Page 1

Instructions-Parts

3A2526F

E-Flo®

E-Flo® E-Flo®

DC

DC DC

Motor

Motor Motor

EN

Electric

Electric Electric

For

For For

See page 3 for model part numbers and

approvals information.

drive

for

low

to

drive drive

for for

low low

professional

professional professional

Important

Important Important

Readallwarningsandinstructionsinthismanual.

Save

Save Save

use

use use

Safety

Safety Safety

these

these these

medium

to to

medium medium

only.

only. only.

Instructions

Instructions Instructions

instructions.

instructions. instructions.

volume

volume volume

paint

circulation

paint paint

circulation circulation

pumps.

pumps. pumps.

PROVENQUALITY.LEADINGTECHNOLOGY.

Page 2

Contents

Contents Contents

Models...............................................................3

BasicModels...............................................3

BasicModelswithRegion-Specic

Approvals.......................................4

AdvancedModels........................................5

AdvancedModelswithRegion-Specic

Approvals.......................................6

Warnings...........................................................7

Installation..........................................................10

FillWithOilBeforeUsingEquipment.............10

PowerSupplyRequirements.........................10

ConnectthePowerSupply...........................11

Grounding...................................................12

IntrinsicallySafeInstallationRequirements

forAdvancedMotors.......................12

Operation...........................................................13

Startup........................................................13

Shutdown....................................................13

PressureReliefProcedure............................13

AdvancedMotorOperation...........................13

BasicMotorOperation..................................14

Maintenance......................................................16

PreventiveMaintenanceSchedule................16

ChangetheOil.............................................16

CheckOilLevel...........................................16

BearingPre-Load.........................................16

ErrorCodeTroubleshooting................................17

Repair................................................................19

ReplaceOutputSealCartridge.....................19

Parts..................................................................20

BasicMotorAssembly..................................20

AdvancedMotorAssembly...........................22

Notes................................................................24

RepairKits,RelatedManuals,and

Accessories..........................................25

ControlBoardReplacementKits24U934,

24U936,24U935,24U937.....................27

Overview.....................................................27

ToolsRequired............................................27

ReplacementInstructions.............................27

EncoderReplacementKit24U938.......................29

Overview.....................................................29

ToolsRequired............................................29

ReplacementInstructions.............................29

PositionSensorReplacementKit16U705............32

Overview.....................................................32

ToolsRequired............................................32

ReplacementInstructions.............................32

AdvancedPowerBoardReplacementKit

24U939................................................34

ToolsRequired............................................34

ReplacementInstructions.............................34

PrepareMotor..............................................34

DisconnectPowerWires...............................34

RemoveControlModuleBracket...................34

RemoveElectronicsCover...........................34

DisconnectPowerBarrierBoard...................35

InstallNewPowerBarrierBoard...................35

ReinstallElectronicsCover...........................35

ReinstallWiringBoxCover...........................35

AttachControlModuleBracket......................36

PowerUnit...................................................36

ReattachPumpLower..................................36

AppendixA-SystemControlDrawing

24N637................................................37

MountingHolePattern........................................42

TechnicalData...................................................43

GracoStandardWarranty....................................44

2

3A2526F

Page 3

Models

Models

Models Models

Basic

Basic Basic

Motor

Motor Motor

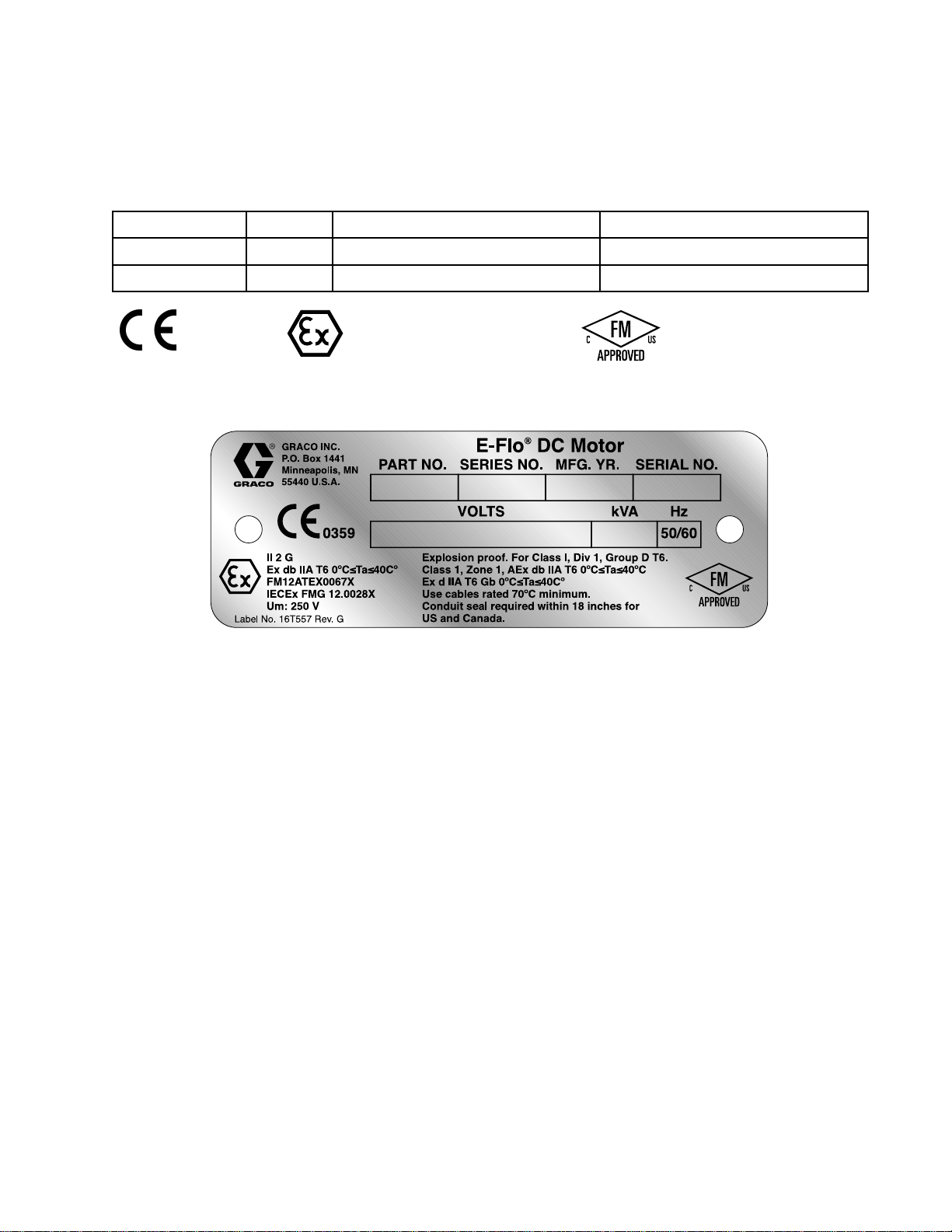

EM0011A1

EM0021A2

Models

Models Models

Part

No.

Part Part

No. No.

0359

0359 0359

Series

Series Series

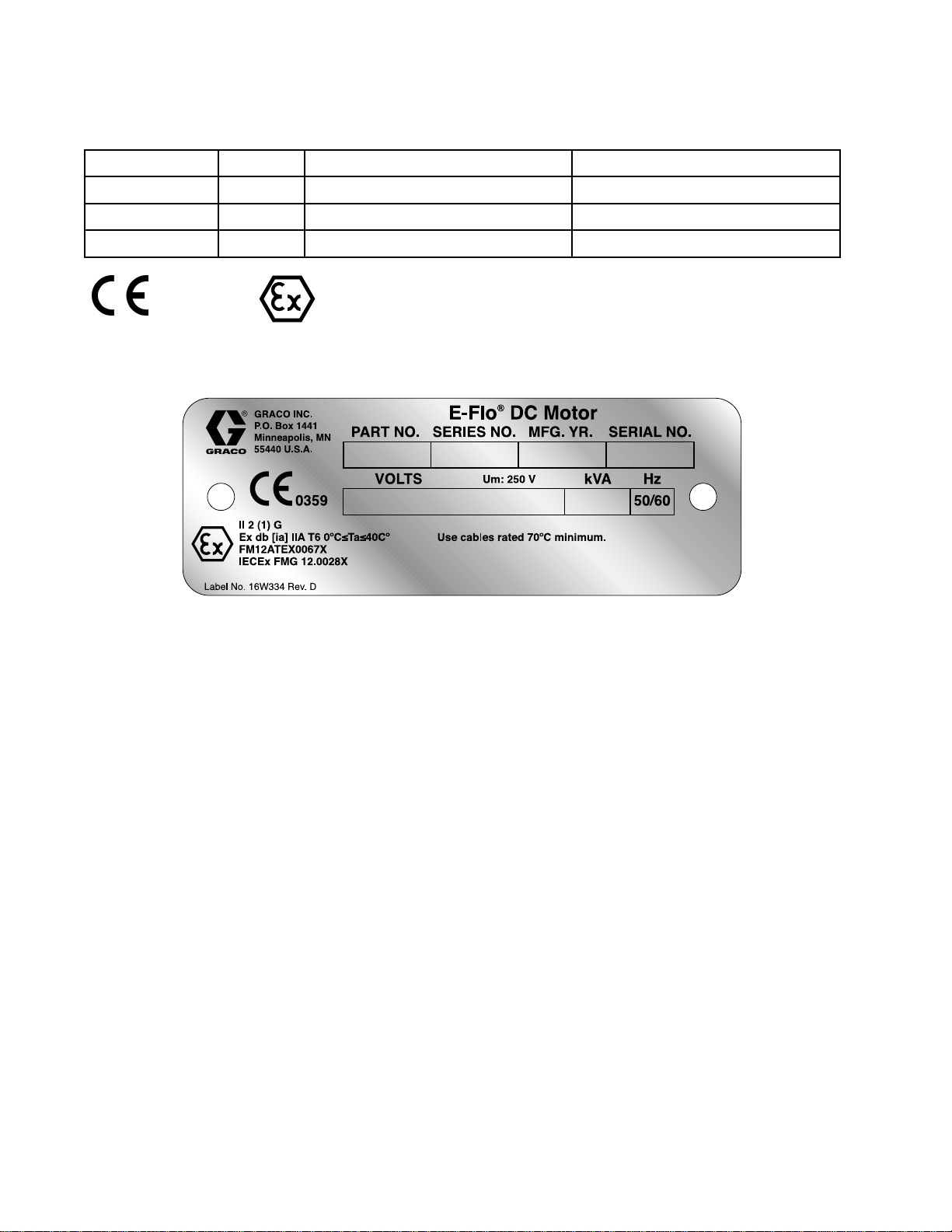

ExdbIIAT60°C≤Ta≤40°C

FM12ATEX0067X

IECExFMG12.0028X

Horsepower

Horsepower Horsepower

II2G

Maximum

Maximum Maximum

1400(6227)

2800(12455)

ForClassI,Div.1,GroupDT6.

Class1,Zone1,AExdbIIAT60°C≤Ta≤40°C

ExdIIAT6Gb0°C≤Ta≤40°C

Force,

Force, Force,

lbf

(N)

lbf lbf

(N) (N)

Figure1BasicMotorIdenticationLabel

List

List List

•IEC60079–0:2011(Ed.6)

•IEC60079–1:2007w/Corr1(Ed6)

•EN60079–0:2012

•EN60079–1:2007

•ANSI/ISA60079–0:2009

•ANSI/ISA60079–1:2009

•FM3615:2006

Specic

Specic Specic

1.Consultthemanufacturerifdimensional

2.Consultthemanufacturerforgenuine

Standards

of ofofStandards Standards

Conditions

Conditions Conditions

informationontheameproofjointisnecessary.

replacementfasteners.M8x30socket-head

capscrewsofClass12.9steelorbetterwitha

minimumyieldstrengthof1100MPa(160,000

psi)areacceptablealternatives.

Use:

of ofofUse: Use:

•CSAC22.2No.0.4:2004(R2009)

•CSAC22.2No.0.5:82(R2008)

•CSAC22.2No.30:M86(R2007)

•CAN/CSA-E60079–0:2011

•CAN/CSA-E60079–1:2011

•CAN/CSAC22.2No.1010.1:2004

3A2526F 3

Page 4

Models

Basic

Basic Basic

Motor

Motor Motor

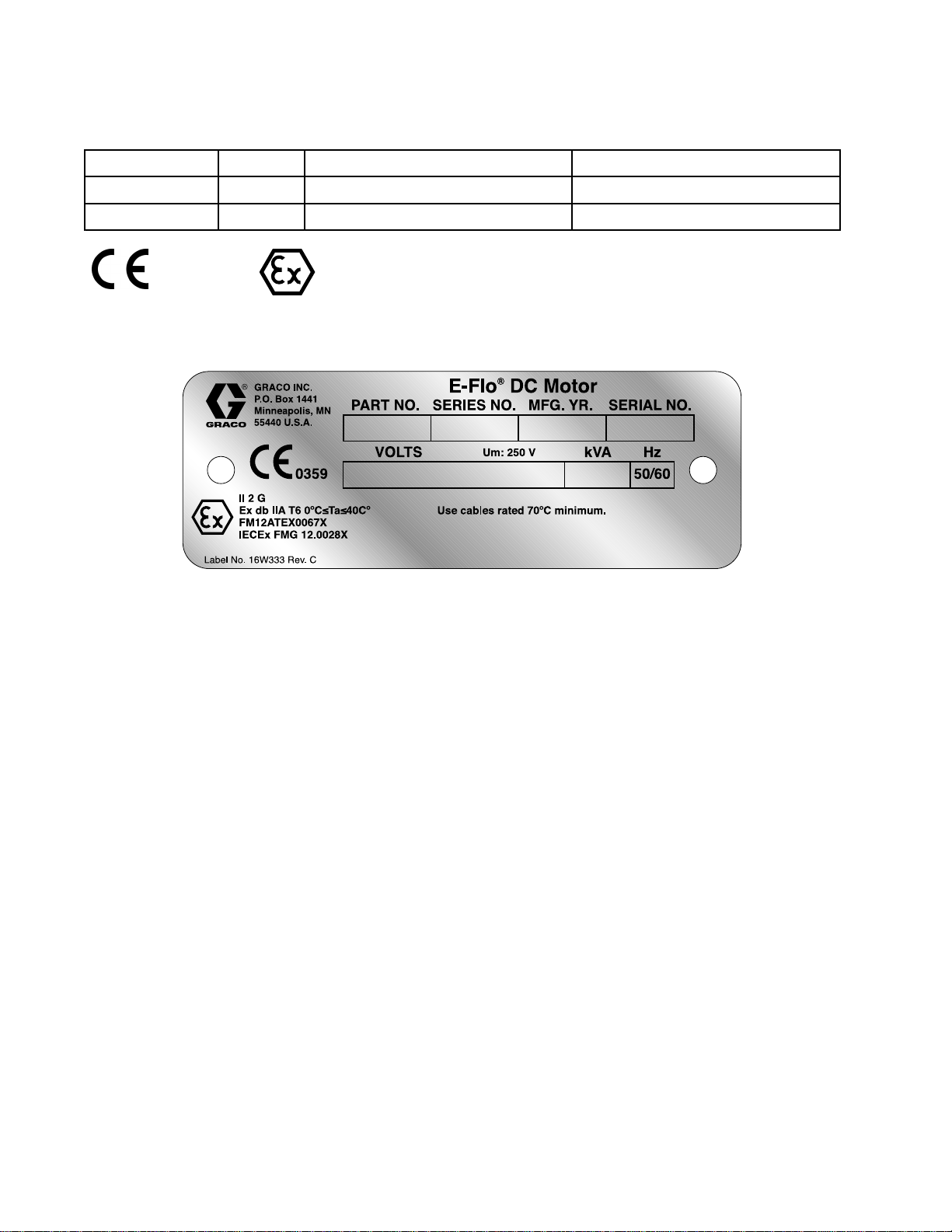

EM0013A1

EM0023A2

Models

Models Models

Part

No.

Part Part

No. No.

0359

0359 0359

with

Region

with with

Region Region

Series

Series Series

ExdIIAT60°C≤Ta≤40°C

FM12ATEX0067X

IECExFMG12.0028X

Specic

- --Specic Specic

Horsepower

Horsepower Horsepower

II2G

Approvals

Approvals Approvals

Maximum

Maximum Maximum

1400(6227)

2800(12455)

Force,

Force, Force,

lbf

(N)

lbf lbf

(N) (N)

Figure2BasicMotorwithRegion-SpecicApprovals

IdenticationLabel

List

List List

•IEC60079–0:2011(Ed.6)

•IEC60079–1:2007w/Corr1(Ed6)

Specic

Specic Specic

1.Consultthemanufacturerifdimensional

2.Consultthemanufacturerforgenuine

Standards

of ofofStandards Standards

Conditions

Conditions Conditions

informationontheameproofjointisnecessary.

replacementfasteners.M8x30socket-head

capscrewsofClass12.9steelorbetterwitha

minimumyieldstrengthof1100MPa(160,000

psi)areacceptablealternatives.

Use:

of ofofUse: Use:

•EN60079–0:2012

•EN60079–1:2007

4

3A2526F

Page 5

Models

Advanced

Advanced Advanced

Motor

Part

Motor Motor

Part Part

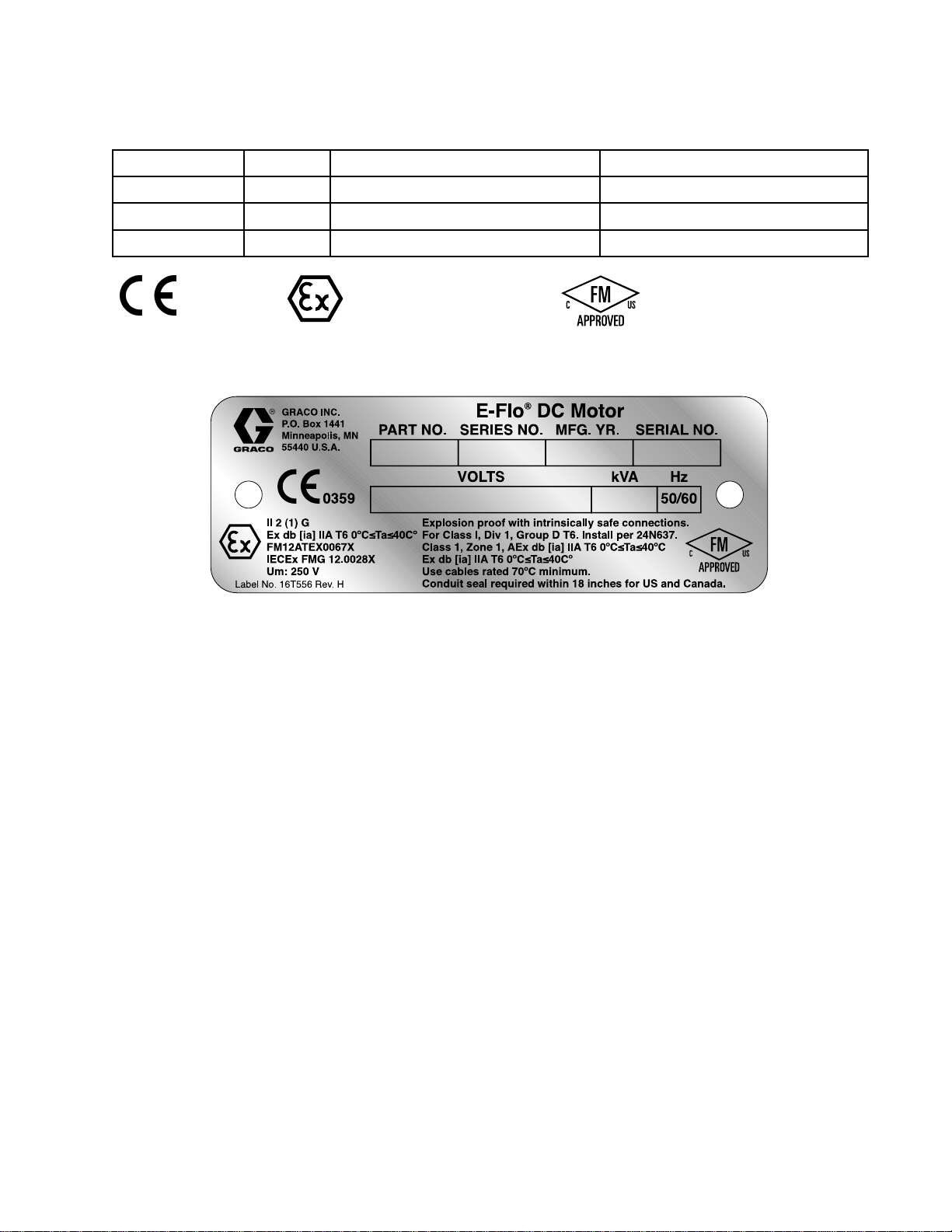

EM0012A1

EM0022A2

EM0025A2

Models

Models Models

No.

No. No.

0359

0359 0359

Series

Series Series

Exdb[ia]IIAT60°C≤Ta≤40°C

FM12ATEX0067X

IECExFMG12.0028X

Horsepower

Horsepower Horsepower

II2(1)G

Maximum

Maximum Maximum

1400(6227)

2800(12455)

2800(12455)

Class1,Zone1,AExdb[ia]IIAT60°C≤Ta≤40°C

Exdb[ia]IIAT60°C≤Ta≤40°C

Force,

Force, Force,

ForClassI,Div.1,GroupDT6.

lbf

(N)

lbf lbf

(N) (N)

Figure3AdvancedMotorIdenticationLabel

List

List List

•IEC60079–0:2011(Ed.6)

•IEC60079–1:2007w/Corr1(Ed.6)

•IEC60079–11:2011(Ed.6)

•EN60079–0:2012

•EN60079–1:2007

•EN60079–11:2012

•FM3600:2011

•FM3610:2010

•FM3615:2006

•FM3810:2005

•CSAC22.2No.0.4:2004(R2009)

Specic

Specic Specic

1.Consultthemanufacturerifdimensional

2.Consultthemanufacturerforgenuine

Standards

of ofofStandards Standards

Conditions

Conditions Conditions

informationontheameproofjointisnecessary.

replacementfasteners.M8x30socket-head

capscrewsofClass12.9steelorbetterwitha

minimumyieldstrengthof1100MPa(160,000

psi)areacceptablealternatives.

Use:

of ofofUse: Use:

•CSAC22.2No.0.5:82(R2008)

•CSAC22.2No.30:M86(R2007)

•CSAC22.2No.157–92(R2006)

•CAN/CSA-E60079–0:2011

•CAN/CSA-E60079–1:2011

•CAN/CSAC22.2No.1010.1:2004

•CAN/CSA-E60079–11:2011

•ANSI/ISA60079–0:2009

•ANSI/ISA60079–1:2009

•ANSI/ISA60079–11:2011

3A2526F 5

Page 6

Models

Advanced

Advanced Advanced

Motor

Part

Motor Motor

Part Part

EM0014A1

EM0024A2

EM0026A2

Models

Models Models

No.

No. No.

0359

0359 0359

with

with with

Series

Series Series

Exd[ia]IIAT60°C≤Ta≤40°C

FM12ATEX0067X

IECExFMG12.0028X

Region

Region Region

Horsepower

Horsepower Horsepower

II2(1)G

Specic

- --Specic Specic

Approvals

Approvals Approvals

Maximum

Maximum Maximum

1400(6227)

2800(12455)

2800(12455)

Force,

Force, Force,

lbf

(N)

lbf lbf

(N) (N)

Figure4AdvancedMotorwithRegion-Specic

ApprovalsIdenticationLabel

List

List List

•IEC60079–0:2011(Ed.6)

•IEC60079–1:2007w/Corr1(Ed.6)

•IEC60079–11:2011(Ed.6)

Specic

Specic Specic

1.Consultthemanufacturerifdimensional

2.Consultthemanufacturerforgenuine

Standards

of ofofStandards Standards

Conditions

Conditions Conditions

informationontheameproofjointisnecessary.

replacementfasteners.M8x30socket-head

capscrewsofClass12.9steelorbetterwitha

minimumyieldstrengthof1100MPa(160,000

psi)areacceptablealternatives.

Use:

of ofofUse: Use:

•EN60079–0:2012

•EN60079–1:2007

•EN60079–11:2012

6 3A2526F

Page 7

Warnings

Warnings Warnings

Thefollowingwarningsareforthesetup,use,grounding,maintenance,andrepairofthisequipment.The

exclamationpointsymbolalertsyoutoageneralwarningandthehazardsymbolsrefertoprocedure-specic

risks.Whenthesesymbolsappearinthebodyofthismanualoronwarninglabels,referbacktothese

Warnings.Product-specichazardsymbolsandwarningsnotcoveredinthissectionmayappearthroughout

thebodyofthismanualwhereapplicable.

WARNING

WARNING WARNING

FIRE

AND

FIRE FIRE

Flammablefumes,suchassolventandpaintfumes,inwork work

preventreandexplosion:

•Useequipmentonlyinwellventilatedarea.

•Eliminateallignitionsources;suchaspilotlights,cigarettes,portableelectriclamps,and

plasticdropcloths(potentialstaticarc).

•Keepworkareafreeofdebris,includingsolvent,ragsandgasoline.

•Donotplugorunplugpowercords,orturnpowerorlightswitchesonoroffwhenammable

fumesarepresent.

•Groundallequipmentintheworkarea.SeeGrounding Grounding

•Useonlygroundedhoses.

•Holdgunrmlytosideofgroundedpailwhentriggeringintopail.Donotusepaillinersunless

theyareantistaticorconductive.

Stop

•Stop Stop

equipmentuntilyouidentifyandcorrecttheproblem.

•Keepaworkingreextinguisherintheworkarea.

EXPLOSION

AND AND

EXPLOSION EXPLOSION

operation

operation operation

immediately

immediately immediately

HAZARD

HAZARD HAZARD

work

area

area area

canigniteorexplode.Tohelp

Grounding

ifstaticsparkingoccursoryoufeelashock,Donotuse

instructions.

Warnings

Staticchargemaybuilduponplasticpartsduringcleaningandcoulddischargeandignite

ammablevapors.Tohelppreventreandexplosion:

•Cleanplasticpartsonlyinwellventilatedarea.

•Donotcleanwithadrycloth.

•Donotoperateelectrostaticgunsinequipmentworkarea.

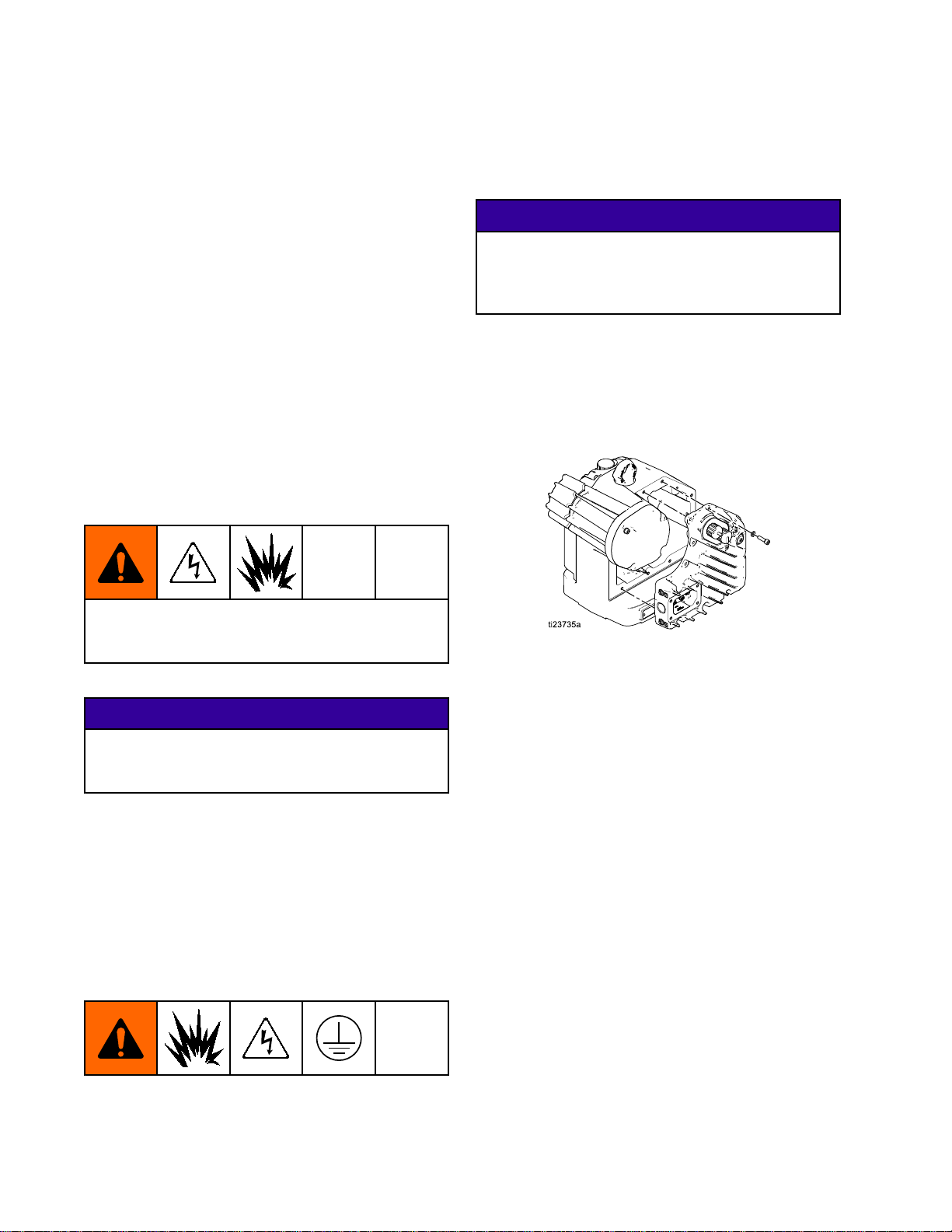

SPECIAL

SPECIAL SPECIAL

•Topreventtheriskofelectrostaticsparking,theequipment’snon-metallicpartsshouldbe

cleanedonlywithadampcloth.

•Thealuminumhousingmaysparkuponimpactorcontactwithmovingparts,whichmay

causereorexplosion.Takeprecautionstoavoidsuchimpactorcontact.

•Allameproofjointsarecriticaltotheintegrityofthemotorasapprovedforhazardous

locationsandarenotrepairableifdamaged.Damagedpartsmustbereplacedonlywith

genuineGracopartswithnosubstitutions.

CONDITIONS

CONDITIONS CONDITIONS

FOR

SAFE

FOR FOR

USE

SAFE SAFE

USE USE

3A2526F

7

Page 8

Warnings

WARNING

WARNING WARNING

ELECTRIC

ELECTRIC ELECTRIC

Thisequipmentmustbegrounded.Impropergrounding,setup,orusageofthesystemcan

causeelectricshock.

•Turnoffanddisconnectpoweratmainswitchbeforedisconnectinganycablesandbefore

servicingorinstallingequipment.

•Connectonlytogroundedpowersource.

•Allelectricalwiringmustbedonebyaqualiedelectricianandcomplywithalllocalcodes

andregulations.

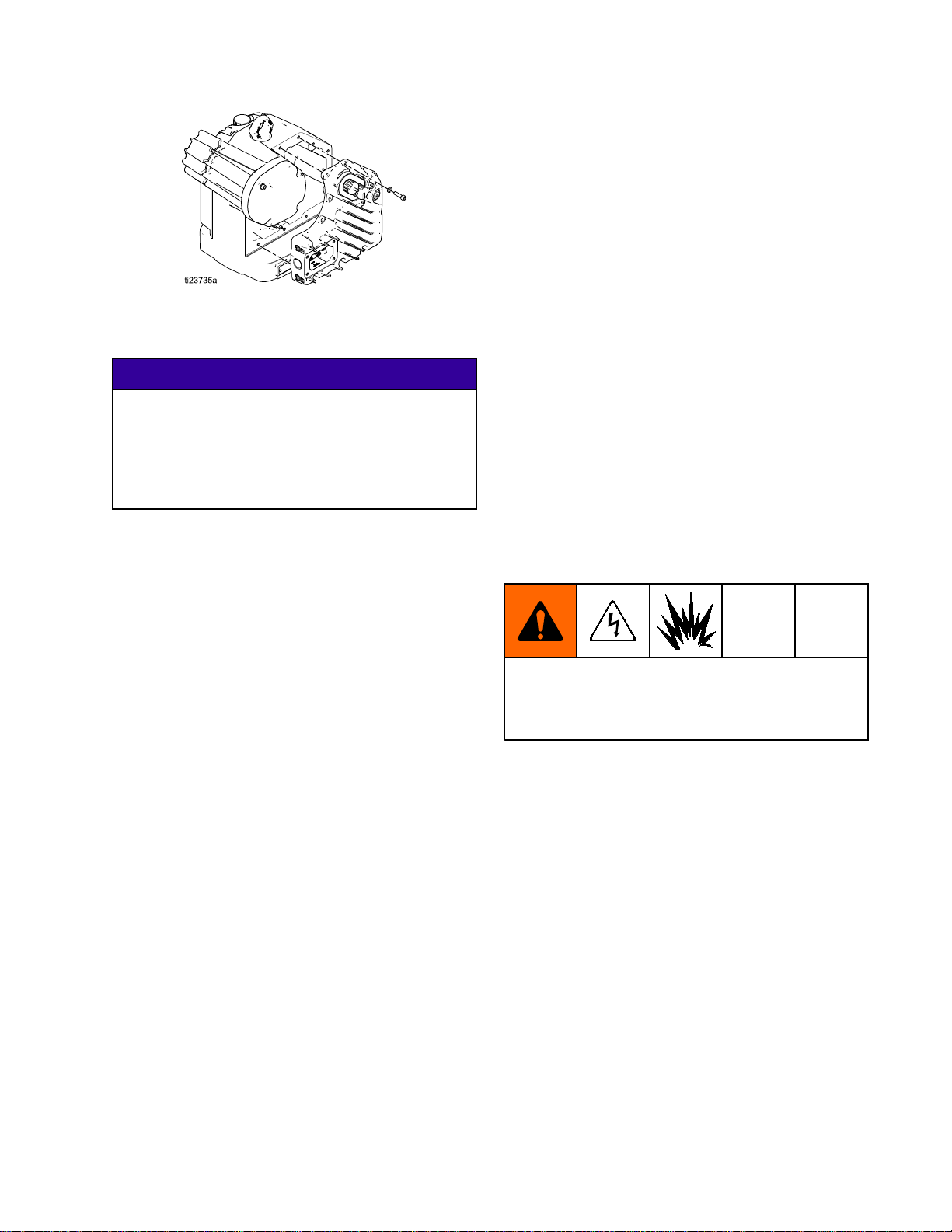

INTRINSIC

INTRINSIC INTRINSIC

Intrinsicallysafeequipmentthatisinstalledimproperlyorconnectedtonon-intrinsicallysafe

equipmentwillcreateahazardousconditionandcancausere,explosion,orelectricshock.

Followlocalregulationsandthefollowingsafetyrequirements.

•Besureyourinstallationcomplieswithnational,state,andlocalcodesfortheinstallationof

electricalapparatusinaClassI,GroupD,Division1HazardousLocation,includingallofthe

localsafetyrecodes,NFPA33,NEC500and516,andOSHA1910.107.

•Equipmentthatcomesincontactwiththeequipment’sintrinsicallysafeterminalsmust

meettheentityparameterrequirementsspeciedinControlDrawing24N637.See

IntrinsicallySafeInstallationRequirementsforAdvancedMotors,page12.Thisincludes

safetybarriers,DCvoltagemeters,ohmmeters,cables,andconnections.Removetheunit

fromthehazardousareawhentroubleshooting.

SHOCK

SHOCK SHOCK

SAFETY

SAFETY SAFETY

HAZARD

HAZARD HAZARD

•Donotinstallanyequipmentapprovedonlyforanon-hazardouslocationinahazardous

area,asdenedinArticle500oftheNationalElectricalCode(USA)oryourlocalelectrical

code.SeetheIDlabelfortheintrinsicsafetyratingforyourequipment.

•Groundthemotor.Usea12gaugeminimumgroundwire,connectedtoatrueearthground.

SeeGrounding,page12.

•Donotoperatethemotorwithanycoverremoved.

•Donotsubstitutesystemcomponents,asthismayimpairintrinsicsafety.

BURN

BURN BURN

Equipmentsurfacesanduidthat’sheatedcanbecomeveryhotduringoperation.Toavoid

severeburns:

•Donottouchhotuidorequipment.

MOVING

MOVING MOVING

Movingpartscanpinch,cutoramputatengersandotherbodyparts.

•Keepclearofmovingparts.

•Donotoperateequipmentwithprotectiveguardsorcoversremoved.

•Pressurizedequipmentcanstartwithoutwarning.Beforechecking,moving,orservicing

HAZARD

HAZARD HAZARD

PARTS

PARTS PARTS

equipment,followthePressure Pressure

HAZARD

HAZARD HAZARD

Pressure

Relief

Procedure

Relief Relief

Procedure Procedure

anddisconnectallpowersources.

8 3A2526F

Page 9

WARNING

WARNING WARNING

PRESSURIZED

PRESSURIZED PRESSURIZED

Fluidfromtheequipment,leaks,orrupturedcomponentscansplashintheeyesoronskin

andcauseseriousinjury.

EQUIPMENT

EQUIPMENT EQUIPMENT

HAZARD

HAZARD HAZARD

Warnings

•FollowthePressure Pressure

cleaning,checking,orservicingequipment.

•Tightenalluidconnectionsbeforeoperatingtheequipment.

•Checkhoses,tubes,andcouplingsdaily.Replacewornordamagedpartsimmediately.

TOXIC

TOXIC TOXIC

Toxicuidsorfumescancauseseriousinjuryordeathifsplashedintheeyesoronskin,

inhaled,orswallowed.

•ReadMSDSstoknowthespecichazardsoftheuidsyouareusing.

•Storehazardousuidinapprovedcontainers,anddisposeofitaccordingtoapplicable

guidelines.

PERSONAL

PERSONAL PERSONAL

Wearappropriateprotectiveequipmentwhenintheworkareatohelppreventseriousinjury,

includingeyeinjury,hearingloss,inhalationoftoxicfumes,andburns.Thisequipmentincludes

butisnotlimitedto:

•Protectiveeyewear,andhearingprotection.

•Respirators,protectiveclothing,andglovesasrecommendedbytheuidandsolvent

manufacturer.

EQUIPMENT

EQUIPMENT EQUIPMENT

Misusecancausedeathorseriousinjury.

•Donotoperatetheunitwhenfatiguedorundertheinuenceofdrugsoralcohol.

•Donotexceedthemaximumworkingpressureortemperatureratingofthelowestrated

systemcomponent.SeeTechnical Technical

•Useuidsandsolventsthatarecompatiblewithequipmentwettedparts.SeeTechnical Technical

inallequipmentmanuals.Readuidandsolventmanufacturer’swarnings.Forcomplete

informationaboutyourmaterial,requestMSDSfromdistributororretailer.

•Donotleavetheworkareawhileequipmentisenergizedorunderpressure.

•TurnoffallequipmentandfollowthePressure Pressure

•Checkequipmentdaily.Repairorreplacewornordamagedpartsimmediatelywithgenuine

manufacturer’sreplacementpartsonly.

•Donotalterormodifyequipment.Alterationsormodicationsmayvoidagencyapprovals

andcreatesafetyhazards.

•Makesureallequipmentisratedandapprovedfortheenvironmentinwhichyouareusingit.

•Useequipmentonlyforitsintendedpurpose.Callyourdistributorforinformation.

•Routehosesandcablesawayfromtrafcareas,sharpedges,movingparts,andhotsurfaces.

•Donotkinkoroverbendhosesorusehosestopullequipment.

•Keepchildrenandanimalsawayfromworkarea.

•Complywithallapplicablesafetyregulations.

Pressure

FLUID

FLUID FLUID

OR

OR OR

PROTECTIVE

PROTECTIVE PROTECTIVE

MISUSE

MISUSE MISUSE

Relief

Procedure

Relief Relief

Procedure Procedure

FUMES

FUMES FUMES

EQUIPMENT

EQUIPMENT EQUIPMENT

HAZARD

HAZARD HAZARD

Technical

whenyoustopspraying/dispensingandbefore

Data

Data Data

inallequipmentmanuals.

Pressure

Relief

Procedure

Relief Relief

Procedure Procedure

whenequipmentisnotinuse.

Technical

Data

Data Data

3A2526F 9

Page 10

Installation

Installation

Installation Installation

Installationofthisequipmentinvolvespotentially

hazardousprocedures.Onlytrainedandqualied

personnelwhohavereadandwhounderstand

theinformationinthismanualshouldinstallthis

equipment.

NOTE:

NOTE: NOTE:

IntrinsicallySafeInstallationRequirementsfor

AdvancedMotors,page12.

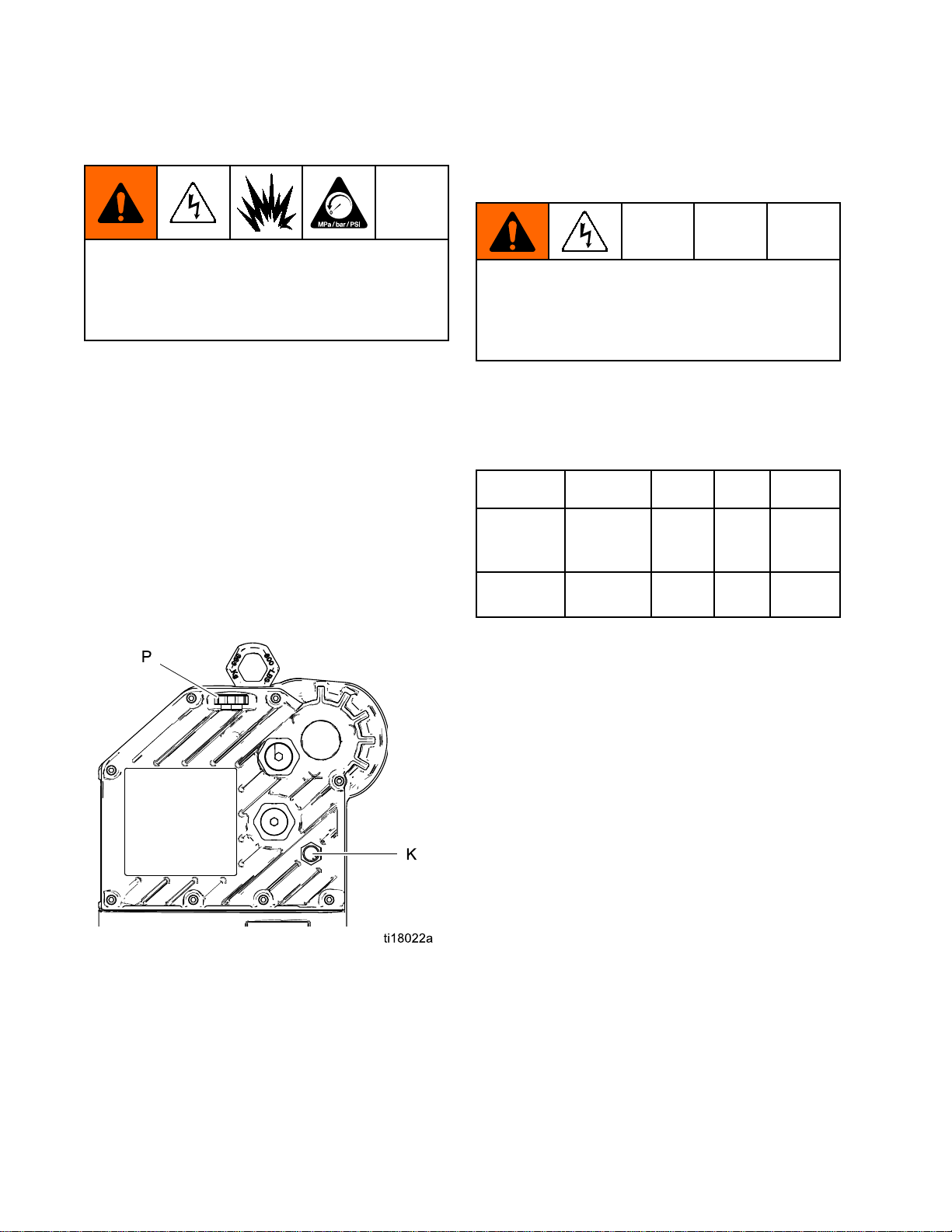

Fill

Fill Fill

Beforeusingtheequipment,openthellcap(P)and

addGracoPartNo.16W645ISO220silicone-free

syntheticgearoil.Checktheoillevelinthesightglass

(K).Filluntiltheoillevelisnearthehalfwaypointof

thesightglass.Theoilcapacityisapproximately1.5

quarts(1.4liters).Do Do

NOTE:

NOTE: NOTE:

suppliedwiththeequipment.

Toinstallanadvancedmotor,alsosee

With

With With

Oil

Before

Oil Oil

Before Before

Do

Two1quart(0.95liter)bottlesofoilare

Using

Using Using

not

overll.

not not

overll. overll.

Equipment

Equipment Equipment

Power

Power Power

Improperwiringmaycauseelectricshockorother

seriousinjuryifworkisnotperformedproperly.

Haveaqualiedelectricianperformanyelectrical

work.Besureyourinstallationcomplieswithall

National,StateandLocalsafetyandrecodes.

SeeTable1forpowersupplyrequirements.The

systemrequiresadedicatedcircuitprotectedwitha

circuitbreaker.

Table

Table Table

Model*

Model* Model*

EM001x100–130

EM002x200–240

*ThelastdigitoftheModelNo.varies.Seethe

Models

Models Models

Supply

Supply Supply

Power

1 11. ..Power Power

Voltage

Voltage Voltage

/200–240

Vac

Vac

tablesonpages3–6.

Requirements

Requirements Requirements

Supply

Supply Supply

Specications

Specications Specications

Phase

Phase Phase

150/601.4

150/602.9

Hz

Hz Hz

kVA

kVA kVA

Figure5SightglassandOilFillCap

Hazardous

Hazardous Hazardous

Requirements

Requirements Requirements

Explosion

Explosion Explosion

Allelectricalwiringinthehazardousareamustbe

encasedinClassI,DivisionI,GroupDapproved

explosion-proofconduit.FollowallNational,State,

andLocalelectriccodes.

Aconduitseal(D)isrequiredwithin18in.(457mm)

ofthemotorfortheUSandCanada.

Allcablesmustberatedat70°C.

Flame

Flame Flame

Useappropriateconduit,connectors,andcable

glandsratedforATEXII2G.FollowallNational,

State,andLocalelectriccodes.

Allcableglandsandcablesmustberatedat70°C.

Area

Cabling

Area Area

Cabling Cabling

Proof

Proof Proof

Proof

Proof Proof

(ATEX)

(ATEX) (ATEX)

and

Conduit

and and

Conduit Conduit

10 3A2526F

Page 11

Installation

Connect

Connect Connect

Improperwiringmaycauseelectricshockorother

seriousinjuryifworkisnotperformedproperly.

Haveaqualiedelectricianperformanyelectrical

work.Besureyourinstallationcomplieswithall

National,StateandLocalsafetyandrecodes.

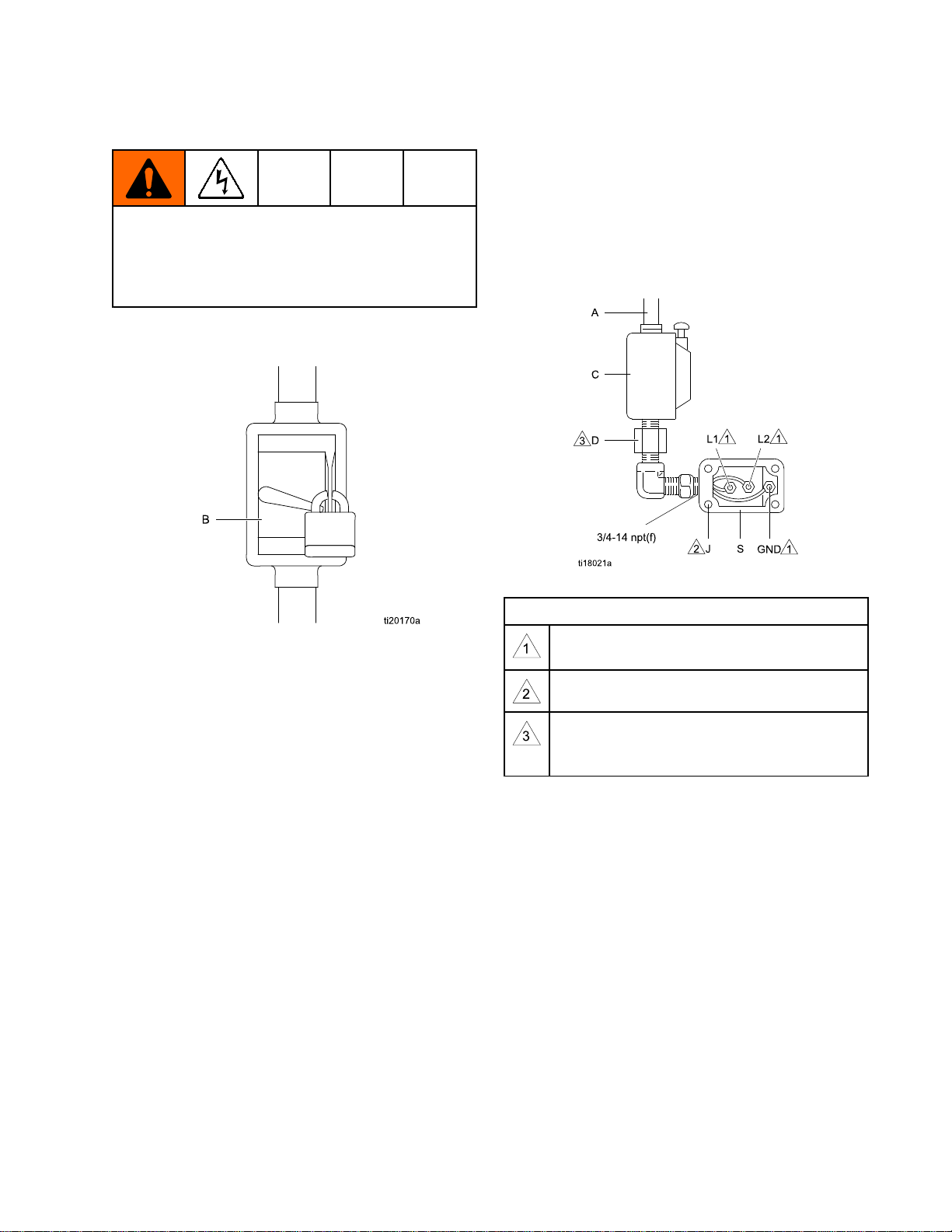

1.Ensurethatthefusedsafetyswitch(B)isshut

offandlockedout.

the

Power

the the

Power Power

Supply

Supply Supply

4.Bringthepowerwiresintotheelectrical

compartmentthroughthe3/4–14npt(f)inletport.

Connectthewirestotheterminals,asshown.

Torquetheterminalnutsto25in-lb(2.8N•m)

Do

not

maximum.Do Do

5.Closetheelectricalcompartment.Torquethe

coverscrews(J)to15ft-lb(20.3N•m).

over-torque.

not not

over-torque. over-torque.

Figure6LockedOutFusedSafetySwitch

2.Installastart/stopcontrol(C)intheelectrical

supplyline(A),withineasyreachofthe

equipment.Thestart/stopcontrolmustbe

approvedforuseinhazardouslocations.

3.Opentheelectricalcompartment(S)onthe

motor.

Figure7ConnectthePowerWires

Notes

for

Fig.

Notes Notes

for for

Tightenallterminalnutsto25in-lb(2.8N•m)

maximum.Do Do

Tightencoverscrewsto15ft-lb(20.3N•m).

Aconduitseal(D)isrequiredwithin18

in.(457mm)ofthemotorfortheUSand

Canada.

7

Fig. Fig.

7 7

Do

not

over

not not

torque.

over over

- --torque. torque.

3A2526F

11

Page 12

Installation

Grounding

Grounding Grounding

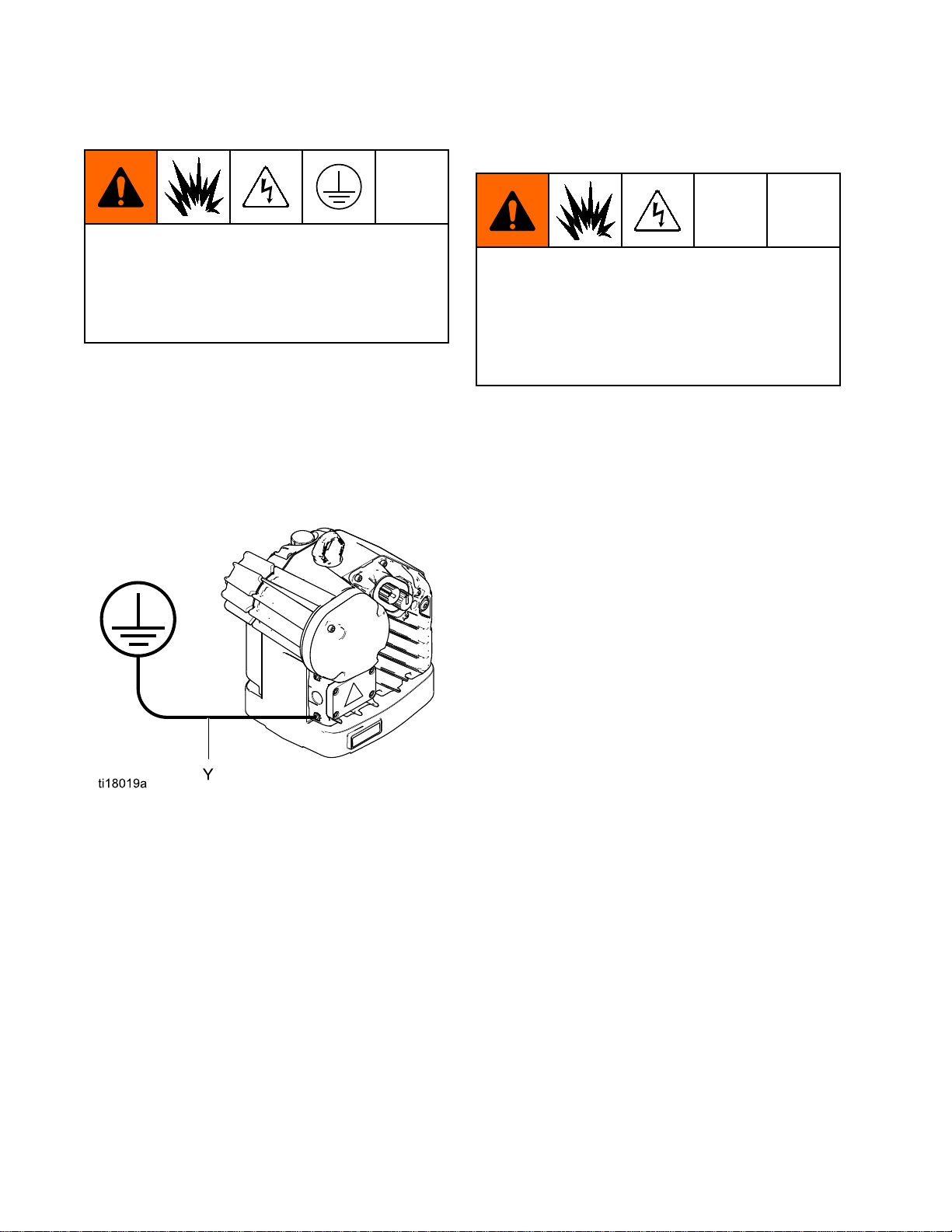

Thisequipmentmustbegroundedtoreducethe

riskofstaticsparkingandelectricshock.Electric

orstaticsparkingcancausefumestoigniteor

explode.Impropergroundingcancauseelectric

shock.Groundingprovidesanescapewireforthe

electriccurrent.

NOTE:

NOTE: NOTE:

EM0022,allmotorsmustbebondedtothe

samehighintegrityequipotentialsystem.See

IntrinsicallySafeInstallationRequirementsfor

AdvancedMotors,page12.

Loosenthegroundscrewandattachagroundwire

(Y).Tightenthegroundscrewsecurely.Connectthe

otherendofthegroundwiretoatrueearthground.

ForadvancedmotorsEM0012and

Intrinsically

Intrinsically Intrinsically

Requirements

Requirements Requirements

Donotsubstituteormodifysystemcomponents

asthismayimpairintrinsicsafety.Forinstallation,

maintenance,oroperationinstructions,read

instructionmanuals.Donotinstallequipment

approvedonlyfornon-hazardouslocationina

hazardouslocation.Seetheidenticationlabelfor

theintrinsicsafetyratingforyourmodel.

SeeAppendixA-SystemControlDrawing24N637,

page37,forinstallationrequirementsandentity

parameters.Followallinstallationinstructionsinyour

systemmanual.

Safe

Safe Safe

Installation

Installation Installation

for

Advanced

for for

Advanced Advanced

Motors

Motors Motors

Figure8GroundWire

12

3A2526F

Page 13

Operation

Operation

Operation Operation

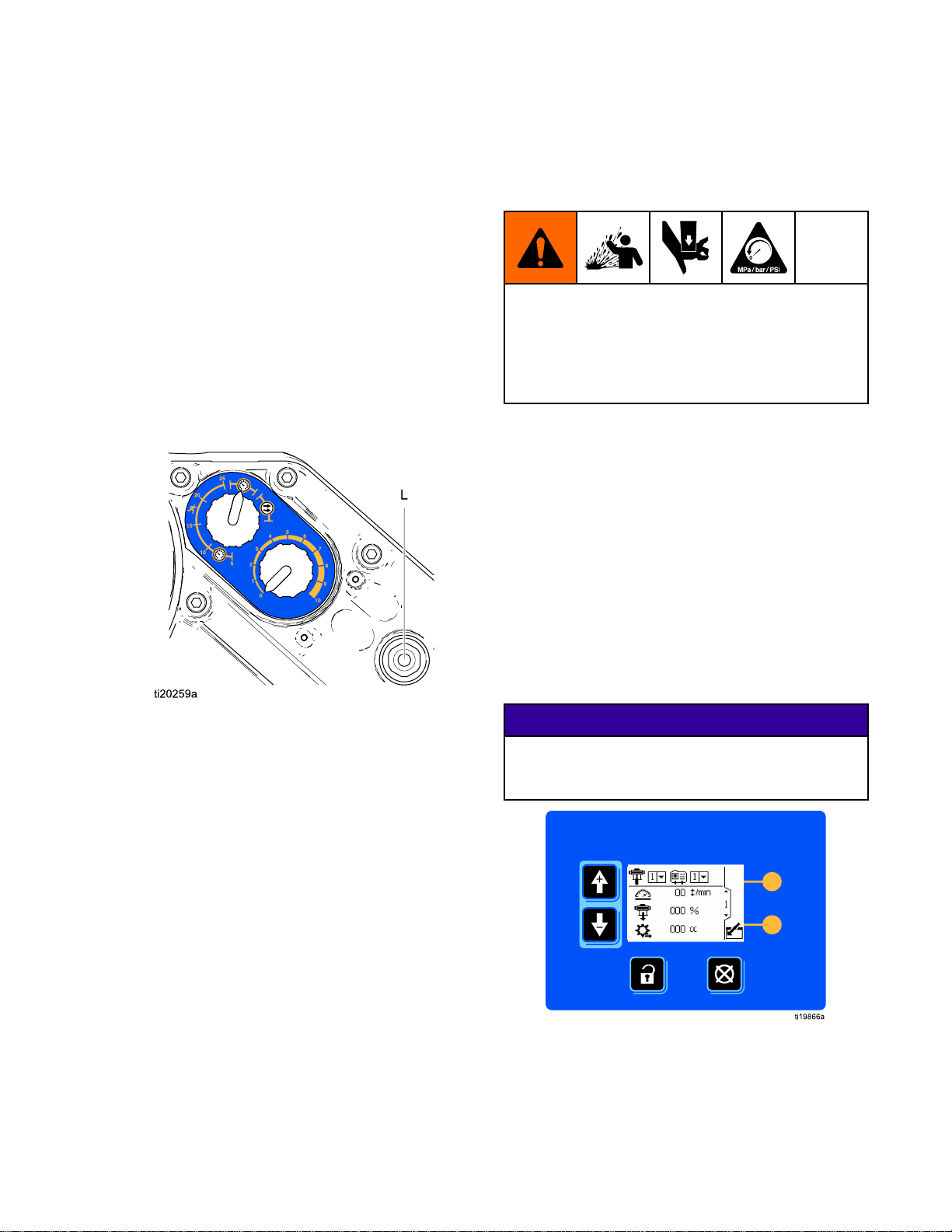

Startup

Startup Startup

1.Unlockthefusedsafetyswitch(B)andturniton.

SeeConnectthePowerSupply,page11

2.Pressthestartpushbutton(C).

3.Checkthatthepowerindicator(L)islit(steady

on).

4.SeeAdvancedMotorOperation,page13or

BasicMotorOperation,page14forfurther

instructions.

Pressure

Pressure Pressure

Thisequipmentstayspressurizeduntilpressureis

manuallyrelieved.Tohelppreventseriousinjury

fromsplashinguidandmovingparts,followthe

PressureReliefProcedurewhenyoustopspraying

andbeforecleaning,checking,orservicingthe

equipment.

1.Disengagethestart/stopcontrol(C).See

ConnectthePowerSupply,page11

2.Shutoffandlockoutthefusedsafetyswitch(B).

3.Relievealluidpressureasexplainedinyour

separateE-FloDCpumpmanual.

Advanced

Advanced Advanced

TheAdvancedE-FloDCmotorsrequireinstallationof

the24P822ControlModuleAccessoryKittoprovide

theinterfaceforuserstoenterselectionsandview

informationrelatedtosetupandoperation.Seethe

ControlModuleAccessoryKitmanualforinstallation

andoperationinformation.

Relief

Relief Relief

Motor

Motor Motor

Procedure

Procedure Procedure

Operation

Operation Operation

Figure9PowerIndicator

Shutdown

Shutdown Shutdown

FollowthePressureReliefProcedure,page13.

NOTICE

NOTICE NOTICE

Topreventdamagetothesoftkeybuttons,donot

pressthebuttonswithsharpobjectssuchaspens,

plasticcards,orngernails.

Figure10ControlModuleAccessory

3A2526F 13

Page 14

Operation

Basic

Basic Basic

Thebasicmotorhasthreeoperatingmodes:

•PressureMode

•PressureModewithIntegratedRunaway

•FlowMode

NOTE:

NOTE: NOTE:

turntheControlKnob(N)fullycounterclockwiseto0.

Pressure

Pressure Pressure

Wheninpressuremode,themotorwilladjustthe

speedtomaintainaconstantuidpressure.

1.TurntheControlKnob(N)fullycounterclockwise

2.PulltheModeSelectswitch(M)outtoset.Turn

3.PulltheControlKnob(N)outtoset.Turnthe

Motor

Motor Motor

Protection

Beforechangingfromonemodetoanother,

to0.

theswitchtoPressure

tolock.

knobclockwisetoincreasethepressure,or

counterclockwisetodecreasethepressure.

Pushtheknobintolock.

Operation

Operation Operation

Mode

Mode Mode

.Pushtheswitchin

Pressure

Pressure Pressure

Protection

Protection Protection

Inpressuremodewithintegratedrunawayprotection,

themotorwilladjustthespeedtomaintainaconstant

uidpressure,butwillshutdownifitexceedsa

user-setspeed.

1.TurntheControlKnob(N)fullycounterclockwise

to0.

2.PulltheModeSelectswitch(M)outtoset.In

theRunaway

desiredshutdownspeedincyclesperminute(5,

10,15,20,or25).Pushtheswitchintolock.

3.PulltheControlKnob(N)outtoset.Turnthe

knobclockwisetoincreasethepressure,or

counterclockwisetodecreasethepressure.

Pushtheknobintolock.

NOTE:

NOTE: NOTE:

speedisexceededfor5cycles.Toreset,turnthe

ControlKnob(N)fullycounterclockwiseto0,then

turntothedesiredpressure.

Mode

Mode Mode

Themotorwillshutdowniftheselected

with

Integrated

with with

Integrated Integrated

range,turntheswitchtothe

Runaway

Runaway Runaway

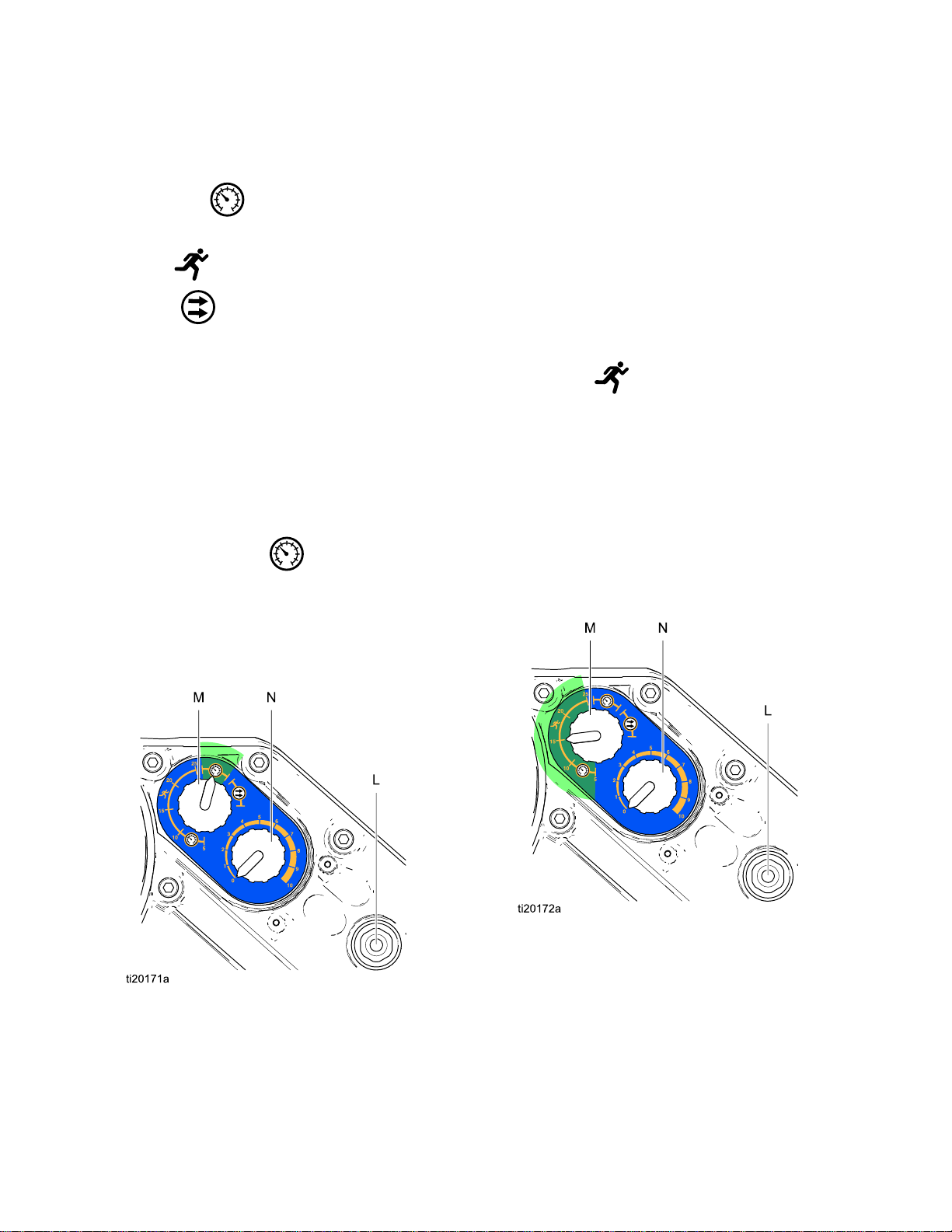

Figure11PressureMode

14

Figure12PressureModewithIntegratedRunaway

Protection

3A2526F

Page 15

Flow

Mode

Flow Flow

Mode Mode

Wheninowmode,themotorwillmaintaina

constantspeedregardlessoftheuidpressure,up

tothepump’smaximumworkingpressure.See

TechnicalData,page43.

1.TurntheControlKnob(N)fullycounterclockwise

to0.

2.PulltheModeSelectswitch(M)outtoset.Turn

Operation

theswitchtoFlow

lock.

3.Theamountofowisdeterminedbythecycle

ratesetwiththeControlKnob(N).Theknob’s

scale(0–10)correspondstoacycleadjustment

rangeof0-30cyclesperminute.TurntheControl

Knob(N)clockwisetoincreasethecyclerate

(ow),orcounterclockwisetodecreasethecycle

rate(ow).

.Pushtheswitchinto

Figure13FlowMode

3A2526F 15

Page 16

Maintenance

Maintenance

Maintenance Maintenance

Preventive

Preventive Preventive

Theoperatingconditionsofyourparticularsystem

determinehowoftenmaintenanceisrequired.

Establishapreventivemaintenancescheduleby

recordingwhenandwhatkindofmaintenanceis

needed,andthendeterminearegularschedulefor

checkingyoursystem.

Change

Change Change

NOTE:

NOTE: NOTE:

200,000–300,000cycles.Afterthebreak-inperiod,

changetheoilonceayear.OrdertwoPartNo.

16W645ISO220silicone-freesyntheticgearoil.

1.Placeaminimum2quart(1.9liter)container

2.Reinstalltheoildrainplug(25).Torqueto25–30

3.Openthellcap(P)andaddGracoPartNo.

Changetheoilafterabreak-inperiodof

undertheoildrainport.Removetheoildrain

plug(25).Allowalloiltodrainfromthemotor.

ft-lb(34–40N•m).

16W645ISO220silicone-freesyntheticgear

oil.Checktheoillevelinthesightglass(K).Fill

untiltheoillevelisnearthehalfwaypointofthe

sightglass.Theoilcapacityisapproximately1.5

quarts(1.4liters).Do Do

Maintenance

Maintenance Maintenance

the

Oil

the the

Oil Oil

Do

not

not not

Schedule

Schedule Schedule

overll.

overll. overll.

Check

Check Check

Checktheoillevelinthesightglass(K).Theoil

levelshouldbenearthehalfwaypointofthesight

glasswhentheunitisnotrunning.Iflow,openthe

llcap(P)andaddGracoPartNo.16W645ISO220

silicone-freesyntheticgearoilasrequired.Theoil

capacityisapproximately1.5quarts(1.4liters).Do Do

not

not not

Figure15SightglassandOilFillCap

Oil

Level

Oil Oil

Level Level

overll.

overll. overll.

Do

4.Reinstallthellcap.

Figure14OilDrainPlug

Bearing

Bearing Bearing

Thebearingpre-loads(R)arefactorysetandarenot

useradjustable.Donotadjustthebearingpre-loads.

Pre

Load

Pre Pre

- --Load Load

16 3A2526F

Page 17

ErrorCodeTroubleshooting

Error

Error Error

Errorcodescantakethreeforms:

•Alarm:alertsyoutothealarmcauseandshuts

downthepump.

•Deviation:alertsyoutotheproblem,butpump

maycontinuetorunpastthesetlimitsuntilthe

system’sabsolutelimitsarereached.

•Advisory:informationonly.Pumpwillcontinueto

operate.

NOTE:

NOTE: NOTE:

pressure(Pcodes)canbedesignatedasalarms

ordeviations.SeeSetup Setup

ModuleManual.

Applicable

Applicable Applicable

Advanced1–2

AdvancedNone

Code

Code Code

OnAdvancedmotors,ow(Kcodes)and

Motor

Motor Motor

Troubleshooting

Troubleshooting Troubleshooting

Setup

Screen

Screen Screen

Blink

Code

Blink Blink

Code Code

4 44intheControl

Display

Display Display

Code

Code Code

K1D?

K2D?

NOTE:

NOTE: NOTE:

thecodeisassociatedwiththedisplayonly.

NOTE:

NOTE: NOTE:

codeisaplaceholderfortheunitnumberwherethe

eventoccurred.

NOTE:

NOTE: NOTE:

indicatoronthemotor.Theblinkcodegivenbelow

indicatesthesequence.Forexample,blinkcode1–2

indicates1blink,then2blinks;thesequencethen

repeats.

NOTE:

NOTE: NOTE:

anindicatorofwhichpumpisactive(

hasbeenpushed,seeRun Run

ModuleManual).

Alarm

Alarm Alarm

Deviation

Deviation Deviation

AlarmFlowisbelowminimumlimit.

DeviationFlowisbelowminimumlimit.

Intheerrorcodeslistedbelow,an“X”means

Intheerrorcodeslistedbelow,a“?”inthe

Theblinkcodeisdisplayedusingthepower

Ablinkcodeof9isnotanerrorcode,but

Run

Screen

Screen Screen

or

or or

Description

Description Description

softkey

1 11intheControl

Basicand

Advanced

AdvancedNone

Advanced1–3

AdvancedNone

Advanced1–4

AdvancedNone

Basicand

Advanced

Basicand

Advanced

Advanced2–3

AdvancedNone

1

2

3

K4D?

K3D?

P1I?

P2I?

P4I?

P3I?

V1I?

V4I?

CAD?

CAC?

AlarmFlowexceedsmaximumtarget;also

indicatespumprunawayconditionexists.

DeviationFlowexceedsmaximumtarget;also

indicatespumprunawayconditionexists.

AlarmPressureisbelowminimumlimit.

DeviationPressureisbelowminimumlimit.

AlarmPressureexceedsmaximumtarget.

DeviationPressureexceedsmaximumtarget.

AlarmBrownout;voltagesuppliedtomotoristoo

low.

AlarmVoltagesuppliedtomotoristoohigh.

Alarm

Alarm

UnitdetectsalossofCANcommunication.

Thisalarmisonlylogged.Noashing

alarmappearsonthedisplay,buttheblink

codedoesoccur.

DisplaydetectsalossofCAN

communication.Flashingalarm

appearsonthedisplay,andtheblinkcode

occurs.

CONTINUED ON THE NEXT PAGE.

3A2526F

17

Page 18

ErrorCodeTroubleshooting

Applicable

Applicable Applicable

Motor

Motor Motor

Advanced2–4

Basicand

Advanced

Advanced1–5

Basicand

Advanced

AdvancedNoneP5DXDeviationMorethanonepumpisassignedtoa

AdvancedNone

Advanced1–6

AdvancedNone

Blink

Code

Blink Blink

Code Code

4

5

Display

Display Display

CAG?

WXD?

WSD?

T3D?

P6CAor

P6CB

P6D?

MND?

Code

Code Code

Alarm

Alarm Alarm

Deviation

Deviation Deviation

Deviation

DeviationForunitswithoutclosedlooppressure

AdvisoryMaintenancecounterisenabledand

or

or or

Alarm

Alarm

Alarm

AlarmForunitswithclosedlooppressurecontrol:

Displaydetectsalossofmodbus

communicationwhencontrolaccessisset

tomodbus.

Aninternalcontrolboardhardwarefailure

isdetected.

Invalidlowersize;occursiftheunitis

operatedbeforesettingupthelowersize.

Overtemperature.

transducer.Theassignmentforthat

transducerisautomaticallyclearedunder

thiscondition.Usermustreassign.

control:Transducer(AorB)isenabled

butnotdetected.

Transducerisenabledbutnotdetected.

countdownreachedzero(0).

Description

Description Description

Basic6NoneAlarm

Basicand

Advanced

Basicand

Advanced

Basicand

Advanced

Basicand

Advanced

Basicand

Advanced

Basicand

Advanced

2–6

3–5

3–4

3–6

4–5

9NoneNone

V1M?

T2D?

WNC?

CCN?

WMC?

TheModeSelectknobissetbetween

PressureandFlow.Setknob

tothedesiredmode.

Alarm

AlarmInternalthermistordisconnected.

Alarm

Alarm

Alarm

ACpowerislost.

Softwareversionsdonotmatch.

Circuitboardcommunicationfailure.

Internalsoftwareerror.

Ablinkcodeof9isnotanerrorcode,but

anindicatorofwhichpumpisactive(see

NOTE

NOTE NOTE

above).

18 3A2526F

Page 19

Repair

Repair

Repair Repair

Replace

Replace Replace

1.Stopthepumpatthebottomofitsstroke.Shut

offandlockoutpowertothemotor.

2.FollowthePressureReliefProcedure,page13.

3.Disconnectthelowerfromthemotor,as

explainedinyourseparateE-FloDCpump

manual.

Output

Output Output

Seal

Seal Seal

Cartridge

Cartridge Cartridge

4.Draintheoilfromthemotor.See

ChangetheOil,page16.

5.Reinstalltheoildrainplug.Torqueto25–30ft-lb

(34–40N•m).

6.Unscrewtheoutputcartridge(19)fromthemotor.

SeeParts,page20.

7.Installthenewoutputcartridge.Torqueto70–80

ft-lb(95–108N•m).

8.Fillwithoil.SeeChangetheOil,page16.

9.Reconnectthelowertothemotor.

10.Turnonpowerandresumeoperation.

3A2526F 19

Page 20

Parts

Parts

Parts Parts

Basic

Basic Basic

EM0011,

EM0011, EM0011,

EM0013,

EM0013, EM0013,

EM0021,

EM0021, EM0021,

EM0023,

EM0023, EM0023,

Motor

Motor Motor

Series

Series Series

Series

Series Series

Series

Series Series

Series

Series Series

Assembly

Assembly Assembly

A,

Horsepower

A, A,

1 11Horsepower Horsepower

A,

Horsepower

A, A,

1 11Horsepower Horsepower

A,

Horsepower

A, A,

2 22Horsepower Horsepower

A,

Horsepower

A, A,

2 22Horsepower Horsepower

Motor

Motor Motor

Motor,

Motor, Motor,

Motor

Motor Motor

Motor,

Motor, Motor,

with

Region-Specic

with with

Region-Specic Region-Specic

with

Region-Specic

with with

Region-Specic Region-Specic

Approvals

Approvals Approvals

Approvals

Approvals Approvals

20 3A2526F

Page 21

Parts

EM0011,

EM0011, EM0011,

EM0013,

EM0013, EM0013,

EM0021,

EM0021, EM0021,

EM0023,

EM0023, EM0023,

Ref

Ref Ref

1

3116343

915F931

1315H525

1424E315

1924K341

24

2515H432

27

33▲16M130LABEL,warning

Part

Part Part

———

———

———

Series

Series Series

Series

Series Series

Series

Series Series

Series

Series Series

A,

A, A,

1 11Horsepower Horsepower

A,

A, A,

1 11Horsepower Horsepower

A,

A, A,

2 22Horsepower Horsepower

A,

A, A,

2 22Horsepower Horsepower

Horsepower

Horsepower

Horsepower

Horsepower

Description

Description Description

HOUSING,motor

SCREW,ground;M5

x0.8

RING,lift

CAP,oilll

SIGHTGLASS

CARTRIDGE,output

seal

SCREW,cap,socket

head;M8x1.25;30

mm

PLUG,oildrain

COVER,electrical

compartment

(EM0011and

EM0021)

Motor

Motor Motor

Motor,

Motor, Motor,

Motor

Motor Motor

Motor,

Motor, Motor,

with

Region-Specic

with with

Region-Specic Region-Specic

with

Region-Specic

with with

Region-Specic Region-Specic

Qty

Qty Qty

1

3

1

1

1

1

4

1

1

1

Approvals

Approvals Approvals

Approvals

Approvals Approvals

Part

Ref

Part Part

Ref Ref

16W360LABEL,warning

34▲196548LABEL,warning1

3616U113KIT,knob;kit

3816W645

———

43

Description

Description Description

(EM0013and

EM0023)

includesreplacement

partsforoneknob

OIL,gear,synthetic;

ISO220silicone-free;

1quart(0.95liter);

notshown

WASHER,lock,

spring;no.8

Qty

Qty Qty

1

2

2

4

▲ReplacementDangerandWarninglabels,tags,

andcardsareavailableatnocost.

Itemsmarked———arenotavailableseparately.

3A2526F

21

Page 22

Parts

Advanced

Advanced Advanced

EM0012,

EM0012, EM0012,

EM0014,

EM0014, EM0014,

EM0022,

EM0022, EM0022,

EM0024,

EM0024, EM0024,

EM0025,

EM0025, EM0025,

EM0026,

EM0026, EM0026,

Motor

Motor Motor

Series

Series Series

Series

Series Series

Series

Series Series

Series

Series Series

Series

Series Series

Series

Series Series

A,

A, A,

A,

A, A,

A,

A, A,

A,

A, A,

A,

A, A,

A,

A, A,

Assembly

Assembly Assembly

Horsepower

1 11Horsepower Horsepower

Horsepower

1 11Horsepower Horsepower

Horsepower

2 22Horsepower Horsepower

Horsepower

2 22Horsepower Horsepower

Horsepower

2 22Horsepower Horsepower

Horsepower

2 22Horsepower Horsepower

Motor

Motor Motor

Motor,

Motor, Motor,

Motor

Motor Motor

Motor,

Motor, Motor,

Motor

Motor Motor

Motor,

Motor, Motor,

with

Region-Specic

with with

Region-Specic Region-Specic

with

Region-Specic

with with

Region-Specic Region-Specic

with

Region-Specic

with with

Region-Specic Region-Specic

Approvals

Approvals Approvals

Approvals

Approvals Approvals

Approvals

Approvals Approvals

22

3A2526F

Page 23

Parts

EM0012,

EM0012, EM0012,

EM0014,

EM0014, EM0014,

EM0022,

EM0022, EM0022,

EM0024,

EM0024, EM0024,

EM0025,

EM0025, EM0025,

EM0026,

EM0026, EM0026,

Ref

Ref Ref

1

3116343

915F931

1315H525

1424E315

1924K341

24

2515H432

27

Part

Part Part

———

———

———

Series

Series Series

Series

Series Series

Series

Series Series

Series

Series Series

Series

Series Series

Series

Series Series

A,

Horsepower

A, A,

1 11Horsepower Horsepower

A,

Horsepower

A, A,

1 11Horsepower Horsepower

A,

Horsepower

A, A,

2 22Horsepower Horsepower

A,

Horsepower

A, A,

2 22Horsepower Horsepower

A,

Horsepower

A, A,

2 22Horsepower Horsepower

A,

Horsepower

A, A,

2 22Horsepower Horsepower

Description

Description Description

HOUSING,motor

SCREW,ground;M5

x0.8

RING,lift

CAP,oilll

SIGHTGLASS

CARTRIDGE,output

seal

SCREW,cap,socket

head;M8x1.25;30

mm

PLUG,oildrain

COVER,electrical

compartment

Motor

Motor Motor

Motor,

Motor, Motor,

Motor

Motor Motor

Motor,

Motor, Motor,

Motor

Motor Motor

Motor,

Motor, Motor,

with

Region-Specic

with with

Region-Specic Region-Specic

with

Region-Specic

with with

Region-Specic Region-Specic

with

Region-Specic

with with

Region-Specic Region-Specic

Qty

Qty Qty

1

3

1

1

1

1

4

1

1

Approvals

Approvals Approvals

Approvals

Approvals Approvals

Approvals

Approvals Approvals

Part

Ref

Part Part

Ref Ref

33▲16M130LABEL,warning

16W360LABEL,warning

34▲196548LABEL,warning1

3816W645

———

43

Description

Description Description

(EM0012,EM0022,

andEM0025)

(EM0014,EM0024,

andEM0026)

OIL,gear,synthetic;

ISO220silicone-free;

1quart(0.95liter);

notshown

WASHER,lock,

spring;no.8

Qty

Qty Qty

1

1

2

4

▲ReplacementDangerandWarninglabels,tags,

andcardsareavailableatnocost.

Itemsmarked———arenotavailableseparately.

3A2526F 23

Page 24

Notes

Notes

Notes Notes

24

3A2526F

Page 25

RepairKits,RelatedManuals,andAccessories

Repair

Repair Repair

Motor

Motor Motor

Allmotorsinthis

manual.

ModelsEM00X1,

EM00X3

Kits,

Kits, Kits,

Part

No.

Part Part

No. No.

Related

Related Related

Description

Description Description

E-FloDCMotors

E-FloDCBasicMotors

Manuals,

Manuals, Manuals,

Kits

Kits Kits

24K341

24P816

255143WallBracket;seemanual312148.

16W645

16U705

24U938Encoder;seeEncoderReplacement,page29

108675WiringPost

16U113

24U934

24U936

and

and and

Accessories

Accessories Accessories

Kit

Description

Kit Kit

Description Description

OutputSealCartridge(19);see

Parts,page20.

ShaftCollectorKit;seemanual406998.

ISO220Silicone-FreeSyntheticGearOil;

1quart(0.95liter);order2

PositionSensor;see

PositionSensorReplacement,page32.

KnobKit(36);seeParts,page20.Includes

replacementpartsforoneknob.

Electric1HPControlBoard;see

ControlBoardReplacement,page27

Electric2HPControlBoard;see

ControlBoardReplacement,page27

ModelsEM0012,

EM0014,

EM0022,

EM0024,

EM0025,and

EM0026

E-FloDCAdvancedMotors

24P822

16P911

16P912

24P979

24R050PressureTransducerKit

16U729

24U935

24U937

24U939Powerboard

ControlModule,forAdvancedMotors;see

manual3A2527.

CANCable,3ft(1m)

CANCable,25ft(8m)

PneumaticControlforBackPressure

Regulator;seemanual332142.

Start/StopSwitch.Allowspumptobeshut

offwhilemaintainingpowertothecontrol

module.

Electric1HPControlBoardsee

ControlBoardReplacement,page27

Electric2HPControlBoard

seeControlBoardReplacement,page27

3A2526F 25

Page 26

RepairKits,RelatedManuals,andAccessories

Motor

Part

Motor Motor

No.

Part Part

No. No.

Description

Description Description

Kits

Kits Kits

Kit

Description

Kit Kit

Description Description

Allmotorsinthis

manual.

Connectionkits,tomountan

E-FloDCMotortoanexisting

pumplower.Kitsincludetie

rods,tierodnuts,adapter,

andcoupler.

288203For3000and4000cc4–BallLowers

288204ForDura-Flo1800and2400Lowers

288205ForDura-Flo600,750,900,and1200

Lowers

288206ForDura-Flo1000Lowers

288207ForXtreme145,180,220,250,and290

Lowers

288209For750,1000,1500,and2000cc4–Ball

Lowers

288860ForXtreme85and115Lowers

26 3A2526F

Page 27

ControlBoardReplacement

Kits 24U934, 24U936, 24U935, 24U937

Control

Control Control

Kits

Kits Kits

Overview

Overview Overview

Themaincontrolboardassemblymanagesthe

operationoftheE-FloDC.Itispermanentlyattached

totheelectronicscover.

Tools

Tools Tools

•6mmHexWrench

•PhillipsScrewdriver(#1)

•TorqueWrench(15ft-lb,20Nm)

Replacement

Replacement Replacement

Toavoidelectricshock,turnoffequipmentpower

andshutoffpoweratmaincircuitbreakerbefore

installing.

Toavoiddamagetothecontrolboardwear

groundingstrap(PartNo.112190)andground

appropriately.

Prepare

Prepare Prepare

1.Removepowerfromthemotor.Follow

24U934,

24U934, 24U934,

Required

Required Required

appropriatelock-out/tag-outprocedures.

Board

Board Board

Instructions

Instructions Instructions

NOTICE

NOTICE NOTICE

Motor

Motor Motor

Replacement

Replacement Replacement

24U936,

24U936, 24U936,

24U935,

24U935, 24U935,

Figure16WiringBoxCover

Remove

Remove Remove

1.Removethe12boltsthatholdontheelectronics

2.Supportthecoveraftertheboltsareremovedto

24U937

24U937 24U937

Electronics

Electronics Electronics

Toavoidequipmentdamage,carefullysupportthe

coverwhenremovingthelastbolt.Holdthecover

horizontallyandtakecarethatthewiresarenot

pulledtight.

coverusinga6mmhexwrench.Placeboltsina

safelocation.

preventputtingexcessstrainonthewiresinside

theE-FloDC.

Cover

Cover Cover

NOTICE

NOTICE NOTICE

2.FollowthePressureReliefProcedure,page13.

3.Decouplethepumplowerfromthemotorperthe

appropriatepumpmanual.

Disconnect

Disconnect Disconnect

1.SeeRemovethe4boltsthatholdonthewiring

boxcoverusinga6mmhexwrench.Placebolts

inasafelocation.

2.Disconnectwiresfrompostandgroundscrew

insideofcover.

3.Removepowercableand/orconduitfrom

electronicscover.

3A2526F

Power

Power Power

Wires

Wires Wires

Figure17ElectronicsCover

Disconnect

Disconnect Disconnect

NOTE:

NOTE: NOTE:

cover.Toreplacethecontrolboardtheentire

electronicscovermustbereplaced.

Control

Control Control

Thecontrolboardisinsidetheelectronics

Board

Board Board

27

Page 28

ControlBoardReplacement

Kits 24U934, 24U936, 24U935, 24U937

1.Todisconnectthecontrolboardunplugthe

positionsensor,encoder,temperaturesensor,

andmotorfromthecontrolboard.

2.Removewiresfromclipinsidehousing.

3.Removeanytiestrapsthatmaybepresent.

4.Settheelectronicscover/controlboardaside.

Foradvancedmodelssee

DisconnectPowerBarrierBoard,page35.

Install

Install Install

1.Plugthepositionsensor,encoder,temperature

2.Secureloosewiresintotheclipinsidethe

Foradvancedmodelssee

InstallNewPowerBarrierBoard,page35.

Reset

Reset Reset

Tocalibratetheunitadipswitchonthecontrolboard

mustbetoggled.Therearetwodipswitcheslocated

ontheuppercontrolboard.Reseteitherdipswitch

bytogglingittotheoppositestate.Thissignals

thecontrolboardthatareplacementparthasbeen

installed.Thenexttimetheunitispowereditwill

proceedwithanauto-calibrationsequence.

NOTE:

NOTE: NOTE:

procedurethedipswitchonlyneedstobetoggled

intotheoppositestateonetime.

New

Control

New New

Control Control

sensor,andmotorintothenewcontrolboard.

housing.

Dip

Switch

Dip Dip

Switch Switch

Ifyouareperformingmorethanonerepair

Board

Board Board

Reinstall

Reinstall Reinstall

Besurethatnowiresarepinchedbetweenthe

electronicscoverandthemotorhousing.Pinched

wiresmaydamagethecontrolboardandwillimpair

explosion-proofsafety.

1.Reinstallelectronicscoverontocenterhousing.

2.Installthe12boltsusinga6mmhexwrench.

NOTE:

NOTE: NOTE:

3.Torquetheboltsto15ft-lb(20Nm).

Reinstall

Reinstall Reinstall

1.Connectwiresfrominsideofwiringbox.Referto

torqueinstructionslistedonplacardinsideofthe

wiringbox.Connectpowercableand/orconduit

totheelectronicscover.

2.Reinstallcoverontowiringbox.

3.Installthe4boltsusinga6mmhexwrench.

NOTE:

NOTE: NOTE:

4.Torquetheboltsto15ft-lb(20Nm).

Power

Power Power

1.Applypowertotheunittostarttheauto-calibration

process.

Electronics

Electronics Electronics

Ensurethelockwashersarestillinplace.

Wiring

Wiring Wiring

Ensurethelockwashersarestillinplace.

Unit

Unit Unit

Cover

Cover Cover

Box

Cover

Box Box

Cover Cover

2.Themotoroutputshaftwillrunupanddownover

thecourseofseveralminutes.

3.Midwaythroughtheauto-calibrationprocessthe

motoroutputshaftwillpauseasitmovestothe

nextstep.

4.Ensuretheauto-calibrationprocessiscomplete

beforecontinuing.

Reattach

Reattach Reattach

Figure18DipSwitch

28 3A2526F

1.Jogtheoutputshaftonthepumplowerand

reconnectthecouplingnut.

2.Torquetotheproperlevelpertheappropriate

pumpmanual.

Pump

Pump Pump

Lower

Lower Lower

Page 29

EncoderReplacement

Kit 24U938

Encoder

Encoder Encoder

Kit

Kit Kit

Overview

Overview Overview

TheencoderisusedbytheE-FloDCfortwo

purposes.First,theencodertellsthecontrolboard

wherethemotorisinitsmechanicalrotationand

usesthatinformationtoproperlycontrolthemotor

torque.Second,itcontrolsstrokelengthbyallowing

thecontrolboardtocountthenumberofcomplete

motorrotations.

Tools

Tools Tools

•6mmHexWrench

•.050inHexWrench

•PhillipsScrewdriver(#1)

•TorqueWrench(15ft-lb,20Nm)

•Blue(medium)threadlockingcompound

Replacement

Replacement Replacement

24U938

24U938 24U938

Required

Required Required

Replacement

Replacement Replacement

Instructions

Instructions Instructions

2.FollowthePressureReliefProcedure,page13.

3.Decouplethepumplowerfromthemotorperthe

appropriatepumpmanual.

Remove

Remove Remove

Toavoidequipmentdamage,carefullysupportthe

coverwhenremovingthelastbolt.Holdthecover

horizontallyandtakecarethatthewiresarenot

pulledtight.

1.Removethe12boltsthatholdontheelectronics

coverusinga6mmhexwrench.Placeboltsina

safelocation.

Electronics

Electronics Electronics

Cover

Cover Cover

NOTICE

NOTICE NOTICE

Toavoidelectricshock,turnoffequipmentpower

andshutoffpoweratmaincircuitbreakerbefore

installing.

NOTICE

NOTICE NOTICE

Toavoiddamagetothecontrolboardwear

groundingstrap(PartNo.112190)andground

appropriately.

Prepare

Prepare Prepare

1.Removepowerfromthemotor.Follow

Motor

Motor Motor

appropriatelock-out/tag-outprocedures.

2.Supportthecoveraftertheboltsareremovedto

preventputtingexcessstrainonthewiresinside

theE-FloDC.

Figure19ElectronicsCover

3A2526F 29

Page 30

EncoderReplacement

Kit 24U938

Remove

Remove Remove

1.Removethe4boltsthatholdonthemotorcover

usinga6mmhexwrench.Placeboltsinasafe

location.

2.Setmotorcoveraside.

Figure20MotorCover

Remove

Remove Remove

Motor

Motor Motor

Encoder

Encoder Encoder

Cover

Cover Cover

AA

Setscrews

AB

Encodermountingange

Phillipsheadmountingscrews

AC

ADMotorhousing

Install

Install Install

1.Placetheencoderconnectorcable(AE)through

New

Encoder

New New

Encoder Encoder

themotorhousinglowerport(AF).

NOTE:

NOTE: NOTE:

thetwoconnections.

Theencoderconnectoristhesmallerof

1.Unplugtheencodercablefromthecontrolboard

andtheencoderandremove.

2.Loosenthe2hubsetscrews(AA)usingthe

included.050”hexwrench.

3.Removethe2mountingscrews(AC)witha

Phillipsheadscrewdriver.

4.Pullencoderoffofrotorshaft.

NOTE:

NOTE: NOTE:

the2Phillipsheadmountingscrews.Allotherbolts

shouldremaininplace.

Thisprocedureonlyrequirestheremovalof

Figure22EncoderCable

AEEncoderconnectorcable

AF

Lowerportofmotorhousing

2.Slidethenewencoderontotherotorshaft.

3.Applyasmallamountofblue(medium)thread

lockertothe2Phillipsheadmountingscrews

(AC)andsecureencodermountingange(AB)

tomotorhousing(AD).

4.Removethe2setscrews(AA)fromtheencoder

hubusingtheincluded.050”hexwrench.

5.Applyasmallamountofblue(medium)thread

lockertothesetscrews(AA)andscrewbackinto

theencoder.Tightenhandtight.

6.Plugencodercableintotheencoderandthe

controlboard.

Figure21Encoder

30 3A2526F

Page 31

EncoderReplacement

Kit 24U938

Figure23Encoder

AA

Setscrews

AB

Encodermountingange

Phillipsheadmountingscrews

AC

ADMotorhousing

Reset

Reset Reset

Tocalibratetheunitadipswitchonthecontrolboard

mustbetoggled.Therearetwodipswitcheslocated

ontheuppercontrolboard.Reseteitherdipswitch

bytogglingittotheoppositestate.Thissignals

thecontrolboardthatareplacementparthasbeen

installed.Thenexttimetheunitispowereditwill

proceedwithanauto-calibrationsequence.

NOTE:

NOTE: NOTE:

procedurethedipswitchonlyneedstobetoggled

intotheoppositestateonetime.

Dip

Switch

Dip Dip

Switch Switch

Ifyouareperformingmorethanonerepair

Reinstall

Reinstall Reinstall

Besurethatnowiresarepinchedbetweenthe

electronicscoverandthemotorhousing.Pinched

wiresmaydamagethecontrolboardandwillimpair

explosion-proofsafety.

1.Reinstallelectronicscoverontocenterhousing.

2.Installthe12boltsusinga6mmhexwrench.

NOTE:

NOTE: NOTE:

3.Torquetheboltsto15ft-lb(20Nm).

Reinstall

Reinstall Reinstall

1.Reinstallmotorcoverontomotorhousing.

2.Installthe4boltsthatholdonthemotorcover

usinga6mmhexwrench.Ensurethelock

washersarestillinplace.

3.Torquetheboltsto15ft-lb(20Nm).

Power

Power Power

1.Applypowertotheunittostarttheauto-calibration

process.

2.Themotoroutputshaftwillrunupanddownover

thecourseofseveralminutes.

3.Midwaythroughtheauto-calibrationprocessthe

motoroutputshaftwillpauseasitmovestothe

nextstep.

4.Ensuretheauto-calibrationprocessiscomplete

beforecontinuing.

Electronics

Electronics Electronics

Ensurethelockwashersarestillinplace.

Motor

Motor Motor

Unit

Unit Unit

Cover

Cover Cover

Cover

Cover Cover

Reattach

Reattach Reattach

1.Jogtheoutputshaftonthepumplowerand

reconnectthecouplingnut.

2.Torquetotheproperlevelpertheappropriate

Figure24DipSwitch

3A2526F 31

pumpmanual.

Pump

Pump Pump

Lower

Lower Lower

Page 32

PositionSensorReplacement

Kit 16U705

Position

Position Position

Kit

Kit Kit

Overview

Overview Overview

ThepositionsensorisusedbytheE-FloDCto

determinewherethemotorisinthestroke.

Tools

Tools Tools

•6mmHexWrenches

•13mmOpen-EndedWrench

•6mmOpen-EndedWrench

•PhillipsScrewdriver(#2)

•TorqueWrench(15ft-lb,20Nm)

Replacement

Replacement Replacement

16U705

16U705 16U705

Required

Required Required

Sensor

Sensor Sensor

Instructions

Instructions Instructions

Replacement

Replacement Replacement

NOTICE

NOTICE NOTICE

Toavoidequipmentdamage,carefullysupportthe

coverwhenremovingthelastbolt.Holdthecover

horizontallyandtakecarethatthewiresarenot

pulledtight.

1.Removethe12boltsthatholdontheelectronics

coverusinga6mmhexwrench.Placeboltsina

safelocation.

2.Supportthecoveraftertheboltsareremovedto

preventputtingexcessstrainonthewiresinside

theE-FloDC.

Toavoidelectricshock,turnoffequipmentpower

andshutoffpoweratmaincircuitbreakerbefore

installing.

NOTICE

NOTICE NOTICE

Toavoiddamagetothecontrolboardwear

groundingstrap(PartNo.112190)andground

appropriately.

Prepare

Prepare Prepare

1.Removepowerfromthemotor.Follow

2.FollowthePressureReliefProcedure,page13.

3.Decouplethepumplowerfromthemotorperthe

Remove

Remove Remove

Motor

Motor Motor

appropriatelock-out/tag-outprocedures.

appropriatepumpmanual.

Electronics

Electronics Electronics

Cover

Cover Cover

Figure25ElectronicsCover

Remove

Remove Remove

1.Unplugthepositionsensorfromthecontrol

board.

2.Unscrewtheshieldground(AT)usingaPhillips

screwdriver.

3.Loosenthepositionsensorjamnut(AS)using

a13mmwrench.

4.Unscrewthepositionsensor(AR)fromthecenter

housingusinga6mmopenendedwrench.

NOTE:

NOTE: NOTE:

topreventtwisting.

Install

Install Install

1.Carefullyscrewthereplacementpositionsensor

intothecenterhousing.

NOTE:

NOTE: NOTE:

wireswillhavetoberotatedwhiletheposition

sensorisinstalledtopreventthemfrombeing

twisted.

Position

Position Position

Allowwirestorotatewithpositionsensor

New

Position

New New

Position Position

Becarefulnottodamagethewires.The

Sensor

Sensor Sensor

Sensor

Sensor Sensor

32 3A2526F

Page 33

PositionSensorReplacement

Kit 16U705

2.Usethe6mmwrenchtocompletetheinstallation

ofthepositionsensor.Becarefulnottouse

excessivetorque.Stoponcethepositionsensor

bottomsoutinthebore.

NOTE:

NOTE: NOTE:

Damagetothepositionsensormayresult.

3.Tightenthejamnutonthepositionsensornger

tight.

NOTE:

NOTE: NOTE:

nut.Damagetothepositionsensormayresult.

4.InstallshieldgroundwireusingaPhillipsscrew

driver.

5.Plugthepositionsensorintothecontrolboard.

Reset

Reset Reset

Tocalibratetheunitadipswitchonthecontrolboard

mustbetoggled.Therearetwodipswitcheslocated

ontheuppercontrolboard.Reseteitherdipswitch

bytogglingittotheoppositestate.Thissignals

thecontrolboardthatareplacementparthasbeen

installed.Thenexttimetheunitispowereditwill

proceedwithanauto-calibrationsequence.

NOTE:

NOTE: NOTE:

procedurethedipswitchonlyneedstobetoggled

intotheoppositestateonetime.

Donotovertightenthepositionsensor.

DoNOTuseawrenchtotightenthejam

Dip

Switch

Dip Dip

Switch Switch

Ifyouareperformingmorethanonerepair

Reinstall

Reinstall Reinstall

Besurethatnowiresarepinchedbetweenthe

electronicscoverandthemotorhousing.Pinched

wiresmaydamagethecontrolboardandwillimpair

explosion-proofsafety.

1.Reinstallelectronicscoverontocenterhousing.

2.Installthe12boltsusinga6mmhexwrench.

NOTE:

NOTE: NOTE:

3.Torquetheboltsto15ft-lb(20Nm).

Power

Power Power

1.Applypowertotheunittostarttheauto-calibration

process.

2.Themotoroutputshaftwillrunupanddownover

thecourseofseveralminutes.

3.Midwaythroughtheauto-calibrationprocessthe

motoroutputshaftwillpauseasitmovestothe

nextstep.

4.Ensuretheauto-calibrationprocessiscomplete

beforecontinuing.

Electronics

Electronics Electronics

Ensurethelockwashersarestillinplace.

Unit

Unit Unit

Cover

Cover Cover

Figure26DipSwitch

Reattach

Reattach Reattach

1.Jogtheoutputshaftonthepumplowerand

reconnectthecouplingnut.

2.Torquetotheproperlevelpertheappropriate

pumpmanual.

Pump

Pump Pump

Lower

Lower Lower

3A2526F 33

Page 34

AdvancedPowerBoardReplacement

Kit 24U939

Advanced

Advanced Advanced

Kit

Kit Kit

Tools

Tools Tools

•6mmHexWrenches

•1/4”NutDriver

•5mmHexWrench

•PhillipsScrewdriver(#2)

•TorqueWrench(15ft-lb,20Nm)

Replacement

Replacement Replacement

24U939

24U939 24U939

Required

Required Required

Toavoidelectricshock,turnoffequipmentpower

andshutoffpoweratmaincircuitbreakerbefore

installing.

Power

Power Power

Instructions

Instructions Instructions

Board

Board Board

Replacement

Replacement Replacement

Figure27WiringBoxCover

Remove

Remove Remove

Ifthecontrolmoduleisbracketmountedtothe

electronicscoveritmustberemovedpriorto

removingtheelectronicscover.

1.Unsnapthecontrolmodulefromthebracketand

disconnectthecablefromtheelectronicscover,

setcontrolmoduleaside.

Control

Control Control

Module

Module Module

Bracket

Bracket Bracket

NOTICE

NOTICE NOTICE

Toavoiddamagetothecontrolboardwear

groundingstrap(PartNo.112190)andground

appropriately.

Prepare

Prepare Prepare

1.Removepowerfromthemotor.Follow

appropriatelock-out/tag-outprocedures.

2.FollowthePressureReliefProcedure,page13.

3.Decouplethepumplowerfromthemotorperthe

appropriatepumpmanual.

Disconnect

Disconnect Disconnect

1.SeeRemovethe4boltsthatholdonthewiring

boxcoverusinga6mmhexwrench.Placebolts

inasafelocation.

2.Disconnectwiresfrompostandgroundscrew

insideofcover.

3.Removepowercableand/orconduitfrom

electronicscover.

Motor

Motor Motor

Power

Power Power

Wires

Wires Wires

2.Removecontrolmodulebracketfromthe

electronicscover,setbracketandhardware

aside.

Remove

Remove Remove

Toavoidequipmentdamage,carefullysupportthe

coverwhenremovingthelastbolt.Holdthecover

horizontallyandtakecarethatthewiresarenot

pulledtight.

1.Removethe12boltsthatholdontheelectronics

coverusinga6mmhexwrench.Placeboltsina

safelocation.

2.Supportthecoveraftertheboltsareremovedto

preventputtingexcessstrainonthewiresinside

theE-FloDC.

Electronics

Electronics Electronics

NOTICE

NOTICE NOTICE

Cover

Cover Cover

34 3A2526F

Page 35

Figure28ElectronicsCover

AdvancedPowerBoardReplacement

tight.Torquesocketheadcapscrewsto15ft-lb

(20Nm).

NOTE:

NOTE: NOTE:

tightening.Thestandoffsshouldbetightened

beforethesocketheadcapscrews.

3.PlugtheCANbuspowerintothepowerbarrier

board.

4.Tightenthetiestraparoundthewirestosecure

themtotheboard.

Putallsixscrewsinplacebefore

Kit 24U939

Disconnect

Disconnect Disconnect

TheCANbusonthepowerbarrierboardis

connectedtothecontrolboardthroughapartition

insidethemotor.Toavoidequipmentdamage,

holdelectronicscoverinplaceuntiltheCANbus

cableisdisconnected.Holdthecoverhorizontally

andtakecarethatthewiresarenotpulledtight.

1.Disconnectbarrierboardpowercablefromthe

controlboard.

2.Removethe4screws(AK)holdingthepartition

(AL)andpowercablebracket(AJ)inplace,set

aside.

3.Removeanytiestrapsthatarepresent.

4.Insertasmallhexkeyintothelowerleftcornerof

thepartitionandpullout.

5.RemovetiestrapconnectingtheCANbuswire

tothepowerbarrierboard(AN).

6.Use1/4”nutdrivertoremovethe4standoffs

(AM)fromthecornersofthepowerbarrierboard,

setaside.

7.Usea5mmhexwrenchtoremovethe2socket

headedcapscrews(AP)fromthepowerbarrier

board,setaside.

8.Removethepowerbarrierboard(AN)fromthe

unit.

Install

Install Install

1.Insertthetiestrapthroughthebackofthepower

2.Putnewpowerbarrierboardinplaceandsecure

New

New New

barrierboard.

usingreservedscrews.Tightenstandoffshand

Power

Power Power

Power

Power Power

Barrier

Barrier Barrier

NOTICE

NOTICE NOTICE

Barrier

Barrier Barrier

Board

Board Board

Board

Board Board

5.Placepartitionbackintoplace.Makecertainthe

notchforthewiresisonthelowerleftsideofthe

partitionandthewiresarenotbeingcrushed.

6.Insertbottomscrewsintothepartitionand

tighten.

7.Placepowerconnectbracketintoplaceand

securewithtwoscrews.

8.Reconnectmotor,temperature,reedswitch,

encoder,andbarrierboardpowerwirestothe

controlboard.

Reinstall

Reinstall Reinstall

Besurethatnowiresarepinchedbetweenthe

electronicscoverandthemotorhousing.Pinched

wiresmaydamagethecontrolboardandwillimpair

explosion-proofsafety.

1.Reinstallelectronicscoverontocenterhousing.

2.Installthe12boltsusinga6mmhexwrench.

NOTE:

NOTE: NOTE:

3.Torquetheboltsto15ft-lb(20Nm).

Reinstall

Reinstall Reinstall

1.Connectwiresfrominsideofwiringbox.Referto

torqueinstructionslistedonplacardinsideofthe

wiringbox.Connectpowercableand/orconduit

totheelectronicscover.

2.Reinstallcoverontowiringbox.

3.Installthe4boltsusinga6mmhexwrench.

NOTE:

NOTE: NOTE:

4.Torquetheboltsto15ft-lb(20Nm).

Electronics

Electronics Electronics

Ensurethelockwashersarestillinplace.

Wiring

Wiring Wiring

Ensurethelockwashersarestillinplace.

Cover

Cover Cover

Box

Cover

Box Box

Cover Cover

3A2526F 35

Page 36

AdvancedPowerBoardReplacement

Kit 24U939

Attach

Attach Attach

1.Connectthecontrolmodulecabletothe

2.Reattachthecontrolmodulemountingbracket

3.Snapthecontrolmoduleintoplaceonthe

Power

Power Power

1.Applypowertotheunittostarttheauto-calibration

2.Themotoroutputshaftwillrunupanddownover

Control

Control Control

electronicscover.

ontotheelectronicscover.

bracket.

Unit

Unit Unit

process.

thecourseofseveralminutes.

Module

Module Module

Bracket

Bracket Bracket

3.Midwaythroughtheauto-calibrationprocessthe

motoroutputshaftwillpauseasitmovestothe

nextstep.

4.Ensuretheauto-calibrationprocessiscomplete

beforecontinuing.

Reattach

Reattach Reattach

1.Jogtheoutputshaftonthepumplowerand

reconnectthecouplingnut.

2.Torquetotheproperlevelpertheappropriate

pumpmanual.

Pump

Pump Pump

Lower

Lower Lower

36 3A2526F

Page 37

AppendixA-SystemControlDrawing24N637

Appendix

Appendix Appendix

NOTES

NOTES NOTES

1.Thenon-intrinsicallysafeterminals(powerrail)

2.Allmotorsmustbebondedtothesamehigh

3.Donotremoveanycoveruntilpowerhasbeen

4.Installationshouldbeinaccordancewith

5.InstallationinCanadashouldbeinaccordance

6.Reservedforfutureuse.

7.Betweenoneandeightmotorsmaybeconnected

8.Therstmotorintheseries(theonewithno

FOR

FOR FOR

mustnotbeconnectedtoanydevicewhichuses

orgeneratesmorethanUm=250Vrmsordc

unlessithasbeendeterminedthatthevoltage

hasbeenadequatelyisolated.

integrityequipotentialsystem.

removed.

ANSI/ISARP12.06.01,installationofintrinsically

safesystemsforhazardous(classied)locations,

andtheNationalElectricalCode(ANSI/NFPA

70).

withtheCanadianElectricalCode,CSAC22.1,

Part1,AppendixF.

inseries.ThemotorsareconnectedwithaCAN

cable(16P911or16P912).Thesideofthecable

withtheredmarkingisconnectedtoPort1of

onemotorandtheunmarkedsideofthecableis

connectedtoPort2ofthenextmotor.

CANcableonPort2)isinstalledwiththepower

jumper24N910connectedtoPort2andPort3.

A

A A

FIG.

16

FIG. FIG.

16 16

System

- --System System

AND

17:

AND AND

17: 17:

Control

Control Control

Drawing

Drawing Drawing

locationoranassociatedISapparatusinthe

non-hazardouslocation.ThesideoftheCAN

cablewiththeredmarkingisconnectedtoPort

1ofthelastmotorandtheunmarkedsideof

thecableisconnectedtotheISorassociated

ISapparatus.

10.TheoutputentityparametersgivenforPins1and

4ineachofPorts1and2arethetotalcurrent

andpoweravailabletobothpinsaddedtogether.

ThecurrentonPin1andPin4addedtogether

willnotexceedthelistedIo,andthepoweroutput

fromPin1andPin4addedtogetherwillnot

exceedthelistedPo.

WARNING:

WARNING: WARNING:

mayimpairintrinsicsafety.

ADVERTISSEMENT:

ADVERTISSEMENT: ADVERTISSEMENT:

decomposantspeutcompromettrela

securiteintrinseque.

Table

Table Table

Calculation

2 22. ..Calculation Calculation

24N637

24N637 24N637

Substitutionofcomponents

Procedures

Procedures Procedures

Zones

Zones Zones

Uo≤Ui

Io≤Ii

Po≤Pi

Co≥Ci+Ccable

Lo≥Li+Lcable

Lo/Ro≥Li/Ri

Lasubstitution

9.The“last”motorintheseriesisconnected

toeitheranISapparatusinthehazardous

3A2526F 37

Page 38

AppendixA-SystemControlDrawing24N637

COMMUNICATION

POWER

1

3

2

COMMUNICATION

POWER

1

3

2

COMMUNICATION

POWER

1

3

2

COMMUNICATION

POWER

1

3

2

COMMUNICATION

POWER

1

3

2

COMMUNICATION

POWER

1

3

2

24N910

IS POWER JUMPER

COMMUNICATION

POWER

1

3

2

ADVANCED COMMUNICATION

MOTOR

EM0012/EM0022

HAZARDOUS LOCATION

HIGH INTEGRITY GROUND

EXPLOSION PROOF

FLAME PROOF

AC POWER

NON-HAZARDOUS

LOCATION

IS

APPARATUS

ASSOCIATED IS

APPARATUS

HAZARDOUS (CLASSIFIED) LOCATION

COMMUNICATION

POWER

1

3

2

ADVANCED COMMUNICATION

MOTOR

EM0012/EM0022

ADVANCED COMMUNICATION

MOTOR

EM0012/EM0022

ADVANCED COMMUNICATION

MOTOR

EM0012/EM0022

ADVANCED COMMUNICATION

MOTOR

EM0012/EM0022

ADVANCED COMMUNICATION

MOTOR

EM0012/EM0022

ADVANCED COMMUNICATION

MOTOR

EM0012/EM0022

ADVANCED COMMUNICATION

MOTOR

EM0012/EM0022

8

9

7

Figure29SystemControlDrawing24N637,Sheet1

38 3A2526F

Page 39

AppendixA-SystemControlDrawing24N637

Figure30SystemControlDrawing24N637,Sheet2

Table

Table Table

Port

Port Port

Port

3:

3 33. ..Port Port

3:

Male

3: 3:

Male Male

Pin

“A”

5 55Pin Pin

“A” “A”

Power

3: 3:

Power Power

M12

M12 M12

Key

Key Key

Barrier

Barrier Barrier

Output

Output Output

Pin

Pin Pin

1

2Power17.96462891681

3

4

5

Parameters

Parameters Parameters

Power

Power Power

CANDataLowNotConnected

CANDataHighNotConnected

Barrier

Barrier Barrier

Units

Units Units

ISGround

Return

Shield

Output

Output Output

Parameters

Parameters Parameters

Voc

Voc Voc

Vmax

Vmax Vmax

—————

—————

Isc

Isc Isc

mA

mA mA

Pt

Pt Pt

mW

mW mW

La

La La

μH

μH μH

Ca

Ca Ca

μF

μF μF

7.7

3A2526F 39

Page 40

AppendixA-SystemControlDrawing24N637

Table

Table Table

Port

Port Port

Port

Port Port

Port

Port Port

Ports

4 44. ..Ports Ports

2:

Male

2: 2:

Male Male

Pin

“B”

5 55Pin Pin

“B” “B”

1:

Male

1: 1:

Male Male

Pin

“A”

5 55Pin Pin

“A” “A”