Page 1

Repair

ti24910a

LineLazer IV 250SPS

Self-Propelled Line Striper

For the application of line striping materials.

For professional use only.

For outdoor use only.

Not for use in hazardous locations or explosive atmospheres.

Maximum Operating Speed: 10 mph (16 kph)

Maximum Operating Pressure: 3300 psi (22.8 MPa, 228 bar)

IMPORTANT SAFETY INSTRUCTIONS

Read all warnings and instructions in this manual

and the engine manual. Save these instructions.

Related Manuals:

3A2090 Operation

3A2598 Parts

311254 Gun

309277 Pump

312307 Auto-Layout Applications Methods

3A2593B

EN

Page 2

Table of Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Component Identification . . . . . . . . . . . . . . . . . . . . 7

Component Identification (Controls) . . . . . . . . . . . 8

Grounding Procedure

(For Flammable Materials Only) . . . . . . . . . . . 9

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . 9

Ground Drive Belt Replacement . . . . . . . . . . . . . 10

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Oil Reservoir Belt Replacement . . . . . . . . . . . . . . 11

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Hydraulic System Purging . . . . . . . . . . . . . . . . . . 12

Ground Drive Pump Replacement . . . . . . . . . . . . 13

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Oil Reservoir Pump Replacement . . . . . . . . . . . . 14

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Hydraulic Gun Manifold Replacement . . . . . . . . . 16

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Paint Pump Replacement . . . . . . . . . . . . . . . . . . . 18

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Hydraulic Motor Replacement . . . . . . . . . . . . . . . 19

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Clutch Replacement . . . . . . . . . . . . . . . . . . . . . . . 20

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Engine Replacement . . . . . . . . . . . . . . . . . . . . . . . 22

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Touch-Pad Replacement . . . . . . . . . . . . . . . . . . . . 24

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

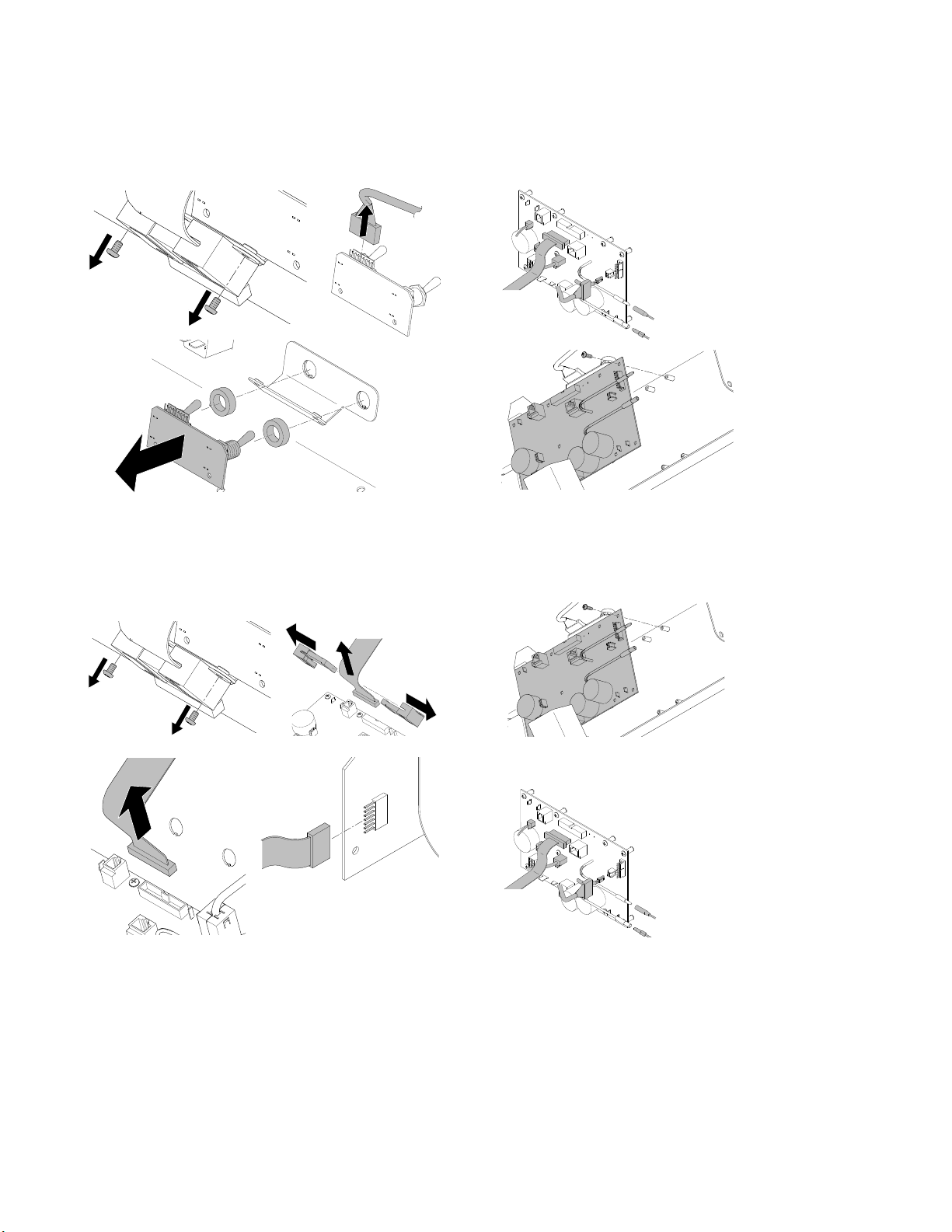

Control Board, Toggle Switches and Display

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . 28

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . 29

Forward/Reverse Cable Replacement . . . . . . . . . 30

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Steering Cable Replacement . . . . . . . . . . . . . . . . 32

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Front Wheel Replacement . . . . . . . . . . . . . . . . . . . 34

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Parking Brake Service . . . . . . . . . . . . . . . . . . . . . . 35

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Rear Wheel and Wheel Motors . . . . . . . . . . . . . . . 36

Rear Wheel Removal . . . . . . . . . . . . . . . . . . . . 36

Rear Wheel Installation . . . . . . . . . . . . . . . . . . . 36

Wheel Motor Removal . . . . . . . . . . . . . . . . . . . . 36

Wheel Motor Installation . . . . . . . . . . . . . . . . . . 37

Wheel Sensor Replacement . . . . . . . . . . . . . . . 37

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Wiring Parts List . . . . . . . . . . . . . . . . . . . . . . . . 44

Hydraulic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . 45

Hydraulic Parts List . . . . . . . . . . . . . . . . . . . . . . 46

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 49

2 3A2593B Repair

Page 3

Models

Model Guns Pressurized Bead System Description

24F307 2 No LLIV 250SPS (North America, Latin America, Asia Pacific)

24K960 1 No LLIV 250SPS (Latin America, Asia Pacific)

24K961 1 No LLIV 250SPS (Europe)

24K962 2 No LLIV 250SPS (Europe)

24M608 1 No FieldLazer G400 (North America)

16V470 1 Yes, 1 Tank LLIV 250 SPS (Latin America, Asia Pacific)

16V471 1 Yes, 1 Tank LLIV 250 SPS (Europe)

16V473 2 Yes, 1 Tank LLIV 250 SPS (North America, Latin America, Asia Pacific)

16V474 2 Yes, 1 Tank LLIV 250 SPS (Europe)

24U561 2 Yes, 2 Tanks LLIV 250 SPS (North America, Latin America, Asia Pacific)

Models

3A2593B Repair 3

Page 4

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

WARNING

TRAFFIC HAZARD

Being struck by other vehicles may result in serious injury or death.

• Do not operate in traffic.

• Use appropriate traffic control in all traffic areas.

• Follow local highway and transportation regulations for traffic control (for example: Manual on Uniform

Traffic Control Devices, U.S. Department of Transportation).

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire

and explosion:

• Use equipment only in well ventilated area.

• Do not fill fuel tank while engine is running or hot; shut off engine and let it cool. Fuel is flammable and can

ignite or explode if spilled on hot surface.

• Keep work area free of debris, including solvent, rags and gasoline.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless they are anti-

static or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment until you

identify and correct the problem.

• Keep a working fire extinguisher in the work area.

INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just a cut,

but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or servic-

ing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

CARBON MONOXIDE HAZARD

Exhaust contains poisonous carbon monoxide, which is colorless and odorless. Breathing carbon monoxide

can cause death.

• Do not operate in an enclosed area.

4 3A2593B Repair

Page 5

Warnings

WARNING

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical reaction and equipment rupture. Failure to follow this warning can result in death, serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids

containing such solvents.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier for

compatibility.

ENTANGLEMENT HAZARD

Rotating parts can cause serious injury.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Do not wear loose clothing, jewelry or long hair while operating equipment.

• Equipment can start without warning. Before checking, moving, or servicing equipment, follow the Pres-

sure Relief Procedure and disconnect all power sources.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, follow

the Pressure Relief Procedure and disconnect all power sources.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system compo-

nent. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all equip-

ment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about your

material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufac-

turer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

• Do not carry passengers.

• Check work area for reduced overhead clearance (e.g. doorways, tree branches, parking ramp ceilings)

and avoid contacting them.

3A2593B Repair 5

Page 6

Warnings

WARNING

BATTERY SAFETY

The battery may leak, explode, cause burns, or cause an explosion if mishandled.

• Only use the battery type specified for use with the equipment. See Technical Data.

• Battery maintenance must only be performed or supervised by personnel knowledgeable of batteries and

the required precautions. Keep unauthorized personnel away from battery.

• Do not dispose of battery in fire. The battery is capable of exploding.

• Follow local ordinances and/or regulations for disposal.

• Do not open or mutilate the battery. Released electrolyte has been known to be harmful to the skin and

eyes and to be toxic.

• Remove watches, rings, or other metal objects.

• Only use tools with insulated handles. Do not lay tools or metal parts on top of battery.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe burns:

• Do not touch hot fluid or equipment.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including eye

injury, hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes but is not limited

to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

CALIFORNIA PROPOSITION 65

The engine exhaust from this product contains a chemical known to the State of California to cause

cancer, birth defects or other reproductive harm.

This product contains a chemical known to the State of California to cause cancer, birth defects or other

reproductive harm. Wash hands after handling.

6 3A2593B Repair

Page 7

Component Identification

ti15841a

13.

8.

11.

3.

12.

10.

OFF

ON

2.

6.

9.

4.

16.1.

14.

7.

5.

15.

17.

ti24911a

Component Identification

1 Operator Platform

2 Paint Filter

3 Prime / Drain Valve

4 Displacement Pump

5 Rear Gun Arm Mount

6 Serial Label

7 Gun Trigger Safety

8 Wheel Motor Bypass Valve

10 Engine ON/OFF Switch

11 Hydraulic Fill Cap / Dipstick

12 Hydraulic Oil Filter

13 Paint Hopper (25 gallon / 95 liter)

14 Handle Bar Height Adjustment Knob

15 Engine Recoil Handle

16 Brake

17 Steering Handle

9 Straight Line Adjuster

3A2593B Repair 7

Page 8

Component Identification (Controls)

2.

1.

on

off

5.

6.

9.

3.4.

11.

1

2

7.

1

2

8.

10.

ti18719a

Component Identification (Controls)

1 Hydraulic Pump Valve

2 Gun Trigger Control

3 Forward / Reverse Lever

4 Display

5 Engine Throttle

6 Engine Choke

7 Gun 1 Selector

8 Gun 2 Selector

9 Engine Kill / Main Power Switch

10 12V Accessory Jack

11 Pressure Control

8 3A2593B Repair

Page 9

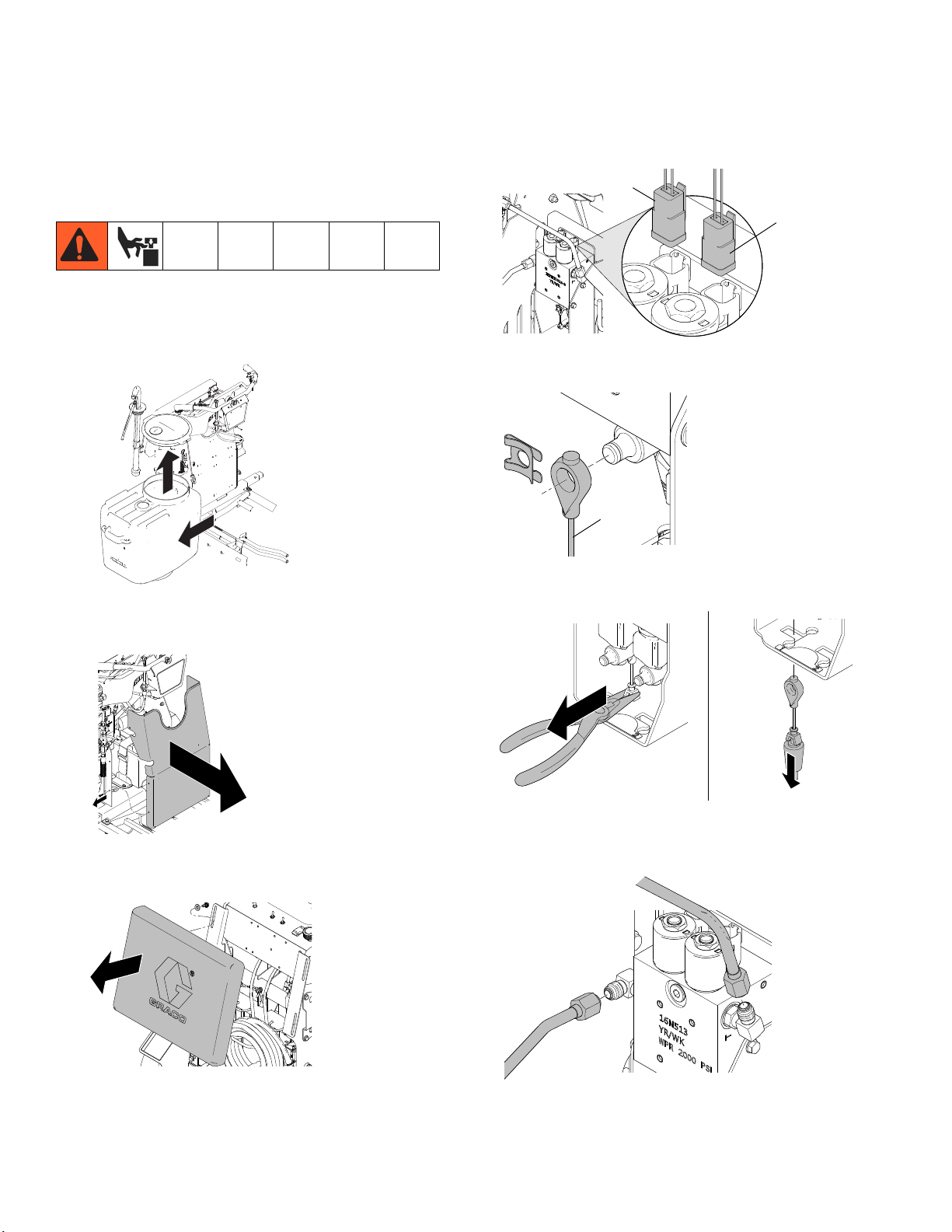

Grounding Procedure (For Flammable Materials Only)

ti6740a

PAINT

ti3305a

ti3441a

ti3324a

ti6473a

Grounding Procedure

(For Flammable Materials Only)

This equipment must be grounded to reduce the risk

of static sparking. Static sparking can cause fumes to

ignite or explode. Grounding provides an escape

wire for the electric current.

1. Position striper so that the tires are not on pavement.

2. Ground sprayer with grounding clamp. Grounding

clamp must attach to grounded object (e.g. metal

sign post).

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the Pressure

Relief Procedure when you stop spraying and before

cleaning, checking, or servicing the equipment.

1. Perform Grounding Procedure if using flammable

materials.

2. Set pump valve OFF. Turn engine OFF.

ti3306a

3. Turn pressure control to lowest setting. Trigger gun

to relieve pressure.

4. Engage gun trigger safety. Turn prime valve down.

3A2593B Repair 9

Page 10

Ground Drive Belt Replacement

ti19128a

ti19130a

ti19131a

ti19133a

ti19134a

ti19132a

ti19129a

ti19128a

Ground Drive Belt

Replacement

Removal

1. Loosen four screws and remove belt cover.

2. Loosen two hold-down bolts.

3. Loosen tension bolt to bring two pulleys closer

together to create slack in the belt.

Installation

1. Install belt onto pulleys.

2. Tighten tensioning bolt to move two pulleys apart

and tighten belt to proper tension (see table).

Ground Drive Belt

Tension Recommendations

New Belt

Used Belt

Gates Sonic Tension Meter

Settings: M = MASS = 85 g/m

3. Install mounting plate and tighten two hold-down

bolts.

Tension 53 +/- 2 Lbf (236 +/- 9 N)

Frequency 167 +/- 3 Hz

Tension 45 +/- 2 Lbf (200 +/- 9 N)

Frequency 155 +/- 3 Hz

W = # of belts = 1

S = Span = 157 mm

4. Remove belt.

10 3A2593B Repair

4. Replace belt cover and tighten four screws.

Page 11

Oil Reservoir Belt Replacement

ti19147a

ti19146a

ti19148a

ti19149a

ti19150a

ti19151a

Oil Reservoir Belt

Replacement

Removal

NOTE: Ground drive belt must be removed before oil

reservoir belt can be replaced (see page 10).

1. Loosen four hold-down bolts.

2. Loosen two adjustment bolts to bring pulleys closer

together to create slack in the belt.

Installation

1. Replace belt.

2. Tighten two adjustment bolts evenly and maintain

belt alignment. Tighten belt to proper tension (see

table).

Oil Reservoir Belt

Tension Recommendations

New Belt

Used Belt

Gates Sonic Tension Meter

Settings: M = MASS = 85 g/m

Tension 55 +/- 2 Lbf (245 +/- 9 N)

Frequency 114 +/- 2 Hz

Tension 48 +/- 2 Lbf (214 +/- 9 N)

Frequency 106 +/- 2 Hz

W = # of belts = 1

S = Span = 236 mm

3. Remove belt.

3A2593B Repair 11

3. Tighten four hold-down bolts.

4. Install Ground Drive Belt and tighten to proper

tension (see page 10).

Page 12

Hydraulic System Purging

ti18587a

Full Range (cold)

+

ti18576a

ti18562a

ti18552a

ti18718a

ti6473a

on

off

ti19669a

Full Range (cold)

Hydraulic System

Purging

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the Pressure

Relief Procedure when you stop spraying and before

cleaning, checking, or servicing the equipment.

Follow this procedure after replacing any hydraulic

component other than the hydraulic gun manifold which

is self-purging.

1. Set LineStriper on blocks so wheels are off ground.

5. Turn on the Main Power Switch to engage clutch.

6. Slowly pull forward/reverse control lever in forward

and reverse directions 10 times.

NOTE: Both rear wheels should turn in the correct

direction. If one wheel is not turning, carefully

restrain the spinning wheel to purge out the wheel

that is not turning.

2. Fill oil reservoir to “Full” range.

3. Make sure drive wheel release is closed (+).

4. Start engine and run at low speed.

12 3A2593B Repair

7. Turn the prime valve down and open the hydraulic

pump valve. Allow the paint pump to stroke 10 times

and then close the hydraulic pump valve.

8. The hydraulic gun manifold is self-purging.

9. Turn engine off and check oil level. Top off to “Full”

range.

Page 13

Ground Drive Pump Replacement

63

71

71

64

82

ti19135a

55

40

3

62

60

Ground Drive Pump

Replacement

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the Pressure

Relief Procedure when you stop spraying and before

cleaning, checking, or servicing the equipment.

Removal

1. Remove Ground Drive Belt, page 10.

2. Use allen wrench to remove two set screws (71)

from pulley (64).

3. Slide pulley (64) off shaft and save key (60).

5. Remove nut (3) and disconnect tie rod (40) underneath pump (63).

6. Remove two mounting bolts (82) and washers (55)

to remove pump (63) from bracket.

Installation

1. Insert pump (63) into bracket (62) and install two

mounting bolts (82) and washers (55).

2. Install tie rod (40) with nut (3) to lever underneath

pump (63).

3. Connect all fittings and hoses to pump (63).

4. Install key (60) onto pump shaft and slide pulley (64)

onto shaft.

5. Align pulley to outer clutch groove and tighten two

set screws (71).

6. Install Ground Drive Belt and tighten to proper tension (see page 10).

4. Disconnect all fittings and hoses from pump (63).

NOTE: Oil will spill out of hoses. Have rags and

waste pail nearby.

7. Purge Hydraulic System, page 12.

3A2593B Repair 13

Page 14

Oil Reservoir Pump Replacement

ti19139a

ti24913a

ti19144a

ti19142a

ti24914a

ti19672a

ti19671a

ti24914a

ti19670a

Oil Reservoir Pump

Replacement

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the Pressure

Relief Procedure when you stop spraying and before

cleaning, checking, or servicing the equipment.

Removal

1. Remove belt cover and Oil Reservoir Belt, page

11.

2. Remove oil filter and disconnect three hydraulic

hoses from oil reservoir.

6. Remove pulley from pump. Remove four screws

and pump from reservoir cover.

Installation

1. Install pump onto oil reservoir cover with four

screws.

3. Loosen nut and slide cable sleeve down to gain

access to cable set screw.

4. Remove set screw and cable.

5. Remove eight screws and oil reservoir cover with

pump.

2. If hydraulic oil is contaminated in reservoir, drain

reservoir and remove contamination. Install oil

reservoir cover with eight screws to the oil reservoir

base.

3. Install pulley on pump shaft and maintain belt alignment to inner groove of the clutch pulley. Tighten

two pulley screws.

14 3A2593B Repair

Page 15

Oil Reservoir Pump Replacement

ti19143a

ti19145a

ti19139a

ti24913a

ti23905a

ti23906a

ti23906a

4. Turn pressure control knob clockwise until seated.

5. Turn hydraulic pump pressure control clockwise

until seated then counterclockwise 1/6 turn.

7. Slide cable sleeve up and tighten screw.

8. Connect three hydraulic hoses to fittings on oil

reservoir. Replace oil filter.

6. Install cable and tighten set screws.

9. Install and tension Oil Reservoir Belt (page 11)

and Ground Drive Belt (page 10).

10. Purge hydraulic system, page 12.

3A2593B Repair 15

Page 16

Hydraulic Gun Manifold Replacement

ti24196a

ti24916a

ti19163a

ti19164a

ti19161a

Gun 2

Gun 1

ti19159a

Gun #

ti19667a

ti19160a

Hydraulic Gun Manifold

Replacement

Removal

1. Remove tank lid and siphon tube.

2. Remove tank from unit.

6. Label wire harnesses GUN 1 and GUN 2. Disconnect two wire harnesses from solenoids.

7. Label gun cables Gun 1 and Gun 2. Disconnect gun

cables from actuators.

8. Use a needle-nose pliers to remove gun cables from

bracket.

3. Remove six screws from front shield.

4. Remove front shield from unit.

5. Loosen four screws and remove pad.

9. Use wrench to disconnect manifold tubes by the

paint pump. NOTE: Oil will spill. Use a rag to con-

tain the oil.

16 3A2593B Repair

Page 17

Hydraulic Gun Manifold Replacement

ti19162a

ti19162a

ti19160a

ti19159a

ti19161a

Gun 2

Gun 1

10. Disconnect manifold tubes at manifold.

11. Remove two mounting bolts and slide hydraulic

manifold down and out from unit.

Installation

1. Slide hydraulic manifold in and up into unit. Install

and tighten two mounting bolts.

4. Push Gun 1 and Gun 2 gun cables into bracket.

NOTE: Be sure to connect Gun 1 cable to the hole

in the bracket closest to center of sprayer.

5. Connect Gun 1 and Gun 2 cables to actuators.

6. Connect two wire harnesses to solenoids.

NOTE: Be sure to connect Gun 1 to coil closest to

center of sprayer.

2. Loosely install manifold tubes to manifold.

3. Loosely install manifold tubes by the paint pump.

Tighten four nuts.

7. Install pad and tighten four screws.

8. Install front shield to unit and tighten six screws.

9. Install tank into unit and connect siphon tube.

NOTE: The hydraulic gun manifold is self-purging.

3A2593B Repair 17

Page 18

Paint Pump Replacement

115

114

107

106

123

ti19138a

116

95

120

105

104

109

197

110

Paint Pump Replacement

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the Pressure

Relief Procedure when you stop spraying and before

cleaning, checking, or servicing the equipment.

Removal

1. Perform Pressure Relief Procedure, page 9.

2. Disconnect suction tube (120).

3. Disconnect hose (123) and fitting (95) from paint

pump (107).

4. Remove screw (115), nut (116) and pump guard

(114).

5. Use hammer to loosen pump jam nut (106).

6. Slide down retainer (104) and remove pin (105).

7. Unscrew and remove paint pump (107).

Installation

1. Extend pump rod out of pump (107).

2. Insert pump rod into hydraulic motor rod and install

pin (105) and retainer (104).

3. Thread pump (107) into hydraulic motor housing

until pump bottoms out. Unscrew pump one full turn

and orient pump outlet (approximately 45°) to clear

ball valve hose.

4. Use hammer to tighten pump jam nut (106).

5. Install guard (114) with screw (115) and nut (116).

6. Install fitting (95) and connect hose (123).

7. Connect suction tube (120).

18 3A2593B Repair

Page 19

Hydraulic Motor Replacement

111

112

113

193

ti19688a

116

110

109

108

196

Hydraulic Motor

Replacement

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the Pressure

Relief Procedure when you stop spraying and before

cleaning, checking, or servicing the equipment.

Removal

1. Perform Pressure Relief Procedure, page 9.

2. Remove Paint Pump, page 18.

3. Disconnect fitting (108) above ball valve (109).

NOTE: Oil will spill out of hoses. Have rags and

waste pail nearby.

4. Disconnect hose (111) and fitting (193) from fitting

(196).

5. Disconnect pump counter (112) with 2 screws (113).

NOTICE

Use a screwdriver to lift pump piston up to gain

access to mounting bolts and avoid contact with piston. Contact with pump mounting bolts can scratch

and damage the pump piston.

6. Remove four mounting bolts (116) from hydraulic

motor and remove motor from sprayer.

Installation

1. Install hydraulic motor with four mounting bolts

(116).

NOTICE

Use a screwdriver to lift pump piston up to gain

access to mounting bolts and avoid contact with piston. Contact with pump mounting bolts can scratch

and damage the pump piston.

2. Install pump counter (112) with two screws (113).

3. Connect hose (111) and fitting (193) to fitting (196).

4. Connect fitting (108) above ball valve (109).

5. Install Paint Pump, page 18.

6. Purge hydraulic system, page 12.

3A2593B Repair 19

Page 20

Clutch Replacement

ti19215a

ti19131a

ti19213a

ti19216a

81

61

ti19697a

ti19696a

ti19214a

56

60

58

59

57

ti19212a

Clutch Replacement

Removal

1. Remove Ground Drive Belt, page 10.

2. Remove Oil Reservoir Belt, page 11.

3. Remove two hold-down bolts for the ground drive

pump bracket.

4. Unscrew tensioning bolt from the ground drive

pump bracket.

7. Remove engine recoil starter and place a screwdriver through the recoil starter cup.

5. Move ground drive pump assembly aside.

6. Remove three bolts (81) and pulley (61).

8. Remove center bolt (59) and remove clutch (57).

9. Disconnect clutch connector to main wire harness.

20 3A2593B Repair

Page 21

Clutch Replacement

ti19214a

56

60

58

59

57

ti19211a

ti19692a

59

58

ti19216a

81

61

ti19704a

ti19212a

ti19908a

Installation

1. Install spacer (56) and key (60) onto crankshaft.

Slide clutch (57) onto crankshaft.

2. Align clutch and wire in bracket.

4. Install pulley (61) and torque three screws (81) to 10

ft-lb (13 N•m).

5. Install recoil starter onto engine.

3. Install heavy washer (58) and bolt (59) onto crankshaft. Torque bolt to 45 +/- 5 ft-lb (61 +/- 7 N•m).

Use screwdriver in recoil starter cup to hold crankshaft.

6. Connect clutch to wire harness.

7. Install ground drive pump assembly with tensioning

and two hold-down bolts.

8. Install and tension Oil Reservoir Belt (page 11)

and Ground Drive Belt (page 10).

3A2593B Repair 21

Page 22

Engine Replacement

ti15307a

ti19186a

ti19183a

ti19185a

ti19188a

ti19187a

ti19703a

Engine Replacement

Removal

1. Remove Clutch, see page 20.

2. Disconnect all wires from engine.

3. Remove air filter cover, element and base.

5. Disconnect choke cable.

6. Tie knot in rope by recoil starter to prevent rope

from being pulled into recoil starter.

7. Take rope handle apart and untie knot in recoil

starter handle.

8. Pull rope through rope guide.

4. Disconnect throttle cable.

9. Remove four mounting bolts from engine.

10. Remove engine. NOTE: Engine voltage regulator is

located below engine mounting plate. Remove two

screws and disconnect wires.

22 3A2593B Repair

Page 23

Engine Replacement

ti19706a

ti19187a

ti19708a

ti20066a

1 in. (25 mm)

ti19686a

ti19690a

ti19186a

ti19668a

Installation

1. Install engine voltage regulator below engine

mounting plate with two screws. Connect regulator

to wire harness.

2. Install engine and tighten four mounting bolts and

nuts.

d. Tighten screw on hex-shaped pivot.

e. Verify proper operation of engine choke.

6. Install throttle cable.

a. Place speed lever to high speed.

b. Insert “Z” bend wire into hole furthest from pivot.

c. Place cable sheathing under clamp and pull

cable against high speed stop screw.

d. Tighten screw on cable clamp.

e. Verify proper operation of speed lever.

3. Use compressed air to feed recoil starter rope

through rope guide.

4. Feed rope through recoil starter handle and tie knot.

5. Install choke cable:

a. Make sure choke knob is pressed down.

b. Insert choke cable wire into hex-shaped pivot.

c. Insert cable sheathing under cable clamp and

tighten screw.

7. Install air filter base, element and cover.

8. Connect three wires to engine.

9. Install Clutch, see page 20.

10. Add gas and oil to engine (see Operation manual).

11. Start engine and verify high speed of 3600 rpm.

3A2593B Repair 23

Page 24

Touch-Pad Replacement

ti19098a

ti19910a

ti19910a

ti19098a

Touch-Pad Replacement

Removal

1. Remove six screws and control shroud.

2. Disconnect ribbon cable from touch-pad at display

board.

Installation

1. Apply touch-pad to sheet metal.

2. Connect ribbon cable from touch-pad at display

board.

3. Install control shroud with six screws.

3. Peel off touch-pad and remove adhesive from sheet

metal.

24 3A2593B Repair

Page 25

Control Board, Toggle Switches and Display Replacement

ti24916a

ti24916a

ti19163a

ti19164a

ti19098a

ti19701a

ti19702a

ti20244a

Control Board, Toggle

Switches and Display

Replacement

Removal

1. Remove Fuse to disconnect battery, page 29.

2. Remove tank lid and siphon tube.

7. Remove six screws and control shroud.

8. Remove two screws and splash shield.

3. Remove tank from unit.

4. Use wrench to remove six screws from front shield.

5. Remove front shield from unit.

6. Remove four screws and remove pad.

9. Remove two toggle switch nuts from control panel.

10. Feed toggle switches through control panel.

3A2593B Repair 25

Page 26

Control Board, Toggle Switches and Display Replacement

ti20135a

ti20133a

ti20136a

ti20133a

ti20132a

ti19910a

ti20245a

ti19199a

ti19198a

ti19199a

ti19198a

11. If replacing the toggle switches loosen two screws

holding the ferrite core. Disconnect cable and

remove toggle switch board.

12. If replacing the display, remove two screws holding

the ferrite core to toggle switch bracket. Pull apart

ferrite core to remove from ribbon cable. Disconnect

display ribbon cable from control board. Disconnect

touchpad ribbon cable from display board. Remove

four screws holding display and remove display.

13. If replacing control board, disconnect all wires from

control board. Remove eight mounting screws and

remove control board.

Installation

1. If replacing control board, install control board with

eight mounting screws.

2. Connect all wires to control board. See Wiring

Diagram, page 43.

3. If replacing display, install display with four screws.

Install touchpad ribbon cable to display board.

Install display ribbon cable to control board. Assemble ferrite core on ribbon cable. Install ferrite core to

toggle switch bracket with two screws.

4. If replacing toggle switches, install toggle switches

into toggle switch bracket. Make sure to place spacers between toggle switches and bracket. Connect

26 3A2593B Repair

cable to toggle switch board.

Page 27

Control Board, Toggle Switches and Display Replacement

ti19691a

ti19705a

ti19098a

ti19171a

ti19200a

ti24917a

ti24917a

5. Feed toggle switches through control panel and

install two toggle switch nuts.

6. Install Fuse, see page 29. Check control, switches

and display.

7. Install splash shield with two screws.

8. Install control shroud with six screws.

10. Install front shield and tighten six screws.

11. Install tank, lid and siphon tube.

9. Install pad and tighten four screws.

12. If control board was replaced, calibrate distance

sensor (see Operation manual).

3A2593B Repair 27

Page 28

Battery Replacement

ti24916a

ti19163a

ti24918a

ti24919a

ti24919a

ti24920a

ti24921a

ti19200a

ti24917a

ti24917a

Battery Replacement

Removal

1. Remove tank lid and siphon tube.

2. Remove tank from unit.

3. Use wrench to remove six screws from front shield.

Installation

1. Install battery.

NOTICE

To reduce the risk of shorting the battery, always

connect NEGATIVE (black wire) last.

2. Connect red wire to positive (+) and black wire to

negative (-) posts of the battery.

3. Install battery hold down strap.

4. Remove front shield from unit.

5. Remove hold down strap from battery.

NOTICE

To reduce the risk of shorting the battery, always disconnect NEGATIVE (black wire) first.

6. Disconnect two wires from battery.

4. Install front shield and use wrench to tighten six

screws into shield.

5. Replace tank and install lid with siphon tube.

7. Remove battery.

28 3A2593B Repair

Page 29

Fuse Replacement

ti19209a

Fuse Replacement

1. Remove fuse cover.

2. Use needle-nose pliers to remove old fuse and

inspect it for open circuit.

3. If fuse is open, a wire has shorted to the frame or

auxiliary lighting requires too much power. Check

wiring or reduce auxiliary lighting before replacing

fuse.

4. Use needle-nose pliers to install new fuse.

5. Replace cover.

3A2593B Repair 29

Page 30

Forward/Reverse Cable Replacement

ti24916a

ti24916a

ti19163a

ti19128a

ti19699a

40

3

148

ti19700a

62

40

3

148

Forward/Reverse Cable

Replacement

Removal

1. Remove tank lid and siphon tube.

6. At the handlebar, remove locknut (3) and ball joint

(40) from handlebar forward/reverse lever. Remove

ball joint (40) from cable (148) and save if not

replacing. Loosen two nuts on cable (148) and

remove from bracket.

7. At the ground drive pump, remove locknut (3) and

ball joint (40) from ground drive pump. Remove ball

joint from cable and save if not replacing. Loosen

two nuts on cable (148) and remove from bracket

(62).

2. Remove tank from unit.

3. Use wrench to remove six screws from front shield.

4. Remove front shield from unit.

5. Loosen four screws and remove belt cover.

8. Install new cable (148) as old cable is removed to

follow same route through frame.

30 3A2593B Repair

Page 31

Forward/Reverse Cable Replacement

ti19700a

62

40

3

148

ti19699a

40

3

148

Installation

1. Install new cable (148) by following same route as

old cable is being removed.

2. At ground drive pump bracket (62), install cable

(148) in bracket slot and tighten two nuts. Install ball

joint (40) onto cable and attach ball joint (40) to

ground drive pump with locknut (3).

3. Install cable (148) into handlebar bracket and

tighten two nuts. Install ball joint (40) onto cable.

Install ball joint into handlebar forward/reverse lever

and tighten locknut (3).

4. Verify that the handlebar forward/reverse lever does

NOT touch handlebar grips. Adjust cable and ball

joints if needed.

5. Install belt cover and tighten four screws.

6. Install front shield onto unit.

7. Use wrench to tighten six screws into front shield.

8. Install tank onto unit.

9. Install siphon tube and tank lid.

3A2593B Repair 31

Page 32

Steering Cable Replacement

ti24916a

ti24916a

ti19163a

ti19164a

ti19098a

ti18550a

ti19695a

40

48

3

ti19698a

3

40

48

Steering Cable

Replacement

Removal

1. Remove tank lid and siphon tube.

2. Remove tank from unit.

3. Use wrench to remove six screws from front shield.

7. Apply parking brake. Raise front wheel off the

ground and support frame on two jack stands.

8. At the handlebar, remove locknut (3) and ball joint

(40) from handlebar. Remove ball joint (40) from

cable (48) and save if not replacing. Loosen two

nuts on cable (48) and remove from bracket.

4. Remove front shield from unit.

5. Loosen four screws and remove pad.

6. Remove six screws and control shroud.

9. On front wheel fork, remove locknut (3) and ball joint

(40) from fork. Remove ball joint (40) from cable

(48) and save if not replacing. Loosen two nuts on

cable (48) and remove from bracket.

10. Note position of cable (48) and cut off all cable ties

that retain cable to frame. Install new cable as old

cable is removed to follow same route through

frame.

32 3A2593B Repair

Page 33

Steering Cable Replacement

ti19685a

Adjust to match

other side

of front fork

ti19698a

3

40

48

ti19685a

Adjust to match

other side

of handlebar

ti19695a

40

48

3

Installation

1. Install new cable (48) by following same route as old

cable is being removed.

2. At front wheel, adjust front nut on cable (48) to

match the threads on the other side of front fork.

Install cable (48) into frame bracket and tighten rear

nut.

3. Install ball joint (40) onto cable (48) and match

threads on other side of front fork. Install ball joint

(40) into fork and tighten locknut (3).

5. Install ball joint (40) onto cable (48) and match

threads on other side of handlebar. Install ball joint

(40) into handlebar and tighten locknut (3).

6. Verify that handlebar is aligned straight with frame.

If misaligned, adjust nuts on cable (48) to straighten

handlebar to frame.

7. Verify that front wheel self-centers and that steering

is tight and responsive. Ball joint (40) should rotate

easily on the ball. If needed, remove ball joint from

fork and adjust ball joint on cable (48).

4. At handlebar, adjust front nut on cable (48) to match

threads on other side of handlebar. Install cable (48)

into bracket and tighten rear nut.

8. Install pad and tighten four screws.

9. Remove jack stands and test drive sprayer to check

steering. Adjust if needed. Install cable ties in locations noted in step 10 of Removal.

10. Verify straight line tracking and adjust if necessary

(see Operation manual).

11. Install control shroud and tighten six screws.

12. Install front shield onto unit.

13. Use wrench to tighten six screws into front shield.

14. Install tank onto unit.

15. Install siphon tube and tank lid.

3A2593B Repair 33

Page 34

Front Wheel Replacement

ti19693a

34

35

37

36

36

39

ti20125a

34

35

37

36

36

39

ti20125a

Front Wheel Replacement

Removal

1. Apply parking brake. Raise front wheel off ground

and support frame on two jack stands.

Installation

1. Insert two spacers (36) into wheel (35) and slide into

fork (34).

2. Remove locknut (39) from axle bolt (37) and remove

axle bolt (37) from fork (34).

3. Remove two spacers (36) and wheel (35) from fork

(34).

2. Insert axle bolt (37) through fork (34), spacers (36)

and wheel (35).

3. Tighten locknut (39) onto axle bolt (37).

NOTE: When properly tightened, the wheel should

not wobble to the left or right and should stop

coasting quickly.

4. Verify front tire pressure is 55-80 psi (380-550 kPa).

5. Remove jack stands and test drive sprayer to verify

straight line tracking. Adjust if necessary (see Operation manual).

34 3A2593B Repair

Page 35

Parking Brake Service

16

17

1313

A

B

15

14

10

AA

ti19684a

A

A

14

A

15

B

13

16

10

17

16

17

1313

A

B

15

14

10

AA

ti19684a

A

A

14

A

15

B

13

16

10

17

Parking Brake Service

Installation

1. Install lever (14) with pin (B) and clip (13).

Removal

1. Remove tire, wheel hub, and fender. See Wheel

Motor Removal, page 36.

2. Remove clips (13) from three pins (A). Remove pins

and levers.

2. Use screwdriver to install spring (15).

3. Install levers (10, 16) with three pins (A) and clips

(13).

4. Install fender, wheel hub, and tire. See Wheel

Motor Installation, page 37.

3. Use screwdriver to remove spring (15). Remove clip

(13) and pin (B).

5. Adjust screw (17) to hold tire when brake lever (16)

is depressed.

4. Replace damaged or worn parts.

3A2593B Repair 35

Page 36

Rear Wheel and Wheel Motors

ti18587a

ti18589a

22

16

ti18588a

ti18589a

22

16

22b

78

21a

79

112

21b

ti18584a

56

19

6

5

4

Rear Wheel and Wheel Motors

Wheel Motor Removal

1. Place jack under frame near wheel and raise jack.

Rear Wheel Removal

1. Set LineStriper on blocks so wheels are off ground.

2. Remove four lug nuts (22) and wheel (16).

2. Remove four lug nuts (22) and wheel (16).

3. Remove pin (56), castle nut (21b) and wheel hub

(22b). Wheel hub may require a wheel puller; not

supplied by Graco.

Rear Wheel Installation

1. Replace wheel and install lug nuts. Alternately

tighten lug nuts opposite of each other.

2. Tilt LineStriper on side and remove blocks.

3. Inflate rear tires to 55 +/- 5 psi (380 +/- 34 kPa).

36 3A2593B Repair

4. Remove four bolts (78), lock nuts (79) and fender

(19).

5. Remove screw (6) and distance sensor (4) with

clamp (5).

6. Disconnect two hydraulic hoses (112) from wheel

motor (21a) and remove wheel motor.

Page 37

Rear Wheel and Wheel Motors

22b

78

21a

79

112

21b

ti18584a

56

19

6

5

4

ti18589a

22

16

ti24916a

ti19163a

ti18589a

22

16

ti19328a

ti19099a

4

5

6

Wheel Motor Installation

1. Connect two hydraulic hoses (112) to wheel motor

(21a) and insert wheel motor (21a) into frame (1).

2. Install distance sensor (4) and clamp (5) with screw

(6).

3. Install wheel motor (21a) and fender (19) with four

bolts (78) and lock nuts (79).

4. Install wheel hub (22b), castle nut (21b), and pin

(56).

2. Remove tank from unit.

3. Use wrench to remove six screws from front shield

and remove front shield from unit.

4. Place jack under frame near pump-side wheel and

raise jack.

5. Remove four lug nuts (22) and wheel (16).

5. Install wheel (16) and four lug nuts (22). Alternately

tighten lug nuts opposite each other.

6. Purge hydraulic system. See Hydraulic System

Purging, page 12.

Wheel Sensor Replacement

Removal

1. Remove tank lid and siphon tube.

6. Disconnect wheel sensor connector from wire harness.

7. Use wrench to remove screw (6), clamp (5), and

wheel sensor (4).

3A2593B Repair 37

Page 38

Rear Wheel and Wheel Motors

ti19099a

4

5

6

ti19328a

ti19329a

ti18564a

ti18589a

22

16

ti19200a

ti24917a

Installation

1. Install wheel sensor (4) and clamp (5) with screw

(6).

2. Connect wheel sensor connector to wire harness.

5. Install wheel (16) and four lug nuts (22).

6. Lower jack.

7. Install front shield with six screws.

3. Verify sensor is working by turning on the main

power switch and press SETUP to display the

MEASURE screen.

4. Press gun trigger control button and rotate hub by

hand exactly three turns.

NOTE: Sensor is working properly if the measure

display reads 12.3 to 12.7 ft (3.75 to 3.87 m).

8. Install tank and siphon tube.

9. Calibrate sprayer. See operation manual.

38 3A2593B Repair

Page 39

Troubleshooting

General

Problem Cause Solution

Troubleshooting

Engine pulls hard

Engine will not start

High engine speed at no load

Machine will not drive

Engine operates, but

displacement pump does

not operate

Excessive hydraulic load. Main power switch

is on.

Engine is out of gas. Refill gas tank. See engine manual.

Fuel shut-off lever is OFF. Move fuel shut-off lever to ON position.

Engine switch is OFF. Turn engine switch ON.

Engine oil level is low.

Engine is cold. Use engine choke.

Spark plug cable is disconnected or damaged. Connect spark plug cable or replace spark plug cable.

Main power switch is stuck in engine stop

position.

Oil is seeping into combustion chamber.

Improperly adjusted high speed setting. Reset high speed to 3600 - 3700 engine rpm at no load.

Worn engine governor. Adjust or replace engine governor.

Main power switch is not turned ON. Turn main power switch ON.

Hydrostatic drive is not engaged. Close wheel motor bypass valve to engage drive.

Drive cable is disconnected or broken. Reconnect or replace cable.

Clutch wire harness is disconnected or broken.

Clutch does not work. Replace clutch.

Ground drive belt is worn or broken. Adjust or replace ground drive belt.

Ground Drive Pump is worn or not working. Replace ground drive pump.

Wheel motor(s) worn or not working. Replace wheel motor.

Main power switch is OFF. Turn main power switch ON.

Pump valve is OFF. Turn pump valve ON.

Pressure setting is too low.

Prime/drain valve is closed and system

is pressurized.

Hydraulic fluid too low. Shut off sprayer. Add fluid*.

Oil reservoir belt is worn, broken, or off

the pulley.

Tip is clogged. Reverse tip to clean. See manual 311254.

Displacement pump piston rod is stuck due to

dried paint.

Hydraulic motor not shifting.

Turn main power switch OFF.

Check oil level and add oil if necessary. See engine

manual.

Replace main power switch.

Remove spark plug. Pull starter 2 to 4 times. Clean or

replace spark plug. Start engine. Keep sprayer upright

to avoid oil seepage.

Reconnect or replace harness as

necessary.

Turn pressure adjusting knob clockwise to increase

pressure. See operation manual.

Open prime/drain valve.

Replace oil reservoir belt. See page 11.

Repair pump. See manual 309277.

Set pump valve OFF. Turn pressure down. Turn engine

OFF. Pry rod up or down until hydraulic motor shifts.

3A2593B Repair 39

Page 40

Troubleshooting

Problem Cause Solution

Displacement pump operates, but

output is low on upstroke

Displacement pump operates but output

is low on downstroke and/or on both

sides

Pump is difficult to prime

Low stall or run pressure shown on

display

Excessive paint leakage into throat

packing nut

Fluid is spitting from gun

Piston ball is not seating. Service piston ball. See manual 309277.

Piston packings are worn or damaged. Replace packings. See manual 309277.

Suction tube strainer is clogged. Clean strainer.

Suction tube air leak. Tighten suction tube.

Pressure setting is too low. Increase pressure. See operation manual.

Fluid filter or tip is clogged or dirty.

Clean filter and tip. See operation manual or gun

manual 311254.

Engine speed is too low. Increase throttle setting. See operation manual.

Intake valve ball is packed with material or is

not seating properly.

Clean intake valve. See manual 309277.

Pump packings are worn or damaged. Replace pump packings. See manual 309277.

Use larger diameter hose and/or reduce overall length

Large pressure drop in hose with heavy

materials.

of hose. Use of more than 100 ft x 1/4 in. hose signifi-

cantly reduces performance of sprayer. Use 3/8 in.

hose for optimum performance.

Oil reservoir hydraulic filter is dirty or clogged. Change hydraulic filter and hydraulic oil.

Intake line to pump inlet is not tight. Tighten intake line to pump inlet.

Hydraulic motor is worn or damaged. Bring sprayer to Graco distributor for repair.

Suction tube strainer is clogged. Clean strainer

Suction tube air leak. Tighten suction tube

Drain line to paint hopper is clogged. Clean drain line

Intake valve is leaking.

Clean intake valve. Be sure ball seat is not nicked or

worn and that ball seats well. Reassemble valve.

Pump packings are worn. Replace pump packings. See manual 309277.

Paint is too thick. Thin the paint according to supplier recommendations.

Engine speed is too high.

New pump or new packings

Decrease throttle setting before priming pump. See

operation manual.

Pump break-in period takes up to 100 gallons

of material.

Faulty transducer Replace transducer.

Throat packing nut is loose.

Remove throat packing nut spacer. Tighten throat

packing nut just enough to stop leakage.

Throat packings are worn or damaged. Replace packings. See manual 309277.

Displacement rod is worn or damaged. Replace rod. See manual 309277.

Air in pump or hose

Check and tighten all fluid connections. Reprime pump.

See operation manual.

Tip is partially clogged. Clear tip. See manual 311254.

Fluid supply is low or empty.

Refill fluid supply. Prime pump. See operation manual.

Check fluid supply often to prevent running pump dry.

40 3A2593B Repair

Page 41

Problem Cause Solution

Troubleshooting

Excessive leakage around hydraulic

motor piston rod wiper

Sprayer overheats

Excessive hydraulic pump noise

Piston rod seal worn or damaged. Replace hydraulic motor piston rod wiper and seal.

Paint buildup on hydraulic components Clean hydraulic components.

Hydraulic oil level is low Fill with hydraulic oil. See operation manual.

Low hydraulic fluid level Shut off sprayer. Add fluid*.

Pulleys loose on hydraulic pumps Remove belt guard. Check and tighten loose pulley.

Main power switch is not turned on Turn main power switch on.

Main fuse is blown Replace fuse. See Fuse Replacement, page 29.

Display does not turn on

Cable between display and board disconnected

or damaged

Display board failure Replace display board.

Fluid pressure not high enough Must be over 800 psi (55 bar) for counter to add.

Gallon (liter) counter not

adding fluid volume

Broken or disconnected wire

Missing or damaged magnet Reposition or replace magnet.

Bad sensor

Machine not calibrated Perform calibration procedure. See Operation manual.

Distance not adding properly

(MEASURE mode will be inaccurate

and speed will be wrong)

Rear tire pressure is too low or too high Adjust tire pressure to 55 +/- 5 psi (380 +/- 34 kPa).

Gear teeth missing or damaged

(pump side only)

Distance sensor is loose or broken Reconnect or replace sensor.

Distance sensor See “Distance not adding properly”.

Mils not calculating

Gallon counter See “Gallon (liter) counter not adding fluid volume”.

Bad or damaged control board Replace control board.

Pressure control knob does not rotate Knob is jammed

Pressure control knob rotates freely

with no pressure change

Set screw at hydraulic pump connection is

loose

Remote cable is broken or disconnected Replace or reconnect cable.

Main power switch is not turned ON Turn main power switch ON.

Gun selector switch is OFF Turn gun selector switch ON.

Display is in AUTO MODE and speed is less

than 0.7 mph (1.1 kph)

Gun does not trigger

System pressure is too low

Gun cable is disconnected or broken Reconnect or replace cable.

Gun trigger control switch is disconnected or

broken

Disconnected or broken wires from control

board to solenoid

Gun triggering is slow

Gun cable is pinched or kinked Change gun cable routing or replace cable.

System pressure is too low Increase fluid pressure up to at least 1000 psi.

Reconnect or replace touch pad.

Check wires and connections. Replace any broken

wires.

Replace sensor. See Hydraulic Motor Replacement,

page 19.

Replace distance gear/wheel hub.

Pull back cover where remote cable connects to

hydraulic pump and turn counter-clockwise (ccw) until

free.

Remove cover and tighten set screw.

Reassemble cover.

Increase ground speed to be greater than 0.7 mph

(1.1 kph).

Increase fluid pressure up to at least

1000 psi.

Reconnect or replace gun trigger control switch.

Reconnect or replace wires.

3A2593B Repair 41

Page 42

Troubleshooting

Problem Cause Solution

AUTO Mode

Line spacing is not accurate

Gun does not trigger See Gun Does Not Trigger, page 41.

Wrong line pattern loaded Reload the correct pattern.

Machine not calibrated Perform calibration routine (see Operation manual).

PARKING LAYOUT Mode

Gun selector switch is OFF Turn gun selector switch ON.

Gun does not apply dots

* Use only Graco approved hydraulic fluid 169236 (5 gallons / 18.9 liter) or 207428 (1 gallon / 3.8 liter)

Dot size setting is too small Increase dot size.

Pressure is too low Increase pressure to 1000 psi.

42 3A2593B Repair

Page 43

Wiring Diagram

TO ENGINE

YELLOW

RED

BLACK

TO GROUND LUG

TO GROUND LUG

TO GROUND LUG

GUN 2

GUN 1

TO GROUND LUG

WHITE

RED

RED

BLACK

BLACK

RED

BLACK

RED

BLACK

RED

RED

YELLOW

BLACK

YELLOW

WHITE

BLACK

RED

BLACK

214e

214c

391

224

225

189

4

112

223

187

238 237 221

150

222

253

54a

57

220

214h

214t

214f

214b

134

54

ti19065a

Wiring Diagram

189a

3A2593B Repair 43

Page 44

Wiring Diagram

Wiring Parts List

Qty

Ref. Part Description

4 15K357 SENSOR, distance 1

54 24N501 KIT, repair, engine, GX270

(includes 54a)

54a 24N502 VOTLAGE REGULATOR 1

57 125877 CLUTCH, electric, LL250 1

112 119720 SWITCH, reed w/connector 1

134 24L904 CONTROL, handlebar 1

150 115753 BATTERY, 33 AH, sealed 1

187 237686 WIRE, ground assembly w/ clamp 1

189 16N513 MANIFOLD, hydraulic, two piston 1

189a 24N577 COIL, solenoid, hydraulic, manifold

(included in 189)

214b 24N565 KIT, repair, control board 1

214c 24N564 KIT, repair, display board 1

Ref. Part Description

.

214e 16N374 SWITCH, membrane 1

214f 24N566 KIT, repair, switch board 1

1

214h 126078 SWITCH, rocker, dpdt 1

214t 16P019 HARNESS, switch board 1

220 16N407 HARNESS, wire, LL250 1

221 16N542 WIRE, positive battery 1

222 16N541 WIRE, negative battery 1

223 16N540 HARNESS, light connection 1

224 16N539 HARNESS, sensor adapter 1

225 16N543 HARNESS, wire, hydraulic actuator 2

237 126095 HOLDER, fuse 1

2

238 126096 FUSE, 30A 1

253 114956 TERMINAL, wire tap, insulated 1

391 24N516 KIT, repair, transducer 1

Qty

.

44 3A2593B Repair

Page 45

Hydraulic Diagram

196

189

2

2

22

63

191

166

166

3XX

327

110

111

366

108

109

198

197

190

333

3XX

193

194

189C

371

189A

189B

3YY

370

366

372

309

320

ti24923a

Hydraulic Diagram

3A2593B Repair 45

Page 46

Hydraulic Diagram

Hydraulic Parts List

Qty

Ref. Part Description

2 125929 MOTOR, wheel 2

22 16M271 HOSE, coupled, assembly, LL250 2

63 247930 KIT, repair, hydraulic pump 1

108 117328 FITTING, nipple, straight 1

109 117441 VALVE, ball 1

110 287175 KIT, repair, hose, hydraulic s 1

111 287176 KIT, repair, hose, hydraulic r 1

166 16M276 HOSE, coupled, feed line, LL250 2

189 16N513 MANIFOLD, hydraulic, two piston

(includes two 189b and two 189c)

189a 24N577 COIL, solenoid, hydraulic, manifold 1

189b 24N490 KIT, repair, solenoid

(includes 189a)

189c 24N491 KIT, repair, actuator piston 1

190 124941 FITTING, long elbow, hydraulic 1

191 116829 FITTING, 90 degree, w/adjustable 1

193 24M625 TUBE, supply, hydraulic 1

Ref. Part Description

.

194 24M626 TUBE, supply, hydraulic 1

196 126082 FITTING, tee, #8 x #8 x #6 JIC 1

197 126080 FITTING, tee, street 1

198 126081 FITTING, nipple, 3/8-18 x #6 JIC 1

309 16M160 COVER, reservoir, LL250, painted 1

320 287179 KIT, repair, pump, 200HS 1

327 246173 KIT, repair, oil filter 1

333 122970 FITTING, hydraulic 1

350 116829 FITTING, 90 degree, w/adjustable

1

o-ring

351 16P776 TUBE, supply, hydraulic 1

366 117607 FITTING, elbow std thd 2

1

370 100139 PLUG, pipe 1

371 15F519 TUBE, hydraulic, supply 1

372 119841 FITTING, tee, branch 1

Qty

.

2

46 3A2593B Repair

Page 47

Notes

Notes

3A2593B Repair 47

Page 48

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 3A2593

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2010, Graco Inc. is registered to ISO 9001

www.graco.com

Revision B, November 2014

Loading...

Loading...