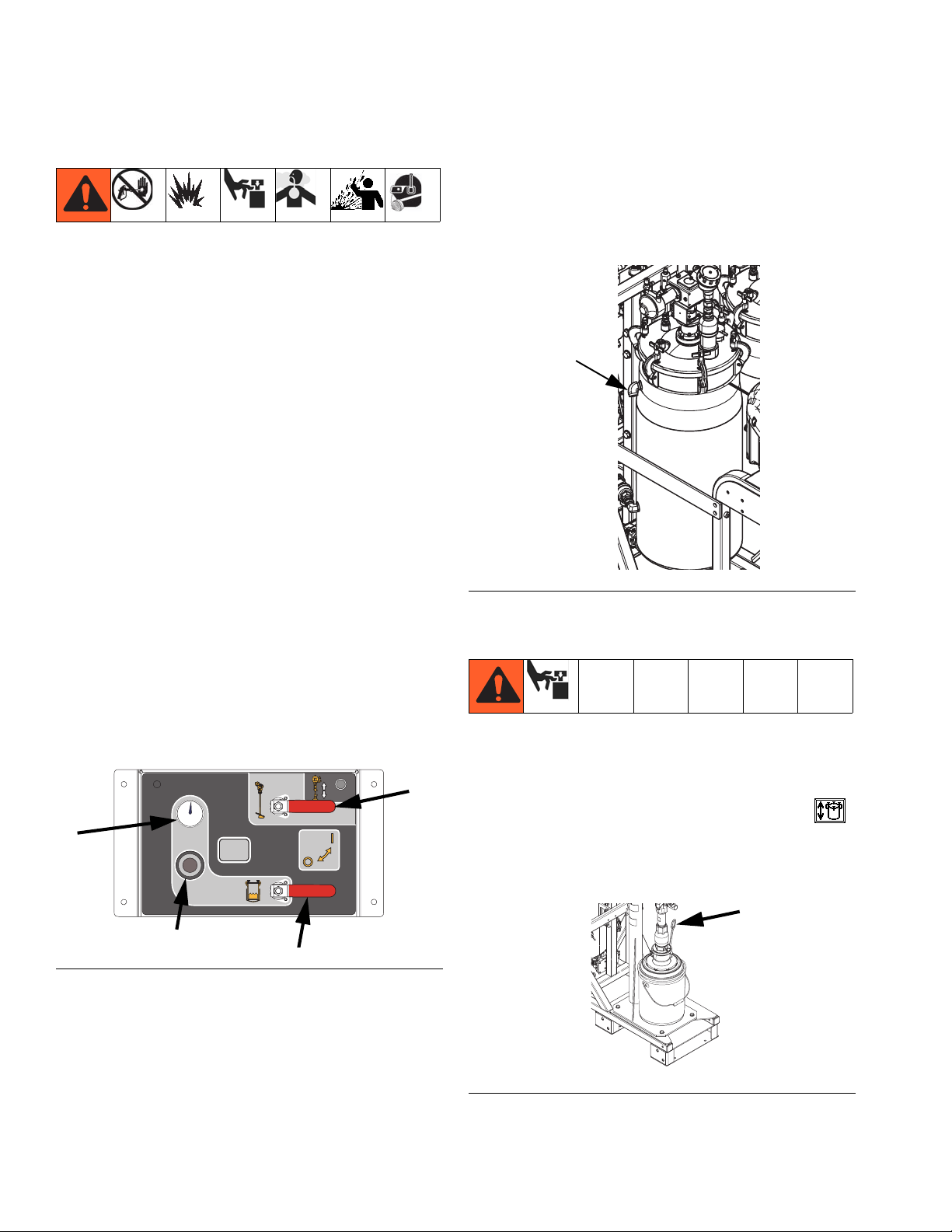

Main Power and Heater Controls

BB BCBD BA

FIG. 4

ti20101a

BA Main Power ON/OFF Switch

BB A Tank Water Heat ON/OFF Switch

BC B Tank Water Heat ON/OFF Switch

BD Optional Heated Water Flush Tank Accessory ON/OFF

Sprayer and Flush Pump Air Controls

CA

CB

FIG. 5

Switch (only used if the water heater accessory has been

added to the machine)

CC

CD

CE

CF

CG

r_XM1A00_312359_313289_14A

CA Metering Pump Air On/Off Control

CB Solvent Pump Air On/Off Control

CC Inlet Air Pressure Gauge

CD Metering Pump Air Regulator

CE Metering Pump Air Regulator Gauge

10 3A2776D

CF Solvent Pump Air Gauge

CG Solvent Pump Air Regulator

Page 11

Feed Module Air Controls

CR

Component Identification

CU

CP

NOTE: Both valves shown open

F

IG

. 6: Supply Controls

CP Tank Air Pressure Regulator

CR Tank Air Pressure Gauge

CS Tank Air Supply Valve

CT Agitator and Heated Water Circulation On/Off Valve

CU Feed Pump Bypass Button

FEED PUMP

BYPASS

ti20127a

CT

CS

Feed Pump Bypass Button

Use the feed pump bypass button to manually run the

feed pump when the automatic tank filling function is not

running the feed pump. See automatic tank filling details

on page 73.

Feed Pump Air Controls

DF

DA RAM Air ON/Exhaust Slider Valve

DB RAM Air Regulator

DC RAM Up/Down Director Valve

DD RAM Blowoff Valve

DE Air Motor Regulator

DF Air Motor ON/Exhaust Slider Valve

DE

RAM Blowoff Valve (DD)

DD

DC

To minimize material splatter, use the minimum air

pressure required to remove platen from pail.

DB

DA

To easily remove the RAM from the pail, press and hold

the RAM Blowoff Valve button while lifting the RAM

platen. A small amount of air pressure will be supplied to

ti20104a

3A2776D 11

the pail to push the pail off of the RAM.

Page 12

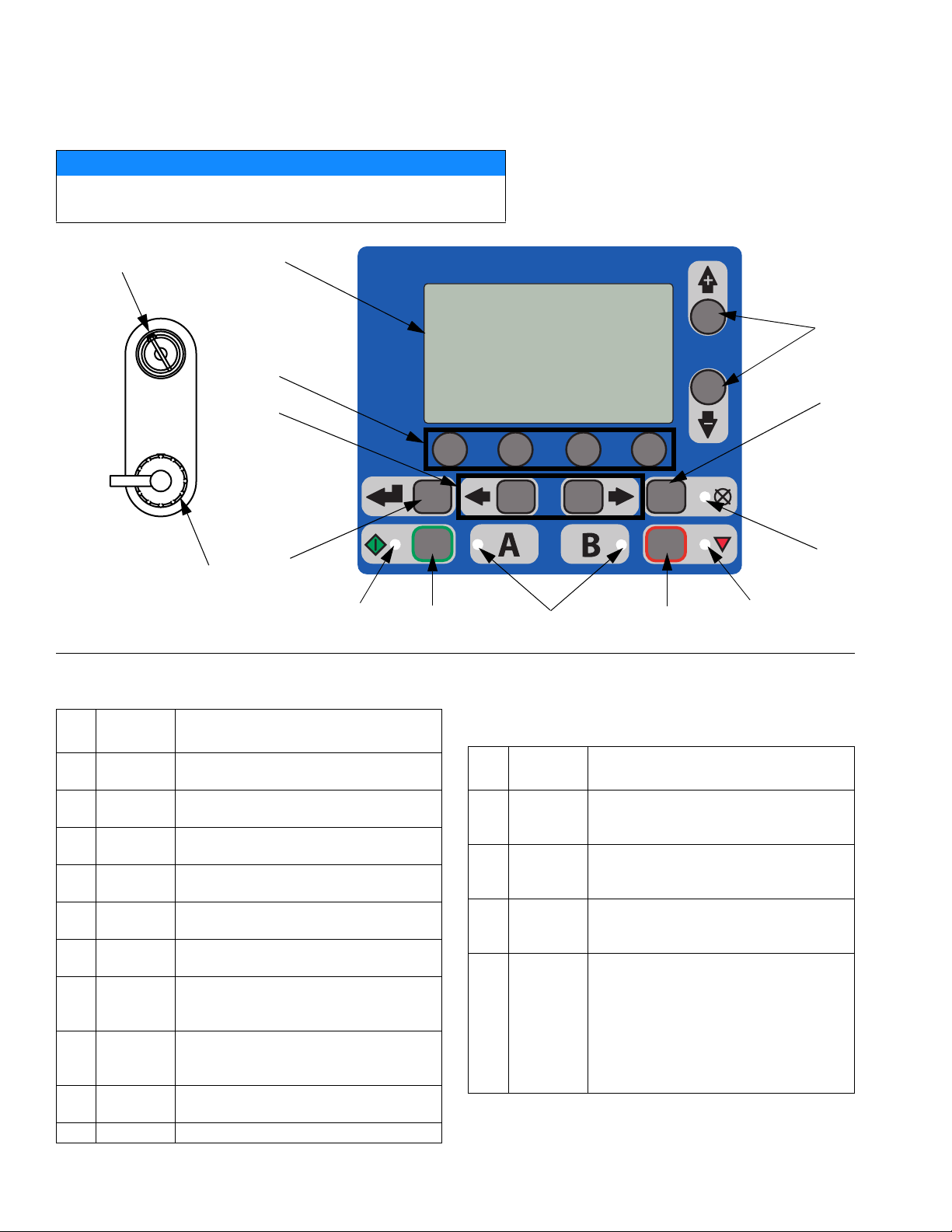

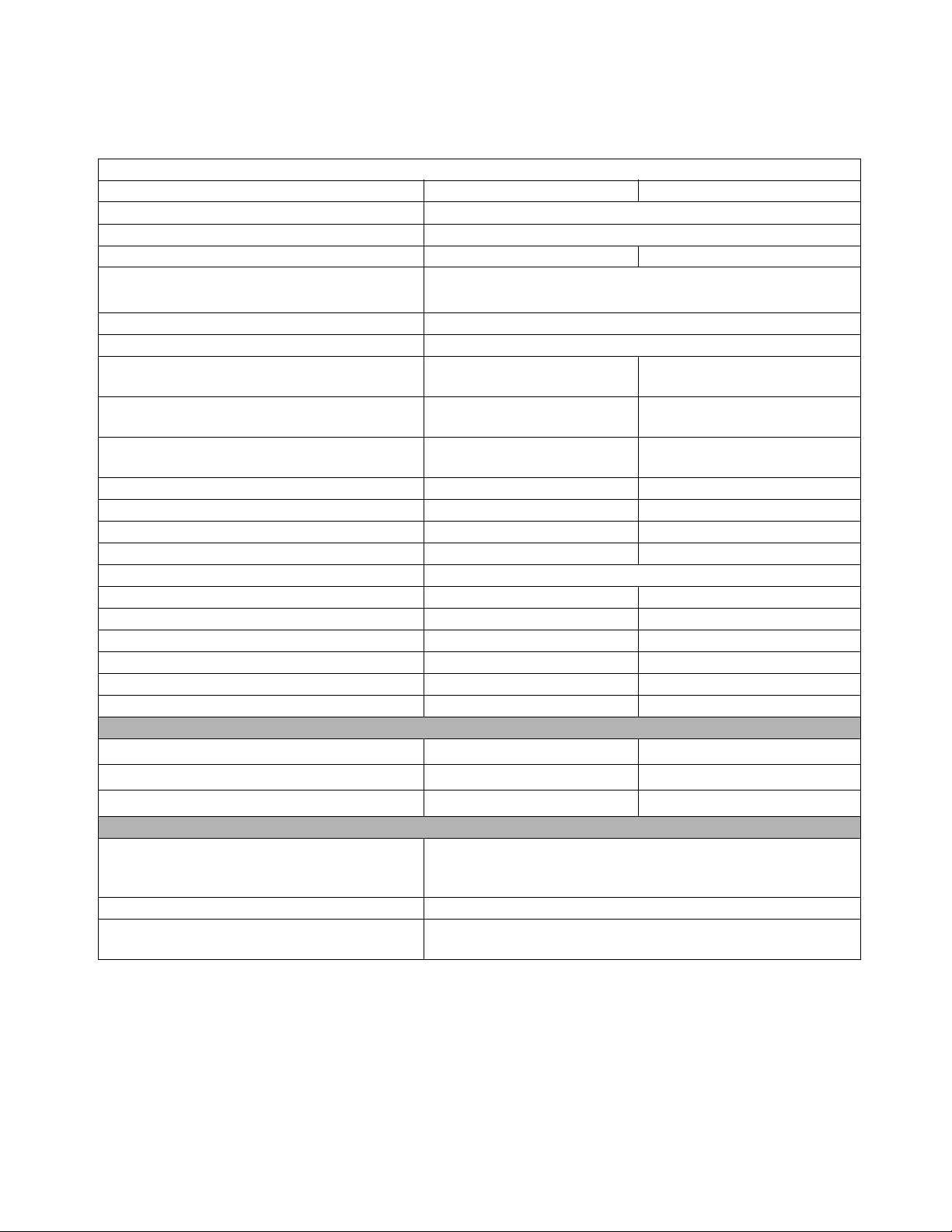

Component Identification

User Interface

NOTICE

To prevent damage to soft key buttons, do not press the buttons

with sharp objects such as pens, plastic cards, or fingernails.

DJ

DR

DA

DG

DF

DD

ti13365a

DH

DE

DP

F

IG

. 7: User Interface

DM

DB

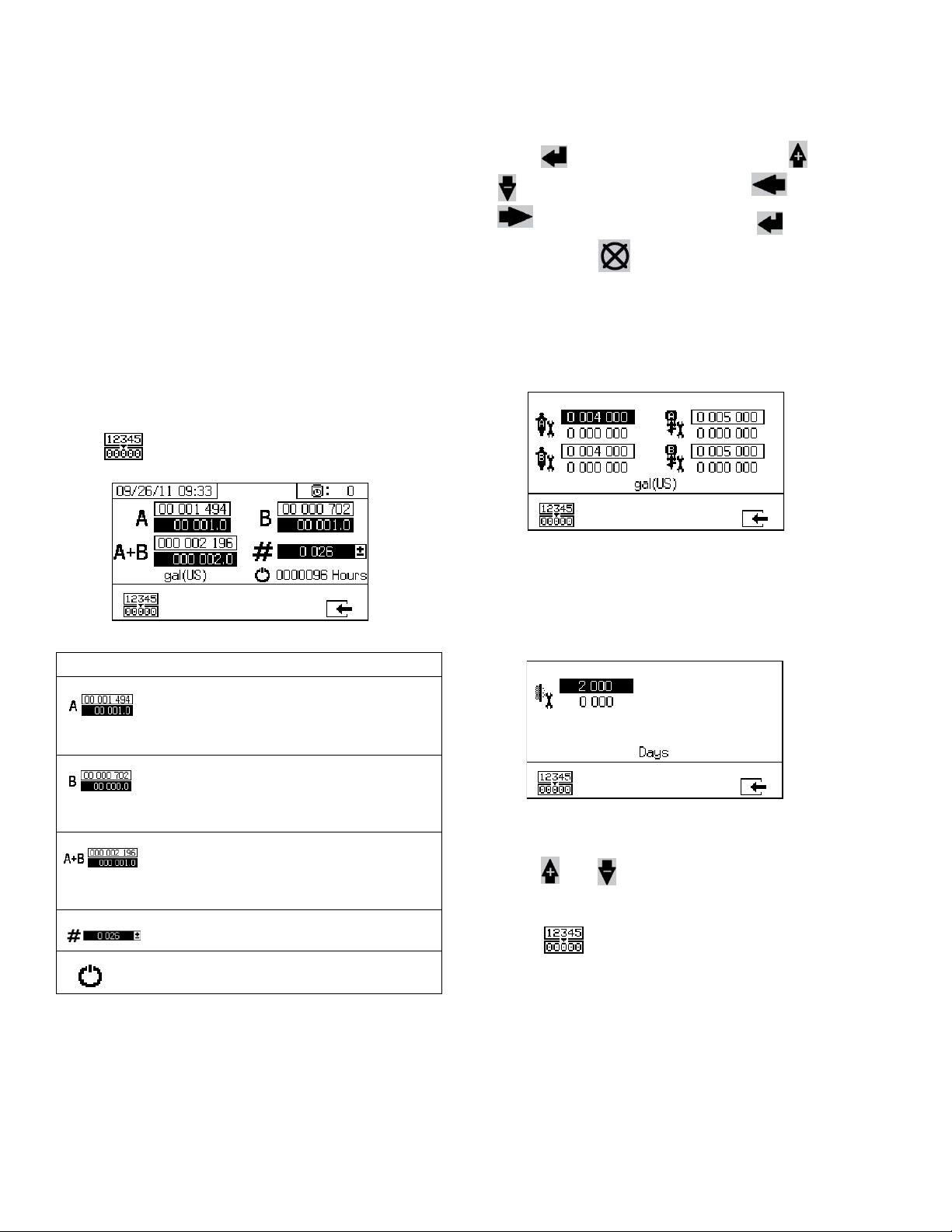

Buttons LEDs

Call

out Button Function

DA Display

Screen

DB Start Initiates Active Run Mode function cur-

DC Stop Terminates Active Run Mode function

DD Enter Press to open drop-down fields, select

DE Alarm

Reset

DF Left/Right Move between screens in run or setup

DG Function Activates mode or action represented by

DH Up/Down Move between drop-down fields, option

DJ Setup Key

Lock

DR USB Port Connection for data download.

Use to view screens. See page 58.

rently selected in Run Screen.

currently selected.

options, and save values.

Resets alarms and advisories.

modes.

the icon above each of the four buttons in

the LCD.

boxes, and selectable values within

Setup screens.

Change ratio or enter Setup mode.

There are four types of LEDs on the display.

Call

out LED Function

DK Blue Dosing valve active

DM Green Spray mode active

DN Red Alarm

DP Yellow Warning

DK

DC

• On - dosing valve is active

• Off - dosing valve is not active

• Spray mode is on (active)

• Spray mode is off (inactive)

• On - alarm is present

• Off - no alarm

• On - is active.

• Off - no warning indicated. Ratio

and setup fields are not changeable.

• Flashing - key is present and

turned. Ratio and setup fields

are changeable.

DN

12 3A2776D

Page 13

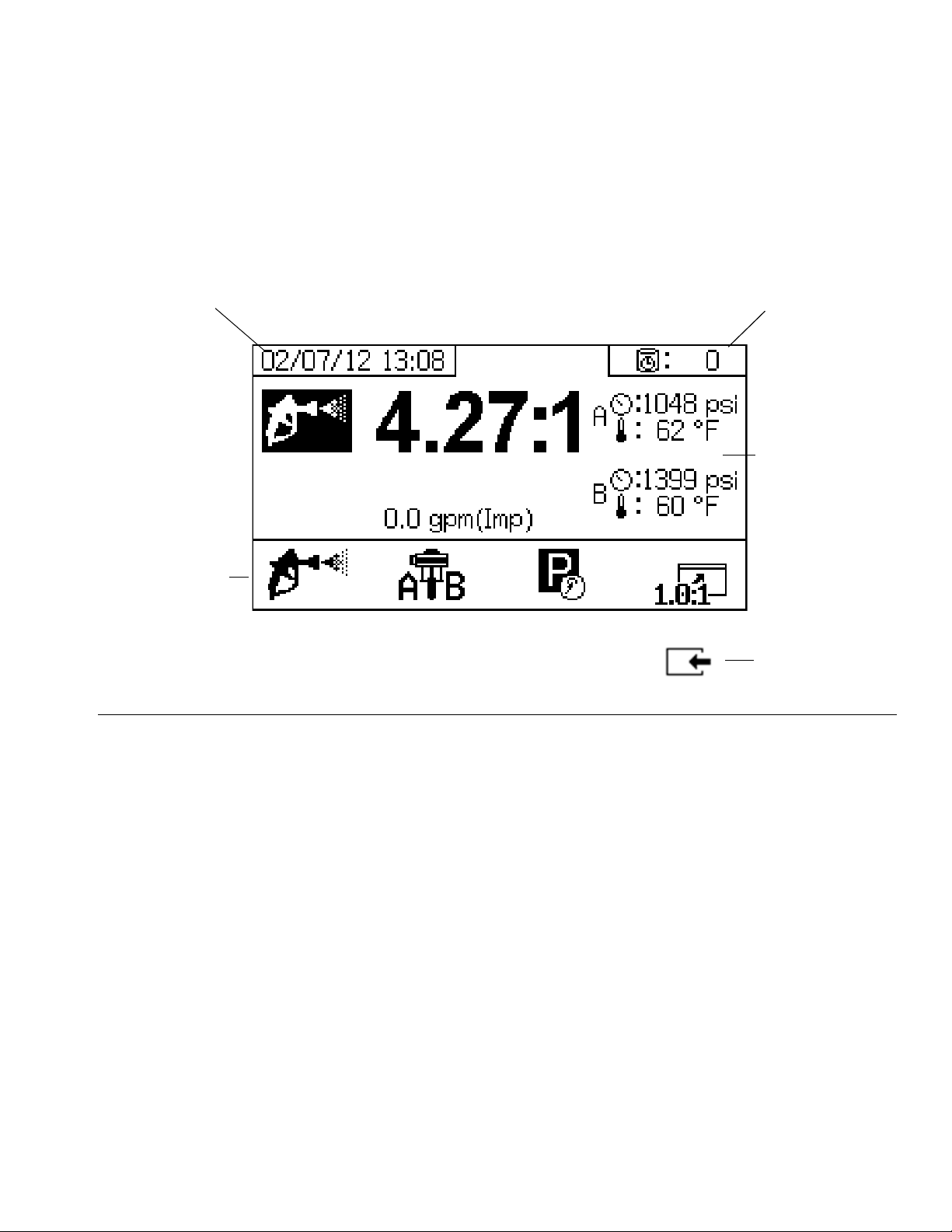

Component Identification

User Interface Display

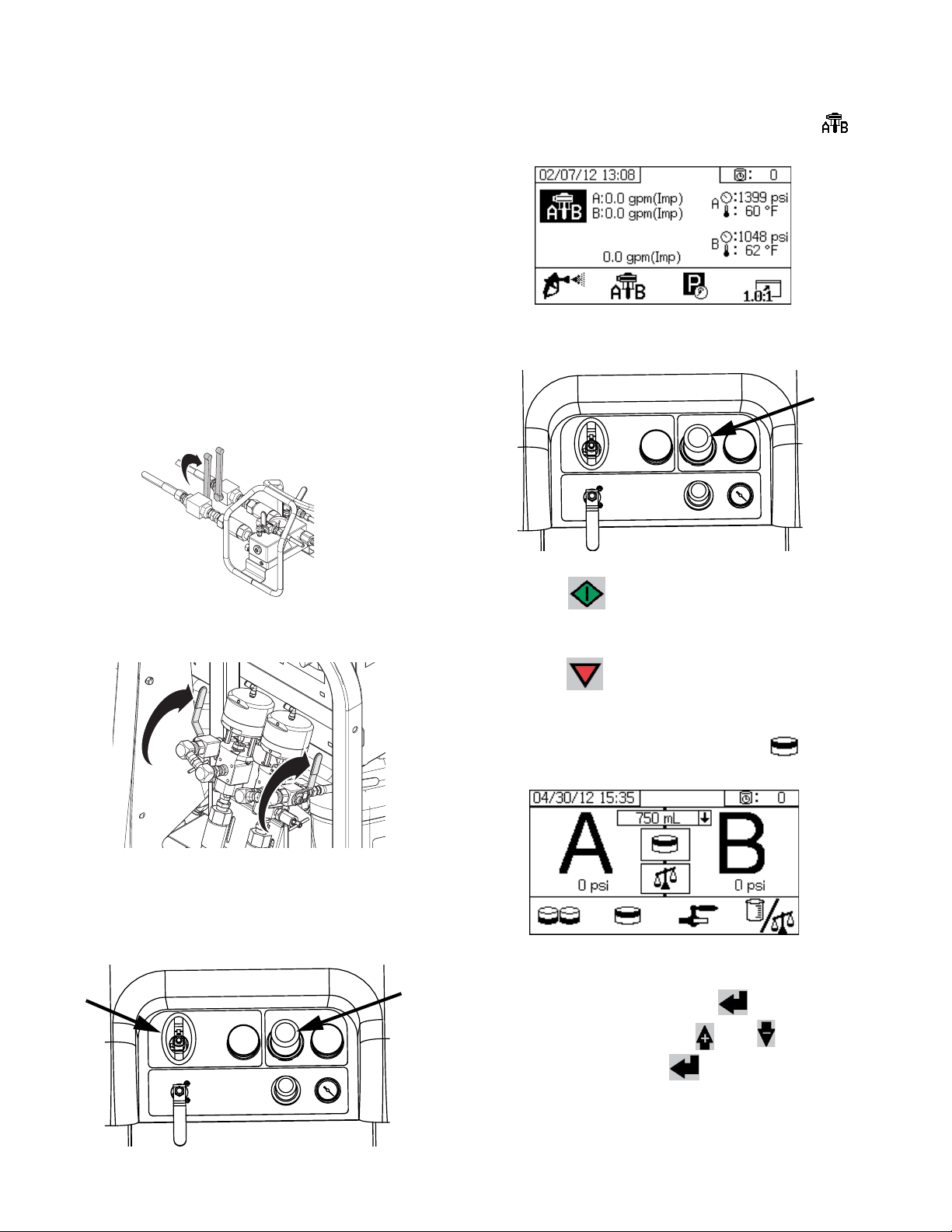

Main Display Screen Components

NOTE: For detailed screens information, see Appendix A - User Interface Display beginning on page 58.

The following figure calls out the navigational, status, and general informational components of each display screen.

Current Date and Time

Navigational Bar

F

IG

. 8: Main Display Screen Components (shown with all display features enabled)

Remaining Potlife Time

Function Display

Go back one screen

3A2776D 13

Page 14

Setup

Setup

Location

Select a non-hazardous location with the required power

and air supply to set up your sprayer. Maintain access

from all sides.

Unboxing

The machine is shipped on two separate pallets, one

with the XM PFP and one with the two feed modules.

Each pallet is wrapped in heavy cardboard with a lid

secured with straps. Cut the lid straps then remove the

lids and cardboard.

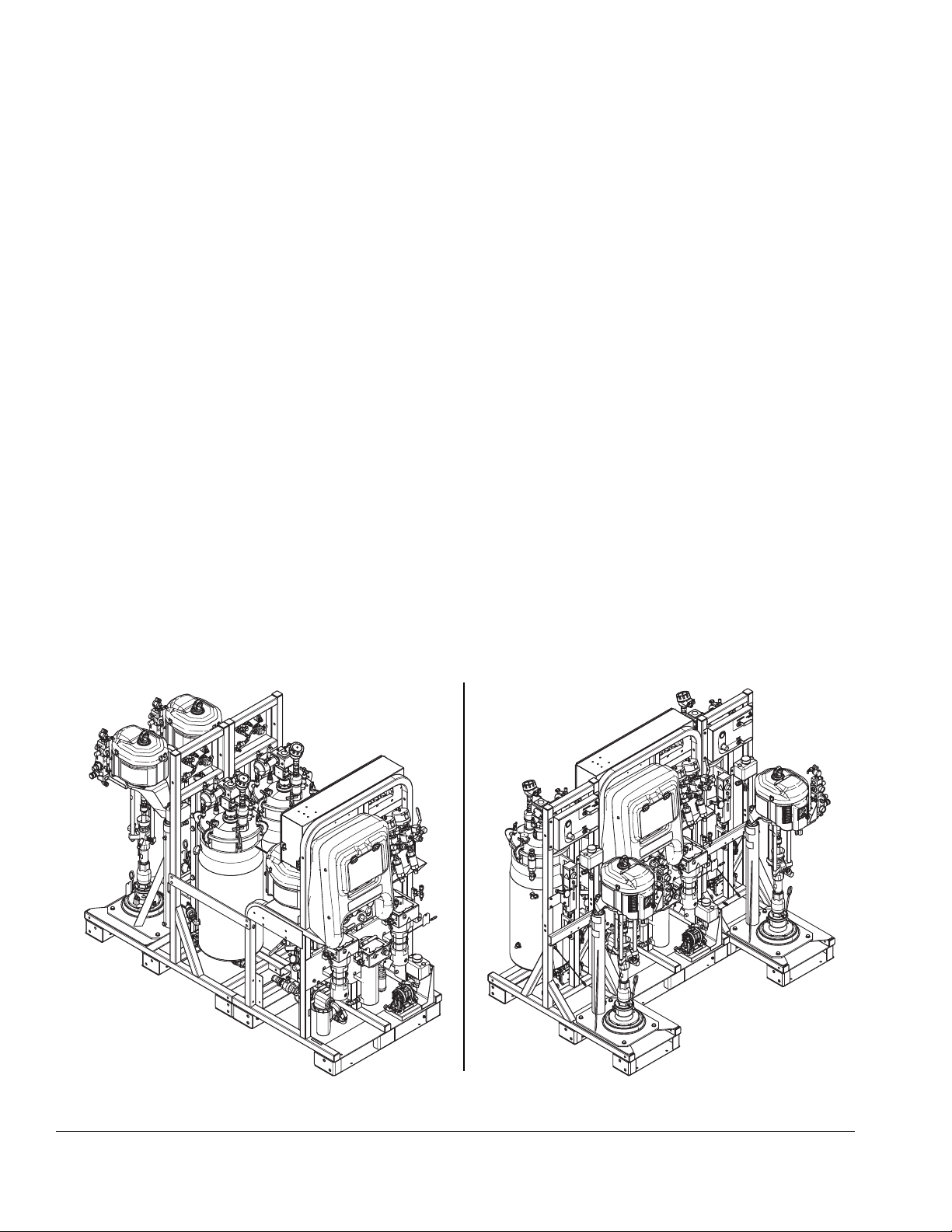

Configuration Options

The system can be laid out two ways:

• Side by side: where the feed modules are on either

side of the system module

• Front to back: where the feed modules are behind

the system module

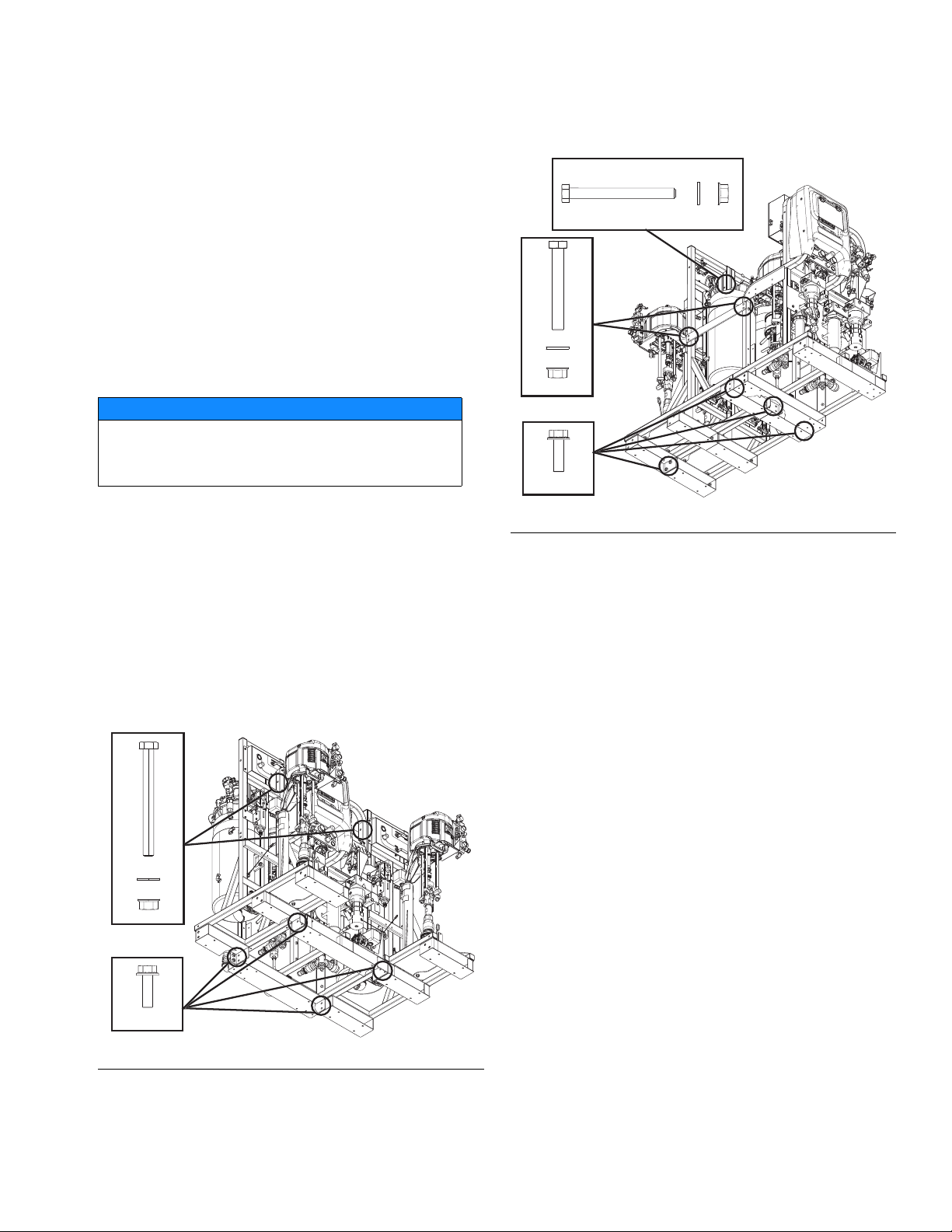

Front to Back Configuration

Side by Side Configuration

ti20267a

F

IG

. 9

14 3A2776D

ti20268a

Page 15

Connect Modules

Regardless of the chosen module configuration, the A

feed module must be on the left and the B feed module

must be on the right when looking at the front of the system module. The A module has a blue A sticker on the

air control panel and a 1/2 in. return fitting into the tanks.

The B module has a green B sticker on the air control

panel and a 3/8 in. return fitting into the tanks.

Setup

5.5 in. long

1x

Choose one of the configurations shown in F

IG

. 9 then

bolt together the three modules on a flat surface. See

F

IG

. 10 or FIG. 11 for bolt locations. The frame bolts are

included in a bag. Once connected, the assembly can

be moved as one piece with a fork-truck.

NOTICE

Do not use lift rings to lift the entire assembly. This

will damage the system. The system must be lifted

from the bottom.

If the modules will not be connected, they must be within

12 in. of each other and in one of the two configurations

in F

IG

. 9 to ensure hoses and cables can reach their

connections.

If the front-to-back module configuration is used, install

the two supplied straight steel braces between each

feed module and the sprayer module, see F

IG

. 11.

These are not used in the side-by-side module configuration.

4x

3.5 in. long

ti20197a

10x

FIG. 11: Bolt Locations (Front to Back)

2x

5.5 in. long

8x

1.5 in. long

F

IG

. 10: Bolt Locations (Side by Side)

3A2776D 15

ti20163a

Page 16

Setup

Grounding

The equipment must be grounded to reduce the risk

of static sparking and electric shock. Electric or static

sparking can cause fumes to ignite or explode.

Improper grounding can cause electric shock.

Grounding provides an escape wire for the electric

current.

Ground the electrical connection properly according to

local codes.

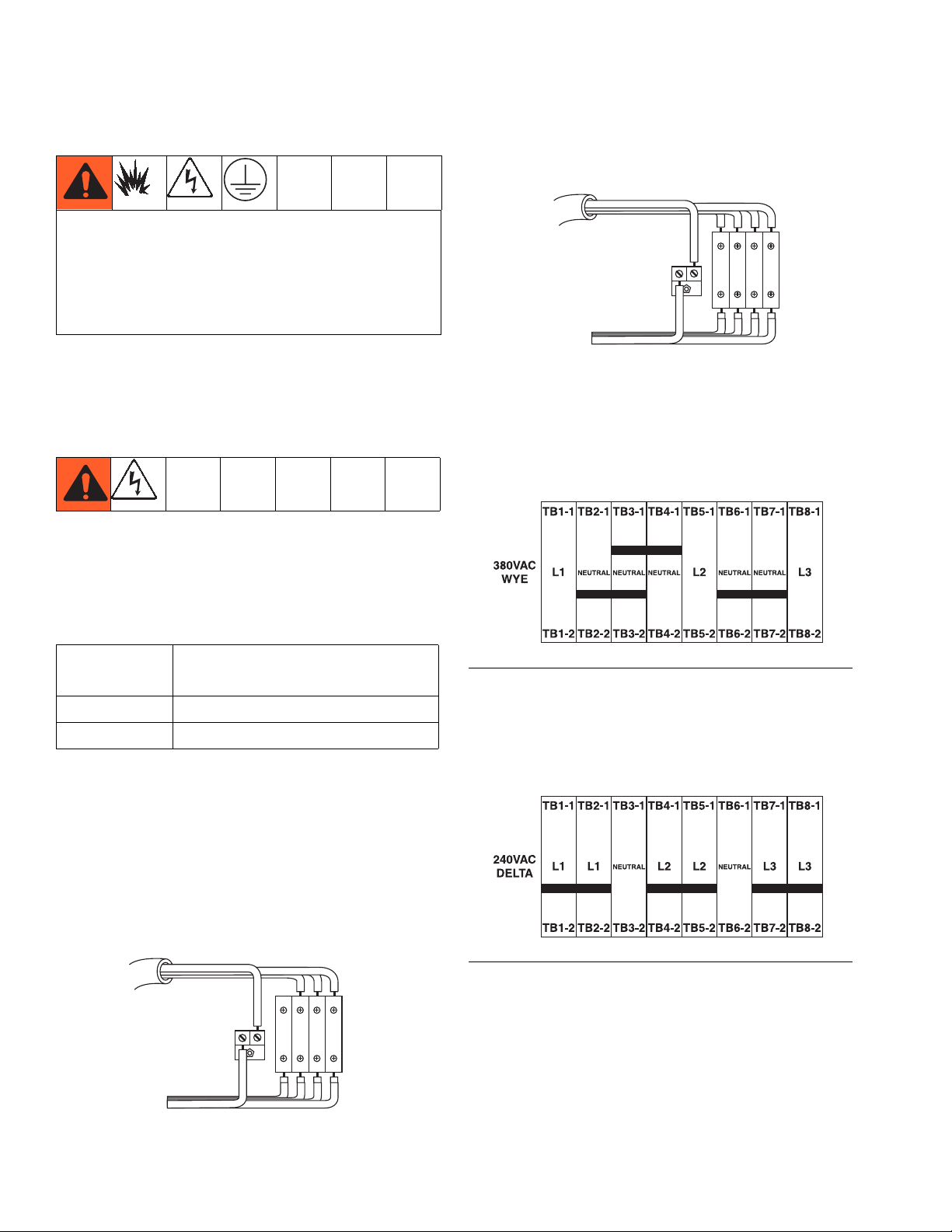

Connect Power

Power must be connected by a qualified electrician.

Graco does not supply heater junction box power cords.

Use the following chart to determine which power cord

your system requires.

380V, 3 Phase WYE: Use a 5/32 in. (4 mm) hex key to

connect the three power leads to the top terminals L1,

L2, and L3. Connect neutral to N. Connect green to

ground (GND).

7L4

N L1 L2 L3

1L1

ti8613a1

4. Find the red power jumpers in the terminal blocks

supplied in a plastic bag in the junction box.

5.

For 380V, 3 Phase installations only,

use pliers to

install the red power jumpers into the terminal

blocks in the correct positions as shown in the following illustration. Push jumpers firmly into position.

Power Cord Requirements

System

Voltage Cord Specification AWG (mm

2

)

240V, 3 PH 6 (13.3) 3 wire + ground

380V, 3 PH 6 (13.3) 4 wire + ground

1. Open junction box cover.

2. Insert power cord through the large empty strain

relief in the bottom of the junction box.

3. Connect power cord as follows.

230V, 3 Phase Delta: Use a 5/32 in. (4 mm) hex key to

connect the three power leads to top terminals L1, L2,

and L3. Connect green to ground (GND).

L1 L2 L3N

1L1

FIG. 12

6.

For 240V, 3 Phase installations only,

use pliers to

install the red power jumpers into the terminal

blocks in the correct position as shown in the following illustration. Push jumpers firmly into position.

F

IG

. 13

7. Close junction box cover.

ti8612a1

16 3A2776D

Page 17

Connect Air Supply

Connect air supply line to the 1 in. npt(f) air supply ball

valve inlet.

NOTE:

Use a 3/4 in. (19.1 mm) ID minimum air hose.

E

ti20105a

NOTE:

Air supply requirement:

maximum; 80 psi (552 kPa, 5.5 bar) minimum (while

running).

150 psi (1.0 MPa, 10.3 bar)

Setup

Flow volume required:

250 scfm (7.1 m

100 scfm (2.8 m3/min) minimum;

3

/min) maximum. Available fluid pressure and flow rate are directly related to available air

volume. A typical single gun XM PFP application will use

125 to 175 scfm (3.5 to 5.0 m

3

/min).

NOTE:

Dosing valves are operated by air. The sprayer will not

operate correctly if the inlet air pressure drops below

80 psi (552 kPa, 5.5 bar) while spraying.

3A2776D 17

Page 18

Setup

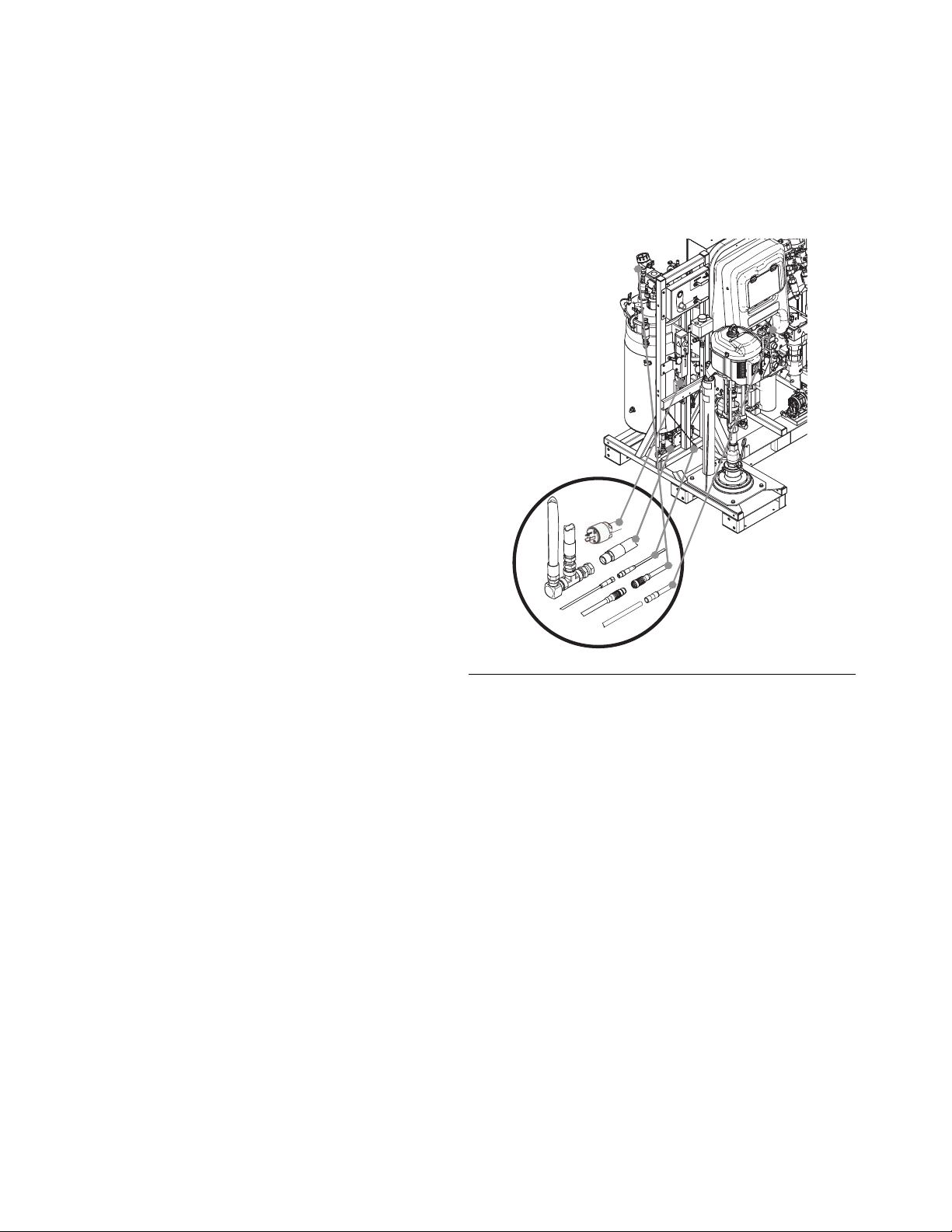

Connect Feed Module Lines to Sprayer Module

1. Connect Modules, page 15.

2. Connect the large diameter green hose from each

tank bottom outlet to the respective metering pump

inlet.

NOTE: There is a vertical swivel union at each end of

the green hose assembly.

NOTE: If desired, the green hose can be trimmed to fit

better.

a. Loosen the tank end of the hose before trying to

connect to the metering pump inlet.

b. Bend the hose as necessary to make it fit.

c. Once the vertical unions are tightened, check

that the hose clamps on the green hose are

tightened to approximately 90-100 in-lb

(10-11 N•m).

3. Connect the two hose bundles with a red air hose

on the sprayer module to the correct connection on

the respective feed module, as described below.

a. Connect the red 1/2 in. air hose to the swivel

union. See the ‘a’ in F

e

IG

. 14.

ti20269a

a

c

d

b

F

IG

. 14

b. Connect the 1/4 in. OD air signal tube to the

tube with a tube connector. This is the feed

pump pilot signal. See the ‘b’ in F

c. Connect the small cable with an M8 connector

to the mating M8 connector. See the ‘c’ in F

14.

d. Connect the larger cable with an M12 connector

to the mating M12 connector. This is the level

sensor connection. See the ‘d’ in F

e. Connect heater power cable to the mating

power connector. See the ‘e’ in F

4. Connect the fluid circulation return hoses.

• The 1/2 in. circulation hose from the dosing

valve connects to the side of the A tank.

• The 3/8 in. circulation hose from the dosing

valve connects to the side of the B tank.

IG

IG

. 14.

IG

. 14.

. 14.

IG

.

18 3A2776D

Page 19

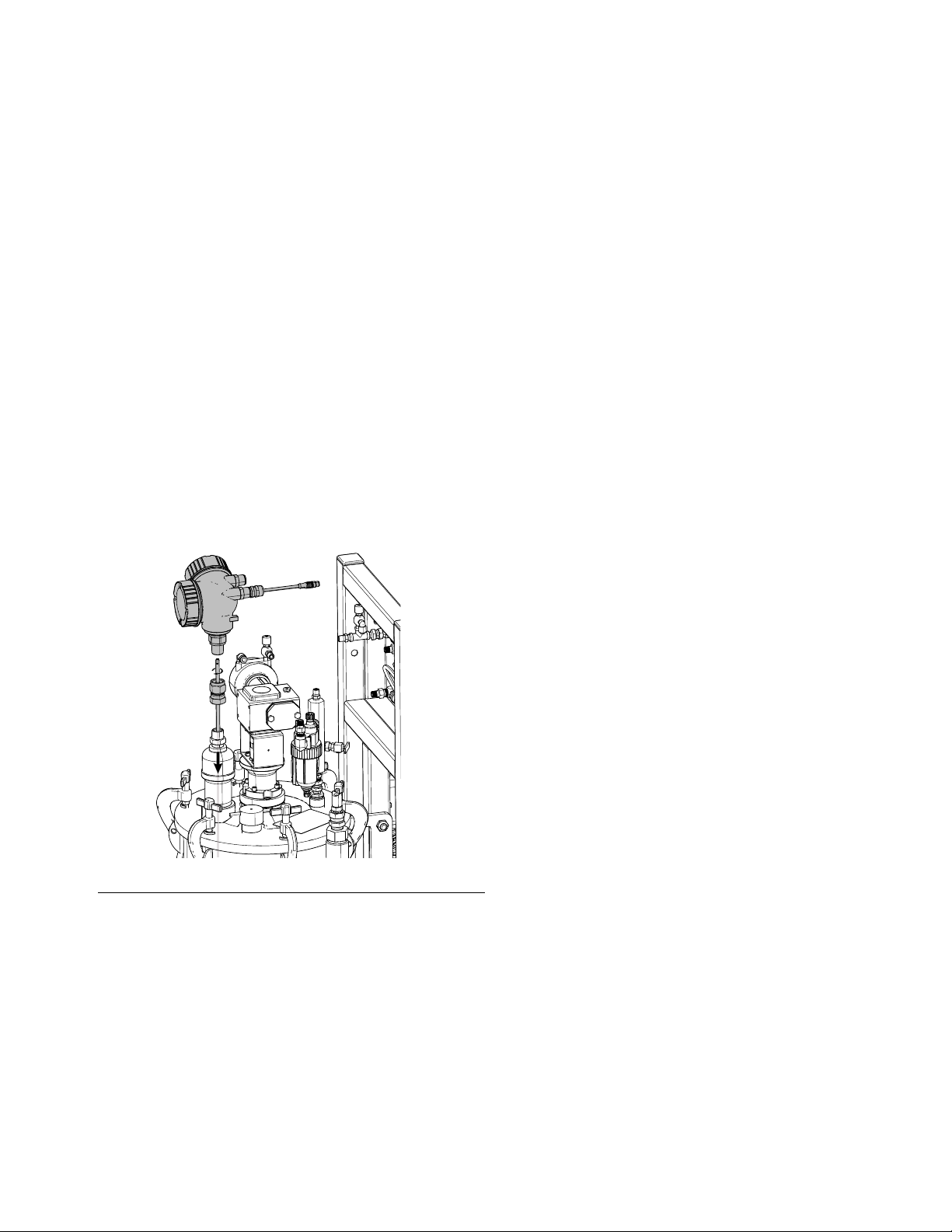

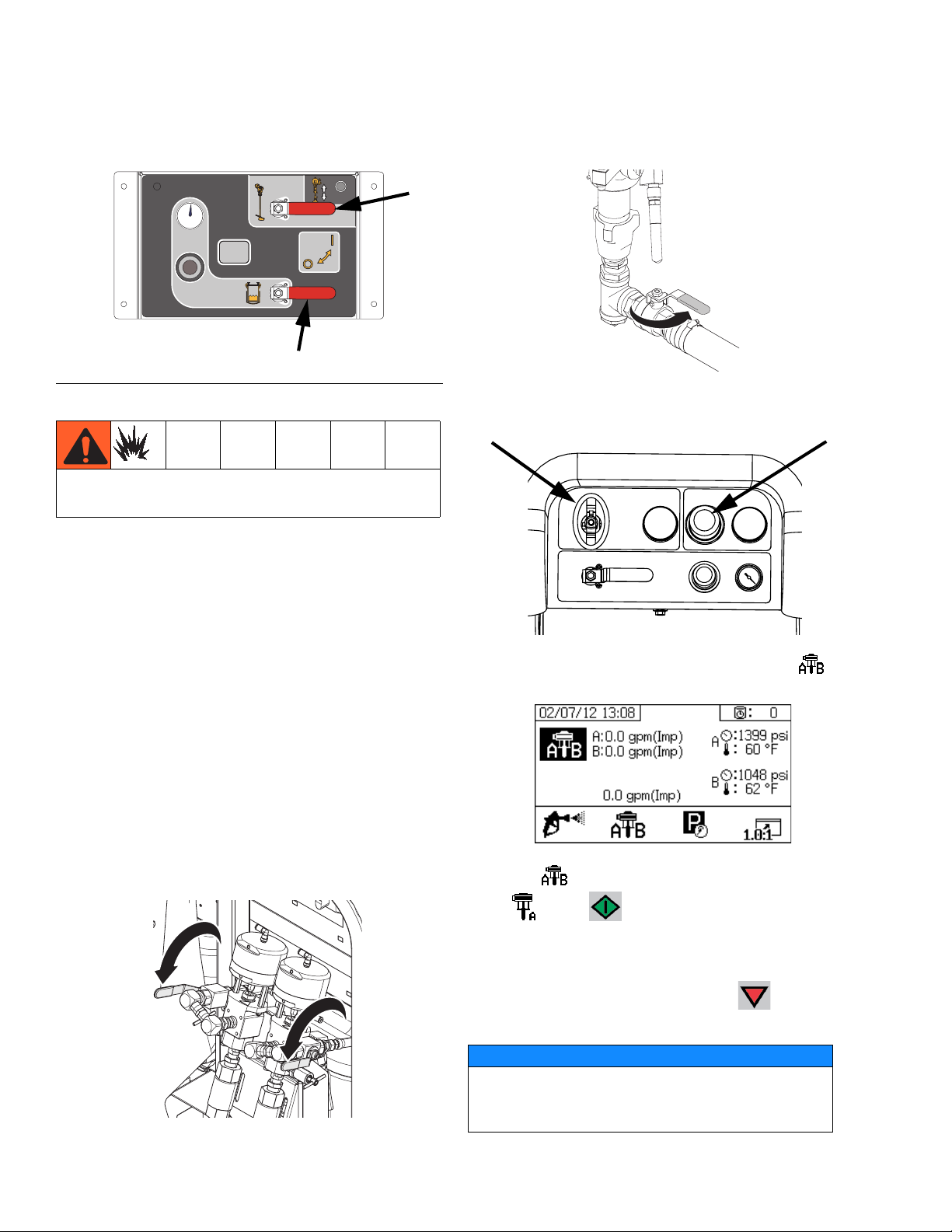

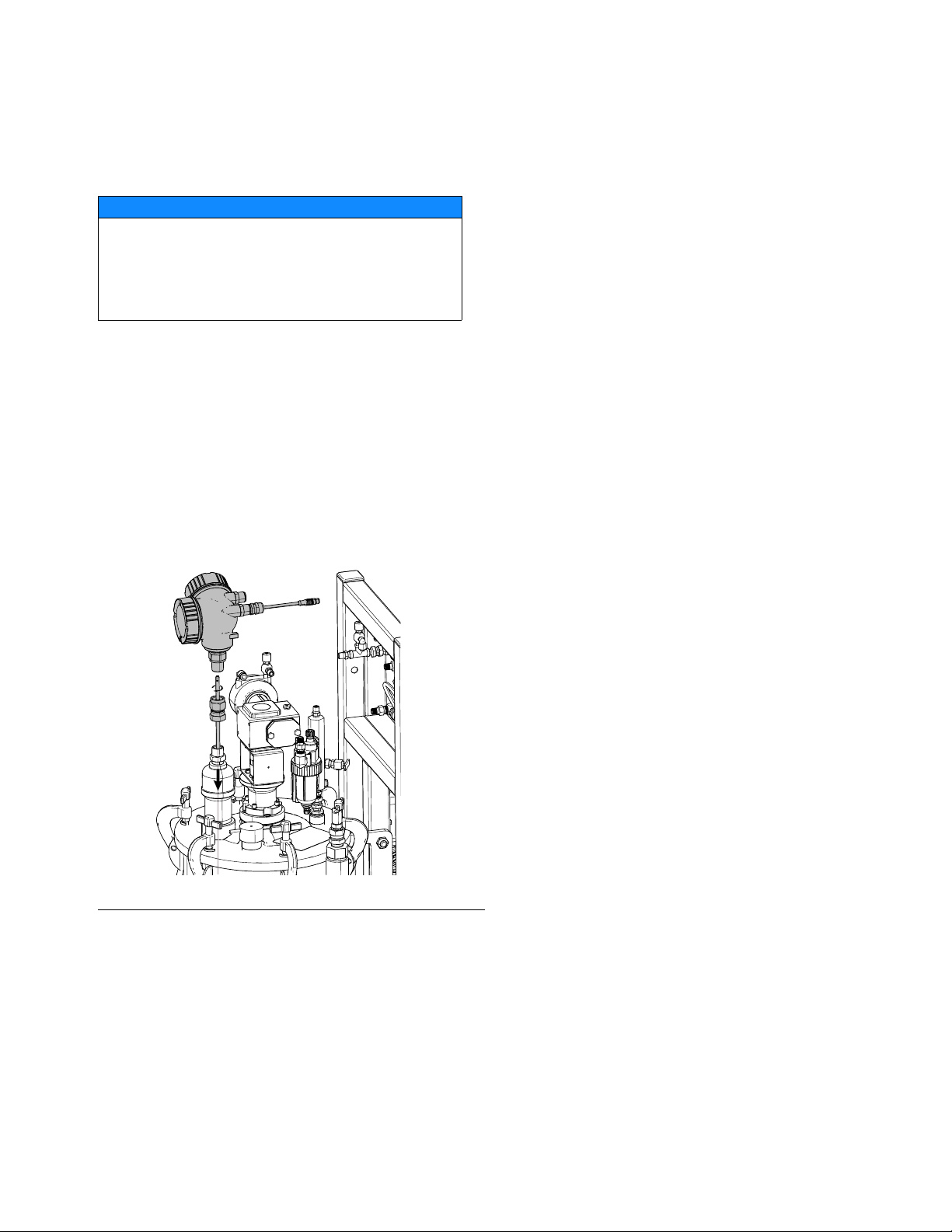

Install Level Sensor Probes

Each tank uses a 37 in (94 cm) stainless steel rod,

which functions as the level sensor probe, that mounts

into the level sensor head and extends down into the

tank. The level sensor probes are tie-wrapped to the

frame of each feed module at the factory prior to shipment. The level sensor probes must be mounted into the

level sensor heads before use.

1. Verify the main power switch is OFF.

2. Disconnect 3/4 in. union that holds the level sensor

on top of the tank.

3. Apply blue thread lock to the threads in the top of

the rod.

4. Feed the rod into the tank and screw the threaded

end up into the sensor head.

5. Use a pliers to grab the flat on the rod and tighten

the rod up into the sensor head. Do not over-tighten.

Setup

WLD

IG

. 15

F

Level Sensor Calibration

Level sensors are factory set to work with these tanks.

Calibration is not necessary unless replacing a sensor.

See manual 3A2989.

3A2776D 19

Page 20

Setup

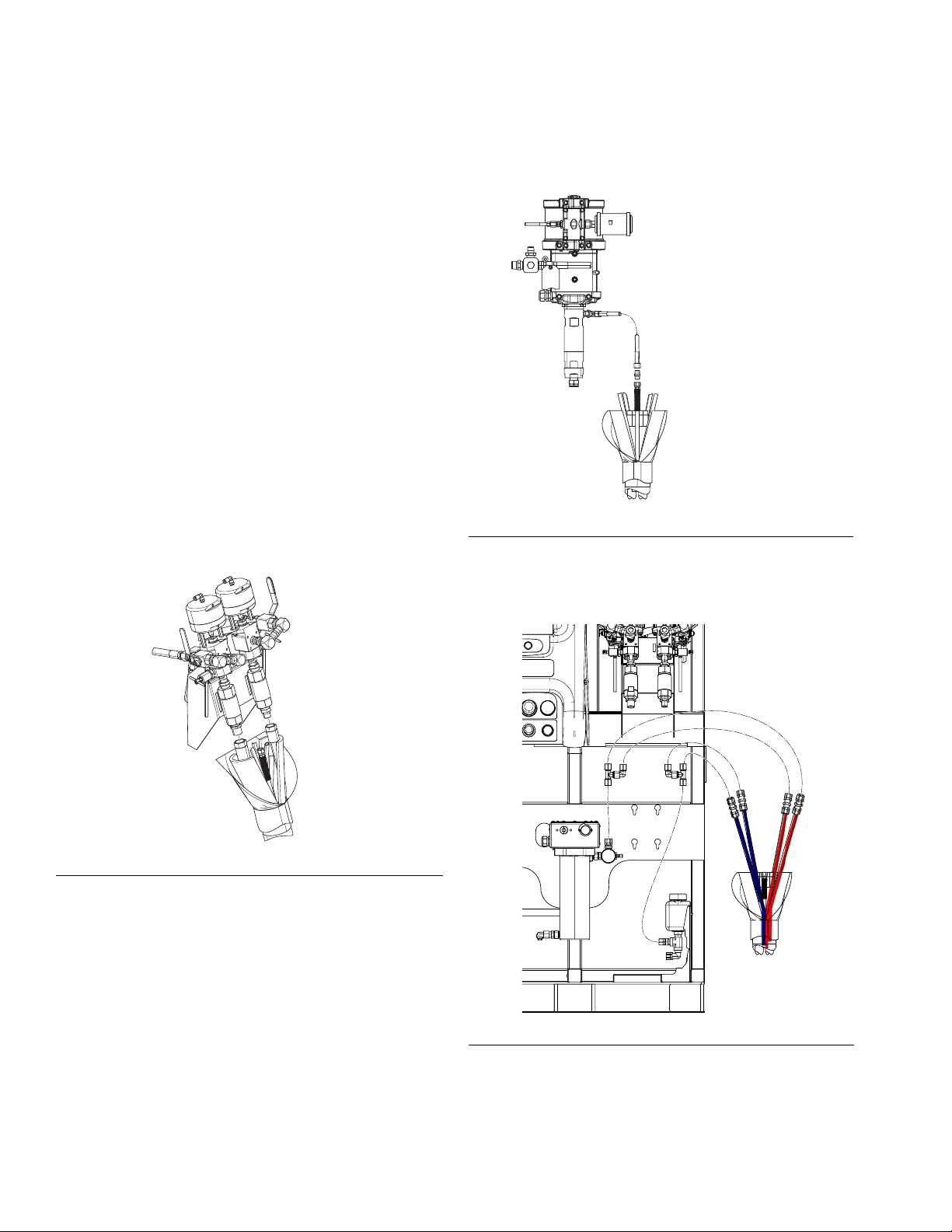

Connect the Fluid Hose Bundle to the System

The system is shipped with a 50 ft (15 m) hose bundle

for connecting the system to the mix manifold.

The bundle contains one 3/4 in. ID A material hose, one

1/2 in. ID B material hose (model 262869) one 3/4 in. ID

B material hose (model 24W626), one 1/4 in. ID flush

hose, and 1/2 in. OD heated fluid circulation tubes. The

hose bundle is insulated and wrapped inside a protective sheath which has a Velcro closure so it can be

opened to change hoses.

1. Position the hose bundle end with the four loose red

and blue tubes at the machine outlet.

Model 262869: Connect the 3/4 in. A and 1/2 in. B

hoses to the respective material outlet check valves

on the front of the system. See F

Model 24W626: Connect the 3/4 in. A and 3/4 in. B

hoses to the respective material outlet check valves

on the front of the system. See F

IG

IG

. 16.

. 16.

2. Connect the short purple flush hose from the solvent

flush pump to the 1/4 npsm hose in the bundle. Use

the 1/4 in. nipple included with the hose bundle to

connect the hoses. See F

IG

. 17.

ti20272a

FIG. 17: Solvent Flush Pump Connection

3. Connect the two red tubes in the bundle to the tube

tee on the red tube on the front of the machine. Do

the same for the blue tubes. See F

IG

. 18.

ti20106a

F

IG

. 16

ti20273a

IG

. 18

F

20 3A2776D

Page 21

Setup

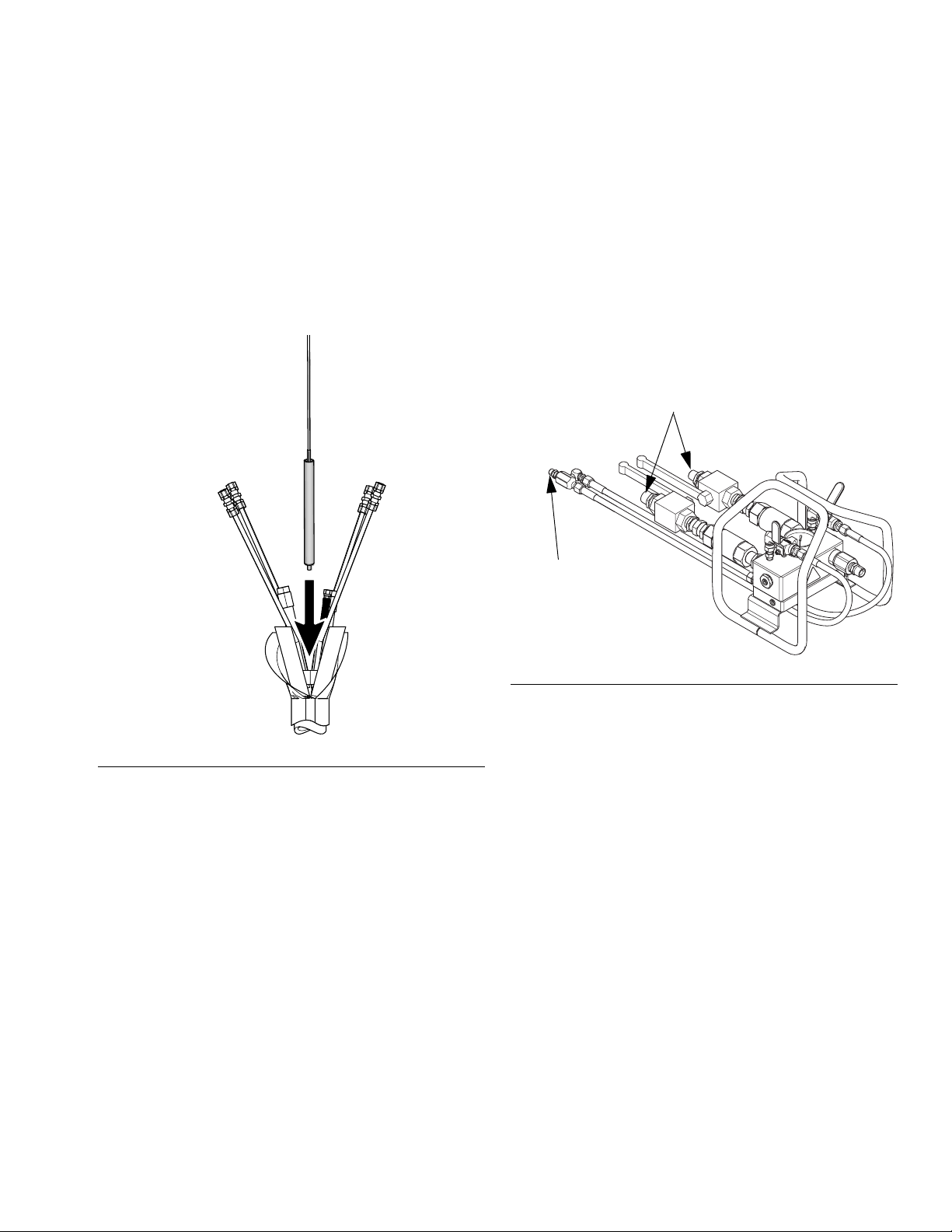

4. Locate the long temperature sensor with black heat

shrink sheath and a connected cable that is

tie-wrapped to the B heater power cable.

a. Cut the temperature sensor loose from the tie

wrap.

b. Insert the sensor down inside the hose bundle

so it is buried in the insulation and up against

the fluid hoses. Be sure the sensor cable will not

get pulled tight by the hose or catch on anything.

Connect the Fluid Hose Bundle to the Mix Manifold

1. Unroll the hose bundle out to the spray area.

2. Model 262869: Connect the 3/4 in. A and 1/2 in. B

hoses to the material inlet ball valves on the mix

manifold. See F

Model 24W626: Connect the 3/4 in. A and 3/4 in. B

hoses to the material inlet ball valves on the mix

manifold. Color code material hoses (green and

blue) with respective color identification on mix

manifold. See F

IG

. 20.

IG

. 20.

Material Inlets

ti20274a

F

IG

. 19

c. Use electrical tape to wrap the hose bundle

from where it connects to the system to the

hose sheath. This insulates and protects the

hose bundle.

Solvent Inlet

ti20088a

FIG. 20

3. Remove the U-shaped tube connectors only from

the end of the longer set of red and blue tubes. Trim

the excess tubing to fit the one set of the red and

blue tubes fully into the two brass compression fittings on the aluminum heat circulation plate under

the main manifold. Tighten the compression fittings.

4. Route the purple solvent flush hoses from the manifold underneath the manifold carriage and connect

to the 1/4 in. flush hose in the hose bundle.

See F

IG

. 20.

5. Use electrical tape to wrap the hose bundle from

where it connects to the system to the hose sheath.

This insulates and protects the hose bundle.

3A2776D 21

Page 22

Setup

Connect the Mix Manifold to the Gun

The following parts are supplied loose. Connect them to

the mix manifold as follows. See F

1. Connect 1/2 in. ID x 2 ft hose to mix manifold (R)

outlet.

R

IG

. 21.

S

T

F

IG

. 21

2. Connect static mixer (S).

3. Connect 1/2 in. ID x 10 ft. hose.

4. Connect 1/2 in. x 3/8 in. nipple.

5. Connect 3/8 in. ID x 3 ft hose.

6. Connect 1/2 x 3/8 nipple.

7. Connect swivel.

8. Connect gun (T).

ti20090a

22 3A2776D

Page 23

Setup

Prime Heated Fluid Circulation System

The heated fluid circulation system includes heated

hoses alongside the material hoses for the length of the

hose bundle, heated fluid circulation through the mix

manifold, and heated fluid circulation through the tank

double-wall which is insulated by a jacket.

Hose Bundle Heating System

1. Add a 50% water, 50% glycol anti-freeze mix to the

small translucent tank located at the bottom right

corner of the front of the sprayer module.

NOTE: Even in warm climates, a water/glycol mix

should be used to keep the circulation system clean and

working properly.

2. With air supply on, adjust the silver knob on top of

the diaphragm pump to start the small black diaphragm pump under the tank. Adjust pump to

approximately 2-3 cycles per second.

3. Continue to add the 50/50 fluid mixture as air is

purged from the fluid lines but make sure the tank is

no more than 1/4 to 1/3 full when cold.

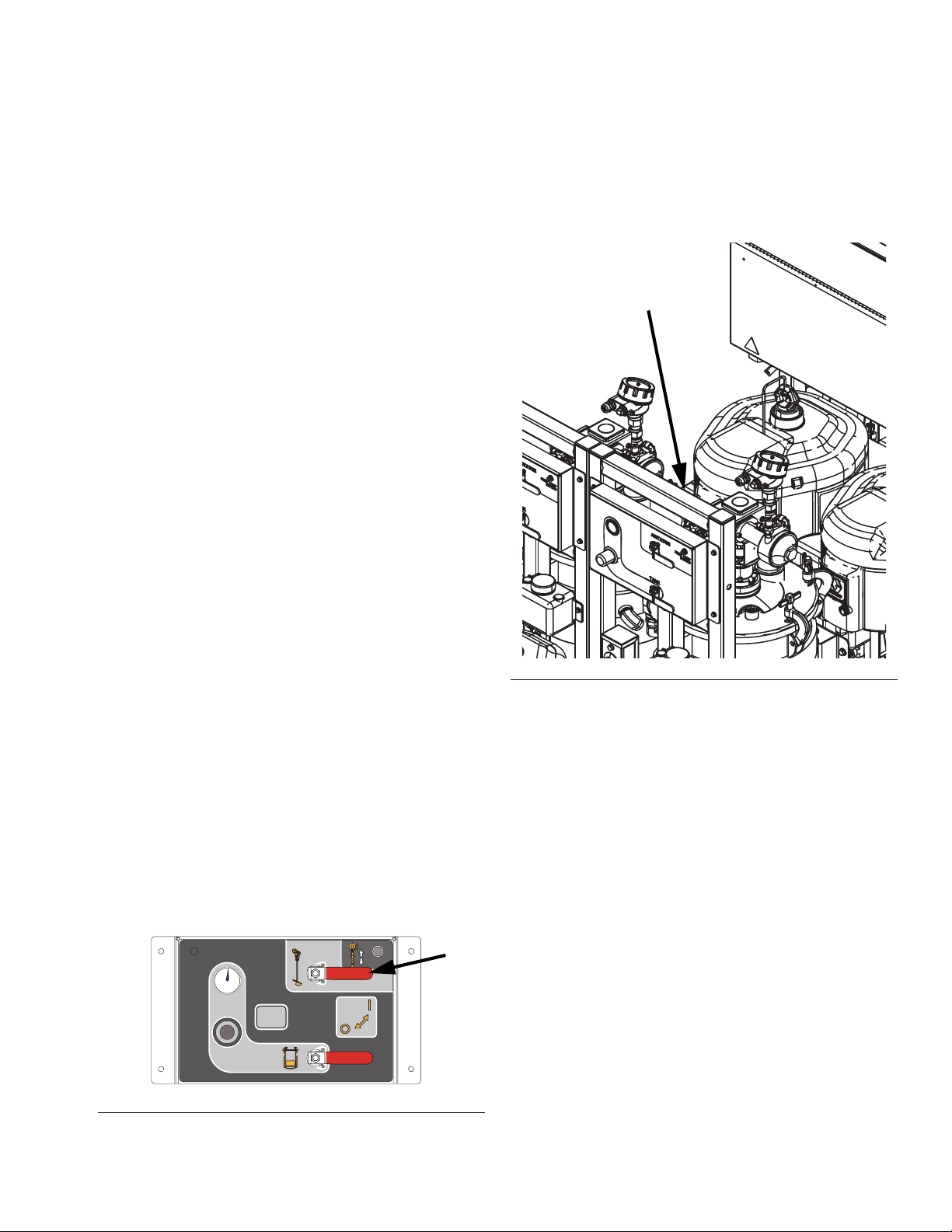

3. Adjust the silver knob located just above the Feed

Module Air Controls. When looking at the Feed

Module Air Controls, the knob will be visible just

above them. See F

IG

. 23. Adjust knob until tank

heated fluid pump reaches approximately 2-3 cycles

per second.

Adjustment Knob Location

ti20126a

NOTE: Re-tighten all heated fluid circulation tube fittings

after the first time the system has been run at full temperature.

Double-Walled Tank Heating System

NOTE: The double-walled tanks are pre-filled with a

water/glycol mix at the factory. If your tanks are already

filled, skip this section.

1. Add a 50% water, 50% glycol anti-freeze mix to the

small translucent tank located between the tank and

feed pump on the feed module.

2. Turn the agitator and tank heated fluid pump air ball

valve ON.

FEED PUMP

BYPASS

ti20127a

F

IG

. 22

FIG. 23

4. Continue to add the 50/50 fluid mixture as air is

purged from the fluid lines but make sure the tank is

no more than 1/4 to 1/3 full when cold.

5. Repeat for other feed module.

NOTE: Re-tighten all heated fluid circulation tube fittings

after the first time the system has been run at full temperature.

3A2776D 23

Page 24

Initial Startup

Initial Startup

Perform this procedure on new systems. Systems are

tested at the factory with mineral oil and there will be

residual oil in the material lines. Flush new systems if A

or B material will not function properly if it contacts mineral oil.

NOTE: If the tank return lines are not disconnected on

the initial priming of the system, all of the oil in the material lines will be pushed back into the tank and mixed

with the material, which will contaminate all of the fluid in

the tank.

1. Verify all procedures in the Setup section beginning

on page 14 have been properly performed.

2. Perform Adjust Packing Nuts on page 52.

3. Turn main power switch (BA) ON and verify the system air inlet ball valve (E) is open. See F

page 10 and F

4.

If your A or B material will not function properly if it

IG

. 1 on page 7.

mixes with a small amount of mineral oil,

IG

. 4 on

perform

the remainder of this Initial Startup procedure once

with grounded pails of solvent instead of A and B

material pails. After performing this entire procedure

once with solvent, perform it a second time with the

A and B materials. Be sure to choose a solvent that

is compatible with your material and with the wetted

parts in this system. See Technical Data on

page 85.

5. Close both feed system air controls ball valves then

open the brass valve on the tank lid air assembly.

Air pressure gauge should read 0 psi. Close the

brass valve.

FEED PUMP

BYPASS

Return line

port

ti20267a

FIG. 25

7. Fill the tanks with material:

NOTE: If adding flush solvent, remove the platen from

the feed pump by loosening the two setscrews and the

air tube. Drop the feed pump directly into the pail.

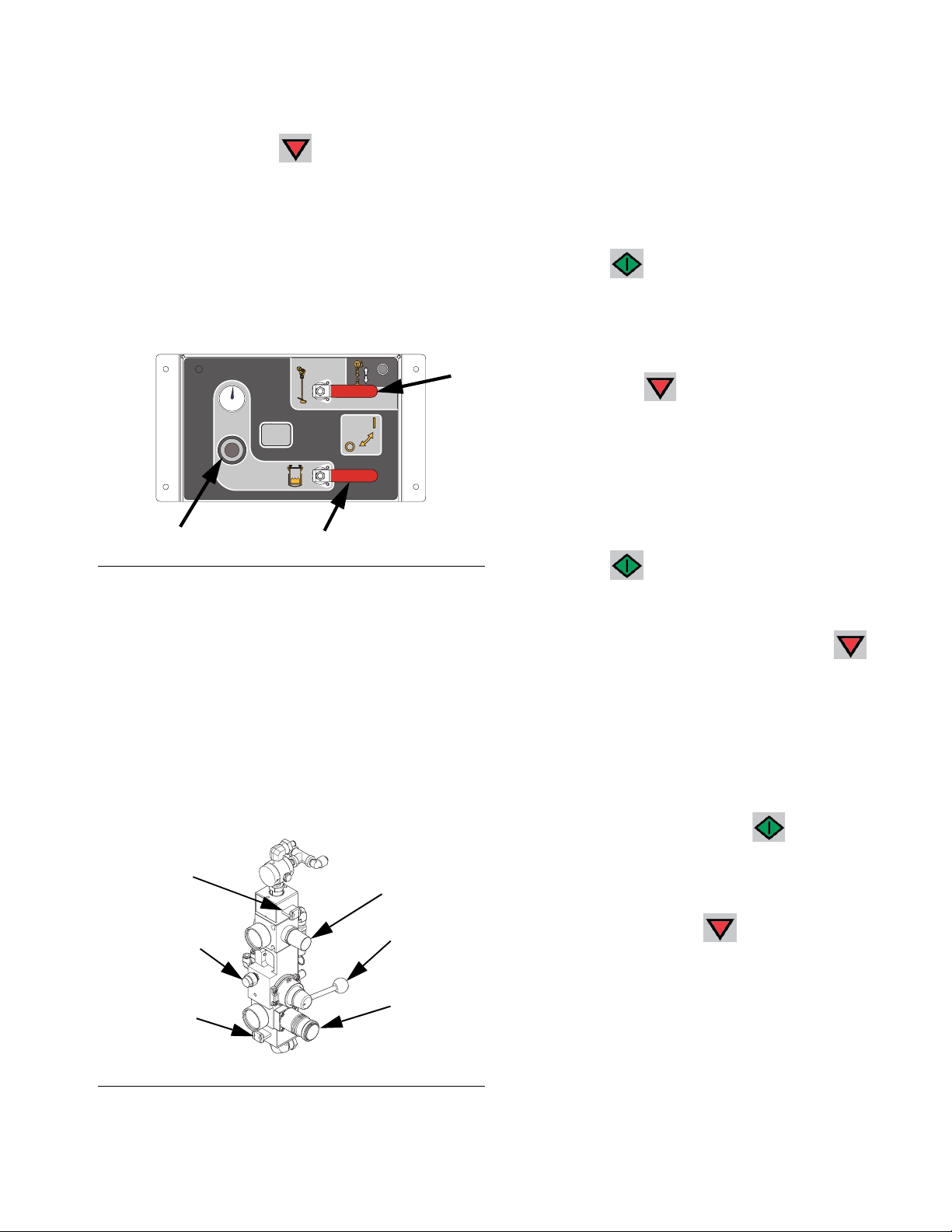

a. Navigate to the Supply screen then press

to activate automatic tank filling. See page 73.

b. Remove the priming stick from the platen.

ti20127a

FIG. 24

6. Disconnect the material circulation return line from

the side of each tank then cap the tank port. This

enables pushing the mineral oil out of the fluid lines.

Route the return lines into waste containers. See

F

IG

. 25.

ti20108a

FIG. 26

24 3A2776D

Page 25

Initial Startup

c. Slide main air slider valve (DA) and air motor

slider valve (DF) to the OFF position. See F

27.

DF

DD

DA

F

IG

. 27: Feed Pump Controls

ti20104a

DE

DC

DB

d. Back out the air regulator (DB) then lift the RAM

director valve (DC).

e. Slide main air slider valve (DA) ON.

f. Slowly adjust the air regulator (DB) to increase

air pressure until the RAM begins to lift. Use air

regulator to adjust RAM speed.

g. Adjust director valve to the neutral position

when the platen is high enough to position the

pail beneath the platen.

h. Install pail of material beneath feed pump

platen.

IG

k. Ensure platen is centered on pail when it con-

.

tacts it. Repeat previous steps until platen is

centered on pail.

l. Adjust air regulator (CB) to increase air pres-

sure until the RAM presses into the pail. Install

priming stick once fluid begins exiting the priming stick hole.

NOTE: New platens components may be stiff and resist

entering the pail. Continue increasing pressure up to 80

psi until platen enters the pail. If it does not enter at 80

psi, the thick clear packing on the platen may need to be

flipped upside down so the wider diameter side is up

and the smaller diameter side is down.

Use the minimum pressure possible to lift the platen

out of the pail to minimize material splattering when

the platen exits the pail.

m. With the platen pressing into the fluid, slide the

air motor slider valve (DF) to the ON position.

See F

IG

. 27. Feed pump will start cycling. Continue pumping until pail is empty or desired

amount of fluid has been added to the tank.

Slide the air motor slider valve (DF) to the OFF

position to stop the feed pump.

n. To lift the platen out of the pail, press the

blowoff button (DD) then lift the director valve.

The feed pump will push pressurized air into the

pail to remove it from the platen. Do not let the

pail lift off of the frame. If it does, lower the

platen then retry.

o. Repeat the previous steps as necessary until

both tanks are filled to desired level. Do not

overfill the tank.

ti20108a

IG

. 28

F

i. Back out the air regulator (DB) then lower the

RAM director valve (DC).

j. Slowly adjust the air regulator (DB) to increase

air pressure until the RAM begins to lower. Use

air regulator to adjust RAM speed.

3A2776D 25

Page 26

Initial Startup

8. Open both ball valves on the feed module air controls.

FEED PUMP

BYPASS

ti20127a

F

IG

. 29

To reduce the risk of explosion, never turn on heaters

when solvent is in the system.

9. If not already set, adjust the feed module settings:

11. Verify the sampling valves are closed.

12. Open metering pump inlet ball valves.

WLD

13. Turn on air supply and set metering pump air regulator to 20 psi (138 kPa 1.38 bar).

a. Use regulator on the feed module air controls to

set tank air pressure to 60 psi.

b. Adjust silver knob on agitator until it reaches

30 rpm.

c. Adjust silver knob on tank heated fluid circula-

tion pump until it reaches 60 cpm.

d.

If there is no solvent in the tanks,

adjust tank

water heater knob until the 4 is at the 12 o’clock

position then check temperature when the

heater indicator light turns off. Adjust setting

then repeat until desired temperature is

achieved.

10. Open the circulation valves.

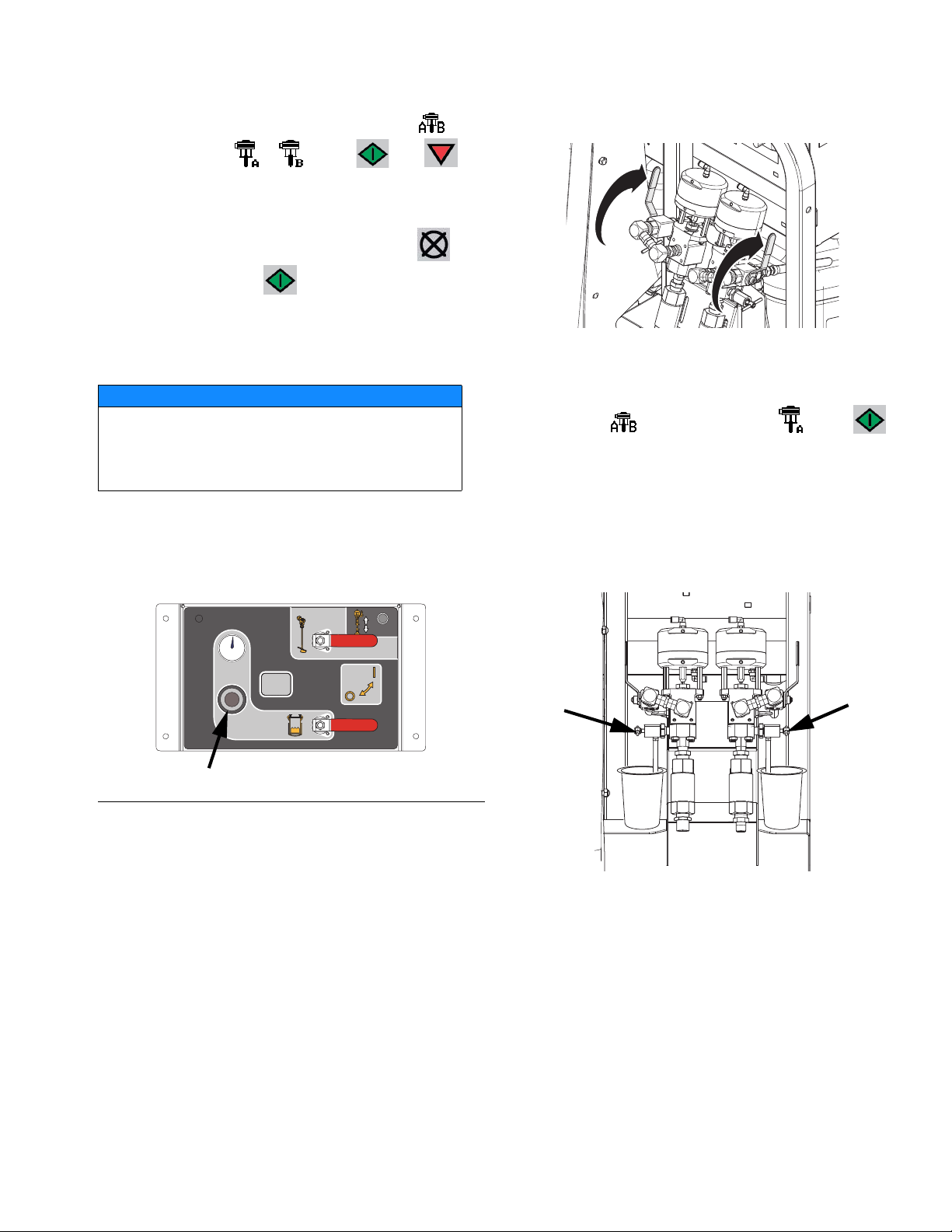

14. At the main run (fluid control) screen, press to

enter manual pump run mode.

15. Press repeatedly to select Metering Pump

A . Press . Slowly turn metering pump air

regulator (CD) clockwise to increase air pressure

until metering pump A starts. Continue to run pump

slowly and dispense into pail until clean material

comes out of the return line. Press to stop

pump. Back out the metering pump air regulator.

NOTICE

Run metering pump as slowly as possible until it is

fully primed to prevent pump damage due to pump

WLD

26 3A2776D

cavitation.

Page 27

Initial Startup

NOTE: To run each side independently, press

repeatedly to set to

or

. Press and as

needed to prime. Monitor containers to avoid overflow.

NOTE: When priming or flushing pumps, it is normal to

get cavitation or pump runaway alarms. Press to

clear alarms then press again as necessary.

These alarms prevent excessive pump speeds, which

will damage pump packings.

16. Repeat the previous step for the B side.

NOTICE

Prior to performing the following step, make sure

the tank is not more than half full. When the tank

pressure is relieved, the fluid will expand, and could

overfill the tank if there is too much in the tank.

17. Back out the tank air pressure regulator on the feed

system air controls and open the brass valve on the

tank lid.

20. Close the circulation valves.

WLD

21. Prime the A sampling valve:

a. Press repeatedly to set to

.

Press .

Slowly turn metering pump air regulator (CD)

clockwise to increase air pressure until metering

pump A starts.

b. With a waste container beneath the valve, open

the A sampling valve slowly until clean material

dispenses then close the sampling valve.

FEED PUMP

BYPASS

ti20127a

F

IG

. 30

18. With the tank air pressure relieved, remove tank

port plugs and reconnect the tank return lines.

19. Adjust the tank air pressure regulator back to the

desired pressure.

ti20109a

22. Repeat the previous step to prime the B sampling

valve.

3A2776D 27

Page 28

Initial Startup

23. Prime the A material hose:

a. Remove the outlet fitting from the mix manifold

so materials can be dispensed without mixing.

b. Place a waste pail under the mix manifold out-

let.

B Valve

A Valve

ti20088a

Outlet

Fitting

c. Open the A side mix manifold inlet ball valve.

d. Press repeatedly to set to

.

Press .

Slowly turn metering pump air regulator (CD)

clockwise to increase air pressure until metering

pump A starts. Continue until clean material dis-

penses from the A material line then press

to stop pump.

e. Close the A side mix manifold inlet ball valve

then reconnect to the mix manifold. Back out

the metering pump air regulator.

f. Repeat for the B material line.

NOTE: Now all of the material lines are primed except

for the section from the mix manifold to the gun.

24. Perform the Prime Solvent Flush Pump procedure

on page 29 to flush out the oil from those lines, and

to finish preparing for spraying.

28 3A2776D

Page 29

Prime Solvent Flush Pump

• The equipment must be grounded to reduce the

risk of static sparking and electric shock. Hold gun

firmly to side of grounded pail when triggering into

pail.

• Do not point gun at anyone or at any part of the

body.

• Solvent can irritate eyes, nose, throat, and skin.

Hot fluid and parts can burn skin. Wear appropriate protective wear when using flush solvents

and/or if fluid temperature exceeds 110° F (43° C).

• Keep clear of moving parts.

1. Turn main power switch ON and verify the XM PFP

air supply ball valve is open.

2. Fill grounded metal pail with solvent.

3. With the mix manifold inlet ball valves and the mix

manifold solvent flush ball valves closed, trigger the

gun into a grounded pail to remove any residual

pressure.

4. Ensure trigger lock is engaged. Remove spray tip.

Prime Solvent Flush Pump

7. Open the solvent flush valves.

ti20110a

8. Disengage trigger lock and trigger gun into a

grounded pail. Press gun against the grounded pail.

Use a pail lid with a hole to dispense through. Seal

around hole and gun with a rag to prevent splash

back.

9. Open solvent pump air valve (CB). Pull out and

slowly turn solvent pump air regulator (CG) clockwise until solvent pump begins to slowly cycle.

CG

CB

10. Continue to dispense until all air is purged.

TI19265a2

5.

If the optional hot water flush kit is not used,

TI19266a

place

solvent flush pump siphon tube in the pail of solvent.

TI1953a

11.

If the optional hot water flush kit is used,

perform the

following steps:

NOTICE

6.

If the optional hot water flush kit is used,

water hose connected to the water inlet. Do not turn

on the water heater yet.

3A2776D 29

turn on the

To avoid burning out the heater element in the

water heater, never turn on the water heater

unless it is filled with water.

Page 30

Prime Solvent Flush Pump

a. After water begins dispensing from the gun, turn

the water heater toggle switch located on the

back of the heater ON.

b. Turn the water heater power switch on the sys-

tem junction box ON.

ti20101a

NOTE: The water heater must be filled with fluid and

turned on at least 45 minutes prior to when flushing will

be required.

12. Close solvent pump air valve (CB) to stop pump

then trigger gun into grounded pail to relieve pressure. Engage gun trigger lock.

TI19265a2

13. Close the solvent flush ball valves on the mix manifold.

30 3A2776D

Page 31

Adjust Ratio and System Settings

Adjust Ratio and System

Settings

1. Turn key to right (setup position). Yellow LED will

flash and the Setup mode Home screen will display.

2. Press and to change the volume ratio setting.

3. When desired ratio is displayed, turn key to left. Yellow LED will turn off.

4. Change all settings in the user-interface to the

desired values. See Appendix A - User Interface

Display on page 58 for detailed screens information, including navigation and instructions.

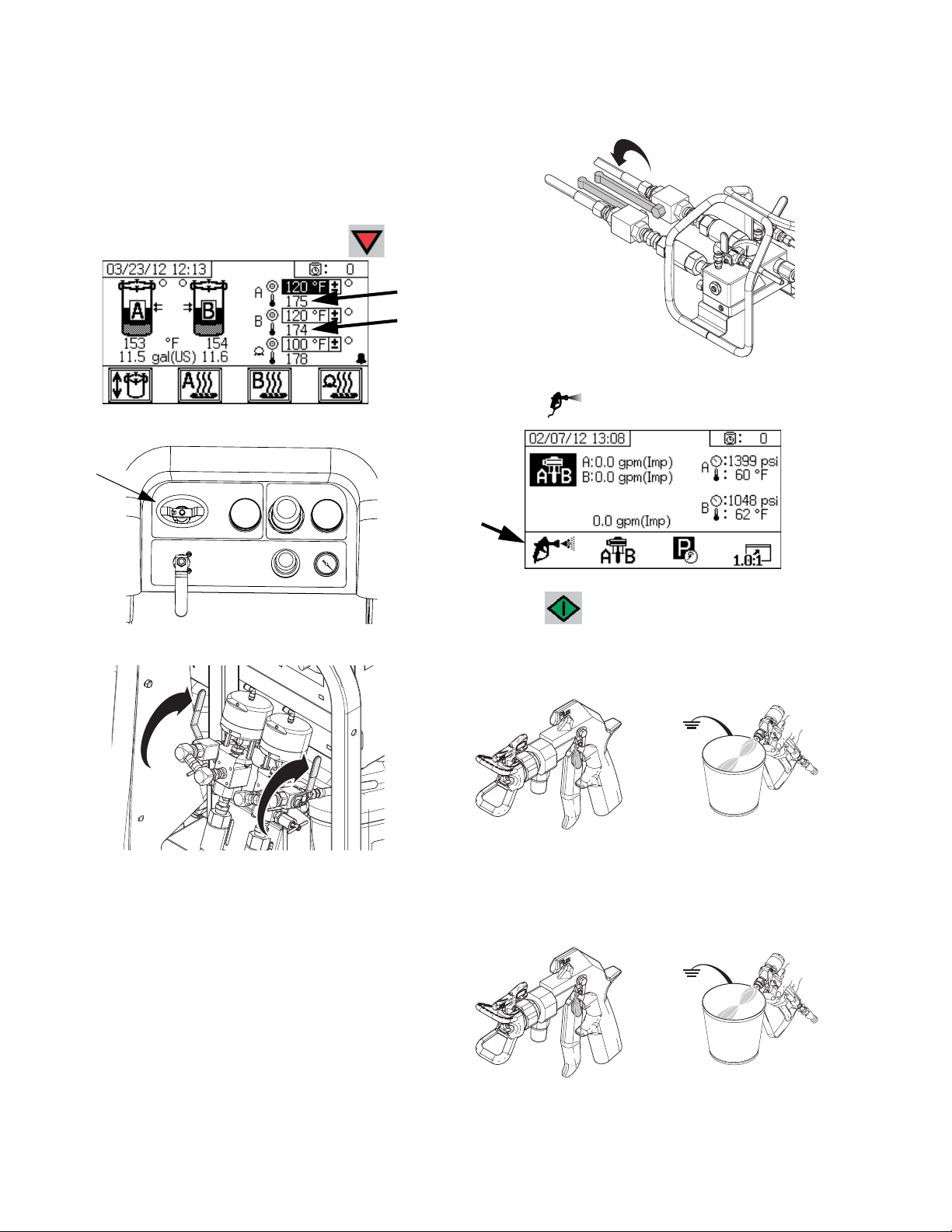

Temperature Settings

2. After the red light goes out, check the temperature

on the gauge and adjust as needed to get desired

temperature.

NOTE: Tank will not heat up faster by increasing the

temperature setting.

A and B Material Temperature

There is one Viscon HF 5400 watt heater for heating

material while in circulation or while dispensing. These

heaters are digitally controlled to your specific setpoint

temperature.

The Supply screen controls and displays the setpoint

and actual temperature.

Set the desired A and B temperature. The box next to

the target is the setpoint. The number next to the thermometer is the actual temperature.

Press and to turn on the A and B primary

heaters.

See Spray procedure for pre-heating procedure to use

prior to spraying.

Set all temperatures per your materials data sheet specifications.

Feed Tanks

Temperature is controlled by an adjustable thermostat

on each tank heater. Power to the tank heaters is supplied from the power switches (BB, BC) next to the main

power switch. Tank material temperature is displayed on

the Supply screen under the tank icon. The circulating

heated fluid temperature is displayed on the temperature gauge next to the heater.

1. Set heater control knob to 4. This is approximately

120°F (49°C).

Hose Bundle Temperature

Set the desired hose bundle temperature on the supply

screen.

Be sure the knob on the Viscon HP hose heater (the

middle of the three heaters on the front of the system) is

turned fully clockwise (full ON position). Always leave in

the full ON position. Heater has a separate digital control module in the junction box.

The heater will heat the water/glycol mixture to 180°F

(82°C) as needed until the hose bundle gets up to the

desired temperature. It will then run at whatever temperature is required to maintain the hose setpoint temperature.

Press to turn the hose bundle heater ON or OFF.

3A2776D 31

Page 32

Spray

Spray

Do not point gun at anyone or at any part of the body.

Solvent can irritate eyes, nose, throat, and skin. Hot

fluid and parts can burn skin. Wear appropriate protective wear when using flush solvents and/or if fluid

temperature exceeds 110° F (43° C).

This procedure includes steps ensure that any settled

fillers are well-mixed with the material, the metering

pump lines are fully primed, the metering pump check

valves are operating smoothly, and materials are up to

temperature prior to spraying the production surface.

When the temperatures displayed on the Supply screen

reach operating temperature, the material is ready to

spray.

After the first day of spraying follow Pressure Relief

Procedure, page 38, then tighten packing nuts on

pumps and dosing valves.

5. Open both ball valves on the feed module air controls.

FEED PUMP

BYPASS

ti20127a

FIG. 31

6. Close mix manifold flush valves.

1. If this is the Initial Startup or if system components

have been replaced, follow the Initial Startup procedure beginning on page 24.

2. Turn main power switch ON and verify the XM PFP

air supply ball valve is open.

3. Perform Prime Solvent Flush Pump, page 29 to

ensure the solvent pump is prepared to quickly flush

out mixed material when done spraying.

NOTE:

If the optional hot water flush kit is used,

the

water heater must be filled with fluid then turned on 45

minutes prior to when flushing will be required.

4. If tank levels are low, fill them with material. See

step 7 on page 24.

ti20095a

7. Close mix manifold ball valves.

ti20129a

32 3A2776D

Page 33

Spray

8. Open recirculation valves.

WLD

9. Ensure metering pump air supply is OFF.

pressure to the metering pumps until the enabled

pump(s) begin running slowly.

CA

13. Turn A and B tank fluid heaters ON.

CD

10. At the main run (fluid control) screen, press to

enter manual pump run mode.

11. Press repeatedly to select . Press to

begin circulating.

NOTICE

Run metering pump as slowly as possible until it is

fully primed to prevent pump damage due to pump

cavitation.

12. Back out the metering pump air regulator (CD) then

turn on the main air shutoff valve (CA). Use metering pump air regulator to slowly increase the air

ti20101a

14. To adjust tank fluid heater temperature, adjust the

numbered knob on the heater.

15. Turn on the primary material heaters.

a. Navigate to the Supply screen. See Operator

Command Mode Screens on page 66.

b. Press and to turn on the A and B pri-

mary heaters, and press to turn on the

hose bundle heater.

16. If desired, press to enable automatic tank filling. See page 73 for automatic tank filling details.

17. Run the metering pumps until the material has

reached the desired temperature.

NOTE: If you circulate the A side metering pump at

pressures greater than 3000 psi (21 MPa, 210 bar), an

advisory is issued and the yellow LED on the display

illuminates. This is a reminder to select Spray mode

prior to spraying and to circulate at a lower pressure to

avoid excessive pump wear.

3A2776D 33

Page 34

Spray

NOTE: If you circulate the A side metering pump above

5200 psi (35.4 MPa, 354 bar), an alarm shuts down the

pump to prevent accidentally spraying material while still

in circulation mode.

18. Once the materials reach the desired temperature

as shown on the supply screen, press .

19. Turn off the main air shutoff valve (CA).

CA

24. Open mix manifold ball valves.

ti20128a

25. Select .

20. Close recirculation valves.

WLD

21. Perform Pump and Metering Test on page 40.

22. Perform Ratio Test (Batch Dispense or Ratio

Test) on page 42.

23. Perform Down Stream Valve Leak Test on

page 43.

26. Press to start the metering pumps.

27. Disengage trigger lock and trigger gun into a

grounded metal pail. Use a metal pail lid with a hole

to dispense through to avoid splashing.

TI19265a1

TI1953a

28. Adjust metering pump air regulator (CD) to 30 psi

(0.21 MPa, 2.1 bar).

29. Dispense until clean, well-mixed epoxy flows from

the gun.

TI19265a1

TI1953a

30. Engage trigger lock.

34 3A2776D

Page 35

31. Perform the Mix and Integration Tests on page 44.

When necessary, engage trigger lock then install

the tip on gun.

Spray

2

TI19265a2

1

NOTE: While spraying, it is best to continuously hold the

trigger. Do not release the trigger unless necessary.

This maximizes the material temperature consistency

and minimizes fiber buildup.

32. Adjust air regulator (CD) to the necessary spraying

pressure and trigger gun to spray material on a test

panel. Look at ratio screen to ensure it is reading

the correct ratio. Continue spraying on the test

panel until the desired pattern results then begin

spraying the production surface.

33. Follow Flush Mixed Material on page 36 when you

are finished spraying if the potlife of the mixed materials in the system could expire before you spray

again.

NOTE: Pot life of the mixed materials in the system is

much shorter than the dry time of dispensed epoxy

because mixed material potlife or working time

decreases with increased temperature.

3A2776D 35

Page 36

Flush Mixed Material

Flush Mixed Material

• The equipment must be grounded to reduce the

risk of static sparking and electric shock. Hold gun

firmly to side of grounded pail when triggering into

pail.

• Do not point gun at anyone or at any part of the

body.

• Solvent can irritate eyes, nose, throat, and skin.

Hot fluid and parts can burn skin. Wear appropriate protective wear when using flush solvents

and/or if fluid temperature exceeds 110° F (43° C).

• Keep clear of moving parts.

This procedure flushes out mixed material from system

to prevent it from curing in the system.

NOTE: Pot life of the mixed materials in the system is

much shorter than the dry time of dispensed epoxy

because mixed material potlife or working time

decreases with increased temperature.

7. Disengage trigger lock and trigger gun into a

grounded pail. Use a pail lid with a hole to dispense

through. Seal around hole and gun with a rag to prevent splash back.

8. Open solvent pump air supply valve. Pull out and

slowly turn solvent pump air regulator clockwise to

increase air pressure. Use lowest pressure needed

to flush material out of hose.

9. Continue dispensing until clean flushing fluid is dispensed.

Follow this procedure when you are finished spraying if

the potlife of the mixed materials in the system could

expire before you spray again.

1. If necessary, Prime Solvent Flush Pump, page 29.

2. Press to stop the metering pumps.

3. Trigger gun into a waste container to relieve pressure then engage trigger lock.

4. Remove spray tip.

5. Close mix manifold ball valves.

ti20129a

TI19265a1

TI1953a

10. Close the open solvent flush valve. Open the other

solvent flush valve. Continue dispensing long

enough for any remaining mixed material

11. Close solvent pump air supply valve.

12. Trigger gun to relieve pressure in solvent lines then

engage trigger lock.

TI19265a2

6. Open one of the solvent flush valves on the mix

manifold.

36 3A2776D

Page 37

Park Metering Pump Rods

13. Close solvent flush valves.

ti20095a

ti20095a

14. Use a rag and solvent to clean spray tip then reinstall on gun.

15. Remove the static mixer. Clean the mix element

then re-install the mixer.

Park Metering Pump Rods

2. Open fluid recirculation valves.

WLD

3. Close mix manifold material ball valves.

ti20129a

4. Open the metering pump air supply ball valve.

NOTE: This procedure is only necessary when the system will not be used for more than a few hours. The primary purpose of this procedure is to prevent material

from hardening on the metering pump shaft by extending the pump so the portion of the shaft that is exposed

to material is not exposed to the air.

1. Close metering pump air supply ball valve then back

out the air pressure regulator.

5. Press then press to start metering

pumps. Slowly adjust air pressure regulator until

pumps begin to move. Each metering pump will circulate materials until they reach the bottom of the

stroke then will stop.

3A2776D 37

Page 38

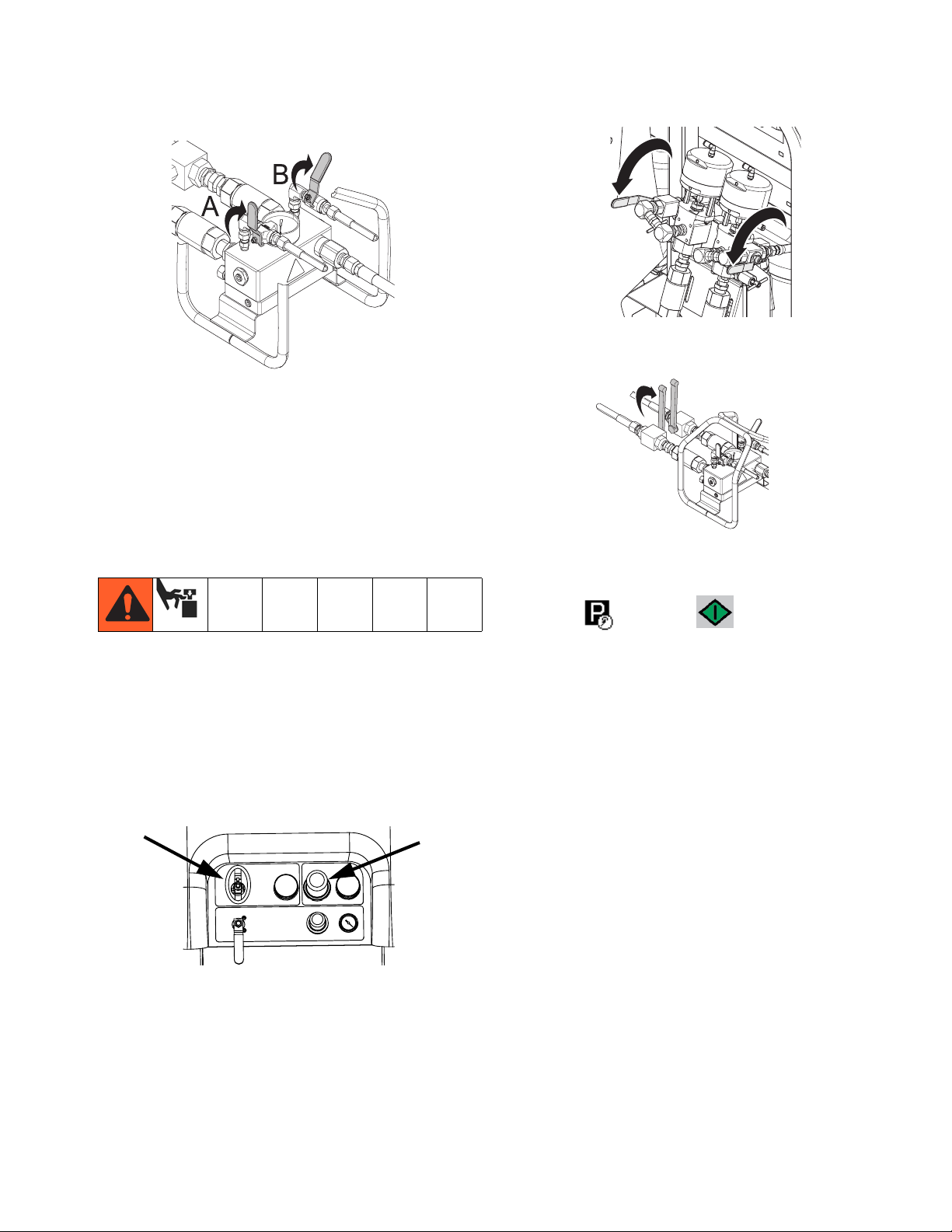

Pressure Relief Procedure

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the Pressure

Relief Procedure when you stop spraying and before

cleaning, checking, or servicing the equipment.

1. Engage trigger lock.

TI19265a2

2.

If the system will be shut down for more than a few

hours,

perform Park Metering Pump Rods proce-

dure on page 37 to prevent fluid hardening on the

metering pump shafts.

NOTICE

The material may expand when air pressure is

removed. This can cause the tank to overfill and

damage the parts attached to the tank lid. To prevent overfilling the tank, never relieve air pressure

in the tank unless the tank is less than half full.

Verify tank material level on the user interface, see

Appendix A - User Interface Display section

beginning on page 58.

5.

If necessary to relieve tank air pressure:

close both

feed system air control ball valves and back out the

air pressure regulator. Open the brass valves on the

tank lids for full tank de-pressurization. Pressure

gauge should read 0 psi.

FEED PUMP

BYPASS

ti20127a

3. Press .

4. Slide the feed pump air supply valve (DF) and director valve air supply valve (DA) to the OFF position.

DF

DD

DA

F

IG

. 32: Feed Pump Air Controls

ti20104a

DE

DC

DB

F

IG

. 33

6. Open mix manifold ball valves.

ti20128a

38 3A2776D

Page 39

Pressure Relief Procedure

7. Open recirculation ball valves.

WLD

8. Disengage trigger lock.

TI19265a1

9. Hold a metal part of the gun firmly to a grounded

metal pail. Trigger gun to relieve pressure in material hoses. Use a pail lid with a hole to dispense

through. Seal around hole and gun with a rag to prevent splash back.

11. Close mix manifold material ball valves.

ti20129a

12. Perform Flush Mixed Material procedure beginning

on page 36 to prevent mixed material curing in the

system and to relieve pressure in the solvent lines.

13.

If the system will be shutdown for more than a few

hours,

fill metering pump A and B packing nuts with

throat seal liquid (TSL).

NOTE: Fluid pressure in the system is now relieved.

10. Engage trigger lock.

TI1953a

TI19265a2

3A2776D 39

Page 40

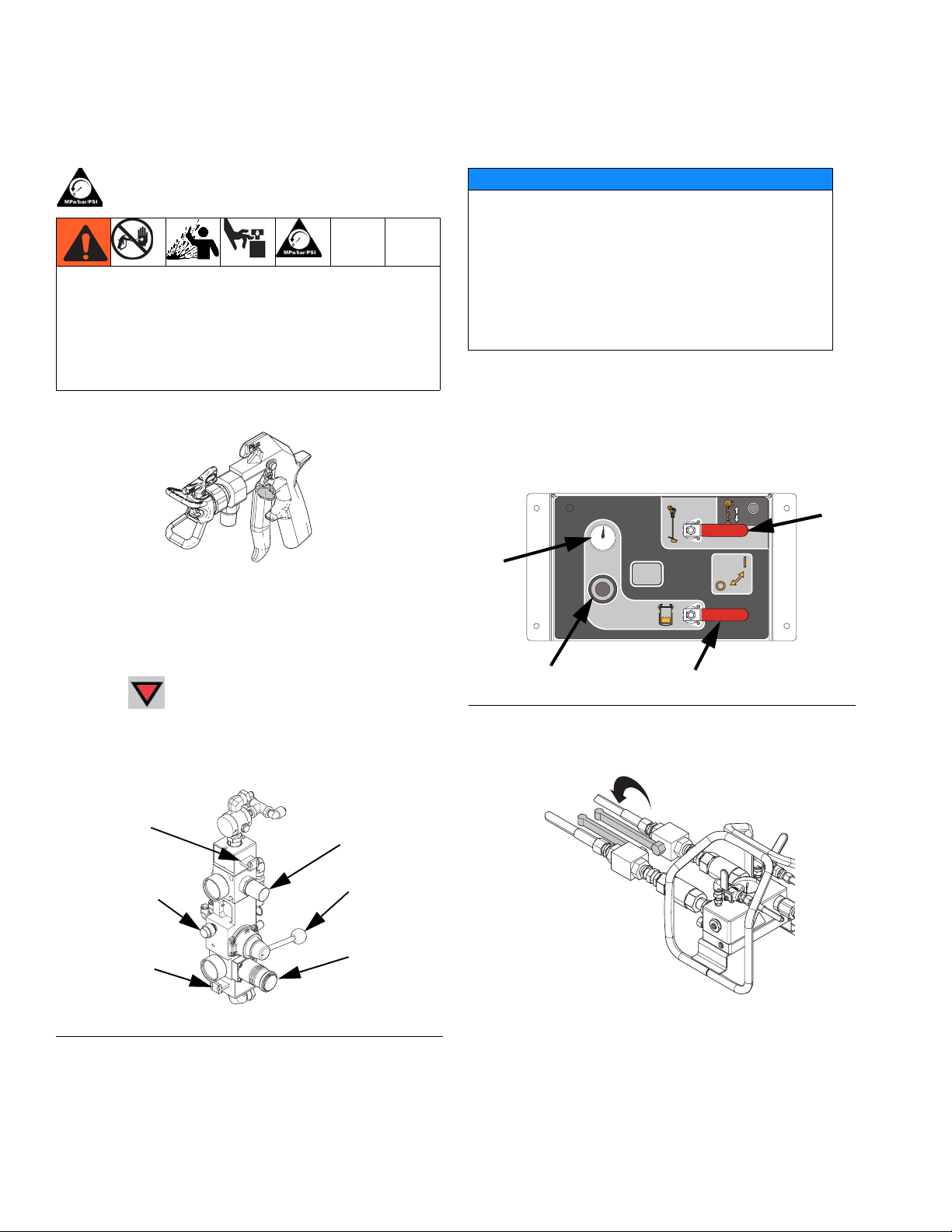

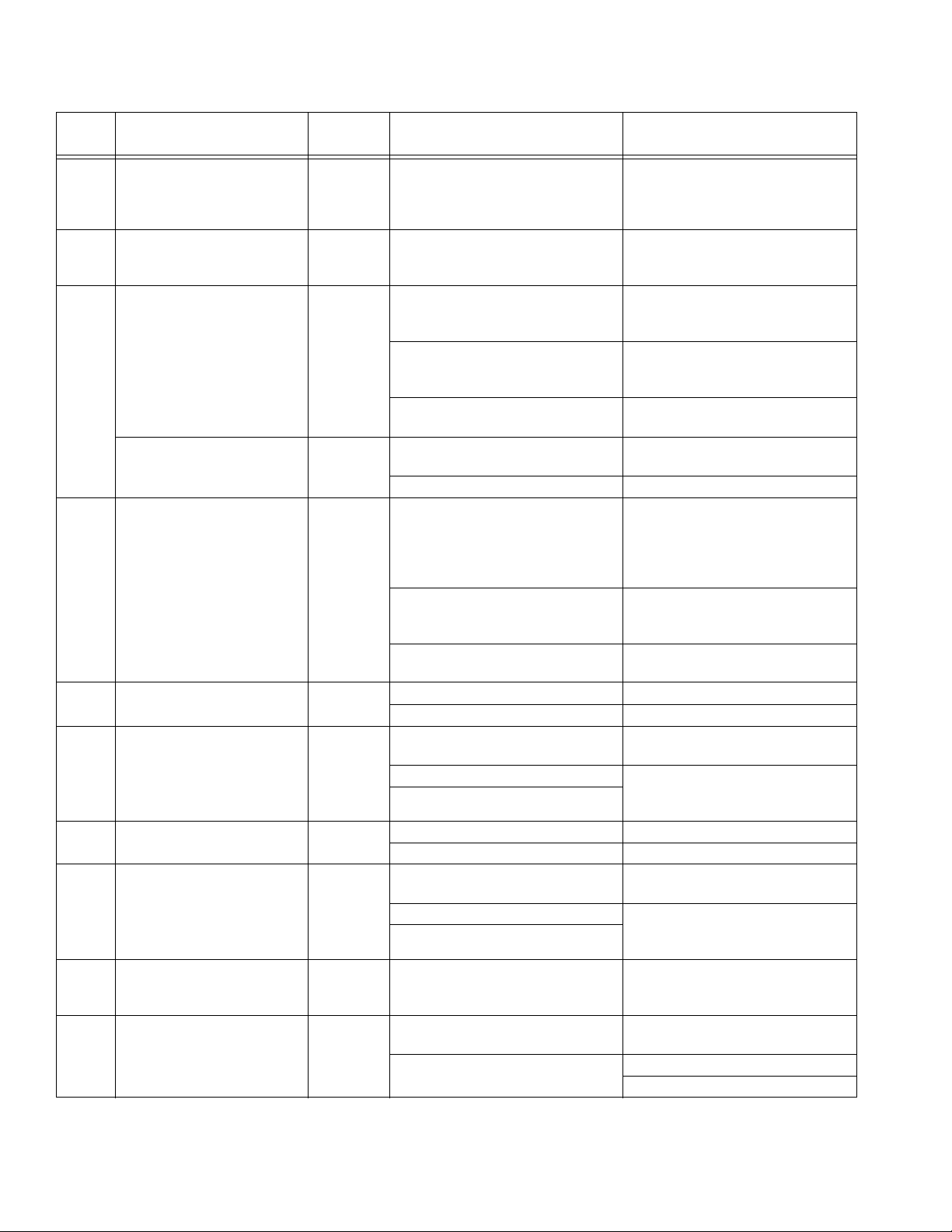

System Verification

System Verification

NOTE: Each sampling valve must be primed prior to

beginning this procedure to ensure best accuracy. If the

clear tube connected to the sampling valve is not filled

with material, prime the sampling valves.

Graco recommends running the following tests daily

prior to spraying on the production surface.

Pump and Metering Test

This test checks the following five items and should be

run every time a new job is started, or if there is a suspected problem.

• Verifies that the metering pumps installed match the

metering pumps selected on the Setup screen by

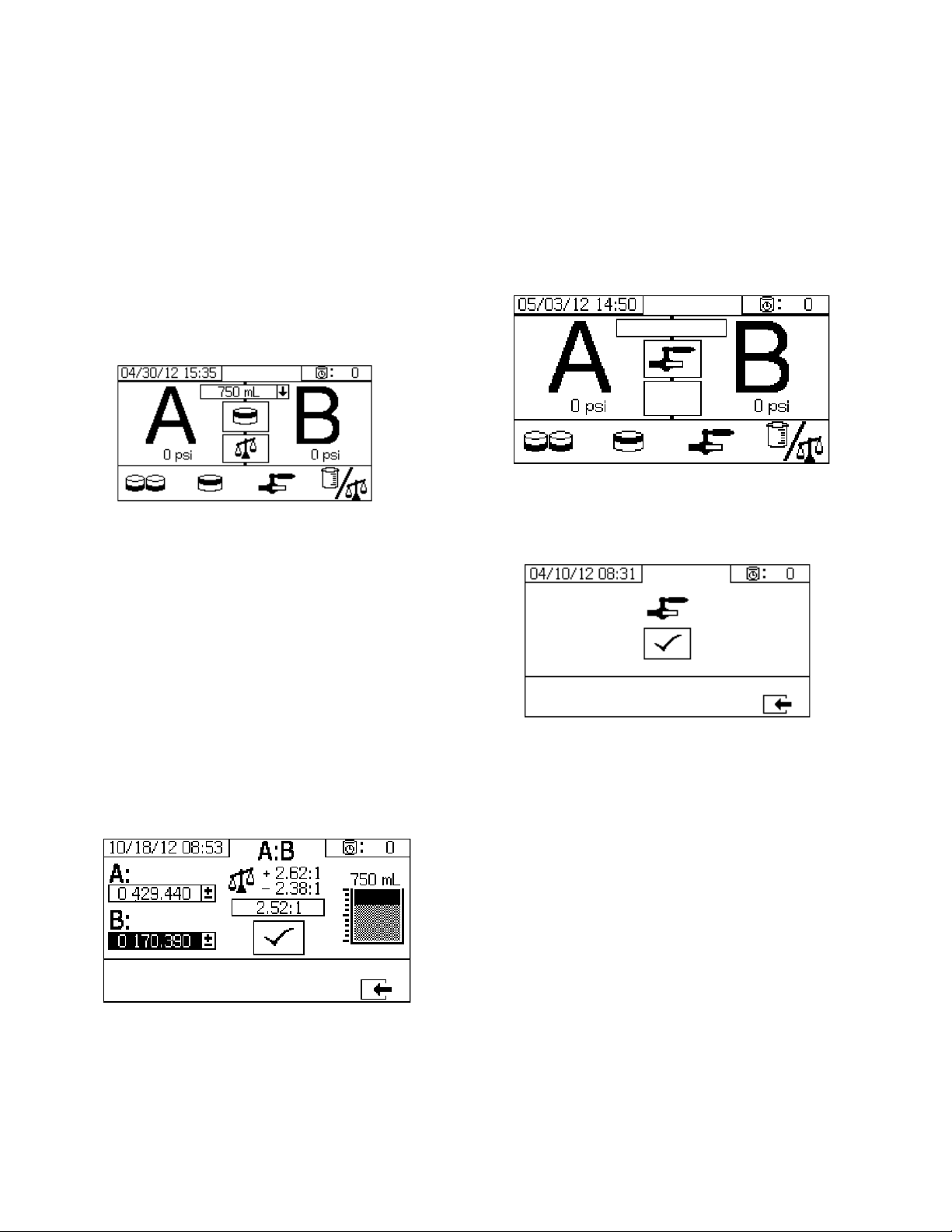

dispensing exactly 750 ml of each material.

• Verifies that each metering pump holds fluid against

the metering pump inlet valve by stalling on the

down stroke.

• Verifies that each metering pump holds fluid against

the metering pump piston valve and packings by

stalling on the upstroke.

• Verifies that each metering valve holds fluid and that

there are no external leaks between the metering

pump and metering valve.

• Verifies that the recirculation valves (AC, AD) are

closed and do not leak.

This test will dispense 750 ml of component A, and then

750 ml of component B. Dispense into separate cups so

the fluid can be returned to the supply tanks.

1. Verify the clear tube connected to each sampling

valve is filled with material. If not, perform the following steps to ensure accuracy of the metering test.

a. Turn metering pump air supply valve on.

b. At the main run (fluid control) screen, press

to enter manual pump run mode.

c. Press repeatedly to select . Press

.

d. With a waste container beneath the sampling

valve, slowly open the valve until material

begins to slowly dispense. Once clean material

dispenses from the sampling valve, and the

clear tube is completely filled with clean mate-

rial, press to stop dispensing. Repeat with

the other side if necessary.

NOTE: During each dispense the flow will stop once to

stall the upstroke, once to stall the downstroke, and then

it will finish the dispense. Do not close the sampling

valve until the fluid flow stops and the blue metering

pump light (DK) goes out.

NOTE: Material hoses from the system to the mix manifold must be filled with material and pressurized for testing to be successful.

40 3A2776D

2. Enter Test mode in the run (fluid control) screen.

See Test Screens on page 69. Select

run pump test.

to

Page 41

System Verification

3. Set metering pump air regulator (CD) pressure to

zero. Open metering pump air valve (CA). Adjust

metering pump air regulator (CD) pressure to 50 psi

(0.35 MPa, 3.5 bar).

CA

4. Dispense fluid A:

a. Close recirculation valves, mix manifold inlet

ball valves, and sampling valves.

b. Place a clean 1 quart (1000 cc) container under

sampling valve A.

5. Dispense fluid B as follows:

a. Place a clean 1 quart (1000 cc) container under

sampling valve B.

CD

ti20112a

b. Slowly open and adjust sampling valve B to

achieve desired flow. Metering pump stops

automatically; twice during test and again when

dispense completes. Metering pump B

light (DK) turns off.

ti20111a

c. Press . Metering pump A light (DK) comes

on.

d. Slowly open sampling valve A until material

begins to dispense. Metering pump stops automatically; twice during test and again when dispense completes. Metering pump A light (DK)

turns off, metering pump B light (DK) turns on.

e. Close sampling valve A (AE).

c. Close sampling valve B.

6. Compare fluid amounts in containers; they should

each equal 750 ml (25.3 fl. oz.). Repeat test if fluids

are not equal. If problem persists, see Alarm Code

Troubleshooting, page 79.

7. Return fluid used in test to corresponding fluid supply container.

Confirm Pump and Metering Test

The Confirm Pump and Metering Test screen displays

when the pump and metering test completes without

error. This screen displays the target weight of material

dispensed into each beaker from each metering pump.

To have your test results entered in the downloadable

USB log files, enter the two weights.

3A2776D 41

Page 42

System Verification

Batch Dispense or Ratio Test

NOTE: This test dispenses a calculated volume of each

fluid based on ratio. The two fluids combined equal the

batch size selected.

Follow this procedure to dispense a batch (into one container) for touch-up work or to verify the dispensed ratio

(use separate containers for fluids A and B).

When checking the ratio, use a scale to tare the two

containers then weight the dispensed materials.

1. Close mix manifold material ball valves.

e. At the main run (fluid control) screen, press

to enter manual pump run mode.

f. Adjust metering pump air regulator pressure to

50 psi (0.35 MPa, 3.5 bar).

ti20129a

2. Close recirculation ball valves.

WLD

3. Pressurize the material lines:

d. Set metering pump air regulator pressure to

zero. Open metering pump air valve.

g. Press .

h. When both the A and B metering pumps stall,

press .

4. Enter Test mode in the run (fluid control) screen.

See Test Screens on page 69. Select

to run

batch dispense test.

5. Adjust dispense amounts from 500 ml to 2000 ml (in

250 ml increments) by pressing to open the

drop-down box. Then press and to select

the desired value. Press to select that value.

6. Close recirculation valves, mix manifold inlet ball

valves, and sampling valves.

42 3A2776D

Page 43

System Verification

7. Place a clean container under sampling valve A.

ti20111a

8. Press . Metering pump A light comes on.

9. Dispense fluid A. Slowly open and adjust sampling

valve A (AE) to achieve desired flow. The metering

pump stops automatically when dispense completes

and metering pump A light (DK) turns off and metering pump B light (DK) turns on.

Batch dispense:

12.

Ratio check

als dispensed.

stir material until mixed.

: compare net weight of A and B materi-

Confirm Batch Dispense Test

The Confirm Batch Dispense Test screen displays when

the batch dispense test completes without error. This

screen displays the selected ratio between the metering

pumps and the weight of material dispensed from each

metering pump.

The gray at the bottom of the beaker represents the volume of material dispensed by metering pump A and the

black at the top of the beaker represents the volume of

material dispensed by pump B.

Enter the weight of each sample in the A and B input

boxes. The system will calculate the ratio and display a

check in the box if it is within tolerance. The result of the

test is also entered in the USB log.

10. Close sampling valve A (AE).

11. Dispense fluid B as follows:

a.

Batch dispense:

pling valve B (AF).

Ratio check

pling valve B (AF).

b. Slowly open and adjust sampling valve B (AF)

to achieve desired flow. The metering pump

stops automatically when dispense completes.

Metering pump B light (DK) turns off.

move container under sam-

: place clean container under sam-

ti20112a

Down Stream Valve Leak Test

This test confirms or troubleshoots leaks in components

located down stream of the dosing valves. Use this test

to detect closed or worn valves, and to detect leaks in

circulation valves installed at a remote mix manifold.

1. Close both mix manifold valves downstream of the

dosing valves.

2. Close recirculation valves (AC, AD).

c. Close sampling valve B (AF).

3A2776D 43

Page 44

System Verification

3. Enter Test mode in the run (fluid control) screen.

See Test Screens on page 69. Select

run down stream valve leak test.

4. Select

(AA, AB) are open by verifying blue LEDs are illumi-

nated for both dosing valves.

5. If test is successful, both metering pumps will stall

against the downstream valves when the dosing

valves (AA, AB) are open. If any movement is

detected in the metering pumps after stalling, an

alarm is issued indicating which side has a leak.

.

Press . Ensure dosing valves

to

Mix and Integration Tests

Use the following tests to check for proper mix and integration.

Butterfly Test

At low pressure, normal flow rate, and without a spray

tip installed, dispense a 1/2 in. (12.7 mm) bead of material onto foil until multiple changeovers of each metering

pump have occurred. Fold the sheet of foil over the fluid

then peel it back and look for unmixed material (appears

marble-like).

Curing Test

Spray a single continuous pattern on foil at typical pressure setting, flow rate, and tip size until multiple changeovers of each metering pump have occurred. Trigger

and de-trigger at typical intervals for the application. Do

not overlap or cross over your spray pattern.

Check curing at various time intervals, listed on the

material data sheet. For example, check for dry to touch

by running your finger along the test pattern’s entire

length at the time listed on the data sheet.

NOTE:

Spots that take longer to cure indicate insufficient integration.

Appearance Test

Spray material onto metal substrate. Look for variations

in color, gloss, or texture that may indicate improperly

catalyzed material.

44 3A2776D

Page 45

Empty and Flush Entire System

a. With director valve (DC) in the neutral position

• Running solvent through heaters can cause a fire

or explosion. Turn off heaters and allow to cool

before flushing. Do not turn on heaters until fluid

lines are clear of solvent.

• Splashing fluid can land on exposed body parts

and irritate the skin. Cover fluid container and use

the lowest possible pressure when flushing to

avoid splashing.

Empty and Flush Entire System

and the RAM air regulator (DB) backed out,

slide main air slider valve (DA) ON.

DF

DD

DE

DC

Only perform this procedure when:

• The system will not be used for more than one

month.

• Changing to a new material in the A or B side.

To flush a new system, see Initial Startup on page 24.

To flush only the mix manifold to the gun, see Flush

Mixed Material, page 36.

NOTE: While hot water is sometimes used to flush

mixed material from the system, it is not recommended

for flushing the entire system. When flushing the entire

system, use a solvent the dissolves the material.

This procedure is designed to minimize the volume of

discarded A and B material when emptying and flushing

the entire system.

1. Flush Mixed Material, page 36.

2.

If applicable,

remove the feed pump from pail:

DA

ti20104a

DB

FIG. 34: Feed Pump Air Controls

b. Lift the director valve to the UP position, the

press and hold the blowoff button (DD) while

increasing the air pressure using the RAM air

regulator. When the feed pump exits the pail,

move the director valve to the neutral position

and release the blowoff button.

3. Empty the feed pump outlet material lines to the

tank:

a. Slide the air motor slider valve (DF) ON.

b. Rotate air motor regulator (DE) to increase air

pressure until feed pump begins to cycle. Continue until all material from outlet line to the tank

have been pushed into the tank. This will be

noticeable by an increase in feed pump cycle

rate.

4. Make sure all heaters are off and cool.

3A2776D 45

Page 46

Empty and Flush Entire System

5. Close the circulation valves.

WLD

6. Empty the A material tank:

a. Close the A side mix manifold inlet ball valve.

b. Disconnect the A material hose from the mix

manifold at the fitting between the ball valve and

check valve.

f. Close the A side mix manifold inlet ball valve.

g. Close the tank air supply ball valve then open

the brass valve on the top of the tank to relieve

tank air pressure.

FEED PUMP

BYPASS

ti20127a

FIG. 35

The tank lid assembly is heavy. To prevent crushing

your fingers if the tank lid is accidentally dropped,

exercise caution while lifting the tank lid.

ti20088a

c. Place the A material hose in a clean container

to salvage the dispensed material. Make sure to

have enough clean containers within reach to

switch to as each container is filled.

d. Open the A side mix manifold inlet ball valve.

e. Press repeatedly to set to

.

Press .

Slowly turn metering pump air regulator (CD)

clockwise to increase air pressure until metering

pump A starts. Continue pumping until the

metering pump speed increases on its own

which signals that the tank is now empty and

there is air at the metering pump inlet. Press

to stop metering pump then back out the

air pressure regulator.

NOTICE

The level sensor is very sensitive. Be careful not to

damage it while lifting the tank lid.

h. Remove the tank lid assembly.

i. Scrape remaining material from the walls of the

tank into the tank outlet.

j. Re-install the tank lid assembly.

k. Close the brass valve on the top of the tank

then open the tank air supply ball valves to

pressurize the tank.