Page 1

Instructions-Parts

ProControl 1KE®

Management of F

Kits for

luid and

Air

Use to monitor and control flow rate and track material use. For professional use only.

Important Safety Instructions

Read all warnings and instructions in this manual. Save these

instructions.

See the G3

(308778)

manual (3

maximum

000 meter manual

or Coriolis meter

13599) for flow meter

working pressure.

3A2614F

EN

See page

includi

ng approvals.

3 for kit information,

PROVEN QUALITY. LEADING TECHNOLOGY.

Page 2

Contents

ProControl 1KE Models and Kits.......................... 3

Warnings ........................................................... 5

Overview............................................................ 8

Installation.......................................................... 9

Non-Hazardous Locations ............................ 9

Hazardous Locations.................................... 10

Grounding ................................................... 12

Cable Connections....................................... 13

Electrical Connections.................................. 14

Air Connections ........................................... 15

Operation........................................................... 18

Pressure Relief Procedure............................ 18

Fluid Regulator Operation............................. 18

Flow Meter Operation................................... 18

Calibrate the Meter ...................................... 18

Set the Modbus Addresses........................... 19

Set the Flow Rate Percent............................ 19

Update the Software .................................... 19

Replace the Battery...................................... 20

Display M

odule................................................... 21

Display

Operati

Screen N

Icons...........................................................22

Information ...................................... 21

on Modes ......................................... 21

avigation and Editing ...................... 21

Run Screens ......................................................24

Password Screen ............................................... 25

Setup Screen

Setup Screen

Setup Screen

Setup Screen

Setup Scree

Setup Scree

Setup Scree

Setup Scree

Setup Scre

Setup Scre

Deviations and Advisories ................................... 31

Troubleshooting.................................................. 32

Parts.................................................................. 34

Accessories........................................................ 43

Mounting Dimensions ......................................... 44

Appendi

Appendix B - Advanced Web Interface................. 48

Technical Data ...................................................53

Graco S

s.................................................... 26

1............................................ 26

2............................................ 27

3............................................ 27

n 4 ............................................ 28

n 5 ............................................ 28

n 6 ............................................ 29

n 7 ............................................ 29

en 8 ............................................ 30

en 9 ............................................ 30

x A - Modbus Variable Map ..................... 45

tandard Warranty.................................... 54

2

3A2614F

Page 3

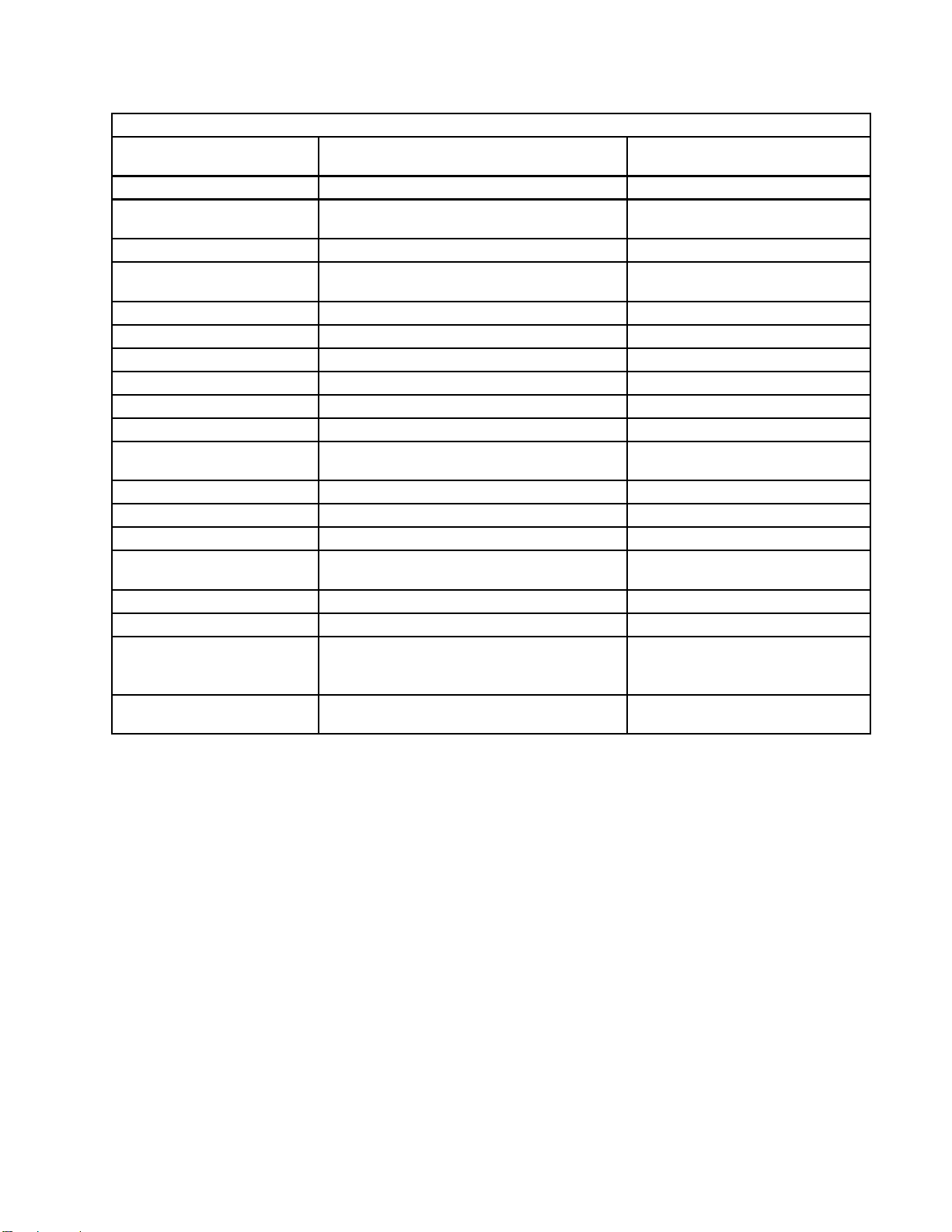

ProControl 1KE M

odels and Kits

ProControl 1K

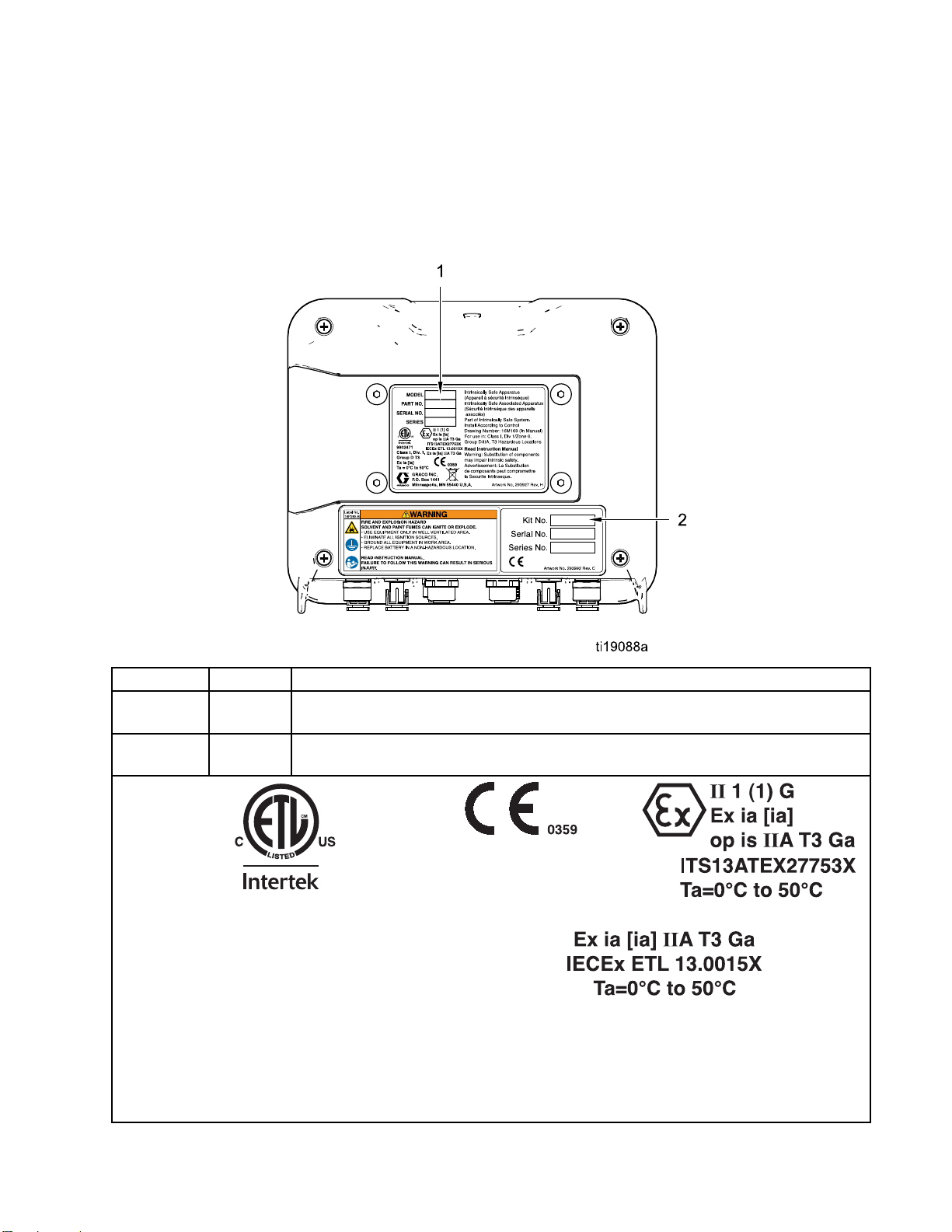

All Advanced Display Control Modules (ADCM) are base model number 24L097 (Ref. 1). Models 24L097 and

24N672 (ADCM with bracket) are not available for separate sale. See approval information in Manual 332013

and on this page. The small label (Ref. 2) on the back of the module shows the ProControl 1KE Kit number.

Available kits are described in the tables that follow.

E Models and Kits

Model No.

24L097

24N672

Intrinsically Safe Apparatus

Part of Intrinsically Safe System.

For use in Class I, Division 1, Group D T3 Hazardous Locations

See Manual 332013, Appendix A, Control Drawing 16M169 for entity parameters.

Series

A

A

Class I,Div. 1,

Group D T3

Ex ia [ia]

Ta=0°C to 50°C

Description

Advanced Display Control Module (ADCM), with no software loaded. See Manual

332013.

Advanced Display Control Module (ADCM) with bracket, with no software loaded.

See Manual 332013.

9902471

3A2614F 3

Page 4

ProControl 1KE M

ProControl 1KE systems are not approved for use in hazardous locations unless all accessories and all

wiring meet local, state, and national codes.

Kit No.

24L083

24R261

24R262

24R263

24L085

24P593

24P595

24L087

24P597

24L089

24L091

Series

A

A

A

A

A

A

A

A

A

A

A

odels and Kits

Kits for Hazardous Locations

Configuration

ProControl

1KE Module

with bracket

(Manual

332013)*

✔✔

✔✔ ✔✔

✔✔ ✔✔✔

✔✔ ✔✔

✔✔✔✔

✔✔✔ ✔

✔✔✔✔

✔✔✔✔✔

✔✔✔✔✔

✔✔✔✔✔✔

✔✔✔

No

Power

* See component manuals for additional approval information.

** Must not be installed in Hazardous Location.

AC

Power

with

barrier**

G3000

Meter

(Manual

308778)*

I/P

Transducer

Fluid

Regulator

(Manual

3A0427)*

Pressure

Transducer

(Manual

407045)*

r Non-Hazardous Locations

Kits fo

Kit No.

84

24L0

24P592

24P594

24L086

24P596

24L088

L090

24

9902471

Conforms to/Certified to UL/CSA Standard 61010–1

Serie

A

A

A

A

A

A

A

s

ntrol 1KE

ProCo

ewithbracket

Modul

✔✔✔✔

✔✔✔ ✔

✔✔✔✔

✔✔✔✔✔

✔✔✔✔

✔✔✔✔✔✔

✔✔✔

AC

Power

Config

G3000

Meter

uration

I/P

Transducer

Fluid

Regulator

Pressure

Transducer

4

3A2614F

Page 5

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance and repair of this equipment. The

exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific

risks. When these symbols appear in the body of this manual or on warning labels, refer back to these

Warnings. Product-specific hazard symbols and warnings not covered in this section may appear throughout

the body of this manual where applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help

prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and

plastic drop cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable

fumes are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless

they are antistatic or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use

equipment until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

Static charge may build up on plastic parts during cleaning and could discharge and ignite

flammable vapors. To help prevent fire and explosion:

• Clean plastic parts only in a well ventilated area.

• Do not clean with a dry cloth.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can

cause electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before

servicing or installing equipment.

• Connect only to grounded power source or grounded electrical outlets.

• Use only 3–wire extension cords.

• Ensure ground prongs are intact on power and extension cords.

• Do not expose to rain. Store indoors.

• All electrical wiring must be done by a qualified electrician and comply with all local codes

and regulations.

3A2614F 5

Page 6

Warnings

WARNING

INTRINSIC SAFETY

Intrinsically safe equipment that is installed improperly or connected to non-intrinsically safe

equipment will create a hazardous condition and can cause fire, explosion, or electric shock.

Follow local regulations and the following safety requirements.

• Be sure your installation complies with national, state, and local codes for the installation of

electrical apparatus in a Class I, Group D, Division 1 Hazardous Location, including all of the

local safety fire codes, NFPA 33, NEC 500 and 516, and OSHA 1910.107.

• Equipment that comes in contact with intrinsically safe terminals must meet the entity

parameter requirements specified in Control Drawing 16M169. See Appendix A in Manual

332013. This includes safety barriers, DC voltage meters, ohmmeters, cables, and

connections. Remove the unit from the hazardous area when servicing.

• If a printer, computer, or other electrical component is connected, it must be used in

conjunction with a safety barrier.

• Without the safety barrier, the equipment is no longer intrinsically safe and must not be

operated in hazardous locations, as defined in article 500 of the National Electrical Code

(USA) or your local electrical code.

• Do not install equipment approved only for non-hazardous location in a hazardous area. See

the ID label for the intrinsic safety rating for your model.

• Ground the power supply. A voltage limiting safety barrier must be properly grounded to be

effective. For proper grounding, use a 12 gauge minimum ground wire. The barrier’s ground

must be within 1 ohm of true earth ground.

• Do not operate the power supply module with the cover removed.

• Do not substitute system components as this may impair intrinsic safety.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Engage trigger lock when not spraying.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking,

or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

6 3A2614F

Page 7

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated

system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data

in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete

information about your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals

and create safety hazards.

• Make sure all equipment is rated and approved for the environment in which youareusingit.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

TOXIC FLUID OR FUMES

Toxic fluids or fumes can cause serious injury or death if splashed in the eyesoronskin,

inhaled, or swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable

guidelines.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury,

including eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective

equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent

manufacturer.

3A2614F

7

Page 8

Overview

Overview

The ProControl 1KE Advanced Display Control

Module is an electronic flow control and fluid

monitoring system. The ProControl 1KE performs the

following functions:

• Manages fluid

• Manages the

•Showsreal-

•Displaysar

• Monitors a

•Alarmsift

the user-s

•Alarmswhe

the user-

•Displays

pressure or flow rate.

fan air.

time fluid flow rate.

esettable batch totalizer.

nd reports overall fluid use.

he flow rate is too fast or too slow for

et targets.

n the maintenance total is reached for

set target.

alogofthelast20alarms.

The ProControl 1KE is available in configurations for

installation in Hazardous Locations or Non-Hazardous

locations. The power supply for Hazardous Locations

comes with one barrier, to power one ProControl

1KE. Up to three additional barriers can be added

to the power supply to power three additional

ProControl 1KEs. See Accessories, page 43 ,to

order additional barriers. Order ProControl 1KE Kit

24R261, 24R262, or 24R263,, based on your choice

of the fluid management compononets. These kits do

not include a power supply.

8 3A2614F

Page 9

Installation

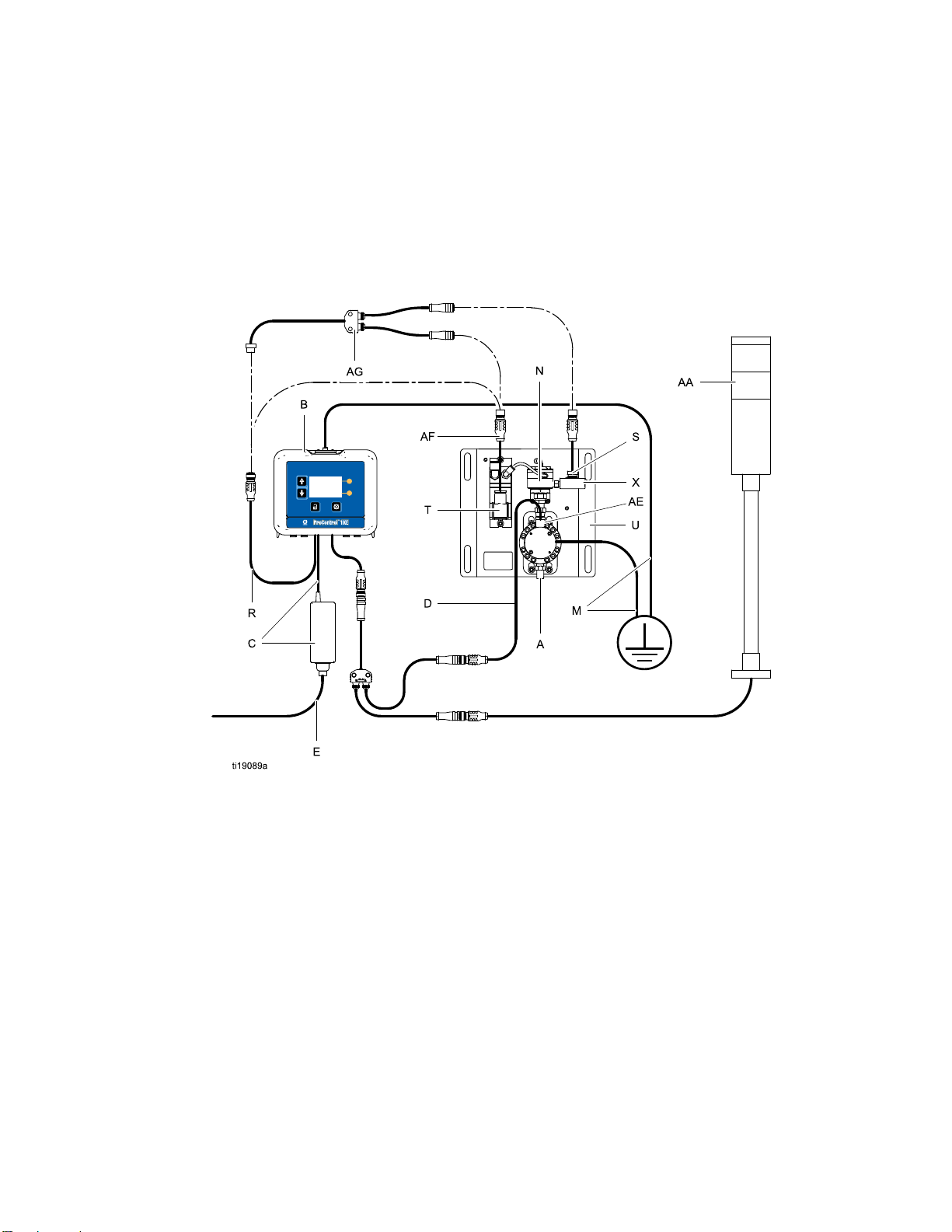

Non-Hazardous Locations

Installation

NOTE: Kits su

Users in area

converter. S

pplied with an AC/DC Converter are shipped with a North American 120 VAC power cord (E).

s with another standard voltage must provide a power supply cord with an IEC 320–C13 female

ee Technical Data, page 53 for power requirements.

Key:

A

B

C Power Supply and Cable (6 ft., 2 m), to

D

E

M

Meter Fluid Inlet, 1/4 npt female

Flow

t/outlet.

inle

ProControl 1KE Module with Bracket

terminal 3. See Cable Connections, page 13.

ter Cable (50 ft., 15 m), to terminal 4. See

Me

ble Connections, page 13.

Ca

Power Cord (10 ft., 3 m), see NOTE above.

Ground wire and clamp. PN 244524 in

included with kits to ground the ProControl

1KE Module. PN 238909 is sold separately

to ground the meter and other components.

N

Fluid Regulator, 1/8 npt (f) outlet

R

Fluid Control Cable

Pressure Transducer

S

T

I/P Transducer (Current to Pressure). See

Air Connections, page 15.

U

Mounting Panel. See

Mounting Dimensions, page 44.

X

AA

AE

AF

ressure Transducer Fitting, 1/8 npt (f) inlet

P

nd outlet

a

Light Tower with Splitter (accessory)

Flow Meter Fluid Outlet, 1/4 npt (f)

Pressure Transducer Cable

3A2614F 9

Page 10

Installation

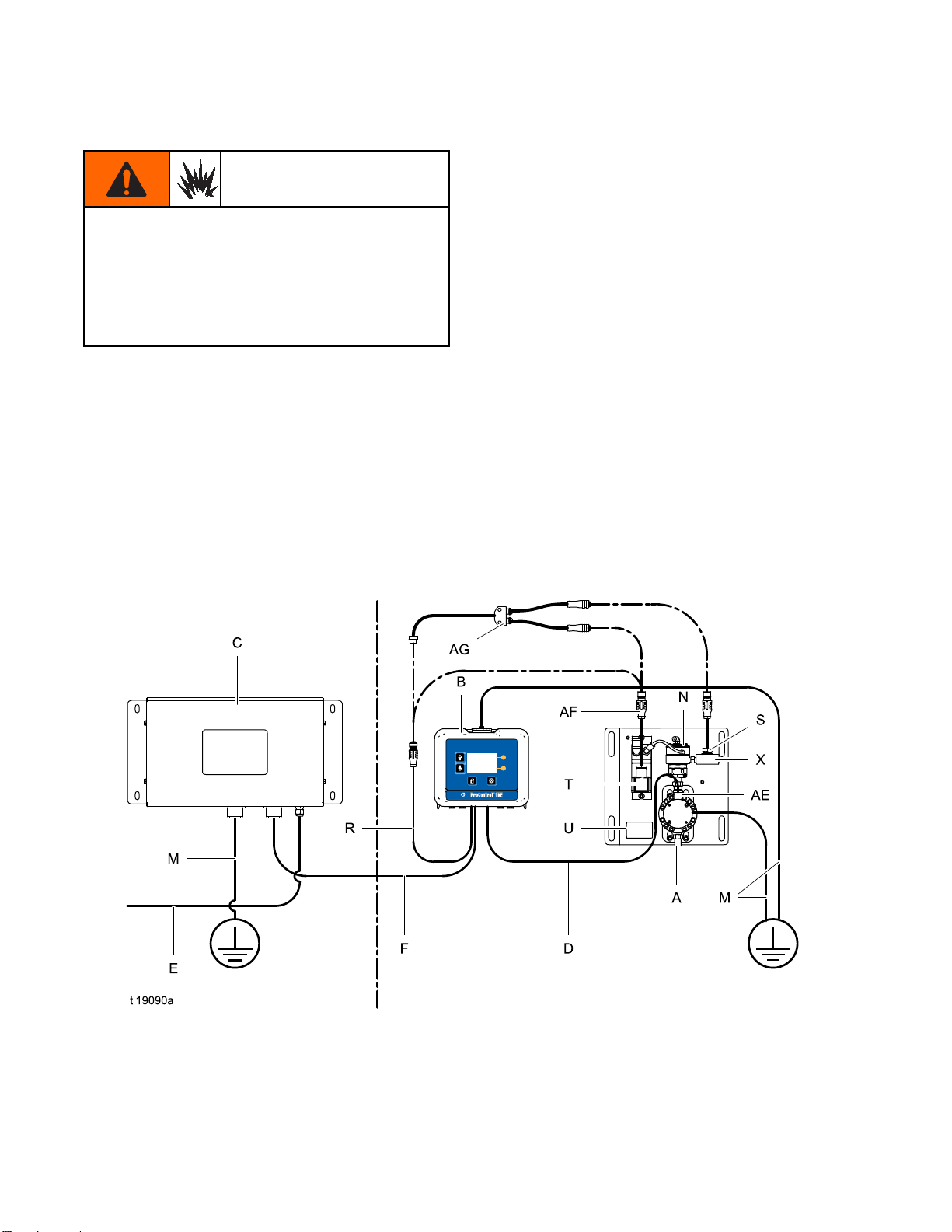

Hazardous Locations

Do not substitute or modify system components

as this may impair intrinsic safety. For installation,

maintenance, or operation instructions, read

instruction manuals. Do not install equipment

approved only for non-hazardous location in a

hazardous location. See the identification label for

the intrinsic safety rating for your model.

Intrinsically safe equipment should not be used with a

power supply that has no barrier. Do not move units

from a non-IS setup to an IS setup. IS equipment

that has been used with a non-IS power supply must

not be returned to a hazardous location. Always use

an intrinsically safe power supply with IS equipment.

• Installation should be in accordance with ANSI/ISA

RP12.06.01, “Installation of Intrinsically Safe

Systems for Hazardous (Classified) Locations,”

and the National Electrical Code® (ANSI/NFPA

70).

• Installation in Canada should be in accordance

with the Canadian Electrical Code, CSA C22.1,

Part 1, Appendix F.

• For ATEX, install per EN 60079-14 and applicable

local and national codes.

• Multiple earthing of components is allowed only

if a high integrity equipotential system is realized

between the points of bonding.

• Do not remove any cover until power has been

removed.

• Install according to Control Drawing Number

16M169. See Appendix A in Manual 332013.

Nonhaza

rdous Location

Hazardo

us Location

10 3A2614F

Page 11

Installation

Key:

A

Flow Meter, 1/4 npt female inlet/outlet

B

ProControl 1KE Module with Bracket

C Power Supply

D

Meter Cable (50 ft., 15 m), to terminal 4. See

Cable Connections, page 13.

E

Power Cord (not supplied)

F

Power Cabl

Cable Conn

M

Ground wire and clamp. PN 244524 is

included with kits to ground the ProControl

1KE Module. PN 238909 is sold separately

to ground the meter or other component.

with Barrier

e(50ft.,15m)toterminal3. See

ections, page 13.

N Fluid Regulato

R

Fluid Control Cable

Pressure Tran

S

T

I/P Transduc

Air Connecti

U

Mounting Panel. See

Mounting Dimensions, page 44.

X

Pressure Transducer Fitting, 1/8 npt (f) inlet

and outlet

AE

Flow Mete

AF

Pressure Transducer Cable

r

sducer

er (Current to Pressure). See

ons, page 15.

r Fluid Outlet, 1/4 npt (f)

3A2614F

11

Page 12

Installation

Grounding

The equipment

risk of static

or static spar

explode. Imp

shock. Groun

electric cur

NOTE: The ProControl 1KE does not provide 500

VAC isolation through the coupling nuts on the

enclosure. The associated apparatus and the field

apparatus cable shields must not be connected to

the ProControl 1KE coupling nuts.

must be grounded to reduce the

sparking and electric shock. Electric

king can cause fumes to ignite or

roper grounding can cause electric

ding provides an escape wire for the

rent.

1. Power Supply 16M167: Connect the ground wire

from the power supply to a true earth ground.

2. ProControl 1KE Module: Connect a ground

wireandclamptothescrewonthetopofthe

bracket. Connect the other end to ground. In an

IS system, the ProControl 1KE also is grounded

by connection to the grounded power supply.

3. Flow Meter: Follow the instructions in manual

308778 (G3000) or manual 313599 (Coriolis) to

ground the flow meter and check its electrical

grounding continuity.

4. Fluid and Air Control: Ground through connection

to the mounting panel that also holds the

grounded flow meter.

5. Fluid Supply: Ground the fluid supply unit.

2

1

3A2614F

Page 13

Installation

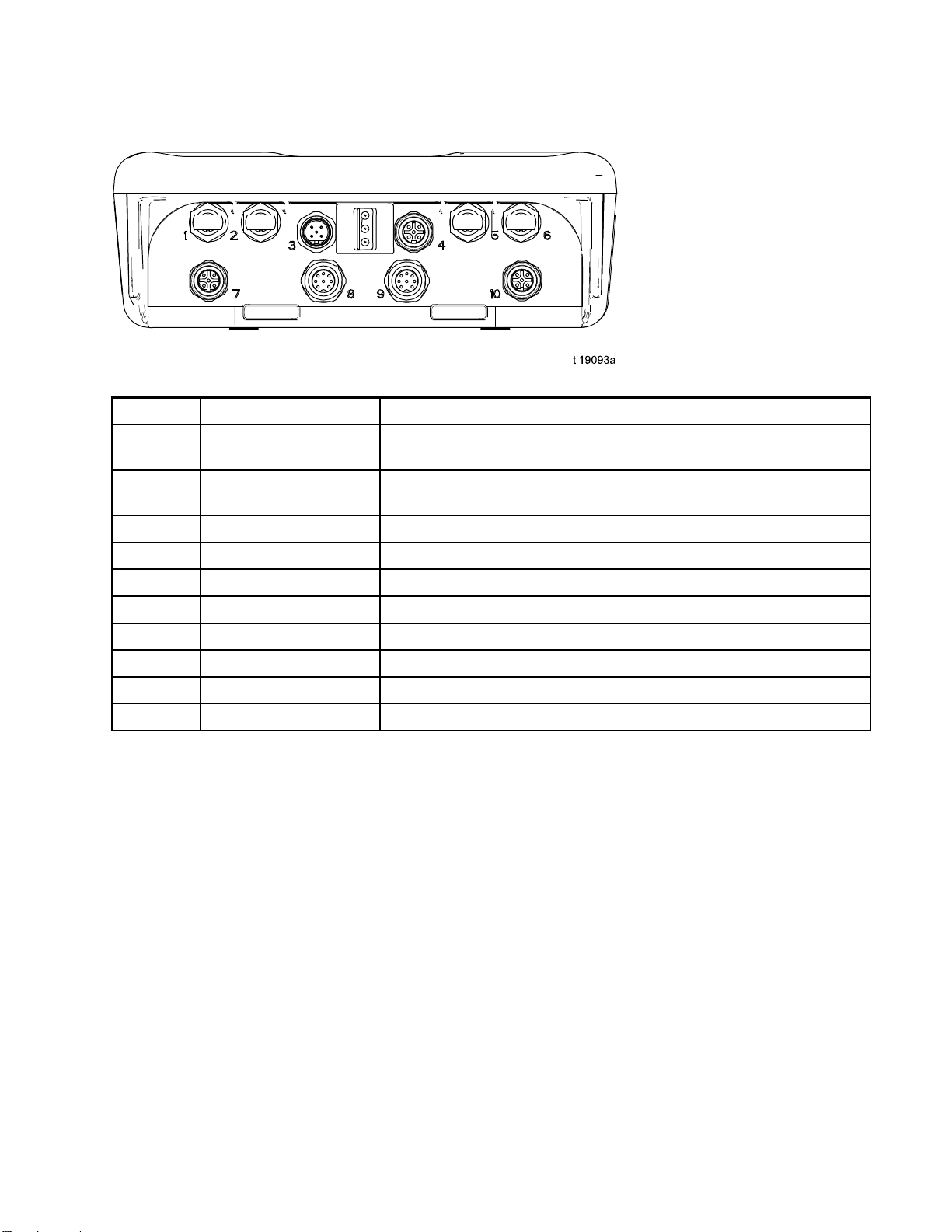

Cable Connect

Port Descripti

1

2

3 Power

4

Fiber Opt

Fiber Optic Transmitter Black Lead to RX on Fiber Optic Converter (PN 16K465) or to Port

Digita

ions

on

ic Receiver

l Input/Output

Connection

RedLeadf

Port6ona

5 on another ProControl 1KE (or Informer)

From Power Supply

To/Fro

rom TX on Fiber Optic Converter (PN 16K465) or from

nother ProControl 1KE (or Informer)

m Meter and Light Tower (Accessory)

5

6

7

8

9

10

Fiber Optic Reciever Black Lead from Port 2 on another ProControl 1KE (or Informer)

Fiber Optic Transmitter Red Lead to Port 1 on another ProControl 1KE (or Informer)

Analog Input

Flow Control To/From Flow Control Cable

Motor Control

gital Input/Output

Di

rom Pressure Transducer Cable

To/F

used.

Not

Not used.

3A2614F 13

Page 14

Installation

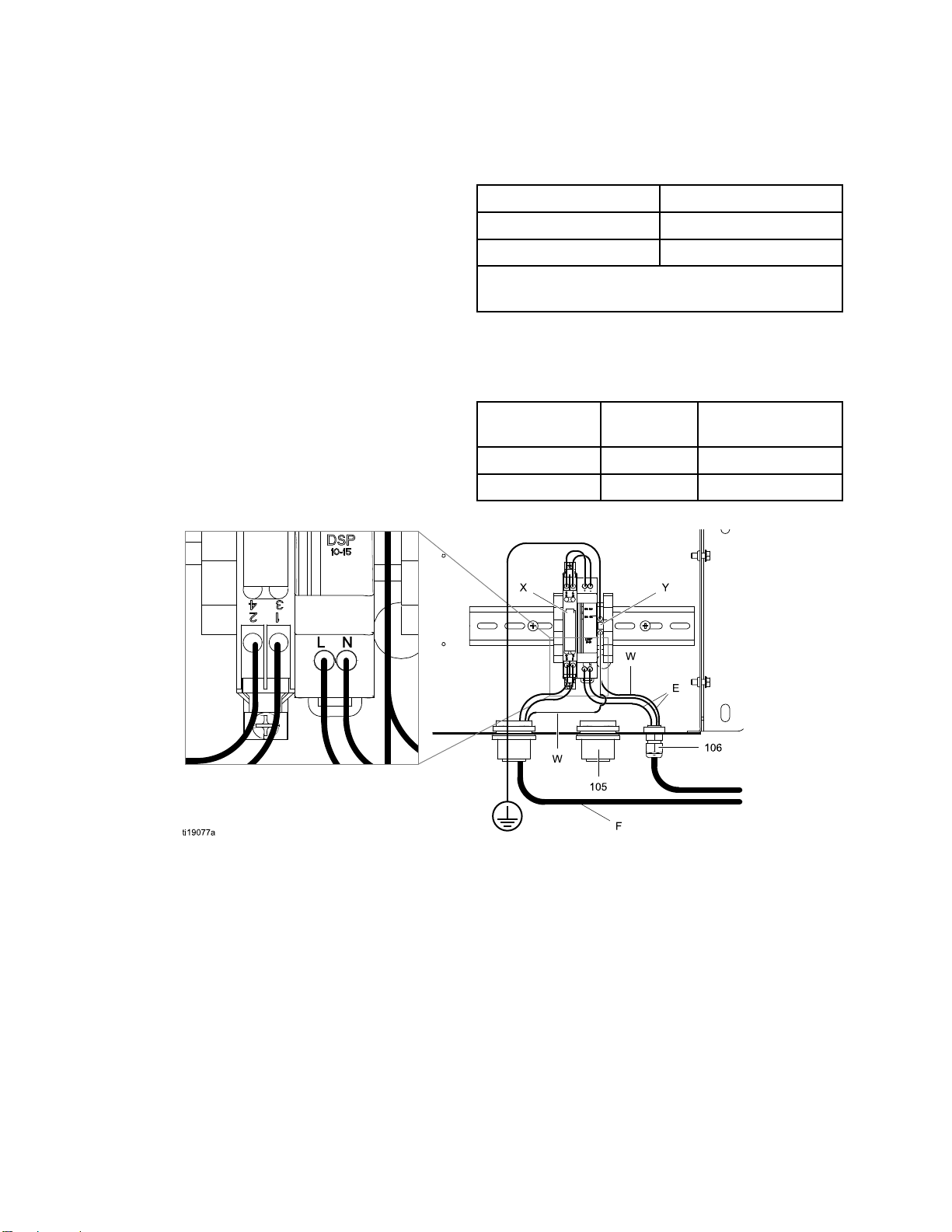

Electrical Co

Install per Graco Control Drawing 16M169, in Manual

332013. See also Figure 1.

1. Connect main

supplied) th

N on the power

Note: Use ei

onthesizeo

2. Connect pow

terminal bl

3. Connect IS

table.

nnections

power supply cord (E, not

rough strain relief to terminals L and

supply unit.

ther strain relief (5) or (6), depending

fthecord.

er cord ground wire (W) to ground

ock (Y).

power cable (F) per the following

Table 1 Power Barrier Wiring Connections

Power Cable Le

Brown (power) Connector 1

Blue (common) Connector 2

Glossy Blac

ground blo

Table 2 I/

Cables 16P790 (non-IS) and 16V142 (IS)

Wiring Table

Wire Color

Gray Control A Connector 1

Blue

P Transducer Wiring Connections;

ads

k (ground) and Black (drain) connect to

ck.

Function

Common Connect

Barrier Conne

DIN Conne

ction

ctor

or 2

Figure 1

KEY

E

F

W

XBarrier

Y

5

6

4

1

Inbound AC Power Cord

ower Cable

P

Ground Wires

Ground Block

Strain Relief Fitting

Strain Relief Fitting

3A2614F

Page 15

Installation

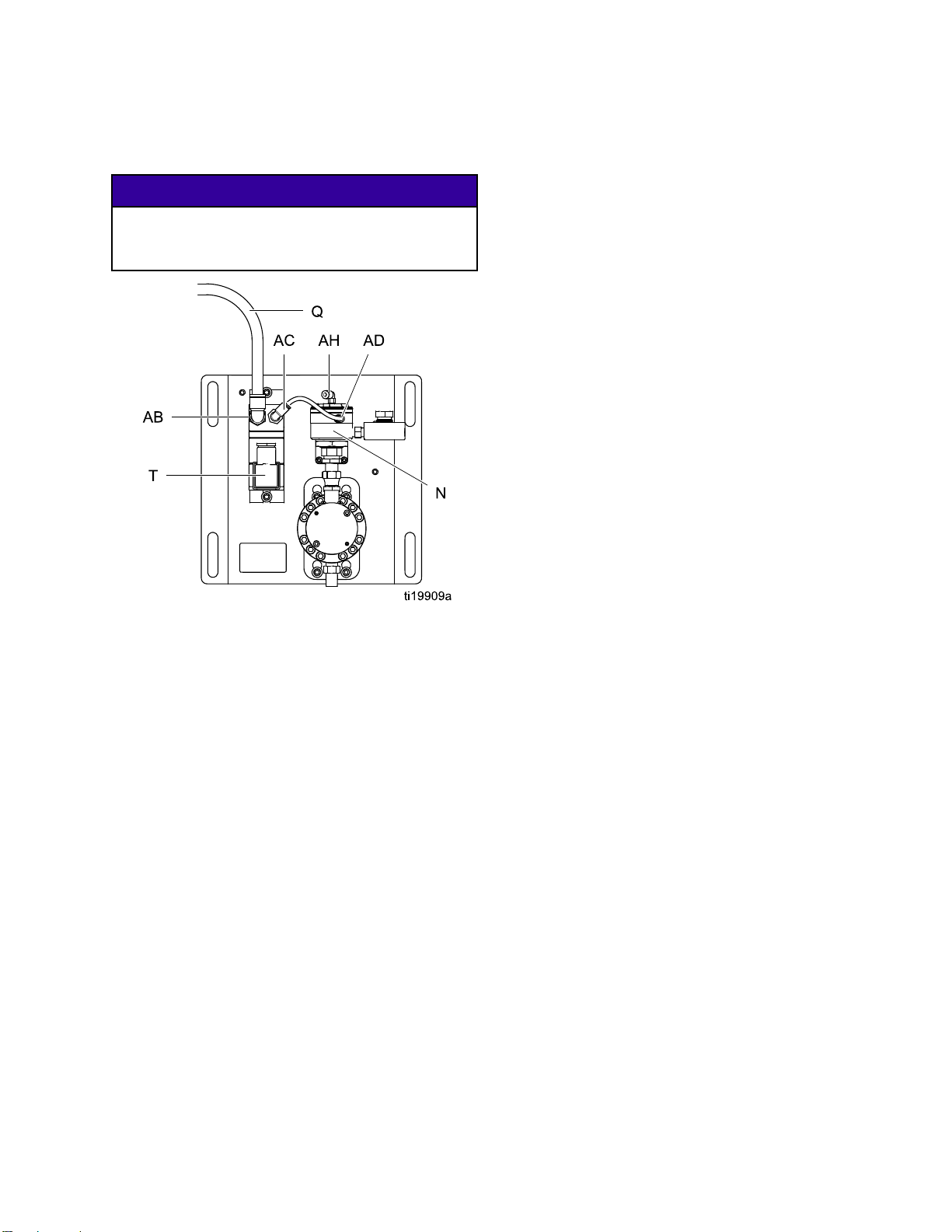

Air Connectio

ns

NOTICE

To avoid damage to the I/P transducer, use clean,

dry, oil-free air, filtered through at least a 40 micron

filter.

1. Connect incom

inlet (AB) on

regulator (S

tube fitting.

2. Kits with flu

is connecte

transducer

regulator (

Other Kits:

The I/P transducer exhausts a small amount of air

whenever air is connected, whether or not the system

is operating.

NOTE:

•Thetoppo

used for h

air sourc

side por

• Flushin

top port

igh-speed flushing with an independent

e. Set the air pressure higher than the

t (AD) air pressure.

g air pressure must be removed from the

(AH) to return to the previous flow setting.

ing air line (Q) to 1/4 in. npt (f)

I/P transducer (T). Kits with a fluid

ee Parts, page 34), include a 3/8

id regulator: Check that the air tube

dfrom5/32tubefitting(AC)onI/P

to 5/32 tube fitting (AD) on fluid

N).

The air outlet is 1/4 in npt (f).

rt (AH) on the fluid regulator can be

Commun

Graco Accessories are available to enable

communication with a Programmable Logic

Controller (PLC) or Personal Computer (PC).

• The Fiber Optic Converter (Graco Kit 24N978)

enables Modbus RTU communication with a

user-supplied PLC using a serial cable.

• A Modbus Gateway (Graco Kit 24N977) used

with a Fiber Optic Converter (Graco Kit 24N978)

enables Modbus TCP communication with a

user-suppled PLC.

ication Options

• A Modbus Gateway (Graco Kit 24N977)

canbeconnectedto(orinstalledin)

an Advanced Web Interface (Graco

Kit 15V377) to enable communication

with a PC using an ethernet cable. See

Appendix B - Advanced Web Interface, page 48,

for instructions.

These communication kits come with installation

and setup directions necessary for their use with the

ProControl 1KE.

3A2614F 15

Page 16

Installation

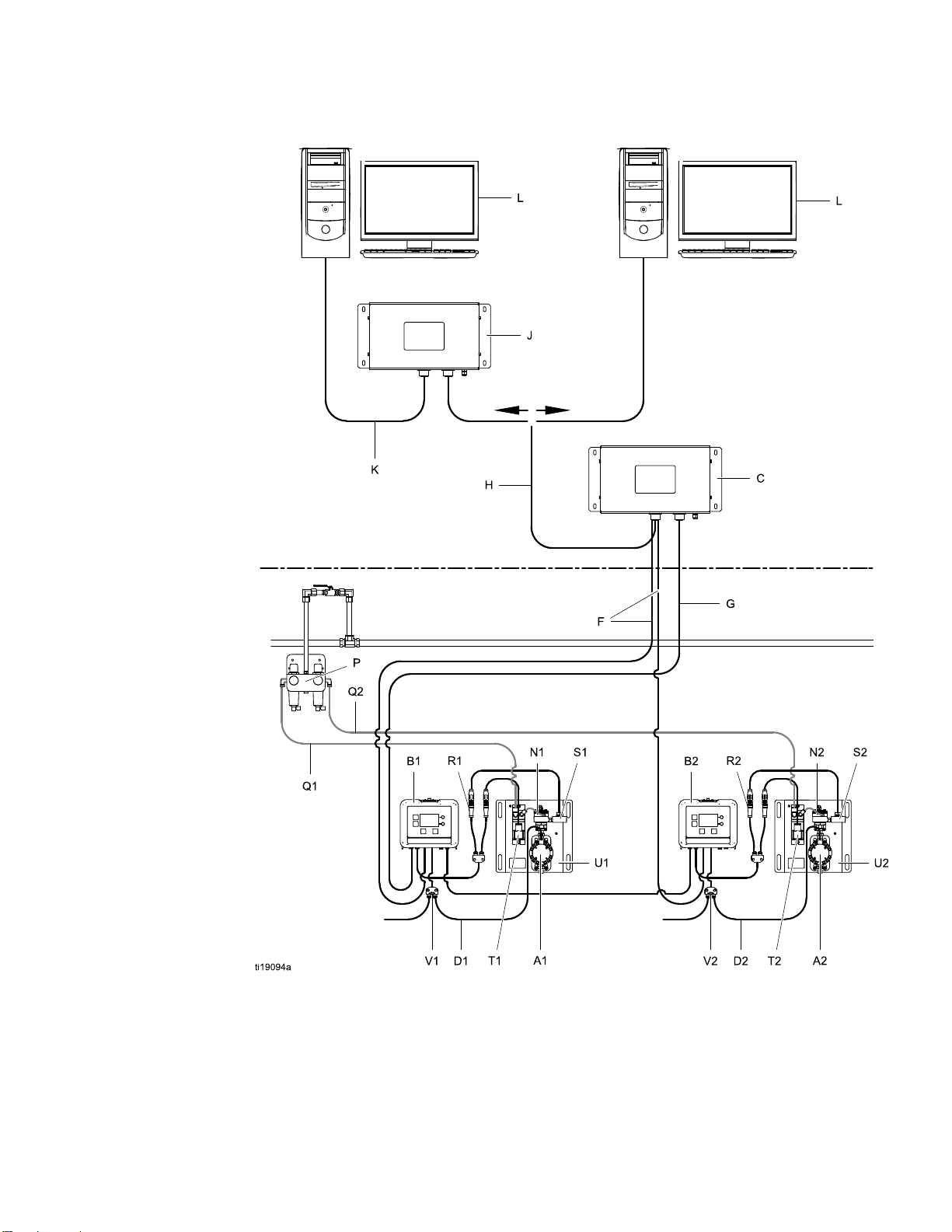

Typical Installation

Non-Hazardous

Location

Hazardous Location

16 3A2614F

Page 17

Installation

Key

A1 and A2

B1 and B2 ProControl 1K

C Power Supply a

D1 and D2 Meter Cable (50 ft., 15 m) Supplied in kits with meter

E

F

G Fiber Optic Cable (100 ft., 30 m)

H

J

K

L Personal computer Not supplied.

N1 and N2

P

Q1 and Q2

R1 and R2 Flow Con

S1 and S

T1 and T2 I/P Transducer (Current to Pressure) Supplied

U1 and U2

V1 and V2 Splitter to meter and light tower

W1 and W2 Pressure Transducer Cable. Supplied in some kits. See

2

Flow Meter

EModulewithBracket

nd Barrier

Power Cord (10 ft., 3 m), not shown Supplied in Non-Hazardous

Power Cable (50 ft., 15 m) Supplied

Serial Cable

Advanced Web Interface

Ethernet Cable

Fluid Regulator

Air Cont

Air Lines Not supplied

Pressure Transducer

Mounti

(non-hazardous installations) or IS cable

kit for hazardous location installations.

rol Module

trol Cable

ng Panel

Supplied in some kits. See

Parts, page 34.

Supplied

SuppliedinHa

Kits

Location Kits

Accessory

Accessory

Accessory

Accessory

Supplied in some kits. See

Parts, page 34.

Accessory

Supplie

Suppli

Parts,

Supplied

Acces

Parts, page 34.

d

ed in some kits. See

page 34.

sory

zardous Location

3A2614F

17

Page 18

Operation

Operation

Pressure Relief Procedure

Follow the Pressure Relief Procedure

whenever you see this symbol.

For information on the G3000 Graco flow meter, see

manual 308778. For information on the Coriolis flow

meter, see manual 313599. Calibrate the meter as

instructed before using the meter for production.

NOTICE

The flow meter gears and bearings can be

damaged if they rotate at too high a speed. To

avoid high speed rotation, open the fluid valve

gradually. Do not over-speed the gear with air or

solvent. To prolong meter life, do not use the meter

above its maximum flow rate.

This equipment stays pressurized until pressure

is manually relieved. To help prevent serious

injury from pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the

Pressure Relief Procedure when you stop spraying

and before cleaning, checking, or servicing the

equipment.

1. Turn off the fluid supply to the mete

2. Set the Flow Rate Percent to at least 50 percent.

3. Follow the Pressure Relief Procedure for your

fluid system dispensing device.

4. Reduce the Flow Rate Percent to 0 percent.

r.

NOTICE

To avoid damage to the I/P transducer, always

set the Flow Rate Percent to 0 before reducing air

pressure to the system.

Fluid Regulator Operation

Follow instructions in the fluid regulato

up, flush, and adjust the fluid regulator p

Flow Meter Operation

r manual to set

rior to use.

Calibrate the Meter

NOTE: See Setup Screen 5 for further screen

information, if needed.

When to Calibrate

• The first time the system is operated.

• Whenever new materials are used in the system,

especially if the materials have viscosities that

differ significantly.

• As part of regular maintenance to retain meter

accuracy.

• Whenever a flow meter is serviced or replaced.

Read Before Calibration

• Meter k-factor on Setup Screen 5 is updated

automatically after the calibration procedure is

completed. You also may manually edit the

k-factor if desired.

• All values on this screen are in cc or cc/pulse,

regardless of the units set in the other Setup

screens.

• Before calibrating the meter, be sure the system

is primed with material.

• Disable alarms before calibration.

Calibration Steps

To reduce the risk of component rupture, which

could cause injury from splashing fluid, do not

exceed the maximum working pressure of your

meter or any component or accessory in your

system.

1. Press

2. Press

3. Press

4. Press

to enter Setup Mode.

to move to Setup Screen 5.

to enter the screen.

to begin the calibration.

18 3A2614F

Page 19

Operation

5. Dispense about 300–500 cc of material into a

graduated cylinder. The amount the system

measures will display in the measured volume

field

6. Press

7. Press

the amount of material in the cylinder.

8. After the volume is entered, the system calculates

the new k-factor

Screen 5.

NOTE: To clear the counter and begin the

calibration again, press

another screen, then return to Setup Screen 4

and start over. If you press

the screen, the counter will continue from where

it is, without clearing.

9. Press

.

to end th

to get to the dispensed volume field

,thenpress to enter the field. Enter

to exit the screen.

e calibration.

and shows it on Setup

,movebrieflyto

without leaving

Set the Flow Ra

1. System Setup: See SetupScreen2,page27to

set the upper and lower limit within which the

operator can adjust the flow rate. The settable

range is 0 to 99.9 percent, but the I/P pressure

transducer requires a minimum of 22 to 25 flow

rate percent target to start flow. Therefore, the

operational range is about 22 to 99.9 percent.

See Table 1.

Table 3

Flow Rate

Target

0–about 20

percent

22%-25%

55% — 60%

99.9%

te Percent

I/P Current Effect

0–4.0 mA

4.4–5.0 mA

11–12 mA

20 mA

No flow

Lowest flow

rate

Middle fl

rate

Highest flow

rate

ow

10. Press

to exit Setup Mode.

Set the Modbus Addresses

etup Screen 7. By default, the Modbus is

See S

oOff

set t

us mode to SLAVE

Modb

ue is between 1 and 247. The modbus address

val

responds to the address of the ProControl 1KE.

cor

Appendix A for further information.

See

. If you need the Modbus, set the

. The address

2. Operator: See Run Screen 1, page 24 to adjust

the flow rate within the set limits.

Update the Software

Software updates are installed using a software token

(PN 16P892), which is sent automatically when a new

version of the software is released. Manual 3A1244

will accompany any necessary software updates.

Follow all instructions and warnings in Manual

3A1244 to update your ProControl 1KE software.

3A2614F 19

Page 20

Operation

Replace the Battery

Replace the ba

after disconn

Sparking can o

Replace the b

location, aw

ttery only if the clock stops functioning

ecting power or a power failure.

ccur when changing the battery.

attery only in a non-hazardous

ay from flammable fluids or fumes.

NOTICE

To avoid damage to the circuit board, wear Part No.

112190 grounding strap, and ground appropriately.

1. Disconnect power.

2. Remove the module from the bracket.

3. Attach the grounding strap.

4. Remove 4 screws, and then remove the access

cover.

5. Use a flathead s

battery.

NOTE: Dispose of battery properly in an

approved container and according to applicable

local guidelines.

6. Replace with new battery. Ensure battery fits

under connector tabs before snapping other end

in place.

NOTE: Us

replace

7. Reassem

8. Snap th

ment.

ble access cover and screws.

e module back into the bracket.

crewdriver to pry out the old

e only Panasonic CR2032 batteries for

20 3A2614F

Page 21

Display Module

Display Module

Display Information

The Display Module provides the interface f

to enter selections and view information r

setup and operation.

The screen backlight is factory set to remain on,

even without screen activity. See Setup Screen 4

to set the backlight timer to your preference. Press

any key to restore.

Keys are used to input numerical data, enter setup

screens, navigate within a screen, scroll through

screens, and select setup values.

or users

elated to

NOTICE

To prevent damage to the softkey buttons, do not

press the buttons with sharp objects such as pens,

plastic cards, or fingernails.

Operation Modes

The ProControl 1KE has two operation modes: Run

Mode and Setup Mode. For detailed information see

Run Screens, page 24, and SetupScreens,page26.

Press

to toggle between these two modes.

3. Use

change.

4. Press

Drop Down Field

1. Use

the dropdown menu.

2. Press

3. Press

Number Field

1. The first digit will be highlighted. Use

to change the number.

2. Press

3. When all digits are correct, press

accept.

4. Press

Check Box Field

A check box field is used to enable or disable features

in the software.

to highlight the data you wish to

to edit.

to highlight the correct choice from

to select.

to cancel.

to move to the next digit.

again to

to cancel.

Screen Navigation and Editing

Refer to this section if you have questions about

screen navigation or about how to enter information

and make selections.

All Screens

1. Use

2. Press

on the screen will highlight.

to move between screens.

to enter a screen. The first data field

1. Press

box.

2. The feature is enabled if a

Reset Field

The reset field is used for totalizers. Press

reset the field to zero.

When all data is correct, press

Then use

to move between Setup Mode and Run Mode.

to toggle between and an empty

is in the box.

to exit the screen.

to move to a new screen, or

to

3A2614F

21

Page 22

Display Module

Icons

As you move through the ProControl 1KE screens, you will notice that most information is communicated

using icons rather than words to simplify global communication. The detailed screen descriptions in

Run Screens, page 24, and Setup Screens, page 26, explain what each icon represents. Icon reference tables

also are provided, on this page and the next. Softkeys are membrane buttons whose function correlates with

the screen content to the immediate left of the button.

Membrane Keys

Press to toggle between Run mode

and Setup Mode.

Error Reset:

has been fixed. Also used to cancel data

entered and return to original data.

Up/Down Arrows:

screens or fields on a screen, or to increment

or decrement the digits in a settable field.

Softkeys:

Use to clear alarm after cause

Usetomovebetween

Use varies by screen.

See column at right.

Softkeys

Enter Screen.

Also changes the function of the Up/Down

arrows so they move between data fields on the

screen, rather than between screens.

Enter.

Right.

Presstoactivateafieldforeditingortoaccept

the highlighted selection on a dropdown menu.

Move to the right when editing number fields. Press

again to accept the entry when all digits are correct.

Highlight data that can be edited.

Exit Screen.

Exit data editing.

Reset.

2

2

Reset totalizer to zero.

Start

Stop

3A2614F

Page 23

Display Module

Screen Icons

Screen number.

The arrows indicate

more screens are

available to view.

Batch Totalizer Batch Units

Maintenance Totalizer

Grand Totalizer Set Grand Total Units

Lock icon indicates

the unit is in Setup.

Maintenance Target

Screen Icons

Set Pressure Units

Set Flow Rate Units

Flow Rate Alarm

Enable

Set Backlight Timer

Actual vo

dispense

lume

d

Set Maximum and

Minimum Flow Rates

Maintenance Totalizer

Alarm Enable

Set Alarm Auto Clear

(to clear alarm on ac-

cessories)

Volume measured

by the meter

K-Factor

Fluid Flow Percent

Target

Fluid Flow Rate

Set Modbus Address Set Serial Port Baudrate

SetSerialPortParity

Set Upper and Lower

Limits for Fluid Flow

Percent

Fluid Pressure

Set Mod

Modbus Functionality is

Off

ProControl 1KE is

bus Mode

Modbus Slave

Select Pressure

Transducer

Display or adjust pres-

sure transducer slope

MF

Maintenance Alarm

Select Correct Date Select Date Format

Set the Correct Time

Set Zero Offset

F3

Flow Rate High Alarm

F2

Flow Rate Low Alarm

Enter User-Set

Password

3A2614F 23

Page 24

Run Screens

Run Screens

When in Run Mode, the ProControl 1KE displays the

flow rate percent target, actual fluid pressure, and

current flow rate on Screen 1. Screen 2 displays

the batch total and grand total for the flow meter to

which it is connected. Screens 3–6 display a log of

the last 20 alarms.

Run Screen 1

Use this screen to view or reset the flow rate percent

target, and to view the actual fluid pressure and flow

rate. Units are set on Setup Screen 1 and Setup

Screen 2.

Key

Enter the screen.

Flow Rate Percent Target — Operator

settable within the range defined on

SetupScreen2.

Displays current fluid pressure if

equipped and set up with a pressure

transducer. Otherwise, this field displays

just 3 dashes.

Displays current flow rate.

Run Screen 2

Use this screen to view or reset the batch totalizer

and to view the grand total flow for the system. The

grand total cannot be reset.

Key

Batch Totalizer - Displays the amount

of fluid measured since the last time the

field was reset to zero.

Reset Batch Totalizer - resets the batch

totalizer to zero.

Grand Totalizer - Displays the grand total

flow for the system. This value cannot

be reset.

Move between Run Screens.

Move between Run Screens.

4

2

3A2614F

Page 25

Password Screen

Run Screens 3 —

Use Screens 3–6 to view the log of recent alarms.

Date on wh

Alarm occ

Time at which the Deviation or Advisory

Alarm occurred.

General

advisor

alarm. F

F3 is th

Deviat

more in

Move between Run Screens.

yalarm. MF is the maintenance

e flow rate high alarm. See

ions and Advisories, page 31,for

formation.

6

Key

ich the Deviation or Advisory

urred.

symbol indicating a deviation or

2 is the flow rate low alarm.

Enter password to enable entry to the Setup screens.

Set the password to 0000 to disable password

protection. See Setup Screen 9 to set or change

the password.

Key

Enter the

Press to activate a field for editing.

Move to the right when editing number

fields. Press again to accept the entry

when all digits are correct.

Enter the user-set password for the

system.

Increm

editin

screen to enter a password.

ent/decrement the digits when

g number fields.

Password Screen

assword has been set, the Password Screen

If a p

displays when

3A2614F 25

is pressed from any Run screen.

Page 26

Setup Screens

Setup Screens

The Setup Mode is used to set up a password

(if desired) and to set parameters for controlling

andmonitoringfluidflowwiththeProControl1KE.

See Screen Navigation and Editing, page 21,for

information on how to make selections and enter

data.

Setup Scree

Use this screen to view and reset the maintenance

totalizer, set the maintenance target value, and set

the batch and grand totalizer units shown on the Run

Screens. Maintenance totalizer units, shown on this

Setup Screen, are always cc.

n1

Reset Mainten

maintenance t

Maintenance Totalizer - Displays the

current maintenance total in cubic

centimeters.

Set your desired maintenance total target

value in this field in cubic centimeters.

See SetupScreen4,page28,tosetor

disable the maintenance alarm.

Batch Totalizer Units - Select from the

following drop down options.

Cubic centimeters

Liters

Gallons

Grand Totalizer Units - Select from the

following drop down options.

Cubic c

Liters

ance Totalizer - resets the

otalizer to zero.

entimeters

Key

Enter the screen to set or change

preferences.

Press to activate a field for editing or

to accept the highlighted selection on a

dropdown menu.

to the right when editing number

Move

s. Press again to accept the entry

field

all digits are correct.

when

Gallons

Exit data editing.

Move between Setup Screens, fields on

a screen, or to increment/decrement the

digits when editing number fields.

26 3A2614F

Page 27

Setup Screens

Setup Screen 2

Use this screen to set the upper and lower limits for

operator adjustment of flow rate percent and to select

your preferred pressure units.

Key

Enter the screen to set or change

preferences.

Press to activate a field for editing or to

accept the highlighted selection on a

dropdown menu.

Move to t

fields.

when al

Set you

and lo

perce

adjus

only w

Pres

foll

transducer.

he right when editing number

Press again to accept the entry

l digits are correct.

r desired upper (first data field)

wer (second data field) fluid flow

nt set limits. The Operator can

t the percentage on Run Screen 1

ithin these limits.

sure units — select from the

owingdropdownoptions.

Select if system has no pressure

SetupScreen3

Use this screen to set your flow rate maximum and

minimum values and to select your preferred flow

rate units.

Key

Enter the screen to set or change

preferences.

Presstoactivateafieldforeditingorto

accept the highlighted selection on a

dropdown menu.

Move to the right when editing number

fields. Press again to accept the entry

when all digits are correct.

Set your desired maximum (first data

field) and minimum (second data field)

flow rates. Flow rates outside of these

parameters will trigger an alarm. See

Setup Screen 4, page 28, to set or

disable the flow rate alarms.

Flow Rate Units - Select from the

following drop down options.

Select if system has no flow

meter.

3A2614F

it data editing.

Ex

Move between Setup Screens, fields on

a screen, or to increment/decrement the

digits when editing number fields.

Exit data editing.

Move between Setup Screens, fields on

a screen, or to increment/decrement the

digits when editing number fields.

27

Page 28

Setup Screens

SetupScreen4

Use this screen to set your alarm preferences. Select

to enable the a

disable the a

Enter the

preferen

Press to t

Maintenance Totalizer Alarm Enable

Flow Rate Alarm Enable

Alarm Auto Clear Enable. If enabled,

whentheflowratereturnstowithinthe

flow limit set points, the flow rate alarm

will clear on the screen and on any

attached accessories, such as a the light

tower.

Set backlight timer. Enter “00” to set the

backlight to remain on.

Exit data editing.

Move between Setup Screens, fields on

a screen, or to increment/decrement the

digits when editing number fields.

larm, or leave the box empty to

larm.

Key

screen to set or change

ces.

oggle between

and blank.

Setup Screen 5

Use this screen to calibrate your meter and

to view or set your meter k-factor. See

Calibrate the Meter, page 18, for procedure.

Key

Enter the screen to set or change

preferences.

Press to activate a field for editing or

to accept the highlighted selection on a

dropdown menu.

Move to

fields.

when al

Start

Stop the calibration.

Displaysthevolumemeasuredbythe

system for the calibration test.

Enter the actual volume dispensed into

the cylinder for the calibration test.

Displays the meter k-factor. User can

set the k-factor manually. The system

automatically updates to the correct

k-factor when the meter is calibrated.

Ex

the right when editing number

Press again to accept the entry

l digits are correct.

the calibration.

it data editing.

Move between Setup Screens, fields on

a screen, or to increment/decrement the

digits when editing number fields.

28 3A2614F

Page 29

Setup Screens

Setup Screen 6

Use this screen to specify your pressure transducer

and set its offset and slope.

Key

Enter the

preferen

Press to

to accep

dropdow

Move to the right when editing number

fields. Press again to accept the entry

when all digits are correct.

Select the correct pressure transducer.

Set the zero offset (the reading on

thegaugewhennopressureisonthe

system).

Pressure transducer slope. This number

is a constant representing millivolts

per bar. The default matches the

selected pressure transducer. Operator

adustable.

Exit data editing.

Move between Setup Screens, fields on

a screen, or to increment/decrement the

digits when editing number fields.

screen to set or change

ces.

activate a field for editing or

t the highlighted selection on a

n menu.

SetupScreen7

Use this screen to set your modbus preferences

for ports 1 and 2. Note that ports 5 and 6 are used

as modbus master devices for connecting to other

ProControl 1KE (or Informer) modules.

Key

Modbus mode. Select off or Slave from

the dropdown options.

Turn off Modbus functionality if

not used.

Use ProC

slave d

Enter or change the Modbus address.

Value is between 1 and 247.

Select serial port baudrate from the

dropdown options: 9600, 19200, 38400,

57600, or 115200.

Select serial port parity from the

dropdown options: NONE, ODD, or

EVEN.

Exit data editing.

Move between Setup Screens, fields on

a screen, or to increment/decrement the

digits when editing number fields.

evice.

ontrol 1KE as Modbus

3A2614F 29

Page 30

Setup Screens

SetupScreen8

Use this screen to set your date format, date, and

time.

Key

Enter the screen to set or change

preferences.

Press to activate a field for editing or

to accept the highlighted selection on a

dropdown menu.

Move to the right when editing number

fields. Press again to accept the entry

when all digits are correct.

Select your preferred date format from

the dropdown menu.

MM/DD

DD/MM/YY

YY/MM/DD

Set the current date.

/YY

Setup Screen 9

Use this screen to enter a password that will be

required to access the Setup screens. This screen

also displays the software version.

Key

Enter the screen to set the password.

Press to activate the field for editing.

Move to the right when editing number

fields. Press again to accept the entry

when all digits are correct.

Enter desired password. Enter “0000” to

disable the password.

Exit data editing.

Move between Setup Screens, fields on

a screen, or to increment/decrement the

digits when editing number fields.

Set the current time.

Exit data editing.

Move between Setup Screens, fields on

a screen, or to increment/decrement the

digits when editing number fields.

30 3A2614F

Page 31

Deviations and Advisories

Deviations and A

dvisories

Therearetwot

are indicated

Deviations, indicated by

not immediately.

Advisories, indicated by

attention.

If a deviation or advisory occurs, the system

continues running. The error code and the

or the flash on the screen. If multiple alarms

occur, F2 and F3 have higher priority than MF. They

will appear first and must be cleared first.

ypes of errors that can occur. Errors

on the display.

, require attention, but

, do not require

Deviations and Advisories

Icon

and

Code

Description

Alarm Log Logi

the system wil

example, if th

flow (F2) and n

only once, to

operator cor

If Alarm Auto Clear is not enabled, each alarm will

log only once if the operator corrects the condition

and then clears the alarm. The alarm will log twice

if the operator clears the alarm before correcting the

condition.

The following table explains the error type that is

associated with each error code and icon.

c: If Alarm Auto Clear is enabled,

l not log the same alarm twice. For

e system goes back forth between low

ormal, the system will log this error

keep the log from filling up before the

rects the condition.

How to Correct and Clear

MF

F2

F3

Advisory alarm. If enabled, the

maintenance totalizer alarm displays

when the user-set maintenance target

value is reached.

Deviation alarm. If enabled, the flow

rate low alarm displays when the

flow rate is lower than the user set

minimum.

Deviation alarm. If enabled, the flow

rate high alarm displays when the

flow rate is higher than the user set

maximum.

Reset Maintenance Totalizer to zero (see

SetupScreen1,page26). Perform maintenance.

Press

Maintenance Totalizer has been reset to zero.

Adjust flow rate, reset minimum flow target (see

SetupScreen3,page27), or disable alarm (see

Setup Screen 4, page 28).

Press

flow rate is still lower than the user set target.

Adjust flow rate, reset maximum flow target (see

SetupScreen3,page27), or disable alarm (see

Setup Screen 4, page 28).

Press

flow rate is still higher than the user set target.

to clear alarm. Alarm will not clear until

to clear screen. The alarm will not clear if the

to clear alarm. The alarm will not clear if the

3A2614F 31

Page 32

Troubleshootin

g

Troubleshooting

Problem

ProControl 1KE is completely

dark.

ProControl

does not fun

Pressure or Flow Rate reads 0

when fluid is flowing.

Pressure o

—allthet

Inaccur

Inaccu

1KE has power but

ction.

r Flow Rate reads — —

ime.

ate flow reading

rate pressure range

Cause Solution

Power is not on

Loose or disconnected power

cable.

Hardware fa

Loose or disconnected flow

meter/pressure transducer cable.

Units in Setup are set to NONE,

indicating that the system has no

pressure transducer and/or fluid

meter.

Faulty fl

Meter needs calibration.

Wrong t

Offs

owmetersensorormeter.

ransducer is selected.

et or slope are set incorrectly.

.

ilure.

Turn power sup

Tighten or connect cable.

Replace Pro

Check the digital input/output

cable going to/from the meter.

Choose preferred units for

each device present. See

SetupScreen2,page27, for pres-

sure, SetupScreen3,page27,for

flow rate.

Replace sensor or meter.

Calibrate meter. See

Calibrate the Meter, page 18.

Choose the correct transducer from the options in

SetupScreen6,page29.

Review and correct settings

for the pressure offset (mV)

and slope (mV/bar). See

SetupScreen6,page29.

ply on.

Control 1KE.

Display readout faulty.

Communication failure

Fluid is not flowing.

Low flow

ssive static discharge.

Exce

Ambient temperature too high. Lower ambient temperature.

orrect data addresses.

Inc

Incorrect communication

parameters.

Incorrect cabling.

Clogs in fluid line or in meter. Clean fluid line and/or meter. See

Gears worn or damaged. Service meter. See meter manual.

Inadequate air supply through the

I/P transducer.

Replace ProControl 1KE.

Check address configuration.

eck communication

Ch

rameters.

pa

Check cabling and wiring. See

Installation, page 9 .

meter manual.

Increase incoming air pressure.

32 3A2614F

Page 33

Troubleshootin

g

Diagnostic In

The LEDs on the bottom of the ProControl 1KE give important information about system function.

formation

LED Signals

Signal

Green On ProControl

Yellow Internal communication in progress.

Red solid

Red flashing Software is updating.

Red flashing slowly Token error; remove token and upload software

Description

ProContro

token again.

l 1KE failure. See Troubleshooting.

1KE is powered up.

3A2614F 33

Page 34

Parts

Parts

Kits for Hazardous Location 24L085, 24P593, 24P595, 24L087, 24P597, 24L089, 24L091

34 3A2614F

Page 35

Table 4 Parts for Hazardous Location Kits

Parts

Ref.

116M167

Part Description

POWER SUPPLY; 90–264 VAC input, 15 VDC output.

Manual 332196. Not included in Kits 24R261, 24R262, and

24R263.

3 24L083

3a

3b 277853

3c▲ 16P265 LABEL, war

4 16V142

5

6 16K509

8 16V381

9 244524

insically safe cables are identified by the blue tags installed on the cables.

*Intr

▲

lacement Danger and Warning labels, tags, and cards are available at no cost.

Rep

———

———

MODULE, ProContol 1KE, includes 3a-3c

MODULE, Pro

BRACKET

CABLE, intrinsically safe*, fluid control, 16 m (52.5 ft)

See Fluid and Air Control Parts, page 38.

CABLE, p

CABLE, intrinsically safe*, pressure transducer; included in Kits

24L089, 24P593, and 24P597

GROUND WIRE, assembly with clamp

Control 1KE, with software

ning, not shown

ower, intrinsically safe*, 50 ft. (15 m)

See

Qty.

1

1

1

1

1

1

3A2614F 35

Page 36

Parts

Kits for Non-H

azardous Location

24L084, 24L086, 24L088, 24L090, 24P592, 24P594, 24P596

36 3A2614F

Page 37

Table 5 Parts for Non-Hazardous Location Kits

Parts

Ref.

2 16V680

3 24L083

3a

3b 277853

3c▲ 16P265 LABEL, war

4 16P790

5

7

8 16V380

9 244524

▲

Replacement Danger and Warning labels, tags, and cards are available at no cost.

Part Description

POWER SUPPLY, 90–264 VAC input, 15 VDC output

MODULE, ProContol 1KE, includes 3a-3c

———

———

245202

MODULE, Pro

BRACKET

CABLE, fluid control

See Fluid and Air Control Parts, page 38.

CORD, se

CABLE, pressure transducer; included in Kits 24L088, 24P592,

and 24P596

GROUND WIRE, assembly with clamp

Control 1KE, with software

ning, not shown

t, power, 10 ft (3 m), 13 Amp, 120 V

Qty.

1

1

1

1

1

1

1

3A2614F 37

Page 38

Parts

Fluid and Air C

ontrol Parts

38 3A2614F

Page 39

Table 6 Fluid and Air Control Parts, Models 24L084, 24L085, 24L086, 24L087

Parts

Ref.

201 16E841 PANEL, mounting 1

202 16P784

4

204 121141

205 15T937

206 104371

207 104116

208

209 289813

210 501867 VALVE, c

211 15U749

212 114182

213 114339

214

Part Description

TRANSDUCER, I/P; includes

ref. 208

16P790

16V142

–——

-——

CABLE, fluid control

CABLE, fluid control, IS

SWIVEL, elbow

SWIVEL, elbow

SCREW, #10

WASHER, #10

BRACKET, transducer

METER, G3000

BRACKET, meter

SCREW, M6`

SWIVEL, union

NUT, hex, 1–12 unf

heck

Qty. 24L084,

24R263

✔✔ ✔✔

1

1

1

1

1

2or6

2or6

1

1

1

1

2

1

1

✔✔ ✔✔

✔✔

✔✔ ✔✔

✔✔ ✔✔

✔✔ ✔✔

✔✔ ✔✔

✔✔ ✔✔

✔✔ ✔✔

24L085 24L086 24L087,

24R262

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

215

216

217 112310

218 100079

219 109466

220

221 24P600

222

2

224

225 113116

24C375 REGULATOR, fluid; includes

———

——

——

–

23

24843

1

16K483

16V074

refs. 214, 216, and 217

KET, regulator

BRAC

W, #8

SCRE

HER, lock, #8

WAS

,#8

NUT

TUBE, air 1

ANSDUCER, pressure,

TR

cludes fitting (ref. 222) and

in

ring (ref. 225)

o-

FITTING, pressure transducer

FITTING

CABLE, meter

CABLE, meter, IS

O-RING

1

1

2

2

2

1

1

1

1

1

1

✔✔ ✔✔

✔✔ ✔✔

✔✔ ✔✔

✔✔ ✔✔

✔✔ ✔✔

✔✔ ✔✔

✔

✔

3A2614F 39

Page 40

Parts

Table 7 Fluid and Air Control Parts, Models 24L088, 24L089, 24L090, 24L091

Ref.

201 16E841 PANEL, mounting 1

202 16P784

4

204 121141

205 15T937

206 104371

207 104116

208

209 289813

210 501867 VALVE, c

211 15U749

212 114182

213 114339

214

Part Description

TRANSDUCER, I/P; includes ref.

208

16P790

16V142

–——

———

CABLE, fluid control

CABLE, fluid control, IS

SWIVEL, elbow

SWIVEL, elbow

SCREW, #10

WASHER, #10

BRACKET, transducer

METER, G3000

BRACKET, meter

SCREW, M6`

SWIVEL, union

NUT, hex1–12 unf

heck

Qty. 24L088 24L089 24L090 24L091

✔✔

1

1

1

1

1

6

6

1

1

1

1

2

1

1

✔✔✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

215

216

217 112310

218 100079

219 109466

220

221 16H282

222 24P600

223

224

225 111316

24C375 REGULATOR, fluid; includes

———

——

——

–

16K483

16V074

refs. 214, 216, and 217

KET, regulator

BRAC

W, #8

SCRE

HER, lock, #8

WAS

,#8

NUT

TUBE, air 1

ANSDUCER, pressure

TR

ANSDUCER, pressure,

TR

cludes fitting (ref. 222) and

in

ring (ref. 225)

o-

FITTING, pressure transducer

CABLE, meter

CABLE, meter, IS

O-RING

1

1

2

2

2

1

1

1

1

1

1

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔

✔

✔✔

40 3A2614F

Page 41

Table 8 Fluid and Air Control Parts, Models 24P592, 24P593, 24P594

Parts

Ref.

201 16E841 PANEL, mounting 1

202 16P784

4

204 121141

205 15T937

206 104371

207 104116

208

209 289813

210 501867 VALVE, check 1

211 15U749

212 114182

213 114339

214

215

216

Part Description

TRANSDUCER, I/P; includes ref. 208

16P790

16V142

–——

———

24C375 REGULATOR, fluid; includes refs.

———

CABLE, fluid control

CABLE, fluid control, IS

SWIVEL, elbow

SWIVEL, elbow

SCREW, #10

WASHER, #

BRACKET,

METER, G

BRACKET

SCREW,

SWIVEL

NUT, hex1–12 unf

214, 216, and 217

BRAC

10

transducer

3000

, meter

M6`

, union

KET, regulator

Qty. 24P592 24P593 24P594

✔

1

1

1

1

1

6

6

1

1

1

2

1

1

1

1

✔✔✔

✔✔

✔

✔

✔

✔✔✔

✔

✔

✔

✔

217 112310

218 100

219 109466

220

221 24P600

222

223 124843

224

225 111316

079

—

—

–——

16K483

16V074

SCREW, #8

WASHER, lock, #8

T, #8

NU

TUBE, air 1

RANSDUCER, pressure, includes

T

tting (ref. 222) and o-ring (ref. 225)

fi

FITTING, pressure transducer

FITTING

CABLE, meter

CABLE, meter, IS

O-RING

2

2

2

1

1

1

1

1

1

✔✔

✔✔

✔

✔✔

3A2614F

41

Page 42

Parts

Table 9 Fluid and Air Control Parts, Models 24P595, 24P596, 24P597

Ref.

201 16E841 PANEL, mounting 1

202 16P784

4

204 121141

205 15T937

206 104371

207 104116

208

209 289813

210 501867 VALVE, check 1

211 15U749

212 114182

213 114339

214

Part Description

TRANSDUCER, I/P; includes ref. 208

16P790

16V142

–——

———

CABLE, fluid control

CABLE, fluid control, IS

SWIVEL, elbow

SWIVEL, elbow

SCREW, #10

WASHER, #10

BRACKET, transducer

METER, G3000

BRACKET, meter

SCREW, M6`

SWIVEL, union

NUT, hex1–12 unf

Qty. 24P595,

24R261

✔✔✔

1

1

1

1

1

6

6

1

1

1

2

1

1

✔✔✔

✔✔

✔✔✔

✔✔✔

✔✔✔

✔

✔

✔

✔

24P596 24P597

✔

✔✔

✔✔

✔✔

215

216

217 112310

218 100079

219 109466

220

221 24P600

222

223 124843

225 111316

Table 10 I/P Transducer Connection Points

Pin

(Ref. 4, F/C Cable)

24C375 REGULATOR, fluid; includes refs.

214, 216, and 217

———

——

—

–—

16K483

6V074

1

KET, regulator

BRAC

W, #8

SCRE

HER, lock, #8

WAS

,#8

NUT

TUBE, air 1

ANSDUCER, pressure, includes

TR

ting (ref. 222) and o-ring (ref. 225)

fit

FITTING, pressure transducer

FITTING

CABLE, meter

CABLE, meter, IS

O-RING

Wire Color

1

1

2

2

2

1

1

1

1224

1

1

Function Pin

✔

(Ref. 202, Transducer)

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

5

7

2

4

Gray Control A

Blue

Common

1

2

3A2614F

Page 43

Accessories

Accessories

Not all accessories and kits are approved for

use in hazardous locations. Refer to the specific

accessory and kit manuals for approval details.

Accessories for Hazardous Locations

Part No. Description

16V077

16K615

16K509

16M172

16M173

16V381

289814

Cable Extension, 50 ft (15 m), for meter

Power Cable, 100 ft (30 m), for power

supply

Power Cab

supply

Fiber Optic Cable, 50 ft (15 m)

Fiber Optic Cable, 100 ft (30 m)

Cable,

G3000HR Meter, Positive displacement,

gear flow meter, 0.01 to 0.5 gpm (38

to 1900 cc/min.), for low to medium

viscosity materials

le, 50 ft (15 m), for power

M12, reverse key, 5–pin

570122 Air Filter and R

includes moun

24P600

24R906

*Ifusingt

Non-Hazar

instead.

Pressure Transducer (low pressure).

Also purchase Hazardous Location

Cable 16V381* to connect the

transducer to the ProControl 1KE

Pressure Transducer (high-pressure),

includes transducer, o-ring, and

fitting. Also purchase Hazardous

Location Cable 16V381* to connect the

transducer to the ProControl 1KE

he pressure transducer in a

dous location, purchase Cable 16V380

egulator assembly,

ting bracket

Accessories for Non-Hazardous Locations

Part No.Descri

16P467 Power Barrier Kit, includes power

16K484

ption

barrier, terminal blocks, wiring, and

power cable. Add to the power supply

to power an additional ProControl 1KE

(or Informer).

Extension, 50 ft (15 m), for meter

Cable

0

28056

258718

24N525

24C471 Fluid Regulator, 1:2, low flow

4C472Fluid Regulator, 1:3, low flow

2

HG6000 Meter, Positive displacement,

helical gear flow meter, 0.013 to 6.0

gpm (50 to 22,712 cc/min.), for high

flow, high viscosity materials

00 Solvent Meter, Positive

S30

placement, gear flow meter, 0.01 to

dis

gpm (38 to 1900 cc/min.), for light

0.5

cosity materials

vis

Coriolis Meter, Non-intrusive mass flow

meter, for abrasive and filled materials,

range of flow rates and materials

16K465

15V

24N807 Light Tower Kit, includes tower and

V380

16

24P006

Fiber Optic to Serial Converter, use to

communicate from the ProControl 1KE

toaPLC.

337

Advanced Web Interface Module, use to

communicate from the ProControl 1KE

toaPLCviaethernet.

splitter cable

Cable, M12, reverse key, 5–pin

igital IO Accessory Cable Kit, includes

D

able and splitter cable for connecting

c

light tower or other accessory to the

a

roControl 1KE system.

P

3A2614F 43

Page 44

Mounting Dimens

ions

Mounting Dimensions

Power Supply 16M167

Fluid and Air Controls Mounting Panel

A

Overall

Width

Component

Fluid and

Air Controls

Mounting

Panel

Power

Supply

16M167

in. (mm)

9.5 (241.3) 9.0 (228.6) 0.5 (12.7) 8.5 x adjustable from 5.0–8.0

16.6 (420.9) 8.7 (221.2) 4.5 (114.8)

B

Overall

Height

in. (mm)

Overall

Depth

in. (mm)

ProControl 1KE Module

Mounting Dimensions

Width (C) x Height (D)

in. (mm)

(212.5 x 127.0–203.2)

15.1 x 6.7

(382.8 x 170.2))

E

Mounting

Hole Size

in. (mm)

0.5 (12.7)

0.31 (7.9)

ProControl

1KE

4

4

7.2 (183) 6.0 (152) 2.8 (71)

2.5 x 3.0

(64 x 76)

0.28 (7)

3A2614F

Page 45

Appendix A - Modb

Appendix A - Modbus Variable Map

Table 11 Device Identification Registers

us Variable Map

Register

Permissions

Read Only

Read Only

Read Only

Read Only

Read Only

Read Only

Read Only

Read Only

Read Only

Read Only

Read Only

Table 12 Run Registers

Register

Permissions

Read/Write 402000 Date, Year 16 Bit YY 1 99

Read/Write 402001 Date, Month 16 Bit MM 1 12

Read/Write 402002 Date, Day 16 Bit DD 1 31

Read/Write 402003 Time, Hour 16 Bit HH 0 23

Read/Write 402004 Time, Minute 16 Bit MM 0 60

Read/Write 402005

Read/Write 402006 Alarms Needing

Informer

Modbus

Register

401040

401042

401044

401072

401074

401076

401078

401080

401082

401084

401086

Informer

Modbus

Register

Description

Software Version Major

Software Version Minor

Software Version Build

Serial Number String - Bytes 0-3

Serial Number String - Bytes 4-7

Serial Number String - Bytes 8-11

Serial Number String - Bytes 12-15

Serial Number String - Bytes 16-19

Serial Number String - Bytes 20-23

Serial Number String - Bytes 24-27

Serial Number String - Bytes 28-31

Description

Time, Second

Acknowledgment

Size

16 Bit

32 Bit

Size

32 Bit

32 Bit

32 Bit

32 Bit

32 Bit

32 Bit

32 Bit

32 Bit

32 Bit

32 Bit

32 Bit

Units Low

Limit

SS

Bitfield

alarms

060

0 0 0b0001–

Units

String, 4 Bytes

String, 4 Bytes

String, 4 Bytes

String, 4 Bytes

String, 4 Bytes

String, 4 Bytes

String, 4 Bytes

String, 4 Bytes

String, 4 Bytes

String, 4 Bytes

String, 4 Bytes

High Limit Notes

High flow

alarm;

0b0010 —

Low Flow

alarm;

0b0100 —

Maint. Target

Set bit to 0

to reset

Read Only

Read/Write 402010

Read/Write 402012

402008

Current Grand Total

Current Batch Total

Current Maintenance Total

32 Bit

32 Bit

32 Bit

cc

cc

cc

032-bit

0 999999 Write 0 to

reset

0 999999 Write 0 to

reset

3A2614F 45

Page 46

Appendix A - Modb

us Variable Map

Register

Permissions

Read Only

Read Only

Read 402018

Read/Write 402019

Read/Write 402020

Read/Write 402022

Table 13 Setup Registers

Register

Permissions

Read/Write 403000

Read/Write 403001

Read/Write 403003

Read/Write 403004

Read/Write 403005

Read/Write 403006 Display, Date Format 16 Bit 0=mm/dd/yy,

Read/Write 403007 Display, Backlight Timer 16 Bit min 0 99

Read/Write 403008 Display, Maintenance Totalizer

Read/Write 403009 Display, Flow Rate Alarm Enable 16 Bit

Read/Write 403010

Read/Write 403011 Flow Meter Enable 16 Bit

Read/Write 403012 Pressure Transducer Enable 16 bit

Read/Write 403013 Units, Flow Rate 16 Bit 0=cc/min,

Read/write 403014 Units, Pressure 16 Bit 0=psi, 1=bar,

Read/Write 403015 Units, Batch Volume 16 Bit 0=cc, 1=l,

Read/Write 403016

Read/Write 403017

Informer

Modbus

Register

402014

402016

Informer

Modbus

Register

Description

Current Flow R

Current Press

Current Pres

Calibration

Calibratio

Calibratio

Volume

Descripti

Communication, Modbus Mode

Communication, Modbus Address

Communication, Modbus Baud

Rate

Communication, Modbus Parity

Communication, Modbus

StopBits

Alarm Enable

Dis

nits, Grand Volume

U

System, Maintenance Target

on

play, Alarm Auto Clear

ate

ure

sure Target

Mode

n, Measured Volume

n, Actual Dispensed

Size

32 Bit cc/min 0 65536

32 Bit bar 0 65536 x 1000

16 Bit

16 Bit

32 Bit pulses 0 32-bit

32 Bit

Units Low

Limit

percent

0-off, 1=on

cc

Size

16 Bit

32 Bit 1-247 1 247

16 Bit 0=9600,

16 Bit 0=None,

16 Bit

16 Bit

16 Bit

16 Bit 0=cc, 1=l,

32 Bit

Units Low

0=off, 1=on

1=19200,

2=38400,

3=578600,

4=115200

1=Odd,

2=Even

none

1=dd/mm/yy,

2=yy/mm/dd

f, 1=on

0=of

ff, 1=on

0=o

ff, 1=on

0=o

ff, 1=on

0=o

ff, 1=on

0=o

1=l/min,

2=gal/min

2=MPa

2=gal

2=gal

cc

0999 0to99.9

01

0 32-bit

Limit

01

04

02

12

02

01

01

01

01

01

02

02

02

02

0 999999

High Limit Notes

percent

High

Limit

(/1000)

Notes

46 3A2614F

Page 47

Appendix A - Modb

us Variable Map

Register

Permissions

Read/Write 403019

Read/Write 403020

Read/Write 403021

Read/Write 403023

Read/Write 403025

Read/Write 403026

Read/Write 403027

Read/Write 403029

Informer

Modbus

Register

Description

System, Fluid

Maximum Set Po

System, Flow Percent Minimum

Set Point

System, Flow Rate Maximum

System, Flow Rate Minimum

System, Meter K-Factor

System, Pressure Transducer

Type

System, Pressure Transducer

Offset

System,

Scale

Flow Percent

int

Pressure Transducer

Size

16 Bit

16 Bit

32 Bit

32 Bit

16 Bit

16 Bit 0=Type 1,

32 Bit mV 0 999999 0 to 9999.99

32 Bit mV/Bar 0 999999 0 to 9.99999

Units Low

percent

percent

cc

cc

cc

1=Type 2

High

Limit

Limit

0 999 0 to 99.9

0 999 0 to 99.9

0 999000

0 999000

10 5000 0.010 to

0 1 Type 1. 100

Notes

percent

percent

5.000 cc

psi

Type 2. 7500

psi

mV

mV/Bar

3A2614F

47

Page 48

Appendix B - Adva

nced Web Interface

Appendix B - Ad

vanced Web Interface

Overview

The Advanced Web Interface (AWI) is Graco PN

15V337. It is an accessory that works with many

Graco devices to enable communication with a PC

via ethernet. The kit includes Manual 332459, which

contains installation and setup information common

to all devices. It includes sections on how to configure

your computer, initialize the system, configure the

main system settings, and set up your network. Refer

to Manual 332459 first, then return to this Appendix

for information specific to the ProControl 1KE.

NOTE: Amod

separatel